Page 1

MS2650/MS2660B/C Series

Spectrum Analyzer

Operation Manual

Vol. 2

(Detailed Operating Instructions

10th Edition

•

For safety and warning information, please read this

manual before attempting to use the equipment.

•

Additional safety and warning information is

provided within the MS2650/MS2660B/C Series

Spectrum Analyzer Operation Manual Vol. 1 (Basic

Operating Instructions). Please also refer to this

document before using the equipment.

•

Keep this manual with the equipment.

)

ANRITSU CORPORATION

Document No.: M-W1251AE-10.0

Page 2

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the

following safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings

of the symbols BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu

equipment. In addition, there may be other labels attached to products that are not shown in the diagrams in this

manual.

Symbols used in manual

DANGER

WARNING

CAUTION

This indicates a very dangerous procedure that could result in serious injury or

death if not performed properly.

This indicates a hazardous procedure that could result in serious injury or death if

not performed properly.

This indicates a hazardous procedure or danger that could result in light-to-severe

injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manual

The following safety symbols are used inside or on the equipment near operation locations to provide information

about safety items and operation precautions. Ensure that you clearly understand the meanings of the symbols

and take the necessary precautions BEFORE using the equipment.

This indicates an obligatory safety precaution. The obligatory operation is

This indicates a warning or caution. The contents are indicated symbolically in or

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

indicated symbolically in or near the circle.

near the triangle.

MS2650/MS2660B/C Series

Spectrum Analyzer

Operation Manual Vol. 2 (Detailed Operating Instructions)

14 March 1997 (First Edition)

7 March 2008 (10th Edition)

Copyright © 1997-2008, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The contents of this manual may be changed without prior notice.

Printed in Japan

ii

Page 3

Equipment Certificate

Anritsu Corporation certifies that this equipment was tested before

shipment using calibrated measuring instruments with direct

traceability to public testing organizations recognized by national

research laboratories, including the National Institute of Advanced

Industrial Science and Technology, and the National Institute of

Information and Communications Technology, and was found to meet the

published specifications.

Anritsu Warranty

Anritsu Corporation will repair this equipment free-of-charge if a

malfunction occurs within one year after shipment due to a manufacturing

fault, under the condition that this warranty is void when:

The fault is outside the scope of the warranty conditions described in

•

the operation manual.

The fault is due to mishandling, misuse, or unauthorized modification

•

or repair of the equipment by the customer.

The fault is due to severe usage clearly exceeding normal usage.

•

The fault is due to improper or insufficient maintenance by the

•

customer.

The fault is due to natural disaster including fire, flooding,

•

earthquake, etc.

The fault is due to use of non-specified peripheral equipment,

•

peripheral parts, consumables, etc.

The fault is due to use of a non-specified power supply or in a

•

non-specified installation location.

In addition, this warranty is valid only for the original equipment

purchaser. It is not transferable if the equipment is resold.

Anritsu Corporation shall assume no liability for injury or financial loss of

the customer due to the use of or a failure to be able to use this equipment.

Anritsu Corporation Contact

In the event that this equipment malfunctions, contact an Anritsu

Service and Sales office. Contact information can be found on the last

page of the printed version of this manual, and is available in a separate

file on the CD version.

iii

Page 4

r

r

Notes On Export Management

This product and its manuals may require an Export License/Approval by

the Government of the product's country of origin for re-export from you

country.

Before re-exporting the product or manuals, please contact us to confirm

whether they are export-controlled items or not.

When you dispose of export-controlled items, the products/manuals need

to be broken/shredded so as not to be unlawfully used for military purpose.

Disposal Procedure

The product that you have purchased contains a rechargeable battery.

The battery is recyclable. At the end of its useful life, under various

state and local laws, it may be illegal to dispose of this battery into the

municipal waste stream. Check with your local solid waste officials fo

details in your area for recycling options or proper disposal.

iv

Page 5

Front Panel Power Switch

To prevent malfunction caused by accidental touching, the front power switch of this

equipment turns on the power if it is pressed continuously for about one second in the

standby state. If the switch is pressed continuously for one second in the power-on state,

the equipment enters the standby state.

In the power-on state, if the power plug is removed from the outlet, then reinserted into it,

the power will not be turned on. Also, if the lines is disconnected due to momentary power

supply interruption or power failure, the power will not be turned on (enters the standby

state) even if the line is recovered.

This is because this equipment enters the standby state and prevents incorrect data from

being acquired when the line has to be disconnected and reconnected.

For example, if the sweep time is 1,000 seconds and data acquisition requires a long time,

momentary power supply interruption (power failure) might occur during measurement

and the line could be recovered automatically to power-on. In such a case, the equipment

may mistake incorrect data for correct data without recognizing the momentary power

supply interruption.

If this equipment enters the standby state due to momentary power supply interruption or

power failure, check the state of the measuring system and press the front power switch to

restore power to this equipment.

Further, if this equipment is built into a system and the system power has to be

disconnected then reconnected, the power for this equipment must also be restored by

pressing the front power switch.

Consequently, if this equipment is built into remote monitoring systems that use MODEMs,

the standby function of this equipment must be modified.

v

Page 6

ABOUT DETECTION MODE

This instrument is a spectrum analyzer which uses a digital storage system. The spectrum

analyzer makes level measurements in frequency steps obtained by dividing the frequency

span by the number of measurement data points (501). This method of measurement

cannot detect the signal peak level if the spectrum of a received signal is narrower than

these frequency steps.

To resolve this problem, this instrument usually operates in positive peak detection mode

and normal detection mode. In the positive peak detection mode, the highest level within

the frequency range between the sample points can be held and traced. In the normal

detection mode, both the positive peak and the negative peak can be traced.

Positive peak detection mode should be used for almost all measurements including normal

signal level measurement, pulsed noise analysis, and others. It is impossible to measure

the signal level accurately in sample detection mode or in negative peak detection mode.

Use of sample detection mode is restricted to random noise measurement, occupied

frequency bandwidth measurement for analog communication systems, and

adjacent-channel leakage power measurement, etc.

Measurement Item

• Normal signal.................................................................................................. POS PEAK

• Random noise.................................................................................................. SAMPLE

• Pulsed noise..................................................................................................... NORMAL (POSI-NEG)

• Occupied frequency bandwidth, adjacent-channel leakage power.......... SAMPLE

(for analog communication systems)

• Occupied frequency bandwidth, adjacent-channel leakage power.......... POS PEAK or SAMPLE

(for digital communication systems)

When a detection mode is specified as one of the measurement methods, make the

measurement in the specified detection mode.

vi

Page 7

ABOUT THIS MANUAL

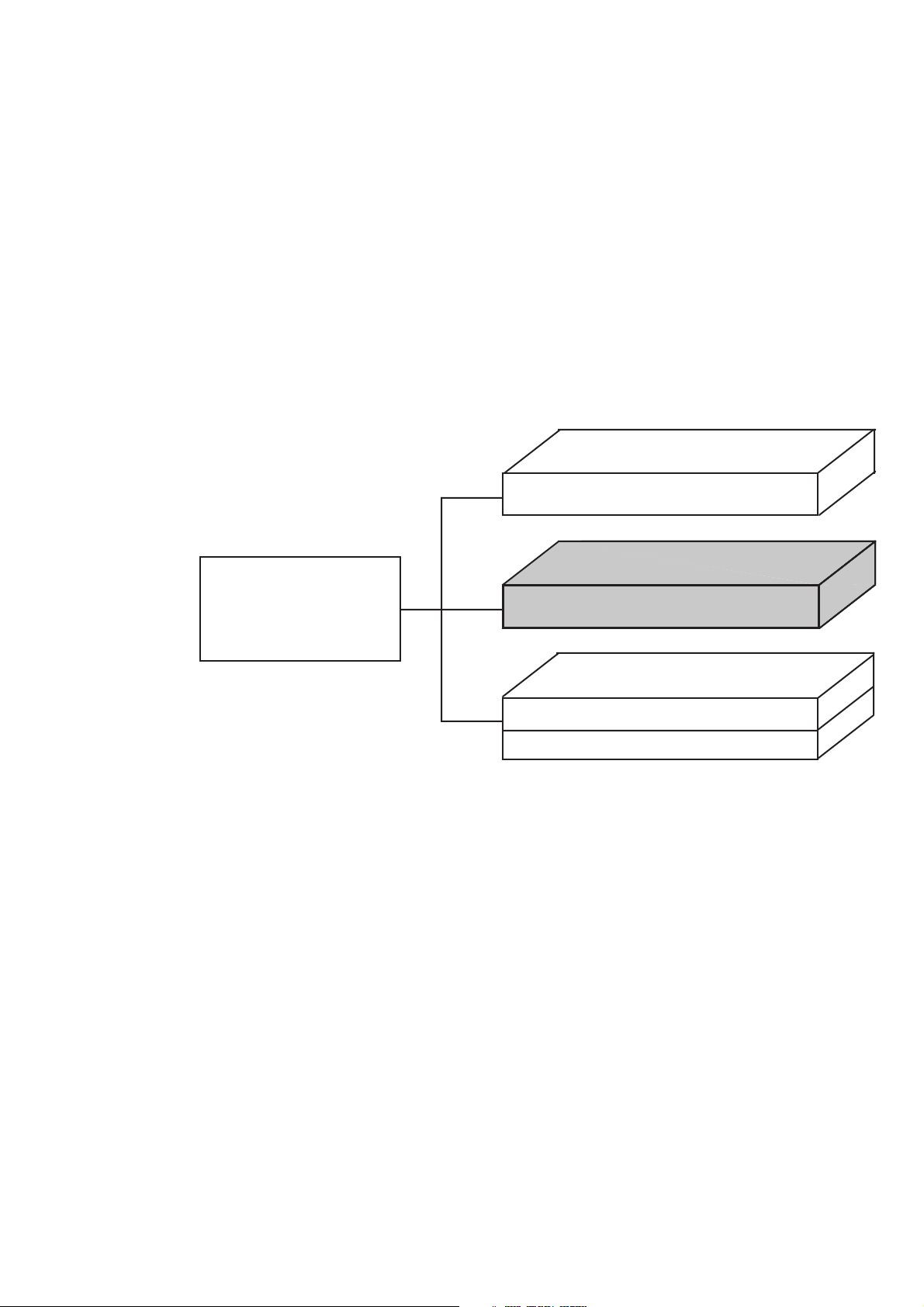

(1) Composition of MS2650/MS2660B/C series spectrum analyzer Operation Manuals

The MS2650/MS2660B/C Spectrum Analyzer operation manuals of the standard type are composed of the

following three documents. Use them properly according to the usage purpose.

Basic operating instruction part

Vol. 1

Detailed operating instruction part

Composition

of

Operation Manuals

Vol. 2

Programming part

Vol. 3

(Remote control part)

(PTA control part)

Basic operating instruction part: Basic Operating Instructions: Provides information on the MS2650/

MS2660B/C series outline, preparation before use, panel description,

basic operation, soft-key menu and performance tests.

Detailed operating instruction part: Detailed Operating Instructions: Provides information on the detailed

panel operating instructions on the spectrum analyzer that expand

on the basic operation and soft-key menu in the Basic Operating

Instruction Part.

Programming part: Composed of the Remote Control Part and PTA Control Part. The

Remote Control Part provides information on RS-232C remote

control GPIB remote control and sample programs, while the PTA

Control Part describes about PTA operation and PTL commands.

I

Page 8

TABLE OF CONTENTS

For Safety ................................................................................................................. iii

ABOUT THIS MANUAL.................................................................................................... I

SECTION 1 BASIC OPERATION PROCEDURE ........................................................ 1-1

Signal Display .............................................................................................................................. 1-3

Marker Operation ......................................................................................................................... 1-6

"Measure" Function Check .......................................................................................................... 1-8

Screen Hard Copy ........................................................................................................................ 1-9

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY .......................................... 2-1

Setting Observation Frequency .................................................................................................... 2-3

Setting Level Range ..................................................................................................................... 2-8

Offsetting Reference Level ........................................................................................................ 2-13

SECTION 3 MARKER FUNCTIONS ......................................................................... 3-1

Changing Zone Marker Position and Width ................................................................................ 3-4

Marker Mode ............................................................................................................................... 3-7

Display Line ............................................................................................................................... 3-10

Multimarker ............................................................................................................................... 3-11

Marker Search ............................................................................................................................ 3-16

Setting Parameters Using Marker Values .................................................................................. 3-22

SECTION 4 SIGNAL SEARCH FUNCTION ............................................................. 4-1

Detecting Peaks ............................................................................................................................ 4-3

Moving the Measurement Point ................................................................................................... 4-5

II

Page 9

SECTION 5 SELECTING THE DISPLAY METHOD ................................................. 5-1

Display Mode ............................................................................................................................... 5-3

Storage Mode ............................................................................................................................. 5-15

Detection Mode .......................................................................................................................... 5-22

Time Domain ............................................................................................................................. 5-26

SECTION 6 SELECTING THE SWEEP METHOD ................................................... 6-1

Sweep Mode ................................................................................................................................ 6-3

Trigger Mode ............................................................................................................................... 6-5

Zone Sweep and Signal Tracking .............................................................................................. 6-12

Time Gate Function ................................................................................................................... 6-14

Domain Sweep ........................................................................................................................... 6-22

SECTION 7 COUPLED FUNCTION ......................................................................... 7-1

From Auto to Manual Operation ................................................................................................. 7-4

SECTION 8 AUTOMATIC CALIBRATION AND

LEVEL CORRECTION FUNCTIONS .................................................... 8-1

Automatic Calibration Function CAL ........................................................................................ 8-3

Preselector tuning ........................................................................................................................ 8-6

Measurement System Level Correction ....................................................................................... 8-8

SECTION 9 SYSTEM SETTING AND PRESET FUNCTION ................................... 9-1

Coupled Function Common/Independent Setting Mode ............................................................. 9-4

SECTION 10 SAVE/RECALL FUNCTION ................................................................ 10-1

Internal Register ......................................................................................................................... 10-4

Memory Card File Management .............................................................................................. 10-11

SECTION 11 COPY/SOUND MONITOR/TV IMAGE MONITOR .............................. 11-1

Direct Plotting ............................................................................................................................ 11-3

Saving Screen Image Data to Memory Card ............................................................................. 11-9

III

Page 10

Displaying a Title ..................................................................................................................... 11-11

SOUND Monitor ...................................................................................................................... 11-12

TV Image Monitor ................................................................................................................... 11-14

SECTION 12 PTA/DEFINE FUNCTIONS ................................................................. 12-1

PTA Program Editing and Loading ........................................................................................... 12-3

User-Definition Function ........................................................................................................... 12-6

SECTION 13 MEASUREMENT ................................................................................ 13-1

Measure Measurement Function ................................................................................................ 13-3

Measurement Examples ............................................................................................................. 13-8

SECTION 14 TRACKING GENERATOR .................................................................. 14-1

Tracking Generator Menus ........................................................................................................ 14-3

Normalize/Instant-Normalize Functions .................................................................................... 14-4

Transmission Characteristics Measurement .............................................................................. 14-6

Reflection Characteristics Measurement ................................................................................. 14-13

Notes on Active Device Measurement .................................................................................... 14-17

SECTION 15 EMC, Measurement of Field Strength ................................................. 15-1

Menu of EMC ............................................................................................................................ 15-3

Field Strength Measurement ...................................................................................................... 15-4

User Antenna Factor Setting, Save/Load to /from a Memory Card .......................................... 15-7

Caution: When Performing Field Strength Automatic Measurement ..................................... 15-13

EMC Measurement .................................................................................................................. 15-15

APPENDIX A SOFT-KEY MENU ............................................................................... A-1

Soft-key Menu List ..................................................................................................................... A-4

Menu Tree ................................................................................................................................... A-6

APPENDIX B KEYWORDS INDEX........................................................................... B-1

IV

.

Page 11

SECTION 1 BASIC OPERATION PROCEDURE

SECTION 1

BASIC OPERATION PROCEDURE

TABLE OF CONTENTS

Signal Display

Turn the power on

Execute automatic calibration

Set the signal to the center of the screen

Enlarge and display the signal

Marker Operation

Check of the zone marker function

The "marker → CF" function check

"Measure" Function Check

Screen Hard Copy

.....................................................................................................................................

.......................................................................................................................

................................................................................................................................

..................................................................................................................

...............................................................................................................................

.....................................................................................................

...................................................................................

....................................................................................................

1-3

1-3

1-4

1-4

1-5

1-6

1-8

1-9

1-1

Page 12

SECTION 1 BASIC OPERATION PROCEDURE

1-2

Page 13

SECTION 1 BASIC OPERATION PROCEDURE

SECTION 1

BASIC OPERATION PROCEDURE

The basic operation procedure of this equipment is

explained here. The operations are listed on the right.

Also, the explanation will advance assuming that a

500 MHz signal is applied to the input connector.

Please read this manual while operating this

equipment.

( : Panel key, : Soft key)

<Actual operations>

Signal Display

Turn the power on

Press the standby button on the rear panel, then

press the power switch (0) on the front panel. In

this case, continue pressing the power switch for

one second or more.

(I) Signal display

1) Turn the power on,

2) execute automatic calibration,

3) set the signal to the center of the screen, and

4) enlarge and display the signal.

(II) Marker operation

Check of the zone marker function.

The "marker → CF" function check.

(III) "Measure" function check

(IV) Screen hard copy

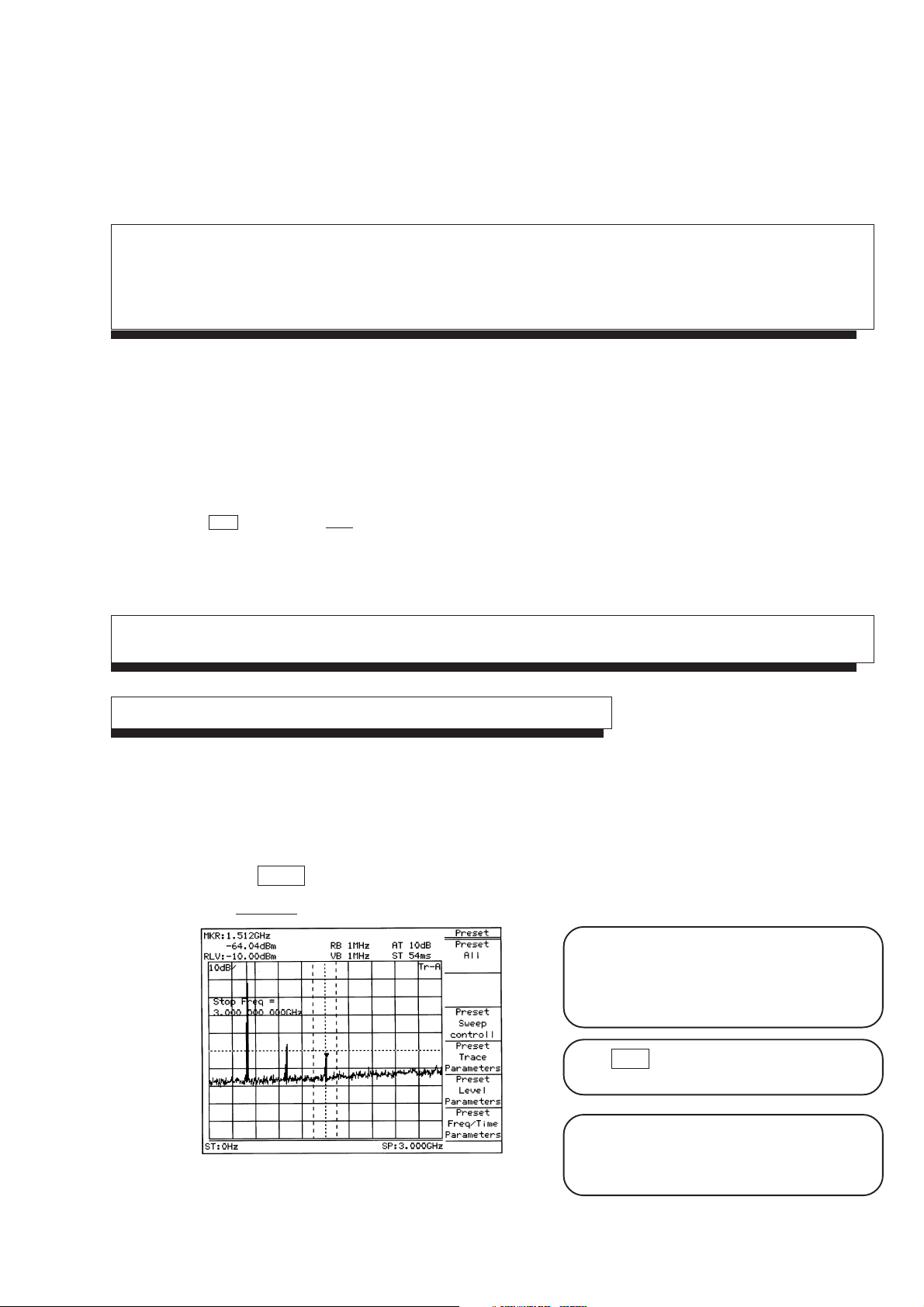

Press Preset key.

Press Preset All key in the menu.

Fig. 1-1

The power is turned on/off only when the power

switch is pressed for one second or more. This

prevents the power from being turned on/off easily

by mistake.

When panel key (hard key) is pressed, the related

soft key menu is displayed.

Partial resettings are enabled. This resetting

includes only the display-related resetting or the

resetting of special modes such as zone sweep.

1-3

Page 14

SECTION 1 BASIC OPERATION PROCEDURE

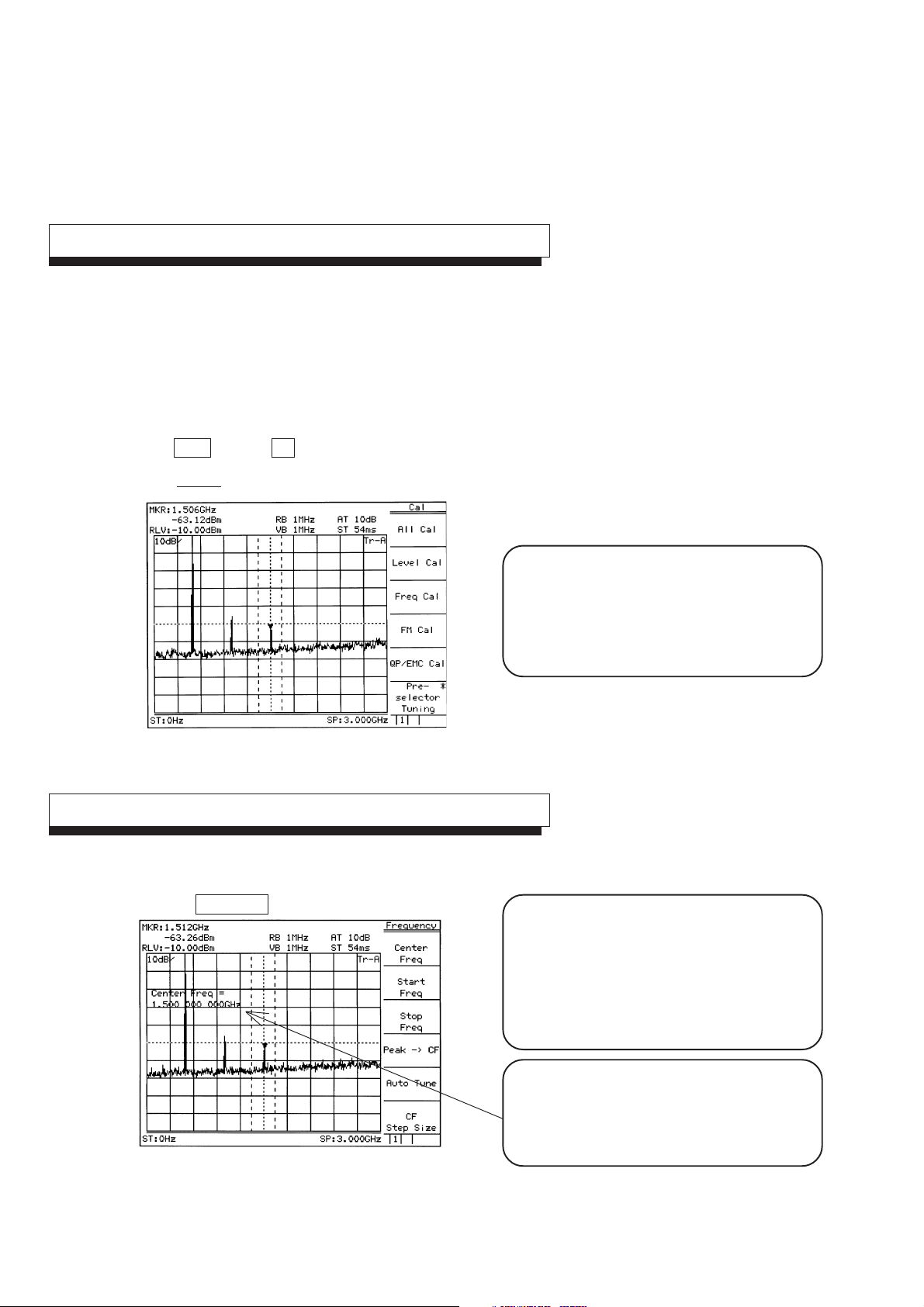

Execute automatic calibration

Wait after switching on the power supply of the

machine (warm up period) till the internal temperature

becomes stable. This period is approximately 10

minutes.

After warm up, execute automatic calibration.

CAL

Press Shift key then 0 key.

Select All Cal from the menu displayed on the display.

Fig. 1-2

Set the signal to the center of the screen

Automatic Calibration is carried out by using an

internal source without need for any external cable

connection.

See "Detailed Operation Instructions" for detail

information about contents of calibration.

1-4

Press Frequency key.

Fig. 1-3

When pressing Frequency, Span, Amplitude or

Coupled Function key(s) which is used frequently,

Center Frequency, Span, Reference Level, RBW

or VBW function is selected and numeric value

for the function can be entered into Entry area.

This reduces key operation times.

This display section is called Entry area. Selecting

the menu displays the current set value of the

parameter. The set value can be changed by

entering data in Entry area.

Page 15

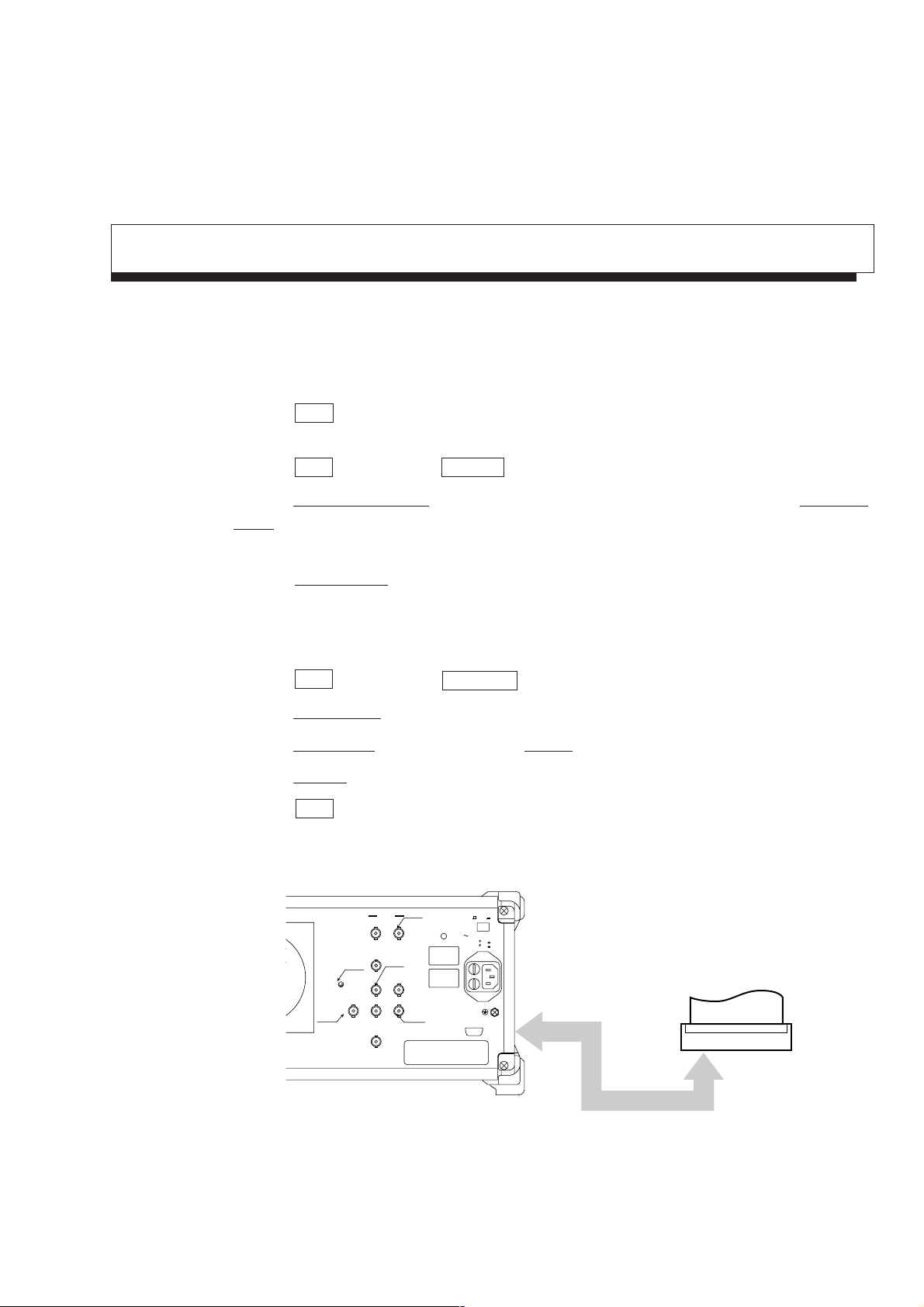

Press Menu On/Off key

Fig. 1-4

Press Menu On/Off key to return to previous screen.

Use the ten-key pad (numeric keys) to enter 500 MHz.

SECTION 1 BASIC OPERATION PROCEDURE

The display of the soft key menu can be switched

on/off using Menu On/Off key. When the menu

disappears, the scale is enlarged. Also, when the

menu is displayed, the scale is reduced.

Fig. 1-5

Enlarge and display the signal

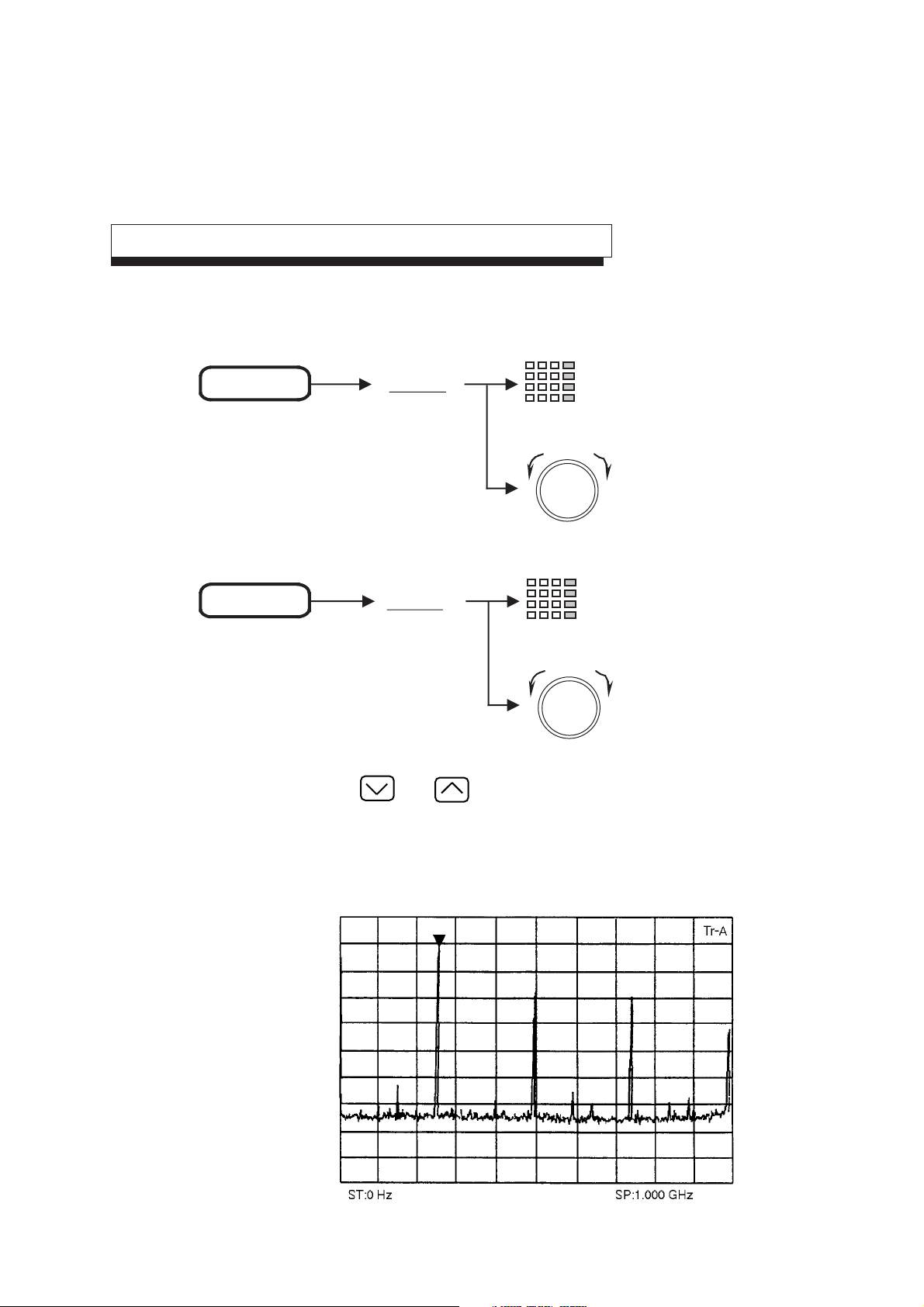

Press Span key , then press the V down key several times to enlarge the signal display.

The following three methods to input numeric

values to parameters are provided: direct input by

the ten-key pad (numeric keys), up/down keys,

and rotary knob.

Fig. 1-6

1-5

Page 16

SECTION 1 BASIC OPERATION PROCEDURE

Marker Operation

Here, checks that the signal frequency and level are displayed in a marker display area. The zone marker

automatically fetches the highest level signal within the zone and displays the frequency and level.

Fig. 1-7

To check Marker→ CF function, shift the signal from the center intentionally.

Press Frequency key and More key in order, and then Scroll → key two times.

The soft key menu marked by an asterisk on the

upper right indicates that the menu can further be

opened by pressing the key. Adversely, the soft

key menu not marked indicates that the menu

cannot be opened any more, so to speak, the end

of menu opening.

The following items can easily be checked by the

soft key menu tab: How many pages of the soft

key menu being displayed currently are there?,

Fig. 1-8

and what page is displayed now?

To turn over the page, press More key.

1-6

Page 17

Press Peak Search key.

Fig. 1-9

The marker fetches the signal.

Press More to open 2nd page, and press Marker →

key.

SECTION 1 BASIC OPERATION PROCEDURE

*Advanced operation memo: It is convenient that

the page can also be turned over by repeatedly

pressing the panel key. This method is used when

key (s), such as Measure key, has a number of

pages. Besides, the Freq/Ampl and Marker-related

keys do not turn over the page by repeatedly

pressing the panel key. For these keys, because

the first page is important specially, it should always

be displayed when the panel key is pressed.

When the soft key menu is pressed, a menu of

function related to the menu is further displayed.

In this case, as shown in the figure on the left, the

thick line (the line on the preceding page) is

displayed at the left of the soft key menu. This

indicates that a new menu is overlapped with the

preceding page.

Fig. 1-10

Press marker → CF key.

The page opened by pressing the soft key can

return to the preceding page by the Return key.

Besides, it can be checked that which soft key

menu was pressed previously to open the current

menu, as the menu title is displayed on the upper

row of the soft key.

Fig. 1-11

Here, return to the screen of Fig. 1-8 and ensure that the screen changes to that of Fig. 1-11 only by pressing

the → CF key.

1-7

Page 18

SECTION 1 BASIC OPERATION PROCEDURE

"Measure" Function Check

Press Preset key and Preset All key in order.

Press Peak Search key.

If the zero beat signal level (local feed through) is larger than the signal level and the marker fetches the zero

beat level, press "Next peak" key and put the marker on the signal.

Fig. 1-12

Press the Measure key and Frequency Count key to set the function of high accuracy frequency measurement

of the marker points.

Then, press the Count On key and start measurement.

Fig. 1-13

The frequency of marker points is displayed at the top left of the screen.

Incidentally, the internal counter correctly operates even at the full span condition, so an operation to reduce

frequency span otherwise required is not necessary in this model.

The soft-key menu display can be switched On/

Off by the Menu On/Off key.

However, keys that condition setting is not

possible unless a menu is On unconditionally

make the soft-key menu display On when pressing

a panel key.

From the screen after executing measurement, press

another panel key and change parameters, and then,

pressing again the Measure key will automatically

return to the menu of this screen and not to page 1

of the menu (page learning function).

It is a useful function when repeating measurement.

1-8

Page 19

Screen Hard Copy

The screen can be hard-copied with the VP-600 printer (Epson) via an RS232C interface, and the procedures

are described below:

1) As illustrated below, connect the RS-232C connector and printer with an attached RS-232C cable.

2) Press the Copy key, and the currently displayed screen is hard-copied.

If the printed copy is improper, check if the RS-232C interface is correctly set in the following sequence.

3) Press the Shift key and then the Interface key.

4) Press the Connect to Controller key several times to get None on the display, and press the Connect to

Prt/Plt key several times and get RS-232C on the display.

Now the printer can be operated with RS-232C.

5) Press the RS232C Setup key and set so that (or check if) the setting of RS-232C interface is the same

between the main body and printer.

(For the setting/checking of the RS-232C interface on the printer side, refer to the instruction manual of

the printer.)

SECTION 1 BASIC OPERATION PROCEDURE

6) Press the Shift key and then the Copy Cont key.

7) Press the Printer/Plotter key and select Printer.

8) Press the Printer Setup key, and then press the VP-600 key.

9) Press the Magnify key several times and make the display 1×1.

10) Press the Copy key, and the currently displayed screen is hard-copied.

Rear panel

OPT01

OPT15

Phone

IF Out(455kHz/10.695MHz)

OPT07

Composite Out

10MHz STD

Ref In Buff Out

0dBm > 2Vp-p

OPT06

Trig/Gate In

(± 10V)

Sweep Status(Z)Video(Y)Sweep(X)

7.5Ω

Buff Out

OPT15

TTL0-0.5V0-10V

Freq Adj.

WARNING

CAUTION

Line Input 320VA Max

50/60/400Hz

100−120V 5A

200−240V 5A

RS−232C

Off

On

RS-232C cable

Printer

Fig. 1-14

1-9

Page 20

SECTION 1 BASIC OPERATION PROCEDURE

1-10

.

Page 21

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

SECTION 2

FREQUENCY/AMPLITUDE DATA ENTRY

This section describes the data entry function related to frequency and amplitude in the Freq/Ampl section on the front panel.

TABLE OF CONTENTS

Setting Observation Frequency

Center-Span Mode

Start-Stop Mode

Setting Step Size with Step Keys

Setting Frequency Scroll Step Size

Fixing the frequency bands

Setting Full Scan

Setting Zero Span

Setting Level Range

Setting Log/Linear Scale

Selecting Reference Level Units

Setting Reference Level

Setting Reference Level Step Size

Offsetting Reference Level

Setting Attenuator

Preamp Setting

Setting 50 Ω→75 Ω Impedance Transformer

Setting Level Frequency Correction Coefficient

......................................................................................................................

..........................................................................................................................

.........................................................................................................................

.......................................................................................................................

............................................................................................................................

.......................................................................................................................

...........................................................................................................................

...........................................................................................................

................................................................................................

.........................................................................................................

.............................................................................................................

.................................................................................................

..............................................................................................................

..................................................................................................................

............................................................................................

.............................................................................................

.............................................................................

..........................................................................

2-3

2-4

2-5

2-6

2-6

2-7

2-8

2-8

2-9

2-10

2-11

2-12

2-13

2-14

2-16

2-16

2-16

2-17

2-1

Page 22

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

2-2

Page 23

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Trig/Gate

MS2661B

Spectrum Analyzer

9kHz–3GHz

RF Input 50Ω

+30dBm

±50V DC Max

+30dBm(PRE AMP On)

Local

Remote

Stby

On

Preset

Multi Mkr

Marker

Frequency

Span

Amplitude

Continuous

Single

Save

Recall

Measure

TG

A/B,A/BG

A,B

A/Time

Time

TV Monitor

CF RLV

Peak

Search

User

Marker

TG Output 50Ω

9kHz–3GHz

RVS PWR

+20dBm

0V DC Max

EntryMarkerFreq/Ampl

dBm

dB

V

sec

mV

msec

µV

µsec

0

Cal

.

– / +

BS

CE

8 9 GHz7

PTA

EMC

HoldDefine

.

Hz

EnterInterface Mem Card

2 3 kHz1

Sound System Title

5 6 MHz4

Copy

Copy Cont

Shift

Peak

Menu On/Off

More

F 1

F 2

F 3

F 4

F 5

F 6

RBW VBW Sweep Time Atten

Display

Coupled Finction

Memory Card

SECTION 2

FREQUENCY/AMPLITUDE DATA ENTRY

Setting Observation Frequency

The observation frequency of the spectrum analyzer is set in the following two modes:

• Center-Span

• Start-Stop

The frequency setting upper and lower limits are For the MS2651B/2661B/2661C, 0 to 3 GHz

For the MS2653B/2663B/2663C, 0 to 8.1 GHz, respectively.

The Frequency key is used as the header key for setting the frequency, and the Span key is used

as the header key for setting the frequency span.

Frequency

Span

2-3

Page 24

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Center-Span Mode

(1) Setting center frequency

Frequency

(2) Setting frequency span

Span

TEN

KEY

TEN

KEY

Key

キー

キー

(1/2/5 sequence)

Key

(Use the CF Step Size key to set the step

size.)

2-4

Note: When frequency span is 200 kHz or less, warming up might be necessary until the observation

frequency becomes stable after turning on the power.

When "Warm Up" message is being indicated at the top right corner of the indicator, please wait

for approximately 3 minutes, and start the measurements after the message disappears.

Page 25

Start-Stop Mode

(1) Start frequency

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Frequency

(2) Stop frequency

Frequency

Notes: • Because the and keys are the step keys for the center frequency, the start and stop

Start Freq

Stop Freq

TEN

KEY

TEN

KEY

frequencies are also changed.

• The stop frequency may also vary depending on the values of the frequency span setting resolution

and start frequency.

2-5

Page 26

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Setting Step Size with Step Keys

To use the keys to change the step size of the center frequency, register the step size as follows:

Frequency CF Step Size

Setting Frequency Scroll Step Size

Frequency

Scroll Step Size

Copy Cont

Stby

Spectrum Analyzer

MS2661B

Preset

Remote

Local

Copy

On

9kHz–3GHz

Memory Card

TEN

KEY

Menu On/Off

TG Output 50Ω

9kHz–3GHz

F 1

F 2

F 3

F 4

F 5

F 6

More

Frequency

Span

Amplitude

Peak

CF RLV

Save

Recall

Measure

Display

A/B,A/BG

A/Time

A,B

Time

Coupled Finction

RBW VBW Sweep Time Atten

RVS PWR

+20dBm

0V DC Max

1 div

2 div

EntryMarkerFreq/Ampl

PTA

8 9 GHz7

EMC

5 6 MHz4

Sound System Title

2 3 kHz1

Cal

0

.

.

CE

BS

HoldDefine

EnterInterface Mem Card

– / +

Hz

RF Input 50Ω

+30dBm

±50V DC Max

+30dBm(PRE AMP On)

Shift

dBm

dB

V

sec

mV

msec

µV

µsec

Multi Mkr

Marker

Marker

Peak

Search

Continuous

Single

TV Monitor

Trig/Gate

User

TG

Select a step size. The selected

scroll step size is highlighted.

5 div

10 div

2-6

2 div

Tr-A

return

Span

Return to the top menu.

Scroll→

The waveform scrolls 2 divs to the right.

Span

←Scroll

The waveform scrolls 2 divs to the left.

Page 27

Fixing the frequency bands

This function is an MS2653B/2663B/2663C dedicated function. It cannot be used in the MS2651B/2661B/

2661C.

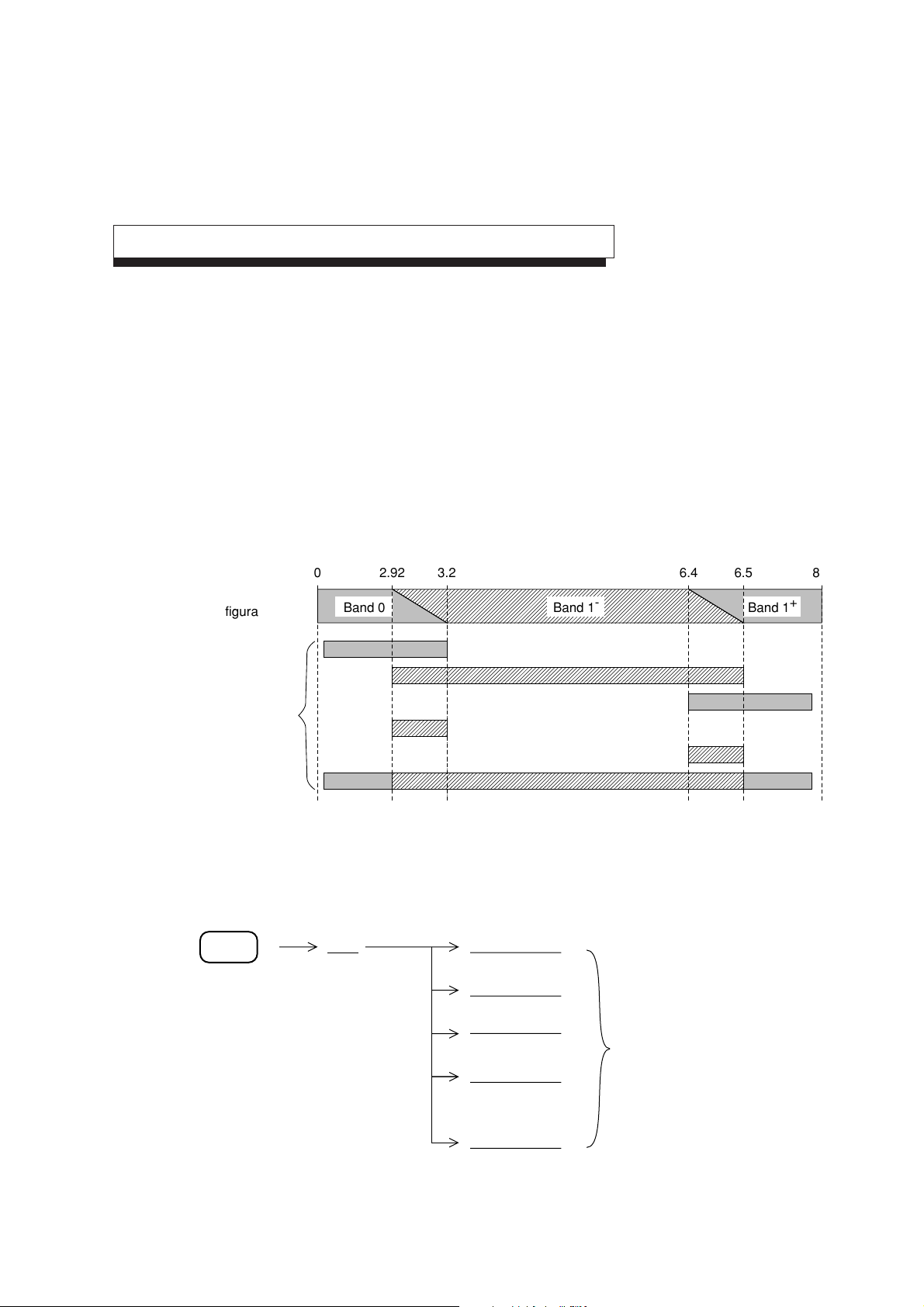

In the MS2653B/2663B/2663C, the 0 to 8.1 GHz frequency range consists of the following three bands:

• Band 0 .................. .0 to 3.2 GHz

• Band 1-................ 2.92 to 6.5 GHz

• Band 1+............... 6.4 to 8.1 GHz

In the initial state, the Auto Band mode that is operated by selecting the optional frequency band is selected

according to the range of frequencies to be observed.

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Frequency band

configuration

Frequency range

to be observed

0 2.92 3.2 6.4 6.5 8.1

Band 0 Band 1

Band 1

(GHz)

+

Selection of frequency bands according to range of frequencies to be observed in Auto Band mode

Perform the following to set the frequency bands, for example, when the frequency bands are switched:

Span

Band

Auto Band

Manual Band 0

Manual Band 1

Manual Band 1

-

Select any of these buttons.

+

return

2-7

Page 28

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Setting Full Scan

In the normal operating state, pressing

analyzer to be swept over the full span. However, this setting also initializes the parameters except the frequency

range.

To set the full span and leave the other parameters unchanged, perform the following key operations.

Span

For the MS2651B/2661B/2661C, 0 to 3 GHz

For the MS2653B/2663B/2663C Auto band, 0 to 8.1 GHz

For Band 0, 0 to 3.2 GHz

For Band 1-, 2.92 to 6.5 GHz

For Band 1+, 6.4 to 8.1 GHz

Setting Zero Span

The Spectrum Analyzer can operate as a selective level meter in which the horizontal axis is graduated as a

time axis by setting the frequency span to 0 Hz. The rising and falling edges of burst waves can also be

observed and measured.

Preset

the key allows the entire frequency range of the spectrum

Full Span

2-8

Performing any of the following key operations allows the spectrum analyzer to operate in the zero panel (time

domain) mode.

Hz

Time

Span

Span

0

Zero Span

•

•

•

For further details on the zero span (time domain) mode, see SECTION 5, "SELECTING THE DISPLAY

METHOD."

In the frequency and time domains, the RBW, VBW, Sweep time and other coupling functions time can be set

to different values. For further details, see SECTION 9, "SYSTEM SETTING AND PRESET FUNCTION."

Page 29

Setting Level Range

The table below shows the types of level display modes and the ranges of the reference level (top graticule of

the amplitude scale) for the different modes. When a preamp (Option) is used, the entire reference level range

is shifted 20 dB.

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

50 Ω (standard) 75 Ω (with Opt.22)

MS2651B/2661B/2661C only

Reference Level rangeUnitsDisplay mode

–100 to +25 dBm

+8.8 to +133.8 dBµV

–51.2 to 73.8 dBmV

2.74 µV to 4.87 V

+14.8 to +139.8 dBµV

100 fW to 316 mW

– – – – – –

274 µV to 4.87 V

Log scale

Linear scale

dBm

dBµV

dBmV

V

dBµV (emf)

W

dBµV/m

V

–100 to +30 dBm

+7 to +137 dBµV

–53 to 77 dBmV

2.24 µV to 7.07 V

+13 to +143 dBµV

100 fW to 1.0 W

– – – – – –

224 µV to 7.07 V

dBm: dBm unit system where 1 mW/50 Ω or 75 Ω is defined as 0 dBm.

dBµV: dBµV unit system where 1µV is defined as 0 dBµV, and the terminal voltage display is

terminated into 50 Ω or 75 Ω.

dBmV: dBmV unit system where 1 mV is defined as 0 dBmV, and the terminal voltage display is

terminated into 50 Ω or 75 Ω.

dBµV (emf): dBµV (emf) unit system based on the open-voltage display, and dBµV +6 dB is fed as the

output value.

The Amplitude key is used as the header key for setting the amplitude level.

Amplitude

Preset

Remote

Local

Copy Cont

Copy

Stby

Spectrum Analyzer

MS2661B

9kHz–3GHz

On

Memory Card

Menu On/Off

TG Output 50Ω

9kHz–3GHz

F 1

F 2

F 3

F 4

F 5

F 6

More

Frequency

Span

Amplitude

Peak

CF RLV

Save

Recall

Measure

Display

A/B,A/BG

A/Time

A,B

Time

Coupled Finction

RBW VBW Sweep Time Atten

RVS PWR

+20dBm

0V DC Max

Multi Mkr

Marker

Marker

Peak

Search

Continuous

Single

TV Monitor

Trig/Gate

User

TG

PTA

8 9 GHz7

EMC

5 6 MHz4

Sound System Title

2 3 kHz1

Cal

0

.

.

EntryMarkerFreq/Ampl

CE

BS

HoldDefine

EnterInterface Mem Card

– / +

Hz

RF Input 50Ω

+30dBm

±50V DC Max

+30dBm(PRE AMP On)

Shift

dBm

dB

V

sec

mV

msec

µV

µsec

2-9

Page 30

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Setting Log/Linear Scale

To set the amplitude scale to log scale or linear scale, perform the following key operations.

(1) Setting log scale

Amplitude

(2) Setting linear scale

Amplitude

Log Scale 10 dB/div

The log scale is set when

this key is pressed.

Linear Scale 10%/div

The linear scale is set when

this key is pressed.

← Select one of the scales.

5 dB/div

2 dB/div

1 dB/div

Return

← Select one of the scales.

5%/div

2%/div

1%/div

Return

2-10

The reference level remains constant, independent of switching between log and linear scales.

When the reference level is set to less than –60 dBm in the log scale mode, the reference level of the linear

scale is switched to 224 µV/50 Ω or 274 µV/75 Ω.

Page 31

Selecting Reference Level Units

In the log scale mode, the spectrum analyzer provides six types of reference level units: dBm, dBµV, dBmV,

V, dBµV (emf), dBµV/m, and W. To select one of the reference level units, perform the following key

operations.

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Amplitude

Because the reference level unit used for the linear scale is only V, there is nothing to select.

Selecting Input Impedance

This function is an standard: 50 Ω model dedicated function.

The input impedance of the spectrum analyzer is 50 Ω. Measurement with 75 Ω can be enabled by using 50

Ω→75 Ω Impedance Transformer. In this case, measured value is level converted.

When the input impedance is set to 75 Ω as shown in the figure below; measured value is level converted, and

displayed according to the level unit of the dBµV/dBmV/dBµV (emf)/V.

Unit dBm

dBuV

dBmV

dBuV (emf)

Input Impedance

Return

1

# To turn the page, press the More key.

dBuV/m

V

W

Return

2

#

← Select one of the units.

Amplitude

Unit 50 ohm

Input

Impedance

75 ohm

return

When the input impedance is set to 75 Ω, "75 ohm" is displayed at the top right of the waveform.

Select input

impedance.

2-11

Page 32

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

When the MA1621A is used as the 50 Ω→75 Ω Impedance Transformer, the insertion-loss frequency

characteristics of the MA1621A must be compensated. The spectrum analyzer has the level-compensation

function. (See p.2-16 "Setting 50 Ω→75 Ω Impedance Transformer (MA1621A)".)

Setting Reference Level

Select the reference level (top graticule of the amplitude scale) by performing the following key operations.

Amplitude

TEN

KEY

Key

キー

ステップサイズは、ログスケールの場合

When the log scale is selected, the value

はRefLevelStepSizeで指定した値、

set by Reference Level Step Size is used

as the step size. When the linear scale is

リニアスケールの場合は1div固定となり

selected, the step size is fixed at 1 division.

ます。

Use the unit key as follows, according to the set reference level unit.

dBm units

dBµV units

dBmV units

dBµV (emf) units

GHz

dBm

dB

2-12

V units

W units

dBµV/V units

MHz

kHz

Enter

Hz

(For W units, read V as W.)

V

sec

mV

msec

µV

µsec

Page 33

Setting Reference Level Step Size

To change the reference level with the keys, set the step size by performing the following key

operations.

(1) Log scale

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

(2) Linear scale

Fixed at 1 division.

Amplitude

Ref Level

Step Size *

Manually enter the step size in dB units from the ten keys.

1 Div

2 Div

5 Div

10 Div

Manual

Return

← Select one.

2-13

Page 34

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Offsetting Reference Level

The reference level and waveform trace can be displayed by adding a given offset.

2-14

The # is displayed to the right of the reference level display above the scale.

Page 35

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Turn the offset display On/Off and set its offset value by performing the following key operations.

Amplitude

Ref Level

Offset *

Ref Level Select reference level offset On or Off.

Offset

On Off

Ref Level

Offset

–10.05 dB

Return

Set the offset value (dB) with the ten keys, up-down

keys, or rotary knob.

The offset value setting range is from –100 to +100 dB. The offset value resolution is 0.01 dB.

The offset can be applied to each trace (A, B, BG, Time), but it cannot be applied when monitoring FM

demodulated waveforms and when using A–B→A function.

2-15

Page 36

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Setting Attenuator

Press the Amplitude key, then press the Attenuator key.

Select manual setting or automatic setting.

For manual setting, enter the attenuator setting in dB units from the ten keys.

Preamp Setting

This function is an MS2651B/2661B/2661C dedicated function.

Press the Amplitude key, then press the Pre Ampl key.

Press the Pre Ampl On/Off key. The 20 dB preamp (Option) is turned On and Off. The preamp gain-frequency

curve is also compensated.

Setting 50 Ω→75 Ω Impedance Transformer

This function is an standard: 50 Ω model dedicated function.

When the optional MA1621A (75Ω→50Ω) impedance transformer is installed to the RF input attenuator (see

the figure below), set the input impedance to 75 Ω.

Press the Amplitude key, then press the Input Transformer key.

Set the MA1621A to On with the On Off key.

When the input impedance is set to On; it is assumed that a 25Ω resistor is connected in series with the input,

the level is converted for 75Ω, the insertion-loss frequency characteristic is corrected, and then the measured

result is displayed.

MA1621A MS2650/60 SPA

75 Ω

25 Ω

50 Ω

2-16

Page 37

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

Setting Level Frequency Correction Coefficient

This function corrects the level-frequency characteristics of the cables and pads (connected to the front end of

the RF Input connector) so that the level becomes flat. Correction tables are written via the RS-232C or GPIB

interface.

Amplitude

Correction *

Correctionb Select correction On or Off by pressing this key.

On Off

Select Corr *

Setup Corr *

Return

Load Corr Set

Display

Directory

/Next

Dir Disp

Detail

Outline

Select the correction table from among the five correction

tables (Corr-1 to 5).

Load the five correction tables from the memory card.

Display the directory on the screen.

When the entire directory cannot be displayed at one time,

display the remaining directory by holding down the key.

Select detailed/outline display by pressing this key.

For further details, see SECTION 8.

Save Corr Set

Load/Save

Media *

Return

Save the five correction tables to the memory card.

Select if memory card 1 or memory card 2 is to be loaded

and saved to the media.

2-17

Page 38

SECTION 2 FREQUENCY/AMPLITUDE DATA ENTRY

2-18

.

Page 39

SECTION 3 MARKER FUNCTIONS

SECTION 3

MARKER FUNCTIONS

This section describes the marker functions for improving the measurement efficiency, such as the zone marker, marker

mode menu, marker search, and the parameters set by marker value.

For a description of marker tracking and zone sweep setting, see SECTION 6 SELECTING THE SWEEP METHOD.

TABLE OF CONTENTS

Changing Zone Marker Position and Width

Changing Zone Marker Width

Changing Zone Marker Position

Marker Mode

Normal Marker

Delta Marker

Marker Off

Switching Marker Search Mode

Display Line

Setting Display Line

Multimarker

Highest 10 Multimarker

Harmonics Multimarker

Marker List

Manual Set

Multimarker Off

.......................................................................................................................................

............................................................................................................................

...............................................................................................................................

...................................................................................................................................

.........................................................................................................................................

.........................................................................................................................................

..................................................................................................................................

..................................................................................................................................

...........................................................................................................................

....................................................................................................................

.....................................................................................................

.................................................................................................

..................................................................................................

...............................................................................................................

...............................................................................................................

........................................................................................

3-4

3-4

3-6

3-7

3-7

3-8

3-9

3-9

3-10

3-10

3-11

3-11

3-12

3-12

3-13

3-14

Marker Search

Peak Search

Next Peak Search

Next Right Peak Search/Next Left Peak Search

Dip Search

.....................................................................................................................................

...............................................................................................................................

.......................................................................................................................

..................................................................................................................................

.........................................................................

3-15

3-15

3-16

3-17

3-18

3-1

Page 40

SECTION 3 MARKER FUNCTIONS

Next Dip Search

Setting Search Resolution

Setting Search Threshold

Setting Parameters Using Marker Values

Mkr → CF/Mkr → RLV

Mkr → CF Step Size

Delta Mkr → Span

Zone → Span

..........................................................................................................................

..........................................................................................................

...........................................................................................................

................................................................................................................

...................................................................................................................

.......................................................................................................................

..............................................................................................................................

...........................................................................................

3-19

3-19

3-20

3-21

3-22

3-23

3-24

3-25

3-2

Page 41

SECTION 3

MARKER FUNCTIONS

The keys inner section are used as the header keys for setting the marker functions.

SECTION 3 MARKER FUNCTIONS

Marker

Multi Mkr

Marker

Marker

Peak

Search

Preset

Remote

Local

Copy Cont

Copy

Stby

Spectrum Analyzer

MS2661B

9kHz–3GHz

On

Memory Card

Menu On/Off

F 1

F 2

F 3

F 4

F 5

F 6

More

TG Output 50Ω

9kHz–3GHz

Frequency

Span

Amplitude

Peak

CF RLV

Save

Recall

Measure

Display

A/B,A/BG

A/Time

A,B

Time

Coupled Finction

RBW VBW Sweep Time Atten

RVS PWR

+20dBm

0V DC Max

Multi Mkr

Marker

Marker

Peak

Search

User

Continuous

Single

TV Monitor

Trig/Gate

TG

PTA

8 9 GHz7

EMC

5 6 MHz4

Sound System Title

2 3 kHz1

Cal

0

.

.

EntryMarkerFreq/Ampl

CE

BS

HoldDefine

EnterInterface Mem Card

– / +

Hz

RF Input 50Ω

+30dBm

±50V DC Max

+30dBm(PRE AMP On)

Shift

dBm

dB

V

sec

mV

msec

µV

µsec

3-3

Page 42

SECTION 3 MARKER FUNCTIONS

Changing Zone Marker Position and Width

The part enclosed in dotted lines in the center of the screen shown in the figure below is called the zone marker.

The current marker within this zone marker normally moves to the maximum level.

The frequency (or time for time domain mode) and level at the current marker point (intensified point) are

displayed at the top left-hand corner of the screen.

Changing Zone Marker Width

The zone marker width is initially set to 1 division, but can be changed from 1 point to 10 divisions by

performing the following key operations.

Marker

The zone marker width can be arbitrarily set from 1 point to 10 divisions by rotary knob.

The zone marker width can be arbitrarily set from 1 point to 10 divisions by the corresponding frequency input

from the ten keys.

3-4

Zone Width *

Spot

1 Div

2 Div

5 Div

10 Div

return

Select one. The selected zone

width is highlighted.

Page 43

SECTION 3 MARKER FUNCTIONS

When the zone marker width is set to 1 point (Spot), the zone marker becomes a vertical line. This is called a

spot marker. Since the marker center frequency and the current marker frequency coincide, the level at the

desired frequency can be measured.

If the zone marker is set to 10 divisions when the zone center frequency is at the center of the frequency axis on

the screen, the current marker will always move to the maximum peak level over the entire range of the

observation frequency.

Since the zone width in the time domain mode always becomes 1 (Spot), it cannot be changed.

3-5

Page 44

SECTION 3 MARKER FUNCTIONS

Changing Zone Marker Position

The center frequency (time) of the zone marker is initially centered on the frequency (time) axis on the screen.

By performing the following key operations, the zone marker can be moved from the left end to the right end

of the frequency axis (time) on the screen.

Marker

TEN

KEY

(Use the ten keys to set the zone marker

position as frequency or time.)

(Use the up-down keys to move the zone

Key

キー

ステップサイズは、ログスケールの場合

marker position in 1 division steps.)

はRefLevelStepSizeで指定した値、

リニアスケールの場合は1div固定となり

ます。

In the delta marker mode, setting the zone marker center frequency (time) with the ten keys results in entry of

the delta marker value (difference between reference marker and current marker).

3-6

Page 45

Marker Mode

Three types of markers can be used with the spectrum analyzer: normal marker, delta marker, and multimarker.

Normal Marker

A single marker is indicated by ▼ at the maximum level within the zone marker. The frequency and level at

that point are displayed digitally.

The normal marker is initially set to ON. When the current state is another marker mode, or when the normal

marker is set to OFF, perform the following key operations to set the normal marker to ON.

SECTION 3 MARKER FUNCTIONS

Marker

MRK : 1.023 GHz

Normal Marker

–32.6 dBm

Current marker

Tr-A

▼

The normal marker displays the absolute level. By setting a display line, the normal marker can also display

the level relative to a given level specified as a reference line.

3-7

Page 46

SECTION 3 MARKER FUNCTIONS

Delta Marker

The current marker position when the delta marker is set to On is fixed as the reference marker (reference

point). Then, as the current marker is moved, the reference marker and current marker frequency (time) and

level differences are displayed digitally as delta marker values.

In the delta marker mode, the reference marker is indicated by .

To set the delta marker to On, perform the following key operations.

Marker

Press the Delta Marker key in the delta maker mode. The reference marker moves to the current marker

position and switches to the delta marker mode with that point as the reference point.

Delta Marker

3-8

Varying the spectrum waveform in the delta marker mode does not change the marker frequency level. The

reference marker is not necessarily always on the waveform because it remains unchanged. Also, when the

reference marker cannot be positioned on the screen by changing the observation frequency and level and

range, it is at the edge of the scale lines.

The marker mode at delta marker-ON becomes the normal mode when the scale mode is changed from log

scale to linear scale and vice-versa. If the scale mode was changed, set the delta marker again.

Page 47

Marker Off

SECTION 3 MARKER FUNCTIONS

Marker

The marker disappears from the screen. When the Normal Marker key is pressed, the marker is displayed.

Marker Off

Switching Marker Search Mode

Searching the maximum value (Peak) or minimum value (Dip) in the zone marker is selected by pressing this

key. Usually select Peak.

Marker

Marker Search Peak Dip

(Display page 2 of the menu by pressing the More key.)

3-9

Page 48

SECTION 3 MARKER FUNCTIONS

Display Line

In the state in which a horizontal line which indicates a given level (frequency deviation for FM demodulated

waveform display) is displayed on the scale, the display line can be used as the frequency response measurement

guideline, or as the reference line of the marker level measurement or pass/fail judgement with a standard line.

Setting Display Line

To turn the display-line On and Off and to set the display-line level (frequency deviation), perform the following

key operations.

Marker

Display Line *

(Display page 2 of the menu by pressing the More key.)

Display Line Turn the display line On and Off by pressing this key.

On Off

Display Line Enter the display line level from the ten keys, etc.

Level

–50.00 dBm

Marker Level Select if the marker level is set by absolute value or relative

Abs Rel value (relative to display line) by pressing this key.

Return

Display-line On and Off are common to all traces (A, B, BG, Time). Also, the display-line level is common

except for FM demodulated waveform display.

3-10

The display-line level and Abs/Rel can be selected independently for each trace.

Page 49

Multimarker

The spectrum analyzer has a marker function which displays up to ten markers displayed simultaneously.

Multimarker can be set by the following four methods:

• Highest 10

• Harmonics

• Marker List

• Manual Set

Highest 10 Multimarker

Allocates up to 10 multimarkers in descending order of signal peak level displayed on the screen.

SECTION 3 MARKER FUNCTIONS

Multi Mkr

Shift

After executing Highest 10, an active marker (with the same functions as the current marker) moves to the

peak point of the maximum level signal.

Note: Each multimarker has a zone as the same as the current marker, and is positioned at the maximum

level point. So, when the next sweep is done after Highest 10 operation, each multimarker position

may be changed. To protect this, execute the Highest 10 after stopping the sweeping or after narrowing

the zone width.

Marker

Highest 10

3-11

Page 50

SECTION 3 MARKER FUNCTIONS

Harmonics Multimarker

Allocates multimarkers to the 2nd to the 10th harmonic signals of the active marker signal as the fundamental

signal.

Shift

Multi Mkr

Marker

Harmonics

Note: If the fundamental and second harmonic signals are not separated by more than the marker zone

Marker List

Shift

width, or when there are larger level signals other than harmonic signals in the frequency range of

the marker zone width centered at the harmonic signals, harmonic signals will be incorrectly detected.

In this case, narrow the marker zone width.

Multi Mkr

Marker List *

Marker List

On Off

Freq/Time

Abs Rel

Level

Abs Rel

Return

Marker

Turn the marker list display On and Off by pressing this key.

Select frequency/time as absolute value or relative value

(relative to frequency/time of active marker) display by pressing this key.

Select level as absolute value or relative value (relative to

active-marker level) display by pressing this key.

3-12

Page 51

SECTION 3 MARKER FUNCTIONS

In Freq/Time Rel mode, frequency and time of the markers

except active marker are displayed in relative values, and

“R” marks are appended at the left.

In Level Rel mode, level of the markers except active

marker are displayed in relative values,

2

4

1: 1.00000GHz

∗

2:R -1.31MHz

3:R 1.41MHz

4:R -2.00MHz

5:R 1.89MHz

6:R 2.20MHz

7:

8:

9:

10:

1

3

Marker List

-15.12dBm

-3.55dB

-3.61dB

-5.96dB

-6.21dB

-6.76dB

5

6

3-13

Page 52

SECTION 3 MARKER FUNCTIONS

Manual Set

Allocates up to 10 multimarkers to arbitrary frequencies or time points.

Shift

Change Active

Maker No

Multi Mkr

Marker

Manual Set *

Selects the active marker from among the markers that are

currently On. Each time this key is pressed, the markers are

scrolled and selected. #

Select Marker

No 4

On with

Auto Select

Off with

Auto Select

Specifies the marker number to be set to On or Off.

At the same time the marker number selected above is set to On,

the selected marker is made the active marker. If the selected

marker is already On, the next higher marker number of the markers

set to Off is set to On. By holding this key down, the multimarkers

are set to On one by one in ascending order of number.

<Example> When marker No.4 is selected when marker

Nos. 3, 4, 5, 8, and 9 are On, the markers are

turned On in No., 6, 7, 10, 1, 2 order.

Sets the marker of the selected No. to Off. If the selected

marker is already Off, the next smaller marker No. of the markers

set to On is set to Off. By holding down this key, the multimarkers

are set to Off one by one in descending order of number. When

the active marker is set to Off, the marker with the next smaller

number is made the active marker.

<Example> When marker No. 7 is selected to be set to Off when

marker Nos. 3, 4, 5, 8 and 9 are On and marker No. 5

is made the active marker, the markers are set to Off

in No. 6, 5, 4, 3, 9 order, then marker No. 8 becomes

the active marker.

3-14

# The active marker is indicated by the ▼ mark. The other

marker Nos. are indicated by the mark. The active marker

can be moved by using the ten keys, up-down keys, or rotary

knob.

Continued

Page 53

SECTION 3 MARKER FUNCTIONS

Clear All

Return

Leaves only the marker number currently made the active marker

and sets all the other multimarkers to Off. The active marker

number is then reset to 1.

Multimarker Off

To return from multimarker to normal marker, perform the following key operations.

Shift

Multi Mkr

Marker

Multi Marker On Off

3-15

Page 54

SECTION 3 MARKER FUNCTIONS

Marker Search

The spectrum analyzer has the following six marker search functions:

• Peak search

• Next Peak search

• Next Right Peak search

• Next Left Peak search

• Dip search

• Next Dip search

Peak Search

Peak Search detects the maximum level point from the entire trace in which a marker is displayed and moves

the marker to that point.

To Execute Peak search, perform the following key operations.

3-16

Page 55

Next Peak Search

Next Peak Search detects the next largest peak relative to the current marker level and moves the marker to that

point. (When there are two or more peaks with the same level on the screen, the leftmost peak is detected.)

Execute Next Peak search by performing the following key operations.

SECTION 3 MARKER FUNCTIONS

Next Peak

The next largest peaks can be detected and the marker can be moved to those peaks by executing Next Peak

Search consecutively.

3-17

Page 56

SECTION 3 MARKER FUNCTIONS

Next Right Peak Search/Next Left Peak Search

Next Right Peak search and Next Left Peak Search detect the adjacent peak level to the right or left of the

current marker and move the marker to that point.

To execute Next Right Peak Search and Next Left Peak Search, perform the following key operations.

Next Right Peak

Next Left Peak

3-18

The adjacent peak level to the right or left can be detected and the marker moved to that peak by executing

Next Right Peak Search or Next Left Peak Search consecutively.

Note: When marker search is executed, the marker is moved to the specified Peak or Dip point, and the

zone marker center frequency is simultaneously moved to the marker point. After that, when sweep

is executed within the zone marker, the marker moves to the maximum point within the zone marker.

Therefore, marker search other than Peak search should be executed with sweep stopped or with the

zone width set to 1 point (spot marker mode).

Page 57

Dip Search

Dip search detects the minimum level point from the entire trace in which a marker is displayed and moves the

marker to that point.

Execute Dip search by the performing the following key operations.

SECTION 3 MARKER FUNCTIONS

Peak

Search

▼

Dip Search

(Display page 2 of the menu by pressing the More key.)

Time domain waveform

Tr-Time

▼

3-19

Page 58

SECTION 3 MARKER FUNCTIONS

Next Dip Search

Next Dip Search detects the next smallest dip relative to the current marker level and moves the marker to that

point. (When there are two or more dips with the same level on the screen, the leftmost dip is detected.)

Execute Next Dip Search by performing the following key operations.

Peak

Search

Next Dip

(Display page 2 of the menu by pressing the MORE key.)

Time domain waveform

The next smallest peaks can be detected one by one and the marker moved to the detected peaks by executing

Next Dip Search consecutively.

Setting Search Resolution

Sets the Peak and Dip search resolution. When searching for the next peak, etc., the marker moves to the point

of the set resolution or higher.

3-20

Peak

Search

Resolution 1.23 dB

(Display page 2 of the menu by pressing the More key.)

Enter the resolution in dB units from the ten keys.

Page 59

Setting Search Threshold

Sets the display line to the threshold and searches for the level above or below the display line.

SECTION 3 MARKER FUNCTIONS

Peak

Search

Threshold *

(Display page 2 of the menu by pressing the More key.)

Treshold

On Off

Search

Above

Below

Threshold

Level

–50.00 dBm

Return

Turn threshold On and Off by pressing this key.

Select search above or below the display line by pressing this

key.

Sets the display line level.

3-21

Page 60

SECTION 3 MARKER FUNCTIONS

Setting Parameters Using Marker Values

The marker value can be set as the parameter value of the observation frequency, reference level, and so on.

This facilitates observation of the desired waveform.

To set parameters using the marker value, the following settings are possible:

• Mkr → CF Sets the marker frequency to the center frequency.

• Mkr → RLV Sets the marker level to the reference level.

• Mkr → CF Step Size Sets the marker frequency to the center frequency step size.

• Delta Mkr → Span Sets the reference marker and current marker frequency to the start frequency and

stop frequency, respectively.

• Zone → Span Sets the zone marker center frequency and zone width to the center frequency and

frequency span, respectively.

In the time domain mode, only Mkr → RLV is valid.

3-22

Page 61

Mkr → CF/Mkr → RLV

Sets the current marker frequency or level to the center frequency or reference level.

SECTION 3 MARKER FUNCTIONS

Marker

Marker → *

Mkr → CF

Mkr → RLV

3-23

Page 62

SECTION 3 MARKER FUNCTIONS

Mkr → CF Step Size

Sets the marker frequency to the center frequency step size (up-down keys resolution).

Marker

Marker → *

Mkr → CF Step Size

Although this action does not cause any change to appear on the screen, when the center frequency is changed

with the up-down keys, the center frequency is changed with the marker frequency as the step size. This

facilitates observation of harmonic waves.

3-24

Page 63

Delta Mkr → Span

In the delta marker mode, this operation sets the delta marker mode current marker frequency and reference

marker frequency to the start frequency and stop frequency, respectively.

SECTION 3 MARKER FUNCTIONS

Marker

Marker → *

Delta Mkr → Span

3-25

Page 64

SECTION 3 MARKER FUNCTIONS

Zone → Span

To set the zone marker center frequency and width to the center frequency and frequency span, respectively,

perform the following key operations.

Marker

Marker → *

Zone → Span

3-26

.

Page 65

SECTION 4 SIGNAL SEARCH FUNCTION

SECTION 4

SIGNAL SEARCH FUNCTION

Signal search facilitates extraction of the objective signal Although the functions of signal search are similar to the marker

function, this section only describes the Signal Search section

TABLE OF CONTENTS

Detecting Peaks

Detecting the Maximum Peak Signal by Automatic Tuning

Moving the Measurement Point

Peak → CF and Peak → RLV

..................................................................................................................................

..........................................................................................................

.....................................................................................................

........................................................

4-3

4-4

4-5

4-6

4-1

Page 66

SECTION 4 SIGNAL SEARCH FUNCTION

4-2

Page 67

SECTION 4