Page 1

9620 Global

OBD II Scan Tool

Page 2

Table of Contents

Vehicle ServiceInformation ......3

Safety Precautions .....................4

Section 1: Vehicle Computer

Systems------------- 5

1.1 Introduction ..................................... 5

1.1.1 What The Computer Controls . 5

1.1.2 What Has Not Changed .......... 5

1.1.3 Computer Control System ...... 5

1.2 Data Link ConnectorandLocation .6

1.3 OBD II Scan Tool Hookup ................ 6

1.3.1 Keyboard .................................7

1.3.2 Display .....................................7

1.3.3 Lists, Menus, and Questions ...7

1.4 Tool Setup .......................................8

1.4.1 Changing Measurement Units 8

1.4.2 Changing Display Contrast .....8

1.4.3 Displaying Tool Information .... 9

1.4.4 Program Mode .........................9

1.5 Personal Computer (PC) and

PrinterInterface..............................9

1.6 Replacing the Battery ..................... 9

1.7 AC Adapter ......................................9

Section 2: Diagnosing with

theScan Tool ---- 10

2.1 Preliminary Checks ..................... 10

2.2 Connecting the Scan Tool ............ 10

2.3 OBD II Functions List ..................... 11

2.3.1 I/M Readiness ........................11

2.3.2 Read Codes .......................... 12

2.3.3 Pending Codes ..................... 12

2.3.4 Erase Codes ......................... 13

2.3.5 View Data .............................. 13

2.3.6 View Freeze Data ................. 15

2.3.7 O2 Monitor Test ..................... 15

2.3.8 Diagnostic Monitor Tests ...... 16

2.3.9 On-Board Systems ............... 17

2.3.10 Record Data .......................... 17

2.3.11 Vehicle Info ........................... 18

2.3.12 Modules Present ................... 19

2.3.13 Review Data .......................... 19

2.3.14 Print Data .............................. 20

Section 3: Diagnostic Trouble

Codes (DTC) ---- 22

3.1 DTC Format .................................. 22

3.2 Code Lookup ................................ 23

3.3 Diagnostic Trouble Code Ranges 24

Section 4: Help and Trouble-

shooting Tips ---- 25

4.1 How to Use Help ........................... 25

4.2 Scan Tool Problems ..................... 25

4.2.1 Scan Tool does not powerup:25

4.2.2 Scan Tool does not Link

withvehicle:........................... 25

4.2.3 One or more modules drops

the communication link: ...... 26

4.2.4 Keyboard does not function

properly: ................................ 26

4.3 Tool Self-Tests .............................. 26

4.3.1 Display Test ........................... 26

4.3.2 Keyboard Test ....................... 26

4.3.3 Memory Test.......................... 27

4.3.4 Printer Test ............................ 27

4.4 Technical Support ........................ 27

Appendix A: Global OBD II PID

List & Definitions 28

Appendix B: -------- Glossary &

Definitions -------- 31

All information, illustrations and specifications contained in this manual are based on the

latest information available from industry sources at the time of publication. No warranty

(expressed or implied) can be made for its accuracy or completeness, nor is any

responsibility assumed by SPX or anyone connected with it for loss or damages

suffered through reliance on any information contained in this manual or misuse of

accompanying product. SPX reserves the right to make changes at any time to this

manual or accompanying product without obligation to notify any person or organization

of such changes.

2 9620 Professional OBD II Scan Tool

Page 3

Vehicle ServiceInformation

The following is a list of publishers who have manuals containing electronic engine

control diagnostic information. Some manuals may be available at auto part stores

or local public libraries. For others, write for availability and pricing, specifying the

make, model and year of vehicle.

Service Manuals:

Chilton Book Company

Chilton Way

Radnor, PA 19089

Haynes Publications

861 Lawrence Drive

Newbury Park, CA 91320

Cordura Publications

Mitchell Manuals, Inc.

Post Office Box 26260

San Diego, CA 92126

Motors Auto Repair Manual

Hearst Company

250 W 55th Street

New York, NY 10019

Manufacturer Service Manuals:

General Motors:

Buick, Cadillac, Chevrolet, GEO,

GMC, Oldsmobile, & Pontiac

Helm Incorporated

Post Office Box 07130

Detroit, MI 48207

Saturn

Adistra Corporation

c/o Saturn Publications

101 Union St.

Post Office Box 1000

Plymouth, MI 48170

Ford Motor Company:

Ford, Lincoln, & Mercury

Ford Publication Department

Helm Incorporated

Post Office Box 07150

Detroit, MI 48207

Chrysler Corporation:

Chrysler, Plymouth, & Dodge

Chrysler Motors Service Training

26001 Lawrence Avenue

Center Line, MI 48015

Suitable manuals have titles, such as:

Electronic Engine Controls

Fuel Injection and Feedback Carburetors

Fuel Injection and Electronic Engine Controls

Emissions Control Manual

. . . or similar titles

9620 Professional OBD II Scan Tool 3

Page 4

Safety Precautions

General Safety Guidelines to Follow When Working on Vehicles

To prevent accidents that could result in serious injury and/or damage

to vehicle or test equipment, carefully follow these safety rules and

test procedures at all times when working on vehicles:

Always wear approved eye protection.

Always operate the vehicle in a well-ventilated area. Do not inhale exhaust

gases they are very poisonous!

Always keep yourself, tools and test equipment away from all moving or hot

engine parts.

Always make sure the vehicle is in Park (Automatic transmission) or neutral

(manual transmission) and that the parking brake is firmly set. Block the

drive wheels.

Never lay tools on vehicle battery. You may short the terminals together

causing harm to yourself, the tools or the battery.

Never use scan tool if its internal circuitry has been exposed to any liquids.

Never smoke or have open flames near vehicle. Vapors from gasoline and/or

charging battery are highly flammable and explosive.

Never leave vehicle unattended while running tests.

Always keep a fire extinguisher suitable for gasoline/electrical/chemical fires

handy.

Always use extreme caution when working around the ignition coil, distributor

cap, ignition wires, and spark plugs. These components contain high voltage

when the engine is running.

When performing a road test, never operate the scan tool alone while driving

the vehicle. Always have one person drive the vehicle while an assistant

operates the tester.

Always turn ignition key OFF when connecting or disconnecting electrical

components, unless otherwise instructed.

Always follow vehicle manufacturers warnings, cautions and service

procedures.

WARNING!:

Some vehicles are equipped with safety air bags. You must follow

vehicle service manual cautions when working around the air bag

components or wiring. If the cautions are not followed, the air bag may

open up unexpectedly, resulting in personal injury. Note that the air

bag can still open up several minutes after the ignition key is off (or

even if the vehicle battery is disconnected) because of a special

energy reserve module.

4 9620 Professional OBD II Scan Tool

Page 5

Section 1: Vehicle Computer Systems

1.1 Introduction

This section describes the engine computer control system, types of sensors and how

the computer controls engine fuel delivery, idle speed and timing. Additional information

may be found in the technical support books at your local library or auto parts store. The

more known about the computer system, the easier the problem can be diagnosed.

Computer controls were originally installed on vehicles to meet federal government

regulations for lower emission levels and improved fuel economy. This began in the early

1980s when basic mechanical systems were no longer able to accurately control key

engine parameters. A computer could be programmed to control the engine under various

operating conditions, making the engine more reliable. While these early systems were

very limited in scope of their diagnostics, providing only 10-14 trouble codes, they did help

guide the vehicle repair process.

In 1994, manufacturers began equipping vehicles with a new class of computer technology

which puts more processing power under dash than ever before. It is called On-Board

Diagnostics version II, or OBD II. It is required on all vehicles sold in the US beginning

January 1, 1996 (though most domestic manufacturers introduced it earlier than required),

and offers increased system monitoring and diagnostic information. This new system stores

a library of more than 650 general trouble codes and another approximately 400

manufacturer-specific codes, all of which can be accessed with the scan tool. These codes

cover Body Systems (B-Codes), Chassis Systems (C-Codes), Communications Codes

(U-Codes), and Powertrain Systems (P-Codes). Now, basic terms are standardized and

all generic codes will share a common format and terminology that manufacturers and the

Society of Automotive Engineers (SAE) designed.

The OBD II Professional Scan Tool performs OBD II functions on ALL makes of OBD II

compliant vehicles from 1996 and up.

1.1.1 What The Computer Controls

The main control areas of the vehicle computer are fuel delivery, idle speed, spark advance,

and emissions controls. Some on-board computers may also control the transmission,

brakes, and suspension systems as well.

1.1.2 What Has Not Changed

A computer-controlled engine is very similar to the older, non-computerized engine. It is still

an internal combustion engine with pistons, spark plugs, valves, and camshaft(s). The ignition,

charging, starting, and exhaust systems are very similar as well. Test and repair of these

systems are the same as before. The technical manuals for these components provide

instruction on how to perform the tests. Additionally, compression gauges, vacuum pumps,

engine analyzers, and timing lights will continue to be used.

1.1.3 Computer Control System

The vehicle on-board computer, or Powertrain Control Module (PCM), is the heart of the

system. It is sealed in a metal box and connected to the rest of the engine by a wiring

harness. The PCM is commonly located in the passenger compartment, behind the

dashboard (kick panel position), although some manufacturers locate the PCM in the

engine compartment. The PCM is programmed by the factory. The program is a complex

list of lookup tables and instructions telling the computer how to control the engine based

on various driving conditions. It does this using sensors to monitor what is happening and

then provide feedback through a network of switches and actuators throughout the vehicle.

9620 Professional OBD II Scan Tool 5

Page 6

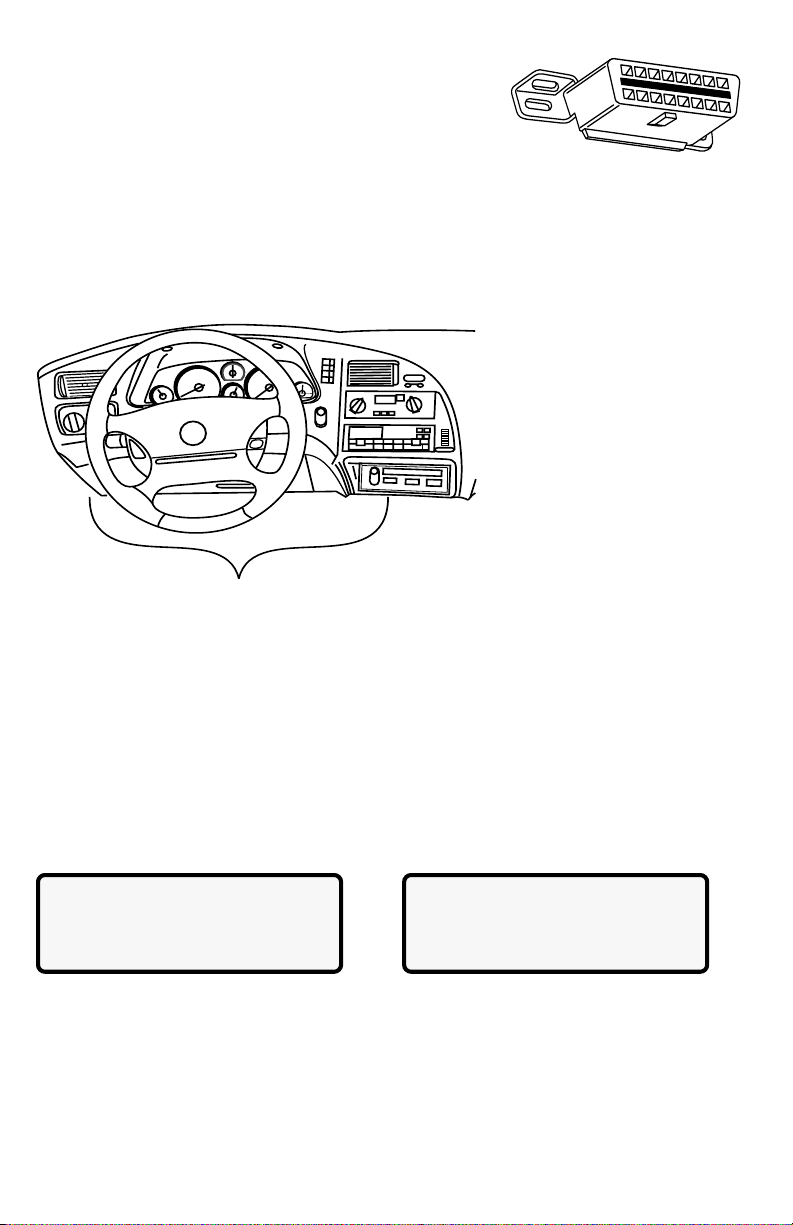

1.2 Data Link ConnectorandLocation

Welcome To

The Global OBDII

SCANTOOL

Press HELP For Key |

Button Information

Press ENTER To Cont

The scan tool communicates with the vehicle PCM via a

data link connector (DLC) also referred to as a J1962

connector. The term J1962 is taken from physical and

electrical specification number assigned by SAE (Society of

Automotive Engineers). A standardized DLC means all compliant

vehicles will use the same DLC with the generic link information available on the same

pins regardless of vehicle make or model. In addition to the connector definitions, is a

guideline on where the connector is to be located in the vehicle. This guideline states

that the DLC should be located under the dashboard on the driver side of the vehicle.

However, not all OBD II DLCs are located under the dash on the driver side. If required,

refer to vehicle service documentation for the DLC location.

DLC Location

1.3 OBD II Scan Tool Hookup

The OBD II cable attached to the scan tool fits the OBD II DLC. Because the OBD II J1962

connector contains dedicated pins for power and ground, only a single cable connection is

required for both scan tool power and PCM communication.

Connect the scan tool to the DLC. This connection will provide power for the scan tool.

The DLC maintains power even when the ignition is turned off. Therefore, connection to

the battery is not required.

When the scan tool powers up, a series of screens are displayed. The screens start with

a Welcome screen and end with a Key Button Help screen.

The screens between the Welcome screen and the Key Button Help screen are for

tool self-tests and software ID. Refer to this software ID when contacting the Actron

technical support line with a problem. To review the key button definitions, push the

(HELP) key; otherwise, press ENTER to continue.

The scan tool requires a minimum of 8 volts to power up. If a problem occurs with powerup, review Section 4: Help and Troubleshooting Tips.

6 9620 Professional OBD II Scan Tool

Page 7

1.3.1 Keyboard

OBDII Function List |

3)Erase Codes ]

4)View Data [

`5)View Freeze Data

The scan tool software was designed for ease of use in navigating through operational

menus. Simply follow instructions that match keyboard symbols.

Keyboard Functions

The scan tool uses 8 keys to navigate through the software-user interface:

ENTER Used to select or answer a software request.

HELP Used to request help when the (|) symbol is displayed in the lower right

hand corner of the display.

BACK Used to move one screen back in scan tool flow.

ARROWS

UP/DOWN Used to move the solid cursor (`) in the direction of the arrow or

scroll the data list in the direction you want to move the list.

LEFT/RIGHT Used to select and deselect items in custom lists. This key is

also used to answer questions by selecting yes or no.

ON/OFF Used to turn scan tool ON and OFF when not powered by vehicle.

Momentarily press and release button when turning ON to allow boot process.

1.3.2 Display

The scan tool has a 4 line x 20 character backlit

Liquid Crystal Display (LCD) for easy viewing. The

backlighting is disabled when the scan tool is

powered by its internal batteries. This gives the

user a large viewing area to display most Help

and Instructional messages. It puts more

information on the display instead of having to refer to printed materials. Again the display will

support a number of helpful characters that will prompt the user through test routines. These

characters are shown below:

| Question Mark in lower right corner means there is help available for this screen or

current selectable item.

` Pointer (cursor) is used to indicate current selectable choice.

[ Down Arrow indicates there is additional information on the next screen.

] Up Arrow indicates there is additional information on previous screen.

« Diamond to the left of item indicates it is selected.

The screen at the right shows how some of these symbols will look on your display.

1.3.3 Lists, Menus, and Questions

The scan tool is designed to be as intuitive as possible. Its functions and controls are easy to

understand and use. All menu and screen lists operate the same way. Use the UP/DOWN

arrow keys to move the cursor to a selection. The ENTER key selects that function or item. The

screen examples below show a few selections available on the OBDII Function List.

For example: to read vehicles DTCs, move cursor to Read Codes and press ENTER.

To make a different choice, use the DOWN arrow key to move the cursor down to View Data

and press ENTER. This will select the View Data function.

Sometimes, a list will be longer than three or four items, and will not fit on a single screen. In

this case, the DOWN arrow symbol ([) is visible in the last column of the display, indicating

that there are more choices on the next screen, as shown below on the left. Use the DOWN

arrow key to move the cursor down the list.

9620 Professional OBD II Scan Tool 7

Page 8

At the bottom of the list, there is now only an UP arrow symbol (]) visible in the last

View Instructions

For Creating Custom

Data List?

Yes <No>

OBDII Function List |

`1) I/M Readiness

2)Read Codes [

3)Pending Codes

OBDII Function List |

4)View Data ]

5)View Freeze Data [

`6)Record Data

Setup Tool For

1) English/Metric

`2)Display Contrast

3)Tool Information

]Increase Contrast

[Decrease Contrast

Press ENTER To Save

Setup Tool For

`1) English/Metric

2)Display Contrast [

3)Tool Information

Measurement Units

`English(Default)

Metric

column indicating the last function in the list has been reached. To return to previous

screens, press the UP arrow key. The UP/DOWN arrow keys work the same way when

scrolling through text such as the Help screen.

The Scan Tool may ask a question which requires a response from user. These will

always be YES or NO questions, and are answered with cursor and Arrow keys.

In these screens, brackets <> will automatically appear next to default response. To

accept default choice, simply press ENTER. Use LEFT/RIGHT arrow key to move brackets

to other response and press ENTER.

1.4 Tool Setup

Only functions of the Main Menu that pertain to getting started with scan tool are discussed

in the following paragraphs. For all other menu selections available, refer to Section 4:

Help and Troubleshooting Tips.

Tool Setup is used to change the scan tool default

unit settings. To change the scan tool settings,

select Tool Setup from the MAIN MENU and

press the ENTER key.

NOTE: Settings chosen will remain until 9 volt battery is dead.

1.4.1 Changing Measurement Units

After selecting Tool Setup option, tool setup menu appears. To choose English or Metric

measurement units, use UP/DOWN arrows to make selection and press ENTER. The

display will look like the following screen:

1.4.2 Changing Display Contrast

From the Tool Setup menu, select Display Contrast and press ENTER. Use the UP/

DOWN arrow keys as indicated on the screen:

8 9620 Professional OBD II Scan Tool

Page 9

1.4.3 Displaying Tool Information

Setup Tool For

1) English/Metric

2)Display Contrast

`3)Tool Information

Tool Information:

`Serial No: 1360447]

SW ID: 86E3H[

HW Ver: 1

From Tool Setup menu, select Tool Information and press ENTER. Use UP/DOWN

arrow keys to view information. Record information in case the need to contact customer

service arises.

1.4.4 Program Mode

Used to update scan tools software. Instructions will be provided with updates.

1.5 Personal Computer (PC) and PrinterInterface

Scan tool is equipped with a standard 9 pin serial interface. Use connection to attach

tool to a PC or compatible printer.

Personal Computer

Use serial adapter to connect to a PC when updating to current available software.

Software updates may be purchased from Actron by calling the toll free number

provided.

Refer to Section 2.4.13 Print Data for default serial port settings and to make

changes to settings.

Printer Connection

Connect a compatible printer cable to the scan tool and Printer using specifications

below:

- If the printer connector is a 25 pin connector or if the gender is not compatible, an

adapter will be required.

- Adapters are available at most local PC stores or electronics outlets.

- A NULL modem adapter is required to be connected in series with scan tool and

printer cable.

1.6 Replacing the Battery

To replace the 9V battery, do the following:

Remove screw from back of scan tool case.

Slide battery cover back to disengage hooks.

Replace 9V battery and place in compartment.

Slide battery cover up, making sure hooks engage scan tool case.

Install screw.

1.7 AC Adapter

The AC power adapter powers the tool when you review codes and print off-vehicle and when

you update the software vial a personal computer. The Scan tool is equipped to accept any

110 Vac12 Vdc AC adapter with the following specifications.

300 mA minimum unregulated wall power adapter.

Dimensions - 5.5 mm Outside Diameter, 2.5 mm Inside Diameter.

9620 Professional OBD II Scan Tool 9

NEG

POS

Page 10

Section 2: Diagnosing with theScan Tool

FRONT

OF CAR

HVAC

CRUISE

BRAKE BOOSTER

TO TRANS

MODE

EGR

VAC

REG

FUEL

PRESS

REG

EGR

VAC

REG

9RAC2LAB

T

ER

P

A.

M

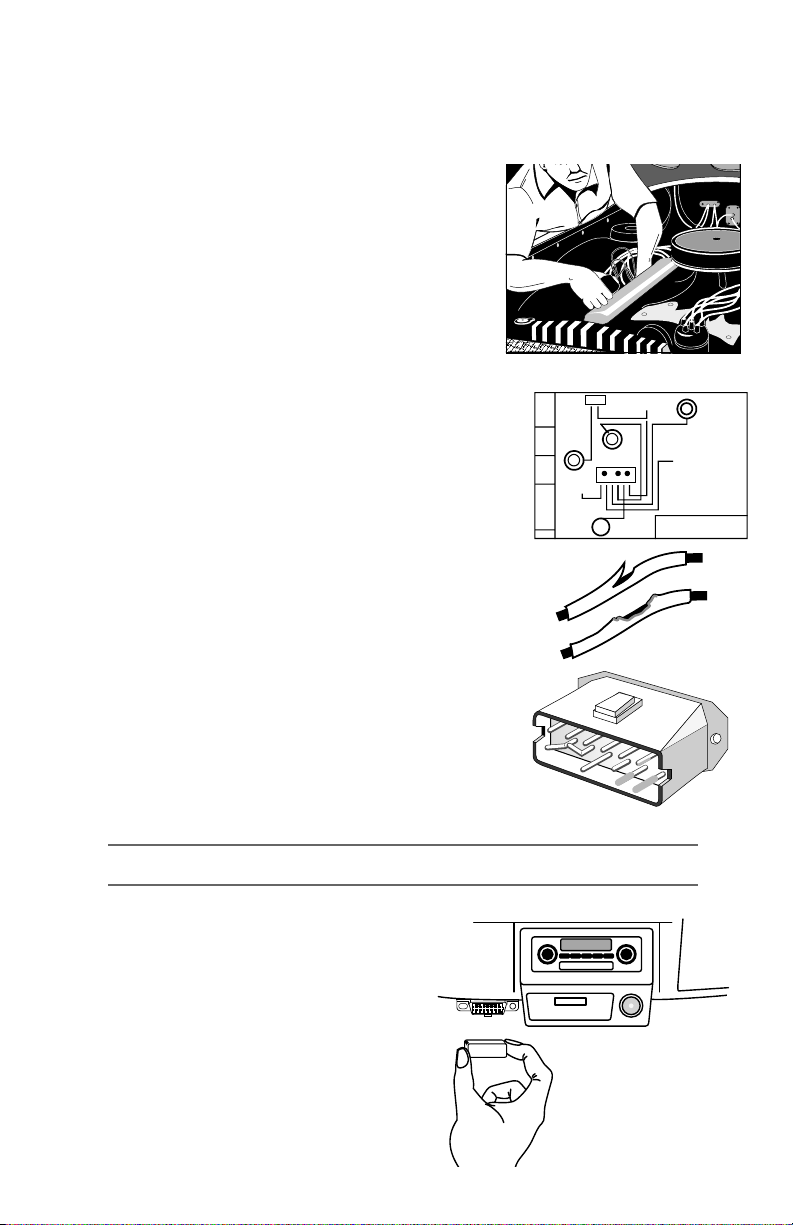

2.1 Preliminary Checks

Before using scan tool, perform a complete visual inspection. Many driveability problems

are found by visual inspection, saving time. Check the following items before proceeding

with scan tool testing:

1. Has vehicle been serviced recently? Sometimes

things get connected in the wrong place, or not at all.

2. Dont take shortcuts. Inspect hoses and wiring which

may be difficult to see because of location beneath air

cleaner housings, alternators and similar

components.

3. Inspect air cleaner and ductwork for defects.

4. Check sensors and actuators for damage.

5. Inspect all vacuum hoses for:

Correct routing. Refer to vehicle service manual, or

Vehicle Emission Control Information (VECI) decal

located in engine compartment.

Pinches and kinks.

Splits, cuts or breaks.

6. Inspect wiring for:

Contact with sharp edges (this happens frequently).

Contact with hot surfaces, such as exhaust manifolds.

Pinched, burned or chafed insulation.

Proper routing and connections.

7. Check electrical connectors for:

Corrosion on pins.

Bent or damaged pins.

Contacts not properly seated in housing.

Bad wire crimps to terminals.

Connector problems are common in engine control

system. Inspect for corrosion, bent, pushed out, or over

expanded pins.

Note: Some connectors use special grease on contacts to prevent corrosion. Do not wipe

off! Obtain grease, from vehicle dealer. It is a special type for this purpose.

2.2 Connecting the Scan Tool

Remove protective cap from data link connector,

if present. Connect scan tool and follow scan

tool prompts. Use scan tool 9V battery to do selftests, review codes, code lookup or print data

when connection to vehicle is not required.

When scan tool powers up, a series of screens

are displayed. The screen starts with Welcome

and ends with a Key Button Help.

10 9620 Professional OBD II Scan Tool

Diagnostic

Connector

Page 11

After pressing ENTER from HELP Screen, the

MAIN MENU |

`1) Vehicle Diagnosis

2)Tool Setup [

3)Tool Self Test

OBDII Function List |

`1) I/M Readiness

2)Read Codes [

3)Pending Codes

Erase Data From

Previous Vehicle

Test?

YES <NO>

Turn Key Off

For 10 Seconds

Then Turn Key On

Then Press ENTER

OBDII Function List |

`1) I/M Readiness

2)Read Codes [

3)Pending Codes

Main Menu displays. Select Vehicle Diagnosis

and press ENTER.

The scan tool asks to erase data from previous

test. Use LEFT/RIGHT arrow keys to select a

response and press ENTER.

A message displays Turn Key Off For 10

Seconds, Then Turn Key On and Then Press

ENTER.

2.3 OBD II Functions List

Use UP/DOWN arrow keys to move cursor(`). Once selection is made, press ENTER.

Press and release BACK key to return to OBD II Function List. Pressing BACK key from

the OBD II Function List returns scan tool to Main

Menu. The first time scan tool communicates with

vehicle, the communication type is automatically

detected, and is used until scan tool is turned

OFF or another vehicle is diagnosed.

Not every vehicle will have every function

listed. If function or part of a function selected is not supported by a vehicle, a

message screen informing of this will be shown.

NOTE: If an Operating Error message is displayed, make sure the OBD II J1962 cable is

securely attached, and ignition key is ON. Cycle ignition key to OFF for 10 seconds,

then ON. This may be required to reset the PCM. If required, select Yes to test again.

If problem still exists, refer to Section 4: Help and Troubleshooting Tips.

2.3.1 I/M Readiness

Purpose of the I/M Readiness test is to display current information on emissions-related

systems. These systems are required by OBD II regulation to be monitored for emissions

testing. OBD II I/M Readiness Monitors are strategies designed to test operations of

emission related systems or components. The computer module uses these monitors

to check for correct operations of system and components as well as out of range values.

The computer module may perform a special test on a system or component to complete

the monitor. It may be required to operate vehicle under certain conditions in order to

perform an accurate test. If computer module loses power, or codes are erased, monitors

may be cleared. The scan tool displays the state of vehicle OBD II Monitors.

To enter I/M Readiness viewing mode, select I/M Readiness from OBD II Function List

and press ENTER.

A list of On-Board system readiness tests and

their status will be displayed. Use vehicle service

manuals for more information on emissionrelated monitors and their status.

Below are examples of completed versus not

completed I/M Readiness screens:

Use the UP/DOWN arrow keys to view monitor list. The monitor list consists of the OBD

II monitor name followed by monitor state. A monitor that is not supported by test vehicle

9620 Professional OBD II Scan Tool 11

Page 12

Code P0443

EVAP Emission

Control System [

Purge Valve C Fault

OBDII Function List |

1) I/M Readiness

2)Read Codes [

`3)Pending Codes

will be followed by n/a. A monitor that has been completed is followed by ok. If not

SINCE DTCS CLEARED

Misfire Monitor ok |

Fuel System Mon inc

Catalyst Mon n/a

OBDII Function List |

1) I/M Readiness

`2)Read Codes [

3)Pending Codes

On-Board Readiness

Tests Are Complete.

Use [ To View Test

Not All Supported

On-Board Readiness

Tests Are Complete.

Use [ To View Test

DTCs Found: 2

Use [ To View DTCs

Write Down Codes

For Reference.

System Pass:

No DTCs Found.

Press BACK For

OBDII Function List

This Driving Cycle

Misfire Monitor n/a

Fuel System Mon ok[

Catalyst Mon inc

completed, inc will be displayed. Use the UP/

DOWN arrow keys to scroll through the list.

NOTE: In addition to displaying the state of the

Press the ENTER key to return to the OBD II

Function List.

monitor since the last time DTCs were

cleared, some vehicles will display the

state of the monitors for this drive cycle.

Use the LEFT/RIGHT arrows to switch

between these screens

2.3.2 Read Codes

The Read Codes function retrieves Diagnostic Trouble Codes (DTCs) from vehicles

computer modules. This function can be performed with the key on and the engine off or

the key on and engine running.

These codes cause the computer to illuminate

the Malfunction Indicator Lamp (MIL) when an

emission-related or driveability fault occurs. The

MIL is also known as the service engine soon

or check engine lamp.

Select Read Codes and press ENTER. The scan tool retrieves the DTCs stored in the

vehicles computer module(s).

The scan tool displays the DTCs or a message

stating SYSTEM PASS: NO CODES FOUND.

Press the DOWN arrow key to view the DTCs or

press the BACK key to return to the OBDII

Function List.

Write down the DTCs for reference, then press BACK to return to the OBDII Function List.

2.3.3 Pending Codes

Pending Codes are also referred as continuous monitor and maturing codes. An

intermittent fault causes computer to store a code in memory. If fault does not occur

again within 40 warm-up cycles, the code clears

from memory. If the fault occurs a specific number

of times, the code matures into a DTC. This

function can be performed with the key on and

engine running or not.

12 9620 Professional OBD II Scan Tool

Page 13

Select Pending Codes and press ENTER key.

P0389 Mod$1E 1 of 2

Crankshaft Position

Sensor B [

CKT Intermittent

Command Sent

Press ENTER To Cont.

OBDII Function List |

`4)Erase Codes ]

5)View Data [

6)View Freeze Data

Erase Diagnostic

Results and Codes?

Are You Sure?

YES <NO>

OBDII Function List |

4)Erase Codes ]

`5)View Data [

6)View Freeze Data

Codes Found: 2

Use [ To View Codes

Write Down Codes

For Reference..

System Pass:

No Faults Detected.

Press BACK Key For

Function List

The scan tool displays codes or a message stating SYSTEM PASS NO FAULT

DETECTED. Press DOWN arrow key to view DTCs or press BACK key to return to OBDII

Function List.

The codes display in same format as Read

Codes. The DTC number and computer module

that stored it display on first line. Use UP/Down

arrow keys to view codes.

Press BACK to return to OBDII Function List.

2.3.4 Erase Codes

The Erase Codes function deletes DTCs from vehicles computer memory. Perform this

function only after systems have been checked completely and DTCs have been

documented. This function should be performed with the key on and the engine off.

After servicing vehicle, delete stored DTCs and verify no codes have been reset. If DTCs

return, the problem has not been corrected or other faults are present.

In addition to clearing DTCs, the Erase Codes function may also erase Freeze Frame,

O2 Sensor Data, System Monitors, and On-Board Monitor test results.

Select Erase Codes and press the ENTER key. A message appears asking if you are

sure. Press LEFT ARROW to move brackets to desired response and press ENTER.

Selecting NO displays a COMMAND CANCELLED message prompting to press ENTER

to return back to OBDII Function List. Selecting YES displays a screen prompting to turn

ignition key to on and engine off and press ENTER key.

The scan tool sends erase command. Press

ENTER to continue and return to OBDII Function

List.

2.3.5 View Data

The View Data function allows viewing of vehicles Parameter Identification data (PID) in

real time. As the computer monitors the vehicle, the information is simultaneously

transmitted to scan tool. Apart from Read Codes, View Data is most useful diagnostic

function for isolating cause of a vehicle

operation problem. Viewing data is also used

for observing sensor data and status of

switches, solenoids, and relays.

Select View Data from OBDII Function List and

press ENTER. The scan tool displays a menu

with display options.

Use the UP/DOWN arrow keys to select an option and press ENTER.

9620 Professional OBD II Scan Tool 13

Page 14

Select Custom List

«ABSLT TPS(%) ]

`«CALC LOAD(%) [

COOLANT(oF)

View Instructions

For Creating Custom

Data List?

YES <NO>

ABSLT TPS(%) 0.0

CALC LOAD(%) 5.3

ENGINE(RPM)($10) 180[

ENGINE(RPM)($1A) 865

Select Display Line

2 Lines ]

3 Lines

`4 Lines(Default)

Entire Data List

Select Data To View

Entire Data List

`Custom Data List

View Data Setup

Select Entire Data List to display all PIDs supported by vehicle under test.

Custom Data List

To display only certain PIDs, select Custom Data

List. The ability to display certain PIDs helps in

diagnosing a specific driveability symptom or

system.

If choosing to view a Custom Data List, the scan

tool asks if help is needed to view the

instructions. Select desired response and press

ENTER.

Use UP/DOWN arrow keys to move

cursor up and down through list.

Use RIGHT arrow key to select or deselect

PIDs. Selected PIDs are marked with «

symbol.

Use LEFT arrow key to deselect all

marked PIDs.

Use the ENTER key to link to the vehicle and retrieve the marked PIDs.

When finished selecting PIDs, press ENTER key to begin viewing them.

NOTE: Refer to Appendix A for a complete list of PIDs.

View Data Setup

View Data Setup allows display of PIDs on one,

two, three or four lines. Selecting fewer lines of

data provides faster update speeds. The scan

tool default is four-line display.

When scan tool links to vehicle, PIDs will display. Navigate through PID list with following

keys:

Press UP/DOWN arrow keys to scroll Up/

Down line-by-line through list.

Press LEFT/RIGHT arrow keys to Page

Up/Page Down.

Press BACK key to return to Select Data

To View menu.

The same parameter may appear twice if vehicle is equipped with more than one computer

module Powertrain Control Module (PCM), Transmission Control Module (TCM), etc. The

scan tool identifies them by identification names (ID) assigned by manufacturer (i.e. $10,

$1A, etc). The computer module ID blinks in parentheses. If one or more modules stops

responding, the scan tool displays a message that the module is not responding and asks to

continue without it. If NO is selected, scan tool attempts to reestablish communication with

that module.

14 9620 Professional OBD II Scan Tool

Page 15

2.3.6 View Freeze Data

FREEZE FRAME DATA

TROUB CODE P0443

CALC LOAD(%) 85.6[

ENGINE(RPM)($10) 1120

OBDII Function List |

4)Erase Codes ]

5)View Data [

` 6)View Freeze Data

FRAME 1 Mod $1A

TROUB CODE P0443

CALC LOAD(%) 85.6[

ENGINE(RPM)($10) 1120

When an emission-related fault occurs, certain vehicle conditions are recorded by the

on-board computer. This information is referred to as a Freeze Frame data. The information

is a snapshot of operating conditions at time of a fault. This data can be overwritten by

faults with a higher priority.

NOTE: If codes were erased, then freeze frame data may not be stored in vehicle memory.

Select View Freeze Data from the OBDII Function

List and press ENTER.

The scan tool links to the vehicle and displays

Freeze Frame data. Use UP/DOWN arrow keys

to scroll through data.

NOTE: If more than one computer module responds

with freeze frame data, then the frame

number and module display on the first line.

Press the LEFT/Right key to change modules.

When done, press BACK key to return to OBDII Function List.

2.3.7 O2 Monitor Test

NOTE: The O2 Monitor Test is NOT AN ON-DEMAND TEST. O2 sensors are NOT tested

when selected via the menu. The O2 sensors are tested when engine operating

conditions are within specified limits.

NOTE: If vehicle communicates using a Controller Area Network (CAN), O2 Monitor Tests

are NOT supported by vehicle. A message is displayed. See Diagnostic Monitor

Test to see O2 Monitor Data.

OBD II regulations require that applicable vehicles monitor and test the oxygen (O2)

sensors to determine problems related to fuel and emissions. The O2 Monitor Test

allows retrieval of completed O2 sensors monitor test results.

O2 sensors are located before (upstream) and after (downstream) catalyst(s). The

sensors are named (xy) for their position relative to both cylinder banks and catalysts.

The O2 sensor for cylinder bank 1 has the prefix 1y while the O2 sensor for

cylinder bank 2 has the prefix 2y.

The O2 sensor upstream of the catalyst (closest to the engine) has the suffix x1

while the O2 sensor downstream of the catalyst has suffix x2. If vehicle contains

more catalysts, the O2 sensor downstream of the second catalyst has the suffix

x3 and the O2 sensor downstream of the next catalyst has the suffix x4.

For example, O2S 21 is the upstream O2 sensor for cylinder bank 2.

9620 Professional OBD II Scan Tool 15

Page 16

The following O2 sensor tests are available:

Low Volts for Switch

O2S 1-1(V) 1.15

O2S 1-2(V) ---[

O2S 2-1(V) 1.28

OBDII Function List |

`7)O2 Monitor Test ]

8)Non-Contin Test [

9)On-Board Systems

O2 Sensor Tests

`1) RICH-LN Thresh

2)LN-RICH Thresh [

3)Lo V For Switch

OBDII Function List |

7)O2 Monitor Test ]

`8)Diag Mon Test [

9)On-Board Systems

Diag Mon Data Avail

` O2 Sensor B1S1

Catalyst B1 [

EVAP (0.090)

Non-Cont Tests Avail

`$0 1

$03 [

$05

Rich to Lean sensor threshold voltage

Lean to Rich sensor threshold voltage

Low sensor voltage for switch time

High sensor voltage for switch time

Rich to Lean sensor switch time

Lean to Rich sensor switch time

Minimum sensor voltage test cycle

Maximum sensor voltage test cycle

Time between sensor transitions

Select O2 Monitor Test from OBDII Function List and press ENTER.

Select desired test from menu and press ENTER. Grouping O2 sensor tests together

makes data easier to compare.

The O2 sensors located upstream (before catalyst) may perform differently than the ones

located downstream (after the catalyst).

Oxygen sensor tests not supported by the vehicle display three dashes as the value.

Press the BACK key to return to the O2 Sensor Tests menu or press ENTER to return to

the OBDII Function List.

2.3.8 Diagnostic Monitor Tests

The Diagnostic Monitor Test function is different for Non-CAN and CAN vehicles.

Non-CAN vehicles Diagnostic Monitor Tests receives test results for emission-related

powertrain components and systems

CAN vehicles Diagnostic Monitor Tests receives test results for emission-related

powertrain components and systems that

The Diagnostic Monitor Test function is useful after servicing or after erasing the vehicles

memory. Test results do not necessarily indicate a faulty component or system.

Vehicle manufacturer is responsible for assigning test and component IDs

Select Diagnostic Monitor Test from the OBDII

Function List and press ENTER. A list of tests

applicable to the vehicle are displayed. Select a

test and press ENTER.

NON-CAN VEHICLE

16 9620 Professional OBD II Scan Tool

not continuously monitored.

are or are not continuously monitored.

CAN VEHICLE

Page 17

Applicable tests are displayed . Select a test and press ENTER.

OBDII Function List |

7)O2 Monitor Test ]

8)Non-Contin Test [

`9)On-Board Systems

OBDII Function List |

`10)Record Data ]

11) Vehicle Info [

12)Modules Present

Diag Mon Data Avail

$01

$05 [

$10 ~

Diag Mon Data Avail

O2 Sensor B1S1

Catalyst B1 [

EVAP (0.090) ~

Requested test results are displayed on Scan Tool

NON-CAN VEHICLES

On Non-CAN vehicles Scan Tool displays:

On the 1st line is where the test data (test ID) came from.

On the 2nd line is the test heading.

On the 3rd and 4th line is the test measurement (MEAS), specification value (SPEC) and

status (STS). Measurements and Specification values are hexadecimal numbers (i.e.,

$1A, $FE, $11.)

On CAN vehicles Scan Tool displays:

On the 1st line is where the monitor test data came from. ($00) represents the

source module id from where the data originated.

On the 2nd line is the test performed. The test performed can be $## if test is not

defined. Refer to vehicle service manual for details.

On the 3rd line are the measured value and units in (Volts, Amps, Seconds, etc.) and

status of monitor test data.

On the 4th line, the minimum and maximum limits are shown for the monitor test data.

If additional tests are present, use the up and down arrow to view test results.

Refer to appropriate vehicle service manual for test IDs and definitions.

Press BACK key to return to the Diag Mon Test menu or press ENTER key to return

to OBDII Function List.

CAN VEHICLES

2.3.9 On-Board Systems

This test allows scan tool to control operation of vehicle components, tests or systems.

Some manufacturers do not allow tools to control vehicle systems. A vehicle not supporting

an on-board system is identified by a message displayed when selected.

NOTE: Refer to vehicle service manual for on-board systems instructions.

Select On-Board Systems from OBDII Function

List and press ENTER. A list of on-board systems

and components available for testing display on

screen.

Select a test and press ENTER to activate test.

The manufacturer is responsible for determining criteria to automatically stop test. Refer

to appropriate vehicle service manual.

2.3.10 Record Data

Record Data function records PIDs while vehicle is parked or being driven. This function

is mainly used for diagnosing intermittent driveability problems that cannot be isolated

by any other method. The scan tool can maintain only one recording at a time. Be sure to

thoroughly review old recording before erasing.

Select Record Data from OBDII Function List

and press ENTER. Follow all instructions on

display.

9620 Professional OBD II Scan Tool 17

Page 18

OBDII Function List |

10)Record Data ]

`11)Vehicle Info [

12)Modules Present

If a recording currently exists in memory, a

Playback Data?

<Yes> No

Cannot Record. Old

Recording Filled Up

Memory. Erase Old?

<YES> NO

Pick Trigger Method

`1) Manual Trigger

2)Trigger On Codes

message prompting to erase data is displayed.

Note: Make sure to review old recorded data

Scan tool retrieves a list of supported PIDs. After list is generated, scan tool prompts to

select type of data to view. Refer to View Data described earlier in this section to setup

Entire or Custom Data Lists.

On next screen, select a method to trigger a

recording. Manual Trigger allows technician to

use ENTER key. Trigger On Codes automati-

cally triggers when a DTC is indicated by vehicle.

Once trigger method is selected, scan tool will begin recording data when trigger event

occurs either a DTC occurs or ENTER key is pressed. The time is recorded and data

from the last five frames is saved. Data will continue to be saved until either the record

memory is full or the technician presses ENTER.

Press ENTER and the scan tool establishes a communication link with the vehicle.

If Manual Trigger is selected, scan tool initializes by recording first five frames. When

done, press ENTER. If Trigger On Codes was selected, then scan tool triggers when a

DTC is stored in vehicle. Press BACK key twice to return to OBDII Function List.

before erasing

WARNING!

TWO PEOPLE SHOULD BE IN VEHICLE WHEN DRIVING ON ROAD,

ONE TO DRIVE AND THE OTHER TO ATTEND TO THE EQUIPMENT.

Scan tool recording times vary. A recording consists of 5 frames of data prior to trigger

and several frames after trigger. Amount of PIDs recorded determine number of frames.

After a recording, scan tool displays a prompt to

playback recording. Answer YES to display

recorded data or NO to return to OBDII Function

List.

2.3.11 Vehicle Info

Vehicle Info function enables scan tool to request vehicles VIN number and calibration

ID(s) which uniquely identifies software version in vehicle control module(s).

This function applies to Model Year 2000 and later OBD II compliant vehicles. The scan

tool cannot verify if data returned is correct for scanned vehicle. This information is

provided by vehicle manufacturer. The Vehicle Info test must be completed with the key in

the ON position and the Engine OFF.

Calibration Verification Numbers (CVNs) are calculated values required by OBD II

regulations with the vehicle engine off. CVNs are reported to determine if emissionrelated calibrations have been altered. Multiple CVNs may be reported for a control

module. The calculation may take several minutes first time the CVNs are requested.

Select Vehicle Info from OBDII Function List and

press ENTER.

If the message INVALID displays on screen, then

data returned is incorrect, or not formatted in

accordance with OBD II specification.

18 9620 Professional OBD II Scan Tool

Page 19

Scan tool displays VIN, Calibration ID, and CVNs

OBDII Function List |

10)Record Data ]

11) Vehicle Info [

`12)Modules Present

OBDII Function List |

`13)Review Data ]

14)Print Data

15)Code Lookup

Review Data

5)O2 Monitor ]

6)Non-Continuous [

`7)Playback

No Link Established

Controller List

Not Available

ID Protocols

$10 ISO*

$18 ISO* [

$1A ISO*

No Recording Is

Present. Please

Make Recording

First.

MIL STATUS ON

CALC LOAD(%) 5.3

ENGINE(RPM)($10) 180[

FRAME: 1 TM: 4.4

VIN # 1 MOD $10

1F1FS11P0S2100001

[

if supported by vehicle. In example screens, MOD

$10 returned data. Use UP/DOWN arrow keys to

scroll . CVNs are shown as a hexadecimal

number.

Press BACK or ENTER to return to OBDII Function List.

2.3.12 Modules Present

OBD II information may be provided by a single

module or many separate modules. The scan

tool identifies module IDs and communication

type for OBD II modules in vehicle.

Select Modules Present from OBDII Function

List and press ENTER.

When selecting this function, scan tool checks for an established communication link. If

no link is made, a message displays stating so. If link was successful, module(s) and

communication type(s) display on screen.

2.3.13 Review Data

Review Data function allows review of information stored in scan tools memory. The

scan tool does not require power from vehicle to perform this function. Internal battery

power can be used.

Select Review Data from OBDII Function List and press ENTER. Only one function,

Playback, needs detailed instructions.

Playback

Playback function is used to play back a recording. This function is very similar to View

Data. The only difference is View Data is real time viewing of PIDs, while Playback is a

viewing of previously recorded PIDs.

To play back recorded PIDs, select Playback and press ENTER key.

9620 Professional OBD II Scan Tool 19

Page 20

Select Baud Rate

`9600(Default)

1200 [

2400

Select Data Bits

`8 (Default)

Select Stop Bits

1 Bit(Default)

`2 Bits

The scan tool informs if a recording does not exist. Otherwise, scan tool plays back

OBDII Function List |

13)Review Data ]

`14)Print Data

15)Code Lookup

Tool Set To Default |

Printer Settings.

Change Settings?

YES <NO>

Entire Data List or Custom Data List, depending on how data was recorded.

The screen is composed of three lines of data and one line for the frame number and

timestamp (in seconds). Negative frames and timestamps indicate data recorded before

the trigger event. Positive frames and timestamps indicate data recorded after the trigger

event.

Use UP/DOWN arrow keys to scroll through the recorded PID data of each frame.

The end of the list is reached when only the (up) icon is visible.

Use the LEFT/RIGHT arrow keys to scroll back and forth through the frames. The

LEFT key advances to the next frame, wrapping around to earliest frame when

the final frame is reached. The RIGHT arrow key goes back to the previous frame,

again wrapping around to the final frame.

Different vehicles communicate at different speeds and support a different number of

PIDs. Therefore, the maximum number of frames that can be recorded will vary.

Some vehicles wait a long period of time to store a trouble code after the driveability

problem occurs. If you selected Trigger On Codes when you made your recording, you

might not see any drastic change in data parameters before and after the trigger point. In

cases like this, the user can manually trigger the recording when the symptom is observed.

When done, press BACK to return to Review Data or to the OBDII Function List.

2.3.14 Print Data

This function allows you to print the diagnostic information stored in the scan tool. The

scan tools internal battery power can be used to print data.

Select Print Data and press the ENTER key. The scan tool informs you of the printer

settings (Custom or Default), then asks if you wish to change them. If settings are not

changed, then skip the next section and continue with on the next page.

Changing the Printer Settings

NOTE: The default values are designated on the display with the word (Default) next to

After selecting YES and pressing ENTER, the

first item to change is the Baud Rate. Use the

UP/DOWN arrow keys to select an option and

press the ENTER key.

Press ENTER when the Select Data Bits screen

displays. There is nothing to select.

In the Select Stop Bits screen, select 1 BIT or

2BITS and press ENTER.

the option. Refer to the printer manual for the settings.

20 9620 Professional OBD II Scan Tool

Page 21

Next, select the parity and press ENTER.

Select Parity

`None (Default)

Odd

Even

Printer

`Fast (Default)

Slow

The ASCII Character

Set Will Be Printed

Once

Press ENTER To Cont.

Select Print Data

1)I/M Readiness

`2)DTC (Codes) [

3)Pending Codes

Make Sure Printer

Is Turned On, Online

& Connected To Tool.

Press ENTER To Cont.

Is Printout OK?

<YES> NO

Select Print Data

5)O2 Monitor ]

6)Non-Continuous [

`7)Playback

Finally, select the printer speed, FAST or SLOW,

and press ENTER.

Now that the printer settings are changed, it is

time to verify the settings. Press the ENTER key

to print the ASCII character set.

Follow the instructions displayed on the screens.

If the printout is OK, press ENTER. Refer to the

settings in the printer manual if the printout is

not OK.

Printing Data (except Playback)

Next, select the data to be printed and press

ENTER. The scan tool displays the menu of

those functions that store data and can be

printed.

Make sure the printer is turned on, on-line and

connected.

When the selected data does not exist in the scan tools memory, a message informs

you to run the function. If the selected data is stored in the scan tool, the data automatically

transmits to the printer.

Press ENTER to return to the Select Print Data screen. Either select another item to print

or press BACK to return to the OBDII Function List.

Printing Playback Data

When printing playback data, the Start Frame and

End Frame need to be defined.

After selecting Playback and pressing ENTER,

the Start Frame screen shows the earliest possible frame. Use the ([) or (]) to change the frame

number and then press ENTER.

Next, the End Frame screen displays the latest possible frame. Use the Scroll Wheel to

change the frame number and then press ENTER.

The scan tool starts transmitting to the printer, frame-by-frame. After all the frames have

been sent, press ENTER to return to the Select Print Data screen. Press the BACK key to

return to the OBDII Function List.

9620 Professional OBD II Scan Tool 21

Page 22

Section 3: Diagnostic Trouble Codes (DTC)

3.1 DTC Format

Diagnostic Trouble Codes (DTCs) consist of a five-digit alphanumeric code. The DTC

format and types are shown below. When the on-board computer recognizes and identifies

a problem, a DTC for that fault is stored in memory. These codes are intended to help you

determine the root cause of a problem.

P 0 1 0 1

Bx - Body

Cx - Chassis

Px - Powertrain

Ux - Network Comm.

x = 0, 1, 2 or 3

Example:

P0101 - Mass or Volume Air Flow

Circuit Range/Performance Problem

Vehicle Specific System

Specific Fault Designation

Powertrain Codes

P0xxx - Generic (SAE)

P1xxx - Manufacturer Specific

P2xxx - Generic (SAE)

P30xx-P33xx - Manufacturer Specific

P34xx-P39xx - Generic (SAE)

Chassis Codes

C0xxx - Generic (SAE)

C1xxx - Manufacturer Specific

C2xxx - Manufacturer Specific

C3xxx - Generic (SAE)

J2012 and ISO 15031-6 are standards for all DTCs, established by SAE, International

Organization for Standardization (ISO) and other governing bodies. Codes and definitions

assigned by this specification are known as Generic OBD II codes. OBD II requires

compliance with standards, and has made it standard for all cars, light trucks, APVs,

MPVs, and SUVs sold in U.S. Codes not reserved by SAE are reserved for manufacturer

and referred to as Manufacturer Specific.

Periodically, new DTCs are defined and approved by SAE, ISO and other governing

bodies. The scan tool software will be periodically updated to reflect these changes. For

more information regarding DTC updates, please call our Technical Support line at

1-800-228-7667 (8:00 6:00 EST Monday Friday).

Body Codes

B0xxx - Generic (SAE)

B1xxx - Manufacturer Specific

B2xxx - Manufacturer Specific

B3xxx - Generic (SAE)

Network Communication Codes

U0xxx - Generic (SAE)

U1xxx - Manufacturer Specific

U2xxx - Manufacturer Specific

U3xxx - Generic (SAE)

22 9620 Professional OBD II Scan Tool

Page 23

Enter Code: P0100 |

Use Arrow Key ^

To Change Or Press

ENTER To Accept

P0A08

DC/DC Converter ]

Status Circuit [

OBDII Function List |

13)Review Data ]

14)Print Data

`15)Code Lookup

Enter Code: P0A08 |

Use Arrow Key ^

To Change Or Press

ENTER To Accept

P1100

Manufacture Contrl ]

[

Fuel Air Metering

3.2 Code Lookup

Code Lookup is used to look up definitions of Diagnostic Trouble Codes (DTCs) stored

in the scan tool. The scan tool does not require power from the vehicle to perform this

function. Internal battery power can be used.

To look up DTC definitions, select Code Lookup

from the OBDII Function List and press ENTER.

NOTE: When entering codes, only one character can be changed at a time.

To enter a code:

Use the LEFT/RIGHT arrow keys to move

the ^ symbol under the character that

needs to be changed. The cursor moves

to the right and wraps around to the

beginning when the end is reached.

Use the UP/DOWN arrow keys to change

the selected character.

Press the ENTER key to display the

definition.

After entering the code and pressing ENTER,

the code and definition display.

If the DTC is manufacturer specific or does not

exist for the vehicle, some information can be

determined based on the range of the DTC (see

page 24)

In the definition screen, pressing the ([) or (]) arrow key increments/decrements the

code and its definition. Undefined codes are skipped.

Press the BACK key to return to the Enter Code screen. Press the BACK key again to

return to the OBDII Function List.

NOTE: Refer to an appropriate vehicle service manual for manufacturer specific codes.

9620 Professional OBD II Scan Tool 23

Page 24

3.3 Diagnostic Trouble Code Ranges

Within each general category, the Diagnostic Trouble Codes are assigned to specific

ranges that cover certain vehicle systems. When displaying manufacturer-specific (or

non-global), the assigned Diagnostic Trouble Codes displays the definition.

Lower Upper Assigned DTC System

P0000 P00FF Fuel and air metering and auxiliary emission controls

P0100 P02FF Fuel and air metering

P0300 P03FF Ignition system or misfire

P0400 P04FF Auxiliary emission controls

P0500 P05FF Vehicle speed, idle control, and auxiliary inputs

P0600 P06FF Computer and auxiliary outputs

P0700 P09FF Transmission

P0A00 P0AFF Hybrid Propulsion

P1000 P10FF Manufacturer controlled fuel, air metering and auxiliary emission

controls

P1100 P12FF Manufacturer controlled fuel and air metering

P1300 P13FF Manufacturer controlled ignition system or misfire

P1400 P14FF Manufacturer controlled auxiliary emission controls

P1500 P15FF Manufacturer controlled vehicle speed, idle control, and auxiliary

P1600 P16FF Manufacturer controlled computer and auxiliary outputs

P1700 P19FF Manufacturer controlled transmission

P2000 P22FF Fuel and air metering and auxiliary emission controls

P2300 P23FF Ignition system or misfire

P2400 P24FF Auxiliary Emissions Controls

P2500 P25FF Auxiliary Inputs

P2600 P26FF Computer and Auxiliary Outputs

P2700 P27FF Transmission

P2900 P32FF Fuel and air metering and auxiliary emission controls

P3300 P33FF Ignition system or misfire

P3400 P34FF Cylinder deactivation

U0000 U00FF Network electrical

U0100 U02FF Network communication

U0300 U03FF Network software

U0400 U04FF Network data

inputs

24 9620 Professional OBD II Scan Tool

Page 25

Section 4: Help and Troubleshooting Tips

Operating Error. |

Check Connections!

Try Again?

<Yes> No

SCANTOOL CAN NOT

COMMUNICATE WITH

VEHICLE. CHECK THE [

FOLLOWING:

1.IGNITION KEY ON?

2.HOOKUP TO VEHICLE ]

TEST CONNECTOR OK? [

3.EMISSIONS LABEL

4.1 How to Use Help

The tester contains Help for specific screens,

functions, and error messages. Help is available

when Help symbol (|) appears in upper righthand corner of display.

To enter Help, press HELP key. Help screens

are in CAPITAL LETTERS to remind viewing Help screens, not screens associated with

a function. If Help message is longer than one screen, then use UP and DOWN arrow

keys to page through message. The symbols ([ and ]) indicate the direction available.

To exit Help and return to the screen you where Help was entered, press the BACK key.

4.2 Scan Tool Problems

If scan tool fails to power up, link to vehicle, pass Tool Self-Tests, or function properly,

then try following Troubleshooting Tips. If these tips fail to resolve problem, contact

Actron Technical Support at 1-800-228-7667 (8:00 - 6:00 EST Monday - Friday). Be

prepared to provide scan tools Software ID.

4.2.1 Scan Tool does not powerup:

Check OBD II connector for power and ground. If no power, check fuse if appli-

cable.

Verify vehicles battery is at least 8 volts.

Unplug and plug back in the Data Link Connector (DLC) to verify connector is

properly seated to vehicle connector.

If scan tool is being powered from an AC/DC 110V to 12V adapter, make sure AC

outlet has power.

4.2.2 Scan Tool does not Link withvehicle:

Make sure cable is correctly connected to DLC. Unplug the DLC adapter from

vehicle and plug back to verify connection.

Verify ignition key is ON not in ACCESSORIES position.

Cycle ignition key OFF for 10 seconds, then ON to reset PCM.

Inspect DLC adapter and computer module connectors for cracked, bent,

corroded or recessed pins, and for any substance that could prevent a good

electrical connection.

In vehicle, verify continuity exists between DLC and computer module. In extreme

cases, broken wire(s) may exist.

Check vehicle computer module for a blown fuse. Refer to vehicle service manual

for fuse location.

Make sure computer module is grounded to vehicle. If the computer module is

grounded to vehicle, then thoroughly clean connection and apply a conductive

grease to mating surfaces.

The vehicle computer module may be defective. Refer to applicable vehicle

service manual for test procedures and diagnostic flowcharts.

9620 Professional OBD II Scan Tool 25

Page 26

MAIN MENU |

1) Vehicle Diagnosis

2)Tool Setup [

`3)Tool Self Test

@@@@@@@@@@@@@@@@@@@@

@@@@@@@@@@@@@@@@@@@@

@@@@@@@@@@@@@@@@@@@@

@@@@@@@@@@@@@@@@@@@@

Tool Self-Test |

`1) Display Test

2) Keyboard Test [

3) Memory Test

ENTER To Test. Look

For Missing Spots

In Display. Press

BACK When Done

Tool Self-Test |

1) Display Test

`2) Keyboard Test [

3) Memory Test

Push Button To Test

Key And Display Name

Key:

BAC When Done

4.2.3 One or more modules drops the communication link:

Module ($41) Has |

Stopped Responding.

Continue Without It?

(YES) NO

Push Button To Test

Key And Display Name

Key: UP ARROW

BAC When Done

When the OBD II System Tester initially links to

the vehicle, it builds a list of all OBD II compliant

computer modules. If in the course of scanning

the vehicle, a module drops the link, a message

will display.

Answering YES will continue operation without the lost module. Answering NO will try to

restore the communication links to get all modules back to an active status.

4.2.4 Keyboard does not function properly:

Perform Keyboard Test by entering Self-Test and select Keyboard Test function.

If the keyboard test shows nothing and you still experience the problem, then

contact Actron Technical Support.

4.3 Tool Self-Tests

Tool Self-Tests are used to test the operation of

the display, keyboard, internal memory, and

printer connection (if applicable).

The Tool Self-Test menu is accessed from the

MAIN MENU. Use the UP/DOWN arrow keys to

select the test and then press the ENTER key.

4.3.1 Display Test

Select Display Test and press the ENTER key. Press ENTER to begin test.

Display Test will fill every pixel of display. Look for

pixels that are not black. Press BACK key to exit

to Tool Self-Test menu. Press BACK key again to

display the MAIN MENU.

4.3.2 Keyboard Test

Keyboard Test checks operation of keys. Select Keyboard Test from Self-Test menu and

press ENTER key. Test screen with instructions is displayed:

Each time a key is pressed , keys name should

appear on display. For example, if UP arrow is

pressed, screen will display Key: UP ARROW. If

name is not displayed, key is not working.

NOTE: When BACK key is pressed, OBD II System Tester returns to Self-Test Menu, If

not then BACK key is not working.

26 9620 Professional OBD II Scan Tool

Page 27

4.3.3 Memory Test

Memory Test Passed!

Press ENTER To Cont

Memory Test Failed

SW ID = F1E8

Press ENTER To Cont

Tool Self-Test |

1) Display Test

2) Keyboard Test [

`3) Memory Test

Memory Test . . . . .

. . . . . . .

Tool Self-Test |

2) Keyboard Test ]

3) Memory Test

` 4) Printer Test

Perform the Memory Test if the scan tool has

trouble displaying code definitions or performing

functions that use internal memory. Select

Memory Test from the Tool Self-Test menu and

press the ENTER key.

The test begins immediately and displays a

message Memory Test followed by periods as

internal memory is tested.

When done, a message displays indicating

whether the test passed or failed. Press ENTER

to return to the Tool Self-Test menu.

4.3.4 Printer Test

If you cannot print from the scan tool, select

Printer Test and press the ENTER key. Refer to

section Changing the Printer Settings on

page20.

4.4 Technical Support

1-800-228-7667 (8:00 - 6:00 EST Monday - Friday). Be prepared to provide the scan

tools Software ID.

9620 Professional OBD II Scan Tool 27

Page 28

Appendix A: Global OBD II PID List &

Definitions

All parameter identification data (PID) listed was verified on actual vehicles to guarantee

accuracy. Definitions used to describe all PIDs were obtained from reliable sources and

are accurate at time of printing. It is possible that some newer vehicles may contain different

data different from that listed. In these cases, refer to an applicable vehicle service manual.

Data Parameter List Format

The PID list is organized in alphabetical order the same way the scan tool does. For each

PID, the type of reading are provided. Remember to always refer to a vehicle service manual

for detailed diagnostic procedures for troubleshooting incorrect PID readings.

Types of Data Parameters

INPUT: These data parameters are obtained from sensor outputs. Sensor outputs

OUTPUT: These data parameters are

CALCULATED: These data parameters are

PCM VALUE: Is information that is stored in the computer module(s) memory and deter-

NOTE: Several different causes can have the same parameter indication. For information on

diagnostics consult vehicle service manuals.

DATA PARAMETER LIST

ABS FRP (0 - 655350kPA) or (0 - 95050.5PSI)

Absolute Fuel Rail Pressure is the fuel pressure at the engine when reading in reference to atmospheric pressure.

ABS LOAD (0 - 100%)

Absolute Load Value is the normal value of air mass per intake stroke displayed as a

percent.

ABSLT TPS (0 - 100%)

Absolute Throttle Position represents normal distance throttle is opened.

ACC POS D,E or F (0 - 100%)

Accelerator Pedal Position represents normal distance gas pedal is pressed.

BARO PRESS (0 - 255kPA) or (0 - 36.9PSI)

Barometric Pressure is normally received from a dedicated barometer, manifold absolute pressure sensor and other inputs during certain modes of driving.

NOTE: The Baro Press may not be the same as some weather services Barometric

Pressure due to being read at sea level.

CALC LOAD (0 - 100%)

Calculated LOAD Value indicates load on engine.

CAT TEMPxy (-40°C - 6513.5°C) or (-40 - 9999.9F)

Catalyst Temperature Bank shall display catalyst substrate temperature for bank catalyst, if used by control module strategy for on board diagnostics monitoring, bank,

sensor catalyst or temperature sensor.

inputs to vehicles computer module(s). For example, if an Oxygen Sen-

are

sor was generating a 400mV signal, then the scan tool displays O2S (v) 0.40.

computer module(s). For example; the ignition spark advance is controlled

by PCM, on most vehicles, monitoring this PID shows spark output from

PCM. The scan tool would display IGN ADV(°) 10.

vehicles computer module(s). For example, the engine load. The PCM

calculates this from sensor inputs and displays it in a percentage.

mined to be useful to service technician. An example of this is TROUBLE

CODE value, the DTC that caused a freeze frame capture.

outputs or commands that come directly from

calculated after analyzing various inputs to the

28 9620 Professional OBD II Scan Tool

Page 29

CLR DST (0km-65,535km) or (0- 40,722miles)

Distance Since Cleared Diagnostic Codes is distance since diagnostic trouble codes

were erased.

CLR TIM (0 - 65535 min or 1092.25 hours)

Time Since Cleared Diagnostic Code is time since diagnostic trouble codes were erased.

CMD EQ RATxy (0 - 1.99)

Commanded Equivalence Ratio is the ratio of the air/fuel mixture.

NOTE: The CMD EQ RAT will read 1.0 while in a closed loop of fuel

COOLANT (-40 - 215°C)or(°F)

Engine Coolant Temperature displays engine coolant temperature from engine coolant temperature or cylinder head temperature sensor.

NOTE: The coolant on many diesels may use Engine Oil Temperature instead.

EGR CMD (0 - 100%)

Commanded Exhaust Gas Recirculation is the percentage of exhaust gas being recirculated.

EGR ERR (-100 - 99.22%)

Exhaust Gas Recirculation Error will show the error from changing from one condition to

another.

ENG RUN (0 - 65,535sec.)

Time since Engine Start is the time the engine is running.

NOTE: ENG RUN stops when engine stalls or engine is turned off for any reason.

ENGINE (0 - 16383.75 RPM)

Engine Revolutions Per Minute (RPM) is the speed engine is running.

EQ RATxy

O2 Sensor Equivalence Ratio for Bank x Sensor y.

EVAP REQ (0-100%)

Commanded Evaporative Purge is the position evaporative purge control valve is open

in percentage.

EVAP VP (-8192PA - 8191PA) OR (-32.8878 - 32.8838 H2O)

Evaporative Emissions System Vapor Pressure is pressure in the fuel tank

FUEL LVL (0 - 100%)

Fuel Level Input is the percentage of fuel with 0% equaling tank is full and 100% when tank

is empty.

FUEL PRES (0 - 765kPa) or (0 - 110psi)

Fuel Rail Pressure is the fuel pressure at the engine in respect to atmospheric pressure.

FUEL SYS (OPEN or CLSD)

Fuel System Status show loop status of fuel system banks.

OPEN: Computer module is operating in Open Loop control strategy. The vehicle has

not yet satisfied conditions for the computer module to go to closed loop.

CLSD: Computer module currently functioning in Closed loop control strategy, using

O2 sensor(s) as feedback for fuel control.

OPEN1: Open Loop control strategy is being used by the PCM due to driving conditions

power enrichment and deceleration enrichment.

OPEN2: Computer module is operating in Open Loop control strategy due to detected

system fault. Certain actuator or sensor faults are usually the cause.

CLSD1: Closed Loop control is current storage being used by PCM, but a fault with at

least one O2 sensor has been detected. The control system may be using

single O2 for fuel control calculations.

9620 Professional OBD II Scan Tool 29

Page 30

IAT TEMP (-40 - 215°C) or (-40 - 419°F)

Intake Air Temperature is a measure of intake air temperature to determine correct air/

fuel ratios and spark timing operations.

IGN ADV (-64 - 63.5°)

Ignition Timing Advance for cylinder is a signal of how much spark advance to add to

base engine timing (expressed in crankshaft degrees).

LT FL FTRM (-100 - 99.22%)

Long Term Fuel Trim Bank is the fuel mixture adjustment in a range with midpoint being 0.

NOTE: Positive reading indicates module commanded a long-term rich mixture correction

in response to a lean operating condition. A negative reading indicates module has

commanded a long-term lean mixture in response to a rich operating condition.

MAF (0 - 655.35 g/s) or (0 - 86.5lb/min)

Mass Air Flow is the air flow rate the sensor sends to the computer module indicating

mass of air entering engine.

MAP (0 - 255kPa) or (Hg)

Intake Manifold Absolute Pressure displays manifold pressure.

MIL DIST (0 - 65535km) or (0 - 40,722miles)

Distance Traveled while Malfunction Indicator Lamp is Active is a counter that displays

distance traveled since Check Engine or Service Engine Soon light came on.

MIL STAT (ON or OFF)

Monitor Status Data Trouble Code state that module is commanding the Malfunction Indicator

Lamp (MIL) to be ON if problem exists.

MIL TIME (0 - 65535min) or (0 - 1092.25Hrs)

The distance traveled since the MIL (Check Engine or Service Engine Soon light) came on.

O2Sxy (0 - 1.275V)

Oxygen Sensor Output Voltage is the voltage generated from the oxygen sensor to

increase and decrease the amount of exhaust gas.

O2Sxy (-128 - 127.996mA)

Oxygen Sensor Output Current is used for linear or wide ratio oxygen sensors to increase

and decrease the amount of exhaust gas

OBD2 STAT (CA, OBDI, US, NONE, EU and/or JA)

On Board Diagnostic shows what vehicle was made for.

Data Parameters:

CA - Indicates test vehicle meets California on board diagnostic ARB requirements

OBD I - Indicates test vehicle does not meet OBDII requirements.

US - Indicates test vehicle meets Federal EPA requirements.

NONE - Indicates test vehicle is not on board diagnostic compliant.

EU - Indicates test vehicle meets European on board diagnostic requirement.

JA - Indicates test vehicle meets Japanese on board diagnostic requirement. Outside Air

Temperature gives temperature outside.

NOTE: The Data Parameters can be used with each other for example CA/US

OUTSID AIR (-40 - 215°C) or (-40 - 419°F)

Outside Air Temperature gives temperature outside.

PTO STATUS (OFF or ON)

Power Take Off Status allows module to keep track of Power at Take-Off.

REL FRP (0 - 5177.27kPa) or (750.9PSI)

Relative Fuel Rail Pressure (Vacuum) is the fuel rail pressure at engine.

30 9620 Professional OBD II Scan Tool

Page 31

REL TPS (0 - 100%)

Relative Throttle Position is relative throttle position at normal position.

SECOND AIR (AIR_STAT: UPS, DNS or OFF)

Commanded Secondary Air Status is on newer vehicles and actuators to control pollution control.

UPS - UP STREAM module is demanding that secondary air be added at exhaust

manifolds

DNS - DOWN STREAM module is demanding secondary air be added at catalytic

converter

OFF - Module is demanding no secondary air to be added.

ST FTRMxy (-100 - 99.22%)

Short-term Fuel Trim Bank calculated value represents the short-term relation of fuel

metering on a fuel-injected engine.

NOTE: Short-term Fuel Trim calculated value that has a positive percentage is a rich fuel

trim and if a negative percentage is present the fuel trim is lean.

ST FLTRMx (-100 - 99.2%)

Short-term Fuel Trim value represents the short-term relation of fuel metering on a fuelinjected engine.

NOTE: Short-term Fuel Trim value with a positive percentage is a rich fuel trim and if a negative

percentage is present the fuel trim is lean.

THR POS (0 - 100%)

Absolute Throttle Position is the position the throttle is located. The more the throttle is

closed the less percent shown.

THROT CMD (0 - 100%)

Commanded Throttle Actuator Control is the position of the throttle. If throttle is closed the

percent will be 0 and if wide open 100%.

TRIPS SNC CLR (0 - 255)

Number of warm-ups since diagnostic trouble codes cleared. Warm-up is when temperature

of coolant rises to at least 22°C (40°F) from engine starting and reaching a minimum temperature of 70°C (160°F). If a diesel engine the engine minimum temperature is 60°C (140°F.)

NOTE: If there is more than 255 that the engine warms up the TRIPS SNC CLR will remain

at 255.

TROUB CODE (00 00 - FF FF)

Trouble Code Parameter will give the diagnostic trouble code that caused a freeze

frame capture. This information is helpful in diagnosing the cause of a driveability. If no

freeze frame data has been captured this PID will be zero.

VEH SPEED (0 - 255K/h) or (0 - 158mph)

Vehicle Speed shows the speed the vehicle is going.

VPWR (0 - 65.535V)

Control Module Voltage is the power input to the control module.