Page 1

5975 Series

Mass Selective

Detectors

Site Preparation Guide

Agilent Technologies

Page 2

Notices

© Agilent Technologies, Inc. 2008

No part of this manual may be reproduced in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

G3170-90001

Edition

Second edition, January 2008

Printed in USA

Agilent Technologies, Inc.

5301 Stevens Creek Boulevard

Santa Clara, CA 95052

Acknowledgements

Microsoft® and Windows® are U.S. registered trademarks of Microsoft Corporation

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Safety Notices

CAUTION

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and

met.

Site Preparation Guide

Page 3

Contents

1 General Information

Instrument Identification 6

5975 MSD versions 6

Important Safety Warnings 7

Many internal parts of the MSD carry dangerous voltages 7

Electrostatic discharge is a threat to MSD electronics 8

Many parts are dangerously hot 8

Hydrogen Safety 9

Chemical Safety 10

Safety and Regulatory Certifications 11

Information 11

Symbols 12

Electromagnetic compatibility 13

Sound emission declaration 13

Cleaning 14

Recycling the Product 14

2 Site Preparation

Overview 16

Customer responsibility 16

Agilent responsibility 17

Other documentation 19

Space and Weight Requirements 20

Communications Requirements 22

Telephone 22

Site LAN network 22

Electrical Requirements 23

Site Preparation Guide 3

Page 4

Voltage ranges of major components 23

Power configurations 24

Power requirements 25

Power plugs and cord 26

Other electrical considerations 27

Air Conditioning and Environmental Requirements 28

Temperature, humidity, and altitude 28

Airborne dust 29

Exhaust venting 29

Fume (exhaust) hood 30

Carrier and Reagent Gas Requirements 31

Regulators, tubing, and fittings 32

Laboratory Supply Requirements 33

Cleaning solvents 33

Data system supplies 33

Spare parts and consumables 34

Receiving the System 37

Delivery and unloading 37

Inspecting for damage 37

Storage 38

Unpacking 38

Installation and Verification 39

Installation 39

Verification 39

Sensitivity specifications 40

APower Cords

4 Site Preparation Guide

Page 5

5975 Series Mass Selective Detectors

Site Preparation Guide

1

General Information

Instrument Identification 6

Important Safety Warnings 7

Hydrogen Safety 9

Chemical Safety 10

Safety and Regulatory Certifications 11

Cleaning 14

Recycling the Product 14

This section provides information on how to identify specifically what type of

MSD you are working with as well as how to properly clean and dispose of the

instrument. Also included in this section are the “Important Safety Warnings”

which list critical safety precautions for all users.

Agilent Technologies

5

Page 6

General Information

Instrument Identification

Each 5975 Series Mass Selective Detector (MSD) is identified by a unique

10-character serial number. This serial number is located on a label on the

lower left side near the front of the instrument. On CI upgrades, a second

serial number is located on the flow module.

When corresponding with Agilent Technologies about your instrument, be

sure to include the model number and both full 10-character serial numbers.

Write the serial number of your 5975 MSD here for reference:

5975 MSD versions

Table 1 shows the kinds of 5975 MSDs available. The product number on the

serial number label identifies your MSD.

Tab l e 1 5975 MSD versions

Model number Product number Pump type Ionization mode

5975 VL MSD G3170A Diffusion Electron Impact (EI) only

5975 inert MSD G3171A Standard turbo Electron Impact (EI) only

G3172A Performance turbo Electron Impact (EI) only

5975 inert XL MSD G3174A Performance turbo Electron Impact (EI)

Negative Chemical Ionization (NCI)

Positive Chemical Ionization (PCI

This site preparation guide will refer to 5975 Series MSDs unless noted

otherwise.

6 Site Preparation Guide

Page 7

Important Safety Warnings

Before moving on, there are several important safety notices that you should

always keep in mind when using the 5975 Series Mass Selective Detector.

Many internal parts of the MSD carry dangerous voltages

If the MSD is connected to a power source, even if the power switch is off,

potentially dangerous voltages exist on:

• The wiring between the MSD power cord and the AC power supply, the AC

power supply itself, and the wiring from the AC power supply to the power

switch.

With the power switch on, potentially dangerous voltages also exist on:

• All electronics boards in the instrument.

• The internal wires and cables connected to these boards.

• The wires for any heater.

General Information

WARNING

All these parts are shielded by covers. With the covers in place, it should be difficult

to accidentally make contact with dangerous voltages. Unless specifically

instructed to, never remove a cover unless the detector, inlet, or oven are turned off.

WARNING

Site Preparation Guide 7

If the power cord insulation is frayed or worn, the cord must be replaced. Contact

your Agilent service representative.

Connecting the MSD to power sources that are not equipped with protective

earth contacts creates a shock hazard for the operator and can damage the

instrument.

Interrupting the protective conductor inside or outside the MSD or

disconnecting the protective earth terminal creates a shock hazard for the

operator and can damage the instrument.

Make sure the power cords supplied with the MSD are appropriate for your

country and site before using them. Maintain easy access to the power cords

so they can be disconnected during maintenance.

Page 8

General Information

Electrostatic discharge is a threat to MSD electronics

Many parts are dangerously hot

The use of incorrect or makeshift fuses or the short-circuiting of fuse holders

creates a shock hazard for the operator and can damage the instrument.

Replace fuses only with fuses of identical current rating and type.

Excessive fluctuations in the line voltage can create a shock hazard and can

damage the instrument. Make sure the supply voltage does not f luctuate more

than +5% or -10% from the rated voltage. This equipment must be installed in a

Category II environment as defined in IEC 664.

The printed circuit (PC) boards in the MSD can be damaged by electrostatic

discharge. Do not touch any of the boards unless it is absolutely necessary. If

you must handle them, wear a grounded wrist strap and take other antistatic

precautions. Wear a grounded wrist strap any time you must remove the MSD

covers.

Many parts of the MSD operate at temperatures high enough to cause serious

burns.

You should always cool heated areas of the MSD to room temperature before

working on them. They will cool faster if you first set the temperature of the

heated zone to room temperature. Turn the zone off after it has reached the

setpoint. If you must perform maintenance on hot parts, use a wrench and

wear gloves. Whenever possible, cool the part of the instrument that you will

be maintaining before you begin working on it.

WARNING

WARNING

Be careful when working behind the gas chromatograph (GC). During cool-down

cycles, the GC emits hot exhaust which can cause burns.

The insulation around the GC inlets, detectors, valve box, and the insulation cups is

made of refractory ceramic fibers. To avoid inhaling fiber particles, we recommend

the following safety procedures: ventilate your work area; wear long sleeves,

gloves, safety glasses, and a disposable dust/mist respirator; dispose of insulation

in a sealed plastic bag; wash your hands with mild soap and cold water after

handling the insulation.

8 Site Preparation Guide

Page 9

Hydrogen Safety

Hydrogen gas may be used as carrier gas, and/or as fuel for certain GC

detectors. When mixed with air, hydrogen can form explosive mixtures.

A detailed discussion of hydrogen safety appears in Chapter 1 of the Agilent

5975 MSD Troubleshooting and Maintenance Manual. Read this material

before using hydrogen with the MSD.

General Information

WARNING

WARNING

When using hydrogen (H2) as the carrier gas or fuel gas, be aware that hydrogen

gas can flow into the oven and create an explosion hazard. Therefore, be sure that

the supply is off until all connections are made, and ensure that the GC inlet and

detector column fittings are either connected to a column or capped at all times

when hydrogen gas is supplied to the instrument.

Hydrogen is flammable. Leaks, when confined in an enclosed space, may create a

fire or explosion hazard. In any application using hydrogen, leak test all

connections, lines, and valves before operating the instrument. Always turn off the

hydrogen supply at its source before working on the instrument.

The MSD cannot detect leaks in gas streams. For this reason, it is vital that column

fittings should always be either connected to a column, or have a cap or plug

installed.

When using hydrogen gas, check the system for leaks as described by your

local Environmental Health and Safety (EHS) requirements to prevent

possible fire and explosion hazards. Always check for leaks after changing a

tank or servicing the gas lines. Always make sure the vent line is vented into a

fume hood.

Site Preparation Guide 9

Page 10

General Information

Chemical Safety

WARNING

The foreline pump exhaust and split vent exhaust will contain traces of the

chemicals you are analyzing. These could potentially be toxic. Vent the foreline

pump exhaust and split vent exhaust outside your laboratory or into a fume hood. Be

sure to comply with all local environmental regulations.

10 Site Preparation Guide

Page 11

Safety and Regulatory Certifications

The 5975 Series MSD conforms to the following safety standards:

• Canadian Standards Association (CSA): CAN/CSA–C22.2 No. 61010–1–04

• CSA/Nationally Recognized Test Laboratory (NRTL): UL 61010–1

• International Electrotechnical Commission (IEC): 61010–1

• EuroNorm (EN): 61010–1

The 5975 Series MSD conforms to the following regulations on

Electromagnetic Compatibility (EMC) and Radio Frequency Interference

(RFI):

• CISPR 11/EN 55011: Group 1, Class A

• IEC/EN 61326

• AUS/NZ

This ISM device complies with Canadian ICES-001. Cet appareil ISM est

conforme a la norme NMB—001 du Canada.

General Information

The 5975 Series MSD is designed and manufactured under a quality system

registered to ISO 9001.

Information

The Agilent Technologies 5975 Series MSD meets the following IEC

(International Electro-technical Commission) classifications: Equipment

Class I, Laboratory Equipment, Installation Category II, Pollution Degree 2.

This unit has been designed and tested in accordance with recognized safety

standards and is designed for use indoors. If the instrument is used in a

manner not specified by the manufacturer, the protection provided by the

instrument may be impaired. Whenever the safety protection of the MSD has

been compromised, disconnect the unit from all power sources and secure the

unit against unintended operation.

Refer servicing to qualified service personnel. Substituting parts or

performing any unauthorized modification to the instrument may result in a

safety hazard.

Site Preparation Guide 11

Page 12

General Information

Symbols

Warnings in the manual or on the instrument must be observed during all

phases of operation, service, and repair of this instrument. Failure to comply

with these precautions violates safety standards of design and the intended

use of the instrument. Agilent Technologies assumes no liability for the

customer’s failure to comply with these requirements.

See accompanying instructions for more

information.

Indicates a hot surface.

Indicates hazardous voltages.

Indicates earth (ground) terminal.

Indicates potential explosion hazard.

Indicates radioactivity hazard.

Indicates electrostatic discharge hazard.

Indicates that you must not discard this

electrical/electronic product in domestic

household waste.

12 Site Preparation Guide

or

Page 13

Electromagnetic compatibility

This device complies with the requirements of CISPR 11. Operation is subject

to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference

that may cause undesired operation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the

user is encouraged to try one or more of the following measures:

1 Relocate the radio or antenna.

2 Move the device away from the radio or television.

3 Plug the device into a different electrical outlet, so that the device and the

radio or television are on separate electrical circuits.

4 Make sure that all peripheral devices are also certified.

5 Make sure that appropriate cables are used to connect the device to

peripheral equipment.

6 Consult your equipment dealer, Agilent Technologies, or an experienced

technician for assistance.

7 Changes or modifications not expressly approved by Agilent Technologies

could void the user’s authority to operate the equipment.

General Information

Sound emission declaration

Sound pressure

Sound pressure Lp < 70 dB according to EN 27779:1991.

Schalldruckpegel

Schalldruckpegel LP < 70 dB am nach EN 27779:1991.

Site Preparation Guide 13

Page 14

General Information

Cleaning

To clean the unit, disconnect the power and wipe down with a damp, lint-free

cloth.

Recycling the Product

For recycling, contact your local Agilent sales office.

14 Site Preparation Guide

Page 15

5975 Series Mass Selective Detectors

Site Preparation Guide

2

Site Preparation

Overview 16

Space and Weight Requirements 20

Communications Requirements 22

Electrical Requirements 23

Air Conditioning and Environmental Requirements 28

Carrier and Reagent Gas Requirements 31

Laboratory Supply Requirements 33

Receiving the System 37

Installation and Verification 39

This section describes how to properly prepare your site for a new MSD.

Follow these instructions carefully as delays due to improper site preparation

may result in loss of instrument use during the warranty period.

Agilent Technologies

15

Page 16

Site Preparation

Overview

Before the 5975 Series MSD system can be installed, the site must be properly

prepared. Site preparation includes, but is not limited to, ensuring that

adequate facilities are available. Among the site requirements are:

• Adequate space is available for the MSD system.

• A suitable supporting bench is available.

• Adequate electrical power is available at the correct voltages and

frequencies.

• Environmental control systems are adequate to maintain a correct, stable

operating environment.

• Preparations for safe exhaust venting are adequate.

• Supplies necessary for instrument operation are available, including

solvents, carrier and reagent gasses, and printer paper.

NOTE

Installation and verification will only be performed using helium carrier gas. CI systems

require methane reagent gas for verification.

Delays due to inadequate site preparation could cause loss of instrument use

during the warranty period. In extreme cases, Agilent Technologies may ask to

be reimbursed for the additional time required to complete the installation.

Agilent Technologies provides service during the warranty period and under

maintenance agreements only if the specified site requirements are met.

Customer responsibility

Unless previous arrangements have been made with Agilent Technologies, site

preparation is the customer’s responsibility. Customer responsibilities

include, but are not limited to:

• Planning, scheduling, and preparing the site according to the specifications

in this manual

• Verifying that the electrical environment is safe and adequate for the MSD

system installation and operation

16 Site Preparation Guide

Page 17

• Complying with all local laws (codes, ordinances, and regulations) for

mechanical, building, and electrical distribution systems, hazardous waste

disposal, and chemical storage.

Compliance must exist prior to installation.

• Providing lifting equipment adequate to unload the system from the

delivery vehicle and transport it to the site where it will be installed

• Providing someone to help lift the MSD onto the laboratory bench

• Providing adequate secure storage space for the system until it can be

installed by an Agilent Technologies representative

Agilent responsibility

An Agilent Technologies service representative will install the MSD and verify

its performance. The service representative’s responsibilities are limited to:

• Unpacking the MSD system and verifying that all components are present

and undamaged

• Connecting the carrier gas line to the instrument from the tank, regulators,

and lines previously installed by the customer

• Installing, connecting, and turning on MSD system components

• Verifying that the system meets Agilent Technologies performance

standards

• Providing basic user familiarization for system hardware and software

• Signing the customer up through the Response Centers for instrument and

software support

Site Preparation

Site Preparation Guide 17

Page 18

Site Preparation

Agilent Technologies is not responsible for:

• Any task not listed in the 5975 Series MSD Troubleshooting and

Maintenance Manual or the installation guides for the GC, data system,

and other accessories

• Installing helium carrier gas or reagent gas tanks and regulators

• Connecting or verifying the performance of hardware and software not

provided by Agilent Technologies

NOTE

NOTE

NOTE

Items that do not include installation by Agilent Technologies must be installed by the

customer.

• Connecting the MSD/ChemStation system to the site network

• Testing the MSD against customer standards or samples

• Providing detailed instruction in the operation of the computer operating

system and MSD software

Contact Agilent Technologies for information concerning training classes.

• Setting up laboratory procedures

Contact Agilent Technologies for information concerning Application Assist or Chemical

Analysis Consulting services.

• Operating the MSD system following installation

18 Site Preparation Guide

Page 19

Other documentation

Additional information is contained in the following documentation:

• 5975 Series MSD Troubleshooting and Maintenance Manual

• 5975 Series MSD Operation manual

• 6890 Series GC manuals

• GC accessories (autosampler, etc.) manuals

• G1701EA MSD Productivity ChemStation software manuals and online help

• The appropriate sensitivity specifications for your instrument. See the

Agilent Technologies website at http://www.agilent.com/chem.

Site Preparation

Site Preparation Guide 19

Page 20

Site Preparation

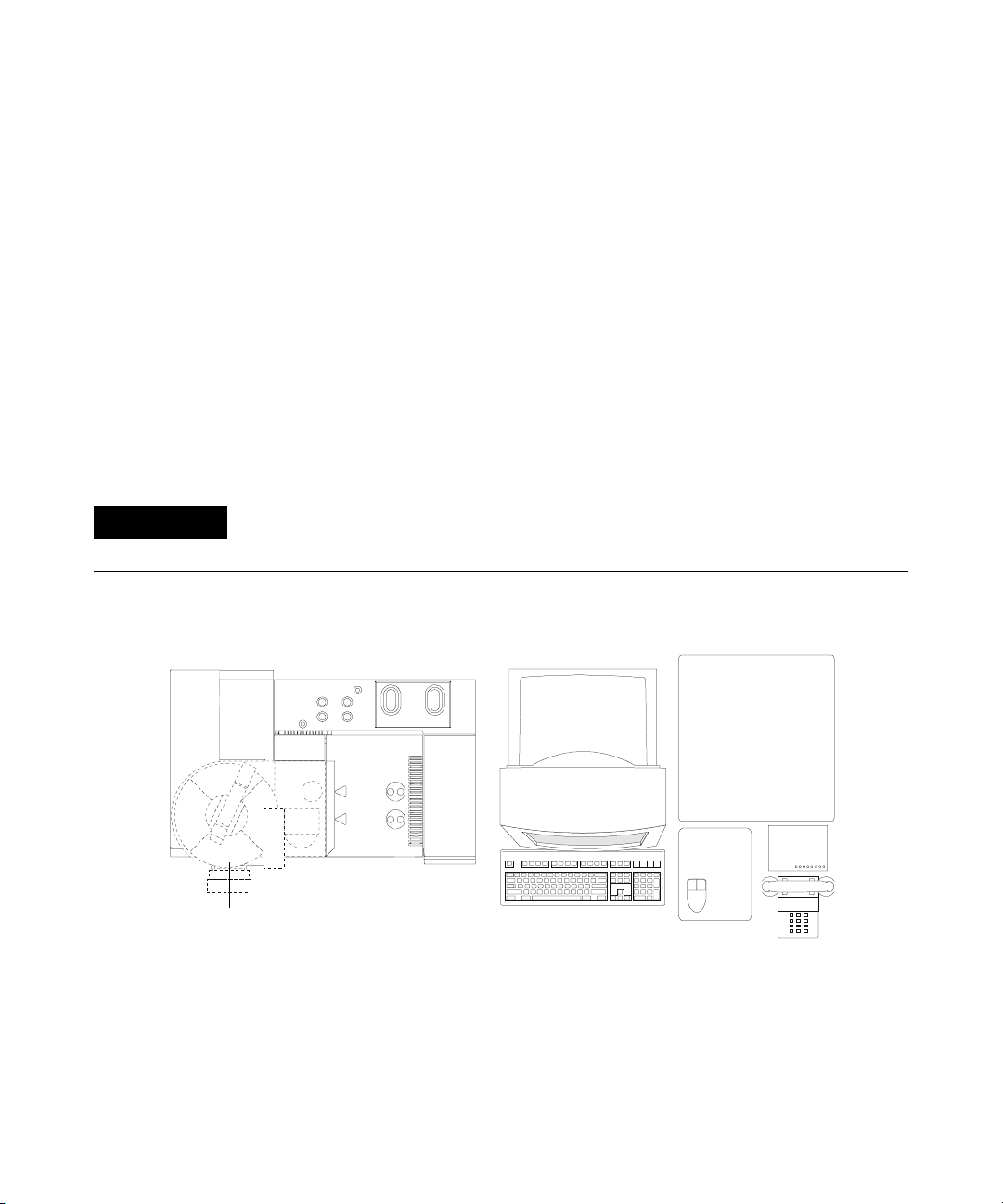

Space and Weight Requirements

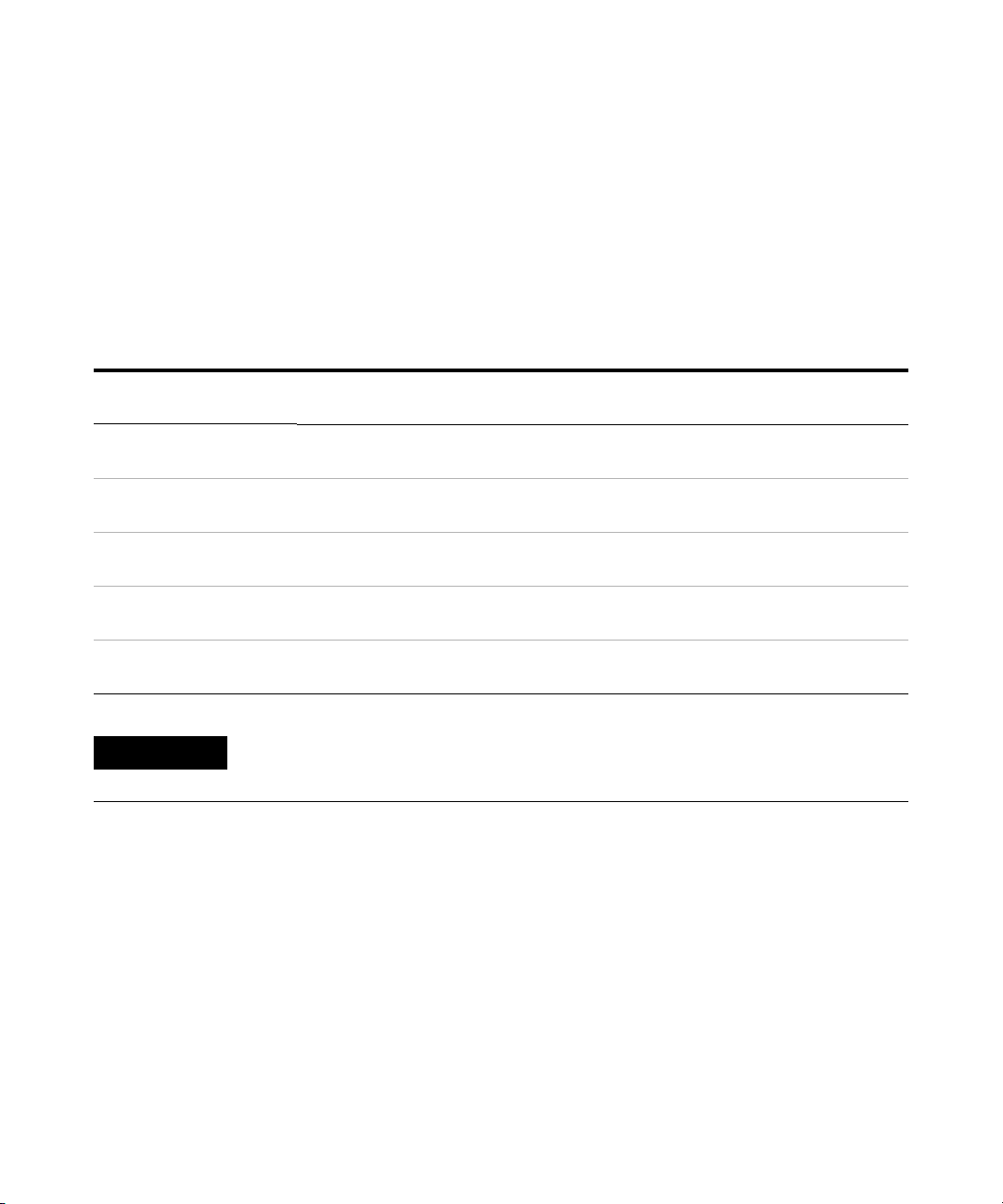

Table 2 lists dimension and weight information for the MSD and related

components. Your site must have enough bench space for the MSD, GC, data

system, and accessories (Figure 1). In addition, there must be sufficient space

around the system for ventilation and maintenance access. At least 30 cm

(12 inches) to the left of the MSD and at least 20 cm (8 1/4 inches) behind the

MSD must be kept clear.

Benches must be sturdy enough to support the weight of the entire system.

The foreline pump can be located on the laboratory bench or on the floor. It

must be close to the MSD because it is connected by a 200-cm (79-inch) hose.

The hose is stiff and cannot be bent sharply.

CAUTION

Do not put the foreline pump on your laboratory bench if vibration-sensitive equipment

is located on the bench.

5975 Series MSD

ALS tray

Figure 1 Top view of typical installation

20 Site Preparation Guide

6890 Series GC Computer with monitor Printer

Page 21

Site Preparation

Tab l e 2 Product dimensions

Approximate Dimensions, cm (in)

Product Height Width Depth Weight, kg (lb)

5975 Series MSD

• G3170A Diffusion EI MSD 41 (16) 30 (12) 54 (21) 39 (85)

• G3171A Standard turbo EI MSD 41 (16) 30 (12) 54 (21) 39 (85)

• G3172A Performance turbo EI MSD 41 (16) 30 (12) 54 (21) 41 (90)

• G3174A EI/PCI/NCI MSD 41 (16) 30 (12) 54 (21) 46 (100)

7890 Series GC 54 (21) 59 (23) 54 (21) 50 (112)

6890 Series GC 50 (20) 58 (23) 55 (22) 50 (110)

6850 Series GC 50 (20) 29 (11) 54 (21) 23 (51)

Data System Data system size and weight depend on the components included in the data

system. Reserve at least 100 cm (39 in) of bench space for the data system. A

typical data system weight is 34 kg (75 lb).

Be sure to allow space for your carrier and reagent gases.

NOTE

The values in Table 2 are for a single MSD ChemStation configuration. Two-MSD

configurations require additional table space. The second GC/MSD system can be located

on a different table and connected to the ChemStation with a network cable.

Site Preparation Guide 21

Page 22

Site Preparation

Communications Requirements

Te l ep h o n e

A telephone with a cord long enough to be used at the computer will allow the

MSD operator to communicate with Agilent Technologies support personnel.

Site LAN network

If you intend to connect your MSD system to your site’s LAN network, you

must have an additional shielded twisted pair network cable.

NOTE

NOTE

Agilent Technologies is not responsible for connecting to or establishing communication

with your site LAN network. The representative will test the 5975 Series MSD’s ability to

communicate on a mini-hub or -switch only.

The IP addresses assigned to the instrument(s) must be fixed (permanently assigned)

addresses. If you intend to connect your MSD system to your site’s network, each piece of

equipment (the MSD, the GC, and the computer) must have a unique IP address assigned to

it.

22 Site Preparation Guide

Page 23

Electrical Requirements

You are responsible for providing appropriate electrical power and power

outlets for all of the components in your 5975 Series MSD system. Power

considerations include:

• Voltage ranges of major components

• Power configurations

• Power requirements

• Power plugs and cords

Voltage ranges of major components

The 5975 Series MSD includes a full-range power supply that can operate

without reconfiguration on either of two wide ranges of single-phase

alternating current (AC) electrical power:

• 120-127 VAC 60 Hz (typical for North America)

• 200-240 VAC, 50/60 Hz (typical for Europe and Japan)

The foreline pump also draws its power from the MSD. However, a different

foreline pump is supplied depending on the voltage range on which the MSD

will be operating. The pump is supplied according to the standard voltage in

the country from which the order originates. For example, if an order

originates from an Agilent Technologies sales office in Germany, the foreline

pump supplied will be configured to operate on the standard voltage and

frequency of electrical power in Germany.

Site Preparation

NOTE

CAUTION

The MSD does not support 100 VAC input power. In countries that have only 100 VAC

power, a step-up transformer must be used to provide the appropriate voltage to the MSD.

If an instrument is being ordered from one location but is to be installed in another

location with different electrical power characteristics, this must be noted on the order.

A special note must also be made if the electrical power at the site is different from the

standard electrical power in that country.

Site Preparation Guide 23

Page 24

Site Preparation

Power configurations

Electrical power for the MSD must be single-phase. The neutral wire cannot be

used for safety grounding. The ground wire should carry zero current except

for ground-fault current or static electric discharge. The entire system should

share an isolated, noise-free electrical ground. This system ground should be

electrically separate from the ground for the rest of the building, back to the

main ground for the facility. Power configurations are provided in Table 3.

WARNING

WARNING

Connecting an MSD to a power source which is not equipped with a protective earth

contact (ground) creates a shock hazard for the operator and can damage the

instrument.

Interrupting the protective conductor inside or outside the MSD or disconnecting the

protective earth terminal (ground) creates a shock hazard for the operator and can

damage the instrument.

Tab l e 3 Power configurations

Configuration Measurement Nominal voltage

Single phase,

120-127 VAC

Single phase,

200-240 VAC

Line to neutral 120 or 127 VAC

Line to ground 120 or 127 VAC *

Ground to neutral < 0.5 V rms

Line to neutral 200, 220, or 240 VAC *

Line to ground 200, 220, or 240 VAC *

Ground to neutral < 0.5 V rms

*

* Varies with country and/or region

24 Site Preparation Guide

Page 25

Power requirements

Table 4 lists the power requirements for the 5975 Series MSD and related

equipment. Extra power capacity for future additions is recommended.

Each product listed requires a dedicated circuit. The gauge controller is

powered by the MSD. The MSD, GC, and data system must each have a

separate circuit breaker. All of the equipment must share a common ground.

Power must meet the stability specifications listed in Table 4. Use a line

monitor to check power stability. If your line power is unstable, you may need

to install a line conditioner.

Tab l e 4 Power requirements

Site Preparation

Product Line voltage Maximum continuous

power consumption

5975 Series MSD

7890A and 6890 GCs

(standard oven) and ALS

7890A and 6890 GCs (fast

oven) and ALS

6850 GC (standard

**

oven)

6850 GC (fast oven)** America: 120 VAC, 48-63 Hz 2400 VA 20 A 1

*

120-127 VAC 60 Hz 900 VA (400 VA for

foreline pump only)

200-240 VAC, 50/60 Hz 900 VA 15 A 1

Americas: 120 VAC

(-10%/+5%), 48-66 Hz

220/230/240V single/split phase

(-10%/+5%), 48-66 Hz

Japan: 200V split phase (-10%/+5%),

48-66 Hz

220/230/240 VAC

(-10%/+5%), 48-66 Hz

America: 120 VAC, 48-63 Hz 1440 VA 15 A 1

Japan: 100 VAC, 48-63 Hz 1440 VA 15 A 1

230 VAC, 48-63 Hz 2000 VA 8-12 A 1

Japan: 200 VAC, 48-63 Hz 2400 VA 12 A 1

†

single phase

‡

single/split phase

2250 VA 20 A 1

2250 VA 15 A 1

2950 VA 15 A 1

2950 VA 15 A 1

Supply

circuit rating

15 A 1

Outlets

required

230 VAC, 48-63 Hz 2400 VA 11 A 1

Site Preparation Guide 25

Page 26

Site Preparation

Tab l e 4 Power requirements (continued)

Product Line voltage Maximum continuous

power consumption

ChemStation computer 100-120 or 220-240 VAC+5/-10%,

50/60 Hz ± 5%

* The MSD operates on either voltage range. The foreline and turbo pumps are supplied for the voltage range suitable to the

country where the order originates

† Americas 120 V requires 20 A dedicated line. Americas 240 V requires 15 A dedicated line.

‡ Option 003, fast oven, is a unit with operating range 198 to 231 V. Most laboratories have 4-wire service resulting in 208 V at

the wall receptacle. It is important to measure the line voltage at the receptacle for the GC.

** Requires an isolated ground and dedicated outlet.

1000 VA 15 A 3 to 5

Supply

circuit rating

Outlets

required

Power plugs and cord

The MSD is supplied with a power cord and plug appropriate for the country

from which the order originates. For example, if an order originates from a

Agilent Technologies sales office in Germany, the power cord and plug

supplied will be compatible with the standard voltage and outlet configuration

in Germany. See “Power Cords" on page 41 for illustrations of the power cords

available.

Data system components also include power cords with plugs appropriate for

the country where the order was placed.

Power cord lengths for the MSD and the data system components and

accessories are approximately 2.3 m (7.5 ft).

CAUTION

If an instrument is being ordered from one location but is to be installed in another

location with different electrical power characteristics, this must be noted on the order.

A special note must also be made if the electrical power at the site is different from the

standard electrical power in that country.

WARNING

Make sure the power cords supplied with the MSD are appropriate for your country

and site before installing the instrument. See “Power Cords” on page 41.

26 Site Preparation Guide

Page 27

Site Preparation

WARNING

NOTE

Do not use extension cords with the MSD or GC. Extension cords normally are not

rated to carry enough power and can be a safety hazard.

Maintain easy access to the power cords so they can be disconnected for maintenance.

Other electrical considerations

Additional electrical considerations include:

• Electromagnetic interference (EMI), such as is generated by NMRs, radio

transmitters, and microwave links, may interfere with system performance.

• Protect the system from static electricity by observing humidity and

temperature requirements. Minimize the presence of nonconductive

products such as carpets and vinyl floor tiles.

• Install emergency-off pushbuttons that can disconnect power to the

ventilation system and all electric equipment in the room except overhead

lighting.

• Provide separate convenience outlets for building maintenance and other

appliances. Convenience outlets must be on circuits separate from the MSD

system. Convenience outlets must share the normal building distribution

ground, not the MSD system ground.

• In some geographical areas it may be advisable to install lightning

protection for personnel and equipment.

Site Preparation Guide 27

Page 28

Site Preparation

Air Conditioning and Environmental Requirements

Air conditioning considerations include temperature, humidity, airborne dust,

and exhaust venting. Each of these is considered in more detail in the

following material.

Temperature, humidity, and altitude

The 5975 Series MSD is specified for operation under the following conditions:

• Operation requires constant temperature

(variations <2 °C/h)

• Operation and storage require a noncondensing, noncorrosive atmosphere

• The temperature and humidity limits in Table 5

• Maximum altitude for operation: 2300 m (7500 ft)

Tab l e 5 Temperature and humidity limits

Temperature Humidity (relative)

Operation 15 °C to 35 °C (59 °F to 95 °F) 40% to 80%

Storage –20 °C to 70 °C (–4 °F to 158 °F) 0% to 95%

Environmental control systems must maintain these temperature and

humidity ranges.

The MSD is rated for 1200 Watts (4000 BTU/h). The GC and the data system

also contribute significantly to the cooling load although the exact amounts

depend on their configurations. Additional allowances should be made for

other heat sources such as heat from other equipment, heat from adjacent

rooms, and heat from laboratory personnel.

28 Site Preparation Guide

Page 29

Airborne dust

Site Preparation

Exhaust venting

WARNING

WARNING

Agilent Technologies recommends a maximum airborne particle density of

55 μg/m

Technologies Customer Service Organization. Customer Engineers with

special training and equipment can test for airborne particle density. They can

offer suggestions for reducing airborne dust.

There are two sources of exhaust on the GC/MSD system: the foreline pump

and the GC split vent. The foreline pump outputs gas removed from the

vacuum manifold by the high vacuum pumps. The foreline pump exhaust will

also contain traces of solvent and sample.

3

. If you suspect your site exceeds this limit, contact your local Agilent

User safety requires that the exhaust gases from the MSD be vented externally to

the building and not recirculated by the environmental control system. Health

hazards include chemical toxicity of solvents, samples, derivitizing agents, pump

fluid vapor, and aerosolized biological samples.

The pump exhaust contains carrier gas and traces of solvents, analytes, and foreline

pump oil. The supplied oil trap stops only pump oil. It does not trap or filter out toxic

chemicals. If you are using toxic solvents or toxic or flammable carrier gas, or

analyzing toxic chemicals, do not install the oil trap. Install a hose to take the pump

exhaust to a fume hood. Do not use the oil trap on any CI MSD.

The foreline pump exhaust cannot be vented into the laboratory if any

hazardous materials will be introduced into the GC/MS system, including

samples, solvents, carrier gases, and reagent gases. It must be vented external

to the building or vacuum exhausted to a fume hood.

If a negative pressure vent is not available, the length of tubing from the

foreline pump to an ambient pressure vent should not exceed 460 cm (15 ft).

The exhaust can

Exhaust gas venting must comply with all local environmental and safety

codes.

Site Preparation Guide 29

not be connected to a positive pressure vent.

Page 30

Site Preparation

Fume (exhaust) hood

See your GC manuals for information on venting the split vent.

An auxiliary work space and fume hood are needed for some maintenance

procedures.

30 Site Preparation Guide

Page 31

Carrier and Reagent Gas Requirements

Table 6 lists the specifications for the carrier and reagent gases. Pressures and

flows are as measured at the bulkhead fittings on the back of the instrument,

not at the gas supply. We recommend that additional shut-off valves be

installed near the instruments.

Tab l e 6 Carrier and reagent gas requirements

Site Preparation

Purity Typical pressure range,

Helium (required) 99.9995% or better and

hydrocarbon-free

Methane reagent gas

(required for CI operation)

Isobutane reagent gas

(optional)

Ammonia reagent gas

(optional)

Carbon dioxide reagent gas

(optional)

WARNING

Research or SFC grade,

99.999%

Instrument grade,

99.99%

Research or SFC grade,

99.9995%

SFC Grade,

99.995%

Methane is flammable and ammonia is corrosive and toxic. Read and follow the

safety information that comes with the gases.

Typ i c al f lo w , m L/ mi n

kPa (psi)

345 to 550 (50 to 80) 20 to 50 (column and split flow)

103 to 172 (15 to 25) 1 to 2

103 to 172 (15 to 25) 1 to 2

34 to 55 (5 to 8) 1 to 2

103 to 138 (15 to 20) 1 to 2

Site Preparation Guide 31

Page 32

Site Preparation

Regulators, tubing, and fittings

You must supply appropriate regulators for your carrier and reagent gas.

• Regulators must be dual-stage.

• Regulators must have stainless-steel (not elastomeric) diaphragms.

• They must supply gas at the pressure specified.

• They must have one outlet with 1/4-inch Swagelok fittings.

See the Agilent Technologies Chemical Analysis Columns and Supplies

Catalog or visit the Agilent Technologies Chemical Analysis website at

http://www.agilent.com/chem for dual-stage regulators available from Agilent

Technologies.

You must supply Swagelok or Swagelok-compatible fittings, ferrules, and

connectors for the 1/8-inch tubing.

32 Site Preparation Guide

Page 33

Laboratory Supply Requirements

Laboratory supply requirements vary with applications.

Cleaning solvents

Cleaning tasks for the MSD require the following HPLC-grade (or better)

solvents:

• Methylene chloride

• Isopropyl alcohol

• Methanol

• Acetone

• Water

Proper storage, handling, and disposal of these chemicals is required for

personal and environmental safety.

Site Preparation

CAUTION

WARNING

Do not use carbon disulfide as a cleaning solvent on or around the MSD. It is corrosive

and will damage the analyzer. Use of carbon disulfide as a cleaner will void the

warranty on the analyzer.

Carbon disulfide may be used as a sample solvent in standard size injections (typically

2 µL or less).

Chemical solvents should be considered hazardous and must be handled with care.

Contact your chemical supplier for solvent handling and safety information,

preferably a material safety data sheet (MSDS).

Data system supplies

You will need paper for printing the results of the testing done during

installation and later for printing reports of your analyses. You will also need

appropriate supplies for making backup copies of your data files.

Site Preparation Guide 33

Page 34

Site Preparation

Spare parts and consumables

The supplies and parts listed in Table 7 are used in the operation and

maintenance of a 5975 Series MSD system. Keeping these parts on hand can

reduce system downtime related to instrument maintenance and repair.

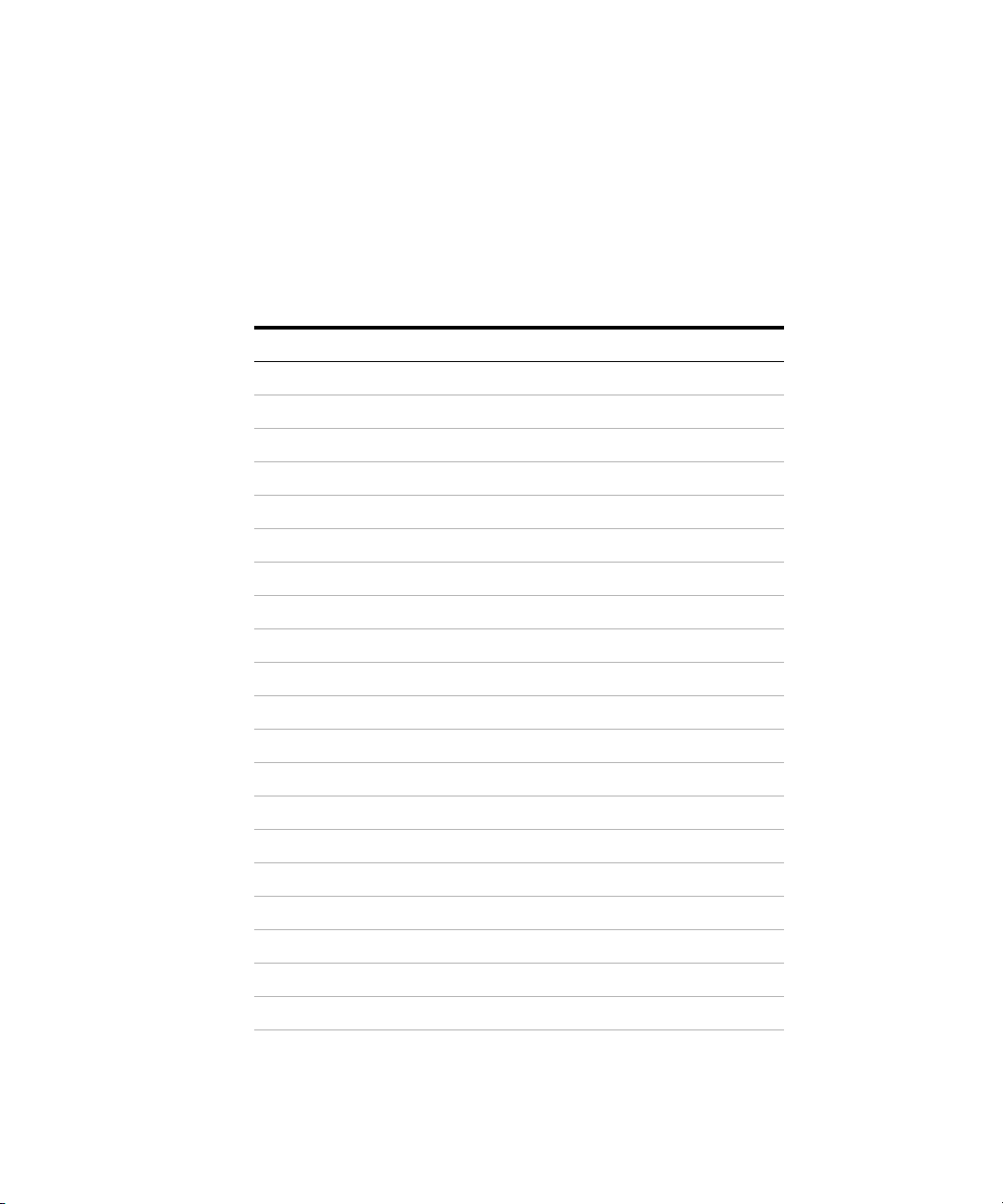

Tab l e 7 Maintenance supplies and consumables

Description Part number

Miscellaneous consumables

One-year maintenance kit 5183-0296

He/H2 gas filter for GC 5182-3468

Abrasive sheets (5/pk) 5061-5896

Cloths, lint-free (15/pk) 05980-60051

Cotton swabs (100/pk) 5080-5400

2,4,6-tris(perfluoroheptyl)-1,3,5-triazine (PFHT)

Foreline pump oil, Inland 45, 1 liter 6040-0834

EI filament (2/pk) 05972-60053

EI high temp filament G2590-60053

Octafluoronapthalene (OFN) 8500-5441

Gloves, clean

large 8650-0030

small 8650-0029

Nitrile rubber gloves, medium 9300-1751

Filaments

CI (2/pk) G1099-80053

EI high temp filament G2590-60053

34 Site Preparation Guide

Page 35

Tab l e 7 Maintenance supplies and consumables (continued)

Chemical Consumables

PFTBA (EI calibration fluid) 05971-60571

PFDTD (CI calibration fluid) 8500-8130

EVAL A (evaluation sample) 05990-60045

OFN (Octafluoronapthalene) 5188-5348

OFN 100 fg/µL 5188-5347

Benzophenone 8500-5440

PFHT 5188-5357

Foreline pump oil, P3, 0.5 liter 6040-0621

Gas Filters

He/H2 gas purifier for GC RMSH-2

Methane/Isobutane gas purifier for CI MSD G1999-80410

Site Preparation

Commonly used tools

Safety glasses 9300-1159

Wrenches

1/2-inch x 9/16-inch, open end 8710-0877

Ferrules

Blank, graphite-vespel 5181-3308

GC/MSD interface

0.3-mm id, 85% Vespel 15% graphite, for 0.10-mm id

columns

0.4-mm id, 85% Vespel 15% graphite, for 0.20-mm id and

0.25-mm id columns

5062-3507

5062-3508

Site Preparation Guide 35

Page 36

Site Preparation

Tab l e 7 Maintenance supplies and consumables (continued)

0.5-mm id, 85% Vespel 15% graphite, for 0.32-mm id

columns

0.8-mm id, 85% Vespel 15% graphite, for 0.53-mm id

columns

GC inlet

0.27-mm id, 90% Vespel 10% graphite, for 0.10-mm id

columns

0.37-mm id, 90% Vespel 10% graphite, for 0.20-mm id

columns

0.40-mm id, 90% Vespel 10% graphite, for 0.25-mm id

columns

0.47-mm id, 90% Vespel 10% graphite, for 0.32-mm id

columns

0.74-mm id, 90% Vespel 10% graphite, for 0.53-mm id

columns

5062-3506

5062-3538

5062-3518

5062-3516

5181-3323

5062-3514

5062-3512

36 Site Preparation Guide

Page 37

Receiving the System

When your MSD system is delivered, it is your responsibility to provide for

removal of the shipping containers from the truck and their storage until

installation. Contact your Agilent Technologies service representative as soon

as your shipment arrives to arrange an installation date.

Delivery and unloading

The shipping containers are large and heavy. The largest container in the

shipment is 121.9 cm (48 inches) × 121.9 cm × 121.9 cm. It contains several

smaller cartons that can be removed from the large container after delivery to

facilitate moving them to the location where the instrument is to be installed.

After removing the smaller cartons and discarding the outer container, the

largest remaining carton, may be as large as:

• 89 cm (35 inches) high

• 81 cm (32 inches) wide

• 74 cm (29 inches) deep

• 60 kg (132 lbs)

Site Preparation

All doorways, hallways, floors, and elevators must be able to accommodate the

largest, heaviest container.

Inspecting for damage

Once the shipping containers are unloaded, examine them for any obvious

external damage. If any of the containers appear damaged, note on the

carrier's bill of lading that there is Apparent damage - subject to inspection

and test. Arrange for both the carrier's claims representative and your Agilent

Technologies service representative to be present when the containers are

unpacked.

Do not open any of the shipping containers unless a representative of Agilent

Technologies is present. Opening any of the containers without an Agilent

Technologies representative present will void the receiving warranty on

the instrument.

Site Preparation Guide 37

Page 38

Site Preparation

Storage

Unpacking

It is your responsibility to store the containers until installation. If your site

does not have adequate storage space, the containers may be stored at your

expense in a bonded warehouse. Allow space for data system and accessory

containers too.

The environment in the storage area should be between 5 °C and 50 °C (41 °F

and 122 °F), 20% to 80% relative humidity, non-condensing and non-corrosive.

Do not open any shipping containers until an Agilent Technologies

representative is present. Warranty claims for missing items will not be

honored unless an Agilent Technologies representative is present to verify the

contents of each container as it is unpacked.

The actual shipping containers become your property and should not be

returned to Agilent Technologies.

38 Site Preparation Guide

Page 39

Installation and Verification

Installation

Once the installation has begun, it should progress in a timely manner to

completion. Delays due to inadequate site preparation could cause loss of

instrument use during the warranty period. In extreme cases, Agilent

Technologies may ask to be reimbursed for the additional time required to

complete the installation.

The primary user and, if possible, all other users of the MSD should be present

during installation to receive familiarization instruction from the Agilent

Technologies service representative.

Verification

The final step in the installation process is system verification. Your Agilent

Technologies service representative will test the system against Agilent

Technologies specifications as documented for the product(s) or system(s) you

have purchased. (Not all tests are performed for every system.)

Site Preparation

The Agilent Technologies service representative will not test your

system against your standards or samples. Further, the Agilent

Technologies service representative will not set up your laboratory

procedures. Assistance with laboratory procedures can be obtained from your

local Agilent Technologies Applications Engineer (AE) on a consulting basis at

additional cost.

Site Preparation Guide 39

Page 40

Site Preparation

Sensitivity specifications

See the appropriate sensitivity specifications for your instrument type. See

the Agilent Technologies Web site at http://www.agilent.com/chem.

NOTE

SIM performance verification is not performed at installation and must be purchased if

desired.

40 Site Preparation Guide

Page 41

5975 Series Mass Selective Detectors

Site Preparation Guide

A

Power Cords

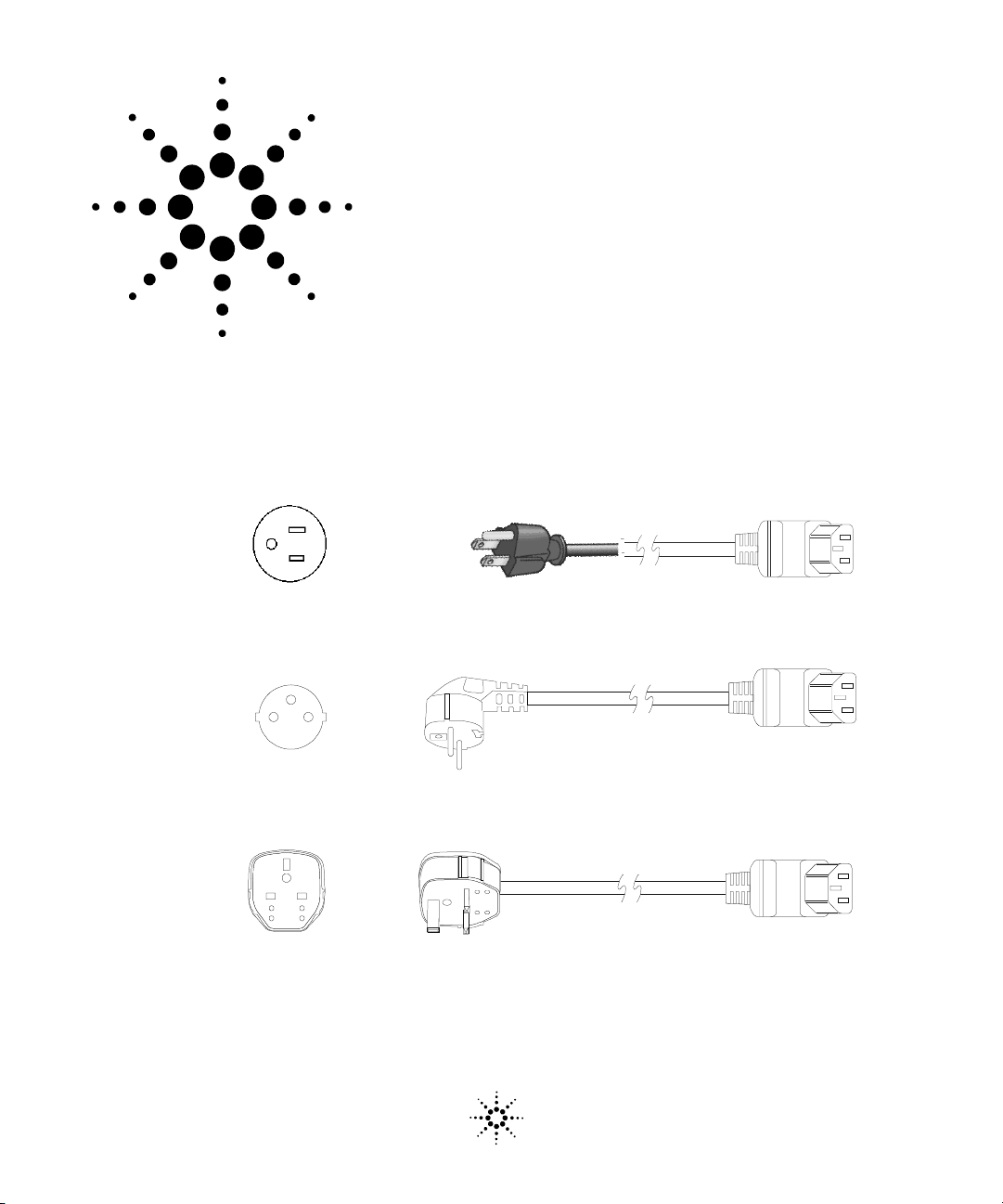

This appendix shows the power cords available for the 5975 Series MSD. See

page 26 for information about ensuring that the correct power cord is supplied

with your system.

US and Canada, NEMA 6-15P (Part number 8120-6825)

European Power, CEE 7/7 (Part number 8120-1689)

UK/Hong Kong, BS 1363 (Part number 8120-1351)

Agilent Technologies

41

Page 42

Power Cords

Denmark/Greenland, IEC 309 (Part number 8120-3997)

Australia/New Zealand, AS 3112-1981 (Part number 8120-1369)

India/South Africa, BS 546 (Part number 8120-4211)

Israel, SI 32 (Part number 8120-5182)

Japan, NEMA L6-20P (Part number G2025-60189)

42 Site Preparation Guide

Page 43

Page 44

Agilent Technologies

© Agilent Technologies, Inc.

Printed in USA, January 2008

Loading...

Loading...