Page 1

OPERATIONS MANUAL

ba76137e01 03/2013

4110 / 4110-3

PH ELECTRODES WITH GEL ELECTROLYTE

Page 2

4110

For the most recent version of the manual, please visit www.ysi.com.

Contact YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Copyright © 2013 Xylem Inc.

2 ba76137e01 03/2013

Page 3

4110 General information

General information

Automatic sensor

recognition

The sensor electronics with the stored sensor data is in the connecting head

of the electrode. The data include, among other things, the sensor type and

series number. With each calibration, the calibration data is written in the

sensor and the calibration history is recorded. The data is recalled by the

meter when the sensor is connected and is used for measurement and for

measured value documentation. Storing the calibration data in the sensor

ensures that the correct slope and asymmetry are automatically used if the

sensor is operated with several meters.

The digital transmission technique guarantees the failure-free communication with the meter even with long connection cables. If the sensor firmware

is enhanced by YSI, it can be updated via the meter.

Technical Data

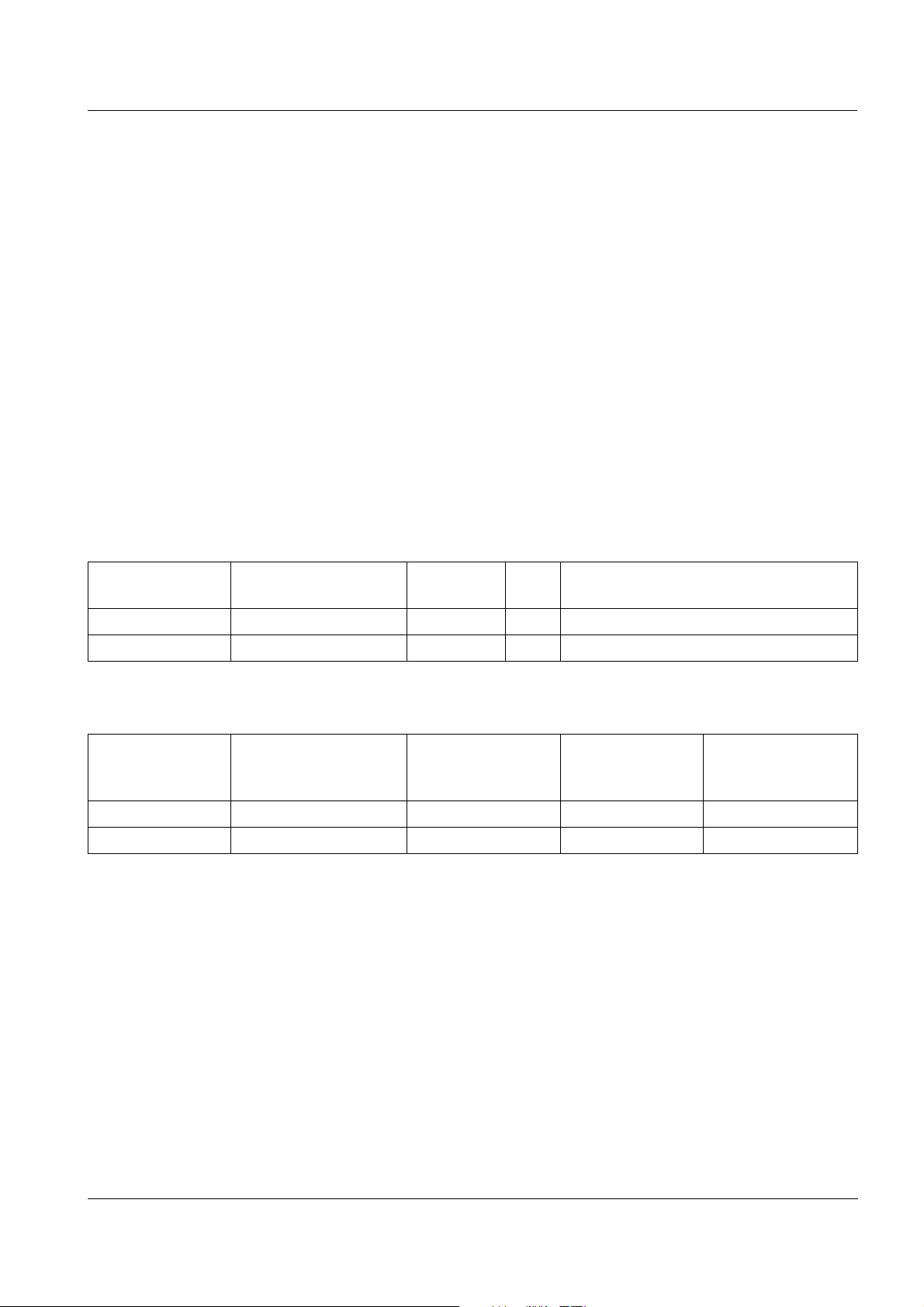

General data

Model Reference

elektrolyte

4110 Gel Fiber Yes Plastic shaft

4110-3 Gel Fiber Yes Plastic shaft

Junction NTC Special fatures

Measurement and application characteristics

Model pH measuring

range

4110 0.000 ... 14.000 0 ... 80 °C < 1 GOhm Field

4110-3 0.000 ... 14.000 0 ... 80 °C < 1 GOhm Field

Allowed

temperature

range

Membrane

resistance at

25 °C

Typical

application

ba76137e01 03/2013

3

Page 4

Commissioning, measuring, calibration 4110

Shaft dimensions, material, electrical connection

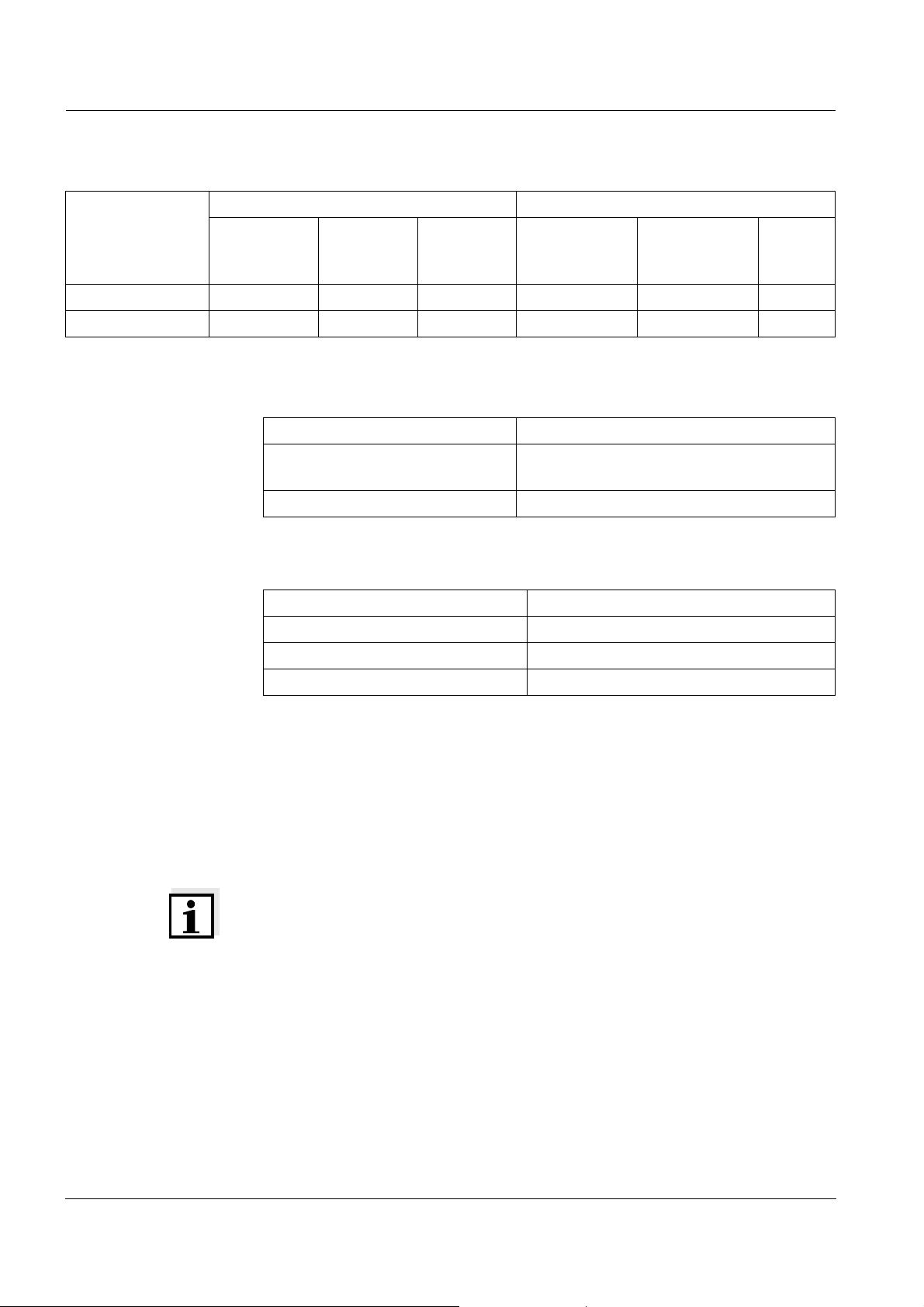

Model Shaft Electrical connection

Length

[mm]

4110 120 12 PPE/PS Fixed cable Digital plug 1.5 m

4110-3 120 12 PPE/PS Fixed cable Digital plug 3 m

Ø [mm] Material Combination

electrode

connection

Meter

connection

Cable

length

Connection cable

Diameter 4.3 mm

Smallest allowed

bend radius

Plug type Socket, 4 pins

Fixed installation: 20 mm

Flexible use: 60 mm

Accuracy of the IDS measuring technique

Measured parameter Accuracy (± 1 digit)

pH ± 0.004

U [mV] ± 0.2

T [°C] ± 0.1

Commissioning, measuring, calibration

Commissioning Prepare the electrode for measuring as follows:

Remove the watering cap from the electrode tip. Possible salt deposits in

the area of the watering cap do not affect the measuring characteristics

and can easily be removed with deionized water.

Note

Please keep the watering cap. It is required for the electrode to be stored.

Always keep the watering cap clean.

Calibration

and measurement:

General rules

4

Remove any gas bubbles behind the pH membrane by shaking.

Connect the electrode to the meter.

Calibrate the electrode according to the operating manual of the meter

and observe the following rules while doing so:

Avoid the carryover of any solution (sample or buffer solution) from one

measurement to the next by taking the following measures:

– Shortly rinse the calibration and sample beakers with the solution the

beakers are to be filled with next.

ba76137e01 03/2013

Page 5

4110 Commissioning, measuring, calibration

– Between measurements, rinse the electrode with the solution that fol-

lows. Alternatively, you can also rinse the electrode with deionized water and then carefully dab it dry.

To measure in aqueous solutions, it is recommended to immerse the elec-

trode in a vertical or slightly tilted position.

Observe the correct depth of immersion and make sure the contact be-

tween the junction and test sample is thorough. The junction is in the area

of the bottom end of the shaft (see arrow).

Subsequent

calibrations

4110

Caution: Only the shaft part of the combination electrode may be immersed!

For measurements in aqueous solutions, provide approximately the same

stirring conditions for measuring as for calibrating.

The frequency of subsequent calibrations depends on the application. Many

meters provide an option where you can enter a calibration interval. After the

calibration interval has expired, the meter will automatically remind you of the

due calibration.

ba76137e01 03/2013

5

Page 6

Aging 4110

Storage

During short

measuring breaks

Overnight or

longer

Immerse the electrode in reference electrolyte (KCl 3 mol/l, Ag+ free). Prior

to the next measurement, shortly rinse the electrode with the test sample or

deionized water.

Note

Do not scratch the pH membrane.

Put the clean electrode in the watering cap that is filled with reference

electrolyte (KCl 3 mol/l, Ag

Note

pH electrodes must not be stored dry or in deionized water. The electrode

could be permanently damaged by this. If the liquid in the watering cap has

dried up, condition the electrode in reference electrolyte (KCl 3 mol/l, Ag

free) for at least 24 hours.

Note

During longer storing periods, salt sediments may develop on the watering

cap. They do not affect the measuring characteristics and can easily be removed with deionized water when the electrode is put into operation again.

+

free).

+

Aging

Every pH electrode undergoes a natural aging process. With aging, the responding behavior becomes slower and the electrode slope and asymmetry

change. Moreover, extreme operating conditions can considerably shorten

the lifetime of the electrode. These are:

Strong acids or lyes, hydrofluoric acid, organic solvents, oils, fats, bro-

mides, sulfides, iodides, proteins

High temperatures

High changes in pH and temperature.

The warranty does not cover failure caused by measuring conditions and

mechanical damage.

6

ba76137e01 03/2013

Page 7

4110 Maintenance and cleaning

Maintenance and cleaning

Cleaning Remove water-soluble contamination by rinsing with deionized water. Other

types of contamination have to be removed as follows while the contact time

with the detergents should be kept as short as possible:

Contamination Cleaning procedure

Fat and oil Rinse with water containing household wash-

ing-up liquid

Lime and hydroxide deposits Rinse with citric acid (10 % by weight)

Note

Hydrofluoric acid, hot phosphoric acid and strong alkaline solutions destroy

the glass membrane.

After cleaning Rinse the electrode with deionized water and condition it in reference

electrolyte solution for at least 1 hour. Then recalibrate the electrode.

Wear parts and accessories

Description Model Order no.

Reference electrolyte solution 250 ml

to fill the watering cap

(KCl 3 mol/l, Ag

+

free)

KCl-250 109 705Y

ba76137e01 03/2013

7

Page 8

Wear parts and accessories 4110

8

ba76137e01 03/2013

Page 9

4110 Contact Information

Contact Information

Ordering & Technical Support

Telephone

Fax

: (937) 767-1058

Email

Mail: YSI Incorporated

Internet

When placing an order please have the following information available:

YSI account number (if available) Name and Phone Number

Model number or brief description Billing and shipping address

Quantity Purchase Order or Credit Card

: (800) 897-4151

(937) 767-7241

Monday through Friday, 8:00 AM to 5:00 PM ET

: environmental@ysi.com

1725 Brannum Lane

Yellow Springs, OH 45387

USA

: www.ysi.com

Service Information

YSI has authorized service centers throughout the United States and

Internationally. For the nearest service center information, please visit

www.ysi.com

directly at 800-897-4151.

When returning a product for service, include the Product Return form

with cleaning certification. The form must be completely filled out for an

YSI Service Center to accept the instrument for service. The Product

Return form may be downloaded at www.ysi.com

‘Support‘ tab.

and click ‘Support’ or contact YSI Technical Support

and clicking on the

ba76137d01 03/2013

9

Page 10

Contact Information 4110

10

ba76137d01 03/2013

Page 11

Page 12

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We're 12,500 people unified in a common purpose: creating innovative solutions

to meet our world's water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem |' m|zīlə

YSI

1725 Brannum Lane

Yellow Springs, OH 45387

Tel: +1 937-767-7241; 800-765-4974

Fax: +1 937-767-1058

Email: environmental@ysi.com

Web: www.ysi.com

©Xylem Inc

Loading...

Loading...