Page 1

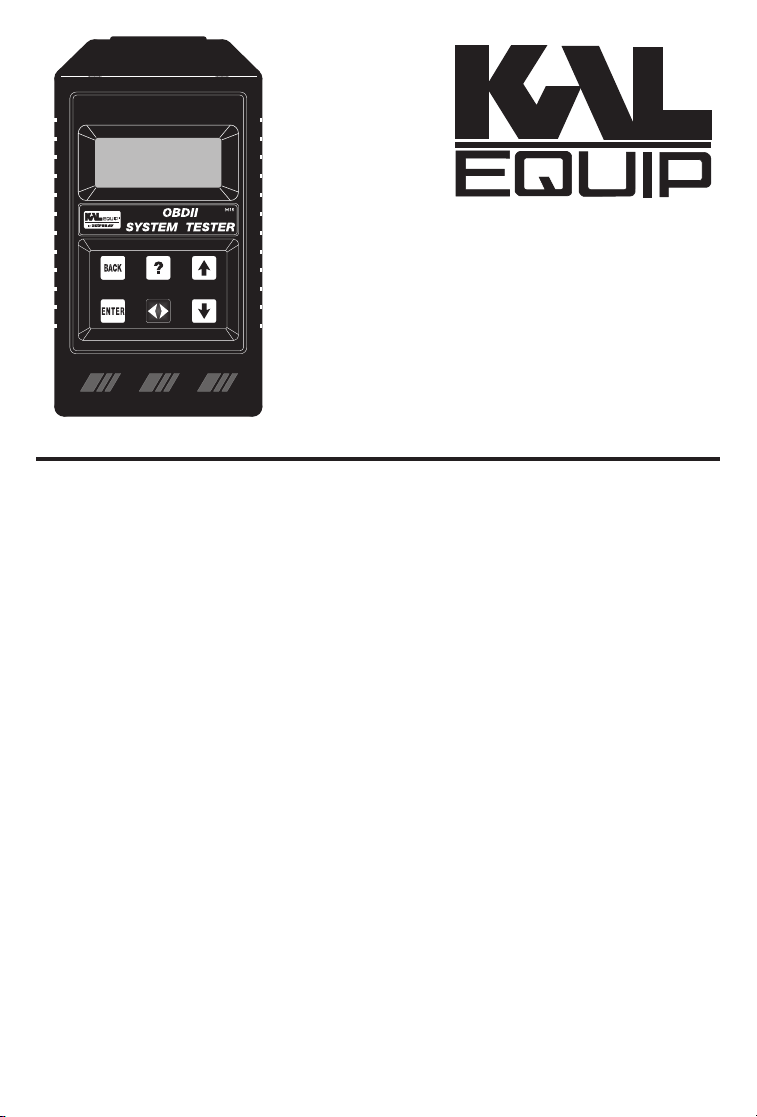

OBD II System

Tester '$#

Table of Contents

Vehicle Service Information . . 2

Safety Precautions . . . . . . . . . . 3

Section 1: Welcome to the OBD II

System Tester . . . . . . 4

1-1 Overview . . . . . . . . . . . . . . . . . . . . . 4

1-2 The OBD II System Tester . . . . . . . . 4

1-3 Diagnostic Connector and Location . 4

1-4 Operating the OBD II System Tester . 5

Powering-Up . . . . . . . . . . . . . . . 5

Keypad . . . . . . . . . . . . . . . . . . . 5

Display . . . . . . . . . . . . . . . . . . . . 6

Lists, Menus and Questions . . . . . 6

Other Functions & Keys . . . . . . . . 7

1-5 OBD II System Tester Setup . . . . . . 7

Section 2: Diagnosing with the

Tester . . . . . . . . . . . . . 8

2-1 Preliminary Checks . . . . . . . . . . . . . 8

2-2 OBD II Functions . . . . . . . . . . . . . . . 8

Read Codes . . . . . . . . . . . . . . . 9

Pending Codes (or Continuous

Test Codes) . . . . . . . . . . . . . 10

Erase Codes . . . . . . . . . . . . . . 11

View Data . . . . . . . . . . . . . . . . . 12

View Freeze Data . . . . . . . . . . . 12

Record Data . . . . . . . . . . . . . . . 13

Playback Data . . . . . . . . . . . . . 14

O2 Monitor Test . . . . . . . . . . . . . 16

Non-Continuous Tests . . . . . . . 17

On-Board Systems . . . . . . . . . . 18

I/M Readiness . . . . . . . . . . . . . 18

Section 3: Diagnostic Trouble Code

Lookup . . . . . . . . . . . 20

Section 4: On-Line Help and

Troubleshooting Tips 22

4-1 How to Use On-Line Help . . . . . . . 22

4-2 Tool Problems . . . . . . . . . . . . . . . 22

4-3 Vehicle Problems . . . . . . . . . . . . . 23

4-4 OBD II System Tester Self-Tests . . 23

Display Test . . . . . . . . . . . . . . . 24

Keyboard Test . . . . . . . . . . . . . 24

Appendix A: Vehicle Computer

Basics . . . . . . . . . 25

Appendix B: Data Parameter List

& Definitions . . . . 31

Appendix C: Glossary of Terms 36

1

Page 2

Vehicle Service Information

The following is a list of publishers who have manuals containing

electronic engine control diagnostic information. Some manuals may

be available at auto parts stores or your local public library. For others,

you need to write for availability and pricing, specifying the make,

model and year of your vehicle.

Vehicle Service Manuals

Chilton Book Company

Chilton Way

Radnor, PA 19089

Haynes Publications

861 Lawrence Drive

Newbury Park, CA 91320

Cordura Publications

Mitchell Manuals, Inc.

Post Office Box 26260

San Diego, CA 92126

Motors Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

Suitable manuals have titles

such as:

Electronic Engine Controls

Fuel Injection and Feedback

Carburetors

Fuel Injection and Electronic

Engine Controls

Emissions Control Manual

. . . or similar titles

Vehicle Service Manuals from General

Motors Corporation:

Buick, Cadillac, Chevrolet, GEO, GMC,

Oldsmobile, & Pontiac

Helm Incorporated

Post Office Box 07130

Detroit, MI 48207

Saturn

Adistra Corporation

c/o Saturn Publications

101 Union St.

Post Office Box 1000

Plymouth, MI 48170

Vehicle Service Manuals from Ford

Motor Company:

Ford, Lincoln, & Mercury

Ford Publication Department

Helm Incorporated

Post Office Box 07150

Detroit, MI 48207

Vehicle Service Manuals from Chrysler

Corporation:

Chrysler, Plymouth, & Dodge

Chrysler Motors Service Training

26001 Lawrence Avenue

Center Line, MI 48015

2

Page 3

Safety Precautions

General Safety Guidelines to Follow When Working on Vehicles

To prevent accidents that could result in serious injury and/or damage

to your vehicle or test equipment, carefully follow these safety rules

and test procedures at all times when working on vehicles:

Always wear approved eye protection.

Always operate the vehicle in a well-ventilated area. Do not inhale exhaust gases

they are very poisonous!

Always keep yourself, tools and test equipment away from all moving or hot engine

parts.

Always make sure the vehicle is in Park (Automatic transmission) or Neutral

(manual transmission) and that the parking brake is firmly set. Block the drive

wheels.

Never lay tools on vehicle battery. You may short the terminals together causing

harm to yourself, the tools or the battery.

Never use OBD II System Tester if its internal circuitry has been exposed to any

liquids.

Never smoke or have open flames near vehicle. Vapors from gasoline and

charging battery are highly flammable and explosive.

Never leave vehicle unattended while running tests.

Always keep a fire extinguisher suitable for gasoline/electrical/chemical fires handy.

Always use extreme caution when working around the ignition coil, distributor cap,

ignition wires, and spark plugs. These components contain High Voltage when the

engine is running.

When performing a road test, Never operate the OBD II System Tester alone while

driving the vehicle. Always have one person drive the vehicle while an assistant

operates the tester.

Always turn ignition key OFF when connecting or disconnecting electrical compo-

nents, unless otherwise instructed.

Always follow vehicle manufacturers warnings, cautions and service procedures.

WARNING!

Some vehicles are equipped with safety air bags. You must follow

vehicle service manual cautions when working around the air bag

components or wiring. If the cautions are not followed, the air bag

may open up unexpectedly, resulting in personal injury. Note that the

air bag can still open up several minutes after the ignition key is off

(or even if the vehicle battery is disconnected) because of a special

energy reserve module.

3

Page 4

Section 1: Welcome to the OBD II System Tester

1-1 Overview

OBD II (On-Board Diagnostic, second generation) systems are designed to meet or

exceed a set of standards and regulations designed to improve air quality. The

Environmental Protection Agency (EPA), in conjunction with California Air Research

Board (CARB), issued these standards and regulations through the Clean Air Act

of1990. OBD II systems are required to monitor the performance of emission related

systems and their components. The ability to detect hard and intermittent faults are

further requirements of an OBD II compliant system. The Society of Automotive

Engineers (SAE) defined several standards for OBD II systems. These standards

include criteria for the diagnostic link connector, communication, Diagnostics trouble

codes (DTCs), descriptor names, and other repair information.

This OBD II System Tester will work on OBD II compliant cars and light trucks. If you

use a vehicle service manual along with the tester, you will be able to diagnose and

repair many automotive-related problems. Before proceeding, make sure you have

read and fully understand the material in this Manual.

1-2 The OBD II System Tester

KAL Equips OBD II System Tester was developed by experts in the automotive

service industry to help diagnose todays vehicles and assist in troubleshooting

procedures. When a problem occurs in the vehicle, its computer will store a record of

the event and take corrective action to adjust the circuit at fault. The OBD II System

Tester will allow you to monitor these vehicle events and read DTCs from the

computers memory to pinpoint problem areas. The OBD II System Tester will

interpret the computer signals and provide you with a real time readout of vehicle

data. In addition, the Code Lookup feature allows you to reference code descriptions

without having to page through an instruction manual. A detailed description of the

functions are provided in Section 2: Diagnosing with the Tester.

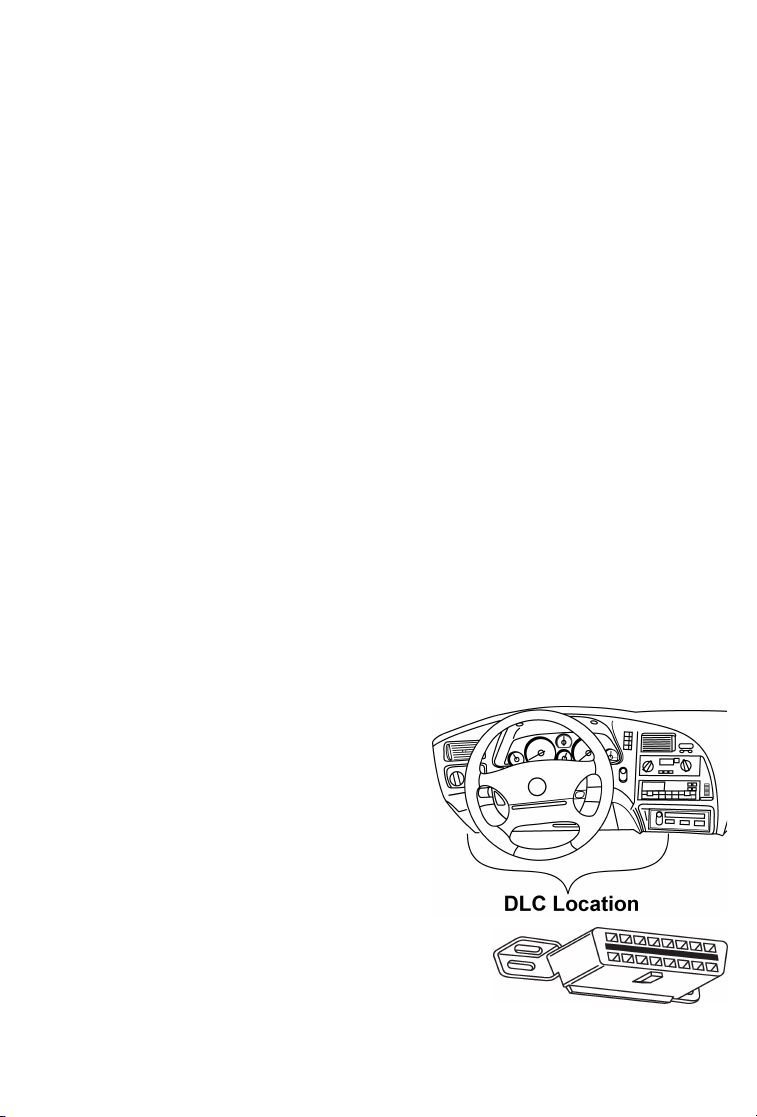

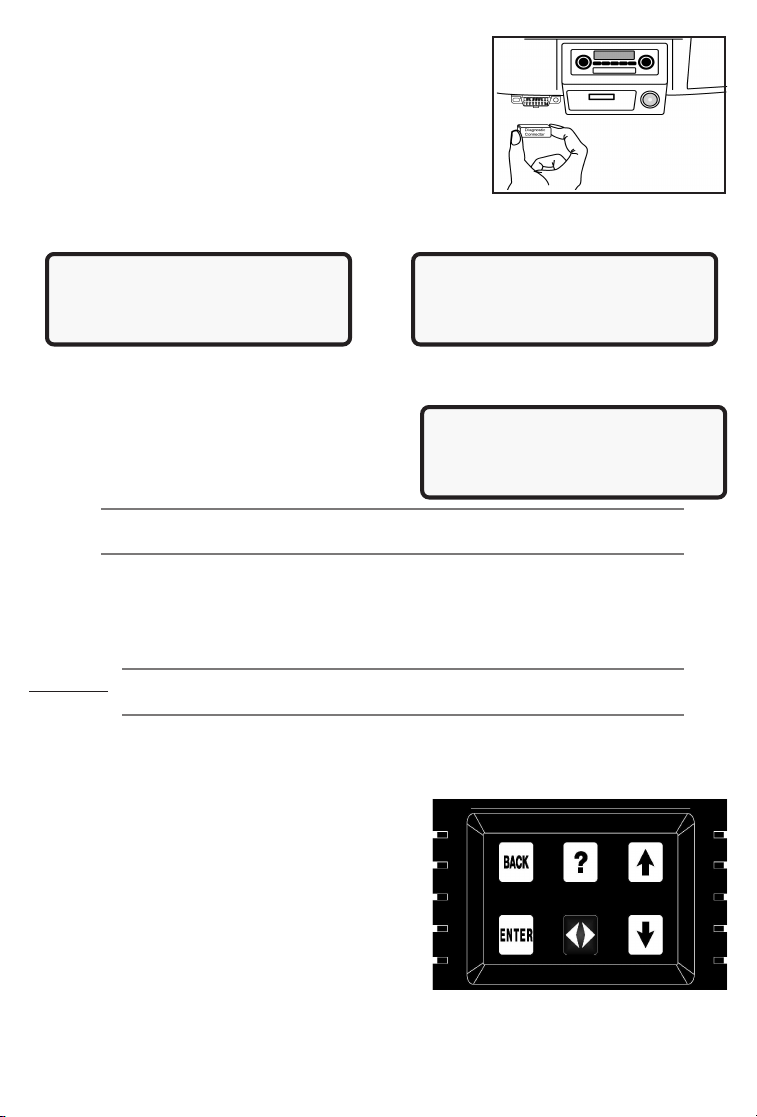

1-3 Diagnostic Connector and Location

The OBD II System Tester communicates with

the vehicle via a diagnostic link connector (DLC).

OBD II Specification J1962 defines the DLCs

physical and electrical properties. The DLC is

known as the J1962 connector. The Specification

J1962 was introduced by the SAE (Society of

Automotive Engineers) to make all compliant

vehicles use the same DLC with the generic link

information available on the same pins, no

matter what make of vehicle. In addition to the

connector specification, there is a guideline on

where to locate the DLC or J1962 connector, which

states it should be located under the dashboard on the

drivers side of the vehicle. Even with this guideline, not

all OBD II DLCs are located under the dash on the

drivers side. If the DLC is not located in the specified area, then a note will be placed

where the DLC should be informing the user of the location. If you cannot find the

DLC, see the vehicle service documentation for its location.

4

Page 5

1-4 Operating the OBD II System Tester

MAIN MENU

`1)OBDII Functions

2)Tool Setup [

3)Tool Self Test |

Welcome To The

OBDII SYSTEM TESTER

by

KAL Equip

Press *|* For

Instructions

Press ENTER To Cont

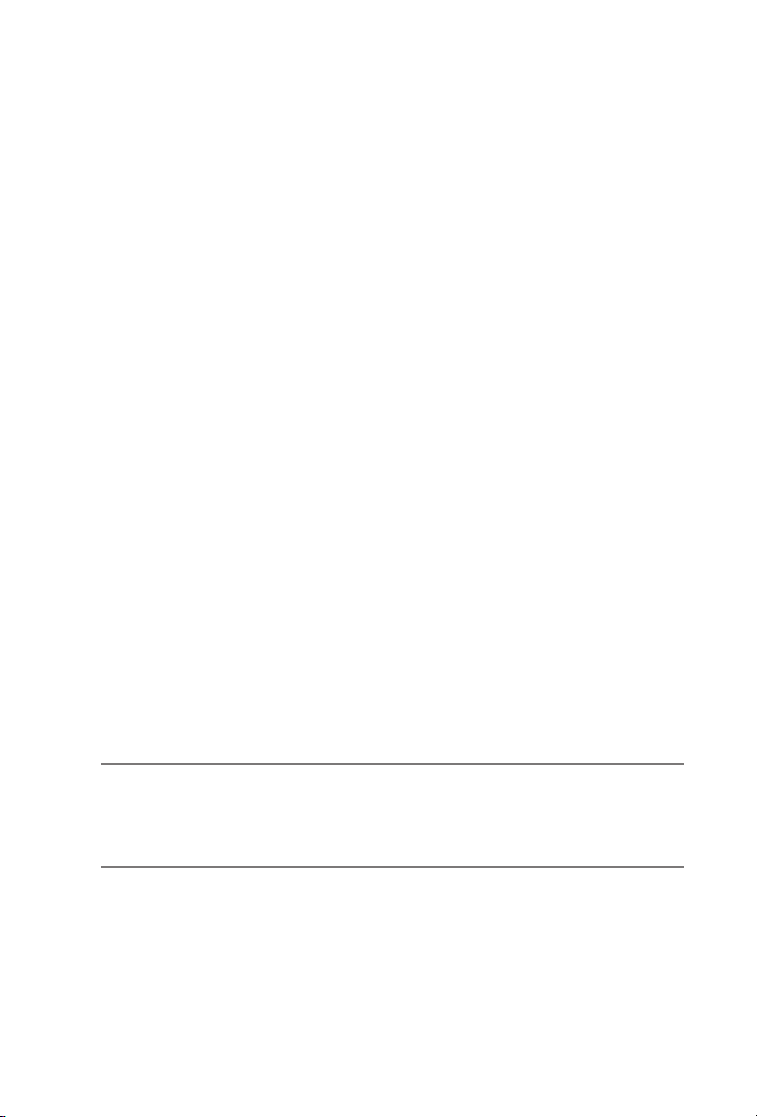

POWERING-UP

Connect the OBD II System Tester to the DLC. This

connection will provide power for the OBD II System

Tester. The DLC contains power even when the ignition

is turned off. Connection to the battery is not necessary.

When the OBD II System Tester powers up, a series of screens are displayed. The

screens start with a Welcome screen and end with a Help for Instructions screen.

Before the Help for Instructions screen, the tool performs a self-test and then displays

the software version SW ID: xxxx. Refer to this software version if you need to contact

Actrons technical support line with a problem.

The Help for Instructions screen allows the

user to review the keypad definitions. Press the

? key for instructions or the ENTER key to

continue and display the MAIN MENU.

NOTE: Your OBD II System Tester requires a minimum of 8 volts to power up. If the

power-up persists, review Section 4-2: Tool Problems to find the cause.

KEYPAD

The OBD II System Tester software was designed for ease in operation and navigation through the menus. Simply follow the instructions that match the keypad symbols

and you will be using your OBD II System Tester like an expert in no time.

CAUTION! DO NOT use solvents like ALCOHOL! This could remove the keypad paint! Use

Keyboard Functions

The OBD II System Tester uses 6 keys to navigate through the user-friendly software:

ENTER - Used to select functions and respond

to requests.

? - Used to request help when the (|) symbol is

displayed on the lower right hand corner of

the display.

BACK - Used to move one screen back in OBD II

System Tester flow.

ARROWS

UP & DOWN - are always used to move the solid

cursor (`) in the direction of the arrow or

scroll the data list in the direction you want to

move the list.

LEFT/RIGHT - The left/right arrow key is used to answer Yes or No questions.

a mild detergent or water to clean. Let dry thoroughly before operating tool.

Tester Keypad

5

Page 6

DISPLAY

2)Pending Codes

`3)Erase Codes ]

4)View Data [

5)View Freeze Data |

OBD II FUNCTION MENU

`1)Read Codes

2)Pending Codes [

3)Erase Codes |

1)Read Codes

2)Pending Codes ]

3)Erase Codes [

`4)View Data |

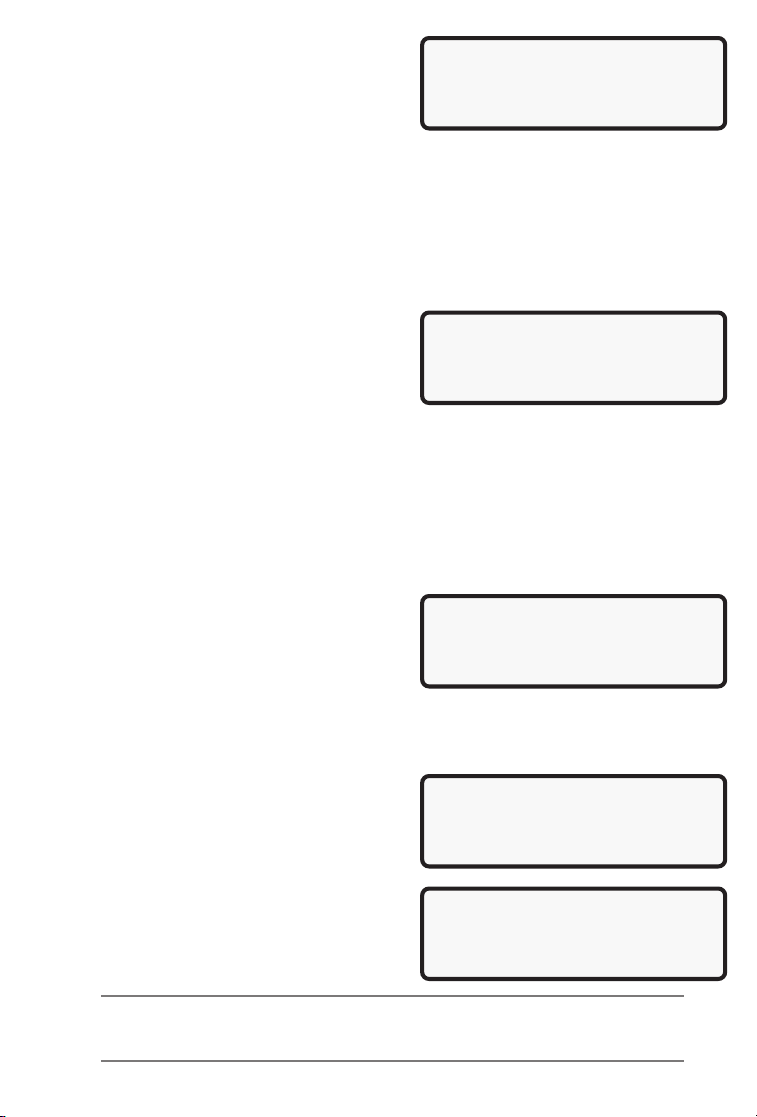

The OBD II System Tester has a 4 line x 20 character liquid crystal display (LCD) for

easy viewing. This helps make the OBD II System Tester more user friendly by

offering a large viewing area to display most Help and Instructional messages. This

puts more information on the display to reduce reference to printed materials. The

display will support a number of helpful symbols that will prompt you through test

routines. These symbols are shown and defined below:

| Question Mark in lower right corner means there is help available for this screen

or current selectable item.

` Pointer (cursor) is used to indicate current selectable choice.

[ Down Arrow indicates there is additional

information on the next screen.

] Up Arrow indicates there is additional

information on previous screen.

LISTS, MENUS AND QUESTIONS

The OBD II System Tester is designed to be as intuitive as possible. That is, its

functions and controls should be easy to understand and use the first time you try it.

All menu and screen lists operate the same way. By using the UP and DOWN arrow

keys, you can move the cursor to a selection of your choice. The ENTER key selects

that function or item. The screen example above illustrates a few selections available

on the OBD II Function Menu.

Notice, in the screen below on the left, how the cursor (`) is pointing at 1)Read

Codes. If you wish to read the vehicles DTCs, press the ENTER key to select that

function. To make a different choice, such as View Data, use the DOWN arrow key to

move the cursor down to 4) View Data and press the ENTER key to select the View

Data function.

Sometimes, a list will be longer than three or four items, and will not fit on a single

screen. In these cases, the down arrow symbol ([) is visible in the last column of the

display, indicating that there are more choices on the next screen, as shown below

on the left. To go to the next choice, use the DOWN arrow key to move the cursor

down the list. Keep going even after you have reached the bottom of the screen. The

display will scroll to the list, shown above on the right:

You should see that there are now arrows in the last column pointing up and pointing

down. This indicates that you can use the UP arrow key to move the cursor to the

previous screen or the DOWN arrow key to move the cursor to the next screen.

Once the bottom of the list is reached, you will notice that there is now only an UP

arrow (]) in the last column. This indicates that you have reached the end of this list,

and that all other choices are on previous screens. You can return to those screens

by pressing the UP arrow key. These up and down arrow characters on the screen

are used throughout the OBD II System Tester. The UP and Down arrow keys work

exactly the same way, even if you are just scrolling through text such as the On-Line

Help screen.

6

Page 7

Occasionally, you may be asked a question by

Operating Error

Check Connections!

Try Again?

<YES> NO |

THE TESTER CAN NOT

COMMUNICATE WITH

VEHICLE. CHECK THE [

FOLLOWING:

1.IGNITION KEY ON?

2.HOOKUP TO VEHICLE ]

TEST CONNECTOR OK? [

3.EMISSION LABEL

MAIN MENU

1)OBDII Functions

`2)Tool Setup [

3)Tool Self Test |

TOOL SETUP MENU

`1)Metric Units

2)English Units

the OBD II System Tester. These will always be

YES or NO questions, and are answered in

almost the same way you make choices in a

Function Menu. In these screens, brackets <>

will automatically appear next to the default response. If you wish to accept the default

choice, simply press the ENTER key. If you wish to change the answer, use the LEFT/

RIGHT arrow key to move the brackets to the other response and press the ENTER key.

OTHER FUNCTIONS & KEYS

As you have reviewed moving through lists and functions in earlier sections, you

probably noticed another symbol on the screen. In the lower right-hand corner of some

screens, there is a |. This question mark indicates that On-Line Help is available for

that particular screen or item. To enter On-Line

Help, press the ? key. The Operating Error

help screen is shown at the right.

The text in On-Line Help screens are in

CAPITAL letters to remind you that you are

viewing On-Line Help screens and not screens associated with a function. Some OnLine Help messages are longer than one screen. If this is the case, the arrow

symbols (][) will appear in the last column of the display. A [ means more

information available on the next screen and a ] means more information available

on the previous screen. Use the UP and DOWN arrow keys to page up or down

through a series of On-Line Help screens.

The On-Line Help screen shown above has a [ in the last column. To view the next

On-Line Help screen, press the DOWN arrow key.

Notice now that both arrow symbols (][) are

visible in the last column of the display. This

indicates that you can either page up to a

previous On-Line Help screen, or page down to

the next On-Line Help screen by using the UP

and DOWN arrow keys. The previous On-Line Help screen is always the one you just

viewed, just as with Function Menu.

1-5 OBD II System Tester Setup

Tool Setup is used to change the OBD II

System Testers default measurement units.

Select the Tool Setup option from the MAIN

MENU and press the ENTER key.

The TOOL SETUP MENU appears. Use the UP

and DOWN arrows to select English or Metric

measurement units and then press the

ENTER key. Press ENTER again to accept or

the BACK key to change.

NOTE: If you change the Measurement Units to a setting other than the default, then

it will revert back to the default settings the next time the OBD II System Tester

is used.

7

Page 8

Section 2: Diagnosing with the Tester

2-1 Preliminary Checks

Before using the OBD II System Tester on your vehicle, it is a good idea to perform a

complete visual inspection. You can find the cause of many driveability problems by

just looking, thereby saving yourself a lot of time. Check the following items before

proceeding with OBD II System Tester testing:

o Has the vehicle been serviced recently? Sometimes things get reconnected in

the wrong place, or not at all.

o Dont take shortcuts. Inspect hoses and wiring which may be difficult to see

because of location beneath air cleaner housings, alternators and similar

components.

o Inspect the air cleaner and ductwork for defects.

o Check sensors and actuators for damage.

o Inspect all vacuum hoses for:

Correct routing. Refer to vehicle service manual, or Vehicle Emission Control

Information (VECI) decal located in the engine compartment.

Pinches and kinks.

Splits, cuts or breaks.

o Inspect wiring for:

Contact with sharp edges (this happens frequently).

Contact with hot surfaces, such as exhaust manifolds.

Pinched, burned or chafed insulation.

Proper routing and connections.

o Check electrical connectors for:

Corrosion on pins.

Bent or damaged pins.

Contacts not properly seated in housing.

Bad wire crimps to terminals.

NOTE: Problems with connectors are common in the engine control system. Inspect

them carefully for corrosion, bent pins, pushed out pins, or over expanded

pins. Some connectors use a special grease on the contacts to prevent

corrosion. Do not wipe off! Obtain extra grease, if needed, from your vehicle

dealer. It is a special type for this purpose.

2-2 OBD II Functions

During the functions described below, a communication link is established, allowing

the OBD II System Tester and the vehicles PCM to exchange information. The way in

which this information is exchanged is referred to as a data stream or data links. The

OBD II Function Menu shows all OBD II Generic functions. Not every vehicle will have

every function that is listed. If the function or part of function selected is not supported

by the vehicle, a message screen informing you of this will be displayed.

8

Page 9

After you select OBDII Functions from the MAIN MENU the OBD II System Tester will

On-Board Readiness

Tests are Complete

Press A Key to Cont

Not All Supported

On-Board Readiness

Tests Are Complete.

Use [ To View Tests

Misfire Monitor OK

Fuel System Mon inc

Comp Component n/a[

Catalyst Mon OK

OBDII Function Menu

`1)Read Codes

2)Pending Codes [

3)Erase Codes

automatically link to the PCM and check the OBD II Readiness Monitors. OBD II

Readiness Monitors are strategies designed to test the operation of emission related

systems or components. The PCM may perform special tests on a system or

component to complete its monitor. The vehicle may have to be operated under

certain conditions to initiate a monitor. If the PCM loses power or the codes are

erased the monitors will be cleared. The OBD II System Tester will display the

condition of vehicles OBD II Monitors.

Below is an example of the screen when the OBD II readiness monitors are completed. If any of the monitors are not completed, the following screen on the right will

be displayed.

Press the down arrow key to view a list of the monitors. The monitor list consists of

the OBD II monitor name followed by the monitors condition. A monitor that is not

supported by the test vehicle will be followed

by n/a, (not applicable). A monitor that has

been completed will be followed by OK. If a

monitor has not been completed, it will be

follower by inc for incomplete.

Press the BACK key and the OBD II Function Menu will display. Use the UP and

DOWN arrow keys to scroll through the choices.

IMPORTANT: If you choose a test that your vehicle does not support, you will get a

message telling you that the test is not applicable.

Read Codes

The Read Codes function is used to retrieve Diagnostic Trouble Codes (DTCs) from

the vehicles on-board computer. Diagnostic Trouble Codes are set when the PCM

recognizes a condition outside preset ranges. A Malfunction Indicator Lamp (MIL) that

is on indicates that a DTC has been recorded. Because DTCs indicate a circuit or

system failure not component failures they are very useful in diagnosing vehicle

concerns.

NOTE: Changing parts without diagnosing the circuit or system may result in good

Select Read Codes from the OBD II Function

Menu and press the ENTER key. The PCM will

check its memory and report trouble conditions that were stored.

NOTE: If you get an Operating Error message, make sure the DLC adapter cable is

components being unnecessarily replaced.

properly attached to the vehicle connector. If the problem remains, refer to

Section 4: On-Line Help and Trouble-Shooting Tips.

9

Page 10

When the tester has finished reading the DTCs, one of two possible screens is

P0101

MAF Or VAF

CKT Range/Perf [

P0102

MAF Or VAF ]

Circuit Low Input

System Pass:

No Faults Detected.

Press Any Key For

Function Menu

Codes Found: 2

Use [ To View Codes

Write Down Codes [

For Reference.

System Pass:

No Faults Detected.

Press Any Key For

Function Menu

OBDII FUNCTION MENU

1)Read Codes

`2)Pending Codes [

3)Erase Codes |

6)Record Data

7)Playback Data ]

8)O2 Monitor Test [

`9)Continuous Test |

displayed. If there are no DTCs stored in the vehicles on-board computer, a

System Pass screen is displayed. If there are DTCs stored in the vehicles onboard computer, then the OBD II System Tester displays the number of codes found.

If codes are retrieved, press the DOWN arrow to view the DTC(s). Definitions for

Generic DTCs (SAE J2012) will be displayed. Manufacturer specific DTCs will just

display the code, no definition. Use an appropriate service manual to obtain code

definitions. When more than one DTC is received, the DOWN arrow will be displayed

on the right of the screen. The arrow indicates additional code information is available. Use the DOWN arrow key to view the codes stored in memory. The last code

screen will just have a

this is the last screen and additional code information is found on previous screens.

Use the BACK key to return to the OBD II Function Menu.

] symbol in the last column of the display. This indicates that

Pending Codes (or Continuous Test Codes)

The purpose of this function is to obtain test results for continuously monitored

emission-related powertrain components and systems. Certain tests are run

continuously as the vehicle is driven within proper operating conditions. Unlike some

trouble codes this function reports the test results after a single drive cycle. The

Pending Codes function is identical to the Continuous Test function and is useful

after a vehicle repair or after clearing the PCMs diagnostic information. Test results

reported by this function do not necessarily indicate a faulty component or system.

To view the test results, select Pending Codes or Continuous Test from the OBDII

Function Menu and press the ENTER key.

If no Pending Codes exist, the OBD II System

Tester will display a single message screen

indicating this condition.

10

Page 11

NOTE: If you get an Operating Error message, make sure the DLC adapter cable is

OBDII FUNCTION MENU

1)Read Codes

2)Pending Codes [

`3)Erase Codes |

Codes Found: 2

Use [ To View Codes

Write Down Codes [

For Reference.

P0123

TP Sensor Circuit

High Input [

Erase Codes And

Diagnostic Results?

Are You Sure?

<Yes> No

Command Sent

Press A Key to Cont

If any of these tests indicate a fault, the DTCs

will be displayed in the same format as Read

Codes. The tester will display codes similar to

trouble codes. Press the DOWN arrow to view

the pending code(s).

A DOWN arrow displayed on the right of the screen indicates additional codes can

be found on the next screens. Use the DOWN arrow key to view the codes stored in

memory. The last screen will just have

a ] symbol in the last column of the display.

This indicates no more codes are available.

Use the UP arrow key to view the previous

codes.

Use the BACK key to return to the OBD II Function Menu.

securely attached, and the ignition key is ON, then try again. If the problem

remains, refer to Section 4: On-Line Help and Trouble-Shooting Tips.

Erase Codes

The Erase Codes function is used to erase the trouble codes from the test vehicles

PCM. This function also erases freeze frame data, O2 sensor test data, and on-board

monitoring test results, and resets the system monitors to the Not Ready status.

Because of this you should erase codes only after you have checked the systems

completely. Erase Codes should be performed at Key On, Engine Off to properly clear

the PCM.

To Erase Codes from your vehicles on-board

computer, select Erase Codes from the OBDII

Function Menu.

A confirmation screen will be displayed to verify

that you wish to erase codes. Select YES to

erase the diagnostic results from the PCM or

NO to cancel and retain the data.

If YES is selected, press the ENTER key and a

message to Turn ignition key ON, engine

OFF will display. Press the ENTER to continue. A Command Sent message is momentarily displayed before returning to the

OBD II Function Menu.

NOTE: If you choose No, a Command Cancelled message appears. Hard codes,

NOTE: If you get an Operating Error message, make sure the DLC adapter cable is

are trouble codes that will remain in the vehicles PCM memory until the

condition is repaired.

securely attached, and the ignition key is ON, then try again. If the problem

remains, refer to Section 4: On-Line Help and Trouble-Shooting Tips.

11

Page 12

ABSLT TPS (%) 0. 0

CALC LOAD (%) 5.3

COOLANT (oF) 180[

ENGINE (RPM) 865

`4)View Data

5)View Freeze Data ]

6)Record Data [

7)Playback Data |

4)View Data

`5)View Freeze Data ]

6)Record Data [

7)Playback Data |

View Data

This function is used to view vehicle Parameter Identification Data (PID) in real time.

Apart from Read Codes, View Data is the most helpful diagnostic function for determining the cause of a driveability problem. View Data is most often used for observing sensor data and the ON/OFF states of switches, solenoids and relays.

NOTE: Multiple Responses to a PID Request - Vehicles equipped with more than

To view your vehicles PIDs, select View Data

from the OBD II Function Menu and press the

ENTER key.

The OBD II System Tester will display the

generic OBD II PIDs supported for the vehicle

under test. Not all vehicles will have the same

PIDs. Do not worry this is normal. The PIDs

covered by the OBD II System Tester are

defined in Appendix B.

Press the BACK key to display the OBD II Function Menu.

NOTE: If you get an Operating Error message, make sure the DLC adapter cable is

one on-board computer, for example a PCM and TCM (Transmission Control

Module), can respond with multiple results to a certain parameter identification data (PID). In View Data, the OBD II Tester identifies the modules with

their manufacturer assigned names such as $10 or $1F by blinking the

module name near the end of the PID name. A PID that receives multiple

responses, such as Engine (RPM), will display on two lines.

securely attached and the ignition key is ON, then try again. If the problem

remains, refer to Section 4: On-Line Help and Trouble-Shooting Tips.

View Freeze Data

When an emission related fault is detected by the PCM the engine conditions are

recorded and stored in memory. This recording is known as a freeze frame. The

freeze frame is like a snapshot of the engine operating conditions at the time of a

fault. Freeze frame data can only be overwritten by another fault with higher priority.

The OBD II System Tester will allow you to look at the freeze frame data stored in the

PCMs memory.

NOTE: If the Erase Codes function was performed, then no freeze frame data will

To view the freeze frame data, select View

Freeze Data from the OBD II Function Menu.

be stored in the vehicles memory.

12

Page 13

After selecting View Freeze Data, the OBD II

COOLANT (oF) 180

ENGINE (RPM) 865]

FUEL PRES (PSIG) 35[

FUEL SYSTEM 1 OPEN

4)View Data

5)View Freeze Data ]

`6)Record Data [

7)Playback Data |

Pick Trigger Method

`1)Manual Trigger

2)Trigger On Codes

No Freeze Frame Data

Stored (Freeze Frame

Event Not Detected)

Press A Key To Cont

Cannot Record. Old

Recording Filled Up

Memory. Erase Old?

<YES> NO

System Tester establishes a communication

link to the vehicles PCM. All PIDs supported by

the vehicle are displayed. Use the UP and

DOWN arrow keys to scroll through all selected data parameters.

When done, press the BACK key to return to the OBD II Function Menu.

If no data exists, a message will display

prompting the user to press any key to return to

the OBD II Function Menu.

NOTE: If you get an Operating Error message, make sure the DLC adapter cable is

securely attached and the ignition key is ON, then try again. If the problem

remains, refer to Section 4: On-Line Help and Trouble-Shooting Tips.

Record Data

The Record Data function is used to record vehicle Parameter Identification Data (PIDs)

while the vehicle is parked or being driven. This function is mainly used for diagnosing

intermittent driveability problems that cannot be diagnosed by any other method. For

example, if your vehicle sometimes loses power while going up steep hills, then you

should start a recording as soon as your vehicle reaches the base of the hill. The OBD II

System Tester records the supported PIDs in Frames at various time intervals. The first

5 Frames are recorded prior to the start time (0.0 seconds) Once started, Frames will

be recorded for 8 to 35 seconds; the number of Frames depends on the vehicles data

rate and quantity of PIDs. The Record Data function allows you to diagnose an intermit-

tent problem by analyzing data leading up to the problem, during the problem, and

possibly after the problem, depending on problem duration. The PIDs covered by the

OBD II System Tester are defined in Appendix B.

Select Record Data from the OBD II Function Menu and press the ENTER key. The

Pick Trigger Method menu is displayed next. Select either Manual Trigger or Trigger

on Codes then press the ENTER key.

If the memory is full from a previous recording,

it must be erased before recording more data.

To erase memory and continue, select YES

and press the ENTER key and then the Pick

Trigger Method options will display. Otherwise,

select NO and press the ENTER key to return

to the OBD II Function Menu.

NOTE: If you get an Operating Error message, make sure the DLC cable is securely

attached, and the ignition key is ON, then try again. If the problem persists,

refer to Section 4 of this Manual: On-Line Help and Trouble-Shooting Tips.

13

Page 14

The OBD II System Tester initializes by

Working

Waiting for VEH

To Respond.

*Please Wait*

**Recording Data**

FRAME: 1 Of 30

Press ENTER to Stop

Playback Data?

<Yes> No

4)View Data

5)View Freeze Data ]

6)Record Data [

`7)Playback Data |

**INITIALIZING**

PRETRIG FRAME: -5

Press BACK to Exit

**Ready To Record**

Press ENTER Anytime

To Start Recording.

Stops Automatically

establishing the time intervals and then

recording the first five Frames of data. When

done, the system tester is ready to record data.

To cancel this function, press the BACK key to

return to the OBD II Function Menu.

If Manual Trigger was selected, then the OBD

II System Tester will start recording when the

ENTER key is pressed.

If Trigger on Codes was selected, then the

tester will automatically start recording when a

trouble code is set in the vehicles on-board

computer. Press the BACK key to cancel and

return to the OBD II Function Menu.

WARNING! Never operate the OBD II System Tester and drive your vehicle at

The tester records for a time of varying duration. Remember, your recording will

consist of 5 Frames of data prior to the start of the recording, and a number of

Frames after with time intervals of 5 seconds or longer (depending on the number of

PIDs). All applicable data parameters will be recorded for your vehicle.

When the recording is in progress, screens

like the example below are displayed for the

duration of the recording, displaying the Frame

Number being recorded. You can record all the

frames or press the ENTER key any time to

stop recording.

Next, You will be asked if you want to play back

the recording now. If you answer YES, then

the Playback Data function will display,

Answering NO returns you to the OBD II

Function Menu.

the same time. Always have one person drive the vehicle while a

helper operates the tester.

Playback Data

The Playback Data function is used to playback a recording. This function is very

similar to View Data. The only difference is that View Data is a real time viewing of

vehicles PIDs, while Playback Data is a viewing of previously recorded ones.

To view the PIDs recorded in the Record Data

function, select Playback Data from the OBD II

Function Menu.

14

Page 15

If a recording does not exist in the OBD II

No Recording Present

Please Make

Recording First

MIL Status ON

ABSLT TPS (%) 0.0

CALC LOAD (%) 5.3[

Frame: 10 TM: 9.5

System Testers memory, then the message

No Recording Present, Please Make Recording First will display. The Record Data function

must be performed in order to play back the

data. Press the BACK key to return to the OBD II OBD II Function Menu and select

Record Data to make a recording.

If recorded data exists, the PIDs, Frame

number and Time are displayed.

NOTE: Multiple-response PIDs (see View Data) are displayed with their module

On the Playback Data screen, lines 1-3 are used to display the vehicles PIDs. Use

the UP/DOWN arrow keys to scroll through the PID list. The end of the list is reached

when only the UP arrow is displayed at the right of line 3. The PID list scrolls line-byline and will not wrap around to the beginning.

Use the LEFT/RIGHT arrow key to move through the Frame/Time index. Frame 0/

Time 0.0 is the trigger point; where the recording was started by either Manually

Triggering or by Triggering On Codes. Frames -5 to -1 contain data prior to the trigger

point.

NOTE: After reaching the last Frame/Time interval, the system tester will wrap to

A Frame is a snapshot of engine operating conditions at a certain time. The

relationship between the Frame index and the Time index are based on the vehicles

on-board computer data rate and the number of PIDs being read. Remember, not all

OBD II vehicles use the same data stream (communication protocol), data rates

(baud) and the same number of PIDs. For this reason, not all vehicles will start and

end with the same Frame number. The Frame number increases every time data is

transmitted from the vehicle to the OBD II System Tester. The intervals when this

occurs increases for slower data rates and larger PID lists. Frame 0 occurs at the

trigger point, Time 0.0. Thus, negative and positive Frame numbers contain data

before and after the trigger point, respectively.

address in one frame and their measurement values in the next frame. Use

the LEFT/RIGHT arrow key to alternate between the frames to identify the PIDs

and their measurement values.

the first Frame/Time interval recorded. The Frame/Time display will change

from a positive to the first negative number viewed. This is normal. The LEFT/

RIGHT arrow may be used to scroll through all time intervals.

NOTE: Some vehicles will wait 3 to 4 minutes after the driveability problem first occurs

When you have finished playing back a recording, press the BACK key to return to

the OBD II Function Menu.

before storing a trouble code in the vehicles on-board computer. If you

selected Trigger On Codes when you made your recording, you might not

see any drastic change in data parameters before and after the trigger point.

In cases like this, it is better to manually trigger the start of the recording when

the driveability symptom is first observed.

15

Page 16

O2 Monitor Test

7)Playback Data

`8)O2 Monitor Test ]

9)Continuous Tests [

10)Non-Contin Tests |

O2 Sensor Tests

1) RICH-LN Thresh

2) LN-RICH Thresh [

`3) Lo V for Switch |

Low Volts for Switch

O2S BNK1 #1(V) 1.28

O2S BNK1 #2(V) 1.28[

O2S BNK2 #1(V) 1.28

NOTE: This is NOT an on-demand test. The O2 sensors are not tested when this

OBD II regulations require the vehicle to monitor and test the oxygen sensors. The O2

Monitor Test selection allows the technician to retrieve the completed test information

on the oxygen sensors from the PCM. Information on the oxygen sensor monitors will

be helpful in recognizing sensor or system problems related to fuel and emissions. The

oxygen sensor test may include the following information:

To view the oxygen sensor test results, select

O2 Monitor Test from the OBD II Function

Menu and press the ENTER key.

Once the O2 Monitor Test has been selected

the recommended oxygen sensor tests list will

be displayed. Select which test you want to

review using the UP/DOWN arrow keys then

press the ENTER key.

The OBD II System Tester will display selected

information for all the vehicles oxygen sensors. Listing the sensors together makes their

data easier to compare. Tests not supported

by the test vehicle will return three dashes after

the sensor name.

menu selection is made. The O2 sensors were tested at an earlier time when

engine operating conditions were correct.

Rich to Lean sensor threshold voltage

Lean to Rich sensor threshold voltage

Low sensor voltage for switch time

High sensor voltage for switch time

Time between sensor transitions

Rich to Lean sensor switch time

Lean to Rich sensor switch time

_ Minimum sensor voltage for test cycle

_ Maximum sensor voltage for test cycle

NOTE: If you get an Operating Error message, make sure the DLC adapter cable is

NOTE: Remember that some sensors are before the catalytic converter (precatalyst)

Press the BACK key to return to the OBD II Function Menu.

securely attached and the ignition key is ON, then try again. If the problem

remains, refer to Section 4: On-Line Help and Trouble-Shooting Tips.

and some are after (postcatalyst). The precatalyst and postcatalyst O2

sensors may act differently. Use the arrow keys to scroll through list if

necessary.

16

Page 17

Non-Continuous Tests

7)Playback Data

8)O2 Monitor Test ]

9)Continuous Tests [

`10)Non-Contin Tests|

Non-Cont Tests Avail

`$01

$03 [

$05

TEST $01

ID MEAS SPEC STS

74 8861 C000min Low

74 8861 C000min Low

The purpose of this function is to obtain test results for emission-related powertrain

components and systems that are not continuously tested. Certain tests are run only

once per drive cycle when the vehicle is within proper operating conditions. This

function reports the test results after a single drive cycle. The Non-Continuous Test

function is useful after a vehicle repair or after clearing the PCMs diagnostic information. Test results reported by this function do not necessarily indicate a faulty component or system. Examples of systems not continuously monitored are catalyst and

evaporative OBD II monitors.

To view the Non-Continuous Monitors test

results, select Non-Contin Test from the OBD II

Function Menu and press the ENTER key.

The OBD II System Tester will request the vehicle to transmit the test IDs for available

non-continuous tests and display them in a list. The vehicle manufacturer is responsible to assign test IDs and component IDs to distinguish between the different

systems and components. Refer to vehicle service manuals for test IDs and definitions.

NOTE: If you get an Operating Error message, make sure the DLC adapter cable is

Select a test ($xx) from the list then press the

ENTER key. Selected test results are requested by the OBD II System Tester may also

include test limits. Only one test limit is usually

included in a responses message and

displayed on the screen. The single limit could be either minimum or a maximum

test limit. The OBD II System Tester will display the test ID, system or component ID

the test measurement, specification and status.

The first line of the display will show the NonContinuous test that was selected using its ID

number. The ID column displays the system or

component ID number, refer to vehicle service

manual for ID definitions and explanations. A

column labeled MEAS will contain the measured data of the test. The test measurement data is displayed in hexadecimal number format (a system based on 16 digits

where letters A through F represent the digits greater than 9. The specification

values for the system tested are found in SPEC column and displayed in hexadecimal number format. The final column, STS (Status) information is calculated by the

OBD II System Tester using the measurement and specification data. The status can

be Low, High or OK, depending upon the measurements relationship to the specification.

Press the BACK key to return to the OBD II Function Menu.

securely attached, and the ignition key is ON, then try again. If the problem

remains, refer to Section 4: On-Line Help and Trouble-Shooting Tips.

17

Page 18

On-Board Systems

11)On-Board Systems

`12)I/M Readiness ]

13)Tool Setup [

14)Tool Self-Test |

`11)On-Board Systems

12)I/M Readiness ]

13)Tool Setup [

14)Tool Self-Test |

Control of On-Board

Systems Unavailable

On This Vehicle.

Press a key to cont

The purpose of this function is to allow the OBD II System Tester to control the

operation of vehicle component, test or system.

Certain manufacturers do not allow OBD II

System Testers to control vehicle systems. A

screen informing you that the vehicle does not

support on boards systems will be displayed

in these cases.

An example of a possible On-Board System application is a test mode that enables

the conditions required to conduct an evaporative system leak test, but does not

actually run the test.

To perform the On-Board Systems function,

select On-Board Systems from the OBD II

Function Menu then press the ENTER key.

A list of On-Board systems and components available for testing will be displayed if

supported by the test vehicle. Select a test and press the ENTER key to activate the

test. The OBD II System Tester informs you that the command was sent. The manufacturer is responsible to determine the criteria to automatically stop the test. Use the

vehicle service manuals for more detailed information on test procedures.

Press the BACK key to return to the OBD II Function Menu.

NOTE: If you get an Operating Error message, make sure the DLC adapter cable is

securely attached, and the ignition key is ON, then try again. If the problem

remains, refer to Section 4: On-Line Help and Trouble-Shooting Tips.

I/M Readiness

The purpose of the I/M (Inspection and Maintenance) Readiness function is to display

the current status of emissions-related systems required by OBD II regulations. The

operation of emission-related systems and components are verified using monitors. .

The scan tool will display the condition of vehicles OBD II Monitors. Monitors are

used by the vehicles PCM to check the proper operation of systems and components

as well as identifying out-of-range values. The PCM may perform a special test on a

system or component to complete its monitor. A vehicle may have to be operated

under certain conditions for the monitor test to be performed. If the vehicles PCM

loses power or the Erase Codes function has been performed, then the status of the

monitors will be reset.

To view the status of supported monitors,

select I/M Readiness from the OBD II Function

Menu and press the ENTER key.

NOTE: If you get an Operating Error message, make sure the DLC adapter cable is

securely attached and the ignition key is ON, then try again. If the problem

remains, refer to Section 4: On-line Help and Trouble-Shooting Tips.

18

Page 19

A message will state whether the On-Board

Misfire Monitor OK

Fuel System Mon inc

Comp Component n/a[

Catalyst Mon n/a

Not All Supported

On-Board Readiness

Tests Are Complete.

Use [ To View Tests

Readiness Tests are Complete or Not All

Supported On-Board Tests are Complete.

Press the down arrow key to view the monitor

list with their status. Use the vehicle service

manuals for detailed information on required

emissions-related monitors and their status.

The monitor list consists of the OBD II

monitor name followed by the monitors

condition. A monitor that is not supported by

the test vehicle will have n/a after it. A

monitor that has been completed will be

followed by OK. If a monitor has not been

completed inc will be displayed after the name. Use the UP/DOWN arrow keys to

scroll through the list.

Press the BACK key to return to the OBD II Function Menu.

19

Page 20

Section 3: Diagnostic Trouble Code Lookup

Lookup Code: P0000

Use Arrow Keys ^

To Select Or Press

ENTER to Lookup. |

Lookup Code: P0600

Use Arrow Keys ^

To Select Or Press

ENTER to Lookup. |

Lookup Code: P0620

Use Arrow Keys ^

To Select Or Press

ENTER to Lookup. |

Lookup Code: P0621

Use Arrow Keys ^

To Select Or Press

ENTER to Lookup. |

12)I/M Readiness

13)Tool Setup ]

14)Tool Self-Test

`15)Code Lookup |

1)OBDII Functions

2)Tool Setup ]

3)Tool Self-Test [

`4)Code Lookup |

Code Lookup is a built-in OBD II Generic Diagnostic Trouble Code (DTC) database.

The database does not include manufacturer specific DTC definitions, only generic.

To look up code definitions, select Code Lookup from either the MAIN MENU or the

OBD II Function Menu, then press the ENTER key.

The OBD II System Tester will display the Code Lookup screen. When entering codes

it is only necessary to enter the last three numbers. The first two characters (P0) of

the DTC are set for OBD II Powertrain.

When the Code Lookup screen is first displayed, a P0000 is displayed in the columns

that mark the code digit locations. Underneath

the third digit there is a

symbol is used as a cursor to identify the digit

that will change when the UP/DOWN arrow keys are pressed to increase/decrease

the digit. The cursor starts at the third digit because the fourth and fifth are fixed

(P0xxx).

_ Entering Third Digit (P0x00)

Set the third digit by using the UP and

DOWN arrow keys to scroll the third digit

characters until the desired character is

displayed.

_ Entering Second Digit (P00x0)

To enter the second code digit, press the

LEFT/RIGHT arrow key to move the cursor

one column to the right. Use the UP/

^

DOWN arrow keys to increase/decrease

the digit.

_ Entering First Digit (P000x)

To enter the first or final digit, press the

LEFT/RIGHT arrow key to move the cursor

to the last column on the right. Use the

^

UP/DOWN arrow keys to increase/decrease the digit.

_ Editing A Code Number

If you make a mistake on any of the digits, simply use the LEFT/ RIGHT arrow key

to move the cursor

and DOWN arrow keys to change the digits value.

symbol. The ^

^

underneath the digit you wish to change. Then use the UP

^

20

Page 21

_ Lookup the Codes Definition

P0003

Undefined Code

ENTER to Try Again.

Lookup Code: P0621

Generator

Lamp L Control

Circuit Malfunction.

Press the ENTER key to display the codes

definition. When done, press the BACK key

to return to the Code Lookup Menu.

_ Scrolling the Code Definitions

Once a code definition screen is displayed, you may use the UP/DOWN arrow

keys to scroll through the library of code definitions.

If the trouble code number does not exist a

No Code Definition Found message will be

displayed. Press the ENTER key to return

to the Code Lookup screen to enter

another trouble code number.

Press the BACK key to return to the Code Lookup screen so a different trouble code

number can be looked up. Press the BACK key again to return to the OBD II Function

Menu.

21

Page 22

Section 4: On-Line Help and Troubleshooting Tips

Operating Error.

Check Connections!

Try Again?

<Yes> No |

THE TESTER CAN NOT

COMMUNICATE WITH

VEHICLE. CHECK THE [

FOLLOWING:

1.IGNITION KEY ON

2.HOOKUP TO VEHICLE ]

TEST CONNECTOR OK? [

3.EMISSIONS LABEL

4-1 How to Use On-Line Help

The tester contains On-Line Help for specific

screens, functions, and error messages.

When the On-Line Help symbol (

the lower right-hand corner of the display, OnLine Help is available.

To enter On-Line Help, press the HELP key. All Help screens are CAPITAL LETTERS.

This is reminder that you are viewing On-Line Help and not screens associated with

a function. Some On-Line Help messages are longer than one screen. Use the UP

and DOWN arrow keys to scroll through a series of On-Line Help screens. For the

screen example above, the help message would look like screens below:

To exit Help and return to the screen you where, press the BACK key.

4-2 Tool Problems

There may be times when your tester does not seem to be communicating with the

vehicle. Since the tester has built-in diagnostics, it is easy to isolate a problem with

the tester. There will be two basic types of problems that you will deal with: vehicle

problems and tool problems. Both might affect your test. Remember, the OBD II

System Tester always goes through a SELF CHECK each time you power the unit up.

Use the troubleshooting tips below to help diagnose OBD II System Tester problems

before calling Actrons Technical Support line:

1. The OBD II System Tester will not power up:

_ Check the OBD II connector for power. If not, check the fuse if applicable.

_ Verify vehicles battery is 8 volts or higher.

_ Unplug and plug back in the Data Link Connector (DLC) to verify the connector is

properly seated to the vehicle connector.

2. Tool will not Link to the vehicle computer:

_ Ignition key is ON.

_ Unplug the DLC adapter from the vehicle and plug it back to verify connection.

3. Your Keyboard does not function properly:

_ Perform the Keyboard Test by entering the Self-Test and select the Keyboard Test

function.

_ If the keyboard test shows nothing and you still experience the problem, then call

Actrons technical support personnel at 1-800-253-9880.

) appears in

|

22

Page 23

4. One or more modules drops the communication link:

One or More Modules

Lost. Continue

Without Them?

<Yes> No |

12)I/M Readiness

13)Tool Setup ]

`14)Tool Self-Test

15)Code Lookup |

1)OBDII Functions

2)Tool Setup ]

`3)Tool Self-Test

4)Code Lookup |

When the OBD II System Tester initially links to the vehicle, it builds a list of all OBD

II compliant computer modules. If in the course scanning the vehicle, a module

drops the link, a message will display.

Answering YES will continue operation

without the lost module. Answering NO try to

restore the communication links to get all

modules back to an active status.

4-3 Vehicle Problems

If your tester is having difficulty linking with the vehicle computer, be sure that you

have double checked the DLC connection. The problem may be with the vehicles

electrical system or with the vehicle computer itself. Check the following:

Verify that the vehicles fuse is OK.

Make sure the vehicles battery exhibits at least 8.0 volts (V), the minimum

voltage to power the OBD II System Tester.

Verify the ignition key is ON and not in the accessories (ACC.) position.

Check the vehicles on-board computer for a blown PCM fuse. The PCM fuse is

located on the fuse block in the passenger compartment. If the PCM fuse is

blown, the vehicles on-board computer cannot transmit data.

Check to be sure your vehicles calibration is OBD II compatible.

Make sure the vehicles on-board computer has a good ground. If your vehicles

on-board computer has a ground going directly to the computers case, then

clean up this connection and apply a conductive grease to the mating surfaces.

As a last resort, the vehicles on-board computer or calibration PROM may be

defective. Check vehicle service manual to determine correct computer tests for

your particular vehicle.

4-4 OBD II System Tester Self-Tests

OBD II System Tester Self-Tests are used to test the operation of the OBD II System

Testers display, keyboard, and internal memory. The tools Self-Tests menu can be

accessed from the MAIN MENU, when the tester is initially powered up, or from the

OBD II Function Menu.

From either menu, use the UP/DOWN arrow keys to select the Tool Self-Tests option,

then press the ENTER key.

23

Page 24

The Tool Self-Test menu will display. Two tests

Tool Self-Test

`1)Display Test

2)Keyboard Test

|

Press A Key To Test

Key: ENTER

Press BACK To Exit.

Look For Missing

Spots in Display.

You Have 10 Seconds

Press ENTER to Test

((((((((((((((((((((

((((((((((((((((((((

((((((((((((((((((((

((((((((((((((((((((

can be selected, the Display Test and the

Keyboard Test. Use the UP/DOWN arrow keys

to move the cursor to option of your choice,

then press the ENTER key.

Display Test

After you have selected Display Test as your choice, a screen detailing the test is

displayed. The Display Test will fill every pixel of the testers LCD display with a solid

black character. Look for pixels that are not black. Press the BACK key to exit to the

Tool Self-Test menu. Press the BACK key again to display the OBD II Function Menu.

Keyboard Test

The Keyboard Test is used to check the functionality of the OBD II System Testers

keypad. Select Keyboard Test from the Tool Self-Test menu then press the ENTER

key. The Keyboard Test screen with instructions is displayed:

Each time you press a key, check OBD II

System Tester display. The key name should

appear. For example, if you press the UP

arrow, the screen will display Key: UP ARROW. If the button name is not displayed, the

key is not working.

The only exception is the BACK key. When the BACK key is pressed, the OBD II

System Tester returns to the Tool Self-Test Menu. If you are not returned to the Tool

Self-Test Menu, then the BACK key is not working

24

Page 25

Appendix A: Vehicle Computer Basics

Basics of Computer-Controlled Vehicles

This section explains the engine computer control system, the types of sensors and

how the computer controls engine fuel delivery, idle speed and timing. Additional

information may be found in technical support books at your local library or auto parts

store. The more you know about the computer system, the better you can diagnose

vehicle computer problems.

Computer controls were originally installed on vehicles to meet federal government

regulations for lower emissions levels and improved fuel economy. This began in the

early 1980s when basic mechanical systems were no longer able to accurately

control key engine parameters. A computer could be programmed to control the

engine under various operating conditions, making the engine more reliable. While

these early systems were very limited in the scope of their control, providing only 1014 trouble codes, they did help guide the vehicle repair process.

Today, computer controls have made cars and trucks faster, cleaner, and more

efficient than ever before.

What the computer controls:

The main control areas of the vehicle computer are fuel delivery, idle speed, spark

advance, and emissions controls. Some on-board computers may also control the

transmission, brakes, and suspension systems as well.

What has not changed?

A computer-controlled engine is very similar to the older, non-computerized engine. It

is still an internal combustion engine with pistons, spark plugs, valves, and

camshaft(s). The ignition, charging, starting, and exhaust systems are very similar as

well. You test and repair these systems just as before. The technical manuals for

these components show you how to perform the tests. Additionally, compression

gauges, vacuum pumps, engine analyzers, and timing lights will continue to be used.

The Engine Computer Control system

The vehicles on-board computer, or Powertrain Control Module (PCM), is the heart

of the system. It is sealed in a metal box and connected to the rest of the engine by a

wiring harness. The PCM is located, in most cases, in the passenger compartment,

behind the dashboard or in the kick panel position, although some manufacturers

locate the computer control module in the engine compartment area. Most PCMs can

withstand a lot of vibration and are built to live in a rugged environment.

The PCM is programmed by the factory. The program is a complex list of lookup

tables and instructions telling the computer how to control the engine based on

various driving conditions. To do its job, the computer uses sensors to know what is

happening and then provide instructions back to a network of switches and actuators

throughout the vehicle.

Sensors give the computer information

Sensors are devices which measure operating conditions and translate them into

signals the computer can understand. Some examples of sensors: thermistors (for

temperature readings), potentiometers (like a throttle position sensor), and signal

generators (such as an 02 sensor).

25

Page 26

The network of sensors has the job of converting

information the computer needs into electrical

signals the computer can understand. Signals

running from sensors to the PCM are referred to as

inputs. Sensors monitor the key parameters

shown in the table.

NOTE: Not all engines use every sensor listed.

Engine Temperature

Throttle position

Incoming Air Temperature

Air Fuel Ratio, in percentage (%)

Intake Manifold Vacuum

Engine RPM

Volume of Incoming air

Relays and Actuators

Relays and Actuators are electric devices energized by the computer to allow commands to perform a specific function. Relays can be called switches (such as the

coolant fan switch). Actuators might include solenoids (such as fuel injector valves)

and small motors (such as the Idle Speed Control). Not all of the computers outgoing signals are routed to relays and actuators. Sometimes information is sent to

other system computers like transmission, brakes, ignition modules, and trip

computers. These signals are also called outputs.

How the computer controls fuel delivery

Engine operation and emissions performance depend upon precise fuel delivery and

ignition control. Early computer systems controlled fuel by electronically adjusting the

carburetor metering and jet systems. Soon, however, this was replaced by the more

precise fuel delivery of fuel injection.

In an electronically carbureted system, the computer simply controls fuel flow based

on how far the throttle is opened by the driver. The computer knows how much air

can flow through the carburetor at various throttle openings, and adds the appropriate

amount of fuel to the mixture at the carburetor.

Fuel injection is some what more sophisticated in the way it delivers fuel. The

computer still adds an appropriate amount of fuel to the entering air, but now it uses

fuel injectors (either in a throttle body or at each intake port). Fuel injectors are far

more precise than carburetor jets, and create a much finer fuel mist for better

combustion and increased efficiency. In addition, most fuel injection systems have

ways of measuring exactly how much air is entering the engine, and can calculate the

proper air/fuel ratio using lookup tables. Computers no longer have to estimate how

much air the engine is using.

In many modern systems, the computer also uses information provided by sensors

to give it an idea of how well it is doing its job, and how to do it better. Sensors can tell

the computer how warm the engine is, how rich or lean the fuel mixture is, and

whether accessories (like the air conditioner) are running. This feedback information

allows the computer to fine tune the air/fuel mixture, keeping the engine operating at

its peak.

What the Computer needs to know:

Engine operating condition. Sensors used are: coolant temperature, throttle

position, manifold pressure (vacuum), air flow and RPM.

Air intake. Sensors used are: mass air flow, manifold absolute pressure, manifold

air temperature and RPM.

Air/fuel mixture status. Sensors used are: oxygen sensor(s).

26

Page 27

Open and Closed Loop Modes:

Open or closed loop operation refers to the way the computer is deciding how much

fuel to add to the air entering the engine. During cold start and other low temperature

situations, the computer operates in open loop mode. This means that it is relying on

a set of internal calculations and data tables to decide how much fuel to add to the

incoming air. It uses sensors such as the coolant temperature sensor (CTS), the

throttle position sensor (TPS), and the manifold absolute pressure sensor (MAP) to

determine optimum mixtures. The important difference here is that it does not check

to see if the mixtures are correct, leaving the computer adjustment loop open.

In closed loop mode, the computer still decides how much fuel to add by using the

sensors listed above, and by looking up the appropriate numbers on a data table.

However, it now checks itself to determine whether the fuel mixture is correct. It is

able to check itself by using the information provided by the oxygen sensor(s) (O2S)

in the exhaust manifold. The oxygen sensors will tell the computer if the engine is

running rich or lean, and the computer can take steps to correct the situation. In this

way, the computer closes the adjustment loop by checking itself and making necessary corrections. It should be noted that the O2 sensors must be at a very high

operating temperature (approximately 650° F) before they will begin to feed information back to the computer. This is why open loop mode is necessaryto give the O2

sensors time to warm up to operating temperature.

As long as the engine and O2 and Coolant Temperature Sensors are at operating

temperature, the computer can operate in the closed loop mode. Closed loop mode

constantly corrects to obtain an air/fuel mixture at the ideal 14.7:1. But in stop and go

cycles, the O2 sensor may in fact cool down enough that the computer will need to

rely on a set of internal parameters and go into open loop mode again. In some

cases, this may also happen during extended periods of idling. Many newer vehicles

now use heated O2 (HO2S) sensors to prevent this condition.

In many vehicles, the computer controls other systems related to open and closed

loop modes, including idle speed, electronic spark control, exhaust gas recirculation,

and transmission torque converter clutches. In open loop mode, some of these

systems will be adjusted to speed the warming of the engine and get the computer

into closed loop mode as quickly as possible.

OBD II

In 1994, manufacturers began equipping vehicles with a new class of computer

technology which puts more processing power under your dash than ever before. It is

called On-Board Diagnostics, Second Generation, or OBD II. It is required on all

vehicles sold in the US beginning January 1, 1996 (though most domestic manufacturers introduced it earlier than required), and offers increased system monitoring

and diagnostic information. This new system stores a library of more than 650

general trouble codes and another approximately 400 manufacturer-specific codes,

all of which you can access with the OBD II System Tester. These codes cover Body

Systems (B-Codes), Chassis Systems (C-Codes), Communications Codes (UCodes), and Power Train Systems (P-Codes). Now, basic terms are standardized

and all generic codes will share a common format and terminology that the manufacturers and the Society of Automotive Engineers (SAE) designed. You will be glad to

know that as your vehicle gets smarter, it will be easier for you to keep track of what is

going on under the hood.

27

Page 28

About Diagnostic Trouble Codes (DTCs)

Where do they come from and what are they for?

Engine computers can find problems

The computer systems in todays vehicles do more than control engine operations

they can help you find problems, too! Special testing abilities are permanently

programmed into the computer by engineers. These tests check the components

connected to the computer which are used for (typically): fuel delivery, idle speed

control, spark timing, emission systems, and transmission shifting. Mechanics have

used these tests for years. Now you can do the same thing by using your Actron OBD

II System Tester!

Engine computers perform special tests

The engine computer runs the special tests, depending on the manufacturer, engine,

model year, etc. There is no universal test that is the same for all vehicles. The tests

examine INPUTS (electrical signals going INTO the computer) and OUTPUTS

(electrical signals coming OUT of the computer), as well as internal calculations

made by the computer. Input signals which have incorrect values, or output circuits

which do not operate properly are noted by the test program and the results are

stored in the computers memory. These tests are important. The computer cannot

control the engine properly if it has incorrect input information or faulty output circuits.

Code numbers reveal test results

The test results are stored by using code numbers, usually called diagnostic trouble

codes or DTCs. For example, a code P0122 might mean throttle position sensor

signal voltage is too low. Generic code meanings are a part of your OBD II System

Testers softwareall you have to do is look them up! Manufacturer specific DTCs will

require the use of a vehicle service manual. See page 2 for more information on

ordering service manuals.

Read Trouble Codes with the OBD II System Tester

You can obtain DTCs from the engine computer by using the OBD II System Tester.

You can also monitor the operation of systems throughout the vehicle, helping to

pinpoint the system where there may be a problem. Once you have read the DTCs,

you can either:

_ Have your vehicle professionally serviced.

or

_ Repair the vehicle yourself using the diagnostic trouble codes to help locate

the source of the problem.

Diagnostic Trouble Codes and Diagnostics help you fix the problem

To find the cause of the problem yourself, you need to perform special test procedures called diagnostics. These procedures are in the vehicles service manual.

There are many possible causes for any problem. For example, suppose you turned

on a wall switch in your home and the ceiling light did not turn on. Is it a bad bulb or

light socket? Are there problems with the wiring or wall switch? Maybe there is no

power coming into the house! As you can see, there are many possible causes. The

diagnostics are written for servicing a particular trouble code take into account all the

possibilities. If you follow these procedures, you should be able to find the problem

causing the code and fix it yourself.

28

Page 29

KAL makes it easy to fix computer-controlled vehicles

Using the KAL OBD II System Tester to obtain trouble codes is fast and easy. Trouble

codes give you valuable knowledge - whether you go for professional service or do it

yourself. Now that you know what trouble codes are and where they come from, you

are well on your way to fixing todays computer-controlled vehicles!

When to Read Codes

Many vehicles have a Malfunction Indicator Lamp or MIL,

which has been referred to as a Check Engine light in the

past. With the advent of OBD II, all engine trouble lights are

now called Malfunction Indicator Lamps or MIL.

About the Malfunction Indicator Lamp

_ Malfunction Indicator Lamp: normal operation

The engine computer turns the Malfunction Indicator Lamp on and off as needed.

This dashboard message is either amber or red and labeled:

Check Engine, Service Engine Soon, Service Engine Now, or marked with a

small engine picture or diagram

The Malfunction Indicator Lamp is normally OFF when the engine is RUNNING.

Use the Malfunction Indicator Lamp to tell you

when trouble codes have

been stored in memory

NOTE: The Malfunction Indicator Lamp will turn on when the ignition key is in ON

position, but the engine is OFF prior to starting the vehicle. This is a normal

test of all the dashboard message lights.

_ Malfunction Indicator Lamp: problem spotted

If the Malfunction Indicator Lamp does not come on, you may have an electrical

problem which needs repair. Refer to the Diagnostic Circuit Check steps in the

Basic Diagnostic Procedures section of your vehicle service manual.

_ Malfunction Indicator Lamp: intermittent problem

When the light remains ON after the engine is RUNNING, the computer sees a

problem that does not go away (known as a current failure). The light will stay on

as long as the problem is present. A trouble code is stored in computer memory

(a history or memory code). Use the OBD II System Tester at the earliest

convenient time to obtain codes.

When the light comes ON, then goes OFF while the engine is RUNNING, the

computer saw a problem, but the problem went away (known as an intermittent

failure). A trouble code is stored in computer memory (a history or memory

code). The light went out because the problem went away, but the code stays in

memory. Use the OBD II System Tester at the earliest convenient time to obtain

codes.

NOTE: The computer will automatically erase these codes after repeated restarts

if the problem does not return.

29

Page 30

Poorly running engine, No Malfunction Indicator Lamp

Most likely, this condition is not due to computer system failures, but reading

codes can still be useful as part of a basic troubleshooting procedure. Check

wiring and bulb for Check Engine light failures. Refer to vehicle service manual

for additional diagnostic information.

On OBD II vehicles, the Malfunction Indicator Lamp also signals an emissionscontrol related failure. The vehicle may not run any differently, but the OBD II

system is designed to note very small changes in the engines operation which

could lead to emissions damage or failure.

30

Page 31

Appendix B: Data Parameter List & Definitions

All data parameters or parameter identification data (PID) listed in Appendix B were

verified on actual vehicles to guarantee their accuracy. Definitions used to describe all

PIDs were obtained from reliable sources and are accurate at the time of printing. It is

possible that some newer vehicles may contain data different from that listed in

Appendix B. Always refer to a vehicle service manual for vehicle-specific PIDs.

Data Parameter List Format

The data parameter list is organized in alphabetical order the same way as on the

OBD II System Tester. For all data parameters, Appendix B will define the data

parameter, tell what type of reading it is (i.e. input, output, or calculated) and give

some helpful tips on what to do if the reading is unsatisfactory. Remember to always

refer to a vehicle service manual for detailed diagnostic procedures for troubleshooting incorrect data parameter readings.

Types of Data Parameters

INPUT: These data parameters are obtained from sensor circuit outputs.

Sensor circuit outputs are inputs to the vehicles PCM. For example, if

the Oxygen Sensor circuit was generating a 400mV signal, then the

OBD II System Tester would display O2S (v) 0.40.

OUTPUT: These data parameters are