Page 1

3Com Switch 4007

Getting Started Guide

http://www.3com.com/

Part No. 10013650

Published May 2000

Page 2

3Com Corporation ■ 5400 Bayfront Plaza ■ Santa Clara, California ■ 95052-8145

Copyright © 2000, 3Com Corporation. All rights reserved. No part of this

documentation may be reproduced in any form or by any means or used to

make any derivative work (such as translation, transformation, or

adaptation) without written permission from 3Com Corporation.

3Com Corporation reserves the right to revise this documentation and to

make changes in content from time to time without obligation on the part

of 3Com Corporation to provide notification of such revision or change.

3Com Corporation provides this documentation without warranty, term, or

condition of any kind, either implied or expressed, including, but not

limited to, the implied warranties, terms, or conditions of merchantability,

satisfactory quality, and fitness for a particular purpose. 3Com may make

improvements or changes in the product(s) and/or the program(s) described

in this documentation at any time.

If there is any software on removable media described in this

documentation, it is furnished under a license agreement included with the

product as a separate document, in the hard copy documentation, or on

the removable media in a directory file named LICENSE.TXT or

!LICENSE.TXT. If you are unable to locate a copy, please contact 3Com and

a copy will be provided to you.

UNITED STATES GOVERNMENT LEGEND

If you are a United States government agency, then this documentation

and the software described herein are provided to you subject to the

following:

All technical data and computer software are commercial in nature and

developed solely at private expense. Software is delivered as “Commercial

Computer Software” as defined in DFARS 252.227-7014 (June 1995) or as

a “commercial item” as defined in FAR 2.101(a) and as such is provided

with only such rights as are provided in 3Com’s standard commercial

license for the Software. Technical data is provided with limited rights only

as provided in DFAR 252.227-7015 (Nov 1995) or FAR 52.227-14 (June

1987), whichever is applicable. You agree not to remove or deface any

portion of any legend provided on any licensed program or documentation

contained in, or delivered to you in conjunction with, this User Guide.

Unless otherwise indicated, 3Com registered trademarks are registered in

the United States and may or may not be registered in other countries.

3Com, CoreBuilder, and Transcend are registered trademarks, and the

3Com logo is a trademark, of 3Com Corporation. 3Com Facts is a service

mark of 3Com Corporation.

Intel is a registered trademark of Intel Corporation.

Windows is a registered trademark of Microsoft Corporation.

UNIX is a registered trademark in the United States and other countries,

licensed exclusively through X/Open Company, Ltd.

All other company and product names may be trademarks of the respective

companies with which they are associated.

Page 3

ONTENTS

C

A

BOUT THIS GUIDE

Conventions 7

Related Documentation 8

Paper Documents 9

Documents on CD-ROM 9

World Wide Web Site 9

3Com Facts Automated Fax Service 10

Year 2000 Compliance 10

A

1

BOUT THE SWITCH

Overview 11

Physical Description 11

Switch Features 12

Management Features 13

Switch 4007 Starter Kits 14

Layer 2 Gigabit Ethernet Starter Kit 14

Layer 3 Gigabit Ethernet Starter Kit 14

Layer 3 Fast Ethernet (10/100BASE-TX) Starter Kit 15

Layer 3 Fast Ethernet (10/100BASE-TX and 100BASE-FX)

Starter Kit 15

Hardware Components 15

Power Supplies 16

930-watt AC Power Supply 16

Fan Tray 17

Module Slots in the Switch 4007 Chassis 17

4007

S

2

WITCH

Overview 19

Switch Fabric Modules 20

Management Modules 21

Fast Ethernet Modules 22

Gigabit Ethernet Modules 23

GBIC Transceivers 25

Slot Restrictions 26

Management Access 26

Where to Go from Here 27

4007 M

9-port Gigabit Ethernet Switch Fabric 20

24-port Gigabit Ethernet Switch Fabric 20

20-port 100BASE-FX (MT-RJ) Fast Ethernet Layer 2

Switching Module 22

36-port 10/100BASE-TX Fast Ethernet RJ-45 Layer 2

Switching Module 22

12-port 10/100BASE-TX Fast Ethernet MultiLayer

Switching Module 23

4-port Gigabit Ethernet Interface Module 24

9-port 1000BASE-SX Gigabit Ethernet Layer 2 Switching

Module 24

4-port Gigabit MultiLayer Switching Module 24

SX GBIC Transceiver 25

LX GBIC Transceiver 25

70-km Long Haul GBIC Transceiver 26

Administration Console Access 26

Web Management Access 27

ODULES

Page 4

I

NSTALLING THE SWITCH

3

Site Requirements for the Switch 4007 30

Location Requirements 30

Precautionary Guidelines 30

Rack-Mount Installation Recommendations 31

Ventilation Requirements 33

Power Requirements 33

Safety Information 34

Denmark Safety Certification 34

Laser Warning 34

FDA Class 1 Laser Device 34

LED Warning 35

Preinstallation Guidelines 35

Rack-Mount Installation Guidelines 35

Installing the Chassis 36

Installing the Chassis in a Rack 36

Installing the Chassis Using Rack-Mount Clip Nuts 37

Installing the Chassis on a Table or Shelf 38

Attaching the Chassis Feet 38

Installing the Chassis on a Table or Shelf 38

Where To Go from Here 39

4007

Features 45

Browser and Platform Requirements 45

Color Recommendations 45

Browser Support 46

Platform Requirements 46

Installing Supplemental Tools 46

Windows Installation 46

UNIX Help Installation 47

Setting Up the Form-specific Help Files 48

Embedded Web Management Applications 48

Interface Description 49

Troubleshooting 49

Web Management and Internet Explorer 50

Improving DeviceView 50

Improving DeviceView Download Speed 50

Enabling Status Log E-mail Options on Internet

Explorer 50

Web Management and Netscape Navigator 51

Troubleshooting the Web Management

Software 51

Examples of Good and Problematic

Settings 52

Additional Resources for Solving Problems 52

CLASSPATH

S

4

5

TART THE SWITCH

Power On the Switch 41

What Occurs During Startup 41

Where to Go from Here 42

M

ANAGEMENT TOOLS

EME Management Module Architecture 43

Switch 4007 Setup Wizard 44

Transcend Network Supervisor 44

Web Management Tools 45

M

6

AINTAINING THE SWITCH

Routine Maintenance 53

Removing and Replacing a Power Supply 54

Removing a 930-watt Power Supply 54

Replacing a 930-watt Power Supply 55

Removing and Replacing a Fan Tray 56

Removing the Fan Tray from a Chassis 57

Replacing the Fan Tray in a Chassis 58

4007

Page 5

Installing a 16 MB Expansion Memory Card 59

Introduction 59

Safety Precautions 59

ESD Safety Information 60

Handling Precautions 60

Unpacking Procedure 60

Removing an EME from the Chassis 61

Installing Expansion Memory 61

Reinstalling the EME 62

Verifying EME Operation 62

S

A

B

PECIFICATIONS

Chassis Specifications 63

Physical 63

Environmental 63

Power 64

Regulatory Compliance 64

Interfaces 65

Power Supply Regulatory Compliance 65

930-watt AC Power Supply 65

I

NTELLIGENT POWER SUBSYSTEM

Intelligent Power Subsystem Features 67

Power Management 68

Power Availability and Power Supply Capacity 68

Power Supply Modes 69

Fault-Tolerant Mode 69

Non-Fault Tolerant Mode 70

T

C

ECHNICAL SUPPORT

Online Technical Services 71

World Wide Web Site 71

3Com Knowledgebase Web Services 71

3Com FTP Site 72

3Com Bulletin Board Service 72

Access by Analog Modem 72

Access by Digital Modem 72

3Com Facts Automated Fax Service 72

Support from Your Network Supplier 73

Support from 3Com 73

Returning Products for Repair 74

G

LOSSARY

I

NDEX

Page 6

Page 7

BOUT

A

T

HIS

G

UIDE

This

Switch 4007 Getting Started Guide

overview of your Switch 4007 and its components,

describes the power management subsystem,

provides information about what occurs when you

start up your switch, explains how to use the online

manuals on CD-ROM, and lists important safety and

preinstallation information.

This guide is intended for the system or network

administrator who is responsible for installing and

managing the network hardware. It assumes a

working knowledge of local area network (LAN)

operations, but it does not assume prior knowledge

of Switch 4007 high-performance networking

equipment.

provides an

If release notes are shipped with your product and

the information there differs from the information

in this guide, follow the instructions in the release

notes.

Most user guides and release notes are available in

Adobe Acrobat Reader Portable Document Format

(PDF) or HTML on the 3Com World Wide Web site:

http://www.3com.com/

Conventions

Table 1 and Table 2 list conventions that are used

throughout this guide.

Ta b le 1

Icon Notice Type Description

Ta b le 2

Convention Description

Screen displays

Syntax

Notice Icons

Information

note

Caution Information that alerts you to potential loss of

Warning Information that alerts you to potential

Text Conventions

Information that describes important features

or instructions

data or potential damage to an application,

system, or device

personal injury

This typeface represents information as it

appears on the screen.

The word “syntax” means that you must

evaluate the syntax provided and then supply

the appropriate values for the placeholders that

appear in angle brackets. Example:

To enable RIPIP, use the following syntax:

SETDefault !<port> -RIPIP

CONTrol = Listen

In this example, you must supply a port number

for <port>.

Page 8

BOUT THIS GUIDE

8

A

Ta b l e 2

Convention Description

Commands

The words “enter”

and “type”

Keyboard key names If you must press two or more keys

Words in

Text Conventions (continued)

The word “command” means that you must

enter the command exactly as shown and then

press Return or Enter. Commands appear in

bold. Example:

To remove the IP address, enter the following

command:

SETDefault !0 -IP NETaddr =

0.0.0.0

When you see the word “enter” in this guide,

you must type something, and then press

Return or Enter. Do not press Return or Enter

when an instruction simply says “type.”

simultaneously, the key names are linked with a

plus sign (+). Example:

Press Ctrl+Alt+Del

italics

Italics are used to:

■

Emphasize a point.

■

Denote a new term at the place where it is

defined in the text.

■

Identify menu names, menu commands, and

software button names. Examples:

From the

Click OK.

Help

menu, select

Contents

Related Documentation

The following documents compose the Switch 4007

documentation set.

Documents are available in three forms:

Paper documents

■

This section lists the paper documents that are

shipped with your system.

CD-ROM

■

The Switch 4007 Online Manuals CD-ROM

contains online versions of the paper documents as

well as other Switch 4007 documents in online

format only.

World Wide Web and Fax Services

■

Various types of documentation and information

are available from the 3Com Web site and fax

services.

To order a paper copy of a document that you see on

the CD-ROM, or to order additional CDs, contact your

.

sales representative, or call the 3Com Customer Call

Center at (800) 724-2447 and choose option 3.

For a list of Switch 4007 documents, see the

Switch 4007 Documentation Overview

.

Page 9

Related Documentation

9

Paper Documents

These documents are shipped with the Switch 4007

chassis:

■

Switch 4007 Getting Started Guide

An overview of the switch and its components

■

A description of the power subsystem

■

Important safety, location, and preinstallation

■

information

How to install the chassis in a rack, on a table,

■

or on a shelf, including prerequisites

How to install or remove a power supply

■

How to start up your Switch

■

How to use the documentation CD-ROM

■

An introduction to the Web Management suite

■

of applications that help you manage your

switch with a Web browser

■

Switch 4007 Documentation Overview

A list of key Switch 4007 documents

Quick Command Reference booklet

■

Outlines the commands in the Administration

Console interface for switching modules and the

command-line interface for the Enterprise

Management Engine (EME) management module.

(this guide)

Module

Quick Start

are shipped with their individual modules or

field-replaceable units, and on the Online Manuals

CD-ROM. These guides provide an overview, LED

status information, and installation instructions for

each interface module, switch fabric module, and

management module.

Documents on CD-ROM

The Documentation CD-ROM contains online versions

of the paper guides that are shipped with your chassis

and other Switch 4007 documents in online format

only, such as:

■

Switch 4007 Implementation Guide

Information about using features of the

Switch 4007 after you install it and attach it to

your network.

■

Switch 4007 Command Reference Guide

Information about the Administration Console

commands that you use to configure the Switch.

World Wide Web Site

Most user guides and release notes are available in

Adobe Acrobat Reader Portable Document Format

(PDF) or Hypertext Markup Language (HTML) from

the 3Com World Wide Web support site at:

http://support.3com.com/

Guides or

Getting Started

Guides

In the

Select by Product Name

list under

Tools, Documents and Information

CoreBuilder

.

Support

, select

Page 10

BOUT THIS GUIDE

10

A

3Com Facts Automated Fax Service

The 3Com FactsSM automated fax service provides

technical articles, diagrams, and troubleshooting

instructions on 3Com products 24 hours a day, 7 days

a week.

Call 3Com Facts using your Touch-Tone telephone:

1 408 727-7021

Year 2000 Compliance

For information on Year 2000 compliance and 3Com

products, visit the 3Com Year 2000 Web page:

http://www.3com.com/products/yr2000.html

Page 11

1

BOUT THE

A

WITCH

S

4007

This chapter contains an overview of the 3Com®

Switch 4007 and describes the Gigabit Ethernet and

Fast Ethernet starter kits.

The topics in this chapter include:

Overview

■

Switch 4007 Starter Kits

■

Hardware Components

■

Overview

The Switch 4007 is a high-performance modular

switch that is designed to aggregate wiring closet

solutions for growing organizations.

The Switch 4007 supports redundant power supplies

and management engines, and a variety of Layer 2

and multilayer 10/100 Fast Ethernet and Gigabit

Ethernet media modules.

3Com enables you to simplify your installation by

selecting from four pre-configured starter kits, each

of which includes:

One 930W AC Power Supply

■

One EME management module

■

One 9-port or 24-port Switching Fabric

■

Two optional Fast Ethernet or Gigabit Ethernet

■

modules

Four empty payload slots for future expansion

■

For more information about Switch 4007 starter kits,

see “Switch 4007 Starter Kits”.

Physical Description

The chassis contains:

One fan tray with four fans.

■

A power supply bay that holds up to two power

■

supplies and facilitates load sharing and

redundancy.

Two slots for management modules.

■

A payload bay with slots for:

■

Six interface modules.

■

One switch fabric module.

■

Page 12

12

HAPTER

C

BOUT THE SWITCH

1: A

4007

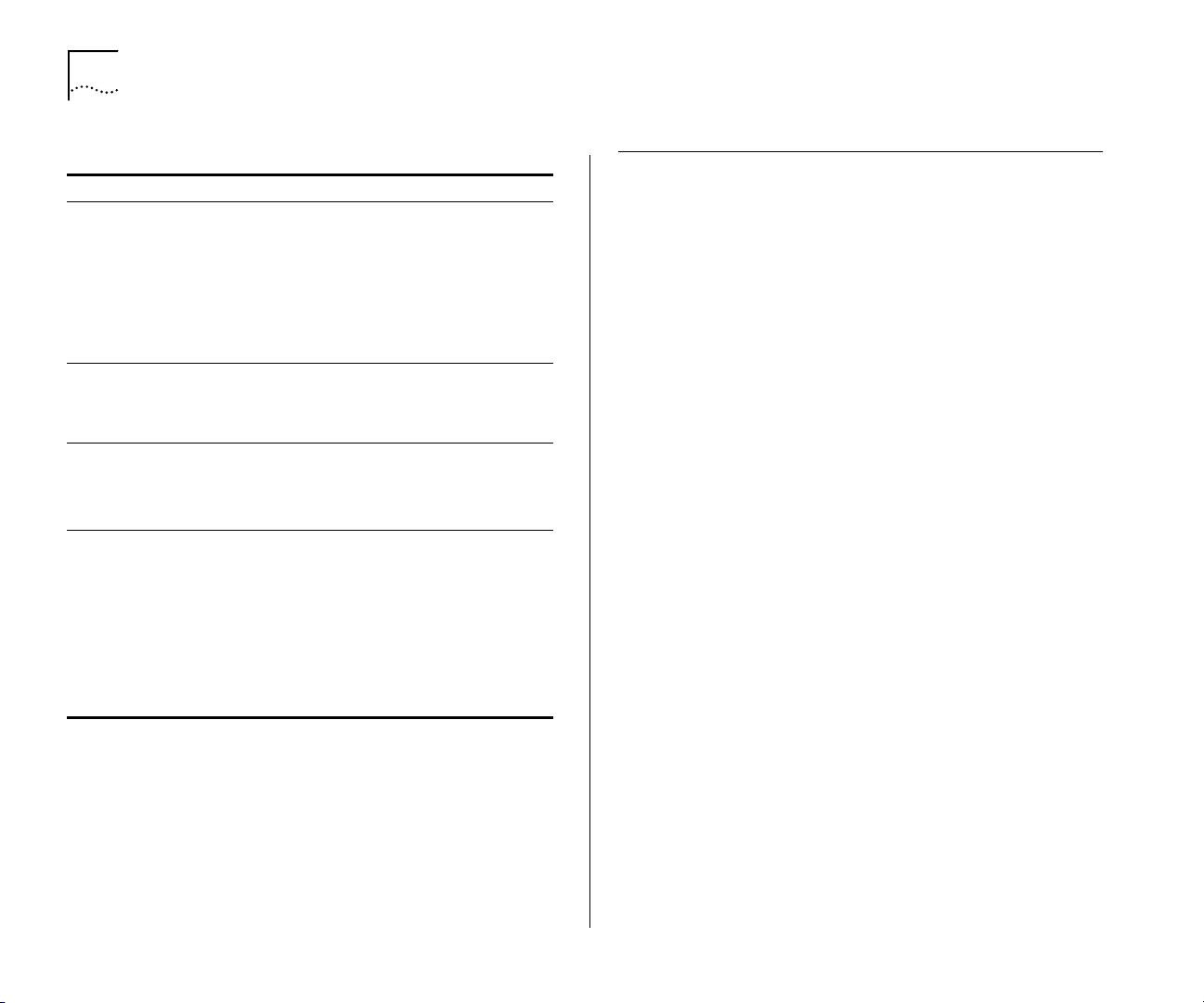

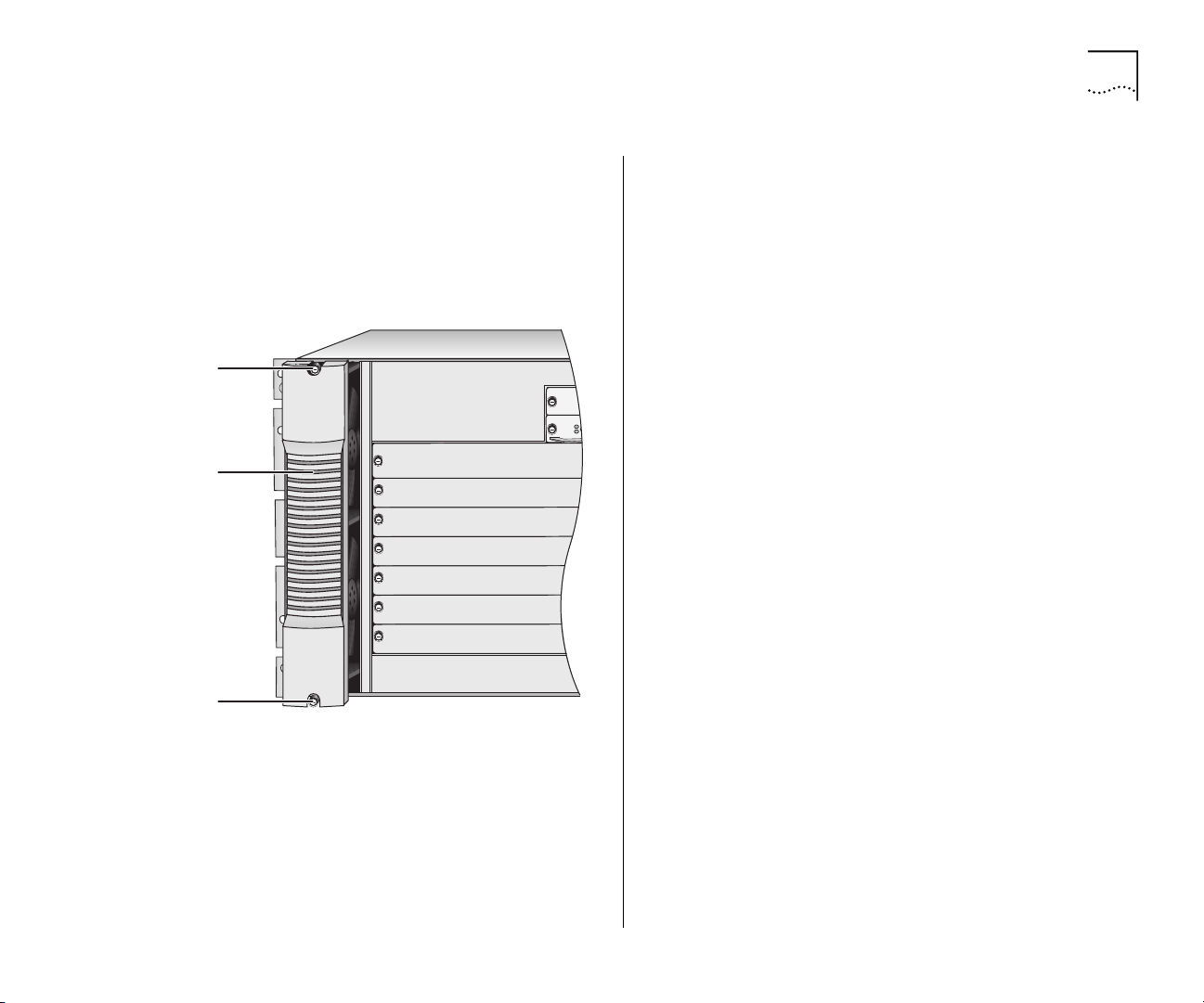

Figure 1 and Figure 2 show the front and the rear,

respectively, of the Switch 4007.

Figure 1

Fan tray

slot

Switch 4007 Chassis Front View

Management

module slots

9

8

7

6

5

4

3

2

1

Switch

fabric module slot

Interface

module slots

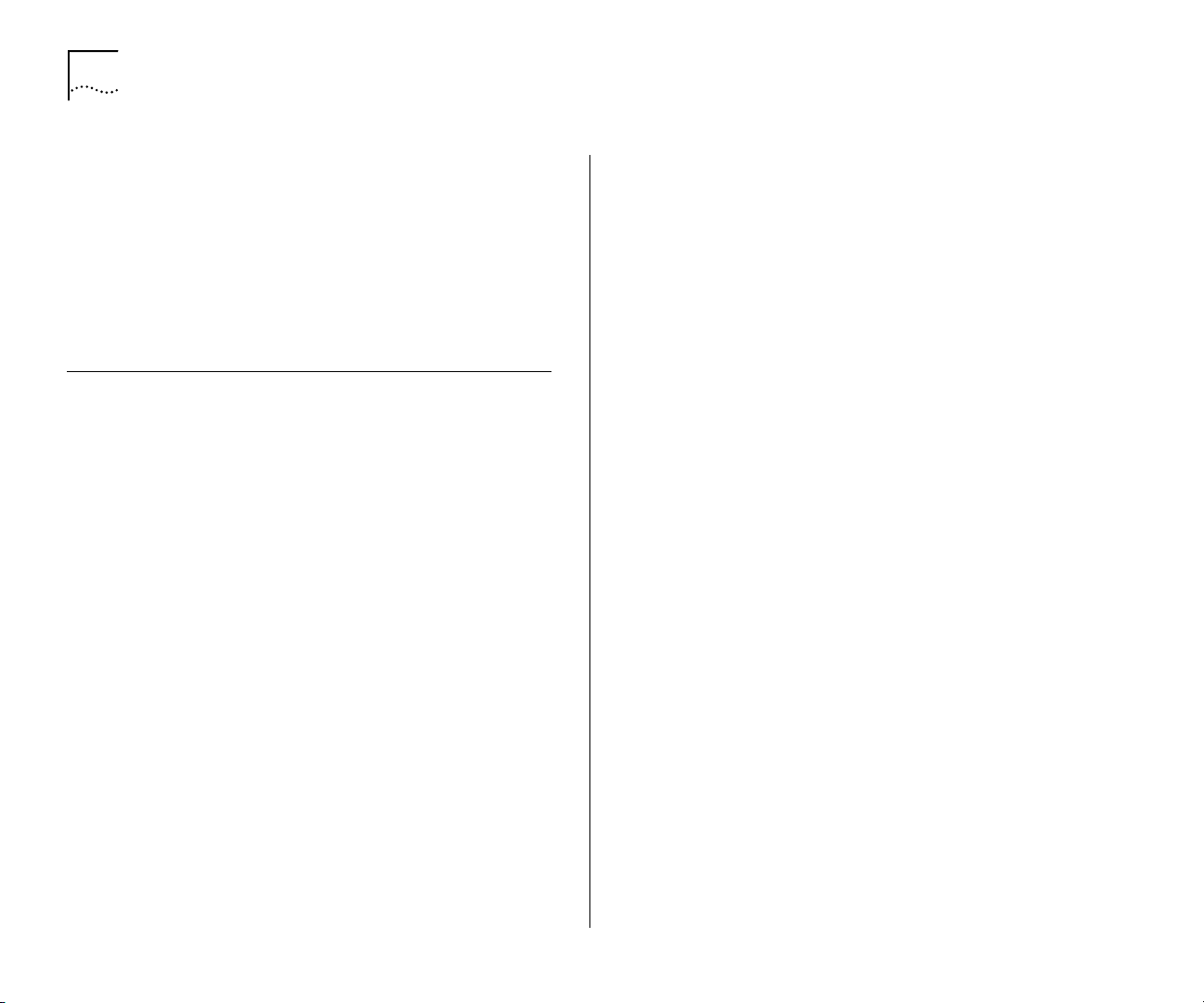

Figure 2

Switch Features

The Switch 4007 has the following features:

An intelligent power management system.

■

An intelligent system inventory management

■

system.

An integrated, high-performance, distributed

■

network management system.

Modules and a fan tray that you can install or

■

remove while the switch is operating (called

swapping

Support for 3Com Transcend® Network Control

■

Services for UNIX or for Windows.

Switch 4007 Chassis Rear View

Power

supply

slot 2

Power

supply

(in slot 1)

hot

), for field upgrades and service.

Page 13

Overview

13

Slots for two Enterprise Management Engine

■

(EME) management modules that do not take up

interface module or switch fabric module space.

Switch 4007 starter kits are supplied with with one

management module (Model Number: 3CB9EME)

installed in the lower slot. You can install a second

management module to provide standby

management support.

The management module uses the management

bus to send commands to all installed interface

modules and the switch fabric module and to

collect information from the modules.

A single passive backplane that enables the use of

■

multiple networking technologies, defined by the

type of switch fabric module that is installed.

One slot for a switch fabric module in the chassis

■

to provide optimal network performance.

Gigabit Ethernet starter kits (Model Numbers

■

3C16810 and 3C16811) have one 24-port

Switching Fabric (Model Number: 3CB9FG24T)

preinstalled in slot 7.

Fast Ethernet starter kits (Model Numbers

■

3C16815 and 3C16816) have one 9-port

Switching Fabric (Model Number: 3CB9FG9)

preinstalled in slot 7.

Slots for two power supplies to supply 930 watts

■

with n + 1 redundancy and 1860 watts without

n + 1 redundancy, depending on the type and

quantity of installed modules.

Switch 4007 starter kits have one 930W AC Power

Supply (Model Number: 3CB9EP9) preinstalled in

the lower bay.

Power supplies that you can add or replace while

■

the chassis is running (referred to as

swapping

Slots for six interface modules. In Switch 4007

■

).

starter kits, modules are preinstalled in slots 1 and

2, and the remaining slots are empty.

Packet switching at an aggregated bandwidth of

■

up to 30 Gbps.

Power fault-tolerant mode where you can reserve

■

the power of a single power supply (930 watts) to

act as a backup if the other power supply fails.

One exhaust fan tray (with the power and

■

reliability of four fans) to make sure that the

chassis maintains the optimal temperature for

operation.

Management Features

You can manage the Switch 4007 through:

An out-of-band terminal interface

■

Simple Network Management Protocol (SNMP)

■

3Com Transcend Network Supervisor

■

3Com Transcend Network Control Services

■

A standard Telnet client-to-server application

■

Embedded Web-based management

■

To learn more about management features, see

Chapter 5, “Management Tools”.

warm

Page 14

14

HAPTER

C

BOUT THE SWITCH

1: A

4007

Switch 4007 Starter Kits

3Com enables you to simplify your installation by

selecting from four pre-configured starter kits.

Four configurations are available:

Layer 2 Gigabit Ethernet Starter Kit

■

Model Number: 3C16810

Layer 3 Gigabit Ethernet Starter Kit

■

Model Number: 3C16811

Layer 3 Fast Ethernet (10/100BASE-TX) Starter Kit

■

Model Number: 3C16815

Layer 3 Fast Ethernet (10/100BASE-TX and

■

100BASE-FX) Starter Kit

Model Number: 3C16816

Layer 2 Gigabit Ethernet Starter Kit

Model Number: 3C16810

The Layer 2 Gigabit Ethernet Starter Kit has 18

Gigabit Ethernet ports.

Two 9-port Gigabit Switching Modules (Model

■

Number: 3CB9LG9MC) in slots 1 and 2

4 empty slots (slots 3,4,5,6)

■

You can expand the system to provide 54 Gigabit

Ethernet ports by installing additional modules into

the empty slots.

Layer 3 Gigabit Ethernet Starter Kit

Model Number: 3C16811

The Layer 3 Gigabit Ethernet Starter Kit has 13

Gigabit Ethernet ports.

This starter kit is preinstalled with the following

options:

EME Management Module (Model Number:

■

3CB9EME) in the lower slot

930W AC Power Supply (Model Number:

■

3CB9EP9)

One 24-port Switching Fabric (Model Number:

■

3CB9FG24T) in slot 7

This starter kit is preinstalled with the following

options:

EME Management Module (Model Number:

■

3CB9EME) in the lower slot

930W AC Power Supply (Model Number:

■

3CB9EP9)

One 24-port Switching Fabric (Model Number:

■

3CB9FG24T) in slot 7

One 9-port Gigabit Switching Module (Model

■

Number: 3CB9LG9MC) in slot 1

One 4-port Gigabit MultiLayer Switching Module

■

(Model Number: 3CB9RG4) in slot 2

4 empty slots (slots 3,4,5,6)

■

You can expand the system to provide 49 Gigabit

Ethernet ports by installing additional modules into

the empty slots.

Page 15

Hardware Components

15

Layer 3 Fast Ethernet (10/100BASE-TX) Starter Kit

Model Number: 3C16815

The Layer 3 FEN (10/100BASE-TX) Starter Kit has 48

copper Fast Ethernet ports and 3 GBIC slots for

uplinks.

This starter kit is preinstalled with the following

options:

EME Management Module (Model Number:

■

3CB9EME) in the lower slot

930W AC Power Supply (Model Number:

■

3CB9EP9)

One 9-port Switching Fabric (Model Number:

■

3CB9FG9) in slot 7

One 36-port 10/100BASE-TX Switching Module

■

(Model Number: 3CB9LF36R) in slot 1

One 12-port 10/100BASE-TX MultiLayer Switching

■

Module (Model Number: 3CB9RF12R) in slot 2

4 empty slots (slots 3,4,5,6)

■

You can expand the system to provide 192 Fast

Ethernet ports by installing additional modules into

the empty slots.

Layer 3 Fast Ethernet (10/100BASE-TX and

100BASE-FX) Starter Kit

Model Number: 3C16816

This starter kit is preinstalled with the following

options:

EME Management Module (Model Number:

■

3CB9EME) in the lower slot

930W AC Power Supply (Model Number:

■

3CB9EP9)

One 9-port Switching Fabric (Model Number:

■

3CB9FG9) in slot 7

One 20-port 100BASE-FX Switching Module

■

(Model Number: 3CB9LF20MM) in slot 1

One 12-port 10/100BASE-TX MultiLayer Switching

■

Module (Model Number: 3CB9RF12R) in slot 2

4 empty slots (slots 3,4,5,6)

■

You can expand the system to provide 112 Fast

Ethernet ports by installing additional modules into

the empty slots.

Hardware Components

This section describes the following chassis

components:

Power Supplies

■

Fan Tray

■

Modules

■

The Layer 3 FEN (10/100BASE-TX and 100BASE-FX)

Starter Kit has 12 copper and 20 fiber Fast Ethernet

ports and 3 GBIC slots for uplinks.

Page 16

16

Spring-loaded

screw

Power supply

handle

Standby/On

switch

AC input

socket

HAPTER

C

BOUT THE SWITCH

1: A

4007

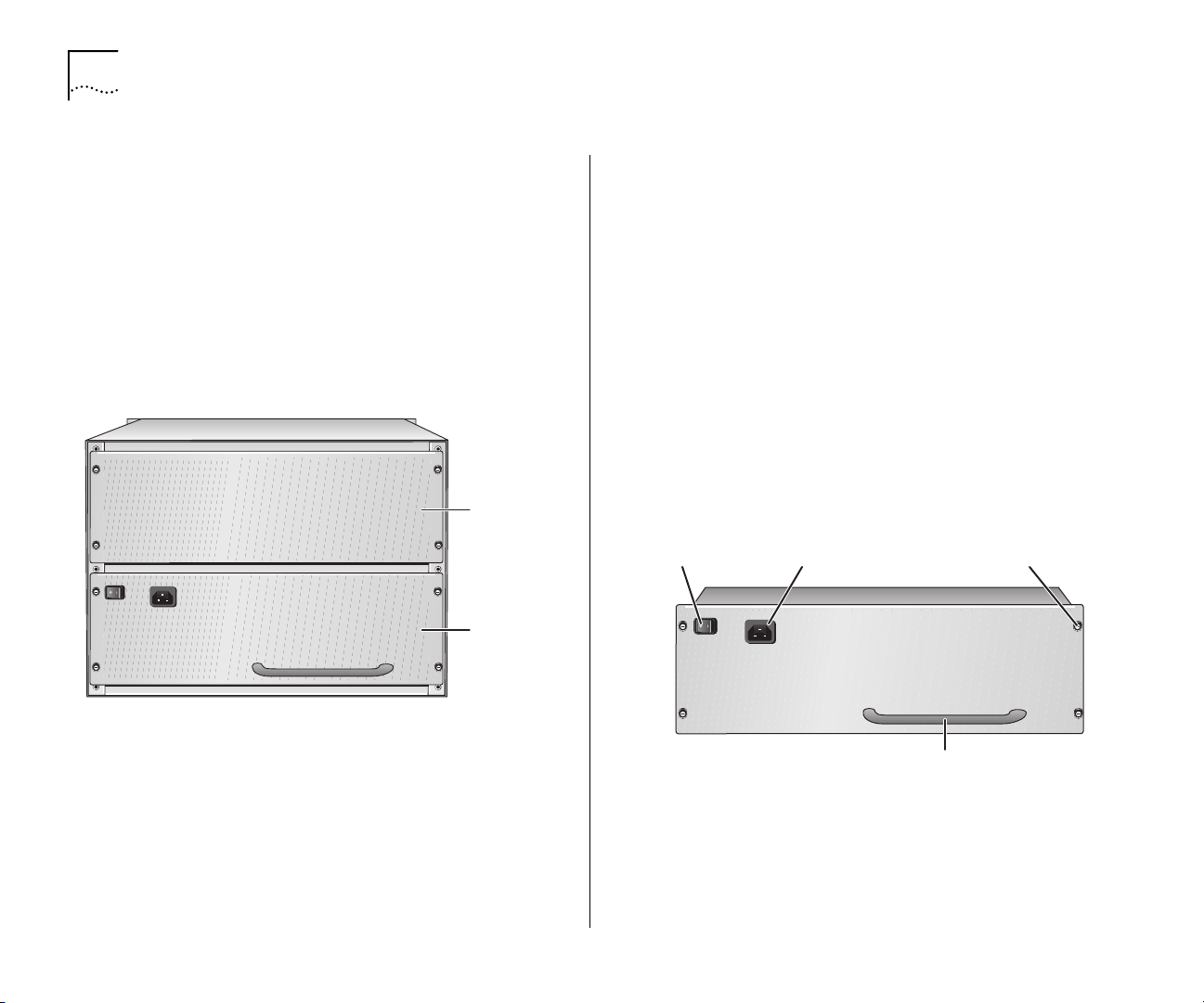

Power Supplies

The Switch 4007 can contain two back-loading,

930-watt, modular AC power supplies (Model

Number 3CB9EP9). The power supplies provide

power to the management modules, switch fabric

module, interface modules, fans, and backplane.

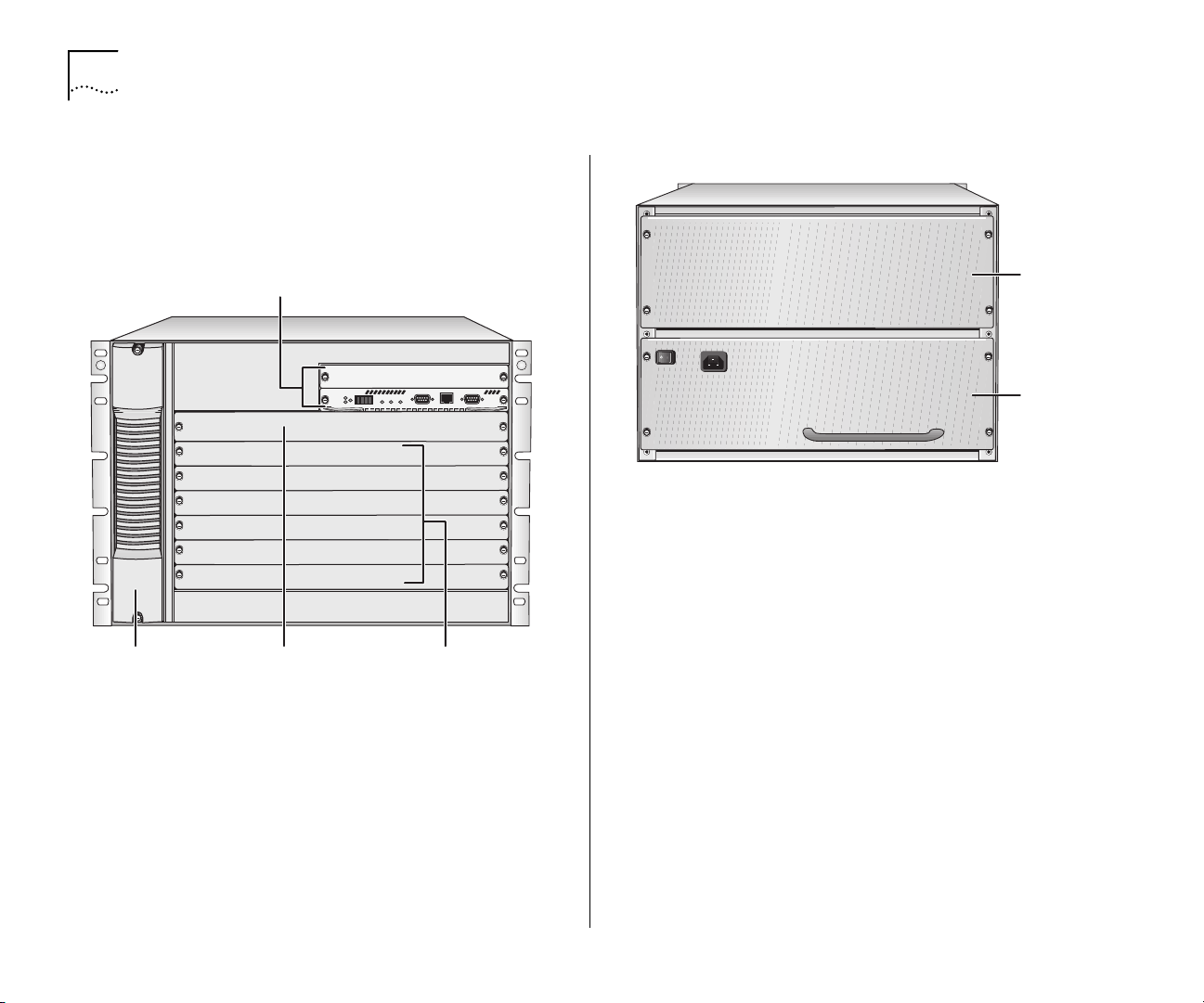

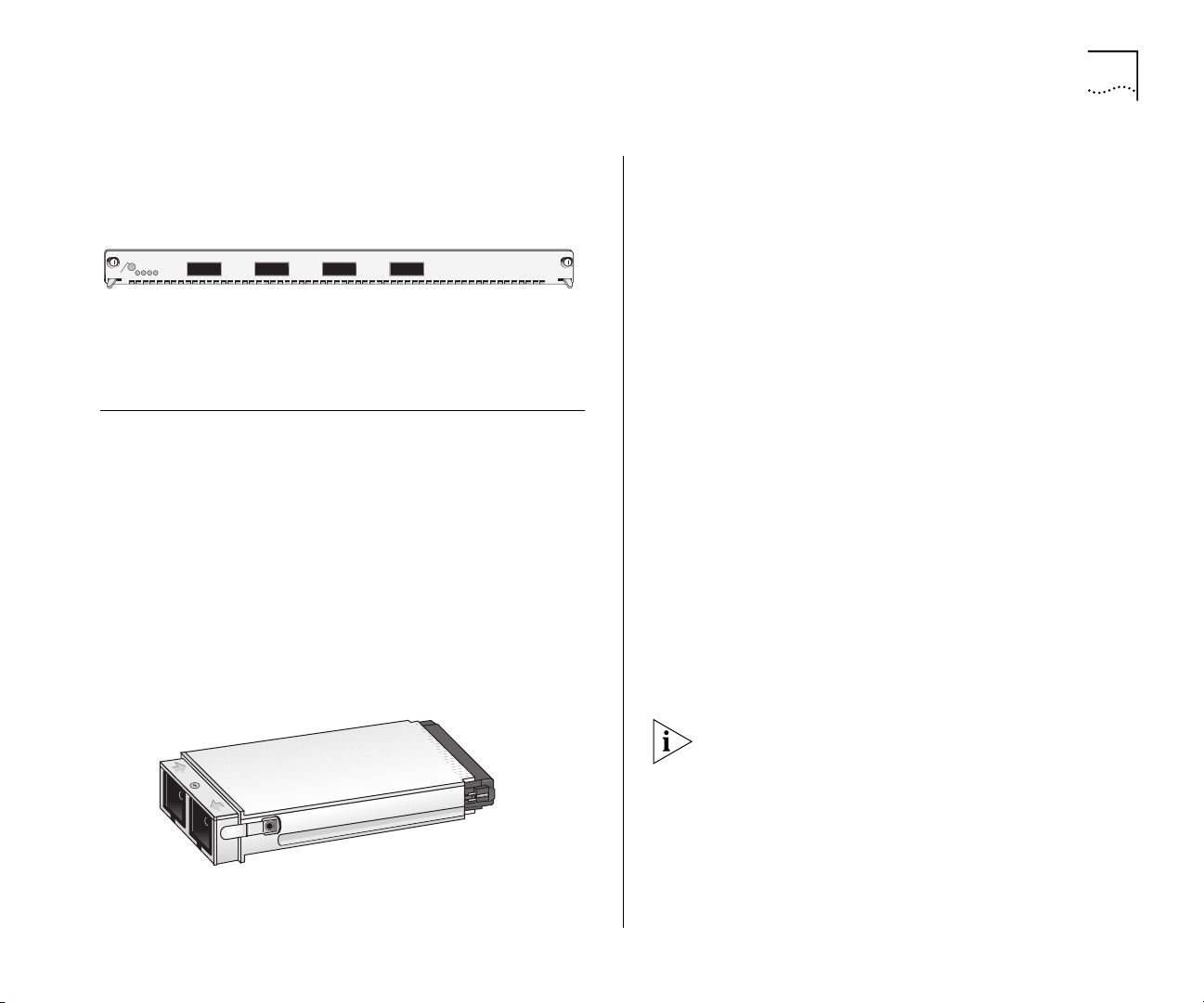

Figure 3 shows a 930-watt AC power supply in a

Switch 4007 chassis.

Figure 3

930-watt AC Power Supply in the Switch 4007

Power

supply

slot 2

Power

supply

(in slot 1)

930-watt AC Power Supply

Switch 4007 power supplies are autosensing. Each

power supply (Figure 3) can automatically sense the

type of input voltage to which it is being connected at

the electrical outlet.

The power supplies are load sharing in that all power

supplies provide an equal amount of the load current.

Each 930-watt power supply has its own power cord

and is shipped separately from the chassis. The type

of power cord depends on your country location.

Figure 4 shows the 930-watt AC power supply for the

Switch 4007 chassis.

Figure 4

930-watt AC Power Supply for the Switch 4007

You can add or replace power supplies while the

chassis is running (referred to as

warm swapping

Chapter 6, “Maintaining the Switch 4007”, for

instructions about how to replace a faulty power

supply.

). See

Page 17

Hardware Components

1

2

3

4

5

6

7

8

9

17

Fan Tray

The Switch 4007 chassis contains one fan tray, which

contains four fans (Model Number 3CBEF7). The fans

cool the interface modules, the switch fabric module,

and the management modules.

Figure 5

Spring-loaded

screw

Fan tra y

handle

Spring-loaded

screw

Switch 4007 Chassis Fan Tray

Module Slots in the Switch 4007 Chassis

You insert modules horizontally into the chassis. Slots

are numbered from bottom to top, with the bottom

slot being number 1.

The chassis contains:

Management slots

■

— There are two slots (slot 8

and slot 9) for management modules:

The Enterprise Management Engine (EME) is an

■

SNMP-based network management module

that manages and controls the Switch 4007 and

its modules. The management module is the

primary communication mechanism into the

switch and modules. You manage other

intelligent modules within the chassis through

the management module.

The Enterprise Management Controller (EMC)

■

module provides standby controller functions

for an EME in a Switch 4007.

Payload slots

■

— There are six slots (slot 1 through

slot 6) for interface modules. The interface

modules offer a selection of packet-based or

cell-based interfaces that work with the switch

fabric module.

Switch fabric slots

■

a Gigabit Ethernet Switch Fabric Module, which is

the central backplane aggregator for the Switch.

To learn more about management, switch fabric, and

Fast Ethernet and Gigabit Ethernet interface modules,

see Chapter 2, “Switch 4007 Modules”.

— There is one slot (slot 7) for

Page 18

18

HAPTER

C

BOUT THE SWITCH

1: A

4007

Page 19

2

WITCH

S

4007 M

ODULES

This chapter contains the following topics:

Overview

■

Switch Fabric Modules

■

Management Modules

■

Fast Ethernet Modules

■

Gigabit Ethernet Modules

■

GBIC Transceivers

■

Slot Restrictions

■

Management Access

■

Where to Go from Here

■

Overview

The 3Com® Switch 4007 is a high performance,

high-density, aggregation switch. The Switch 4007

has a modular 7-slot chassis that contains slots for the

following types of modules:

Management Modules (see page 21)

■

The EME management module exchanges

information with all modules through the

management bus. The EME uses the management

bus to send commands to all chassis modules and

to collect information from interface modules.

The Switch 4007 is required to have a minimum of

one EME (Enterprise Management Engine)

management module. You can install a second

EME for redundant management operation.

Switch Fabric Modules (see page 20)

■

The Gigabit Ethernet (GEN) switch fabric module is

the central backplane aggregator for the chassis.

Switch fabric modules fit into slot 7 of the

Switch 4007 chassis.

Fast Ethernet Modules (see page 22) and Gigabit

■

Ethernet Modules (see page 23)

Interface modules pass data through the switch

fabric module. The data may get sent back out to

other modules or sent out through a switch fabric

module front panel port to another device.

The Switch 4007 contains six slots for interface

modules. Fast Ethernet or Gigabit Ethernet

modules can occupy every slot except slot 7. The

six interface modules access five 2 Gbps serial

channels, which are wired to one dedicated switch

fabric module slot.

Page 20

20

HAPTER

C

2: S

WITCH

4007 M

ODULES

Switch Fabric Modules

The Switch 4007 supports 9-port and 24-port Gigabit

Ethernet Switch Fabric modules. Both switch fabric

modules fit into slot 7 of the Switch 4007 chassis.

3Com enables you to simplify your installation by

selecting from four pre-configured starter kits.

Fast Ethernet starter kits are pre-configured with

■

one 9-port Switching Fabric (Model Number:

3CB9FG9) in slot 7.

Gigabit Ethernet starter kits are pre-configured

■

with one 24-port Switching Fabric (Model Number:

3CB9FG24T) in slot 7.

The Switch Fabric modules support the following key

features:

18 Gbps or 48 Gbps switching capacity

■

Hot-swapping of modules

■

IEEE 802.1D Spanning Tree Protocol bridging for

■

Gigabit Ethernet

Multicast packet firewall to limit broadcast storms

■

Port trunking support for 12 groups, with up to six

■

ports in a group

IEEE 802.1Q VLAN tagging for up to 126 groups of

■

port-based virtual LANs (VLANs)

Embedded Simple Network Management Protocol

■

(SNMP) management agent

Support for four RMON-1 groups: Ethernet

■

Statistics, History, Events, and Alarms

9-port Gigabit Ethernet Switch Fabric

Model Number: 3CB9FG9

The 9-port Gigabit Ethernet (GEN) Switch Fabric

Module is optimized for use in wiring closets. The

module has six non-blocking Gigabit Ethernet ports

that connect directly to the chassis backplane to

provide high-speed, low-latency connectivity between

Switch 4007 interface modules. Its front panel

features three non-blocking Gigabit Interface

Converter (GBIC) interface ports that accept optional

GBIC transceivers (see “GBIC Transceivers” on

page 25). Figure 6 shows the front panel.

Front Panel of 9-port Switch Fabric Module

T

L

N

E

O

N

A

R

P

F

9

X

X

X

T

R

R

8

7

T

E

A

S

T

S

D

O

M

I

R

P

Figure 6

C

2

1

345

678

To learn more about this module, refer to the

Gigabit Ethernet Switch Fabric Module Quick Start

on the Online Manuals CD-ROM.

Guide

24-port Gigabit Ethernet Switch Fabric

Model Number: 3CB9FG24T

The 24-port Gigabit Ethernet (GEN) Switch Fabric

Module is designed for use in network backbones,

data centers, and other high-density network

segments. The 24-port GEN Switch Fabric Module has

24 nonblocking Gigabit Ethernet ports that connect

to the chassis backplane to provide high-speed,

low-latency connectivity between Switch 4007

switching modules. Figure 7 shows the front panel.

X

T

X

X

R

T

9

9-Port

3CB9FG9

Page 21

Management Modules

21

Front Panel of 24-port Switch Fabric Module

0

4

4

6

8

2

1

1

1

2

2

2

3

5

7

9

1

3

1

1

1

1

2

2

T

A

S

T

S

D

O

M

Figure 7

C

E

0

1

1

I

123456789

R

1

P

2

1

To learn more about this module, refer to the

Gigabit Ethernet Switch Fabric Module Quick Start

on the Online Manuals CD-ROM.

Guide

Management Modules

The Switch 4007 chassis contains two slots

(slots 8 and 9) for Management Modules

management modules. These modules do not occupy

module payload slots. Figure 8 shows the front panel.

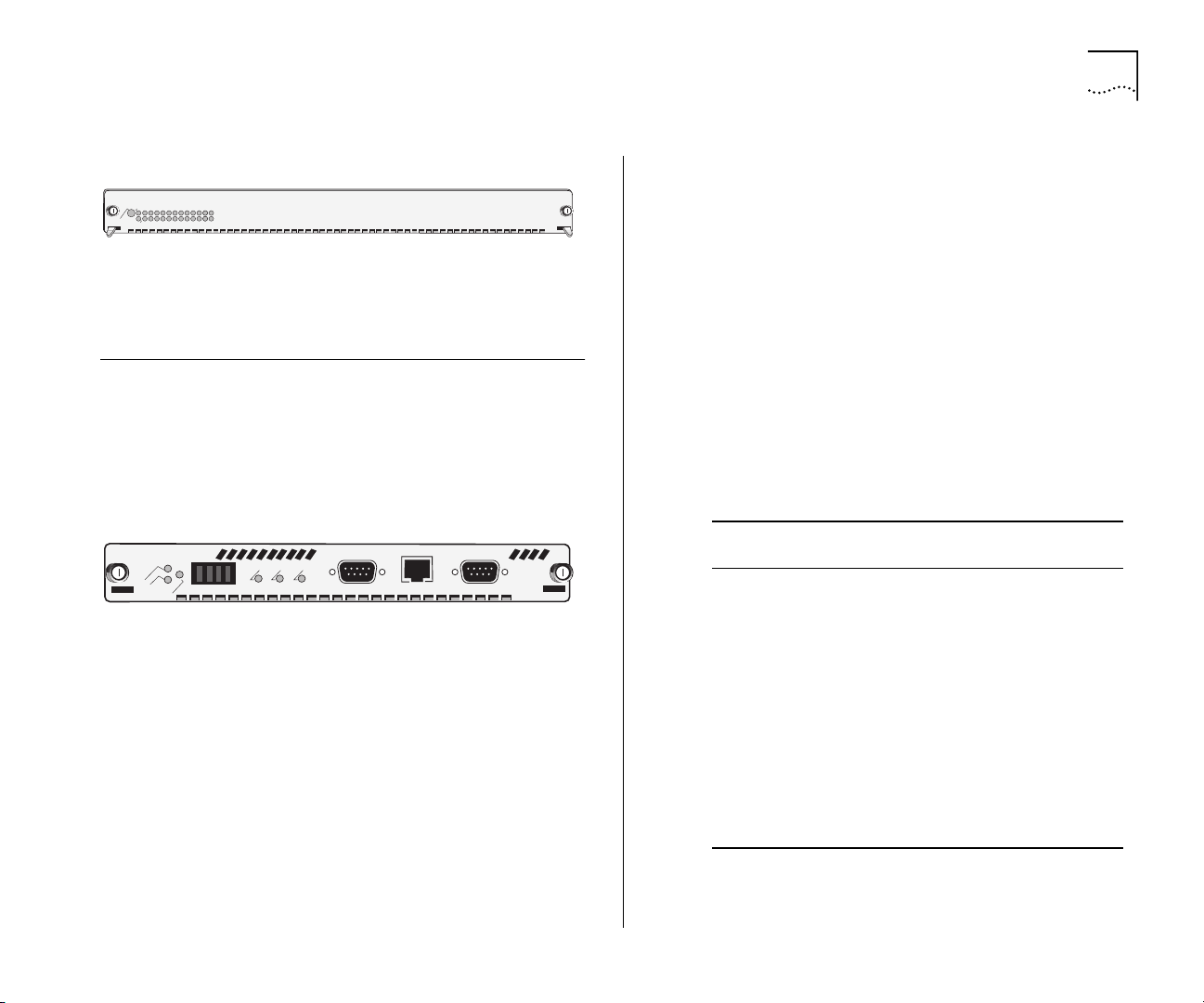

Figure 8

E

IV

T

C

Y

A

B

T

S

B

0

1

You can communicate through an RS-232 connector

(for connection to a terminal) or an RJ-45 port (for

connection to Ethernet networks) on the front panel

of the EME to configure and report on switch and

module operation.

The Switch 4007 EME is an SNMP-based network

management module that allows you to configure

and manage the Switch 4007 chassis and modules.

The EME backplane services generate, control, and

monitor the Switch. The management modules

provide power management functions.

Front Panel of EME Management Module

T

IS

E

S

T

Y

E

S

S

E

L

E

M

A

S

P

E

R

E

H

S

R

C

-T

D

You manage the switch through:

The EME command interface, which you access

■

3CB9FG24T

24-Port

through the serial port, or through SNMP (Simple

Network Management Protocol).

The Switch 4007 Web Management suite of

■

applications.

3Com Transcend Network Control Services.

■

An EME combines the functions of a management

module and a controller module. You can install a

second EME to provide standby management support

if the first EME is unavailable for any reason.

Table 3 describes the EME access mechanisms.

.

Ta b le 3

Access

Mechanism

2

3

2

S

R

-T

B

0

1

X

U

A

3CB9EME

Terminal Connect directly to the

Modem Access the command

IP Access the command

EME Access Mechanisms

Allows you to Using

command interface.

interface from remote

sites.

interface using the

rlogin or telnet

commands, or use an

external SNMP

management

application to

communicate with the

embedded SNMP agent.

RS-232 serial

port

Auxiliary RS-232

serial port

10BASE-T

Ethernet port

assigned to an IP

interface

Page 22

22

HAPTER

C

2: S

WITCH

4007 M

ODULES

For information about how to install the EME and

how to perform an initial configuration, see the

Enterprise Management Engine Quick Start Guide

the Online Manuals CD-ROM.

Fast Ethernet Modules

The frame-based switching modules are intelligent

Layer 2 and Layer 3 modules that have their own

embedded agent. These modules are physically

connected to the backplane ports of the switch fabric

module in the chassis. These modules switch between

the front panel ports and the backplane ports.

Switching interface modules provide network

connectivity functions.

Fast Ethernet Interface Modules are available in these

port configurations:

20-port 100BASE-FX (MT-RJ) Fast Ethernet Layer 2

■

Switching Module

36-port 10/100BASE-TX Fast Ethernet RJ-45 Layer

■

2 Switching Module

12-port 10/100BASE-TX Fast Ethernet MultiLayer

■

Switching Module

20-port 100BASE-FX (MT-RJ) Fast Ethernet Layer 2 Switching Module

Model Number: 3CB9LF20MM

The 100BASE-FX (MT-RJ) Fast Ethernet Layer 2

Switching Module has twenty 100 Mbps Ethernet

fiber-optic ports with MT-RJ connectors on its front

panel and two 1-Gigabit ports for connection to the

on

chassis backplane. It operates as a Layer 2 switch and

occupies a single interface module slot in the

Switch 4007 chassis.

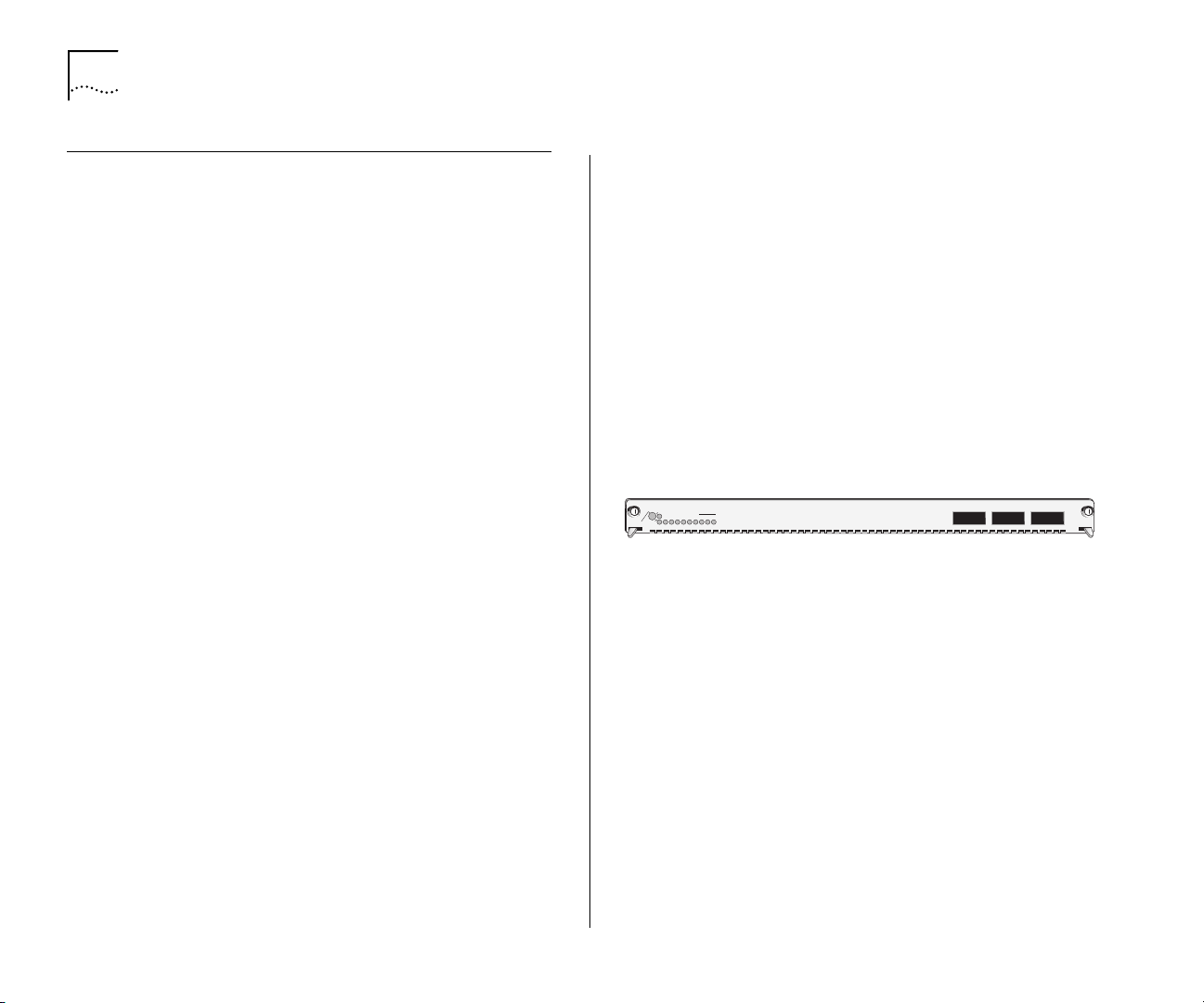

Figure 9 identifies the components on the front panel

of the module. The front panel ports on the module

are numbered 1 through 20. The two 1-Gigabit ports

on the back of the module are numbered 21 and 22.

Figure 9

A

A

T

T

S

S

D

D

O

O

M

M

Front Panel of Module 3CB9LF20MM

4

4

1

1

T

T

7

7

5

5

4

4

3

3

1

2

6

1

2

6

X

X

X

X

4

3

2

1

4

3

2

1

X

X

X

X

8

7

6

5

8

7

6

5

X

X

X

1

0

X

9

1

0

1

1

9

1

1

X

X

5

4

3

2

2

4

3

1

1

1

1

1

1

1

To learn more about this module, refer to the

X

X

7

6

6

5

1

1

1

1

X

X

X

X

0

9

8

8

7

1

1

1

3CB9LF20R

0

9

2

1

2

1

3CB9LF20MM

20-Port

100BASE-FX (MT-RJ) Fast Ethernet Layer 2 Switching

Module Quick Start Guide

on the Online Manuals

CD-ROM.

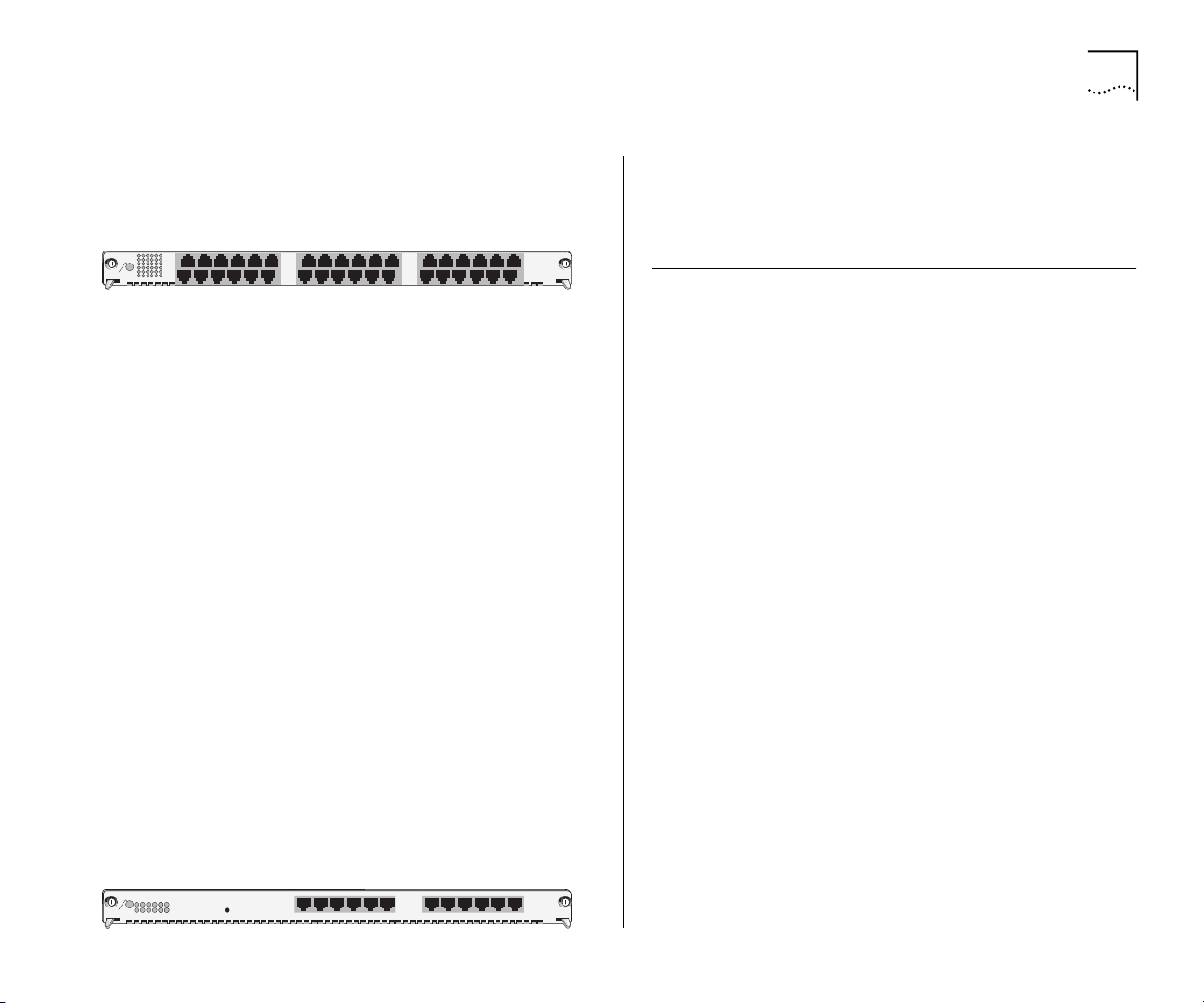

36-port 10/100BASE-TX Fast Ethernet RJ-45 Layer 2 Switching Module

Model Number: 3CB9LF36R

The 10/100BASE-TX Fast Ethernet RJ-45 Layer 2

Switching Module (36-port FEN RJ-45 Switching

Module) has thirty-six 10/100 Mbps Ethernet ports

with RJ-45 connectors on its front panel, and two

1-Gigabit ports on the back for connection to the

chassis backplane. It operates as a Layer 2 switch and

occupies a single interface module slot in the

Switch 4007 chassis.

Page 23

Gigabit Ethernet Modules

23

Figure 10 identifies the components on the front

panel of the module.

Figure 10

6

1

3

3

T

X

A

T

7

S

D

O

M

X

1

6

1

To learn more about this module, refer to the

Front Panel of Module 3CB9LF36R

X

9

1

X

3

1

X

1

3

X

5

2

36-Port

10/100BASE-TX Fast Ethernet RJ-45 Layer 2 Switching

Module Quick Start Guide

on the Online Manuals

CD-ROM.

12-port 10/100BASE-TX Fast Ethernet MultiLayer Switching Module

Model Number: 3CB9RF12R

The 12-port 10/100BASE-TX Fast Ethernet MultiLayer

Switching Module is a multiprotocol module designed

for the Switch 4007. The module has twelve

10/100BASE-TX Fast Ethernet front panel ports that

provide a 100 Mbps connection over UTP-Category 5

cables, and one nonblocking Gigabit Ethernet port

that connects through the backplane to the switch

fabric module. The module has two groups of six

ports, operates as a Layer 3 router switch, and

occupies a single interface module slot in the

Switch 4007 chassis.

Figure 11 identifies the components on the front

panel of the module.

Figure 11

Front Panel of Module 3CB9RF12R

3CB9LF36R

To learn more about this module, refer to the

10/100BASE-TX Fast Ethernet Layer 3 Switching

Module Quick Start Guide

CD-ROM.

Gigabit Ethernet Modules

The Gigabit Ethernet (GEN) Interface Modules are

two-port interface modules for the 3Com

Switch 4007. The GEN interface modules serve as a

2–Gigabit data channel between the Gigabit Ethernet

Switch Fabric Module and other 802.3z–compliant

Gigabit Ethernet devices. GEN Interface Modules use

SC connectors.

Because Gigabit Ethernet interface modules are not

intelligent, you cannot access them directly; all

communication takes place through the switch fabric

module. GEN interface modules serve as a

two-Gigabit data channel between the GEN Switch

Fabric Module and other 802.3z-compliant Ethernet

devices.

For information about how to install these modules,

see the module’s

with each module.

Gigabit Ethernet Interface Modules are available in

these port configurations:

4-port Gigabit Ethernet Interface Module

■

9-port 1000BASE-SX Gigabit Ethernet Layer 2

■

Switching Module

Quick Start Guide

12-Port

on the Online Manuals

that is shipped

4-port Gigabit MultiLayer Switching Module

T

1

0

2

A

1

1

9

1

8

7

T

S

D

O

M

5

4

3

1

2

6

4

3

2

1

6

5

0

2

1

9

8

7

1

1

1

3CB9RF12R

■

Page 24

24

HAPTER

C

2: S

WITCH

4007 M

ODULES

4-port Gigabit Ethernet Interface Module

Model Number: 3CB9LG4

The 4-port Gigabit Ethernet (GEN) Interface Module

(GBIC) is an interface for gigabit rate data between

the Switch 4007 chassis backplane and other

802.3z-compliant Gigabit Ethernet devices. The

module provides four Gigabit Ethernet fiber-optic

connections on the front panel, using plug-in Gigabit

Interface Converter (GBIC) transceivers. The module

occupies a single interface module slot in the

Switch 4007 chassis.

Each module has four ports on the front panel.

Figure 12 identifies the components on the front

panel of the module.

Front Panel of Module 3CB9LG4

X

R

X

X

R

T

1

2

X

X

T

X

R

T

3

X

X

R

T

4

T

A

T

S

D

O

M

2

1

Figure 12

4

3

To learn more about this module, refer to the

Gigabit Ethernet Interface Module (GBIC) Quick Start

on the Online Manuals CD-ROM.

Guide

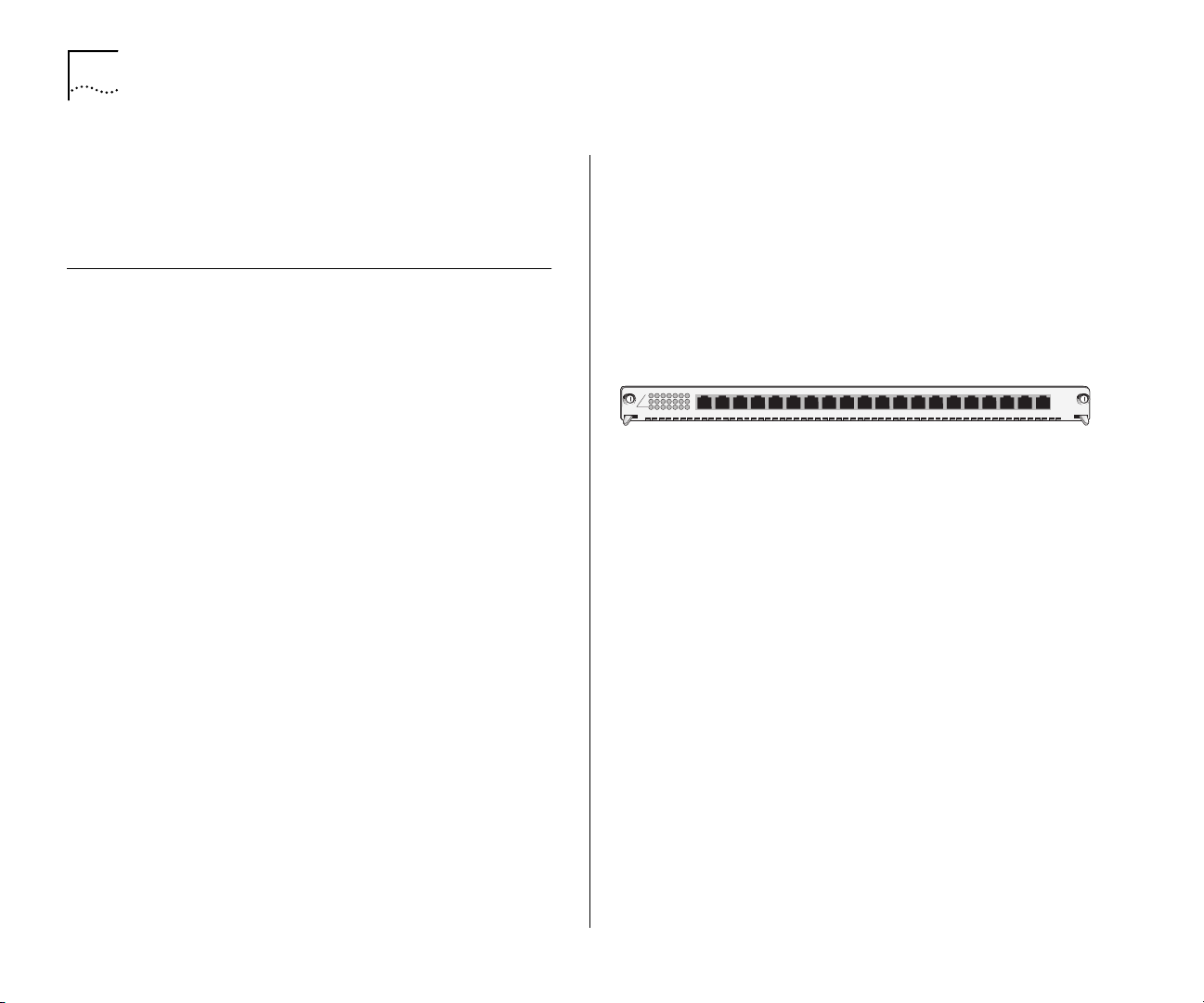

9-port 1000BASE-SX Gigabit Ethernet Layer 2 Switching Module

Model Number: 3CB9LG9MC

The 9-port 1000BASE-SX Gigabit Ethernet Layer 2

Switching Module can switch Gigabit Ethernet (GEN)

connections to corporate backbones and servers. The

module has nine 1000BASE-SX GEN front panel

ports. It has 3 backplane ports for connection to the

3CB9LG4

4-Port

24-port GEN Switch Fabric Module, and 1 backplane

port for connection to the 9-port GEN Switch Fabric

Module. The module occupies a single interface

module slot in the Switch 4007 chassis.

Figure 13 identifies the components on the front

panel of the module.

Front Panel of Module 3CB9LG9MC

X

X

X

X

X

R

T

T

R

2

1

3

X

X

R

T

X

X

R

R

T

4

5

X

R

T

6

X

R

T

T

7

8

X

X

X

T

A

7

6

T

S

D

O

M

1

2

Figure 13

X

T

9

8

5

4

3

To learn more about this module, refer to the

1000BASE-SX Gigabit Ethernet Layer 2 Switching

Module Quick Start Guide

on the Online Manuals

CD-ROM.

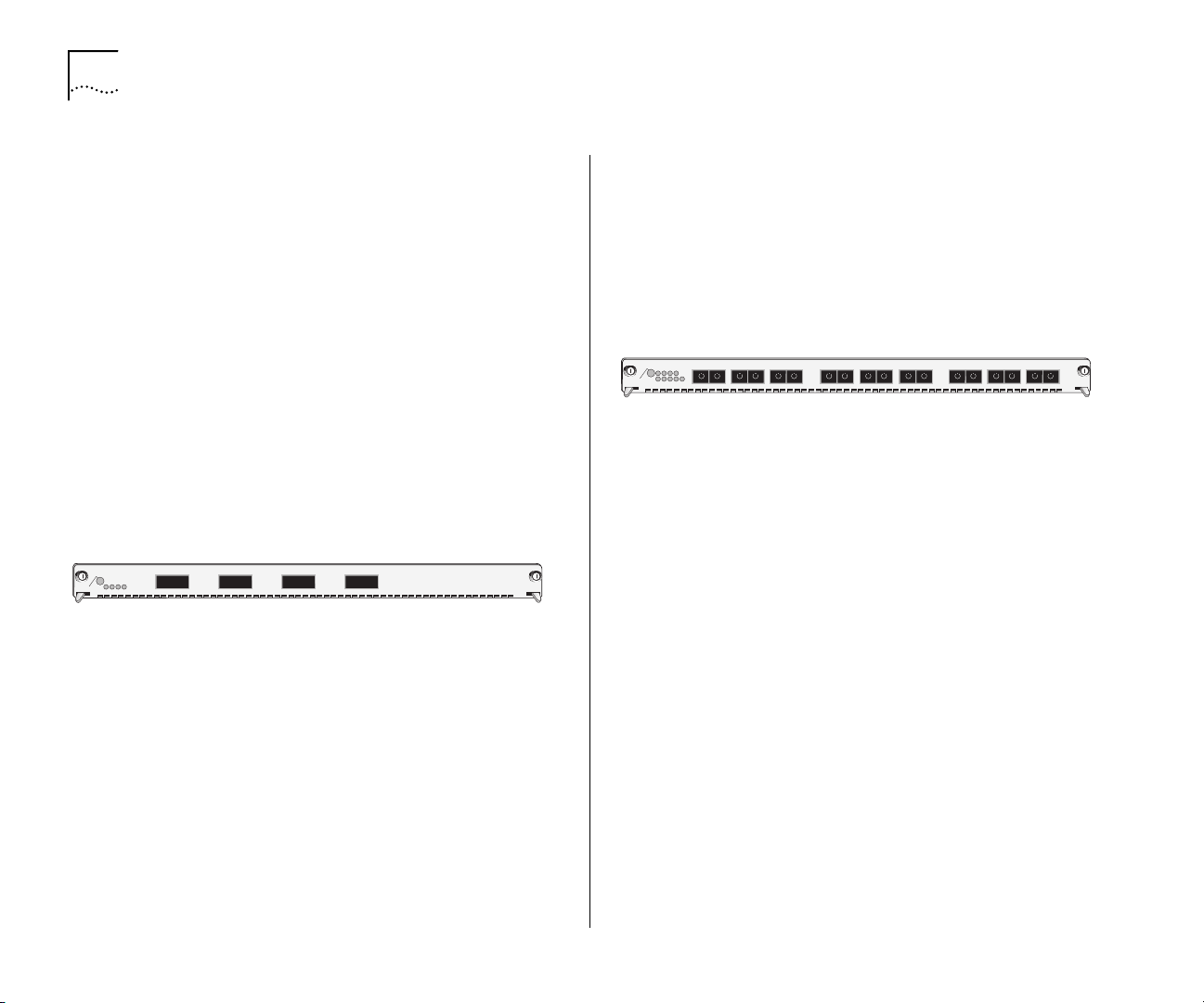

4-port Gigabit MultiLayer Switching Module

Model Number: 3CB9RG4

The 4-port Gigabit Ethernet Layer 3 Switching

Module (GBIC) for the Switch 4007 provides

high-port-density, line speed, Gigabit Ethernet

switching and routing on backbone networks running

at Open Systems Interconnection (OSI) Layer 3.

The module provides 4 Gigabit Interface Converter

(GBIC) ports on the front panel that can be either

1000BASE-LX (single-mode fiber) or 1000BASE-SX

(multimode fiber). 4 Gigabit Ethernet ports connect

the module to the chassis backplane.

X

R

X

X

R

T

9

9-Port

3CB9LG9MC

Page 25

GBIC Transceivers

25

Figure 14 identifies the components on the front

panel of the module.

Front Panel of Module 3CB9RG4

1

T

A

T

S

D

O

M

123

Figure 14

4

To learn more about this module, refer to the

Gigabit Ethernet Layer 3 Switching Module (GBIC)

Quick Start Guide

GBIC Transceivers

The Gigabit Interface Converter (GBIC) ports on your

system connect to Gigabit Ethernet networks through

a GBIC transceiver (Figure 1), providing a high-speed

connection over fiber-optic cable. The transceiver

connects to the network using a fiber-optic duplex

subscriber connector (SC). You can remove and

replace the transceiver with the system powered on,

which is called hot-swapping.

Figure 15

GBIC Fiber-Optic Transceiver

2

3

4

on the Online Manuals CD-ROM.

3CB9RG4

4-Port

The following transceivers are available:

SX GBIC Transceiver

■

LX GBIC Transceiver

■

70-km Long Haul GBIC Transceiver

■

SX GBIC Transceiver

Model Number: 3CGBIC91

The 1000BASE-SX GBIC transceiver supports a direct

connection to 62.5-micron or 50-micron multimode

fiber-optic cable.

To learn more about this transceiver, refer to the

Transceiver Installation Guide

CD-ROM.

LX GBIC Transceiver

Model Number: 3CBGIC92

The 1000BASE-LX GBIC transceiver supports a direct

connection to single-mode fiber-optic cable, or

connection to multimode fiber through a conditioned

launch cable.

GBIC

on the Online Manuals

To ensure optimal performance, compatibility, and

regulatory compliance, use only conditioned launch

cables that 3Com supports. For a list of supported

conditioned launch cables, see this 3Com Web site:

http://www.3Com.com/gigabit_ethernet/gbics

To learn more about this transceiver, refer to the

Transceiver Installation Guide

on the Online Manuals

GBIC

CD-ROM.

Page 26

26

HAPTER

C

2: S

WITCH

4007 M

ODULES

70-km Long Haul GBIC Transceiver

Model Number: 3CGBIC97

The 70-km Gigabit Ethernet GBIC Fiber-Optic

Transceiver connects to the network using a

fiber-optic duplex SC connector.

To learn more about this transceiver, refer to the

70-km Gigabit Ethernet GBIC Transceiver Installation

on the Online Manuals CD-ROM.

Guide

Slot Restrictions

Table 4 lists slot restrictions in the Switch 4007

chassis.

Ta b l e 4

Module type Slot number

Management modules 8 and 9

Switch fabric module 7

Interface modules 1, 2, 3, 4, 5, 6

Slot Restrictions

Management Access

You can access and manage your Switch 4007

modules using several methods:

Administration Console

■

Web Management suite of applications

■

External SNMP-based network management

■

application, such as Transcend

Services

®

Network Control

The Administration Console and most of Web

Management are embedded parts of the software

and are available for immediate use to manage your

modules.

Administration Console Access

To manage the module from the Administration

Console:

Log in to the EME.

1

For information about logging in to the EME, see the

Enterprise Management Engine User Guide.

At the prompt, enter:

2

connect <slot>.1

Where

<slot>

is the chassis slot number of the

module that you want to manage, and the number

after the decimal point is a subslot number (which is

always 1).

The Administration Console displays the top-level

menu prompt. For example, if you installed a 20-port

100BASE-FX Fast Ethernet Switching Module in slot

4, then the prompt appears as follows:

CB9000@4.1 [20-E/FEN-FX-L2] ():

Enter commands to manage the module.

3

For example, to display a module baseline, enter:

module baseline display

For more information about Administration Console

module commands, see the multiplatform

Reference Guide.

Command

Page 27

Web Management Access

Web Management applications are an embedded

part of the Switch 4007. They include Web Console,

DeviceView, and Performance monitoring tools.

Additional installable applications include online Help.

After you have set up your IP address for the Switch,

you can access the Web Management applications

directly in your Web browser by entering the IP

address. For information about setting up your IP

address, see the

Quick Start Guide

Enterprise Management Engine

.

For additional information about Web Management,

see Chapter 5, “Management Tools”.

Where to Go from Here

For more information about Switch 4007 see the

following documents, which are supplied in PDF

format on the Online Manuals CD-ROM:

Where to Go from Here

■

12-Port 10/100BASE-TX Fast Ethernet Layer 3

Switching Module Quick Start Guide

■

4-Port Gigabit Ethernet Interface Module (GBIC)

Quick Start Guide

■

9-Port 1000BASE-SX Gigabit Ethernet Layer 2

Switching Module Quick Start Guide

■

4-Port Gigabit Ethernet Layer 3 Switching

Module (GBIC) Quick Start Guide

Switch fabric modules

■

■

24-Port Gigabit Ethernet Switch Fabric Module

Quick Start Guide

■

9-port Gigabit Ethernet Switch Fabric Module

Quick Start Guide

GBIC transceivers

■

■

GBIC Transceiver Installation Guide

■

70-km Gigabit Ethernet GBIC Transceiver

Installation Guide

27

Management modules

■

■

Enterprise Management Engine Quick

Start Guide

■

Switch 4007 Implementation Guide

■

Switch 4007 Command Reference Guide

Interface modules

■

■

20-Port 100BASE-FX (MT-RJ) Fast Ethernet Layer

2 Switching Module Quick Start Guide

■

36-Port 10/100BASE-TX Fast Ethernet RJ-45

Layer 2 Switching Module Quick Start Guide

The Switch 4007 is based on 3Com

CoreBuilder

®

9000 technology and supports a range

of CoreBuilder 9000 components.

The Quick Start Guides that are supplied with many

product options describe installation and setup procedures for the CoreBuilder 9000. However, you can

install supported components into a Switch 4007

chassis as you would install them into the CoreBuilder

9000 7-slot chassis.

Page 28

28

HAPTER

C

2: S

WITCH

4007 M

ODULES

Page 29

3

NSTALLING THE

I

WITCH

S

4007

This chapter contains the following topics:

Site Requirements for the Switch 4007

■

Preinstallation Guidelines

■

Installing the Chassis

■

Figure 16 summarizes the installation procedure.

For a Switch 4007 starter kit, you can simplify

the installation proceedure because the chassis is

pre-configured with one power supply, one

management module, one switch fabric module,

and two interface modules.

Figure 16

Troubleshoot Problems

•

Command Reference Guide

•

Implementation Guide

Configure the Switch for

Management

•

Command Reference Guide

•

Implementation Guide

Power On the Switch

• Chapter 4 (In this guide)

Switch 4007 Installation Procedure

Administer and Operate

the Switch

•

Command Reference Guide

•

Implementation Guide

Install Interface Modules

• Interface module quick start or

getting started guides

•

Interface module user guides

(if available)

Determine Site Requirements

• Chapter 3 (In this guide)

12

11

10

9

Install a Switch Fabric

8

Module

• Switch fabric module quick

start or getting started guides

• Switch fabric module

user guides (if available)

7

6

5

4

3

2

1

9

8

Switch 4007

Unpack the Switch 4007

Chassis

1

• “Unpacking Instructions”

(In this guide)

Install the Chassis and

Optional Devices

• Chapter 3 (In this guide)

Install a Power Supply

•

7-Slot Chassis Power Supply

Installation Guide

Install a Power Cable

•

7-Slot Chassis Power Supply

Installation Guide

Install an EME Management

Module

•

Enterprise Management Engine

Quick Start Guide

7

2

3

4

5

6

Page 30

30

HAPTER

C

NSTALLING THE SWITCH

3: I

4007

Site Requirements for the Switch 4007

This section describes the following site requirements

for setting up your Switch 4007:

Location Requirements

■

Precautionary Guidelines

■

Ventilation Requirements

■

Power Requirements

■

Safety Information

■

Location Requirements

Install a Switch 4007 in an area that meets the

following requirements:

Ambient (room) temperature: 0 °C to 50 °C (32 °F

■

to 122 °F). The default internal operating

temperature threshold for the Switch 4007 is

approximately 60 °C (140 °F).

Relative humidity: between 10 and 90 percent,

■

noncondensing.

The table or rack on which you mount the chassis

■

supports at least three times the weight of a fully

loaded chassis.

The recommended minimum space that is required

■

between the front of the chassis and another

vertical surface (such as a rack door) is 8 cm (3 in.).

There is a sufficient amount of space on each side

■

of the Switch 4007 chassis to accommodate any

cables along the side of the chassis.

There is at least 7 cm (2.76 in.) on each side of the

■

Switch 4007 chassis to ensure proper cooling in

the chassis.

There is at least 91.4 cm (36 in.) in back of the

■

chassis to:

Remove and replace power supplies.

■

Maintain proper cooling.

■

If the chassis is the first device in your rack, then

■

mount it about 10.2 cm (4 in.) up from the floor.

The power source is within approximately 2 meters

■

(6.6 feet) of the location where you plan to install

the Switch 4007.

Each of the power supplies connects to a

■

dedicated circuit. Do not connect the power

supplies to a power strip.

The surface on which you want to locate the

■

Switch 4007 chassis is level.

Have the required cables available at your site to

■

make physical connections in your switch

configuration.

Precautionary Guidelines

Ambient temperature for the Switch 4007 must

■

not exceed 50 °C (122 °F).

Safety regulations stipulate that for a Switch 4007

■

chassis, the table, shelf, or rack on which the

switch rests can support at least 115.65 kg (255

lb), which is three times the weight of a fully

loaded Switch 4007 chassis.

Page 31

For rack installations, the selected rack is grounded

■

in accordance with the rack manufacturer’s

recommendations.

To reduce the possibility of personal injury or

■

serious damage to the chassis, use

people

to install the chassis. This is especially

at least two

important for rack installations, because you must

hold the chassis in place while you secure the

chassis to the rack.

Bolt the rack to the floor.

■

Make certain that the rack is properly aligned and

■

squared. Use a framing tool to ensure that the rack

is squared.

Brace the top of the rack against the wall.

■

Provide sufficient space in front of and behind the

■

chassis so that you can service it easily and provide

proper ventilation.

Provide at least 7 cm (2.76 in.) on each side of

■

the Switch 4007 chassis to ensure proper

cooling in the chassis.

Provide at least 91.4 cm (36 in.) in back of the

■

switch to remove and replace power supplies in

the Switch 4007 chassis.

Use the following guidelines to tighten screws to

■

Torque Specification:

Faceplate thumbscrews — 3-5 in/lb

■

(inch-pounds)

#10 screws for holding the chassis onto the

■

rail — 22-25 in/lb

Power supplies to the chassis — 5-7 in/lb

■

Site Requirements for the Switch 4007

31

To ensure that you tighten screws to Torque

Specification, use a torque screwdriver.

The following list shows the amount of rack space

that is needed to install a Switch 4007 chassis in a

Telco rack or a Metric rack.

Height — 30.98 cm / 12.2 in.

■

The height of the chassis, allowing for some

extension beyond the location of the upper and

lower unit dividing lines.

Telco Rack Unit — 7 RU

■

The unit of measure is 1 Rack Unit (1.75 in. or

4.45 cm).

Metric Rack Unit — 12.5 SU

■

The unit of measure is 1 System Unit

(25 millimeters).

Front clearance — 8 cm / 3 in.

■

This is the recommended minimum space required

between the front of the chassis and another

vertical surface (such as a rack door).

Rack-Mount Installation Recommendations

Use at least two people to install any chassis.

Before you install a chassis into a rack, make certain

that the rack you are using is properly aligned and

squared. Use a framing square to ensure that the rack

is squared. Doing so makes installing the chassis into

the rack easier.

Page 32

32

1

2

3

4

5

6

7

8

9

HAPTER

C

NSTALLING THE SWITCH

3: I

4007

WARNING:

To maintain proper cooling in the chassis

and to maintain safety compliance, make certain that

blank faceplates cover any empty slots.

If you install more than one chassis in a rack, install

■

the bottom chassis first. Make certain that there is

sufficient space between the bottom chassis and

the top chassis.

If you install the chassis in a Metric rack slot, install

■

the rack-mount clips and screws in the closed slots

of the rack-mount flanges. If you install the chassis

in Telco rack slots, position the chassis and then

install the screws and rack-mount clips in the open

slots.

Figure 17 shows the Telco and Metric slots and the

location of the preinstalled rack-mount flange on a

Switch 4007 chassis.

Figure 17

Preinstalled Rack-mount Flange Location and Slot

Types on the Switch 4007 Chassis

Preinstalled

flange pin

Telco rack

open slot

Metric rack

closed slot

Page 33

Site Requirements for the Switch 4007

33

Ventilation Requirements

This section describes ventilation requirements for the

Switch 4007. The chassis contains one fan tray that

contains four fans.

To ensure that installed fans are able to provide

adequate ventilation, maintain at least 7 cm (2.76 in.)

between the sides of the Switch 4007 chassis and the

nearest wall (or other vertical surface). Also provide at

least 91.4 cm (36 in.) behind the chassis to be able to

remove and replace power supplies in the

Switch 4007 chassis.

When you face the front of the Switch 4007 chassis,

the inlet is on the right and the exhaust is on the left.

CAUTION:

Operate a Switch 4007 chassis with four

fans running. If one fan in the fan tray fails, replace

the fan tray as soon as possible.

Power Requirements

This section list power requirements for the 930-watt

AC (Model Number 3CB9EP9) power supply.

The Switch 4007 chassis can contain two modular

930-watt power supplies. The 930-watt power

supplies provide AC power to the Switch. The

930-watt power supplies are autosensing. Each

power supply can automatically sense the type of

input voltage to which it is being connected at the

electrical outlet.

Table 5 lists power requirements for each country.

Ta b le 5

Location Volts Hz Ampere

Asia 220 - 240 Volts 50 Hz 15-ampere

Australia 220 - 240 Volts 50 Hz 10-ampere

Canada 120 Volts 60 Hz 20-ampere

Europe 220 - 230 Volts 50 Hz 16-ampere

Japan 100 Volts 50/60 Hz 15-ampere

South Africa 220 - 250 Volts 50 Hz 16-ampere

U.K. 240 Volts 50 Hz 13-ampere

U.S.A. 120 Volts 60 Hz 20-ampere

Power Requirements Per Country

One power cord per power supply is required. The

power cord that you require depends on your country

location.

Table 6 lists the power cords for each country.

Ta b le 6

Location Power Cord Type

Asia C19/AS3112

Australia C19/AS3112 special- 10A - C19

Canada C19/NEMA 5-20P

Europe C19/CEE7

Japan C19/NEMA 5-15P

South Africa C19/SABS164

U.K. C19/BS1363A

U.S.A. C19/NEMA 5-2 OP

Power Cord Description for Your Location

Page 34

34

CLASS 1

LASER PRODUCT

HAPTER

C

NSTALLING THE SWITCH

3: I

4007

Safety Information

This section lists warning notices to read before you

install the Switch 4007 and its components.

WARNING:

by trained service personnel.

WARNING:

and maintain safety compliance, make certain that

blank faceplates cover any empty slots.

WARNING:

the Switch. Do not place hands or objects into the

switch or touch components on an inserted module.

WARNING:

table, shelf, or rack must be able to support at least

three times the weight of a fully loaded Switch. A

fully loaded Switch 4007 chassis weighs

approximately 38.55 kg (85 lb). Therefore, the

selected table or shelf must support at least 115.65

kg (255 lb).

Denmark Safety Certification

The following warning is required for Denmark safety

certification:

The Switch 4007 must be installed only

To maintain proper cooling in the chassis

Hazardous energy levels exist inside of

Safety regulations state that the selected

WARNING:

Ved brug i Danmark, skal hver 3CB9EP9

stromforsyning modtage strom fra en separat,

dedikeret stikkontakt med en 16-ampere sikring i

installationen.

Laser Warning

The following warning is required when you install

fiber-optic communication modules into the

Switch 4007:

WARNING:

To ensure optical safety when you install

a fiber-optic interface module, comply with the

following precaution:

Although the data communication LEDs and Lasers

used in this product meet the regulatory

requirements for casual exposure to the eye, as with

any source of bright light, 3Com

®

recommends that

you do not look into the light source.

Laser Safety Information:

IEC 825 and EN60825,

Class 1 Laser Device. For connection only to Class 1

Laser Devices.

WARNING:

power supply must receive power from a separately

dedicated socket outlet having a 16-ampere fuse in

the installation. This product must be mounted in a

fixed installation such as a permanent rack.

For use in Denmark, each 3CB9EP9

FDA Class 1 Laser Device

This product complies with U.S. Department of Health

and Human Services Rules 21 CFR Subchapter J

applicable at date of manufacture.

Page 35

Preinstallation Guidelines

35

LED Warning

The following warning is required when you install

fiber-optic communication modules into the

Switch 4007:

WARNING:

To ensure optical safety when you install

a fiber-optic interface module, comply with the

following precaution:

Although the data communication LEDs that are used

in this product meet the regulatory requirements for

casual exposure to the eye, as with any source of

bright light, 3Com recommends that you do not look

into the light source.

LED Safety Information:

IEC 825, Class 1 LED

Device. For connection only to Class 1 LED Devices.

CLASS 1

LED PRODUCT

Preinstallation Guidelines

Use the following installation guidelines to ensure

your safety and optimal performance. Review all

guidelines before you install the Switch 4007.

Rack-Mount Installation Guidelines

Before you attempt to mount the chassis in a rack:

Select a rack that can support at least 115.65 kg

■

(255 lb), which is three times the weight of a fully

loaded Switch 4007 chassis, and that provides

sufficient vertical space for each chassis that you

want to install.

Make certain that the rack that you use is properly

■

aligned and is squared. Use a framing square to

ensure that the rack is squared.

To maintain proper cooling in the chassis and to

■

maintain safety compliance, make certain that

blank faceplates cover any empty slots.

Bolt the rack to the floor.

■

Brace the top of the rack against the wall.

■

Page 36

36

HAPTER

C

NSTALLING THE SWITCH

3: I

4007

Figure 18 shows two types of racks that you may use

to install the Switch 4007 chassis.

Figure 18

Move the Switch 4007 chassis close to where you

■

Rack Types

plan to install it. Place the chassis in front of the

rack, table, or shelf that you plan to use.

For a rack installation, make certain that you have

■

a Phillips screwdriver and a flat-blade screwdriver,

and at least 8 of the 12 screws (from the hardware

kit) available when you begin to install the chassis.

Position the rack-mount clips if you are going to

■

use them for the rack-mount installation.

For a tabletop or shelf installation, make certain

■

that you have a Phillips screwdriver or flat-blade

screwdriver and the hardware kit available.

Because the equipment rack environment can

■

cause increased ambient temperatures and

reduced air flow, review the chassis specifications

and site requirements.

Use the following guidelines to tighten screws to

Torque Specification:

Faceplate thumbscrews — 5-7 in/lb (inches per

■

pound)

#10 screws for holding the chassis onto the rack

■

rail — 22-25 in/lb

Installing the Chassis

This section contains:

Installing the Chassis in a Rack

■

Installing the Chassis Using Rack-Mount Clip Nuts

■

Installing the Chassis on a Table or Shelf

■

You may have other types of racks at your site. Follow

the manufacturer’s suggested installation procedures.

Installing the Chassis in a Rack

Follow these steps to mount the chassis in a rack. Use

at least two people to perform this installation.

Locate and mark the holes on the rack where you

1

want to place the chassis.

Two people lift the chassis through the front of the

2

rack, until both chassis rack-mount flanges are flush

with the front of the rack.

Page 37

Installing the Chassis

37

Use the preinstalled flange pins in the Telco rack slot

3

to position the chassis in the rack.

Support the back of the chassis until the two bottom

screws are fully inserted.

While you support the back of the chassis, insert one

4

screw on each side of the chassis and then

bottom

tighten the screw.

Tighten the #10 screws that hold the chassis onto the

rail to a Torque Specification of 22-25 in/lb (inches per

pound).

Insert one

5

screw on each side of the chassis and

top

then tighten the screw.

Install all remaining screws and tighten them.

6

Installing the Chassis Using Rack-Mount Clip Nuts

Follow these steps to mount the chassis in a rack

when you use rack-mount clip nuts.

Not all racks require that you use rack-mount clips.

Use whatever method of rack-mount equipment that

you have to meet installation requirements in a rack.

Use at least two people to perform this installation.

Mark and locate the holes on the rack where you

1

want to place the clip nuts.

Install the clip nuts on the rack in the positions that

2

you selected. See Figure 8.

The rack slots are not equally spaced, so align the clip

nuts to the slots properly for the screws to be easily

installed.

Figure 19

10-32 inch screw

Be sure to thread the screw

through this nut to securely

attach each clip to the rack

Two people lift the chassis through the front of the

3

Installing a Rack-mount Clip in the Rack

Rack rail

Top view

rack, until both chassis rack-mount flanges are up

against the rack.

Using the preinstalled flange pins for guidance, match

4

the slots on the rack-mount flange to each clip nut on

the rack.

Support the back of the chassis until the two bottom

screws are fully inserted.

Secure the chassis to the rack with the screws pro-

5

vided (eight 10-32 inch screws) and with the

rack-mount clips.

Install one screw on each side in the bottom slot

a

on

Install the remaining screws.

b

Tighten all screws completely.

c

rack-mount flange.

each

Tighten the #10 screws that hold the chassis onto the

rail to a Torque Specification of 22-25 in/lb (inches per

pound).

Page 38

38

HAPTER

C

NSTALLING THE SWITCH

3: I

4007

Installing the Chassis on a Table or Shelf

This section describes how to attach plastic feet to the

chassis and how to install the chassis on a table or a

shelf.

WARNING:

Safety regulations state that the selected

table or shelf must be able to support at least 115.6

kg (255 lb), which is three times the weight of a fully

loaded chassis.

Attaching the Chassis Feet

To install plastic, molded feet on the Switch 4007

chassis, follow these steps:

Using two people, lift the chassis onto the table or

1

shelf.

Position the chassis on its side so that you can access

2

the bottom of the chassis.

Remove the four feet and the four 6-32 Phillips-head

3

screws from the hardware kit.

Using a Phillips screwdriver, screw the feet to the

4

bottom of the chassis. See Figure 9.

Figure 20

Attaching Plastic Feet to the Switch 4007 Chassis

Installing the Chassis on a Table or Shelf

To install the chassis on a table or on a shelf, follow

these steps:

Lift and turn the chassis upright on its installed plastic

1

feet.

Position the chassis on the table or shelf so that the

2

chassis rests upright squarely on the table or on the

shelf (on all four feet).

Ensure that the front, sides, and the rear of the chas-

3

sis are unobstructed and easy to reach.

Page 39

Where To Go from Here

After you have installed the chassis, use the following

information to proceed:

Ta s k See this document

Install power supplies

Install an EME

Install a switch fabric

module

Install an interface

module

Configure the Switch

Power Supply Installation Guide

Enterprise Management Engine Quick

Start Guide

Gigabit Ethernet Switch Fabric Module

Quick Start Guide

Module Quick Start Guide

Switch 4007 Implementation Guide

Switch 4007 Command Reference Guide

Where To Go from Here

39

Page 40

40

HAPTER

C

NSTALLING THE SWITCH

3: I

4007

Page 41

4

TART THE

S

WITCH

S

This chapter summarizes what happens when you

power on your Switch 4007 after you have installed

all the switch components.

Before you power on the Switch 4007, review the

setup tasks (Figure 16 on page 29) and make certain

that all the tasks have been performed.

Power On the Switch

Attach the power supply cables to the connections on

1

the Switch.

Plug the power cord into the electrical socket.

2

Turn on the power switch.

3

Watch the LEDs on installed modules

4

To verify that the Switch 4007 modules have been

installed correctly, examine the LED status on each

module. To obtain information about a module’s LEDs

and status indicators, see the

Started Guide

module.

Quick Start Guide

, or

User Guide, Getting

specific to that

What Occurs During Startup

After you turn on the power switch, the following

occurs:

The power supplies begin operating.

■

The fans start rotating.

■

The Enterprise Management Engine LEDs blink

■

green.

Table 7 shows the sequence of characters that appear

on the EME management module LED character

display during a switch power-on.

Ta b le 7

Characters in Display Indication

random characters Power-on has begun.