Page 1

Instruction

EXAtrac RF20H (Extract 810 and 820)

Manual

Process retractable holder

IM 12B06K05-E-E

1st Edition

Page 2

2

Table of contents

1 Safety and protection measures 4

1.1 General safety instructions 4

1.2 Proper use 4

1.3 Hazard areas and residual hazards 4

1.4 Equipment 5

1.5 Safety equipment 5

1.6 Staff 5

1.7 Disposal 5

1.8 Symbols and pictograms 5

2 Product description 6

2.1 RF20H (Extract 810 and 820) automatic retractable holder 6

2.2 Process integration 7

3 Delivery 8

3.1 Package contents 8

3.2 Checking the delivery 8

4 Installation 9

4.1 Preparing the system 9

4.2 Preparing the holder 9

4.3 Installing the holder 9

4.4 Adjusting the protection cage 9

4.5 Installing the cleaning pipes 10

4.6 Installing the pneumatic tubes 10

4.7 Installing the sensor 10

5 Operation 12

5.1 Commissioning the holder 12

5.2 Automatic operation of the holder 12

6 Servicing 13

6.1 Servicing instructions 13

6.2 Checking wetted sealings 13

6.3 Removing the sensor 13

6.4 Removing the pneumatic tubes 13

6.5 Removing the cleaning chamber with process connection 14

6.6 Replacing the wetted sealings 14

6.7 Removing the insertion rod 15

6.8 Installing the insertion rod 16

6.9 Assembling the drive unit and cleaning chamber 16

6.10 Replacing the drive unit 16

6.11 Servicing plan 16

6.12 Disposal 16

IM 12B06K05-E-E

Page 3

7 Trouble shooting 17

7.1 Holder does not move from the “service” position to the “measuring” position 17

7.2 Holder does not move from the “measuring” position to the “service” position 17

7.3 Incorrect position reply 17

7.4 No position reply 17

7.5 Frequent contamination of sensor 17

7.6 Sensor breaks frequently 18

7.7 Leakage of process liquid at inspection window 18

7.8 Compressed air emitted at inspection window 18

8 Technical specifications 19

8.1 Standards 19

8.2 Material properties 19

8.3 Cleaning ports 19

8.4 Sensors 19

8.5 Pneumatic equipment 19

8.6 Dimensions 20

8.7 Ambient conditions 21

8.8 Process conditions RF20H (Extract 810 and 820) S.S./Hastelloy 21

8.9 Process conditions RF20H (Extract 810 and 820) plastic 21

8.10 Ordering structure RF20H (Extract 810 and 820) S.S./Hastelloy 22

3

9 Parts and accessories 23

10 Certificates 24

10.1 Statement of compliance 24

10.2 Atex certificate 25

IM 12B06K05-E-E

Page 4

4

1. Safety and protection measures

1.1 General safety instructions

The RF20H (Extract 810 and 820) retractable

holder is designed in a way that when the operation

manual is observed the product does not cause any

hazards.

• Read the operation manual before use.

• Do only install and operate the retractable holder

before having read and understood all notes on

the safe and proper use.

• Keep the operation manual for future reference.

• Operate the retractable holder only in trouble-free

condition.

• In addition, observe laws, regulations, guidelines

and standards applicable in the operator’s country

and at the site of use.

1.2 Proper use

The RF20H (Extract 810 and 820) retractable holder

is attached to tanks or piping. A sensor is inserted

in the process liquid by the drive unit in order to

measure chemical or physical properties. The

procedure is controlled automatically and can not

be operated manually.

The choice of material properties of holder and

equipment depends on the process properties.

The retractable holder should be serviced on a

regular basis.

• Establish a service plan adapted to your process.

• Only perform the service, maintenance described

in the operation manual!

• Modifications to the holder must be agreed with

the manufacturer.

The manufacturer is not liable for any damages

resulting from improper or inappropriate use.

1.3 Hazard areas and residual hazards

Retractable holders are connected to tanks and

piping that may be under pressure. Leaking of

process liquid only occurs in case of negligence and

improper operation.

• Prior to commissioning and after every servicing,

ensure that all seals and connections are

complete and in working order.

• Never remove the lower and top housing cramp

screws during operation of the holder.

• Take applicable protection measures prior to

touching the holder as parts of the retractable

holder may adopt the process temperature.

1.4 Equipment

Only use certified and approved accessories and

equipment.

Seals Choose material properties

of process seals and O rings

according to process medium and

cleaning liquid(s).

Observe swelling ability and acid

and alkaline resistance of seal

material.

Sensor Choose a suitable sensor and

observe information in chapter 8

“technical specifications”.

Pressure air Filter (40 µm), clean and deoil

compressed air.

Ensure that the pressure is between

4 and 6 bar.

Cleaning Choose cleaning liquid and

liquid/ detergent according to process,

detergent holder, and seal material and

dispose it an appropriate way.

IM 12B06K05-E-E

Page 5

5

CAU TI ON!

CAU TI ON!

DAN GE R!

1.5 Safety equipment

Position The retract protection prevents the

“service” insertion rod from retracting without

sensor in the process as this would

cause a leakage of process liquid.

• The sensor can only be installed/

removed when the holder is in the

“service” position.

• Disabling the retract protection is

considered as negligence.

Position In the “measuring” position the

“measuring” sensor is immersed in the drive unit.

• You cannot remove the sensor.

• Trying to remove the sensor

in the “measuring” position is

considered as negligence!

Protection You may adjust the protection cage

cage at the end of the insertion rod in

order to protect the sensor from

mechanical impacts.

1.6 Staff

Qualifications Leave installation and servicing of

the retractable holder to trained staff!

Protective The operation staff must wear

clothing goggles and applicable protective

clothing during commissioning and

servicing works.

Accident Observe work safety laws and

prevention regulations applicable in the

regulations operator’s country and at the site of

use!

1.7 Disposal

Observe regulations and rules for waste disposal

applicable in the operator’s country and at the site

of use.

1.8 Symbols and pictograms

Pictograms and symbols are used in

the operation manual to provide better

orientation.

DAN GE R!

The safety note with the DANGER! signal

indicates the risk of personal danger and

high material damage in case of failure to

observe the instructions.

CAU TI ON!

The safety note with the CAUTION! signal

indicates the risk of material damage in case

of failure to observe the instructions.

Indicates an important note!

This sign indicates that the operations

should be carried out in the specified order.

1.9 Reliable Use in Explosive

Atmospheres

For a reliable use under potential explosive

conditions please regard the following remarks:

• Avoid electrostatic charges on the top of the drive

unit. Wipe with an antistatic cloth only.

• The electrostatic charge must be taken into

account in case of parts not made of a conductive

material. This applies particularly for nonconductive fluids.

• The sensor must conform to Directive 94/9EC and

the ambient temperatures must be observed.

• It must be ensured that the compressed air does

not contain a potentially explosive atmosphere.

• It must be ensured that the extension and

retraction movements of the sensor do not

damage the connection.

• The various temperature classes of the different

materials must be observed.

• A liquid potential equalisation must be ensured.

IM 12B06K05-E-E

Page 6

6

2. Product description

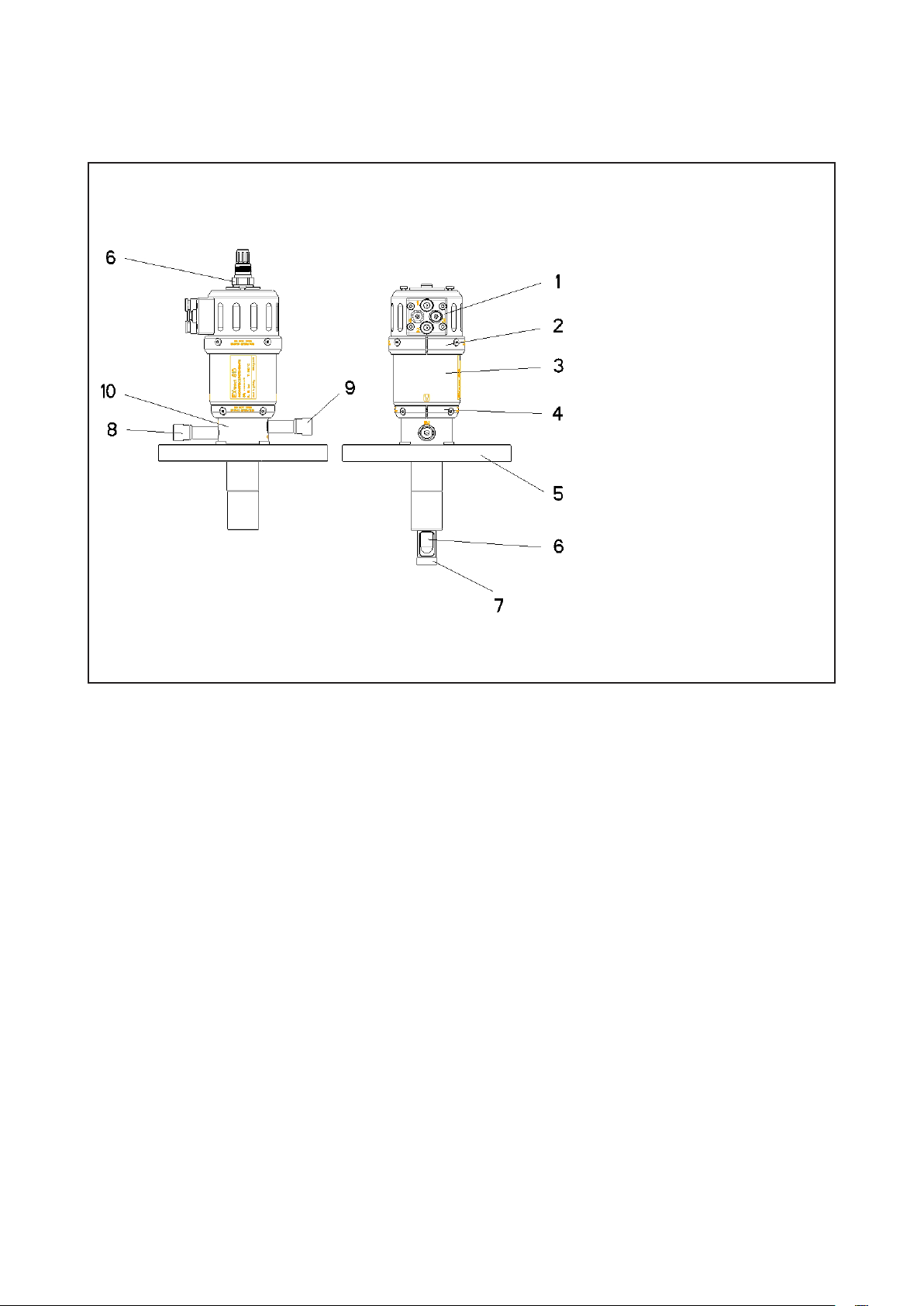

2.1 RF20H (Extract 810 and 820) automatic retractable holder

Components

1. Pneumatic connections 1-4

2. Top housing cramp

3. Drive unit

4. Lower housing cramp

5. Process connection

6. Sensor

7. Insertion rod with protection cage

8. Cleaning port “IN”

Fig. 1: Retractable holder

Variations

Retractable holders are attached to tanks or piping

by an applicable process connection. In order to

comply with the various process properties the

RF20H (Extract 810 and 820) retractable holder is

fabricated of stainless steel, Alloy C-22 or plastic.

You can further choose between different process

and cleaning ports, sealing materials, and sensors.

Drive

Compressed air is supplied via the pneumatic

connections on the drive unit. The drive unit inserts

the insertion rod in the process medium up to the

maximal insertion depth. For safety reasons this is

only possible with a sensor installed.

9. Cleaning port “OUT”

10. Cleaning chamber

Service

Cleaning, rinsing and calibration of the sensor

is possible while the process is running. For

this purpose the holder must be moved to the

“service” position. Another pneumatic position

signal feedback is given when the final position is

reached. In the “service” position the insertion rod

seals the cleaning chamber against the process

to prevent leakage of process liquid. The required

liquid is introduced into the cleaning chamber via

the cleaning port “IN” and subsequently drained via

the cleaning port “OUT”.

Measuring

When reaching the final position of the “measuring”

position, the control receives a pneumatic position

feedback signal. In this position the sensor head is

immersed in the drive unit and cannot be removed.

The sensor measures the chemical or physical

properties of the process liquid.

IM 12B06K05-E-E

Page 7

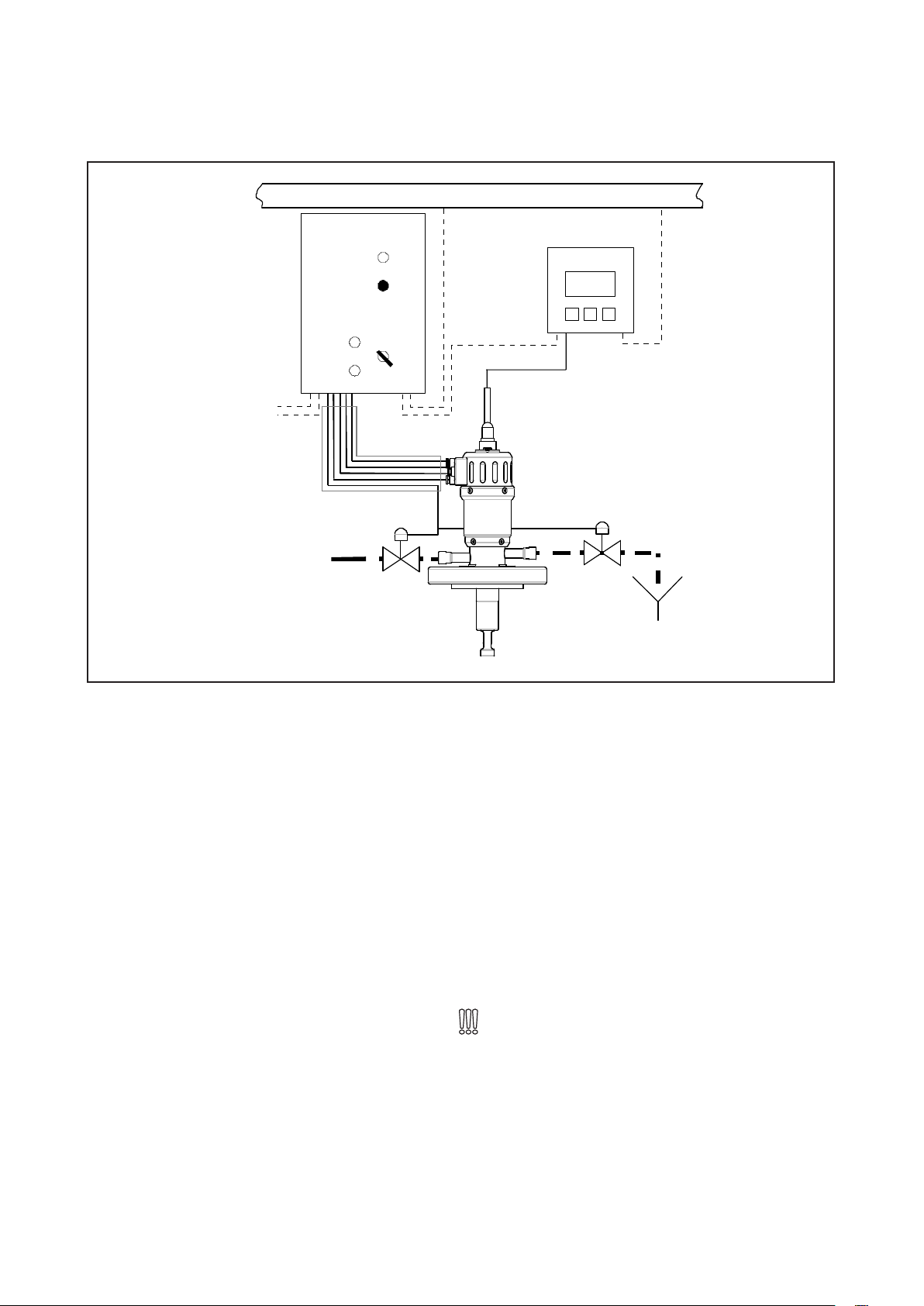

2.2 Process integration

24V DC

Air 4-6 bar

7

Process Control System

RF20M

(Exmatic 450)

Transmitter

Cleaning

solution

Fig. 2: Process flow

Control

The RF20H (Extract 810 and 820) retractable holder

can be operated by the automatic control EXmatic.

It optimally matches the functions of the holder.

Transmitter

The retractable holder inserts a sensor in the

process liquid transmitting its measuring results to a

transmitter.

Drain

Process control

The external control and the transmitter can

be connected to a process control unit. The

measuring and cleaning intervals are then controlled

automatically according to the measuring results.

Pressure Temperature

The choice of the applicable holder is subject to

the pressure and temperature conditions of the

process. The retractable holder of stainless steel or

Alloy C-22 can be used for a pressure of up to 16

bar and the plastic model up to 10 bar according to

the temperature. The process temperature should

be between -10° and 140°C.

Observe pressure and temperature charts in

chapter 8!

Installation position

The operation of the holder is generally possible in

any position. The reliability of the measuring results

depends on the properties of the selected sensor.

The sensor should be connected in a position less

than 15º to the hozizontal plane.

IM 12B06K05-E-E

Page 8

8

CAU TI ON!

DAN GE R!

3. Delivery

3.1 Package contents

The retractable holder is inspected at the factory

and delivered ready for installation in a packaging

providing optimal protection for the holder.

Package contents:

• RF20H (Extract 810 and 820) holder

• hexagon key 2.5mm

• 4 spare screws M 4 x 8 (DIN 912)

• 2 spacer for sensors

• operation manual

For the RF20H (Extract 810) S.S./Hastelloy holder

you will additionally receive a material certificate

Store the holder in the packaging. This

ensures optimal protection until the

installation.

3.2 Checking the delivery

Before approving the retractable holder

for installation the following should be

ensured:

• packaging and device are in apparent

good order.

• the data plate of the retractable holder

corresponds to the specifications on the

order.

EXtract 810

4404-FPM-255-D50-G14-PN

SN: 8000008

P:16 bar T:140ºC

made in germany www.e-p-e.com

Fig. 3a: Data plate Alloy C-22

Fig. 3b: Data plate Plastic

In case of further inquiries please directly

contact your dealer.

IM 12B06K05-E-E

Page 9

9

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

CAU TI ON!

4. Installation

4.1 Preparing the system

Ensure that

• Sufficient working space for operation of

the retractable holder is available.

• The process is shut off.

• Tank and tubing are pressure-free, empty

and clean.

• Connection flange and process

connection of the retractable holder fit

together.

• The process seal is positioned on the

connection flange.

• Ensure that there is no potentially

explosive atmosphere

4.2 Preparing the holder

The holder must be in the “service”

position!

• The insertion rod (process end) is completely

inserted in the cleaning chamber.

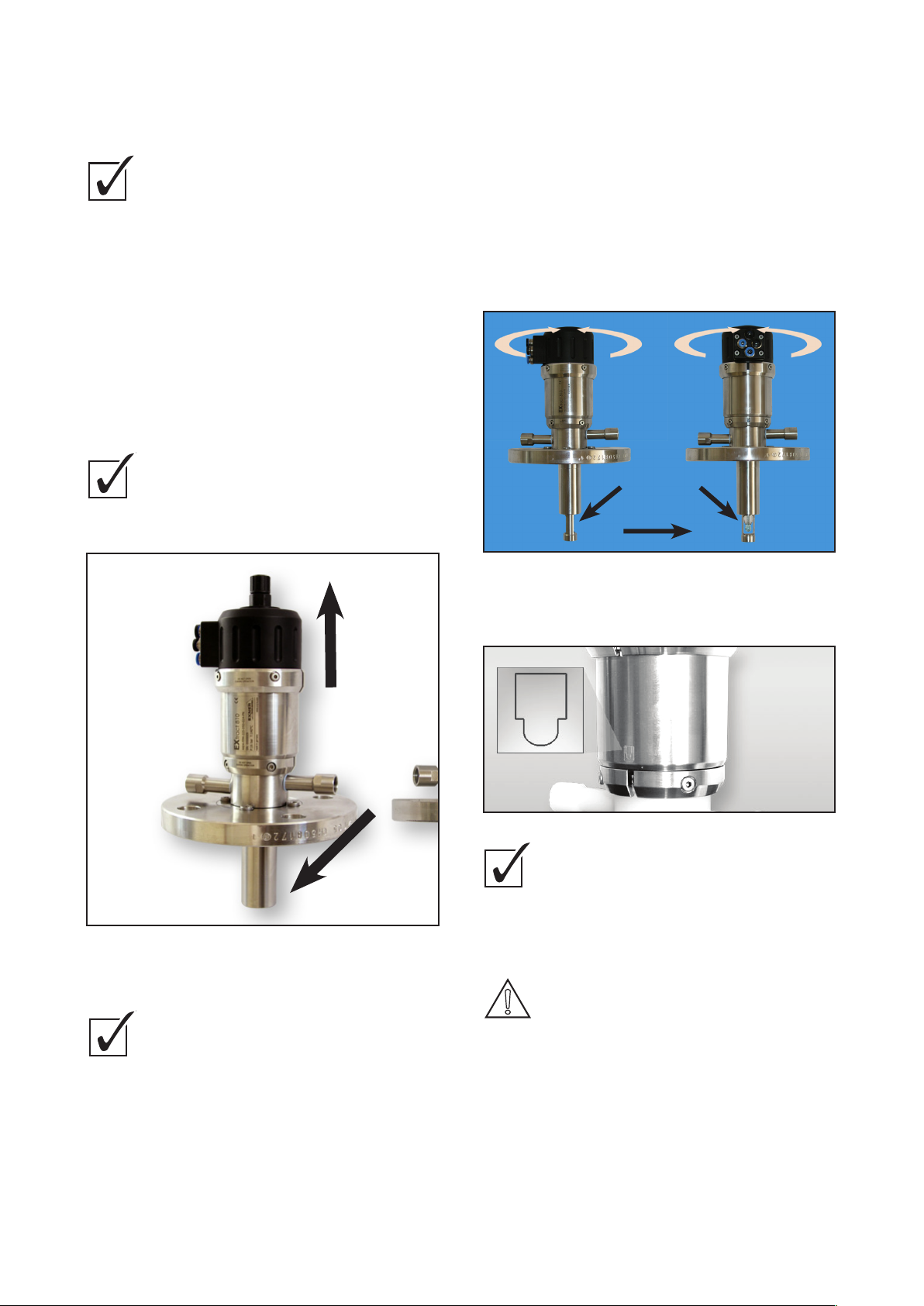

4.4 Adjusting the protection cage

A protection cage is fitted to the lower end of the

insertion rod and can be adjusted with the flow

direction. The symbol on the drive unit cylinder

indicates the position of the opening in the insertion

rod. If the symbol is parallel to the flow direction the

insertion rod is fully flown through. If the symbols

are vertical to the flow the sensor is fully protected

from direct flow. The insertion rod can be adjusted

in any intermediate position.

A

flow direction

B

Fig. 4: “service” position

4.3 Installing the holder

Prior to installation, ensure this:

• The system is prepared (chapter 4.1).

• The holder is prepared (chapter 4.2).

How to install the holder:

• Position retractable holder on process

seal.

• Tighten process connection.

A) Sensor maximally streamed

B) Sensor minimally streamed

Fig. 5: Protection cage

Fig. 6: Symbol

Ensure that:

• The process is shut off.

• Tank piping and tubing are pressure-free,

empty and clean.

• There is no potentially explosive atmosphere

DAN GE R!

Leakage of process liquid when

housing cramp is opened during

running process!

Burns or tissue destruction depending on

process liquid property.

• Stop process!

• Tanks and tubing must be pressure-free!

How to adjust the protection cage:

• Loosen screws of lower housing cramp.

• Rotate drive unit and adjust symbol in flow direction.

• Tighten screws of lower housing cramp.

IM 12B06K05-E-E

Page 10

10

CAU TI ON!

CAU TI ON!

DAN GE R!

4.5 Installing the cleaning pipes

Cleaning of the sensor is possible while the process

is running. This requires supply and draining of

cleaning liquid to the cleaning chamber. If cleaning

of the sensor is not desired the cleaning ports must

be sealed by pegs.

A

B

How to install the cleaning pipes:

1) Install valve and dirt trap in the cleaning

pipe for the cleaning liquid supply.

2) Attach supply cleaning pipe to the

cleaning port “IN”. .

3) Install valve in cleaning pipe for drainage

of the cleaning liquid.

4) Attach cleaning pipe to the cleaning port

“OUT”.

5) Check all connections for tightness.

To avoid premature contamination of the

sensor the pressure of the cleaning liquid

should be at least 1 bar!

4.6 Installing the pneumatic tubes

The RF20H (Extract 810 and 820) retractable holder

is operated with compressed air. The extension

of the cylinder of the drive unit is fitted with four

compressed air connections.

Fig. 7: Cleaning ports

A Cleaning port “IN”

B Cleaning port “OUT”

DAN GE R!

Leakage of process liquid through the

open cleaning port!

Burns or tissue destruction depending on

process liquid property.

• Cleaning pipes must be installed

or

• cleaning ports “IN” and “OUT” must be

sealed by pegs!

CAU TI ON!

If the process pressure is higher than

the cleaning pressure

process liquid enters the cleaning pipes

while the holder is moving to the service

position.

• A cleaning pipe with valve must be

installed at the cleaning ports “IN” and

“OUT”!

CAU TI ON!

If the cleaning liquid pressure exceeds

6 bar

holder and sensor may be damaged.

CAU TI ON!

• Install a pressure reducer, if necessary!

Contaminated cleaning liquid

can cause damage to the holder.

• Install a cleaning pipe with dirt trap at the

cleaning port “IN”!

IM 12B06K05-E-E

Fig. 8: Pneumatic connections 1 - 4

CAU TI ON!

Emitted compressed air

can cause material or personal damage.

Ensure tightness of pneumatic tubes before

supplying compressed air.

CAU TI ON!

Contaminated compressed air

causes damages to the drive unit!

• Use filtered (40 µm), water-free and

deoiled compressed air!

CAU TI ON!

You will need:

• 2 pneumatic tubes ø = 4mm

• 2 pneumatic tubes ø = 6mm.

Page 11

11

How to install the pneumatic tubes:

1 Insert pneumatic tube ø = 6mm in connection 1

(blue) for the air supply “service” position.

2 Insert pneumatic tube ø= 6mm in connection 2

(black) for air supply, “meassuring position”.

3 Insert pneumatic tube ø = 4mm in connection 3

(blue) for the reply signal “service” position.

4 Insert pneumatic tube ø = 4mm in connection 4

(black) for the reply signal “measuring position”.

4.7 Installing the sensor

Sensors with a diameter of 12mm and a connection

thread PG 13.5 must be used in the RF20H (Extract

810 and 820) retractable holder.

The length of the sensor depends on the sensor

type and the selected holder.

Observe information in chapter 8.4

“Sensors”!

Ensure that

• the holder is in the “service” position.

• all seals connected to the sensor are available.

• the sensor is not longer than the specified length.

> 5mm

Wrong!

5 - 7mm

Right!

How to install the sensor:

1) Insert sensor and tighten

2) Attach sensor cable

Fig. 9: Sensor filled with gel (top), sensor filled

with liquid (bottom)

CAU TI ON!

To long Sensors

could be damaged during installation

• Check the sensor length and use delivered

spacer if necessary!

The retractable unit is now ready for operation.

IM 12B06K05-E-E

Page 12

12

CAU TI ON!

DAN GE R!

CAU TI ON!

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

5. Operation

5.1 Commissioning the holder

DAN GE R!

Risk of injury by leaking process liquid!

Burns or tissue destruction depending on

process liquid property.

• Wear goggles and protective clothing!

• Check all seals and connections of holder

before starting the process.

Wear goggles and protective clothing during

commissioning of the holder!

Prior to the commissioning ensure the following:

• Seals are complete and in good working condition.

• Sensor is installed and tightened.

• Cleaning ports are sealed with pegs.

or:

• Cleaning pipes are installed and tight.

• Pneumatic tubes are installed and tight.

• Protection cage is adjusted correctly.

5.2 Automatic operation of the holder

An external control is required for automatic

operation of the retractable holder.

Observe the functions of the pneumatic

connections!

Connection 1: Air supply “service” position

Connection 2: Air supply “measuring” position.

Connection 3: Reply “service” position

Connection 4: Reply “measuring” position.

Use the external control to move the

retractable holder from the “service” position

to the “measuring” position and vice versa.

IM 12B06K05-E-E

Page 13

13

CAU TI ON!

DAN GE R!

servicing works.

manual!

manufacturer!

before disconnecting the holder from the process

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

CAU TI ON!

CAU TI ON!

DAN GE R!

6 Servicing

6. Servicing

6.1 Servicing instructions

• Establish a service plan adapted to your process!

• Leave servicing works to qualified staff.

• Always wear applicable protective clothes when

performing servicing works.

• Do only perform the service works described in

the operation manual!

• Constructional modifications must be agreed with

the manufacturer!

• Tubing and tanks must be pressure-free, empty

and clean before disconnecting the holder from

the process

• Ensure that there is no potentially explosive

atmosphere

6.2 Checking wetted sealings

The retractable holder is fitted with an inspection

window situated between the lower housing

cramps.

Check inspection window for leaking

process liquid on a regular basis.

6.3 Removing the sensor

How to remove the sensor:

1) Move holder to “service” position.

2) Remove sensor cable.

3) Remove PG cable gland.

4) Remove sensor.

DAN GE R!

Broken glass sensor!

Broken glass may damage the wetted

sealings.

• Check wetted sealings and replace if

necessary.

• Observe instructions in chapter 6.6!

6.4 Removing the pneumatic tubes

How to remove all four pneumatic tubes:

1) Move holder to "service" position.

2) Stop compressed air supply.

3) Press plastic ring “A” on pneumatic

connection.

4) At the same time pull pipe “B”.

Fig. 10: Inspection window on lower housing

cramp

WARN IN G!

Process liquid leaking on the inspection

window!

Risk depending on process liquid property!

• Replace wetted sealings.

• Observe instructions in chapter 6.6!

Fig. 11: Removing the pneumatic tubes

IM 12B06K05-E-E

Page 14

14

CAU TI ON!

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

CAU TI ON!

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

6.5 Removing the cleaning chamber

with process connection

DAN GE R!

System is under pressure.

Process liquid will leak when holder

is disconnected from process in an

inappropriate way.

• Tubing or tanks must be pressure-free,

empty, clean and without potentially

explosive atmosphere.

Interrupt the process.

Ensure that the system is pressure-free,

empty, clean and without potentially

explosive atmosphere.

How to remove the cleaning chamber:

1) Move holder to “service” position.

2) Switch off compressed air supply.

WARN IN G!

Emitted compressed air

can cause material damage or personal injury.

• Switch off compressed air supply before

removing the pneumatic tubes.

3) Remove pneumatic tubes (chap. 6.4).

4) Remove sensor (chap. 6.3).

5) Loosen process connection.

6) Remove process seals and holder.

7) Loosen lower housing cramp screws (Fig. 10).

8) Disconnect cleaning chamber with process

connection “A” from drive unit “D”.

9) Remove cleaning cartridge from insertion rod “C”.

6.6 Replacing the wetted sealings

DAN GE R!

System is under pressure.

Process liquid will leak when holder

is disconnected from process in an

inappropriate way.

• Ensure that system is pressure-free before

replacing the sealings.

• Drain and clean tubing or tanks.

• Ensure that there is no potentially

explosive atmosphere

WARN IN G!

Emitted compressed air

can cause material damage or personal

injury.

• Switch off compressed air supply before

removing the pneumatic tubes.

Install the seals chosen according to the

holder and the process!

• Do only use original parts!

How to replace the seals:

1) Remove cleaning chamber with process

connection (chap. 6.5).

2) Remove and replace outer O rings “A”, "B" and

inner O ring "C" on insertion rod.

A B C D

Fig. 12: Removing the cleaning chamber and

process connection (refer to image!)

A) Cleaning chamber with process connection

B) Cleaning cartridge

C) Insertion rod

D) Drive unit

IM 12B06K05-E-E

B A

Fig. 13: O rings on insertion rod

O rings ø in [mm] A 18.72 x 2.62

B 10.77 x 2.62

B is left out

3) Remove and replace O rings “D” on cleaning

cartridge.

D

Fig. 14:O ring on cleaning cartridge

O ring ø in [mm] D 21.95 x 1.78

Page 15

15

Scraper

∅

in [mm]

E 19 x 6 x 1

O ring

∅

in [mm]

F 21.89 x 2.62

Scraper

∅

in [mm]

E 19 x 6 x 1

O ring

∅

in [mm]

F 21.89 x 2.62

Scraper

∅

in [mm]

E 19 x 6 x 1

O ring

∅

in [mm]

F 21.89 x 2.62

CAU TI ON!

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

6 Servicing

insertion rod.

pneumatic tubes.

6.5).

A Cylinder extension

B Piston

C Insertion rod

D Cylinder

E 2 x M4 x 8

F 2 x pins

4) Remove PTFE scraper “E” on cleaning chamber

5) Remove and replace O ring “F”.

6) Position PTFE scraper “E” on O ring “F”.

F

Fig. 15: O rings/scraper on cleaning chamber

Scraper ø in [mm] E 19 x 6 x 1

O ring ø in [mm] F 21.89 x 2.62

Remove the PTFE scraper (E) as follows:

6.7 Removing the insertion rod

DAN GE R!

System is under pressure.

Process liquid will leak when holder

E

• Ensure that system is pressure-free before

• Drain and clean tubing or tanks.

WARN IN G!

Emitted compressed air

can cause material damage or personal injury.

• Switch off compressed air supply before

How to remove the insertion rod from

1) Remove cleaning chamber and process

2) Remove outer O rings on insertion rod

3) Remove top housing cramp screws.

4) Remove cylinder “D” from cylinder

is disconnected from process in an

inappropriate way.

removing the insertion rod.

removing the pneumatic tubes.

the drive unit:

connection (chap. 6.5).

(Fig. 13: “A” and “B”).

extension “A” (Fig. 17)

Only applicable for RF20H (Extract 810 and 820)

811/812 with separated cleaning chamber:

7) Separated cleaning chamber: Remove and

replace O ring “G”.

Fig. 16: Cleaning chamber 811/821

O ring ø in [mm] G 30 x 1.5

Fig. 17: Removing the cylinder

A Cylinder extension

B Piston

F

C Insertion rod

D Cylinder

5) Loosen screws “E” and remove pins “F” (Fig. 18).

Fig. 18: Removing the fixing elements

E 2 x M4 x 8

F 2 x pins

6) Remove insertion rod “C” from piston “B”.

IM 12B06K05-E-E

Page 16

16

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

CAU TI ON!

CAU TI ON!

DAN GE R!

CAU TI ON!

DAN GE R!

6.8 Installing the insertion rod

The descriptions refer to Fig. 17 and Fig. 18

in chap. 6.7 Removing the insertion rod!

How to assemble the insertion rod and the

drive unit:

1) Adjust slots in insertion rod “C” to piston “B”

and put together.

2) Insert pins “F”

3) Tighten screws “E”.

4) Grease inside wall of cylinder “D”.

5) Slide cylinder “D” over insertion rod “C”.

6) Adjust cylinder “D” to cylinder extension “A”.

7) Press until cylinder snaps into place.

8) Bring top housing cramp in position

and tighten screws.

9) Insert O rings at insertion rod

(Fig. 13: “A” and “B”).

6.9 Assembling the drive unit and

cleaning chamber

Ensure that

• all seals are installed and in good working

condition.

• insertion rod and drive unit are assembled

(chap. 6.8).

How to install the cleaning chamber:

1) Insert cleaning cartridge in cleaning chamber until

it snaps into place.

2) Insert drive unit with insertion rod.

3) Press both components tightly together.

4) Adjust drive unit until it snaps into place in the

cleaning chamber.

5) Adjust protection cage (chap. 4.4).

6) Bring lower housing cramp in position and tighten.

The holder can now be reinstalled in the

process. Also observe the instructions in

chapter 4:

• 4.3 Installing the holder

• 4.4 Adjusting the protection cage

• 4.5 Installing the cleaning

• 4.6 Installing the pneumatic

• 4.7 Installing the sensor

6.10 Replacing the drive unit

• Ensure that there is no potentially

explosive atmosphere

WARN IN G!

Emitted compressed air

can cause material damage or personal injury.

• Switch off compressed air supply before

removing the pneumatic tubes.

The new drive unit can now be installed:

Prior to installation,

• remove cleaning chamber with process

connection (chap. 6.5).

• remove insertion rod (chap. 6.8).

• Clean and dispose off cylinder, cylinder

extension, pivot, housing cramps, if required.

How to install the new drive unit:

1) Remove screws from top housing cramp.

2) Remove cylinder “D” from cylinder extension “A”

(Fig. 17).

3) Install insertion rod (chap. 6.8).

4) Assemble the drive unit and cleaning chamber

(chap. 6.9).

6.11 Servicing plan

Carry out maintenance works in the

recommended intervals!

weekly

Checking wetted sealings (chap. 6.2)

Check process connection.

Check cleaning pipes.

Check pneumatic connections.

quarterly

Check and tighten screws of top and lower

housing cramps.

once a year

Replace wetted sealings (chap. 6.6).

Remove and inspect insertion rod (chap. 6.7).

every 3 years

Replace drive unit (chap. 6.10).

6.12 Disposal

Holder

Ensure that the holder is free from

hazardous and toxic substances. Depending

on your material the individual components

must be disposed off separately.

DAN GE R!

System is under pressure.

Process liquid will leak when holder

is disconnected from process in an

inappropriate way.

• Ensure that system is pressure-free before

replacing the drive unit.

• Drain and clean tubing or tanks.

IM 12B06K05-E-E

Observe regulations and rules for waste

disposal applicable in the operator’s country

and at the site of use.

Packaging

The packaging is made of card board and

can be disposed off with the waste paper.

Page 17

7. Trouble shooting

Refer to the instructions and warnings in the specified chapters.

7.1 Holder does not move from the "service" position to the "measuring" position

possible reason measure

no compressed air check pneumatic tubes (chap. 6.4, 4.6)

pressure too low pressure must be between 4 and 6 bar (chap. 4.6)

no sensor Installing the sensor (chap. 4.7)

loose sensor tighten sensor (chap. 4.7)

7.2 Holder does not move from the "measuring" position to the "service" position

possible reason measure

no compressed air check pneumatic tubes (chap. 6.4, 4.6)

pressure too low Pressure must be between 4 and 6 bar (chap. 4.6)

Insertion rod or protection cage is blocked. • Preparing the system (chap. 4.1)

• Holder remains in “measuring” position

• Removing the cleaning chamber with process

connection (chap. 6.5)

• Removing the insertion rod (chap. 6.7)

17

7.3 Incorrect position reply

possible reason measure

pneumatic tubes are connected incorrectly check pneumatic tubes (chap. 6.4, 4.6)

7.4 No position reply

possible reason measure

no compressed air check pneumatic tubes (chap. 6.4, 4.6)

pressure too low pressure must be between 4 and 6 bar (chap. 4.6)

drive unit defect Replacing the drive unit (chap. 6.10)

7.5 Frequent contamination of sensor

possible reason measure

cleaning pipes incorrectly connected check cleaning pipes (chap. 4.5)

cleaning liquid pressure too low raise cleaning pressure.

cleaning chamber is blocked pressure must be between 1 and 4 bar (chap. 4.6)

cleaning liquid not adequate choose adequate cleaning liquid

cleaning period too short extend cleaning period

cleaning interval too long reduce cleaning interval

IM 12B06K05-E-E

Page 18

18

7.6 Sensor breaks frequently

possible reason measure

sensor too long choose adequate sensor (chap. 4.7)

seals on sensor are missing insert seals on sensor (chap. 4.7)

Process liquid contains solids Adjusting the protection cage(chap. 4.4)

7.7 Leakage of process liquid at inspection window

possible reason measure

wetted sealings are defect Replacing the wetted sealings (chap. 6.6)

7.8 Compressed air emitted at inspection window

possible reason measure

drive unit defect Replacing the drive unitit (chap. 6.10)

IM 12B06K05-E-E

Page 19

8. Technical specifications

8.1 Standards

Pressure equipment directive

8.2 Material properties RF20H (Extract 810 and 820)

Wetted components

Holder

metal plastic seals

RF20H 1.4404/316L Alloy C22, 2.4602 PVDF PEEK EPDM / FPM / FFKM

Drive unit)

cylinder cylinder extension seals

RF20H 1.4404/316 PA66 GF30 EPDM

8.3 Cleaning ports

Thread

without gland G 1/8" (internal)

G¼" (internal)

thread with gland NPT ¼" (internal)

19

Cleaning pressure

1 - 4 bar

8.4 Sensors RF20H (Extract 810 and 820)

Gel filled sensor

l [mm] d [mm] PG

RF20H 225 12 13.5

Sensor filled with liquid with refill connection

l [mm] d [mm] PG

RF20H 280 12 13.5

8.5 Pneumatic equipment

Pneumatic tubes

ø - external ø - internal

for control air 6 mm 4 mm

for position reply 4 mm 2 mm

Compressed air

• Filtered 40µm, water- and oil free

• 4 - 6 bar

• no continuous air consumption!

IM 12B06K05-E-E

Page 20

20

EXTRACT EXTRACT

810 811 820 821

350 480 350 480

A B C D

Flange 4404 Flange C22 NPT TriClamp

8.6 Dimensions

Holder

Dimensions RF20H RF20H

Metal (Extract 810) Plastic (Extract 820)

A1 [mm] 180 180

A2 [mm] 350 350

B [mm] 95 95

Process connections RF20H Metal (Extract 810)

A B C D

Flange 4404 Flange C22 NPT TriClamp

Dimensions

E1 [mm] 71 66 34 39

E2 [mm] 107 102 70 75

D1 [mm] 19 19 19 19

D2 [mm] 31 31 31 31

D3 [mm] - - - 64

IM 12B06K05-E-E

Page 21

Process connections RF20H in Plastic (Extract 820)

8 Technical specifications

A B

Flange NPT

8 Technical specifications

0

5

10

15

20

-10

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

TS in [°C]

PS in [bar]

1.4404 und 2.4602

TRACT 810/811

A B

Flange NPT

Dimensions

E1 [mm] 58 29

E2 [mm] 94 65

D1 [mm] 19 19

D2 [mm] 31 30.5

8.7 Ambient conditions

Ambient temperature - 10 - 70 °C

Transport and storage temperature - 20 - 80 °C

8.8 Process conditions RF20H in Metal (Extract 810)

max. allowed pressure PS: 16 bar

max. allowed temperature TS: 140 °C

21

20

15

10

5

PS in [bar]

0

-10

0

10

Fig. 19: Pressure temperature diagram RF20H Metal (Extract 820)

8.9 Process conditions RF20H in Plastic (Extract 820)

max. allowed pressure PS 10 bar

max. allowed temperature TS 140 °C

12

10

8

6

4

PS in [bar]

2

0

0

10

-10

20

30

20

30

40

50

TS in [°C]

1.4404 und 2.4602

40

50

TS in [°C]

60

70

80

90

100

110

120

60

70

80

90

100

110

120

130

140

130

140

Fig. 20: Pressure temperature diagram RF20H in Plastic (Extract 810)

IM 12B06K05-E-E

Page 22

22

8.10 Ordering structure RF20H (Extract 810 and 820) S.S./Hast.

RF20H (Extract 810 and 820)

RF20H pH-Retractable Holder RF20H remark

Material (wetted parts) -PP PP Extract 820

-PF PVDF Extract 820

-PK PEEK Extract 820

-SS Stainless Steel 1.4404 / 316L Extract 810

-HC Alloy C22 2.4602 Extract 810

Sealing Material -EPD EPDM

(wetted sealings) -FPM FPM (Viton)

-FKM FFKM (Kalrez)

Sensor -225 Suitable for 225mm PG13.5 Gel-filled

-280 Suitable for 280mm PG13.5 Liquid-filled

Process Connection -D32 Flange DN32 PN16 SS/Hast only

-D40 Flange DN40 PN16 SS/Hast only

-D50 Flange DN50 PN16

-A14 Flange ANSI 1 1/4” 150lbs SS/Hast only

-A12 Flange ANSI 1 1/2” 150lbs SS/Hast only

-A20 Flange ANSI 2” 150lbs

-N14 NPT M 1 1/4”

-T20 Tri Clamp 2” SS/Hast only

Cleaning Connection -G18 G 1/8” thread female

-G14 G 1/4” thread female

-N14 1/4” NPT female

Position switch -PN Pneumatic

Spareparts

Partnumber Description

10/2-123-40-001 Sealing Set EPDM

10/2-123-41-001 Sealing Set FPM

10/2-123-42-001 Sealing Set FFKM (Kalrez)

10/2-075-03-001 Drive Unit - sensor 225/325 pneum. position switch

10/2-075-03-002 Drive Unit - sensor 280/380 pneum. position switch

10/2-061-33-004 Insertion rod RF20H (Extract 810 and 820) 1.4404 / 316L

10/2-061-34-004 Insertion rod RF20H (Extract 810 and 820) 2.4602 / Alloy C22

10/2-061-22-004 Insertion rod RF20H (Extract 810 and 820) PP

10/2-061-23-004 Insertion rod RF20H (Extract 810 and 820) PVDF/Alloy C22

10/2-061-29-004 Insertion rod RF20H (Extract 810 and 820) PEEK

10/2-086-32-001 Set blind plug G1/8” 1.4301/316 for cleaning chamber

IM 12B06K05-E-E

Page 23

9. Parts and accessories

Drive unit with pneumatic position reply

RF20H (Extract 810 and 820) Part Item number

Metal and Plastic Drive unit for sensor L = 225mm 10/2-075-03-001

Metal and Plastic Drive unit for sensor L = 280mm 10/2-075-03-002

Seal kits

RF20H (Extract 810 and 820) Part Item number

Metal and Plastic Seal kit EPDM 10/2-123-40-001

Seal kit FPM 10/2-123-41-001

Seal kit FFKM 10/2-123-42-001

Insertion rods

RF20H (Extract 810 and 820) Part Item number

Metal Insertion rod 1.4404 / 316L 10/2-061-33-004

Insertion rod 2.4602 / Alloy C22 10/2-061-34-004

Plastic Insertion rod PP 10/2-061-22-004

Insertion rod PVDF / Alloy C22 10/2-061-23-004

Insertion rod PEEK / Alloy C22 10/2-061-29-004

23

Please state serial number of your holder when ordering parts and accessories.

IM 12B06K05-E-E

Page 24

24

10. Certificates

Statement of compliance

Atex certificate

IM 12B06K05-E-E

Page 25

25

IM 12B06K05-E-E

Page 26

26

IM 12B06K05-E-E

Page 27

27

IM 12B06K05-E-E

Page 28

YOKOGAWA ELECTRIC CORPORATION

World Headquarters

9-32, Nakacho 2-chome, Musashino-shi

Tokyo 180-8750

Japan

www.yokogawa.com

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

USA

www.yokogawa.com/us

YOKOGAWA EUROPE BV

Euroweg 2

3825 HD AMERSFOORT

The Netherlands

www.yokogawa.com/eu

YOKOGAWA ELECTRIC ASIA Pte. LTD.

5 Bedok South Road

Singapore 469270

Singapore

www.yokogawa.com/sg

YOKOGAWA CHINA CO. LTD.

3F Tower D Cartelo Crocodile Building

No.568 West Tianshan Road Changing District

Shanghai, China

www.yokogawa.com/cn

YOKOGAWA MIDDLE EAST B.S.C.(c)

P.O. Box 10070, Manama

Building 577, Road 2516, Busaiteen 225

Muharraq, Bahrain

www.yokogawa.com/bh

Yokogawa has an extensive sales and

distribution network.

Please refer to the European website

(www.yokogawa.com/eu) to contact your

nearest representative.

IM 12B06K05-E-E

Subject to change without notice Printed in The Netherlands, 01-1012 (A) I

Copyright©

Loading...

Loading...