Page 1

General

Specications

Model RAGK

Small Glass ROTAMETER

GS 01R01B07-00E-E

Rotameter RAGK is designed for the measurement of

clean liquids and gases.

The conical glass metering tube has a free rotating

oat. The Rotameter is mounted in a vertical pipeline

with ow direction upwards. The ow is indicated by

the top of the oat and can be read from a scale on

the measuring tube or from an attached scale.

FEATURES

• Large selection of measuring ranges

• High repeatability by a free rotating oat even at low

ow rates

• Low pressure loss

• Visual check of the medium

• Non-powered local indication

• Large selection of scales

• Optional built-in regulation valve

• Optional limit switches

Typical Applications

• Transparent liquids

• Low viscous liquids

• Gases

RAGK41 with K-tube

without valve with valve

Contents

Features page 1

Standard Specications page 2

Model Specications page 6

Options

Dimensions and weights page 8

Rota Yokogawa GmbH & Co. KG

Rheinstr. 8

D-79664 Wehr

Germany

page 7

RAGK41 with M-tube

without valve with valve

GS 01R01B07-00E-E

© Copyright 2004 (RYG)

15th edition, April 2020 (RYG)

Page 2

2

0 %

5 %

10 %

15 %

20 %

25 %

30 %

35 %

40 %

45 %

0 %20 %40 %60 %80 %100 %

Error

Flow

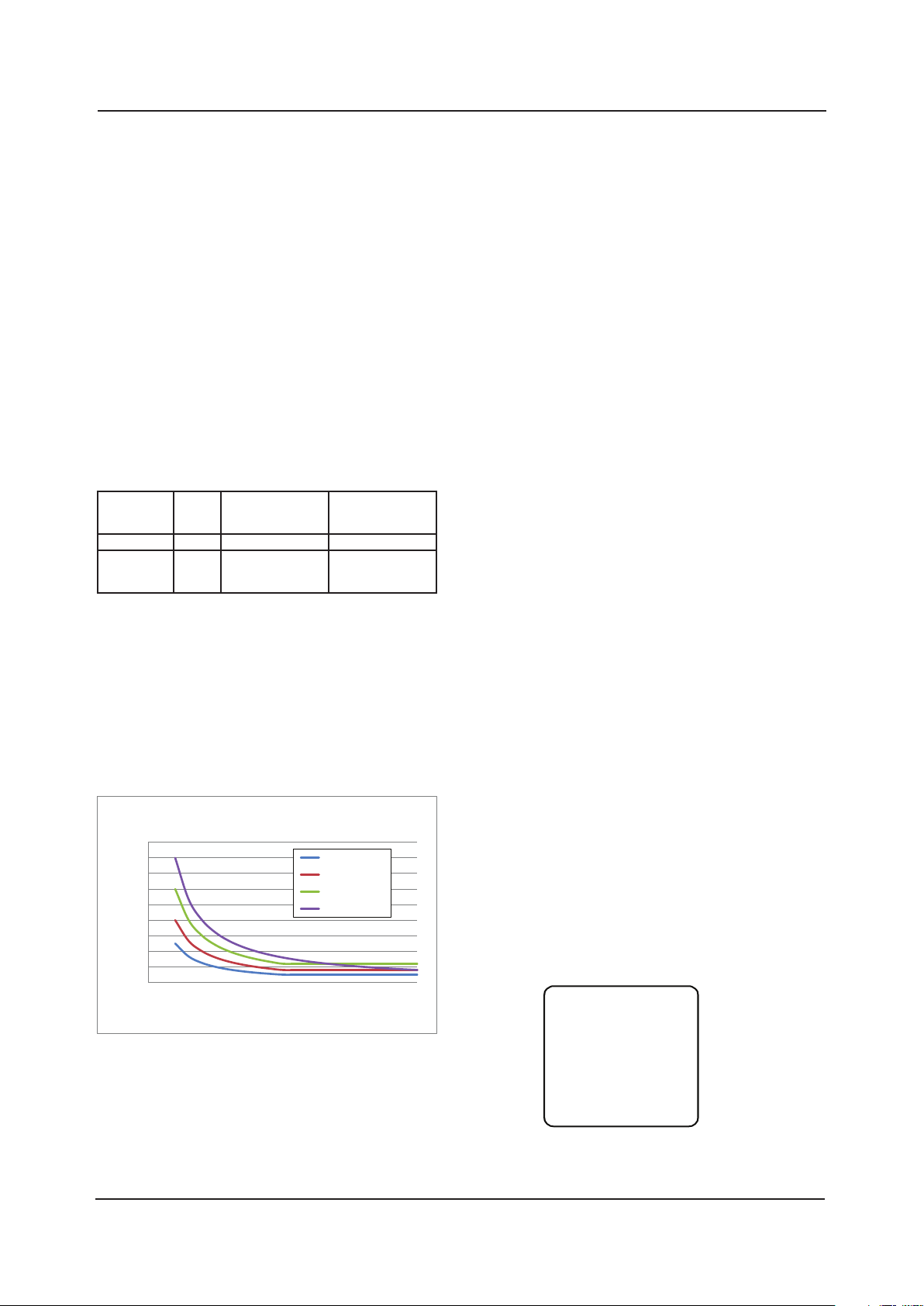

Accuracy specification

2.5 %, qG=50 %

4 %, qG=50 %

6 %, qG=50 %

4 %, qG=100 %

ROTA YOKOGAWA

S/N: D1L123456

Manufactured: 2019.08

PS: 16 bar

TS: -10°C/+130°C

RAGK

FIC 1102

STANDARD SPECIFICATIONS

RoHS Directive 2011/65/EU:

RoHS conform according to EN 50581

Measurable ow rates:

• Water, 20 °C (68 °F):

0.002 l/h to 630 l/h

(0.0005 gph to 166 gph)

• Air, 20 °C (68 °F), 1 bar abs.:

0.2 l/h to 6300 l/h

(0.05 gph to 1664 gph)

The measureable ow rates are depending from

density and viscosity of the uid. To nd the uid

specic measuring range please use the Yokogawa

FlowCongurator: www.FlowCongurator.com.

Measuring range: ≈10:1

Measuring tubes: K6xx; M6xx; K7xx; M7xx; M3xx

K, M: length code

6, 7, 3: diameter code

xx: cone code

Table 1: Measuring accuracy

Glass

metering tube

K631 - K743 75 mm 4 % (for ball 6 %) -----

M613 - M622

M624 - M747

M352 - M357

For detailed accuracy calculation please use the Yokogawa

FlowCongurator: www.FlowCongurator.com.

The accuracy is given under calibration conditions. For

liquid service it has to be taken into account, that the

indication is viscosity dependent and the accuracy can

only be kept if the temperature is constant.

Calibration conditions:

Air, 18 °C to 25 °C (64.4 °F to 77 °F)

atmospheric pressure

Length Measuring accuracy

150 mm

150 mm

150 mm

acc. VDI/VDE 3513

sheet 2 (qG=50 %)

-----

2.5 %

2.5 %

Measuring accuracy

acc. VDI/VDE 3513

sheet 2 (qG=100 %)

4 %

-----

-----

Process and ambient temperature:

• Head material stainless steel(SS): -20 °C to 130 °C

(-4 °F to 266 °F)

• Head material polypropylene(PP): 0 °C to 80 °C

(32 °F to 176 °F)

• Scale G, N, D, F: max. 100 °C (212 °F)

• Scale with option /IB: max. 130 °C (266 °F)

• With option /GR or /GM: 0 °C to 65 °C

(32 °F to 149 °F)

• With option /NBR: -20 °C to 100 °C

(-4 °F to 212 °F)

• With option /R1 or /R3: -20 °C to 80 °C

(-4 °F to 176 °F)

Material wetted parts:

SS is 316L (1.4404), 316 Ti (1.4571) or 1.4408

• Process connection:

• female thread: PP; SS

The threads are directly machined in the head.

• Cutting ring: SS

• Nozzle for hose connection: SS

• Swagelok® connection: SS

• Heads: PP; SS

• O-rings:

• standard: FPM (Viton)

• option /NBR: NBR (Perbunan)

• option /Kal: FFKM (Kalrez)

• Glass: Borosilicate 3.1

• Floats: SS, titan, glass ball,

MU-metal, PVDF,

aluminum oxide,

SS ball, PP, PVDF

• Valve: SS spindle,

PTFE spindle seal,

RAGK41 with silver seat,

RAGK42 with PTFE seat

Vales are plug -in valves

• Float stopper:

• standard: PTFE

• option /S1: SS

• Protection cover: Polycarbonate

• Valve knob: Polyamide

Installation length:

• with K-tubes: 90 mm (3.54")

• with M –tubes: 165 mm (6.5")

• RAGK42: 175 mm (6.89")

Pressure loss: 2 mbar to 18 mbar at

the oat

(0.029 psi to 0.261psi)

The pressure loss at the oat is given by the

FlowCongurator: www.FlowCongurator.com.

Valves will create additional pressure loss.

Weight: see table 4

Attached scale:

Made from hard plastic material with milled letters black in

white, for high visibility.

Limit switches are not possible with attached scale.

Marking:

Fig. 1 Accuracy specication overview

GS 01R01B07-00E-E 15th edition, April 01, 2020-00

Fig. 2: Example of name plate

All Rights Reserved. Copyright © 2004, Rota Yokogawa

Page 3

050100 150200 250

-4

46

96

146

196

246

-20

0

20

40

60

80

100

120

140

024681012141618

Pressure in psi

Ambient or process

temperature in °F

Ambient or process

temperature in °C

Pressure in barg

Temperature/pressure specification

PP with valve

SS with or w/o valve, with option /IB

PP without valve

APPROVALS IN EAEU AND CIS COUNTRIES

Eurasian Conformity (EAC)

RAGK with options /GR complies to applicable Technical

Regulations valid in EAEU countries Russia, Belarus,

Kazakhstan, Armenia and Kyrgyzstan.

• TR CU 004

• TR CU 020

Pattern Approval certicate of Measuring Instruments

RAGK has “Pattern Approval Certicate of Measuring

Instruments”

and is registered as a measuring instrument in Russia.

Option /QR: Primary verication approval with technical

passport

For export to other CIS countries please contact your

Yokogawa representative.

3

Fig.3: Temperature/pressure specication

Further temperature restrictions are applicable in case of

option /GM (limit switches), option /NBR and option /R1

and /R3.

Table 2: Kvs and Cvs value of the valves

Cone 13 to 21 22 to 41 42 to 47 52 to 57

Kvs 0.024 m3/h 0.06 m3/h 0.24 m3/h 1.125 m3/h

Cv

All Rights Reserved. Copyright © 2004, Rota Yokogawa

0.028 gpm 0.07 gpm 0.28 gpm 1.316 gpm

s

GS 01R01B07-00E-E 15th edition, April 01, 2020-00

Page 4

4

LIMIT SWITCH, option /GR1 to /GR8 for RAGK41

With limit switches no protection cover for the tube is

provided.

Floats:

• Mumetal (MU) or PVDF (PD)

• Qmin > 0.004 l/h water or 0.3 l/h air

(Qmin > 0.001 gph water or 0.076 gph air)

Type:

Bistable inductive ring sensor to be used with the

appropriate power supply

Power supply: 4.5 V to 15 V DC

Current levels: acc. DIN EN 60947-5-6

Temperature range: -20 °C to +65 °C

(-4 °F to 149 °F)

Protection: IP 67

Electrical connection: 2 x 0.14 mm²,

with shield 0.4 mm²,

2 m (78") long

EMC compliance:

According to EN 60947-5-2 table 8 (for use in

industrial locations). Based on EMC compliance the

limit switch is marked with CE, EAC and RCM mark.

LVD compliance:

EN 60010-1 and EN 60010-2-030 for option /GM

Hazardous area use (option /KS1, /ES1):

Temperature range: -20 °C to +60 °C

(-4 °F to 140 °F)

Certicate No.:

• PTB 03 ATEX 2111 (/KS1)

• IECEx PTB13.0023 (/ES1)

Protection: Ex ia IIC T6 Gb

Safety relevant input Parameter:

Ui = 12 V, Ii = 22 mA , Pi = 66 mW,

Li = 20 mH, Ci = 200 nF

CE-marking: II 2 G

Markings on the label of the limit switch:

CE, EAC, China RoHS, RCM, Morocco

LIMIT SWITCH, option /GM1 to /GM5 for RAGK42

Floats: PP with insertion M

Type: bistable reed contact

Max. switching voltage: 230 V

Max. switching current: 0.6 A

Max. switching capacity: 12 VA or 12 W

Temperature range: -10 °C to +70 °C

(-14 °F to 158 °F)

Protection: IP 65

Internal capacity: 0 nF

Internal inductance: 0 mH

Connection cable: LIYY 2 x 0.34 mm²; length: 1 m

Housing: Polystyrene

Hazardous area use

Intrinsic safe acc. IEC 60079-11 chapter 5.7,

EN 60079-11 chapter 5.7 and ANSI/ISA 60079-11

chapter 5.7 as “Simple Apparatus” and therefore

does not require a specic hazardous area approval

by a notied body.

Temperature range:

-10 °C to +70 °C (14 °F to 158 °F)

Installation area (ATEX, IECEx):

IIC T6 2G

Installation area (NEC):

Class I, Zone 1, Groups A, B, C, D, T6

Safety relevant input Parameter:

Ui = 15 V; Ii = 50 mA; Pi = 187 mW

Li ≈ 0 mH; Ci ≈ 0 nF

Markings on the label of the limit switch:

CE, RCM, Morocco

POWER SUPPLY FOR LIMIT SWITCHES,

option /WA

and /WB

Type:

Acc. to

•

•

•

Power supply:

• 230 V AC ± 10 %, 45 to 65 Hz

• 115 V AC ± 10 %, 45 to 65 Hz

• 24 V DC ± 25 %

Relay output:

1 or 2 potential-free change over contact(s)

Switching capacity:

Max. 250 V AC, max. 2 A

EN 60947-5-6

KFA5-SR2-Ex*-W (115 V AC);

KFA6-SR2-Ex*-W (230 V AC);

KFD2-SR2-Ex*-W (24 V DC); * = 1 or 2

* = 1 or 2

* = 1 or 2

POWER SUPPLY FOR INTRINSICALLY SAFE LIMIT

SWITCHES,

Technical data same as above.

Type:

Acc. to

•

•

•

Approvals:

•

•

•

•

• EAC: RU С-DE.EX01.В.00102/19

• NEPSI: GYJ17.1283

•

•

•

•

• NEPSI: GYJ17.1283

•

•

•

•

• EAC: RU С-DE.EX01.В.00102/19

• NEPSI: GYJ17.1284

Control circuit (ATEX):

[

Ex ia] IIC; group II; category (1)GD

Entity parameter:

See certicates

option /WA and /WB

EN 60947-5-6

KFA5-SR2-Ex*-W (115 V AC);

KFA6-SR2-Ex*-W (230 V AC);

KFD2-SR2-Ex*-W (24 V DC); * = 1 or 2

KFA5-SR2-Ex*-W

ATEX: PTB 00 ATEX 2081

FM: ID 3011578

IECEx: PTB11.0031

KFA6-SR2-Ex*-W

ATEX: PTB 00 ATEX 2081

FM: ID 3011578

IECEx: PTB11.0031

• EAC: RU С-DE.EX01.В.00102/19

KFD2-SR2-Ex*-W

ATEX: PTB 00 ATEX 2080

FM: ID 3011578

IECEx: PTB11.0034

:

:

:

* = 1 or 2

* = 1 or 2

GS 01R01B07-00E-E 15th edition, April 01, 2020-00

All Rights Reserved. Copyright © 2004, Rota Yokogawa

Page 5

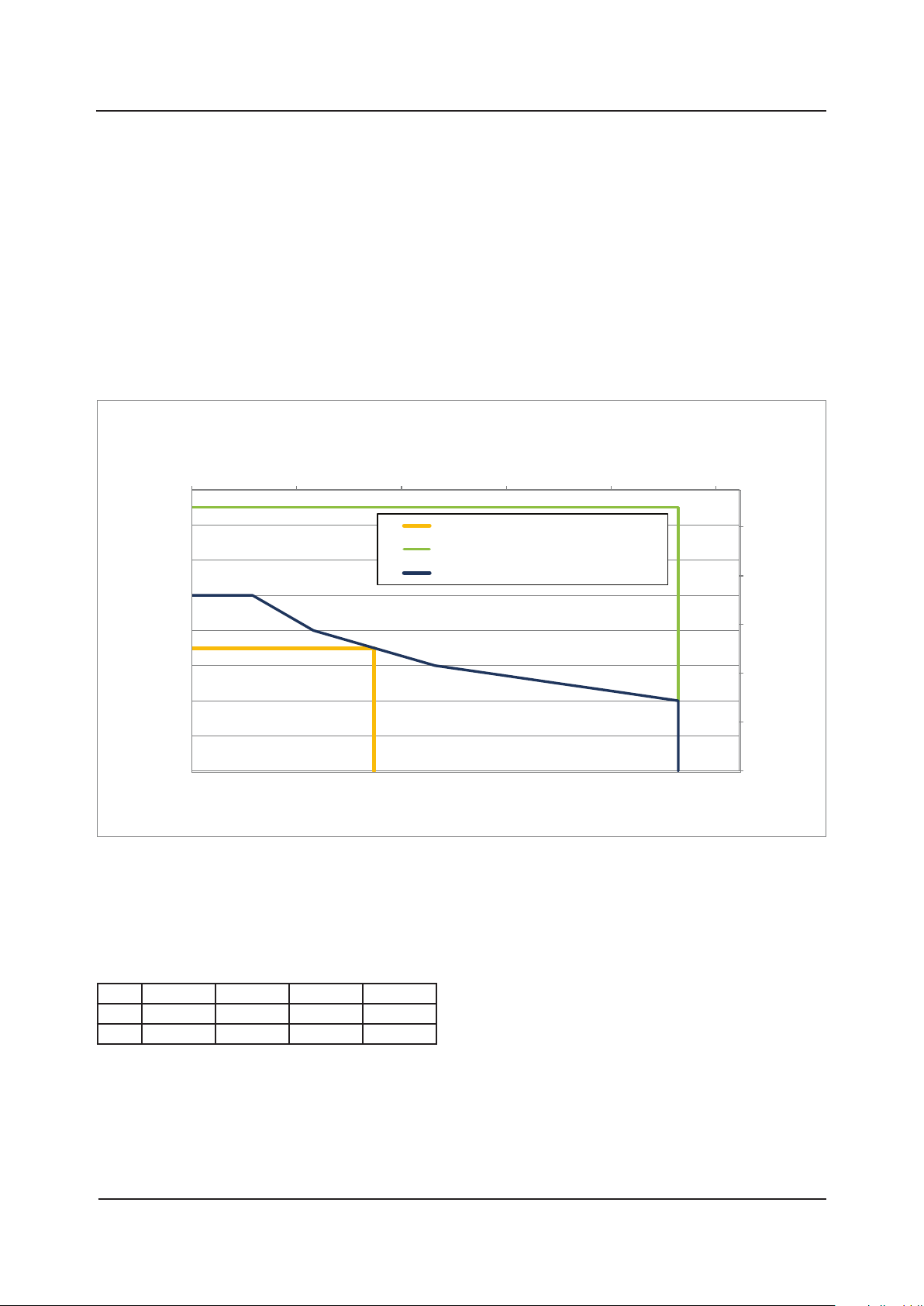

FLOW CONTROLLER, option /R1 and /R3 for

0123

05

RAGK41

Flow regulator for constant ow in case of variations in

process pressure.

These are no valves to reduce the pressure.

• Flow Controller /R1 for liquids and gases

The regulator keeps the ow rate constant in case of

a variable inlet pressure and constant back pressure.

For gases the process conditions are the back

conditions. The inlet pressure should be minimum

400 mbar larger than the back pressure (see Fig.3).

• Flow Controller /R3 for gases with uctuations of

the back pressure and constant inlet pressure.

The process conditions are the inlet conditions.

The inlet pressure should be minimum 400 mbar

larger than the back pressure.

Max. liquid ow: 100 l/h (26.4 gph)

Max. gas ow: 3250 l/h (858.56 gph)

Max. pressure: 25 bar (362.6 psi)

Temperature range: -20 °C to +80 °C

(-4 °F to 176 °F)

Table 3: Material of the controllers

Housing Diaphragm Springs

/R1 or /R3 SS PTFE SS

1000

100

Flow in l/h, air at 20 °C, backpressure 1 bar

5

Control characteristic for /R1

flow 6

flow 5

flow 4

flow 3

flow 2

flow 1

10

Prepressure in barg

Control characteristic for /R1

1000

flow 6

flow 5

flow 4

100

10

Flow in gph, air at 68 °F, backpressure 68 psi

1

01020304

Prepressure in psi

Fig. 4 Control characteristic for /R1

The above curves show the control characteristic of the

inlet ow regulator /R1 with air for 6 different owrates,

each with xed valve position, back pressure 1 bar (14.5 psi)

(atmosphere conditions).

For the smallest owrate the regulation works best from

0.4 bar (5.8 psi) to 3 bar (43.5 psi) (or more) inlet pressure

change, for the largest owrate from 0.9 bar (13 psi) to

3 bar (43.5 psi) (or more).

flow 3

flow 2

flow 1

0

All Rights Reserved. Copyright © 2004, Rota Yokogawa

GS 01R01B07-00E-E 15th edition, April 01, 2020-00

Page 6

6

MODEL SPECIFICATIONS

Model Suffix code Description Restrictions

RAGK41 For K- and M-tubes

RAGK42 For M3-tubes

Process

connections

Material process

connections and

heads

Val ve NNN Without valve

Tube length -K 75 mm (2.95")

Tube diameter 6 10 mm (0.39") *)

Tube cone combination XX *)

Fluid scale G Fluid specication sticker scale on tube,

Float material -AL Float aluminum *)

Float diameter A 1.6 mm (0.06") *)

Flow mark L RAGK41, liquid *)

Float insertion N Standard

*)To be determined with the FlowCongurator

-T0 RAGK41: Female thread, ¼" NPT

RAGK42: Female thread, 3/8" NPT

-R0 RAGK41: Female thread, ¼" Rp

RAGK42: Female thread, 3/8" Rp

PP-PP Polypropylene head

SS-SS Stainless steel head

SV1 RAGK41, inlet valve, silver seat

SV2 RAGK41, outlet valve, silver seat

GV1 RAGK42, inlet valve, PTFE seat

GV2 RAGK42, outlet valve, PTFE seat

-M 150 mm (5.91")

7 17 mm (0.67") *)

3 28 mm (1.10") *)

recommended

A Fluid specication attached scale, blank

tube

N mm scale, sticker scale on tube Tmax = 100 °C (212 °F)

D Dual scale: G and A

F Dual scale: N and A

-GL Ball glass, black For gasses only *)

-KR Sintered oat Al2O3, red *)

-MU Float mumetal *)

-PD Float PVDF, milky white *)

-PP Float PP, light grey *)

-SR Ball SS For liquids only *)

-SS Float SS *)

-TT Float titan *)

B 3.2 mm (0.13") *)

C 6.3 mm (0.25") *)

D 9.5 mm (0.37") *)

3 15.7 mm (0.62") *)

G RAGK41, gas *)

2 RAGK42, liquid *)

3 RAGK42, liquid *)

6 RAGK42, gas *)

7 RAGK42, gas *)

M Float with magnet insertion

not with PP-PP

Tmax = 100 °C (212 °F)

Not with /GR or /GM

Not with /GRor /GM, Tmax =

100 °C (212 °F)

Not with /GRor /GM, Tmax =

100 °C (212 °F)

Mandatory for option /GM

GS 01R01B07-00E-E 15th edition, April 01, 2020-00

All Rights Reserved. Copyright © 2004, Rota Yokogawa

Page 7

OPTIONS

Options Option code Description Restrictions

Marking

Process

adapters as

added part

Limit switches

Hazardous area

app.

Scale /IB Scale imprinted on the tube and burned in Not for scale A, T max = 130 °C (266 °F)

Tests and

certicates

O-Rings

Alternative oat

stop

Accessories

Controller

Country specic

delivery

Country specic

application

Power supply

Special order /Z Customer specic design, must be specied separately. If /Z is selected, several suffix of Model Code can be changed to Z.

/B1

/BG Customer specic notes

/C01 Cutting ring in SS for 6 mm outer diameter tubes Only for RAGK41-T0

/C02 Cutting ring in SS for 8 mm outer diameter tubes Only for RAGK41-T0

/C03 Cutting ring in SS for 10 mm outer diameter tubes Only for RAGK41-T0 or RAGK42-T0

/C04 Cutting ring in SS for 12 mm outer diameter tubes Only for RAGK41-T0 or RAGK42-T0

/P01 Nozzle in SS, for exible hoses inner diameter 6 mm Only for RAGK41-R0

/P02 Nozzle in SS, for exible hoses inner diameter 8 mm Only for RAGK41-R0

/P03 Nozzle in SS, for exible hoses inner diameter 10 mm Only for RAGK42-R0

/W01 Swagelok® in SS for 6 mm outer diameter tubes Only for RAGK41-T0

/W02 Swagelok® in SS for 8 mm outer diameter tubes Only for RAGK41-T0

/W03 Swagelok® in SS for 10 mm outer diameter tubes Only for RAGK41-T0

/W04 Swagelok® in SS for 12 mm outer diameter tubes Only for RAGK41-T0

/GM1 Magnetic Min-contact Only for RAGK42, insertion code M

/GM2 Magnetic Max-contact Only for RAGK42, insertion code M

/GM3 Magnetic Min-Max-contact Only for RAGK42, insertion code M

/GM4 Magnetic Min-Min-contact Only for RAGK42, insertion code M

/GM5 Magnetic Max-Max-contact Only for RAGK42, insertion code M

/GR1 Bistable inductive ring sensor

/GR2 Bistable inductive ring sensor

/GR3 Bistable inductive ring sensor

/GR4 Bistable inductive ring sensor

/GR5 2 bistable inductive ring sensors (2 x /GR1)

/GR6 2 bistable inductive ring sensors (2 x /GR2)

/GR7 2 bistable inductive ring sensors (2 x /GR3)

/GR8 2 bistable inductive ring sensors (2 x /GR4)

/KS1 ATEX intrinsically safe “ia“ Only for /GR1 to /GR8

/ES1 IECEx intrinsically safe “ia“ Only for /GR1 to /GR8

/H1 Oil and fat free for wetted surface acc. to Yokogawa specication Not with /R1, /R3

/P2 Certicate of compliance with the order acc. to EN 10204: 2004-2.1

/P3 As /P2 + Test report acc. to EN 10204: 2004-2.2

/PP Pressure test report for measuring system

/PT Flow table for recalculation to other uid Only for N and F scale, uid data must be provided

/NBR NBR O-rings for tube and valve (if ordered) Temperature range: -20 °C to 100 °C (-4 °F to 212 °F)

/KAL Kalrez O-rings for tube and valve (if ordered) Only for RAGK41

/S1 Float spring stops made of SS 1.4571

/QP Means for panel mounting Only for RAGK41

/QB With tapped holes in the connecting heads for mounting Only for RAGK41

/QF Foot stand Only for RAGK41

/QC Colored caps for valve knob (red, blue, yellow, green) Only with valve, only for RAGK41

/R1 Flow regulator for alternating pre-pressure

/R3 Flow regulator for alternating back-pressure

/KC KC-mark for Korea

/CN China RoHS mark

/VR Pattern Approval for Russia

/QR Primary Vercation for Russia Only with /VR. Not for cones 13 to 24

/W1A KFA5-SR2-Ex1.W, 115 V AC, 1 channel For /GM1, GM2 and /GR1 to GR4

/W1B KFA5-SR2-Ex2.W, 115 V AC, 2 channels For /GM3 to /GM5 and /GR5 to GR8

/W2A KFA6-SR2-Ex1.W, 230 V AC, 1 channel For /GM1, GM2 and /GR1 to GR4

/W2B KFA6-SR2-Ex2.W, 230 V AC, 2 channels For /GM3 to /GM5 and /GR5 to GR8

/W4A KFD2-SR2-Ex1.W, 24 V DC, 1 channel For /GM1, GM2 and /GR1 to GR4

/W4B KFD2-SR2-Ex2.W, 24 V DC, 2 channels For /GM3 to /GM5 and /GR5 to GR8

By use of the FlowCongurator www.FlowCongurator.com restrictions are automatically taken into account.

Tag plate(SS) fastened with wire, plate: 12 x 40 mm; marking

must be provided by the customer

max. 45 characters

Only for oat MU AN

Only for oat PD BN or MU BN

Only for oat PD CN

Only for oat MU CN, MU DN, PD DN

Only for oat MU AN, not for K-tube

Only for oat PD BN or MU BN, not for K-tube

Only for oat PD CN, not for K-tube

Only for oat MU CN, MU DN, PD DN, not for

K-tube

Only for RAGK41, only with SS-head, only with

inlet valve

Only for RAGK41, only with SS-head, only with

outlet valve, only for gasses

Only with option /GMor /GR

7

All Rights Reserved. Copyright © 2004, Rota Yokogawa

GS 01R01B07-00E-E 15th edition, April 01, 2020-00

Page 8

8

A

B

B

A

Process connection -T0 or -R0 approx. 135mm (5.3")

Process connection

as add. part

Process connection

as add. part

B

A

Process connection -T0 or -R0 approx. 135mm (5.3")

A

B

DIMENSIONS AND WEIGHTS

Fig. 5 RAGK41 with valve

Fig. 6 RAGK42 with valve

Fig. 7 Version with inlet valve and inlet ow controller option /R1

Fig. 8 Version with outlet valve and outlet ow controller option /R3

GS 01R01B07-00E-E 15th edition, April 01, 2020-00

All Rights Reserved. Copyright © 2004, Rota Yokogawa

Page 9

Table 4: Weights and dimensions

E

A

A

L

t = 0.5 mm

to 10 mm

view A

Dimensions in mm (inch) Weight in g (lbs)

Measuring

tube

K6; K7 111 (4.37) 90 (3.54) 150 (0.33) 340 (0.75) 1060 (2.33)

M6; M7 186 (7.32) 165 (6.5) 230 (0.51) 500 (1.1) 1220 (2.89)

M3 208 (8.19) 175 (6.89) 540 (1.19) 1160 (2.56) ---

A B w/o controller PP w/o controller SS with controller SS

I

F

9

H

G

Fig. 9 Head dimensions (with or w/o valve) with tapped holes for option /QB

Table 5: Dimensions of heads

Model Dimensions in mm (inch)

E F G H I

RAGK41 with K6/K7/ M6/ M7

RAGK42 with M3

29 (1.14) 12,5 (0.49) 25 (0.98) 19 (0.75) 33 (1.3) 3 (M3 screw)

42 (1.65) 20 (0.79) 40 (0.157) 20 (0.79) 42 (1.69) 5 (M5 screw)

Drill hole

diameter in

mm

Table 6: Slot dimensions in the panel

Model Dimensions in mm (inch)

A L

RAGK41 with K6/K7

RAGK41 with M6/M7

26 (1.02) 115 (4.53)

26 (1.02) 190 (7.45)

Fig. 10 Option /QP, means for panel mounting

All Rights Reserved. Copyright © 2004, Rota Yokogawa

GS 01R01B07-00E-E 15th edition, April 01, 2020-00

Page 10

10

YOKOGAWA ELECTRIC CORPORATION

YOKOGAWA CORPORATION OF AMERICA

YOKOGAWA AMERICA DO SUL LTDA.

YOKOGAWA EUROPE B. V.

Euroweg 2, 3825 HD Amersfoort,

THE NETHERLANDS

Phone : 31-88-4641000

Fax : 31-88-4641111

YOKOGAWA INDIA LTD.

Plot No.96, Electronic City Complex,

Hosur Road, Bangalore - 560 100,

INDIA

Phone : 91-80-4158-6000

Fax : 91-80-2852-1442

YOKOGAWA AUSTRALIA PTY. LTD.

Tower A, 112-118 Talavera Road,

Macquarie Park NSW 2113,

AUSTRALIA

Phone : 61-2-8870-1100

Fax : 61-2-8870-1111

YOKOGAWA MIDDLE EAST & AFRICA B.S.C.(C)

P.O. Box 10070, Manama, Building 577,

Road 2516, Busaiteen 225, Muharraq,

Kingdom of BAHRAIN

Phone : 973-17358100

Fax : 973-17336100

Headquarters

2-9-32, Nakacho, Musashino-shi,

Tokyo, 180-8750 JAPAN

Phone : 81-422-52-5555

Branch Sales Offices

Osaka, Nagoya, Hiroshima,

Kurashiki, Fukuoka, Kitakyusyu

Head Office

12530 West Airport Blvd, Sugar Land,

Texas 77478, USA

Phone : 1-281-340-3800

Fax : 1-281-340-3838

Georgia Office

2 Dart Road, Newnan, Georgia 30265, USA

Phone : 1-800-888-6400/ 1-770-253-7000

Fax : 1-770-254-0928

Praca Acapulco, 31 - Santo Amaro, Sáo Paulo/SP,

BRAZIL, CEP-04675-190

Phone : 55-11-5681-2400

Fax : 55-11-5681-4434

YOKOGAWA ELECTRIC CIS LTD.

Grokholskiy per 13 Building 2, 4th Floor 129090,

Moscow, RUSSIA

Phone : 7-495-737-7868

Fax : 7-495-737-7869

YOKOGAWA CHINA CO., LTD.

3F Tower D, No.568 West Tianshan RD.

Shanghai CHINA, 200335

Phone : 86-21-62396262

Fax : 86-21-62387866

YOKOGAWA ELECTRIC KOREA CO., LTD.

(Yokogawa B/D, Yangpyeong-dong 4-Ga),

21, Seonyu-ro 45-gil, Yeongdeungpo-gu,

Seoul, 150-866, KOREA

Phone : 82-2-2628-6000

Fax : 82-2-2628-6400

YOKOGAWA ENGINEERING ASIA PTE. LTD.

5 Bedok South Road, Singapore 469270,

SINGAPORE

Phone : 65-6241-9933

Fax : 65-6241-2606

ISO 9001

A

view A

158 (16.22“)

adjustable screw

134 (5.28“)

Fig. 11 Option /QF, foot stand, dimensions in mm (inch)

REGISTERED TRADEMARKS

Rotameter® is a trademark of Rota Yokogawa GmbH & Co. KG, a subsidiary of Yokogawa Electric Corporation, Japan.

In the United Kingdom Rotameter

Swagelok®: Registered trademark of Swagelok Company, Solon, Ohio, USA

GS 01R01B07-00E-E 15th edition, April 01, 2020-00

TM

is a trademark of Emerson Electric Co.

All Rights Reserved. Copyright © 2004, Rota Yokogawa

Loading...

Loading...