Page 1

Zebra® KR203

Kiosk Receipt Printer

Windows® CE

Software Integrator

P1028251-001 Rev. A

Guide

Page 2

© 2011 ZIH Corp. The copyrights in this manua l and th e so f tware and/or firm ware in the

printer described therein are owned by ZIH Corp. Unauthorized reproduction of this

manual or the software and/or firmware in the printer may result in imprisonment of up to

one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to

civil liability.

®

This product may contain ZPL

Equalizer

®

Circuit; E3®; and Monotype Imaging fonts. Software © ZIH Corp. All rights

, ZPL II®, and ZebraLink™ programs; Element Energy

reserved worldwide.

ZebraLink and all product names and numbers are trademarks, an d Zebra, the Zebra

logo, ZPL, ZPL II, Element Energy Equalizer Circuit, and E

3

Circuit are registered

trademarks of ZIH Corp. All rights reserved worldwide.

All other brand names, product names, or trademarks belong to their respective holders.

Proprietary Statement This man ual contains proprietary information of Zebra

Technologies Corporation and it s subsid iaries (“Zeb ra Technologies”). It is intended solely

for the information and use of parties operating and ma in taining the eq uipm en t de scr ibe d

herein. Such proprietary information may not be used, reproduced, or disclosed to any

other parties for any other purpose without the express, written pe rmission of Zebra

Technologies.

Product Improvements Continuous improvement of products is a policy of Zebra

Technologies. All specifications and designs are subject to change without notice.

Liability Disclaimer Zebra Technologies takes steps to ensure that its published

Engineering specifications and manuals are correct; however, errors do occur. Zebra

Technologies reserves the right to correct any such errors and disclaims liability resulting

therefrom.

Limitation of Liability In no event shall Zebra Technologies or anyone else involved in

the creation, production, or delivery of the accompanying produ ct (including hardwar e and

software) be liable for any damages whatsoever (including, without limitation,

consequential damages including loss of business profits, business interruption, or loss of

business information) arising out of the use of, the results of use of, or inability to use such

product, even if Zebra Technologies has been advised of the possibility of such damages.

Some jurisdictions do not allow the exclusion or limitation of incidental or conseque ntial

damages, so the above limitation or exclusion may not apply to you.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 3

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Who Should Use This Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How This Document Is Organized. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Windows CE Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Windows CE Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Printer Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Port Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Print Spooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Status Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GetPrinterStatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Panel Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

KR203CPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Printer and Driver Parameter Setting and Maintenance . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Driver Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Update Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

UI Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Command Line Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Printer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Device Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Media Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Media Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Darkness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Max Print Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Media Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Top Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8/6/2010 KR203 Software Integrator Guide P1028248-001 Rev. A

Page 4

ii

Contents

Bottom Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cutter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Partial Cut Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Presenter Loop Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Eject Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Present Length Addition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Presenter Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Clear Presenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

About. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting Black Mark Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Status Light Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Application LED States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Application User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Print Quality Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Media Sensing Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Other Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Resetting the Factory Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Contact Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

KR203 Status codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Programming Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Background. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Monitoring While Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Monitoring While Idle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

P1028248-001 Rev. A KR203 Software Integrator Guide 8/6/2010

Page 5

Who Should Use This Document

This guide is intended for use by any person who need s to setup the KR203 printer for use

with a Windows CE device.

1

Introduction

How This Document Is Organized

The manual is set up as follows:

Introduction

Windows CE Driver Installation, updates, preferences, and properties.

Troubleshooting

Appendix A KR203 status codes.

Appendix B Programming samples

This manual will be updated from time to time as printer functions and features may be

added or amended. You will always find the latest edition on our web site (http://

www.zebra.com). If you require information for functions not found in this manual edition,

please contact Technical Support for your region or the Zebra partner the printer was

purchased from.

Contact information, document conventions.

Sta tu s light description, user interf ace, error handling,

and fixes to common printing problems.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 6

Introduction

2

Contacts

Contacts

Technical Support via the Internet is available 24 hours per day, 365 days per year.

Web Site: www.zebra.com

E-mail Back Technical Library:

• E-mail address: emb@zebra.com

• Subject line: Emaillist

Self Service Knowledge Base: www.zebra.com/knowledgebase

Online Case Registration: www.zebra.com/techrequest

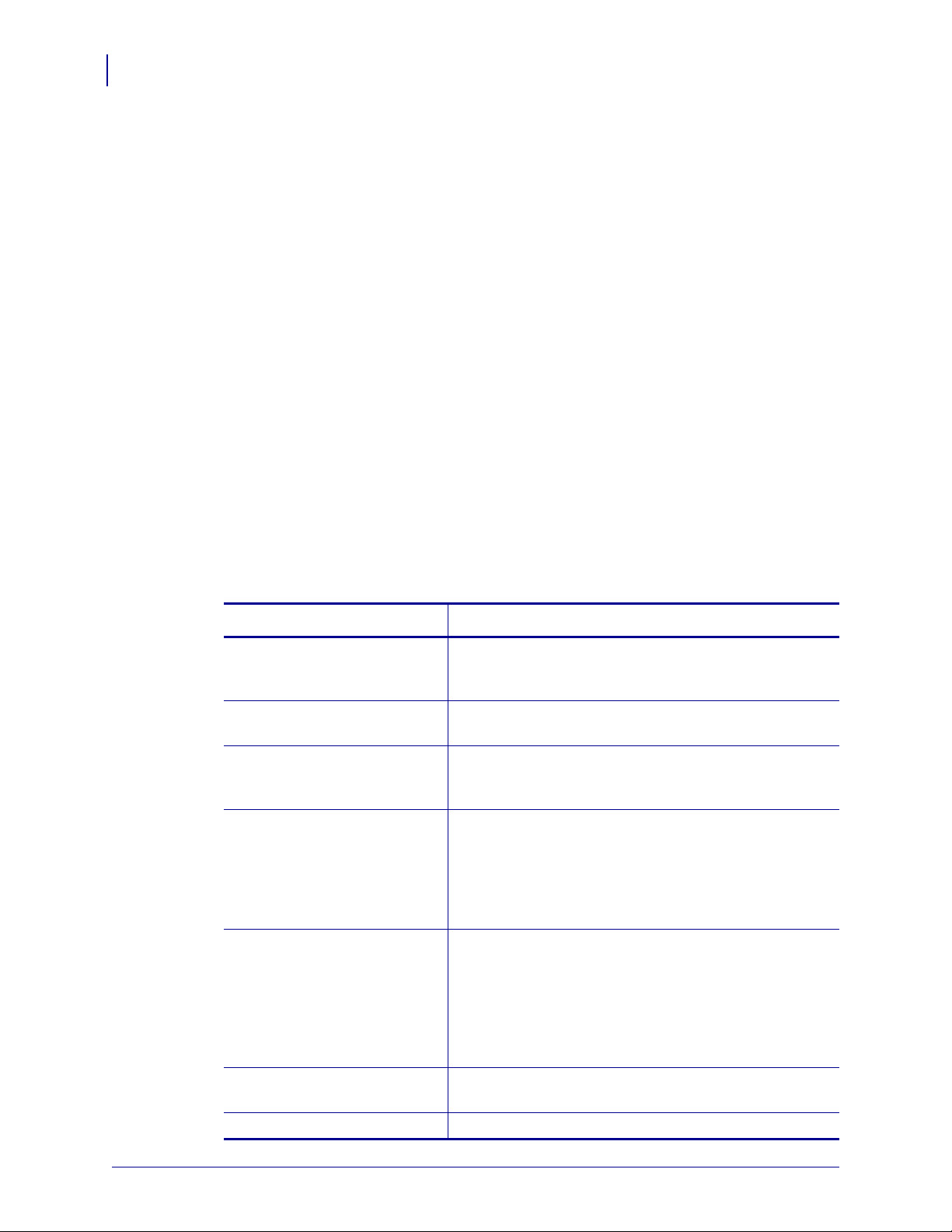

Which Department

Do You Need?

Regional Headquarters

Technica l Sup port

For questions on the operation

of Zebra equipment and

software, please call your

distributor. For additional

assistance, contact us.

Please have your model and

serial numbers available.

Repair Service Department

For back-to-base service and

repair.

Techni cal Training

Department

For Zebra product training

courses.

Inquiry Department

For product literature and

distributor and dealer

information.

Customer Service

Department (US)

Internal Sales Department

(UK)

For printers, parts, media, and

ribbon, please call your

distributor or contact us.

Key:

T: Telephone

F: Facsimile

E: E-mail

The Americas

Zebra Technologies Inter national,

LLC

475 Half Day Road, Suite 500

Lincolnshire, IL 60069 USA

T: +1 847 634 6700

Toll-free +1 866 230 9494

F: +1 847 913 8766

T: +1 877 ASK ZEBRA (275 9327)

F: +1 847 913 2578

Hardware: ts1@zebra.com

Software: ts3@zebra.com

Kiosk Printers:

T: +1 866 322 5202

kiosksupport@zebra.com

T: +1 877 ASK ZEBRA (275 9327)

F: +1 847 821 1797

E: repair@zebra.com

To request a repair in the U.S.,

go to www.zebra.com/repair

T: +1 847 793 6868

T: +1 847 793 6864

F: +1 847 913 2578

E: ttamerica@zebra.com

T: +1 877 ASK ZEBRA (275 9327)

E: inquiry4@zebra.com

T: +1 877 ASK ZEBRA (275 9327)

E: clientcare@zebra.com

.

Europe, Africa,

Middle East, India

Zebra Technologies Europe Limited

Dukes Meadow

Millboard Road

Bourne End

Buckinghamshire, SL8 5XF

United Kingdom

T: +44 (0) 1628 556000

F: +44 (0) 1628 556001

T: +44 (0) 1628 556039

F: +44 (0) 1628 556003

E: Tseurope@zebra.com

T: +44 (0) 1772 693069

F: +44 (0) 1772 693046

New requests: ukrma@zebra.com

Status updates:

repairupdate@zebra.com

T: +44 (0) 1628 556000

F: +44 (0) 1628 556001

E: Eurtraining@zebra.com

T: +44 (0) 1628 556037

F: +44 (0) 1628 556005

E: mseurope@zebra.com

T: +44 (0) 1628 556032

F: +44 (0) 1628 556001

E: cseurope@zebra.com

Asia Pacific

Zebra Technologies Asia Pacific

Pte. Ltd.

120 Robinson Road

#06-01 Parakou Building

Singapore 068913

T: + 65 6858 0722

F: +65 6885 0838

T: +65 6858 0722

F: +65 6885 0838

E: China: tschina@zebra.com

All other areas:

tsasiapacific@zebra.com

T: +65 6858 0722

F: +65 6885 0838

E: China: tschina@zebra.com

All other areas:

tsasiapacific@zebra.com

T: + 65 6858 0722

F: +65 6885 0838

E: China: tschina@zebra.com

All other areas:

tsasiapacific@zebra.com

E: China:

GCmarketing@zebra.com

All other areas:

AP ACChannelmarketing@zebra.co

m

T: +65 6858 0722

F: +65 6885 0836

E: China: order-csr@zebra.com

All other areas:

csasiapacific@zebra.com

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 7

Document Conventions

The following conventions are used in this document to convey certain information:

Alternate Color – Cross-references contain links to othe r sections in this guide. If you are

viewing this guide online, click the blue text to jump to its location.

Note • Indicates information that emphasizes or supplements important points of the main

text.

Introduction

Document Conventions

3

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 8

Introduction

4

Document Conventions

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 9

Description

APPLICATION

GDI

DISPLAY DRIVER

PRINTER DRIVER

PORT MONITOR

USB

PORT

PRINTER

Windows CE Driver

2

Windows CE Driver

The following description applies to CE 5.0 and CE 6.0.

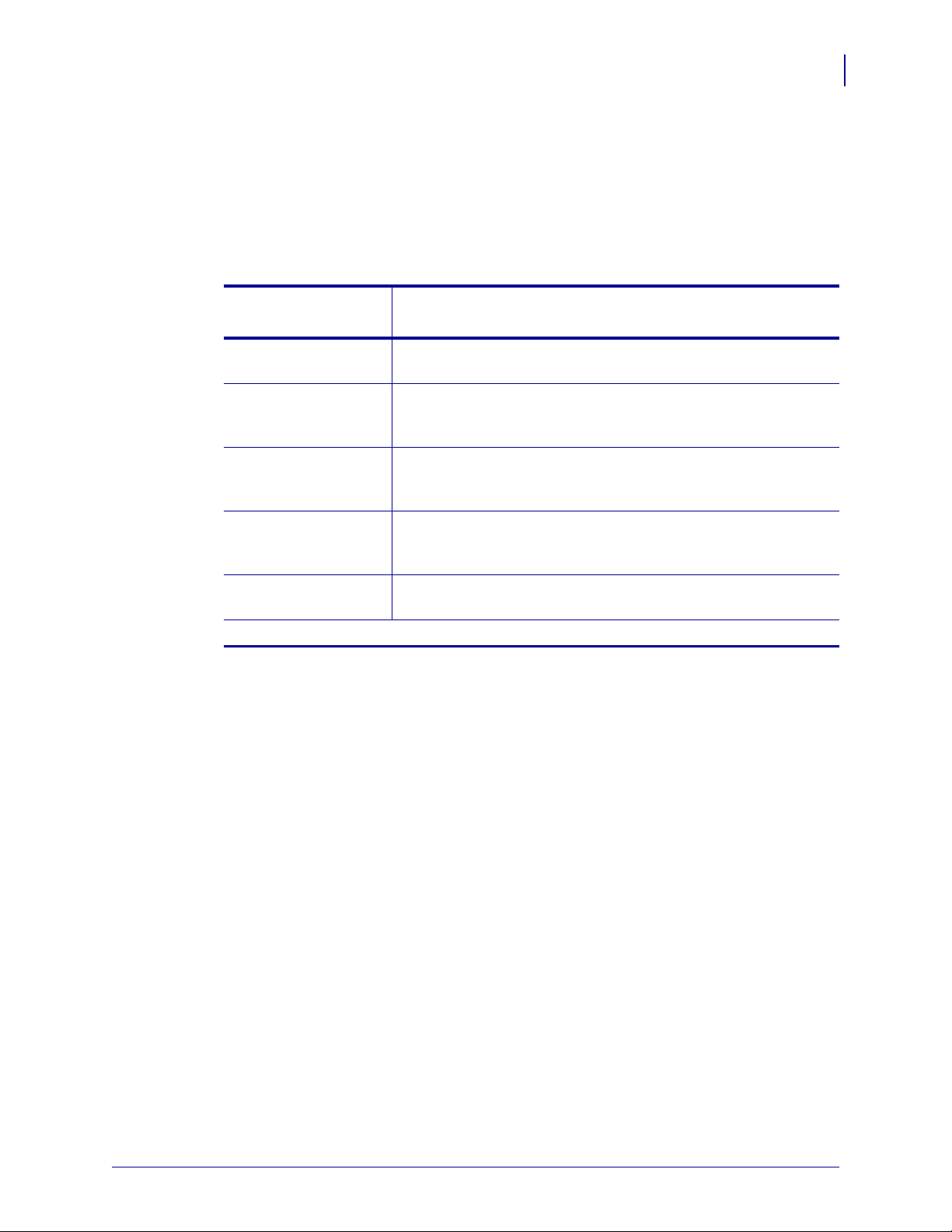

The illustration shows the relationship between the various system components involved

in printing.

Figure 2-1 • System Flowchart

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 10

Windows CE Driver

6

Description

Printer Driver

The printer driver for the KR203 is named KR203.DLL. The Windows CE graphics device

interface (GDI) and display driver perform most of the work involved in printing. At the

beginning of the printing process, GDI creates a device context with attributes that are

retrieved from the printer driver during a call to DrvEnablePDEV. The display driver, not

the printer driver, is used to render subsequent drawing commands that are issued from

the application into the device context. Theref ore, some drawing functions that are pre sent

in a printer driver, such as DrvS tro kePath, are ne ver ca lled because the printer d river only

renders the document internally.

The printer driver converts the bitmap dat a from a GDI bitmap format into the for mat that is

recognized by the printer. This can include such operations as color reduction to the color

space of the printer , dat a compression, and d ata conversion in to the format that is used by

the printer – a format sometimes known as a page-description la ngu age (PDL) . Then, th e

printer driver calls the port monitor to send the rendered image to the printer.

Only a small number of the graphics driver functions defined for printer drivers are

required in printer drivers for Windows CE. Printer drivers are required to implement only

those graphics driver functions that are necessary for gathering printe r m etrics, setting up

the printer, starting and ending print jobs, and preparing content for printing.

The following table shows the functions implemented in the driver:

T able 2-1 • Driver Functions

Function Description

DrvCopyBits Translates between device-managed raster surfa ces

and graphics device interface (GDI) standard format

bitmaps.

DrvDisablePDEV Used by MGDI to notify a driver that the specified

PDEV structure is no longer needed.

DrvDisableSurface Used by the GDI to notify a driver that the surface

created by the DrvEnableSurface function for the

current device is no longer needed.

DrvEnableDriver Specifies the initial driver entry point exported by the

driver DLL for devices that link directly to GWES, such

as display drivers and printer drivers. It fills a

DRVENABLEDATA structure with the driver version

number and calling addresses of functions supported

by the driver

DrvEnablePDEV Enables a device context for drawing and returns

device metrics for the target printer or display device in

a GDIINFO structure. Printer drivers call a display

driver's DrvEnablePDEV function to create and

initialize the device context, and then substitute the

printer's device metrics before returning the device

context to the GDI for bitmap rendering.

DrvEnableSurface Sets up a surface to be drawn on and associates it with

a specified PDEV.

DrvEndDoc Called by the GDI to finish or abort a print job.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 11

Windows CE Driver

Description

T able 2-1 • Driver Functions

Function Description

DrvGetModes Lists the modes supported by a specified device.

DrvStartDoc Called by the GDI to start a print job.

DrvStartPage Called by the GDI to start printing the next page of a

print job.

GetPrinterInfo Obt ains information about printers, such as the name

of the printer or whether the printer can print in color.

PrinterClose Closes a printer handle previously opened by a call to

the PrinterOpen function.

PrinterOpen Opens a specified printer port and return s a handle to

the printer.

PrinterSend Sends a block of data to a printer.

ReportPrinterS tatus Returns the st atus of a pr inter or printing operation that

is in progress.

GetPrinterSt atus Returns a specific KR203 status.

7

Note • The table includes links to descriptions of the driver functions.

Port Monitor

The port monitor for the KR203 is called KRPort.DLL. Printing is supported over universal

serial bus (USB) port only. The printing architecture provides application programming

interfaces (APIs) that are exposed by the Graphics, Windowing, and Events Subsystem

(GWES) to communicate with the printer driver. The printer driver communicates with the

port driver that sends the print data over the supported bus. Therefor e, the pr inter driver i s

independent of the bus and the corresponding bus driver.

Print Spooling

No separate printer spooler component exist s in Windows CE, unlike the desktop ver sions

of the Windows OS. With Windows CE, spooling or background printing is implemented in

the printer driver itself. However, because print spooling typically consumes a lot of

memory, limited memory might be a problem. A practical print spooler usually has to

implement a complicated compression scheme to store spooled documents before

printing.

Status Monitoring

In order to allow applications to get status from the printer, there are two functions

implemented: 1) the default ReportPrinterStatus function described in the MSDN

documentation, and; 2) a new function GetPrinterStatus that returns the actual printer

status (see Table 2-2, Printer Status Codes on page 8).

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 12

Windows CE Driver

8

Description

GetPrinterStatus

This function gets the specific Printer status for the KR203.

Syntax DWORD WINAPI GetPrinterStatus(HANDLE hPrinter,

LPPRINTERSTATUS status)

Parm

hPrinter - HANDLE - Handle to the printer

status - LPPRINTERSTATUS - The status to be set.

Return DWORD - Returns

ERROR_SUCCESS if everything went Ok, else :

ERROR_UNKNOWN_PORT - If hPrinter is

INVALID_HANDLE_VALUE

ERROR_READ_FAULT - If read fail

ERROR_WRITE_FAULT - If write fail

ERROR_NOT_SUPPORTED - If hPrinter is not supported

The following table contains all status codes that can be reported by the KR203 printer

from the application.

T able 2-2 • Printer Status Codes

Number Name Type Group

0 Ok Normal Informational Solid green

1 Paper jam in presenter Normal Severe 1 red flash

2 Cutter Jam Normal Severe 2 red flashes

4 Print head lifted Normal Severe 4 red flashes

3 Out of paper Normal Severe 3 red flashes

5 Paper feed error Normal Severe 5 red flashes

6 Head temperature error Normal Severe auto-

clear

10 Black mark not found One-time Informational Not signaled

11 Black mark calibration

error

12 Index error One-time Informational Not signaled

16 Timeout Occurred One-time Informational Not signaled

18 Out of range One-time Informational Not signaled

One-time Informational Not signaled

LED

Reporting

Yellow

flashing

19 Paper low Normal Warning Not signaled

20 Media in presenter Normal Informational Not signaled

24 Invalid operation One-time Informational Not signaled

26 Target is read only One-time Informational Not signaled

40 Printer entered USB bus One-time Informational Not signaled

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 13

T able 2-2 • Printer Status Codes

Windows CE Driver

Description

9

Number Name Type Group

41 System calibration error One-time Informational Not signaled

42 System calibration

success

One-time Informational Not signaled

Control Panel Extension

In order to open the control panel and double click the program icon, a control panel

extension is supplied with the driver.

KR203CPL

This component enables users to change settings for the printer and printer driver.

You can access the Control Panel through Start->Settings->Control Panel

Printer and Driver Parameter Setting and Maintenance

To provide an easy interface to set printer and driver parameters on the CE device, an

application is provided that handles device settings, and offers a Tools tab (see “Tools” on

page 17) to perform ce rtain main tena nce functions and print a printer configuration she e t.

LED

Reporting

The driver settings are done via the KR203 Settings application that can be found in the

Control Panel.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 14

Windows CE Driver

10

Installation

Installation

Driver Installation

The Zebra CE driver ZIP package includes the following files:

• Control Panel extension

• KR203CPL.CPL - This component enables users to change settings for the printer

and printer driver.

• KR203.DLL - The Printer Driver.

• KRPort.DLL - The Port Monitor.

• KRErr.DLL - The error handler.

• KR203.CPY - A sample copy file.

• KRDevice.EXE - The Parameter setup application.

• KRConfig.DLL - A helper DLL for the parameter setup applic ation.

• FWDownload.EXE - The firmware update application

Extract the Zebra CE driver files for the KR203 from the ZIP file and deploy the driver files

(KR203, KRPort, KRErr and KR203CPL) to the Windows directory. The sample copy file

(KR203.CPY) is included as a template for writing a copy file. This file is used during each

restart to copy files from permanent storage to their respective directories.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 15

Update Firmware

UI Option

Check the firmware version installed on the printer by printing a configuration label (see

“Tools” on page 17), the firmware version will be shown.

Go to the Zebra Website at www.zebra.com and follow the instructions to download the

latest version to your computer.

Copy the firmware package to the device to which the printer is connected and that runs

the driver. Select the port the target printer is connected to and then click “Select FW”.

Navigate to the firmware file and click “Download Firmware”. Confirm the installation by

clicking “Y es”. The status light on the printer will flash intermittently between green and red

indicating that a firmware update is in progress. The printer will reset when it has fini shed

the upload.

Command Line Option

Windows CE Driver

Update Firmware

11

The download application also offers a command line option to allow for remote

deployment of the firmware file and application and execution via a short cut link.

The following shows a sample command line:

\Application\Zebra\FWDownload.exe /P LPT1: /F

\Application\Zebra\K69_1_1.bin

Where /P is the port used to send data to the printer and /F is the firmware file including

directory location where the file is stored.

The following is a sample short cut link:

78#\Application\Zebra\FWDownload.exe /P LPT1: /F

\Application\Zebra\K69_1_1.bin

After the program has finished, a log file (KR203FWDownload.log) showing the actions

and results during the update process will be saved to the system root directory.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 16

Windows CE Driver

12

Printer Settings

Printer Settings

Device Setting

This dialog is used to control the Printer and driver settings:

Figure 2-2 • Device Settings Tab

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 17

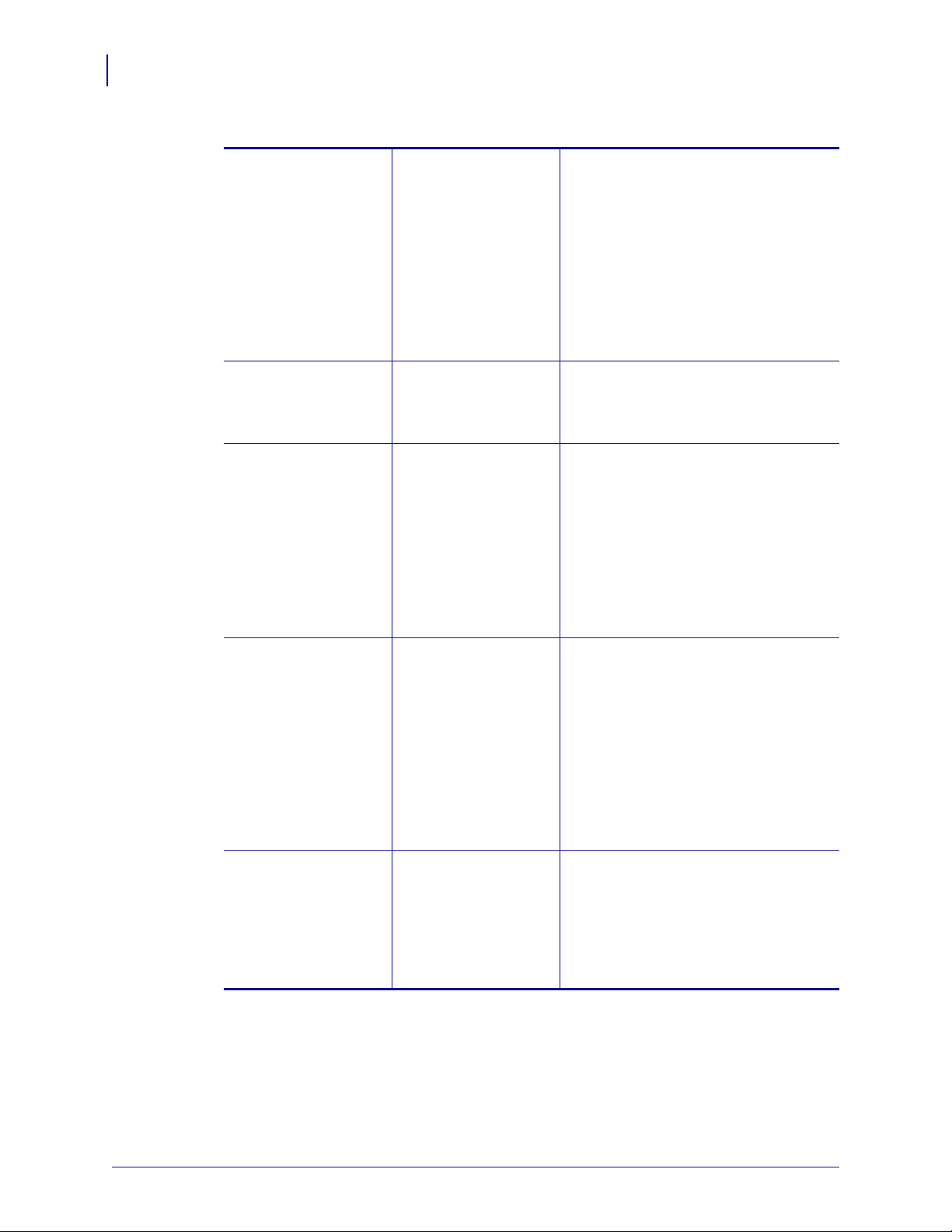

The following table describes the values and defaults of the parameters:

Table 2-3 • Parameter Settings and Defaults

Parameter Value Range Default Value

Media Width 58mm, 60mm, 80mm, 82mm 80mm

Media Height 100mm to 600mm 100mm

Darkness 0 to 30 20

Max Print Speed 75mm to 152mm 152mm

Media Tracking Continuous, Variable Length,

Mark Sensing

Top Margin 2mm to 12mm 12mm

Bottom Margin 0 to 9mm 0

Cutter Mode None, Every Page, End of

Document

Partial Cut Width 0, 10mm to 60mm 0

Presenter Loop Length 0 to 600mm 400mm

Eject Length 20mm to 600mm 50mm

Present Length Addition 0 to 255mm 0

Variable Length

Every Page

Windows CE Driver

Printer Settings

13

Presenter Timeout 0 to 300 seconds 0

Clear Presenter Disable, Enable Disable

The OK button will apply the parameter and exit the program.

The Cancel button will not apply the parameter and exit the program.

The Apply button will apply the parameter but not exit the program.

The Default button with set all parameters to factory default.

After the settings application has saved all the parameters these will be used during print

jobs.

The following settings will be sent to the printer during each print job:

Media Width

The media width can be set to 58 mm, 60 mm , 80 mm and 82.5 mm . The defa ult setting is

80 mm

Media Height

The media height can be set between the minimum page length of 100 mm and the

maximum page length of 600 mm. The default setting is 100 mm

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 18

Windows CE Driver

14

Printer Settings

Darkness

The Darkness can be set between 0 and 30 with zero being the lightest. The default

setting is 20.

Figure 2-3 • Darkness set to 20 (default)

Max Print Speed

The max print speed can be set between 75 mm and 152 mm per second (mm/s). The

default setting is 152 mm/s. The actual print speed may vary depending on the darkness

and the content printed.

Media Tracking

Media Tracking sets Continuous, Variable Length, or Mark Sensing with the default set to

Variable Length. When media tracking is set to Continuous, the driver sends the full page

size to the printer (Page Mode), the page length will always be the same as the selected

paper size (e.g. if 58mm x 200mm Media is selected, the print will be 200mm long in Page

Mode). When media tracking is set to Variable Length, the driver will shorten the print to

the length of the page. The driver will end the print after the last printed element (text,

barcode, or graphic) then send a feed, cut, and eject command. The p age length may vary

from page to page but will always be a minimum of 92mm. When Mark Sensing is set, the

driver will send the page size to the printer, the printer will restrict the print to the area

between the black marks. If the printed area is larger than the space between the black

marks, it will print additional pages (receipts). The margin values in the receipt application

must be corrected after setting the driver values. If the margin in the application is set to

9mm and the driver is set to 2mm, the application setting will be enforced unless the driver

is changed accordingly.

Figure 2-4 • Darkness set to 0 (zero)

Compression sets whether the data is sen t to the printer co mpressed or unco mpressed. If

the data is sent uncompressed, this may result in longer print times.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 19

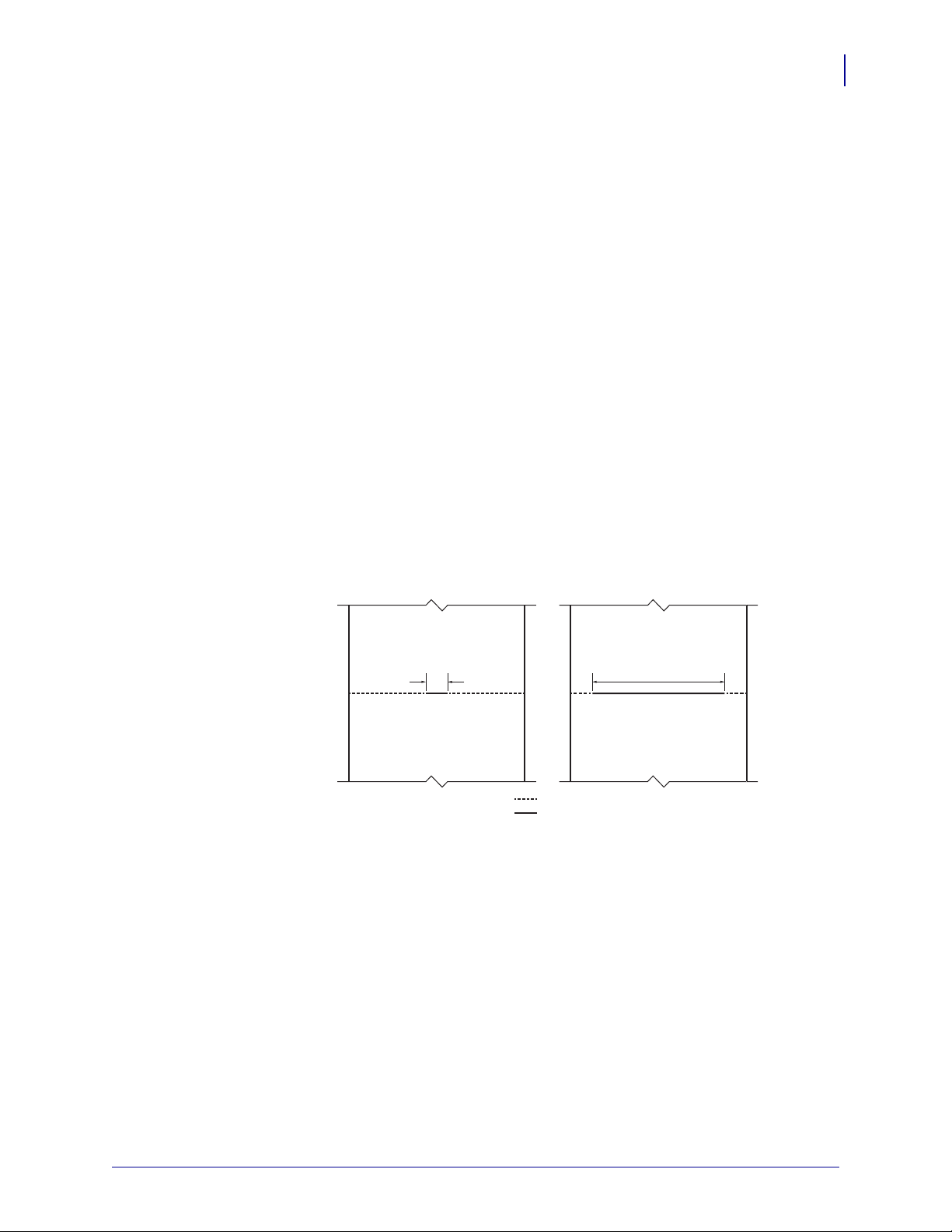

Top Margin

10 mm

Page 1

Page 2

Page 1

Page 2

Cut

Not Cut

60 mm

The Top Margin is the equivalent to the distance between the cutter and the print head and

is by default 12 mm. If it is set between the minimum of 2 mm or 11 mm it will reverse the

paper.

Bottom Margin

The Bottom margin can be set between 0 and 9 mm and will be added to the bottom of the

page in Variable Mode and will limit the printable area in Continuous Mode and Mark

Sensing. The default is 0.

Cutter Mode

Cutter Mode can be set to None, Every Page and Cut at the document end. Th e default is

Every Page. When set to Every Page and a multi-page document is printed each page will

be cut. If set to Cut at document end and a multi-page document is printed all pages will

print and only one cut at the end of the document will be issued. Partial Cut Width is used

with Cut at document end.

Partial Cut Width

Windows CE Driver

Printer Settings

15

Partial cut leaves multi-page receipts attached at the specified width. The p artial cut wid th

can be set to 0 and between 10 and 60 mm; the default is 0 and it disables partial cut (full

cut). Partial cut can only be used with the Cut at document endselection in Cutter Mode.

Presenter Loop Length

Presenter Loop Length determines how much paper is held in the presenter loop. The

presenter loop length can be set between 0 and 6 00 mm and the default val ue is 400 m m.

A setting of 0 disables the presenter loop and media feed directly through the presenter.

Figure 2-5 • Partial Cut Diagram

Eject Length

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Eject Length determines how much paper is exposed for the customer. The range is from

20mm to 600mm with the default set to 50mm. If the eject length is set larger than the

length of the receipt, the printer will retain a portion of the receipt in the presenter unless

the “Clear Presenter” option is set to “Enable”.

Page 20

Windows CE Driver

16

Printer Settings

Present Length Addition

Presenter Length Addition is an additional length to compensate for the thickness of the

kiosk wall. The range is from 0 to 255mm with the default set to 0.

Presenter Timeout

Presenter Timeout determines how long the presenter will hold the receipt before ejecting

it. The range for the timeout is from 0 to 300 seconds with the default set at 0.

Clear Presenter

Clear Presenter determines if a receipt is retained, or if it is ejected from the presenter

after the timeout. Clear Presenter should not be used with Page Hold and will be set to

“Disable” if Page Hold is selected.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 21

Tools

The Tools tab enables printer maintenance functions.

Windows CE Driver

Printer Settings

17

Figure 2-6 • Tools Tab

Printer Port setting – Tells the driver which port the printer is connected to.

Clear Kiosk Presenter – Ejects any media in the presenter.

Send PRN File – Sends a saved PRN file to the printer.

Set Black Mark Mode – Sets the printer to use black mark media.

Set Continuous Mode – Set the printer to print continuous pages.

Feed One Receipt – Feeds a single blank receipt.

Print Config Label – Prints a page with the printer configuration information .

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 22

Windows CE Driver

18

Printer Settings

About

The About Tab shows the current driver version.

Figure 2-7 • About Tab

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 23

Setting Black Mark Mode

The printer is optimized to detect black marks printed with IR sensitive ink and ignore

preprint in IR blind ink. For information on black mark media requirements, refer to the

Hardware Integrator Guide (P1028247).

For 80 and 82.5mm media, the black marks will be centered 30mm to the right of the

paper center when viewing the imaged side of the receipt and print direction is downwa rd;

for 58 and 60mm media, the black marks will be centered 22mm to the left of the paper

when viewing the imaged side of the receipt and the print direction is downward.The

printer will support media with black mark thickn es s in printin g dir ec tio n of 2. 5 -9 .0 mm ,

and a width of 5.0 - 10.0mm when the black mark is centered on the sensor.

Refer to the Hardware Integrator Guide (P1028247) for black mark media requirements.

1. Choose the correct media guide for the desired media width. Refer to the Hardware

Integrator Guide (P1028247) for media guide installation instructions.

2. Perform a media guide calibration. Refer to "Application User Interface" on page 21.

Windows CE Driver

Setting Black Mark Mode

19

3. Load the desired media.

4. In the Tools tab of the Windows driver, click “Set Black Mark Mode”. A dialog box will

appear asking to confirm your selection, click “Yes”.

5. The printer will feed media, detect the black marks, and eject the media. Press the

Feed button on the printer several times to confirm the printer is cutting directly in the

center of the black marks.

6. In the device settings tab of the Windows driver, set the media tracking to “Mark

Sensing”. If you revert back to Continuous mode, set the media tracking back to

Continuous or Variable.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 24

Windows CE Driver

20

Setting Black Mark Mode

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 25

Troubleshooting

Status Light Descriptions

Application LED States

3

Immediately after power is applied to the printer, a brief self test is performed and the

status light will report the following conditions:

Table 3-1 • Application LED States

Solid Green 0 - OK This code is reported when no other

codes are active. It indicates the

printer is functioning normally.

One Red Flash 1 - Paper Jam in

Presenter

Two Red Flashes 2 - Cutter Jam This code indicates that the printer

This code indicates that media is stuck

in the presenter . This error is set when

the printer attempts to eject the media

but cannot complete the operation.

This error is cleared by removing the

media from the presenter sensor.

could not find the cutter blade or could

not properly manage its position. The

error is set when the printer attempts

to cut but fails after three retries. This

error is cleared by cycling the power

off and on.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 26

Troubleshooting

20

Status Light Descriptions

Table 3-1 • Application LED States

Three Red Flashes 3 - Out of Paper This code indicates that the selected

EOP sensor has detected no media

present. This value is signaled wither

when the mark engine has detected a

mark larger than "TOF marker length”

plus 5mm, or when the A/D reading of

the EOP sensor drops below the “End

of paper threshold”. This error is

cleared after successful media load

(either via calibration of via regular

media load).

Four Red Flashes 4 - Print Head Lifted This code indicates that the print head

has been lifted. This error is cleared

by returning the print head to its

locked position.

Five Red Flashes 5 - Paper Feed Error This code indicates that the paper

failed to reach the presenter sensor

within the expected amount of time.

The error is signaled if the media does

not reach the presenter sensor after

feeding the length from the cuter to the

sensor plus 15mm. This error is

cleared by opening and closing the

print head, or by cycling power off and

on.

Y ellow Flashing 6 - Head Temperature

Error

This code indicates that the print head

has exceeded the maximum permitted

temperature. This status code is set

when the print head temperature

exceeds 65° C (149° F). When this

condition occurs, the printer feeds

100mm (4 inches) of blank media,

cuts, and presents. This error is

cleared automatically when the print

head temperature falls below 55° C

(131° F).

Rapid Amber

Flashing

Firmware missing or

corrupt

This code indicates that the bootware

has detected an incorrect or missing

checksum in the firmware. This error is

cleared when the firmware is reloaded

or updated. Refer to the Software

Integrator Guide for firmware upload

procedure.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 27

Application User Interface

With the printer power on, press and hold the feed button. Continue holding the feed

button until the status indicator flash sequence occurs. The next flash sequence occurs

after completion of the previous flash sequence. The flash sequences perform the

following functions:

Table 3-2 • Application User Interface

Troubleshooting

Print Quality Problems

21

Status Flash

Sequence

One Flash, then Solid

Green

Two Flash, then So lid

Green

Three Flash, then

Solid Green

Four Flash, then Solid

Green

Five Flash, then Solid

Green

If the feed button remains pressed after the fi ve flash sequence, the status light goes off.

Printer status is also reported during normal operation when an error occurs, or a status

request can be sent to the printer via the Windows driver. for error codes reported by the

Windows driver.

Appears for one second. This will print an internal self-test

page.

Appears for one second. Performs system calibration – must

be started with paper out of presenter and from under

printhead, and with no error signaled.

Appears for one second. Performs a simulated USB cable

connect and reconnect causing a USB plug-and-play event to

occur.

Appears for one second. Sets all printer settings to the default

with the exception of media guide calibration, then it will

perform the media guide calibration.

Appears for one second. Prints a 50% gray pattern, ejects it

and then prints a diagonal line pattern and ejects it.

Action

Print Quality Problems

No print on the label.

• The media may not be direct thermal media, or the thermal media coating is not facing

upward.

• Is the media loaded correctly? Is the thermal media coating facing upward?

• The printhead may be dirty or damaged.

• The printhead is dirty. Clean the printhead. Refer to the Service Manual

(P1028249) for instructions.

• The printhead is damaged. Replace the printhead. Refer to the Service Manual

(P1028249) for instructions.

• The printhead wiring may be damaged or not connected properly.

• Check the wiring connections at the printhead and the main logic board.

• Check for damage to the wiring. Replace the wiring if damaged.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 28

Troubleshooting

22

Print Quality Problems

The printed image does not look right.

• The printhead is dirty. Clean the printhead. Refer to the Service Manual (P1028249)

for instructions.

• The printhead has worn out. The printhead is a consumable item and will wear out

due to friction between the media and printhead. Using unapproved media may

shorten life or damage your printhead. Replace the printhead. Refer to the Service

Manual (P1028249) for instructions.

• Adjust the print darkness and/or print speed. See "Device Setting" on page 12.

• The Windows printer driver or application software may change these settings

and may require a change to optimize print quality.

• The media being used is incompatible with the printer. Be sure to use the

recommended media for your application, and always use Zebra-approved media.

• The platen (driver) roller maybe losing traction due to:

• Foreign objects attached to its surface.

• The rubbery smooth surface has become polished and slippery.

• The platen may need cleaning or replacement. Refer to the Service Manual

(P1028249) for instructions.

There are long tracks of missing print (blank vertical lines) on

several labels.

• The printhead may be dirty or damaged.

• The printhead is dirty. Clean the printhead. Refer to the Service Manual

(P1028249) for instructions.

• The printhead is damaged. Replace the printhead. Refer to the Service Manual

(P1028249) for instructions.

• The printhead has worn out. The printhead is a consumable item and will wear out

due to friction between the media and printhead. Using unapproved media may

shorten life or damage your printhead. Replace the printhead. Refer to the Service

Manual (P1028249) for instructions.

The printing does not start at the top of the receipt or misprinting of

one to three receipts.

• The printer needs to be calibrated (refer to the two-flash sequence of "Application

User Interface" on page 21).

• Reload the media. Refer to the Hardware Integrator Guide (P1028247) for

instructions.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 29

Media Sensing Problems

The KR203 printer default media mode is Continuous. The printer will remain in this mode

until it is changed by the Windows Driver.

The KR203 printer has automatic media calibration capability for black mark media. Once

the printer is printing or feeding media, the printer continually checks and adjusts the

media sensing to accommodate for minor changes in media p arameters from page to

page on a roll, and from roll to roll of media. The printer will automatically initiate a media

length calibration if the expected media length or the page to page gap distance has

exceeded the acceptable variation range when starting a print job or feeding media.

If the printer does not detect blacklines (or notches with black mark sensing) after feeding

the media the default maximum label length distance of 24 inches (610mm), then the

printer will report a media error.

Optionally, the printer can be set to do a short media calibration after loading media or

when closing the printhead with power on. The printer will then feed up to three labels

while calibrating.

Troubleshooting

Media Sensing Problems

23

The printer will not load the media.

• The media has changed, or a different media guide has been installed.

• Make sure the appropriate media guide is installed for the media being used.

Refer to the Hardware Integrator Guide (P1028247) for instructions.

• Perform the two-flash procedure to recalibrate the printer and then perform the

four-flash procedure to reset the printer default settings. Re fer to "Application LED

States" on page 19. Reload the media (refer to the Hardware Integrator Guide

(P1028247) for media loading procedures).

• Load the media manually. Refer to the Hardware Integrator Guid e (P1028247 ) for

instructions.

• The platen (driver) roller maybe losing traction due to:

• Foreign objects attached to its surface.

• The rubbery smooth surface has become polished and slippery.

• The platen may need cleaning or replacement. Refer to the Service Manual

(P1028249) for instructions.

• The media sensor may be dirty or damaged. Refer to th e Service Manual (P10 28249)

for instructions.

• The printhead assembly is not closed.

• Check the status light on either side of the printer . If the status light is showing four

red flashes then the printhead is not closed. Push down on the printhead

assembly until it locks into place.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 30

Troubleshooting

24

Other Problems

The printer will not eject the media.

• There is a jam under the printhead. Refer to the Service Manual (P1028249) fo r

instructions.

• The large media roll may be over torquing the feed motor. Install the large media roll

adapter. Refer to the Hardware Integrator Guide (P1028247) for instructions.

• The presenter rollers are dirty or damaged.

• The presenter rollers are dirty. Refer to the Service Manual (P1028249) for

instructions.

• The presenter rollers are damaged. Refer to the Service Manual (P1028249) for

instructions.

• There is a jam under the presenter. Refer to the Service Manual (P1028249) for

instructions.

• The presenter sensor may be dirty or damaged.

• The presenter sensor is dirty. Refer to the Service Manual (P1028249) for

instructions.

• The presenter sensor is damaged. Refer to the Service Manual (P1028249) for

instructions.

• The presenter has not cleared the previous receipt.

• Check the status light on either side of the printer. If the status light is showing one

red flash then the printer is reporting media in the presenter. Remove any media

that may be in the presenter.

• The presenter motor may need to be replaced. Refer to the Service Manual

(P1028249) for instructions.

• The presenter drive gears may be damaged or worn. Refer to the Service Manua l

(P1028249) for instructions.

Other Problems

The receipts are not cutting properly.

• The cutter blade may be worn. Replace the cutter blades. Refer to the Service Manual

(P1028249) for instructions.

• The cutter tensioner may be worn or damaged. Replace the cover plate assembly.

Refer to the Service Manual (P1028249) for instructions.

• Check the Cutter Mode setting, and the Partial Cut Width setting in the Windows

driver.See"Device Setting" on page 12.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 31

• The cutter motor may need to be replaced. Refer to the Service Manual (P1028249)

for instructions.

• The cutter drive gear, drive pin, or cutter actuator may be damaged or worn. Refer to

the Service Manual (P1028249) for instructions.

• Check for the latest firmware and driver version.

There are no lights on the printer.

• Make sure there is power applied to the printer.

• The control panel may be dirty or damaged. Refer to the Service Manua l (P1028249)

for instructions.

• The main logic board may be damaged. Refer to the Service Manual (P1028249) for

instructions.

• Check for the latest firmware and driver version.

Troubleshooting

Other Problems

25

A receipt format was sent to, but not recognized by, the printer.

• If the status LED is on or flashing, refer to "Application LED States" on page 19.

• Make sure the USB cable is correctly installed. Refer to the Hardware Integrator

Guide (P1028247) for instructions.

• A communications problem has occurred. Perform a USB detect (refer to the threeflash sequence of "Application User Interface" on page 21).

The receipts are not cutting at the black mark.

• Make sure you are using the appropriate media guide for the desired media width.

Refer to the Hardware Integrator Guide (P1028247) for media guide installation

instructions.

• Perform a media guide calibration. Refer to the two-flash sequence of "Application

User Interface" on page 21.

• Make sure you are using the appropriate media. Refer to the Hardware Integrator

Guide (P1028247) for black mark media requirements.

• Use the Windows driver to set the printer to black mark mode. See "Setting Black

Mark Mode" on page 19.

• Reload the media. Refer to the Hardware Integrator Guide (P1028247) for

instructions.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 32

Troubleshooting

26

Resetting the Factory Default Values

Resetting the Factory Default Values

Sometimes, resetting the printer to the factory defaults may solve some problems. Refer

to the four-flash sequence of "Application User Interface" on page 21.

Contact Technical Support

Technical Support via the Internet is available 24 hours per day, 365 days per year.

www.zebra.com

For questions on the operation of Zebra equipment and software, please call your

distributor. For additional assistance, contact us.

Please have your model and serial numbers available.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 33

Appendix A

KR203 Status codes

Table A-1 • Status Codes

Number Name Type Group LED

Reporting

0 Ok Normal Informational Solid green

1 Paper jam in presenter Normal Severe 1 red flash

2 Cutter Jam Normal Severe 2 red flashes

4 Print head lifted Normal Severe 4 red flashes

3 Out of paper Normal Severe 3 red flashes

5 Paper feed error Normal Severe 5 red flashes

6 Head temperature error Normal Severe auto-

clear

10 Black mark not found One-time Informational Not signaled

11 Black mark calibration error One-time Informational Not signaled

12 Index error One-time Informational Not signaled

16 Timeout Occurred One-time Informational Not signaled

18 Out of range One-time Informational Not signaled

19 Paper low Normal Warning Not signaled

20 Media in presenter Normal Informational Not signaled

24 Invalid operation One-time Informational Not signaled

26 Target is read only One-time Informational Not signaled

40 Printer entered USB bus One-time Informational Not signaled

41 System calibration error One-time Informational Not signaled

Yellow

flashing

42 System calibration success One-time Informational Not signaled

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 34

A-2

Appendix A

KR203 Status codes

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Page 35

Programming Example

Background

In order to incorporate the way status monitoring works for the KR203 printer setup, it is

important to understand what happ ens in a kiosk when you print, and when status

monitoring should take place.

Status monitoring can be handled in two ways:

Appendix B

• Monitoring in the printing application.

• Monitoring in a separate application.

When monitoring takes place in the printing application, normally the printer is observed

before sending a print job to see if the printer is "OK" and then send the print job . After the

print job is signaled as being printed, the status is checked again to see if the printer has

any errors or if the paper has been taken, etc.

Monitoring in a separate application usually doesn't allow direct interaction with the printed

job so the printer is polled as often as possible to get most accurate information on what

the printer is doing. This is usually very time consuming and care must be taken to achieve

synchronization and control over the current print job.

Monitoring While Printing

Status monitoring has been implemented in the internal printing structure of the driver.

When a document is opened, printed, and closed, the driver will check the printer status

before and after printing and will also react to write errors if any occur. It will then set the

printer status and raise the error event.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Page 36

B-2

Appendix B

Programming Example

Monitoring While Idle

In order to get status any time a status thread has to be implemented which reads printer

status and provides changed status informatio n in the same manner. The following code

snippet in C# may be used as a guide to develop such an application. The code is using

the KRConfig DLL.

KRConfig config = new KRConfig();

config.Load();//Load settings from registry

string msg = "";

try

{

config.open("LPT1:");

//getStatus is not synchronized with other read/write

functions

byte status = config.getStatus();

msg = "Status : " + status;

config.close("LPT1:");

}

catch (Exception ex)

{

msg = ex.Message;

MessageBox.Show("Status : " + msg);

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Loading...

Loading...