Page 1

Haustechnik,

: die weiterdenkt

О

Ш

<

WSP 2010, WSP 3010,

WSP 4010, WSP 5010,

WSP 6010, WSP 7010

Wärmespeicher

Standard-Baureihe

Gebrauchs- und Montageanweisung

Deutsch

WSP 2010, WSP 3010,

WSP 4010, WSP 5010,

WSP 6010, WSP 7010

Electric Storage Heaters

Standard Series

Operating and Installation instructions

WSP 2010, WSP 3010,

WSP 4010, WSP 5010,

WSP 6010, WSP 7010

Accumulateurs de chaleur

English

Français

Série standard

Notice d'utilisation et de montage

WSP 2010, WSP 3010,

WSP 4010, WSP 5010,

WSP 6010, WSP 7010

Warmteaccumulator

standaard sérié

Gebruiks- en montagehandleiding

Nederlands

Page 2

шш005<

ч

ÍZ^

вг

iiiiiiimiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiimmiiimiiiiiimiiiiiiiiiiniiMi \T

HiiiiiiiiiMiiiiiiiiiiiiiuimiiiiiiHiiuiiiiiiiiiHiiHiiiinininiiiimiLiL

ÌT”“ F

9

/I

rrm

81 £l (SN)6L

О

иш

шшо01<

LUUJ00l<

LULilO¿<

UJUJ00L< .

LUlUOt'^

u

±

mi

Page 3

60-

П

п

464

3 2

■п 3

г ^

3

3

I =>^

п 12

2

2

2

2

► 2-1

1 т

1 1

1

1

ъ

Page 4

61

I I I 1 1 1 1 1 1 1 1 l i l i 1 1 1 1 1 1 1 1 1 1 i ' l l

- - - - - - - - - - - - - - - - -

f n 1

о

О

идим»

\

.......................

nil

............

HHIIIIlillllll

......................

О

iiiiiiiiiiiiiii

HIIIIItlHIHIlllHI 1

! I II

0=^

81

9L

¿I

9L

Page 5

Deutsch

English

Inhaltsverzeichnis

1. Gebrauchsanweisung

Für den Benutzer

1.1 fieräteheschreibung

1.9 Bedienung

1 2 Sirherheitshinweise

14 Pflege und Wartung

1 .S Wichtiger Hinweis

Wa.s tun wenn ... ?

2. Montageanweisung

Für den Installateur

2.1 Technische Daten

2 2 fieräteheschreibunq

2.3 Vorschriften und Bestimmungen

2.4 Montageort

2..S Gerätemontage

2 fi Erstinbetriehnahme

2.7 Instandsetzung, Umbau des Gerätes

2.8 Übergabe

3. Kundendienst und Garantie

3.1 Entsorgung von

Verpackung und Altaerät

____

10

11

12

12

16

16

16

19

20

Table of Contents

1. Operating instructions

For the user

6

6

7

7

8

8

9

1.1 Teehnical description

1.2 Operation

1.3 Safety instructions

1.4 Care and maintenance

1.R Important note

What to do when . . ?

2. Installation instructions

For the fitter

2.1 Technical data

2.2 Technical description

2.3 Rules and regulations

2.4 Installation

2.R Unit installation

2.fi First-time operation

2.7 Repair, conversion of unit

2.8 Transfer

3. Environment and recycling

21

21

22

22

23

23

24

25

26

27

27

31

31

31

34

Français

Sommaire

1. Notice d'utilisation

A l'intention de l'utilisateur

1.1 Description de l'appareil

1.2 Commande

1 3 Consignes de sécurité

1 4 Entretien et maintenance

1 .R Remarque importante

Que faire si ... ?

2. Notice de montage

A l'intention de l'installateur

2 1 Caractéristiques techniques

2.2 Description de l'appareil

2.3 Consignes et réglementations

2 4 Site de montage

2 R Montage de l'appareil

2 fi Première mise en service

2.7 Réparation, modification de l'appareil.

2 8 Remise à l'utilisateur

3. Environnement et recyclage

35

35

36

36

37

37

38

39

40

41

41

45

. 45

45

48

Nederlands

Inhoudsopgave

1. Gebruiksaanwijzing

Voor de gebruiker

1.1 Beschrijving van bet apparaat

1.2 Bediening

1.3 Veiligheidsvoorschriften

1.4 Verzorging en onderhoud

1.R Belangrijke aanwijzina

Wat te doen wanneer... ?

2. Montagehandleiding

Voor de installateur

2.1 Technische gegevens

2.2 Beschrijving van het apparaat

2 3 Voorschriften en bepalinaen

2.4 Montageplaats

2.R Montage van apparaat

2.6 Eerste inbedriifstellina

2.7 Reparatie, ombouwen van het apparaat 59

2.8 Aflevering

3. Milieu en recycling

49

49

50

50

51

51

52

53

54

55

55

59

59

62

Page 6

For the User

1. Operating Instructions

1.1 Technical Description

Storage heaters store electrically generated heat during low-cost electricity tariff periods

(depending on the electricity supply company, mainly during the night hours). This is then

discharged according to the desired room temperature as hot air by a fan and to a smalt extent

through the surface of the heater.

1.2 Operation

The unit is operated by the control panel (1) on the right side wall (fig. 1).

1.2.1 Heat Storage

The degree of heat storage (charging) is determined by the selector knob (fig. 17).

A distinction needs to be made here between operation of the storage heater with or without

central weather-controlled charging control unit (is in the sub-distributor).

If there is no central, weather-controlled charging control unit (manual operation, fig. 18), the

selector knob should be set as follows:

• = no charging

1 = Transitional period (Spring/Autumn) - corresponds to about 1/3 full charge

2 = Mild Winter days - corresponds to about 2/3 full charge

3 = Winter days - corresponds to full charge

After a short while you will soon have the necessary experience to find the right setting every

time.

If there is a central, weather-controlled charging control unit (automatic operation), the selector

knob should be set to position 3. The weather-controlled charging control unit then takes care of

the right charging. For varying control of individual storage heaters, the charging volume can be

adapted manually with the selector knob even when a charging control unit is available.

cn

■C:: ■

1.2.2 Heat Discharge

The heat discharge is controlled by a wall-mounted or integrated AEG room temperature

regulator (special accessory).

The desired room temperature must be set at the room temperature regulator which then controls

the heat discharge automatically with the fan so that the set room temperature is kept constant.

On very cold days it is advisable to leave the room temperature regulator switched on during long

periods of absence (several days) to keep the temperature at about 10 “C for example so that the

building or room does not go cold (protection against frost).

21

Page 7

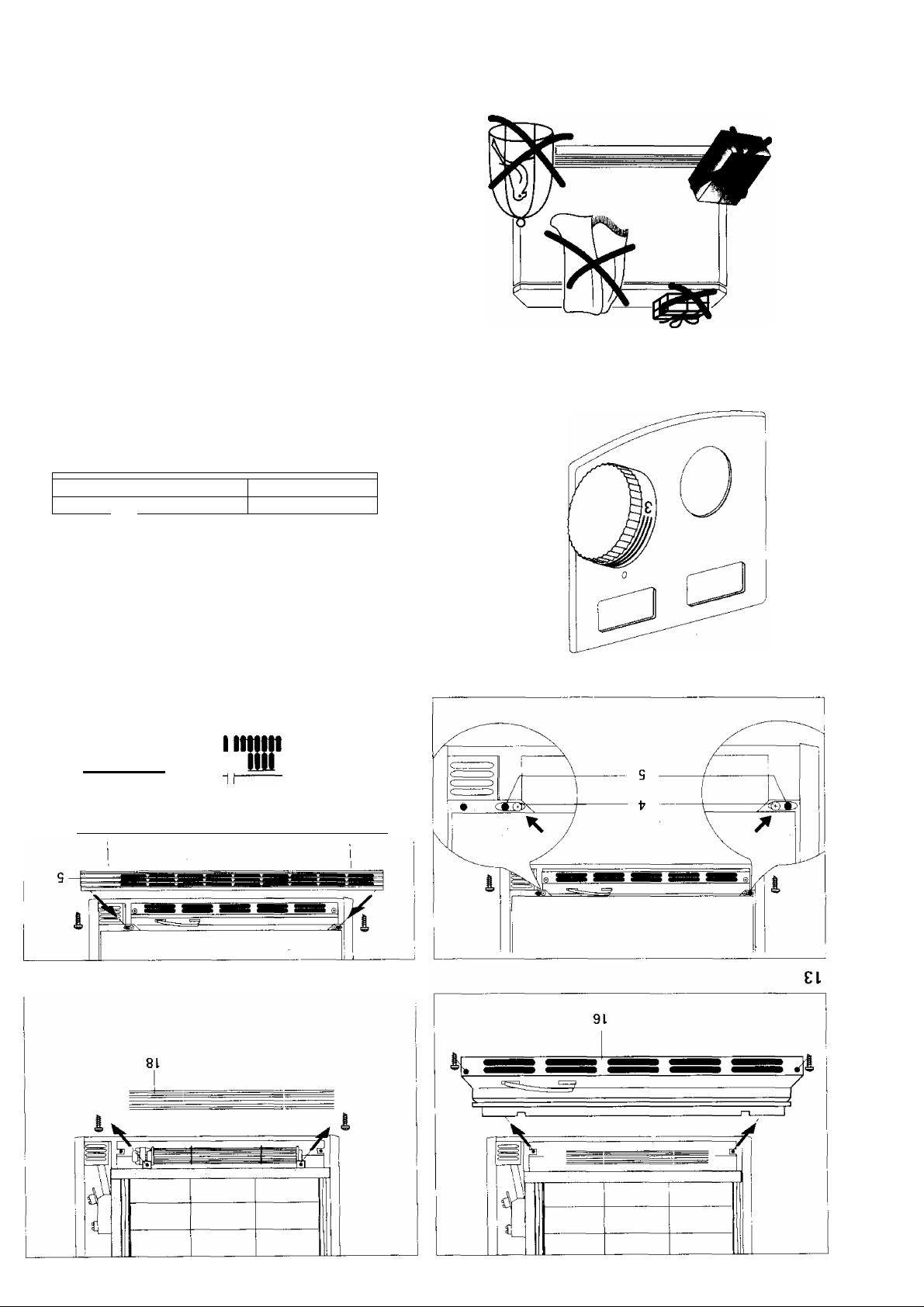

1.3 Safety Instructions

The unit must not

- be operated in rooms where there is a risk of fire or explosion due to chemicals, dust, gases or

fumes:

^|\ - be operated in the immediate vicinity of pipes or containers which carry or contain inflammable

/ " ^ or explosive substances:

- be operated when the minimum distances from adjacent object surfaces are not kept.

• This unit must only be installed (electrical installation), commissioned and maintained by an

authorised expert according to these instructions.

• The unit must on no account be operated when work on floors such as laying, sanding, sealing,

cleaning with petrol and caring (spray, wax) and similar is being performed.

Then the room must be adequately aired before charging.

• The heater's casing surfaces and the air outlet grille can heat up to temperatures above 80 “C.

Therefore no inflammable, ignitable or heat insulating objects or materials such as washing,

blankets, newspapers, containers of floor wax or petrol, aerosol cans and similar may be placed

on or in the immediate vicinity of the heater. Washing must never be hung over the heater to

dry. Danger of catching fire!

• The following minimum distances must be kept from the heater by all kinds of objects, e.g.

furniture, curtains and textiles or other flammable and non-flammable materials especially from

the air outlet grid (fig. 2):

to the air outlet grille => 500 mm

from the right side wall (for installation clearance) => 100 mm

from the left side wall =i> 70 mm

from the left side wall with two storage heaters next to one another =:> 100 mm

from the cover (e. g. window ledge) 40 mm

from the cover (curtains, inflammable materials) => 100 mm

The hot air must be able to discharge unhindered (fig. 19)!

• The label enclosed with these operating and installation instructions "Do not place objects on or

lean them against the heater" must be affixed well visibly on the top of the heater in

commercially used rooms such as hotels, holiday homes, schools etc.

For the User

1.4 Care and Maintenance

If slight brown discoloration of the unit housing should occur, this should be rubbed off

immediately with a soft cloth.

The device should be cleaned cold with normal cleaners.

Abrasive and aggressive cleaners should be avoided.

Do not spray cleaning spray into the air vents.

The ventilation duct behind the air outlet grille (5) should be checked by a specialist every two

years. Slight dirt deposits may accumulate here.

We recommend that you have the inspection and control elements checked during regular

maintenance. Safety, inspection and control elements as well as the entire charging and discharge

control system should be checked by a specialist 10 years after first commissioning at the latest.

1.4.1 Cleaning the Fluff Screen (fig. 3)

The fluff screen (7) located in the air inlet grille (6) must be cleaned regularly,

so that fault-free discharging of the storage heater is guaranteed.

The fans switch off when the fluff screen is blocked.

Proceed as follows to clean the fluff screen.

- Press the air inlet grille (6) down slightly on both sides, tip forward at the front and remove;

- Press the fluff screen out of the grille with a screwdriver for example and clean with a brush,

vacuum cleaner or similar;

Replace the fluff screen in the grille and snap in the lugs.

- Place the air inlet grille at an angle on the lugs in the unit base and snap in under the air outlet

grille by pressing lightly (fig. 16).

22

Page 8

For the User and Fitter

1.5 Important Note

Keep these instructions in a safe place, pass on to the new owner in case of a change of ownership.

Make them available to the specialist in the case of repair work.

What to do when ... ?

the storage heater

does not get hot

the storage heater

housing should get

extraordinarily

hot even in mild

weather

For the User

Check whether...

... the selector knob is set to

position 3.

... the corresponding fuses in

your fuse box are defective or

the FI switch has switched off.

Eliminate the cause!

If the following day the

storage heaters have still not

heated up, call a specialist.

Check whether...

... the fan can be switched on

with the room temperature

regulator.

If not, call a specialist

... the fluff screen in the air inlet

grille is blocked.

Eliminate cause as described

in section 1.4.1 !

For the specialist

Check whether...

... the control of the heating

element contactor is OK.

... there is a voltage at terminals

L1/L2/L3.

... whether the safety temperature

limiter (FI) has triggered.

"CUC"

A HIM LH ^ ^ ^ i

(J. r t' tr/C- ii'.ii'C-

Check whether...

... the room temperature

regulator has switched on and

voltage is applied at terminal

LE.

... the fans are turning.

... the safety temperature

regulator "(N5, see page 3,

fig. 1) in the air outlet has

switched off.

... the control signal Z1 of the

charging control unit is applied

at terminal Al/Zl in the

storage heater.

23

Page 9

2. Installation Instructions

2.1 Technical Data

For the Fitter

650

245

О о

30

The unit must be installed and connected by a specialist under consideration of these installation

instructions.

WSP 2010

Width "B" mm 605

Weight (with storage blocks)

Distance "X" mm

Connection

Power

Reference charging

max. charging

Storage blocks

Number of packages (blocks)

Block weight

Control resistance kn 2.78 2.78

Supplementary heating (special accessories)

Power

* WSP 2010 also with 1/N/PE 50 Hz 230 V connectable

kg

kW

kWh

kWh 17.0

pcs.

kg

kW 0.35

Л8

415

■It

2.0

16.0

6 (12)

85

WSP 3010

780

169 220 271

590

3,0 4.0 5.0 6.0 7.0

24.0 32.0 40.0 48.0

25.5 35.0

9 (18) 12 (24) 15 (30) 18 (36) 21 (42)

128 170

0.5 0.8 1.0 1.2 1.5

WSP 4010

955

765 940

3/N/PE - 50 Hz 400 V

2.78

WSP 5010 WSP 6010 WSP 7010

1130 1305 1480

322

1115 1290

42.0 51.0 61.5

213 256 298

2.78 2.78 2.78

373

56.0

24

Page 10

For the Fitter

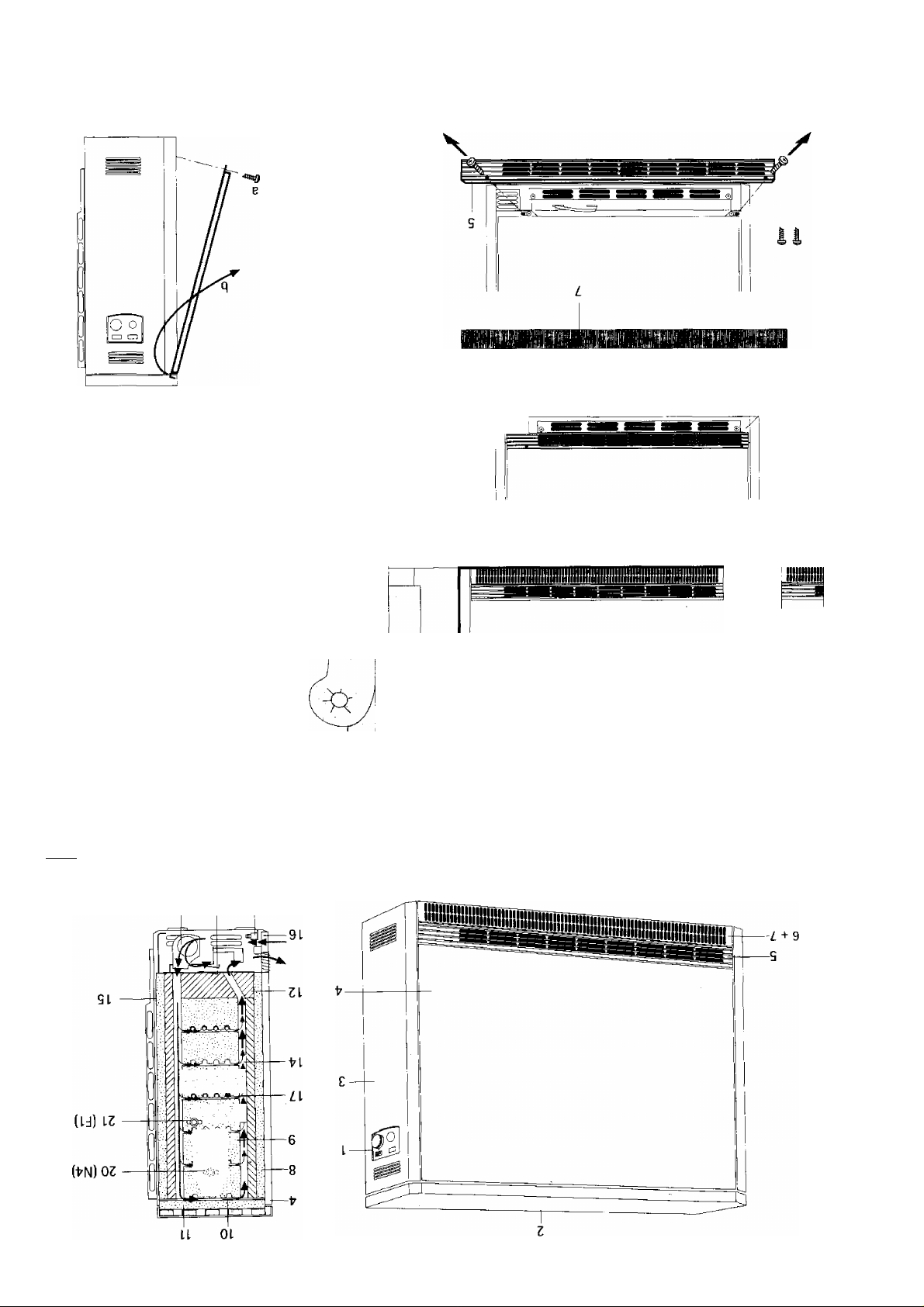

2.2 Technical Description (page 3, fig. 1)

1 Control panel

2 Cover

3 Right side wall

4 Front wall

5 Air outlet grille

6 Air inlet grille

7 Fluff screen

8 Inside front wall

9 Storage blocks

10 Cover plate

11 Thermal insulation

12 Floor thermal insulation

13 Mixing air flap

14 Air duct

15 Cable duct

16 Air guidance assembly

17 Fleating element

18 Fan

19 Safety temperature regulator - discharging (N5)

20 Safety temperature regulator - charging (N4)

21 Safety temperature limiter (FI)

S'-

№

:■ C' ::

tu

2.2.1 Function Principle

The storage blocks are heated up by the heating elements between the rows of storage blocks.

Charging is set continuously with the charging control unit (selector knob fig. 17)

Start and duration of the charging time are determined by the responsible electricity supply

company.

Two built-in safety temperature regulators (19, 20) and a safety temperature limiter (21) prevent

overheating of the unit. Whilst the safety temperature regulators switch on again automatically,

the safety temperature limiter must be switched back on by the technician by pressing in the knob

in the middle of the limiter after eliminating the cause of the error.

The heat stored in this way is then discharged with the aid of a fan, also partly through the heater

surface. In this case, the room air is sucked in through the air inlet grille (6) by the fan (18) and

blown through the air ducts of the storage blocks (9) which heats them up.

Before being output through the air outlet grille (5) the hot air generated in this way is mixed via

two mixing air flaps with colder room air so that the emitted air does not exceed the maximum

permissible temperature. The position of the mixing air flap and thus the

mixing ratio of the air is controlled by a bi-metal controller.

25

Page 11

2.2.2 Reducing the Output

By moving or removing bridges at the terminals, the connection rating, factory wired to 100 % can

be reduced by three levels (see the table).

The dimensioning of the line cross sections and the fusing should correspond to the maximum

possible output of the unit

A single-phase connection may be made according to the "Technical connection conditions" of

/ 7 \ the energy supply company only up to 2 kW (WSP 2010).

For the Fitter

Power

variants kW

Connection

variants

Model

WSP 2010

WSP 3010

WSP 4010

WSP 5010

WSP 6010

WSP 7010

О

3

3/N/PE - 50 Hz 400 V

Ф

100 o/o

2.0 1.83

3.0 2.75

4.0 3.66

5.0 4.58

6.0 5.50

7.0 6.42

100 % P ,,

(series wiring)

2 1 L3

75 % P

rated

L2 Ll

IN I L3 I L21 LI

rated

8h heating elements

(series)

(D

91.6 %

XI

83.3 %

1.67

2.50

3.33

4.16

5.00

5.83

©

3/N/PE - 50 Hz 400 V

® Ф

1

L3 L2 LI

100%

L3lL2lLl

75%

1.50

2.25

3.00

3.75

4.50

5.25

91.6% P

Г

1

3 2

я;

100 % P,,,,. 2kW

2.0

-

-

6h heating element fitt

(special accessory!

100 %

2.7 2.47

-

-

-

4.1

5.5 5.04

6.5 5.96

8.1 7.42

9.0 8.24

XT

91.6% 83.3 %

2.25

3.75

© Г

L

3/N/PE - 50 Hz 400 V

3.42

4.58

5.42

6.75

83.3 % P

3 2

ng set

75%

7.5

rated

1 L3 L2

In lL3lL2lL1

®

2.03

3.07

4.13

4.88

6.08

6.75

LI XI

©

3

2 1 L3

3/PE - 50 Hz 400 V

L2 Ll

Il3 IlzIli

2.3 Rules and Regulations

• Pay attention to the packing slip!

• The national building and garage regulations must be taken into account

• The installation area must have a sufficient floor load capacity.

In case of doubt a building surveyor should be consulted (for weights of the storage heaters, see

"Technical Data").

• The minimum distance from adjacent object surfaces must be kept (figs. 2 and 2a).

• All electrical connection and installation work must be performed in accordance with the VDE

regulations (0100), the regulations of the electricity supply company responsible and the

pertinent national and regional regulations.

• The device must be disconnectable from the mains at all poles by an supplementary device with a

disconnection distance of at least 3 mm. Contactors, fuses and similar can be connected for this.

• A later increase in the output must be approved separately by the responsible electricity supply

company. Failure to notify the electricity supply company of the increase in the output

constitutes a breach of the electricity supply contract

• The operating equipment must be designed for the rated consumption of the units.

• The unit’s rating plate must be observed!

The specified voltage must match the rated voltage.

• The unit must be fixed to meet the VDE standing safety requirement

XI

©

1/N/PE-50 Hz 230 V

3 2

1

L2 Ll

L3

XI

LI

26

Page 12

For the Fitter

2.4 Installation Site

The unit may not

- be operated in rooms where there is a risk of fire or explosion due to chemicals, dust, gases or

fumes;

A

- be operated in the immediate vicinity of pipes or containers which carry or contain inflammable

or explosive substances;

- be operated when the minimum distances from adjacent object surfaces are not kept.

In rooms in which exhaust fumes, oil and petrol smells occur, the unpleasant smell may linger and

could possibly cause soiling.

Installation wall

Check whether a wall of sufficient stability is available for fastening the unit.

If no suitable fastening wall is available, the unit must be fixed to the floor (screwed directly to the

floor or to another floor console [special accessory]).

Floors

The standing surface of the unit must be level and sufficiently stable so that the housing is not

deformed.

A temperature resistance of the fastening wail of at least 85 X and of the floor of at least 80 X

must be ensured. The units can be placed on any conventional floor but changes may occur in the

rail area on PVC, parquet and long pile carpeted floors under the influence of pressure and tem

perature. In this case heat-resistant underlay tiles must be used (to be provided on site).

x:.

i/i

O)

c:

2.5 Unit Installation (fig. 3-14)

The storage heater must be secured by a wall or floor fixture (fig. 8) to meet the VDE standing

safety requirement.

The screws and plugs necessary for fixing the unit are not included in delivery. They must be

selected and provided by a qualified fitter depending on the respective wall material.

Wall fastening

There is a hole in the unit rear wall in the vicinity of the switching area through which a suitable

screw can be inserted for fixing to a sufficiently stable wall (fig. 8).

Before fixing the unit, make sure that the permissible minimum distances from adjacent objects

are kept.

Floor fastening

The unit is fixed to the floor by screwing the bottom of the unit to the floor through 4 9 mm holes

(see "Technical Data", page 9 for dimensions).

This type of fixture is only possible with the air outlet and inlet grilles and the fan drawer removed.

27

Page 13

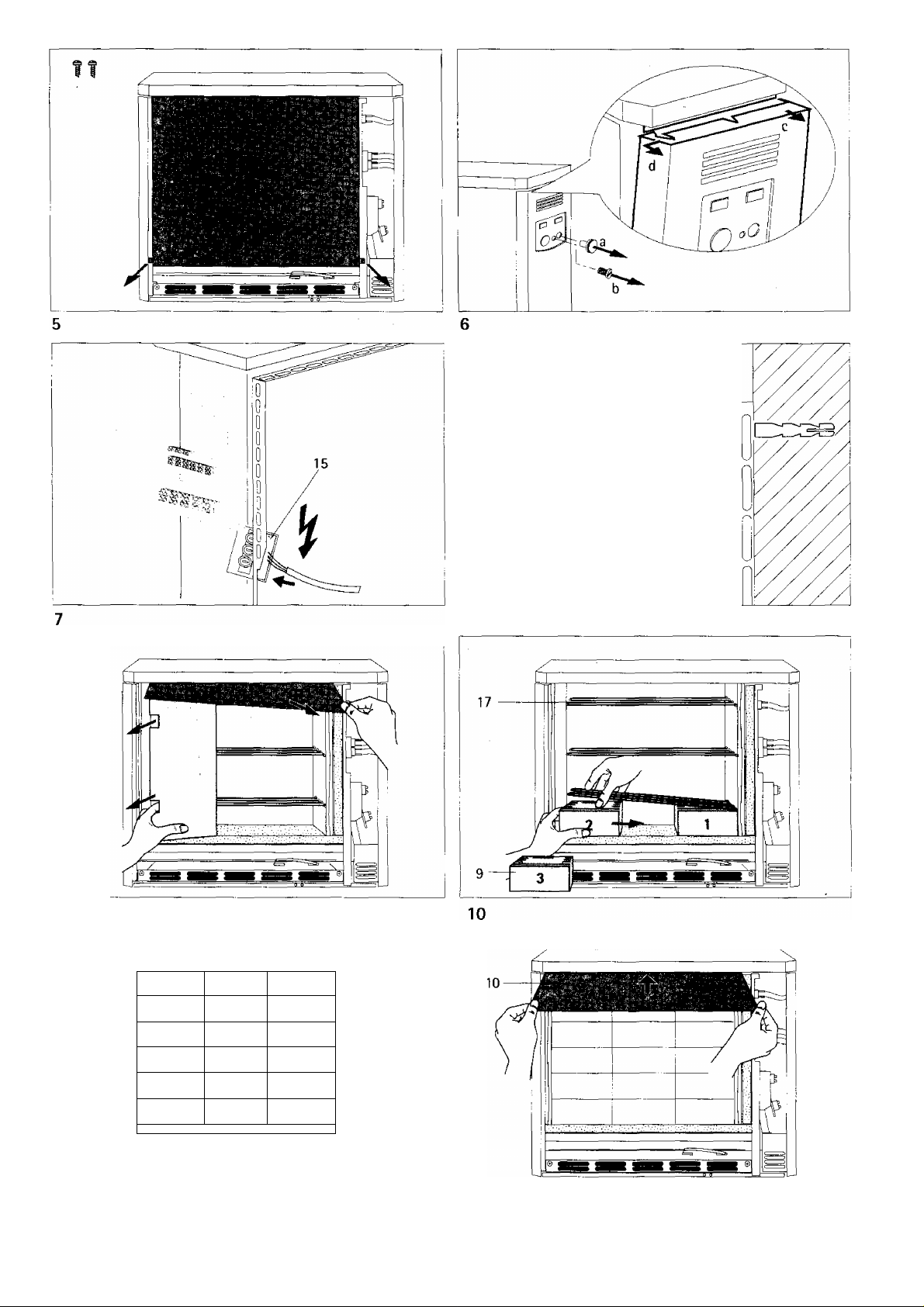

2.5.1 Unit Installation (fig. 3-6)

• Press the air inlet grille (6) down slightly on both sides, tip forward at the front and remove.

Unscrew both screws at the air outlet grille (5) and remove the grille (fig. 3).

• Loosen the front wall (4) with 2 screws at the bottom (inside threaded holes), lift the front wall

slightly and remove (fig. 4). Loosen the inside front wall with 2 screws at the bottom and remove

(fig. 5).

• Disassembly of the right side wall (3): Remove the rotary knob (a), screw (b) on the side wall (3),

pull the side wall slightly to the side at the back (c), push forward, tilt to the side at the top (d),

lift and remove (fig. 6).

• Feed the power cables and connecting cables for charging control unit and discharge control

unit through the opening in the unit rear wall (15) and connect according to section 2.5.2 (lay

connecting cable about 210 mm and shorten as required so that it does not obstruct the air

vents in the side wall);

• Place the unit at the planned location and screw to the wall (or to the floor if floor fixing is

necessary).

• Remove cover plate (10), cardboard inlays and operating button from inside (fig. 9). This must be

completely free of foreign bodies such as packing leftovers.

For the Fitter

^4

2.5.2 Electrical Connection

/. this.

/l\ When connecting the unit to an automatic charging control unit, voltages may occur at the

/ * \ terminals Al/Zl and A2/Z2 even when the fuses are removed.

Check the thermal insulation in the unit for transportation damage and replace if necessary.

Insert the storage blocks (fig. 10 and 11)

The storage blocks are delivered packed separately.

Storage blocks with slight transportation damage may still be used. This does not impair the

function of the heater.

The heating elements (17) must be lifted slightly to insert the storage blocks (9) (fig. 10).

Place the first storage block with the heating element recess at the top some distance away from

the right thermal insulation under the heater and push to the right and rear thermal insulation.

The elongated holes form the heating channels.

When lifting the heating elements, make sure that the through holes in the side thermal insulation

are not widened by the heating elements.

Then push the cover plate (10) removed from the interior over the top storage blocks (fig. 12).

The heating elements are connected electrically with 3/N/PE -- 50 Hz 400 V or in the

units WSP 2010 also with 1/N/PE - 50 Hz 230 V.

Direct connection with NYM is possible. The number of supply cables and wires as well as cable

cross sections depends on the connection rating of the unit and the type of mains connection and

on special electricity supply company regulations. Observe the appropriate circuit diagrams for

Connection

Relieve the strain on the electrical connecting leads as required and connect according to the

electrical circuit diagram in the device (on the inside of the right side panel) or the connection

diagram.

If the bracket in the switching area for holding the mains terminals is poorly accessible due to too

small a spacing, it can be swung forward during connection work after loosening the screw (not

removing) in the rear panel.

28

Page 14

For the Fitter

A

A bridged must be inserted between "N" and "/KljlT for operation with "single-wire control"**!

Power adaptation according to rated charging time

By moving or removing bridges at the terminals, the output can be adapted to the rated charging

time specified by the electricity supply company.

Heating element model

Rated charging time

Connection variants (kW)

Model

WSP 2010

WSP 3010

WSP 4010

WSP 5010

WSP 6010

WSP 7010

8 h

100 o/o P

(series wiring)

©

Unit rating plate

Г

3

L

3/N/PE-50 Hz 400 V

2

rated

1

1

L3 L2

©3 I L21 LI

8h (series)

8h

Ф CD

2.0

3.0

4.0

5.0

6.0

7.0 6.42 5.83

LI

©

XI

9h

1.83

2.75 2.5 4.1

3.66 3.33 5.5

4.58

5.5

9 h

91.6% P

21L3 L2

3

In lL3lL2lL1

3/N/PE-50 Hz 400 V

lOh

1.67

4.16

5.0 8.1

rated

LI

6h (heating element 1

5h

Ф

2.7

6.5

9.0

©

XI

3/N/PE-50 Hz 400 V

2.47

3.76

5.04

5.96

7.42

8.24

10 h

83.3 % P

3

2

Mn

6h

1

rated

L3 L2

L3IL2IL1

fitting set)

7h

(D

2.25

3.42

4.58

5.42

6.75

7.5

LI

XI

Ш ’

Observe the labelling on the rating plate and the circuit diagram!

After connecting electrically, the box corresponding to the connection rating and rated charging

time of the unit on the rating plate and the circuit diagram in these installation instructions

should be marked with a smear-proof ballpoint pen.

2.5.3 Unit Ready for Operation

Cleaning the unit (fig. 13 and 14)

The open unit must be cleaned after installation and insertion of the storage blocks.

The fans and the air guidance assembly must be removed for this.

• Unscrew and remove the air guidance assembly (16)

• Lift and remove the fan (18) after loosening (not removing) the screws at the front of the

support brackets (pay attention to cable laying!).

In some units, the discharge temperature control unit (19) including support plate must be

unscrewed.

Make sure the wires are not damaged when setting down the removed parts.

• Clean the floor plate and fan (avoid damage to lamellasi). Then re-install the fans, possibly the

temperature limiter and the air guidance module (correct cable laying!).

Close the unit (fig. 15 and 16)

• Hang in the inside front wall with thermal insulation swung forward slightly at an angle at the

top edge and screw at the bottom edge with 2 screws;

• Hang in the right side wall at the bottom, tilt up, hang in at top and fix with screw; (reverse

order see 2.5.1 - disassembly right side wall fig. 6)

• Hang in front wall at top, swing to the heater at the bottom and fix with 2 screws (always use

the two inside threaded holes) (fig. 15);

• Screw on the air outlet grille, screwing the screws hand tight and then back about 1 turn

(fig. 16):

• Place the air inlet grille at an angle on the lugs in the heater base, swing round at the top and

snap in behind the air outlet grille (fig. 16).

29

Page 15

Connection diagram ...

for wall-mounted room temperature regulators

For the Fitter

... for single-phase connection (max. 2 kW)

liN/PE ~ SO H! 230 V

for storage heater replaeement "old-new" with wall-mounted

room temperature regulator and missing daytime electricity supply

(N| I (N)

li ] 1 1 u

□Oli

"Single wire control"

Charging control unit

room temperature

regulator

L1/L2ÌL3

iposs- via heating contactor£

N/PE - 50 Hz 400 V

-----------------

____________

1

f-

\-l\-J

(N)

XI

XI

L>

u

30

Page 16

For the Fitter

2.6 First-time Operation

2.6.1 Function Test

Check the function of the fan for the storage unit by switching on the room temperature

regulator.

2.6.2 Charging

The units can be started without initial heating up after the function test. Charging takes place

either manually with the adjuster of the mechanical charging control unit or automatically with

the available Elfamatic charging control unit.

During initial charging, the charging in kWh must be determined and compared with the

maximum permissible charging from the cold state specified in the "Technical Data". The

determined charging may not exceed the maximum permissible charging from the cold state.

During initial charging, a smell may be produced, the room should therefore be adequately aired

Xl\ {1.5 times air change, e.g. tilted windows). Initial charging in the bedroom should not take place

/ • \ when sleeping in it if possible.

2.7 Repair, Conversion of Unit

Proceed according to these installation instructions as for the initial installation for re-installation

of a unit which has been dismantled for repairs or which was in operation somewhere else.

In these cases the following must be paid special attention: Parts of the thermal insulation at

which there are visible signs or damage or change which could impair the safety must be replaced

by new parts. The insulation must be tested and the rated consumption measured before commis

sioning.

O)

lS

2.7.1 Conversion of the Unit

The instructions enclosed with the respective fitting set are applicable for conversions, additions

and installations.

2.8 Transfer

Explain the functions of the unit to the user. Draw his attention to the safety instructions in

particular.

Hand over the operating and installation instructions to the user.

AEG

WSP 7010

E-No. 956 042 710 F-No, 2(^200504

-E№

A

357 kg

1/N/PE AC 230V 50Hz

a

1,5 kW

26 W

Symbols of the rating plate

(Example WSP 7010)

Q Total weight

) Charging

Discharging

-EMT Supplementary heater

A fan

-

C € Made in Germany

31

Page 17

Circuit diagram WSP 2010 - 7010

For the Fitter

El - E6: Heating element (storage heater)

E7: Heating resistor

F1 : Safety temperature limiter

Ml - M3: Fan

N1 : Temperature limiter - charging

N5: Temperature limiter - fan drawer

N4: Temperature limiter - charging

XI: Mains terminal

X2: Terminal

I I ^

1 N2 [llTi

! 1

1 N3 1

________

_

_____

I

U Ilh Lh Ile I i7| X2

I

1

i I

K/J

s, -, I

k I

_____

,--X t ^ i

N6

I ri 4i

52^^, ЦJ

!

______I____

‘ '

L,

r Pi

“ LJ

1 i

□

E9:

N6:

S2:

Zl:

□

E8:

N2:

N3:

SI:

----------------

Integr. room temperature regulator

Heating resistor

Temperature regulator - discharging

Rocker switch - discharging

Radio interference suppressor

Supplementary heater

Supplementary heating element

Temperature regulator - supplementary heater

Temperature regulator - supplementary heater

Rocker switch - supplementary heater

1 1

N5 /

I ! ^

L.

0

N N N U L-SH VI

0

AC-signal 230 V

Charging control signal

1/N/PE - 50 Hz 230 V

Series circuit

100 % P _

3/N/PE - 50 Hz 400 V 3/N/PE - 50 Hz 400 V 3/N/PE - 50 Hz 400 V 3/PE - 50 Hz 400 V 1/N/PE - 50 Hz 230 V

91.6 o/o P

* when external RT is connected

83.3 % P

r

Control circuit

3/N/PE ~ 50 Hz 400 V

75 % P

32

Only for WSP 2010

100 % P _

Page 18

For the Fitter

Caution! On a 3/PE AC 50 Hz 230 V mains

Rewiring of the storage heater load circuit necessary!

Circuit diagram for 3/PE AC 50Hz 230 V

Rewiring necessary in the storage heater!

XXX pull off vi wire from E2 and plug to E6

XX pull off br wire from E6 and plug to E4

X pull off ws wire from E4 and plug to E2

E1 - E6:(storage) heater

FI: protective temperature limiter

N1 ; temperature limiter - charging

N4: temperature limiter - charging

X1: mains terminal

O)

c

Jumpers must be wired by customer on site.

2

3

1

XI

L3

3/PE AC 50 Hz 230V

L2 L1

XI

33

Page 19

Environment and recycling

3. Environment and recycling

Please help us to protect the environment by disposing of the packaging in accordance with the

national regulations for waste processing.

Guarantee

For guarantee please refer to the respective terms and conditions of supply for your country.

The installation, electrical connection and first operation of this appliance should be carried out by

a qualified installer.

The company does not accept liability for failure of any goods supplied which are not installed in

accordance with the manufacturer’s instructions.

34

Loading...

Loading...