York ZX, ZY Technical Guide

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

1068152-YTG-A-1013

TECHNICAL GUIDE

ZX/ZY SERIES

3 - 12.5 TON

60 HERTZ

1068152-YTG-A-1013

2 Johnson Controls Unitary Products

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Factory Installed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Field Installed Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

AHRI COOLING RATING TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Capacity Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Airflow Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Power Exhaust Blower Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Economizer Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

GUIDE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Product Highlights

• Assembled in Norman, OK

• ASHRAE 90.1 Compliant

• R-410A Refrigerant

• Cooling Only and Gas/Electric configurations available

• Scroll Compressors

• Up to 15.4 SEER and 12.2 EER on the Energy Star

Compliant Energy Level

• Up to 13.0 SEER and 11.2 EER on the ASHRAE 90.1

Compliant Standard Efficiency Level

• State of the art Microprocessor Controls with specific

programming for unitary product applications

• MicroChannel Condenser Coils

• Evaporator coils utilize copper tube/aluminum fin design

for proven reliability and performance.

• TXV (ASHRAE 90.1 Compliant Standard Efficiency Level

5 - 12.5 ton models and Energy Star Compliant Efficiency

Level 3 - 10 ton models)

• Single-stage (3 -6 ton models)

• Two-stage (7.5 - 12.5 ton models)

• Alternate Motor and Drives

Options and Accessories

• Economizers with Barometric Relief

• Louvered Hail Guards

• Non-fused Disconnect

• Power Exhaust

• Propane Heating Conversion Kits

• High Altitude Heating Conversion Kits

• Flue Exhaust Extension Kit

• Flue Heat Shield

• Optional Stainless Steel Heat Exchanger (Standard on 3-

5 Ton Low-NOx Models)

• Thru-The-Base Connections for power, gas and control

wiring.

• IntelliSpeed

TM

with Premium Efficiency indoor motors to

meet ASHRAE 90.1-2010 requirements (10-12.5 ton

models)

1068152-YTG-A-1013

Johnson Controls Unitary Products 3

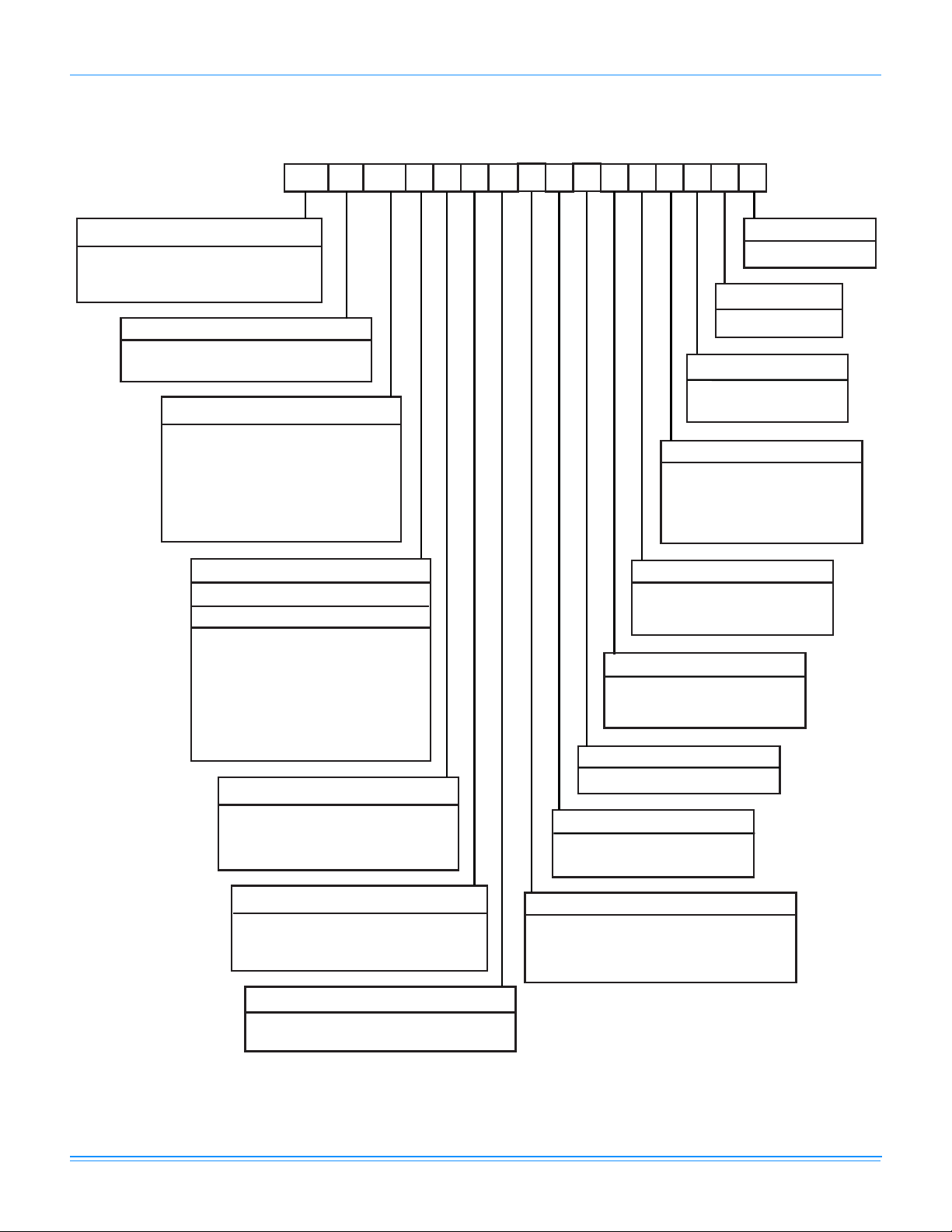

Component Location

Cooling With Gas Heat (3 Through 5 Ton)

Click on the letters to see a description of the features.

B

D

E

F

G

H

J

A

B

C

E

F

G

1068152-YTG-A-1013

4 Johnson Controls Unitary Products

Features and Benefits

Two Tiers of Efficiency - Entry level efficiency provides a cost

effective 13 SEER/11.2 EER product that meets the ASHRAE

90.1 requirements. The Mid-efficiency

meetsthe

requirementsfor Energy Star that exceeds 15 SEER and 12

EER. Gas/electric units have electronic spark ignition and

power vented combustion steady state efficiencies of 80%.

These efficiencies meet or exceed all legislated minimum levels

providing operating costs.

A All models utilize a scroll compressor that are

environmentally friendly by utilizing R-410A refrigerant. Use of

the scroll compressor technology means a simple internal

design, fewer moving parts, equating to a quiet, reliable, easy to

service and efficient system. Internal compressor protection is

standard and compressors include protection to prevent liquid

damage.

Total system design - A TXV is used for precise metering on

the 6-12.5 Ton products and a fixed orifice is used to keep the

cost of the product down on the 3-5 ton product. Two

independent refrigerant circuits and compressors are used on

the 7.5- 12.5 ton units for economical and precise control. A

single circuit, single compressor design is used on the 3-6 ton

units for cost effectiveness, reliability without compromising

quality.

System Protection - Liquid line filter-driers, high and low

pressure safeties are standard on each independent refrigerant

circuit. Suction line sensors monitor temperature to prevent

possible liquid flood back to the compressors and also protect

against loss of charge and coil frosting.

B Balanced outdoor fan design makes for a quieter unit -

The outdoor condenser fans are dynamically balanced for

better performance and reliability. The direct drive fan design

mounted to the fan grill allows for quick and easy service.

Where other's components might fail at extreme temperatures

UPG's units are tested and rated up to 125°F ambient cooling

operation.

C Convertible Filter Rack - There are no tools required for

easy field conversion of the filter rack to accommodate either 2”

or 4” filters. Units will ship with 2" MERV 4 throwaway filters as

standard but MERV 8 and MERV 13 filters can be easily added

through the tool-free filter access panel to meet LEED

requirements. Refer to physical data tables for filter size details.

1068152-YTG-A-1013

Johnson Controls Unitary Products 5

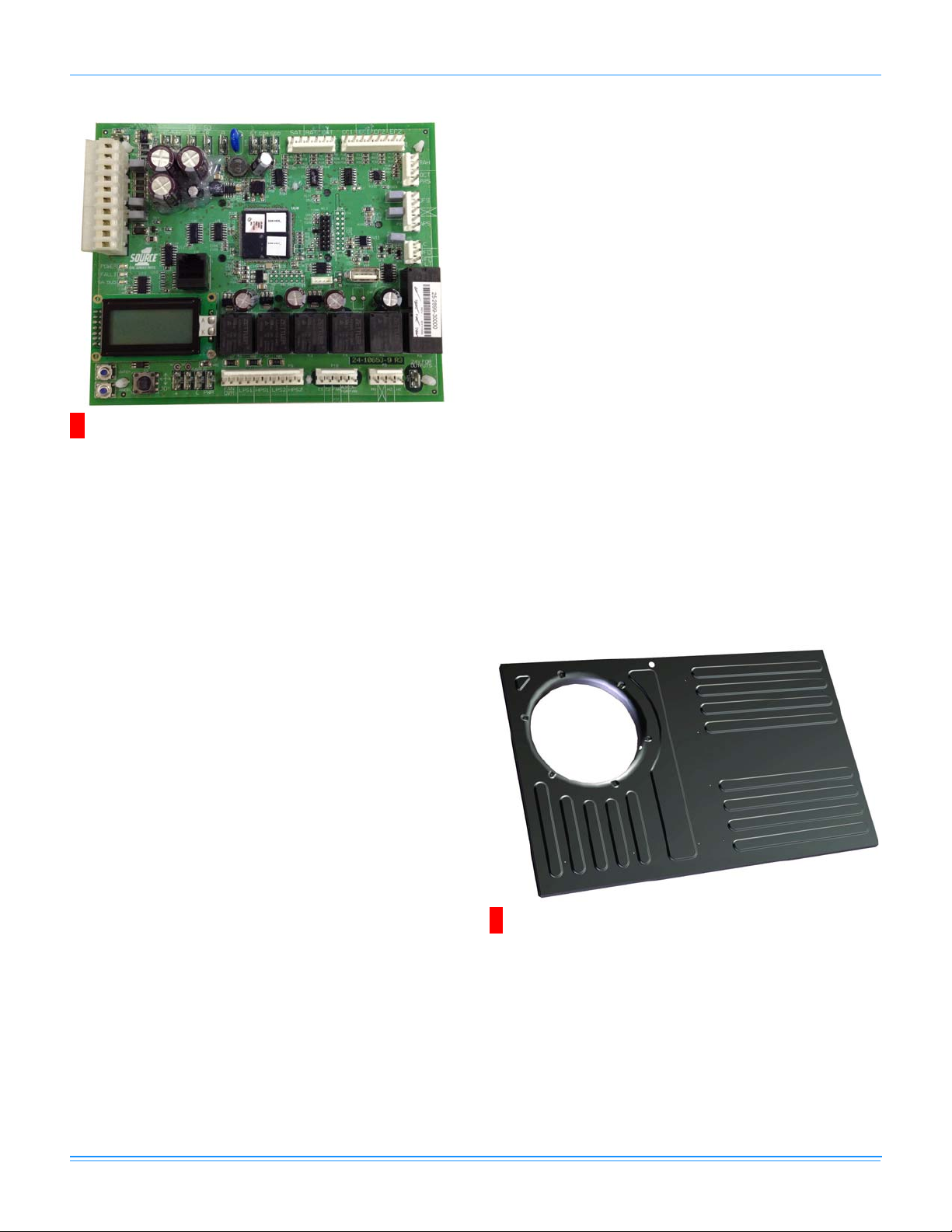

D Units will come with the new state of the art Simplicity SE

(Smart Equipment) control system standard. This new unit

control takes the best of the already proven (Simplicity) unitary

controls and makes the equipment smarter. The goal of this

control is to make the equipment easier to install, operate, and

service while keeping up with technologies and regulations.

Factory commissioned, configured, and tested.

Versatile - The Simplicity SE control can be configured to use a

standard thermostat (easy to connect screw terminals), a

sensor, or communicate with multiple protocols to integrate with

building automation systems.

Reduce field installed complex ity - Each unit com es

equipped with factory installed supply, return, and outdoor air

temperature sensors to reduce field installed complexity.

On-board USB Port - The new control comes with a long list of

features including Data Logging, schedules, previous faults and

down loadable update capabilities to a removable memory and

extracted via an on-board USB port to and from a flash drive.

Energy base-lining capabilities to track and make your building

work more efficiently at all times and occupancy levels. Self test

and start-up reports also available from the board.

Embedded LCD Display - The board has a built-in LCD

display that along with easy to use navigation buttons allows

the user to quickly navigate through functions and fault codes.

No more flash codes needed with the clear language fault

description on the LCD screen.

Safety Monitoring - The control board monitors each

independent refrigerant circuit's high, low-pressure switches,

suction temperature, outdoor, return and supply temperatures.

On units with heating the gas valve and high temperature limit

switches are monitored on gas and electric heating units. The

control also monitors the voltage supplied to the unit and will

protect the unit if low voltage due to a brown out, or other

electrical issue occurs.

Low Ambient - An integrated low-ambient control allows all

units to operate in the cooling mode down to 0°F outdoor

ambient without additional assistance. Optionally, the control

board can be programmed to lockout the compressors when

the outdoor air temperature is low or when free cooling is

available.

Anti-Short Cycle Protection - To aid compressor life, an anti-

short cycle delay is incorporated into the standard controls.

Compressor reliability is further ensured by programmable

minimum run times. For testing, the anti-short cycle delay can

be temporarily overridden with the push of a button.

Fan Delays - Fan on and fan off delays are fully programmable.

Furthermore, the heating and cooling fan delay times are

independent of one another. All units are programmed with

default values based upon their configuration of cooling and

heat.

Nuisance Trip Protection and Strikes - To prevent nuisance

calls, the control board uses a three times, you're out

philosophy. The high, low-pressure switch, anti-freeze

protection, low voltage or heating high limit must trip three times

within two hours before the unit control board will lock out the

Unit. The same safety must trip three times before a hard or soft

lockout will occur (Refer to Installation Manual for specific

lockout information. This includes specifics on duration and

type of lockout.).

E Robust design - Each unit is designed with an embossed

top to increase structural support and ensure rigidity. The unit

has a powder paint exterior finish including a industry leading

1000 hour salt spray rating. All units are painted with a long

lasting, powder paint that stands up over the life of the unit. The

paint used has been proven by a 1000 hour salt spray test and

is the leader in the industry.

1068152-YTG-A-1013

6 Johnson Controls Unitary Products

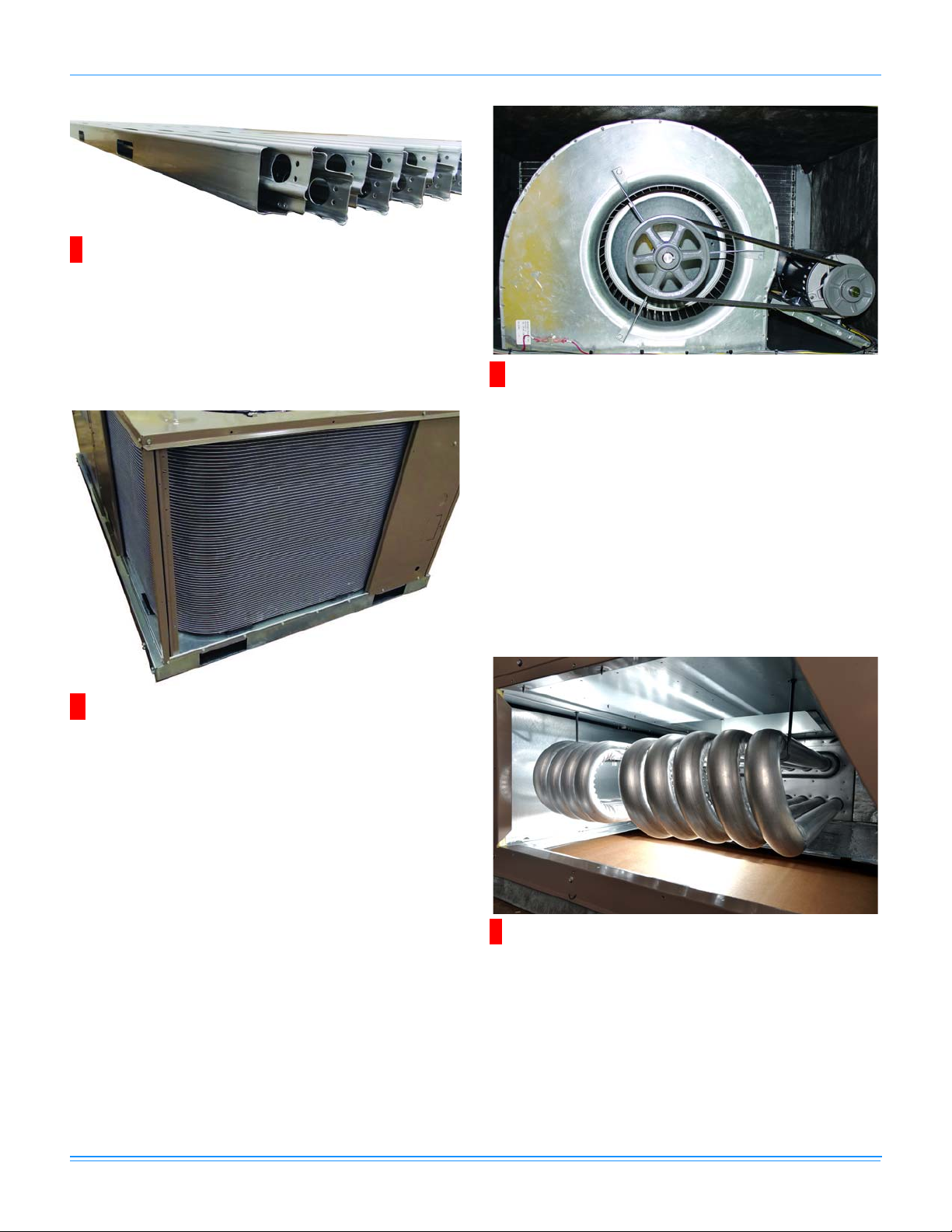

F Full Perimeter base rail that fits on many existing curbs

with the stability to withstand an earthquake - This product

was designed with the replacement market in mind which is

why it will fit on many existing curbs in the field but it also takes

into account the new construction market by being versatile and

sturdy. This unit is equipped with heavier gauge and

innovatively designed base rails to prevent damage from

transporting and rigging.

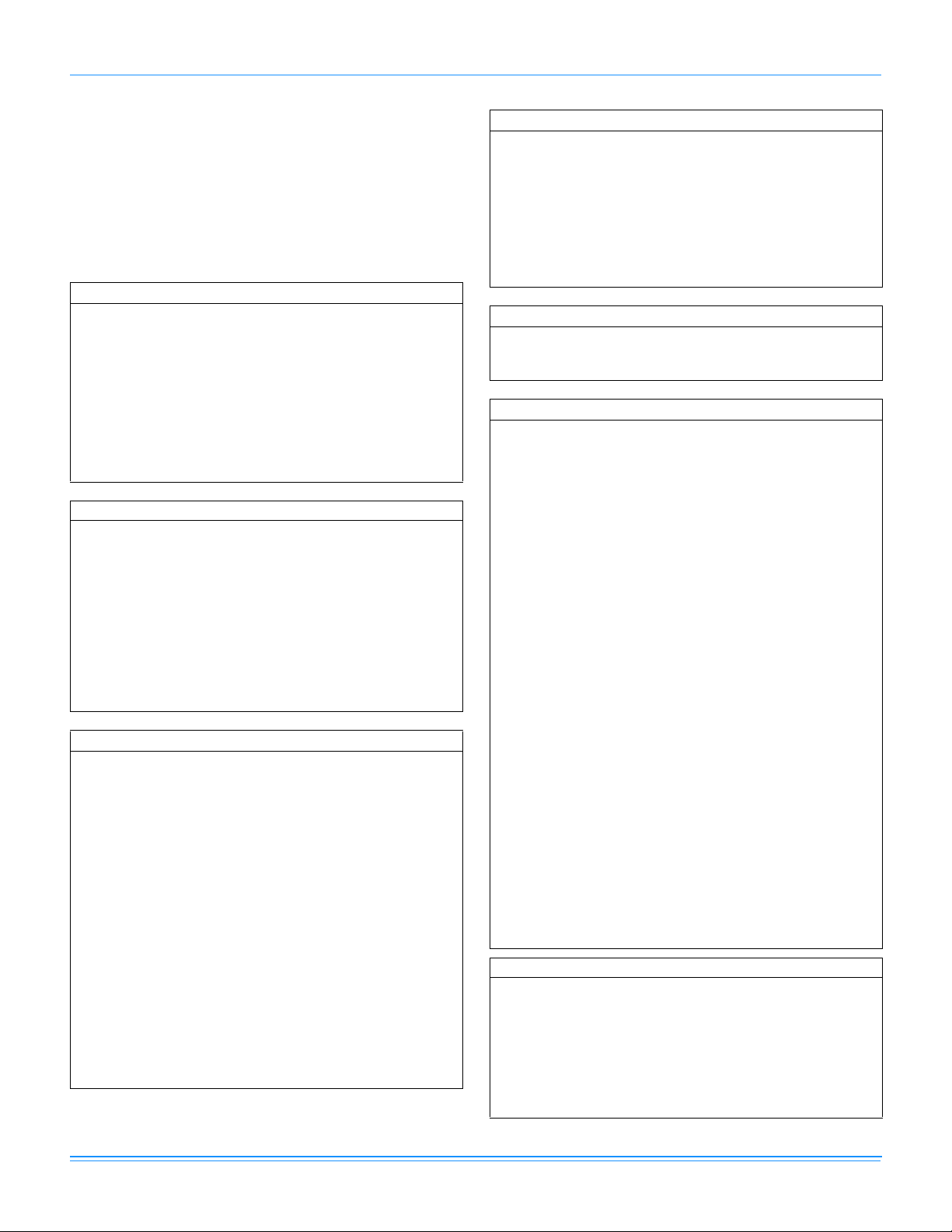

G Coils - All units utilize Micro-Channel "all-aluminum"

condenser coils that provides improved heat transfer

capabilities and reduced refrigerant charge volumes. This

equates to all units meeting LEED EA Credit 4 Requirements

for Enhanced Refrigerant Management. (Make sure to use the

EA 4 Credit 4 Calculator available at UPG net.com to ensure

that the entire project meets the requirements). MicroChannel

coils are also much easier to clean than your typical fin/tube

designs.

All evaporator coils utilize copper tube with aluminum fin design

for proven reliability and performance.

H Rigid Mounted Blower Assembly - Dynamically balanced

indoor fans ensure better performance and reliability. Large

access panels for easier access, service, and maintenance.

X13 Direct drive (Standard Static Option) and belt drive

(Medium Static and High Static Options) options available on 3-

5 ton products. The belt drive option is standard on 6-12.5 ton

products. Low, Medium, and High Static drive options for airflow

versatility up to 2" ESP with no field installed drive packages

necessary. The X13 motor technology offers several benefits w/

respect to efficiency, operation, comfort, and cost when

compared to other motors. Premium efficiency indoor motors

are standard on ZY06 and ZX14. The IntelliSpeed option is

available on 10 & 12.5 ton products to meet ASHRAE 90.1 and

Title 24 Requirements. The blower section includes a dual

density insulation to ensure good indoor air quality practices.

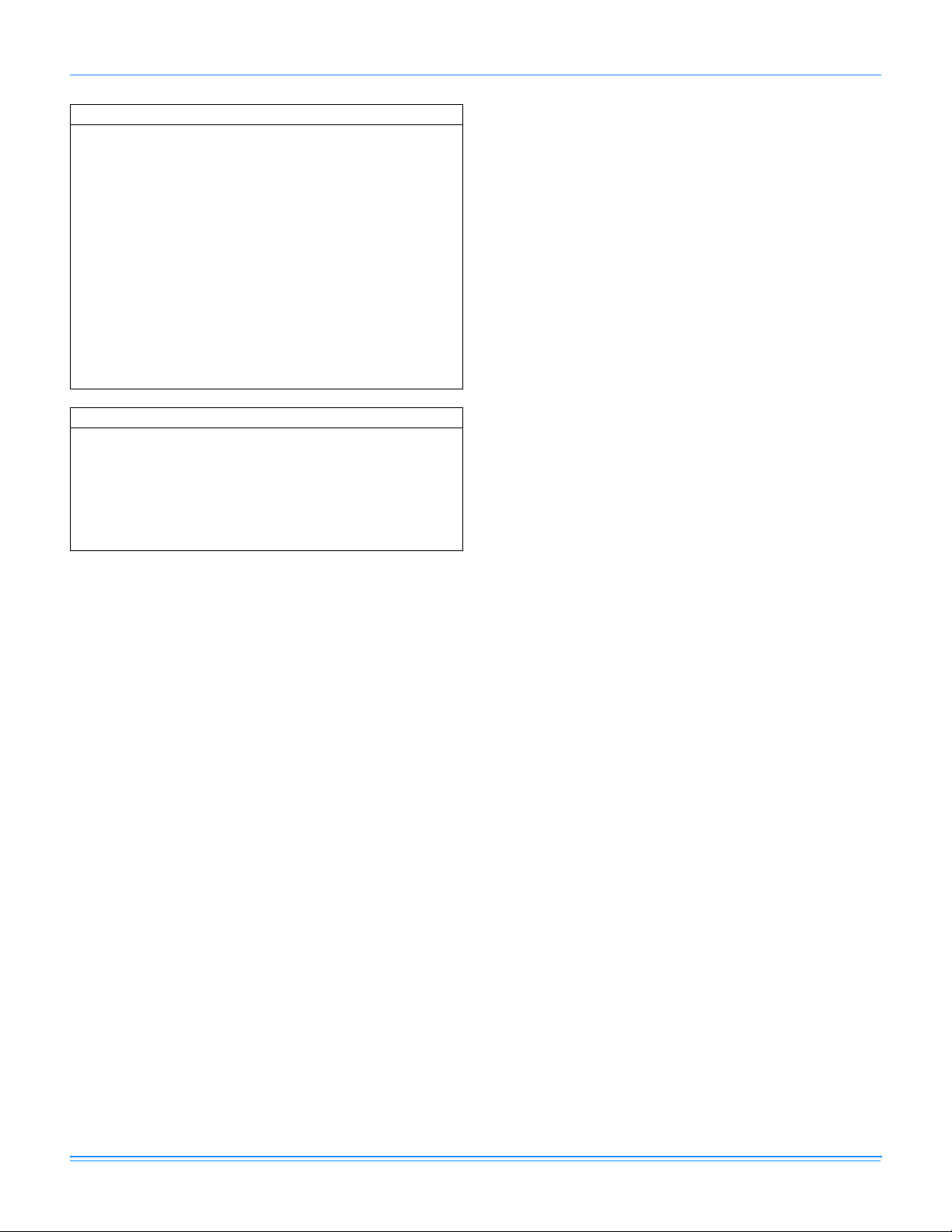

J Balanced Heating - The two stage gas heating offers

ultimate heating comfort with a balance between 1st and 2nd

stage gas heating. The first stage of a two stage gas heat

option provides approximately 70% or the heating capacity in all

3-12.5 tons two stage gas heat models. Balanced heating

allows the unit to better maintain desired temperatures and

helps saves energy. Low-NOx comes standard with a stainless

steel heat exchanger to meet California environmental

requirements. The heat exchanger section includes foil faced

insulation that is not only environmentally friendly but meets all

NFPA codes.

1068152-YTG-A-1013

Johnson Controls Unitary Products 7

Warranty - All models include a 1-year limited warranty on the

complete unit. Compressors and electric heater elements each

carry a 5-year warranty. Aluminized steel heat exchangers

carry a 10-year warranty and stainless steel heat exchangers

carry a 15- year warranty.

Factory Installed Options

(Nomenclature Digit Position)

Airflow Options (8)

Alternate Indoor Blower Motor - For applications with high

static restrictions, units are offered with optional indoor motors

providing higher external static capability and/or higher airflow,

depending upon the installer's needs.

• A=Standard Static (Direct Drive for 3-5 ton; Belt Drive

for 6-12.5 Ton)

• B=Medium Static (Belt Drive for 3-12.5 Ton)

• C=High Static (Belt Drive for 3-12.5 Ton; 3 Phase

Models Only)

VFD/VAV Options (9)

IntelliSpeed™ Supply Fan Control Option (ASHRAE 90.1

compliant, section 6.4.3.10) - Units configured with the

IntelliSpeed™ Supply Fan Option will contain a VFD for

variable volume supply fan operation. This option allows the

supply fan RPM to vary based on the number of compressors

or heating stages energized. The economizer's minimum

position will also be configurable.

• 1=None (Comes with standard constant volume

controls)

• 3=VFD IntelliSpeed

Coil Options (10)

ElectroFin® E-coat Coils – Coils are coated with an epoxy

polymer coating to protect against corrosion. A 3-year

warranty is added when this option is selected.

• A=Standard Indoor & Outdoor Coils (fin/tube design on

indoor coil and MicroChannel design used on outdoor

coil with no ElectroFin coating added).

• B=Standard Indoor Coil & ElectroFin Coil Outdoor Coil

(fin/tube design on indoor coil and MicroChannel design

used on outdoor coil. ElectroFin coating added to

outdoor coil)

• C= ElectroFin Indoor Coil & Standard Outdoor Coil (fin/

tube design on indoor coil and MicroChannel design

used on outdoor coil. ElectroFin coating added to indoor

coil)

• D= ElectroFin Indoor Coil & Standard Outdoor Coil (fin/

tube design on indoor coil and MicroChannel design

used on outdoor coil. ElectroFin coating added to indoor

and outdoor coil)

Controls (11)

Simplicity SE (Smart Equipment) or SES - This is the

Standard microprocessor control with capabilities to work with

a sensor or thermostat only. SES along with BAS will include

an addition to the board that allows for communication to a

BACnet open-protocol system.

•A=SES

• B=SES + BAS (Standard Simplicity SE with BacNet

communication)

Sensor Options (12)

• 1=None (Units come standard with factory installed

supply air, return air, and outdoor ai r te mpe rature

sensors)

Economizer/Damper (13)

Down flow Economizers (with barometric relief) - All units

offer a variety of optional factory installed down flow

economizers that are shipped, installed and wired with low

leak dampers that are designed to meet ASHRAE 90.1-2010

and AMCA 511 certification requirements. Each economizer

goes through a rigorous 60,000 cycle test. Dry bulb, single

enthalpy, and dual enthalpy (with field installed kit) can be

selected. All economizer options are ful ly in tegrated into the

Simplicity SE controls. The economizer has spring return, fully

modulating damper actuators and is capable of introducing up

to 100% outdoor air. As the outdoor air intake dampers o pe n,

the return air dampers close. The changeover from

mechanical refrigeration to economizer operation is regulated

by the outdoor air dry bulb temperature or the outdoor air

enthalpy input. The dual enthalpy kit provides a second input

used to monitor the return air (field installed). The installer

needs only to assemble the outdoor air hood, attach the

enthalpy control the hood and mount the hood to the unit

(Hood and control are provided).

Dry Bulb Economizer - Economizer operation is enabled by

the outdoor air temperature bein g l ess than the setpoint of the

economizer module.

Enthalpy Economizer - The added outdoor air enthalpy

sensor enables economizer operation if the outdoor enthalpy

is less than the setpoint of the economizer logic module.

• A=None

• B=Dry Bulb Economizer

• C=Enthalpy Economizer

Convenience Outlet (14)

Convenience Outlet - (Non-Powered) - This option locates a

120V single-phase GFCI outlet with cover, on the corner of the

unit housing adjacent to the compressors. The Non-powered

option requires the installer to provide the 120V single-phase

power source and wiring. Factory installed option only.

•1=None

• 2=Non-powered Convenience Outlet

1068152-YTG-A-1013

8 Johnson Controls Unitary Products

Field Installed Accessories

• Downflow Economizers/Horizontal Economizers (with

barometric relief) - All units offer a variety of optional

factory installed down flow economizers that are shipped,

installed and wired with low leak dampers that are

designed to meet ASHRAE 90.1- 2010 AMCA 511

certification requirements. Each economizer goes through

a rigorous 60,000 cycle test. Dry bulb, single enthalpy,

and dual enthalpy (with field installed kit) can be selected.

All economizer options are fully integrated into the

Simplicity SE controls. The economizer has spring return,

fully modulating damper actuators and is capable of

introducing up to 100% outdoor air. As the outdoor air

intake dampers open, the return air dampers close. The

changeover from mechanical refrigeration to economizer

operation is regulated by the outdoor air dry bulb

temperature or the outdoor air enthalpy input. The dual

enthalpy kit provides a second input used to monitor the

return air (field installed). The installer needs only to

attach the already assembled hood and attach the

enthalpy control to the hood and mount the hood to the

unit (Hood and control are provided).

• Dry Bulb Economizer - Economizer operation is enabled

by the outdoor air temperature being less than the

setpoint of the economizer module.

• Single Enthalpy Control, Accessory for Economizer -

All field installed economizers will come standard as a dry

bulb economizer. This kit adds an outdoor air enthalpy

sensor which enables economizer operation if the outdoor

enthalpy is less than the setpoint of the economizer logic

module.

• Dual Enthalpy Control, Accessory for Economizer - All

field installed economizers will come standard as a dry

bulb economizer. This kit adds an outdoor air enthalpy

sensor and return air enthalpy sensor which enables

economizer operation if the outdoor enthalpy is less than

the setpoint of the economizer logic module.

• Power Exhaust - This accessory installs in the unit with a

down flow economizer or in the ductwork for a horizontal

application.

• Louvered Hail Guard - This kit includes a decorative

louvered panel hood which installs over the outside

condenser coil and prevents damage to the coil fins from

hail strikes.

• Flue Exhaust Extension Kit - In locations with wind or

weather conditions which may interfere with proper

exhausting of furnace combustion products, this kit can be

installed to prevent the flue exhaust from entering nearby

fresh air intakes.

• Gas Heat High Altitude Kit - This kit converts a gas heat

unit to operate at high altitudes, 2,000 to 6,000 feet.

Conversion kits are available for natural gas and propane.

• Gas Heat Propane Conversion Kit - This kit converts a

gas-fired heater from natural gas to propane. It contains

the main burner orifices and gas valve replacement

springs.

• Roof Curbs - The roof curbs have insulated decks and

are shipped disassembled The roof curbs are available in

14 and 24 heights.

• Thermostat - The units are designed to operate with 24-

volt electronic and electro-mechanical thermostats. All 7.5

thru 12.5 ton units operate with two-stage heat/two-stage

cool or two-stage cooling only thermostats, depending

upon unit configuration.

Electrical Options (15)

Disconnect Switch - Gas heat units and cooling units

equipped with electric heat include an optional, non-fused

disconnect properly sized for the unit is provided. For cooling

only units, a switch sized to the largest electric heat available

for the particular unit is provided. Factory installed option only.

Thru-the-pan Utility Connections -

Special design for thru

the base and thru the curb applications insuring a sealed

connection to avoid water entry.

•1=None

• 2=Non-fused Disconnect

• 3=Thru-the-pan Utility Connection

• 4=Non-fused Disconnect & Thru-the-pan Utility

Connections

Cabinet Options (16)

Louvered Hail Guard - This kit includes a decorative

louvered panel hood which installs over the outside

condenser coil and prevents damage to the coil fins from hail

strikes.

• 1=None

• 2=Louvered Panels

1068152-YTG-A-1013

Johnson Controls Unitary Products 9

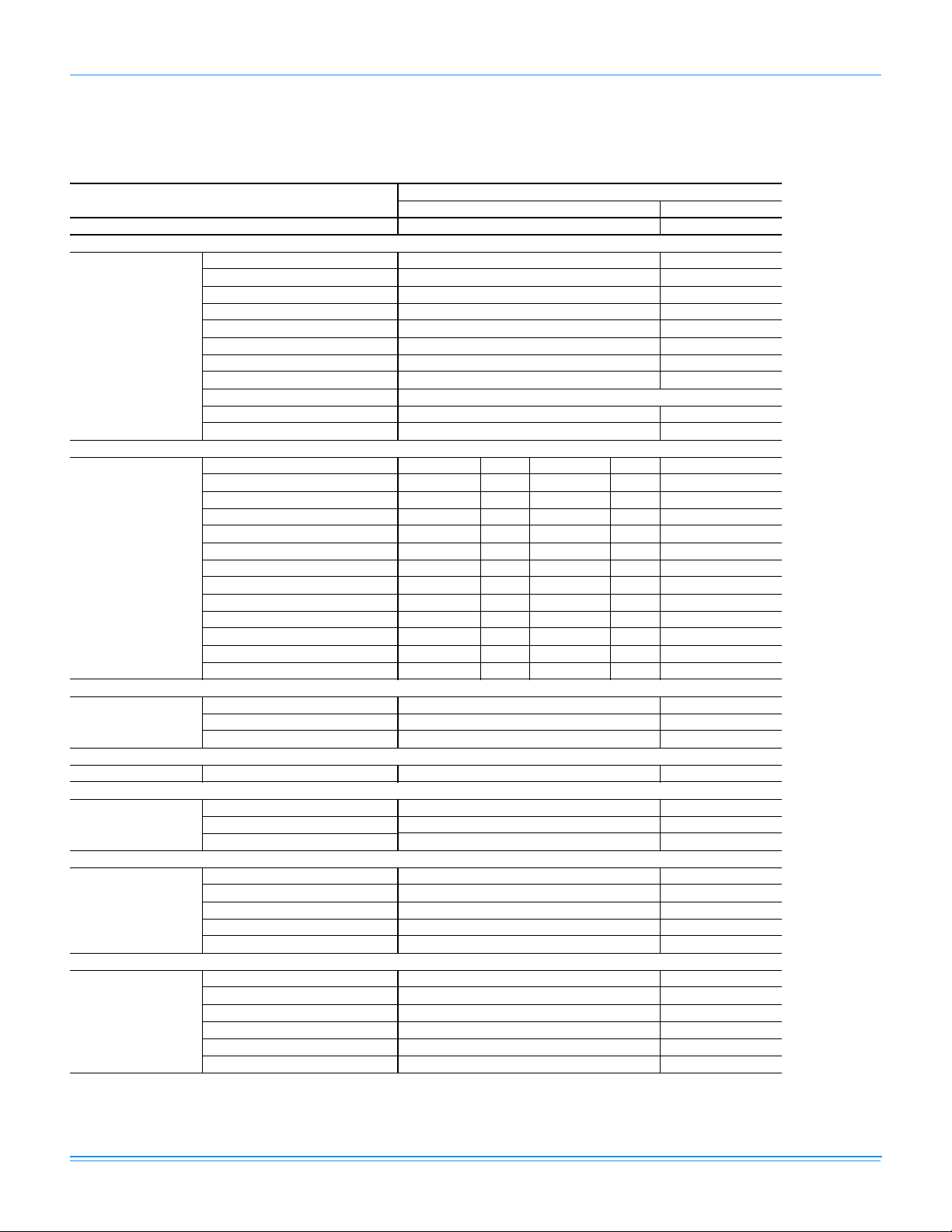

Nomenclature

ZX G 04 D 2 A 1 A 1 1 1 A 1

Product Category

ZX = Pkg AC R410A ASHRAE 90.1 Efficiency

ZY = Pkg AC R410A Energy Star Efficiency

A = Standard Static

Airflow

B = Medium Static

C = High Static

Product Generation

1 = First Generation

Heat Type (3)

E = No Heat

G = Gas Heat

D = Low Heat

E = Medium Heat

F = High Heat

L = Low Heat (Low NOx)

M = Medium Heat (Low NOx)

N = High Heat (Low NOx)

R = Low Heat (Stainless Steel)

S = Medium Heat (Stainless Steel)

T = High Heat (Stainless Steel)

Gas Heat

Nominal Cooling Capacity

04 = 3 Ton

05 = 4 Ton

06 = 5 Ton

07 = 6 Ton

08 = 7-1/2 Ton

09 = 8-1/2 Ton

12 = 10 Ton

14 = 12-1/2 Ton (Standard Efficiency Only)

Voltage

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

Special Options

A = None

1 = None

2 = Louvered Panels Installed

Cabinet Options

1 = None

2 = Non-fused Disconnect

3 = Thru-the-base Utility Connections

4 = Non-fused Disconnect &

Thru-the-base Utility Connections

1 = None

2 = Non-powered

3 = Powered

Economizer / Damper

A = None

B = Dry Bulb Economizer

C = Enthalpy Economizer

1 = None

Electrical Options

1 = None

3 = VFD IntelliSpeed (ZX12, ZX14 & ZY12 Only)

Airflow Options

A = Standard Indoor & Outdoor Coils

B = Standard Indoor Coil & ElectroFin Outdoor Coil

C = ElectroFin Indoor Coil & Standard Outdoor Coil

D = ElectroFin Indoor & Outdoor Coils

3-12.5 Ton Model Number Nomenclature

Heat Size

A = No Heat (Cooling Only)

A = Simplicity™ SE

B = Simplicity™ SE + BAS

Coil Options

1 = 208/230-1-60 (3-5 Ton Only)

Convenience Outlet

Sensor Options

Controls

1A

A

Note: Not all options may be available. Contact

local distributor.

1068152-YTG-A-1013

10 Johnson Controls Unitary Products

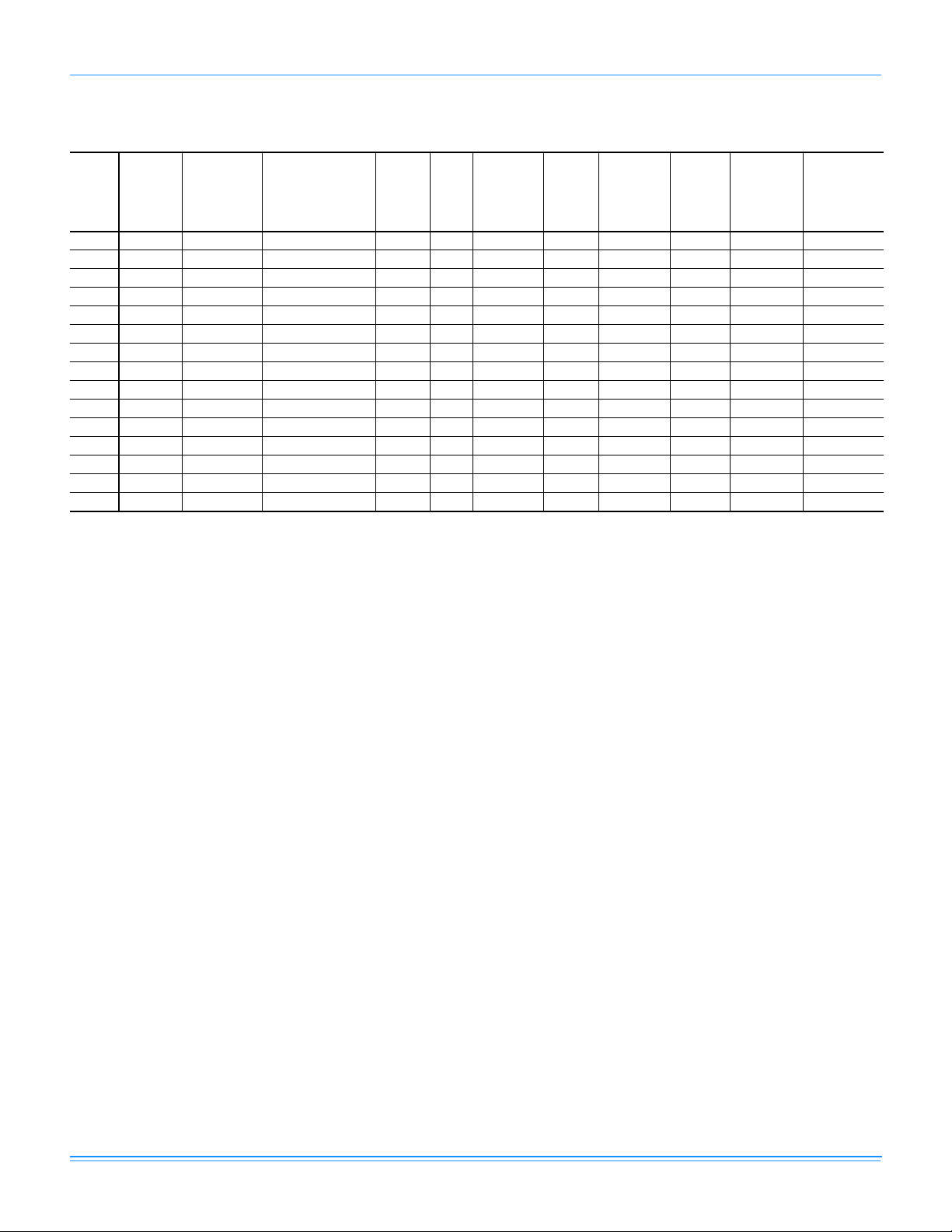

Accessories

Accessory Kit

Number

Description Where Used Voltage

2EE04706124 Econ, DB, Vertical Flow, Small Footprint ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 All

2EE04706224 Econ, DB, Vertical Flow, Large Footprint ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 All

2EE04706324 Econ, DB, Horizontal Flow, Small Footprint, Short Cabinet ZX04, ZX05, ZX06, ZY04 All

2EE04706424 Econ, DB, Horizontal Flow, Small Footprint, Tall Cabinet ZX07, ZY05, ZY06 All

2EE04706524 Econ, DB, Horizontal Flow, Large Footprint, Short Cabinet ZX08, ZY07 All

2EE04706624 Econ, DB, Horizontal Flow, Large Footprint, Tall Cabinet ZX09, ZX12, ZX14, ZY08, ZY09, ZY12 All

2EC0401 Kit, Single Enthalpy Field Installed All All

2EC0402 Kit, Dual Enthalpy Field Installed All All

1HG0419 Hail Guard Kit Small Footprint, Short Cabinet ZX04, ZX05, ZX06, ZY04 All

1HG0420 Hail Guard Kit Small Footprint, Tall Cabinet ZX07, ZY05, ZY06 All

1HG0421 Hail Guard Kit Large Footprint, Short Cabinet ZX08, ZY07 All

1HG0422 Hail Guard Kit Large Footprint, Tall Cabinet ZX09, ZX12, ZX14, ZY08, ZY09, ZY12 All

1RC0456 Curb Rigid 14" Small Footprint ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 All

1RC0457 Curb Rigid 14" Large Footprint ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 All

1RC0458 Curb Rigid 24" Small Footprint ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 All

1RC0459 Curb Rigid 24" Large Footprint ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 All

2PE04704206 Power Exhaust Vert Flow Small Footprint 208V-230V 1-ph ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 208/230-1-60

2PE04704225 Power Exhaust Vert Flow Small Footprint 208V-230V 3-ph ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 208/230-3-60

2PE04704246 Power Exhaust Vert Flow Small Footprint 460V 3-ph ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 460-3-60

2PE04704258 Power Exhaust Vert Flow Small Footprint 575V 3-ph ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 575-3-60

2PE04704306 Power Exhaust Vert Flow Large Footprint 208V-230V 1-ph ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 208/230-1-60

2PE04704325 Power Exhaust Vert Flow Large Footprint 208V-230V 3-ph ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 208/230-3-60

2PE04704346 Power Exhaust Vert Flow Large Footprint 460V 3-ph ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 460-3-60

2PE04704358 Power Exhaust Vert Flow Large Footprint 575V 3-ph ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 575-3-60

2PE04704406 Power Exhaust Horiz Flow Small Footprint 208V-230V 1-ph ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 208/230-1-60

2PE04704425 Power Exhaust Horiz Flow Small Footprint 208V-230V 3-ph ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 208/230-3-60

2PE04704446 Power Exhaust Horiz Flow Small Footprint 460V 3-ph ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 460-3-60

2PE04704458 Power Exhaust Horiz Flow Small Footprint 575V 3-ph ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 575-3-60

2PE04704506 Power Exhaust Horiz Flow Large Footprint 208V-230V 1-ph ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 208/230-1-60

2PE04704525 Power Exhaust Horiz Flow Large Footprint 208V-230V 3-ph ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 208/230-3-60

2PE04704546 Power Exhaust Horiz Flow Large Footprint 460V 3-ph ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 460-3-60

2PE04704558 Power Exhaust Horiz Flow Large Footprint 575V 3-ph ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 575-3-60

1TB0401 Small Footprint Thru The Base Electrical & Thru The Curb Gas ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 All

1TB0402 Large Footprint Thru The Base Electrical & Thru The Curb Gas ZX08, ZX09, ZX12, ZX14, ZY07, ZY08, ZY09, ZY12 All

1TB0403 Small Footprint Thru The Base Electrical & Gas ZX04, ZX05, ZX06, ZX07, ZY04, ZY05, ZY06 All

1TB0404 Large Footprint Thru The Base Electrical & Gas ZX08, ZY07, ZX09, ZX12, ZX14, ZY08, ZY09, ZY12 All

1068152-YTG-A-1013

Johnson Controls Unitary Products 11

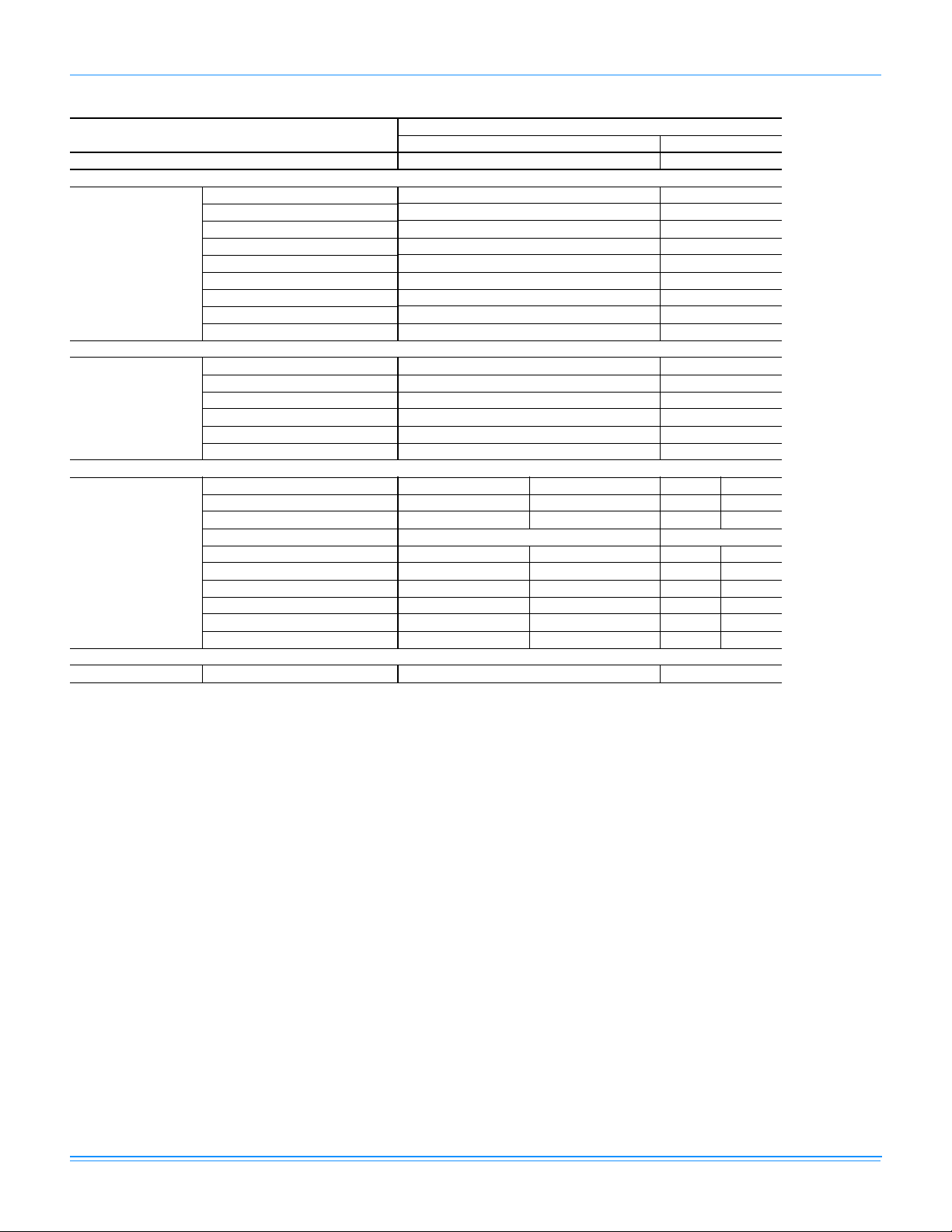

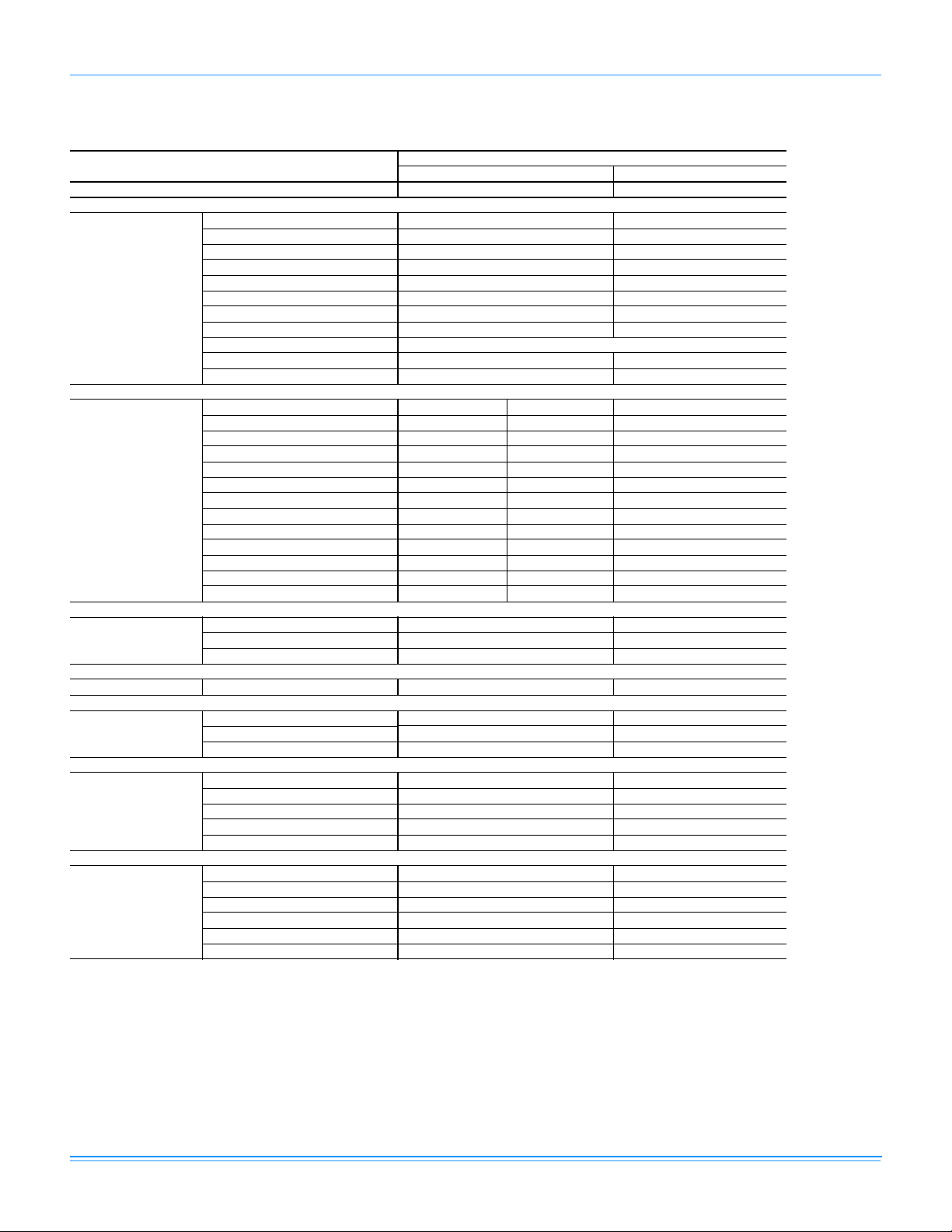

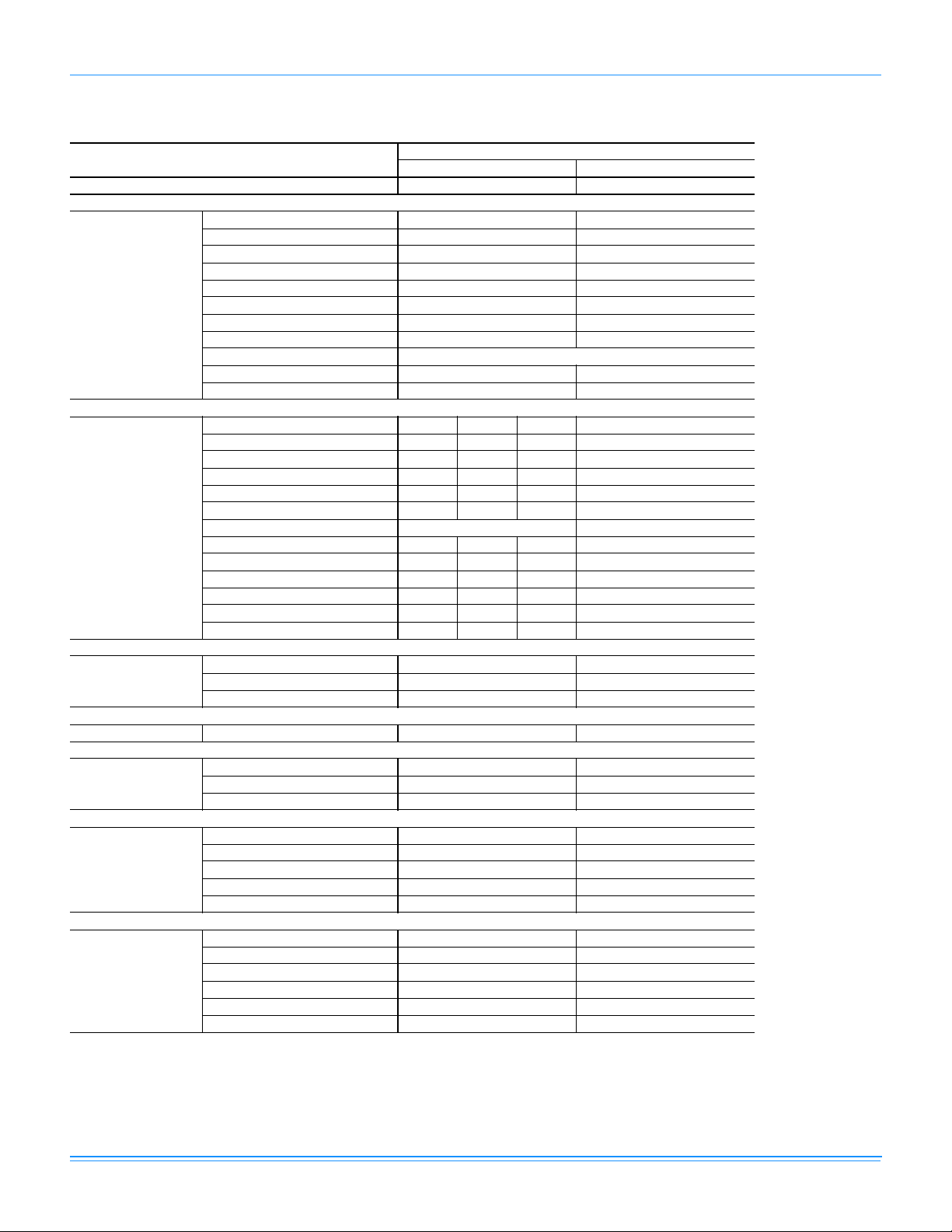

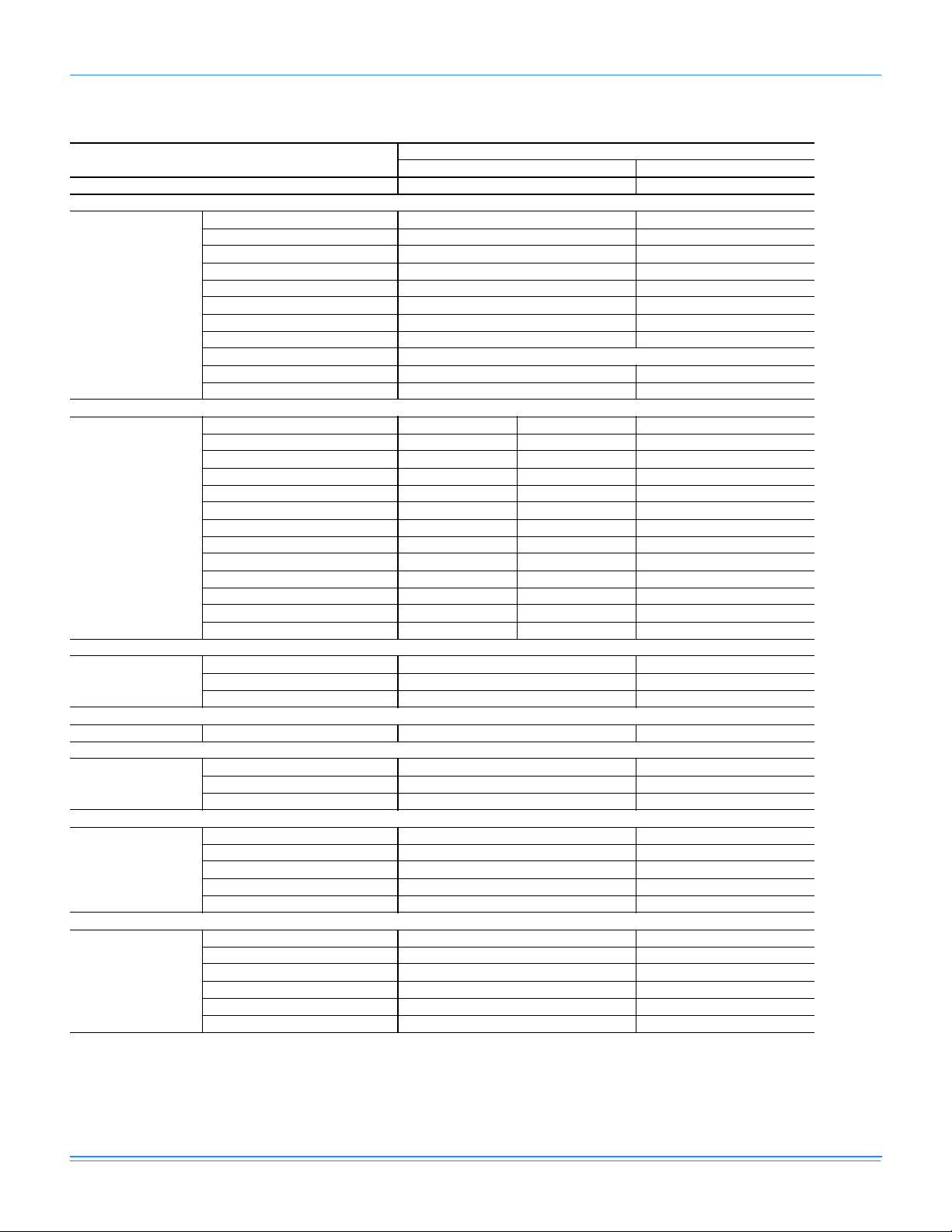

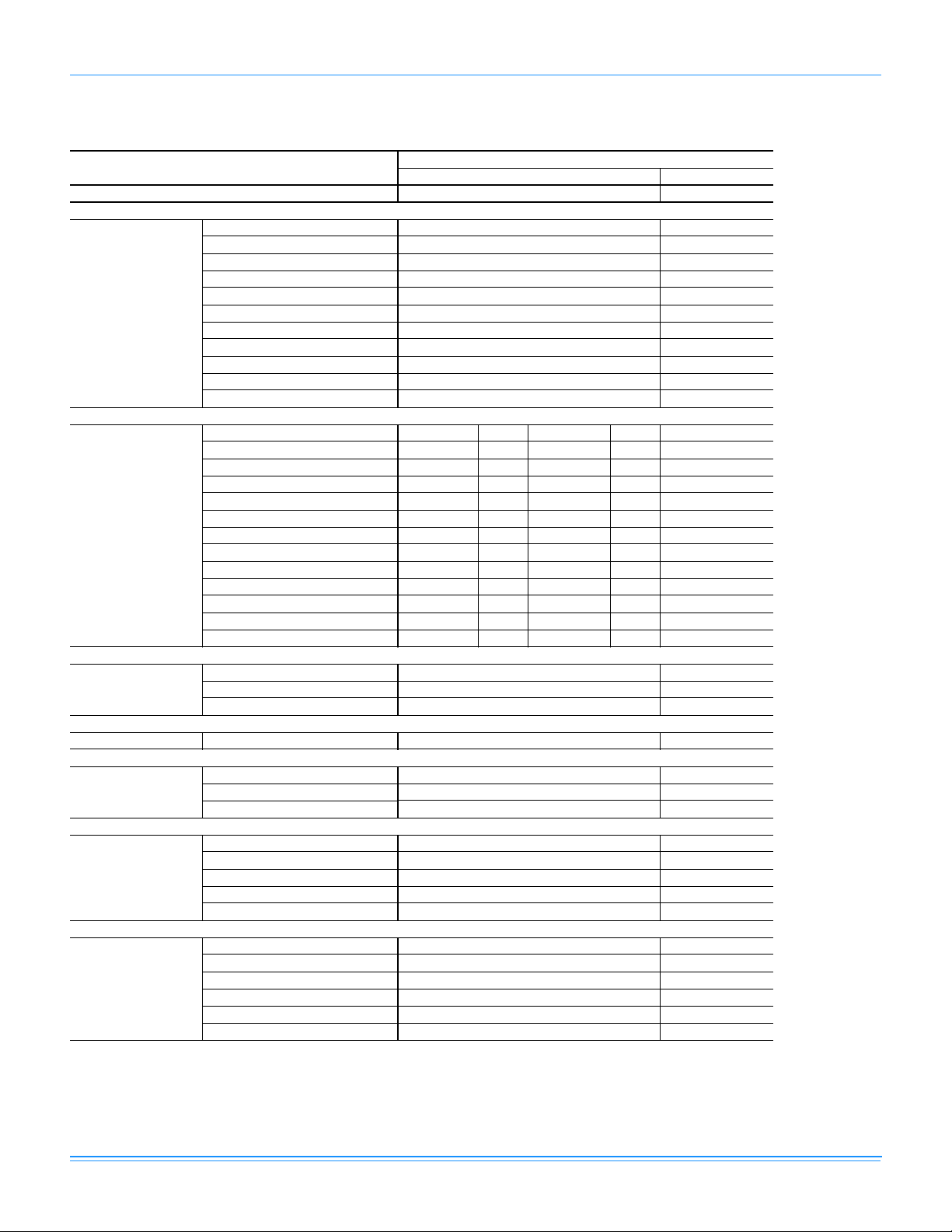

AHRI COOLING RATING TABLE

UNIT

COOLING

STAGES

NOM.

COOLING

CAPACITY

(TONS)

NET

COOLING

CAPACITY (MBH)

TOTAL

POWER

(kW)

SEER

EER

(COOLING

ONLY)

EER

(A/C

WITH

GAS

HEAT)

IEER

(COOLING

ONLY)

IEE R

(A/C WITH

GAS

HEAT)

IEER WITH

IntelliSpeed

(COOLING

ONLY)

IEER WITH

IntelliSpeed

(GAS HEAT)

ZX04 1 3 34.6 2.8 13.0 11.0 11.0 --- --- --- ---

ZX05 1 4 45.0 3.6 13.0 11.0 11.0 --- --- --- ---

ZX06 1 5 59.0 4.6 13.0 11.0 11.0 --- --- --- ---

ZX07 1 6 69.0 5.1 --- 11.2 11.0 12.1 11.9 --- ---

ZX08 2 7.5 85.0 6.6 --- 11.2 11.0 11.6 11.5 --- ---

ZX09 2 8.5 99.0 7.7 --- 11.2 11.0 11.9 11.7 --- ---

ZX12 2 10.0 116.0 9.2 --- 11.2 11.0 12.0 11.8 14.8 14.4

ZX14 2 12.5 135.0 10.8 --- 11.0 10.8 11.2 11.0 13.0 12.75

ZY04 1 3 36.0 2.6 15.0 12.0 12.0 --- --- --- ---

ZY05 1 4 49.0 3.5 15.4 12.0 12.0 --- --- --- ---

ZY06 1 5 58.0 4.4 15.2 12.0 12.0 --- --- --- ---

ZY07 1 6 72.0 5.0 --- 12.2 12.0 12.8 12.6 --- ---

ZY08 2 7.5 89.0 6.6 --- 12.2 12.0 12.6 12.4 --- ---

ZY09 2 8.5 98.0 7.3 --- 12.2 12.0 12.6 12.4 --- ---

ZY12 2 10.0 116.0 8.9 --- 11.7 11.0 11.8 11.6 14.4 14.4

1068152-YTG-A-1013

12 Johnson Controls Unitary Products

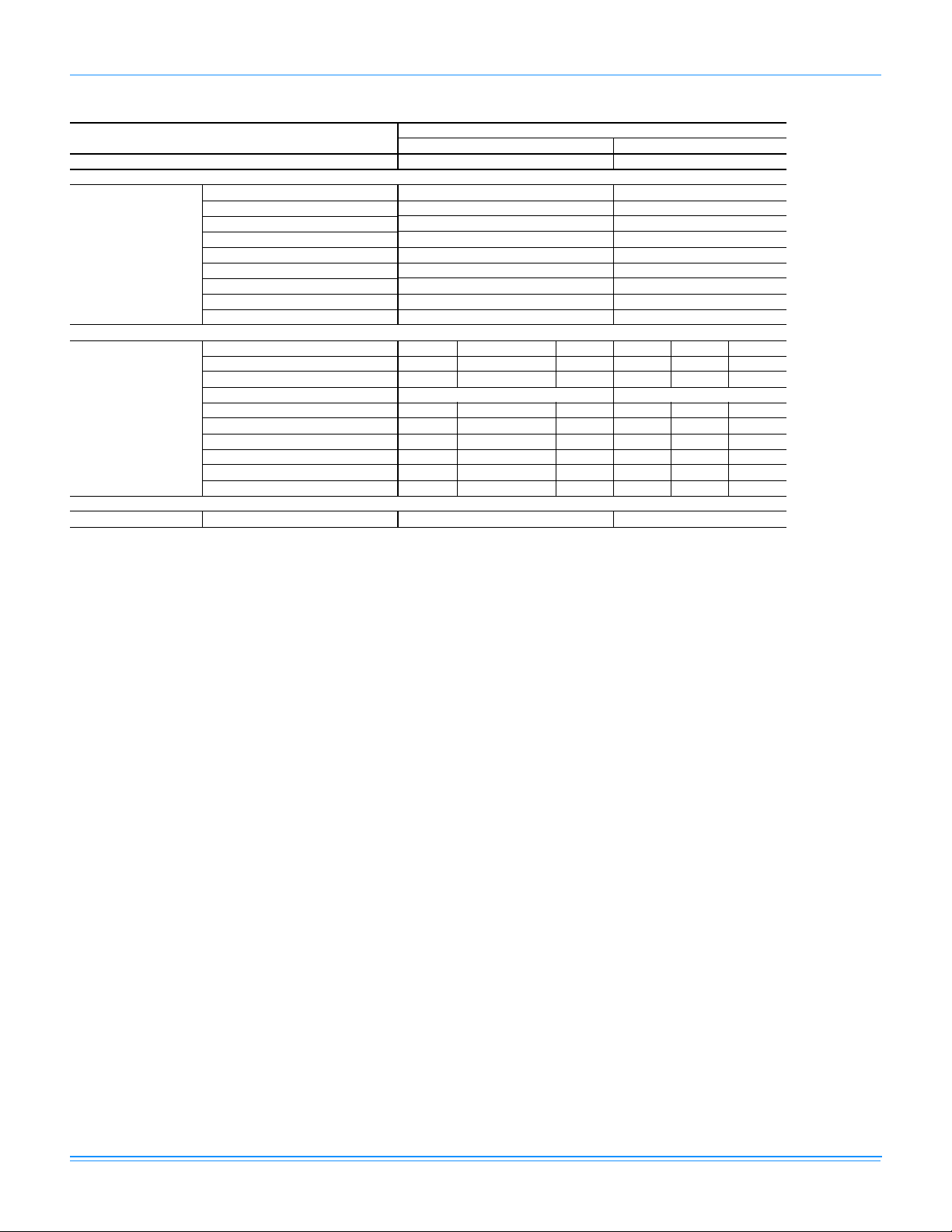

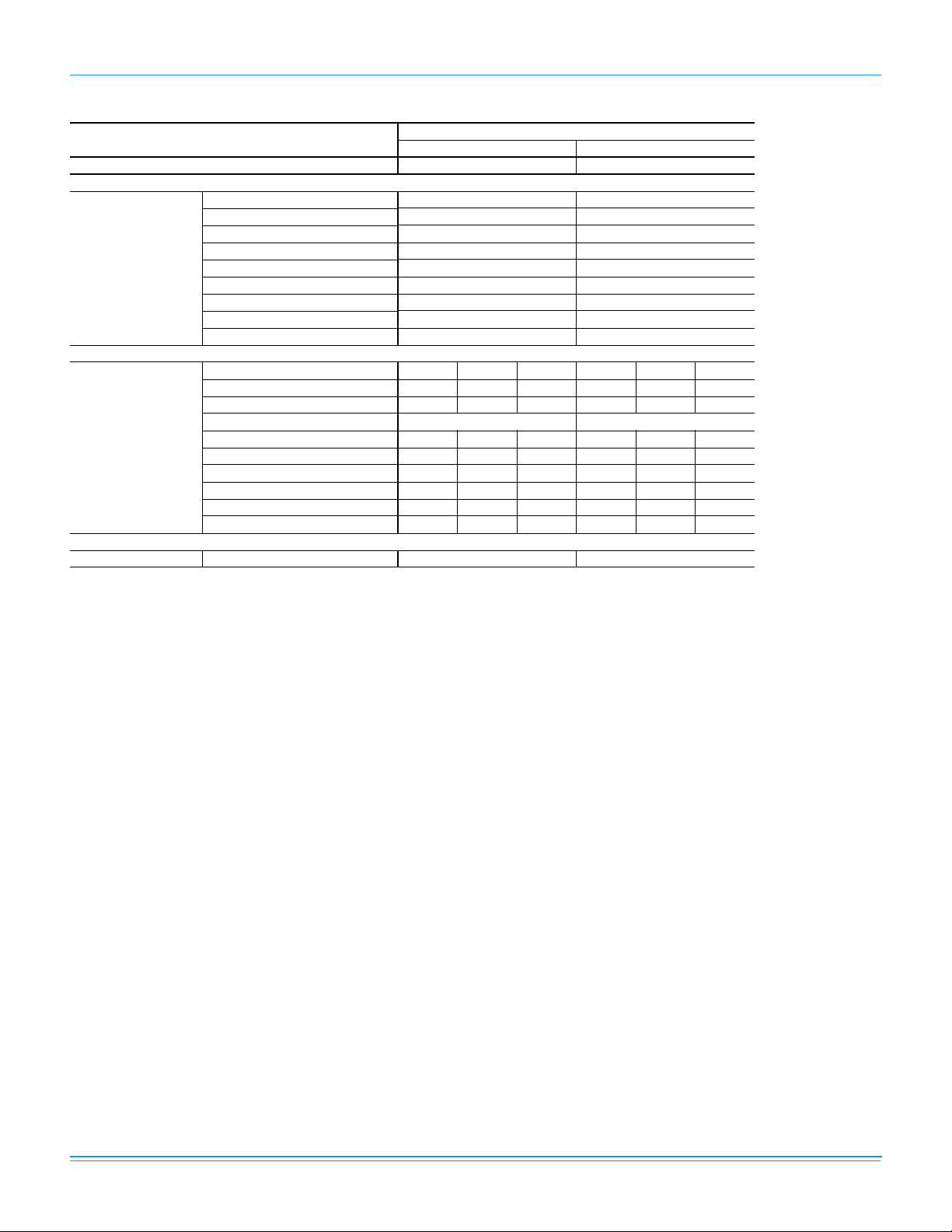

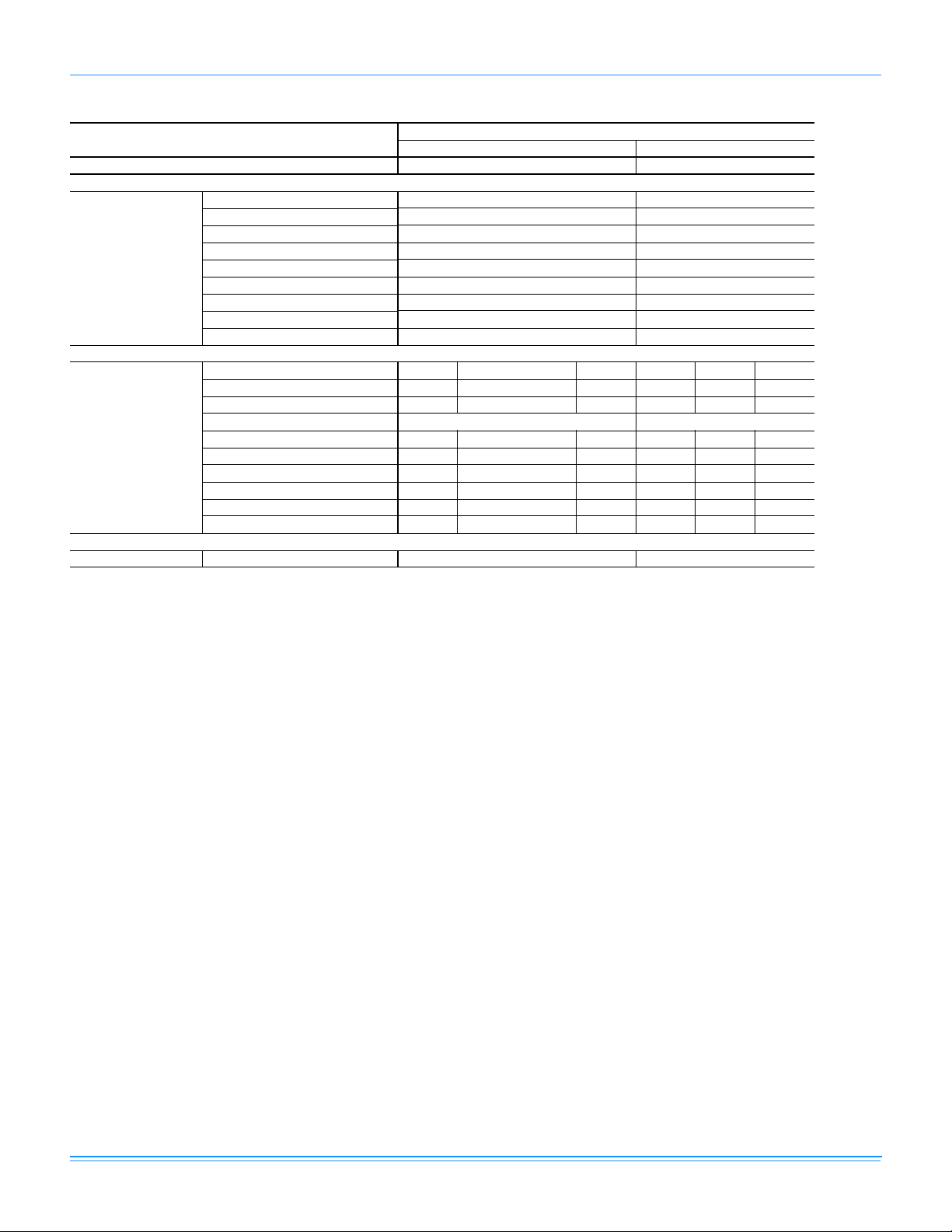

Physical Data

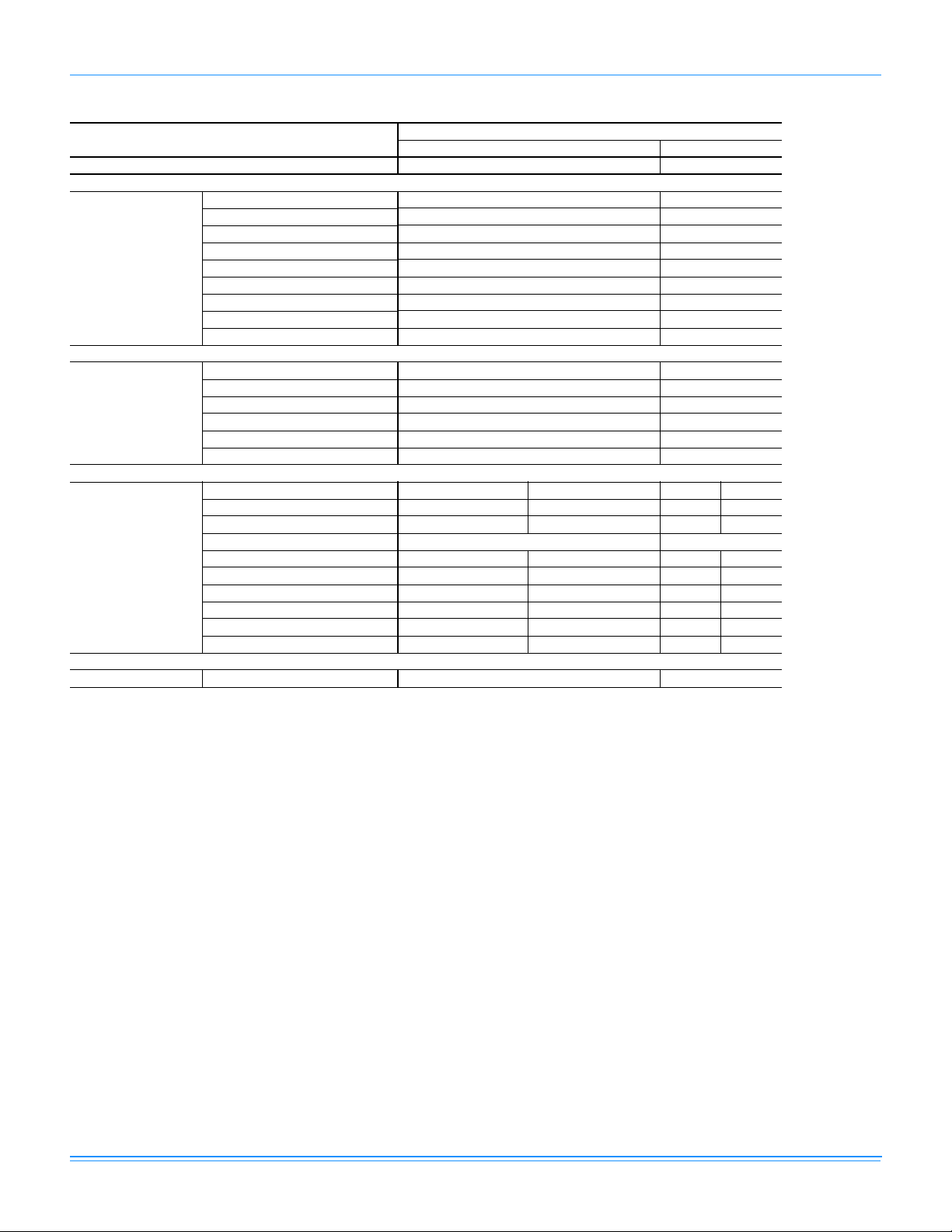

ZX04 Physical Data

Component

Models

ZXG04 ZXE04

Nominal Tonnage 3 3

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 38200 38200

AHRI net capacity (Btu) 34600 34600

EER 11 11

SEER 13 13

IEER - -

Nominal CFM 1200 1200

System power (KW) 2.8 2.8

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 3-13 3-13

System 2 - -

AHRI HEATING

PERFORMANCE

Heating Option L D M E -

Heating model Low (Low-NOx) Low Med (Low-NOx) Med -

1st. Stage Heat input (K Btu) - - - - -

2nd. Stage Heat input (K Btu) 60 70 90 114 -

1st. Stage Heat output (K Btu) - - - - -

2nd. Stage Heat output (K Btu) 48 56 72 91 -

AFUE % -

Steady state efficiency (%) 80 80 80 80 -

No. burners 2 2 3 3 -

No. stages 1 1 1 1 -

Temperature Rise Range (ºF) 30-49 35-58 44-74 56-80 -

Gas Limit Setting (ºF) 150 150 140 140 -

Gas piping connection (in.) 1/2 1/2 1/2 1/2 -

DIMENSIONS (inches)

Length 74.1 74.1

Width 48.9 48.9

Height 32.5 32.5

OPERATING WT. (lbs.) 515 469

COMPRESSORS

Type Scroll Scroll

Quantity 1 1

Unit Capacity Steps (%) 100 100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 16.3 16.3

Rows 1 1

Fins per inch 23 23

Tube diameter (in./MM) .63/16 .63/16

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 5.5 5.5

Rows 2 2

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control Orifice Orifice

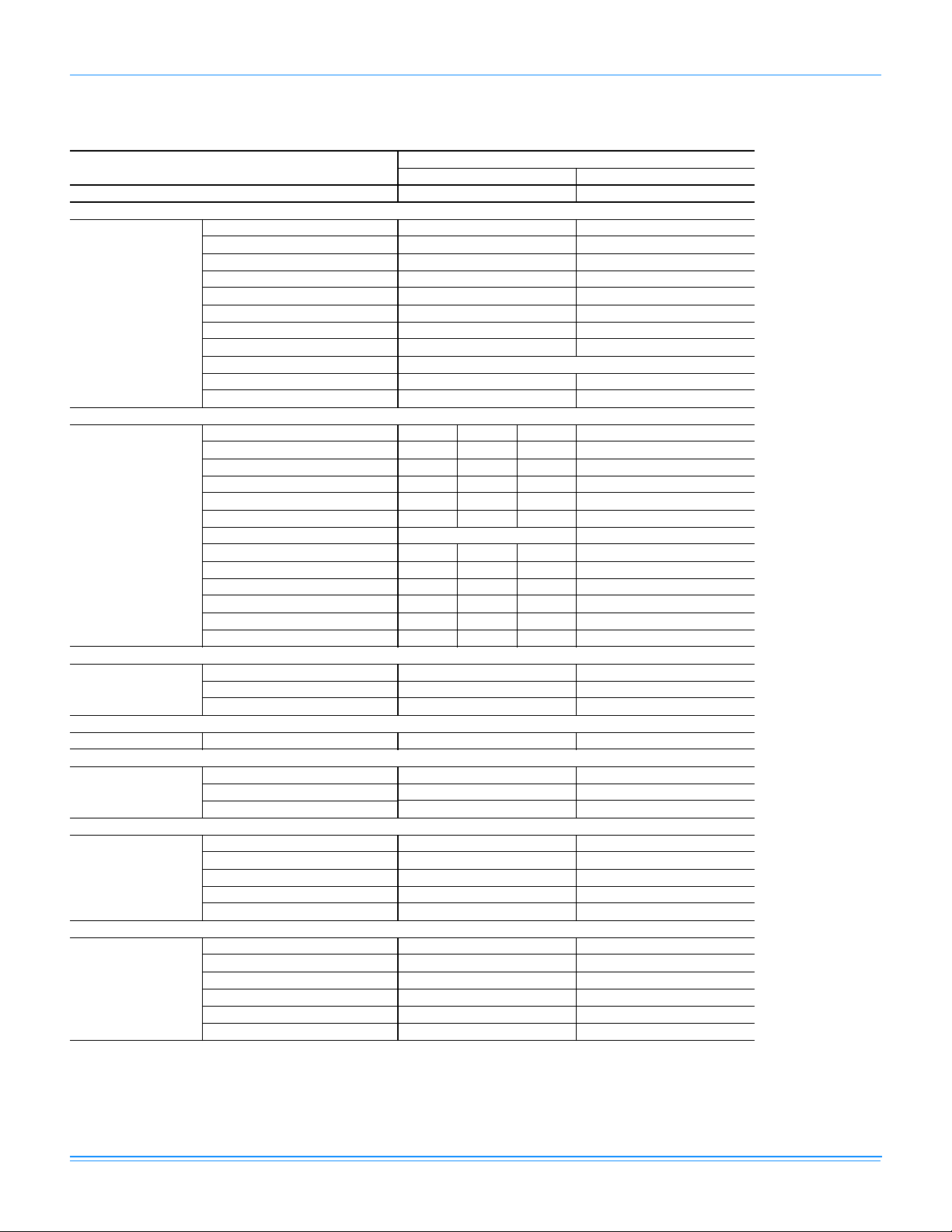

1068152-YTG-A-1013

Johnson Controls Unitary Products 13

CONDENSER

FAN DATA

Quantity of fans 1 1

Fan diameter (Inch) 22 22

Type Prop Prop

Drive type Direct Direct

Quantity of motors 1 1

Motor HP each 1/4 1/4

No. speeds 1 1

RPM 1100 1100

Nominal total CFM 3800 3800

EVAP FAN DATA

DIRECT DRIVE

Airflow Option A A

Quantity 1 1

Fan Size (Inch) 10 x 10 10 x 10

Type Centrifugal Centrifugal

Motor HP 3/4 3/4

RPM 1050 1050

EVAP FAN DATA

BELT DRIVE

Airflow Option B C B C

Quantity 1 1 1 1

Fan Size (Inch) 10 x 10 10 x 10 10 x 10 10 x 10

Type Centrifugal Centrifugal

Motor Sheave 1VL34 1VL44 1VL34 1VL44

Blower Sheave AK46 AK46 AK46 AK46

Belt A39 A40 A39 A40

Motor HP each 1.5 1.5 1.5 1.5

RPM 1725 1725 1725 1725

Frame size 56Y 56Y 56Y 56Y

FILTERS Quantity - Size 2 - (16 x 25 x 2)

1

2 - (16 x 25 x 2)

1

1. 2 in. Throwaway, Standard, MERV 4 (Minimum Efficiency Reporting Value).

ZX04 Physical Data (Continued)

Component

Models

ZXG04 ZXE04

Nominal Tonnage 3 3

1068152-YTG-A-1013

14 Johnson Controls Unitary Products

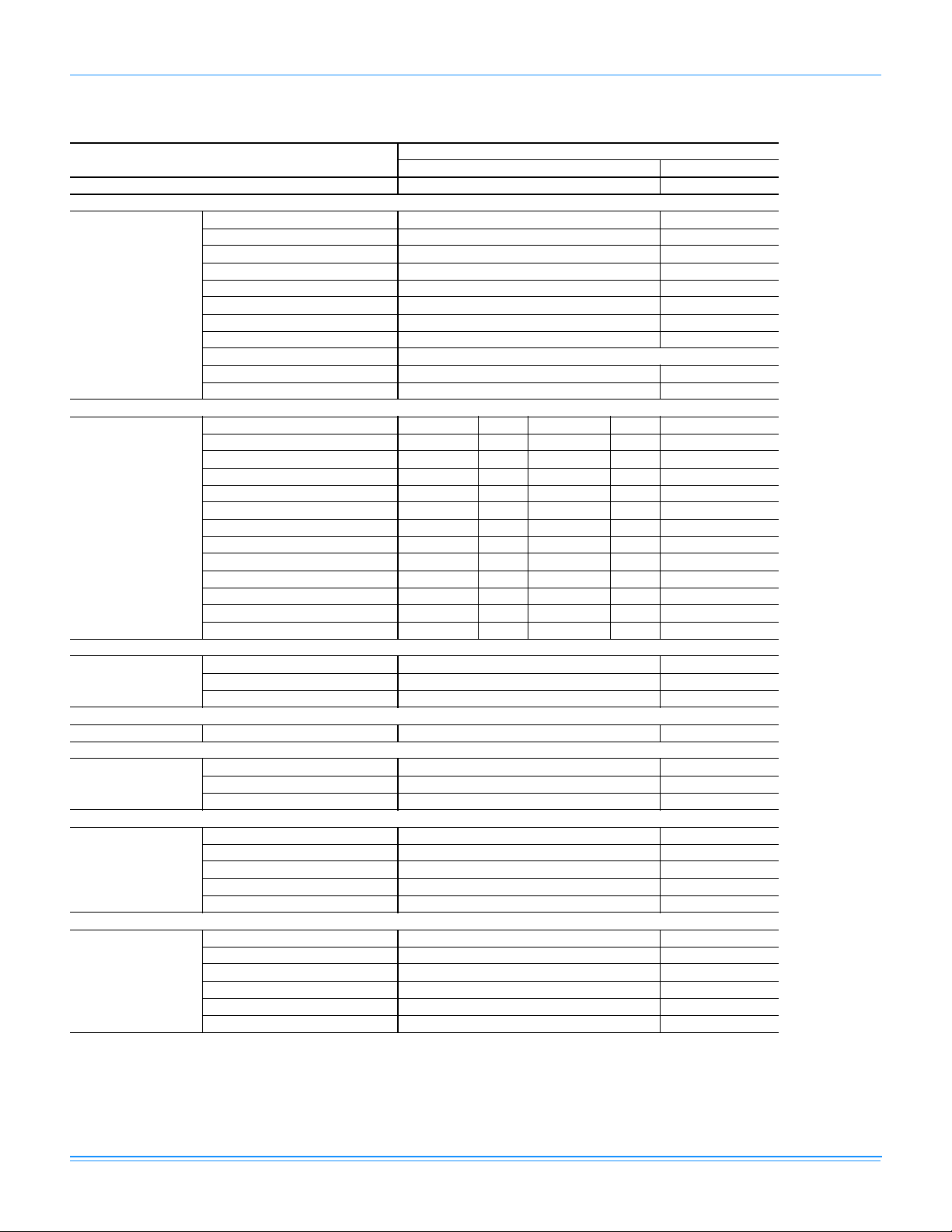

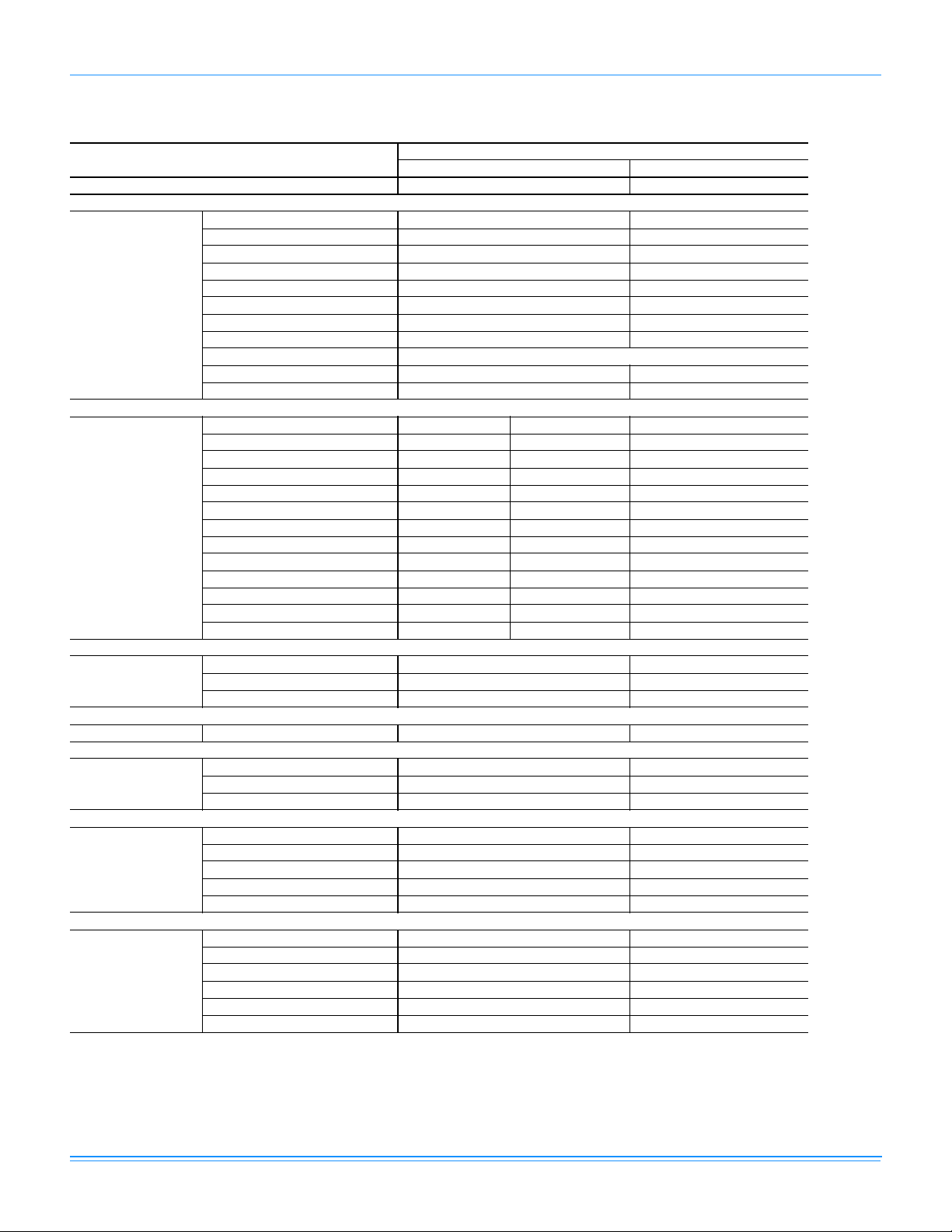

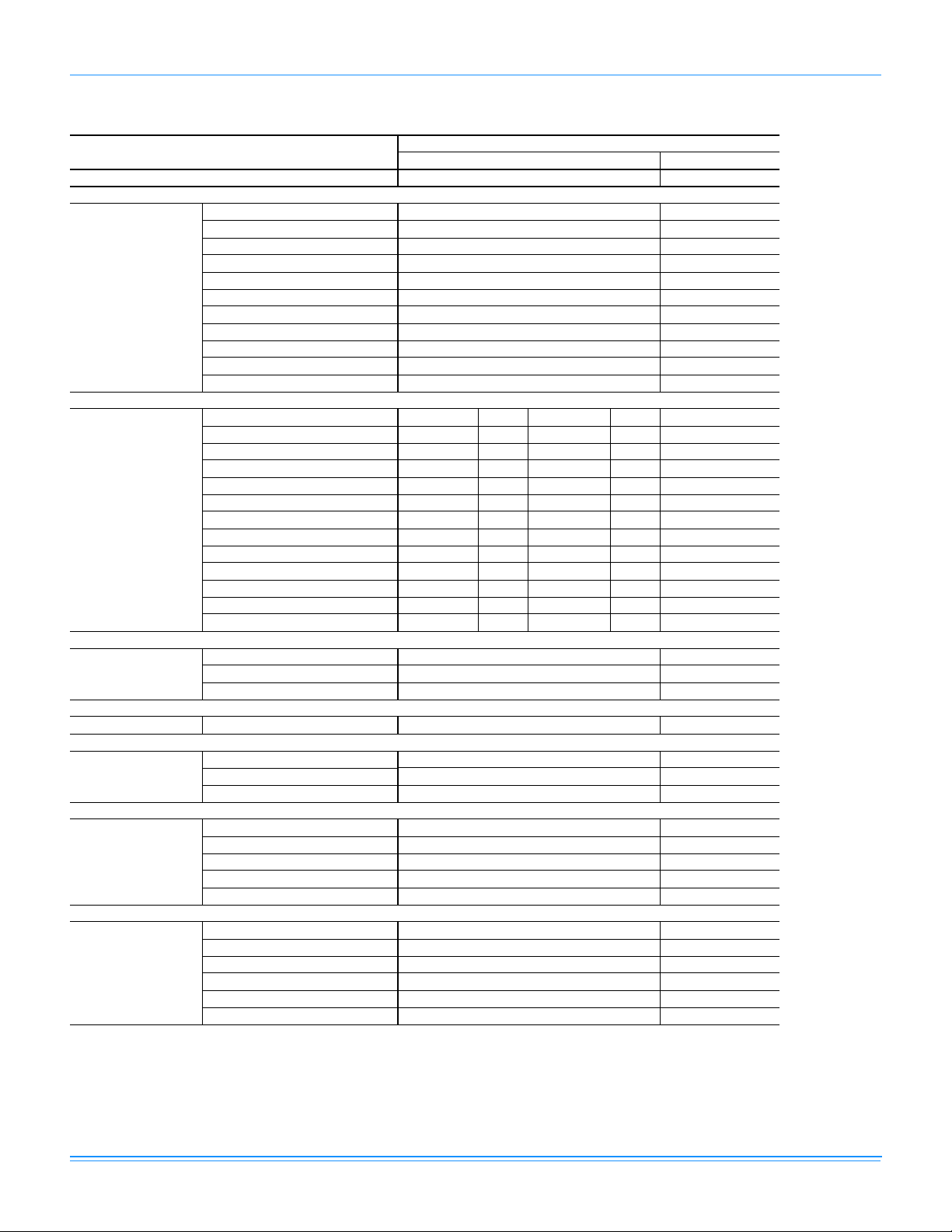

ZX05 Physical Data

Component

Models

ZXG05 ZXE05

Nominal Tonnage 4 4

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 49700 49700

AHRI net capacity (Btu) 45000 45000

EER 11 11

SEER 13 13

IEER - -

Nominal CFM 1600 1600

System power (KW) 3.6 3.6

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 3-12 3-12

System 2 - -

AHRI HEATING

PERFORMANCE

Heating Option L D M E -

Heating model Low (Low-NOx) Low Med (Low-NOx) Med -

1st. Stage Heat input (K Btu) - - - 82 -

2nd. Stage Heat input (K Btu) 60 70 90 114 -

1st. Stage Heat output (K Btu) - - - 66 -

2nd. Stage Heat output (K Btu) 48 56 72 91 -

AFUE % -

Steady state efficiency (%) 80 80 80 80 -

No. burners 2 2 3 3 -

No. stages 1 1 1 2 -

Temperature Rise Range (ºF) 22-37 26-43 33-56 42-70 -

Gas Limit Setting (ºF) 150 150 140 140 -

Gas piping connection (in.) 1/2 1/2 1/2 1/2 -

DIMENSIONS (inches)

Length 74.1 74.1

Width 48.9 48.9

Height 32.5 32.5

OPERATING WT. (lbs.) 552 498

COMPRESSORS

Type Scroll Scroll

Quantity 1 1

Unit Capacity Steps (%) 100 100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 16.3 16.3

Rows 1 1

Fins per inch 23 23

Tube diameter (in./MM) .63/16 .63/16

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 5.5 5.5

Rows 3 3

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control Orifice Orifice

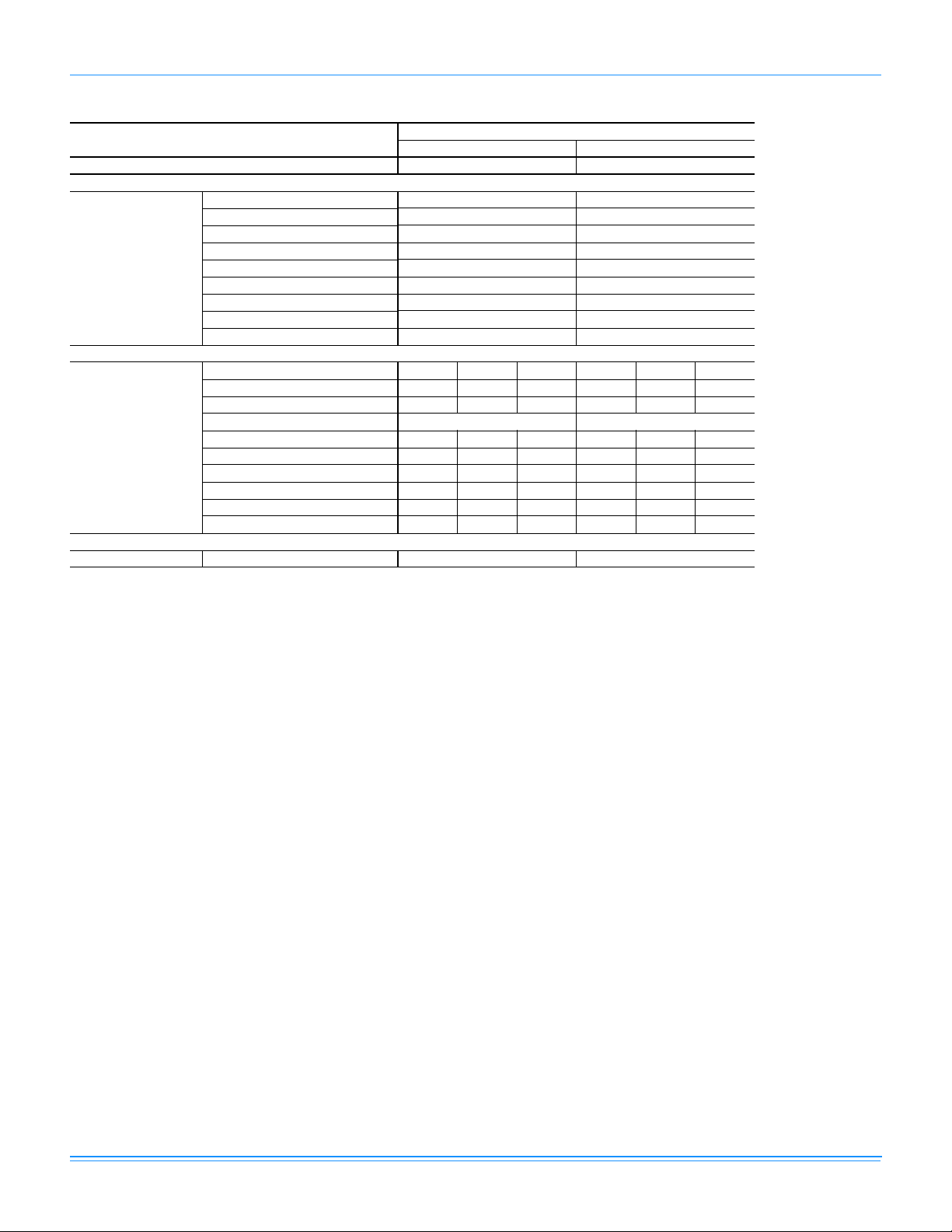

1068152-YTG-A-1013

Johnson Controls Unitary Products 15

CONDENSER

FAN DATA

Quantity of fans 1 1

Fan diameter (Inch) 22 22

Type Prop Prop

Drive type Direct Direct

Quantity of motors 1 1

Motor HP each 1/4 1/4

No. speeds 1 1

RPM 1100 1100

Nominal total CFM 3800 3800

EVAP FAN DATA

DIRECT DRIVE

Airflow Option A A

Quantity 1 1.0

Fan Size (Inch) 10 x 10 10 x 10

Type Centrifugal Centrifugal

Motor HP 1 1

RPM 1050 1050

EVAP FAN DATA

BELT DRIVE

Airflow Option B C B C

Quantity 1 1 1 1

Fan Size (Inch) 10 x 10 10 x 10 10 x 10 10 x 10

Type Centrifugal Centrifugal

Motor Sheave 1VL34 1VL44 1VL34 1VL44

Blower Sheave AK46 AK46 AK46 AK46

Belt A39 A40 A39 A40

Motor HP each 1.5 1.5 1.5 1.5

RPM 1725 1725 1725 1725

Frame size 56Y 56Y 56Y 56Y

FILTERS Quantity - Size 2 - (16 x 25 x 2)

1

2 - (16 x 25 x 2)

1

1. 2 in. Throwaway, Standard, MERV 4 (Minimum Efficiency Reporting Value).

ZX05 Physical Data (Continued)

Component

Models

ZXG05 ZXE05

Nominal Tonnage 4 4

1068152-YTG-A-1013

16 Johnson Controls Unitary Products

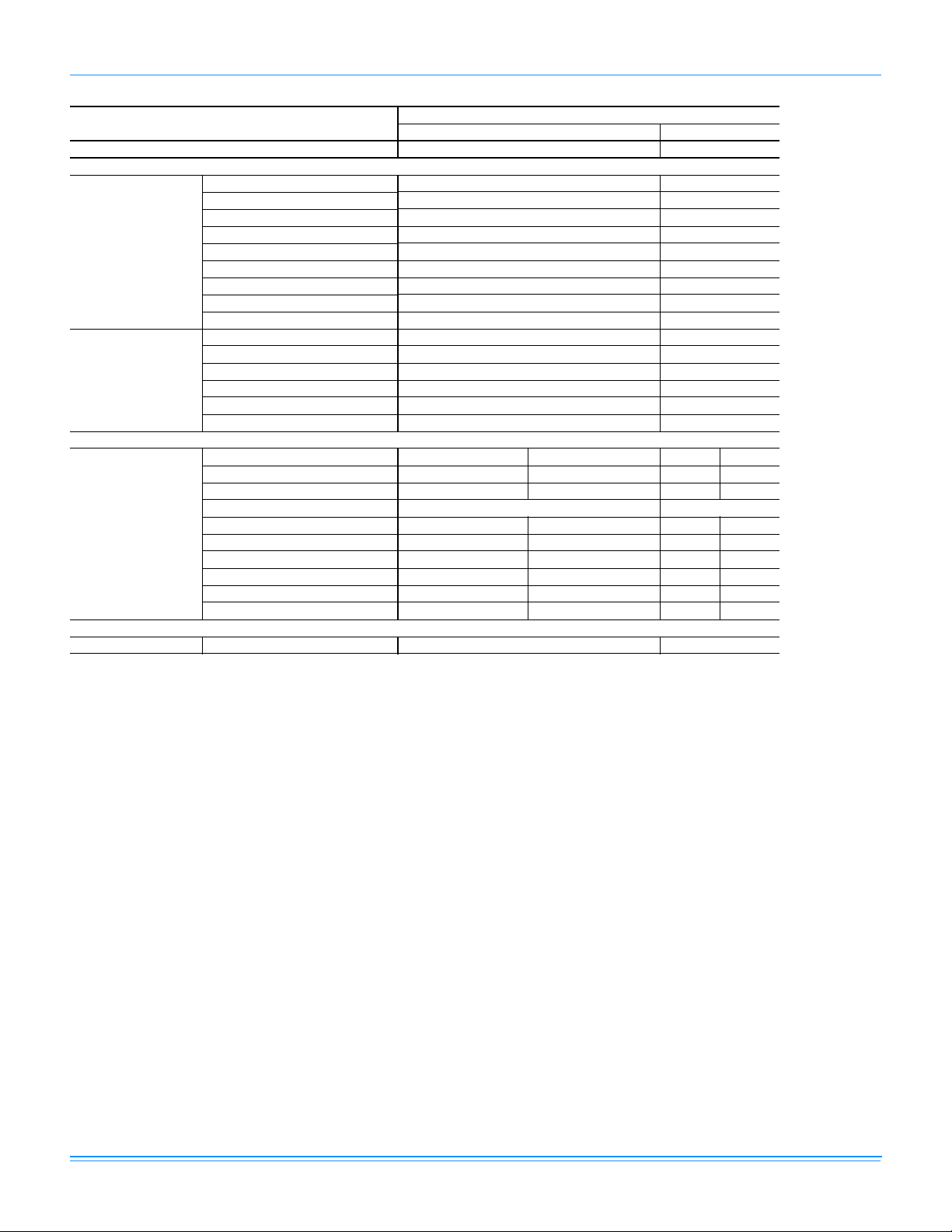

ZX06 Physical Data

Component

Models

ZXG06 ZXE06

Nominal Tonnage 5 5

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 63700 63700

AHRI net capacity (Btu) 59000 59000

EER 11 11

SEER 13 13

IEER - -

Nominal CFM 1800 1800

System power (KW) 4.6 4.6

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 5-4 5-4

System 2 - -

AHRI HEATING

PERFORMANCE

Heating Option L D M E -

Heating model Low (Low-NOx) Low Med (Low-NOx) Med -

1st. Stage Heat input (K Btu) - - - - -

2nd. Stage Heat input (K Btu) 60 70 90 114 -

1st. Stage Heat output (K Btu) - - - - -

2nd. Stage Heat output (K Btu) 48 56 72 91 -

AFUE % -

Steady state efficiency (%) 80 80 80 80 -

No. burners 2 2 3 3 -

No. stages 1 1 1 1 -

Temperature Rise Range (ºF) 18-30 21-35 27-44 34-56 -

Gas Limit Setting (ºF) 150 150 140 140 -

Gas piping connection (in.) 1/2 1/2 1/2 1/2 -

DIMENSIONS (inches)

Length 74.1 74.1

Width 48.9 48.9

Height 32.5 32.5

OPERATING WT. (lbs.) 584 530

COMPRESSORS

Type Scroll Scroll

Quantity 1 1

Unit Capacity Steps (%) 100 100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 16.3 16.3

Rows 1 1

Fins per inch 23 23

Tube diameter (in./MM) .79/20 .79/20

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 5.5 5.5

Rows 4 4

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control TXV TXV

1068152-YTG-A-1013

Johnson Controls Unitary Products 17

CONDENSER

FAN DATA

Quantity of fans 1 1

Fan diameter (Inch) 22 22

Type Prop Prop

Drive type Direct Direct

Quantity of motors 1 1

Motor HP each 1/2 1/2

No. speeds 1 1

RPM 1085 1085

Nominal total CFM 4500 4500

EVAP FAN DATA

DIRECT DRIVE

Airflow Option A A

Quantity 1 1

Fan Size (Inch) 10 x 10 10 x 10

Type Centrifugal Centrifugal

Motor HP 1 1

RPM 1050 1050

EVAP FAN DATA

BELT DRIVE

Airflow Option B C B C

Quantity 1 1 1 1

Fan Size (Inch) 10 x 10 10 x 10 10 x 10 10 x 10

Type Centrifugal Centrifugal

Motor Sheave 1VL34 1VL44 1VL44 1VL44

Blower Sheave AK41 AK41 AK41 AK41

Belt A37 A39 A37 A39

Motor HP each 1.5 2 1.5 2

RPM 1725 1725 1725 1725

Frame size 56Y 56Y 56Y 56Y

FILTERS Quantity - Size 2 - (16 x 25 x 2)

1

2 - (16 x 25 x 2)

1

1. 2 in. Throwaway, Standard, MERV 4 (Minimum Efficiency Reporting Value).

ZX06 Physical Data (Continued)

Component

Models

ZXG06 ZXE06

Nominal Tonnage 5 5

1068152-YTG-A-1013

18 Johnson Controls Unitary Products

ZX07 Physical Data

Component

Models

ZXG07 ZXE07

Nominal Tonnage 6 6

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 76600 76600

AHRI net capacity (Btu) 69000 69000

EER 11 11

SEER - -

IEER 11.9 12.1

Nominal CFM 2300 2300

System power (KW) 5.1 5.1

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 6-14 6-14

System 2 - -

AHRI HEATING

PERFORMANCE

Heating Option D E -

Heating model Low Med -

1st. Stage Heat input (K Btu) - - -

2nd. Stage Heat input (K Btu) 70 114 -

1st. Stage Heat output (K Btu) - - -

2nd. Stage Heat output (K Btu) 56 91 -

AFUE % -

Steady state efficiency (%) 80 80 -

No. burners 2 3 -

No. stages 1 1 -

Temperature Rise Range (ºF) 17-29 28-47 -

Gas Limit Setting (ºF) 150 140 -

Gas piping connection (in.) 1/2 1/2 -

DIMENSIONS (inches)

Length 74.1 74.1

Width 48.9 48.9

Height 40.6 40.6

OPERATING WT. (lbs.) 646 592

COMPRESSORS

Type Scroll Scroll

Quantity 1 1

Unit Capacity Steps (%) 100 100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 21.1 21.1

Rows 1 1

Fins per inch 23 23

Tube diameter (in./MM) .79/20 .79/20

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 7.3 7.3

Rows 4 4

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control TXV TXV

1068152-YTG-A-1013

Johnson Controls Unitary Products 19

CONDENSER

FAN DATA

Quantity of fans 1 1

Fan diameter (Inch) 22 22

Type Prop Prop

Drive type Direct Direct

Quantity of motors 1 1

Motor HP each 1/2 1/2

No. speeds 1 1

RPM 1085 1085

Nominal total CFM 4600 4600

EVAP FAN DATA

BELT DRIVE

Airflow Option A B C A B C

Quantity 1 1 1 1 1 1

Fan Size (Inch) 11 x 10 11 x 10 11 x 10 11 x 10 11 x 10 11 x 10

Type Centrifugal Centrifugal

Motor Sheave 1VL34 1VL44 1VP50 1VL34 1VL44 1VP50

Blower Sheave AK51 AK51 AK51 AK51 AK51 AK51

Belt A39 A40 A41 A39 A40 A41

Motor HP each 1.5 2 3 1.5 2 3

RPM 1725 1725 1725 1725 1725 1725

Frame size 56Y 56Y 56HZ 56Y 56Y 56HZ

FILTERS Quantity - Size 4 - (16 x 16 x 2)

1

4 - (16 x 16 x 2)

1

1. 2 in. Throwaway, Standard, MERV 4 (Minimum Efficiency Reporting Value).

ZX07 Physical Data (Continued)

Component

Models

ZXG07 ZXE07

Nominal Tonnage 6 6

1068152-YTG-A-1013

20 Johnson Controls Unitary Products

ZX08 Physical Data

Component

Models

ZXG08 ZXE08

Nominal Tonnage 7.5 7.5

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 94000 94000

AHRI net capacity (Btu) 85000 85000

EER 11 11.2

SEER - -

IEER 11.5 11.6

Nominal CFM 2900 2900

System power (KW) 6.6 6.6

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 4-8 4-8

System 2 4-12 4-12

AHRI HEATING

PERFORMANCE

Heating Option D E F -

Heating model Low Med High -

1st. Stage Heat input (K Btu) 90 125 176 -

2nd. Stage Heat input (K Btu) 125 180 220 -

1st. Stage Heat output (K Btu) 72 100 141 -

2nd. Stage Heat output (K Btu) 100 144 176 -

AFUE % -

Steady state efficiency (%) 80 80 80 -

No. burners 3 4 5 -

No. stages 2 2 2 -

Temperature Rise Range (ºF) 25-41 36-59 43-72 -

Gas Limit Setting (ºF) 140 160 150 -

Gas piping connection (in.) 3/4 3/4 3/4 -

DIMENSIONS (inches)

Length 87.1 87.1

Width 61.7 61.7

Height 40.6 40.6

OPERATING WT. (lbs.) 893 791

COMPRESSORS

Type Scroll Scroll

Quantity 2 2

Unit Capacity Steps (%) 50/100 50/100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 21.1 21.1

Rows 1 1

Fins per inch 23 23

Tube diameter (in./MM) 1/25 1/25

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 8.9 8.9

Rows 3 3

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control Orifice Orifice

1068152-YTG-A-1013

Johnson Controls Unitary Products 21

CONDENSER

FAN DATA

Quantity of fans 2 2

Fan diameter (Inch) 22 22

Type Prop Prop

Drive type Direct Direct

Quantity of motors 2 2

Motor HP each 1/2 1/2

No. speeds 1 1

RPM 1085 1085

Nominal total CFM 7600 7600

EVAP FAN DATA

BELT DRIVE

Airflow Option A B C A B C

Quantity 111111

Fan Size (Inch) 15 X 15 15 X 15 15 X 15 15 X 15 15 X 15 15 X 15

Type Centrifugal Centrifugal

Motor Sheave 1VL34 1VL44 1VP50 1VL34 1VL44 1VP50

Blower Sheave AK74 AK74 AK74 AK74 AK74 AK74

Belt A47 A48 A48 A47 A48 A48

Motor HP each 1.5 2 3 1.5 2 3

RPM 1725 1725 1725 1725 1725 1725

Frame size 56Y 56Y 56HZ 56Y 56Y 56HZ

FILTERS Quantity - Size 4 - (16 x 20 x 2)

1

4 - (16 x 20 x 2)

1

1. 2 in. Throwaway, Standard, MERV 4 (Minimum Efficiency Reporting Value).

ZX08 Physical Data (Continued)

Component

Models

ZXG08 ZXE08

Nominal Tonnage 7.5 7.5

1068152-YTG-A-1013

22 Johnson Controls Unitary Products

ZX09 Physical Data

Component

Models

ZXG09 ZXE09

Nominal Tonnage 8.5 8.5

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 105600 105600

AHRI net capacity (Btu) 99000 99000

EER 11 11.2

SEER - -

IEER 11.7 11.9

Nominal CFM 3300 3300

System power (KW) 7.70 7.70

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 5-4 5-4

System 2 5-4 5-4

AHRI HEATING

PERFORMANCE

Heating Option D E F -

Heating model Low Med High -

1st. Stage Heat input (K Btu) 90 125 176 -

2nd. Stage Heat input (K Btu) 125 180 220 -

1st. Stage Heat output (K Btu) 72 100 141 -

2nd. Stage Heat output (K Btu) 100 144 176 -

AFUE % -

Steady state efficiency (%) 80 80 80 -

No. burners 3 4 5 -

No. stages 2 2 2 -

Temperature Rise Range (ºF) 22-36 31-52 38-64 -

Gas Limit Setting (ºF) 140 160 150 -

Gas piping connection (in.) 3/4 3/4 3/4 -

DIMENSIONS (inches)

Length 87.2 87.2

Width 61.7 61.7

Height 48.6 48.6

OPERATING WT. (lbs.) 954 852

COMPRESSORS

Type Scroll Scroll

Quantity 2 2

Unit Capacity Steps (%) 50/100 50/100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 25.5 25.5

Rows 1 1

Fins per inch 23 23

Tube diameter (in./MM) 1/25 1/25

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 11.1 11.1

Rows 3 3

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control Orifice Orifice

1068152-YTG-A-1013

Johnson Controls Unitary Products 23

CONDENSER

FAN DATA

Quantity of fans 2 2

Fan diameter (Inch) 22 22

Type Prop Prop

Drive type Direct Direct

Quantity of motors 2 2

Motor HP each 1/2 1/2

No. speeds 1 1

RPM 1085 1085

Nominal total CFM 8600 8600

EVAP FAN DATA

BELT DRIVE

Airflow Option A B C A B C

Quantity 111111

Fan Size (Inch) 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15

Type Centrifugal Centrifugal

Motor Sheave 1VL34 1VL44 1VP50 1VL34 1VL44 1VP50

Blower Sheave AK74 AK74 AK74 AK74 AK74 AK74

Belt A47 A48 A50 A47 A48 A50

Motor HP each 1.5 1.5 3 1.5 1.5 3

RPM 1725 1725 1725 1725 1725 1725

Frame size 56Y 56Y 56HZ 56Y 56Y 56HZ

FILTERS Quantity - Size 4 - (20 x 20 x 2)

1

4 - (20 x 20 x 2)

1

1. 2 in. Throwaway, Standard, MERV 4 (Minimum Efficiency Reporting Value).

ZX09 Physical Data (Continued)

Component

Models

ZXG09 ZXE09

Nominal Tonnage 8.5 8.5

1068152-YTG-A-1013

24 Johnson Controls Unitary Products

ZX12 Physical Data

Component

Models

ZXG12 ZXE12

Nominal Tonnage 10 10

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 125600 125600

AHRI net capacity (Btu) 116000 116000

EER 11 11.2

SEER - -

IEER 11.8 12.0

Nominal CFM 3400 3400

System power (KW) 9.2 9.2

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 5-12 5-12

System 2 5-12 5-12

AHRI HEATING

PERFORMANCE

Heating Option D E -

Heating model Low Med -

1st. Stage Heat input (K Btu) 125 176 -

2nd. Stage Heat input (K Btu) 180 220 -

1st. Stage Heat output (K Btu) 100 141 -

2nd. Stage Heat output (K Btu) 144 176 -

AFUE % -

Steady state efficiency (%) 80 80 -

No. burners 4 5 -

No. stages 2 2 -

Temperature Rise Range (ºF) 27-44 33-54 -

Gas Limit Setting (ºF) 160 150 -

Gas piping connection (in.) 3/4 3/4 -

DIMENSIONS (inches)

Length 87.2 87.2

Width 61.7 61.7

Height 48.6 48.6

OPERATING WT. (lbs.) 985 879

COMPRESSORS

Type Scroll Scroll

Quantity 2 2

Unit Capacity Steps (%) 50/100 50/100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 25.5 25.5

Rows 1 1

Fins per inch 23 23

Tube diameter (in./MM) 1/25 1/25

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 11.1 11.1

Rows 4 4

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control Orifice Orifice

1068152-YTG-A-1013

Johnson Controls Unitary Products 25

CONDENSER

FAN DATA

Quantity of fans 2 2

Fan diameter (Inch) 22 22

Type Prop Prop

Drive type Direct Direct

Quantity of motors 2 2

Motor HP each 1/2 1/2

No. speeds 1 1

RPM 1085 1085

Nominal total CFM 8600 8600

EVAP FAN DATA

BELT DRIVE

Airflow Option A B C A B C

Quantity 1 1 1 1 1 1

Fan Size (Inch) 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15

Type Centrifugal Centrifugal

Motor Sheave 1VL44 1VP50 1VP56 1VL44 1VP50 1VP56

Blower Sheave AK79 AK79 BK85 AK79 AK79 BK85

Belt A50 A50 BX52 A50 A50 BX52

Motor HP each 1.5 3 5 1.5 3 5

RPM 1725 1725 1725 1725 1725 1725

Frame size 56Y 56HZ 145TY 56Y 56HZ 145TY

FILTERS Quantity - Size 4 - (20 x 20 x 2)

1

4 - (20 x 20 x 2)

1

1. 2 in. Throwaway, Standard, MERV 4 (Minimum Efficiency Reporting Value).

ZX12 Physical Data (Continued)

Component

Models

ZXG12 ZXE12

Nominal Tonnage 10 10

1068152-YTG-A-1013

26 Johnson Controls Unitary Products

ZX14 Physical Data

Component

Models

ZXG14 ZXE14

Nominal Tonnage 12.5 12.5

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 145000 145000

AHRI net capacity (Btu) 135000 135000

EER 10.8 11.0

SEER - -

IEER 11 11.2

Nominal CFM 4000 4000

System power (KW) 10.8 10.8

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 6-8 6-8

System 2 6-12 6-12

AHRI HEATING

PERFORMANCE

Heating Option D E -

Heating model Low Med -

1st. Stage Heat input (K Btu) 125 176 -

2nd. Stage Heat input (K Btu) 180 220 -

1st. Stage Heat output (K Btu) 100 141 -

2nd. Stage Heat output (K Btu) 144 176 -

AFUE % -

Steady state efficiency (%) 80 80 -

No. burners 4 5 -

No. stages 2 2 -

Temperature Rise Range (ºF) 21-36 26-43 -

Gas Limit Setting (ºF) 160 150 -

Gas piping connection (in.) 3/4 3/4 -

DIMENSIONS (inches)

Length 87.2 87.2

Width 61.7 61.7

Height 55.26 55.26

OPERATING WT. (lbs.) 1047 941

COMPRESSORS

Type Scroll Scroll

Quantity 2 2

Unit Capacity Steps (%) 50/100 50/100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 24.9 24.9

Rows 1 1

Fins per inch 21 21

Tube diameter (in./MM) 1.26/32 1.26/32

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 11.1 11.1

Rows 4 4

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control TXV TXV

1068152-YTG-A-1013

Johnson Controls Unitary Products 27

CONDENSER

FAN DATA

Quantity of fans 1 1

Fan diameter (Inch) 30 30

Type Prop Prop

Drive type Direct Direct

Quantity of motors 1 1

Motor HP each 1 1/2 1 1/2

No. speeds 1 1

RPM 1140 1140

Nominal total CFM 10600 10600

EVAP FAN DATA

BELT DRIVE

Airflow Option A B C A B C

Quantity 1 1 1 1 1 1

Fan Size (Inch) 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15

Type Centrifugal Centrifugal

Motor Sheave 1VL44 1VP50 1VP56 1VL44 1VP50 1VP56

Blower Sheave AK79 AK79 BK85 AK79 AK79 BK85

Belt A50 A52 BX54 A50 A52 BX54

Motor HP each 2.9 3.7 5.25 2.9 3.7 5.25

RPM 1750 1750 1750 1750 1750 1750

Frame size 56Z 184TZ 184TZ 56Z 184TZ 184TZ

FILTERS Quantity - Size 4 - (16 x 16 x 2)

1

4 - (16 x 16 x 2)

1

1. 2 in. Throwaway, Standard, MERV 4 (Minimum Efficiency Reporting Value).

ZX14 Physical Data (Continued)

Component

Models

ZXG14 ZXE14

Nominal Tonnage 12.5 12.5

1068152-YTG-A-1013

28 Johnson Controls Unitary Products

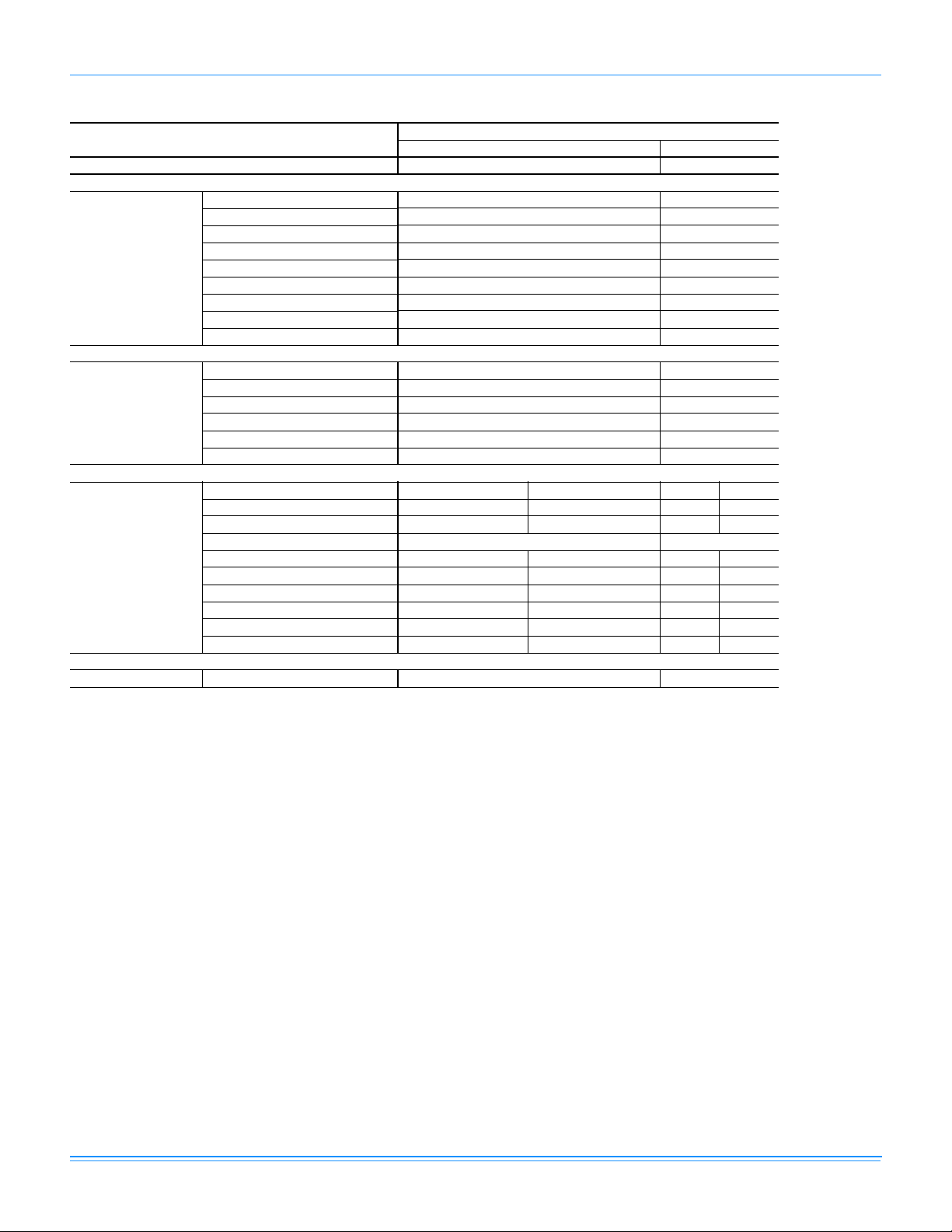

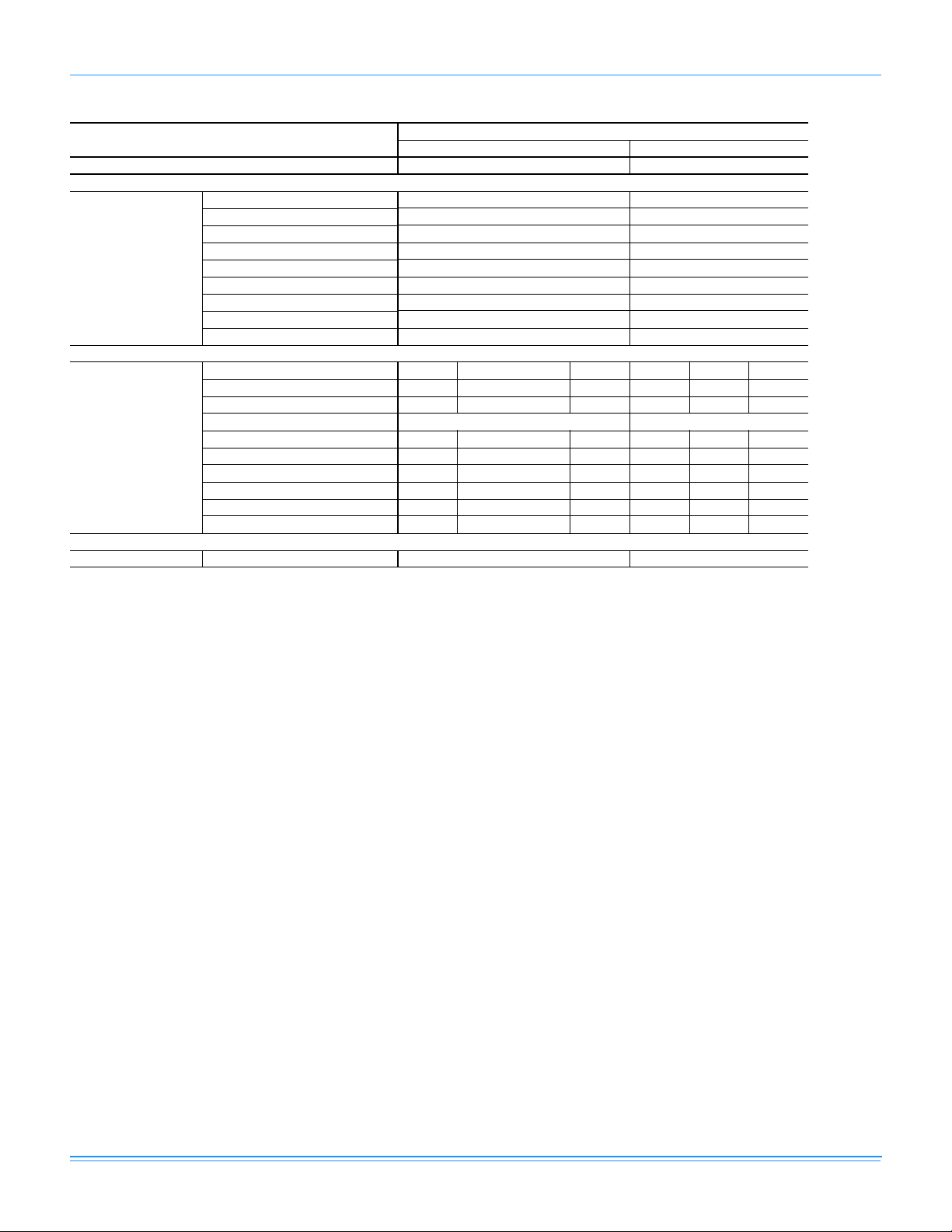

ZY04 Physical Data

Component

Models

ZYG04 ZYE04

Nominal Tonnage 3 3

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 40700 40700

AHRI net capacity (Btu) 36000 36000

EER 12 12

SEER 15 15

IEER - -

Nominal CFM 1200 1200

System power (KW) 2.60 2.60

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 4-10 4-10

System 2 - -

AHRI HEATING

PERFORMANCE

Heating Option L D M E -

Heating model Low (Low-NOx) Low Med (Low-NOx) Med -

1st. Stage Heat input (K Btu) - 49 - 82 -

2nd. Stage Heat input (K Btu) 60 70 90 114 -

1st. Stage Heat output (K Btu) - 39 - 66 -

2nd. Stage Heat output (K Btu) 48 56 72 91 -

AFUE % -

Steady state efficiency (%) 80 80 80 80 -

No. burners 2 2 3 3 -

No. stages 1 2 1 2 -

Temperature Rise Range (ºF) 30-49 35-58 44-74 56-80 -

Gas Limit Setting (ºF) 150 150 140 140 -

Gas piping connection (in.) 1/2 1/2 1/2 1/2 -

DIMENSIONS (inches)

Length 74.1 74.1

Width 48.9 48.9

Height 32.5 32.5

OPERATING WT. (lbs.) 527 481

COMPRESSORS

Type Scroll Scroll

Quantity 1 1

Unit Capacity Steps (%) 100 100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 16.3 16.3

Rows 1 1

Fins per inch 23 23

Tube diameter (in./MM) .63/16 .63/16

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 5.5 5.5

Rows 3 3

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control TXV TXV

1068152-YTG-A-1013

Johnson Controls Unitary Products 29

CONDENSER

FAN DATA

Quantity of fans 1 1

Fan diameter (Inch) 22 22

Type Prop Prop

Drive type Direct Direct

Quantity of motors 1 1

Motor HP each 1/4 1/4

No. speeds 1 1

RPM 1100 1100

Nominal total CFM 3800 3800

EVAP FAN DATA

DIRECT DRIVE

Airflow Option A A

Quantity 1 1

Fan Size (Inch) 10 x 10 10 x 10

Type Centrifugal Centrifugal

Motor HP 3/4 3/4

RPM 1050 1050

EVAP FAN DATA

BELT DRIVE

Airflow Option B C B C

Quantity 1 1 1 1

Fan Size (Inch) 10 x 10 10 x 10 10 x 10 10 x 10

Type Centrifugal Centrifugal

Motor Sheave 1VL34 1VL44 1VL34 1VL44

Blower Sheave AK46 AK46 AK46 AK46

Belt A39 A40 A39 A40

Motor HP each 1.5 1.5 1.5 1.5

RPM 1725 1725 1725 1725

Frame size 56Y 56Y 56Y 56Y

FILTERS Quantity - Size 2 - (16 x 25 x 2)

1

2 - (16 x 25 x 2)

1

1. 2 in. Throwaway, Standard, MERV 4 (Minimum Efficiency Reporting Value).

ZY04 Physical Data (Continued)

Component

Models

ZYG04 ZYE04

Nominal Tonnage 3 3

1068152-YTG-A-1013

30 Johnson Controls Unitary Products

ZY05 Physical Data

Component

Models

ZYG05 ZYE05

Nominal Tonnage 4 4

AHRI COOLING

PERFORMANCE

Gross Capacity @ AHRI A point (Btu) 54800 54800

AHRI net capacity (Btu) 49000 49000

EER 12 12

SEER 15.4 15.4

IEER - -

Nominal CFM 1600 1600

System power (KW) 3.50 3.50

Refrigerant type R-410A R-410A

Refrigerant charge (lb-oz)

System 1 6-8 6-8

System 2 - -

AHRI HEATING

PERFORMANCE

Heating Options L D M E -

Heating model Low (Low-NOx) Low Med (Low-NOx) Med -

1st. Stage Heat input (K Btu) - 49 - 82 -

2nd. Stage Heat input (K Btu) 60 70 90 114 -

1st. Stage Heat output (K Btu) - 39 - 66 -

2nd. Stage Heat output (K Btu) 48 56 72 91 -

AFUE % -

Steady state efficiency (%) 80 80 80 80 -

No. burners 2 2 3 3 -

No. stages 1 2 1 2 -

Temperature Rise Range (ºF) 22-37 26-43 33-56 42-70 -

Gas Limit Setting (ºF) 150 150 140 140 -

Gas piping connection (in.) 1/2 1/2 1/2 1/2 -

DIMENSIONS (inches)

Length 74.1 74.1

Width 48.9 48.9

Height 40.6 40.6

OPERATING WT. (lbs.) 618 564

COMPRESSORS

Type Scroll Scroll

Quantity 1 1

Unit Capacity Steps (%) 100 100

CONDENSER

COIL DATA

Face area (Sq. Ft.) 21.1 21.1

Rows 1 1

Fins per inch 23 23

Tube diameter (in./MM) .79/20 .79/20

Circuitry Type 2-pass Microchannel 2-pass Microchannel

EVAPORATOR

COIL DATA

Face area (Sq. Ft.) 7.3 7.3

Rows 3 3

Fins per inch 15 15

Tube diameter 0.375 0.375

Circuitry Type Intertwined Intertwined

Refrigerant control TXV TXV

Loading...

Loading...