Page 1

Technical

Information

Rotameter

RAGK and RAGL

Detailed Description of Options

TI 01K01B04-01EN-R

Contents

1 Purpose ................................................................................................................. 2

2 Target model .......................................................................................................... 2

3 Specication..........................................................................................................2

4. Detailed description of options ........................................................................... 3

4.1 Marking ............................................................................................................ 3

4.2 Process adapters as added parts ................................................................. 4

4.3 Limit switches ................................................................................................ 6

4.4 Hazardous area approvals ............................................................................ 8

4.5 Scale types ...................................................................................................... 8

4.6TestandCerticate........................................................................................9

4.7 O-Rings ........................................................................................................... 10

4.8 Float stop ....................................................................................................... 10

4.9Accessories...................................................................................................11

4.10 Controller ..................................................................................................... 12

4.11Countryspecicdelivery.............................................................................12

4.12Countryspecicapplication.......................................................................13

4.13 Power supply ................................................................................................13

Rota Yokogawa GmbH & Co. KG

Rheinstr. 8

D-79664 Wehr

Germany

TI 01K01B04-01EN-R

© Copyright 2020 (RYG)

1st edition, April 2020 (RYG)

Page 2

2

1 Purpose

This document describes all relevant options of Glass Rotameter RAGK and RAGL produced at Rota

Yokogawa.

2 Target model

Rotameter Glass RAGK and Rotameter Glass RAGL.

3 Specication

This document is complementary to the Rotameter Glass RAGK GS (GS 01R01B07-00E-E) and to the

Rotameter Glass RAGL GS (GS 01R01B08-00E-E). All technical specications and restrictions are specied

in the GS. This TI is to explain the most relevant options further in detail.

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 3

3

4 Detailed description of options

4.1 Marking

4.1.1 Option /B1 - Tag plate (1.4404/316L) fastened with wire, plate: 12 mm x 40 mm

A small SS tag plate is fastened to the instrument with a SS wire. Max characters: 45. The text has to be

provided via ordering instructions. The text is asked by the FowCongurator after activating “complete sizing”

and has to be transmitted with the order.

Fig. 1 Input of Tag. No. in FlowCongurator

Fig. 2 Tag plate

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 4

4

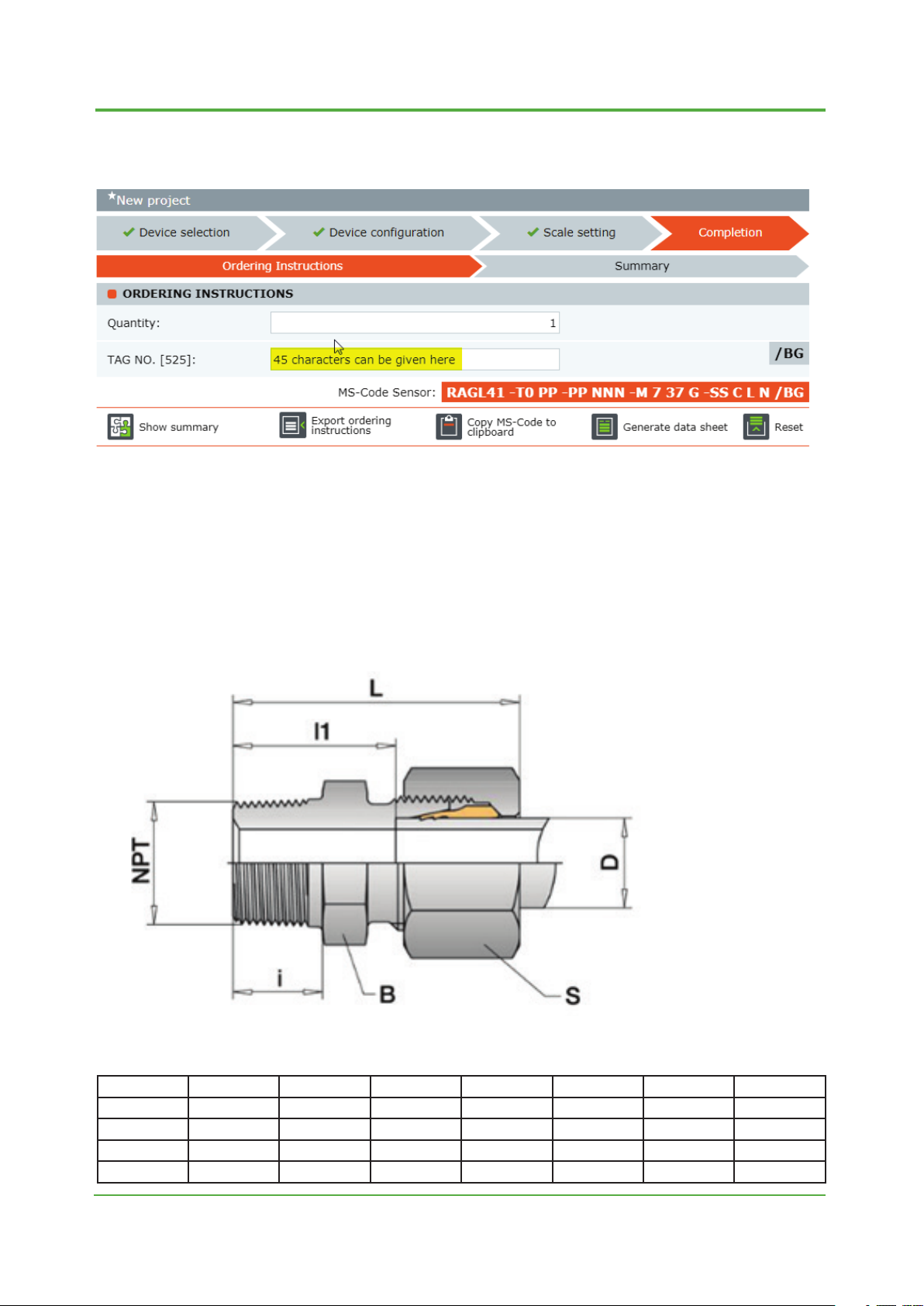

4.1.2 Option /BG – Customer specic notes

The notes are printed on the name plate. Max 45 characters. The text is asked by the FlowCongurator

after activating “complete sizing” and has to be transmitted with the order.

Fig. 3 Input of Tag. No. in FlowCongurator

4.2 Process adapters as added parts

The process adapters are added to the instrument as separate parts. The customer has to screw the

adapters in the NPT process connections with a suitable sealing, normally Teon sealing tape.

4.2.1 Options /C01, /C02, /C03 Cutting ring

Note: This document is applicable to the products manufactured at Rota Yokogawa GmbH &

Co. KG

Fig. 4 Dimensions of cutting ring

Table 1 Dimensions of cutting ring (in mm)

L l1 B S i D Weight in g

6 mm 37.5 23 17 14 15 6 40

8 mm 38 23 17 17 15.1 8 44

10 mm 39 24 17 19 15.1 10 49

12 mm 49 25 19 22 15.1 15 62

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 5

5

4.2.2 Options /P01, /P02, /P03 Nozzle for exible hoses

Fig. 5 Dimensions of nozzle

Table 2 Dimensions of nozzle (in mm)

G L L1 SW DN Dmax Dmin Weight in g

6 mm R1/4" 44 10 15 3.6 6 5 18

8 mm R1/4" 43 8 15 5.6 9 7. 5 18

10 mm R3/8" 52 10 19 7 10 8.5 37

4.2.3 Options /W01, /W02, /W03, /W04 Swagelok® cutting ring

F Wrench size

Fig. 6 Dimensions of Swagelok® cutting ring

Table 3 Dimensions of Swagelok® cutting ring (in mm)

NPT A D E

6 mm R1/4" 37.9 15.3 4.8 14

8 mm R1/4" 38.9 16.2 6.4 15

10 mm R1/4" 40.9 1 7. 2 7. 1 18

12 mm R1/4" 43.4 22.8 7. 1 22

*)

F

*)

Minimum diameter

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 6

6

Limit switch /GM1 or /GM2

Float with magnet

Nut

4.3 Limit switches

4.3.1 Options /GM1, /GM2, /GM3, /GM4, /GM5

These limit switches are for RAGK42. It is a reed contact, so if selected the oat must incorporate a

magnet. This limit switch is considered as a simple apparatus according to

EN/IEC/ANSI/ISA 60079-11 and therefore does not require a specic hazardous area approval by

a notied body. A self-declaration regarding the compliance to EN 60079 is available on the Flow

Center Pages: RAGK_RAGN_Ex_Declaration_Option-GMx.

The /GM can be used together with a power supply option /WA or /WB.

The back panel of the meter has an opening for proper mounting of the contact.

Fig. 7 Installation of limit switch /GM

LIMIT SWITCH GM

GRENZWERTSCHALTER GM

CONTACT LIMITE GM

ROTAMETER RAGN with option /GMx (x = 1 ... 5)

EN 60947-5-6 (NAMUR)

Fig. 8 Connection diagram of limit switch /GM

OPTION: /W4B 24VDC

KFD2-SR2-Ex.W

MAINS / NETZ / TENSION

(L+ (L-)

1 1

1

3

4

6

ONE CHANNEL TRANSMITTER .....-SR2-EX1.W CONNECTION LIKE LIMIT "MAX"

EINKANALIGE VERSTÄRKER .......-SR2-EX1.W ANSCHLUSS WIE GRENZWERT "MAX"

UN CANAL AMPLIFICATEUR ........-SR2-EX1.W RACCORD COMME LIMITE "MAX"

+

-

+

-

TRANSFORMER ISOLATED BARRIER

AMPLIFICATEUR SEPARATEUR

OPTION: /W2B 230VAC

KFA6-SR2-Ex.W

9

LIMIT/ GRENZWERT/ LIMITE

8

MAX

7

1

LIMIT/ GRENZWERT/ LIMITE

1

MIN

1

ÄTRENNSCHALTVERST RKER

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 7

7

15

4

6

3

1

14

12

10

11

8

7

9

U

Mains / Netz / Tension

One channel transmitter: ...-SR2-Ex1.W, connection like limit MAX

Einkanaliger Verstärker: ...-SR2-Ex1.W, Anschluss wie Grenzwert MAX

Un canal amplificateur: ...-SR2-Ex1.W, raccord comme limite MAX

Transmitter Relay

Trennschaltverstärker

Amplificateur Separateur

Limit / Grenzwert / Limite MIN

Limit / Grenzwert / Limite MAX

Max

Min

EN 60947-5-6 (Namur)

-

+

-

+

~ ~

+

-

+

-

Option /W4B 24VDC

KFD2-SR2-Ex2.W

Option /W2B 230VAC

KFA6-SR2-Ex2.W

Inductive ring sensor

Induktiver Ringinitiator

Bague inductive

Rotameter RAGN option /GRx (x = 2 ... 8)

4.3.2 Options /GR1, /GR2, /GR3, /GR4, /GR5, /GR6, /GR7, /GR8

These ring initiators are for RAGK41 and for RAGL41. These are inductive bipolar limit switches,

which means that the oat must have ferromagnetic features. The matching oat must therefore be

made from Mu-metal.

The /GR can be used together with a power supply option /WA or /WB.

The ring initiator is mounted directly over the tube, so the protection cover is not possible.

By its design the ring initiator is sensitive to strong electromagnetic impulses, so installation should be

on sufficient distance from such sources.

Fig. 9 Installation of limit switch /GR

Fig. 10 Connection diagram of limit switch /GR

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 8

8

1 2 3 4

4.4 Hazardous area approvals

Hazardous area approvals ATEX(/KS1) and IECEx(/ES1) are available for inductive ring sensor

options /GR.

The certicate can be found on the Flow Center pages:

RAGK_RAGL_RAGN_Cert_ATEX_RI20_Option-GR_E,

RAGK_RAGL_RAGN_Cert_IECEx_RI20_Option-GR_E.

Fig. 11 Labels on limit switch /GR

1: for all types

Additionally to 1:

2 and 3: for hazardous area types

4: for non- hazardous area types

4.5 Scale types

The offered scale types for RAGL and RAGK have the following characteristics:

Table 4

Visibility Chemical

resistance

G Fluid spec. sticker scale on tube, recomm. middle middle high no

A Fluid spec. attached scale, blank tube high high ---- yes

N mm- scale, sticker scale on tube middle middle high no

Chemical

resistance

with

option /IB

Exchangable

4.5.1 Scale types G and N

If the atmosphere is very aggressive and the user might have concerns about the chemical resistance of the sticker scale, option /IB is very suitable. With option /IB the scale will be directly printed

and burned in on the tube. The burned in scale will be printed permanently on the tube and cannot be

exchanged. For normal atmosphere the sticker scale is completely sufficient.

The scale type A can be combined with the scale types G and N. In combination with /IB, scale types

G or N are replaced by the burned-in scale.

4.5.2 Dual scale types, suffix code D and F

If two different uids run through the meter or if two quite different process conditions exist (more

typical for gas), two different scales can be provided with the meter.

With suffix code F only one scale design is sufficient. In this case the attached scale will be engraved

with the uid specic data, whereas the mm scale is fastened on the tube.

With suffix code D, two different sets of process conditions and scale designs must be delivered as

ordering instructions to the manufacturing. The rst scale design (a) is fastened as a sticker on the

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 9

9

tube, the second scale design (b) is engraved in the attached scale.

To generate the 2 sets of ordering instructions in the FlowCongurator and SAP proceed as follows:

• Size rst the uid for the (a) scale

• Press “Export ordering instruction for YGS” and store the le ((a) scale)

Fig. 12 Window Ordeing Instruction, FlowCongurator

• Note the Model Code from the rst sizing.

• Start a second sizing. Make sure by varying the second max ow range, that you get the same

model code. If the second sizing gets a different cone, the instrument is physically not producible.

If the uid data and ow ranges of the two uids are too different, a dual scale may not be possible.

• Press “Export ordering instruction for YGS (dual scale)” and store the le ((b) scale).

• Import the model code in SAP and upload (a) scale rst and then additional the (b) scale as

ordering instructions with the same upload function.

4.6 Test and Certicates

4.6.1 Option /H1: Oil and fat free for wetted surfaces according Yokogawa specication

For specic description, please see document TI 01K01B03-01EN-R.

4.6.2 Option /P2: Certicate of compliance with the order acc. to EN 10204: 2004-2.1

At the nal check a test will be processed which guarantees the compliance with the order.

This compliance is guaranteed with a certicate. An example can be found on the Flow Center page:

RAGK_Cert_example_2-1 compliance with the order_E_D.

4.6.3 Option /P3: As /P2 + Test report acc. to EN 10204: 2004-2.2

The protocol of the test will be delivered additional to the certicate. An example can be found on the

Flow Center page: RAGK_Cert_example_2-2_test_report_E_D.

4.6.4 Option /PP: Pressure test report for measuring system

The instrument is pressurized with factor 1.6 above its nominal pressure (burst pressure test) and is

inspected for tightness. A result report regarding the test is delivered. An example can be found on

the Flow Center page: RAMC_Cert_PP_Pressure test report Certicate Example.

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 10

10

4.6.5 Option /PT: Flow table for recalculation to other uid

In case of scale N and F, only mm graduation is on the tube. To “translate” the height in mm in ow

units, a recalculation table is required. This table shows the uid data the Rotameter is sized with.

On the left side of the table you nd the height of the oat in mm and the calibration conditions, and

on the left side the process uid.

Fig. 13 Sample of ow table

4.7 O-Rings

The small glass Rotameter are in standard equipped with Viton O-rings. However if other O-ring

material is requested, /NBR (NBR, trivial names: Buna or Perbunan) or /KAL (Kalrez) can be selected.

For RAGK O-rings are used in the valve and for the sealing of the tube.

For RAGL O-rings are only used in the valve. The tube is sealed with a PTFE press tting.

4.8 Float stop

The standard oat stoppers are made from PTFE. The standard oat stoppers can be exchanged with

spring SS stoppers via option /S1.

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 11

11

A

A

L

t = 0.5 mm

to 10 mm

view A

X

4.9 Accessories

4.9.1 Option /QP: means for panel mounting

At customer site, a suitable slot must be machined in the panel. The size of the slot is given in the GS.

Fig. 14 RAGK with option /QP Fig. 15 Panel mounting

Two of the parts marked in the drawing (see Fig. 15) with the “X” are delivered with the instrument.

The parts are inserted from the front as shown in the slot. The instrument is moved between the

parts and fastened with the 4 cross-head screws. Then the total construction is xed with the 2 long

screws from the back side at the panel.

4.9.2 Option /QB: With tapped holes in the connecting heads for mounting

These holes for M3 screws are for example used for the foot stand or to screw the means for the

panel mounting. They are offered for the case that the customer wants to establish his own xing of

the instrument. The detailed dimensions are given in the GS.

4.9.3 Option /QF: Foot stand

One possibility to x the instrument. The foot stand incorporates a level for proper adjustment of the

instrument. See also drawing in the GS

4.9.4 Option /QC: Colored caps for valve knob (red, blue, yellow, green)

The valve knob has a removable cap for mounting. Normally it is black. This option provides a small

plastic bag with 4 caps in the colour red, blue, yellow, green to mark the valve knob. So in a row

installation different uids can be high visible marked by the colour of the knob cap.

Fig. 16 Colored caps for valve knob

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 12

12

4.10 Controller

4.10.1 Option /R1: Flow regulator for changing pre- pressure

As described in the GS.

4.10.2 Option /R3: Flow regulator for changing back-pressure

As described in the GS.

4.11 Country specic delivery

4.11.1 Option /KC: KC-Mark for Korea

This option is necessary for delivery to to Korea. The KC mark is printed on a sticker and attached to the

back side of the instrument. The equivalent certicates can be found on the Flow Center Page:

RAGK_Cert_Korea_KC-mark, RAGL_Cert_Korea_KC-mark.

Fig. 17 KC-Mark

4.11.2 Option /CN: China RoHS mark

This option is necessary for delivery of electrical equipment to China. It conrms the agreement with

Chinese RoHS regulations. The CN mark is printed on the name plate of the ring-initiator (/GR) or the

Reed-contact (/GM). The conformation is declared with a special IM which is delivered with the instrument. It can be found on the FlowCenter Pages in the category Instruction Manuals:

Rotameter_IM_option_CN_RoHS_IM01A01B01-00ZH-R.

Fig. 18 China RoHS mark

4.11.3 Option /VR: Pattern Approval for Russia

The pattern approval certicate can be found on the Flow Center Pages:

RAGN_RAGK_RAGL_RAQN_Pattern Approval_RU.

The approval mark is not printed or attached to the instrument.

When option /VR is selected for RAGL and RAGK, option /QR is also required.

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Page 13

13

1

3

4

6

2

5

13 15

12

9107

14

11

8

KFA6-SR2-Ex2.W

1

2

OUTCHK PWR

S2

S1

S3

III

Front view

LED yellow:

Relay output I

LED red:

LB/SC channel I

LED yellow:

Relay output II

LED red:

LB/SC channel II

Switch S3

(LB/SC-monitoring)

LED green:

Power supply

Removable terminals

green

Removable terminals

blue

Switch S1

(Mode of operation channel I)

Switch S2

(Mode of operation channel II)

2+

3-

1+

Zone 2

Div. 2

Non-Ex

Zone 0, 1, 2

Div. 1, 2

7

8

9

10

11

12

I

II

I

II

230 V AC

115 V AC

24 V DC

14+

15-

5+

6-

4+

KF-SR2-Ex2.W

4.12 Country specic application

4.12.1 Option /QR: Primary Verication for Russia

The calibration certicate is sent to a notied body registered in Russia together with a technical

passport.

The calibration rigs of RYG are approved by this notied body to be sufficient to do the primary verication. The notied body checks the calibration certicate and conrms the primary verication with a

stamp in the technical passport. The technical passport is resent to Rota Yokogawa and later delivered

with the instrument.

4.13 Power supply

The power supplies for the limit switches can be ordered with option /WA or /WB. These are available

with one or two channels.

Fig. 19 Front view of power supply (Source: Pepperl & Fuchs)

Fig. 20 Connections of 2- channel power supply (Source: Pepperl & Fuchs)

TI 01K01B04-01EN-R: 1st edition, April 01, 2020-00

Copyright © 2019, Rota Yokogawa GmbH & Co. KG. All rights reserved.

Subject to change without notice

Loading...

Loading...