Page 1

Service Guide

Agilent Technologies

ESG Family Signal Generators

Serial Number Pref i xes :

(Affix Label Here)

Part No. E4400-90335

Printed in USA

August 2003

© Copyright 1999-2003 Agilent Technologies Inc.

Page 2

ii

Page 3

Contents

1. Initial Troubleshooting and RF Block Diagrams

Before You Begin Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Using this Service Guide to Troubleshoot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Signal Generator Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Contacting Agilent Technologies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Check the Basics before Contacting Agilent Technologies . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Review the Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Calling Agilent Technologies Sales and Service Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Returning Y our Signal Generator for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Equipment Required for Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Initial Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Step 1: Observe the Front and Rear Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Step 2: Power On the Signal Generator and Check for Error Messages . . . . . . . . . . . . . .1-13

Step 3: Functional Check the Front Panel Keys and Display . . . . . . . . . . . . . . . . . . . . . .1-14

Step 4: Visually Check the Individual Voltage Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Step 5: Measure the Individual Vo ltage Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Step 6: Isolate the Failed Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-19

Step 7: Check for Basic CPU Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Additional Information for Troubleshooting the ESG-AP and ESG-DP Series . . . . . . . . . .1-23

ESG-A Series RF Block Diagram (Standard & Option 1E6) . . . . . . . . . . . . . . . . . . . . . . . . .1-25

ESG-D Series RF Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

ESG-D Series RF Block Diagram (Options UN3 & UN4) . . . . . . . . . . . . . . . . . . . . . . . . . . .1-29

ESG-D Series RF Block Diagram (Option UN8 or UN9) Rev C or D . . . . . . . . . . . . . . . . . .1-31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-32

ESG-D Series RF Block Diagram (Options UN8 & UN9) Rev B. . . . . . . . . . . . . . . . . . . . . .1-35

ESG-D Series RF Block Diagram (Option UND) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-37

ESG-D Series RF Block Diagram (Option UN7, UN8/UN9, & 300) . . . . . . . . . . . . . . . . . . .1-39

ESG-AP Series RF Block Diagram (Standard & Option 1E6). . . . . . . . . . . . . . . . . . . . . . . .1-41

ESG-DP Series RF Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-43

ESG-DP Series RF Block Diagram (Option UN7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-45

ESG-DP Series RF Block Diagram (Options UN8 & UN9) . . . . . . . . . . . . . . . . . . . . . . . . . .1-47

ESG-DP Series RF Block Diagram (Option UND). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-49

Blue Repair Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-51

2. Assembly-Level Troubleshooting with Block Diagrams

Before You Begin Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Using this Chapter with Service Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

A5 Dual Arbitrary Waveform Generator Block Diagram (Option UND) . . . . . . . . . . . . . . . .2-5

A6 Bit Error Rate Test Block Diagram (Option UN7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

A7 Baseband Generator Block Diagram (Options UN3 & UN4). . . . . . . . . . . . . . . . . . . . . . .2-9

A7 DBMIC Baseband Generator Block Diagram (Options UN8 & UN9). . . . . . . . . . . . . . .2-11

A8 Data Generator Block Diagram (Options UN3 & UN4). . . . . . . . . . . . . . . . . . . . . . . . . .2-13

A8 Data Generator - Rev. A & B Block Diagram (Options UN8 & UN9) . . . . . . . . . . . . . . .2-15

A8 Flex Data Generator - Rev. C & D Block Diagram (Options UN8 & UN9) . . . . . . . . . . .2-17

A9 Output ABUS Nodes (ESG-A Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

A9 Output Block Diagram (ESG-A Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

A9 Output ABUS Nodes (ESG-D Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

A9 Output ABUS Nodes (ESG-AP, & ESG-DP Series). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

A9 Output Block Diagram (ESG-D, ESG-AP, & ESG-DP Series) . . . . . . . . . . . . . . . . . . . . .2-27

A11 Reference ABUS Nodes (ESG-A & ESG-D Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

A11 Reference Block Diagram (ESG-A & ESG-D Series) . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

iii

Page 4

Contents

A11 Reference ABUS Nodes (ESG-AP & ESG-DP Series) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

A11 Reference Block Diagram (ESG-AP & ESG-DP Series). . . . . . . . . . . . . . . . . . . . . . . . . 2-35

A12 Synthesizer/Doubler ABUS Nodes (ESG-A & ESG-D Series) . . . . . . . . . . . . . . . . . . . . 2-37

A12 Synthesizer/Doubler Block Diagram (ESG-A & ESG-D Series) . . . . . . . . . . . . . . . . . . 2-39

A14 CPU/Motherboard ABUS Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

A14 CPU/Motherboard Block Diagram (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

A14 CPU/Motherboard Block Diagram (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

A20 Downconvertor Block Diagram (Option 300) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

A21 Demodulator Block Diagram (Option 300). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

A22 YIG Driver ABUS Nodes (ESG-AP & ESG-DP Series) . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

A22 YIG Driver Block Diagram (ESG-AP & ESG-DP Series). . . . . . . . . . . . . . . . . . . . . . . . 2-53

A23 Sampler ABUS Nodes (ESG-AP & ESG-DP Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

A23 Sampler Block Diagram (ESG-AP & ESG-DP Series). . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

A24 Frac-N/Divider ABUS Nodes (ESG-AP & ESG-DP Series . . . . . . . . . . . . . . . . . . . . . . 2-59

A24 Frac-N/Divider Block Diagram (ESG-AP & ESG-DP Series . . . . . . . . . . . . . . . . . . . . . 2-61

AT1 Electronic Attenuator/RPP Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

AT1 Mechanical Attenuator and A19 RPP Block Diagram (Option UNB) . . . . . . . . . . . . . 2-65

ESG-A Series Power Supply and Ground Interconnects Block Diagram. . . . . . . . . . . . . . . 2-67

ESG-D Series Power Supply and Ground Interconnects Block Diagram (1 of 2) . . . . . . . . 2-69

ESG-D Series Power Supply and Ground Interconnects Block Diagram (2 of 2) . . . . . . . . 2-71

ESG-A Series Modulation and Signal Interconnects Block Diagram. . . . . . . . . . . . . . . . . . 2-73

ESG-D Series Modulation and Signal Interconnects Block Diagram (1 of 2) . . . . . . . . . . . 2-75

ESG-D Series Modulation and Signal Interconnects Block Diagram (2 of 2) . . . . . . . . . . . 2-77

3. Replaceable Parts (ESG-A and ESG-D Series)

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Call (800) 227-8164 to Order Parts Fast (U.S. Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Save Money with Rebuilt-Exchange Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Shipping the Defective Assembly Back to Agilent Technologies. . . . . . . . . . . . . . . . . . . . . 3-4

Abbreviations Used in Part Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Major Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Top View (ESG-D Series - Option 300) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Right Side Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Disassembled Front Panel View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Inside Rear Panel View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Top View (ESG-A Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Top View (ESG-D Series - Options UN3/4, UN7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Top View (ESG-D Series - Options UN7, UN8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Top View (ESG-D Series - Option UND). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Top View (ESG-D Series - Options UN3/4, UN7 with 1EM) . . . . . . . . . . . . . . . . . . . . . . . 3-24

Top View (ESG-D Series - Options UN7, UN8 with 1EM). . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Top View (ESG-D Series - Options UN7, UN8, UND) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Top View (ESG-D Series - Option UND with 1EM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Top View (ESG-D Series - Option 300) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Inside Front Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Electronic Attenuator/RPP View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

iv

Page 5

Contents

Electronic Attenuator/RPP View (with Option 1EM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

Mechanical Attenuator View (Option UNB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40

Mechanical Attenuator View (Option UNB with 1EM) . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

Pulse Modulator View (Option 1E6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-44

Hardware and Other Instrument Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-45

Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-46

Downconvertor View (Option 300) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-48

Disassembled Mechanical Attenuator View (Option UNB) . . . . . . . . . . . . . . . . . . . . . . . .3-49

Disassembled Pulse Modulator View (Option 1E6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-50

Disassembled Pulse Modulator View (Option 1E6/UNB). . . . . . . . . . . . . . . . . . . . . . . . . .3-51

Front Panel View (ESG-A Series). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-52

Front Panel View (ESG-D Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-54

Disassembled Front-Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-56

Daughterboard Card Cage View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-58

Inside Rear-Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-59

Rear-Panel View (ESG-A Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-60

Rear-Panel View (ESG-A Series - Option 1EM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-62

Rear-Panel View (ESG-D Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-64

Rear Panel View (ESG-D Series - Option 1EM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-66

Instrument Chassis with Top and Right-Side Hardware . . . . . . . . . . . . . . . . . . . . . . . . . .3-68

Power Supply Shield and Left-Side Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-70

Motherboard and Bottom-Side Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-71

Instrument Cover and Associated Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-72

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-74

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-74

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-75

Electrostatic Discharge (ESD) Protective Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-78

Upgrade and Retrofit Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-78

4. Replaceable Parts (ESG-AP and ESG-DP Series)

Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Call (800) 227-8164 to Order Parts Fast (U.S. Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Save Money with Rebuilt-Exchange Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Shipping the Defective Assembly Back to Agilent Technologies . . . . . . . . . . . . . . . . . . . . .4-4

Abbreviations Used in Part Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Major Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Right Side Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Disassembled Front Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Inside Rear Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Top View (ESG-DP Series - Options UN7, UN8). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Top View (ESG-DP Series - Option UND) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Top View (ESG-DP Series - Options UN7, UN8 with 1EM). . . . . . . . . . . . . . . . . . . . . . . .4-20

Top View (ESG-DP Series - Options UN7, UN8, UND) . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Top View (ESG-DP Series - Option UND with 1EM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Side View — YIG Driver Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

v

Page 6

Contents

Inside Front Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Electronic Attenuator/RPP View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Electronic Attenuator/RPP View (with Option 1EM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Mechanical Attenuator View (Option UNB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Mechanical Attenuator View (Option UNB with 1EM) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Pulse Modulator View (Option 1E6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Hardware and Other Instrument Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

YIG Driver View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Disassembled Mechanical Attenuator View (Option UNB). . . . . . . . . . . . . . . . . . . . . . . . 4-43

Disassembled Pulse Modulator View (Option 1E6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Disassembled Pulse Modulator View (Option 1E6/UNB) . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Front Panel View (ESG-AP Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Front Panel View (ESG-DP Series). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Disassembled Front-Panel View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Daughterboard Card Cage View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Inside Rear-Panel View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Rear-Panel View (ESG-AP Series). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Rear-Panel View (ESG-AP Series - Option 1EM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

Rear-Panel View (ESG-DP Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Rear Panel View (ESG-DP Series - Option 1EM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Instrument Chassis with Top and Right-Side Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Power Supply Shield and Left-Side Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

Motherboard and Bottom-Side Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Instrument Cover and Associated Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Miscellaneous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-69

Electrostatic Discharge (ESD) Protective Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72

Upgrade and Retrofit Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72

5. Assembly Replacement

Before You Replace an Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

After Replacing an Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Assemblies That You Can Replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

A1 Front Panel Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

A2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

A2DS1 Fluorescent Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

A3 Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

vi

Page 7

Contents

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

A4 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

A4 Power Supply (with Option 1EM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

A14 CPU/Motherboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

A14BT1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

A14Q501 Transistor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

A15 Daughterboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-30

A16 Line Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

A17 and A18 Rear Panel Interface Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

A19 Reverse Power Protection (RPP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-37

A20 Downconvertor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-39

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-39

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-39

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-39

A22 YIG Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

A25 Pulse Modulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

vii

Page 8

Contents

A25 Pulse Modulator (with Option UNB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

AT1 Electronic Attenuator/RPP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

AT1 Mechanical Attenuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

B1 Small Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

B2 Large Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

Daughterboard Card Cage Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

Digital Card Cage Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

Instrument Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6 4

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

Rear Panel (with Option 1EM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

Semi-Rigid Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

viii

Page 9

Contents

6. Post-Repair Procedures

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

7. Safety and Regulatory

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Lithium Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

ix

Page 10

Contents

x

Page 11

ESG Family Signal Generators

1Initial Troubleshooting and RF

Block Diagrams

This chapter will help you begin troubleshooting your signal generator. The procedures in

this chapter primarily check your instrument for failures that affect the power supplies or

CPU function. An RF block diagram of your signal generator is at the end of this chapter.

Service Guide 1-1

Page 12

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Before You Begin Troubleshooting

Before You Begin Troubleshooting

Be sure to review the warning and caution statements described in Chapter 7 prior to

troubleshooting your signal generator.

Using this Service Guide to Troubleshoot

Several chapters in this service guide work together to help you troubleshoot and repair

your signal generator.

• Chapter 1, “Initial Troubleshooting and RF Block Diagrams,” helps you get

started with some basic checks and instructions.

• Chapter 2, “Assembly-Level Troubleshooting with Block Diagrams,” helps you

identify and verify the failed assembly.

• Chapter 3, “Replaceable Parts (ESG-A & ESG-D),” helps you locate the failed

assembly or cable in the signal generator and also provides you with part numbers and

ordering information.

• Chapter 4, “Replaceable Parts (ESG-AP & ESG-DP),” helps you locate the failed

assembly or cable in the signal generator and also provides you with part numbers and

ordering information.

• Chapter 5, “Assembly Replacement,” gives you step-by-step instructions on how to

remove and replace an assembly.

• Chapter 6, “Post-Repair Procedures,” lists the performance tests and adjustments

that must be performed after an assembly has been repaired or replaced.

1-2 Service Guide

Page 13

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Signal Generator Options

Signal Generator Options

This section lists the hardware, software, and documentation options you can order with a

new signal generator. Some of the options can be retrofitted into your existing signal

generator. Order a retrofit by requesting either the post-sales option number or the part

number.

Hardware and Software Options Available for New Instruments

Desired

Option

100 X X UND

101 X X UND

1CM X X X X

1CN X X X X

1CP X X X X

1EM X X X X

1E5 X X

1E6 X X

200

201

300 X X UN7, UN8 UND

UN5 X X UND

UN7 X X UN3,UN4,or

UN8 X X

UN9 X X UN8

UNA X X UN8 UNB

UNB X X UNA

UND X X

ESG-A ESG-D ESG-AP ESG-DP

Standard Standard

X X UN8

X X UN8

Required

Options

UN8

Incompatible

Options

Service Guide 1-3

Page 14

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Signal Generator Options

Adding Hardware and Software Options to Existing Instruments

Desired

Option

100 UND 150

101 UND 151

200 UN8 250

201 UN8

300 UN7, UN8

UN5 UND 005

UN7 UN3, UN4, or UN8 007 E4400-60143

UN8 008 E4400-60170

UN8 UN3 or UN4 E4400-60160

UN8 and UN9 009 E4400-60185

UN8 andUN9 UN3 or UN4 E4400-60184

UND 004 E4400-60166

UND UN3 or UN4 E4400-60181

Existing

Option

Required Options

Post-Sales

Option

251

Part Number

1-4 Service Guide

Page 15

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Signal Generator Options

Option Description

100 Option 100 has two implementations:

Multichannel W-CDMA (Revision 1.0-1.2) Personality - This first

implementation of Option 100 simulates multichannel forward and

reverse link signals according to the developing W-CDMA international

standards. Spreading and frame structure of these signals are

implemented according to March 1999 ARIB 1.0 - 1.2 specification.

Multichannel W-CDMA (3GPP 3.1 12-99) Personality - This second

implementation of Option 100 simulates multichannel downlink and

uplink signals according to the developing W-CDMA international

standards. This option implements a chip rate of 3.84 Mcps, and is based

on the December 1999 3GPP 3.1 specification.

101 Multichannel CDMA2000 Personality - This option simulates

multichannel forward and reverse link signals according to the developing

CDMA2000 standard revision 8.

1CM Rack Mount Flanges without Handles - This option adds two flanges and

the necessary hardware to rack mount the signal generator in a System II

or System II Plus cabinet.

1CN Front Handles - This option adds two front handles with the necessary

hardware to attach the handles to the front of the signal generator.

1CP Rack Mount Flanges with Handles - This option adds two front handles,

two flanges, and the necessary hardware to rack mount the signal

generator in an System II or System II Plus cabinet.

1E5 High Stability Timebase - This option replaces the standard timebase

reference assembly with a high-stability timebase reference assembly that

has improved specifications over the standard assembly, including

warranted specifications for aging rate. This feature is standard on

ESG-AP and ESG-DP Series Signal Generators.

1E6 High Performance Pulse Input - This option provides high performance

pulse capabilities with rise and fall times < 10 ns and on/off ratios > 70 dB.

1EM Move All Front Panel Connectors to Rear Panel - This option moves all of

the front panel connectors to the rear panel. If you order Option 1EM in

combination with any option that adds front panel connectors,

Option 1EM will cause all of the front panel connectors to be moved to the

rear panel and, in addition, some of the connectors will be changed from

BNC to SMB connectors.

Service Guide 1-5

Page 16

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Signal Generator Options

200 Fully Coded 3GPP W-CDMA Personality - This option can be used to

provide fully-coded, multichannel downlink and uplink signals in

compliance with 3GPP specifications. Support for this 3GPP W-CDMA

solution may require the use of two ESG signal generators.

201 Multichannel Real-Time cdma2000 Personality - This option can be used

to provide fully-coded, multichannel forward and reverse link signals

supporting both the IS-95 and IS-2000 CDMA standards.

Support for IS-2000 may require the use of two ESG signal generators.

Because IS-2000 provides backward compatibility with IS-95 in RC1 and

RC2 configurations, the Option 201 personality also supports the IS-95

standard.

300 Base Station BERT Extension for Option UN7 - This option adds bit error

rate testing for GSM base stations to the ESG/VSA combination.

ES1 This option indicates that a more recent version of firmware is resident in

the signal generator than was originally shipped. The operating features

in the new firmware may be different than those documented in your

original manual set.

UN3 I/Q Baseband Generator with 1 Mbit Pattern RAM (Obsolete) - This option

is no longer available. Option UN3 provided an I/Q baseband generator

with DECT, GSM, NADC, PDC, PHS, and TETRA digital modulation

formats. Option UN3 is replaced by Option UN8.

UN4 I/Q Baseband Generator with 8 Mbit Pattern RAM (Obsolete) - This option

is no longer available. Option UN4 provided an I/Q baseband generator

with DECT, GSM, NADC, PDC, PHS, and TETRA digital modulation

formats. Pre-modulation filtering selections and PRBS capability were

provided. Option UN4 is replaced by Option UN8 with Option UN9.

UN5 Multi-Channel CDMA - This option provides multi-channel IS-95 CDMA

capability, which provides flexible, coded-channel setups for CDMA base

stations or mobiles, components, or sub-system test.

UN7 Bit Error Rate Test - This option adds a bit error rate test function that

evaluates PN9 or PN15 bit streams for errors. Configuration of data, clock,

and clock gate inputs allow testing of demodulated TDMA or CDMA

formats. A baseband generator must be part of the instrument

configuration.

UN8 Real-time I/Q Baseband Generator - This option provides a custom

modulation generator with 1 Mbit of pattern RAM. The custom

modulation generator provides generic symbol building, variable symbol

rates, and variable filter capabilities in addition to TDMA protocols.

UN9 +7 MBits RAM - This option adds an additional 7 Mbits of pattern RAM to

Option UN8 for very long data pattern generation. You must purchase

Option UN8 in conjunction with Option UN9.

UNA Alternate Timeslot Power Level Control - This option provides alternate

timeslot power level control for adjacent timeslots in TDMA applications.

1-6 Service Guide

Page 17

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Signal Generator Options

UNB High Power with Mechanical Attenuator - This option provides a

mechanical attenuator that provides 4 to 6 dB more output power than the

standard electronic attenuator.

UND Internal Dual Arbitrary Waveform Generator - This option provides an

internal dual arbitrary waveform generator that contains an on-board

digital signal processor capable of playing back downloaded waveforms to

generate complex, digitally modulated signals. A 1 Megasample per

channel memory accepts I/Q files from different waveform generation

programs, such as Omnisys and Matlab. 14 bit DACs optimize dynamic

range and reduce noise.

Service Guide 1-7

Page 18

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Contacting Agilent Technologies

Contacting Agilent Technologies

This section prepares you for contacting Agilent Technologies should you have a problem

with your signal generator.

Check the Basics before Contacting Agilent Technologies

Often problems may be solved by repeating what was being done when the problem

occurred. A few minutes spent in performing these simple checks may eliminate time

spent waiting for instrument repair.

• Check that the signal generator is plugged into the proper ac power source.

• Check that the line socket has power.

• Check that the signal generator is turned on.

• Check that the other equipment, cables, and connectors are connected properly and

operating correctly.

• Check the equipment settings in the procedure that was being used when the problem

occurred.

• Check that the test being performed and the expected results are within the

specifications and capabilities of the signal generator. (Refer to the calibration guide.)

• Check the signal generator display for error messages. (Refer to the Error Messages

guide.)

• Check operation by performing the verification procedures in the calibration guide.

Record all results in the performance test record.

Review the Warranty

If there is still a problem, read the warranty printed in Chapter 7, “Safety and Regulatory.”

If your signal generator is covered by a separate maintenance agreement, be familiar with

its terms.

Agilent Technologies offers several maintenance plans to service your signal generator

after warranty expiration. Call your Agilent Technologies sales and service office for full

details.

Calling Agilent Technologies Sales and Service Offices

Sales and service offices are located around the world to provide complete support for your

signal generator. To obtain servicing information, contact the nearest Agilent Technologies

Sales and Service office listed in Table 1-1. For information on ordering parts refer to

Chapter 3 or Chapter 4.

In any correspondence or telephone conversation, refer to the signal generator by its model

number and full serial number. With this information, the Agilent Technologies

representative can quickly determine whether your unit is still within its warranty period.

1-8 Service Guide

Page 19

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Contacting Agilent Technologies

Table 1-1 Agilent Technologies Sales and Service Offices

UNITED STATES

Instrument Support Center

Agilent Technologies

(800) 403-0801

EUROPEAN FIELD OPERATIONS

Headquarters

Agilent Technologies S.A.

150, Route du Nant-d’Avril

1217 Meyrin 2/ Geneva

Switzerland

(41 22) 780.8111

France

Agilent Technologies France

1 Avenue Du Canada

Zone D’Activite De

Courtaboeuf

F-91947 Les Ulis Cedex

Germany

Agilent Technologies GmbH

Agilent Technologies Strasse

61352 Bad Homburg v.d.H

Germany

(49 6172) 16-0

France

(33 1) 69 82 60 60

Great Britain

Agilent Technologies

Eskdale Road, Winnersh

Triangle Wokingham,

Berkshire RG41 5DZ

England

(44 118) 9696622

INTERCON FIELD OPERATIONS

Headquarters

Agilent Technologies

3495 Deer Creek Rd.

Palo Alto, CA 94304-1316

USA

(650) 857-5027

Australia

Agilent Technologies Australia

Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

(61 3) 895-2895

Canada

Agilent Technologies

(Canada) Ltd.

17500 South Service Road

Trans-Canada Highway

Kirkland, Quebec H9J 2X8

Canada

(514) 697-4232

Japan

Agilent Technologies Japan,

Ltd.

9-1 Takakura-Cho, Hachioji

Tokyo 192, Japan

(81 426) 60-2111

Singapore

Agilent Technologies

Singapore (Pte.) Ltd.

150 Beach Road

#29-00 Gateway West

Singapore 0718

Taiwan

Agilent Technologies Taiwan

8th Floor, H-P Building

337 Fu Hsing North Road

Taipei, Taiwan

(886 2) 712-0404

(65) 291-9088

China

China Agilent Technologies

38 Bei San Huan X1 Road

Shuang Yu Shu

Hai Dian District

Beijing, China

(86 1) 256-6888

Service Guide 1-9

Page 20

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Contacting Agilent Technologies

Returning Your Signal Generator for Service

Use the information in this section if you need to return the signal generator to

Agilent Technologies.

Packaging the Signal Generator

Use the following steps to package the signal generator for shipment to Agilent

Technologies for service:

1. Fill out a blue repair tag (available at the end of this chapter) and attach it to the

instrument. Be as specific as possible about the nature of the problem. Send a copy of

any or all of the following information:

• Any error messages that appeared on the signal generator display.

• A completed performance test record from the calibration guide for your instrument.

• Any other specific data on the performance of the signal generator.

2. Use the original packaging materials or a strong shipping container that is made of

double-walled, corrugated cardboard with 159 kg (350 lb) bursting strength. The carton

must be both large enough and strong enough to accommodate the signal generator and

allow at least 3 to 4 inches on all sides of the signal generator for packing material.

CAUTION Signal generator damage can result from using packaging materials other

than those specified. Never use styrene pellets, in any shape, as packaging

materials. They do not adequately cushion the instrument or prevent it from

shifting in the carton. Styrene pellets cause equipment damage by generating

static electricity and by lodging in the signal generator fan.

3. Surround the instrument with at least 3 to 4 inches of packing material, or enough to

prevent the instrument from moving in the carton. If packing foam is not available, the

best alternative is SD-240 Air Cap™ from Sealed Air Corporation (Hayward, CA

94545). Air Cap looks like a plastic sheet covered with 1-1/4 inch air-filled bubbles. Use

the pink Air Cap to reduce static electricity. Wrap the instrument several times in the

material to both protect the instrument and prevent it from moving in the carton.

4. Seal the shipping container securely with strong, nylon adhesive tape.

5. Mark the shipping container “FRAGILE, HANDLE WITH CARE” to ensure careful

handling.

6. Retain copies of all shipping papers.

1-10 Service Guide

Page 21

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Equipment Required for Troubleshooting

Equipment Required for Troubleshooting

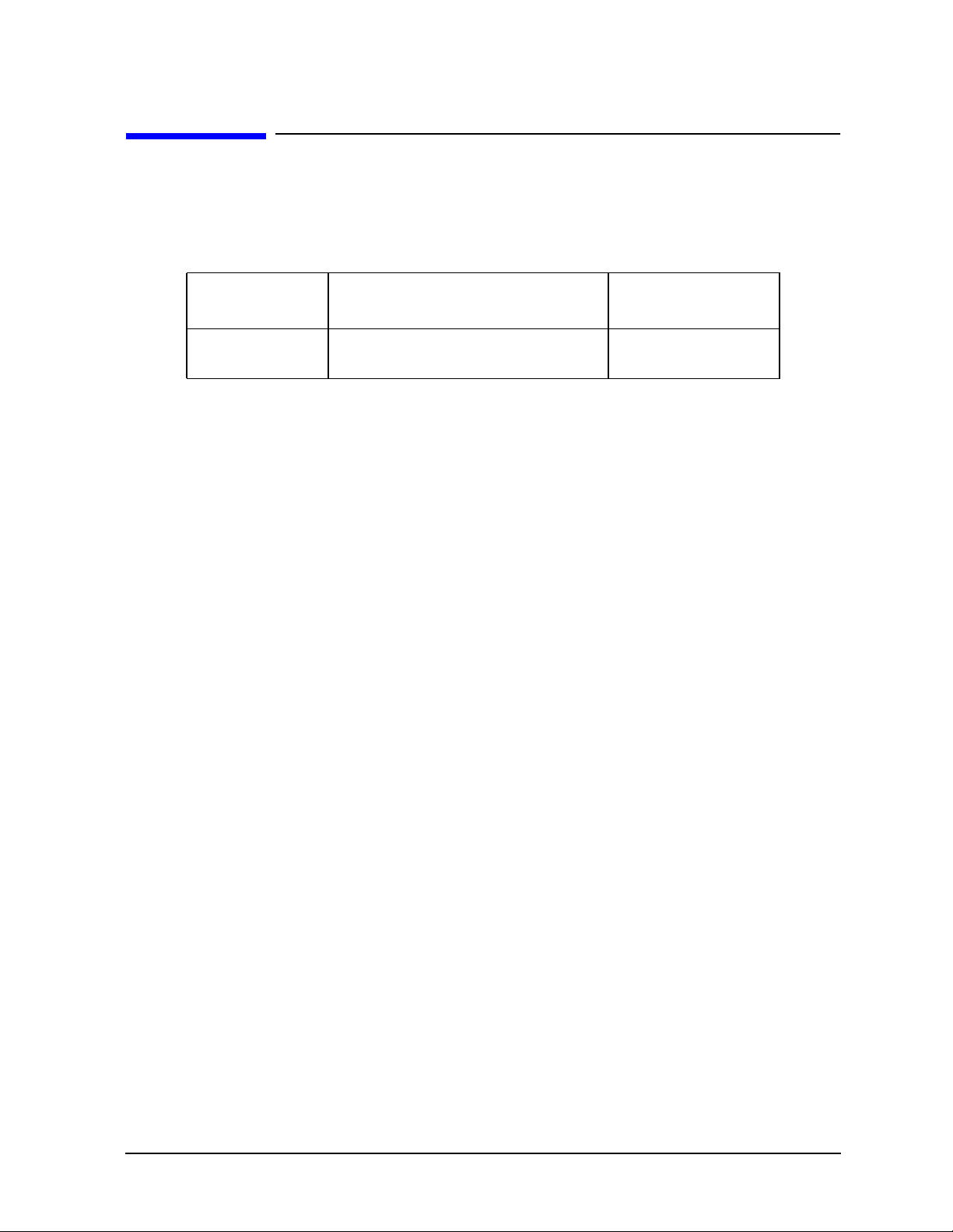

Table 1-2 lists the equipment required to troubleshoot your signal generator. You may use

the recommended model or an equivalent that meets the critical specifications.

Table 1-2 Recommended Test Equipment

Equipment

Digital

Multimeter

Critical Specifications for

Equipment Substitution

Input Resistance: ≤10MΩ Accuracy:

10 mV on 100 V range

Recommended

Model Number

Agilent 3458A

Service Guide 1-11

Page 22

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Initial Troubleshooting

Initial Troubleshooting

Perform the following troubleshooting steps in the order they are presented. If you are

unable to identify the failed assembly, go to Chapter 2, “Assembly-Level Troubleshooting

with Block Diagrams,” for further instruction.

NOTE Do not attempt to replace any fuses within the power supply to correct a

problem with your signal generator. If you determine that the power supply is

the failed assembly, replace the power supply.

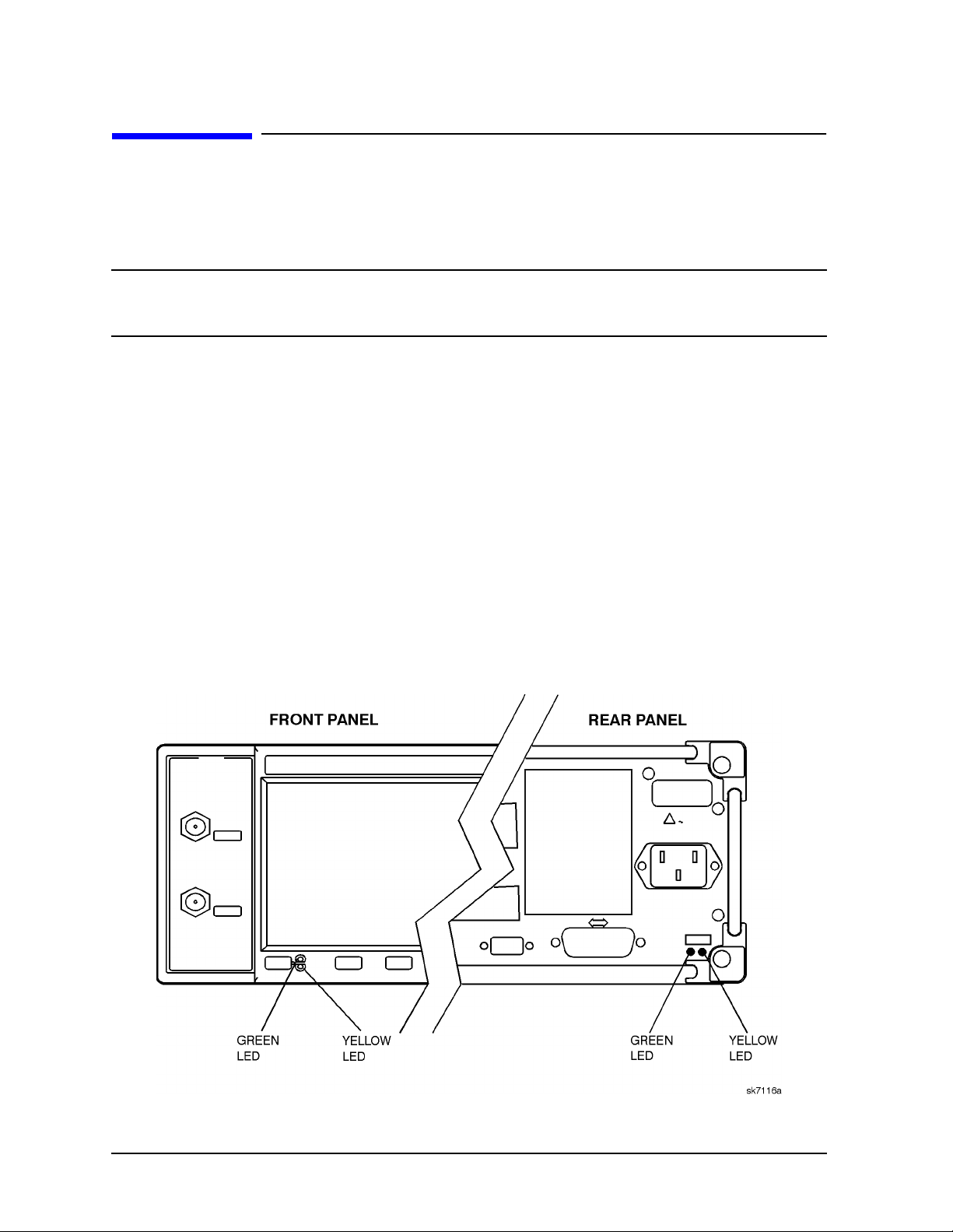

Step 1: Observe the Front and Rear Panel LEDs

Observing the LEDs on the front and rear panel of the signal generator will determine if

there is a catastrophic failure in the power supply assembly.

1. Ensure the signal generator is plugged in (do not switch the power on) and verify that

the yellow LED on both the front and rear panels is lit. Refer to Figure 1-1 for LED

locations. A lit yellow LED (+15 V_STBY) indicates that line voltage is present.

2. Power on the signal generator and verify that the green LED on both the front and rear

panels is lit. A lit green LED indicates the power supply has received an “ON”

command. The ON/OFF switch toggles a flip-flop latch which biases the proper

transistors in the LED control circuit. This circuit is powered by VBAT, the

battery-backed SRAM supply, so that the on-off state is “remembered” even when the

instrument is unplugged.

Figure 1-1 LED Locations on the Front and Rear Panels

1-12 Service Guide

Page 23

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Initial Troubleshooting

Step 2: Power On the Signal Generator and Check for Error Messages

This procedure verifies that the signal generator powers up and that the internal

instrument check identifies no errors. The internal check evaluates the correctness of

operation and returns an error message if a problem is detected.

1. Switch on the signal generator. Let the signal generator warm up for at least five

minutes.

NOTE For ESG-AP, ESG-DP, and Option 1E5 signal generators, ERROR 514,

Reference Oven Cold will occur whenever the signal generator is powered

up within five minutes of being connected to AC line power. The

annunciator and the ERR annunciator will both turn on. The OVEN COLD

annunciator will automatically clear after approximately five minutes. The

error queue cannot be cleared, however, until the

OVEN COLD annunciator has

turned off.

2. Cycle the power to the signal generator and verify that the green LED on both the front

and rear panels is lit. Refer to Figure 1-1.

OVEN COLD

3. When the display is lit, check to see if the

4. If the

ERR annunciator is turned on, review the error messages in the queue by pressing

Utility > Error Info > View Next Error Message. The first error message in the queue will be

ERR annunciator is turned on.

shown in the text area of the display. Refer to the Error Messages guide for descriptions

of error messages.

If there is more than one error message (each message will be designated as 1 of n),

continue pressing the

View Next Error Message softkey until you have seen and recorded all

of the messages.

5. If you were able to resolve all of the error messages, press Utility > Error Info >

Clear Error Queue(s) to delete the list of error messages.

Service Guide 1-13

Page 24

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Initial Troubleshooting

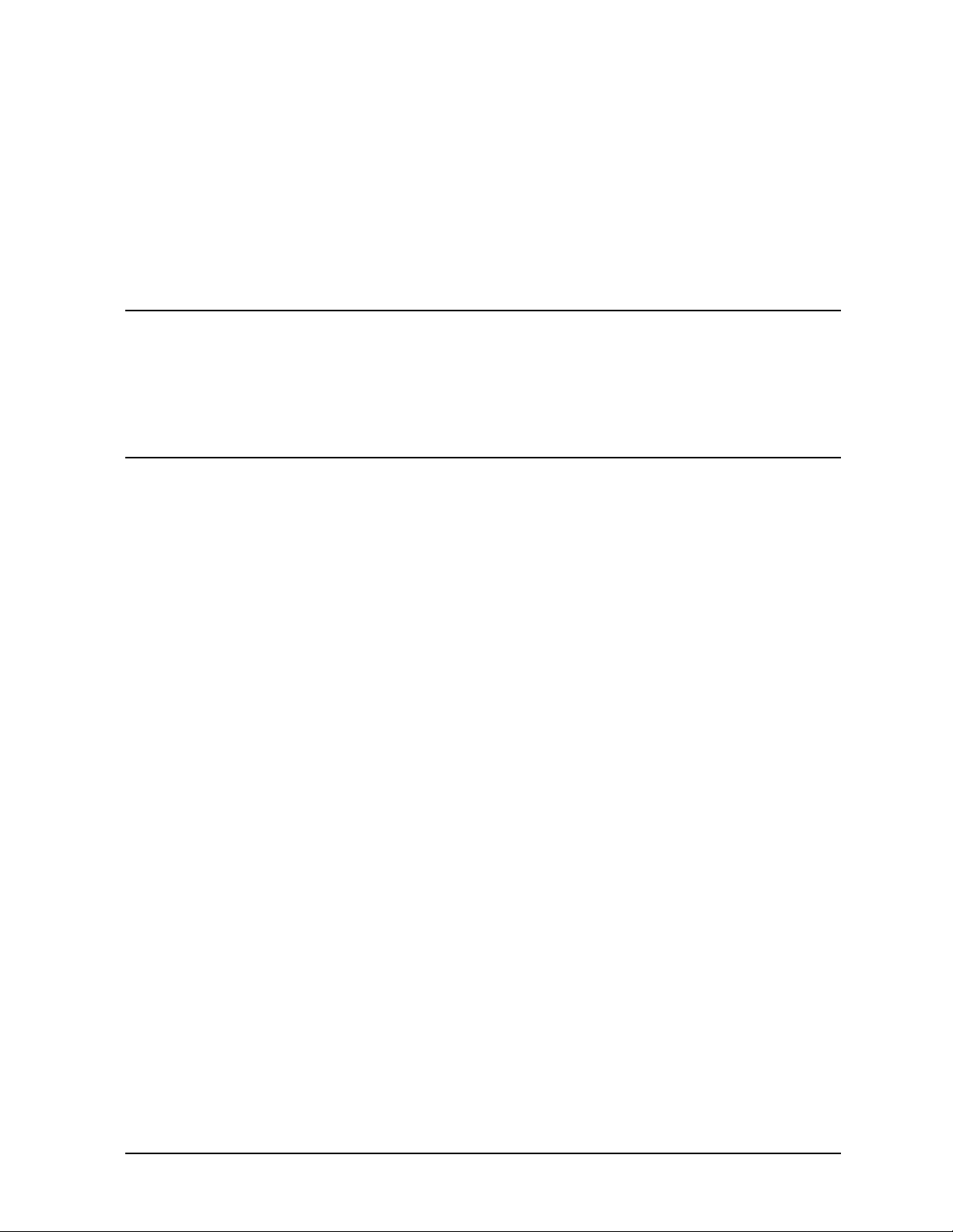

Step 3: Functional Check the Front Panel Keys and Display

1. Press various front panel hardkeys and softkeys to verify they function as expected.

2. Use the contrast keys to verify that the display can be lightened and darkened. Refer to

Figure 1-2.

Figure 1-2 Contrast Keys

1-14 Service Guide

Page 25

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Initial Troubleshooting

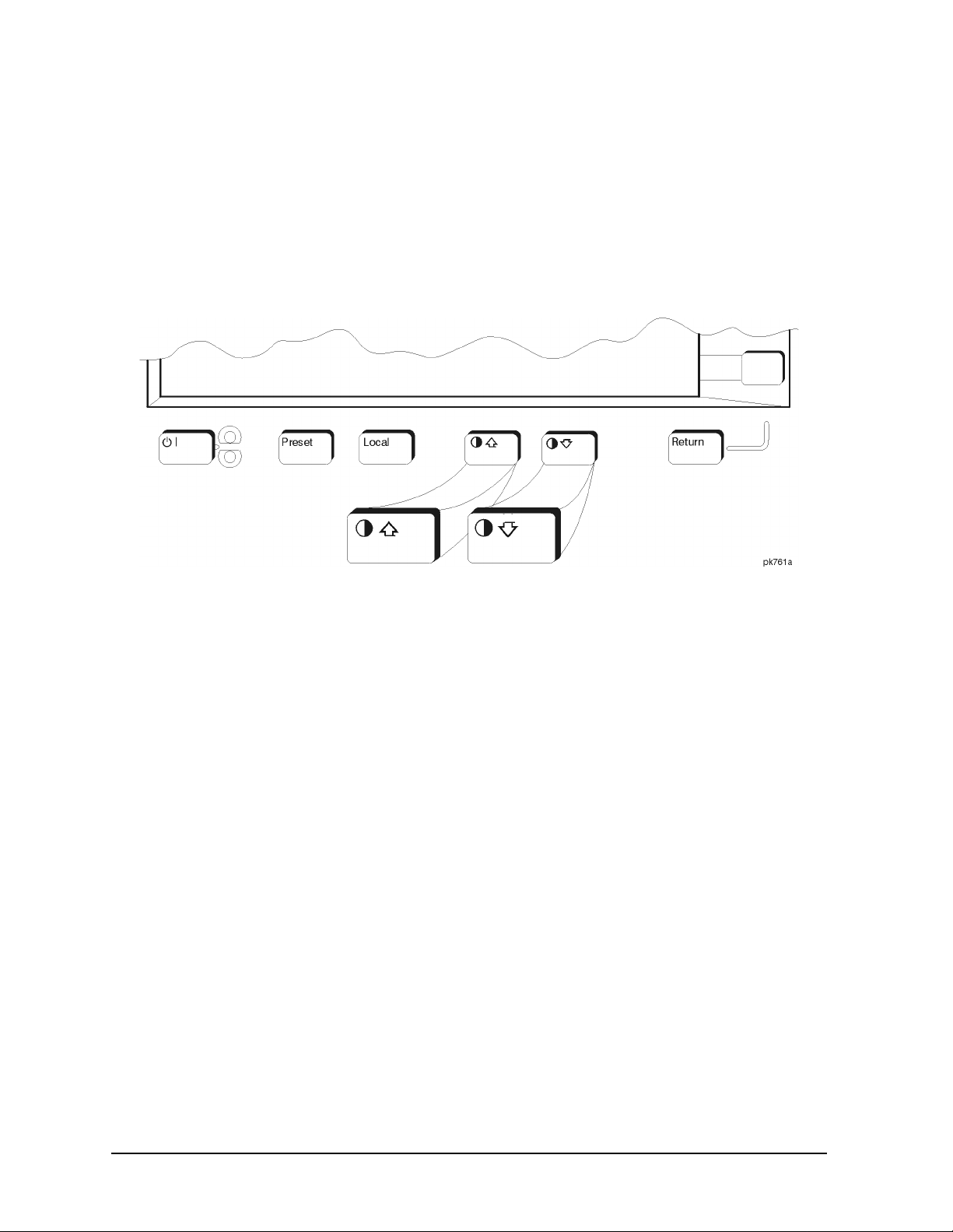

Step 4: Visually Check the Individual Voltage Supplies

1. Unplug the signal generator and remove the instrument cover. Refer to Chapter 5,

“Assembly Replacement,” for removal instructions.

2. Expose the motherboard by removing the top cover. It is secured by 11 screws.

3. Plug in the signal generator and allow it to warm up for at least five minutes.

4. If possible, clear the error queue(s) of messages. Press

Queue(s)

.

Utility > Error Info > Clear Error

5. On the motherboard, locate the 10 LEDs that correspond to the individual voltage

supplies (see Figure 1-3). Verify that all the LEDs are lit. If one or more LEDs are off,

proceed to “Step 6: Isolate the Failed Assembly”.

Figure 1-3 LED Locations on the Motherboard

Service Guide 1-15

Page 26

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Initial Troubleshooting

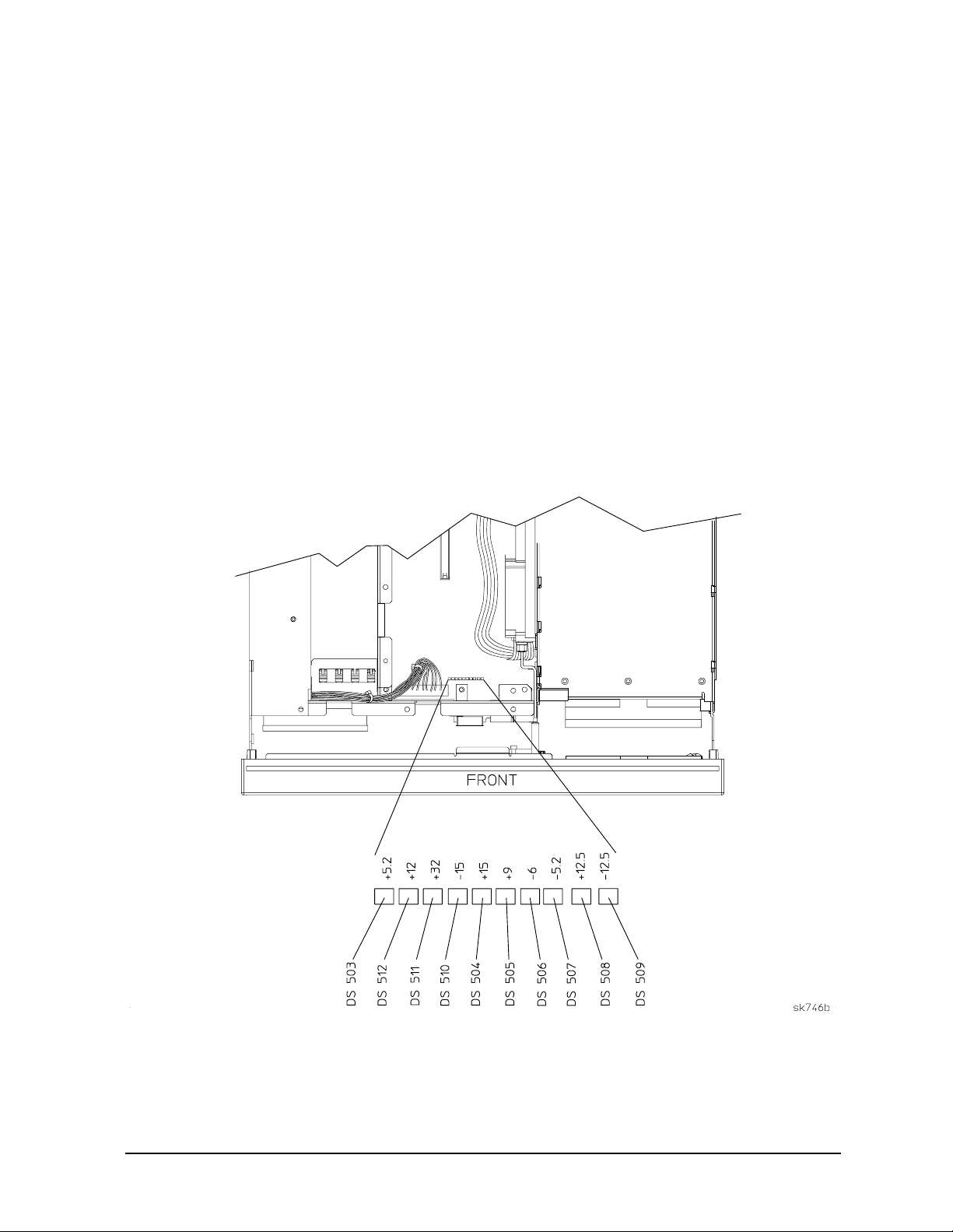

Step 5: Measure the Individual Voltage Supplies

The voltages supplied as inputs from the power supply via J6 to the motherboard are

+15 V (TP502), +15 V standby (+15 V_STBY), −15 V (TP503), +12 V (TP505), and

+5.2 V (TP302). DGND (TP301) is associated with these supplies.

The −6 V (TP508) and −5.2 V (TP509) supplies receive their input from the +5.2 V digital

supply (5.2 VD at TP506). The +5.2 V digital line is filtered to prevent the switching power

supply noise from being induced onto the +5.2 VD supply lines. The −6 V is a bias voltage

for circuits on the output board and other RF circuitry. The −5.2 V is used by the emitter

coupled logic (ECL) digital ICs. The LCD display driver voltage (VLCD), a −14 V to −24 V

source, also receives input from the +5.2 VD supply.

The input to the +32 V supply (TP504) is the +12 V supply.The +32 V supply is used by the

synthesizer/doubler assembly. This supply also includes an LC noise filter.

The +12.5 V regulated supply (TP510) originates from the +15 V input. The −12.5 V

regulated supply (TP511) originates from the −15 V input. These two supplies are used by

the solid-state attenuator and the reverse power protection (RPP). The +10 V reference

(TP501) originates from the +15 V input. The +9 V supply (TP507) originates from the

+10 V reference and the +12 V supply.

1. Unplug the signal generator and turn it upside-down.

2. Expose the motherboard by removing the bottom cover. It is secured by 15 screws.

3. Plug in the signal generator.

4. Measure the voltage of each supply to verify they are within the tolerances listed in

Table 1-3. The voltage supply test point locations are shown in Figure 1-4. If all the

voltages are within tolerance, proceed to “Step 7: Check for Basic CPU Functionality”.

1-16 Service Guide

Page 27

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Initial Troubleshooting

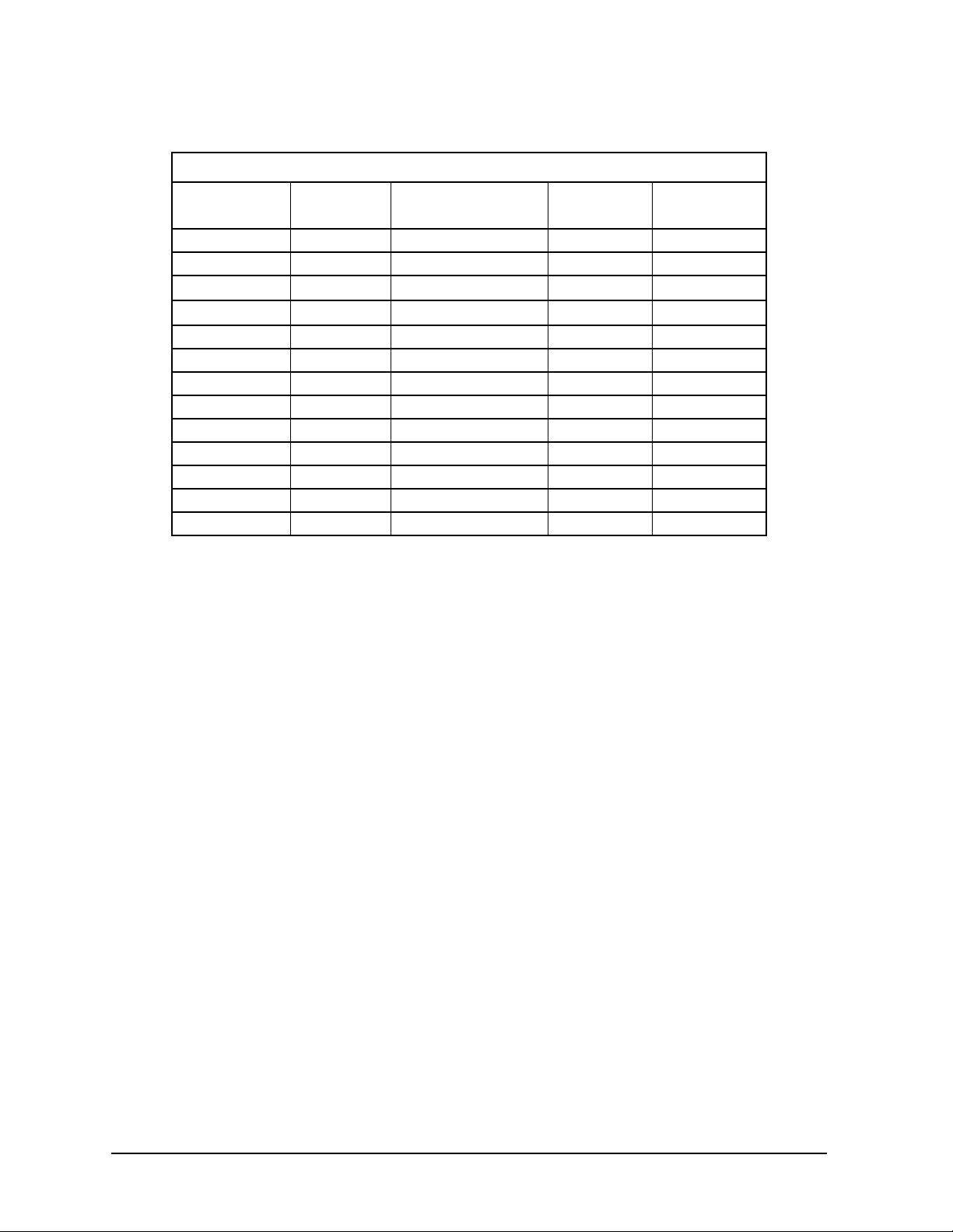

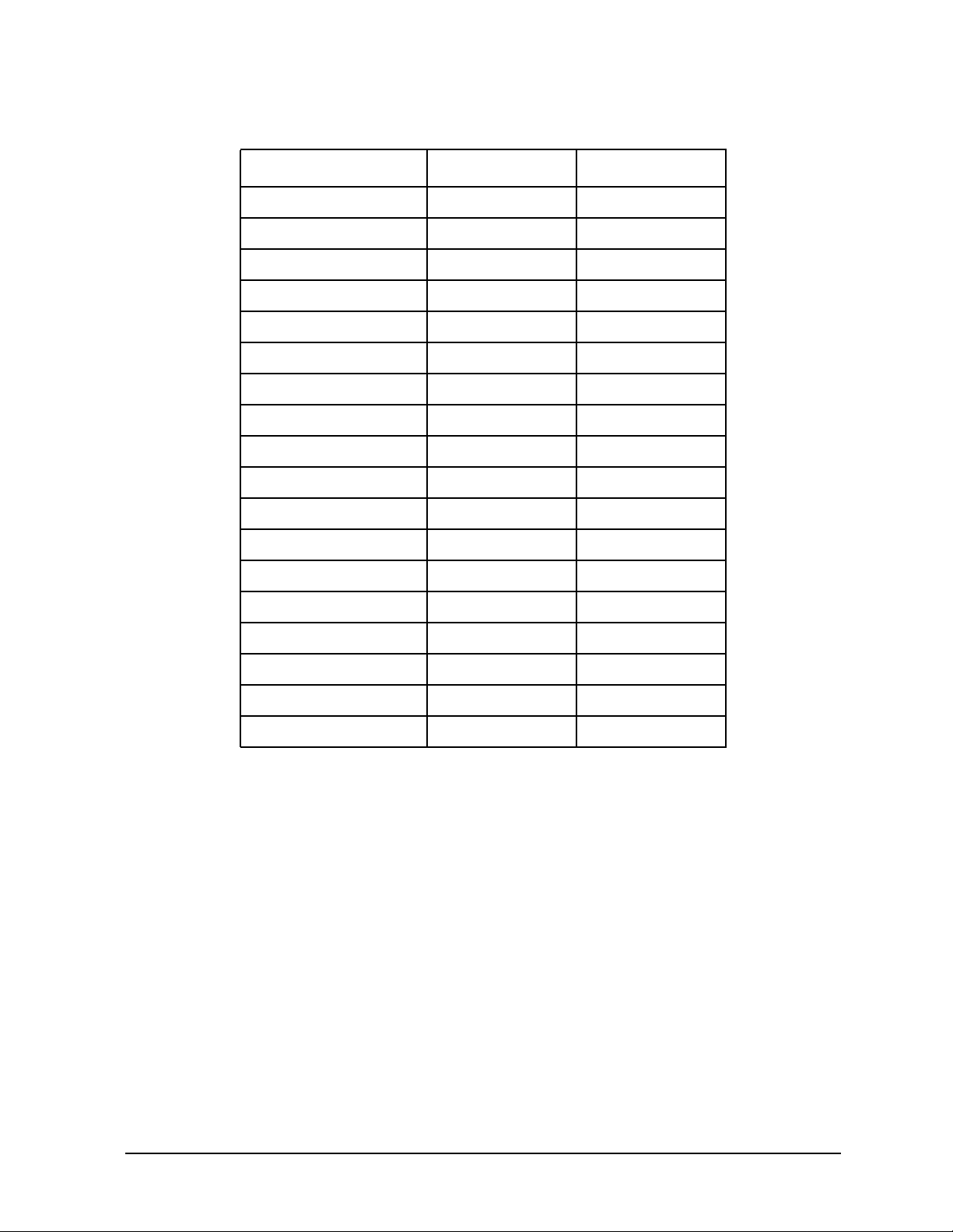

Table 1-3 Voltage Supply Tolerances

Test Point Supply Voltage Tolerance

J6 (pins 2, 3, 12, 13) +5.2 V +/− 3%

J6 (pin 20) +15 V +/− 3%

J6 (pin 18) −15 V +/− 3%

J6 (pin 19) +12 V +/− 3%

J6 (pin 17) +15 V_STBY +/− 5%

TP301 DGND N/A

TP302 +5.2 V +/− 3%

TP501 +10 V_REF +/− 3%

TP502 +15 V +/− 3%

TP503 −15 V +/− 3%

TP504 +32 V +/− 4%

TP505 +12 V +/− 3%

TP506 +5.2 VD +/− 4%

TP507 +9 V +/− 4%

TP508 −6 V +/− 4%

TP509 −5.2 V +/− 4%

TP510 +12.5 V +/− 4%

TP511 −12.5 V +/− 4%

Service Guide 1-17

Page 28

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Initial Troubleshooting

Figure 1-4 Motherboard Test Point Locations

1-18 Service Guide

Page 29

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Initial Troubleshooting

Step 6: Isolate the Failed Assembly

1. Switch off the signal generator.

2. Remove or disconnect an assembly. Below is a suggested order of removal/disconnection

based upon ease.

For the ESG-A and ESG-D Series:

a. A5 Dual Arbitrary Waveform Generator Board (Option UND)

b. A6 Bit Error Rate Test Board (Option UN7)

c. A7 Baseband Generator Board (Options UN3, UN4, UN8, UN9)

d. A8 Data Generator Board (Options UN3, UN4, UN8, UN9)

e. A21 Demodulator Board (Option 300)

f. Front Panel - disconnect A1W1 ribbon cable

g. A3 Inverter - disconnect A3W1

h. A2 Display - disconnect W10

i. AT1 Electronic Attenuator/RPP - disconnect W13

AT1 Mechanical Attenuator and A19 RPP (Option UNB) - disconnect W13 and

A19W1

j. A25 Pulse Modulator (Option 1E6) - disconnect A25W1

k. B1 Fan - disconnect B1W1 (disconnect only temporarily)

l. B2 Fan - disconnect B2W1 (disconnect only temporarily)

m.A9 Output Board

n. A11 Reference Board

o. A12 Synthesizer/Doubler Board

p. A20 YIG Down Convertor Assembly (Option 300) - disconnect W31

NOTE Refer to Chapter 3, “Replaceable Parts (ESG-A and ESG-D Series),” for

information on locating assemblies. Refer to Chapter 5, “Assembly

Replacement,” for information on removing or disconnecting assemblies.

For the ESG-AP and ESG-DP Series:

a. A5 Dual Arbitrary Waveform Generator Board (Option UND)

b. A6 Bit Error Rate Test Board (Option UN7)

c. A7 Baseband Generator Board (Options UN3, UN4, UN8, UN9)

d. A8 Data Generator Board (Options UN3, UN4, UN8, UN9)

e. Front Panel - disconnect A1W1 ribbon cable

f. A3 Inverter - disconnect A3W1

Service Guide 1-19

Page 30

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Initial Troubleshooting

g. A2 Display - disconnect W10

h. AT1 Electronic Attenuator/RPP - disconnect W13

AT1 Mechanical Attenuator and A19 RPP (Option UNB) - disconnect W13 and

A19W1

i. A25 Pulse Modulator (Option 1E6) - disconnect A25W1

j. B1 Fan - disconnect B1W1 (disconnect only temporarily)

k. B2 Fan - disconnect B2W1 (disconnect only temporarily)

l. A9 Output Board

m.A11 Reference Board

n. A23 Sampler Board

o. A24 Frac-N/Divider Board

p. A22 YIG Driver Assembly - disconnect W35

NOTE Refer to Chapter 4, “Replaceable Parts (ESG-AP and ESG-DP Series),” for

information on locating assemblies. Refer to Chapter 5, “Assembly

Replacement,” for information on removing or disconnecting assemblies.

3. Switch on the signal generator and check the voltage supply LEDs (see Figure 1-3). If

the LEDs are lit, you have likely identified the failed assembly. If one or more LEDs are

still off, switch off the signal generator and replace/reconnect the assembly and repeat

this procedure.

1-20 Service Guide

Page 31

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Initial Troubleshooting

Step 7: Check for Basic CPU Functionality

The Digital Signal Processor (DSP) performs a self-diagnostic test at power up. If the DSP

is not working, the CPU reports an error.

If the DSP does not seem to be working and the CPU did not report the error, then check

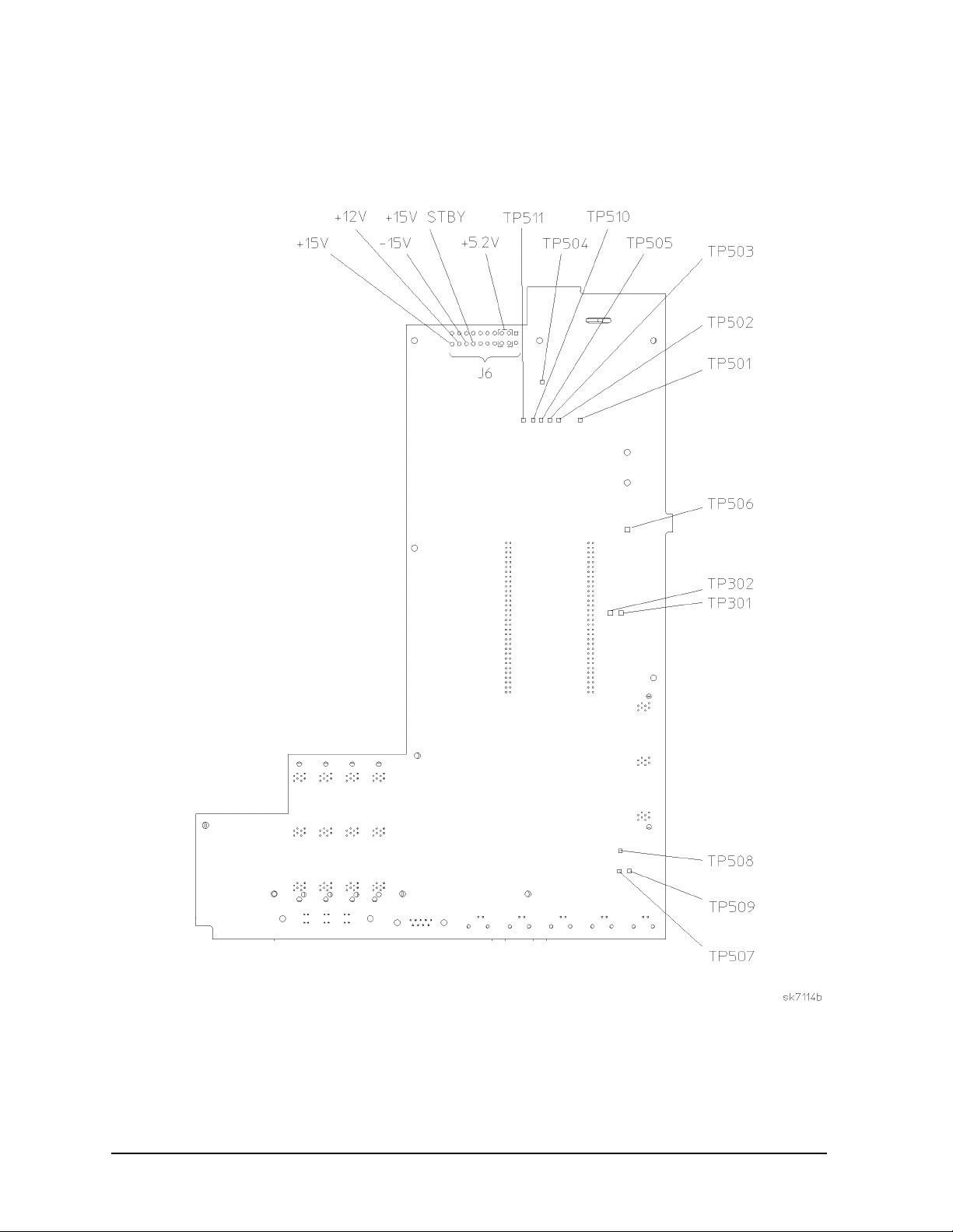

the CLK_OUT signal at TP701. It should be a 16 MHz signal. (Refer to Figure 1-5.)

The eight LEDs of DS201 (see Figure 1-5) indicate the status of the boot and flash ROM for

the CPU. The LEDs form a binary code that can be described as a two digit hexadecimal

code. Table1-4 shows the test sequence and the LED pattern (binary representation) of the

test that is running. If an error occurs and the test is halted, the LED pattern will indicate

which self test halted the process. The LED closest to R201 is the place holder for the Least

Significant Bit (LSB) in the pattern.

Table 1-4 Sequence for DSP Self-Diagnostic Tests

Test Description

LEDs at start of test FF 1111 1111

Checksum test FE 1111 1110

Bootrom RAM test FD 1111 1101

RAM test FC 1111 1100

I/O bus test FB 1111 1011

Main firmware checksum test FA 1111 1010

CPU test AA 1010 1010

Test done and OK 00 0000 0000

Hexadecimal

Code

Binary

Equivalent

MSB LSB

Service Guide 1-21

Page 32

Initial Troubleshooting and RF Block Diagrams ESG Family Signal Generators

Initial Troubleshooting

Figure 1-5 Location of TP701 and DS201-208 on CPU/Motherboard

1-22 Service Guide

Page 33

ESG Family Signal Generators Initial Troubleshooting and RF Block Diagrams

Additional Information for Troubleshooting the ESG-AP and ESG-DP Series

Additional Information for Troubleshooting the

ESG-AP and ESG-DP Series

Table 1-5 provides frequency-dependent settings for selected points in the RF signal flow of

the ESG-AP and ESG-DP Series Signal Generators.Notice that the settings are relative to

the RF output frequency. This information can improve your understanding of the signal

generator circuitry, especially when used with the RF block diagram.

NOTE The values for Table 1-5 assume FM modulation is turned off.

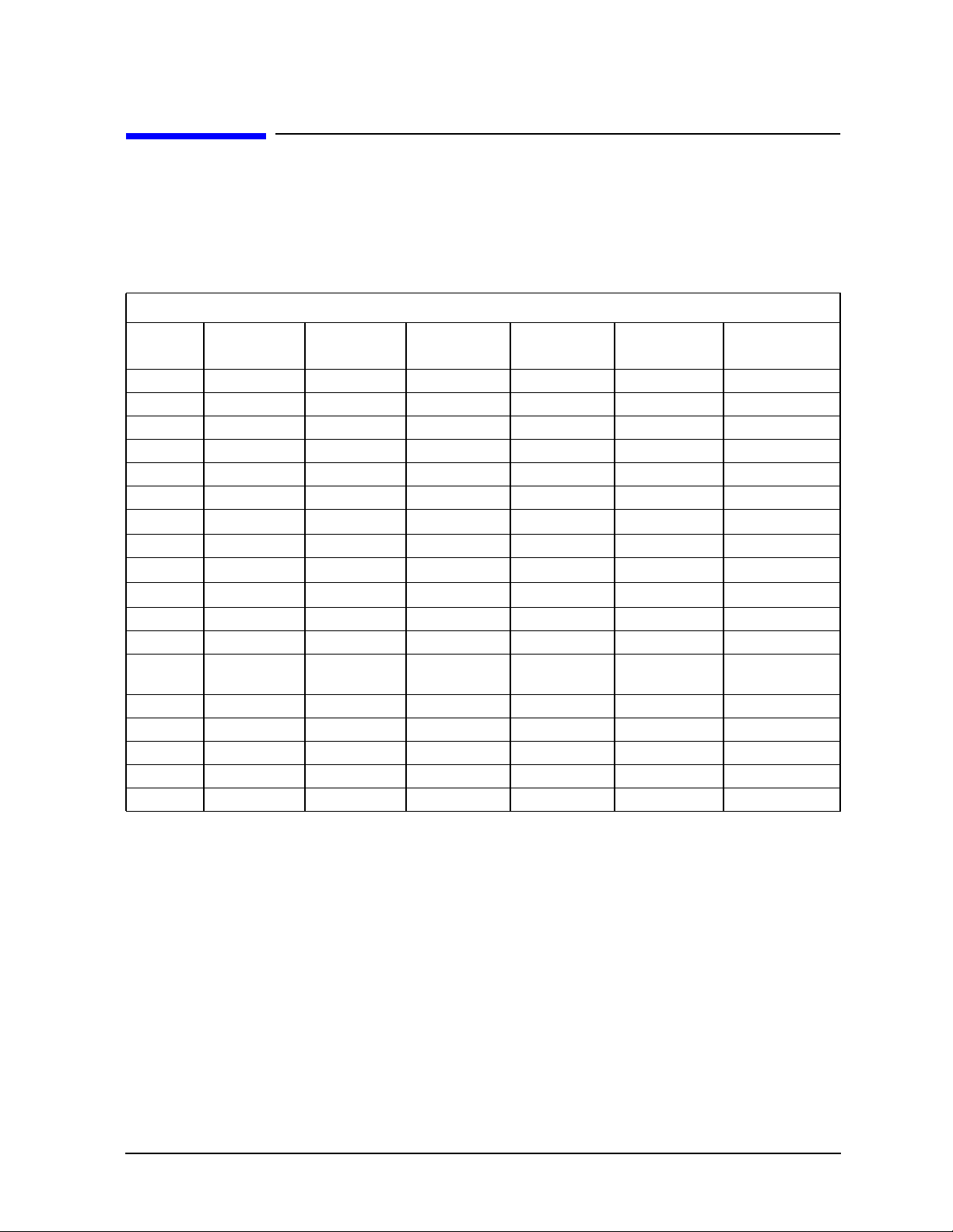

Table 1-5 Frac-N, YO, and Other Selected Frequency-Dependent Settings for Several

RF Output Frequencies

Freq

Out

(MHz)

4000 8000 9 8 593.75000 37.1093750 884.7656250 High 2

3000 6000 7 10 644.53125 32.2265625 852.5390625 High 2

2271 4542 7 10 605.62500 30.2812500 644.5312500 Low 2

1500 6000 7 10 644.53125 32.2265625 852.5390625 High 4

1001 4004 5 10 685.46875 34.2734375 793.9453125 High 4

1000 8000 9 8 593.75000 37.1093750 884.7656250 High 8

700 5600 7 10 847.65625 42.3828125 793.9453125 High 8

300 4800 6 10 726.56250 36.3281250 793.9453125 High 16

240 6080 7 10 603.90625 30.1953125 864.2578125 High 8

100 7200 8 9 928.12500 51.5625000 893.5546875 High 8

1 7992 9 8 887.62500 55.4765625 881.8359375 High 8

Freq

YO

(MHz)

NP

Frac-N

(MHz)

Fif (MHz) Fs (MHz)

Hi/Low

Output

Divider

Service Guide 1-23

Page 34

ESG-A SERIES RF BLOCK DIAGRAM

(STANDARD & OPTION 1E6)

1 GHz REF

LF OUT

A SYNTHESIZER BOARD

.5-1 GHz

F

f

2

Om

/

FM

d/dt

D REFERENCE BOARD

VARIABLE

MODULUS

PRESCALER

FRACTIONAL

DIVIDE

5 MHz

X2

X2

B OUTPUT BOARD

.75-1 GHz

.0-.25 GHz

OPTION 1E6

E PULSE MOD

ALC

.25-4 GHz

MODULATOR

2

ALC

MODULATOR

DRIVER

BURST

MODULATOR

.25-4 GHz

ALC

HOLD

ALC

DETECTOR

50

PULSE

INPUT

C ATTENUATOR

/RPP

DETECTOR

FEED FORWARD AM

SHAPING

ALC REF

5dB STEP

ATTENUATOR

DAC

BURST

MODULATOR

DRIVER

HOLD ALC

ALC_REF

IN_BAND_AM

RPP

RF Out

EXT REF

sk766b

EXT 1

INPUT

EXT 2

INPUT

PLL

10 MHz PLL

10 MHz BW

1 GHz PLL

PLL

NC

FM_MOD

LIN_AM_MOD

PULSE MOD

10 MHz

SYNTH

10 MHz

OUT

1 GHz

REF

LIN_AM_MOD

PULSE MOD

ESG-A SERIES RF BLOCK DIAGRAM

(STANDARD & OPTION 1E6)

Page 35

ESG-D SERIES RF BLOCK DIAGRAM

A SYNTHESIZER BOARD

.5-1 GHz

VARIABLE

MODULUS

PRESCALER

FRACTIONAL

DIVIDE

F

f

5 MHz

2

Om

/

FM

D REFERENCE BOARD

LF OUT

d/dt

10 MHz SYNTH

X2

X2

1 GHz REF

B OUTPUT BOARD

.25-4 GHz

ALC

HOLD

.0-.25 GHz.0-.25 GHz

ALC

DETECTOR

DETECTOR

SHAPING

DAC

C ATTENUATOR

/RPP

5dB STEP

50

ALC REF

ATTENUATOR

RPP

.75-1 GHz.75-1 GHz

AUX

OUT

(COHERENT

CARRIER)

2

.25-4 GHz

VBLO

DAC

QUAD

IQ MODULATOR

90

ALC

MODULATOR

0

ALC

MODULATOR

DRIVER

BURST

MODULATOR

DAC

CAL

VOLTAGE

Q OFFSET

DAC

DAC

Q GAIN

BURST

MODULATOR

DRIVER

FEED FORWARD AM

HOLD ALC

EXT

I INPUT

EXT

Q INPUT

I OFFSET

DAC

DAC

I GAIN

CAL

VOLTAGE

EXT 1

INPUT

EXT 2

INPUT

EXT REF

PLL

10 MHz PLL

10 MHz BW

PLL

1 GHz PLL

FM_MOD

LIN_AM_MOD

PULSE MOD

10 MHz

SYNTH

10 MHz

OUT

1 GHz

REF

ALC_REF

IN_BAND_AM

LIN_AM_MOD

PULSE MOD

sk773b

ESG-D SERIES RF BLOCK DIAGRAM

Page 36

ESG-D SERIES RF BLOCK DIAGRAM

(OPTIONS UN3 & UN4)

1 GHz REF

B OUTPUT BOARD

LF OUT

EXT 1

INPUT

EXT 2

INPUT

EXT REF

A SYNTHESIZER BOARD

.5-1 GHz

Om

/

FM

d/dt

D REFERENCE BOARD

10 MHz BW

10 MHz PLL

PLL

1 GHz PLL

PLL

F

f

VARIABLE

MODULUS

PRESCALER

FRACTIONAL

DIVIDE

5 MHz

2

10 MHz SYNTH

FM_MOD

LIN_AM_MOD

PULSE MOD

10 MHz

SYNTH

10 MHz

OUT

1 GHz

REF

X2

X2

2

10 MHz DIG

EXT 13 MHz

DATA_CLOCK

DATA

EXT_SYNC

EXT_BURST

PATTERN

TRIG

EVENT 1

EVENT 2

AUX

OUT

(COHERENT

CARRIER)

.25-4 GHz

VBLO

DAC

IQ MODULATOR

QUAD

DAC

I OFFSET

DAC

DAC

EXT

I INPUT

EXT

Q INPUT

I GAIN

E BASEBAND GENERATOR BOARD

PLL_LCK_SIG

MASTER_CLK

BUF_DATA_IN

SYMBOL_SYNC

L DATA_CLK

BBG_BIT_CLK

SUB_I_COUNT

L_BURST

SCRAMBLE_RUN

SYMBOL_SYNC

BURST_GATE

INTERNAL DATA

GENERATOR

(PATTERN RAM)

UN3=1M

UN4=8M

DATA

GENERATION

CONTROL

USER_DATA

PLL_CLOCK

SWITCH

MASTER

CLOCK-PLL

DATA

F DATA GENERATOR BOARD

90

DAC

DAC

CONTROL

BURST & DELAY

BURST_PLS

-1V_REF

CAL

VOLTAGE

SWITCH & FILTERS

BURST_PULSE

0

CAL

VOLTAGE

BURST MOD

Q OFFSET

DAC

DAC

Q GAIN

BURST_ENVELOPE

INT_ Q_MOD

INT_ I_MOD

ALC

MODULATOR

ALC

MODULATOR

DRIVER

FEED FORWARD AM

LIN_BURST

MODULATOR

BURST

MODULATOR

DRIVER

LOG_BURST

BURST

HOLD ALC

BURST

ALC_REF

IN_BAND_AM

.75-1 GHz.75-1 GHz

.25-4 GHz

ALC

HOLD

.0-.25 GHz.0-.25 GHz

ALC

DETECTOR

DETECTOR

SHAPING

DAC

C ATTENUATOR

/RPP

5dB STEP

50

ALC REF

ATTENUATOR

RPP

sk774b

LIN_AM_MOD

PULSE MOD

ESG-D SERIES RF BLOCK DIAGRAM (OPTIONS UN3 & UN4)

Page 37

ESG-D SERIES RF BLOCK DIAGRAM

(OPTION UN8 or UN9) Rev C or D

1 GHz REF

B OUTPUT BOARD

LF OUT

EXT 1

INPUT

EXT 2

INPUT

EXT REF

A SYNTHESIZER BOARD

.5-1 GHz

VARIABLE

MODULUS

PRESCALER

FRACTIONAL

DIVIDE

F

f

Om

/

d/dt

FM

10 MHz SYNTH

D REFERENCE BOARD

10 MHz BW

10 MHz PLL

PLL

1 GHz PLL

PLL

5 MHz

2

FM_MOD

LIN_AM_MOD

PULSE MOD

10 MHz

SYNTH

10 MHz

OUT

1 GHz

REF

X2

X2

2

10 MHz DIG

EXT 13 MHz

DATA_CLOCK

DATA

EXT_SYNC

EXT_BURST

PATTERN

TRIGGER

EVENT 1

EVENT 2

AUX

OUT

(COHERENT

CARRIER)

.25-4 GHz

VBLO

DAC

IQ MODULATOR

90

QUAD

DAC

I OFFSET

DAC

DAC

EXT

I INPUT

EXT

Q INPUT

I GAIN

CAL

VOLTAGE

E BASEBAND GENERATOR BOARD

MASTER

CLOCK-PLL

MPU

GLOBAL CLOCK INPUTS

INTERNAL DATA

GENERATOR

(PATTERN RAM)

UN8=1M

UN8&UN9=8M

EVENT1_OUT

USER_DATA_EN

PLL_LCK_SIG

MASTER_CLK

BBG_BIT_CCK

SUB_I_CLK

MPU BUS

DATA

GENERATION

CONTROL

BASEBAND

GEN. I/O

FPGA

FPGA

FPGA

FPGA BUS

DAC

DAC

CONTROL

BURST & DELAY

BURST_PLS

-1V_REF

F DATA GENERATOR BOARD

0

CAL

VOLTAGE

BURST MOD

SWITCH &

FILTERS

BURST_PULSE

Q OFFSET

DAC

DAC

Q GAIN

BURST_ENVELOPE

INT_ Q_MOD

INT_ I_MOD

LIN_AM_MOD

ALC

MODULATOR

ALC

MODULATOR

DRIVER

FEED FORWARD AM

LIN_BURST

PULSE_MOD

BURST

MODULATOR

BURST

MODULATOR

DRIVER

LOG_BURST