Page 1

User´s

Model RAGN

Manual

IM 01R01B10-00E-E

Glass ROTAMETER

Rota Yokogawa GmbH & Co. KG

Rheinstr. 8

D-79664 Wehr

Germany

IM 01R01B10-00E-E

©Copyright 2011 (Rü)

2nd edition: November 2011 (Rü)

Page 2

Blank Page

Page 3

<CONTENTS>

Contents

1. Introduction ......................................................................................... 1-1

1.1 ATEX Documentation ......................................................................................1-3

1.2 General description .........................................................................................1-4

1.3 Principle of measurement .............................................................................. 1-4

1.4 Intended use ....................................................................................................1- 4

2. Transportation and Storage ..............................................................2-1

3. Product description ...........................................................................3-1

3.1 Metering Tube ..................................................................................................3-1

3.2 Bistable inductive ring sensor (Option /GR2 to /GR8) ...............................3-2

3.3 Magnetic contact (Option /GM1 to /GM5) .....................................................3-2

i

3.4 Marking ............................................................................................................3-3

4. Installation ...........................................................................................4-1

4.1 General .............................................................................................................4-1

4.2 Piping ...............................................................................................................4-2

4.3 Bistable inductive ring sensor (Option /GR2 to /GR8) ...............................4-3

4.4 Magnetic contact (Option /GM1 to /GM5) .....................................................4-4

4.5 Connection box (Option /GD1 or /GD2) ........................................................4-5

5. Service ................................................................................................5-1

5.1 Customer maintenance part list (CMPL) ......................................................5-1

5.2 Template for sending back to service ..........................................................5-4

6. Explosion protected type instruments ............................................6-1

6.1 Bistable inductive ring sensor (Option /GR2 to /GR8) ...............................6-1

6.2 Magnetic contact (Option /GM1 to /GM5) .....................................................6-3

7. Instructions for PED ........................................................................... 7-1

8. Technical Data ....................................................................................8-1

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 4

ii

<Contents>

APPENDIX 1. Safety Instrumented Systems Installation .................. A1-1

A1.1 Scope and Purpose ................................................................................... A1-1

A1.2 Using RAGN for a SIS Application ........................................................... A1-1

A1.2.1 Safety Function ................................................................................................. A1-1

A1.2.2 Diagnostic Response Time .............................................................................. A1-2

A1.2.3 Setup .................................................................................................................. A1-2

A1.2.4 Proof Testing ..................................................................................................... A1-2

A1.2.5 Repair and replacement ................................................................................... A1-2

A1.2.6 Startup Time ...................................................................................................... A1-3

A1.2.7 Reliability data ..................................................................................................A1-3

A1.2.8 Lifetime limits .................................................................................................A1-3

A1.2.9 Environmental limits ......................................................................................... A1-3

A1.2.10 Application limits ............................................................................................ A1-3

A1.3 Denitions and Abbreviations ................................................................... A1-4

A1.3.1 Denitions .........................................................................................................A1-4

A1.3.2 Abbreviations ....................................................................................................A1-4

A1.4 Assessment results .................................................................................... A1-4

A1.4.1 Safety related parameters ................................................................................ A1-4

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 5

1. Introduction

WARNING

CAUTION

IMPORTANT

NOTE

WARNING

< 1. INTRODUCTION>

1-1

Before use, read this manual thoroughly and

familiarize yourself fully with the features,

operations and handling of Rotameter RAGN to

have the instrument deliver its full capabilities and

to ensure its efficient and correct use.

Notices Regarding This Manual

• This manual should be passed to the end user.

• The contents of this manual are subject to

change without prior notice.

• All rights reserved. No part of this document

may be reproduced or transmitted in any form or

by any means without the written permission of

Rota Yokogawa (hereinafter simply referred to as

Yokogawa).

• This manual neither does warrant the

marketability of this instrument nor it does

warrant that the instrument will suit a particular

purpose of the user.

• Every effort has been made to ensure accuracy

in the contents of this manual. However, should

any questions arise or errors come to your

attention, please contact your nearest Yokogawa

sales office that appears on the back of this

manual or the sales representative from which

you purchased the product.

• This manual is not intended for models with

custom specications.

• Revisions may not always be made in this

manual in conjunction with changes in

specications, constructions and/or components

if such changes are not deemed to interfere with

the instrument’s functionality or performance.

Notices Regarding Safety and Modication

• For the protection and safety of personnel, the

instrument and the system comprising the

instrument, be sure to follow the instructions on

safety described in this manual when handling

the product. If you handle the instrument in a

manner contrary to these instructions, Yokogawa

does not guarantee safety.

• If this instrument is used in a manner not

specied in this manual, the protection provided

by this instrument may be impaired.

• As for explosion proof model, if you yourself

repair or modify the instrument and then fail to

return it to its original form, the explosion

protected construction of the instrument will be

impaired, creating a hazardous condition. Be

sure to consult Yokogawa for repairs and

modications.

The following safety symbols and cautionary

notes are used on the product and in this

manual:

This symbol is used to indicate that a hazardous

condition will result which, if not avoided, may

lead to loss of life or serious injury. This manual

describes how the operator should exercise care

to avoid such a risk..

This symbol is used to indicate that a hazardous

condition will result which, if not avoided, may

lead to minor injury or material damage. This

manual describes how the operator should

exercise care to avoid a risk of bodily injury or

damage to the instrument.

This symbol is used to call your attention to a

condition that must be observed in order to avoid

the risk of damage to the instrument or system

problems.

This symbol is used to call your attention to

information that should be referred to in order to

know the operations and functions of the

instrument.

For Safe Use of Rotameter RAGN

• If the process uid is harmful to personnel,

handle Rotameter RAGN carefully even after it

has been removed from the process line

for maintenance or other purposes. Exercise

extreme care to prevent the uid from coming

into contact with human esh and to avoid

inhaling any residual gas.

• In case of Explosion proof type instrument,

further requirements and differences are

described in Chapter 6 "EXPLOSION

PROTECTED TYPE INSTRUMENTS”. The

description in Chapter 6 is prior to other

descriptions in this instruction manual.

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 6

1-2

WARNING

IMPORTANT

< 1. INTRODUCTION>

Warranty

• The warranty of this instrument shall cover the

period noted on the quotation presented to the

Purchaser at the time of purchase. The Seller

shall repair the instrument free of charge when

the failure occurred during the warranty period.

• All inquiries on instrument failure should be

directed to the Seller’s sales representative from

whom you purchased the instrument or your

nearest sales office of the Seller.

• Should the instrument fail, contact the Seller

specifying the model and instrument number of

the product in question. Be specic in describing

details on the failure and the process in which

the failure occurred. It will be helpful if

schematic diagrams and/or records of data are

attached to the failed instrument.

• Whether or not the failed instrument should be

repaired free of charge shall be left solely to the

discretion of the Seller as a result of an

inspection by the Seller.

The Purchaser shall not be entitled to

receive repair services from the Seller free

of charge, even during the warranty period,

if the malfunction or damage is due to:

• improper and/or inadequate maintenance of the

instrument in question by the Purchaser.

• handling, use or storage of the instrument in

question beyond the design and/or specications

requirements.

• use of the instrument in question in a location

not conforming to the conditions specied in the

Seller’s General Specication or Instruction

Manual.

• retrotting and/or repair by an other party than

the Seller or a party to whom the Seller has

entrusted repair services.

• improper relocation of the instrument in question

after delivery.

• reason of force measure such as res,

earthquakes, storms/ oods, thunder/lightning, or

other reasons not attributable to the instrument

in question.

• YOKOGAWA gives no warranty for the improper

use of glass ow meters. Due to the uncontrollably

of the material YOKOGAWA cannot guarantee

that the material is fracture-proof.

• When removing the instrument from hazardous

processes, avoid contact with the uid and the

interior of the meter.

• In case of Explosion proof type instrument,

further requirements and differences are

described in Chapter 6 " EXPLOSION

PROTECTED TYPE INSTRUMENTS”. The

description in Chapter 6 is prior to other

descriptions in this instruction manual.

Notices regarding EMC

The Rotameter RAGN with option /GR2 ... /GR8

is conform to the European EMC Guideline and

fullls the following standards:

DIN EN 61000-4-2 : level 3

DIN EN 61000-4-3 : level 2

DIN EN 61000-4-4 : level 3

DIN EN 61000-4-6 : level 2

DIN EN 55011 : group 1 / class A

The RAGN with option /GR2 ... /GR8 is a class A

product and should be used and installed properly

according to the EMC Class A requirements.

Although the inductive ring sensor has been

designed to resist high frequency electrical

noise, if a radio transceiver is used near the

transmitter or it external wiring, the transmitter

may be affected by high frequency noise pickup.

To test for such effects, bring the transceiver in

use slowly from a distance of several meters from

the transmitter, and observe the measurement

loop for noise effects. Thereafter, always use the

transceiver outside the area affected by noise.

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 7

1.1 ATEX Documentation

This is only applicable to the countries in European Union.

< 1. INTRODUCTION>

1-3

GB

DK

E

NL

SK

CZ

I

LT

LV

EST

PL

SF

P

F

D

S

SLO

H

BG

RO

M

GR

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 8

1-4

FG = FF + FB = Equilibrium

R

10

20

30

40

50

60

70

80

90

100l/h

Equilibrium

F

G

F

B

F

F

< 1. INTRODUCTION>

1.2 General description

This manual describes installation, operation and maintenance of the RAGN. Please read it carefully before using

this device.

Further, please note that customer features are not described in this manual. When modifying specications,

construction or parts, this manual is not necessarily revised unless it can be assumed that these changes will

impair RAGN functions or performance.

All units are thoroughly tested before shipping. Please check the received units visually to ensure that they

have not been damaged during transport. In case of defects or questions please contact your nearest

YOKOGAWA service centre or sales office. Please describe any defect precisely and indicate model code as

well as serial number.

YOKOGAWA refuses any liability for units which have been repaired by the user without prior consent and do

not meet the specications as a consequence.

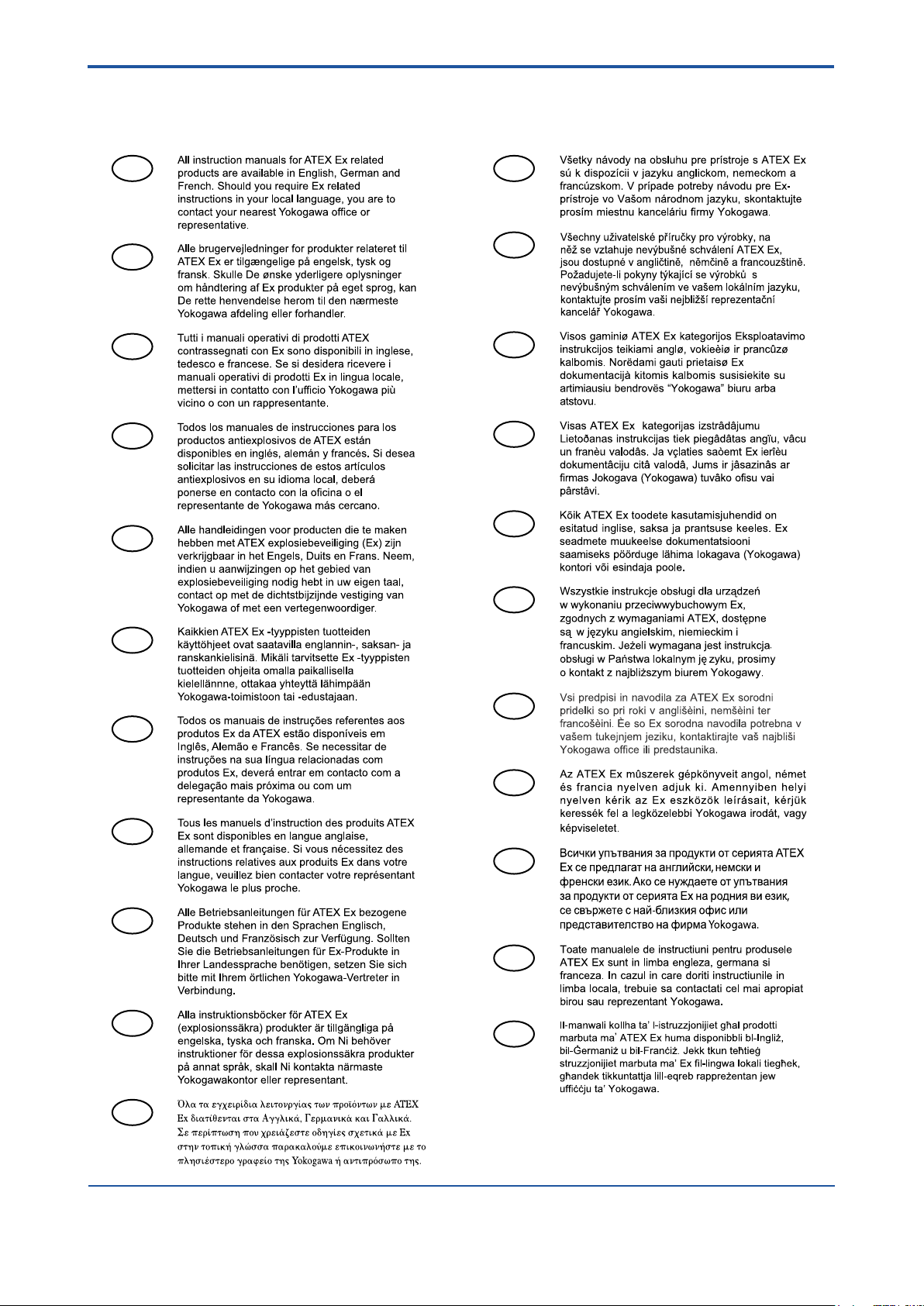

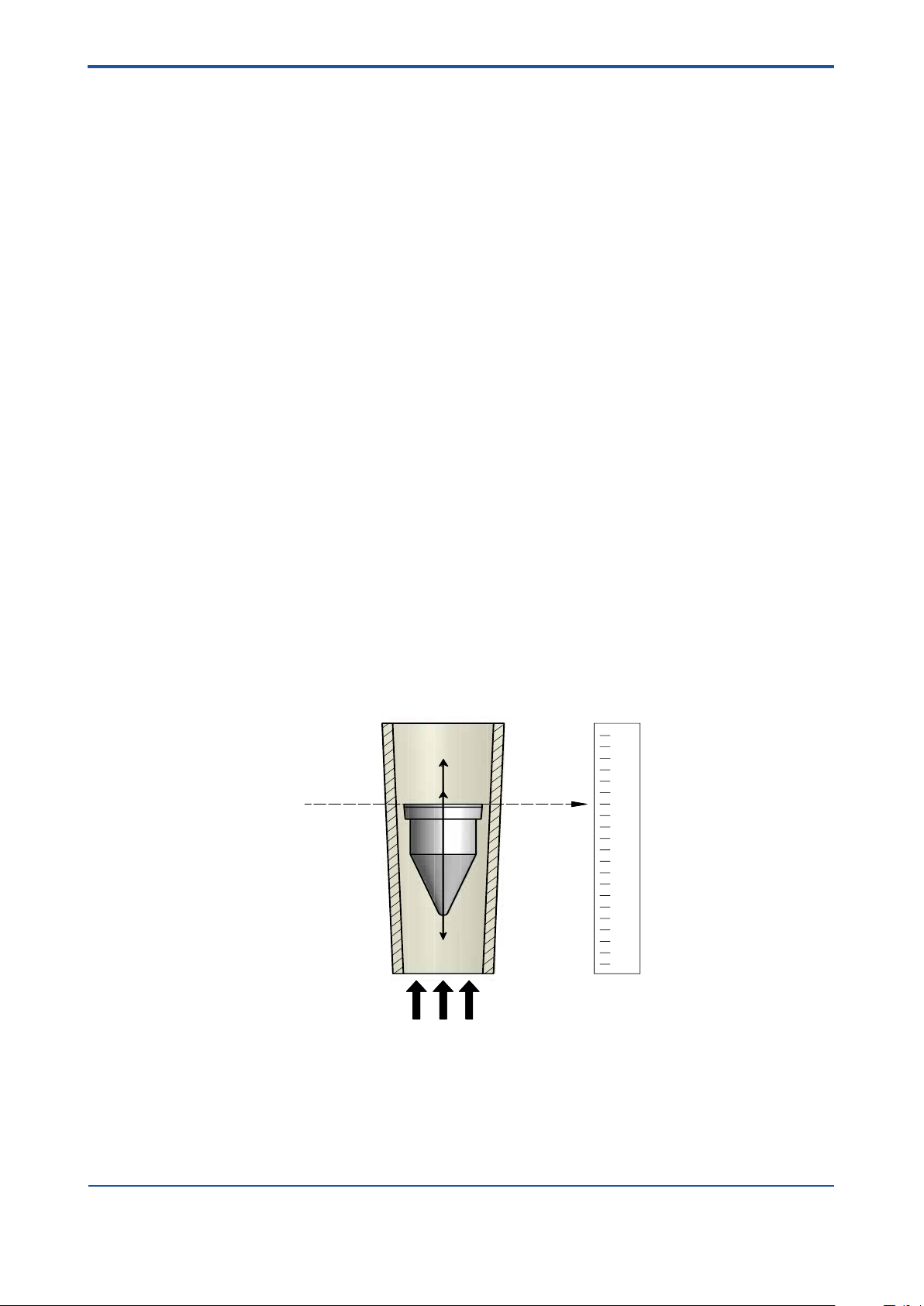

1.3 Principle of measurement

A Rotameter measures the ow of liquids, gases and steam by using a oat inside a conical tube.

The gap between the tube and oat is larger at the top to allow a greater ow to pass through the meter. As gravity

works in a vertical orientation so the tube needs to be vertically oriented.

Rota Yokogawa developed the free rotating oat which stabilises its position in the centre of the cone to provide a

more stable ow measurement.

The medium passes through the metering tube from bottom to top and consequently rises the oat until there is an

annular gap between the inside surface of the metering tube and the oat and equilibrium of the following forces

has been achieved.

Buoyancy / Gravity / Friction force

The Rotameter principle is one of the oldest and mature principles in ow measurement. This mechanical principle

is as simple as it is reliable. The ow is indicated by the top of the oat and can be read from the standard scale on

the metering tube. The RAGN can be equipped with limit switches option /GR2 to /GR8 and /GM1 to /GM5.

All units are calibrated with water or air by the manufacturer. By adjusting the calibration values to the measured

substance’s state of aggregation (density, viscosity), the ow rate scale for each measuring tube can be determined.

When the process conditions have changed the scale is not accurate any longer and the glass tube needs to be

replaced.

1.4 Intended use

The RAGN is designed for the continuous ow measurement of liquids or gases and can be used in all industries.

Typical applications are:

- Visual uid monitoring

- Industrial gas measurement

- Controlling of water circuits

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 9

<2. TRANSORTATION AND STORAGE>

2-1

2. Transportation and Storage

Transportation instructions

When transporting the instrument, you must observe the following safety instructions in order to avoid lethal

injury, damage to the instrument and other material damage.

The steps involved in transport may only be carried out by qualied persons taking into account the safety

instructions.

• Observe the transport instructions on the packaging.

• Observe the below mentioned storage conditions.

• Use only the original packaging.

• The packaging material must be disposed of in accordance with the regulations.

• The transport braces must not be removed until installation.

• Read the chapter “Safety instructions”.

• To avoid any damages, unpack the ow meter only at the installation site.

• Mechanical shocks are to be avoided.

Storage conditions

Please note the following for storage purposes :

• The instrument should be stored in its transport packaging.

• Choose a storage place that meets the following requirements:

• Protection from rain and humidity

• Free of mechanical vibration and shocks

• Ambient temperature between -25°C to 60°C

• Atmospheric humidity ranging from 0 to 100%. Operation above 95% for longer times is not recommended

Before storing a used ow meter remove any uid from the ow meter and clean it in order to avoid fouling.

Properties of the instrument can change when stored outdoors.

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 10

2-2

<2. TRANPORTATION AND STORAGE>

Blank Page

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 11

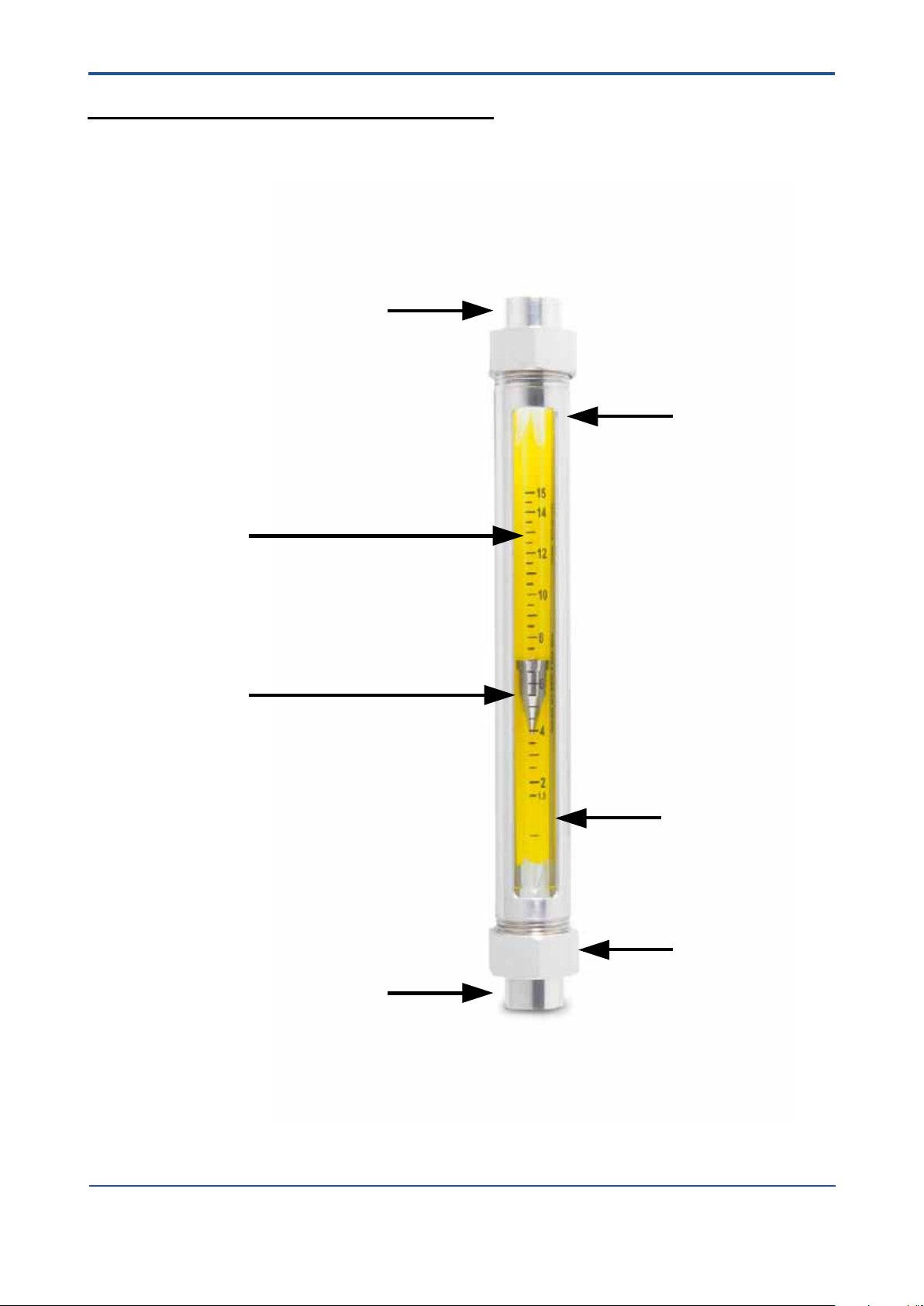

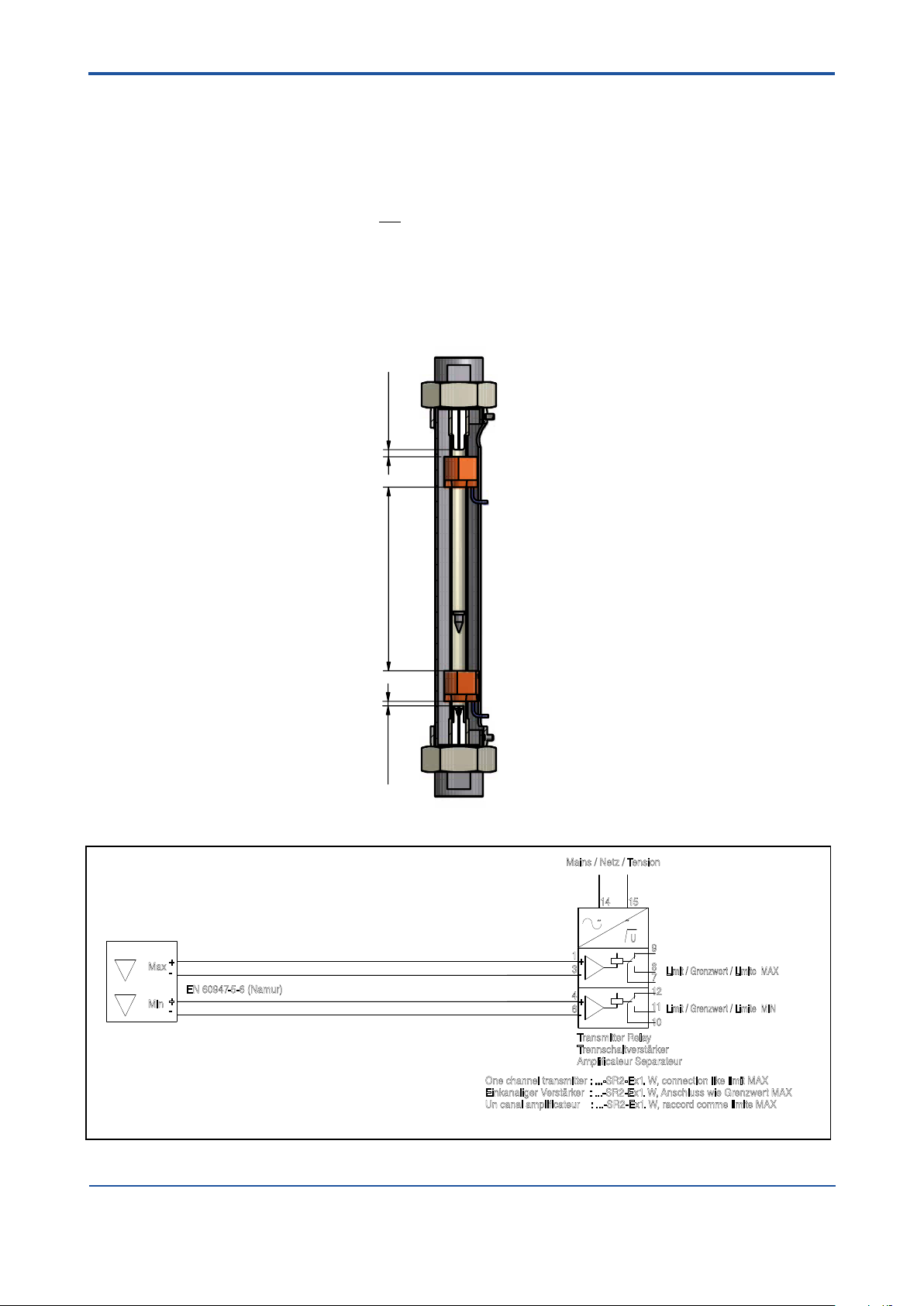

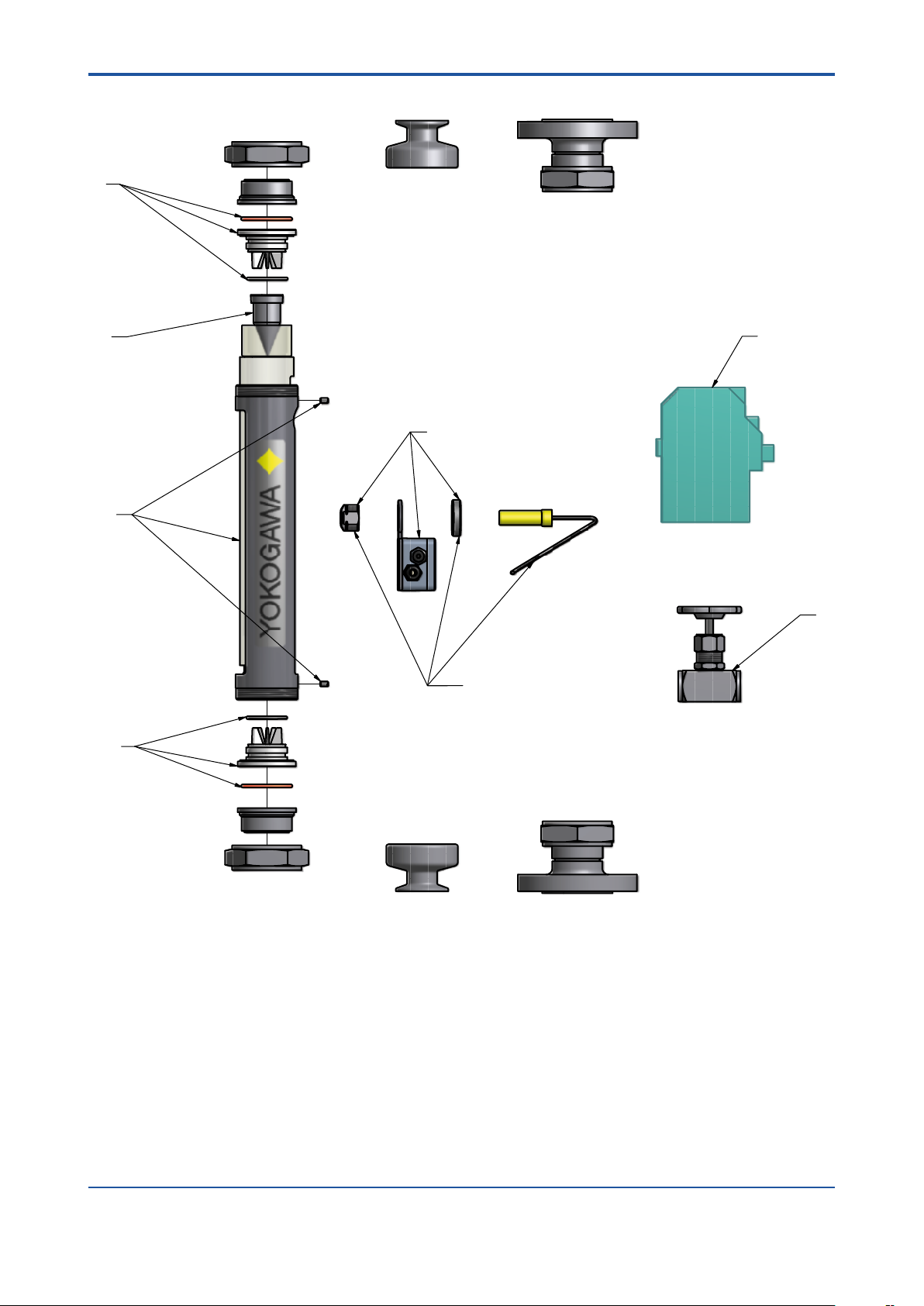

3. Product description

Process connection

Process connection

Float

Scale on tube

Nuts

Tubular frame

Splinter shield

3.1 Metering Tube

<3. PRODUCT DESCRIPTION>

3-1

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 12

3-2

<3. PRODUCT DESCRIPTION>

3.2 Bistable inductive ring sensor (Option /GR2 to /GR8)

The ring sensor type RI20 is intended for connection to glass Rotameters. It indicates whether the oat is

positioned above or below the sensor.

The oat must have ferromagnetic properties (e.g. a PVDF oat with iron core).

The device is offered into 3 versions:

Type Option Diameter of tube Possible oat (Yokogawa Code)

RI20-10 G /GR2, /GR6 10mm -PD B_N

RI20-17 K /GR3, /GR7 17mm -PD C_N

RI20-17 G /GR4, /GR8 17mm -PD D_N

The RI20 is bistable, i.e. if the oat is below the switch point, current consumption is always < 1 mA and it is

> 2.2 mA, if the oat is above the switch point. After power on or after power fail the RI20 shows

I < 1 mA. To nd the correct oat position the oat has to move once through the RI20.

It is intended for connection to a non-bistable isolation-switch amplier complying with DIN EN 50227

(NAMUR) (e.g. options /Wxx). With its plastic housing and its sealed-in electronic equipment, the RI20

meets the requirements for protection class IP67 and can also be operated safely in aggressive

atmospheres.

The RI20 is maintenance-free.

See chapter 6 "EXPLOSION PROTECTED TYPE INSTRUMENTS” for devices in ATEX version.

3.3 Magnetic contact (Option /GM1 to /GM5)

The limit switch is mounted to a Rotameter type RAGN, if a magnetic oat is used and indicates if the ow

falls below the set limit (MIN-contact) or exceeds the set limit (MAX-contact).

When reaching the switch point the Reed contact with bias by a permanent magnet opens when the oat

enters the alarm range. The Reed contact closes when the oat leaves the alarm range. Opened or closed

the Reed contact remains because of its bistability in its position no matter how far the oat moves away.

Due to the low switch output of the Reed contact (max, 10 VA/(W), max. 0.5 A, max. 230 V AC) a

transformer isolated barrier (e.g. option /Wxx) should be connected to the GM.

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 13

3.4 Marking

Rota Yokogaw

Rheinstr. 8

D-79664 Wehr

Type : RI20-10-K

U = 4.5 ... 15V

SN : ..............

ROTA YOKOGAWA D-79664 Wehr

S/N D1L301985

RAGN01-D4SS-L624-TTBLN/B1/B4/L12/V1/GM1/GD/MN/P6/H1

PS:16bar TS:-25°C-100°C PTmax:24bar

100% = 650 l/min Wasser 20°C

Tag-No:123456789012345678901234567890123456789012345

KCC-REMRYG-GR-RAGN

*)

**)

*) only for RAGN04, RAGN05, RAGN06 **) only with option /KC

Name plate of RAGN:

Name plate of inductive ring sensor (option /GR2 to /GR8)

<3. PRODUCT DESCRIPTION>

3-3

Rota Yokogawa

Rota Yokogaw

Rheinstr. 8

Rheinstr. 8

D-79664 Wehr

D-79664 Wehr

Type : RI20-10-K

Type : RI20-10-K

U = 4.5 ... 15V

U = 4.5 ... 15V

SN : ..............

SN : ..............

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 14

3-4

<3. PRODUCT DESCRIPTION>

Blank Page

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 15

<4. INSTALLATION>

4-1

4. Installation

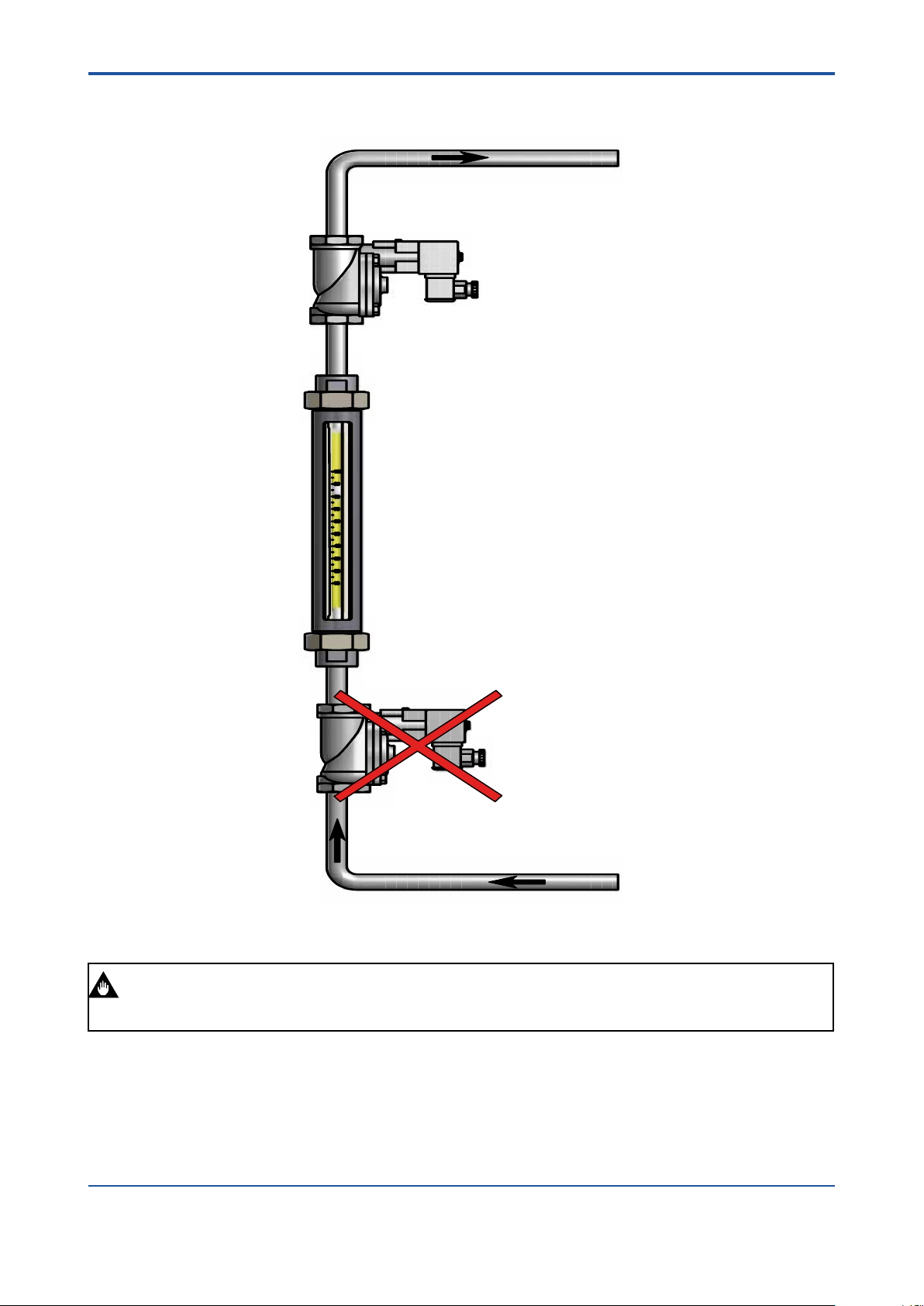

4.1 General

Installation:

All packaging material must be removed. The transportation lock for the oat must be removed.

The piping shall be ushed before installing the owmeter. Piping must be dried for gas applications. Rotameters must be installed vertically. The ow direction is from bottom to top. Prevent the device from mechani-

cal stress and vibration by aligning and supporting the piping. Avoid large volumes of gas downstream and

upstream of the device, this can cause vibration due to compression. Install the On/Off valve downstream in order

to avoid

damage when opening the valve. In case of gas applications, increase the ow pressure slowly. Avoid pressure

surges and temperature shocks to the owmeter at any time.

Refer to the pressure and temperature limits of the device. For owmeters with limit switches please see

chapter 4.3, 4.4 and 4.5.

Further installation hints can be found in VDI/VDE 3513 sheet 3.

Commissioning:

When functioning properly, the oat moves freely in the ow. With oats with notches this can be easily seen

by their rotation. If the oat does not move, please check the installation.

The ow rate can be read directly from the scale on the tube. Refer to the scale mark to which the oat adjusts

its top edge when reading.

Maintenance:

With common applications and normal operating conditions the device is maintenance free. In case of soiling

we recommend to clean the measuring tube by using a bottle brush and soap water. Make sure not to scratch

the measuring tube. If oat or measuring tube show signs of wear and tear, we recommend replacing them.

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 16

4-2

IMPORTANT

4.2 Piping

<4. INSTALLATION

On/Off- valve must be installed downstream !

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 17

<4. INSTALLATION>

15

4

6

3

1

14

12

10

11

8

7

9

U

Mains / Netz / Tension

One channel transmitter : ...-SR2-Ex1. W, connection like limit MAX

Einkanaliger Verstärker : ...-SR2-Ex1. W, Anschluss wie Grenzwert MAX

Un canal amplificateur : ...-SR2-Ex1. W, raccord comme limite MAX

Transmitter Relay

Trennschaltverstärker

Amplificateur Separateur

Limit / Grenzwert / Limite MIN

Limit / Grenzwert / Limite MAX

Max

Min

EN 60947-5-6 (Namur)

-

+

-

+

~ ~

+

-

+

-

Option /W4B 24VDC

KFD2-SR2-Ex2.W

Option /W2B 230VAC

KFA6-SR2-Ex2.W

Inductive ring sensor

Induktiver Ringinitiator

Bague inductive

Rotameter RAGN option /GRx (x = 2 ... 8)

F41.EPS

min. 6 mmmin. 4 mm min. 25 mm

4-3

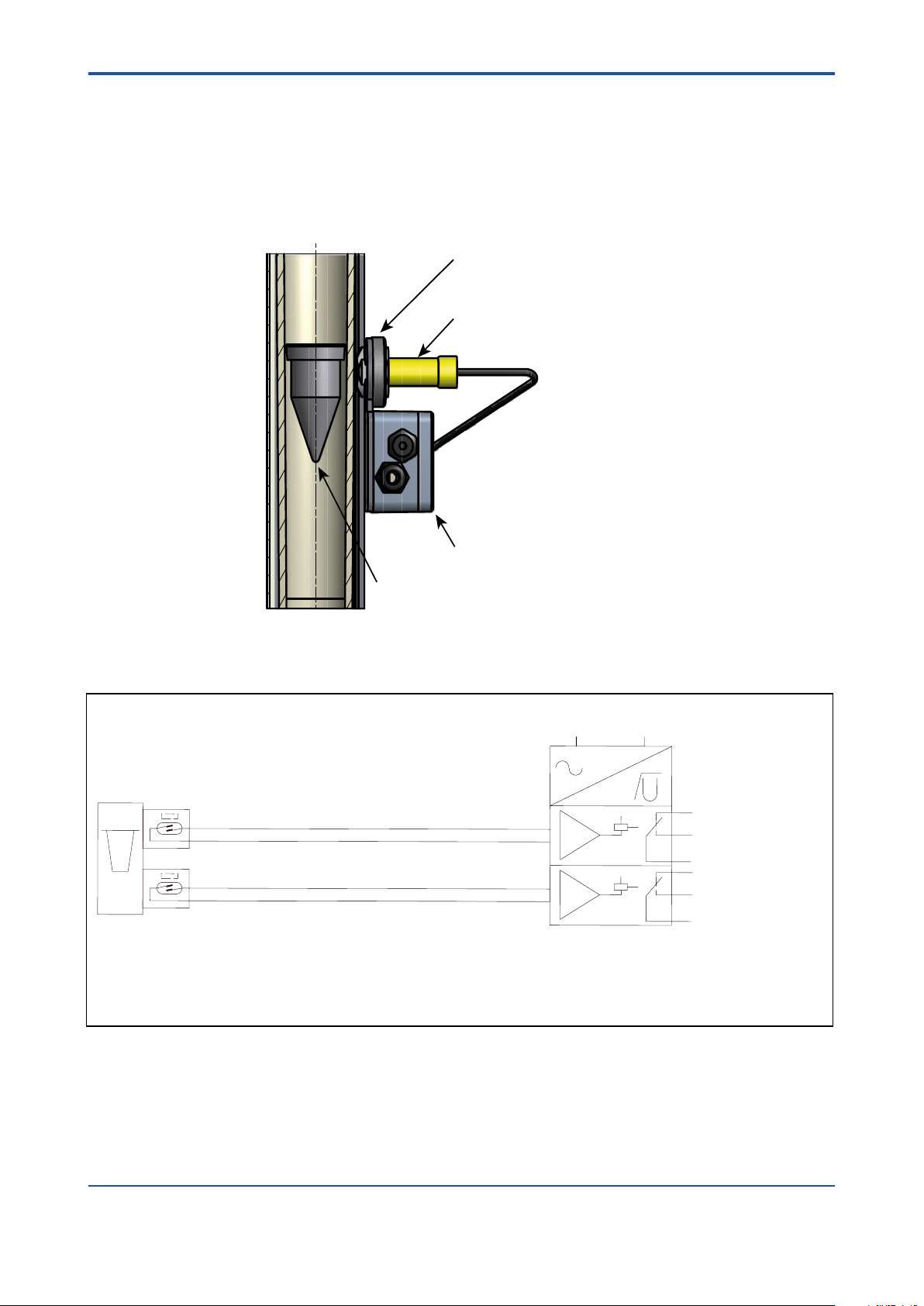

4.3 Bistable inductive ring sensor (Option /GR2 to /GR8)

- The ring sensor should be connected to a mono stable transmitter relay.

- Connection to transmitter relay (s. installation diagram below)

white cable → +

shielding → –

- The installation regulations in accordance with IEC 364 have to be taken into account.

- The shielding of the connection cable is not for earthing of the ring sensor. A ring sensor with a damaged

cable insulation may not be used

- The device has to be protected from strong electromagnetic elds.

- Power lines have to be installed separated from the signal lines.

- Switches, power relays and engines can change the switching state of the ring sensor (in unfavorable orders).

- Metal parts should have a minimum distance of 50 mm to the ring sensor.

- If the oat is above the ring sensor after power on or after power fail, the oat has to move once through

the ring sensor to nd the correct oat position.

Connection to transmitter relay :

For installation in hazardous area see chapter 6 "EXPLOSION PROTECTED TYPE INSTRUMENTS”.

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 18

4-4

Optional connection box /GD1

Limit switch /GM1 or /GM2

Float with magnet

Nut

F45.EPS

GRENZWERTSCHALTER GM

LIMIT SWITCH GM

CONTACT LIMITE GM

ROTAMETER RAGN with option /GMx (x = 1 ... 5)

EN 60947-5-6 (NAMUR)

MAINS / NETZ / TENSION

OPTION: /W4B 24VDC

KFD2-SR2-Ex.W

OPTION: /W2B 230VAC

KFA6-SR2-Ex.W

9

8

1

1

1

7

1 1

1

3

4

6

+

-

+

-

LIMIT/ GRENZWERT/ LIMITE

MAX

MIN

ÄTRENNSCHALTVERST RKER

TRANSFORMER ISOLATED BARRIER

AMPLIFICATEUR SEPARATEUR

(L+ (L-)

EINKANALIGE VERSTÄRKER .......-SR2-EX1.W ANSCHLUSS WIE GRENZWERT "MAX"

ONE CHANNEL TRANSMITTER .....-SR2-EX1.W CONNECTION LIKE LIMIT "MAX"

UN CANAL AMPLIFICATEUR ........-SR2-EX1.W RACCORD COMME LIMITE "MAX"

LIMIT/ GRENZWERT/ LIMITE

<4. INSTALLATION

4.4 Magnetic contact (Option /GM1 to /GM5)

a) Loose the nut at the guide sleeve.

b) If 2 limit switches were ordered install the Max-contact in the top position and the Min- contact

in the low position (see print on housing).

c) Put the limit switch from the outer side on the guide rail of the Rotameter.

d) Adjust the distance between limit switch to tube to 1 mm; check function and correct if necessary.

e) Fix limit switch with the nut to guide rail.

Connection to transmitter relay :

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 19

<4. INSTALLATION>

Option /GD1

4-5

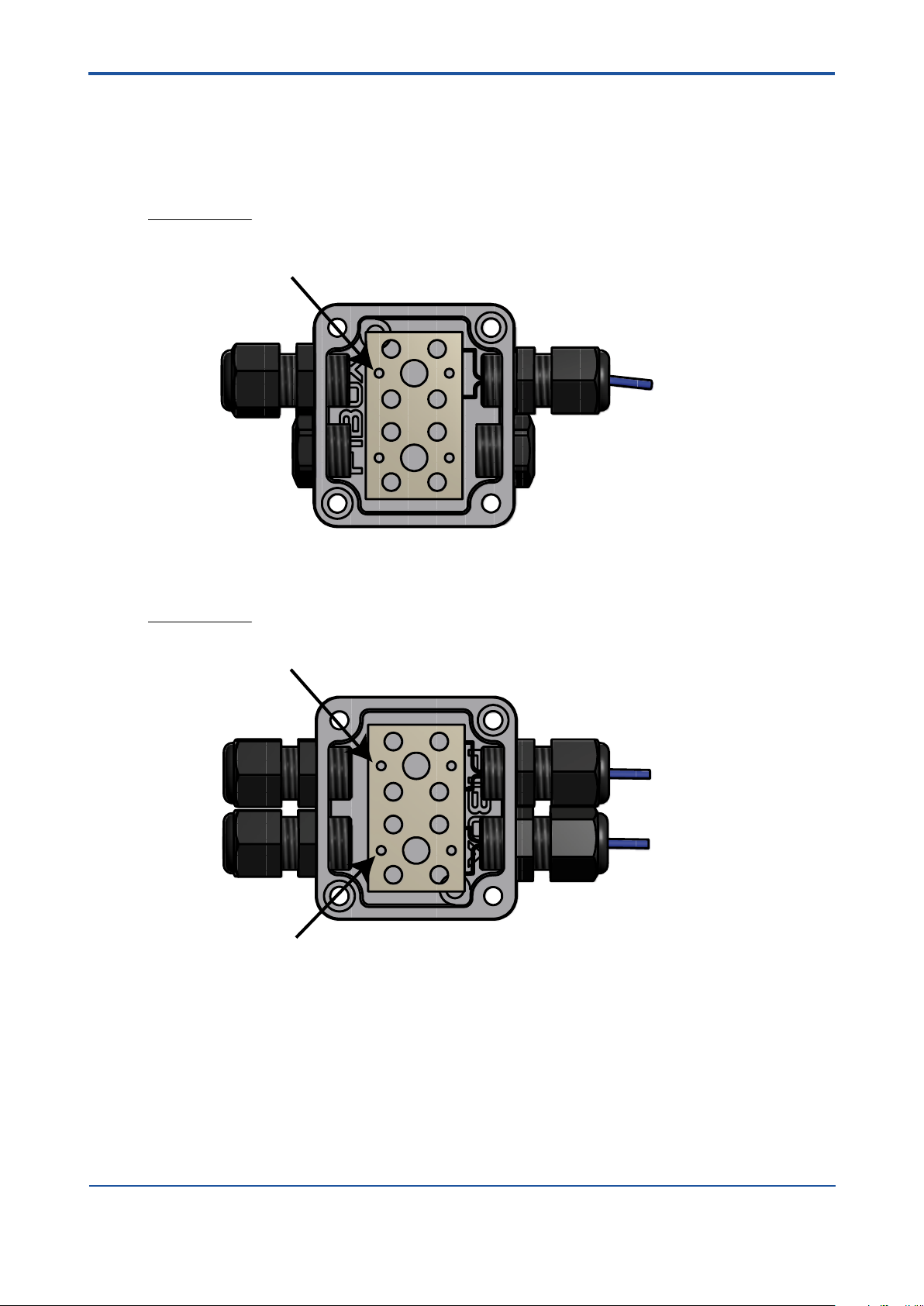

4.5 Connection box (Option /GD1 or /GD2)

For one limit switch the connection box with option /GD1 and for two limit switches the connection box with

option /GD2 is available.

Please make the connections in the connection box as shown below.

Te rminals for limit switch control unit,

e.g. transmitter relay option /Wxx

from limit switch

/GRx or /GMx

Option /GD2

Te rminals for limit switch control unit, e.g. transmitter relay option /Wxx

from limit switch

/GRx or /GMx

from limit switch

/GRx or /GMx

Te rminals for limit switch control unit, e.g. transmitter relay option /Wxx

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 20

4-6

<4. INSTALLATION

Blank Page

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 21

<5. SERVICE>

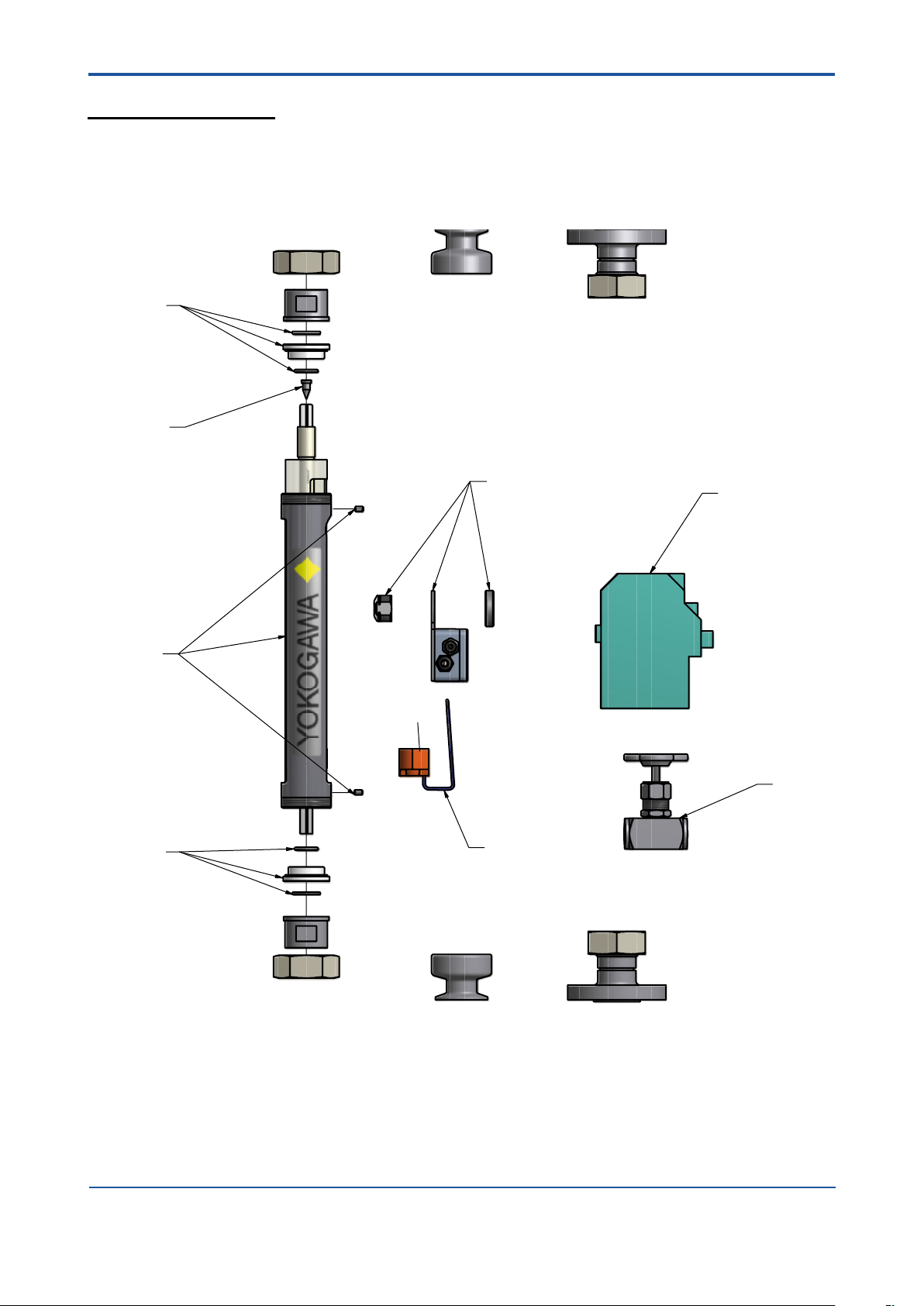

5. Service

5.1 Customer maintenance part list (CMPL)

L- TUBE :

1

2

5-1

4

3

1

5

7

8

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 22

5-2

P- TUBE :

1

<5. SERVICE>

2

7

4

3

8

6

1

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 23

<5. SERVICE>

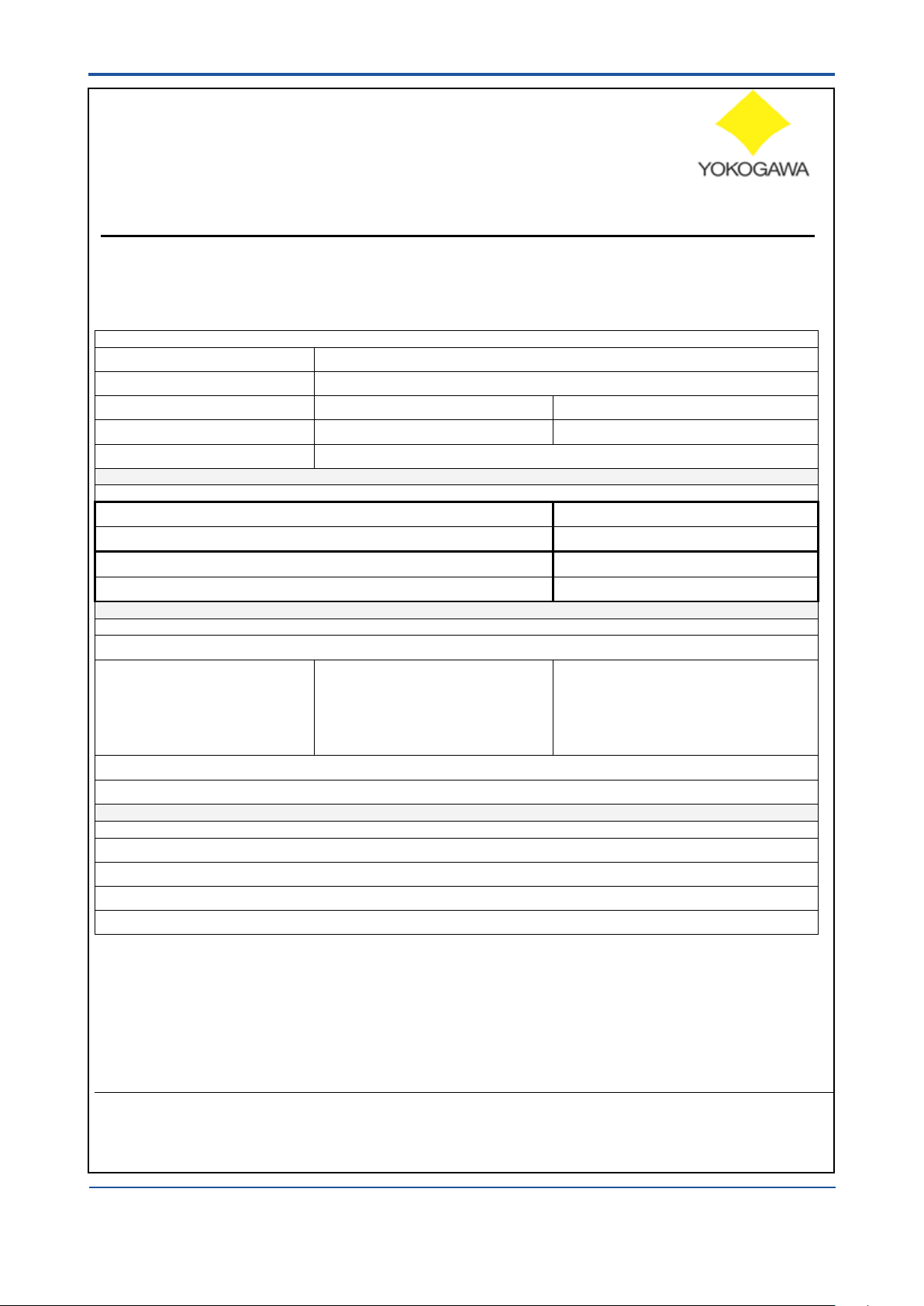

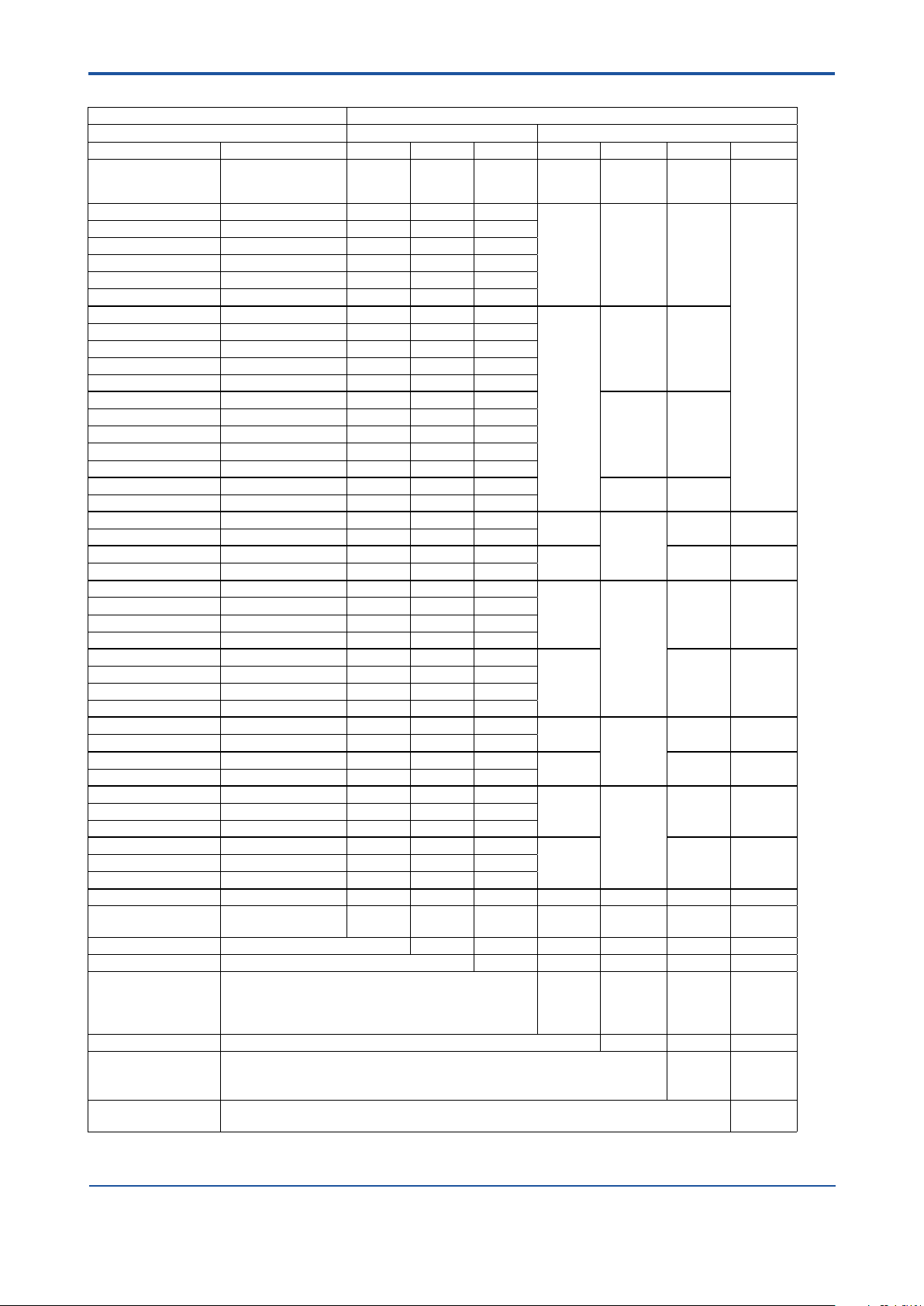

Item Part-No. Descriptions

L6 tube

M3810TA-SP Set of bottom and top stoppers and Buna, Viton, EPDM gaskets for L6 tube x

M3810TB-SP Set of bottom and top stoppers and Buna, Viton, EPDM gaskets for L7 tube x

M3810TC-SP Set of bottom and top stoppers and Buna, Viton, EPDM gaskets for P0 tube x

1

M3810TD-SP Set of bottom and top stoppers and Buna, Viton, EPDM gaskets for P1 tube x

M3810TE-SP Set of bottom and top stoppers and Buna, Viton, EPDM gaskets for P2 tube x

M3810TF-SP Set of bottom and top stoppers and Buna, Viton, EPDM gaskets for P4 tube x

M3810TK-SP Spare oat PD12M x

M3809MK-SP Spare oat PD17M x

M3810TL-SP Spare oat SS13N x

M3810TM-SP Spare oat SS13M x

M3810TN-SP Spare oat PF16N x

M3809MC-SP Spare oat PD22M x

M3809ME-SP Spare oat PD27M x

2

M3810TP-SP Spare oat SS23N x

M3810TQ-SP Spare oat SS23M x

M3810TR-SP Spare oat PF26N x

M3809MD-SP Spare oat PD42M x

M3809MF-SP Spare oat PD47M x

M3810TS-SP Spare oat SS43N x

M3810TT-SP Spare oat SS43M x

M3810TW-SP Spare oat PF46N x

M3810TG-SP Splinter shield incl. 2 slotted set screws with at point for tube L6,L7,P0,P1 x x x x

3

M3810TH-SP Splinter shield incl. 2 slotted set screws with at point for tube P2 x

M3810TJ-SP Splinter shield incl. 2 slotted set screws with at point for tube P4 x

M3810GM-SP Connection box for 1 limit switch x x x x x x

4

M3810GN-SP Connection box for 2 limit switches x x x x x x

M3810TX-SP Bistable inductive ring sensor for oat PDB__ (/GR2 or /GR6)) x

5

M3810TY-SP Bistable inductive ring sensor for oat PDC__ (/GR3 or /GR7) x

M3810TZ-SP Bistable inductive ring sensor for oat PDD__ (/GR4 or /GR8) x

M3810GD-SP Magnetic MIN-contact for oat with insertion code ____M (/GM1) x x x x

M3810GE-SP Magnetic MAX-contact for oat with insertion code ____M (/GM2) x x x x

6

M3810GF-SP Magnetic MIN-MAX-contact for oat with insertion code ____M (/GM3) x x x x

M3810GG-SP Magnetic MIN-MIN-contact for oat with insertion code ____M (/GM4) x x x x

M3810GH-SP Magnetic MAX-MAX-contact for oat with insertion code ____M (/GM5) x x x x

M3810WA-SP Transmitter relay KFA5-SR2-Ex1.W / 115 V AC, 1 channel (/W1A) x x x x x x

M3810WB-SP Transmitter relay KFA5-SR2-Ex2.W / 115 V AC, 2 channel (/W1B) x x x x x x

M3810WC-SP Transmitter relay KFA6-SR2-Ex1.W / 230 V AC, 1 channel (/W2A) x x x x x x

7

M3810WD-SP Transmitter relay KFA6-SR2-Ex2.W / 230 V AC, 2 channel (/W2B) x x x x x x

M3810WE-SP Transmitter relay KFD2-SR2-Ex1.W / 24 V DC, 1 channel (/W4A) x x x x x x

M3810WF-SP Transmitter relay KFD2-SR2-Ex2.W / 24 V DC, 2 channel (/W4B) x x x x x x

M3810EQ-SP Valve made of SS 316Ti (1.4571) G 1/2" (/V1) x x x

M3810ER-SP Valve made of SS 316Ti (1.4571) G 1" (/V2) x

M3810ES-SP Valve made of SS 316Ti (1.4571) G 1 1/2" (/V3) x

8

M3810ET-SP Valve made of brass G 1/2" (/V4) x x x

M3810EW-SP Valve made of brass G 1" (/V5) x

M3810EX-SP Valve made of brass G 1 1/2" (/V6) x

IM 01R01B10-00D-E Printed Instruction Manual in German x x x x x x

9

IM 01R01B10-00E-E Printed Instruction Manual in English x x x x x x

L7 tube

P0 tube

5-3

P1 tube

P2 tube

P4 tube

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 24

5-4

<5. SERVICE>

5.2 Template for sending back to service

Sending an instrument back to service

Installation and operation of the Rotameter RAGN in compliance with this manual is generally trouble-free.

In case a RAGN has to be sent for repairs or checking to our service, please observe the following:

Due to legislation for the protection of the environment and for the safety of our staff, YOKOGAWA may only

ship, repair and check sent devices on the condition that this does not constitute any risk to environment

and staff.

YOKOGAWA can only process your returned RAGN if you attach a certicate of harmlessness according to

the following sample.

If the unit has been in contact with corrosive, poisonous, ammable or water polluting substances, you

must,

- ensure that all parts and hollow spaces of the unit are free of these dangerous substances.

- attach a certicate of harmlessness to the returned unit.

Please understand that YOKOGAWA cannot process your returned unit without such a certicate.

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 25

<5. SERVICE>

ROTA YOKOGAWA GmbH & Co. KG

Service & Repair Department

Rheinstraße 8; D - 79664 Wehr

Phone no.: +49 (0)7761-567-190

Fax no.: +49 (0)7761-567-285

e-Mail: services.flow@de.yokogawa.com

Declaration of Decontamination

Legal regulations for the safety of our employees and operating equipment determine that we need

the declaration of decontamination before your order can be handled.

Please make sure to include it with the shipping documents, attached to the outside of the

packaging you use for shipment.

Customer data

Company:

Address:

Contact person: E-Mail:

Phone no.: Fax no.:

Reference/Order no.:

Instrument data*

Type: Serial no.:

Type: Serial no.:

*If not enough, note on separate sheet

Process data

Process medium:

Medium is: [ ] toxic

[ ] corrosive

[ ] explosive

[ ] biological hazardous

[ ] unknown if dangerous

[ ] non hazardous

Remarks:

Cleaning agent:

Kind of cleaning :

Other remarks / Reason of return:

We hereby confirm that this statement is filled in completely and truthfully. The returned

instruments were carefully cleaned and are thus free from product residue and dirt. I agree

that if this arrangement does not match with the instruments, they will be sent back to the

above mentioned customer address at our expenses.

Name Date Signature

5-5

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 26

5-6

<5. SERVICE>

Blank Page

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 27

<6. EXPLOSION PROTECTED INSTRUMENTS>

WARNING

WARNING

6-1

6. Explosion protected type instruments

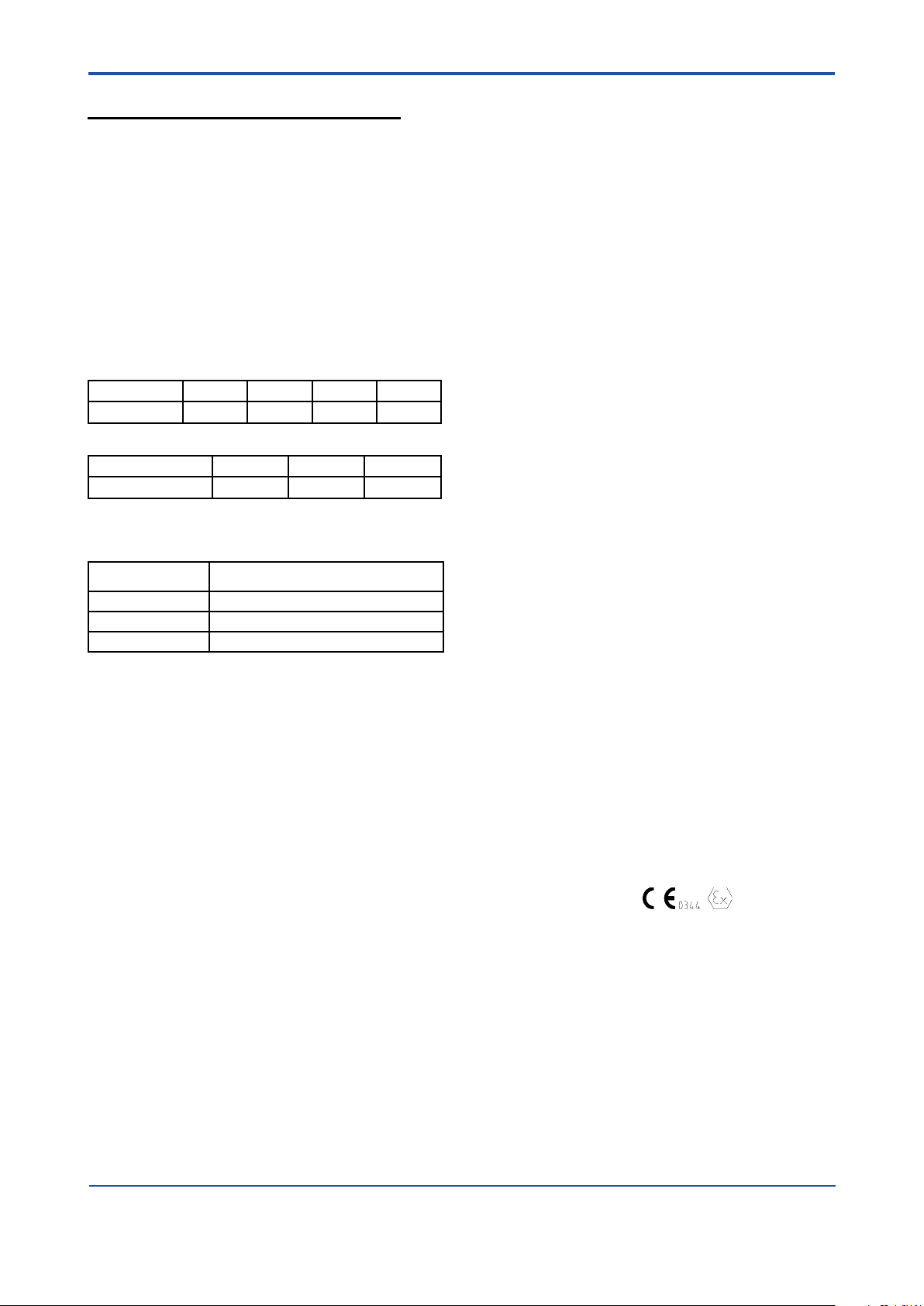

6.1 Bistable inductive ring sensor (Option /GR2 to /GR8)

- Only trained persons may use the instrument in the industrial area.

- It is forbidden to users to carry out specication changes and other changes at the device. Repairs at

the device aren’t permitted.

- To ensure explosion protection of the RI20, a suitable explosion-proof transmitter relay must be used.

- The maximum ambient temperature and the maximum temperature of the medium, which ows through

the tube, may not exceed 60°C.

- The connection cable may not be exposed to mechanical loads. The maximum axial strength is 30 N.

The inductive ring sensor RI20 is an intrinsic safe device. This is certied for hazardous areas of zone 1

(category 2) and zone 2 (category 3). They are not homologated for zone 0 (category 1). The classications

in brackets are given according to EU- Regulation 94/9/EG (ATEX).

Temperature range : -25°C to +60°C

EC- Type Examination Certicate number: PTB 03 ATEX 2111

The identication in accordance with regulation 94/9/EG (ATEX)

- Manufacturer : Rota Yokogawa, Rheinstr. 8, D-79664 Wehr

- Type : RI20-10 or RI20-17

- Serial number and year of the production:

7yymmxxx (yy=year, mm=month, xxx= incremented number (e.g. 70309001)

- Protection : Ex ia

- Group : IIC

- Category : 2

- Explosive atmosphere : G

- Temperature class : T6

- Certicate No. : PTB 03 ATEX 2111

- Entity parameters : Ui = 12 V, Ii = 22 mA , Pi = 66 mW,

Li = 20 mH, Ci = 200 nF

or

see certicate for data

- Marking according to regulation 94/9/EG : II 2 G

- The electrical connection of the RI20 is provided with free ends of the cables with cable hulls. Please

regard the installation regulations in accordance with IEC 364.

- The shielding of the connection cable is not for grounding of the RI20. A RI20 with damaged cable

isolation may not be used.

- Static charges of the RI20 housing have to be avoided. A corresponding warning note has to be attached

at the device.

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 28

6-2

15

4

6

3

1

14

121011

8

7

9

U

Mains / Netz / Tension

One channel transmitter : ...-SR2-Ex1.W, connection like limit MAX

Einkanaliger Verstärker : ...-SR2-Ex1.W, Anschluss wie Grenzwert MAX

Un canal amplificateur : ...-SR2-Ex1.W, raccord comme limite MAX

Transmitter Relay

Trennschaltverstärker

Amplificateur Separateur

Limit / Grenzwert / Limite MIN

Limit / Grenzwert / Limite MAX

Max

Min

EN 60947-5-6 (Namur)

Maximum medium- and ambient temperature :

Maximale Mediums- und Umgebungstemperatur :

Temperature ambiante et temperature de fluide maximale :

Tamax = 60°C

-

+

-

+

~ ~

+

-

+

-

Ci = 200nF

Ex ia IIC T6

Li = 20mH

RI20-10, RI20-17

Pi = 66mW

Ii = 22mA

Ui = 12V

PTB 03 ATEX 2111

C = 2320nF

I = 19,1mA

P = 51mW

U = 10.6V

L = 97mH

PTB 00ATEX 2081

EEx ia / ib IIC

KFA6-SR2-Ex2.W

ooo

o

o

C = 2410nF

I = 13mA

P = 34mW

U = 10.5V

L = 210mH

PTB 00ATEX 2080

EEx ia / ib IIC

KFD2-SR2-Ex2.W

ooo

o

o

Hazardous Area

Ex- Bereich

Zone Ex

Safe Area

Sicherer Bereich

Hors Zone

Option /W4B 24VDC

KFD2-SR2-Ex2.W

Option /W2B 230VAC

KFA6-SR2-Ex2.W

Inductive ring sensor RI20

Induktiver Ringinitiator RI20

Bague inductive RI20

Rotameter

RAGN

option /GRx (x = 2 ... 8)

F2.EPS

Installation in Hazardous area:

<6. EXPLOSION PROTECTED INSTRUMENTS>

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 29

Marking:

WARNING

<6. EXPLOSION PROTECTED INSTRUMENTS>

6-3

Rota Yokogawa

Rota Yokogaw

Rheinstr. 8

Rheinstr. 8

D-79664 Wehr

D-79664 Wehr

Type : RI20-10-K

Type : RI20-10-K

U = 4.5 ... 15V

U = 4.5 ... 15V

SN : ..............

SN : ..............

Ex ia IIC T6

PTB 03 ATEX 2111

II 2 G

see certificate

for data

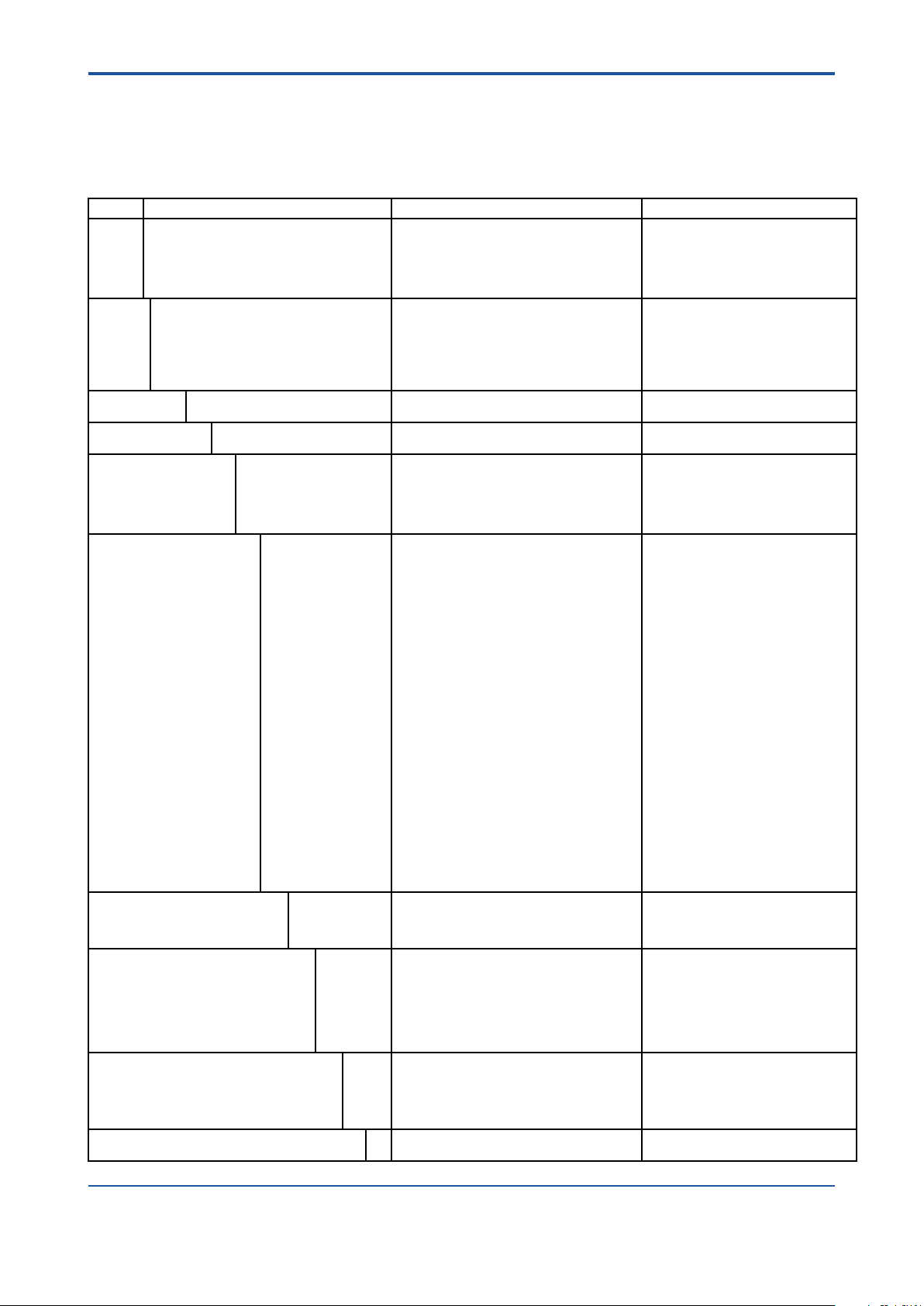

6.2 Magnetic contact (Option /GM1 to /GM5)

• Only trained persons may use the instrument in the industrial area.

• It is forbidden to users to carry out specication changes and other changes at the device. Repairs at

the device aren’t permitted.

• To ensure explosion protection of the GM, a suitable explosion-proof transformer isolated barrier must

be used.

• The maximum ambient temperature and the maximum temperature of the medium, which ows through

the tube, may not exceed 70°C.

• The connection cable may not be exposed to mechanical loads. The maximum axial strength is 30 N.

• Static charge of the GM case has to be avoided. A corresponding warning note has to be attached at

the device.

The limit switch GM is classied according EN 60079-11 chapter 5.7, IEC 60079-11 chapter 5.7 and ANSI/

ISA 60079-11 chapter 5.7 as "Simple Apparatus".

For use in hazardous area the limit switch must be connected to a suitable explosion-proof transformer isolated

barrier, which does not exceed the following maximum values :

Maximum voltage Uo : 15 V

Maximum current Io : 50 mA

Maximum power Po : 187 mW

Classication :

- Type : GM1 or GM2

- Protection : intrinsic safe

- ATEX / IECEx : IIC 2G

- FM : I, 1, A, B, C, D

- Temperature class : T6

- Entity parameters : Ui = 15 V ; Ii = 50 mA ; Pi = 187 mW ; Li ≈ 0 mH ; Ci ≈ 0 nF

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 30

6-4

F3.EPS

EX - BEREICH

HAZARDOUS AREA

ZONE EX

GRENZWERTSCHALTER GM

LIMIT SWITCH GM

CONTACT LIMITE GM

ROTAMETER RAGN with option /GMx (x = 1 ... 5)

MAXIMALE MEDIUMS UND UMGEBUNGSTEMPERATUR

MAXIMUM MEDIUM AND AMBIENT TEMPERATURE

TEMPERATURE AMBIANTE ET TEMPERATURE DE FLUIDE MAXIMALE

T = 70°C

amax

EN 60947-5-6 (NAMUR)

GM1, GM2

Ex IIC T6

I = 50mA

max

max

U = 15V

L = 0mH

T = 70°C

C = 0nF

P = 187mW

amax

max

ACHTUNG! ATTENTION! ATTENTION!

DIESE KONFIGURATION IST NUR IN ZONE 1 UND 2

EINSETZBAR

THIS CONFIGURATION IS ONLY FOR ZONE 1 AND 2

SICHERER BEREICH

SAFE AREA

HORS ZONE

NETZ / MAINS / TENSION

OPTION: /W4B 24VDC

KFD2-SR2-Ex.W

OPTION: /W2B 230VAC

KFA6-SR2-Ex.W

9

8

1

1

1

7

1 1

1

3

4

6

+

-

+

-

GRENZWERT / LIMIT / LIMITE

MAX

GRENZWERT / LIMIT / LIMITE

MIN

TRENNSCHALTVERSTÄRKER

TRANSFORMER ISOLATED BARRIER

AMPLIFICATEUR SEPARATEUR

T = 60°C

L = 210mH

C = 2410nF

P = 34mW

I = 13mA

(EEx ib) IIC

KFD2-SR2-Ex2.W

U = 10,5V

amax

o

o

o

o

o

T = 60°C

L = 97mH

C = 2320nF

P = 51mW

I = 19.1mA

U = 10,6V

(EEx ib) IIC

amax

o

o

o

o

o

KFA6-SR2-Ex2.W

(L+ (L-)

PTB 00 ATEX 2080

PTB 00 ATEX 2081

EINKANALIGE VERSTÄRKER .......-SR2-EX1.W ANSCHLUSS WIE GRENZWERT "MAX"

ONE CHANNEL TRANSMITTER .....-SR2-EX1.W CONNECTION LIKE LIMIT "MAX"

UN CANAL AMPLIFICATEUR ........-SR2-EX1.W RACCORD COMME LIMITE "MAX"

<6. EXPLOSION PROTECTED INSTRUMENTS>

Installation in Hazardous area:

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 31

<7. INSTRUCTIONS FOR PED>

7- 1

7. Instructions for PED

The meters RAGN 04-..., RAGN05-... and RAGN06-... are produced according the determinations of directive 97/23/EG

(directive for Pressure – Equipment / PED ).

The units are classied as pipe according item 3, number 1, 3. letter, a) rst dash or according diagram 6 after

appendix II :

- Classication as pipe

- For Fluid Group 1 (article 9 chapter (2)).

- Medium uid and gas

The basic safety requests (for design, production and testing) for all units according to category I are generally

determined for the requests of category I.

The units, which are not excluded by PED article 3 paragraph 3, are checked by a conformity-valuation-method

according appendix III ´module A´.

IMPORTANT

The user is responsible for the use of our owmeters regarding suitability and use as agreed.

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 32

7- 2

<7. INSTRUCTIONS FOR PED>

Blank Page

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 33

<8. TECHNICAL DATA>

8-1

8. Technical Data

STANDARD SPECIFICATIONS

Fluids to be measured : Liquids and gas

Measurable ow rates :

- Water (20 °C) : 0.002 l/h to 10 m3/h

- Air (20 °C; 1 bar abs.) : 0.1 l/h to 160 m3/h

Turndown :

- P metering tube : 10:1

- L metering tube : 20:1

Metering tubes : L6; L7; P0; P1; P2; P4 (length 300 mm)

Process temperature : -25°C to +100°C

Process pressure :

Metering tube L6;L7 P0;P1 P2 P4

Pmax (bar) 16 10 8 6

Installation length :

Process connection Thread Clamp Flange

Length [mm] 375 375 425

Weight : Depending on design (see page 7)

Accuracy :

Tube Measuring accuracy acc.

Directive VDI/VDE 3513 sheet 2 (qG= 50%)

L613 - L623 2.5%

L624 - L747 1.6%

P051 - P471 1.6%

Materials :

Threads G, NPT : AISI 316L (1.4404)

Flange EN / ASME : AISI 316L (1.4404)

Clamp ISO 2852 : AISI 316L (1.4404)

Housing : AISI 304 (1.4301)

N ut : AISI 316 (1.4401) (or galvanized steel)

Stoppers (L6, L7 tube) : PFA

Stoppers (P0 - P4 tube) : PVDF, AISI 316L (1.4404)

Measuring cone : Borosilicate glass

Float (L6, L7 tube ) : Titanium, PVDF

Float (P0 - P4 tube) : PTFE, PVDF (FDA conform),

AISI 316Ti (1.4571)

Gaskets : NBR, FKM,EPDM (FDA conform)

OPTION SPECIFICATIONS

Limit switch (option /GM1 to /GM5):

( for P- tubes with PVDF- or SS- oat with magnet only)

Type : reed contact with bistable switching

Max. switching voltage : 230 V

Max. switching current : 2 A

Max. switching capacity : 40 W/VA

Temperature range : -10°C to +70°C

Protection : IP65

Internal capacity : 0 nF

Internal inductivity : 0 mH

Electrical connection : LIYY 2 x 0.34 mm²; length 1 m

Housing : Polystyrene

Weight : 35 g

Explosion proof :

Intrinsic safe acc. EN 60079-11 chapter 5.7,

IEC 60079-11 chapter 5.7 and ANSI/ISA 60079-11

chapter 5.7 as "Simple Apparatus".

Group : IIC

Category : 2G

Temperature class : T6

Entity parameter : Ui = 15 V ; Ii = 50 mA ; Pi = 187 mW

Li ≈ 0 mH ; Ci ≈ 0 nF

Limit switch (option /GR2 to /GR8):

(for L- tubes with PVDF oat only)

Type : Bistable inductive ring sensor

Power supply : 4.5 V to 15 V DC

Consumption : acc. DIN EN 60947-5-6 (NAMUR)

Float below ring sensor : < 1 mA

Float above ring sensor : > 2.2 mA

Temperature range : -25°C to +65°C non-Ex- type

Protection : IP 67

Electrical connection : 2 x 0.14 mm² , with shield 0.4 mm²,

2 m long

Explosion proof type (option /KS1):

Temperature range : -25°C to +60°C

Marking acc. guideline 94/9/EG :

Manufacturer : Rota Yokogawa, Rheinstr.8,

D-79664 Wehr

Type : RI20-10K/G or RI20-17K/G

Year of production : in serial number

Protection : Ex ia

Group : IIC

Category : 2G

Temperature class : T6

Certicate No. : PTB 03ATEX 2111

Safety relevant data (see also certicate for data):

Ui = 12 V, Ii = 22 mA , Pi = 66 mW,

Li = 20 mH, Ci = 200 nF

Pressure Equipment Directive (PED) Directive 97/23/EG:

Models : RAGN04, RAGN05, RAGN06

Tubes :

- Modul : A

- Fluid Group : 1 (liquid, gases)

- Produced acc. to category

: I

FDA-Conformity:

RAGN with P- tube, PVDF- or SS- oat and EPDM- gaskets

(option /ME).

Stoppers and oats made of PVDF:

21 CFR § 177 2510(a)

O-rings made of EPDM:

21 CFR § 177 2600-21

Compliance with safety application acc. IEC 61508: 2010

and ISO 13849:

Please refer to the FMEDA report and instruction manual.

All Rights Reserved. Copyright © 2011, Rota Yokogawa

CE-marking

: II 2 G

Power supply for limit switch (option /W__):

Type :

acc.

DIN EN 60947-5-6 (NAMUR)

- KFA5-SR2-Ex*-W (115 V AC),

- KFA6-SR2-Ex*-W (230 V AC),

* = 1 or 2

* = 1 or 2

- KFD2-SR2-Ex*-W (24 V DC), * = 1 or 2

- KHA6-SH-Ex1 (115/230 V AC), Fail Safe, 1 channel

- KFD2-SH-Ex1 (24 V DC), Fail Safe, 1 channel

Power supply :

- 230 V AC ± 10%, 45-65Hz

- 115 V AC ± 10%, 45-65Hz

- 24 V DC ± 25%

Relay output :

1 or 2 potential-free changeover contact(s)

Switching capacity :

max. 250 V AC, max. 2 A

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 34

8-2

<8. TECHNICAL DATA>

Explosion proof : Intrinsic safe [Ex ia] IIC

PTB 00 ATEX 2081 (/W1A, /W1B, /W2A, /W2B)

PTB 00 ATEX 2080 (/W4A, /W4B)

PTB 00 ATEX 2042 (/W4E, /W4F)

PTB 00 ATEX 2043 (/W2E, /W2F)

Note :

For safety application fail safe power

W2F, /W4E or /W4F must be selected in combination with

options /GR_.

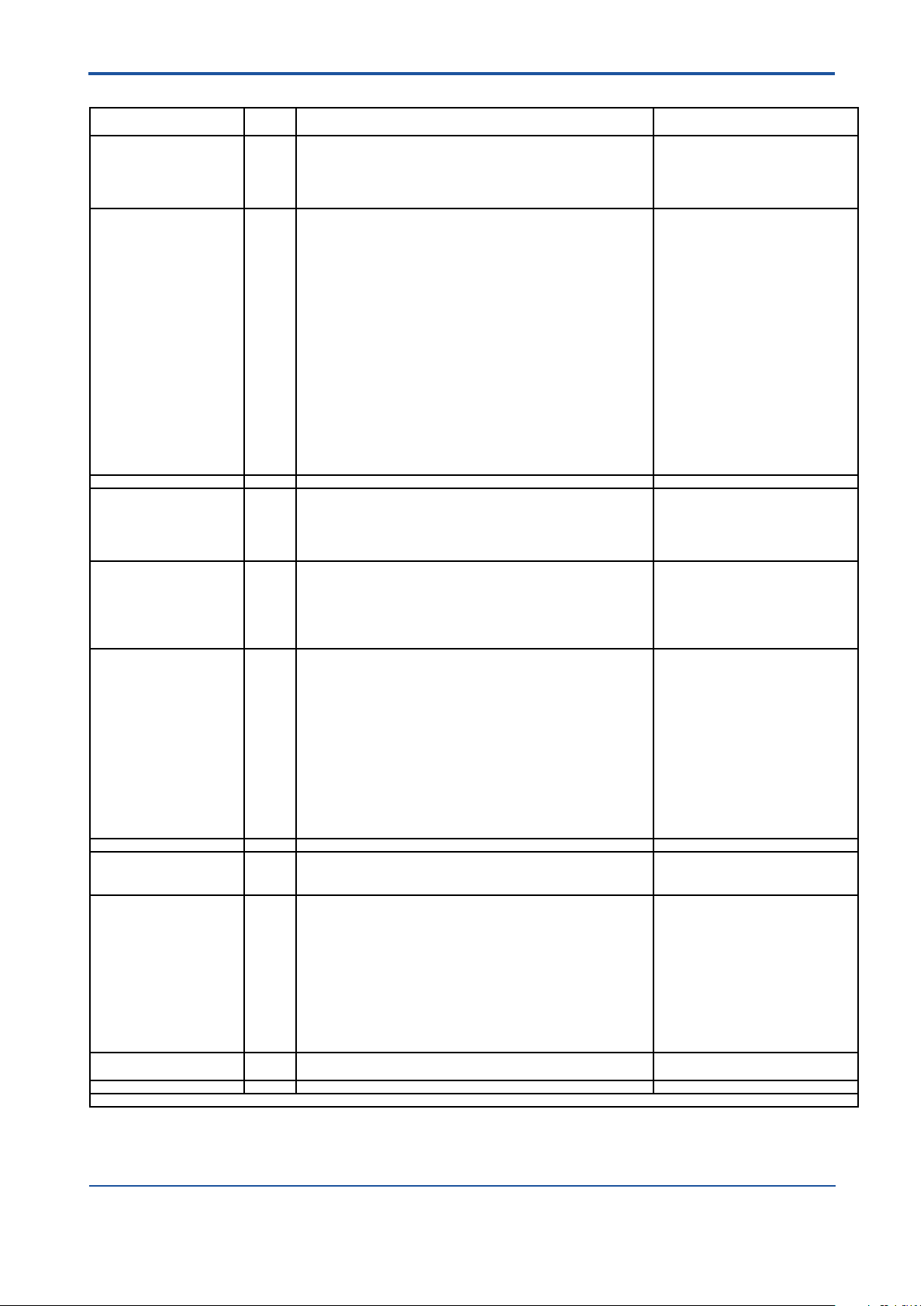

MODEL SPECIFICATIONS

Model Suffix code Description Restrictions

RAGN01

RAGN23

RAGN02

RAGN04

RAGN05

RAGN06

Process

connection

Material of process

connections

Metering tube

Diameter of metering tube 1)6

Cone

Float material

Diameter of oat

Medium / Float factor

Float insertion

1)

Combinations see tables on page 8-3 and 8-4

-D4

-A1

-G0

-T0

-S4

SS Stainless steel

1)

1)

1)

1)

-L

-P

7

0

1

2

4

13

14

17

21

22

23

24

27

31

32

33

34

37

41

42

43

44

47

51

52

53

54

57

61

62

63

64

67

71

-SS

-PF

-PD

-TT

1)

1)

A

B

C

D

0

1

2

4

L

G

2

3

6

7

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Size DN 15 (½ inch)

Size DN 20 (¾ inch)

Size DN 25 (1 inch)

Size DN 40 (1½ inch)

Size DN 50 (2 inch)

Size DN 65 (2½ inch)

EN ange PN 40, process connection dimension +

facing acc. EN 1092-2 Form B1

ASME ange class 150, process connection dimension

+ facing acc. ASME B 16.5

Inner thread G

Inner thread NPT

Clamp ISO 2852

L-tube (300 mm)

P-tube (300 mm)

10 mm

17 mm

20 mm

34 mm

48 mm

81 mm

1.4571 / AISI 316 Ti

PTFE

PVDF

Titanium

1.59

3.18

6.35

9.53

12.2 (P0-oat)

21.6 (P1-oat)

31.2 (P2-oat)

54.1 (P4-oat)

For liquid

For gas

For water

For water

For air

For air

NMWithout magnet

With magnet

All Rights Reserved. Copyright © 2011, Rota Yokogawa

for D4, A1, G0, T0, S4 with L6, L7, P0, P1

for G0, T0 with L6, L7, P0, P1

for D4, A1, G0, T0, S4 with L6, L7, P0, P1, P2

for D4, A1, G0, T0 with P2, P4

for D4, A1, with P2, P4; for G0, T0 with P4

for G0, T0 with P4

supply option /W2E, /

Page 35

<8. TECHNICAL DATA>

FLOW TABLE WITH METERING TUBE-FLOAT-COMBINATION FOR WATER / LIQUIDS

Flow table Suffix code metering tube - oat- combination

Water / liquids 20°C Metering tube Float

-x x xx -xx x x x

Max.

Flow

[l/h]

0.025 1 L 6 13

0.04 1 L 6 14

0.063 2 L 6 17

0.1 2 L 6 21

0.16 3 L 6 22

0.25 4 L 6 23

0.4 1 L 6 24

0.63 1 L 6 27

1 2 L 6 31

1. 6 3 L 6 32

2.5 4 L 6 33

4 2 L 7 34

6.3 2 L 7 37

10 3 L 7 41

16 4 L 7 42

25 5 L 7 43

40 5 L 7 44

63 10 L 7 47

63 10 P 0 51

100 16 P 0 52

100 16 P 0 51

160 24 P 0 52

160 15 P 1 53

250 16 P 1 54

400 18 P 1 57

630 26 P 1 61

250 15 P 1 53

400 16 P 1 54

630 18 P 1 57

1000 26 P 1 61

1000 11 P 2 62

1600 13 P 2 63

1600 26 P 2 62

2500 30 P 2 63

2500 16 P 4 64

4000 18 P 4 67

6300 21 P 4 71

4000 40 P 4 64

6300 44 P 4 67

10000 53 P 4 71

Length metering tube 300 mm .....................

Diam. metering tube 10 mm to 81 mm .......................... x

Cone metering tube See ow table .................................................. xx

Float material 1.4571 ..................................................................................

Float diameter 1.6 mm to 54 mm .................................................................................... x

Flow mark For liquid .....................................................................................................................

Float insertion Without magnet ..............................................................................................................................

1)

Max. viscosity 2 mPas*s

2)

For option limit switch /GM1 to /GM5

Pressure loss

Length

Diameter

Cone

Material

Diameter

Flow

mark

[mbar]

Code

Code

Code

Code

TT A

Code

Code

1)

L

B L

TT;PD

C L

D L

PD

2 M

0

SS 3

PD

2 M

1

SS 3

PD

2 M

2

SS 3

PD

2 M

4

SS 3

Description

P

300 mm .....................

L

SS

Titanium ...............................................................................

PTFE ....................................................................................

PVDF ...................................................................................

TT

PF

PD

L

For water ......................................................................................................................

For water ......................................................................................................................

2

3

With magnet ...................................................................................................................................

Insertion

Code

N

M 2);

N

M 2);

N

M 2);

N

M 2);

N

N

2)

M

8-3

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 36

8-4

<8. TECHNICAL DATA>

FLOW TABLE WITH METERING TUBE-FLOAT-COMBINATION FOR AIR / GASES

Flow table Suffix code metering tube - oat- combination

Air/Gases 20°C, 1 bar abs Metering tube Float

-x x xx -xx x x x

Max. Flow

[l/h]

1. 9 1 L 6 13

3 1 L 6 14

4.4 2 L 6 17

6.5 2 L 6 21

10 3 L 6 22

14 4 L 6 23

23 2 L 6 24

33 2 L 6 27

50 2 L 6 31

70 3 L 6 32

100 4 L 6 33

180 3 L 7 34

250 3 L 7 37

400 3 L 7 41

630 4 L 7 42

1000 5 L 7 43

1600 5 L 7 44

2400 10 L 7 47

1600 4 P 0 51

2500 6 P 0 52

2400 8 P 0 51

3800 11 P 0 52

6000 6 P 1 53

9300 7 P 1 54

14500 8 P 1 57

23000 10 P 1 61

400 5 P 1 53

6300 5 P 1 54

10000 6 P 1 57

16000 8 P 1 61

35000 11 P 2 62

55000 13 P 2 63

25000 8 P 2 62

40000 10 P 2 63

88000 29 P 4 64

140000 32 P 4 67

220000 34 P 4 71

63000 13 P 4 64

100000 14 P 4 67

160000 17 P 4 71

Length metering tube 300 mm .....................

Diam. metering tube 10 mm to 81 mm .......................... x

Cone metering tube See ow table .................................................. xx

Float material Titanium ...............................................................................

Float diameter 1.6 mm to 54 mm .................................................................................... x

Flow mark For gas .......................................................................................................................

Float insertion Without magnet ..............................................................................................................................

1)

For option limit switch /GM1 to /GM5

Pressure loss

Length

Diameter

Cone

Material

Diameter

Flow

mark

[mbar]

Code

Code

Code

Code

Code

Code

TT A G

B G

PD;TT

C G

D G

PF

6

0

PD 7 M

PD 1 7 M

PF 1 6 N

PD 2 7 M

PF 2 6 N

PD 4 7 M

PF 4 6 N

Description

300 mm ..................... PL

TT

PTFE ....................................................................................

PVDF ...................................................................................

PF

PD

G

For air ..........................................................................................................................

For air ..........................................................................................................................

6

7

With magnet ...................................................................................................................................

Insertion

Code

N

1)

1)

1)

1)

N

1)

M

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 37

<8. TECHNICAL DATA>

8-5

OPTIONS

Options Option

Marking /B1

Limit switches /GM1

Ex-proof type /KS1 ATEX intrinsically safe „ia“ Only for /GR2 to /GR8

Installation lengths

(s. also table on page 8-6)

Valves

(inner thread,

double tting is attached,

not for FDA)

Test and certicates /H1

Delivery to Korea /KC With KC-mark in Korea

Accessories for metering

tube

Power supply for limit

switches (transmitter

relay)

Instruction manuals /IEn

Special order /Z Special design must be specied in an extra text.

*) If no instruction manual is selected, only a Short IM and in case of limit switches a CD with instruction manuals is shipped with the owmeter.

Code

/B4

/BG

/B10

/BD

/GM2

/GM3

/GM4

/GM5

/GR2

/GR3

/GR4

/GR6

/GR7

/GR8

/GD1

/GD2

/L12

/L13

/L14

/L15

/L16

/V1

/V2

/V3

/V4

/V5

/V6

/P2

/P3

/P6

/PP

/PT

/PM2

/PM4

/MV

/ME

/MN

/W1A

/W1B

/W2A

/W2B

/W2E

/W2F

/W4A

/W4B

/W4E

/W4F

/IDn

Description Restriction

Tag plate (SS)

Neutral version

Customer specic notes on name plate

Percentage scale

Dual scale

Magnetic MIN-contact

Magnetic MAX-contact

Magnetic MIN-MAX-contact

Magnetic MIN-MIN-contact

Magnetic MAX-MAX-contact

Bistable inductive ring sensor

Bistable inductive ring sensor

Bistable inductive ring sensor

2 bistable inductive ring sensors

2 bistable inductive ring sensors

2 bistable inductive ring sensors

Connection box for 1 limit switch

Connection box for 2 limit switches

Installation length 500 mm

Installation length 356 mm

Installation length 368 mm

Installation length 386 mm

Installation length 394 mm

Valve made of 1.4571 G ½´´ (parts attached)

Valve made of 1.4571 G 1´´ (parts attached)

Valve made of 1.4571 G 1½´´ (parts attached)

Valve made of brass G ½´´ (parts attached)

Valve made of brass G 1´´ (parts attached)

Valve made of brass G 1½´´ (parts attached)

Oil + fat free for wetted surfaces acc. Yokogawa specication

Certicate of Compliance with the order acc. EN 10204: 2004- 2.1

As /P2 +Test report acc. to EN 10204: 2004- 2.2

Material certicate for Insertion parts or ange connections

acc. EN 10204: 2004- 3.1

Pressure test report for metering system

With ow table for recalculation + mm- scale

PAMI test (2 test points)

PAMI test (4 test points)

Gasket FKM (Viton)

Gasket EPDM (conform to FDA, -30°C to +100°C)

Nut galvanized steel

KFA5-SR2-Ex1.W / 115 V AC, 1 channel

KFA5-SR2-Ex2.W / 115 V AC, 2 channel

KFA6-SR2-Ex1.W / 230 V AC, 1 channel

KFA6-SR2-Ex2.W / 230 V AC, 2 channel

KHA6-SH-Ex1 / 115/230 V AC, 1 channel, Fail Safe

2x KHA6-SH-Ex1 / 115/230 V AC, 1 channel, Fail Safe

KFD2-SR2-Ex1.W / 24 V DC, 1 channel

KFD2-SR2-Ex2.W / 24 V DC, 2 channel

KFD2-SH-Ex1 / 24 V DC, 1 channel, Fail Safe

2x KFD2-SH-Ex1 / 24 V DC, 1 channel, Fail Safe

Quantity of instruction manuals in English

Quantity of instruction manuals in German

Plate 12 x 40 mm; max. 45 digits

Not with /KS1

Max. 45 digits

Only for tube P

Only for tube P0 to P4 and oat

insertion code M (with magnet)

Only for tube P0 to P4 and oat

insertion code M (with magnet)

Only for tube P0 to P4 and oat

insertion code M (with magnet)

Only for tube P0 to P4 and oat

insertion code M (with magnet)

Only for tube P0 to P4 and oat

insertion code M (with magnet)

Only for tube L6 with oat code PDB

Only for tube L7 with oat code PDC

Only for tube L7 with oat code PDD

Only for tube L6 with oat code PDB

Only for tube L7 with oat code PDC

Only for tube L7 with oat code PDD

Only with /GM1 to 2, /GR2 to 4

Only with /GM3 to 5, /GR6 to 8

Only for D4, A1

Only for size 01 and G0, T0

Only for size 01, 23, 02 and G0, T0

Only for size 02, 04 and G0, T0

Only for size 05, 06 and G0, T0

Only for G0 and tube L6, L7, P0

Only for G0 and tube P1

Only for G0 and tube P2

Only for G0 and tube L6, L7, P0

Only for G0 and tube P1

Only for G0 and tube P2

Only for insertion and ange

connections

Not with /V1 to /V6

Only for connections G0, T0, S4

except RAGN04-G0SS-P2 and

RAGN04-T0SS-P2

Only for connections A1, D4 and

RAGN04-G0SS-P2 and

RAGN04-T0SS-P2

conform with FDA -30°C to +100°C

not for S4 and RAGN04 with P2

n = 1 to 9 selectable *)

n = 1 to 9 selectable *)

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 38

8-6

1

2

4

6

8

0101

6

2

1

4

8

10

6

2

1

4

8

L

L

L

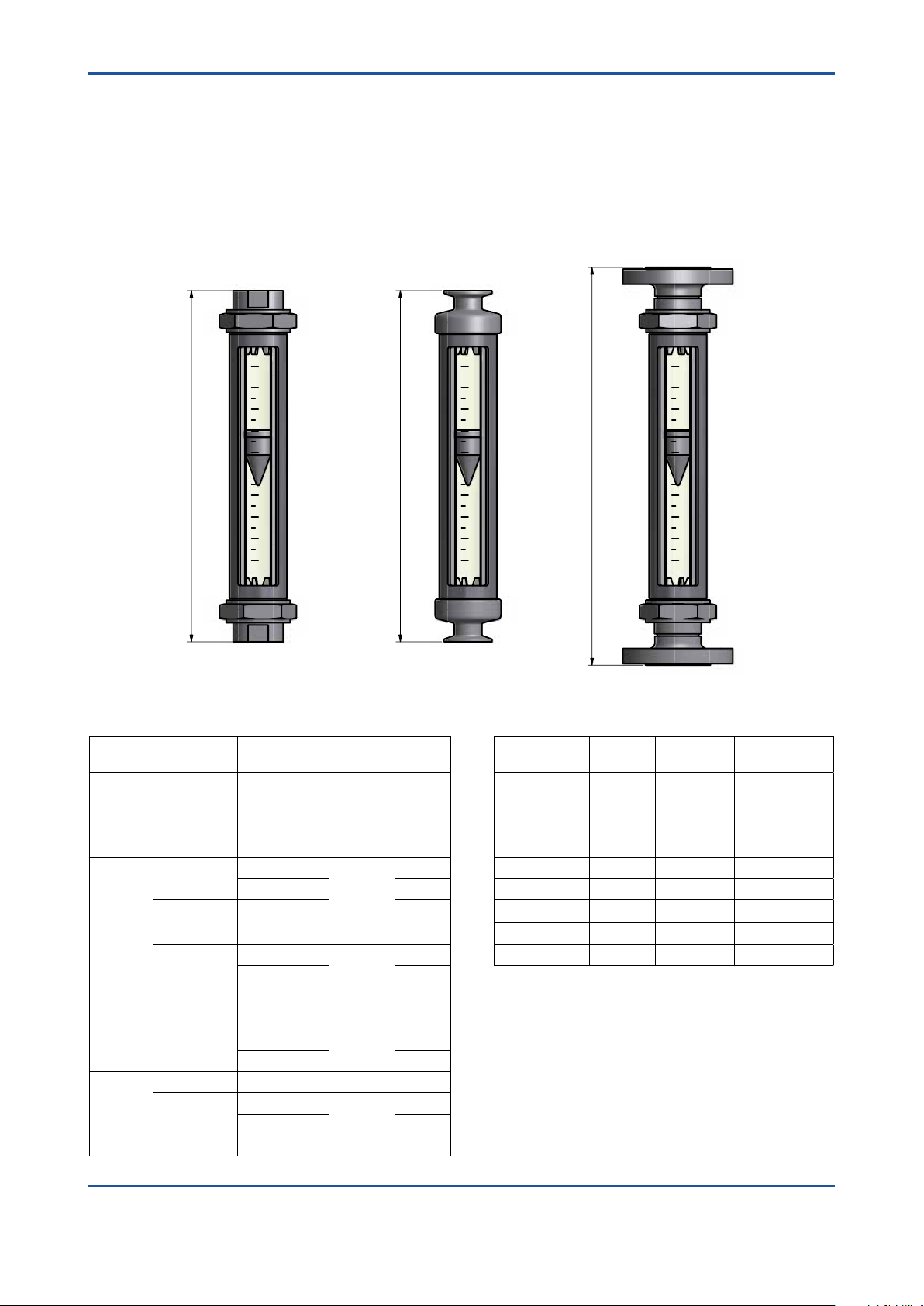

Inner thread type (T0; G0) Clamp type (S4) Flange type (D4; A1)

<8. TECHNICAL DATA>

PROCEDURE TO SELECT THE MODEL CODE

Please specify in the following order

- Measuring range for water/liquid or air/gas

- With or without optional limit switch

First select the required measuring range from the ow table (last column) and specify the oat insertion for the optional limit switch.

Then the suffix code for the combination metering tube - oat can be xed.

To size the Rotameter for other medium - process- conditions use sizing program Durep V.

DIMENSIONS

METERING TUBE

Installation lengths and weights:

Model Process

RAGN01

RAGN23 Inner thread 375 1. 7

RAGN02

RAGN04

RAGN05

RAGN06 Inner thread P4 375 7. 7.1 1

connection

Inner thread

Clamp 375 1. 9

Flange 425 2.5

Inner thread

Clamp

Flange

Inner thread

Flange

Inner thread P4 375 7. 1

Flange

Tube Length LmmWeight

375 1. 7

L6; L7; P0; P1

L6; L7; P0; P1

P2 2.6

L6; L7; P0; P1 2.0

P2 2.8

L6; L7; P0; P1

P2 3.9

P2

P4 7. 1

P2

P4 8.7

P2

P4 11. 1

375

425

375

425

425

kg

1. 7

3.3

2.6

5.2

6.6

Compatibility with former Rotameter RAGG / RAGH:

Former model Tube Installation

length mm

RAGH01 L6;L7;G0 356 RAGN01..../L13

RAGH02 G1 368 RAGN02..../L14

RAGH04 G2 386 RAGN04..../L15

RAGH06 G4 394 RAGN06..../L16

RAGH23 G1 368 RAGN23..../L14

RAGH05 G4 394 RAGN05..../L16

RAGG01 G0;G1 500 RAGN01..../L12

RAGG02 G2 500 RAGN02..../L12

RAGG04 G4 500 RAGN04..../L12

Model RAGN

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 39

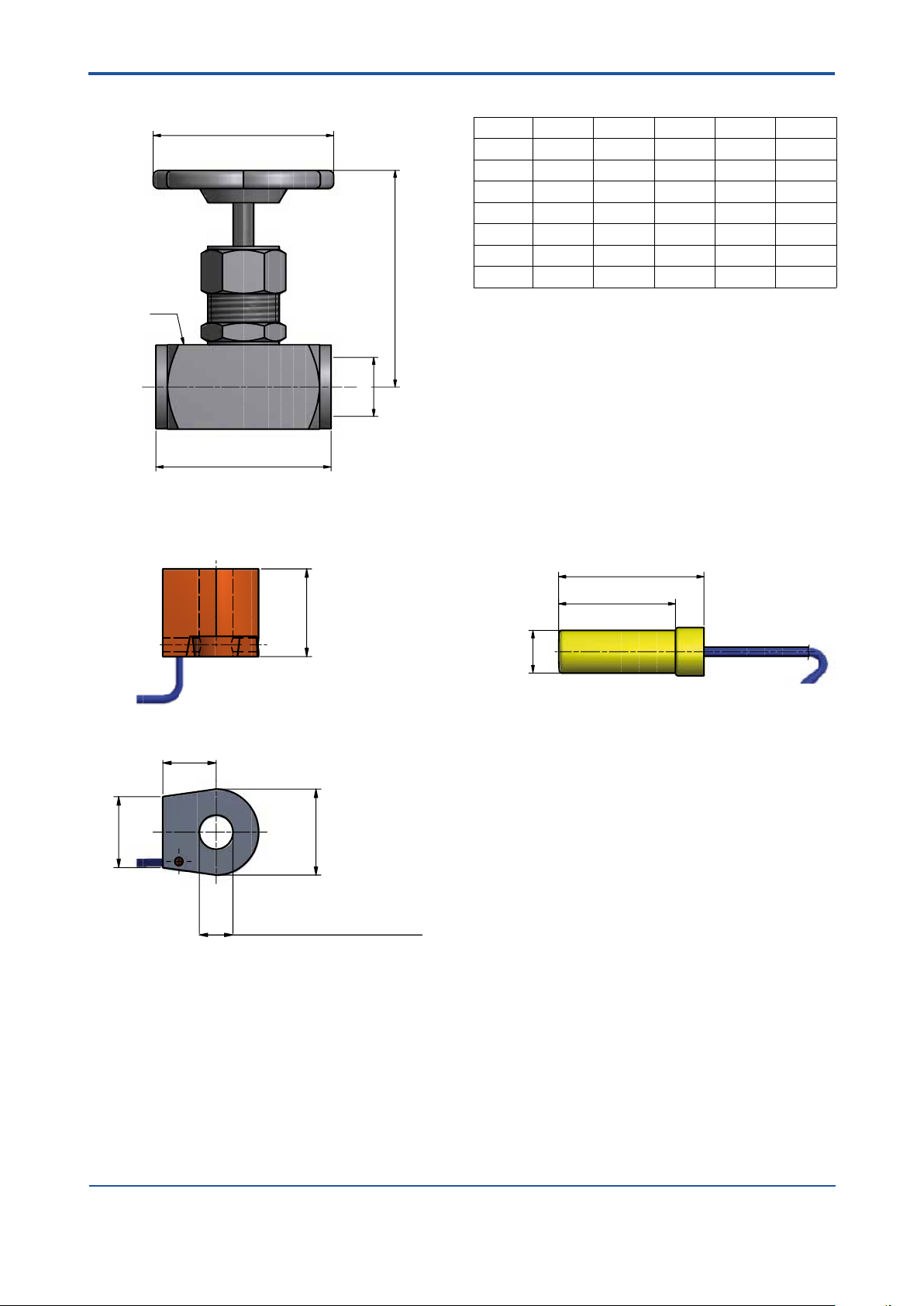

e

d

b

c

a

VALVE /Vx

2

1

2

5

.5

2

6

16 /GR2, /GR6

19.5 /GR3, /GR4, /GR7, /GR8

Ø 10.1 /GR2 /GR6

Ø 17.1 /GR3, /GR4, /GR7, /GR8

Ø

1

4

41

51

<8. TECHNICAL DATA>

Option a b c d e

Thread mm mm mm mm

/V1 G ½´´ 60 88 SW 30 63

/V2 G 1´´ 100 11 0 SW 45 90

/V3 G 1½´´ 130 145 SW 70 100

/V4 G ½´´ 55 78 SW 25 63

/V5 G 1´´ 75 93 SW 41 63

/V6 G 1½´´ 11 0 118 SW 60 90

8-7

LIMIT SWITCH /GRx LIMIT SWITCH /GMx

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 40

8-8

<8. TECHNICAL DATA>

Blank Page

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 41

<A1. SAFETY INSTRUMENTED SYSTEMS INSTALLATION>

WARNING

A1-1

APPENDIX 1. Safety Instrumented

Systems Installation

The contents of this appendix are cited from exida.com safety manual on the Rotameter RAGN Flowmeter

specically observed for the safety transmitter purpose. When using the RAGN for Safety Instrumented

Systems (SIS) application, the instructions and procedures in this section must be strictly followed in order

to preserve the meter for that safety level.

A1.1 Scope and Purpose

This document provides an overview of the user responsibilities for installation and operation of the Rota

Yokogawa RAGN variable area ow meter, herein referred to as RAGN Glass Rotameter, in order to maintain

the designed safety level. Items that will be addressed are proof testing, repair and replacement of the ow

meter, reliability data, lifetime, environmental and application limits, and parameter settings.

A1.2 Using RAGN for a SIS Application

A1.2.1 Safety Function

Suitable for use in Safety Instrumented Systems are the versions listed in table 1 only. The safety related data

listed in this manual does not apply to other versions of RAGN.

Table 1 Versions of RAGN suitable for Safety Instrumented Systems

[V1] RAGN with Reed-switch(es)

[V2] RAGN with Ring Initiator, fail-safe state: LOW

[V3] RAGN with Ring Initiator, fail-safe state: HIGH

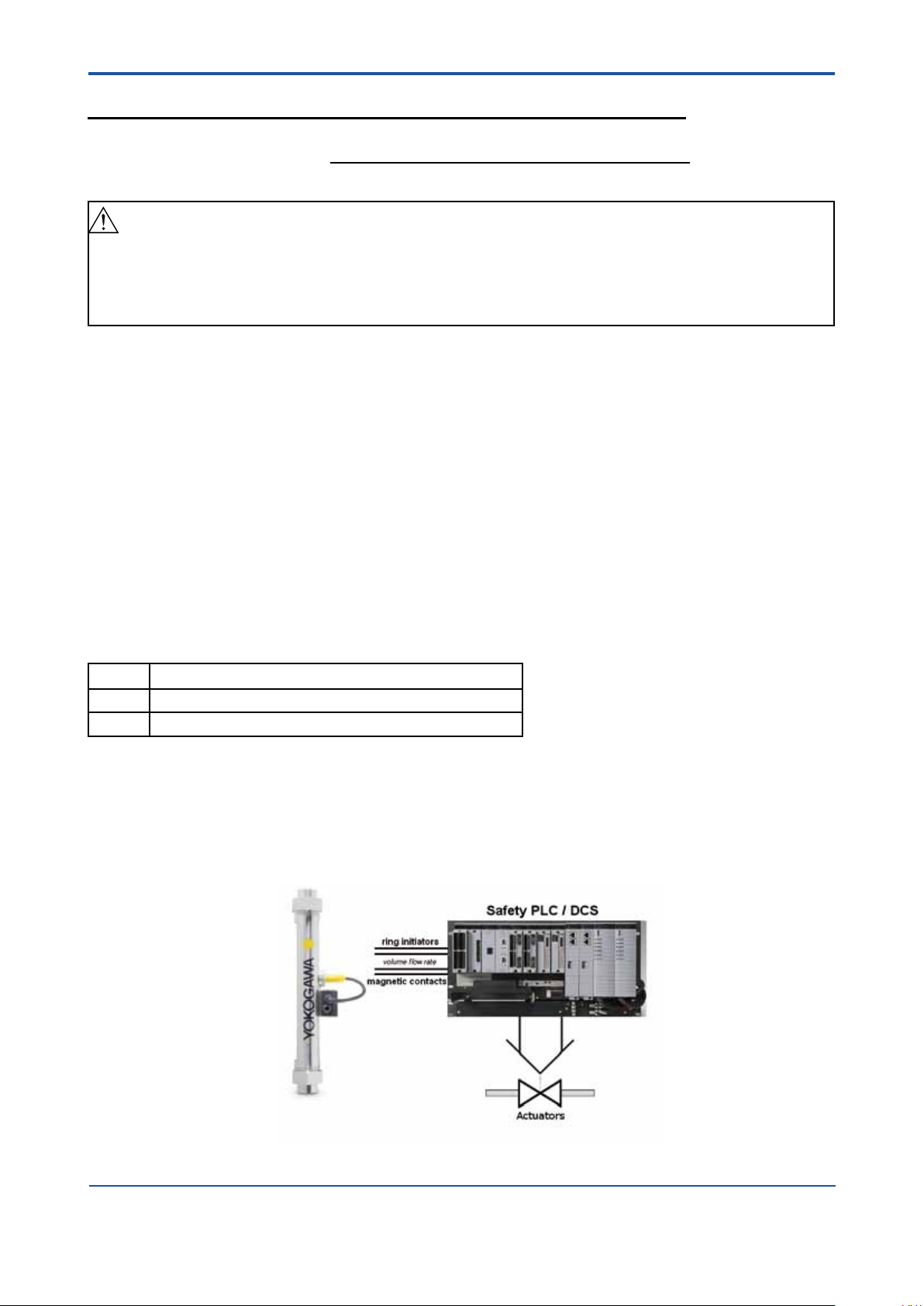

This variable area ow meter is intended for use as a volume ow monitoring component in a Safety

Instrumented System. It has either inductive ring sensors [V2], [V3] or magnetic reed contacts [V1] to indicate

limits. The ow meter may be used with the limit switches to feed signals to a logic solver that is part of the

safety instrumented function (SIF) as shown in Figure 1. The fault annunciation mechanism is a trip of one

of the limit switches. In order to take credit for the automatic diagnostics in the ow meter, this annunciation

mechanism must be connected.

Any valve delivered together with RAGN Glass Rotameter is not covered by the assessment.

Figure 1 Example Safety Instrumented Function

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 42

A1-2

<A1. SAFETY INSTRUMENTED SYSTEMS INSTALLATION>

A1.2.2 Diagnostic Response Time

There is neither diagnostic in the magnetic reed contacts [V1] nor in the inductive ring sensors [V2], [V3].

A1.2.3 Setup

A setup of the ow meter is not required. Installation shall be done according to the manual.

Precautions for use of ring sensors [V2], [V3] in Safety Instrumented Functions:

The high output current should be used as the preferred “safe state”. Therefore to achieve highest reliability of

the system, the orientation of the ring sensors should be set according to the application to set high current

as safe state. For more information on assembly see User’s Manual, Model RAGN Glass Rotameter,

IM 01R01B10-00E-E.

A1.2.4 Proof Testing

The objective of proof testing is to detect failures within the ow meter. Of main concern are undetected

failures that prevent the safety instrumented function from performing its intended function.

The frequency of the proof tests (or the proof test interval) is to be determined in the reliability calculations

for the safety instrumented functions for which the ow meter is applied. The actual proof tests must be

performed more frequently or as frequently as specied in the calculation in order to maintain required safety

integrity of the safety instrumented function.

The following tests need to be specically executed when a proof test is performed. The results of the proof

test need to be documented and this documentation should be part of a plant safety management system.

Failures that are detected should be reported to Yokogawa.

Proof test for RAGN Glass Rotameter with magnetic contacts and inductive ring sensors:

Step Action

1 Take appropriate action to avoid a false trip

2 Inspect the device for any visible damage, corrosion or contamination.

3a Force the RAGN Glass Rotameter to reach a dened “MAX” threshold value and verify that the

magnetic contact or inductive ring initiator goes into the safe state.

Note: only applicable if RAGN is equipped with a “MAX” contact.

3b Force the RAGN Glass Rotameter to reach a dened “MIN” threshold value and verify that the

magnetic contact or inductive ring initiator goes into the safe state.

Note: only applicable if RAGN is equipped with a “MIN” contact.

4 Restore the loop to full operation

5 Restore normal operation

When all the tests listed above are executed a proof test coverage of approximately 99% of possible DU

failures in the RAGN Glass Rotameter can be claimed.

The following tools need to be available to perform proof testing:

Measurement instrument to verify output status of the magnetic reed contacts [V1] or inductive ring sensors

[V2], [V3]

The person(s) performing the proof test of the Yokogawa RAGN Glass Rotameter should be trained in SIS

operations including bypass procedures, ow meter maintenance and company management of change

procedures.

A1.2.5 Repair and replacement

Maintenance information can be found in section Service of the User’s Manual, Model RAGN Glass

Rotameter, IM 01R01B10-00E-E.

If repair is to be performed with the process online the Rota Yokogawa RAGN Glass Rotameter will need to

be bypassed during the repair. The user should setup appropriate bypass procedures for that.

Contact the Yokogawa sales office if this instrument requires repair

The person(s) performing the repair and / or replacement of the Rota Yokogawa RAGN Glass Rotameter

should have a sufficient skill level.

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Page 43

<A1. SAFETY INSTRUMENTED SYSTEMS INSTALLATION>

A1-3

A1.2.6 Startup Time

The ow meter will generate a valid signal within 0.5 seconds of power-on startup.

A1.2.7 Reliability data

A detailed Failure Mode, Effects, and Diagnostics Analysis (FMEDA) report is available from Rota Yokogawa

with all failure rates and failure modes. Rota Yokogawa RAGN Glass Rotameter is intended for use in a Low

Demand Mode. Low Demand Mode means the average interval between dangerous conditions occurs

infrequently.

The Rota Yokogawa RAGN Glass Rotameter is certied up to SIL1 for use in a simplex (1oo1) conguration,

depending on the PFDAVG calculation of the entire Safety Instrumented Function.

A1.2.8 Lifetime limits

The expected lifetime of the Yokogawa Rota Yokogawa RAGN Glass Rotameter is 10 years. The reliability

data listed in A1.2.7 is only valid for this period. The failure rates of the Rota Yokogawa RAGN Glass

Rotameter may increase sometime after this period. Reliability calculations based on the data listed in A1.2.7

for Rota Yokogawa RAGN Glass Rotameter lifetimes beyond 10 years may yield results that are too optimistic,

i.e. the calculated Safety Integrity Level will not be achieved.

A1.2.9 Environmental limits

The environmental limits of Rota Yokogawa RAGN variable area ow meter are specied in the User’s

Manual, Model RAGN Glass Rotameter, IM 01R01B10-00E-E.

A1.2.10 Application limits

The application limits of the Rota Yokogawa RAGN variable area ow meter are specied in the User’s

Manual, Model RAGN Glass Rotameter, IM 01R01B10-00E-E. If the ow meter is used outside of the

application limits the reliability data listed in A1.2.7 becomes invalid.

All Rights Reserved. Copyright © 2011, Rota Yokogawa

IM 01R01B10-00E-E 2nd edition: November 01, 2011-00

Page 44

A1-4

<A1. SAFETY INSTRUMENTED SYSTEMS INSTALLATION>

A1.3 Denitions and Abbreviations

A1.3.1 Denitions

Safety Freedom from unacceptable risk of harm

Functional Safety The ability of a system to carry out the actions necessary to achieve or to maintain a

dened safe state for the equipment / machinery / plant / apparatus under control of

the system.

Basic Safety The equipment must be designed and manufactured such that it protects against

risk of damage to persons by electrical shock and other hazards and against

resulting re and explosion. The protection must be effective under all conditions of

the nominal operation and under single fault condition.

Verication The demonstration for each phase of the life-cycle that the (output) deliverables of

the phase meet the objectives and requirements specied by the inputs to the

phase. The verication is usually executed by analysis and / or testing.

Validation The demonstration that the safety-related system(s) or the combination of safety-

related system(s) and external risk reduction facilities meet, in all respects, the

Safety Requirements Specication. The validation is usually executed by testing

Safety Assessment The investigation to arrive at a judgment - based on evidence - of the safety

achieved by safety-related systems

Further denitions of terms used for safety techniques and measures and the description of safety related

systems are given in IEC 61508-4.

A1.3.2 Abbreviations

FMEDA Failure Mode, Effects and Diagnostic Analysis

SIF Safety Instrumented Function

SIL Safety Integrity Level

SIS Safety Instrumented System