Page 1

FBD-NT Press Brake

Installation Guide

Summary...........................................................................................2

Environmental conditions ..............................................................2

Power supply.................................................................................2

Machine installation.......................................................................3

Location ............................................................................................4

Carrying ............................................................................................5

Using a crane ................................................................................5

Using rollers ..................................................................................6

Foundation ........................................................................................7

Cleaning............................................................................................7

Supplying hydraulic oil ......................................................................8

Removing shipping brackets.............................................................9

Supplying electric power ..................................................................10

Changing power supply parts.......................................................10

Connecting power cable...............................................................13

Checking wiring connections........................................................15

Re-origin ..........................................................................................16

Connecting air compressor..............................................................16

Leveling............................................................................................17

Paralleling upper and lower beams .................................................18

Checking movement of each axis....................................................19

Installing stopper fingers..................................................................20

Making final checks..........................................................................20

1

Page 2

SUMMARY

Environmental conditions

• The higher the humidity in the place where the machine is installed,

the lower the insulation performance of its electric parts becomes.

This results in the premature degradation of the electric parts. Do

not install the machine in such a humid place.

• Where the ambient temperature is not higher than 5°C (41°F), keep

the machine and hydraulic unit energized during the day's work.

• Install the machine in a place where it is not subjected to dust, dirt,

and organic or corrosive gases.

• Keep the machine at least 10 m (33 ft) away from a welder or any

other equipment that may produce electric noise and magnetic fields.

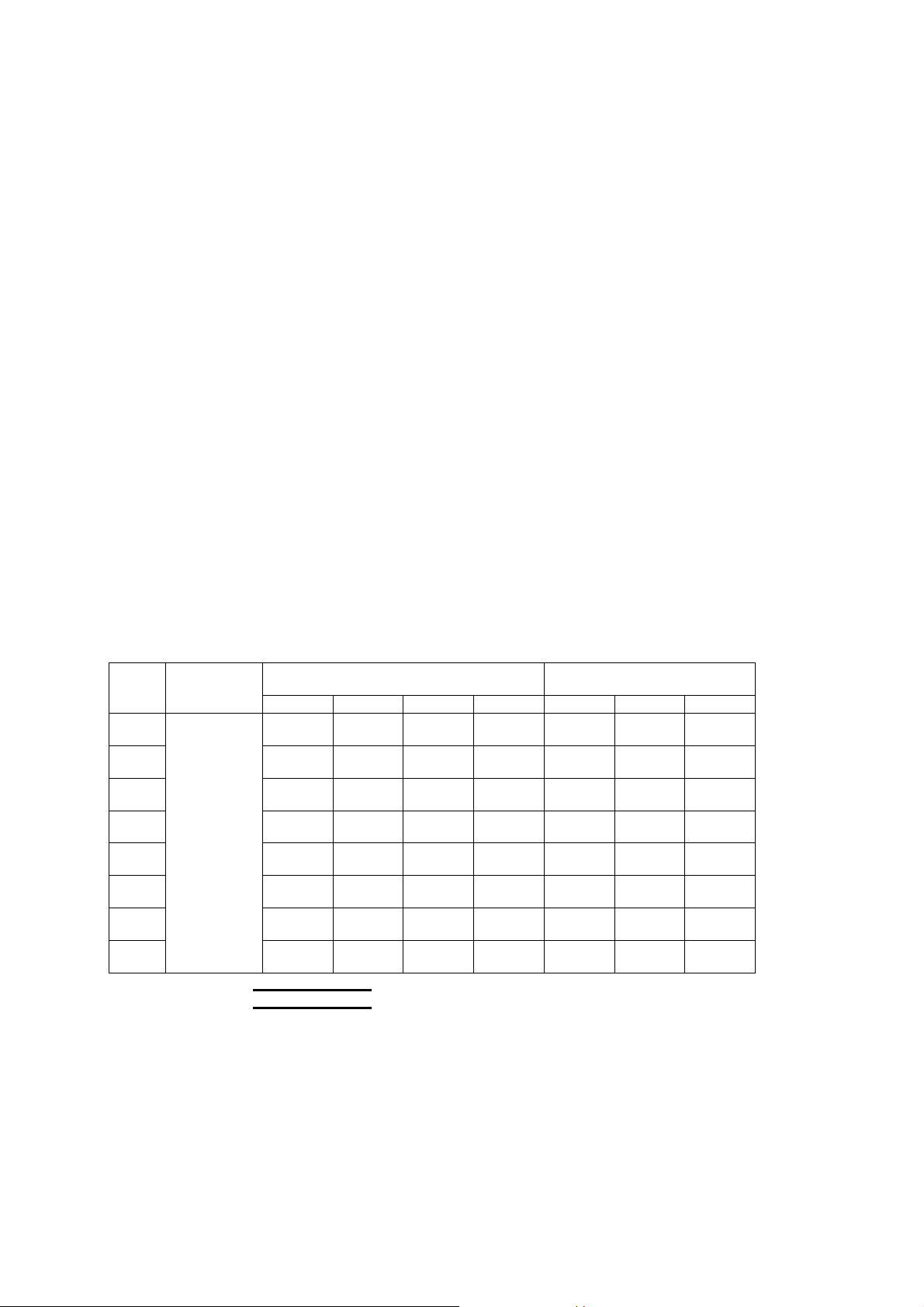

Power supply

Power requirement: 200/230/400/460 V, AC, 3 phases, 50/60 Hz

Power cable: Composed of four conductors (including grounding

conductor) and thick enough to carry required power

Model Power voltage

200 V 230 V 400 V 460 V 200/230V 400 V 460 V

3512 37 A 32.2 A 18.5 A 15.9 A

5012 44 A 38.3 A 22 A 18.9 A

5020 44 A 38.3 A 22 A 18.9 A

8020 44 A 38.3 A 22 A 18.9 A

8025 44 A 38.3 A 22 A 18.9 A

1025 59 A 51.3 A 29.5 A 25.4 A

1030 59 A 51.3 A 29.5 A 25.4 A

1253

200/230/400

/460 V

59 A 51.3 A 29.5 A 25.4 A

Full load current

NOTICE

● Supply the machine from a power source independent of a welder or any

other equipment that may produce line voltage variations.

Power cable and ground

conductor (AWG)

2

2

2

2

2

2

2

2

5.5 mm2

(10)

2

8 mm

(8)

2

8 mm

(8)

2

8 mm

(8)

2

8 mm

(8)

14 mm

(6)

14 mm

(6)

14 mm

(6)

2

2

2

8 mm

(8)

14 mm

(6)

14 mm

(6)

14 mm

(6)

14 mm

(6)

22 mm

(4)

22 mm

(4)

22 mm

(4)

5.5 mm2

(10)

8 mm2

(8)

8 mm2

(8)

8 mm2

(8)

8 mm2

(8)

14 mm2

(6)

14 mm2

(6)

14 mm2

(6)

2

Page 3

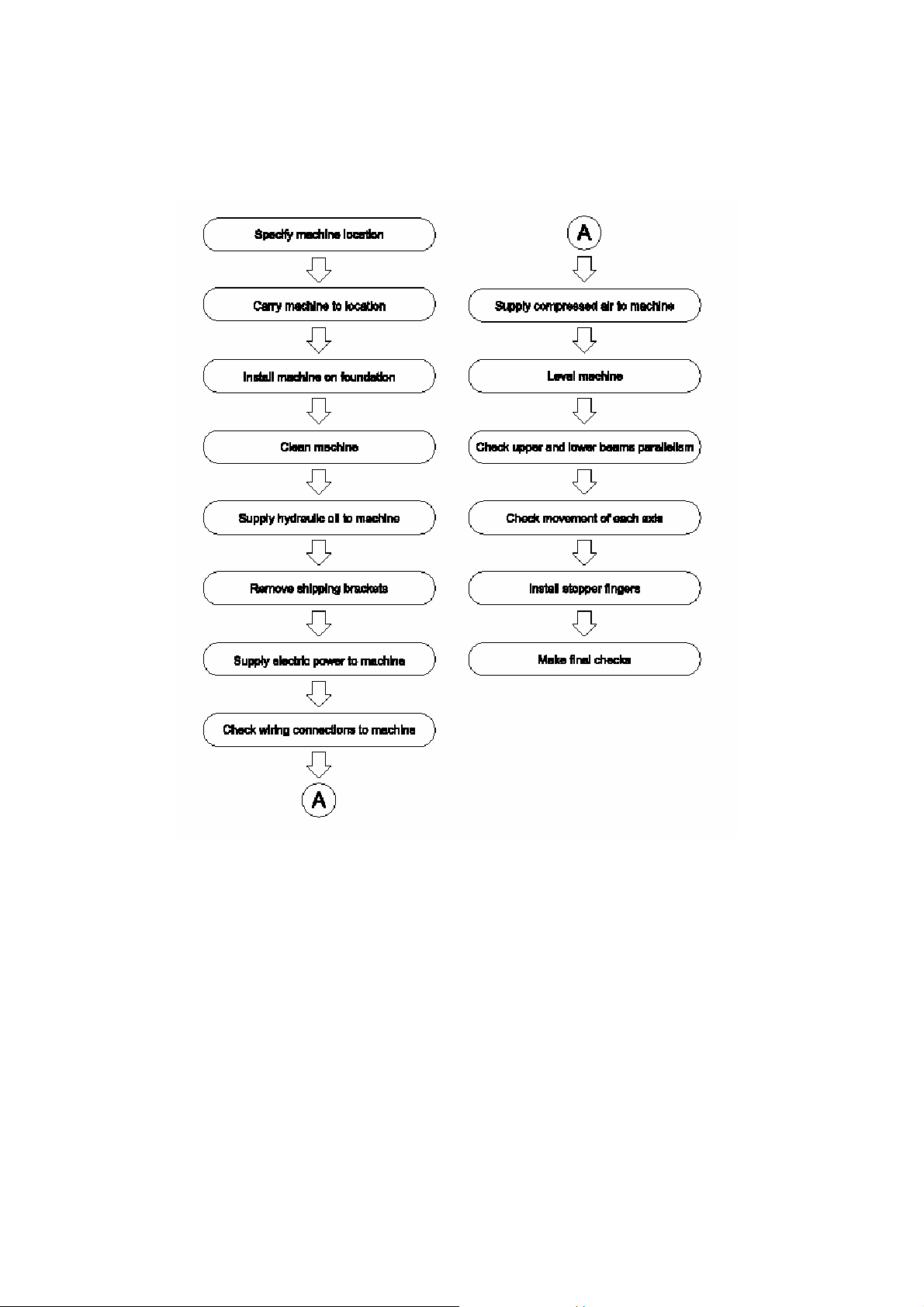

Machine installation

3

Page 4

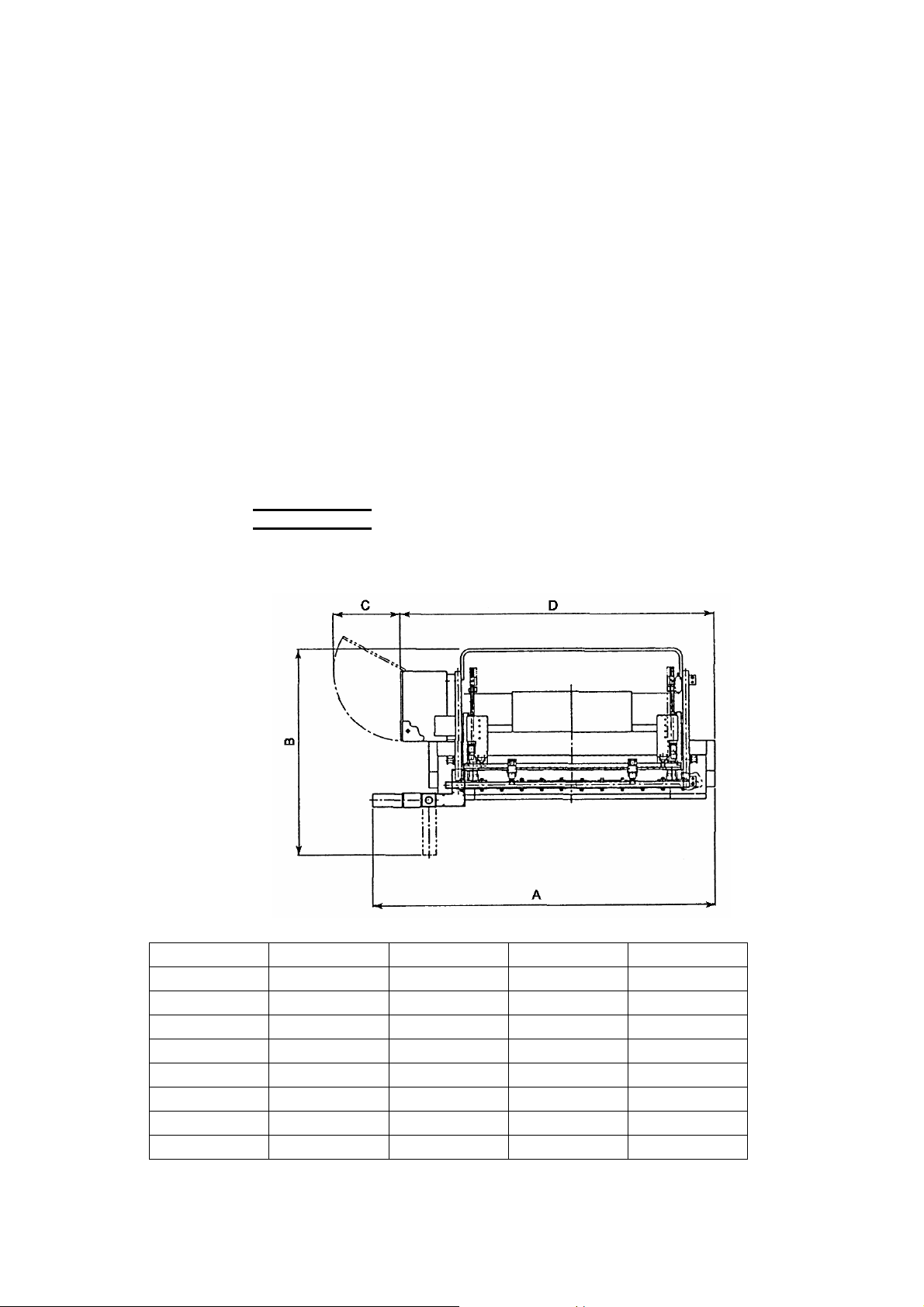

LOCATION

The place where the machine is to be installed must have an ample

floor space. Refer to the machine dimensions given in the table below.

Also take the following points into account:

• There must be no pillars and other obstacles in the area where the

tools are mounted and removed. (At least 835 mm (32.9 in.) long

tools must be able to be horizontally mounted and removed.)

• The ceiling must be at least 1000 mm (40 in.) from the top of the

machine.

• There must be an additional space to place a tool storage case and

an air compressor.

• There must be a work space where the worksheets can be easily

moved in and out and where maintenance and part quality check can

be smoothly performed. Especially, a work space of 1000 mm (40

in.) or more must be available at the rear of the machine, and an

enough space must be available for the door of the electrical

enclosure to be opened.

NOTICE

● Do not install the machine in a place where it is exposed to dust from such

operations as sandblasting and to direct sunlight, rain or wind.

Unit: mm (in.)

Model A B C D

3512 2040 (80.38) 1990 (78.41) 680 (26.79) 1890 (74.47)

5012 2040 (80.38) 1990 (78.41) 680 (26.79) 1890 (74.47)

5020 2860 (112.69) 1985 (78.21) 680 (26.79) 2570 (101.26)

8020 2880 (113.48) 2060 (81.17) 680 (26.79) 2610 (102.84)

8025 3380 (133.18) 2060 (81.17) 680 (26.79) 3110 (122.54)

1025 3380 (133.18) 2060 (81.17) 680 (26.79) 3110 (122.54)

1030 3875 (152.68) 2060 (81.17) 680 (26.79) 3610 (142.24)

1253 3905 (153.86) 2075 (81.76) 680 (26.79) 3630 (143.03)

4

Page 5

CARRYING

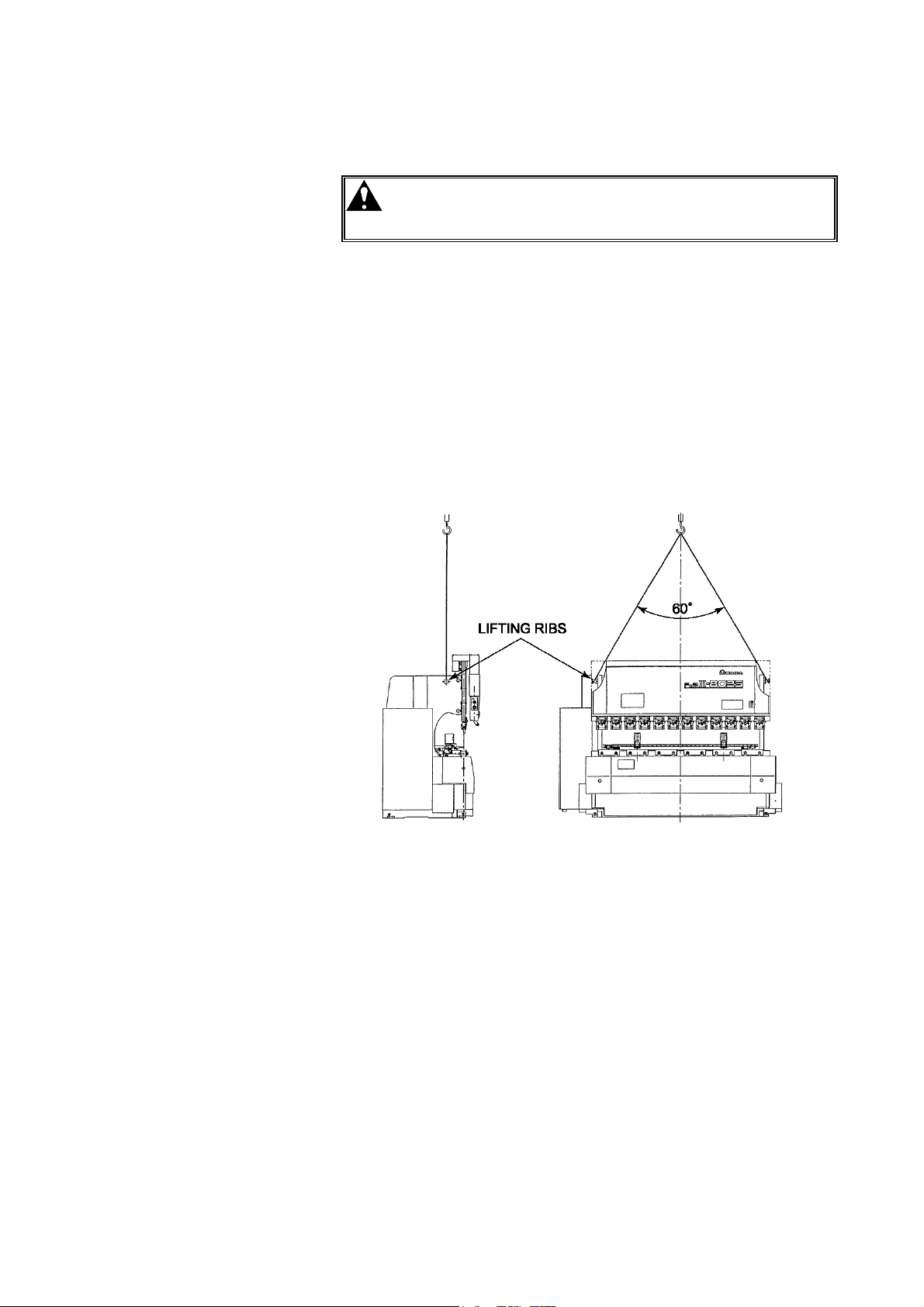

Using a crane

When lifting the machine, apply the wire rope sling to the lifting ribs at

the top of the frame, slowly lift and carry the machine to the location,

and slowly lower the machine at the location. The wire rope sling must

be strong enough to carry the weight of the machine. (For the weight

of the machine, see the serial number plate attached to the machine.)

WARNING

● Carrying the machine is very dangerous.

Have a qualified contractor perform the

carrying work.

5

Page 6

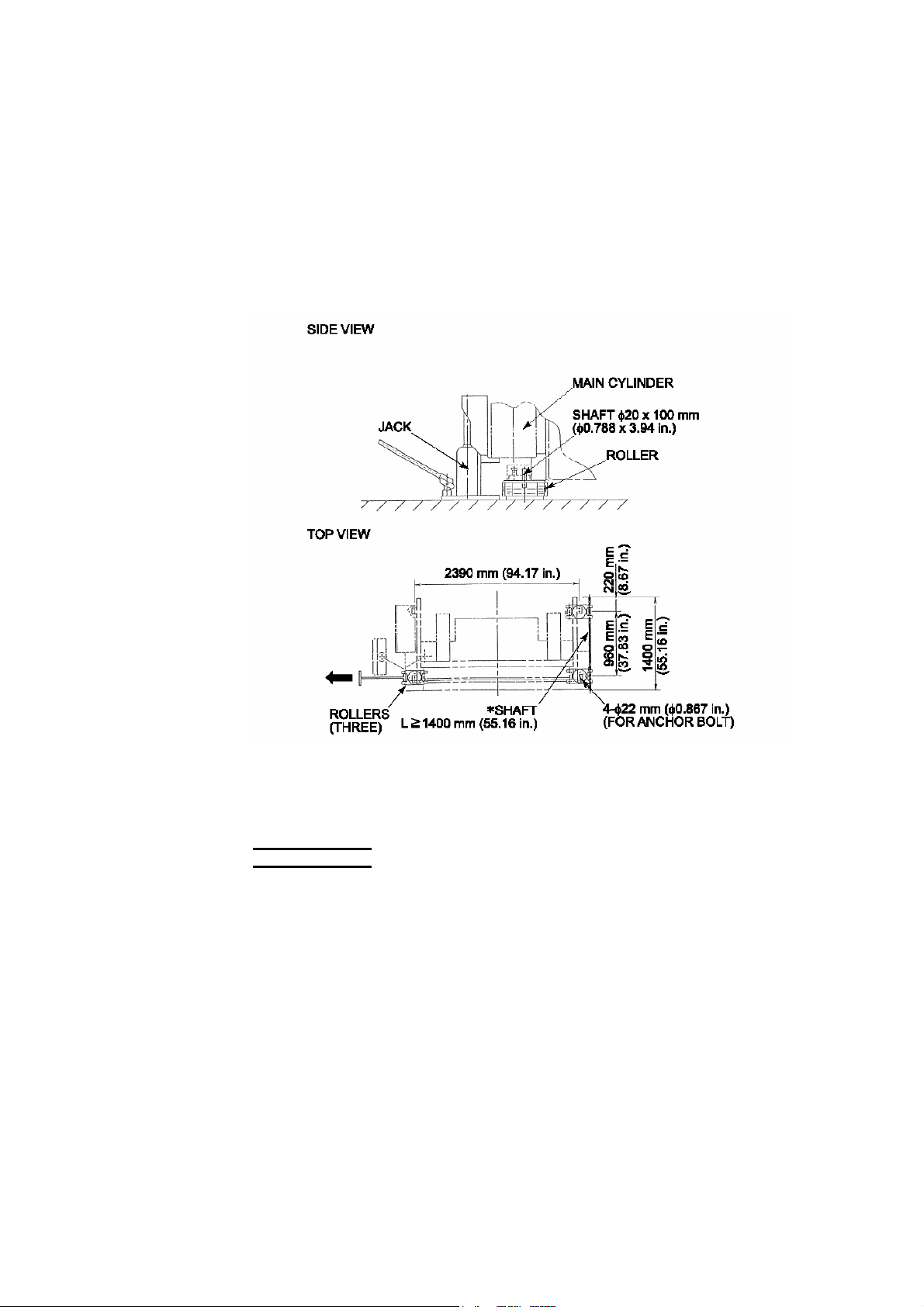

Using rollers

First jack up the front bottom of the machine under the left and right

main cylinders, and place rollers under the front feet of the machine.

Then slowly jack up the rear bottom of the machine, and place rollers

under the rear feet of the machine. Pay attention to the balance of the

machine when jacking up. Fix the rollers to the machine through the

anchor bolt holes. Slowly roll the machine to its location.

The shaft marked by an asterisk (✼) is used to connect the two rollers

at the right side of the machine. (Three rollers are shown in the

drawing.)

NOTICE

● Be sure to first jack up the front bottom of the machine under the main

cylinders.

● The machine has a center of gravity at its front. If the rear bottom of the

machine is jacked up without paying attention to its balance, the machine

may tip over, resulting in a very dangerous situation.

6

Page 7

FOUNDATION

To maintain bending accuracy, install the machine on a flat concrete

floor that is strong enough to carry the weight of the machine and is not

likely to subside.

Unit: mm (in.)

CLEANING

Model A B

3512 2570 (101.26) 1990 (78.41)

5012 2570 (101.26) 1990 (78.41)

5020 3250 (128.05) 1985 (78.21)

8020 3290 (129.63) 2060 (81.17)

8025 3790 (149.33) 2060 (81.17)

1025 3790 (149.33) 2060 (81.17)

1030 4290 (169.03) 2060 (81.17)

1253 4310 (169.81) 2075 (81.76)

After the machine is installed on the foundation, clean it. Particularly,

remove all rust-preventive grease from the punch holders, the die

holders, and the top surface of the lower beam, using cleaning oil.

NOTICE

● Do not use a solvent or scraper that removes the paint of the machine.

7

Page 8

SUPPLYING HYDRAULIC OIL

The hydraulic unit is located at the rear of the machine. Remove the

cover of the hydraulic unit, and pour the recommended hydraulic oil into

the hydraulic unit tank to slightly above the center mark of the oil gauge

when the lower beam is at the lower limit.

Model Tank capacity

3512, 5012, 5020, 8020, 8025 70 (18.4)

1025, 1030, 1253 90 (23.7)

Recommended oil

For use at normal temperature: Esso Teresso 46 and Shell Tellus Oil 46

(ISO VG56 Viscosity Index 113)

For use at lower temperature: Esso Spinesso 22 and Shell Tellus Oil

C22

Liters (US gal)

8

Page 9

REMOVING SHIPPING BRACKETS

After the machine has been installed in place, remove the shipping

brackets securing the backgauge. The shipping brackets are each

fixed with two bolts. (Replace the bolts in their holes.)

9

Page 10

SUPPLYING ELECTRIC POWER

WARNING

NOTE

● The machine needs a 200/230/400/460 V and 3-phase power supply.

● Use the power cable and grounding conductor that suit the power to be

handled.

● Have a qualified electrician perform all

electric work to prevent accidents and

damage.

● Before making the electrical connections,

be sure to turn off the shop circuit

breaker.

● Be sure to connect the grounding

conductor for safety.

● Use the shop circuit breaker and

grounding conductor exclusively for the

machine, and separate from those of other

equipment such as welders, drills,

sanders, and grinders.

Changing power supply parts

If the power supply voltage is different from the transformer and motor

connection voltage shown on the label affixed to the electrical

enclosure of the machine, the power supply parts must be changed.

For the wiring of each part, refer to the electric circuit diagram in the

appendix.

Change the power supply parts as described below.

1 Turn off the shop circuit breaker.

2 Open the door of the electrical enclosure at the left side of the

machine.

3 Turn off the circuit breaker QF1.

4 Turn off the motor circuit breaker QM1.

5 Change the following parts:

• Circuit breaker QF1

• Motor circuit breaker QM1

• Thermal relay FR1

• Fuses F1 and F2

• Varistors RV1 to RV3

10

Page 11

6 Change the main motor power cables.

• When changing from 200/230 V to 400/460 V

Disconnect the three cables between the thermal relay and the

lower terminal block XT2, and install two jumper connectors at

the lower terminal block XT2.

• When changing from 400/460 V to 200/230 V

Remove the two jumper connectors from the lower terminal

block XT2, and connect the three cables between the thermal

relay and the lower terminal block XT2.

200/230 V connections

No. From Marker tube Length Marker tube To

1 FR1-2 U 350 Y XT2-Y (upper)

2 FR1-4 V 350 Z XT2-Z (upper)

3 FR1-6 W 350 X XT2-X (upper)

400/460 V connections

No. From Marker tube Length Marker tube To

1 XT2-X

(upper)

2 XT2-Y

(upper)

X 150 Y XT2-Y

Y 150 Z XT2-Z

(upper)

(upper)

11

Page 12

7 Change the primary taps of the transformer TC1 as shown below.

8 Set the thermal relay FR1 at the values shown in the table below.

Model 3512 5012 5020 8020 8025 1025 1030 1253

Hydraulic pump motor

output: kW (HP)

200 V 22.4 29.9 29.9 29.9 29.9 40.3 40.3 40.3

Thermal relay

setting: A

230 V 19.5 26 26 26 26 35 35 35

400 V 13.2 17.8 17.8 17.8 17.8 20.7 20.7 20.7

460 V 11.5 15.5 15.5 15.5 15.5 18 18 18

5.5

(7.5)

7.5

(10)

7.5

(10)

7.5

(10)

7.5

(10)

11

(15)

11

(15)

11

(15)

12

Page 13

Connecting power cable

Connect the power cable to the machine as described below.

1 Turn off the shop circuit breaker.

2 Open the door of the electrical enclosure at the left side of the

machine.

3 Turn off the machine circuit breaker.

4 Run the power cable from the shop circuit breaker through the

hole into the electrical enclosure.

5 Connect the power cable to the power input terminals L1, L2, and

L3 in the electrical enclosure.

6 Connect the grounding conductor to the ground terminal PE.

NOTE

● Use a grounding conductor of at least the same size as that of the

power cable conductors.

7 After the electric wiring connections are completed, check the

voltage with a tester.

When the power supply parts are changed, check the voltage with

a tester as described below.

(1) Turn off the shop circuit breaker.

(2) Change the machine to the following conditions:

• Turn off the circuit breaker QF1.

• Turn off the motor circuit breaker QM1.

• Remove the fuse FU3.

• Turn off the circuit protectors QF3 to QF5.

(3) Turn on the shop circuit breaker.

(4) Check the input voltage between the terminals L1 and L2, L2

and L3, and L1 and L3 at the lower terminal block.

(5) Check the input voltage between the terminals L1 and L2, L2

and L3, and L1 and L3 at the primary side (upper terminal

block) of the circuit breaker QF1.

(6) Turn on the circuit breaker QF1.

(7) Check the input voltage between the terminals L11 and L21,

L21 and L31, and L11 and L31 at the secondary side (lower

terminal block) of the circuit breaker QF1.

(8) Check the output voltage at the secondary side of the

transformer TC1.

(9) Check the input voltage between the terminals L11 and L21,

L21 and L31, and L11 and L31 at the primary side (upper

terminal block) of the motor circuit breaker QM1.

(10) Turn on the motor circuit breaker QM1.

13

Page 14

(11) Check the input voltage between the terminals L12 and L22,

L22 and L32, and L12 and L32 at the secondary side (lower

terminal block) of the motor circuit breaker QM1.

(12) If the above voltage checks find no problems, turn off the

circuit breaker QF1.

(13) Return the machine to the following conditions:

• Replace the fuse FU3.

• Turn on the circuit protectors QF3 to QF5.

8 Replace the cover of the electrical enclosure.

14

Page 15

Checking wiring connections

CAUTION

Check the wiring connections as described below.

1 Turn on the shop circuit breaker.

2 Turn on the machine circuit breaker, and check that the POWER

light comes on.

3 Turn the POWER ON/OFF switch to ON. When the initial NC

display is shown and a beep is heard, the hydraulic pump motor

can be started.

4 Press the HYDRAULIC ON button. The hydraulic pump motor

starts, and the HYDRAULIC ON button lights.

5 Check the rotational direction of the hydraulic pump motor. The

correct rotational direction is indicated by the arrow in the figure

below. If the hydraulic pump motor runs in the reverse direction,

immediately press the HYDRAULIC OFF button, turn off the

machine circuit breaker, and interchange two of the three

conductors connected to the terminals L1, L2, and L3.

● When turning on the power of the machine

for the first time as described below, keep

one hand at the POWER ON/OFF switch

so that you can turn off the power of the

machine as soon as possible.

NOTICE

● The hydraulic pump will fail if its motor is left to run in the reverse

direction for a long period of time. When the hydraulic pump motor is

found running in the reverse direction after the HYDRAULIC ON button

is pressed, immediately press the HYDRAULIC OFF button.

15

Page 16

RE-ORIGIN

After the power of the machine is turned on, be sure to zero-return the

machine. Unless the zero-return is performed, each axis cannot

move.

Zero-return the machine as described below.

1 Touch the SETUP button shown on the screen.

2 Press and hold the UP foot pedal. Each axis zero-returns.

CONNECTING AIR COMPRESSOR

When the backgauge is equipped with optional flip-up stopper fingers,

compressed air must be supplied to the machine.

The air combination unit is located at the rear of the machine (inside the

right side frame). Fully connect the pipe or hose (inner diameter of

3/8 in.) from the air compressor to the air inlet (joint of 3/8 in.).

The required air pressure for the machine is 0.5 MPa (5 kg/cm

psi). The air compressor used should have a output of 0.75 kW (1

HP) or more.

2

, 70.97

NOTICE

● If a pipe or hose with an inner diameter of less than 3/8 in. is used, the air

flow will be limited and the air pressure will be reduced.

● Install the air compressor near the machine. If the air compressor is away

from the machine, the air pressure will be reduced.

Air combination unit

16

Page 17

LEVELING

Level the machine as described below.

1 Turn the MODE SELECT switch to OFF with the HYDRAULIC ON

button lighted and the hydraulic pump motor running.

2 Place a spirit level on the lower beam.

3 Attach square spirit levels to the working surface at the rear of the

left and right side plates of the machine.

If square spirit levels are not available, place spirit levels at the left

and right edges of the top surface of the lower beam.

4 Turn the leveling bolts to level the machine to 0.03 mm/1m (0.001

in./1ft.) or less in the left-to-right and front-to-back directions.

17

Page 18

PARALLELING UPPER AND LOWER BEAMS

Check that the upper and lower beams are parallel at the left edge D1

and right edge D2 as shown below. If not, parallel them as described

below.

1 Remove the punch holders at the left and right edges.

2 Turn the MODE SELECT switch to UPPER LOCK.

3 Raise the lower beam to 140 mm (5.52 in.), and measure the

dimensions D1and D2.

4 If the dimension D2 is greater than the dimension D1 (0.00), add

the difference to the grid shift of the dimension D1.

If the dimension D2 is smaller than the dimension D1, add the

difference to the grid shift of the dimension D2.

NOTE

● The grid shift is adjusted by changing the value of a system parameter.

For the method of displaying the system parameter, refer to the

adjustment specification.

5 Turn off the power and then back on, and repeat steps 1 to 3.

6 Repeat steps 1 to 5 so that the difference between the dimensions

D1and D2 becomes 0.01 mm (0.0004 in.).

7 When the paralleling of the upper and lower beams is completed,

check that the machine is level with the lower beam positioned

140 mm (5.52 in.). If not, level the machine again.

18

Page 19

CHECKING MOVEMENT OF EACH AXIS

Be sure to check the movement of each axis. Manually move each

axis, and check that each axis moves free of trouble.

NOTE

● If the lower beam tilts or stops midway, lower the lower beam as described

below.

1 Turn the POWER ON/OFF switch to ON.

2 Press and hold the RAM DOWN button until the lower beam

reaches the bottom dead center.

3 Turn the POWER ON/OFF switch to OFF and then back to ON.

4 Re-origin the machine.

19

Page 20

INSTALLING STOPPER FINGERS

WARNING

The machine is shipped with the stopper fingers removed. Install

them as described below.

1 Move the stoppers to the position where they can be reached

through the gap.

2 Turn the MODE SELECT switch to OFF.

3 Install a stopper finger of the same number as that marked on the

stopper as shown below.

● Never reach through the space between

the punches and dies to change the

stopper fingers. Turn the MODE SELECT

switch to OFF during the change.

MAKING FINAL CHECKS

• Interference of lower beam with cover

Move up the lower beam over a full stroke, and press the

EMERGENCY STOP button. Press the RAM DOWN button

intermittently to bring down the lower beam. When the lower beam

does not interfere with the cover, move up and down the lower beam

continuously, and check it for any interference with the cover.

• Oil leakage and air removal

Check for any oil leak. After tools are mounted, move up the lower

beam to apply pressure to the tools for a few seconds. This forces

air out of the hydraulic unit.

20

Loading...

Loading...