Page 1

User´s

Model RAKD

Manual

Small Metal ROTAMETER

IM 01R01B30-00E-E

Rota Yokogawa GmbH & Co. KG

Rheinstr. 8

D-79664 Wehr

Germany

IM 01R01B30-00E-E

4th edition, April 2007

Page 2

Blank Page

Page 3

CONTENTS

Contents

1. Introduction ......................................................................................... 1-1

1.1 Template ........................................................................................................1-3

1.2 ATEX Documentation ...................................................................................1-6

1.3 General description ......................................................................................1-8

1.4 Principle of measurement ............................................................................1-8

1.5 Overview ........................................................................................................1-9

2. Precautions .......................................................................................... 2-1

2.1 Transportation and Storage .........................................................................2-1

2.2 Installation .....................................................................................................2-1

3. Installation ........................................................................................... 3-1

3.1 Installation in the pipeline ............................................................................3-1

3.2 Wiring.............................................................................................................3-1

3.2.1 Connecting diagrams ....................................................................................... 3-1

3.2.2 Conductor connection (Quickon) .................................................................... 3-4

4. Start of operation ................................................................................ 4-1

4.1 Hints on flow rate measurement ................................................................. 4-1

4.2 Pulsation and pressure shock .....................................................................4-1

4.3 Start of operation of electronic transmitter ................................................ 4-1

5. Limit switches (Option /K1 to /K8) .....................................................5-1

6. Maintenance......................................................................................... 6-1

6.1 Function test .................................................................................................6-1

6.2 Measuring tube, float ....................................................................................6-1

6.3 Explosion drawings ...................................................................................... 6-2

6.4 Electronic transmitter ................................................................................... 6-3

6.5 Exchange of scale ........................................................................................6-3

6.6 Exchange of indicator .................................................................................. 6-3

6.7 Troubleshooting............................................................................................6-4

7. Technical Data ..................................................................................... 7-1

7.1 RAKD Type-, Suffix-codes and Options......................................................7-1

7.2 Specifications ............................................................................................... 7-6

7.3 Dimensions and weights ..............................................................................7-9

7.4 Temperatue curves .....................................................................................7-13

All Rights Reserved, Copyright

2003. Rota Yokogawa GmbH & Co. KG

i

IM 01R01B30-00E-E

4th edition, April 2007

Page 4

CONTENTS

8. Explosion-protected Type Instruments ............................................. 8-1

8.1 General ......................................................................................................... 8-1

8.2 Intrinsically safe ATEX certified RAKD (/KS1) ...........................................8-2

8.2.1 Technical data ................................................................................................... 8-2

8.2.2 Installation ......................................................................................................... 8-4

8.3 Non incendive RAKD for Category 3 (ATEX) (/KN1) ..................................8-5

8.4 Dust proofed limt switches (ATEX) (/KS2) ..................................................8-6

8.5 Intrinsically safe SAA (Australia) certified limit switches (/SS1) .............8-6

8.6 Intrinsically safe CSA (USA + Canada) limit switches (/CS1) ...................8-6

8.7 Intrinsically safe NEPSI (China) certified RAKD (/NS1) ............................. 8-9

IM 01R01B30-00E-E

4th edition, April 2007

ii

Page 5

1. Introduction

T

1. INTRODUCTION

Before use, read this manual thoroughly and

familiarize yourself fully with the features,

operations and handling of Rotameter RAKD to

have the instrument deliver its full capabilities and

to ensure its efficient and correct use.

Notices Regarding This Manual

• This manual should be passed to the end user.

• The contents of this manual are subject to

change without prior notice.

• All rights reserved. No part of this document may

be reproduced or transmitted in any form or by

any means without the written permission of

Rota Yokogawa (hereinafter simply referred to as

Yokogawa).

• This manual neither does warrant the

marketability of this instrument nor it does

warrant that the instrument will suit a particular

purpose of the user.

• Every effort has been made to ensure accuracy

in the contents of this manual. However, should

any questions arise or errors come to your

attention, please contact your nearest Yokogawa

sales office that appears on the back of this

manual or the sales representative from which

you purchased the product.

• This manual is not intended for models with

custom specifications.

• Revisions may not always be made in this

manual in conjunction with changes in

specifications, constructions and/or components

if such changes are not deemed to interfere with

the instrument’s functionality or perfor-mance.

Notices Regarding Safety and Modification

• For the protection and safety of personnel, the

instrument and the system comprising the

instrument, be sure to follow the instructions on

safety described in this manual when handling

the product. If you handle the instrumentin a

manner contrary to these instructions, Yokogawa

does not guarantee safety.

• If this instrument is used in a manner not

specified in this manual, the protection provided

by this instrument may be impaired.

• As for explosionproof model, if you yourself

repair or modify the instrument and then fail to

return it to its original form, the explosionprotected

construction of the instrument will be

impaired, creating a hazardous condition. Be

sure to consult Yokogawa for repairs and

modifications.

The following safety symbols and cautionary

notes are used on the product and in this

manual:

WARNING

This symbol is used to indicate that a hazardous

condition will result which, if not avoided, may

lead to loss of life or serious injury. This manual

describes how the operator should exercise care

to avoid such a risk..

CAUTION

This symbol is used to indicate that a hazardous

condition will result which, if not avoided, may

lead to minor injury or material damage. This

manual describes how the operator should

exercise care to avoid a risk of bodily injury or

damage to the instrument.

IMPORTAN

This symbol is used to call your attention to a

condition that must be observed in order to avoid

the risk of damage to the instrument or system

problems.

NOTE

This symbol is used to call your attention to

information that should be referred to in order to

know the operations and functions of the

instrument.

For Safe Use of Rotameter RAMC

WARNING

• If the process fluid is harmful to personnel,

handle Rotameter RAKD carefully even after it

has been removed from the process line for

maintenance or other purposes. Exercise

extreme care to prevent the fluid from coming

into contact with human flesh and to avoid

inhaling any residual gas.

• In case of Explosion proof type instrument,

further requirements and differences are

described in Chapter 8 " INSTRUCTIONS FOR

EXPLOSION PROTECTED RAKD”. The

description in Chapter 8 is prior to other

descriptions in this instruction manual.

1-1

IM 01R01B30-00E-E

4th edition, April 2007

Page 6

1. INTRODUCTION

T

CAUTION

• When carrying Rotameter RAKD around,

exercise extreme care to avoid dropping it

accidentally and causing bodily injury.

Warranty

• The warranty of this instrument shall cover the

period noted on the quotation presented to the

Purchaser at the time of purchase. The Seller

shall repair the instrument free of charge when

the failure occurred during the warranty period.

• All inquiries on instrument failure should be

directed to the Seller’s sales representative from

whom you purchased the instrument or your

nearest sales office of the Seller.

• Should the instrument fail, contact the Seller

specifying the model and instrument number of

the product in question. Be specific in describing

details on the failure and the process in which

the failure occurred. It will be helpful if

schematic diagrams and/or records of data are

attached to the failed instrument.

• Whether or not the failed instrument should be

repaired free of charge shall be left solely to the

discretion of the Seller as a result of an

inspection by the Seller.

The Purchaser shall not be entitled to

receive repair services from the Seller free

of charge, even during the warranty period,

if the malfunction or damage is due to:

• improper and/or inadequate maintenance of the

instrument in question by the Purchaser.

• handling, use or storage of the instrument in

question beyond the design and/or

specifications

requirements.

• use of the instrument in question in a location

not conforming to the conditions specified in the

Seller’s General Specification or Instruction

Manual.

• retrofitting and/or repair by an other party than

the Seller or a party to whom the Seller has

entrusted repair services.

• improper relocation of the instrument in question

after delivery.

• reason of force measure such as fires,

earthquakes, storms/ floods, thunder/lightning,

or

other reasons not attributable to the instrument

in question.

WARNING

• When removing the instrument from hazardous

processes, avoid contact with the fluid and the

interior of the meter.

• In case of Explosion proof type instrument,

further requirements and differences are

described in Chapter 8 " INSTRUCTIONS FOR

EXPLOSION PROTECTED RAKD”. The

description in Chapter 8 is prior to other

descriptions in this instruction manual..

Restriction on Use of Radio Transceiver

IMPORTAN

Although the transmitter has been designed to

resist high frequency electrical noise, if a radio

transceiver is used near the transmitter or it

external wiring, the transmitter may be affected by

high frequency noise pickup. To test for such

effects, bring the transceiver in use slowly from a

distance of several meters from the transmitter,

and observe the measurement loop for noise

effects. Thereafter, always use the transceiver

outside the area affected by noise.

IM 01R01B30-00E-E

4th edition, April 2007

1-2

Page 7

1. INTRODUCTION

1.1 Template

Sending an instrument back to service

Installation and operation of the Rotameter RAKD in compliance with this manual is generally trouble-free.

In case a RAKD has to be sent for repairs or checking to our service, please observe the following:

Due to legislation for the protection of the environment and for the safety of our staff, YOKOGAWA may

only ship, repair and check sent devices on the condition that this does not constitute any risk to

environment and staff.

YOKOGAWA can only process your returned RAKD if you attach a certificate of harmlessness according

to the following sample.

If the unit has been in contact with corrosive, poisonous, flammable or water polluting substances, you

must,

- ensure that all parts and hollow spaces of the unit are free of these dangerous substances.

- attach a certificate of harmlessness to the returned unit.

Please understand that YOKOGAWA cannot process your returned unit without such a certificate.

1-3

IM 01R01B30-00E-E

4th edition, April 2007

Page 8

1. INTRODUCTION

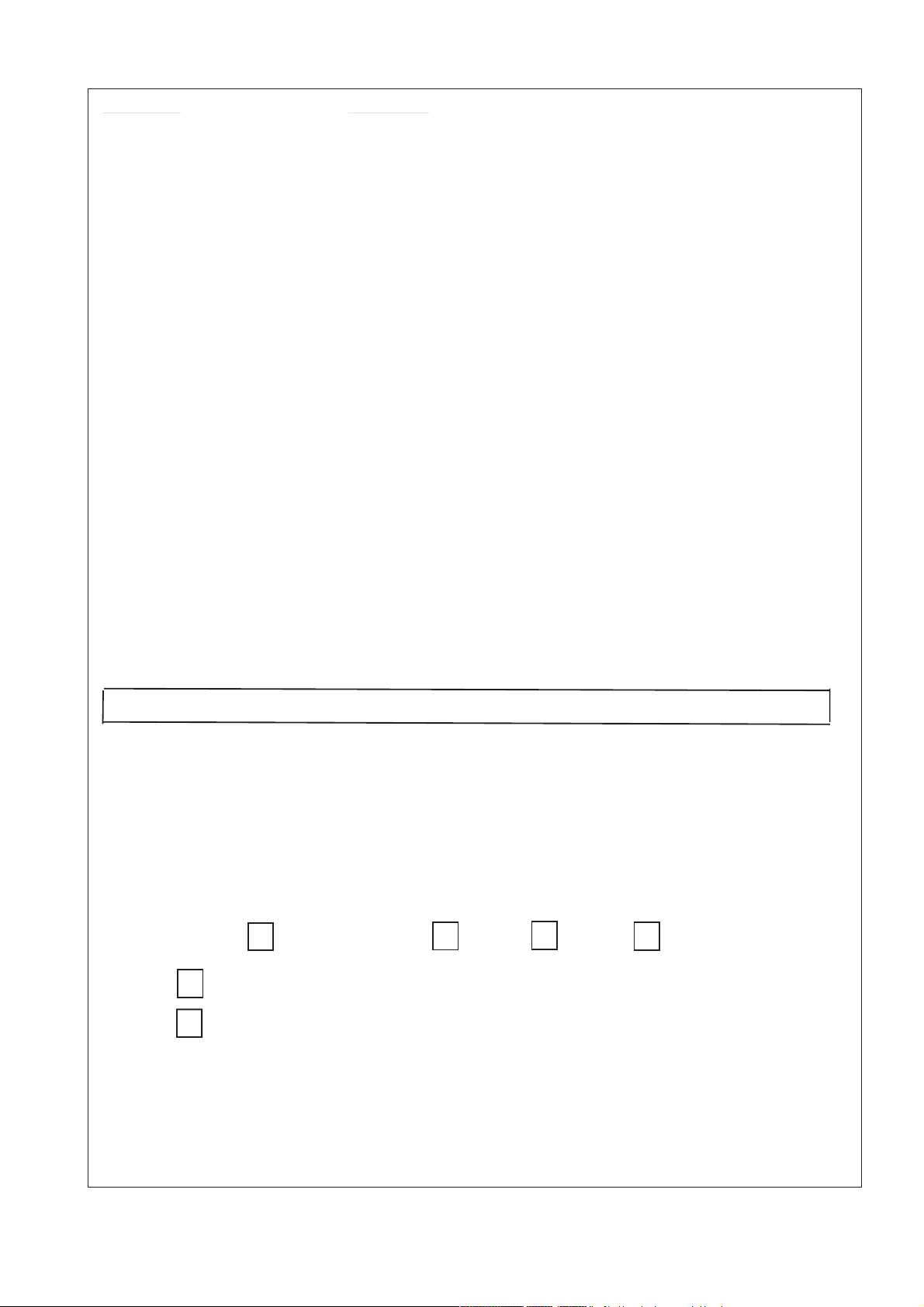

Receiver : Sender :

Delivery Note (for EU-Countries) Date :

Ref. REPAIR for comm. no. __________________________

We are sending following type of article

via forwarding agent : Yusen Air ; Raunheim/Frankfurt

Item Article Unit Price Total Price

Type (MS-Code)

________________________________ € __________ €__________

(nominal value)

Charges for airworthy packing

and delivery FOB €___________

Total value € ___________

Value for customs purpose only € _________

(current value)

Gross weight . _____________________kg

Net weight : _____________________kg

Customs Tariff No. : _____________________

Country og origin : Federal Republic of Germany

Delivery note 2-fold accompanis the goods

SPECIMEN Certificate

Company : ________________________ Address : ______________________

Department : ________________________ Name : ______________________

Telephone : ________________________ Fax : ______________________

Der beiliegende Durchflussmesser :

Type : ______________________________ Comm. no.. ___________

has been operated with following liquids: ___________________________________________

Because the liquid is water-endangeringnd toxic caustic flammable

we have

checked, that all cavities in the flowmeter are free fromsuch substances

flushed out and neutralised all cavities in the flowmeter

Please check applicable description

We confirm that there is no risk to man or enviroment through any residual liquid containes in this flowmeter.

Date : _____________________ Signature : _______________________

Company stamp:

IM 01R01B30-00E-E

4th edition, April 2007

1-4

Page 9

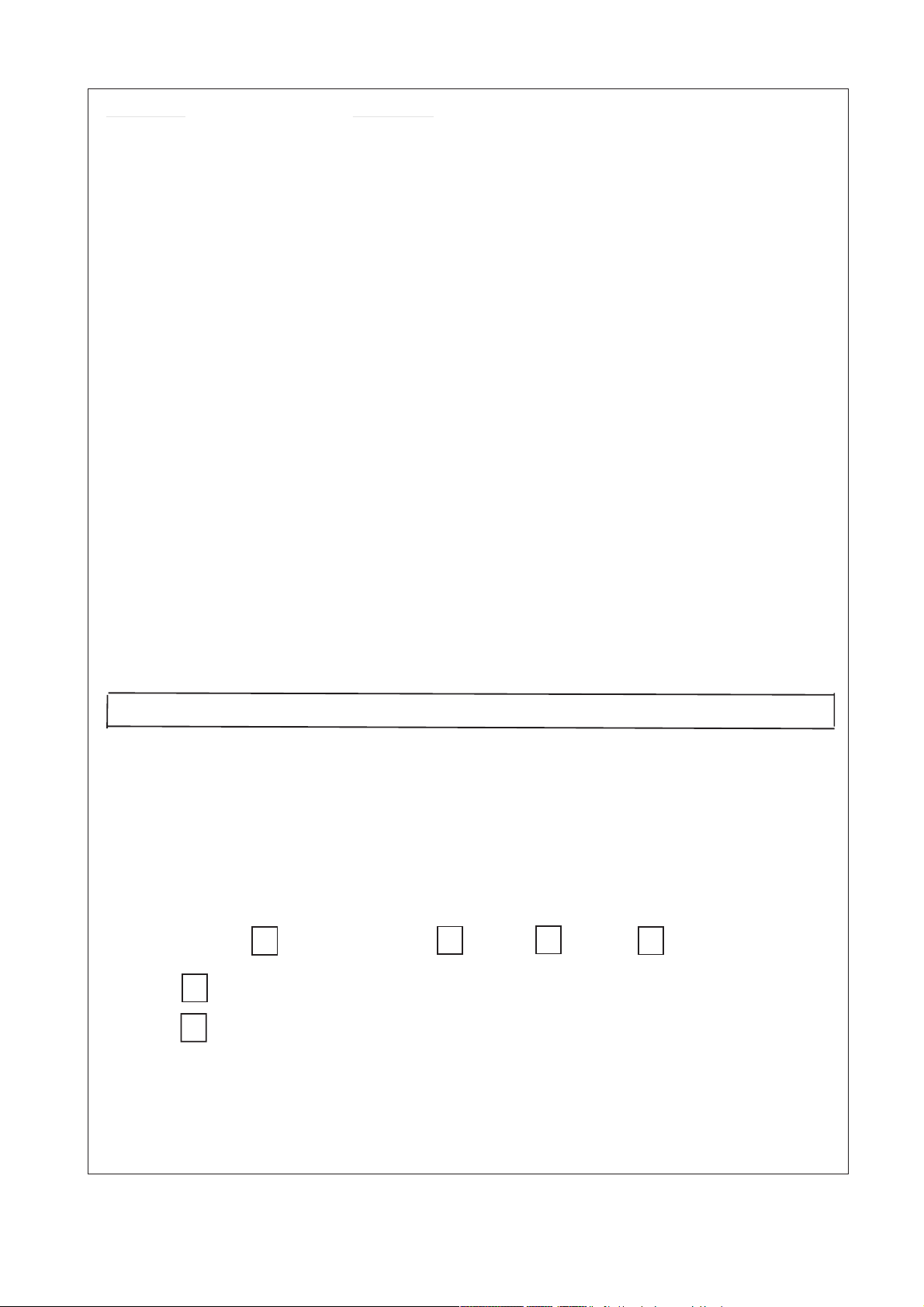

Receiver : Sender :

PROFORMA INVOICE (for Third-party-Countries) Date :

Ref. REPAIR for comm. no. __________________________

We are sending following type of article

via forwarding agent : Yusen Air ; Raunheim/Frankfurt

Item Article Unit Price Total Price

Type (MS-Code)

________________________________ € __________ €__________

(nominal value)

Charges for airworthy packing

and delivery FOB €___________

1. INTRODUCTION

Total value € ___________

Value for customs purpose only € _________

(current value)

Gross weight . _____________________kg

Net weight : _____________________kg

Customs Tariff No. : _____________________

Country og origin : Federal Republic of Germany

Delivery note 2-fold accompanis the goods

SPECIMEN Certificate

Company : ________________________ Address : ______________________

Department : ________________________ Name : ______________________

Telephone : ________________________ Fax : ______________________

Der beiliegende Durchflussmesser :

Type : ______________________________ Comm. No. ___________

has been operated with following liquids: ___________________________________________

Because the liquid is water-endangeringnd toxic caustic flammable

we have

checked, that all cavities in the flowmeter are free fromsuch substances

flushed out and neutralised all cavities in the flowmeter

Please check applicable description

We confirm that there is no risk to man or enviroment through any residual liquid containes in this flowmeter.

Date : _____________________ Signature : _______________________

Company stamp:

1-5

IM 01R01B30-00E-E

4th edition, April 2007

Page 10

1. INTRODUCTION

1.2 ATEX Documentation

This procedure is only applicable to the countries

in European Union.

GB

All instruction manuals for ATEX Ex related

products are available in English, German and

French. Should you require Ex related instructions

in your local language, you are to contact your

nearest Yokogawa office or representative.

DK

Alle brugervejledninger for produkter relateret til

ATEX Ex er tilgængelige på engelsk, tysk og

fransk. Skulle De ønske yderligere oplysninger om

håndtering af Ex produkter på eget sprog, kan De

rette henvendelse herom til den nærmeste

Yokogawa afdeling eller forhandler.

SF

Kaikkien ATEX Ex -tyyppisten tuotteiden

käyttöhjeet ovat saatavilla englannin-, saksan- ja

ranskankielisinä. Mikäli tarvitsette Ex -tyyppisten

tuotteiden ohjeita omalla paikallisella kielellännne,

ottakaa yhteyttä lähimpään Yokogawa-toimistoon

tai -edustajaan.

P

Todos os manuais de instruções referentes aos

produtos Ex da ATEX estão disponíveis em

Inglês, Alemão e Francês. Se necessitar de

instruções na sua língua relacionadas com

produtos Ex, deverá entrar em contacto com a

delegação mais próxima ou com um

representante da Yokogawa.

F

I

Tutti i manuali operativi di prodotti ATEX

contrassegnati con Ex sono disponibili in inglese,

tedesco e francese. Se si desidera ricevere i

manuali operativi di prodotti Ex in lingua locale,

mettersi in contatto con l’ufficio Yokogawa più

vicino o con un rappresentante.

E

Todos los manuales de instrucciones para los

productos antiexplosivos de ATEX están

disponibles en inglés, alemán y francés. Si desea

solicitar las instrucciones de estos artículos

antiexplosivos en su idioma local, deberá ponerse

en contacto con la oficina o el representante de

Yokogawa más cercano.

NL

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex) zijn

verkrijgbaar in het Engels, Duits en Frans. Neem,

indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen taal,

contact op met de dichtstbijzijnde vestiging van

Yokogawa of met een vertegenwoordiger.

Tous les manuels d’instruction des produits ATEX

Ex sont disponibles en langue anglaise, allemande et française. Si vous nécessitez des

instructions relatives aux produits Ex dans votre

langue, veuillez bien contacter votre représentant

Yokogawa le plus proche.

D

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch,

Deutsch und Französisch zur Verfügung. Sollten

Sie die Betriebsanleitungen für Ex-Produkte in

Ihrer Landessprache benötigen, setzen Sie sich

bitte mit Ihrem örtlichen Yokogawa-Vertreter in

Verbindung.

S

Alla instruktionsböcker för ATEX Ex

(explosionssäkra) produkter är tillgängliga på

engelska, tyska och franska. Om Ni behöver

instruktioner för dessa explosionssäkra produkter

på annat språk, skall Ni kontakta närmaste

Yokogawakontor eller representant.

IM 01R01B30-00E-E

4th edition, April 2007

1-6

Page 11

1. INTRODUCTION

j

GR

Ολα τα εγχειριδια λειτουργιαζ τωυ προιουτϖυ µε

ΑΤΕX Εx διατιΘευται στα Αγγλικα, Γερµαυικα

και Γαλλικα. Σε περιπτωση που χρειαζεοτε

οδηγιεζ σχετικα µε Ex στηυ τοπικη γλωσσα

παρακαλουµε επικοιυωυηστε µε το πλησιεστερο

γραϕειο τηζ Yokogawa η αντιπροσωπο τηζ.

SK

Všetky návody na obsluhu pre prístroje s ATEX

Ex sú k dispozícii v jazyku anglickom, nemeckom

a francúzskom. V prípade potreby návodu pre Exprístroje vo Vašom národnom jazyku, skontaktujte

prosím miestnu kanceláriu firmy Yokogawa.

CZ

Všechny uživatelské příručky pro výrobky, na

něž se vztahuje nevýbušné schválení ATEX Ex,

sou dostupné v angličtině , němčině a francouzštině .

Požadujete-li pokyny týkající se výrobků s

nevýbušným schválením ve vašem lokálním jazyku,

kontaktujte prosím vaši nejbližší reprezentační

kancelář Yokogawa.

PL

Wszystkie instrukcje obsługi dla urządzeń

w wykonaniu przeciwwybuchowym Ex,

zgodnych z wymaganiami ATEX, dostępne

są w języku angielskim, niemieckim i

francuskim. Jeżeli wymagana jest instrukcja

obsługi w Państwa lokalnym ję zyku, prosimy

o kontakt z najbliższym biurem Yokogawy.

SLO

Vsi predpisi in navodila za ATEX Ex sorodni

pridelki so pri roki v anglišèini, nemšèini ter

francošèini. Èe so Ex sorodna navodila potrebna

v vašem tukejnjem jeziku, kontaktirajte vaš najbliši

Yokogawa office ili predstaunika.

H

Az ATEX Ex mûszerek gépkönyveit angol, német

és francia nyelven adjuk ki. Amennyiben helyi

nyelven kérik az Ex eszközök leírásait, kérjük

keressék fel a legközelebbi Yokogawa irodát, vagy

képviseletet.

BG

LT

Visos gaminiø ATEX Ex kategorijos

Eksploatavimo instrukcijos teikiami anglø, vokieèiø

ir prancûzø kalbomis. Norëdami gauti prietaisø Ex

dokumentacijà kitomis kalbomis susisiekite su

artimiausiu bendrovës “Yokogawa” biuru arba

atstovu.

LV

Visas ATEX Ex kategorijas izstrâdâjumu

Lietoðanas instrukcijas tiek piegâdâtas angïu,

vâcu un franèu valodâs. Ja vçlaties saòemt Ex

ierîèu dokumentâciju citâ valodâ, Jums ir

jâsazinâs ar firmas Jokogava (Yokogawa) tuvâko

ofisu vai pârstâvi.

EST

Kõik ATEX Ex toodete kasutamisjuhendid on

esitatud inglise, saksa ja prantsuse keeles. Ex

seadmete muukeelse dokumentatsiooni

saamiseks pöörduge lähima Iokagava

(Yokogawa) kontori või esindaja poole.

Всички упътвания за продукти от серията АТЕХ

Ех се предлагат на английски, немски и

френски език. Ако се нуждаете от упътвания

за продукти от серията Ех на родния ви език,

се свържете с най-близкия офис или

представителство на фирма Yokogawa.

RO

Toate manualele de instructiuni pentru produsele

ATEX Ex sunt in limba engleza, germana si

franceza. In cazul in care doriti instructiunile in

limba locala, trebuie sa contactati cel mai apropiat

birou sau reprezentant Yokogawa.

M

Il-manwali kollha ta’ l-istruzzjonijiet għal prodotti

marbuta ma’ ATEX Ex huma disponibbli bl-Ingliż,

bil-Ġermaniż u bil-Franċiż. Jekk tkun teħtieġ

struzzjonijiet marbuta ma’ Ex fil-lingwa lokali tiegħek,

għandek tikkuntattja lill-eqreb rappreżentan jew

uffiċċju ta’ Yokogawa.

1-7

IM 01R01B30-00E-E

4th edition, April 2007

Page 12

1. INTRODUCTION

1.3 General description

This manual describes installation, operation and maintenance of the RAKD. Please read it carefully before

using this device.

Further, please note that customer features are not described in this manual. When modifying specifications,

construction or parts, this manual is not necessarily revised unless it can be assumed that these changes will

impair RAKD functions or performance.

All units are thoroughly tested before shipping. Please check the received units visually to ensure that they

have not been damaged during transport. In case of defects or questions please contact your nearest

YOKOGAWA service centre or sales office. Please describe any defect precisely and indicate model code as

well as com. no. number.

YOKOGAWA refuses any liability for units which have been repaired by the user without prior consent and do

not meet the specifications as a consequence..

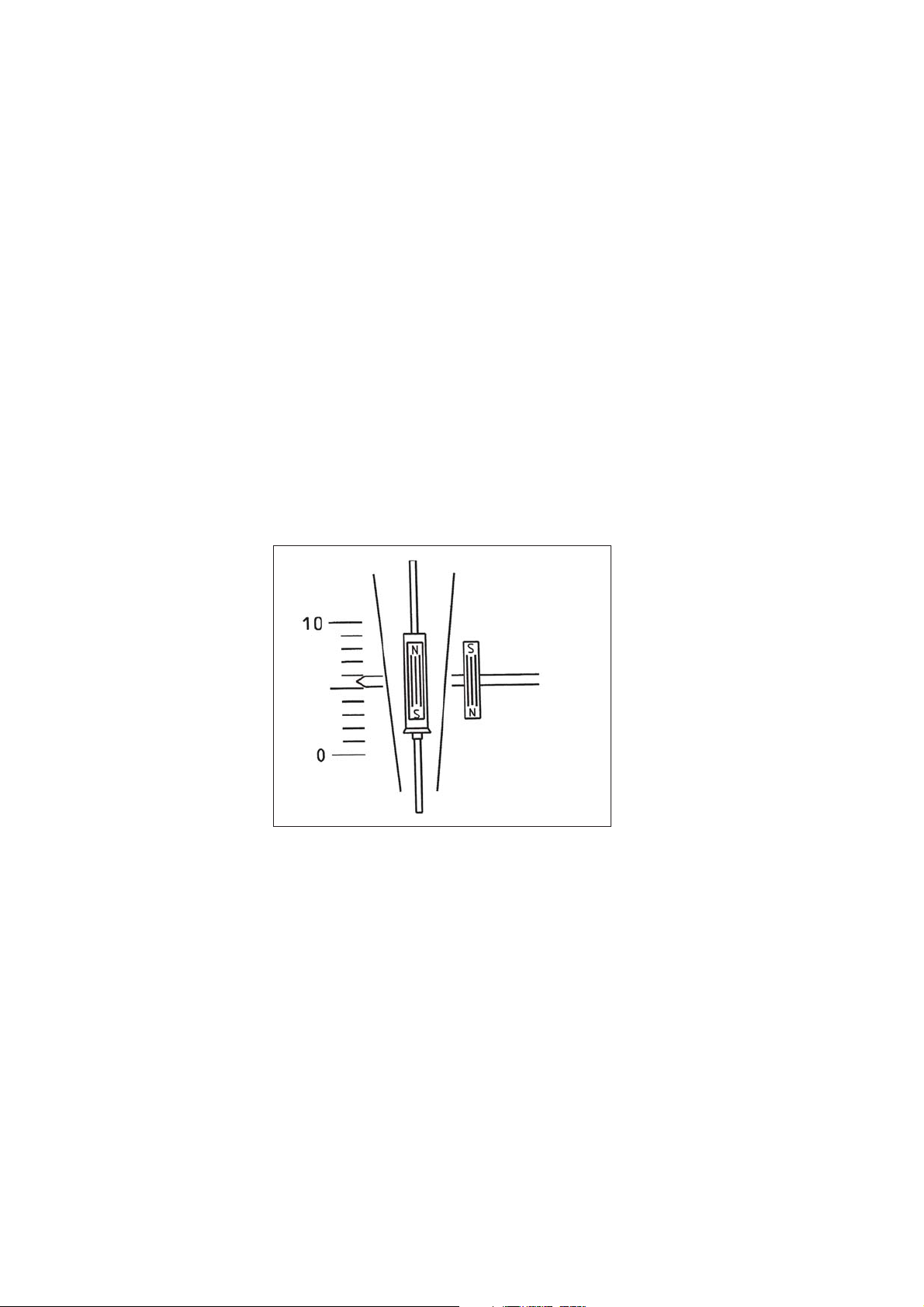

1.4 Principle of measurement

The RAKD is a Variable Area Flow Meter for volume and mass measurements of gases and liquids.

A float, whose movement is nearly independent of viscosity is guided concentrically in a specially shaped

cone.

The position of the float is transferred magnetically to the indicator, which shows the measurement values by

a pointer on a scale. The indicator can be equipped with limit switches and an electronic transmitter.

F10.EPS

Fig. 1.1

All units are calibrated with water or air by the manufacturer. By adjusting the calibration values to the

measured substance’s state of aggregation (density, viscosity), the flow rate scale for each measuring tube

can be determined.

IM 01R01B30-00E-E

4th edition, April 2007

1-8

Page 13

1.5 Overview

1. INTRODUCTION

Tube

Limit switch MAX

below scale

Cable connection

Quickon

Limit switch MIN

below scale

Indicator

Pointer

Scale

F11.EPS

Skalenbeispiel :

Flow scale

Flow unit

Ex-marking

Ex-data electronic

transmitter

Limit switch

Ex-data limit switch

50

10

100

l/h

Manufactured: 2000

Kom.Nr.: 200000/001

MS-Code: RAKD41-T6SS-33NNNE80NNN*A/K1/XE

Wasser

0,99831 g/cm

1 mPas

20 Grad C

1.1 bar abs.

KEMA 00ATEX 1037X

EEx ia IIC T6

Transmitter

Ui= 30V Ii= 100mA

Pi= 0.75W

Li= 0.73mH Ci= 2.4nF

Limit Switch: SC2-N0

KEMA 00ATEX 1037X

EEx ia IIC T6

see certificate for data

Made in Germany D-79660 Wehr

0344

II2G

Com. no..

Model code

Medium data

Ex-marking

1-9

F12.EPS

IM 01R01B30-00E-E

4th edition, April 2007

Page 14

Blank Page

Page 15

2. PRECAUTIONS

2. Precautions

2.1 Transportation and Storage

Before transporting the unit, it is recommended to fix the float with a card-board strip in the same way as

when shipped from factory. Prevent foreign objects from entering the tube (e.g. by covering openings).

To protect the unit and especially the tube’s interior from soiling, store it only at clean and dry locations

2.2 Installation

Ambient temperature and humidity of the installation location must not exceed the specified ranges. Avoid

locations in corrosive environments. If such environments are unavoidable, ensure sufficient ventilation.

Although the RAKD features a very solid construction, the instrument should not be exposed to strong

vibration or impact stress.

Please note that the RAKD is magnetic sensing system can be influenced by external inhomogeneous

magnetic fields (such as solenoid valves). Alternating magnetic fields (≥ 10Hz) as well as homogeneous, static

magnetic fields (in the area of the RAKD), like the geomagnetic field have no influence. Asymmetric

ferromagnetic bodies of considerable mass (e.g. steel girders) should be kept at a distance of at least 250 mm

from the RAKD.

To avoid interference, the distance between two adjacent RAKDs must be at least 300 mm.

Do not expose the unit to pressures higher than the indicated maximum operating pressure (refer to

specifications)

Make sure that wetted parts are resistante against the process medium.

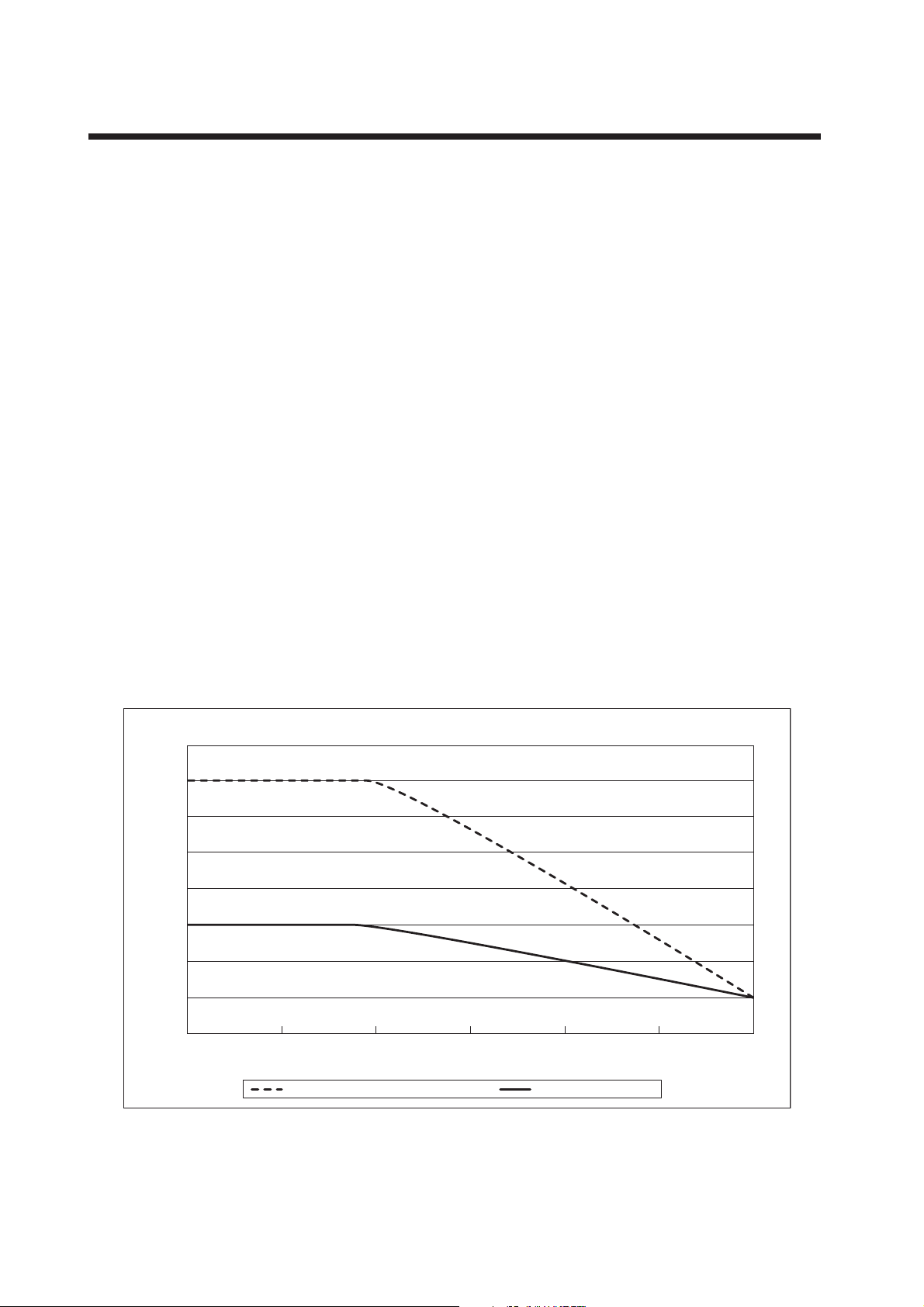

Ambient- and process-temperature may exceed specified maximum values. Note the temperature curves in

fig. 2-1 and chapter 7 "Technical data".

The Rotameter must be mounted verticaly. The flow direction is upwards.

Illustration of maximum allowable operation temperature depending on

275

250

225

200

175

150

125

Max. operation temperature [°C]

100

75

50 55 60 65 70

ambient temperature for Rotameter type RAKD

Ambient temperatur [°C]

Version without valve Version with valve

75 80

F21.EPS

Fig. 2-1. For option /KS!1or /KN1 (Ex-version) the maximum values for ambient and process temperature

according to the respective temperature class mentioned in fig. 3-2 and tables 7-2 to 7-5 must be

regarded. The minimum ambient temperature is -25°C.

2-1

IM 01R01B30-00E-E

4th edition, April 2007

Page 16

2. PRECAUTIONS

Check movability of the float (5)* by watching the pointer. The pointer should follow the movement of the float.

If this is not the case, float and measuring tube (1;21) should be cleaned.

Check the movability of the pointer by careful moving it with your fingers and watching whether it responds to

the scale value. If it does not work properly, the mechanical display unit (14) must be changed.

To avoid damage of the float and of the stopper do not use magnetic valves. In the phase of start up increase

the flow slowly to the desired flow rate.If a sudden rise of the pressure can not be avoides (with use of magnetic

valves) the flow must be limited to the maximum used value (e.g by valve).

*: Position numbers are illustrated in the explosion drawings in chapter 6.

IM 01R01B30-00E-E

4th edition, April 2007

2-2

Page 17

3. INSTALLATION

3. Installation

3.1 Installation in the pipeline

The pipe has to be so stabilized that vibrations on the pipe are avoided. Additional recommendations can be

found in guideline VDI/VDE 3513 sheet 3.

If pollution of the metering tube may appear a bypass-pipe is recommended, which permits the removal (see.

chapter 6 “maintenance”) of the Rotameter for cleaning without interruption of the flow.

Before installing the Rotameter, make sure there are no parts of packing or securing inside the Rotameter.

It has to be taken care at the connection of units with internal thread that no residues of the sealing compound

come into the tube (e.g. remains of the PTFE sealing compound).

In case of devices without valve but with process connection internal thread the float shaft of tubes with cone

44 and bigger sizes may move into the range of the threaded joint. Keep attention not to bend the guide bar

when screwing up the connection. The inner diameter of the connector must be at least 8 mm for cone sizes

44 - 51 resp. 10 mm for cone sizes 52 and 53.

To avoid float bouncing in case of gas applications, attend to VDI/VDE 3515 sheet 3.

For devices without valve use a throttle either in the inlet or outlet (to install at that side with the bigger

volume).

For installation of several instruments in parallel tubes take care that the distance between the middle axis is

at least 300 mm to avoid magnetic influence. The distance to other ferritic material should not be less than

250 mm. Take care that the strength of external magnetic fields is approximately 0 mT.

3.2 Wiring

3.2.1 Connecting diagrams

Please regard the drawings of this chapter.

RAKD with electrinic transmitter or with limit switches have one or two Quickon connectors at the rear.

In the connecting diagramst he lower one is named "S" and the upper une "T".

Not used connector positions are closed with a blind plug.

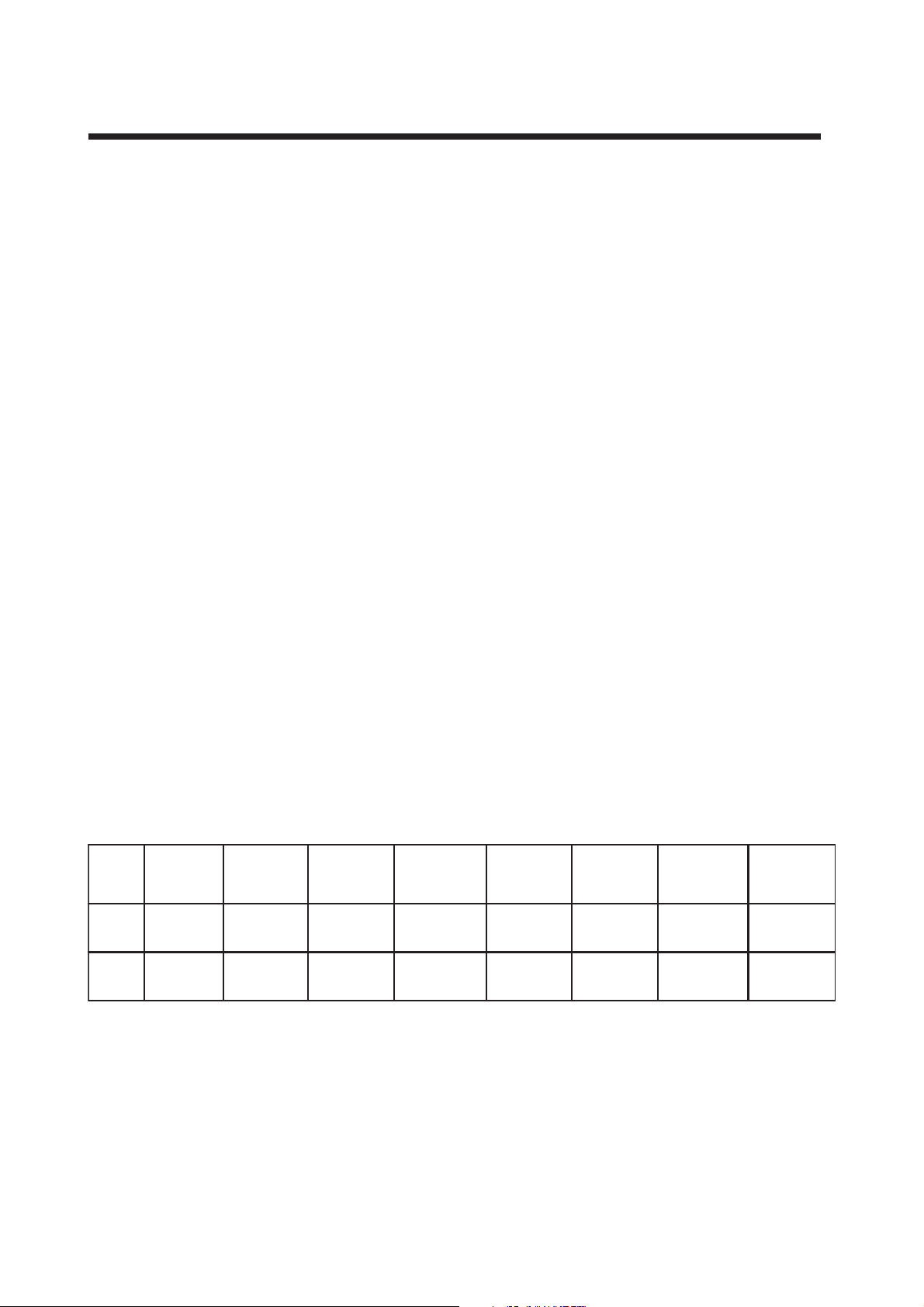

The following table shows the connections for the respective equipment configuration.

Type T

without contact

Quickon

upper "T"

Quickon

lower "S"

--- --- MAX contact MAX contact Current output Current output Current output Current output

--- MIN contact --- MIN contact --- MIN contact MAX contact Puls output

The load resistance of metering or indicating instruments, which are connected serial to the current output,

may not exceed (U- 13.5 V) / 20 mA .

Type T

with MIN contact

/K1 o r /K6

Type T

with MAX contact

/K2 or /K7

Type T

with MIN/MAX

contact /

K3 or /K8

Type E

without contact

without pulse

Type E

with MIN contact

/K1 o r /K6

Type E

with MAX contact

/K2 o r /K7

Type E

with

pulse output

/CP

T31.EPS

3-1

IM 01R01B30-00E-E

4th edition, April 2007

Page 18

3. INSTALLATION

Power supply U

4-20mA

RL

Power supply U / V

RL /

13.5V ...30V

< (U-13.5V) / 20mA

RAKD-E80

G

2

+

T

-

1

F

T = QUICKON connector

Fig. 3-1 RAKD with electronic Transmitter

Hazardous Area

RAKD - T80

BN

MAX

MIN

F

Limit Switches

EN 60947-5-6 (NAMUR)

BU

BN

BU

+

T

-

+

S

-

+

Power supply U

-

4-20mA

RL

Power supply U / V

13.5V ...30V

RL /

Ω

< (U-13.5V) / 20mA

Safe Area

Supply 230V AC

14 15

~ ~

U

1

2

1

2

1

+

3

-

4

+

6

-

Transmitter Relay

KFA6-SR2-Ex2.W

9

8

Limit MAX

7

12

11

Limit MIN

10

Limit Switch Type 2

EEx ia IIC T6...T5

U = 16V

i

I = 25mA

i

P = 64mW

i

C = 150nF

i

L = 0.15mH

i

KEMA 00ATEX 1037X

KFA6-SR2-Ex2.W

EEx ia IIC

U = 10.6V

o

I = 19,1mA

o

P = 51mW

o

C = 2320nF

o

L = 97mH

o

PTB 00ATEX 2081

T; S = QUICKON Connector

Fig. 3-2 RAKD with 2 limit switches in combination with transmitter relay in Ex- version

IM 01R01B30-00E-E

4th edition, April 2007

3-2

F3.EPS

Page 19

Limit / Pulse

T; S = QUICKON connector

EEx ia IIC T6...T5

U = 16V

P = 64mW

I = 20mA

C = 0nF

L = 0mH

KEMA 00ATEX 1037X

Pulsoutput

EEx ia IIC T6...T5

U = 10.6V

KEMA 00ATEX 1037X

L = 0.15mH

C = 150nF

U = 16V

I = 25mA

P = 64mW

PTB 00ATEX 2081

L = 97mH

C = 2320nF

I = 19.1mA

P = 51mW

Limit Switch Type 2

EN 60947-5-6 (NAMUR)

Limit switch or

KFA6-SR2-Ex1.W

KFA6-SR2-Ex1.W

Transmitter Relay

EEx ia IIC

Output

4-20mA

Supply

230V AC

L-

L+

BU

1 K

15 K

14

15

BN

+/~

IN

-/~

IN

10

OUT

OUT

Hazardous Area Safe Area

3. INSTALLATION

4-20mA output

EEx ia IIC T6...T5

U = 30V

i

I = 100mA

i

P = 0.75W

i

C = 2.4nF

i

L = 0.73mH

i

KEMA 00ATEX 1037X

RAKD-E80 Option /XE

G

F

Limit switch or

pulse output

EN 60947-5-6 (NAMUR)

15 K

1 K

SINEAX B 811

EEx ia IIC

U = 21V

o

I = 75mA

o

P = 660mW

o

C = 178nF

o

L = 6.7mH

o

Tamax = 55°C

PTB 97 ATEX 2083

Transmitter power supply

Option: /U2F

SINEAX B 811

L+

2

6

IN

+

OUT

T

IN

-

L-

BN

BU

1

1

+

S

-

2

1

-/~

5

14

OUT

+/~

10

15

+

T

-

Supply

230V AC

9

Output

4-20mA

4

~ ~

1

P

+

S

P

-

2

1

+

3

-

U

9

8

Limit / Pulse

7

Transmitter Relay

KFA6-SR2-Ex1.W

KFA6-SR2-Ex1.W

Pulsoutput

EEx ia IIC T6...T5

U = 16V

i

I = 20mA

i

P = 64mW

i

C = 0nF

i

L = 0mH

i

KEMA 00ATEX 1037X

Limit Switch Type 2

EEx ia IIC T6...T5

U = 16V

i

I = 25mA

i

P = 64mW

i

C = 150nF

i

L = 0.15mH

i

KEMA 00ATEX 1037X

EEx ia IIC

U = 10.6V

o

I = 19.1mA

o

P = 51mW

o

C = 2320nF

o

L = 97mH

o

PTB 00ATEX 2081

T; S = QUICKON connector

Fig. 3-3 RAKD in Ex-version with electronic transmitter in combination with power supply

and additional limt switch or pulse output with transmitter relay.

3-3

IM 01R01B30-00E-E

4th edition, April 2007

Page 20

3. INSTALLATION

3.2.2 Conductor connection (Quickon)

To connect the conductor, please observe in particular the following steps :

- Strip the sheath to a length of approx. 15 mm

(fig. 3-4) and slide the union nut (1), the cap (2)

and the rubber seal (3) onto the conductor.

5

3

Fig. 3-4

2

4

1

15 mm

F6.EPS

F7.EPS

Fig. 3-5

- Slide the rubber seal as far as the rim of the insulation and then slide the cap onto the rubber seal.

This provides the strain relief for the conductor (fig. 3-5).

IM 01R01B30-00E-E

4th edition, April 2007

3-4

Page 21

3. INSTALLATION

- insert the core ends into the feed through of the splice ring (fig. 3-6). In order to guarantee a clear

assignment of the cores, the individual core feed throughs of the splice ring are numbered (1, 2,…).

Fig. 3-6

- Cut off the projecting core ends. Make sure that

the core ends are flush with the splice ring (5):

they can protrude by up to 3 mm, but must not

be too short.

F8.EPS

- Insert the prepared conductor into the QUICKON

contact carrier (4). Turn the conductor with the

splice ring until the coding noses fit exactly into

the corresponding guides (fig. 3-7).

Fig. 3-7

- Close the gland by tightening the union nut. This

presses the core ends into the insultation

displacement terminal blocks, cuts open the core

insultation and creates the electrical contact (IDC

connection system).

3-5

F9.EPS

IM 01R01B30-00E-E

4th edition, April 2007

Page 22

Blank Page

Page 23

4. START OF OPERATION

4. Start of operation

4.1 Hints on flow rate measurement

The measured fluid should neither consist of a multi-phase mixture nor contain ferrite ingredients or large

solidmass particles.

The RAKD scale is adjusted to the state of operation/aggregation of the measured fluid by the manufacturer. If

the state of operation changes, it might become necessary to establish a new scale.

This depends on several factors:

- If the RAKD is operated in the given viscosity independent range, only the density of the float as well as the

operational density of the previous and new substance have to be considered. In case the operational

density only changes marginally (≤ 0.5%), the present scale can be used.

- If the RAMC is operated outside the given viscosity independent range, the viscosities at the previous and

new state of operation as well as the mass and diameter of the float have to be taken into account.

To establish a new scale, please refer to the folder “Anweisung zur Skalenumrechnung” (Instructions for Scale

Conversion) as well as the conversion table or order a new scale.

4.2 Pulsation and pressure shock

Strong pressure impact or flow pulsations can impair measuring operation considerably and should be avoided

(→ open valves slowly, raise operating pressure slowly).

4.3 Start of operation of electronic transmitter

Ensure that the device has been connected correctly according to section 3-2 and that the used power supply

meets the requirements indicated on the scale.

Switch on the power supply..

The RAMC is now ready for operation..

The transmitter is prepared and calibrated according to its model code as a 2 wire unit.

4-1

IM 01R01B30-00E-E

4th edition, April 2007

Page 24

Blank Page

Page 25

5. LIMIT SWITCHES (OPTION /KN)

5.

The optional limit switches are available as maximum or minimum type switches. They are proximity switches

according to EN 60947-5-6 (NAMUR). Maximal two switches can be installed. The option (/W__) includes the

respective transmitter relay.

These switches have been specified for hazadous area. However, the transmitter relay has to be installed

outside any hazadous area.

The limit switches are connected to the transmitter relays via Quickon connectors as indicated in section 3-2.

The terminals for the limit switches are on a small board on top of the transmitter case.

The MIN-MIN and MAX-MAX functions (refer to option /K3) have been integrated at the factory as MIN-MAX

switches in the RAMC. The MIN-MIN or MAX-MAX function is set by adjusting the switching direction of the

transmitter relay. The following table shows the assignment:

Channel 1

Limit switches (Option /K1 to /K8)

Switching direction of

transmitter relay

Channel 1

normal

normal

inverted

Channel 2

normal

inverted

normal

T50.EPS

MIN

MIN

MAX

Function

Channel 2

MAX

MIN

MAX

Note: switching direction “normal” means : inversion “OFF”

“inverted switching” means : inversion “ON”.

When using limit switches as a safety option, the switching directions hould be always set to normal

(inversion “OFF”) on the transmitter relay.

To ensure functional safety the transmitter relay has to be applied as protection technology.

Please notice chapter 7.2 "Standard specifications".

For questions regarding protection technology, please consult your YOKOGAWA service centre.

5-1

IM 01R01B30-00E-E

4th edition, April 2007

Page 26

Blank Page

Page 27

6. MAINTENANCE

T

6.

Maintenance

6.1 Function test

Checking free movement of pointer:

- Remove housing cover (4 screws).

- After deflecting the pointer by hand, it must return to measurement value. If the pointer pivots to different

values upon repeated deflections, there is too much friction in the bearings. In this case, send indication unit

to service.

Checking free movement of float:

- First, free movement of pointer has to be ascertained.

- Check visually if pointer follows each flow rate change. If not, clean float and measuring tube.

Unit with electronic transmitter:

- Without flow, the output current must be 4 mA. At a flow rate of 100% the current must be 20 mA.

6.2 Measuring tube, float

The Rotameter does not normally require any maintenance. However cleaning is necessary if the measuring

cone or flat has been contaminated by the process. To clean, the Rotameter must be removed from the

pipeline.

For all kind of intervention in the Rotameter like tightening the packing of the valve the pressures in

pressurized pipelines has to be reduced. Take care that the counter screw is tighten after screwing the valve.

Disassembling the tube

Please perform the following steps to clean the measuring tube and the float:

• Disassemble the Rotameter from the pipe

• Unscrew hollowed top threaded bolt (6) (for cone 31 – 43)

resp. remove top snap ring and socket (for cone 44 – 51)

resp. only top snap ring (for cone 52 – 53)

• Remove top float stop (3)

• Disassemble float – Attention: Do not bend the float

• For version with valve in the inlet remove first the top head pipe plug (8)

• For version with valve in the outlet remove first the lower head pipe plug;

in that case the disassembling of all parts start from down to top

• Cleaning of metering tube and float

• To clean the valve loose screw nut (10) in the head. Afterwards you can unscrew spindle (12) with PTFE

packing box plus thrust collar (9)

IMPORTAN

Please don’t expose the float to any strong magnetic alternating fields.The floating body and particularly

its measuring edge may not be damaged.

Assembling the tube

Mounting starts in opposite sequence.

Assembling the float take care that the lower guide bar of the float is fixed in the middle boring of the lower

stop. The guide bar should not be bended.

6-1

IM 01R01B30-00E-E

4th edition, April 2007

Page 28

6. MAINTENANCE

6.3 Explosion drawings

Fig. 6-1 RAKD without valve and controllerr

F61.EPS

No. in Fig. 6-1 and 6-2

1

Tube for unit with valve

and controller

Part

2 Socket

3 Float stop

4 Cone

5 Float

6 Threaded bolt

7 Gasket

8 Screw sealing plug

9 ; 10 ; 11 ; 12 ; 13 Packing for valve

14 Indicator

15 Nut M5

16 ; 19 Nozzle

17 ; 20 Cutting ring fitting

18 Controller

21

Tube for unit without

valve and controller

T61.EPS

Fig. 6-2 RAKD with valve and

IM 01R01B30-00E-E

4th edition, April 2007

F62.EPS

6-2

Page 29

6. MAINTENANCE

T

T

6.4 Electronic transmitter

The electronic transmitter is maintenance-free. The electronic section is sealed and can not be repaired.

The transmitter is tuned with the mechanical components in factory, therefore sigle components can be

replaced only by loss of accuracy.

6.5 Exchange of scale

Preparations :

· Check commision no., code, and data of new parts.

· Switch off power supply.

· Remove the cover of the indicator

IMPORTAN

Do not bend or twist the pointer on its axis !

Exchange of scale:

- Untighten the screw of the scala.

- Remove the screw and the small cover.

- Pull the scale out of the indicator to the left in which the scale raised on the right to raise it from the 2 pins.

- Shove the new scale correspondingly below the pointer from the left until the 2 pins click into the

accompanying holes.

- Establish the small cover and fix the scale with the screw.

Final actions:

· Fix the cover of the indicator.

· Switch power on.

· Check the unit for a faultless function.

6.6 Exchange of indicator

The indicator can be replaced by the same type if the scale of the old unit is put into the new indicator,

Procedure with RAKD with electronic transmitter (type "E" ):

· Switch off power supply.

· Remove the cover of the indicator

- Disconnect the cables from the Quickon connectors.

- Remove the old scale and put in the new one.

IMPORTAN

- Please not the hints for exchange of schale

- Remove the old indicator from the tube und replace it by the new one.Please take care to mount the

washers and spacers in the same positions as they were before dismantling.

6-3

IM 01R01B30-00E-E

4th edition, April 2007

Page 30

6. MAINTENANCE

6.7 Troubleshooting

In case the RAMC does not work properly, use the following flow charts for troubleshooting, then check,

isolate and remedy the fault.

Precision problems with "T" unit: execute test acc. fig. 6-3

SIf the indicated countermeasure do not remedy the fault or in case of troubles which cannot be remedied by

the user, please contact your YOKOGAWA service centre.

Fig. 6-3

IM 01R01B30-00E-E

4th edition, April 2007

F63.EPS

6-4

Page 31

7. Technical Data

7.1 RAKD Type-, Suffix-codes and Options

options

/

T

E

80

NNN

424

-wire,

7. TECHNICAL DATA

80

SS

Indicator

Version

Max. Flow Cone

With valve in inlet

Air

(l/h)

Water

(l/h)

Type:

Local indicator

VSE

Gasket Valve seat

PTFE Silver

31

32

40

1

1.6 60

Indicator with

electric output

VPE

PTFE PCTFE

With valve in outlet

34

37

33

2.5 100

41

200

4.0 150

6.0

10 325

Material: 1.4571

Housing type:

Stainless steel

VSA

VPA

Valve seat

Gasket

PTFE Silber

PTFE PCTFE

42

43

44

1400

16 500

25 800

40

SS

47

51

3250

60 2000

100

Power supply:

none,

∆p mbar

Cone

31-37 6

for local indicator „T“

for electric type „E“,

24V DC, 2

51 11

41-43 8

44-

20mA

4-

C3

C3

KD

41 T3

41 R3

A

R

Process

connection

Internal thread:

Rp 1/4 PN 25

RAKD with valve and controller (optuion /R1 and /R3) 1.0 - 100 l/h water / 40 - 3250 l/h air: –

1/4 NPT PN 25

53 C3

54

Cutting ring:

∅ 6 PN 25

∅ 8 PN 25

C3

55

∅ 10 PN 25

56

∅ 12 PN 25

7-1

W3

53 W3

54

Swagelok:

∅ 6 PN 25

∅ 8 PN 25

W3

55

∅ 10 PN 25

W3

P1

56

53

54 P1

For calculation to other fluids / process conditions please use our

Nozzle:

8 PN 10

∅ 6 PN 10

∅

4th edition, April 2007

∅ 12 PN 25

sizing program Durep_V.

T6.EPS

IM 01R01B30-00E-E

Page 32

7. TECHNICAL DATA

424

NNN

options

/

T

E

80

wire,

Indicator

80

Type:

Local indicator

Indicator with

Valve seat

Silver

electric output

Housing type:

Stainless steel

Power supply:

none,

Version

With valve in input

Gasket

PTFE

PTFE PCTFE

With valve in output

Gasket Valve seat

PTFE Silver

PTFE PCTFE

-20mA

for local indicator „T“

for electric type „E“,

24V DC, 2

– 8000 l/h air:

SS

– 250 l/h water / 40

KD

A

R

Air

(l/h)

Max. Flow Cone

Water

(l/h)

31

32

33

60

1 40

1.6

2.5 100

41 G4

41 G6

41 T4

34

37

41

4.0 150

6.0 200

10 325

Materila: 1.4571

41 T6

42

500

16

53 C4

43

44

800

25

40 1400

C4

53 C6

54

47

51

60 2000

100 3250

SS

C4

54 C6

55

52

53

5000

8000

160

250

55 C6

56 C4

56 C6

∆p mbar

Konus

31-37 6

41-43 8

44-51 11

52-53 13

W4

53 W4

53 W6

54

54 W6

W4

55

For calculation to other fluids / process conditions please use our

sizing program Durep_V.

P1

55 W6

56 W4

56 W6

53 P1

54

le:

RAKD with valve 1.0

IM 01R01B30-00E-E

4th edition, April 2007

Swagelok:

∅ 6 PN 40

∅ 6 PN 100

∅ 8 PN 40

∅ 8 PN 100

∅ 10 PN 40

∅ 10 PN 100

∅ 12 PN 40

Process

connection

Internal thread:

G 1/4 PN 40

G 1/4 PN 100

1/4 NPT PN 40

1/4 NPT PN 100

Cutting ring:

∅ 6 PN 40

∅ 6 PN 100

∅ 8 PN 40

∅ 8 PN 100

∅ 10 PN 40

∅ 10 PN 100

∅ 12 PN 40

∅ 12 PN 100

∅ 12 PN 100

Nozz

∅ 6 PN 10

∅ 8 PN 10

T7.EPS

7-2

Page 33

7. TECHNICAL DATA

options

/

80

NNN

– 3250 l/h air:

T

E

Indicator

Version

Type:

Local indicator

NNN

Without valve

Indicator with

31

32

33

80

electric output

Housing type:

34

Stainless steel

37

41

42

43

44

47

424

NNN

Power supply:

none,

for local indicator „T“

for electric type „E“,

24V DC, 2-wire,

51

4-20mA

SS

KD

A

R

RAKD without valve 1.0 – 100 l/h water / 40

∆p mbar

Air

(l/h)

Max. Flow Cone

Water

(l/h)

1 40

1.6 60

2.5 100

4.0 150

6.0 200

10 325

16 500

Material: 1.4571

D4

01

02 D4

01 A1

02 A1

01 A2

02 A2

Process

connection

Flange:

DN 15 PN 40

DN 25 PN 40

ANSI ½ 150 lbs

ANSI 1 150 lbs

ANSI ½ 300 lbs

ANSI 1 300 lbs

25 800

40 1400

41 G6

Internal thread:

G 1/4 PN 100

3250

60 2000

100

SS

41 G7

41 T6

G 1/4 PN 160

1/4 NPT PN 100

Cone

31-37 6

41 T7

53 C6

1/4 NPT PN 160

Cutting ring:

∅ 6 PN 100

41-43 8

44-51 11

For calculation to other fluids / process conditions please use our

sizing program Durep_V.

53 C7

∅ 6 PN 160

54 C6

54 C7

8 PN 160

∅ 8 PN 100

∅

55 C6

∅ 10 PN 100

W7

W6

54

54 W7

8 PN 160

∅ 8 PN 100

∅

W7

55 W6

55

56 W6

10 PN 100

10 PN 160

∅

∅

∅ 12 PN 100

C7

53 W6

Swagelok:

∅ 6 PN 100

53

∅ 6 PN 160

55 C7

56 C6

56

∅ 10 PN 160

∅ 12 PN 100

∅ 12 PN 160

56 W7

∅ 12 PN 160

Nozzle:

T8.EPS

1

53 P

54 P1

6 PN 10

8 PN 10

∅

∅

7-3

IM 01R01B30-00E-E

4th edition, April 2007

Page 34

7. TECHNICAL DATA

options

T

E

80

NNN

424

/

80

NNN

– 8000 l/h air:

Indicator

NNN

Version

Without valve

Cone

Type:

Local indicator

52

53

Indicator with

electric output

Housing type:

Stainless steel

-wire,

Power supply:

none,

for local indicator „T“

for electric type „E“,

24V DC, 2

4-20mA

SS

Max. Flow

– 250 l/h water / 5000

KD

A

R

Process

RAKD without valve 160

connection

Air

Water

(l/h)

(l/h)

Flange:

∆p mbar

5000

160

250 8000

Cone

Material: 1.4571

D4

01 D4

02

01 A1

02 A1

01 A2

DN 15 PN 40

DN 25 PN 40

ANSI ½ 150 lbs

ANSI 1 150 lbs

ANSI ½ 300 lbs

13

52-53

A2

G6

02

42

ANSI 1 300 lbs

Internal thread:

G 3/8 PN 100

SS

G7

42

42 T6

42 T7

G 3/8 PN 160

3/8 NPT PN 100

3/8 NPT PN 160

56 C6

12 PN 100

Cutting ring:

∅

C7

56

Swagelok:

∅ 12 PN 160

W7

56 W6

56

12 PN 100

∅

∅ 12 PN 160

T9.EPS

For calculation to other fluids / process conditions please use our

sizing program Durep_V.

IM 01R01B30-00E-E

4th edition, April 2007

7-4

Page 35

7. TECHNICAL DATA

Options Option code Description

Indicator

Marking

Limit switches

Pulse output /CP

Ex-proof type

Test and certificates

GOST approvals

Controlller

/A12 US-engineering units

/B1

/B4

/B8

/BG

/BD

/K1

/K2

/K3

/K6

/K7

/K8

/KS1

/KS2

/KN1

/CS1

/SS1

/NS1

/PP

/P2

/P3

/P6

/PM1

/PM4

/PM5

/QR1

/QR2

/R1

Tag plate (SS) fixed by wire and marking on scale

Neutral version

Customer provided marking on label

Customer specific notes on scale

Dual Scale

MIN-contact

MAX-contact

MIN-MAX-contact

MIN-contact "Fail Safe"- version

MAX-contact "Fail Safe"- version

MIN-MAX-contact "Fail Safe"- version

Pulse output, acc. NAMUR EN50227

ATEX intrinsically safe "ia"

ATEX gas and dust proof limit switches, category 2G 1D

ATEX category 3G "nL" / 3D

CSA intrinsic safe approval for limit switches (US+CAN)

SAA approval for limit switches (Australia)

NEPSI approval (China)

Pressure test report measuring system

Certificate of Compliance with the order acc. to

EN 10204: 2004- 2.1

As /P2 +Test report acc. to EN 10204: 2004- 2.2

Material certificate acc. to EN 10204: 2004- 3.1

PAMI test (1 test point : metering tube)

PAMI test (4 test points : metering tube, connection

heads, sealing plug)

PAMI test (5 test points : metering tube, connection

pieces, slip on flanges)

Russian GOST approval

Kasachian GOST approval

Pre pressure controller 1.4571 (only with valve in inlet;

for gas with variable pre pressure and liquids with

variable pre and back pressure)

/R3

Back pressure controller 1.4571 (only with valve in outlet;

for gas with variable back pressure)

Power supply for

electronic transmitter

Power supply for

limit switch(es)

(transmitter relay)

Instruction manuals /IEn

/U2F

/U3F

/W1A

/W1B

/W2A

/W2B

/W2E

/W4A

/W4B

/W4E

/IDn

/IFn

SINEAX B811, 85 - 250 V AC, EEx i

SINEAX B811, 24 V AC/DC, EEx i

KFA5-SR2-Ex1.W / 115 V AC, 1 channel

KFA5-SR2-Ex2.W / 115 V AC, 2 channels

KFA6-SR2-Ex1.W / 230 V AC, 1 channel

KFA6-SR2-Ex2.W / 230 V AC, 2 channels

KHA6-SH-Ex1 / 230 V AC, 1 channel, Fail Safe

KFD2-SR2-Ex1.W / 24 V DC, 1 channel

KFD2-SR2-Ex2.W / 24 V DC, 2 channels

KHD2-SH-Ex1 / 24 V DC, 1 channel, Fail Safe

Quantity of instruction manuals in English

Quantity of instruction manuals in German

Quantity of instruction manuals in French

Restrictions

Only for indicator E

Plate 12 x 40 mm; max. 45 digits

Not with option /P6 and Ex-proof type

Max. 45 digits

Adjustment only possible for 1 fluid

Only for indicator T

Only for indicator T

Only for indicator E; not with limit switches

Not for indicator T without limit switches

Only for indicator T with limit switches

Not for indicator T without limit switch

Only for indicator T with limit switches

Only for indicator T with limit switches

Not for indicator T without limit switches

Only for tube, connection heads, screw

sealing plug

Only for models with valve

Only for models with process connection D4,

A1, A2

Only for process connection R3, T3, C3, W3,

P1; only with valve

Only for process connection R3, T3, C3, W3,

P1; only with valve

Only for indicator E

Only for indicator E

Only for limit switches /K1 + /K2 + /K3

Only for limit switches /K1 + /K2 + /K3

Only for limit switches /K1 + /K2 + /K3

Only for limit switches /K1 + /K2 + /K3

Only for limit switches /K6 + /K7 + /K8

Only for limit switches /K1 + /K2 + /K3

Only for limit switches /K1 + /K2 + /K3

Only for limit switches /K6 + /K7 + /K8

n = 1 to 9 selectable *)

n = 1 to 9 selectable *)

n = 1 to 9 selectable *)

*) if no instruction manual is selected, only a

CD with instruction manuals is shipped with

the flowmeter

7-5

IM 01R01B30-00E-E

4th edition, April 2007

Page 36

7. TECHNICAL DATA

7.2 Specifications

STANDARD SPECIFICATIONS

The responsiblity with respect to the suitability and

according application of our flowmeter is only situated by

the customer.

METERING TUBES

Materials of wetted parts : Stainless steel AISI 316Ti

(1.4571)

other materials on request

Fluids to be measured : Liquid or gas

Measuring range : see flow table

Measuring range ratio : 10:1

Process connections :

– Inner thread : G 1/4; 1/4 NPT; G 3/8; 3/8 NPT

– Cutting ring : 6 mm; 8 mm; 10 mm; 12 mm

– Cutting ring (Swagelok) : 6 mm; 8 mm; 10 mm; 12 mm

– Nozzle : 6 mm; 8 mm

– Flange : - acc. EN 1092-1

DN15 and DN25 PN40;

- acc. ASME B 16.5 ½” and 1”

150lbs, 300lbs

Process pressure : depends on process

connection; see model code

Process temperature : without valve -25°C to 250°C

with valve -25°C to 150°C

See also fig. 6. Lower

temperatures on request.

Accuracy : class 4 acc. VDI/VDE 3513

± 4% f.s.

Installation :

– Installation position : vertical

– Flow direction : upwards

– Face to face length : 125 mm (with flange 250 mm)

Weight : see table 9

Process-/ Ambient temperature

: see fig. 6

LOCAL INDICATOR

(Indicator/Code -T)

Principle :

The indication is made by magnetic coupling of a magnet

enclosed in the float and a magnet in the indication unit,

which follows the movements of the float.

Indication scale : Flow units

Housing

– Material : Stainless steel AISI 304

(1.4301)

– Protection : IP 65

Transportation and storage condition

: - 40°C to +110°C

ELECTRONIC TRANSMITTER

(Indicator/Code -E)

Temperature range : -25°C to 65°C

Transportation and storage condition :

: - 40°C to +70°C

Power supply : 13.5-30 V DC

Load resistance : (U-13.5V) /20mA

Analog output : 4-20 mA

Linearity : ≤ ± 0.25% f.s.

Hysteresis : ≤ ± 0.15% f.s.

Repeatability : ≤ ± 0.16% f.s.

Influence of power supply : ≤ ± 0.1% f.s.

Temp. coefficient of analog output

: ≤ ± 0.5% /10 K f.s.

AC-part of analog output : ≤ ± 0.15% f.s.

Long time stability : ≤ ± 0.2% / year

Maximum output current : 21.5 mA

Output current in case of failure

: ≤ 3.6 mA (NAMUR NE 43)

Response time (99%) : appr. 1 s

Electrical connection : QUICKON

- Cable diameter : 4-6 mm

- Cable cross section : 0.34 to 0.75 mm

2

Pulse output ( Option /CP) : Electronic switch with

galvanic isolation

acc. EN 60947-5-6 (NAMUR)

- Pulse length : 200 ms

- Max. frequency : 4 Hz

- Pulse rate : Qmax ≤ 1 → 0.0001

: 1 < Qmax ≤ 10 → 0.001 etc.

e.g.. Qmax = 1 m3/h →

1 Puls = 0.0001 m

3

= 0.1 l

POWER SUPPLY FOR ELECTRONIC TRANSMITTER

(Option /U__)

Type : power supply with

Supply voltage : 24 V to 60 V AC/DC

Maximum load : 750 Ω

Output signal : 0/4 mA - 20 mA

galvanically separated input

and output

SINEAX B811

85 V to 230 V AC

LIMIT SWITCHES IN STANDARD VERSION

(option /K1 to /K3)

Type : Inductive proximity switch

SC2-NO

acc. DIN EN 60947-5-6

Nominal voltage : 8V DC

Output signal : ≤ 1 mA or ≥ 3 mA

Hysteresis : < 0.5mm

LIMIT SWITCHES IN FAIL SAFE VERSION

(option /K6 to /K8)

Type : Inductive proximity switch

SJ2-SN

acc. DIN EN 60947-5-6

Nominal voltage : 8V DC

Output signal : ≤ 1 mA or ≥ 3 mA

Hysteresis : < 0.5mm

POWER SUPPLY FOR LIMIT SWITCHES

(Option /W__)

Type : Transmitter relay

acc. DIN EN 50227 (NAMUR)

- KFA6-SR2-Ex1-W (230 VAC)

- KFA5-SR2-Ex1-W (115 VAC)

- KFD2-SR2-Ex1-W (24 V DC)

Power supply : - 230 V AC ± 10%, 45-65Hz

- 115 V AC ± 10%, 45-65Hz

- 24 V DC ± 25%

Relay output : 1 or 2 potential-free

changeover contact(s)

Switching capacity : max. 250V AC, max. 2 A

SWITCHING LEVELS FOR LIMIT SWITCHES

Table 7-1

Function

MAX

MIN

GW = limit

Pointer

above GW

below GW

above GW

below GW

Switch

on

off

off

on

SC 2-N0

Signal

1mA

3mA 3mA

3mA 3mA

1mA

SJ 2-SN

Switch Signal Fail safe

1mA

on

off

off

1mA

on

1mA

1mA

T1.EPS

IM 01R01B30-00E-E

4th edition, April 2007

7-6

Page 37

7. TECHNICAL DATA

S

CONTROLLER (Option /R1 and /R3)

Differential pressure controller for a constant flow at

fluctuations of the process pressure.

These are no valves to reduce the pressure.

- Controller /R1 for liquids with variable inlet or

outlet pressure and for gases with variable inlet pressure

and constan back pressure.

- Controller /R3 for gases with fluctuations of the

back pressure.

Max. liquid flow : 100 l/h

Max. gas flow : 3250 l/h

Max. pressure : 25 bar

Recommended differential pressure

: >400 mbar

Temperature range : -25°C to + 80°C

Materials

Housing Diaphragm Springs

R1 / R3

CrNi-Steel PTFE CrNi-Steel

T5.EPS

l/h air at 20°C ; 1.013 bar abs.

Entity parameter :

Table 7-2

Ui [V]

Ii [mA]

Pi [mW]

Li [mH]

Ci [nF]

Analog output Puls output

30 16 16 16

100 20 25 52

750 64 64 169

0.73 0 0.15 0.15

2.4 0 150 150

Limit switch

Type 2

Limit switch

Type 3

Tex1.EPS

Temperature specification :

Version 1: RAKD with indicator “T” and limit switch type 2 :

Table 7-3

Temperature class T6T5T5T4T4

Max. ambient temperature 65

Max. process temperature 65

°C80°C

°C80°C

59°C100°C73

100°C100°C135

Tex2.EPS

°C

°C

Version 2: RAKD with indicator “T” and limit switch type 3::

Table 7-4

Temperature class T6 T5 T5 T4 T4 T4

Max. ambient temperature 24°C 37°C 34°C 57°C 54°C 48°C

F2.EP

inlet pressure

Fig. 7-1 Diagram controller characteristic

HAZARDOUS AREA SPECIFICATIONS

RAKD with ATEX- certification “intrinsic safe”

(Option /KS1)

Certificate :

KEMA 00ATEX 1037X

Output signal :

4–20 mA

Explosion proof :

EEx ia IIC T6; group II ; category 2G

Max. process temperature 65°C 80°C 100°C 80°C 100°C 135°C

Version 3 : RAKD with indicator “E” and with or without

Tex3.EPS

limit switch type 2 :

Table 7-5

Temperature class T6 T5 T5 T4

°C

50

°C

45

°C

Max. ambient temperature 65

Max. process temperature 65

°C

80

°C

100°C135

38

Tex4.EPS

Version 4 : RAKD with indicator “E” with limit switch type 3:

The smaller environmental temperature must be found

according to the available temperature class and the

maximum process temperature from table 4 and 5.

RAKD “non incendive” (Option /KN1)

Type “n” (non incendive) acc. EN 60079-15.

Explosion proof :

EEx nL IIC T6 protection „nL”; group II ; category 3G

Dust proof :

EEx II 3D; group II ; category 3D

Max. surface temperature : 80°C

Entity parameter :

table 7-6

Analog output Pulse output

Ui [V]

Ii [mA]

Pi [mW]

Li [µH]

Ci [nF]

30

100

750

730

2,4

Limit switch

/CP

16

20

64

0

0

SC2 -N0, /K1...3

150

150

20

25

64

Limit switch

SJ2-SN, /K6...8

20

25

64

100

30

°C

°C

T12.EPS

7-7

IM 01R01B30-00E-E

4th edition, April 2007

Page 38

7. TECHNICAL DATA

RAKD with NEPSI- certification “intrinsic safe”

(China) ( with /NS1) :

Certificate :

GYJ05153

Output signal :

4–20 mA

Explosion proof :

Ex ia IIC T6

Max. Tamb. :

65°C

Entity parameter of electronic transmitter :

see ATEX in table 2

Limit switches :

option /K1 to /K8

Entity parameter of limit switches :

see certificate NEPSI GYJ06542X

Intrinsically safe and dust proof limit switches

with ATEX-certification (only for indicator T

with option /K1 .. /K8 with /KS2) :

Certificate :

- PTB 99 ATEX 2219X ( SC2-NO)

- PTB 00 ATEX 2049X (SJ 2-S.N)

- ZELM 03 ATEX 0128X (for dust proof)

Explosion proof :

EEx ia IIC T6, group II category 2G

Dust proof:

EEx iaD 20 T 108 °C, group I I category 1D

Max. surface temperature : T108°C

Entity parameter :

see certificate of conformity

Power Supply for the intrinsically safe electronic

transmitter (option /U__)

Type : Intrinsically safe power

supply with galvanically

separated input and output

- SINEAX B811

Certificate : PTB 97 ATEX 2083

Supply voltage : - 24 V to 60 V AC/DC

- 85 V to 230 V AC

Maximum load impedance : 750 Ω

Output signal : 0/4 mA - 20 mA

Control circuit : Intrinsically safe [EEx ia] IIC

group II, category (1)G

Entity parameters : see fig 5 or certificate

Power supply for intrinsically safe limit switches

(option W__)

Type : - KFA6-SR2-Ex1-W (230 V AC)

- KFA5-SR2-Ex1-W (115 V AC)

- KFD2-SR2-Ex1-W (24 V DC)

Certificate : - PTB 00 ATEX 2081

(115/230 V AC)

- PTB 00 ATEX 2080

(24 V DC)

Control circuit : [EEx ia] IIC; group II ;

category (1)GD

Entity parameter : see fig 3 or certificate

Intrinsically safe limit switches with SAAcertification (Australia)(only for indicator T with

option /K1 .. /K8 with /SS1) :

Certificate :

AUS Ex 02.3838X

Explosion proof :

Ex ia IIC T1 ... T6

Entity parameter :

see certificate of conformity

Intrinsically safe limit switches with CSAcertification (USA + Canada) (only for indicator T

with option /K1 .. /K8 with /CS1) :

Certificate :

1007121 (LR 96321-2)

Explosion proof :

Cl. I, Div. 1, Grp A, B, C, D

Cl. II, Div. 1, Grp. E, F, G

Cl. III, Div. 1

or

Class I, Zone 0, Gp. IIC T6 (Ta = 60°C)

Entity parameter :

see FM-control drawing 116-0165b

IM 01R01B30-00E-E

4th edition, April 2007

7-8

Page 39

7.3 Dimensions and weights

7. TECHNICAL DATA

F7.EPS

F8.EPS

Fig. 7-2 Version without valve Fig. 7-3 Version with flange connection

Fig. 7-4 Back view with mounting

7-9

F13.EPS

IM 01R01B30-00E-E

4th edition, April 2007

Page 40

7. TECHNICAL DATA

Cutting ring

Fig. 7-5 Version with inlet valve

F9.EPS

Cutting ring

F12.EPS

Fig. 7-6 Version with outlet valve

IM 01R01B30-00E-E

4th edition, April 2007

7-10

Page 41

7. TECHNICAL DATA

Fig. 7-7 Version with inlet valve and inlet controller

F10.EPS

Fig. 7-8 Version with outlet valve and back pressure controller

7-11

F11.EPS

IM 01R01B30-00E-E

4th edition, April 2007

Page 42

7. TECHNICAL DATA

CONNECTION TYPES

TABLE 7-7

Size

Cone 31-51 Cone 52-53 Cone 31-53 Cone 31-51

G 1/4 G 3/8 G 1/4 Rp 1/4

Thread

1/4 NP T 3/8 NPT 1/4 NPT 1/4 NPT

abc

T2.EPS

INSTALLATION LENGTHS DEPENDING ON CONNECTION TYPE AND SIZE

TABLE 7-8

Size

Process connection NW Cone 31-51 Cone 52-53 Cone 31-53 Cone 31-51

6 mm 178 mm ---- 54.5 mm 142.5 mm

8 mm 172 mm ---- 51.5 mm 139.5 mm

Cutting ring

10 mm 174 mm ---- 52.5 mm 140.5 mm

12 mm 174 mm 177 mm 52.5 mm 140.5 mm

6 mm 182 mm ---- 56.5 mm 144.5 mm

Nozzle

8 mm 182 mm ---- 56.5 mm 144.5 mm

L1 L2 L3

T3.EPS

WEIGHTS

TABLE 7-9

Weight

without valve with valve with controller

approx. 600g approx. 1000g approx. 1800g

T4.EPS

IM 01R01B30-00E-E

4th edition, April 2007

7-12

Page 43

7.4 Temperatue curves

Illustration of maximum allowable operation temperature depending on

275

250

225

200

175

150

125

Max. operation temperature [°C]

100

75

50 55 60 65 70

ambient temperature for Rotameter type RAKD

Ambient temperature [°C]

7. TECHNICAL DATA

75 80

Version without valve Version with valve

F6.EPS

Fig. 7-9. For option /KS1 or /KN1 (Ex-version) the maximum values for ambient and process temperature

according to the respective temperature class mentioned in fig. 3-3 and tables 7-2 to 7-5 must

be regarded. The minimum ambient temperature is -25°C. Lower temperatures on request.

7-13

IM 01R01B30-00E-E

4th edition, April 2007

Page 44

Blank Page

Page 45

8. INSTRUCTIONS FOR EXPLOSION-PROTECTED RAKD

8. Explosion-protected Type Instruments

8.1 General

WARNING

To ensure intrinsically safety, it is not permitted to repair or to modify the electronic transmitter and the limit

switches

The RAKD with electronic transmitter type "E" as well the limit switches (option/ K_) is an intrinsically safe

device. The RAKD (option /KS1) is ATEX certified for hazardous areas of zone 1 (category 2) and zone 2

(category 3). It is not homologated for zone 0 areas (category 1) (option /KS1 for category 2 and 3, option /

KN1 only for category 3). The classification in brackets is given according to the EU regulation ATEX, 94/9/EG.

The limit switches but not the electronic transmitter are ATEX dust proof certified (option/KS2).

The RAKD with electronic transmitter type "E" as well as the limit switches (option/ K_) are also NEPSI

certified for China (option /NS1)

The limit switches are also certified for USA and Canada by CSA (option /CS1) and for Australia by SAA

(option /SS1).

The RAKD must be connected to an intrinsically safe, certified power supply with a maximum voltage and

output power below the maximum values of the RAKD (refer to Technical data, section 7). The combined

internal inductance and capacity of the RAKD and connecting cables must be less than the permitted external

inductance and capacity of the power supply. Accordingly, the limit switches have to be connected to intrinsically

safe, certified isolating switching amplifiers. The relevant maximum safety values must be heeded at all times.

Power supply and transmitter relay are assigned devices and should be installed outside any hazardous zone.

Especially in the case of high fluid temperatures, heated metering tubes or heat radiation by heat tracing,

make sure that the temperature in the indicator housing does not exceed the permissible maximum ambient

temperature of the transmitter (refer to Technical data, section 7).

To ensure intrinsically safety, it is not permitted to repair or modify the measuring transmitter.

8-1

IM 01R01B30-00E-E

4th edition, April 2007

Page 46

8. INSTRUCTIONS FOR EXPLOSION-PROTECTED RAKD

8.2 Intrinsically safe ATEX certified RAKD (/KS1)

8.2.1 Technical data

EC-Type Examination Certificate Nr.: KEMA 00ATEX1037X

The RAKD with electronic transmitter and limit switches is an intrinsically safe device. This device is certified for

hazardous areas of zone 1 (category 2) und zone 2 (category 3). It is not homologated for zone 0 (category 1).

The classifications in brackets are given according to EU-Regulation 94/9/EG (ATEX).

Identification in accordance with regulation 94/9/EG (ATEX) :

II 2 G

Data of electronic transmitter type -E :

Type of protection : Intrinsically safe EEx ia IIC T6

Ambient temperature : -25°C ... +65°C

Safety relevant maximum values:

Supply (current output):

Maximum voltage : Ui= 30 V

Maximum current : Ii= 100 mA