Page 1

Operating Manual

February 2013

ZEN 2012 (black edition)

Lightsheet Z.1

Page 2

Carl Zeiss Copyright Lightsheet Z.1

Knowledge of this manual is required for the operation of the instrument. Would you therefore please

make yourself familiar with the contents of this manual and pay special attention to hints concerning the

safe operation of the instrument.

The specifications are subject to change; the manual is not covered by an update service.

© Unless expressly authorized, forwarding and duplication of this document, and the utilization and

communication of its contents are not permitted. Violations will entail an obligation to pay

compensation.

All rights reserved in the event of granting of patents or registration of a utility model.

Issued by Carl Zeiss Microscopy GmbH

Carl-Zeiss-Promenade 10

07745 Jena, Germany

microscopy@zeiss.com

www.zeiss.com/microscopy

II 000000-1790-528 02/2013

Page 3

INTRODUCTION

Lightsheet Z.1 Carl Zeiss

Contents of this Manual

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Annex

Hardware

Sample Preparation

Quick Guide

Software Operation

Lightsheet Z.1 - Overview

02/2013 000000-1790-528 III

Page 4

Page 5

CHAPTER 1 - HARDWARE Lightsheet Z.1 Content Carl Zeiss

CHAPTER 1 HARDWARE

CONTENT

Page

1 MAINTENANCE AND CLEANING ......................................................................... 3

1.1 Maintenance of the Liquid Cooling System ................................................................. 5

2 ERGODRIVE OPERATING PANEL ......................................................................... 6

3 USER INTERFACES ............................................................................................... 9

3.1 Installation and Deinstallation of the Detection Modules ........................................ 10

3.2 Adjustment – Detector Recognition ........................................................................... 15

3.2.1 Adjustment – Automatic Detector Alignment .................................................................. 15

3.2.2 Adjustment – Manual Detector Alignment ...................................................................... 17

3.2.3 Adjust the Grating Focus for the Automatic or Manual Detector Alignment Tool .............. 19

3.2.4 Cable Connections for the Detection Module "PCO.Edge" .............................................. 22

3.2.5 Cable Connections for the Detection Module "Standard" ............................................... 23

3.3 Assembly of the Sample Chamber ............................................................................. 24

3.3.1 Assembly of the Sample Chamber Windows ................................................................... 24

3.3.2 Assembly of the Sample Chamber Body and the Sample Chamber Dove Tail Slide ............ 27

3.3.3 Insertion of the Drain Connector, Luer-Lock Connectors and Blind Plugs .......................... 29

3.3.4 Insertion of Accessories for Incubation ............................................................................ 30

3.4 Removing and Inserting the Sample Chamber .......................................................... 31

3.5 Assembly of the Sample Holder ................................................................................. 32

3.5.1 Assembly of the Sample Holder for Capillary ................................................................... 32

3.5.2 Assembly of Sample Holder for Syringes .......................................................................... 34

3.6 Inserting and Removing the Sample Holder .............................................................. 35

3.7 Installation of the Incubation Modules ...................................................................... 37

3.7.1 Heating Components ..................................................................................................... 37

3.7.2 CO

3.7.3 Heating Device Humidity S1 ............................................................................................ 41

3.7.4 Registration of the incubation modules ........................................................................... 41

3.8 Switch Incubation ON and OFF ................................................................................... 43

02/2013 000000-1790-528 1

-Module Lightsheet Z.1 ............................................................................................. 39

2

Page 6

CHAPTER 1 - HARDWARE

Carl Zeiss Content Lightsheet Z.1

3.9 Illumination and Detection Optics ............................................................................. 43

3.9.1 Removing and Inserting the Illumination Optics Unit ....................................................... 45

3.9.2 Removing and Inserting the Detection Optics Unit........................................................... 46

3.10 Removing and Inserting the Reflector Turret for Emission Selection ...................... 47

3.11 Removing and Inserting the Reflector Turret for Laser Blocking Filter .................... 49

4 INDEX ................................................................................................................. 52

2 000000-1790-528 02/2013

Page 7

CHAPTER 1 - HARDWARE

Lightsheet Z.1 Maintenance and Cleaning Carl Zeiss

1 Maintenance and Cleaning

The maintenance to be carried out by the customer is limited to cleaning the painted surfaces, replacing

glass windows and rubber seals on the sample chamber, cleaning and disinfecting the system cavity and

sample chamber, temperature sensors and detection optics unit, replenishment of coolants for the

incubation device and liquid cooling of the detection module as necessary, as well as the replacement of

CO

sterile filters for the incubation device.

2

a) To clean painted surfaces proceed as follows:

• Switch the device off completely and pull the mains plug.

• Make sure that no cleaning fluid is allowed to enter the system.

• Wipe the painted surfaces with a clean cloth moistened with water to which a small amount of

cleaning agent has been added. Do not use a solvent. Dry off with a lint-free cloth.

b) To clean and disinfect the system cavity proceed as follows:

• Switch the device off completely and pull the mains plug.

• Make sure that no cleaning fluid is allowed to enter the system.

• Take care not to touch the front lens of the illumination and detection optics units. Remove these

optics as necessary.

• Remove the sample chamber for cleaning.

• Cleaning the system cavity:

Wipe the inner surfaces of the system cavity with a clean cloth moistened with water to which a

small amount of cleaning agent has been added. Do not use a solvent. Dry off with a lint-free

cloth.

• Disinfecting the system cavity:

Carefully wipe the inner surfaces of the sample chamber with a lint-free cloth soaked in 70

ethanol or 70

% isopropyl. Allow the solution to react for a few seconds. Repeat the procedure

%

once or twice as necessary. Carefully wipe off the inner surfaces with a lint-free cloth soaked in

distilled water.

02/2013 000000-1790-528 3

Page 8

CHAPTER 1 - HARDWARE

Carl Zeiss Maintenance and Cleaning Lightsheet Z.1

c) To clean and disinfect the sample chamber proceed as follows:

• Remove the sample chamber and dismantle it into individual parts. Different procedures are required

for cleaning and disinfecting the various parts of the sample chamber.

− The cover glasses must be properly disposed of in the glass waste.

− The steel parts of the chamber must be cleaned and disinfected as follows:

Rinse the parts with distilled water.

Lay the parts in an ultrasonic bath containing distilled water to which a few drops of detergent

have been added.

Then rinse the steel parts thoroughly with distilled water until all detergent residue has been

removed.

The parts may be laid in a disinfecting bath of 70

% ethanol (> 1 hour) and then thoroughly

rinsed with distilled water.

The steel parts of the sample chamber may also be autoclaved as necessary.

− Sealing rings, hose connectors and blank plugs must be cleaned and disinfected as follows:

These parts may not be autoclaved.

First of all lay these parts in distilled water and then in a 70 % ethanol solution for max. one

hour. Rinse them thoroughly with distilled water.

d) To clean and disinfect the temperature sensor proceed as follows:

• Remove the temperature sensor from the sample chamber and loosen the connections to the main

system module Lightsheet Z.1.

• Once removed, thoroughly rinse the temperature sensor with distilled water and then suspend it for

one hour in a 70

% ethanol solution. Make sure that the contact plug remains dry. Complete the

cleaning process by rinsing thoroughly with distilled water.

4 000000-1790-528 02/2013

Page 9

CHAPTER 1 - HARDWARE

Lightsheet Z.1 Maintenance and Cleaning Carl Zeiss

e) To clean and disinfect the detection optics unit proceed as follows:

• Make sure that no cleaning fluid is allowed to enter the system.

• To avoid scratches, do not wipe the front lens of the optics with dry lens paper and lens cloths.

• Remove these optics from the system cavity as necessary.

• Clean the front lens of optical elements according to general recommendations (see "The clean

microscope" www.zeiss.com/microscopy) using an optical cleaning solution (Carl Zeiss optical cleaning

solution: 85

% n - hexan, 15 % isopropanol. This solution is not sold by Carl Zeiss Microscopy GmbH)

and a suitable lens cleaning paper or high purity cotton wool.

• In addition to the cleaning procedure described above, for special sterility requirements the front lens

area of the detection modules can be cleaned several times with a lint-free lens cloth or lens paper

soaked in 100

% ethanol. Here again, observe the general notes on cleaning the optics

("The clean microscope").

1.1 Maintenance of the Liquid Cooling System

If detection modules in your Lightsheet Z.1 are connected to a liquid cooling system, consider that the pH

value of the cooling liquid changes over time.

To prevent corrosion in the cooler of the detection module, the pH value of the cooling liquid must be

checked at least once a year and the liquid replaced as necessary. Observe the directions of the cooling

system manufacturer in the supplied operating manual.

If you have signed a service agreement with Carl Zeiss, our service staff will perform the check as part of

the maintenance procedure.

The safety data sheet for the cooling liquid should also be observed.

02/2013 000000-1790-528 5

Page 10

CHAPTER 1 - HARDWARE

Carl Zeiss ErgoDrive Operating Panel Lightsheet Z.1

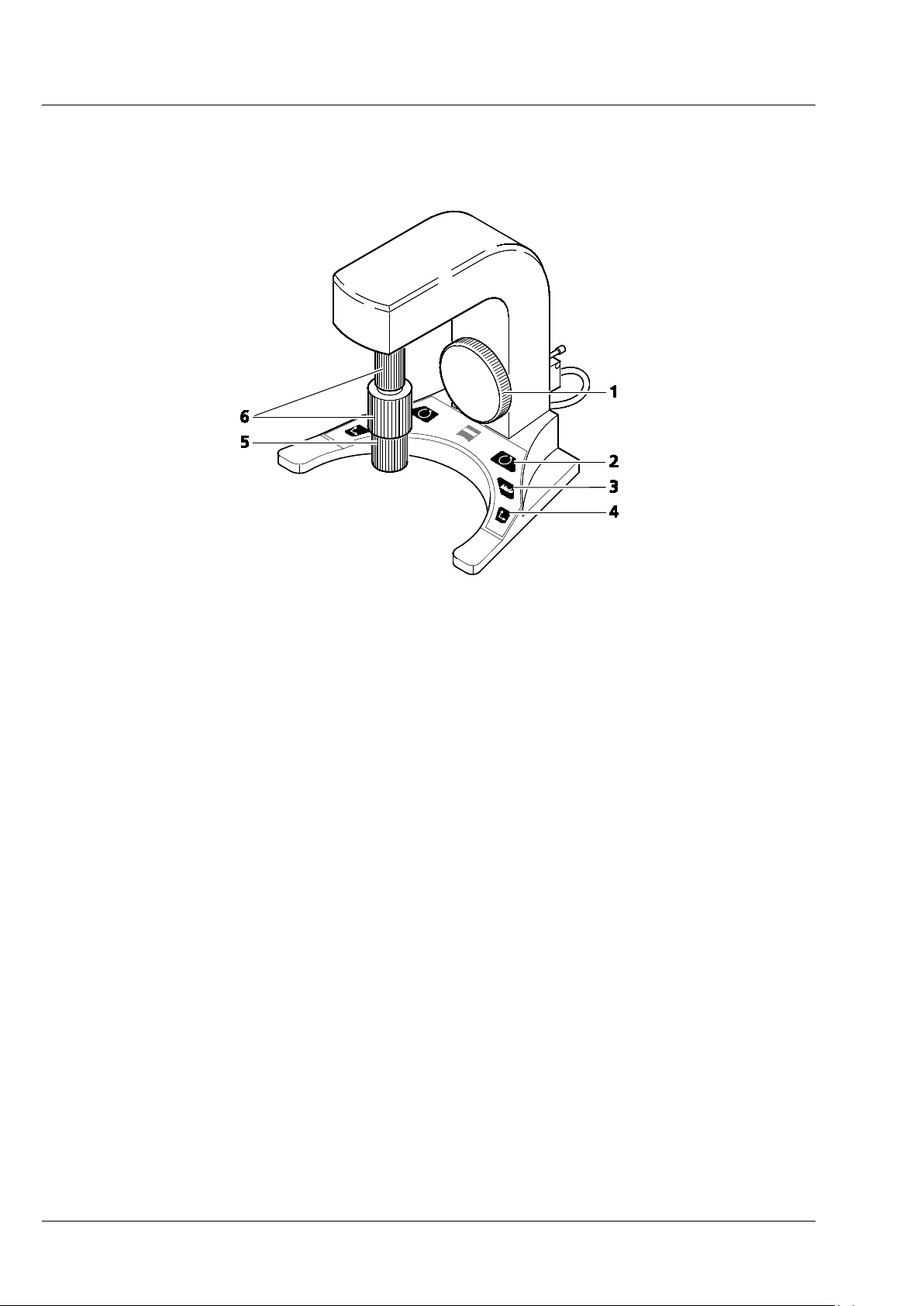

2 ErgoDrive Operating Panel

1 Z-axis control

2 Rotation button (switches 6 to rotation drive)

3 Mode button (fine / coarse)

4 Axis button (switches 6 to y-axis drive)

5 X-axis control

6 Y-axis / Rotation control

Fig. 1 ErgoDrive operating panel

6 000000-1790-528 02/2013

Page 11

CHAPTER 1 - HARDWARE

Lightsheet Z.1 ErgoDrive Operating Panel Carl Zeiss

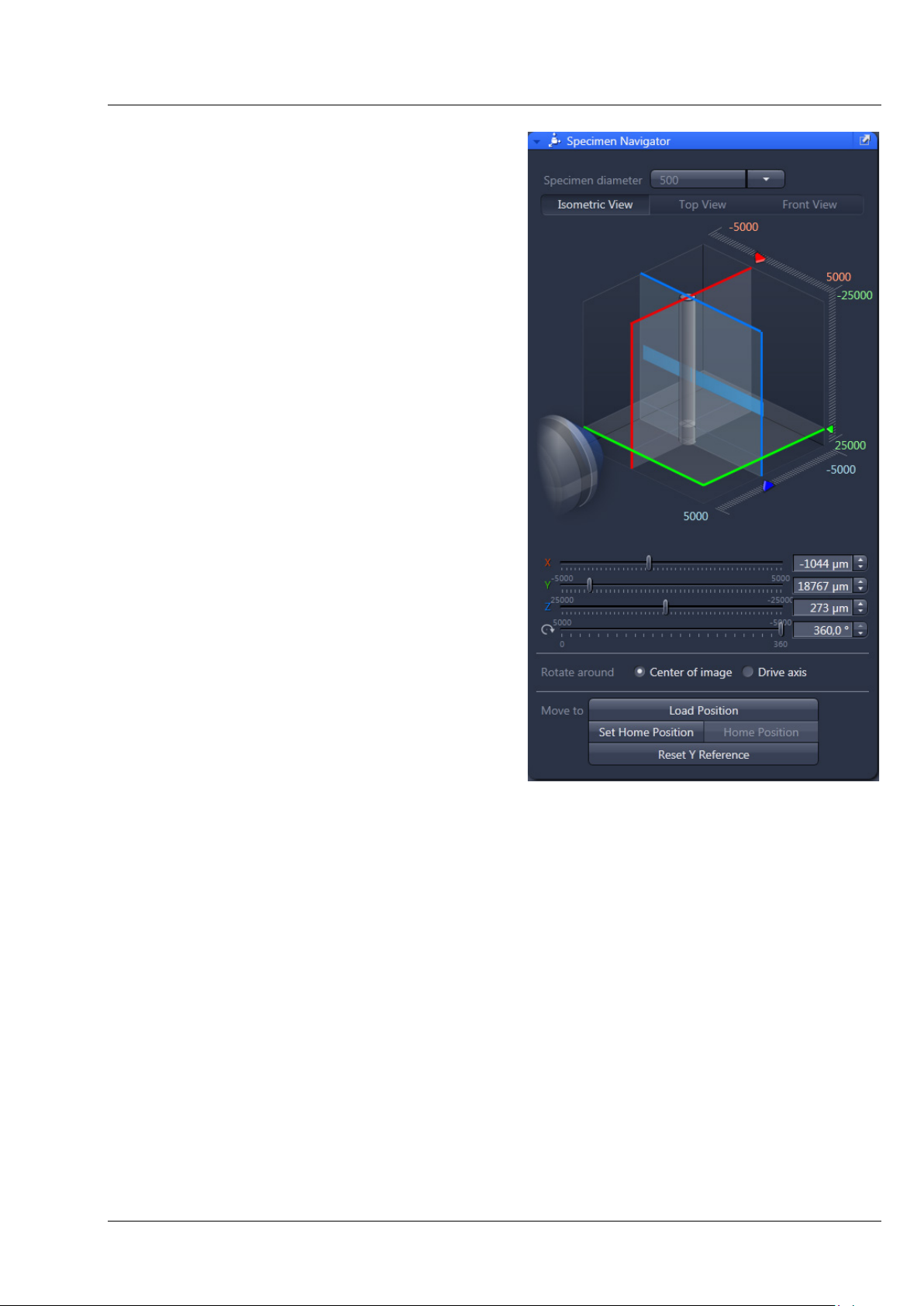

With the ErgoDrive operating panel the movement

of the sample holder and therefore the sample can

be controlled. It is the manual equivalent of sliders

in the Specimen Navigator tool in the ZEN

software (Fig. 2), with which the movement of the

specimen can be controlled as well.

The function to rotate around the center of the

image, Rotate around Center of image (Fig. 2) is

only available through the software interface. Even

if chosen there, the rotation controlled by the

ErgoDrive operating panel will always rotate

around the axis of the motor drive.

The steering elements are two vertical rotary

controls for the x, y and rotation movement.

The large rotary wheel controls the z movement

(Fig. 1).

Fig. 2 ZEN software, Specimen Navigator

tool window

02/2013 000000-1790-528 7

Page 12

CHAPTER 1 - HARDWARE

Carl Zeiss ErgoDrive Operating Panel Lightsheet Z.1

The following control elements are part of the ErgoDrive operation panel:

Buttons:

The Mode button (Fig. 1/3) changes the speed of the drive from coarse to fine and back.

The Rotation button (Fig. 1/2) changes the upper rotary control to move the rotation drive (Fig. 1/6).

The Axis button (Fig. 1/4) changes the upper rotary control to move the y drive (Fig. 1/6).

Rotation control:

Upper rotary control (Fig. 1/6), after pressing the Rotation button (Fig. 1/2):

Clockwise: clockwise rotation of the sample; the angle is reduced in the software interface

Counter-clockwise: counter-clockwise rotation of the sample, the angle is increased in the

software interface

Y axis control:

Upper rotary control (Fig. 1/6), after pressing Axis button (Fig. 1/4):

Clockwise: upward movement of the sample

Counter-clockwise: downward movement of the sample

X axis control:

Lower rotary control (Fig. 1/5):

Clockwise: right movement of the sample

Counter-clockwise: left movement of the sample

Z axis control:

Large rotary wheel (Fig. 1/1):

Clockwise: sample movement towards the detection optic

Counter-clockwise: sample movement away from the detection optic

8 000000-1790-528 02/2013

Page 13

CHAPTER 1 - HARDWARE

nd lower system cavity doors and the upper

system door are equipped with a safety interlock system to guarantee laser safety. These

be manipulated. Other interfaces not described here are reserved for

ervice personnel. The following devices

Lightsheet Z.1 User Interfaces Carl Zeiss

3 User Interfaces

The ports of the detection modules, upper a

locking devices must not

service and may only be used by authorized Carl Zeiss s

may be mounted and dismounted by, or are accessible to, the user:

− Detection modules

− Sample chamber

− Sample Holder

− Incubation components

− Illumination optics

− Detection optics

− Reflector turret.

Customized Sample Chamber

The sample chamber delivered with the Lightsheet Z.1 can be used with a multitude of media (e.g. PBS,

cell culture medium, artificial sea water) and is carefully designed to produce optimal results with the

Lightsheet Z.1 system. However, if applications demand changes to the original sample chamber, Carl

Zeiss Microscopy GmbH provides the CAD files and the corresponding technical drawing of our sample

chamber for your convenience, in accordance with the following disclaimer:

Carl Zeiss Microscopy GmbH (hereinafter “we”) hereby informs you that we will warrant the specified and

agreed performance of the Lightsheet Z.1 system only if sample chambers are applied and used that

either are delivered or explicitly approved by us.

The sample chamber design has been optimized to ensure the most established applications of Light

Sheet Fluorescence Microscopy. Exceptional applications may require a slightly modified sample chamber

design. In order to enable customized modifications of the existing sample chamber we also provide the

corresponding CAD file and a technical drawing. We explicitly advise you that already minor deviations of

the dimensions and tolerances specified in these documents will cause a significant loss of image quality

and can potentially result in a liquid leakage. Therefore, you will not hold us or one of our affiliates liable

for any damages caused by the employment of self-built or third-party-built sample chambers, the use of

such self-built or third-party-built sample chambers will be solely on your own risk. Furthermore we want

to inform you, that we will not render any assistance relating to the production and application of such

self-built or third-party-built sample chambers.

02/2013 000000-1790-528 9

Page 14

CHAPTER 1 - HARDWARE

o cool the

Carl Zeiss User Interfaces Lightsheet Z.1

3.1 Installation and Deinstallation of the Detection Modules

A cooling liquid defined as a hazardous substance is used in the Lightsheet Z.1 t

detection modules (depending on configuration). The supplied safety data sheet with notes on

hazards and safety measures must be observed when handling the cooling liquid.

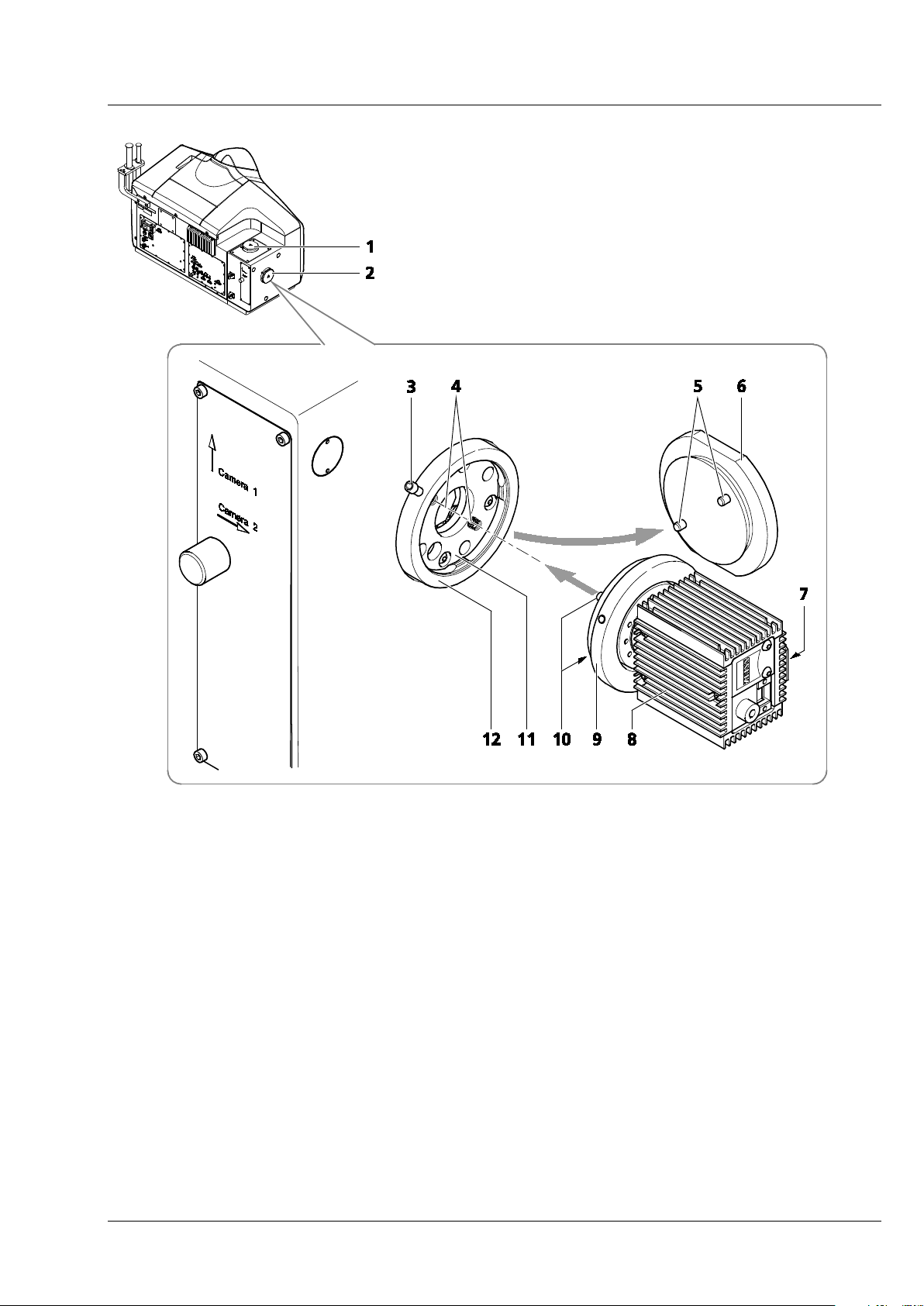

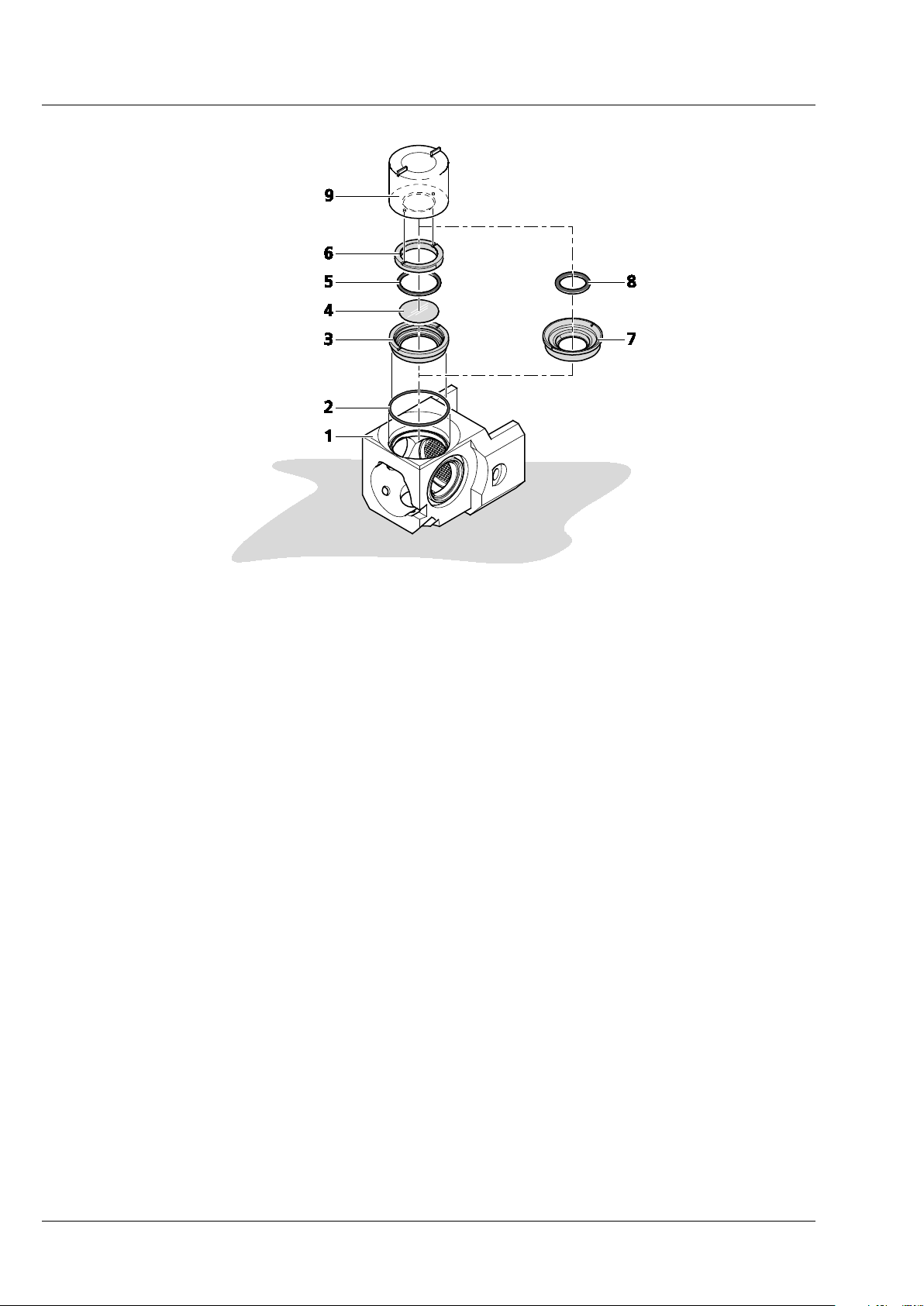

The ports of the detection modules, reflection (Cam1) (Fig. 3/1) and transmission (Cam2) (Fig. 3/2), on

the main system module Lightsheet Z.1 are equipped with a hardware interlock device. The contact rings

(Fig. 3/9) are connected to the detection modules (Fig. 3/8) and adjusted in the factory. When handling

the detection modules, ensure that neither tilting nor rotation forces are exerted on this connection to

avoid misalignment. The detection module should be gripped as close as possible to the contact ring.

A rotation guard plate (Fig. 3/7) is mounted on the contact ring of each detection module. When

mounting on both ports this must point toward the front side of the Lightsheet Z.1. It prevents rotation

of the detection module and carries the laser protection notice.

Never remove the rotation guard plates of the detection module adapters. Do not modify or

manipulate the detection module adapters.

The lock is functioning when the sensors (Fig. 3/4) of the sensor disk (Fig. 3/11) are pressed down by the

pins of the contact ring (Fig. 3/10 or 5 for blind cap). If this is not the case, e.g. the space between the

two devices is too large, the laser is blocked and the system cannot be used.

If the system does not function after a detection module has been attached to or removed from a

port with a safety interlock, check the connection of the contact ring on the respective detection

module or blind cap (Fig. 3/9 or 6) to the sensor ring.

10 000000-1790-528 02/2013

Page 15

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

1 Detector port 1 (reflection, Cam1)

2 Detector port 2 (transmission, Cam2)

3 Securing screw

4 Sensors (2×) in sensor ring

5 Contact pins (2×) on blind cap

6 Blind cap

7 Rotation guard plate with laser protection notice

8 Detection module (varies)

9 Contact ring of the detection module

10 Contact pins (2×) on contact ring

11 Sensor disk

12 Sensor ring

Fig. 3 Mounting and dismounting the detection modules

02/2013 000000-1790-528 11

Page 16

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

The exchange of the detection modules on your Lightsheet Z.1 can be divided into two parts. One deals

with the actual mounting and dismounting of the detection modules and their connections to the

system. The second part deals with the registration and alignment of the detection module using specific

software tools.

The Lightsheet Z.1 must be completely turned off before changing detection modules.

No sample, capillary or similar object must be in the beam path while the alignment and calibration

tasks are performed.

1) Dismounting and Mounting of Detection Modules

− Disconnect all cables from the detection module.

− The connection of the liquid cooling can stay in place, but the power plug for the liquid cooling

unit must be pulled when the detection module is not in use.

− Now disconnect all cables from the Lightsheet Z.1 system and the PC for system control. Even if the

detection modules are regularly switched no cable should remain on the system.

− Hold the detection module firmly in one hand.

− Loosen the securing screw with an Allen wrench (Fig. 3/3) on the sensor ring (Fig. 3/12) of the

detector port (Fig. 3/1 and 2).

− Carefully pull away the detection module (Fig. 3/8) with contact ring (Fig. 3/9) using a slight tilting

motion if necessary.

− Cover the detector port (Fig. 3/1 and 2) on the main system module Lightsheet Z.1 and on the

detection module with the caps provided (Fig. 3/6).

− For mounting the new detection module, proceed in the reverse order. Tighten the securing screw

(Fig. 3/3) on the sensor ring (Fig. 3/12) of the detector port (Fig. 3/1 and 2) without applying force.

− With the detection module "PCO.Edge," note that part of the optics projects beyond the contact

ring. To protect it from damage and fingerprints, first push the optics into the port and then

connect the contact ring to the sensor ring.

− Connect all necessary cables to the detection module, the Lightsheet Z.1 and the PC for system

control (see section 3.2.4 Cable Connections for the Detection Module "PCO.Edge" and

3.2.5, Cable Connections for the Detection Module "Standard").

− Use the cable holder (Fig. 3/3) on the system table to connect the cables (Fig. 3/1) of the detection

modules without tension.

12 000000-1790-528 02/2013

Page 17

CHAPTER 1 - HARDWARE

Fig.

Lightsheet Z.1 User Interfaces Carl Zeiss

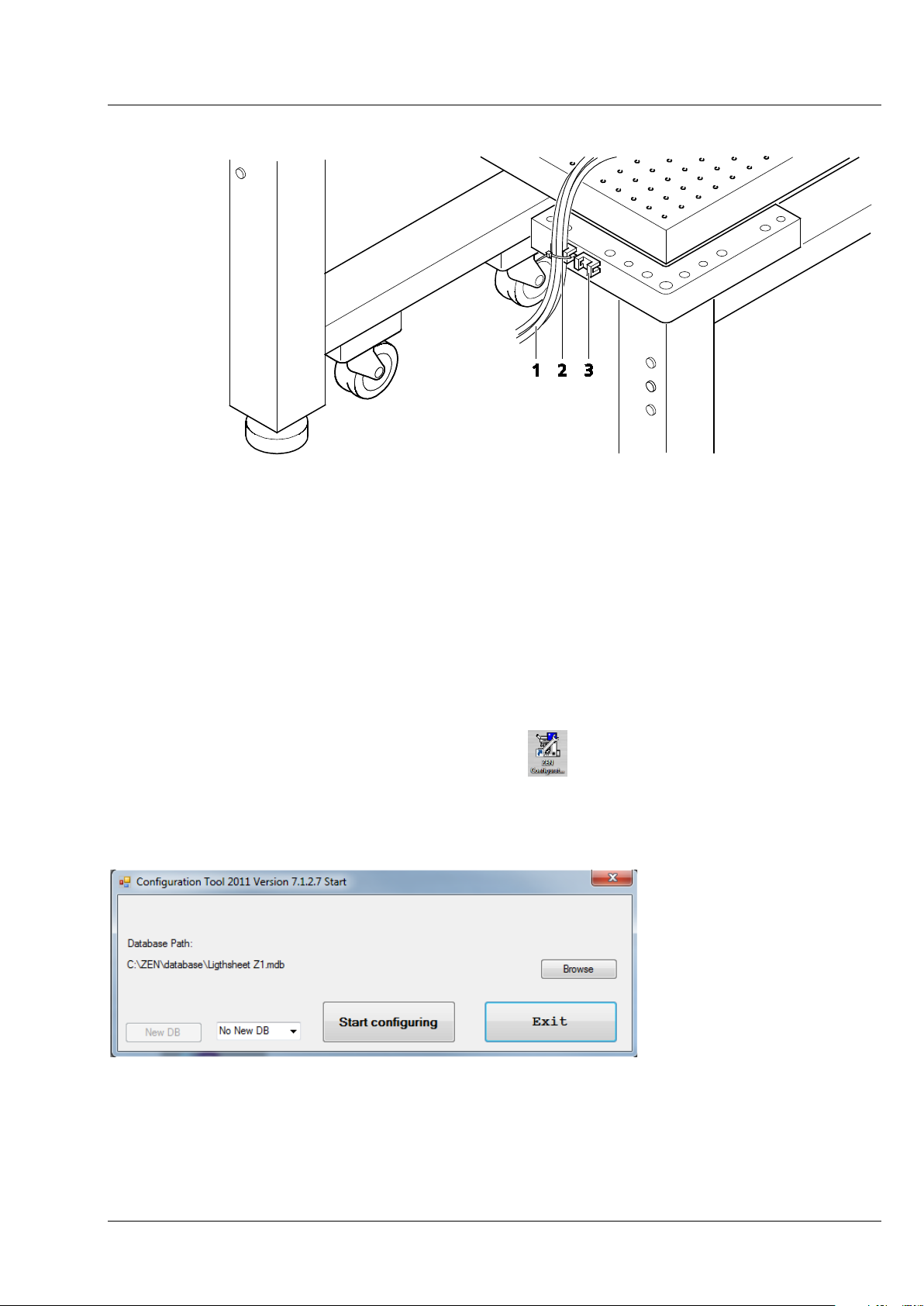

1 Cable (e. g. of the detection modules)

2 Cable tie

3 Cable holder on system table

Fig. 4 Cable strain relief

− Turn on the system (see CHAPTER 4, SYSTEM OPERATION).

2) Registration and Alignment of the detection modules

− After the Lightsheet Z.1 and the PC for system control are turned on and the operation system has

booted, start the software ZEN Configuration Tool

. This can be found either as a shortcut on

your desktop or in this directory: C:\ZEN\HWT as Configuration Tool 2012.exe.

− In the opening window press the Start configuring button (Fig. 5).

5 ZEN Configuration Tool Start-up window

02/2013 000000-1790-528 13

Page 18

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

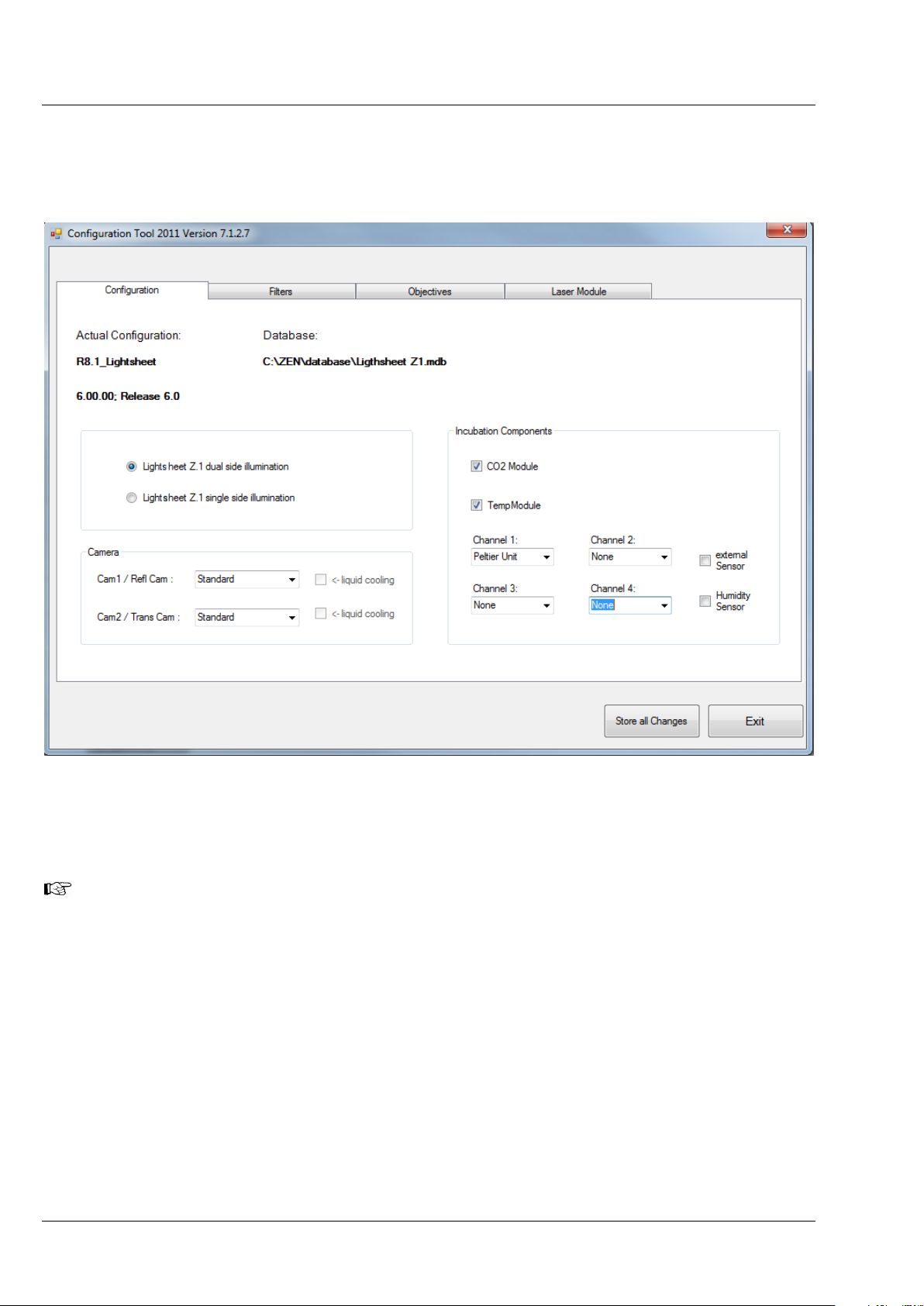

− On the Configuration tab (Fig. 6) you will find a Camera field with a drop – down menu for both

detector ports (Cam1, Cam2). Select the detection module(s) you are planning to use. When you

use the PCO.Edge, the checkbox liquid cooling will be marked automatically.

Fig. 6 ZEN Configuration Tool, Configuration tab

− Press the Store all Changes button and then exit the Configuration Tool. This will save the

changes you have made into the database of your system.

If you plan to exchange detection modules on a regular basis, it can be helpful to create two

databases, one for each detection module type. To do so, copy the original database with a

different name (you find it in the directory: C:\ZEN\database) and modify it with the Configuration

Tool accordingly. Make sure to always keep the original database. Name both databases, to easily

identify them. When ZEN is started open the Boot Status with the black arrow and then the

Hardware configuration database the same way (Fig. 7). Here you can choose which database

to use. The Recent… button shows all databases that have been used lately. The Choose… button

opens a window explorer window which allows one to search for a database to use.

14 000000-1790-528 02/2013

Page 19

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

− Now start the ZEN (black edition) software

and perform the following tasks found in the

Maintain tab:

• Detector recognition

• Automatic Detector Alignment; and

if necessary

• Manual Detector Alignment.

− It might be necessary to adjust the focus

of the calibration grating (Fig. 8) for

the Automatic or Manual Detector

Alignment task. Start one of these tasks to

get a live image of the grating for evaluating

and adjusting the focus if applicable (see

section 3.2.2 Adjustment – Manual

Detector Alignment).

Fig. 7 ZEN Start-up window

3.2 Adjustment – Detector Recognition

When the detection modules are exchanged or attached to the Lightsheet Z.1 system for the first time,

the system must identify which detection module is present for which channel. Pressing the button

Detector recognition will start an identification routine to do this job. A progress bar is visible during

the process. When the Cancel button is pressed, the operation is aborted without saving any result. This

routine must be conducted before the Automatic or Manual Detector Alignment. At the end of this

process you be informed if the detector recognition had to perform any changes. If so, please restart the

ZEN software before continuing.

3.2.1 Adjustment – Automatic Detector Alignment

This adjustment is necessary for one or two detection modules, when:

• detection modules have been exchanged

• reflector turrets have been removed and inserted (restart ZEN before the alignment task)

• recognition of a pixel shift between channels

• the zoom is not centered.

No sample should be present. The necessary correction plate and grating is present for each channel

within the system and needs no additional activation.

The Automatic Detector Alignment will align the image center with the detection module center (zoom

center). For two detection modules, it will additionally align both to have overlapping pixels.

After detection module exchange, first press the Detector recognition button in the Adjustment

tool window.

02/2013 000000-1790-528 15

Page 20

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

After pressing the Automatic Detector Alignment button, a wizard window (Fig. 8) will open that

guides you through the process. Press the Next button after each step to continue or the Previous

button to move one step back. If you press Cancel you will abort the process without saving any results.

The first step (Fig. 8) automatically positions the

necessary grating into the light path and adjusts

brightness and contrast. A progress bar is present

in the lower part of the window. You can follow

the process in the displayed live image. You find

the following text below the live image:

“This will start detector alignment for all available

detectors and filter positions in the system. Autoadjustment of brightness and contrast, please

wait.”

If the live image of the grating shows the

grid pattern out-of-focus, cancel the

Fig. 8 Automatic Detector Alignment, first

step

Automatic Camera Alignment wizard and

first manually adjust the focus of the grating.

The necessary steps are described in section

3.2.3 Adjust the Grating Focus for the

Automatic or Manual Detector

Alignment Tool.

In Step 2 the movement of the correction plates is calibrated for both channels. There is no interaction

needed. Press the Next button to continue after the task is done. The following text is displayed:

“Calibration of correction plate movement, please wait.”

In Step 3 the zoom center is determined. A graphic of the grating is displayed at the left hand side of the

window (Fig. 9). Two squares are labeled with white crosses in this image. On the right hand side, a live

image of the grating is shown. Now mark the same squares as shown in the graphic in the live image by

simply clicking on them with the left mouse button. This will be repeated for a second zoom step. The

following text will be shown: “Determining the detector center. Please click on the two squares in the

right live image of the grid that are shown with the white cross within the left image display. Repeat for

both zoom settings, then continue.”

16 000000-1790-528 02/2013

Page 21

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

Step 4 is the final step in which the alignment for

all filters and detection module channels is

performed. A progress bar is present at the bottom

of the window. When the procedure is finished the

Finish button becomes available, press it to save

all adjustments and leave the wizard. This text is

displayed: “Detector Alignment for all available

filters in progress, please wait.”

If you still encounter pixel shifts between the two

channels after the Automatic Camera Alignment

tool, you can fine tune settings using the Manual

Detector Alignment tool, see section 3.2.3 Adjust

the Grating Focus for the Automatic or

Manual Detector Alignment Tool.

Fig. 9 Automatic Detector Alignment,

third step

3.2.2 Adjustment – Manual Detector Alignment

This adjustment is necessary for one or two

detection modules when you recognize a pixel shift

between channels, or when the zoom is not

centered.

The Automatic Detector Alignment

should always be performed first since it

might already solve the problems.

Furthermore it defines the settings for the

combination Channel 1 (Cam1) and

position 1 of the Emission Selection Filter,

which should be used as the reference

during the Manual Detector Alignment.

The Zoom in the Acquisition tool window

is fixed to 1 while performing the Manual

Detector Alignment.

Fig. 10 Manual Detector Alignment

window

02/2013 000000-1790-528 17

Page 22

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

No sample should be present when performing this task. When pressing the Manual Detector

Alignment button, a window will open (Fig. 10). A grating is automatically inserted into the light path

and a live image of it is shown in a new image container within the ZEN software. The Set Exposure

button is activated automatically to adjust brightness. All components of the light path can be controlled

in the Manual Detector Alignment window. The light source is the LED white light source to ensure

the visibility of the grating independent of the filters in the light path. All other controls for adjusting

imaging settings should be controlled in the tool windows of the main software.

The activated (blue) Automatic button loads the

settings which have been previously defined with

the Automatic Detector Alignment for each light

path.

After pressing the Continuous button in the

Manual Detector Alignment window or in the

Main tool tabs a new image will open with a live

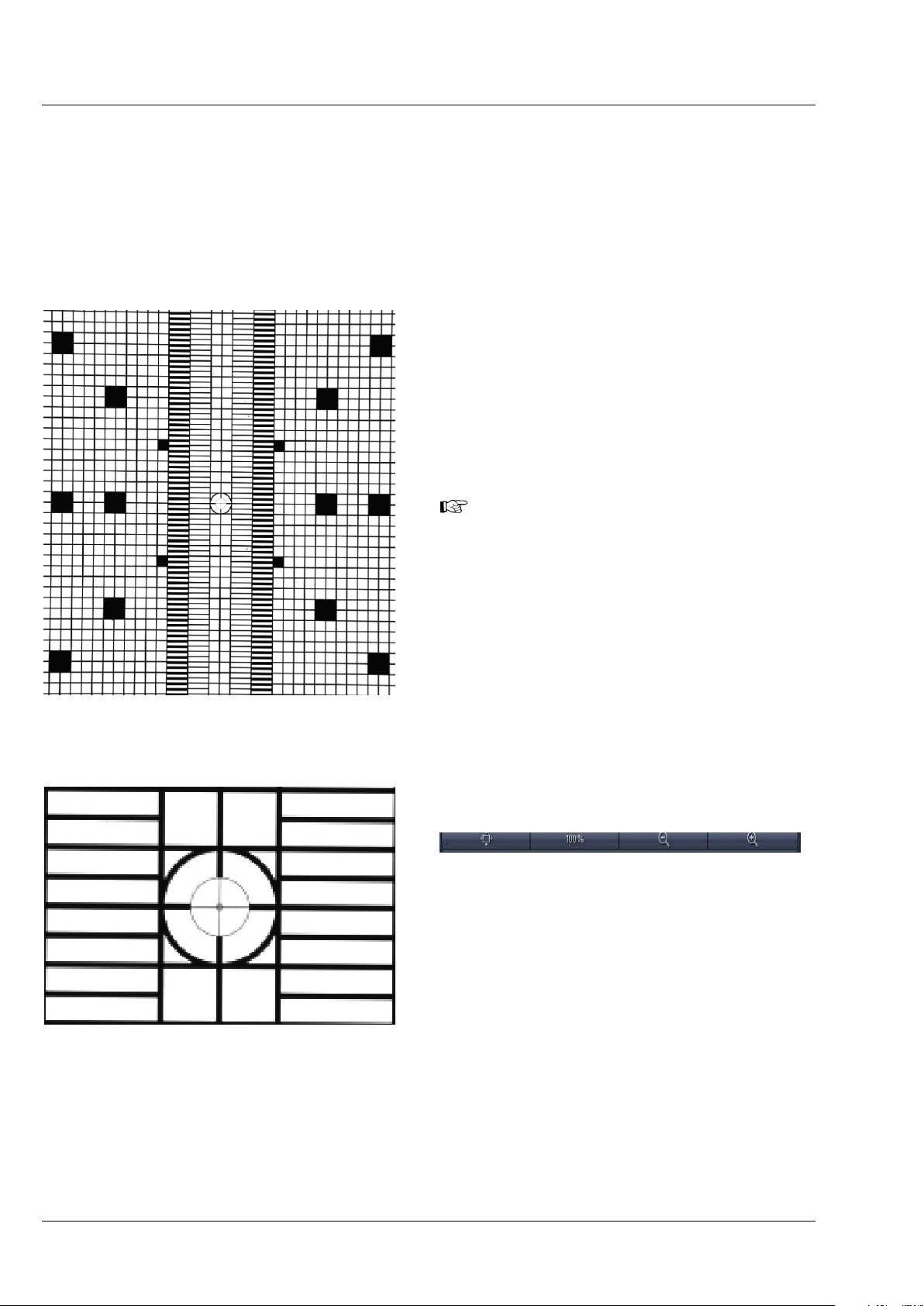

image of the grating (Fig. 11)

Fig. 11 Manual Detector Alignment,

Grating at Zoom 1

When the grating is out of focus, you need

to refocus it for the relevant channel by

performing the steps described in section

3.2.3. To check the focus, zoom into the

image using the Zoom function and look at

the center cross within the square (Fig. 12). If

the white portions within the inner most

circle are recognizable, the grating is in

focus.

To zoom into the image you can use these

buttons:

As a reference, the combination of Emission

Selection filter position 1 and Cam 1 should be

taken (see above). This combination should be the

first live image. Here mark a structure close to the

middle of the circled cross using the Graphics

View control. This cross will be the reference for

the following steps.

Now change the light path to the combination of

Fig. 12 Manual Detector Alignment,

Grating, center part zoomed in

Emission Selection filter and Channel (Cam 1 or

Cam 2) that you wish to adjust. The live image will

now show the grating with the current settings.

18 000000-1790-528 02/2013

Page 23

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

Use the sliders or the input box with arrows of Cam 1 X and Cam 1 Y (for Channel 1, Cam1) or Cam 2 X

and Cam 2 Y (for Channel 2, Cam 2) to move the previously chosen structure of the grating to overlay

with the cross. Finish this step by pressing the Store Current Settings button.

Repeat the procedure for all desired Emission Selection filters and channels, always using the cross

marker as the reference.

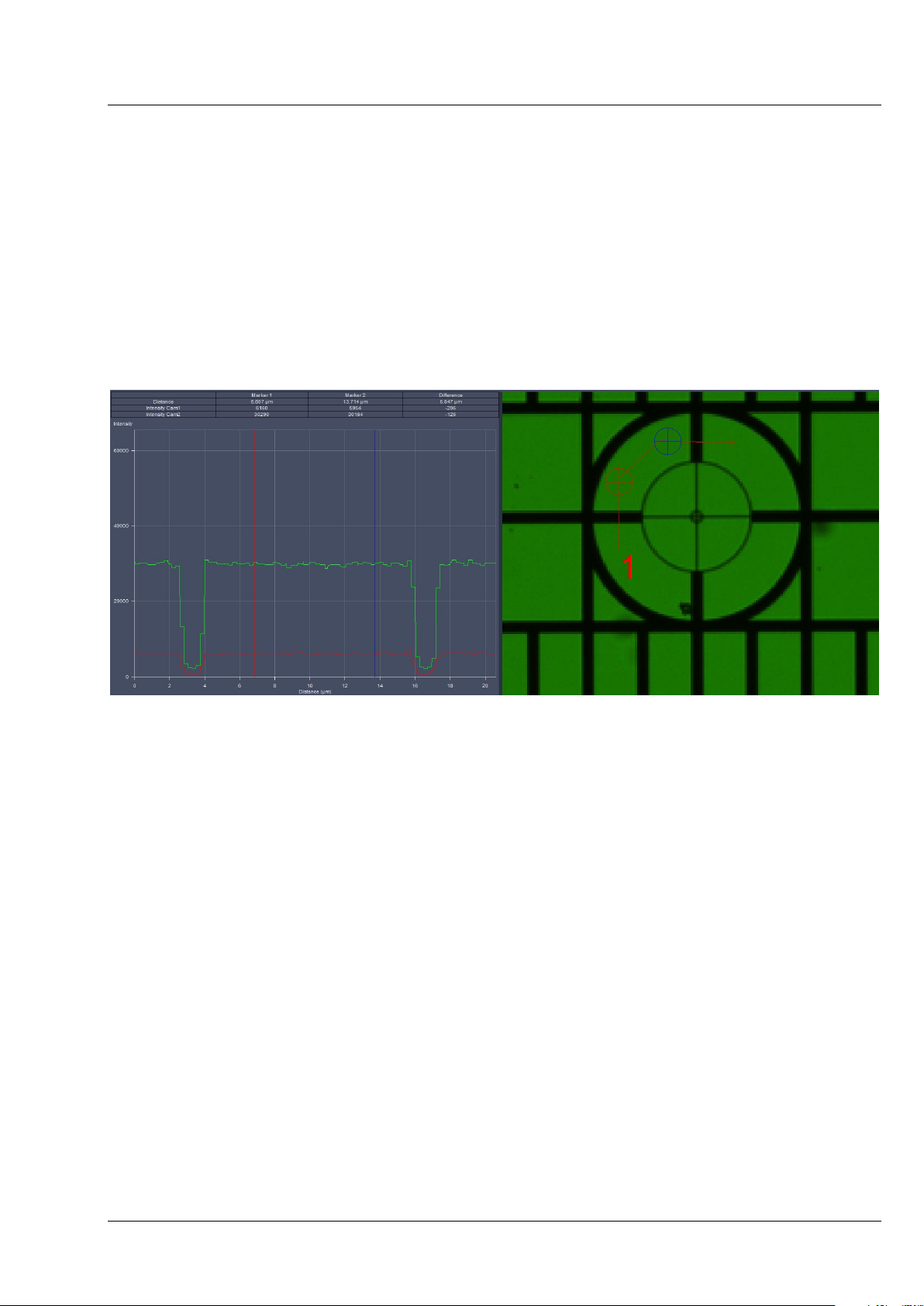

It is helpful, especially after an Automatic Detector Alignment has been performed, to use the Profile

View tab in order to evaluate if the image of Cam 1 and Cam 2 overlay. While the grating is

continuously imaged, press the Profile View tab and draw a line or an arrow poly-line on the grating

(Fig. 13). Use the sliders or the input box with arrows of Cam 1 X and Cam 1 Y (for Channel 1, Cam1) or

Cam 2 X and Cam 2 Y (for Channel 2, Cam 2) to move the lines of the grating to overlay each other.

Fig. 13 Manual Detector Alignment, Grating, Profile view tab

You can leave the Manual Detector Alignment by pressing the Close button at the bottom of the

window.

3.2.3 Adjust the Grating Focus for the Automatic or Manual Detector Alignment Tool

During the Automatic Detector Alignment tool wizard and the Manual Detector Alignment tool a

grating is brought into the light path which can be imaged on each channel. When the grating is out-offocus, you need to refocus it for the relevant channel. For checking the focus, it helps to zoom into the

image using the Zoom function and look at the center cross within the square (Fig. 12) If the white

portions within the inner most circle are recognizable, the grating is in focus.

To adjust the focus of the grating start the Manual Detector Alignment by pressing the button in the

Adjustment tool window. The grating will be brought into the beam path and an image is generated

and displayed in the image container of the main software.

02/2013 000000-1790-528 19

Page 24

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

Set focus for Cam 1 (Channel 1)

• Use the Light Path of the Manual Detector Alignment to first activate channel 1 (Cam1) and press

afterwards the Continuous button. The resulting live image shows the grating on channel 1 (Cam1).

• Use the Zoom tools of the Manual Detector Alignment to zoom into the center region of the image.

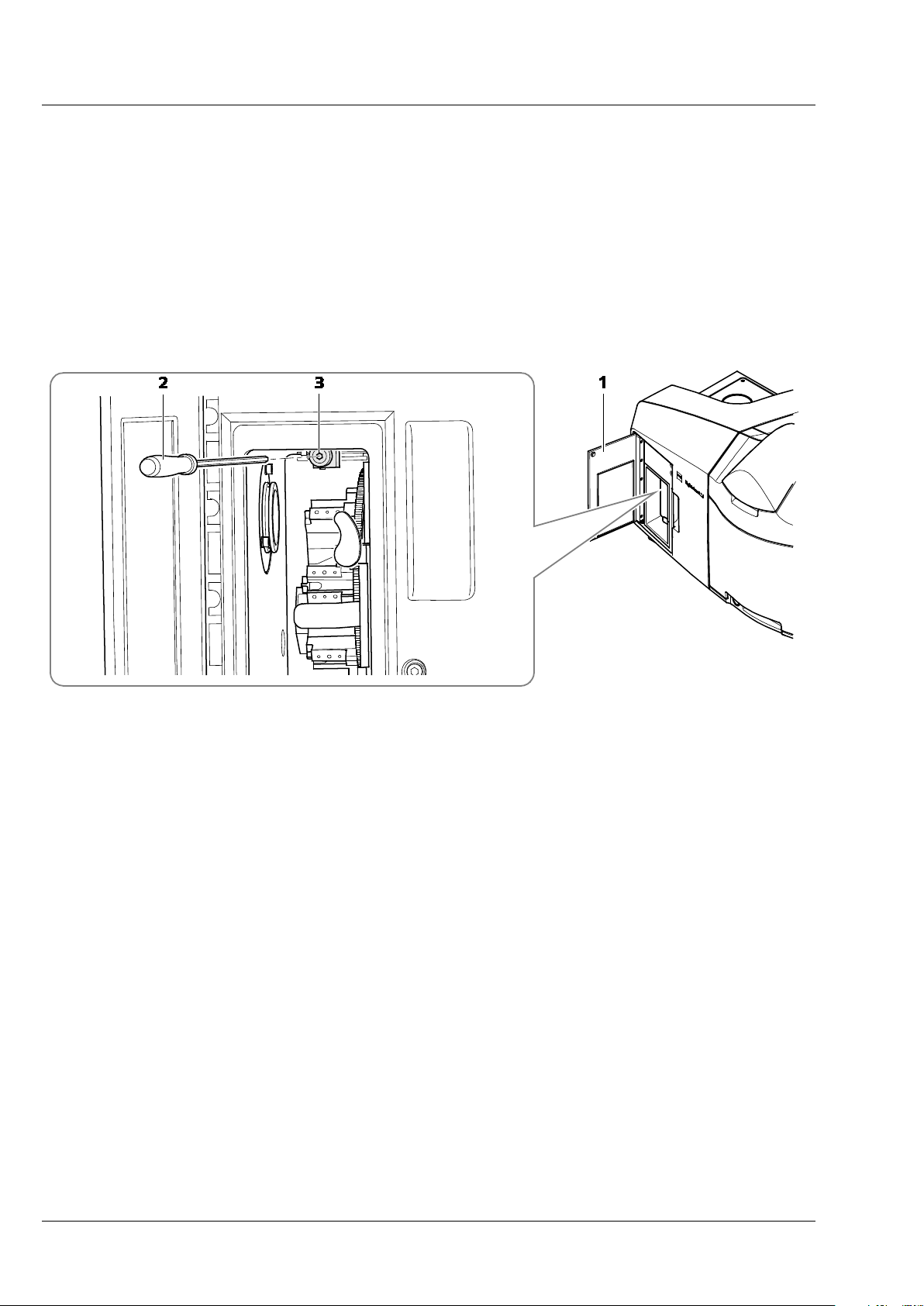

• With the live image running, open the front system door (Fig. 14/1) to the reflector turret for

emission filter selection. This system door has no safety interlock, and opening it will not terminate

image acquisition.

• Turn the screw which is above the turret (Fig. 14/3) with the long Allen wrench (Fig. 14/2).

1 Front system door

2 Allen wrench

3 Screw

Fig. 14 Position of the screw to adjust the focus of the grating for Cam 1 (channel 1)

• Monitor the live image of the grating while you turn the screw in any direction and find the position

of the screw that results in the sharpest image.

• Stop the continuous scan and close the front system door.

Set focus for Cam 2 (Channel 2)

• Use the Light Path of the Manual Detector Alignment to direct light towards channel 2 and

activate channel 2 (Cam2).

• Press afterwards the Continuous button. The resulting live image shows the grating on channel 2

(Cam2).

• Use the Zoom tools for the Manual Detector Alignment to zoom into the center region of the image.

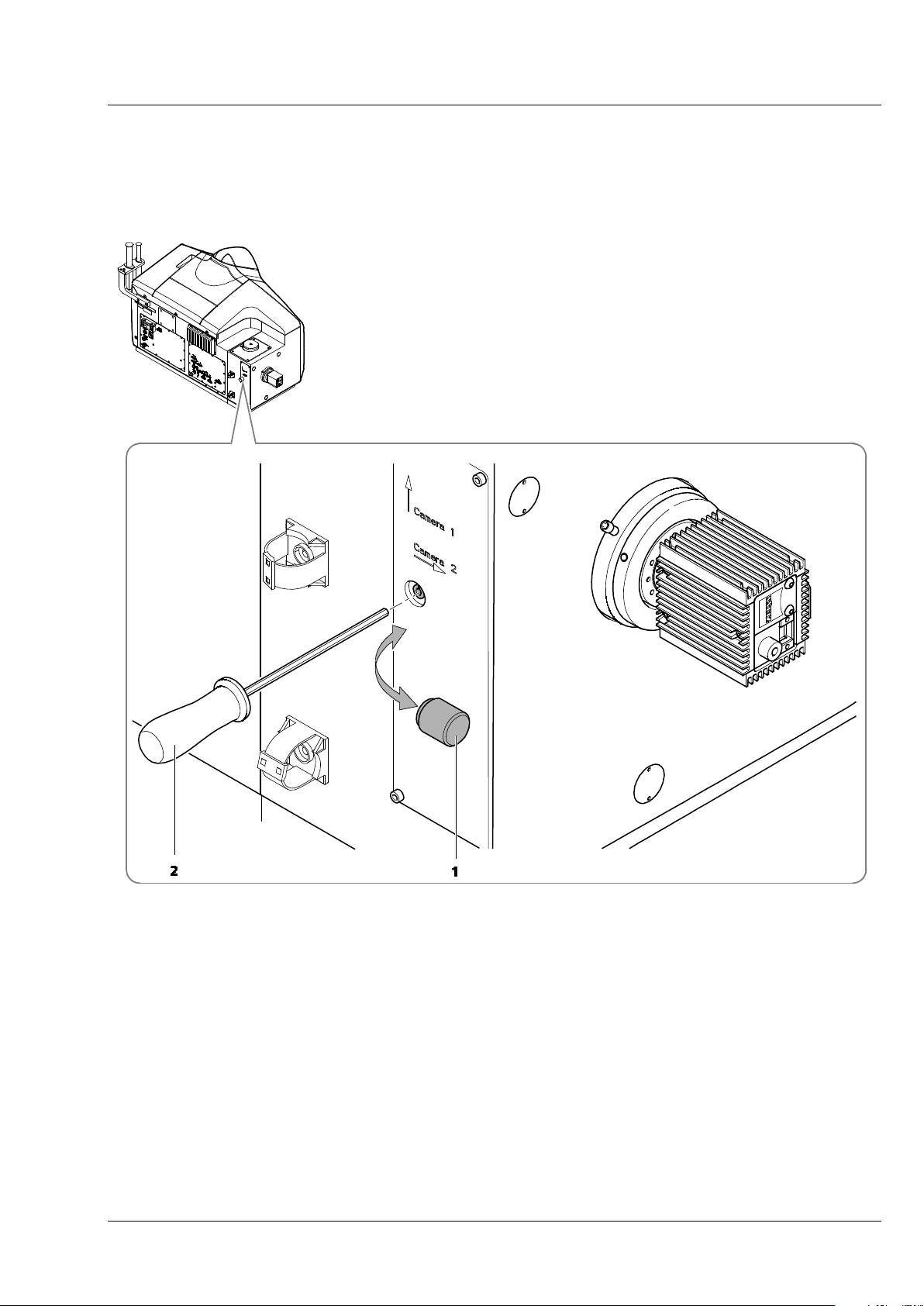

• While the imaging continues remove the black screw cap (Fig. 15/1) on the back of the main system

module Lightsheet Z.1. This opening gives way to a screw that can be turned with an Allen wrench

(Fig. 15/2).

20 000000-1790-528 02/2013

Page 25

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

• Monitor the live image of the grating while you turn the screw in any direction and find the position

of the screw that results in the sharpest image.

• Stop the continuous scan and place the black screw cap back on the system.

1 Black screw cap

2 Allen wrench

Fig. 15 Position of the screw to adjust the focus of the grating for Cam 2 (channel 2)

02/2013 000000-1790-528 21

Page 26

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

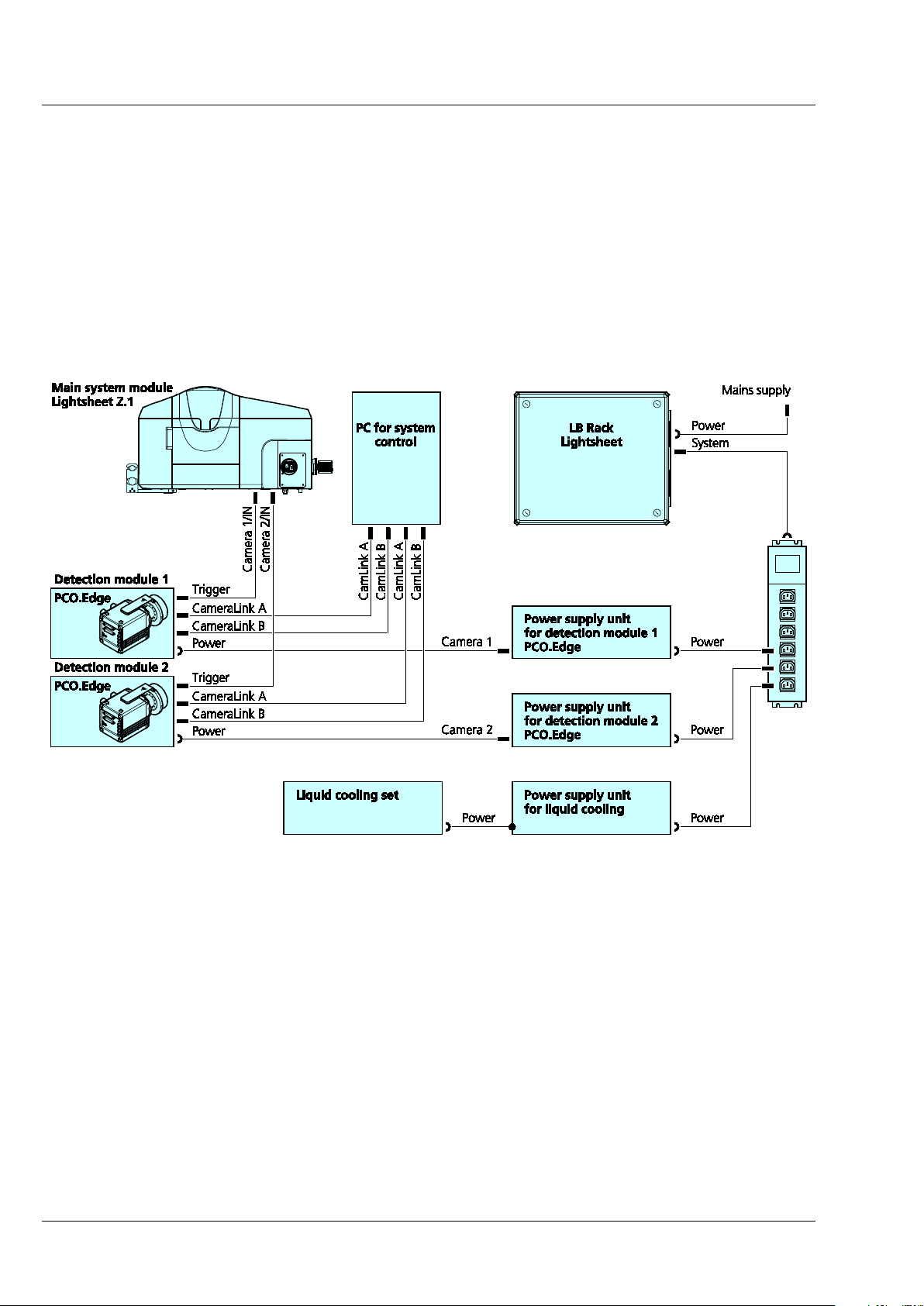

3.2.4 Cable Connections for the Detection Module "PCO.Edge"

The detection module "PCO.Edge" is equipped with a liquid cooling system. Please read the safety notes

of the Lightsheet Z.1 system, as well as the separate safety data sheet for the liquid cooling system. The

power supply unit (PSU) for the cooling is connected to the system's power strip at the rear of the laser

module. The cooling hoses should be as short as possible. The connection creates a closed circuit, starting

from the cooling unit leading to the detection module 1 (approx. 200 cm hose length) reflection port

(Cam1). From the latter a hose (approx. 200 cm) leads either back to the cooling unit or, if a second

detection module is used, first to the transmission port (Cam2) (approx. 100 cm) and then a third hose

(approx. 200 cm) leads back to the cooling unit.

Fig. 16 Cable connections for the detection module "PCO.Edge"

The detection module cables are connected as follows:

− CameraLink cables A and B are each plugged into the PC for system control. The upper slots of the

PC for system control are assigned to the detection module of the reflection port (Cam1), [CamLink

A] right and [CamLink B] left. The lower slots are assigned to the transmission port (Cam2),

[CamLink A[ right and [CamLink B] left.

− The power cable is connected to the power strip of the system on the rear of the LB Rack

Lightsheet.

− The trigger cable is always connected to the detection module with [1/IN] and on the rear side of

the main system module Lightsheet Z.1 to [Camera 1/IN] (refection port, Cam1) or [Camera 2/IN]

(transmission port, Cam2).

− The detection module is switched on with the toggle switch on the module itself.

22 000000-1790-528 02/2013

Page 27

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

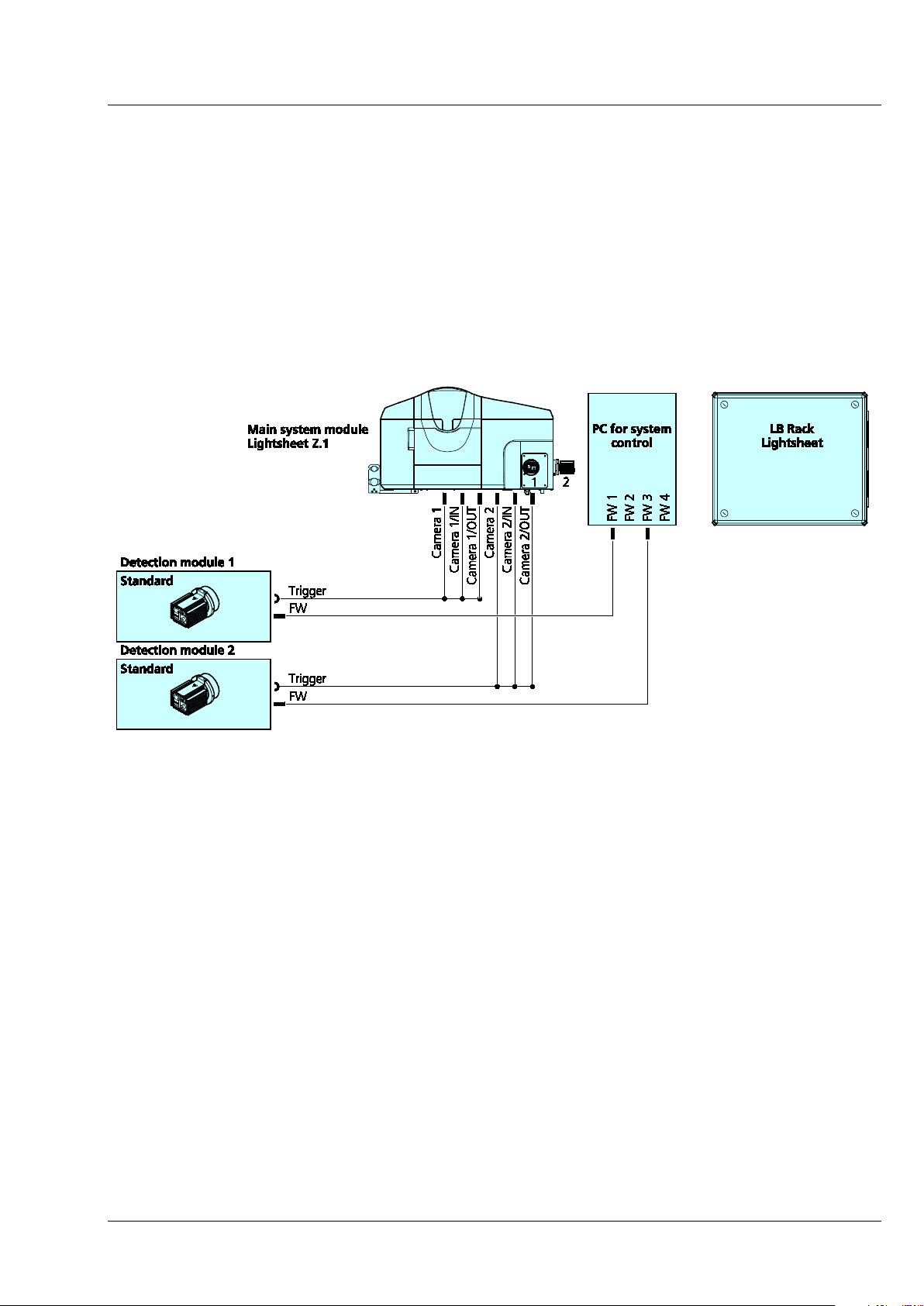

3.2.5 Cable Connections for the Detection Module "Standard"

− The following connections exist for this detection module:

− The firewire cable must be plugged into the PC for system control. There are four firewire sockets

on the PC for system control; the detection module from the reflection port (Cam1) is connected to

position [FW 1], from the transmission port (Cam2) to position [FW 3].

− The trigger cable is plugged into the respective detection module and the three ends on the rear

side of the main system module Lightsheet Z.1 to [Camera 1] or [Camera 2], as well as [Camera

1/IN] and [Camera 1/OUT] (reflection port, Cam1) or [Camera 2/IN] and [Camera 2/OUT]

(transmission port, Cam2).

Fig. 17 Cable connections for the detection module "Standard"

02/2013 000000-1790-528 23

Page 28

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

3.3 Assembly of the Sample Chamber

− Wear powder-free gloves to avoid fingerprints on the cover slips as well as to protect your hands

from sharp edges.

3.3.1 Assembly of the Sample Chamber Windows

− Assemble the three sample chamber body windows (for the illumination optics on the sides and

the front chamber window for the overview camera with LED white illumination) using the

following steps:

1 Sample chamber body

2 Cover slip

3 O-ring (18 mm O-ring, black)

4 Illumination adapter ring

5 Sample chamber window tool

Fig. 18 Assembly of the three sample chamber windows for illumination optics and overview

camera

1. Take the sample chamber body (Fig. 18/1) and lay it onto the table so that one of the three smaller

windows are facing you.

2. Using a forceps or gloved hands, remove one clean circular 18 mm cover slip; place cover slip into

the empty sample chamber body window so it fits into the smallest groove (Fig. 18/2) – you will

need a fine forceps.

3. Now place the O-ring (18 mm O-ring, black) into the corresponding groove (Fig. 18/3). Make sure

not to disturb the positioning of the cover slip.

4. Take the silver illumination adapter ring (Fig. 18/4) and lay it into the window making sure the flat

side with the four pinholes is facing you.

5. Using the sample chamber window tool (Fig. 18/5), position the circular pins into the pinholes and

turn clockwise until finger-tight. Adapter should be flush with the sample chamber body.

24 000000-1790-528 02/2013

Page 29

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

6. Repeat step 1 - 6 for each of the three windows.

− Assemble the sample chamber window for the detection optic.

1. Turn the sample chamber body (Fig. 19/1) to the largest opening window for the detection

optics.

2. Using a small spatula or the opposite end of a forceps position the blue O-ring tightly into

the groove to ensure no leaking (Fig. 19/2).

3. Assemble the chamber window for the detection optic according to the following steps.

Depending on the detection optics used, insert the correct detection optic adapter:

4. For the detection optic 5x/0.16:

a) Place the large silver detection optic adapter 5x (Fig. 19/3) onto the table with the

grooves facing you.

b) Remove one clean circular 18 mm glass cover slip; place cover slip (Fig. 19/4) into

the large silver detection optic adapter 5x (Fig. 19/3) making sure it is positioned

into the smallest groove – adjust the coverslip position with the forceps if necessary.

c) Now place the O-ring (18 mm O-ring, black) into the corresponding groove on top

of the cover slip (Fig. 19/5).

d) Take the silver retaining ring (Fig. 19/6) and place it inside the detection optics

adapter 5x with the flat side with two notches facing you. Using the circular pin-side

of the sample chamber window tool (Fig. 19/9), turn clockwise until finger-tight.

e) Placing the assembled detection optic adapter 5x into the sample chamber body

window. Using the squared pins of the sample chamber window tool, turn clockwise until finger-tight.

5. For the detection optic 20x/1.0, 40x/1.0, 63x/1.0:

a) Use the corresponding detection optic adapter (see the detection optic adapter

catalogue number and magnification engraving) (Fig. 19/7).

b) Insert the detection optic adapter into the sample chamber body window for

detection with the flat side facing you.

c) Using the sample chamber window tool (squared pin-side) (Fig. 19/9) turn adapter

clock-wise until finger-tight.

d) Take a 15 mm black O-ring (Fig. 19/8) and position the O-ring into the groove inside

the middle of the detection optic adapter using the blunt end of a forceps if

necessary.

02/2013 000000-1790-528 25

Page 30

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

1 Sample chamber body

2 O-ring (blue)

3-6 For the detection optic 5x/0.16

− 3 Detection optic adapter 5x/0.16

− 4 Cover slip

− 5 O-ring (18mm O-ring, black)

− 6 Retaining ring

7-8 For the detection optic 20x/1.0, 40x/1.0, 63x/1.0

− 7 Detection optic adapter (20x/1.0, 40x/1.0, 63x/1.0

− 8 O-ring (15mm O-ring, black)

9 Sample chamber window tool

Fig. 19 Assembly of sample chamber window for the detection optic

26 000000-1790-528 02/2013

Page 31

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

3.3.2 Assembly of the Sample Chamber Body and the Sample Chamber Dove Tail Slide

1 Mesh screen

2 Sample chamber body

Fig. 20 Placing the mesh screen

− Place the mesh screen (Fig. 20/2) into the middle of the sample chamber body (Fig. 20/1) to reduce

turbulence stress on the specimen when the chamber is filled.

− For cleaning, it can be carefully removed by a forceps or via a teflon-tip-free end of a capillary

plunger.

− If a Heating component is used, proceed first with chapter 3.7.1 (see PeCon manual for specific

heating component) and screw it onto the bottom of sample chamber body.

• The sample chamber body (Fig. 21/3) can now be attached to the sample chamber dove tail slide

(Fig. 21/1).

• Lay down the sample chamber dove tail slide with the two positioning pins facing upwards (Fig. 21/2).

• Take the sample chamber body and position it on to the sample chamber dove tail slide with the

detection optic adapter window facing to the back relative to the sample chamber dove tail slide grip.

• Invert the sample chamber body with the sample chamber dove tail slide so that the four screw-holes

(Fig. 21/4) that were on the bottom are now facing you.

• Insert the four screws (diameter = M3, length = 14 mm) (Fig. 21/5) into the four screw-holes and

tighten using and Allen wrench (2.5).

02/2013 000000-1790-528 27

Page 32

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

1 Sample chamber dove tail slide

2 Positioning pins

3 Sample chamber body

4 Screw-holes

5 Screws (diameter = M3, length = 14 mm)

Fig. 21 Assembly of the sample chamber body and the sample chamber dove tail slide

28 000000-1790-528 02/2013

Page 33

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

3.3.3 Insertion of the Drain Connector, Luer-Lock Connectors and Blind Plugs

− Turn the assembled sample chamber body with dove tail slide so that the dove tail slide is on the

table with the grip facing you (Fig. 22/1).

− Take the grey drain connector and screw this into the upper left hole of the sample chamber body

until finger-tight (Fig. 22/6). This will guide excess liquid to the drain.

− Take a Luer-Lock-connector (white) and screw it into the lower right corner of the sample chamber

body (Fig. 22/4). The Luer Lock connectors (white) are used to fill or perfuse the sample chamber

with liquids and / or gasses.

− For CO

incubation, the Luer-Lock connector must be positioned at the upper right corner of the

2

sample chamber (Fig. 22/2). For syringe based perfusion one can use any of the three lower screw

holes. The lower right corner screw hole is recommended for convenience (Fig. 22/4).

− For perfusion pump use the right side bottom screw hole for the perfusion input and either of the

front lower corner screw holes for the perfusion output.

− Close all remaining sample chamber screw hole openings by inserting the black blind plugs

(Fig. 22/3; Fig. 22/5).

1 Sample chamber body with dove tail slide

2 Luer-Lock-connector (white); position recommend for CO

3 Blind plug (black)

4 Luer-Lock-connector (white); position recommend for syringe based perfusion

5 Blind plug (black)

6 Drain connector (grey)

Fig. 22 Insertion of the Drain connector, Luer-Lock-connectors and Blind plugs

incubation

2

02/2013 000000-1790-528 29

Page 34

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

3.3.4 Insertion of Accessories for Incubation

• A temperature sensor (Fig. 23/1) can be used in the sample chamber body.

− Hold the temperature sensor so that it shows you the letter “J”. Slide the temperature sensor

sleeve (Fig. 23/3) onto the top horizontal part of the J-shaped temperature sensor.

− Dip the temperature sensor with sleeve into the sample chamber body and position the

temperature sensor sleeve securely into the sample chamber body groove (Fig. 23/2).

1 Temperature sensor

2 Sample chamber body groove

3 Temperature sensor sleeve

Fig. 23 Insertion of temperature sensor

− Place a cover on top of the sample chamber body (Fig. 24/3). This will minimize evaporation of

medium or contamination of the sample chamber. If CO

module Lightsheet Z.1 is used

2

(configuration dependent, chapter 2.7.2) the cover is recommended to maintain the CO

concentrations.

− Keep the opening as small as possible. Use the 3 mm opening cover for capillaries (Fig. 24/1) and

7 mm opening cover for syringes (Fig. 24/2). The cover only rests on top of the sample chamber

body and is free to move.

gas

2

30 000000-1790-528 02/2013

Page 35

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

1 Cover for capillaries (3 mm opening)

2 Cover for syringes (7 mm opening)

3 Sample chamber body with dove tail slide

Fig. 24 Placing cover on top of the sample chamber body

3.4 Removing and Inserting the Sample Chamber

The sample chamber can be removed from the system. For removal, proceed as follows:

− Open the front system cavity door (Fig. 25/1) of the main system module Lightsheet Z.1.

− Remove the liquid from the sample chamber (Fig. 25/6) using the hose with the corresponding

syringe (Fig. 25/9).

− Ensure that no sample protrudes into the sample chamber. Remove the sample, if necessary,

through the upper sample opening (Fig. 25/2) below the upper system cavity door (Fig. 25/3).

− If necessary, remove the connections for the incubation device (Fig. 25/8).

− Loosen the screw (Fig. 25/4) on the sample chamber and pull the sample chamber out by the grip

(Fig. 25/5).

− Inserting the sample chamber:

− Take hold of the sample chamber by the lower grip (Fig. 25/5) and push the sample chamber

(Fig. 25/6) into the guide rails (Fig. 25/7).

− Tighten the screw (Fig. 25/4) without exerting force. The sample chamber has been correctly

inserted when its lower edge is flush with the guide rail.

− Plug in the cable to the incubation unit (Fig. 25/8) as necessary.

02/2013 000000-1790-528 31

Page 36

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

1 Front system cavity door 6 Sample chamber

2 Upper sample opening 7 Guide rails

3 Upper system cavity door 8 Connections for incubation

4 Securing screw 9 Hose and syringe

5 Sample chamber grip

Fig. 25 Removing and inserting the sample chamber

/ sample chamber mount

3.5 Assembly of the Sample Holder

Depending on the size of the sample there are two different types of sample holders available: sample

holder for capillaries (inner diameter of capillary size 1 / ~0.68 mm, size 2 / ~1 mm, size 3/ ~1.5 mm,

size 4 / ~2.15 mm) and syringes (1 ml). Always use the minimal cylinder diameter necessary for your

specimen size to avoid excessive amounts of embedding medium.

3.5.1 Assembly of the Sample Holder for Capillary

1. Select the corresponding colored sleeves (Fig. 26/3) to match the color of the capillary of choice

(Fig. 26/6).

2. The capillary should hold the sample and the appropriate plunger (Fig. 26/5), see as well the

CHAPTER 2 SAMPLE PREPARATION in this manual. The plungers that fit into capillary size 2 - 4

have to be used with corresponding Teflon tips that are already assembled onto the plungers. Note

that in addition 10x Teflon tips of each as well as matching Teflon tip tools are provided in the

Chamber & Sample Holder Starter Kit Lightsheet Z.1 (Tab. 1). The Teflon tips can be assembled as a

replacement onto the matching tip-less plungers.

32 000000-1790-528 02/2013

Page 37

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

Capillary size

(inner diameter)

Capillary

Color coding/

Plunger

Reference number

Teflon tip Teflon tip too

Color coding

Reference number

Size 1 (~0.68 mm) Red/701902 #701996 - -

Size 2 (~1mm) Black/701904 #701997 Size 2 Clear

Size 3 (~1.5mm) Green/701908 #701998 Size 3 Green

Size 4 (~2.15mm) Blue/701910 #701999 Size 4 Blue

Tab. 1 Capillary components in the Chamber & Sample Holder Starter Kit Lightsheet Z.1

3. The sleeves are tube-shaped with four slits at one end. Insert the sleeves into the capillary sample

holder stem (Fig. 26/2) so that the two slit endings point outwards and the non-slit endings face

toward the center.

4. Take the clamp screw (Fig. 26/4) and position it onto the capillary sample stem holder turning

clockwise three times (360° each turn).

1 Sample holder disc for capillaries 5 Plunger

2 Capillary sample holder stem 6 Capillary with color-coded marking

3 Sleeves (color-coded) 7 Ejection tool

4 Clamp screw

Fig. 26 Assembly of the sample holder for capillary

02/2013 000000-1790-528 33

Page 38

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

5. Take the capillary by the glass portion (avoiding the plunger) with the agarose embedded specimen

inside and carefully place it into the center of the clamp screw sample holder top.

6. Push the capillary within the holder downwards until the color-coded capillary marking becomes

visible (Fig. 26/6 right hand side).

Newly bought sleeves can be slightly tight at their slit opening ends so that in can be difficult to

push the capillary within the holder. In this case take the capillary with matching plunger and insert

it carefully into the corresponding sleeves at their non-slit endings. Make sure that the slits point

outwards. Position the capillary surrounded by the sleeves into the sample holder stem and place

the clamp screw. You can proceed with step 6).

7. Tighten the clamp screw. Take the sample holder disc (Fig. 26/1) with the protruding side with

positioning notch facing you. Carefully position the capillary stem holder with specimen into the

sample disc holder until the ball bearing click-position is felt.

8. Before taking the capillary out (chapter 2.6), retract the sample back inside the capillary glass via

using plunger.

9. For removal, loosen the clamp screw and carefully pull the capillary through the stem sleeve by

using the glass end nearest the color-coded marking.

10. Unscrew the clamp screw completely and remove the sleeves by using the ejection tool (Fig. 26/7)

for the capillary sleeves removal.

The sleeves as well as the glass portion of the capillary can be cleaned with a lint-free cloth moistened

with water.

3.5.2 Assembly of Sample Holder for Syringes

− Place the sample holder disc for syringes (Fig. 27/1) so the flat side is facing you.

− Take the adapter ring (Fig. 27/2) and place it into the center of the sample holder disc with the

larger diameter of the ring facing you.

− Pick up the sample disc holder with adapter ring in one hand. Take the syringe carrying your

specimen (Fig. 27/3) and insert it completely into the sample disc holder (avoiding touching the

plunger).

− Touching the syringe body and turn clock-wise to position the syringe body into the two clamps

(Fig. 27/6).

34 000000-1790-528 02/2013

Page 39

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

1 Sample holder disc for syringes 4 Ball bearings

2 Adapter ring 5 Syringe body

3 Syringe 6 Clamp

Fig. 27 Assembly of sample holder for syringes

3.6 Inserting and Removing the Sample Holder

• To insert the sample holder move the stage of

the Lightsheet Z.1 system to the Load position

via the Specimen Navigator tool (Fig. 28) in

the ZEN software (see CHAPTER 4 SYSTEM

OPERATION).

• Open the upper system cavity door (Fig. 28/1).

• Take the sample holder for capillaries or syringes by the sample holder disc with the capillary or the

syringe facing downwards (Fig. 29/3).

Fig. 28 Load Position in the Specimen

Navigator

• Insert the sample holder gliding the sample holder disc along the guide rails (Fig. 29/2). It is placed

correctly into a click position if the sample holder disc ball bearings lock into the three holes.

• Notice the white line marking at the outer edge of the disc. It can be used as a reference point for

reorienting the sample holder disc once it was taken out.

• Close the upper system cavity door (Fig. 29/1) and position the capillary and the sample as described in

CHAPTER 4 SYSTEM OPERATION.

02/2013 000000-1790-528 35

Page 40

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

1 Upper system cavity door

2 Guide rails

3 Capillary

4 Hole for disc ball bearings

Fig. 29 Inserting the Sample Holder

− Before taking the sample holder out, retract the sample back inside the capillary glass via using

plunger.

− Move to the Load position via the Specimen Navigator tool (Fig. 28) in the ZEN software (see

CHAPTER 4 SYSTEM OPERATION).

− Open the upper system cavity door (Fig. 29/1).

− Take the sample holder out by gliding the sample holder disc along the guide rails (Fig. 30).

Fig. 30 Removing the Sample Holder

36 000000-1790-528 02/2013

Page 41

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

3.7 Installation of the Incubation Modules

The incubation of the Lightsheet Z.1 is configuration dependent. It is used to control and monitor

temperature and CO

various configurations.

− The configuration dependent modules should be placed on a level surface next to the system and

are stacked on top of each other (Fig. 31). For further information see the individual component

manuals from PeCon.

The installation of incubation modules on the

Lightsheet Z.1 can be divided into two parts. One

deals with the actual assembly of hardware

components of the incubation modules and their

connections to the system. The second part deals

with the registration of the incubation modules

using specific software tools.

supply to the sample environment. The TempModule S1 is required for all of the

2

Fig. 31 Incubation modules stacked on top

of each other

3.7.1 Heating Components

There are two different heating components available: (1) Heating Block Sample Chamber

Lightsheet Z.1 enables to heat the sample chamber from ambient temperature to 42 °C. (2) Peltierblock

Sample Chamber Lightsheet Z.1 permits heating and cooling of the sample chamber in the range from

10 °C to 42 °C.

(1) Heatingblock Sample Chamber Lightsheet Z.1 is controlled by the TempModule S1 providing

electrical power supply and closed-loop temperature control. The system allows to heat the sample

chamber from ambient temperature to 42 °C.

Connect the Heating Block LSFM and the TempModule S via connecting cable. For proper electrical

connection please follow the connection diagram in the individual component manuals from

PeCon.

02/2013 000000-1790-528 37

Page 42

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

Make sure that the temperature inside the sample chamber is in accordance with the desired

temperature value required for the experiment. The ZEN software displays the temperature of the

heating block itself and does not register the actual temperature in the sample chamber that can

be lower (due thermal loss) or higher.

• To assemble the heating block to the sample chamber remove first of all the sample chamber dove tail

slide from the assembled sample chamber (Fig. 1, section 3.3.2 Assembly of the Sample Chamber

Body and the Sample Chamber Dove Tail Slide).

• Take the heating block and screw it onto the bottom of sample chamber body following the

instructions of the individual component manuals from PeCon.

• The sample chamber body can now be assembled together with the sample chamber dove tail slide

(Fig. 1, section 3.3.2).

• Insert the sample chamber as described in chapter 2.4 and plug in the 8 pin connector of the

connection cable into the right side of the front system cavity / sample room following the individual

component manuals from PeCon (Fig. 32/6) shows the connection exemplary for the Peltier Block S).

(2) Peltier Block S is part of the TempModule CZ-LSFM. The Peltier Block helps adjust the sample

chamber temperature by heating or cooling the sample chamber within the range of 10 °C to 42 °C (up

to 1.5°/min heating, up to 1.0°/min cooling). The temperature inside the sample chamber is monitored by

a temperature sensor (Fig. 23/1; Fig. 32/3). For insertion of the temperature sensor in the sample

chamber refer to section 3.3.4 Insertion of Accessories for Incubation).

The TempModule CZ-LSFM contains a water based coolant reservoir. For safety reasons (Risk of

electrical shock as a result of leakage) the unit must be placed directly on a level table and is thus

the base for all other incubation related modules (Fig. 31).

− Connect the TempModule S, the TempModule CZ-LSFM, the Lightsheet Z.1 and the Peltier Block

according to the individual component manuals from PeCon.

− To assemble the Peltier Block to the sample chamber remove first of all the sample chamber dove

tail slide from the assembled sample chamber (section 3.3.2; Fig. 21).

− Take the Peltier Block and screw it onto the bottom of sample chamber body following the

instructions of the individual component manuals from PeCon.

− The sample chamber body can now be assembled together with the sample chamber dove tail slide

(Fig. 21) and insert it into the Lightsheet Z.1 as described (section 3.3.2 ).

− Insert the accessories for incubation (temperature sensor, cover recommended) into the sample

chamber (section 3.3.4, Fig. 23, Fig. 24).

− Connect the Peltier Block (Fig. 32/6) to the Lightsheet Z.1 by the two provided silicone tubes

(Fig. 32/7-8) and plug in the 8 pin connector of the connection cable into the right side of the front

system cavity / sample room (Fig. 32). For proper electrical connections and tube connections follow

the instructions of the PeCon manual.

38 000000-1790-528 02/2013

Page 43

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

Heating component Temperature range Incubation modules

Heating Block Heating from ambient

temperature to 42 °C

Peltier Block Heating and cooling in the

range from 10 °C to 42 °C

(1) TempModule S1

(2) Heating Block LSFM

(1) TempModule S1

(2) TempModule CZ-LSFM (including Peltier

Block and Temperature sensor)

Tabelle 1 Overview Heating components

3.7.2 CO

The CO

-Module Lightsheet Z.1 controls and monitors adjustable CO2 concentration (from 0 % to 10 %)

2

in the sample chamber and requires CO

-Module Lightsheet Z.1

2

supply, sterile filter and Humidifier S1 to provide CO2-enriched

2

air.

− At least 3h (or more) may be needed until a stable pH value is reached due to the small surface

area in relation to sample chamber volume.

− For assembly of hardware components of the CO

Module and its connections to the system, as

2

well as the calibration procedure needed follow the instructions from the PeCon manual.

− After CO

calibration, the Lightsheet Z.1 system must be completely turned off before work with

2

the system can continue.

− Position the Luer-Lock connector for CO

incubation at the top right corner of the sample chamber.

2

Place a cover on top of the sample chamber body (Fig. 24, chapter 3.3.4) to maintain the CO

concentrations.

− The sterility of the CO

sample chamber by following the cleaning instruction of all parts of the CO

-enriched air is given by the sterile filter. Take control of the sterility in your

2

-module (see PeCon

2

manual) as well as the components of the sample chamber (see CHAPTER 1 HARDWARE).

Please clamp all incoming or outgoing tubing (Fig. 32/2, Fig. 32/5, Fig. 32/9, Fig. 32/10) into the

provided clamping grooves. This will avoid possible disconnection problems after closing the front

system cavity door.

Note that for the sake of completeness Fig. 26 shows the connection diagram for the usage of a

perfusion pump (Fig. 32/5, Fig. 32/9). Alternatively a syringe based-perfusion can be used (position

Fig. 32/5). Consequently, Fig. 32/9 has to be replaced by a bling plug.

gas

2

02/2013 000000-1790-528 39

Page 44

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

1 Drain connector

2 Luer-Lock connector for CO

3 Temperature sensor with 4-pin connection cable

4 Blind plug

5 Luer-Lock connector for perfusion pump-in with tubing (or alternatively for syringe based perfusion)

6 Peltier Block S with 8-pin connector

7 Cooling liquid (Silicon tube with male connector)

8 Cooling liquid (Silicon tube with male connector)

9 Luer-Lock connector for perfusion pump-out with tubing

10 Drain connector with tubing

11 Drain tray

incubation with tubing

2

Fig. 32 Incubation connections for sample chamber body

-Module Lightsheet Z.1 can be extended with Heating Device Humidity S1 to improve thermal

CO

2

equilibrium in the sample chamber.

40 000000-1790-528 02/2013

Page 45

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

3.7.3 Heating Device Humidity S1

For a better humidification of incubation atmosphere the Humidifier of the corresponding CO

-Module

2

Lightsheet Z.1 can be inserted into the Heating Device Humidity S1. The Heating Device Humidity S1

enables to improve thermal equilibrium in the sample chamber and avoid condensation in the tubing.

3.7.4 Registration of the incubation modules

• After the Lightsheet Z.1 and the PC for system control are turned on and the operation system has

booted start the software ZEN Configuration Tool. You find it either as a shortcut on your desktop or

in this directory : C:\ZEN\HWT as Configuration Tool 2012.exe.

• On the opening window press the Start configuring button (Fig. 33):

Fig. 33 ZEN Configuration Tool Start-up window

• On the Configuration tab (Fig. 34) you find an Incubation Components field with check boxes for

Module and TempModule that you can activate or deactivate depending on your incubation

CO

2

configuration. These modules will show up later as Atmosphere (%) panel and Temperature (

o

C)

panel respectively in the ZEN software (see CHAPTER 4 SYSTEM OPERATION).

02/2013 000000-1790-528 41

Page 46

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

Fig. 34 ZEN Configuration Tool Incubation Components field

• A drop-down menu enables to assign heating components (Heatingblock, Peltier Block) as well as the

Heating Device Humidity to four distinct channels.

Make sure that the assignment of incubation components to the corresponding channels in the

Configuration Tool is in accordance with the electrical connection of the incubation components

into the TempModule S1 (“Channel 1-4”, “Control Sensor”).

• We recommend to assign Channel 1 to the heating component (Heatingblock, Peltier Block) and

Channel 4 to the Heating Device Humidity if available.

• Do not check the check boxes for external Sensor as well as an Humidity Sensor. These

components are not part of the Lightsheet Z.1 incubation modules.

• Leave the Configuration Tool with the Store all Changes button. This will write all changes into the

database of your system.

42 000000-1790-528 02/2013

Page 47

CHAPTER 1 - HARDWARE

Lightsheet Z.1 illumination

optics 5× / 0.1

Lightsheet Z.1 illumination

optics 10× / 0.2

Lightsheet Z.1 User Interfaces Carl Zeiss

3.8 Switch Incubation ON and OFF

• Before you turn ON the incubation, all incubation components you wish to use during the imaging

session must be attached to the Lightsheet Z.1 system before starting ZEN software.

• Set the "Incubation" switch on the remote control to the ON position. Make sure that all incubation

components are switched on.

• Once ZEN is running you can detach and reattach components.

• To turn OFF the incubation, uncheck the corresponding checkboxes in the Incubator tool window

(see CHAPTER 4 SYSTEM OPERATIONl) or deactivate the incubation components by setting the

"Incubation" switch to the OFF position.

Be aware that all incubation components will continue working with the in Incubator tool window

specified parameters after ZEN has been shut down or stopped working. This will keep your sample

alive under precisely defined conditions, even if ZEN stops unexpected during an experiment.

3.9 Illumination and Detection Optics

In the Lightsheet Z.1, one or a pair of illumination optics plus one detection optic are always required.

We recommend the following combinations:

Lightsheet Z.1 detection optics

5× / 0.16

Lightsheet Z.1 detection optics

20× / 1.0

Lightsheet Z.1 detection optics

40× / 1.0

Lightsheet Z.1 detection optics

63× / 1.0

yes no

no yes

no yes

no yes

02/2013 000000-1790-528 43

Page 48

CHAPTER 1 - HARDWARE

Detection

Optic

0.36x

0.7x

1.0x

2.5x

Detection

Optic

0.36x

0.7x

1.0x

2.5x

Carl Zeiss User Interfaces Lightsheet Z.1

The area that can be imaged with the combination of detection optics with the detection module on the

Lightsheet Z.1 is summarized *

1)

in the following tables:

Zoom

x (µm) y (y

*2)

µm) x (µm) y (µm) x (µm) y (µm) x (µm) y (µm)

5× / 0.16 4815 4815 2496 2496 1733 1733 693 693

20× / 1.0 1204 1204 624 624 433 433 173 173

40× / 1.0 602 602 312 312 217 217 87 87

63× / 1.0 382 382 198 198 138 138 55 55

Tabelle 2 Detection module PCO.Edge

Zoom

x (µm) y

*2)

(µm) x (µm) y

*2)

(µm) x (µm) y (µm) x (µm) y (µm)

5× / 0.16 4157 5570 2138 2864 1497 2005 599 802

20× / 1.0 1039 1392 534 716 374 501 150 201

40× / 1.0 520 696 267 358 187 251 75 100

63× / 1.0 330 442 170 227 119 159 48 64

Tabelle 3 Detection module Standard

*1) Typical values for Lightsheet Z.1 systems

*2) Be aware, a homogenous light sheet illumination with full intensity is limited to about 2800 µm in the y direction. Above

and below this center, the illumination intensity will fade towards the edges in the y direction.

44 000000-1790-528 02/2013

Page 49

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

3.9.1 Removing and Inserting the Illumination Optics Unit

The illumination optics unit (Fig. 35/2) can easily be removed and inserted after the removal of the sample

chamber (see section 3.4 Removing and Inserting the Sample Chamber).

To protect the front lenses, secure the appropriate protective caps (Fig. 35/3) over each of the

illumination optics (Fig. 35/2) and protective cap (Fig. 35/4) over the detection optic (Fig. 35/5). The

illumination optics can then be unscrewed by turning anticlockwise.

To insert the illumination optics, proceed in the reverse order by screwing it clockwise into the unit until

finger-tight.

Finally, the protective caps can be removed and the sample chamber inserted.

After the illumination optic has been exchanged, the currently used optic must be registered in the ZEN

software. The necessary software interface can be found in the Objectives tool window under the

Maintain tab.

1 Front system cavity door 4 Protective cap for detection optics unit

2 Illumination optics (2×) 5 Detection optics unit

3 Protective cap for illumination optics unit (2×) 6 Threaded shaft for illumination optics unit (r and l)

Fig. 35 Removing and inserting the illumination optics

02/2013 000000-1790-528 45

Page 50

CHAPTER 1 - HARDWARE

Carl Zeiss User Interfaces Lightsheet Z.1

3.9.2 Removing and Inserting the Detection Optics Unit

In order to remove the detection optics unit (Fig. 36/3) located in the rear zone of the system cavity, the

sample chamber must first be removed (see Section 3.4). To prevent damage to the illumination optics

units, these must also be removed (see Section 3.9.1). Secure the appropriate protective cap (Fig. 36/4)

onto the detection optics unit.

Grab the detection optics unit as close as possible to the base and remove it by turning anticlockwise.

Caution: the detection optics unit is heavy.

To insert the detection optics unit, it must be screwed in a clockwise direction without exerting force.

Subsequently the protective cap should be removed before re-inserting the illumination optics unit and

the sample chamber.

After the detection optic has been exchanged, the currently used optic must be registered in the ZEN

software. The necessary software interface can be found in the Objectives tool window under the

Maintain tab.

Each detection optic unit is labeled with an individual serial number. It ensures that the specific

calibration file for this lens, necessary for optimal performance, is used when identified within the

software. The calibration file is created by a Carl Zeiss service personnel representative during system

installation, or when a detection optic is newly purchased. Ensure that the correct detection optic unit is

chosen in the ZEN software interface, based on its name and the specific serial number of the detection

optic in use.

1 Front system cavity door

2 Threaded shaft for detection optics unit

3 Detection optics unit

4 Protective cap

Fig. 36 Removing and inserting the detection optics

46 000000-1790-528 02/2013

Page 51

CHAPTER 1 - HARDWARE

Lightsheet Z.1 User Interfaces Carl Zeiss

3.10 Removing and Inserting the Reflector Turret for Emission Selection

The reflector turret (Fig. 37/5) can be accessed by opening the left-hand-side front system door

(Fig. 37/1).

After the reflector turret for emission selection has been exchanged, the Automatic Detector

Alignment should be performed. The ZEN software should be restarted if the reflector turret was

removed, while ZEN was still running.

To remove, first of all turn the silver-colored lever (Fig. 37/2), then pull-out the reflector turret by using

the grip (Fig. 37/6).

When inserting, it is recommended that the reflector turret first of all be held by the short grip (Fig. 37/5)

and inserted into the guide rail (Fig. 37/3) and then pushed in as far as it will go using the long pull rod

(Fig. 37/6). Return the locking lever to its original position. Finally, close the system door.

1 Front system door 4 Reflector turret

2 Silver-colored lever 5 Short grip

3 Guide rail 6 Grip

Fig. 37 Removing and inserting the reflector turret for emission selection

The filters are not push and click filters and cannot be taken out as a whole. The filter cube and the

beam splitter were installed and aligned in the factory. Do not try to take out single filter cubes or

beam splitters, it will damage the filters and the alignment, rendering the system in the worst case

unusable.

02/2013 000000-1790-528 47

Page 52

CHAPTER 1 - HARDWARE

Fig.

Carl Zeiss User Interfaces Lightsheet Z.1

The emission filters can be exchanged on the filter turret (Fig. 37/4).

− Use the provided tool to loosen the retaining ring around the emission filter you wish to exchange

and remove the ring.

− Take out the emission filter, best when wearing powder-free laboratory gloves to prevent

fingerprints on the filter, by carefully tilting the filter wheel.

− Insert the new emission filter, the arrow mark on its edge must indicate the direction of the light

beam. If no arrow marking is present, the reflective side of the filter must point towards the light

source.

− Put the ring on top of the filter and tighten it with the same tool without applying force.

The emission filters facing towards the side of the turret are part of the channel 1 (Cam1, Emission

Filter 1) light path; the filters facing the top are part of channel 2 (Cam2, Emission Filter 2).

After replacing the reflector turret for emission selection with new filters, the filter modules must be

registered into the database using the Configuration Tool software (Fig. 38) or modified in the ZEN

software under the Maintain tab, Filters tool window. The position number on the turret is on the left

side of the filter. These numbers correspond with the numbering in the ZEN software.

38 Configuration Tool, Filters tab

48 000000-1790-528 02/2013

Page 53