YSI 705IQTS User Manual

OPERATIONS MANUAL

ba75950e02 11/2012

CarboVis 701 IQ TS

CarboVis 705 IQ TS

OPTICAL SENSOR FOR CARBON SUM PARAMETERS AND TOTAL SUSPENDED SOLIDS (TSS)

CarboVis 70x IQ TS

For the most recent version of the manual, please visit www.ysi.com.

Contact YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Copyright © 2012 Xylem Inc.

2 ba75950e02 11/2012

CarboVis 70x IQ TS Contents

CarboVis 70x IQ TS - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 How to use this component operating manual . . . . . . . . 1-1

1.2 Fields of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Measuring principle of the UV-VIS sensor . . . . . . . . . . . 1-2

1.4 Structure of the UV-VIS sensor . . . . . . . . . . . . . . . . . . . 1-3

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Safety information in the operating manual . . . . 2-1

2.1.2 Safety signs on the product . . . . . . . . . . . . . . . .2-1

2.1.3 Further documents providing safety information 2-1

2.2 Safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Requirements for safe operation . . . . . . . . . . . . 2-2

2.2.3 Unauthorized use . . . . . . . . . . . . . . . . . . . . . . . 2-2

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 IQ SENSOR NET system requirements . . . . . . . . . . . . . . 3-1

3.2 Scope of delivery of the CarboVis 70x IQ TS . . . . . . . . . 3-1

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.1 Mounting the sensor . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.2 Mounting the shock protectors . . . . . . . . . . . . . 3-4

3.3.3 Connecting the sensor to the IQ S

3.4 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.1 General information . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.2 Sensor structure . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.4.3 Settings for the main sensor . . . . . . . . . . . . . . . 3-9

3.4.4 Settings for virtual sensors . . . . . . . . . . . . . . .3-12

3.4.5 Settings of the secondary sensor (TSS measure-

ment) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

ENSOR NET .3-5

4 Measuring / Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Determination of measured values . . . . . . . . . . . . . . . . 4-1

4.2 Measuring operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.2 User calibration . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.3 Sensor check/

Zero adjustment

. . . . . . . . . . . . . 4-8

ba75950e02 11/2012

0 - 1

CarboVis 70x IQ TS

5 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Sensor cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.1 Cleaning agents and accessories . . . . . . . . . . .5-1

5.2.2 General steps to be taken . . . . . . . . . . . . . . . . .5-2

5.2.3 Basic cleaning . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.2.4 Cleaning the measuring gap . . . . . . . . . . . . . . .5-4

6 Spare parts, maintenance equipment, accessories . . . .6-1

7 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

8 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.1 Measurement characteristics . . . . . . . . . . . . . . . . . . . . .8-1

8.2 Application conditions . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.3 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

8.4 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

9 Indexes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.1 Explanation of the messages . . . . . . . . . . . . . . . . . . . . .9-1

9.1.1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.1.2 Info messages . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

9.2 Status info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

10 Appendix: Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

11 Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

11.1 Ordering & Technical Support . . . . . . . . . . . . . . . . . . .11-1

11.2 Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

0 - 2

ba75950y01 11/2012

CarboVis 70x IQ TS Overview

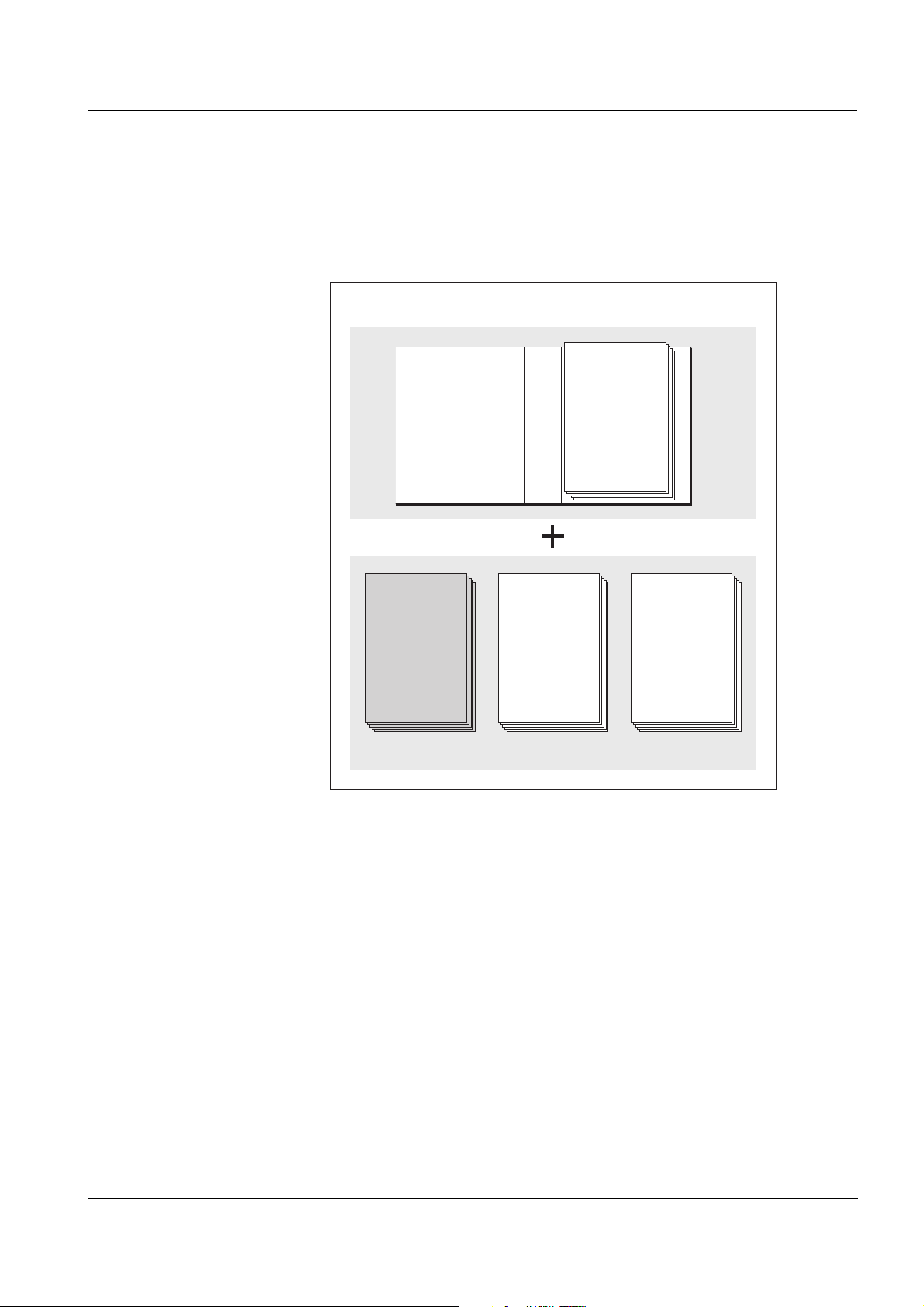

IQ Sensor Net Operating Manual

System

Operating

Manual

(Ring Binder)

IQ Sensor

Operating

Manual

MIQ Module

Operating

Manual

MIQ Terminal

Operating

Manual

Component Operating Manuals

1Overview

1.1 How to use this component operating manual

Structure of the

IQ SENSOR NET operating

manual

ba75950e02 11/2012

Fig. 1-1 Structure of the

IQ SENSOR NET operating manual

The IQ SENSOR NET operating manual has a modular structure like the

IQ S

ENSOR NET itself. It consists of a system operating manual and the

operating manuals of all the components used.

Please file this component operating manual into the ring binder of the

system operating manual.

1 - 1

Overview CarboVis 70x IQ TS

1.2 Fields of application

The range of application comprises control, feedback control and monitoring.

Measuring location

Ultrasound cleaning

system

Compressed air cleaning

(option)

CarboVis 701 IQ

TS

CarboVis 705 IQ

TS

Inlet or outlet for higher parameter values (see

section 8.1 M

EASUREMENT CHARACTERISTICS)

Outlet for lower parameter values (see section

EASUREMENT CHARACTERISTICS)

8.1 M

The ultrasound cleaning system ensures low maintenance and longterm reliable measurement operation.

The ultrasound source integrated in the sensor excites the measurement windows to produce vibrations in the ultrasound range. The

movement of the surface as a result of this prevents the growth of

pollution in almost all cases and, thus, ensures reliable measured

values during continuous operation.

The sensor is designed to be equipped with an additional compressed

air-driven cleaning system, which supports the ultrasound cleaning

system as necessary.

1.3 Measuring principle of the UV-VIS sensor

The UV-VIS sensor operates according to the measuring principle of

UV-VIS spectrometry.

1 - 2

Any substance contained in a measuring solution attenuates a light

beam that penetrates the measuring solution. The attenuation (absorbance) of the light beam is measured for different wavelengths. The

wavelength dependent distribution produces the absorbance spectrum.

The wavelength range where an absorbance occurs is characteristic of

the substance. The extent of the absorbance depends on the amount

of the substance.

The influence of typical interference matrix variants occurring at municipal waste water treatment plants can be eliminated by including the

entire absorbance spectrum.

With this measuring principle, measuring does not take place continuously but at intervals.

ba75950e02 11/2012

CarboVis 70x IQ TS Overview

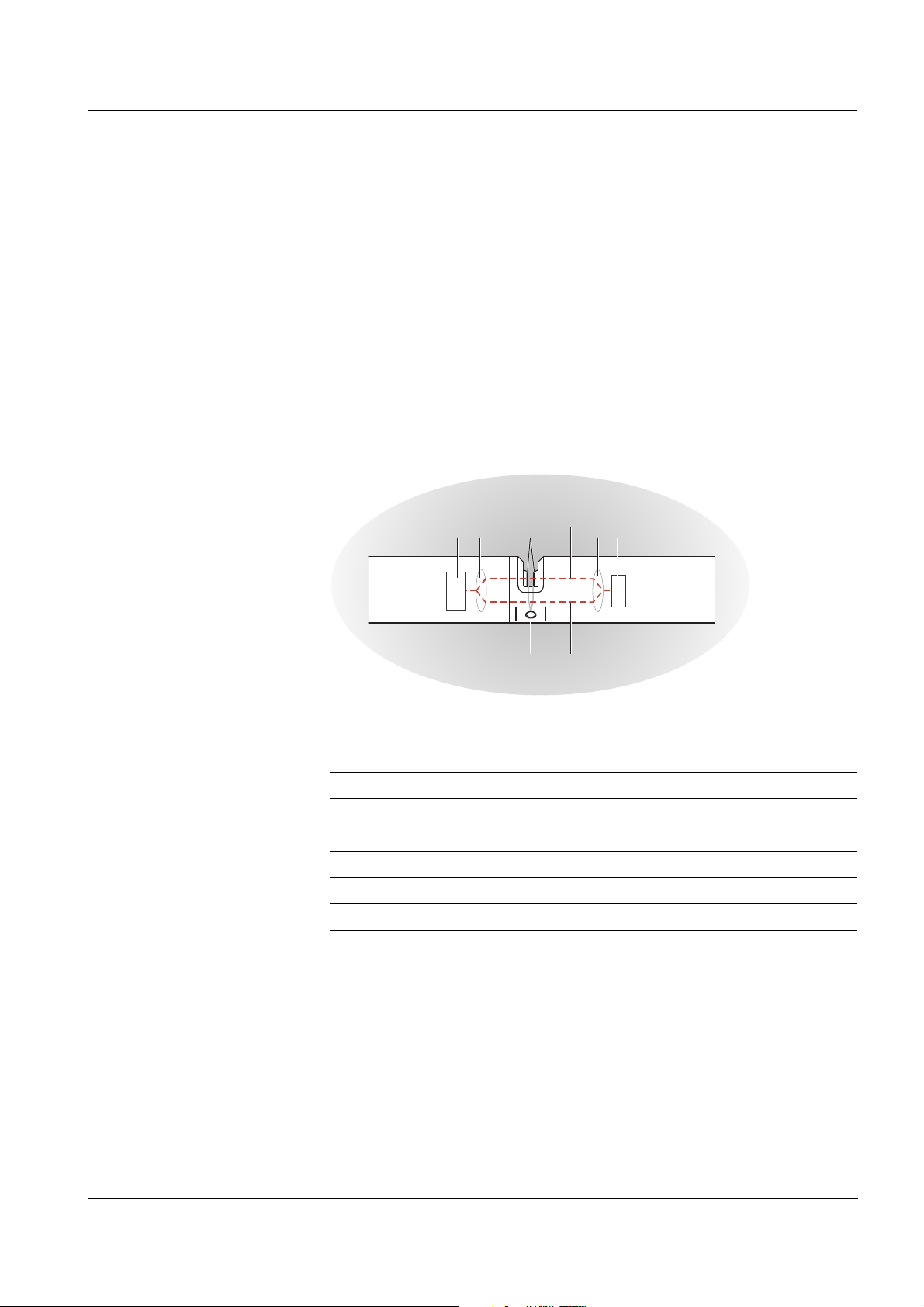

7

6

34

8

21 5

1.4 Structure of the UV-VIS sensor

A UV-VIS sensor contains a light source (1), a measuring gap (3) to

enable the contact of light with the measuring solution, and a detector

(5) to measure the attenuated light beam.

The sender of the optical system (2) directs a light beam, the measuring

beam (6), through the measuring solution and a second light beam, the

reference beam (8), over a distance without measuring solution. The

test sample is between both measurement windows (3) in the

measuring gap.

The receiver of the optical system (4) directs the measuring beam and

reference beam to the detector. In the detector, the light is received by

fixed photo diodes.

Fig. 1-2 Structure of a UV-VIS sensor

1 Light source

2 Sender of the optical system

3 Measuring gap between the measurement windows

4 Receiver of the optical system

5 Detector

6 Measuring beam

7 Reference beam

8 Connection for the optional compressed air cleaning system

ba75950e02 11/2012

1 - 3

Overview CarboVis 70x IQ TS

1 - 4

ba75950e02 11/2012

CarboVis 70x IQ TS Safety

2Safety

2.1 Safety information

2.1.1 Safety information in the operating manual

This operating manual provides important information on the safe operation of

the product. Read this operating manual thoroughly and make yourself familiar

with the product before putting it into operation or working with it. The operating

manual must be kept in the vicinity of the meter so you can always find the information you need.

Important safety instructions are highlighted in this operating manual. They are

indicated by the warning symbol (triangle) in the left column. The signal word

(e.g. "CAUTION") indicates the danger level:

WARNING

indicates a possibly dangerous situation that can lead to serious (irreversible)

injury or death if the safety instruction is not followed.

CAUTION

indicates a possibly dangerous situation that can lead to slight (reversible) injury

if the safety instruction is not followed.

Note

indicates a situation where goods might be damaged if the actions mentioned

are not taken.

2.1.2 Safety signs on the product

Note all labels, information signs and safety symbols on the product. A warning

symbol (triangle) without text refers to safety information in this operating

manual.

2.1.3 Further documents providing safety information

The following documents provide additional information, which you should

observe for your safety when working with the measuring system:

Operating manuals of other components of the IQ S

(power packs, controller, accessories)

ENSOR NET system

ba75950y01 11/2012

Safety datasheets of calibration and maintenance equipment (e.g. cleaning

solutions).

2 - 1

Safety CarboVis 70x IQ TS

2.2 Safe operation

2.2.1 Authorized use

The authorized use of the CarboVis 70x IQ TS consists of its use as a sensor in

the IQ S

the instructions and technical specifications given in this operating manual is

authorized (see chapter 8 T

thorized.

2.2.2 Requirements for safe operation

Note the following points for safe operation:

The product may only be operated according to the authorized use specified

The product may only be supplied with power by the energy sources men-

The product may only be operated under the environmental conditions men-

ENSOR NET. Only the operation and running of the product according to

ECHNICAL DATA). Any other use is considered unau-

above.

tioned in this operating manual.

tioned in this operating manual.

The product may not be opened.

2.2.3 Unauthorized use

The product must not be put into operation if:

it is visibly damaged (e.g. after being transported)

it was stored under adverse conditions for a lengthy period of time (storing

conditions, see chapter 8 T

ECHNICAL DATA).

2 - 2

ba75950y01 11/2012

CarboVis 70x IQ TS Commissioning

3 Commissioning

3.1 IQ SENSOR NET system requirements

Software statuses of the

controller and terminal

components

For cleaning with

compressed air via a relay

The operation of the CarboVis 70x IQ TS requires the following software versions in the IQ S

ENSOR NET:

DIQ/S 182 Controller software: Version 3.45 or higher

MIQ/MC2 Controller software: Version 3.37 or higher

MIQ TC 2020 XT Controller software: Version 3.37 or higher

IQ Software pack

ONNECT

C

Software version: Version 1.00 or higher

MIQ/CR3 Software version: Version 2.88 or higher

MIQ/R6 Software version: Version 2.88 or higher

MIQ/CHV PLUS Software version: Version 2.88 or higher

DIQ/S 182 (XT) Software version: Version 3.44 or higher

3.2 Scope of delivery of the CarboVis 70x IQ TS

The following parts are included in the scope of delivery of the

CarboVis 70x IQ TS:

UV-VIS sensor

Sensor sleeve

Shock protectors

Operating manual

ba75950e02 11/2012

3 - 1

Commissioning CarboVis 70x IQ TS

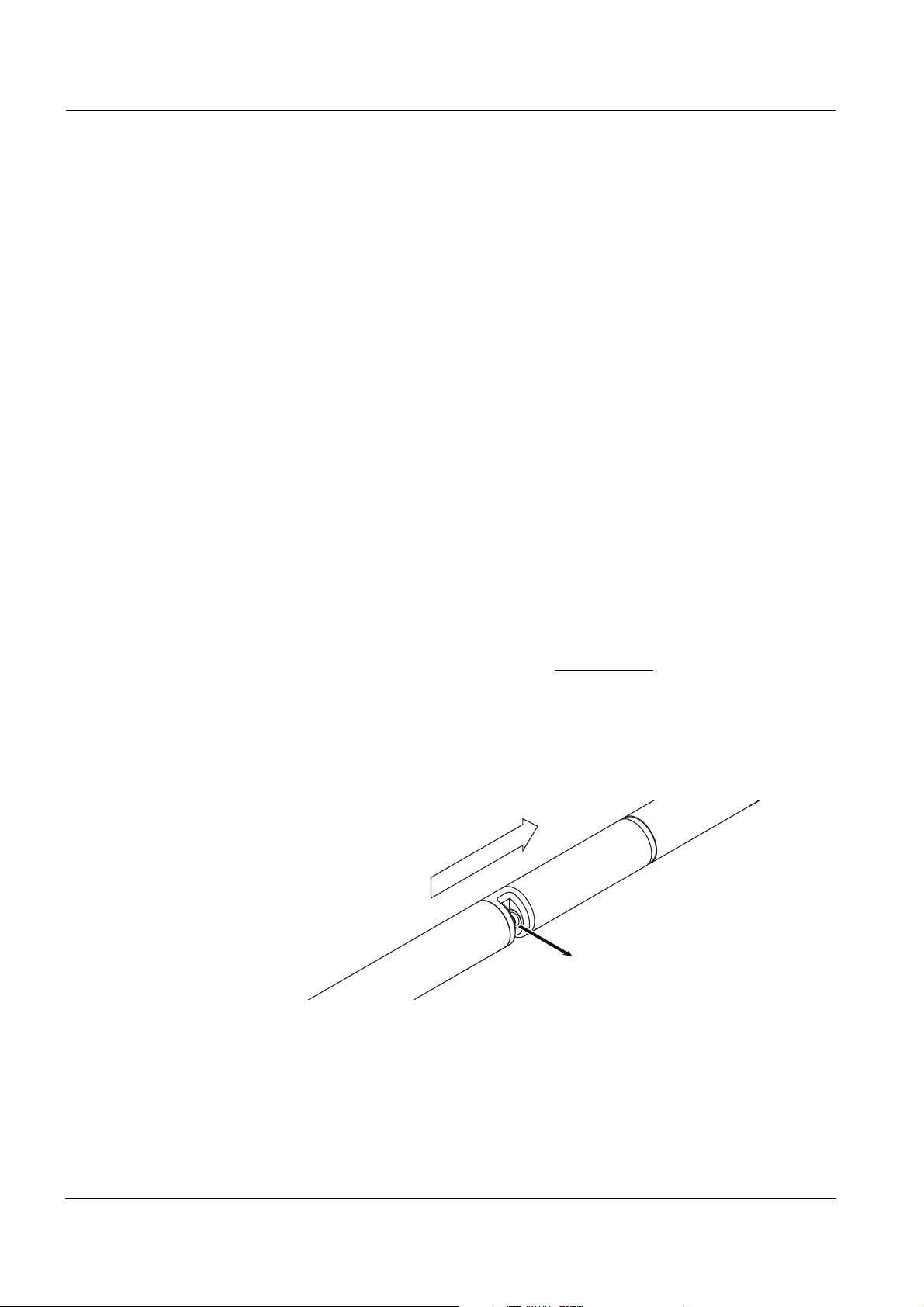

Measuring gap opening

Flow direction

3.3 Installation

3.3.1 Mounting the sensor

Note

The sensor is an optical precision instrument that is to be protected

against shocks. Make sure the distances to the wall, bottom and other

installation surroundings are sufficient. If necessary, protect the sensor

from hitting with the protective ring provided. Mount any fixing elements

only on the stable metal shaft.

Note

Always make sure the surface of the enclosure is not damaged by

sharp-edged objects. The enclosure of the sensor may not touch any

metallic objects in order to prevent contact corrosion.

Note

Do not suspend the sensor on the sensor connection cable. Risk of cable break and water penetration at the cable gland.

A wide range of mounting accessories is available for the installation of

the CarboVis 70x IQ TS (see chapter 6 S

EQUIPMENT, ACCESSORIES). Thus, all prevalent ways of mounting are

PARE PARTS, MAINTENANCE

possible.

Generally, observe the following general rules

when mounting the

sensor at the measuring location:

Horizontal installation When mounting the sensor horizontally, the measuring gap opening

should be on the side. Thus, any air bubbles can escape upward after

cleaning and no sediment can collect in the measuring gap. The sensor

should be aligned in parallel with the flow direction.

Fig. 3-1 Horizontal installation

3 - 2

ba75950e02 11/2012

CarboVis 70x IQ TS Commissioning

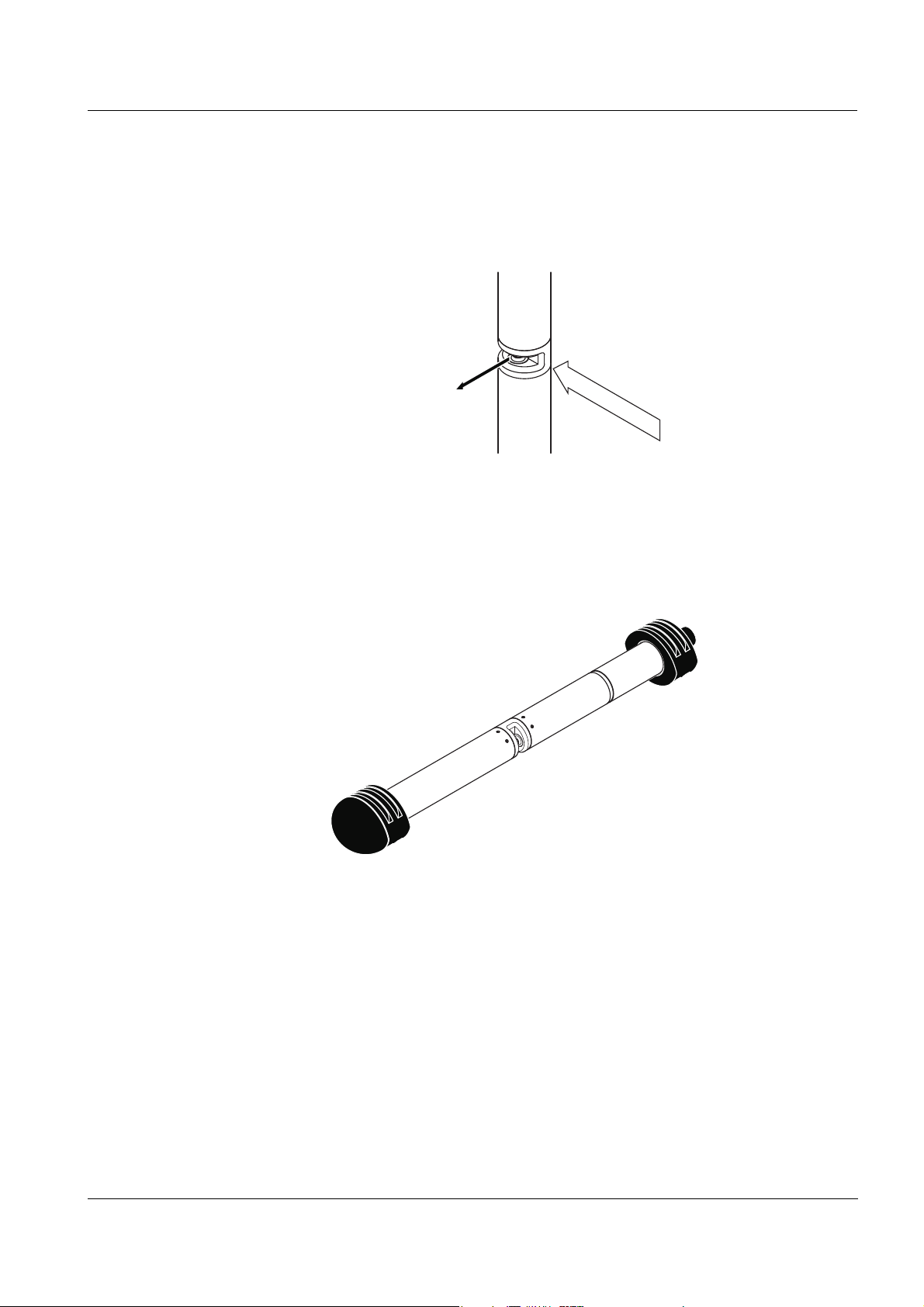

Flow direction

Vertical installation For vertical installation, mount the sensor in a position that allows inter-

fering elements in the measuring gap to escape with the current. In the

case of vertical installation, the minimum flow rate is 0.2 m/s so the

measuring gap is kept clean optimally.

Fig. 3-2 Vertical installation

Protection against shocks When installing the sensor, always make sure it cannot knock against

a wall or another obstacle. Make sure the safety margins are sufficient

(e. g. with suspended mounting).

Mount the enclosed shock protectors (see section 3.3.2). Their soft rubber compound absorbs hard impacts.

ba75950e02 11/2012

Fig. 3-3 Sensor with mounted shock protectors

3 - 3

Commissioning CarboVis 70x IQ TS

1

3

2

Sensor with mounted

shock protectors

3.3.2 Mounting the shock protectors

The shock protectors consist of two rings, a cap and four cable ties. To

mount the shock protectors, proceed as follows:

Fig. 3-4 Mounting the shock protectors

1. Plug the cap (pos. 2 in Fig. 3-4) on one of the two rings (pos. 1).

2. Put the assembled unit on the sensor end and fix it with 2 cable

ties (pos. 3) as shown in Fig. 3-4.

3. Put the second ring on the cable end of the sensor and fix it

with the remaining two cable ties in the same way.

3 - 4

ba75950e02 11/2012

CarboVis 70x IQ TS Commissioning

3.3.3 Connecting the sensor to the IQ SENSOR NET

Connection cable A sensor connection cable of the SACIQ or SACIQ SW type is required

to connect the sensor. The cable is available in different lengths.

Compared to the standard model SACIQ, the SACIQ SW sensor

connection cable is optimized regarding its corrosion resistance in

seawater and brackish water and adapted for use in conjunction with

the CarboVis 70x IQ TS . Information on this and other IQ S

ENSOR NET

accessories is given in the WTW catalog and on the Internet.

How to connect the SACIQ (SW) sensor connection cable to the terminal strip of an MIQ module is described in chapter 3 I

IQ S

ENSOR NET system operating manual.

NSTALLATION of the

Are the plug connections

dry?

Before connecting the sensor and sensor connection cable, please

make sure the plug connections are dry. If moisture gets into the plug

connections, first dry the plug connections (dab them dry or blow them

dry using compressed air).

Note

Do not suspend the sensor on the sensor connection cable but use the

suitable mounting equipment. Information on this and other

IQ S

ENSOR NET accessories is given in the WTW catalog and on the In-

ternet.

ba75950e02 11/2012

3 - 5

Commissioning CarboVis 70x IQ TS

SACIQ (SW)

1

2

Connecting the sensor to

the sensor connection

cable

1. Take the protective caps off the plug connections of the sensor

and the SACIQ (SW) sensor connection cable and keep them

safe.

2. Plug the socket of the SACIQ (SW) sensor connection cable

onto the plug head connector of the sensor. At the same time,

rotate the socket so that the pin in the plug head connector (1)

clicks into one of the two holes in the socket.

3. Then screw the coupling ring (2) of the sensor connection

cable onto the sensor up to the stop.

Fig. 3-5 Connecting the sensor

3 - 6

ba75950e02 11/2012

CarboVis 70x IQ TS Commissioning

3.4 Initial commissioning

3.4.1 General information

CAUTION

Never look into the measuring window or put objects into the measuring window during operation! The emitted UV radiation can damage the

eyes!

In the case of authorized use, inadvertent eye contact with the light

beam is not possible.

Measuring location The sensor is prepared for operation in the outlet of the waste water

treatment plant and calibrated in the factory. For use in the inlet you

only have to change the

The sensor is immediately ready to measure.

How to adjust the settings is described in the following section (section

3.4.3).

Measuring location

setting.

User calibration after initial

commissioning

On the basis of a reference measurement ("laboratory value"), check

whether the default settings deliver sufficiently accurate measured

values or whether you want to carry out a user calibration (see section

ALIBRATION).

4.3 C

ba75950e02 11/2012

3 - 7

Commissioning CarboVis 70x IQ TS

3.4.2 Sensor structure

The physical sensor is the sensor with the instrument or model designation, CarboVis 70x IQ TS. The physical sensor processes the measurement signal (absorbance spectrum) and supplies up to 5

measurement results to the IQ S

ENSOR NET. The measurement results

are administrated like 5 sensors that differ in hierarchy as follows:

Main sensor The sensor for carbon measurement is the main sensor.

It registers on the system under the designation, CarboVis 70x IQ TS

and the series number of the physical sensor.

Secondary sensor The sensor for the measurement of total suspended solids is the

secondary sensor.

It registers on the system under the designation, SolidVis 70x IQ and

the series number of the physical sensor.

Virtual sensors All other sensors for carbon measurement are virtual sensors.

You register on the system under the designation, CarboVis 70x IQ TS

and the series number of the physical sensor.

Sensor overlapping

settings and functions

Some settings and functions are sensor overlapping. Sensor overlapping settings are generally edited in the setting menu of the main sensor.

These are the most important sensor overlapping settings and functions:

Measuring location

Times of the measuring cycle (

Meas. interval, Cleaning duration, Adjustment phase

Signal smoothing

etc.)

Details on sensor overlapping functions are given in the following

section.

3 - 8

ba75950e02 11/2012

CarboVis 70x IQ TS Commissioning

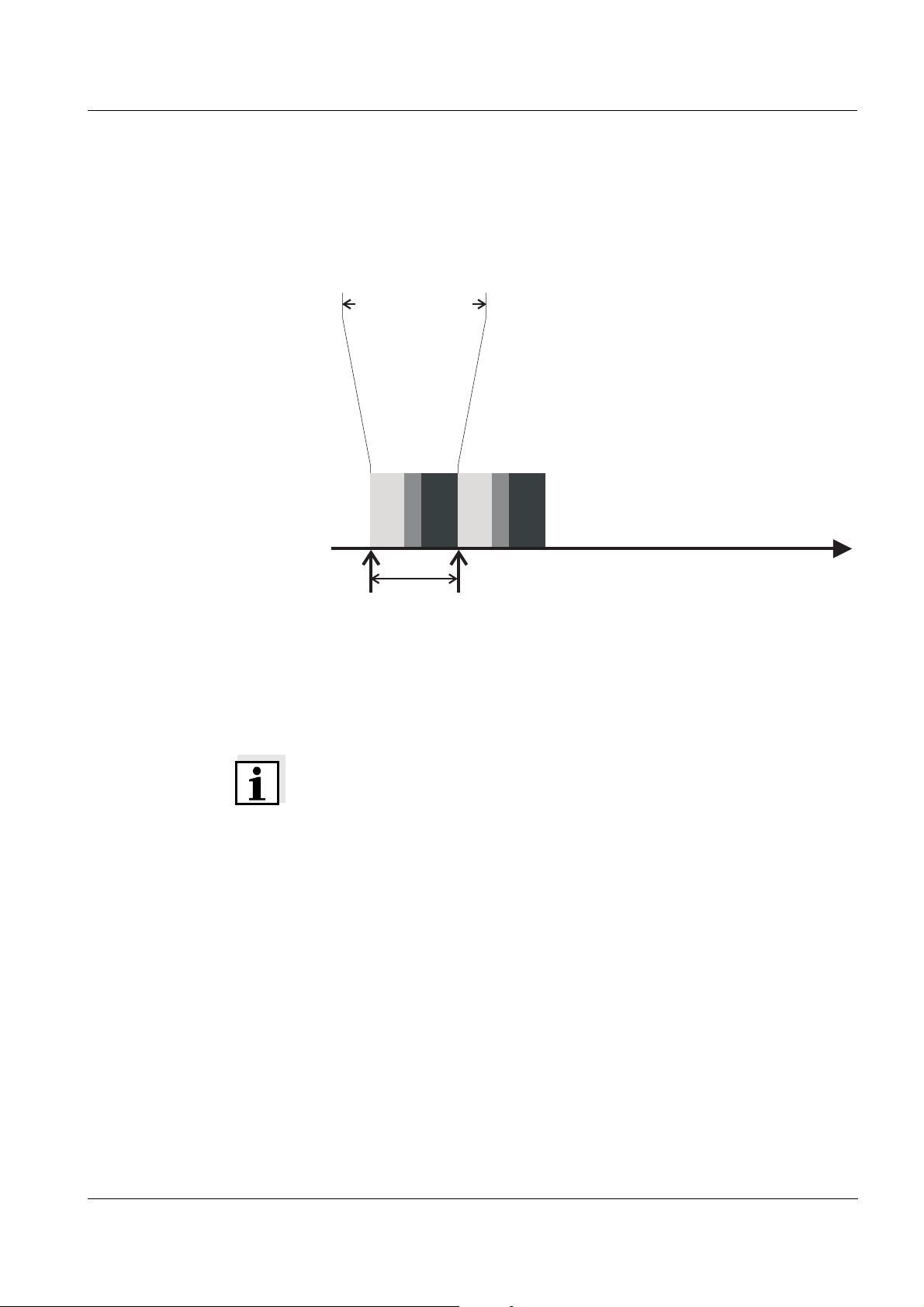

Time

Adjustment time

Measurement

Measuring

cycle

Measuring interval

Cleaning

3.4.3 Settings for the main sensor

Measuring cycle A measuring cycle consists of the cleaning procedure, the adjustment

time for the measuring system and the determination of the measured

value. The following graphic demonstrates the relevant settings:

Fig. 3-6 Measuring cycle of the UV-VIS sensor

Carrying out settings Using <S>, switch from the measured value display to the main menu

of the settings. Then navigate to the setting menu (setting table) of the

sensor. The procedure is described in detail in your IQ S

ENSOR NET

system operating manual.

A change of the following settings will take some time (up to a few minutes) until it can be seen in the measured value display:

Measuring mode

Measuring location

Number of C-sensors

Further changes can only be made when the last changes are visible

in the measured value display.

Default values are marked in bold.

ba75950e02 11/2012

3 - 9

Commissioning CarboVis 70x IQ TS

Menu item Settings Explanations

Measuring mode

Measuring location

COD spectr., total

COD spectr., dissolv

TOC spectr., correl.

BOD spectr., correl.

DOC spectr., correl.

SAC 254, total

SAC 254, dissolved

UVT 254

Outlet

Inlet

Activation

The measured parameter is displayed

in the selected citation form.

When changing the

setting, always check the

location

If the previously set measurement location is not available for the selected

measuring mode, the measurement

location is automatically changed..

Measurement location or application of

the sensor.

The possible measurement loca-

The sample matrix on which the cal-

The measurement location

can only be selected for

mode

setting.

tions are displayed depending on the

currently set measuring mode.

culation of the measured value is

based changes with the location of

the sensor.

COD spectr., dissolv

Measuring mode

Measuring

Activation

Measuring

.

Measuring range -

Cal - # raw value 1

Cal - ref. value 1

Value pairs of the user calibration (see section 4.3.2).

Note:

Leave those values unchanged during the initial commission-

ing.

Cal - # raw value 2

Cal - ref. value 2

Zero adjustment Factory

User

Signal smoothing

On

Off

Display of the measuring range

(see chapter 8 T

Setting of which zero adjustment is

used in the sensor.

Factory zero adjustment or

Zero adjustment carried out last

Switching on/off the signal smoothing.

For more details, see

t90

.

ECHNICAL DATA).

Response time

3 - 10

ba75950e02 11/2012

Loading...

Loading...