P1028247-001 Rev. C

Zebra® KR203

Kiosk Receipt Printer

Hardware Integrator

Guide

© 2014 ZIH Corp. The copyrights in this manual and the software and/or firmware in the printer

described therein are owned by ZIH Corp. Unauthorized reproduction of this manual or the software and/or

firmware in the printer may result in imprisonment of up to one year and fines of up to $10,000

(17 U.S.C.506). Copyright violators may be subject to civil liability.

This product may contain ZPL®, ZPL II®, and ZebraLink™ programs; Element Energy Equalizer®Circuit;

E3®; and Monotype Imaging fonts. Software © ZIH Corp. All rights reserved worldwide.

ZebraLink and all product names and numbers are trademarks, and Zebra, the Zebra logo, ZPL, ZPL II,

Element Energy Equalizer Circuit, and E3Circuit are registered trademarks of ZIH Corp. All rights reserved

worldwide.

All other brand names, product names, or trademarks belong to their respective holders. For additional

trademark information, please see “Trademarks” on the product CD.

Proprietary Statement This manual contains proprietary information of Zebra Technologies Corporation

and its subsidiaries (“Zebra Technologies”). It is intended solely for the information and use of parties

operating and maintaining the equipment described herein. Such proprietary information may not be used,

reproduced, or disclosed to any other parties for any other purpose without the express, written permission

of Zebra Technologies.

Product Improvements Continuous improvement of products is a policy of Zebra Technologies. All

specifications and designs are subject to change without notice.

Liability Disclaimer Zebra Technologies takes steps to ensure that its published Engineering

specifications and manuals are correct; however, errors do occur. Zebra Technologies reserves the right to

correct any such errors and disclaims liability resulting therefrom.

Limitation of Liability In no event shall Zebra Technologies or anyone else involved in the creation,

production, or delivery of the accompanying product (including hardware and software) be liable for any

damages whatsoever (including, without limitation, consequential damages including loss of business

profits, business interruption, or loss of business information) arising out of the use of, the results of use of,

or inability to use such product, even if Zebra Technologies has been advised of the possibility of such

damages. Some jurisdictions do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

Contents

1 • Introduction .................................................... 1

Who Should Use This Document ............................................ 1

How This Document Is Organized ........................................... 1

Contacts ............................................................... 2

Technical Support .................................................... 2

2 • Design Overview ................................................ 3

KR203 Kiosk Receipt Printer ............................................... 3

Package Contents ....................................................... 4

Unpack and Inspect the Printer .......................................... 4

Design Considerations Overview ............................................ 5

3 • Printer Overview ................................................ 7

Printer Dimensions ....................................................... 7

Printer Orientation ....................................................... 8

Printer Features ......................................................... 9

Opening the Printhead ................................................ 11

Opening the Presenter ................................................ 11

Printer Information ...................................................... 12

Media Types ........................................................ 13

Printer Mounting ........................................................ 13

Mounting Orientations ................................................ 15

Design Your Own Mounting ............................................... 16

Printing ............................................................... 17

Looping Presenter ................................................... 17

Page Modes ........................................................ 18

Printer Configuration Methods and Tools .................................. 18

06/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

ii

Buttons, Indicators and Sensors ........................................... 19

Feed Button ........................................................ 19

Power Indicator ..................................................... 19

Sensing and Error Reporting ........................................... 20

Manual Printer Reset .................................................... 20

4 • Connections .................................................... 7

Cabling and Cable Routing ................................................ 7

Large Media Roll Adapter Accessory ..................................... 7

Attaching Power ......................................................... 8

Electrostatic Discharges and Earth Currents ................................ 9

Connecting the Printer to the Host .......................................... 11

Interface Cable Requirements .......................................... 11

USB Interface Requirements ........................................... 11

Communicating with the Printer ......................................... 12

5 • Media ........................................................ 13

Designing Your Own Media Dispensing System ............................... 13

Designing a Roll Support .............................................. 14

Designing Media Guides .............................................. 14

Designing for Fan-Fold Media .......................................... 14

Media Mounting Considerations ........................................... 15

Media Supply Method ................................................ 16

Media Input Aperture ................................................. 16

Media Guide ........................................................... 18

Installing the Media Guide ............................................. 18

Media Guide Calibration .............................................. 19

Determining Thermal Media Types ......................................... 19

Black Mark Media Requirements ........................................... 20

Preparing a Media Roll for Use ............................................ 22

Loading Media ......................................................... 24

Automated Media Loading ............................................. 24

Manual Media Loading ............................................... 25

Clearing Paper Jams .................................................... 25

Printing a Test Receipt ................................................... 26

6 • Accessories ................................................... 27

Accessories Overview ................................................... 27

Nozzle Bezel Kit – P1011185 ............................................. 29

Quick-Fit Hubs – 103939 ................................................. 30

Quick Fit Leaf Spring Retainer – 01473-000 .................................. 30

Wall Mount Roll Holder – P1014123 ........................................ 31

Roll Support ........................................................... 33

P1028247-001 Rev. C KR203 Hardware Integrator Guide 06/22/2014

Media Roll Low Sensor .................................................. 34

Small Core Media Roll Adapter – P1027727 .................................. 35

Printer Mounting Plate – 104208 ........................................... 36

Universal Roll Holder – P1014125 .......................................... 37

Printer Power Supply – 808099-004 ........................................ 41

Attaching the Power Supply ............................................ 41

Universal Serial Bus (USB) Cable – P1027715 ................................ 43

Large Media Roll Adapter – P1026858 ...................................... 44

Attaching to the Printer ............................................... 45

Loading Media ...................................................... 46

Mounting Plate for Large Media Roll Adapter – P1027728 ....................... 47

Attaching to the Printer ............................................... 47

Using other Accessories with the Large Media Roll Adapter ...................... 48

Universal Roll Holder ................................................. 48

Routing Cables with the Large Media Roll Adapter ............................. 49

Media Roll Low Sensor ............................................... 49

PowerCable........................................................ 50

Data Cables ........................................................ 50

iii

7 • Troubleshooting ................................................ 51

Status Light Descriptions ................................................. 51

Application LED States ............................................... 51

Application User Interface ............................................. 53

Print Quality Problems ................................................... 54

Media Sensing Problems ................................................. 55

Other Problems ........................................................ 57

Resetting the Factory Default Values ........................................ 58

Contact Technical Support ................................................ 58

06/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

iv

P1028247-001 Rev. C KR203 Hardware Integrator Guide 06/22/2014

Who Should Use This Document

This guide is intended for use by any person who needs to develop a kiosk using the KR203

printer, operate, or to troubleshoot problems with the printer.

1

Introduction

How This Document Is Organized

The manual is set up as follows:

Chapter Description

Introduction What is covered in this document, contact information.

Design Overview Introduction to the KR203 Printer and package contents,

design considerations overview.

Printer Overview Dimensions, orientation, and other features.

Connections Power and communication connections

Media Loading, mounting, and feed angles.

Accessories Available options to enhance the kiosk design.

Troubleshooting Covers operational issues and resolutions for status

indicator codes and poor print quality.

6/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

Introduction

2

Contacts

Contacts

Technical Support

Technical Support is available via Internet 24 hours per day, 365 days per year at

www.zebra.com. You can also email or call us using the following contact information.

The Americas Europe, Middle East, and Africa (EMEA) China Asian Pacific (except China) and India -

Zebra Technologies Corporation

Zebra Technologies Corporation

475 Half Day Road, Suite 500

Lincolnshire, IL 60069 USA

T: +1 847 634 6700

Toll-free +1 866 230 9494

F: +1 847 913 8766

Zebra Technologies Europe Limited

Dukes Meadow

Millboard Road

Bourne End

Buckinghamshire, SL8 5XF, UK

T: +44 (0)1628 556000

F: +44 (0)1628 556001

Zebra Technologies Asia Pacific, LLC

120 Robinson Road

#06-01 Parakou Building

Singapore 068913

T: +65 6858 0722

F: +65 6885 0838

tschina@zebra.com

kiosksupport@zebra.com

tsasiapacific@zebra.com

tseurope@zebra.com

P1028247-001 Rev. C KR203 Hardware Integrator Guide 6/22/2014

Design Overview

KR203 Kiosk Receipt Printer

The Zebra KR203 Hardware Integrator model is the best-in-class thermal kiosk printer

with a good range of features. The KR203 Hardware Integrator printer provides direct

thermal printing at speeds up to 150mm/s (5.9 ips) at a 203 dpi print density. The KR203

supports a driver based printing protocol.

2

The KR203 Hardware Integrator printer features:

• Patented Looping Presenter - To reduce jamming and print image distortion

caused by the user attempting to withdraw the receipt before imaging is finished,

the KR203 employs an innovative "looping station". The receipt is retained inside

the print mechanism until imaging is complete, then it is presented to the user for

removal.

• Media Pull Detection - When the user grasps the receipt and applies force to

remove it, the KR203 Hardware Integrator senses the force and dispenses the

receipt in a controlled fashion to prevent tearing or jamming.

• Easy Media Loading - Automatic media loading and preparation for printing.

Optional media low sensing.

• Flexible Media Support - Supports continuous, fanfold and black line receipt

media with automatic media sensing and calibration.

• Flexible Mounting - Horizontal and vertical printer mounting covering 90° of printer

orientation.

• Bar Code Support - Will image any font, barcode and graphic supplied by the

application through the printer driver.

• Interface Support - USB v1.1 (2.0 compatible)

6/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

Design Over view

4

Package Contents

The KR203 printers offer a wide range of printer options and accessories:

• 58, 60, 80, and 82.5mm media guide widths

• 70 watt external printer power module

• Multiple printer media roll mounting accessory configurations and options

• Media Roll Low sensor for use with Zebra and custom media roll mounting.

This integrators guide provides information you will need to develop a kiosk using the

KR203 printer and accessories.

Package Contents

The KR203 Hardware Integrator package comes with the following items:

• The KR203 Hardware Integrator printer.

• Warranty information.

Note • To minimize cost and reduce waste, the KR203 Hardware Integrator does not

include unneeded components or accessories. Additional items are required to make the

printer operational.

Unpack and Inspect the Printer

When you receive the printer, open the package immediately and inspect the contents for

shipping damage.

• Save all packing materials.

• Check all exterior surfaces for damage.

• Open and close the printer and remove any media or test prints in the printer.

If you discover shipping damage upon inspection:

• Immediately notify the shipping company and file a damage report. Zebra

Technologies Corporation is not responsible for any damage incurred during

shipment of the printer and will not cover the repair of this damage under its

warranty policy.

• Keep all packaging material for shipping company inspection.

• Notify your authorized Zebra reseller.

P1028247-001 Rev. C KR203 Hardware Integrator Guide 6/22/2014

Design Considerations Overview

The kiosk designer needs to consider how the printer will be used, operated (media supply

and maintenance), serviced, integrated with other kiosk components, and integrated into

the enclosure itself. The KR203 Hardware Integrator printer requires some basic design

elements to function properly, safely, and easily for the operator. The general issues are:

• Locking Enclosure – The KR203 Hardware Integrator printer should always be

installed in a secure enclosure. The user or untrained personnel should not have

access to, operate, or service the printer.

• Mounting orientation.

• Mounting of the printer to the kiosk.

• Printer Power Requirements and DC power connector.

• Connection of the printer to the host computer.

• Media Handing – The design of the kiosk should consider the type of media to be

used: roll or fan-fold media; the appropriate media dispensing system; the location

of the media in the kiosk relative to the printer; and the overall size of the media

package (roll diameter or stack height).

Design Overview

Design Considerations Overview

5

• Operator Access – The operator needs access to:

• The printer's control panel for status lights and also access to view and

press the feed button while observing the status lights for media loading,

setup, and servicing the printer. (See Buttons, Indicators and Sensors

on page 21)

• Open and clean the pr inthead or remove jams. (see Clearing Paper Jams

on page 42)

• The media path between the printer and media (roll or fan-fold). A

minimum clearance of 250 mm on one or the other side of the printer,

printer controls, and media is needed.

• Service and printer replacement: Access to mounting hardware.

• Designing for the operator - ideas for a more intuitive media loading,

media preparation and use of media loading labels and documents.

• Ambient Lighting and external light sources which can affect printer sensors.

• Cooling - The printer needs space on both sides of the printer to allow for

convection cooling of the printer. This becomes more important with kiosk

installations that are in extreme environments or have high printer usage.

6/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

Design Over view

6

Design Considerations Overview

P1028247-001 Rev. C KR203 Hardware Integrator Guide 6/22/2014

Printer Dimensions

The illustration below outlines the basic printer mounting dimensions to install the printer in a

kiosk. These basic printer dimensions do not illustrate the unique integration requirements

needed to use the printer with specific printer accessories, operator servicing access, media

mounting, power and cabling access, and printer media handling.

3

Printer Overview

Figure 3-1 • Printer Dimensions

6/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

Printer Over view

8

Printer Orientation

Printer Orientation

REAR

Media IN

RIGHT

FRONT

Media Out

LEFT

Figure 3-2 • Printer Orientation

P1028247-001 Rev. C KR203 Hardware Integrator Guide 6/22/2014

Printer Features

Printer Overview

Printer Features

9

Figure 3-3 • Printer Features

Table 1 • Printer Features

Printhead Release Bar Cutter Bar

Printhead Platen (drive) Roller

Media Present Sensor Cutter

Control Panel Media Sensors

6/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

Printer Over view

10

Printer Features

Printer Features (continued)

Figure 3-4 • Printer Features

Table 2 • Printer Features

USB Port Power Input

Media Roll Low Sensor Input

P1028247-001 Rev. C KR203 Hardware Integrator Guide 6/22/2014

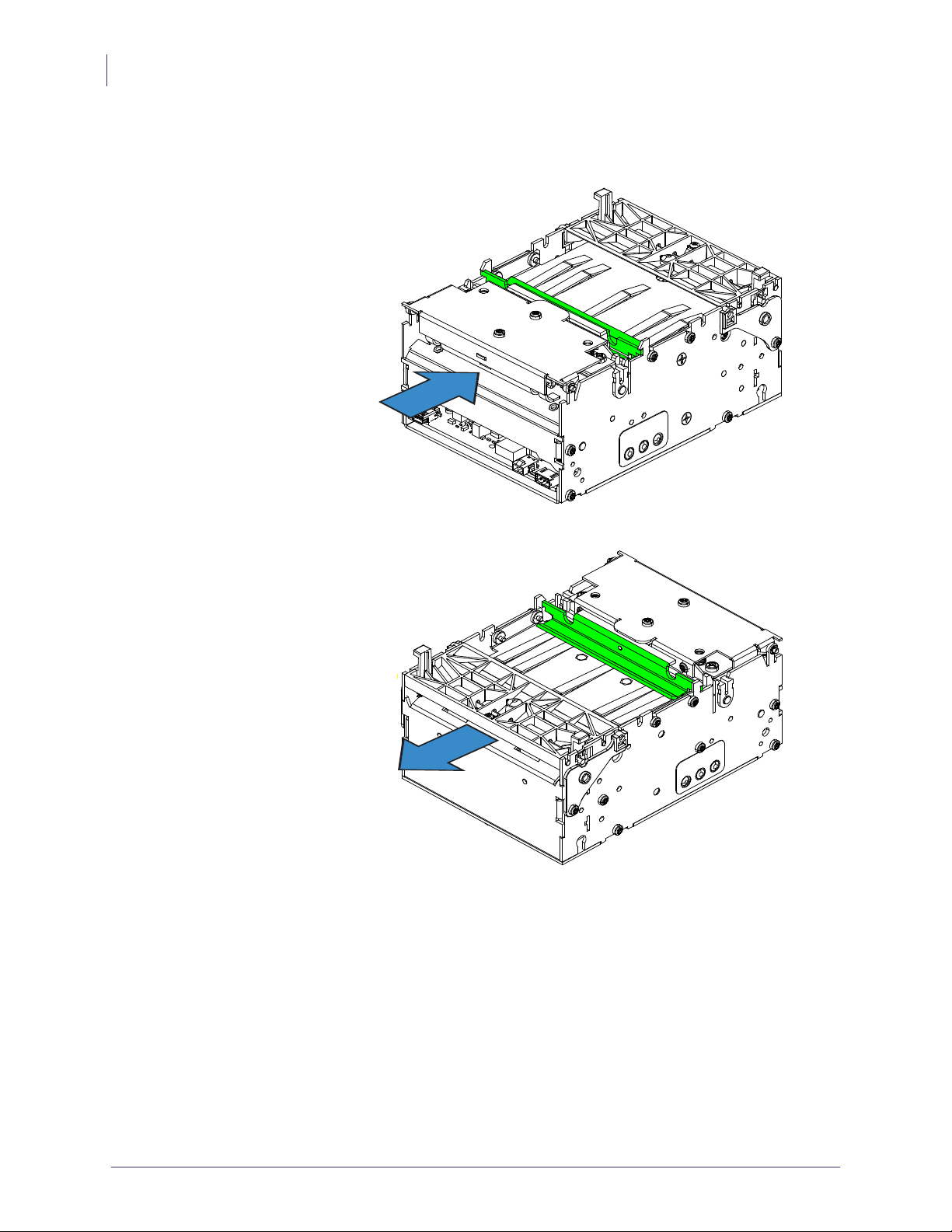

Opening the Printhead

When cleaning or servicing the printer, it is sometimes necessary to access the printhead.

1. Press the green printhead release bar to unlock the printhead.

2. Rotate the printhead assembly upward.

Printer Overview

Printer Features

11

Opening the Presenter

When cleaning or servicing the printer, it is sometimes necessary to access the presenter.

1. Squeeze the two presenter locking tabs together to unlock the presenter assembly.

2. Rotate the presenter assembly upward.

Figure 3-5 • Opening the Printhead

Figure 3-6 • Opening the Presenter

Note • When closing the presenter, make sure to close securely with an audible click on both

locking tabs.

6/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

Printer Over view

12

Printer Information

Printer Information

Printer control Printer Control Panel - Allows very basic printer

configuration setup that includes a test page.

Print method Direct thermal page printing using thermal sensitive media.

Resolution 8 dots/mm (203 dpi)

Print speed 152 mm/s (6.0 inches/sec.) — Default

127 mm/sec.(5 inches/sec.)

101.6 mm/sec. (4 inches/sec.)

76.2 mm/sec. (3 inches/sec.)

Note: Printer media is rated for specific speed ranges and

some media types and materials will print better at slower

speeds.

Present speed 300 mm/s (11.81 inches/sec)

The KR203 Hardware Integrator uses the Looping Presenter

modes.

In pass-through presenter mode (loop size set to zero)

presenter speed matches the print speed.

Print duty cycle Up to 33%

Media Sensors Out of paper, paper in presenter, black mark, and an optional

external paper-low sensor.

Maximum print width 80 mm = 640 pixels

Auto Selected Print Widths

58 and 60 mm guide 60 mm = 480 pixels maximum

80 and 82.5 mm guide 80 mm = 640 pixels maximum

P1028247-001 Rev. C KR203 Hardware Integrator Guide 6/22/2014

Media Types

Printer Overview

Printer Mounting

13

Receipt Media Supply

Type

Outer Roll diameter 250 mm (9.84 inches) maximum

Spindle (core) diameter 25 mm minimum (typical core size)

Paper width 58, 60, 80, and 82.5 mm (common receipt roll widths)

Paper Thickness or Caliper 0.054 – 0.11 mm

Paper Density or

Grammage

Outside Wound Continuous Roll: Plain receipt, receipt with

black marks, and pre-printed receipt media with black marks.

Fanfold: Stacked receipt media with black marks and preprinted receipt media with black marks.

Note: The maximum roll diameter is dependent upon roll

holder in use and the kiosk design.

40 mm maximum

12 mm minimum with Small Core Media Roll Adapter

For information on ordering media, refer to Contacts

on page 2.

2

55 –110 g/m

Note - This is an approximate area density measurement that

varies by country, paper type and measurement method

applied.

(or gsm)

Printer Mounting

The printer can only be mounted to the kiosk using the four printer mounting screw holes

shown in the illustration below. The printer is most secure when using all four of the mounting

positions connecting the printer’s base to a rigid metal base plate in the kiosk. The kiosk’s

metal printer mounting plate should be connected to the kiosks electrical (earth) ground for

6/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

Printer Over view

14

Printer Mounting

purposes of controlling static discharge and electrical noise.

1b

2

1a

Figure 3-7 • Printer Mounting

Table 3 • Mounting Configuration

Mounting Positions Kiosk’s Print Base Mounting Variation Details

1a and 1b Full coverage of printer’s

base plate

• Minimum mount positions.

• Supports the Quick-Fit Hubs

• Supported by most Zebra

accessory mounting solutions.

1a and 2 Partial (and Full) coverage

1 (a and b) and 2

of the printer’s base plate

• Minimum three point mounting

to fight torsional forces.

For information on ordering accessories, refer to Contacts on page 2.

P1028247-001 Rev. C KR203 Hardware Integrator Guide 6/22/2014

Printer Overview

Printer Mounting

15

X

Table4•M3Metric Mounting Screw Length

X 1.5mm minimum Printer mounting surface

Y 1.5mm Printer base plate thickness

Z 2mm maximum Penetration into circuit board area

X + Y = minimum length

X + Y + Z = maximum length

Mounting Orientations

The printer can be mounted horizontally or vertically depending on the design of the kiosk.

The maximum angle that the printer can operate from the nominal vertical or horizontal

orientations is dependent upon environmental conditions and the media in use.

M3 Screw

Figure 3-8 • Printer Mounting

Y

Z

Environmental conditions that may affect operation: Humidity, temperature, air circulation air

in the kiosk, and static buildup on adjacent kiosk components and surfaces, etc.

Media considerations:Receipt length, partial cut of receipt in receipt design, curl at the end of

the media roll, thickness and weight, perforations on fan-fold or receipt media, etc.

Other considerations: Media mounting, media path, media access, printer maintenance,

cabling, etc.

Note • In vertical mounting orientation the small core media adapter may be used to ensure

that media enters the present path.

The area of primary concern is the ‘loop area’ – this area requires special attention when

designing the kiosk. The printer requires space to store the printed receipt before presenting it

to the customer. The longer the receipt, the greater the area needed. When mounting the printer

at angles other than the nominal vertical or horizontal orientations, simulated receipt printing

operations should be observed with the chosen media for use in the kiosk and in the

environmental conditions that it will operate on-site.

6/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

Printer Over view

16

Design Your Own Mounting

Design Your Own Mounting

The illustration below gives an example of a printer-mounting shelf:

Figure 3-9 • Printer Mounting

Additional space is required for paper loading and service access. Consider mounting the

printer on a movable platform so that the printer can be maintained outside the printer

enclosure.

Note • We recommend making the output slot 97 mm wide. This width should accommodate

all paper widths that the KR203 Hardware Integrator printers can handle.

Caution • NEVER use screws that go into the printer more than 4 mm! This will damage or

destroy the electronics inside. See Printer Mounting on page 13.

P1028247-001 Rev. C KR203 Hardware Integrator Guide 6/22/2014

Printing

Printer Overview

Printing

The printing sequence starts with the leading edge of the media resting at the cut position after

loading media or printing a previous receipt. The printer begins printing the page upon

completion of the transfer of the image to the printer. When the page has finished printing, the

printer cuts the receipt to finish.

The printer then presents the receipt to the kiosk client. When the client pulls the receipt, the

printer immediately detects the roller movement and causes the printer to accelerate the receipt

out of the printer. This helps prevent damage to the receipt.

17

Media Input - Use Auto or Manual

media loading procedure.

Loop area- stores receipt until printing

completed.

Media Cutter - Full or partial media

cuts.

Looping Presenter

The looping presenter mechanism has many benefits:

• It handles documents of various lengths by storing the printed paper in a loop.

• It holds the printout until fully printed and cut before presenting the completed printout to

the customer. This eliminates issues many other printers have when the kiosk client tries

to remove media before printing has finished.

• A portion of the printout is presented. When the customer takes the receipt, the printer

detects a movement and issues the rest of the receipt at 300 mm/s to help ensure receipt is

removed undamaged. The amount of media presented can be customized to account for

differences in the thickness of the kiosk wall.

Figure 3-10 • Printing Sequence

Table 5 • Printing Sequence

Printhead and Platen (Drive) Roller.

Media Drive Roller and Loop Stop

(forward only.)

Media Present - Detects a media pull

with motor.

6/22/2014 KR203 Hardware Integrator Guide P1028247-001 Rev. C

Printer Over view

18

Printing

Page Modes

The printer sets the following modes using the Windows driver.

Variable Page Mode The length of the page (receipt) varies with the contents. Pages

shorter than the minimum page (receipt) length will be extended

to the minimum length. Pages (receipts) longer than the

maximum page (receipt) length will print the maximum page

(receipt) length, then place the extra data on additional pages

(receipts).

Fixed Page Mode The length of the page (receipt) is fixed. The printer will always

create a page (receipt) of the defined length. If the page (receipt)

image is shorter than the defined length, blank media will be fed

until the defined length is reached. Any data beyond the defined

length will be placed on subsequent pages (receipts). Between

pages (receipts), the cut behavior (full or partial) specified for

the print job will occur.

Black Mark Mode Marks on the paper set the form length. Black mark mode can

work with either fixed or variable length pages (receipts). In

fixed page mode, the printer will force a cut at every black mark

and multiple pages can be imaged for one document. In variable

page mode, the printer will cut ar the next black mark after the

end of the data.

Printer Configuration Methods and Tools

The KR203 Hardware Integrator printer has a variety of printer configuration methods for the

software and hardware integrator. Each is designed to assist you with various kiosk design and

integration tasks. These integration tasks include printer startup, proof of concept, receipt

design, status reporting, multi-printer configuration, and kiosk application design. The

configuration methods from hardware to programming application include:

• Media Guides — Sets the printer’s maximum print width. See Media Guide

on page 18 and Installing the Media Guide on page 18.

• Control Panel — The printer’s control panel (Feed Button) provides access self test,

media guide detection, test prints, and resetting the printer to factory defaults. See the

Feed Button on page 19.

• Windows Drivers — Quickly allows the developer to use the printer, test

configuration options, send programming commands or files, and print directly from

Windows applications. Refer to the Software Integrator Guide (P1028248) for

additional information.

P1028247-001 Rev. C KR203 Hardware Integrator Guide 6/22/2014

Loading...

Loading...