Page 1

User's

ROTAMASS 3-Series

Manual

addition to

IM 01R04B04-00E

Coriolis - Massflowmeter

Integral Type RCCT3

Remote Type RCCF31 + RCCS3

Fieldbus Communication Type

IM 01R04B05-00E-E

Rota Yokogawa GmbH & Co. KG

Rheinstr. 8

D-79664 Wehr

Germany

IM 01R04B05-00E-E

2nd edition, June 2007

Page 2

Blank Page

Page 3

CONTENTS

Contents

1. INTRODUCTION ..................................................................................1-1

1.1 Using the Coriolis Flowmeter Safely ...............................................................1-2

1.2 Warranty .............................................................................................................1-3

1.3 Instruction according EMC ............................................................................... 1-3

1.4 ATEX Documentation ........................................................................................ 1-4

1.5 Disposal, Cleaning and Return ........................................................................1-6

2. AMPLIFIER FOR FIELDBUS COMMUNICATION..............................2-1

3. ABOUT FIELDBUS ..............................................................................3-1

3.1 Outline ................................................................................................................ 3-1

3.2 Internal Structure of Rotamass ........................................................................3-1

3.2.1 System/Network Management VFD...................................................................... 3-1

3.2.2 Function Block VFD ............................................................................................... 3-1

3.3 Logical Structure of Each Block ......................................................................3-2

3.4 Wiring System Configuration ...........................................................................3-2

4. GETTING STARTED ...........................................................................4-1

4.1 Connection of Devices ..................................................................................... 4-1

4.2 Host Setting .......................................................................................................4-2

4.3 Power-on of Rotamass and Bus ...................................................................... 4-2

4.4 Integration of DD ...............................................................................................4-3

4.5 Reading the Parameters ...................................................................................4-3

4.6 Continuous Record of Values ..........................................................................4-3

4.7 Generation of Alarm...........................................................................................4-3

5. CONFIGURATION ................................................................................5-1

5.1 Network Design .................................................................................................5-1

5.2 Network Definition.............................................................................................5-1

5.3 Function Block Link Definitions.......................................................................5-2

5.4 Setting of Tags and Addresses ........................................................................5-3

5.5 Communication Setting ....................................................................................5-4

5.5.1 VCR Setting ............................................................................................................ 5-4

5.5.2 Function Block Execution Control ...................................................................... 5-5

5.6 Block Setting .....................................................................................................5-5

5.6.1 Link Objects ........................................................................................................... 5-5

5.6.2 Trend Objects ........................................................................................................ 5-5

5.6.3 View Objects .......................................................................................................... 5-6

5.6.4 AI Function Block Parameters ............................................................................ 5-12

All Rights Reserved, Copyright 2003. Rota Yokogawa GmbH & Co. KG

i

IM 01R04B05-00E-E

2nd edition, June 2007

Page 4

CONTENTS

6. IN-PROCESS OPERATION .................................................................6-1

6.1 Mode Transition .................................................................................................6-1

6.2 Generation of Alarm...........................................................................................6-1

6.2.1 Indication of Alarm ................................................................................................. 6-1

6.2.2 Alarms and Events ................................................................................................ 6-3

6.3 Simulation Function ..........................................................................................6-3

7. DEVICE STATUS ................................................................................ 7-1

8. GENERAL SPECIFICATIONS ............................................................8-1

9. EXPLOSION PROTECTED TYPE INSTRUMENTS ..........................9-1

9.1 ATEX .................................................................................................................. 9-1

9.1.1 Technical Data ....................................................................................................... 9-1

9.1.2 Installation .............................................................................................................. 9-3

9.1.3 Operation................................................................................................................ 9-5

9.1.4 Maintenance and repair ........................................................................................ 9-5

9.1.5 Name Plates ........................................................................................................... 9-5

9.1.6 I.S. fieldbus system complying with FISCO ......................................................... 9-7

9.2 FM .......................................................................................................................9-9

9.2.1 Technical Data ....................................................................................................... 9-9

9.2.2 Installation ............................................................................................................ 9-10

9.2.3 General warnings .................................................................................................9-11

9.2.4 Name Plates ......................................................................................................... 9-12

9.2.5 Control drawings ................................................................................................. 9-13

9.3 IECEx ................................................................................................................9-16

9.3.1 Technical Data ..................................................................................................... 9-16

9.3.2 Installation ............................................................................................................ 9-18

9.3.3 Operation.............................................................................................................. 9-19

9.3.4 Maintenance and repair ...................................................................................... 9-19

9.3.5 Name Plates ......................................................................................................... 9-19

9.3.6 I.S. fieldbus system complying with FISCO (only /EF4).................................... 9-22

9.4 INMETRO (Brazil).............................................................................................9-22

APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF

Rotamass ............................................................................................ A-1

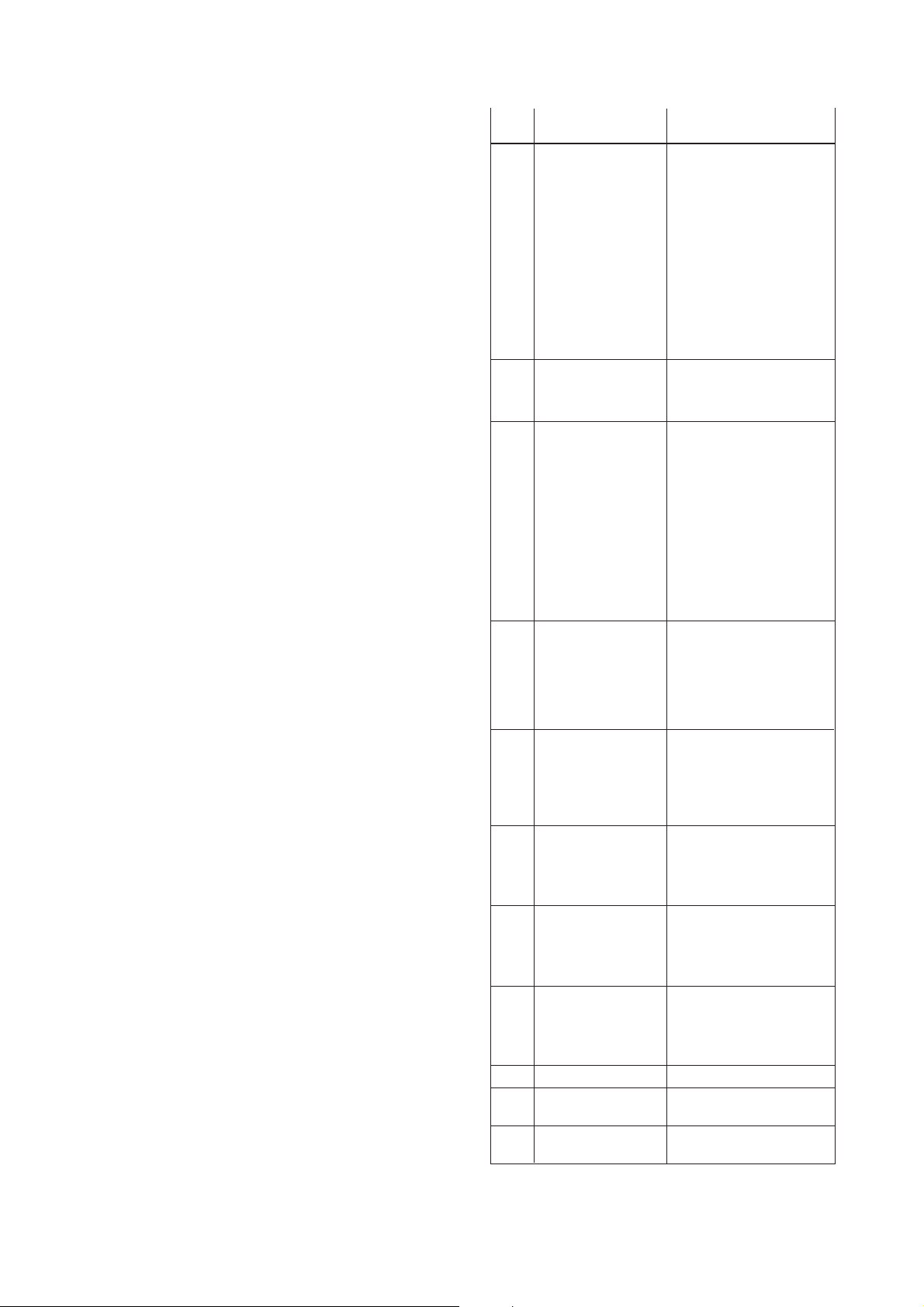

A1.1 Resource Block ................................................................................................ A-1

A1.2 Al Function Block .............................................................................................. A-4

A1.3 Transducer Block .............................................................................................. A-8

A1.4 Intergartor (IT) Block........................................................................................ A-14

APPENDIX 2. APPLICATION, SETTING AND CHANGE OF BASIC PA-

RAMETERS ....................................................................................... A-27

A2.1 Applications and Selection of Basic Parameters............................................. A-27

A2.2 Setting and Change of

Basic Parameters............................................................................................... A-28

A2.3 Setting the AI Function Blocks ......................................................................... A-28

A2.4 Setting the Transducer Block .......................................................................... A-30

IM 01R04B05-00E-E

2nd edition, June 2007

ii

Page 5

CONTENTS

APPENDIX 3. OPERATION OF EACH PARAMETER IN FAILURE MODE

A-33

APPENDIX 4. FUNCTION DIAGRAMS OF FUNCTION BLOCKS .... A-41

A4.1 AI Function Block......................................................................................... A-41

APPENDIX 5. PID BLOCK .................................................................. A-43

A5.1 Function Diagram ........................................................................................ A-43

A5.2 Functions of PID Block ............................................................................... A-43

A5.3 Parameters of PID Block ............................................................................. A-44

A5.4 PID Computation Details ............................................................................. A-46

A5.4.1 PV-proportional and -derivative Type PID (I-PD) Control Algorithm versus PV-

derivative Type PID (PI-D) Control Algorithm ....................................................... A-46

A5.4.2 PID Control Parameters .................................................................................... A-46

A5.5 Control Output ............................................................................................. A-46

A5.5.1 Velocity Type Output Action .............................................................................. A-46

A5.6 Direction of Control Action .......................................................................... A-46

A5.7 Control Action Bypass ................................................................................ A-47

A5.8 Feed-forward ................................................................................................ A-47

A5.9 Block Modes................................................................................................. A-47

A5.9.1 Mode Transitions............................................................................................... A-48

A5.10 Bumpless Transfer .................................................................................... A-48

A5.11 Setpoint Limiters ........................................................................................ A-48

A5.11.1 When PID Block Is in AUTO Mode ................................................................. A-48

A5.11.2 When PID Block Is in CAS or RCAS Mode .................................................... A-48

A5.12 External-output Tracking........................................................................... A-49

A5.13 Measured-value Tracking .......................................................................... A-49

A5.13.1 CONTROL_OPTS ............................................................................................ A-49

A5.14 Initialization and Manual Fallback (IMAN) ................................................ A-49

A5.15 Manual Fallback ......................................................................................... A-50

A5.15.1 STATUS_OPTS ................................................................................................ A-50

A5.16 Auto Fallback .............................................................................................. A-50

A5.17 Mode Shedding upon Computer Failure ................................................. A-50

A5.17.1 SHED_OPT ....................................................................................................... A-50

A5.18 Alarms ......................................................................................................... A-51

A5.18.1 Block Alarm (BLOCK_ALM) ............................................................................ A-51

A5.18.2 Process Alarms ................................................................................................ A-51

A5.19 Example of Block Connections ................................................................ A-52

APPENDIX 6. SOFTWARE DOWNLOAD ........................................... A-53

iii

IM 01R04B05-00E-E

2nd edition, June 2007

Page 6

CONTENTS

APPENDIX 7. LINK MASTER FUNCTIONS ....................................... A-61

A7.1 Link Active Scheduler ..................................................................................... A-61

A7.2 Link Master..................................................................................................... A-61

A7.3 Transfer of LAS .............................................................................................. A-62

A7.4 LM Functions .................................................................................................. A-63

A7.5 LM Parameters .............................................................................................. A-64

A7.5.1 LM Parameter List ............................................................................................. A-64

A7.5.2 Descriptions for LM Parameters ..................................................................... A-66

(1) DlmeLinkMasterCapabilitiesVariable ............................................................... A-66

(2) DlmeLinkMasterInfoRecord .............................................................................. A-66

(3) PrimaryLinkMasterFlagVariable ........................................................................ A-66

(4) LiveListStatusArrayVariable .............................................................................. A-66

(5) MaxTokenHoldTimeArray .................................................................................. A-66

(6) BootOperatFunctionalClass .............................................................................. A-66

(7) CurrentLinkSettingRecord and ConfiguredLinkSettingsRecord ................. A-66

(8) DlmeBasicInfo ..................................................................................................... A-67

(9) PlmeBasicCharacteristics ................................................................................. A-67

(10) ChannelStates .................................................................................................. A-67

(11) PlmeBasicInfo ................................................................................................... A-67

(12) LinkScheduleActivationVariable ..................................................................... A-67

(13) LinkScheduleListCharacteristicsRecord ...................................................... A-67

(14) DlmeScheduleDescriptor ................................................................................ A-68

(15) Domain ............................................................................................................... A-68

A7.6 FAQs.............................................................................................................. A-68

APPENDIX 8. DEVICEVIEWER WINDOW EXECUTED FROM PRM

(Plant Resource Manager) ............................................................. A-71

IM 01R04B05-00E-E

2nd edition, June 2007

iv

Page 7

1. INTRODUCTION

T

1. INTRODUCTION

This instrument has been adjusted at the factory

before shipment.

To ensure correct use of the instrument, please

read this manual thoroughly and fully understand

how to operate the instrument before operating it.

NOTE

This manual describes the hardware and software configurations of the Rotamass Coriolis

Massflowmeter.

Regarding This User's Manual

• This manual should be provided to the end

user.

• Before use, read this manual thoroughly to

comprehend its contents.

• The contents of this manual may be changed

without prior notice.

• All rights are reserved. No part of this manual

may be reproduced in any form without

Yokogawa's written permission.

• Yokogawa makes no warranty of any kind with

regard to this material, including, but not limited

to, implied warranties of merchantability and

suitability for a particular purpose.

• All reasonable effort has been made to ensure

the accuracy of the contents of this manual.

However, if any errors or omissions are found,

please inform Yokogawa.

• Yokogawa assumes no responsibilities for this

product except as stated in the warranty.

• Please note that this user's manual may not be

revised for any specification changes,

construction changes or operating part changes

that are not considered to affect function or

performance.

• If the customer or any third party is harmed by

the use of this product, Yokogawa assumes no

responsibility for any such harm owing to any

defects in the product which were not

predictable, or for any indirect damages.

Safety and Modification Precautions

• The following general safety precautions must be

observed during all phases of operation, service,

and repair of this instrument. Failure to comply

with these precautions or with specific

WARNINGS given elsewhere in this manual

violates safety standards of design,manufacture,

and intended use of the instrument. Yokogawa

assumes no liability for the customer's failure to

comply with these requirements. If this

instrument is used in a manner not specified in

this manual, the protection provided by this

instrument may be impaired.

• The following safety symbol marks are used in

this user's manual and instrument.

WARNING

A WARNING sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in injury or death of personnel.

CAUTION

A CAUTION sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in damage to or destruction of

part or all of the product.

IMPORTAN

An IMPORTANT sign denotes that attention is

required to avoid damage to the instrument or

system failure.

NOTE

A NOTE sign denotes information necessary for

essential understanding of operation and features.

1-1

IM 01R04B05-00E-E

2nd edition, June 2007

Page 8

1. INTRODUCTION

Protective grounding terminal

Functional grounding terminal

(This terminal should not be used as a

protective grounding terminal.)

Alternating current

Direct current

1.1 Using the Coriolis Flowmeter Safely

WARNING

(1) Installation

• Installation of the Coriolis flowmeter must be

performed by expert engineer or skilled personnel. No operator shall be permitted to perform

procedures relating to installation.

• The Coriolis flowmeter is a heavy instrument.

Be careful that no damage is caused to personnel through accidentally dropping it, or by

exerting excessive force on the Coriolis

flowmeter. When moving the Coriolis flowmeter,

always use a trolley and have at least two

people carry it.

• When the Coriolis flowmeter is processing hot

fluids, the instrument itself may become

extremely hot. Take sufficient care not to get

burnt.

• Where the fluid being processed is a toxic

substance, avoid contact with the fluid and

avoid inhaling any residual gas, even after the

instrument has been taken off the line for

maintenance and so forth.

• All procedures relating to installation must

comply with the electrical code of the country

where it is used.

(2) Wiring

• The wiring of the Coriolis flowmeter must be

performed by expert engineer or skilled personnel. No operator shall be permitted to perform

procedures relating to wiring.

• When connecting the wiring, check that the

supply voltage is within the range of the voltage

specified for this instrument before connecting

the power cable. In addition, check that no

voltage is applied to the power cable before

connecting the wiring.

• The protective grounding must be connected

securely at the terminal with the mark to

avoid danger to personnel.

(3) Operation

• Do not open the cover until the power has been

off for at least 10 minutes. Only expert engineer

or skilled personnel are permitted to open the

cover.

(4) Maintenance

• Maintenance on the Coriolis flowmeter should

be performed by expert engineer or skilled

personnel. No operator shall be permitted to

perform any operations relating to maintenance.

• Always conform to maintenance procedures

outlined in this manual. If necessary, contact

Yokogawa.

• Care should be taken to prevent the build up of

dirt, dust or other substances on the display

panel glass or data plate. If these surfaces do

get dirty, wipe them clean with a soft dry cloth.

(5) European Pressure Equipment Directive (PED)

• When using the instrument as a PED-compliant

product, be sure to read Chapter 10 before use.

(6) Hazardous Duty Type Instruments

• For explosion proof type instruments the

description in chapter 9 "EXPLOSION

PROTECTED TYPE INSTRUMENT" has

priority to the other descriptions in this instruction

manual.

• All instruction manuals for ATEX Ex related

products are availabel in English, German and

French. Should you require Ex related instructions

in your local language, you should contact

your nearest Yokogawa office or representative.

• Only trained personal should install and

maintain instruments in hazardous areas.

• The protective grounding terminal must be

connected to a suitable IS grounding system.

• Avoid mechanical generated sparks while

working on the equipment and peripherial

devices in hazardous areas.

IM 01R04B05-00E-E

2nd edition, June 2007

1-2

Page 9

1. INTRODUCTION

T

1.2 Warranty

• The warranty terms of this instrument that are

guaranteed are described in the quotation. We

will make any repairs that may become

necessary during the guaranteed term free of

charge.

• Please contact our sales office if this instrument

requires repair.

• If the instrument is faulty, contact us with

complete details about the problem and the

length of time it has been faulty, and state the

model and serial number. We would appreciate

the inclusion of drawings or additional information.

• The results of our examination will determine

whether the meter will be repaired free of

charge or on an at-cost basis.

The guarantee will not apply in the following

cases:

• Damage due to negligence or insufficient

maintenance on the part of the customer.

• Problems or damage resulting from handling,

operation or storage that violates the intended

use and specifications.

• Problems that result from using or performing

maintenance on the instrument in a location that

does not comply with the installation location

specified by Yokogawa.

• Problems or damage resulting from repairs or

modifications not performed by Yokogawa or

someone authorized by Yokogawa.

• Problems or damage resulting from inappropriate installation after delivery.

• Problems or damage resulting from disasters

such as fires, earthquakes, storms, floods, or

lightning strikes and external causes.

1.3 Instruction

according EMC

The ROTAMASS Coriolis flowmeter is conform to

the European EMC Guideline and fulfills the

following standards:

- EN 61326-1

- EN 55011

- EN 61000-3-2

- EN 61000-3-3

ROTAMASS is a class A product and should be

used and installed properly according to the EMC

Class A requirements

Restriction on Use of Radio Transceiver :

IMPORTAN

Although the products has been designed to

resist high frequency electrical noise, if a radio

transceiver is used near the flowmeter or its

external wiring, the transmitter may be affected by

high frequency noise pickup. To test for such

effects, bring the transceiver in use slowly from a

distance of several meters from the flowmeter,

and observe the measurement loop for noise

effects. Thereafter, always use the transceiver

outside the area affected by noise.

Installation

CAUTION

The function ground terminal or the PE-terminal

have to be connected to protective ground to

ensure electro-magnetic interference protection.

To ensure the EMC specifications the following

measures must be carried out :

1. Put the power cables through the ferrite core

clamp before connecting to the terminals as

shown in chapter ´ Installation ´(Power supply

wiring).

2. Put the I/O- cables through the ferrite core

clamp before connecting to the terminals as

shown in chapter ´ Installation ´(Power supply

wiring).

3. Connect protective ground conductor of power

supply to PE-terminal in the terminal box (see

chapter ´ Installation ´(Power supply wiring).

4. In case of Explosion proof type instrument,

further requirements are described in chapter 9

“EXPLOSION PROTECTED TYPE INSTRUMENT”.

The description in this chapter is prior to other

descriptions in this instruction manual.

1-3

IM 01R04B05-00E-E

2nd edition, June 2007

Page 10

1. INTRODUCTION

1.4 ATEX Documentation

This procedure is only applicable to the countries

in European Union.

GB

All instruction manuals for ATEX Ex related

products are available in English, German and

French. Should you require Ex related instructions

in your local language, you are to contact your

nearest Yokogawa office or representative.

DK

Alle brugervejledninger for produkter relateret til

ATEX Ex er tilgængelige på engelsk, tysk og

fransk. Skulle De ønske yderligere oplysninger om

håndtering af Ex produkter på eget sprog, kan De

rette henvendelse herom til den nærmeste

Yokogawa afdeling eller forhandler.

SF

Kaikkien ATEX Ex -tyyppisten tuotteiden

käyttöhjeet ovat saatavilla englannin-, saksan- ja

ranskankielisinä. Mikäli tarvitsette Ex -tyyppisten

tuotteiden ohjeita omalla paikallisella kielellännne,

ottakaa yhteyttä lähimpään Yokogawa-toimistoon

tai -edustajaan.

P

Todos os manuais de instruções referentes aos

produtos Ex da ATEX estão disponíveis em

Inglês, Alemão e Francês. Se necessitar de

instruções na sua língua relacionadas com

produtos Ex, deverá entrar em contacto com a

delegação mais próxima ou com um representante

da Yokogawa.

F

I

Tutti i manuali operativi di prodotti ATEX

contrassegnati con Ex sono disponibili in inglese,

tedesco e francese. Se si desidera ricevere i

manuali operativi di prodotti Ex in lingua locale,

mettersi in contatto con l’ufficio Yokogawa più

vicino o con un rappresentante.

E

Todos los manuales de instrucciones para los

productos antiexplosivos de ATEX están

disponibles en inglés, alemán y francés. Si desea

solicitar las instrucciones de estos artículos

antiexplosivos en su idioma local, deberá ponerse

en contacto con la oficina o el representante de

Yokogawa más cercano.

NL

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex) zijn

verkrijgbaar in het Engels, Duits en Frans. Neem,

indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen taal,

contact op met de dichtstbijzijnde vestiging van

Yokogawa of met een vertegenwoordiger.

Tous les manuels d’instruction des produits ATEX

Ex sont disponibles en langue anglaise, allemande

et française. Si vous nécessitez des instructions

relatives aux produits Ex dans votre langue,

veuillez bien contacter votre représentant

Yokogawa le plus proche.

D

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch,

Deutsch und Französisch zur Verfügung. Sollten

Sie die Betriebsanleitungen für Ex-Produkte in

Ihrer Landessprache benötigen, setzen Sie sich

bitte mit Ihrem örtlichen Yokogawa-Vertreter in

Verbindung.

S

Alla instruktionsböcker för ATEX Ex

(explosionssäkra) produkter är tillgängliga på

engelska, tyska och franska. Om Ni behöver

instruktioner för dessa explosionssäkra produkter

på annat språk, skall Ni kontakta närmaste

Yokogawa kontor eller representant.

IM 01R04B05-00E-E

2nd edition, June 2007

1-4

Page 11

1. INTRODUCTION

j

GR

Ολα τα εγχειριδια λειτουργιαζ τωυ προιουτϖυ µε

ΑΤΕX Εx διατιΘευται στα Αγγλικα, Γερµαυικα

και Γαλλικα. Σε περιπτωση που χρειαζεοτε

οδηγιεζ σχετικα µε Ex στηυ τοπικη γλωσσα

παρακαλουµε επικοιυωυηστε µε το πλησιεστερο

γραϕειο τηζ Yokogawa η αντιπροσωπο τηζ.

SK

Všetky návody na obsluhu pre prístroje s ATEX

Ex sú k dispozícii v jazyku anglickom, nemeckom

a francúzskom. V prípade potreby návodu pre Exprístroje vo Vašom národnom jazyku, skontaktujte

prosím miestnu kanceláriu firmy Yokogawa.

CZ

Všechny uživatelské příručky pro výrobky, na

něž se vztahuje nevýbušné schválení ATEX Ex,

sou dostupné v angličtině , němčině a francouzštině .

Požadujete-li pokyny týkající se výrobků s

nevýbušným schválením ve vašem lokálním jazyku,

kontaktujte prosím vaši nejbližší reprezentační

kancelář Yokogawa.

PL

Wszystkie instrukcje obsługi dla urządzeń

w wykonaniu przeciwwybuchowym Ex,

zgodnych z wymaganiami ATEX, dostępne

są w języku angielskim, niemieckim i

francuskim. Jeżeli wymagana jest instrukcja

obsługi w Państwa lokalnym ję zyku, prosimy

o kontakt z najbliższym biurem Yokogawy.

SLO

Vsi predpisi in navodila za ATEX Ex sorodni

pridelki so pri roki v anglišèini, nemšèini ter

francošèini. Èe so Ex sorodna navodila potrebna

v vašem tukejnjem jeziku, kontaktirajte vaš najbliši

Yokogawa office ili predstaunika.

H

Az ATEX Ex mûszerek gépkönyveit angol, német

és francia nyelven adjuk ki. Amennyiben helyi

nyelven kérik az Ex eszközök leírásait, kérjük

keressék fel a legközelebbi Yokogawa irodát, vagy

képviseletet.

BG

LT

Visos gaminiø ATEX Ex kategorijos

Eksploatavimo instrukcijos teikiami anglø,

vokieèiø ir prancûzø kalbomis. Norëdami gauti

prietaisø Ex dokumentacijà kitomis kalbomis

susisiekite su artimiausiu bendrovës “Yokogawa”

biuru arba atstovu.

LV

Visas ATEX Ex kategorijas izstrâdâjumu

Lietoðanas instrukcijas tiek piegâdâtas angïu,

vâcu un franèu valodâs. Ja vçlaties saòemt Ex

ierîèu dokumentâciju citâ valodâ, Jums ir

jâsazinâs ar firmas Jokogava (Yokogawa) tuvâko

ofisu vai pârstâvi.

EST

Kõik ATEX Ex toodete kasutamisjuhendid on

esitatud inglise, saksa ja prantsuse keeles. Ex

seadmete muukeelse dokumentatsiooni

saamiseks pöörduge lähima Iokagava

(Yokogawa) kontori või esindaja poole.

Всички упътвания за продукти от серията АТЕХ

Ех се предлагат на английски, немски и

френски език. Ако се нуждаете от упътвания

за продукти от серията Ех на родния ви език,

се свържете с най-близкия офис или

представителство на фирма Yokogawa.

RO

Toate manualele de instructiuni pentru produsele

ATEX Ex sunt in limba engleza, germana si

franceza. In cazul in care doriti instructiunile in

limba locala, trebuie sa contactati cel mai apropiat

birou sau reprezentant Yokogawa.

M

Il-manwali kollha ta’ l-istruzzjonijiet għal prodotti

marbuta ma’ ATEX Ex huma disponibbli bl-Ingliż,

bil-Ġermaniż u bil-Franċiż. Jekk tkun teħtieġ

struzzjonijiet marbuta ma’ Ex fil-lingwa lokali tiegħek,

għandek tikkuntattja lill-eqreb rappreżentan jew

uffiċċju ta’ Yokogawa.

1-5

IM 01R04B05-00E-E

2nd edition, June 2007

Page 12

1. INTRODUCTION

1.5 Disposal, Cleaning

and Return

For safe use

WARNING

If the process fluid is harmful to personnel, handle

the instrument carefully even after it has been

removed from the process line for maintenance or

other purposes. Exercise extreme care to prevent

the fluid from coming into contact with human skin

and to avoid inhaling any residual gas. Before

sending it to the Seller for examination and/or

repair please clean the instrument thoroughly and

make sure, that no harmful chemicals are in or at

the meter. If the instrument contains unknown

fluids the Seller will send it back to the Purchaser

for cleaning on their cost.

WARNING

ROTAMASS might be heavy instruments. Please

give attention to prevent that persons are not

injured by carrying or installing. It is preferable

when carrying the instrument to use a cart and be

done by two or more persons. When removing

the instrument from hazardous processes, avoid

contact with the fluid and the interior of the meter.

the failure occurred. It will be helpful if schematic

diagrams and/or records of data are attached to

the failed instrument. Whether or not the failed

instrument should be repaired free of charge shall

be left solely to the discretion of the Seller as a

result of an inspection by the Seller.

The Purchaser shall not be entitled to receive

repair services from the Seller free of charge,

even during the warranty period, if the malfunction

or damage is due to improper and/or inadequate

maintenance of the instrument in question by the

Purchaser handling, use or storage of the

instrument in question beyond the design and/or

specifications requirements, use of the

instrument in question in a location no conforming

to the conditions specified in the Seller’s General

Specification or Instruction Manual retrofitting and/

or repair by an other party than the Seller or a

party to whom the Seller has entrusted repair

services. improper relocation of the instrument in

question after delivery reason of force measure

such as fires, earthquakes, storms/ floods,

thunder/lightning, or other reasons not attributable

to the instrument in question.

For disposal and recycling please refer to your

national regulations.

Please find following help. After remove of all

products rests the instruments can be

disassembled and the parts treated different.

Warranty

The warranty of the instruments shall cover the

period noted on the quotation presented to the

purchaser at the time of purchase. The Seller

shall repair the instrument free of charge when

the failure occurred during the warranty period.

All inquiries on instrument failure should be

directed to the Seller’s sales representative from

whom you purchased the instrument or your

nearest sales office of the Seller.

Should the instrument fail, contact the Seller,

specifying the model and instrument number of

the product in question. Be specific in describing

details on the failure and the process in which

IM 01R04B05-00E-E

2nd edition, June 2007

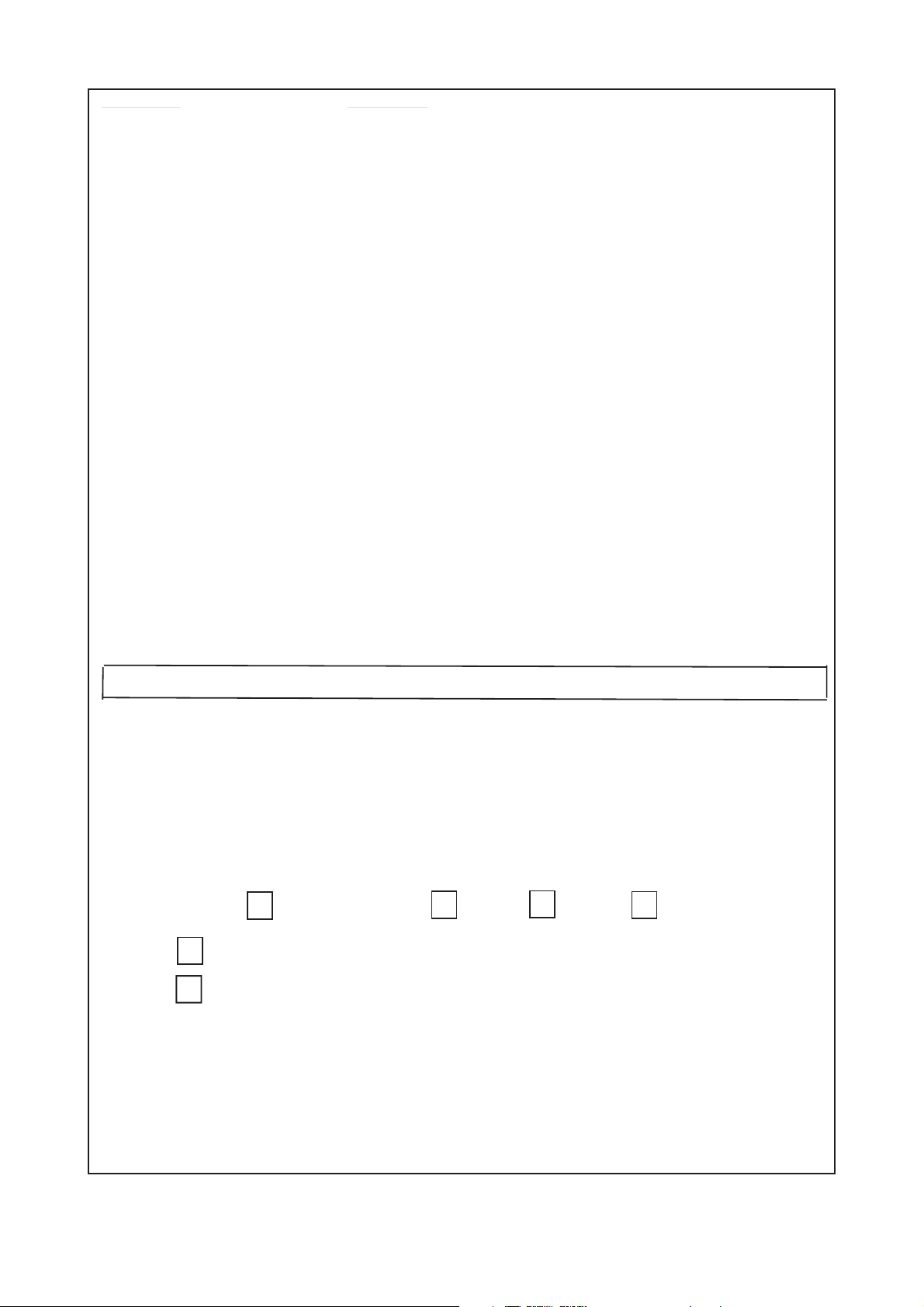

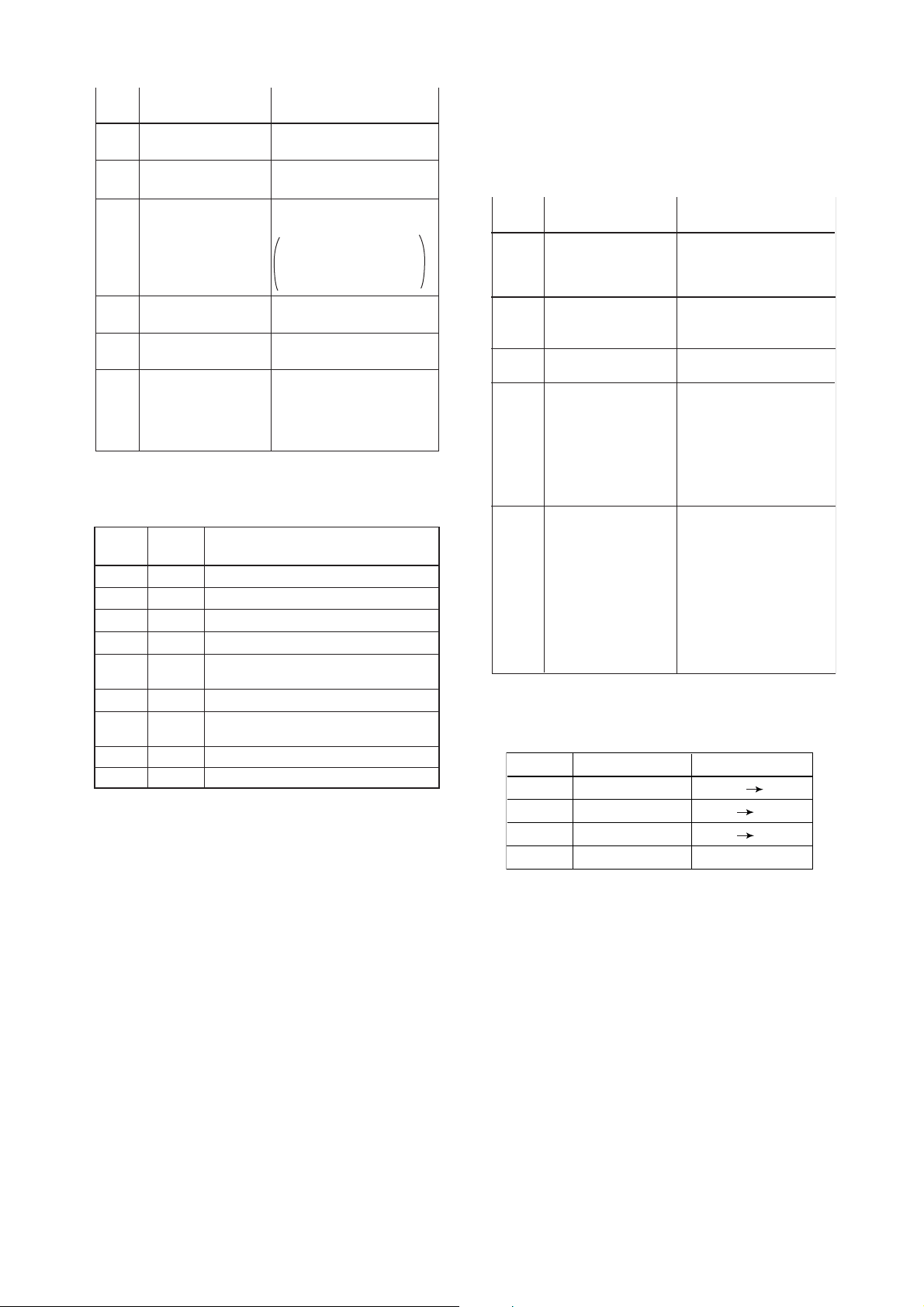

Naming: R = recycling, D = disposal, Sd = special

disposal, Na = not applicable

Name of

Product

Rotamass

Body Converter

housing

SS R Al R

Cap with

window

Al +

glass

In case of return of flowmeters to Yokogawa for

testing or repair purposes please fillout one of the

following forms and send it with the equipment to

YOKOGAWA.

1-6

D

Electronics

Sd

T1.EPS

Page 13

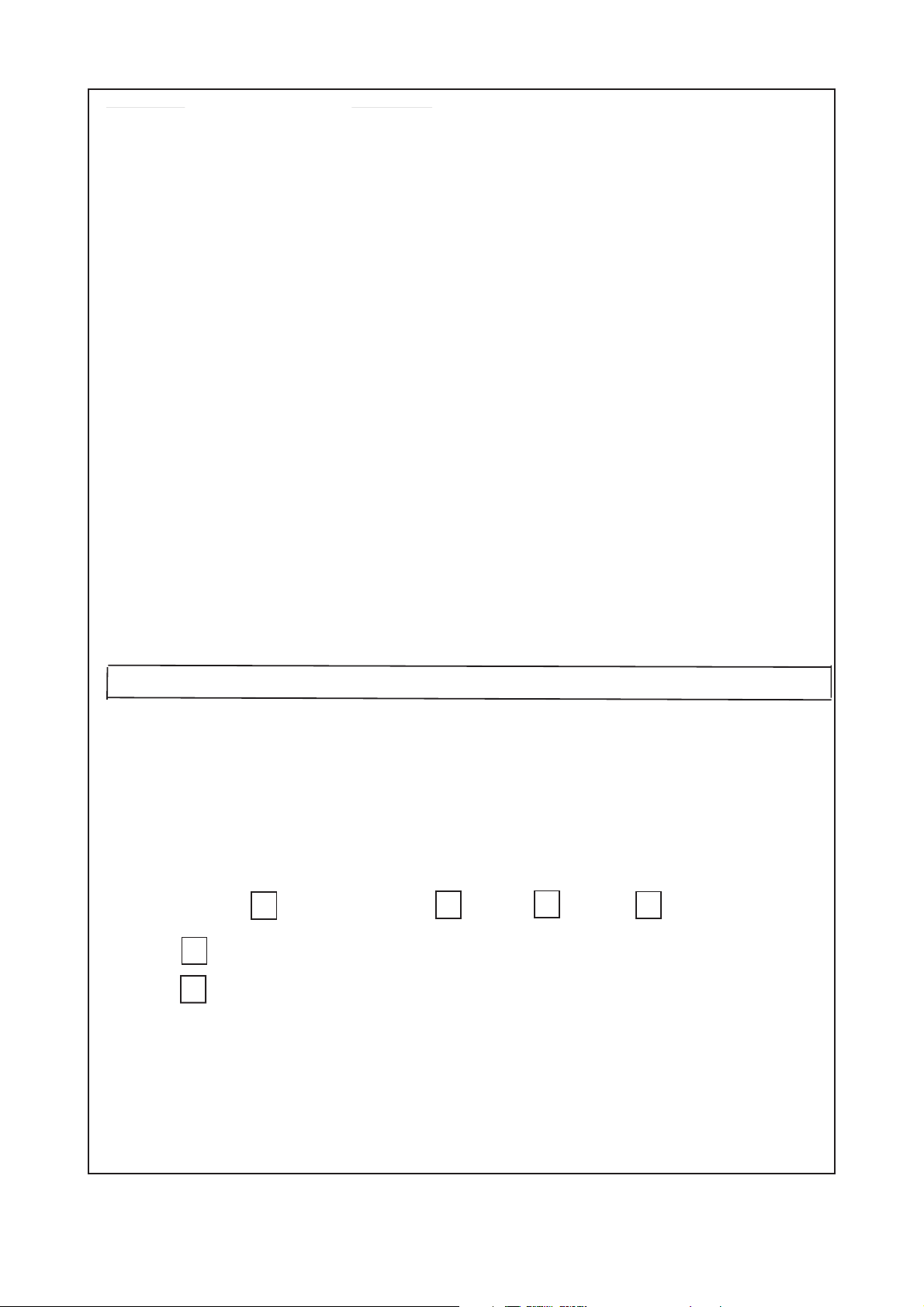

Receiver : Sender :

Delivery Note (for EU-Countries) Date :

Ref. REPAIR for serial no. __________________________

We are sending following type of article

via forwarding agent : Yusen Air ; Raunheim/Frankfurt

Item Article Unit Price Total Price

Type (MS-Code)

________________________________ € __________ €__________

(nominal value)

Charges for airworthy packing

and delivery FOB €___________

Total value € ___________

1. INTRODUCTION

Value for customs purpose only € _________

(current value)

Gross weight . _____________________kg

Net weight : _____________________kg

Customs Tariff No. : _____________________

Country og origin : Federal Republic of Germany

Delivery note 2-fold accompanis the goods

SPECIMEN Certificate

Company : ________________________ Address : ______________________

Department : ________________________ Name : ______________________

Telephone : ________________________ Fax : ______________________

The attached flowmeter :

Type : ______________________________ Order- or Serial No. ___________

has been operated with following liquids: ___________________________________________

Because the liquid is water-endangering toxic caustic flammable

we have

checked, that all cavities in the flowmeter are free from such substances

flushed out and neutralised all cavities in the flowmeter

Please check applicable description

We confirm that there is no risk to man or enviroment through any residual liquid containes in this flowmeter.

Date : _____________________ Signature : _______________________

Company stamp:

1-7

IM 01R04B05-00E-E

2nd edition, June 2007

Page 14

1. INTRODUCTION

Receiver : Sender :

PROFORMA INVOICE (for Third-party-Countries) Date :

Ref. REPAIR for serial no. __________________________

We are sending following type of article

via forwarding agent : Yusen Air ; Raunheim/Frankfurt

Item Article Unit Price Total Price

Type (MS-Code)

________________________________ € __________ €__________

(nominal value)

Charges for airworthy packing

and delivery FOB €___________

Total value € ___________

Value for customs purpose only € _________

(current value)

Gross weight . _____________________kg

Net weight : _____________________kg

Customs Tariff No. : _____________________

Country og origin : Federal Republic of Germany

Delivery note 2-fold accompanis the goods

SPECIMEN Certificate

Company : ________________________ Address : ______________________

Department : ________________________ Name : ______________________

Telephone : ________________________ Fax : ______________________

The attached flowmeter :

Type : ______________________________ Order- or Serial No. ___________

has been operated with following liquids: ___________________________________________

Because the liquid is water-endangering toxic caustic flammable

we have

checked, that all cavities in the flowmeter are free from such substances

flushed out and neutralised all cavities in the flowmeter

Please check applicable description

We confirm that there is no risk to man or enviroment through any residual liquid containes in this flowmeter.

Date : _____________________ Signature : _______________________

Company stamp:

IM 01R04B05-00E-E

2nd edition, June 2007

1-8

Page 15

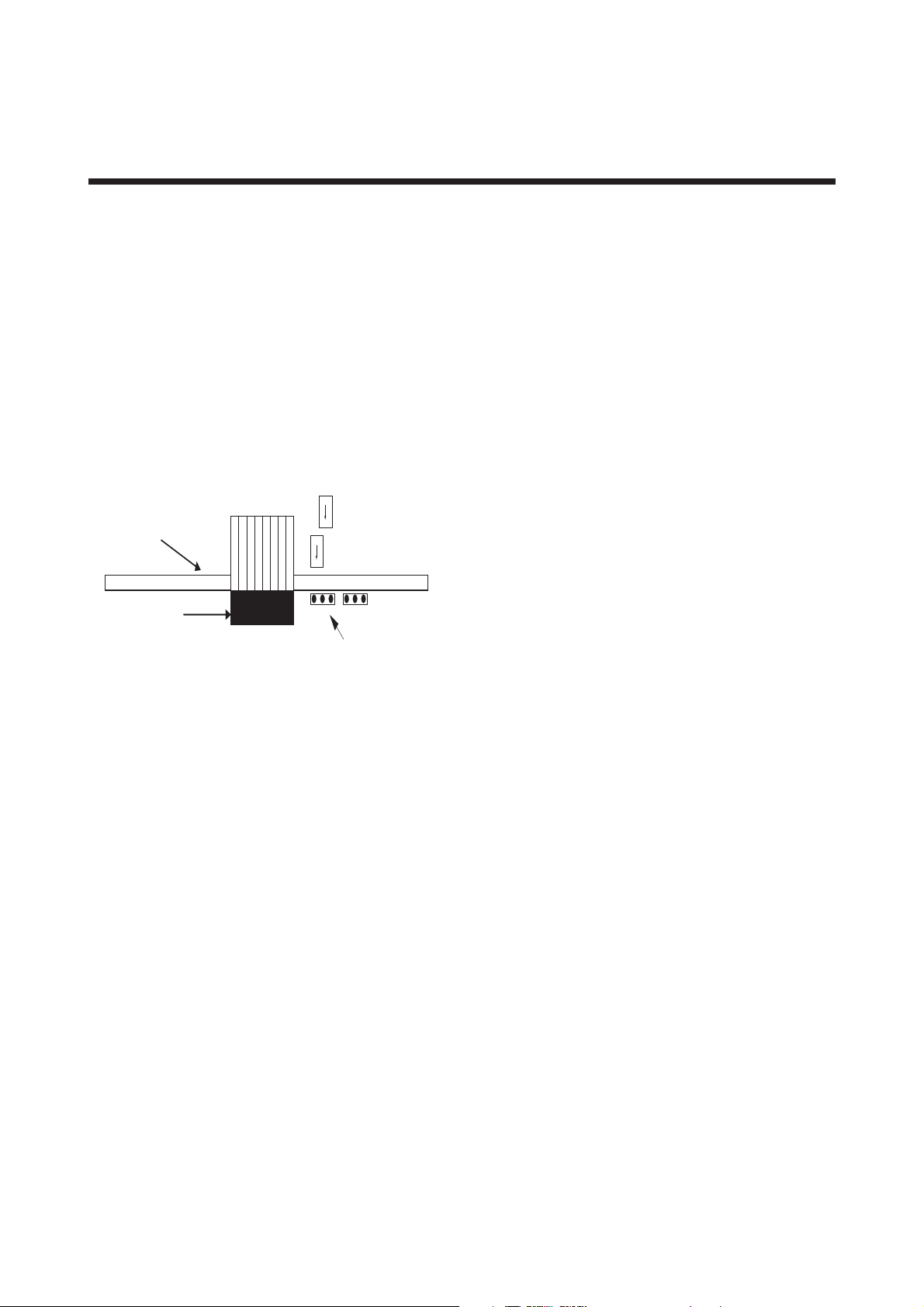

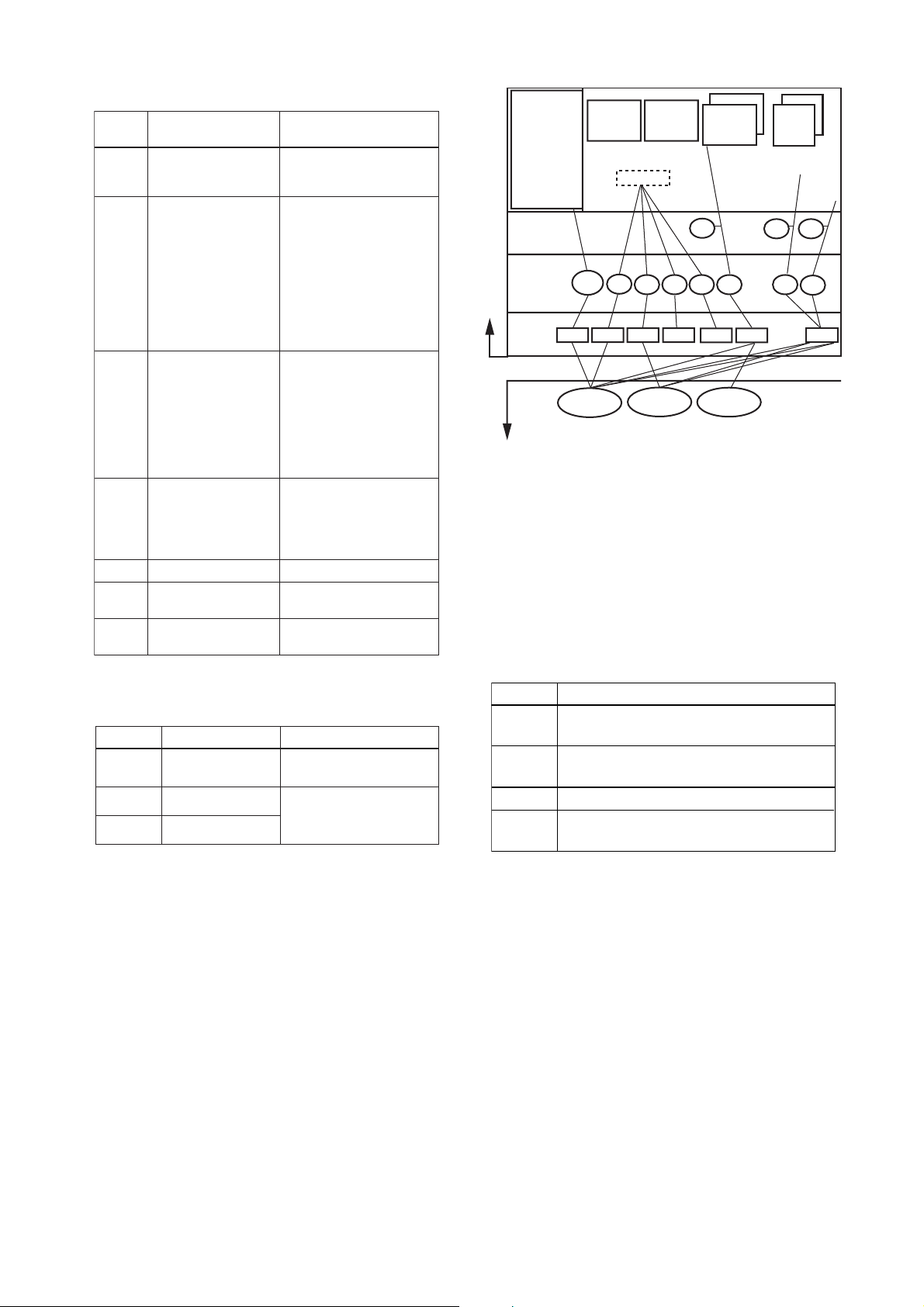

2. AMPLIFIER FOR FIELDBUS COMMUNICATION

2. AMPLIFIER FOR FIELDBUS

COMMUNICATION

Refer to IM 01R04B04-00E for the details of the

amplifier. This section encompasses topics

applicable to only the Fieldbus communication

type.

(1) The Fieldbus communication type has no local

key access function.

(2) The Fieldbus communication type has no

HART terminal connection pin.

(3) The Fieldbus communication type has a

simulation function. The SIMULATE_ENABLE

jumper is mounted on the amplifier. Refer to

Section 6.3, “Simulation Function” for details of

the simulation function.

Std

FF Board

Simu

Cable to display

JP1 (Simulate_Enable)

Figure 2.1 Amplifier for Fieldbus Communication

F0201.EPS

2-1

IM 01R04B05-00E-E

2nd edition, June 2007

Page 16

2. AMPLIFIER FOR FIELDBUS COMMUNICATION

Blank Page

IM 01R04B05-00E-E

2nd edition, June 2007

2-2

Page 17

3. ABOUT FIELDBUS

3. ABOUT FIELDBUS

3.1 Outline

Fieldbus is a bi-directional digital communication

protocol for field devices, which offers an advancement in implementation technologies for

process control systems and is widely employed

by numerous field devices.

The Fieldbus communication type of the Rotamass

employs the specification standardized by the

Fieldbus FOUNDATION, and provides interoperability

between Yokogawa devices and those produced

by other manufacturers. Featuring 6 AI and two IT

function blocks in each, the Fieldbus communication type’s software enables a flexible instrumentation system to be implemented.

For information on other features, engineering,

design, construction work, startup and maintenance of Fieldbus, refer to “Fieldbus Technical

Information” (TI 38K3A01-01E).

3.2 Internal Structure of

ROTAMASS

Each Rotamass contains two Virtual Field Devices

(VFDs) that share the following functions.

3.2.1 System/Network Management VFD

• Sets node addresses and Physical Device

tags (PD Tag) necessary for communication.

• Controls the execution of function blocks.

• Manages operation parameters and

communication resources (Virtual

Communication Relationship: VCR).

- Converts the flow sensor output to the

process fluid density and transfers to an AI

function block (AI3).

- Converts temperature sensor output to the

process fluid temperature and transfers to

an AI function block (AI4).

- Calculates the volumetric flow rate from

the fluid density and the mass flow rate

and transfers to an AI function block (AI2).

(3) AI function blocks (six)

• The AI blocks condition raw data from the

transducer block, including scaling and

damping (with a first-order lag), and allow

input simulation.

• AI1 outputs mass flow rate signals, and AI2

outputs volumetric flow rate signals.

• AI3 outputs density signals, and AI4 outputs

temperature signals.

• AI5 outputs concentration measurement

signals (option), and AI6 outputs net flow

rate signals (option).

(4) IT Integrator blocks (two)

• IT1 totalizes mass-, volume or net flow rate.

• IT2 totalizes mass-, volume or net flow rate.

(5) PID function block (optional)

• Performs the PID computation based on the

deviation of the measured value from the

setpoint.

3.2.2 Function Block VFD

(1) Resource (RS) block

• Manages the status of Rotamass hardware.

• Automatically informs the host of any

detected faults or other problems.

(2) Transducer (TB) block

• Converts the flow sensor output to the mass

flow rate signal and transfers to an AI

function block (AI1).

3-1

IM 01R04B05-00E-E

2nd edition, June 2007

Page 18

3. ABOUT FIELDBUS

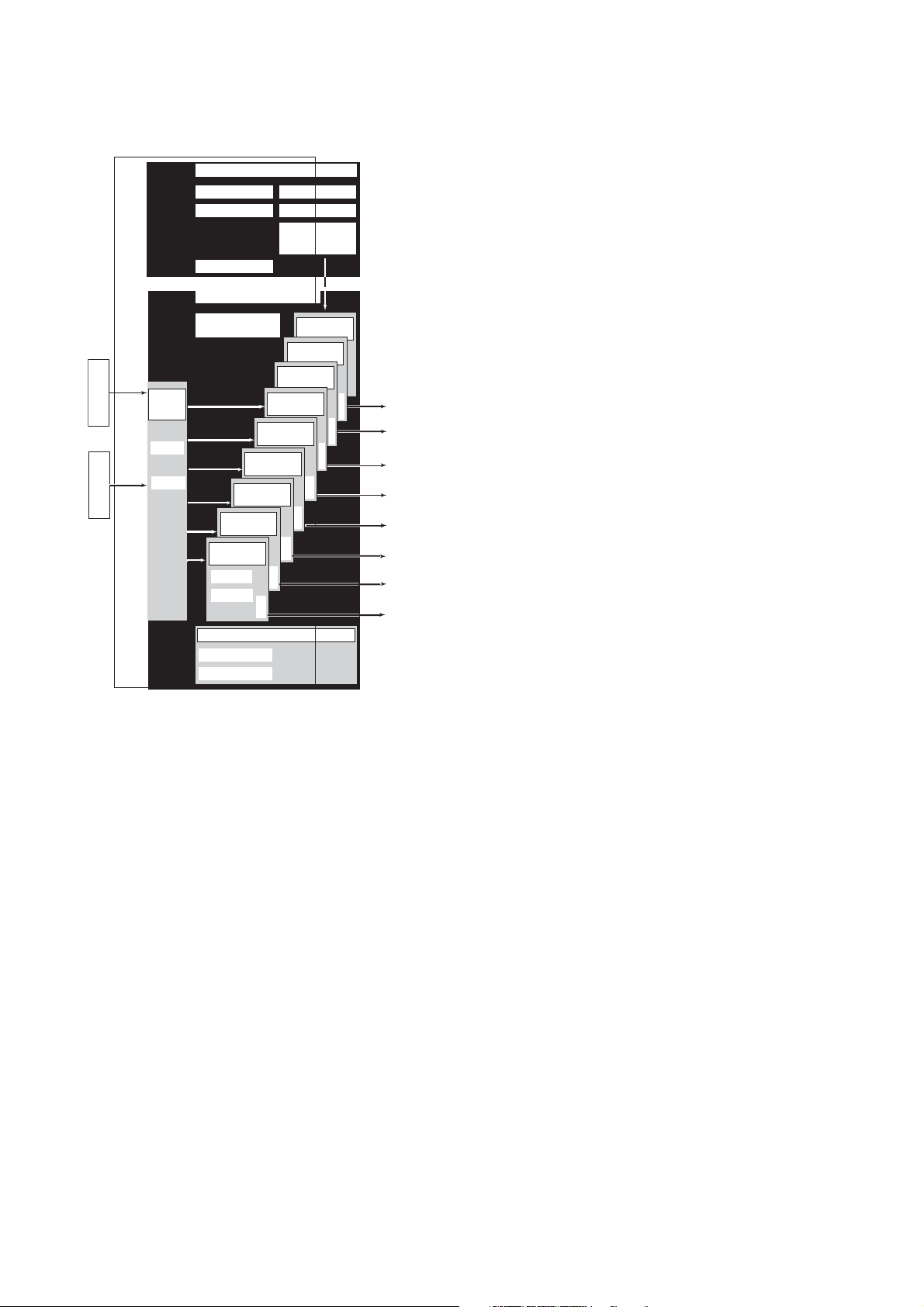

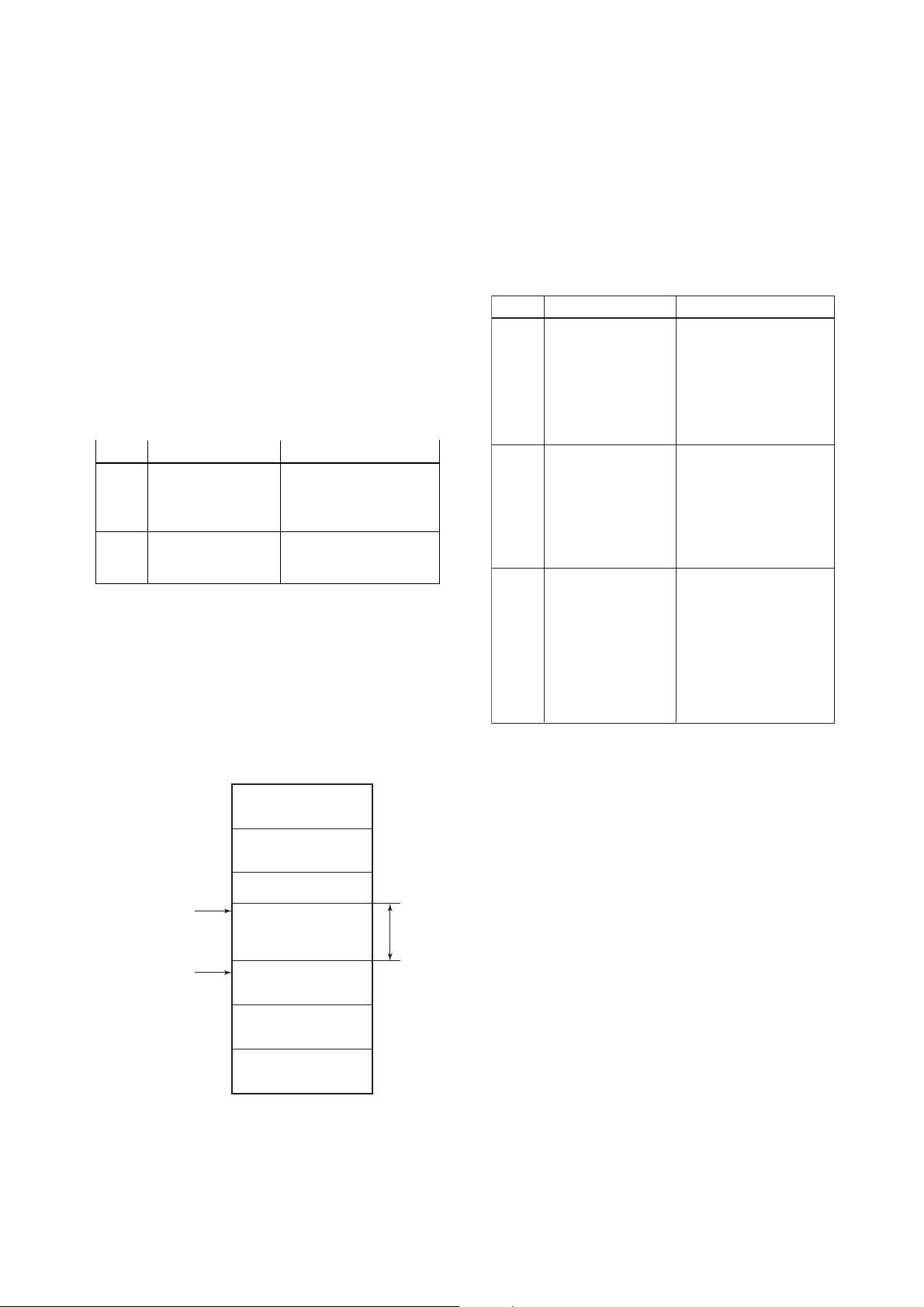

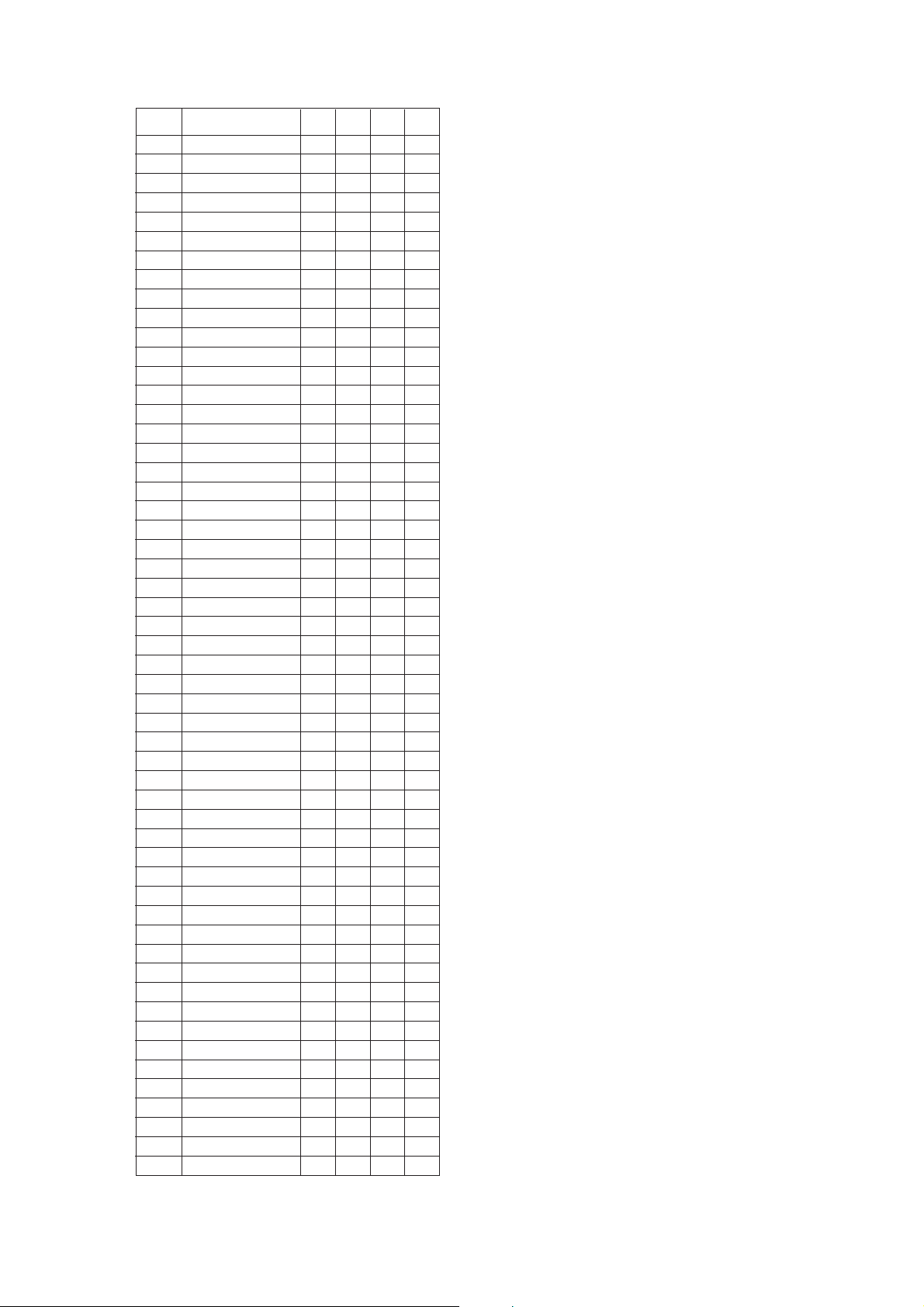

3.3 Logical Structure of Each Block

Rotamass

Sensor

input

Sensor Coils

Sensor

input

Temp. sensor

Transducer

Block tag

Parameters

System/network management VFD

PD tag

Node address

Link master

Function block VFD

Software download

function

(optional)

block

AI4 function

AI3 function

block

AI2 function

block

AI1 function

block

Block tag

Parameters

Resource block

Block tag

Parameters

Communication parameters

VCR

Function block

execution schedule

PID function block

(optional)

IT 2 Integrator

block

IT 1 Integrator

block

AI6 function

block

AI5 function

block

block

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

F0301.EPS

3.4 Wiring System Configuration

The number of devices that can be connected to a

single bus and the cable length vary depending on

system design. When constructing systems, both

the basic and overall design must be carefully

considered to allow device performance to be fully

exhibited.

Output

Figure 3.1 Logical Structure of Each Block

Various parameters, the node address, and the

PD tag shown in Figure 3.1 must be set before

using the device. Refer to Chapter 4 for the

setting procedures.

IM 01R04B05-00E-E

2nd edition, June 2007

3-2

Page 19

4. GETTING STARTED

S

S

4. GETTING STARTED

Fieldbus is fully dependent upon digital communication protocol and differs in operation from

conventional 4 to 20 mA transmission and the

HART communication protocol. It is recommended

that novice users use fieldbus devices in

accordance with the procedures described in this

section. The procedures assume that fieldbus

devices will be set up on a bench of an instrument

shop.

4.1 Connection of Devices

The following instruments are required for use

with Fieldbus devices:

• Power supply:

Fieldbus requires a dedicated power supply. It

is recommended that current capacity be well

over the total value of the maximum current

consumed by all devices (including the host).

Conventional DC current cannot be used as is.

• Host:

Used for accessing field devices. A dedicated

host (such as DCS) is used for an

instrumentation line while dedicated communication tools are used for experimental purposes.

For operation of the host, refer to the instruction

manual for each host. No details of the host are

explained in the rest of this manual.

• Cable:

Used for connecting devices. Refer to “Fieldbus

Technical Information” (TI 38K3A01-01E) for

details of instrumentation cabling. If the total

length of the cable is in a range of 2 to 3

meters for laboratory or other experimental use,

the following simplified cable (a twisted pair wire

with a cross section of 0.9 mm2 or more and

cycle period of within 5 cm (2 inches) may be

used). Termination processing depends on the

type of device being deployed. For the

ROTAMASS, clamp terminal are used. Some

hosts require a connector.

• Terminator:

Fieldbus requires two terminators. Refer to the

supplier for details of terminators that are

attached to the host.

• Field devices:

Connect your Fieldbus communication type

ROTAMASS RCCT3 to a fieldbus. Two or more

ROTAMASS RCCT3 and other field devices can

be connected. For the terminal assignment on

the ROTAMASS RCCT3, see Table 4.1.

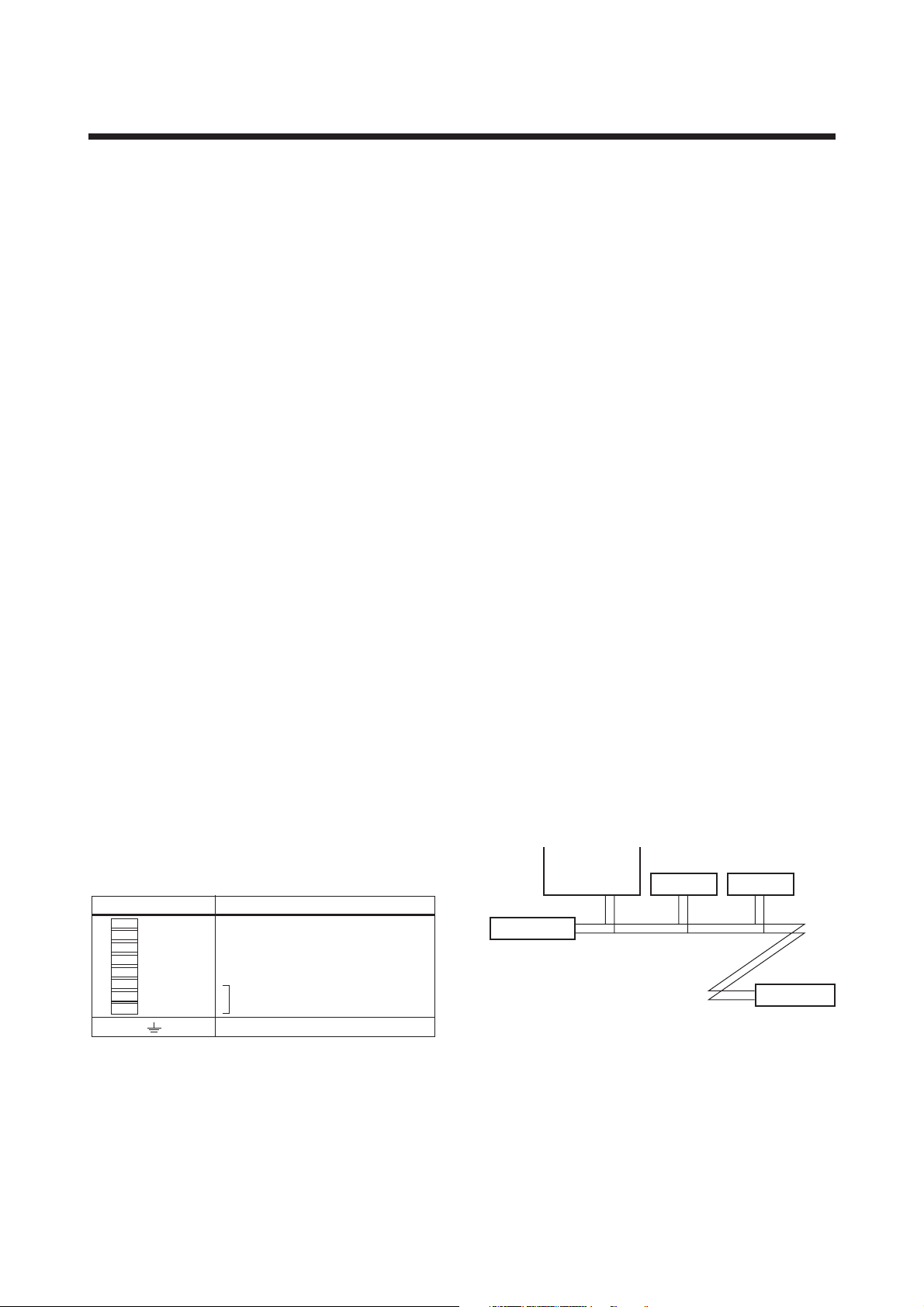

Table 4.1 Terminal Connection for ROTAMASS RCCT3

Terminal Symbols Description

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

–

FF out

FF out

Fieldbus communication signal

+

Ground Terminal

F0401.EP

Refer to Yokogawa when making arrangements to

purchase the recommended equipment.

Connect the devices as shown in Figure 4.1.

Connect the terminators at both ends of the trunk,

with a minimum length of the spur laid for connection.

The polarity of signal and power must be maintained.

Fieldbus power

supply

Terminator

Figure 4.1 Device Connection

Rotamass

+

–

HOST

Terminator

F0402.EP

4-1

IM 01R04B05-00E-E

2nd edition, June 2007

Page 20

4. GETTING STARTED

T

T

Before using a Fieldbus configuration tool other

than the existing host, confirm it does not affect

the loop functionality in which all devices are

already installed in operation. Disconnect the

relevant control loop from the bus if necessary.

IMPORTAN

Connecting a Fieldbus configuration tool to a

loop with its existing host may cause communication data scrambles resulting in a functional

disorder or a system failure.

4.2 Host Setting

To activate Fieldbus, the following settings are

required for the host.

IMPORTAN

Do not turn off the main power supply and

fieldbus power supply immediately after setting.

When the parameters are saved to the

EEPROM, the redundant processing is executed

for the improvement of reliability. If the power is

turned off within 60 seconds after setting is

made, the modified parameters are not saved

and the settings may return to the original values.

0x00

Not used

0x0F

0x10

Bridge device

0x13

0x14

V(FUN)

V(FUN)+V(NUN)

Rotamass (0xF6)

Note 1: L M devic e : with bus con trol fu nc tion ( L ink Mas ter fu nc tion)

Note 2: B AS IC de vice: with out bus control function

Figure 4.2 Available Address Range

0xF7

0xF8

0xFB

0xFC

0xFF

LM device

Unused V(NUN)

BASIC device

Default address

P ortable devic e a ddress

F0403.E PS

4.3 Power-on of ROTAMASS and Bus

Turn on the power to the host, bus, and

ROTAMASS. If any segments do not light, or if a

current anomaly occurs, check the voltage of the

power supply for the ROTAMASS.

Using the host device display function, check that

the ROTAMASS is in operation on the bus. Unless

otherwise specified, the following settings are in

effect when shipped from the factory.

Table 4.2 Operation Parameters

Symbol Parameter Description and Settings

V (ST) Slot-Time

V (MID)

V (MRD)

V (FUN) First-Unpolled-Node

V (NUN)

IM 01R04B05-00E-E

2nd edition, June 2007

Minimum-Inter-PDUDelay

Maximum-ResponseDelay

Number-ofconsecutiveUnpolled-Nodes

Set 4 or greater value.

Set 4 or greater value.

Set so that V (MRD) 3 V

(ST) is 12 or greater

Indicate the address next

to the address range used

by the host. Set 0x15 or

greater.

Unused address range.

Rotamass addess is

factory set to 0xF6. Set

this address to be within

the range of BASIC device

in Figure 4.2.

T0401.EPS

PD tag: FT1004

Node address: 246 (hexadecimal F6)

Device ID: 594543000Dxxxxxxxx (xxxxxxxx = a

total of 8 alphanumeric characters)

If no ROTAMASS is detected, check the available

address range. If the node address and PD Tag

are not specified when ordering, default value is

factory set. If two or more ROTAMASS are

connected at a time with default value, only one

ROTAMASS will be detected from host as

ROTAMASS have the same initial address.

Connect the ROTAMASS one by one and set a

unique address for each.

4-2

Page 21

4. GETTING STARTED

4.4 Integration of DD

If the host supports DD (Device Description), the

DD of the ROTAMASS needs to be installed.

Check if host has the following directory under its

default DD directory.

594543000D

(594543 is the manufacturer number of

Yokogawa Electric Corporation, and 000D is the

ROTAMASS device number, respectively.)

If this directory is not found, the DD for the

ROTAMASS has not yet been installed. Create

this directory and copy the DD files (0m0n.ffo and

0m0n.sym to be supplied separately where m and

n are numerals) to it. If you do not have the DD

files for the ROTAMASS, you can download them

via Internet from

http://www.yokogawa.com/fld/FIELDBUS/fldfieldbus-01en.htm

Once the DD is installed in the directory, the

name and attribute of all parameters of the

ROTAMASS are displayed.

Off-line configuration is possible using the

capabilities file.

When using a capabilities (CFF) file, make sure

you use the right file for the intended device. The

ROTAMASS is offered in two types in terms of

capabilities:

(1) Without LC1 option: Featuring six AI function

blocks and two IT function blocks

(2) With LC1 option: A PID function block is

added

Using the wrong CFF file may result in an error

when downloading the configured data to the

device. Also, use the right DD files that

accommodate the revision of the intended device.

4.5 Reading the Parameters

To read ROTAMASS parameters, select the AI

block of the ROTAMASS from the host screen and

read the OUT parameter. The current flow rate is

displayed. Check that MODE_BLOCK of the

function block and resource block is set to AUTO.

4.6 Continuous Record of Values

If the host has a function of continuously recording

the indications, use this function to list the

indications (values). Depending on the host being

used, it may be necessary to set the schedule of

Publish (the function that transmits the indication

on a periodic basis).

4.7 Generation of Alarm

If the host is allowed to receive alarms, generation

of an alarm can be attempted from the

ROTAMASS. In this case, set the reception of

alarms on the host side. ROTAMASS’s VCR-7 is

factory-set for this purpose. For practical purposes,

all alarms are placed in a disabled status; for this

reason, it is recommended that you first use one

of these alarms on a trial basis. Set the value of

link object-3 (index 30002) as “0, 299, 0, 6, 0”.

Refer to section 5.6.1 Link Object for details.

Since the LO_PRI parameter (index 4029) of the AI

block is set to “0”, try setting this value to “3”.

Select the Write function from the host in operation, specify an index or variable name, and write

“3” to it.

The LO_LIM parameter (index 4030) of the AI

block determines the limit at which the lower

bound alarm for the process value is given. In

usual cases, a very small value is set to this limit.

Set smaller value than 100% value of XD_SCALE

(same unit). Since the flow rate is almost 0, a

lower bound alarm is raised. Check that the alarm

can be received at the host. When the alarm is

confirmed, transmission of the alarm is

suspended.

This chapter briefly explained how to connect the

ROTAMASS to a fieldbus and start using it. In

order to take full advantage of the performance and

functionality of the device, it is recommended that

it be read together with Chapter 5, where

describes how to use the ROTAMASS.

4-3

IM 01R04B05-00E-E

2nd edition, June 2007

Page 22

4. GETTING STARTED

Blank Page

IM 01R04B05-00E-E

2nd edition, June 2007

4-4

Page 23

5. CONFIGURATION

5. CONFIGURATION

This chapter contains information on how to adapt

the function and performance of the ROTAMASS to

suit specific applications. Because two or more

devices are connected to Fieldbus, settings

including the requirements of all devices need to

be determined. Practically, the following steps

must be taken.

(1) Network design

Determines the devices to be connected to

Fieldbus and checks the capacity of the power

supply.

(2) Network definition

Determines the PD tag and node addresses for

all devices.

(3) Definition of combining function blocks

Determines the method for combination

between each function block.

(4) Setting tags and addresses

Sets the PD Tag and node addresses one by

one for each device.

(5) Communication setting

Sets the link between communication

parameters and function blocks.

(6) Block setting

Sets the parameters for function blocks.

The following section describes each step of the

procedure in the order given. Using a dedicated

configuration tool allows the procedure to be

significantly simplified. This section describes the

procedure to be assigned for a host which has

relatively simple functions. Refer to Appendix 6

when the ROTAMASS is used as Link Master

(option).

consumed by all devices (including the host).

Conventional DC current cannot be used as

power supply.

• Terminator

Fieldbus requires two terminators. Refer to the

supplier for details of terminators that are

attached to the host.

• Field devices

Connect the field devices necessary for instrumentation. the ROTAMASS has passed the

interoperability test conducted by The Fieldbus

Foundation. In order to properly start Fieldbus,

it is recommended that the devices used satisfy

the requirements of the above test.

• Host

Used for accessing field devices. A minimum of

one device with bus control function is needed.

• Cable

Used for connecting devices. Refer to Fieldbus

Technical Information (TI 38K3A01-01E) for

details of instrumentation cabling. Provide a

cable sufficiently long to connect all devices.

For field branch cabling, use terminal boards or

a connection box as required.

First, check the capacity of the power supply. The

power supply capacity must be greater than the

sum of the maximum current consumed by all

devices to be connected to Fieldbus. For the

ROTAMASS, the maximum current (power supply

voltage: 9 to 32 VDC) is 15 mA. The cable must

have the spur in a minimum length with

terminators installed at both ends of the trunk.

5.2 Network Definition

5.1 Network Design

Select the devices to be connected to the

Fieldbus network. The following instruments are

necessary for operation of Fieldbus.

• Power supply

Fieldbus requires a dedicated power supply. It

is recommended that current capacity be well

over the total value of the maximum current

Before connection of devices with Fieldbus, define

the Fieldbus network. Allocate PD tags and node

addresses to all devices (excluding such passive

devices as terminators).

PD tags are the same as conventional tag

numbers assigned to devices. Up to 32

alphanumeric characters may be used for

definition of the PD tag for each device. Use

hyphens as delimiters as required.

5-1

IM 01R04B05-00E-E

2nd edition, June 2007

Page 24

5. CONFIGURATION

t

0x00

V

)

S

Node addresses are used to locate devices for

communication purposes. Since a PD tag is too

long for a data value, the host substitutes the

node addressed for PD tags in communication.

Node addresses can be set to numbers in a range

of decimal 16 to 247 (hexadecimal 10 to F7).

Assign devices having link master functionality

(i.e., LM devices) from the smallest address

number (0x10) in order, and other devices (i.e.,

basic devices) from the largest (0xF7). Assign an

address in the range for basic devices to a

ROTAMASS. Only when using a ROTAMASS

with the optional LM functionality as an LM device,

assign an address in the range for LM devices to

it. These address ranges are determined by the

following parameters.

Table 5.1 Parameters for Setting Address Range

Symbol

V (FUN) First-Unpolled-Node

V (NUN) Number-of-

Parameters Description

Indicates the address nex

to the address range used

for the host or other LM

device.

Unused address range

consecutiveUnpolled-Node

Any devices within an address range written as

“Unused” in Figure 5.1 cannot join the fieldbus.

Other address ranges are periodically scanned to

find any devices newly joining the fieldbus. Do

not widen the available address ranges

unnecessarily; the fieldbus communication

performance may be severely degraded.

Unused

0x0F

0x10

Bridge device

0x13

0x14

V(FUN)

(FUN)+V(NUN)

Figure 5.1 Available Range of Node Addresses

0xF7

0xF8

0xFB

0xFC

0xFF

LM devices

Unused V(NUN

Basic devices

Default addresses

Portable device addresses

F0501.EP

To ensure stable operation of Fieldbus, determine

the operation parameters and set them to the LM

devices. While the parameters in Table 5.2 are to

be set, the worst-case value of all the devices to

be connected to the same Fieldbus must be used.

Refer to the specification of each device for

details. Table 5.2 lists ROTAMASS specification

values.

Table 5.2 Operation Parameter Values of digitalYEWFLO

to be Set to LM Device

S

ymbol

V (S T) S lot-Time

V (MID) Minimum-Inter-P DU -

V (MRD) Maximum-R esponse-

Delay

Delay

P

arameters

D

escription a

Indica tes the time

necessa ry for immediate

reply of the device. Unit of

time is in octets (256 µs).

S et ma ximum s pecification

for all devices. F or a

Rotamass, set a value of 4

or greater.

Minimum value of

communication data

interva ls . Unit of time is in

octets (256 µs). S et the

maximum specifica tion for

all devices . For a

Rotamass, set a value of 4

or greater.

T he worst cas e time

ela ps ed until a reply is

recorded. T he unit is S lottime; s et the va lue s o th a t

V (MR D) 3V (ST) is the

maximum value of the

specifica tion for all devices .

For a Rotamass, value of

V(MRD)3V (ST) must be 12

or greater.

nd Setting

T0502.E PS

5.3 Function Block Link Definitions

Link the input/output parameters of function blocks

to each other as necessary. For a ROTAMASS,

the output parameters of six AI blocks (OUTs), two

integrator blocks and input/output parameters of

an optional PID block should be linked to parameters of different function blocks. Specifically, link

settings must be written to the link object in the

ROTAMASS For details, refer to Section 5.6,

“Block Setting.” It is also possible to read values

from the host at appropriate intervals instead of

linking the outputs of ROTAMASS’s function

blocks to other blocks.

s

IM 01R04B05-00E-E

2nd edition, June 2007

5-2

Page 25

5. CONFIGURATION

T0503.EPS

F

S

C

S

T

F0503.EPS

A

F0504.EPS

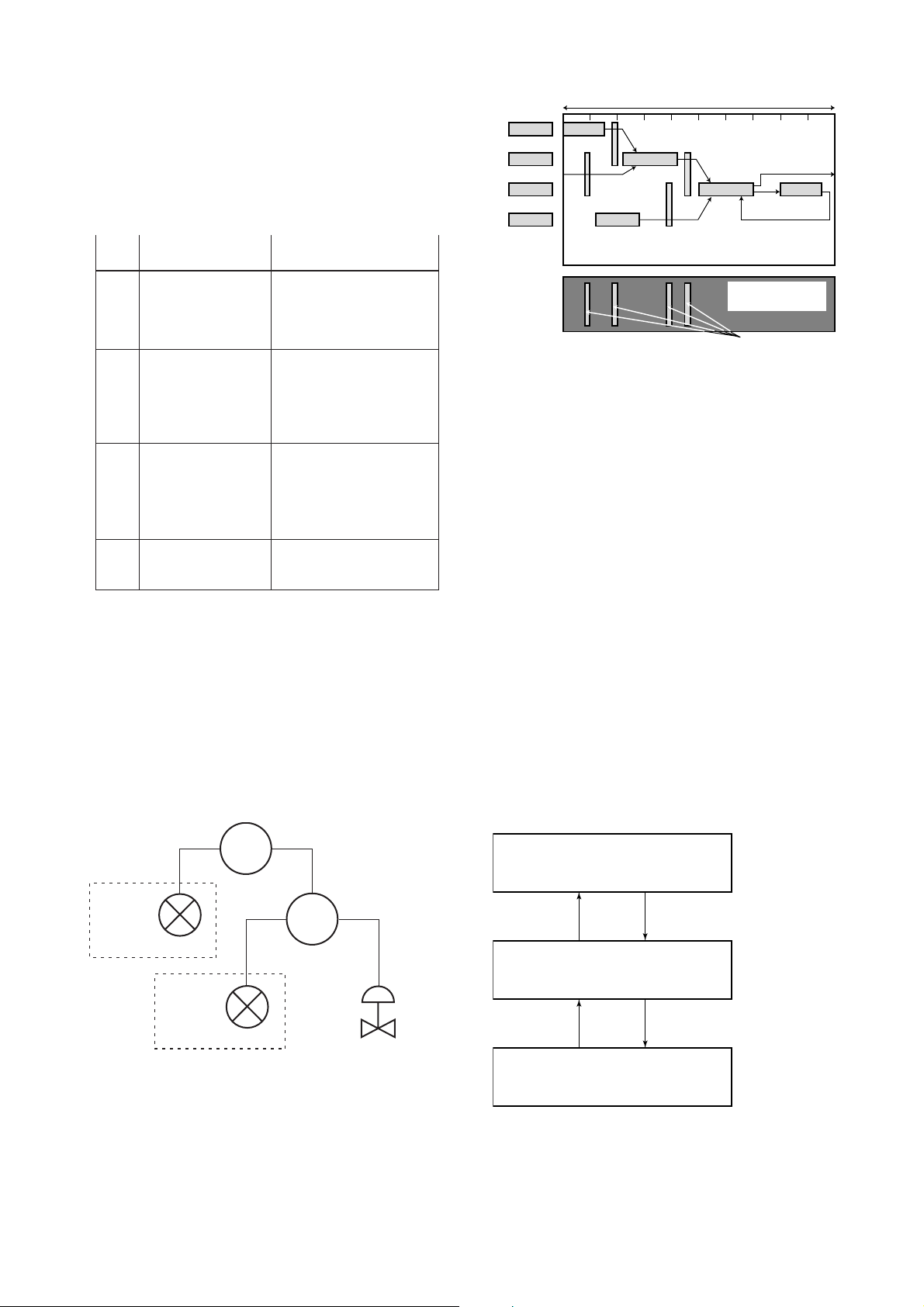

The linked blocks need to be executed synchronously with other blocks and the communication

schedule. In this case, change the schedule of

the ROTAMASS according to Table 5.3, in which

factory settings are shown in parentheses.

Table 5.3 Function Block Execution Schedule of

ROTAMASS

Index Parameters

269

MACROCYCLE_DURATION

(SM)

276

FB_START_ENTRY.1 Start time of the AI1 block

(SM)

277

FB_START_ENTRY.2 Start time of the PID block

(SM)

278 (SM)

FB_START_ENTRY.3 to

to

FB_START_ENTRY.14

289 (SM)

Setting (Factory Setting in

Parentheses)

Repetition period of control

or measurement, i.e.,

macrocycle; to be set as a

multiple of 1/32 ms (32000 =

1 second)

represented as the elapsed

time from the start of each

macrocycle; to be set as a

multiple of 1/32 ms (0 = 0

ms)

(optional) represented as

the elapsed time from the

start of each macrocycle; to

be set as a multiple of 1/32

ms (9600 = 300 ms)

Not set.

Macrocycle (Control Period)

FI103

FC100

FC200

FI200

unction

Block

chedule

ommu-

nication

chedule

Figure 5.3 Functionn Block Schedule and Communica-

FI100

OUT

BKCAL_IN

FI200

tion Schedule

IN

FIC100

OUT

CAS_IN

FIC200

IN

BKCAL_IN

Unscheduled

Communication

BKCAL_OUT

FC100

BKCAL_OU

Scheduled

Communication

When the control period (macrocycle) is set to

more than 4 seconds, set the following interval to

be more than 1% of the control period.

- Interval between “end of block execution” and

“start of sending CD from LAS”

- Interval between “end of block execution” and

“start of the next block execution”

A maximum of 30 ms is taken for execution of

each AI block. Arrange the communication

schedule for an AI block’s data that is to be

transferred to its downstream block in such a way

that it starts after a lapse of longer than 30 ms.

Figure 5.3 shows typical function block and

communication schedules for the loop shown in

Figure 5.2.

FIC 100

Rotamass

#1

FI100

Rotamass

#2

FI200

Figure 5.2 Example of Loop Connecting Function Blocks

of two ROTAMASS with other Devices

FIC 200

FC 100

F0502.E PS

5

.4 Setting of Tags and Addresses

This section describes the steps in the procedure

to set the PD tags and node address in the

ROTAMASS. There are three states of Fieldbus

devices as shown in Figure 5.4, and if the state is

other than the lowest SM_OPERATIONAL state,

no function block is executed. Whenever you have

changed the PD tag or address of a ROTAMASS,

transfer its state to SM_OPERATIONAL.

UNINITIALIZED

(No tag nor address is set)

Tag clear Tag setting

INITIALIZED

(Only tag is set)

ddress clear

SM_OPERATIONAL

(Tag and address are retained, and

the function block can be executed.)

Address setting

Figure 5.4 Status Transition by Setting PD Tag and Node

Address

IM 01R04B05-00E-E

2nd edition, June 2007

5-3

Page 26

5. CONFIGURATION

In each ROTAMASS, the PD tag and node

address are set to “FT1004” and 246 (hexadecimal

F6), respectively, before shipment from the factory

unless otherwise specified. To change only the

node address, clear the address once and then

set a new node address. To set the PD tag, first

clear the node address and clear the PD tag, then

set the PD tag and node address again.Devices

whose node address was cleared will await at the

default address (randomly chosen from a range of

248 to 251, or from hexadecimal F8 to FB). At the

same time, it is necessary to specify the device ID

in order to correctly specify the device. The device

ID of the ROTAMASS is 594543000Dxxxxxxxx.

(The xxxxxxxx at the end of the above device ID is

a total of 8 alphanumeric characters.)

5.5 Communication Setting

To set the communication function, it is necessary

to change the database residing in SM (System

Management)-VFD.

5.5.1 VCR Setting

Set VCR (Virtual Communication Relationship),

which specifies the called party for communication

and resources. Each ROTAMASS has 33 VCRs

whose application can be changed, except for the

first VCR, which is used for management.

Each ROTAMASS has VCRs of four types:

Server (QUB) VCR

A server responds to requests from a host. This

communication needs data exchange. This type

of communication is called QUB (Queued Usertriggered Bidirectional) VCR.

Source (QUU) VCR

A source multicasts alarms or trends to other

devices. This type of communication is called

QUU (Queued User-triggered Unidirectional)

VCR.

Publisher (BNU) VCR

A publisher multicasts outputs of the AI blocks,

IT blocks, and PID block to other function

blocks. This type of communication is called

BNU (Buffered Network-triggered Unidirectional)

VCR.

Subscriber (BNU) VCR

A subscriber receives output of another function

block(s) by PID block.

Each VCR has the parameters listed in Table 5.4.

Parameters must be changed together for each

VCR because modification for each parameter

may cause a contradiction.

Table 5.4 VCR Static Entry

Sub-

ind

ex

1 Fas ArTypeAndRole

2 FasDllLocalAddr

3 F as DllC onfigured

4 F as DllS D AP

5 Fas DllMa xC onfirm

6 Fas DllMa xC onfirm

7 F as DllMa xDls duS ize

8 F as DllR e sidua l

9 F as DllT imeline ss C las s

10 F as DllP ublis herT ime

11 F as DllP ublis her

P

aramete

R emoteAddr

DelayO nConnect

DelayOnData

A cti vity S up por ted

WindowS ize

S ynchronizaingDlcep

r

D

escription

Indica tes the ty pe a nd role of

communication (VCR ). The

following 4 types a re use d

for the R ota mass .

0x32: Server (R esponds to

requests from host.)

0x44: Source (Transmits

alarm or trend.)

0x66: Publisher (S ends AI,

DI block output to

other blocks.)

0x76: S ubscriber (R eceives

output of other blocks

by P ID bloc k.)

S ets the loc a l a ddre s s to

specify a VCR in the

R ota ma s s. A range of 20 to

F 7 in hexadecimal.

S ets the node address of the

called party for

communication and the

addres s (DLS AP or D LCE P )

used to specify VCR in that

addres s. F or DLS AP or

DLC E P, a range of 20 to F7

in hexadecimal is us ed.

Addresses in Subindex 2

a nd 3 need to be s et to the

s a me c on tents of the V CR

as the called party (local and

remote are reversed).

S pecifies the quality of

communication. Usually, one

of the following types is set.

0x2B: S erver

0x01: Source (Alert)

0x03: Source (Trend)

0x91: P ublishe r/S ubs criber

To es tablish c onnection for

communication, a ma ximum

wait time for the calle d

party's response is set in

ms . T ypical value is 60

secounds (60000).

For reques t of data, a

maximum wait time for the

called party's response is

set in ms . Typica l value is

60 secounds (60000).

S pecifies maximum DL

S ervice Da ta unit Size

(DLS DU). S et 256 for Server

and Trend V C R , and 64 for

other VCR s.

S pecifies whether

connection is monitored. S et

T R U E (0xff) for S erve r. This

parameter is not us ed for

other communication.

Not used for the Rotamas s

Not used for the Rotamas s.

Not used for the Rotamas s.

T0504-1.E PS

IM 01R04B05-00E-E

2nd edition, June 2007

5-4

Page 27

5. CONFIGURATION

)

Sub-

ind

ex

12 F as DllS ubs cribe rTime

13 FasDllS ubscriber

14 FmsVfdId

1 5 F m s Ma xO u ts ta ndin g

1 6 F m s Ma xO u ts ta ndin g

17 FmsFeatures

P

aramete

WindowS ize

S ynchronizationDlcep

S erviceC a lling

S erviceC a lled

S upported

r

D

escription

Not used for the Rotamass.

Not used for the Rotamass.

S ets VF D for the R ota mas s

to be u s e d.

0x1: Sys tem/network

mana geme nt VF D

0x1234: Function block

VFD

S et 0 to S e rver. It is not

us ed for other a pplica tions .

S et 1 to S e rver. It is not

us ed for other a pplica tions .

Indica tes the type of s e rv ic es

in the a pplica tion layer. In the

R ota mass, it is a utomatically

s e t a cco rding to s pec ific

applications.

T0504-2.E PS

These 33 VCRs are factory-set as shown in Table 5.5.

Table 5.5 VCR List

I

nd

ex

)

VCR

N

umber

5

7

9 to 33

R emote Address=0x111)

Alert Source (LocalAddr = 0x07,

R emote Address=0x110)

Not set

(SM

293 For system management (Fixed)1

294 S erver (L ocalAddr = 0xF 3)2

295 S erver (L ocalAddr = 0xF 4)3

296 S erver (L ocalAddr = 0xF 7)4

297 Trend S ource (LocalAddr = 0x07,

298 Publisher (LocalAddr = 0x20)6

299

300 S erver (LocalAddr = 0xF 9)8

301 to 325

F

actory Setting

T0505.E PS

5.5.2 Function Block Execution Control

According to the instructions given in Section 5.3,

set the execution cycle of the function blocks and

schedule of execution.

5.6 Block Setting

Set the parameter for function block VFD.

5.6.1 Link Objects

A link object combines the data voluntarily sent by

the function block with VCR. Each ROTAMASS

has 40 link objects. A single link object specifies

one combination. Each link object has the param-

eters listed in Table 5.6. Parameters must be

changed together for each VCR because the

modifications made to each parameter may cause

inconsistent operation.

Table 5.6 Link Object Parameters

Sub-

ind

ex

1LocalIndex

2VcrNumber

3 R emoteIndex

4 S erviceOperation

5 S taleC ountLimit

P

arameters

D

escription

S ets the index of func tion

block parame ters to be

combined; set “0” for Trend

and Alert.

S ets the index of V C R to

be combined. If set to “0”,

this link object is not used.

Not us ed in the R ota ma ss .

S et to “0 ”.

S et one of the following.

S et only one ea ch for link

object for Alert or Trend.

0: Undefined

2: P ublisher

3: Subscriber

6: Alert

7: Trend

S et the ma ximum number

of consecutive stale input

values which may be

received before the input

status is set to BAD. To

avoid the unneces s ary

mode tra ns itio n c a used

when the da ta is not

correctly received by

subscriber, set this

parameter to “2” or more.

Link objects are not factory-set. Set link objects as

shown in Table 5.7.

Table 5.7 Settings of Link Objects (example)

Index Link Object #

30000

30001 2

30002 3

30003 to 30039

1

Settings(example

AI. OUT VCR#6

Trend VCR#5

Alert VCR#7

No used4 to 40

5.6.2 Trend Objects

It is possible to make settings so that a function

block automatically transmits the trend. For this,

each ROTAMASS has ten trend objects: eight for