Page 1

Operating Manual

Agilent Technologies

Electronic Load Mainframes

Models 6050A and 6051A

For instruments with Serial Numbers:

Agilent 6050A-2908A-00101 and Above

Agilent 6051A-2927A-00101 and Above

Agilent Part No. 5959-3368 Printed in USA: October, 1997

Microfiche Part No. 5959-3369 Reprinted April, 2000

Page 2

CERTIFICATION

Agilent Technologies certifies that this product met its published specifications at time of shipment from the factory. Agilent

Technologies further certifies that its calibration measurements are traceable to the United States National Bureau of

Standards, to the extent allowed by the Bureau’s calibration facility, and to the calibration facilities of other International

Standards Organization members.

WARRANTY

This Agilent Technologies hardware product is warranted against defects in material and workmanship for a period of three

years from date of delivery. Agilent Technologies software and firmware products, which are designated by Agilent

Technologies for use with a hardware product and when properly installed on that hardware product, are warranted not to

fail to execute their programming instructions due to defects in material and workmanship for a period of 90 days from date

of delivery. During the warranty period Agilent Technologies will, at its option, either repair or replace products which

prove to be defective. Agilent Technologies does not warrant that the operation of the software, firmware, or hardware shall

be uninterrupted or error free.

For warranty service, with the exception of warranty options, this product must be returned to a service facility designated

by Agilent Technologies Customer shall prepay shipping charges by (and shall pay all duty and taxes) for products returned

to Agilent Technologies for warranty service. Except for products returned to Customer from another country, Agilent

Technologies shall pay for return of products to Customer.

Warranty services outside the country of initial purchase are included in Agilent Technologies product price, only if

Customer pays Agilent Technologies international prices (defined as destination local currency price, or U.S. or Geneva

Export price).

If Agilent Technologies is unable, within a reasonable time to repair or replace any product to condition as warranted, the

Customer shall be entitled to a refund of the purchase price upon return of the product to Agilent Technologies

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by the Customer,

Customer-supplied software or interfacing, unauthorized modification or misuse, operation outside of the environmental

specifications for the product, or improper site preparation and maintenance. NO OTHER WARRANTY IS EXPRESSED

OR IMPLIED. AGILENT TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE THE CUSTOMER’S SOLE AND EXCLUSIVE REMEDIES. AGILENT

TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

ASSISTANCE

The above statements apply only to the standard product warranty. Warranty options, extended support contracts, product

maintenance agreements and customer assistance agreements are also available. Contact your nearest Agilent

Technologies Sales and Service office for further information on Agilent Technologies’ full line of Support Programs.

2

Page 3

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation, service, and repair of this

instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the instrument. Agilent Technologies assumes no liability for the

customer’s failure to comply with these requirements.

BEFORE APPLYING POWER.

Verify that the product is set to match the available line voltage and the correct fuse is installed.

GROUND THE INSTRUMENT.

This product is a Safety Class 1 instrument (provided with a protective earth terminal). To minimize shock hazard, the instrument chassis

and cabinet must be connected to an electrical ground. The instrument must be connected to the ac power supply mains through a threeconductor power cable, with the third wire firmly connected to an electrical ground (safety ground) at the power outlet. For instruments

designed to be hard-wired to the ac power lines (supply mains), connect the protective earth terminal to a protective conductor before any

other connection is made. Any interruption of the protective (grounding) conductor or disconnection of the protective earth terminal will

cause a potential shock hazard that could result in personal injury. If the instrument is to be energized via an external autotransformer for

voltage reduction, be certain that the autotransformer common terminal is connected to the neutral (earthed pole) of the ac power lines

(supply mains).

FUSES.

Only fuses with the required rated current, voltage, and specified type (normal blow, time delay, etc.) should be used. Do not use repaired

fuses or short circuited fuseholders. To do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be made by qualified

service personnel. Do not replace components with power cable connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power, discharge circuits and remove external voltage sources before

touching components.

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is present.

DO NOT EXCEED INPUT RATINGS.

This instrument may be equipped with a line filter to reduce electromagnetic interference and must be connected to a properly grounded

receptacle to minimize electric shock hazard. Operation at line voltages or frequencies in excess of those stated on the data plate may

cause leakage currents in excess of 5.0 mA peak.

SAFETY SYMBOLS.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized modification to the

instrument. Return the instrument to an Agilent Technologies Sales and Service Office for service and repair to ensure that safety features

are maintained.

Instruction manual symbol: the product will be marked with this symbol when it is necessary for the user to refer to the

instruction manual (refer to Table of Contents) .

Indicates hazardous voltages.

Indicate earth (ground) terminal.

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign until the

indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which, if not correctly

performed or adhered to, could result in damage to or destruction of part or all of the product. Do not proceed

beyond a CAUTION sign until the indicated conditions are fully understood and met.

Instruments which appear damaged or defective should be made inoperative and secured against unintended operation until they can be

repaired by qualified service personnel.

3

Page 4

SAFETY SUMMARY (continued)

GENERAL

Any LEDs used in this product are Class 1 LEDs as per IEC 825-l.

ENVIRONMENTAL CONDITIONS

This instruments is intended for indoor use in an installation category II, pollution degree 2 environment. It is designed to

operate at a maximum relative humidity of 95% and at altitudes of up to 2000 meters. Refer to the specifications tables for

the ac mains voltage requirements and ambient operating temperature range.

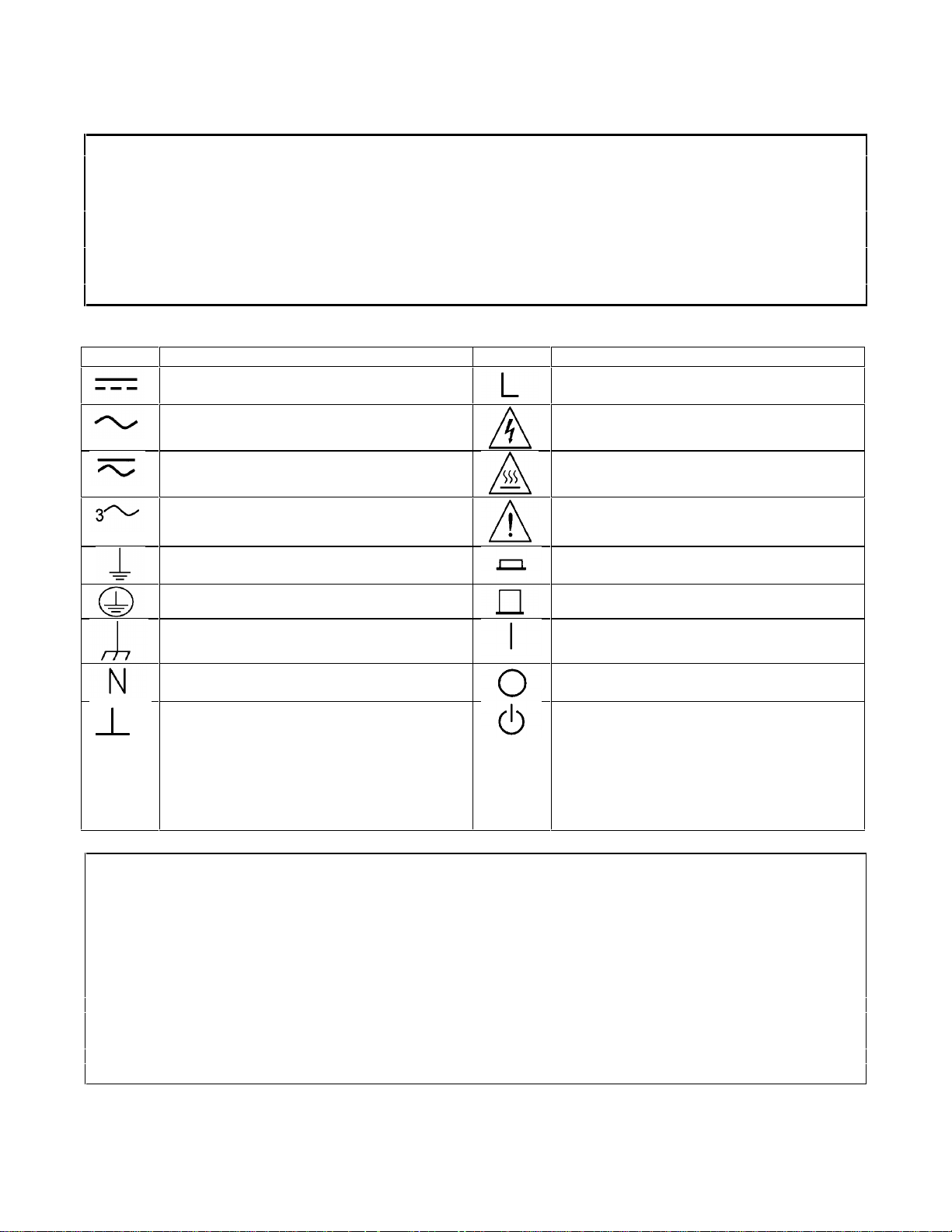

SAFETY SYMBOL DEFINITIONS

Symbol Description Symbol Description

Direct current Terminal for Line conductor on permanently

installed equipment

Alternating current Caution, risk of electric shock

Both direct and alternating current Caution, hot surface

Three-phase alternating current Caution (refer to accompanying documents)

Earth (ground) terminal In position of a bi-stable push control

Protective earth (ground) terminal Out position of a bi-stable push control

Frame or chassis terminal On (supply)

Terminal for Neutral conductor on permanently

installed equipment

Terminal is at earth potential(Used for

measurement and control circuits designed to

be operated with one terminal at earth

potential.)

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der Maschinenläminformationsverordnung vom 18

Januar 1991.

* Schalldruckpegel Lp <70 dB(A) * Am Arbeitsplatz * Normaler Betrieb * Nach EN 27779 (Typprufung).

Manufacturer’s Declaration

This statement is provided to comply with the requirements of the German Sound Emission Directive, from 18 January

1991.

Off (supply)

Standby (supply)

Units with this symbol are not completely

disconnected from ac mains when this switch is

off. To completely disconnect the unit from ac

mains, either disconnect the power cord or

have a qualified electrician install an external

switch.

* Sound Pressure Lp <70 dB(A) *At Operator Position * Normal Operation * According to EN 27779 (Type Test).

4

Page 5

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Agilent Technologies, Inc.

Manufacturer’s Address: New Jersey Division

150 Green Pond Road

Rockaway, NJ 07866 U.S.A.

declares that the product

Product Name: Load mainframe and modules

Model Number(s): Agilent 6050A, 6051A mainframes with modules

Agilent 60501A/B, 60502A/B, 60503A/B, 60504A/B, 60507A/B

conform(s) to the following Product Specifications:

Safety: IEC 348:1978 / HD401 S1:1981

1

EMC: CISPR 11:1990 / EN 55011:1991 Group 1, Class B

IEC 801-2:1991 / EN 50082-1:1992 4kV CD, 8 kV AD

IEC 801-3:1984 / EN 50082-1:1992 3 V/m

IEC 801-4:1988 / EN 50082-1:1992 0.5 kV Sig. Lines, 1 kV Power Lines

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC

Directive 89/336/EEC and carries the CE-marking accordingly.

Note 1: The product family was introduced prior to 12/93

--------------------------------------------------------

New Jersey, January 1997 Bruce Krueger / Quality Manager

European Contact: Your local Agilent Technologies Sales and Service Office or Agilent Technologies GmbH,

Department TRE, Herrenberger Strasse 130, D-71034 Boeblingen (FAX:+49-7031-14-3143)

Printing History

The current edition of this guide is indicated below. Reprints of this guide containing minor corrections and updates may

have the same printing date. New editions are identified by a new printing date and, in some cases, by a new part number.

A new edition incorporates all new or corrected material since the previous edition. Changes to the guide occurring

between editions are covered by change sheets shipped with the guide. Also, if the serial number prefix of your power

module is higher than those listed on the title page of this guide, then it may or may not include a change sheet. That is

because even though the higher serial prefix indicates a design change, that change may not affect the content of the guide.

Edition 3 May, 1993 Copyright 1993 Agilent Technologies, Inc.

..................... October, 1997

Update ......... April, 2000

This document contains proprietary information protected by copyright. All rights are reserved. No part of this document

may be photocopied, reproduced, or translated into another language without the prior consent of Agilent Technologies The

information contained in this document is subject to change without notice.

5

Page 6

If you are a first-time user, start with this manual, paying particular attention to Chapter 2. After installation (Chapter 3),

read Chapter 4 to learn front-panel operation. Programming users should then read Chapter 5 before going to the

Programming Reference Guide. Experienced programming users will probably refer only to the Programming Reference

Guide.

Agilent 6050A/6051A Operating Manual

Agilent Part No. 5959-3368

(this manual)

Specifications

System Overview

Installation Procedures

Front-Panel Operation Remote

Programming Introduction

Calibration Procedures

Module-Specific Pages

Agilent Models 60501A/B, 60502A/B, 60503A/B,

60504A/B, 60507B

Specifications

Programming Ranges

Factory Default Settings

Calibration Information

Agilent Technologies Electronic Load Family

Programming Reference Guide

Agilent Part No. 06060-90005

Introduction to HPSL

Introduction to Programming

Language Dictionary

Status Reporting

Agilent 6050A/605L4 Service Manual

Module Service Manuals

* Supplied with Agilent 6050A/6051A Electronic Load Mainframe.

** Supplied with individual load modules.

*** Available for purchase. Supplied with instrument if ordered as Option 910.

6

Page 7

Table of Contents

1. General Information

What’s in this Manual ................................................................................................................................11

Options.......................................................................................................................................................11

Safety Requirements...................................................................................................................................12

Specifications .............................................................................................................................................12

2. Operation Overview

Introduction................................................................................................................................................15

Front Panel Description..............................................................................................................................16

Remote Programming.................................................................................................................................16

Local/Remote Control................................................................................................................................16

Extended Power Operation.........................................................................................................................17

Programmable Features..............................................................................................................................17

Modes of Operation.................................................................................................................................17

Constant Current CC (Mode) ..................................................................................................................18

Ranges.....................................................................................................................................................18

Immediate Current Level.........................................................................................................................18

Triggered Current Level..........................................................................................................................18

Transient Current Level...........................................................................................................................19

Software Current Limit............................................................................................................................19

Slew Rate.................................................................................................................................................19

Constant Resistance (CR) Mode..............................................................................................................19

Ranges.....................................................................................................................................................20

Immediate Resistance Level....................................................................................................................20

Triggered Resistance Level.....................................................................................................................20

Transient Resistance Level......................................................................................................................20

Slew Rate.................................................................................................................................................20

Constant Voltage (CV) Mode..................................................................................................................20

Range.......................................................................................................................................................20

Immediate Voltage Level ........................................................................................................................21

Triggered Voltage Level .........................................................................................................................21

Transient Voltage Level ..........................................................................................................................21

Slew Rate.................................................................................................................................................21

Transient Operation.................................................................................................................................21

Continuous Transient Operation..............................................................................................................22

Pulsed Transient Operation .....................................................................................................................22

Toggled Transient Operation...................................................................................................................23

Triggered Operation ................................................................................................................................24

Slew Rate and Minimum Transition Time...............................................................................................25

Input Current, Voltage, and Power Measurement ...................................................................................26

Short On/Off............................................................................................................................................26

Input On/off.............................................................................................................................................27

Saving and Recalling Settings.................................................................................................................27

Reading Remote Programming Errors.....................................................................................................27

Status Reporting......................................................................................................................................28

Protection Features.....................................................................................................................................28

Resetting Latched Protection...................................................................................................................28

Overvoltage.............................................................................................................................................29

7

Page 8

Overcurrent..............................................................................................................................................29

Overpower...............................................................................................................................................29

Overtemperature......................................................................................................................................30

Reverse Voltage ......................................................................................................................................30

Control Connector......................................................................................................................................30

Remote Sensing.......................................................................................................................................30

Monitor Outputs......................................................................................................................................30

External Programming Input...................................................................................................................31

Fault.........................................................................................................................................................31

Port On/Off..............................................................................................................................................31

3. Installation

Introduction................................................................................................................................................33

Inspection...................................................................................................................................................33

Installing The Modules...............................................................................................................................33

Procedure ................................................................................................................................................34

Channel Number......................................................................................................................................35

Installing The Mainframes..........................................................................................................................35

Cooling....................................................................................................................................................36

Rack Mounting........................................................................................................................................36

Turn-On Checkout......................................................................................................................................36

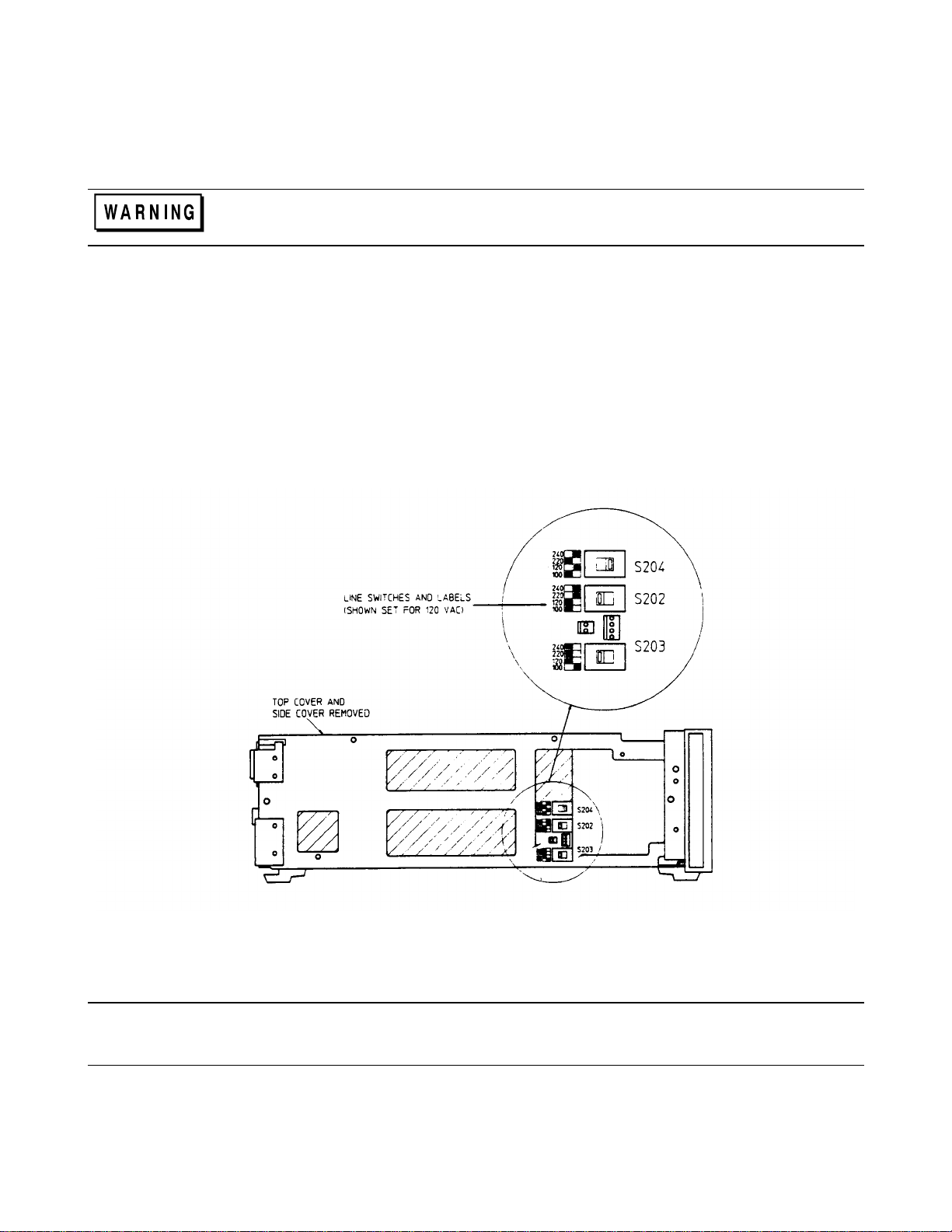

Changing Line Voltage............................................................................................................................37

Turn-On/Selftest......................................................................................................................................38

Power Test...............................................................................................................................................39

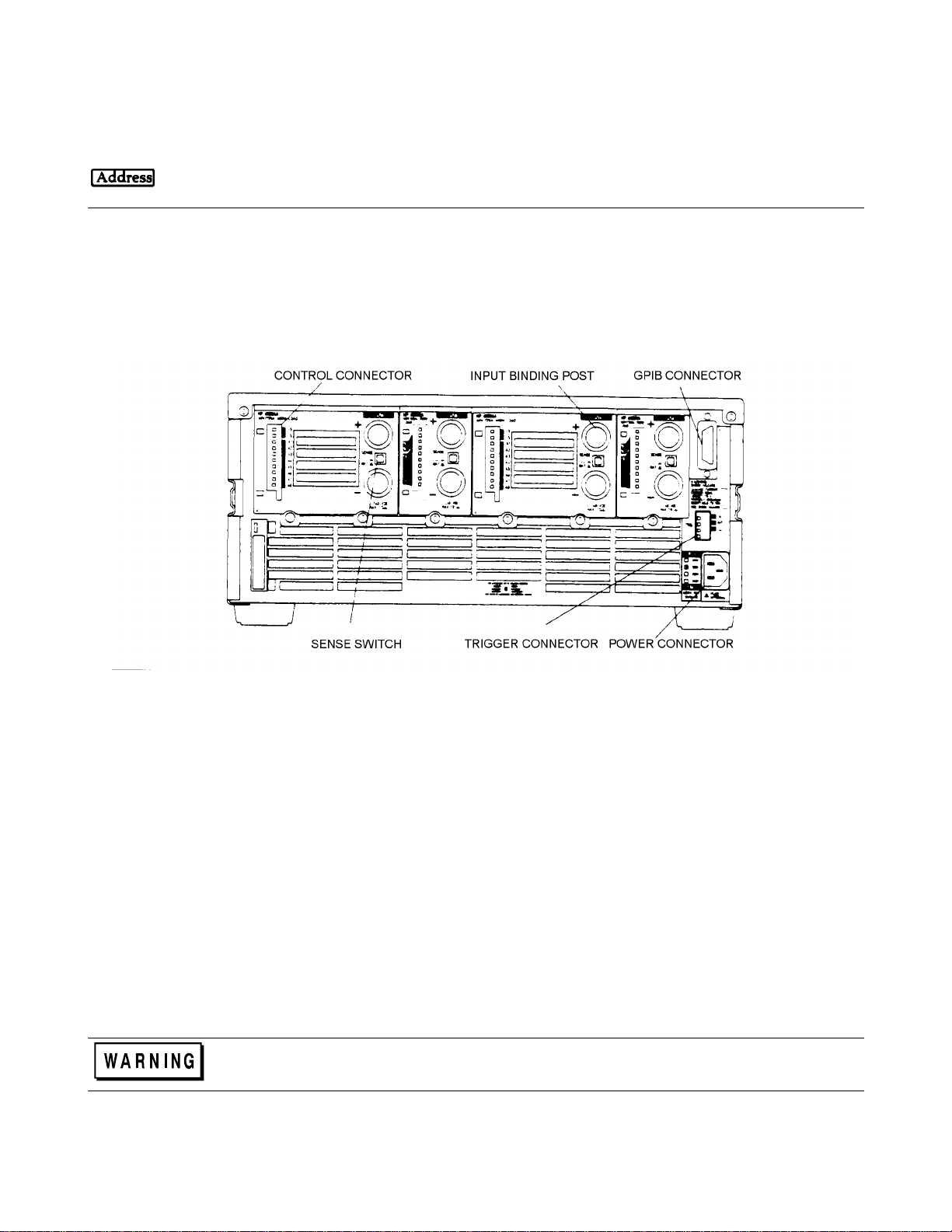

Controller Connection................................................................................................................................39

GPIB Address..........................................................................................................................................40

Rear Panel Connectors and Switches .........................................................................................................40

Input Binding Posts .................................................................................................................................40

Control Connector...................................................................................................................................41

Sense Switch............................................................................................................................................41

Trigger Connector ...................................................................................................................................43

Application Connections............................................................................................................................43

Wiring Considerations.............................................................................................................................43

Local Sense Connections.........................................................................................................................44

Remote Sense Connections .....................................................................................................................44

Parallel Connections................................................................................................................................44

Zero-Volt Loading Connections..............................................................................................................45

Table of Contents (continued)

4. Local Operation

Introduction................................................................................................................................................49

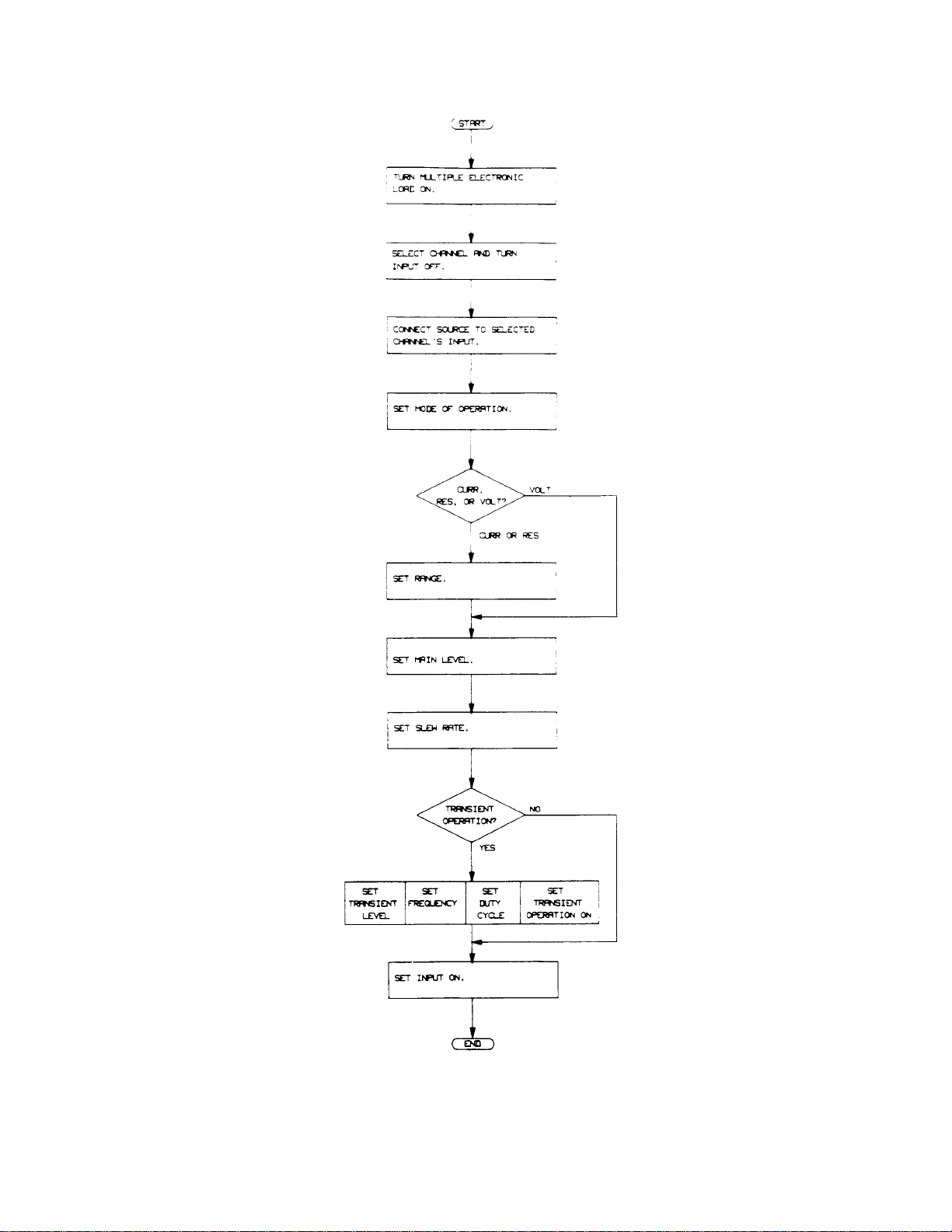

Local Control Overview.............................................................................................................................52

Using The CHAN Keys..............................................................................................................................53

Selecting the Channel..............................................................................................................................54

Identifying the Selected Channel.............................................................................................................54

Using The Function Keys...........................................................................................................................54

Turning the Input On/Off ........................................................................................................................54

Setting the Mode of Operation ................................................................................................................56

Setting CC Values ...................................................................................................................................56

Programming Ranges ..............................................................................................................................56

8

Page 9

Examples.................................................................................................................................................56

Setting CR Values ...................................................................................................................................57

Programming Ranges ..............................................................................................................................57

Examples............... .................................................................................................................................58

Setting CV Values...................................................................................................................................59

Programming Range................................................................................................................................59

Examples.................................................................................................................................................59

Transient Operation.................................................................................................................................60

Shorting the Input....................................................................................................................................61

Resetting Latched Protection...................................................................................................................61

Using The System Keys..............................................................................................................................62

Setting the GPIB Address........................................................................................................................62

Displaying Error Codes...........................................................................................................................62

Saving and Recalling Settings.................................................................................................................62

Changing "Wake-up" Settings.................................................................................................................63

Recalling the Factory Default Values......................................................................................................63

5. Remote Operation

Introduction................................................................................................................................................65

Enter/Output Statements.............................................................................................................................65

GPIB Address...............................................................................................................................................65

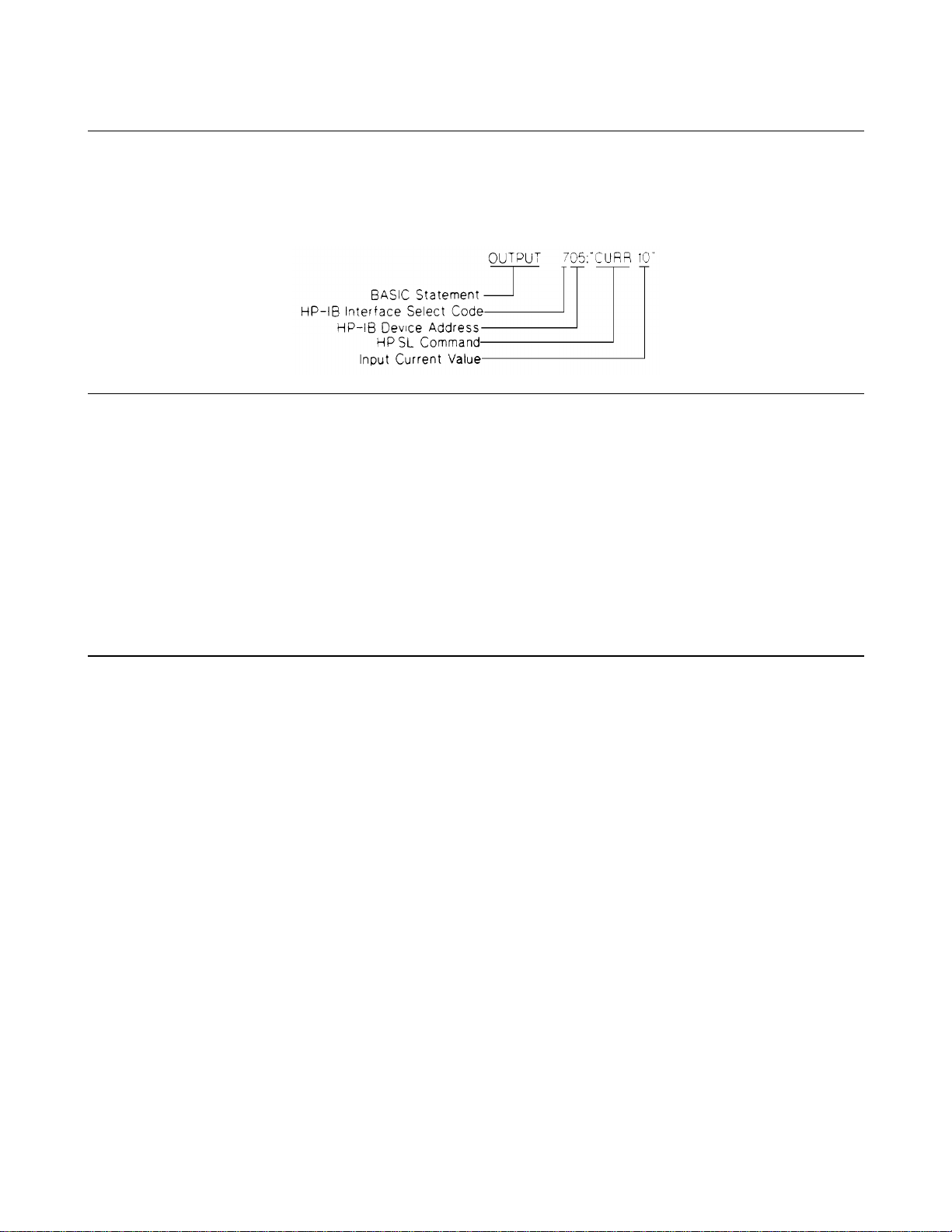

Sending A Remote Command....................................................................................................................66

Selecting A Channel...................................................................................................................................66

Getting Data Back......................................................................................................................................66

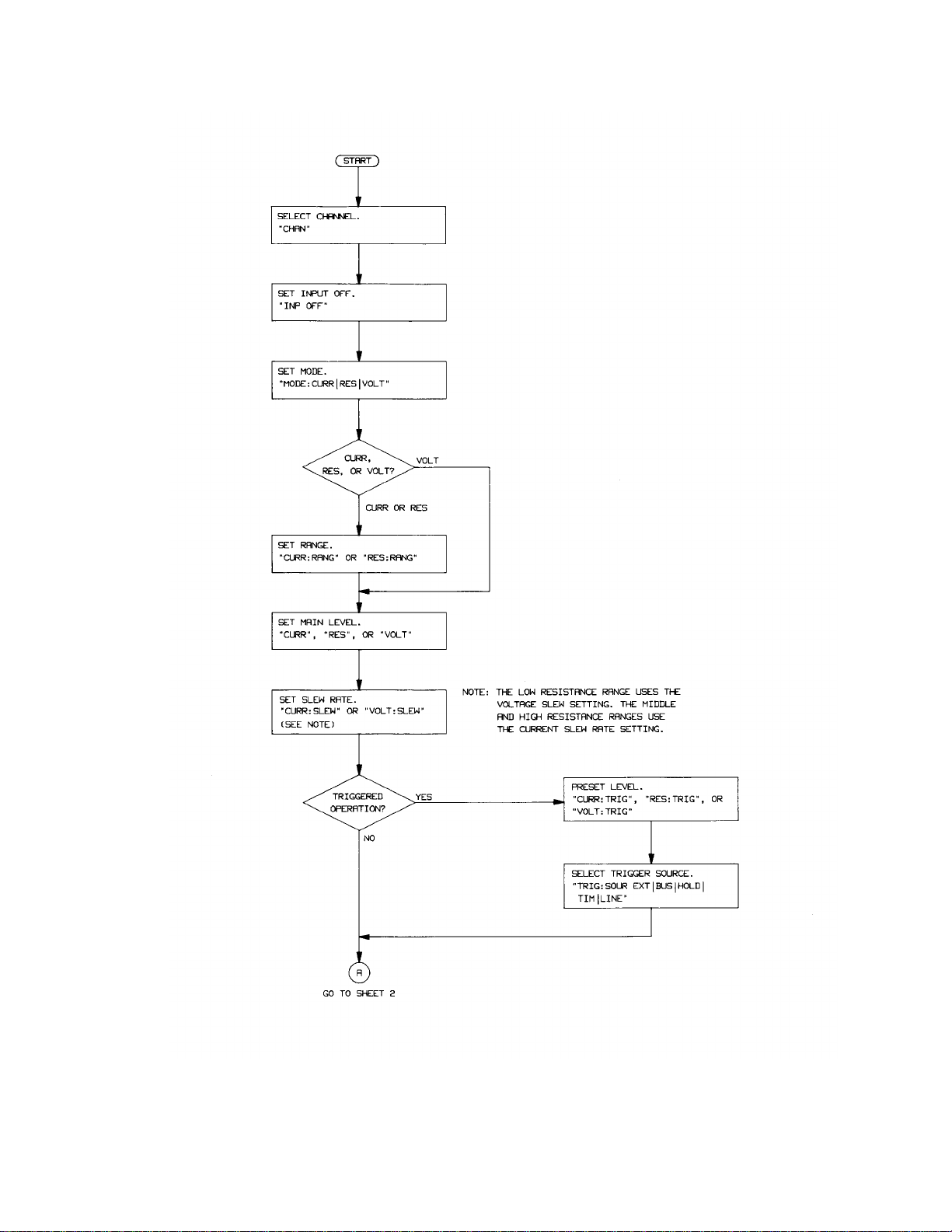

Remote Programming Commands..............................................................................................................67

CC Mode Example..................................................................................................................................68

CV Mode Example..................................................................................................................................68

CR Mode Example..................................................................................................................................71

Continuous Transient Operation Example...............................................................................................71

Pulsed Transient Operation Example ......................................................................................................72

Synchronous Toggled Transient Operation Example..............................................................................72

Table of Contents (continued)

6. Calibration

Introduction................................................................................................................................................75

Equipment Required...................................................................................................................................75

Calibration Commands...............................................................................................................................76

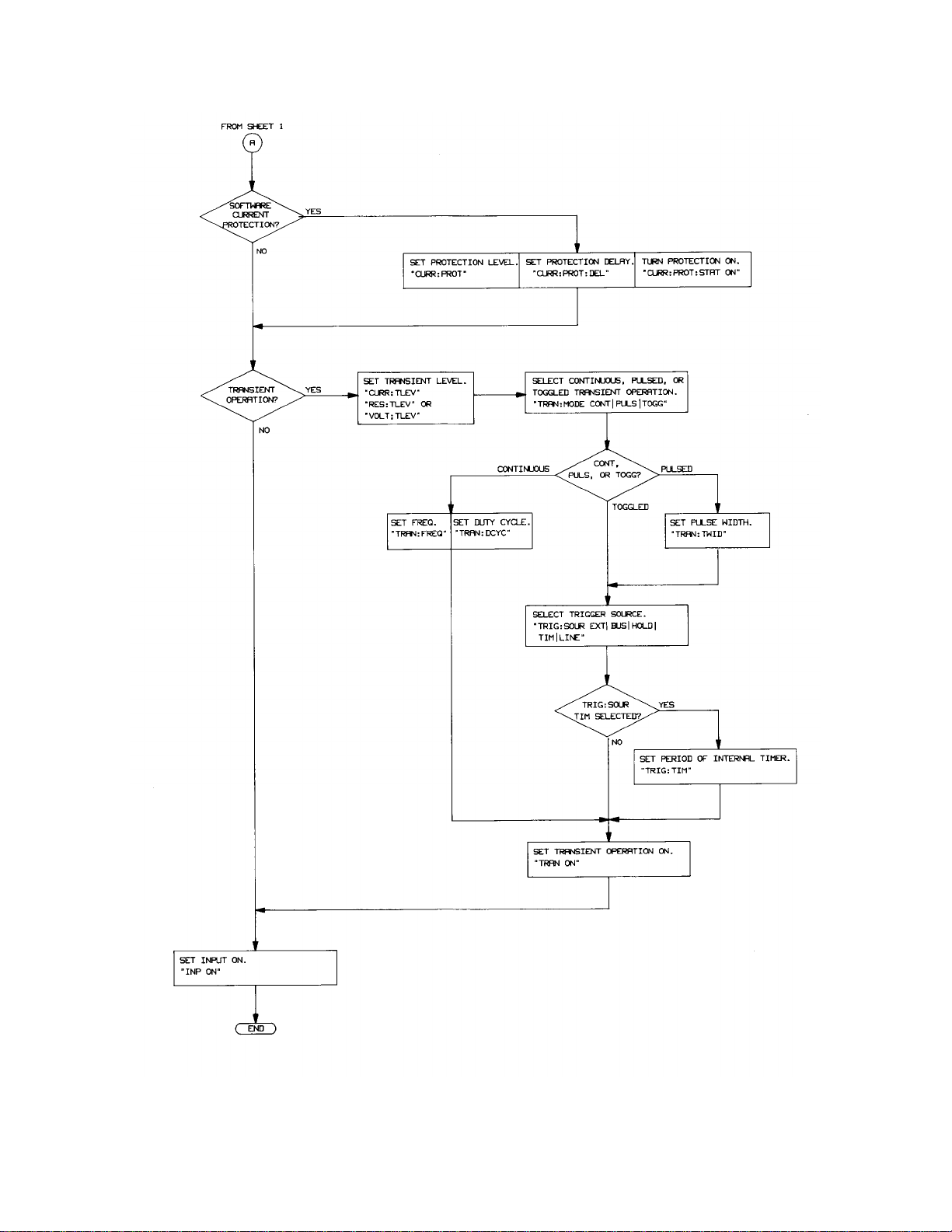

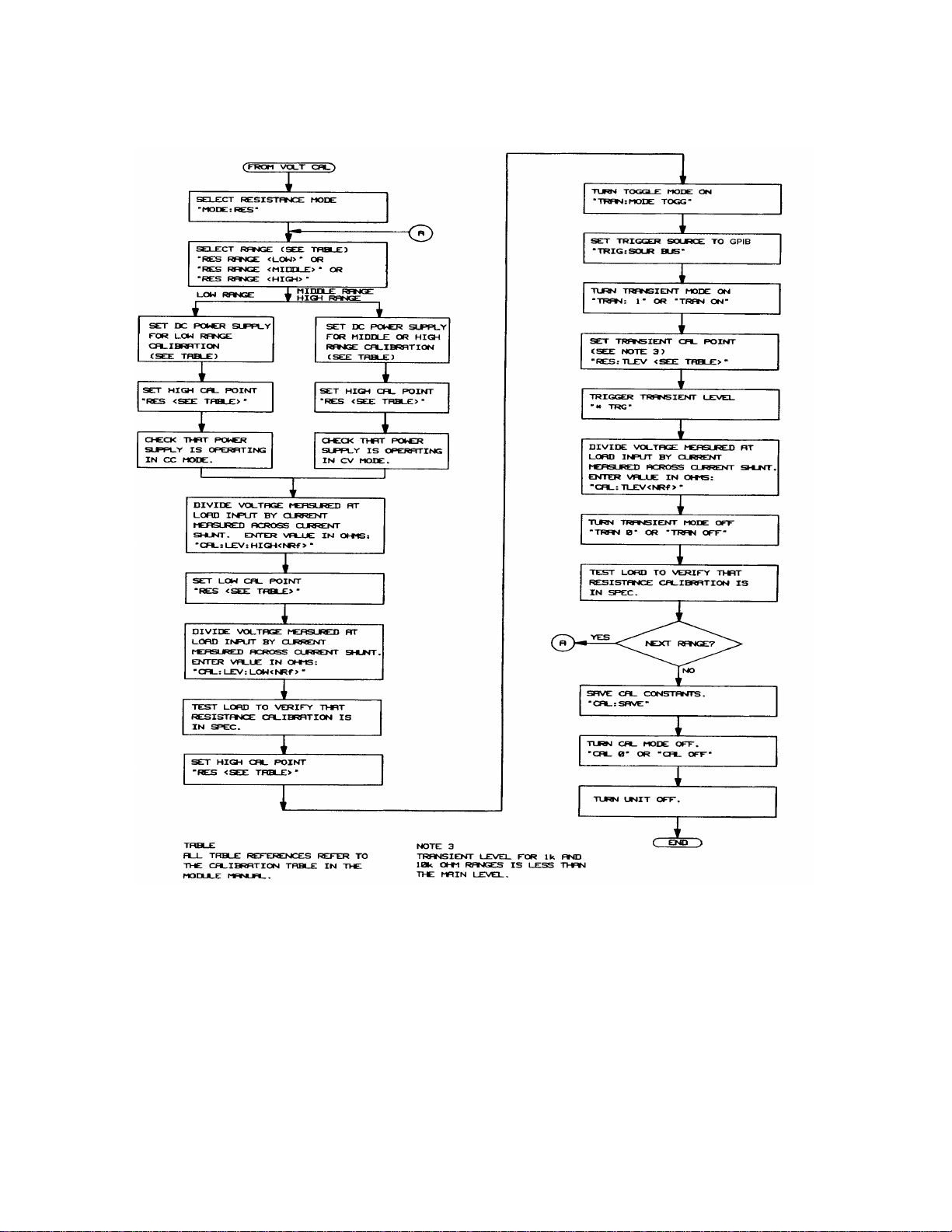

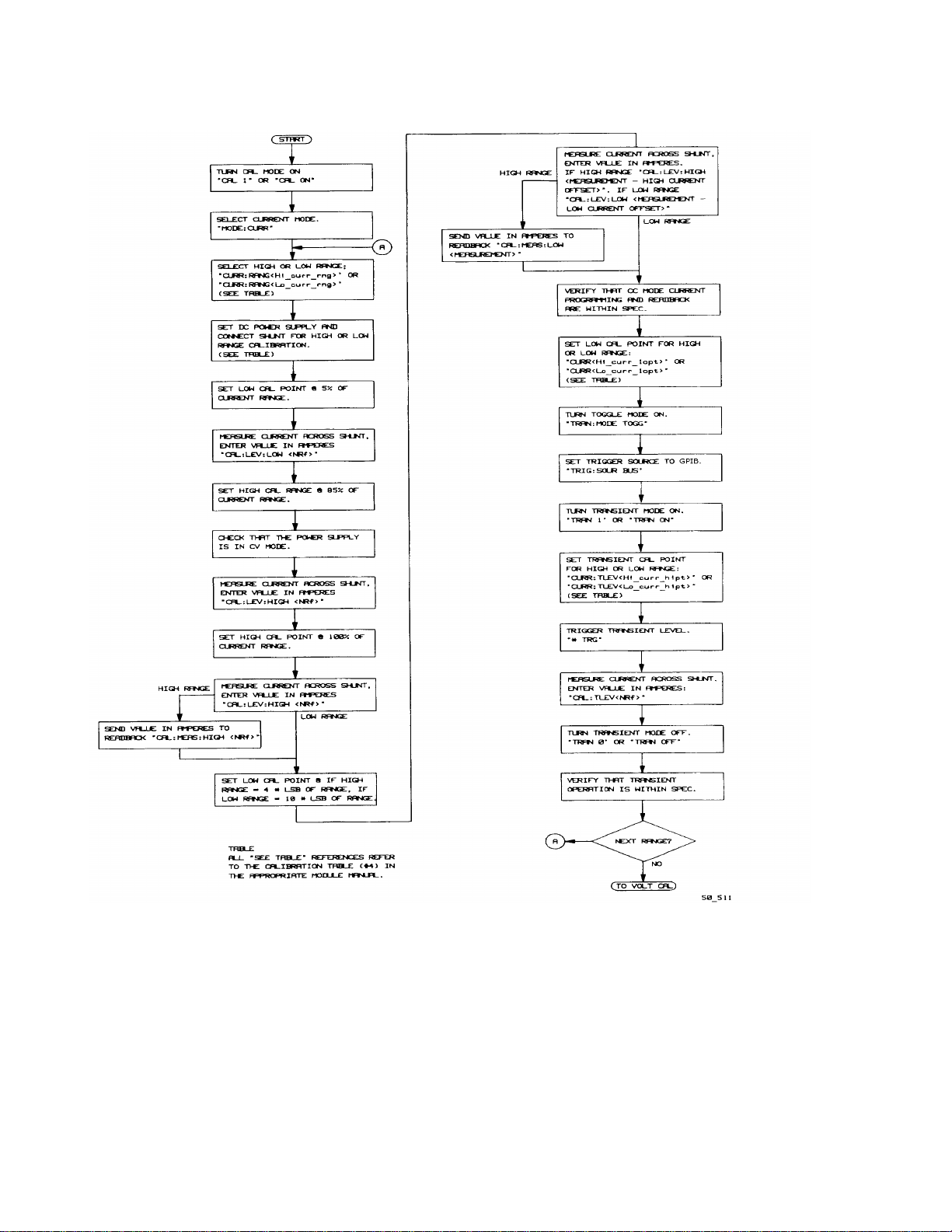

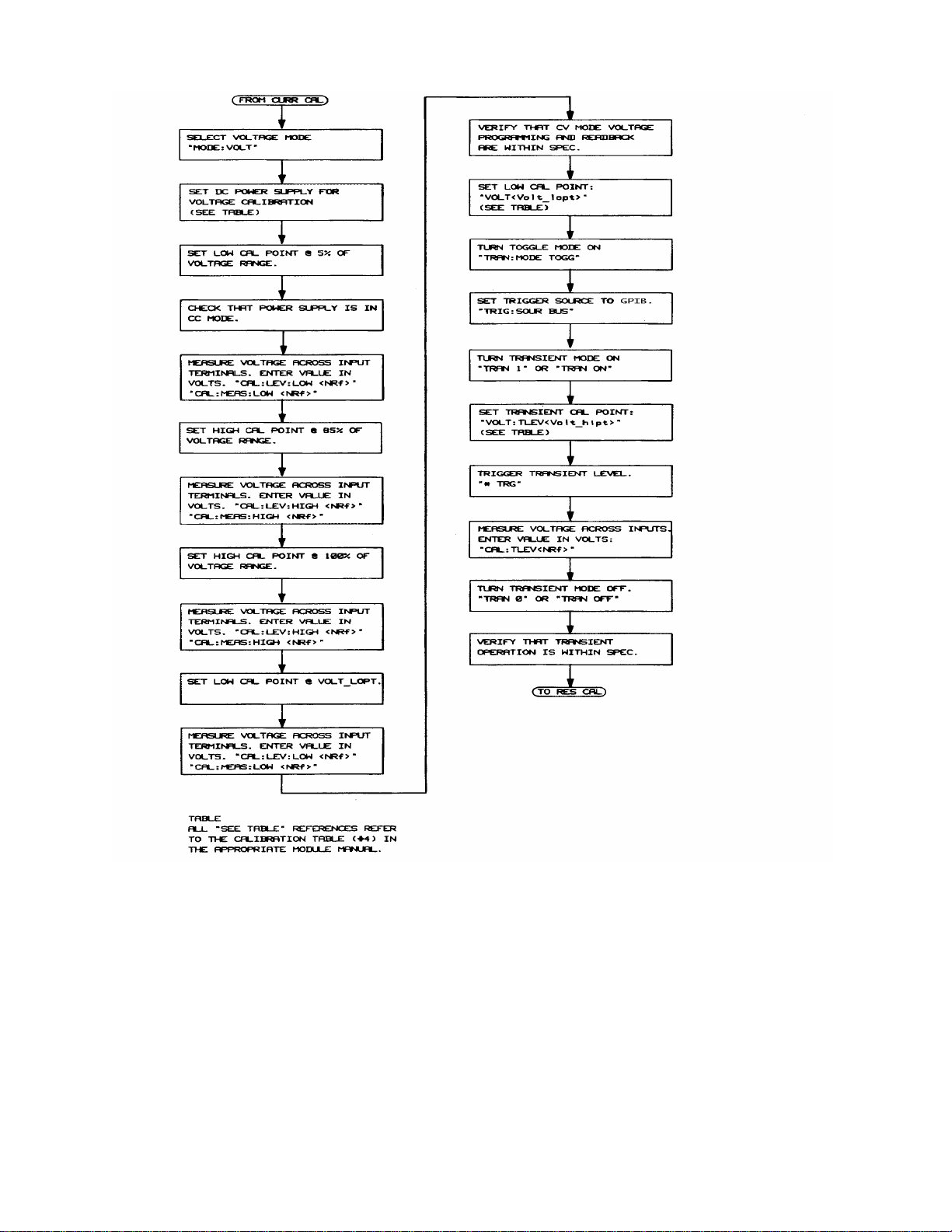

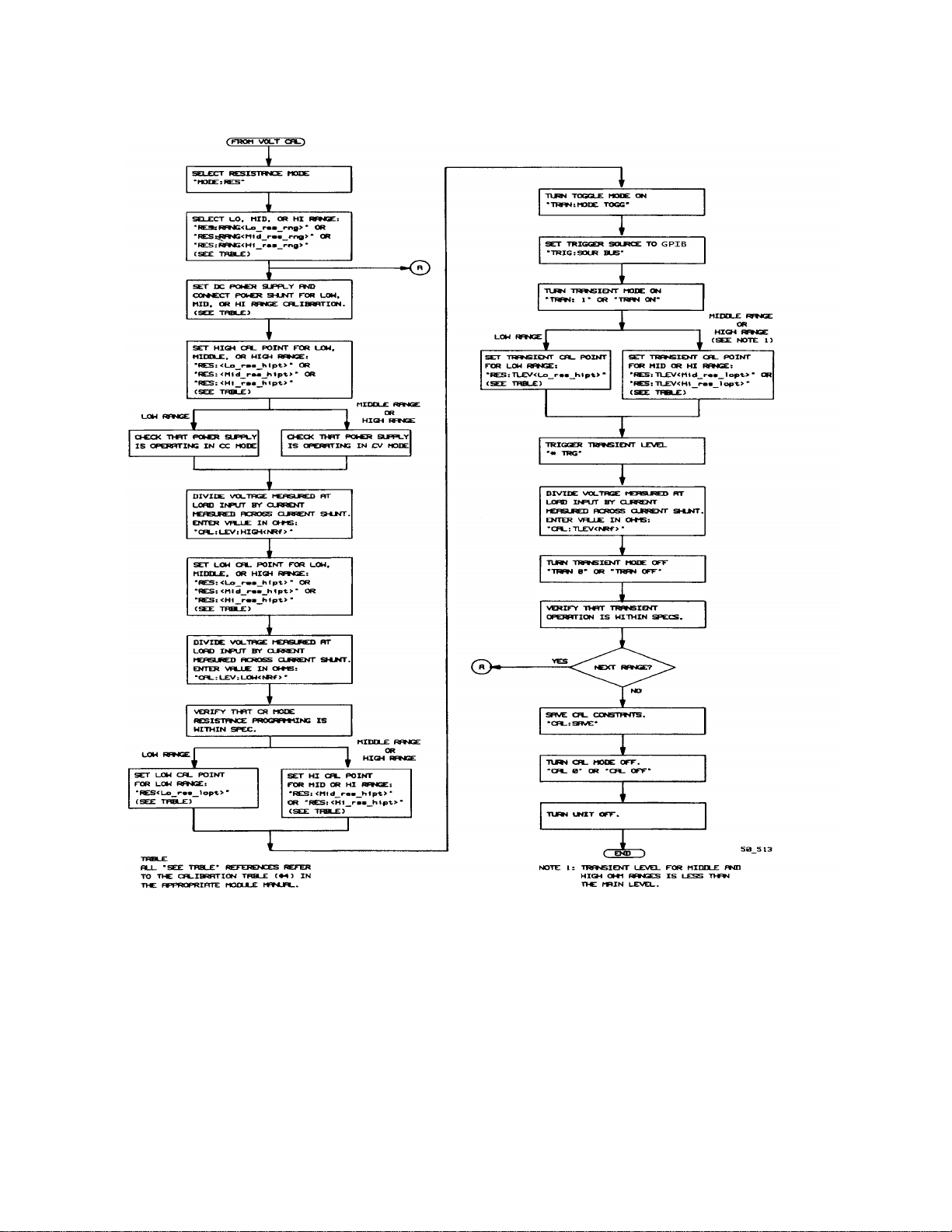

Calibration Flowcharts ...............................................................................................................................77

Example Programs .....................................................................................................................................77

A. Considerations for Operating in Constant Resistance Mode .......................................................91

Index.............................................................................................................................................................93

Agilent Sales and Support Offices..............................................................................................................97

9

Page 10

Page 11

1

General Information

What’s In This Manual

This manual applies to both the Agilent 6050A and Agilent 6051A Electronic Load mainframes. The two mainframes are

functionally identical, but the Agilent 6051A is a half-rack width unit, with only two slots for load modules. Most of the

information given in this manual applies to both mainframes. Where differences occur, information specific just to the

Agilent 6051A is given in parentheses following information that applies only to the Agilent 6050A, for example: ... a total

of 1800

(600) watts...

This chapter contains specifications that apply to the Agilent 6050A and Agilent 6051A Electronic Load mainframes, as

well as information concerning options and safety requirements. The remaining chapters in this manual contain instructions

for installing, operating, programming, and calibrating the Electronic Load as follows

Chapter 2 "Operation Overview": describes all of the Electronic Load’s functions and briefly describes how they can be

controlled locally at the front panel and/or remotely via a GPIB controller.

Chapter 3 "Installation": provides instructions for installing load modules in the mainframe, controller and

application connections, and turn-on checkout procedures.

Chapter 4 "Local Operation": describes in detail how to operate the Electronic Load at the front panel.

Chapter 5 "Remote Operation": provides an introduction to remote programming.

Chapter 6 "Calibration": contains calibration procedures for the Electronic Load and gives sample calibration

programs. Yearly calibration intervals are recommended.

Specifications and other information pertinent to a specific load module are given in the module-specific pages provided

with each load module.

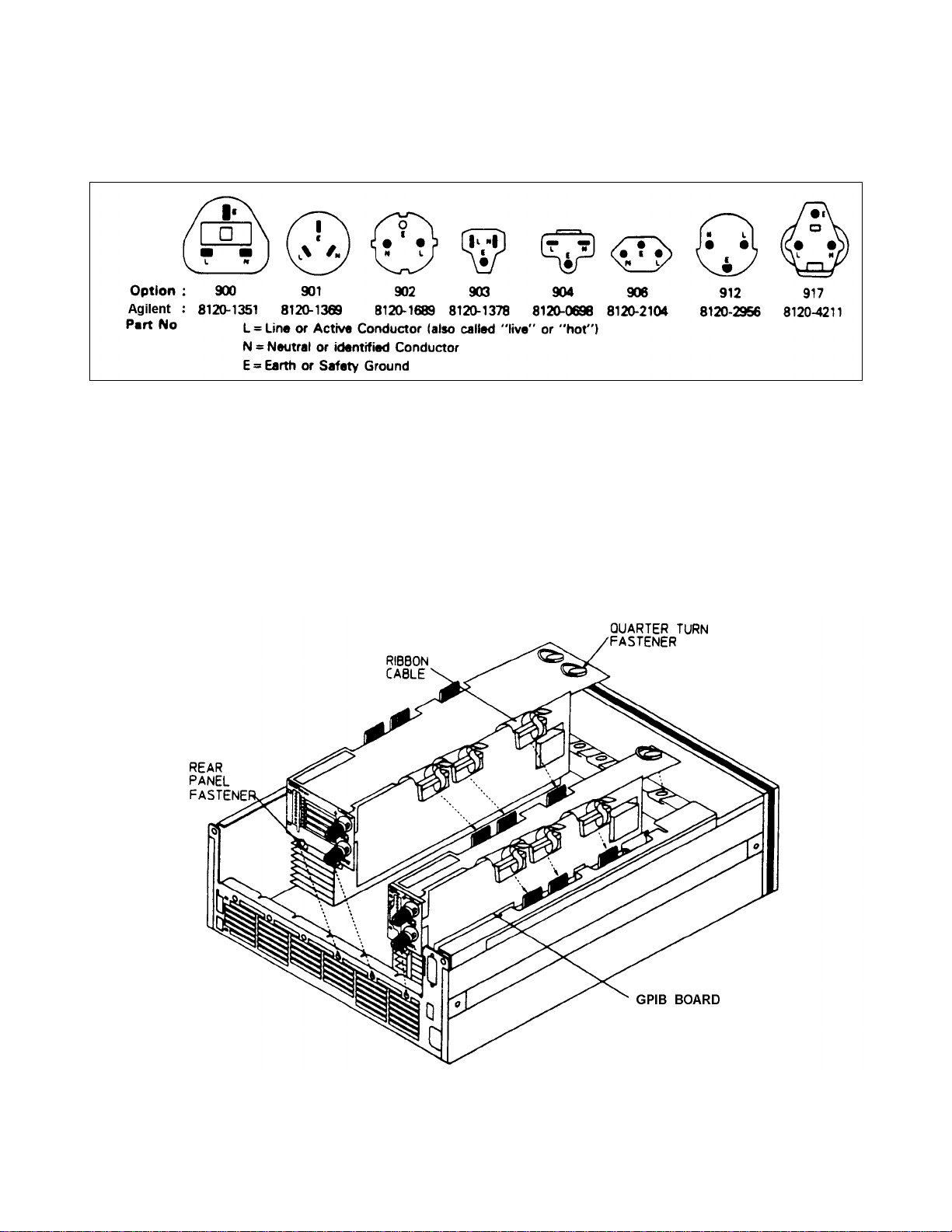

Options

Unless one of the following line voltage options is ordered, the unit is shipped from the factory set for 120 Vac, 48-63 Hz ac

input power. If Option 100, 220, or 240 is ordered, the unit will be factory set for the appropriate line voltage.

For information about changing the line voltage setting, see "Turn-On Checkout" in Chapter 3.

100: Input Power, 100 Vac, 48-63 Hz

220: Input Power, 220 Vac, 48-63 Hz

240: Input Power, 240 Vac, 48-63 Hz

Additional options are:

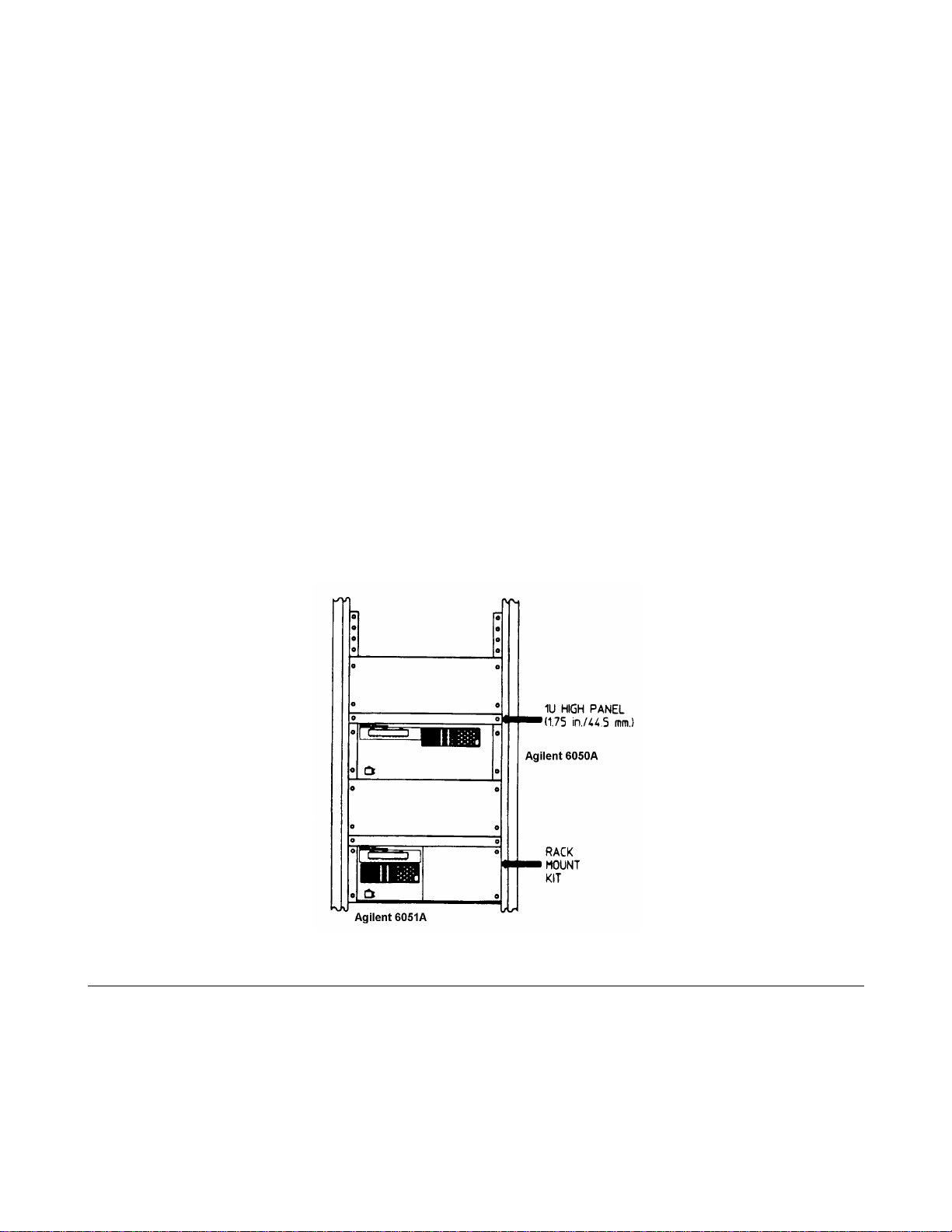

800: One rack mount kit for two half-rack units side by side (Agilent 6051A only)*

908: One rack mount kit*

909: One rack mount kit with handles (Agilent 6050A only)*

910: One service manual with extra Operating Manual and Programming Reference Guide

*Support rails are required for Options 800, 908, and 909.

General Information 11

Page 12

Safety Requirements

This product is a Safety Class 1 instrument, which means that it is provided with a protective earth ground terminal. This

terminal must be connected to an ac source that has a 3-wire ground receptacle. Review the instrument rear panel and this

manual for safety markings and instructions before operating the instrument. Refer to the Safety Summary page at the

beginning of this manual for a summary of general safety information. Specific safety information is located at appropriate

places in this manual.

The Electronic Load is designed to comply with the following safety and environmental requirements:

•

IEC 348-Safety requirements for electronic measuring apparatus.

•

CSA 22.2 No. 231-Electronic instruments and scientific apparatus for special use and applications.

•

UL 1244-Electrical and electronic measuring and testing equipment.

Specifications

Table 1-1 lists the specifications and supplemental characteristics for the Agilent 6050A/6051A Electronic Load mainframe.

All specifications apply over an operating range of 0 to +55°C for the mainframe. Specifications are guaranteed through the

warranty of the product. Supplemental characteristics are type-tested or typical values based on a product sample and, while

representative, are not guaranteed for all instruments.

Table 1-1. Agilent 6050A/6051A Specifications and Supplemental Characteristics

Specifications:

AC Input:

Three internal switches permit operation from 100, 120, 220, or 240 Vac lines.

Amplitude: -13% to +6% nominal line voltage

Frequency: 48 to 63 Hz

Supplemental Characteristics:

AC Input:

Fuse: The ac input is protected by internal fuses.

Maximum VA: 635

GPIB Programming Command Processing Time (Time required for a GPIB command processed by the

Electronic Load): 70 milliseconds (typical)

GPIB Interface Capabilities:

SH1, AH1, T6, L4, SR1, RLI, DT1, DC1

Trigger Input:

Vlo = 0.9 V maximum at Ilo = -1 mA

Vhi = 3.15 V minimum (pull-up resistor on input)

Trigger Input:

Vlo = 0.72 V maximum at Ilo = 1 mA

Vhi = 4.4 V minimum at Ilo = -20 µA

12 General Information

Page 13

Table 1-1. Agilent 6050A/6051A Specifications and Supplemental Characteristics (continued)

Weight:

Net (mainframe only): Agilent 6050A, 9.5 kg (21 lb.)

Agilent 6051A, 5.5 kg (12 lb.)

Shipping: Agilent 6050A, 14 kg (31 lb.)

Agilent 6051A, 7.5 kg (17 lb.)

Dimensions:

Width: Agilent 6050A, 425.5 mm (16.75 in.)

Agilent 6051A, 213 mm (8.4 in.)

Height: 178 mm (7 in.), add 10 mm (0.4 in.) for removable feet

Depth: 625 mm (24.6 in.), including input connectors on modules

General Information 13

Page 14

Page 15

2

Operation Overview

Introduction

The Agilent 6050A and Agilent 6051A Multiple Input Electronic Load Mainframes are used for design, manufacturing, and

evaluation of dc power supplies, batteries, and power components. Other applications include use as a power circuit

breaker or crowbar, high-current function or pulse generator, fuel-cell and photovoltaic cell test, and de-energizing

superconducting magnets.

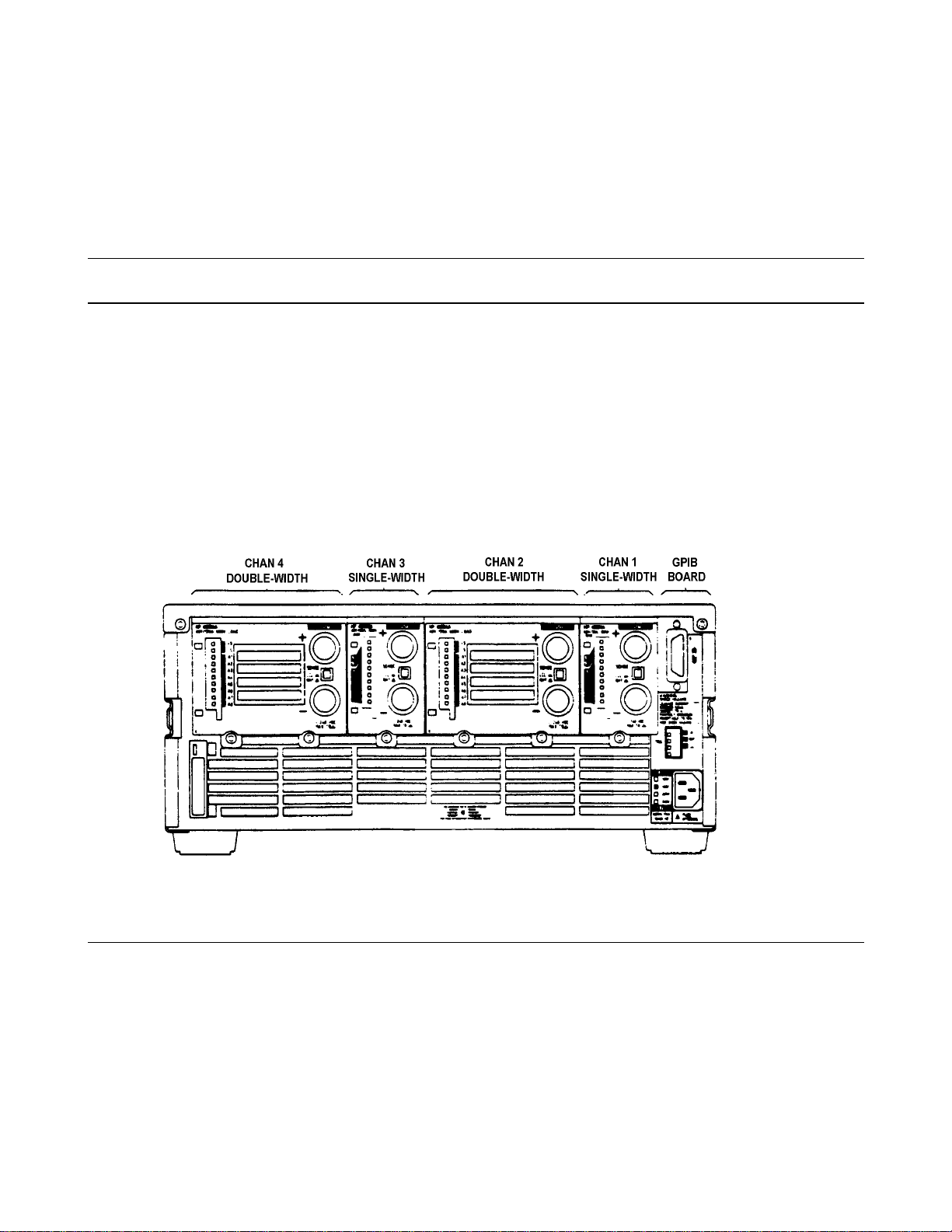

The mainframe contains six (two) slots for load modules. Load modules occupy either 1 or 2 slots, depending on the power

rating of the module. The mainframe can dissipate up to 300 watts per slot, to a total of 1800 (600) watts for a fully loaded

mainframe. An individual module may have either 1 or 2 channels, each of which has its own channel number. Each

module contains its own input connectors. The mainframe contains a processor, GPIB connector and interface circuits,

trigger circuits, front-panel keypad and display, and other circuits common to all the load modules.

Each module can operate independently in constant current (CC) mode, constant voltage (CV) mode , or constant resistance

(CR) mode. In addition, each input can be turned on or off (open circuit) or short circuited.

Features include built-in GPIB interface and built-in pulse generator, both standard. Pulse mode allows dynamic testing of

power supplies and components, without giving the device under test time to heat up. The flexible pulse mode provides six

triggering methods, allowing synchronization with a wide variety of events. A Save/Recall feature allows you to save up to 7

complete instrument setups, one of which can be saved in non-volatile memory so that it is recalled automatically at poweron. Also standard is GPIB readback of actual input voltage and current, and extensive protection and status reporting

capability.

The mainframe contains two (one) cooling fans whose speed automatically increases or decreases as the module

temperatures rise and fall. This feature reduces overall noise level because the fans do not run at maximum speed at all

times.

The input power rating curve for each module is shown in the module-specific pages. See the extended power paragraphs in

this section for a description of the power rating curves. Note that regardless of a module’s power rating, input current is

derated linearly from 2 volts down to 0 volts.

Each load module can be individually controlled either via GPIB or locally via the front panel. Once a channel is selected

or addressed, all subsequent commands go to that channel until another channel is selected or addressed. Operation of all

models is similar, regardless of power ratings. Therefore, the operating instructions given in this manual are generic, and

apply to all modules. The module-specific pages provided with each module include specifications and other information

pertinent just to a particular model. Some examples described here may use values that are not appropriate for your module,

but the example is valid. Some descriptions refer to ranges, limits, full-scale values, and similar terms (for example, low

range and high range). Refer to the module-specific pages provided with each module for the actual values.

Programs written for the Agilent 6060 series of single Electronic Loads can be used with the multiple loads, easing program

development for applications using various members of the Agilent Electronic Load family. (Triggering via the ac line

frequency or the load’s internal timer is available only in the multiple load mainframe.)

If your application requires a greater power or current capacity than one module can provide, load modules can be

connected in parallel in CC or CR mode.

Operation Overview 15

Page 16

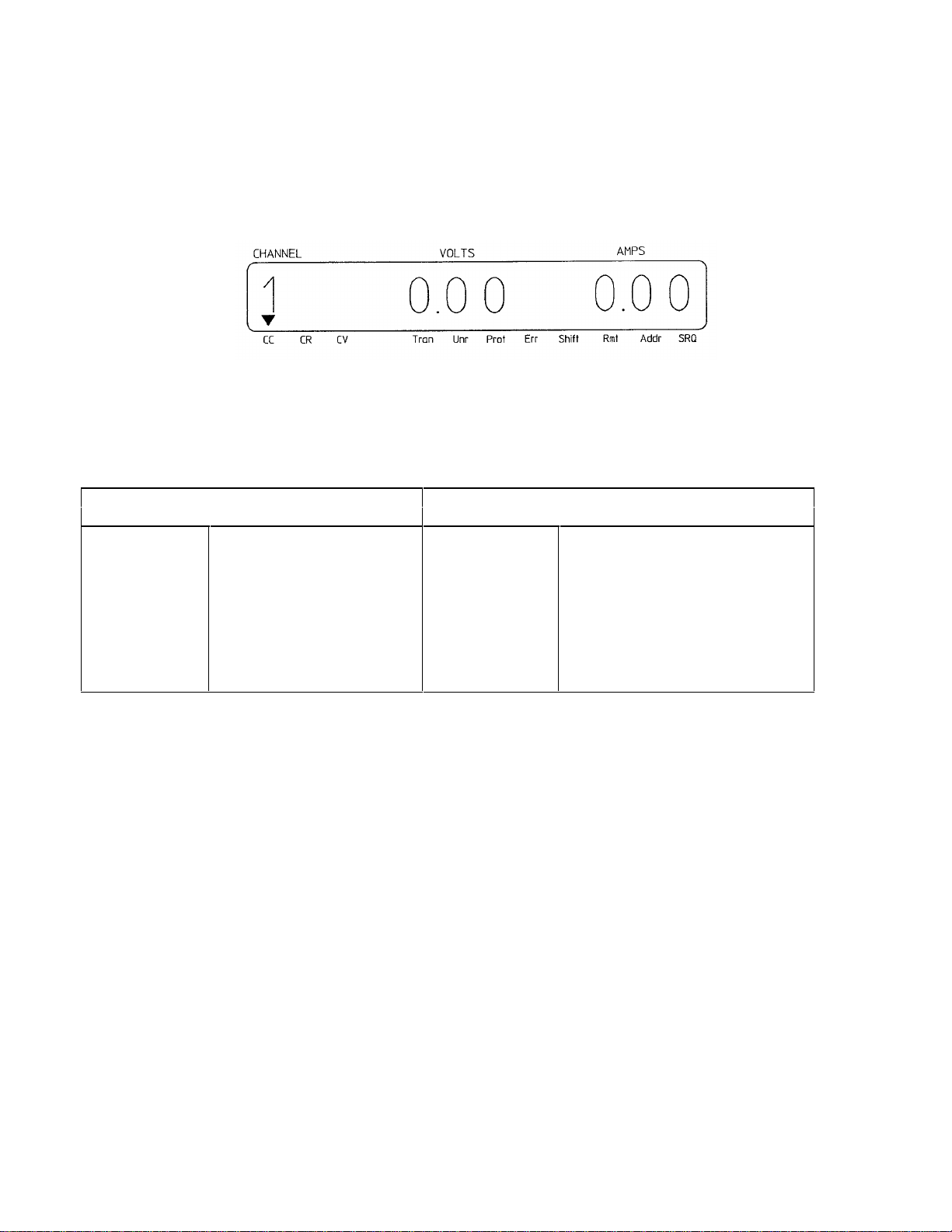

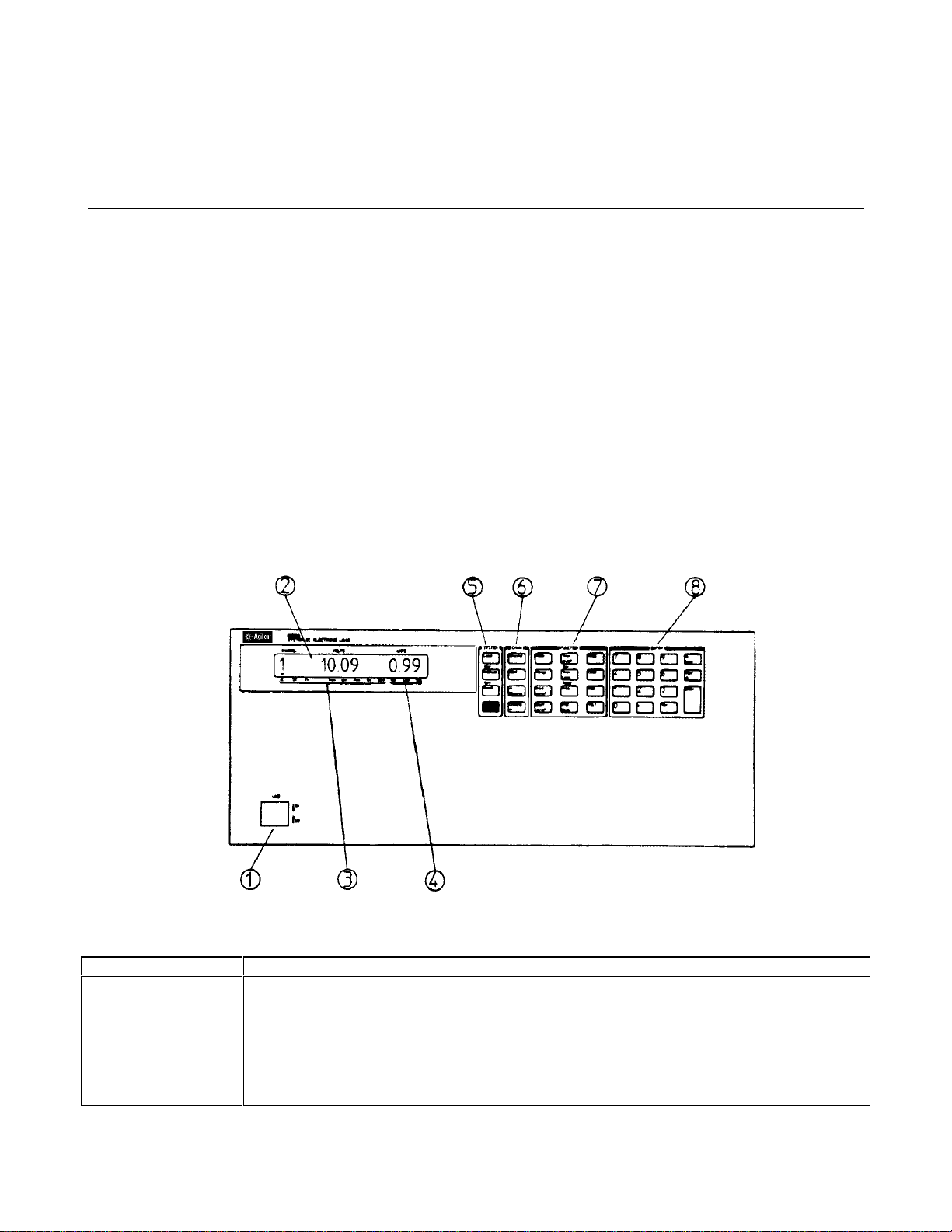

Front Panel Description

The front panel includes a 12-character alphanumeric display, 11 status indicators, and four groups of keypads. Ordinarily

the alphanumeric display shows the number of the channel presently under front-panel control, and the input voltage and

current of that channel. By using the

protection-circuit status. If any protection circuits are active, that status will be displayed first when you use the

key. If you change channels via the front panel, any fault information will be displayed first for the new channel. Then you

can key through the display in the normal sequence. The alphanumeric display also shows what function is being performed

when you use the keypads.

The display also includes 11 annunciators that point to the 11 status labels printed on the front panel. The Constant

Current, Constant Resistance, Constant Voltage, Transient, and Unregulated status annunciators are specific to the channel

displayed. The Protection, Error, Shift, Remote, Address, and Service ReQuest status annunciators are channel

independent.

Four of the keys perform two functions, with the alternative function labeled in blue above the key. The alternative

function is selected by first pressing the blue (shift) key, which turns on the Shift annunciator and enables the alternative

function.

Note that the front-panel display operates independently from the GPIB CHANNEL command. In other words, you can

select a channel locally (front panel) for which the display will show the input voltage and current, and the controller can

subsequently send commands to other channels without changing the channel being displayed.

key you can sequentially display input power, programming error codes, and

Remote Programming

Commands sent to the Electronic Load via GPIB are decoded by the mainframe microprocessor, which detects syntax and

range errors. The mainframe processor also prescales data sent to the modules, and maintains status registers for each

module. Three commands have aliases for compatibility with other HPSL instruments. MODE can also be called

FUNCtion, INPut can also be called OUTPut, and CHANnel can also be called INSTrument. OUTPut and INSTrument

would typically be used if you want your program to refer to the load modules in terms of the device or instrument under

test. Be careful if using INSTrument for CHANnel in systems that have more than one Electronic Load mainframe;

someone looking at the listing in the future may be misled.

Local/Remote Control

Local (front panel) control is in effect immediately after power is applied. The front panel keypad and display allow manual

control of each individual module when the Electronic Load is used in bench test applications. Remote (computer) control

goes into effect (front panel Rmt annunciator is on) as soon as the mainframe receives a command via the GPIB. A built-in

GPIB interface and HPSL compatible commands allow control and readback of all functions when the Electronic Load is

used in computer controlled applications.

With remote control in effect, only the computer can control the Electronic Load; the front panel keypad has no effect. You

can, however, still use the front panel display to view the input voltage and current readings. You can return the Electronic

Load to local control from remote control by pressing

the local-lockout command has been received from the GPIB computer.

Most of the functions that can be performed remotely over the GPIB can also be performed locally at the front panel. The

names on the keys reflect the HPSL commands that are used to program the various functions. Consequently, learning to

operate the Electronic Load from the front panel will aid you when you start to write computer programs.

Details of local operation are covered in Chapter 4 - Local Operation and fundamentals of remote programming are given

in Chapter 5 - Remote Operation. Complete HPSL programming details are given in the Agilent Electronic Loads

Programming Reference Guide. The remaining paragraphs in this chapter describe the operating modes, transient

. This will return the Electronic Load to local control, unless

16 Operation Overview

Page 17

operation, protection features, and other operating features of the Electronic Load.

Extended Power Operation

Note: Extended power operation is not available on "B " load modules (Agilent Models 60501B-60507B).

In addition, this feature may not be present in "A" modules produced after 1989.

The extended power feature allows a module to dissipate considerably more than its nominal power rating in many cases.

The primary factor limiting the amount of power that can be dissipated is the temperature of the current-control pass

transistors, as sensed at the heatsink. A module’s nominal power rating is specified for continuous power at high ambient

temperature, but in many applications average power is less than 100%, and ambient temperature is considerably lower than

the highest specified full-power temperature. In these less-than-extreme applications, each load module can safely dissipate

as much as one third more power than its nominal power rating for a limited time.

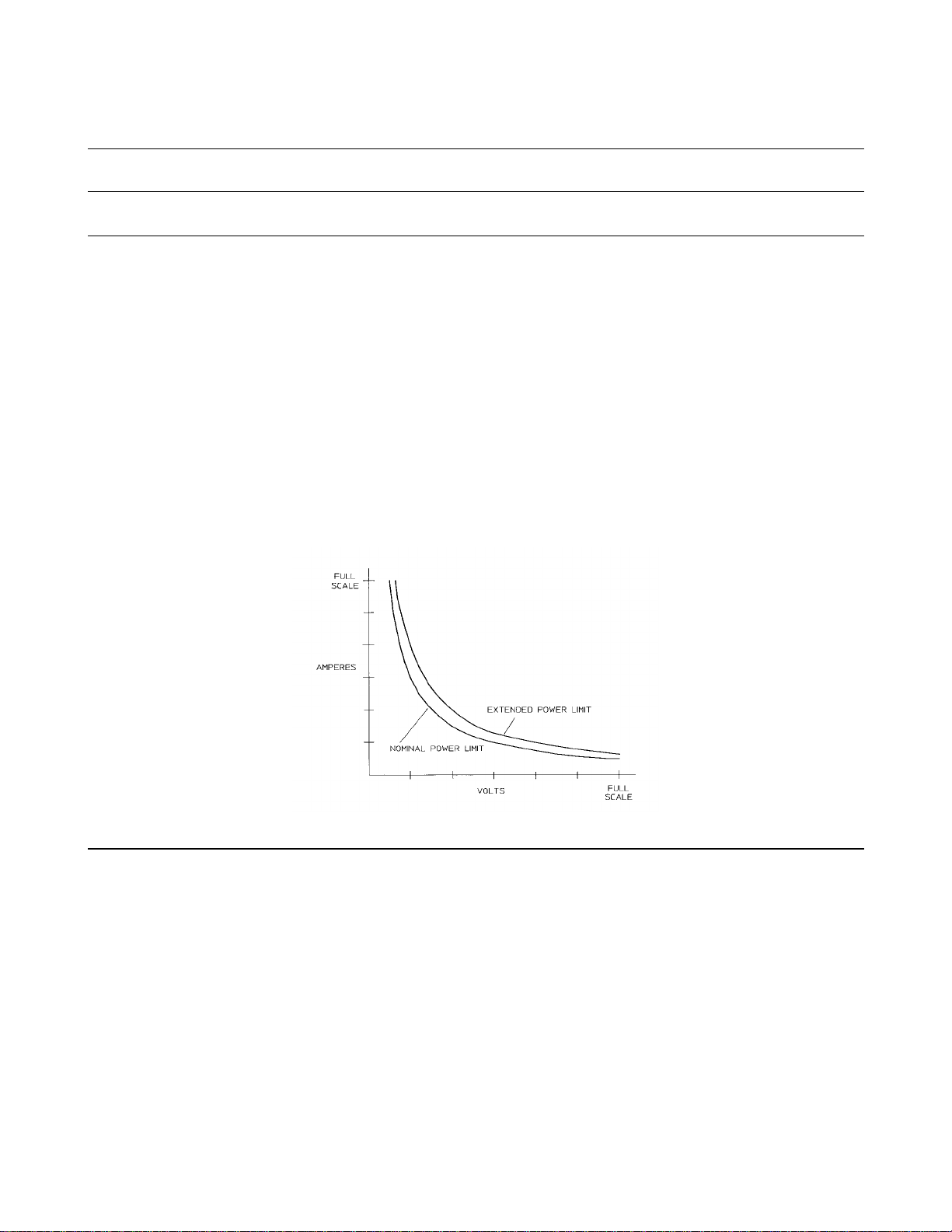

In effect, each module has two power-limit curves, as shown in Figure 2-1. Whether the module is operating with the

nominal power-limit curve or the extended power-limit curve is determined by heatsink temperature. The module turns on

with extended power available and extended power continues to be available unless and until the internal temperature rises

beyond a safe operating point for extended power. At the point, the module automatically reduces the power-limit curve to

the module’s nominal power rating, and sets the Extended Power Unavailable (EPU) bit in the status registers. Extended

power is available any time the EPU bit (bit 9) is not set. A graph provided in the module-specific specifications under DC

Input Rating shows the typical time that a module can operate at full extended power after having stabilized at a given

average power before extended power becomes unavailable.

Programmable Features

Modes of Operation

The three modes of operation are:

• constant current (CC)

• constant voltage (CV)

• constant resistance (CR)

Figure 2-1. Power Limit Curves

Operation Overview 17

Page 18

When programmed to a mode, a module remains in that mode until the mode is changed or until a fault condition, such as an

overpower or overtemperature, occurs. When changing modes, the module’s input is momentarily disabled (non-conducting

state) before the new mode is enabled. This insures that there will be minimum overshoots when changing modes.

The current, resistance, and voltage mode parameters described in subsequent paragraphs can be programmed whether or

not the mode is presently selected. When a mode is selected via the front panel or via the GPIB, most of the associated

parameters will take effect at the input (exceptions are noted in the mode descriptions).

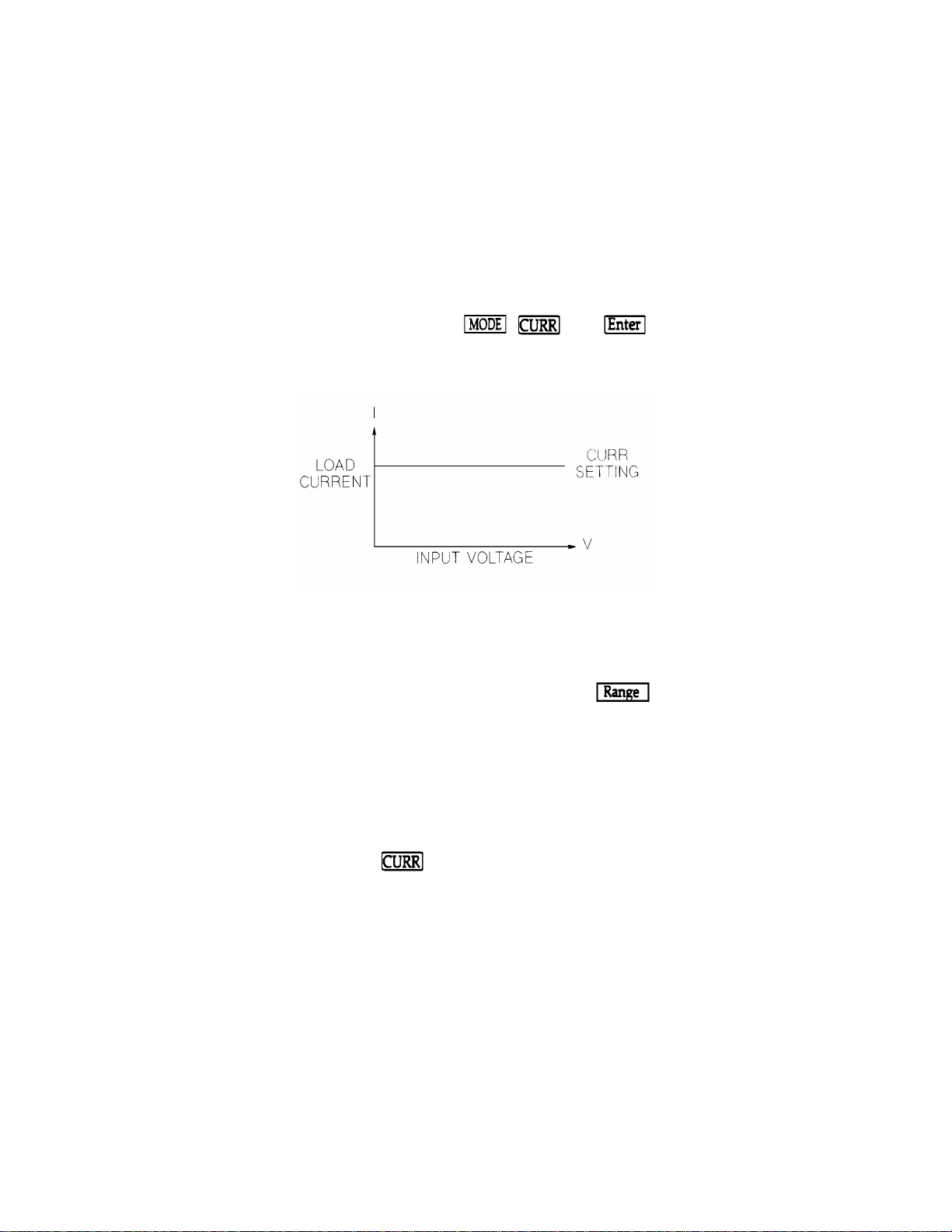

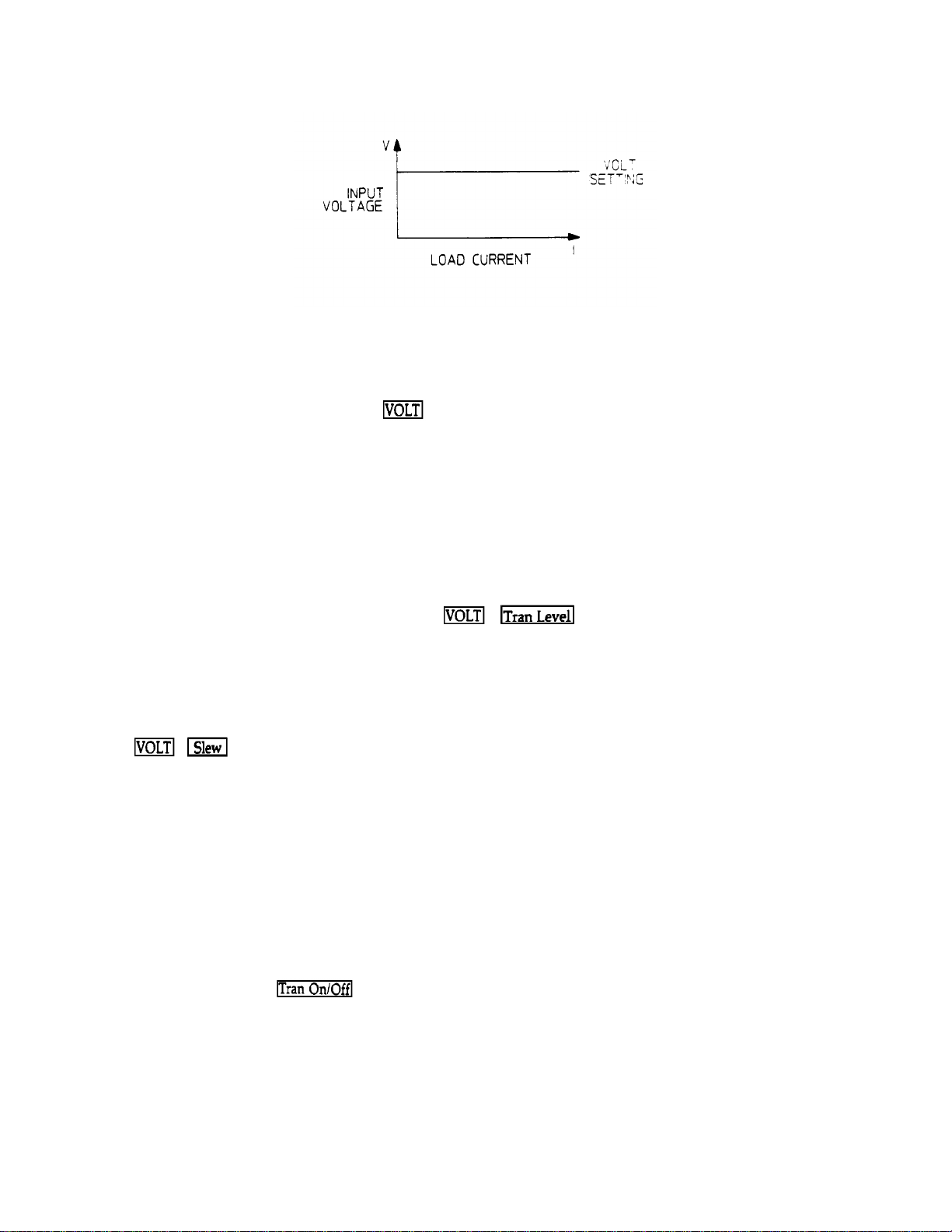

Constant Current CC (Mode)

In this mode, the module will sink a current in accordance with the programmed value regardless of the input voltage (see

Figure 2-2). The CC mode can be set with front panel keys(

(MODE:CURR command). The CC mode parameters are discussed in the following paragraphs.

, , and ) or via the GPIB

Figure 2-2. Constant Current Mode

Ranges

Current may be programmed in either of two overlapping ranges, a low range and a high range. The low range provides

better resolution at low current settings. The range can be set at the front panel (

GPIB (CURR:RANG command). Any value in the low range selects the low range. Any value above the maximum of the

low range selects the high range. Changing the range affects the module in the same manner as changing modes; i.e., it

causes the input to go through a non-conducting state. Note that the values of the present current settings may be

automatically adjusted to fit the new range. For example, if 10 A is the present setting and the 0 to 6 A range is then

programmed, the current setting will automatically be changed to 6 A; see Chapter 4 - Local Operation.

Immediate Current Level

The current level can be set at the front panel (

mode is the active mode, the new setting immediately changes the input at a rate determined by the slew setting (described

below). If the module is not in the CC mode, the new setting is saved for use when the mode is changed to CC.

Triggered Current Level

The current level can be preset (stored in the Electronic Load) allowing the input to be updated when a trigger is received

instead of immediately as described above. The current level can only be preset via the GPIB (CURR:TRIG command).

The preset capability is not available at the front panel.

If the CC mode is the active mode, the preset current level will become the actual value and the input will be updated when

a trigger occurs. If the CC mode is not the active mode, the preset current level will become the actual value when a trigger

occurs but there will be no effect on the input until the CC mode becomes active. Once a level is triggered, subsequent

triggers will have no effect on the input unless another CURR:TRIG command is sent. The trigger sources available to the

and ENTRY keys) or via the GPIB (CURR command). If the CC

and ENTRY keys) or via the

18 Operation Overview

Page 19

Electronic Load are described later in this chapter. The Electronic Load has a status reporting capability to keep track of

pending triggers and other operating conditions. The status reporting capability is described in detail in the Agilent

Electronic Loads Programming Reference Guide.

Transient Current Level

The transient current level can be set at the front panel (

(CURR:TLEV command). The transient current level determines the higher current level when transient operation

(described later in this chapter) is turned on. The module input will switch between the main level and the transient level

when transient operation is turned on.

Software Current Limit

The Electronic Load allows the user to set a current limit (0 to 102% of full scale) for each module via the GPIB

(CURR:PROT command) which will shut down the input if the current limit is exceeded beyond a programmable time

delay. Note that the software current limit is in effect for any mode of operation (not just the CC mode). The software

current limit feature is described later in this chapter under Protection Features.

Slew Rate

Slew rate determines the rate at which the current input to a module changes to a new programmed value. Slew rate can be

set at the front panel (

remains in effect for the immediate, triggered, and transient level changes previously described.

There are 12 discrete current slew rates within each slewrate range. Any slew rate value can be sent to a module (there are

no upper and lower limits that would cause an error), and a module will automatically select one of the 12 rates that is

closest to the programmed value. The slew rate is rescaled to the closest fit in the 1-of-12 discrete steps if the

current range is changed.

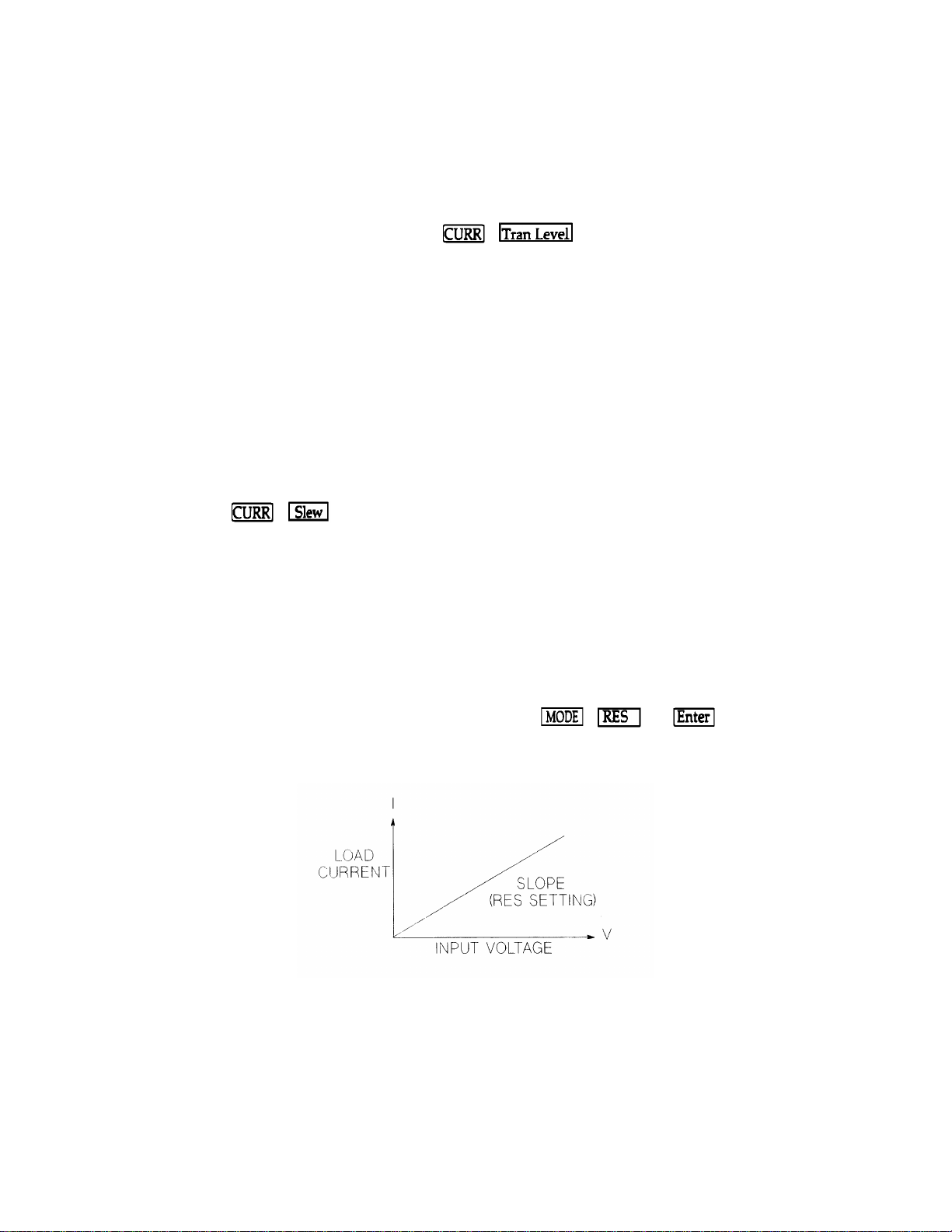

Constant Resistance (CR) Mode

, and ENTRY keys) or via the GPIB (CURR:SLEW command). This slew rate

, and ENTRY keys) or via the GPIB

In this mode, the module will sink a current linearly proportional to the input voltage in accordance with the programmed

resistance (see Figure 2-3). The CR mode can be set at the front panel (

(MODE:RES command). The CR mode parameters are described in the following paragraphs (see also Appendix A).

Figure 2-3. Constant Resistance Mode

, and keys) or via the GPIB

Operation Overview 19

Page 20

Ranges

Resistance may be programmed in any of three overlapping ranges (low, middle, high). The range can be set at the front

panel (

the low range. Any value that is within the middle range and above the maximum low-range value selects the middle range.

Any value that is within the high range and above the maximum middle-range value selects the high range. Note that the

values of the present resistance settings may be automatically adjusted to fit within the new range.

Immediate Resistance Level

, , and ENTRY keys) or via the GPIB (RES:RANG command). Any value in the low range selects

The resistance level can be set at the front panel (

mode is the active mode, the new setting immediately changes the input at a rate determined by the voltage or current slew

setting (see description below). If the module is not in the CR mode, the new setting is saved for use when the mode is

changed to CR.

Triggered Resistance Level

The resistance level can be preset (stored in the Electronic Load) allowing the input to be updated when a trigger is received

instead of immediately as described above. The resistance level can only be preset via the GPIB (RES:TRIG command).

The preset capability is not available at the front panel.

If the CR mode is the active mode, the preset resistance level will become the actual value and the input will be updated

when a trigger occurs. If the CR mode is not the active mode, the preset resistance level will become the actual value when

a trigger occurs but there will be no effect on the input until the CR mode becomes active. Once a level is triggered,

subsequent triggers will have no effect on the input unless another CURR:TRIG command is sent.

Transient Resistance Level

The transient resistance level can be set at the front panel (

(RES:TLEV command). The transient level and the main level are used in transient operation, which is described later in

this chapter. In the low resistance range, the transient level must be set to a higher resistance value than the main level.

However, in the middle and high resistance ranges, the transient level must be set to a lower resistance value than the main

level.

Slew Rate

and ENTRY keys) or via the GPIB (RES command). If the CR

, and ENTRY keys) or via the GPIB

Slew rate in resistance mode is not programmed in ohms/second. In the low resistance range, slew rate is programmed in

volts/second. Whatever value is programmed for the voltage slew rate is also used for the low resistance range.

In the middle and high resistance ranges, slew rate is programmed in amps/second. Whatever value is programmed for the

current slew rate is also used for the middle or high resistance ranges.

Constant Voltage (CV) Mode

In this mode, the module will attempt to sink enough current to control the source voltage to the programmed value (see

Figure 2-4). The module acts as a shunt voltage regulator when operating in the CV mode. The CV mode can be set

at the front panel (

parameters are described in the following paragraphs.

Range

Voltage mode has only one range

20 Operation Overview

, and keys) or via the GPIB (MODE:VOLT command). The CV mode

Page 21

Immediate Voltage Level

Figure 2-4. Constant Voltage Mode

The voltage level can be set at the front panel (

mode is the active mode, the new setting immediately changes the input at a rate determined by the voltage slew setting. If

the module is not in the CV mode, the new setting is saved for use when the mode is changed to CV.

Triggered Voltage Level

The voltage level can be preset (stored in the Electronic Load) allowing the input to be updated when a trigger is received

instead of immediately as described above. The voltage level can only be preset via the GPIB (VOLT:TRIG) command.

Transient Voltage Level

The transient voltage level can be set at the front panel (

(VOLT:TLEV + command). The module input will switch between the main level and the transient level when transient

operation is turned on. The transient voltage level determines the higher voltage level.

Slew Rate

Slew rate determines the rate at which the voltage changes to a new programmed setting. Slew rate can be set at the front

panel (

the immediate, triggered and transient voltage level changes described above.

There are 12 discrete slew rates that can be programmed for CV Mode slew rate. Any slew-rate value can be sent to a

module (there are no upper and lower limits that would cause an error). The module will automatically select one of the 12

rates that is closest to the programmed value. It is important to note that the fastest slew rates cannot be achieved because of

bandwidth limitations. The module-specific pages list the usable slew rates.

, , and ENTRY keys) or via the GPIB (VOLT:SLEW command). This slew rate remains in effect for

and ENTRY keys) or via the GPIB (VOLT command). If the CV

, and ENTRY keys) or via the GPIB

Transient Operation

Transient operation enables the module to periodically switch between two load levels, as might be required for testing

power supplies. A power supply’s regulation and transient characteristics can be evaluated by monitoring the supply’s output

voltage under varying combinations of load levels, frequency, duty cycle, and slew rate. Transient operation can be turned

on and off at the front panel (

on transient operation, you should set the desired mode of operation as well as all of the parameters associated with transient

operation. Transient operation may be used in the CC, CR, or CV modes and can be continuous, pulsed, or toggled. Note

that the pulsed or toggled operation cannot be programmed from the front panel.

key) or via the GPIB (TRAN ON and TRAN OFF commands). Before you turn

Operation Overview 21

Page 22

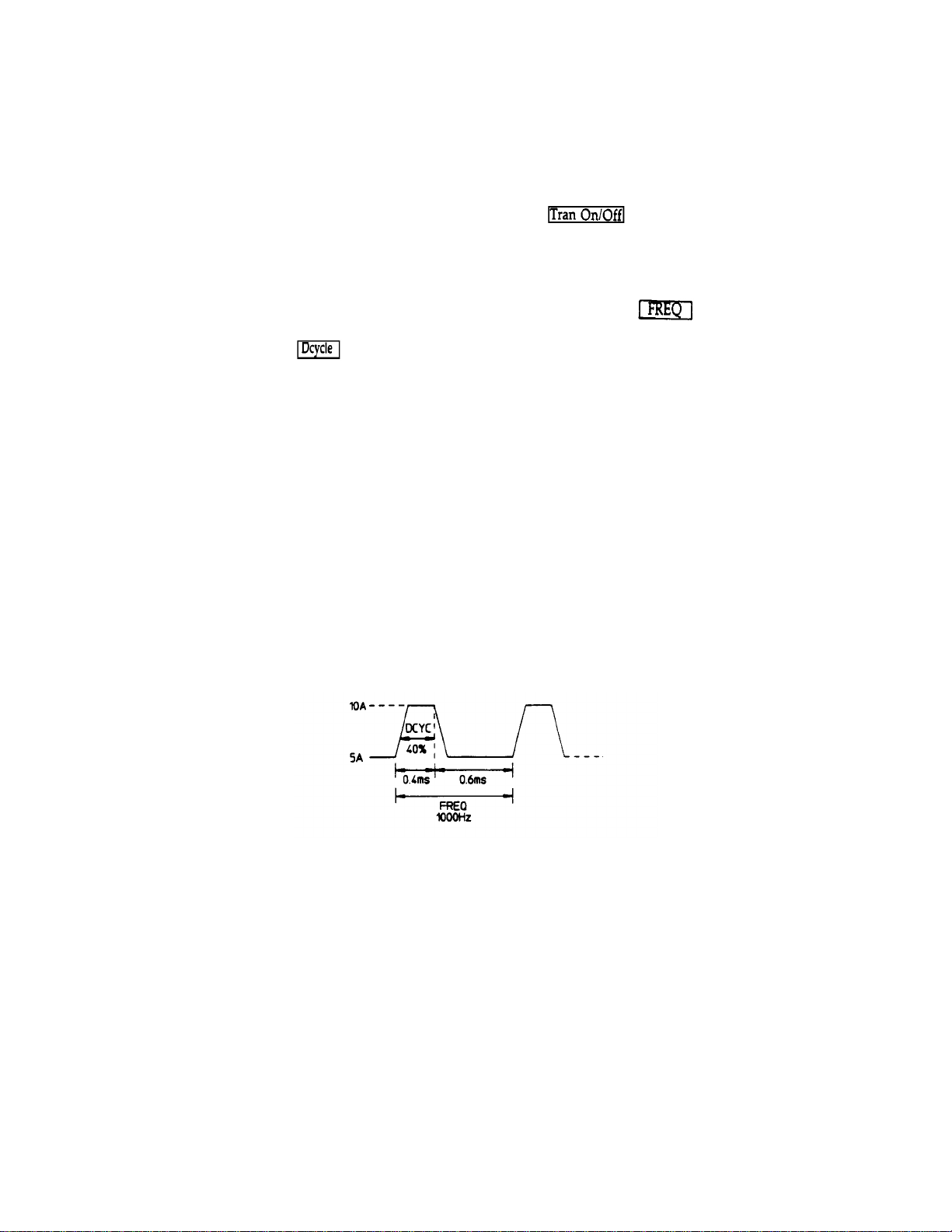

Continuous Transient Operation

In continuous operation, a repetitive pulse train switches between two load levels. Continuous transient operation is

selected via the GPIB using the TRAN:MODE CONT command. For front panel operation, continuous transient

operation is automatically selected when transient operation is turned on(

The two load levels in the transient operation are the previously described main level (immediate or triggered) and transient

level for current, resistance, or voltage. The rate at which the level changes is determined by the slew rate (see slew rate

descriptions for CV, CR, or CV mode as applicable). In addition, the frequency and duty cycle of the continuous pulse train

are programmable. The frequency can be set from 0.25 to 10000 Hz at the front panel (

the GPIB (TRAN:FREQ command) The duty cycle can be set from 3% to 97% (0.25 Hz to 1 kHz) or from 6% to 94%

(above 1 kHz) at the front panel(

For example, assume that the CC mode is active, the slew rate is at the default setting (maximum rate), and the applicable

transient operation parameters have been set as follows:

and ENTRY keys) or via the GPIB (TRAN:DCYC command).

key).

and ENTRY keys) or via

HPSL Command

TRAN:MODE CONT

CURR 5

CURR:TLEV 10

TRAN:FREQ 1000

TRAN:DCYC 40

TRAN ON

Figure 2-5 shows the waveform that would result in this example. The module input current will slew to and remain at 10

amps for 40% of the period (400 µs), then slew to and remain at 5 amps for the remaining 60% (600 µs) of that cycle.

The load module starts conduction at the main level (in this case 5 amps). When transient operation is turned on and at a

time specified by the frequency setting the input level starts increasing at a rate determined by the slew rate. When the value

specified by the transient level setting is reached, it stays there for the remainder of the time determined by the frequency

and duty cycle settings. After this time has elapsed, the input level decreases to the main level again at the rate specified by

the slew setting and stays there for the remainder of the period prescribed by the frequency setting.

Description

Sets continuous operation.

Sets main current level to 5 amps.

Sets transient current level to 10 amps.

Sets transient generator frequency to 1 kHz.

Sets transient generator duty cycle to 40%.

Turns on transient operation.

Figure 2-5. Continuous Transient Operation

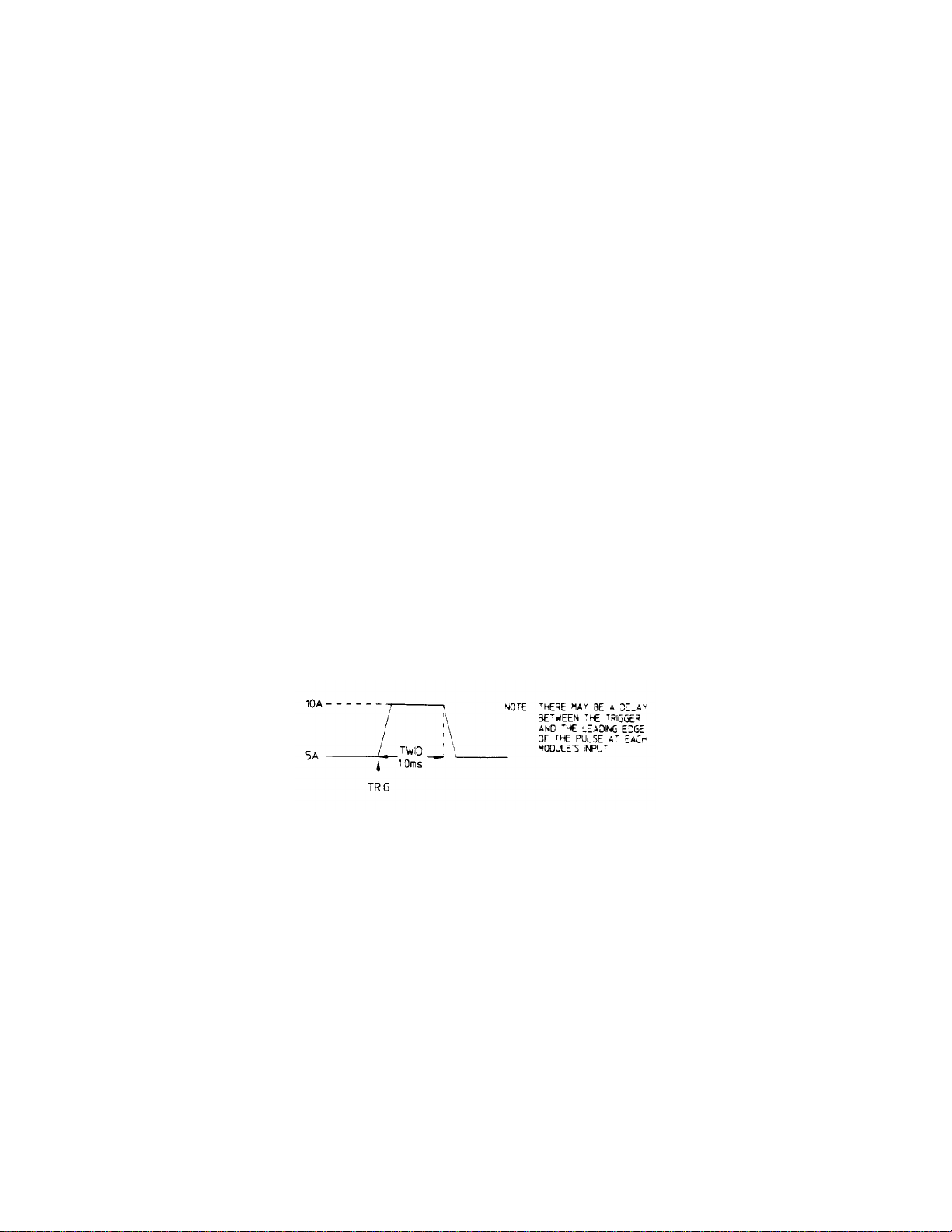

Pulsed Transient Operation

Pulsed transient operation is similar to continuous operation with the following exceptions:

a. In order to get a pulse, an explicit trigger is required. The trigger can be an external trigger signal received via the

TRIGGER input on the rear panel, the GPIB GET function, the *TRG common HPSL command, the TRIG

subsystem HPSL command, or the ac line or internal timer signal.

22 Operation Overview

Page 23

b. One pulse results from each trigger. Therefore, frequency cannot be programmed. The main level, transient level,

and slew rate are programmed as described for continuous operation. The pulse width is programmable from

0.00005 to 4 seconds via the GPIB (TRAN:TWID command). Pulsed transient operation cannot be programmed at

the front panel.

c. The appearance of the pulse at each module’s input may be delayed from the trigger signal. For pulse widths of 17

ms or greater, delay is less than 1.6% of the pulse width. For pulse widths of less than 17 ms, delay is less than 4%

of the pulse width.

In this example, assume that the CC mode is active, the slew rate is at the factory default setting (maximum rate), an external

trigger input is connected to the Electronic Load’s rear panel, and the applicable transient operation parameters have been

set as follows:

HPSL Command Description

TRIG:SOUR EXT Selects the external trigger input.

TRAN:MODE PULS Selects pulsed transient operation.

CURR 5 Sets main current level to 5 amps.

CURR:TLEV 10 Sets transient current level to 10 amps.

TRAN:TWID.001 Sets pulse width to 1 millisecond.

TRAN ON Turns on transient operation.

Figure 2-6 shows the waveform that would result in this pulsed transient operation example. The Electronic Load starts

conduction at the main current level setting (5 amps). When the transient mode is turned on and an external trigger signal is

received, the input level starts increasing at a rate determined by the slew rate. When the value specified by the transient

level setting (10 amps) is reached, it stays there for the remainder of the time determined by the pulse width setting (1

millisecond). After this time has elapsed, the input level decreases to the main level again at the rate specified by the slew

setting and remains there until another trigger is received. Any triggers that occur during the time the transient level is in

effect will be ignored.

Figure 2-6. Pulsed Transient Operation

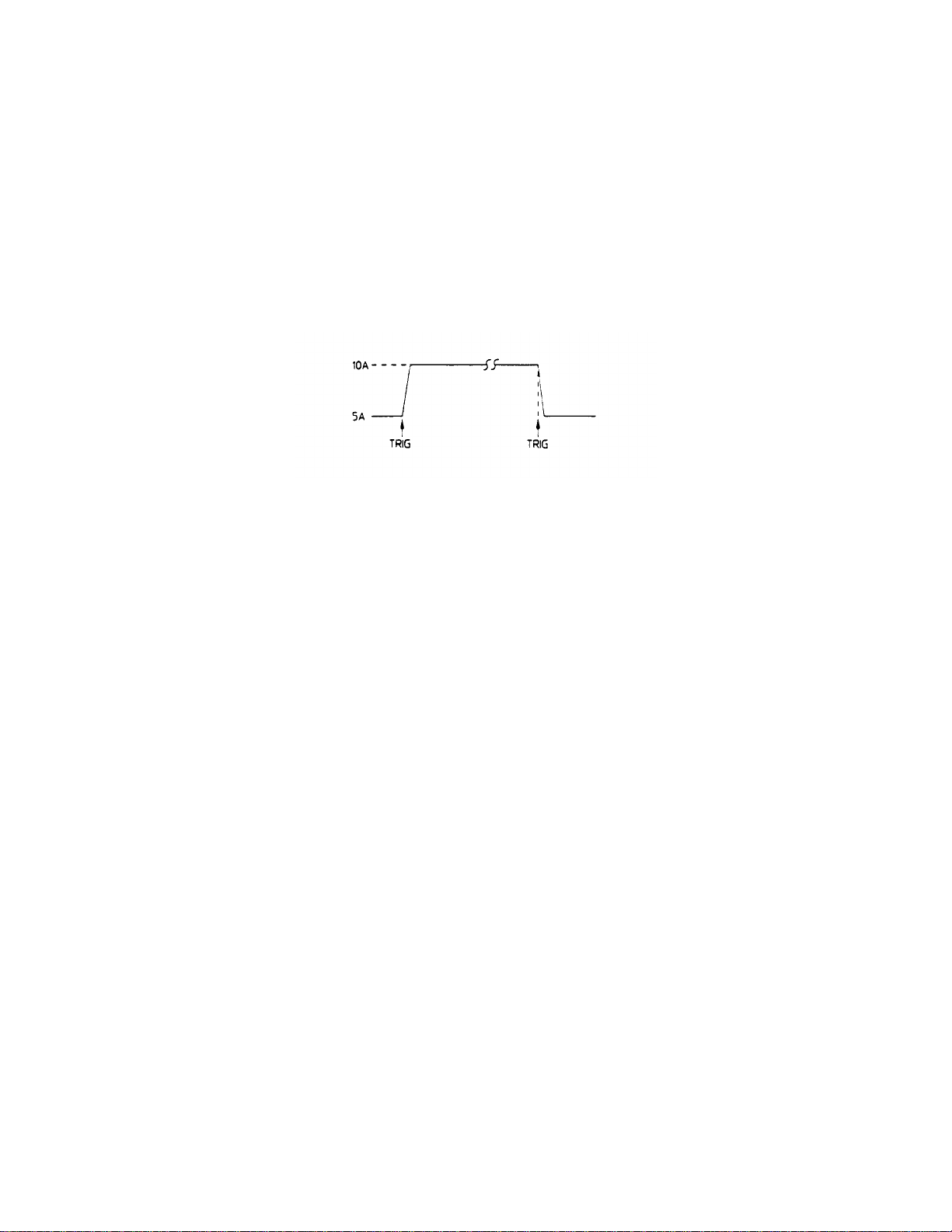

Toggled Transient Operation

Toggled transient operation causes the module input to alternate between two predefined levels as in continuous operation

except that the transient points are controlled by explicit triggers instead of the internal transient generator. As in pulsed

transient operation, the trigger signal can be an external trigger signal, the GPIB GET function, the *TRG command, the

TRIG command, or the ac line or internal timer signals. Note that toggled transient operation can only be programmed via

the GPIB (TRAN:TOGG command); it cannot be programmed at the front panel.

In this example, assume that the CC mode is active, the slew rate is at the factory default setting (maximum rate), an external

trigger input signal is connected to the Electronic Load’s rear panel, and the applicable transient operation parameters have

been set as follows:

Operation Overview 23

Page 24

HPSL Command Description

TRIG:SOUR EXT Selects the external trigger input source.

TRAN:MODE TOGG Selects toggled operation.

CURR 5 Sets main current level to 5 amps.

CURR:TLEV 10 Sets transient current level to 10 amps.

TRAN ON Turns on transient operation.

Figure 2-7 shows the waveform that would result for this toggled transient operation example. Operation is similar to that

described for continuous and pulse operation, except that each time a trigger is received the input alternates between the

main and transient current levels.

Figure 2-7. Toggled Transient Operation

Triggered Operation

The Electronic Load has various triggering modes to allow synchronization with other test equipment or events. The

triggering circuits are located in the mainframe, and all modules receive the trigger simultaneously (although each module is

programmed individually as to what operation, if any, will be triggered. As described previously, triggering can be used for

the following applications:

Triggering a preset level

Triggering a transient pulse

Toggling

Three triggering methods are available over the GPIB: the GET function, the *TRG common HPSL command, and the

TRIG subsystem HPSL command (refer to Agilent Electronic Loads Programming Reference Guide). The HPSL TRIG

subsystem allows you to select either the ac line frequency, internal timer, or TRIG command as the trigger source. There

is also a TRIGGER connector on the rear panel for external trigger inputs. Triggering cannot be done via the front panel.

*TRG and the TRIG command are both synchronous with other commands; that is, the modules are not triggered until

pending operations are completed. GET, external triggers, ac-line triggers, and internal-timer triggers are all asynchronous;

that is, the modules are triggered as soon as the trigger signal is received.

If the ac line is selected via the GPIB as the trigger source, triggers will be generated once for each cycle of ac input power.

An ac line frequency of 60 Hz produces a trigger period of 16.67 ms; 50 Hz line frequency produces a trigger

period of 20 ms.

Transfers all pending preset levels to the actual level. For the presently active mode, the

new level appears at the input. For the modes which are not presently active, the preset

levels will not take effect at the input until the applicable mode becomes active.

Generates a transient pulse of programmable width when pulsed transient operation is in

effect.

Changes the input between the main level and the transient level when toggled transient

operation is in effect.

24 Operation Overview

Page 25

The rear-panel TRIGGER connector also provides a trigger output signal. This signal is generated synchronously with the

trigger signal sent by the mainframe to the modules. The trigger output signal can be used to trigger an external device such

as an oscilloscope, DVM, or another Electronic Load mainframe.

The Electronic Load has a status reporting capability to keep track of trigger operations. Refer to ’Status Reporting’ in the

Agilent Electronic Loads Programming Reference Guide.

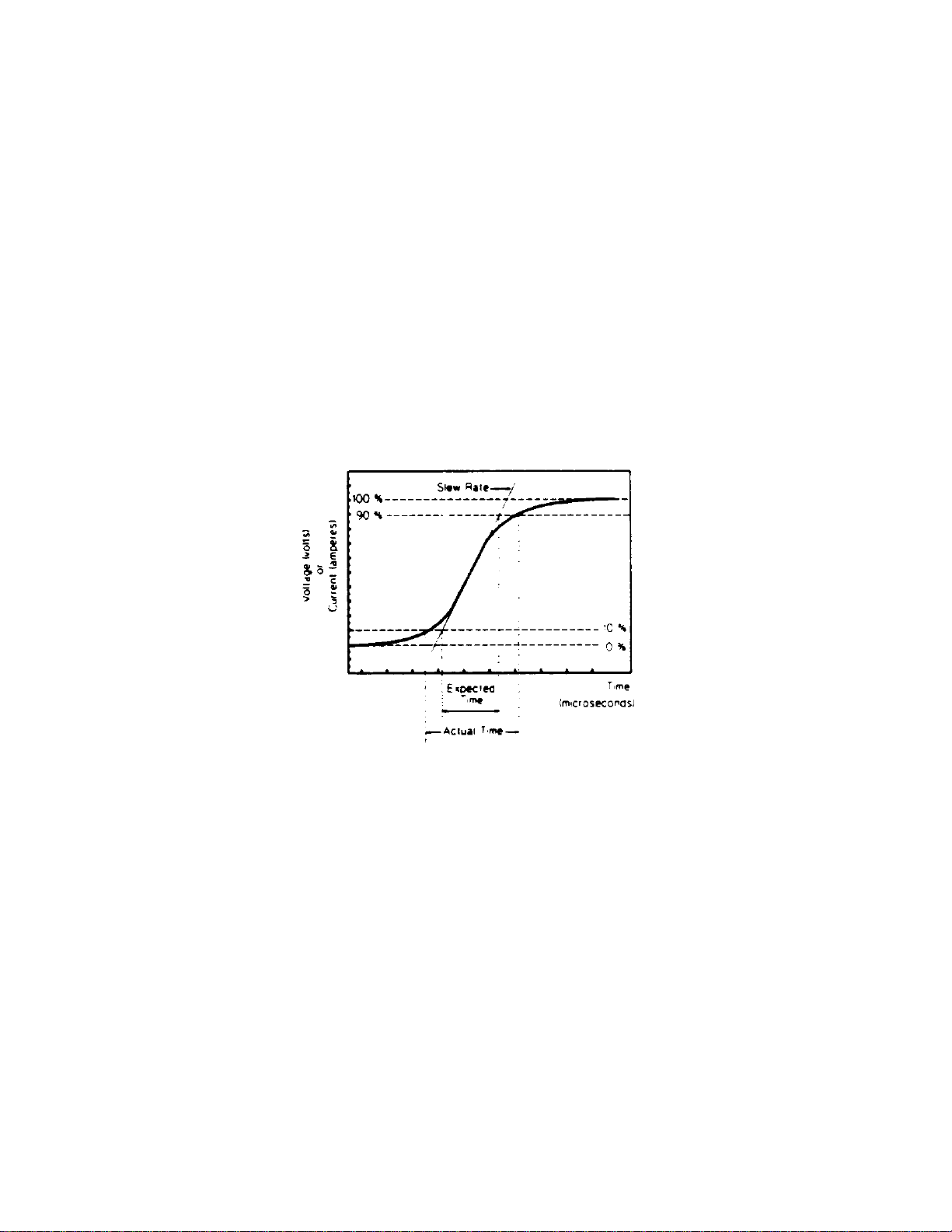

Slew Rate And Minimum Transition Time

Slew rate is defined as the change in current or voltage over time. A programmable slew rate allows a controlled transition

from one load setting to another to minimize induced voltage drops on inductive power wiring, or to control induced

transients on a test device (such as would occur during power supply transient response testing).

In cases where the transition from one setting to another is large, the actual transition time can be calculated by dividing the

voltage or current transition by the slew rate. The actual transition time is defined as the time required for the input to

change from 10% to 90% or from 90% to 10% of the programmed excursion. In cases where the transition from one setting

to another is small, the small signal bandwidth of the load limits the minimum transition time for all programmable slew

rates. Because of this limitation, the actual transition time is longer than the expected time based on the slew rate, as shown

in Figure 2-8.

Figure 2-8. Risetime Transition Limitation

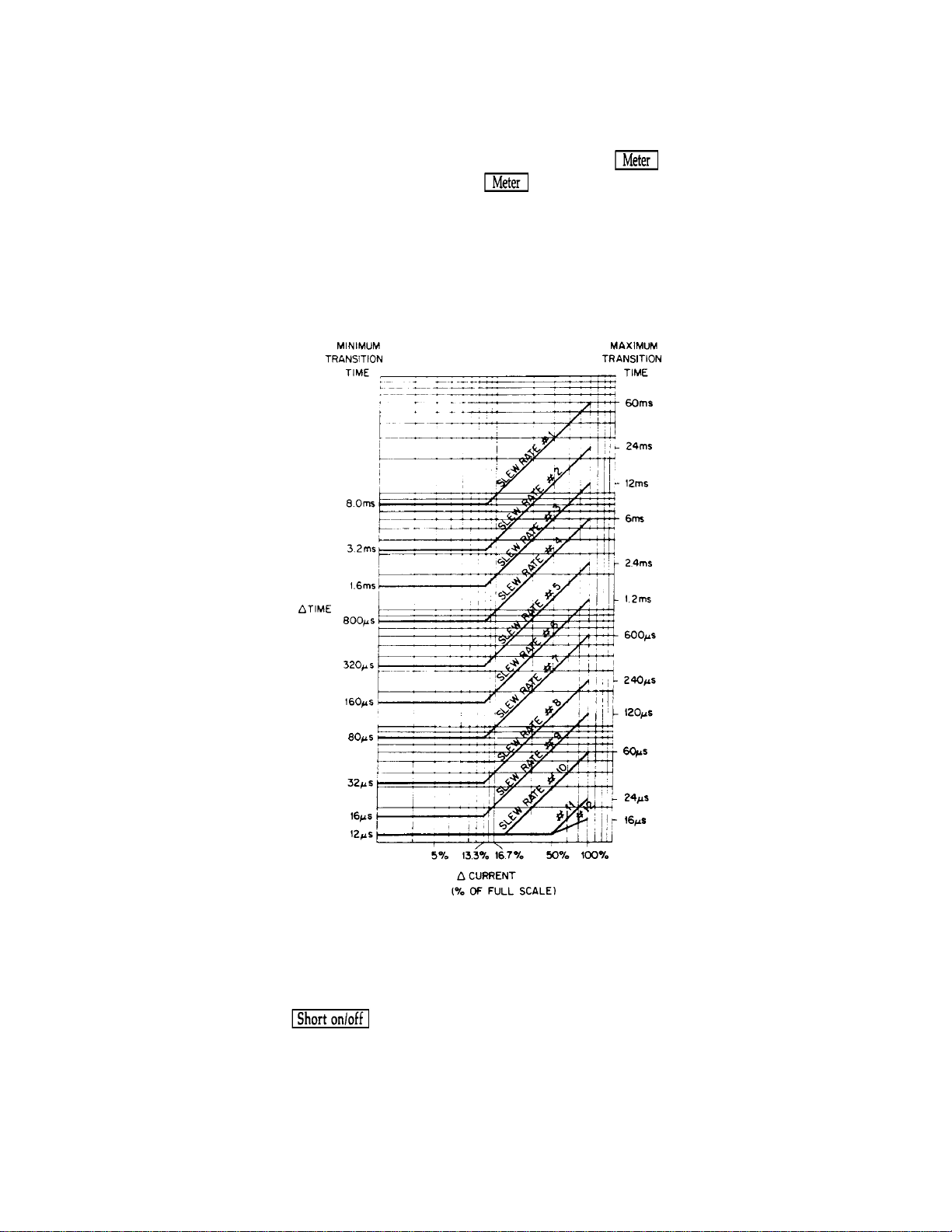

Therefore, both minimum transition time and slew rate must be considered when determining the actual transition time. This

is shown in Figure 2-9 for the twelve programmable slew rates in current mode operation. The actual transition time will be

either the total slew time (transition divided by slew rate), or the minimum transition time, whichever is longer.

In voltage mode, all minimum transition times are based on a low-capacitance current source. These transition times are

affected by capacitive loading of the inputs. For example, a capacitance of 2.2 microfarads increases the 85 microsecond

minimum transition time (shown in the specifications table) to 110 microseconds. Therefore, no graph is provided for

minimum transition time and slew rate in voltage mode operation.

In resistance mode, the low resistance range uses the slew rate that has been programmed for voltage mode. The middle

resistance range uses the slew rate that has been programmed for the high current range. The high resistance range uses the

slew rate that has been programmed for the low current range.

Operation Overview 25

Page 26

Input Current, Voltage, and Power Measurement

Each module’s input current, voltage, and power can be measured at the front panel (

command). With local (front panel) control in effect, pressing

current input values, the computed power value, and various status conditions for the selected channel.

With remote control in effect, a module may be instructed to measure its dc input voltage, current, or power by sending the

appropriate query command (e.g. MEAS:CURR). The results will be read back when the Electronic Load is addressed to

talk. Voltage and current measurements are performed with approximately 12-bit resolution of full scale ratings. Power is

computed from this information.

will continually step the display through voltage and

key) or via the GPIB (MEAS

Figure 2-9. Transition Times and Slew Rates

Short On/Off

A module can simulate a short circuit at its input by turning the load on with full-scale current. The short circuit can be

toggled on/off at the front panel

on/off change uses the slew rate setting of the active mode and range.

26 Operation Overview

key) or via the GPIB (INPUT:SHORT ON|OFF command). The short

Page 27

The actual value of the electronic short is dependent on the mode and range that are active when the short is turned on. In

CV mode it is equivalent to programming zero volts. In CC mode it is equivalent to programming full-scale current for the

present current range. In CR mode it is equivalent to programming the minimum resistance for the present resistance range.

Note that turning the short on in CV mode may cause the load to draw so much current that the software current limit

operates, which may turn the input off.

Turning the short circuit on does not affect the programmed settings, and the load input will return to the previously

programmed values when the short is turned off.

Pressing the Short On/Off key with certain user applications may cause damage to the equipment being

tested, which may result in personal injury. Contact your Agilent Sales and Service office if you need

to have the Short On/Off key disabled.

Input On/Off

A module’s input can be toggled on/off at the front panel (

The input on/off change does not use the slew rate setting so the input will change at the maximum slew rate.

Turning the input off (zero current) does not affect the programmed settings. The input will return to the previously

programmed values when the input is turned on again. Note that the Input On/Off command supersedes the mode

commands and Short On/Off command.

Saving and Recalling Settings

The Electronic Load has internal registers in which settings (mode, current, voltage, resistance, slew, transient level, etc.)

for each module can be saved. By saving settings and recalling them later you can save programming time.

The present settings for all channels are saved in the specified register (0 to 6) at the front panel (

GPIB (*SAV command). All of the settings are saved in the specified location in the mainframe’s memory. Settings saved

in locations 1 through 6 will be lost when ac line power is cycled. However, the *SAV 0 command will cause the settings to

be stored in non-volatile memory; and, the next time the Electronic Load is turned on, these settings will become the poweron settings.

You can recall the saved settings from the specified register (0 to 6) at the front panel (

command). All of the parameters for each module which were saved by the *SAV command are set to the saved values. At

power-on, the Electronic Load automatically executes a *RCL 0, which recalls the values saved in nonvolatile memory.

You can recall the factory default settings at the front panel (

Remember that Save and Recall operate on all channels, not just the presently addressed or selected channel.

key) or via the GPIB (INPUT ON|OFF command).

key) or via the

key) or via the GPIB (*RCL

) or via the GPIB (*RST command).

Reading Remote Programming Errors

Remote programming errors can be read via the GPIB (SYST:ERR? query) or at the front panel (

annunciator indicates when remote programming errors have occurred. The errors are negative numbers grouped into

blocks of 100 as follows:

-lxx Command errors

-2xx Execution errors

-3xx Device-specific errors

-4xx Query errors

Operation Overview 27

key). The Err

Page 28

The SYST:ERR? query (or

up to 30 entries). Once the error is read back it is removed from the list. A value 0 indicates there is no error; and 0 will be

returned when all errors in the list have been read. Pressing the

SYST:ERR? query returns the error number and a short description of the error to the computer. Refer to Chapter 6 in the

Agilent Electronic Loads Programming Reference Guide.

Local programming errors generated by front panel operations are not put into the error list, but are immediately put on the

Electronic Load’s front panel display; e.g., ’OUT OF RANGE’.