Page 1

DVD/CD/TUNER/AMPLIFIER

PLAYER

Model:

DVR4035VSMC

SERVICE MANUAL

www.akai.ru

Page 2

DVD/CD/TUNER/AMPLIFIER PLAYER

DV-R4035VSMC

SERVICE MANUAL

Page 3

Table of contents

Safety information----------------------------3

1. General guide---------------------------3

2. Low zeta potential leaking inspection------3

3. High zeta potential leaking inspection------3

▲ Device avoiding ES (Electric susceptible)

Influence of ESD (Electric Susceptible

Discharge)----3

▲ Electric specification-------------------4

▲ Mechanical diagram---------------- -------8

Mechanical parts list-------------------- 9

Packing and accessories--------------10

▲

Disassemble and assemble-----------11

▲

1. Take out disc from trouble player-------11

2. PCB position------------------------11

▲ Disassemble and assemble parts of the unit----12

8.Control board silk screen diagrqm--- -----------------------33

▲ Attachment 3------------------------------34

▲ Component list

1. Decoder board component list------------------35

2. Amplifier board component list----------------38

3. Control board component list-------------------41

1. Can open the tray by electricity---------12

2. Can not open the tray by electricity-----12

3. Assemble the case-------------------------12

▲ Attachment 1------------------------- 13

▲ Block diagram/Circuit diagram--------13

1. Block diagram--------------------------------14

2. Connecting diagram-------------------------15

3. Decoder board diagram---------------------16

4. Amplifier board diagram-------------------21

5. Control Board diagram---------------------24

▲ Attachment 2-------------------------25

▲ PCB diagram

1. Upper decoder board PCB diagram----26

2. Upper decoder board silk screen diagram-------27

3. Lower decoder board PCB diagram-------------28

4. Amplifier board PCB diagram-------------------29

5. Amplifier board silk screen diagram------------30

6. Upper control board PCB diagram -------------31

7. Lower control board PCB diagram------------32

2

Page 4

Safety information

General guide

1.Observe the original circuit during maintenance. If short

circuit occurs, change the over-hot or damaged components.

2.Observe all the protective device after maintenance, such

as whether the shielding cover or paper is assembled well.

3.To avoid electric shock, please inspect electricity leakage

after maintenance

Low zeta potential leaking inspection

1.Take out AC cord and connect a piece of wire between two

legs of the outlet.

2.Use Gear R x 10K of the voltmeter to measure the spares

on AC outlet and exposed metallic part with short circuit.

The resistance between screw cap, control shaft should be

unlimited.

of discharge of distortion(ESD)exceeded the

restrained figure, electric shock should be

possibly suffered. Do maintain the unit and

inspect once more before return to the user.

Device avoiding ES influence of ESD.

Some solid semi-conductor devices are easy to be

damaged by static electricity. These devices are generally

called ES device. The typical devices are IC, field effect

component and semi-conductor laser diode.

The following technology helps to abate the danger of

ESD on body before handle any semi-conductor or

semi-conductor component. Or wear the ESD bangle availed

from the market to eliminate the threate n of static electricity

on human body.

2.Put the electronic parts with ES device on the surface of

conductor such as aluminium foil after take them out in order

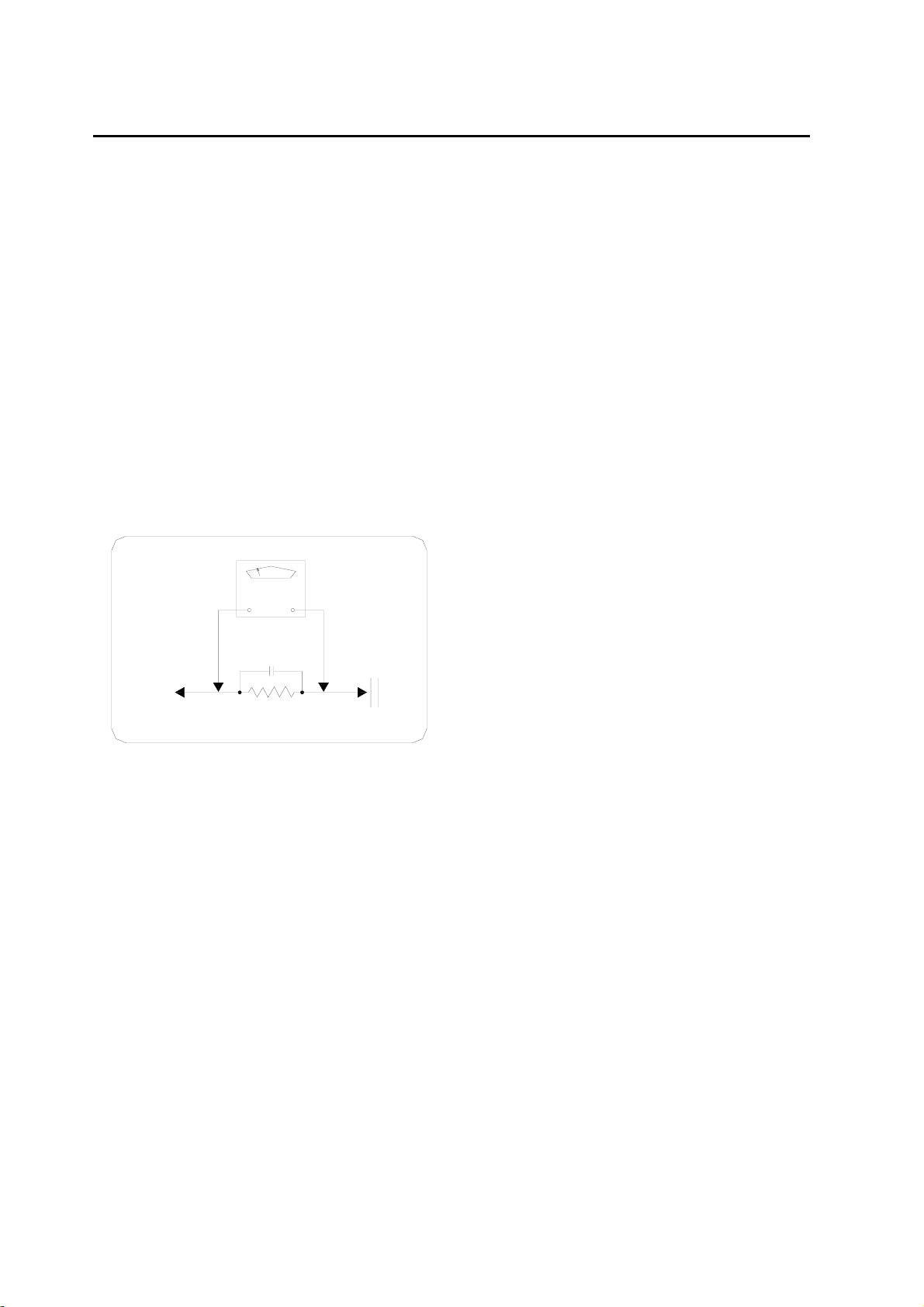

Electric leakage inspection

To device with

exposed metal parts

AC voltmeter

0.15

uF

1.5KΩ 10W

Cold water pipe

(connecting to

ground)

to protect static electricity from accumulation and explosion.

3.Solder or disassemble ES device through iron connecting

the earth.

4. Utilize device only anti-static electricity to disassemble

soldering tin. Non-anti static electricity device (ESC

protection) will release ES that damage ES device.

5.Do not use chemical volatile releasing static electricity

that leads to damage ES device

Picture1

High zeta potential leakage inspection

.As illustrated 1, Connect Resistor with 1.5K, 10W and

capacitor 0.15 between exposed metallic part and device of

fine connection to the earth (water pipe etc.).

2.Plug-in AC cord directly to AC outlet. Do not inspect with

shield adaptor.

3.Utilize 1000 or more sensitive voltmeter to measure

alternating voltage.

4.Turn back the AC plug-in from AC outlet then iterate the

inspection as above.

5.Inspect the voltage of the resistor between other exposed

metallic parts and the earth with the same way.

6. The voltage must not be over than 0.75Vrms at any points

on the resistor. Electric leakage should not be over 0.5mA

when processing high voltage leakage testing through

prevent ed static of keenness(ES)setting is exposedto static

6. Unless preparation for pre-assembling has been made,do

not take out the ES device to be changed from the protective

packings( most of the changed ES devices are packed

together with anti-static electrical foam or similar electric

material, besides, countermeasures for down-lead short

circuit are taken.).

7. Protective material should connect the model or the circuit

component to be assembled in it before taking out the

protective material from the ES device.

Note: do not bear electricity to the model or the circuit, and

pay attention to all the other safety information.

8. When disassembling and replacing the ES device, try to

reduce body movement (Or, the movement of legs, the

friction of fibrous of clothes, or elevating the legs from the

floor will generate static electricity ESD, causing damage to

the ES device.)

3

Page 5

Electric Specification

MW electric index Model No.: DVP-0601-1

Test condition:

1. Supply voltage: AC230V 50Hz 2. Standard power output: 1W

3.Speaker impedance: 4Ω(FL、FR、SL、SR),8Ω(C),6Ω(SW)

4.Standard modulating: 400Hz 30%

No.

1 Intermediate frequency KHz 450 +/-3

2 Cover with area KHz 522-1620 +/-5

4 Utility delicacy

5 S/N ratio(999 KHz,input 5mV/M) dB 40 30

6 Intermediate Frequency restrain rate(612KHz) dB 45 35

7 Mirror restrain rate(1404KHz) dB 35 30

8 Auto plus control(input 100mV/M) dB 30 20

Distortion

9

degree

10 -6dB bandwidth(20dB S/N) KHz 8 5-10

11 zip (input 5mV/M,IFx1 IFx2) % 3 10

Output

12

power

13 +/-10KHz selectivity (1000KHz 20dB S/N) dB 14 8

14 Frequency respond (-6 dB,input 5mV/M) Hz 40~4K 100~3.15K

15 Modulating AC volume (input 100mV/M) dB 40 35

16 The least noise mV 1 3

17 Sensitivity of station locking dB ≤90

5mV/M input,30% % 1 3

100mV/M input,80% % 3 5

Vol ume max W

Distortion degree: 10%,60% modulation

degree,input 5mV/M

Test items

S/N 20dB,612KHz uV/M 600 3000

S/N 20dB,999KHz uV/M 600 3000

S/N 20dB,1395KHz uV/M 600 3000

4

Unit Standard Limit error

W 4.5 3

Page 6

FM electric index Model No.: DVP-0601-1

Test condition:

1. Supply voltage: AC230V 50Hz 2. Standard output power: 1W

3. Antenna impedance: 75Ω 4. Standard modulating: 1KHz 22.5KHz

5. Speaker impedance: 4Ω(FL、FR、SL、SR),8Ω(C),6Ω(SW)

No.

1 Intermediate frequency MHz 10.7 +/-0.1

2 Cover with area MHz 87.5-108 +/-0.1

3 Utility delicacy

4 S/N ratio (98MHz,input 1mV) dB 50 34

5 -3dB limit delicacy uV 10 20

6 Intermediate Frequency Restrain Rate(90MHz) dB 50 45

7 Mirror Restrain Rate(106MHz) dB 28 22

8 Distortion degree (1mV input) % 0.6 1.5

9 Modulating AC volume(input 5mV) dB 50 40

10 Auto frequency control range(1mV input,-3dB) KHz

11 AM restrain(1mv input,modulate degree 30%) dB 32 26

Power output(distortion degree 10%,60KHz,1mv input)

12

13 Frequency response(-3dB) Hz 40~12.5K 100~8K

14 Noise of minimum volume mV 1 3

15 Sensitivity of station locking dB ≤35

16 Passage separating dB 25 ≥20

Test items Unit Standard Limit Error

S/N 30dB,90MHz dB 22 26

S/N 30dB,98MHz dB 22 26

S/N 30dB,106MHz dB 22 26

W 10

5

Page 7

DVD electric index Model No.: DVP-0601-1

1:Video section

No. Test item Test point Performance require Unit Remark

1

outp

2 S-Video

3

4

5

ut

rang

e

Y、Cr、Cb/Y、Pr、Pb

R、G、B

Horizontal distinguish

Video

Y

Chroma

C

Color

synchronization

6 Bandwidth (+3/-6dB)

7 Differential phase DP

Lum Non-Linear Distortion

8

≤5 %

9 Differential Gain DG

10

11

C

SNR

Y ≥56

U passage ≥50

V passage ≥50

R R passage ≥50

12

G G passage ≥50

B B passage ≥50

2:Audio section (testing signals:TCD-784)

No. Test item

Audio output level

1

Amplitude/Frequency response

2

Test point Performance require

1.8+0.2/-0.8 Vrms DVD(LPCM)、CD

3 S/N ratio

4

Distortion THD

5 Dynamic range

0.02 %

6 Separate degree

Passage imbalance

7

Coaxial output range

8

Optical output wavelength (λp)

9

0.5±20%

660±30

3:Other characteristics

No. Test it em Test point

Performance require

1 Disc reading time

Remote control distance

2

Supply voltage input

3

Consume power

4

Storing temperature -20℃~+55℃

5

Image signal system NTSC/PAL

6

7

Free falling

Disc format

8

230V(-10%/+10%)

Suitable for request of GB/T2423.8-1995

1)DVD Player: 12cm single face,single layer;12cm single face,double layer;8cm single face ,single

layer;8cm single face,double layer;(2)CD disc:12cm disc,8cm disc.

1.0±0.2

0.7±0.14

0.88±0.176

0.3±0.06

0.7+/-0.14

0.7+/-0.14

≥500 Line

≥5.5

≤2

≤2

±2

≥85

90

65

≤1.5

10~20

≥5

110

Vp-p

Vp-p

Vp-p

Vp-p

Vp-p

Vp-p

MHz

degree

100KHz 0dB

75Ω load

75Ω load

%

dB

dB

dB

dB

dB

dB

75Ω load

75Ω load

75Ω load

75Ω load

75Ω load

75Ω load

75Ω load

Unit Remark

dB

dB

DVD(LPCM)20Hz~20KHz

JIS-A (20KHz LPF)

1KHz JIS-A

dB

dB

dB

Vp-p

nm

1KHz JIS-A

1KHz JIS-A

DVD(LPCM)、CD

75Ω±1% load

Unit Remark

S

m

W

Normal working

50Hz

4:Test condition

1. Environment condition: normal temperature, normal voltage.

2. Supply voltage:AC230V 50Hz。

6

Page 8

Amplifier board electric index Model No.:DVP-0601-1

No. Test item Unit Typical Limit Test condition

Power supply

1 Voltage input VAC 230±10%

2 Rated output voltage & current +5V 1.3A +5V 1.5A

+12V 150mA +12V 200mA

-12V 50mA -12V 100mA

+22V 3.5A +25V 3.5A

~3.7V 100mA ~3.7V 120mA

-24V 50mA -24V 50mA

3 Output power W 110 Voltage input AC230±10%V

4 +5 wavelength output mV <50

4 Power modulating (+5V point) % 5 Voltage input AC230±10%V

6 Load modulating (+5V point) % 5 Current 10mA-1.5A

7 Standby power W ≤10

Amplifier section

1 Working voltage V +22 +26 Rated load

2 Static current mA 180 300

3 Rated load (FR/FL/SR/SL)

4 Rated load (C/SW)

Rated output power (FR/FL/SR/SL)

5

Maximum output power

6

(FR/FL/SR/SL)

7 Rated output power (C) W 15

8 Maximum output power (C) W ≧20 ≧25

9 Rated output power (SW) W 25

10 Maximum output power (SW) W ≧30 ≧35

Band distortion (FR/FL/SR/SL/C)

11

12 Band distortion (SW) % 0.25 Rated load; PO=1W;f=100Hz

13 Channel output mix dB 55

14 Channel output mix dB 55

15 S/N dB >75 JIS-A

Amplitude/Frequency response L/R/C/SL/SR

16

Amplitude/Frequency response SW

17

1 Circuit level output V

2 Circuit S/N rate output dB 90 85

3 Circuit level input V

4 Circuit impedance input Ω 10K±10%

Ω

Ω

W 12.5

W ≧16 ≧18

% 0.25 Rated load; PO=1W;f=1KHz

dB +/-2 +/-3 50Hz~20KHz

dB +/-2 +/-3 20Hz~200Hz

Audio input, output

1.5±20%

RMS

1.5±0.5

RMS

4

8

THD=10% RL=4Ω

Maximum volume RL=4Ω

THD=10% RL=8Ω

Maximum volume RL=8Ω

THD=10% RL=6Ω

Maximum volume RL=6Ω

f=1KHz

f=10KHz

Test condition

1. Test condition:Normal temperature,Normal voltage

2. Supply voltage:AC230V 50Hz。

7

Page 9

Mechanical diagram

44

44

36

44

38

37

19

45

44

24

22

48

32

48

28

42

3

8

7

9

10

13

11

15

16

4

23

22

25

3

4

31

42

5

14

6

17

45

43

20

43

47

35

43

42

1

42

12

39

41

34

40

26

45

23

25

2

18

47

44

44

46

45

24

30

44

29

21

46

21

45

43

43

43

47

46

21

46

27

45

47

21

45

47

33

8

Page 10

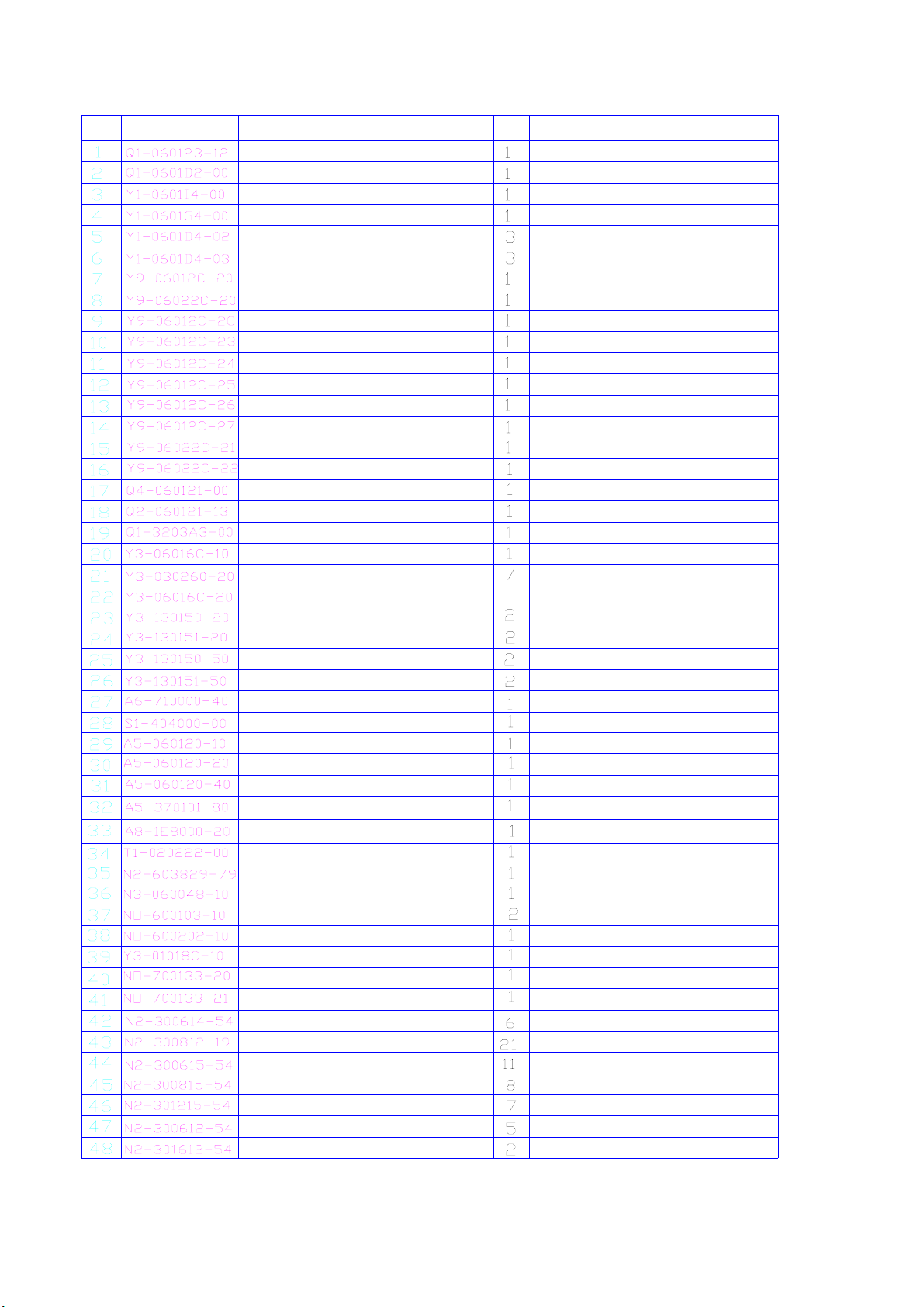

Mechanical

parts list

Material No.

No.

Name

Panel(with card reader)

decoration board

Power button

Volume button

Function button(up)

Function button(down)

Lens

Lens-A

Lens-B

Lens-C

Lens-D

Lens-E

Lens-F

Lens-G

Lens-H

Lens-I

Mother board

Back board

Top cover

Top cover holder

PCB holder(hight 7.0mm)

PCB holder(height 11.0mm)

Front feet

Rear feet

Front feet mat

Rear feet mat

Pick up CMS-S71SG6

Power switch PS4E-A-040

Decoder board

Amplifier board

Control board

Card reader board

ALPS tuner TFCF1E800A

Transformer 230V/110W/VDE

bolt H6.0×38.0mm

nut M6×4.8mm

mat φ6.0×13×1.0mm

Spring mat φ6.0×2.0mm

Fix piece for transformer φ65×6.5×1.2mm

rubber mat φ65× 7.0×1.3mm

rubber mat φ80× 7.0×1.3mm

Screw ST3X6KTT

Screw ST3X8PA

Screw ST3×6PWTT

Screw ST3×8PWTT

Screw ST3×12PWTT

Screw ST3×6PTT

Screw ST3×16PTT

Nickel

Nickel

Nickel

Nickel

Nickel

Nickel

Nickel

QTY

Remark

2

Pannel/Mother board

unit feet、loader/mother board

Amplifier board, decoder board/mother board

Mother board/rear board,tuner

Card reader board/mother board

9

Page 11

Packing and accessories

1.Disassemble

1

2

6

2.Material list

No.

1

2

3

4

5

6

Material No.

A1-060120-11

O7-060120-L0

O7-060120-R1

O7-060160-S2

A3-060120-01

O6-060127-12

4

4

Name

Remote control

Poly foam(left)

Poly foam(right)

Speaker poly foam

SPP-0301-0 type speaker

Gift box (unit+speaker)

QTY

1

1

1

2

1

1

3

5

10

Page 12

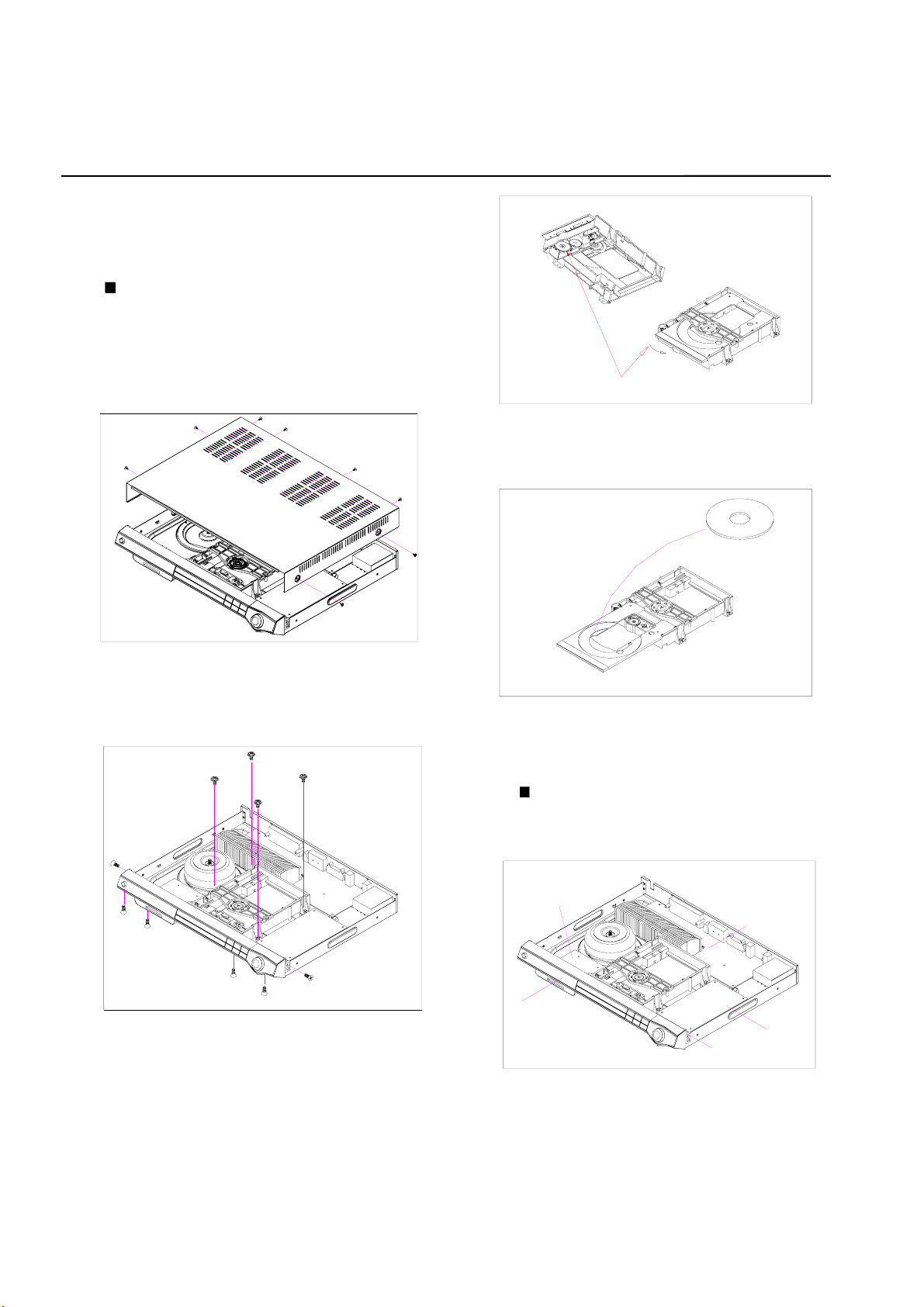

Disassemble and assemble

The unit comprises mechanical and electric part

including:front panel, base panel, top panel,

back panel and loader, AV output board,decoder,etc.

Take out disc from trouble player

If you can not take out disc even press OPEN/CLOSE

key,please pull power cord from the socket and follow

as below:1. Wring 8 screws out then pull left and

right side to take away top panel that rear part is

upper(illustrated

A)

Gear

Graph C Rotate white gear

2.Wring 6 screws out connected base panel with bottom

board then wrest 4 screws connected loader with bottom

board (illustrated B)

Graph A Dispart cabinet

Graph D Take out disc

PCB position

All PCB assemblies locate as illustrated H

card reader board

AV output board

front control board

Graph B Dispart front panel and loader

decoder board

Volume zeta board

3.Take out front panel and loader carefully, there is one

white plastic gear under the loader.Rotate the gear as

illustrated C to stretch DVD tray and door (illustrated D),

you may take disc out carefully.

Graph H PCB boards location

11

Page 13

Disassemble and assemble parts list

1.Take out top panel

See as illustrated A

2.Take out front panel

Able to open the disc tray by electricity

2.1 Operate after completely take out top panel

2.2 Press OPEN/CLOSE button to open disc tray

Be careful not to damage disc when take it out if it is in the tray.

2.3 Press OPEN/CLOSE button to close tray then pull

out power plug.

Take out PCB board on front panel and cords connected with

2.4

other circuit board.Wring out 5 screws connected front panel and

bottom panel,untie two catches on left and right side of the panel

then take out front panel.(See illustrated E)

catch

catch

catch

catch

Graph E Location of catch on front panel

Unable to open the disc tray by electricity

Unable to open disc tray when press OPEN/CLOSE button

2.1 Take out disc as illustrated A,B,C,D.

2.2 Take out front panel

Assemble the case

Assemble the case by reversing disassembly.

After maintenance,switching on power on the condition

that assembly and connection have no mistake then loader

and electric circuit return to original place automatically.

The unit works normally.

12

Page 14

Attachment 1: Block diagram, circuit diagram

Block diagram/ Connecting diagram

Decoder board diagram

Amplifier board diagram

Control board diagram

13

Page 15

Analogue audio 5.1ch

output

Digital audio output &

input (Coaxial, Optical)

Video/YUV/RGB output

SCART output

Stereo analogue audio

input/output

audio DAC-WM8772

Loader

MT1389FE

decoder, servo

Analogue amplifier

ALPS

Digital tuning FM/AM

Control board +VFD

display

+23--+27

+5V

+12V

-12V

+5V

+3V

-3V

-24V

230V

input

TRANSF.

Linear power

USB card reader

Remote control

Block diagram

14

Page 16

~230V/50HZ

SW+

SW-

AC17.5

AC17.5

AC11

ANNULAR

TRANSFORMER

P

O

W

E

R

S

W

SL

GND GND

GND

AC8.4

AC11

AC8.4

SR

RL

FR

CENT+

GND CENT- Cr

GND

Cb

COAXTAL

ML

Y

MR

SCART

VIDEO

S-VIDEO

COAXTAL

IN

POWER AMPLIFER

GND

5V

GND

AC4.5

AC4.5

AC20.8

AC20.8

GND

-3.5V

-24V

+5V

GND

+3.5V

5V

见龙机架+CMS-S71SG6

1

F-

+5V

GND

GND

-3.5V

+3.5V

-24V

O

A

F

O

R

I

F+

T+

T-

C

GND

F

A

B

D

1

I

O

1

2

D

D

O

O

M

L

I

I

NC

E

VCC

V20

VCC

G/Y

STB

B/U

GND

GND

GND

GND

R/V

-9V

+9V

2

O

D

L

NC

GND

GND

GND

GND

CVBS

GNDSYGND

SC

SR

GND

16:9

GND

CENT

LEF

RGB-C

SLED1

SLED2

SPI+

SPI+5V

GND

MLD1

MLD2

CL SW

GND

OP SW

SL

PANEL CONTROL

AUXINL

GND

DET

VSM

R

+9V

L

GND

D

O

C

L

D

I

C

E

3.3

V

RXD

TXD

GND

AM ANTENNA IN

FM ANTENNA IN

FM/AMRECEIVER

S

M

/

C

M

M

/

M

S

/

D

S

CARD

I

I

/

I

F

C

OPTICAL

IN

AUXINR

A

D

T

O

N

P

C

G

5V

GND

5V

GND

+9V

OPT

GND

COA

F

R

I

E

R

X

D

-

T

U

P

M

U

ML

GND

AUXL

GND

A

DM-L

D

S

M

MR

-9V

GND

STB

R/V

GND

B/U

GND

G/Y

GND

CVBS

GND

SY

GND

SC

RGB-C

16:9

GND

GND

LEF

GND

CENT

GND

SR

GND

SL

GND

MR

GND

ML

DM-L

MUTE

DM-R

SPDIF

AUXL

AUXR

SLED1

SLED2

SPI+

SPI+5V

GND

Progressive Scan Decoder

MLD1

MLD2

CL SW

GND

GND

DOUT

CLK

STB

IR

DIN

OP SW

O

D

X

DOUT

CLK

GND

T

GND

DIN

STB

IR

GND

E

T

VSM

RD

+9V

L

GND

D

O

C

L

D

I

C

E

FF+

TT+

C

D

IOA

RFO

A

B

F

GND

V20

VCC

E

NC

IO1

IO2

LDO

1

MDI

1

VCC

NC

LDO

2

GND

V

3

.

3

RXD

Connecting diagram

15

Page 17

Decoder board diagram(1)

16

Page 18

17

Decoder board diagram(2)

Page 19

Decoder board diagram(3)

18

Page 20

Decoder board diagram(4)

19

Page 21

Decoder board diagram(5)

20

Page 22

Amplifier board diagram(1)

21

Page 23

Amplifier board diagram(2)

22

Page 24

Amplifier board diagram(3)

23

Page 25

Control board diagram

24

Page 26

Attachment 2:PCB diagram

Upper decoder board PCB diagram

Upper decoder board silk screen diagram

Lower decoder board PCB diagram

Amplifier board PCB diagram

Amplifier board silk screen diagram

Upper control board PCB diagram

Lower control board PCB diagram

Control board silk screen diagram

25

Page 27

Upper decoder board PCB diagram

26

Page 28

Upper decoder board silk screen diagram

27

Page 29

Lower decoder board PCB diagram

28

Page 30

Amplifier board PCB diagram

29

Page 31

Amplifier board silk screen diagram

30

Page 32

Upper control board PCB diagram

31

Page 33

Low control board PCB diagram

32

Page 34

Control board silk screen diagram

33

Page 35

Attachment 3:Component list

Decoder board component list

Amplifier board component list

Control board component list

34

Page 36

Component list

Decoder board component list

No. Material No. Name Encase No. QTY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

D2-010420-12 Decoder PCB board 94V0 1

C1-200500-JA 0603 capacitor 20p±5% 50V C4 1

C1-330500-JA 0603 capacitor 33p±5% 50V C10-11、125、127 4

C1-101500-JA 0603 capacitor 101±5% 50V C22、93、95、97 4

C1-151500-JA 0603 capacitor 151±5% 50V C41-42 2

C1-221500-JA 0603 capacitor 221±5% 50V C59、61、63、65、67、 8

C69、119、122

C1-331500-JA 0603 capacitor 331±5% 50V C37-38,C113 3

C1-391500-JA 0603 capacitor 391±5% 50V C1 1

C1-102500-KA 0603 capacitor 102±10% 50V C6 1

C1-152500-KA 0603 capacitor 152±10% 50V C35 1

C1-202500-KA 0603 capacitor 202±10% 50V C60、62、64、66、68、 8

C72、120、124

C1-222500-KA 0603 capacitor 222±10% 50V C3、74 2

C1-472500-KA 0603 capacitor 472±10% 50V C108 1

C1-153500-KA 0603 capacitor 153±10% 50V C40 1

C1-333500-KA 0603 capacitor 333±10% 50V C14 1

C1-473500-KA 0603 capacitor 473±10% 50V C17-18 2

C1-104500-MA 0603 capacitor 104±20% 50V

CB59-62、67、71-98、

CB101-102、

C7-9、12-13、21、

C29-30、33-34、36、39、

C43-47、92、121、123

C1-474500-MA 0603 capacitor 474±20% 50V C19、110-111 3

C1-105500-MA 0603 capacitor 1u±20% 50V C15-16、23-27 7

C2-106160-M9 Electrolyte capacitor 10u±20% 16V CE1、11、15、40、 25

CE43-44、46、48-49、

CE51、53-57、59-61、

C101-103、105、109、

C126、128、

C2-476160-M0 Electrolyte capacitor 47u±20% 16V CE16-18、21-22、28、42、 12

CE64-66、

C106-107

C2-107160-M0 Electrolyte capacitor 100u±20% 16V CE7、9、20、24、58、 8

C98-99、112

C2-227160-M0 Electrolyte capacitor 220u±20% 16V CE2、4-6、8、12-14、19、 10

CE26

C2-337160-M0 Electrolyte capacitor 330u±20% 16V CE23 1

R1-4S7103-J1 Carbon resistor 4.7Ω±5% 3w R168 1

CB1-7、10、12-36、41-50、

98

35

Page 37

Component list

Decoder board component list

No. Material No. Name Encase No. QTY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

R4-1S0008-J4 0805 resistor 1Ω±5% 1/8w R42-45 4

R4-100008-J4 0805 resistor 10Ω±5% 1/8w R170-171 2

R4-0S0010-J3 0603 resistor 0Ω±5% 1/10w R9、11、21、26-30、212 11

R61-62

R4-1S0010-J3 0603 resistor 1Ω±5% 1/10w R22 1

R4-4S7010-J3 0603 resistor 4.7Ω±5% 1/10w R120、126、181 3

R4-100010-J3 0603 resistor 10Ω±5% 1/10w R24、39、41、L48 4

R4-330010-J3 0603 resistor 33Ω±5% 1/10w R63-66、77-79、105、191,192,194 22

R138-139、142-145、217、

R222-224、L23

R4-750010-F3 0603 resistor 75Ω±1% 1/10w R31、73、75、81、84、 8

R91、94、100

R4-221010-J3 0603 resistor 220Ω±5% 1/10w R57、60、97、99 4

RC-357S0A-F3 0603 resistor 357Ω±1% 1/10w R5 1

R4-561010-F3 0603 resistor 560Ω±1% 1/10w R25 1

RC-681S0A-F3 0603 resistor 681Ω±1% 1/10w R6、98 2

R4-102010-J3 0603 resistor 1KΩ±5% 1/10w R13、48、68-69、173-174、 7

R200

R4-122010-J3 0603 resistor 1.2KΩ±5% 1/10w R187 1

R4-222010-J3 0603 resistor 2.2KΩ±5% 1/10w R101、103、107、208 4

R4-472010-J3 0603 resistor 4.7KΩ±5% 1/10w R106、133、169、186、 5

R201

R4-512010-J3 0603 resistor 5.1KΩ±5% 1/10w R116、128、136、148、 8

R154、164、220、226

R4-103010-J3 0603 resistor 10KΩ±5% 1/10w R1-2、33-34、50、52、 27

R54-55、58、67、70、115、

R127、135、147、153、

R163、182-185、219、225、

R239-242

R4-153010-J3 0603 resistor 15KΩ±5% 1/10w R14、49、110、123、132、 10

R146、152、158、218、

R221

R4-183010-J3 0603 resistor 18KΩ±5% 1/10w R47 1

R4-203010-J3 0603 resistor 20KΩ±5% 1/10w R46、51、53、56 4

R4-104010-J3 0603 resistor 100KΩ±5% 1/10w R7、16、32、35、59、102,245 7

R4-154010-J3 0603 resistor 150KΩ±1% 1/10w R17、19 2

R4-684010-J3 0603 resistor 680KΩ±5% 1/10w R10、15 2

R4-754010-J3 0603 resistor 750KΩ±5% 1/10w R3 1

R6-33004J-30 0603 resistor 4×33Ω±5% RN1-2 2

L4-016008-60 0603 magnetism bead 100MHz 600 L6、17、19、26-27、 9

36

Page 38

Component list

Decoder board component list

No. Material No. Name Encase No. QTY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

L30、43、47、49

L4-020012-60 0805 magnetism bead 100MHz 600Ω L1-2、7-9、11、20、 12

L24、38、L44-46

L1-100001-J0 Inductance 10uH ±5% L4-5 2

V1-141480-10 Diode 1N4148 D3-15 13

V1-5S1002-20 Zener 5.1V 1/2W D23-25 3

V1-6S8002-20 Zener 6.8V 1/2W D22 1

Z1-27S006-00 Basic oscillator 27MHz 49S type Y1 1

VC-230180-60 MOSFET 2SK3018 SC-70 Q2-3 2

VB-211320-10 Transistor 2SB1132R SOT89 Q4-5 2

VB-239040-10 Transistor SST3904/2N3904 SOT23 Q1、14-15、20 4

VB-239060-10 Transistor SST3906/2N3906 SOT23 Q16 1

V2-855000-10 Transistor 8550 TO-92 Q6-7、17 3

V2-805000-10 Transistor 8050 TO-92 Q8-9 2

IC-111700-21 IC AS1117M3/AK174J SOT223 U1 1

IC-111733-20 IC B1117N-33M142 SOT223 U2 1

IC-111700-20 IC AS1117M(3.3V) SOT223 U2

IC-138900-22 IC MT1389EE LQFP256 U4 1

IC-595400-20 IC BA5954FP HSOP-28 U5 1

IC-565400-20 IC AT5654 HSOP-28 U5

IC-126416-20 IC M12L64164A-7T TSOP54 U9 1

IC-264160-27 SDRAM N2SV6416DT-7K TSOP54 U9

IC-291607-20 IC 29LV160BE-70PFTN TSOP-48 U11 1

IC-291609-29 IC MX29LV160BTC-90 TSOP-48 U11

IC-241600-20 IC AT24C16 SO8NB U12 1

IC-455800-20 IC JRC4558 SO8NB U13、15、20、23-24 5

IC-877200-20 IC WM8772 TSSOP28 U14 1

IC-841500-20 IC CS8415A TSSOP28 U16 1

IC-744052-20 IC 74HC4052 SO16NB U18 1

IC-174200-20 IC PCM1742 SSOP-16 U22 1

IC-780900-10 IC LM7809 TO-220 Q11 1

X4-020003-10 Pin jack 3PIN/2.0mm 1800 J9 1

X4-020004-10 Pin jack 4PIN/2.0mm 1800 J8 1

X4-020005-10 Pin jack 5PIN/2.0mm 1800 J4 1

X4-020006-10 Pin jack 6PIN/2.0mm 1800 J1、7 2

X4-012511-10 Connector 11PIN/1.25mm 1800 J6 1

X4-005024-40 Pin jack 24PIN/0.5mm 900 J2 1

X3-254402-30 Pin jack 40PIN/2.54mm 1800 J10 1

37

Page 39

Component list

Amplifier board component list

No. Material No. Name Encase No. QTY

D1-060120-22 Amplifier PCB board

1

Y3-06016C-12 Heat sink holder Big heat sink 2

2

N8-182032-00 Big heat sink U4-5 1

3

N8-046017-03 Small heat sink U2 1

4

N5-049010-10 Soldering terminal X12 1

5

RA-S10002-J0 Carbon resistor 0.1Ω±5% 1/2w R2 1

6

RA-S22008-J1 Carbon resistor 0.22Ω±5% 1/8w R40-41 2

7

R1-100008-J2 Carbon resistor 10Ω±5% 1/8w R1、74 2

8

R1-330008-J1 Carbon resistor 33Ω±5% 1/8w R18、67 2

9

R1-101008-J2 Carbon resistor 100Ω±5% 1/8w R38、50 2

10

R1-121008-J2 Carbon resistor 120Ω±5% 1/8w R8 1

11

R1-151008-J2 Carbon resistor 150Ω±5% 1/8w R21 1

12

R1-221008-J2 Carbon resistor 220Ω±5% 1/8w R20、43 2

13

R1-361008-J2 Carbon resistor 360Ω±5% 1/8w R9 1

14

R1-102008-J2 Carbon resistor 1KΩ±5% 1/8w R6、48-49、68 4

15

R1-222008-J2 Carbon resistor 2.2KΩ±5% 1/8w R45-46 2

16

R1-332008-J2 Carbon resistor 3.3KΩ±5% 1/8w R16、30、69 3

17

R1-472008-J2 Carbon resistor 4.7KΩ±5% 1/8w R7、65 2

18

R1-622008-J2 Carbon resistor 6.2KΩ±5% 1/8w R19、23 2

19

R1-103008-J2 Carbon resistor 10KΩ±5% 1/8w R3、25、33-34、47、59、 10

20

R62-64、66

21

R1-153008-J2 Carbon resistor 15KΩ±5% 1/8w R35-37、39、60-61 6

22

R1-104008-J2 Carbon resistor 100KΩ±5% 1/8w R42 1

23

R1-4S7004-J2 Carbon resistor 4.7Ω±5% 1/4w R5、14-15、31、44、70-72 8

24

C1-560500-M2 Ceramic capacitor 56p±20% 50V C32

25

C1-104500-M2 Ceramic capacitor 104±20% 50V C4、26、30、33-34、40、 11

26

76-78、87、89

27

C4-104101-K3 Terylene capacitor 104±10% 50V C10、19、21、23-25、 8

28

C36-37

29

C2-474500-M9 Electrolyte capacitor 50V 0.47±20% C15-17、45-47

30

C2-105500-M9 Electrolyte capacitor 50V 1u±20% C12、49-50 3

31

C2-226350-M0 Electrolyte capacitor 35V 22u±20% C22、28 2

32

C2-476160-M0 Electrolyte capacitor 16V 47u±20% C27 1

33

C2-476350-M0 Electrolyte capacitor 35V 47u±20% C2 1

34

C2-107160-M0 Electrolyte capacitor 16V 100u±20% C90 1

35

C2-227250-M0 Electrolyte capacitor 25V 220u±20% C18、20、88 3

36

C2-337160-M0 Electrolyte capacitor 16V 330u±20% C14 1

37

C2-477250-M0 Electrolyte capacitor 25V 470u±20% C3 1

38

39

40

C2-108160-Z0

C2-108250-Z0

Electrolyte capacitor 16V 1000u+80/-20%

Electrolyte capacitor 25V 1000u+80/-20%

1

C86 1

C1、9、29、31、79 5

1

6

38

Page 40

Component list

Amplifier board component list

No. Material No. Name Encase No. QTY

C2-228100-Z0 Electrolyte capacitor 10V 2200u+80/-20% C6 1

1

C2-478160-Z9 Electrolyte capacitor 16V 4700u+80/-20% C5 1

2

C2-478350-Z9 Electrolyte capacitor 35V 4700u+80/-20% C7、8 2

3

F1-6S3011-00 Fuse T6.3AL 250V 5×20mm F1 1

4

F2-010000-00 Fuse jack F1 2

5

V1-401000-40 Bridge pile KBL401 U1 1

6

V1-140040-10 Diode 1N4004 V1-2、4-6, 5

7

C2-106160-M0 Electrolyte capacitor 16V 10u±20% C55,C59 2

8

V1-141480-10 Diode 1N4148 V8、13、 2

9

V1-560000-10 Diode SB560 D1-4 4

10

V1-5S1002-20 Zener 5.1V 1/2W V3 1

11

V1-130002-20 Zener 13V 1/2W V16 1

12

V2-273300-10 Triode A733 TO-92 V7、19-21 4

13

V2-294500-10 Triode C945 TO-92 V10-12、17-18 5

14

L4-035060-40 Magnetism bead Φ3.5×6mm100MHz60Ω L3-13、16-17、21 14

15

L1-1S8001-J0 Twist inductance 1.8uH±5% L14-15、18-20、22 6

16

L1-101001-J0 Twist inductance 100uH±5% L2 1

17

L1-101101-J0 Standing inductance 100uH±5% 2A L1 1

18

V2-781200-10 IC LM7812 TO-220 U9 1

19

IC-108400-11 ICAZ1084T-ADJ TO-220 U2 1

20

IC-894700-10 IC TDA8947J DBS17P U4-5 2

21

X1-550000-00 Optical output jack GPIFA550TZ X10 1

22

X7-284130-30 Concentric jack AV2-8.4-13A X5 1

23

Up red, Down white

24

X7-683440-30 Concentric jack AV6-8.3-44Q X11 1

25

Up white green blue, Down red yellow red

26

X1-105000-00 21 pin jack CS105 X12 1

27

X1-200000-30 S-Video + Video concentric jack SAV2 X13 1

28

X8-121000-00 Amplifier board output jack WP12-1 X9 1

29

X3-396031-31 Pin jack 3PIN/3.96 1800 X3 1

30

X4-025006-10 Pin jack 6PIN/2.54 1800 X4 1

31

X4-025009-10 Pin jack 9PIN/2.54 1800 X2 1

32

X3-254402-30 Double pin 40PIN/2.54 1800 X6 1

33

J1-0605S0-00 Jumper wire Φ0.6×5mm JMP13-14、18、25、29、 7

34

JMP39、51

35

J1-0607S0-00 Jumper wire Φ0.6×7mm JMP5 1

36

J1-0607S5-00 Jumper wire Φ0.6×7.5mm JMP8、11-12、15-17、 22

37

38

39

40

JMP20-23、26、28、30、

JMP33、36-37、40、42、

JMP43、45、48-49

39

Page 41

Component list

Amplifier board component list

No. Material No. Name Encase No. QTY

J1-060100-00 Jumper wire Φ0.6×10mm JMP3、35、41、44、46 5

1

J1-060120-00 Jumper wire Φ0.6×12.5mm JMP2、4、6、9-10、19、 14

2

JMP27、31-32、34、50、

3

JMP52-54

4

J1-060170-00 Jumper wire Φ0.6×17.5mm JMP7 1

5

J1-060200-00 Jumper wire Φ0.6×20mm JMP1 1

6

N0-300051-10 Soldering terminal X8 1

7

N2-300615-54 Screw ST3×6PWTT Nickel

8

Small heat sink and U2

9

N2-301015-54 Screw ST3×10PWTT Nickel Big heat sink and U4-5 4

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Amplifier board, big heat sink

and holder

5

40

Page 42

Component list

Control board component list

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Material No. Name Encase No.

D2-060220-4K Key board

D2-060220-4V

D2-060220-40

O8-012012-20 VFD rubber mat VFD1 2

O8-070707-10 Sponge mat 7×7×7mm IC2 1

W1-351036-10 3PIN flat ribbon wires 5mm L=350mm J5-J6 1

W1-381056-10 5PIN flat ribbon wires 5mm L=380mm J7-J8 1

W3-501066-10 6PIN/2.0 flat ribbon wires L=500mm J3 1

W3-551066-20 6PIN/2.5 flat ribbon wires L=550mm J2 1

C1-104500-Z2 Ceramic capacitor 50V 104-20%+80% C1-4,C7 5

C2-107100-M0 Electrolyte capacitor 10V 100uF±20% C5,C6 2

C2-107350-M0 Electrolyte capacitor 35V 100uF±20% C8 1

R4-100016-J3 Chip resistor 1/16W 10Ω±5% R13 1

R4-330016-J3 Chip resistor 1/16W 33Ω±5% R1 1

R4-221016-J3 Chip resistor 1/16W 220Ω±5% R2 1

R4-103016-J3 Chip resistor 1/16W 10KΩ±5% R3-R4,R14-R17 6

R4-333016-J3 Chip resistor 1/16W 33KΩ±5% R9-R11,R18 4

R4-472016-J3 Chip resistor 1/16W 4.7KΩ±5% R5,R6,R8 3

R4-470016-J3 Chip resistor 1/16W 47Ω±5% R12 1

R4-563016-J3 Chip resistor 1/16W 56KΩ±5% R7 1

L4-120160-30 Magnetism annulus: K5BT16×12×8 2

V1-141480-10 Diode 1N4148 D1-2 2

V1-5S1002-20 Zener 5.1V 1/2W D3 1

V1-253021-30 LBD Φ3 red D4 1

S5-162420-00 Digital encoder EC16E-24C-20F-C S4 1

N3-090020-10 Nut M9×2mm Coding switch 1

NO-900053-10 Mat Φ9×Φ20×0.5mm Coding switch 1

Y7-010008-40 Varnished tube Φ1.0×8mm D4 2

S3-665000-00 Soft touch switch 6×6×5 S1-3 5-7 6

P3-085600-00 Display screen HNVC08SS56 VFD1 1

IC-354000-10 Receiver SRM-354VF IC2 1

IC-401300-10 IC CD4013 DIP-14 IC3 1

IC-163110-20 IC uPD16311 or CS16311 IC1 1

Decoder board

VFD board

1

1

1

QTY

41

Loading...

Loading...