Loop-Powered 4–20 mA

a

FEATURES

Instrumentation Amplifier Front End

Loop-Powered Operation

Precalibrated 30 mV or 60 mV Input Spans

Independently Adjustable Output Span and Zero

Precalibrated Output Spans: 4–20 mA Unipolar

0–20 mA Unipolar

12 6 8 mA Bipolar

Precalibrated 100 V RTD Interface

6.2 V Reference with Up to 3.5 mA of Current Available

Uncommitted Auxiliary Amp for Extra Flexibility

Optional External Pass Transistor to Reduce

Self-Heating Errors

PRODUCT DESCRIPTION

The AD693 is a monolithic signal conditioning circuit which

accepts low-level inputs from a variety of transducers to control a

standard 4–20 mA, two-wire current loop. An on-chip voltage

reference and auxiliary amplifier are provided for transducer

excitation; up to 3.5 mA of excitation current is available when the

device is operated in the loop-powered mode. Alternatively, the

device may be locally powered for three-wire applications when

0–20 mA operation is desired.

Precalibrated 30 mV and 60 mV input spans may be set by

simple pin strapping. Other spans from 1 mV to 100 mV may

be realized with the addition of external resistors. The auxiliary

amplifier may be used in combination with on-chip voltages to

provide six precalibrated ranges for 100 Ω RTDs. Output span

and zero are also determined by pin strapping to obtain the

standard ranges: 4–20mA, 12 ± 8 mA and 0–20 mA.

Active laser trimming of the AD693’s thin-film resistors result

in high levels of accuracy without the need for additional

adjustments and calibration. Total unadjusted error is tested on

every device to be less than 0.5% of full scale at +25°C, and less

than 0.75% over the industrial temperature range. Residual

nonlinearity is under 0.05%. The AD693 also allows for the use

of an external pass transistor to further reduce errors caused by

self-heating.

For transmission of low-level signals from RTDs, bridges and

pressure transducers, the AD693 offers a cost-effective signal

conditioning solution. It is recommended as a replacement for

discrete designs in a variety of applications in process control,

factory automation and system monitoring.

The AD693 is packaged in a 20-pin ceramic side-brazed DIP,

20-pin Cerdip, and 20-pin LCCC and is specified over the

–40°C to +85°C industrial temperature range.

Sensor Transmitter

AD693

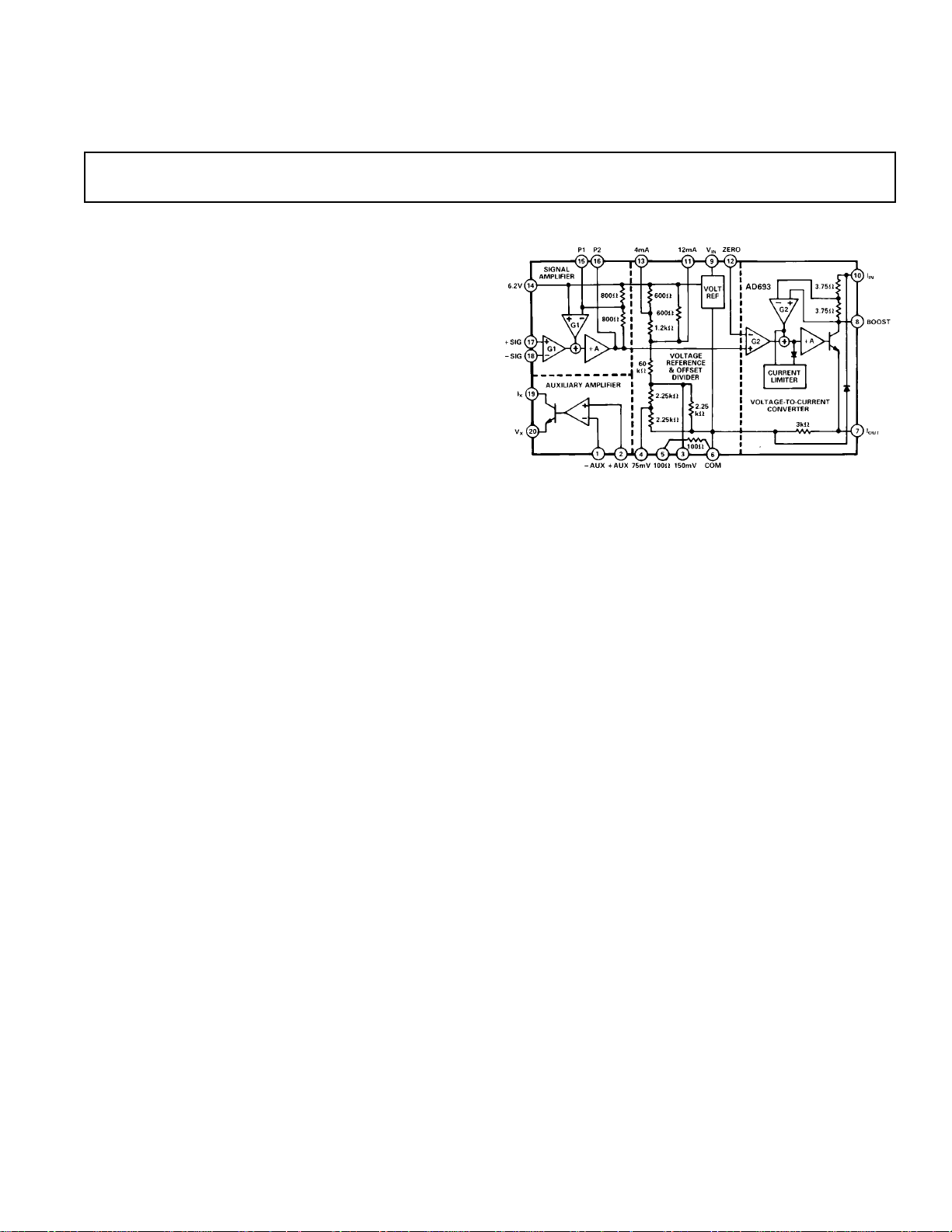

FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

1. The AD693 is a complete monolithic low-level voltage-tocurrent loop signal conditioner.

2. Precalibrated output zero and span options include

4–20 mA, 0–20 mA, and 12 ± 8 mA in two- and three-wire

configurations.

3. Simple resistor programming adds a continuum of ranges

to the basic 30 mV and 60 mV input spans.

4. The common-mode range of the signal amplifier input

extends from ground to near the device’s operating voltage.

5. Provision for transducer excitation includes a 6.2 V

reference output and an auxiliary amplifier which may be

configured for voltage or current output and signal

amplification.

6. The circuit configuration permits simple linearization of

bridge, RTD, and other transducer signals.

7. A monitored output is provided to drive an external pass

transistor. This feature off-loads power dissipation to

extend the temperature range of operation, enhance

reliability, and minimize self-heating errors.

8. Laser-wafer trimming results in low unadjusted errors and

affords precalibrated input and output spans.

9. Zero and span are independently adjustable and noninteractive

to accommodate transducers or user defined ranges.

10. Six precalibrated temperature ranges are available with a

100 Ω RTD via pin strapping.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

(@ +258C and VS = +24 V. Input Span = 30 mV or 60 mV. Output Span = 4–20 mA,

AD693–SPECIFICATIONS

RL = 250 V, VCM = 3.1 V, with external pass transistor unless otherwise noted.)

Model AD693AD/AQ/AE

Conditions Min Typ Max Units

LOOP-POWERED OPERATION

TOTAL UNADJUSTED ERROR

T

to T

MIN

MAX

100 Ω RTD CALIBRATION ERROR

LOOP POWERED OPERATION

Zero Current Error

4

vs. Temp. Zero = 4 mA ±0.5 ±1.5 µA/°C

Power Supply Rejection (RTI) 12 V ≤ V

Common-Mode Input Range (See Figure 3) 0 +V

Common-Mode Rejection (RTI) 0 V ≤ V

Input Bias Current

T

to T

MIN

Input Offset Current

MAX

7

7

1, 2

2

±0.25 60.5 % Full Scale

±0.4 60.75 % Full Scale

3

(See Figure 17) ±0.5 ±2.0 °C

Zero = 4 mA ±25 680 µA

Zero = 12 mA ±40 6120 µA

Zero = 0 mA

0 V ≤ V

5

6

≤ 36V

OP

≤ 6.2 V

CM

≤ 6.2 V ±10 630 µV/V

CM

+7 +35 +100 µA

±3.0 65.6 µV/V

6

– 4 V

OP

+5 +20 nA

+7 +25 nA

V

= 0 ±0.5 63.0 nA

SIG

Transconductance

Nominal 30 mV Input Span 0.5333 A/V

60 mV Input Span 0.2666 A/V

Unadjusted Error ±0.05 60.2 %

vs. Common-Mode 0 V ≤ V

≤ 6.2 V

CM

30 mV Input Span ±0.03 ±0.04 %/V

60 mV Input Span ±0.05 ±0.06 %/V

Error vs. Temp. ±20 ±50 ppm/°C

Nonlinearity

8

30 mV Input Span ±0.01 60.05 % of Span

60 mV Input Span ±0.02 60.07 % of Span

V

OPERATIONAL VOLTAGE RANGE

Operational Voltage, V

OP

6

+12 +36 V

Quiescent Current Into Pin 9 +500 +700 µA

OUTPUT CURRENT LIMIT +21 +25 +32 mA

COMPONENTS OF ERROR

SIGNAL AMPLIFIER

9

Input Voltage Offset ±40 6200 µV

vs. Temp ±1.0 ±2.5 µV/°C

Power Supply Rejection 12 V ≤ V

OP

≤ 36 V

6

±3.0 65.6 µV/V

0 V ≤ VCM ≤ 6.2 V

V/I CONVERTER

Zero Current Error Output Span = 4–20 mA ±30 ±80 µA

Power Supply Rejection 12 V ≤ V

9, 10

≤ 36 V

OP

6

±1.0 ±3.0 µA/V

Transconductance

Nominal 0.2666 A/V

Unadjusted Error ±0.05 ± 0.2 %

6.200 V REFERENCE

9, 12

Output Voltage Tolerance ±3 612 mV

vs. Temp. ±20 ±50 ppm/°C

Line Regulation 12 V ≤ V

Load Regulation

Output Current

11

13

0 mA ≤ I

Loop Powered, (Figure 10) +3.0 +3.5 mA

OP

REF

6

≤ 36 V

±200 6300 µV/V

≤ 3 mA ±0.3 60.75 mV/mA

3-Wire Mode, (Figure 15) +5.0 mA

–2–

REV. A

Model AD693AD

Conditions Min Typ Max Units

AD693

AUXILIARY AMPLIFIER

Common-Mode Range 0 +V

OP

– 4 V

6

V

Input Offset Voltage ±50 ±200 µV

Input Bias Current +5 +20 nA

Input Offset Current +0.5 ±3.0 nA

Common-Mode Rejection 90 dB

Power Supply Rejection 105 dB

Output Current Range Pin I

Output Current Error Pin VX – Pin I

TEMPERATURE RANGE

Case Operating

14

OUT +0.01 +5 mA

X

X

T

MIN

to T

MAX

–40 +85 °C

±0.005 %

Storage –65 +150 °C

NOTES

1

Total error can be significantly reduced (typically less than 0.1%) by trimming the zero current. The remaining unadjusted error sources are transconductance and

nonlinearity.

2

The AD693 is tested as a loop powered device with the signal amp, V/I converter, voltage reference, and application voltages operating together. Specifications are

valid for preset spans and spans between 30 mV and 60 mV.

3

Error from ideal output assuming a perfect 100 Ω RTD at 0 and +100°C.

4

Refer to the Error Analysis to calculate zero current error for input spans less than 30 mV.

5

By forcing the differential signal amplifier input sufficiently negative the 7 µA zero current can always be achieved.

6

The operational voltage (VOP) is the voltage directly across the AD693 (Pin 10 to 6 in two-wire mode, Pin 9 to 6 in local power mode). For example, VOP = VS –

(I

× RL) in two-wire mode (refer to Figure 10).

LOOP

7

Bias currents are not symmetrical with input signal level and flow out of the input pins. The input bias current of the inverting input increases with input signal volt-

age, see Figure 2.

8

Nonlinearity is defined as the deviation of the output from a straight line connecting the endpoints as the input is swept over a 30 mV and 60 mV input span.

9

Specifications for the individual functional blocks are components of error that contribute to, and that are included in, the Loop Powered Operation specifications.

10

Includes error contributions of V/I converter and Application Voltages.

11

Changes in the reference output voltage due to load will affect the Zero Current. A 1% change in the voltage reference output will result in an error of 1% in the

value of the Zero Current.

12

If not used for external excitation, the reference should be loaded by approximately 1 mA (6.2 kΩ to common).

13

In the loop powered mode up to 5 mA can be drawn from the reference, however, the lower limit of the output span will be increased accordingly. 3.5 mA is the

maximum current the reference can source while still maintaining a 4 mA zero.

14

The AD693 is tested with a pass transistor so TA ≅ TC.

Specifications subject to change without notice.

Specifications shown in boldface are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min

and max specifications are guaranteed, although only those shown in boldface are tested on all production units.

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +36 V

Reverse Loop Current . . . . . . . . . . . . . . . . . . . . . . . . . 200 mA

Signal Amp Input Range . . . . . . . . . . . . . . . . . . –0.3 V to V

OP

Reference Short Circuit to Common . . . . . . . . . . . . Indefinite

Auxiliary Amp Input Voltage Range . . . . . . . . . . 0.3 V to V

OP

Auxiliary Amp Current Output . . . . . . . . . . . . . . . . . . . 10 mA

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature, 10 sec Soldering . . . . . . . . . . . . . +300°C

Max Junction Temperature . . . . . . . . . . . . . . . . . . . . . +150°C

ORDERING GUIDE

Package Package

Model Description Option

AD693AD Ceramic Side-Brazed DIP D-20

AD693AQ Cerdip Q-20

AD693AE Leadless Ceramic Chip E-20A

Carrier (LCCC)

REV. A

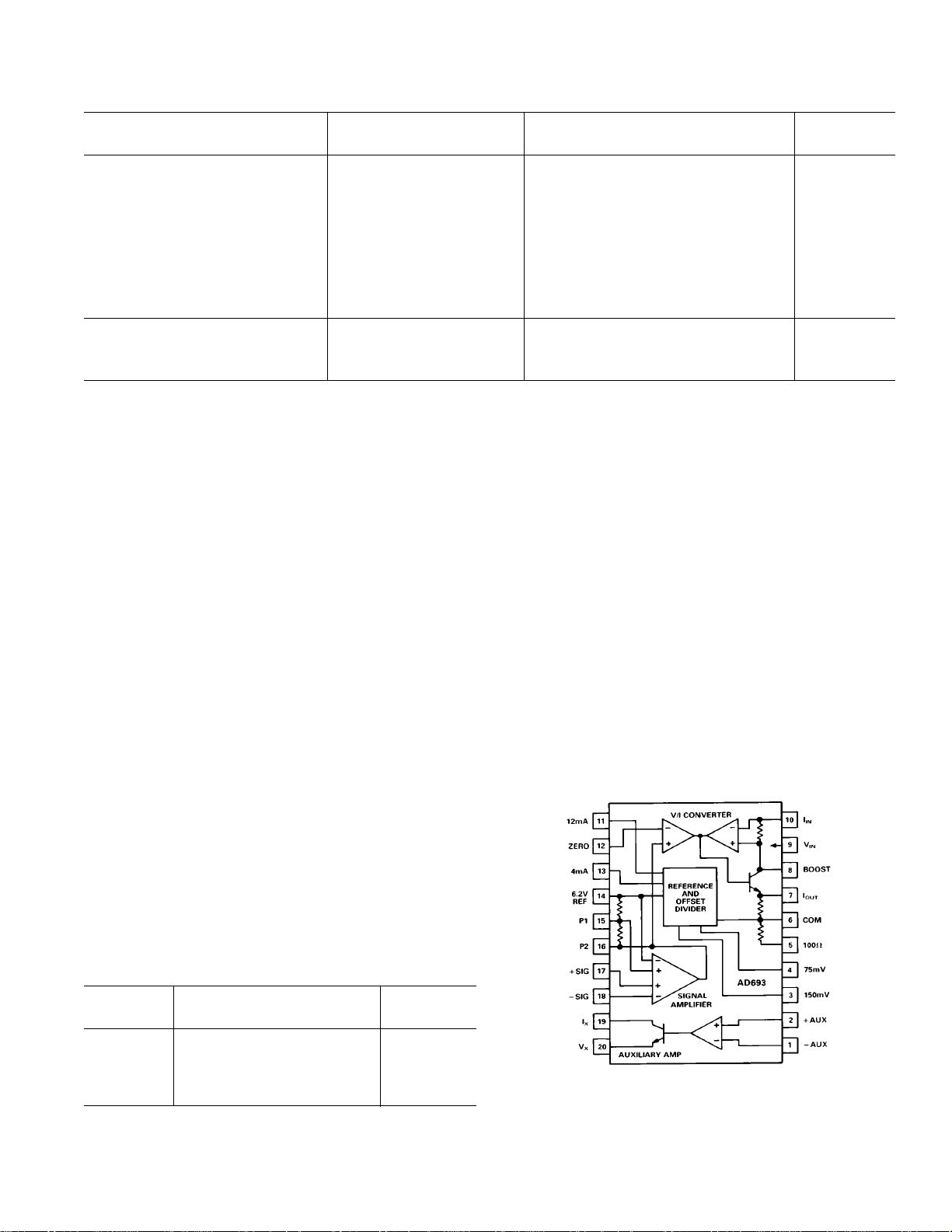

AD693 PIN CONFIGURATION

(AD, AQ, AE Packages)

Functional Diagram

–3–

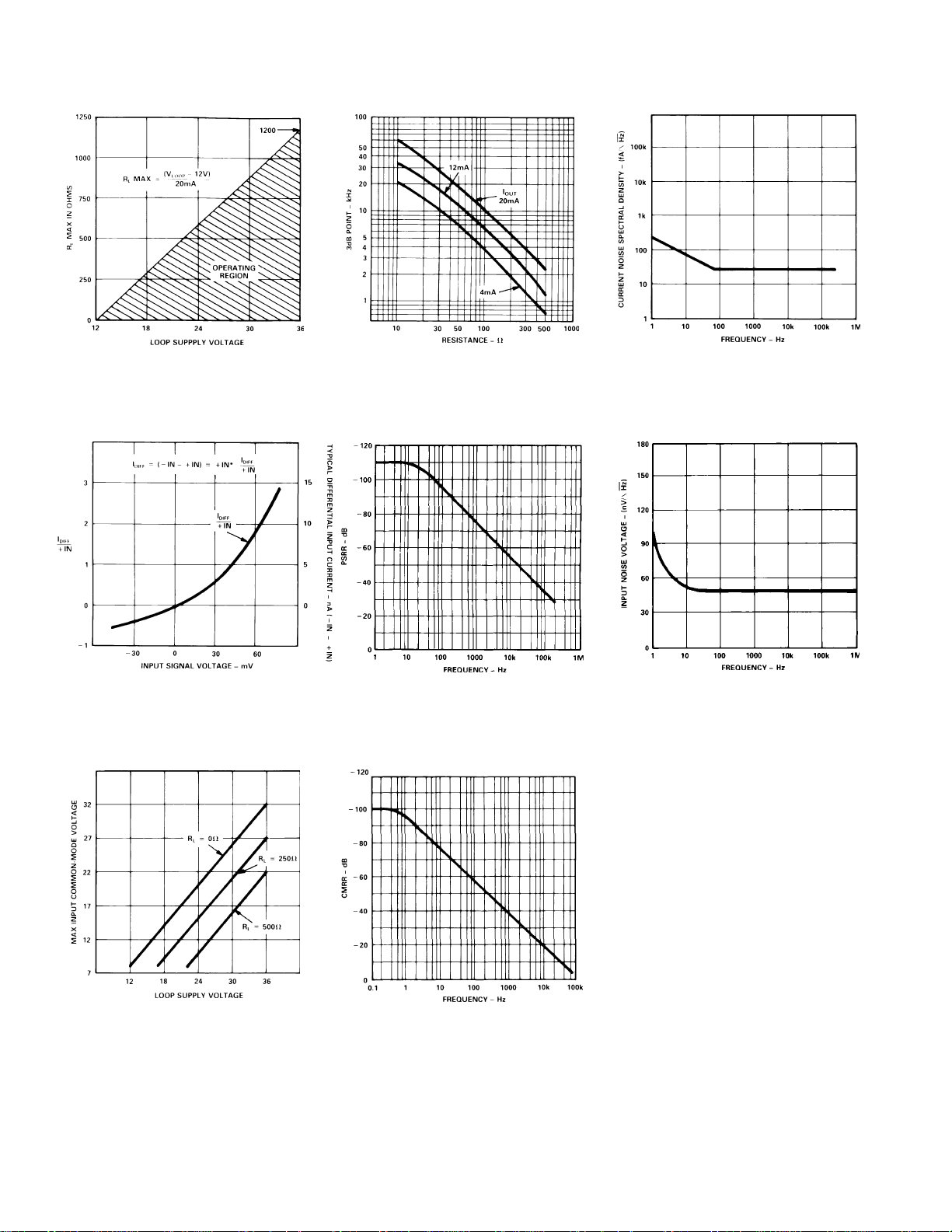

AD693–Typical Characteristics

Figure 1. Maximum Load Resistance

vs. Power Supply

Figure 2. Differential Input Current vs.

Input Signal Voltage Normalized to +IN

Figure 4. Bandwidth vs. Series Load

Resistance

Figure 5. Signal Amplifier PSRR vs.

Frequency

Figure 7. Input Current Noise vs.

Frequency

Figure 8. Input Voltage Noise vs.

Frequency

Figure 3. Maximum Common-Mode

Voltage vs. Supply

Figure 6. CMRR (RTI) vs. Frequency

REV. A–4–

AD693

FUNCTIONAL DESCRIPTION

The operation of the AD693 can be understood by dividing the

circuit into three functional parts (see Figure 9). First, an

instrumentation amplifier front-end buffers and scales the lowlevel input signal. This amplifier drives the second section, a V/I

converter, which provides the 4-to-20mA loop current. The

third section, a voltage reference and resistance divider, provides

application voltages for setting the various “live zero” currents.

In addition to these three main sections, there is an on-chip

auxiliary amplifier which can be used for transducer excitation.

VOLTAGE-TO-CURRENT (V/I) CONVERTER

The output NPN transistor for the V/I section sinks loop current

when driven on by a high gain amplifier at its base. The input for

this amplifier is derived from the difference in the outputs of the

matched preamplifiers having gains, G2. This difference is caused

to be small by the large gain, +A, and the negative feedback

through the NPN transistor and the loop current sampling resistor

between I

and Boost. The signal across this resistor is compared

IN

to the input of the left preamp and servos the loop current until

both signals are equal. Accurate voltage-to-current transformation

is thereby assured. The preamplifiers employ a special design

which allows the active feedback amplifier to operate from the most

positive point in the circuit, I

IN.

The V/I stage is designed to have a nominal transconductance of

0.2666 A/V. Thus, a 75 mV signal applied to the inputs of the

V/I (Pin 16, noninverting; Pin 12, inverting) results in a

full-scale output current of 20 mA.

The current limiter operates as follows: the output of the feedback preamp is an accurate indication of the loop current. This

output is compared to an internal setpoint which backs off the

drive to the NPN transistor when the loop current approaches

25 mA. As a result, the loop and the AD693 are protected from the

consequences of voltage overdrive at the V/I input.

VOLTAGE REFERENCE AND DIVIDER

A stabilized bandgap voltage reference and laser-trimmed

resistor divider provide for both transducer excitation as well as

precalibrated offsets for the V/I converter. When not used for

external excitation, the reference should be loaded by approximately 1 mA (6.2 kΩ to common).

The 4 mA and 12 mA taps on the resistor divider correspond to

–15 mV and –45 mV, respectively, and result in a live zero of

4 mA or 12 mA of loop current when connected to the V/I

converter’s inverting input (Pin 12). Arranging the zero offset in

this way makes the zero signal output current independent of

input span. When the input to the signal amp is zero, the

noninverting input of the V/I is at 6.2 V.

Since the standard offsets are laser trimmed at the factory,

adjustment is seldom necessary except to accommodate the zero

offset of the actual source. (See “Adjusting Zero.”)

SIGNAL AMPLIFIER

The Signal Amplifier is an instrumentation amplifier used to

buffer and scale the input to match the desired span. Inputs

applied to the Signal Amplifier (at Pins 17 and 18) are amplified

and referred to the 6.2 V reference output in much the same way as

the level translation occurs in the V/I converter. Signals from the

two preamplifiers are subtracted, the difference is amplified, and

the result is fed back to the upper preamp to minimize the

difference. Since the two preamps are identical, this minimum will

occur when the voltage at the upper preamp just matches the

differential input applied to the Signal Amplifier at the left.

Since the signal which is applied to the V/I is attenuated across

the two 800 Ω resistors before driving the upper preamp, it will

necessarily be an amplified version of the signal applied between

Pins 17 and 18. By changing this attenuation, you can control

the span referred to the Signal Amplifier. To illustrate: a 75 mV

signal applied to the V/I results in a 20 mA loop current.

Nominally, 15 mV is applied to offset the zero to 4 mA leaving a

60 mV range to correspond to the span. And, since the nominal

attenuation of the resistors connected to Pins 16, 15 and 14 is

2.00, a 30 mV input signal will be doubled to result in 20 mA of

loop current. Shorting Pins 15 and 16 results in unity gain and

permits a 60 mV input span. Other choices of span may be

implemented with user supplied resistors to modify the

attenuation. (See section “Adjusting Input Span.”)

The Signal Amplifier is specially designed to accommodate a

large common-mode range. Common-mode signals anywhere up

to and beyond the 6.2 V reference are easily handled as long as

V

is sufficiently positive. The Signal Amplifier is biased with

IN

respect to V

and requires about 3.5 volts of headroom. The

IN

extended range will be useful when measuring sensors driven,

for example, by the auxiliary amplifier which may go above the

6.2 V potential. In addition, the PNP input stage will continue

to operate normally with common-mode voltages of several

hundred mV, negative, with respect to common. This feature

accommodates self-generating sensors, such as thermocouples,

which may produce small negative normal-mode signals as well

as common-mode noise on “grounded” signal sources.

REV. A

Figure 9. Functional Flock Diagram

AUXILIARY AMPLIFIER

The Auxiliary Amplifier is included in the AD693 as a signal

conditioning aid. It can be used as an op amp in noninverting

applications and has special provisions to provide a controlled

current output. Designed with a differential input stage and an

unbiased Class A output stage, the amplifier can be resistively

loaded to common with the self-contained 100 Ω resistor or

with a user supplied resistor.

As a functional element, the Auxiliary Amplifier can be used in

dynamic bridges and arrangements such as the RTD signal

conditioner shown in Figure 17. It can be used to buffer, amplify

and combine other signals with the main Signal Amplifier. The

Auxiliary Amplifier can also provide other voltages for excitation

–5–

AD693

if the 6.2 V of the reference is unsuitable. Configured as a simple

follower, it can be driven from a user supplied voltage divider

or the precalibrated outputs of the AD693 divider (Pins 3 and

4) to provide a stiff voltage output at less than the 6.2 level, or

by incorporating a voltage divider as feedback around the amplifier,

one can gain-up the reference to levels higher than 6.2 V. If

large positive outputs are desired, I

output current supply, should be strapped to either V

, the Auxiliary Amplifier

X

IN

or

Boost. Like the Signal Amplifier, the Auxiliary requires about

3.5 V of headroom with respect to V

of difference between I

and the voltage to which VX is required

X

at its input and about 2 V

IN

to swing.

The output stage of the Auxiliary Amplifier is actually a high

gain Darlington transistor where I

is the collector and VX is the

X

emitter. Thus, the Auxiliary Amplifier can be used as a V/I

converter when configured as a follower and resistively loaded.

I

functions as a high-impedance current source whose current

X

is equal to the voltage at V

divided by the load resistance. For

X

example, using the onboard 100 Ω resistor and the 75 mV or

150 mV application voltages, either a 750 µA or 1.5 mA current

source can be set up for transducer excitation.

The I

terminal has voltage compliance within 2 V of VX. If the

X

Auxiliary Amplifier is not to be used, then Pin 2, the noninverting

input, should be grounded.

REVERSE VOLTAGE PROTECTION FEATURE

In the event of a reverse voltage being applied to the AD693

through a current-limited loop (limited to 200 mA), an internal

shunt diode protects the device from damage. This protection

mode avoids the compliance voltage penalty which results from

a series diode that must be added if reversal protection is

required in high-current loops.

Applying the AD693

CONNECTIONS FOR BASIC OPERATION

Figure 10 shows the minimal connections for basic operation:

0–30 mV input span, 4–20 mA output span in the two-wire,

loop-powered mode. If not used for external excitation, the

6.2 V reference should be loaded by approximately 1 mA

(6.2 kΩ to common).

USING AN EXTERNAL PASS TRANSISTOR

The emitter of the NPN output section, I

, of the AD693 is

OUT

usually connected to common and the negative loop connection

(Pins 7 to 6). Provision has been made to reconnect I

OUT

to the

base of a user supplied NPN transistor as shown in Figure 11.

This permits the majority of the power dissipation to be moved

off chip to enhance performance, improve reliability, and extend

the operating temperature range. An internal hold-down resistor

of about 3k is connected across the base emitter of the external

transistor.

The external pass transistor selected should have a BV

CEO

greater

than the intended supply voltage with a sufficient power rating for

continuous operation with 25 mA current at the supply voltage.

Ft should be in the 10 MHz to 100 MHz range and β should be

greater than 10 at a 20 mA emitter current. Some transistors

that meet this criteria are the 2N1711 and 2N2219A. Heat

sinking the external pass transistor is suggested.

The pass transistor option may also be employed for other

applications as well. For example, I

can be used to drive an

OUT

LED connected to Common, thus providing a local monitor of

loop fault conditions without reducing the minimum compliance

voltage.

ADJUSTING ZERO

In general, the desired zero offset value is obtained by

connecting an appropriate tap of the precision reference/voltage

divider network to the inverting terminal of the V/I converter.

As shown in Figure 9, precalibrated taps at Pins 14, 13 and 11

result in zero offsets of 0 mA, 4 mA and 12 mA, respectively,

when connected to Pin 12. The voltages which set the 4 mA and

12 mA zero operating points are 15 mV and 45 mV negative

with respect to 6.2 V, and they each have a nominal source

resistance of 450 Ω. While these voltages are laser trimmed to

high accuracy, they may require some adjustment to

accommodate variability between sensors or to provide

additional ranges. You can adjust zero by pulling up or down on

the selected zero tap, or by making a separate voltage divider to

drive the zero pin.

The arrangement of Figure 12 will give an approximately linear

adjustment of the precalibrated options with fixed limits. To

find the proper resistor values, first select I

, the desired range

A

Figure 10. Minimal Connection for 0–30 mV Unipolar Input, 4–20 mA Output

–6–

REV. A

AD693

R

S1

=

400 Ω

30 mV

S

−1

Figure 11. Using an External Pass Transistor to Minimize Self-Heating Errors

of adjustment of the output current from nominal. Substitute

this value in the appropriate formula below for adjustment at the

4 mA tap.

R

= (1.6 V/I

Z1

= R

R

Z2

) – 400 Ω and

A

× 3.1 V/(15 mV + IA × 3.75 Ω)

Z1

Use a similar connection with the following resistances for

adjustments at the 12 mA tap.

RZ1 = (4.8 V/I

= R

R

Z2

) – 400 Ω and

A

× 3.1 V/(45 mV + IA × 3.75 Ω)

Z1

These formulae take into account the ±10% tolerance of tap

resistance and insure a minimum adjustment range of I

example, choosing I

= 200 µA will give a zero adjustment range

A

. For

A

of ±1% of the 20 mA full-scale output. At the 4 mA tap the

maximum value of:

R

= 1.6 V/200 µA – 400 Ω = 7.6 kΩ and

Z1

= 7.6 kΩ × 3.1 V/(15 mV + 200 µA × 3.75 Ω) = 1.49 MΩ

R

Z2

Figure 12. Optional 4 mA Zero Adjustment (12 mA Trim

Available Also)

These can be rounded down to more convenient values of

7.5 kΩ and 1.3 MΩ, which will result in an adjustment range

comfortably greater than ± 200 µA.

ADJUSTING INPUT SPAN

Input Span is adjusted by changing the gain of the Signal

Amplifier. This amplifier provides a 0-to-60 mV signal to the

V/I section to produce the 4-to-20 mA output span (or a

REV. A

0-to-75 mV signal in the 0-to-20 mA mode). The gain of this

amplifier is trimmed to 2.00 so that an input signal ranging from

0-to-30 mV will drive the V/I section to produce 4-to -20 mA.

Joining P1 and P2 (Pins 15 and 16) will reduce the Signal Amplifier gain to one, thereby requiring a 60 mV signal to drive the V/I

to a full 20 mA span.

To produce spans less than 30 mV, an external resistor, R

S1

be connected between P1 and 6.2 V. The nominal value is given

by:

where S is the desired span. For example, to change the span to

6 mV a value of:

R

400 Ω

=

S1

30 mV

6 mV

=100 Ω

−1

is required. Since the internal, 800 Ω gain setting resistors

exhibit an absolute tolerance of 10%, R

should be provided

S1

with up to ±10% range of adjustment if the span must be well

controlled.

For spans between 30 mV and 60 mV a resistor R

should be

S2

connected between P1 and P2. The nominal value is given by:

R

=

S2

400 Ω 1−

30 mV

S

60 mV

S

−1

For example, to change the span to 40 mV, a value of:

R

S2

=

400 Ω 1 −

30 mV

40 mV

60 mV

40 mV

−1

= 800 Ω

is required. Remember that this is a nominal value and may

require adjustment up to ±10%. In many applications the span

must be adjusted to accommodate individual variations in the

sensor as well as the AD693. The span changing resistor should,

therefore, include enough adjustment range to handle both the

sensor uncertainty and the absolute resistance tolerance of P1

and P2. Note that the temperature coefficient of the internal

resistors is nominally –17 ppm/°C, and that the external

resistors should be comparably stable to insure good temperature performance.

–7–

, can

AD693

An alternative arrangement, allowing wide range span adjustment between two set ranges, is shown in Figure 13. R

R

are calculated to be 90% of the values determined from the

S2

S1

and

previous formulae. The smallest value is then placed in series

with the wiper of the 1.5 kΩ potentiometer shown in the figure.

For example, to adjust the span between 25 mV and 40 mV, R

and R

are calculated to be 2000 Ω and 800 Ω, respectively.

S2

S1

The smaller value, 800 Ω, is then reduced by 10% to cover the

possible ranges of resistance in the AD693 and that value is put

in place.

Figure 13. Wide Range Span Adjustment

A number of other arrangements can be used to set the span as

long as they are compatible with the pretrimmed noninverting

gain of two. The span adjustment can even include thermistors

or other sensitive elements to compensate the span of a sensor.

In devising your own adjustment scheme, remember that you

should adjust the gain such that the desired span voltage at the

Signal Amplifier input translates to 60 mV at the output. Note

also that the full differential voltage applied to the V/I converter

is 75 mV; in the 4-20 mA mode, –15 mV is applied to the

inverting input (zero pin) by the Divider Network and +60 mV

is applied to the noninverting input by the Signal Amplifier. In

the 0–20 mA mode, the total 75 mV must be applied by the

Signal Amplifier. As a result, the total span voltage will be 25%

larger than that calculated for a 4-20 mA output.

Finally, the external resistance from P2 to 6.2 V should not be

made less than 1 kΩ unless the voltage reference is loaded to at

least 1.0 mA. (A simple load resistor can be used to meet this

requirement if a low value potentiometer is desired.) In no case

should the resistance from P2 to 6.2 V be less than 200 Ω.

Input Spans Between 60 mV and 100 mV

Input spans of up to 100 mV can be obtained by adding an

offset proportional to the output signal into the zero pin of the

V/I converter. This can be accomplished with two resistors and

adjusted via the optional trim scheme shown in Figure 14. The

resistor divider formed by R

and RE2 from the output of the

E1

Signal Amplifier modifies the differential input voltage range

applied to the V/I converter.

In order to determine the fixed resistor values, R

measure the source resistance (R

) of the internal divider network.

D

and RE2, first

E1

This can be accomplished (power supply disconnected) by

measuring the resistance between the 4 mA of offset (Pin 13)

and common (Pin 6) with the 6.2 V reference (Pin 14) connected

to common. The measured value, R

R

and RE2 via the following formula:

E1

, is then used to calculate

D

–8–

R

E 2

and R

= R

= 412 R

E1

D

S −60 mV

S

−1.0024

E2

Figure 14 shows a scheme for adjusting the modified span and

4 mA offset via R

connect both signal inputs to the 6.2 V Reference, set R

zero and then adjust R

and RE4. The trim procedure is to first

E3

so that 4 mA flows in the current loop.

E3

to

E4

This in effect, creates a divider with the same ratio as the

internal divider that sets the 4 mA zero level (–15 mV with

respect to 6.2 V). As long as the input signal remains zero the

voltage at Pin 12, the zero adjust, will remain at –15 mV with

respect to 6.2 V.

Figure 14. Adjusting for Spans between 60 mV and

100 mV (R

and RE2) with Fine-Scale Adjust (RE3 and RE4)

E1

After adjusting RE3 place the desired full scale (S) across the

signal inputs and adjust R

so that 20 mA flows in the current

E4

loop. An attenuated portion of the input signal is now added

into the V/I zero to maintain the 75 mV maximum differential.

If there is some small offset at the input to the Signal Amplifier,

it may be necessary to repeat the two adjustments.

LOCAL-POWERED OPERATION FOR 0–20 mA OUTPUT

The AD693 is designed for local-powered, three-wire systems as

well as two-wire loops. All its usual ranges are available in threewire operation, and in addition, the 0–20 mA range can be used.

The 0-20 mA convention offers slightly more resolution and

may simplify the loop receiver, two reasons why it is sometimes

preferred.

The arrangement, illustrated in Figure 15, results in a 0–20 mA

transmitter where the precalibrated span is 37.5 mV. Connecting P1 to P2 will double the span to 75 mV. Sensor input

and excitation is unchanged from the two-wire mode except for

the 25% increase in span. Many sensors are ratiometric so that

an increase in excitation can be used instead of a span

adjustment.

In the local-powered mode, increases in excitation are made

easier. Voltage compliance at the I

terminal is also improved;

IN

the loop voltage may be permitted to fall to 6 volts at the

AD693, easing the trade-off between loop voltage and loop

resistance. Note that the load resistor, R

current into Pin 10, I

, so as not to confuse the loop current

IN

, should meter the

L

with the local power supply current.

REV. A

Figure 15. Local Powered Operation with 0–20 mA Output

OPTIONAL INPUT FILTERING

Input filtering is recommended for all applications of the

AD693 due to its low input signal range. An RC filter network

at each input of the signal amplifier is sufficient, as shown in

Figure 16. In the case of a resistive signal source it may be

necessary only to add the capacitors, as shown in Figure 18.

The capacitors should be placed as close to the AD693 as

possible. The value of the filter resistors should be kept low to

minimize errors due to input bias current. Choose the 3 dB

point of the filter high enough so as not to compromise the

bandwidth of the desired signal. The RC time constant of the

filter should be matched to preserve the ac common-mode

rejection.

Figure 16. Optional Input Filtering

AD693

INTERFACING PLATINUM RTDS

The AD693 has been specially configured to accept inputs from

100 Ω Platinum RTDs (Resistance Temperature Detectors).

Referring to Figure 17, the RTD and the temperature stable

100 Ω resistor form a feedback network around the Auxiliary

Amplifier resulting in a noninverting gain of (1 + R

where R

is the temperature dependent resistance of the RTD.

T

The noninverting input of the Auxiliary Amplifier (Pin 2) is

then driven by the 75 mV signal from the Voltage Divider (Pin

4). When the RTD is at 0, its 100 Ω resistance results in an

amplifier gain of +2 causing V

to be 150 mV. The Signal

X

Amplifier compares this voltage to the 150 mV output (Pin 3) so

that zero differential signal results. As the temperature (and

therefore, the resistance) of the RTD increases, V

increase according to the gain relationship. The difference

between this voltage and the zero degree value of 150 mV drives

the Signal Amp to modulate the loop current. The AD693 is

precalibrated such that the full 4-20mA output span corresponds

to a 0 to 104°C range in the RTD. (This assumes the European

Standard of α = 0.00385.) A total of 6 precalibrated ranges for

three-wire (or two-wire) RTDs are available using only the pin

strapping options as shown in Table I.

A variety of other temperature ranges can be realized by using

different application voltages. For example, loading the Voltage

Divider with a 1.5 kΩ resistor from Pin 3 to Pin 6 (common)

will approximately halve the original application voltages and

allow for a doubling of the range of resistance (and therefore,

temperature) required to fill the two standard spans. Likewise,

/100 Ω),

T

will likewise

X

Figure 17. 0-to-104°C Direct Three-Wire 100Ω RTD lnterface, 4-20mA Output

REV. A

–9–

Table I. Precalibrated Temperature

Range Options Using a European

Standard 100Ω RTD and the AD693

Temperature

Range Pin Connections

0 to + 104°C 12 to 13

0 to +211°C 12 to 13, and

+25°C to +130°C 12 to 14

+51°C to +266°C 12 to 14, and

–50°C to +51°C 12 to 11

–100°C to +104°C 12 to 11 and

15 to 16

15 to 16

15 to 16

AD693

increasing the application voltages by adding resistance between

Pins 14 and 3 will decrease the temperature span.

An external voltage divider may also be used in conjunction

with the circuit shown to produce any range of temperature

spans as well as providing zero output (4 mA) for a non 0

temperature input. For example, measuring V

with respect to a

X

voltage 2.385 times the excitation (rather than 2 times) will

result in zero input to the Signal Amplifier when the RTD is at

100°C (or 138.5 Ω).

As suggested in Table I, the temperature span may also be adjusted

by changing the voltage span of the Signal Amplifier. Changing the

gain from 2 to 4, for example, will halve the temperature span to

about 52°C on the 4-20mA output configuration. (See section

“Adjusting Input Span.”)

The configuration for a three-wire RTD shown in Figure 17 can

accommodate two-wire sensors by simply joining Pins 1 and 5

of the AD693.

INTERFACING LOAD CELLS AND METAL FOIL STRAIN GAGES

The availability of the on-chip Voltage Reference, Auxiliary

Amplifier and 3 mA of excitation current make it easy to adapt

the AD693 to a variety of load cells and strain gages.

The circuit shown in Figure 18 illustrates a generalized approach in

which the full flexibility of the AD693 is required to interface to a

low resistance bridge. For a high impedance transducer the

bridge can be directly powered from the 6.2 V Reference.

Component values in this example have been selected to match

the popular standard of 2 mV/V sensitivity and 350 Ω bridge

resistance. Load cells are generally made for either tension and

compression, or compression only; use of the 12 mA zero tap

allows for operation in the tension and compression mode. An

optional zero adjustment is provided with values selected for

+2% FS adjustment range.

Because of the low resistance of most foil bridges, the excitation

voltage must be low so as not to exceed the available 4 mA zero

current. About 1 V is derived from the 6.2 V Reference and an

external voltage divider; the Aux-Amp is then used as a follower

to make a stiff drive for the bridge. Similar applications with

higher resistance sensors can use proportionally higher voltage.

Finally, to accommodate the 2 mV/V sensitivity of the bridge,

the full-scale span of the Signal Amplifier must be reduced.

Using the load cell in both tension and compression with 1 V of

excitation, therefore, dictates that the span be adjusted to 4 mV.

By substituting in the expression, R

= 400 Ω/[(30 mV/S) – 1],

S1

the nominal resistance required to achieve this span is found to

be 61.54 Ω. Calculate the minimum resistance required by

subtracting 10% from 61.54 Ω to allow for the internal resistor

tolerance of the AD693, leaving 55.38 Ω (See “Adjusting Input

Span.”) The standard value of 54.9 Ω is used with a 20 Ω

potentiometer for full-scale adjustment.

If a load cell with a precalibrated sensitivity constant is to be

used, the resultant full-scale span applied to the Signal Amplifier is

found by multiplying that sensitivity by the excitation voltage.

(In Figure 18, the excitation voltage is actually (10 kΩ/62.3 kΩ)

(6.2 V) = 0.995 V).

THERMOCOUPLE MEASUREMENTS

The AD693 can be used with several types of thermocouple

inputs to provide a 4-20 mA current loop output corresponding

to a variety of measurement temperature ranges. Cold junction

compensation (CJC) can be implemented using an AD592 or

AD590 and a few external resistors as shown in Figure 19.

From Table II simply choose the type of thermocouple and the

appropriate average reference junction temperature to select

values for R

R

as a result of the AD592 1 µA/K output and is added to

COMP

and RZ. The CJC voltage is developed across

COMP

the thermocouple loop voltage. The 50 Ω potentiometer is

biased by R

to provide the correct zero adjustment range

Z

appropriate for the divider and also translates the Kelvin scale of

the AD592 to °Celsius. To calibrate the circuit, put the

thermocouple in an ice bath (or use a thermocouple simulator

set to 0) and adjust the potentiometer for a 4 mA loop current.

The span of the circuit in °C is determined by matching the

signal amplifier input voltage range to its temperature equivalent

Figure 18. Utilizing the Auxiliary Amplifier to Drive a Load Cell, 12 mA ± 8 mA Output

–10–

REV. A

Figure 19. Thermocouple Inputs with Cold Junction Compensation

Table II. Thermocouple Application—Cold Junction Compensation

AD693

POLARITY MATERIAL TYPE TEMP RCOMP RZ RANGE RANGE

AMBIENT TEMP TEMP

+ IRON J 25° 51.7 Ω 301K

– CONSTANTAN 75° 53.6 Ω 294K

+ NICKEL-CHROME 25° 40.2 Ω 392K

_ NICKEL-ALUMINUM K 75° 42.2 Ω 374K

+ NICKEL-CHROME 25° 60.4 Ω 261K

E 413°C 787°C

– COPPER-NICKEL 75° 64.9 Ω 243K

+ COPPER 25° 40.2 Ω 392K

T USE WITH GAIN >2

– COPPER-NICKEL 75° 45.3 Ω 340K

via a set of thermocouple tables referenced to °C. For example,

the output of a properly referenced type J thermocouple is

60 mV when the hot junction is at 1035°C. Table II lists the

maximum measurement temperature for several thermocouple

types using the preadjusted 30 mV and 60 mV input ranges.

More convenient temperature ranges can be selected by determining the full-scale input voltages via standard thermocouple

tables and adjusting the AD693 span. For example, suppose

only a 300°C span is to be measured with a type K thermocouple. From a standard table, the thermocouple output is

12.207 mV; since 60 mV at the signal amplifier corresponds to a

16 mA span at the output a gain of 5, or more precisely 60 mV/

12.207 mV = 4.915 will be needed. Using a 12.207 mV span in

the gain resistor formula given in “Adjusting Input Span” yields

a value of about 270 Ω as the minimum from P1 to 6.2 V. Adding

a 50 Ω potentiometer will allow ample adjustment range.

With the connection illustrated, the AD693 will give a full-scale

indication with an open thermocouple.

ERROR BUDGET ANALYSIS

Loop-Powered Operation specifications refer to parameters

tested with the AD693 operating as a loop-powered transmitter.

The specifications are valid for the preset spans of 30 mV,

60 mV and those spans in between. The section, “Components

of Error,” refers to parameters tested on the individual functional

blocks, (Signal Amplifier, V/I Converter, Voltage Reference, and

Auxiliary Amplifier). These can be used to get an indication of

device performance when the AD693 is used in local power

mode or when it is adjusted to spans of less than 30 mV.

REV. A

–11–

30 mV 60 mV

546°C 1035°C

721°C—

Table III lists the expressions required to calculate the total

error. The AD693 is tested with a 250 Ω load, a 24 V loop supply

Table III. RTI Contributions to Span and Offset Error

RTI Contributions to Offset Error

Error Source Expression for RTI Error at Zero

I

Zero Current Error IZE/X

ZE

PSRR Power Supply Rejection Ratio (|V

CMRR Common-Mode Rejection Ratio |V

IOS Input Offset Current R

RTI Contributions to Span Error

Error Source Expression for RTI Error at Full Scale

Transconductance Error V

X

SE

X

Transconductance PSRR1|RL – 250 Ω| × IS × PSRR

PSRR

X

Transconductance CMRR |VCM – 3.1 V| × V

CMRR

XNLNonlinearity V

I

Differential Input Current2RS × I

DIFF

Abbreviations

Zero Current (usually 4 mA)

I

Z

Output span (usually 16 mA)

I

S

R

Input source impedance

S

R

Load resistance

L

Loop supply voltage

V

LOOP

V

Input common-mode voltage

CM

V

Input span

SPAN

X

Nominal transconductance in A/V

S

1

The 4–20 mA signal, flowing through the metering resistor, modulates the power supply voltage seen

by the AD693. The change in voltage causes a power supply rejection error that varies with the

output current, thus it appears as a span error.

2

The input bias current of the inverting input increases with input signal voltage. The differential

input current, I

Figure 2. I

ies with signal. If the change in differential input current with input signal is approximated as a

linear function, then any error due to source impedance may be approximated as a span error. To

calculate I

input voltage for your application. Multiply by + In max to get I

impedance to get the input voltage error at full scale.

, equals the inverting input current minus the noninverting input current; see

DIFF

, flowing into an input source impedance, will cause an input voltage error that var-

DIFF

, refer to Figure 2 and find the value for I

DIFF

S

– 24 V| + [|RL – 250 Ω| × IZ]) × PSRR

LOOP

– 3.1 V| × CMRR

CM

× IOS

S

× X

SPAN

SE

× X

SPAN

. Multiply I

CMRR

DIFF

SPAN

×

X

NL

DIFF

/ + In corresponding to the full-scale

DIFF

DlFF

by the source

AD693

and an input common-mode voltage of 3.1 V. The expressions

below calculate errors due to deviations from these nominal

conditions.

The total error at zero consists only of offset errors. The total

error at full scale consists of the offset errors plus the span

errors. Adding the above errors in this manner may result in an

error as large as 0.8% of full scale, however, as a rule, the

AD693 performs better as the span and offset errors do not tend

to add worst case. The specification “Total Unadjusted Error,”

(TUE), reflects this and gives the maximum error as a % of full

scale for any point in the transfer function when the device is

operated in one of its preset spans, with no external trims. The

TUE is less than the error you would get by adding the span

and offset errors worst case.

Thus, an alternative way of calculating the total error is to start

with the TUE and add to it those errors that result from

operation of the AD693 with a load resistance, loop supply

voltage, or common-mode input voltage different than specified.

(See Example 1 below.)

ERROR BUDGET FOR SPANS LESS THAN 30 mV

An accommodation must be made to include the input voltage

offset of the signal amplifier when the span is adjusted to less

than 30 mV. The TUE and the Zero Current Error include the

input offset voltage contribution of the signal amplifier in a gain

of 2. As the input offset voltage is multiplied by the gain of the

signal amplifier, one must include the additional error when the

signal amplifier is set to gains greater than 2.

For example, the 300K span thermocouple application discussed

previously requires a 12.207 mV input span; the signal amplifier

must be adjusted to a gain of approximately 5. The loop transconductance is now 1.333 A/V, (5 × 0.2666 A/V). Calculate the

total error by substituting the new values for the transconductance

and span into the equations in Table III as was done in Example

I. The error contribution due to V

2 × V

is already included in the TUE and the Zero Current

OS

is 5 × V

OS

, however, since

OS

OUTLINE DIMENSIONS

D-20

Dimensions shown in inches and (mm).

20-Lead Side Brazed Ceramic DIP

Error it is necessary to add an error of only (5 – 2) × V

to the

OS

error budget. Note that span error may by reduced to zero with

the span trim, leaving only the offset and nonlinearity of the

AD693.

EXAMPLE I

The AD693 is configured as a 4-20mA loop powered transmitter

with a 60 mV FS input. The inputs are driven by a differential

voltage at 2 V common mode with a 300 Ω balanced source

resistance. A 24 V loop supply is used with a 500 Ω metering

resistance. (See Table IV below.)

Trimming the offset and span for your application will remove

all span and offset errors except the nonlinearity of the AD693.

Table IV. Example 1

OFFSET ERRORS

I

Already included in the TUE spec . 0.0 µV

Z

PSRR PSRR = 5.6 µV/V; (|24 V – 24 V| + [| 500 Ω – 250 Ω × 4 mA]) × 5.6 µV/V =5.6 µV

V

= 24 V

LOOP

RL = 500 Ω IZ = 4 mA

CMRR CMRR = 30 µV/V; |2 V –3.1 V| × 30 µV/V = 33.0 µV

VCM = 2 V

IOS IOS = 3 nA, RS = 300 Ω; 300 Ω × 3 nA = 0.9 µV

Total Additional Error at 4 mA 39.5 µV

As % of full scale; (39.5 µV × 0.2666 A/V)/20 mA × 100% = 0.053 % of FS

SPAN ERRORS

XSEAlready included in the TUE spec 0.0 µV

X

PSRR = 5.6 µV/V; (|500 Ω – 250 Ω| × 16 mA) × 5.6 µV/V = 22.4 µV

PSRR

RL = 500 Ω, IS = 16 mA

X

CMRRXCMRR

I

DIFFVSPAN

XNLAlready included in the TUE 0.0 µV

Total Additional Span Error at Full Scale 74.0µV

Total Additional Error at Full Scale; e

As % of Full Scale; (113.5 µV × 0.2666A V)/20 mA × 100% = 0.151% of FS

New Total Unadjusted Error @ FS; e

= 0.06%/V; |2 V – 3. 1 V| × 60 mV × 0.06%/V = 39.6 µV

VCM = 2 V, V

= +60 mV; 300 Ω × 2 × 20 nA 12.0 µV

I

/ + In = 2

DIFF

from Figure 2)

SPAN

= 60 mV

OFFSET

TUE

+ e

= 39.5 µV + 74.0 µV = 113.5 µV

SPAN

+ e

= 0.5% +0.151% = 0.651% of FS

ADDITIONAL

Q-20

20-Lead Cerdip

C1050a–9–10/87

E-20A

20-Terminal Leadless Chip Carrier

–12–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...