Page 1

USER’S GUIDE

Multi-Cell Charger/Discharger

Agilent Model E4370A

Powerbus Load

Agilent Model E4371A

64-Channel Charger/Discharger

Agilent Models E4374A and E4375A

Agilent Part No. 5964-8138

Microfiche No. 5964-8139

September 2001

Page 2

Warranty Information

CERTIFICATION

Agilent Technologies certifies that this product met its published specifications at time of shipment from the factory.

further certifies that its calibration measurements are traceable to the United States National Institute of Standards

and Technology, to the extent allowed by the Institute's calibration facility, and to the calibration facilities of other

International Standards Organization members.

WARRANTY

This Agilent Technologies hardware product is warranted against defects in material and workmanship for a period

of one year from date of delivery. Agilent Technologies software and firmware products, which are designated by

Agilent Technologies for use with a hardware product and when properly installed on that hardware product, are

warranted not to fail to execute their programming instructions due to defects in material and workmanship for a

period of 90 days from date of delivery. During the warranty period Agilent Technologies will, at its option, either

repair or replace products which prove to be defective. Agilent Technologies does not warrant that the operation for

the software firmware, or hardware shall be uninterrupted or error free.

For warranty service, with the exception of warranty options, this product must be returned to a service facility

designated by Agilent Technologies . Customer shall prepay shipping charges by (and shall pay all duty and taxes)

for products returned to Agilent Technologies for warranty service. Except for products returned to Customer from

another country, Agilent Technologies shall pay for return of products to Customer.

Warranty services outside the country of initial purchase are included in Agilent Technologies' product price, only if

Customer pays Agilent Technologies international prices (defined as destination local currency price, or U.S. or

Geneva Export price).

If Agilent Technologies is unable, within a reasonable time to repair or replace any product to condition as warranted,

the Customer shall be entitled to a refund of the purchase price upon return of the product to Agilent Technologies .

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by the

Customer, Customer-supplied software or interfacing, unauthorized modification or misuse, operation outside of the

environmental specifications for the product, or improper site preparation and maintenance. NO OTHER

WARRANTY IS EXPRESSED OR IMPLIED. AGILENT TECHNOLOGIES SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE THE CUSTOMER'S SOLE AND EXCLUSIVE REMEDIES. AGILENT

TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

ASSISTANCE

The above statements apply only to the standard product warranty. Warranty options, extended support contacts,

product maintenance agreements and customer assistance agreements are also available. Contact your nearest

Agilent Technologies Sales and Service office for further information on Agilent Technologies' full line of Support

Programs.

2

Page 3

Safety Summary

F

y

s

A

y

The following general safety precautions must be observed during all phases of operation of this instrument.

ailure to comply with these precautions or with specific warnings elsewhere in this manual violates safet

tandards of design, manufacture, and intended use of the instrument.

for the customer's failure to comply with these requirements.

GENERAL

This product is a Safety Class 1 instrument (provided with a protective earth terminal). The protective features of

this product may be impaired if it is used in a manner not specified in the operation instructions.

Any LEDs used in this product are Class 1 LEDs as per IEC 825-1.

ENVIRONMENTAL CONDITIONS

This instrument is intended for indoor use in an installation category II, pollution degree 2 environment. It is

designed to operate at a maximum relative humidity of 95% and at altitudes of up to 2000 meters. Refer to the

specifications tables for the ac mains voltage requirements and ambient operating temperature range.

BEFORE APPLYING POWER

Verify that all safety precautions are taken. Note the instrument's external markings described under "Safety

Symbols".

gilent Technologies assumes no liabilit

GROUND THE INSTRUMENT

To minimize shock hazard, the Agilent MCCD Mainframe chassis and cover must be connected to an electrical

ground. The mainframe must be connected to the ac power mains through a grounded power cable, with the ground

wire firmly connected to an electrical ground (safety ground) at the power outlet. Any interruption of the protective

(grounding) conductor or disconnection of the protective earth terminal will cause a potential shock hazard that

could result in personal injury.

The Agilent Powerbus Load does not connect to ac mains. Connect the ground terminal of the load to the ground

terminal of the external dc source. Use a #14 AWG wire as a minimum.

ATTENTION: Un circuit de terre continu est essentiel en vue du fonctionnement sécuritaire de l'appareil.

Ne jamais mettre l'appareil en marche lorsque le conducteur de mise … la terre est d‚branch‚.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

DO NOT REMOVE THE INSTRUMENT COVER

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be

made only by qualified service personnel.

Instruments that appear damaged or defective should be made inoperative and secured against unintended

operation until they can be repaired by qualified service personnel.

3

Page 4

Safety Symbols

SAFETY SYMBOLS

Direct current Caution, risk of electric shock

Earth (ground) terminal Caution, hot surface

Protective earth (ground) terminal

(Intended for connection to external

protective conductor.)

On - power (Indicates connection to the

ac mains.)

Off - power (Indicates disconnection

from the ac mains.)

Caution (Refer to accompanying documents.)

On - equipment (Identifies the on condition of

part of the equipment.)

Off - equipment (Identifies the off condition of

part of the equipment.)

Document Scope

This document describes and specifies the “standard” version of the Agilent Multi-Cell

Charger/Discharger System. It contains installation instructions, connection information, programming

information, example programs, and specifications. Information about the Agilent MCCD User Interface

is provided online. System options are described on a separate option sheet that is shipped with this

manual. All information is this manual is subject to change. Updated editions will be identified by a new

printing date.

Notice

This document contains proprietary information protected by copyright. All rights are reserved. No part

of this document may be photocopied, reproduced, or translated into another language without the prior

consent of Agilent Technologies. The information contained in this document is subject to change

without notice.

Copyright 1999, 2000, 2001 Agilent Technologies, Inc.

4

Page 5

Table of Contents

Warranty Information 2

Safety Summary 3

Document Scope 4

Table of Contents 5

1 - GENERAL INFORMATION 9

Agilent MCCD System Capabilities 9

Basic Functions 10

Additional Features 10

Hardware Description 10

Agilent E4370A MCCD Mainframe 10

Agilent E4374A and E4375A 64-Channel Charger/Discharger Cards 12

Agilent E4371A Powerbus Load 12

External Power Source 14

Multiple Agilent MCCD Configurations 14

Measurement Capability 16

Voltage Measurements 16

Current Measurements 17

Capacity Measurements 17

Cell Resistance 18

Probe Resistance 18

Data Logging 18

Protection Features 19

Internal Protection Functions 20

External Digital I/O Protection Functions 20

If AC Power Fails 20

Remote Programming Interface 21

Application Programming Interface (API) 21

Web Accessible Agilent MCCD User Interface 21

Example of a Cell Forming Process 21

2 - INSTALLATION 23

Inspection 23

Parts and Accessories 23

Location 25

Agilent E4370A MCCD Mainframe 25

Agilent E4371A Powerbus Load 25

Channel Connections 25

Voltage Drops and Wire Resistance 26

Remote Sense Connections 27

Power Bus Connections 28

Power Bus Wiring Information 28

Power Bus Configuration Examples 29

Digital Connections 32

General Purpose I/O 32

Special Functions 32

Wiring Guidelines 33

RS-232 Connections 34

Auxiliary Output Connection 35

Installing the API Library and Measurement Log Utility 36

Visual C++ Configuration 36

5

Page 6

3 - CONFIGURATION 37

Configuring the LAN 37

1. Configure the HyperTerminal program 37

2. Connect the Agilent E4370A MCCD to the COM port on the PC 38

3. Fill Out the Agilent MCCD Configuration Screens 38

Network Configuration 39

Identification Configuration 40

Miscellaneous Configuration 41

Configuring the Digital I/O 41

Mixed Configuration Example 44

Accessing Calibration 44

4 - AGILENT MCCD USER INTERFACE 45

Description 45

PC Requirements 45

Browser Settings 45

Security 45

Localization 46

Access 46

Using the Interface 46

Using the Agilent MCCD Measurement Log Utility 47

5 - PROGRAMMING OVERVIEW 49

A Cell Forming Overview 49

Cell Forming Example 50

Function Call Overview 53

Cell Grouping 53

Grouping Functions 54

Step/Test Functions 54

Sequence Control 55

Output Configuration 56

Instrument Protection 57

Power Fail Operation 58

Instrument State Storage 58

Status 59

Measurement Log 60

Time Stamp Function 61

Output Measurements 61

Direct output control 62

General Server functions 62

Selftest 63

Calibration 63

Serial port 64

Digital port 64

Probe check 65

6 - LANGUAGE DICTIONARY 67

API Usage Guidelines 67

API Function Summary 68

API Function Definitions 70

cfAbort 70

cfCal 70

cfCalStandard 70

6

Page 7

cfCalTransfer 71

cfClose 71

cfDeleteGroup 71

cfGetCellStatus 72

cfGetCellStatusString 72

cfGetCurrent 72

cfGetDigitalConfig 73

cfGetDigitalPort 73

cfGetGroups 73

cfGetInstIdentify 74

cfGetInstStatus 74

cfGetMeasLogInterval 75

cfGetOutputConfig 75

cfGetOutputProbeTest 75

cfGetOutputState 76

cfGetRunState 76

cfGetSense 76

cfGetSenseProbeTest 77

cfGetSeqStep 77

cfGetSeqTest 77

cfGetSeqTestAnd 78

cfGetSeqTime 78

cfGetSerialConfig 78

cfGetSerialStatus 78

cfGetShutdownDelay 79

cfGetShutdownMode 79

cfGetStepNumber 79

cfGetTrigSource 79

cfGetUserIdentify 79

cfGetVoltage 80

cfInitiate 80

cfMeasACResistance 80

cfMeasCapacityAS 80

cfMeasCapacityWS 81

cfMeasCurrent 81

cfMeasDCResistance 81

cfMeasOutputProbeResistance 81

cfMeasProbeContinuity 82

cfMeasSenseProbeResistance 82

cfMeasVoltage 83

cfOpen 83

cfOpenGroup 83

cfProtect 84

cfProtectClear 84

cfReadMeasLog 84

cfReadSerial 86

cfReadTestLog 87

cfReset 87

cfResetSeq 87

cfRestart 88

cfSaveOutputConfig 88

cfSelftest 88

cfSetAutoConnect 89

cfSetCurrent 89

cfSetDigitalConfig 90

7

Page 8

cfSetDigitalPort 92

cfSetErrorFunction 92

cfSetGroup 93

cfSetMeasLogInterval 93

cfSetOutputConfig 93

cfSetOutputProbeTest 94

cfSetOutputState 94

cfSetSense 95

cfSetSenseProbeTest 95

cfSetSeqStep 95

cfSetSeqTest 97

cfSetSeqTestAnd 99

cfSetSerialConfig 99

cfSetServerTimeout 99

cfSetShutdownDelay 100

cfSetShutdownMode 100

cfSetTimeout 100

cfSetTrigSource 100

cfSetVoltage 100

cfShutdown 101

cfStateDelete 101

cfStateList 102

cfStateRecall 102

cfStateSave 102

cfTrigger 102

cfWriteSerial 103

7 - C PROGRAM EXAMPLES 105

Example 1 105

Example 2 107

Example 3 112

A - SPECIFICATIONS 115

B - CALIBRATION 119

Calibration Types 119

Full Calibration 119

Transfer Calibration 120

Mainframe Reference Calibration 120

Calibration Connections 120

Accessing Calibration 122

Calibration Error Messages 123

C - DIMENSION DRAWINGS 125

D - SENSE AND POWER CONNECTOR PINOUTS 127

E - IN CASE OF TROUBLE 135

Introduction 135

Selftest Error Messages 136

INDEX 137

8

Page 9

1

General Information

Agilent MCCD System Capabilities

The Agilent Multi-Cell Charger/Discharger (MCCD) System has been designed to address the unique

requirements and needs of lithium-ion cell manufacturing. The Agilent MCCD System can accurately

charge, discharge, and measure lithium ion cells. It consists of an Agilent E4370A Multi-Cell

Charger/Discharger mainframe with up to four Agilent E4374A or E4375A 64-Channel

Charger/Discharger cards. When fully loaded each mainframe has 256 input/output channels.

Mainframes and modules can be combined in different configurations to form a low cost, high

performance cell charge/discharge station in a cell manufacturing process.

NOTE: You cannot mix Agilent E4374A and E4375A 64-Channel Charger/Discharger cards in

the same E4370A mainframe. Mainframes can only operate with identical-model cards.

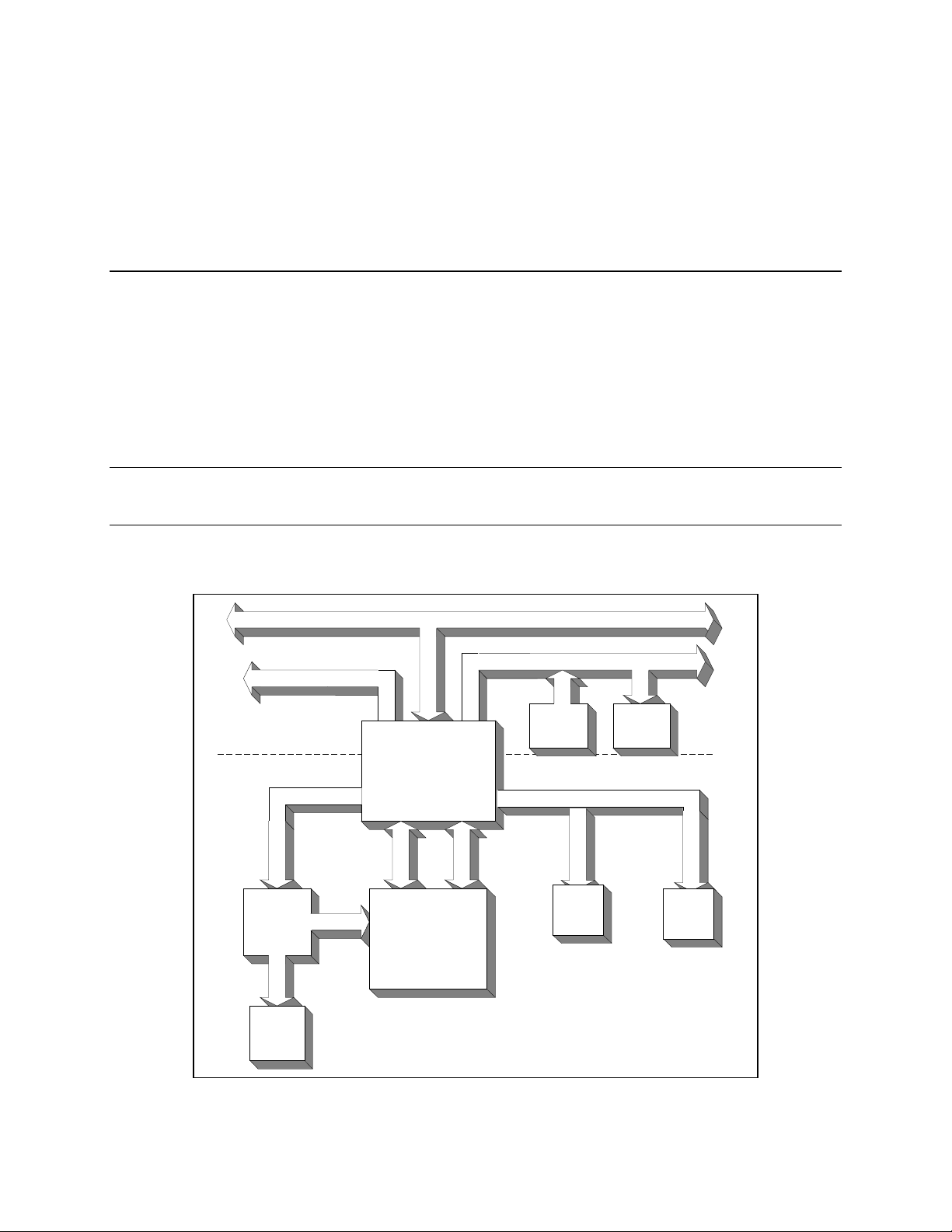

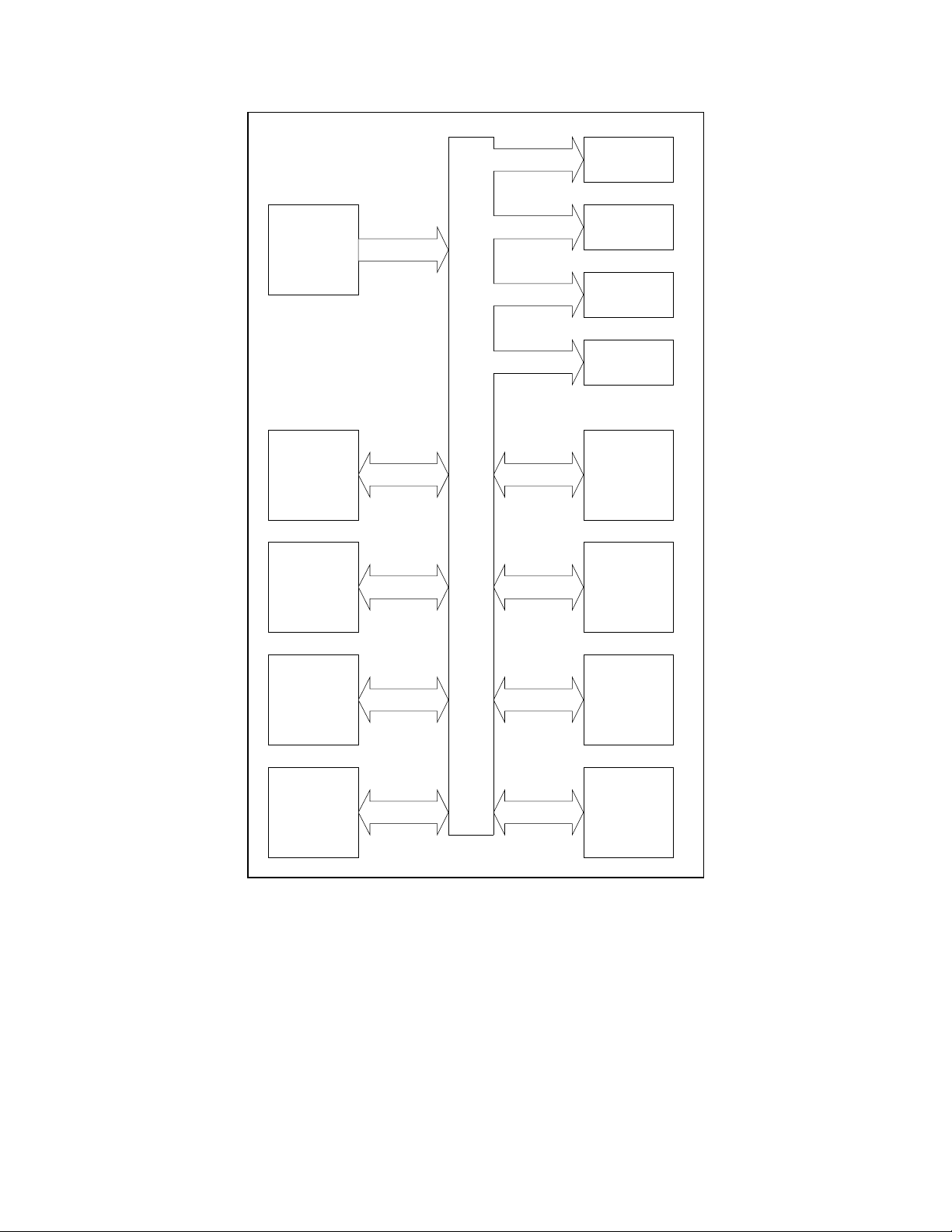

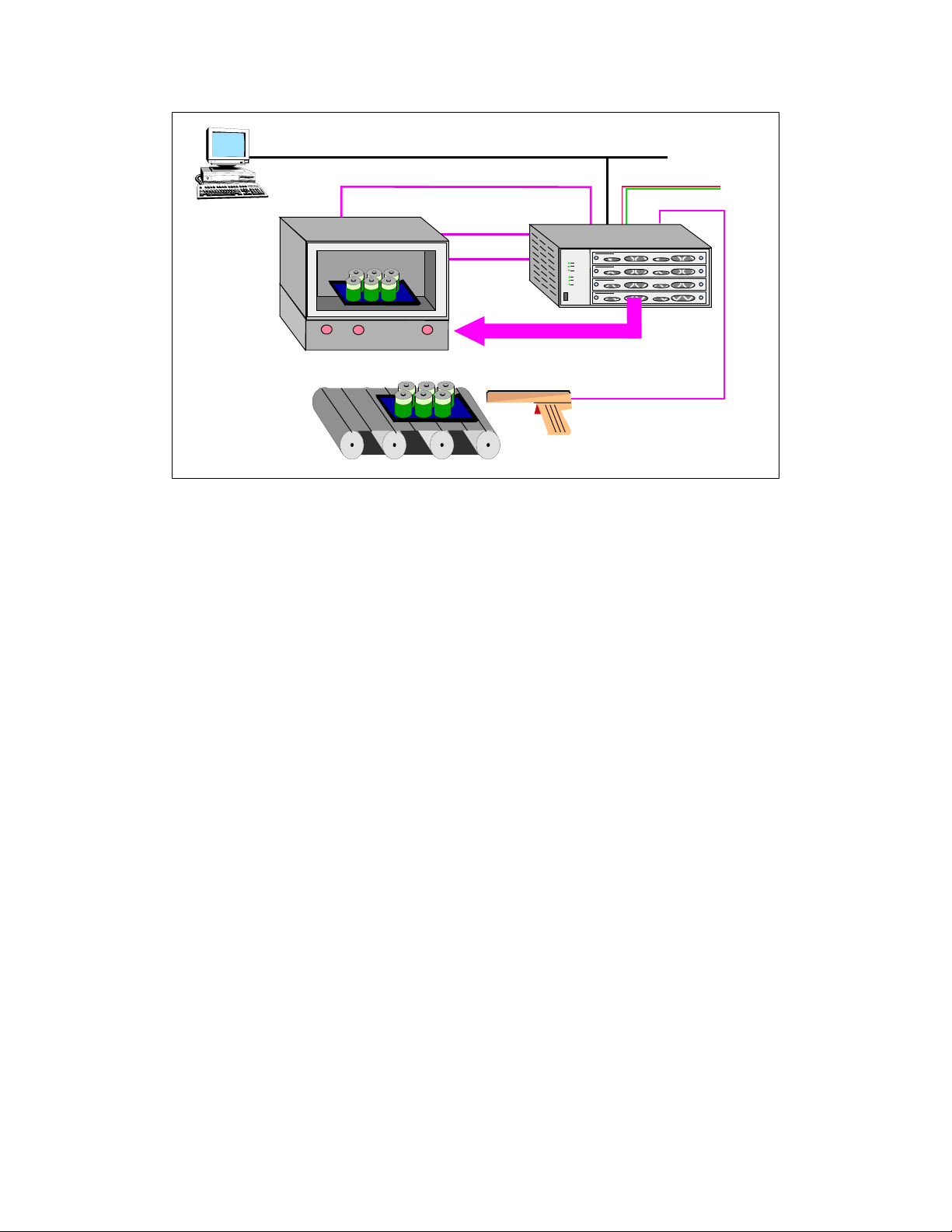

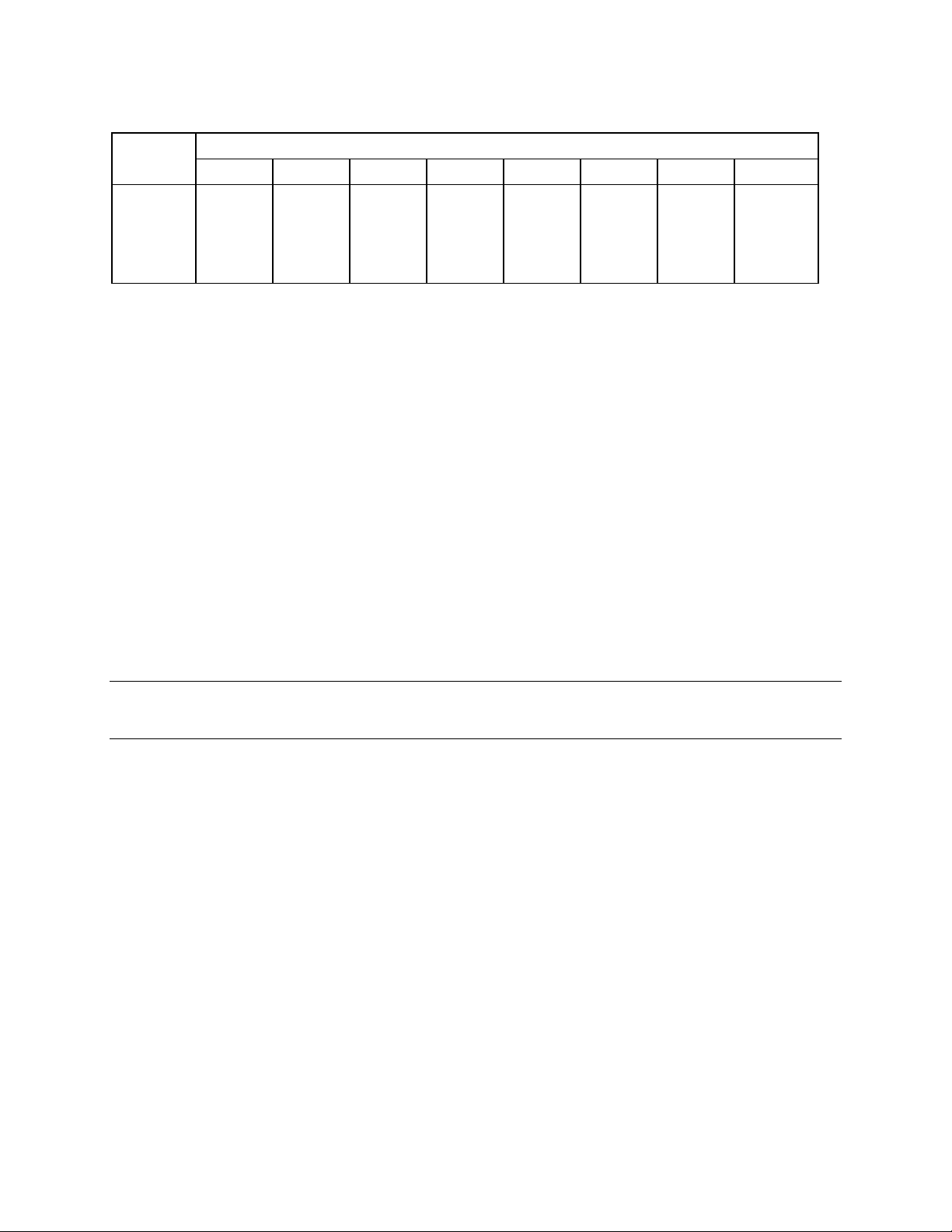

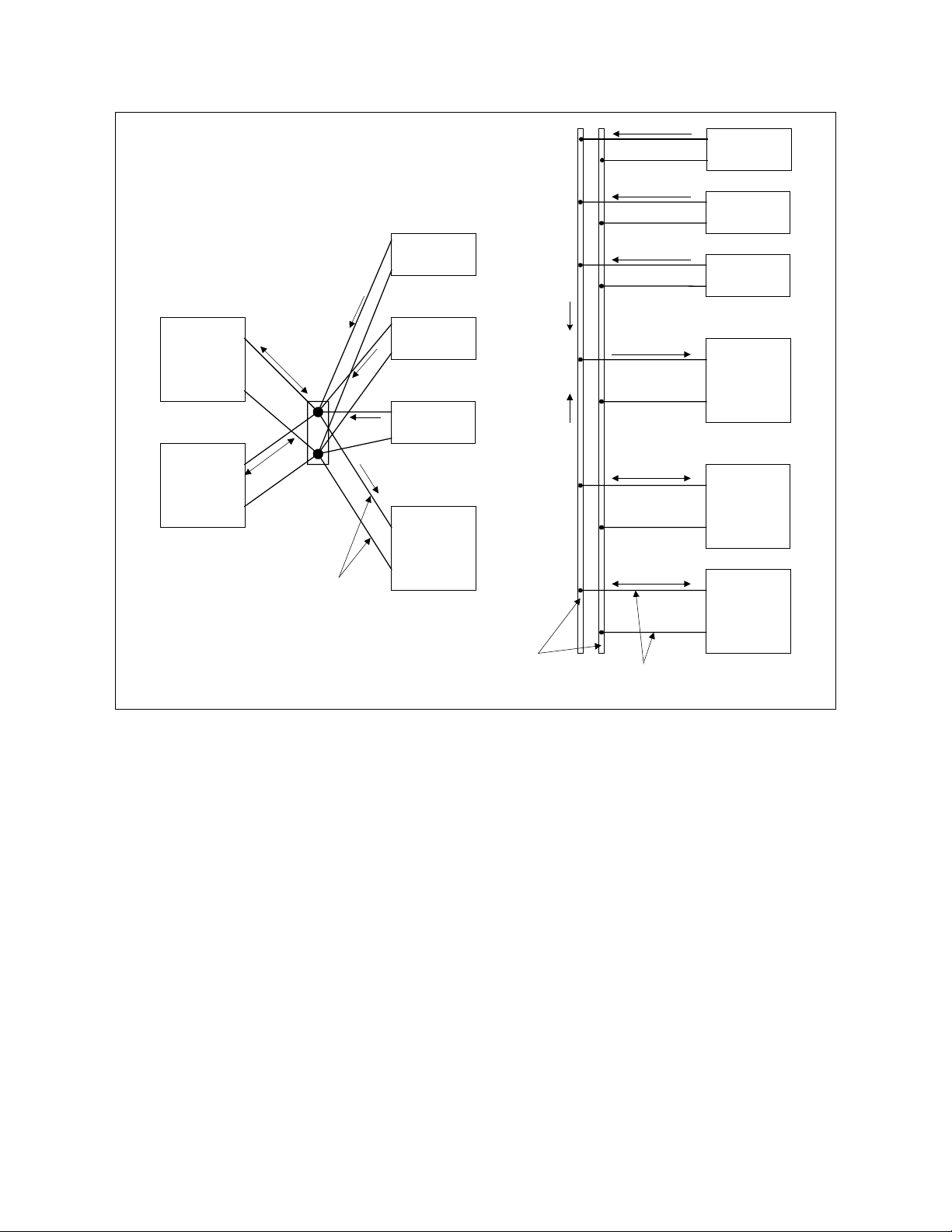

The following figure is a simplified block diagram of the Agilent MCCD System. It is followed by a brief

description of the system’s basic as well as advanced features.

10 Base T Ethernet to remote monitoring and control

Powerbus

Digital I/O to outside world

Remote

Rail power

source

Powerbus

Load

Multi-cell

Local

charger /

discharger

Digital I/O

Fixture

control and

local

start/stop

Local

controls

Power

Multiple cell

tray

Sense

Serial

Local

terminal

Figure 1-1. Block Diagram of Agilent MCCD System

Serial

Local

barcode

reader

9

Page 10

1 - General Information

Basic Functions

♦ Charger – The Agilent MCCD can deliver accurately controlled current and voltage into a cell for

proper forming. Each cell is independently paced through the cell forming sequence. This means that

some cells can be charging and others discharging if they are at different points in the sequence.

♦ Discharger – The Agilent MCCD can draw accurately controlled current from a cell for both

forming and capacity measurement.

♦ Measurement – The Agilent MCCD can monitor several parameters of the cell while charging,

discharging, and resting. Measurements include voltage, current, time, internal resistance, amperehours, and watt-hours. These measurements are used to adjust the cell forming sequence for safety,

reliability, and or proper cell forming.

♦ Digital I/O control – The Agilent MCCD can monitor and stimulate digital I/O connected to it. This

simplifies wiring, allows ease of expansion, and is more reliable than a centralized control system. Its

high-speed capability is ideal for fast fault detection and system shutdown.

♦ RS-232 control – The Agilent MCCD can support peripherals connected to its serial ports for adding

printers, bar code readers, local terminals, robots and other types of local additional hardware via

pass-through control from the host computer.

♦ Equipment Protection – The Agilent MCCD has extensive safety features to protect both the cells

under formation and the hardware from equipment failure, programming errors, cell failures and

other types of external faults.

Additional Features

♦ LAN 10 base-T control using a web-server graphical user interface and an application programming

interface (API).

♦ Comprehensive data storage capability and remote data collection.

♦ Easily removable charger/discharger cards for minimum downtime if repair is required.

♦ Charge/discharge sequences that can be modified in software, allowing for simple, rapid changes to

the manufacturing process without changes to system hardware.

♦ Define and configure groups of contiguous blocks of cells or channels. This lets you simultaneously

run different sequences on groups of cells.

♦ Continuous calibration is performed on the programming circuits during the entire charge/discharge

sequence to eliminate errors due to temperature drift.

♦ Bi-directional power transfer and reuse of energy by using energy from discharging cells to provide

energy to charging cells.

Hardware Description

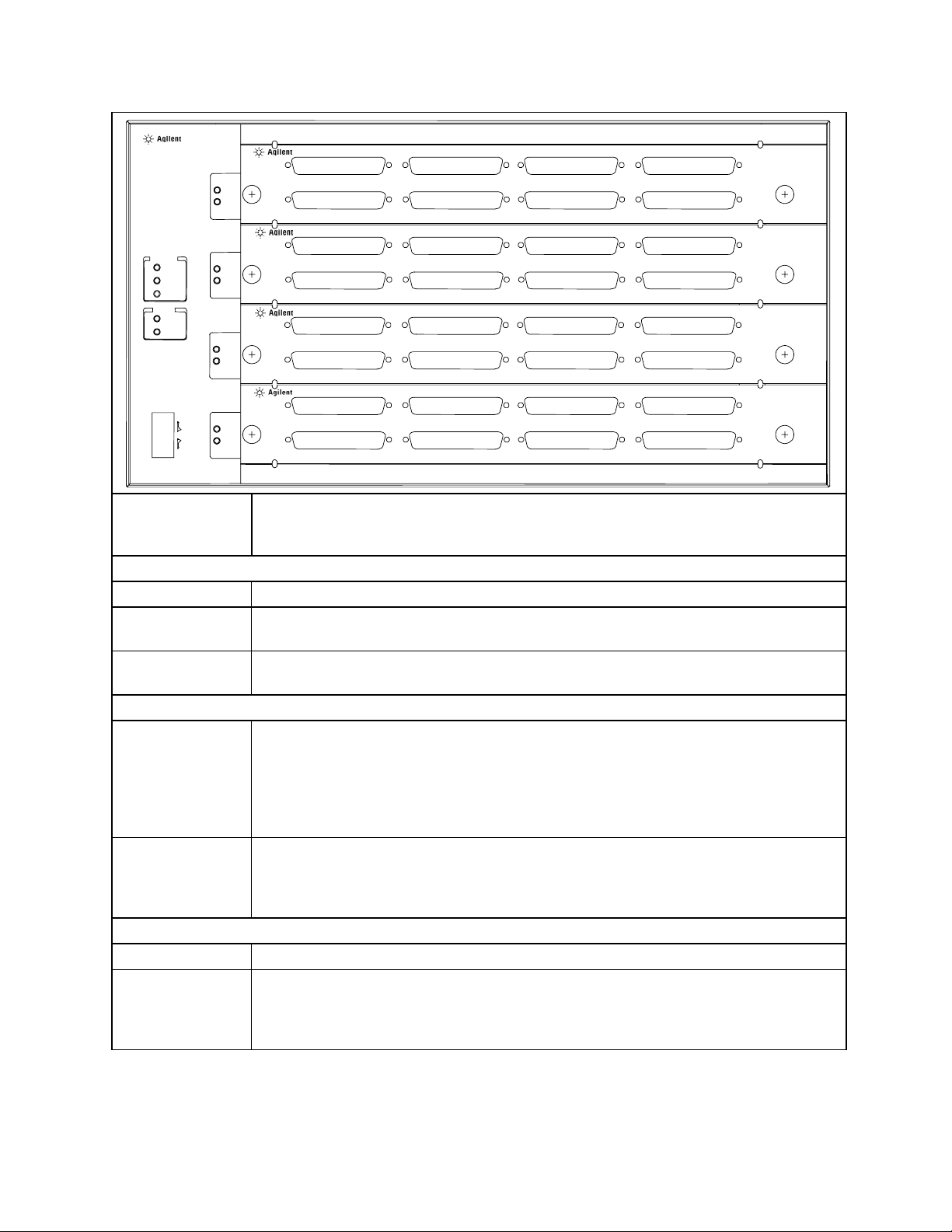

Agilent E4370A MCCD Mainframe

The Agilent E4370A MCCD mainframe is a full-width rack box that has 4 slots to hold either the Agilent

E4374A or Agilent E4375A 64-Channel Charger/Discharger cards. LEDs on the front of the mainframe

indicate system as well as card status (see Figure 1-2).

10

Page 11

General Information - 1

E4370A

MULTICELL CHARGER/DISCHARGER

SYSTEM

Power

Ready

Active

FAULT

External

Internal

LINE

LINE

1

Ready

Fault

2

Ready

Fault

3

Ready

Fault

4

On

Ready

Fault

Off

E4374A CHARGER/DISCHARGER

E4374A CHARGER/DISCHARGER

E4374A CHARGER/DISCHARGER

E4374A CHARGER/DISCHARGER

1

2

1

2

1

2

1

2

Applies and removes ac power from the Agilent MCCD. Relays inside the unit that connect

the power bus are disengaged when power is off, so the power bus is also disconnected from

the unit by this switch.

SYSTEM

Power

Ready

When lit, indicates that the mainframe is powered on.

When lit, indicates that the unit is ready for operation.

When off, indicates that the external power bus voltage is either too high or too low.

Active

When lit, indicates that data communication is present on the LAN cable.

When flashing, indicates that LAN communication is in progress.

FAULT (Refer to Appendix E to clear any fault conditions)

External

When lit, indicates an external fault such as:

External digital fault signal received,

Power fail shutdown signal received,

High power bus voltage after power on,

Low power bus voltage after power-on.

Overtemperature

Internal

When lit, indicates an internal hardware fault such as:

Selftest failure,

Calibration error,

Hardware error.

1, 2, 3, 4

Ready

Fault

Indicates the card is powered up and ready to be used

When lit, indicates an internal hardware fault such as:

Selftest failure,

Calibration error,

Hardware error.

3

4

3

4

3

4

3

4

5

6

5

6

5

6

5

6

7

8

7

8

7

8

7

8

Figure 1-2. Agilent E4370A MCCD Mainframe Front Panel Controls and Indicators

11

Page 12

1 - General Information

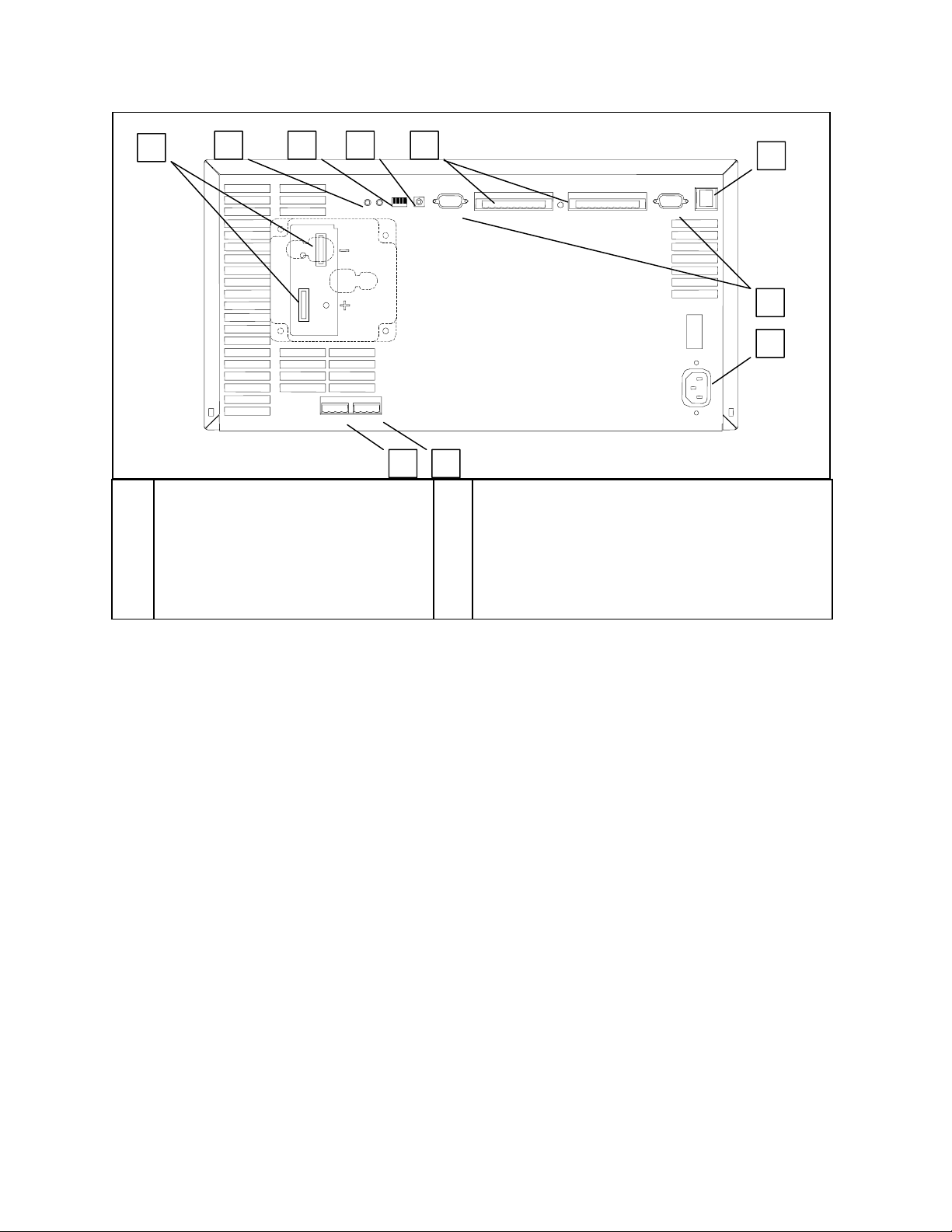

A

B C D E

+ and - Power bus connectors

A

(- bus bar is connected to chassis ground)

B

Calibration status LEDs

C

Configuration switches

D

Transfer Calibration switch

E

Digital I/O connectors

F

LAN connection

RS-232

PORT A

RS-232

PORT B

K J

RS-232 connectors (ports A and B)

G

AC line connection (a universal AC input for line

H

voltages from 87 Vac to 250 Vac, 50/60 Hz.)

Auxiliary output connection

J

Calibration port

K

F

G

H

Figure 1-3. Agilent E4370A MCCD Mainframe Rear Panel Connections

Agilent E4374A and E4375A 64-Channel Charger/Discharger Cards

The Agilent E4374A and 4375A 64-Channel Charger/Discharger cards contain the circuitry that

independently charges and discharges each cell connected to the front of the mainframe. Up to four

identical-model cards can be installed in each mainframe. Agilent E4374A cards charge cells at at up to

5V and 2A. Agilent E4375A cards charge cells at up to 5V and 3A.

Each output channel has a maximum available compliance voltage of 5.5V for Agilent E4374A cards and

6.0V for Agilent E4375A cards. Compliance voltage is defined as the voltage required at the cell plus

any fixture/wiring voltage drops. Having this higher compliance voltage allows the full programmable 5

V to be applied directly to the cell with up to 0.5-volt loss in the wiring for Agilent E4374A cards and up

to 1.0-volt loss in the wiring for Agilent E4375A cards.

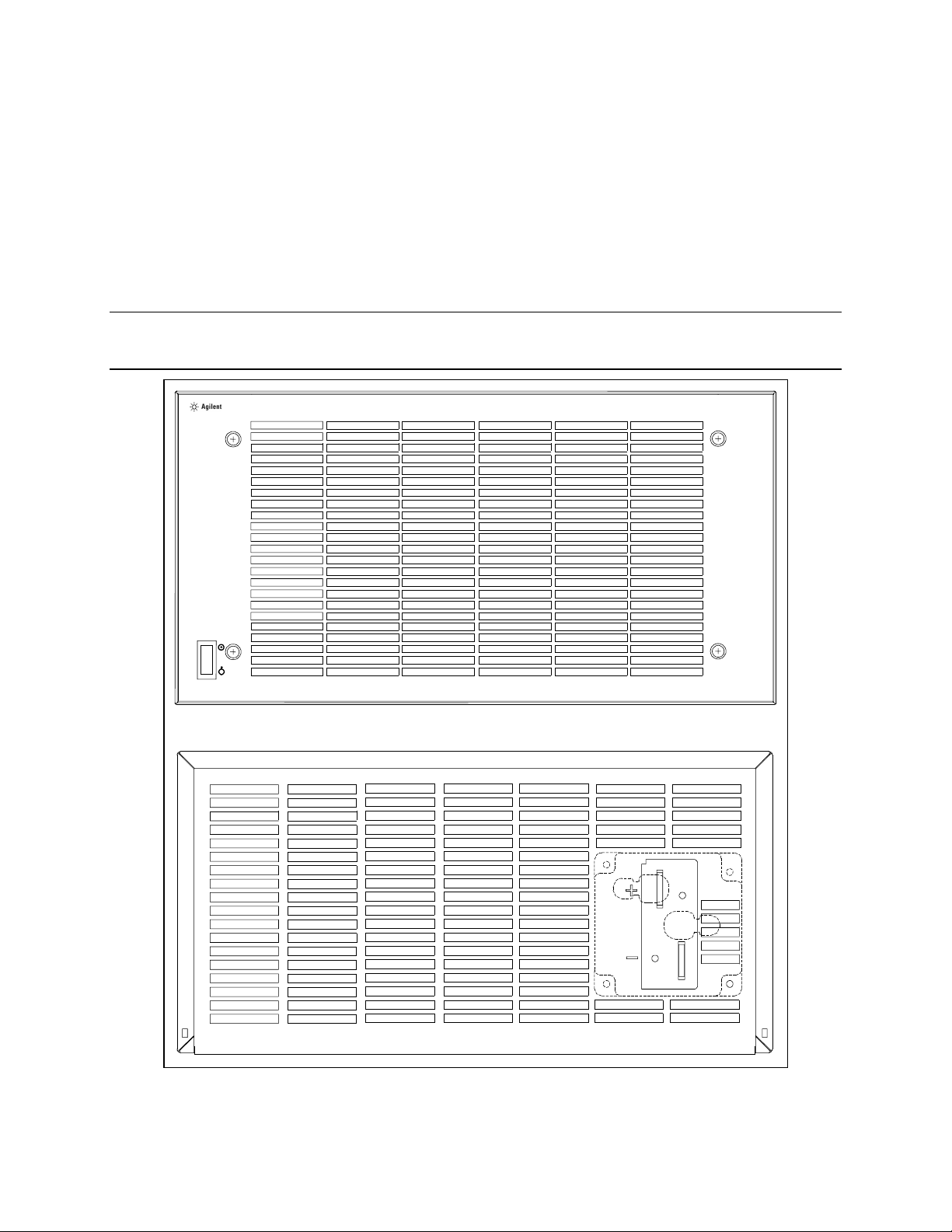

Agilent E4371A Powerbus Load

For the discharging cycle, an Agilent E4371A Powerbus Load is required to dissipate excess power from

discharging cells. The load operates in constant voltage mode only and sequentially switches internal

resistors on and off to regulate the voltage on the power bus around a midpoint of 26.75 volts. The

number of load units required depends on the number of Agilent MCCD mainframes in your system.

Each Agilent E4371A Powerbus Load is capable of the dissipating the full power from eight Agilent

E4374A 64-Channel Charger/Discharger cards or eight Agilent E4375A 64-Channel Charger/Discharger

cards.

12

Page 13

General Information - 1

The Agilent E4371A Powerbus Load has a + and a − power bus connector on its rear panel. There is also

a ground connection. To meet safety requirements, connect the ground terminal of the Agilent Powerbus

Load to the ground terminal of the external dc source. The load receives its operating power from the

power bus. If the dc voltage on the power bus drops below 22.8 volts, or if there is no power available on

the power bus, the load will not operate. Note that the load is not programmable. It is set at the factory

for the correct operating voltage and does not require calibration.

The On/Off switch on the load simply connects or disconnects the load from the power bus. Note that the

internal fans draw approximately 1.5 amperes of current from the power bus.

CAUTION: When discharging its maximum rated power, the Agilent E4371A Powerbus Load

becomes hot to the touch.

A

2

3

7

E

4

POWERBUS LOAD

Figure 1-4. Agilent E4371A Powerbus Load Front and Rear Panels

13

Page 14

1 - General Information

External Power Source

For the charging cycle, each Agilent MCCD mainframe requires an external dc power source to power

the cells. The external power source connects to the power bus terminals on the back of the mainframe. It

must be rated at 24 volts and be able to source 125% of the required cell charging power.

For example, to provide the cell charging power for a 256-channel system at 5.5 volts, 2 amperes per

channel (or 2.8 kW), the dc power source must deliver approximately 3.5 kW to each Agilent MCCD

mainframe (24 V @ 146 A). To provide the cell charging power for a 256-channel system at 6 volts, 3

amperes per channel (or 4.6 kW), the dc power source must deliver approximately 5.76 kW to each

Agilent MCCD mainframe (24 V @ 240 A).

The current rating of the power source may be reduced if the charging current is reduced accordingly. For

example, to provide a maximum output current of 1 ampere per cell in a 256-channel system, a source

rated at least 24 volts, 72 amperes may be used.

Additionally, a single supply of sufficient amperage may be shared among multiple mainframes that are

connected to a common power bus - provided that the total current can be supplied while meeting the

voltage specification at the power bus terminals at the rear of the Agilent MCCD.

NOTE: If the external dc power source has an overvoltage protection circuit, it must be set

higher than 30 volts to avoid the possibility of shutting itself down during the discharge

cycle.

Multiple Agilent MCCD Configurations

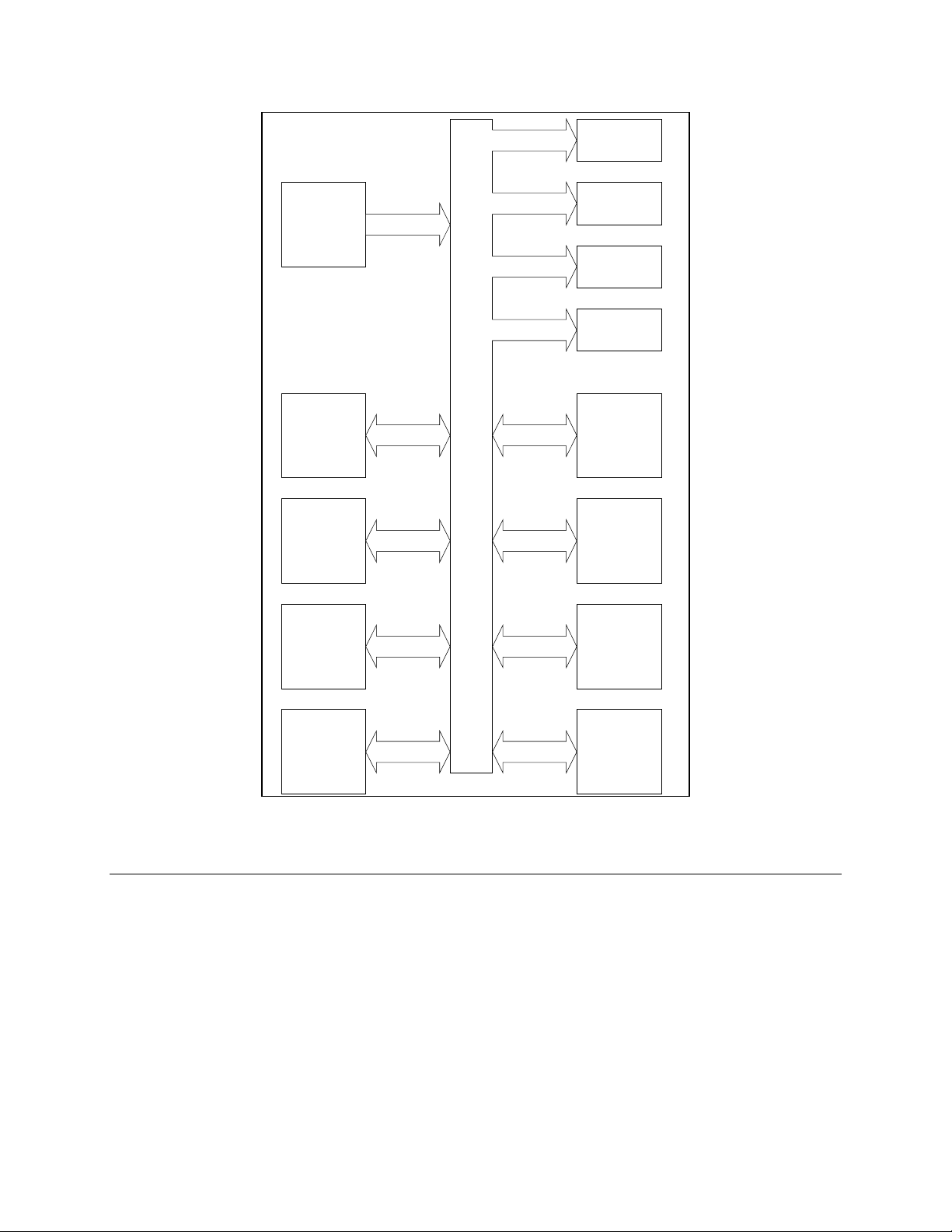

Figures 1-5 and 1-6 illustrate two configurations of Agilent E4370A MCCD systems with eight fully

loaded mainframes.

The power required for such systems can be as high as 46 kilowatts (when using Agilent E4375A cards).

A single power source of sufficient total amperage may be shared among multiple mainframes connected

to the power bus, provided the total current can be provided while meeting the nominal 24-volt dc input

requirement at the power bus terminals on the rear of each mainframe. Multiple paralleled 24-volt dc

sources may be used in place of the single dc source shown in the figures.

To achieve improvements in energy efficiency, the Agilent E4370A MCCD system can re-use discharge

energy to supplement the energy provided by an external power source when charging other cells in a

multi-unit system. This is possible because of the bi-directional power transfer capability between

charging and discharging cells when connected to a common power bus. To take advantage of this energy

transfer requires that some mainframes in the system must be operating in discharge mode at the same

time that others are operating in charging mode.

No special control system is required for this configuration. The regulation circuits of the 24 volt dc

power source, the Agilent E4370A MCCD mainframe, and Agilent E4371A Powerbus Load will operate

properly without any special hardware control lines or additional software being required.

NOTE: Adequate size power bus wiring is required to carry high currents. Refer to Table 2-5.

14

Page 15

Agilent E4371A

Powerbus Load

General Information - 1

28 kW

Power Source

(24 V @

1167A)

Agilent E4370A

+4 E4374A cards

(256 channels)

Agilent E4370A

+4 E4374A cards

(256 channels)

Agilent E4371A

Powerbus Load

Agilent E4371A

Powerbus Load

Agilent E4371A

Powerbus Load

Agilent E4370A

+4 E4374A cards

(256 channels)

POWERBUS

Agilent E4370A

+4 E4374A cards

(256 channels)

Agilent E4370A

+4 E4374A cards

(256 channels)

Agilent E4370A

+4 E4374A cards

(256 channels)

Agilent E4370A

+4 E4374A cards

(256 channels)

Agilent E4370A

+4 E4374A cards

(256 channels)

Figure 1-5. System Diagram Using Agilent E4374A Cards

15

Page 16

1 - General Information

Agilent E4371A

Powerbus Load

46 kW

Power Source

(24 V @

1920A)

Agilent E4370A

+4 E4375A cards

(256 channels)

Agilent E4370A

+4 E4375A cards

(256 channels)

Agilent E4370A

+4 E4375A cards

(256 channels)

Agilent E4371A

Powerbus Load

Agilent E4371A

Powerbus Load

Agilent E4371A

Powerbus Load

Agilent E4370A

+4 E4375A cards

(256 channels)

POWERBUS

Agilent E4370A

+4 E4375A cards

(256 channels)

Agilent E4370A

+4 E4375A cards

(256 channels)

Agilent E4370A

+4 E4375A cards

(256 channels)

Agilent E4370A

+4 E4375A cards

(256 channels)

Figure 1-6. System Diagram Using Agilent E4375A Cards

Measurement Capability

The Agilent MCCD mainframe and charger/discharger cards have a high speed scanning system that

makes voltage and current measurements on all channels. Refer to Appendix A for technical data about

the measurement system. The following measurements are available:

Voltage Measurements

The Agilent MCCD measures the voltage of each channel using a calibrated internal measurement

circuit. In local sensing mode, the voltage measurement is made at the power connector. In remote

sensing mode, the voltage is measured at the end of the remote sense leads. The advantage of remote

16

Page 17

General Information - 1

sensing over local sensing is that when the remote sense leads are connected to the cell, the actual voltage

of the cell will be measured. Any voltage drops in the load leads will not affect the measurement. Refer

to chapter 2 under "Remote Sensing" for more information.

NOTE: If your Agilent MCCD system is configured for local sensing, the measured output

voltage may not reflect the actual voltage at the cell. This is because any voltage drops in

the wires due to wire resistance, probe resistance, connector resistance, etc. will reduce

the available voltage at the cell.

Current Measurements

The Agilent MCCD measures actual current in the output current path for each channel using a calibrated

internal measurement circuit.

Capacity Measurements

Amp-hour capacity - the Agilent MCCD determines amp-hour cell capacity by making calculations

based on continuous current measurements.

During charge, every time the Agilent MCCD makes a measurement, it calculates the actual incremental

amp-hours put into the cell during each measurement interval by multiplying the measured current times

the measurement interval. It then adds this incremental amount to the accumulated amp-hour value to

determine the total amp-hours delivered into the cell. Amp-hour capacity will be positive during charge.

Thus, accurate amp-hour capacity measurements can be made even when charge current is not constant,

such as during constant voltage charging.

During discharge, every time the Agilent MCCD makes a measurement, it calculates the actual

incremental amp-hours taken out of the cell by multiplying the measured current times the measurement

interval. It then adds this incremental amount to the accumulated amp-hour value to determine the total

amp-hours removed from the cell. Amp-hour capacity will be negative during discharge. Thus, accurate

amp-hour capacity measurements can be made even when discharge current is not constant.

Watt-hour capacity - the Agilent MCCD determines watt-hour cell capacity by making calculations

based on continuous current and voltage measurements.

During charge, every time the Agilent MCCD makes a measurement, it calculates the actual incremental

watt-hours put into the cell during each measurement interval by multiplying the measured current times

the measured voltage times the measurement interval. It then adds this incremental amount to the

accumulated watt-hour value to determine the total watt-hours delivered into the cell. Watt-hour capacity

will be positive during charge. Thus, accurate watt-hour capacity measurements can be made even when

charge current and voltage is varying.

During discharge, every time the Agilent MCCD makes a measurement, it calculates the actual

incremental watt-hours taken from the cell during each measurement interval by multiplying the

measured current times the measured voltage times the measurement interval. It then adds this

incremental amount to the accumulated watt-hour value to determine the total watt-hours taken from the

cell. Watt-hour capacity will be negative during discharge. Thus, accurate watt-hour capacity

measurements can be made even when discharge current and voltage is varying.

17

Page 18

1 - General Information

Cell Resistance

In addition to continuous voltage, current, and capacity measurements, the Agilent MCCD can also

measure ac and dc cell resistance. This measurement is available on command when a sequence is not

running, or as its own step in the forming sequence.

The Agilent MCCD measures the ac cell resistance by first disconnecting the charge/discharge circuits

from all cells. An ac waveform generator in the Agilent MCCD mainframe is connected sequentially to

each cell. The ac waveform generator momentarily passes a small excitation current through each cell

while the measurement system measures the cell’s output voltage and current. By using a narrow band

tuned filter and computing the magnitude and phase angle of voltage relative to current, an ac resistance

measurement of the cell can be made. This method is very similar to the method used by LCR meters.

Since this measurement happens sequentially for each channel, the other channels stay at rest during this

test.

The Agilent MCCD measures the dc cell resistance by first disconnecting the charge/discharge circuits

from all cells. A pulse generator in the Agilent MCCD mainframe is connected sequentially to each cell.

The pulse generator passes a short-duration pulsed current through each cell while the measurement

system digitizes the cell voltage and current using a high accuracy, high-speed A/D converter. Using

proprietary algorithms to calculate the change in voltage relative to the change in pulsed current, a dc (or

pulse) resistance measurement of the cell can be made. Since this measurement happens sequentially for

each channel, the other channels stay at rest during this test.

Probe Resistance

Probe resistance measurements can also be performed. The Agilent MCCD uses the remote sense to

measure the resistance of both the power and sense probes. Probe resistance measurements can be made

on command when a sequence is not running.

The measured probe resistance is the total resistance in the signal path, which includes wiring resistance,

probe resistance, and the resistance of any connectors in the signal path. For the sense probe

measurement, the resistance measurement includes the internal scanner resistance, which is typically

1000 ohms. The power and sense probe measurements return the actual measured value in ohms.

In addition to the on-command probe resistance measurements, the probes are continuously checked

while the sequence is running. See chapter 5 under “Probe Check” for more information about probe

check verification.

Data Logging

During a charge/discharge sequence, the Agilent MCCD is constantly making voltage, current, and

capacity measurements. Instead of logging each and every measurement into a data buffer, the data

logging can be controlled so that only critical measurements are logged to the data buffer. This is called

event-based data logging, which means that whenever an important event occurs, a data log record will

be written into the data buffer. Buffer memory is used most efficiently when only critical measurements

are stored.

18

Page 19

The following events can be used to trigger critical measurements:

General Information - 1

Change in voltage

(∆∆∆∆V)

Change in current

(∆∆∆∆I)

Change in time

(∆∆∆∆t)

The acceptable range of values for ∆V, ∆I and ∆t are 0 to infinity. Setting the value to 0 or near 0 will

cause all readings to be logged in the buffer, because every reading will exceed the ∆V, ∆I or ∆t value of

zero. This will fill up the measurement log very quickly. Setting the value to a high number or to infinity

will cause no readings to be logged in the buffer because no reading will exceed the ∆V, ∆I or ∆t value.

The comparison test to see if any of the ∆V, ∆I, and ∆t values have exceeded the values of the last logged

entry in the buffer is done at the end of each measurement interval. Therefore, the fastest rate at which

records can be written into the data buffer is the measurement rate of the Agilent MCCD. Any

combination of events can be specified, so that a data log record is written into the data buffer when any

of the events occur.

If the trigger is ∆∆∆∆V, a data log record will be written to the buffer when a user-

specified voltage change is exceeded. If ∆V is set to 100 mV, then each time the

voltage reading changes by more than 100 mV from the last logged entry, a

record is written to the buffer.

If the trigger is ∆∆∆∆I, a data log record will be written to the buffer when a user-

specified current change is exceeded. If ∆I is set to 100 mA, then each time the

current reading changes by more than 100 mA from the last logged entry, a

record is written to the buffer.

If the trigger is ∆∆∆∆t, a data log record will be written to the buffer when a user-

specified time interval is exceeded. If ∆t is set to 1 second, then every second a

record is written to the buffer. ∆t is effectively a clock-driven data log.

Each record in the data buffer contains the following information: status (including CV/CC and step

number), elapsed time, voltage, current, amp-hours, and watt-hours. The total number of readings that

can be stored is given in the specification table. The data log is a circular queue, which lets you

continuously log data into the data buffer. When the data buffer is full, the oldest data in the buffer will

be overwritten by new data. To avoid data loss, the controller must read the data from the buffer before it

is overwritten. Data can be read out of the data buffer at any time during the test sequence.

NOTE: Information in the data buffer is lost when an ac power failure occurs. To prevent data

loss in the event of a power failure, use the cfShutdown function to save the data in nonvolatile memory. Refer to Power Fail Operation in chapter 5 for more information. To

allow the Agilent E4370A to ride through temporary ac power interruptions, connect the

mainframe to a 600 VA uninterruptible power supply (UPS).

A measurement log utility is included in the software that is provided with the Agilent E4373A

Documentation package. You can use this utility to read the data log and place the information in a file

on your PC. See chapter 4 for information on how to use the Agilent MCCD Measurement Log Utility.

Protection Features

The Agilent MCCD provides extensive capability to protect both the hardware and the individual cells

being formed from catastrophic damage. The Agilent MCCD can also communicate its protection status

to other parts of the manufacturing system for more sophisticated forms of protection.

19

Page 20

1 - General Information

Internal Protection Functions

There are internal relays between the power bus and the Agilent E4374A/E4375A Charger/Discharger

cards. These relays protect the Agilent MCCD from overvoltage and undervoltage conditions on the

power bus. They also protect the Agilent MCCD if an external fault condition is detected. Output

regulators include several features to protect the cell from failures in the hardware. Internal circuits

connected in series with each channel protect the system from reverse cell polarity, cell failure, and

regulator failure. Internal thermal sensors check for maximum heat rise to avoid failures due to excessive

temperature excursions. A fan keeps the internal temperature at an acceptable level.

Finally, the Agilent MCCD has an extra level of safety - a built-in hardware watchdog timer. The

hardware watchdog timer is independent of CPU, software, or firmware activities. If, due to some

internal firmware or software fault, the CPU in the Agilent MCCD should stop functioning for more than

a few seconds, the hardware watchdog timer will reset the Agilent MCCD to the power-on state. In this

state, the channels outputs are disconnected from the cells.

NOTE: Overvoltage and overcurrent tests can be included as part of a test sequence to

implement overvoltage and overcurrent protection (see chapter 5).

External Digital I/O Protection Functions

The Digital I/O subsystem on the Agilent MCCD can be configured to provide protection capabilities.

These digital I/O signals operate independently, so that if there is a problem with the computer or the

LAN connection the protection functions of the Agilent MCCD are not compromised. As explained in

chapter 2, the 16 digital I/O signals can be individually configured to provide one of the following

protection functions:

External Fault Input

External Fault

Output

External Interlock

External Trigger

In addition to protection capabilities, the digital I/O can also be used as general purpose I/O. When

configured as a general purpose I/O, the input or output signals on the digital connector are directly

controlled with API programming commands over the LAN.

This function can be used to stop the cell forming sequence if an external

fault condition sets the input true.

This function can be used to signal external circuitry or another Agilent

MCCD that either an external fault condition or an internal fault condition

has occurred.

This function can be used to stop the cell forming sequence for reasons

other than an external fault condition.

This function can be used to start a cell forming sequence.

If AC Power Fails

Should the ac line fail, the CPU in the Agilent MCCD will shut down. Any charging and discharging

activity will stop, and the current sequence, test data, and programmed settings will be lost.

Note: A 600 VA uninterruptible power supply (UPS) can be used to provide ac power to the

Agilent E4370A MCCD mainframe to prevent any data loss during a power failure.

20

Page 21

General Information - 1

When power fails, the power bus is also disconnected from the Agilent MCCD because of the bias

powered relays inside the Agilent MCCD. Thus, should a power failure occur which causes the Agilent

MCCD to lose ac power, in order to provide for safety, these internal relays would be disengaged and any

further charging or discharging would stop, even if the power bus were still powered and active.

Also, should a power failure occur which does not effect the Agilent MCCD but which causes the power

bus to drop in voltage, this will be detected by the Agilent MCCD as a power bus undervoltage condition

and the relays will open, thus preventing any further charging or discharging of connected cells.

Remote Programming Interface

The remote programming interface to the Agilent MCCD is through a LAN-based TCP/IP

communication protocol. The connection to the LAN is through a standard 8-pin 10Base-T connector on

the rear panel, which must first be configured according to the directions in chapter 3. The LAN

communication protocol is implemented in two ways:

Application Programming Interface (API)

The application programming interface runs under Windows 95 or Windows NT 4.0 using supplied Clanguage function calls. These function calls are documented in chapters 5 and 6, and provide the most

comprehensive method of controlling the Agilent MCCD. The API interface is the preferred method of

control when the Agilent MCCD is connected to a remote computer as part of an automated

manufacturing process.

Web Accessible Agilent MCCD User Interface

The Agilent MCCD has a built-in web server with a graphical user interface that is accessed through

standard web browsers such as Netscape Navigator version 3.03 and up or Microsoft Internet Explorer

version 3.02 and up. This Agilent MCCD User Interface allows monitoring of individual cell state,

measuring cell voltages and currents while the test is running, and also complete monitoring and control

of test status. The Agilent MCCD User Interface is the preferred method of control when evaluating the

test system, prototyping a process, or debugging a program.

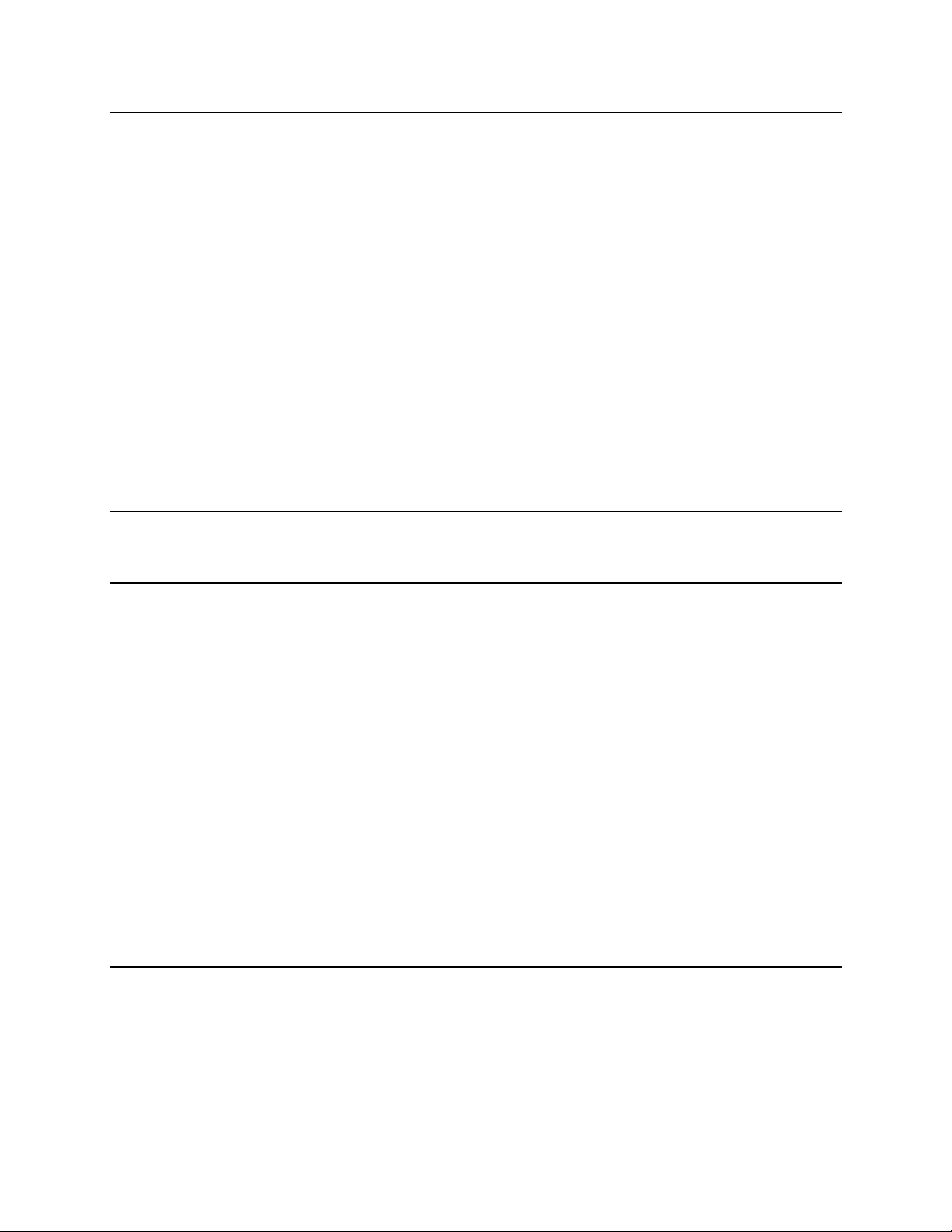

Example of a Cell Forming Process

The Agilent E4370A MCCD is designed to be the integral part of a complete cell forming process as

shown in Figure 1-7. As shown in the figure, many of the previously mentioned protection and external

signal capabilities of the Agilent E4370A MCCD are implemented using the digital I/O connections. The

serial ports on the back of the Agilent MCCD are used to control local peripherals directly from the host

computer. The remote programming interface to the Agilent MCCD lets you seamlessly integrate all of

these capabilities into the cell forming process.

The following cell forming example describes how an Agilent E4370A MCCD may be used to run a

semi-automated process where the only human actions required are: entering data with a barcode

scanner, loading and unloading a test fixture, and manually starting the cell forming process. Chapters 5

and 6 describe all of the function calls that are available to implement a cell forming process.

21

Page 22

1 - General Information

Control PC

Fixture

LAN

Ready

Tray of cells

Dig I/O for fire/smoke detector

Dig I/O for fixture

open/close

Dig I/O for

buttons and

indicators

Test Start

Bar Code Scanner

H

Power + Sense lines

communications

Powerbus

MCCD

Serial

Figure 1-7. Typical Cell Forming Station

The control PC sends a signal via the LAN to the digital I/O to turn on the Ready light on the test

♦

fixture. This tells the operator that the system is ready for another tray of cells. The control PC also

begins polling for serial data on the RS-232 buffer of the Agilent MCCD.

♦ The operator scans the bar code on the tray of cells sitting on the conveyor belt. The operator then

loads the tray into the test fixture and closes the fixture.

♦ After detecting that data is available on the RS-232 buffer, the control PC reads the bar code data.

Based on the data, it downloads the correct forming sequence into the Agilent MCCD. It also

downloads setup information such as which channel outputs to enable, probe check settings, trigger

source, etc.

♦ The control PC then polls the digital I/O lines for the Start button.

♦ When the operator presses Start, the control PC detects it and polls the digital I/O lines to make sure

the fixture is closed. It sends a signal to turn off the Ready light and turn on the Test light, indicating

to the operator that the cell forming sequence has started.

♦ The control PC then sends a trigger to the Agilent MCCD to start the forming sequence. It also starts

polling the instrument status for the completion of the test sequence.

♦ The cell forming sequence runs. The test sequence automatically applies a stimulus to the cells,

monitors cell parameters to determine if a cell passes or fails, and stores the test results. During the

test sequence, the Agilent MCCD monitors the dedicated digital I/O lines that are connected to the

fire and smoke detectors. This allows rapid response in case of a problem.

♦ When the instrument status in the Agilent MCCD shows that the sequence is complete, the control

PC sends commands to the Agilent MCCD to measure the internal resistance of all cells and then

upload all measurement data.

♦ Finally, the control PC sends a signal to turn off the Test light and light the Ready light. The

operator knows that it is now safe to remove the tray from the fixture and start another batch.

Chapter 7 contains several programming examples written in C. The purpose of these examples is to

show you how to implement the various functions of the Agilent MCCD so that you can develop your

own application programs. Program #2 matches the example described here.

22

Page 23

2

Installation

Inspection

When you receive your equipment, inspect it for any obvious damage that may have occurred during

shipment. If there is damage, notify the shipping carrier and the nearest Agilent Sales and Support Office

immediately. The list of Agilent Technologies Sales and Support Offices is at the back of this guide.

Warranty information is printed in the front of this guide.

Until you have checked out the Agilent MCCD, save the shipping carton and packing materials in case

the unit has to be returned. If you return the Agilent MCCD for service, attach a tag identifying the model

number, serial number, and the owner. Also include a brief description of the problem.

Parts and Accessories

Table 2-1 lists items that are included with your Agilent MCCD System.

Table 2-2 lists accessory items that are not included with the Agilent MCCD System, but must be

purchased separately. Except for the User’s Guide, all of these items are required to make connections

from the Agilent MCCD to either the computer, test fixture, or external devices that will be controlled by

the Agilent MCCD.

You can either order these items by ordering the appropriate kit, or order them directly from the

manufacturer. Table 2-3 lists the addresses of the manufacturers of the connector parts.

Table 2-1. Supplied Items

Item Part Number Description

Power Cord (1) Contact your

Agilent Sales and

Support office

Table 2-2. Accessories

Item Manufacturer’s

Part Number

Digital connectors (2) Phoenix

MSTB-2.5/10-STF

Calibration connector (1)

Auxiliary bias connector (1)

Phoenix

MSTB-2.5/4-ST

A power cord appropriate for your location.

Description

10-pin terminal plugs that connect to the digital

connectors on the back of the unit.

4-pin terminal plugs that connect to the

calibration and auxiliary connectors on the back

of the unit.

23

Page 24

2 - Installation

Table 2-2. Accessories (continued)

Item Manufacturer’s Part

Description

Number

Documentation Package Agilent E4373A Contains user documentation, software

drivers, and utility programs .

Serial cable Agilent 34398A RS-232 null-modem cable for port A or B.

(see figure 2-4 for schematic)

37-pin

D-sub connector

AMP 205210-2 Mating connector for front panel channel

connectors. Eight connectors are required

for each 64-channel card.

(Connector pins on 64-channel cards are

rated at 5 A maximum.)

Connector hood for 37pin connector

AMP 749916-2 Eight connector hoods are required for each

64-channel card.

Crimp style contacts for

37-pin connector

AMP 66506-9 Crimp contact for 37 pin connector

16 contacts are required for each connector.

(Pins only accept wires sized 20-24 AWG.)

Crimp tool for crimp

AMP 58448-2 Hand crimp tool

style contacts

Solder style contacts for

37-pin connector

AMP 66570-2 Crimp contact for 37 pin connector

16 contacts are required for each connector.

No tooling is required.

(Pins only accept wires sized 18 AWG.)

Front Panel Filler Panel Agilent p/n 5002-1505 One blank filler panel is required for every

empty slot in Agilent MCCD mainframes.

Rack mount Flange Kit Agilent p/n 5062-3979 Includes 2 flanges, fasteners, and mounting

screws

Rack mount Flange Kit

with Handles

Agilent p/n 5062-3985 Includes 2 handles, 2 flanges, fasteners, and

mounting screws

Table 2-3. Manufacturer's Addresses

Company Address Contact

Phoenix Contact P.O. Box 4100

Harrisburg, PA 17111-0100

Phone:717-944-1300

Fax: 717-944-1625

http://www.phoenixcontact.com/index.html

AMP Harrisburg, PA 17111 http://www.amp.com/

Agilent Technologies See list at back of this manual http://www.agilent.com/

24

Page 25

Installation - 2

Location

Agilent E4370A MCCD Mainframe

The outline diagrams in Appendix C give the dimensions of your Agilent MCCD mainframe. The

mainframe may be installed free-standing, but must be located with sufficient space at the sides and back

of the unit for adequate air circulation. You can rack mount the mainframe in standard 600 mm (23.8 in.)

width system cabinets. This provides sufficient clearance for airflow. Support rails are also required

when rack mounting the mainframe. These are usually ordered along with the cabinet.

A fan cools the Agilent MCCD mainframe by drawing air in on the left side of the unit and discharging it

through the back and side. Minimum clearance is 9 cm (3.5 inches) along the sides. Minimum clearance

behind the mainframe is 23 cm (9 inches). Do not block the fan exhaust at the rear or the side.

NOTE: To ensure proper cooling of the Agilent MCCD mainframe, there should be no open slots

in the front of the mainframe. If an Agilent 64-Channel Charger/Discharger Card is

either not installed or has been removed from a slot, a blank filler panel must be installed

in the opening. Refer to Table 2-2.

Agilent E4371A Powerbus Load

CAUTION: To ensure adequate airflow to cool the Agilent Powerbus Load requires you to leave 0.6

meters (2 feet) of open space in front of the load and directly behind the load. If you are

rack-mounting the load, leave the rack door off.

When discharging its maximum rated power, the Agilent E4371A Powerbus Load

becomes hot to the touch.

The outline diagrams in Appendix C give the dimensions of your Agilent Powerbus Load. The unit may

be installed free-standing, but must be located with sufficient space at the front and back of the unit for

adequate air circulation. Fans cool the unit by drawing air in on front and discharging it through the back.

Maximum airflow is 10 cubic meters per minute (350 cubic feet per minute).

You can rack mount the Agilent E4371A Powerbus Load in standard 600 mm (23.8 in.) width system

cabinets, provided that you remove the rear door. This provides sufficient clearance for airflow. Rack

mount kits are described in Table 2-2. Support rails are required when rack mounting the unit. To meet

safety requirements, connect the ground terminal of the Agilent Powerbus load to the ground terminal of

the external dc source.

Channel Connections

Each Agilent E4370A MCCD mainframe can control up to 256 individual charge/discharge cells when

four Agilent 64-Channel Charger/Discharger cards are installed. Each charger/discharger card contains

64 channels. Note that in the programming sections of this manual, channels are also referred to as

outputs. When fully loaded, the 256 charge/discharge channels are configured as follows:

25

Page 26

2 - Installation

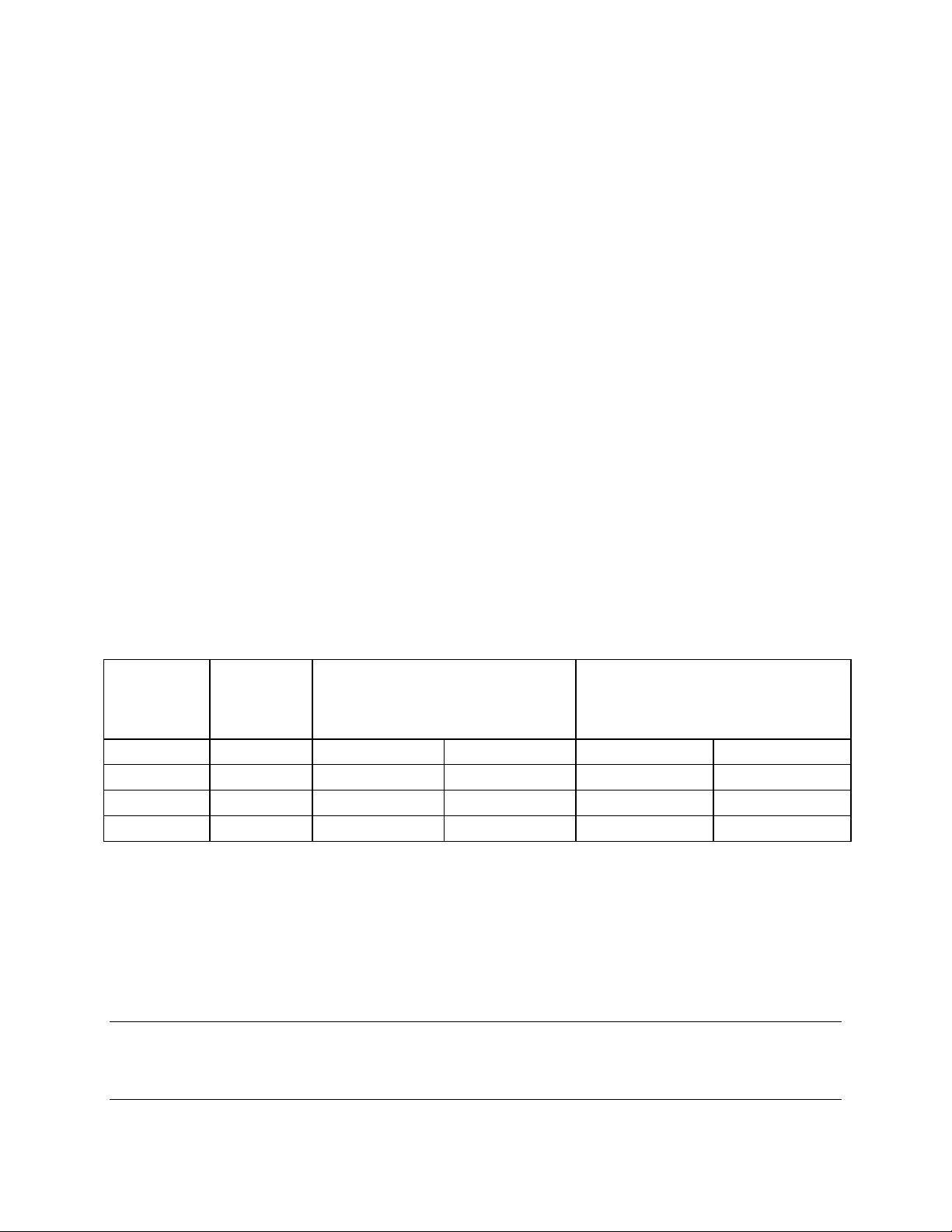

Table 2-4. Channel Configuration

Card Connector Number

Number 1234567 8

1

2

3

4

1 - 8 9 - 16 17 - 24 25 - 32 33 - 40 41 - 48 49 - 56 57 - 64

65 - 72 73 - 80 81 - 88 89 - 96 97 - 104 105 - 112 113 - 120 121 - 128

129 - 136 137 - 144 145 - 152 153 - 160 161 - 168 169 - 176 177 - 184 185 - 192

193 - 200 201 - 208 209 - 216 217 - 224 225- 232 233 - 240 241 - 248 249 - 256

Power connections on each Agilent 64-Channel Charger/Discharger Card are through eight 37 pin Dsubminiature connectors. These connectors allow for shielding and strain relief. Corresponding sense

connections are also available on the connectors. Refer to Table 2-2 for information about ordering the

mating connectors. As indicated in the table, mating connectors accept wire sizes from AWG 24 up to

AWG 18, depending on the type of connector that you are using. You must wire up the mating connector

to make your wire connections. Install the mating connector on the front of the charger/discharger card

when complete. Refer to Appendix D for detailed pinout assignments of the front panel connectors.

If specific channels are not being used, you can configure them to be inactive. Inactive channels are

open-circuited. Note that there are two ways to configure the channel outputs, each having different

effects when the unit is powered on.

♦ If you configure the channel outputs using the cfSetOutputConfig() function (see chapter 6), the

settings are NOT saved in non-volatile memory. Each time you power up the unit, you must

reprogram the settings.

♦ If you configure the channel outputs using the Sequence setup page in the Agilent MCCD User

interface (see chapter 4), the settings ARE saved in non-volatile memory. The unit will wake up with

those settings when it is powered up.

NOTE: If the mainframe has empty card slots, the channels that are normally reserved for those

card slots will be treated as inactive channels.

Voltage Drops and Wire Resistance

Agilent E4374A Charger/Discharger Cards have a maximum of 5.5V and 2A available at the power

connector of each channel. Agilent E4375A Charger/Discharger Cards have a maximum of 6V and 3A

available at the power connector of each channel.

This means that at the rated output of 5V, the Agilent E4374A cards will tolerate up to a 0.5 volt drop,

and the Agilent E4375A cards will tolerate up to a 1.0 volt drop in the load leads due to wire resistance,

probe resistance, connector resistance, etc. Higher voltage drops will reduce the available voltage at the

cell. Proper wiring design including using larger gauge wires and low-resistance fixture contacts can

minimize voltage losses in the wiring and maximize the available voltage for charging the cells.

The length of the leads from the power connector to the cells is determined by how much voltage drop

your system can tolerate. The voltage drop is directly determined by the wire, connector, and probe

resistance (see table 2-5). Refer to Remote Sense Connections for more information.

To optimize performance and minimize the possibility of output instability and output noise, please

observe the following guidelines:

26

Page 27

Installation - 2

♦ It is good engineering practice to either twist or shield the sense and power wires.

♦ Twist the power wires together and keep them as short as possible.

♦ Twist the sense wires together but do not twist them together with the power wires.

♦ If possible, shield the sense wires. Connect the shield to the case.

♦ Keep the total cable length as short as possible.

♦ Use low resistance fixture contacts.

Remote Sense Connections

The sense connections provide remote sense capability at the fixture. Sense connections on each card are

through the same connectors that house the power connections.

Remote sensing allows the output voltages to be sensed at the cell, thus compensating for any losses in

the wiring. On the Agilent E4374A cards, the compliance voltage (the voltage that the Agilent MCCD

can provide in excess of the programmable rating) can be up to 5.5 volts to compensate for any voltage

drop caused by resistance in the wiring between the channel output and the cell connections. On the

Agilent E4375A cards, the compliance voltage can be up to 6.0 volts.

The following table gives the resistance values of various wire sizes so that you can calculate the voltage

drops for various wire lengths and diameters. Larger and shorter wires result in lower voltage drops. The

table also gives an example of the maximum allowable wire lengths that can be used when taking the

compliance voltage capability of the charger/discharger cards into consideration. The voltage drop used

in the example is based on a minimum of 4.1 volts available to charge a typical lithium ion cell.

Table 2-5. Resistance of Stranded Copper Conductors

AWG No. mm

18 0.825 0.022 0.0066 31 28

20 0.519 0.034 0.0105 20 18

22 0.324 0.055 0.0169 12 11

24 0.205 0.087 0.0267 8 7

2

Resistance (at 20 deg. C)

ΩΩΩΩ/m ΩΩΩΩ/ft

Maximum length in meters

(total length of + and - leads)

to limit voltage drop to:

1.4 V @ 2A 1.9 V @ 3A

As an example, assume that you are using AWG #24 wire for your power connections and your charging

voltage is 4.1 volts at 2 amperes. Using this diameter wire and assuming a maximum current of 2

amperes, the maximum distance from the power connector to the cell is limited to about 4 meters. This is

because with a total wire length of 8 meters for both the + and − power leads, the maximum voltage drop

in the wiring is 1.4 volts (2A X 0.7

Ω). With a charging voltage of 4.1 volts required at the cell, this is the

maximum voltage drop that an Agilent E4374A card can tolerate. Note that the Agilent E4375A card can

tolerate up to a 1.9 volt drop in the load wiring.

NOTE: This example does not account for any additional lead path resistance that may be

present such as fixture contact resistance, or fixture relays. If additional resistance is

present, lead length must be reduced yet further.

27

Page 28

2 - Installation

Power Bus Connections

CAUTION: Observe polarity when making the power bus connections to both the Agilent MCCD

mainframe and the Agilent Powerbus Load. Reversed polarity connections will result in

damage to both the Agilent MCCD mainframe and the Agilent Powerbus load. The

negative (−−−−) bus bar on the Agilent MCCD mainframe is connected to chassis

ground.

Connections to the power bus are made via + and − bus bars on the back of the Agilent E4370A MCCD

mainframe and Agilent E4371A Powerbus Load units. These bus bars let you interconnect multiple

mainframes, external power sources, and other loads. Bus bars have mounting holes that accept 7 mm

diameter bolts.

NOTE: Fasten a suitable terminal lug to each power bus cable. Do not connect bare wires

directly to the bus bars. Stranded cables with more and smaller diameter wires are easier

to work with than cables with fewer and large diameter wires.

When making your power connections you can use discrete terminated wires, bus bars, or combinations

of both. For proper operation all power bus configurations should have minimum loop area for low

magnetic radiation and should be kept away from CRTs. The following guidelines may be helpful in

deciding whether to use wires or bus bars.

Discrete terminated wires:

♦ Are the better solution for connecting individual units to each other in small systems and to bus bars

in large systems.

♦ Have minimal alignment, insulation or routing problems.

♦ Are preferred for small cell charging systems.

Bus bars:

♦ Are the better solution for high current carrying requirements.

♦ Can be custom designed or purchased; can use standard high current building parts.

♦ Use nuts and bolts or self tapped holes for connections.

♦ Require careful surface preparation and cleaning at connection points.

WARNING ENERGY HAZARD. If high current power bus connections touch, severe arcing

may occur - resulting in burns, ignition, or welding of parts. Do not attempt to

make any connections to the power bus when the power bus is live.

Power Bus Wiring Information

The following table provides information about the resistance and ampacity of several standard wire

sizes that may be suitable for power bus connections. This information is important because the

resistance of the power bus wiring will cause a voltage drop in the power bus wires. If the voltage drop is

large enough, it may prevent the Agilent E4370A MCCD mainframe from operating correctly in charging

mode, or the Agilent E4371A Powerbus Load from operating correctly in discharging mode.

28

Page 29

Installation - 2

Table 2-6. Ampacity and Resistance of Stranded Copper Conductors

AWG No. Area

in mm

10

8

6

4

2

1/0

2/0

3/0

4/0

5.26

8.36

13.3

21.1

33.6

53.5

67.4

85.0

107

Ampacity Resistance

2

40

60

80

105

140

195

225

260

300

in ΩΩΩΩ/meter

0.00327

0.00206

0.00129

0.00081

0.00051

0.00032

0.00025

0.00020

0.00016

Resistance

in ΩΩΩΩ/feet

0.00099

0.00062

0.00039

0.00025

0.000156

0.000098

0.000078

0.000062

0.000049

Notes

1. Wire ampacities are based on

30° C ambient temperature with

conductor rated at 60° C.

2. Resistance is nominal at 20° C

wire temperature.

Power Bus Configuration Examples

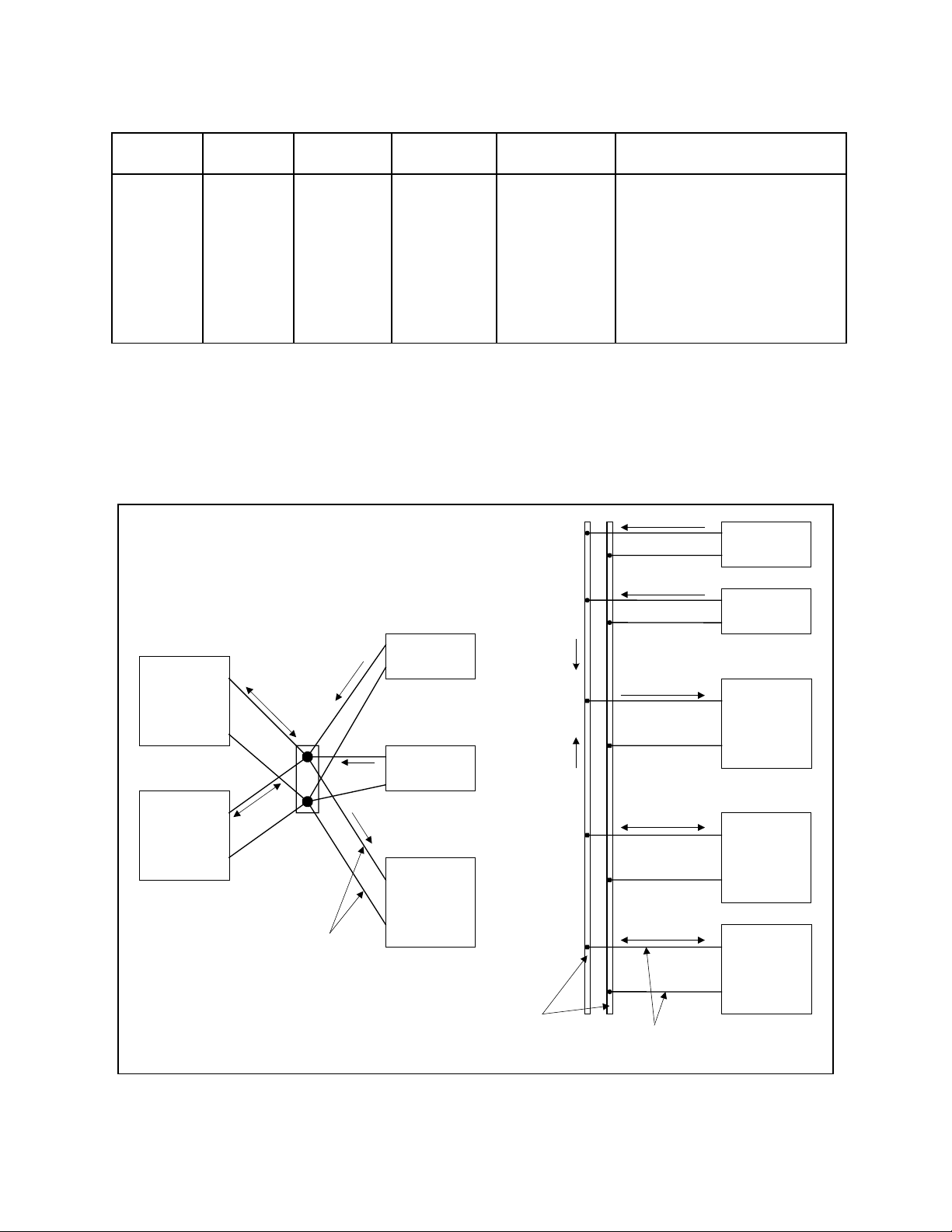

Figures 2-1 and 2-2 illustrate two typical power bus configurations consisting of two Agilent E4370A

MCCD mainframes connected to one Agilent E4371A Powerbus Load and two external dc power

supplies. As shown in the figures, current requirements may vary widely based on the way the equipment

is connected to the power bus.

+ -

Charging values based on:

Power/channel = 11W

Efficiency = 80%

Power bus voltage = 24V

E

A

t

e

g

l

n

i

+4 E4374A cards

(256 channels)

A

g

e

l

i

n

E

t

+4 E4374A cards

(256 channels)

+

4

0

3

A

7

4

0

3

7

_

+

A

_

146A/70

7

/

A

6

4

1

Flexible Wires

charging = 146A

Discharging values based on:

Power/channel = 9W

Efficiency = 80%

Power bus voltage = 26.5V

maximum

charging

+

P

o

w

S

e

o

r

e

u

c

r

6

1

V

2

(

4

_

A

6

4

1

A

+

P

o

+

146A

_

A

0

T

e

n

i

m

a

r

l

B

o

l

k

c

(24 V @ 146 A)

_

1

4

0

A

+

A

g

Powerbus Load

_

w

e

l

i

A

@

)

4

r

S

e

o

u

e

c

r

E

4

n

t

7

1

3

A

current = 292A

maximum

discharging

current = 140A

charging = 146A

discharging = 140A

charging = 146A

discharging = 70A

charging = 146A

discharging = 70A

+

o

P

r

e

S

o

w

1

(

4

@

V

2

_

+

P

o

w

S

o

e

r

(24 V @ 146 A)

_

+

E

n

A

t

e

g

l

i

Powerbus Load

_

+

A

e

g

l

n

i

E

t

+4 E4374A cards

(256 channels)

_

+

A

E

e

g

l

n

i

t

+4 E4374A cards

(256 channels)

_

r

u

c

e

4

6

A

)

e

u

c

r

3

7

4

1

A

4

3

A

7

0

4

3

A

7

0

STAR CONFIGURATION

Rigid Bars

BUS BAR CONFIGURATION

Flexible Wires

Figure 2-1. Typical Power Bus Configuration for Agilent E4374A cards

29

Page 30

2 - Installation

Charging values based on:

Power/channel = 18W

Efficiency = 80%

Power bus voltage = 24V

E

t

n

l

e

i

g

A

+4 E4375A cards

(256 channels)

E

t

n

l

e

i

g

A

+4 E4375A cards

(256 channels)

+

A

0

7

3

4

2

40A/98A

_

+

+

A

0

7

3

4

4

2

_

STAR CONFIGURATION

_

A

8

9

/

A

0

m

r

i

n

e

T

l

o

B

k

c

Flexible Wires

Discharging values based on:

Power/channel = 13.5W

Efficiency = 75%

Power bus voltage = 26.5V

+

e

P

w

o

2

(

_

A

0

6

1

+

o

P

2

(

_

A

0

6

1

+

P

(24 V @ 160 A)

_

1

9

6

A

+

g

A

Powerbus Load

_

o

160A

l

a

c

r

u

o

S

r

0

6

1

@

V

4

w

r

u

o

S

r

e

c

0

6

1

@

V

4

w

r

u

o

S

r

e

c

t

n

l

e

i

7

3

4

E

e

e

e

1

A

A

A

)

)

maximum

charging

current = 480A

maximum

discharging

current = 196A

Rigid Bars

+ -

charging = 160A

charging = 160A

charging = 160A

discharging = 196A

charging = 240A

discharging = 98A

charging = 240A

discharging = 98A

Flexible Wires

+

_

+

_

+

_

+

_

+

+4 E4375A cards

_

+

+4 E4375A cards

_

BUS BAR CONFIGURATION

o

P

w

S

r

e

o

c

r

u

V

4

@

2

(

1

0

6

P

w

e

o

2

(

P

o

(24 V @ 160 A)

g

A

Powerbus Load

g

A

(256 channels)

g

A

(256 channels)

c

r

S

u

o

r

0

6

V

1

4

@

S

w

r

e

c

r

u

o

4

E

t

n

e

l

i

7

3

E

t

n

l

e

i

7

3

4

7

3

4

E

t

n

l

e

i

e

)

A

e

A

)

e

A

1

A

0

A

0

Figure 2-2. Typical Power Bus Configuration for Agilent E4375A cards

The star configuration on the left is designed so that each section of the power bus carries no more

current than the rating of the equipment that it is connected to. This configuration lets you use longer

lead lengths because the voltage drop in each lead is directly related to the amount of current flowing in

the lead. However, this configuration requires you to run separate leads from each Agilent MCCD

mainframe to the load as well as the power supply, thus increasing the total amount of wiring required.

The bus bar configuration on the right is designed to minimize the amount of wiring between the

equipment. However this requires larger diameter wires or bus bars. This is because the leads from the

power supplies as well as the leads to the load are required to carry the full charging and discharging

current for two Agilent E4370A MCCD mainframes. Larger currents result in larger voltage drops in the

wiring, which may prove unacceptable with long lead lengths.

Charging Mode Guidelines:

Power bus wires must be capable of handing the full charging current requirements of all Agilent

E4370A MCCD units connected to the power bus. In the example that follows, the calculations are for

worst case current requirements. Calculate the input current requirement of one fully loaded Agilent

E4370A MCCD as follows:

30

Page 31

Installation - 2

1. Multiply the power used by one cell times the number of cells in the Agilent MCCD. Divide the

result by the efficiency of the unit to determine the total input power required for that mainframe.

The efficiency of the unit in charging mode is assumed to be 80%, which is a worst-case value as far

as calculating the total power required by the mainframe.

#_of_cells × power_per_cell

0.8

2. Divide the input power requirements of the Agilent MCCD by the minimum voltage required at the

input terminals of the Agilent MCCD (22.8 volts). The result will be the maximum charging current

required by the Agilent MCCD. (Double this current if you are simultaneously charging two Agilent

MCCD mainframes as illustrated in Figures 2-1 and 2-2.)

Max_ power_in

Power_source_voltage

3. Determine the voltage drop that the maximum current will produce in the power bus leads using the

resistance values in Table 2-6.

4. Add this voltage drop to the minimum voltage required at the input terminals of the Agilent MCCD

to determine the output voltage setting of the dc power supply.

5. The voltage at the input terminals of the Agilent MCCD during charging mode must be between 25.2

and 22.8 volts. If the sum of the voltage drops in both the + and − power bus leads causes the voltage

at the mainframe power terminals to drop below 22.8 volts, the Agilent E4370A MCCD will shut

down due to an undervoltage condition. Use a larger size wire to reduce the voltage drop.

Discharging Mode Guidelines:

Power bus wires must also capable of handing the full discharging current requirements of all Agilent

E4370A MCCD units connected to the power bus. In the example that follows, the calculations are also

for worst case current requirements. Calculate the output current of one fully loaded Agilent E4370A

MCCD as follows:

= Max_powerbus_current

= Max_power_in

1. Multiply the power generated by one cell times the number of cells in the Agilent MCCD. Multiply

the result by the efficiency of the unit to determine the total output power produced by that

mainframe. The efficiency of the unit in discharging mode is approximately 80% with Agilent

E4374A cards and 75% with Agilent E4375A cards. This percentage represents the highest

efficiency possible for calculating the total power that is generated by the mainframe in discharge

mode.

(#_of_cells × power_per_cell) × Efficiency

2. Divide the power generated by the Agilent MCCD by the input voltage of the Agilent Powerbus

Load. At an input voltage of 26.5 volts, the result will be the maximum discharging current that will

be absorbed by the Agilent Powerbus Load. (Double this current if you are simultaneously

discharging two Agilent MCCD mainframes as illustrated in Figure 2-5.)

Max_ power_out

26.5

3. Determine the voltage drop that the maximum current will produce in the power bus leads using the

resistance values in Table 2-6.

4. The sum of the voltage drops in both the + and

voltage drop exceeds 1.5 volts in discharging mode, the Agilent MCCD will shut down due to an

overvoltage condition at the mainframe terminals. Use a larger size wire to reduce the voltage drop.

= Max_powerbus_current

= Max_power_out

−−−−

power bus leads cannot exceed 1.5V. If the

31

Page 32

2 - Installation

Digital Connections

Each Agilent E4370A MCCD mainframe has a 16-bit digital I/O port. Digital I/O configuration can be

done with the Agilent MCCD Configuration Screens as described in chapter 3 or with the Agilent MCCD

User Interface as described in chapter 4. All pins do not have to be configured the same. Some can be

used as isolated outputs while others are single ended I/O. The functions can also be mixed, some pins

can be general purpose I/O while others have a specific purpose. The polarity of a bit can also be

configured as either high true or low true. The following list documents the types of digital I/O

configurations: