Anritsu MS2090A-0743, MS2090A-0754, MS2090A-0709, MS2090A-0732, MS2090A-0714 User Manual

...Page 1

User Guide

Field Master Pro™ MS2090A

Spectrum Analyzer

MS2090A-0709 9 kHz to 9 GHz (Option 709)

MS2090A-0714 9 kHz to 14 GHz (Option 714)

MS2090A-0720 9 kHz to 20 GHz (Option 720)

MS2090A-0726 9 kHz to 26.5 GHz (Option 726)

MS2090A-0732 9 kHz to 32 GHz (Option 732)

MS2090A-0743 9 kHz to 43.5 GHz (Option 743)

MS2090A-0754 9 kHz to 54 GHz (Option 754)

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

Part Number: 10580-00444

Published: September 2019

Copyright 2019 Anritsu Company

Revision: C

Page 2

Unauthorized Use or Disclosure

Anritsu Company has prepared the product user documentation for use by Anritsu Company personnel and

customers as a guide for the proper installation, operation, and maintenance of Anritsu Company equipment and

software programs. The drawings, specifications, and information contained therein are the property of Anritsu

Company, and any unauthorized use or disclosure of these drawings, specifications, and information is prohibited;

they shall not be reproduced, copied, or used in whole or in part as the basis for manufacture or sale of the equipment

or software programs without the prior written consent of Anritsu Company.

Export Management

The Anritsu products identified herein and their respective manuals may require an Export License or approval by

the government of the product country of origin for re-export from your country. Before you export these products or

any of their manuals, please contact Anritsu Company to confirm whether or not these items are export-controlled.

When disposing of export-controlled items, the products and manuals must be broken or shredded to such a degree

that they cannot be unlawfully used for military purposes.

Front-2 PN: 10580-00444 Rev. C MS2090A UG

Page 3

Table of Contents

Chapter 1—General Information

1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Instrument Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-3 Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Instrument Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

User Interface Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Available Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Available Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4 Instrument Care and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Ventilation and Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

ESD Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-5 Calibration and Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-6 Contacting Anritsu for Sales and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2—Instrument Overview

2-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Instrument Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-3 Connector Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Top Connector Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Side Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-4 Tilt Bail Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-5 Battery Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-6 Turning On the MS2090A Field Master Pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Power/Charge LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Shutting Down and Restarting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-7 GUI Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Operating the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Common GUI Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

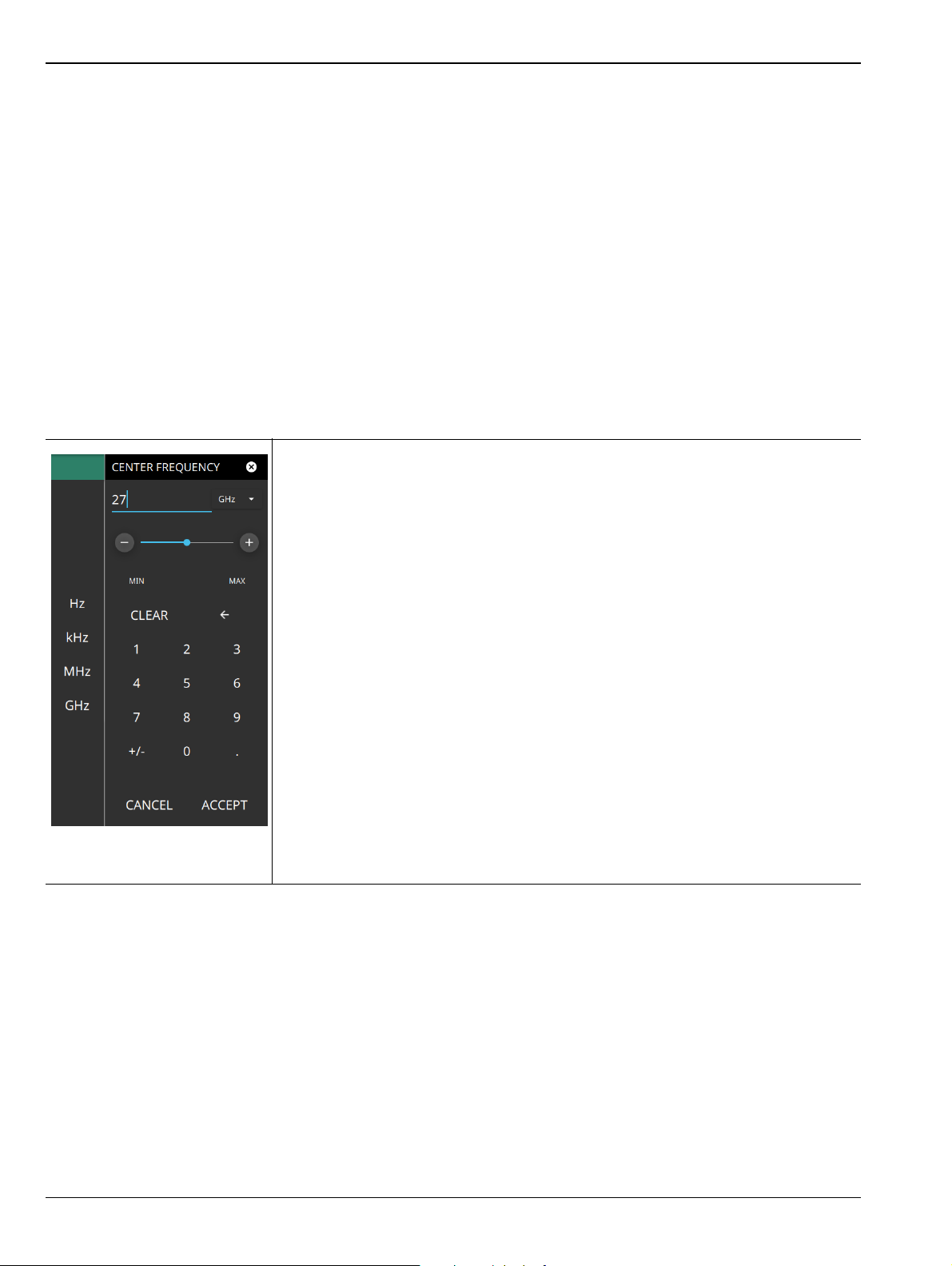

Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Scroll Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-8 Title Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2-9 Selecting the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2-10 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Notifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

MS2090A UG PN: 10580-00444 Rev. C Contents-1

Page 4

Table of Contents (Continued)

2-11 Settings Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Sound Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Ethernet Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Wi-Fi Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

GPS/GNSS Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Screenshot Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Date Time Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Port Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Reference and Trigger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Options Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Reset Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2-12 File Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

File Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

File Management Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Previewing Screenshots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2-13 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Battery Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Service Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

2-14 Software Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Installing the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Chapter 3—Spectrum Analyzer Measurements

3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Selecting the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

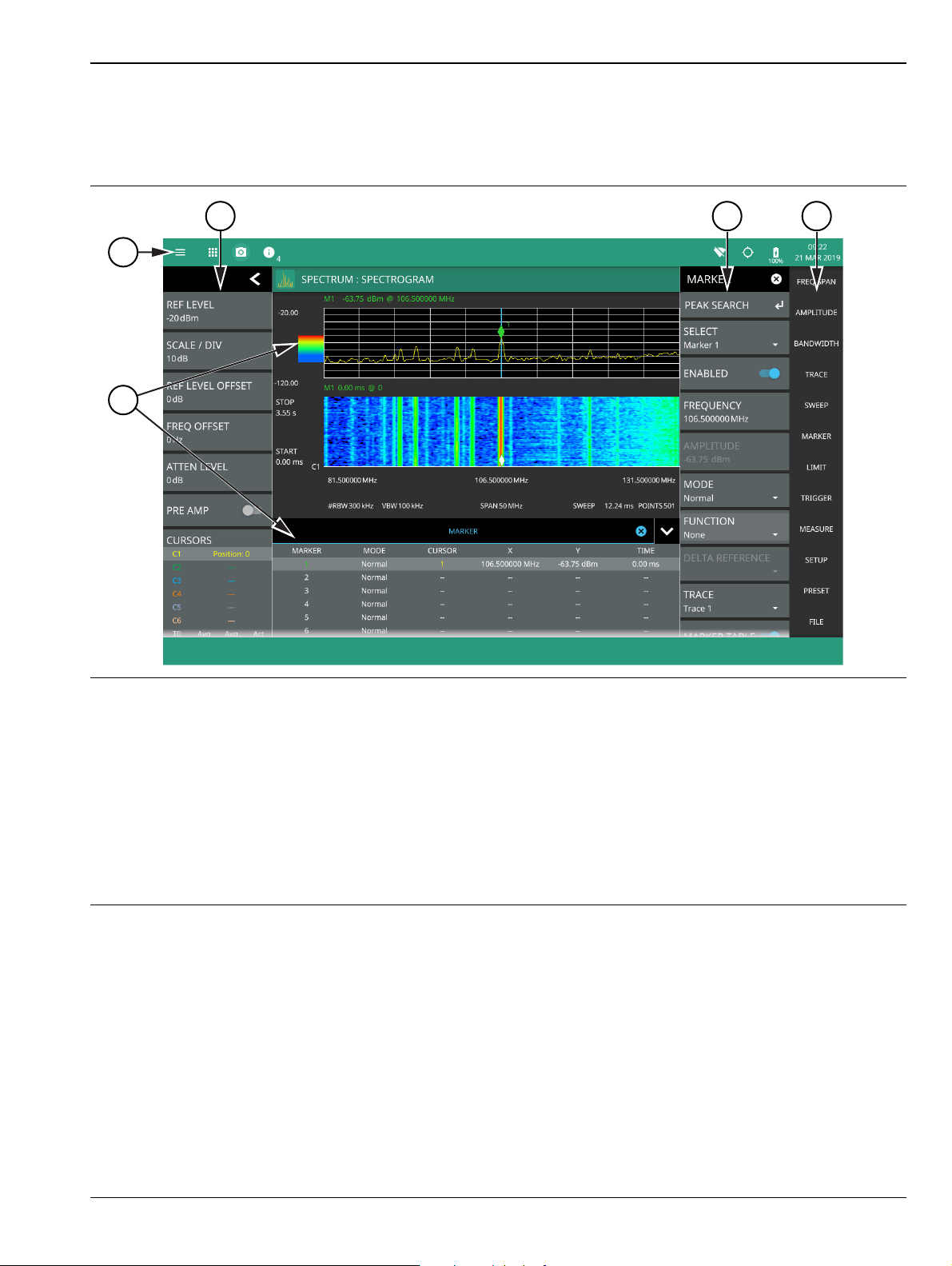

3-3 Spectrum Analyzer GUI Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Normal Spectrum View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Spectrogram View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-4 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Using Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-5 Status Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-6 Making Spectrum Analyzer Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-7 Setting Frequency Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Entering Start and Stop Frequencies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Entering a Center Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Using Offset Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Setting the Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Zero Span IF Output (Option 89) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

FREQ / SPAN Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

FREQ / SPAN Zero Span Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

IF OUTPUT Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

GESTURES Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Contents-2 PN: 10580-00444 Rev. C MS2090A UG

Page 5

Table of Contents (Continued)

3-8 Setting Amplitude Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting Amplitude Reference Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting Amplitude Range and Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Reference Level Offset for External Loss or External Gain. . . . . . . . . . . . . . . . . . . . . . . . 3-15

Attenuator Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Preamplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Indications of Excessive Signal Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

AMPLITUDE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-9 Setting Bandwidth Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Resolution Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Video Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Setting Frequency Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Setting Bandwidth Auto Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

BANDWIDTH Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3-10 Setting Trace and Cursor Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Traces in Spectrum View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

TRACE Menu (Spectrum View). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Trace Detector Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Cursors in Spectrogram View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

TRACE Menu (Spectrogram View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

TRACE CURSOR Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

3-11 Setting Sweep Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Single/Continuous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Trace Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Sweep Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

SWEEP Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Gated Sweep (Option 90) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

GATED SWEEP Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

POWER VS TIME Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3-12 Setting Up Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Placing a Normal Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Placing a Fixed Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Placing a Delta Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

MARKER Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

MARKER PEAK SEARCH Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Marker Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Spectrogram with Cursors and Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Marker Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

3-13 Setting Up Limit Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Simple Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Limit Line Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

LIMIT Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

LIMIT EDIT Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

LIMIT MOVE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

LIMIT ENVELOPE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

MS2090A UG PN: 10580-00444 Rev. C Contents-3

Page 6

Table of Contents (Continued)

3-14 Setting Up Triggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

TRIGGER Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

TRIGGER Menu in Zero Span. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

3-15 Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

SETUP Menu (Spectrum View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

SETUP Menu (Spectrogram View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

3-16 Setting Up Advanced Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

MEASURE Menu (Spectrum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3-17 Channel Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

SETUP Menu (Channel Power). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

3-18 Occupied Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

SETUP Menu (Occupied BW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

3-19 Adjacent Channel Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

SETUP Menu (ACP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

3-20 Spectrum Emission Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

Spectrum Emission Mask Measurement Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

SETUP Menu (SEM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

3-21 Interference Finder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

SETUP Menu (Interference Finder) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

3-22 Presetting the Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

PRESET Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

3-23 Saving and Recalling Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

Saving a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

Recalling a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

FILE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

SAVE ON EVENT Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

Chapter 4—Real-Time Spectrum Analyzer Measurements

4-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Selecting the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-3 RTSA GUI Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Normal RTSA View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Spectrogram View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-4 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Using Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-5 Status Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-6 Making RTSA Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Contents-4 PN: 10580-00444 Rev. C MS2090A UG

Page 7

Table of Contents (Continued)

4-7 Setting Frequency Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Entering Start and Stop Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Entering a Center Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Using Offset Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Setting the Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

FREQ / SPAN Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

GESTURES Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-8 Setting Amplitude Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Setting Amplitude Reference Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Setting Amplitude Range and Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Reference Level Offset for External Loss or External Gain. . . . . . . . . . . . . . . . . . . . . . . . 4-13

Attenuator Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Preamplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Indications of Excessive Signal Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

AMPLITUDE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-9 Setting Bandwidth Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Resolution Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Setting Frequency Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Setting Bandwidth Auto Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

BANDWIDTH Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4-10 Setting Trace and Cursor Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Traces in Normal View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

TRACE Menu (Normal View). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Trace Detector Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Cursors in Spectrogram View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

TRACE Menu (Spectrogram View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

TRACE CURSOR Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4-11 Setting Sweep Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Single/Continuous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

SWEEP Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4-12 Setting Up Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Placing a Normal Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Placing a Fixed Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Placing a Delta Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

MARKER Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

MARKER PEAK SEARCH Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Marker Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Spectrogram with Cursors and Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Marker Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

4-13 Setting Up Limit Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Simple Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Limit Line Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

LIMIT Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

LIMIT EDIT Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

LIMIT MOVE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

LIMIT ENVELOPE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

MS2090A UG PN: 10580-00444 Rev. C Contents-5

Page 8

Table of Contents (Continued)

4-14 Setting Up Triggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

TRIGGER Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

4-15 Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

SETUP Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

4-16 Setting Up Advanced Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

MEASURE Menu (Spectrum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4-17 Presetting the Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

PRESET Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

4-18 Saving and Recalling Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Saving a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Recalling a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

FILE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Chapter 5—5G Measurements

5-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Selecting the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-3 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Using Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-4 Setting Frequency and Band Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Configuring the Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

FREQUENCY Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

BAND CONFIG Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

GESTURES Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-5 Setting Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Setting Amplitude Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Reference Level Offset for External Loss or External Gain . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Attenuator Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Indications of Excessive Signal Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

AMPLITUDE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-6 Setting Bandwidth Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

BANDWIDTH Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-7 Setting Trace Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

TRACE Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5-8 Setting Sweep Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

SWEEP Menu – Summary Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

SWEEP Menu – RF Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Gated Sweep (Option 90) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

GATED SWEEP Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

POWER VS TIME Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Contents-6 PN: 10580-00444 Rev. C MS2090A UG

Page 9

Table of Contents (Continued)

5-9 Setting Up Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Placing a Normal Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Placing a Fixed Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Placing a Delta Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

MARKER Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

MARKER PEAK SEARCH Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Marker Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Marker Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5-10 5G Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

MEASURE Menu (5G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5-11 5GNR Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5GNR Summary Multi Beam View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5GNR Summary Single Beam View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5GNR Multi PCI Scanner View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5GNR Multi PCI Table View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

SETUP Menu (5GNR Summary and Multi PCI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Status Panel (5GNR Summary/Multi PCI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5-12 5G Channel Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

SETUP Menu (5G Channel Power). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Status Panel (5G Channel Power) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5-13 5G Occupied Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

SETUP Menu (5G OBW). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Status Panel (5G OBW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

5-14 5G EIRP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

SETUP Menu (5G EIRP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Status Panel (5G EIRP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

5-15 Presetting the Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

PRESET Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

5-16 Saving and Recalling Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

Saving a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

Recalling a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

FILE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Appendix A—Instrument Messages and Troubleshooting

A-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A-2 Self-Test Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A-3 File Management Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A-4 Informational Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A-5 Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

A-6 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A-7 System Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Install SW to SLOT X. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Boot Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

MS2090A UG PN: 10580-00444 Rev. C Contents-7

Page 10

Appendix B—Software Option Upgrades

B-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B-2 Exporting a Software Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B-3 Importing Software License . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Contents-8 PN: 10580-00444 Rev. C MS2090A UG

Page 11

Chapter 1 — General Information

1-1 Introduction

The MS2090A Field Master Pro User Guide is part of a set of manuals that cover all of the instrument

functions and their use. This manual covers the instrument overview, system functions, and other common

features, along with a brief guide to basic measurement concepts and setups. Most instrument operations are

covered in specific chapters of this manual as listed below. Remote programming is covered in the

programming manual.

Before You Begin

• Read the Field Master Pro MS2090A Information, Compliance, and Safety Guide (PN: 10100-00069) for

important safety, legal, and regulatory notices before operating the equipment.

• Charge the instrument battery using the supplied battery charger until fully charged.

Note The instrument may reboot when the battery charge level is low and external power is removed.

• Review Section 1-2 “Instrument Description” on page 1-2 and Section 1-4 “Instrument Care and

Preventive Maintenance” on page 1-4.

• Chapter 2, “Instrument Overview” provides information on the physical instrument, connectors, and

other hardware interfaces.

• Chapter 3, “Spectrum Analyzer Measurements” provides information on the software user interface,

such as instrument settings, measurement features, and menu overviews, for the spectrum analyzer.

• Chapter 4, “Real-Time Spectrum Analyzer Measurements” provides information on the software user

interface, such as instrument settings, measurement features, and menu overviews, for the real-time

spectrum analyzer.

• Chapter 5, “5G Measurements” provides information on the software user interface, such as instrument

settings, measurement features, and menu overviews, for the 5G analyzer.

Additional Documentation

Table 1-1. Related Manuals

Document Part Number Description

10100-00069 Important Product Information, Compliance, and Safety Notices

11410-01000 MS2090A Field Master Pro Technical Data Sheet

10580-00445 Programming Manual

For additional information and literature covering your product, visit the product page of your instrument and

select the Library tab:

http://www.anritsu.com/en-US/test-measurement/products/ms2090a

MS2090A UG PN: 10580-00444 Rev. C 1-1

Page 12

1-2 Instrument Description General Information

1-2 Instrument Description

The MS2090A Field Master Pro is a synthesizer-based handheld signal analyzer that provides quick and

accurate measurement results. The instrument is designed for monitoring, measuring, and analyzing signal

environments. Measurements can easily be made by using the main instrument functions: frequency, span,

amplitude, and bandwidth. A 10.1" capacitive touchscreen enables fast, easy data entry.

Typical measurements include in-band interference and transmit spectrum analysis, plus cell site and

802.11a/b/g interference testing. Options are available for RF, advanced demodulation, and over-the-air (OTA)

measurement. A full range of marker capabilities (such as peak, center, and delta functions) are provided for

faster, more comprehensive analysis of displayed signals. Upper and lower multi-segmented limit lines are

available to create quick, simple pass/fail measurements.

Time and date stamping of measurement data is automatic. The internal memory provides for the storage and

recall of up to 1000 measurement setups and up to 1000 traces. Measurements and setups can be stored

internally on the instrument or on a USB flash drive for later recall.

Note

Not all after-market USB drives are compatible with Field Master Pro. The USB drive must contain a

single partition using FAT32 format.

1-3 Document Conventions

The following conventions are used throughout the MS2090A documentation set.

Instrument Identification

When identifying a frequency option for the MS2090A, that option number is appended after the model

number; example: MS2090A-0709.

User Interface

The MS2090A user interface consists of menus, buttons, toolbars, and dialog boxes.

User Interface Navigation

Elements in navigation paths are separated as follows: MARKER > PEAK SEARCH > NEXT PEAK.

1-2 PN: 10580-00444 Rev. C MS2090A UG

Page 13

General Information 1-3 Document Conventions

Available Models

Table 1-2 lists the frequency options available with the MS2090A Field Master Pro.

Table 1-2. Field Master Pro Frequency Options

Model Frequency Range

MS2090A-0709 Signal Analyzer, 9 kHz to 9 GHz

MS2090A-0714 Signal Analyzer, 9 kHz to 14 GHz

MS2090A-0720 Signal Analyzer, 9 kHz to 20 GHz

MS2090A-0726 Signal Analyzer, 9 kHz to 26.5 GHz

MS2090A-0732 Signal Analyzer, 9 kHz to 32 GHz

MS2090A-0743 Signal Analyzer, 9 kHz to 43.5 GHz

MS2090A-0754 Signal Analyzer, 9 kHz to 54 GHz

Available Options

Available options for the Field Master Pro are listed in Table 1-3.

Table 1-3. Available Options

Option Description

MS2090A-0024 Interference Finder

MS2090A-0031 GPS Receiver (requires external GPS antenna)

MS2090A-0089 Zero Span IF Output

MS2090A-0090 Gated Sweep

MS2090A-0103 50 MHz Analysis Bandwidth

MS2090A-0104 100 MHz Analysis Bandwidth

MS2090A-0199 Real Time Spectrum Analyzer

MS2090A-0888 5G NR Downlink Measurements (requires GPS option MS2090A-0031)

MS2090A-xxxx-0097 Accredited Calibration to ISO17025 and ANSI/NCSL Z540-1.

MS2090A-xxxx-0098 Standard Calibration to ISO17025 and ANSI/NCSL Z540-1.

MS2090A-xxxx-0099 Premium Calibration to ISO17025 and ANSI/NCSL Z540-1.

a. xxxx is the frequency option number of the instrument.

a

Includes calibration certificate, test report, and uncertainty data.

Includes calibration certificate.

Includes calibration certificate, test report, and uncertainty data.

MS2090A UG PN: 10580-00444 Rev. C 1-3

Page 14

1-4 Instrument Care and Preventive Maintenance General Information

1-4 Instrument Care and Preventive Maintenance

Instrument care and preventive maintenance consist of proper operation in a suitable environment, occasional

cleaning of the instrument, and inspecting and cleaning the RF connectors and all accessories before use.

Clean the instrument with a soft, lint-free cloth dampened with water or water and a mild cleaning solution.

Caution To avoid damaging the display or case, do not use solvents or abrasive cleaners.

Ventilation and Cooling

The Field Master Pro provides active cooling of the internal components to prevent damage from overheating.

The airflow vents on the edges and bottom of the instrument must be kept clear and unobstructed while the

instrument is powered on. When using the Field Master Pro on a desktop or bench, the tilt bail can be used or

the instrument can be placed flat on its back to facilitate increased airflow.

Caution

Do not operate or store the Field Master Pro in extreme environments. Refer to the instrument

Technical Data Sheet for the specified operating and storage conditions.

Connector Care

Clean the RF connectors and center pins with a cotton swab dampened with denatured alcohol. Visually

inspect the connectors. The fingers of the N(f) connectors and the pins of the N(m) connectors should be

unbroken and uniform in appearance. If you are unsure whether the connectors are undamaged, gauge the

connectors to confirm that the dimensions are correct. Visually inspect the test port cable(s). The test port

cable should be uniform in appearance and not stretched, kinked, dented, or broken.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the Type-N connectors.

The recommended torque is 12 lbf · in to 15 lbf· in (1.36 N·m to 1.70 N · m). Inadequate torque settings can

affect measurement accuracy. Over-tightening connectors can damage the cable, the connector, the

instrument, or all of these items.

Visually inspect connectors for general wear, cleanliness, and for damage such as bent pins or connector rings.

Repair or replace damaged connectors immediately. Dirty connectors can limit the accuracy of your

measurements. Damaged connectors can harm the instrument. Connection of cables carrying an electrostatic

potential, excess power, or excess voltage can damage the connector, the instrument, or both.

1-4 PN: 10580-00444 Rev. C MS2090A UG

Page 15

General Information 1-4 Instrument Care and Preventive Maintenance

Connecting Procedure

1. Carefully align the connectors. The male connector center pin must slip concentrically into the contact

fingers of the female connector.

2. Align and push connectors straight together. Do not twist or screw them together. A slight resistance can

usually be felt as the center conductors mate.

3. To tighten, turn the connector nut, not the connector body. Major damage can occur to the center

conductor and to the outer conductor if the connector body is twisted.

4. If you use a torque wrench, initially tighten by hand so that approximately 1/8 turn or 45 degrees of

rotation remains for the final tightening with the torque wrench.

Relieve any side pressure on the connection (such as from long or heavy cables) in order to assure

consistent torque. Use an open-end wrench to keep the connector body from turning while tightening

with the torque wrench.

Do not over-torque the connector.

Disconnecting Procedure

1. If a wrench is needed, use an open-end wrench to keep the connector body from turning while loosening

with a second wrench.

2. Complete the disconnection by hand, turning only the connector nut.

3. Pull the connectors straight apart without twisting or bending.

MS2090A UG PN: 10580-00444 Rev. C 1-5

Page 16

1-5 Calibration and Verification General Information

ESD Caution

The Field Master Pro, like other high performance instruments, is susceptible to electrostatic discharge (ESD)

damage. Coaxial cables and antennas often build up a static charge, which (if allowed to discharge by

connecting directly to the instrument without discharging the static charge) may damage the Field Master Pro

input circuitry. Instrument operators must be aware of the potential for ESD damage and take all necessary

precautions.

Operators should exercise practices outlined within industry standards such as JEDEC-625 (EIA-625),

MIL-HDBK-263, and MIL-STD-1686, which pertain to ESD and ESDS devices, equipment, and practices.

Because these apply to the Field Master Pro, it is recommended that any static charges that may be present be

dissipated before connecting coaxial cables or antennas to the instrument. This may be as simple as

temporarily attaching a short or load device to the cable or antenna prior to attaching to the Field Master Pro.

It is important to remember that the operator may also carry a static charge that can cause damage. Following

the practices outlined in the above standards will ensure a safe environment for both personnel and

equipment.

1-5 Calibration and Verification

The Field Master Pro comes fully calibrated from the factory and there are no field-adjustable components.

Anritsu recommends annual calibration and performance verification by local Anritsu service centers.

Accredited calibration to ISO17025 and ANSI/NCSL Z540-1 are available and can include a calibration

certificate, test report, and uncertainty data. Contact Anritsu sales and service centers for more information.

1-6 Contacting Anritsu for Sales and Service

To contact Anritsu, visit the following URL and select the services in your region:

http://www.anritsu.com/contact-us

1-6 PN: 10580-00444 Rev. C MS2090A UG

Page 17

Chapter 2 — Instrument Overview

2-1 Introduction

This chapter provides an overview of the Anritsu MS2090A Field Master Pro. It describes the instrument

hardware features, touch screen display, general system settings and instrument configurations, and the

connector panels. For detailed information on the instrument’s user interface and functions, refer to these

sections:

• Chapter 3, “Spectrum Analyzer Measurements”

• Section 3-6 “Making Spectrum Analyzer Measurements”

• Section 3-18 “Occupied Bandwidth”

• Section 3-17 “Channel Power”

• Section 3-19 “Adjacent Channel Power”

• Section 3-20 “Spectrum Emission Mask”

• Section 3-21 “Interference Finder”

• Chapter 4, “Real-Time Spectrum Analyzer Measurements”

• Section 4-6 “Making RTSA Measurements”

• Chapter 5, “5G Measurements”

• Section 5-11 “5GNR Summary”

• Section 5-12 “5G Channel Power”

• Section 5-13 “5G Occupied Bandwidth”

• Section 5-14 “5G EIRP”

MS2090A UG PN: 10580-00444 Rev. C 2-1

Page 18

2-2 Instrument Front Panel Instrument Overview

1

4

4

3

3

3

2

5

6

7

8

2-2 Instrument Front Panel

The Field Master Pro uses a touch screen for data input. The menus can vary depending on the current

measurement configuration, installed options, and selected instrument function.

1. Touch Screen Display

2. “Top Connector Panel” on page 2-3

3. Shoulder Strap D-Ring Mount

4. Fan Ventilation Ports

5. “Side Connector Panel” on page 2-5

6. Battery Cover (see “Replacing the Battery” on page 2-9)

7. Power LED/Button and Battery Charge LED (see Section 2-6 “Turning On the MS2090A Field Master Pro”)

8. Handle and Stylus

Figure 2-1. Front Panel Overview

2-2 PN: 10580-00444 Rev. C MS2090A UG

Page 19

Instrument Overview 2-3 Connector Panels

1

345678

2

2-3 Connector Panels

The MS2090A Field Master Pro uses two connector panels to provide for all physical IO. These panels use a

variety of connector types intended for their purpose.

RF Connectors

The main RF input connector can be Type N, Type K, or Type V, depending on the frequency option that is

installed. These are ruggedized 50 Ω connectors. Type N connectors are female and Type K and V are male.

Additional IO is provided with the SMA and SMB style connectors. The SMA connectors are 50 Ω female and

the SMB connectors are 50 Ω jack slip-on connectors.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the connectors.

Caution

Top Connector Panel

Figure 2-2 shows the top connector panel on the MS2090A.

Do not overtighten the connector. The recommended torque for Type K and V is 8 lbf·in (0.9 N·m or

90 N·cm). The recommended torque for Type N is 12 lbf·in (1.35 N·m or 135 N·cm).

Figure 2-2. Test Panel Connectors

1. RF In Port

This is a 50 Ω ruggedized connector of the following:

• Type N female with options 709, 714, and 720

• Type K male with options 26, 32, and 43

• Type V male with option 754

To prevent damage to your instrument, do not try to mate incorrect connector types or use pliers or a plain

wrench to tighten the connector. Do not overtighten the connector. The recommended torque for Type K and V

is 8 lbf·in (0.9 N·m or 90 N·cm). The recommended torque for Type N is 12 lbf·in (1.35 N·m or 135 N·cm).

2. IF Out

This 50 Ω SMB jack connector provides internal IF output. The nominal frequency range is 325 MHz with

FFT capture bandwidth ≤ 32 MHz and 300 MHz with FFT capture bandwidth = 100 MHz. The nominal

RF output level is –4 dBm with a 10 MHz, –20 dBm input, and with 0 dB input attenuation and preamp off.

The spectrum can be inverted in certain RF input bands. Refer to “Zero Span IF Output (Option 89)”

on page 3-10. This is a slip-on connector that should seat with a click.

MS2090A UG PN: 10580-00444 Rev. C 2-3

Page 20

2-3 Connector Panels Instrument Overview

3. USB Interface – Type A

The Field Master Pro has three Type A USB connectors that accept USB storage devices for saving

measurements, setup data, and screen images. Two connectors are located on the top panel and one is located

in the side panel.

4. GPS Antenna Connector

The GPS antenna connection on the Field Master Pro is type SMA female. This connector also provides

5.0/3.3 VDC for an active GPS antenna. To prevent damage to your instrument, do not use pliers or a wrench to

tighten the connector.

5. Bias Voltage

The power supply is set up to provide 1 V to 34 V with a resolution of 0.1 V. The maximum current is 1 A, but

with at total maximum power of 15 W.

6. Trigger In/Out

A TTL signal that is applied to the external trigger 50 Ω SMB jack input connector causes a single sweep to

occur. In spectrum analysis, triggering is generally used in zero span, and triggering occurs on the rising edge

of the signal. After the sweep is complete, the resultant trace is displayed until the next trigger signal arrives.

This is a slip-on connector that should seat with a click.

7. Trigger In/Out / Ref Out (10 MHz)

This port can be configured as a trigger in/out as above or as a reference output. The reference output port is a

50 Ω SMB male connector that provides 10 MHz at approximately –7 dBm to 0 dBm. This is a slip-on connector

that should seat with a click.

8. Ref In

The external reference input port is a 50 Ω SMB jack connector that provides for input of an external frequency

reference. Refer to your Technical Data Sheet for valid frequencies. This is a slip-on connector that should seat

with a click. The instrument automatically selects the frequency reference in the following order of priority:

external, GPS, then the internal time base.

2-4 PN: 10580-00444 Rev. C MS2090A UG

Page 21

Instrument Overview 2-3 Connector Panels

1

2

3

4

5

6

7

Data Out

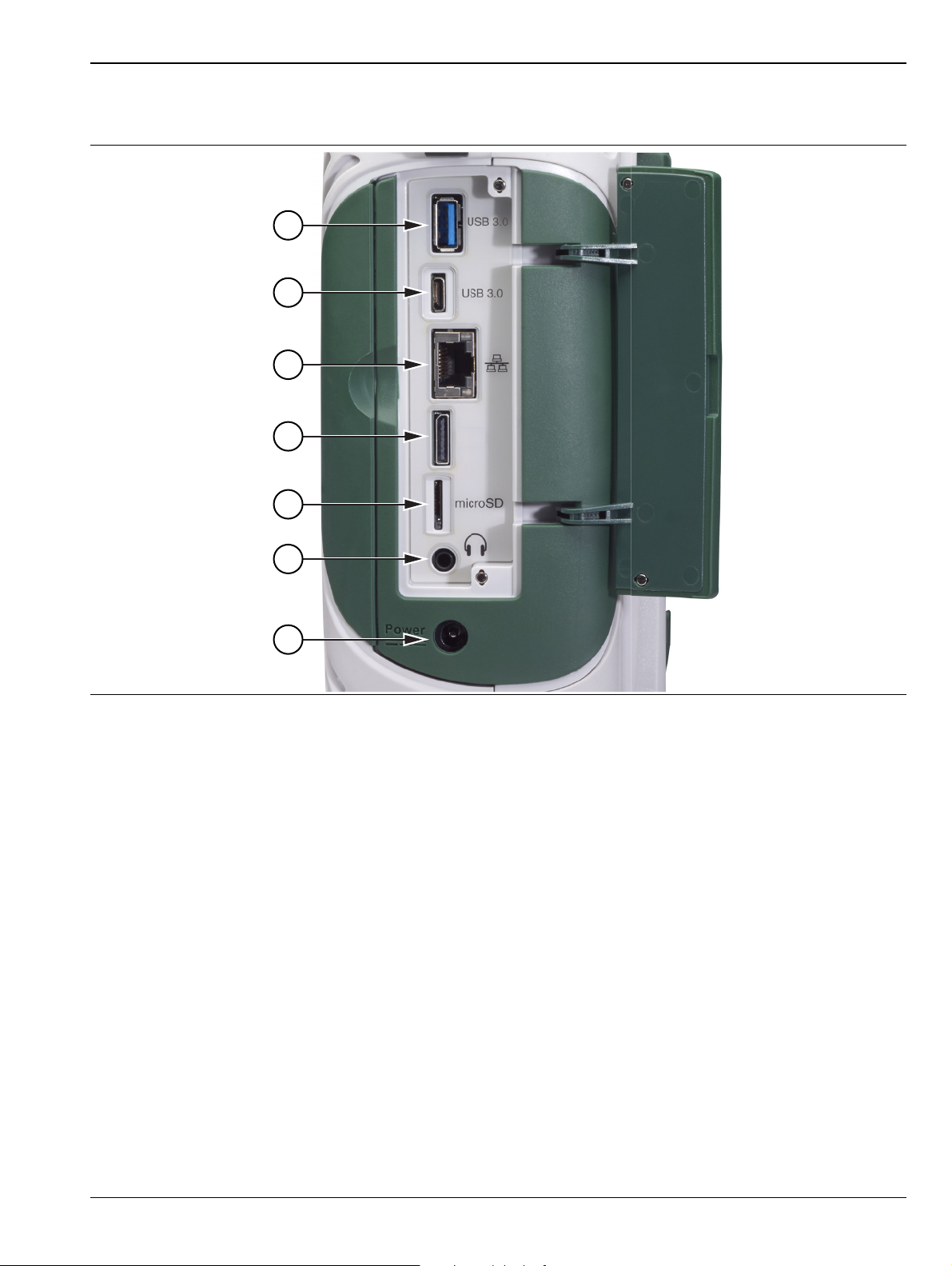

Side Connector Panel

Figure 2-3 shows the MS2090A side connector panel.

Figure 2-3. Side Panel Connectors

1. USB Interface – Type A

The Field Master Pro has three Type A USB connectors that accept USB storage devices for saving

measurements, setup data, and screen images. Two connectors are located on the top panel and one more is

located in the side panel.

2. USB Interface – Type C

The USB Type-C interface is not yet enabled. The interface will be used to connect the Field Master Pro

directly to a PC.

3. LAN Connection

The RJ-45 connector is used to connect the Field Master Pro to a local area network or directly to a PC with an

Ethernet crossover cable. See “Ethernet Connection” on page 2-25 for more details.

MS2090A UG PN: 10580-00444 Rev. C 2-5

Page 22

2-3 Connector Panels Instrument Overview

4. Data Out Port

The Data Out port is not yet enabled. This is a multi-purpose, hot pluggable input/output (I/O) interface. These

connectors are designed to fit all popular mechanical architectures and support Generation 1 PCIe data rates

at 2.5 Gbps through Generation 2 data rates at 5.0 Gbps.

Note

The Data Out port is not currently active. Functionality will be added via an upcoming software

update.

5. MicroSD

The Micro Secure Digital slot is a small expansion slot located on the side panel. The slot accepts industry

standard MicroSD storage cards and can be used for storing measurements, setup data, and screen images

similar to USB storage devices.

Note

The MicroSD slot is not currently active. Functionality will be added via an upcoming software

update.

6. Headset Jack

Note The headset jack is not yet enabled. Functionality will be added via an upcoming software update.

The 3-wire headset jack provides audio output from the built-in sounds generated by the instrument. The jack

accepts a 3.5 mm 3-wire miniature phone plug such as those commonly used with cellular telephones.

7. External Power

This is a 2.5 mm by 5.5 mm barrel connector, 15 VDC, 5 A, center positive. The external power connector is

used to power the unit and for battery charging. An orange blinking LED power button indicates that the

instrument battery is being charged by the external charging unit. The indicator is a steady green when the

battery is fully charged.

When using the AC-DC Adapter, always use a three-wire power cable that is connected to a

Warning

three-wire power line outlet. If power is supplied without grounding the equipment in this manner, the

user is at risk of receiving a severe or fatal electric shock.

Refer to “Turning On the MS2090A Field Master Pro” on page 2-10.

2-6 PN: 10580-00444 Rev. C MS2090A UG

Page 23

Instrument Overview 2-4 Tilt Bail Stand

2-4 Tilt Bail Stand

The attached tilt bail can be used for desktop operation. The tilt bail provides a backward tilt for improved

stability and air flow. To deploy the tilt bail, pull the bottom of the tilt bail away from the back of the

instrument. To store the tilt bail, push the bottom of the bail towards the back of the instrument and snap the

bail into the clips on the back of the instrument.

Figure 2-4. Tilt Bail Stand

MS2090A UG PN: 10580-00444 Rev. C 2-7

Page 24

2-5 Battery Information Instrument Overview

2-5 Battery Information

The batteries that are supplied with the Field Master Pro may need charging before use. They can be charged

using either the provided AC-DC adapter or the DC adapter. Refer to “Battery Status” for a description of the

battery status and information panel. The batteries can be charged in the instrument or removed for charging

in an optional battery charger. The batteries are installed at the factory and can be replaced by the user. Refer

to the next section for information on removing the batteries. Battery status is shown in “Battery Information”

on page 2-37.

Use only Anritsu-approved batteries, adapters, and chargers with this instrument. The batteries will

charge at a faster rate when the instrument is turned off. To prolong the useful battery life, the

Note

Caution

Note Anritsu Company recommends removing the battery for long-term storage of the instrument.

internal charging circuit monitors the battery temperature. Normal charging occurs when the battery

temperature is between 0 °C and 45 °C. Charging is paused if the internal battery temperature is

outside this range.

When using the automotive cigarette lighter adapter, always verify that the supply is rated for a

minimum of 75 Watts @ 15 VDC, and that the socket is clear of any dirt or debris. If the adapter plug

becomes hot to the touch during operation, discontinue use immediately.

2-8 PN: 10580-00444 Rev. C MS2090A UG

Page 25

Instrument Overview 2-5 Battery Information

Data Out

Replacing the Battery

The battery can be replaced without the use of tools. The battery compartment door is located on the lower

right side of the instrument (when you are facing the measurement display). To remove the battery:

1. Push in and slide the battery door tab to disengage it.

2. Remove the battery door.

3. Pull straight out on the lanyard to remove the battery pack from the instrument.

Note

When inserting the battery, the battery contacts should face up and slide in first. If the battery door

does not close tightly, the battery may be inserted incorrectly.

Figure 2-5. Battery Removal

MS2090A UG PN: 10580-00444 Rev. C 2-9

Page 26

2-6 Turning On the MS2090A Field Master Pro Instrument Overview

2-6 Turning On the MS2090A Field Master Pro

The Anritsu MS2090A Field Master Pro is capable of approximately two hours of continuous operation from a

fully charged, field-replaceable battery (refer to “Battery Information” on page 2-8). The instrument can also be

operated from a 15 VDC source (which will simultaneously charge the battery). This can be achieved with

either the Anritsu AC-DC adapter or the automotive power adapter, which can be purchased as an optional

accessory. Refer to the instrument Technical Data Sheet for more options and accessories.

When using the Automotive Power Adapter, always verify that the supply is rated for a minimum of

Caution

To turn on the Field Master Pro, briefly press the power button on the lower right of the touchscreen (see

Figure 2-1 on page 2-2).

The Field Master Pro takes approximately 60 seconds to complete power-up and to load the instrument

software. At the completion of this process, the instrument is ready for use.

75 Watts @ 15 VDC, and that the socket is clear of any dirt or debris. If the adapter plug becomes

hot to the touch during operation, discontinue use immediately.

Note

Keep the fan inlet and exhaust ports clear of obstructions at all times for proper ventilation and

cooling of the instrument.

Power/Charge LED Indicators

The power/charge LED is integrated with the power button. The LED has the following indicators:

• Solid white when the instrument is on or booting up.

• Slowly blinks orange when the instrument is off and connected to an external power source, and the

battery is charging.

• Solid green when the instrument is off and connected to an external power source, and the battery is

fully charged.

• Solid red when the instrument is off and connected to an external power source, and the battery is NOT

installed or has a fault.

Shutting Down and Restarting

To shut down or restart the instrument, briefly press the power button (a shutdown dialog will be displayed),

then select RESTART INSTRUMENT or POWER OFF. The current setup is saved when the instrument is

shut down or is restarted. Once the instrument shuts down, it will either power off completely (if running on

batteries) or it will go into a low power state (if running on external power).

2-10 PN: 10580-00444 Rev. C MS2090A UG

Page 27

Instrument Overview 2-7 GUI Overview

1

3 4

2

5

2-7 GUI Overview

The MS2090A Field Master Pro software controls all instrument functions. The software runs locally on the

instrument and primary operation is through the touch screen display. The figure below identifies the main

display areas, which are each described in more detail later in this chapter.

1. The title bar provides quick access to the system settings and informational dialogs.

2. The status and trace panel is used to show common settings and controls, and to provide trace and cursor

information. The information displayed on this panel depends on the current measurement and view settings.

Refer to the appropriate chapter in this guide for information about this panel.

3. Menus are used to configure measurement settings such as frequency, amplitude, and bandwidth, and to

enable measurement modes and views such as Spectrogram view, OBW, ACP, and SEM measurements.

4. The main menu provides access to setting menus and other instrument controls.

5. The upper area typically displays graphical data such as spectrum trace and spectrogram plots. The lower area

typically displays tabular measurement data such as marker data, demodulation results, or other measurement

data depending on the selected measurement.

Figure 2-6. GUI Overview (sample display elements)

MS2090A UG PN: 10580-00444 Rev. C 2-11

Page 28

2-7 GUI Overview Instrument Overview

Operating the Touch Screen

Field Master Pro uses common touch gestures to achieve a variety of operations. These include interactions on

hot areas by pressing, double pressing (or tapping), dragging, and pinching.

Single Press: Most controls require a single press or

tap. Touch the screen briefly and then release.

Double Press: Some controls require a double press or

tap. This action is similar to a double mouse click. If a

second press is not detected in a certain time period, the

action is dismissed or considered a single press.

Figure 2-7. Touch Screen Gestures

Press and Drag: Some items can be dragged to a new

location. This action is accomplished by pressing and

holding the item lightly while dragging it to a new

location, then releasing. You can drag items such as

markers, limit line nodes, and the center frequency by

dragging the trace to the left or right.

Pinch: Some items can be reduced or expanded. This

action is accomplished by simultaneously pressing the

item with two fingers and holding the item lightly when

dragging the fingers in closer together or out farther

apart, and then releasing. You can pinch items in or out,

such as the frequency span by touching and holding the

trace in two positions, and then dragging your fingers

closer together to narrow the span or dragging your

fingers farther apart to widen the span.

2-12 PN: 10580-00444 Rev. C MS2090A UG

Page 29

Instrument Overview 2-7 GUI Overview

Common GUI Controls

In addition to the touch gestures described in the previous section, the following lists the most common

controls that you will encounter when working with the Field Master Pro.

The 3-line icon provides quick access to system information, settings, file

management, and built-in diagnostic tools. Refer to Section2-10“System Menu”

on page 2-20.

The 9-dot icon provides access for selecting the analyzers. Refer to

Section 2-9 “Selecting the Analyzer” on page 2-19.

The camera icon will capture a screen image and save it to a file. Refer to

“Screenshot Setup” on page 2-29.

The notification icon provides access to informational and error messages. If

displayed, the number indicates the number of notifications. Refer to “Notifications”

on page 2-21 and Appendix A, “Instrument Messages and Troubleshooting”.

The software update icon is displayed when the instrument detects a valid software

package. Pressing this icon opens an updated dialog to select the software to

install. Refer to Section 2-14 “Software Update” on page 2-39.

The wireless networking icon shows connection status (no connection, weak

connection, strong connection) and relative signal strength. Pressing the icon

opens the Wi-Fi settings menu. Refer to “Wi-Fi Settings” on page 2-27.

The GPS icon shows connection status (no connection, no fix, good fix, using last

good fix). Pressing the icon opens the GPS/GNSS settings menu. Refer to

“GPS/GNSS Settings” on page 2-28.

The battery icon shows the current battery charge state and indicates that the

battery is charging with a lightning bolt. A question mark (?) indicates that the

battery is not installed or has a malfunction. Touching the icon opens the battery

information dialog. Refer to “Battery Information” on page 2-37.

The close icon is used to close menus and other dialogs.

The chevron will expand and collapse the status and table displays. A similar

chevron on the virtual keyboard may be for capital letters or to scroll through key

sets.

Toggle icon will enable and disable the feature. When highlighted in blue, the item

is enabled.

The drop-down icon exposes a list of items from which to choose.

The refresh icon will restart a process, such as a sweep or averaging count.

The edit icon allows editing of a feature or label.

The enter icon accepts an entry. A similar icon is found on menu buttons to indicate

an additional menu.

Gesture lock and unlock icons indicate when the drag and pinch gestures have

been toggled on or off. Refer to “GESTURES Menu” on page 3-14.

Figure 2-8. Common GUI Controls

MS2090A UG PN: 10580-00444 Rev. C 2-13

Page 30

2-7 GUI Overview Instrument Overview

Data Entry

User input can be in the form of numeric values for instrument or measurement settings, selected values from

a preset list, or alphanumeric text when entering file names, for example. To view or change a parameter

value, access the appropriate menu or control, then enter data using the data entry control or attached

physical keyboard. Some items can be accessed directly on the annotated display by touching their value.

Invalid Entries

When setting parameters or entering other types of data, if an entry is out of range or is otherwise invalid,

Field Master Pro will shade the background display and may provide a message indicating a valid range. In

this case, clear or cancel the entry and enter a valid value or change the units by using either the drop-down

selection next to the data entry window, or with the unit terminators to the left of the keypad.

Numeric Values

To modify a numeric parameter setting that is displayed on a menu or annotated field, press the item to make

it active and to display the numeric keypad data entry control. Use the touch screen to enter or change the

value.

The keypad typically provides controls to:

• Enter new values directly, such as frequency entries in Hz, kHz, MHz, or

GHz. There are two places on the keypad to enter unit terminators when

applicable, on left side pop-out that occurs as frequency keypad entries are

selected, or on the top right corner drop-down of the entry field.

• Drag a parameter value within its settable range using a sliding control.

• Increment the parameter value up or down. At each end of the slider are plus

(+) and minus (–) controls that increment the parameter value. Most

parameters have a fixed increment, such as bandwidth that follows a 1:3:10

sequence and span that follows a 1:2:5:10 sequence. In the case of

frequency, you can set a custom frequency step increment value. Once the

entry is complete, press the desired unit or press ACCEPT to complete the

entry.

• Set the parameter to the maximum or minimum possible value.

• CLEAR the entire entry.

• Left arrow to backspace and delete the entry

• CANCEL to terminate any entries made for that particular setting. Note that

pressing the "X" to close the keypad is the same as pressing cancel.

Pressing CANCEL will restore settings back to the state they were in before

the keypad opened, even if changes from the +/- controls are already

reflected in the data display.

• ACCEPT to operate with the settings displayed on the keypad.

Figure 2-9. Touchscreen Keypads

A physical keyboard connected via USB can also be used to enter values in a similar manner and the keyboard

ENTER key used to accept the new value.

2-14 PN: 10580-00444 Rev. C MS2090A UG

Page 31

Instrument Overview 2-7 GUI Overview

Selection Lists

Some parameters and instrument functions are selectable from a list. These list boxes display the available

selections and value limits as applicable. Use the touch screen to scroll through the list and select the desired

entry.

Figure 2-10. Touch Screen Keypads

To cancel the selection, touch somewhere else on the display or close the menu.

MS2090A UG PN: 10580-00444 Rev. C 2-15

Page 32

2-7 GUI Overview Instrument Overview

1

2

Scroll Indication

In some cases, menus, status panels, or other lists contain more information than can be displayed in the