Page 1

Agilent 490

Micro Gas

Chromatograph

User Manual

Agilent Technologies

Page 2

Notices

CAUTION

WARNING

© Agilent Technologies, Inc. 2017

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from

Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

Manual Part Number

G3581-90001

Edition

Sixth edition, November 2017

Printed in China

Agilent Technologies, Inc.

412 Ying Lun Road

Waigoaqiao Freed Trade Zone

Shanghai 200131 P.R.China

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection

with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a

license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Safety Notices

A CAUTION notice denotes a

hazard. It calls attention to an operating procedure, practice, or the

like that, if not correctly performed

or adhered to, could result in

damage to the product or loss of

important data. Do not proceed

beyond a CAUTION notice until the

indicated conditions are fully

understood and met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and met.

If software is for use in the performance of

a U.S. Government prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S.

Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14

Page 3

Contents

1 Introduction

Safety Information 8

Important safety warnings 8

Hydrogen safety 8

Safety symbols 9

Safety and regulatory information 10

General safety precautions 10

Shipping Instructions 13

Cleaning 13

Instrument Disposal 13

2 Instrument Overview

Principle of Operation 16

Front View 17

Back View 18

Inside View 19

Carrier Gas Connection 21

Power 23

Power source 23

Power Requirements 23

Disposal 24

Specifications 24

Ambient Pressure 25

Ambient Temperature 25

Maximum Operation Altitude 25

Micro GC Cycle with Constant Pressure 26

Micro GC Cycle with Ramped Pressure 27

3 Installation and Use

Pre-Installation Requirements 30

490 Micro GC User Manual 3

Page 4

Inspect the Shipping Packages 30

Unpack the Micro GC 31

Review the Packing List 32

490 Micro GC Installation 33

Step 1: Connect carrier gas 33

Step 2: Connect to calibration gas or checkout sample 33

Step 3: Install power supply 33

Step 4: Connect to computer or local network 34

Step 5: Install Chromatography Data System 34

Step 6: Assign IP address 34

Restore the Factory Default IP Address 38

Create the Test Method 40

Perform a Series of Runs 41

Shut Down Procedure 42

Long Storage Recovery Procedure 42

4 Sample Gas Handling

5 GC Channels

Using the external filter unit 46

Heated sample lines 47

How to connect your sample to the 490 Micro GC 48

Rear inlet (heated or unheated) 48

Internal inlet 49

Internal bracket for Genie filter 51

490-Micro GC Optional Pressure Regulators 53

G3581-S0003 53

G581-S0004 56

Manual Injection 59

Manual injection guidelines 59

Injection Procedure 60

Field upgrade kits 60

Manual injection flow diagrams 61

Carrier Gas 66

Micro Electronic Gas Control (EGC) 67

Inert Sample Path 67

Injector 67

4 490 Micro GC User Manual

Page 5

Column 68

Molsieve 5Å columns 69

CP-Sil 5 CB columns 70

CP-Sil CB columns 71

PoraPlot 10m column 72

Hayesep A 40 cm heated column 73

COX and AL203/KCI columns 74

MES (NGA) and CP-WAX 52 CB columns 75

Column conditioning 76

Backflush Option 77

Tuning the backflush time (except on a HayeSep A channel) 79

Tuning the backflush time on a HayeSep A channel 80

To disable backflush 81

Backflush to Detector 82

CP-Sil 5 CB Backflush to detector 82

Al2O3 Backflush to detector 82

Tuning the backflush time 83

To disable backflush 85

Set invert signal time 85

Checkout information 86

C6+ Calorific value calculation 88

TCD Detector 88

6 Channel Exchange and Installation

Tools required 90

Replacement procedure for Micro GC channel 91

Replacement procedure for Micro GC channel with RTS option 99

Replacement procedure for Molsieve filters with the RTS option 103

Carrier gas Tube Stop Modification Kit 105

7 Communications

Access the Connection Ports 108

490 Chromatography Data Systems 110

Ethernet Networks 111

IP Addresses 112

Example network configurations 112

USB VICI Valve 116

Configure Multiple VICI Valves with OpenLab EZchrom 116

USB Wi-Fi 118

490 Micro GC User Manual 5

Page 6

8 Errors

Frequently Asked Questions (FAQ) 121

Glossary of network terms 121

External Digital I/O 123

External Analog I/O 124

Error Handling 126

Error List 127

6 490 Micro GC User Manual

Page 7

Agilent 490 Micro Gas Chromatograph

User Manual

1

Introduction

Safety Information 8

Shipping Instructions 13

Cleaning 13

Instrument Disposal 13

This chapter provides important information about using the

Agilent 490 Micro Gas Chromatograph (Micro GC) safely. To

prevent any injury to you or any damage to the instrument it is

essential that you read the information in this chapter.

Agilent Technologies

7

Page 8

1 Introduction

WARNING

WARNING

Safety Information

Important safety warnings

There are several important safety notices that you should always

keep in mind when using the Micro GC.

When handling or using chemicals for preparation or use within

the Micro GC, all applicable local and national laboratory safety

When

practices must be followed. This includes, but is not limited to,

correct use of Personal Protective Equipment, correct use of

storage vials, and correct handling of chemicals, as defined in the

laboratory’s internal safety analysis and standard operating

procedures. Failure to adhere to laboratory safety practices could

lead to injury or death.

Hydrogen safety

Hydrogen is a commonly used GC carrier gas. When mixed with air,

hydrogen can form explosive mixtures and has other dangerous

characteristics.

When using hydrogen (H2) as the carrier gas, be aware that hydrogen gas

can create a fire or explosion hazard. Be sure that the supply is turned off

until all connections are made.

Hydrogen is flammable. Leaks, when confined in an enclosed space, may

create a fire or explosion hazard. In any application using hydrogen, leak

test all connections, lines, and valves before operating the instrument.

Always turn off the hydrogen supply at its source before working on the

instrument.

• Hydrogen is combustible over a wide range of concentrations. At

atmospheric pressure, hydrogen is combustible at concentrations

from 4 % to 74.2 % by volume.

• Hydrogen has the highest burning velocity of any gas.

• Hydrogen has a very low ignition energy.

• Hydrogen that is allowed to expand rapidly from high pressure into

the atmosphere can self-ignite.

• Hydrogen burns with a nonluminous flame which can be invisible

under bright light.

8 490 Micro GC User Manual

Page 9

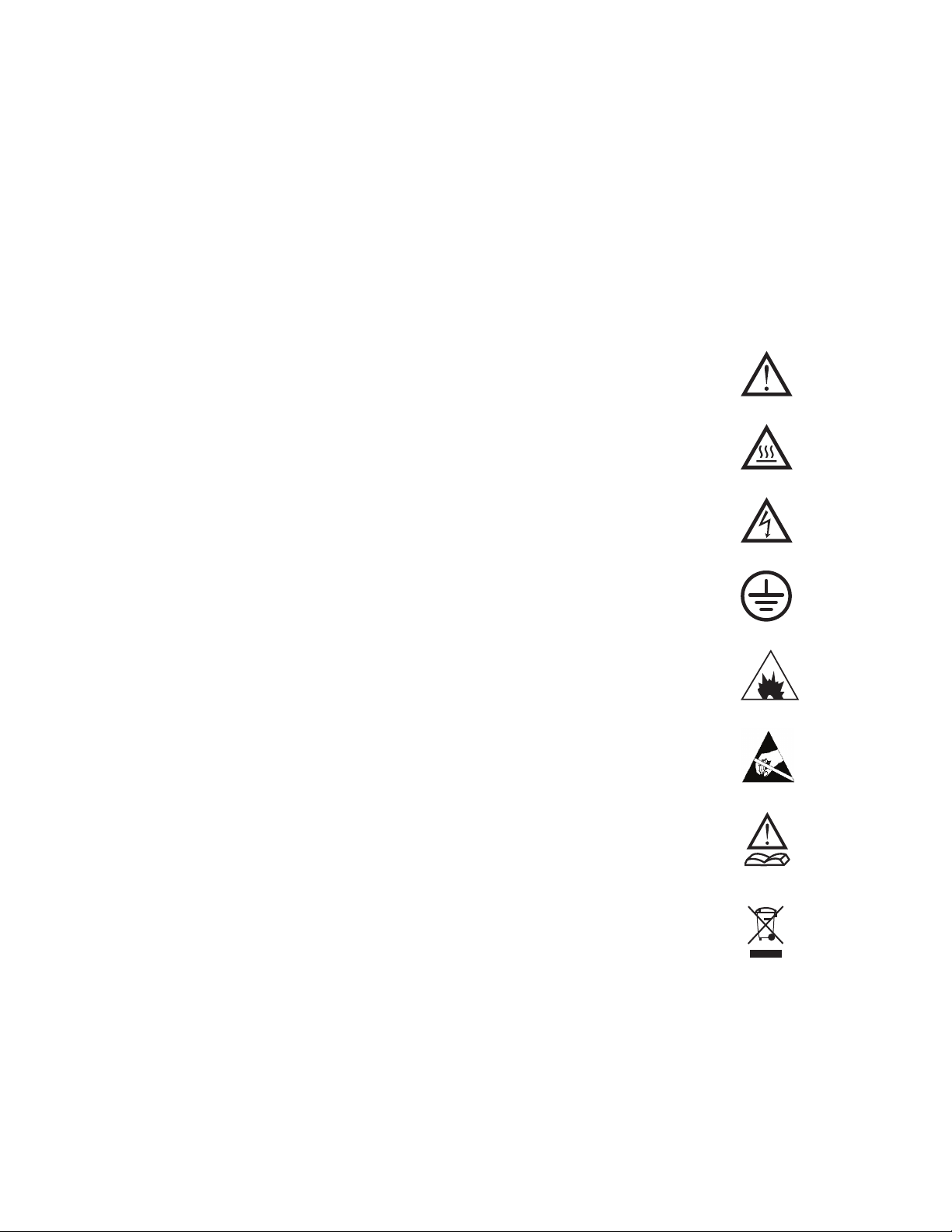

Safety symbols

Introduction 1

Warnings in the manual or on the instrument must be observed during

all phases of operation, service, and repair of this instrument. Failure

to comply with these precautions violates safety standards of design

and the intended use of the instrument. Agilent Technologies assumes

no liability for the customer’s failure to comply with these

requirements.

See accompanying instructions for more

information.

Indicates a hot surface.

Indicates hazardous voltages.

Indicates earth (ground) terminal.

Indicates potential explosion hazard.

Indicates electrostatic discharge hazard.

Indicates a hazard. See the Agilent 490 GC user

documentation for the item labeled.

Indicates that you must not discard this

electrical/electronic product in domestic

household waste

490 Micro GC User Manual 9

Page 10

1 Introduction

Safety and regulatory information

This instrument and its accompanying documentation comply

with the CE specifications and the safety requirements for

electrical equipment for measurement, control, and laboratory

use (CEI/IEC 1010-1)

This device has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC

rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

CSAUS and FCC-b.

C

NOTICE This instrument has been tested per applicable

requirements of EMC Directive as required to carry the

European Union CE Mark. As such, this equipment may be

susceptible to radiation/interference levels or frequencies,

which are not within the tested limits.

General safety precautions

Follow the following safety practices to ensure safe equipment

operation:

• Perform periodic leak checks on all supply lines and

pneumatic plumbing.

• Do not allow gas lines to become kinked or punctured. Place

lines away from foot traffic and extreme heat or cold.

• Store organic solvents in fireproof, vented and clearly

labeled cabinets so they are easily identified as either toxic,

or flammable, or both types of materials.

• Do not accumulate waste solvents. Dispose of such materials

through a regulated disposal program and not through

municipal sewage lines.

10 490 Micro GC User Manual

Page 11

Introduction 1

WARNING

WARNING

This instrument is designed for chromatographic analysis of

appropriately prepared samples. It must be operated using

appropriate gases or solvents and within specified maximum

ranges for pressure, flows, and temperatures as described in this

manual. If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

It is the responsibility of the customer to inform Agilent customer

support representatives if the instrument has been used for the

analysis of hazardous samples, prior to any instrument service

being performed or when an instrument is being returned for

repair.

• Avoid exposure to potentially dangerous voltages.

Disconnect the instrument from all power sources before

removing protective panels.

• When it is necessary to use a non-original power cord and

plug, make sure the replacement cord adheres to the color

coding and polarity described in the manual and all local

building safety codes.

• Replace faulty or frayed power cords immediately with the

same type and rating.

• Place this instrument in a location with sufficient ventilation

to remove gases and vapors. Make sure there is enough space

around the instrument for it to cool off sufficiently.

• Before plugging the instrument in or turning the power on,

always make sure that the voltage and fuses are set

appropriately for your local power source.

• Do not turn on the instrument if there is a possibility of any

kind of electrical damage. Instead, disconnect the power cord

and contact your local Agilent sales office.

• The supplied power cord must be inserted into a power

outlet with a protective ground connection. When using an

extension cord, make sure that the cord is also properly

grounded.

• Do not change any external or internal grounding

connections, as this could endanger you or damage the

instrument.

490 Micro GC User Manual 11

Page 12

1 Introduction

• The instrument is properly grounded when shipped. You do

not need to make any changes to the electrical connections or

to the instrument chassis to ensure safe operation.

• When working with this instrument, follow the regulations

for Good Laboratory Practices (GLP). Take care to wear

safety glasses and appropriate clothing.

• Do not place containers with flammable liquids on this

instrument. Spilling liquid over hot parts may cause fire.

• This instrument may use flammable or explosive gases, such

as hydrogen gas under pressure. Before operating the

instrument be sure to be familiar with and to follow

accurately the operation procedures prescribed for those

gases.

• Never try to repair or replace any component that is not

described in this manual without the assistance of an Agilent

service engineer. Unauthorized repairs or modifications will

result in rejection of warranty claims.

• Always disconnect the AC power cord before attempting any

type of maintenance.

• Use proper tools when working on the instrument to prevent

danger to you or damage to the instrument.

• Do not attempt to replace any battery or fuse in this

instrument other than as specified in the manual.

• Damage can result if the instrument is stored under

unfavorable conditions for prolonged periods. (For example,

damage will occur if stored while subject to heat, water, or

other conditions exceeding the allowable operating

conditions).

• Do not shut off column flow when the oven temperature is

high, since this may damage the column.

• This unit has been designed and tested in accordance with

recognized safety standards and designed for use indoors.

• If the instrument is used in a manner not specified by the

manufacturer, the protection provided by the instrument

may be impaired.

• Substituting parts or performing any unauthorized

modification to the instrument may result in a safety hazard.

• Changes or modifications not expressly approved by the

responsible party for compliance could void the user's

authority to operate the equipment.

12 490 Micro GC User Manual

Page 13

Shipping Instructions

Cleaning

Introduction 1

If your Micro GC must be shipped for any reason, it is very

important to follow these additional shipping preparation

instructions:

• Place all the vent caps on the back of the Micro GC (see

Figure 3 on page 18).

• Always include the power supply.

• Include, if used, the inlet filter(s).

To clean the surface of the Micro GC:

1 Switch the Micro GC off.

2 Remove the power cable.

Instrument Disposal

3 Put protection plugs on the sample and carrier gas inlets.

4 Put protection plugs on the column vents.

5 Use a soft brush (not hard or abrasive) to carefully brush

away all dust and dirt.

6 Use a soft, clean cloth dampened with mild detergent to

clean the outside of the instrument.

• Never clean the inside of the instrument.

• Never use alcohol or thinners to clean the instrument;

these chemicals can damage the case.

• Be careful not to get water on the electronic components.

• Do not use compressed air to clean the instrument.

When the Micro GC or its parts have reached the end of their

useful life, dispose of them in accordance with the

environmental regulations that are applicable in your country.

490 Micro GC User Manual 13

Page 14

1 Introduction

14 490 Micro GC User Manual

Page 15

Agilent 490 Micro Gas Chromatograph

User Manual

2

Instrument Overview

Principle of Operation 16

Front View 17

Back View 18

Inside View 19

Carrier Gas Connection 21

Power 23

Ambient Pressure 25

Ambient Temperature 25

Maximum Operation Altitude 25

Micro GC Cycle with Constant Pressure 26

Micro GC Cycle with Ramped Pressure 27

There are several versions of the Agilent 490 Micro GC. All of

them use GC channels, each of which consists of an Electronic

Gas Control (EGC) injector, column, and detector.

The Micro GC is a self-contained package with all of the normal

GC components. It is available as a dual channel cabinet version

(one or two GC channels) or a quad channel cabinet version (up

to four GC channels). A computer with a chromatography data

system (CDS) is needed to complete the system.

This chapter provides a brief overview of the 490 Micro GC.

Agilent Technologies

15

Page 16

2 Instrument Overview

Principle of Operation

The 490 Micro GC can be equipped with one to four

independent column channels. Each column channel is a

complete, miniaturized GC with electronic carrier gas control,

micro-machined injector, narrow-bore analytical column and

micro thermal conductivity detector (µ TCD), Figure 1.

Figure 1 490 Micro GC setup

The 490 Micro GC analytical channels can optionally be

equipped with a back flush option. The advantages include the

protection of the stationary column phase against moisture and

carbon dioxide. Next to that, it results in shorter analysis times

as late elution compounds, which are not of interest, do not

enter the analytical column.

16 490 Micro GC User Manual

Page 17

Front View

Ready LED

LED OFF: System not ready

LED ON: System is ready

Run LED

LED OFF: No run

LED blinking: Run in progress

Error LED

LED OFF: No error

LED blinking: Error present

See “Error List” on page 127

Power LED

LED OFF: No power

LED ON: Power OK

LED blinking: Voltage < 10 Volt

Sample 1 and Sample 2

Sample gas inlet connector (for unheated front

inlets)

See “Manual Injection” on page 59

Power On/Off Switch

Switch the Micro GC ON or OFF

Instrument Overview 2

Figure 2 Front view of the 490 Micro GC

490 Micro GC User Manual 17

Page 18

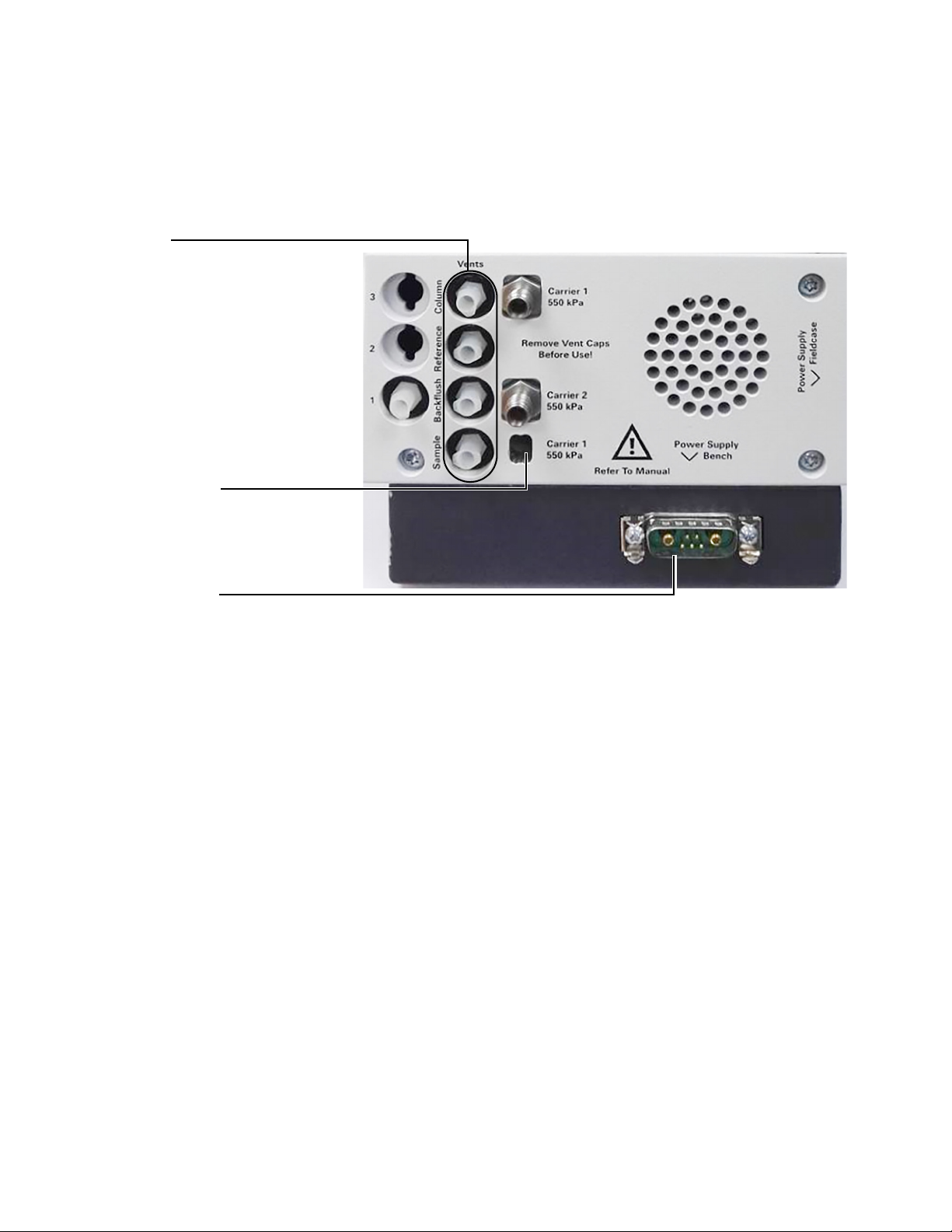

2 Instrument Overview

Power connector

Power connector (male)

See “Power” on page 23

Vents

It is possible to connect long vent lines to

these fittings in order to safely guide

hazardous fumes to a fume hood or other

appropriate vent.

Carrier gas input

Carrier gas input connector

See “Carrier Gas Connection” on

page 21

Back View

Figure 3 Back view of the 490 Micro GC

18 490 Micro GC User Manual

Page 19

Inside View

Assign IP address switch

See “Ethernet Networks” on

page 111.

LAN indicators

Red LED: Transmit data

Green LED: Receive data

Ethernet (LAN)

connector

Ethernet RJ45

connector.

See “Ethernet

Networks” on page 111.

COM 1

RS-232 communication

interface

Digital I/O

Digital input and output

signals, such as

start_stop, ready_out,

and start_in.

See “External Digital

I/O” on page 123.

COM 3 and COM 4

RS-485 (4-wire)

communication interface.

See Table 1 on page 20.

Analog I/O

External analog I/O signals.

See “External Analog

I/O” on page 124.

COM 2

RS-232 (2-wire)

communication interface.

See “490 Chromatography

Data Systems” on

page 110.

USB

communication interface.

See “USB VICI Valve” on

page 116 and “USB

Wi-Fi” on page 118

SD Card Slot

No function supported.

Instrument Overview 2

Open the right side cover and the cable connectors will be

visible. See Figure 4.

Figure 4 Cable connectors (main board G3581-65000 shown)

490 Micro GC User Manual 19

Page 20

2 Instrument Overview

The Micro GC provides communications ports as shown in

Table 1, depending on the model.

Table 1 Micro GC communication ports

Port Connection 490 Micro GC 490-Mobile Micro GC 490-PRO Micro GC

LAN Ethernet Interface with PC Interface with PC Interface with PC

COM 1 RS232 Not available Not available Valco stream selector;

Serial MODBUS

COM 2 RS232 Valco stream selector

Field case

†

LCD

COM 3 RS485

RS232

RS422

COM 4 RS485

RS232

RS422

Not available

Not available

Not available

Not available

Not available

Not available

Valco stream selector

Field case

†

LCD

Not available

Not available

Not available

Not available

Not available

Not available

Valco stream selector;

Serial MODBUS

†

LCD

Serial MODBUS

Not available

Not available

Serial MODBUS

Not available

Not available

*

*

;

*

*

Analog I/O Analog I/O Analog I/O Analog I/O

Digital I/O Digital I/O;

ready in - ready out;

start in - start out;

extension boards

‡

USB VICI Valves, WIFI interface VICI Valves, WIFI interface,

Digital I/O;

ready in - ready out;

start in - start out;

extension boards

‡

USB Storage

Digital I/O;

ready in - ready out;

start in - start out;

extension boards

‡

VICI Valves, WIFI interface,

USB Storage

* Optional PRO license required

† Optional accessory

‡ Extension boards not included

20 490 Micro GC User Manual

Page 21

Carrier Gas Connection

CAUTION

Instrument Overview 2

The carrier gas line is connected to the Micro GC at the back

panel Carrier 1 or Carrier 2 port.

Do not use any kind of plastic tubing since air will diffuse through the

tubing, which may cause noisy baselines and decreased sensitivity. The

metal tubing must be clean for GC use. Buy either flamed or chromatographically clean tubing.

Specifications for the carrier gas:

Pressure: 550 kPa ± 10 kPA (80 psi ± 1.5 psi)

Purity: 99.999 % minimum

Dry and free of particles: Gas Clean filters recommended

Gas Clean filters are recommended to remove any traces of

moisture and oxygen. For low-level analysis, consider using a

better grade of carrier gas.

Gas Clean filters are filled with nitrogen. If you are not using

nitrogen as the carrier gas, flush filters and gas lines after

installation of a new filter.

The type of analysis you want to perform dictates the type of

carrier gas to use. The difference between the relative thermal

conductivity of the carrier gas and the sample components

should be as high as possible. See Table 2 for several relative

thermal conductivities.

Table 2 Relative thermal conductivities

Relative thermal

Carrier gas

Hydrogen 47.1 Ethane 5.8

Helium 37.6 Propane 4.8

Methane 8.9 Argon 4.6

Oxygen 6.8 Carbon dioxide 4.4

Nitrogen 6.6 Butane 4.3

Carbon monoxide 6.4

conductivities

Carrier gas

Relative thermal

conductivities

490 Micro GC User Manual 21

Page 22

2 Instrument Overview

WARNING

WARNING

Your Micro GC is configured for a specific carrier gas, either

He and H2 or N2 and Ar. Make certain that any carrier gas

selection in your Agilent data system corresponds to the carrier

gas physically connected to your Micro GC. Use only the carrier

gas corresponding to this configuration. If you change the carrier

gas type plumbed to the Micro GC, you must change the

corresponding carrier gas type in the data system.

Hydrogen is flammable. If you are using hydrogen as a carrier gas,

pay particular attention to possible leaks at connections inside

and outside of the Micro GC (use an electronic leak tester).

22 490 Micro GC User Manual

Page 23

Power

CAUTION

Instrument Overview 2

Power source

• 90 to 264 Vac, frequency between 47 to 63 Hz.

• The room power outlet circuit must be exclusively reserved

for the instrument(s).

• The network should be properly grounded.

• Installation Category (overvoltage category): II

Power Requirements

The Micro GC requires 12 V Vdc, 150 W.

The Gasifier requires 12 V Vdc, 150 W.

Only use the power supply provided with your Micro GC.

This Power Supply, see Figure 5, is tailored to meet the power

needs of your Micro GC. See Table 3 on page 24 for

specifications.

Figure 5 Model GST220A12-AG1 (P/N G3581-60080)

490 Micro GC User Manual 23

Page 24

2 Instrument Overview

Disposal

Specifications

Disposal of the Power Supply must be carried out in accordance

with all environmental regulations applicable in your country.

Table 3 Power supply specifications

Feature Model: GST220A12-AG1

Input voltage 85 Vac to 264 Vac

Input frequency 47-63 Hz

Inrush current 120A/230VAC

Output voltage 12.0 Vdc

Voltage adjust ± 5 %

Output power 180 W

Over voltage protection 105 %-135 % rated output voltage

Ripple and noise 80mV Vp-p

Operating temperature -30 °C to +70 °C

Storage temperature -40 °C to +85 °C

Humidity 20 % to 90 % non condensing

Safety standard UL60950-1, TUV EN60950-1, BSMI CNS14336, CSA

C22.2, CCCGB4943, PSE J60950-1 Approved

RFI/EMC standard In compliance with CISPR22 (EN55022) Class B and

FCC Part 15/CISPR 22 class B, CNS13438 class B,

GB9254, EN61000-3-2, EN61000-3-3, EN61000-4-2,

EN61000-4-3, EN61000-4-4, EN61000-4-5,

EN61000-4-6, EN61000-4-8, EN61000-4-11 (light

industry level, criteria A)

Dimensions 210 × 85 × 46 mm (L×W×H)

Weight 1.1 kg approximately

24 490 Micro GC User Manual

Page 25

Ambient Pressure

The Micro GC automatically shuts down if the ambient pressure

is greater than 120 kPa.

Ambient Temperature

The Micro GC automatically shuts down if the ambient

temperature exceeds 65 °C.

Maximum Operation Altitude

Certified up to 2000 meters above sea level.

Instrument Overview 2

490 Micro GC User Manual 25

Page 26

2 Instrument Overview

Pressure

Time

Initial

pressure

Run started

Equilibration

time

Sample

time

Pressurization

time

Download

method

Inject time Run time

Inject Start data

acquuisition

Run finished

After the run sampling is

begun. This means that the

sample is (mostly) sucked

into the sample loop.

Pressurization delay

(120 mS), used to

pressurize the sample

to the same pressure

as the column head

pressure.

During injection time the

sample is transported to the

column by the carrier gas.

Before a run is

started all used

method parameters

must be downloaded

via the data system.

Fixed equilibration

delay of 40 ms.

This time allows

the sample to

settle in the

sample loop.

The run can be started

when the Micro GC is

ready (Ready LED is lit).

The data system will wait

until data is received

from the Micro GC.

The real analysis

(run) and data

acquisition starts.

After the specified run

time has elapsed, the

run is finished.

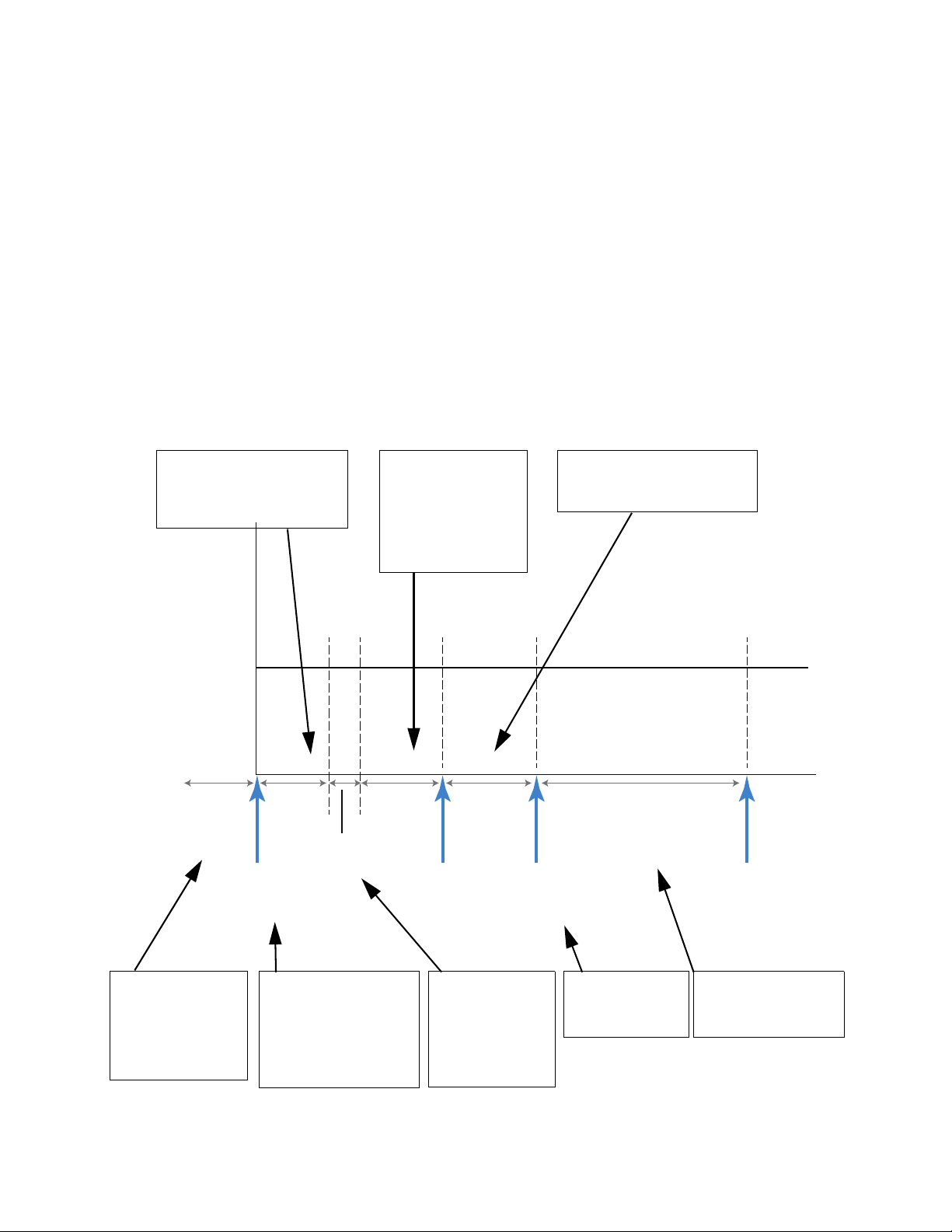

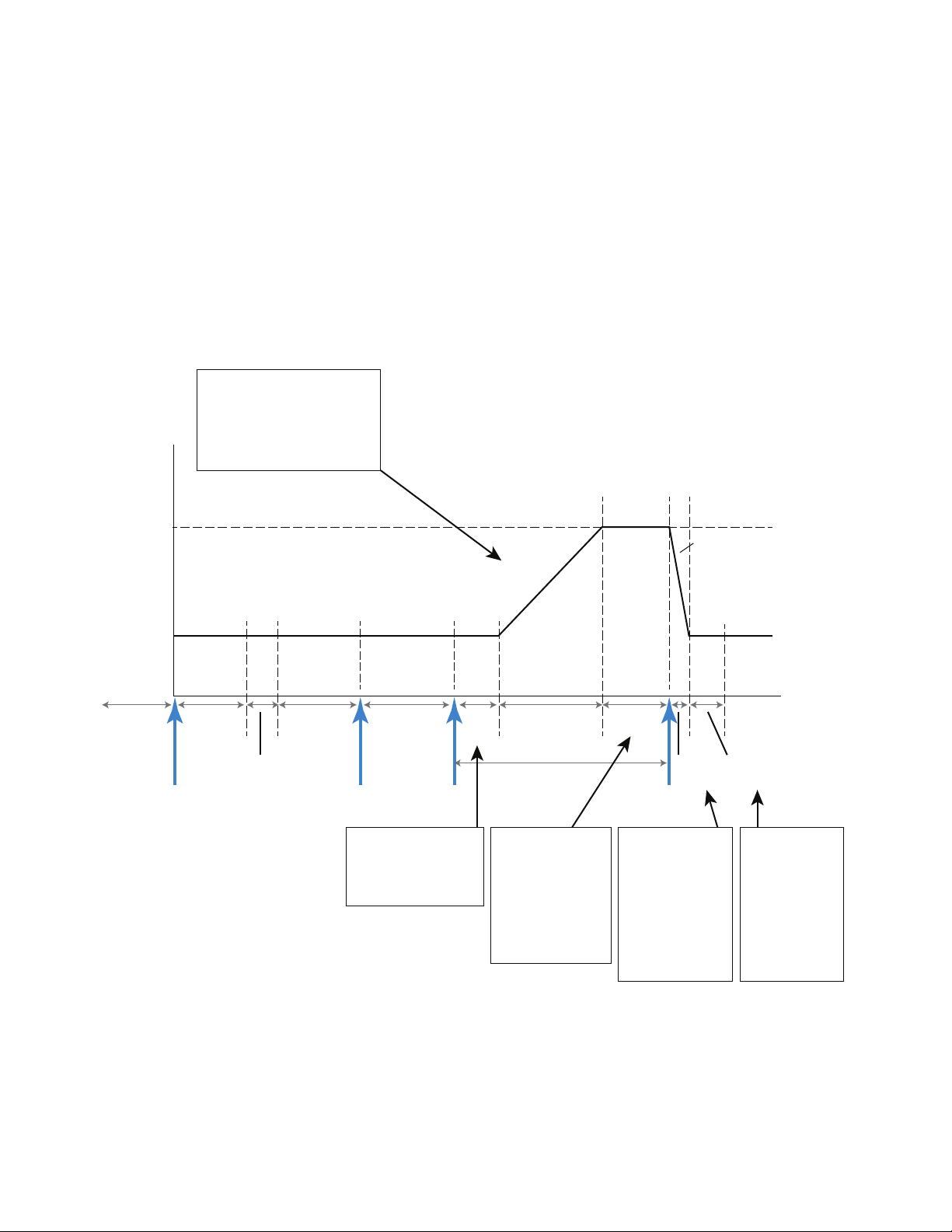

Micro GC Cycle with Constant Pressure

The timing diagram below provides an overview of the constant

pressure cycle of the Micro GC.

This description is only for one channel. In most cases a

dual-channel system is used. When a dual-channel system is

used, the sequence is the same, but the timing settings can

differ. If the sample time on channel A and channel B are

different, the longest time is used for both channels. Also the

run time can be specified per channel; the data acquisition

stops per channel as soon as the run time has elapsed. The total

analysis time depends on the longest run time.

26 490 Micro GC User Manual

Page 27

Micro GC Cycle with Ramped Pressure

Pressure

Time

Initial

pressure

Run started

Equilibration

time

Sample

time

Pressurization

time

Download

method

Inject time

Run time

Inject Start data

acquuisition

Run

finished

Final

pressure

Not ready

Pressure

release

Pressure

rise

Ready

Ready

Initial

time

Rise time Final time

Relieve

time

Stabilization

time

The remaining final time depends on the total run time, the duration of

the initial time and the pressure rise. This means that it is possible that

the final time is zero. Another situation is that the final pressure is

limited because of these settings. The software will check all parameter

values and change them into realistic values.

Note: During the run time, there can be only one pressure ramp to a

higher pressure.

The pressure rise is started,

the duration is depending on

two (2) parameters:

• Pressure rise

• Final pressure

Stabilization

time for the

pressure after it

has been

returned to the

initial pressure.

Fixed at 500 mS.

Relieve time, the

time needed to

decrease the

column head

pressure from the

final pressure to

the initial

pressure.

As soon as the

final pressure is

reached, the rise

stops and the final

time begins. The

pressure remains

the same.

During initial time

the column head

pressure remains

the same.

The timing diagram below provides an overview of the ramped

(programmed) pressure cycle of the Micro GC. The timing before

the injection is identical to the constant pressure cycle.

Instrument Overview 2

490 Micro GC User Manual 27

Page 28

2 Instrument Overview

28 490 Micro GC User Manual

Page 29

Agilent 490 Micro Gas Chromatograph

User Manual

3

Installation and Use

Pre-Installation Requirements 30

Inspect the Shipping Packages 30

Unpack the Micro GC 31

Review the Packing List 32

490 Micro GC Installation 33

Restore the Factory Default IP Address 38

Create the Test Method 40

Perform a Series of Runs 41

Shut Down Procedure 42

Long Storage Recovery Procedure 42

This chapter describes how to install and use the instrument.

For an initial installation, an example of a typical packing list is

also included. The actual packing list and included parts

depend on the options ordered.

Agilent Technologies

29

Page 30

3 Installation and Use

Pre-Installation Requirements

Prepare the installation site as described in the Site Preparation

Guide (G3581-90002), including the recommended Gas Clean

filters.

Inspect the Shipping Packages

The Micro GC will arrive in one large box and one or more

smaller cartons. Inspect the cartons carefully for damage or

signs of rough handling. Report damage to the carrier and to

your local Agilent office.

30 490 Micro GC User Manual

Page 31

Unpack the Micro GC

WARNING

CAUTION

Protective shipping

caps

Installation and Use 3

Unpack the Micro GC and accessories carefully and transfer

them to the work area using proper handling techniques.

Inspect the instrument and accessories carefully for damage or

signs of rough handling. Report damage to the carrier and to

your local Agilent office.

Avoid back strain or injury by following all safety precautions

when lifting heavy objects.

The instrument has been protected during shipment by protective caps.

See Figure 6. Before use, remove these caps, including those on the back

panel.

Figure 6 Protective shipping caps

490 Micro GC User Manual 31

Page 32

3 Installation and Use

Review the Packing List

Table 4 shows a typical packing list. The actual packing list and

included parts depend on the options ordered.

Table 4 Typical Micro GC packing list

Item Part number Quantity Units of

measure

Installation Kit Micro GC CP740388 1 EA

CD-ROM - Micro GC - User Information G3581-90010 1 EA

Ethernet crossover cable 2.8m CP740292 1 EA

Locking nut CP420200 4 EA

Male luer CP420100 4 EA

Fittings 1/8 inch Brass 20/pk 5080-8750 1 EA

Tee, 1/8 inch Brass Union 2/PK 5180-4160 1 PK

1/8 in x 0.065in Copper tubing G3581-20061 5 M

External Sample Filter kit CP736729 1 EA

Front and Back ferrule 1/16 CP471201 3 EA

1/16inch Ferrule set SST 0100-1490 3 EA

Stainless Nut 1/16 in 0100-0053 3 EA

Manual User Ext. Sample Filter CP505260 1 EA

Capil. Ext. Filter CP736879 1 EA

Tubing,SS,pre-tsd,1/16in. OD×1.0mm ID,

1/p

Tubing, SS,1/16in. OD×1.0mm ID, 1 mL,

1/p

Fingertight Fitting PEEK CP23050 1 EA

5 FILTERS for EXT. FILTER Assembly CP736467 1 EA

External Filter Male CP736737 1 EA

External Filter FeMale CP736736 1 EA

CP4008 80 MM

CP4009 0.080 M

Micro GC power supply, 12V, 150W G3581-60080 1 EA

32 490 Micro GC User Manual

Page 33

490 Micro GC Installation

Step 1: Connect carrier gas

Installation and Use 3

If you are installing the 490 Micro GC for the first time, follow

the steps as described below.

If you are performing a re-installation, see “Long Storage

Recovery Procedure” on page 42.

Install gas regulators and set pressures

Carrier gas cylinders should have a two-stage pressure regulator to

adjust the carrier gas pressure to 550 kPa ± 10 kPA (80 psi ± 1.5 psi).

Set cylinder regulator pressure to match the gas inlet pressure.

Connect carrier gas to the Micro GC

The Micro GC supports the use of helium, nitrogen, argon and

hydrogen. The recommended purity for carrier gas is 99.999 %

minimum. Connect the carrier gas to the Micro GC Carrier 1

fitting (and Carrier 2 fitting, if available) and turn on the gas

flow. See “Carrier Gas Connection” on page 21.

Step 2: Connect to calibration gas or checkout sample

Install the external filter unit as described in “Using the external

filter unit” on page 46.

For an unheated GC channel: Connect the sample to the Micro

GC using the sample-in connector situated at the front of the

instrument (see “Front View” on page 17).

For a heated GC channel: Connect the sample to the heated

sample as described in “How to connect your sample to the 490

Micro GC” on page 48.

Step 3: Install power supply

Connect the power connector to the Micro GC, and then plug the

power cord into an appropriate power source. See “Power” on

page 23. Ensure the power supply is placed in such a way that the

mains appliance inlet or adapter is easy to reach for the operator, as

it functions as a power disconnect switch.

The Power LED will light. The Ready LED lights when all parameter set

points in the system are reached. (See “Front View” on page 17.)

490 Micro GC User Manual 33

Page 34

3 Installation and Use

Step 4: Connect to computer or local network

Your Micro GC is shipped from the factory with default settings.

The following is relevant information on the factory default

states and settings:

• When the Micro GC is turned on, the power LED lights up

and the system begins the flush cycle procedure. The flush

cycle is a 2-minute cycle in which the various valves are

activated and deactivated to flush entrapped air from the

manifold, valves, and tubing.

• After the flush cycle is finished, the method (the default

method in this case), which was last active before the

instrument was shutdown, is activated.

• All heated zones are set at 30 °C.

• The detector filaments are set to OFF.

The 490 Micro GC requires a connection with a computer, that

has Chromatography Data System installed, for initial method

development. This connection uses TCP/IP over Ethernet or

Wi-Fi via USB. For more details and setup procedures see

“Ethernet Networks” on page 111 or “USB Wi-Fi” on page 118

Step 5: Install Chromatography Data System

For further instructions about installation of the

chromatography data system, see the corresponding

installation manual and help file.

Step 6: Assign IP address

Upon arrival from the factory, the Micro GC has a default static

IP address configured. The active IP address is specified on the

sticker together with the MAC address and the mainboard serial

number (see Table 5 on page 35).

34 490 Micro GC User Manual

Page 35

Installation and Use 3

DHCP Switch

Table 5 Factory default IP address settings

Default IP address 192.168.100.100

Subnet mask 255.255.255.0

Host name microgc

Default Gateway N/A (not used)

To complete this procedure, the Micro GC must be in static

1

IP address Mode. To verify this, be sure the DHCP switch

(indicated as 1 on the mainboard), is in the left position. The

DHCP switch is located on the back of the mainboard. (See

Figure 7).

490 Micro GC User Manual 35

Figure 7 DHCP Switch

2 Change the IP address of your laptop or PC to an address in

the same range as the current IP address as the Micro GC.

3 Start up your web browser.

4 Connect to the Micro GC’s website. Type the IP address of

the Micro GC in the address field of the web browser.

5 On the web page, click Network.

6 Log in as administrator. Use the factory default login and

password:

• Login name: admin

• Password: agilent

Page 36

3 Installation and Use

Figure 8 Web server authentication

7

In the network webpage, the upper section shows the

current IP configuration. Type the IP Address, Subnet mask,

and Gateway you want to assign to the Micro GC in the

corresponding fields.

Figure 9 Micro GC website

8 Click Save to save the IP configuration.

36 490 Micro GC User Manual

Page 37

Installation and Use 3

This IP address is now the active IP address.

9

Communication with the Micro GC will be lost, since the

active IP address has changed.

10 Change the IP address of your laptop or PC to an address in

the same range as the new IP address of the Micro GC.

11 To reestablish communication, type the new IP address in

the web browser address bar.

Step 7: Complete Micro GC configuration in Chromatography Data System

1 If not already configured, complete any additional

configuration for the Micro GC in the Chromatography Data

System. Ensure the carrier gas types match the gas actually

supplied to the Micro GC.

2 Start the Micro GC’s online instrument session.

490 Micro GC User Manual 37

Page 38

3 Installation and Use

Restore the Factory Default IP Address

Shipped from the factory, the 490 Micro GC (with mainboard

G3581-65000) is configured with a default static IP address, see

Table 6 on page 39 for the settings. A reset button on the

mainboard enables the possibility to restore these default IP

settings when required. When IP address setting are not known,

this functionality can be used to be able to reconnect to the

instrument and change to custom IP settings.

Figure 10 Reset button on mainboard

The reset button can be accessed behind the right panel on the

mainboard, see Figure 10. To restore the factory default IP

address, follow this procedure:

1 Power off the Micro GC.

2 Press and hold the reset button and power on the Micro GC.

3 Release the reset button shortly after powering on the GC

(approximately 3 seconds).

Note 1: When the reset button is released too quickly (less

than 1 second), it may result in the IP setting not reverting

to its factory defaults.

38 490 Micro GC User Manual

Page 39

Installation and Use 3

Note 2: Holding the reset button too long (more than

10 seconds), will result in an instrument reboot, without

restoring the default IP settings.

4 The default IP address is now restored. See Table 6 for

details.

Table 6 Factory default IP address settings

Default IP address 192.168.100.100

Subnet mask 255.255.255.0

Host name microgc

Default Gateway N/A (not used)

490 Micro GC User Manual 39

Page 40

3 Installation and Use

CAUTION

Create the Test Method

At first startup, perform a checkout to make sure the Micro GC

is functioning properly.

A test method for each standard column type has been provided

in the sections listed in Table 7.

If you ordered a Molsieve column, make sure it is conditioned before use.

See Tab le 10 on page 69 for parameters.

Table 7 Test method listings

Column type Table

Molsieve 5Å Table 10 on page 69

CP Sil 5 CB Table 11 on page 70

CP Sil CB Table 12 on page 71

PoraPlot 10 m Table 13 on page 72

Hayesep A 40 cm Table 14 on page 73

CO

1 m and AL2O3/KCI Table 15 on page 74

x

MES(NGA) and CP-WAX 52 CB Table 16 on page 75

Use the data system to set up the checkout parameters for each

GC channel. Apply the checkout method settings to the Micro

GC and allow the instrument to stabilize at the initial operating

conditions. Monitor the instrument status using the data

system’s status display (refer to the data system help for

details).

Each test method has been designed to determine if the

instrument channel is functioning properly and includes an

example test chromatogram.

40 490 Micro GC User Manual

Page 41

Perform a Series of Runs

Installation and Use 3

1 Create a short sequence of at least three runs using the test

sample and method.

2 Run the sequence.

3 After the first run, the results for each channel should

become similar to the example chromatograms.

490 Micro GC User Manual 41

Page 42

3 Installation and Use

CAUTION

Shut Down Procedure

The detector can be damaged by improper shut down. If shutting

down the instrument for more than a few days, carry out the procedure below.

1 Create a method for all channels with these settings:

• Filaments switched OFF.

• Column temperature set at 30 °C.

• Injector temperature set at 30 °C.

• Pressure set at 50 kPa.

2 Apply the method to the Micro GC.

3 Wait until the temperature of the columns and injectors are

< 40 °C (to protect the column), then switch off the Micro

GC.

4 Remove the carrier gas tubing and plug all the vents and

carrier gas connections with 1/8-inch brass nuts or plastic

caps.

Before using the instrument again, perform the “Long Storage

Recovery Procedure” described below.

Long Storage Recovery Procedure

Follow this recovery procedure if your Micro GC has been

stored for a long period of time.

1 Remove the 1/8-inch brass nuts and plastic caps from all of

the vents and carrier gas connections.

2 Connect the carrier gas tubing and apply pressure to the

Micro GC. Refer to the Site Preparation Guide for supply

pressures and other gas requirements.

3 Wait at least 10 minutes before switching ON the Micro GC.

4 Immediately check if the detector filaments are switched

OFF. Switch OFF if necessary.

42 490 Micro GC User Manual

Page 43

Installation and Use 3

Set the column(s) temperature(s) to the maximum allowed

5

temperature (160 °C or 180 °C depending on the column

limit).

6 Condition the GC column, preferably overnight. This will

ensure that all the water has been removed from the column

module and no damage will occur to the TCD filaments.

490 Micro GC User Manual 43

Page 44

3 Installation and Use

44 490 Micro GC User Manual

Page 45

Agilent 490 Micro Gas Chromatograph

CAUTION

User Manual

4

Sample Gas Handling

Using the external filter unit 46

Heated sample lines 47

How to connect your sample to the 490 Micro GC 48

490-Micro GC Optional Pressure Regulators 53

Manual Injection 59

The Micro GC is built for the analysis of gases and vapors only.

You are advised to prepare a noncondensing gaseous standard

sample for routine checkup of the instrument. Sample pressure

should be between 0 and 100 kPa (0 to 15 psi), the temperature

between 0 and 110 °C ± 5 °C of the analyzer ambient

temperature, and it must be filtered, preferably through a 5-mm

filter. Agilent always recommends the use of the external filter

kit (CP736729) between the injector and the sampling device.

For more details, see “Using the external filter unit” on page 46.

Liquids will seriously damage the instrument and should be avoided!

Agilent Technologies

45

Page 46

4 Sample Gas Handling

Filter female

(CP736736)

Filter male

(CP736737)

From

sample line

Filter element 5 microns

(CP736467, 5 pieces)

To “Sample In”

Micro GC

1/16-inch nut

Finger tight fitting

(CP23050)

1/16-inch nut

From

sample line

Filter element 5 microns

(CP736467, 5 pieces)

1/16-inch nut

1/16 inch nut and

front and back ferrule

Filter female

(CP736736)

Filter male

(CP736737)

To ”Sa mpl e In”

Micro GC

1/16-inch nut

Using the external filter unit

The male part of the filter must be hand-tightened into the

female part, followed by a 1/8 turn with a 7/16-inch wrench. See

Figure 11 as shown below and Figure 12 on page 46. Orient the

arrow on the female half of the filter towards the fingertight

fitting.

Replace the external filter unit at regular intervals. See “Review

the Packing List” on page 32 for part numbers.

Figure 11 Unheated injector connection

Figure 12 Heated injector connection

Whenever possible, remove moisture from samples introduced

to the Micro GC.

46 490 Micro GC User Manual

Page 47

Heated sample lines

Sample Gas Handling 4

A heated sample line is always combined with a heated injector.

A heated injector and sample line is an option for a channel

unit, and is used to prevent sample from condensing in the

sample lines when analyzing condensable samples.

The heated sample and injector can be controlled between 30 °C

and 110 °C.

490 Micro GC User Manual 47

Page 48

4 Sample Gas Handling

WARNING

Male 1/16-inch

Swagelok fitting

CAUTION

How to connect your sample to the 490 Micro GC

The following sections describe how to connect your sample to

the 490 Micro GC depending on the sample inlet configuration.

The metal surfaces of the sample line heater can be very hot.

Before connecting a sample line, allow the sample line heater to

cool down to ambient temperature.

Rear inlet (heated or unheated)

Connect the sample line to the heated or unheated sample inlet

at the rear of the Micro GC using 1/16-inch male Swagelok

fittings.

Figure 13 Rear sample inlet

Insulate the sample line connected to the Micro GC to prevent damage to

communications cables.

48 490 Micro GC User Manual

Page 49

Internal inlet

Internal sample inlet –

1/16-inch Swagelok fitting

Sample Gas Handling 4

For connecting the micro-gasifier, Enrichment and Desorption

Unit (EDU) and a heat-traced sample line, the system's internal

sample inlet should be used.

Figure 14 Open the side panel, remove the top insulation and loosen the internal sample inlet.

490 Micro GC User Manual 49

Figure 15 Remove the rear panel by unscrewing the three bolts.

Page 50

4 Sample Gas Handling

Internal sample inlet –

1/16-inch Swagelok fitting

Figure 16 Remove the PEEK block by unscrewing two bolts.

Figure 17 Install the back panel and micro-gasifier, and connect the

micro-gasifier sample line to the internal sample inlet using a

1/16-inch Swagelok fitting.

50 490 Micro GC User Manual

Page 51

Sample Gas Handling 4

Micro-gasifier vent – 1/16-inch Swagelok fitting

Micro-gasifier sample inlet – 1/16-inch Swagelok fitting

Figure 18 Sample line and vent line connection of the micro-gasifier.

Internal bracket for Genie filter

This section explains how to connect your sample if an optional

internal bracket with Genie filter(s) is installed on your 490

Micro GC.

Connect the sample line to the rear inlet of the 490 Micro GC

using 1/16-inch Swagelok fittings. The Genie filter outlet is

pre-plumbed and connected to the Micro GC column channels.

490 Micro GC User Manual 51

Page 52

4 Sample Gas Handling

Bolts for membrane

Genie filter

Bypass

Rear sample inlet -

Inspection and exchange

1/16-inch Swagelok fitting

CAUTION

Figure 19 Internal bracket with Genie filters.

Ensure separated liquids are properly drained via the bypass tubing outside of the Micro GC. To operate properly, the bypass must remain free of

blockage.

To access the Genie filter membrane for inspection or exchange,

unscrew the two bolts, identified in Figure 19, and lift the upper

part of the filter.

52 490 Micro GC User Manual

Page 53

490-Micro GC Optional Pressure Regulators

Agilent offers two optional sample inlet pressure regulator

assemblies for the 490-PRO Micro GC. These assemblies are

provided fully assembled and require field installation on the

rear of the GC.

G3581-S0003 provides a pressure regulator, Genie filter (for

sample drying) and needle valve, along with the required

mounting bracket and hardware required for installation.

G3581-S0004 provides a pressure regulator and needle valve,

along with the required mounting bracket and hardware

required for installation.

Installation instructions for both assemblies are provided

below.

G3581-S0003

Sample Gas Handling 4

The Agilent pressure regulator assembly (G3581-S0003)

provides a pressure regulator, Genie filter (for sample drying)

and needle valve, along with the required mounting bracket and

hardware required for installation.

Figure 20 shows the components and connection points for the

Agilent pressure regulator assembly (G3581-S0003).

Dried sample to

analytical channels -

rear sample inlet of GC

Out

Genie 170

In Vent

Pressure

regulator

Sample

IN

Needle

valve

Sample

OUT

(Drain)

Figure 20 Agilent pressure regulator assembly (G3581-S0003) functional

block diagram

490 Micro GC User Manual 53

Page 54

4 Sample Gas Handling

NOTE

WARNING

The pressure regulator is factory set, and has been tested to the

following, fixed specifications:

Attribute Specification

Input 25 bar (2.5 Mpa)

Output 0.7 bar (10.1 psi or 70 Kpa)

Flow 20 mL/min

The sample flows through the pressure regulator and into the

Genie filter. Dried sample is then applied to the rear sample

inlet of the GC.

The minimum working pressure of the Genie filter is 0.5 bar. Sample will

not flow through the filter if this working pressure is not maintained.

Vented sample flows through a needle valve for draining.

G3581-S0003 Installation

The G3581-S0003 pressure regulator assembly is supplied fully

assembled, and ready to install at the rear of the GC. To install

the assembly, do the following:

1 Shut down the GC, and allow the column and injector to

cool. See “Shut Down Procedure” on page 42.

The metal surfaces of the column, injector and sample inlet can be

very hot. Before connecting a sample line, allow the GC

components to cool to ambient temperature.

2 At the rear of the GC, disconnect any existing sample line

from the rear sample inlet.

54 490 Micro GC User Manual

Page 55

Sample Gas Handling 4

Rear sample inlet

Lower mounting

bolt

Sample IN

Needle valve

Sample OUT

(drain)

Sample to rear

sample inlet

Figure 21 Rear sample inlet and lower mounting bolt

Remove the lower mounting bolt from the rear panel of the

3

GC.

4 Position the G3581-S0003 pressure regulator assembly at

the rear of the GC, and secure using the lower mounting

bolt.

Figure 22 G3581-S0003 pressure regulator assembly installed

490 Micro GC User Manual 55

5 Connect the filter outlet to the sample inlet on the rear of

the GC using a 1/16 inch Swagelok fitting.

Page 56

4 Sample Gas Handling

WARNING

G581-S0004

The pressure regulator has a maximum inlet pressure of 3,000 psi.

Applying higher pressures may result in serious personal injury

and equipment damage.

6

Connect the Sample IN port on the pressure regulator to the

sample input line.

7 Start the GC (see “Long Storage Recovery Procedure” on

page 42).

8 Leak test the system to ensure that all connections are leak

free.

G3581-S0004 provides a pressure regulator and needle valve,

along with the required mounting bracket and hardware

required for installation.

The block diagram below shows the components and connection

points for the G3581-S0004 pressure regulator assembly.

Sample to rear sample

inlet of GC

Pressure

regulator

Sample

IN

Needle

valve

Sample

OUT

(Drain)

Figure 23 G3581-S0004 pressure regulator assembly functional block

diagram

The pressure regulator is factory set and has been tested to the

following, fixed specifications:

Attribute Specification

Input 25 bar (2.5 Mpa)

Output 0.7 bar (10.1 psi or 70 Kpa)

Flow 20 mL/min

The sample flows through the pressure regulator and into the

rear sample inlet of the GC.

A needle valve provides for venting the sample for draining.

56 490 Micro GC User Manual

Page 57

Sample Gas Handling 4

WARNING

Rear sample inlet

Lower mounting

bolt

G3581-S0004 Installation

The G3581-S0004 sample inlet pressure regulator assembly is

supplied fully assembled and ready to install at the rear of the

GC. The install the assembly, do the following:

1 Shut down the GC and allow the column and injector to cool.

See “Shut Down Procedure” on page 42.

The metal surfaces of the column, injector and sample inlet can be

very hot. Before connecting a sample line, allow the GC

components to cool to ambient temperature.

2 At the rear of the GC, disconnect any existing sample line

from the rear sample inlet.

Figure 24 Rear sample inlet and lower mounting bolt

3 Remove the lower mounting bolt from the rear panel of the

GC.

490 Micro GC User Manual 57

Page 58

4 Sample Gas Handling

Sample IN

Needle valve

Sample OUT

(drain)

Sample to rear

sample inlet

WARNING

4

Position the G3581-S0004 assembly at the rear of the GC and

the secure using the lower mounting bolt.

Figure 25 G3581-S0004 installed

5 Connect the regulator outlet to the sample inlet on the rear

of the GC using a 1/16 inch Swagelok fitting.

The pressure regulator has a maximum inlet pressure of 3,000 psi.

Applying higher pressures may result in serious personal injury

and equipment damage.

6 Connect the Sample IN port on the pressure regulator to the

sample input line.

7 Start the GC (see “Long Storage Recovery Procedure” on

page 42).

8 Leak test the system to ensure that all connections are leak

free.

58 490 Micro GC User Manual

Page 59

Manual Injection

Front sample inlet –

1/16-inch fitting (internal)

Sample Gas Handling 4

Manual injection is possible with the optional front inlet

installed that can accommodate a 1/16-inch sample line. Refer

to the Agilent 490 Micro GC Manual Injection Port Field Kit

documentation (G3581-90000) for detailed information.

Figure 26 Front inlet (unheated)

Manual injection guidelines

• Use sample pump mode and set sampling time 10-20 seconds

in the method. This clearly marks when injector loop is

flushed (sound of the pump). Then gently push the syringe

during that period.

• Flush the sample path 6-10 times. Bulkhead union,

additional tubing, pressure relieve valve, and ball valve adds

dead volume to the system, estimated at 500 to 1000 µl.

• Total sample volume is dependent on the internal volume of

the Micro GC (option# 060-063 have different internal

volumes) and the number of times flushed and the sampling

time in the method.

490 Micro GC User Manual 59

Page 60

4 Sample Gas Handling

NOTE

Injection Procedure

1 Use pump mode (configuration)

2 Measure total pump flow (rear of the instrument)

3 Calculate required pump time that sample path is flushed

sufficiently (6 to 10 times)

4 Initiate sequence in software, use manual trigger type in

method (OLCDS)

5 Insert or connect syringe and start the run

6 Gently inject when pump starts to aspirate

When performing manual injection with a luer lock valve, use

a10 ml gas tight syringe (Agilent p/n 5190-1543: syringe 10 ml,

PTPE, luer lock valve).

There may be unique syringe requirements when performing

Septum nut injection.

Field upgrade kits

The manual syringe injection would lead to increase the repeatibiltiy

(RSD%) compared to automated pump or continous flow mode.

Table 8 Field upgrade kits

Option PN (Field upgrade kit) Description

Opt# 060 CP490204 Septum nut injection port

Opt# 061 CP490205 Luer lock injection port

Opt# 062 CP490206 Septum nut injection port and

standard sample inlet (incl. ball

valve)

Opt# 063 CP490207 Luer lock injection port and

standard sample inlet (incl. ball

valve)

60 490 Micro GC User Manual

Page 61

Manual injection flow diagrams

Relief Valv e

Sample-in

connector

Septum nut for

syringe injection

Sample Gas Handling 4

Figure 27 CP742701 Septum Nut for Syringe

490 Micro GC User Manual 61

Page 62

4 Sample Gas Handling

Relief Valve

Sample-in

connector

Luer lock

injection port

Relief Valve

3/2 Ball Valv e

Manual select

syringe- or

standard

injection

Sample-in

connector

Standard

Sample inlet

Septum nut for

syringe injection

Figure 28 CP742702 Luer lock injection port

Figure 29 CP742703 Septum Nut for Syringe, Selectable

62 490 Micro GC User Manual

Page 63

Sample Gas Handling 4

Relief Valve

3/2 Ball Valv e

Manual select

syringe- or

standard

injection

Sample-in

connector

Luer lock

injection port

Standard

Sample inlet

Figure 30 CP742703 Luer lock injection port, Selectable

490 Micro GC User Manual 63

Page 64

4 Sample Gas Handling

64 490 Micro GC User Manual

Page 65

Agilent 490 Micro Gas Chromatograph

User Manual

5

GC Channels

Carrier Gas 66

Micro Electronic Gas Control (EGC) 67

Inert Sample Path 67

Injector 67

Column 68

Backflush Option 77

Backflush to Detector 82

TCD Detector 88

The instrument contains up to 2 channels in a dual channel

cabinet, or up to 4 channels for a quad channel cabinet. A GC

channel contains a gas regulator, an injector, a column, and a

TCD detector. See Figure 31 on page 66.

This chapter provides a brief discussion on the major

components in the Micro GC and the backflush option.

Agilent Technologies

65

Page 66

5 GC Channels

CAUTION

Carrier gas

Gas Clean unit

(optional)

Microelectronic

gas control

(EGC)

µTCD

Reference vent

Injector

Columns

(analytical and

reference)

Column vent

Sample Out

Sample

in

Carrier Gas

The Micro GC is configured for use with either He and H2 or

and Ar.

N

2

Agilent recommends you use gases with a minimum purity of

99.999 %. Since the injection valve is operated pneumatically,

there is a limit of 550 kPa ± 10 kPA (80 psi ± 1.5 psi) to the main

gas supply.

Your Micro GC is configured either for carrier gas He and H2 or N2 and Ar.

Use the carrier gas type for which your instrument is configured, otherwise

the detector filaments can be damaged.

Figure 31 Gas flow diagram

66 490 Micro GC User Manual

Page 67

Micro Electronic Gas Control (EGC)

The Micro GCs have built-in regulators that can be adjusted to

get a constant or programmed pressure control, which, once

constant or programmed pressure control is obtained, results in

a constant or programmed flow through the injector, column

and detector. The pressure range is from 50 to 350 kPa (7 to

50 psi). This pressure sets a continuous flow of carrier gas of

about 0.2 to 4.0 mL/min (depending on column length and

type).

A typical pressure rise is 200 kPa/min, which will give a

significant pressure increase during the run without excessive

baseline disturbance. In most cases baseline subtraction may

improve the quality of chromatograms that suffer from baseline

drift.

Inert Sample Path

GC Channels 5

Injector

The 490 Micro GC is equipped with an UltimetalTM-treated

sample path. This deactivation method ensures the integrity of

the sample and helps to achieve the best detection limits

possible.

The deactivation is applied to tubing running from the sample

inlet to the injector.

The injector has a built-in 10-µL sample loop that is filled with

the gaseous sample. The pressure of the sample should be

between 0 and 100 kPa (0 to 15 psi) and the sample temperature

within 5 to 110 °C ± 5 °C of the analyzer.

When the chromatographic data system sends a START

command, the vacuum pump draws the gas sample through the

loop and the injector injects the gas sample from the sample

loop into the gas stream. A typical injection time is 40

milliseconds (ms). This equals an average injection volume of

200 nL. Injection time will be rounded to a multiple of 5 ms. A

practical minimum value is 40 ms. A value of 0 to 20

milliseconds might result in no injection.

490 Micro GC User Manual 67

Page 68

5 GC Channels

CAUTION

Column

A variety of column configurations are possible on the Micro

GC. The columns you require for your specific analyses have

been installed at the factory. Other configurations are, of

course, possible, but altering the GC channels is a delicate

matter that can only be handled by an Agilent service engineer.

Table 9 shows several standard columns as supplied in the

Micro GCs and selected applications. Other columns are

available by contacting Agilent Technologies.

Table 9 Agilent Micro GC columns and applications

Column/Phase type Target components

Molsieve 5Å Permanent gases (N

for O

-Ar baseline separation). Natural gas and biogas analysis. Optional Retention

2

separation), methane, CO, NO, and so forth. 20 m required

2/O2

Time Stability (RTS) configuration.

Hayesep A Hydrocarbons C

CP-Sil 5 CB Hydrocarbons C

CP-Sil 19 CB Hydrocarbons C

, N2, CO2, air, volatile solvents, natural gas analysis.

1–C3

, aromatics, organic solvents, natural gas analysis.

3–C10

, high boiling solvents, BTX.

4–C10

CP-WAX 52 CB Polar volatile solvents, BTX.

PLOT Al

PoraPLOT U Hydrocarbons C

/KCl Light hydrocarbons C1–C5 saturated and unsaturated. Refinery gas analysis.

2O3

, halocarbons/freons, anesthetics, H2S, CO2, SO2, volatile

1–C6

solvents. Separation of ethane, ethylene, and acetylene.

PoraPLOT Q Hydrocarbons C

, halocarbons/freons, anesthetics, H2S, CO2, SO2, volatile

1–C6

solvents. Separation of propylene and propane, coelution of ethylene and acetylene.

CP-CO

CO, CO2, H2, Air (coelution of N2 and O2 ), CH4.

X

CP-Sil 19CB for THT THT and C

CP-Sil 13CB for TBM TBM and C

+

in Natural Gas Matrix.

3–C6

+

in Natural Gas Matrix.

3–C6

MES NGA Unique column specially tested for MES in natural gas (1 ppm).

All columns except the HayeSep A (160 °C) and MES (110 °C) columns can

be used up to 180 °C, the maximum temperature of the column oven.

Exceeding this temperature will cause the column to lose efficiency

instantly and the column module will need replacement. All channels have

a built-in protection that prevents a setpoint above the maximum temperature.

68 490 Micro GC User Manual

Page 69

GC Channels 5

mV

Molsieve 5Å 4 m heated

0

2

4

6

8

10

12

14

Seconds

1

2

3

0 5 10 15 20 25

Molsieve 5Å 10 m unheated

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

seconds

mV

1

2

3

4

5

0 20 40 60 80 100 120 140 160

Molsieve 5Å 20 m unheated

0

50

100

150

200

250

300

350

400

450

mV

Seconds

4

3

2

5

1

0 50 100 150 200 250

Molsieve 5Å columns

The Molsieve 5Å column is designed to separate: hydrogen,

carbon monoxide, methane, nitrogen, oxygen, and some noble

gases. Higher molecular weight components have much higher

retention times on this column.

Table 10 Molsieve 5Å instrument parameters

Parameter 4m Heated 10m Unheated 20m Unheated

Column temperature 110°C 40°C 40 °C

Injector temperature 110°C NA NA

Column pressure 100 kPa (15 psi) 150 kPa (21 psi) 200 kPa (28 psi)

Sample time 30 s 30 s 30 s

Injection time 40 ms 40 ms 40 ms

Run time 25 s 140 s 210 s

Detector sensitivity Auto Auto Auto

Peak 1 Hydrogen 1.0 % Neon 18 ppm Neon 18 ppm

Peak 2 Argon/Oxygen 0.4 % Hydrogen 1.0 % Hydrogen 1.0 %

Peak 3 Nitrogen 0.2 % Argon 0.2 % Argon 0.2 %

Peak 4 _________ Oxygen 0.2 % Oxygen 0.2 %

Peak 5 _________ Nitrogen 0.2 % Nitrogen 0.2 %

490 Micro GC User Manual 69

Page 70

5 GC Channels

-5

5

15

25

35

45

55

05

Seconds

mV

CP Sil 5 CB 4 m heated CP Sil 5 CB 6 m unheated

12

3

4

5

10 15 20 25 30 35

-1

4

9

14

19

24

29

34

mV

Seconds

1

4

5

010 2030 40506070

3

2

CP-Sil 5 CB columns

The natural gas components, mostly hydrocarbons, separate in

the same order on the non-polar and medium-polar CP-Sil CB

columns. Nitrogen, methane, carbon dioxide, and ethane are not

separated on these columns. They produce a composite peak.

For separation of these components, consider a HayeSep A

column.

Table 11 CP-Sil 5 CB instrument parameters

Parameters 4m Heated 6m Unheated

Column temperature 50 °C 50 °C

Injector temperature 110 °C NA

Column pressure 150 kPa (21 psi) 150 kPa (21 psi)

Sample time 30 s 30 s

Injection time 40 ms 40 ms

Run time 30 s 30 s

Detector sensitivity Auto Auto

Peak 1 Composite Balance Composite Balance

Peak 2 Ethane 8.1 % Ethane 8.1 %

Peak 3 Propane 1.0 % Propane 1.0 %

Peak 4 i-Butane 0.14 % i-Butane 0.14 %

Peak 5 n-Butane 0.2 % n-Butane 0.2 %

70 490 Micro GC User Manual

Page 71

CP-Sil CB columns

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

Seconds

mV

CP Sil 13 CB

12 m heated (TBM)

CP Sil 19 CB

6 m unheated (THT)

1

2

0 102030405060708090

mV

-2

-1.5

-1

-0.5

0

0.5

Seconds

1

2

3

0 102030405060

Table 12 CP-Sil CB instrument parameters

Parameter CP-Sil 13 CB 12m Heated (TBM) CP-Sil 19 CB 6m Heated (THT)

Column temperature 40°C 85 °C

Injector temperature 50°C 85 °C

Column pressure 250 kPa (38 psi) 200 kPa (25 psi)

Sample time 30 s 30 s

Injection time 255 ms 255 ms

Run time 80 s 35 s

Detector sensitivity Auto Auto

Peak 1 Methane balance Helium balance

Peak 2 TBM 6.5 ppm THT 4.6 ppm

GC Channels 5

Peak 3 ________ n-Decane 4.5 ppm

490 Micro GC User Manual 71

Page 72

5 GC Channels

mVmV PoraPlot Q 10 m heatedPoraPlot U 10 m heated

SecondsSeconds

-20

80

180

280

380

480

580

680

1

4

3

2

5

1

4

3

2

5

0102030405060

50

45

40

35

30

25

20

15

10

5

2 6 10 14 18 22 26 30 34 38 42 46 50

0

PoraPlot 10m column

Table 13 PoraPlot 10m instrument parameters

Parameter PoraPlot u 10m Heated PoraPlot Q 10m Heated

Column temperature 150°C 150 °C

Injector temperature 110°C 110 °C

Column pressure 150 kPa (21 psi) 150 kPa (21 psi)

Sample time 30 s 30 s

Injection time 40 ms 40 ms

Run time 100s 50 s

Detector sensitivity Auto Auto

Peak 1 1 Composite Balance

Peak 2 2 Ethane 8.1 %

72 490 Micro GC User Manual

Peak 3 3 Propane 1.0 %

Peak 4 4 i-Butane 0.14 %

Peak 5 5 n-Butane 0.2 %

Page 73

Hayesep A 40 cm heated column

WARNING

The HayeSep A column separates oxygen, methane, carbon

dioxide, ethane, acetylene, ethylene, and selected sulfur gases.

Nitrogen coelutes with oxygen. Components with a higher

molecular weight than propane have long retention times on

this column.

Maximum allowable column temperature is 160 °C.

Table 14 Hayesep instrument parameters

Parameter Hayesep A 40 cm Heated

Column temperature 50 °C

Injector temperature 110 °C

Column pressure 150 kPa (21 psi)

Sample time 30 s

GC Channels 5

Injection time 40 ms

Run time 60 s

Detector sensitivity Auto

Peak 1 Nitrogen 0.77 %

Peak 2 Methane Balance

Peak 3 Ethane 8.1 %

mV Hayesep A 40 cm heated

345

295

245

195

145

95

45

-5

2

1

0 10203040506070

3

Seconds

490 Micro GC User Manual 73

Page 74

5 GC Channels

COX and AL203/KCI columns

Table 15 COX and Al203/KCI instrument parameters

Parameter COX 1m Unheated AL203/KCI 10m Heated

Column temperature 80 °C 100

°C

Injector temperature NA 110 °C

Column pressure 200 kPa (28 psi) 150 kPa (21 psi)

Sample time 30 s 30 s

Injection time 40 ms 40 ms

Run time 204 s 60 s

Detector sensitivity Auto Auto

Peak 1 Hydrogen 1.0 % Composite Balance

Peak 2 Nitrogen 1.0 % Ethane 8.1 %

Peak 3 CO 1.0 % Propane 1.0 %

Peak 4 Methane 1.0 % i-Butane 0.14 %

Peak 5 CO

1.0 % n-Butane 0.2 %

2

Helium Balance

Seconds

mV

115

1

2

95

75

55

35

15

-5

0 10203040506070

3

5

4

Seconds

mV

COX 1 m unheated Al2O3/KCl 10 m heated

3.5

2

3

3

2.5

2

1.5

1

0.5

1

0

-0.5

0 50 100 150 200 250

4

5

74 490 Micro GC User Manual

Page 75

MES (NGA) and CP-WAX 52 CB columns

-500

0

500

1000

1500

2000

2500

3000

3500

4000

mV MES 10 m heated (NGA) CP-WAX 52 CB 4 m heated

Seconds

1

0

20 40 60 80 100 120 140

-0.3

0.1

0.5

0.9

2

3

80 90 100 110 120 130

-2

3

8

13

mV

Seconds

1

4

3

2

1 6 11 16 21 26 31 36

Table 16 MES (NGA) and CP-WAX 52 CB instrument parameters

Parameter MES 10m Heated (NGA) CP-WAX 52 CB 4m Heated

Column temperature 90 °C 60 °C

Injector temperature 110 °C 110 °C

Column pressure 70 kPa (10 psi) 150 kPa (21 psi)

Sample time 30 s 30 s

Injection time 500 ms 40 ms

Run time 120 s 35 s

Detector sensitivity Auto Auto

Peak 1 Nitrogen Balance Nitrogen 0.75 %

Peak 2 n-Decane 11.2 ppm Acetone 750 ppm