Page 1

V

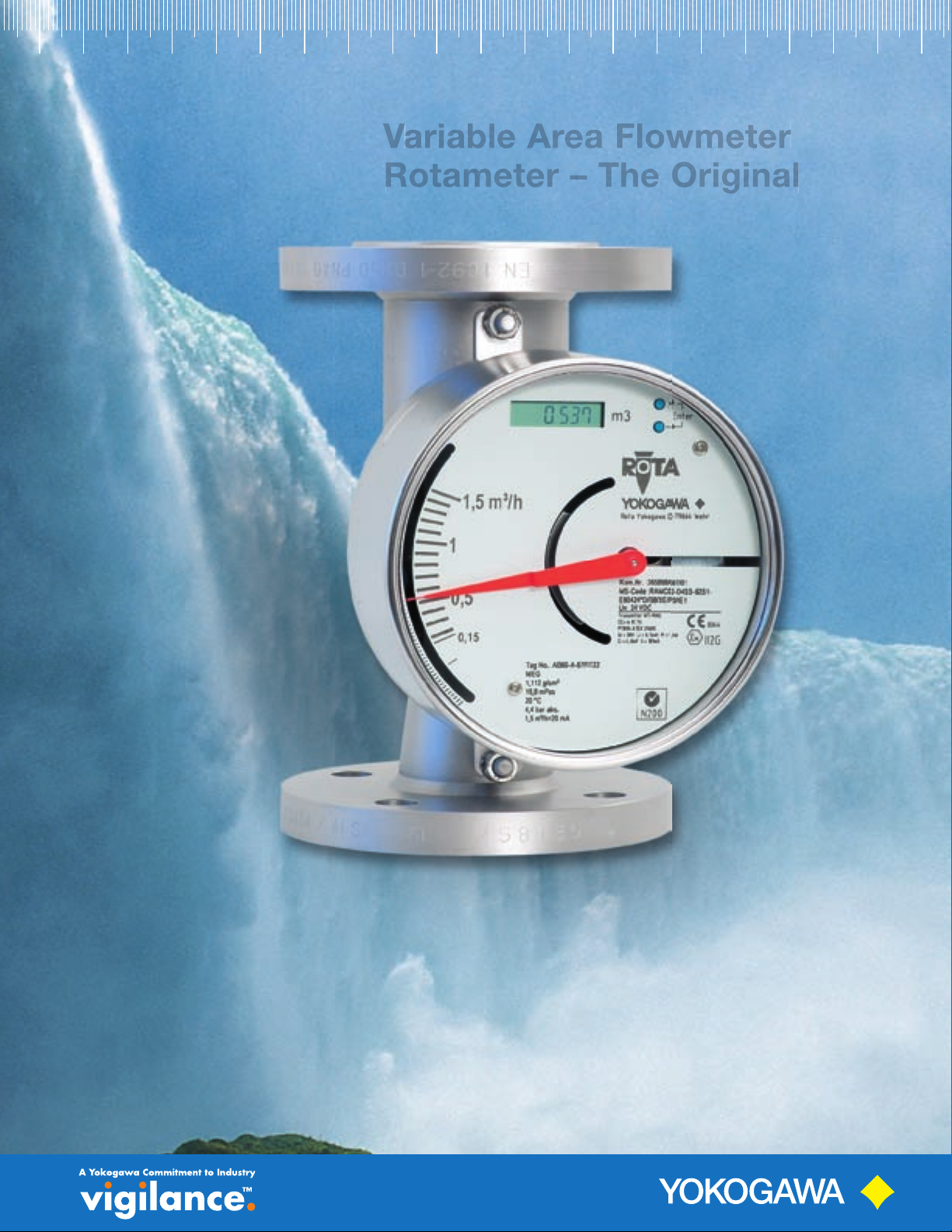

Variable Area Flowmeter

Rotameter – The Original

• precise measurement of liquids and gases

• robust and universal

• proven device with an installed base of more

than 500,000 worldwide

• a wide product range

• many options and different materials

available

Page 2

Proven technology:

Economical:

The Rotameter

(variable area) principle

The Rotameter is one of the oldest and

mature principles in flow measurement.

A float is guided inside a conically

shaped tube. The float rises within the

tube as the flow increases. This mechani-

cal principle is as simple as it is reliable.

Due to its operating principle the Rotameter

is usually installed in vertical pipes. Once the

process medium flows through the tube, the

gravimetric force, balances with the flow

resistive force in such a way that the position

of the float indicates the flow rate value.

Modular and flexible

Rotameter are completely modular

and flexible. The measuring tube

can be made of glass, plastic or

metal – depending on the application.

If the tube is made of metal the float

position is transferred to an outside indi-

cator via a magnetic coupling. In the case

of glass and plastic tubes you can simply

view the float position to get a reliable

reading of the flow rate.

The mechanical nature of the measuring

principle provides a flow device that does

not require any electrical power supply.

However, there are many applications in

process plants that do require electronic

indication and transmission of the measu-

red variable of flow to other associated

devices. This capability has considerably

expanded the range of applications for the

variable area flowmeter.

Page 3

Robust and universal: Rotameter RAMC

Small and robust: Rotameter RAKD

What makes this Rotameter different

from other brands is known by many

users, who value the ease of installation

and trouble-free operation.

The RAKD is the smaller brother of the

RAMC – is robust in design – for low

flows and high pressure applications.

At first glance the instrument looks impressive

with its all stainless steel design. A closer look

reveals a unique patented “float blockage”

detection systems. Operational safety is

of the utmost importance in any flowmeter,

and the RAMC is no exception – wetted

parts are available in a variety of materials,

and intrinsically safe outputs are available

as an option.

If you value flexibility in a flowmeter – from

the measurement of air to highly aggressive

liquids – in situ replacement of the indicator

without degradation of performance – and

the inter-changeability of floats, – then the

RAMC is for you.

The RAMC combines all the advantages

of the variable area principle with robust

design, reliable measurement, with or

without auxiliary energy, culminating in a

truly universal flowmeter for gases, liquids

and steam applications.

Sizes DN 15 to DN 150 (1/2“ to 6“)

Design Options

Male thread DIN 11851, Triclamp

Female thread G & NPT

Measuring range

2.5 l/h to 130 m³/h

Air 20° C (68° F); 1 bar (15 psi) abs:

75 l/h to 1400 m³/h

Material 1.4404 (AISI 316L); PTFE

Process Temp. Range

Pressure Range up to

Ambient temp.

Accuracy Class 1.6/2.5 VDI/VDE

Indicator Analog scale plate / LCD

Ex-approval

Inputs/Outputs Analog 0-20 mA / 4-20 mA

Communication HART, PC tool Pactware

Power Supply

24 V DC 3-wire, 24 V DC 2-wire

Protection Class

Comments Limit switches available

Float blocking detection

Housing: plastic, aluminium, stainless steal

Special design on request

DIN EN Flanges, ASME Flanges

Water 20° C (68° F):

-180° C to +370° C (-292° F to 698° F)

400 bar (5800 psi)

-20° C to 100° C (-4° F to 212° F)

ATEX / SAA

230 V AC 4-wire, 115 V AC 4-wire

IP 65 (IP 67 on request)

The RAKD differentiates itself from other

comparable variable area meters by means

of its light and guided float design. This

feature avoids oscillations caused by gas

compressibility leading to very stable

measurement.

This design has a direct bearing on sta-

bility – pressure loss is lower by 2/3

compared to other comparable meters.

Measurement of low flows is best handled

by the RAKD with its established technology.

The RAKD represents the latest generation

in low flow metal flowmeters.

The RAKD variable area flowmeter is highly

accurate, particularly for low flows and

high pressure applications. Once again no

auxiliary energy is required.

Sizes DN 15 to DN 25

1/2“ to 1“, 6 to 12 mm

Design Options

Female thread G & NPT

Measuring range Water 20° C (68° F):

0.1 l/h to 250 l/h

Air 20° C (68° F); 1bar (15 psi) abs:

4 l/h to 8000 l/h

Material 1.4571 (AISI 316 TI)

Process Temp. Range

Process Pressure up to

Ambient temp.

Accuracy Class 4 VDI/VDE

Indicator Analog scale plate

Ex-approval

Signal Outputs/ Inputs

Communication Service Box

Power Supply

Protection Class

Comments Limit switches available

Valves available

Differential pressure regulator available

Special design on request

DIN EN Flanges, ASME Flanges

Cutting ring, Flexible tube connection

-80° C to +200° C (-112° F to +292° F)

160 bar (2320 psi)

-20° C up to 100° C (-4° F up to 212° F)

ATEX

Analog 4-20 mA

24 V DC 2-wire

IP 65

Page 4

Trust your own eyes:

No limitation:

Rotameter RA-series

The flow metering tube is transparent

giving you full insight into the process

and position of the float – a scale on the

outside of the tube indicates the true

flow rate. All the measurement tubes in

this series of variable area flowmeters

are made of either glass or plastic.

A Rotameter is like a puzzle. The combinati-

on of a cone, a float, a scale and a process

connection build up a Rotameter. Due to this

flexible and modular system it can be equip-

ped with additional features and various

materials suited for all kind of applications.

An example is our glass meter which resists

highly corrosive mediums, is antistatic and

especially suitable for low flow gas measu-

rement.

RAGK/RAGL

Rotameter Customized Solutions

The Rotameter is known all over the world as a

reliable measurement instrument and nowadays

as a synonym for variable area meters. We built

this reputation on customer oriented solutions.

RAGH RAGG RAQN

Rotameter stands for rotating floats. Special

sloping notches cause the float to rotate.

This eliminates the friction and guarantees

very stable behaviour and highest accuracy;

oscillations are eliminated by using low

density floats.

This simple and affordable instrument has

an enormous application range and a smart

design with a proven performance over

decades.

Sizes 1/4“ to 3/8“, 6 to 12 mm 1/4“ to 2 1/2“ DN 15 to DN 40 3/8“ to 2“

Design Options NPT; cutting ring; Female threads; flexible tube Female threads

flexible tube; Swagelok connection; adhesive fittings; adhesive fittings

DIN EN flanges

Measuring range

Water 20° C (68° F): 0.0025 l/h to 600 l/h 0.0025 ml/h to 10 m³/h 10 l/h to 10 m³/h

Air 20° C (68° F); 1 bar (15 psi) abs:

Material 1.4571 (AISI 316 TI); 1.4571 (AISI 316 TI); Steel, PVC;

Polypropylene; PTFE; Steel; PVC; PTFE; various float material available

various float materials available various float materials available

Measuring tube

Process Temp. Range

(32° F up to +266° F) (32° F to +140° F) (32° F to +212° F)

Pressure Range up to

6 to 16 bar (87 to 232 psi)

Ambient temp.

(32° F up to 176° F) 0° C to 60° C 0° C to 80° C

(32° F to 140° F)

Accuracy Class 4/2.5 (sphere 6) VDI/VDE Class 1.6 VDI/VDE Class 4/2,5 VDI/VDE

Indicator Direct reading scale Direct reading scale Direct reading scale

Comments Limit switches available Limit switches available Limit switches available

Special design on request Special design on request Special design on request

Valves available; Differential Valves available

pressure regulator available

Borosilicate Glass Borosilicate Glass Polyamid or Polysulfone

0° C up to 80° C 0° C up to 80° C (32° F up to 176° F) Polyamid Polysulfone

RAGK/RAGL RAGH/RAGG RAQN

0.2 l/h to 6200 l/h 0.1 l/h to 250 m³/h 160 l/h to 250 m³/h

Polyamid Polysulfone

0° C to +130° C max. 130° C (266° F) 0° C to +60° C 0° C to +100° C

16 bar (232 psi) Depending on measuring tube size: 10 bar (145 psi)

(32° F to 176° F)

We have the ability to design and manu-

facture customer specific solutions.

Especially on Rotameter where we have

almost a century of experience in manu-

facturing specific sizes, utilizing special

materials or creating special scales. All you

need to do is tell us what is necessary to

fulfil your requirements and we will provi-

de the solution. Our customers have the opportunity to

develop with us a specific solution for

their application and take advantage of

almost 100 years of experience. The result

is a Rotameter designed and built for your

specific application.

Page 5

Yokogawa’s

Flow Center of Excellence:

Rota Yokogawa

In 1995 Yokogawa acquired the former

Rota Company well known and

synonymous with the world famous

Rotameter variable area flow meter.

Rota Yokogawa, still located in southern

Germany, looks back on almost a century

of experience in flow measurement and

has successfully managed the transition

from a traditional enterprise into a com-

pany operating in the global Yokogawa

network. The Rotameter and Rotamass

are developed and manufactured for the

global market at Rota Yokogawa.

commitment

means building

the future to last

YOKOGAWA ELECTRIC CORPORATION

World Headquarter

2-9-32, Nakacho 2-chome, Musashino-shi,

Tokyo 180-8750, Japan

http://www.yokogawa.com

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road, Newnan, GA 30265−1094, USA

http://www.us.yokogawa.com

YOKOGAWA EUROPE B.V.

Databankweg 20, 3821 Amersfoort, The Netherlands

http://www.yokogawa.com/eu

Calibration Facility of Rota Yokogawa, 79664 Wehr, Rheinstr. 8, Germany

What does vigilance™ mean to Yokogawa ? For starters, always, always making sure

the products and solutions that leave our research & developement labs a re the best the

world has seen – from day one throughout your business live cycle. Our innovative

technologies and committed experts help design, install and manage your production

systems efficiently and dynamically. In an ever-changing business environment, we

help plan for the future to ensure continuity and flexibility in your automation strategies.

Yokogawa goes the extra mile to do things right. Let us be vigilant about your business.

Represented by:

YOKOGAWA ENGINEERING ASIA PTE. LTD

5 Bedok South Road, Singapore 469270, Singapore

http://www.yokogawa.com/sg

Any information is subject to change without prior notice.

Rotameter™ is a trademark of Rota Yokogawa GmbH & Co. KG,

a subsidiary of Yokogawa Electric Corparation, Japan.

Except in the United Kingdom where Rotameter™ is a trademark of Roxboro Group PLC.

[Ed: XX/X] Printed in Germany, All rights Reserved. Copyright © 2004 Rota Yokogawa Gmbh & Co. KG

© AXXISS • 79730 Murg • 9/2004 Responsible for the content: Jürgen W. Fischer

Loading...

Loading...