Page 1

$JLOHQW 7HFKQRORJLHV

Agilent 5DX Service Guide

Manual Version A

Revision Number

June 26, 2000 11:25 am

5DX

6HULHV

Page 2

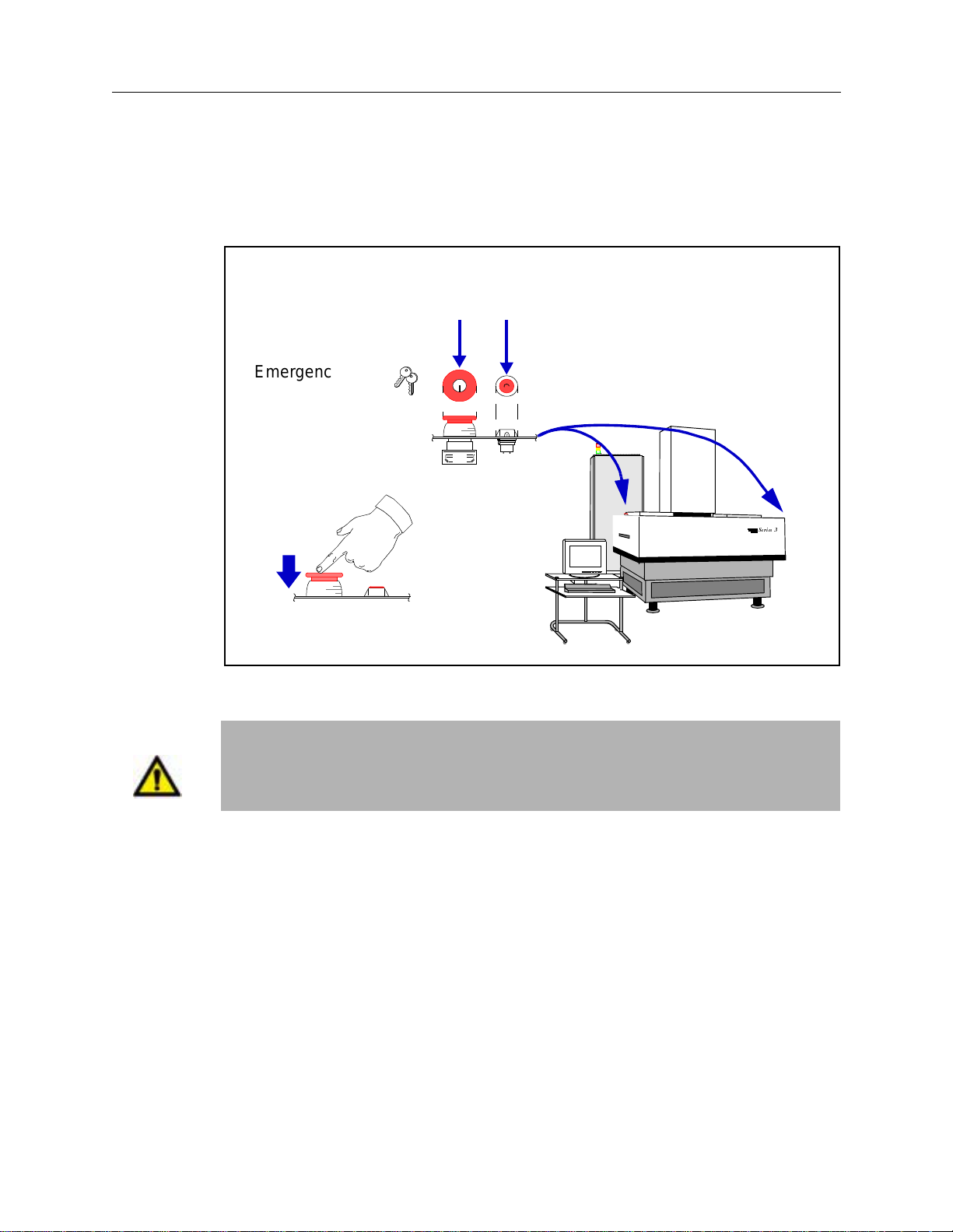

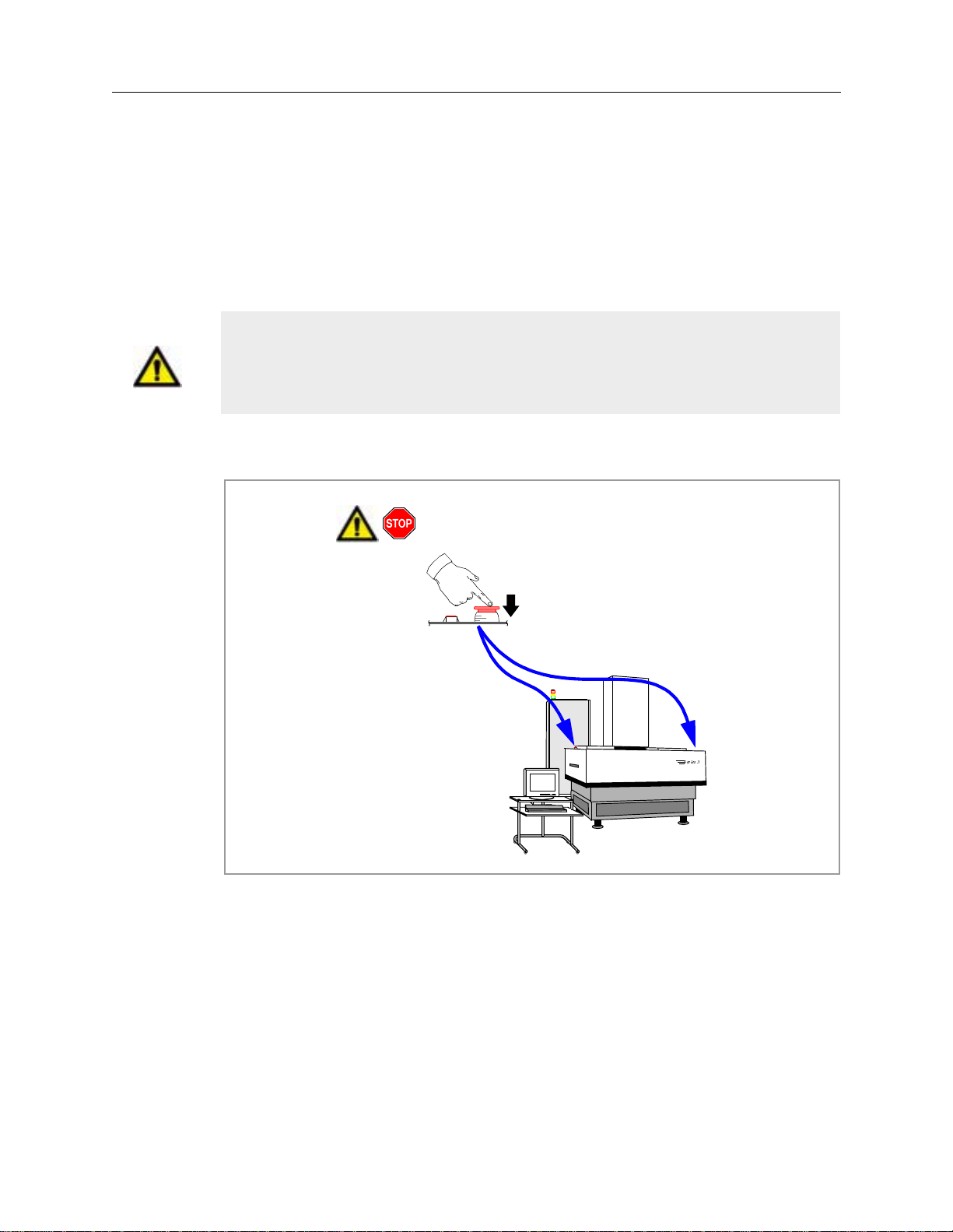

Emergency Shut Down Procedure

In the event of a disaster or system emergency, shut down the 5DX by pressing one

of the Emergency Stop Buttons, as shown in the figure below.

Emergency Stop Button

(Locking Switch)

Emergency Stop

Release Keys

X-ray On Indicator

5DX Series 3

5DX

6HULHV

WARNING

Emergency Stop Button

locks when pressed

120 Volt AC Power Connections are for Agilent Installed Accessories ONLY. Do

not use these connections as utility outlets. Improper handling of these

connections can result in electrical shock.

For additional information on Safety and the 5DX System, see the Chapter 2,

Safety Summary.

Page 3

Warranty and Regulatory Data

Notices

© Copyright Agilent Technologies, Inc. 2000.

All Rights Re s erved.

Printed in U S A

N7200-90041 Printed: May 2000

NOTICE

This manual is provided “as is” and is subject to change with out notice.

AGILENT TECHNOLOGIES MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT

LIMITED TO, THE IMPLIED WARRANTIES OF NONINFRINGEMENT, MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. Agilent Technologies shall not be liable for errors cont ai ned herein, nor for direct, indire ct , gen era l, special, incidental or consequen-

tial damages in connection with the furnishing, performance, or use of thi s ma te ri al .

Adobe™ is a trademark of Adobe Systems Incorporated which may be registered in certain jurisdictions.

Microsoft

Windows

This page lists this manual’s printing history and the system’s software revisions. If you receive manual updates or system software revisions, a new

Printing History Page will acco m pany the updates and revisions. It is important that you insert the new Pri nting History Page in the manual and

®

Manual Printing History And System Software Revisions:

®

is a U.S. registered trademark of Microsoft Corp.

and MS Windows® are U.S. registered trademarks of Microsoft Corp.

remove the old one.

Software Revision Manual Revision

7.0 Rev. A.1, May 2000

Agilent 5DX Service Guide iii

Page 4

Notices 5DX Series 3

WARRANTY

AGILENT TECHNOLOGIES WARRANTY STATEMENT

AGILENT PRODUCT DURATION OF WARRANTY

Agilent 5DX AXI System and Accessories1 (One) Year

1. Agilent warrants Agilen t h ardwar e, acce ssorie s and supplies a gainst defec ts in ma terial s and work manship f or the p er iod specified above.

If Agilent receives notice of such defects during the warrant y period, Agilent will, at its optio n, either repair or replace pro ducts whic h

prove to be defective. Repl ac ement products may be either new or like-new.

2. Agilent warrants that Agil ent sof tware will not fail to exe cute its progra mm ing i nstructio ns, for the p eriod speci fied above , due to d efect s

in material and wo rkmanship when properly in stalled and used. If Agil ent receives notice of such defects during the warranty period,

Agilent will replace software media which does not exec ut e it s programming instructions due to suc h defects.

3. Agilent does not warrant tha t the operation of Agilent product s w il l be un in te rrupted or error free. If Agilent is un able, within a reason a b le

time, to repair or repla ce any p rodu ct to a cond itio n as w arranted , cust ome r will b e entit led t o a refu nd of th e p urcha se pric e upon p rompt

return of the product.

4. Agilent products may cont ain remanufactured parts equivalent to new in performanc e or ma y have been subject to incidenta l use .

5. The warranty period begins on the date of delivery or on the date of installation if installed by Agilent. If customer schedules or delays

Agilent installation more th an 30 days after delivery, warranty begins on the 31st day from de li ve ry.

6. Warranty does not apply to defects resulting from (a) improper or inadequate maintenance or calibration, (b) software, interfacing, parts or

supplies not supplied by Agilent, (c) unauthorized modification or misuse, (d) operation outside of the published environmental

specifications for the product, or (e) improper site preparation or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES ARE EXCLUSIVE ANDNO OTHER WARRANTY

OR CONDITION, WHETHER WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED A ND AGILENT SPECIFICALLY DISCLAIMS

ANY IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY, SATISFACTORY QUALITY, AND FITNESS FOR A

PARTICULAR PURPOSE.

8. Agilent will be l iabl e for d ama ge to tang ible prop erty per in cide nt up to the g reate r of $3 00,00 0 o r th e ac tual amo unt pa id for th e p rod uct

that is the subject of th e claim, and for dama ge s for bodily injury or death, to the extent that all such damages are determ ined by a court of

competent jurisdiction to ha ve been directly caused by a defective Agilent product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS WARRANTY STATEMENT ARE CUSTOMER’S SOLE

AND EXCLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL AGILENT OR ITS SUPPLIERS BE

LIABLE FOR LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST PROFIT OR

DATA), OR OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS STATE-

MENT, EXCEPT TO THE EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE, RESTRICT OR MODIFY AND ARE IN ADDITION

TO THE MANDATORY STATUTORY RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

iv Warranty and Regulatory Data

Page 5

5DX Series 3 Notices

PLACE OF PERFORMANCE

A. Within Agilent service travel areas, warranty and installation services for products installed by Agilent and certain other products

designated by Agilent will be perfo rmed at Customer’s facility at no charge. Outside Ag ilent service travel areas, warr anty and installat ion

services will be performed at Customer’s facility only up on Agilent’s prior agreement and Customer shall pay Agilent’s round-trip travel

expenses and applicable add it io nal expenses for such services.

B. On-site warranty services are provided only at the initial installation point. If products eligible for on-site warranty and installation services

are removed from the initial installation point, the warranty will remain in effect only if Customer purchases additional inspection or

installation services at the new site.

C. For product warranties re quiring return to Agilent, prod ucts must be returned to a service facility designated by Ag ilent. The Customer

shall prepay shipping ch arges (and shall pay al l dut y and t axes) f or pr oduct s retur ned to Agi lent for w arra nty se rvice. Exce pt for prod uct s

returned to Customer from anot he r country, Agilent shall pay for return of products to Customer.

D. Install ation and wa rranty servic es outside the country of in itial purchas e are includ ed in Agilent’s product price only if Customer pays

Agilent international prices (defined as destination local currency price, or U.S., or Geneva Export price). Service outside the country of

initial purchase is subject to the conditions regarding Agil ent service travel areas and init ial in sta ll ation point described above.

LIMITATION OF REMEDIES AND LIABILITY

A. Agilent will not be liabl e for performance delays or for non-performance, due to cause s beyond its reasonable control.

B. Pro ducts not specifically designed, man ufactured or intended for sale as part s, components or assemblies for plann ing, construction,

maintenance, or direct operat ion of a nuc lear f acility. Customer is solely liable if Produ cts or Suppo rt purch ased by Cu stome r are used for

these applications. Cu stom e r w i ll in de mnify and hold Agilent ha rm le ss from all loss, damage, ex pense or liability in co nnection with such

use.

C. Agilent will be liable for damage to tangible property per incident up to the greater of $300,000 or the actual charges paid to Agilent for the

product that is the subject of the claim, a nd for damages for bodi ly injury or death, t o the extent that al l su ch damages are de termine d by a

court of competent juri sd ic ti on to have been directly caused by a defective Product sold here under.

D. For any material breach of Support services by Agilent, Customer’s remedy and Agilent’s liability will be limited to a refund of the related

Support charges paid during the perio d of breach, up to a maximum of 12 mon ths.

E. THE REMEDIES IN THIS AGREEMENT ARE CUSTOMER’S SOLE AND EXCLUSIVE REMEDIES. EXCEPT AS INDICATED

ABOVE, IN NO EVENT WILL AGILENT OR ITS SUBCONTRACTORS BE LIABLE FOR LOSS OF DATA OR FOR DIRECT,

SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST PROFIT), OR OTHER DAMAGE WHETHER BASED IN

CONTRACT, TORT, OR OTHERWISE.

U.S. Government Restricted Rights

The Software and Documentation have bee n developed entirely at pr iva te expense. They are d el iv ered and licensed as “commercial computer

software” as defined in DFARS 252.227-7013 (Oct 1988), DFARS 252.211- 7015 (May 1991) or DFARS 252.22 7-7014 (Jun 1995), as a

“commercial item” as defined in F A R 2. 101(a), or as “Restricted comput er soft wa re” as defined in FAR 52.227-19 (Jun 1987) (or any equivalent

agency regulation or contract clause), whichever is applicable. You hav e onl y those rights provided for such Software and Docum entation by the

applicable FAR or DFARS claus e o r th e Agilent standard software agreement for the product involved .

Agilent 5DX Service Guid e v

Page 6

Notices 5DX Series 3

Regulatory Information

Agilent Technologies i s registered with federal and state agencies to sell and service its own X-ray equipment manufactured in Loveland,

Colorado, USA. The equipment was designed, and is used, to inspect printed circuit boards only. The X-ray equipment is classified in the United

States and internationally as an “Industrial Cabinet X-ray System”. It is not large enough for human entry. The equipme nt has be en de sig ned and

constructed to be safely us ed in any area.

The Agilent 5DX System utilizes an X-ray Tube opera ting at 160 kilovolts, 100 microa mps shielded within the lead cabinet. The tube is rated for

continuous duty operation with beam filtration of 0.07 inches Beryllium and 0.010 inches stainless steel.

The lead cabinet is fully int erlocked such that the main pow er to the X-ray Tube is removed when any access panel is opened.

When the 5DX System is installed at the customer’s site, the equipment is surveyed by trained service people. A full radia ti on safety survey is

performed and a report gener a ted. The survey is made using a Geiger Mu eller and a health ph ysics ion chamber according to procedures on record

with the CDRH.

The end user is responsible for regi ster i ng th e equipment with their local and state authorities.

Agilent Technologies warrants that the 5DX automated process test systems meets X-ray safety reg ulations in the following countries:

Canada Reference Statutes of Canada Chapter R-1, Chapter 1370, Schedule 1, Section 15, Schedule II and Part XV.

England Reference BS5724, (ISO 9000 601-1).

Germany Reference BGBII, S.114 & Din 54113 and the “Law on the Protection Against Injury or Damage Due to X-Rays” a.k.a. “X-Ray

Decree”.

Japan Reference Ministry of Labor, Industrial Safety and Health, Law #57 a nd Ca binet ordinance #38.

Korea Reference Presidential Decree, Article 65, Chapter VII, of the Atomic Energy Act.

The Nordic Regions of Denmark, Finland, Iceland, Norway and Sweden,

Reference the Radiat io n Protection Institutes and the Radiation Protection Act.

United States

Regulation 21CFR 1010.2 , 10 10. 3, and 1020.40 administered by th e D e partment of Health and Human Servi c es, Food and Drug

Administration, Center for D evices and Radiological Health (CDRH).

vi Warranty and Regulatory Data

Page 7

5DX Series 3 Safety Information

Safety Information

WARNING

WARNING

!

This product produces X-rays. Do not attempt to open any part of the product.

Exposure to X-rays can cause serious bodily injury. Refer all servicing to

service-trained personnel.

This product produces X-rays. Do not oper ate t his produc t or turn on the X-r ays

source unless all shielding is in place. Operation without shielding in place can

result in seriou s bod ily in ju ry.

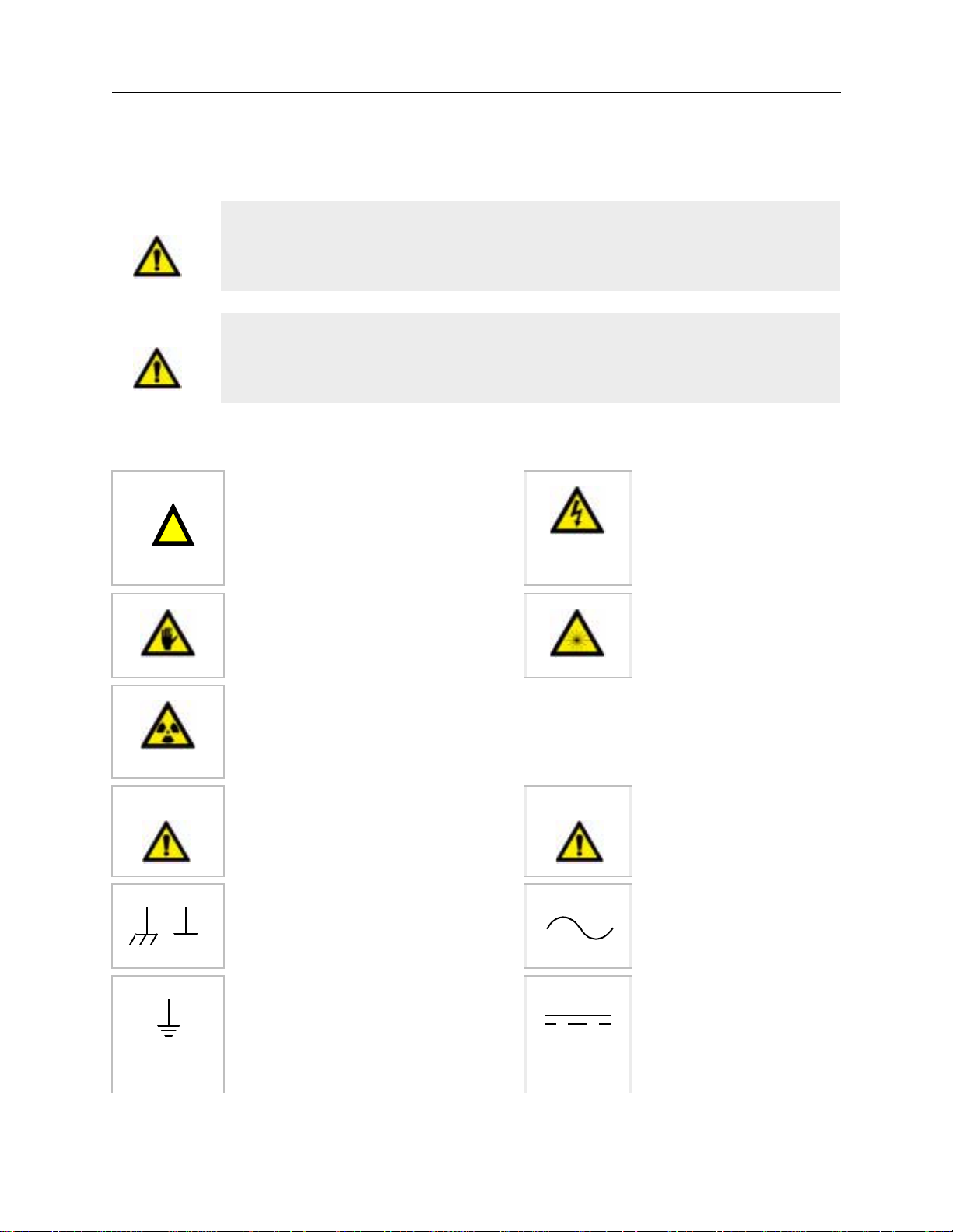

SAFETY SYMBOLS

Instruction symbol affixed to

product. Indicates that the user must

refer to the manual for spe ci fi c

WARNING or CAUTION

information to avoid personal injury

or damage to the product.

Calls attention to pinch hazards.

Keep hands away to avoid injur y.

Indicates hazardous voltage.

Indicates thi s equipment produces

laser radiation when energized.

WARNING

Indicates this equipment pro duc e s Xrays when energized.

Calls attention to a procedure,

practice, or condition that coul d

result in bodily injury or death.

Frame or chassis ground terminal —

typically connects to the equipment’s

metal frame.

Indicates the field wiring termina l

that must be connecte d to earth

ground before operating the

equipment — prote c ts against

electrical shock in case of fa ult .

Caution

Calls attention to a proced ure,

practice, or condition that could

cause damage to equipment or

permanent loss of data.

Alternating current (ac).

Direct current (dc).

Agilent 5DX Service Guide vii

Page 8

Safety Informa tion 5 D X S e ries 3

WARNINGS

The following general safe ty precautions must be observ ed during all phases of operati on, service, and repair of this prod uct. Failure to comply

with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and intended use of the

product. Agilent Technologi es, Inc. assumes no liability for the Customer ’s failure to comply with these requirements.

Ground the Equipment For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth ground must

be provided from the mains pow er source to the product input wiring terminals or supplied pow er cab le .

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gases or fumes.

For continued protection aga in s t fir e, replace the line fuses(s) only with the fuse(s) of the same voltage and current rating and type. DO NOT use

repaired fuses or short-circuited fuse holders.

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Procedures involving the removal of covers or

shields are for use by service-train ed personnel only. Under certain conditions, dangerous voltages ma y exi s t even with the equipment switched

off. To avoid dangerous electrical shock, DO NOT perform procedures involv ing cov er or shield removal unless you are qu alified to do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into this product have been impaired,

either through physical damage, excessive moisture, or by any other reason, REMOVE POWER and do not use the product until safe operation can

be verified by service-trained personnel. If necessary, return the product to a Agilent Technologies Sales and Service Office for service and repair

to ensure that safety features are maintained.

Do not service or adjust alone: Do not attempt internal service or adjust m en t unl ess a nother person, capable of ren de ring first aid and

resuscitation, is present.

Do not substitute parts or modify equipment: Because of the danger of introducing additional hazards, do not install substitute parts or perform

any unauthorized mod ifi ca tion to the product. Return th e product to a Agilent Tech nologies Sales and Service Offi ce for se rvice and repair to

ensure that safe ty fea tures are maintained.

viii Warranty and Regulatory Data

Page 9

5DX Series 3 Safety Information

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Agilent Technolo gies, Inc.

Manufacturin g Te st Division

Manufacturer’s Address: 815 14th Street S .W.

Loveland, Colorado 80537

declares, that the products: Agilent Model 5DX Systems

and to which this declaration relates, are in conformity with the protection requirements of:

The EMC Directive 89/336/EEC (inclusive 93/68/EEC) and carries the “CE” marking accordingly.

Attestation is provided according to article 10 (2) of the Directive by a Technical Construction File.

Technical File Number: 95-0900-003-TCF Rev: A Dated: 31 March, 1995

The following standards are referenced in the file:

EMC: CISPR 11:1990/EN55011 (1991)

IEC 801-2:1991/EN50082-1 (1992)

IEC 801-3:1984/EN50082-1 (1992)

IEC 801-4:1988/EN50082-1 (1992)

A Technical Report/Certificate has been issued in accordance with P art V (Reg 50) of the UK

Regulations (SI 1992 No. 2372) by a UK appointed Competent Body, namely,

Interference Technology International Limited

41-42 Shrivenham Hundred Business Park

Shrivenham, Swindon, Wilts. SN6 8TZ

England, UK

Certificate Number: C134FPI1.JES Dated: 1 April, 1996

Supplementary Information:

This product also herewith complie s with th e require m ents of th e Low Voltage Directive 73/23/EEC

(inclusive 93/68/EEC).

Safety: IEC 1010-1 (1990) I ncl. Amend 1 (1992)/EN6 1010-1 (1993)

CSA C22.2 #1010.1 (1992)

UL 3111

April 1, 1996 Loveland Quality Manager

European Contact: Your local Agilent Technolo gi es Sal es a nd Se rvice Office or Agilent Techno logies GmbH,

Department HQ-TRE, Herrenberger Straße 130, D-71034 Böbli ngen (FAX: +49-7031-143 143).

Agilent 5DX Service Guid e ix

Page 10

Electromagnetic Compatibility Requirements 5DX Series 3

Electromagnetic Compatibility Requirements

This product complies with EN 55011 (CISPR 11) Group 1, Class A for conduc ti ng emissions. The product excee ds the EN 55011 (CISPR 11)

Group 1, Class A limit for radiated emissi ons by less than 10 dB when measured on a test site at a distance of 30 meters. Therefore, some site

preparations may have to be don e in order to comply with the Class A lim it in th e frequency range of 30 MHz to 1 GHz for ra diated emissions at

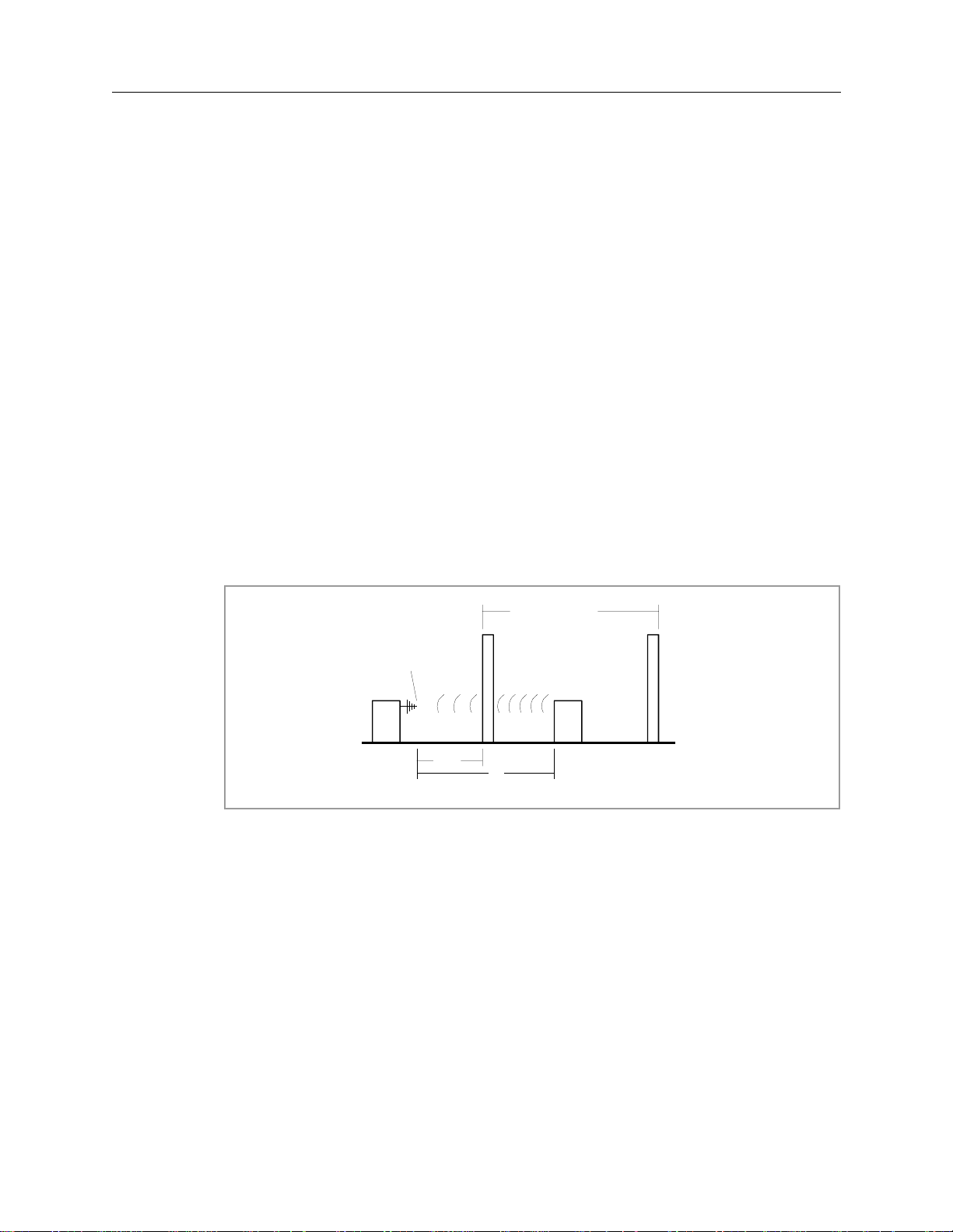

30 meters from the exterior wall of a buil di ng i n w hi ch t he equi pm ent is installed. See the figure bel ow for an illustration of the site calculations.

To obtain the necessary at te nua ti on at the Customer’s site, perfor m t he se ca lc ul at ions (if the calculated site attenuation (A) is less than 10 dB,

contact the Technical Regulatory Support Engine er (T RSE) in your country):

1. The attenuation of a concrete wall (W) (without any openings) = 10 dB

2. The distance (D) (the distance from the equipment to the exterior wall plus 30 meters) increases the attenuation by X and can be calculated

as follows:

X = 20 * log (D/30)

Where: X = attenuation in dB

D = distance in meters

3. The total attenuation (A) is calculated as follows:

A = n * W + X

Where: A = total attenuation in dB

n = number of concrete wa ll s w ith in dist ance D

W = 10 (dB)

Building in which the

Equipment is installed

W

Measuring Po i nt

30 m

D

Equipme nt

QBEMC.WPG

Figure 1: Electromagnetic Emission Measurement

x Warranty and Regulatory Data

Page 11

5DX Series 3 Emergency Stop

Emergency Stop

The Emergency Stop Subsystem is used to quickly shutdown the power to the

Agilent 5DX Main Cabinet. The Emergency Stop Subsystem is intended for crisis

situations only and should not be used as the normal means to stop the Agilent

5DX.

Caution

The Emergency Stop Buttons are intended for use in emergency situations

and should not be used for normal system shutdown. Repeated misuse of

only

the Emergency Stop Buttons will eventually cause damage to certain

components or the loss of dat a or both.

The 5DX System is equipped with two Emergency Stop Buttons. Refer to Figure 2

for their locations.

Push down the Emergency Stop Button, or

switch the AC “Mains” to the “0” or off posit ion

in an emergency situation.

The Emergency

Stop Butt on locks

OFF when pushed.

View from the front of the

5DX System.

5DX

6HULHV

Figure 2: Emergency Stop Locations

The Emergency Stop Buttons are located on either side of the 5DX System Main

Cabinet just above the input or output barriers. When either Emergency Stop

Button is pressed it will immediately interrupt the switched system power. The

Emergency Stop Button will lock in the power off position and remain in the

locked position until released with the Emergency Stop release key. See the

Agilent 5DX Power Subsystem chapter of the Agilent 5DX Series 3 Service

Guide for a step-by-step procedure for restoring system power after an Emergency

Stop procedure has been performed.

Agilent 5DX Service Guid e xi

Page 12

Emergency Stop 5DX Series 3

xii Warranty and Regulatory Data

Page 13

Table of Contents

Warranty and Regulatory Data

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Electromagnetic Compatibility Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

1. Introduction and Overview

What’s in the Agilent 5DX Service Guide?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

What’s New With the Series 3? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

What is the 5DX Automated X-ray Inspection System? . . . . . . . . . . . . . . . . . . . . . .1-4

How It Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

The 5DX System Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

5DX Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Electronics Bay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Subsystems of the Agilent 5DX System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Safety Interlock Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

X-ray High Voltage Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Panel Handling Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Surface Map Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Imaging Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Pneumatics Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

System Controller and Expansion Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Agilent 5DX Service Gui d e xiii

Page 14

2. Safety Summary

Safety Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Emergency Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

X-ray Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Effects of Radiation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

X-ray Dose Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Definition of a Cabinet X-ray System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Built-In Safety Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Registration Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

X-ray Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

X-ray Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

High Voltage Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

High Voltage Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Power Distribution Unit (PDU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Agilent 5DX System Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

5DX Series 3

3. Safety Interlock Subsystem

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Safety Interlock Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Normal Operation LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Diagnostic LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Safety Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Safety Interlock Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Safety Interlock Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Safety Interlock Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Operator Control Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Adjusting the Safety Interlocks on the Inner Barrier. . . . . . . . . . . . . . . . . . . . .3-15

Adjusting the Outer Barrier’s Primary Safety Interlock . . . . . . . . . . . . . . . . . .3-18

Adjusting the Outer Barrier’s Secondary Safety Interlock . . . . . . . . . . . . . . . .3-23

xiv Table of Contents

Page 15

5DX Series 3

4. Power Subsystem

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Power Distribution Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Input Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Switched Output Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Unswitched Output Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

High/Low Line Monitoring/Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Emergency Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

PDU Circuit Breakers and Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Low Voltage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Focus Coil Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

VacIon Pump Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Camera Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

X-ray High Voltage Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Emergency Stop Buttons and X-Ray Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Long Term Shutdown For the Agilent 5DX System . . . . . . . . . . . . . . . . . . . . . . . .4-22

Startup Procedure For the Agilent 5DX System . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Recover From an Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

System Status Beacon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

5. Panel Handling Subsystem

Panel Handling Subsystem Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Agilent 5DX Panel Handling Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Panel Handling Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Configuring a System for Right to Left Flow Through. . . . . . . . . . . . . . . . . . . .5-6

Dual Panel Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

SMEMA Interface Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Communication Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

SMEAMA Connections through the Digital I/O Assembly . . . . . . . . . . . . . . .5-11

Panel Handling Subsystem Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

X-ray Cabinet and Barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Outer Cabinet and Outer Barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Inner Cabinet and Inner Barrier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

XYZ Stage Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

X-Axis and Y-Axis Servomotors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

Z-Axis Stepper Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Agilent 5DX Service Guid e xv

Page 16

5DX Series 3

XYZ Stage Panel Conveyor Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

XYZ Stage Panel Conveyor Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

Motion Control Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Motion Control Diagnostic Access Module . . . . . . . . . . . . . . . . . . . . . . . . . . .5-29

Servo Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

Automatic Wi dth Adj ust ( AWA) an d Z- Axis Stepper Drivers . . . . . . . . . . . . .5-33

Motion Enable Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

Motor Relay Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-35

Motion Controller PCI Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

Motion Controller PCI 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

Motion Controller PCI 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

Digital I/O Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-42

Panel Handling Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-51

6. Pneumatic Subsystem

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -2

Pneumatic Subsystem Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Pneumatic Gauge, Regulator, and Filter Assembly. . . . . . . . . . . . . . . . . . . . . . .6-4

Main Safety Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Internal Manifold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Inner Barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Barrier Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Adjusting the Air Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Other Inner Barrier Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Adjustment/Replacement of the Inner Barrier Encoder . . . . . . . . . . . . . . . . . .6-16

Setting the Positions for the Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

xvi Table of Contents

Page 17

5DX Series 3

7. Surface Map Subsyste m

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

XYZ Panel Orientation (Loaded). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Panel Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Alignment Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Surface Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

OFFSET (X&Y) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Laser Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Surface Map Subsystem Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Surface Map Laser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Laser Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Laser View Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Panel View Camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

8. Imaging Subsystem

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Image Generation Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Image Acquisition Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

Image Acquisition Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

Image Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

Imaging Subsystem Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Image Generation Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Image Acquisition Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Image Analysis Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

System Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

X-ray Scan Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Rotary Scintillator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-20

Interface Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-24

Frame Grabbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-25

X-ray Image Camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-25

9. System Controller

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

System Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Expansion Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

Agilent 5DX Service Guide xvii

Page 18

10. Maintenance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Preventative Maintenance (PM) Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

General Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

Electronics Bay Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-15

Main Cabinet Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Software Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-42

5DX Series 3

Maintenance Activity Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

Check the Operation of the System Status Beacon . . . . . . . . . . . . . . . . . . . . . .10-7

Check X-ray High Voltage Power Supply Status . . . . . . . . . . . . . . . . . . . . . . .10-9

Check X-ray Tube Dielectric Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

Check the Panel View Camera Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-13

Check the Focus Coil Power Supply Setting. . . . . . . . . . . . . . . . . . . . . . . . . .10-15

Clean All Filters and Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-18

Check the Vac-Ion Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Check the System Air Pressure/Low Pressure Regulator . . . . . . . . . . . . . . . .10-26

Inspect the Laser Camera Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-27

Inspect Main Cabinet Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-29

Inspect the XYZ Stage Conveyor Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-30

Inspect Left and Right PIP Sensor Flags. . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-31

Lubricate the XYZ Stage Lead Screws and Rails . . . . . . . . . . . . . . . . . . . . . .10-33

Clean and Inspect the Rotary Scintillator Shield. . . . . . . . . . . . . . . . . . . . . . .10-36

Check the Auto Width Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-37

Clean and Inspect the Main Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-39

Lubricate XYZ Stage Rail Cars. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-40

Replace the XYZ Stage Conveyor Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-41

Replace the Conveyor Belt Motor Control Relays . . . . . . . . . . . . . . . . . . . . .10-41

Check the Inner Barrier Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-42

Run Position Repeatability Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-43

Run Resolution Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-44

Run X-ray Safety Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-45

Run the Confirmation and Adjustment Procedures. . . . . . . . . . . . . . . . . . . . .10-45

Backup the Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-45

xviii Table of Contents

Page 19

1.Introduction and Overview

In this chapter...

This chapter describes the following topics:

n What’s in the Agilent 5DX Service Guide?, 1-2

n What’s New With the Series 3?, 1-3

n What is the 5DX Automated X-ray Inspection System?, 1-4

n 5DX Overview, 1-7

Figure 1-1: 5DX Series 3 Syste m

5DX

6HULHV

Agilent 5DX Service Guid e 1-1

Page 20

What’s in the Agilent 5DX Service Guide? 5DX Series 3

What’s in the Agilent 5DX Service Guide?

The Agilent 5DX Series 3 Service Guide provides information about servicing

the Agilent 5DX System. This chapter gives an overview of the service guide, an

introduction to the Agilent 5DX Series 3 System and an overview of the 5DX

components.

The warranty and regulatory pages provide information about the Agilent 5DX

System’s compliance with various government regulations. The 5DX System is

designed, manufactured and registered in accordance with strict criteria

established by the Center for Devices and Radiological Health (CDRH),

Department of Health and Human Services, X-ray Products Branch. Agilent

Technologies certifies that the 5DX System meets or exceeds U.S Federal

Requirements, 21 CFR 1020.40, subchapter J, for cabinet X-ray systems used in an

industrial environment.

The section or chapter titled Safety Summary describes necessary precautions

that should be taken by personnel that work in close proximity to the 5DX System

as well as the safety features of the 5DX.

Detailed descriptions and diagrams for each subsystem are provided in the

following sections of this manual, including:

• Safety Interlock Subsystem

• Power Subsystem

• Panel Handling Subsystem

• Pneumatic Subsystems

• Surface Map Subsystem

• Imaging Subsystem

• System Controller

• Imaging Diagnostics

To keep the 5DX System in optimum working condition, Agilent recommends

following the Preventive Maintenance schedules and procedures given in the

chapter titled Maintenance.

1-2 Introduction and Overview

Page 21

5DX Series 3 What’s New With the Series 3?

What’s New With the Series 3?

The Agilent 5DX Series 3 includes the following upgrades and changes from the

Series II/2L:

• Panel Handling and motion control have been redesigned.

• The motion control driver assembly is integrated into the Motion Control

Assembly. There is no motion control power supply

• XYZ Stage initialization has been improved.

• Brushless motors are now used, eliminating the need to change motor

brushes.

• A mechanical “middle rail” option is available so two boards or panels can

be tested simultaneously for increased through put.

• The Power Subsystem has changed

• There are only nine power options available, reducing confusion of which

one to use.

• The isolation transformer and Brute power supply have been eliminated.

• The PDU now controls servo module power.

• External power outlets have been eliminated to reduce confusion about

what is or is not 5DX power.

• A new controller and expansion chassis are used.

• The new controller provides faster handling of information.

• The new expansion chassis uses primarily PCI bus components instead of

the older ISA components.

Agilent 5DX Service Guid e 1-3

Page 22

What is the 5DX Automated X-ray Inspection System? 5DX Series 3

What is the 5DX Automated X-ray Inspection System?

The 5DX System uses X-ray Laminography to examine solder joints on plated

through-hole, single and double-sided surface mount technologies (all common

package types), solder paste and grid arrays (solder bump, Ball Grid Array,

connectors), as well as, fine pitch Chip-On-Board assemblies.

The 5DX System can operate inline with the Printed Circuit Assembly

manufacturing process equipment and is designed to be used on PCA’s only.

X-ray Laminography is used to separate solder joints into individual layers, the

resulting detailed slice images are easily analyzed through gray level (256 gray

scale) processing.

The 5DX System is capable of a testing a single or double-sided board or a panel

of boards with an area of up to 455 x 455mm (17.5 x 17.5 inches).

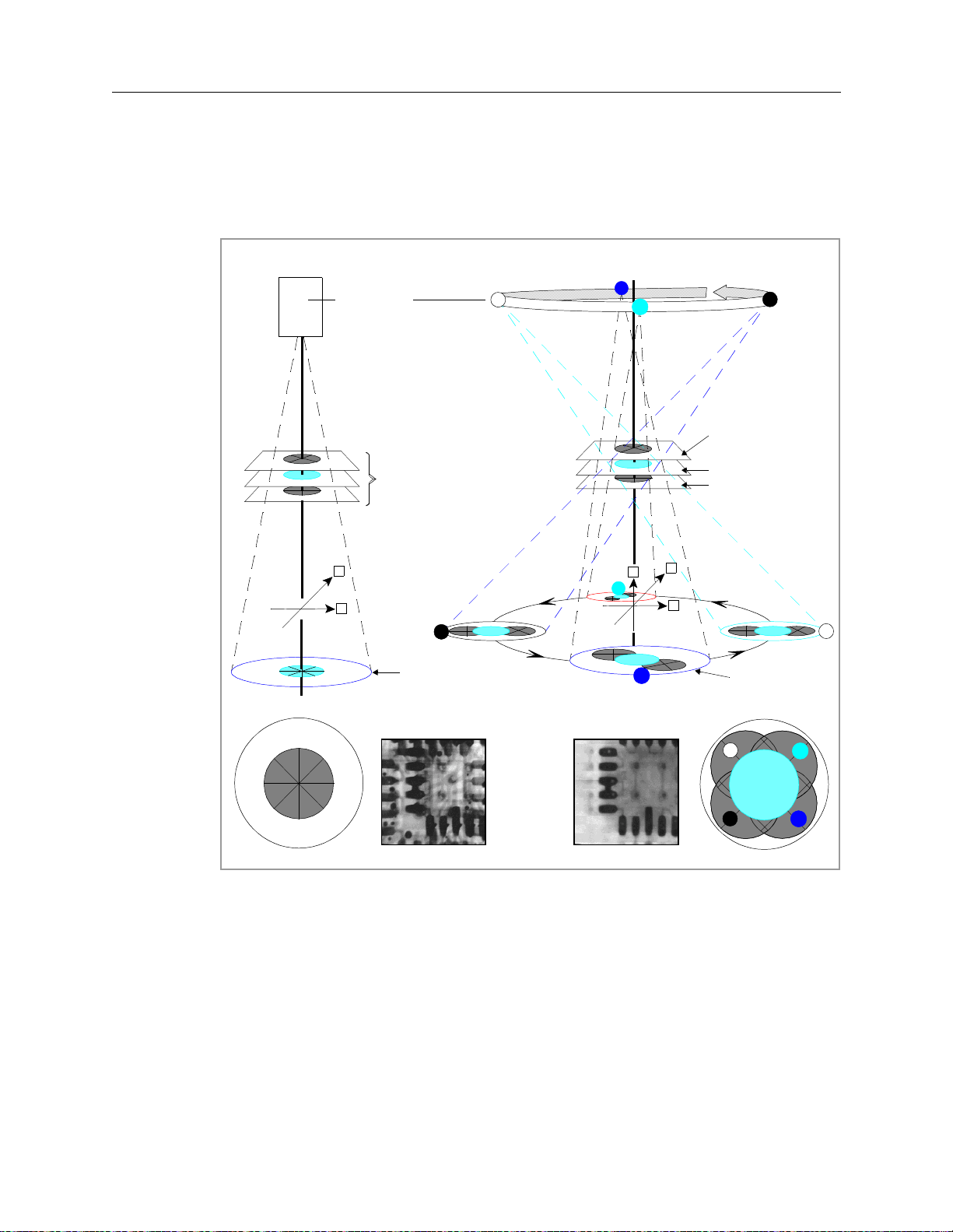

How It Works

X-ray Laminography produces high-resolution cross-sectional slice images of

solder joints of a printed circuit assembly (panel). An electron beam generated by

the X-ray Tube is magnetically steered in a circular synchronous motion. The

electron beam is 180° out-of-phase from a rotating capture device called the

Rotary Scintillator. The Plane of Focus is produced in the area between the source

and the scintillator, thereby, ima ging a sli ce ima ge on the scint illator of the Rotary

Scintillator Assembly.

When a PCA is positioned within the Plane of Focus, the X-ray beam acts as a

penetrating source of illumination t hat forms a negative shadow on the scinti llator.

The phosphor molecules coating the scintillator become excited and radiate light.

The light is then viewed by the X-ray Image Camera and information is passed to

the imaging subsystem. The process of image averaging blurs out objects that

occupy areas above and below the Plane of Focus, while the area within the Plane

of Focus is clear. By this means various layers of the solder joints can be imaged

by moving the panel up and down through the Plane of Focus.

1-4 Introduction and Overview

Page 23

5DX Series 3 What is the 5DX Automated X-ray Inspection System?

Figure 1-2 illustrates the X-ray geometry for Transmissive X-ray Imaging and X-

ray Laminography in a 3-dimensional imaging plane.

7UDQVPLVVLYH;UD\,PDJLQJ

X-RAY SOURCE

DEFECT

Y

X

3ODQHRI)RFXV

3

6WDWLRQDU\

6FLQWLOODWRU

;UD\/DPLQRJUDSK\

1

4

2

3

$ERYHWKH3ODQH

RI)RFXV

3ODQHRI)RFXV

%HORZWKH3ODQHRI

)RFXV

Y

Z

2

X

1

4

5RWDU\

6FLQWLOODWRU

7UDQVPLVVLYH;UD\,PDJLQJ

;UD\/DPLQRJUDSK\

1

680

',))

3 4

Figure 1-2: X-ray Laminogr aphy versus Transmissive X-ray Imaging

Agilent 5DX Service Guid e 1-5

2

Page 24

What is the 5DX Automated X-ray Inspection System? 5DX Series 3

The 5DX System Process

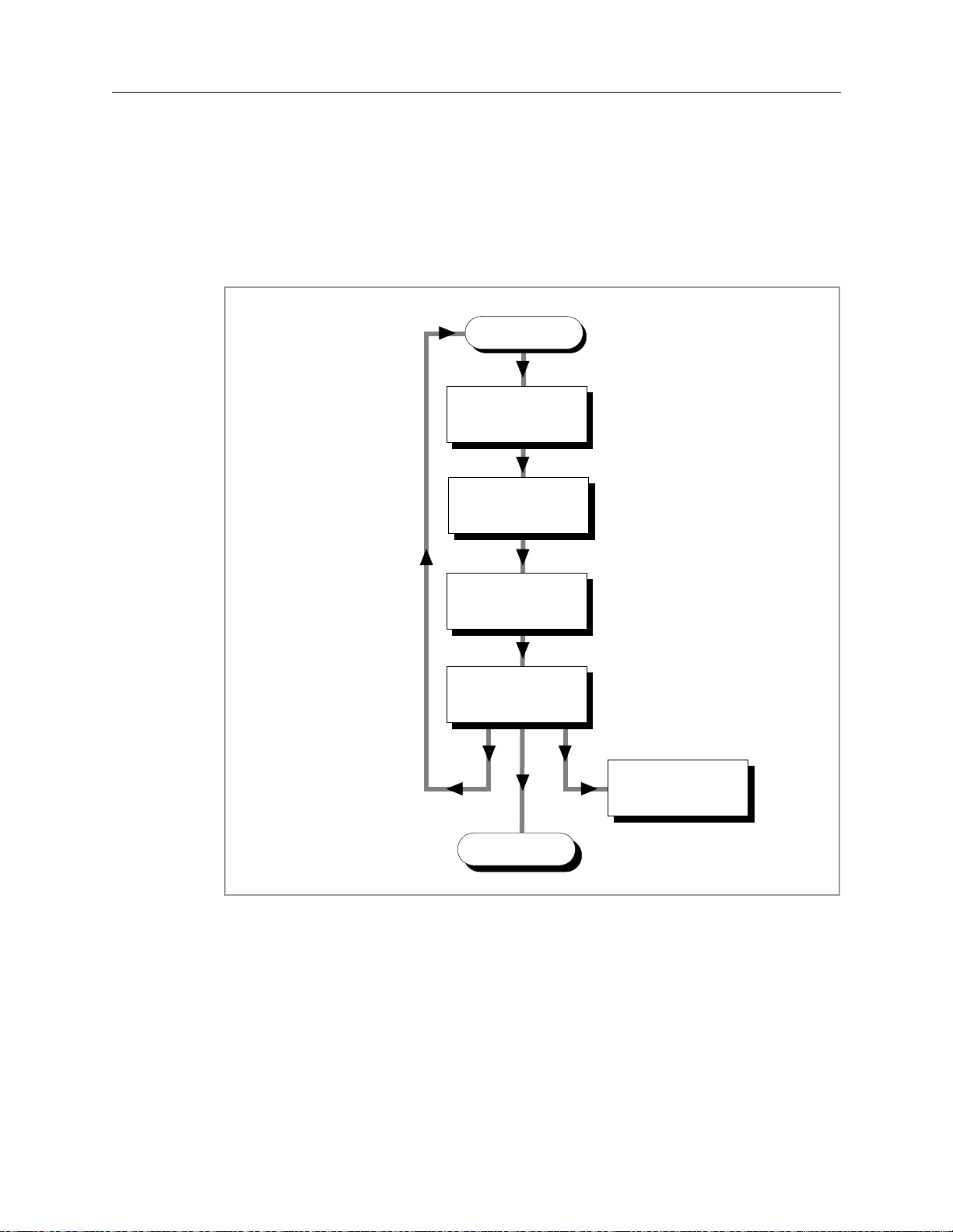

Figure 1-3 is a flow chart illustrating the process that a panel goes through within

the 5DX System.

/RDG

)LUVWWLPH$OLJQ

6XUIDFH0DSDQG

&KHFN&$'

$XWR$OLJQ

6XUIDFH0DS

/RDGQH[WSDQHO

6HOHFWDQG7XQH

$OJRULWKPV

6HOHFWDQG5XQ7HVW

6HOHFW2XWSXWDQG

)RUPDW

8QORDG

(MHFWWHVWHGSDQHOWR

FRQYH\RUV\VWHP

Figure 1-3: Test Process Flow Chart

The PCA is loaded into the 5DX. For the 5DX to correctly test the solder joints,

the PCA has to be aligned. A surface map is made to compensate for variations in

the manufacturing process. The solder joints are measured and these

measurements are analyzed by the a lgorithms to determin e if they pass or fa il. The

algorithm thresholds, set up by the user will determine the pass or fail criteria. The

PCA is then unloaded from the 5DX.

1-6 Introduction and Overview

Page 25

5DX Series 3 5DX Overview

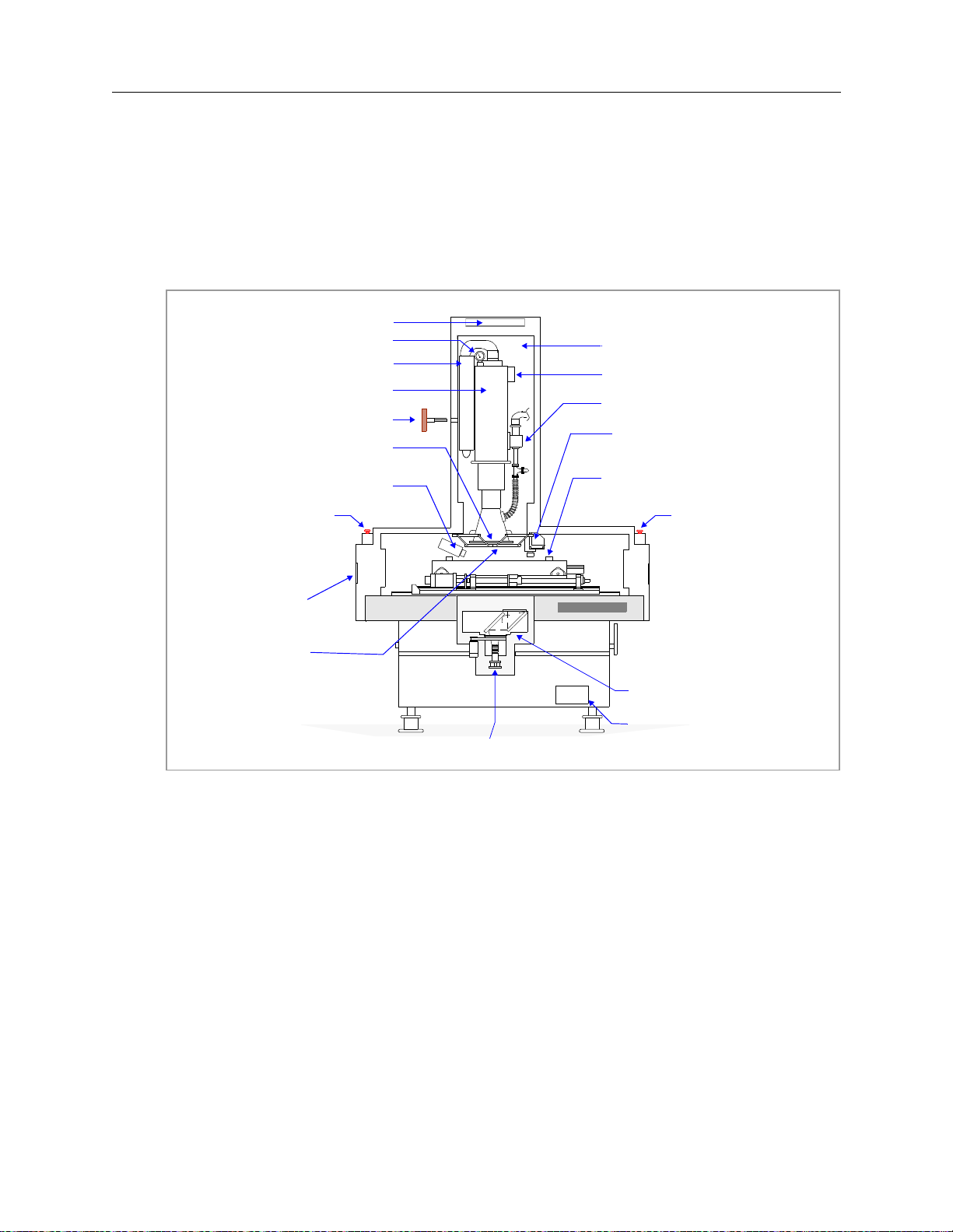

5DX Overview

The Main Cabinet (cutaway diagram shown in Figure 1-4), provides a shielded

housing and vibration resistant structure for the imaging and mechanical

assemblies of the 5DX System.

;UD\7RZHU&RROLQJ)DQ

3UHVVXUH*DXJH

,QWHJUDWHG+93RZHU6XSSO\

;UD\7XEH

;UD\7RZHU.H\

;UD\7XEH7DUJHW

3DQHO9LHZ&DPHUD

(PHUJHQF\6WRS

%XWWRQDQG;UD\

2Q,QGLFDWRU

2XWHU%DUULHU

,QQHU%DUULHU

;UD\,PDJH&DPHUD

GRANITE BASE

;UD\+LJK9ROWDJHN9GFIURPWKH

;UD\+LJK9ROWDJH3RZHU6XSSO\

;UD\7XEH'LHOHFWULF3UHVVXUH6HQVRU

,RQ3XPS

0DS3RLQW&DPHUDDQG/DVHU

;<=6WDJH$VVHPEO\

(PHUJHQF\6WRS

%XWWRQDQG;UD\

2Q,QGLFDWRU

5RWDU\6FLQWLOODWRU$VVHPEO\

9DF,RQ3XPS3RZHU6XSSO\

Figure 1-4: Agilent 5DX System Main Cabinet (I nternal Assembli es)

Agilent 5DX Service Guid e 1-7

Page 26

5DX Overview 5DX Series 3

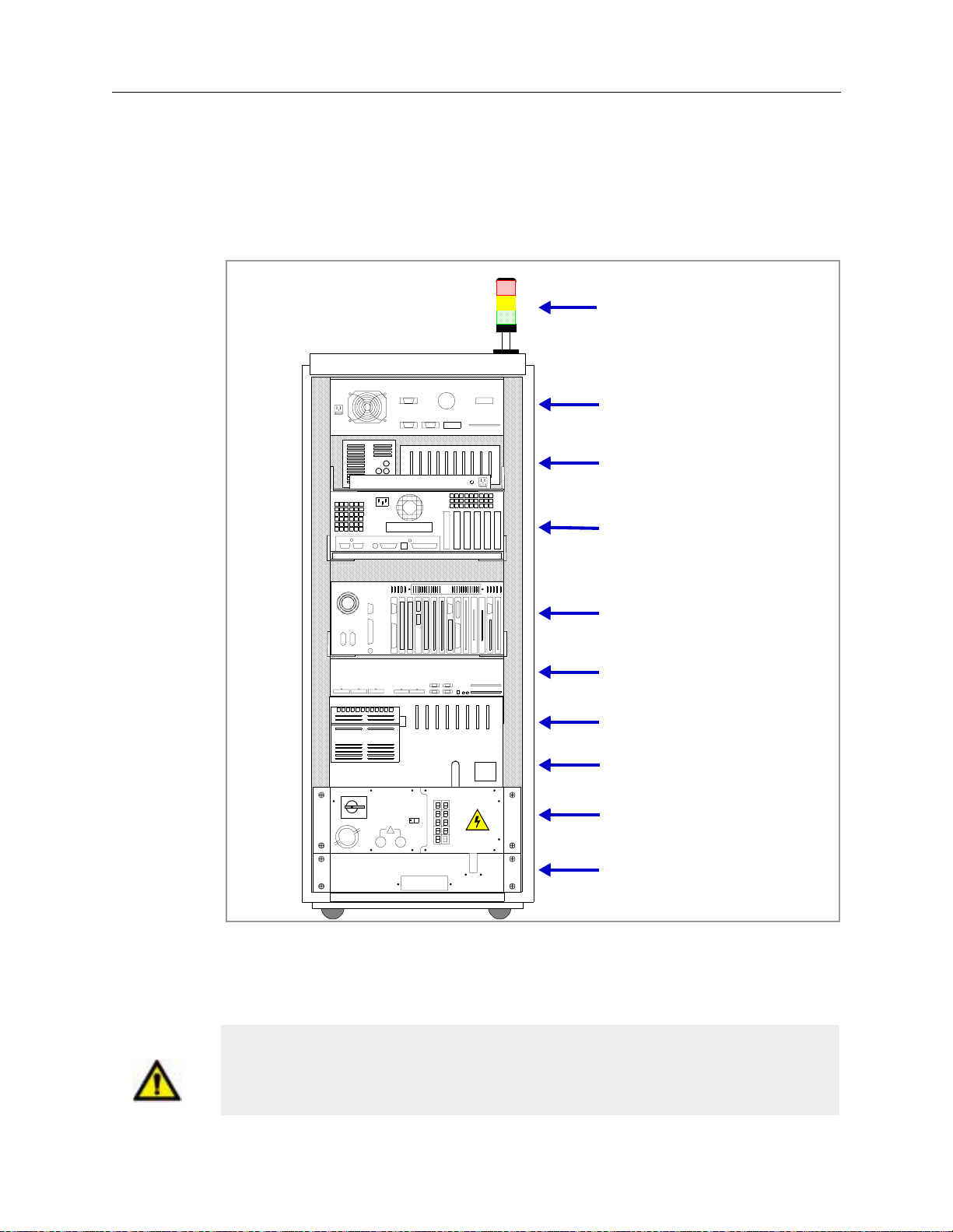

Electronics Bay

The electronics bay, shown in the following figures, contains the 5DX System

control, communications and processing equipment.

Front View

The front view, shown in Figure 1-5 identifies the units housed within the

electronics bay. Note that in the figure below, the electronics bay is shown without

the front door.

System

Status

(contains

motion control

board #1 and

#2)

Motor Enable

Control

(inside front panel)

X, Y1, Y2, R

Servo Modules

(inside front panel)

X-ray Scan

Controller

Low Vol tage

Power

Supplies

System

Controller

PCI Expansion

Chassis

Digital I/O

Assembly

Motion Control

Assembly

Diagnostic

Access Panel

(inside front

panel)

Figure 1-5: 5DX Series 3 Elect ronics Bay (F ront V iew)

1-8 Introduction and Overview

Page 27

5DX Series 3 5DX Overview

Rear View

The rear view (Figure 1-6) identifies units housed within the electronics bay

.

System Status Beacon

X-ray Scan

Controller

Low Vol tage Power

Supply Tray

System

Controller

Expansion

Chassis

Digital I/O

Laser Displacement Unit

Motion Control

Assembly

1

0

!

Power

Distribution Unit

Wire Egress

Figure 1-6: 5DX Series 3 Elect ronics Bay (Rea r V i ew)

.

Caution The ac accessory outlets are for Agilent Technologies installed accessories

ONLY. Plugging any other equipment into these accessory outlets may cause

damage to either the device or the 5DX.

Agilent 5DX Service Guid e 1-9

Page 28

5DX Overview 5DX Series 3

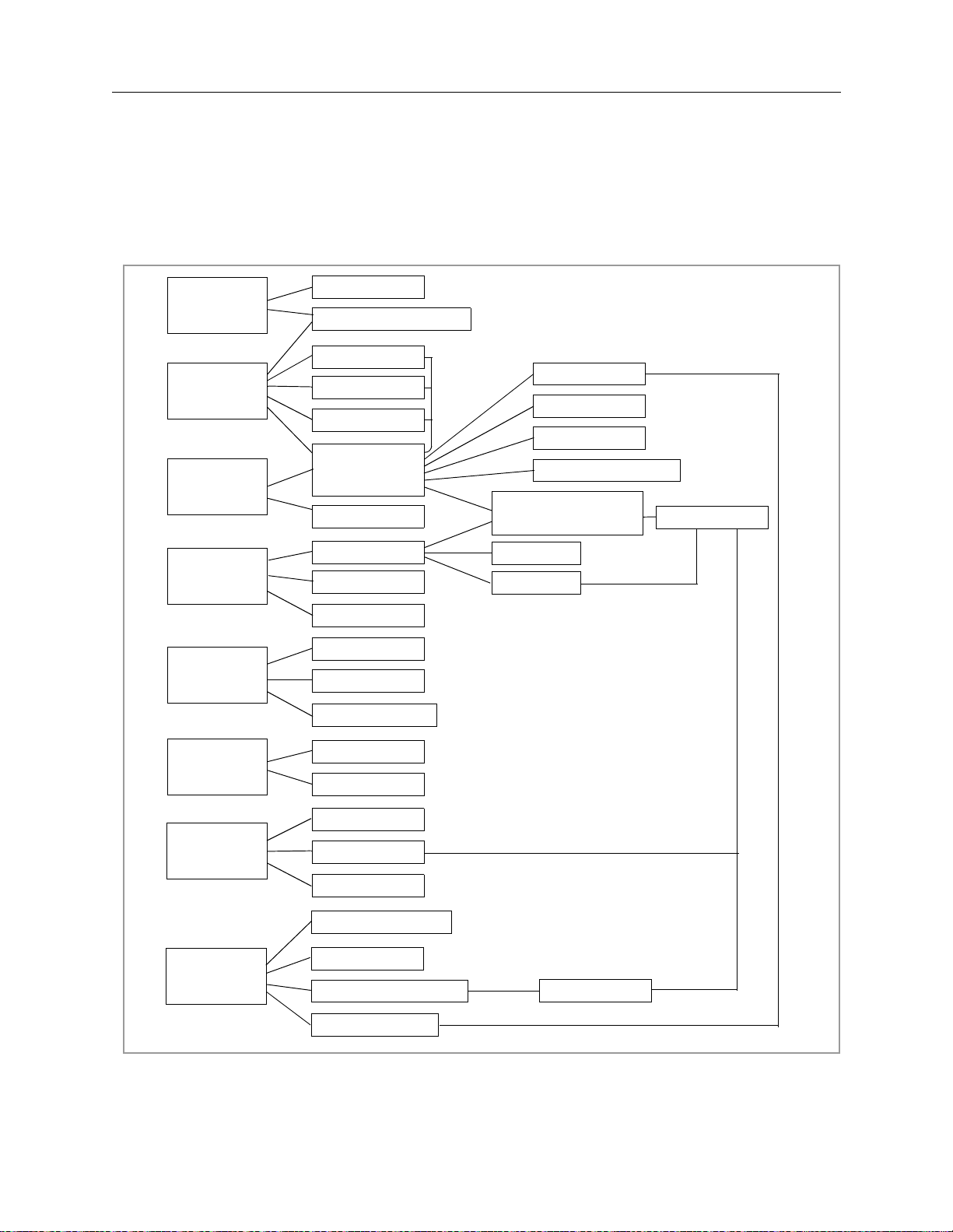

Subsystems of the Agilent 5DX System

The 5DX System consists of several subsystems. These subsystems provide the

overall system functions. A heirarchical diagram is shown in Figure 1-7.

X-ray Tube

HV/XRAY

SYSTEM

POWER

SYSTEM

CONTROL

HV Power Supply

PDU

LV Pwr Sply

Auxilliary PS

Electronics

Bay

Operator MWT

Controller

Expander

Digital I/O

X-ray Scan Cntrlr

Motion Control

Assembly

Servo Modules

PANEL

HANDLING

PNEUMATIC

INTERLOCKS

SURFACE

MAP

IMAGING

Stage

Barriers

Digital I/O

Barriers

Panel Clamps

Valves/Controls

Interlocks

Sensors

Lasers

Z motors

Laser Camera

X-ray Scan Cntrlr

Image Camera

Rotary Scintillator

Middle Rail

X/Y Motors

R motor

Frame Grabber

Figure 1-7: System Heirar chical Dia gram

1-10 Introduction and Overview

Page 29

5DX Series 3 5DX Overview

Safety Interlock Subsystem

The Safety Interlock Subsystem prevents the X-ray, Laser and Motion Driver

assemblies from operating in the event that any access panel is open. The Safety

Interlocks are used to prevent injury to personnel, the 5DX System and printed

circuit assemblies under test

127(

The X-ray Tube Dielectric Pressure Sensor is also connected to the

Safety Interlock Subsystem, and will automatically shut OFF power

to the X-rays if the vessel pressure fal ls below safe operating limits

(less than 2.8 kg/cm2 (40 psi)).

X-ray High Voltage Power Supply

The X-ray High Voltage Power Supply provides -160 kilovolts dc of conditioned

power required to operate the X-ray Tube. It also supplies +15 volts dc and -15

volts dc for the X-ray Tube Electronics. The X-ray HV Power Supply also

provides software controlled monitoring facilities, necessary to maintain a stable

X-ray source.

WARNING There are high voltages inside of the X-ray High Voltage Power Supply and

running through the High Voltage Cable. There are no User serviceable

parts inside of the X-ray High Voltage Power Supply. Do Not attempt to

open or otherwise service this item. Do Not remove the High Voltage Cable.

The X-ray High Voltage Power Supply produces -160 kilovolts dc of conditioned

power to drive the X-ray Tube, +15 volts dc and -15 volts dc for the X-ray tube

electronics. The X-ray High Voltage Power Supply is discussed in the power

subsystem chapter

Agilent 5DX Service Guid e 1-11

Page 30

5DX Overview 5DX Series 3

Panel Handling Subsystem

The Panel Handling Subsystem provides loading and unloading of printed circuit

assemblies (panels) for testing. The Panel Handling subsystem supports Surface

Mount Equipment Manufacturers Association (SMEMA) interface standards.

The Panel Handling Subsystem also positions the panel under test. This is done by

controlling the three mechanical motion axes (X, Y and Z) and the Autowidth

Adjust Motors. The X-Axis and Y-Axis are driven by servomotors, while the ZAxis is driven by four vertically positioned stepper motors. The rails in the XYZ

Stage Assembly are adjusted to the size of the panel by the autowidth adjust

motors.

Surface Map Subsystem

The Surface Map Subsystem maps the surface characteristics of each panel.

Components of the Surface Map Subsystem include the laser, the laser camera and

the surface mapping software. Surface measurement is required to facilitate the

accurate positioning of the Z-Axis in relationship to the Plane of Focus.

Imaging Subsystem

The Imaging Subsystem contains image acquisition hardware and software

necessary to generate slice image data. The process begins with the Electron Beam

and resultant Video images are digitized into 256 gray levels and analyzed.

Pneumatics Subsystem

The 5DX System contains several pneumatic assemblies. Pneumatics operate the

inner and outer barriers, the panel clamps on the XYZ Stage Assembly, and the

panel in place mechanical actuator.

System Controller and Expansion Chassis

Combined, the System Controller and Expansion Chassis provide the necessary

hardware I/O connections to operate the 5DX System. The System Controller

controls the 5DX System operations. Interaction is provided by the User Interface.

The System Controller contains the Frame Grabber PCA, the Transceiver PCA, the

floppy and hard disk drives, the DAT tape unit and the CD-ROM drive. The

Expansion Chassis contains a fourteen-slot backplane and is where the Motion

Control, Camera Control, Modem, Serial Port and Receiver PCAs reside.

1-12 Introduction and Overview

Page 31

5DX Series 3 5DX Overview

User Interface

The User Interface is a software environment used to provide menu-based access

to invoke programs which control system access, confirmation, diagnostic utilities,

programming and test operations. The User Interface will be covered in this guide

for the purpose of performing diagnostics only. See the 5DX User Guide for

additional information concerning the User Interface.

Operator Control

The Operator Control Console provides the user to machine interface that permits

operation of the 5DX System. The Operator Control Console provides key

operated system power, the power activation button for the X-ray Subsystem,

status indicators for monitoring the state of the safety interlocks and X-ray

emissions. The Operator Control Console is located on mobile workstation table.

Caution The System Controller slides out the left side of the Electronics Bay on a tray.

Do Not attempt to move the Electronics Bay while this tray is out.

Caution The Expansion Chassis slides out the front of the Electronics Bay on a tray.

Do Not attempt to move the Electronics Bay while this tray is out.

Caution The front panel of the Motion Controll Assembly opens on the front of the

Electronics Bay . Do Not attempt to move the Electronics Bay while this door

is open.

Agilent 5DX Service Guid e 1-13

Page 32

5DX Overview 5DX Series 3

1-14 Introduction and Overview

Page 33

2.Safety Summary

In this chapter...

This chapter describes the following topics:

n Safety Summary, 2-2

n Warnings, 2-3

n Emergency Stop, 2-4

n Emergency Procedures, 2-6

n X-ray Safety, 2-8

n X-ray Safety, 2-10

n High Voltage Safety, 2-11

n Laser Safety, 2-14

n Additional Information, 2-14

Agilent 5DX Service Guid e 2-1

Page 34

Safety Summary 5DX Series 3

Safety Summary

Prior to operating or performing maintenance activities on the Agilent 5DX

System, personnel should be aware of system safety precautions. The 5DX is

designed to be extremely safe, provided proper use and service precautions are

observed. All users should be aware of the following areas of safety:

• Emergency Stop — How to shut off the 5DX Main Cabinet in an emergency

situation.

• X-ray Safety — Effects of Radiation and the safeguards against exposure.

• High Voltage Safety — High Voltage and safe servicing practices.

• Mechanical Safety — Mechanical motion and safety precautions.

• Laser Safety — Laser optics and safety precautions.

The labels used on the equipment are shown in Figure 2-1.

,QYLVLEOHODVHUUDGLDWLRQFRQWDLQHG

ZKHQHQHUJL]HG'RQRWDWWHPSWWR

GHIHDWVDIHW\,QWHUORFNVP:QP

&ODVV,,,%/DVHU6XE6\VWHP&ODVV,

/DVHU3URGXFW

On the Operator Control Panel

WARNING or

Caution

Other 5DX Locations

Electrical Hazard

THIS EQUIPMENT

PRODUCES X-RAYS

Pinch Hazard

Figure 2-1: Labels Used on Equip ment

2-2 Safety Summary

Page 35

5DX Series 3 Warnings

Warnings

WARNING This product produces X-rays. Do not attempt to open any part of the

product. Do not operate this product or turn on the X-ray source unless all

shielding is in place. Operation without shielding in place can result in

exposure to X-rays. Exposure to X-rays can cause serious bodily injury.

Refer servicing to service-trained personnel.

WARNING This product produces High Voltage. Do not attempt to open any part of the

product. High Voltage can cause electrical shock resulting in serious bodily

injury. Refer servicing to service-trained personnel.

WARNING This product produces Laser Light Emissions. Do not attempt to open any

part of the product. Laser Light Emissions can cause serious eye injury.

Refer servicing to service-trained personnel

WARNING Do not, for ANY reason, attempt to defeat the built-in safety interlocks.

Operation without the Safety Interlock Subsystem functional can result in

exposure to X-rays, high voltage or laser light emissions. Exposure to Xrays can cause serious bodily injury. Contact with high voltage can cause

electrical shock resulting in serious bodily injury. Exposure to laser light

emissions can cause serious eye injury

WARNING Always DISCHARGE all high voltage connections prior to servicing

WARNING There is a service key that can be used to override motion control interlocks

for diagnostic purposes. NEVER place any body part (hand, arm, etc.) or

any other object inside the 5DX when this override is enabled.

This machine is classified as a Class I Laser Product containing a Class IIIB Laser

Subsystem, with an output of 780 nM <5 mW.

Use only QUALIFIED personnel to service this equipment.

Agilent 5DX Service Guid e 2-3

Page 36

Emergency Stop 5DX Series 3

Emergency Stop

Caution The Emergency Stop Buttons are intended for use in emergency situations only

and should not be used for normal system shutdown. Repeated misuse of the

Emergency Stop Buttons will eventually cause damage to certain components or

the loss of data or both.

127(

The AC “Mains” power disconnect is a circuit breaker i nstalled by the

end user and is to be located within 15 feet of the 5DX System

Power Distribution Unit (PDU). Local c odes and needs will def ine the

accessibility, configuration, and size of this disconnect. This

disconnect will disconnect all power to the 5DX System.

The Emergency Stop is used to quickly shutdown power to the 5DX Main Cabinet.

The Emergency Stop is intended for crisis situations only and should not be used

as the normal means to stop the 5DX.

The 5DX System is equipped with two Emergency Stop Buttons. The Emergency

Stop Buttons are located on either side of the 5DX System Main Cabinet, centered

above the outer barrier panels. Refer to Figure 2-2 for locations of the Emergency

Stop Buttons. Whenever one of the Emergency Stop Buttons is pressed, all power

is immediately removed from the 5DX subsystems, with the exception of the

System Controller and the monitor.

To restart the 5DX System after the Emergency Stop Button has been pushed

requires the Emergency Stop Release Key and the normal 5DX System startup

procedure, provided the condition which caused the operator to engage the

Emergency Stop Button is cleared.

2-4 Safety Summary

Page 37

5DX Series 3 Emergency Stop

Push down the Emergency Stop

Button, or toggle the AC “Mains”

Disconnect in an emergency

situation.

The Emergency Stop

Button locks OFF when

pushed.

View from the front of the 5DX System.

Figure 2-2: Emergency Stop Locations

5DX

6HULHV

Agilent 5DX Service Guid e 2-5

Page 38

Emergency Procedures 5DX Series 3

Emergency Procedures

In case of a disaster such as fire, explosion, flood, or strong earthquake, the X-ray

Tube must be de-energized immediately. In an emergency, de-energize the X-ray

Tube by one of the following methods:

• Turn the X-ray Control Key to the Off Position.

• Press the X-ray Control Off Button on the Operator Control Console as shown

in Figure 2-3 Location of X-ray Control Off Button (Series II).

• Press one of the Emergency Stop Buttons, refer to Figure 2-2.

• Open the AC “Mains” Disconnect circuit breaker supplying power to the 5DX

System.

Once de-energized, the X-ray Tube emits no radiation. After a disaster that may

have resulted in damage to the 5DX System shielding, an X-ray Safety Test of the

5DX must be performed prior to placing it back in operation. Consult the Agilent

Response Center before attempting to return the 5DX System to operation. An

electrical brownout or electrical power off, due to storms, does not constitute an

emergency since the system will simply shut itself off and may be restarted in the

normal manner after the power returns.

2-6 Safety Summary

Page 39

5DX Series 3 Emergency Procedures

X-ray Contro l

Off Button

Figure 2-3: Locati on of X-ray Contr ol Off Button

Agilent 5DX Service Guid e 2-7

Page 40

X-ray Safety 5DX Series 3

X-ray Safety

Effects of Radiation

There are a variety of natural and man-made emissions that are classified as

radiation. X-rays are included in most definitions. It should be noted that the

5DX System will not produce X-rays unless power is specifically provided to the

X-ray Tube, and will cease immediately upon removal of power. In addition, it

should be noted that the 5DX System is not designed to admit humans.

A complete description of the biological effects of radiation is outside the scope of

this guide, but is generally available at any library or local government office.

WARNING This product produces X-ray emissions. Do not attempt to open any part of

the product while X-rays are engaged. Do not attempt to defeat any of the

Safety Interlocks. Do not alter the shielding of the 5DX System. X-ray

emissions are dangerous and may cause side effects or even death if

encountered in large doses. Service must be performed by personnel

certified by Agilent.

X-ray Dose Limits

The State of California (see California Radiation Control Regulations, Title 17,

California Administrative Code, Section 30265), and other Agreement States, have

established maximum dose limits for individuals working in an area considered to

be uncontrolled (not under constant monitoring). These limits are the maximum

of no more than:

• 2 millirem / hour

• 100 millirem / 7 days

• 500 millirem / year

These limits were considered when the United States federal government

established the limit of 0.5 millirem/hour at 5 cm from the surface of any Cabinet

Radiography system. Agilent certifies that the 5DX System X-ray emissions are

less than the United States Government and International Safety Standards for

Cabinet X-ray Systems.

2-8 Safety Summary

Page 41

5DX Series 3 X-ray Safety

Definition of a Cabinet X-ray System

A Cabinet X-ray System is one that produces little or no X-ray exposure to the user

and is safe to operate and to be in close proximity to under foreseeable conditions.

The 5DX System is certified to produce not more than 0.5 millirem per hour at a

distance of 5 cm from the machine surface. Agilent warrants that the 5DX System

meets all Federal Regulations regarding a Cabinet Radiography Systems.

The 5DX System is classified as a “Cabinet X-Ray System” by the United States

Code of Federal Regulations: 21 CFR 1020.40 (X-Ray) and CFR 1040.10 (Laser).

The 5DX System is designed, manufactured and registered in accordance with

strict criteria established by the Department of Health and Human Services, Food

and Drug Administration, Center for Devices and Radiological Health (CDRH),

Department of Health and Human Services (DHHS), X-ray Products Branch.

Agilent certifies that the 5DX System X-ray emissions are less than United States

Government and International Safety Standards for a “Cabinet X-ray Systems.”

Built-In Safety Features

The 5DX System is enclosed in shielding that limits X-ray exposure to normal

background levels and all of the 5DX System access ports are safety interlocked to

prevent any accidental radiation exposure. In addition, Agilent performs an X-ray

Safety Test three times on every system prior to customer use:

1. At the completion of manufacture

2. Prior to shipment from Agilent’s facility, and

3. At the user’s facility.

Agilent further warrants and certifies that the 5DX System fully passes the

approved Certification Test for compliance with 21 CFR 1020.40 after shipping

and installation at the customer's facility.

Several 5DX Systems are currently in operation throughout the world. These

systems meet local and government X-ray exposure standards.

Registration Requirements

Customers are directed to check with their state radiation control program director

for registration requirements.

Agilent 5DX Service Guid e 2-9

Page 42

X-ray Safety 5DX Series 3

X-ray Safety

Each of the following steps must be followed for the safety of personnel and

responsible equipment handling:

X-ray Safety Precautions

• Do not attempt to defeat the Safety Interlocks. The Safety Interlocks are

designed to prevent operation of the 5DX System if the access panels are not in

place.

• Do not substitute any shielding panels.

• Do not drill or modify the shielding panels in ANY way.

• Do not place any strong magnets near the X-ray Tube. The X-ray Tube is

designed to have a scanned beam. The beam scanning coils are designed to

limit the deflection of the electron beam to the target area. Any magnets

stronger than 50 gauss placed immediately at the position of the deflection

coils could cause the electron beam to hit the side of the X-ray Tube. The entire

X-ray Tube is shielded in the 5DX System, so, no additional radiation will be

emitted from the system. However, proper operation of the machine would not

be possible in a strong magnetic field.

• Do not apply pressure to, modify or damage the X-ray vacuum window. The

X-ray vacuum window supports the tungsten target material. If the X-ray

vacuum window is broken, the X-ray Tube will cease to operate.

• Do not kink or sharply bend the High Voltage Cable, as it is used to supply a

ground and the high voltage to the X-ray Tube. Sharp bending tends to lower

the dielectric strength of the High Voltage Cable and may lead to failure of the

system. Since one ground is provided through the shielding of the High

Voltage Cable, the cable should be kept free of cracks in the insulation, kinks

or punctures.

• Do not operate the X-ray High Voltage Power Supply without the High

Voltage Cable connecting it to the X-ray Tube properly installed. The high

voltage connections are not user serviceable. Refer service to Agilent

personnel only.

• Do not insert any portion of the body into the XYZ Stage Assembly or the

Loader Assembly , as these contain moving mechanisms and harm may come to

the user, even though movable barriers are present.

2-10 Safety Summary

Page 43

5DX Series 3 High Voltage Safety

Safety Requirements

• Do consult the Agilent Response Center before attempting to service any

components of the X-ray Subsystem.

• Do properly follow ALL Warnings and Cautions.

• Do verify that the X-ray T ub e has an external green ground wire going directly

to the ground connection on the X-ray High Voltage Power Supply . This safety

ground is in addition to the ground supplied by the High Voltage Cable and the

X-ray Tube Mount.

High Voltage Safety

The 5DX System has no exposed high voltage potentials. High voltages are

contained within subsystems, and should only be accessed by Agilent personnel.

WARNING This product produces High Voltage potentials. Do not attempt to open any

part of the product. Contact with High Voltage can cause serious bodily

injury. Refer all servicing to service-trained personnel.

High Voltage Subsystem

127(

The High Voltage Subsystem’s high voltages are contained within the X-ray High

Voltage Power Supply, the High Voltage Power Supply Cable, and the X-ray Tube

Assembly . Under no conditions are the High Voltage Subsystems user serviceable.

The X-ray High Voltage Power Supply produces up to 160,000 volts direct current

(dc). Should any damage occur to any of the high voltage components, remove

power from the system, and contact the Agilent Response Center prior to

attempting any further operation of the 5DX System.

For support purposes, the following components make up the High

Vol tage Subsystem: X-ray Tube Assembly, X-ray High V oltage

Power Supply and the High Voltage Power Supply Cable.

Agilent 5DX Service Guid e 2-11

Page 44

High Voltage Safety 5DX Series 3

Power Distribution Unit (PDU)

The 5DX System is powered by line voltage alternating current (ac) of 200 to 415

volts, at 50 or 60 Hertz (cycles), three phase. Prior to distribution to the subsystem

modules, this supply voltage is transformed to the appropriate voltage levels for

the various components. The lines have thermal circuit breakers at both voltage

levels. This power distribution is engaged by the Emergency Stop Contactor,

which is controlled by 12 volts dc, and may be interrupted in an emergency by any

of the following:

• Pressing one of the Emergency Stop Buttons.

• Open the AC “Mains” Disconnect circuit breaker supplying power to the 5DX

System.

WARNING Do not disconnect any motor cables from the motor or servo module unless

you are certain the motor is not spinning. A spinning motor can generate

hazardous voltages. This is especially true for the Rotary Scintillator. Be

sure it stops spinning before disconnecting any cables.

Mechanical Safety

WARNING This product contains high speed motion components. The motion

components can cause severe bodily injury. Do not attempt to open any part

of this product while the motion components are operational. Do not

attempt to defeat the Safety Interlocks.

WARNING The Rotary Scintillator spins at 750 revolutions per minute. The rotation of

the Rotary Scintillator Assembly can cause sever bodily injury. The safety

interlocks do not stop the Rotary Scintillator. Remove power to the Motion

Driver Assembly and wait until the Rotary Scintillator Assembly stops

spinning before removing the clear plastic safety cover.

The motion mechanics of the 5DX System involve high speed mechanical

assemblies, including the panel conveyors and the XYZ Stage Assembly.

Mishandling could result in bodily injury. To help prevent any risk of injury, the

major motion components of the 5DX System are enabled through the Safety

Interlock Subsystem. If an access panel is open, or if an incorrect sensor state is

2-12 Safety Summary

Page 45

5DX Series 3 High Voltage Safety

sensed, the X-Axis, Y-Axis and X-ray Subsystem functions are ceased. There is an

override to this using a Service Key for diagnostic purposes.

WARNING There is a service key that can be used to override motion control interlocks

for diagnostic purposes. NEVER place any body part (hand, arm, etc.) or

any other object inside the 5DX when this override is enabled.

Agilent 5DX Service Guid e 2-13

Page 46

Laser Safety 5DX Series 3

Laser Safety

WARNING The 5DX System contains a class IIIB laser subsystem. The laser is capable

of causing optical (eye) damage. Do not attempt to defeat any Safety

Interlock. Do not attempt to operate the laser with the access panels open.

The 5DX System uses a solid-state laser to perform a Surface Map of the panel.

This laser has an output of less than 5 mW (milliwatt) at 780 nm (nanometers, or

10-9 meters). Because this laser is capable of causing optical (eye) damage, it is