Anritsu HFE0503 Kurzrok

60 High Frequency Electronics

High Frequency Design

TEST ACCESSORIES

Simple Lab-Built Test

Accessories for RF, IF,

Baseband and Audio

By Richard Kurzrok

RMK Consultants

E

very engineering

lab bench needs a

supply of handy

test accessories—cables,

adapters, attenuators,

couplers, combiners, filters, detectors, limiters,

etc. This article describes

several accessories that

can be built quickly (and cheaply), yet they

provide sufficient performance from DC to 100

MHz. This frequency range includes most

audio, baseband and intermediate frequency

circuits, as well as many RF applications from

VLF through VHF.

Connector-Mounted Accessories

Low cost tests pieces can be realized using

BNC panel jacks and associated hardware,

although improvements can be attained using

UHF connectors and panel jacks, as well as

the higher quality N and TNC connectors.

SMA and similar microwave connectors can

certainly be used, but most hand-built circuits

will not require their microwave performance.

Low cost test pieces can be constructed

readily, via machine screw and solder assembly, using four hole coaxial panel jacks without

printed circuit boards or enclosures. This technique has been demonstrated for passive circuits using BNC connectors [1], and UHF connectors have been extensively used with low

cost transmission line transformers [2].

Connector Performance

Some coaxial panel jack characteristics

are shown in Table 1. With BNC hole spacing

of 0.500 inch and #4-40 screws, the working

cross section area of BNC and TNC connectors

is 0.500 – 0.125 = 0.375 inch. The corresponding working cross section of N and UHF connectors is 0.718 – 0.138 = 0.580 inch. The additional area can permit construction of test

pieces with larger components such as half

inch diameter toroidal inductors.

Typical small quantity unit costs for commercial grade coaxial connectors from economical distributors are $1.25 for BNC panel

jacks, $2.50 for TNC panel jacks, $2.50 for N

panel jacks and $0.65 to $1.00 for UHF panel

Here are some practical

tips for making simple test

accessories to use at your

engineering workbench:

filters, detectors, attenua-

tors and return loss bridges

for audio and RF/IF

Connector Flange Size Hole C/L Hole Dia. Peak Volts Max. Freq.

BNC .687 or .750 .500 or .531 .125 500 4 GHz

TNC .687 .500 .125 500 11 GHz

N 1.000 .718 .125 1,500 11 GHz

UHF 1.000 .718 .125 or .138 500 300 MHz

Notes: 1. BNC, TNC, and N connectors have 50 ohm impedance. UHF impedance is not specified.

2. Flange is square with rounded corners. Dimensions are in inches.

3. 0.125 holes provide clearance for #4-40 screws; 0.138 holes are for #6-32.

4. Some BNC and TNC connectors are tapped for #3-48 instead of 0.125 diameter. These holes must

be drilled if larger hardware is desired.

Table 1 · Mechanical and electrical characteristics of common coaxial connectors.

From May 2003 High Frequency Electronics

Copyright © 2003 Summit Technical Media, LLC

62 High Frequency Electronics

High Frequency Design

TEST ACCESSORIES

jacks, depending on quality and manufacturer. Quantity discounts have

not been considered. Since UHF connectors have the lowest unit cost and

are readily available, this article will

emphasize low cost test pieces using

UHF connectors. These costs will

change with time, and higher prices

will be paid for military grade connectors, different quality commercial

connectors, and for retail purchase.

UHF Panel Jack Performance

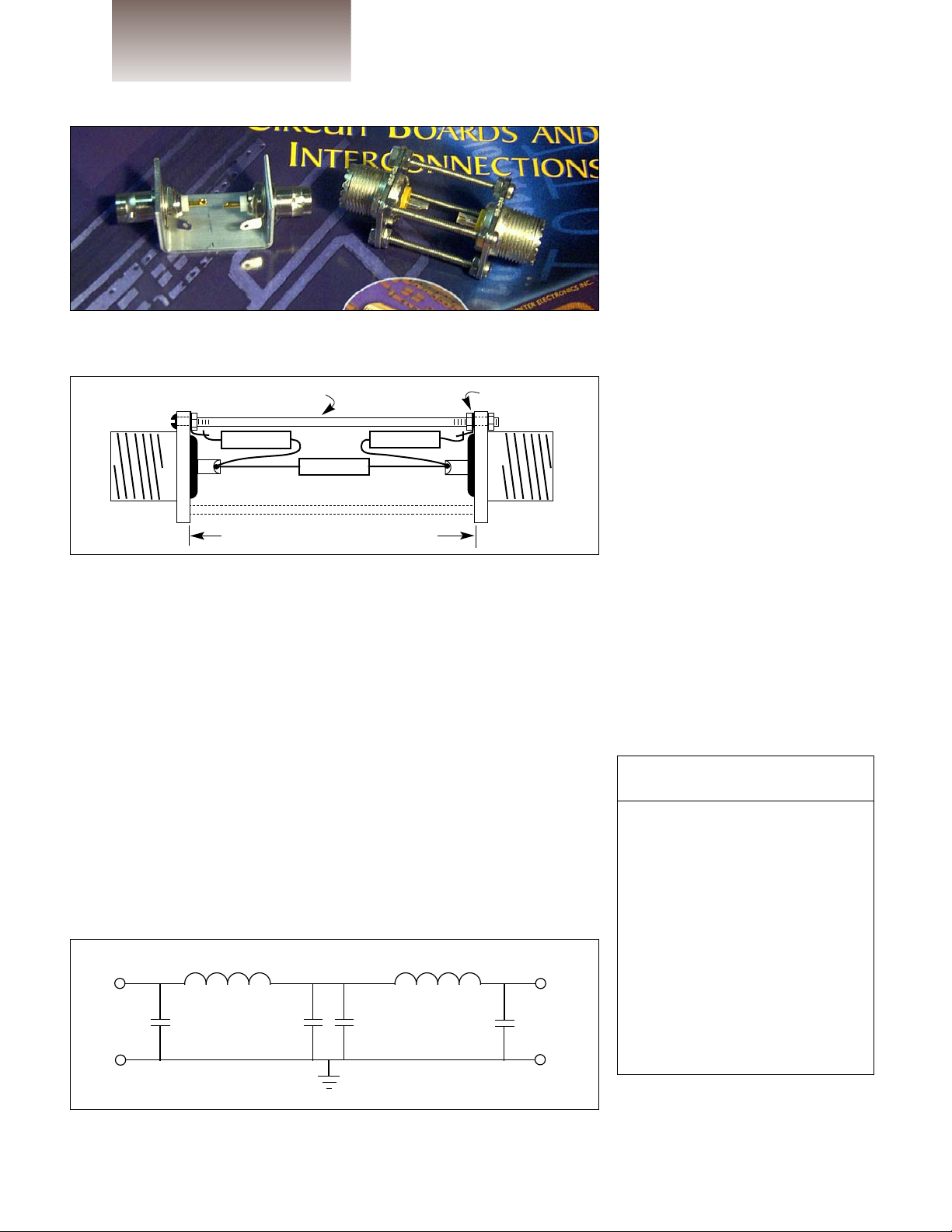

Figure 1 is a photo that shows two

UHF connectors in a mounting that

allows various circuits to be con-

structed with components supported

by their leads. Also in this photo is an

assembly of two BNC jacks mounted

to a U-shaped bracket, which allows

similar circuit assembly using these

connectors.

The upper frequency limit for

UHF connectors is 300 MHz and the

impedance is not specified. To evaluate these connectors, a preliminary

50 ohm test piece was constructed

using two UHF panel jacks interconnected back-to-back with no special

concern for impedance matching.

Insertion losses were less than 0.1 dB

up to 90 MHz.

Practical Test Circuits

A pi-section fixed pad attenuator,

using two UHF panel jacks and associated hardware, is illustrated in

Figure 2. This simple circuit is displayed mainly for illustrative purposes—resistive pads are readily available and inexpensive, but custom

attenuators with non-standard values can be made in this manner.

Another test piece with two UHF

jacks separated by two inch long #632 screws was constructed and tested. This unit is a five pole low pass filter with nominal 0.02 dB passband

ripples, three dB cutoff of 2.2 MHz,

and 50 ohm impedance. The filter

schematic is shown in Figure 3. All

shunt capacitors are polypropylene

units with two percent tolerance. The

series inductors use 34 turns of #26

magnet wire on MicroMetals T50-2

toroids, which have a nominal 0.5

inch outside diameter. Measured test

data is shown in Table 2.

Other Useful Circuits

As we have seen, low cost 50 ohm

test pieces operating at typical frequencies from 100 kHz to 100 MHz

can be readily constructed using

UHF panel jacks and other connectors, soldered components, hand

Frequency Insertion Loss

(MHz) (dB)

0.3 <0.1

0.7 <0.1

1.0 0.1

1.3 0.2

1.6 0.3

1.8 0.4

2.0 1.1

2.2 3.5

2.4 7.2

2.9 18.0

3.5 27.0

4.0 34.3

10.0 >40

20.0 >40

Table 2 · Measured amplitude

response for the 2.2 MHz lowpass filter mounted on UHF connectors.

Figure 1 · Back-to-back mounting of low-cost coaxial connectors allows

easy construction of test circuits.

Figure 2 · Assembly diagram of a simple UHF connector-based pi-section

attenuator (not to scale).

Figure 3 · Circuit diagram of a 2.2 MHz lowpass filter.

R1

R3

R2

L2 – 6.02 µH

C1

1,500 pF

C4

1,500 pF

C3

1,500 pF

C6

1,500 pF

L5 – 6.02 µH

1-3/16 inch typical with 1-1/2 in. screws

Solder lugs

#4-40 or 6-32 screws, lockwashers, nuts

Loading...

Loading...