Page 1

3B SCIENTIFIC3B SCIENTIFIC

3B SCIENTIFIC®

3B SCIENTIFIC3B SCIENTIFIC

PHYSICSPHYSICS

PHYSICS

PHYSICSPHYSICS

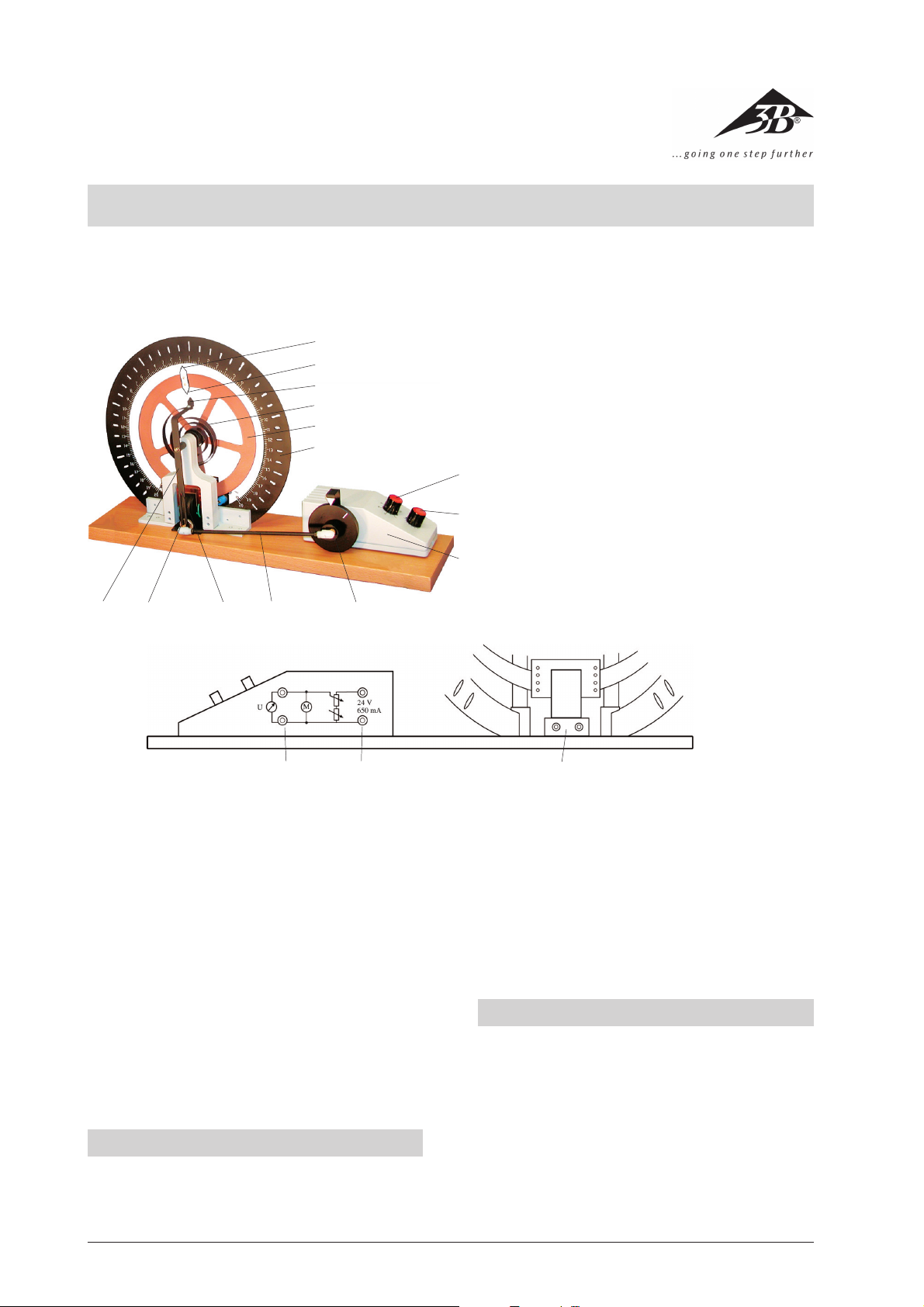

U15040 Torsion pendulum according to Professor Pohl

Operating instructions

12/03 ALF

9

8

7

6

5

4

bl bm bn bo bp

bq br bs

1 Exciter motor

2 Control knob for fine adjustment of the exciter voltage

3 Control knob for coarse adjustment of the exciter voltage

4 Scale ring

5 Pendulum body

6 Coil spring

7 Pointer for the exciter phase angle

8 Pointer for the pendulum’s phase angle

9 Pointer for the pendulum’s deflection

3

bl Exciter

bm Eddy current brake

bn Guide slot and screw to set the exciter amplitude

2

bo Connecting rod

bp Eccentric drive wheel

bq 4-mm safety socket for exciter voltage measurement

1

br 4-mm safety sockets for the exciter motor power supply

bs 4-mm safety sockets for the eddy current brake power

supply

The torsion pendulum may be used to investigate free,

forced and chaotic oscillations with various degrees of

damping.

Experiment topics:

• Free rotary oscillations at various degrees of damp-

ing (oscillations with light damping, aperiodic oscillation and aperiodic limit)

• Forced rotary oscillations and their resonance

curves at various degrees of damping

• Phase displacement between the exciter and reso-

nator during resonance

• Chaotic rotary oscillations

• Static determination of the direction variable D

• Dynamic determination of the moment of inertia J

1. Safety instructions

• When removing the torsional pendulum from the

packaging do not touch the scale ring. This could

lead to damage. Always remove using the handles

provided in the internal packaging.

• When carrying the torsional pendulum always hold

it by the base plate.

• Never exceed the maximum permissible supply

voltage for the exciter motor (24 V DC).

• Do not subject the torsional pendulum to any un-

necessary mechanical stress.

2. Description, technical data

The Professor Pohl torsional pendulum consists of a

wooden base plate with an oscillating system and an

electric motor mounted on top. The oscillating system

is a ball-bearing mounted copper wheel (5), which is

connected to the exciter rod via a coil spring (6) that

provides the restoring torque. A DC motor with coarse

and fine speed adjustment is used to excite the torsional pendulum. Excitement is brought about via an

eccentric wheel (14) with connecting rod (13) which

6

Page 2

unwinds the coil spring then compresses it again in a

periodic sequence and thereby initiates the oscillation

of the copper wheel. The electromagnetic eddy current brake (11) is used for damping. A scale ring (4)

with slots and a scale in 2-mm divisions extends over

the outside of the oscillating system; indicators are

located on the exciter and resonator.

The device can also be used in shadow projection demonstrations.

A DC power supply unit for the torsional pendulum

U11755 is required to power the equipment.

Natural frequency: 0.5 Hz approx.

Exciter frequency: 0 to 1.3 Hz (continuously adjustable)

Terminals:

Motor: max. 24 V DC, 0.7 A,

via 4-mm safety sockets

Eddy current brake: 0 to 24 V DC, max. 2 A,

via 4-mm safety sockets

Scale ring: 300 mm Ø

Dimensions: 400 mm x 140 mm x 270 mm

Ground: 4 kg

2.1 Scope of supply

1 Torsional pendulum

2 Additional 10 g weights

2 Additional 20 g weights

3. Theoretical Fundamentals

3.1 Symbols used in the equations

D = Angular directional variable

J = Mass moment of inertia

M = Restoring torque

T = Period

T0= Period of an undamped system

Td= Period of the damped system

= Amplitude of the exciter moment

M

E

b = Damping torque

n = Frequency

t = Time

Λ = Logarithmic decrement

δ = Damping constant

ϕ

= Angle of deflection

ϕ

= Amplitude at time t = 0 s

0

ϕ

= Amplitude after n periods

n

ϕ

= Exciter amplitude

E

ϕ

= System amplitude

S

ω0= Natural frequency of the oscillating system

ωd= Natural frequency of the damped system

ωE= Exciter angular frequency

ωE

= Exciter angular frequency for max. amplitude

res

Ψ0S= System zero phase angle

3.2 Harmonic rotary oscillation

A harmonic oscillation is produced when the restoring

torque is proportional to the deflection. In the case of

harmonic rotary oscillations the restoring torque is

proportional to the deflection angle ϕ:

M = D ·

ϕ

The coefficient of proportionality D (angular direction

variable) can be computed by measuring the deflection angle and the deflection moment.

If the period duration T is measured, the natural resonant frequency of the system ω0 is given by

ω

= 2 π/T

0

and the mass moment of inertia J is given by

D

2

ω

=

0

J

3.3 Free damped rotary oscillations

An oscillating system that suffers energy loss due to

friction, without the loss of energy being compensated

for by any additional external source, experiences a

constant drop in amplitude, i.e. the oscillation is

damped.

At the same time the damping torque b is proportional

to the deflectional angle

.

ϕ

.

The following motion equation is obtained for the

torque at equilibrium

.

..

JbD⋅+⋅+⋅=

ϕϕϕ

0

b = 0 for undamped oscillation.

If the oscillation begins with maximum amplitude

ϕ

at t = 0 s the resulting solution to the differential equation for light damping (δ² < ω0²) (oscillation) is as follows

–δ ·t

ϕ

ϕ

=

· e

· cos (

ω

0

d

· t)

δ = b/2 J is the damping constant and

2

ωωδ

=−

d

2

0

the natural frequency of the damped system.

Under heavy damping (δ² > ω0²) the system does not

oscillate but moves directly into a state of rest or equilibrium (non-oscillating case).

The period duration Td of the lightly damped oscillating system varies only slightly from T0 of the undamped

oscillating system if the damping is not excessive.

By inserting t = n · Td into the equation

–δ ·t

ϕ

ϕ =

and ϕ =

ϕ

tain the following with the relationship

ϕ

ϕ

· e

· cos (

ω

0

for the amplitude after n periods we ob-

n

n

0

δ

−⋅

n

=⋅

eT

d

d

· t)

ω

= 2 π/T

d

d

and thus from this the logarithmic decrement Λ:

Λ

=⋅ =⋅

δ

T

d

ϕ

1

In In

n

ϕ

n

0

ϕ

n

=

ϕ

n+1

0

7

Page 3

By inserting δ = Λ / Td ,

Ψ

ω

= 2 π / T0 and

0

ω

= 2π / T

d

into the equation

2

ωωδ

=−

d

2

0

we obtain:

2

TT

=⋅+1

d0

Λ

2

4

π

whereby the period Td can be calculated precisely provided that T0 is known.

3.4 Forced oscillations

In the case of forced oscillations a rotating motion with

sinusoidally varying torque is externally applied to the

system. This exciter torque can be incorporated into

the motion equation as follows:

.

..

JbD M t⋅+⋅+⋅= ⋅ ⋅

ϕϕϕ ω

sin

E

()

E

After a transient or settling period the torsion pendulum oscillates in a steady state with the same angular

frequency as the exciter, at the same time ωE can still

be phase displaced with respect to ω0. Ψ0S is the system’s zero-phase angle, the phase displacement between the oscillating system and the exciter.

ϕ

ϕ

=

· sin (

ω

· t –

Ψ

S

E

The following holds true for the system amplitude

M

ϕ

=

ωω δω

()

02E

J

2

2

−

)

0S

E

2

+⋅

4

ϕ

2

E

The following holds true for the ratio of system amplitude to the exciter amplitude

M

ϕ

S

=

ϕ

E

ω

E

−

14

ω

0

E

J

2

2

+

2

δ

ω

0

2

ω

E

⋅

ω

0

d

Stronger damping does not result in excessive amplitude.

For the system’s zero phase angle Ψ0S the following is

true:

arctan

ωω

=

0S

δω

2

22

−

ω

0

For ωE = ω0 (resonance case) the system’s zero-phase

angle is Ψ0S = 90°. This is also true for δ = 0 and the

oscillation passes its limit at this value.

In the case of damped oscillations (δ > 0) where

ωE < ω0, we find that 0° ≤ Ψ0S ≤ 90° and when ωE > ω

0

it is found that 90° ≤ Ψ0S ≤ 180°.

In the case of undamped oscillations (δ = 0), Ψ0S = 0°

for ωE < ω0 and Ψ0S = 180° for ωE > ω0.

4. Operation

4.1 Free damped rotary oscillations

• Connect the eddy current brake to the variable volt-

age output of the DC power supply for torsion pendulum.

• Connect the ammeter into the circuit.

• Determine the damping constant as a function of

the current.

4.2 Forced oscillations

S

• Connect the fixed voltage output of the DC power

supply for the torsion pendulum to the sockets (16)

of the exciter motor.

• Connect the voltmeter to the sockets (15) of the

exciter motor.

• Determine the oscillation amplitude as a function

of the exciter frequency and of the supply voltage.

• If needed connect the eddy current brake to the

variable voltage output of the DC power supply for

the torsion pendulum.

4.3 Chaotic oscillations

• To generate chaotic oscillations there are 4 supple-

mentary weights at your disposal which alter the

torsion pendulum’s linear restoring torque.

• To do this screw the supplementary weight to the

body of the pendulum (5).

In the case of undamped oscillations, theoretically

speaking the amplitude for resonance (ωE equal to ω0)

increases infinitely and can lead to “catastrophic resonance”.

In the case of damped oscillations with light damping

the system amplitude reaches a maximum where the

exciter’s angular frequency ω

is lower than the sys-

E res

tem’s natural frequency. This frequency is given by

2

δ

ωω

=⋅−1

Eres 0

2

2

ω

0

8

Page 4

5. Example experiments

5.1 Free damped rotary oscillations

• To determine the logarithmic decrement Λ, the

amplitudes are measured and averaged out over

several runs. To do this the left and right deflections of the torsional pendulum are read off the

scale in two sequences of measurements.

• The starting point of the pendulum body is located

at +15 or –15 on the scale. Take the readings for

five deflections.

• From the ratio of the amplitudes we obtain Λ us-

ing the following equation

ϕ

n

Λ

=

In

n

ϕ

n+1

ϕ

–

ϕ

+

0 –15 –15 –15 –15 15 15 15 15

1 –14.8 –14.8 –14.8 –14.8 14.8 14.8 14.8 14.8

2 –14.4 –14.6 –14.4 –14.6 14.4 14.4 14.6 14.4

3 –14.2 –14.4 –14.0 –14.2 14.0 14.2 14.2 14.0

4 –13.8 –14.0 –13.6 –14.0 13.8 13.8 14.0 13.8

5 –13.6 –13.8 –13.4 –13.6 13.4 13.4 13.6 13.6

nØ

ϕ

– Ø

ϕ

+

Λ

–

Λ

+

0 –15 15

1 –14.8 14.8 0.013 0.013

2 –14.5 14.5 0.02 0.02

3 –14.2 14.1 0.021 0.028

4 –13.8 13.8 0.028 0.022

5 –13.6 13.5 0.015 0.022

• The average value for Λ comes to Λ = 0.0202.

• For the pendulum oscillation period T the follow-

ing is true: t = n · T. To measure this, record the

time for 10 oscillations using a stop watch and calculate T.

T = 1.9 s

• From these values the damping constant δ can be

determined from δ = Λ / T.

δ

= 0.0106 s

–1

• For the natural frequency ω the following holds

true

2

π

2

ω

=

ω

= 3.307 Hz

T

2

δ

−

5.2 Free damped rotary oscillations

• To determine the damping constant δ as a function of the current Ι flowing through the electromagnets the same experiment is conducted with

an eddy current brake connected at currents of

Ι = 0.2 A, 0.4 A and 0.6 A.

ΙΙ

Ι = 0.2 A

ΙΙ

n

ϕ

– Ø

ϕ

– Λ –

0 –15 –15 –15 –15 –15

1 –13.6 –13.8 –13.8 –13.6 –13.7 0.0906

2 –12.6 –12.8 –12.6 –12.4 –12.6 0.13

3 –11.4 –11.8 –11.6 –11.4 –11.5 0.0913

4 –10.4 –10.6 –10.4 –10.4 –10.5 0.0909

5 9.2 –9.6 –9.6 –9.6 –9.5 0.1

• For T = 1.9 s and the average value of Λ = 0.1006

we obtain the damping constant: δ = 0.053 s

ΙΙ

Ι = 0.4 A

ΙΙ

n

ϕ

– Ø

ϕ

– Λ –

–1

0 –15 –15 –15 –15 –15

1 –11.8 –11.8 –11.6 –11.6 –11.7 0.248

2 –9.2 –9.0 –9.0 –9.2 –9.1 0.25

3 –7.2 –7.2 –7.0 –7.0 –7.1 0.248

4 –5.8 –5.6 –5.4 –5.2 –5.5 0.25

5 –4.2 –4.2 –4.0 –4.0 –4.1 0.29

• For T = 1.9 s and an average value of Λ = 0.257 we

ϕ

– Λ –

–1

obtain the damping constant: δ = 0.135 s

ΙΙ

Ι = 0.6 A

ΙΙ

n

ϕ

– Ø

0 –15 –15 –15 –15 –15

1 –9.2 –9.4 –9.2 –9.2 –9.3 0.478

2 –5.4 –5.2 –5.6 –5.8 –5.5 0.525

3 –3.2 –3.2 –3.2 –3.4 –3.3 0.51

4 –1.6 –1.8 –1.8 –1.8 –1.8 0.606

5 –0.8 –0.8 –0.8 –0.8 –0.8 0.81

• For T = 1.9 s and an average value of Λ = 0.5858

we obtain the damping constant: δ = 0.308 s

–1

5.3 Forced rotary oscillation

• Take a reading of the maximum deflection of the

pendulum body to determine the oscillation amplitude as a function of the exciter frequency or

the supply voltage.

T = 1.9 s

Motor voltage V

ϕ

3 0.8

4 1.1

5 1.2

6 1.6

7 3.3

7.6 20.0

8 16.8

9 1.6

10 1.1

9

Page 5

• After measuring the period T the natural frequency

of the system ω0 can be obtained from

ω

= 2 π/T = 3.3069 Hz

0

• The most extreme deflection arises at a motor voltage of 7.6 V, i.e. the resonance case occurs.

• Then the same experiment is performed with an

eddy current brake connected at currents of

Ι = 0.2 A, 0.4 A and 0.6 A.

ΙΙ

Ι = 0.2 A

ΙΙ

Motor voltage V

ϕ

3.0 0.9

4.0 1.1

5.0 1.2

6.0 1.7

7.0 2.9

7.6 15.2

8.0 4.3

9.0 1.8

10.0 1.1

ΙΙ

Ι = 0.6 A

ΙΙ

Motor voltage V

5.0 1.3

6.0 1.8

7.0 3.6

7.6 7.4

8.0 3.6

9.0 1.6

10.0 1.0

3.0 0.9

4.0 1.1

5.0 1.2

6.0 1.6

7.0 2.8

7.6.0 3.6

8.0 2.6

9.0 1.3

10.0 1.0

ϕ

ΙΙ

Ι = 0.4 A

ΙΙ

Motor voltage V

3.0 0.9

4.0 1.1

A

[skt]

20

15

10

• From these measurements the resonance curves can

be plotted in a graph depicting the amplitudes

ϕ

against the motor voltage.

• The resonant frequency can be determined by find-

ing the half-width value from the graph.

I=0,0A

I=0,2A

I=0,4A

5

1

012

Resonance curves

3

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com • Technical amendments may occur

567 8910

4

10

I=0,6A

u[v]

Loading...

Loading...