Page 1

YSI Environmental

Pure Data for a Healthy Planet.™

YSI 9600

Nitrate Monitor

Operations

Manual

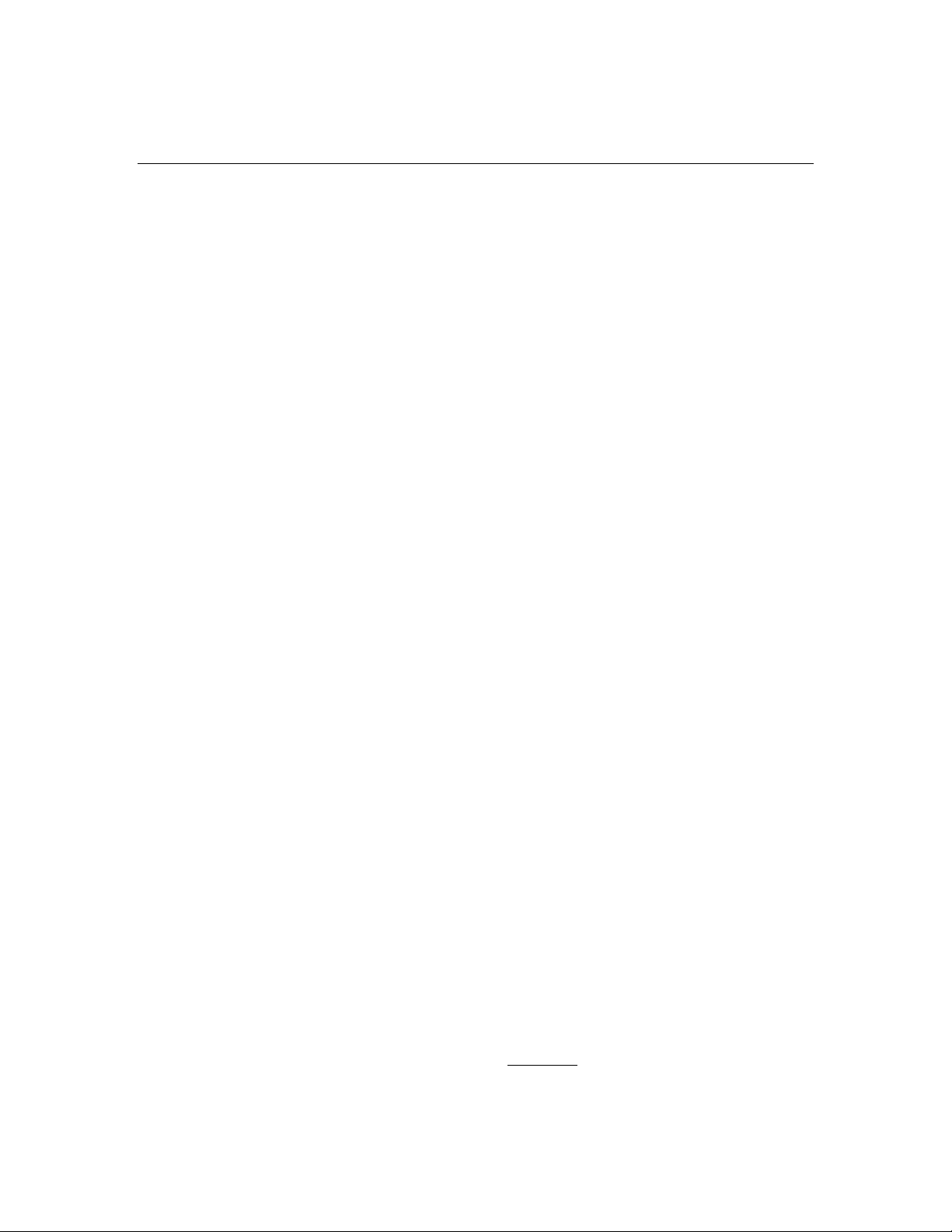

NITRATE MONITIORING WITH YSI 9600 AT

FRESHWATER SITE; 1 HOUR SAMPLE INTERVAL

6

5

4

3

mg/L NO3-N

2

1

0

7/10/03 0:00 7/15/03 0:00 7/20/03 0:00 7/25/03 0:00 7/30/03 0:00

Time

9600

USER QC

YSI QC

Page 2

YSI Environmental 2 Model 9600 Nitrate Monitor

Page 3

TABLE OF CONTENTS

SECTION 1 INTRODUCTION TO THE 9600 7

SECTION 2 GETTING STARTED 8

2.1 UNPACKING 8

2.2 UNDERSTANDING THE 9600 MODE OF OPERATION 12

2.3 PREPARING REAGENTS 13

2.4 FILLING THE REAGENT BAGS 16

2.5 PREPARING THE CADMIUM COLUMN 18

2.6 INSTALLING THE CADMIUM COLUMN 20

2.7 INSTALLING THE REAGENT BAGS 22

2.8 USING THE WASTE BAGS 23

2.9 ASSEMBLING THE NITRATE MONITOR 25

SECTION 3 PREPARING FOR A 9600 DEPLOYMENT 27

3.1 INSTALLING THE NUviewTM PC SOFTWARE 27

3.2 CHOOSING A CABLE FOR THE 9600 28

3.3 POWERING THE 9600 29

3.4 ATTACHING THE SECOND STANDARD BAG 31

3.5 INTERFACING WITH THE 9600 32

SECTION 4 STARTING A 9600 DEPLOYMENT 34

4.1 UNDERSTANDING CALIBRATION OF THE 9600 34

4.2 CHECK LIST FOR DEPLOYMENT READINESS 34

4.3 PREDEPLOYMENT SYSTEM CHECK 36

4.4 PREDEPLOYMENT SET-UP 39

4.5 INSTALLING THE INLET FILTER 42

SECTION 5 USING THE 9600 IN THE FIELD 44

5.1 PICKING A DEPLOYMENT SITE 44

5.2 POWERING THE 9600 DURING A DEPLOYMENT 44

5.3 VIEWING AND UPLOADING DATA DURING A DEPLOYMENT 45

5.4 STOPPING A DEPLOYMENT 49

5.5 DEPLOYING THE 9600 WITH A DATA COLLECTION PLATFORM 49

5.6 9600 POSTDEPLOYMENT TEST – QUALITY ASSURANCE 56

5.7 9600 MAINTENANCE AND NEW DEPLOYMENTS 56

SECTION 6 MANAGING 9600 FILES 58

6.1 INTRODUCTION 58

6.2 DIRECTORY 58

6.3 UPLOAD FILES TO YOUR PC 59

6.4 DELETING FILES 59

6.5 DETERMINING AVAILABLE FILE MEMORY 60

SECTION 7 ANALYZING DATA WITH ECOWATCH FOR WINDOWS 61

7.1 INTRODUCTION 61

7.2 INSTALLING ECOWATCH FOR WINDOWS 61

7.3 GLOSSARY 61

7.4 VIEWING AND PLOTTING NITRATE DATA 63

7.5 USING TOOLBAR SHORTCUTS 68

YSI Environmental 3 Model 9600 Nitrate Monitor

Page 4

SECTION 8 PRINCIPLES OF OPERATION 70

8.1 CHEMISTRY 70

8.2 EFFECT OF PH 71

8.3 FLOW SYSTEM DETAILS 71

8.4 PUMPING SEQUENCES 72

8.5 FLOW RESTRICTION PROBLEMS 72

8.6 CALIBRATION OF SAMPLE AN D STANDARD PUMPS 72

8.7 CALIBRATION DETAILS 72

8.8 SYSTEM LINEARITY 73

8.9 TEMPERATURE EFFECTS 74

SECTION 9 UPGRADING 9600 FIRMWARE AND SOFTWARE 76

9.1 UPGRADING 9600 MONITOR FIRMWARE 76

9.2 UPGRADING NUVIEW PC SOFTWARE 77

SECTION 10 TROUBLESHOOTING 78

SECTION 11 FERRITE BEAD INSTALLATION 80

SECTION 12 9600 SAFETY CONSIDERATIONS 81

SECTION 13 WARRANTY AND SERVICE INFORMATION 82

SECTION 14 REQUIRED NOTICE 85

SECTION 15 9600 SPECIFICATIONS 86

15.1 SENSORS 86

15.2 SYSTEM 86

SECTION 16 ACCESSORIES 87

SECTION 17 FREQUENTLY ASKED QUESTIONS 88

APPENDIX A ECOWATCH FOR WINDOWS COMMANDS 96

YSI Environmental 4 Model 9600 Nitrate Monitor

Page 5

SAFETY AND EMC CONSIDERATIONS

9600 NITRATE MONITOR

Before using the 9600, the user should carefully read the caution messages listed below and should

review Sections 11 and 12 of this manual on Safety and EMC considerations.

CAUTION: Operation of the YSI 9600 Nitrate Monitor requires the use of a variety of

chemicals. With one exception (elemental cadmium), the user is required to purchase these

chemicals from a vendor of their choice. Users should consult the Material Safety Data Sheets

(MSDS) supplied by these vendors for all reagents before their use. Users should ALWAYS wear

appropriate personal protective equipment including gloves and safety glasses with side shields when

handling any of these chemicals.

For proper operation of the YSI 9600, cadmium metal MUST be purchased in packaged form as the

YSI Model 9612 Cadmium Column Assembly. An MSDS for the material captured in the cadmium

column is automatically supplied to the user by YSI. To protect against potential hazards

associated with inhalation of cadmium dust, the cadmium column should be handled in a fume hood

during activation. After the reducing capacity of the cadmium column has been exhausted, the entire

sealed column should be disposed of in accordance with regulatory requirements, e.g. hazardous

waste. Users should NEVER open the cadmium column in attempts at regeneration. If the

cadmium is accidentally spilled, appropriate spill measures should be taken.

The waste generated from use of the YSI 9600 contains potentially toxic organic chemicals, but most

importantly, contains Cd

Users should NEVER discharge waste from the YSI 9600 into the environment, instead retaining it in

the waste bags that are provided with the instrument. Likewise, unless specifically approved by the

local wastewater authority, users should NEVER dispose of the reaction waste into a sanitary or

storm sewer. The waste should be disposed of in accordance with regulatory requirements with an

approved waste handler.

2+

that according to the USEPA is toxic and a probable human carcinogen.

CAUTION FOR INSTRUMENTS USE D IN EUROPEAN CO M MUNITY (CE)

COUNTRIES:

Nitrate Analyzer complies with the Residential, Commercial and Light Industrial Class B Limits for

radio-frequency

laboratory equipment with no qualifiers. However, if you are using your YSI 9600 Nitrate Monitor in a

European Community (CE) country or in Australia or New Zealand, when communicating with the

instrument you must attach a ferrite bead to the interface cable in order to comply with the industrial

immunity specified in EN61326 for Industrial, Scientific and Medical laboratory equipment. The

ferrite bead (YSI Item Number 699296) is NOT supplied as standard equipment with the 9600 and

should be purchased as an accessory by customers requiring its use. Attachment of the bead is shown

graphically in Section 11.

YSI Environmental 5 Model 9600 Nitrate Monitor

As described in the Declaration of Conformity (YSI Item # 699298), the YSI 9600

emissions specified in EN55011 (CISPR11) for Industrial, Scientific and Medical

Page 6

YSI Environmental 6 Model 9600 Nitrate Monitor

Page 7

SECTION 1 INTRODUCTION TO THE 9600

The YSI 9600 Nitrate Monitor is a powerful instrument that allows the user to continuously record nitrate

levels at a variable sample interval and thus provides a much greater capability to detect nutrient events

than the spot sampling activities which have historically been carried out. The 9600 can be custom

configured with regard to detector cell to provide maximum accuracy for the type of water that you

normally monitor. For applications where typical nitrate levels are over 2 mg/L of nitrate-nitrogen, the

9600 should be configured with a 2 mm cell (designated 9600-02 for ordering purposes). For applications

where typical nitrate levels are below 2 mg/L, the monitor should be equipped with a 10 mm detector cell

and designated 9600-10. The 9600-02 and 9600-10 are designed primarily for freshwater and

estuarine/near coastal applications, respectively, but there may be some cases where the greater range of the

9600-02 will be required for brackish water studies and some cases where freshwater nitrate levels are

consistently low enough to require the greater accuracy of the 9600-10. Note that users cannot change the

detector cell that was purchased with their particular 9600 in order to meet the requirement of a new

application. While detector cells can be switched from 2 mm to 10 mm or vice versa, this action must be

carried out by factory-trained personnel.

To accurately measure nitrate, the 9600 uses flow injection technology combined with a chemical reaction

sequence which is defined in literature from both the USEPA and Standard Methods for the Examination of

Water and Wastewater. The intensity of the color produced by the chemical reaction sequence is

determined by standard absorbance spectroscopy and compared to that of a standard of known

concentration in order to quantify the amount of nitrate in an environmental sample. The use of flow

injection technology minimizes the amount of reagents required and the amount of waste generated.

Key features of the YSI 9600:

• Works on standard cadmium reduction/diazotization principle. Standard Methods #4500-NO

• Can be custom configured relative to detector cell for most freshwater applications (2 mm) or for most

estuarine and near coastal applications (10 mm).

• Easy-to-use NUview

Windows

provided with each instrument.

• Easy access to reagent and waste bags and internal battery pack for field replacement.

• Good battery life (approx. 70 days at a 1 hour sample interval at 20 C) with internal D-cell battery

pack. Also can be powered externally by 12 V lead acid battery, AC adapter, or data collection

platform for longer deployments.

TM

software for data analysis and custom presentations. Both software packages are

TM

PC software for simple set-up and deployment. Proven EcoWatch for

• Automatic calibration at user-selected interval. Calibration points do not affect data continuity for

sample intervals of 30 minutes and greater.

• SDI-12 and RS-232 interfaces standard for use with computers and data collection platforms.

• Waste collection system included with instrument to avoid cadmium

• Minimal waste volume because of pump design – approximately 7 liters of waste in 30 days at a 1 hour

sample interval.

• CE and Australian C-Tick Compliance

2+

discharge into the environment

3

-

E.

YSI Environmental 7 Model 9600 Nitrate Monitor

Page 8

• Large, non-volatile memory for data storage.

• System can be used at depths up to 200 feet.

• All firmware and software is user-upgradeable via the YS I Web page.

SECTION 2 GETTING STARTED

This section is designed to quickly familiarize you with the hardware and s oftware components of the YSI

9600 and its accessories. By the end of Section 2 you will have...

Unpacked the 9600 Nitrate Monitor and confirmed that all components are present

Become familiar with the general features and set-up configurations of your 9600

Prepared the required reagent solutions

Filled and installed the collapsible reagent delivery bags and the waste bags

Activated and installed the cadmium column

Assembled the instrument in preparation for a deployment or laboratory test

Successful completion of the above list is essential for you to continue on to Section 3, which focuses on

setting up the hardware to allow a successful computer interface with the 9600. In subsequent sections, you

will learn about how to set up the 9600 to log data during a deployment , deploy the monit or, and manage the

data files which are generated during field studies.

2.1 UNPACKING

When unpacking your 9600 Nitrate Monitor, be certain not to discard any parts or supplies that were

supplied with the instrument. As you proceed through the unpacking process, use the packing list

(available immediately after opening the box) to ensure that all items are included. Finally, be sure to

inspect all assemblies and components for damage. Proceed by the following steps to unpack the 9600:

• Open the flaps at the top of the box and remove the packing list and sealed information packet which

contains several items, including the manual and the software necessary to interface with the 9600 and

analyze the data, and set the items aside.

• After removing the cardboard tray that contains the information packet, remove the 9600 from the

shipping box by grasping the bail and pulling straight up as shown in the picture below. It may be

prudent to have two people present for this initial unpacking step: one to lift the instrument by the bail

and another to pull the box from the assembly. Note carefully that the 9600 weighs approximately 30

pounds with no chemicals present so make certain that the person removing the instrument from the

box is capable of lifting this amount of weight.

YSI Environmental 8 Model 9600 Nitrate Monitor

Page 9

• After removal from the box, place the 9600 on a flat surface, usually the floor, and inspect it for any

damage that might have occurred in transport. If any parts are damaged or missing, contact your YSI

representative immediately. If you do not know which YSI dealer you obtained your YSI 9600 from,

refer to Section 13 of this manual for contact information.

• If no damage is present, proceed with the removal of the carousel from the outer housing of the 9600

as defined in the steps below:

• Using a large Phillips head screwdriver, remove the four (4) screws from the sides of the instrument

assembly which hold the inner carousel to the outer assembly as shown in the picture below. Make

certain to retain the screws in a safe place for reassembly prior to use of the 9600.

• After the screws hav e been removed, grasp the bail and lift straight up to remove the carousel as shown

in the picture below. If the carousel binds to the outer shell, have a second person hold the outer shell.

Place the carousel in an upright position on the floor or a bench top after removal.

Lift by Bail

Remove these screws

YSI Environmental 9 Model 9600 Nitrate Monitor

Page 10

• Locate the package containing the cadmium column and remove the box from the carousel. Also

locate the 9615 Syringe Kit which is near the cadmium column. Set these items aside for later use.

• Locate the seven (7) one liter reagent bags that are present in the individual compartments of the

carousel. Note that one of the bags is loose in the compartment and has a tubing assembly attached to

its middle port. This bag should be removed immediately and set aside for later use. Note that the

other six bags are attached to tubing by multicolored threaded fittings. Note also that each bag has a

colored tie-wrap on the top of the container that is coordinated with the color of the fitting to which the

bag is attached.

• As you inspect the reagent bags, note carefully that there is a small (50 mL) plastic bag that is

permanently attached to the side of the internal cylinder as shown in the picture below. This bag

MUST NOT BE REMOVED as it contains silicon oil. The 50-mL bag is designed to expand and

contract with temperature and depth changes to equalize the pressure between the pump chamber and

the water at the site.

Note Permanent

Attachment

Lift straight up by bail

YSI Environmental 10 Model 9600 Nitrate Monitor

Page 11

• Using only your fingers (no tools), remove each 1 L reagent bag from its color-coded fitting by

grasping the bag-end of the assembly with one hand and turning the nut counterclockwise with the

other as shown in the picture below. Set the bags aside for later use.

• Inspect the detector cell that protrudes from the underside of the pressure manifold as shown in the

pictures below and confirm that it is correct according to your order – either a 9600-02 with a 2 mm

cell or a 9600-10 with a 10 mm cell. Besides the label that is attached to the cell as an identifier, it is

also possible to differentiate the cells by the fact that the 10 mm cell has two tan colored nuts attaching

the tubing while the 2 mm cell has one tan colored nut and one smaller stainless steel fitting.

2 mm Detector Cell 10 mm Detector Cell

• Remove the battery lid by loosening the four (4) knurled screws on the top of the battery lid as shown

in the picture below. If the screws cannot be turned, use any slotted screwdriver to loosen them

slightly and then screw them out until the battery lid can be removed

YSI Environmental 11 Model 9600 Nitrate Monitor

Page 12

CAUTION: The battery lid screws are captive. Do NOT continue to turn them after the

battery lid can be removed.

• Confirm that the battery pack is present in the compartment, but do NOT connect its battery lead to the

mating connector at this time.

• Replace the battery lid.

After completing the unpacking and inspection sequence outlined above, proceed to Section 2.2 below to

gain a basic understanding of the Model 9600 mode of operation.

Loosen 4 battery lid screws

and lift battery lid straight up

2.2 UNDERSTANDING THE 9600 MODE OF OPERATION

The Model 9600 is designed to allow users to monitor the nitrate concentration in env ironmental water over

long periods of time with minimal maintenance required. It is NOT designed for spot sampling of nitrate

since the minimal interval between samples is 15 minutes. The system operates by the principle of

injection analysis (FIA) using a series of precise low-volume pumps to mix an aliquot of the water at an

environmental site with user-prepared reagents that produce a colored solution. The intensity of the color

is measured in a detector cell using a green light-emitting-diode (LED) as the light source and a photodiode

as the detector and this intensity is proportional to the concentration of nitrate in the sample. The detector

cell is also equipped with a reference photodiode to automatically compensate for any changes in LED

intensity during a study. Because the pumps are low-volume, minimal waste is generated by the 9600 FIA

system during field studies and this waste can readily be captured in the containers supplied to prevent

environmental contamination.

It is important to understand that, in its normal configuration with the cadmium column in place, the 9600

measures the sum of the nitrate AND nitrite in the water being monitored. Normally, however, because

the biological process of nitrification is active at most sites, there is very little nitrite in most environmental

water and therefore the 9600 reports its readings as nitrate. Users who are concerned that there is indeed a

significant quantity of nitrite in the water at their monitoring sites should either carry out studies with the

9600 with no cadmium column in place or should collect water samples at the site and perform laboratory

analyses for nitrite to determine if its presence is having a significant effect on the overall accuracy of the

measurement.

Users interface to the Model 9600 via a PC that is running the YSI software designated as NUview

which is supplied with each nitrate monitor as part of the information packet. This software provides a

simple interface for set-up and deployment of the nitrate monitor that is ideal for the vast majority of

studies. Under the standard set-up routine, the user inputs specific information about the pending

flow

TM

YSI Environmental 12 Model 9600 Nitrate Monitor

Page 13

deployment, such as study name, sample interval, and the frequency of auto calibration, into a “Wizard”

based interface, with this portion of the set-up taking a minute or less. The Wizard then guides the user

through a predeployment pumping routine which takes approximately 60 minutes to assure that the

instrument is functioning properly and provides error messages if any problem is apparent. After a

successful predeployment test, the user simply starts the deployment and transports the 9600 to the desired

site for deployment. The study can either be started immediately during laboratory set-up of the nitrate

monitor, or delayed by several hours to allow the study to start after deployment. The key is that the

default FIA sequence for the pumps is ideal for the monitoring of nitrate, and no user “programming” of the

9600 hardware is required.

During deployments, a blank (puri fi ed wat e r ) and a standard (made up to a concentration that matches the

typical nitrate values at a particular site) are automatically run at an interval selected by the user. Use of

these periodic blank and standard reagents allows the instrument software to automatically compensate the

data for any instrument drift during deployment and provides an on-board quality assurance methodolog y.

For most deployments, it will be sufficient to run a blank and standard twice during each 24 hour logging

period. For sample intervals of 30 minutes and greater (typical for most deployments), the calibration

reagents are run through the system

The overall length of a deployment is generally limited by a combination of the quantity of reagents present

in the instrument assembly at the beginning of the study and the sample interval chosen by the user. For

example, the reagents will be expended in approximately 30 days if an interval of 1 hour is chosen between

samples, but approximately 60 days if the interval is set to 2 hours.

While most studies will be carried out using the pumping sequence (number of pumping pulses for each

particular pump at a specified time in the overall routine ) for “typical” nitrate-N concentrations in the 0-5

mg/L range, NUview software also allows users who are monitoring water with very high nitrate

concentrations (5-10 mg/L) to select a special pumping sequence to enhance their accuracy.

You now should have a basic understanding of the capabilities of the YSI 9600 and be ready to proceed to

the next section where you will prepare reagents for use in the deployment of the nitrate monitor.

between samples so that no discontinuity occurs in the logged data.

2.3 PREPARING THE REAGENTS

Four different reagent solutions and distilled or deionized water are required for the use of the Model 9600

nitrate monitor. In this section, you will be given instructions on how to prepare these reagents. In

addition, the 9600 utilizes a column of elemental cadmium which must be “activated” prior to use and

instructions for this procedure are also provided.

CAUTION: All chemicals are potentially harmful and should be handled with care. Be sure to

consult the MSDS for each of the chemicals before preparing any of the reagent solutions. It is very

important to wear appropriate protective equipment including safety glasses with side shields and

use disposable gloves when handling solid chemicals and when preparing and transferring solutions

of these chemicals.

2.3.1 PURCHASING THE REAGENTS

The sources used for the various reagents that have been used in YSI development studies on the 9600 are

provided below. However, users can purchase reagents from any source of their choosing as long as the

chemicals are (a) identical in formulation and (b) equivalent in purity – ACS Reagent Grade or better. An

appropriate quantity of the reagents should be purchased based on the frequency of deployment of your

9600.

YSI Environmental 13 Model 9600 Nitrate Monitor

Page 14

Ammonium Chloride – Fisher Scientific, Item Number A661-500

Sulfanilamide – Sigma , Item Number S-9251

N-(1-napthyl)ethylenediam i ne dihydrochloride (NED) – Aldrich, Item Number 22,248-8

Potassium Nitrate -- Alfa Aesar Chemical, Item Number 13443

Hydrochloric Acid (10 % v/v; 1.2 M) -- Fisher Scientific, Item Number LC15070-6 (10 liter container)

Copper Sulfate Solution (10 % w/v) -- Spectrum Chemical Mfg. Corp., Item Number C-283

BRIJ 35 Surfactant, Sigma -- 430AG-6

Kodak Photo-Flo 200 Wetting Agent -- Warehouse Photographic, Carrollton, TX, 800-400-8203,

www.warehousephoto.com, 146-4502. Alternatively, this chemical can be purchased at most camera

stores or photo supply houses.

2.3.2 REQUIRED EQUIPMENT AND CONTAINERS

Before proceeding with solution preparation, YSI recommends that you first make sure that you have

available the necessary equipment and storage vessels. First, you should have the proper bottles for storage

of at least 1.5 liters of each reagent. The plastic bottles recommended by YSI for this purpose are 2 liters

in capacity and are graduated so that 1.5 liters of solution can be prepared to the required accuracy for most

of the reagents. These bottles can be purchased from Fisher Scientific in packs of 6 or 12 as Fisher Item

Number 03-311-3g. Second, for preparation of the nitrate standards in various concentrations, you will

need a 1000 mL glass volumetric flask to obtain the desired accuracy. Third, users will require an

adjustable volume pipet for the 0 to 1 mL range such as the Brinkman Eppendorf model which can be

ordered from Fisher Scientific under Item Number 05-402-50. Fourth, if you wish to prepare nitrate

standards above 2 mg/L, you will need glass pipets with the appropriate volumes. For example, to prepare

a 5 mg/L nitrate standard, you will need a 5 mL glass pipet. Finally, users will require a balance that will

weigh accurately to at least 0.01 gram and preferably one which has an accuracy of 0.001 gram. In

summary, the following parts are required prior to reagent preparation:

• Graduated Plastic Bottles with 2 L capacity (at least 6)

• Volumetric Flask for 1000 mL (at least 1)

• Adjustable pipetter for 0-1 mL volumes (at least 1)

• Glass pipet s of va ri o us deno minations (depending on standard concentrat i ons req ui re d)

• Laborato ry bal a nce wit h wei ghi n g accuracy of 0.0 1 g

2.3.3 SOLUTION PREPARATION

The following instructions should be followed to prepare the aqueou s solutions that will be required for use

with the 9600 Nitrate Monitor. At least 1.5 L of the reagents and 3 L of the final standard should be

prepared in order to have enough solution volume to set up the nitrate monitor properly for a deployment.

CAUTION: Be sure to consult the MSDS for each chemical before proceeding and use safe

laboratory practices as outlined above during their handling.

BUFFER – Weigh 128 g of ammonium chloride to the nearest gram and place the solid in a 2 L graduated

plastic bottle. Add 1.5 L of purified water (distilled or deionized) and stir or shake until the solid is

completely dissolved. Using the adjustable pipetter, add 75 uL of 10 % copper sulfate solution and shake

well to mix.

YSI Environmental 14 Model 9600 Nitrate Monitor

Page 15

SULFANILAMIDE – Weigh 15 g of sulfanilamide to the nearest gram and place the solid in a 2 L

graduated plastic bottle. Add 1.5 L of 10 % hydrochloric acid and shake or stir until all of the solid is

dissolved. Using the adjustable pipetter, add 1.5 mL of BRIJ 35 surfactant.

NED – Weigh 1.50 g of N-(1-napthyl)-ethylenediamine dihydrochloride (NED) to the nearest 0.01 g and

place the solid in a 2 L graduated plastic bottle. Add approximately 1.5 L of purified water and shake or

stir until the solid is completely dissolved. Then add 3.75 mL of Photo-Flo 200 and sh ake well to mix.

NOTE CAREFULLY: The NED reagent is light sensitive and the storage bottle should be either

kept in the dark or covered with some material, e.g., aluminum foil, to prevent premature

degradation.

WASH – Place 1.5 L of water in a 2 L graduated plastic bottle. Add 3.75 mL of Photo-Flo 200 and shake

well to mix.

CAUTION: It is CRITICAL for proper operation of the 9600 for the Photo-Flo 200 to be included in

both the NED and Wash reagents. Do not attempt to deploy without adding the Photo-Flo to these

solutions.

1000 MG/L NITRATE-NITROGEN STANDARD – Weigh 7.22 g of potassium nitrate to the nearest

0.01 g and quantitatively transfer the solid to a 1000 mL volumetric flask. Add approximately 500 mL of

purified water and swirl the mixture until the solid is completely dissolved. Then add additional water to

fill the flask to the top graduation mark. Mix well by repeated inversion of the flask. Transfer the

standard to a dry 2-L plastic bottle for storage. YSI recommends that this standard be stored in a

refrigerator and then warmed to ambient temperature prior to use. If refrigerated, the standard will be

stable for approximately 3 months.

VARIABLE NITRATE-NITROGEN STANDARDS – Nitrate-nitrogen standards in various

concentrations can be prepared by diluting the 1000 mg/L standard prepared in the section above. Using

this method, accurate aliquots of the concentrated standard are transferred to the 1000 mL volumetric flask

and then the flask is filled to the top graduation mark and inverted repeatedly to assure good solution

homogeneity. Examples of the amount of 1000 mg/L standard to dilute to 1000 mL are shown in the Table

below:

Final Nitrate-N Standard Conc Amount of 1000 mg/L Standard Final Volume

6 mg/L 6.00 mL 1000 mL

4 mg/L 4.00 mL 1000 mL

2 mg/L 2.00 mL 1000 mL

1 mg/L 1.00 mL 1000 mL

0.50 mg/L 0.50 mL 1000 mL

0.20 mg/L 0.20 mL 1000 mL

0.10 mg/L 0.10 mL 1000 mL

NOTE: Users can also purchase 1.0 mg/L nitrate-N standard from YSI in 500 mL quantities as Model

Number 3885.

SELECTING A NITRATE STANDARD CONCENTRATION – For your initial deployment using

either a 9600-02 (2 mm detector cell) or a 9600-10 (10 mm detector cell), YSI recommends using a

standard that is 1mg/L in nitrate-nitrogen (nitrate-N). This standard will assure readings that are accurate

to 5 % of the reading or 0.2 mg/L whichever is greater, with the 9600-02 and 5 % of the reading or 0.02

mg/L, whichever is greater, with the 9600-10. Once you obtain more information about the typical high

and low limits of nitrate concentration at a particular site, you might want to use standards of different

values to maximize accuracy. For example, with a 9600-02, if the water at your site is known to

YSI Environmental 15 Model 9600 Nitrate Monitor

Page 16

consistently contain concentrations of nitrate higher than 6 mg/L, then users might consider employing a

higher standard concentration such as 6 mg/L nitrate-N. For many estuarine and near coastal studies,

where nitrate concentrations may always be below 0.5 mg/L nitrate-N, the use of a 0.2 mg/L standard will

probably improve the data accuracy. Note, however, that YSI does not recommend using standards less

than 0.1 mg/L of nitrate-N.

CAUTION: Use of standards with concentrations higher than 8 mg/L of nitrate-N may compromise the

accuracy of the 9600.

NOTE: The procedure noted above for the variable nitrate-nitrogen standards will have to be carried out

multiple times in order to generate enough standard to fill the two reagent bags as described below.

Alternatively, a larger volumetric flask can be used in the preparation as long as the amount of 1000 mg/L

standard shown in the table is increased appropriately.

After preparing the reagent solutions, be sure to label each storage bottle appropriately.

BLANK– The blank is typically purified water which has a salinity which is roughly that of the water at

the site for brackish and oceanographic applications and simply deionized or distilled water for freshwater

applications.

2.4 FILLING THE REAGENT BAGS

Under deployment conditions, chemical reagents are fed into the FIA system of the Model 9600 from

collapsible reagent bags that you unpacked and set aside in Section 2.1 above. Thus, to operate the nitrate

monitor, you must transfer solutions from the storage bottles to the bags prior to each deployment. The

bags are nominally 1 L, but will in fact require approximately 1.2 L of solution for complete filling and

maximum deployment times.

CAUTION: Be sure to wear appropriate protective equipment including safety glasses and gloves

while filling the reagent bags. In addition, be certain to point the reagent bag fittings away from

your face when you are expelling air from the bag through the partially-open fittings as described

below.

NOTE: The reagent bags are color-coded to match the threaded fittings on the nitrate monitor tubing to

facilitate installation. Be sure to put each reagent in the proper color-coded bag according to the

information in the table below:

REAGENT BAG COLOR

Standard – 2 bags White

Blank – Purified Water Black

Buffer Blue

NED + Photo-Flo 200 Red

Sulfanilimide + BRIJ Yellow

Wash – Purified Water + Photo-Flo 200 Green

It may also be prudent for the user to label each bag with a “magic marker” prior to filling.

NOTE: For the Predeployment Check of the analyzer as described in Section 4.2 below, you will need

TWO 1 liter bags filled with your standard solution. Note that you have been furnished with two

bags labeled with a white tie-wrap, one of which has a tubing assembly attached.

YSI recommends that the method outlined below be used to fill each of the reagent bags:

YSI Environmental 16 Model 9600 Nitrate Monitor

Page 17

• Locate the 60 mL plastic syringe that was supplied with your Model 9600 in the 9615 Syringe Kit and

remove the plunger. Clamp the syringe to a ringstand with the Luer Lock bottom fitting “down” and

the syringe opening “up”.

• Remove the Luer Lock plug from the side port on the reagent bag and make sure that the pinch clamp

on the middle port of the bag is open. CAUTION: Make sure that you save the side port plug for

resealing the bag after filling.

• Attach the reagent bag via the side port to the Luer Lock fitting at the bottom of the syringe and tighten

securely. See the pictures below for the proper set-up to begin filling reagent bags.

• Make sure that the pinch clamp on the middle port of the bag is in the “open” position.

• Pour the appropriate reagent into the 60-mL syringe and allow it to drain into the reagent bag. Repeat

the addition of reagent until the bag is full and reagent overflows slightly out of the middle port of the

bag.

• Close the pinch clamp on the middle port of the reagent bag so that no solution can escape via this

route.

• Carefully remove the syringe from the side port of the reagent bag and seal the side port with the plug

which was set aside above. With the bag completely sealed, invert the bag back and forth several

times to loosen any bubbles that might be present.

• Now hold the bag in your hand with the connectors “up” and move it slightly back and forth until any

bubbles present are near the side Luer Lock fitting. Loosen the Luer Lock plug slightly (Do no t

remove it) and squeeze the bag gently to expel any bubbles out through the port as shown in the picture

below. Then quickly retighten the Luer Lock plug. See the picture below.

YSI Environmental 17 Model 9600 Nitrate Monitor

Page 18

The reagent bag is now ready for installation in the nitrate analyzer.

Repeat the filling process for all six reagent bags. Note that the wash (green fitting) and blank (black

fitting) bags should be filled with purified water only.

NOTE: Be sure to rinse the 60 mL syringe with purified water before switching reagents to avoid cross

contamination in the reagent bags.

2.5 PREPARING THE CADMIUM COLUMN

The cadmium column that was set aside during the unpacking process in Section 2.1 is a key ingredient in

the Model 9600 function and MUST be activated prior to use in the nitrate monitor. Activation should be

carried out according to the instructions below.

CAUTION: Cadmium, according to the USEPA, is toxic and a probable human carcinogen. Be sure

to handle the column and perform the activation process in an approved fume hood. Be sure to

wear appropriate personal protective equipment including eye protection and wear gloves while

handling the column and performing the activati on process. Failure to observe these precautions

may lead to potentially serious health problems.

To activate the cadmium column, you must locate the 10-mL plastic syringe assembly that is part of the

9615 Syringe Kit that was supplied with the nitrate monitor. Note that the syringe is fitted with tubing and

a threaded fitting. This syringe is used to push reagents through the cadmium column during the activation

process. You will also require the following reagents that were prepared or purchased above:

• Hydr ochloric Acid (10 % v/v)

• Ammonium Chloride Buffer Solution

• Copper Sulfate Solution (10 % w/v)

Once the reagents and the 10 mL syringe assembly have been located, you are ready to proceed to the next

step.

2.5.1 PREPARING THE COPPER SULFATE REAGENT

The copper sulfate solution (10 % w/v), purchased as described in 2.3.1 above, MUST be diluted prior to

its use in cadmium column activation. Perform the dilution by placing 2 mL of the purchased 10 % (w/v)

YSI Environmental 18 Model 9600 Nitrate Monitor

Page 19

reagent in a beaker or other suitable container and adding 8 mL of purified water. The resulting 2 % (w/v)

solution will be used as part of the cadmium column activation process.

2.5.2 CADMIUM COLUMN ACTIVATION

CAUTION: In case an inadvertent leak occurs during the following procedure, it is prudent to

perform all operations with the apparatus placed in a flat glass baking dish with dimensions of about

9” x 18 “ x 1”. This procedure allows all leaks to be contained and allows for proper cleanup and

disposal of any spilled reagents.

Working in an approved fume hood, open the box and remove the cadmium column assembly – shown

•

in the picture below.

• Wearing appropriate protective equipment, remove the threaded plugs at the ends of the column

assembly and set aside for later reassembly.

• Place about 15 mL of 10 % (v/v) hydrochloric acid in a beaker or other suitable vessel. With the

syringe plunger fully depressed, place the threaded fitting at the bottom of the syringe assembly in the

reagent and withdraw 10 mL into the syringe by pulling back on the plunger.

• Connect the threaded connector on the syringe assembly to one end of the cadmium column and

tighten by hand – no tools should be used. Mark the direction of flow that you have chosen through

the column by using a marker to place an arrow on the cadmium column assembly.

• Hold the open end of the cadmium column over a beaker or other suitable vessel and then depress the

plunger on the syringe assembly to push the acid steadily through the column as shown in the picture

below. The entire injection process should take approximately 15 seconds.

YSI Environmental 19 Model 9600 Nitrate Monitor

Page 20

• Rinse and fill the syringe assembly with 10 mL of purified water and repeat the injection procedure

through the column to rinse out the acid. Again, the injection process should take approximately 15

seconds.

• Rinse the syringe assembly with purified water and fill it with the 2 % (w/v) copper sulfate solution

prepared in 2.5.1 above. Connect the syringe assembly to the cadmium column and slowly inject 5 mL

of the reagent into the column while holding the open end of the column over a beaker. The injection

of the 5 mL aliquot of reagent should take approximately 30 seconds. Do not remove the syringe

assembly (which still should contain 5 mL of solution) from the cadmium column .

• Reinsert the threaded plug in the open end of the column assembly.

• Set the entire assembly aside for at least 15 minutes to allow proper activation. No damage to the

column will occur if the assembly is left for several hours in this state.

• After the initial activation, remove the threaded plug from the open end of the column, slowly inject

the remaining 5 mL of the copper sulfate solution into the cadmium column and again set the assembly

aside for 15 minutes or longer after reinserting the plug in the open end of the column.

• Remove the syringe from the assembly and rinse it with purified water. Remove the threaded plug

from the other end of the column assembly .

• Fill the syringe with 10 mL of the ammonium chloride buffer solution which was prepared as

described in 2.3.3 above. Inject all of the buffer reagent through the cadmium column at a rate so that

the entire injection takes about 15 seconds.

• Remove the syringe from the column assembly and reinsert the threaded plugs in each end of the

assembly.

The cadmium column is now activated and ready for installation.

2.6 INSTALLING THE CADMIUM COLUMN

The next step in setting up for deployment is to install the cadmium column in the carousel of the nitrate

analyzer. Remove the carousel from the outer shell of the analyzer and place it on the floor or a bench top

in the vertical position supported by its three legs.

YSI Environmental 20 Model 9600 Nitrate Monitor

Page 21

g

Locate the two black straps in one of the carousel segments that will be used to retain the cadmium column

assembly. Note that there is a section of tubing within the straps with two ends with brown threaded

fittings that are connected by a translucent nut.

NOTE: For optimum performance, the cadmium column should be installed in the flow system of the

carousel so that the direction of flow through the column is the SAME as that used in its activation.

To make sure that the direction of flow through the cadmium column is correct, note that one of the

sections of tubing within the carousel straps tubing goes to a circular tan fitting with two other pieces of

tubing connected to it. This fitting on this section should be attached to the OUTLET of the cadmium

column as marked during the activation process. See the picture below left to identify the tubing nut that

goes to the cadmium tube outlet.

Loosen the straps by pushing up on the tab and pulling on the strap as shown in the picture ab ove right.

Remove the translucent coupling nut so that the two threaded brown fittings are free. As noted above,

identify the threaded nut that goes to the circular tan adapter. Remember that this nut should be attached to

the OUTLET of the cadmium column assembly.

Screw the threaded fittings on the tubing ends into the ends of the cadmium column assembly after

removing the plugs from the column. Use only finger tightening to make the connection – no tools should

be used.

Align the connected cadmium column assembly vertically within the strap clamps and pull the end of the

straps so that the column assembly is held in place firmly as shown in the picture below. Note that the

straps should fit within the indentations on the cadmium column assembly.

Outlet

CAUTION: Be certain to retain the two black plugs that were removed from the cadmium

column prior to its installation. These plugs will be required to seal the column assembly

for proper disposal after its reducing capacity has been expended.

Circular Fittin

YSI Environmental 21 Model 9600 Nitrate Monitor

Page 22

Now proceed to the installation of the reagent bags as described in Section 2.7 below.

2.7 INSTALLING THE REAGENT BAGS

The next step in setting up the Model 9600 for field use is to install the six 1-liter reagent bags containing

solutions prepared in Section 2.4 above into the nitrate monitor carousel. Remove the carousel from the

outer shell of the analyzer and place it on the floor or a bench top in the vertical position supported by the

three legs. Then follow the step-by-step instructions below to install the reagent bags.

• Locate the six lines of reagent tubing which have color-coded threaded fitting on the ends. The ends

of the tubing with threaded fittings will be found hanging below the middle plate of the carousel and

should be retrieved manually. Note that these are the only loose fittings within the carousel, so their

identification should not be a problem.

• Note that there are three compartments in the top section of the carousel and that each compartment

must hold two reagent bags. The bags will be placed on the hooks that are hanging from the top plate

of the reagent compartments.

• Retrieve one of the fittings which is hanging in the carousel, note its color and then locate the filled

reagent bag with the same colored tie-wrap on its middle port. Make sure that each bag has the proper

reagent as shown in the table below. As long as the color code was followed in the filling of the

reagent bags, no possibility of error exists at this step. Make sure that the recovered tubing is routed

through the hole in the middle of the bottom plate rather than around the edges.

REAGENT BAG COLOR

Standard – 2 bags White

Blank – Purified Water Black

Buffer Blue

NED Red

Sulfanilimide Yellow

Wash – Purified Water Green

• Make the tubing to reagent bag connection by screwing the threaded fitting on the tubing into the

middle port of the reagent bag. Tighten securely with fingers only – no tools should be used.

• Hang the connected bag from one of the six hooks in the upper plate of the carousel.

• Repeat the sequence for the remaining five reagent bags making sure that t here are tw o b ags hanging

in each compartment, one on each hook.

• Open the pinch clamps on all bags and flick the middle port of each of the bags with your finger to

cause any remaining air bubbles to move to the top (closed end) of the reagent bags as shown in the

picture below.

YSI Environmental 22 Model 9600 Nitrate Monitor

Page 23

Flick fitting to force

bubbles to top of bag

2.8 USING THE WASTE BAGS

As received by the user, the two 5 liter waste bags will already be connected and reside in the bottom

compartment of the carousel. However, YSI sugg est s that u sers become acquainted with the routing of the

tubing to the bags from the pump manifold so that reattachment after each deployment will be easier.

Note that each waste bag is enclosed in a plastic net that will support the weight of the liquid waste during a

deployment. The net material is an integral part of the waste bag assembly and should NOT be removed.

The waste bag assembly is attached via the metal clips to two hooks on the bottom of the carousel’s middle

plate. Each of the two waste bag assemblies should be attached to two different hooks for proper function.

Note also that a single waste line from the manifold connects to a “T” fitting which distributes the effluent

from the system between the bags as shown in the picture below. Because the flow path to one bag may be

slightly more facile than the other, it is not uncommon for effectively all of the waste to accumulate in a

single bag until it is full and then the waste stream shift to the other bag. Users should not be concerned by

this phenomenon.

2.8.1 REMOVING THE WASTE BAGS

To remove the waste bags, place the carousel on the floor or on a bench in a vertical orientation, supported

by its three legs. Then follow the step-by-step instructions below:

From Pump Manifold

T-Fitting

To Waste Bags

YSI Environmental 23 Model 9600 Nitrate Monitor

Page 24

• Make certain that the pinch clamps on the two waste bags are CLOSED.

• Remove the threaded fittings from the middle ports of the waste bags.

• Remove the waste bag assemblies (waste bag enclosed in netting) from the hooks on the underside of

the center plate of the carousel.

• Set the waste bag assemblies aside for proper disposal of the waste.

CAUTION: The waste solution will contain potentially hazardous organic compounds, hydrochloric

acid, and, most importantly, cadmium ions (Cd

carcinogen. Users should be aware of two important warnings when dealing with this waste

solution:

• Be certain to wear appropriate personal protective equipment including disposable

gloves and proper protective eyewear when handling the waste bags and the waste

solution.

• Be certain to dispose of the waste properly. Unless specifically allowed by your local

wastewater authority, the waste should NOT be emptied into a sanitary sewer, i.e. a sink

drain. Instead, the waste should be collected in a suitable container and disposed of

with an approved waste handler. This waste handler should be contacted BEFORE you

accumulate waste in laboratory or field studies so that the proper storage vessels are

available and a schedule for waste pick-up has been arranged.

• To empty each bag into the appropriate container, invert the bag so that the port is in the “down”

position and is over the waste container. Then carefully open the pinch clamp and allow the waste

solution to flow out of the bag. Use gentle pressure on the bag to facilitate the process and make sure

that all of the solution has been removed. Note, however, that it is not important to rinse the waste

bag before reinstallation.

2.8.2 ATTACHING THE WASTE BAGS

To install the waste bags prior to deployments, place the carousel on the floor or bench in a vertical

position supported by its three legs, as shown in the pictures above, and follow the step-by-step instructions

below.

• Open the pinch clamp on the port of the waste bag and place the bag assembly on a flat surface.

• Place your hand on the closed end of the bag and move it across the bag toward the end with the

fitting, squeezing out any air through the pinch clamp fitting.

• Close the pinch clamp.

• Locate one of the tan-colored threaded fittings on the waste lines and attach it to the pinch clamp port

of the waste bag. Tighten securely with fingers only – no tools sho ul d be use d.

• Hang the empty waste bag assembly (waste bag in netting) on two of the hooks on the underside of the

center plate of the carousel.

• Install the second waste bag repeating the steps above.

2+

) which are toxic and a potential human

YSI Environmental 24 Model 9600 Nitrate Monitor

Page 25

• Open the pinch clamps on the ports of the waste bags.

2.9 ASSEMBLING THE NITRATE MONITOR

Before assembling the Model 9600 nitrate monitor for deployment, make sure the following has been done:

• The cadmium column has been activated properly and installed in the carousel.

• The six reagent bags have been filled, attached to the proper connectors, are properly installed, i.e.,

hanging from individual hooks in the carousel, and all of their pinch clamps have been OPENED.

• The two waste bag assemblies are properly attached to the effluent lines and the metal rings at the tip

of each assembly are attached to the hooks on the bottom of the carousel center plate. OPEN the

pinch clamps on the waste bag assemblies.

CAUTION: Make absolutely certain that the pinch clamps on all of the bags (reagent and waste) are

OPEN so that fluid can be pumped within the system. Failure to open ALL pinch clamps will result

in total failure and may damage the pumps.

After this check list has been completed, assemble the 9600 by following the instructions below:

• Place the outer shell of the monitor on the floor near the carousel.

• Lift the carousel by the bail, raising it above the top of the outer shell as shown in the picture below:

• Slide the carousel into the outer shell making sure that the two rectangular indentations on the top plate

of the carousel are aligned with the black strips on the outside of the outer shell as shown in the

pictures below. Note carefully that the inlet filter should be on the side of the strip that has two

YSI Environmental 25 Model 9600 Nitrate Monitor

Page 26

eyebolts attached to it. The picture on the left below shows th e correct orientation; the one on the

right shows the incorrect placement of the carousel within the outer shell.

CAUTION: Make certain that no sections of tubing are pinched between the outer shell and the

carousel during the assembly process.

• With the carousel supported by the outer shell and the top plate slots aligned with the outer shell strips,

press down on the top plate until the outer shell is seated in the circular slot on the carousel top plate

and the four (4) side screw holes in the strips on the outer shell are aligned properly with the holes in

the top plate.

• Install the four screws that were set aside in the disassembly process described in Section 2.1 above.

Use either a standard Phillips head screwdriver for this process or a battery powered driver with a

Phillips bit.

CAUTION: If a power driver is used, make sure that it is on a minimal torque setting to avoid

overtightening the screws.

CAUTION: The eyebolts which are used to attach the bail to the top of the carousel are DESIGNED

TO BE AT AN ANGLE as shown in the picture below. Do NOT attempt to straighten the alignment

of the eyebolts.

Correct

Incorrect

DO NOT CHANGE ALIGNMENT

OF EYEBOLTS

YSI Environmental 26 Model 9600 Nitrate Monitor

Page 27

SECTION 3 PREPARING FOR A 9600 DEPLOYMENT

In Section 2, you set up the physical components of your Model 9600 – cadmium column, reagent bags,

and waste bags. In this section, you will learn how to install the PC software which allows interface to

your 9600, power your instrument with either a battery pack or a power supply, attach a cable to the 9600,

and establish an interface between the nitrate monitor and your PC.

3.1 INSTALLING NUVIEW PC SOFTWARE

Locate the NUview CD-ROM which was shipped as part of your 9600 package and which you unpacked in

Section 2.1 above. The CD contains a file that will install software to your PC that will allow you to interface

to the 9600 in order to:

• Configure y our inst rument for a depl oyment

• Start a depl oyment

• Interact wit h the 9600 during depl oyment s to upload data

• Stop a deployment

This software is designated NUview and the Model 9600 can ONLY be operated from a computer which is

running this software.

3.1.1 SYSTEM REQUIREMENTS

NUview software will run properly on computers with the following characteristics:

• IBM Compatible PC

• Windows

• 32 MB memory

• 20 MB available disk space

• CD-ROM Drive

• RS-232 Serial Port

• Monit o r ca pable of 800 x 600 resolution or better

3.1.2 SOFTWARE INSTALLATION

To install NUview software to your computer, perform the following steps:

• Place the NUview CD-ROM into the CD drive of your computer.

• Use Windows Explorer or My Computer to view files on the CD-ROM. Double-click on the

The display will indicate that the set-up routine is proceeding. Follow the instructions on the screen as the

installation proceeds. For most applications, the default settings should work without problems. After

installation, there is no need to restart the computer.

®

2000, or XP

Setup.exe file.

YSI Environmental 27 Model 9600 Nitrate Monitor

Page 28

3.2 CHOOSING A CABLE FOR THE 9600

Depending on your applications, several YSI cables can be used to interface your 9600 to a computer

running NUview software. The use of each of the cable types is explained below.

3.2.1 MODEL 6067B LABORATORY CABLE

The 6067B is a short cable with a slide-in connector for the 9600 communication port on one end and a

DB-9 (for serial computer connection) on the other. The cable also has an MS-4 connector which can be

used to input power to the 9600 from the optional 9689 power supply – see section 3.3.2 below for more

information on the 9689. If your applications involve the remote deployment of the 9600 where the

instrument is powered on internal batteries and then recovered for data upload, then the relativelyinexpensive 6067B is probably the ideal cable interface to your 9600. The cable can be used in the

laboratory to set up the instrument for deployments as described in Section 4 below and to upload data in

the laboratory or in the field when no provision for a water tight connection to the 9600 is required.

However, users should note the following limitation of the 6067B before choosing to purchase this cable

for use with the 9600:

• The connection between the cable and the 9600 is NOT watertight and so the cable cannot remain in

place for field deployments

To use the 6067B with your 9600, simply align the keys on the “sonde” end of the cable and the

communication port on top of the 9600 and press the connectors together. Then plug the DB-9 end of the

connector into a serial port on a computer running NUview software. To power the instrument using the

9689 power supply, connect the MS-4 connector on the 9689 to the mating connector on the cable.

3.2.2 STANDARD YSI 6-SERIES CABLES

Users of the 9600 who also have YSI 6-series field cables, su ch as the Models 6090, 6091, 6092, or 6093,

can utilize these cables for interface to the 9600 under limited conditions. These cables have a silver,

water-tight “sonde” connector with a knurled nut on one end and a smaller military-style (MS) connector

on the other end. When using these cables to interface to the 9600, the optional YSI 6095B MS-8 to DB-9

adapter must be connected to the MS-8 end of the cable. Place the MS-8 ends of the cable and adapter

together, and rotate until the alignment pins engage and the male and female portions of the connector slide

together. Once the bodies of the connectors are fully engaged, twist the knurled ring on the cable until the

two pieces lock together.

Once the cable is assembled, attach the knurled silver connector to the communication port on the top of

your 9600. Rotate the knurled end until the metal “key” engages and then tighten the connector by turning

the knurled nut clockwise using fingers only – no tools should be used.

Connect the DB-9 end of the cable assembly to a serial port of the PC on which you have installed NUview

software in Section 3.1 above.

CAUTION: Users with existing 6-series field cables should be aware of the following limitation for use

with the 9600.

• The 9600 CANNOT be powered by auxiliary devices such as the 9689 power supply, 12 volt lead acid

batteries, or data collection platforms during deployments using these cables. The current draw when

the 9600 is actually making measurements is too great for the wires in the cable.

YSI Environmental 28 Model 9600 Nitrate Monitor

Page 29

3.2.3 MODEL 9600 FIELD CABLES

As noted in Sections 3.2.1 and 3.2.2 above, the major limitation of the use of existing YSI cables with the

9600 is that the nitrate monitor CANNOT be powered externally through these cables during deployments

using the 9689 power supply, auxiliary batteries, or data collection platforms. However, special field

cables such as the 9691, 9692, and 9693 are available for use with the 9600 under these conditions. These

cables utilize heavier gauge wires than the standard YSI cables such that the 9600 can be remotely powered

for distances of up to 100 feet between the power supply and the nitrate monitor.

NOTE CAREFULLY: The 96XX series field cables can be identified by the YELLOW plastic

overmold on each of the connectors. The standard YSI 6-series cables have BLACK plastic

overmolds on the connectors.

As described above for the standard 6-series cables in Section 3.2.2, users must utilize a 6095B adapter

with the 96XX cables in order to interface to a computer running NUview software

Remember that if you will be powering your 9600 IN THE FIELD USING AUXILIARY POWER OF

ANY TYPE you will need to use a 96XX field cable – a standard 6-series cable will NOT function in this

mode.

Once you have selected the cable that is suitable for your application, proceed to the next section on

applying power to the 9600.

3.3 POWERING THE 9600

3.3.1 INSTALLING AND USING THE BATTERY PACK

For remote deployments, the Model 9600 operates off a factory sealed battery pack containing 14 alkaline

D batteries operating at an initial voltage of approximately 10.5 volts. A battery pack has been shipped

with your 9600 and will be found in the battery compartment as described above in the unpacking

instructions.

NOTE: For initial set-up of the 9600, YSI recommends using the battery pack as described below.

However, if you have purchased the Model 9689 power supply, you may also use this item to power the

instrument during the set-up process. If you wish to use the 9689 in the absence of batteries, proceed to

Section 3.3.2 below.

CAUTION: Users should use ONLY battery packs which have been purchased from YSI for use with

the 9600. Use of alternative battery packs could damage the instrument.

To properly install the Model 9600 battery pack, follow the step-by-step instructions belo w:

• With the assembled Model 9600 in a vertical position on the floor or a benchtop, locate the battery lid

on top of the instrument as shown in the picture below left:

YSI Environmental 29 Model 9600 Nitrate Monitor

Page 30

• Using your fingers only, loosen the four captive screws on the battery lid until they turn freely.

NOTE: If the screws are too tight to remove by hand, it is permissible to use a slotted screwdriver to

loosen them.

• Grasp the handle on the battery lid and pull straight up to remove it, exposing the battery compartment

as shown in the picture above right. Set the lid aside for later reassembly.

• Locate the hexagonal battery pack that is stored in the battery compartment and is shown in the picture

above right. Note that there is a cable attached to the battery pack with a 2-wire connector.

• Note that there is also a cable coming out of the side of the battery compartment that also has a mating

2-wire connector.

• Connect the two 2-wire connectors together to power the instrument from the battery pack.

• Replace the battery lid and tighten the four screws using your fingers only.

IMPORTANT: If the two battery cables are connected, then the batteries are slowly being

discharged even if the instrument is not being used actively. Therefore, for periods of inactivity

lasting more than a few hours, YSI recommends that you remove the battery lid and disconnect the

two connectors in order to maximize the lifetime of your battery pack.

Battery Lid

CAUTION: The battery lid screws are captive. Do NOT continue to turn them after the

battery lid can be removed.

Battery Pack

3.3.2 USING THE MODEL 9689 POWER SUPPLY

Although the Model 9600 has internal batteries, using the optional Model 9689 power supply for laboratory

studies and for instrument calibration and set-up is often convenient and extends battery life. The 9689 will

automatically convert line voltages of 90 to 264 VAC to 12 VDC and allows for the use of line input cords

from most countries world-wide. The Model 9689 is supplied with an American/Canadian cord.

To use the 9689, attach the four-pin connector from the power supply to the mating connector on the 6067B

cable or the 6095B adapter when using a field cable. Twist the connectors together and then simply plug

the power cord into the appropriate AC outlet. The 9600 is equipped with reverse voltage protection so

Lift

YSI Environmental 30 Model 9600 Nitrate Monitor

Page 31

that both the battery pack described in 3.3.1 above and the 9689 power supply can both be plugged in with

no concern about damage to the alkaline batteries.

CAUTION: Remember that it will ONLY be possible to power the 9600 with the 9689 for field

applications when a special 96XX cable with yellow plastic ends is used. While the 9689 can be used

with standard YSI cables for instrument set-up and data upload, it cannot be used to power the

instrument for actual field studies.

CAUTION: Note that, while physically compatible with the 9600 cables (see below), other YSI power

supplies such as the 6037, 6038, and 6123 should NOT be used with the 9600 since they do not supply

enough power to operate the pumps correctly, regardless of the cable used.

3.4 ATTACHING THE SECOND STANDARD BAG

For the Predeployment Check described in Section 4.2 below, the “sample” which is run should be

identical to the standard used for the deployment. To carry out this step, you must locate the second

standard bag which has tubing assembly attached to its middle port and which was filled with standard in

Section 2.4 above.

To install the second standard bag for the predeployment check, follow the step-by-step instructions below:

• Use the picture below to locate the inlet filter and its guard which are located on the top of the top plate

of the carousel.

• Remove the inlet filter guard by unscrewing it in a counterclockwise direction and set it aside for later

use.

• Remove the inlet filter assembly by unscrewing it in a counter clockwise direction and set it aside for

later use. Be sure to unscrew the entire assembly by grasping it close to the inlet port rather than

grasping just the filter itself.

• Lay the second standard bag on the top of the carousel and attach the white threaded fitting on its

tubing assembly to the inlet filter port as shown in the picture below. Tighten with finger pressure

only – no tools should be used.

Inlet filter and guard

YSI Environmental 31 Model 9600 Nitrate Monitor

Page 32

• Open the pinch clamp on the middle port of the second standard bag.

• Hold the bag vertically so that the ports are on the bottom and tap the middle port to cause any trapped

air to move to the bottom of the bag.

If you have followed the step-by-step instructions above, your 9600 should be:

• Equipped with full reagent bags.

• Equipped with empty waste bags.

• Reassembled with the carousel inside the outer shell.

• Have the second standard bag attached to the 9600 inlet port.

• Powered using either the internal battery pack or the 9689 power supply.

• Attached to a serial port on a PC on which you have installed NUview software.

Make certain that all of these steps are complete before proceeding to the next section where you will

interface to the 9600 using NUview software.

3.5 INTERFACING TO THE 9600

To run NUview software, click on the Windows Start button. Go to Programs>NUview and click on the

NUview icon.

The program will display the following screen.

YSI Environmental 32 Model 9600 Nitrate Monitor

Page 33

Clicking on the System selection in the top menu bar and then choosing the Select entry will display the

following screen that allows you to set up several items for later use.

Before proceeding, you should enter the following information in the System menu:

• Select a designation for your 9600 and type it in under Unit ID. This entry must be 15 characters or

less.

• Select an SDI12 address for your unit if you are going to use it with a data collection platform. YSI

recommends leaving the value at the default of zero (0) unless you have a specific reason to change it.

• Enter the date format by clicking on the arrow and selecting the preferred format.

• In time, you will be able to select from a variety of languages for the NUview menus. At the time of

release, however, only English is available, so no choice is possible for this item.

The “Board Info” data at the bottom of the display cannot be changed by the user and shows the current

versions of firmware in the two circuit boards that are present in the 9600.

Clicking on the Help|About selection in the top menu bar will display the following screen and will allow

you to ascertain the current version of NUview software on your PC.

Now proceed to Section 4 of the manual where you will begin a 9600 deployment.

YSI Environmental 33 Model 9600 Nitrate Monitor

Page 34

SECTION 4 STARTING A 9600 DEPLOYMENT

4.1 UNDERSTANDING CALIBRATION OF THE 9600

As described above, part of the reagent package of the 9600 is a standard (usually 1mg/L or higher

concentration for a 9600-02 and 1 mg/L or lower for a 9600-10) and a blank (purified water with no nitr ate

present). These reagents are run through the system periodically during a deployment providing on-board

calibration that compensates for any instrument drift. These calibration points are used to convert the

optical readings from actual samples into nitrate values in mg/L of nitrate-N. This calibration protocol is

transparent to the user.

When starting a 9600 deployment, users will have to make three choices that will affect the calibration of

the instrument during the study. These choices are input to the 9600 software in the deployment “Wizard”

which is described in Section 4.4 below.

1. The first choice is the frequency of calibration, i.e., how often the standard and blank are run during a

deployment. YSI generally recommends that calibration be carried out every 12 hours and no less

often than once every 24 hours. The number that you will enter is the number of samples between

calibration points. Thus, if you want to calibrate every 12 hours and your sample interval is 1 hour,

you would enter 12. However, if your sample interval were 30 minutes (0.5 hours) you would enter

24 to obtain a calibration every 12 hours.

2. The second choice is the concentration value for the nitrate standard in units of mg/L of nitrate-N.

YSI recommends the use of a standard with a concentration of 1 mg/L for your first deployment at a

given site. If it turns out that the nitrate levels at this location are consistently lower or higher than this

value, then you can choose standards of other concentrations for subsequent studies.

3. The final choice is your sample interval that does in fact have an indirect effect on the timing of the

calibration. A standard calibration protocol (blank and standard analyzed by the 9600 flow system)

takes slightly less than 15 minutes to complete. This means that it is not possible to run the calibration

routine between samples at the lowest allowed sample interval of 15 minutes. If a 15 minute sample

interval is selected, the calibration sequence will thus displace one data point, slightly interrupting the

continuous data stream. For sample intervals over 15 minutes, the calibration will automatically occur

between samples and a continuous data stream will be logged at the user-selected interval.

NOTE CAREFULLY: When using your 9600 with a data collection platform (DCP) via an SDI-12

interface, the MINIMUM SAMPLE INTERVAL ALLOWED IS 30 MINUTES. See Section 5.5

below for details on the setting up of your instrument for DCP interface.

More information on these selections is found in Section 4.4 below.

4.2 CHECK LIST FOR DEPLOYMENT READINESS

After interfacing to the 9600 with NUview software as described above, the following display will be

shown.

YSI Environmental 34 Model 9600 Nitrate Monitor

Page 35

4.2.1 PREDEPLOYMENT BATTERY VOLTAGE CHECK

The voltage associated with your alkaline batteries will help you to determine if you have sufficient battery

capacity prior to a deployment. To read the battery voltage, click on the System selection in the top menu

bar and the display shown below left will appear. Click on the Check Battery Voltage selection and the

current battery voltage will be displayed as shown below right.

With regard to the battery voltage, YSI recommends the following:

• Check your battery voltage before each deployment.

• Make sure that the battery voltage is at least 10.0 volts prior to any deployment of 30 days or greater.

4.2.2 PREDEPLOYMENT HARDWARE CHECK

To continue the process of setting up the 9600 for a field de pl oy ment, click on the Start Deployment button

to move to the screen shown below left. This screen is designed as a reminder to perform a critical system

check prior to moving to the next step. Carefully read each item and when you are sure that the action has

been completed, click the box to activate a check mark. Note that all items MUST be checked as shown

below right before it is possible to proceed to the next step.

YSI Environmental 35 Model 9600 Nitrate Monitor

Page 36

After all items have been checked, click the Next button to proceed to the Predeployment System Check as

described in Section 4.3 below

4.3 PREDEPLOYMENT SYSTEM CHECK

After clicking the Next button in the Check List box, the following screen will appear:

First, select the range in which you anticipate your field nitrate readings to be – 0-5 mg/L for “Normal”

readings and 5-10 mg/L for “High” readings – by clicking the proper button. Note that you should always

select the “Normal” setting when using a 9600-10 with a 10 mm detector cell.

Now make a decision on the running of a Predeployment System Check as described below.

From the above screen, you have the ability to choose one of two options:

• Run a Pre-Deployment System Check which will assure that your instrument will function correctly in

an upcoming deployment by clicking the button as shown in the figure above.

• Bypass the Predeployment System check and proceed immediately to the next portion of the

Deployment Wizard by clicking the Next button as shown in the figure below.

CAUTION: YSI strongly recommends that you perform a predeployment check prior to each

deployment. If you do NOT carry out the test, you may deploy your instrument for several days and

then find that your data is flawed because of some instrument malfunction, e.g., improperly installed

reagent bags or pinched tubing. Further, without the predeployment test, the accuracy of your data

may be compromised by the fact that you will not have calibrated the relative volumes of the sample

and standard pumps as described in Section 8.6 below. Finally, if you deploy without performing a

Predeployment Check and experience any difficulties with the system performance, it will be much

more difficult for the problem to be isolated by YSI Technical Support personnel. With this in

mind, USERS SHOULD

THE SPECIAL CONDITIONS DESCRIBED BELOW IS RELEVANT.

ALWAYS PERFORM A PREDEPLOYMENT CHECK UNLESS ONE OF

Click Here to Run

Predeployment Check

Click Here to Bypass

Predeployment Check ,

But See Caution Below

YSI Environmental 36 Model 9600 Nitrate Monitor

Page 37

• You wish to start a deployment study IN THE FIELD as described in Section 4.4 below and you have

already run (and passed) a Predeployment Check in the laboratory.

• After performing and passing the Predeployment Check and starting a deployment as described below,

you realize that a mistake has been made in one or more of the entries you made in the Predeployment

Setup Wizard as shown below. These entries include the sample interval, the file and site names, the

standard concentration, and the time for starting the deployment. Under these conditions, you should

stop the deployment and then return immediately to the Predeployment Setup screen, and then

bypassing the Predeployment Check by clicking the Next button.

• After deploying an instrument following a successful Predeployment Check and valid Predeployment

Setup entries, you return to the field, access the instrument in real-time with a laptop PC and decide

that conditions warrant a change in either file/site name (you might be moving the instrument to a new

location) or sample interval. As above, you should then stop the deployment, return immediately to

the Predeployment Setup screen, and then bypass the Predeployment Check by clicking the Next

button.

For most deployments, click the “Start Predeployment System Check” button to proceed. The following

screen will appear indicating that the predeployment check has begun. Note that a countdown timer will

indicate the progress of the test and that the test will take approximately 1 hour. If you want to stop the

test for any reason, simply click the “Cancel” button at the top of the window.

After the test is complete, one of two types of display will appear – indicating that the test was successful

or that it failed the test criteria – as shown below.

YSI Environmental 37 Model 9600 Nitrate Monitor

Page 38

If the test was passed, simply click “OK” and then click the Next button to proceed to the final set-up

screen.