Page 1

Service Guide

Publication Number 54622-97037

December 2002

For Safety Information, Warranties, and Regulatory information, see the pages

at the end of this book.

© Copyright Agilent Technologies 2000, 2002

All Rights Reserved

Agilent 54621A/22A/24A

Oscilloscope and

Agilent 54621D/22D

Mixed-Signal Oscilloscope

Page 2

The Oscilloscope At a Glance

Choose from a variety of oscilloscopes for capturing

long, non-repeating signals

with 200 MSa/s sample rate and 2 MBytes of

MegaZoom deep memory per channel.

• Agilent 54621A - 2-channel, 60-MHz bandwidth

• Agilent 54621D - 2-channel +16 logic channels, 60MHz bandwidth

• Agilent 54622A - 2-channel, 100-MHz bandwidth

• Agilent 54622D - 2-channel +16 logic channels,

100-MHz bandwidth

• Agilent 54624A - 4-channel, 100-MHz bandwidth

Display shows current input signals

• All analog and digital (54621D/22D) channels

displayed in main and delayed mode

• Indicators for channel, time base, digital (54621D/

22D) channel activity, trigger and acquisition

status

• Softkey labels

• Measurement results

Digital channel controls select, position, and label

inputs (54621D/22D)

• Turn channels on or off individually or in groups

of 8

• Rearrange order of channels to group related

signals

• Create and display labels to identify channels

Run control keys begin and end data acquisition

• Run/Stop starts and stops continuous

acquisitions

• Single performs one acquisition

• Infinite persistence accumulates and displays the

results of multiple acquisitions

Horizontal Controls select sweep speed and delay

parameters

• Sweep speeds from 5 ns/div to 50 ns/div

• Delay control moves waveform display to point of

interest

• Delayed mod e and delay allow zoom ing in to show

a portion of waveform in detail (split screen)

Trigger keys define what data the oscilloscope will

trigger on

• Source key allows conventional oscilloscope

triggering

• Modes include Edge, Pulse Width, Pattern, CAN,

Duration, I

triggering

General controls measure, save and restore results,

and configure the oscilloscope

• Waveform math including FFT, subtract, multiply,

integrate, and differentiate

• Use Quick Meas to make automatic

measurements Integrated counter included with

Quick Meas.

• Use cursors to make manual measurements

• Save or recall measurement configurations or

previous results

• Autoscale performs simple one-button setup of

the oscilloscope

Softkeys extend the functionality of command keys

Select measurement types, operating modes, trigger

specifications, label data, and more

Digital channel inputs through a flexible probing

system (54621D/22D)

• Sixteen channels through a dual 8-channel cable

with micro-clips

• Set logic levels as TTL, CMOS, ECL, or to a userdefinable voltage

Utilities

• Dedicated parallel printer port, controller

operation, floppy disk storage

Built in Quick Help system

• Press and hold any key front-panel key or softkey

to get help in 11 languages.

2

C, LIN, Sequence, SPI, TV, and USB

ii

Page 3

In This Book

This book provides the service information for the Agilent 54621A/22A/24A

Oscilloscope and the Agilent 54621D/22D Mixed-Signal Oscilloscope.

This manual is divided into these chapters:

Chapter 1 provides general information and specifications.

Chapter 2 shows you how to prepare the oscilloscope for use.

Chapter 3 gives performance tests.

Chapter 4 covers calibration and adjustment procedures.

Chapter 5 provides troubleshooting information.

Chapter 6 gives the procedures and techniques for replacing assemblies and

other parts.

Chapter 7 includes a list of replaceable parts, part ordering information, and

shipping information.

At the back of the book you will find Safety information, Warranties, and

Regulatory information.

iii

Page 4

Contents

1 General Information

To inspect package contents 1-3

To inspect options and accessories 1-6

Performance Characteristics 1-9

2 Preparing the Oscilloscope for Use

Setting up the Oscilloscope 2-3

To adjust the handle 2-4

To power-on the oscilloscope 2-5

To adjust the display intensity 2-6

To connect the oscilloscope probes 2-7

To compensate your probe 2-7

To use the digital probes (mixed-signal oscilloscope only) 2-8

To connect a printer 2-12

To connect an RS-232 cable 2-12

To verify basic oscilloscope operation 2-13

Getting started using the oscilloscope interface 2-14

Using Quick Help 2-16

Selecting a language for Quick Help when the oscilloscope starts up 2-16

Selecting a language for Quick Help after you have been operating the

oscilloscope 2-17

Loading a language from floppy disk 2-18

Cleaning the oscilloscope 2-19

3 Testing Performance

List of Test Equipment 3-3

To construct the test connector 3-4

To test the 54621D/22D Oscilloscope digital channels 3-5

To verify threshold accuracy 3-6

To verify voltage measurement accuracy 3-10

To verify bandwidth 3-13

To verify horizontal Dt and 1/Dt accuracy 3-15

To verify trigger sensitivity 3-17

Agilent 54622A/22D/24A Performance Test Record 3-20

Agilent 54621A/21D Performance Test Record 3-21

Contents-1

Page 5

Contents

4 Calibrating and Adjusting

To adjust the power supply 4-4

To perform User Cal 4-7

To adjust the oscilloscope display 4-8

5 Troubleshooting

Solving General Problems with the Oscilloscopes 5-3

If there is no trace display 5-3

If the trace display is unusual or unexpected 5-4

If you cannot see a channel 5-5

Troubleshooting the Oscilloscope 5-6

To construct your own dummy load 5-7

To check out the oscilloscope 5-8

To check the Low Voltage Power Supply 5-11

To run the internal self-tests 5-13

6 Replacing Assemblies

To remove the cabinet 6-4

To remove the fan 6-5

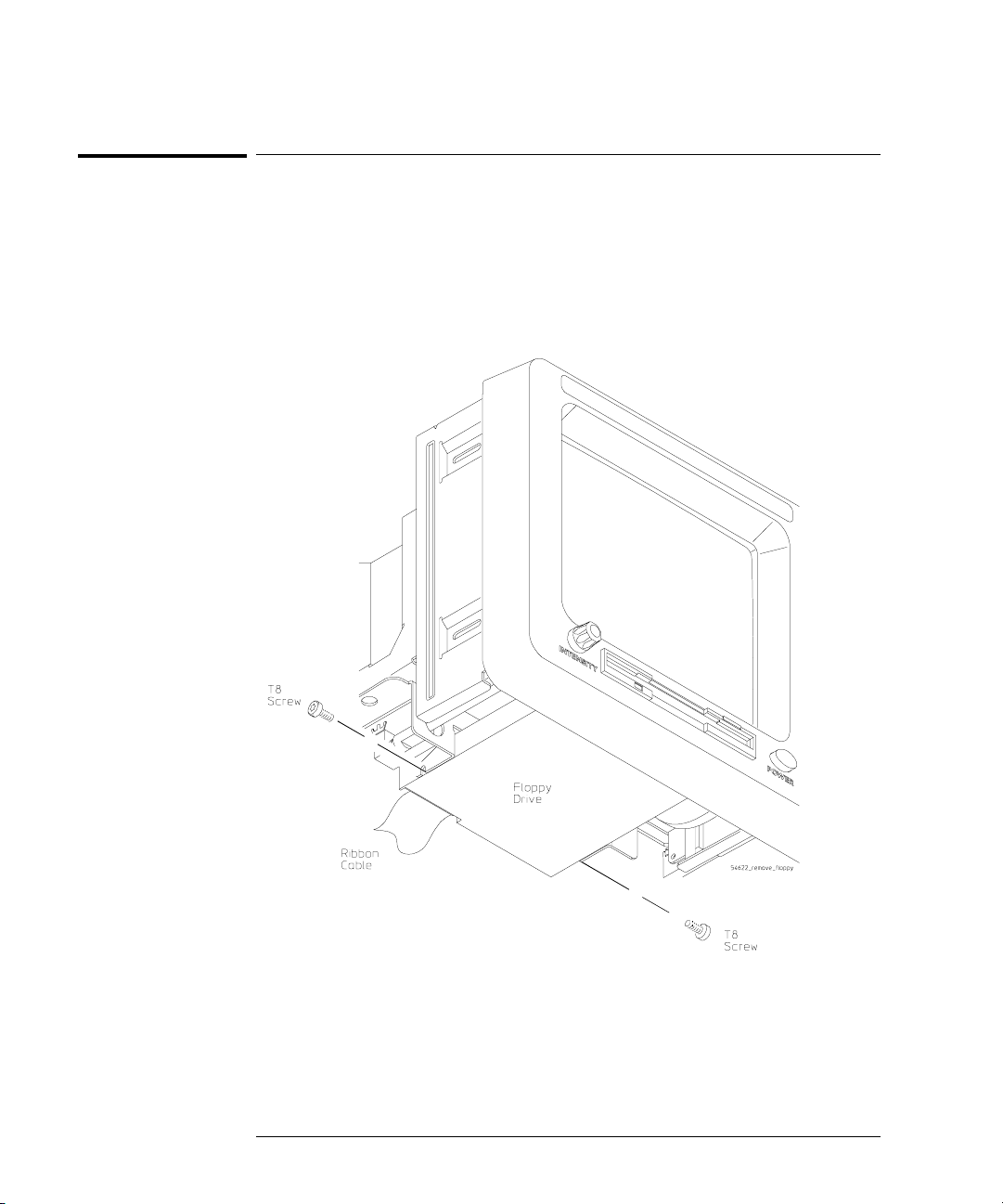

To remove the floppy drive 6-6

To remove the front panel 6-7

To remove the display 6-8

To remove the system board 6-10

To remove the power supply 6-12

To remove the keyboard assembly 6-15

To remove the handle 6-16

7 Replaceable Parts

To order a replacement part 7-3

Contents-2

Page 6

1

General Information

Page 7

General Information

This chapter lists general information for the Agilent 54620-series

Oscilloscopes. It also includes performance characteristics and

specifications for the oscilloscopes.

1-2

Page 8

General Information

To inspect package contents

❏ Inspect the shipping container for damage.

If your shipping container appears to be damaged, keep the shipping container

or cushioning material until you have inspected the contents of the shipment

for completeness and have checked the oscilloscope mechanically and

electrically.

❏ Verify that you received the following items and any optional accessories in

the oscilloscope packaging (see figure following).

• 54620-Series Oscilloscope (54621A, 21D, 22A, 22D, or 24A)

• 10074C 10:1 150 MHz passive probes with ID:

(2) for 54621A, 21D, 22A, or 22D oscilloscopes

(4) for 54624A oscilloscope

• 54620-68701 digital probe kit (for 54621D or 22D)

• Accessory pouch and front-panel cover (standard for 54622A, 22D, and 24A)

(optional on 54621A and 21D; order N2726A)

• Power cord (see table 1-3)

• IntuiLink for 54600-series Oscilloscopes software and RS-232 cable (for

54622A, 22D, or 24A).

IntuiLink is a Windows application that makes it very easy for you to

download images, waveform data, or oscilloscope setups from the

oscilloscope to your pc using either Microsoft Word or Microsoft Excel. After

installation of IntuiLink, a tool bar in these Microsoft applications will make

connection and data transfer from the oscilloscope very simple.

IntuiLink software is available free on the web at:

www.agilent.com/find/5462xsw

RS-232 cable may be ordered separately, part number 34398A

If anything is missing, contact your nearest Agilent Sales Office. If the shipment

was d amaged, contact th e carrier, then cont act the ne arest Agil ent Sale s Office.

1-3

Page 9

General Information

• Agilent IntuiLink Data Capture (for 54622A, 22D, or 24A)

IntuiLink Data Capture is a standalone program for downloading waveform

data from the oscilloscopes to your PC via GPIB or RS-232 interface. It

provides the capability to transfer deep memory data out of the oscilloscope,

allowing up to 4MB (scope channels) and 8MB (logic channels). The

IntuiLink for 54600-Series limits the size of acquisition data available to a

maximum of 2,000 points regardless of actual number of acquisition points

on the screen. With the IntuiLink Data Capture, the amount of points

transferred will be the actual number of acquisition points currently

displayed or you may select the number of points to download. It provides

the following functionality:

• Download waveform data and display the data as a simple chart

• Save the data as binary or text files

• Copy the chart and a selected portion of the data to the clipboard. The

maximum data saved to the clipboard is 50,000 point

• Load saved waveform data back into the application

IntuiLink Data Capture software is available free on the web at:

www.agilent.com/find/5462xsw

RS-232 cable may be ordered separately, part number 34398A

❏ Inspect the oscilloscope

• If there is mechanical damage or a defect, or if the oscilloscope does not

operate properly or does not pass the performance tests listed in the Service

Guide, notify your Agilent Sales Office.

• If the shipping container is damaged, or the cushioning materials show signs

of stress, notify the carrier and your Agilent Sales Office. Keep the shipping

materials for the carrier’s inspection. The Agilent Sales Office will arrange

for repair or replacement at Agilent’s option, without waiting for claim

settlement.

1-4

Page 10

Figure 1-1

General Information

54620-Series Oscilloscope

Accessories pouch and

front-panel cover**

Power cord

54620-68701 digital probe kit*

54620-61801 16-channel cable***

IntuiLink for 54600-series

software, Data Capture

software and serial cable**

5959-9334 2” Probe

ground lead (qty 5)

5090-4833 Grabber

(qty 20)

10074C Probes

s

s1

* 54621D /22D only

** 54622A/22D/24A only

** The following additional replacement parts (not included) are available for the digital cable:

5959-9333 replacement probe leads (qty 5)

5959-9335 replacement pod grounds (qty 5)

01650-94309 package of probe labels

Package contents for 54620-Series Oscilloscopes

1-5

Page 11

General Information

To inspect options and accessories

❏ Verify that you received the options and accessories you ordered and that none

were damaged.

If anything is missing, contact your nearest Agilent Sales Office. If the shipment

was damaged, or the cushioning materials show signs of stress, notify the carrier

and your Agilent Sales Office.

Some of the options and accessories available for the 54620-Series Oscilloscopes

are listed in tables 1-1 am 1-2. Contact your Agilent Sales Office for a complete

list of options and accessories.

Table 1-1

Options available

Option Description

003 Shielding Option for use in severe environments or with sensitive devices under

test–shields both ways (in and out):

RS-03 magnetic interface shielding added to CRT, and

RE-02 display shield added to CRT to reduce radiated interference.

1CM Rackmount kit (same as Agilent 1186A)

A6J ANSI Z540 compliant calibration service

See table 1-3 for power cord options

1-6

Page 12

General Information

Table 1-2

Accessories available

Model Description

01650-61607 16:16 logic cable and terminator (for use with 54621D/22D)

54620-68701 16:2 x 8 logic input probe assembly (shipped standard with 54621D/22D)

1146A 100 kHz current probe, ac/dc

1183A Testmobile scope cart

1185A Carrying case

1186A Rackmount kit

10070C 1:1 passive probe with ID

10072A Fine-pitch probe kit

10073C 10:1 500 MHz probe with ID

10075A 0.5 mm IC clip kit

10076A 100:1, 4 kV 250 MHz probe with ID

10100C 50

10833A GPIB cable, 1 m long

34398A RS-232 cable (standard with 100 MHz models)

E2613B 0.5 mm Wedge probe adapter, 3-signal, qty 2

E2614A 0.5 mm Wedge probe adapter, 8-signal, qty 1

E2615B 0.65 mm Wedge probe adapter, 3-signal, qty 2

E2616A 0.65 mm Wedge probe adapter, 8-signal, qty 1

E2643A 0.5 mm Wedge probe adapter, 16-signal, qty 1

E2644A 0.65 mm Wedge probe adapter, 16-signal, qty 1

N2726A Accessory pouch and front-panel cover (standard with 100 MHz models)

N2727A Thermal printer and pouch

N2728A 10 rolls of thermal printer paper

N2757A GPIB Interface Module

N2758A CAN Trigger Module

N2771A 1000:1, 15 kV, 50 MHz high voltage probe

N2772A 20 MHz differential probe

N2773A Differential probe power supply

N2774A 50 MHz current probe, ac/dc

N2775A Power supply for N2774A

Ω termination

1-7

Page 13

General Information

Table 1-3. Power Cords

Plug Type Cable Part Number Plug Type Cable Part Number

Opt 900 (U.K.) 8120-1703 Opt 918 (Japan) 8120-4754

Opt 901 (Australia) 8120-0696 Opt 919 (Israel) 8120-6799

Opt 902 (Europe) 8120-1692 Opt 920 (Argentina) 8120-6871

Opt 903 (U.S.A.) 8120-1521 Opt 921 (Chile) 8120-6979

Opt 906 (Switzerland) 8120-2296 Opt 922 (China) 8120-8377

Opt 912 (Denmark) 8120-2957 Opt 927 (Thailand) 8120-8871

Opt 917 (Africa) 8120-4600

1-8

Page 14

General Information

Acquisition: Analog Channels

Performance Characteristics

* Denotes Warranted Specifications, all others are typical. Specifications are valid after a 30-minute warm-up period and

±10 °C from firmware calibration temperature.

Acquisition: Analog Channels

Max Sample rate 200 MSa/s

Max Memory Depth 4 MB interleaved, 2 MB each channel

Vertical Resolution 8 bits

Peak Detection 5 ns

Averages selectable from 2, 4, 8, 16, 32, 64 ...to 16383

High Resolution Mode 12 bits of resolution when

Filter: Sinx/x interpolation (single shot BW = sample rate/4 or bandwidth of scope, whichever

is less) with vectors on.

≥500 us/div, average mode with average = 1

Acquisition: Digital Channels (on 54621D and 54622D only)

Max Sample Rate 400 MSa/s

Max Memory Depth 8 MB

Vertical Resolution 1 bit

Glitch Detection (min pulse width) 5 ns

1-9

Page 15

General Information

Vertical System: Analog Channels

* Denotes Warranted Specifications, all others are typical. Specifications are valid after a 30-minute warm-up period and

±10 °C from firmware calibration temperature.

Vertical System: Analog Channels

Analog channels 54621A/21D, 54622A/22D: Ch1 and 2 simultaneous acquisition

Bandwidth (-3dB)* 54621A/22D: dc to 60 MHz

ac coupled 54621A/21D: 3.5 Hz to 60 MHz

Calculated rise time

(= 0.35/bandwidth)

Single Shot Bandwidth 50 MHz

1

Range

Maximum Input CAT I 300 Vrms, 400 Vpk

Offset Range ±5 V on ranges <10 mV/div

Dynamic Range Lesser of ±8 div or ±32 V

Input Resistance 1 M

Input Capacitance ~ 14 pF

Coupling ac, dc, ground

BW Limit ~ 20 MHz selectable

Channel-to-Channel Isolation

(with channels at same V/div)

Probes 10:1 10074C shipped standard for each analog channel

Probe ID (Agilent/HP &

Tek Compatible)

1

1 mV/div is a magnification of 2 mV/div setting. For vertical accuracy calculations, use full scale of 16 mV for 1 mV/div sensitivity setting.

54624A: Ch 1, 2, 3, and 4 simultaneous acquisition

54622A/22D/24A: dc to 100 MHz

54622A/22D/24A: 3.5 Hz to 100 MHz

54621A/22D: ~5.8 ns

54622A/22D/24A: ~3.5 ns

1 mV/div to 5 V/div

CAT II 100 Vrms, 400 Vpk

with 10074C 10:1 probe: CAT I 500 Vpk, CAT II 400 Vpk

±25 V on ranges 10 mV/div to 199 mV/div

±100 V on ranges

≥200 mV/div

Ω ±1%

dc to 20 MHz > 40 dB

20 MHz to max bandwidth > 30 dB

Auto probe sense

1-10

Page 16

General Information

Vertical System: Analog Channels (continued)

* Denotes Warranted Specifications, all others are typical. Specifications are valid after a 30-minute warm-up period and

±10 °C from firmware calibration temperature.

Vertical System: Analog Channels (continued)

ESD Tolerance ±2 kV

Noise Peak-to-Peak 2% full scale or 1 mV, whichever is greater

Common Mode Rejection Ratio 20 dB @ 50 MHz

DC Vertical Gain Accuracy*

1

±2.0% full scale

DC Vertical Offset Accuracy < 200 mV/div: ±0.1 div ±1.0 mV ±0.5% offset

≥200 mV/div: ±0.1 div ±1.0 mV ±1.5% offset value

Single Cursor Accuracy

Dual Cursor Accuracy*

1

1 mV/div is a magnifica tion of 2 mV/div setting. For vertical a ccuracy calculations, use full scale of 1 6 mV for 1 mV/div sensitivity s etting.

1

1

±{DC Vertical Gain Accuracy + DC Vertical Offset

Accuracy + 0.2% full scale (~1/2 LSB) }

Example: For 50 mV signal, scope set to 10 mV/div (80 mV full scale), 5 mV offset,

accuracy = ±{2.0%(80mV) + 0.1 (10 mV) + 1.0 mV + 0.5% (5 mV) + 0.2%(80 mV)} = ± 3.78 mV

±{DC Vertical Gain Accuracy + 0.4% full scale (~1 LSB)}

Example: For 50 mV signal, scope set to 10 mV/div (80 mV full scale), 5 mV offset,

accuracy = ±{2.0%(80 mV) + 0.4%(80 mV)} = ±1.92 mV

Vertical System: Digital Channels (54621D and 54622D only)

Number of Channels 16 Digital – labeled D15 – D0

Threshold Groupings Pod 1: D7 - D0

Threshold Selections TTL, CMOS, ECL, user-definable (selectable by pod)

User-Defined Threshold Range ±8.0 V in 10 mV increments

Maximum Input

Voltage

Threshold Accuracy* ±(100 mV + 3% of threshold setting)

Input Dynamic Range ±10 V about threshold

Minimum Input Voltage Swing 500 mV peak-to-peak

Input Capacitance ~ 8 pF

Input Resistance 100 k

Channel-to-Channel Skew 2 ns typical, 3 ns maximum

Pod 2: D15 - D8

±40 V peak CAT I

Ω ±2% at probe tip

1-11

Page 17

General Information

Horizontal

* Denotes Warranted Specifications, all others are typical. Specifications are valid after a 30-minute warm-up period and

±10 °C from firmware calibration temperature.

Horizontal

Range 5 ns/div to 50 s/div

Resolution 25 ps

Vernier 1-2-5 increments when off, 25 minor increments between major settings when on

Reference Positions Left, Center, Right

Delay Range

Pre-trigger (negative delay)

Post-trigger (positive delay)

Analog Delta-t Accuracy

Same Channel*

Greater of 1 screen width or 10 ms

500 seconds

±0.01% reading ±0.1% screen width ±40 ps

Example: for signal with pulse width of 10 us, scope set to 5 us/div (50 us screen width),

delta-t accuracy = ±{.01%(10 us) + 0.1% (50 us) + 40 ps} = 51.04 ns

Channel-to-Channel

Digital Delta-t Accuracy

Same Channel

Channel-to-Channel

Delay Jitter 10 ppm

RMS Jitter 0.025% screen width + 30 ps

Modes Main, Delayed, Roll, XY

XY

Z blanking

Bandwidth

Phase error @ 1 MHz

±0.01% reading ±0.1% screen width ±80 ps

(non-Vernier settings)

±0.01% reading ±0.1% screen width ±(1 digital sample period, 2.5 or 5 ns based on

sample rate of 200/400 MSa/s)

Example: for signal with pulse width of 10 us, scope set to 5 us/div (50 us screen width),

and single pod active (400 MSa/s), delta-t accuracy = ±{.01%(10 us) + 0.1% (50 us) + 2.5

ns} = 53.5 ns

±0.01% reading ±0.1% screen width ±(1 digital sample period, 2.5 or 5 ns)

±chan-to-chan skew (2 ns typical, 3 ns maximum)

1.4 V blanks trace (use External trigger)

Max bandwidth

1.8 degrees

1-12

Page 18

General Information

Trigger System

* Denotes Warranted Specifications, all others are typical. Specifications are valid after a 30-minute warm-up period and

±10 °C from firmware calibration temperature.

Trigger System

Sources: 54621A/22A: Ch 1, 2, line, ext

Modes Auto, Auto level, Triggered (normal), Single

Holdoff Time ~60 ns to 10 seconds

Selections Edge, Pattern, Pulse Width, CAN, Duration, I

Edge Trigger on a rising or falling edge of any source.

Pattern Trigger on a pattern of high, low, and don’t care levels and a rising or falling edge

Pulse Width Trigger when a positive- or negative-going pulse is less than, greater than, or within a

CAN Trigger on CAN (Controller Area Network) version 2.0A and 2.0B signals. It can trigger

Duration Trigger on a multi-channel pattern whose time duration is less than a value, greater

2

C Trigger on I2C (Inter-IC bus) serial protocol at a start/stop condition, a restart, a missing

I

LIN Trigger on LIN (L ocal Interconnect Network) sync br eak at beginning of message frame.

Sequence Find event A, trigger on event B, with option to reset on event C or time delay.

SPI Trigger on SPI (Serial Peripheral Interface) a data pattern during a specific framing

USB Trigger on USB (Universal Serial Bus) Start of Packet, End of Packet, Reset Complete,

TV Trigger on any analog channel for NTSC, PAL, PAL-M, or SECAM broadcast standards

Autoscale Finds and displays all active analog and digital (for 54621D/54622D) cha nnels, sets edge

54621D/22D: Ch 1, 2, line, ext, D15 - D0

54624A: Ch 1, 2, 3, 4, line, ext

2

C, Sequence, SPI, TV, USB

established ac ross any of the sources . The analog channel’s high or low level is defi ned

by that channel’s trigger level.

specified range on any of the source channels.

Minimum pulse width setting: 5 ns

Maximum pulse width setting: 10 s

on the Start of Fra me bit of a data frame, a remote trans fer request frame, or an overlo ad

frame.

than a value, greater than a time value with a timeout value, or inside or outside of a set

of time values.

Minimum duration setting: 5 ns

Maximum duration setting: 10 s

acknowledge, or user defined frame with address and/or data values. Also trigger on

Missing Acknowledge, Restart, EEPROM read, and 10-bit write.

period. Supp ort positive and negative Chip Select framing ad well as clock Idle framing

and user-specified number of bits per frame.

Enter Suspend, or Exit Suspend on the differential USB data lines. USB low speed and

high speed are supported.

on either positive or negative composite video signals. Modes supported include Field

1, Field 2, or both, all lines, or any line within a field. Also supports triggering on noninterlaced fields. TV trigger sensitivity: 0.5 division of synch signal.

trigger mode on h ighest numbered channel, se ts vertical sensitivity on analog channels

and thresholds on di gital channels, time base to displ ay ~1.8 periods. Requires minimum

voltage >10 mVpp, 0.5% duty cycle and minimum frequency >50 Hz.

1-13

Page 19

General Information

Analog Channel Triggering

* Denotes Warranted Specifications, all others are typical. Specifications are valid after a 30-minute warm-up period and

±10 °C from firmware calibration temperature.

Analog Channel Triggering

Range (Internal) ±6 div from center screen

Sensitivity* Greater of 0.35 div or 2.5 mV

Coupling AC (~3.5 Hz), DC, noise reject, HF reject and LF reject (~ 50 kHz)

Digital (D15 - D0) Channel Triggering (54621D and 5462 2D)

Threshold Range (user-defined) ±8.0 V in 10 mV increments

Threshold Accuracy* ±(100 mV + 3% of threshold setting)

Predefined Thresholds TTL = 1.4 V, CMOS = 2.5 V, ECL = -1.3 V

External (EXT) Triggering

Input Resistance 1 MΩ ±3%

Input Impedance ~ 14 pF

Maximum Input CAT I 300 Vrms, 400 Vpk

CAT II 100 Vrms, 400 Vpk

with 10074C 10:1 probe:CAT I 500 Vpk, CAT II 400 Vpk

Range ±10 V

Sensitivity dc to 25 MHz, < 75 mV

Coupling AC (~ 3.5 Hz), DC, noise reject, HF reject and LF reject (~ 50 kHz)

Probe ID (Agilent/HP & Tek

Compatible)

25 MHz to max bandwidth, < 150 mV

Auto probe sense for 54621A/22A

1-14

Page 20

General Information

Display System

* Denotes Warranted Specifications, all others are typical. Specifications are valid after a 30-minute warm-up period and

±10 °C from firmware calibration temperature.

Display System

Display 7-inch raster monochrome CRT

Throughput of Analog Channels 25 million gray scale vectors/sec per channel

Resolution 255 vertical by 1000 horizontal points (waveform area)

Controls Waveform intensity on front panel

Built-in Help System Key-specific help in 11 languages displayed by pressing and holding key or softkey of

Real Time Clock Time and date (user setable)

32 levels of gray scale

Vectors on/off; infinite persistence on/off

8 x 10 grid with continuous intensity control

interest

Measurement Features

Automatic Measurements Measurements are continuously updated

Voltage (analog channels only) Peak-to-Peak, Maximum, Minimum, Average, Amplitude, Top, Base, Overshoot,

Time Frequency, Period, + Width, - Width, and Duty Cycle on any channels.

Counter Built-in 5-digit frequency counter on any channel. Counts up to 125 MHz

Threshold Definition Variable by percent and absolute value; 10%, 50%, 90% default for time measurements

Cursors Manually or automatically placed readout of Horizontal (X,

Waveform Math 1-2, 1*2, FFT, differentiate, integrate.

Cursors track current measurement

Preshoot, RMS (DC)

Rise time, Fall time, X at Max (Time at max volts), X at Min (Time at min volts), Delay,

and Phase on analog channels only.

∆X, 1/∆X) and

Vertical (Y,

hex values

Source of FFT: differentiate, integrate, analog channels 1 or 2 (or 3 or 4 for 54624A), 12, 1+2, 1*2

∆Y). Additionally digital or analog channels can be displayed as binary or

1-15

Page 21

General Information

FFT

* Denotes Warranted Specifications, all others are typical. Specifications are valid after a 30-minute warm-up period and

±10 °C from firmware calibration temperature.

FFT

Points Fixed at 2048 points

Source of FFT Analog channels 1 or 2 (or 3 or 4 for 54624A), 1+2, 1-2, 1*2

Window Rectangular, Flattop, Hanning

Noise Floor -70 to -100 dB depending on averaging

Amplitude Display In dBV

Frequency Resolution: 0.097656/(time per div)

Maximum Frequency 102.4/(time per div)

Storage

Save/Recall (non-volatile) 3 setups and traces can be saved and recalled internally

Floppy Disk

Image formats

Data formats

Trace/setup formats

3.5” 1.44 MB double density

TIF, BMP

X and Y (time/voltage) values in CSV format

Recalled

I/O

RS-232 (serial) standard port 1 port; XON or DTR; 8 data bits; 1 stop bits; parity=none; 9600, 19200, 38400, 57600 baud

Parallel standard port Printer support

Printer Compatibility HP DeskJet, HP LaserJet with HP PCL 3 or greater compatibility

Optional GPIB Interface Module Fully programmable with IEEE488.2 compliance

rates

Compatibility– black and white @150x150 dpi

gray scale @ 600x600 dpi

Epson–black and white @180x180 dpi

Seiko–DPU-414 black and white

Typical GPIB throughput of 20 measurements or twenty 2000-point records per second.

1-16

Page 22

General Information

General Characteristics

* Denotes Warranted Specifications, all others are typical. Specifications are valid after a 30-minute warm-up period and

±10 °C from firmware calibration temperature.

General Characteristics

Physical:

Size

Weight

Calibrator Output Frequency ~1.2 kHz; Amplitude ~5 V

Trigger Out 0 to 5 V with 50

Printer Power 7.2 to 9.2 V, 1 A

Kensington lock Connection on rear panel for security

32.26 cm wide x 17.27 cm high x 31.75 cm deep (without handle)

6.35 kgs (14 lbs)

Ω source impedance; delay ~ 55 ns

Power Requirements

Line Voltage Range 100 - 240 VAC ±10%, CAT II, automatic selection

Line Frequency 47 to 440 Hz

Power Usage 100 W max

Environmental Characteristics

Ambient Temperature Operating -10 °C to +55 °C

Humidity Operating 95% RH at 40 °C for 24 hr

Altitude Operating to 4,570 m (15,000 ft)

Vibration HP/Agilent class B1 and MIL-PRF-28800F Class 3 random

Shock HP/Agilent class B1 and MIL-PRF-28800F (operating 30 g, 1/2 sine, 11-ms duration, 3

Pollution degree2 Normally only dry non-conductive pollution occurs. Occasionally a temporary

Indoor use only This instrument is rated for indoor use only

Non-operating -51 °C to +71 °C

Non-operating 90% RH at 65 °C for 24 hr

Non-operating to 15,244 m (50,000 ft)

shocks/axis along major axis. Total of 18 shocks)

conductivity caused by condensation must be expected.

1-17

Page 23

2

Preparing the Oscilloscope for Use

Page 24

Preparing the Oscilloscope for Use

To prepare your oscilloscope for use, you need to do the following tasks.

A ft er y ou ha ve co mp l et ed th em , y ou wi ll be re a dy to us e t he o sc il lo sc op e.

In the following topics you will:

• adjust the handle

• power-on the oscilloscope

• adjust the display intensity

• connect the oscilloscope probes

• connect the digital probes (with 54621D and 54622D)

• connect a printer

• connect a RS-232 cable

• verify basic oscilloscope operation

• get started using the oscilloscope interface

• learn how to use Quick Help

This chapter also tells you how to:

• clean the oscilloscope

2-2

Page 25

Setting up the Oscilloscope

After you have done a few basic tasks, you will connect probes to the

oscilloscope. The number of probes, and the type of probes that you will

use depends on the oscilloscope model that you have.

• When using the Agilent 54621A and 54622A 2-channel Oscilloscopes, and

the Agilent 54624A 4-channel Oscilloscope, you will connect and use analog

probes to examine analog signals.

Analog channels

(2 or 4, depending

on the oscilloscope

model)

• When using the Agilent 54621D and 54622D Mixed-Signal Oscilloscopes, you

will connect and use both analog and digital probes to examine analog and

digital signals.

Analog channels (2)

Digital channels (16)

2-3

Page 26

Preparing the Oscilloscope for Use

To adjust the handle

To adjust the handle

1 Grasp the handle pivot points on each side of the instrument and pull

the pivot out until it stops.

54622D

Agilent

MIXED SIGNAL OS CILLOSCOPE

CHANNEL

Select

Time/Div

150

5 ns1 s

INPUTS

2 Without releasing the pivots, swivel the handle to the desired position.

Then release the pivots. Continue pivoting the handle until it clicks into

a set position.

2-4

Page 27

Preparing the Oscilloscope for Use

To power-on the oscilloscope

To power-on the oscilloscope

1 Connect the power cord to the rear of the oscilloscope, then to a suitable

ac voltage source.

The oscilloscope power supply automatically adjusts for input line voltages in the

range 100 to 240 VAC. Therefore, you do not need to adjust the input line voltage

setting. The line cord provided is matched to the country of origin. Ensure that

you have the correct line cord. See table 1-3

2 Press the power switch.

Trigger out

~5V

Some front panel key lights will come on and the oscilloscope will be operational

in about 5 seconds.

2-5

Page 28

Preparing the Oscilloscope for Use

To adjust the display intensity

To adjust the display intensity

The Intensity control is at the lower left corner of the front panel.

• To decrease display intensity, rotate the Intensity control counterclockwise.

• To increase display intensity, rotate the Intensity control clockwise.

Dim Bright

Intensity control

The grid or graticule intensity on the display can be adjusted by pressing the

Display key, then turn the Entry knob (labeled on the front panel) to adjust

the Grid control.

2-6

Page 29

Preparing the Oscilloscope for Use

To connect the oscilloscope probes

To connect the oscilloscope probes

1 Connect the Agilent 10074C 1.5-meter, 10:1 oscilloscope probe to the

analog channel 1 or 2 BNC connector input on the oscilloscope, or

channel 1 through channel 4 on the 54624A.

Maximum input voltage for analog inputs:

CAT I 300 Vrms, 400 Vpk

CAT II 100 Vrms, 400 Vpk

with 10074C 10:1 probe: CAT I 500 Vpk, CAT II 400 Vpk

2 Connect the retractable hook tip on the probe tip to the circuit point of

interest. Be sure to connect the probe ground lead to a ground point on

the circuit.

The probe ground lead is connected to the oscilloscope chassis and the ground

wire in the power cord. If you need to connect the ground lead to a point in the

circuit that cannot be grounded to power ground, consider using a differential

probe.

Perfectly compensated

Over compensated

Under compensated

To compensate your probe

You should compensate you probes to match their characteristics to the

oscilloscope. A poorly compenstated probe can introduce measurement errors.

To compensate a probe, follow these steps:

1 Connect the probe from channel 1 to the Probe Comp signal on the lower-

right corner of the front panel.

2Press

3 Use a nonmetallic tool to adjust the trimmer capacitor on the probe for

Autoscale.

the flattest pulse possible.

comp.cdr

2-7

Page 30

Preparing the Oscilloscope for Use

To use the digital probes (mixed-signal oscilloscope only)

To use the digital probes (mixed-signal oscilloscope

only)

1 If you feel it’s necessary, turn off the power supply to the circuit under

test.

Off

Turning off power to the circuit under test would only prevent damage that

might occur if you accidentally short two lines together while connecting

probes. You can leave the oscilloscope powered on because no voltage appears

at the probes.

2 Connect the digital probe cable to D15 - D0 connector on the front panel

of the mixed-signal oscilloscope. The digital probe cable is indexed so

you can connect it only one way. You do not need to power-off the

oscilloscope.

Use only the Agilent part number 54620-68701 digital probe kit supplied with

the mixed-signal oscilloscope.

2-8

Page 31

Preparing the Oscilloscope for Use

To use the digital probes (mixed-signal oscilloscope only)

3 Connect a grabber to one of the probe leads. Be sure to connect the

ground lead. (Other probe leads are omitted from the figure for clarity.)

Grabber

4 Connect the grabber to a node in the circuit you want to test.

2-9

Page 32

Preparing the Oscilloscope for Use

To use the digital probes (mixed-signal oscilloscope only)

5 For high-speed signals, connect a ground lead to the probe lead, connect

a grabber to the ground lead, and attach the grabber to ground in the

circuit under test.

Signal Lead

Ground Lead

Grabber

6 Connect the ground lead on each set of channels, using a probe grabber.

The ground lead improves signal fidelity to the instrument, ensuring

accurate measurements.

Channel

Pod Ground

Circuit

Ground

2-10

Page 33

Preparing the Oscilloscope for Use

To use the digital probes (mixed-signal oscilloscope only)

7 Repeat steps 3 through 6 until you have connected all points of interest.

Signals

Ground

8 If you need to remove a probe lead from the cable, insert a paper clip

or other small pointed object into the side of the cable assembly, and

push to release the latch while pulling out the probe lead.

Replacement parts are available. See the “Replaceable Parts” chapter for details.

2-11

Page 34

Preparing the Oscilloscope for Use

To connect a printer

To connect a printer

The oscilloscope connects to a parallel printer through the Parallel output

connector on the rear of the oscilloscope. You will need a parallel printer cable

to connect to the printer.

1 Attach the 25-pin small “D” connector to the Parallel output connector

on the rear of the oscilloscope. Tighten the thumbscrews on the cable

connector to secure the cable.

2 Attach the larger 36-pin “D” connector to the printer.

3 Set up the printer configuration on the oscilloscope.

a Press the Utility key, then press the Print Confg softkey.

b Press the Print to: softkey and set the interface to Parallel.

c Press the Format softkey and select your printer format from the list.

For more information on printer configuration, refer to the “Utilities” chapter

in the User’s Guide.

To connect an RS-232 cable

The oscilloscope can be connected to a controller or a PC through the RS-232

connector on the rear of the oscilloscope. An RS-232 cable is shipped with each

54622A/22D/24A oscilloscope and may be purchased for the 54621A/21D

oscilloscopes.

1 Attach the 9-pin “D” connector on the RS-232 cable to the RS-232

connector on the rear of the oscilloscope. Tighten the thumbscrews on

the cable connector to secure the cable

2 Attach the other end of the cable to your controller or pc.

3 Set up the RS-232 configuration on the oscilloscope.

a Press the Utility key, then press the I/O softkey.

b Press the Controller softkey and select RS-232.

c Press the Baud softkey and set the baud rate to match your controller or pc.

d Press the XON DTR softkey and set the handshake to match your controller

or pc.

For more information on RS-232 configuration, refer to the “Utilities” chapter

in the User’s Guide.

2-12

Page 35

Preparing the Oscilloscope for Use

To verify basic oscilloscope operation

To verify basic oscilloscope operation

1 Connect an oscilloscope probe to channel 1.

2 Attach the probe to the Probe Comp output on the lower-right side of

the front panel of the oscilloscope.

Use a probe retractable hook tip so you do not need to hold the probe.

3Press the Save/Recall key on the front panel, then press the Default Setup

softkey under the display.

The oscilloscope is now configured to its default settings.

4Press the Autoscale key on the front panel.

You should then see a square wave with peak-to-peak amplitude of about 5

divisions and a period of about 4 divisions as shown below. If you do not see

the waveform, ensure your power source is adequate, the oscilloscope is

properly powered-on, and the probe is connected securely to the front-panel

channel input BNC and to the Probe Comp calibration output.

Verifying Basic Oscilloscope Operation

2-13

Page 36

Getting started using the oscilloscope interface

When the oscilloscope is first turned on, it performs a self-test, then

momentarily shows a startup screen as shown below.

This menu is only accessible when the oscilloscope first starts up.

2-14

Page 37

Preparing the Oscilloscope for Use

To verify basic oscilloscope operation

•Press the Getting Started softkey to view the symbols used in the

oscilloscope softkey menus.

Use the Entry knob labeled to adjust the parameter.

Press the softkey to display a pop up with a list of choices. Repeatedly

press the softkey until your choice is selected.

Use the Entry knob labeled or press the softkey to adjust the

parameter.

✓ Option is selected and operational.

Feature is on. Press the softkey again to turn the feature off.

Feature is off. Press the softkey again to turn the feature on.

Press the softkey to view the menu.

Press the softkey to return to the previous menu.

Links you to another menu.

2-15

Page 38

Using Quick Help

The oscilloscope has a Quick Help system that provides user help for

each front-panel key and softkey on the oscilloscope. To view Quick Help

information:

1Press

2 Release the key after reading the message. Releasing the key returns

and hold down the key for which you would like to view help.

the oscilloscope to the previous state.

Selecting a language for Quick Help when the oscilloscope starts up

When the oscilloscope first powers up, you can press the Language softkey to

select a language for viewing Quick Help. Successive press the Language s of tk ey

until the desired language in the list selected.

You can also select and load a language later from the Utility Language menu.

2-16

Page 39

Preparing the Oscilloscope for Use

Selecting a language for Quick Help after you have been operating the oscilloscope

Selecting a language for Quick Help after you have been

operating the oscilloscope

1Press the Utility key, then press the Language softkey to display the

Language menu.

2Press the

Language softkey until the desired language in the list selected.

If the language you want to load is grayed-out in the list, you will need to load

the language from floppy disk. The language file can be downloaded from

www.agilent.com/find/5462xsw

disk for your instrument

or call an A gilent cen ter an d req uest a lan guage

2-17

Page 40

Preparing the Oscilloscope for Use

Loading a language from floppy disk

Loading a language from floppy disk

Language files can be downloaded from www.agilent.com/find/5462xsw or call

an Agilent center and request a language disk for your instrument.

1 Insert the floppy disk with a language file into the floppy disk drive on

the oscilloscope.

2Press the

Language menu.

3Press the

the oscilloscope.

4Press the

For more information about loading and deleting languages, refer to the

“Utilities” chapter in the User’s Guide.

Utility key, then press the Language softkey to display the

Load Languages softkey to load the updated language file into

Language softkey and select the language to be viewed.

2-18

Page 41

Cleaning the oscilloscope

1 Disconnect power from the instrument.

CAUTION Avoid Damage to Sensitive Electronic Components!

Do not use too much liquid in cleaning the oscilloscope. Water can enter the

front-panel keyboard, control knobs, or floppy disk damaging sensitive

electronic components.

2 Clean the oscilloscope with a soft cloth dampened with a mild soap and

water solution.

3 Make sure that the instrument is completely dry before reconnecting to

a power source.

2-19

Page 42

3

Testing Performance

Page 43

Testing Performance

This chapter explains how to verify correct oscilloscope operation and

perform tests to ensure that the oscilloscope meets the performance

specifications.

To completely test and troubleshoot the mixed-signal oscilloscope, you

will create and use a test connector accessory, as described in this

chapter.

• The test connector makes it easy for you to connect the oscilloscope

probes to function generators and measurement equipment with

minimum electrical distortion.

• The connector is used in the digital channel threshold accuracy test.

Let the Equipment Warm Up Before Testing For accurate test results, let

the test equipment and the oscilloscope warm up 30 minutes before testing.

Verifying Test Results During the tests, record the readings in the

Performance Test Record at the end of this chapter for your oscilloscope. To

verify whether a test passes, verify that the reading is within the limits in the

Performance Test Record.

If a performance test fails

If a performance test fails, first perform the User Cal procedure given in Chapter 4.

If the User Cal procedure does not correct the problem , refer to Chapter 4, Calibrating

and Adjusting.

3-2

Page 44

Testing Performance

List of Test Equipment

List of Test Equipment

Below is a list of test and equipment and accessories required to perform

the performance test verification procedures.

Equipment Critical Specifications Recommended Model/

Test connector, 8-by-2 Not required if 01660-63801 Test Fixture is available

See “To construct the test connector”

later in this chapter

Test fixture For testing digital channel threshold accuracy Agilent 01660-63801

Digital Multimeter 0.1 mV resolution, 0.005% accuracy Agilent 34401A

Power Splitter Outputs differ by 0.15 dB Agilent 11667B

Power Supply DC offset voltage of -5.5 V to 35.5 V, 0.1 mV resolution Agilent 3245A

Oscilloscope Calibrator 25 MHz—100 MHz sine wave, 5 ppm Fluke 5820A

BNC banana cable Agilent 11001-60001

BNC cable (qty 3) Agilent 10503A

Probe cable Agilent 01650-61607

Shorting Cap BNC Agilent 1250-0774

Adapter BNC(f) to banana(m) Agilent 1251-2277

Feedthrough 50

Adapter BNC Tee (m) (f) (f) Agilent 1250-0781

Blocking capacitor Agilent 10240-60001

Adapter (qty 3) N(m) to BNC(f) Agilent 1250-0780

Ω, BNC (m) and (f) Agilent 11048C

Part Number

n/a

3-3

Page 45

Testing Performance

To construct the test connector

To construct the test connector

The Agilent 54621D/22D Mixed-Signal Oscilloscope has digital channels that

you will need to connect to test equipment during testing. To easily connect the

digital channels, you will construct a test connector only if the 01660-63801

Test Fixture is not available.

Construct Test Connector only if Test Fixture is not available

The test connector is not required if 01660-63801 Test Fixture is available.

Table 3-1

Figure 3-1

Materials Required to Construct the Test Connectors

Description Recommended Part Qty

BNC (f) Connector Agilent 1250-1032 1

Berg Strip, 8-by-2 1

Jumper wire

1

Obtain a BNC connector and an 8-by-2 section of Berg strip.

2 On one side of the Berg strip, solder a jumper wire to all of the pins.

3 On the other side of the Berg strip, solder another jumper wire to all of

the pins.

4 Solder the center of the BNC connector to a center pin on one of the

rows on the Berg strip.

5 Solder the ground tab of the BNC connector to a center pin on the other

row on the Berg strip.

Constructing the 8-by-2 Connector

3-4

Page 46

Testing Performance

To test the 54621D/22D Oscilloscope digital channels

To test the 54621D/22D Oscilloscope digital channels

Only the 54621D/22D Mixed-Signal Oscilloscope has Digital Channels

You need to perform these instructions only if you will be testing the digital channels

on the Agilent 54621D/22D Mixed-Signal Oscilloscope.

The acquisition system testing provides confidence that the acquisition system

is functioning correctly. It does not, however, check a particular specification.

1

Disconnect all probes from the circuit under test and from any other

input source.

2 Using probe leads and grabbers, connect digital channels D0, D1, D2,

and D3 to the calibration point on the 54621D/22D front panel.

3 Press the Autoscale key.

If four square waves appear, the acquisition system is functioning correctly.

If the square waves do not appear, go to the “Troubleshooting” chapter. Then

return here to finish testing the digital channels.

4

Disconnect the digital channels from the calibration point.

5 Use steps 2 and 3 to test the following sets of digital channels. After you

test one set of digital channels, remove them before connecting the next

set.

• D4, D5, D6, D7

• D8, D9, D10, D11

• D12, D13, D14, D15

3-5

Page 47

Testing Performance

To verify digital channel threshold accuracy

To verify digital channel threshold accuracy

This test verifies the digital channel threshold accuracy specification of the

Agilent 54621D/22D Mixed-Signal Oscilloscope.

Test Threshold Accuracy only on the 54621D/22D Mixed-Signal Oscilloscope

You need to perform these instructions only if you will be testing the Agilent

54621D/22D Mixed-Signal Oscilloscope.

Threshold accuracy test limits= ±(100 mV + 3% of threshold setting)

When to Test You should perform this test every 24 months or after 4000

hours of operation, whichever comes first.

What to Test Use these instructions to test the threshold settings of digital

channels D7-D0. Then, use the same instructions to test digital channels

D15-D8.

Table 3-2

Verifying Test Results After each threshold test, record the voltage reading

in the Performance Test Record at the end of this chapter. To verify whether a

t e st p a s se s , v er i fy t h at t he v o l ta g e r e a d in g i s wi t h i n th e l im i ts i n t he P e r fo r ma n c e

Test Rec ord.

Equipment Required to Test Threshold Accuracy

Equipment Critical Specifications Recommended Model/Part

Digital Multimeter 0.1 mV resolution, 0.005%

accuracy

Oscilloscope Calibrator DC offset voltage 6.3 V Fluke 5820A

BNC-Banana Cable Agilent 11001-60001

BNC Tee Agilent 1250-0781

BNC Cable Fluke 50

BNC Test Connector, 8-by-2 User-built (See “Obtain a BNC

Test Fixture PV test fixture Agilent 01660-63801

Probe Cable Agilent 01650-61607

Agilent 34401A

Ω cable, P/N 686318

connector a nd an 8-by-2 section

of Berg strip.” on page 3-4.)

3-6

Page 48

Figure 3-2

Save/Recall

Mixed Signal Oscilloscope

Trigg er ou t

!

!

Testing Performance

To verify digital channel threshold accuracy

1

Turn on the test equipment and the oscilloscope. Let them warm up for

30 minutes before starting the test.

2 Set up the oscilloscope calibrator.

a Set the oscilloscope calibrator to provide a DC offset voltage at the

Channel 1 output.

b Use the multimeter to monitor the oscilloscope calibrator DC output

voltage.

3

Use either method 1 or method 2, described in the following, to connect

the digital channels for testing.

a Method 1 — Using the Test Connector

Use the 8-b y- 2 t est co nn ec to r an d th e B NC cab le as sem bl y to co nn ec t di gi tal

channels D0-D7 to one side of the BNC Tee. Then connect the D0-D7 ground

lead to the ground side of the 8-by-2 connector. See figure 3-2.

Oscilloscope

Calibrator

Digital

Multimeter

54620A

16 CHANNEL 500 MSa/s

HP 34401A

Channels 8 - 15

BNC-Banana

cable

Test

Connector

Setting Up Equipment and Test Connector for the Threshold Test

Ext trigge r in

STORAGE

Entry

TRIGGERHORIZONTAL

Delay

Time/Div

INPU TS

!

Measure time

CHANNEL

Select

Position

Line

Channels 0 - 7

hrh.r

3-7

Page 49

Figure 3-3

Save/Recall

Mixed Signal Oscillos cope

STORAGE

TRIGGER

Trigger out

!

Delay

!

!

Digital

Multimeter

Oscilloscope

Calibrator

Testing Performance

To verify digital channel threshold accuracy

b Method 2 — Using the Test Fixture

Use the Agilent 01660-63801 Performance Verification Test Fixture and the

Agilent 01650-61607 cable, BNC Tee, and BNC cable to connect the digital

channels D0 - D15 to the oscilloscope calibrator. See figure 3-3.

$

16 CHANNEL 500 MSa/s

HP 34401A

01650-61607

Cable

Measure time

Entry

HORIZONTAL

CHANNEL

Time/Div

Select

INPUTS

Posit io n

Ext trig ger in

Line

01660-63801

BNC-Banana

Test Fixture

cable

Setting Up Equipment and Test Fixture for the Threshold Test

4 Use a BNC-banana cable to connect the multimeter to the other side of

the BNC Tee.

5 Connect the BNC Tee to the Channel 1 output of the calibrator as shown

in figure 3-2 and figure 3-3.

6 On the oscilloscope, press the D7 Thru D0 key, then press the Threshold

softkey.

3-8

Page 50

To verify digital channel threshold accuracy

7

Press the oscilloscope User softkey, then turn the Entry knob () on

the front panel

on the oscilloscope to set the threshold test settings as

shown in Table 3-3.

Table 3-3 Threshold Accuracy Voltage Test Settings

Testing Performance

Threshold voltage setting

(in oscilloscpe User softkey)

+5.00 V +5.250 V ±1 mV dc Lower limit = +4.750 V

–5.00 V –4.750 V ±1 mV dc Lower limit = –5.250 V

0.00 V +100m V ±1 mV dc Upper limt = +100 mV

8

Do the following steps for each of the threshold voltage levels shown

DC offset voltage setting

(on oscilloscope calibrator)

Limits

Upper limit = +5.250 V

Upper limit = –4.750 V

Lower limit = –100 mV

in Table 3-3.

a Set the threshold voltage shown in the User softkey using the Entry knob on

the oscilloscope.

b Enter the corresponding DC offset voltage on the oscilloscope calibrator

front panel. Then use the multimeter to verify the voltage.

Digital channel activity indicators are displayed on the status line at the top

of the oscilloscope display. The activity indicators for D7-D0 should show all

of the channels at digital high levels.

c Use the knob on the oscilloscope calibrator to decrease the offset voltage,

in increments of 10 mV, until the activity indicators for digital channels

D7-D0 are all at digital low levels. Record the oscilloscope calibrator voltage

in the performance test record.

d Use the knob on the oscilloscope calibrator to increase the offset voltage,

in increments of 10 mV, until the activity indicators for digital channels

D7-D0 are all at digital high levels. Record the oscilloscope calibrator

voltage in the performance test record.

Before proceeding to the next step, make sure that you have recorded the

oscilloscope calibrator voltage levels for each of the threshold settings shown

in Table 3-3.

Use the 8-by-2 test connector or the Agilent 01660-63801 Test Fixture

9

to connect digital channels D15-D8 to the output of the oscilloscope

calibrator. Then connect the D15-D8 ground lead to the ground side of

the 8-by-2 connector.

10 Repeat this procedure for digital channels D15-D8 to verify threshold

accuracy and record the threshold levels in the Performance Test

Record.

3-9

Page 51

Testing Performance

To verify voltage measurement accuracy

To verify voltage measurement accuracy

This test verifies the voltage measurement accuracy. In this test, you will

measure the output of a power supply using dual cursors on the oscilloscope,

and compare the results with the multimeter reading.

Test limits: ±2.0% of full scale ±1 LSB*

• Full scale is defined as 16 mV on the 1 mV/div range.

• Full scale on all other ranges is defined as 8 divisions times the

V/div setting.

*1 LSB = 0.4% of full scale

Table 3-4

Equipment Required to Verify Voltage Measurement Accuracy

Equipment Critical Specifications Recommended Model/Part

Power supply 14 mV to 35 Vdc,

0.1 mV resolution

Digital multimeter Better than 0.01% accuracy Agilent 34401A

Cable BNC, Qty 2 Agilent 10503A

Shorting cap BNC Agilent 1250-0774

Adapter BNC (f) to banana (m) Agilent 1251-2277

Adapter BNC tee (m) (f) (f) Agilent 1250-0781

Blocking capacitor Agilent 10240B

Fluke 5820A or Agilent 3245A

Do this procedure first for Channel 1. Then repeat the procedure for Channel 2.

1

Set up the oscilloscope.

a Adjust the channel 1 position knob to place the baseline at approximately

0.5 division from the bottom of the display.

3-10

Page 52

Testing Performance

To verify voltage measurement accuracy

b Set the Volts/Div setting to the value in the first line in Table 3-5.

Table 3-5

Settings Used to Verify Voltage Measurement Accuracy

Volts/Div Setting Power Supply Setting Test Limits

5 V/Div 35 V 34.04 V to 35.96 V

2 V/Div 14 V 13.616 V to 14.384 V

1 V/Div 7 V 6.808 V to 7.192 V

0.5 V/Div 3.5 V 3.404 V to 3.596 V

0.2 V/Div 1.4 V 1.3616 V to 1.4384 V

0.1 V/Div 700 mV 680.8 mV to 719.2 mV

50 mV/Div 350 mV 340.4 mV to 359.6 mV

20 mV/Div 140 mV 136.16 mV to 143.84 mV

10 mV/Div 70 mV 68.08 mV to 71.92 mV

5 mV/Div 35 mV 34.04 mV to 35.96 mV

2 mV/Div 14 mV 13.616 mV to 14.384 mV

1 mV/Div* 7 mV 6.616 mV to 7.384 mV

*Full scale is defined as 16 mV on the 1 mV/div range.

Full scale on all other ranges is defined as 8 divisions times the V/div setting.

c Press the Acquire key. Then press the Averaging softkey and set #Avgs to 64.

Wait a few seconds for the measurement to settle.

2

Press the Cursors key, set the Mode softkey to Normal, then press the XY

softkey and select

(labeled

Y. Press the Y1 softkey, then use the Entry knob

on the front panel) to set the Y1 cursor on the baseline of

the signal.

3-11

Page 53

Testing Performance

To verify voltage measurement accuracy

3

Use the BNC tee and cables to connect the oscilloscope calibrator

/power supply to both the oscilloscope and the multimeter.

4 Adjust the output so that the multimeter reading displays the first

Volts/div supply setting value in Table 3-5.

Wait a few seconds for the measurement to settle.

5 Press the Y2 softkey, then position the Y2 cursor to the center of the

voltage trace using the Entry knob.

The ∆Y value on the lower line of the display should be within the test limits of

Table 3-5. If a result is not within the test limits, see the “Troubleshooting”

chapter. Then return here.

6

Continue to check the voltage measurement accuracy with the

remaining Volts/div setting values in Table 3-5.

7 When you are finished checking all of the power supply setting values,

disconnect the power supply from the oscilloscope.

8 Repeat this procedure for Channels 2, 3, and 4, if applicable on your

oscilloscope model.

Use a Blocking Capacitor to Reduce Noise

On the more sensitive ranges, such as 1 mV/div, 2 mV/div, and 5 mV/div, noise may

be a factor. To eliminate the noise, use a BNC Tee, blocking capacitor, and BNC

shorting cap to shunt the noise to ground. See figure 3-4.

Figure 3-4

To Power Supply or

Calibrator

To oscilloscope input

Using a Blocking Capacitor to Reduce Noise

3-12

Blocking

Capacitor

BNC shorting

cap

Page 54

Testing Performance

To verify bandwidth

To verify bandwidth

This test verifies bandwidth. In this test you will use an oscilloscope calibrator

with a level sinewave output.

Yo u wi l l u s e t h e p e ak - to - pe a k v o lt a ge b ot h at 1 M Hz an d at ba n dw i dt h fr e qu e nc y

to verify the bandwidth response of the oscilloscope.

54622A, 54622D, and 54624A

Test limits at 1 mV/div to 5 V/div:

• All channels (±3 dB)

• dc to 100 MHz

• ac coupled 10 Hz to 100 MHz

54621A and 54621D

Test limits at 1 mV/div to 5 V/div:

• All channels (±3 dB)

• dc to 60 MHz

• ac coupled 10 Hz to 60 MHz

Table 3-6

Equipment Required to Verify Bandwidth

Equipment Critical Specifications Recommended Model/Part

Oscilloscope Calibrator Fluke 5820A

Cable * Type N (m), 24-inch Agilent 11500B

Feedthrough 50

* The oscilloscope calibrator is supplied with 2 or more coaxial cables N (m), BNC (m),

1 meter long, Fluke P/N 686318.

Ω, BNC (m) and (f) Agilent 11048C

3-13

Page 55

Testing Performance

To verify bandwidth

1

Connect the oscilloscope calibrator output through a 50Ω feedthrough

to the oscilloscope channel 1 input.

2 Set up the oscilloscope.

a Set the time base to 500 ns/div.

b Set the Volts/Div for channel 1 to 200 mV/div.

c Press the Acquire key, then press the Averaging softkey.

d Turn the Entry knob to set #Avgs to 8 averages.

Set the calibrator to “Level Sine” and OPR/STBY to “OPR”.

3

4 Set the calibrator for 1 MHz and six divisions of amplitude.

5 Press Autoscale on the oscilloscope.

6 Press the Quick Meas key, then press the Peak-Peak softkey.

Wait a few seconds for the measurement to settle (averaging is then complete).

View the Pk-Pk reading at the bottom of the display.

Record the reading: V

7

Change the frequency of the signal generator to the value shown below

= _______ V.

p-p

for your instrument.

Table 3-7 Signal Generator Frequency Setting

Selected Channel 54621A/21D 54622A/22D 54624A

Channel 1 60 MHz 100 MHz 100 MHz

Channel 2 60 MHz 100 MHz 100 MHz

Channel 3 ——100 MHz

Channel 4 ——100 MHz

8

Change the time base to 5 ns/div.

a Wait a few seconds for the measurement to settle.

b View the Pk-Pk reading at the bottom of the display.

c Record the reading: V

9

Calculate the response using this formula:

Step8Result

20 10log

------------ ------------- -------

⋅

Step6Result

= ______ mV.

p-p

If the result is not ±3 dB, see the “Troubleshooting” chapter. Then return here.

10 Repeat this procedure (steps 1 to 9) for channel 2, 3, and 4, as applicable

to your oscilloscope model.

Proceed to the next step after you have completed the procedure for channels

2, 3, and 4, as applicable.

3-14

Page 56

Testing Performance

To verify horizontal Dt and 1/Dt accuracy

To verify horizontal ∆t and 1/∆t accuracy

This test verifies the horizontal ∆t and 1/∆t accuracy. In this test, you will use

the oscilloscope to measure the output of a time mark generator.

Test limits: ±0.01% of reading ±0.1% of full scale ±40 ps (same channel)

Table 3-8

Equipment Required to Verify Horizontal ∆t and 1/∆t Accuracy

Equipment Critical Specifications Recommended Model/Part

Oscilloscope Calibrator Stability 5 ppm after 1/2 hour Fluke 5820A

Cable BNC, 3 feet Agilent 10503A

Feedthrough 50

1

Connect the oscilloscope calibrator to channel 1 using the 50 Ω

feedthrough at the oscilloscope input. Then, select

calibrator for 100

2 Set up the oscilloscope.

a Press the Display key, then set the Vectors softkey to off.

b Press the Autoscale key.

c Set the time base to 20 µs/div.

d Press the Main/Delayed key, then set the Time Ref softkey to Left.

e Adjust the Trigger Level knob to obtain a stable display.

Press the Quick Meas softkey, set the Source softkey to 1, then select and

3

measure

Frequency 10 kHz — The test limits are 9.98 kHz to 10.02 kHz.

Period 100 µs — The test limits are 99.79 µs to 100.2 µs.

If the measurements are not within the test limits, see the “Troubleshooting”

chapter. Then return here.

Frequency and Period. Measure the following:

Ω, BNC connectors (m) and (f) Agilent 11048C

Marker and set the

µs markers.

3-15

Page 57

54622A/22D/24A only

54621A and 54621D

only

Testing Performance

To verify horizontal Dt and 1/Dt accuracy

4

Change the calibrator to 1-µs markers. Change the time base to

200 ns/div. Adjust the trigger level to obtain a stable display.

5 Measure the following:

Frequency 1 MHz — The test limits are 997.9 kHz to 1.002 MHz.

Period 1 µs — The test limits are 997.9 ns to 1.002 µs.

If the measurements are not within the test limits, see the “Troubleshooting”

chapter. Then return here.

Change the calibrator to 10-ns markers. Change the time base to

6

5 ns/div. Adjust the trigger level to obtain a stable display.

7 Measure the following:

Frequency 100 MHz — The test limits are 99.10 MHz to 100.9 MHz.

Period 10 ns — The test limits are 9.91 ns to 10.09 ns.

If the measurements are not within the test limits, see the “Troubleshooting”

chapter. Then return here.

8

Change the calibrator to 20 ns markers. Change the time base to 5 ns/div.

Adjust the trigger level to obtain a stable display.

9 Measure the following:

Frequency 50 MHz — The test limits are 49.77 MHz to 50.23 MHz.

Period 20 ns — The test limits are 19.91 ns to 20.09 ns.

If the measurements are not within the test limits, see the “Troubleshooting”

chapter. Then return here.

3-16

Page 58

To verify trigger sensitivity

Th is test verifie s the tr igger s ensiti vity. I n this test, you will apply 25 MHz to the

oscilloscope. You will then decrease the amplitude of the signal to the specified

levels, and check to see if the oscilloscope is still triggered. You will then repeat

the process at the upper bandwidth limit.

Test limits for the Internal trigger:

1 mV to 5 V/div (dc to max bandwidth): greater of 0.35 div or 2.5 mV

Test limits for the External trigger:

dc to 25 MHz: <75 mV

25 MHz to max bandwidth: <150 mV

Table 3-9 Equipment Required to Verify Trigger Sensitivity

p-p

p-p

Testing Performance

To verify trigger sensitivity

p-p

Equipment Critical Specifications Recommended Model/Part

Oscilloscope Calibrator 25-MHz, 60-MHz and 100-MHz sine

waves

Power splitter Outputs differ < 0.15 dB Agilent 11667B

Cable * BNC, Qty 3 Agilent 10503A

Adapter N (m) to BNC (f), Qty 3 Agilent 1250-0780

Feedthrough 50

* The oscilloscope calibrator is supplied with 2 or more coaxial cables N (m), BNC (m),

1 meter long, Fluke P/N 686318.

Ω, BNC connectors (m) and (f) Agilent 11048C (2 required)

Fluke 5820A

3-17

Page 59

Testing Performance

To verify trigger sensitivity

Test Internal Trigger Sensitivity

1

Press the Save/Recall key, then press the Default Setup softkey.

2 Connect the calibrator to channel 1 using a 50Ω feedthrough at the

oscilloscope input.

3 Verify the trigger sensitivity at 25 MHz and 0.35 divisions.

a Set the output of the calibrator to 25 MHz, and set the amplitude to about

100 mV

b Press the Autoscale key.

c Set the time base to 50 ns/div.

d Set channel 1 to 100 mV/div.

e Decrease the output of the calibrator until 0.35 vertical divisions of the

p-p

.

signal are displayed.

The trigger should be stable. If the trigger is not stable, try adjusting the

trigger level. If adjusting the trigger level makes the trigger stable, the test

still passes. If adjusting the trigger does not help, see the “Troubleshooting”

chapter. Then return here.

f Record the result as Pass or Fail in the Performance Test Record.

Verify the trigger sensitivity at maximum bandwidth and 0.35 division.

4

a Change the output of the calibrator to 100 MHz for the 54622A/22D/24A or

60 MHz or the 54621A/21D, and set the amplitude to about 100 mV

b Set the time base to 10 ns/div.

c Decrease the output of the calibrator until 0.35 vertical divisions of the

p-p

.

signal is displayed.

The trigger should be stable. If the trigger is not stable, try adjusting the

trigger level. If adjusting the trigger level makes the trigger stable, the test

still passes. If adjusting the trigger does not help, see the “Troubleshooting”

chapter. Then return here.

d Record the result as Pass or Fail in the Performance Test Record.

Repeat this procedure for channels 2, 3, and 4, as applicable to your

5

oscilloscope model.

3-18

Page 60

Testing Performance

To verify trigger sensitivity

Test External Trigger Sensitivity

Verify the external trigger sensitivity at these settings:

100 MHz (54622A/22D/24A), <150 mV

60 MHz (54621A/21D), <150 mV

25 MHz (All models), <75 mV

p-p

p-p

p-p

1 Use the power splitter to connect the calibrator to both the channel 1

input and the external trigger input. The Ext Trigger input is on the rear

panel of the mixed-signal oscilloscope and the 4-channel oscilloscope.

Connect 50

2 Change the output of the calibrator to 100 MHz for the 54622A/22D/24A

or 60 MHz for the 54621A/21D, and set the amplitude to 106 mV

(300 mV

The power splitter divides the 300 mV

of the oscilloscope inputs.

3

Press the Autoscale key.

4 Press the Trigger Edge key, then press the Ext softkey to set the trigger

source to

5 Check for stable triggering, and adjust the trigger level if necessary.

6 Record the results as Pass or Fail in the Performance Test Record.

If the test fails, see the “Troubleshooting” chapter. Then return here.

7 Change the output of the calibrator to 25 MHz and set the amplitude to

25.74 mV

8 Check for stable triggering, and adjust the trigger level if necessary.

9 Record the results as Pass or Fail in the Performance Test Record.

If the test fails, see the “Troubleshooting” chapter. Then return here.

Ω feedthroughs to the oscilloscope inputs.

).

p-p

so that 150 mV

p-p

external trigger.

rms

(75 mV

p-p

).

rms

is applied to each

p-p

3-19

Page 61

Agilent 54622A/22D/24A Performance Test Record

Agilent 54622A/54622D/54624A

Serial No. ______________________________________ Test by _____________________________

Test Interval ____________________________________ Work Order No. ______________________

Recommended Next Testing ________________________ Temperature ____________

Threshold Specification Limits Ch D7-D0 Ch D15-D8

Accuracy Test

(100 mV + 3% of

threshold setting)

Voltage Measurement Accuracy

Range Power Supply Setting Test Limits Channel 1 Channel 2 Channel 3 Channel 4

5 V/Div 35 V 34.04 V to 35.96 V ________ ________ ________ ________

2 V/Div 14 V 13.616 V to 14.384 V ________ ________ ________ ________

1 V/Div 7 V 6.808 V to 7.192 V ________ ________ ________ ________

500 mV/Div 3.5 V 3.404 V to 3.596 V ________ ________ ________ ________

200 mV/Div 1.4 V 1.3616 V to 1.4384 V ________ ________ ________ ________

100 mV/Div 700 mV 680.8 mV to 719.2 mV ________ ________ ________ ________

50 mV/Div 350 mV 340.4 mV to 359.6 mV ________ ________ ________ ________

20 mV/Div 140 mV 136.16 mV to 143.84 mV ________ ________ ________ ________

10 mV/Div 70 mV 68.08 mV to 71.92 mV ________ ________ ________ ________

5 mV/Div 35 mV 34.04 mV to 35.96 mV ________ ________ ________ ________

2 mV/Div 14 mV 13.616 mV to 14.384 mV ________ ________ ________ ________

1 mV/Div 7 mV 6.616 mV to 7.384 mV ________ ________ ________ ________

5 V - 250 mV 4.750 V ________ ________

5 V + 250 mV 5.250 V ________ ________

-5 V - 250 mV -5.250 V ________ ________

-5 V + 250 mV -4.750 V ________ ________

0 V - 100 mV -100 mV ________ ________

0 V + 100 mV 100 mV ________ ________

Bandwidth Test Limits Channel 1 Channel 2 Channel 3 Channel 4

Horizontal ∆t and 1/∆t Accuracy

Frequency 10 kHz 9.98 kHz to 10.02 kHz ________

Period 100

Frequency 1 MHz 997.9 kHz to 1.002 MHz ________

Period 1

Frequency 100 MHz 99.10 MHz to 100.9 MHz ________

Period 10 ns 9.91 ns to 10.09 ns ________

Trigger Sensitivity Test Limits Channel 1 Channel 2 Channel 3 Channel 4

Generator Setting Test Limits Results

µs 99.79 µs to 100.2 µs ________

µs 997.9 ns to 1.002 µs ________

Internal trigger 25 MHz at 0.35 division ________ ________ ________ ________

External trigger 25 MHz at <75 mV

3 dB at 100 MHz ________ ________ ________ ________

100 MHz at 0.35 division ________ ________ ________ _______

Ext

________

p-p

100 MHz at <150 mV

p-p

________

3-20

Page 62

Agilent 54621A/21D Performance Test Record

Agilent 54621A/54621D

Serial No. ______________________________________ Test by _____________________________

Test Interval ____________________________________ Work Order No. ______________________

Recommended Next Testing ________________________ Temperature ____________

Threshold Specification Limits Ch D7-D0 Ch D15-D8

Accuracy Test

(100 mV + 3% of

threshold setting)

Voltage Measurement Accuracy

Range Power Supply Setting Test Limits Channel 1 Channel 2 Channel 3 Channel 4

5 V/Div 35 V 34.04 V to 35.96 V ________ ________ ________ ________

2 V/Div 14 V 13.616 V to 14.384 V ________ ________ ________ ________

1 V/Div 7 V 6.808 V to 7.192 V ________ ________ ________ ________

500 mV/Div 3.5 V 3.404 V to 3.596 V ________ ________ ________ ________

200 mV/Div 1.4 V 1.3616 V to 1.4384 V ________ ________ ________ ________

100 mV/Div 700 mV 680.8 mV to 719.2 mV ________ ________ ________ ________

50 mV/Div 350 mV 340.4 mV to 359.6 mV ________ ________ ________ ________

20 mV/Div 140 mV 136.16 mV to 143.84 mV ________ ________ ________ ________

10 mV/Div 70 mV 68.08 mV to 71.92 mV ________ ________ ________ ________

5 mV/Div 35 mV 34.04 mV to 35.96 mV ________ ________ ________ ________

2 mV/Div 14 mV 13.616 mV to 14.384 mV ________ ________ ________ ________

1 mV/Div 7 mV 6.616 mV to 7.384 mV ________ ________ ________ ________

Bandwidth Test Limits Channel 1 Channel 2

Horizontal ∆t and 1/∆t Accuracy

Frequency 10 kHz 9.98 kHz to 10.02 kHz ________

Period 100

Frequency 1 MHz 997.9 kHz to 1.002 MHz ________

Period 1

Frequency 50 MHz 49.77 MHz to 50.23 MHz ________

Period 20 ns 19.91 ns to 20.09 ns ________

5 V - 250 mV 4.750 V ________ ________

5 V + 250 mV 5.250 V ________ ________

-5 V - 250 mV -5.250 V ________ ________

-5 V + 250 mV -4.750 V ________ ________

0 V - 100 mV -100 mV ________ ________

0 V + 100 mV 100 mV ________ ________

3 dB at 60 MHz ________ ________

Generator Setting Test Limits Results

µs 99.79 µs to 100.2 µs ________

µs 997.9 ns to 1.002 µs ________

Trigger Sensitivity Test Limits Channel 1 Channel 2

Internal trigger 25 MHz at 0.35 division ________ ________

60 MHz at 0.35 division ________ ________

External trigger 25 MHz at <75 mV

60 MHZ at <150 mV

p-p

p-p

Ext

________

________

3-21

Page 63

4

Calibrating and Adjusting

Page 64

Calibrating and Adjusting

This chapter explains how to adjust the oscilloscope for optimum

operating performance. You should perform the hardware adjustments

and self-calibration according to the following recommendations.

• Perform hardware adjustments every 12 months or after 2,000 hours

of operation.

• Perform self-calibration: