YSI 700 IQ User Manual

OPERATING MANUAL

ViSolid 700 IQ

ViSolid 700 IQ H

ViSolid 700 IQ SW

ba76040e04 05/2014

®

ViSolid

700 IQ

®

ViSolid

700 IQ SW

®

ViSolid

IQ SENSORNET TOTAL SUSPENDED SOLIDS SENSOR

700 IQ H

ViSolid®700 IQ (SW)

For the most recent version of the manual, please visit www.ysi.com.

Contact YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Copyright © 2014 Xylem Inc.

ba76040e04 05/2014

ViSolid®700 IQ (SW) Contents

ViSolid®700 IQ (SW) - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 How to use this component operating manual . . . . 1-1

1.2 Structure of the ViSolid®700 IQ (SW) total suspended solids sensor 1-2

1.3 Recommended fields of application . . . . . . . . . . . . 1-2

1.4 Features of the ViSolid®700 IQ (SW) . . . . . . . . . . 1-3

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Hazard warnings in this operating manual . 2-1

2.1.2 Safety information on the product . . . . . . . 2-1

2.2 Safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Requirements for safe operation . . . . . . . . 2-2

2.2.3 Unauthorized use . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Hazardous location use (ViSolid®700 IQ H) . . . . . 2-3

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 IQ SENSORNET system requirements . . . . . . . . . . . 3-1

3.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3.1 Safety guidelines for installation in a hazardous location

(H-models only) . . . . . . . . . . . . . . . . . . . . . 3-1

3.3.2 General information . . . . . . . . . . . . . . . . . . 3-2

3.3.3 Flow direction . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.4 Sensor angle . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.5 Sensor orientation . . . . . . . . . . . . . . . . . . . 3-4

3.3.6 Distances from the ground and wall . . . . . . 3-5

3.4 Installation examples . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.1 Measurement in an open pool or channel . 3-6

3.4.2 Measurement in pipelines . . . . . . . . . . . . . 3-8

3.5 Commissioning / Readiness for measuring . . . . . 3-10

3.5.1 Connect the sensor . . . . . . . . . . . . . . . . . 3-10

3.5.2 Selecting the Measuring mode . . . . . . . . . 3-12

3.5.3 Setting tableViSolid®700 IQ (SW) . . . . . . 3-13

4 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Measuring operation . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Calibration for TSS measurement . . . . . . . . . . . . . 4-2

4.2.1 General information . . . . . . . . . . . . . . . . . . 4-2

ba76040e04 05/2014 0 - 1

Contents ViSolid®700 IQ (SW)

4.2.2 Default calibration . . . . . . . . . . . . . . . . . . . . 4-3

4.2.3 Correction factor . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.4 User calibration . . . . . . . . . . . . . . . . . . . . . . 4-7

5 Maintenance, cleaning, accessories . . . . . . .5-1

5.1 General information . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Cleaning the sensor shaft and measurement windows 5-1

5.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

6 What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . .6-1

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.1 Measuring characteristics . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Application characteristics . . . . . . . . . . . . . . . . . . . 7-2

7.3 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.4 Instrument safety . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.4.1 General instrument safety . . . . . . . . . . . . . 7-4

7.4.2 Hazardous location ratings (H models) . . . 7-4

7.5 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

8 Indexes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.1 Explanation of the messages . . . . . . . . . . . . . . . . . 8-1

8.1.1 Error messages . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.2 Info messages . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2 Status info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

9 Contact Information . . . . . . . . . . . . . . . . . . . . .9-1

9.1 Ordering & Technical Support . . . . . . . . . . . . . . . . 9-1

9.2 Service Information . . . . . . . . . . . . . . . . . . . . . . . . 9-1

10 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

10.1 Check calibration values . . . . . . . . . . . . . . . . . . . 10-1

0 - 2 ba76040e04 05/2014

ViSolid®700 IQ (SW) Overview

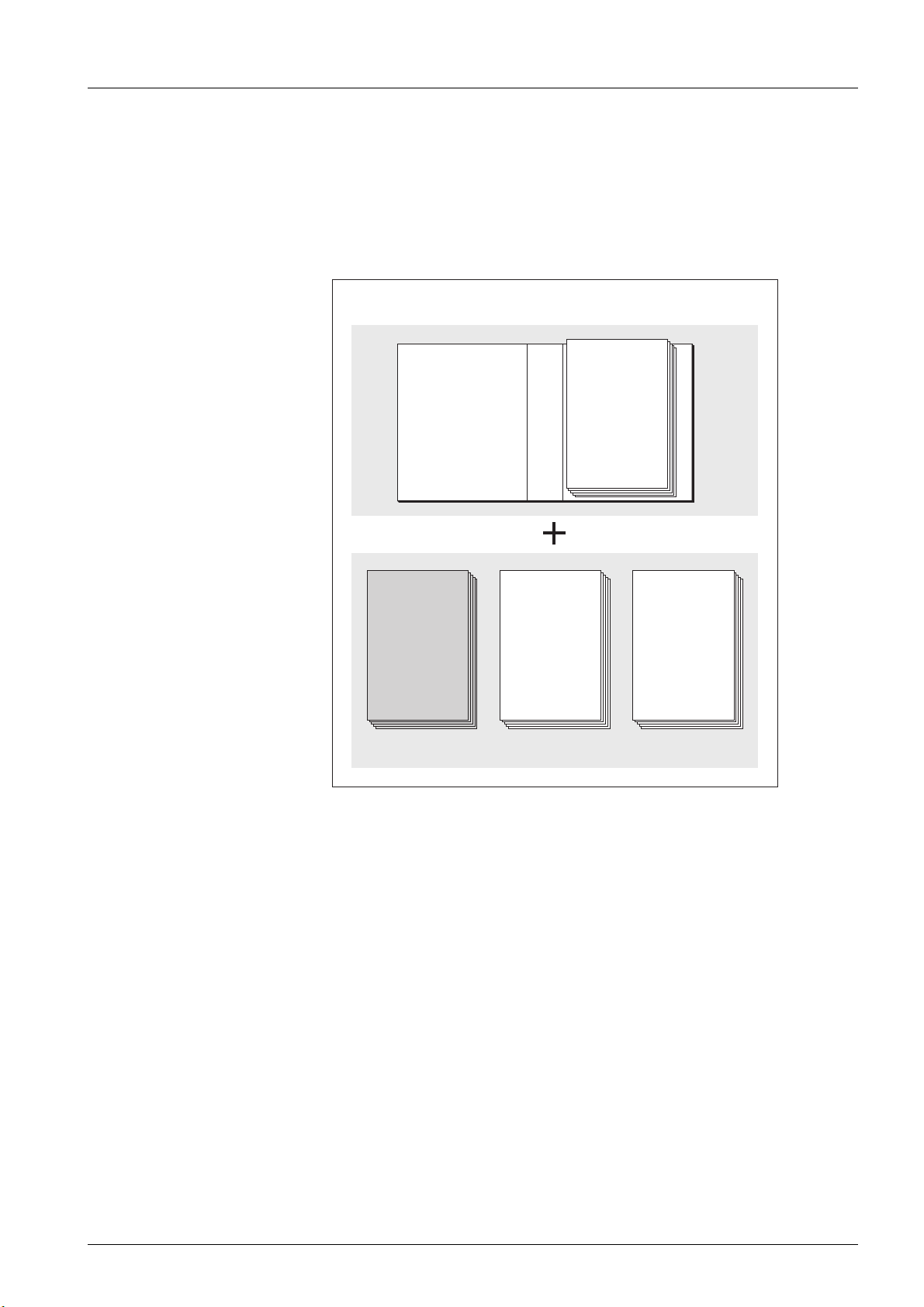

IQ Sensor Net Operating Manual

System

Operating

Manual

(Ring Binder)

IQ Sensor

Operating

Manual

MIQ Module

Operating

Manual

MIQ Terminal

Operating

Manual

Component Operating Manuals

1Overview

1.1 How to use this component operating manual

Structure of the

ENSORNET operating

IQ S

manual

Fig. 1-1 Structure of the IQ SENSORNET operating manual

The IQ SENSORNET operating manual has a modular structure like the

ENSORNET system itself. It consists of a system operating manual

IQ S

and the operating manuals of all the components used.

Please file this component operating manual into the ring binder of the

system operating manual.

ba76040e04 05/2014 1 - 1

Overview ViSolid®700 IQ (SW)

3

12

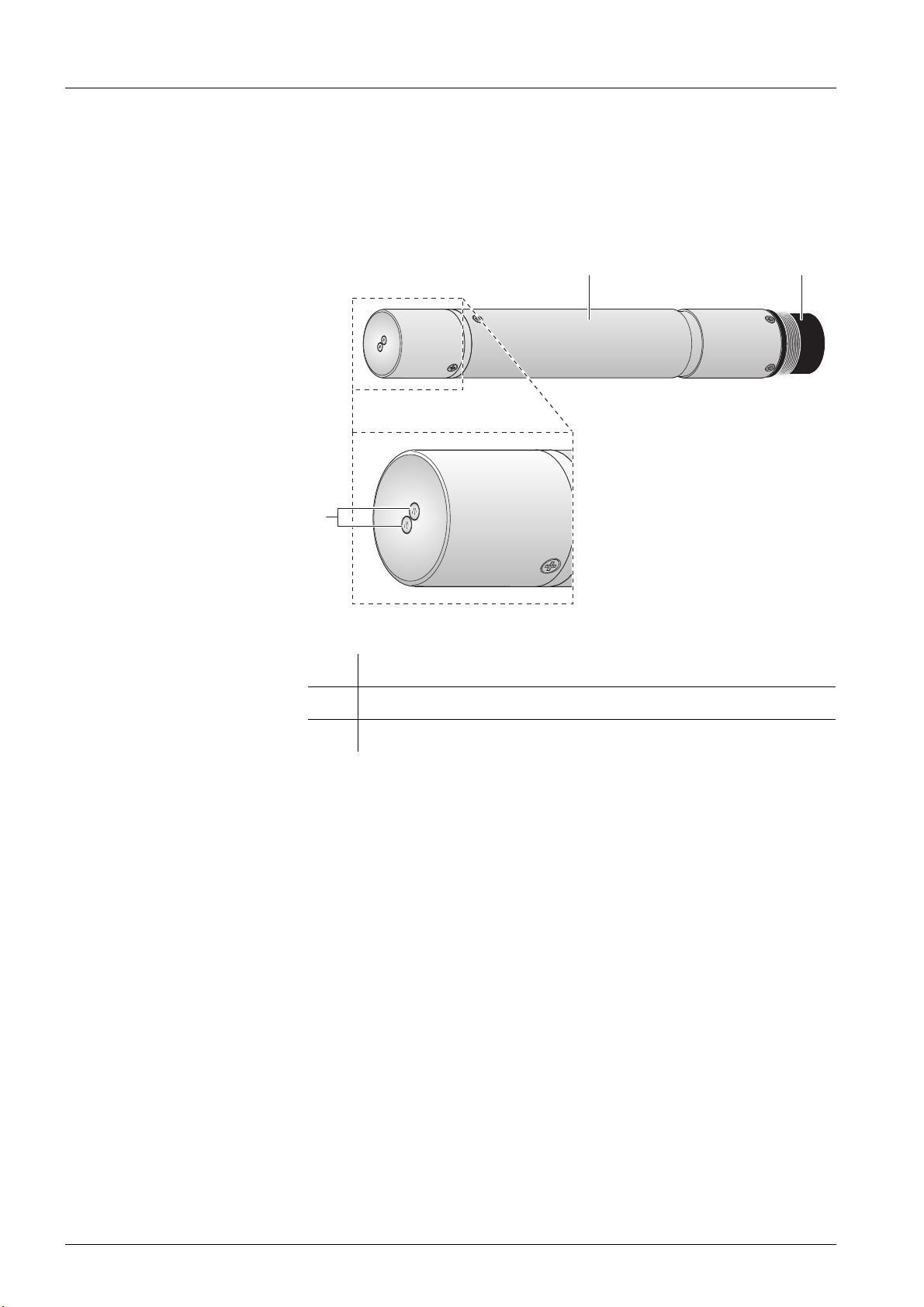

1.2 Structure of the ViSolid®700 IQ (SW) total suspended solids sensor

Fig. 1-2 Structure of the total suspended solids sensor (example: ViSolid®700 IQ)

1Shaft

2 Connection head

3 Optical measurement window made of sapphire

1.3 Recommended fields of application

ViSolid® 700 IQ Stationary measurement of the total suspended solids in slurries and in

water/wastewater applications.

ViSolid

®

ViSolid

700 IQ SW Stationary measurements in seawater and brackish water, aquacul-

ture.

The ViSolid

®

700 IQ (SW) is particularly well suited for applications in

polluted measuring media, e.g. in wastewater treatment plants, thanks

to its robust construction and its efficient ultrasound cleaning system. It

provides very high measurement accuracy with low maintenance costs.

®

700 IQ H Stationary measurements in water/wastewater applications in Class I

Division 2 hazardous locations.

1 - 2 ba76040e04 05/2014

ViSolid®700 IQ (SW) Overview

1.4 Features of the ViSolid®700 IQ (SW)

Total suspended solids

measurement

The measurement of the total suspended solids in aqueous media with

®

the ViSolid

700 IQ (SW) is carried out as a scattered light measurement. This records the suspended proportion of total suspended solids

(TSS).

Ultrasound cleaning

system

The ultrasound cleaning system ensures low maintenance and longterm reliable measurement operation.

The ultrasound source integrated in the sensor excites the front face

containing the measurement windows to oscillations in the ultrasound

range. The resulting movement of the surface prevents the growth of

pollution right from the start and, thus, ensures reliable measured

values during continuous operation.

AutoRange function Within the enormously large measuring range (0 - 40000 mg/l SiO2

and 0 - 40000 mg/l TSS depending on the measured material), the

AutoRange function selects the optimum resolution for the respective

measured value.

SensCheck function This monitoring function that is integrated in the sensor is used to

continually check the sensor function and to register any malfunctions

caused by the measuring medium. The correct operation of the ultrasound cleaning system is also continuously monitored.

ba76040e04 05/2014 1 - 3

Overview ViSolid®700 IQ (SW)

1 - 4 ba76040e04 05/2014

ViSolid®700 IQ (SW) Safety

2 Safety

2.1 Safety information

2.1.1 Hazard warnings in this operating manual

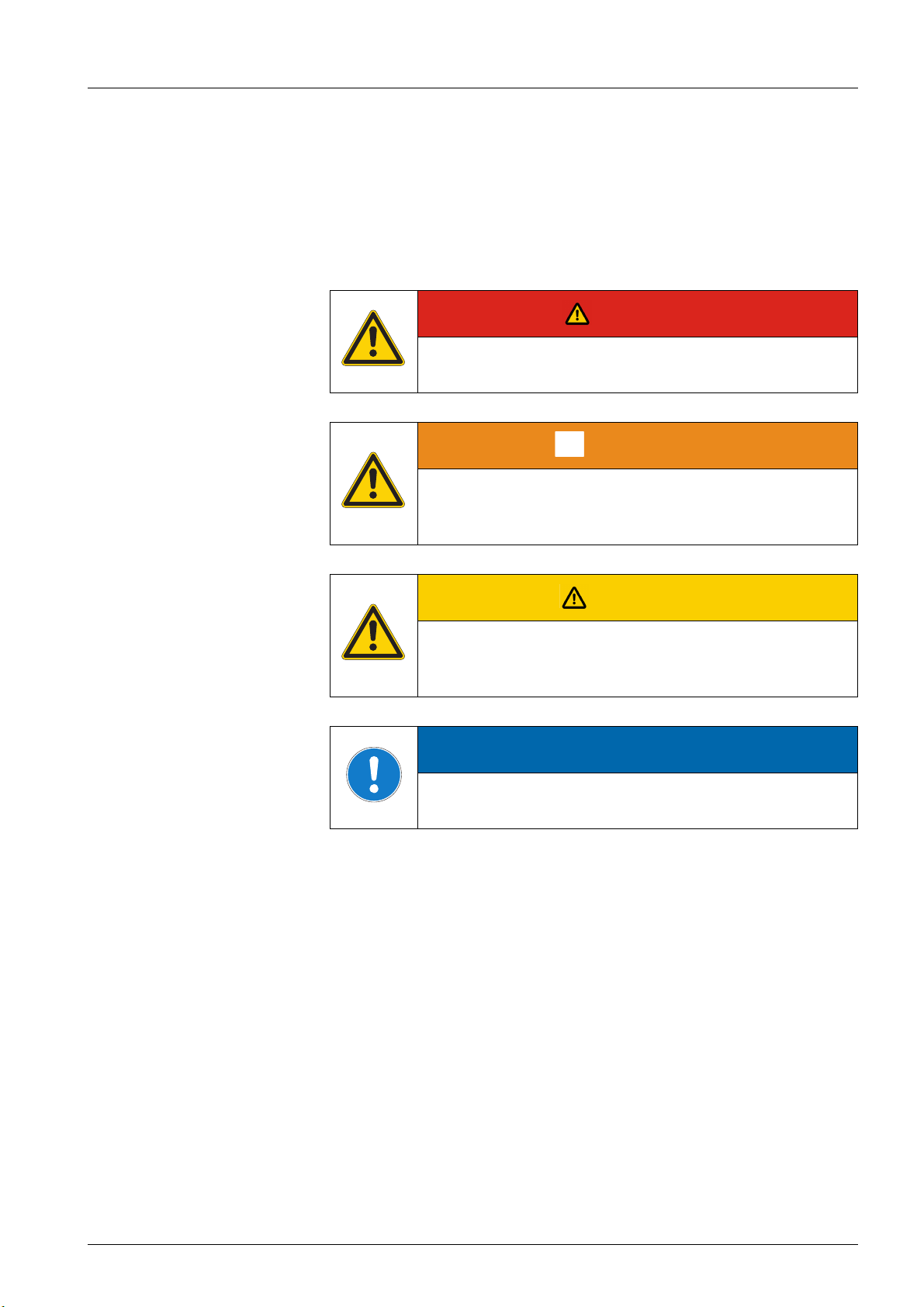

The hazard warnings are defined for the following levels of danger:

DANGER

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

NOTICE

NOTICE is used to address practices not related to per-

sonal injury.

2.1.2 Safety information on the product

Note all labels, information signs and safety symbols on the product.

ba76040e04 05/2014 2 - 1

Safety ViSolid®700 IQ (SW)

2.2 Safe operation

2.2.1 Authorized use

The authorized use of the ViSolid

a total suspended solids sensor in the IQ S

®

700 IQ (SW) consists of its use as

ENSORNET.

Please observe the technical specifications according to chapter 7

ECHNICAL DATA. Only operation according to the instructions given in

T

this operating manual is considered to be authorized.

Any other use is considered to be unauthorized. Unauthorized use

invalidates any claims with regard to the guarantee.

NOTICE

The sensor warms up during operation in the air.

Consequently, pollution can collect in the vicinity of

the measurement window due to the evaporation of

liquid. Therefore, avoid any lengthy operation in the

air.

2.2.2 Requirements for safe operation

Note the following points for safe operation:

The product may only be operated according to the authorized use

specified above.

The product may only be supplied with power by the energy sources

specified in this operating manual.

The product may only be operated under the environmental condi-

tions specified in this operating manual.

The product or its components may only be opened if this is required

for installation and maintenance work and described in the operating

manual.

2.2.3 Unauthorized use

The product must not be put into operation if:

it is visibly damaged (e.g. after being transported)

it was stored under adverse conditions for a lengthy period of time

(storing conditions, see chapter 7 T

ECHNICAL DATA)

2 - 2 ba76040e04 05/2014

ViSolid®700 IQ (SW) Safety

######

######

######

ViSolid 700 IQ H

28124

#########

###############

####################

#################

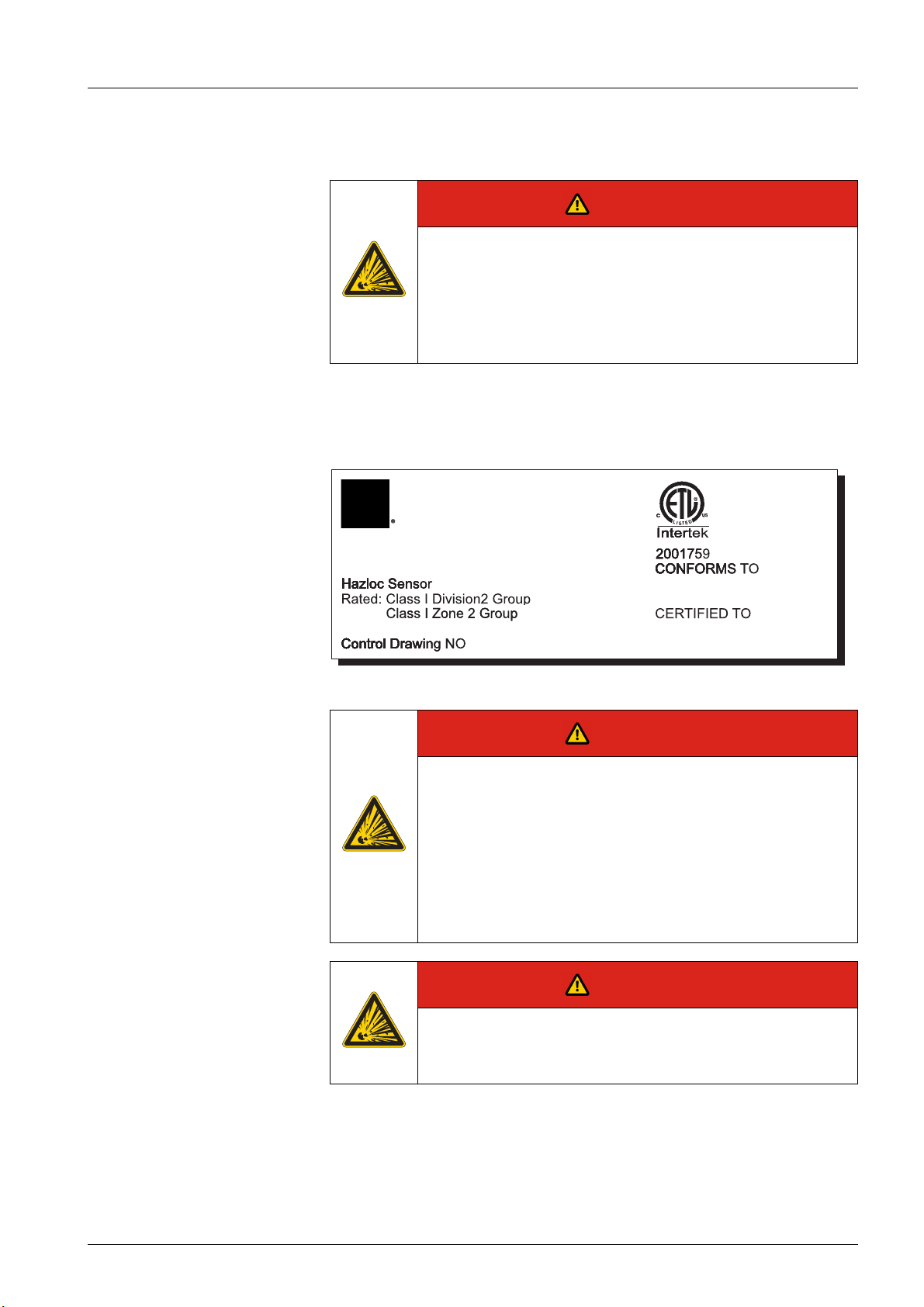

2.3 Hazardous location use (ViSolid®700 IQ H)

DANGER

Explosion hazard.

Only hazardous location rated sensor models

("Hazloc Sensor") must be used in hazardous

locations. Read the name plate on the sensor shaft

and verify that the sensor is rated for your specific

application.

Rated sensor models The ViSolid

location use. Hazardous location rated sensors are identified by the

name plate with the rating details engraved on the sensor shaft:

Name plate of a Hazloc

sensor (example)

®

700 IQ H (YSI-Order No. 207012Y) is rated for hazardous

DANGER

Explosion hazard.

The associated apparatus MIQ/BB2 (YSI part no.

207002Y) has to be used for connection. Refer to the

following documents for proper installation:

Control drawing, YSI document no. 28124

(see MIQ/BB2 operating manual)

MIQ/BB2 operating manual

All applicable electrical code regulations.

ba76040e04 05/2014 2 - 3

DANGER

Explosion hazard.

This product does not meet the requirements of the

directive 94/9/EC (ATEX).

Safety ViSolid®700 IQ (SW)

2 - 4 ba76040e04 05/2014

ViSolid®700 IQ (SW) Commissioning

3 Commissioning

3.1 IQ SENSORNET system requirements

Software statuses of the

controller and terminal

components

The operation of the ViSolid®700 IQ (SW) requires the following software versions in the IQ S

MIQ/MC2 Controller software: Version 3.42 or higher

MIQ/TC 2020 XT Terminal software: Version 3.42 or higher

DIQ/S 182 Controller software: Version 3.47 or higher

®

ViSolid

700 IQ (SW) Sensor software: Version 2.50 or higher

ENSORNET:

3.2 Scope of delivery

Total suspended solids sensor, ViSolid®700 IQ (SW)

Operating manual

3.3 Installation

3.3.1 Safety guidelines for installation in a hazardous location

(H-models only)

DANGER

Explosion hazard.

Only hazardous location rated sensor models

("Hazloc Sensor") must be used in hazardous

locations. Verify the rating on the product name

plate on the sensor shaft.

The associated apparatus MIQ/BB2 (YSI part no.

207002Y) has to be used for connection. Refer to the

following documents for proper installation:

Control drawing, YSI document no. 28124

(see MIQ/BB2 operating manual)

MIQ/BB2 operating manual

All applicable electrical code regulations.

ba76040e04 05/2014 3 - 1

Commissioning ViSolid®700 IQ (SW)

3.3.2 General information

®

The measuring principle of the ViSolid

700 IQ (SW) (scattered light

measurement) places specific requirements on the measurement location and on the installation of the sensor.

If there is a low level of total suspended solids (< 2000 mg/l SiO2 or

< 1000 mg/l TSS), infrared light penetrates deep into the sample. Thus,

the measuring environment can have a significant effect on the measured value displayed. Light that is reflected or scattered by the ground

or wall can strike the detector in the sensor and, thus, simulate an

increased level of total suspended solids.

Scattered light can be kept away from the measurement windows to a

great extent by favorable positioning of the sensor. Therefore, an optimum installation position is particularly important for the measurement

of lower values of total suspended solids.

Always maintain a distance of at least 10 cm from the

ground and wall.

The following factors affect the measurement of the TSS contents:

Inclination of the sensor (see section 3.3.4)

Sensor orientation around its longitudinal axis (see section 3.3.5)

Distances from the ground and wall (see section 3.3.6)

Light-colored, heavily light-scattering surfaces in the measuring ves-

sel (e.g. vessel inner surfaces) or in the measuring environment.

Unfavorable geometry of the measuring vessel or unfavorable posi-

tioning of the sensor in the measuring vessel.

Spatial proximity of two optical sensors.

Very bright ambient light at the measuring location, e.g. direct sun-

light in the open channel

3 - 2 ba76040e04 05/2014

ViSolid®700 IQ (SW) Commissioning

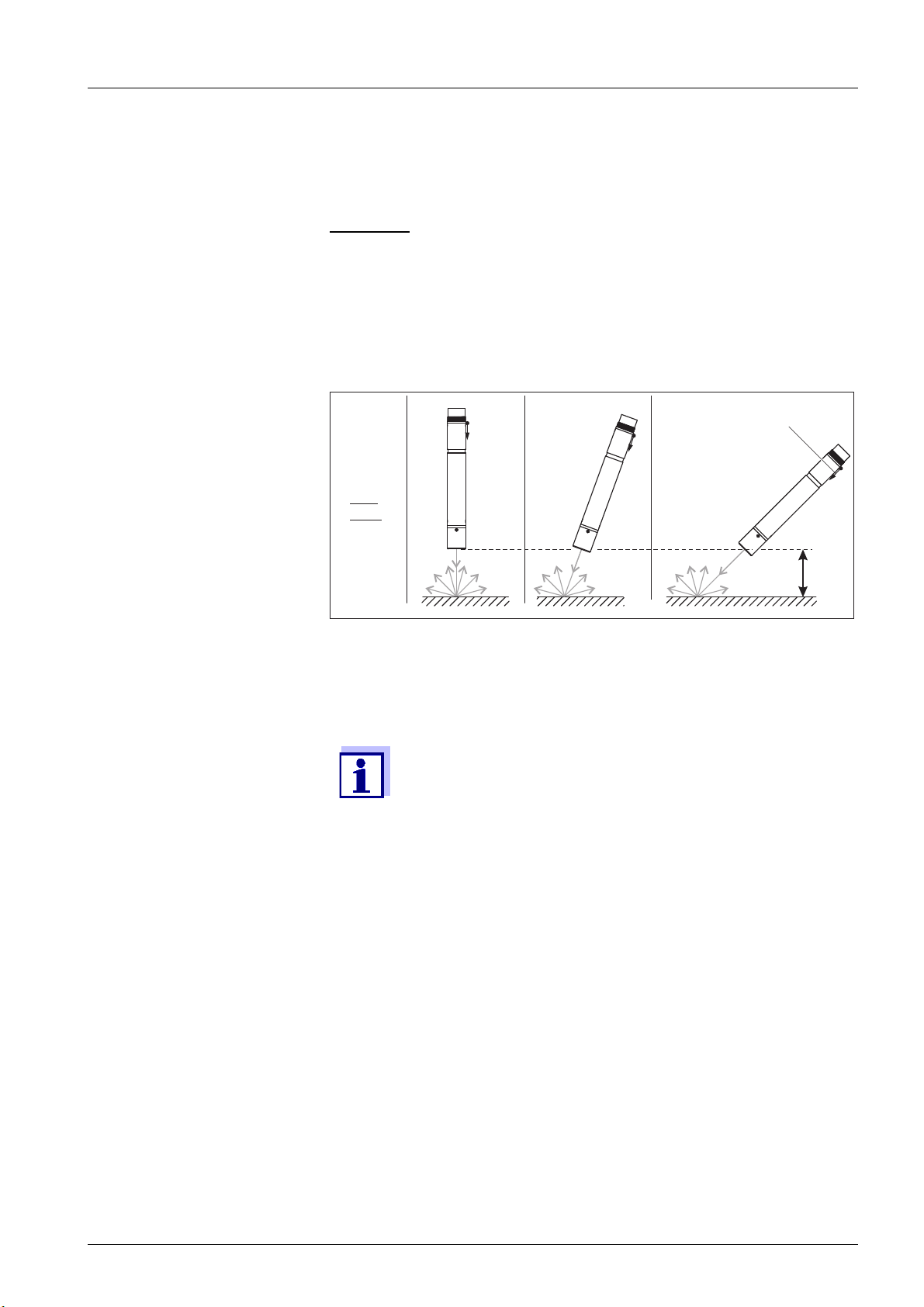

0 ° 20 ° 45 °

10 cm

Side

view:

Marking

3.3.3 Flow direction

Generally, in flowing media, the measurement window should be

clearly pitched towards the flow (angle of incidence approx. 20 to 45 °).

Exception:

If there is a high proportion of foreign bodies with fibrous or

flat profiles such as, e.g. hair, twines or foliage, it can be advantageous

to tilt the sensor in the direction of flow so that the measurement

window is turned away from the flow.

3.3.4 Sensor angle

Fig. 3-1 Effect of the sensor angle on scattering and reflection from the ground and

wall

Scattering and reflection are lowest at a sensor angle of

45° and at a minimum distance of 10 cm to the ground and

walls (see section 3.3.6).

ba76040e04 05/2014 3 - 3

Commissioning ViSolid®700 IQ (SW)

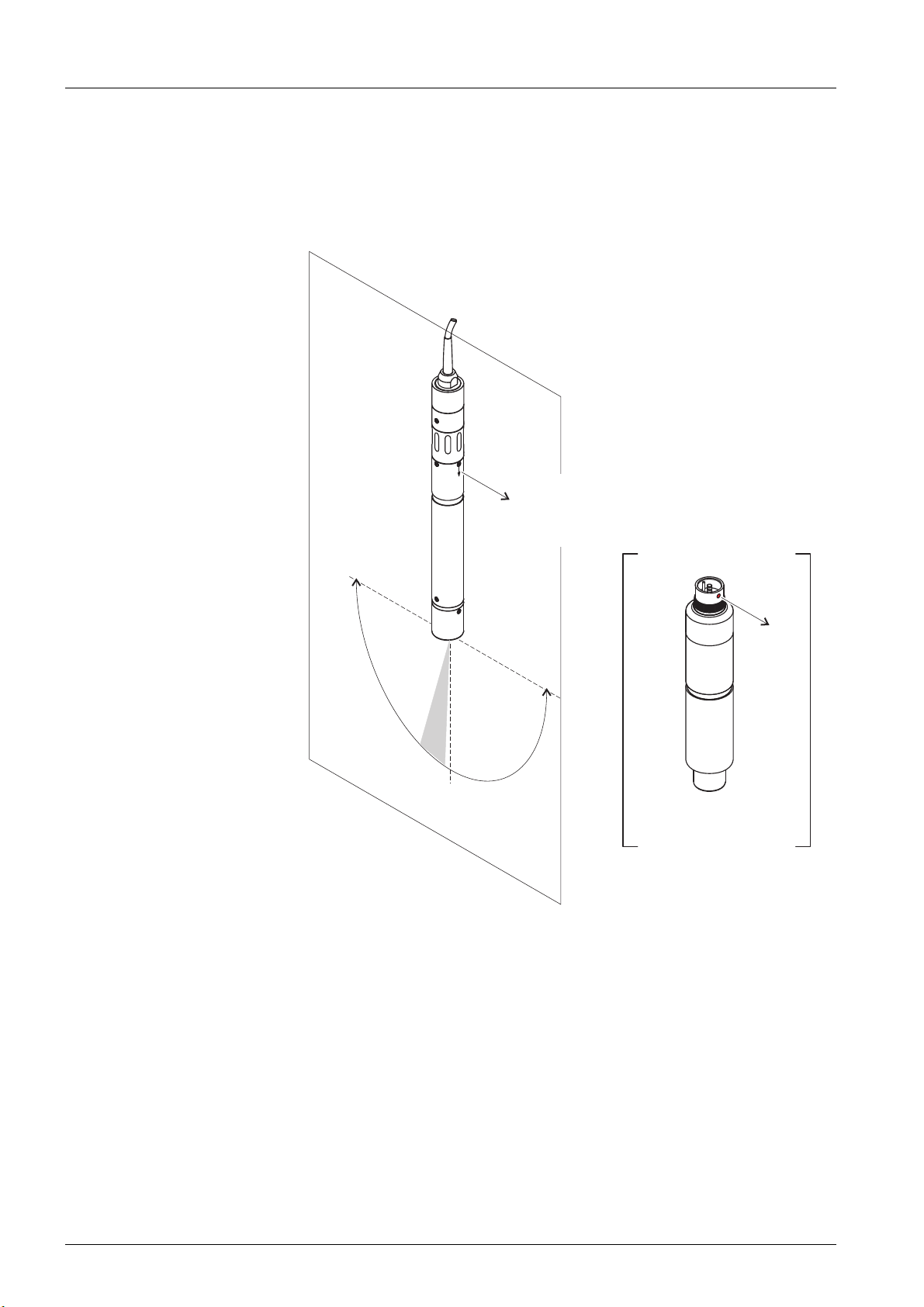

Marking

in this

direction

Infrared beam

ViSolid 700 IQ SW

3.3.5 Sensor orientation

The sensor has a marking (arrow symbol on the shaft or glue dot on

connection head). The infrared beam emerges from the front of the

sensor at a small angle in the direction opposite the marking.

3 - 4 ba76040e04 05/2014

Fig. 3-2 Direction of the infrared beam relative to the marking

The angle of incidence to the ground and walls can be affected by

rotating the sensor around its longitudinal axis. The sensor should be

turned so that as little light as possible that is scattered or reflected by

the wall or ground strikes the measurement window again.

ViSolid®700 IQ (SW) Commissioning

Pretended additional amount of

total suspended solids [1000 mg/l SiO2]

Distance x [cm]

2.0

0,9

1.6

0,7

1.2

0,5

0.8

0,3

0.4

0,1

0

048121620

24

28 32 36 40

Aluminium (in drinking water each)

x

Aluminium (in water with 1000 mg/l SiO2)

Black plastic material

3.3.6 Distances from the ground and wall

If there is a low level of total suspended solids (< 2000 mg/

l SiO2 or < 1000 mg/l TSS), the effects of the measurement

environment can simulate a higher content of total sus-

pended solids. The effect of the measurement environment

can be reduced by ensuring the optimum conditions (see

section 3.3.2).

The following graphic indicates the minimum distances of the measurement windows to the ground or wall, which must be observed. The

effect of the distances on the measured value has been determined for

various wall materials (aluminum, black plastic) in the case of a sensor

placed vertically to the wall in drinking water or water with 1000 mg/l

SiO2.

ba76040e04 05/2014 3 - 5

Fig. 3-3 Effect of ground and wall distances on the measurement of TSS

At low levels of total suspended solids, a minimum distance

of at least 10 cm must be kept from the ground or wall.

If an optimum installation is not possible due to the struc-

tural conditions at the measuring location (e.g. in narrow

pipelines), the effects of the measurement environment

can be compensated by user calibration (see section

4.2.4).

Commissioning ViSolid®700 IQ (SW)

3.4 Installation examples

As a rule, the ViSolid®700 IQ (SW) will measure interference-free

when the distances and angles etc. specified are observed. However,

interferences at the measuring location (see section 3.3.2) may require

special adaptations of the installation.

3.4.1 Measurement in an open pool or channel

Measurement in a pool The total suspended solids sensor can be suspended in the pool on a

chain (e.g. with EH/F 170 swing mounting assembly and EH/U 170

sensor holder). Make sure the sensor cannot bump against any walls

or obstacles.

Alternatively, the sensor can be immersed in the sample using a

pendulum mounting assembly, e.g. EH/P 170 pendulum mounting

assembly, (please note the minimum immersion depth).

3 - 6 ba76040e04 05/2014

Loading...

Loading...