Page 1

2601

CRESTVIEW

INSTRUCTION

MANUAL

DRIVE + POST

OFFICE

BOX

111 « NEWBERG,

OREGON

97132

USA * TELEPHONE

503/538-7478

#4

Page 2

“aídec

Operation

and

Maintenance

Instructions

Pac

Model

|

(portable)

3420

Page 3

Wa

How

this

Section

rranty

to

Use

Manual

1

A-dec™

workmanship

warranty

product

incidental,

Written

The

accident

cleaning,

cover

(operation

A-dec

of

ders

manufacturing

warranty.

No

This

Your

maintenance.

questions

mation.

Set-up

warrants

is

(excluding

and

notice

warranty

or

disinfecting

light

bulbs.

and

warrants

purchase

already

other

warranties

manual

manual

and

to

misuse. The

of

should

all

products

for

one

year

provide

coincidental

of

does

maintenance

the

in

the

related

describes

is

Each

repacking

parts

labor).

breach

not

or

Failure

A-dec

dental

chair

field.

irregularities.

as

divided

section

help

cover

in

this

catalog

from

time

of

for

the

repair,

The

buyer

shall

damages

of

warranty

damage

warranty

sterilization

to

follow

instructions)

chair

or

the

The

warranty

to

merchantability

your

into

addresses

you

determine

The

How

or

must

does

chemicals

instructions

cylinders,

cylinder.

Stool

PAC I Portable

three

sections:

unit

do I repack

storage?

against

delivery.

or

at

its

have

are

excluded.

be

given

resulting

not

This

covers

just

from

cover

and

provided

may

void

both

warranty

chair

cylinders

or

otherwise

Delivery

Set-up

specific

which

arrived,

м

defects

A-dec’s

option,

no

other

to

improper

damage

processes.

the

lift

cylinders

are

information,

section

how

the

Field

in

sole

to

remedy.

A-dec

resulting

in

the

warranty.

and

tilt,

is

retroactive

A-dec

covered

are

made.

System,

and

repacking,

to

check

do I set

unit

material

obligation

provide

within

installation

The

A-dec

for

under

and

for

or

the

All

special,

the

from

warranty

Owner’s

ten

years

to

A-dec

finds

A-dec’s

|

,

Model

operation,

the

when

it

up?

transportation

under

the

replacement

warranty

or

the

to

3420

following

you

period.

maintenance,

use

of

also

does

Guide

from

the

chair

cylin-

have

one-year

and

list

need

not

date

of

infor-

wa

e

ワー

F

レレ

>

T

sa

ği

pa

J

Section

Section

2

3

Operation

Maintenance

We

understand

anywhere.

comprehensive.

contact

For

your

that

you

this

reason,

If

you

have

authorized

A-dec

How

do I operate

What

How

do I make

What

How

do I clean

How

does

What

Something

may

be

we

have

questions

dealer.

do

the

do

the

the

are

the

using

made

it?

controls

routine

accessories

it?

unit

work?

major

is

wrong,

this

after

components?

how

portable

the

Maintenance

reading

do?

adjustments?

do?

dental

the

|

can I fix

delivery

section

appropriate

it?

system

quite

section(s),

virtually

Ja

m.

e”

一

Æ

a

αλ

する

Page 4

Contents

Setup

Institutional

Field

All

Operation

About

Control

Instructions

| |

Unit:

AssembletheU-fame......................................

Mount

Assemble t e

Mount

Place

Install

Install

Install

InstalltheTrayHolder

Connect

PAC I Field

Testing

Repacking

the

Institutional

jn

“

sos. e 3

Tripo

the

Field

Pac I Portable

the

Han

and

Syringe

the

the

Optional

and

Optional

Your

PUNCHONS

Your

In

Self-Contained

Steril-Vac

the

Supply

Repair

Pac I Unit

the

Pac I Field

PAC

Puis,

Unit

Control

店

Lee

Unit

Control

Units:

othe 나 lde;

the

Air

Tool

0...

eee»

Ho

STB

Water

ie

Saliva

Kit

Ejector

.....................................

Air

Tubing

Kit

.........

иене

Unit..................... 5 General

Head

resezione

Bottle

.................... 4 Care

iii

een

1

Head

....

1

1

1

................ 2 How

3

ーー

.......... 3 Steril-Vac

(ASE)

ss

3

3

........ 3 Cleaning

4

‚.

5

5

6

7

Pre-Cleaning

sterilizatio

H

andpiece

H 때 Often

Flushing

Self-Contained

How

ICX

Water

ICX

Water

Operating

Oil

Collector

İnstructions

Maintenance

Farts

Cleaning

Tool

How

Your

Schematic

es

10

...................................

Tubing

the

it

Works

to

Choose

Your

Servicelnformation.............................

Imspection

Internal

and

Repair

PAC 1 Works

Diagram

Flush

Shel d ;

Handpiece

Water

Treatment

Treatment

Treatment

Your

Steril-Vac

Steril-Vac

.........................

eee

Parts

Kits

ーー

|

System........................

Flush?

System

Tablet.

Protocol

ϱϱ”ϱ””ϱ-

т

Tubings

M

............

Di.

.............

Water...

............................

........................

リー

Le

ОИ

リー

|

ος

10

11

11

11

11

11

12

12

12

13

13

‚

.

13

14

14

15

15

15

16

17

18

O

Han

Drive

“Coolant

Coolant

Air

Pressure

System

Drive

Foot

O

R

poa

outine A justments

an

Han

Handpiece

A-dec

Autoclavable

Syringe

Disconnecting

A-dec

Changing

SyringeandlipAsepsis...................................

Oise

piece

Selector

Air

Pressure

Air

Flow

Water

GAUBES

AirPressureGâuge

ーーーーーーーー

Control

Control...

Flow

Controls

„<

eee

............................

AirPressureGauge.................................

Control

ory

10081

一

μα

Air

ώρας

piece

Autoclava

Flow

Syringe

ipBlowerButton

Lene

ae

Ὃ

Coo

Coolani

Syringe

Adjustment

Tips

the

Syringe

Air

ant

le

Syringe

the

Syringe

ee

NS

Pressure

Air

Water

Operation

Tip...

FLOW

Flow

ee

nn

ии

................... 7 Servicing

i

Pe

„re

me

DS

......................

Head

ee

e

7

7

ss

7

ne

naa

renanas 8 Autoclavable

ο

nn

ene

10

10

7

7

/

7

7

7

7

8

8

8

9

9

2

?

9

Basic

Air

Filter/Regulator

Century

Operating

Troubleshooting

Foot

Troubleshooting

Signal

Troubleshooting

ServicingthefFlushValve................................

Exploded

Repair

Replace

Replace

Replace

Steril-Vac

Button

AVS

PAC I Tool

Troubleshooting..................................…

II

Control

Principles

Assembiy

Blocks

...................

ーーー

ニー

nn

Control

Relay

Air

II

Valve

.........................

ーー………

Valve

the

Handpiece

SYLinge

Drawing

INStructions

Valve

Assemblies................................

the

Sytinge

the

Terminal

Service

Replacement … せ

Tube

.....

Replacement..............................

and

Repair

Selector

semen.

with

...........

Tip

Barb

Kits

|

Valve

Part

Numbers

ii

Retainer

O-rings

ーー

eee

Listing

.............

нии

nn

...........

..........

O-rings

...............

Co

Lu

ἀ----

…

....

19

20

21

21

23

26

26

27

28

29

29

30

30

31

31

32

32

83

33

33

34

.

té

Page 5

Setup

and

Follow

Institutional

Instructions

Institutional

instructions

the

Pac

Unit

for

|

for

Field

model.

your

Field

Assemble

1.

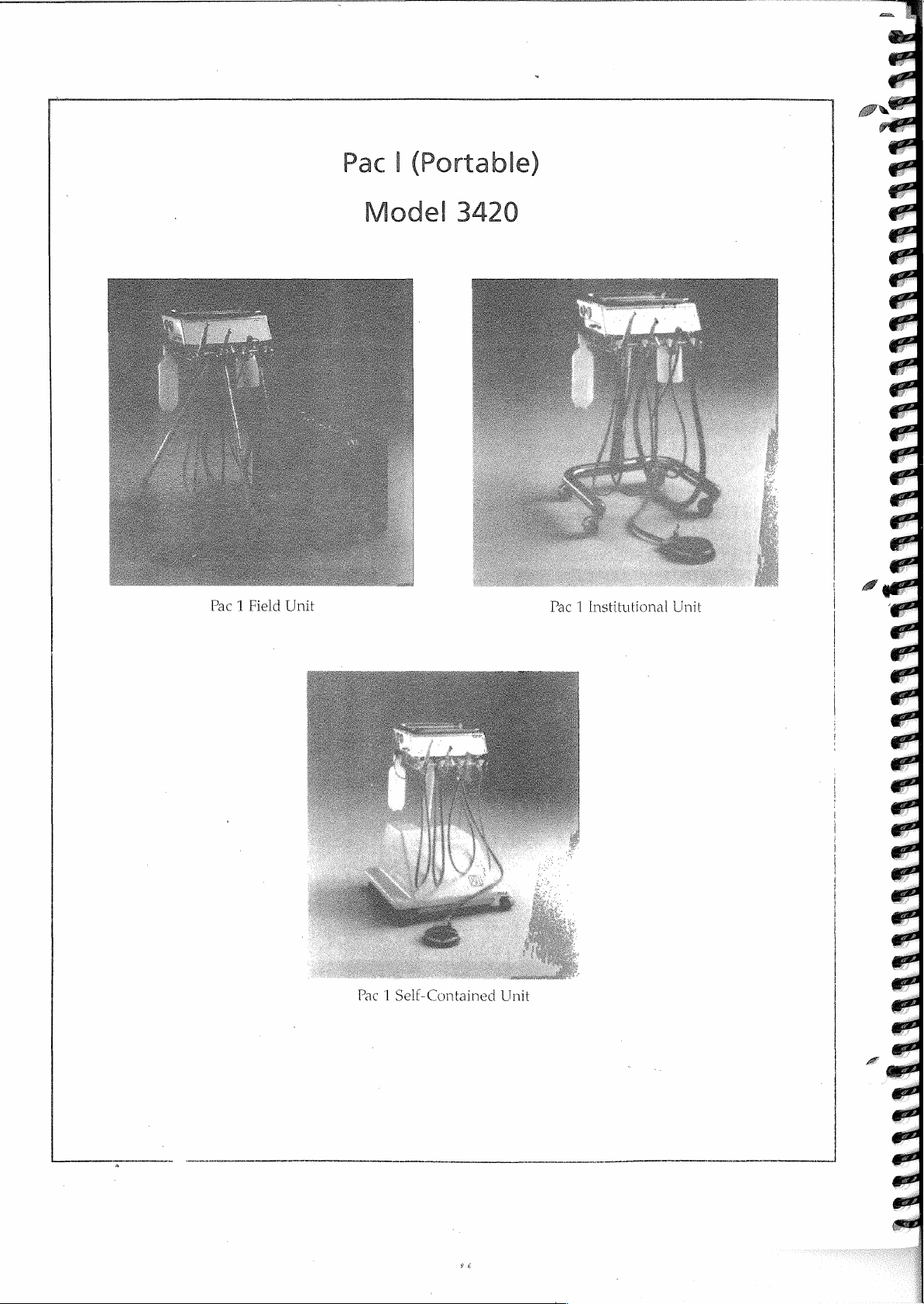

Unit

Remove

the

control

the

the

Tripod

foot

control

head

(see

Base

and

Figure.

place

4).

it

on

top

of

Assemble

Using a 1/4"

support

mm)

Mount

Figure

1.

2.

the

1.

Align

U-frame

head

Using a 5/32"

the

control

the

U-Frame

hex

to

the

U-frame

long

socket-head

Institutional

Assemble

the

control

upright

on

the

upright

hex

head

key,

attach

with

screw

Unit

^

the

u-frame.

head

mounting

support

support

key,

tighten

hub

(see

the

the

(see

Control

and

place

(see

the

Figure

upright

1-1/4"

Figure

hub

with

the

control

Figure

setscrew

3).

(32

1).

Head

the

2).

in

a

Control

54

Figure

2.

4.

Remove

and

set

2

~

Remove

the

supply

it

aside.

the

foot

air

control.

“

tubing

(see

Figure

5)

€ontrol

Figure

control

Go

Syringe

85.0681.00

3.

Place

to

head

2.

Mount

head.

the

foot

Place

Rev H 2004-05

in

the

the

the

control

Handpiece

Holders.

(04052)

setscrew.

where

Tubings

desired.

:

and

Figure

3.

Unsnap

©

the

5.

case.

No

08

Remove

the

divider

the

supply

to

access

air

tubing.

the

other

side

of

Page

1

Page 6

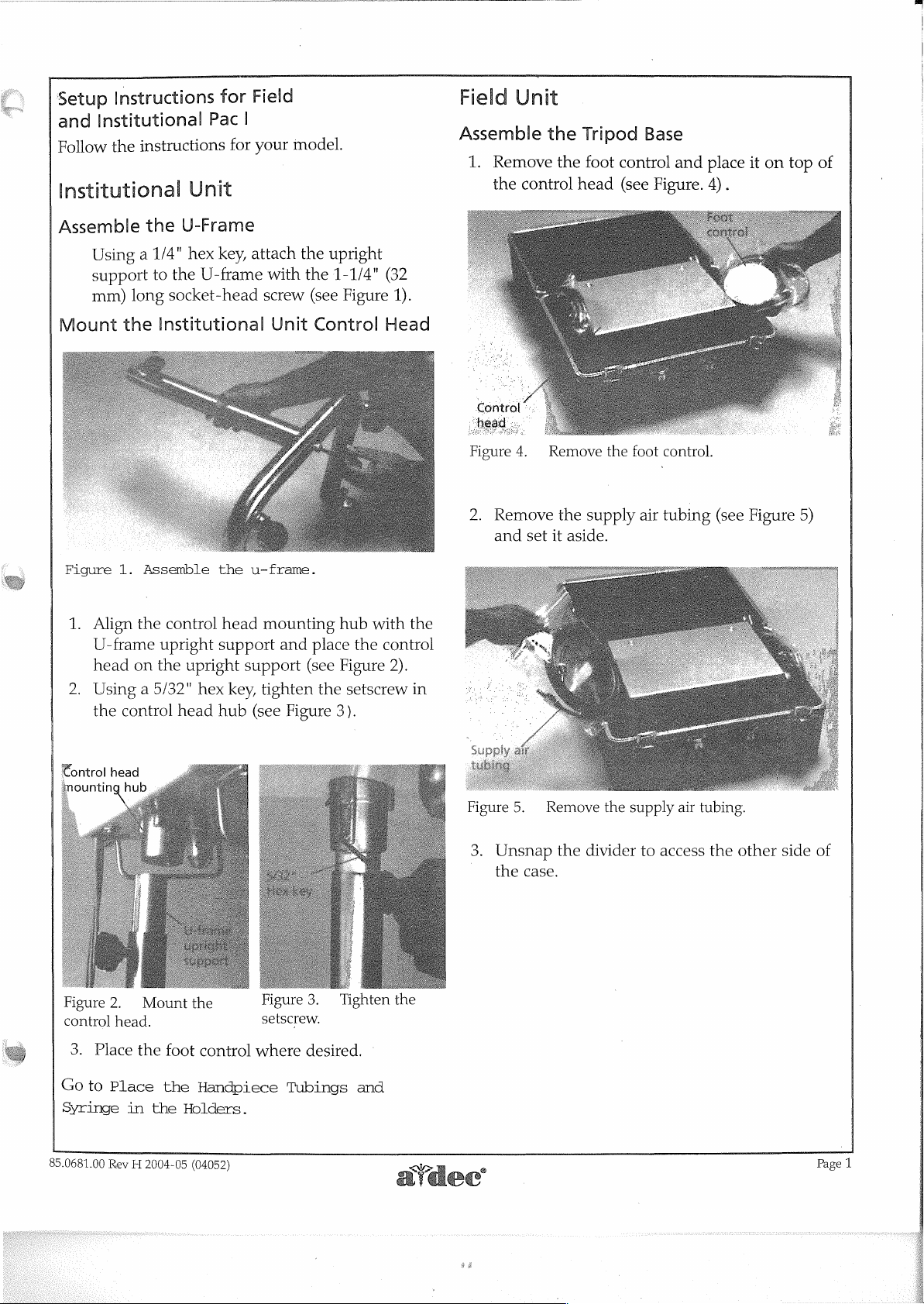

Pac | (Portable)

Pac 1 Field

Unit

Pac

1

Se

IEC

ont

aine

dů

e?

Pa

t

M

|

h

nst

tutional

i

Unit

Page 7

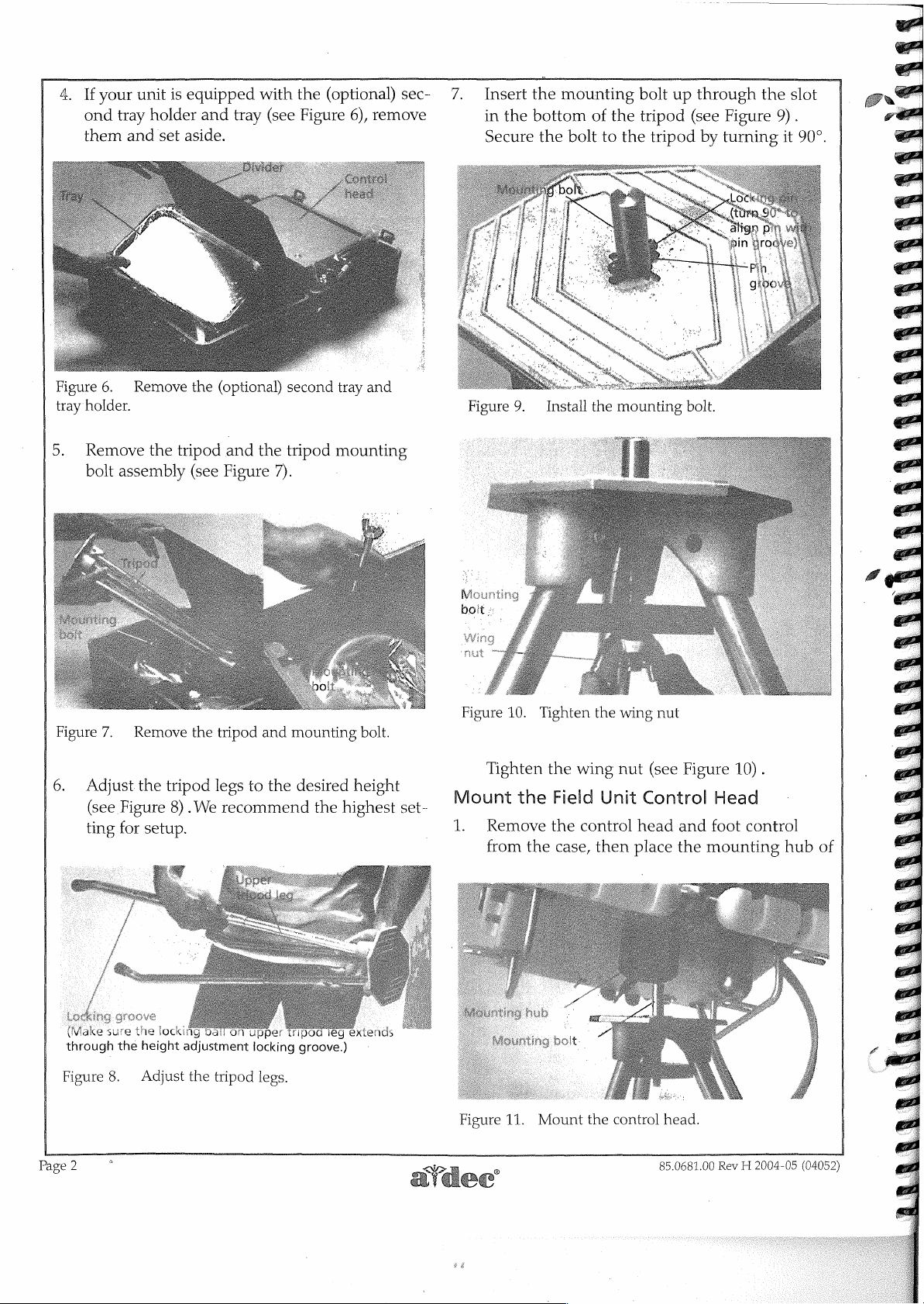

4. If

ーー

2

oa

の

。

ond

them

^

mm

7

TO

a

>

2202

27

your

tray

and

-

/

ντ

24

7

unit

is

holder

set

/

equipped

and

tray

aside.

with

(see

the

(optional)

Figure

6),

remove

sec-

7.

Insert

in

the

Secure

the

mounting

bottom

the

bolt

LA

of

to

the

the

τη

CO

и

bolt

up

tripod

tripod

LILI

~

%

through

(see

Figure

by

turning

9

K

eee

es

|

Kamal

1

nà

4

i

Re

κ

Dr

the

9).

it

slot

90°.

Figure

tray

holder.

5.

Remove

bolt

6.

Adjust

(see

ting

6.

Remove

assembly

Remove

the

Figure

for

setup.

the

tripod

tripod

8) . We

the

(optional)

and

(see

Figure

the

tripod

legs

recommend

the

and

to

second

tripod

7).

mounting

the

desired

tray

mounting

height

the

highest

and

bolt.

“E,

2

set-

Figure

Figure

Mount

1.

9. | Install

e

10.

Tighten

Tighten

the

Remove

from

the

the

wing

Field

the

case,

the

mounting

the

wing

nut

Unit

control

then

head

place

bolt.

nut

(see

Figure

Control

and

the

22

ーー

ca

10).

Head

foot

control

mounting

hub

of

MV

through

Figure

the

8.

height

Adjust

|

the

ON

tripod

adjustment

Upper

locking

legs.

Tripod

groove.)

Page

2

ley

extienda;

SSS

X

Figure

11.

Mount

the

control

85.0681.00

head.

Rev H 2004-05

(04052)

Page 8

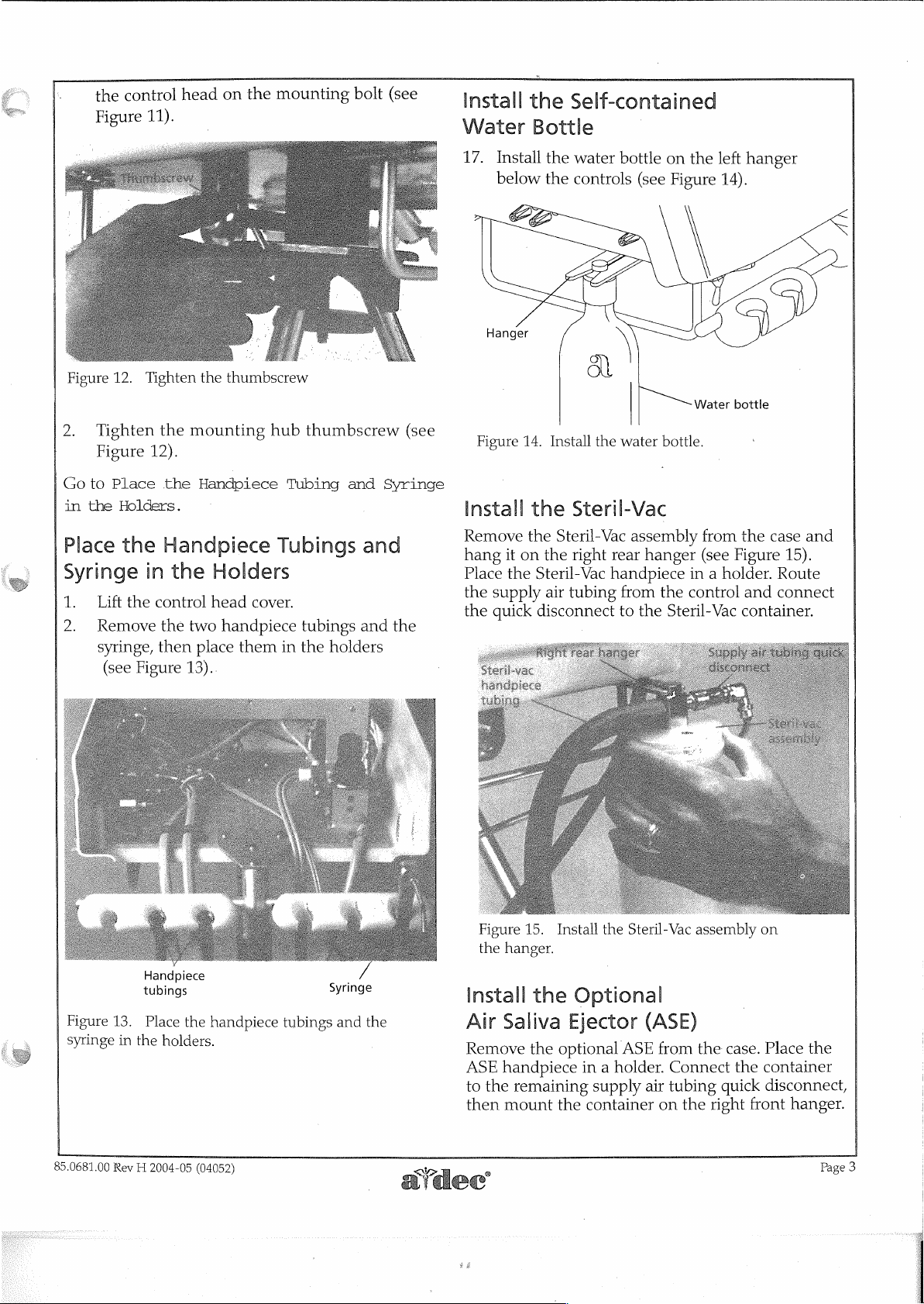

k

the

control

Figure

11).

head

on

the

mounting

bolt

(see

2

Install

Water

17.

>

the

Bottle

Install

below

Hanger

Self-contained

the

water

bottle

the

controls

(see

q

on

the

Figure

left

hanger

14).

Figure

2.

Goto

in

Place

Syringe

1.

2.

12.

Tighten

Figure

Place

the

Holders.

the

Lift

the

Remove

syringe,

(see

Tighten

12).

in

Figure

the

the

mounting

the

Handpiece

Handpiece

the

control

the

two

then

place

13)..

thumbscrew

hub

Tub

Holders

head

cover.

handpiece

them

in

thumbscrew

Tubing

tubings

the

and

ngs

holders

Syringe

and

and

(see

the

Figure

Install

Remove

hang

Place

the

the

14.

the

the

it

on

the

supply

quick

Install

the

Steril-Vac

Steril-Vac

the

right

rear

Steril-Vac

air

disconnect

handpiece

tubing

water

bottle.

assembly

hanger

from

the

to

the

Steril-Vac

Water

bottle

'

from

the

case

(see

Figure

in a holder.

control

and

container.

and

15).

Route

connect

e

Handpiece

tubings

Figure

syringe

85.0681.00

13.

Place

the

in

the

holders.

Rev H 2004-05

handpiece

(04052)

tubings

Syringe

and

the

Figure

the

Install

Air

Remove

ASE

to

then

15.

hanger.

the

Saliva

the

handpiece

the

remaining

mount

Install

Optional

Ejector

optional

the

the

Steril-Vac

(ASE

ASE

from

in a holder.

supply

container

air

tubing

on

assembly

the

Connect

quick

the right

on

case.

Place

the

container

disconnect,

front

the

hanger.

Page

|

|

|

|

3

Page 9

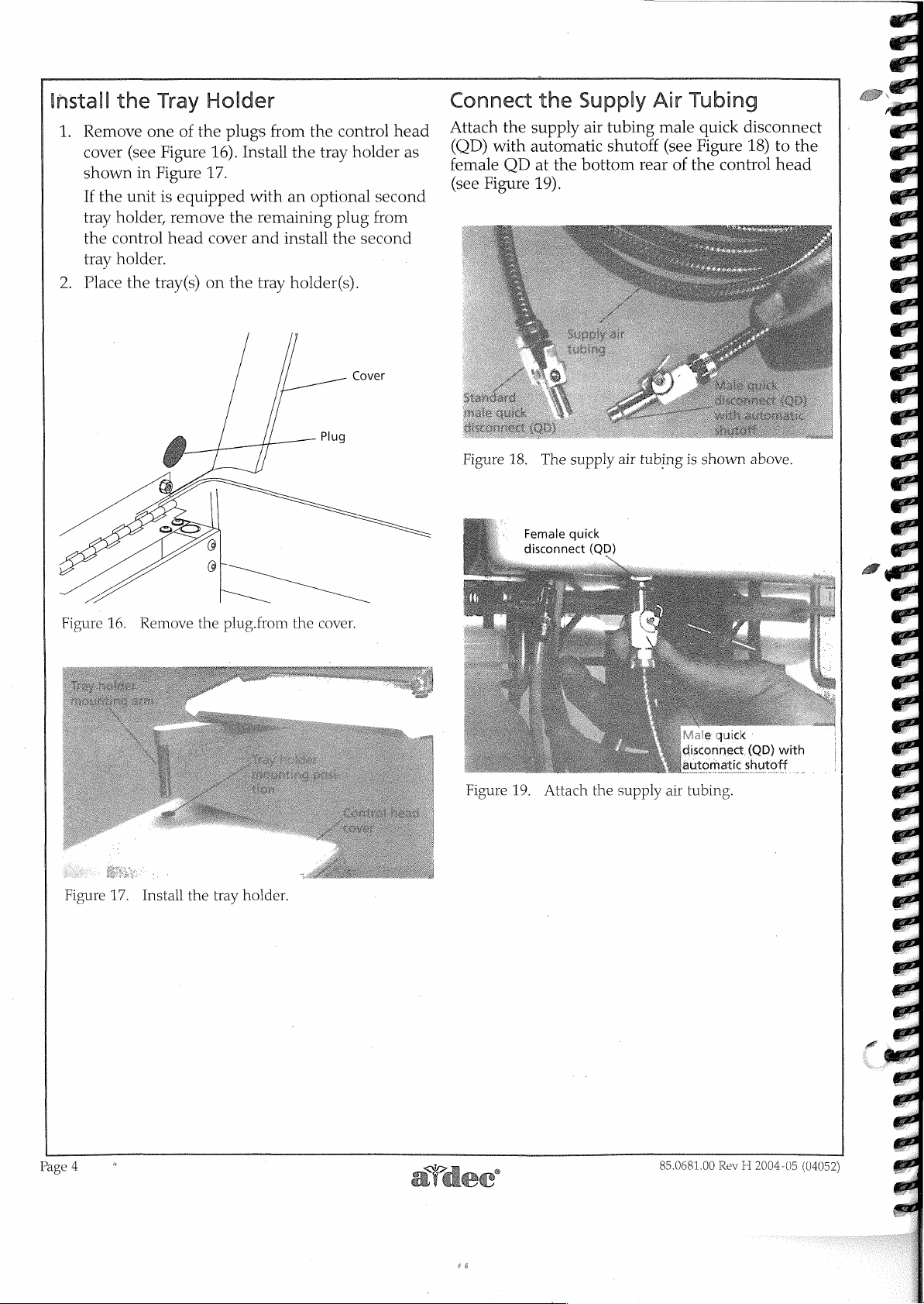

Install

1.

2.

Figure

the

Remove

own

If

the

tray

holder,

the

control

tray

holder.

Place

16.

one

Fi

Fato

im

unit

the

tray(s)

Tray

is

Holder

of

the

16).

177

i

.

equipped

remove

head

cover

on

plugs

from

Install

me

. .

with

the

remaining

and

the

tray

the

control

tray

the

Hay

S

an

optional

plug

install

the

holder(s).

Plug

hold

nl

second

from

second

Cover

head

Connect

Attach

(QD)

female

(see

the

with

OD

Figure

the

supply

automatic

the

at

19).

9

S

a

Remove

the

plug.from

the

—_

—

cover.

:.

Female

disconnect

quick

Supply

air

tubing

shutoff

bottom

(QD)

rear

Air

male

(see

of

Tubing

quick

disconnect

Figure

the

18)

control

the

to

head

ο

ο...

Figure

17.

Install

the

ンク

tray

holder.

7

©

22

の

の

Figure

19.

Attach

the

supply

air

tubing.

ick

]

Page

4

>

85.0681.00

#6

Rev H 2004-05

(04052)

Page 10

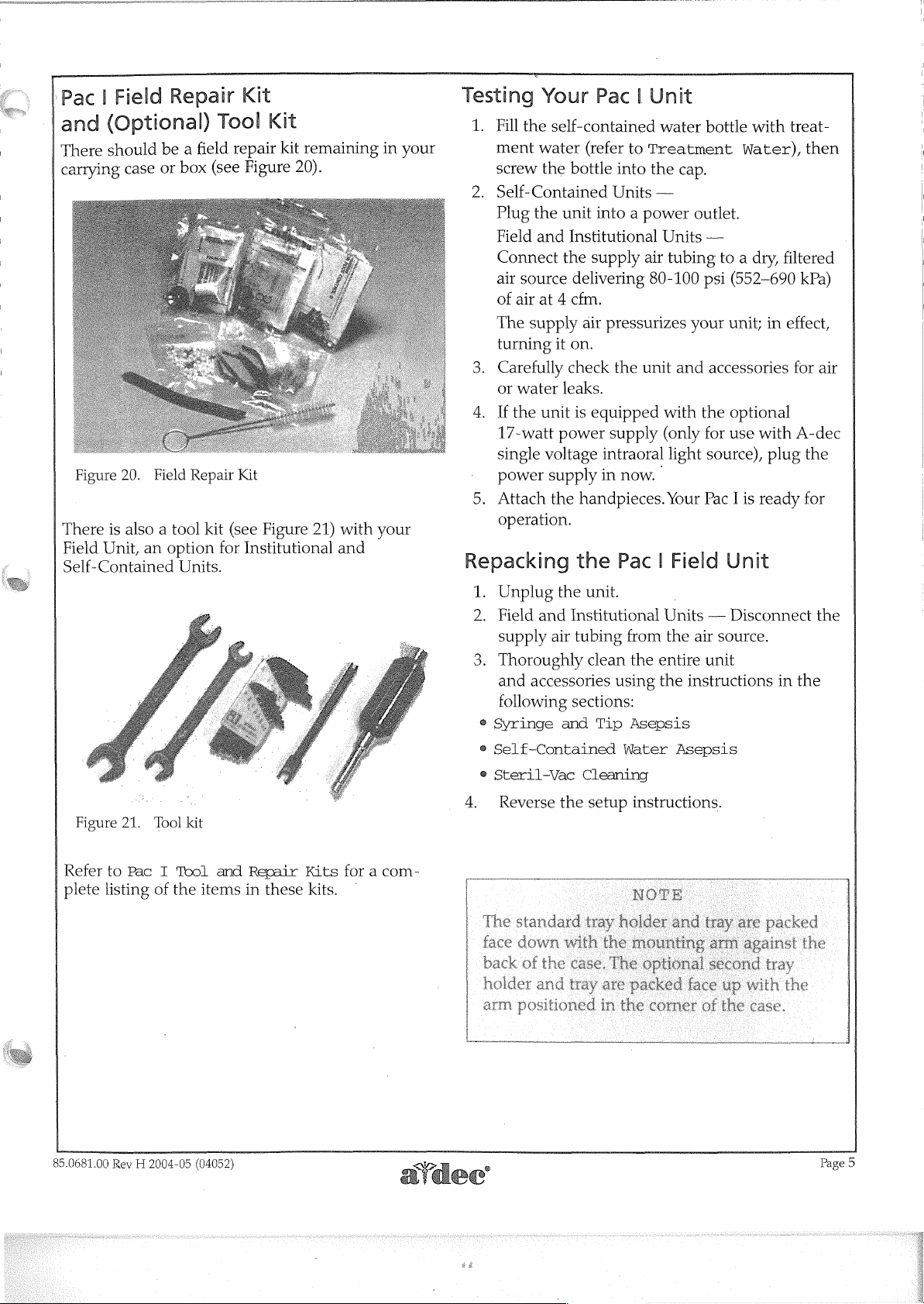

Field

|

‘Pac

and

There

carrying

(Optional)

should

case

Figure

20.

There

is

also a tool

Field

Unit,

an

Self-Contained

Repair

be a field

or

box

Field

Repair

option

Units.

Kit

Tool

repair

(see

Figure

Kit

kit

(see

for

Institutional

Kit

kit

remaining

20).

Figure

21)

with

and

Figure

21.

Tool

kit

in

your

your

Testing

1.

2.

3.

4.

5.

©

Repacking

1.

2.

3.

®

Syringe

®

Self-Contained

e

Steril-Vac

Your

Fill

the

self-contained

ment

water

screw

the

Self-Contained

Plug

the

Field

and

Connect

air

source

of

air

at 4 cfm.

The

supply

turning

Carefully

or

water

If

the

unit

17-watt

single

power

Attach

operation.

Unplug

Field

supply

Thoroughly

and

following

Reverse

voltage

supply

the

and

air

accessories

Pac | Unit

(refer

to

Treatment

bottle

unit

Institutional

the

it

on.

check

leaks.

power

the

Institutional

and Tip

the

into

Units

into a power

supply

delivering

air

is

equipped

handpieces.

the

unit.

tubing

clean

sections:

Cleaning

setup

air

pressurizes

the

unit

supply

intraoral

in

now.

Pac | Field

from

the

using

Asepsis

Water

instructions.

water

bottle

with

Water),

the

cap.

—

outlet.

Units

—

tubing

80-100

with

(only

light

Your

Units — Disconnect

the

entire

the

to a dry,

psi

(652-690

your

unit;

and

accessories

the

optional

for

use

with

source),

Pac I is

air

unit

instructions

Asepsis

ready

Unit

source.

in

plug

treat-

then

filtered

kPa)

effect,

for

air

A-dec

the

for

the

in

the

Refer

to

Pac I Tool

plete

listing

85.0681.00

of

Rev H 2004-05

the

and

items

(04052)

Repair

in

these

Kits

kits.

for a com-

|

The

face

arm

|

standard

down

k

of

positioned

with

the

case.

d

tray

tray

Nora

holder

the

mo:

The

optional

are

packed

in

the

7

and

|

it

gama

face

corner

second

up

of

the

with

case.

tray

the

Page

5

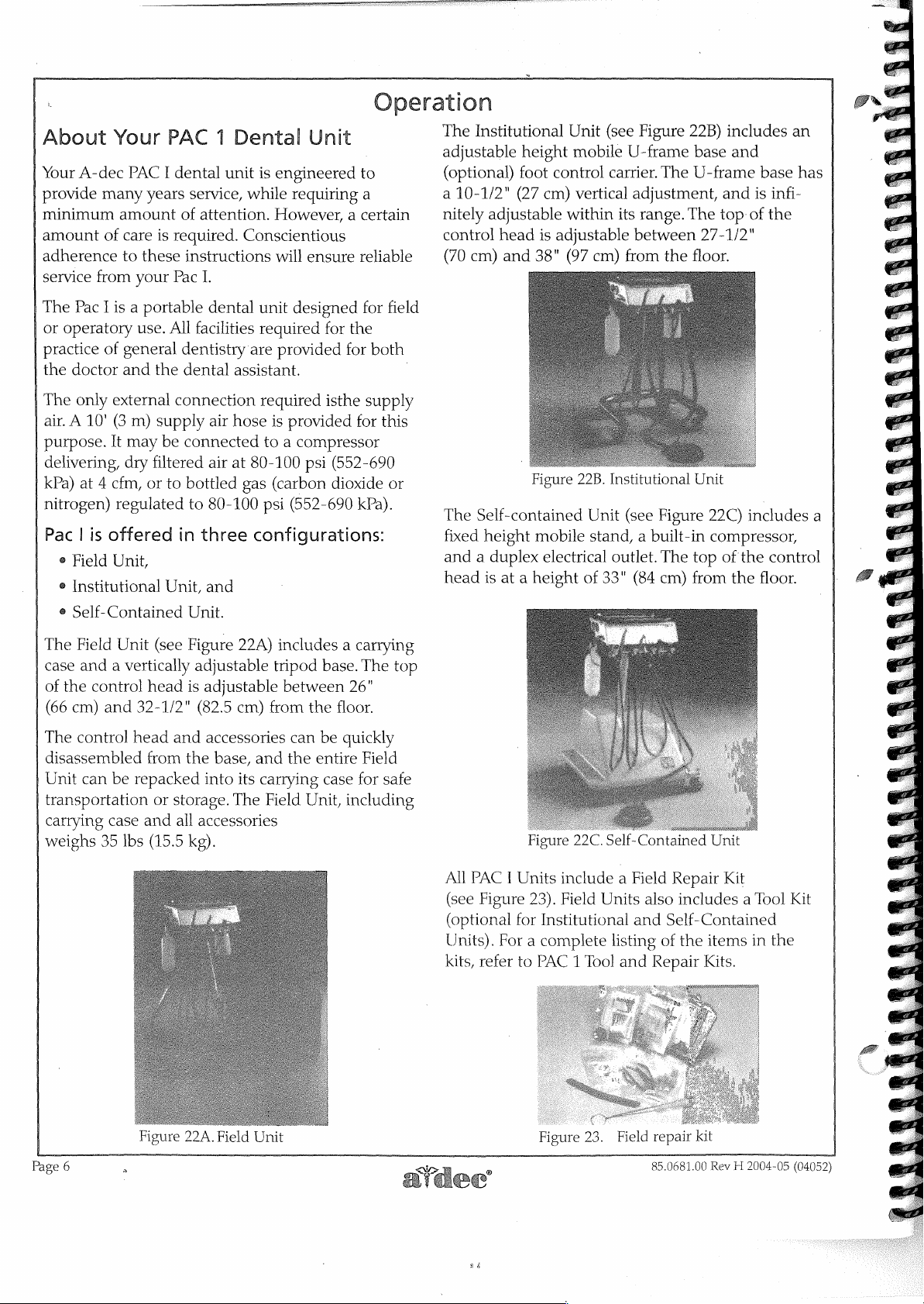

Page 11

About

Your

provide

minimum

amount

adherence

service

The

or

operatory

practice

the

The

air. A 10'

purpose.

delivering,

kPa)

nitrogen)

Pac | is

e

e

©

Your

A-dec

Pac I is a portable

doctor

only

at 4 cfm,

Field

Institutional

Self-Contained

PAC I dental

many

amount

of

care

to

from your

of

general

and

external

(3

It

may

dry

regulated

offered

Unit,

PAC 1 Dental

years

service,

of

attention.

is

required.

these

instructions

Pac

I.

dental

use.

All

facilities

dentistry

the

dental

connection

m)

supply

be

filtered

or

air

connected

air

to

bottled

to

80-100

in

three

Unit,

and

Unit.

Unit

unit

is

engineered

while

requiring

However, a certain

Conscientious

will

ensure

unit

designed

required

are

provided

assistant.

required

hose

is

to a compressor

at

80-100

gas

(carbon

psi

configurations:

for

isthe

provided

psi

(552-690

peration

to

a

reliable

for

field

the

for

both

supply

for

this

(552-690

dioxide

or

kPa).

The

adjustable

(optional)

a

10-1/2"

nitely

control

(70

|

The

fixed

and a duplex

head

Institutional

height

foot

control

(27

cm)

adjustable

head

cm)

and

Self-contained

height

is

at a height

within

is

adjustable

38"

(97

Figure

mobile

electrical

Unit

(see

Figure

mobile

vertical

22B.

U-frame

carrier.

cm)

Institutional

Unit

stand, a built-in

outlet.

of

33"

The

adjustment,

its

range.

between

from

the

(see

Figure

The

(84

cm)

22B)

includes

base

and

U-frame

and

The

top

27-1/2"

floor.

Unit

22C)

compressor,

top

of

the

from

the

an

base

has

is

infi-

of

the

includes

control

floor.

a

The

Field

Unit

(see

case

and a vertically

of

the

control

(66

cm)

The

control

disassembled

Unit

can

transportation

carrying

weighs

and

head

be

repacked

case

35

lbs

head

32-1/2"

from

or

and

(15.5

Figure

adjustable

is

adjustable

(82.5

cm)

and

accessories

the

base,

into

its

storage.

all

The

accessories

kg).

22A)

includes a carrying

tripod

from

and

carrying

Field

base.

between

the

floor.

can

be

the

entire

case

Unit,

The

top

26"

quickly

Field

for

safe

including

All

PAC I Units

(see

Figure

(optional

Units).

kits,

For a complete

refer

Figure

22C.

include a Field

23).

Field

for

Institutional

to

PAC 1 Tool

Self-Contained

Repair

Units

also

includes a Tool

and

Self-Contained

listing

and

of

the

Repair

Unit

Kit

items

Kits.

in

Kit

the

Figure

Page

6

a

22A

Field

Unit

Figure

23.

Field

repair

kit

85.0681.00

Rev H 2004-05

(04052)

He

Page 12

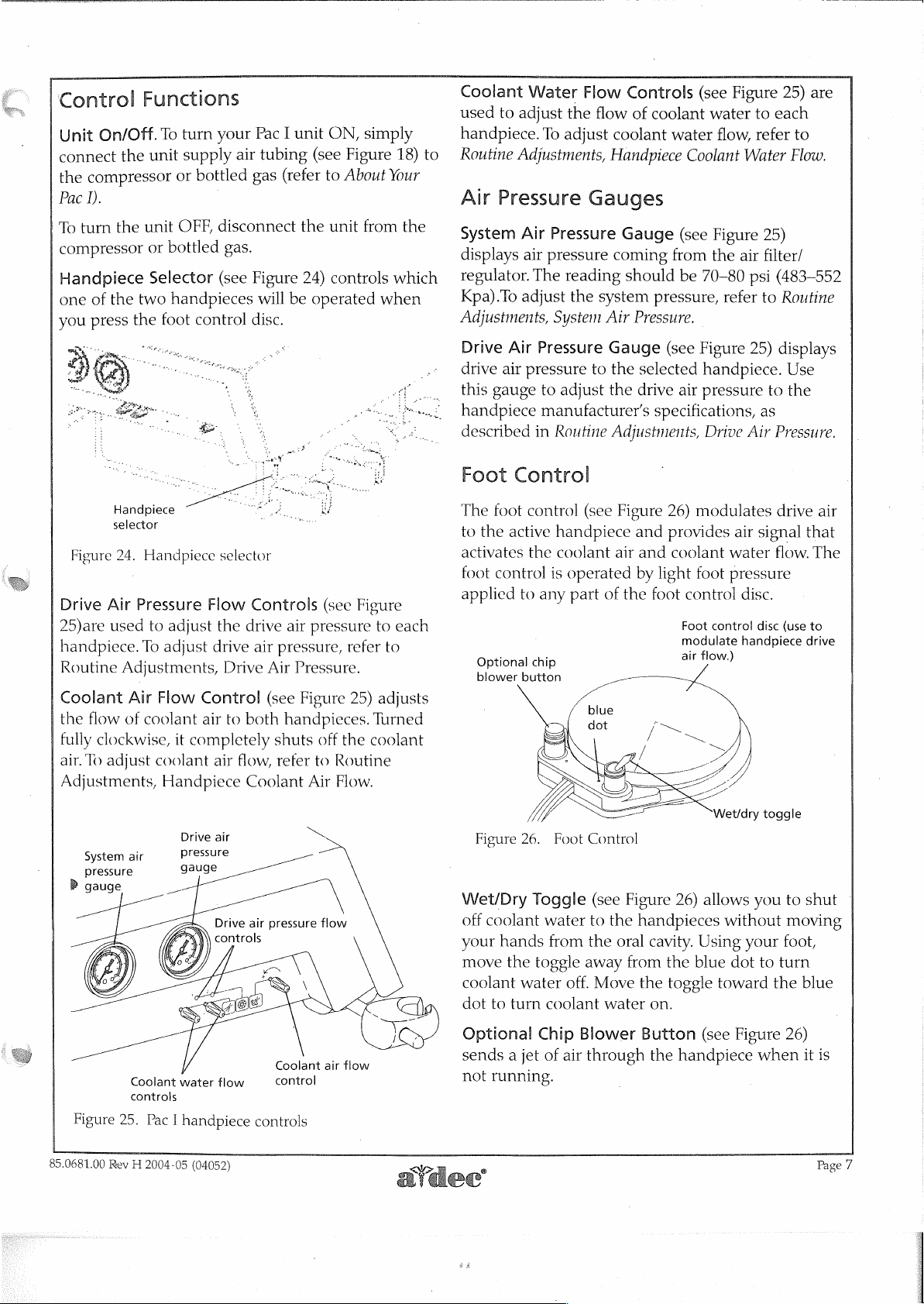

Control

On/Off.

Unit

connect

the

Pac

To

compressor

Handpiece

one

you

the

compressor

I).

turn

the

of

the

press

the

Functions

turn

To

unit

supply

or

bottled

unit

OFF,

or

bottled

Selector

two

handpieces

foot

control

Pac

your

air

tubing

gas

|

disconnect

gas.

(see

Figure

will

disc.

ON,

unit

I

(see

(refer

to

the

24)

be

operated

simply

Figure

About

unit

from

controls

when

18)

Your

the

which

Coolant

used

handpiece.

Routine

to

Air

System

displays

regulator.

Kpa).To

Adjustments,

Water

to

adjust

Adjustments,

the

To

adjust

Pressure

Air

Pressure

air

pressure

The

reading

adjust

the

System

Flow Controls

flow

of

coolant

coolant

Handpiece

water

Coolant

Gauges

Gauge

coming

should

system

Air

Pressure.

(see

from

be

pressure,

-

(see

Figure

water

flow,

Figure

the

70-80

refer

to

refer

Water

25)

air

filter/

psi

to

25) are

each

to

Flow.

(483-552

Routine

Drive

25)are

handpiece.

Routine

Coolant

the

fully

air.

Adjustments,

Handpiece

selector

Figure

24.

Air

used

Adjustments,

flow

of

clockwise,

To

adjust

Handpiece

Pressure

to

adjust

To

adjust

Air

Flow

coolant

it

coolant

Handpiece

selector

Flow

Controls

the

drive

drive

air

Drive

Air

Control

air

completely

air

(see

to

both

flow, refer

Coolant

Ш

o

(see

air

pressure

pressure,

Pressure.

handpieces.

shuts

refer

Figure

off

to

Routine

Air

Flow.

25)

the

Figure

to

each

to

adjusts

Turned

coolant

Drive

drive

this

handpiece

described

The

to

activates

foot

applied

gauge

Foot

foot

the

control

Optional

blower

Air

air

pressure

Control

control

active

the

to

chip

button

Pressure

to

adjust

manufacturer's

in

Routine

handpiece

coolant

is

any

Gauge

to

the

the

Adjustments,

(see

Figure

air

operated

part

of

the

selected

drive

and

and

by

(see

Figure

handpiece.

air

pressure

specifications,

26)

modulates

provides

coolant

light

foot

foot

control

Foot

modulate

air

flow.)

Drive

air

water

pressure

disc.

control

handpiece

25)

to

as

Air

signal

disc

displays

Use

the

Pressure.

drive

air

that

flow.

The

(use

to

drive

Drive

air

System

air

pressure

P

gauge

Coolant

controls

Figure

25.

85.0681.00

Rev H 2004-05

pressure

gauge

o

AM

|

water

Pac I handpiece

(04052)

AT

Drive

controls

flow

air

controls

OA

pressure

Coolant

control

flow

air

flow

Figure

26.

Wet/Dry

off

coolant

your

move

coolant

dot

Optional

sends a jet

not

Toggle

hands

the

toggle

water

to

turn

Chip

running.

Foot

Control

(see

water

to

from

the

away

off.

Move

coolant

Blower

of

air

through

Figure

the

handpieces

oral

cavity.

from

the

water

on.

Button

the

26)

allows

without

Using

the

blue

toggle

toward

(see

handpiece

you

your

dot

to

Figure

when

to

shut

moving

foot,

turn

the

blue

26)

it

©

is

Page

7

Page 13

Routine

System

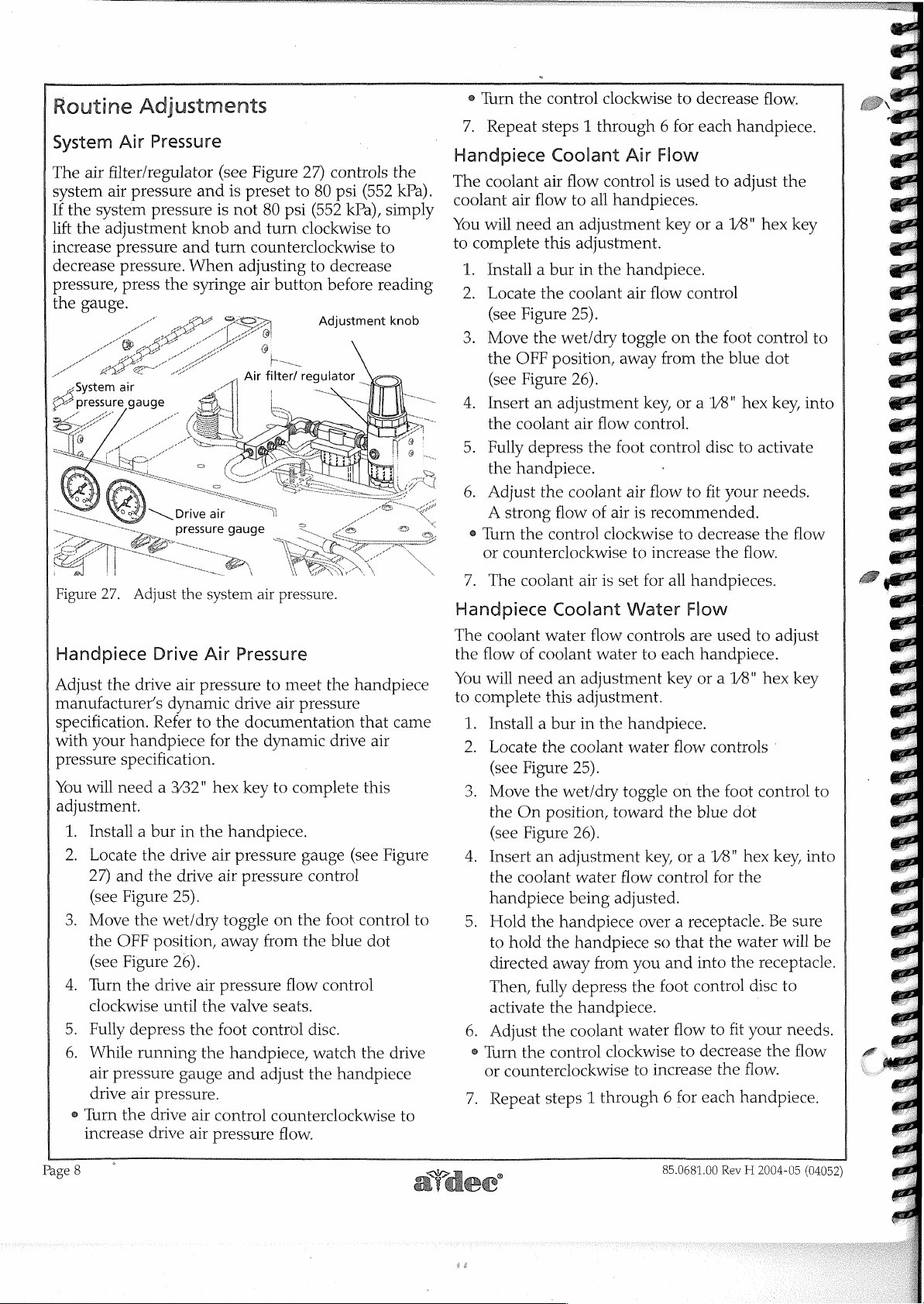

The

air

system

If

the

system

lift

the

adjustment

increase

decrease

pressure,

the

gauge.

Adjustments

Air

Pressure

filter/regulator

air

pressure and

pressure

pressure

pressure.

press

the

) — Drive

pressure

(see

is

knob

and

turn

When

syringe

air

is

not

and

gauge

Figure

preset

counterclockwise

adjusting

air

to

80

psi

turn

button

27)

controls

80

psi

(552

kPa),

clockwise

to

decrease

before

Adjustment

the

(552

kPa).

simply

to

to

reading

knob

e

Turn

the

7.

Repeat

Handpiece

The

coolant

coolant

You

to

1.

2.

3.

4.

5.

6.

air

will

need

complete

Install a bur

Locate

(see

Figure

Move

the

OFF

(see

Figure

Insert

the

coolant

Fully

depress

the

handpiece.

Adjust

A

strong

@

Turn

the

or

counterclockwise

=

control

steps 1 through 6 for

Coolant

air

flow

this

the

the

position,

an

the

control

clockwise

Air

flow

control

to

all

handpieces.

an

adjustment

adjustment.

in

the

handpiece.

coolant

25).

wet/dry

26).

adjustment

air

coolant

flow

air

toggle

away

flow

the foot

air

of

air

clockwise

Flow

is

key

flow

on

from

key,

control.

control

flow

is

recommended.

to

increase

to

decrease

each

handpiece.

used

to

adjust

or a 18"

control

the foot

the

blue

or a V8" hex

disc

to

to

fit

your

to

decrease

the

flow.

flow.

the

hex

key

control

dot

activate

needs.

the

key,

flow

to

into

Figure

27.

Adjust

Handpiece

Adjust

manufacturer’s

specification.

with

pressure

You

adjustment.

Page

the

your

specification.

will

need a 332"

1.

Install a bur

2.

Locate

27)

and

(see

Figure

3.

Move

the

OFF

(see

Figure

4.

Turn

clockwise

5.

Fully

6.

While

air

pressure

drive

e

Turn

the

increase

8

handpiece

the

the

depress

air

the

Drive

drive

air

dynamic

Refer

in

the

drive

the

drive

25).

wet/dry

position,

26).

drive

until

the

running

gauge

pressure.

drive

drive

air

system

Air

Pressure

pressure

drive

to

the

documentation

for

the

hex

key

the

handpiece.

air

pressure

air

pressure

toggle

away

air

pressure

the

valve

foot

the

handpiece,

and

air

control

pressure

air

pressure.

to

meet

air

dynamic

to

complete

on

the

from

flow

seats.

control

adjust

counterclockwise

flow.

the

handpiece

pressure

that

drive

this

gauge

the

(see

control

foot

control

blue

control

disc.

watch

the

the

handpiece

came

air

Figure

dot

drive

to

to

<>

7.

The

Handpiece

The

coolant

the

flow

You

will

to

complete

1.

Install a bur

2.

Locate

(see

3.

Move

the

(see

4.

Insert

the

handpiece

Hold

DI

to

directed

Then,

activate

6.

Adjust

e

Turn

or

7.

Repeat

m

ἵ

coolant

of

need

Figure

On

Figure

coolant

the

hold

the

counterclockwise

air

is

set

Coolant

water

flow

coolant

this

the

the

position,

an

the

fully

the

steps 1 through 6 for

water

an

adjustment

adjustment.

in

the

coolant

25).

wet/dry

26).

adjustment

water

being

handpiece

handpiece

away

from

depress

the

handpiece.

coolant

control

clockwise

toward

flow

adjusted.

for

all

handpieces.

Water

controls

handpiece.

water

toggle

over a receptacle.

you

the

water

to

Flow

are

to

each

handpiece.

key

or a 1/8"

flow

on

the foot

the

blue

key,

or a 1/8”

control

so

that

and

into

foot

control

flow

to

decrease

increase

each

85.0681.00

used

controls

dot

hex

for

the

the

water

the

to

fit

the

handpiece.

Rev H 2004-05

to

adjust

hex

key

control

Be

receptacle.

disc

|

your

the

flow.

key,

into

sure

will

to

needs.

flow

(04052)

to

be

Page 14

1.

Autoclavable

designed

The

are

use

located

is

this

of

sure

is

syringe

provided

in

be

can

manual.

Syringe

the

(refer

syringe

Your

operatory.

normal

which

instructions

section

Autoclavable

1.

Make

2.

Insert a syringe

retainer

3.

Air — Depress

4.

Water — Depress

5.

Spray — Depress

Syringe

be

to

subject

parts

a

in

repair

field

the

the

found

unit

to

in

is

tip

into

Changing

the

right

the

both

Operation

on.

the

left

buttons.

serviced

easily

wear

to

syringe

button.

button.

repair

Repair

kit.

Maintenance

syringe

the

Syringe

tip

the

in

under

kit

Tip).

Adjust

flow.

29),

e

e

2.

Press

time

flow

desired

9

©

Disconnecting

the

Press

then

turn

Turn

the

adjustment

decrease

Turn

(out)

Turn

decrease

Turn

(out)

water

the

adjustment

to

increase

the

air

for

spray

adjustment

spray.

the

adjustment

the

adjustment

to

increase

water

spray.

the

and

the

to

left

the

flow.

water

(see

screw

achieve

(water)

water

flow

screw

screw

water

Syringe

Figure

to

screw

screw

spray.

flow.

buttons

29),

achieve

the

desired

button

adjustment

clockwise

counterclockwise

at

then

clockwise

counterclockwise

Head

(see

the

turn

the

rate

Figure

screw.

(in)

to

same

the

(in)

to

of

air

Air

y

LA

Figure

Syringe

The

dual

(see

controls

flow,

pinch

the

water

the

Air

manifold

28.

syringe

pinch

Figure

follow

valve.The

air

filter

tubing

control

filter

Le

Deği

`

Adjust

Flow

air

valve

28).

the

air

each

regulator

is

head.

Dual

|

Water

SÅ

the

syringe

Adjustment

and

water

flow

located

To

flow

length

syringe

connected

pinch

inside

identify

which

and

which

of

tubing

air

manifold

to

valve

tubing

air

and

are

controlled

the

control

adjustment

controls

through

is

and

the

the

red

Autoclavable

ως

Syringe

Spray

\

LA

water

flows.

by

head

screw

the

water

the

connected

syringe

tubing

inside

gez?

$555

97

2

a

dual

to

Disconnect

the

system

Turn

the

syringe

syringe

syringe

When

water,

tubing,

A-dec

separates

head

the

syringe

which

will

Syringe

the

of

air

away

is

drip

air

supply.

and

handle

from

from

head

left

inside

out.

Tips

Use

the

syringe

water

pressure.

counterclockwise

the

handle

the

is

disconnected a little

of

then

terminal.

the

syringe

to

until

pull

head

bleed

the

the

and

Figure

29.

Adjust

85.0681.00

Rev H 2004-05

the

system

(04052)

air

pressure.

i

TT

hree

Saeco

grooves

"a"

mark

Page

9

Page 15

A-dec

Changing

To

of

the

To

is

important

Syringe

remove

syringe

ensure

À

Figure

30.

Push

the

assembly.

“clicks”

assembly

two

use

retainer

syringe

assembly

as

“clicks”

the

syringe.

assembly

tip

the

Syringe

the

A-dec

tip

that

the

that

you

o

CN

Changing

syringe

As

you

O-rings

slide

into

when

The

to

be

ejected.

must

be

Tips

Tip

syringe

retainer

syringe

tip

push

inside

installing

are

repaired

assembly

will

install

=.

an

A-dec

into

the

the

the

the

grooves.

O-rings

damaged

The

tip

before

tip,

pull

perform

the

tip

New

grooves

A-dec

syringe

syringe

in

you

syringe

If

the

syringe

inside

and

syringe

it

straight

(see

Figure

properly,

correctly.

tip

has

three

and

an

“a”

marking

tip.

tip

retainer

will

feel

tip

retainer

you

do

not

tip,

do

the

syringe

may

allow

tip

retainer

using

the

syringe.

out

30).

it

two

feel

not

tip

the

Syringe

All

syringe

must

syringe

heat

Pre-Cleaning

1.

Remove

retainer

syringe

Syringe

2.

If

gently

nylon

Remove

Go

4.

“solution

5.

your

6.

and

tips

be

heat

sterilized

and

syringe

sterilized.

the

and

terminal

Head

the

threads

brush

or

brass

the

Immerse

Clean

instructions

Purge

syringe

the

until

the

ultrasonic

all

cleaning

tips.

Tip

Asepsis

are

considered

tips

syringe

remove

(refer

on

page

on

the

the

threads

bristle

syringe

tip

in

ready

syringe

provided

cleaning

critical

between

have

tip

the

syringe

tip

an

for

tips

agents

patients.

been

designed

from

the

syringe

to

Disconnecting

9).

head

free

of

brush.

for

sterilization.

appropriate

ultrasonic

ultrasonically.

by

the

manufacturer

equipment.

from

items

The

syringe

head

from

appear

debris

holding

cleaning.

Follow

the

syringe

and

to

be

tip

the

the

dirty,

using

of

and

a

the

When

the

Figure

After

and

tip

An

water

properly

A-dec

Correct

31.

installing a tip,

press

is

properly

improperly

to

enter

installed,

syringe

No

showing.

is

properly

installed.

Installing

the

tip

grooves

this

air

button

installed.

installed

the

air

none

of

the

are

visible

are

tip

the

A-dec

point

several

A-dec

tubing

Incorrect

syringe

the

syringe

syringe

in

(see

A

This

installed.

times

the

syringe

groove

grooves

Figure

is

tip

is

improperly

tip.

at

the

to

be

tip

allows

tip.

on

31).

showing.

floor

sure

the

Sterilization

1.

Rinse

the

syringe

in

clear

water.

2.

Use a dispensing

alcohol

the

3.

Sterilize

e

Sterilize

steam

[135°C]

(340°F

e

Sterilize

autoclave

(275°F

or

Harvey’s

tips.

the

syringe

autoclave

maximum

[170°C]

the

or

[135°C]

syringe

syringe

chemical

and

syringe

bottle

tips

or

maximum

maximum

to

Vapo-Steril®

tips

using

chemical

temperature),

using

vapor

tips

flush

isopropyl

through

and/or

temperature).

temperature).

the

methods

vapor

the

methods

syringe.

(275°F

or

dry

of

heat

of

steam

Page

10

85.0681.00

Rev H 2004-05

(04052)

Page 16

Handpiece

Your

handpiece

A-dec’s

flushes

than

control

connected

How

Handpiece

After

At

Flushing

Locate

underside

handpiece

more

is

normally

only.

Often

Each

Flush

the

Beginning

Flush

the

water

The

when

Tubings?

Patient:

the

handpiece

of

the

Tubing

control

possible

handpieces

flushing

Should | Flush

the

tubings

of

the

tubings

Handpiece

control

Flush

system

tubing

through

when

the

for

Each

Day:

for

flush

head

flush

the

should

tubings.

20-30

2-3

Tubings

toggle

System

in

equipped

system.

tubings

operating

the

minutes.

(see

The

not

seconds.

on

the

Figure

Handpiece

toggle

in

less

the

be

32).

with

system

time

foot

flush

Self-Contained

The

A-dec

to

optimize

allows

from

©

e

e

Air

(regulated

40

psi

Figure

self-contained

the

quality

you

to

control

dental

Arin

(connected

the

to

source

handpieces

Selecting a quality

treatment

Performing

waterlines

Maintaining

prevent

control

yellow

[276

34.

water

asepsis

with

clean

accumulation

一

一 一

一 一

inside

head

tubing)

to

Kpal)

Adjust

the

Water

of

the

and

proper

system

System

water

system

your

dental

quality

source

and

dental

ἛἊ

of

syringes

for

treatment

disinfectant

unit

of

contaminates.

air

pressure.

is

designed

unit

water.

water

expelled

by:

dental

unit

of

your

waterlines

Water

out

(connected

the

control

to

red

tubing)

It

to

inside

head

Figure

32.

Pac I flush

Gather

coolant

Figure

water

receptacle.

Move

for

between

day.

in

Replace

85.0681.00

up

and

33).

will

the

flush

the

appropriate

patients

Water

the

On

the

Rev H 2004-05

all

the

hold

Be

sure

be

directed

toggle

flows

position.

handpiece

toggle

handpiece

them

over a water

you

hold

away

to

the

time

required,

or

flushing

only

as

long

tubings

(04052)

tubings

the

tubings

from

you

On

position

at

the

as

you

in

that

use

receptacle

so

that

and

into the

|

and

either

their

for

beginning

hold

the

holders.

water

(see

the

hold

flushing

of

the

toggle

How

It

Works

Air,

regulated

water

bottle

the

bottle

the

water

tube

and

the

syringes.

Benefits

system

conjunction

treatment

monitoring.

water

bottle,

How

The

self-contained

depends

municipal

the

whenever

procedure,

source

are

system

and a water

to

correct

self-contained

quality.

to

through a restrictor

cap.

The

from

out

to

of

using

only

with

protocol

The

include

Choose

water

water

on

the

source

treatment

that

40

psi

air

pressure

the

bottle

the

handpiece

the

A-dec

fully

realized

an

A-dec

and

three

main

the

treatment

Treatment

to

use

system

quality

and

the

water

water

you

are

(276

kPa),

is

supplied

barb

attached

in

the

bottle

up

into

the

water

control

self-contained water

when

recommended

followed

components

treatment

protocol.

Water

in

your

(for

of

water

goals

you

system.

is

specified

consistent

blocks

used

by

periodic

water,

A-dec

patient

available

have

It

is

important

for

in

your

to

the

to

forces

pickup

and

in

waterline

of

the

the

water

treatment)

from

your

for

using

that

a

water

Page

11

Page 17

Tap

water

If

you have

ered

by

using

system.

tion

with

dures

procedures

water

counts.

Distilled

If

you

delivered

ommend

under

Pharmacopoeia

standards

tions.

operate

|

ICX

Water

A-dec

flushing

contamination

waterlines.

bottle

continuously

was

developed

effective

Page

12

confidence

your

municipal

fresh

tap

water

Use

of

tap

the

operation

prescribed

in

this

that

contains

water

have

concerns

through

the

use

the

standards

(U.S.P.).

has

been

Most

reputable

under

ICX

refill, a low

U.S.P.

Treatment

offers a unique

and

maintenance.

and

By

adding

assured

to

method

ES

in

the

quality

supply,

in

your

self-contained

water

must

and

maintenance

in

this

manual.

manual

higher

your

of

water

processed

WARNING

maintains

concentration

be

for

can

than

about

of

standards.

treating

the

municipal

which

the

United

Water

bottled

Tablet

solution

It

one

tablet

in

the

dental

the

most

water

helps

self-contained

you

be

done

Failure

result

normal

quality

supply,

has

distilled

in

optimum

clean

of

of

compatible

of

water

may

consider

in

conjunc-

proce-

to

follow

in

dental

microbe

of

water

we

been

distilled

States

under

condi-

companies

“pi

SAFA

LE

Ware

for

waterline

prevent

dental

ICX

cleaner

unit

unit

to

each

is

water.

and

deliv-

water

all

unit

rec-

these

ar

ICX

dental

al

unit

water

systems.

waterline

A-dec

ICX

A-dec

an

empty

The

The

regular

How

Before

water

higher

Waterline

use.

have

Association

Center

500

Standards

Refer

recommendations

steps

1.

2.

3.

4.

5.

NOTE:

ἵ

maintenance

ICX

water

Water

ICX

is

self-contained

tablet

is

®

Eliminate

e

Help

deter

e

Provide a residual

clean

ICX

tablet

testing

to

Use

using

quality.

than

Preparation

Recommendations

been

published

for

Disease

cfu/ml.

specify a maximum

to

your

below

Before

day,

empty

the

bottle.

Drop

tablet

contamination,

Fill

bottle

dental

Wait

60

Connect

unit

ON.

If

you

equipment

recommend a special

prepare

Waterline

©

A-dec's

is

treatment

Treatment

an

effervescing

formulated

odors

prevent

contamination

waterlines

ICX

A-dec

your

(ADA)

European

describe

refilling

unit.

seconds

build-up

during

should

of

If

results

national

with

the

are

the

be

treatment

ICX

water

for

by

not

Control

Union

regulatory

specific

how

bottle

any

remaining

into

empty

avoid

water,

for

air

supply

using

that

has

system

Preparation

for

indicate

quality

for

to

this

recommendation

based

bottle

to:

effect

used

the

tablet

on

tablet.

Protocol

tablet

before

of

deposits

in

dental

that

periods

in

conjunction

water.

the

first

bacterial

goals,

ICX,

otherwise

dental

exceed

(CDC)

to

to

and

touching

and

product

already

startup

for

unit

American

200

Drinking

of

100

authorities

your

use

ICX.

at

the

water

bottle.

connect

to

fully

tubing

been

the

usage

for

ICX).

85.0681.00

daily

that

unit

helps

time,

not

local

(To

the

and

for

procedure

Rev H 2004-05

for

use

of

is

added

each

filling.

and

help

waterlines

maintain

of

non-use.

test

counts

proceed

begin

water

Dental

cfu/ml

to

Water

cfu/ml.

start

left

prevent

dissolve.

|

the

in

of

quality

and

exceed

for

area.

The

of

every

in

tablet.)

to

turn

the

first

time

use,

we

to

ICX

(see

the

to

with

your

to

daily

the

on

(04052)

Page 18

-Steril-Vac

A-dec

Your

central

evacuation

System)

handpiece

liter)

waste

liter)

waste

Operating

Air

is

(QD)

To

actuate

button

button

Steril-vac

disconnect

Steril-Vac

vacuum.

system

handpiece.

forces

container.

container

supplied

tubing

the

on

the

is

spring

quick

Supply

air

tubing

quick

disconnect

(QD)

is

It

using

the

Your

by

attaching

to

the

vacuum,

AVS

loaded

(QD)

eliminates

operated

air

an

A-dec’s

Vacuum

debris

An

is

Steril-Vac

steril-vac

handpiece

Waste

container

created

into

(optional)

available.

the

QD

press

and

(see

to

the

Off

need

the

oral

(Air

AVS

πε

at

the

one

two

quick

disconnect

(see

Figure

hold

the

Figure

position.

AVS

handpiece

Actuation

button

a

for

Vacuum

|

quart

quart

35).

35).

The

(.95

(1.9

Cleaning

After

thoroughly

the

AVS

the

system

the

tubing.

Remove

disinfecting.

recommendations.

Daily

prevent

cleaners

vacuum

dealers.

follow

use a sudsing

Use

the

clean

way

past

of

the

hold

purged

The

Steril-Vac

and

disinfected

Your

each

patient,

rinsed

handpiece.

for a few

the

handpiece

Consult

cleaning

accumulation

systems

If

the

brush

the

AVS

the

from

of

with

disinfectant

you

use

manufacturer’s

detergent

provided

AVS

handpiece.

the

cross

handpiece.

button

the

waste

Steril-Vac

the

Steril-Vac

by

drawing

After

rinsing,

seconds

tip

for

your

dental

the

AVS

handpiece

of

debris.

properties

are

available

one

of

these

recommendations.

to

in

the

Push

tube

to

clean

Rinse

down

each

until

tubing.

container

time

it

clean

to

clear

cleaning

Several

from

cleaners,

clean

field

the

with

all

the

should

is

emptied.

should

water

draw

all

supply

is

for

dental

the

AVS.

repair

brush

the

lower

clean

water

be

be

through

air

through

water

from

and

dealer

necessary

special

dental

be

water,

supply

sure

Never

kit

to

all

the

portion

then

has

been

cleaned

for

to

to

|

Figure

35.

Steril-Vac

85.0681.00

Rev H 2004-05

(04052)

Page

13

Page 19

Oil

The

your

normal

e

e

®

lection

Co

gauze

pad

unit

needs

usage.

Remove

discard

Fold

in

gauze

the

jar.

Screw

Do

not

System

(2x2)

inside

to

be

changed

Change

the

the

quarters a new

pad

the

oil

overtighten.

more

oil

collector

old

gauze

and

place

collector

the

oil

collector

once a week

often

for

jar

from

(see

Figure

two-inch

against

jar

onto

the

the

jar

for

heavy

the

unit

36).

square

spring

unit.

on

use.

and

inside

Care

For

refer

Publication

Instructions

recommended

to

Equipment

No.85.0696.00).

asepsis

Asepsis

instructions,

Owner's

Guide

(A-dec

Gauze

(2x2)

Figure

pad

36.

>YL

|

Oil

Collection

collector

Oil

System

-一

Discard

gauze

jar

—

used

pad

Page

14

85.0681.00

Rev H 2004-05

(04052)

Page 20

aintenance

General

Parts

the

In

will

find

for

possible

The

seal

an

O-ring),

the

seal

Defects

A

careful

surfaces

flaws

When

gaskets

install

components.

re-used,

cracks.

Cleaning

Service

Inspection

troubleshooting

references

area

groove

in

any

examination

with a magnifier

that

are

servicing

or

diaphragms

new

ones

carefully

Internal

defect,

is

comprised

the

bore

in

the

of

these

too

small

components

when

If

the

inspect

Information

sections

to

the“seal

which

old

will

of

the

or

seat

in

valve

stem

areas

may

of

all

sealing

is

essential

to

see

that

it

is

generally

reassembling

gasket

the

item

Parts

manual

this

in

area"

as

a

location

allow

a

valve

seal

itself

the

valve

body,

or

piston.

result

in

parts

for

detecting

otherwise.

have

rubber

advisable

the

or

diaphragm

for

pin

you

to

leak.

(usually

and

leakage.

and

to

is

to

holes

or

O-ring

These

miniature

the

four

equipment.

tools

are

-

Figure

|

Hemostats

Hemostats

air

or

water

troubleshooting

be

Tools

tools

allow

components.

smallest

Instructions

included

37.

O-ring

are

flow

quick

O-ring

with

一

575

6

O

Ó- < ンプ

Tools

useful

through

or

repairing

field

repair

The

three

sizes

in

for

the

the

set.

a

σσ

<

ング

(A-dec

for

Part

temporarily

the

tubing

the

of

tools

A-dec

use

of

^

^

No.

unit.

most

A-dec

in

this

the

O-

-ring

009.013.00)

stopping

while

|

set

fit

When

component

cleaned

reassembly.

parts

most

Any

cloth.

them

Tool

Included

(Part

equipped

Institutional

like

A-dec

Unit

for a complete

The

useful

servicing

disassembled

and

inspected

The

is

largely

effective

wiping

Flush

in

and

No.

to

order

for

Tool

following

for

cleaner

should

all

isopropyl

Repair

with

your

45.0439.00).

with a tool

and

the

the

Pac I Institutional

Kit

(Part

Pac I maintenance

dental

lubricant

impervious

parts

listing

items

systems,

should

for

defects

recommended

to

is a hot

be

done

with

clear,

alcohol.

Kits

Pac I Unit

The

Pac I Field

kit.

If

you have

Self-Contained

tool

kit,

ask

No.

45.0438.00).

of

the

are

not

the

parts

be

thoroughly

before

chemical

detergent

with a soft,

hot

is a Field

your

or

items

necessary

and

solvents.

solution.

lint

water

Repair

Unit

the

Unit

and

dealer

Self-Contained

Refer

in

these

but

service.

of

any

for

these

free

and

rinse

is

Pac 1 '

would

or

call

to

page

kits.

may

The

Kit

34

be

Figure

Valve

The

pilot-operated

used

75

10x

The

parts

Test

valve

to

psi

(518

Figure

(A-dec

Magnifier

10x

for

38.

Hemostats

Syringe

test

syringe

valves.

apply a static

kPa).

39.

Valve

Part

No.

magnifier

defects.

S

~ 一 ~

(A-dec

is

used

The

valve

pressure

Test

Syringe

98.0050.00)

is

used

to

«II

Part

No.

to

make

test

syringe

of 5 (34.5

inspect

23

009-008-00)

quick

tests

can

kPa)

to

miniature

valve

of

be

85.0681.00

Rev H 2004-05

(04052)

Figure

40..

10X

Magnifier

(A-dec

Part

No.

009.009.00)

Page

15

Page 21

Test

Gauge

The

test

ous

points

required

e

One

A-dec

®

One

A-dec

e

One

A-dec

e

Two

A-dec

e

1/8"

A-dec

gauge

is

used

while

troubleshooting

for

use

of

1%"

(3.2mm)

Part

No.

washer,

Part

No.

plastic

uni-clamps

(3.2mm)

Part

No.

Part

No.

Part

No.

tee,

to

check

this

gauge:

barb,

023.028.00.

004.005.00.

023.014.00.

for

1/8"

(3.2mm)

025.007.00.

Clear

tubing,

024.015.00.

air

pressure

the

system.

2'

(610mm)

at

vari-

Also

tubing,

long,

A-dec

The

Sleeve

A-dec

14"

(6.4mm)

place

when

Figure

44.

Hex

Wrench

A

complete

wrenches

A-dec

wrenches

eguipment.

Tool

(included

Sleeve

Sleeve

that

together

Tool

and

1/8"

installing

Tool

Set

(included

hex

wrench

might

The

and

is

used

(3.2mm)

the

tubing

(A-dec

in

set

be

reguired

plastic

easily

in

the

tool

kit)

to

press

the

tubing

Part

No.

the

which

holder

identifiable.

sleeves

on

barb

98.0072.00)

tool

kit)

includes

in

servicing

keeps

in

fittings.

all

hex

the

hex

Figure

Snap

Ring

The

snap

both

internal

snap

ring

Figure

Tubing

These

1/8"

(3.2mm)

41.

Test

Gauge

Pliers

ring

pliers

and

sizes

42.

Snap

Pliers

modified

tubing

=

一

are

external

used

in

Ring

Pliers

pliers

onto

GE

(A-dec

used

snap

A-dec

(A-dec

are

used

the

Part

No.

026.014.00)

to

install

rings.

It

equipment.

Part

No.

to

push

barbed

fittings.

—

and

remove

fits

all

the

009.007.00)

|

Figure

45.

Hex

Lubrication

A-dec

silicone

nal

moving

tor

valves.

Before

of

silicone

installation

O-ring

tute

for

Silicone

(included

silicone

base

parts

installing

lubricant.

of

from

being

A-dec

Lubricant.

Wrench

In

lubricant

grease.

the

It

such

O-rings

This

O-ring

damaged.

lubricant

Set

(A-dec

the

field

is a high

is

ideal

for

as

O-rings

always

makes

easier

is

the

and

An

Dow-Corning®

Part

No.

009.018.00)

repair

guality

apply a light

acceptable

kit)

lubricating

and

oral

will

inter-

evacua-

coat

prevent

substi-

No.

the

103

>

Figure

43.

Tubing