Page 1

ba76071e01 02/2012

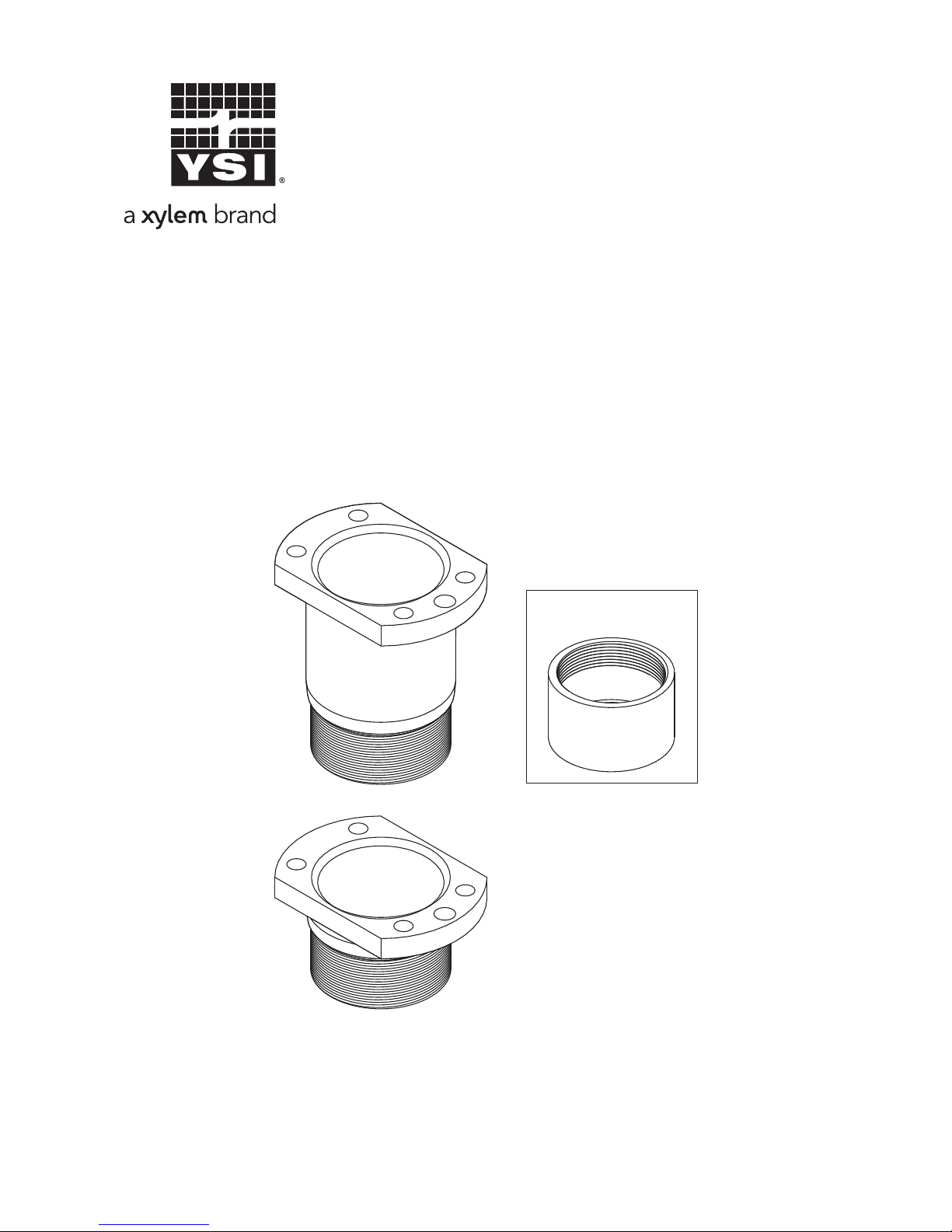

ADA-WA 1

ADA-WA 4

Installation instructions

ADA-WA1ADA-WA1

ADA-WA4ADA-WA4

Fixing ring

for SensoLyt

Sensor adapter for installation in the

retractable armatures WA700/2 and WA 700/10

Page 2

ADA-WA 1; ADA-WA 4

2

ba76071e01 02/2012

Important information for using this adapter

together with a SensoLyt armature:

Observe the following note when you want to use a

SensoLyt measuring armature with the aid of the adapter:

Warning

For safety reasons, use only electrodes especially

specified for high pressure and temperature loads (for

example pH combination electrode SensoLyt SEA-HP,

order no. 109 118). For more information, refer to the

YSI catalog or the Internet. YSI assumes no liability for

damages caused by using different electrodes.

Page 3

ADA-WA 1; ADA-WA 4 Installation recommendations

3

ba76071e01 02/2012

Installation recommendations

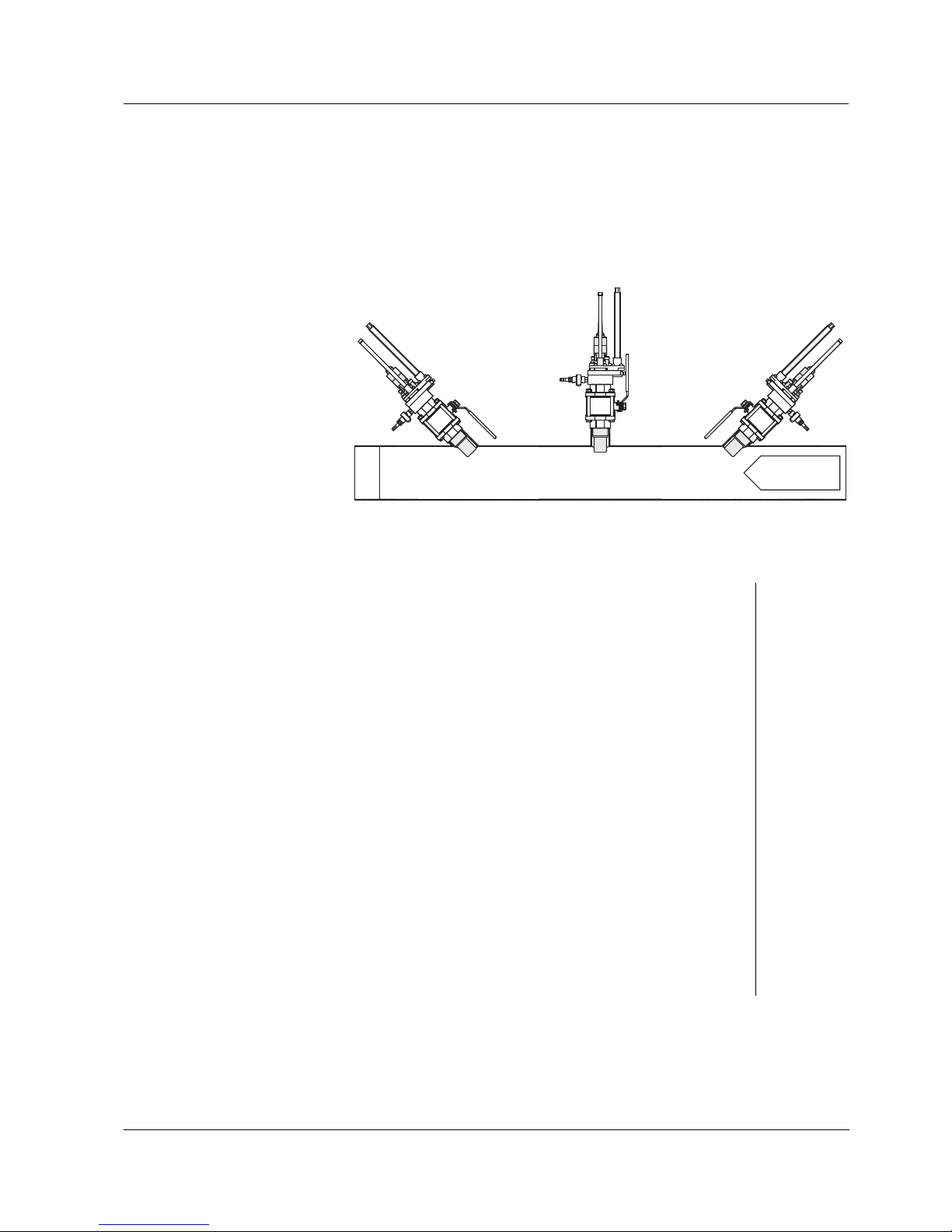

General installation recommendations

Basic types of

installation

The optimum installation location must be individually determined for the type of sensor and the application.

Influential factors

The table on the following pages contains recommendations

and the special characteristics of the individual sensors.

Flow

direction

Minimum distance: 80 mm

A

45 ° 45 °

BC

Good

Sufficient flow of the

sensor element

A, B

Burdening of the measuring medium with

long fibers - avoidance of them getting

caught on the sensor (rake effect)

C

Burdening of the sample with small stones

and abrasive particles - avoidance of any

damage to the sensor element

C

Avoidance of malfunctions of the optical

measurement (turbidity/total suspended solids) by captured air bubbles and particles

A, B

Avoidance of malfunctions of the optical

measurement (turbidity/total suspended solids) by wall surfaces

A, C

Page 4

Installation recommendations ADA-WA 1; ADA-WA 4

4

ba76071e01 02/2012

Overview of the recommended installation locations

Note

Always follow the I

NSTALLATION chapter of the respective sensor operating manual.

Sensor type Installation

location

(see

diagram on

page 3)

Advantages (+) /

Disadvantages (-)

Conclusion / Comments

TriOxmatic 700 IQ,

TriOxmatic 701 IQ,

TriOxmatic 702 IQ

FDO 700 IQ

B + Good flow

+ Low susceptibility to contamina-

tion

+ Low risk of membrane damage

TetraCon 700 IQ B + Good flow

+ Low susceptibility to contamina-

tion

Check and adjust cell constants

after installation (see sensor operating manual)

SensoLyt 700 IQ C + Good flow

+ Low susceptibility to contamina-

tion

- Danger of small stones damaging

the electrode

The enclosed fixing ring instead

of the protective hood improves

the incident flow.

Attention

: It is no protection

against small stones!

The best incident flow is

achieved when the diaphragm

points against the flow direction.

TFK 700 IQ C + Good flow

+ Low susceptibility to contamina-

tion

The enclosed fixing ring instead

of the protective hood improves

the incident flow.

Page 5

ADA-WA 1; ADA-WA 4

5

ba76071e01 02/2012

Overview of the recommended installation locations (continued)

Sensor type Installation

location

(see diagram

on page 3)

Advantages (+) /

Disadvantages (-)

Conclusion / Comments

VisoTurb 700 IQ,

ViSolid 700 IQ

Note

:

Please note the

special installation

recommendations

in the following

section.

A + Optimum flow of the sapphire disc

so there is no capture of air bubbles or large particles in front of

the sensor

- Susceptible to fibers getting

caught

- Risk of damage from stones and

abrasive particles

Optimum installation location

for measuring media without

contamination from fibers,

stones, or abrasive particles.

C + No risk of contamination by long fi-

bers

+ Low risk of damage from stones

and abrasive particles

- Susceptible to the capture of air

bubbles or large particles in front

of the sapphire disc (turbulence

effect)

In the case of contamination by

fibers, less prone to contamination than A.

B + Good flow of the sapphire disc, so

there is no interference from air

bubbles or large particles in front

of the sensor

- Risk of light reflections in narrow

containers

Good possibility in sufficiently

large containers or high values

of turbidity/total suspended solids.

Page 6

Installation recommendations ADA-WA 1; ADA-WA 4

6

ba76071e01 02/2012

Special installation recommendations:

VisoTurb 700 IQ and ViSolid 700 IQ

Note

Please also observe the general basic information in the

I

NSTALLATION chapter of the sensor operating manual. There

you will find important notes on optimizing the installation.

45 ° pipe installation

Pipe diameter at the installation location of at least DN 80.

The pipe should be straight and not tapered for a length

of at least 50 cm (VisoTurb 700 IQ) or 25 cm

(ViSolid 700 IQ) in the direction of observation. Angled or

tapered pipes can cause interference effects in the case

of low turbidity.

The front part of the sensor is pitched towards the flow.

Exception:

If there are high quantities of foreign bodies with fibrous

or large surfaces, as for example hairs, strings or leaves,

it may be of advantage to incline the sensor in the

direction of the flow so that the sapphire disc does not

face the flow.

Min. 80 mm

ESS/WA...

WA 700/...

Marking aid in

this direction

Flow

direction

ADA-WA1

straight pipe

VisoTurb: min. 50 cm

ViSolid: min. 25 cm

Page 7

ADA-WA 1; ADA-WA 4 Installation recommendations

7

ba76071e01 02/2012

The marking on the sensor shaft points towards the

pipeline. On page 9 you will find a description of how to

correctly align the sensor with the aid of a marking aid on

the sensor plug head connector.

90 ° pipe installation

Note

The 90 ° pipe installation is only suitable for large pipe

diameters and high turbidity/total suspended solids values

respectively. For other cases, the 45 °installation should be

preferred.

For installation, select a location with a pipe diameter as

big as possible.

Rotate the sensor so that the marking on the shaft (arrow

symbol) points in the direction of the pipe axis. On page 9

you will find a description of how to correctly align the

sensor with the aid of a marking aid on the sensor plug

head connector.

ESS/WA...

WA 700/...

Marking aid in

this direction

Large ballcock

turned

ADA-WA1

Page 8

Installation recommendations ADA-WA 1; ADA-WA 4

8

ba76071e01 02/2012

Other containers

Installation angle 90 °

The distance between the mounting opening and the wall

opposite should be as great as possible.

The area in front of the measuring windows (hatched area

in the drawing) has to be free of interfering surfaces.

10 cm

ESS/WA...

WA 700/...

Large ballcock

turned

ADA-WA1

No interfering surfaces

in this area!

Page 9

ADA-WA 1; ADA-WA 4 Installation

9

ba76071e01 02/2012

Installation

Note

Please also observe the I

NSTALLATION chapter of the sensor

operating manual as well as the operating manual of the

retractable armature.

VisoTurb 700 IQ,

ViSolid 700 IQ:

Attaching the

marking aid

(if necessary)

Preparing the

sensor for

installation

Note:

The parts (1), (2) and (4) are contained in the scope of

delivery of the retractable armature.

1 Connect the SACIQ

sensor connection cable

to the plug head

connector of the sensor

and screw it tight.

2 Attach a marking aid

(adhesive strips or

similar) in the same

position as the arrow

symbol on the sensor

shaft to the plug head

connector.

3 To continue the

installation, unscrew the

plug connection again.

Marking

Marking aid

1 Assemble both halves of

the retaining ring (1) and

the thin O-ring (2).

2 Push the retaining ring

over the sensor and

make it lock in place in

the groove (3).

3

1

2

WA 700

Page 10

Installation ADA-WA 1; ADA-WA 4

10

ba76071e01 02/2012

3 Insert the sensor with the

retaining ring in the

receiving tube (4) up to

the stop.

4 Screw the sensor

adapter (5) on the unit.

The sensor is ready to be

installed in the

retractable armature.

5 Install the sensor in the

retractable armature (see

operating manual of the

retractable armature).

6 Connect the SACIQ

sensor connection cable

to the plug head

connector of the sensor.

7 If necessary, rotate the

sensor by means of the

marking aid until it is in

the correct position.

* The receiving tube for installation with the ADA-WA 1 is

included in the scope of delivery of the retractable

armature. For installation with the ADA-WA 4, use the

special (longer) receiving tube provided with the adapter in

order to ensure the correct length compensation.

ADA-WA1ADA-WA1

4 *

5

Page 11

ADA-WA 1; ADA-WA 4 Technical data

11

ba76071e01 02/2012

Technical data

Operating pressure

Operating

temperature

0 ... +60 °C (32 ... 140 °F), frost-free

Total length

Materials

Pressure difference

P

inner

- P

outer

Max. +106Pa

(10 bar overpressure)

ADA-WA 1 69 mm

ADA-WA 4 35 mm

Adapter Stainless steel 1.4571

Fixing ring POM

Loading...

Loading...