Page 1

User´s

Model RAKD

Manual

IM 01R01B30-00E-E

Small Metal ROTAMETER

Rota Yokogawa GmbH & Co. KG

Rheinstr. 8

D-79664 Wehr

Germany

IM 01R01B30-00E-E

©Copyright 2003 (Rü)

5th edition, January 2013 (Rü)

Page 2

Blank Page

Page 3

<CONTENTS>

Contents

1. Introduction ......................................................................................... 1-1

1.1 ATEX Documentation ......................................................................................1-3

1.2 General description .........................................................................................1-4

1.3 Principle of measurement .............................................................................. 1-4

1.4 Overview ........................................................................................................... 1-5

2. Precautions .........................................................................................2-1

2.1 Transportation and Storage ...........................................................................2-1

2.2 Installation .......................................................................................................2-1

3. Installation ..........................................................................................3-1

3.1 Installation in the pipeline .............................................................................3-1

i

3.2 Wiring ..............................................................................................................3-1

3.2.1 Connecting diagrams .......................................................................................... 3-1

3.2.2 Conductor connection with Quickon ............................................................... 3-4

3.2.3 Conductor M12 connection (Option /A29 or /A30) ........................................ 3-6

4. Start of operation ...............................................................................4-1

4.1 Hints on ow rate measurement ...................................................................4-1

4.2 Pulsation and pressure shock .......................................................................4-1

4.3 Start of operation of electronic transmitter .................................................4-1

5.

Limit switches (Option /K1 to /K10) .............................................................................5-1

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 4

ii

6.

Service .......................................................................................................... 6-1

<CONTENTS>

6.1 Maintenance ....................................................................................................6-1

6.1.1 Function test ......................................................................................................... 6-1

6.1.2 Measuring tube, oat ........................................................................................... 6-1

6.1.3 Explosion drawings ............................................................................................. 6-2

6.1.4 Electronic transmitter .......................................................................................... 6-3

6.1.5 Exchange of scale ................................................................................................ 6-3

6.1.6 Exchange of indicator .......................................................................................... 6-3

6.1.7 Troubleshooting .................................................................................................... 6-4

6.2 Template for sending back to service ..........................................................6-5

7. Technical Data .....................................................................................7-1

7.1 RAKD Type-, Suffix-codes and Options ......................................................... 7- 1

7.2 Standard Specications ..................................................................................7-6

7.3 Dimensions and weights .............................................................................. 7-11

7.4 Temperature curves ...................................................................................... 7-15

8. Explosion-protected Type Instruments ............................................8-1

8.1 General .............................................................................................................8-1

8.2 Intrinsically safe ATEX certied RAKD (/KS1) .............................................8-2

8.2.1 Technical data ...................................................................................................... 8-2

8.2.2 Installation ............................................................................................................ 8-4

8.3 Intrinsically safe IECEx certied RAKD (/ES1) ............................................8-5

8.3.1 Technical data ...................................................................................................... 8-5

8.3.2 Installation ............................................................................................................ 8-7

8.4 Non incendive RAKD for Category 3 (ATEX) (/KN1) ...................................8-8

8.5 Dust proofed limit switches (ATEX) (/KS2) ..................................................8-8

8.6 Intrinsically safe "ic" RAKD for Category 3G (ATEX /IECEx) (/KS3, /ES3) 8-9

8.7 Intrinsically safe FM / CSA (USA + Canada) components (/FS1, /CS1) ............8-10

8.7.1 Limit switches option /K1 ... /K10 (/FS1 for USA) ............................................ 8-10

8.7.2 Limit switches option /K1 ... /K10 (/CS1 for Canada) ...................................... 8-10

8.8 Intrinsically safe NEPSI (China) certied RAKD (/NS1) ......................................8-16

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 5

<CONTENTS>

APPENDIX 1. Safety Instrumented Systems Installation .................. A1-1

A1.1 Scope and Purpose ................................................................................... A1-1

A1.2 Using RAKD for a SIS Application ........................................................... A1-1

A1.2.1 Safety Function ................................................................................................. A1-1

A1.2.2 Diagnostic Response Time .............................................................................. A1-2

A1.2.3 Setup .................................................................................................................. A1-2

A1.2.4 Proof Testing ..................................................................................................... A1-2

A1.2.5 Repair and replacement ................................................................................... A1-2

A1.2.6 Startup Time ...................................................................................................... A1-3

A1.2.7 Reliability data ..................................................................................................A1-3

A1.2.8 Lifetime limits ....................................................................................................A1-3

A1.2.9 Environmental limits .........................................................................................A1-3

iii

A1.2.10 Application limits ............................................................................................ A1-3

A1.3 Denitions and Abbreviations ................................................................... A1-4

A1.3.1 Denitions .........................................................................................................A1-4

A1.3.2 Abbreviations ....................................................................................................A1-4

A1.4 Assessment results .................................................................................... A1-5

A1.4.1 Safety related parameters ................................................................................ A1-5

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 6

iv

<CONTENTS>

Blank Page

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 7

1. Introduction

WARNING

CAUTION

IMPORTANT

NOTE

WARNING

<1. INTRODUCTION>

1-1

Before use, read this manual thoroughly and

familiarize yourself fully with the features,

operations and handling of Rotameter RAKD to

have the instrument deliver its full capabilities and

to ensure its efficient and correct use.

Notices Regarding This Manual

• This manual should be passed to the end user.

• The contents of this manual are subject to

change without prior notice.

• All rights reserved. No part of this document may

be reproduced or transmitted in any form or by

any means without the written permission of

Rota Yokogawa (hereinafter simply referred to as

Yokogawa).

• This manual neither does warrant the

marketability of this instrument nor it does

warrant that the instrument will suit a particular

purpose of the user.

• Every effort has been made to ensure accuracy

in the contents of this manual. However, should

any questions arise or errors come to your

attention, please contact your nearest Yokogawa

sales office that appears on the back of this

manual or the sales representative from which

you purchased the product.

• This manual is not intended for models with

custom specications.

• Revisions may not always be made in this

manual in conjunction with changes in

specications, constructions and/or components

if such changes are not deemed to interfere with

the instrument’s functionality or perfor-mance.

Notices Regarding Safety and Modication

• For the protection and safety of personnel, the

instrument and the system comprising the

instrument, be sure to follow the instructions on

safety described in this manual when handling

the product. If you handle the instrument in a

manner contrary to these instructions, Yokogawa

does not guarantee safety.

• If this instrument is used in a manner not

specied in this manual, the protection provided

by this instrument may be impaired.

• As for explosion proof model, if you yourself

repair or modify the instrument and then fail to

return it to its original form, the explosion protected

construction of the instrument will be

impaired, creating a hazardous condition. Be

sure to consult Yokogawa for repairs and

modications.

The following safety symbols and cautionary

notes are used on the product and in this

manual:

This symbol is used to indicate that a hazardous

condition will result which, if not avoided, may

lead to loss of life or serious injury. This manual

describes how the operator should exercise care

to avoid such a risk..

This symbol is used to indicate that a hazardous

condition will result which, if not avoided, may

lead to minor injury or material damage. This

manual describes how the operator should

exercise care to avoid a risk of bodily injury or

damage to the instrument.

This symbol is used to call your attention to a

condition that must be observed in order to avoid

the risk of damage to the instrument or system

problems.

This symbol is used to call your attention to

information that should be referred to in order to

know the operations and functions of the

instrument.

For Safe Use of Rotameter RAMC

• If the process uid is harmful to personnel,

handle Rotameter RAKD carefully even after it

has been removed from the process line for

maintenance or other purposes. Exercise

extreme care to prevent the uid from coming

into contact with human esh and to avoid

inhaling any residual gas.

• In case of Explosion proof type instrument,

further requirements and differences are

described in Chapter 8 " INSTRUCTIONS FOR

EXPLOSION PROTECTED RAKD”. The description in Chapter 8 is prior to other descriptions in this instruction manual.

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 8

1-2

CAUTION

WARNING

IMPORTANT

<1. INTRODUCTION>

• When carrying Rotameter RAKD around,

exercise extreme care to avoid dropping it

accidentally and causing bodily injury.

Warranty

• The warranty of this instrument shall cover the

period noted on the quotation presented to the

Purchaser at the time of purchase. The Seller

shall repair the instrument free of charge when

the failure occurred during the warranty period.

• All inquiries on instrument failure should be

directed to the Seller’s sales representative from

whom you purchased the instrument or your

nearest sales office of the Seller.

• Should the instrument fail, contact the Seller

specifying the model and instrument number of

the product in question. Be specic in describing

details on the failure and the process in which

the failure occurred. It will be helpful if

schematic diagrams and/or records of data are

attached to the failed instrument.

• Whether or not the failed instrument should be

repaired free of charge shall be left solely to the

discretion of the Seller as a result of an

inspection by the Seller.

• When removing the instrument from hazardous

processes, avoid contact with the uid and the

interior of the meter.

• In case of Explosion proof type instrument,

further requirements and differences are

described in Chapter 8 " INSTRUCTIONS FOR

EXPLOSION PROTECTED RAKD”. The

description in Chapter 8 is prior to other

descriptions in this instruction manual..

Restriction on Use of Radio Transceiver

Although the transmitter has been designed to

resist high frequency electrical noise, if a radio

transceiver is used near the transmitter or it

external wiring, the transmitter may be affected by

high frequency noise pickup. To test for such

effects, bring the transceiver in use slowly from a

distance of several meters from the transmitter,

and observe the measurement loop for noise

effects. Thereafter, always use the transceiver

outside the area affected by noise.

The Purchaser shall not be entitled to

receive repair services from the Seller free

of charge, even during the warranty period,

if the malfunction or damage is due to:

• improper and/or inadequate maintenance of the

instrument in question by the Purchaser.

• handling, use or storage of the instrument in

question beyond the design and/or specications

requirements.

• use of the instrument in question in a location

not conforming to the conditions specied in the

Seller’s General Specication or Instruction

Manual.

• retrotting and/or repair by an other party than

the Seller or a party to whom the Seller has

entrusted repair services.

• improper relocation of the instrument in question

after delivery.

• reason of force measure such as res,

earthquakes, storms/ oods, thunder/lightning, or

other reasons not attributable to the instrument

in question.

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 9

1.1 ATEX Documentation

This is only applicable to the countries in European Union.

<1. INTRODUCTION>

1-3

GB

DK

E

NL

SK

CZ

I

LT

LV

EST

PL

SF

P

F

D

S

SLO

H

BG

RO

M

GR

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 10

1-4

F10.EPS

<1. INTRODUCTION>

1.2 General description

This manual describes installation, operation and maintenance of the RAKD. Please read it carefully before

using this device.

Further, please note that customer features are not described in this manual. When modifying specications,

construction or parts, this manual is not necessarily revised unless it can be assumed that these changes will

impair RAKD functions or performance.

All units are thoroughly tested before shipping. Please check the received units visually to ensure that they

have not been damaged during transport. In case of defects or questions please contact your nearest

YOKOGAWA service centre or sales office. Please describe any defect precisely and indicate model code as

well as com. no. number.

YOKOGAWA refuses any liability for units which have been repaired by the user without prior consent and do

not meet the specications as a consequence..

1.3 Principle of measurement

The RAKD is a Variable Area Flow Meter for volume and mass measurements of gases and liquids.

A oat, whose movement is nearly independent of viscosity is guided concentrically in a specially shaped cone.

The position of the oat is transferred magnetically to the indicator, which shows the measurement values by a

pointer on a scale. The indicator can be equipped with limit switches and an electronic transmitter.

Fig. 1.1

All units are calibrated with water or air by the manufacturer. By adjusting the calibration values to the measured

substance’s state of aggregation (density, viscosity), the ow rate scale for each measuring tube can be

determined.

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 11

1.4 Overview

F11.EPS

Tube

Indicator

Pointer

Scale

Limit switch MIN

below scale

Limit switch MAX

below scale

Cable connection

Quickon

100

10

50

l/h

II2G

Ui= 30V Ii= 100mA

KEMA 00ATEX 1037X

Ex ia IIC T6

Transmitter

Li= 0.73mH Ci= 2.4nF

Pi= 0.75W

KEMA 00ATEX 1037X

see certificate for data

Ex ia IIC T6

Limit Switch: SC2-N0

F12.EPS

Flow scale

Ex-marking

Ex-data electronic

transmitter

Limit switch

Ex-data limit switch

Ex-marking

Made in Germany D-79660 Wehr

20 Grad C

1.1 bar abs.

Wasser

0,99831 g/cm

1 mPas

MS-Code: RAKD41-G6SS-33NNN-

Kom.Nr.: 200000/001

E80424/K1/KS1

Manufactured: 2009

Com. no..

Model code

Medium data

Flow unit

<1. INTRODUCTION>

1-5

Example for scale :

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 12

1-6

<1. INTRODUCTION>

Blank Page

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 13

<2. PRECAUTIONS>

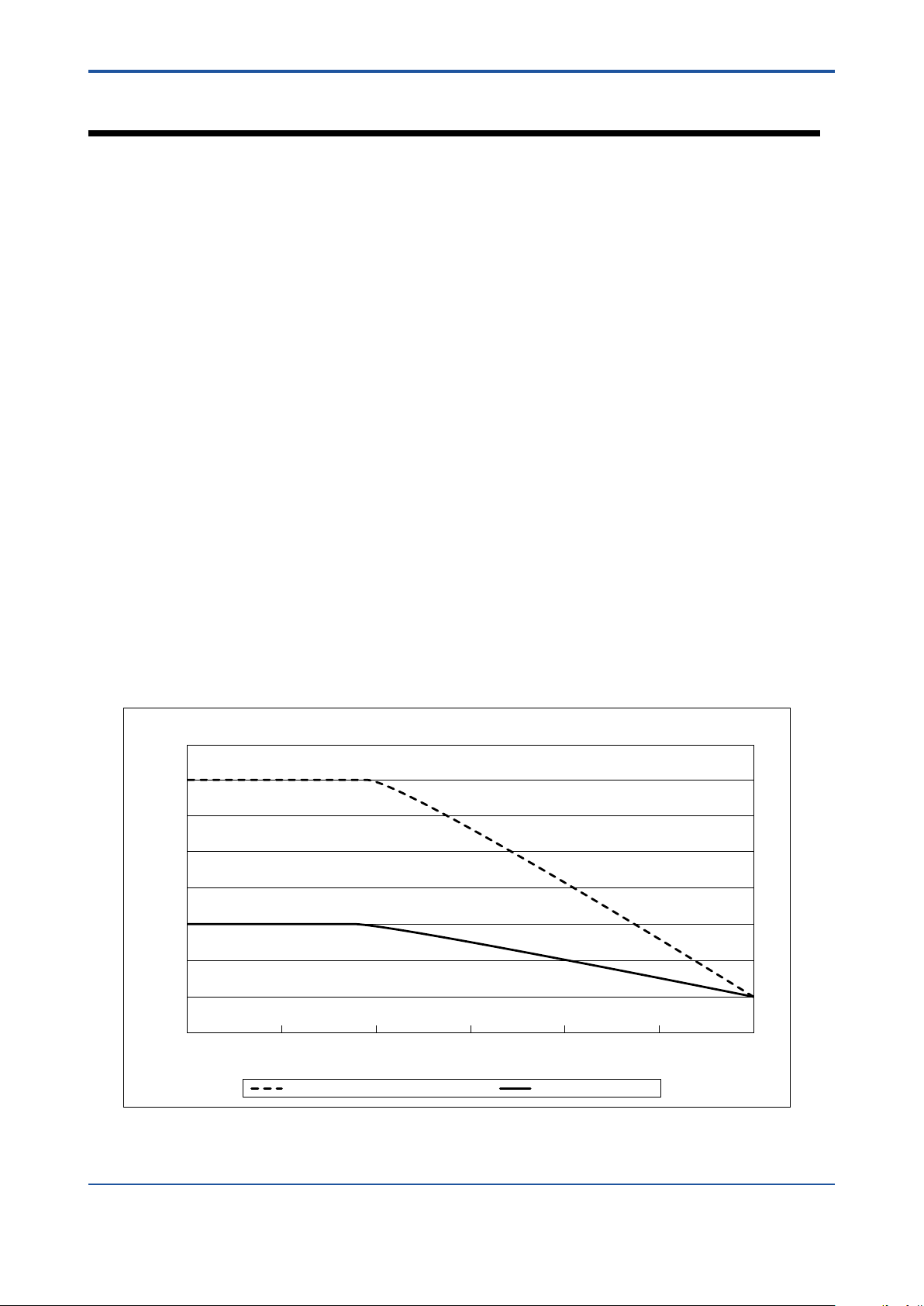

50 55 60 65 70

75

100

200

Illustration of maximum allowable operation temperature depending on

ambient temperature for Rotameter type RAKD

Max. operation temperature [°C]

Ambient temperatur [°C]

75 80

125

150

175

225

250

275

Version without valve Version with valve

F21.EPS

2. Precautions

2.1 Transportation and Storage

Before transporting the unit, it is recommended to x the oat with a card-board strip in the same way as

when shipped from factory. Prevent foreign objects from entering the tube (e.g. by covering openings).

To protect the unit and especially the tube’s interior from soiling, store it only at clean and dry locations

2.2 Installation

Ambient temperature and humidity of the installation location must not exceed the specied ranges. Avoid

locations in corrosive environments. If such environments are unavoidable, ensure sufficient ventilation.

Although the RAKD features a very solid construction, the instrument should not be exposed to strong

vibration or impact stress.

Please note that the RAKD is magnetic sensing system can be inuenced by external inhomogeneous

magnetic elds (such as solenoid valves). Alternating magnetic elds (≥ 10Hz) as well as homogeneous,

static magnetic elds (in the area of the RAKD), like the geomagnetic eld have no inuence. Asymmetric

ferromagnetic bodies of considerable mass (e.g. steel girders) should be kept at a distance of at least 250 mm

from the RAKD.

To avoid interference, the distance between two adjacent RAKDs must be at least 120 mm.

Do not expose the unit to pressures higher than the indicated maximum operating pressure (refer to

specications)

Make sure that wetted parts are resistant against the process medium.

Ambient- and process-temperature may exceed specied maximum values. Note the temperature curves in

g. 2-1 and chapter 7 "Technical data".

The Rotameter must be mounted vertically. The ow direction is upwards.

2-1

Fig. 2-1. For option /KS1or /KN1 (Ex-version) the maximum values for ambient and process temperature

according to the respective temperature class mentioned in g. 3-2 and tables 7-2 to 7-5 must

be regarded. The minimum ambient temperature is -25°C.

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 14

2-2

<2. PRECAUTIONS>

Check movability of the oat (5)* by watching the pointer. The pointer should follow the movement of the oat.

If this is not the case, oat and measuring tube (1;21) should be cleaned.

Check the movability of the pointer by careful moving it with your ngers and watching whether it responds to

the scale value. If it does not work properly, the mechanical display unit (14) must be changed.

To avoid damage of the oat and of the stopper do not use magnetic valves. In the phase of start up increase

the ow slowly to the desired ow rate. If a sudden rise of the pressure can not be avoided (with use of

magnetic valves) the ow must be limited to the maximum used value (e.g. by valve).

*: Position numbers are illustrated in the explosion drawings in chapter 6.

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 15

<3. INSTALLATION>

Type T

without contact

Type T

with MIN contact

/K1 or /K 6

Type T

with MAX contact

/K2 or /K 7

Type T

with MIN/MAX

contact /

K3 or /K8

Type E

without contact

without pulse

Type E

with MIN contact

/K1 or /K 6

Type E

with MAX contact

/K2 or /K 7

Type E

with

pulse output

/CP

Quickon

upper "T"

--- MIN contact --- MIN contact --- MIN contact MAX contact Puls output

Quickon

lower "S"

--- --- MAX contact MAX contact Current output Current output Current output Current output

T31.EPS

3-1

3. Installation

3.1 Installation in the pipeline

The pipe has to be so stabilized that vibrations on the pipe are avoided. Additional recommendations can be

found in guideline VDI/VDE 3513 sheet 3.

If pollution of the metering tube may appear a bypass-pipe is recommended, which permits the removal (see.

chapter 6 “maintenance”) of the Rotameter for cleaning without interruption of the ow.

Before installing the Rotameter, make sure there are no parts of packing or securing inside the Rotameter.

It has to be taken care at the connection of units with internal thread that no residues of the sealing compound

come into the tube (e.g. remains of the PTFE sealing compound).

To avoid stress in the connecting pipes, the connecting anges must be aligned in parallel and axial direction.

Bolts and gaskets have to be selected according to the maximum operating pressure, the temperature range

and corrosion conditions. Centre gaskets and tighten nuts with a torque appropriate for the pressure range.

If contamination or soiling of the RAKD is to be expected, a bypass should be installed to allow the removal of

the instrument without interruption of the ow.

Please read also chapter 2.2. For further instructions on installation please refer to VDI/VDE3513.

In case of devices without valve but with process connection internal thread the oat shaft of tubes with cone

44 and bigger sizes may move into the range of the threaded joint. Keep attention not to bend the guide bar

when screwing up the connection. The inner diameter of the connector must be at least 8 mm for cone sizes

44 - 51 resp. 10 mm for cone sizes 52 and 53.

To avoid oat bouncing in case of gas applications, attend to VDI/VDE 3515 sheet 3.

For devices without valve use a throttle either in the inlet or outlet (to install at that side with the bigger volume).

For installation of several instruments in parallel tubes take care that the distance between the middle axis is

at least 120 mm to avoid magnetic inuence. The distance to other ferritic material should not be less than

60 mm. Take care that the strength of external magnetic elds is approximately 0 mT.

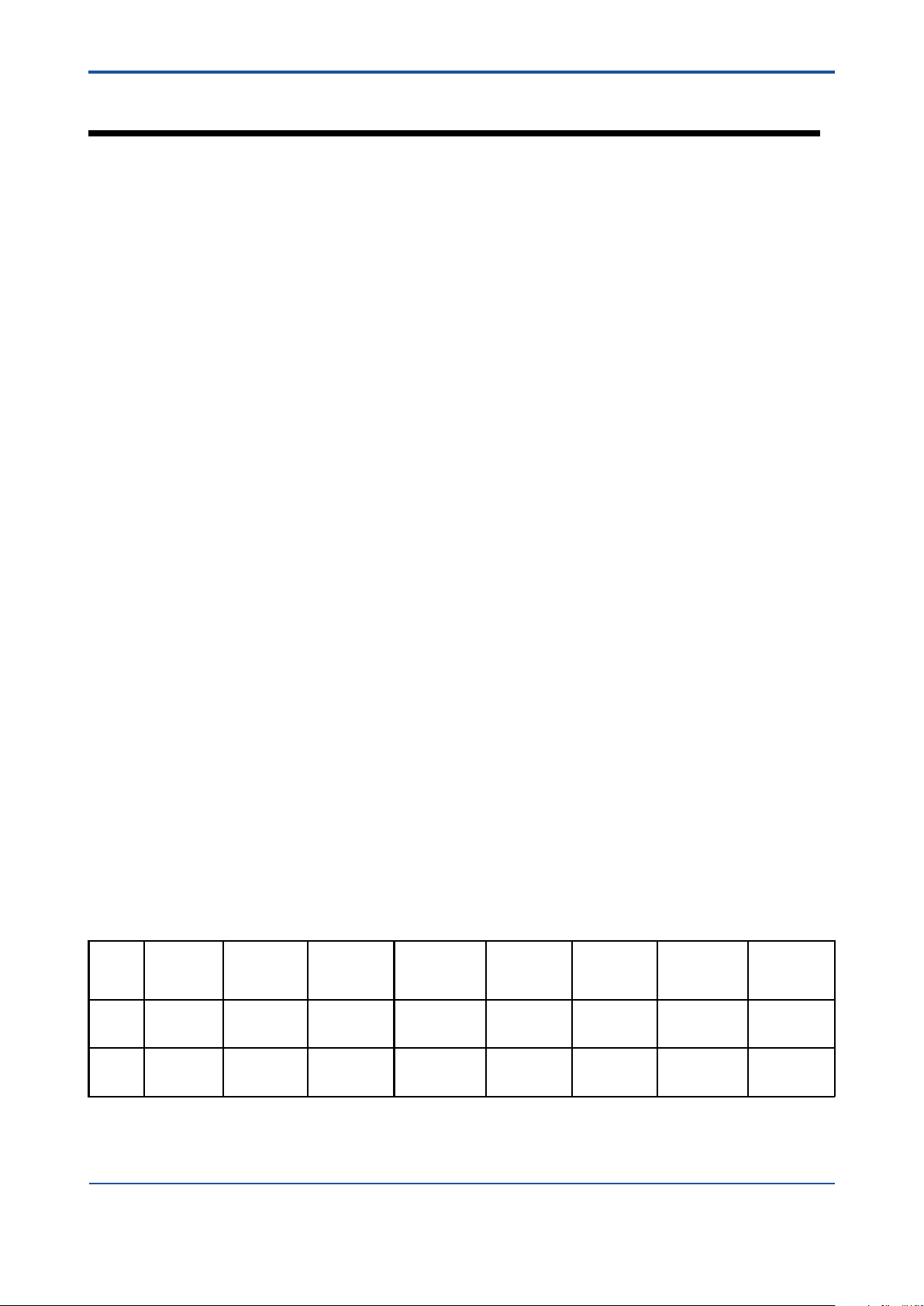

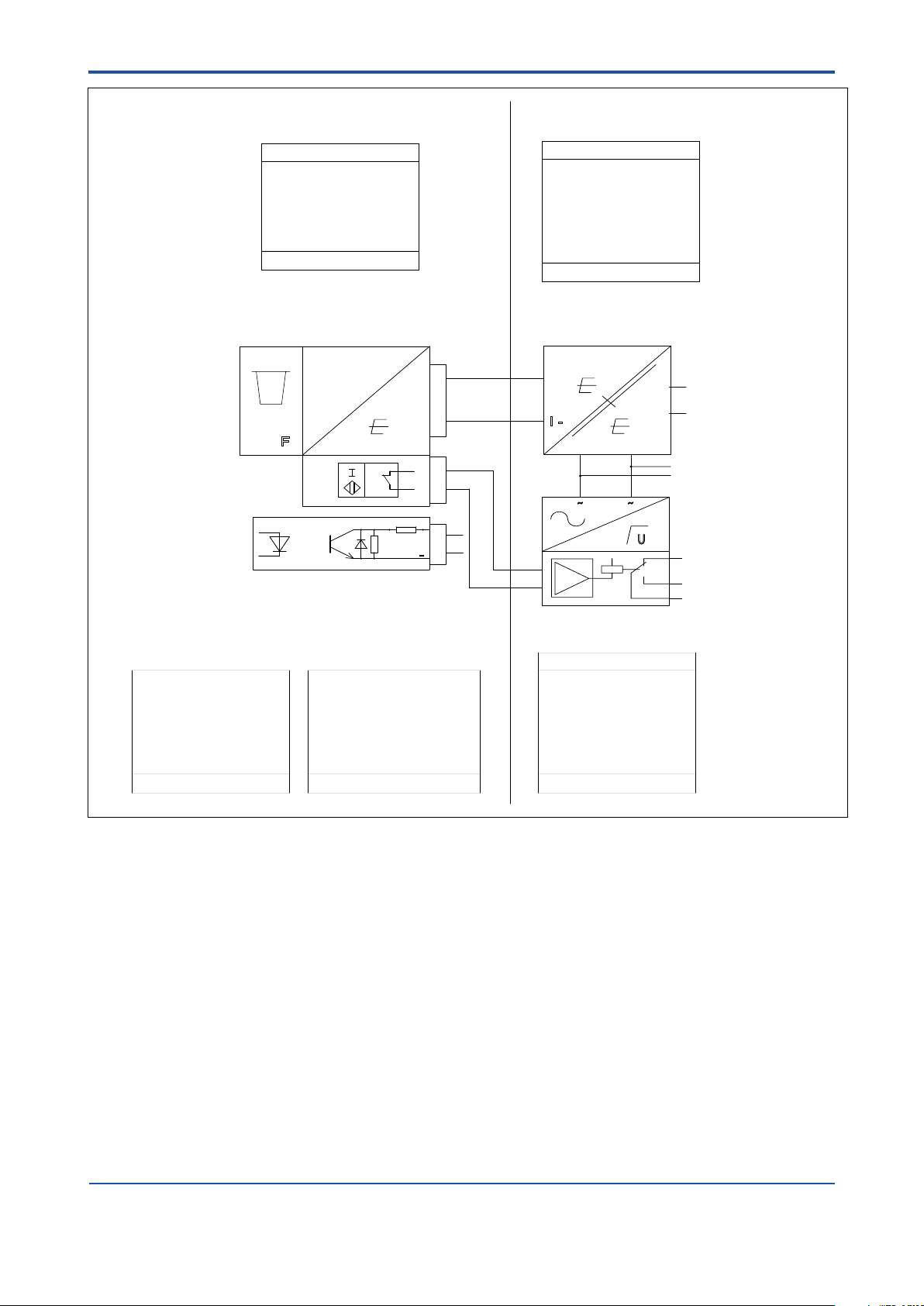

3.2 Wiring

3.2.1 Connecting diagrams

Please regard the drawings of this chapter.

RAKD with electronic transmitter or with limit switches have one or two Quickon connectors at the rear.

In the connecting diagrams he lower one is named "S" and the upper one "T".

Not used connector positions are closed with a blind plug.

The following table shows the connections for the respective equipment conguration.

The load resistance of metering or indicating instruments, which are connected serial to the current output, may

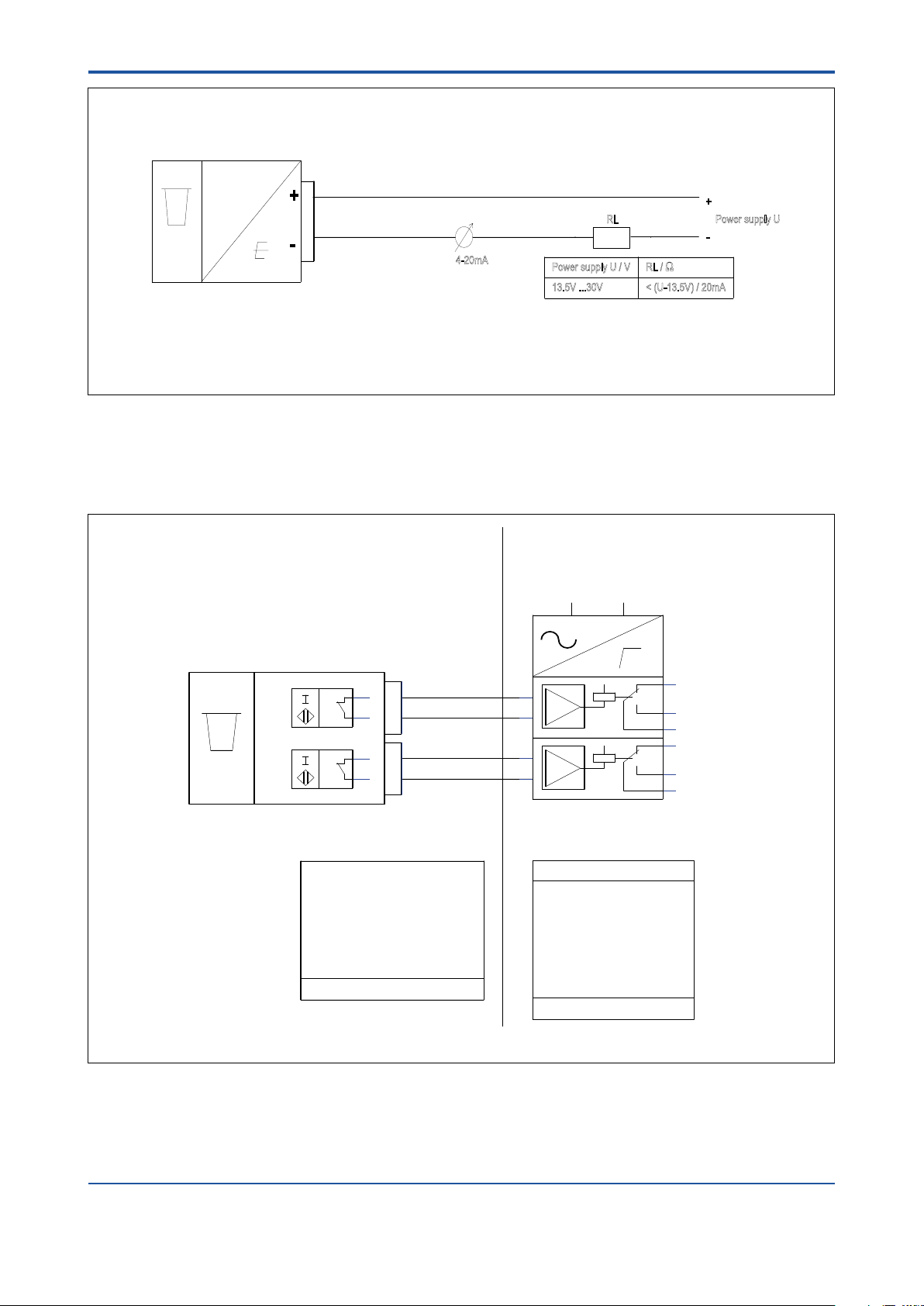

not exceed (U- 13.5 V) / 20 mA .

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 16

3-2

T = QUICKON connector

F

RAKD-E80

G

T

2

-

+

1

Power supply U

4-20mA

RL

-

+

Power supply U / V RL /

Ω

13.5V ...30V < (U-13.5V) / 20mA

i

i

i

i

i

-

+

+

-

o

o

o

o

o

-

+

-

+

~ ~

Limit Switch Type 2

I = 25mA

P = 64mW

L = 0.15mH

C = 150nF

KEMA 00ATEX 1037X

Ex ia IIC T6...T4 Gb

U = 16V

EN 60947-5-6 (NAMUR)

Limit Switches

RAKD - T80

PTB 00ATEX 2081

L = 97mH

C = 2320nF

I = 19,1mA

P = 51mW

Transmitter Relay

KFA6-SR2-Ex2.W

U = 10.6V

Ex ia IIC

KFA6-SR2-Ex2.W

Supply 230V AC

Limit MIN

Limit MAX

BU

2

BN

BU

BN

1

2

1

10

12

6

4

3

1

11

7

8

9

14 15

MIN

F

MAX

S

T

U

Hazardous Area

Safe Area

F3.EPS

<3. INSTALLATION>

Fig. 3-1 RAKD with electronic Transmitter

Fig. 3-2 RAKD with 2 limit switches in combination with transmitter relay in Ex- version

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 17

<3. INSTALLATION>

Limit switch / Puls

Ex ia IIC T6...T4 Gb

U = 16V

P = 64mW

I = 20mA

C = 0nF

L = 0mH

KEMA 00ATEX 1037X

Puls output

Ex ia IIC T6...T4 Gb

U = 10.6V

KEMA 00ATEX 1037X

L = 0.15mH

C = 150nF

U = 16V

I = 25mA

P = 64mW

PTB 00ATEX 2081

L = 97mH

C = 2320nF

I = 19.1mA

P = 51mW

Limit switch type 2

EN 60947-5-6 (NAMUR)

Limit switch or

Pulse output

KFA6-SR2-Ex1.W

Transmitter relay

Option: /W2A

[Ex ia] IIC

4-20mA output

I = 100mA

U = 30V

KEMA 00ATEX 1037X

L = 0.73mH

C = 2.4nF

P = 0.75W

Ex ia IIC T6...T4 Gb

RAKD-E80 Option /KS1

Option: /UT

Transmitter power supply

PTB 00ATEX 2018

Tamax = 50°C

C = 86nF

L = 5.2mH

RN221N-B1

U = 27.3V

P = 0.597W

[Ex ia] IIC

I = 87.6mA

Output 4-20mA

Power supply

230V AC

i

i

i

i

i

o

i

i

i

i

i

o

o

o

o

-

P

+

P

-

-

+

~ ~

i

i

i

i

i

o

+

L-

L+

I -

I +

o

o

o

o

BU

1 K

15 K

2

1

2

3

1

14

7

8

9

15

BN

1

1

2

L/+N/-

O -

O+

S

S

U

F

G

T

Hazardous Area Safe Area

3-3

Fig. 3-3 RAKD in Ex-version with electronic transmitter in combination with power supply

and additional limit switch or pulse output with transmitter relay.

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 18

3-4

1

2

3

5

15 mm

4

F6.EPS

F7.EPS

<3. INSTALLATION>

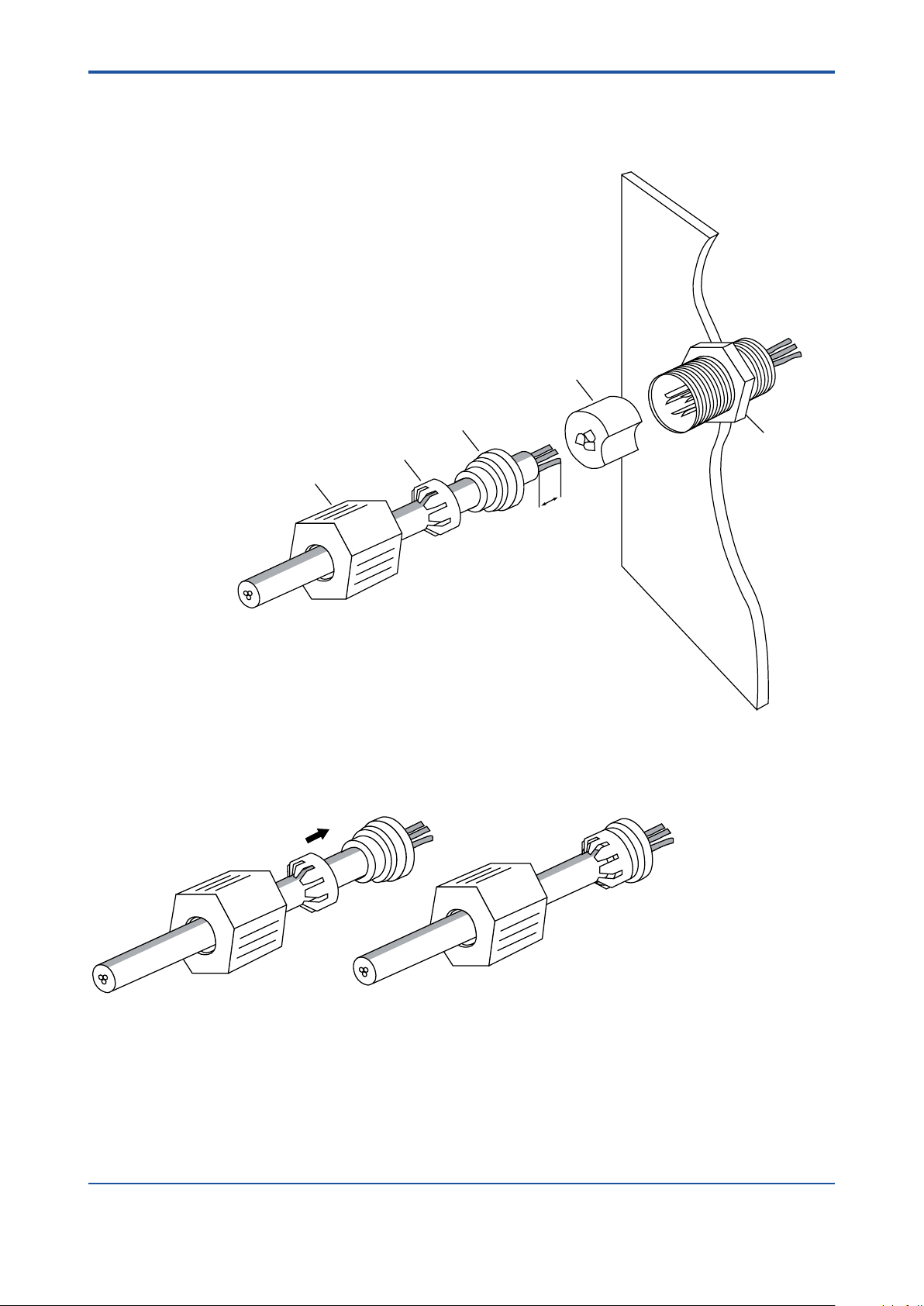

3.2.2 Conductor connection with Quickon

To connect the conductor, please observe in particular the following steps :

- Strip the sheath to a length of approx. 15 mm

(g. 3-4) and slide the union nut (1), the cap (2)

and the rubber seal (3) onto the conductor.

Fig. 3-4

Fig. 3-5

- Slide the rubber seal as far as the rim of the insulation and then slide the cap onto the rubber seal.

This provides the strain relief for the conductor (g. 3-5).

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 19

<3. INSTALLATION>

F8.EPS

F9.EPS

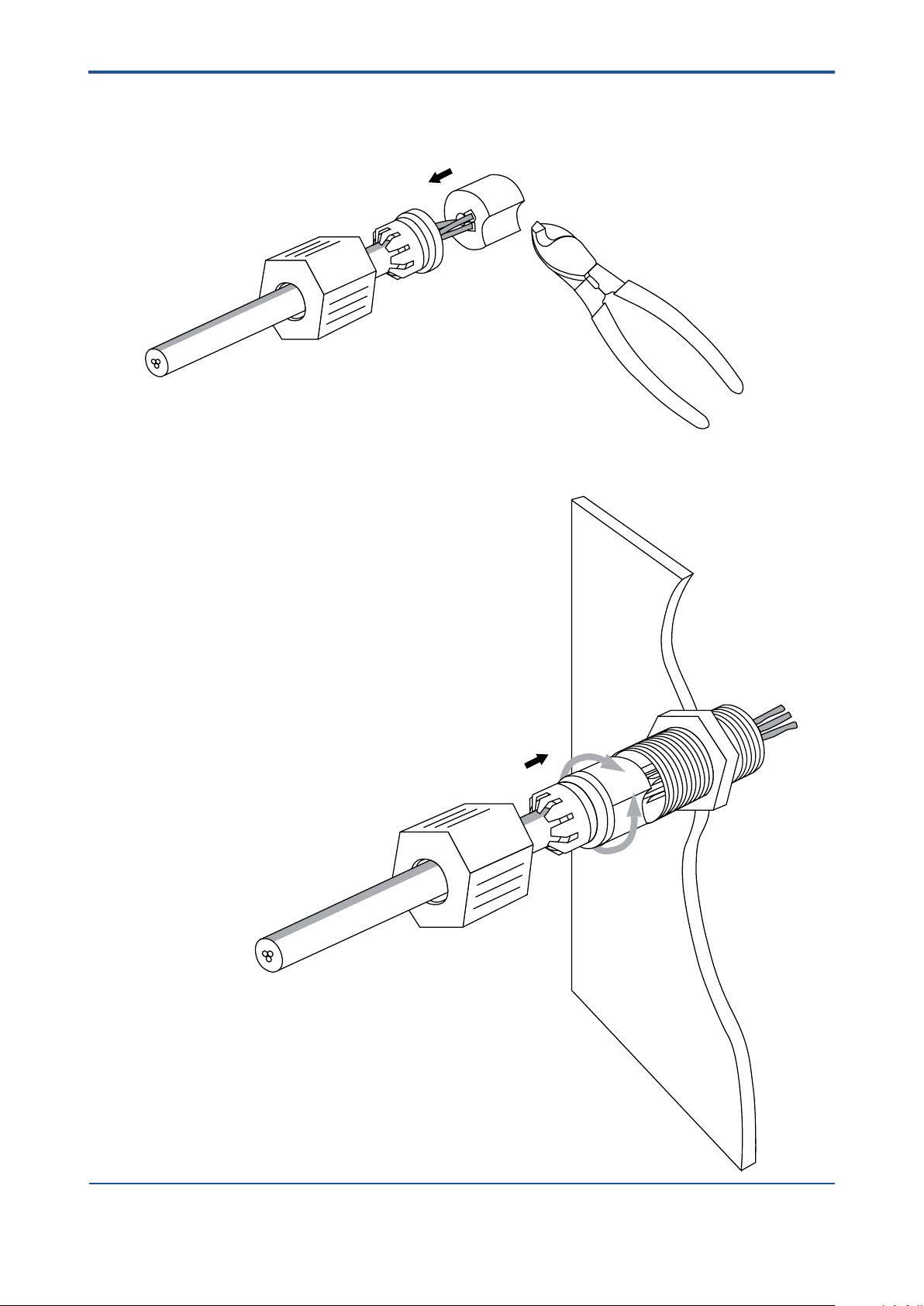

- insert the core ends into the feed through of the splice ring (g. 3-6). In order to guarantee a clear

assignment of the cores, the individual core feed thorough of the splice ring are numbered (1, 2,…).

Fig. 3-6

- Cut off the projecting core ends. Make sure that

the core ends are ush with the splice ring (5):

they can protrude by up to 3 mm, but must not

be too short.

3-5

- Insert the prepared conductor into the QUICKON

contact carrier (4). Turn the conductor with the

splice ring until the coding noses t exactly into

the corresponding guides (g. 3-7).

Fig. 3-7

- Close the gland by tightening the union nut. This

presses the core ends into the insultation

displacement terminal blocks, cuts open the core

insulation and creates the electrical contact (IDC

connection system).

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 20

3-6

<3. INSTALLATION>

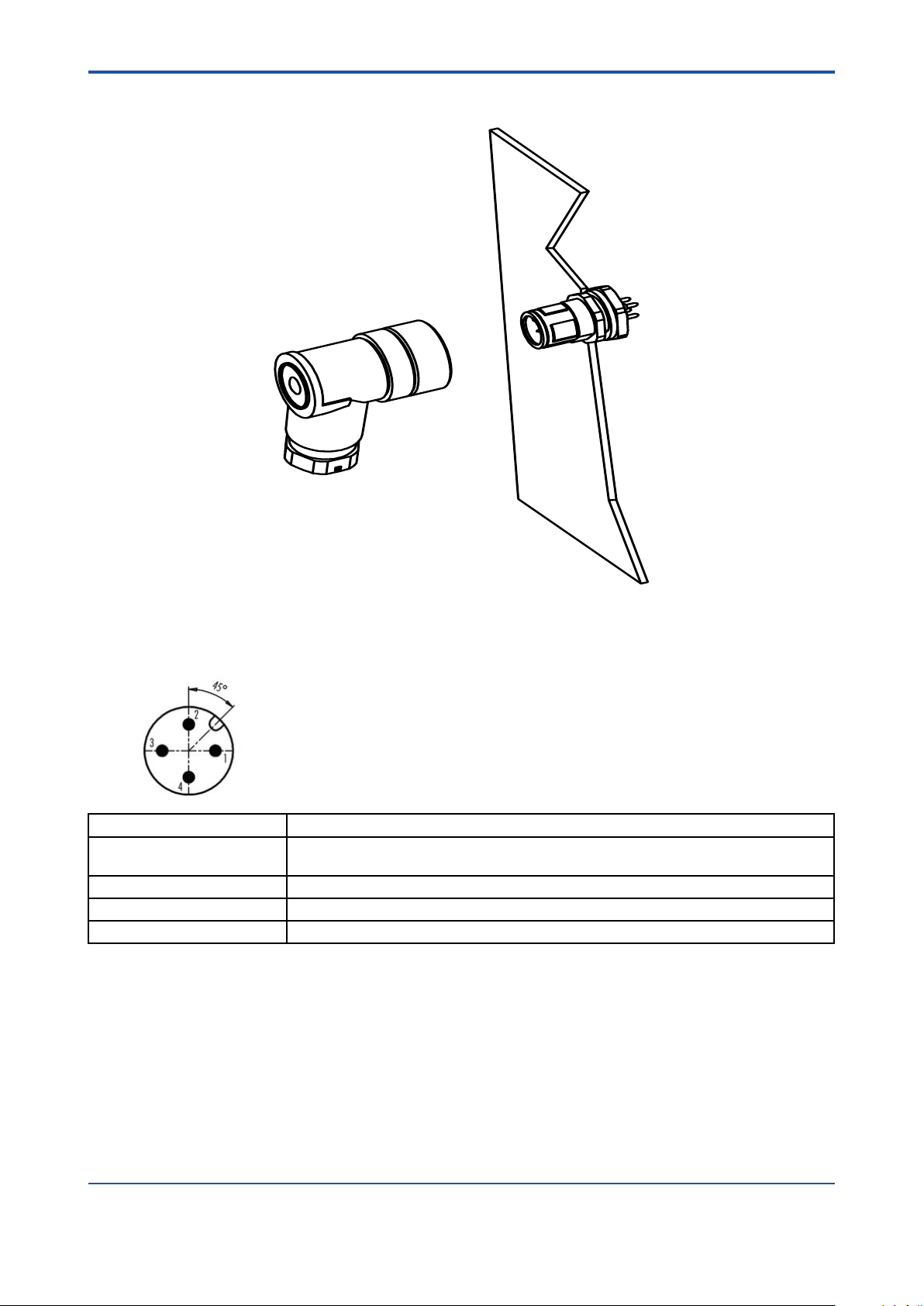

3.2.3 Conductor M12 connection (Option /A29 or /A30)

Fig. 3-8

Angular mating connector is only factory delivered with option /A30.

Pin assignment:

Connection Signal

Upper connector 1 (+) 2 (-) One limit switch /K1, /K2, /K6, /K7

Two limit switches /K3, /K8, /K9, /K10: lower switch, e.g. MIN MAX ==> MIN

Upper connector 3 (+) 4 (-) Two limit switches /K3, /K8, /K9, /K10: upper switch, e.g. MIN MAX ==> MAX

Lower connector 1 (+) 2 (-) Electronic transmitter, 4-20 mA supply

Lower connector 3 (+) 4 (-) Electronic transmitter, pulse output (option /CP)

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 21

<4. START OF OPERATION>

4-1

4. Start of operation

4.1 Hints on ow rate measurement

The measured uid should neither consist of a multi-phase mixture nor contain ferrite ingredients or large solid

mass particles.

The RAKD scale is adjusted to the state of operation/aggregation of the measured uid by the manufacturer. If

the state of operation changes, it might become necessary to establish a new scale.

This depends on several factors:

- If the RAKD is operated in the given viscosity independent range, only the density of the oat as well as the

operational density of the previous and new substance have to be considered. In case the operational

density only changes marginally (≤ 0.5%), the present scale can be used.

- If the RAMC is operated outside the given viscosity independent range, the viscosities at the previous and

new state of operation as well as the mass and diameter of the oat have to be taken into account.

To establish a new scale, please refer to the folder “Anweisung zur Skalenumrechnung” (Instructions for

Scale Conversion) as well as the conversion table or order a new scale.

4.2 Pulsation and pressure shock

Strong pressure impact or ow pulsations can impair measuring operation considerably and should be avoided

open valves slowly, raise operating pressure slowly).

4.3 Start of operation of electronic transmitter

Ensure that the device has been connected correctly according to section 3-2 and that the used power supply

meets the requirements indicated on the scale.

Switch on the power supply..

The RAMC is now ready for operation..

The transmitter is prepared and calibrated according to its model code as a 2 wire unit.

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 22

4-2

<4. START OF INSTALLATION>

Blank Page

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 23

<5. LIMIT SWITCHES OPTION /K1 TO /K10>

5-1

5.

The optional limit switches are available as maximum or minimum type switches. They are proximity switches

according to EN 60947-5-6 (NAMUR). Maximal two switches can be installed. The option (/Wnn) includes the

respective transmitter relay.

These switches have been specied for hazardous area. However, the transmitter relay must be installed

in safe area.

The limit switches are connected to the transmitter relays as indicated in chapter 3.2.

The terminals for the limit switches are on a small board on top of the transmitter case.

Use of 2 standard limit switches (option /K3):

The MIN-MIN and MAX-MAX functions have been integrated at the factory as MIN-MAX switches in the RAKD

The MIN-MIN or MAX-MAX function is set by adjusting the switching direction of the transmitter relay. The

concerning 2- channel transmitter relays are:

Option /W1B: KFA5-SR2-Ex2.W

Option /W2B: KFA6-SR2-Ex2.W

Option /W4B: KFD2-SR2-Ex2.W

The following table shows the assignment:

Limit switches (Option /K1 to /K10)

Function Switching direction of transmitter relay *

Channel 1 Channel 2 Channel 1 Channel 2

MIN MAX S1 position I S2 position I

MIN MIN S1 position I S2 position II (ON)

MAX MAX S1 position II (ON) S2 position I

* see following gure for S1 and S2 on transmitter relay.

Use of Fail Safe limit switches (option /K6 ... /K10):

For Fail Safe application only 1- channel transmitter relays are available.

Option /W2E: KHA6-SH-Ex1.W

Option /W2F: 2 x KHA6-SH-Ex1.W

Option /W4E: KFD2-SH-Ex1.W

Option /W4F: 2 x KFD2-SH-Ex1.W

If other transmitter relays are used as the above mentioned types, the transmitter relay has to be applied

as protection technology to ensure functional safety.

Please notice chapter 7.2 "Standard specications".

For questions regarding protection technology, please consult your YOKOGAWA service center.

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 24

5-2

<5. LIMIT SWITCHES OPTION /K1 TO /K10>

Blank Page

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 25

<6. SERVICE>

IMPORTANT

6-1

6.

Service

6.1 Maintenance

6.1.1 Function test

Checking free movement of pointer:

- Remove housing cover (4 screws).

- After deecting the pointer by hand, it must return to measurement value. If the pointer pivots to different

values upon repeated deections, there is too much friction in the bearings. In this case, send indication unit

to service.

Checking free movement of oat:

- First, free movement of pointer has to be ascertained.

- Check visually if pointer follows each ow rate change. If not, clean oat and measuring tube.

Unit with electronic transmitter:

- Without ow, the output current must be 4 mA. At a ow rate of 100% the current must be 20 mA.

If only the pointer is moved to 100%, the current may not exeed 17mA.

6.1.2 Measuring tube, oat

The Rotameter does not normally require any maintenance. However cleaning is necessary if the measuring

cone or at has been contaminated by the process. To clean, the Rotameter must be removed from the

pipeline.

For all kind of intervention in the Rotameter like tightening the packing of the valve the pressures in pressurized

pipelines has to be reduced. Take care that the counter screw is tighten after screwing the valve.

Disassembling the tube

Please perform the following steps to clean the measuring tube and the oat:

• Disassemble the Rotameter from the pipe

• Unscrew hollowed top threaded bolt (6) (for cone 31 – 43)

resp. remove top snap ring and socket (for cone 44 – 51)

resp. only top snap ring (for cone 52 – 53)

• Remove top oat stop (3)

• Disassemble oat – Attention: Do not bend the oat

• For version with valve in the inlet remove rst the top head pipe plug (8)

• For version with valve in the outlet remove rst the lower head pipe plug;

in that case the disassembling of all parts start from down to top

• Cleaning of metering tube and oat

• To clean the valve loose screw nut (10) in the head. Afterwards you can unscrew spindle (12) with PTFE

packing box plus thrust collar (9)

Please don’t expose the oat to any strong magnetic alternating elds. The oating body and particularly

its measuring edge may not be damaged.

Assembling the tube

Mounting starts in opposite sequence.

Assembling the oat take care that the lower guide bar of the oat is xed in the middle boring of the lower

stop. The guide bar should not be bended.

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 26

6-2

F61.EPS

F62.EPS

<6. SERVICE>

6.1.3 Explosion drawings

No. in Fig. 6-1 and 6-2 Part

1 Tube for unit with valve and

controller

2 Socket

3 Float stop

4 Cone

5 Float

6 Threaded bold

7 Gasket

8 Screw sealing plug

9 ; 10; 11; 12; 13 Packing for valve

14 Indicator

15 Nut M5

16; 19 Nozzle

17; 20 Cutting ring tting

18 Controller

21 Tube for unit without valve

and controller

Fig. 6-1 RAKD without valve and controller

Fig. 6-2 RAKD with valve and controller

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 27

<6. SERVICE>

IMPORTANT

IMPORTANT

6.1.4 Electronic transmitter

The electronic transmitter is maintenance-free. The electronic section is sealed and can not be repaired.

The transmitter is tuned with the mechanical components in factory, therefore single components can be

replaced only by loss of accuracy.

6.1.5 Exchange of scale

Preparations :

· Check commision no., code, and data of new parts.

· Switch off power supply.

· Remove the cover of the indicator

Do not bend or twist the pointer on its axis !

Exchange of scale:

- Untighten the screw of the scale.

- Remove the screw and the small cover.

- Pull the scale out of the indicator to the left in which the scale raised on the right to raise it from the 2 pins.

- Shove the new scale correspondingly below the pointer from the left until the 2 pins click into the

accompanying holes.

- Establish the small cover and x the scale with the screw.

6-3

Final actions:

· Fix the cover of the indicator.

· Switch power on.

· Check the unit for a faultless function.

6.1.6 Exchange of indicator

The indicator can be replaced by the same type if the scale of the old unit is put into the new indicator,

Procedure with RAKD with electronic transmitter (type "E" ):

· Switch off power supply.

· Remove the cover of the indicator

- Disconnect the cables from the Quickon connectors.

- Remove the old scale and put in the new one.

- Please not the hints for exchange of scale

- Remove the old indicator from the tube and replace it by the new one. Please take care to mount the

washers and spacers in the same positions as they were before dismantling.

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 28

6-4

F63.EPS

<6. SERVICE>

6.1.7 Troubleshooting

In case the RAMC does not work properly, use the following ow charts for troubleshooting, then check,

isolate and remedy the fault.

Precision problems with "T" unit: execute test acc. g. 6-3

If the indicated countermeasure do not remedy the fault or in case of troubles which cannot be remedied by

the user, please contact your YOKOGAWA service centre.

Fig. 6-3

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 29

<6. SERVICE>

6-5

6.2 Template for sending back to service

Sending an instrument back to service

Installation and operation of the Rotameter RAKD in compliance with this manual is generally trouble-free.

In case a RAKD has to be sent for repairs or checking to our service, please observe the following:

Due to legislation for the protection of the environment and for the safety of our staff, YOKOGAWA may only

ship, repair and check sent devices on the condition that this does not constitute any risk to environment

and staff.

YOKOGAWA can only process your returned RAKD if you attach a certicate of harmlessness according to

the following sample.

If the unit has been in contact with corrosive, poisonous, ammable or water polluting substances, you

must,

- ensure that all parts and hollow spaces of the unit are free of these dangerous substances.

- attach a certicate of harmlessness to the returned unit.

Please understand that YOKOGAWA cannot process your returned unit without such a certicate.

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 30

6-6

ROTA YOKOGAWA GmbH & Co. KG

Service & Repair Department

Rheinstraße 8; D - 79664 Wehr

Phone no.: +49 (0)7761-567-190

Fax no.: +49 (0)7761-567-285

e-Mail: services.flow@de.yokogawa.com

Declaration of Decontamination

Legal regulations for the safety of our employees and operating equipment determine that we need

the declaration of decontamination before your order can be handled.

Please make sure to include it with the shipping documents, attached to the outside of the

packaging you use for shipment.

Customer data

Company:

Address:

Contact person: E-Mail:

Phone no.: Fax no.:

Reference/Order no.:

Instrument data*

Type: Serial no.:

Type: Serial no.:

*If not enough, note on separate sheet

Process data

Process medium:

Medium is: [ ] toxic

[ ] corrosive

[ ] explosive

[ ] biological hazardous

[ ] unknown if dangerous

[ ] non hazardous

Remarks:

Cleaning agent:

Kind of cleaning :

Other remarks / Reason of return:

We hereby confirm that this statement is filled in completely and truthfully. The returned

instruments were carefully cleaned and are thus free from product residue and dirt. I agree

that if this arrangement does not match with the instruments, they will be sent back to the

above mentioned customer address at our expenses.

Name Date Signature

<6. SERVICE>

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 31

<7. TECHNICAL DATA>

7- 1

7. Technical Data

7.1 RAKD Type-, Suffix-codes and Options

RAKD with valve and controller (option /R1 and /R3) 1.0 - 100 l/h water / 40 - 3250 l/h air

Water (l/h) Air (l/h) With valve in inlet Type:

1. 5 100 33 PTFE PCTFE VPE

RAKD ------- SS ------------- ------------------------------------------ 80 / options

Process connection Max. Flow Cone Version Indicator

Internal thread:

Rp 1/4 PN 25 41 R3 1 40 31 Gasket Valve seat Local indicator T

1/4 NPT PN 25 41 T3 1. 6 60 32 PTFE Silver VSE Indicator wit electronic output E

Cutting ring: 4 150 34 Housing type:

Ø 6 PN 25 53 C3 6 200 37 With valve in outlet Stainless steel 80

Ø 8 PN 25 54 C3 10 325 41 Gasket Valve seat

Ø 10 PN 25 55 C3 16 500 42 PTFE Silver VSA Power supply:

Ø 12 PN 25 56 C3 25 800 43 PTFE PCTFE V PA none, for type ´T´ NNN

All Rights Reserved. Copyright © 2003, Rota Yokogawa

40 1400 44 24V, 2- wire, 4 - 20mA, for type ´E´ 424

Material: 1.4571 / AISI 316Ti

Nozzle: 60 2000 47

Ø 6 PN 10 53 P1 SS 100 3250 51

Ø 8 PN 10 54 P1

Cone Dp mbar

Swagelok: 31 - 37 6

Ø 6 PN 25 53 W3 41 - 43 8

Ø 8 PN 25 54 W3 44 - 51 11

Ø 10 PN 25 55 W3

Ø 12 PN 25 56 W3

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 32

7- 2

<7. TECHNICAL DATA>

RAKD with valve 1.0 - 250 l/h water / 40 - 8000 l/h air

Water (l/h) Air (l/h) With valve in inlet Type:

RAKD ------- SS ------------- ------------------------------------------ 80 / options

Process connection Max. Flow Cone Version Indicator

Internal thread:

G 1/4 PN 40 41 G4 1 40 31 Gasket Valve seat Local indicator T

G 1/4 PN 100 41 G6 1. 6 60 32 PTFE Silver VSE Indicator wit electronic output E

1/4 NPT PN 40 41 T4 1. 5 100 33 PTFE PCTFE VPE

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

1/4 NPT PN 100 41 T6 4 150 34 Housing type:

6 200 37 With valve in outlet Stainless steel 80

Cutting ring: 10 325 41 Gasket Valve seat

Ø 6 PN 40 53 C4 16 500 42 PTFE Silver VSA Power supply:

Ø 6 PN 100 53 C6 25 800 43 PTFE PCTFE V PA none, for type ´T´ NNN

Ø 8 PN 40 54 C4 40 1400 44 24V, 2- wire, 4 - 20mA, for type ´E´ 424

Material: 1.4571 / AISI 316Ti

Ø 8 PN 100 54 C6 60 2000 47

Ø 10 PN 40 55 C4 SS 10 0 3250 51

Ø 10 PN 100 55 C6 160 5000 52

Ø 12 PN 40 56 C4 250 8000 53

Cone Dp mbar

Ø 12 PN 100 56 C6

Nozzle: 31 - 37 6

All Rights Reserved. Copyright © 2003, Rota Yokogawa

52 - 53 13

Ø 6 PN 10 53 P1 41 - 43 8

Ø 8 PN 10 54 P1 44 - 51 11

Swagelok:

Ø 6 PN 40 53 W3

Ø 6 PN 100 53 W6

Ø 8 PN 40 54 W3

Ø 8 PN 100 54 W6

Ø 10 PN 40 55 W3

Ø 10 PN 100 55 W6

Ø 12 PN 40 56 W3

Ø 12 PN 100 56 W6

Page 33

RAKD without valve 1.0 - 100 l/h water / 40 - 3250 l/h air

T

E

80

NNN

424

<7. TECHNICAL DATA>

7- 3

Type:

Local indicator

Without valve NNN

Water (l/h) Air (l/h)

Indicator wit electronic output

Housing type:

Stainless steel

Power supply:

16 500 42

none, for type ´T´

24V, 2- wire, 4 - 20mA, for type ´E´

25 800 43

Dp mbar

Cone

31 - 37 6

Material: 1.4571 / AISI 316Ti

RAKD ------- SS ------------- NNN ------------------------------------------- 80 / options

Process connection Max. Flow Cone Version Indicator

Flange: *)

DN 15 PN 40 01 D4 1 40 31

DN 25 PN 40 02 D4 1. 6 60 32

ANSI 1/2 150 lbs 01 A1 1. 5 100 33

ANSI 1 150 lbs 02 A1 4 150 34

ANSI 1/2 300 lbs 01 A2 6 200 37

ANSI 1 300 lbs 02 A2 10 325 41

Internal thread:

All Rights Reserved. Copyright © 2003, Rota Yokogawa

G 1/4 PN 100 41 G6 40 1400 44

G 1/4 PN 160 41 G7 60 2000 47

1/4 NPT PN 100 41 G6 SS 10 0 3250 51

1/4 NPT PN 160 41 G7

Cutting ring:

Ø 6 PN 100 53 C6 41 - 43 8

Ø 6 PN 160 53 C7 44 - 51 11

Ø 8 PN 100 54 C6

Ø 8 PN 160 54 C7

Ø 10 PN 100 55 C6

Ø 10 PN 160 55 C7

Ø 12 PN 100 56 C6

Ø 12 PN 160 56 C7

Nozzle:

Ø 6 PN 10 53 P1

Ø 8 PN 10 54 P1

Swagelok:

Ø 6 PN 100 53 W6

Ø 6 PN 160 53 W7

Ø 8 PN 100 54 W6

Ø 8 PN 160 54 W7

Ø 10 PN 100 55 W6

Ø 10 PN 160 55 W7

Ø 12 PN 100 56 W6

Ø 12 PN 160 56 W7 *) Gasket PTFE

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 34

7- 4

<7. TECHNICAL DATA>

RAKD without valve 160 - 250 l/h water / 5000 - 8000 l/h air

T

E

80

NNN

424

Type:

Local indicator

Without valve NNN

Water (l/h) Air (l/h)

Indicator wit electronic output

Housing type:

Stainless steel

Power supply:

24V, 2- wire, 4 - 20mA, for type ´E´

Material: 1.4571 / AISI 316Ti

RAKD ------- SS ------------- NNN ------------------------------------------- 80 / options

Process connection Max. Flow Cone Version Indicator

Flange: *)

DN 15 PN 40 01 D4 160 5000 52

DN 25 PN 40 02 D4 250 8000 53

ANSI 1/2 150 lbs 01 A1

ANSI 1 150 lbs 02 A1 Cone Dp mbar

ANSI 1/2 300 lbs 01 A2 52 - 53 13

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

ANSI 1 300 lbs 02 A2

Internal thread: none, for type ´T´

G 3/8 PN 100 42 G6

G 3/8 PN 160 42 G7

3/8 NPT PN 100 42 G6 SS

3/8 NPT PN 160 42 G7

Cutting ring:

Ø 12 PN 100 56 C6

Ø 12 PN 160 56 C7

Swagelok:

Ø 12 PN 100 56 W6

*) Gasket PTFE

Ø 12 PN 160 56 W7

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 35

<7. TECHNICAL DATA>

OPTIONS

Options Option

Indicator /A12

Marking /B1

Limit switches /K1

Pulse output /CP Pulse output, acc. EN 60947-5-6 (NAMUR) Only for indicator E; not with limit switches

Hazardous area

approvals

Test and certicates /H1

Gost approval /QR1

Controller /R1

Delivery to Korea /KC With KC-mark for Korea

Power supply for

electronic transmitter

Power supply

for limit switches

(transmitter relay)

code

/A29

/A30

/B4

/B8

/B10

/BG

/BD

/K2

/K3

/K6

/K7

/K8

/K9

/K10

/KS1

/KS2

/KS3

/KN1

/ES1

/ES3

/FS1

/CS1

/NS1

/PP

/P2

/P3

/P6

/PM1

/PM4

/PM5

/QR2

/QR3

/R3

/UT RN221N-B1, 20 ... 250V DC/AC, Ex i Only for indicator E

/W1A

/W1B

/W2A

/W2B

/W2E

/W2F

/W4A

/W4B

/W4E

/W4F

Instruction manuals /IEn

/IDn

/IFn

Special order /Z Special design must be specication on extra sheet

*) if no instruction manual is selected, only a DVD with instruction manuals is shipped with the owmeter

Description Restriction

US- engineering units

M12- connector acc. IEC 61076-2-101 (in preparation)

M12- connector with plug connector acc. IEC 61076-2-101 (in preparation)

Tag plate (SS) xed by wire and customer specied tag number on

scale

Neutral version

Customer provided marking on label

Percent scale

With customer specied tag number on scale

Dual Scale

MIN- contact

MAX- contact

MIN-MAX- contact, MIN-MIN- contact, MAX-MAX- contact

MIN- contact “Fail safe” version

MAX- contact “Fail safe” version

MIN-MAX- contact “Fail safe” version

MIN-MIN- contact “Fail safe” version

MAX-MAX- contact “Fail safe” version

ATEX intrinsically safe „ia“

ATEX gas and dust proof limit switches, category 2G 1D

ATEX intrinsically safe „ic“

ATEX category 3G „nL“ / 3D

IECEx intrinsically safe „ia“

IECEx intrinsically safe „ic“

FM intrinsically safe / non incendive limit switches (USA)

CSA intrinsically safe / non incendive limit switches (Canada)

NEPSI approval (China)

Oil + fat free for wetted surfaces

Pressure test report measuring system

Certicate of Compliance with the order acc. to EN 10204: 2004- 2.1

As /P2 +Test report acc. to EN 10204: 2004- 2.2

Material certicate acc. to EN 10204: 2004- 3.1

PAMI test (1 test point : metering tube)

PAMI test (4 test points : metering tube, connection heads, sealing plug)

PAMI test (5 test points : metering tube, connection pieces, slip on anges)

Primary Calibration and Test Conrmation valid in Russia

Primary Calibration and Test Conrmation valid in Kazakhstan

Primary Calibration and Test Conrmation valid in Uzbekistan

Pre pressure controller 1.4571 (only with valve in inlet; for gas

variable pre pressure and liquids with variable pre and back pressure)

Back pressure controller 1.4571 (only with valve in outlet; for gas

with variable back pressure)

KFA5-SR2-Ex1.W / 115 V AC, 1 channel

KFA5-SR2-Ex2.W / 115 V AC, 2 channel

KFA6-SR2-Ex1.W / 230 V AC, 1 channel

KFA6-SR2-Ex2.W / 230 V AC, 2 channel

KHA6-SH-Ex1 / 115/230 V AC, 1 channel, Fail Safe

2x KHA6-SH-Ex1 / 115/230 V AC, 1 channel, Fail Safe

KFD2-SR2-Ex1.W / 24 V DC, 1 channel

KFD2-SR2-Ex2.W / 24 V DC, 2 channel

KFD2-SH-Ex1 / 24 V DC, 1 channel, Fail Safe

2x KFD2-SH-Ex1 / 24 V DC, 1 channel, Fail Safe

Quantity of instruction manuals in English

Quantity of instruction manuals in German

Quantity of instruction manuals in French

Only for indicator E

Only for indicator E or T with limit switches

Only for indicator E or T with limit switches

Plate 12 x 40 mm; max. 45 digits

Not with Ex-proof type

Max. 45 digits

Adjustment only possible for 1 uid

Only for indicator T

Only for indicator T

Only for indicator T

Only for indicator T

Not for indicator T without limit switches

Only for indicator T with limit switches

Not for indicator T without limit switches

Not for indicator T without limit switches

Not for indicator T without limit switches

For indicator T only with limit switches

For indicator T only with limit switches; limit switches

only /K1, /K2, /K3, only in combination with power

supply /WxA or /WxB

Not for indicator T without limit switches

Not for /R1 and /R3

Only for tube, connection heads, screw sealing plug

Only for models with valve

Only for models with process connection D4, A1, A2

See page 4

See page 4

See page 4

with

Only for process connection R3, T3, C3, W3, P1;

only with valve

Only for process connection R3, T3, C3, W3, P1;

only with valve

Only for limit switches /K1, /K2, /K3 or /CP

Only for limit switches /K1, /K2, /K3

Only for limit switches /K1, /K2, /K3 or /CP

Only for limit switches /K1, /K2, /K3

Only for limit switches /K6, /K7

Only for limit switches /K8, /K9, /K10

Only for limit switches /K1, /K2, /K3 or /CP

Only for limit switches /K1, /K2, /K3

Only for limit switches /K6, /K7

Only for limit switches /K8, /K9, /K10

n = 1 to 9 selectable *)

n = 1 to 9 selectable *)

n = 1 to 9 selectable *)

7- 5

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 36

7- 6

<7. TECHNICAL DATA>

7.2 Standard Specications

The responsibility with respect to the suitability and

according application of our owmeter is only situated by

the customer.

MEASURING TUBE

Materials of wetted parts : Stainless steel AISI 316Ti

(1.4571)

other materials on request

Fluids to be measured : Liquid or gas

Measuring range : see ow table

Measuring range ratio : 10:1

Process connections :

– Inner thread :

– Cutting ring : 6 mm; 8 mm; 10 mm; 12 mm

– Cutting ring (Swagelok) : 6 mm; 8 mm; 10 mm; 12 mm

– Nozzle : 6 mm; 8 mm

– Flange : - acc. EN 1092-1

DN15 and DN25 PN40;

150 lbs, 300 lbs

- gasket PTFE

Process pressure : depends on process

connection; see model code

Process temperature : without valve -25°C to 250°C

with valve -25°C to 150°C

See also g. 6. Lower

temperatures on request.

Measurement accuracy : acc. Directive VDI/VDE 3513

sheet 2 (qG=50%) 4%

Installation :

– Installation position : vertical

– Flow direction : upwards

– Face to face length :

Weight : see table 7-14

LOCAL INDICATOR

(Indicator/Code -T)

Principle :

The indication is made by magnetic coupling of a magnet

enclosed in the oat and a magnet in the indication unit,

which follows the movements of the oat.

Indication scale : Flow units

Indicator housing

– Material : Stainless steel AISI 304

(1.4301)

– Degree of Protection : IP66/67

Scales :

- Standard : removable aluminium plate with scale

(double scale as option)

Transportation and storage condition

: - 40°C to +110°C

.

G1/4; 1/4 NPT; G 3/8; 3/8; NPT

acc. ASME B 16.5 ½” and 1”

125 mm (with ange 250 mm)

ELECTRONIC TRANSMITTER

(Indicator/Code -E)

Temperature range

: -25°C to +65°C

Transportation and storage condition

: -40°C to +70°C

Process-/ Ambient temperature :

The dependency of the process temperature from the

ambient temperature is shown in g.6.

Power supply : 14 ... 30 V DC

Load resistance : (U - 14V) / 20 mA, max. 500 Ω

Analog output : 4-20 mA

Linearity : ≤ ± 0.25% f.s.

Hysteresis : ≤ ± 0.15% f.s.

Repeatability : ≤ ± 0.16% f.s.

Inuence of power supply

: ≤ ± 0.1% f.s.

Temp. coefficient of analog output

: ≤ ± 0.5% /10 K f.s.

AC-part of analog output

: ≤ ± 0.15% f.s.

Long time stability : ≤ ± 0.2% / year

Maximum output current

: 21.5 mA

Output current in case of failure

: ≤ 3.6 mA (NAMUR NE 43)

Response time (99%)

: approx. 1 s

Pulse output (Option /CP)

: Electronic switch with galvanic

isolation

acc. EN 60947-5-6 (NAMUR)

- Pulse length : 200 ms

- Max. frequency : 4 Hz

- Pulse rate : Qmax ≤ 1 → 0.0001

: 1 < Qmax ≤ 10 → 0.001 etc.

e.g.. Qmax = 1 m3/h →

1 Puls = 0.0001 m3 = 0.1

Electromagnetic compatibility (EMC)

- EN 61326-1: 2006, Class A, Table 2

EN 61326-2-3 : 2006

POWER SUPPLY FOR ELECTRONIC TRANSMITTER

(Option /UT)

Type :

Power supply with galvanically separated input and output

- RN221N-B1, HART- compatible

Supply voltage :

20 ... 250 V DC / AC 50/60 Hz

Maximum load :

700 Ω

Output signal :

4 - 20 mA

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

ELECTRICAL CONNECTION (Indicator/Code -E) :

Type : Quickon

Cable diameter : 4 – 6 mm

Maximum cross section of core

: Ø 0.34 to 0.75 mm

All Rights Reserved. Copyright © 2003, Rota Yokogawa

2

Page 37

<7. TECHNICAL DATA>

7- 7

LIMIT SWITCHES IN STANDARD VERSION

(option /K1 to /K3)

Type : Inductive proximity switch SC2-NO

acc. DIN EN 60947-5-6

Nominal voltage : 8V DC

Output signal : ≤ 1 mA or ≥ 3 mA

Hysteresis : < 0.5mm

LIMIT SWITCHES IN FAIL SAFE VERSION

(option /K6 to /K10)

Type : Inductive proximity switch

SJ2-SN; SJ2-S1N acc. DIN EN 60947-5-6

Nominal voltage : 8V DC

Output signal : ≤ 1 mA or ≥ 3 mA

Hysteresis : < 0.5mm

HYSTERESIS OF LIMIT SWITCHES

Min-contact / Max-contact :

- pointer movement : ≈ 0.8 mm

- oat movement : ≈ 0.8 mm

Minimum distance between 2 contacts

: ≈ 8 mm

ELECTRICAL CONNECTION (option /K1 to /K10) :

Type : Quickon

Cable diameter : 4 – 6 mm

Maximum cross section of core

: Ø 0.34 to 0.75 mm

2

POWER SUPPLY FOR LIMIT SWITCHES (Option /W__)

Type : Transmitter relay

Fail Safe, only one channel

- KFD2-SH-Ex1 (24 V DC),

Fail Safe, only one channel

Power supply : - 230 V AC ± 10%, 45-65Hz

- 115 V AC ± 10%, 45-65Hz

- 24 V DC ± 25%

Relay output : 1 or 2 potential-free change over

contact(s)

Switching capacity

: max. 250V AC, max. 2 A

Note :

If Fail-Safe limit switch option /K6 or /K7 is ordered, for power

supply option /W2E or /W4E must be selected.

If Fail-Safe limit switch option /K8, /K9 or /K10 is ordered,

for power supply option /W2F or /W4F must be selected.

acc. DIN EN 50227 (NAMUR)

- KFA6-SR2-Ex1-W (230 V AC)

- KFA5-SR2-Ex1-W (115 V AC)

- KFD2-SR2-Ex1-W (24 V DC)

- KHA6-SH-Ex1 (115/230 V AC),

SWITCHING LEVELS FOR LIMIT SWITCHES

Table 7-1 Min, Max and Min-Max-contact in standard version

Option /K1 Option /K2 Option /K3

Function Pointer

above LV

MAX

below LV

Function Pointer

above LV

MIN

below LV

Note: LV = Limit value

Table 7-2 Min, Max and Min-Max-contact in fail-safe version

Function Pointer

above LV

MAX

below LV

Fail Safe

Function Pointer

above LV

MIN

below LV

Fail Safe

Note: LV = Limit value

Table 7-3 Limit switch as Min-Min-contact in fail-safe version

Function Pointer

above LV

MIN

below LV

Fail Safe

Function Pointer

above LV

MIN

below LV

Fail Safe

Note: LV = Limit value

Table 7-4 Limit switch as Max-Max-contact in fail-safe version

Function Pointer

above LV

MAX

below LV

Fail Safe

Function Pointer

above LV

MAX

below LV

Fail Safe

Note: LV = Limit value

Signal Signal Signal

SC2-N0 SC2-N0 SC2-N0

----

----

Signal Signal Signal

SC2-N0 SC2-N0 SC2-N0

3 mA

1 mA

Option /K6 Option /K7 Option /K8

Signal Signal Signal

SJ2-SN SJ2-SN SJ2-SN

----

----

----

Signal Signal Signal

SJ2-SN SJ2-SN SJ2-SN

3 mA

1 mA

1 mA

Option /K9

Signal

SJ2-S1N

3 mA

1 mA

1 mA

Signal

SJ2-SN

3 mA

1 mA

1 mA

Option /K10

Signal

SJ2-SN

1 mA

3 mA

1 mA

Signal

SJ2-S1N

1 mA

3 mA

1 mA

1 mA

3 mA

----

----

1 mA

3 mA

1 mA

----

----

----

1 mA

3 mA

3 mA

1 mA

1 mA

3 mA

1 mA

3 mA

1 mA

1 mA

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 38

7- 8

<7. TECHNICAL DATA>

CONTROLLER (Option /R1 and R3)

Differential pressure controller for a constant ow at

uctuations of the process pressure.

These are no valves to reduce the pressure.

- Controller /R1 for liquids with variable inlet or

outlet pressure and for gases with variable inlet pressure

and constant back pressure.

- Controller /R3 for gases with uctuations of the back pressure.

Max. liquid ow : 100 l/h

Max. gas ow : 3250 l/h

Max. pressure : 25 bar

Recommended differential pressure

: >400 mbar

Temperature range : -25°C to + 80°C

Materials :

Table 7-5

Housing Diaphragm Springs

/R1 / /R3 CrNi-Steel PTFE CrNi-Steel

l/h air at 20°C ; 1.013 bar abs.

Inlet pressure

Fig. 7-1 Diagram controller characteristic

COMPLIANCE WITH IEC 61508

RAKD with local indicator and standard or fail safe limit

switches (RAKD[][]-[][]SS-[][][][][]-T[][]NNN/K1…K10):

Suitable for application in safety functions up to and including

SIL2.

RAKD with valve and controller with local indicator and

standard or fail safe limit switches

(RAKD[][]-[][]SS-[][]V[][]-T[][]NNN/R[]/K1…K10):

Suitable for application in safety functions up to and including

SIL1.

Reliability data available on request in FMEDA report.

COMPLIANCE WITH ISO 13849

For Safety Metrics acc. to ISO 13849-2 please refer to the

FMEDA report.

METROLOGICAL REGULATION IN CIS (GOST)

RAKD has “Pattern Approval Certicate of Measuring

Instruments” and is registered as a measuring instrument in

Russia, Kazakhstan, Uzbekistan, Belarus and Ukraine.

The calibration laboratory of Rota Yokogawa is approved by

Federal Agency on Technical Regulating and Metrology in

Russia and other Metrological Organizations in CIS countries

to issue primary calibration conrmations for RAKD, option

/QR[].

Furthermore RAKD is RTN (GGTN) approved for installation

in hazardous areas.

For export to CIS countries please contact your Yokogawa

representative.

HAZARDOUS AREA SPECIFICATIONS

RAKD with ATEX- certication “intrinsic safe”

(option /KS1)

Certicate :

KEMA 00ATEX 1037X

Output signal :

4–20 mA / Pulse output / Limit switches

Explosion proof :

Ex ia IIC T6 ... T4 Gb

Entity parameter :

Table 7-6

Analog

output

Ui [V] 30 16 16 16 16 16

Ii[ mA] 100 20 25 52 25 52

Pi [mW] 750 64 64 169 64 16 9

Li [mH] 0.73 0 0.15 0.15 0.1 0.1

Ci [nF] 2.4 0 150 150 30 30

Temperature specication :

Table 7-7

Congura-

tion

Transmitter

4-20mA /

Pulse

Limit

switch(es)

type 2

Limit

switch(es)

type 3

For the conguration where a transmitter is combined with

limit switches, the temperature class is determined by the

most restrictive combinations of maximum ambient temperature

and maximum process temperature.

Description of limit switch type 2 and 3 see ATEX certicates

from Pepperl & Fuchs:

- PTB 99 ATEX 2219X ( SC2-NO) for /K1 to /K3

- PTB 00 ATEX 2049X (SJ2-S.N) for /K6 to /K10

RAKD “non incendive” (option /KN1)

Type “n” (non incendive) acc. EN 60079-15.

Explosion proof :

Ex nL IIC T6 protection „nL”; group II ; category 3G

Dust proof :

Ex II 3D; group II ; category 3D

Max. surface temperature : 80°C

Entity parameter :

see table 7-6

Temperature specication :

see table 7-7

Pulse

output

Max.

ambient

temperature

65°C 65°C

50°C 80°C

45°C 100°C T5

38°C 135°C T4

65°C 65°C T6

80°C 80°C

59°C 100°C

100°C 100°C

73°C 135°C

24°C 65°C T6

37°C 80°C

34°C 100°C

57°C 80°C

48°C 135°C

Limit

switch

type 2

/K1-/K3

process tem-

perature

Limit

switch

type 3

/K1-/K3

Max.

switch

type 2

/K6-/K8

Limit

Limit

switch

type 3

/K6-/K8

Temperature

class

T6

T5

T4

T5

T454°C 100°C

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 39

<7. TECHNICAL DATA>

7- 9

RAKD with ATEX- certication “intrinsic safe ic”

(option /KS3)

Output signal :

4–20 mA / Pulse output / Limit switches

Explosion proof :

Ex ic IIC T6; Gc group II ; category 3G

Entity parameter :

see table 6

Temperature specication :

see table 7

RAKD with IECEx- certication “intrinsic safe”

(option /ES1)

Certicate :

IECEx DEK 12.0003X

Output signal :

4–20 mA / Pulse output / Limit switches

Explosion proof :

Ex ia IIC T6 ... T4 Gb

Entity parameter :

Table 8

Analog

output

Ui [V] 30 16 16 16 16 16

Ii[ mA] 100 20 25 52 25 52

Pi [mW] 750 64 64 169 64 16 9

Li [mH] 0.73 0 0.15 0.15 0.1 0.1

Ci [nF] 2.4 0 150 150 30 30

Temperature specication :

Table 9

Congura-

tion

Transmitter

4-20mA /

Pulse

Limit

switch(es)

type 2

Limit

switch(es)

type 3

For the conguration where a transmitter is combined with

limit switches, the temperature class is determined by the

most restrictive combinations of maximum ambient temperature

and maximum process temperature.

Description of limit switch type 2 and 3 see IECEx certicates

from Pepperl & Fuchs:

- IECEx PTB 11.0091X ( SC2-NO) for /K1 to /K3

- IECEx PTB 11.0092X (SJ2-S.N) for /K6 to /K10

Pulse

output

ambient

temperature

Max.

Limit

switch

type 2

/K1-/K3

process tem-

Limit

switch

type 3

/K1-/K3

Max.

perature

switch

type 2

/K6-/K8

65°C 65°C

50°C 80°C

45°C 100°C T5

38°C 135°C T4

65°C 65°C T6

80°C 80°C

59°C 100°C

100°C 100°C

73°C 135°C

24°C 65°C T6

37°C 80°C

34°C 100°C

57°C 80°C

48°C 135°C

Limit

Limit

switch

type 3

/K6-/K8

Temperature

class

T6

T5

T4

T5

T454°C 100°C

RAKD with IECEx- certication “intrinsic safe ic”

(option /ES3)

Output signal :

4–20 mA / Pulse output / Limit switches

Explosion proof :

Ex ic IIC T6; Gc group II ; category 3G

Entity parameter :

see table 8

Temperature specication :

see table 9

RAKD with NEPSI- certication “intrinsic safe”

(China) (option /NS1) :

Certicate :

GYJ101552

Output signal :

4–20 mA

Explosion proof :

Ex ia IIC T5/T6

Max. Tamb. :

65°C

Limit switches :

option /K1 to /K8, see certicates GYJ11.1505X

Entity parameter :

Table 10

Ui [V] 30 16 16 16 16 16

Ii[ mA] 10 0 20 25 52 25 52

Ui [V] 30 16 16 16 16 16

Pi [mW] 750 64 64 169 64 169

Ii[ mA] 10 0 20 25 52 25 52

Li [mH] 0.73 0 0.15 0.15 0.1 0.1

Pi [mW] 750 64 64 169 64 169

Ci [nF] 2.4 0 150 150 30 30

Li [mH] 0.73 0 0.15 0.15 0.1 0.1

Ci [nF] 2.4 0 150 150 30 30

Analog

output

Analog

output

Pulse

output

Pulse

output

Limit

switch

type 2

Limit

/K1-/K3

switch

type 2

/K1-/K3

Limit

switch

type 3

Limit

/K1-/K3

switch

type 3

/K1-/K3

Limit

switch

type 2

Limit

/K6-/K8

switch

type 2

/K6-/K8

Temperature specication :

Table 11

Max. ambient

temperature

Max. process

temperature

Temperature

65°C 65°C T6

50°C 80°C T6

45°C 95°C T5

Description of limit switch type 2 and 3 see ATEX certicates

from Pepperl & Fuchs:

- PTB 99 ATEX 2219X ( SC2-NO) for /K1 to /K3

- PTB 00 ATEX 2049X (SJ2-S.N) for /K6 to /K10

RAKD with PESO- certication (India)

Option /KS1 must be selected. PESO- certicate is available

at your Yokogawa Sales Office.

RAKD with KOSHA- certication (Korea)

Option /ES1 must be selected.

Same data as for IECEx certication.

class

Limit

switch

type 3

Limit

/K6-/K8

switch

type 3

/K6-/K8

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 40

7- 10

<7. TECHNICAL DATA>

Intrinsically safe and dust proof limit switches

with ATEX-certication (only for indicator T

with option /K1 ... /K10) (option /KS2) :

Certicate :

- PTB 99 ATEX 2219X ( SC2-NO)

- PTB 00 ATEX 2049X (SJ 2-S.N)

- ZELM 03 ATEX 0128X (for dust proof)

Explosion proof :

EEx ia IIC T6, group II category 2G

Dust proof:

Ex iaD 20 T 108 °C, group I I category 1D

Max. surface temperature : T108°C

Entity parameter :

see certicate of conformity

Intrinsically safe / non incendive limit switches

with FM-

certication (USA) (only for indicator T

with option /K1 ... /K10) (option /FS1) :

Explosion proof :

IS : Cl. I, Div. 1, Gp. ABCD, T6, Ta = 60°C,

Nl : Cl. I, Div. 2, Gp. ABCD, T5, Ta = 50°C

Cl. II, Div. 1, Gp. EFG

Cl. III, Div. 1

Entity parameter :

see FM-control drawing 116-0165 for IS

see FM-control drawing 116-0155 for Nl

Intrinsically safe limit switches with CSAcation (Canada) (only for indicator T

with option

certi-

/K1 ... /K3) (option /CS1) :

Explosion proof :

Cl. I, II, III, Div. 1, Gp. ABCDEFG

Entity parameter :

see drawing 116-0047

Only in combination with option /WxA or /WxB.

Power Supply for the intrinsically safe electronic

transmitter (option /UT)

Type :

Power supply with galvanically separated input and out-

put

- RN221N-B1, HART- compatible

Certicate :

PTB 00 ATEX 2018

Supply voltage :

20 ... 250 V DC / AC 50/60 Hz

Maximum load impedance :

700 Ω

Output signal :

4 - 20 mA

Control circuit :

Intrinsically safe [Ex ia] IIC; group II ; category (1)GD

Entity parameters :

see g. 5

Power supply for intrinsically safe limit switches

(option W__) :

Type :

acc. DIN EN 50227 (NAMUR)

- KFA5-SR2-Ex*-W (115 V AC)

- KFA6-SR2-Ex*-W (230 V AC)

- KFD2-SR2-Ex*-W (24 V DC)

- KHA6-SH-Ex1 (115/230 V AC), Fail Safe, 1 channel

- KFD2-SH-Ex1 (24 V DC), Fail Safe, 1 channel

Certicates :

- KFA5-SR2-Ex*-W

CSA : 1029981 (LR 36087-19)

FM : ID 3011578

IECEx : PTB11.0031

PESO

KOSHA : 2009-BO-0157

- KFA6-SR2-Ex*-W

CSA : 1029981 (LR 36087-19)

FM : ID 3011578

IECEx : PTB11.0031

PESO

KOSHA : 2009-BO-0157

- KHA6-SH-Ex1

- KFD2-SR2-Ex*-W

CSA : 1029981 (LR 36087-19)

FM : ID 3011578

IECEx : PTB11.0034

PESO

KOSHA : 2009-BO-0157

NEPSI : GYJ12.1081

- KFD2-SH-Ex1

NEPSI : GYJ091350

Control circuit (ATEX):

Entity parameter: see g. 5 (ATEX) and certicate

Power supply :

- 230 V AC ± 10%, 45-65Hz

- 115 V AC ± 10%, 45-65Hz

- 24 V DC ± 25%

Relay output : 1 o r 2 p o t e n t i a l - f r e e c h a n g e o v e r

contact(s)

Switching capacity : max. 250V AC, max. 2 A

: ATEX : PTB 00 ATEX 2081

: ATEX : PTB 00 ATEX 2081

: ATEX : PTB 00 ATEX 2043

: ATEX : PTB 00 ATEX 2080

: ATEX : PTB 00 ATEX 2042

[Ex ia] IIC; group II; category (1)GD

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

Page 41

7.3 Dimensions and weights

F7.EPS

F8.EPS

F13.EPS

<7. TECHNICAL DATA>

7- 11

Fig. 7-2 Version without valve Fig. 7-3 Version with ange connection

Fig. 7-4 Back view with mounting

All Rights Reserved. Copyright © 2003, Rota Yokogawa

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

Page 42

7- 12

F9.EPS