Page 1

YSI ADV6600

Environmental Monitoring System

Operations

Manual

Page 2

Page 3

Table of Contents

Table of Contents.....................................................................................................3

Section 1. Introduction to the ADV6600..........................................................1

1-1. About the ADV6600 ......................................................................................1

1-2. About YSI, Inc...............................................................................................1

1-3. How to Use This Manual...............................................................................2

1-4. Unpacking and Inspection............................................................................3

1-5. Safety Considerations....................................................................................3

Section 2. Preparing the System for Field Studies..........................................5

2-1. Preparing the Dissolved Oxygen Probe.......................................................5

2-1.1. Preparation of the DO Electrolyte Solution...................................................................... 5

2-1.2. Membrane Installation without the DO Probe Installed in the Sonde............................... 5

2-1.3. Membrane Installation with the DO Probe Installed in the Sonde.................................... 6

2-2. Installing Water Quality Probes..................................................................8

2-2.1. Removing the Port Plugs...................................................................................................8

2-2.2. Bulkhead Diagram............................................................................................................ 9

2-2.3. O-Ring Lubrication......................................................................................................... 10

2-2.4. Installing the Optical Probes........................................................................................... 10

2-2.5. Installing the Conductivity/Temperature, DO, and pH/ORP Probes .............................. 10

2-2.6. Installing the ISE Probes................................................................................................. 10

2-2.7. Installing the Probe Guard.............................................................................................. 11

2-3. Attaching Your Sonde to a Computer.......................................................11

2-3.1. Installing the Batteries .................................................................................................... 11

2-3.2. Preparing the Cable......................................................................................................... 12

2-3.3. Using the AC Power Supply........................................................................................... 12

2-3.4. Attaching the Cable......................................................................................................... 13

Section 3. Configuring Your ADV6600 – Installation of ADVantage 6600

Software and Sonde Firmware Set-up .................................................................15

3-1. ADVantage 6600 Software – System Requirements.................................15

3-2. Installing ADVantage 6600 Software ........................................................15

3-3. Launching the Software..............................................................................15

ADV6600 Y S I Environmental iii

Page 4

Table of Contents

3-4. Connecting to the System............................................................................16

Settings....................................................................................................................... ............... 16

Baud Rate.................................................................................................................................. 17

3-5. Understanding the Firmware of the ADV6600.........................................18

3-6. Setting up the Water Quality Sensor Firmware.......................................18

3-6.1. Setting Up the Water Quality Sensors ............................................................................ 18

3-6.2. Water Quality Menu Flowchart...................................................................................... 20

3-6.3. Setting Up Installed Sensors........................................................................................... 21

3-6.4. Setting Up Reports.......................................................................................................... 21

3-6.5. Advanced Menu Features................................................................................................24

3-7. Setting up the ADV Sensor Firmware.......................................................28

3-7.1. Setting the System Time................................................................................................. 28

3-7.2. Setting Up the ADV Parameter Output........................................................................... 28

3-8. Exiting the ADV6600 Firmware ................................................................30

3-9. ADV6600 Firmware Upgrades...................................................................30

Section 4. Calibration and Diagnostics..........................................................35

4-1. Beam Check Basics......................................................................................35

4-2. Running the ADV Beam Check .................................................................35

4-2.1. Laboratory Beam Check Procedure................................................................................ 36

4-2.2. Creating a Beam Check File........................................................................................... 38

4-2.3. Opening a Recorded Beam Check File........................................................................... 38

4-2.4. Viewing a Recorded Beam Check File........................................................................... 40

4-2.5. Interpreting Your Laboratory Beam Check Data............................................................ 40

4-2.6. Beam Check Feature Summary....................................................................................... 42

4-3. Calibrating the Compass ............................................................................43

Compass Calibration Procedure................................................................................................ 44

4-4. Changing the Pressure Sensor Offset........................................................45

4-5. Water Quality Sensors – Preparing for Calibration................................46

4-5.1. Health and Safety............................................................................................................ 47

4-5.2. Materials Required.......................................................................................................... 47

4-5.3. Calibration Tips .............................................................................................................. 47

4-5.4. Use of the Calibration Cup.............................................................................................. 48

4-5.5. Recommended Volumes of Calibration Reagents........................................................... 49

4-6. Water Quality Sensors - Calibration Procedures.....................................49

4-6.1. Temperature.................................................................................................................... 50

4-6.2. Conductivity.................................................................................................................... 50

4-6.3. Dissolved Oxygen for Unattended Monitoring Studies.................................................. 51

4-6.4. Dissolved Oxygen for Spot Sampling Studies................................................................ 52

4-6.5. pH ................................................................................................................................... 52

4-6.6. ORP................................................................................................................................. 53

ADV6600 Y S I Environmental Page iv

Page 5

Table of Contents

4-6.7. Ammonium..................................................................................................................... 54

4-6.8. Nitrate............................................................................................................................. 56

4-6.9. Chloride .......................................................................................................................... 57

4-6.10. Turbidity ....................................................................................................................... 59

4-6.11. Chlorophyll................................................................................................................... 61

4-6.12. Rhodamine WT............................................................................................................. 64

4-7. Establishing Default Calibration – “UNCAL” Command......................66

Section 5. Field Mounting and Installation...................................................67

5-1. Mounting Methods......................................................................................67

5-1.1. Deploying Using the YSI 6650 Clamps.......................................................................... 68

5-1.2. Deploying in a PVC Pipe................................................................................................ 70

5-1.3. Deploying on a Simple Tether........................................................................................ 72

5-2. Mounting Cautions......................................................................................73

5-2.1. Bottom Interference........................................................................................................ 73

5-2.2. Flow Interference............................................................................................................ 75

5-2.3. Interference from Magnetic Material.............................................................................. 75

Section 6. Using Your ADV6600 In The Field..............................................77

6-1. Checking Your Battery Voltage.................................................................77

6-2. Real-time Data Collection...........................................................................78

6-3. Unattended Data Collection........................................................................79

6-4. SDI-12 Data Collection................................................................................82

Section 7. Downloading ADV6600 Data........................................................87

7-1. Important Information on Downloading Data.........................................87

7-2. Data Location – Features of the Recorder ................................................87

7-3. Data Download Procedure..........................................................................89

Section 8. ADVantage 6600 Software – Post-Processing of Data................91

8-1. Opening a Saved File...................................................................................91

8-1.1. Workspaces..................................................................................................................... 91

8-2. Exporting Data to a Spreadsheet ...............................................................92

8-3. Using the Visual Data Display....................................................................93

8-4. Toolbars........................................................................................................95

8-4.1. Main Toolbar .................................................................................................................. 95

8-4.2. Data Toolbar................................................................................................................... 95

8-4.3. Display Toolbar .............................................................................................................. 95

8-4.4. Data Collection Toolbar..................................................................................................96

8-5. Menu Features.............................................................................................96

ADV6600 Y S I Environmental Page v

Page 6

Table of Contents

8-5.1. File.................................................................................................................................. 96

8-5.2. Edit.................................................................................................................................. 97

8-5.3. View................................................................................................................................ 97

8-5.4. System............................................................................................................................. 98

8-5.5. Tools............................................................................................................................... 99

8-5.6. Window......................................................................................................................... 100

8-5.7. Help............................................................................................................................... 100

Section 9. Principles of Operation................................................................101

9-1. Acoustic Doppler Velocimeter (ADV) .....................................................101

9-2. Velocity Data Coordinate System ............................................................102

9-2.1. ENU.............................................................................................................................. 102

9-2.2. XYZ.............................................................................................................................. 103

9-3. Effect of Salinity Variation on Velocity Accuracy..................................103

9-4. Pressure......................................................................................................103

9-4.1. Effect of Atmospheric Pressure Variations................................................................... 104

9-5. Temperature ..............................................................................................104

9-6. Conductivity...............................................................................................104

9-6.1. Effect of Temperature................................................................................................... 105

9-7. Salinity........................................................................................................105

9-8. TDS .............................................................................................................106

9-8.1. Calculation of the TDS Constant.................................................................................. 106

9-9. Dissolved Oxygen.......................................................................................106

9-9.1. Method of Operation..................................................................................................... 107

9-9.2. Effect of Temperature................................................................................................... 108

9-9.3. Flow Dependence.......................................................................................................... 108

9-10. pH..............................................................................................................109

9-10.1. Effect of Temperature................................................................................................. 1 09

9-11. ORP...........................................................................................................110

9-11.1. Effect of Temperature................................................................................................. 1 10

9-12. Nitrate.......................................................................................................110

9-13. Ammonium and Ammonia.....................................................................112

9-14. Chloride....................................................................................................114

9-15. Turbidity ..................................................................................................115

9-15.1. Effect of Fouling......................................................................................................... 116

9-15.2. Effect of Temperature................................................................................................. 1 16

9-15.3. Effect of Particle Size ................................................................................................. 116

9-16. Chlorophyll ..............................................................................................117

9-16.1. In Vivo Measurement.................................................................................................. 118

9-16.2. Effect of Fouling......................................................................................................... 119

9-16.3. Effect of Temperature................................................................................................. 1 19

ADV6600 Y S I Environmental Page vi

Page 7

Table of Contents

9-16.4. Effect of Particle Size ................................................................................................. 120

9-16.5. Effect of Turbidity...................................................................................................... 120

9-16.6. Limitations of In Vivo Measurement........................................................................... 120

9-17. Rhodamine WT........................................................................................122

9-17.1. Calibration and Effect of Temperature........................................................................ 124

9-17.2. Effect of Turbidity...................................................................................................... 124

9-17.3. Effect of Chlorophyll.................................................................................................. 124

Section 10. Care, Maintenance, and Storage.................................................125

10-1. Protection from Biological Fouling........................................................125

10-1.1. Sonde Housing............................................................................................................ 125

10-1.2. ADV............................................................................................................................ 125

10-1.3. Conductivity/Temperature Probe ................................................................................ 126

10-1.4. DO Probe.................................................................................................................... 127

10-1.5. pH and pH/ORP Probes.............................................................................................. 127

10-1.6. ISE Probes................................................................................................................... 127

10-1.7. Optical Probes............................................................................................................. 127

10-2. Sonde Care and Maintenance ................................................................128

10-2.1. O-Rings....................................................................................................................... 128

10-2.2. Probe Ports.................................................................................................................. 129

10-2.3. Cables and Connectors................................................................................................ 129

10-3. Probe Care and Maintenance.................................................................130

10-3.1. ADV............................................................................................................................ 130

10-3.2. Conductivity/Temperature Probe ................................................................................ 130

10-3.3. DO Probe.................................................................................................................... 130

10-3.4. pH and pH/ORP Probes.............................................................................................. 131

10-3.5. ISE Probes ................................................................................................................. 132

10-3.6. Optical Probes............................................................................................................. 132

10-4. Short-term Storage..................................................................................133

10-5. Long-term Storage...................................................................................133

10-5.1. ADV6600.................................................................................................................... 133

10-5.2. ADV............................................................................................................................ 133

10-5.3. Temperature Probe...................................................................................................... 134

10-5.4. Conductivity Probe..................................................................................................... 134

10-5.5. DO Probe.................................................................................................................... 134

10-5.6. pH and ORP Probes.................................................................................................... 134

10-5.7. ISE Probes................................................................................................................... 135

10-5.8. Optical Probes............................................................................................................. 135

Section 11. Troubleshooting ...........................................................................137

11-1. Calibration Errors...................................................................................137

11-1.1. High DO Charge......................................................................................................... 137

ADV6600 Y S I Environmental Page vii

Page 8

Table of Contents

11-1.2. Out of Range............................................................................................................... 137

11-1.3. Illegal Entry ................................................................................................................ 137

11-2. Communication Problems ......................................................................138

11-2.1. Cannot Communicate With ADV6600....................................................................... 138

11-2.2. Data Missing From Unattended Deployment..............................................................138

11-3. ADV Performance Problems..................................................................138

11-3.1. Beam Check Data Output ........................................................................................... 138

11-3.2. Noisy Velocity Data.................................................................................................... 141

11-3.3. Seeding for Scattering Environments..........................................................................142

11-4. Water Quality Sensor Problems.............................................................142

Section 12. Warranty and Service Information............................................145

12-1. Warranty..................................................................................................145

12-2. Limitation of Warranty ..........................................................................145

12-3. Authorized Service Center......................................................................146

12-4. Cleaning Instructions..............................................................................146

12-5. Packing Instructions and Product Return Form..................................147

Section 13. Additional Support ......................................................................151

Appendix A. Accessories and Calibration Standards .................................153

A-1. Probes and Probe Replacement Parts.................................................... 153

A-2. Optional Accessories and Replacement Parts........................................154

A-3. Optional Accessories and Replacement Parts........................................155

A-4. Reagents.....................................................................................................156

Appendix B. Specifications............................................................................157

Appendix C. Required Notice........................................................................159

Appendix D. Frequently Asked Questions...................................................161

D-1. System Description and General Questions...........................................161

D-2. What does the system measure?..............................................................164

D-3. Installing the System ................................................................................166

D-4. Applications...............................................................................................168

D-5. Collecting and Analyzing Data................................................................170

D-6. Software and Firmware...........................................................................171

D-7. Calibration and Maintenance..................................................................173

D-8. Technical Support ....................................................................................174

ADV6600 Y S I Environmental Page viii

Page 9

Table of Contents

Appendix E. Chlorophyll Measurements.....................................................177

Appendix F. Percent Air Saturation.............................................................185

F-1. “DOsat %” Convention............................................................................185

F-2. “DOsat % Local” Convention .................................................................186

F-3. Effects of DO mg/L Calibration...............................................................187

F-4. Activation of the “DOsat % Local” Parameter .....................................187

Appendix G. Quick Start Deployment Guide ..............................................189

ADV6600 Y S I Environmental Page ix

Page 10

Page 11

Section 1. Introduction to the ADV6600

1-1. About the ADV6600

The ADV6600 is a fully integrated system that measures both water velocity and water quality. The

instrument combines the Acoustic Doppler Velocimeter (ADV) technology of the established

Argonaut ADV instrument from SonTek with most of the water quality sensors of the 6600 sonde

from YSI.

The appearance of the ADV6600 is similar to other YSI 6-Series sondes and the 6600 and ADV

sensors function in an identical fashion to that of their “parent” instruments. The principal design

differences between the ADV6600 and its parent instruments are the interface capabilities. For

example, the ADV6600 uses new cable assemblies for interface to a PC or DCP, rather than the

standard YSI 6-series cables and, at this time, there is no capability to interface to a handheld field

display other than a laptop computer. In addition, interface with the ADV6600 occurs through a

specially designed software package called ADVantage 6600 rather than EcoWatch for Windows

which is used with 6-series sondes. The ADVantage 6600 software (provided with the ADV6600 as

part of the standard package) allows the user to set up the instrument, calibrate sensors, deploy the

instrument, download data, and perform data analysis.

A full range of parameters can be measured using the ADV6600. The system comes standard with

the ADV, compass/tilt, conductivity and temperature sensors. In addition, the instrument may be

outfitted with sensors for pressure, pH, ORP, dissolved oxygen, two optical parameters (chlorophyll,

turbidity, or rhodamine WT), and two ISE parameters (chloride, ammonium, or nitrate).

The ADV6600 instrument is suitable for a variety of different applications including the monitoring

of streams and estuaries. It is also ideal for low flow applications in wetlands and marshes. The

common theme among all of the ADV6600 applications is to correlate patterns of water movement

with data from traditional water quality sensors such as dissolved oxygen, conducti vit y, and pH.

1-2. About YSI, Inc.

From a three-man partnership at Antioch College in Yellow Springs, Ohio, in 1948, YSI Inc. has

grown into a commercial enterprise that designs and manufactures precision sensors and

instrumentation for users around the world. Through our broad range of products, YSI provides

innovative solutions to sustain the environment and enhance life. Our four major markets are water

testing and monitoring, health care, bioprocessing, and OEM temperature measurement.

In the 1950s, Hardy Trolander and David Case made the first practical electronic thermometer using

a thermistor. This equipment was developed for Dr. Leland Clark’s original heart-lung machine. In

the 1960s, YSI refined a Clark invention, the membrane-covered polarographic electrode, and

commercialized oxygen sensors and meters that revolutionized how dissolved oxygen is measured

in wastewater treatment plants and environmental water. Today, geologists, biologists,

ADV6600 Y S I Environmental Page 1

Page 12

Section 1. Introduction to the ADV6600

environmental enforcement personnel, officials of water utilities, and fish farmers, to name a few,

recognize YSI as the leader in dissolved oxygen measurement. In the 1970s, YSI commercialized

another Clark invention, the enzyme membrane, which resulted in the first practical use of a

biosensor to measure blood sugar accurately and rapidly. Over the years, this technology was

extended to applications in biotechnology, health care, and sports medicine.

In the 1990s, YSI launched a product line of multi-parameter water monitoring systems to address

the emerging need to measur e non-point source pollution. YSI has tho usands of instruments in the

field that operate with the push of a button, store data internally, and communicate with computers.

These instruments are ideal for profiling and monitoring water conditions in industrial and

municipal wastewater effluents, lakes, rivers, wetlands, estuaries, and coastal waters. With o n-board

battery power, the instruments may be left unattended for weeks with measurement parameters

sampled at the user’s choice of time interval and data securely saved in the unit’s internal memory.

The fast response of YSI’s sensors makes the systems ideal fo r vertical pr o filing and their s mall size

allows them to fit down 2-inch diameter monitoring wells. All YSI multi-parameter systems feature

the patented Rapid Pulse

YSI Incorporated is an international company with world headquarters in Yellow Springs, Ohio.

The employee-owned company manufactures and markets sensor technologies dedicated to

ecological sustainability. Its three strategic business units include YSI Environmental, YSI

Temperature, and YSI Life Sciences.

SonTek, founded in 1992 and acquired by YSI in 2001, is a world leader in the field of water

velocity measurement. SonTek manufactures affordable, reliable acoustic Doppler current profilers,

velocimeters, Doppler velocity logs, and integrated systems for use in oceans, rivers, lakes, harbors,

estuaries and laboratories.

YSI has established a worldwide network of selling partners in 54 countries that includes laboratory

supply dealers, manufacturers’ representatives, and YSI’s sales force. Subsidiaries are located in the

United Kingdom, Japan, Hong Kong, and China.

Employee-owned since 1983 and named ESOP Company of the Year in 1994 by the national ESOP

Association, every YSI employee is one of its owners. YSI is proud of its products and is committed

to serving its customers.

TM

Dissolved Oxygen sensor, which exhibits low stirring dependence.

1-3. How to Use This Manual

The manual is organized to let you quickly understand and operate the YSI ADV6600

Environmental Monitoring System. However, it cannot be stressed too strongly that informed and

safe operation is more than just knowing which buttons to push. An understanding of the principles

of operation, calibration techniques, and system setup is necessary to obtain accurate and

meaningful results.

ADV6600 Y S I Environmental Page 2

Page 13

Section 1. Introduction to the ADV6600

If you have any questions about this product or its application, please contact YSI’s Technical

Support department or authorized dealer for assistance.

1-4. Unpacking and Inspection

Inspect the outside of the shipping box for damage. If any damage is detected, contact your shipping

carrier immediately. Remove the equipment from the shipping box. Some parts or supplies may be

loose in the shipping box so check the packing material carefully. Check off all of the items on the

packing list and inspect all of the assemblies and components for damage.

If any parts are damaged or missing, contact your YSI r epresentative immediately. If you purc hased

the equipme nt directly fr om YSI, or if you do not know which YSI representative your equipment

was purchased from, please call 1-800-897-4151 for assistance.

1-5. Safety Considerations

The acoustic pulses transmitted from the ADV6600 sensor poses no safety concerns under all

normal operating conditions which are likely to be encountered by the user. However, YSI does

recommend that users avoid direct skin contact with the transmit transducer (the circular yellow disk

in the center of the Doppler arm) while the Doppler sensor is active.

Transmit Transducer

Please contact YSI Technical Support at 800-897-4151 if you have any questions about the use of

your ADV6600.

ADV6600 Y S I Environmental Page 3

Page 14

Page 15

Section 2. Preparing the System for Field Studies

Before using your ADV6600 in field studies to correlate water movement with water quality

parameters, you will need to prepare the dissolved oxygen sensor for use, install the water quality

probes into their proper ports, supply a power source, and attach a cable between the ADV6600 and

your PC. This section provides detailed instructions for this setup procedure.

2-1. Preparing the Dissolved Oxygen Probe

The DO probe is shipped with a dry, protective membrane secured by an o-ring. This membrane

requires replacement before initial use of the sonde. Subsequent membrane changes should be

performed before each deployment of the sonde and at least once every 30 days during sampling

applications, or more frequently as needed.

Initial DO membrane installation can be performed before the 6562 DO probe is installed in the

sonde. However, after installation of the probe, it is recommended that removal of the probe from

the body of the ADV6600 be limited and future membrane changes should be performed while the

probe is installed.

WARNING! Wash hands before installation and do not allow finger oils or O-ring lubricant to

touch the probe face or the membrane.

2-1.1. Preparation of the DO Electrolyte Solution

Unpack the 6562 DO Probe Kit. Locate the 5775 DO

Membrane Kit and prepare the electrolyte solution.

Dissolve the KCl (Potassium Chloride) in the dropper

bottle by filling it to the neck with deionized or distilled

water and shaking until the solids are fully dissolved.

After the KCl is dissolved, wait a few minutes until the

solution is free of bubbles before using.

2-1.2. Membrane Installation without the DO Probe Installed in the

Sonde

• Remove the protective cap and the dry membrane from the YSI 6562 DO Probe. Handle the

probe with care to prevent the sensor tip from becoming scratched or contaminated.

• Leave the protective cap in place over the connector end of the probe to prevent contamination

by the electrolyte.

A DD DI OR DIS T IL L E D

WATER

ADV6600 Y S I Environmental Page 5

Page 16

Section 2. Preparation of the Sonde

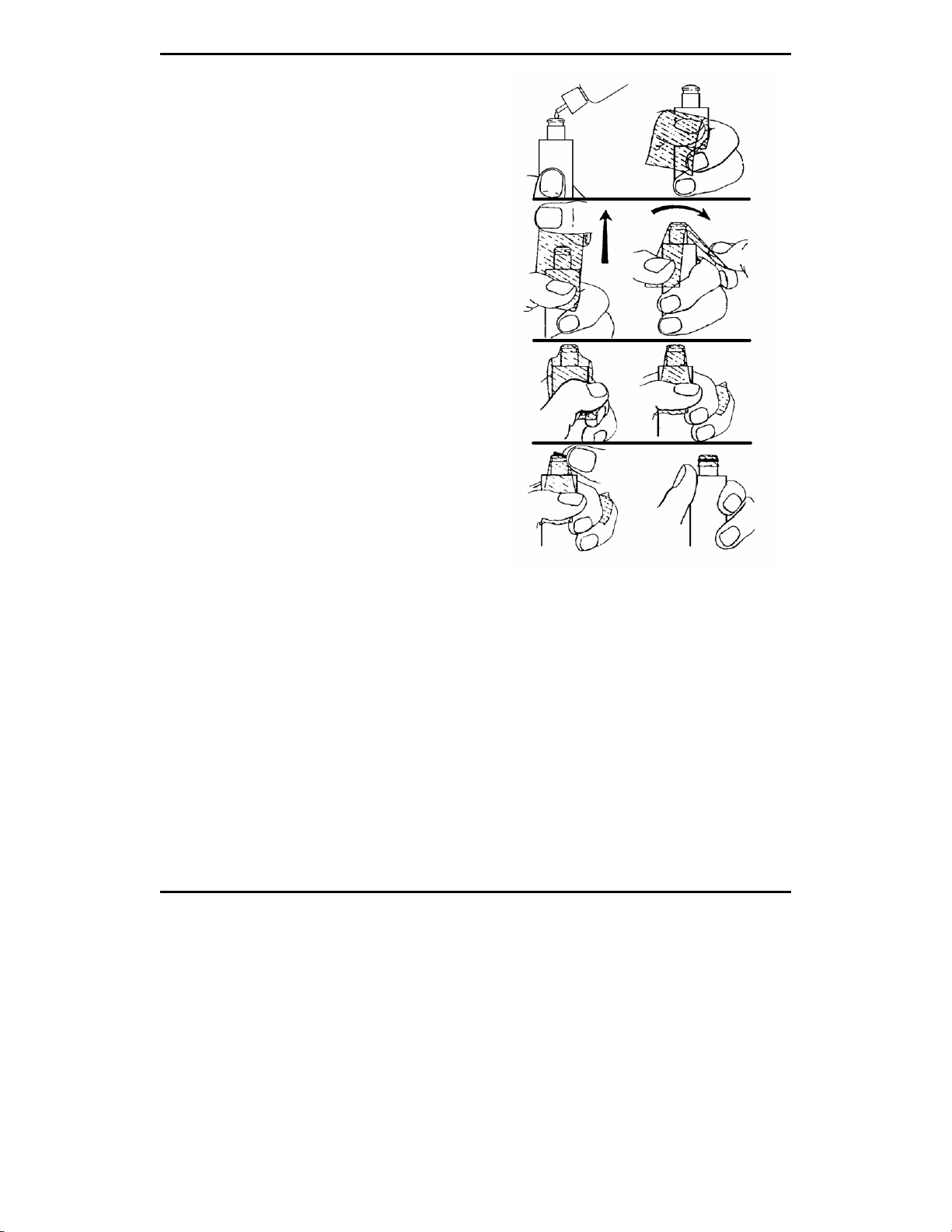

• Hold the probe in a vertical position and apply a

few drops of electrolyte solution to the tip. The

fluid should completely fill the small moat

around the electrodes and form a meniscus on

the tip of the sensor. Be sure no air bubbles are

visible. If necessary, shake off the electrolyte

and start over.

• Secure a membrane between your thumb and the

probe body. Always handle the membrane

with care, touching it only at the ends.

• With the thumb and forefinger of the opposite

hand, grasp the free end of the membrane. With

one continuous motion, gently stretch it up, over ,

and down the other side of the sensor. Do not

hesitate to stretch the membrane until it

conforms to the face of the sensor. Secure the

membrane with the forefinger of the hand

holding the probe body.

• Roll the o-ring over the end of the probe, being

careful not to touch the membrane surface with

your fingers. There should be no wrinkles or air

bubbles. If any are present, remove the

membrane and repeat the installation procedure

with a new membrane. Squeeze the o-ring every

90 degrees to equalize the tension. Do not use

grease or lubricant of any kind on the o-ring.

• Trim off any excess membrane with a sharp knife, a scalpel, or scissors. Make the cut about

1/8-inch below the o-ring. Rinse off any excess KCl solution, but be careful not to get any

water in the connector.

Note: You may find it more convenient to mount the probe vertically in a vise with rubber jaws

while applying the electrolyte and membranes to the sensor tip.

2-1.3. Membrane Installation with the DO Probe Installed in the

Sonde

• Secure the sonde in a vertical position using a vise, or a clamp with rubber jaws and ring stand.

Secure it tightly so that it will not move during membrane installation. Position the sonde with

the sensors upright. Remove the calibra tion cup or pr obe guard from t he sonde.

ADV6600 Y S I Environmental Page 6

Page 17

Section 2. Preparation of the Sonde

• Remove the old DO membrane and clean the probe tip with water and lens cleaning tissue.

Make sure to remove any debris or deposits from the O-ring groove. Handle the probe with

care to prevent the sensor tip from becoming scratched or contaminated.

• Apply a few drops of electrolyte solution to the tip of the probe. The fluid should completely

fill the small moat around the electrodes and form a meniscus on the tip of the sensor. Be sure

no air bubbles are visible. If necessary, shake off the electrolyte and start over.

• Hold the membrane so that all four corners are supported, but do not stretch the membrane

laterally. Always handle the membrane with care, touching it only at the ends.

• Position the membrane over the probe, keeping it parallel to the probe face.

• Using one continuous downward motion, stretch the membrane over the probe face. Do not

hesitate to stretch the membrane until it conforms to the face of the sensor.

ADV6600 Y S I Environmental Page 7

Page 18

Section 2. Preparation of the Sonde

• Roll the o-ring over the end of the probe, being careful not to touch the membrane surface with

your fingers. There should be no wrinkles or air bubbles. If any are present, remove the

membrane and repeat the installation procedure with a new membrane. Squeeze the o-ring

every 90 degrees to equalize the tension. Do not use grease or lubricant of any kind on the oring.

• Trim off any excess membrane with a sharp knife, a scalpel, or scissors. Make the cut about

1/8-inch below the o-ring. Rinse off any excess KCl solution.

• Use caution when replacing the prob e gua rd that you do not touch the membrane. If you

suspect that the membrane has been damaged, replace it immediately.

2-2. Installing Water Quality Probes

Remove the calibration/transport cup from your ADV6600 by hand to expose the bulkhead.

Note: The ADV probe is a non-removable sensor.

2-2.1. Removing the Port Plugs

Using the long extended end of the probe installation tool supplied in the YSI 6570 Maintenance

Kit, remove the port plugs by unscrewing them from the b ulkhead of the sonde. Save all the port

plugs for possible future use. If the provided tool is misplaced or lost, you may use 7/64” and 9/64”

hex keys as substitutes.

NOTE: You may need pliers to remove the ISE port plugs, but do not

probes. Hand-tighten only.

use pliers to tighten the ISE

ADV6600 Y S I Environmental Page 8

Page 19

Section 2. Preparation of the Sonde

V

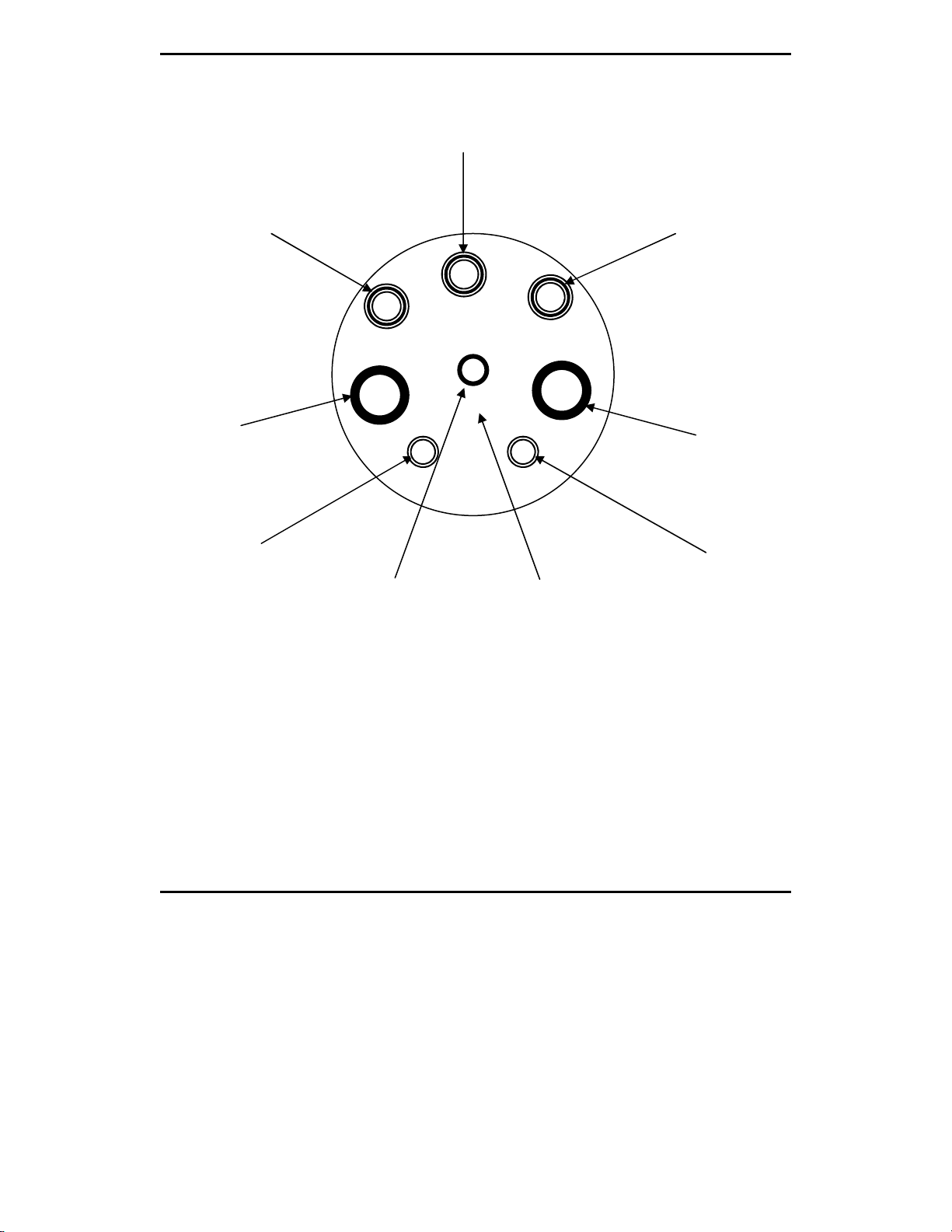

2-2.2. Bulkhead Diagram

Conductivity/Temperature

pH /ORP

º

Optical

ISE

AD

ADV Probe = Non-removable

Pressure Sensor = Non-removable

6562 Dissolved Oxygen (DO) probe = 3-pin connector

6560 Conductivity/Temperature = 6-pin connector

6561 pH probe = 4 pin connector

6565 Combination pH/ORP probe = 4 pin connector

6882 Chloride (ISE) Probe = leaf spring connector

6883 Ammonium (ISE) Probe = leaf spring connector

6884 Nitrate (ISE) Probe = leaf spring connector

6026 Turbidity (Optical) Probe, Wiping = 8 pin connector

6136 Turbidity (Optical) Probe, Wiping = 8 pin connector

6025 Chlorophyll (Optical) Probe, Wiping = 8 pin connector

6130 Rhodamine WT (Optical) Probe, Wiping = 8 pin connector

Pressure

DO

Optical

ISE

ADV6600 Y S I Environmental Page 9

Page 20

Section 2. Preparation of the Sonde

2-2.3. O-Ring Lubrication

Apply a very thin coat of o-ring lubricant, supplied in the YSI 6570 Maintenance Kit, to the o-rings

on the connector end of each probe to be installed. After application, the o-ring lubricant should not

be visible, but rather it will add a slight shine to the o-ring. If the lubricant can visibly be seen,

remove the excess very carefully with a piece of lens tissue (or equivalent non-shedding material,

i.e. fibreless q-tips), being careful not to get any on the probe connectors.

Caution! Make sure that there are no contaminants between the o-ring and the probe.

Contaminants that are present under the o-ring may cause the seal to leak when the sonde is

deployed.

2-2.4. Installing the Optical Probes

If you have a turbidity, chlorophyll, and/or rhodamine WT probe, it is recommended that the optical

sensors be installed first. If you are not installing one of these probes, do not remove the port plug,

and go on to the next probe installation.

Install the probe into the port, seating the pins of the two connectors before you begin to tighten.

Tighten the probe nut to the bulkhead using the short extended end of the tool supplied with the

probe. Do not over-tighten. Be careful not to cross-thread the probe nut.

The optical ports of the ADV6600 are labeled “T” and “C” on the sonde bulkhead. Each port can

accept any of the four optical sensors. Be sure to take note of which sensor is installed in which port

so that you will later be able to set up the sonde software correctly.

2-2.5. Installing the Conductivity/Temperature, DO, and pH/ORP

Probes

Insert the probe into the proper port using the diagram on the previous page as a guide and rotate the

probe until the pins engage. Seat the pins of the two connectors together as far as possible before

you begin to tighten.

The probes are held in place with slip nuts. With the connectors aligned and the two connector

halves engaged, hand-tighten the probe nut and then use the long extended end of the probe

installation tool to snug it. Do not over-tighten. Be careful not to cross-thread the probe nuts.

2-2.6. Installing the ISE Probes

The ammonium, nitrate, and chloride ISE probes do not

without tools. Use only your fingers to tighten. Make sure that the probe body of the ISE probes is

seated directly on the sonde bulkhead. This will ensure that connector seals will not allow leakage.

have slip nuts and should be installed

ADV6600 Y S I Environmental Page 10

Page 21

Section 2. Preparation of the Sonde

Any ISE probe can be installed in either of the two ports labeled “3” or “4” on the sonde bulkhead.

Be sure to take note of which sensor was installed in which po rt so that you will later be able to set

up the sonde software correctly.

2-2.7. Installing the Probe Guard

Included with your sonde is a probe guard. The probe guard protects the probes during calibration

and measurement procedures. Once the probes are installed, the guard can be installed by aligning it

with the threads on the bulkhead and turn the guard clockwise until secure. Be sure not to damage

the DO membrane during installation of the probe guard.

2-3. Attaching Your Sonde to a Computer

2-3.1. Installing the Batteries

The ADV6600 utilizes 8 C-size alkaline batteries which were supplied with the instrument. These

batteries are not rechargeable and should be properly disposed of when expended.

Install the batteries into the ADV6600 according to the following directions:

1. Loosen the battery lid screws. If necessary, a flathead screwdriver may be used. It can be

helpful to press the battery lid while unscrewing retaining thumb screws such that the lid or

thumb screws do not bind.

2. Remove the battery lid and install the batteries, as

shown. Observe the correct polarity noted on the

outside of the battery lid before inserting each

battery into the battery chamber.

3. Check the O-ring and sealing surfaces for any

contaminates which could interfere with the O-ring

seal of the bat t ery cham b e r . Remove any

contaminates present.

4. Return the b a tt ery lid an d ti g hten the sc r ews by

hand. It can be helpful to apply some pressure to

the battery lid while screwing the thumb screws to

prevent binding or non-uniform compression.

Note: Always power the system off when not in use to avoid draining the system batteries.

ADV6600 Y S I Environmental Page 11

Page 22

Section 2. Preparation of the Sonde

2-3.2. Preparing the Cable

The cable purchased with your ADV6600 has an Impulse

ADV6600 end and a military-style 8 pin connector (MS-8) on the interface end. Before

communicating with the ADV6600 through this cable, the YSI 6095B MS-8 to DB-9 adapter

(supplied with each sonde) must be connected to the MS-8 end of the cable. Place the MS-8 ends

of the cable and adapter together, and rotate until the alignment pins engage and the male and

female portions of the connector slide together. Once the bodies of the connectors are fully

engaged, twist the knurled ring on the cable until the two pieces lock together.

TM

MCIL-8-MP connector on the

2-3.3. Using the AC Power Supply

Although the ADV6600 has internal batteries, using the optional Model 6651 power supply for

laboratory studies and for sonde calibration and setup is often convenient and extends battery life.

The 6651 will automatically convert line voltages of 90 to 264 to 12 VDC and allows for the use of

line input cords from most countries world-wide. The 6651 is supplied with an American/Canadian

cord.

To use the 6651, attach the four-pin connector from the power supply to the mating connector on the

6095B adapter by twisting them together and then simply plug the power cord into the appropriate

AC outlet. Once the power and communications cable has been powered, be sure that the exposed

8-pin connector does not come in contact with water, metal, or other shorting material as this can

cause permanent and irreversible damage to the connector.

ADV6600 Y S I Environmental Page 12

Page 23

Section 2. Preparation of the Sonde

Y

Y

Y

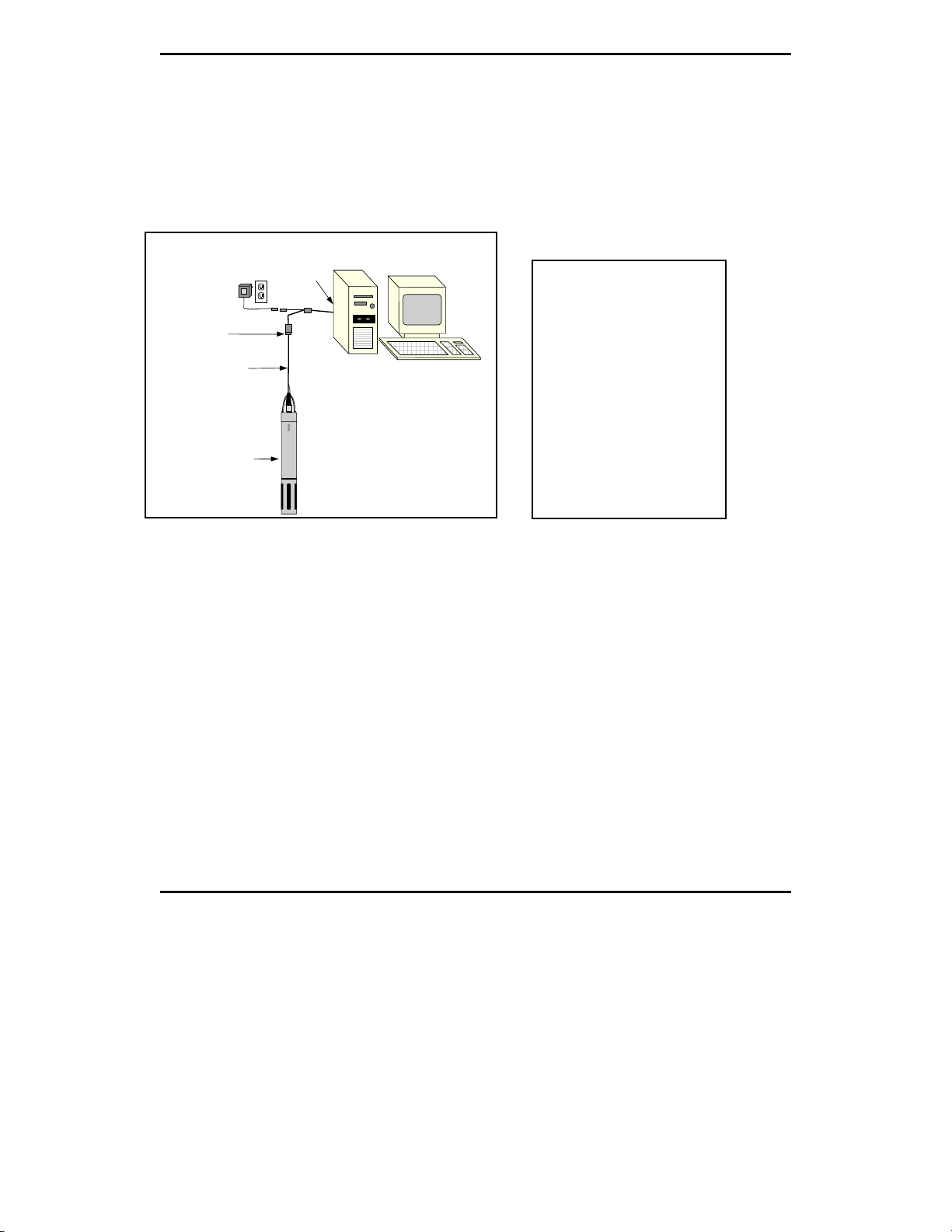

2-3.4. Attaching the Cable

Attach your ADV6600 to a computer for initial setup by connecting the proper end of the cable to

the sonde connector and attaching the strain relief connector to the sonde bail. Then connect the

other end of the cable assembly (DB-9) to a serial port on your computer. Use the diagram and

picture below to make sure that your connections are correct.

Power Supply*

MS-8

Sonde to Computer

DB-9

6095B

Adapter

Field Cable

ou will need...

❑

+

+

--

S

S

I

I

69

69

Sonde

Not required if you use

*

sonde battery

20

20

Now that the Water Quality sensors, power source, and cable have been installed on your

ADV6600, you are ready to proceed to installation of ADVantage 6600 PC software and the setup

of the firmware which resides within the sonde. These activities are detailed in Section 3.

Sonde

❑

Field Cable

❑

Computer with Com Port

❑

6095B MS-8/DB-9 Adapter

❑

605389 Power Supply *

ADV6600 Y S I Environmental Page 13

Page 24

Page 25

Section 3. Configuring Your ADV6600 –

Installation of ADVantage 6600 Software and

Sonde Firmware Set-up

In Section 2, you set up the physical components of your ADV6600 – sensors, power source, and

cable. In this section, you will learn how to install the PC software which allows interface to your

ADV6600 and how to use this interface to correctly configure the firmware packages in the sonde

which control the velocity and water quality sensors.

3-1. ADVantage 6600 Software – System Requirements

• IBM Compatible PC with Pentium processor or above

• Windows

• 32 MB memory

• 5 MB available disk space

• CD-ROM Drive

• RS-232 Serial Port

• Monitor capable of 800 x 600 resolution or better

3-2. Installing ADVantage 6600 Software

To install ADVantage 6600 software to your computer, perform the following steps:

• Place the ADVantage 6600 CD-ROM into the CD drive of your computer.

• Use Windows Explorer or My Computer to view files on the CD-ROM. Doub l e-click on

The display will indicate that ADVantage 6600 is proceeding with the setup routine. Follow the

instructions on the screen as the installation proceeds. For most applications, the default settings

should work without problems. After installation, there is no need to restart the computer.

3-3. Launching the Software

To run ADVantage 6600, click on the Windows Start button. Go to Programs>YSI

Software>ADVantage 6600; or click on the icon located on your desktop.

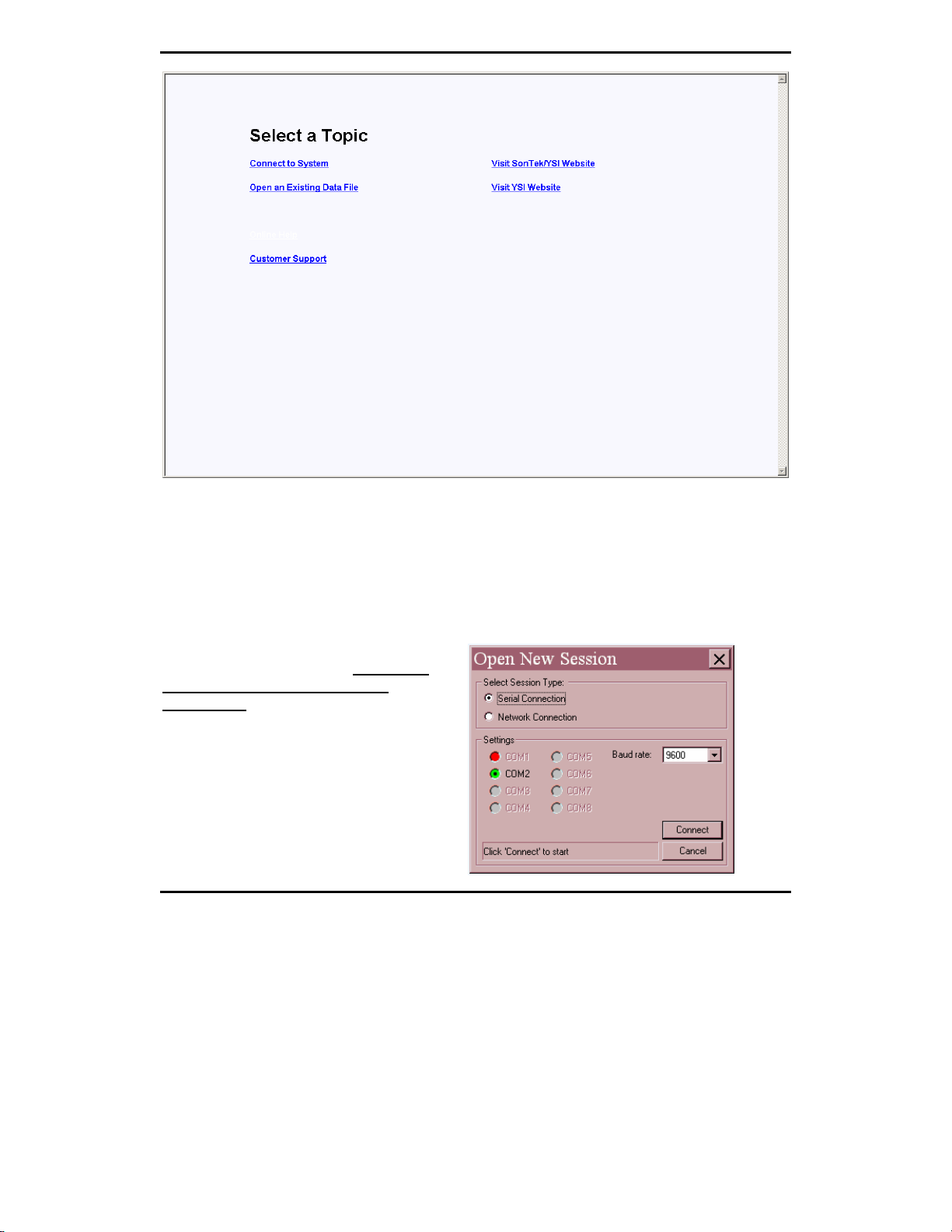

The program will display the following screen.

®

98, NT, 2000, ME, or XP

the ADVantage 6600_setup.exe file.

ADV6600 Y S I Environmental Page 15

Page 26

Section 3. Installation and Setup

3-4. Connecting to the System

When choosing the “Connect to System” selection, the Open New Session dialog box will appear

as shown below. A Session is used to describe a mode in which the software will be utilized. The

type of session may be selected by clicking on the appropriate button.

The default settings in the dialog box establish a Serial Connection which allows direct connection

between the ADV6600 and your computer

through a serial (COM) port. This option

should be used for most ADV6600

applications. You will need to select the

COM port to which your ADV6600 is

attached and confirm that the baud rate is set

to 9600.

Settings

This area displays the available COM ports on

your computer and the COM port being used

ADV6600 Y S I Environmental Page 16

Page 27

Section 3. Installation and Setup

for the current session. There are a maximum of eight available COM ports.

The COM port radio buttons (labeled COM1 through COM8) will display in one of three colors –

green = available for use by an instrument; red = in use or not available for use by an instrument;

gray = not detected on the computer. Additionally, the “active” radio button (the one with a black

dot in the middle) shows which COM port is connected to th e instrument being used by the

currently selected session.

If no radio button is “active” for the selected session, you can click on the appropriate COM port

radio button to connect to the instrument via ADVantage 6600 software.

Baud Rate

This dropdown list lets you change the communications baud rate of your instrument for special

applications. The default baud rate is set to 9600 at the factory and this setting should be used for

all typical ADV6600 applications. The baud rate should NOT be changed from 9600 except on

advice from YSI Technical Support personnel.

You may also select the Network Connection option by clicking the appropriate button and the

following dialog box will be shown. This option is for connections established through SonTek’s

SonGate software. A network (TCP/IP or LAN) must be in place and the host computer must be

running for this option to be used. When a network connection is chosen, the user will have the

option to select an existing network connection setup, create a new setup, or edit an existing setup

using the buttons on the right of the dialog box. When the setup information is entered and selected,

click on Connect to display the options for communicating with the instrument

.

REMEMBER: Unless advised o therwise by YSI Technical Support personnel, use the Serial

Connection option at a baud rate of 9600 to interface to your ADV6600.

ADV6600 Y S I Environmental Page 17

Page 28

Section 3. Installation and Setup

3-5. Understanding the Firmware of the ADV6600

There are three sets of software being utilized when working with the ADV6600. The ADVantage

6600 interface software which was just installed resides in your PC. The other two software

packages reside within the ADV6600 itself and are termed firmware

called “ADV Firmware” in this manual is designated as the “Master” of the two firmware

components and controls the ADV, compass/tilt, and pressure sensors as well as the lo gging and

data retrieval functions. The other firmware (called the “Water Quality Firmware” in this manual) is

designated as the “Slave” and controls only the water quality sensors

When communication is established with the ADV6600 from ADVantage 6600, the PC-based

software begins direct communication with the ADV firmware. If information is required from the

water quality sensors, the ADV firmware communicates in turn with the Water Quality firmware to

retrieve the data. Prior to using your ADV6600 in field studies it is necessary to set up both the

ADV and Water Quality firmware packages to provide the output appropriate to your studies and

this procedure is described in the following two sections.

. One firmware package is

3-6. Setting up the Water Quality Sensor Firmware

3-6.1. Setting Up the Water Quality Sensors

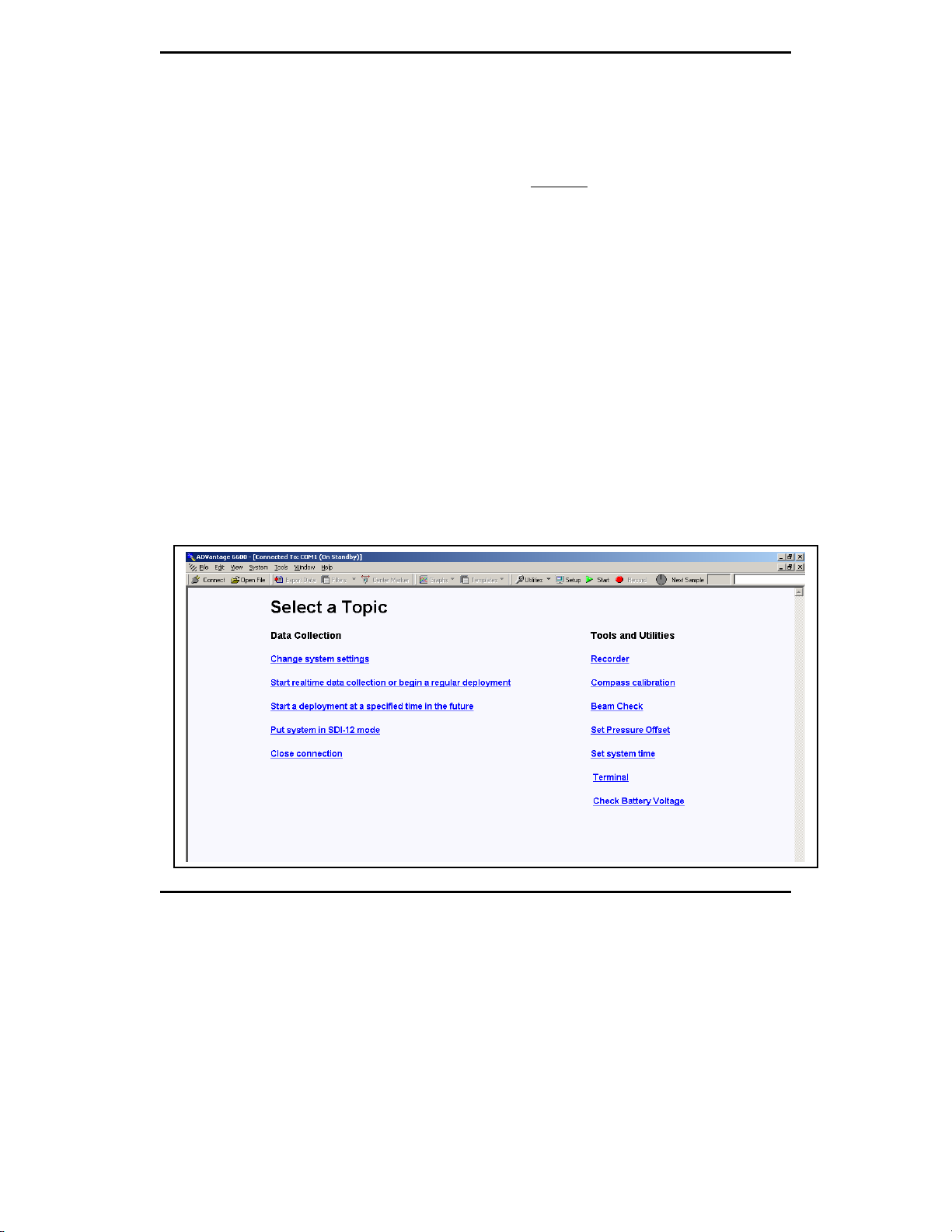

After connecting to the system and opening a new session, the following screen will appear:

ADV6600 Y S I Environmental Page 18

Page 29

Section 3. Installation and Setup

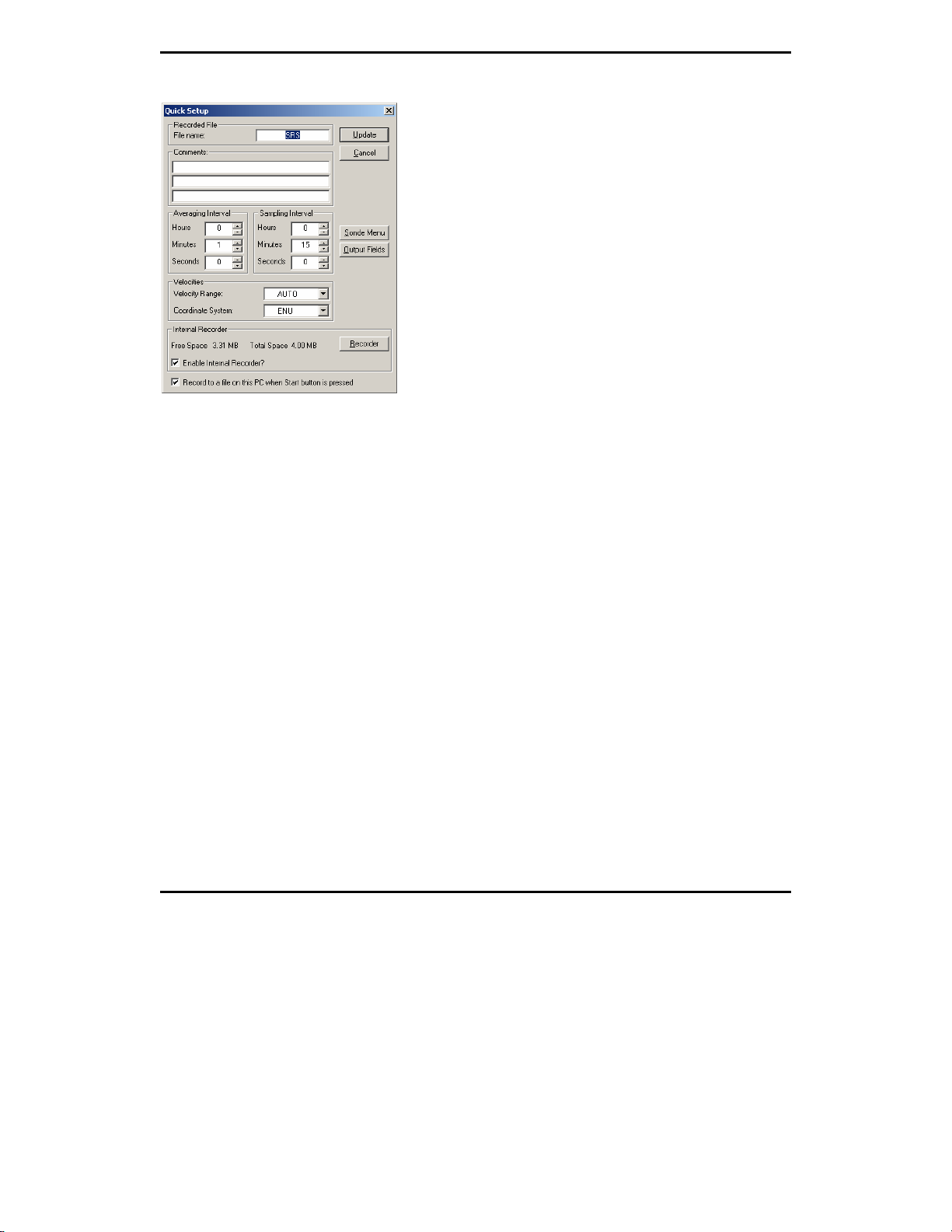

Select Change System Settings to display the Quick Setup dialog box as shown below.

Click on Sonde Menu to open a dialog window so that selections specific to the water quality

sensors can be viewed as shown below.

The water quality sensor items are selected by typing their corresponding number (e.g., 1 for

Calibrate). It is not necessary to press Enter to confirm a selection. When moving between menus

within the sonde software structure, use the 0 or Esc to back up to the previous menu. It is possible

to display the sonde command line (#) by pressing 0 or Esc until the question “Exit menu (Y/N)?”

ADV6600 Y S I Environmental Page 19

Page 30

Section 3. Installation and Setup

appears and then typing Y. To return to the Main menu of the sonde menu, type Menu after the “#”

and press Enter. The command line function may be useful during troubles hooting discussions

with YSI Technical Support personnel.

To save power, the Water Quality hardware will power down automatically if no interaction from

the keyboard occurs for approximately 60 seconds. When the firmware is in this “sleep” mode, the

first subsequent keystroke simply “wakes it up” and has no visible effect on the display. The next

keystroke after the unit is “awakened” will be input to the firmware in the intended manner. Thus,

if you press a key after the sonde has been inactive for some time and receive no response, press the

key again.

3-6.2. Water Quality Menu Flowchart

Several menu functions available on previous YSI sondes are no longer available on the ADV6600.

Due to the master-slave relationship between the ADV and the Water Quality hardware packages,

accessibility to these functions was removed, preventing interruption of communications bet ween

the firmware of each component.

SONDE MENU

ADV6600

1. Conductivity

1. Calibrate

2. Report

3. Sensor

4. Advanced

1. (

) Time

2. (

) Temperature

3. (

) Conductivity

▼ MORE ▼

2. Dissolved Oxy

3. ISE1 pH

▼ MORE ▼

1. (

) Date

2. (

) Time hh : mm : ss

3. (

) Temp C

▼ MORE ▼

1. Cal constants

2. Setup

3. Sensor

ADV6600 Y S I Environmental Page 20

Page 31

Section 3. Installation and Setup

3-6.3. Setting Up Installed Sensors

To activate the water

quality sensors that are

installed in the

ADV6600, select 3-

Sensor from the Sonde

Main menu. The

Sensor menu allows

you to Enable or

Disable (turn on or off)

any available sensor

and, in some cases, to

select the port in which

your sensor is installed.

Enter the corresponding number or letter to enable the sensors that are installed on your sonde. An

asterisk indicates that the sensor is enabled.

When selecting ISE3, ISE4, or any of the Optical ports, a submenu will appear. When this occurs,

make certain the sensor selected corresponds to the port in which the sensor is physically installed .

Note:

• Only ORP can be enabled as ISE2.

• ISE ports 3 and 4 can have one of three probes (nitrate, ammonium, or chloride) installed as

indicated by the submenus.

• Each optical port can have one of four probes (6026 turbidity, 6136 turbidity, chlorophyll, or

rhodamine WT) installed as indicated by the submenus.

• Only one probe of any type can be installed and activated in the ADV6600 sonde. For example,

it is not possible to use chlorophyll probes in both the Optic T and Optic C ports. However, it is

possible to use both the 6026 and the 6136 turbidity probes simultaneously

After all installed sensors have been enabled, press Esc or 0 to return to the Main Menu.

3-6.4. Setting Up Reports

The Report menu allows you to select the parameters and units of measure that will be output from

the Water Quality sensors and eventually be available for display in the ADVantage 6600 software.

Select 2-Report from the sonde Main menu. The menu below, or a similar menu

The parameters listed will depend on the sensors available and enabled on your sonde.

, will be displayed.

ADV6600 Y S I Environmental Page 21

Page 32

Section 3. Installation and Setup

The asterisks (*) that follow the numbers or letters indicate that the parameter will appear on all

outputs and reports. To turn a parameter on or off, type the number or letter that corresponds to the

parameter.

For parameters with multiple unit options such as temperature, conductivity, specific conductance,

resistivity and TDS, a submenu will appear as shown, allowing selection of desired units for this

parameter.

After configuring your instrument with the desired parameters, press Esc or 0 to return to the Main

menu.

Please note the following:

• Even if all of the Water Quality sensors available on the ADV6600 are enabled, the

measurements for those sensors will not appear on your display unless the parameter is

selected in Report setup.

• Only the exact Report parameters and their selected units as selected in Report will be

logged to internal memory during logging studies and you will NOT be able to obtain

ADV6600 Y S I Environmental Page 22

Page 33

Section 3. Installation and Setup

calculated parameters after the fact. For example, if you want to log specific conductance

during an unattended study, it MUST be active in the Report at the time the study is begun.

If only conductivity is active in the report, it will NOT be possible to automatically convert

the readings to specific conductance at a later time with ADVantage 6600 software.

The following table provides a complete listing of the abbreviations utilized for the various

parameters and units available in the Report setup menu.

Parameter Description

Date Day/Month/Year (format selectable)

Time Hour:Minute:Second (24-hour clock format)

Temp C Temperature in degrees Celsius

Temp F Temperature in degrees Fahrenheit

Temp K Temperature in degrees Kelvin

SpCond mS/cm Specific Conductance in milliSiemens per centimeter

SpCond uS/cm Specific Conductance in microSiemens per centimeter

Cond mS/cm Conductivity in milliSiemens per centimeter

Cond uS/cm Co nductivity i n microSiemens per centimeter

Resist MOhm*c m Resistivity in MegaOhms * centimete r

Resist Kohm*cm Resistivity in KiloOhms * centimeter

Resist Ohm*cm Resi stivity in Ohms * centi meter

TDS g/L Total dissolved solids in grams per liter

TDS kg/L Total dissolved solids in kilograms per liter

Sal ppt Salinit y in parts per thousand (set to local barometer at

calibration)

DO sat % Dissolved oxyge n in % air saturation

DO mg/L Dissolved oxygen in milligra ms per liter

DO chg Dissolved oxygen sensor charge

pH pH in standard units

pH mV millivolts associated with the pH reading

ORP mV Oxidation reduction potential value in millivolts

NH4+ N mg/L Ammonium Nitroge n i n milligrams/liter

NH4+ N mV Ammonium Nitrogen in millivolt reading

NH3 N mg/L Ammonia Nitrogen in milligrams/liter

NO3- N mg/L Nitrate Nitrogen in milligrams/liter

NO3- N mV Nitrate Nitrogen in millivolt reading

Cl- mg/L Chloride in milligrams/liter

Cl- mV Chloride in millivolt reading

Turbid NTU Turbidity in nephelometric turbidity units from 6026 sensor

Turbid+ NTU Turbidity in nephelometric turbidity units from 6136 sensor

Chl ug/L Chlorophyll in micrograms/liter

Fluor %FS Fluorescence in percent Full Scale

Rhod ug/L Rhodamine WT in micrograms/liter

ADV6600 Y S I Environmental Page 23

Page 34

Section 3. Installation and Setup

DOsat % Local Dissolved oxygen in % air saturation (set to 100 % at

calibration)

3-6.5. Advanced Menu Features

From the Sonde Main menu select 4-Advanced to display the sensor calibration constants,

additional setup options, and sensor coefficients/co nstants as shown below. The parameters listed

will depend on the sensors installed and enabled.

Select 1-Cal constants to display the calibration constants. Note that values only appear for the

enabled

relative to the calibration constants. Error messages will appear during calibration if values are

outside the indicated operating range unless the designation is “not checked”.

sensors. The following table provides the default value, operating range, and comments

Parameter Default Operating Range Comments

Cond 5 4 to 6 Traditional cell constant

DO Gain 1

ORP offset mV

pH offset 0.0 -400 to 400

pH gain -5.0583 -6.07 to -4.22

NH4 J 51.2 Not checked

NH4 S 0.195 0.15 to 0.217

NH4 A 1.092 Not checked

NO3 J 99.5 Not checked

NO3 S -0.195 -0.217 to -0.15

ADV6600 Y S I Environmental Page 24

0.0 -100 to 100

0.5 to 2.0

Page 35

Section 3. Installation and Setup

Parameter Default Operating Range Comments

NO3 A 2.543 Not checked

Cl J 99.5 Not checked

Cl S -0.195 -0.217 to -0.15

Cl A 2.543 Not checked

Turb Offset 0 -10 to 10

Turb A1 500

Turb M1 500

Turb A2 1000

Turb M2 1000

Chl Offset 0 -30 to 20

Chl A1 500

Chl M1 500

Chl A2 1000

Chl M2 1000

Rhod Offset 0 -10 to 10

Rhod A1 500

Rhod M1 500

Rhod A2 1000

Rhod M2 1000

0.6 to 1.5

0.6 to 1.5

0.6 to 1.5

0.6 to 1.5

0.6 to 1.5

0.6 to 1.5

Range is ratio of M1 to A1

Range is ratio of (M2-M1) to

(A2-A1)

Range is ratio of M1 to A1

Range is ratio of (M2-M1) to

(A2-A1)

Range is ratio of M1 to A1

Range is ratio of (M2-M1) to

(A2-A1)

From the Advanced menu, select 2-Setup to activate or deactivate Auto sleep RS-232. Activation

of this feature enables a power savings system within the sonde. When enabled, power is only

applied to the sensors during sampling or calibration. The most important aspect of this feature is

its effect on the dissolved oxygen protocol. For this reason, the feature should be activated for most

applications. The selection should only be deactivated if you are running spot sampling studies

where the Averaging Interval and Sample Interval are set to the same value (see later).

From the Advanced menu, select 3-Sensor to display and change user-configurable consta nts as

shown. Select the appropriate number to view these parameters.

ADV6600 Y S I Environmental Page 25

Page 36

Section 3. Installation and Setup

The number of items on this menu depends on the sensors that are available and enabled on your

sonde. Below we describe every possible item on this menu. Your sonde may not

have every item described.

NOTE: The user is cautioned to retain the default settings unless advised to change them by YSI

Technical Support. Changes should only be necessary for special applications.

TDS constant

Default: 0.65

Salinity

Default: 0

Pres psi

Default: 0

DO temp co %/C

Default: 1.1

DO warm up sec

Default: 60

Wipes

Default: 1

This selection allows you to set the constant used to calculate TDS. TDS

in g/L is calculated by multiplying this constant times the sp ecific

conductance in mS/cm. This item will only appear if the conductivity

sensor is enabled in the “Sensors enabled” menu.

This selection allows you to input a manually-acquired value of salinity

for calculating DO mg/L. This item is not used or displayed if the

conductivity sensor

This selection allows you to set a value of pressure for calculating other

parameters like salinity.

This selection allows a user to input the dissolved oxygen temperature

coefficient. Do not change this value unless you consult YSI Technical

Support. This item will only appear if the DO sensor is enabled in the

Sensors menu.

This selection allows a user to change the warm up period for the

dissolved oxygen sensor. This setting should always be equal to the

averaging interval established in the Quick Setup dialog box.

This selection will determine the number of cleaning cycles that will

occur when an optical probe wiper is activated manually or

is enabled in the Sensors menu.

ADV6600 Y S I Environmental Page 26

Page 37

Section 3. Installation and Setup

automatically. The wiper functions bi-directionally. A selection of “1”

results in three passes of the wiper over the optical face, twice in one

direction and once in the reverse direction. In most applications, a single

cleaning cycle is adequate to keep the optical surface free of bubbles and

fouling. However, in particularly harsh enviro nments addit ional cleaning

cycles may be needed. This item will only appear if a turbidity,

chlorophyll, or rhodamine WT sensor is enabled in the Sensor menu.

Wipe interval

Default: 1

SDI12-M/wipe

Default: 1

Turb temp co %/C

6026 Default: 0.3

6136 Default: 0.6

(* ) TurbSpike Filter W hen this ite m is activated, the output of the turbidity sensor is

In applications where the instrument is collecting data in SDI-12

communication mode, the wiper mechanism of the probe should be

activated automatically in a periodic manner to clean the optical surface

for fouling and bubbles. The value entered at this selection is the number

of minutes between each automatic cleaning cycle. Thus, if Wipe Int is

set to “5” and the instrument is in the Run mode, the wiper will activate

every 5 minutes with no manual input. This item will only appear if a

turbidity, chlorophyll, or rhodamine WT sensor is enabled in the Sensors

menu.

The value of Wipe Int is sometimes overridden when the instrument is

set up in the Unattended sampling mode. Under these conditions, the

wiper will be automatically activated at the interval assigned in the

Unattended setup rather than that assigned in Wipe Int. Thus, in an

Unattended study setup at a 15 minute sampling interval, the wiper will

be activated only once every 15 minutes rather than at the indicated Wipe

Int of 1 minute.

CAUTION: If Wipe Int is set to zero, then no wiping will occur either in

Discrete or Unattended Sampling. Make certain that Wipe Int is set to

some finite value prior to setting up an Unattended study or no automatic

cleaning will occur.

This is the number of wiping cycles when the sonde is in SDI12 mode.

The wiper will automatically wipe each time this many SDI12 “M”

commands have been issued. If this value is set to zero, then no

automatic wiping will occur. This item will only appear if a turbidity,

chlorophyll, or rhodamine WT sensor is enabled in the Sensors menu.

This entry sets the coefficient for the temperature compensation of

turbidity readings from the 6026 and 6136 sensors. The default values

should not be changed by the user without consulti ng YSI Technical

Support. This item will only appear if a turbidity sensor is enabled in the

Sensor menu.

ADV6600 Y S I Environmental Page 27

Page 38

Section 3. Installation and Setup

mathematically processed to minimize the effect of unusual (or “bad”)

readings on the overall data presentation. In most cases, these “spike”

events are the result of the chance passage of large suspended particles

across the probe optics just at the time a reading is taken. Activation of

this option generally results in a better display of the “average” turbidity

of the water under examination and its use is recommended for most

sampling and unattended applications. This item will only appear if a

turbidity sensor is enabled in the Sensors menu.

Chl temp co %/C

Default: 0.0

This entry sets the coefficient for the temperature compensation of

chlorophyll readings from the 6025 sensor. The default value of zero

should only be changed by the user after establishing the temperature

compensation factor for the phytoplankton sample in question. This item

will only appear if a chlorophyll sensor is enabled in the Sensors menu.

3-7. Setting up the ADV Sensor Firmware

The ADV firmware controls the velocity, pressure, and compass/tilt sensors. In addition, the real

time clock which controls the overall ADV6600 system and is recorded with each data string, is part

of the ADV firmware. Prior to using your ADV6600 in field studies, you must set the real time

clock and customize your ADV parameter output as described in the sections below.

3-7.1. Setting the System Time

When establishing a connection to the ADV6600 for the first time from a new PC or laptop, it is

advisable to set the time of the instrument. First, verify that the time shown on your computer is

correct. Next, connect to the ADV6600 and open a new session. Under the Tools and Utilities

screen options, select Set system time. The time in the ADV6600 will automatically be reset to

match the time of the computer it is connected to.

3-7.2. Setting Up the ADV Parameter Output

The ADV parameter output format can be configured from the Quick Setup dialog box which is

accessed by clicking the Change System Settings selection under the Data Collection screen menu.

A typical Quick Setup box is shown below. To show a list of ADV parameters, click on the Output

Fields selection as shown below.

ADV6600 Y S I Environmental Page 28

Page 39

Section 3. Installation and Setup

Under most circumstances, the user is advised to make sure that all of the items in the Fields listing

are active, i.e., a check mark appears in all boxes. Outputting all parameters to the PC during real

time studies and to the ADV6600 internal memory during unattended monitoring studies will allow

the full capability of the ADV6600 system to be realized. If the user does not want to view some of

the information in reports and plots, parameter outputs can easily be “masked” using the

ADVantage 6600 software package, but still retained in the data files for use in later data analysis.

Therefore, YSI strongly recommends that all fields be left active for studies where the data is stored

to a PC or internal memory. The selection is present primarily to limit the ADV6600 output for

SDI-12 studies as described in Section 6.3. However, there may be unusual circumstances in non

SDI-12 studies where the user will want to eliminate some of the ADV parameters and this can be

accomplished by clicking on the boxes to remove the check mark.

Note that many of the ADV parameters have subparameters bundled within the same item. For

example, the velocity parameter contains three separate outputs (V

, VN, and VU) which represent

E

the velocity in the “East”, “North”, and “Up” directions relative to the earth coordinate system (and

are derived using the velocity from the ADV and internal compass). Detailed descriptions of the

parameters listed in the Fields dialog box are provided in the table below.

Sample Number Sequential numbers (incremented by one unit) starting with “1” which

are incremented by one unit and are displayed and/or logged time a

sample is taken.

Time The date and time stamps which are displayed and/or logged with each

set of data points.

Speed and Direction The speed and direction of the water.

Vel The three components of water velocity (East, North, Up)

Vel Std Dev The Standard Deviation of the water velocity

ADV6600 Y S I Environmental Page 29

Page 40

Section 3. Installation and Setup

Amplitude The level of returned signal based on the concentration and/or particle

size found in the water.

Compass The heading, pitch, and roll data from the compass which is applied to

the raw velocity data to convert it to East, North, Up components.