Page 1

Agilent 4UHV Ion Pump Controller User Manual

Page 2

A

gilent 4UHV Ion Pump

Controller

Models

929-9010, 929-9011, 929-9020, 929-9021,

929-9022, 929-9101, 929-9200, 929-9201,

929-9210, 929-9211, 929-9212, 929-9213,

929-9400, 929-9401, 929-9402

Manuale di Istruzioni

Bedienungshandbuch

Notice de Mode D’Emploi

User Manual

87-900-137-01 (A)

03/2011

Page 3

Notices

© Agilent Technologies, Inc. 2011

No part of this manual may be

reproduced in any form or by any

means (including electronic storage

and retrieval or translation into a

foreign language) without prior

agreement and written consent from

Agilent Technologies, Inc. as governed

by United States and international

copyright laws.

Manual Part Number

Publication Number: 87-900-137-01 (A)

Edition

Edition 03/2011

Printed in ITALY

Agilent Technologies Italia S.p.A.

Vacuum Products Division

Via F.lli Varian, 54

10040 Leinì (TO)

ITALY

Warranty

The material contained in this

document is provided “as is,” and is

subject to being changed, without

notice, in future editions. Further, to

the maximum extent permitted by

applicable law, Agilent disclaims all

warranties, either express or implied,

with regard to this manual and any

information contained herein,

including but not limited to the

implied warranties of merchantability

and fitness for a particular purpose.

Agilent shall not be liable for errors

or for incidental or consequential

damages in connection with the

furnishing, use, or performance of

this document or of any information

contained herein. Should Agilent and

the user have a separate written

agreement with warranty terms

covering the material in this

document that conflict with these

terms, the warranty terms in the

separate agreement shall control.

Technology Licenses

The hardware and/or software

described in this document are

furnished under a license and may be

used or copied only in accordance

with the terms of such license.

Restricted Rights Legend

If software is for use in the

performance of a U.S. Government

prime contract or subcontract,

Software is delivered and licensed as

“Commercial computer software” as

defined in DFAR 252.227-7014 (June

1995), or as a “commercial item” as

defined in FAR 2.101(a) or as

“Restricted computer software” as

defined in FAR 52.227-19 (June 1987)

or any equivalent agency regulation or

contract clause. Use, duplication or

disclosure of Software is subject to

Agilent Technologies’ standard

commercial license terms, and nonDOD Departments and Agencies of the

U.S. Government will receive no

greater than Restricted Rights as

defined in FAR 52.227-19(c)(1-2) (June

1987). U.S. Government users will

receive no greater than Limited Rights

as defined in FAR 52.227-14 (June

1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Trademarks

Windows and MS Windows are U.S.

registered trademarks of Microsoft

Corporation.

Safety Notices

CAUTION

A CAUTION notice denotes a hazard.

It calls attention to an operating

procedure, practice, or the like that, if

not correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not

proceed beyond a CAUTION notice

until the indicated conditions are fully

understood and met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or the

like that, if not correctly performed

or adhered to, could result in

personal injury or death. Do not

proceed beyond a WARNING notice

indicated conditions are

until the

fully understood and met.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 4

4UHV Ion Pump Controller

4UHV Ion Pump Controller

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 3/104

Page 5

4UHV Ion Pump Controller

4/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 6

Contents

Contents

1 Istruzioni per l’uso 7

Informazioni Generali 8

Immagazzinamento 9

Preparazione per l’installazione 10

Installazione 11

Uso 13

Manutenzione 18

2 Gebrauchsanleitung 19

Allgemeines 20

Lagerung 21

Vor der Installation 22

Installation 23

Gebrauch 25

Wartung 30

3 Mode d’emploi 31

Indications Generales 32

Emmagasinage 33

Preparation pour l’Installation 34

Installation 35

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 5/104

Page 7

Contents

Utilisation 37

Entretien 42

4 Instructions for Use 43

General Information 44

Storage 45

Prior to Installation 46

Installation 47

Usage 49

Maintenance 54

5 Technical Information 55

4UHV Controller Description 57

Specifications 59

Operating Mode 65

Start-Up 67

Serial 73

Display and Menus 91

Orderable Parts 98

6/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 8

Agilent 4UHV Ion Pump Controller User Manual

1 Istruzioni per l’uso

Informazioni Generali 8

Immagazzinamento 9

Preparazione per l’installazione 10

Installazione 11

Uso 13

Accensione del controller dal

pannello frontale (modalità LOCAL) 15

Manutenzione 18

Smaltimento 18

Traduzio

ne delle istruzioni originali

7/104

Page 9

Istruzioni per l’uso

A

1

Informazioni Generali

Informazioni Generali

Questa apparecchiatura è destinata ad uso professionale. L’utente

deve leggere attentamente il presente Manuale di istruzioni ed ogni

altra informazione addizionale fornita dalla Agilent prima

dell’utilizzo dell’apparecchiatura. La Agilent declina ogni

responsabilità dovuta alla mancata osservanza totale o anche

parziale delle istruzioni fornite in questo documento, all’uso

improprio dell’apparecchiatura da parte di personale non addestrato,

all’esecuzione di interventi non autorizzati o alla mancata osservanza

delle specifiche normative nazionali.

Nei paragrafi seguenti sono riportate tutte le informazioni necessarie

a garantire la sicurezza dell’operatore durante l’utilizzo

dell’apparecchiatura. Nel appendice “Technical Information” vengono

fornite delle informazioni dettagliate.

Questo manuale utilizza le seguenti convenzioni:

ATTENZIONE!

VVERTENZA!

NOTA

8/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

I messaggi di attenzione sono visualizzati prima di procedure che, se non

osservate, potrebbero causare danni all’apparecchiatura.

I messaggi di avvertenza attirano l’attenzione dell’operatore su una

procedura o una pratica specifica che, se non eseguita in modo corretto,

potrebbe provocare gravi lesioni personali.

Le note contengono informazioni importanti estrapolate dal testo.

Page 10

Immagazzinamento

Per trasportare e immagazzinare il controller occorre osservare le

seguenti condizioni ambientali:

Temperatura: da -20 °C a +70 °C

Umidità relativa: da 0 a 95% (senza condensa)

Istruzioni per l’uso

Immagazzinamento

1

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 9/104

Page 11

Istruzioni per l’uso

1

Preparazione per l’installazione

Preparazione per l’installazione

Il controller viene fornito in un imballo protettivo speciale; nel caso

in cui si presentassero segni di danni che potrebbero essere stati

causati durante il trasporto, contattare l’ufficio vendite locale.

Durante l’operazione di disimballo, prestare particolare attenzione a

non lasciar cadere il controller e a non sottoporlo ad urti.

Il materiale dell’imballo è completamente riciclabile e risponde alla

direttiva CEE 85/399 per la tutela dell’ambiente.

Figura 1 Imballo del controller

10/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 12

A

Installazione

Istruzioni per l’uso

Installazione

1

VVERTENZA!

ATTENZIONE!

Per la sicurezza dell’operatore il controller 4UHV deve essere alimentato con

un cavo di alimentazione a 3 fili dotato di una spina approvata a livello

internazionale. Utilizzare questo cavo e spina insieme ad una presa

adeguatamente connessa a terra per evitare scosse elettriche e soddisfare i

requisiti delle norme CE. Le alte tensione che si sviluppano nel controller

possono provocare gravi lesioni o la morte.

Dopo lo spegnimento dell’unità rimane dell’energia residua all’interno del

controller per un po’ di tempo.

Attendere circa 1 minuto per essere sicuri che l’energia residua sia stata

dissipata.

Il controller può essere utilizzato sia come unità da tavolo che come modulo

installato in un rack. In ogni caso deve essere posizionato in modo tale che l’aria

possa circolare liberamente attraverso i fori di areazione presenti sulla copertura.

Nel caso in cui il controller viene utilizzato come modulo rack, DEVE essere

installato in un’adattatore alto quattro unità rack per evitare che cada all’interno

del rack stesso (vedere la tabella delle parti ordinabili). Il pannello frontale del

controller 4UHV non è previsto per reggere il peso dell’unità.

Non installare o utilizzare il controller in ambienti esposti ad agenti atmosferici

(pioggia, neve, ghiaccio), nella presenza di polvere, gas corrosivi o in ambienti

esplosivi o ad alto rischio di infiammabilità.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 11/104

Page 13

Istruzioni per l’uso

1

Installazione

ATTENZIONE!

NOTA

ATTENZIONE!

Il controller 4UHV appartiene alla seconda categoria di installazione (o

sovratensione) prevista dalla normativa EN 61010-1. Connettere quindi il

dispositivo ad una linea di alimentazione che soddisfi tale categoria.

Il controller 4UHV ha dei connettori per gli ingressi/uscite e per la comunicazione

seriale che devono essere connessi ai circuiti esterni in modo che nessuna parte

sotto tensione sia accessibile. Assicurarsi che l’isolamento del dispositivo

connesso al controller 4UHV abbia un isolamento adeguato anche in condizione di

guasto singolo come previsto dalla normativa EN 61010-1.

Nel caso in cui il controller viene installato in un rack, rimuovere i quattro piedini in

modo che venga posizionato con almeno 30 mm di spazio sotto e sopra.

In casi rari di guasto il controller potrebbe emettere fumo. Se il cliente usa il

controller in camere pulite è necessario prevedere adeguate protezioni per evitare

di contaminare l’ambiente con l’eventuale fumo.

Durante il funzionamento, occorre che siano rispettate le seguenti

condizioni ambientali:

Temperatura: da 0 °C a +40 °C

Umidità relativa: 0 - 90% (senza condensa)

12/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 14

A

Uso

Istruzioni per l’uso

Uso

In questo paragrafo vengono riportate le principali procedure

operative. Per ulteriori informazioni e per le procedure riguardanti

collegamenti o particolari opzioni fare riferimento al paragrafi

“UTILIZZO” nell’appendice “Technical Information”.

Prima di utilizzare il controller effettuare tutti i collegamenti elettrici

e fare riferimento al manuale della pompa collegata.

1

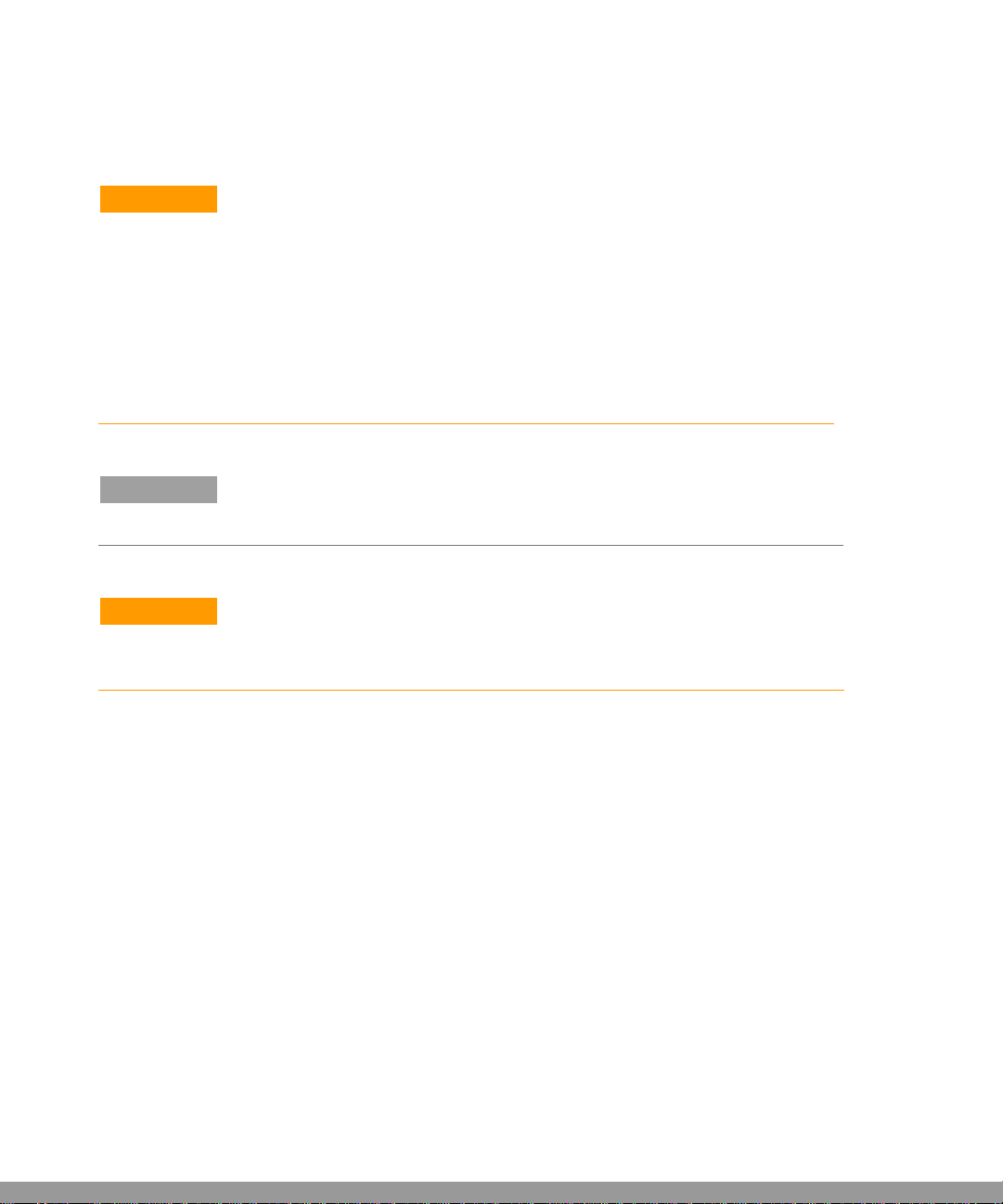

VVERTENZA!

Accendere i canali di alta tensione solo se connessi alle pompe ioniche

tramite gli appositi cavi di alta tensione dotati del cavo di interlock.

L’uso del controller è inteso con cavo di alta tensione provvisto di interlock.

4UHV

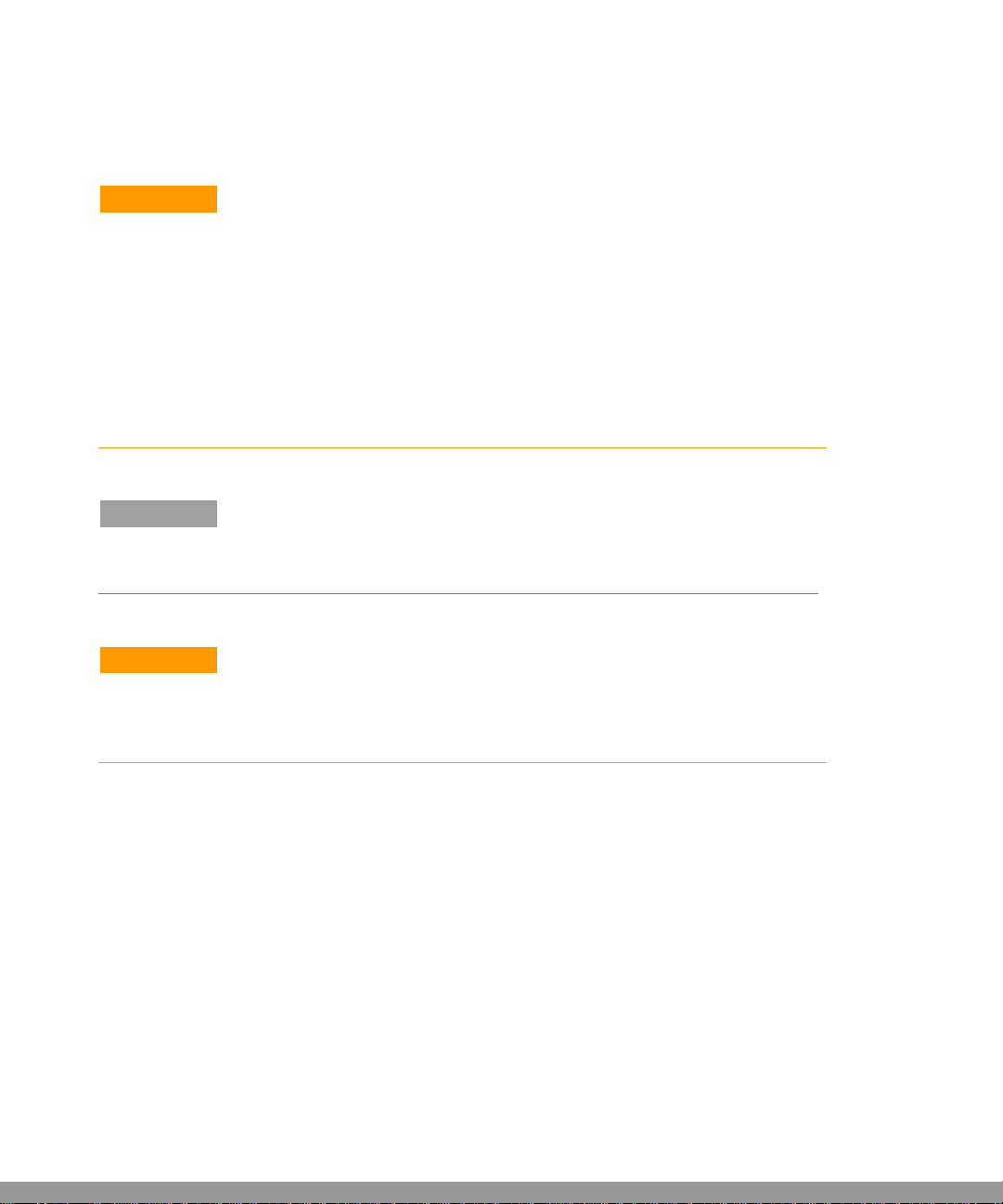

Figura 2 Collegamenti delle masse

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 13/104

Page 15

Istruzioni per l’uso

1

Uso

NOTA

Se si vuole utilizzare un cavo HV senza interlock nel sacchetto accessori è

fornito un apposito kit di cavetti per interlock preassemblati. Con questo utilizzo

si perde la funzionalità di sicurezza offerta dall’utilizzo dell’interlock.

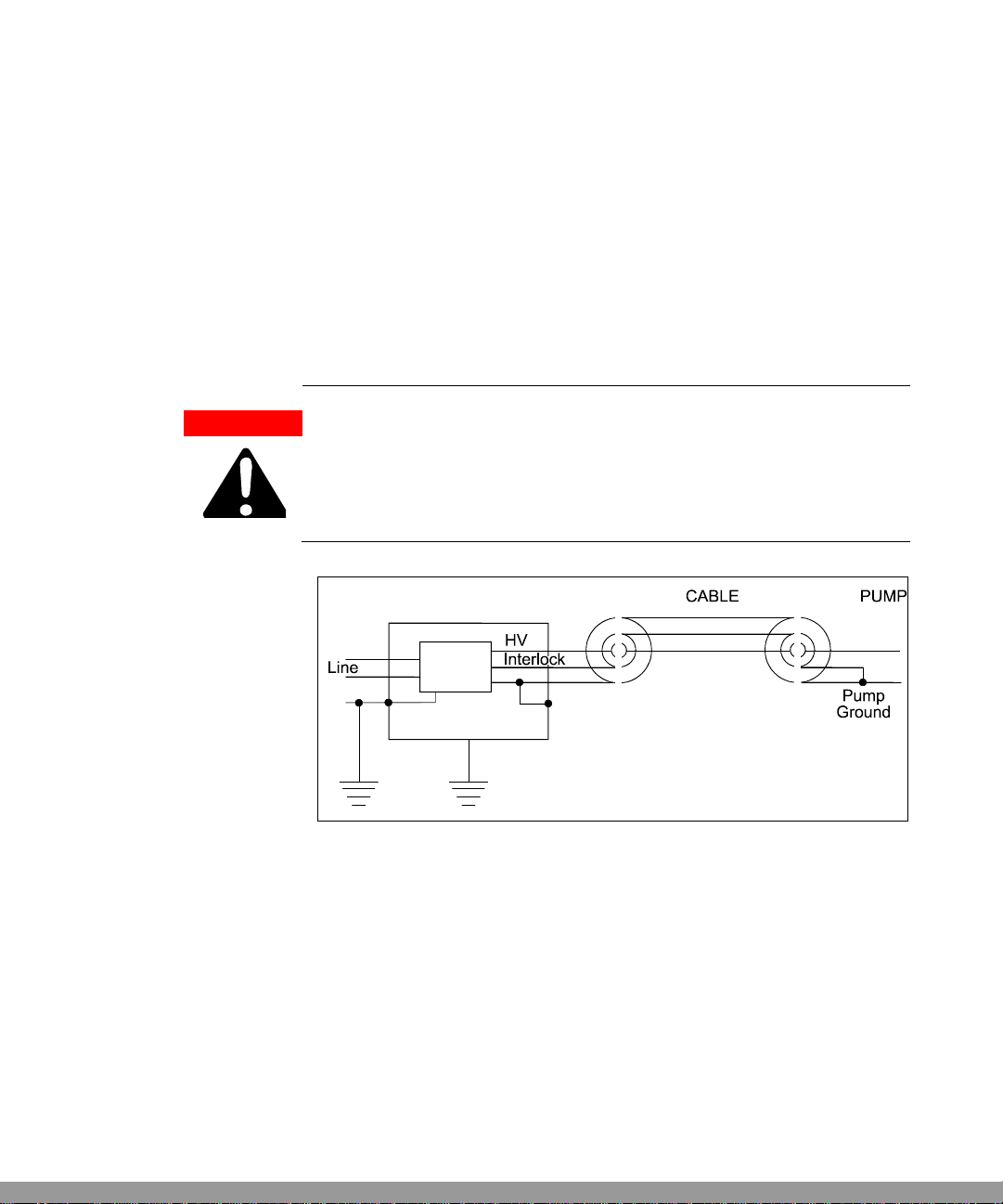

Fare riferimento alla seguente figura per montare correttamente il

cavo di interlock fornito nel sacchetto accessori, qualora si voglia

rinunciare al cavo di alta tensione dotato di interlock.

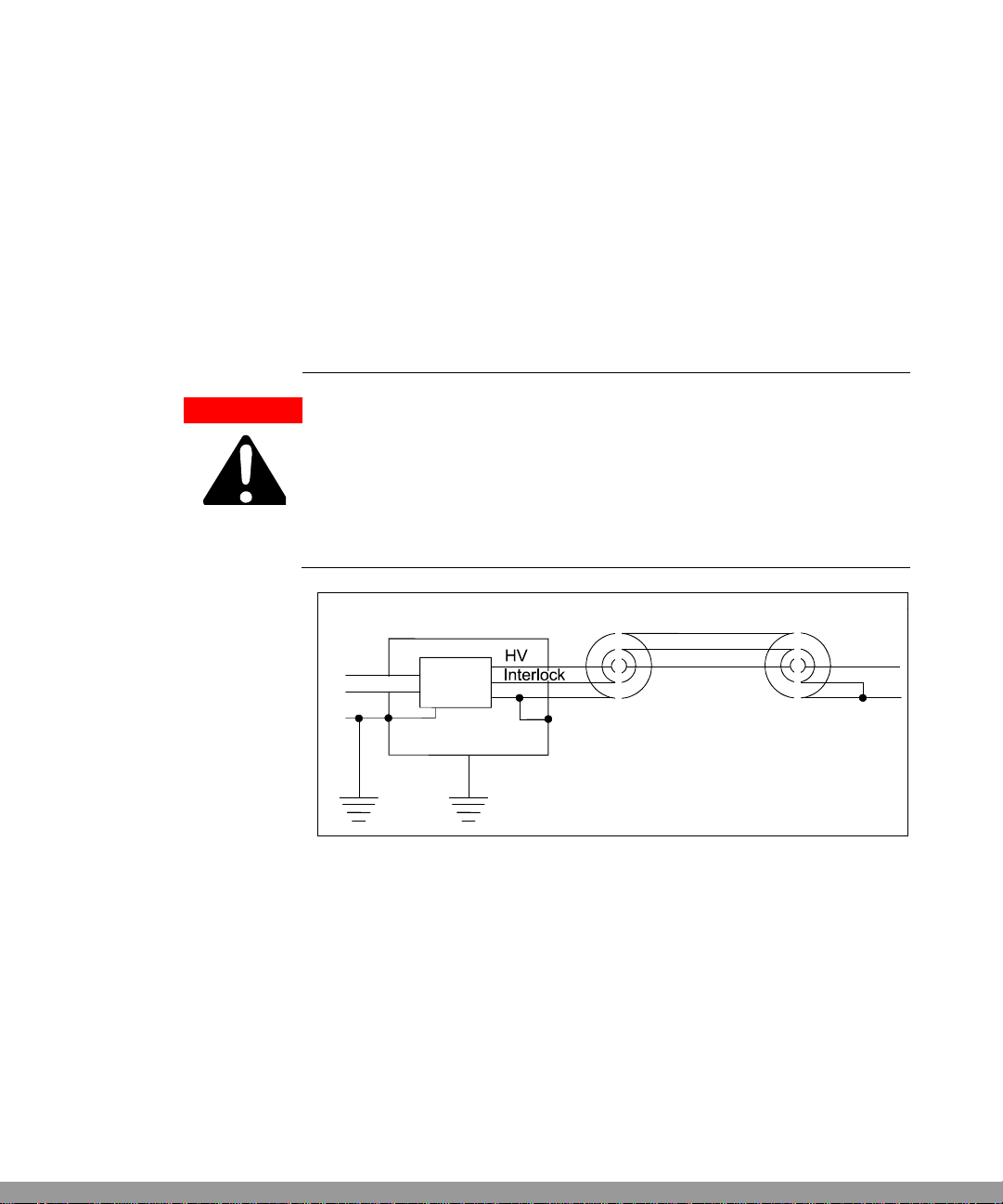

Figura 3

NOTA

14/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

L’interlock del cavo viene chiuso sulla massa della pompa. Se il collegamento è

interrotto l’alta tensione viene disabilitata.

L’interlock del cavo viene chiuso sulla massa della pompa. Se il

collegamento è interrotto l’alta tensione viene disabilitata. Per

collegare il controller alla pompa, utilizzare un cavo HV dotato di

interlock (vedere nelle parti ordinabili).

Page 16

Istruzioni per l’uso

Uso

Nella figura “Collegamenti delle masse” sono riportati i corretti

legamenti delle masse, del cavo HV tra il controller e la pompa e

col

del cavo di interlock.

1

ATTENZIONE!

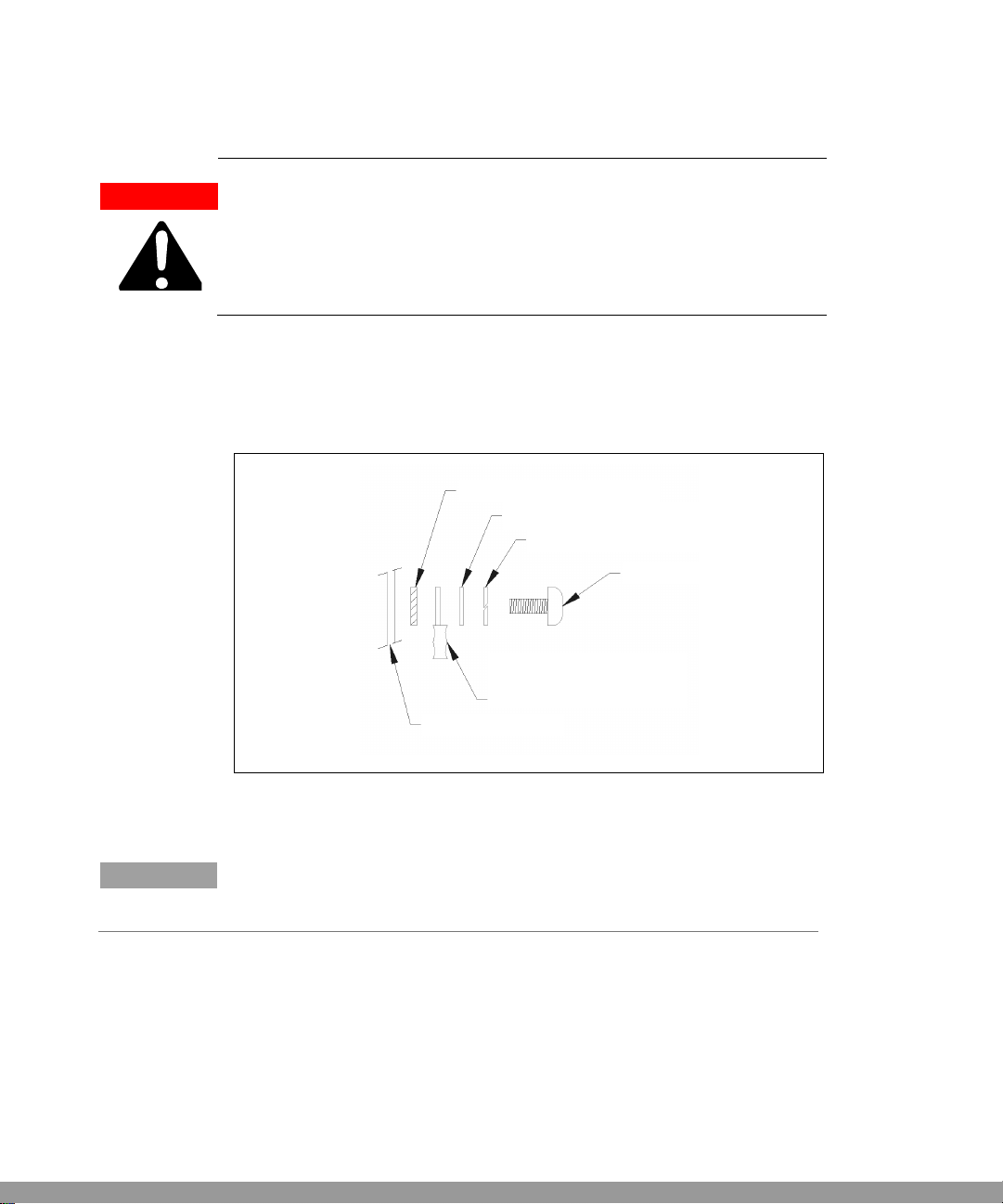

Accensione del controller dal pannello frontale (modalità LOCAL)

NOTA

Se si monta il cavo di interlock fornito nel sacchetto accessori fare molta

attenzione affinchè nessuna parte cada accidentalmente all’interno del

controller.

Per accendere l’alta tensione (HV) occorre che l’interlock del cavo HV (cable

interlock) sia chiuso (connettore inserito).

Procedere come segue per alimentare il controller e abilitare la

tensione sui connettori di alta tensione (H.V.):

Spegnere il controller.

Collegare il cavo HV e l’interlock del cavo H.V. nei relativi

connettori sul pannello posteriore.

Selezionare la modalità LOCAL premendo per breve tempo il

tasto “MODE” fino a quando appare sul display la scritta LOCAL.

Tenere premuto il pulsante HV ON/OFF (2) mentre si preme il

pulsante HV-x (3,4,5,6) dove x è il numero del canale che si vuole

accendere o spegnere.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 15/104

Page 17

Istruzioni per l’uso

1

Uso

(2)

(1) (3) (4)

(5) (6)

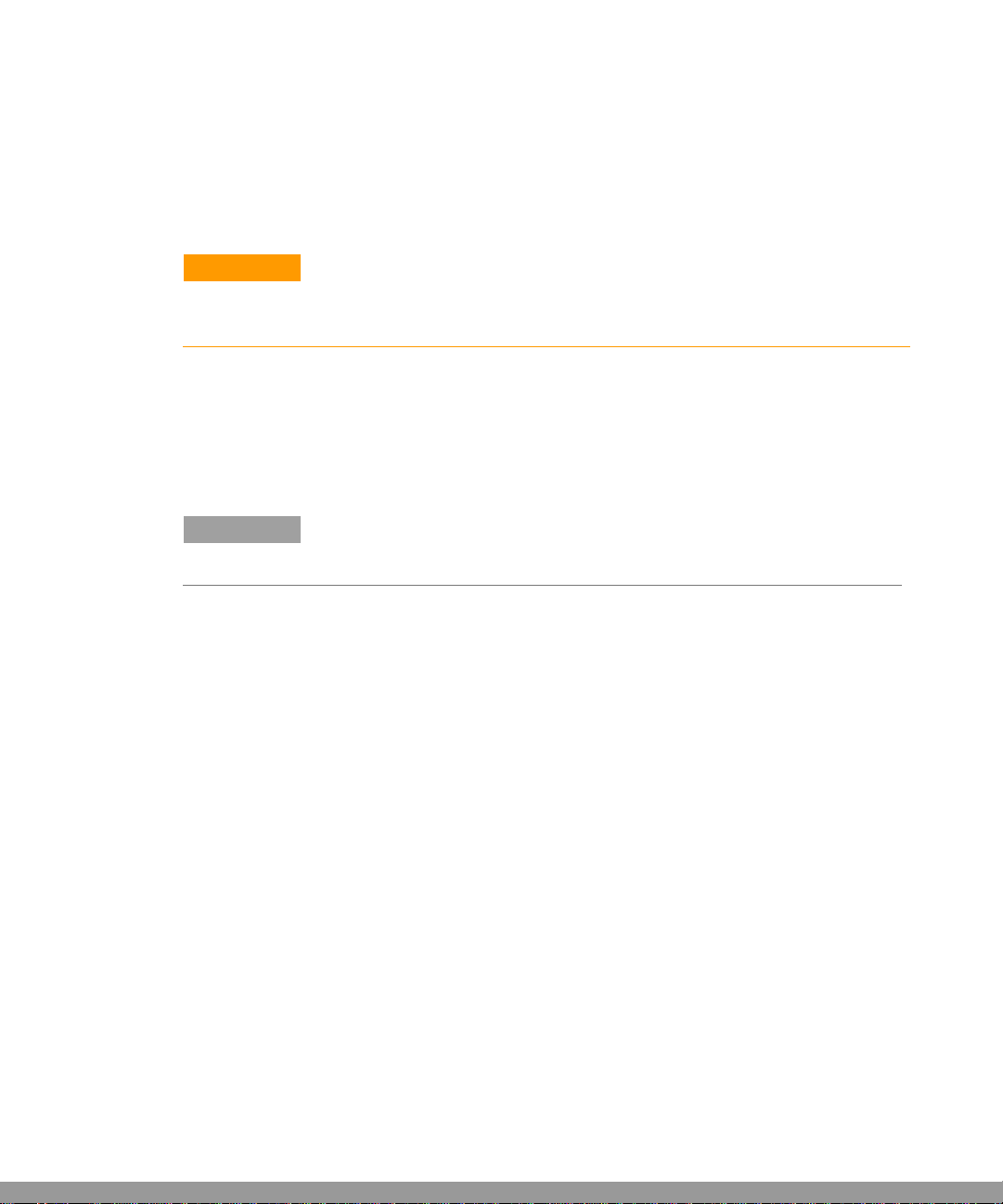

Figura 4 Front Panel 4UHV Ion Pump Controller

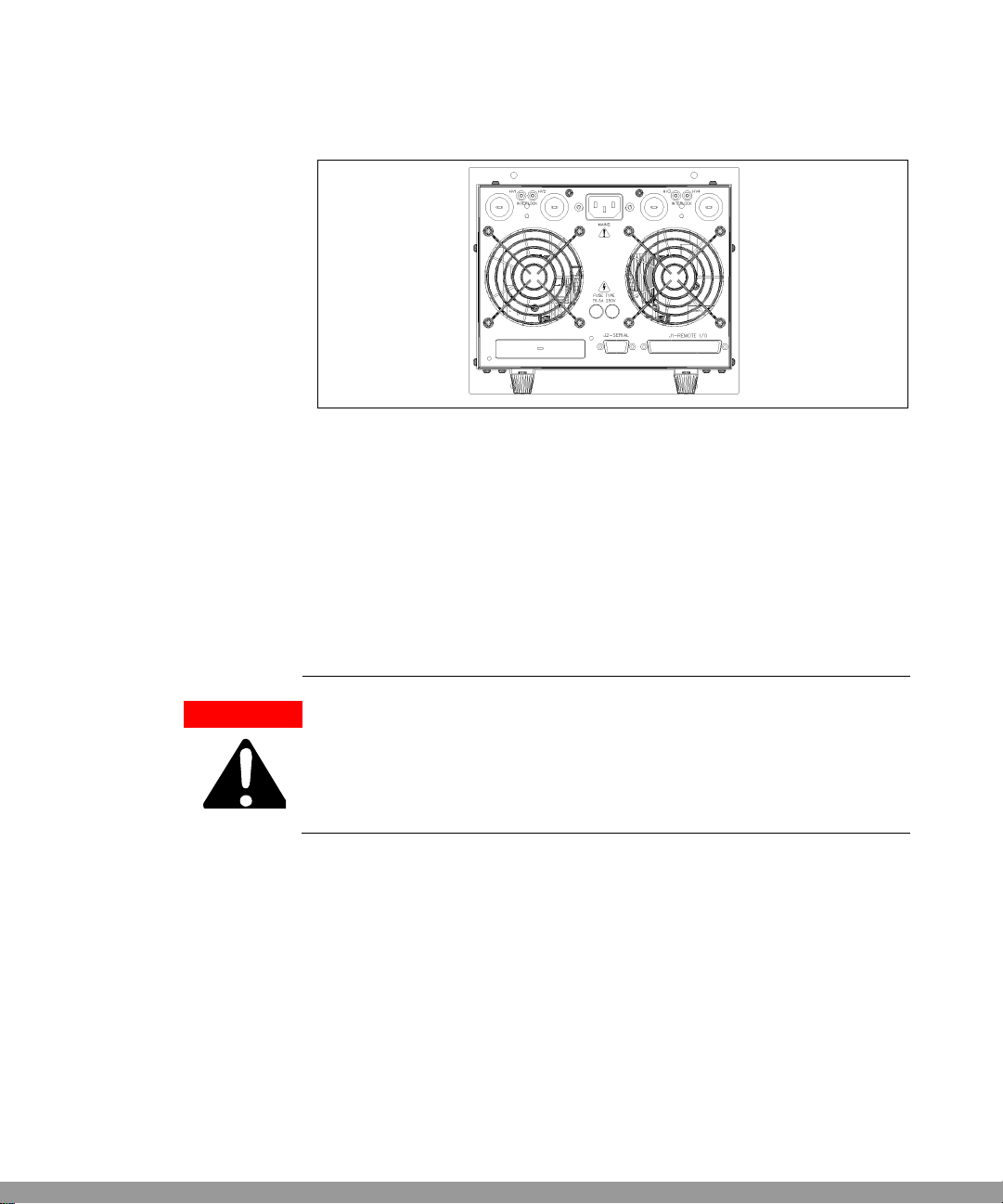

Figura 5 Rear Panel 4UHV Ion Pump Controller

Per spegnere i canali HV:

Tenere premuto il pulsante HV ON/OFF (2) mentre si preme il

pulsante HV-x (3,4,5,6) dove x è il numero del canale che si vuole

accendere o spegnere.

Per ulteriori dettagli sull’uso del controller e sulla descrizione delle

informazioni del display fare riferimento alla sezione “Technical

Information”.

16/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 18

Istruzioni per l’uso

A

Uso

1

VVERTENZA!

In condizioni di emergenza per spegnere l’unità e tutti i canali alta tensione

disattivare l’interruttore generale (1) posto sul pannello anteriore.

Mettendo in off l’interruttore generale si spegnerà l’unita HV.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 17/104

Page 19

Istruzioni per l’uso

1

Manutenzione

Manutenzione

Il controller 4UHV non richiede alcun intervento di manutenzione.

Qualsiasi tipo di intervento sull’unità deve essere eseguito da

personale tecnico autorizzato. In caso di guasto è possibile usufruire

del servizio di riparazione Agilent o del "Agilent advanced exchange

service", che permette di ottenere un controller rigenerato in

sostituzione di quello guasto.

Qualora un controller dovesse essere rottamato, procedere nel

rispetto delle normative nazionali specifiche.

Smaltimento

Significato del logo "WEEE" presente sulle etichette. Il simbolo qui

sotto riportato è applicato in ottemperanza alla direttiva CE

denominata "WEEE". Questo simbolo (valido solo per i paesi della

Comunità Europea) indica che il prodotto sul quale è applicato, NON

deve essere smaltito insieme ai comuni rifiuti domestici o industriali,

ma deve essere avviato ad un sistema di raccolta differenziata. Si

invita pertanto l'utente finale a contattare il fornitore del dispositivo,

sia esso la casa madre o un rivenditore, per avviare il processo di

raccolta e smaltimento, dopo opportuna verifica dei termini e

condizioni contrattuali di vendita.

18/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 20

Agilent 4UHV Ion Pump Controller User Manual

2 Gebrauchsanleitung

Allgemeines 20

Lagerung 21

Vor der Installation 22

Installation 23

Gebrauch 25

Einschalten des Controllers vo

Schalttafel (LOKAL-Modus) 28

Wartung 30

Entsorgung 30

etzung der Originalanleitungen

Übers

n der vorderen

19/104

Page 21

Gebrauchsanleitung

2

Allgemeines

Allgemeines

Dieser Apparat ist für Fachbetriebe bestimmt. Vor Gebrauch sollte

der Benutzer dieses Handbuch sowie alle weiteren mitgelieferten

Zusatzdokumentationen genau lesen. Bei Nichtbeachtung - auch

teilweise - der enthaltenen Hinweise, unsachgemäßem Gebrauch

durch ungeschultes Personal, nicht autorisierten Eingriffen und

Missachtung der einheimischen, hier zur Geltung kommenden

Bestimmungen übernimmt die Firma Agilent keinerlei Haftung.

In den folgenden Abschnitten sind alle erforderlichen Informationen

für die Sicherheit des Bedieners bei der Anwendung des Geräts

aufgeführt. Detaillierte technische Informationen sind im Anhang "

Technical Information " enthalten.

In dieser Gebrauchsanleitung werden Sicherheitshinweise

folgendermaßen hervorgehoben:

VORSICHT!

WARNUNG!

HINWEIS

20/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Die Vorsichtshinweise vor bestimmten Prozeduren machen den Bediener darauf

aufmerksam, dass bei Nichteinhaltung Schäden an der Anlage entstehen

können.

Die Warnhinweise lenken die Aufmerksamkeit des Bedieners auf bestimmte

Vorgänge oder Praktiken, die bei unkorrekter Ausführung schwere

Verletzungen hervorrufen können.

Die HINWEISE enthalten wichtige Informationen, die im Text hervorgehoben

werden.

Page 22

Lagerung

Gebrauchsanleitung

Lagerung

Bei Transport und Lagerung der Controller müssen folgende

Umgebungsbedingungen eingehalten werden:

Temperatur: -20 °C bis +70 °C

Rel. Luftfeuchtigkeit: 0-95 % (nicht kondensierend)

2

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 21/104

Page 23

Gebrauchsanleitung

2

Vor der Installation

Vor der Installation

Der Controller wird mit einer speziellen Schutzverpackung geliefert.

Eventuelle Transportschäden müssen sofort der zuständigen

örtlichen Verkaufsstelle gemeldet werden.

Das Verpackungsmaterial muss korrekt entsorgt werden. Es ist

vollständig recyclebar und entspricht der EG-Richtlinie 85/399 für

Umweltschutz.

Abbildung 1 Verpackung des Controllers

22/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 24

Installation

Gebrauchsanleitung

Installation

2

WARNUNG!

VORSICHT!

Zur Sicherheit des Controller-Bedieners muss der 4UHV an ein 3-DrahtSpeisekabel mit einem international anerkannten Stecker angeschlossen

sein. Dieses Kabel und dieser Stecker müssen an eine angemessen geerdete

Steckdose angeschlossen sein, um Stromschläge zu vermeiden und den

Anforderungen der CE-Normen gerecht zu werden. Die Hochspannungen, die

im Controller entstehen, können schwere Verletzungen oder den Tod

verursachen.

Nach Ausschalten des Geräts bleibt noch einige Zeit lang Reststrom im

Controller.

Warten Sie etwa 1 Minute, um sicher zu sein, dass der restliche Strom

dissipiert ist.

Der Controller kann auf einen Tisch oder ein Gestell montiert werden. In beiden

Fällen muß eine ungehinderte Zirkulation der Kühlluft durch die im Gehäuse

vorne und unten eingelassen Luftöffnungen gewährleistet sein.

Wenn der Controller in einem Gestell montiert wird, MUSS er in einer vier

Rackeinheiten hohen Adapter-Einheit installiert werden, um zu vermeiden, daß

der Controller nicht in das Gestell fällt (siehe dazu Tabelle der bestellbaren

Zubehörteile). Die vordere Schalttafel des 4 HV-Controllers ist nicht geeignet, das

gesamte Gewicht der Einheit zu tragen.

Der Controller darf nicht in Umgebungen installiert u/o benutzt werden, die

Witterungseinflüssen (Regen, Frost, Schnee), Staub und aggressiven Gasen

ausgesetzt sind und in denen Explosions- und erhöhte Brandgefahr besteht.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 23/104

Page 25

Gebrauchsanleitung

2

Installation

VORSICHT!

HINWEIS

VORSICHT!

Der Controller 4UHV gehört zu der zweiten Einbaukategorie (oder auch

Überspannung), die von der Norm EN 61010-1 geregelt ist. Schließen Sie daher

das Gerät an eine Stromleitung an, die dieser Kategorie gerecht wird.

Der Controller 4UHV hat Anschlüsse für die Ein-/Ausgänge und die

Serienkommunikation, die an externe Kreisläufe angeschlossen sein müssen, so

dass man zu keinem unter Strom stehenden Teil Zugriff hat. Vergewissern Sie

sich, dass die Isolierung des Gerätes, das an den Controller 4UHV angeschlossen

ist, auch bei Einzelstörungen, wie sie von der Vorschrift EN 61010-1 vorgesehen

sind, angemessen isoliert ist.

Wenn der Controller in einem Gestell installiert werden soll, müssen alle vier

Füße abmontiert und über- und unterhalb wenigstens 30 mm (1,2 Zoll) Platz

gelassen werden.

In seltenen Fällen könnte der Controller bei Störungen Rauch ausstoßen. Wenn

der Controller in sauberen Räumlichkeiten verwendet wird, muss er mit

angebrachten Schutzvorrichtungen versehen werden, um zu verhindern, dass die

Räumlichkeiten durch den Rauch verschmutzt werden.

Während des Betriebs müssen folgende Umgebungsbedingungen

eingehalten werden:

Temperatur: 0 °C to +40 °C

Rel. Luftfeuchtigkeit: 0 - 90 % (nicht kondensierend)

24/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 26

Gebrauch

Gebrauchsanleitung

Gebrauch

In diesem Kapitel sind die wichtigsten Betriebsvorgänge aufgeführt.

Für weitere Hinweise bezüglich Anschluß und Montage des

bestellbaren Zubehörs verweisen wir auf das Kapitel "Gebrauch" im

Anhang zu "Technical Information". Vor Benutzung des Controllers

müssen sämtliche elektrischen Anschlüsse ausgeführt und die

Betriebsanleitung der angeschlossenen Pumpe durchlesen werden.

2

WARNUNG!

Schalten Sie die Hochspannungsleitungen erst ein, wenn diese mit Hilfe der

dafür bestimmten Hochspannungskabel des Interlock-Kabels an die

Ionenpumpen angeschlossen sind.

Der Gebrauch des Controllers muss unter Verwendung eines

Hochspannungskabels mit Interlock erfolgen.

4UHV KABEL PUMPE

LEITUNG

PUMPEN-ERDE

Abbildung 2 Erdung

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 25/104

Page 27

Gebrauchsanleitung

2

Gebrauch

WARNUNG!

Soll ein HV-Kabel ohne Interlock zum Einsatz kommen, befindet sich in dem

Zubehörbeutel ein dafür bestimmtes Kabelset für vormontierte Interlock-Teile.

Bei diesem Gebrauch geht die Sicherheitsfunktion verloren, die man bei der

Interlock-Verwendung hat.

Sehen Sie sich folgende Abbildung genau an, um das im

Zubehörbeutel mitgelieferte Interlock-Kabel richtig zu montieren,

wenn auf das Hochspannungskabel mit Interlock verzichtet werden

soll.

ZAHNSCHEIBE

UNTERLEGSCHEIBE

FEDERRRING

SCHRAUBE

INTERLOCK-KABEL

1 oder 2 Stk.

RÜCKSEITE

Abbildung 3

HINWEIS

Die Verriegelung des Kabels wird auf der Masse der Pumpe geschlossen. Wenn

die Verbindung unterbrochen wird, wird die Hochspannung deaktiviert.

Die Verriegelung des Kabels wird auf der Masse der Pumpe

geschlossen. Wenn die Verbindung unterbrochen wird, wird die

Hochspannung deaktiviert. Beim Anschluss des Controller an die

Pumpe ist ein HV-Kabel mit Interlock (siehe Bestellteile) zu

verwenden.

26/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 28

Gebrauchsanleitung

Gebrauch

Auf der Abbildung “Anschlüsse” sind die richtigen Anschlüsse der

Erdungen, des HV-Kabels des Controller an die Pumpe und des

Interlock-Kabels ersichtlich.

2

VORSICHT!

Beim Montieren des im Zubehörbeutel mitgelieferten Interlock-Kabels gehen Sie

sehr vorsichtig vor, damit dabei kein Teil in den Controller fällt.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 27/104

Page 29

Gebrauchsanleitung

(2) (1) (3) (4) (5) (6)

2

Gebrauch

Einschalten des Controllers von der vorderen Schalttafel (LOKAL-Modus)

HINWEIS

Um die Hochspannung (HV) einzuschalten, muss der Interlock des HV-Kabels

(Kabel-Iinterlock) geschlossen sein (Verbinder eingesteckt).

Gehen Sie wie folgt vor, um den Controller mit Strom zu versorgen

und die Spannung an den Hochspannungsverbindern (H.V.)

freizugeben:

Schalten Sie den Controller aus.

Schließen Sie das HV-Kabel und den Interlock des H.V-Kabels an

die jeweiligen Verbinder am Rückenteil.

Wählen Sie die Modalität LOCAL, indem Sie kurz die Taste

“MODE” drücken bis auf dem Display die Aufschrift LOCAL

erscheint.

Halten Sie die Taste HV ON/OFF (2) ) gedrückt und drücken Sie

gleichzeitig die Taste HV-x (3,4,5,6) ), wobei x die Nummer der

Leitung ist, die ein- oder ausgeschaltet werden soll.

Abbildung 4

28/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Vorderteil 4UHV Ionenpumpen-Controller

Page 30

Gebrauchsanleitung

2

Gebrauch

WARNUNG!

Abbildung 5

Rückenteil 4UHV Ionenpumpen-Controller

Um die HV-Leitungen auszuschalten:

Halten Sie die Taste HV ON/OFF (2) gedrückt und drücken Sie

gleichzeitig die Taste HV-x (3,4,5,6), wobei x die Nummer der

Leitung ist, die ein- oder ausgeschaltet werden soll.

Weitere Einzelheiten zum Gebrauch des Controllers und zur

Beschreibung der Display-Angaben entnehmen Sie bitte dem

Abschnitt “ Technical Information ”.

Bei Not-Aus schalten Sie den Hauptschalter (1) auf dem vorderen Bedienfeld

aus, um das Gerät und sämtliche Hochspannungsleitungen auszuschalten.

Wenn Sie den Hauptschalter auf Off stellen, wird das HV-Gerät ausgeschaltet.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 29/104

Page 31

Gebrauchsanleitung

2

Wartung

Wartung

Entsorgung

Die 4UHV-Controller sind wartungsfrei. Eventuell erforderliche

Eingriffe müssen von dazu befugtem Fachpersonal ausgeführt

werden. Bei Störungen kann der Agilent-Reparaturdienst in

Anspruch genommen werden oder schließen Sie einen Vertrag für

“Agilent Advanced Exchange Service” ab, mit dem ein defekter

Controller gegen einen general-überholten ausgetauscht wird.

Eine eventuelle Verschrottung muß unter Einhaltung der

einschlägigen landesüblichen Vorschriften erfolgen.

Bedeutung des "WEEE" Logos auf den Etiketten.

Das folgende Symbol ist in Übereinstimmung mit der EURichtlinie

WEEE (Waste Electrical and Electronic Equipment) angebracht.

Dieses Symbol (nur in den EU-Ländern gültig) zeigt an, dass das

betreffende Produkt nicht zusammen mit Haushaltsmüll entsorgt

werden darf sondern einem speziellen Sammelsystem zugeführt

werden muss.

Der Endabnehmer sollte daher den Lieferanten des Geräts - d.h. die

Muttergesellschaft oder den Wiederverkäufer - kontaktieren, um den

Entsorgungsprozess zu starten, nachdem er die Verkaufsbedingungen

geprüft hat.

30/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 32

Agilent 4UHV Ion Pump Controller User Manual

3 Mode d’emploi

Indications Generales 32

Emmagasinage 33

Preparation pour l’Installation 34

Installation 35

Utilisation 37

Allumage du Contrôleur du Panneau Frontal

(Modalité LOCAL)

Entretien 42

Mise au Rebut 42

Traduction de la

40

mode d’emploi originale

31/104

Page 33

Mode d’emploi

A

3

Indications Generales

Indications Generales

Cet appareillage a été conçu en vue d'une utilisation professionnelle.

Il est conseillé à l'utilisateur de lire attentivement cette notice

d'instructions ainsi que toute autre indication supplémentaire

fournie par Agilent, avant l'utilisation de l'appareillage. Agilent

décline par conséquent toute responsabilité en cas d'inobservation

totale ou partielle des instructions données, d'utilisation incorrecte

de la part d'un personnel non formé, d'opérations non autorisées ou

d'un emploi contraire aux réglementations nationales spécifiques.

Les paragraphes suivants donnent toutes les indications nécessaires

à garantir la sécurité de l'opérateur pendant l'utilisation de

l'appareillage. Des renseignements plus détaillés se trouvent dans

l'appendice " Technical Information ".

Cette notice utilise les signes conventionnels suivants:

ATTENTION!

VERTISSEMENT!

NOTE

32/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Les messages d'attention apparaissent avant certaines procédures qui, si elles

ne sont pas observées, pourraient endommager sérieusement l'appareillage.

Les messages d’avertissement attirent l'attention de l'opérateur sur une

procédure ou une manoeuvre spéciale qui, si elle n'est pas effectuée

correctement, risque de provoquer de graves lésions.

Les notes contiennent des renseignements importants, isolés du texte.

Page 34

Emmagasinage

Pour transporter et emmagasiner le contrôleur il faut observer les

conditions suivantes d’environnement:

température: de -20°C à +70°C

humidité relative: 0 - 95 % (non condensante).

Mode d’emploi

Emmagasinage

3

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 33/104

Page 35

Mode d’emploi

3

Preparation pour l’Installation

Preparation pour l’Installation

Le contrôleur est fourni dans un emballage de protection spécial; si

l'on constate des dommages pouvant s'être produits pendant le

transport, contacter tout de suite le bureau de vente local. Pendant

l'opération d'ouverture de l'emballage, veiller tout particulièrement à

ne pas laisser tomber le contrôleur et à ne lui faire subir aucun choc.

Le matériel est entièrement recyclable et il est conforme aux

directives CEE 85/399 en matière de protection de l'environnement.

Figure 1 Emballage du contrôleur

34/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 36

A

Installation

Mode d’emploi

Installation

3

VERTISSEMENT!

ATTENTION!

Pour la sécurité de l’opérateur, le contrôleur 4UHV doit être alimenté par

un câble d’alimentation à 3 fils doté d’une prise mâle approuvée à un

niveau international. Brancher le câble avec prise mâle à une prise

femelle raccordée à la terre de façon adéquate afin d’éviter tout risque

d’électrocution et de pouvoir remplir les conditions de conformité

prescrites par les normes CE. Les hautes tensions qui se développent à

l’intérieur du contrôleur peuvent être susceptibles de provoquer des

blessures graves voire de causer la mort.

Après l’extinction de l’unité, il reste de l’énergie à l’intérieur du

contrôleur pendant quelques instants.

Attendre environ 1 minute pour être sûr que l’énergie résiduelle s’est

dissipée.

Le contrôleur peut être utilisé soit comme unité de table que comme module

installé dans une armoire. De toute façon, il doit être placé de manière à ce

que l’air puisse circuler librement à travers les trous d’aération présents dans

la couverture.

Lorsque le contrôleur est utilisé comme module armoire il DOIT être installé

dans un adaptateur d’une hauteur de quatre unités armoire afin d’éviter qu’il

ne tombe à l’intérieur de l’armoire même (voir tableau des pièces détachées).

Le panneau frontal du contrôleur n’est pas prévu pour supporter le poids de

l’unité. Ne pas installer ou utiliser le contrôleur 4UHV dans des milieux

exposés aux agents atmosphériques (pluie, neige, glace). En présence de

poussière, de gaz corrosifs ou dans des milieux explosifs ou à fort risque

d’inflammabilité.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 35/104

Page 37

Mode d’emploi

3

Installation

ATTENTION!

NOTE

ATTENTION!

Le contrôleur 4UHV appartient à la seconde catégorie d’installation (ou

surtension) prévue par la norme EN 61010-1. Il est donc nécessaire de brancher

le dispositif à une ligne d’alimentation qui soit adaptée à cette catégorie

d’appareils.

Le contrôleur 4UHV dispose de connecteurs pour entrées/sorties et pour la

communication en série qui doivent être branchés à des circuits externes de

façon à ce qu’aucune des parties sous tension ne soitaccessible. Veiller à ce que

le système d’isolation du dispositif branché au contrôleur 4UHV soit adapté,

même en cas de pannes individuelles, et ce, tel que prévu par la norme EN

61010-1.

Si le contrôleur est installé dans une armoire, enlever les quatre pieds de

manière à ce qu’il soit placé avec au moins 30 mm d’espace en haut et en bas.

Dans quelques rares cas de panne, il est possible que le contrôleur dégage de la

fumée. Si l’unité est utilisée dans des environnements propres, il est nécessaire

de prévoir la mise en place de protections adéquates afin d’éviter que la fumée

ne puisse contaminer la pièce.

Pendant le fonctionnement, il est nécessaire de respecter les

conditions d’environnement suivantes:

température: de 0°C à +40°C

humidité relative: 0 - 90% (non condensante).

36/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 38

A

Utilisation

Mode d’emploi

3

Utilisation

Dans ce paragraphe, on indique les principales procédures

opérationnelles. Pour tous autres détails et pour les procédures

concernant des connexions ou des éléments en option, se reporter au

paragraphe "Usage" de l'appendice "Technical Information". Avant

d'utiliser le contrôleur, effectuer toutes les connexions électriques et

se reporter à la notice de la pompe connectée.

VERTISSEMENT!

N’allumer les canaux haute tension que s’ils ont été branchés aux

pompes ioniques par l’intermédiaire des câbles haute tension prévus à

cet effet et dotés de câble Interlock.

L’usage du contrôleur est subordonné à l’usage d’un câble haute tension

doté d’Interlock.

4UHV

LIGNE

BRANCHEMENT

DE TERRE DE

LA POMPE

Figure 2 Connexions des masses

POMPE

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 37/104

Page 39

Mode d’emploi

3

Utilisation

NOTE

Si l’opérateur veut utiliser un câble HV sans interlock, le sachet d’accessoires

contient un kit spécial de câbles pour interlocks préassemblés. L’utilisation de

ces accessoires provoque la perte des fonctions de sécurité offertes par

l’utilisation de l’interlock.

Consulter la figure ci-dessous pour monter correctement le câble

d’interlock contenu dans le sachet d’accessoires en cas de non

utilisation du câble de haute tension équipé d’un interlock.

Figure 3

NOTE

38/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

L’interlock du câble est serré sur la masse de la pompe. Si le branchement est

coupé, la haute tension est interrompue.

L’interlock du câble est serré sur la masse de la pompe. Si le

branchement est coupé, la haute tension est interrompue.

Pour relier le contrôleur à la pompe, utiliser un câble HV équipé d’un

interlock (voir le bordereau de commande des pièces).

Page 40

Mode d’emploi

Utilisation

Les branchements corrects des masses, du câble HV entre le

contrôleur et la pompe, ainsi que du câble d’interlock sont reportés

sur la figure “Connexions des masses”.

3

ATTENTION!

En cas d’utilisation du câble d’interlock contenu dans le sachet d’accessoires, il

faut veiller en particulier à ce qu’aucune pièce ne tombe à l’intérieur du

contrôleur.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 39/104

Page 41

Mode d’emploi

3

Utilisation

Allumage du Contrôleur du Panneau Frontal (Modalité LOCAL)

NOTE

Pour allumer la haute tension (HV), il faut que l’interlock du câble HV (câble

interlock) soit fermé (connecteur branché).

Procéder comme suit pour alimenter le contrôleur et habiliter la

tension au niveau des connecteurs de haute tension (H.V.) :

Eteindre le contrôleur.

Brancher le câble HV et l’interlock du câble H.V. sur les

connecteurs correspondants situés sur le panneau arrière.

Appuyer brièvement sur la touche "MODE" pour sélectionner la

modalité LOCAL jusqu’à ce que l’inscription LOCAL s’affiche sur

l’écran.

Maintenir le bouton HV ON/OFF (2) enfoncé tout en appuyant sur

le bouton HV-x (3,4,5,6) ; x correspond au numéro du canal à

allumer ou à éteindre.

(2)

(1) (3) (4)

Figure 4 Panneau avant 4UHV sur le contrôleur de pompe

40/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

(5) (6)

Page 42

Mode d’emploi

3

Utilisation

Figure 5 Panneau arrière 4UHV sur le contrôleur de pompe

Pour éteindre les canaux HV :

Maintenir le bouton HV ON/OFF (2) enfoncé tout en appuyant sur

le bouton HV-x (3,4,5,6)) ; x correspond au numéro du canal à

allumer ou à éteindre.

Pour plus de renseignements sur l’usage du contrôleur et sur la

description des informations de l’écran, consulter la section “

Technical Information ”.

AVERTISSEMENT!

En cas de situation d’urgence nécessitant un arrêt immédiat de l’unité et

de tous les canaux haute tension, désactiver l’interrupteur général (1)

situé sur le panneau avant.

En plaçant l’interrupteur général sur OFF, l’unité H.T. s’arrête.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 41/104

Page 43

Mode d’emploi

3

Entretien

Entretien

Mise au Rebut

Le contrôleur 4UHV n’a besoin d’aucun entretien. N’importe quel

entretien sur l’unité doit être effectué par un personnel technique

autorisé. En cas de panne contacter le Support technique Agilent ou

bien s’abonner au Agilent Advanced Exchange Service” où le

contrôleur endommagé est remplacé par un contrôleur

reconditionné.

En cas de mise au rebut du contrôleur, procéder à son élimination

conformément aux réglementations nationales en la matière.

Signification du logo "WEEE" figurant sur les étiquettes.

Le symbole ci-dessous est appliqué conformément à la directive CE

nommée "WEEE".

Ce symbole (uniquement valide pour les pays de la Communauté

européenne) indique que le produit sur lequel il est appliqué NE doit

PAS être mis au rebut avec les ordures ménagères ou les déchets

industriels ordinaires, mais passer par un système de collecte

sélective. Après avoir vérifié les termes et conditions du contrat de

vente, l’utilisateur final est donc prié de contacter le fournisseur du

dispositif, maison mère ou revendeur, pour mettre en oeuvre le

processus de collecte et mise au rebut.

42/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 44

Agilent 4UHV Ion Pump Controller User Manual

4 Instructions for Use

General Information 44

Storage 33

Prior to Installation 46

Installation 47

Usage 49

Powering On the Controller from the Front Panel

(LOCAL Mo

Maintenance 54

Disposal 54

al Instructions

Origin

de) 52

43/104

Page 45

Instructions for Use

4

General Information

General Information

This equipment is intended for professional use. Prior to using this

equipment the user must carefully read this Instruction Manual in its

entirety and any additional information provided by Agilent. Agilent

declines all responsibility for damage caused by the total or partial

misuse of the instructions provided herein, by the improper use of

the equipment by untrained personnel, by unauthorized

interventions or by negligence in complying with any specific

national rule or regulation.

The following sections provide you with all the information needed to

guarantee the operator’s safety when using the equipment. Detailed

information is provided in the appendix entitled “Technical

Information”.

The following conventions are used in this manual:

CAUTION!

WARNING!

NOTE

44/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Caution messages are provided before procedures that could cause damage to

the equipment if not complied with.

Warning

operation that could cause serious injury if not performed correctly.

Notes provide you with important information extracted from the text.

messages call the operator’s attention to a specific procedure or

Page 46

Storage

Instructions for Use

Storage

The following environmental conditions must be met when

transporting and storing the controller:

Temperature: -20 °C to +70 °C

Relative humidity: 0 - 95% (non-condensing)

4

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 45/104

Page 47

Instructions for Use

4

Prior to Installation

Prior to Installation

The controller comes in a special protective packaging; if there is any

sign of damage that could have been caused during transportation,

contact your local sales office immediately.

When unpacking the controller, be particularly careful to avoid

dropping it or knocking it against anything.

The packaging material is totally recyclable and complies with EEC

directives 85/399 for the safeguard of the environment.

Figure 1 Controller Packaging

46/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 48

Installation

Instructions for Use

Installation

4

WARNING!

CAUTION!

For the safety of the operator, the 4UHV controller must be powered with a 3wire power cable connected to a plug approved at international level. Use

this cable and plug together with an adequately earthed socket so as to

prevent electrical shocks and satisfy the requirements of EC norms. The high

voltages that develop in the controller can provoke serious injuries or death.

After switching off the unit, residual energy is present inside the controller for

some time.

Wait approx. 1 minute to be sure that the residual energy has been

dissipated.

The controller can be used either as a desktop unit or as a rack module. In any

case it must be positioned in a way that the air can circulate freely through the

ventilation slots on the cover.

If the controller is used as a rack module, it MUST be inserted into a four-rack

high adapter to prevent it from falling inside the rack itself (see the table of

orderable parts). The 4UHV controller front panel is not designed to support the

weight of the unit.

Do not install or use the controller in an environment exposed to atmospheric

agents (rain, snow, ice), in the presence of dust, corrosive gases or in a highly

flammable or explosive environment.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 47/104

Page 49

Instructions for Use

4

Installation

CAUTION!

NOTE

CAUTION!

The 4UHV controller belongs to the second installation category (or overvoltage)

as provided for in normative EN 61010-1. Therefore the device must be

connected to a power supply line satisfying the requirements for this category.

The 4UHV controller has connectors for inputs/outputs and for serial

communications that must be connected to the external circuits in such a way

that no powered part is accessible. Make sure that the insulation of the device

connected to the 4UHV controller provides an adequate insulation even in the

case of a single fault condition as stipulated in the EN 61010-1 normative.

If the controller is installed in a rack, remove its four feet and place it so as to

leave at least 30 mm (1.2 inches) of free space above and below.

In rare circumstances, a controller fault could result in the emission of smoke. If

the customer is using the controller in clean environments, they should take

adequate measures to avoid the environment being contaminated by any

eventual smoke.

The controller must be used in the following environmental

conditions:

Temperature: 0 °C to +40 °C

Relative humidity: 0 - 90% (non-condensing).

48/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 50

Usage

Instructions for Use

Usage

This section provides you with the major operating procedures. For

more information and for the procedures that concern connections

or specific options, refer to the section “USAGE” in the “Technical

Information” appendix. Before using the controller, perform all

electrical connections and refer to the manual of the connected

pump.

4

WARNING!

Switch on the high voltage channels only if they are connected to the ionic

pumps by means of the special purpose high voltage cables equipped with

interlock cable.

It is assumed that the controller will be used together with the high voltage

cable having a safety interlock.

4UHV

Figure 2 Ground Connections

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 49/104

Page 51

Instructions for Use

4

Usage

WARNING!

If an HV cable without interlock is to be used, the accessories bag contains a

specific kit of preassembled interlock leads. However, with this type of use,

the safety capability furnished using the interlock is lost.

Refer to the figure below for correct assembly of the interlock cable

furnished in the accessories bag in the case in which an HV cable

with interlock is not used.

Figure 3

NOTE

50/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

The cable interlock closes on pump ground. The high voltage is disabled if the

connection is interrupted.

The cable interlock closes on pump ground. The high voltage is

disabled if the connection is interrupted. To connect the controller to

the pump, use a HV cable with interlock (see parts that can be

ordered).

Correct connection of masses, of the HV cable between the controller

and pump and of the interlock cable is illustrated in the

“Connections” figure.

Page 52

Instructions for Use

Usage

4

CAUTION!

When using the interlock cable furnished in the accessories bag, make sure that

no parts drop accidentally inside the controller.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 51/104

Page 53

Instructions for Use

4

Usage

Powering On the Controller from the Front Panel (LOCAL Mode)

NOTE

To switch on the High Voltage (HV), the interlock of the HV cable (cable

interlock) must be closed (connector inserted).

Proceed as follows to power the controller and apply voltage to the

high voltage (HV) connectors:

Switch off the controller.

Connect the HV cable and the interlock of the HV cable in the

related connectors on the rear panel.

Select LOCAL mode, briefly pressing the “MODE” key until

LOCAL is shown on the display.

Hold down the HV ON/OFF button (2) while pressing the HV-x

(3,4,5,6) button where x is the number of the channel to be

switched on/off.

(2)

(1) (3) (4)

Figure 4 Front Panel 4UHV Ion Pump Controller

52/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

(5)

(6)

Page 54

Instructions for Use

4

Usage

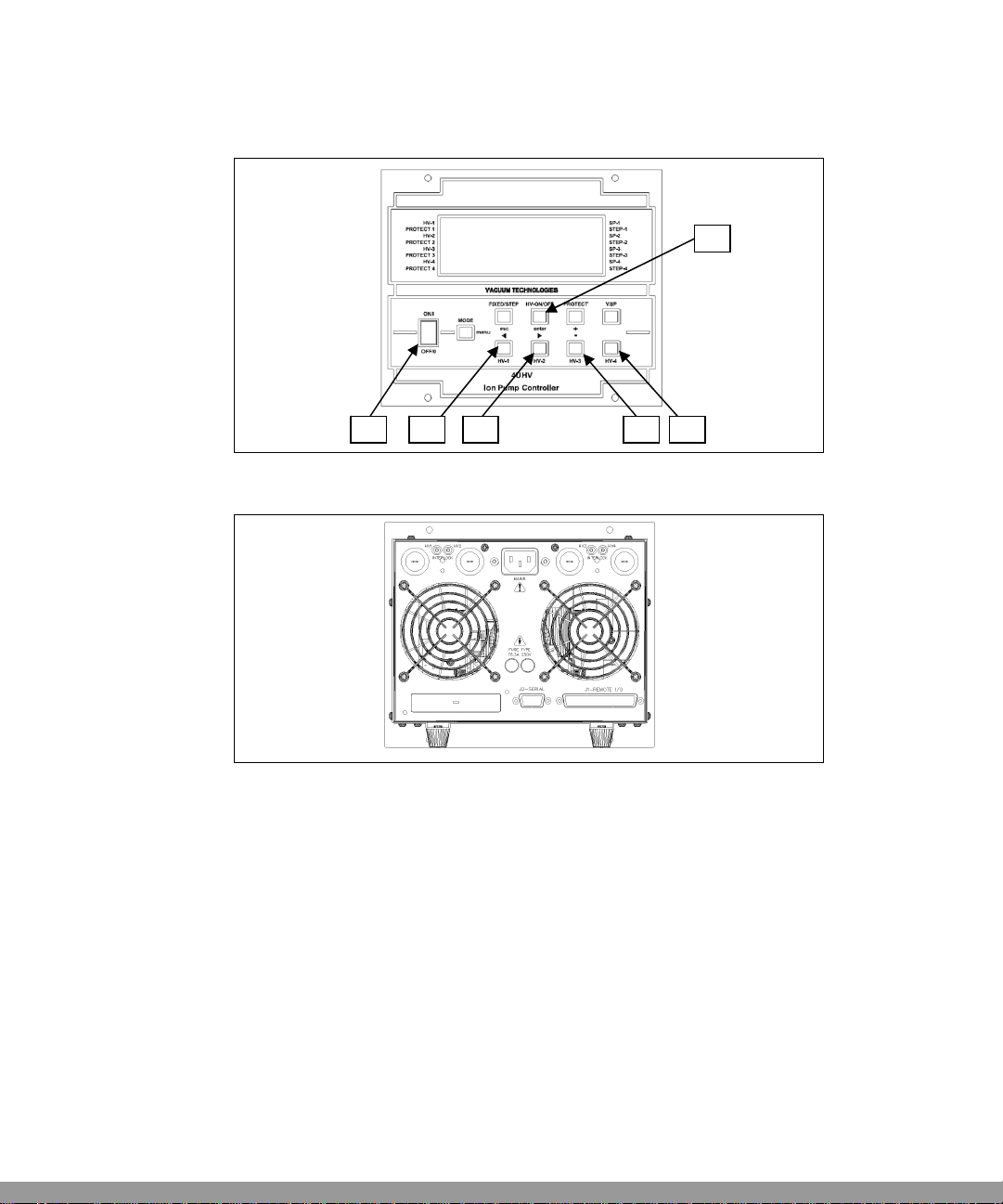

Figure 5 Rear Panel 4UHV Ion Pump Controller

To switch off the HV channels:

Hold down the HV ON/OFF (2) button while pressing the HV-x

(3,4,5,6) button where x is the number of the channel to be

switched on/off.

For further details on using the controller and for a description of the

information appearing on the display, refer to the section “Technical

Information”.

WARNING!

In situations of emergency, to switch off the unit and all the high voltage

channels, turn off the main power switch (1) situated on the front panel.

When the main switch is turned off, the HV unit is switched off.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 53/104

Page 55

Instructions for Use

4

Maintenance

Maintenance

The 4UHV controller does not require any maintenance. Any form of

servicing on the unit must be performed by authorized personnel.

If servicing is needed, contact Agilent Technical Support or subscribe

to the “Agilent Advanced Exchange Service” where the faulty

controller is replaced by a refurbished one.

If the controller needs to be scraped, proceed to do so in compliance

with the specific national norms.

Disposal

Meaning of the "WEEE" logo found in labels

The following symbol is applied in accordance with the EC WEEE

(Waste Electrical and Electronic Equipment) Directive.

This symbol (valid only in countries of the European Community)

indicates that the product it applies to must NOT be disposed of

together with ordinary domestic or industrial waste but must be sent

to a differentiated waste collection system.

The end user is therefore invited to contact the supplier of the device,

whether the Parent Company or a retailer, to initiate the collection

and disposal process after checking the contractual terms and

conditions of sale.

54/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 56

Agilent 4UHV Ion Pump Controller User Manual

5 Technical Information

4UHV Controller Description 57

Specifications 59

Controller Outline 60

Front Panel Description 61

Keys 61

Rear Panel Description 63

Operating Mode 65

Selecting “Operating Mode” from Front Panel 65

Selecting “Operating Mode” via Serial 66

Start-Up 67

Connection of Input remote 72

Serial 73

Connector Examples 74

Window Protocol 74

Error Description 84

Error Code 84

Old Serial Protocol (“Binary Pr

Original Instructions

otocol”) 87

55/104

Page 57

Technical Information

5

Display and Menus 91

Displaying Channel-Related Inf

Commands 93

Menu 94

Orderable Parts 98

ormation 74

56/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 58

4UHV Controller Description

The 4UHV controller is a power supply for ion pumps. It supplies a

high voltage on output, selectable as 3kV, 5kV or 7kV, and measures

the output current.

The controller has the following features:

Front panel with keypad and a 4-row display (4x20, 146 x 62

mm) for displaying the operating values (voltage, current,

pressure)

Remote I/O card with DB37 connector

RS232 and RS485 serial communications.

Technical Information

4UHV Controller Description

5

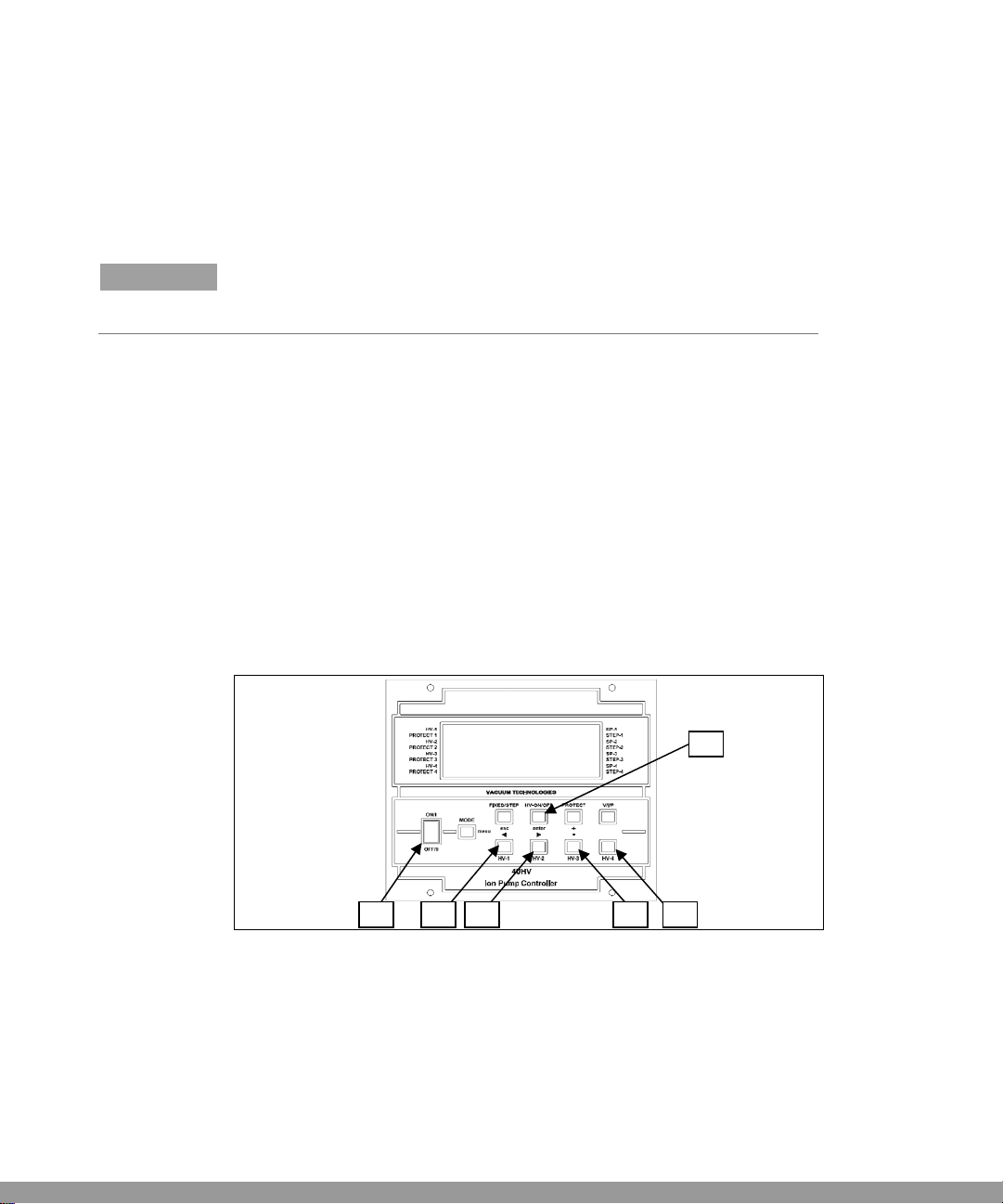

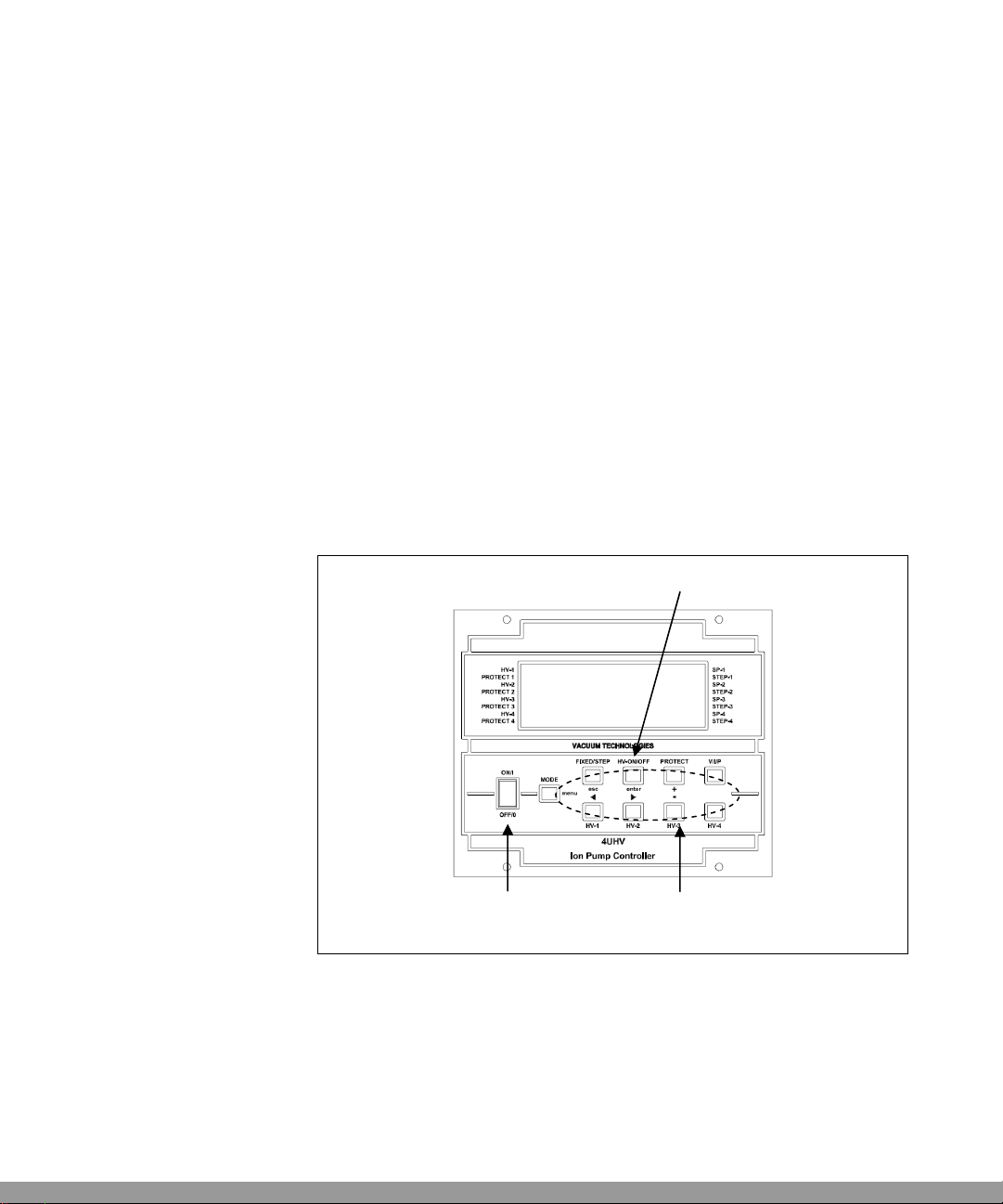

Figure 6 4 UHV Controllers

The controller contains one or two high voltage modules.

Each high voltage module can have one 200 W channel or one 120 W

channel or two 80 W channels.

Some examples of how HV channels can be configured are given

below (for details see the Orderable Parts table):

Four independent channels with a maximum of 80 W power per

channel

Two independent channels with a maximum of 200 W power per

channel

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 57/104

Page 59

Technical Information

5

4UHV Controller Description

One 200 W channel and two 80W channels.

One 120 W channel

The 4UHV controller can be operated in the modes: LOCAL, SERIAL

or REMOTE.

58/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 60

Specifications

Table 1 Specifications

Component Description

Input Voltage 100 - 240 Vac (+/-10%)

Input Frequency 50/60 Hz

Input Power 600 VA

Output HV Voltage +/- 7000 Vdc +/- 5%

Output HV Short

circuit current

Output HV Power

max

Operating

temperature

Storage

temperature

Fuse 5x20 T6.3A 250V

Voltage

measurement

Current

measurement

Weight 6.5 kg

Compliance with: EN 61010-1 2001: Safety requirements for electrical

Technical Information

Specifications

40 mA (for 80W channels) 100 mA (for 200 W channels)

200 W or 80 W each channel

0 °C to 40 °C

-20 °C to +70 °C

Resolution 100 V

Accuracy: +/- 5%

Measurement range: 10 nA to 100 mA, logarithmic scale

Resolution : 2 digit of the mantissa (maximum 10 nA)

Accuracy: +/- 6%

equipment for measurement control and laboratory use.

EN 61326-1 2006: Electrical equipment for measurement

control and laboratory use EMC requirements

5

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 59/104

Page 61

Technical Information

5

Specifications

Controller Outline

8000

7000

6000

5000

4000

Voltage (V)

3000

2000

1000

0

020406080100120

Output curve (200W) Output curve (80W)

Current (mA)

Figure 7 Output voltage vs Output current

The outline dimensions for the 4UHV controller are shown in the

following figures:

Figure 8 Controller Model Dimensions

Front View

211.40

141.20

177.00

164.30

Rear View

60/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 62

Technical Information

5

Specifications

Front Panel Description

Figure 9 Front Panel

Keys

Table 2 Keys

Main Power This is the main switch for switching on and off the controller.

HV-ON/OFF To switch a high voltage channel on or off, keep the HV-ON/OFF key

pressed while you press the HV-x key, where x is the number of the

channel you want to switch on or off.

Fixed/Step To change the output voltage choosing between: 7kV, 5kV, 3kV, Step-Mode

and Fixed-Mode, keep the Fixed/Step key pressed while you press the HV-x

key, where x is the number of the channel for which you want to change

the output voltage.

The output voltage will change cyclically between “STEP, 7kV, 5kV, 3kV”.

Protect To activate or disactivate Protect mode, keep the Protect key pressed while

you press the HV-x key, where x is the number of channel for which you

want to activate or disactivate the “Protect” functionality.

Mode By pressing this key briefly (< 2 sec), the ”operating mode” changes

cyclically between: Serial, Front, Remote. You exit from this display

automatically after 5 seconds. By keeping this key pressed for a long time

(> 2 sec), you enter the menu. To exit from the menu, press the Mode key

again for a long time.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 61/104

Page 63

Technical Information

5

Specifications

Graphic Signals

Four black squares are present for each channel indicating,

respectively, the 4 states of the channel. The meaning of the 4

indicators is the following:

1. HV-x Square lit (black)= HV on

Square not lit = HV off

Square flashing = Error

2. Protect-x Square lit (black)= Protect on

Square not lit = Protect off

Square flashing = Protect error

3. SP-x Square lit (black)= Set-point activate

Square not lit = Set-point not active

4. Step-x Square lit (black)= Step

Square not lit = Fixed

62/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 64

Technical Information

5

Specifications

Rear Panel Description

HV Connectors

Interlock

connector

Fuses

Serial

Port

Remote I/O

Figure 10 Rear Panel

The following are present on the rear panel:

The HV connectors ( 1, 2, 3 or 4 according to model)

The interlock connectors associated to each channel

The fuses

The DB9 connector for RS232 and RS485 serial communication

The DB37 connector for Remote I/O signals.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 63/104

Page 65

Technical Information

5

Specifications

Fuse Holder

The following figure shows the location of this assembly.

Figure 11 Rear Panel

Proceed as follows to replace one or both fuses:

1 Disconnect the mains cable

2 Waiting for 15 second

3 Remove the fuse with a small screwdriver

4 Replace the fuse

5 Use only 5x20 T6.3A 250V fuses

64/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 66

Operating Mode

The controller 4UHV for ion pumps can be operated in three different

modes:

Local

Serial

Remote.

The commands sent to the controller (for example, HVON/OFF,

Target voltage etc) can only be given in the mode chosen, while the

data (for example, current, pressure, voltage etc…) can be read in all

the modes.

E.g.: If you select Local mode, the HV channels can only be switched

on via the keys on the Front Panel, but the current supplied can be

read via the Front Panel, Serial and Remote.

Change from one mode to the next can be done either via the Front

Panel or a serial command.

Technical Information

Operating Mode

5

NOTE

Change from one mode to another can be done with the high voltage switched

on. However, the channels switch off if Remote mode is selected but no

commands for switching on are present on the remote connector.

Selecting “Operating Mode” from Front Panel

To display the current mode, press the Mode key briefly (less than 2

seconds).

To change mode, press the Mode key again. The three modes will be

displayed in a cyclic fashion: Local, Serial, Remote.

After selecting the required mode, wait approximately 5 seconds to

return to the previous screen.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 65/104

Page 67

Technical Information

5

Operating Mode

Selecting “Operating Mode” via Serial

Using serial communications via the protocol “WIN protocol” (see

chapter: SERIAL – Window Protocol), write the chosen value in

window 8:

Table 3 Keys

Value Description

0 Serial

1 Remote

2 Local

66/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 68

Start-Up

Technical Information

Start-Up

This chapter explains how to switch on and off the unit and the high

voltage channels. In the following chapters, all the functions of the

controller are explained in detail.

1 Put the main power switch situated on the front panel to OFF

2 Insert the power cable into the correct connector on the rear

panel

3 Connect the HV cables to the controller and to the ion pumps

4 Make sure that “Interlock” of HV cable is connected

5 To switch on the unit, put the main power switch to ON

6 Select Local for the Operating mode

7 Press the keys HV-ON/OFF keys and HV-x, where x is the number

of the channel you want to switch on.

Key HV-ON/OFF

5

Figure 12 Front Panel

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 67/104

Main power switch

Keys HV-x

Page 69

Technical Information

5

Start-Up

Table 4

Component Description

Remote I/O Signal Listing

Pin 4 +24V +/- 10%, max. current 60mA

Pin 5 Reserved

Fault A unique fault relay for all channels and for all

Pin 12 NC Fault Relay

Pin 13 NO Fault Relay

Pin 31 Common Fault Relay

Channel 1

Input

Pin 6 CH1 on/off

Pin 7 CH1 protect

Pin 8 CH1 step

Pin 22 Digital Gnd

Analog Output

Pin 1 Analog 1

Pin 3 Analog Gnd

Digital Output

Pin 17 CH1 NC Set-point Relay

Pin 18 CH1 (Common) Relay

Pin 19 CH1 NO Set-point Relay

Channel 2

Input

Pin 9 CH2 on/off

Pin 10 CH2 protect

Pin 11 CH2 step

Pin 22 Digital Gnd

Analog Output

Pin 2 Analog 2

Pin 3 Analog Gnd

errors.

68/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 70

Technical Information

5

Start-Up

Digital Output

Pin 14 CH2 NC Set-point Relay

Pin 15 CH2 (Common) Relay

Pin 16 CH2 NO Set-point Relay

Channel 3

Input

Pin 23 CH3 on/off

Pin 24 CH3 protect

Pin 25 CH3 step

Pin 22 Digital Gnd

Analog Output

Pin 20 Analog 3

Pin 3 Analog Gnd

Digital Output

Pin 35 CH3 NC Set-point Relay

Pin 36 CH3 (Common) Relay

Pin 37 CH3 NO Set-point Relay

Channel 4

Input

Pin 26 CH4 on/off

Pin 27 CH4 protect

Pin 28 CH4 step

Pin 22 Digital Gnd

Analog Output

Pin 21 Analog 4

Pin 3 Analog Gnd

Digital Output

Pin 32 CH4 NC Set-point Relay

Pin 33 CH4 (Common) Relay

Pin 34 CH4 NO Set-point Relay

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 69/104

Page 71

Technical Information

A

5

Start-Up

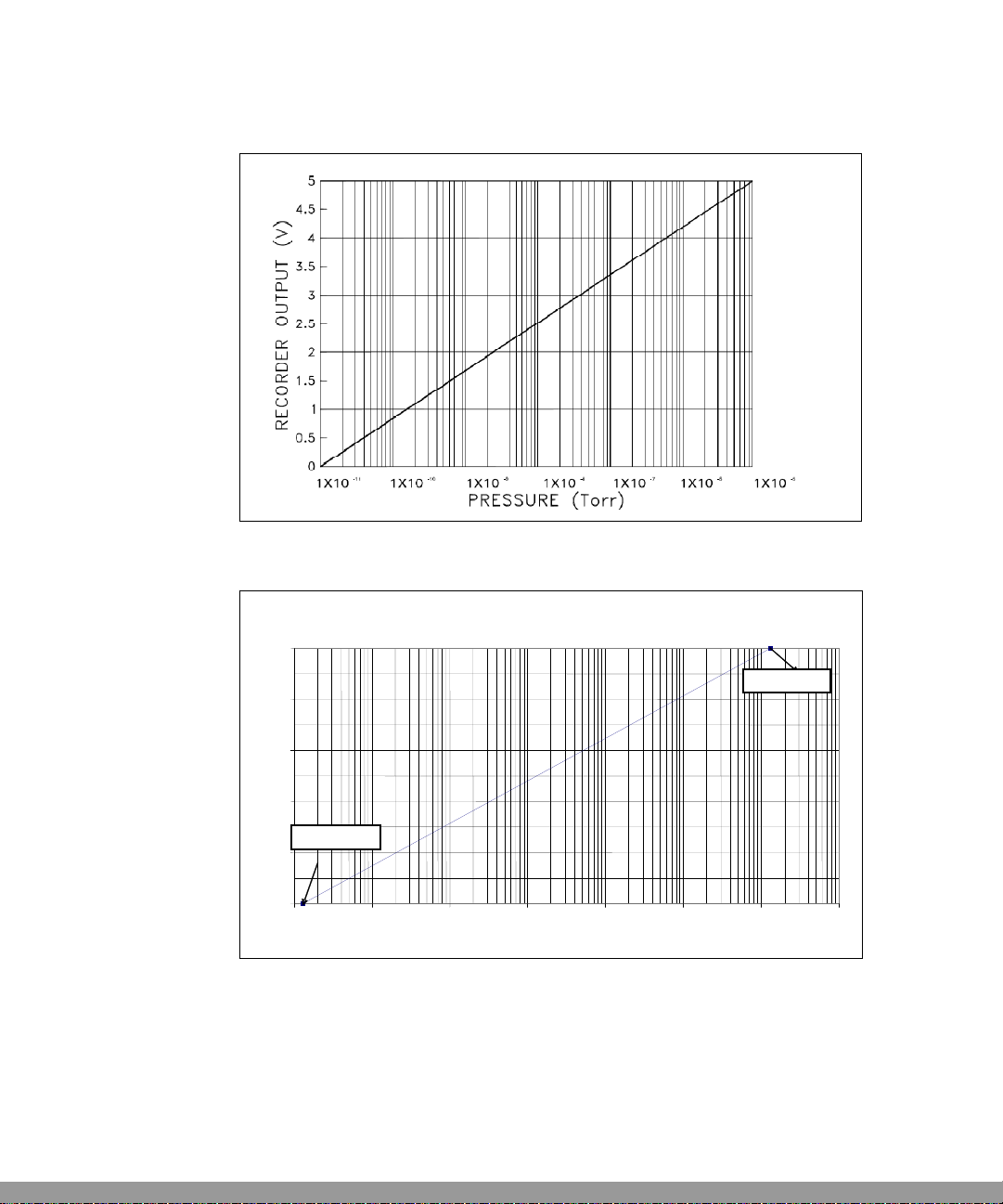

Figure 13 Recorder Output Pressure

nalog remote vs Pressure

5.0

4.0

Analog remote (Volt)

3.0

2.0

1.3E-12 kPa

1.0

0.0

1.0E-12 1.0E-11

1.0E-10 1.0E-09 1.0E-08 1.0E-07 1.0E-06 1.0E-05

Pressure (kPa)

1.3E-6 kPa

Figure 14 Analog remote vs Pressure (kPa)

70/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 72

Technical Information

4

5

Start-Up

Analog remote vs Pressure

5.0

4.0

3.0

2.0

Ana log remote (V olt)

1.0

1.3E-11 mbar

0.0

1.0E-11 1.0E-10 1.0E-09 1.0E-08 1.0E-07 1.0E-06 1.0E-05 1.0E-0

Pressure (mbar)

Figure 15 Analog remote vs Pressure (mbar)

1.3E-5 mbar

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 71/104

Page 73

Technical Information

5

Start-Up

Connection of Input remote

In order to activate the inputs remote (CH on/off, Ch protect, CH

Step) connect the pins as following:

+24V

A

Controller

Figure 16 Input

72/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Customer

device’s

Page 74

Serial

Technical Information

Serial

The following figure shows the 4UHV interconnections.

Figure 17 4UHV interconnections

This is a 9-pin D-type serial input/output connector that allows the

4UHV to be controlled via an RS232 or RS485 connection.

Table 5

PIN No. Signal Name

1 +5 V (OUT)

2 TX (RS232)

3 RX (RS232)

4 Reserved

5 GND

6 A + (RS485)

7 Reserved

8 B - (RS485)

9 Reserved

5

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 73/104

Page 75

Technical Information

5

Serial

Connector Examples

5

2

PC

3

Figure 18 RS–232 Connection

Ion controller 1

Ion controller 2

Figure 19 RS–485 Connection

5

2

3

Cont ro ll er

4UHV

Window Protocol

Both RS232 and the RS485 interfaces are available on the 9-pin Dtype serial input/output connector. The communications protocol is

the same (see the structure below), but only the RS485 handles the

address field. Therefore, to enable the RS485, you need to select both

the type of communication and the device address using the front

panel menu or the Navigator software.

74/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 76

Technical Information

5

Serial

The Window Protocol is the same of the Turbo Pump, but the

meaning of the Window is different (see the below chapter: Windows

Description).

Communications Format

8 data bit

No parity

1 stop bit

Baud rate: 9600

Communications Protocol

The communications protocol is of MASTER/ SLAVE type, where:

Host = MASTER

Controller = SLAVE

The communication takes place as follows:

1 The host (MASTER) sends a MESSAGE + CRC to the controller

(SLAVE)

2 The controller answers with an ANSWER + CRC to the host.

3 The MESSAGE is a string in the following format:

4 <STX>+<ADDR>+<WIN>+<COM>+<DATA>+<ETX>+<CRC>

NOTE

When data is indicated between two quotes (‘...’), it implies that the data

indicated is the corresponding ASCII character.

Where:

<STX> (Start of transmission) = 0x02

<ADDR> (Unit address) = 0x80 (for RS232)

<ADDR> (Unit address) = 0x80 + device number (0 to 31) (for

RS485)

<WIN> (Window) = a string of 3 numerics indicating the window

number (from ‘000’ to ‘999’); for the meaning of each window, see

the relevant paragraph.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 75/104

Page 77

Technical Information

5

Serial

<COM> (Command) = 0x30 to read the window, 0x31 to write in

the window

<DATA> = an alphanumeric ASCII string with the data to be

written in the window. In the case of a read command, this field

is not present. The field length varies according to the data type,

as shown in the following table:

76/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 78

Technical Information

5

Serial

Table 6

Data Type Field Length Valid Characters

Logic (L) 1 ‘0’ = OFF

‘1’ = ON

Numeric (N) 6 ‘-‘, ‘.’, ‘0’ . . . ‘9’ right justified with ‘0’

Alphanumeric (A) 10 From blank to ‘_’ (ASCII)

<ETX> (End of transmission) = 0x03

<CRC> = XOR of all characters following <STX> and including the

<ETX> terminator. The value is hexadecimal coded and

represented by two ASCII characters.

The SLAVE addressed responds with an ANSWER whose structure

depends on the MESSAGE type.

When the MESSAGE is a read command, the SLAVE responds

transmitting a string with the same structure as the MESSAGE.

NOTE

Using the RS485 interface, the message structure is identical to that used for

the RS232 interface, the only difference being the value assigned to the

ADDRESS <ADDR>.

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 77/104

Page 79

Technical Information

5

Serial

The controller can reply with the following types of response:

Table 7

Type Length Value Description

Logic - After a read instruction of a logic window.

Numeric 6 bytes - After a read instruction of a numeric window.

Alphanumeric 10 bytes - After a read instruction of a alphanumeric window.

ACK 1 byte (0x6) Execution of the command has been successful.

NACK 1 byte (0x15) Execution of the command has failed.

Unknown Window 1 byte (0x32) The window specified in the command is not a valid window.

Data Type Error 1 byte (0x33) The data type specified in the command (Logic, Numeric or

Alphanumeric) is not in agreement with the Window

specified.

Out of Range The value expressed during a write command is not within

the range value for the specified window.

Win Disabled 1 byte (0x35) The window specified is Read Only or is temporarily disabled.

Table 8 Windows Description

WIN R/W Type Description Range

11 R/W L HV ON/OFF

CH1

12 R/W L HV ON/OFF

CH2

13 R/W L HV ON/OFF

CH3

14 R/W L HV ON/OFF CH4 0 = OFF(def) ; 1=ON

108 R/W N Baud rate (1-4) [1200-2400-4200-9600]

205 R N Status

206 R N Error code

319 R/W Controller Model

323 R/W Controller Serial number

503 R/W N RS485 Serial Address [0-31]; 1=def

504 R/W L Serial Type Select 0= RS232(def) ;

0 = OFF(def) ; 1=ON

0 = OFF(def) ; 1=ON

0 = OFF(def) ; 1=ON

78/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 80

Technical Information

Serial

WIN R/W Type Description Range

1= RS485

505 R/W N Channel Selection (see below)

600 R/W N Unità di misura

Pressione

601 R/W A Operating Mode (see below)

602 R/W A Protect (see below)

603 R/W A Fixed/Step (see below)

610 R/W N Device Number CH1 (see below)

612 R/W N Power max CH1 20 W – 80 W

613 R/W N V target CH1 [3000,7000] V

614 R/W N I protect CH1 [1,100] step 1 mA

615 R/W A Set Point CH1 [X.XE-XX]

620 R/W N Device Number CH1 (see below)

622 R/W N Power max CH2 20 W – 80 W

623 R/W N V target CH2 [3000,7000] V

624 R/W N I protect CH2 [1,100] step 1 mA

625 R/W A Set Point CH2 [X.XE-XX]

630 R/W N Device Number CH3 (see below)

632 R/W N Power max CH3 20 W – 80 W

633 R/W N V target CH3 [3000,7000] V

634 R/W N I protect CH3 [1,100] step 1 mA

635 R/W A Set Point CH3 [X.XE-XX]

640 R/W N Device Number CH4 (see below)

642 R/W N Power max CH4 20 W – 80 W

643 R/W N V target CH4 [3000,7000] V

0 = Torr ;

1=mBar (def) ;

2=Pa

step 1000;

def=7000

step 1000;

def=7000

step 1000;

def=7000

5

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 79/104

Page 81

Technical Information

5

Serial

WIN R/W Type Description Range

step 1000;

def=7000

644 R/W N I protect CH4 [1,100] step 1 mA

645 R/W A Set Point CH4 [X.XE-XX]

800 R N Temperature

FAN

801 R N Temperature

HV1

802 R N Temperature

HV2

803 R A Interlock Status (see below)

804 R A Status Set Point (see below)

808 R N Temperature

HV3

809 R N Temperature

HV4

810 R N V measured CH1 [0, 7000] V ;

811 R A I measured CH1 [1E-10, 9E-1] A

812 R N Pressure CH1 [X.XE-XX]

820 R N V measured CH2 [0, 10000] V ;

821 R A I measured CH2 [1E-10, 9E-1] A

822 R N Pressure CH2 [X.XE-XX]

830 R N V measured CH3 [0, 10000] V ;

831 R A I measured CH3 [1E-10, 9E-1] A

832 R N Pressure CH3 [X.XE-XX]

840 R N V measured CH4 [0, 10000] V ;

841 R A I measured CH4 [1E-10, 9E-1] A

842 R N Pressure CH4 [X.XE-XX]

[0, 200] °C

[0, 200] °C

[0, 200] °C

[0, 200] °C

[0, 200] °C

step 100 V

step 100 V

step 100 V

step 100 V

80/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 82

Technical Information

5

Serial

Example:

Turn ON Channel 1

PC

´ Controller

02 80 30 31 31 31 31 03 42 33

STX ADDR WINDOW WR DATA ETX CRC

Controller ´ PC

02 80 06 03 38 33

STX ADDR ACK ETX CRC

Turn OFF Channel 1

PC

´ Controller

02 80 30 31 31 31 30 03 42 32

STX ADDR WINDOW WR DATA ETX CRC

Controller ´ PC

02 80 06 03 38 35

STX ADDR ACK ETX CRC

Read Pressure (win 812) Channel 1

PC

´ Controller

02 80 38 31 32 30 03 38 38

STX ADDR WINDOW RD ETX CRC

Controller ´ PC

02 80 38 31 32 30 20 20 20 31 2E 35 45 2D 30 38 03 45 32

STX ADDR WINDOW WR DATA ETX CRC

Data=1.5E-8

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 81/104

Page 83

Technical Information

5

Serial

Read Voltage (win 810) Channel 1

´Controller

PC

02 80 38 31 30 30 03 38 41

STX ADDR WINDOW RD ETX CRC

Controller ´ PC

02 80 38 31 32 30 30 30 33 30 30 30 03 38 39

STX ADDR WINDOW WR DATA ETX CRC

Data=3000

Read Current (win 811) Channel 1

PC

´ Controller

02 80 38 31 31 30 03 38 42

STX ADDR WINDOW RD ETX CRC

Controller ´ PC

02 80 38 31 31 30 20 20 20 32 2E 39 45 2D 30 35 03 45 33

STX ADDR WINDOW WR DATA ETX CRC

Data=2.9E-5

Operating mode (Win 601)

Autostart ON

PC

´Controller

02 80 36 30 31 30 30 30 30 30 30 30 30 30 30 31 03 38 34

STX ADDR WINDOW WR DATA ETX CRC

Controller ´ PC

02 80 06 03 38 35

STX ADDR ACK ETX CRC

Autostart OFF

PC

´ Controller

02 80 36 30 31 31 30 30 30 30 30 30 30 30 30 30 03 38 35

STX ADDR WINDOW WR DATA ETX CRC

82/104 Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A)

Page 84

Technical Information

5

Serial

Controller

02 80 06 03 38 35

STX ADDR ACK ETX CRC

´ PC

Protect (Win 602)

PC

´ Controller

02 80 36 30 32 30 03 38 37

STX ADDR WINDOW RD ETX CRC

Controller ´ PC

02 80 36 30 32 30 30 30 30 30 30 30 30 31 30 30 03 38 36

STX ADDR WINDOW WR DATA ETX CRC

Fixed/Step (603)

PC

´ Controller

02 80 36 30 33 30 03 38 36

STX ADDR WINDOW RD ETX CRC

Controller ´ PC

02 80 36 30 33 30 30 30 30 30 30 30 30 30 30 31 03 38 37

STX ADDR WINDOW WR DATA ETX CRC

Status Set Point (804)

PC

´ Controller

02 80 38 30 34 30 03 38 46

STX ADDR WINDOW RD ETX CRC

Controller ´ PC

02 80 38 30 34 30 30 30 30 30 30 30 30 30 30 31 03 38 45

STX ADDR WINDOW WR DATA ETX CRC

Agilent 4UHV Ion Pump Controller User Manual / 87-900-137-01 (A) 83/104

Page 85

Technical Information

5

Serial

Error Description

Controller errors can be displayed in two windows:

WIN 505 where the user writes the channel whose error is to be

viewed

WIN 206 where the controller shows the error code of the

channel written in window 505.

If the value 0 is written in window 505, the errors of all the channels

remain displayed in window 206.

Table 9

WIN 505 value Channel

0 All channels

1

2

3

4

Channel 1

Channel 2

Channel 3

Channel 4

Error Code

The error code is displayed in decimal format. Binary representation

of this number provides indications regarding the type of error that

has occurred.

The error table is shown below:

Table 10

Error code in decimal

format

0 0000000000000 No error

1 0000000000001 FAN error

2 0000000000010 Power input error from HV

4 0000000000100 Power input error from PFC

8 0000000001000 Overtemp PFC