Page 1

Agilent 4396B

Analyzer

User's Guide

Network/Spectrum/Impedance

SERIAL

This

manual applies

number

NUMBERS

directly to

prex JP1KE.

instruments which

have

the

serial

Agilent Part No. 04396-90051

Printed in Japan May 2003

Fifth Edition

Page 2

c

Copyright 1997, 2000, 2002, 2003 Agilent Technologies Japan, Ltd.

Page 3

Manual Printing

History

The manual

edition. The

printing date

printing date

(Minor corrections

cause the

date to

extensive technical

March 1997

July 1997

March 2000

::

::

::

:

::

:

:

:

November 2002

May 2003

:

:

:

:

:

and part

changes when

and updates

change.)

changes are

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

that are

The

manual

incorporated.

:

:

:

First

Second

:

:

Third

F

ourth

:

:

Fifth

number indicate

a new

edition is

incorporated at

part

number

Edition

Edition

Edition

Edition

Edition

(part

number:

(part

number:

(part number:

(part

number:

(part number:

its current

printed.

reprint do

changes

04396-90021)

04396-90031)

04396-90031)

04396-90041)

04396-90051)

not

when

iii

Page 4

Certication

Warranty

Agilent

specications

T

echnologies further

traceable

T

echnology,

facility

Organization

This

defects

the

listed

be

T

echnologies

prove to

For

service facility

Technologies

,or

Agilent T

in material

date

of

in

General

for

the

be

warranty

at the

to the

to the

to the

members.

echnologies

shipment,

specied

will,

defective

service

designated by

United States

shipping charges

shall pay

Buyer shall

returned to

shipping

pay

Agilent

all

certies that

time of

certies that

this product

shipment from

its calibration

National Institute

extent allowed

by the

calibration facilities

instrument

and

workmanship

except

Information

period.

at

its

During

option,

that

of

either

in

this

.

or

repair

,

this

Agilent

to

Agilent

charges

shipping

T

echnologies

T

echnologies

to

return

charges

from

met its

the factory

measurements are

of Standards

Institution's calibration

of other

product

for

the

manual,

the

warranty

repair

product

T

echnologies

the

,

duties

another

International

is

a

period

case

of

or

must

and

Agilent

product

,

and

warranted

of

certain

the

warranty

period,

replace

be

.

to

taxes

country

published

. Agilent

one

year

components

Agilent

products

returned

Buyer

Buyer

shall

T

echnologies

.

for

products

.

and

Standards

against

from

shall

that

to

a

prepay

However

,

Limitation

Of

W

arranty

Agilent

designated

execute

instrument.

of

error

The

improper

software or interfacing, unauthorized modication or misuse

T

its

the

instrument,

free

foregoing

echnologies

by

Agilent

programming

Agilent

.

warranty

or

inadequate

warrants

T

echnologies

instruction

T

echnologies

or

software

shall

maintenance

that

,

not

or

its

software

for

use

when

does

not

rmware

apply

to

by

with

property

warrant

will

defects

Buyer

and

rmware

an

instrument

installed

that

the

be

uninterrupted

resulting

,

Buyer-supplied

will

on

that

operation

or

from

,

operation outside the environmental specications for the product, or

improper site preparation or

No other warranty is expressed

specically disclaims the implied warranties of

tness for a particular purpose

maintenance.

or implied. A

.

gilent Technologies

merchantability and

iv

Page 5

Exclusive Remedies

Assistance

The remedies

remedies.

indirect, special,

on contract,

provided herein

Agilent

Technologies

incidental, or

tort, or

Product maintenance

agreements are

F

or

any

assistance

and

Service

available for

,

contact

Oce

.

are buyer's

any other

agreements and

Agilent

your

A

ddresses

are

sole and

shall not

be liable

for any

consequential damages

legal

theory

.

other

customer

T

echnologies

nearest

provided

Agilent

at

products

T

echnologies

the

back

exclusive

direct,

, whether

assistance

.

of

this

based

Sales

manual.

v

Page 6

Safety

Summary

The

following general

phases

comply

in

In

intended

The

failure

of operation,

with these

this manual

addition it

use of

Agilent

to comply

safety precautions

service,

precautions or

may impair

violates safety

the instrument.

Technologies

with these

and repair

with specic

the protection

standards of

assumes no

requirements.

must be

of this

observed during

instrument. F

WARNINGS

provided by

design, manufacture

liability for

the

all

ailure to

elsewhere

the equipment.

,and

customer's

Ground

DO

NOT

K

eep

A

The

Operate

way

Note

Note

Instrument

In

An

From

Live

4396B

DEGREE

LEDs

CLASS

T

o

avoid electric

must

cable

Explosive

Do

not

fumes

constitutes

Circuits

Operating

replacement

maintenance

cable

exist

disconnect

comply

2

in

IEC1010-1.

in

this

product

1

LED

be

connected to

with

earth blade

Atmosphere

operate

.

Operation

a

denite

personnel

and

personnel.

connected.

even

with

power

with

INST

are

PRODUCT

shock hazard,

a safety

.

the

instrument

of

any

safety

must

internal

Under

the

power

and

discharge

ALLA

TION

4396B

Class

are

1

in

the instrument

earth ground

in

electrical

hazard.

not

remove

adjustments

Do

not

replace

certain

cable

conditions

removed.

circuits

CA

TEGORY

INDOOR

USE

accordance with

by the

the

presence

instrument

in

instrument

must

be

components

,

dangerous

T

o

avoid injuries

before

II

and

product.

IEC825-1.

chassis

supplied

of

ammable

such

covers

made

by

with

touching

POLLUTION

and

cabinet

power

gasses

an

environment

.

Component

qualied

the power

voltages

may

, always

them.

or

DO

NOT

DO NOT

vi

Service

Or

Substitute P

A

djust Alone

Do not attempt internal service or adjustment unless another person,

capable of rendering rst aid and resuscitation, is present.

arts Or Modify Instrument

Because of the danger of introducing additional hazards

install substitute parts or perform unauthorized modications to the

instrument. Return the instrument to a Agilent T

Service Oce for service and repair to ensure that safety features are

maintained.

, do not

echnologies Sales and

Page 7

Dangerous

Procedure

W

arnings

W

procedures

warnings

arnings

,

such

as

throughout

must

be

the

example

this

followed.

below

manual.

,

precede

Instructions

potentially dangerous

contained

in the

W

arning

Dangerous voltages

instrument. Use

adjusting this

extreme caution

instrument.

,

capable

of

causing

when handling,

death,

are

testing,

present

in

and

this

vii

Page 8

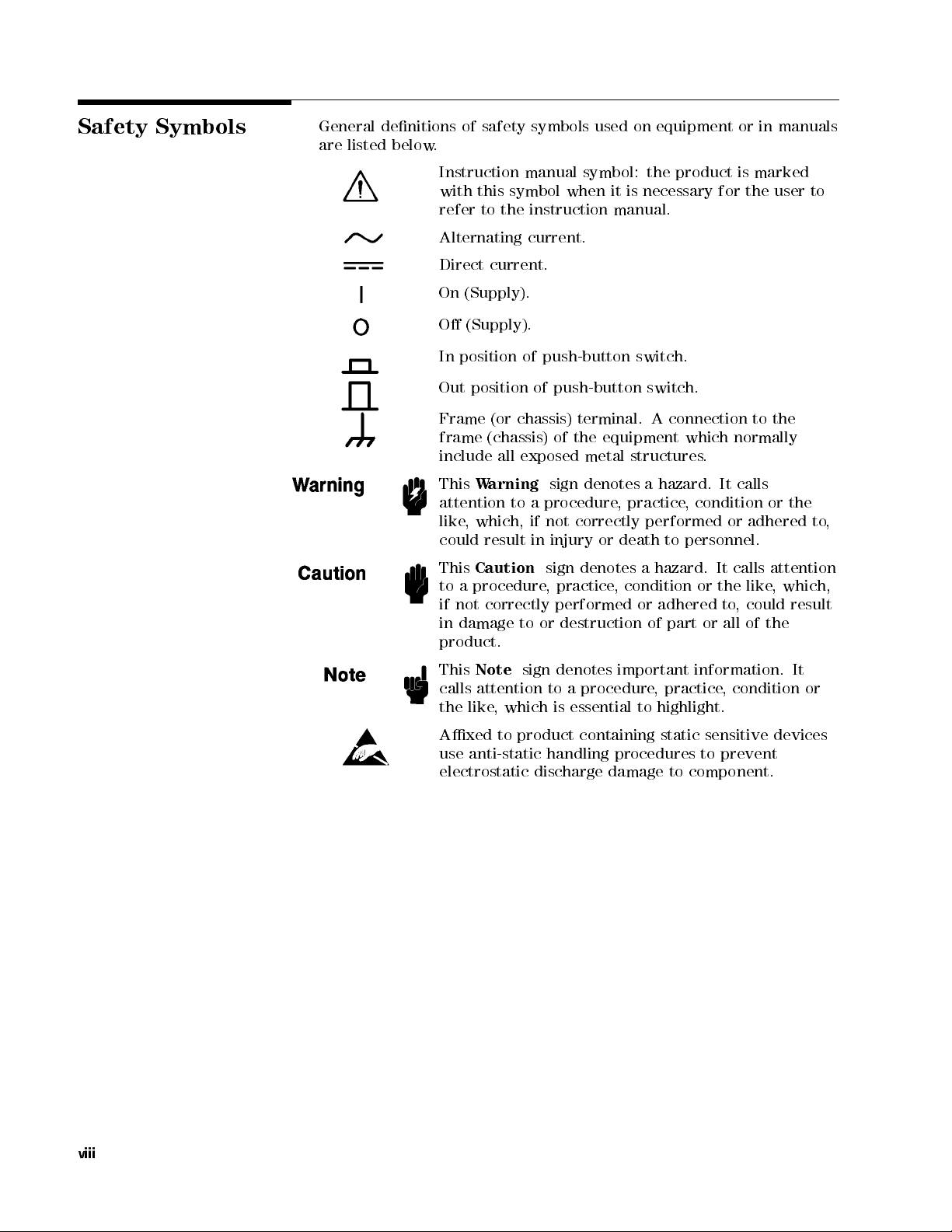

Safety

Symbols

General

are

listed below

denitions of

.

safety symbols

used on

equipment or

in manuals

Instruction

with

refer

Alternating

Direct

On

(Supply).

O

(Supply).

In position

Out

position

Frame

manual symbol:

this symbol

to the

instruction manual.

current.

current.

of push-button

of

(or

chassis)

frame (chassis)

include

This

attention to

like,

could result

This

to

if

in

all exposed

W

arning

which,

Caution

a

procedure

not

correctly

damage

a procedure

if

in

to

product.

when it

push-button

terminal.

of

the

metal

sign

denotes

not

correctly

injury

sign

,

or

denotes

practice

performed

or

destruction

the product

is necessary

switch.

switch.

A

equipment

structures

a

hazard.

,

practice

performed

death

to

a

hazard.

,

condition

or

adhered

of

part

for the

connection

which

normally

.

It

,

condition

or

personnel.

It

calls

or

the

to

,

or

all

is marked

user to

to

the

calls

or

the

adhered

attention

like

,

which,

could

result

of

the

to

,

This

Note

calls

attention

the

like

,

which

Axed

use

to

anti-static

electrostatic

sign

denotes

to

is

product

handling

discharge

important

a

procedure

essential

containing

procedures

damage

information.

,

practice

to

highlight.

static

to component.

,

condition

sensitive

to

prevent

It

or

devices

viii

Page 9

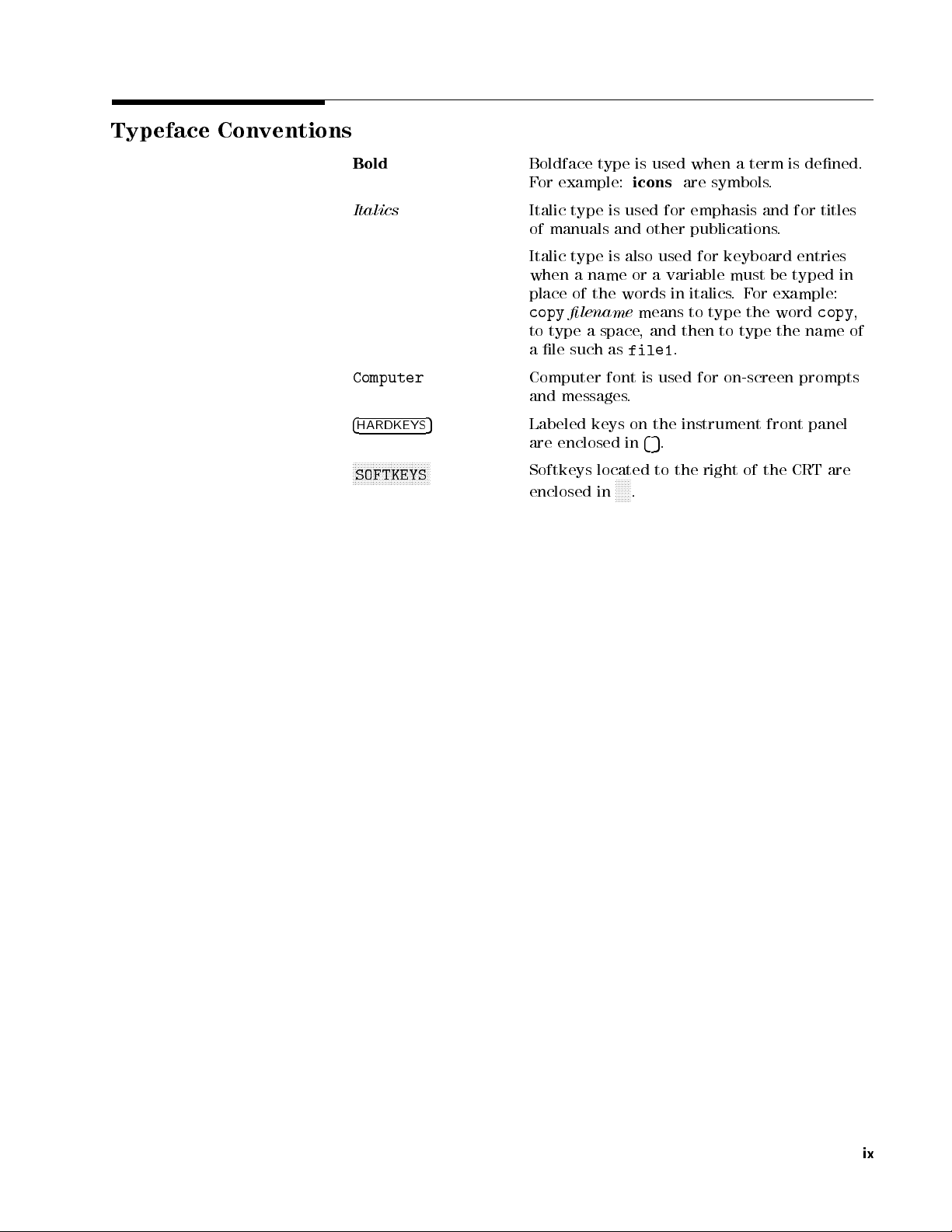

Typeface Conventions

Bold

Italics

Computer

4

HARDKEYS

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

SOFTKEYS

Boldface type

F

or example:

Italic type

of

manuals

Italic

type is

when

a name

place

of the

copy

lename

to

type a

a

le

such

Computer font

and

messages.

5

N

N

N

N

N

N

Labeled keys

are

enclosed

Softkeys

enclosed

is used

icons

is used

and

also used

or a

words in

space,

as

file1

on the

in

located

N

N

N

N

N

.

in

when a

are

for emphasis

other

publications

for keyboard

variable must

italics.

means

to type

and then

.

is used

for

instrument

5

.

4

to

the

symbols.

For

to type

on-screen

right

of

term is

and for

.

entries

be typed

example:

the word

the

prompts

front

the

CRT

dened.

titles

in

copy

name

of

panel

are

,

ix

Page 10

How T

o Use

This Manual

Installation

Quick Start

and

Setup

Tour

Measurement Examples

This is

a user's

manual contains

installation and

more information.

Guide

Chapters

initial

inspection,

connection.

rst.

Chapters

operating

you

will

become

Chapter

network

2

analyzer mode

Chapters 4

and spectrum

examples

contains

examples

guide for

two quick

the 4396B

start tours

setup guide

1

provides

If

2

and

the

analyzer

is

for

power

you

3

provide

familiar

the

installation

line

do

not

prepare

step-by-step

for

the

with

spectrum

.

and 5

provide

how

measurement. Chapter

of

spectrum measurement

of network

Network/Spectrum Analyzer

and a

table that

information

setting,

test-set

the

rst

time

the

basic

analyzer

to

use

applications

measurement

, measurement

tells you

that

includes

setup

,and

analyzer yet,

instructions

.By

performing these

operations

mode

,

and

chapter

the

analyzer

4

contains

measurement

,

and

applications

examples,

where to

keyboard

read this

for

you

of

the analyzer

for

typical

chapter

.

an

3

if

you

is

. This

an

nd

section

are

tours,

.

for

the

network

5

F

or

More

Information

Appendix

need

in

A

provides

the

documentation

a

table

set.

that

helps

you

nd

the

information

you

x

Page 11

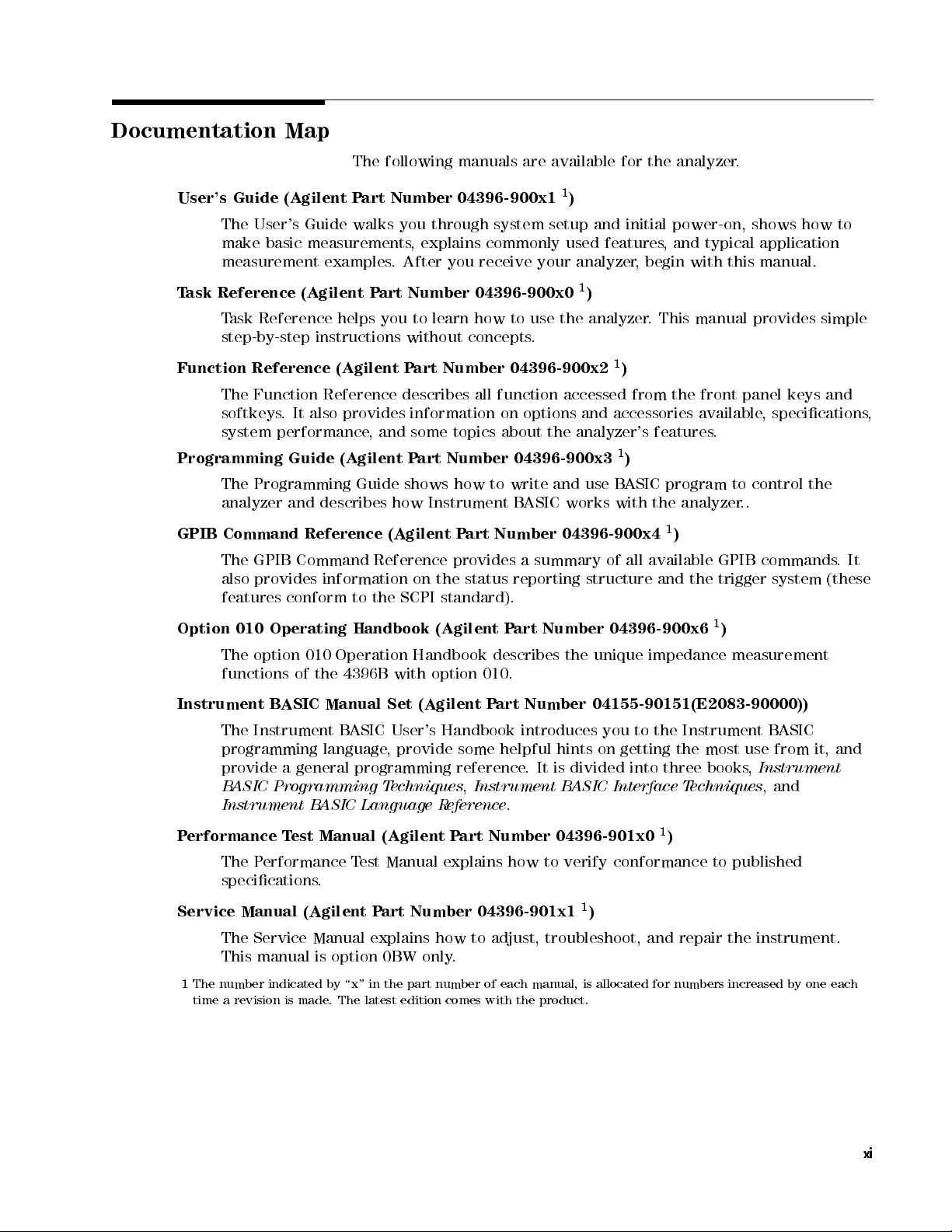

Documentation Map

User's Guide

The

User's

make

basic

measurement

T

ask

Reference

T

ask

Reference

step-by-step

Function

Reference (Agilent

The

Function

softkeys

system

Programming

The

Programming

analyzer

GPIB

Command

The

GPIB

also

provides

features

Option

010

Operating

The following

(Agilent P

Guide

walks you

measurements

examples

(Agilent

helps

instructions

Reference

.

It

also

provides

performance

Guide

(Agilent

Guide

and

describes

Reference

Command

information

conform

to

Handbook

art

Number

.

After you

P

art

Number

you

without

Part

describes

,

and

P

shows

how

(Agilent

Reference

the

SCPI

manuals are

04396-900x1

through system

, explains

commonly used

receive your

04396-900x0

to

learn

how

concepts

Number

all

information

some

topics

art

Number

how to

Instrument B

P

art

provides

on

the

status

standard).

(Agilent

available for

1

setup and

to

use

the

.

04396-900x2

function

accessed

on options

about

the

04396-900x3

write and

ASIC works

Number

04396-900x4

a

summary

reporting

P

art

Number

the analyzer

)

initial power-on,

features,

analyzer,

1

)

analyzer

begin with

.

1

)

from

and accessories

analyzer's

use B

1

)

ASIC

features

with the

of

all

available

structure

04396-900x6

and typical

This

manual

the front

available

program

analyzer..

1

)

and

the

.

shows

application

this

manual.

provides simple

panel keys

,

specications

.

to

control

GPIB

commands

trigger

1

)

system

how

the

to

and

.

It

(these

,

The

option

functions

Instrument

The

Instrument

programming

provide

B

ASIC

Instrument

P

erformance T

The Performance T

010

Operation

of

the

4396B

B

ASIC

Manual

B

ASIC

language

a

general

programming

Programming

B

ASIC

est

Manual

Handbook

with

Set

(Agilent P

User's

,

provide

T

echniques

Language

(Agilent

option

Handbook

R

describes

010.

art Number

some

reference

,

Instrument

eference

P

art

Number

introduces

helpful

.

It

.

the

unique

impedance

04155-90151(E2083-90000))

you

to

the

Instrument

hints

on

getting

is

divided

B

ASIC

Interface

04396-901x0

into

the

three

1

)

T

most

books

echniques

measurement

est Manual explains how to verify conformance to published

specications.

1

Service Manual (Agilent

Part Number 04396-901x1

)

The Service Manual explains how to adjust, troubleshoot, and repair the instrument.

This manual is option 0BW only

1

The number

indicated by \x" in the part number of each manual, is allocated for numbers increased by one each

.

time a revision is made. The latest edition comes with the product.

B

ASIC

use

from

,

Instrument

,

and

it,

and

xi

Page 12

Page 13

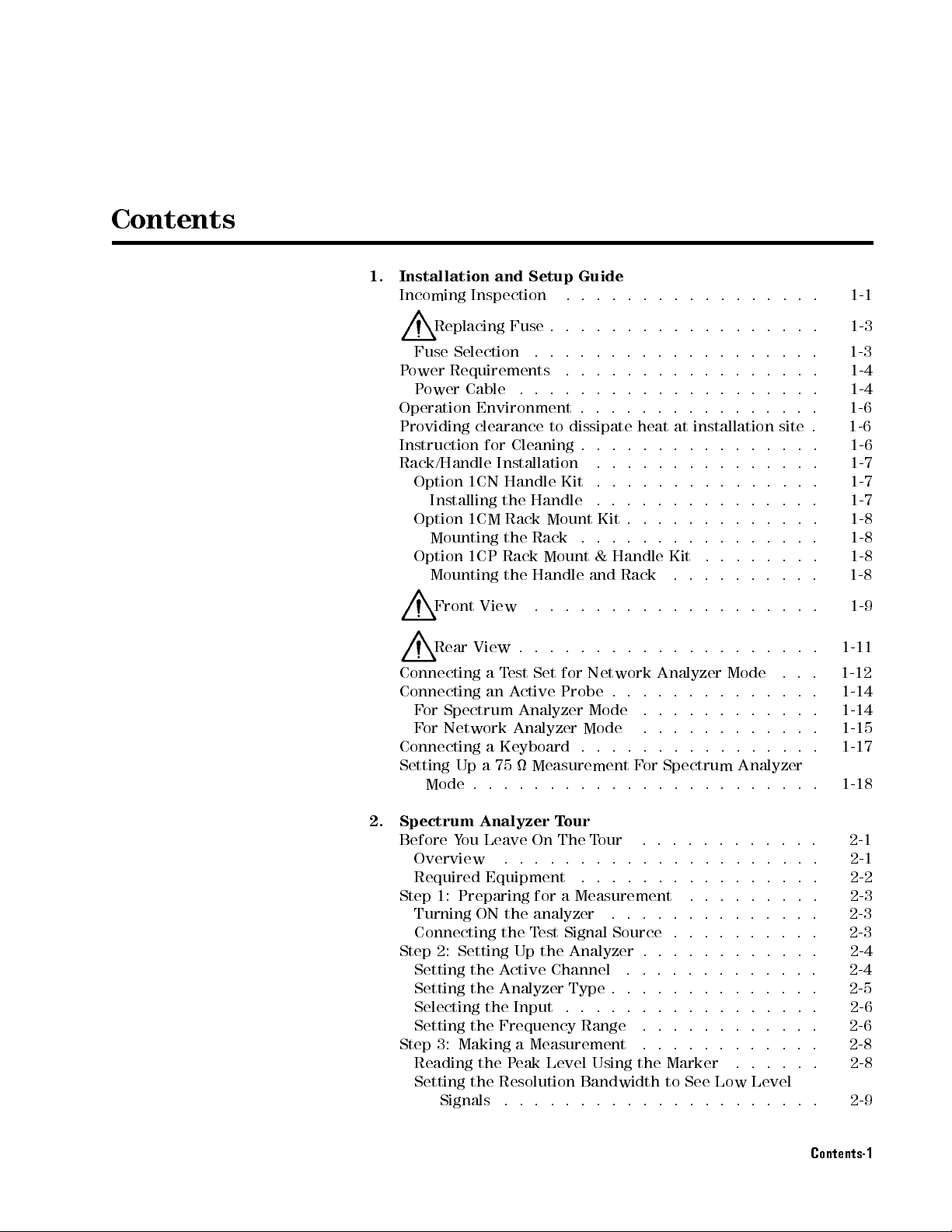

Contents

1.

Installation

Incoming

and

Setup

Inspection

Guide

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

1-1

Replacing

Fuse

Selection

Power

Operation Environment

Providing clearance

Instruction

Rack/Handle

Connecting a

Connecting an

Connecting

Setting

Requirements .

Power

Option

Installing

Option

Mounting

Option

Mounting

Front

Rear

For

Spectrum Analyzer

F

or

Network

Up

Mode

Fuse .

Cable .

for

Installation

1CN

Handle

the

1CM

Rack

the

1CP

Rack

the

View

View

Test

Active

a

Keyboard

a

75

.

.

.

..

.

.

to dissipate

Cleaning

Handle

Mount

Rack

Mount

Handle and

.

.

.

.

.

Set

Analyzer

Measurement

.

.

.

..

..

.

.

.

..

.

Kit

.

.

.

.

.

for

Network

Probe

Mode .

Mode

.

.

.

..

..

.

.

.

.

..

.

..

.

.

.

.

.

.

Kit

.

.

&

Handle

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

heat

.

.

.

..

.

..

.

.

.

.

Rack

.

.

.

.

.

.

.

.

.

F

or

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

at

installation

.

.

.

.

..

..

..

..

..

..

.

..

..

..

..

Kit

.

.

.

.

.

.

.

.

.

.

.

.

Analyzer

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Spectrum

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

..

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

Mode

.

.

.

.

.

.

.

.

.

.

.

.

Analyzer

..

..

.

.

.

.

.

.

.

.

.

.

site

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

. 1-18

1-3

1-3

1-4

1-4

1-6

1-6

1-6

1-7

1-7

1-7

1-8

1-8

1-8

1-8

1-9

1-11

1-12

1-14

1-14

1-15

1-17

2.

Spectrum

Before

Overview ............

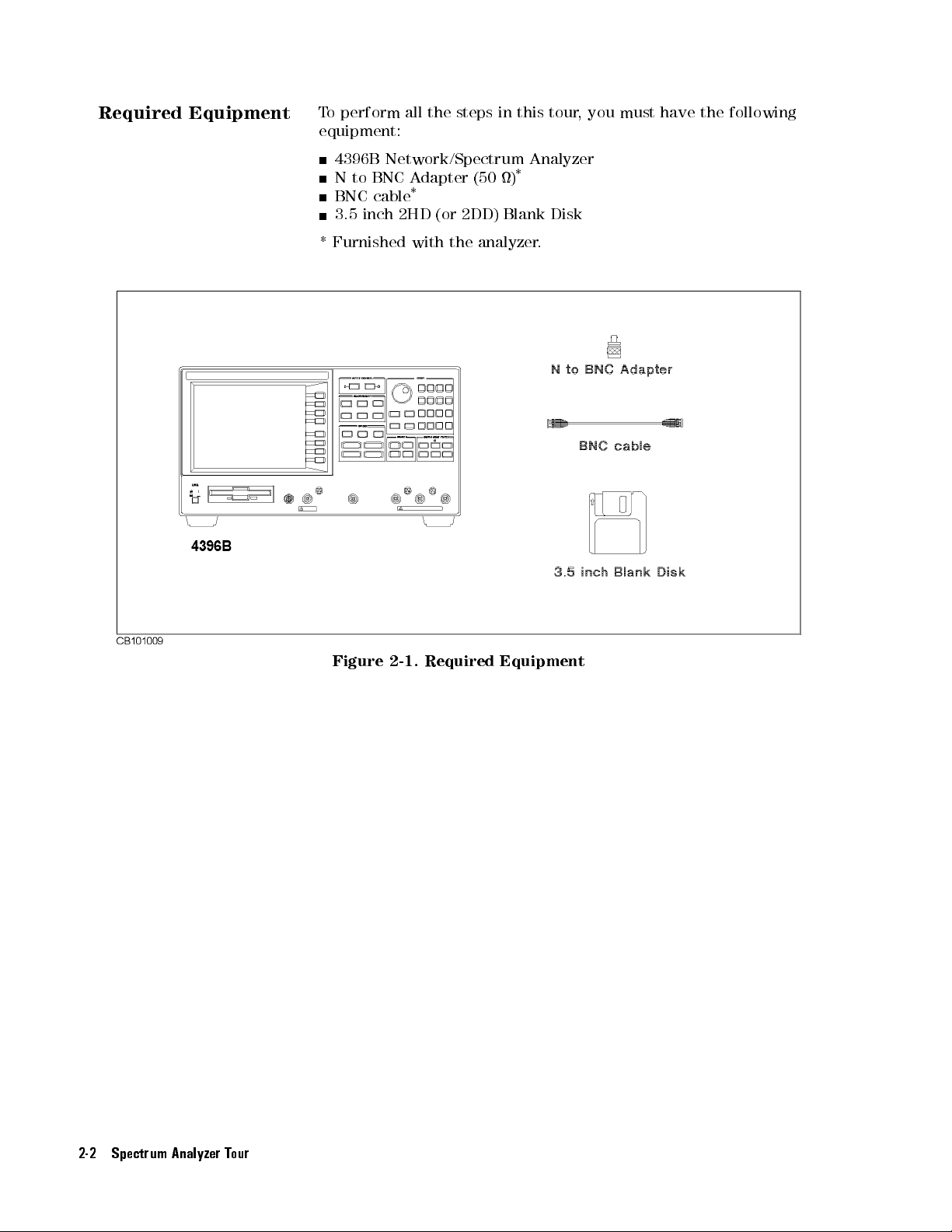

Required Equipment

Step 1: Preparing for a Measurement

Turning ON the analyzer

Connecting the T

Step 2: Setting Up the Analyzer . . . . . . . . . . . .

Setting

Setting the

Selecting the Input . . . . . . . . . . . . . . . . . 2-6

Setting the Frequency Range ............ 2-6

Step 3: Making a Measurement ............ 2-8

Reading the Peak Level Using the Marker ...... 2-8

Setting the Resolution Bandwidth to See Low Level

Analyzer

Y

ou

Leave

the A

Analyzer Type . . . . . . . . . . . . . .

Signals ..................... 2-9

T

our

On

The

T

our .

...........

est Signal Source . . . . . . . . . .

ctive Channel .............

.

.

.

.

.

.

.

.

.

.

.........

.....

...... ..

...... ..... ...

. 2-1

2-1

2-2

. 2-3

2-3

2-3

2-4

2-4

2-5

Contents-1

Page 14

3.

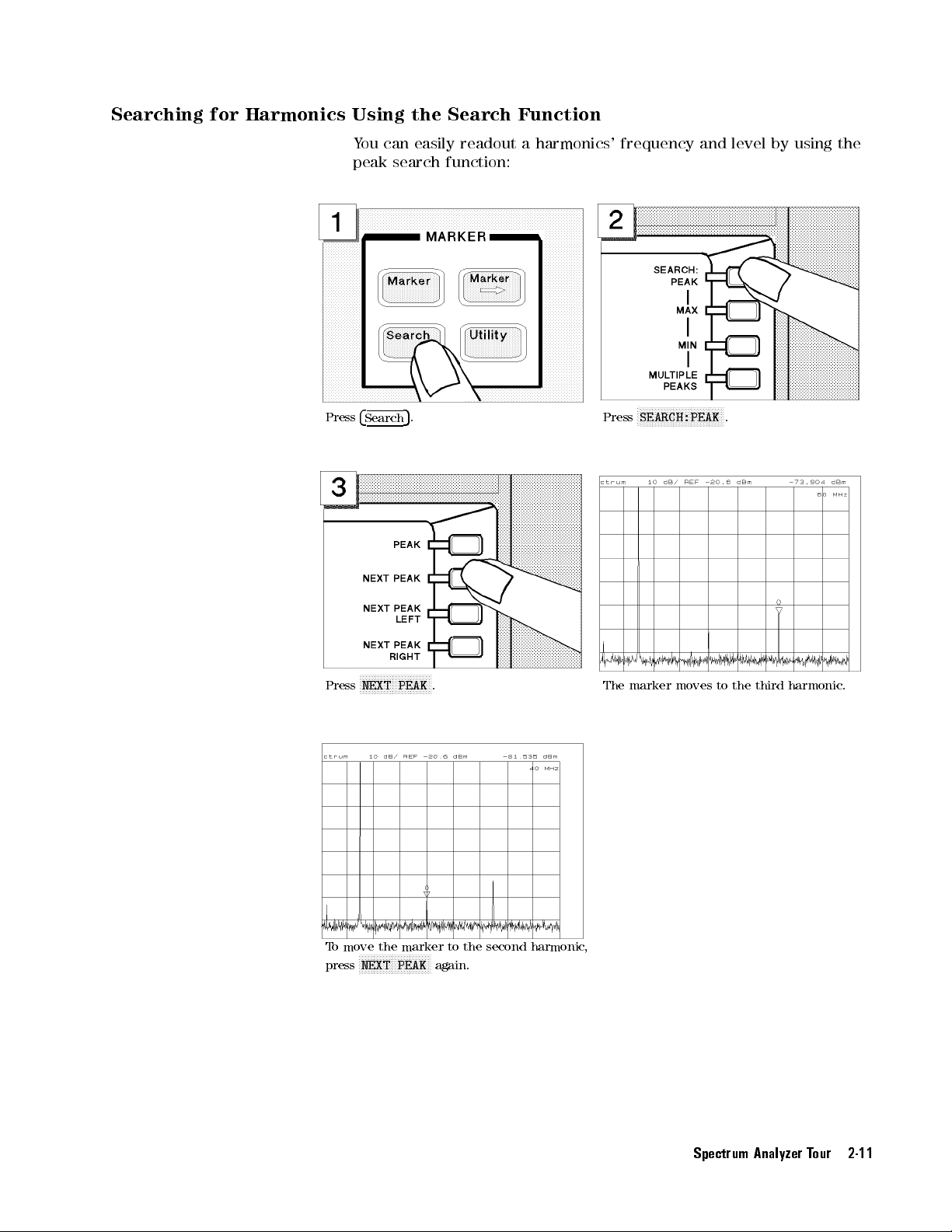

Searching

Step

4: Saving

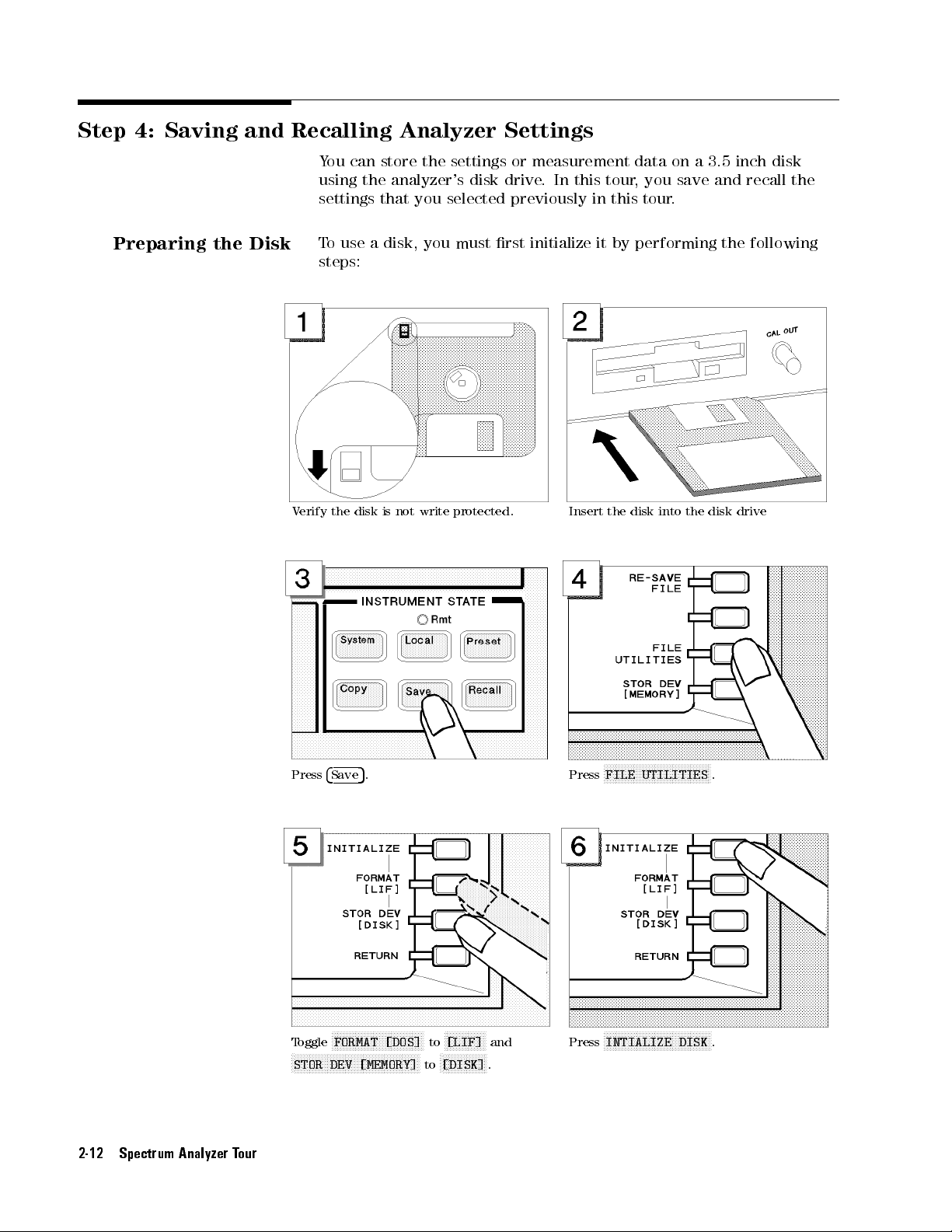

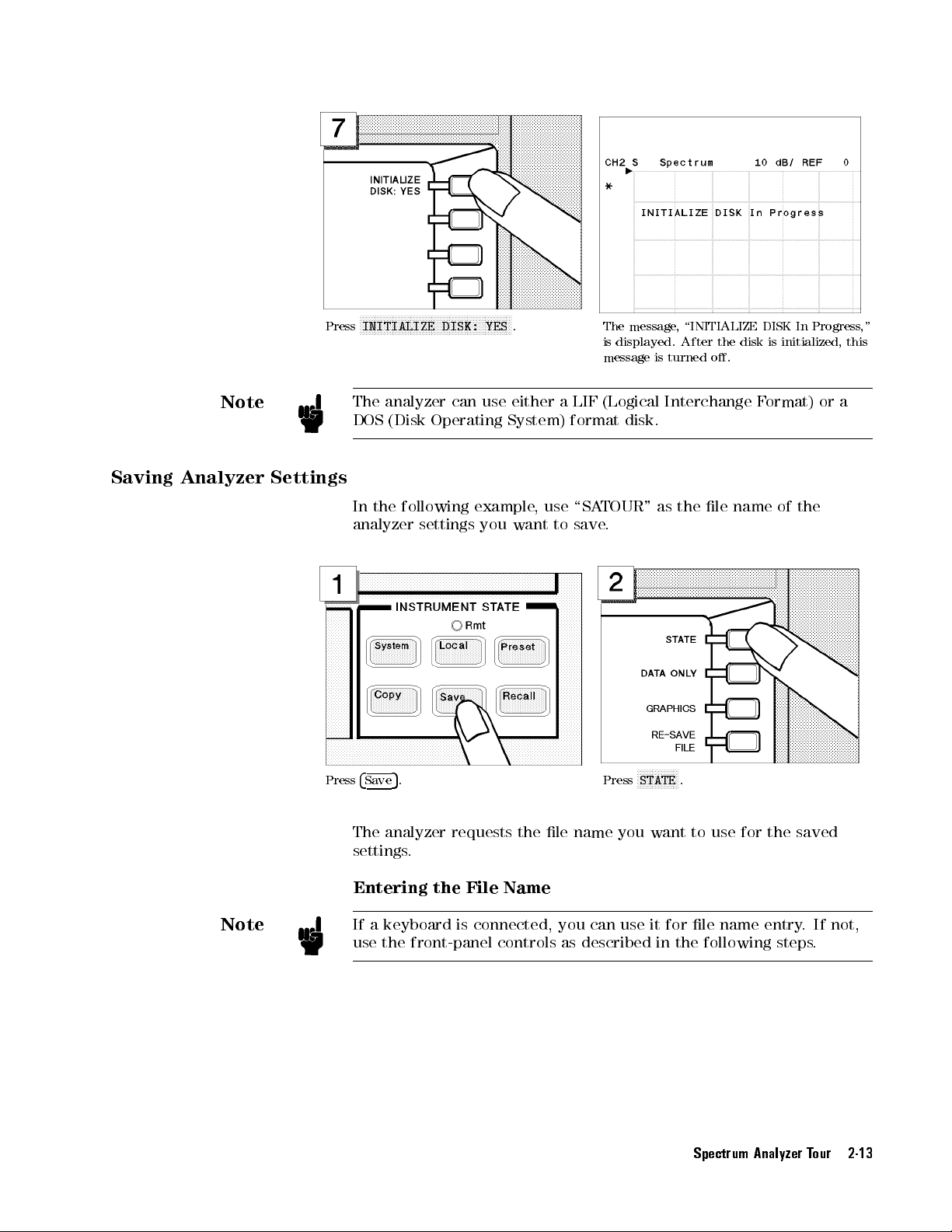

Preparing

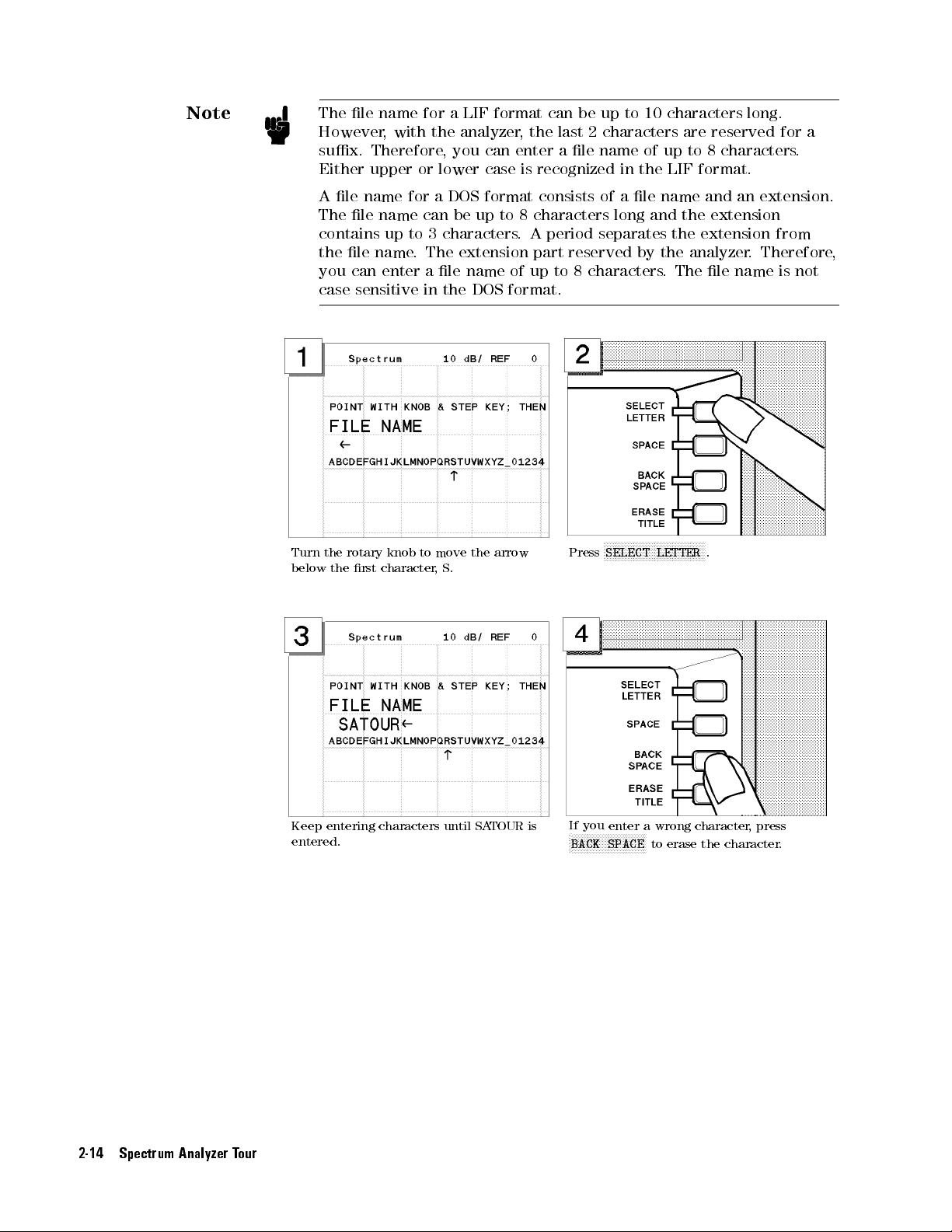

Saving

Entering

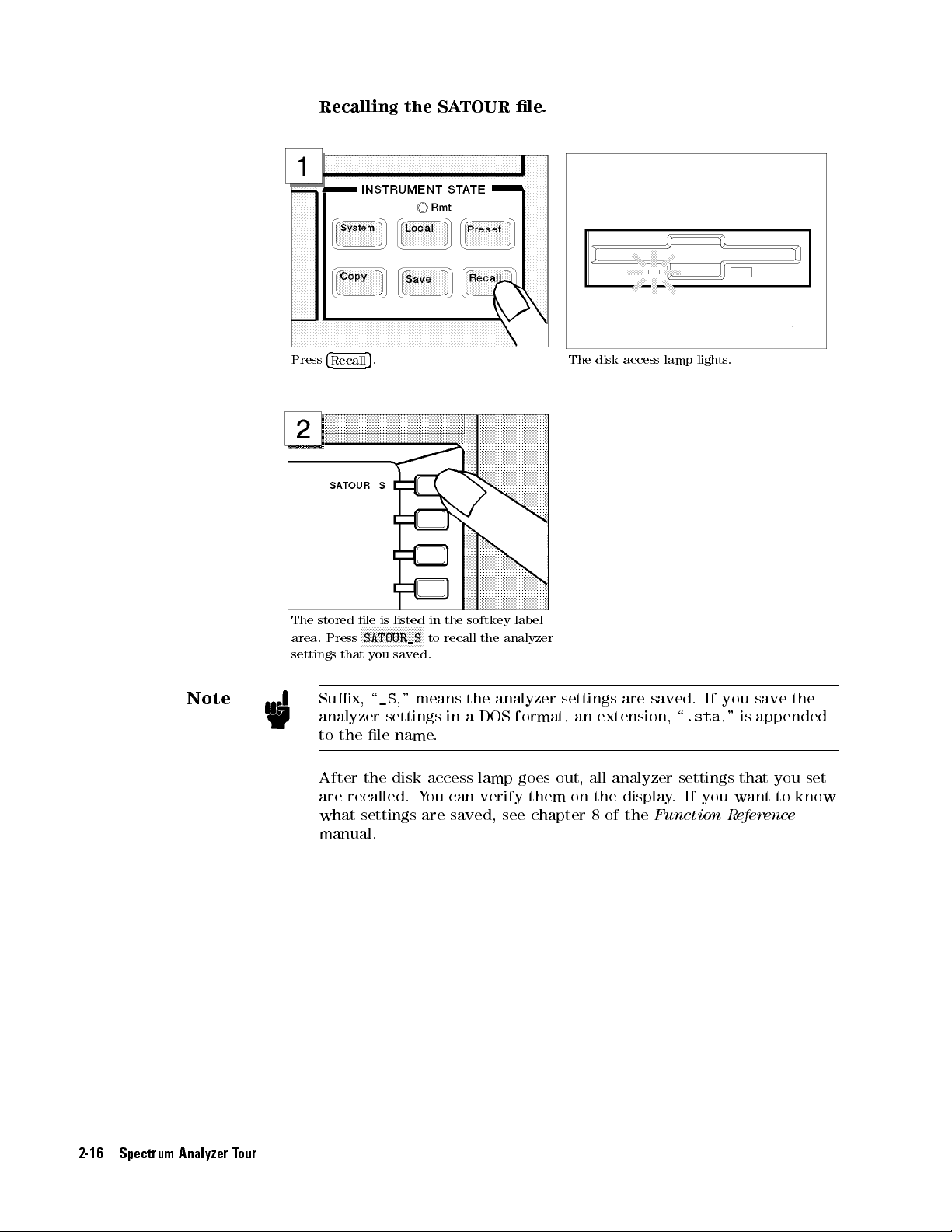

Recalling

Network

Before

Step

Step

Step

Step

Step

Y

Overview

Required

1:

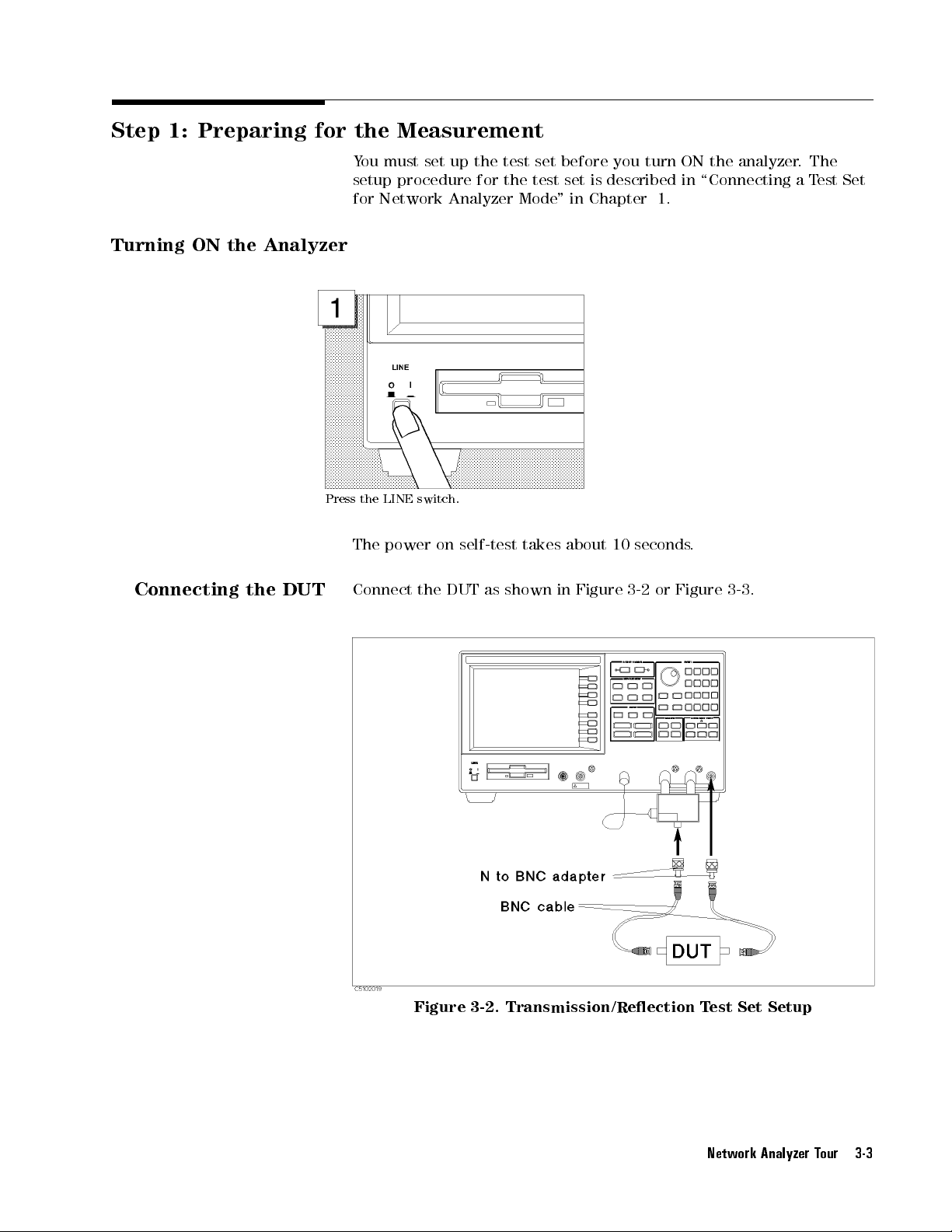

Turning

Connecting

2:

Setting

Setting

Selecting

Setting

P

erforming

3:

4:

Reading

5:

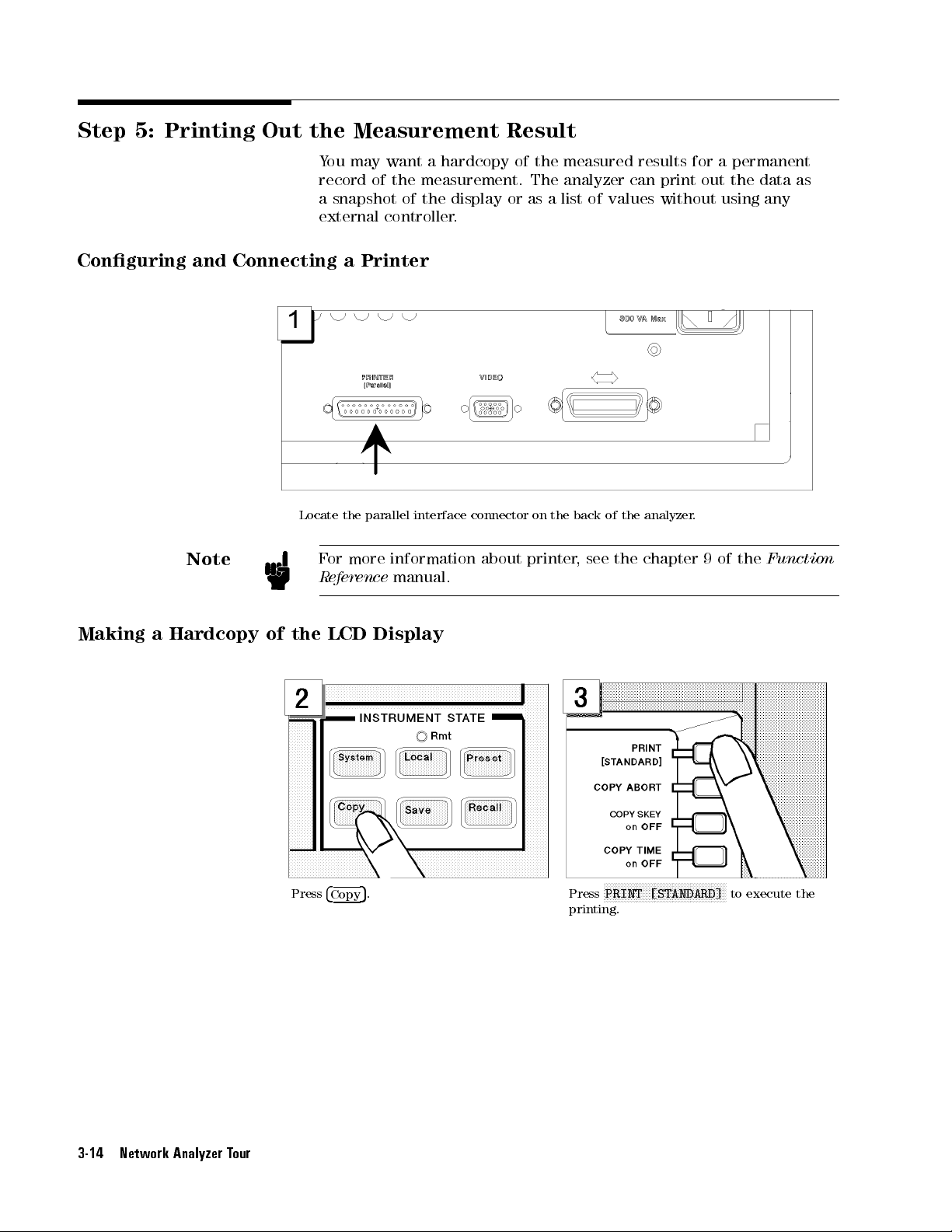

Conguring

Making

for Harmonics

and

Recalling

the Disk

Analyzer Settings

the File

the Analyzer

Analyzer

ou

Leave

.

Equipment

Preparing

ON

the

the

Setting

the

A

ctive

the

Analyzer

the

the

Frequency

the

Making

Reading

a

Measured

Printing

and

a

Hardcopy

Name

T

our

On

The

.

.

.

for

the

Analyzer

DUT

up

the

Channel

Input

A

utomatic

a

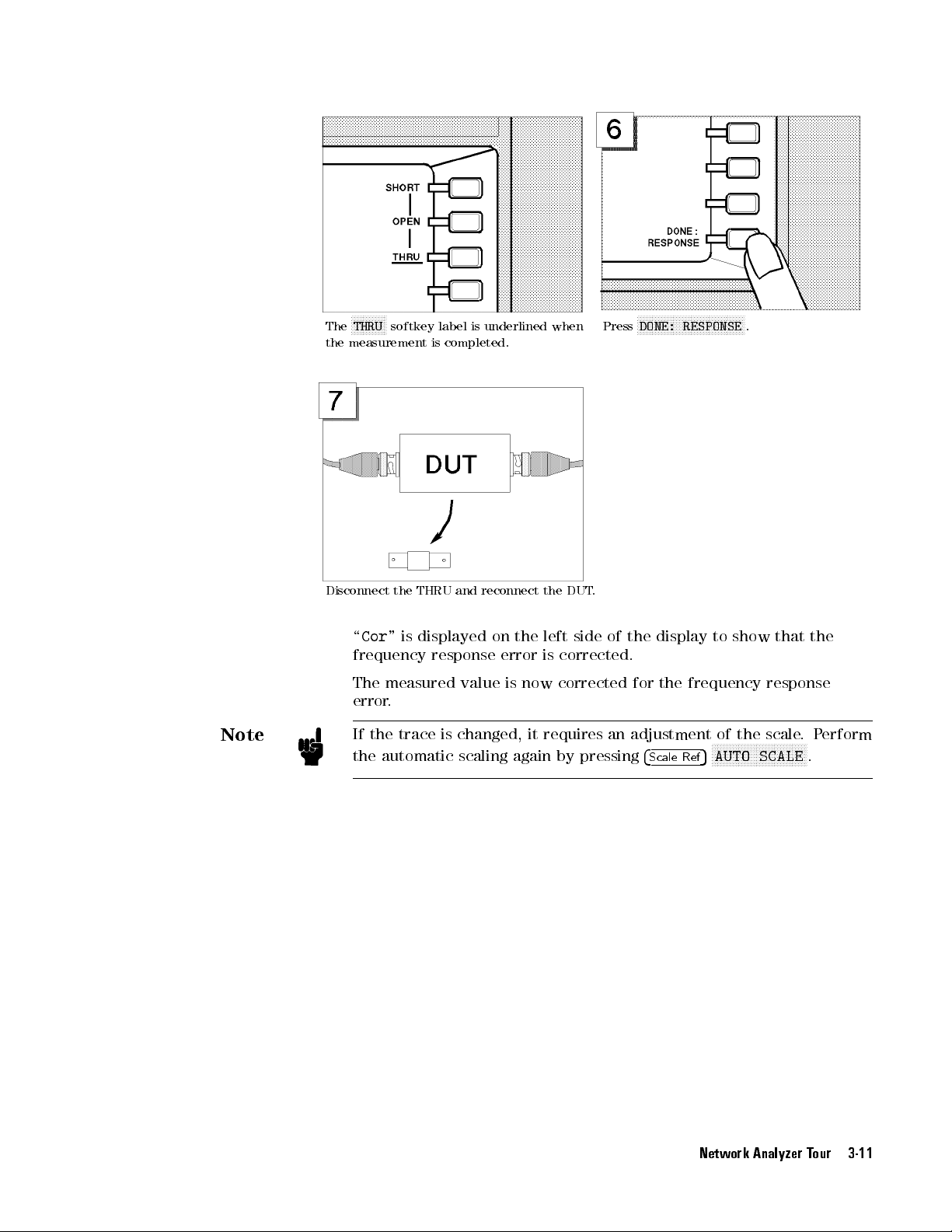

Calibration

a

Measurement

Out the

Connecting

of

Using the

Analyzer

.

.

.

.

.

.

.

.

.

Settings

T

our

.

.

.

.

.

.

.

.

.

Measurement

.

.

.

.

.

.

Analyzer

.

Type

.

.

.

.

.

.

.

Range

Scaling

.

Value

by Using

Measurement Result

a Printer

the

LCD Display

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Result

Search

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

Marker

Function

Settings

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

..

..

.

.

.

.

.

.

..

..

.

.

.

..

.

.

..

.

.

.

.

.

.

..

..

.

.

.

.

..

..

..

..

..

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

..

.

..

..

.

.

..

..

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

. 2-13

..

.

. 2-15

..

..

..

..

..

.

..

..

.

.

.

.

.

. 3-8

.

.

.

.

..

.

.

.

.

.

.

.

.

2-11

2-12

2-12

2-13

3-1

3-1

3-2

3-3

3-3

3-3

3-5

3-5

3-6

3-7

3-9

3-10

3-12

3-12

3-14

3-14

3-14

4.

Spectrum

Basic

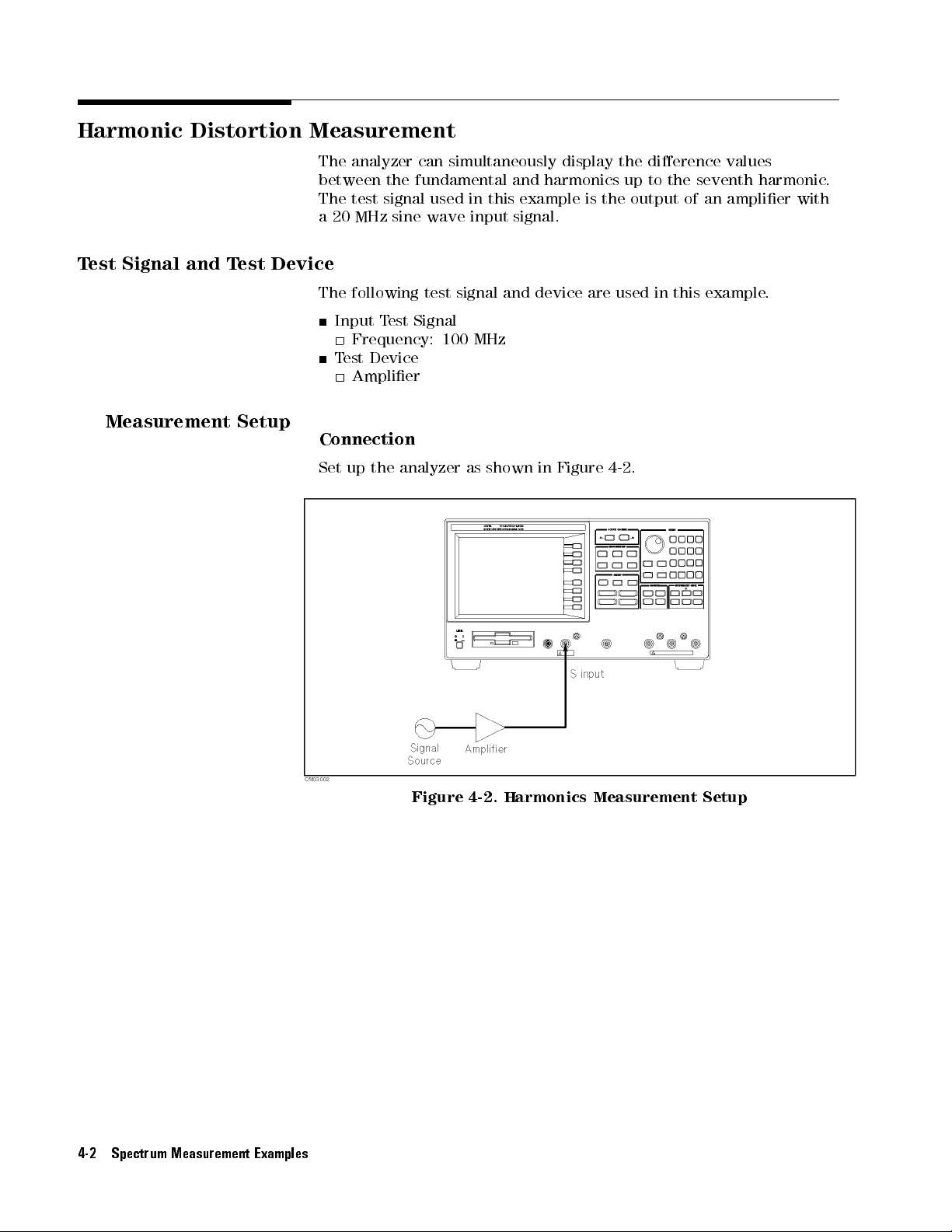

Harmonic

T

est Signal

Measurement

Connection

Analyzer

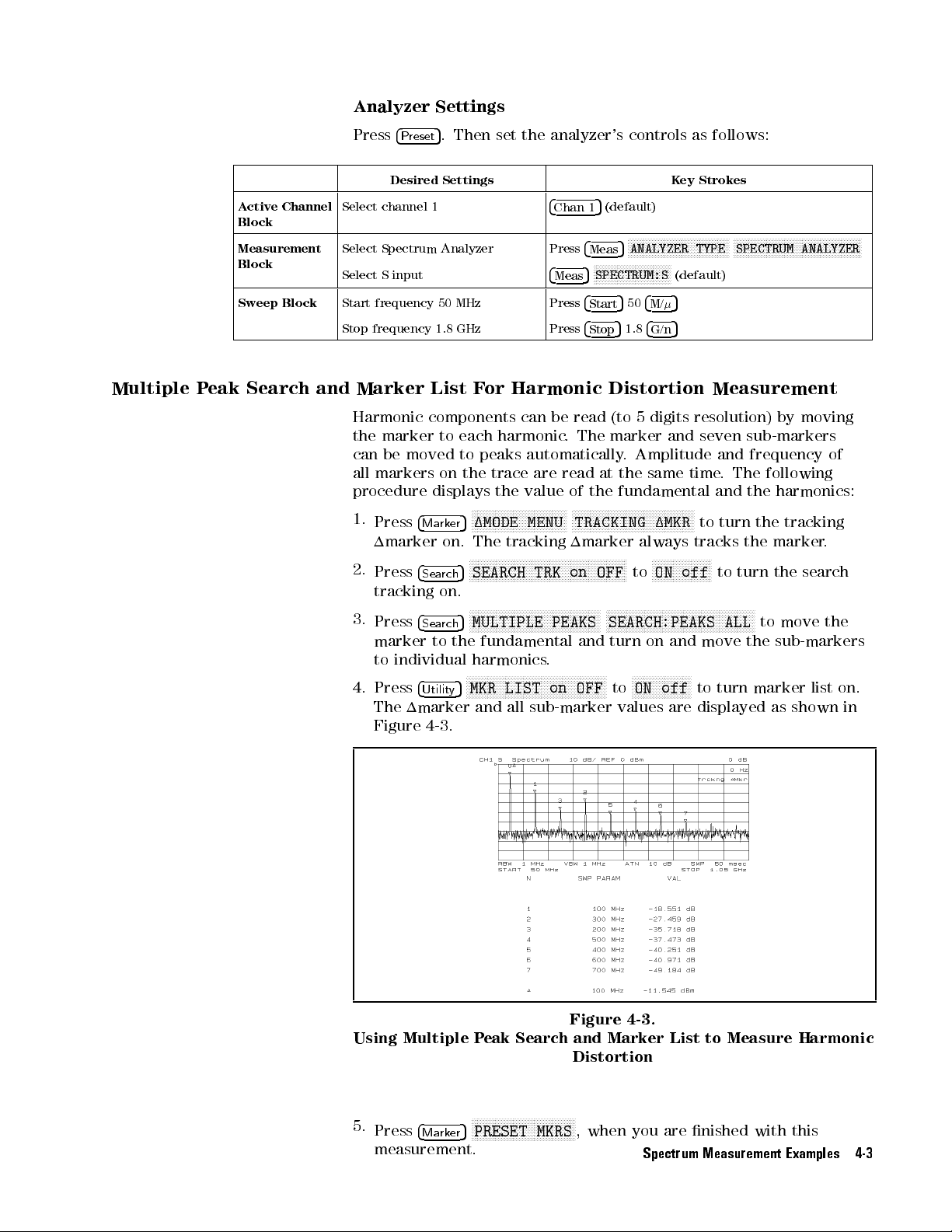

Multiple

C/N

T

est

Measurement

Connection

Analyzer Settings . . . . . . . .

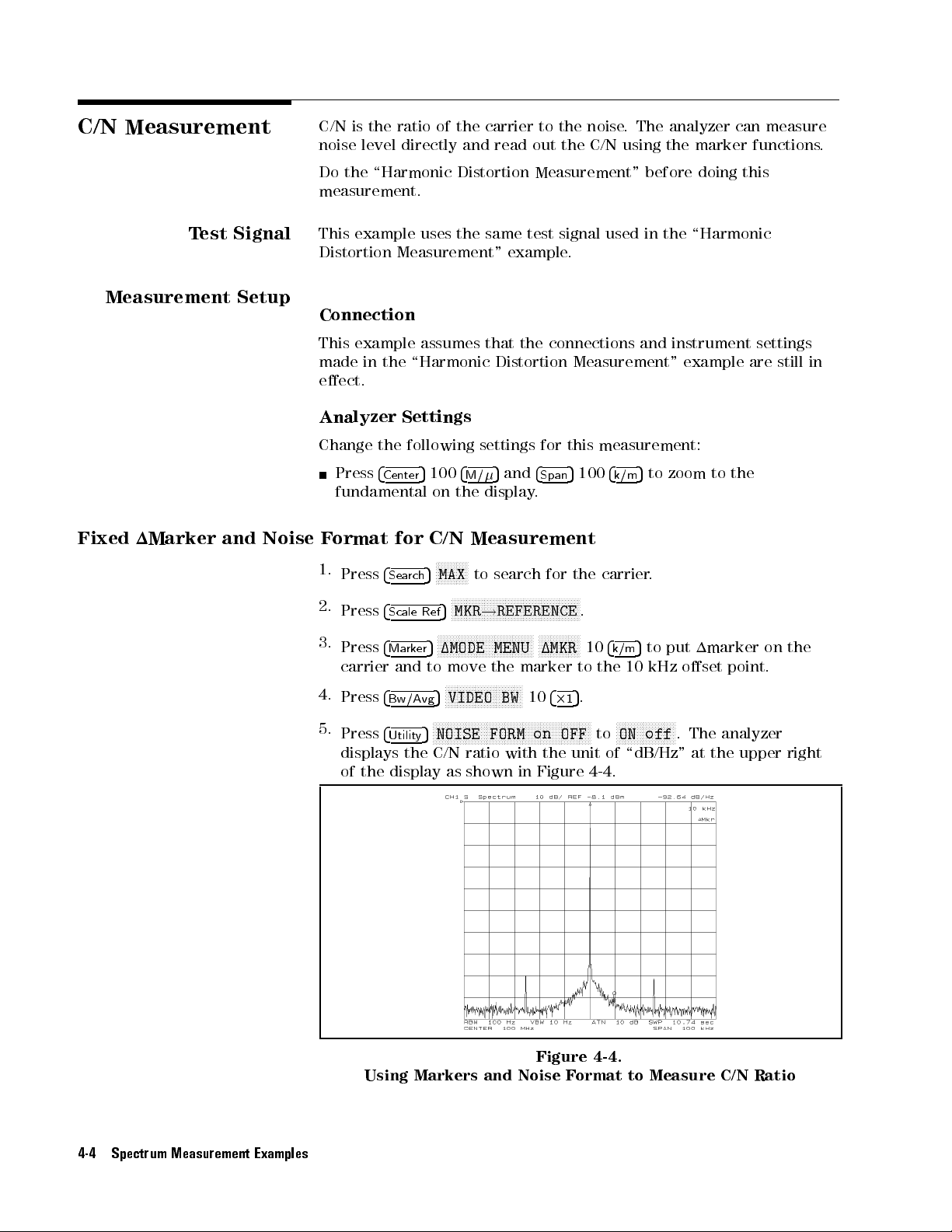

Fixed 1Marker and Noise F

Tracking a Drifting Signal . . . . . . . .

Test Signal . . . . . . . . . . . . . . . . . . .

Measurement Setup . . . . . . . . . . . . . . . . .

Connection . . . . . . . . . . . . . . . . . . . .

Analyzer Settings . . . . . . . . . . . . . . . . .

Tracking an Unstable Signal . . . . . . . . . . . . .

Network Measurement with Spectrum Monitor . . . . . 4-7

Measurement Setup . . . . . . . . . . . . . . . . . 4-7

Connection . . . . . . . . . . . . . . . . . . . . 4-7

Analyzer Settings . . . . . . . . . . . . . . . . . 4-8

Performing Calibration ...... ...... ... 4-8

Network Measurement ............... 4-8

Measurement

Setup

Distortion

Measurement

Signal

.

Distortion

and

Setup .

Settings

P

eak

Measurement

.

Setup

.

.

.

.

Measurement

T

est

Device

.

.

.

.

.

Search

.

.

.

.

.

.

.

.

.

.

.

Examples

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

and

Marker

.

.

.

..

..

.

.

.

..

.

ormat for C/N Measurement

.

.

.

.

..

..

.

.

List

F

or

Harmonic

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

..

.

.

.

.

.

.........

.......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

..

.

.

..

.

.

.

.

.

.

..

..

.

.

..

..

.

.

.

.

.

.

.

.

.

. 4-3

.

.

..

.

.

.

.

..

4-1

4-2

4-2

4-2

4-2

4-3

4-4

4-4

4-4

4-4

4-4

4-4

4-5

4-5

4-5

4-5

4-5

4-6

Contents-2

Page 15

Monitoring

Spectrum

AM

Signal Measurement

T

est Signal

Measurement

Connection

Analyzer

Carrier

the

Modulating

Measurement

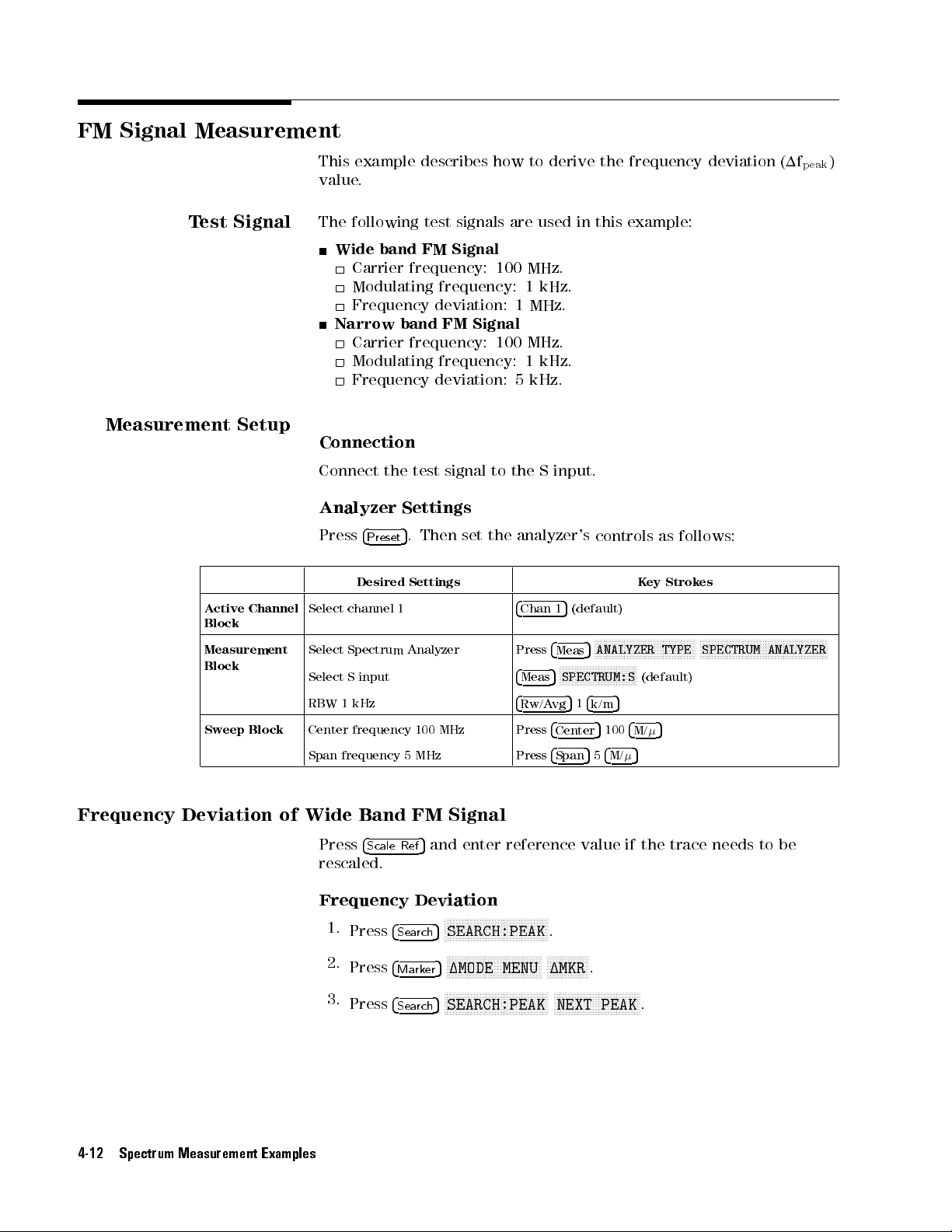

FM

Signal

T

est

Signal

Measurement

Connection

Analyzer

Frequency

Frequency

Carrier

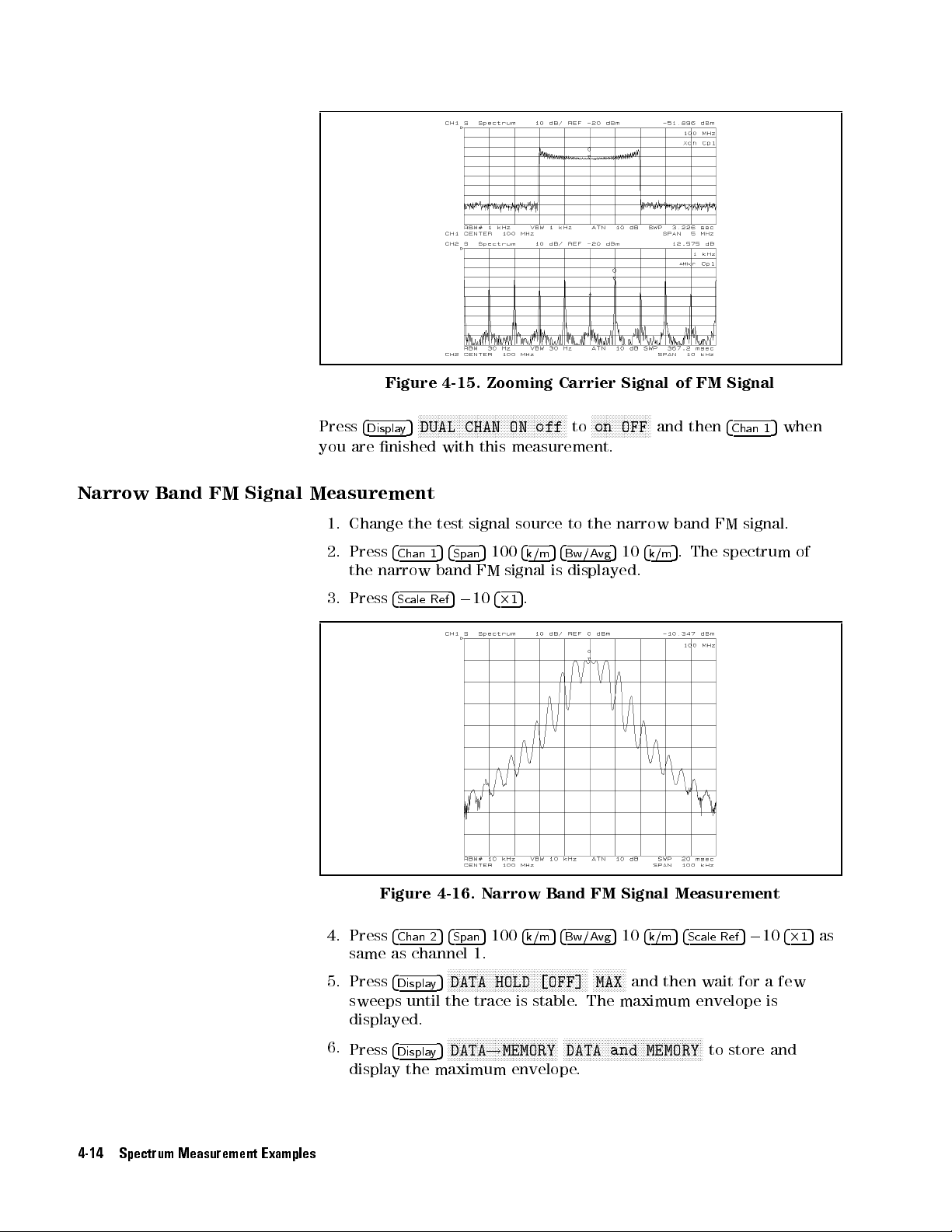

Narrow

Burst

Signal

T

est

Signal

Measurement

Connection

Analyzer

Gated

Zero

the Leakage

Settings

Amplitude

Marker

Frequency

Measurement

Settings

Deviation

Level

Band

Measurement

Settings

Sweep

Span

for

Monitor .

.

.

.

.

Setup .

..

.

.

.

Using

.

.

.

.

Setup

.

.

.

Deviation

and

FM

Signal

.

.

.

.

Setup

.

.

..

for

Burst

Time

Signal at

.

.

.

.

.

.

.

.

.

.

.

.

.

and

Frequency

.

.

.

and

1Marker

.

.

.

.

.

.

.

.

.

.

.

.

.

.

of

Wide

.

Modulating

Measurement

.

.

.

..

.

..

..

.

..

Signal

Domain

the

B

Input

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Measurement

.

.

.

.

.

.

.

Modulation

.

.

.

..

..

.

.

.

.

.

.

.

.

.

Band

.

.

.

Frequency

.

.

.

..

..

.

.

.

.

..

.

Measurement .

Measurement .

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

..

.

.

..

.

.

FM

.

.

..

..

.

.

.

.

.

Index

.

..

.

.

Signal

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

..

.

.

..

.

..

..

..

..

.

.

.

..

.

.

.

.

.

.

.

.

Using

.

..

.

..

..

..

..

..

Using

..

.

.

..

.

.

..

..

..

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

the

..

..

..

..

..

..

..

.

.

..

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4-9

4-10

4-10

. 4-10

. 4-10

. 4-10

. 4-10

.

4-11

.

4-12

.

4-12

.

4-12

.

4-12

.

4-12

.

4-12

.

4-12

.

4-13

.

4-14

.

4-16

.

4-16

.

4-16

.

4-16

.

4-16

.

4-17

.

4-17

5.

Network

Basic

Example

Measuring

Measurement

Read

3

Ripple

Measuring Phase Response

Using the Expanded Phase Mode

Measuring Electrical Length . . . . . . . . .

Measurement Setup . . . . . . . . . . . . . . . . .

Electrical Length A

Measuring Phase Distortion

Measurement Setup . . . . . . . . . . . . . . . . .

Deviation from Linear Phase ............ 5-10

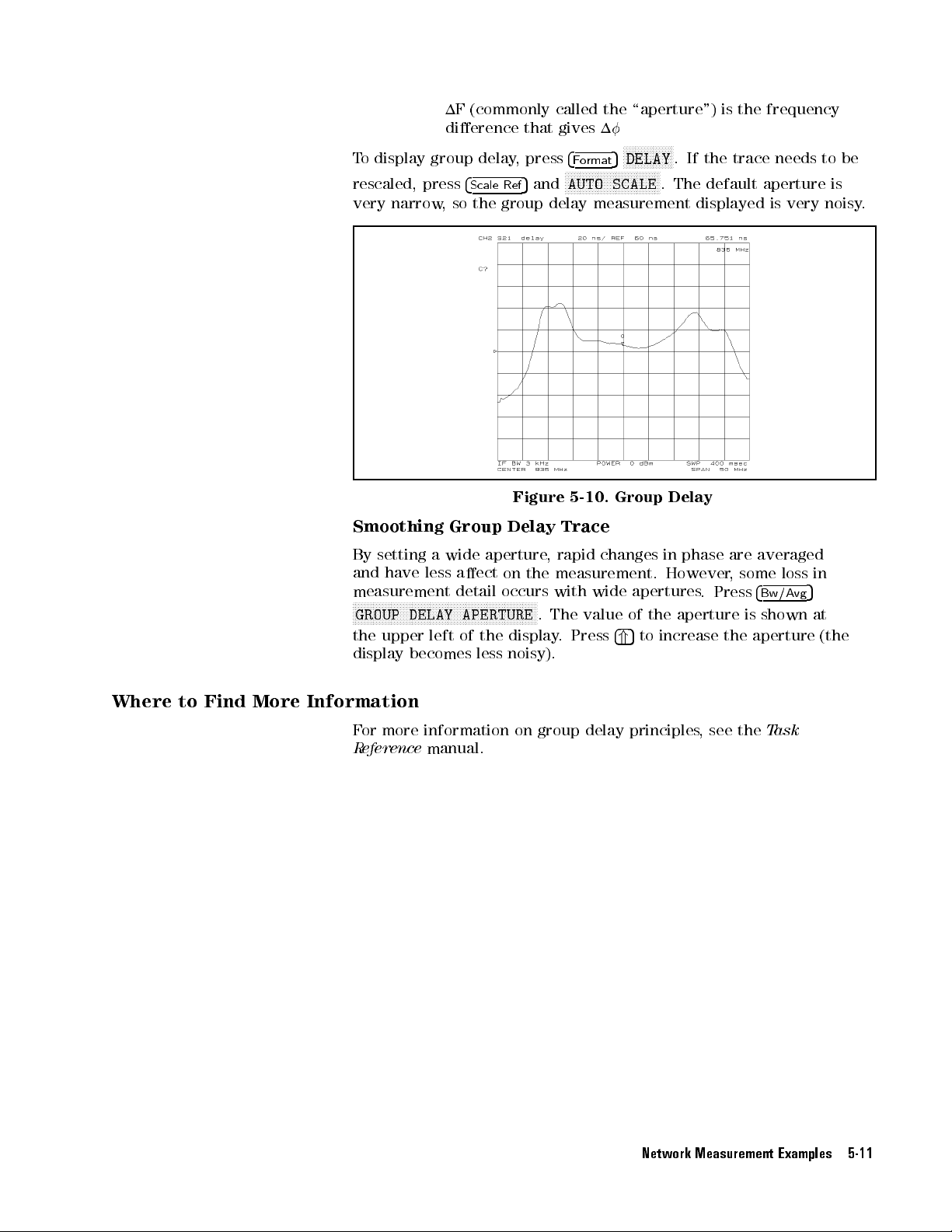

Group Delay Measurement ............. 5-10

Where to Find More Information .......... 5-11

Reection Measurement . . . . . . . . . . . . . . . . 5-12

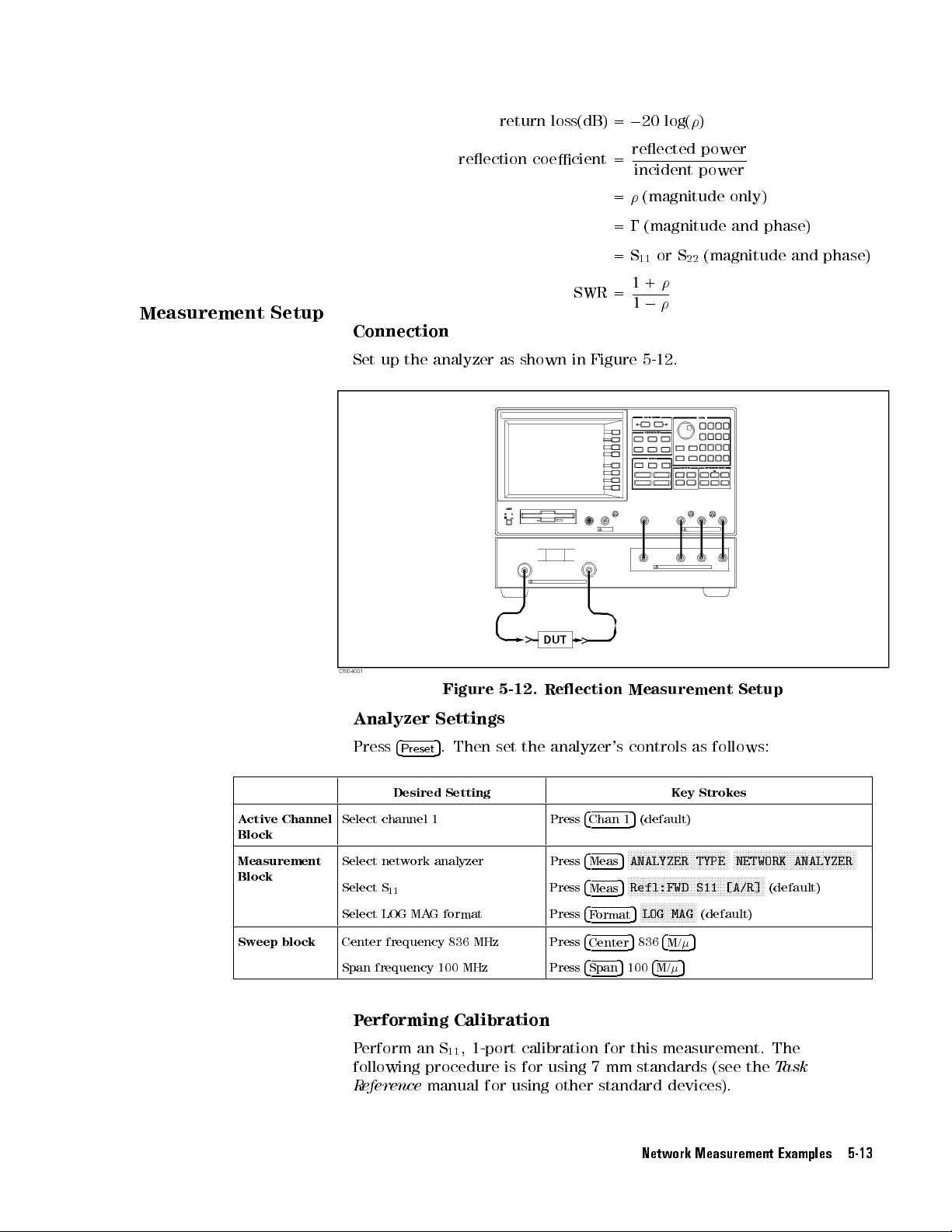

Measurement Setup . . . . . . . . . . . . . . . . . 5-13

Measurement

Setup

Connection

Analyzer

P

erforming

Measurement

Out

dB

Bandwidth

Measurement . . . . . . . . . . . . . . . . . . .

Smoothing Group Delay Trace . . . . . . . . . . . 5-11

Connection........ ...... ..... . 5-13

.

.

.

DUT .

Transmission Characteristics

Setup

.

.

Settings

Calibration

.

Insertion

or

Flatness

Examples

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

of

a

Filter

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Loss

Using

.

.

.

.

.

djustment ............

the

Marker

..

..

..

..

..

..

.

.

.

.

.

.

.

...... .

......

...... ...... ..

.

.

.

.

..

..

..

.

.

..

.

.

.

.

.

..

..

.

.

.

.

.

..

.

.

.

.

.

.

..

......

....

.....

.

5-1

.

5-1

.

5-2

. 5-2

. 5-2

. 5-2

. 5-2

5-3

.

5-3

.

5-4

5-5

5-6

5-7

5-8

5-8

5-8

5-8

5-10

5-10

Contents-3

Page 16

Analyzer

P

erforming Calibration

Measurement

Return

Standing

S-P

arameters Measurement

Data

Impedance

A

dmittance

List

Sweep

Sweep

Analyzer

Creating

P

erforming

Dynamic

Filter

T

esting

Example

Analyzer

Creating

P

erforming

Separated

Gain

Compression

Measurement

Connection

Analyzer

P

erformance

Measurement

Absolute

Settings .

Loss and

Wave

Readout

Measurement

Measurement

.

.

.

Time

Reduction

Settings

a

Sweep

List

Range

Using

of

Limit

Settings

Limit

Limit

Limit

Setup

.

Settings

Output

..

..

.

.

.

Reection

Ratio

Enhancement

.

Calibration

.

.

.

Using

the

Marker

.

.

.

.

.

.

.

.

.

List

.

Sweep

Limit

Lines

Lines

F

or

.

.

.

Lines

Lines

Measurement

.

Level

.

T

est

.

.

.

.

..

..

..

.

..

.

.

..

Measurement

.

.

.

.

.

.

.

.

.

.

.

.

Coecient

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Filter

T

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

.

..

.

.

.

.

.

.

esting

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

.

.

.

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

.

..

.

.

..

..

..

.

.

..

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

..

.

.

.

.

.

.

.

..

..

..

..

..

..

.

..

..

.

..

.

.

.

..

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

. 5-13

. 5-13

..

.

.

..

..

.

. 5-16

..

. 5-18

.

.

..

.

.

..

. 5-21

..

. 5-22

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

5-14

5-14

5-15

5-16

5-17

5-19

5-19

5-19

5-20

5-20

5-22

5-22

5-22

5-23

5-24

5-25

5-25

5-25

5-25

5-26

5-26

5-27

A.

F

or

Index

More

Information

Contents-4

Page 17

Figures

1-1. P

ower

Cable

Supplied

1-2. Rack

1-3. Connecting

1-4. Connecting

1-5. Spectrum

1-6.

1-7.

1-8.

1-9.

2-1.

3-1.

3-2.

3-3. S-P

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

4-10.

4-11.

4-12.

4-13.

4-14.

4-15.

4-16. Narrow Band FM Signal Measurement

4-17. Maximum and Minimum Envelopes of

4-18. Superimposing Spectrum and Envelopes

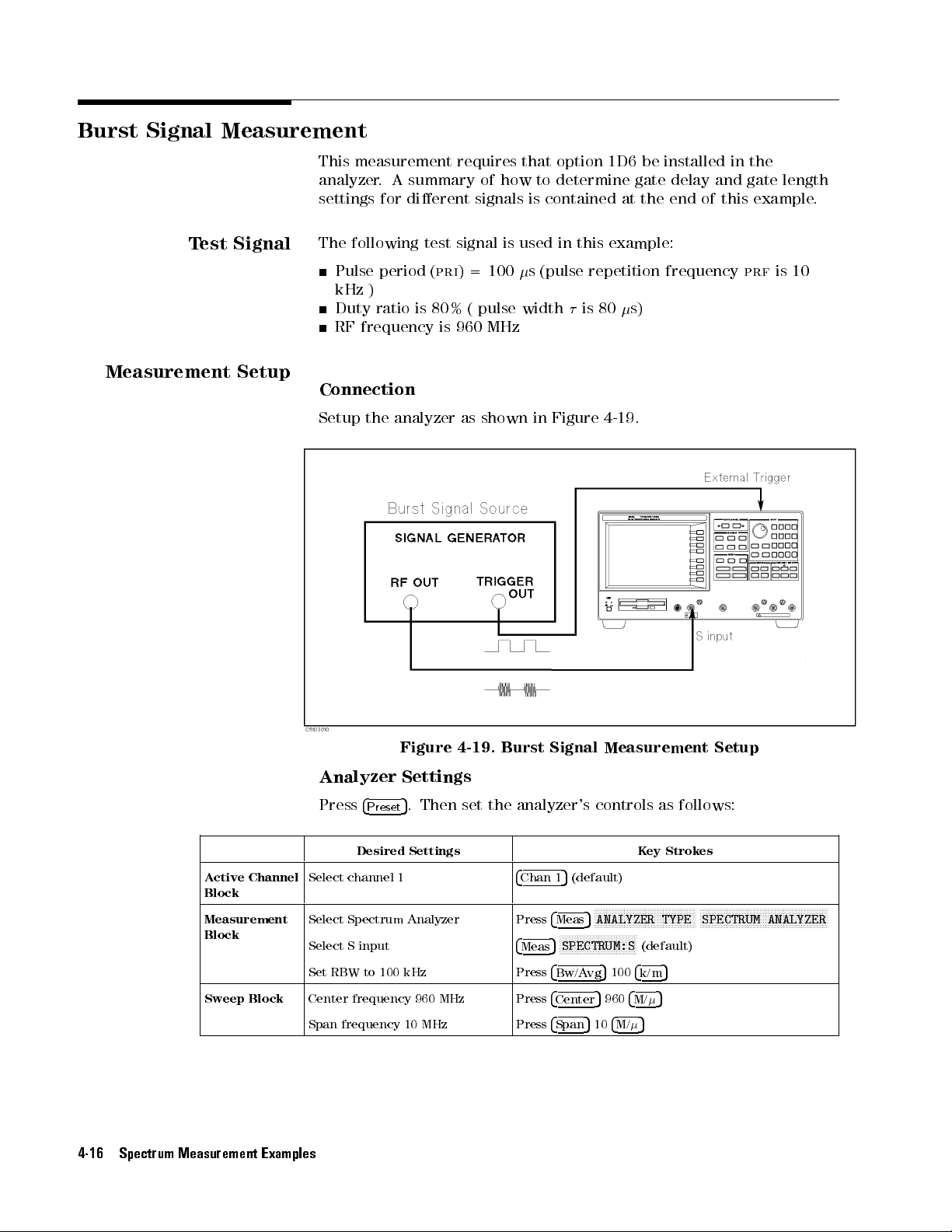

4-19. Burst Signal Measurement Setup . . .

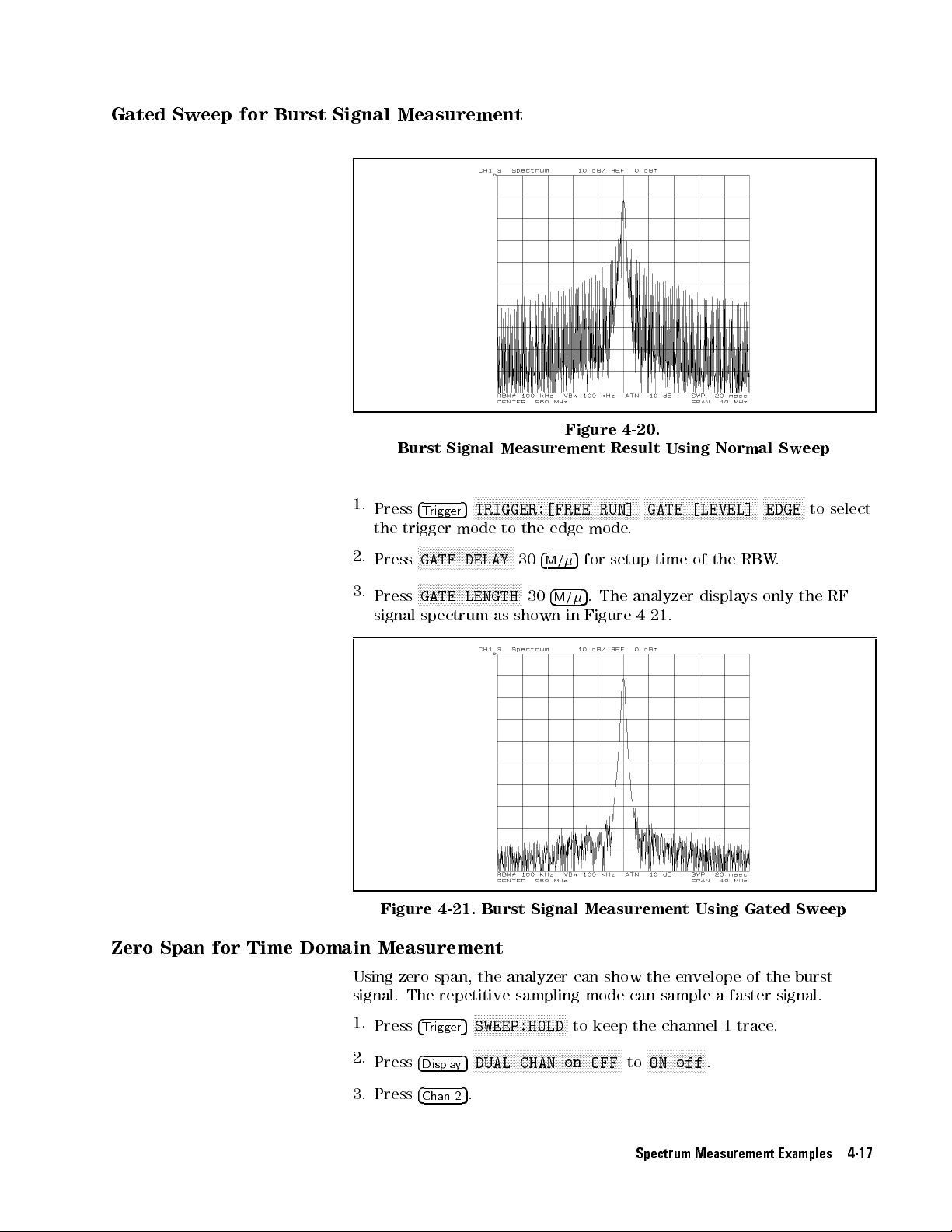

4-20. Burst Signal Measurement Result Using Normal Sweep

4-21. Burst Signal Measurement Using Gated Sweep

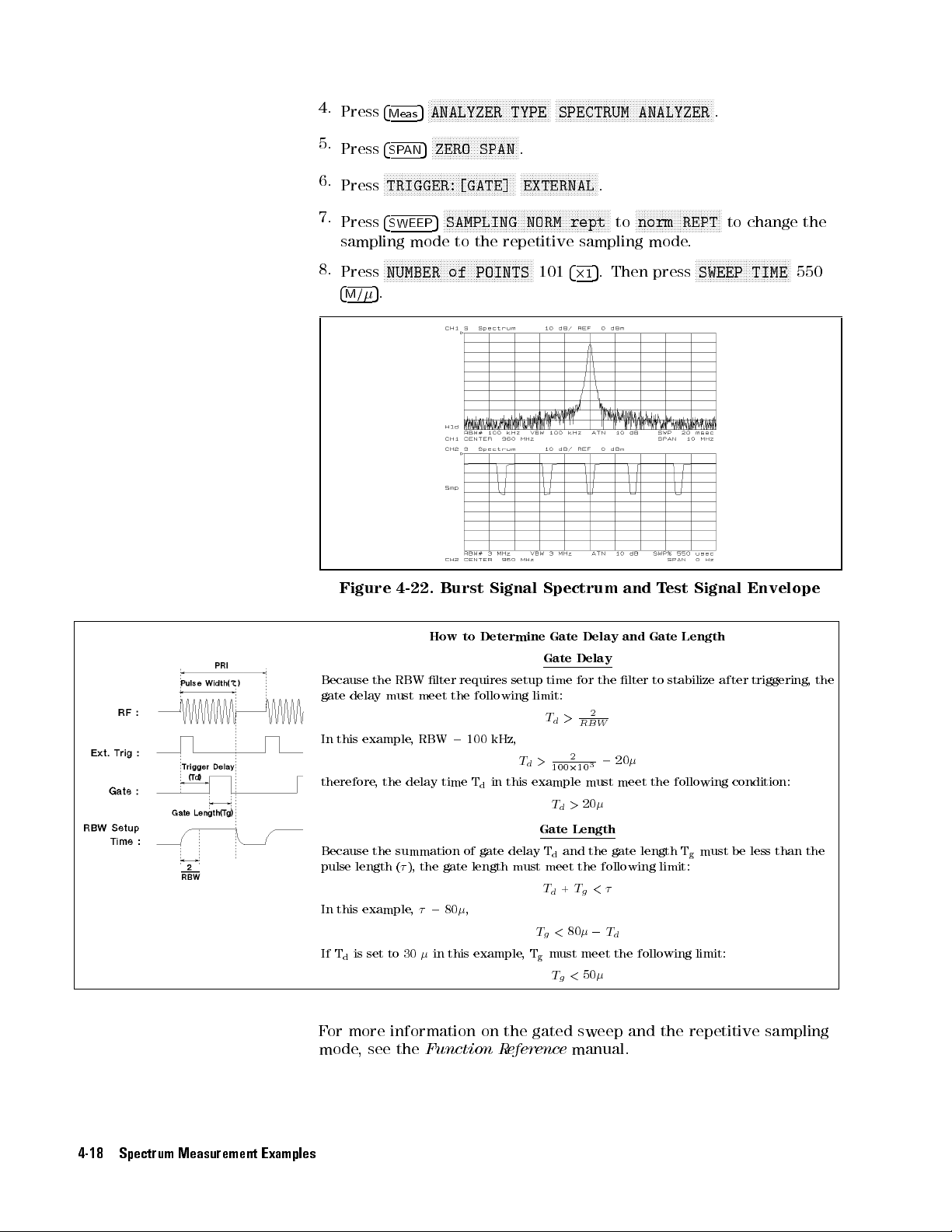

4-22. Burst Signal Spectrum and T

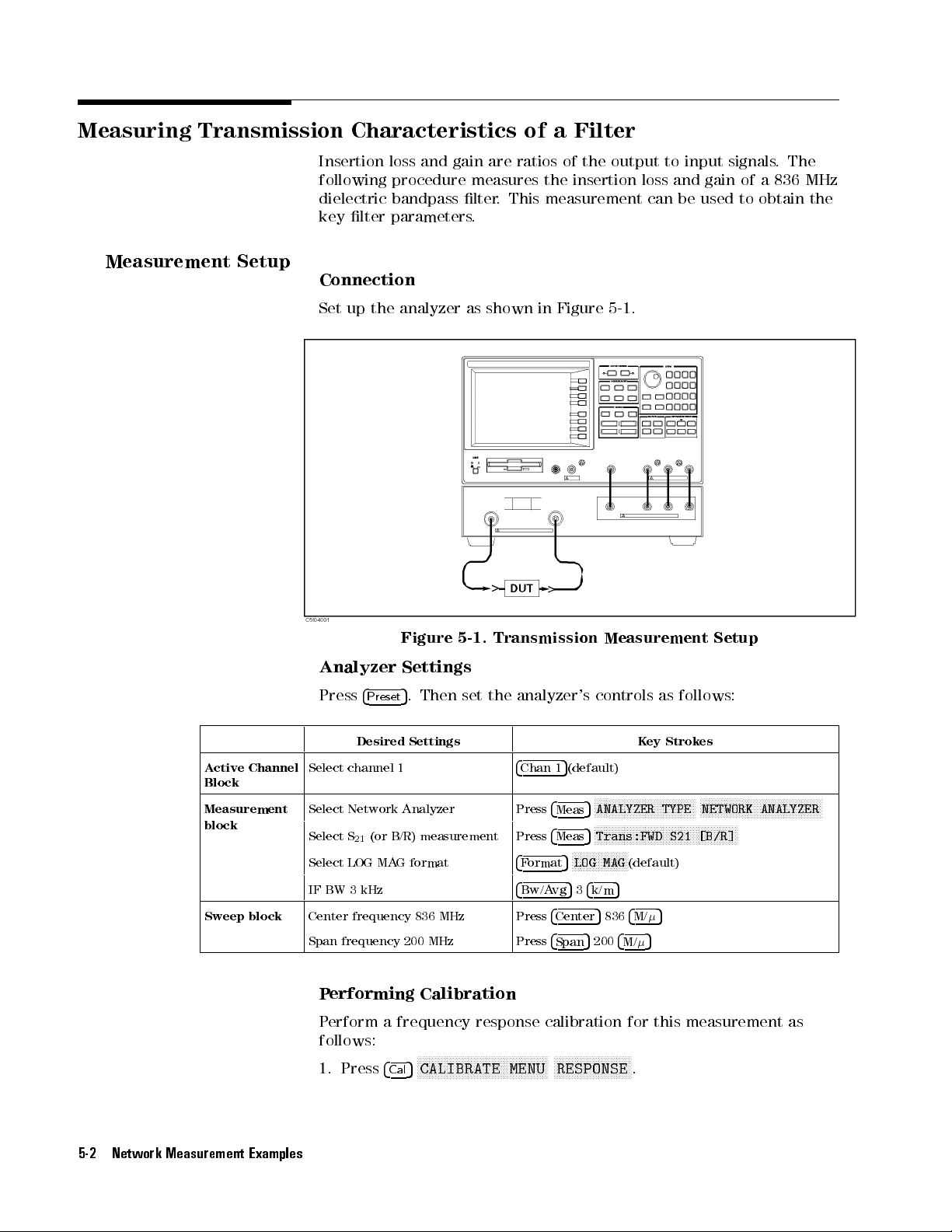

5-1. Transmission Measurement Setup .......... 5-2

5-2. Response of a Dielectric Filter . . . . . . . . . . . . 5-3

5-3. Using the Marker to Determine 3 dB Bandwidth ... 5-4

5-4. Using Peak Search to Determine Ripple ....... 5-5

5-5. Amplitude and Phase Response of a Dielectric Filter . 5-6

5-6. Expanded Phase Mode ............... 5-7

Mount

Network

Network

Using

a

Connecting

Required

Required

Transmission/Reection

arameter

Basic

Connection

Harmonics

Using

Multiple

Harmonic

Using

Markers

Display

Display

Inuence

an

Network

Transmission

Leakage)

Spectrum

Dual Display

Carrier Amplitude

Modulating Frequency

Wide Band

Zooming

Signal .. ....

Kits

a

Transmission/Reection

an

S-parameter

Analyzer

Analyzer

Analyzer

Transmission/Reection

a

Keyboard

Equipment

Equipment

T

est

Measurement

P

eak

Distortion

and

When

After

A

djacent

Starting

Signal

on

Network

Circuit

Measurement

Measurement

.

.

Monitoring

of Network

FM Signal

Carrier

.

.

.

Installation

T

Mode

(One

Mode

(One

Mode

(Two

.

.

.

.

.

.

.

.

T

est

Set

Setup

for

Spectrum

Setup

Search

Noise

Has

.

.

and Frequency

Signal

and

.

.

F

ormat

Signal

Drifted

Measurement

.

.

With

Result

.

.

..

Result

and Spectrum

of AM

Measurement .

of

FM

...... ...... ...

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

T

est

Set

est

Set

.

.

.

.

.

A

ctive

Probe)

A

ctive

Probe)

A

ctive

Probes)

T

est

Set

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Set

Setup

.

.

.

.

.

Measurement

.

.

.

Marker

.

.

.

.

.

to

Measure

Track

.

Spectrum

at

Signal .

Signal

est Signal Envelope

.

.

by

.

.

..

(Inuenced

..

..

the

B

Input

of AM

.

.

Monitor

.

Narrow Band FM

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

List

to

.

.

.

.

C/N

.

.

.

.

.

.

.

.

Leakage

..

.

.

..

.

.

.

..

Measurement

Signal .

..

.

.

..

..

.

.

.

..

........

...

........

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Measure

.

.

Ratio

.

.

.

.

from

.

.

Setup

by

.

.

..

.

.

.

.

.

....

....

...

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 3-4

.

.

.

.

..

.

.

.

.

.

.

.

.

.

. 4-9

.

.

.

.

.

.

.

.

.

1-12

1-13

1-14

1-15

1-16

1-17

1-18

4-11

4-11

4-13

4-14

4-14

4-15

4-15

4-16

4-17

4-17

4-18

1-5

1-7

2-2

3-2

3-3

4-1

4-2

4-3

4-4

4-6

4-6

4-7

4-7

4-8

4-9

Contents-5

Page 18

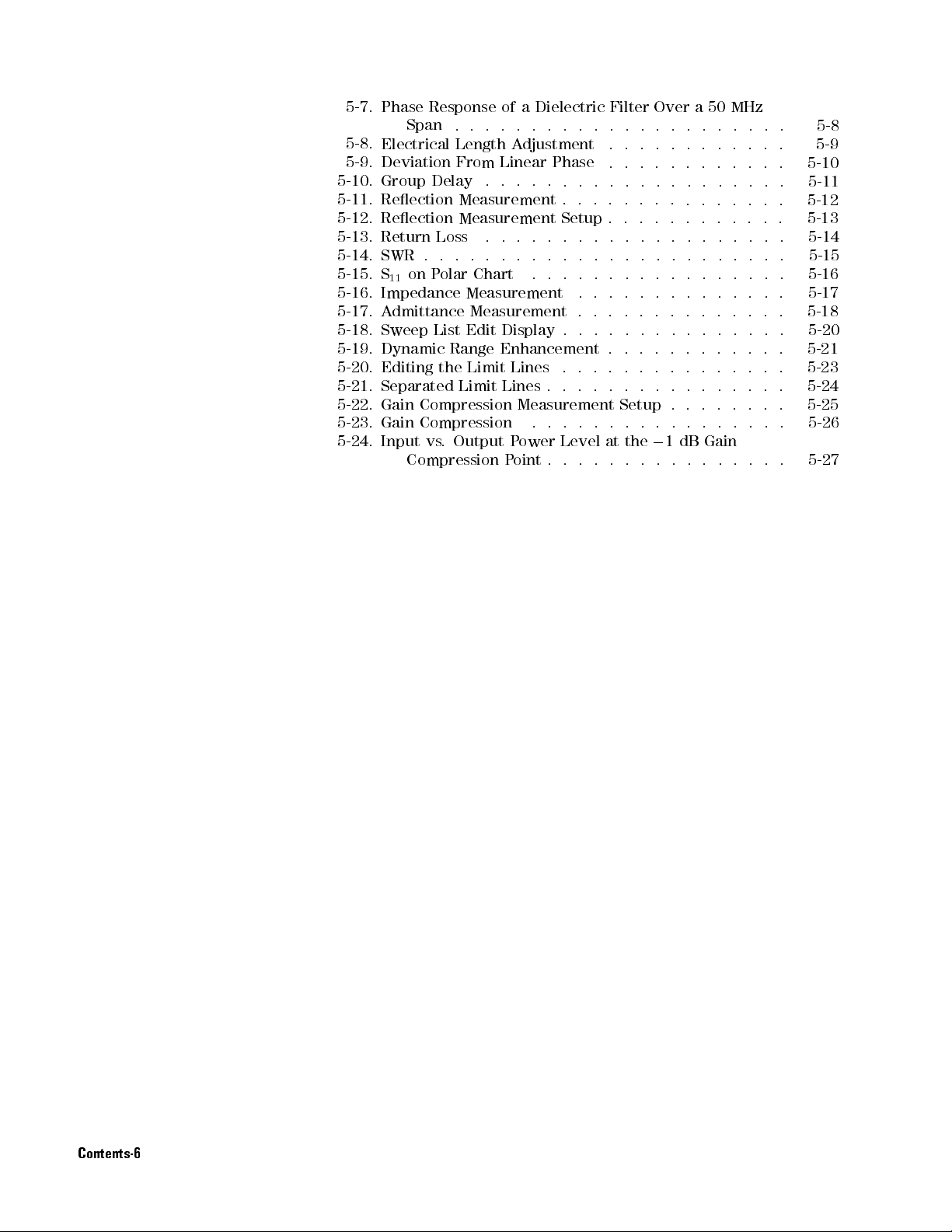

5-7.

Phase Response

Span

5-8.

Electrical Length

5-9.

Deviation From

5-10.

Group Delay

5-11.

Reection Measurement

5-12.

Reection

5-13.

Return

5-14.

SWR

5-15.

S

11

5-16.

Impedance

5-17.

A

dmittance

5-18.

Sweep

5-19.

Dynamic

5-20.

Editing

5-21.

Separated

5-22.

Gain

5-23.

Gain

5-24.

Input

..

Loss

.

.

.

on

P

olar

List

Range

the

Compression

Compression

vs

.

Output

Compression

of a

Dielectric

.

.

.

.

A

djustment

Linear

.

.

.

.

Measurement

.

.

.

.

.

.

.

.

.

Chart

.

Measurement

Measurement

Edit

Display

Enhancement

Limit

Lines

Limit

Lines

Measurement

.

P

ower

P

oint

.

.

Phase

.

.

.

Setup

.

.

.

.

.

.

.

.

.

.

.

.

Level

.

.

Filter

Over

a

50

MHz

.

.

.

.

.

..

..

..

..

. 5-8

.

.

.

.

.

.

.

.

.

..

. 5-9

.

.

.

.

.

.

.

.

.

..

. 5-10

.

.

.

.

.

..

..

..

..

. 5-11

.

.

.

.

.

.

.

.

.

.

..

..

5-12

.

.

.

.

.

.

.

.

.

.

..

5-13

.

.

.

.

.

..

..

..

..

.

5-14

.

.

..

..

..

..

.

.

.

.

5-15

.

.

.

.

.

.

.

..

..

..

. 5-16

.

.

.

.

.

.

.

.

.

.

.

..

. 5-17

.

.

.

.

.

.

..

..

..

..

5-18

.

.

.

.

..

..

..

..

.

.

5-20

.

.

.

.

.

.

.

.

..

..

5-21

.

.

.

.

.

.

..

..

..

.

.

5-23

.

.

.

.

.

.

..

..

..

.

.

5-24

Setup

.

.

.

at

.

.

.

.

the

.

..

0

.

.

.

..

1

.

.

dB

.

.

.

.

.

Gain

.

.

.

.

.

.

.

.

.

..

. 5-25

.

5-26

.

5-27

Contents-6

Page 19

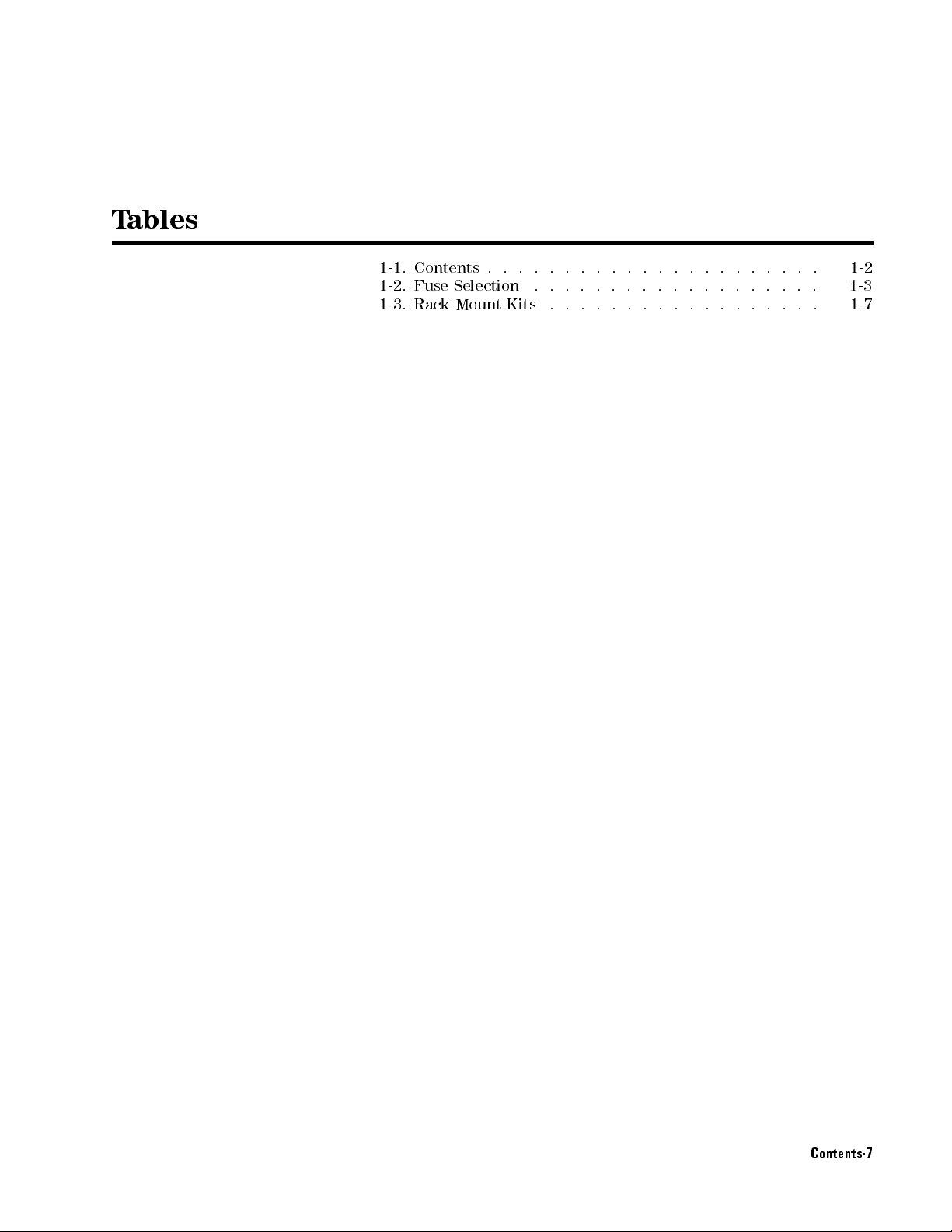

T

ables

1-1. Contents

1-2.

Fuse

Selection

1-3.

Rack

Mount

..

.

Kits

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

. 1-2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

. 1-3

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

. 1-7

Contents-7

Page 20

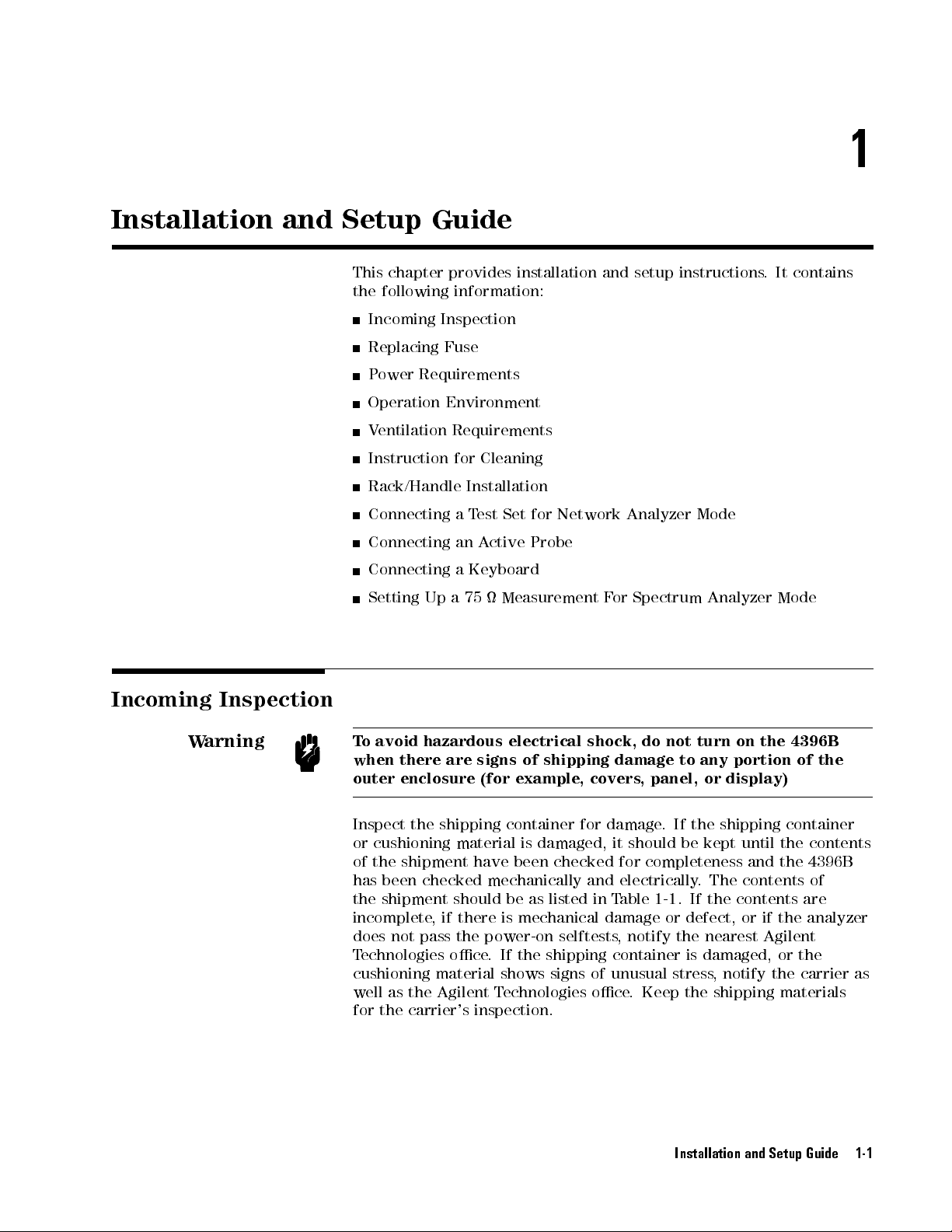

Page 21

1

Installation

and Setup

This chapter

the following

Incoming Inspection

Replacing Fuse

P

ower

Operation

V

entilation

Instruction

Rack/Handle Installation

Connecting

Connecting

Connecting

Setting

Guide

provides

information:

Requirements

Environment

Requirements

for

Cleaning

a

T

est

Set

an

A

ctive

a

Keyboard

Up

a

75

Measurement

installation

for

Network

Probe

and

Analyzer

F

or

setup

instructions

Spectrum

Mode

Analyzer

.

It

Mode

contains

Incoming

Warning

Inspection

T

o

avoid

when

outer

Inspect

or

cushioning

of the shipment have been checked for

has been checked mechanically and electrically

the shipment should be as listed in T

hazardous

there are

signs

enclosure (for

the

shipping

material

electrical

of

shipping

example,

container

is

damaged, it

shock,

covers

for damage

do

damage

,

panel,

.If

should

not

turn

to

any

or

the shipping

be

kept

portion

display)

completeness and the 4396B

.The

able 1-1. If the contents are

on

the

4396B

of

container

until

the

contents of

the

contents

incomplete, if there is mechanical damage or defect, or if the analyzer

does not pass the power-on selftests

Technologies oce

. If the shipping container is damaged, or the

cushioning material shows signs of unusual stress

well as the Agilent T

echnologies oce

, notify the nearest Agilent

, notify the carrier as

. Keep the shipping materials

for the carrier's inspection.

Installation and Setup Guide 1-1

Page 22

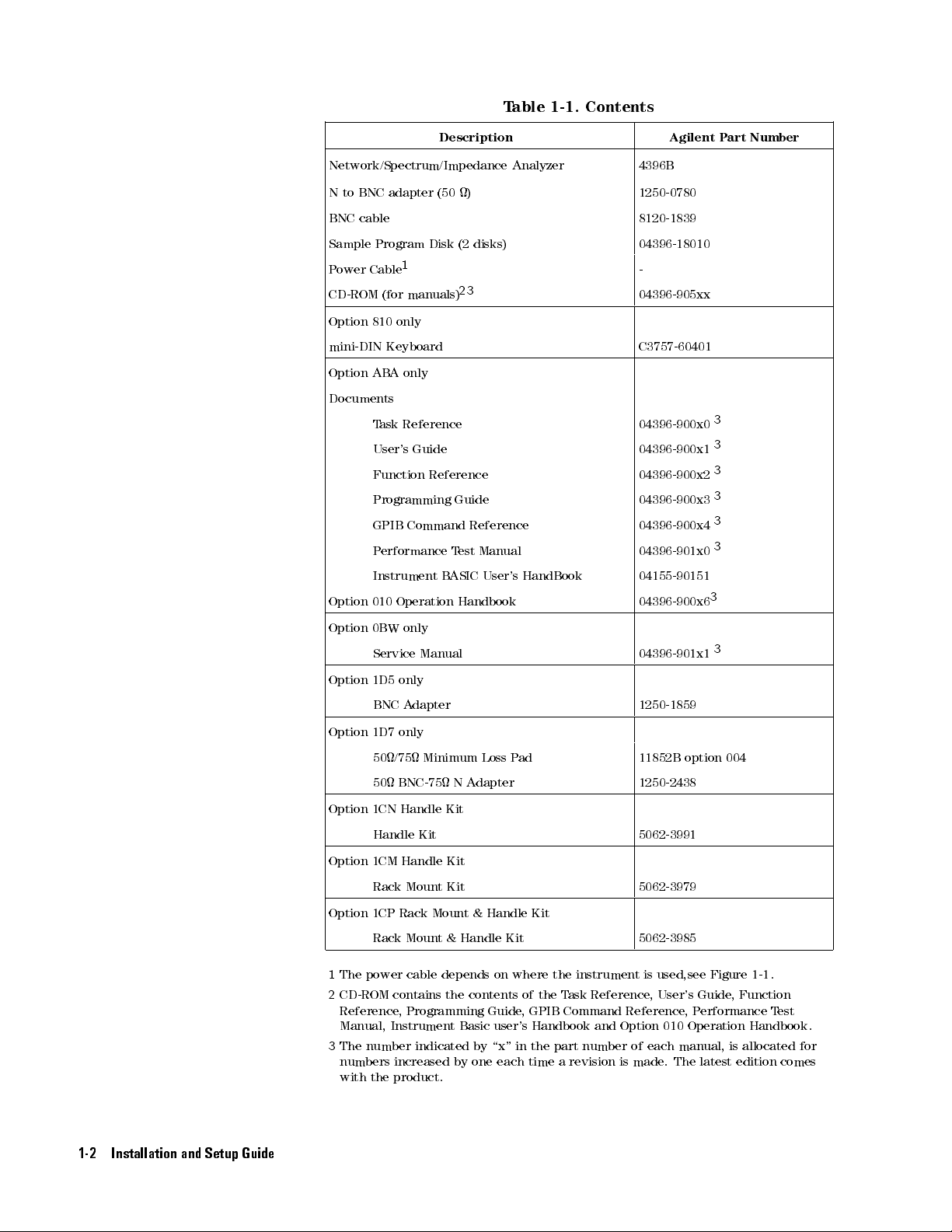

T

able 1-1.

Contents

Description Agilent

Network/Spectrum/Impedance Analyzer 4396B

N

to

BNC

BNC

cable

Sample

P

ower

CD-ROM

Option

mini-DIN

Option

adapter

Program

1

Cable

(for manuals)

810

only

Keyboard

AB

A

only

(50

Disk

)

(2 disks)

2

3

1250-0780

8120-1839

04396-18010

-

04396-905xx

C3757-60401

Documents

04396-900x0

04396-900x1

04396-900x2

04396-900x3

04396-900x4

04396-901x0

04155-90151

04396-900x6

Option

T

ask

Reference

User's

Guide

Function

Reference

Programming

GPIB

Command

P

erformance

Instrument

010

Operation

Guide

Reference

T

est

B

ASIC

Handbook

Manual

User's

HandBook

P

art

Number

3

3

3

3

3

3

3

Option

0BW

only

Service

Option

1D5

BNC

Option 1D7

50/75 Minimum

50 BNC-75

Option

1CN

Handle

Manual

only

A

dapter

only

Handle

Kit

Kit

N

Loss P

A

dapter

ad

04396-901x1

1250-1859

11852B option

1250-2438

5062-3991

3

004

Option 1CM Handle Kit

Rack Mount Kit 5062-3979

Option 1CP Rack Mount & Handle Kit

Rack Mount & Handle Kit 5062-3985

1

The

power cable depends on where the instrument is used,see Figure 1-1 .

Reference, Programming Guide, GPIB Command Reference,Performance Test

Manual, Instrument Basic user's Handbook and Option 010 Operation Handbook.

3

The number indicated by \x" in the part number of each manual, is allocated for

numbers increased by one each time a revision is made. The latest edition comes

with the product.

1-2 Installation and Setup Guide

Page 23

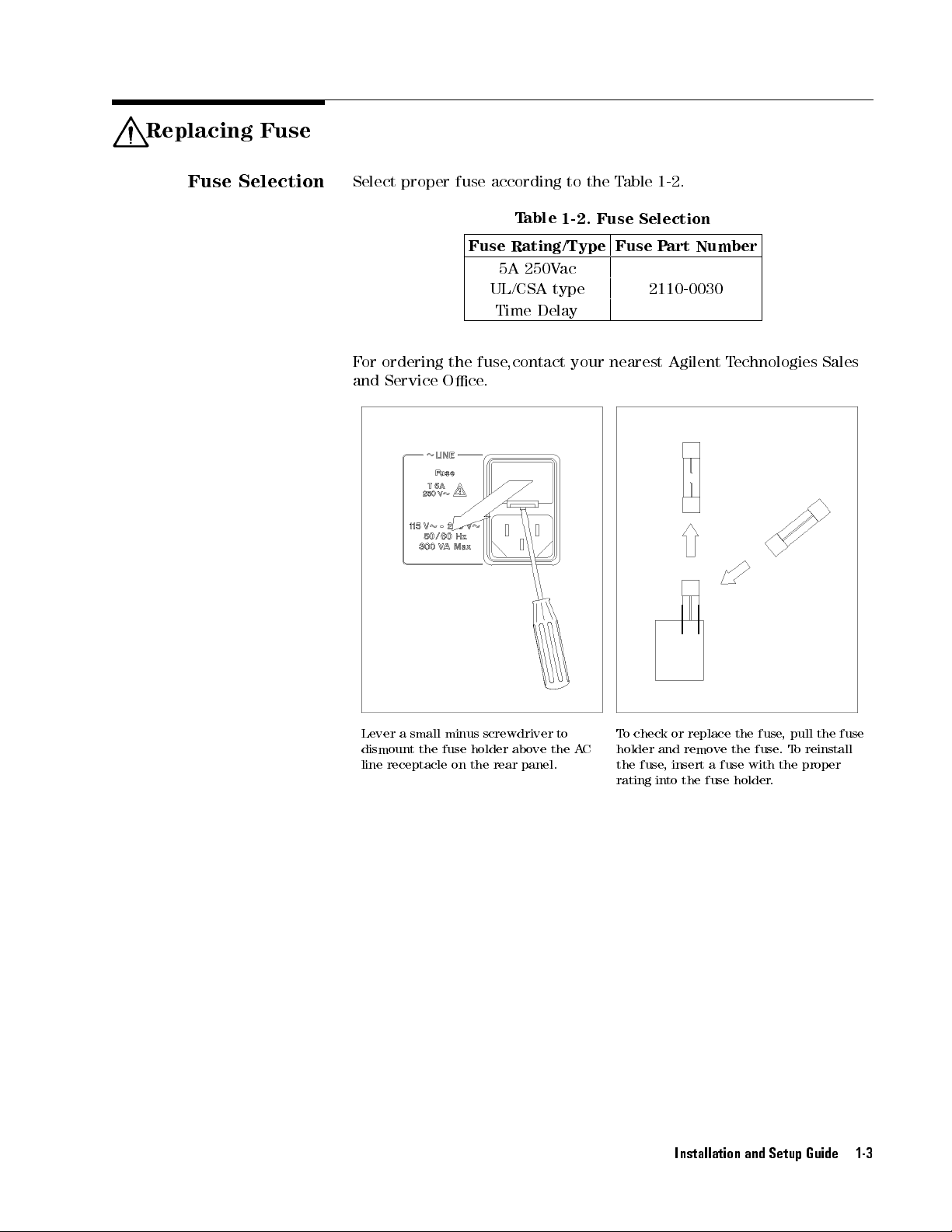

Replacing Fuse

Fuse

Selection

Select

F

or

ordering

and

proper fuse

Service

Fuse

the

Oce

according to

T

able

Rating/Type

5A

250V

UL/CSA

Time

Delay

fuse

,contact

.

1-2.

ac

type

your

the T

Fuse

nearest

able

Selection

Fuse

2110-0030

1-2

.

P

art

Agilent

Number

T

echnologies Sales

Lever

a

dismount

line

receptacle

small

the fuse

minus

holder above

on the

screwdriver

rear panel.

to

the

T

o

check

or

replace

the

fuse

,

pull

the

fuse

holder

the

rating

and remove

fuse

,insert

into

the

A

C

afuse

fuse

the fuse

with the

holder

.

T

o

reinstall

proper

.

Installation and Setup Guide 1-3

Page 24

Power

Requirements

P

ower

W

arning

Cable

The 4396B

Voltage

requires the

:90

Frequency :

Power

:300

In accordance

is equipped

with a

appropriate ac

frame.

The type

the country

of the

F

or

must

The

protective

of power

of destination.

power cables

protection

not

be

power

plug

earth

following power

to 132

47 to

VA

Vac

,198

63 Hz

maximum

with international

three-wire power

power outlet,

cable

shipped

Refer

available

from

electrical

defeated.

must

be

plugged

ground

connection.

to 264

V

ac

safety standards

cable.

this

cable

with

each

to

Figure

.

shock,

into

source:

When

grounds

instrument

1-1

the

power

an outlet

,this

instrument

connected

the

instrument

depends

for

the

part

cable

that provides

to

numbers

ground

an

on

a

1-4 Installation and Setup Guide

Page 25

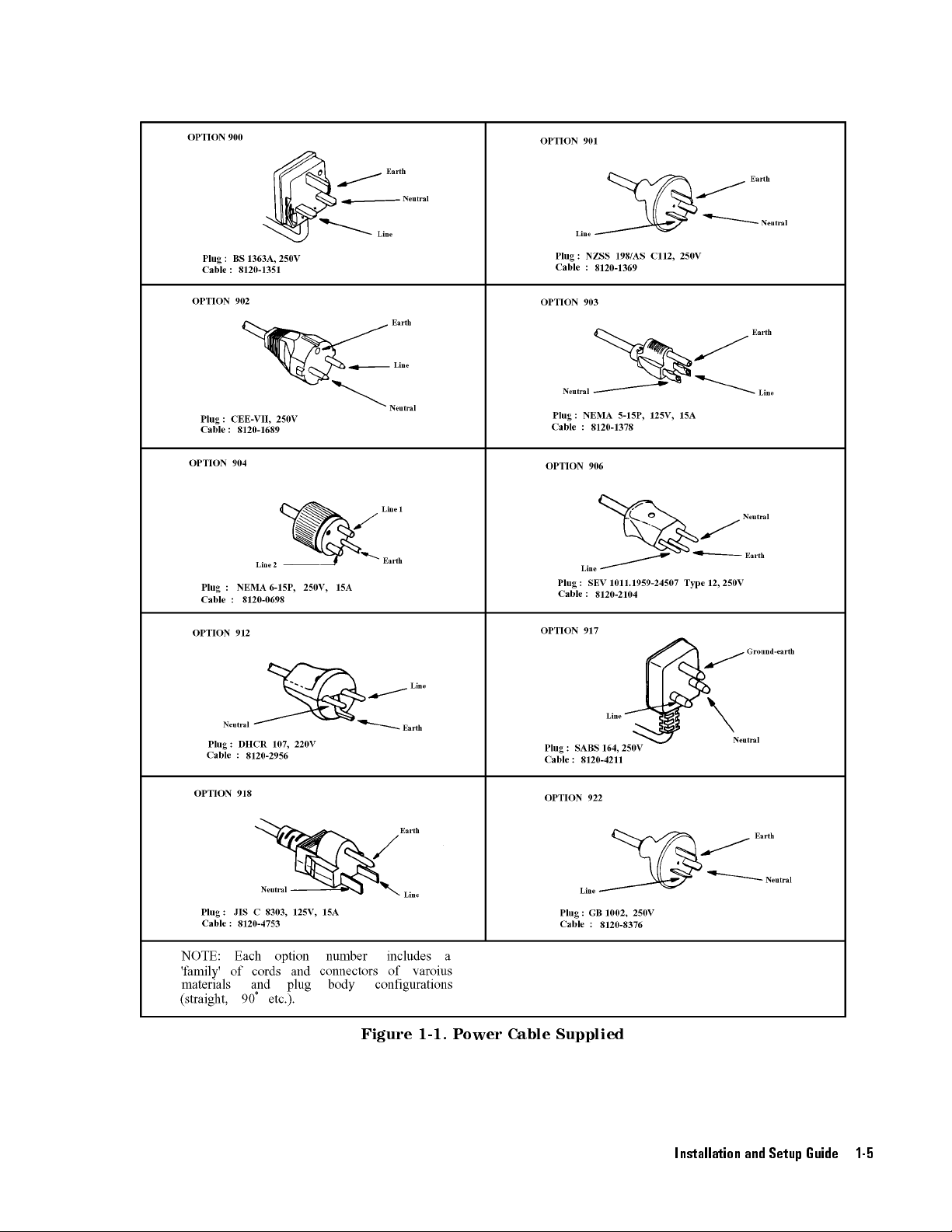

Figure 1-1. Power Cable Supplied

Installation and Setup Guide 1-5

Page 26

Operation Environment

Providing

Note

clearance

The 4396B

conditions,

must be

and sucient

avoid obstructing

Temperature:

Humidity: less

The

4396B

cause

to

dissipate

T

o

ensure

product,

within

around

air-cooling

temperature

the

product,

Reference

When

temperature

to

\Operation

the

product

Furthermore

conrmed

safety

must

condensation

the

you must

the

specied

the

product

inside

to

refer

.

the

ambient

range

conforms

,

that

standard

operated under

the air

Cto

0

40

than 95%

be

protected

within

heat

at

specications

keep

ambient

range

or

,

for

the

rack

satisfy

the

to

\Specications"

temperature

of

the

Conditions"

to

the

under

that

the

product

when it

temperature environment,

is enclosed

within the

space must

ow of

C

RH at

from

the

be kept

the cooling

40

temperature

instrument.

installation

and

measurement

temperature

by

providing

the

rackmount

housing.

F

or

specications

in

around

operating

in

Chapter

environment

10

requirements

still conforms

with cooling

following environment

behind the

fans.

C

extremes

site

accuracy

around

appropriate

type

,

by

information

and

measurement

Chapter

the

product

of

the

function

of

the

to the

requirements

4396B to

which could

of

the

the

product

cooling

forcefully

on

ambient

accuracy

10

of

the

Function

is

kept

specication

reference),

safety

standard.

it has

been

clearance as

clearance

within

the

(refer

of

the

follows:

of

Instruction for Cleaning

To prevent electrical shock, disconnect the 4396B power cable from

the receptacle before cleaning. Wipe with a dry cloth or a soft cloth

that is soaked with water and wrung tightly without undeue pressure

to clean the casing. Do not attempt to clean the 4396B internally.

1-6 Installation and Setup Guide

Conditions

Rear 180 mm

Side 60 mm

Page 27

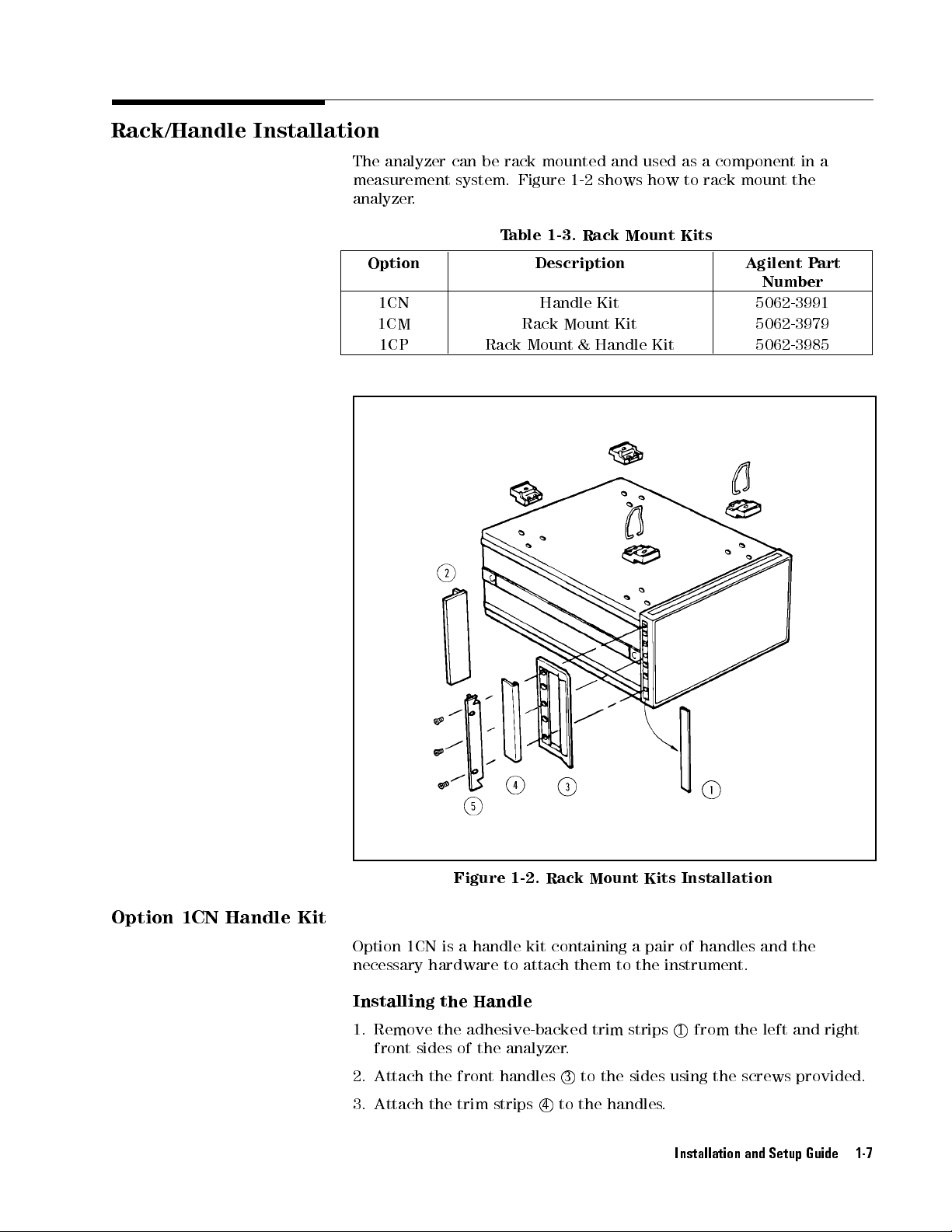

Rack/Handle Installation

The analyzer

measurement system.

can be

rack mounted

Figure 1-2

and used

shows how

as a

component in

to rack

mount the

analyzer.

Table

1-3. Rack

Mount Kits

Option Description Agilent P

Number

1CN Handle

Kit

1CM Rack Mount

1CP Rack

Mount &

Handle

Kit

Kit

5062-3991

5062-3979

5062-3985

a

art

Option 1CN Handle Kit

Figure 1-2. Rack Mount Kits Installation

Option

necessary hardware

1CN is a handle kit containing a pair of handles and the

to attach them to the instrument.

Installing the Handle

1. Remove the adhesive-backed trim strips1

front sides of the analyzer.

2. Attach the front handles3

3. Attach the trim strips4

to the sides using the screws provided.

to the handles.

Installation and Setup Guide 1-7

from the left and right

Page 28

Option

1CM

Rack

Mount

Kit

Option

1CP Rack

Mount &

Option

1CM

necessary

rack

with

Mounting

1.

Remove

front

sides

2.

Attach

the

analyzer

3.

Remove

slide

the

Handle

Option

1CP

necessary

handles

attached,

spacing.

Mounting

1.

Remove

front

sides

is

a

rack

mount

hardware

482.6

the

the

the

all

foot

to

mount

mm

(19

inches)

Rack

adhesive-backed

of

the

analyzer

rack

using

four

toward

mount

feet

the

(lift

the bar).

ange

screws

Kit

is a

rack

mount

hardware

the

to

mount them

in

an

equipment

Handle and

the adhesive-backed

of

the

analyzer.

kit

containing

them

to

the instrument

horizontal spacing.

trim

strips

.

2

to the

provided.

bar

on

the inner

kit

containing

to

an

rack

with

Rack

trim strips

a

pair

of anges

1

from the

left and

right front

side of

a

pair

of

instrument

482.6

1

from

in an

left and

the foot,

anges

which

mm (19

the

left

and the

equipment

right

sides

and

and

the

has

inches)

and

right

of

2.

Attach

on

the

provided.

3. Remove

slide the

the

left

all

front

and

foot

four

toward

handle

right

feet

3

and

front sides

(lift

bar

on

the

bar).

the

of

the

rack

the

inner

mount

analyzer

side

ange

using

of

the

5

the

foot,

together

screws

and

1-8 Installation and Setup Guide

Page 29

Front View

1.

LCD

system

2.

4

LINE

3.

3.5 inch

instrument

displays

5

switch

measured

messages,

turns

disk drive

settings

results

error

messages

the analyzer

is used

,

display

, softkey

,

and

ON

to store

images

menus,

Instrument

and

OFF

measurement

,

and

Instrument B

current settings

B

ASIC

.

results

ASIC

programs

,

programs.

4.

CAL OUT (spectrum analyzer calibration output port)

supplies a reference signal (20 MHz, -20 dbm) for reference level

calibration.

5.

S input (spectrum analyzer input)

receives a signal for a

spectrum measurement.

INSTALLATION CATEGORY I

6.

RF OUT (RF signal output port)

supplies a source signal for

network measurements.

Installation and Setup Guide 1-9

,

.

Page 30

7.

R,

A,

and

for network

measurement inputs

B inputs

(RF signal

measurements,

.

but can

inputs)

also be

mainly

used as

accept signals

spectrum

INSTALLA

8.

MARKER

9.

INSTRUMENT

TION CA

block

STA

analyzer functions

10.

ENTRY

block

contains

increment/decrement keys

11.

Rotary

12.

SWEEP

13.

MEASUREMENT

functions

14.

ACTIVE

15.

Softkeys

pressing

function

knob

changes

block

contains

.

CHANNEL

used

with

hardkeys

or

accesses

TEGORY I

contains

TE block

.

displayed

block

block

hierarchical

.

Pressing

a

lower

keys related

contains keys

numerical keys

, edit

keys,

value

keys

related

controls

selects

to

the

the

menus

a

softkey

level

menu.

to the

, rotary

marker

related

knob

functions

to

setting

,

and unit-terminator

by

turning

the

measurement

active

that are

activates the

sweep

channel

displayed by

the

knob

functions

and

as

displayed

keys

.

.

display

1

or

2.

.

.

1-10 Installation and Setup Guide

Page 31

Rear View

Caution

16.

If you

may

TEST

test

set to

connect a

cause

SET-I/O

the analyzer

printer with

damage

to

the

connector.

17.

Parallel interface

18.

GPIB interface

connects the printer to the analyzer

controls an GPIB instrument or can be controlled

by an external controller

19.

Power cable receptacle

in the cover of the receptacle

INTERCONNECT

connects

.

the TEST

printer

.

SET-I/O INTERCONNECT

Do

not

connect

.

connects the power cable

.

Installation and Setup Guide 1-11

the

a

printer

. Fuse

S-parameter

,it

to this

.

is held

Page 32

Connecting a

Test

Set for

Network Analyzer

To

use the

required to

the device

You

can use

set or

the 85046A/B

measures reection

The 85046A/B

reverse directions

For

more

Function R

network analyzer

measure the

under test

either the

(DUT).

87512A/B

S-parameter test

and transmission

S-parameter test

without reconnection.

information

eference

about

manual.

Mode

mode of

the analyzer

transmission and

transmission/reection

set.

in the

set measures

the

test

sets

,a

test

set

is

reection characteristics

(T/R)

The

,

see

87512A/B

forward

both

chapter

the

T/R

direction

forward

9

of

the

test

test

only

of

set

.

and

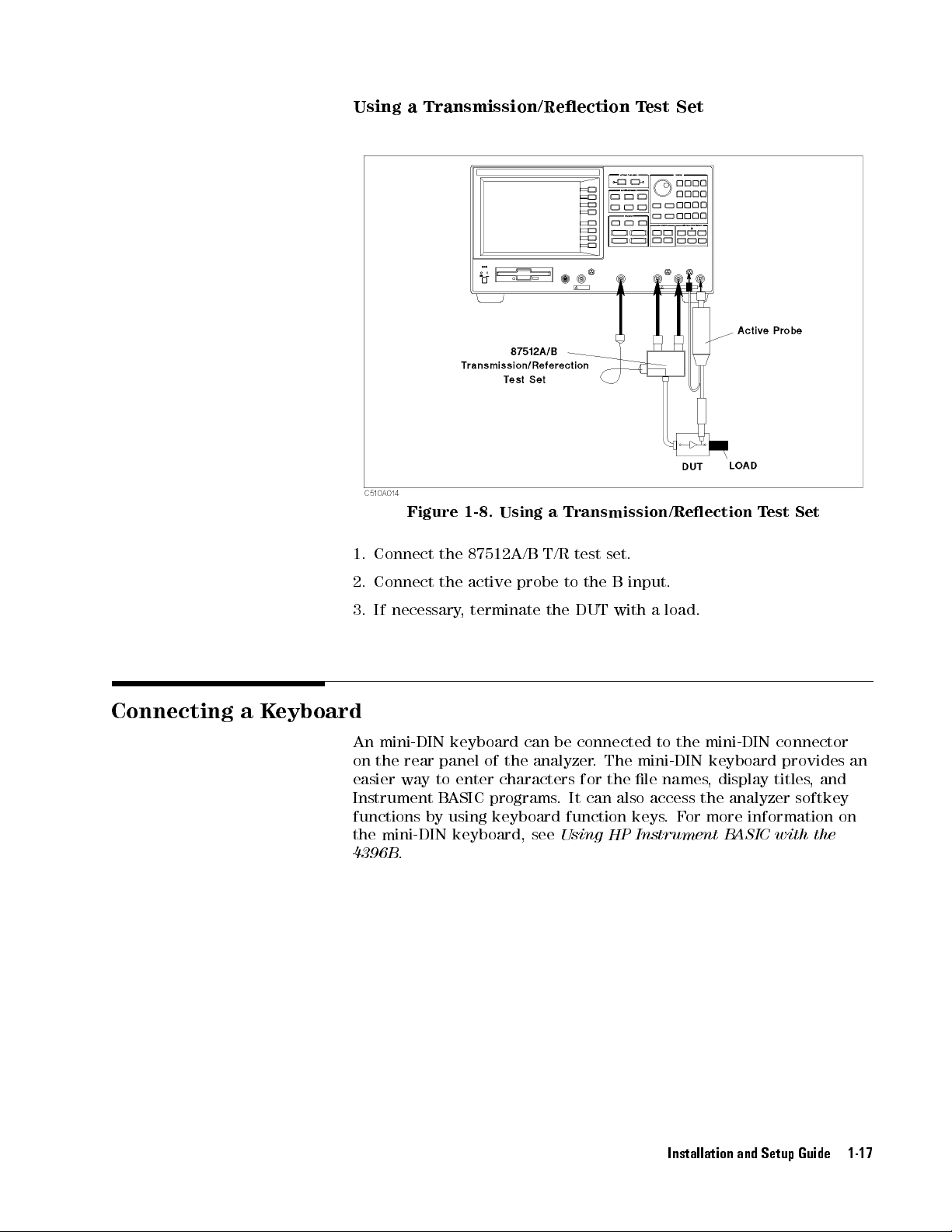

Connecting a

Transmission/Reection

T

est

Set

1-12 Installation and Setup Guide

Figure 1-3. Connecting a Transmission/Reection T

est Set

1. Place the transmission/reection (T/R) test set in front of the

analyzer.

2. Connect the R and A ports of the analyzer and the T/R test set to

each other.

3. Connect the RF OUT port of the analyzer and the RF IN port of the

T/R test set with a semi-rigid cable.

Page 33

Note

When

4

5

2

1

to

you

set

use

the

the

characteristic

87512B

,

press

impedance

4

Cal

5

N

N

N

N

N

N

N

N

MORE

(Z

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

NN

N

0

)

SET

to

75

NN

Z0

NN

.

NN

N

.

Then

press

5

5

4

4

7

5

Connecting

an

S-parameter

T

est

Set

Note

Figure

1.

Place

the

2.

Connect

rear

panel

INTERCONNECT

with

the test

3. Connect the RF OUT

analyzer

the

TEST

of

the

set.

1-4.

Connecting

on

the

S-parameter

SET-I/O

analyzer

interface

, R, A, and B inputs of the analyzer to the

S-parameter test set to each other

When you use the 85064B

5

to

4

2

set the characteristic impedance (Z

1

, press

an

S-parameter

test set.

INTERCONNECT

and

the

NETWORK ANAL

of

the

test

set

.

N

NNNN

NNNN

NNNNNNNNN

5

MORE

4

Cal

)to

0

interface

using

NNNNNNNNNNNNNNNN

SET Z0

75 .

T

est

Set

on the

YZER-I/O

the cable

. Then press

furnished

4

7545

5

Installation and Setup Guide 1-13

Page 34

Connecting an

Active

Probe

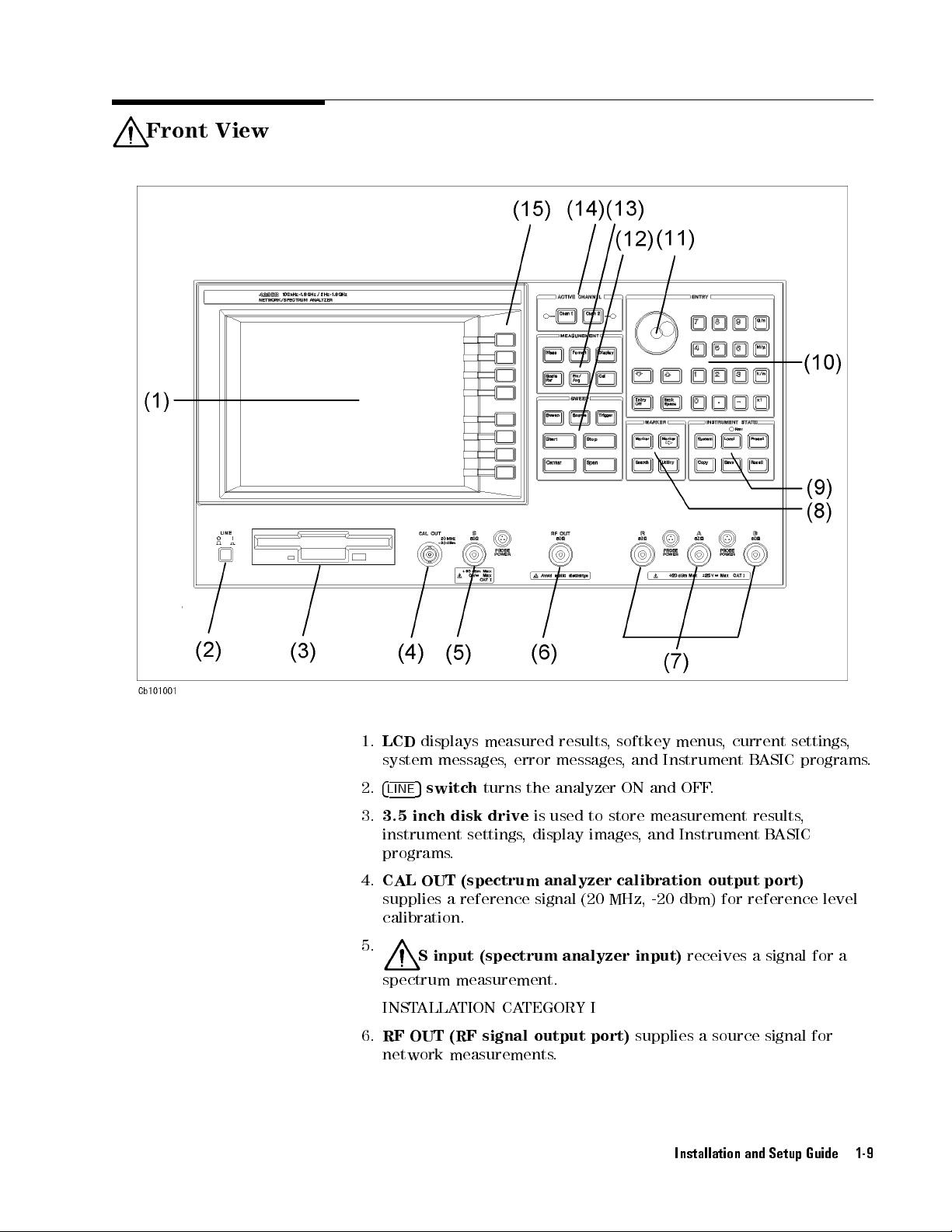

F

or Spectrum

The active

that has

be used

The analyzer

85024A High

41800A A

41802A 1

51701A A

11945A Close-eld

1141A Dierential

F

or

Function

Analyzer Mode

more

probe allows

no port

for both

can use

Frequency Probe

ctive Probe

M

Input

ctive

information

R

eference

you to

for connecting

spectrum and

the following

(5 Hz

A

dapter

Probe

(DC

Probe

to

Set

Probe

about

these

manual.

analyze an

to the

in-circuit signal

test set.

The active

network measurements

to

500

(5

2.5

active

(300 kHz

Hz

GHz)

active

MHz)

to

100

probes:

to

3

MHz)

probes

GHz)

,

see

.

chapter

or device

probe

can

9

of

the

1-14 Installation and Setup Guide

Figure 1-5. Spectrum Analyzer Mode (One A

ctive Probe)

1. Connect the output connector of the active probe to the S port of

the analyzer

2. Plug the probe power plug into

.

the PROBE POWER connector

.

Page 35

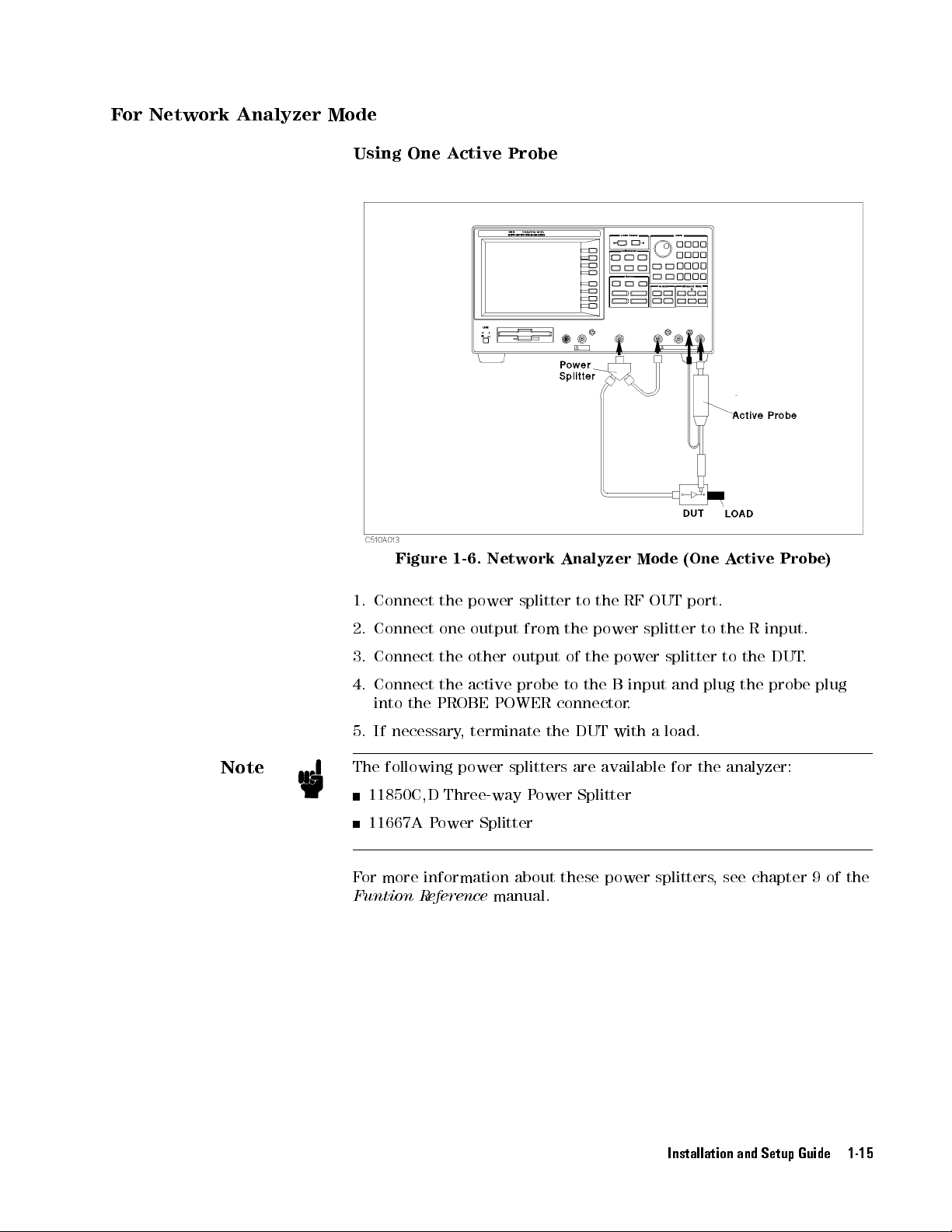

F

or

Network

Analyzer

Mode

Using

1.

Connect

One A

Figure

ctive Probe

1-6.

Network

the

power

splitter

Analyzer

to the

Mode

RF

OUT

(One

port.

Active

Probe)

Note

2.

Connect

3.

Connect

4. Connect

into the

5. If

necessary,

The

following power

11850C,D

11667A

one

output

the

other

the

active

PROBE

terminate

Three-way P

Power

Splitter

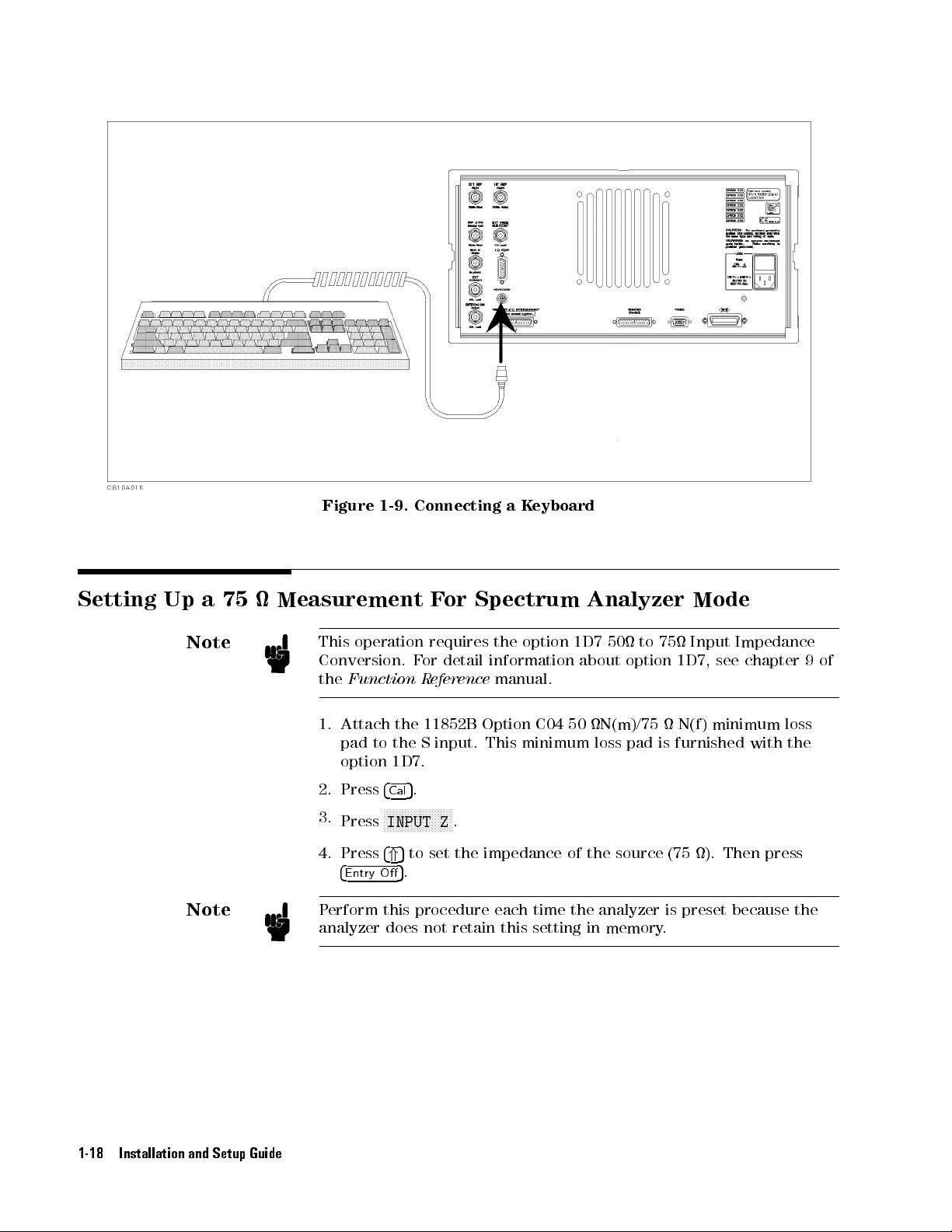

POWER