Page 1

BERTWave Series

•

For safety and warning information, please read this

•

Additional safety and warning information is provided

BERTWave

.

•

Remote Control

Operation Manual

11th Edition

manual before attempting to use the equipment.

within the MP2100A/MP2101A/MP2102A

Operation Manual, MP2100B BERTWave Operation

Manual or MP2110A BERTWave Operation Manual

Please also refer to them before using the equipment.

Keep this manual with the equipment.

ANRITSU CORPORATION

Document No.: M-W3773AE-11.0

Page 2

DANGER

WARNING

CAUTION

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the

following safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of

the symbols BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu

equipment. In addition, there may be other labels attached to products that are not shown in the diagrams in this

manual.

Symbols used in manual

This indicates a very dangerous procedure that could result in serious injury or

death if not performed properly.

This indicates a hazardous procedure that could result in serious injury or death if

not performed properly.

This indicates a hazardous procedure or danger that could result in light-to-severe

injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manual

The following safety symbols are used inside or on the equipment near operation locations to provide information

about safety items and operation precautions. Ensure that you clearly understand the meanings of the symbols and

take the necessary precautions BEFORE using the equipment.

This indicates an obligatory safety precaution. The obligatory operation is

This indicates a warning or caution. The contents are indicated symbolically in or

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

indicated symbolically in or near the circle.

near the triangle.

BERTWave Series

Remote Control Operation Manual

4 September 2015 (First Edition)

24 April 2019 (11th Edition)

Copyright © 2015-2019, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The contents of this manual may be changed without prior notice.

Printed in Japan

ii

Page 3

This product and its manuals may require an Export License/Approv al by

the Government of the product's country of origin for re-export from your

country.

Before re-exporting the product or manuals, please contact us to confirm

whet

When you dispose of export-controlled items, the products/manuals need

to be broken/shredded so as not to be unlawfully used for military purpose.

Notes On Export Management

her they are export-controlled items or not.

iii

Page 4

iv

Page 5

About This Manual

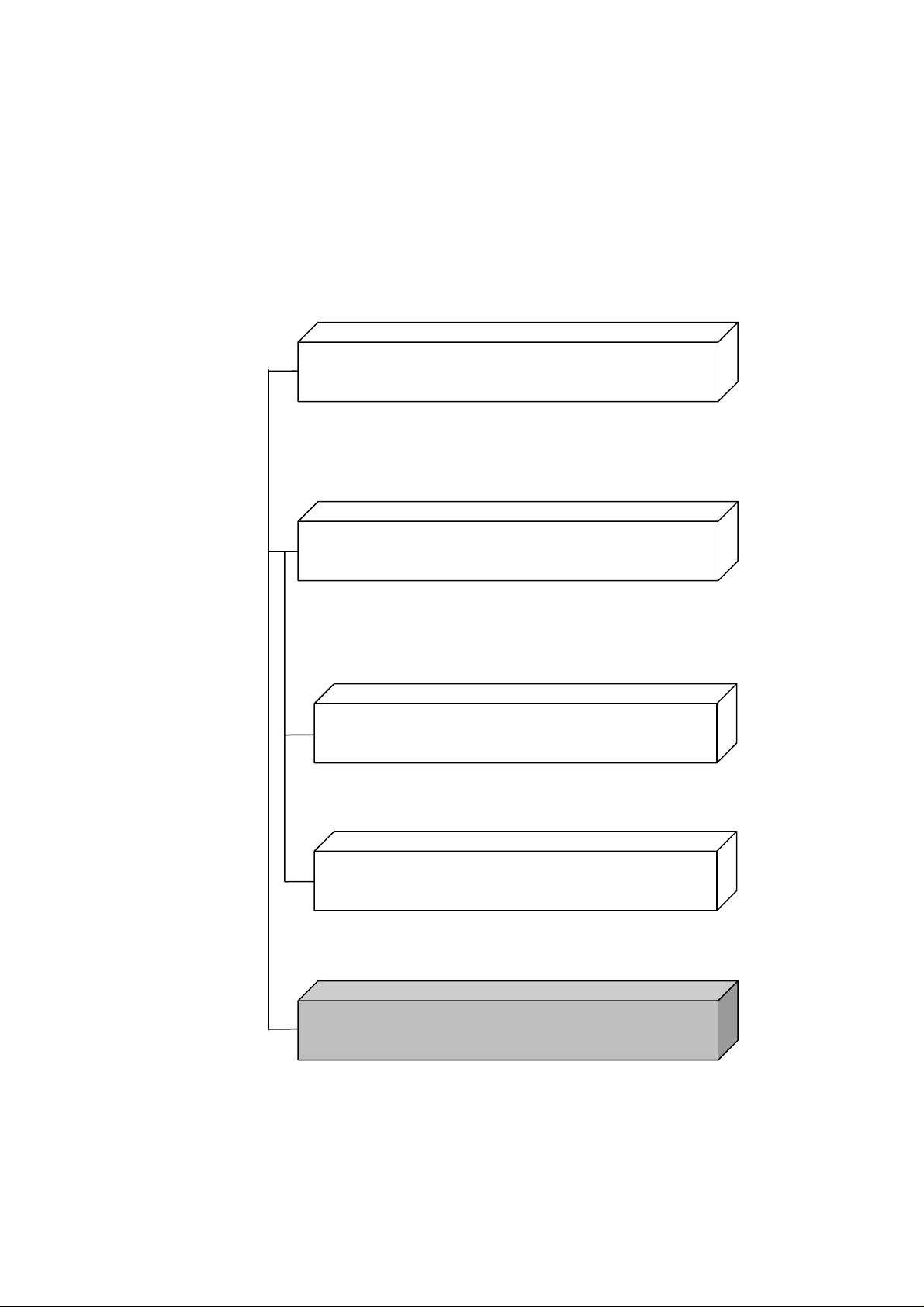

The manual set for the BERTWave Series consists of the following five

operation manuals:

MP2110A BERTWave Operation Manual

(M-W3831AE)

This manual is intended for those who use the MP2110A BERTWave,

and explains the installation procedure, handling precautions,

connector connection procedures, panel operations, maintenance

procedures, specifications and various functions.

MP2100B BERTWave Operation Manual

(M-W3772AE)

This manual is intended for those who use the MP2100B

BERTWave, and explains the installation procedure, handling

precautions, connector connection procedures, panel operations,

maintenance procedures, specifications and various functions.

MX210001A Jitter Analysis Software

Operation Manual (M-W3569AE)

This manual explains the operation method and remote control

commands for the MX210001A Jitter Analysis Software.

MX210002A Transmission Analysis Software

Operation Manual (M-W3571AE)

This manual explains the operation method and remote control

commands for the MX210002A Transmission Analysis Software.

BERTWave series Remote Control

Operation Manual (M-W3773AE) (This Manual)

This manual explains the commands to control the BERTWave,

status register structure, and sample programs.

I

Page 6

Also, there is the manual “

PE MP2102A BERTWave SS Operation Manual

(M-W3349AE)”. MP2100A, MP2101A, and MP2102A are the

discontinued products.

This manual explains the remote control commands.

This manual assumes the reader has the following information:

● The reader has read through the

Manual

● The reader can create the C or Basic program.

For the connection of the power source and peripheral devices, panel

operation, and maintenance, refer to the following manual:

or

MP2110A BERTWave Operation Manual

MP2100A BERTWave MP2101A BERTWave

(Operation)

MP2100B BERTWave Operation

.

MP2100B BERTWave Operation Manual

MP2110A BERTWave Operation Manual

In this manual, the models of BERTWave are described as follows.

MP210xA: MP2100A, MP2101A, and MP2102A

this instrument: MP2100A, MP2101A, MP2102A, MP2100B, and

MP2110A

BERTWave: MP2100A, MP2101A, MP2102A, MP2100B, and

MP2110A

II

Page 7

Table of Contents

1

About This Manual................................................. I

Chapter 1 Overview ........................................... 1-1

1.1 What is Remote Control? .............................................. 1-2

1.2 Main Uses for Remote Control ..................................... 1-3

1.3 Abbreviations ................................................................ 1-5

1.4 Restrictions on Software Versions ................................ 1-6

2

3

Appendix Index

Chapter 2 Before Use ........................................ 2-1

2.1 Connection Types of Remote Controlling ..................... 2-2

2.2 Multiple Sessions (Version 5 or later) ........................... 2-3

2.3 Required Equipment ..................................................... 2-4

2.4 Connecting Equipment ................................................. 2-5

2.5 Setting Interface ............................................................ 2-8

2.6 Checking Connection .................................................. 2-10

2.7 Message Format ......................................................... 2-12

2.8 Checking Instrument Status ........................................ 2-17

2.9 Checking If Message Execution Is Completed ........... 2-29

Chapter 3 Message List ..................................... 3-1

3.1 Rules for Describing Messages .................................... 3-3

3.2 Correspondence Between Panel and Messages ......... 3-4

3.3 Messages Corresponding to Common Operations .... 3-43

3.4 Status Register ........................................................... 3-61

3.5 Specifying Module and Channel ................................. 3-8 4

3.6 BERT(PPG/ED) Messages ......................................... 3- 86

3.7 XFP/SFP+ specific Messages

(MP210xA, MP2100B) .............................................. 3-134

3.8 O/E messages .......................................................... 3-137

3.9 Scope-specific messages ......................................... 3-138

III

Page 8

Appendix A Command Compatibility With

Existing Products ......................... A-1

Appendix B Error Codes .................................. B-1

Appendix C Sample Program .......................... C-1

Appendix D Bibliography ................................. D-1

Index .................................................. Index-1

IV

Page 9

Table of Messages

1

TRM .................................................................................... 3-43

GTL (Go to local) ................................................................... 3-43

:SYSTem:BEEPer:SET ......................................................... 3-44

:SYSTem:VERSion? ............................................................. 3-45

*IDN? (Identification) ............................................................. 3-45

*OPT? (Option Identification Query) ..................................... 3-45

:SYSTem:INFormation? ........................................................ 3-48

:SYSTem:{DATE|TIME}? ...................................................... 3-48

:SYSTem:ERRor? ................................................................. 3-48

:SYSTem:ERRor:HCLear ..................................................... 3-50

:SYSTem:ERRor:HISTory? ................................................... 3-50

:SYSTem:DISPlay:ALARm ................................................... 3-51

:SYSTem:INFormation:ERRor? ............................................ 3-51

*RST (Reset) ......................................................................... 3-52

:SYSTem:MMEMory:RECall ................................................. 3-53

:SYSTem:MMEMory:STORe ................................................ 3-54

:SYSTem:DISPlay:RESult .................................................... 3-56

:SYSTem:PRINt:COPY ......................................................... 3-57

:SYSTem:DISPlay:DATA? .................................................... 3-58

:DISPlay:ACTive ................................................................... 3-60

:DISPlay:ACTive:ACResult ................................................... 3-60

*CLS (Clear Status) ............................................................... 3-61

:STATus:PRESet .................................................................. 3-62

*STB? (Status Byte) .............................................................. 3-63

*SRE (Service Request Enable) ........................................... 3-64

*ESR? (Standard Event Status Register) ............................. 3-65

*ESE (Event Status Enable) ................................................. 3-66

:STATus:OPERation:CONDition? ......................................... 3-67

:STATus:OPERation[:EVENt]? ............................................. 3-67

:STATus:OPERation:ENABle ............................................... 3-68

:STATus:OPERation:NTRansition ........................................ 3-69

:STATus:OPERation:PTRansition ........................................ 3-70

:INSTrument:PE<ch>:RESet ................................................ 3-71

:INSTrument:PE<ch>:CONDition? ........................................ 3-71

:INSTrument:PE<ch>[:EVENt]? ............................................ 3-72

:INSTrument:PE<ch>:NTRansition ....................................... 3-73

:INSTrument:PE<ch>:PTRansition ....................................... 3-74

:INSTrument:WAV:RESet ..................................................... 3-75

:INSTrument:WAV:CONDition? ............................................ 3-75

:INSTrument:WAV[:EVENt]? ................................................. 3-76

:INSTrument:WAV:NTRansition ............................................ 3-76

2

3

Appendix Index

V

Page 10

:INSTrument:WAV:PTRansition ............................................ 3-77

:INSTrument:XSFP:RESet .................................................... 3-78

:INSTrument:XSFP:CONDition? ........................................... 3-78

:INSTrument:XSFP[:EVENt]? ............................................... 3-78

:INSTrument:XSFP:NTRansition .......................................... 3-79

:INSTrument:XSFP:PTRansition ........................................... 3-80

*OPC (Operation Complete) ................................................. 3-81

*WAI (Wait to Continue) ........................................................ 3-81

:SOURce:OUTPut:ASET ...................................................... 3-82

*TRG (Trigger) ...................................................................... 3-82

:SENSe:MEASure:ASTP ...................................................... 3-83

:SENSe:MEASure:ASTate? .................................................. 3-83

:MODule:ID ........................................................................... 3-84

:DISPlay:RESult .................................................................... 3-86

:OUTPut:RCLock .................................................................. 3-87

:OUTPut:RCLock:SELect ...................................................... 3-88

:OUTPut:CMU:EXTClock ...................................................... 3-89

:OUTPut:RCLock:STATus? .................................................. 3-89

:OUTPut:RCLock:APPLy ...................................................... 3-90

:OUTPut:CLOCk:SOURce:CHANnel .................................... 3-91

:OUTPut:CLOCk:DIVRate? ................................................... 3-91

:OUTPut:SYNC:SOURce ...................................................... 3-92

:BERT:ALL:PARam:TRACking ............................................. 3-93

:SENSe:PARam:TRACking .................................................. 3-94

:OUTPut:BITRate:STANdard ................................................ 3-95

:INPut:BITRate:STANdard .................................................... 3-98

:OUTPut:BITRate .................................................................. 3-99

:INPut:BITRate .................................................................... 3-100

:OUTPut:BITRate:OFFSet .................................................. 3-101

:OUTPut:BITRate:DIVRate ................................................. 3-102

:INPut:BITRate:DIVRate? ................................................... 3-103

:SOURce:PATTern:TYPE ................................................... 3-104

:SENSe:PATTern:TYPE ..................................................... 3-105

:SOURce:PATTern:LOGic .................................................. 3-106

:SENSe:PATTern:LOGic ..................................................... 3-106

:SOURce:MMEMory:PATTern:RECall ................................ 3 - 10 7

:SENSe:MMEMory:PATTern:RECall .................................. 3-108

:SOURce:PATTern:DATA:LENGth? ................................... 3-108

:SENSe:PATTern:DATA:LENGth? ..................................... 3-109

:OUTPut:DATA:OUTPut ..................................................... 3-110

:OUTPut:DATA:AMPLitude ................................................. 3-111

VI

Page 11

1

:OUTPut:DATA:ATTFactor ................................................. 3-111

:OUTPut:DATA:RELative? .................................................. 3-112

:SOURce:PATTern:EADDition:SET .................................... 3-112

:SOURce:PATTern:EADDition:VARiation ........................... 3 -1 13

:SOURce:PATTern:EADDition:SINGle ............................... 3-113

:SOURce:PATTern:EADDition:RATE ................................. 3-114

:INPut:DATA:INTerface ....................................................... 3-115

:INPut:DATA:ATTFactor ..................................................... 3-116

:INPut:DATA:THReshold .................................................... 3-117

:SENSe:PATTern:SYNC:ASYNc ........................................ 3-118

:SENSe:PATTern:SYNC:THReshold .................................. 3-119

:SENSe:PATTern:SYNC:PSMode ...................................... 3-120

:SENSe:PATTern:SYNC:FPOSition ................................... 3-121

[:BERT:ALL]:DISPlay:RESult:EALarm:HRESet .................. 3-122

[:BERT:ALL]:CALCulate:DATA:MONitor? .......................... 3-122

[:BERT:ALL]:CALCulate:DATA:MONitor:HISTory? ............ 3-123

[:BERT:ALL]:SENSe:MEASure:IMMediate? ....................... 3-124

[:BERT:ALL]:CALCulate:DATA:EALarm? ........................... 3-126

:SENSe:MEASure:EALarm:MODE ..................................... 3-128

:SENSe:MEASure:EALarm:PERiod .................................... 3-129

:DISPlay:RESult:EALarm:MODE ........................................ 3-130

[:BERT:ALL]:SENSe:MEASure:STARt ............................... 3 -1 30

[:BERT:ALL]:SENSe:MEASure:STOP ................................ 3- 13 1

[:BERT:ALL]:SENSe:MEASure:EALarm:STATe? .............. 3-131

:SENSe:MEASure:EALarm:STARt? ................................... 3-132

:SENSe:MEASure:EALarm:STOP? .................................... 3-132

:SENSe:MEASure:EALarm:ELAPsed? ............................... 3-132

:SENSe:MEASure:EALarm:TIMed? .................................... 3-133

:CALCulate:OPTical:STATus? ............................................ 3-134

:SOURce:OPTical:SIGNal:WLENgth? ................................ 3-134

:SOURce:OPTical:SIGNal:OUTPut .................................... 3-135

:SOURce:OPTical:XFP:REFClock ...................................... 3-136

:INPut:{CHA|CHB|CHC|CHD|ALL} ...................................... 3-138

:CONFigure:MEASure:CHANnel ........................................ 3-138

:CONFigure:MEASure:TYPe .............................................. 3-140

:CONFigure:MEASure:AMPTime:DISPlay.......................... 3-141

:DISPlay:WINDow:GRAPhics:CLEar .................................. 3-142

:SAMPling:STATus ............................................................. 3-142

:DISPlay:WINDow:AUTOscale ........................................... 3-143

:DISPlay:WINDow:MODE ................................................... 3-144

:DISPlay:WINDow:ZOOM

................................................... 3-144

2

3

Appendix Index

VII

Page 12

:DISPlay:SIGNal .................................................................. 3-145

:DISPlay:MODE .................................................................. 3-145

:DISPlay:MODE:EYE:FAST ................................................ 3-146

:OPTion:MAX:SAMPles:NUMber ........................................ 3-146

:ACCUmulation:TYPe ......................................................... 3-148

:ACCUmulation:LIMit........................................................... 3-148

:ACCUmulation:PERSistency ............................................. 3-150

:ACCUmulation:AVERaging ................................................ 3-150

:TIME:CRU .......................................................................... 3-151

:TIME:CRU:RATE:STANdard ............................................. 3-151

:TIME:CRU:RATE ............................................................... 3-152

:TIME:CRU:LBWidth ........................................................... 3-153

:TIME:CRU:STATus? .......................................................... 3-153

:TIME:CRU:FREQuency? ................................................... 3-154

:INPut:CLKRecovery ........................................................... 3-155

:CONFigure:CLKRecovery .................................................. 3-155

:EYEPulse:PRINt:COPY ..................................................... 3-156

:PRINt:GRATicule ............................................................... 3-157

:PRINt:INVerse .................................................................... 3-157

:DISPlay:WAVeform:COLor ................................................ 3-158

:DISPlay:WAVeform:COLor:GSCale[:TEQualizer][:

{CHA|CHB|CHC|CHD|ALL}] ..................................... 3-158

:DISPlay:MASK:COLor ....................................................... 3-159

:DISPlay:INFormation ......................................................... 3-160

:DISPlay:LABel .................................................................... 3-160

:DISPlay:LABel:DALL ......................................................... 3-161

:TMEMory:REFerence:SET ................................................ 3-162

:TMEMory:REFerence:CLEar ............................................. 3-162

:TMEMory:CHANnel ............................................................ 3-162

:CALibrate:TEMPerature? ................................................... 3-164

:CALibrate:AMPLitude? ...................................................... 3-164

:CALibrate:APPLication ...................................................... 3-165

:TIME:TRACking ................................................................. 3-166

:TIME:TRACking:STATus? ................................................. 3-167

:CONFigure:TRACking:DRATe ........................................... 3-167

:CONFigure:TRACking:DRATe:MASTer ............................ 3-168

:TIME:ACQClock? ............................................................... 3-169

:TIME:CLKRate ................................................................... 3-170

:TIME:DATRate ................................................................... 3-171

:TIME:DIVRatio ................................................................... 3-172

:TIME:AUTodetect ............................................................... 3- 173

VIII

Page 13

1

:TIME:PTRigger .................................................................. 3-173

:TIME:PTRigger:RESet ....................................................... 3-174

:DISPlay:WINDow:X:UNIT .................................................. 3-175

:DISPlay:WINDow:X:BITs ................................................... 3-175

:DISPlay:WINDow:X:OFFSets ............................................ 3-176

:TIME:PATTern:TYPE ......................................................... 3-177

:TIME:PATLength ................................................................ 3-177

:CONFigure:TRACking:PATLength .................................... 3-178

:CONFigure:TRACking:PATLength:MASTer ...................... 3-179

:CONFigure:SKEW:{CHA|CHB|CHC|CHD} ........................ 3-180

:CONFigure:SKEW:ALIGn .................................................. 3-181

:DISPlay:WINDow:CHANnel:BOTH .................................... 3-182

:DISPlay:WINDow:Y:DIVision:{CHA|CHB|CHC|CHD} ........ 3-182

:DISPlay:WINDow:Y:OFFSets:{CHA|CHB|CHC|CHD} ....... 3-183

:INPut:ATTenuation[:{CHA|CHB|CHC|CHD|ALL}] .............. 3-184

:CALCulate:CHANnel:MATH .............................................. 3-185

:CALCulate:CHANnel:MATH:DEFine ................................. 3-186

:DISPlay:WINDow:Y:DIVision:CHMath ............................... 3-186

:DISPlay:WINDow:Y:OFFSets:CHMath .............................. 3 -1 87

:CALibrate:OEPower[:JUDGe] ............................................ 3-188

:INPut:WAVLength .............................................................. 3-189

:CALibrate:CGain ................................................................ 3-189

:CALibrate:SYSTem:CGain ................................................ 3-190

:CALibrate:RESPonsivity .................................................... 3-191

:CALibrate:AUTocorrect ...................................................... 3-191

:CALibrate:CALPower ......................................................... 3-192

:FILTer ................................................................................. 3-193

:INPut:FILTer:ENABle ......................................................... 3-195

:INPut:FILTer ....................................................................... 3-196

:CONFigure:EXRCorrection ................................................ 3-198

:CONFigure:EXRCorrection:FACTor .................................. 3-199

:CONFigure:MEASure:DISPlay:ADD .................................. 3-200

:CONFigure:MEASure:DISPlay:ADELete

[:{CHA|CHB|CHC|CHD|ALL}] ................................... 3-200

:CONFigure:MEASure:AMPTIME{1|2|3|4} .......................... 3-201

:CONFigure:MEASure:AREa:DISPlay ................................ 3-202

:CONFigure:MEASure:AREa:ITEM .................................... 3-203

:CONFigure:MEASure:PAM:TIMing .................................... 3-204

:CONFigure:MEASure:PAM:CENTer .................................. 3-204

:CONFigure:

:CONFigure:MEASure:PAM:LINearity:DEFinition .............. 3-205

MEASure:PAM:EOPening .............................. 3-205

2

3

Appendix Index

IX

Page 14

:CONFigure:MEASure:PAM:TDECQ:SER.......................... 3-206

:CONFigure:MEASure:PAM:TDECQ:SER:VARiable ......... 3-206

:CONFigure:MEASure:PAM:TDECQ:OTHReshold ............ 3-207

:CONFigure:MEASure:PAM:TEQualizer:{CHA|CHB} ......... 3-207

:CONFigure:MEASure:PAM:TEQualizer:DISPlay

[:{CHA|CHB|CHC|CHD|ALL}] ................................... 3-208

:CONFigure:MEASure:PAM:TEQualizer:ETYPe

[:{CHA|CHB|CHC|CHD|ALL}] ................................... 3-208

:CONFigure:MEASure:PAM:TEQualizer:CALCulate

[:{CHA|CHB|CHC|CHD|ALL}] ................................... 3-209

:CONFigure:MEASure:PAM:TEQualizer:CALCulate:RESult

[:{CHA|CHB|CHC|CHD|ALL}] ................................... 3-209

:CONFigure:MEASure:PAM:TEQualizer:NPRecursors

[:{CHA|CHB|CHC|CHD|ALL}] ................................... 3-210

:CONFigure:MEASure:PAM:TEQualizer:OPTimization

[:{CHA|CHB|CHC|CHD|ALL}] ................................... 3-211

:CONFigure:MEASure:PAM:TEQualizer:TAPS:COUNt

[:{CHA|CHB|CHC|CHD|ALL}] ................................... 3-211

:CONFigure:MEASure:PAM:TEQualizer:TAPS:

{CHA|CHB|CHC|CHD} .............................................. 3-212

:CONFigure:MEASure:DEFine ........................................... 3-213

:CONFigure:MEASure:TRANsition:CORRection ................ 3-213

:CONFigure:MEASure:TRANsition:CORRect:FACTor ....... 3-214

:CONFigure:MEASure:EYEBoundary:OFFSet ................... 3-214

:CONFigure:MEASure:EYEBoundary:WIDTh .................... 3-215

:CONFigure:MEASure:NOISe ............................................. 3-216

:CONFigure:MASK .............................................................. 3-217

:CONFigure:MASK:RECall ................................................. 3-217

:CONFigure:MASK:TYPe .................................................... 3-218

:CONFigure:MASK:ALGorithm ........................................... 3-220

:CONFigure:MASK:UPDate ................................................ 3-220

:CONFigure:MASK:USER:MARKer .................................... 3-220

:CONFigure:MASK:USER:LOCation:{X1|XDELta} ............. 3-221

:CONFigure:MASK:USER:LOCation:{Y1|YDELta} ............. 3-222

:CONFigure:MASK:MARGin:CONTupdate ......................... 3-223

:CONFigure:MASK:MARGin ............................................... 3-223

:MEASure:MASK:MARGin? ................................................ 3-224

:SAMPles:JUDGe:TYPE ..................................................... 3-224

:SAMPles:JUDGe ................................................................ 3-225

:SAMPles:JUDGe:RATE ..................................................... 3-226

:CONFigure:MASK:AREa:RESTriction ............................... 3-227

X

Page 15

1

:CONFigure:MASK:AREa:RESTriction:ANGLe .................. 3-227

:CONFigure:MASK:AREa:RESTriction:WIDTh ................... 3-228

:CONFigure:HISTogram ..................................................... 3-229

:CONFigure:HISTogram:AXIS ............................................ 3-229

:HISTogram:CENTer ........................................................... 3-230

:HISTogram:{X1|X2} ............................................................ 3-230

:HISTogram:{Y1|Y2} ............................................................ 3-231

:FETCh:AMPTime:QUEStionableeye? ............................... 3 -2 32

:FETCh:AMPTime:QUEStionableeye:STATus:

{CHA|CHB|CHC|CHD|ALL}? .................................... 3-232

:FETCh:AMPLitude:<meas_item>? .................................... 3-233

:FETCh:TIME:<meas_item>]? ............................................ 3-237

:FETCh:MASK:<meas_item>? ............................................ 3-240

:FETCh:HISTogram:AMPLitude:<meas_item>? ................. 3-242

:FETCh:HISTogram:TIME:<meas_item>? .......................... 3-243

:TRACe:{CHANnelA|CHANnelB|CHANnelC|CHANnelD|

CHANnels}? .............................................................. 3-244

:TRACe:PREPare ............................................................... 3-246

:TRACe:END ....................................................................... 3-247

:CALCulate:MARKer:AOFF ................................................ 3-248

:CALCulate:MARKer:CENTer ............................................. 3-248

:CALCulate:MARKer:{X1|X2|Y1|Y2} ................................... 3-248

:CALCulate:MARKer:LOCation:{X1|X2} .............................. 3-249

:CALCulate:MARKer:LOCation:XDELta? ........................... 3-249

:CALCulate:MARKer:LOCation:

{CHA|CHB|CHC|CHD}:{Y1|Y2} ................................. 3-250

:CALCulate:MARKer:LOCation:

{CHA|CHB|CHC|CHD}:YDELta? .............................. 3-250

:JITTer:RESult:ERRor? ....................................................... 3-251

:JITTer:MEASure:PDJ......................................................... 3-251

:JITTer:MEASure:PDJ:STANdard ....................................... 3-252

:JITTer:MEASure:PDJ:FILTer ............................................. 3-252

:JITTer:MEASure:EDGE:TYPE ........................................... 3-253

:JITTer:MEASure:TJ:BER[:{CHA|CHB}] ............................. 3-254

:JITTer:MEASure:RJ:FIXed[:{CHA|CHB}] ........................... 3-255

:JITTer:MEASure:RJ:FIXed:VALue[:{CHA|CHB}] ............... 3-255

:JITTer:MEASure:CORRection[:{CHA|CHB}] ..................... 3-256

:JITTer:MEASure:CORRection:DJ:SCALe

[:{CHA|CHB|CHC|CHD|ALL}] ................................... 3-257

:JITTer:MEASure:CORRection:RJ:SCALe[:{CHA|CHB}] ... 3-257

:JITTer:MEASure:CORRection:RJ:RMS[:{CHA|CHB}] ....... 3-258

2

3

Appendix Index

XI

Page 16

:JITTer:MEASure:CROSsing[:{CHA|CHB}] ......................... 3-259

:JITTer:MEASure:CROSsing:MANual ................................ 3-259

:JITTer:GRAPh:ESTimate:RJDJ[:{CHA|CHB|CHC|CHD}] .. 3-260

:JITTer:GRAPh:ESTimate:RJPJ ......................................... 3-260

:JITTer:GRAPh:DDJ:{ALL|FALL|RISE} ............................... 3-261

:JITTer:MEASure:PJ:FREQuency:CALCulate .................... 3-261

RTM? ...................................................................................... A-9

INF? ...................................................................................... A-9

:SYSTem:MEMory:INITialize .................................................. A-9

INI .................................................................................... A-10

HCP .................................................................................... A-10

OON .................................................................................... A-10

:SENSe:MEASure:ASTRt ..................................................... A-11

SAT .................................................................................... A-11

SOT .................................................................................... A-11

STT? .................................................................................... A-11

:OUTPut:CMU:REFClock ...................................................... A-12

RFC .................................................................................... A-12

CRE .................................................................................... A-13

CEC .................................................................................... A-13

SOP .................................................................................... A-14

:SENSe:PARam:AEXecute ................................................... A-15

:OUTPut:CLOCk:OPERation ................................................ A-16

OPE .................................................................................... A-17

:OUTPut:CLOCk:FREQuency ............................................... A-19

:OUTPut:CMU:FREQuency .................................................. A-19

CRF .................................................................................... A-20

:OUTPut:CMU:RESolution .................................................... A-20

CRS .................................................................................... A-21

:OUTPut:CLOCk:OFFSet:PPM ............................................. A-22

COP .................................................................................... A-22

PTS .................................................................................... A-23

LGC .................................................................................... A-24

DLN? .................................................................................... A-25

DON .................................................................................... A-25

DAP .................................................................................... A-26

DAT .................................................................................... A-26

PRO? .................................................................................... A-27

EAD .................................................................................... A-27

EAV .................................................................................... A-28

XII

Page 17

1

ESI .................................................................................... A-28

ERT .................................................................................... A-29

DSD .................................................................................... A-30

DTH .................................................................................... A-30

SYN .................................................................................... A-31

SYE .................................................................................... A-32

SYM .................................................................................... A-33

FPS .................................................................................... A-33

HRE .................................................................................... A-34

MTR? .................................................................................... A-34

ERS? .................................................................................... A-35

:SENSe:PARam:AEXecute? ................................................. A-36

END? .................................................................................... A-38

ER? .................................................................................... A-39

EC? .................................................................................... A-39

CC? .................................................................................... A-40

FRQ? .................................................................................... A-40

MOD .................................................................................... A-41

PRD .................................................................................... A-42

CUR .................................................................................... A-42

STA .................................................................................... A-43

STO .................................................................................... A-43

MSR? .................................................................................... A-43

MSA? .................................................................................... A-43

MSO? .................................................................................... A-44

MLP? .................................................................................... A-44

ETI? .................................................................................... A-44

:FETCh:AMPLitude:MEASurement? ..................................... A-45

:FETCh:TIME:MEASurement? .............................................. A-46

:MEASure:AMPLitude[:{CHA|CHB}]? ................................... A-47

:MEASure:TIME? .................................................................. A-48

:MEASure:MASK? ................................................................. A-49

:MEASure:HISTogram:AMPLitude? ...................................... A-50

:MEASure:HISTogram:TIME? ............................................... A-51

2

3

Appendix Index

XIII

Page 18

XIV.

Page 19

Overview

Chapter 1 Overview

This chapter explains the outline of the remote control.

1.1

What is Remote Control? ............................................ 1-2

1.2 Main Uses for Remote Control .................................... 1-3

1.3 Abbreviations .............................................................. 1-5

1.4 Restrictions on Software Versions ............................... 1-6

1

1-1

Page 20

Chapter 1 Overview

1.1 What is Remote Control?

The remote control function sends commands via the communications

interface from the control PC to set the measuring instrument and read

the measurement results and measuring instrument conditions.

The BERTWave supports the Ethernet or GPIB as a control interface.

For MP210xA and MP2100B, the Option 030 is required to use GPIB

interface.

When using either interface, set the number to distinguish the

BERTWave from other equipment. This number must be an IP address

and TCP port number when using the Ethernet interface, or the GPIB

address when using GPIB connection.

The character strings for controlling the BERTWave are called

“command”. The command is composed of the ASCII character strings.

For example, the following command is used to output the signal of the

pulse pattern generator (hereafter, PPG) to the connector.

:OUTput:DATA:OUTput ON

A command for reading data from the BERTWave is called “query”. A

query command has the question symbol (?) appended to the end of string.

For example, sending the following command queries the PPG bit rate set

at the instrument.

:OUTput:BITRate?

1-2

The control PC receives the following response to the query from the

instrument.

1250000

The bit rate is 1250000 kbit/s.

When the BERTWave is measured via remote control, the Remote lamp

on the screen is lit. Only the power switch and the key

on the system menu are valid in this situation. This situation is called

panel lock. To unlock the panel, touch

menu.

Local/Panel Unlock on the system

Local/Panel Unlock

Page 21

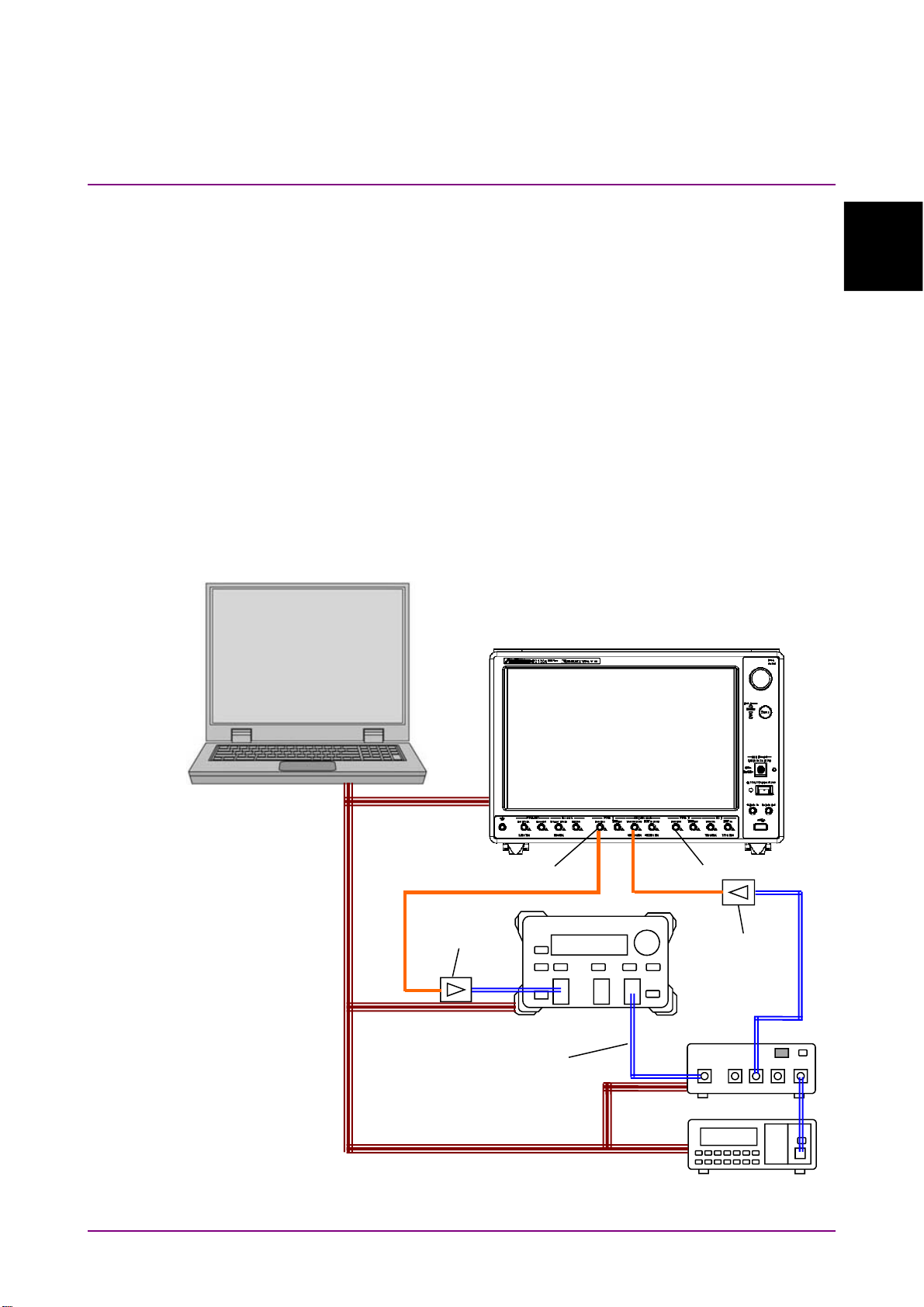

1.2 Main Uses for Remote Control

The main uses for remote control are:

Automation of measurement

To control measuring instruments by executing a program, instead of

touch-panel operations. Measurement can be automated by describing the

control procedures for controlling the measuring instruments, in the

program.

Remote control of instruments

To collect measurement data by controlling measuring instruments

installed at remote locations, over communications lines.

Control of multiple measuring instruments

To measure the characteristics of DUTs via the remote control of multiple

measuring instruments.

1.2 Main Uses for Remote Control

1

Overview

Control PC

E/O

Converter

Optical Fiber

PPG Output

Optical Attenuator

BERTWave

ED1 Input

Optical Receiver

(DUT)

Optical Switch

Optical Power Meter

Figure 1.2-1 Example of Controlling Multiple Instruments

1-3

Page 22

–25.034

0.011442

–24.523

0.0048758

–24.031

0.001631

–23.536

0.00044241

–23.030

0.000078419

–22.523

0.0000088616

–22.031

0.000000616

–21.524

0.000000016

–21.037

0.00000000028235

Chapter 1 Overview

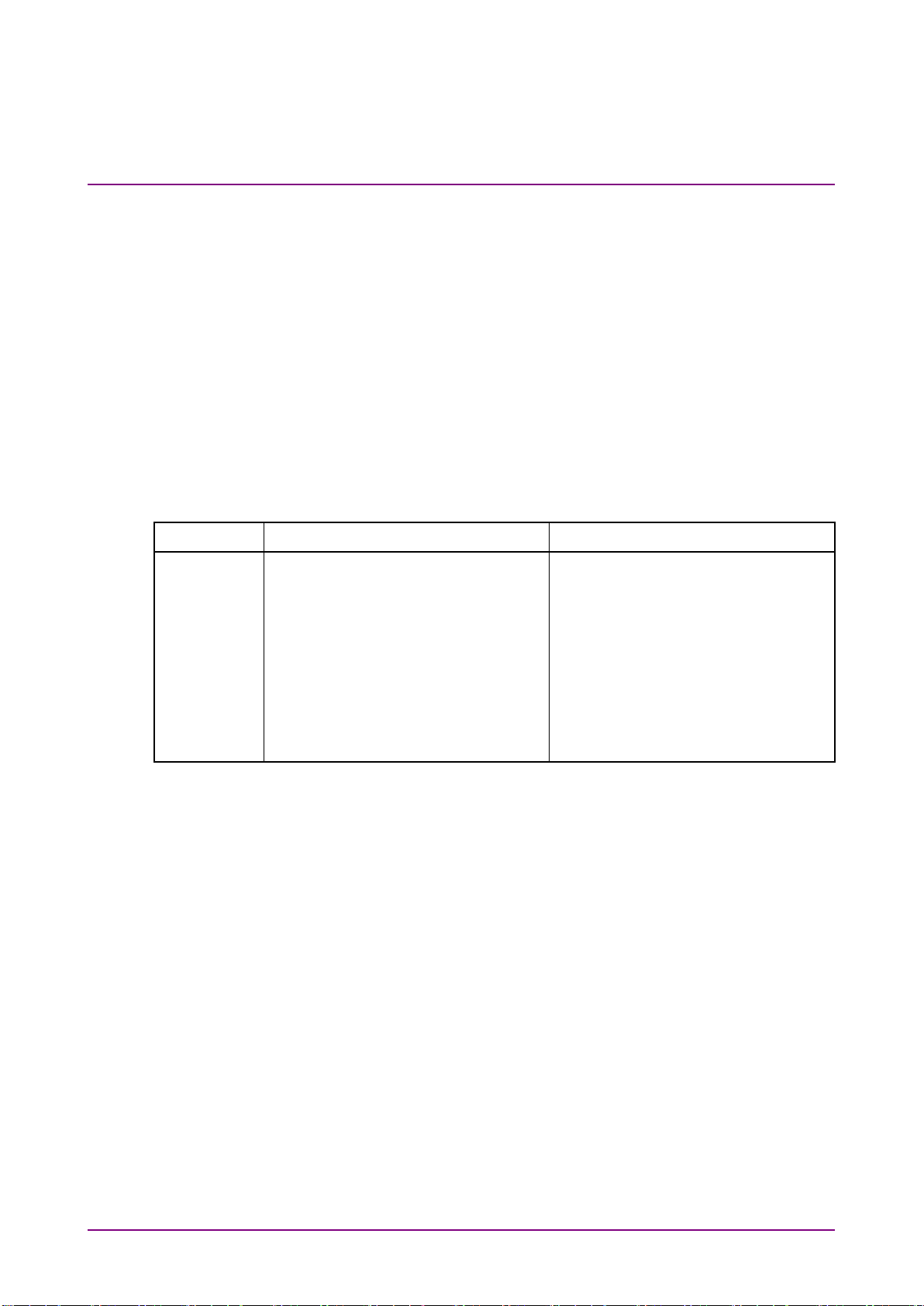

Figure 1.2-1 shows an example of controlling multiple instruments. In

this example, the bit error rates are measured with changes in the optical

input level of the optical receiver. On the control PC, set the attenuation

of the optical attenuator to read the optical power level measured by the

optical power meter, and the bit error rate measured by the BERTWave.

Table 1.2-1 shows the measurement results that are obtained by changing

the optical attenuation.

Table 1.2-1 Bit Error Rate of Optical Receiver

Optical Power (dBm) Bit Error Rate

1-4

Page 23

Overview

1.3 Abbreviations

ASCII

American Standard Code for Information Interchange

CR

Carriage Return

ED

Error Detector

EOI

End or Identify

ESER

Event Status Enable Register

ESR

Event Status Register

GPIB

General Purpose Interface Bus

HiSLIP

High Speed LAN Instrument Protocol

IEC

International Electrotechnical Commission

IEEE

Institute of Electrical and Electronics Engineers

LAN

Local Area Network

LF

Line Feed

MAV

Message Available

MSS

Master Summary Status

OSER

Operation Status Enable Register

OSR

Operation Status Register

PC

Personal Computer

PPG

Pulse Pattern Generator

SCPI

Standard Commands for Programmable Interfaces

SRER

Service Request Enable Register

SRQ

Service Request

STB

Status Byte Register

TR

Transition Filter

VISA

Virtual Instrument Software Architecture

VXI-11

VMEbus Extensions for Instrumentation-11

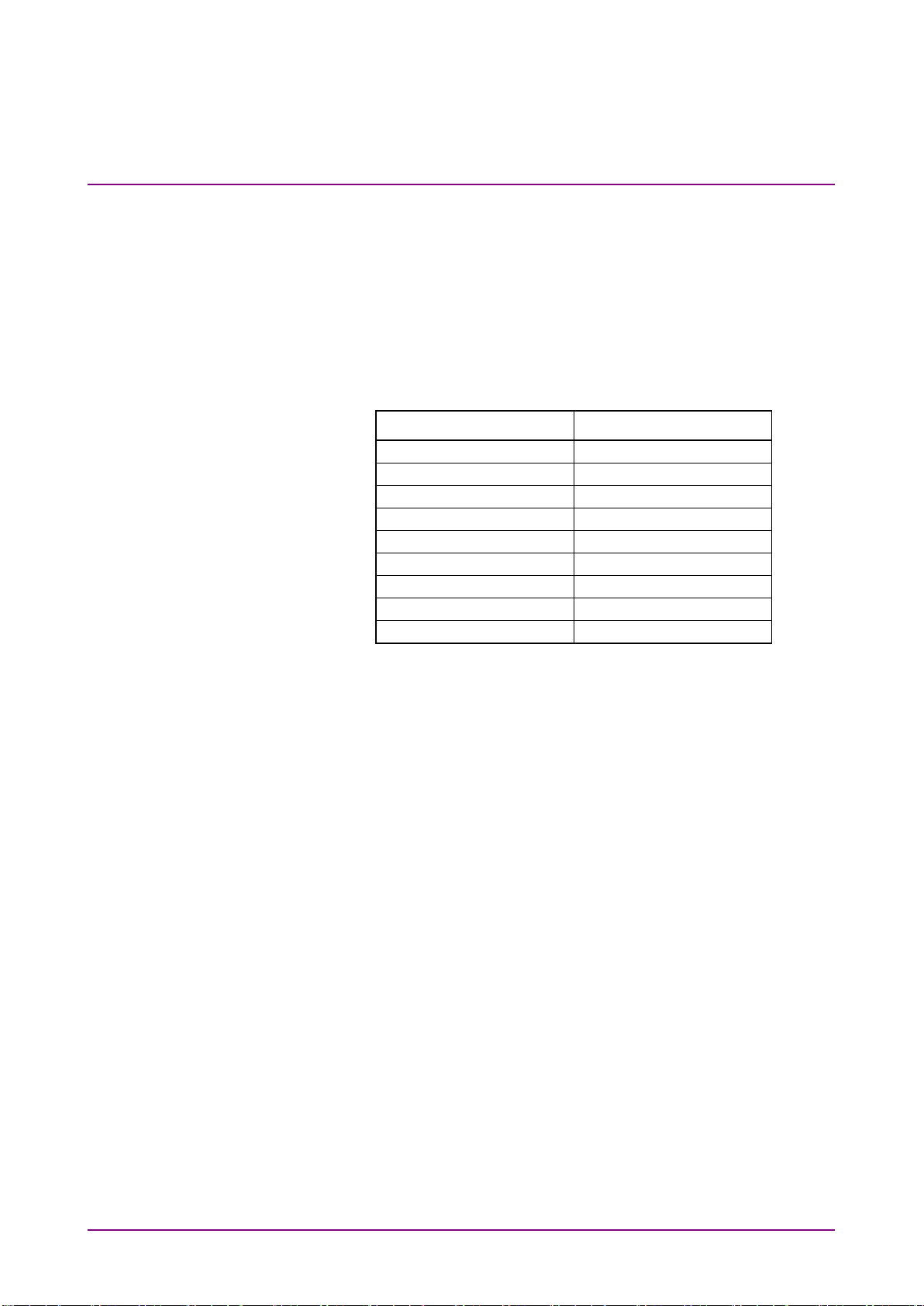

Table 1.3-1 shows the abbreviations used in this operation manual.

Abbreviation Formal name

1.3 Abbreviations

1

Table 1.3-1 Abbreviations

1-5

Page 24

Chapter 1 Overview

1.4 Restrictions on Software Versions

Some of the commands described in this manual are only available in a

specific version of the MX210000A BERTWave Control Software.

In MP2100B (version 4) and MP2110A (version 5 or later), the

MX210000A version is displayed at the upper right of the application

window.

Figure 1.4-1 Display of Software Version Number (MP2100B, MP2110A)

1-6

Page 25

1.4 Restrictions on Software Versions

Overview

For MP210xA (version 3 or earlier), confirm the version of MX210000A in

Information dialog box of Setup Utility.

1

Figure 1.4-2 Display of Software Version Number (MP210xA,

MP2100B)

1-7

Page 26

Chapter 1 Overview

1-8.

Page 27

Before Use

Chapter 2 Before Use

This chapter explains the preparations for using remote control.

2.1

Connection Types of Remote Controlling .................... 2-2

2.2 Multiple Sessions (Version 5 or later) .......................... 2-3

2.3 Required Equipment ................................................... 2-4

2.4 Connecting Equipment ................................................ 2-5

2.4.1 Connecting Ethernet ....................................... 2-5

2.4.2 Connecting GPIB ............................................ 2-6

2.5 Setting Interface .......................................................... 2-8

2.5.1 MP210xA and MP2100B ................................. 2-8

2.5.2 MP2110A ........................................................ 2-9

2.6 Checking Connection ................................................ 2-10

2.6.1 When using Ethernet (Windows 7) ................ 2-10

2.6.2 When using GPIB.......................................... 2-11

2.7 Message Format ....................................................... 2-12

2.7.1 Message Types ............................................. 2-12

2.7.2 Message Configuration ................................. 2-13

2.7.3 Common Commands .................................... 2-16

2.7.4 Device Dependent Commands ...................... 2-16

2.8 Checking Instrument Status ...................................... 2-17

2.8.1 Register Structure ......................................... 2-17

2.8.2 Status Byte Register ..................................... 2-19

2.8.3 Standard Event Status Register .................... 2-21

2.8.4 Operation Status Register ............................. 2-23

2.8.5 Device Dependent Registers ......................... 2-26

2.9 Checking If Message Execution Is Completed ........... 2-29

2.9.1 When using Ethernet ..................................... 2-29

2.9.2 When using GPIB.......................................... 2-30

2

2-1

Page 28

Raw Socket

TCPIP[0]::<IP address|host

TCPIP::192.168.20.3::5001::SOCKET

VXI-11

TCPIP[0]:: <IP address|host name

TCPIP::192.168.20.3::inst0::INSTR

HiSlip

TCPIP[0]:: <IP address|host name

TCPIP::192.168.20.3::hislip::INSTR

GPIB

GPIB[0]::<primary

address>]::INSTR

GPIB::1::INSTR

Chapter 2 Before Use

2.1 Connection Types of Remote Controlling

The following connections can be performed when controlling BERTWave

remotely.

Raw Socket connection

•

VXI-11 connection (version 5 or later)

•

HiSLIP connection (version 5 or later)

•

GPIB connection

•

Table 2.1-1 lists the resource names when performing the connection

using VISA.

Table 2.1-1 VISA Resource Name List

Protocol VISA Resource Name Example

name>::<Port number>::SOCKET

>::inst0::INSTR

>::hislip[0] [,<Port number >]::INSTR

address>[::<secondary

2-2

Page 29

2.2 Multiple Sessions (Version 5 or later)

Before Use

Raw Socket

30 sessions

VXI-11

30 sessions

HiSLIP

8 sessions

GPIB

1 session

2.2 Multiple Sessions (Version 5 or later)

When Raw Socket, VXI-11, or HiSLIP is used as the protocol, multiple

PCs can connect with MP2110A simultaneously. If the different types of

protocols are used, these PCs are not connected with MP2110A

simultaneously. When controlling the multiple sessions using VXI-11 or

HiSLIP, the session can be locked to perform the exclusion control of the

sessions.

Table 2.2-1 lists the maximum number of sessions for each protocol.

Table 2.2-1 List of Maximum Number of Sessions

2

Protocol

Maximum Number of

Sessions

2-3

Page 30

Chapter 2 Before Use

2.3 Required Equipment

The equipment required for remote control is as follows

Control PC

•

Ethernet interface

•

GPIB interface*

•

Program development tool

•

Control PC

Prepare the PC that meets the operating environment for the GPIB

interface and program development tools.

Ethernet Interface

Prepare Ethernet-compliant interface and cable.

GPIB Interface*

Prepare IEEE 488.2-compliant GPIB interface and cable.

Program Development Tool

Prepare a tool for developing and running programs for performing

remote control. For the requirements specification of the program

development tool, refer to the manuals that come with the tool you

prepared.

VISA is required for using the sample program explained in Appendix C.

*: The option 030 is required for using GPIB in MP210xA and

MP2100B.

2-4

Page 31

Before Use

2.4 Connecting Equipment

Control PC

Connecting via LAN

Control PC

Connect using LAN

Network hub

2.4.1 Connecting Ethernet

Connect the Ethernet connector on the side-panel of the BERTWave and

Control PC using LAN cables.

The Ethernet connector is located on the left side panel for MP210xA and

MP2100B, and on the rear panel for MP2110A

Use a LAN cable to connect the BERTWave and Control PC directly. Use a

LAN cable via a network hub when connecting to multiple external

devices.

2.4 Connecting Equipment

2

cable

Figure 2.4.1-1 Direct Connection between BERTWave and Control PC

cables.

External device

Figure 2.4.1-2 Sample Connection with Multiple External Devices

Notes:

MP210xA and MP2100B cannot connect to the network

•

including the address range from 192.168.1.0 to 192.168.1.255.

The control PC may have difficulty in communicating with the

•

BERTWave, depending on the status of communications

between them. The direct connection is recommended to ensure

communication stability.

2-5

Page 32

GPIB

GPIB connector

GPIB cable

Total cable length: Up to 20 m

Number of devices that can be connected: Up to 15

Chapter 2 Before Use

2.4.2 Connecting GPIB

Connect the GPIB connector on the rear panel of the BERTWave and an

external device using a GPIB cable.

Up to 15 devices, including the control PC can be connected to one

BERTWave unit. Always follow the conditions shown below when

connecting devices.

CAUTION

Always connect the GPIB cable BEFORE turning on the

power to the BERTWave. Connecting it while the power is

on may damage internal circuits.

Cable length between devices: Up to 4 m

2-6

Figure 2.4.2-1 GPIB Cable Connection 1

Page 33

Before Use

Connect cables without forming loops.

(a) Daisy Chain

(b) Star

(c) Loop

2.4 Connecting Equipment

2

Figure 2.4.2-2 GPIB Cable Connection 2

2-7

Page 34

Chapter 2 Before Use

2.5 Setting Interface

For details on how to set the interface, refer to 2.14 “Setting Interface for

Remote Control” in the

4.3.10 “Remote Control” in the

2.5.1 MP210xA and MP2100B

1. Switch on the power to the MP210xA or MP2100B.

MP2100B BERTWave Operation Manual

MP2110A BERTWave Operation Manual

and

.

2. Touch

3. Touch

4. In order to use Ethernet, touch the Active Interface button to set the

button display to

GPIB.

When the Option 030 is not installed, the Active Interface button is

disabled.

5. When using Ethernet, set the IP address, subnet mask, gateway and

port number.

The gateway address can be omitted.

The port number can be set from 1024 to 5001.

When using GPIB, set the GPIB address.

6. Touch Apply, and then the settings are completed.

Touch

Note:

Setup Utility at the Selector screen.

Remote Control.

Ethernet. To use GPIB, set the button display to

Exit, and then the set value is deleted.

Do not set the following IP address.

192.168.1.xxx

2-8

Page 35

Before Use

2.5.2 MP2110A

2.5 Setting Interface

1. Switch on the power to the MP2110A.

2. Click

3. Click

4. Set the GPIB address, IP address, subnet mask, gateway and port

5. Click

Note:

System Menu.

Remote Control.

number.

The gateway address can be omitted.

The port number can be set from 1024 to 5001.

OK, and then the settings are completed.

Click Cancel, and then the set value is deleted.

Do not set the following IP address.

169.254.1.xxx

2

2-9

Page 36

Chapter 2 Before Use

2.6 Checking Connection

This section describes how to check if the Control PC can recognize the

BERTWave.

For MP210xA and MP2100B, start Main Application before checking the

connection.

1. If the Setup Utility dialog box is displayed, touch

Exit.

2. On the Selector screen, touch

2.6.1 When using Ethernet (Windows 7)

This section explains how to use the free software, Tera Term Version

4.69.

1. When starting Tera Ter m , the

Enter the IP address and TCP port number in the Host.

Set the service to

Click OK.

If the BERTWave IP address is set to 192.168.100.2, and the port

number is set to 5001, set as follows.

Other and protocol to IPv4.

Main Application.

New connection window is opened.

2-10

2. When Ter a Te r m recognizes the BERTWave, the communication

window is displayed.

3. Click

Settings (S) - Terminal (T).. on the menu.

Page 37

2.6 Checking Connection

Before Use

4. Under New-line, set Receive to LF and Transmit to CR+LF. Select

the Local echo check box and click OK.

5. Send *IDN?.

Confirm that the response is displayed from the BERTWave.

2

2.6.2 When using GPIB

1. Install the software drivers for the GPIB interface.

2. Run the software.

For the operation method, refer to the GPIB interface operation

manual.

3. Check the displayed instrument address.

2-11

Page 38

Chapter 2 Before Use

2.7 Message Format

2.7.1 Message Types

Messages are composed of the character strings indicating message and

message end. The character string indicating the message end is LF (Line

Feed) or CR (Carriage Return) +LF.

Note:

If LF or CR+LF is not attached to the message end, a timeout error

occurs because the communication does not end.

Messages are composed of the following types depending on the

transmission direction:

Program Messages

Messages sent from control PC to instrument

There are two types of the program messages:

Command

•

This can be used for measurement condition settings and

measurement start.

Query

•

This queries the status and settings of the measuring instrument.

When transmitting the query, the instrument creates a response

message to the query.

Response Messages

Messages sent from instrument to control PC

2-12

Page 39

Before Use

2.7.2 Message Configuration

The messages are composed of header and data parts separated by more

than a half width space. Program messages always have a header but

sometimes have no data. Response messages always have data but

sometimes have no header.

Header

The command header has the following types:

Simple header

•

The header is composed of alphanumeric characters and underbars,

and the initial character is an alphabetic character.

Example:

Common command header

•

The header is composed of alphanumeric characters and underbars,

and the initial character is an asterisk (*).

Example:

Multiple headers

•

Single headers are linked by colons. Colons can be used at the header.

Multiple headers can be used to configure layered processing.

Example:

Queries have a question mark (?) appended to the header.

STA

*CLS

:SENSE:MEASURE:START

2.7 Message Format

2

Example:

:CONFIGURE?

Data

The data format is character string data, numeric data, and binary data.

String data is ASCII code enclosed in quotation marks.

An example of the program message when inputting

the title is shown below.

Example:

:SYSYEM:MEMORY:STORE 'Model ANR-005',0,ALL

:SYESEM:MEMORY:STORE "Model ANR-005",0,ALL

When quotation marks are included in the character string, paired marks

are used.

Example:

He said "Good product". → "He said ""Good Product""."

He said 'Good product'. → 'He said ''Good Product''.

'

*ESE?

Model ANR-005

at

2-13

Page 40

Chapter 2 Before Use

In addition, paired quotation marks can be used inside other paired

quotation marks.

Example:

He said "Good product". → 'He said "Good Product".'

He said 'Good product'. → "He said 'Good Product'."

The numeric values can be described by using numeric data, input

numeric values either as decimal, binary, octal, or hexadecimal numbers.

When using the binary, octal, or hexadecimal numbers, put #B, #O, or #H

before the data.

Example:

When using decimal numbers, use integer number, fixed point, or floating

point. The following examples indicate the same values.

Example:

For the binary data, the head string starts with a sign (#) and continues

with data after a numeric value indicating the data length.

Example:

4 digits 2002 bytes binary data

10 #B1010 #O12 #HA

1550 #B11000001110 #O3016 #H60E

-10 -10.00 -1E1

1250 1250.000 1.25E3

0.0023 2.3E-4

#42002an%*qe4445+\…

2-14

Page 41

2.7 Message Format

Before Use

When there are multiple data in a message, separate each of them with

commas (,).

Example:

:SENSE:MEASURE:EALARM:PERIOD 0,0,1,0

When concatenating multiple program messages, separate the messages

with semicolons (;).

Example:

Note:

When sending multiple messages separated by semicolons, the

maximum length of the concatenated string is 1024 bytes.

When sending a concatenated string of query messages, response

messages are separated by semicolons.

Example:

:INPUT:DATA:ATTFACTOR 1,6

:MOD:ID 5;:DISP:MODE EYE;:SAMP:STAT RUN

:MOD:ID 1;:OUTP:BITR:STAN?;:OUTP:BITR?

>"10G_LAN";10312500

2

2-15

Page 42

*CLS

Clears stand event register and output queue

*ESE

Sets and queries standard event enable register

*ESR

Queries standard event register

*IDN

Queries product information

*OPC

Sets/queries bit setting and bit 0 for status byte

indicating message processing completion

*OPT

Queries option information

*RST

Initializes BERTWave setting conditions

*SRE

Sets and queries SRER

*STB

Queries status byte register

*TRG

Starts measurement

*WAI

Waits previous sent message completion

Chapter 2 Before Use

2.7.3 Common Commands

The GPIB specifications (IEEE 488.2) define equipment commands. In

this manual, these defined commands are called common commands.

The common commands are divided into mandatory and option

commands. The BERTWave supports the common commands listed in

Table 2.7.3-1.

Command Explanation

Table 2.7.3-1 Common Commands

2.7.4 Device Dependent Commands

In this manual, commands that differ according to the functions of the

measuring instrument are called Device Dependent Commands.

This instrument has two types of Device Dependent Commands.

SCPI

•

Commands meeting SCPI standard

Native

•

Commands consisting of at least three ASCII characters

2-16

Page 43

Before Use

2.8 Checking Instrument Status

Status Byte Register

Output Queue

Bit

0

Bit

Standard Event Status Register

Power On

Execution Error

Query Error

Logical Sum

Not Used

Bit

0

Operation Status Register

Not Used

Logical Sum

MAV

Logical Sum

Generating

Service Request

Status Register

Bit

Bit

Bit

0

Device Dependent Register

Not Used

CAL Alarm (Yellow)

Not Used

PLL Unlock

Not Used

LOS

Bit

Bit

Bit

*: Version 6 or later

The BERTWave has registers indicating status, such as errors and

command execution status. This section explains these registers.

2.8 Checking Instrument Status

2.8.1 Register Structure

Figure 2.8.1-1 shows the structure of the registers indicating the

instrument status.

15

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

ED measurement

Not Used

Not Used

Not Used

Not Used

Not Used

Command Error

Not Used

Operation Complete

14

13

12

11

10

9

8

7

6

5

4

3

2

1

7

6

5

4

3

2

1

0

Insertion Error

CR Unlock

SYNC Loss

Bit Error

Not Used

Not Used

Not Used

PPG/ED Ch1 to Ch4

Status Register

15

15

:

:

5

5

4

4

3

3

2

2

1

1

0

0

XFP/SFP+

15

:

4

3

2

PT phase unlock

1

0

CAL Alarm (Red)

15

15

:

:

5

5

4

4

3

3

2

2

1

1

0

0

Scope

Status Register

CRU Unlock*

Not Used

Not Used

2

15

:

8

7

6

5

4

3

2

1

MSS

ESB

Not Used

Not Used

Figure 2.8.1-1 Register Structure

7

6

5

4

3

2

1

2-17

Page 44

0 1 8

256

1 2 9

512

2 4 10

1024

3 8 11

2048 4 16

12

4096 5 32

13

8192 6 64

14

16382

7

128

15

32764

Chapter 2 Before Use

Each register uses 8-bit or 16-bit data. The register output values are the

decimal totals for each bit shown in Table 2.8.1-1.

Table 2.8.1-1 Register Bit Decimal Conversion Values

Bit

The register has a corresponding bit enable register.

Decimal

value

Bit

Decimal

value

2-18

Page 45

Before Use

2.8.2 Status Byte Register

Bit

7

6

5

4

3

2

1

0

Status Byte Register

Execution Status

Standard Event Status

Send Queue

Not used

Query Error

Not used

Not used

Logical Sum

Bit

7

6

5

4

3

2

1

0

Service Request

Enable Regist

er

Service

Request

Logical

Product

The status byte register (STB) displays the status of equipment defined

by the GPIB standards. When the equipment status changes, the value in

the STB changes too. It can be used to generate interrupts to the Control

PC. These interrupts are called service requests.

There is a service request enable register (SRER) for the STB. The SRER

can select the status byte bit generating the service request.

2.8 Checking Instrument Status

2

Figure 2.8.2-1 Configuration of Status Byte Register and Service

Request Enable Register

Note:

When using the GPIB interface, the service request is enabled.

The following methods are used to read the status byte register.

Using common *STB? command

•

Using GPIB serial poll (when the Option 030 is installed for MP210xA

•

or MP2100B)

Read the GPIB interface manual for the serial poll method.

When using serial polling, even if bit 6 is 1, it becomes 0 after reading

once.

The

*SRE

and

*SRE?

common commands can be used for setting and

reading the SRER for setting reading of the status byte register. To output

the STB data, set the bit corresponding to the SRER to 1.

2-19

Page 46

7

This is the logical sum of each bit of the logical product of

the OSR and its event enable register.

6

MSS (Master Summary Register)

of the STB and the SRER.

5

This is the logical sum of each bit of the logical product of

enable register.

4

MAV (Message Available summary)

3

Not used; always 0

2

Becomes 1 at System Error

1

Not used; always 0

0

Not used; always 0

Chapter 2 Before Use

The definition of each bit of the STB is shown in the following table.

Table 2.8.2-1 Bit Definition of Status Byte Register

Bit

It is the logical sum of the bit 5 to 0, bit 7 logical product

the standard event status register and standard event

This is always 1 when there is a response message in the

output queue of this instrument

Bit 7 of the STB indicates information about the OSR.

For details about the information, refer to section 2.8.4 “Operation Status

Register”.

Bit 6 of the STB is called the master summary status (MSS) bit. When it

is 1, there is a notification from BERTWave to the control PC. When it

changes to 1 from 0, a service request is generated.

Explanation

Bit 5 of the STB indicates information about the standard event register.

For details about the information, refer to section 2.8.3 “Standard Event

Status Register”.

The device dependent register data is not indicated in the STB.

Bits 7 and 5 of the STB can be set to 0 using the *CLS common command.

When *CLS is sent after a command or when a query is sent after *CLS,

the send queue is cleared and bit 4 is set to 0.

The SRER cannot be set to 0 by *CLS, so use *SRE.

2-20

Page 47

Before Use

2.8.3 Standard Event Status Register

Bit

7

6

5

4

3

2

1

0

Standard Event Status

Register

Power-on

Not used

Command error

Execution error

Device dependent error

Not used

Not used

Operation completed

Logical Sum

Bit

7

6

5

4

3

2

1

0

Standard Event Status

Enable Register

Status Byte

Register bit 5

Logical

Product

There is a standard event status enable register (ESE) for the standard

event status register (ESR). The logical product of these two registers and

the logical sum of each bit of this result is output to bit 5 of the STB.

2.8 Checking Instrument Status

2

Figure 2.8.3-1 Configuration of Standard Event Status Register and

Standard Event Status Enable Register

2-21

Page 48

7

1 if the BERTWave is powered on.

6

Not used; always 0

5

1 if a command error occurs.

Refer to Appendix B, “Error Codes” for details.

4

1 if an execution error occurs.

Refer to Appendix B, “Error Codes” for details.

3

1 if a device-dependent error occurs.

Refer to Appendix B, “Error Codes” for details.

2

Not used; always 0

1

Not used; always 0

0

Operation Complete

sending response data to a query has ended.

Chapter 2 Before Use

The definition of each bit of the ESR is listed in the table below.

Table 2.8.3-1 Bit Definition of Standard Event Status Register

Bit

Changed to 0 if a program message is received.

Becomes 1 when the entire command operation has

completed after *OPC command operation or when

Bit 7 to bit 0 of the ESR can be read by the

The standard event register returns to 0 when read.

The ESE can be set and read using the

output standard event register data, set the bit corresponding to the

enable register to 1.

Explanation

*ESR?

*ESE

and

command.

*ESE?

commands. To

2-22

The bit 0 can be read using the

The standard register can be set to 0 using the

*OPC

command.

*CLS

command.

Page 49

Before Use

2.8.4 Operation Status Register

The operation status register (OSR) is composed of the following registers:

Operation status condition register

•

Transition filter

•

Operation status event register

•

Operation status enable register (OSER)

•

The operation status condition register indicates changes in the status.

When the status changes, the value of this register also changes.

The OSER records changes in the value of the execution status condition

register. There is a transition filter that defines the write condition before

the OSER. The transition filter sets the OSER to 1 under any of the

following conditions:

2.8 Checking Instrument Status

2

When bit changes from 0 to 1

•

When bit changes from 1 to 0

•

When bit changes from 0 to 1 and bit changes from 1 to 0

•

The OSER sets the OSER output at each bit. The logical product of these

two registers is obtained and the logical sum of each bit of the result is

output at bit 7 of the STB.

2-23

Page 50

Bit

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Operation Status

Event Register

Not used

Not used

Not used

Not used

During PPG/ED pattern setting

Not used

Not used

Not used

Not used

Not used

Not used

During ED Measuring

Not used

Not used

Not used

Not used

Logical Sum

Bit

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Operation Status

Enable Register

Status Byte

Register Bit 7

Logical

product

Bit

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Transition Filter

Detecting

Status Change

Bit

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Operation Status

Condition Register

15 to 12

Not used; always 0

11

1 during execution of PPG/ED pattern setting.

10 to 5

Not used; always 0

4

1 during execution of ED measurement.

3 to 0

Not used; always 0

Chapter 2 Before Use

Figure 2.8.4-1 Configuration of Operation Status Condition Register, Operation Status Event

Register, Operation Status Enable Register, and Transition Filter

Each bit definition of the execution status is as follows.

2-24

The commands for confirming the execution start or end time at the OSR

are shown in the following table.

Table 2.8.4-1 Bit Definition of Operation Status Register

Bit

Explanation

Page 51

2.8 Checking Instrument Status

Before Use

11

:SENSe:MMEMory:PATTern:RECall

:SOURce:PATTern:TYPE

4

[:BERT:ALL]:SENSe:MEASure:STARt

Table 2.8.4-2 Commands for Confirming Execution of operation at

Operation Status Register

Operation

Status

Register Bit

Command

:SENSe:PATTern:TYPE

:SOURce:MMEMory:PATTern:RECall

[:BERT:ALL]:SENSe:MEASure:STOP

To detect the execution start, set the corresponding bit of the transition

filter to 1 using STATus:OPERation:PTRansition

To detect the execution end, set the corresponding bit of the transition

filter to 1 using STATus:OPERation:NTRansition.

The OSER can be read using :STATus:OPERation[:EVENt]?. When the

register is read, the OSR returns to 0.

The operation status condition register can be read

using :STATus:OPERation:CONDition?.

To set the OSER, use :STATus:OPERation:ENBle. To read the OSER, use

STATus:OPERation:ENBle?. To output the OSR data, set the bit for the

status setting enable register to 1.

When sending :STATus:OPERation:RESet, the operation status event

register is set to 0.

However, sending :STATus:OPERation:RESet does not reset the OSER.

2

2-25

Page 52

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Detecting Status Change

Chapter 2 Before Use

2.8.5 Device Dependent Registers

The following registers are called the device dependent registers.

PPG/ED Ch1 to 4 Status Register

•

XFP/SFP+ Status Register

•

Scope Status Register

•

The device dependent register has condition register, transition filter, and

event register as the operation status register does. However there is no

enable register for switching the output at each bit on/off.

Device Dependent

Condition Register

Bit

15

14

Not used

Not used

Not used

Not used

Not used

Status 2

Status 1

Status 0

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Transition Filter

Bit

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Device Dependent

Event Register

Bit

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

2-26

Figure 2.8.5-1 Configuration of Device Dependent Register

When the value of the device dependent register changes, there is no

effect on the STB. As a result, a service request is not generated to the

control PC.

Page 53

2.8 Checking Instrument Status

Before Use

15 to 6

Not used; always 0

5

Indicates Omission Error occurs.

4

Indicates Insertion Error occurs.

3

Indicates CR Unlock occurs.

2

Indicates SYNC Loss occurs.

1

Indicates Bit Error occurs.

0

Indicates PLL Unlock occurs.

15 to 2

Not used; always 0

1

Indicates LOS occurs.

0

Indicates Ready status.

15 to 9

Not used; always 0

8

Not used; always 0

7

Indicates CRU Unlock occurs.*1

6

Indicates that Precision Trigger is out of synchronized

5

Indicates that the frequency of trigger input signal is

abnormal. *2

4

Indicates PLL Unlock (No trigger input) occurs.

3

Not used; always 0

2

Indicates CAL alarm (Orange) occurs.

1

Indicates CAL alarm (Red) occurs.

0

Indicates CAL alarm (Yellow) occurs.

Each bit definition of the device dependent register is as follows.

Table 2.8.5-1 Bit Definition of PPG/ED Ch1 to Ch4 Status Register

Bit

Explanation

2

Table 2.8.5-2 Bit Definition of XFP/SFP+ Status Register

Bit

Table 2.8.5-3 Bit Definition of Scope Status Register

Bit

Explanation

Explanation

status. *2

*1: Software version 6 or later

*2: Software version 5 or later

To detect the occurrence of these phenomena, set the transition filter bit

to 1 using the following commands:

:INSTrument:PE{1|2|3|4}:PTRansition

:INSTrument:XSFP:PTRansition

:INSTrument:WAV:PTRansition

To detect the end of these phenomena, set the transition filter bit to 1

using the following commands:

2-27

Page 54

Chapter 2 Before Use

:INSTrument:PE{1|2|3|4}:NTRansition

:INSTrument:XSFP:NTRansition

:INSTrument:WAV:NTRansition

The device dependent event register can be read using the following

queries:

:INSTrument:PE{1|2|3|4}[:EVENt]?

:INSTrument:XSFP[:EVENt]?