Page 1

Service

PT500 Maintenance mode

Manual

Operation manual

SM80B22M02E

Yokogawa Denshikiki Co.,Ltd.

Yokogawa Denshikiki Co.,Ltd.Yokogawa Denshikiki Co.,Ltd.

Yokogawa Denshikiki Co.,Ltd. 5th edition 6th edition

2005.09 2006.05

Page 2

Page 3

SM80B22M02E

In this manual, the function and the operation of the maintenance mode of the PT500 series

autopilot are described. As for these maintenance modes, it is a prohibition of use and the

miss-operation prevention by the crew is achieved by the password.

An

An An

Any operation described in this manual must be carried out by personnel of Yokogawa

y operation described in this manual must be carried out by personnel of Yokogawa y operation described in this manual must be carried out by personnel of Yokogawa

y operation described in this manual must be carried out by personnel of Yokogawa

authorized service station or with the assistance of our service engineer.

authorized service station or with the assistance of our service engineer.authorized service station or with the assistance of our service engineer.

authorized service station or with the assistance of our service engineer.

Contents

Chapter1 Normal/Maintenance mode ·········································· 1-1

Chapter 2 I/F Set-up (MAINTENANCE 1) ······································· 2-1

1. Select the I/F set-up data ········································· 2-1

2. Hardware setting ··················································· 2-4

2.1 Hardware setting of the Gyrocompass ···························· 2-5

2.2 Hardware setting of the External heading ······················· 2-10

2.3 Hardware setting of the INS/GPS ································ 2-11

3. Software setting ··················································· 2-12

3.1 Software setting of the Gyrocompass input ······················ 2-13

3.2 Software setting of the External compass input ················· 2-21

3.3 Software setting of the INS/GPS input ·························· 2-22

3.4 Software setting of the INS/GPS output ························· 2-30

Chapter 3 Memory Access-FIX (1 bite) (MAINTENANCE 2) ······················· 3-1

Chapter 4 Memory Access-FLT(4 bite) (MAINTENANCE 3) ························ 4-1

Chapter 5 DAC Output (MAINTENANCE 4) ······································ 5-1

Chapter 6 Actual rudder angle output (MAINTENANCE 5) ······················· 6-1

Chapter 7 Course deviation output (MAINTENANCE 6) ························· 7-1

Chapter 8 Display of the analogue input (MAINTENANCE 7) ···················· 8-1

Chapter 9 Program version number (MAINTENANCE 8) ··························· 9-1

Chapter 10 Program cold start (MAINTENANCE 9) ······························ 10-1

Chapter 11 Input and Calculate the ship’s parameter (PT500A)(MAINTENANCE 10) 11-1

Chapter 12 Display the result of identification(PT500A)(MAINTENANCE 11) ·· 12-1

Chapter 13 Off course alarm SW(MAINTENANCE 12) ··························· 13-1

Chapter 14 Bar graph SW (MAINTENANCE 13) ································· 14-1

Chapter 15 Beep of the key operation SW (MAINTENANCE 14) ················ 15-1

Chapter 16 Select the course after auto override steering (MAINTENACE 15) ·· 16-1

Chapter 17 Display analogue voltage value (MAINTENANCE 16) ················· 17-1

Chapter 18 Option setting mode (MAINTENANCE 17) ···························· 18-1

Chapter 19 Alarm threshold of servo loop failure ·························· 19-1

Chapter 20 Gyrocompass moving average time of CMZ300X format ··············· 20-1

Chapter 21 Analog recorder output for wide rudder angle mode ·············· 21-1

Chapter 22 Speed gain compensation (PT500D・SUB AUTO) ····················· 22-1

Chapter 23 Select the heading monitor function ···························· 23-1

Chapter 24 Alarm threshold of Rudder Erroneous ···························· 24-1

Chapter 25 Alarm threshold of Heading Erroneous ··························· 25-1

Chapter 26 Boundary of Speed status output ································ 26-1

Chapter 27 Special flag setting (MAINTENANCE 18) ··························· 27-1

Chapter 28 Notice ························································· 28-1

【【【【NOTE】】】】This maintenance mode manual is applied for revision 10 of PT500A Version “K”

(CR155K10).

Page 4

SM80B22M02

Page 5

1-1

SM80B22M02E

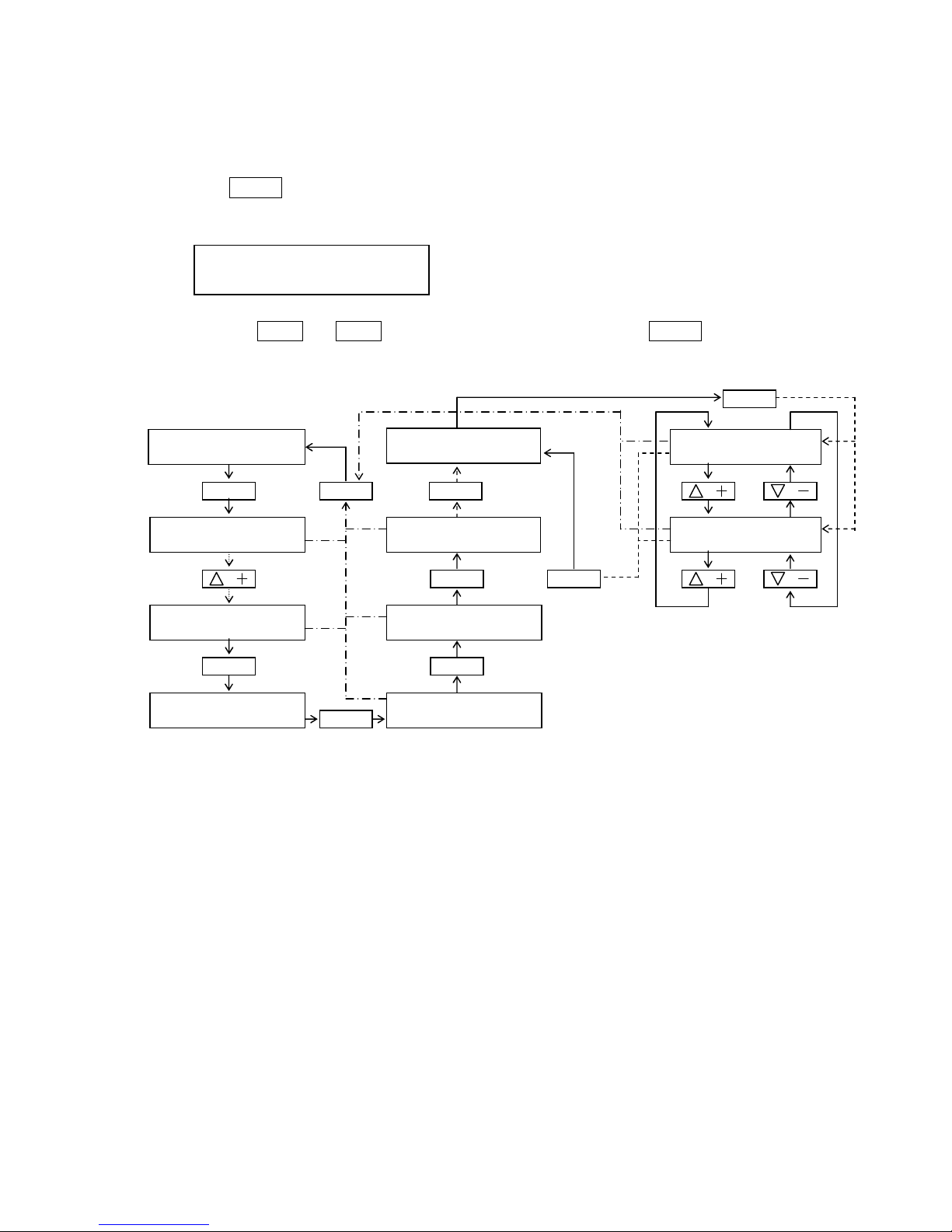

Chapter 1. Normal / Maintenance mode

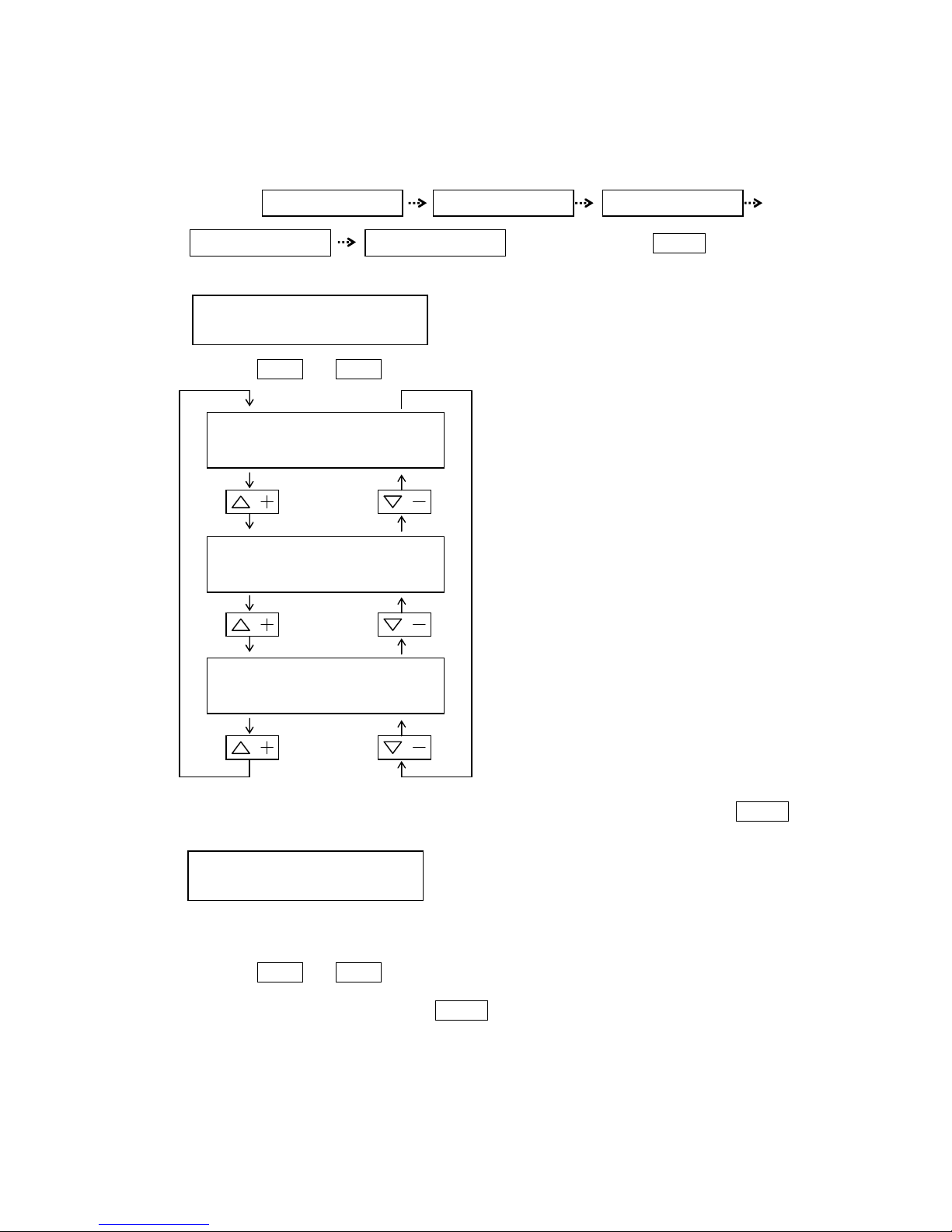

1.Maintenance mode

How to access the maintenance mode.

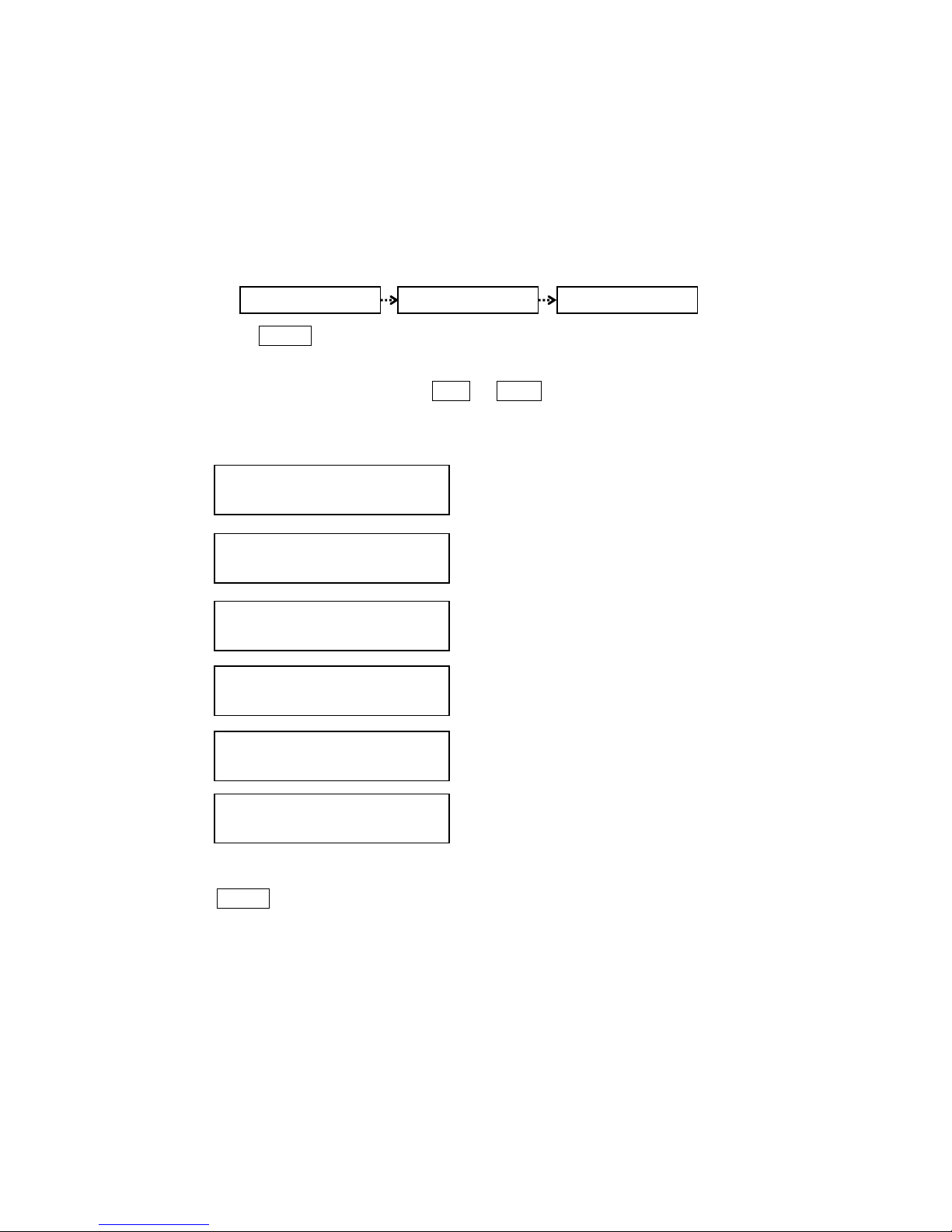

(1)Press the ADJUST

ADJUSTADJUST

ADJUST key. The LCD display becomes ready condition for adjusting mode.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key and select the "

ADJUST MODE 99

…………““““

(3)Press ENTER

ENTERENTER

ENTER key. The LCD display become PASSWORD mode.

(4)Input the password

PT500A :

→ → →

PT500D:

→ → →

SUB AUTO:

→ → →

(5)Press ENTER

ENTERENTER

ENTER key after input the password. Software mode is changed Normal to Maintenance mode.

Note)When you selected the Maintenance mode, you can use all operation in Normal mode and

maintenance mode.

ADJUST MODE 99

…

MAINTENANCE MODE

MAINTENANCE MODE

PASSWORD [ ]

OPERATION

MODE

RATE

RADIUS

SPEED

RUDDER

LIMIT

RUDDER

LIMIT

RUDDER

LIMIT

OPERATION

MODE

OFF CRS

ALARM

RUDDER

LIMIT

RUDDER

LIMIT

OFF CRS

ALARM

RUDDER

LIMIT

MAINTENANCE 1

…

MAINTENANCE MODE

Page 6

1-2

SM80B22M02

2.Normal mode(Release the maintenance mode)

Normal mode means to prohibit the maintenance mode

(1)Press the △△△△ ++++ or ▽▽▽▽ ---- key when the maintenance mode is selected.

In case of the PT500A type, you select the "

MAINTENANCE 19

… "

In case of the PT500D and SUBAUTO type, you select the "

MAINTENANCE 17

… "

PT500A: PT500D・SUBAUTO:

(2)Press ENTER

ENTERENTER

ENTER key. Software mode is changed to Normal mode

Note)The maintenance mode is automatically released by selecting the normal mode or when the

operator has kept the condition without key operation more than 1 hours.

MAINTENANCE 19

…

MAINTENANCE OFF

MAINTENANCE 17

…

MAINTENANCE OFF

ADJUST MODE 99

…

MAINTENANCE OFF

Page 7

1-3

SM80B22M02E

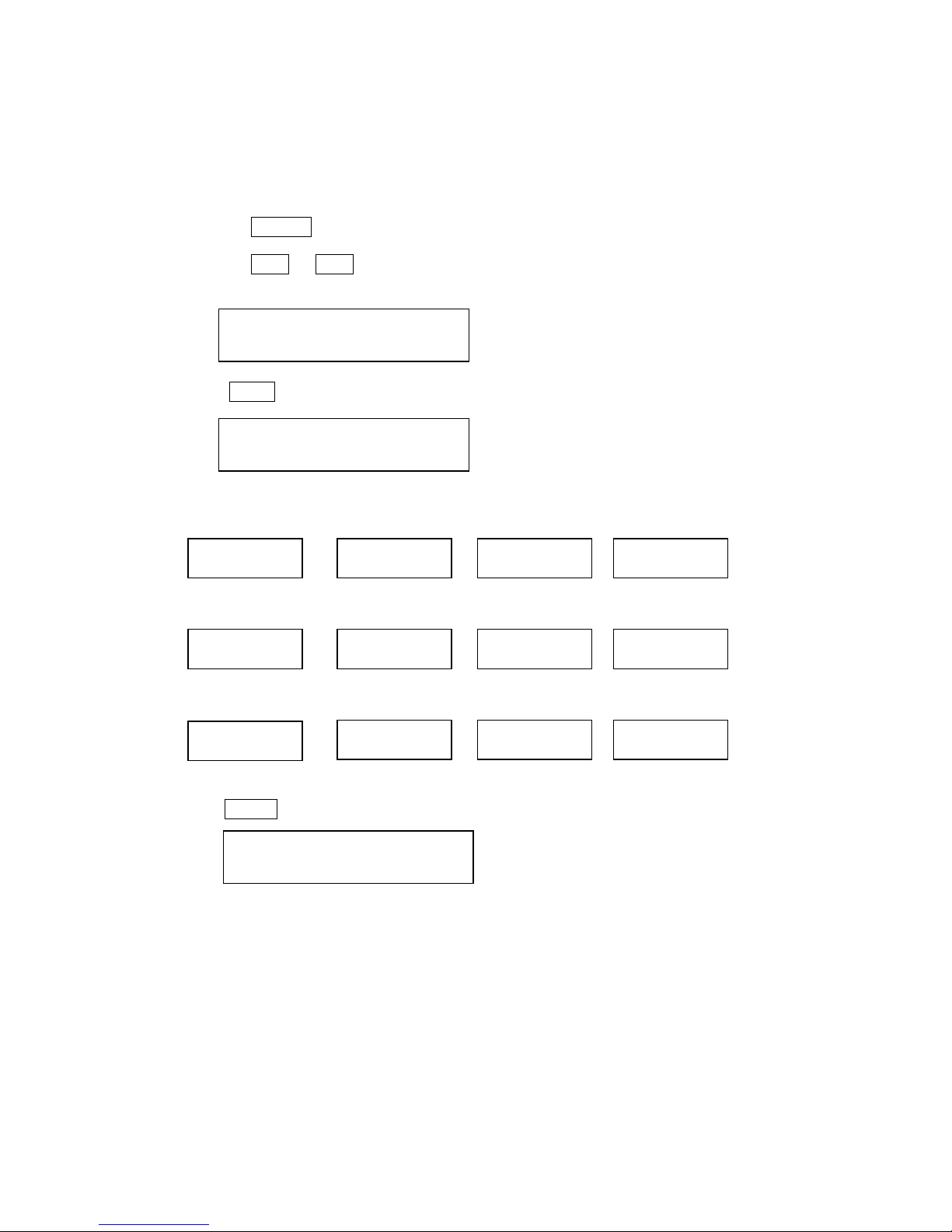

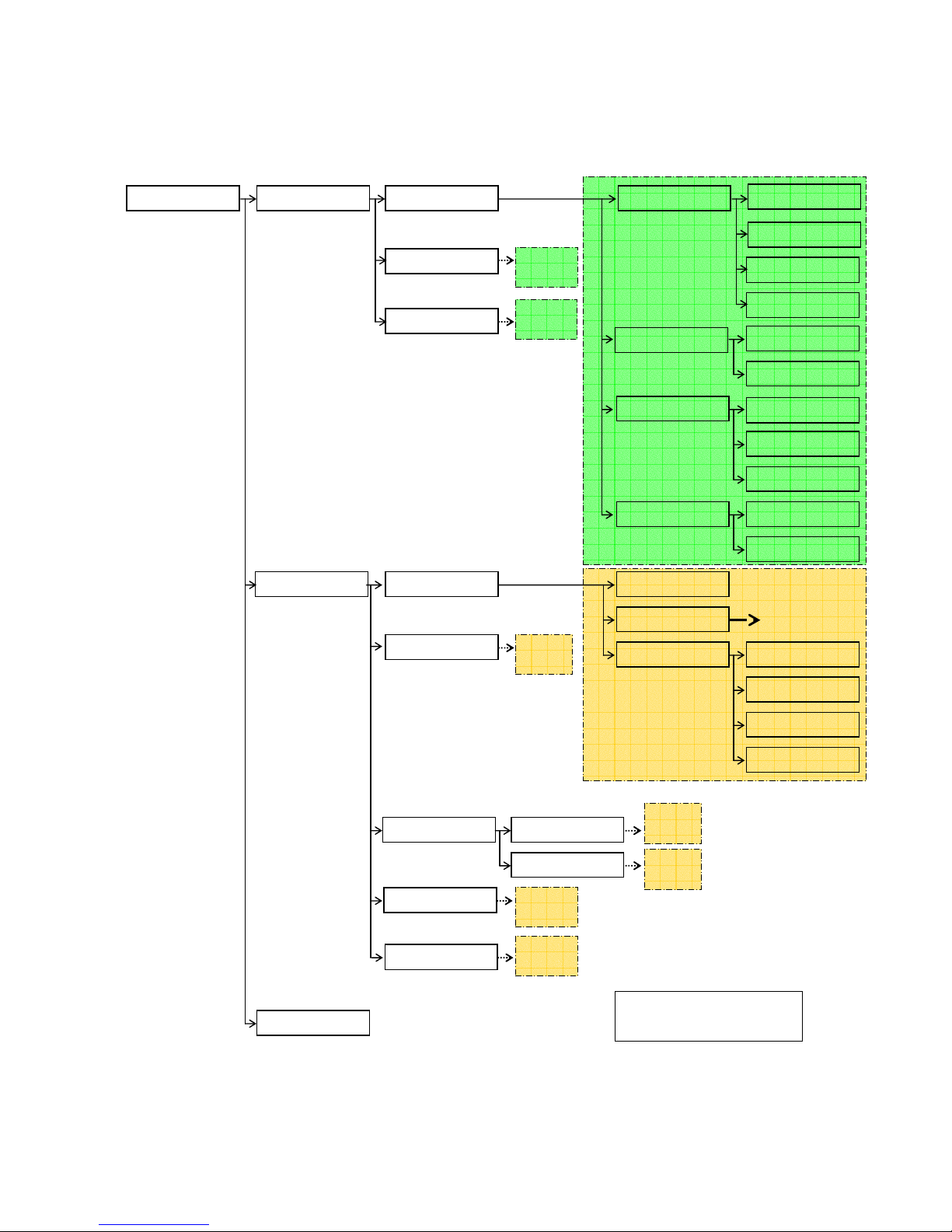

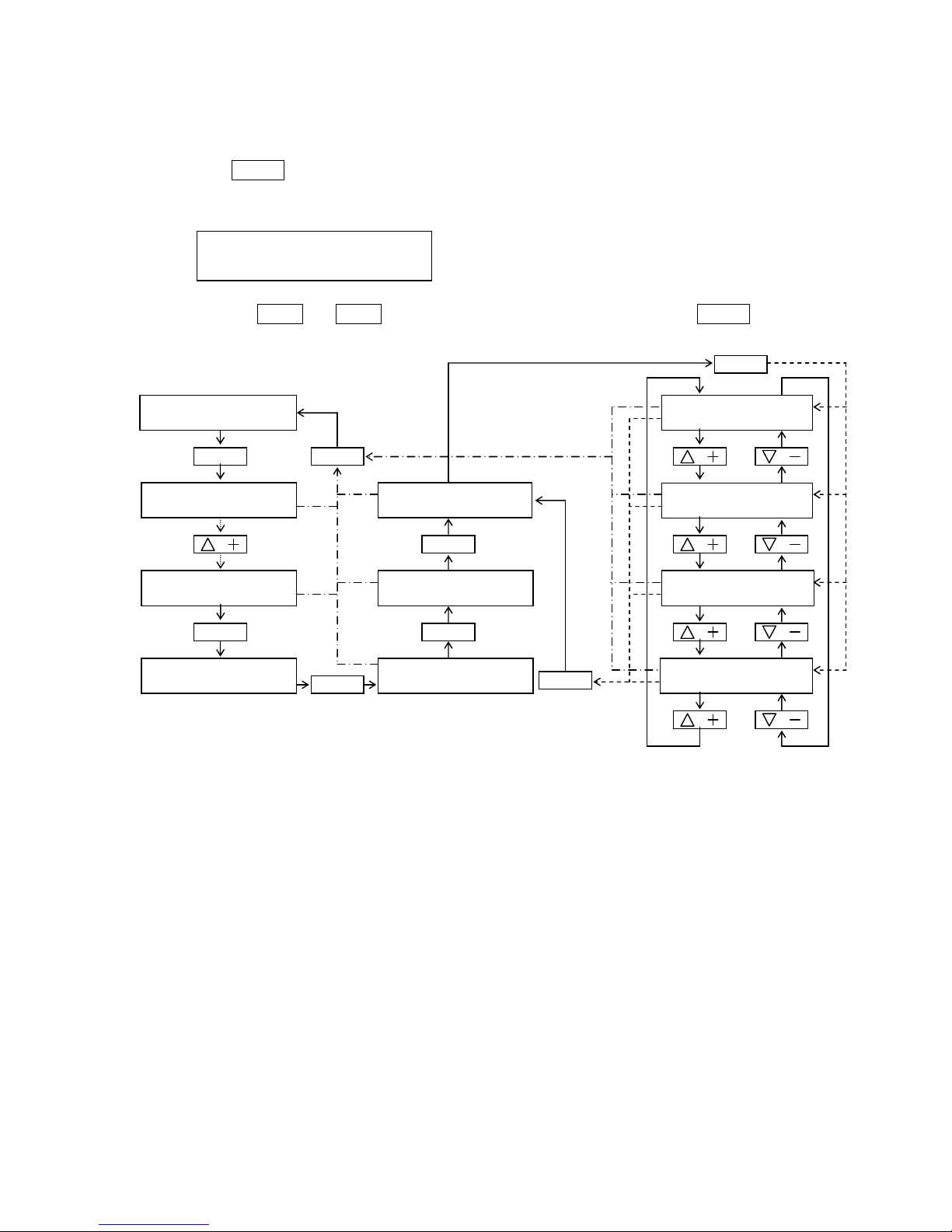

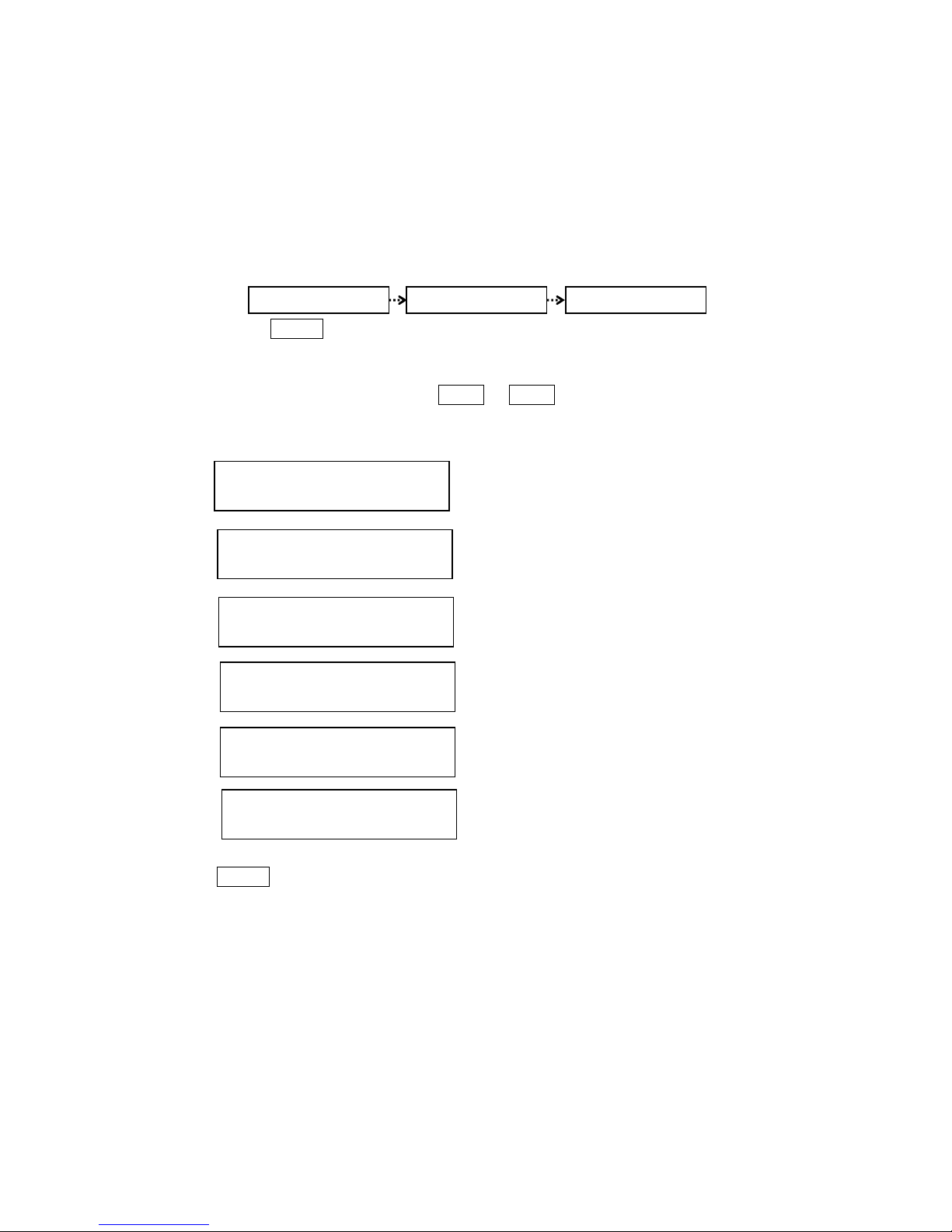

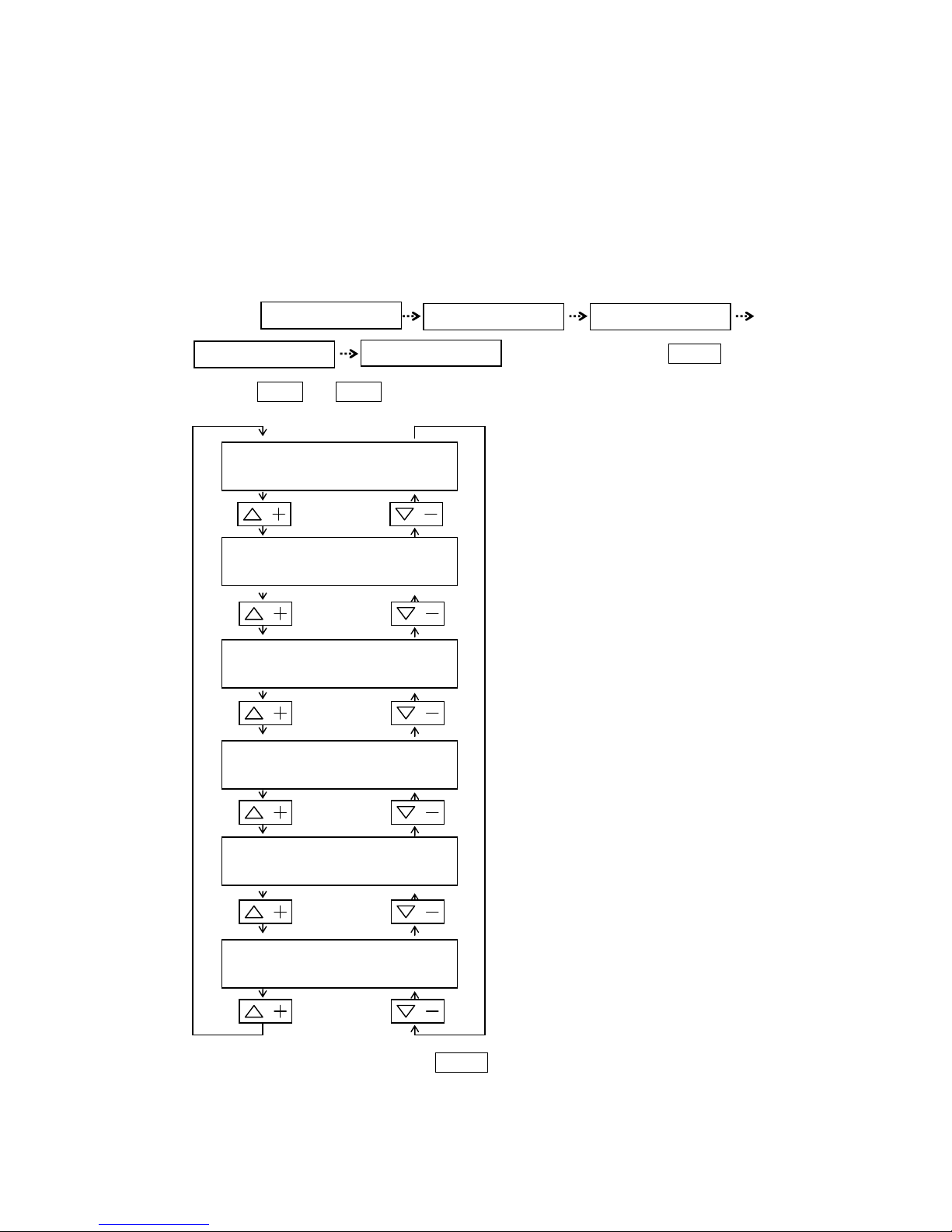

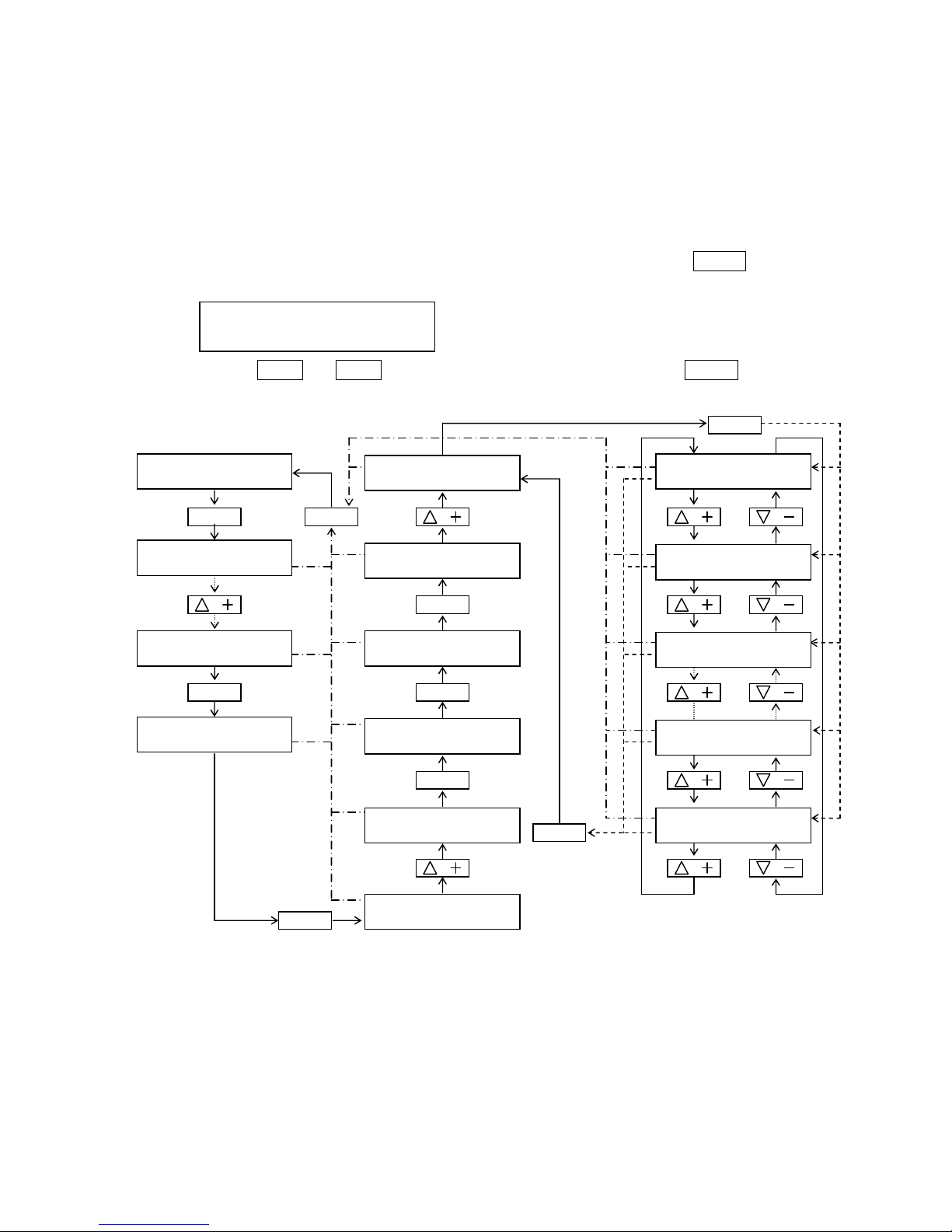

3.Selection of the maintenance mode

(1)Display the

"MAINTENACE 1

… "on the data display then Press the ENTER

ENTERENTER

ENTER key.

The data display is displayed I/F SET-UP mode.

(2)You can change the each maintenance item by pressing the △△△△ ++++ or ▽▽▽▽ ---- key.

PT500A:

①⇔②⇔③⇔④⇔⑤⇔⑥⇔⑦⇔⑧⇔⑨⇔⑩⇔⑪⇔⑫⇔⑬⇔⑭⇔⑮⇔⑯⇔⑰⇔⑱⇔⑲⇔①

①

⑪

②

⑫

③

⑬

④

⑭

⑤

⑮

⑥

⑯

⑦

⑰

⑧

⑱

⑨

⑲

⑩

Press ENTER

ENTERENTER

ENTER key after you selected the maintenance number. Then the maintenance function become valid

mode .

MAINTENANCE 19

…

MAINTENANCE OFF

MAINTENANCE 18

…

Special Data

MAINTENANCE 17

…

Option Set

MAINTENANCE 16

…

LINK-SLAVE DATA

MAINTENANCE 15

…

OVERRIDE COURSE

MAINTENANCE 14

…

KEY CLICK SW

MAINTENANCE 8

…

PROGRAM VERSION

MAINTENANCE 7

…

ADC POINT DISP

MAINTENANCE 6

…

CDV OUT

MAINTENANCE 5

…

RDA OUT

MAINTENANCE 4

…

AUTO RUDDER OUT

MAINTENANCE 13

…

BARGRAPH SW

MAINTENANCE 12

…

OFFCRS ALARM SW

MAINTENANCE 11

…

IDENT. DISP

MAINTENANCE 3

…

MEM ACCESSS-FLX

MAINTENANCE 2

…

MEM ACCESSS-FIX

MAINTENANCE 1

…

I/F SET-UP

MAINTENAN

CE 9

…

PROG.COLD START

MAINTENANCE 10

…

SHIP PARA. CALC

Page 8

1-4

SM80B22M02

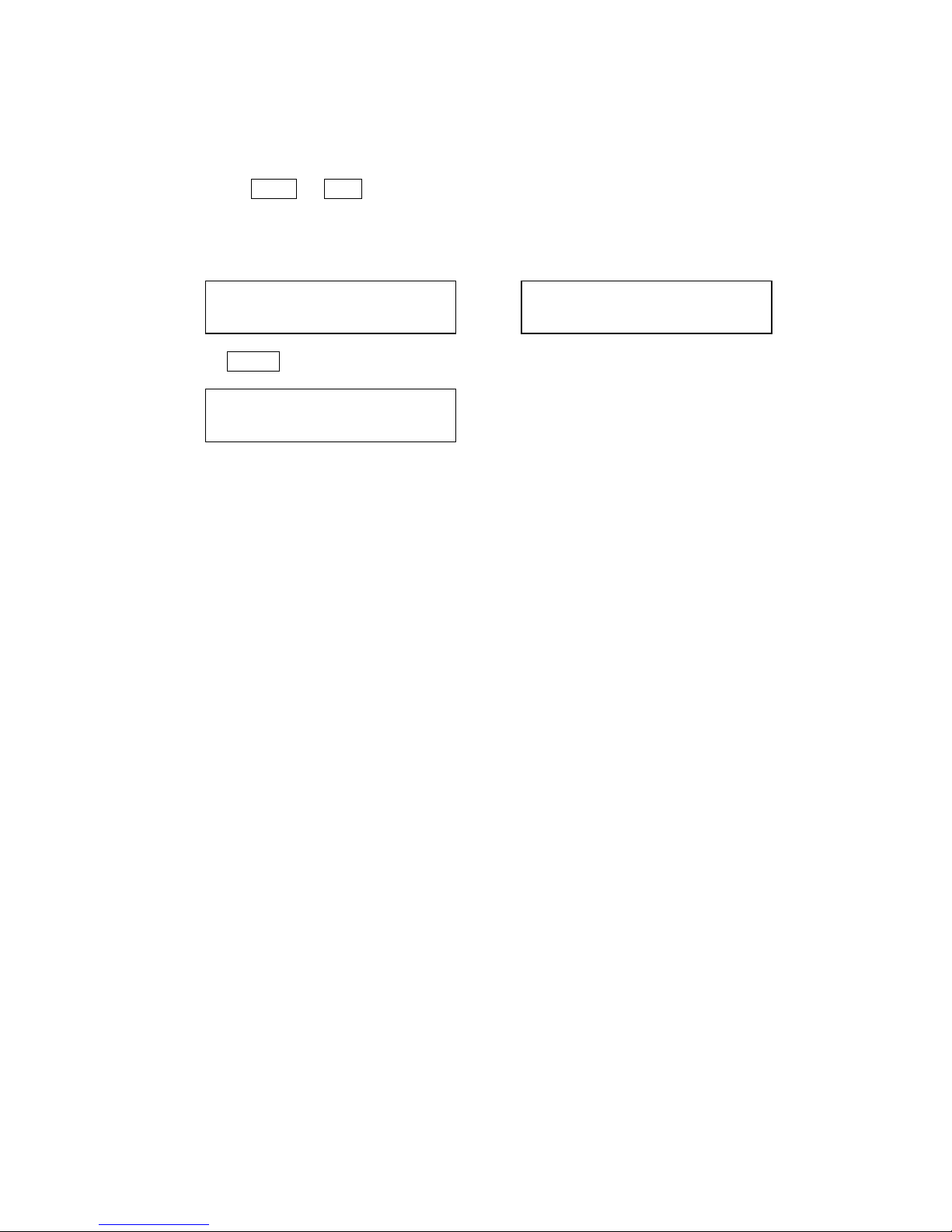

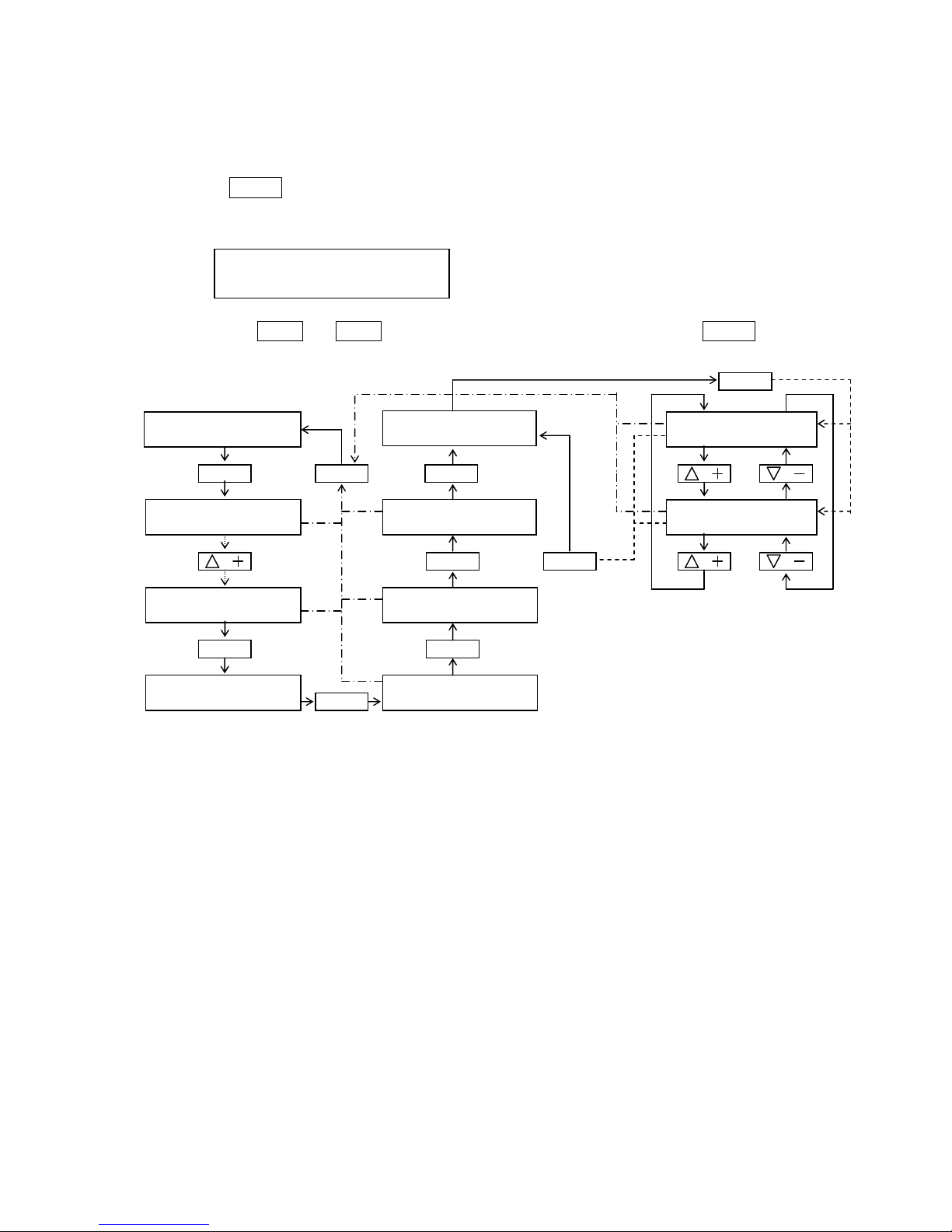

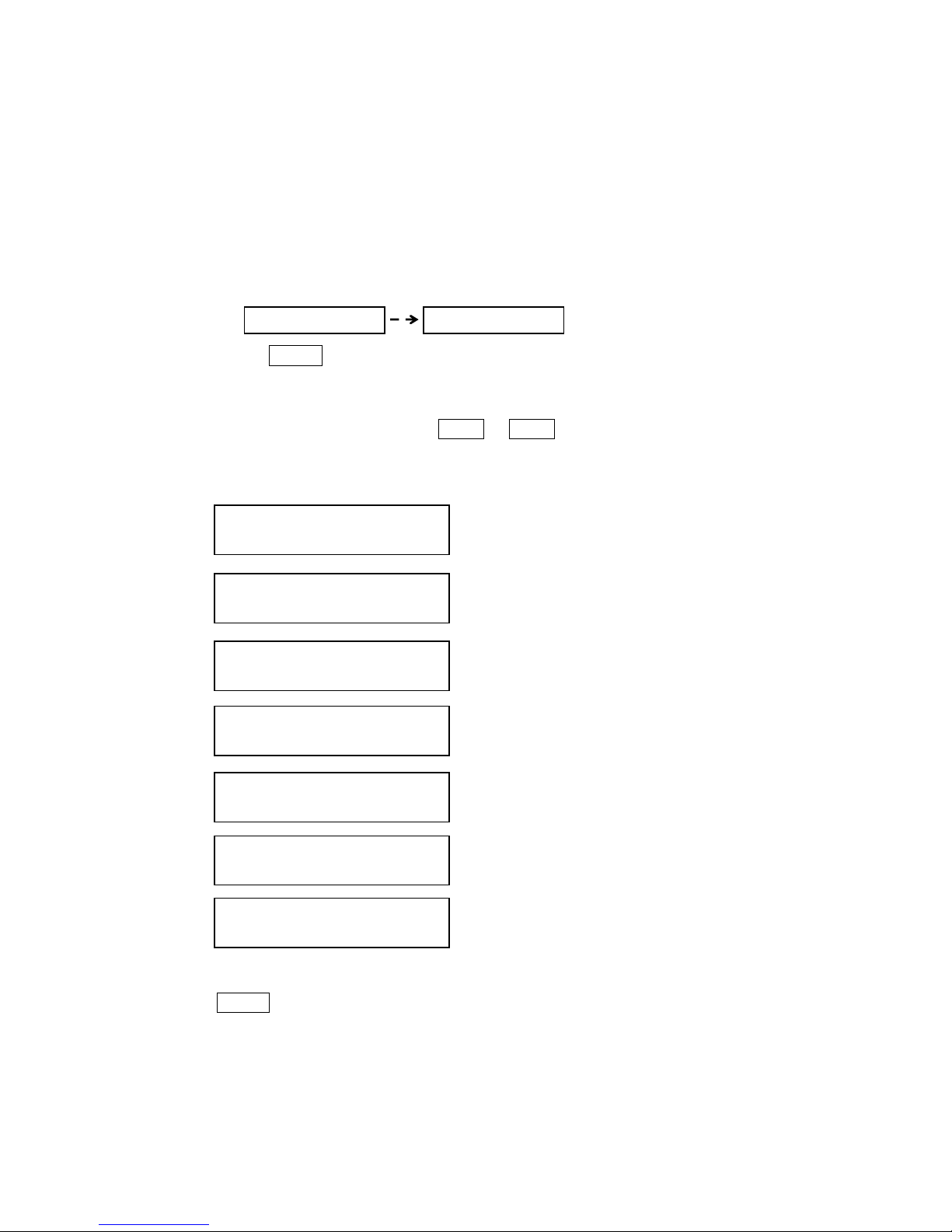

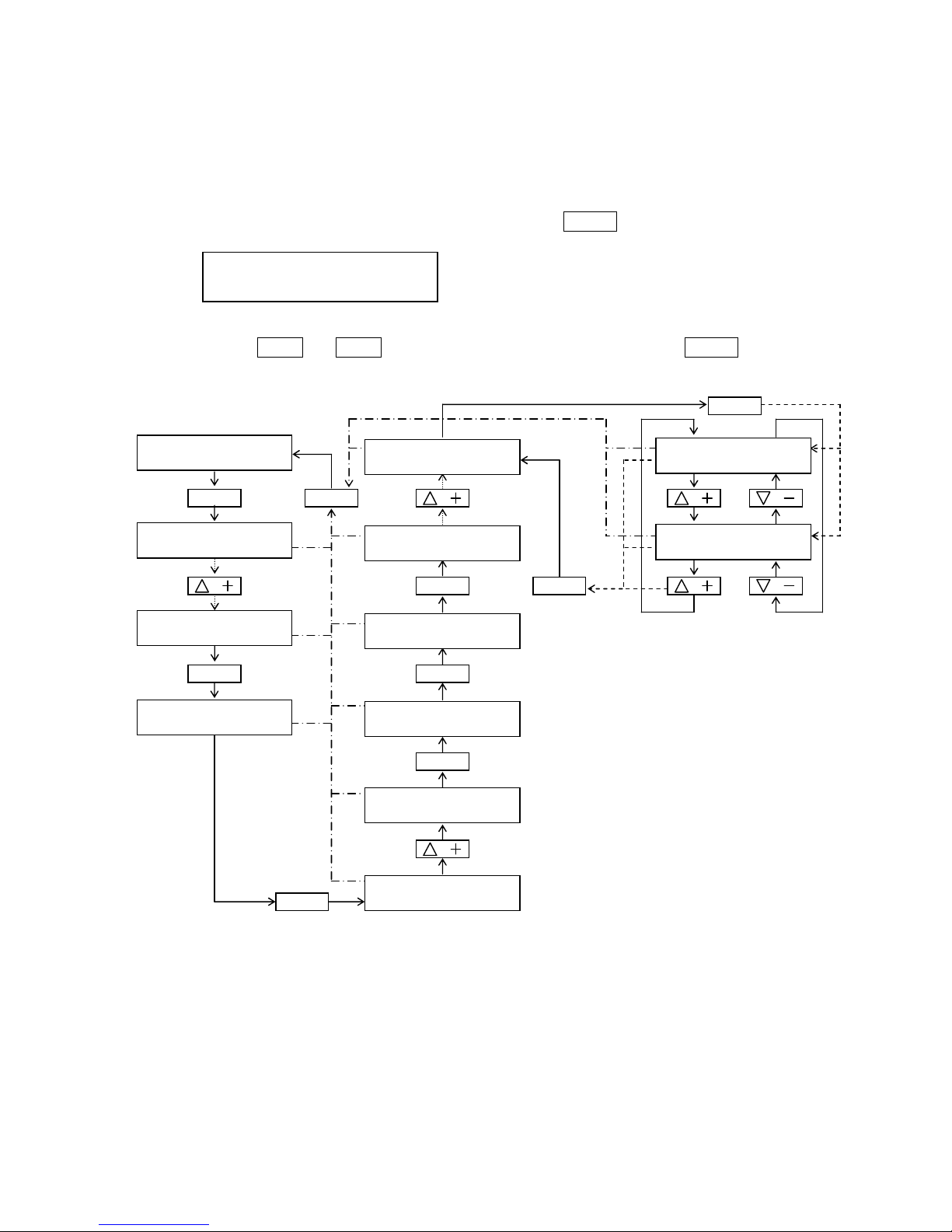

PT500D・SUBAUTO:

①⇔②⇔③⇔④⇔⑤⇔⑥⇔⑦⇔⑧⇔⑨⇔⑩⇔⑪⇔⑫⇔⑬⇔⑭⇔⑮⇔⑯⇔⑰⇔①

①

⑪

②

⑫

③

⑬

④

⑭

⑤

⑮

⑥

⑯

⑦

⑰

⑧

⑨

⑩

Press ENTER

ENTERENTER

ENTER key after you selected the maintenance number. Then the maintenance function become valid

mode .

MAINTENANCE 10

…

OFFCRS ALARM SW

MAINTENANCE 9

…

PROG.COLD START

MAINTENANCE 17

…

MAINTENANCE OFF

MAINTENANCE 16

…

Special Data

MAINTENANCE 15

…

Option Set

MAINTENANCE 14

…

LINK-SLAVE DATA

MAINTENANCE 13

…

OVERRIDE COURSE

MAINTENANCE 12

…

KEY CLICK SW

MAINTENANCE 8

…

PROGRAM VERSION

MAINTENANCE 7

…

ADC POINT DISP

MAINTENANCE 6

…

CDV OUT

MAINTENANCE 5

…

RDA OUT

MAINTENANCE 4

…

AUTO RUDDER OUT

MAINTENANCE 11

…

BARGRAPH SW

MAINTENANCE 3

…

MEM ACCESSS-FLX

MAINTENANCE 2

…

MEM ACCESSS-FIX

MAINTENANCE 1

…

I/F SET-UP

Page 9

2-1

SM80B22M02E

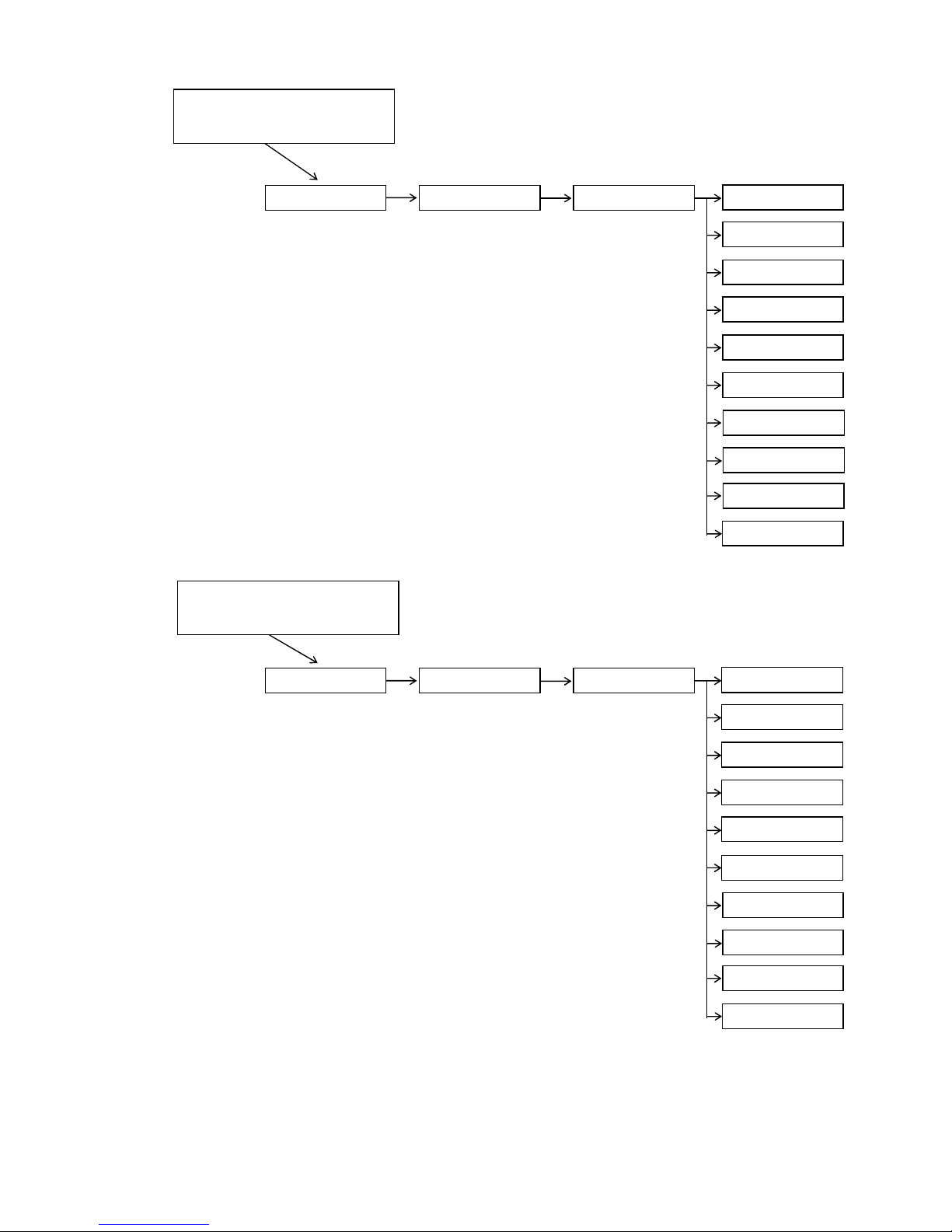

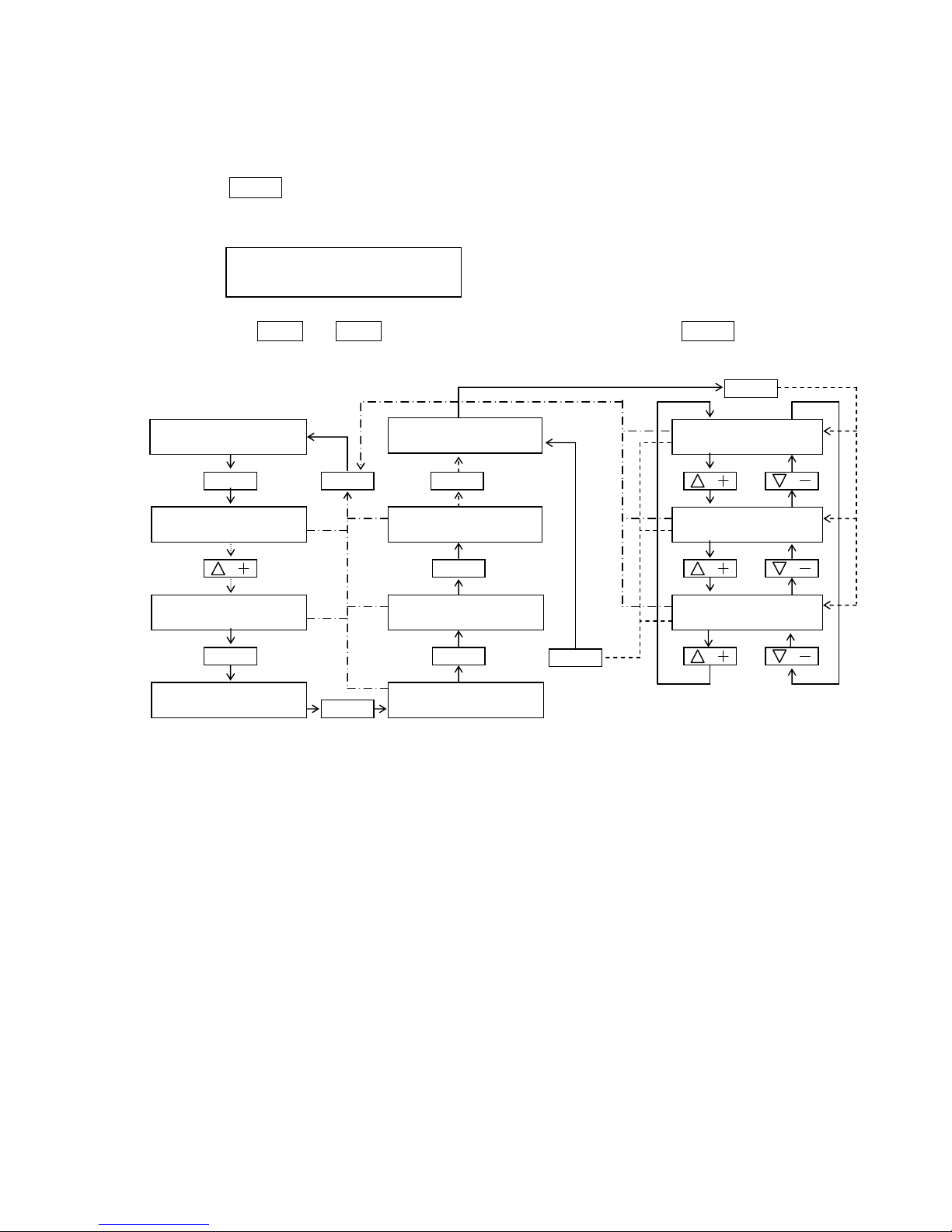

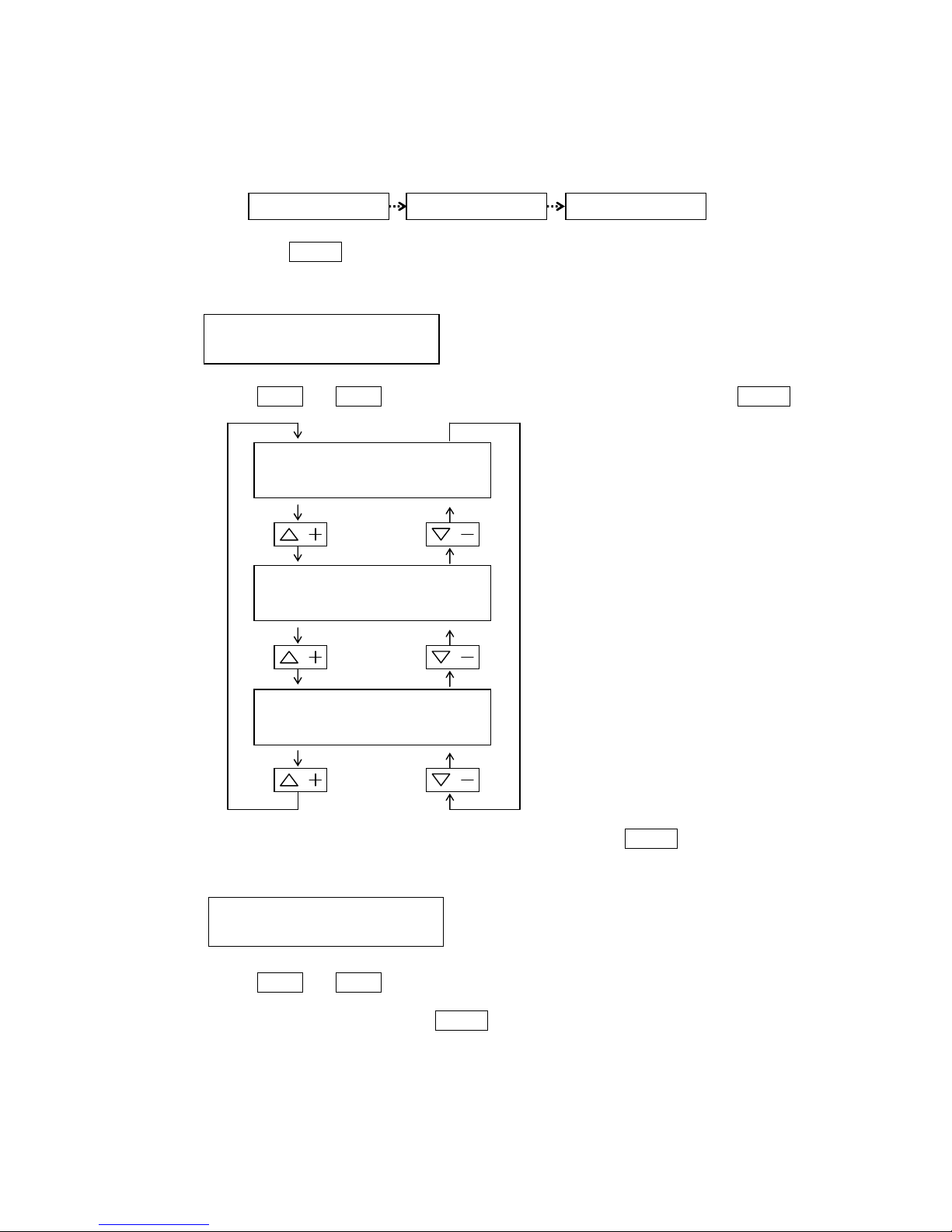

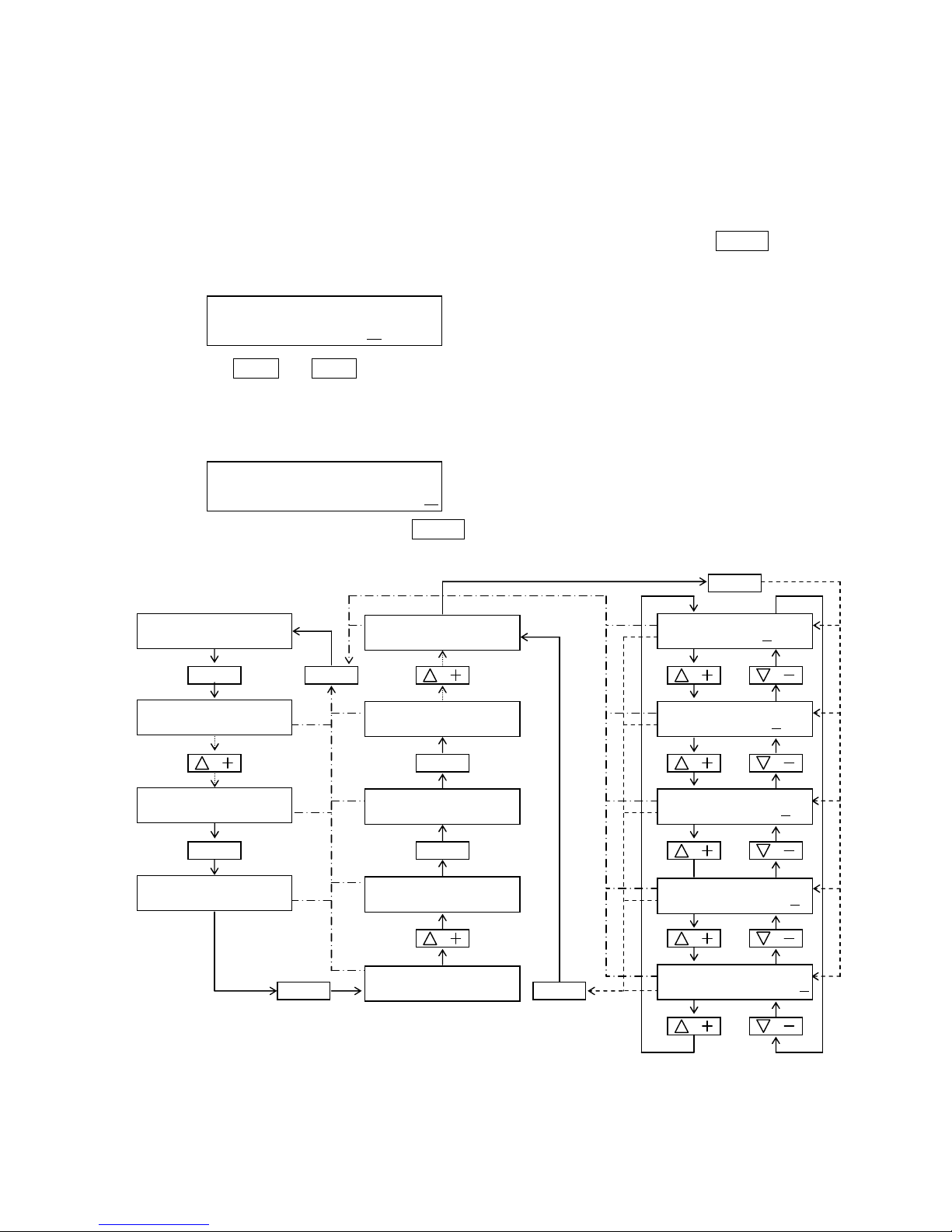

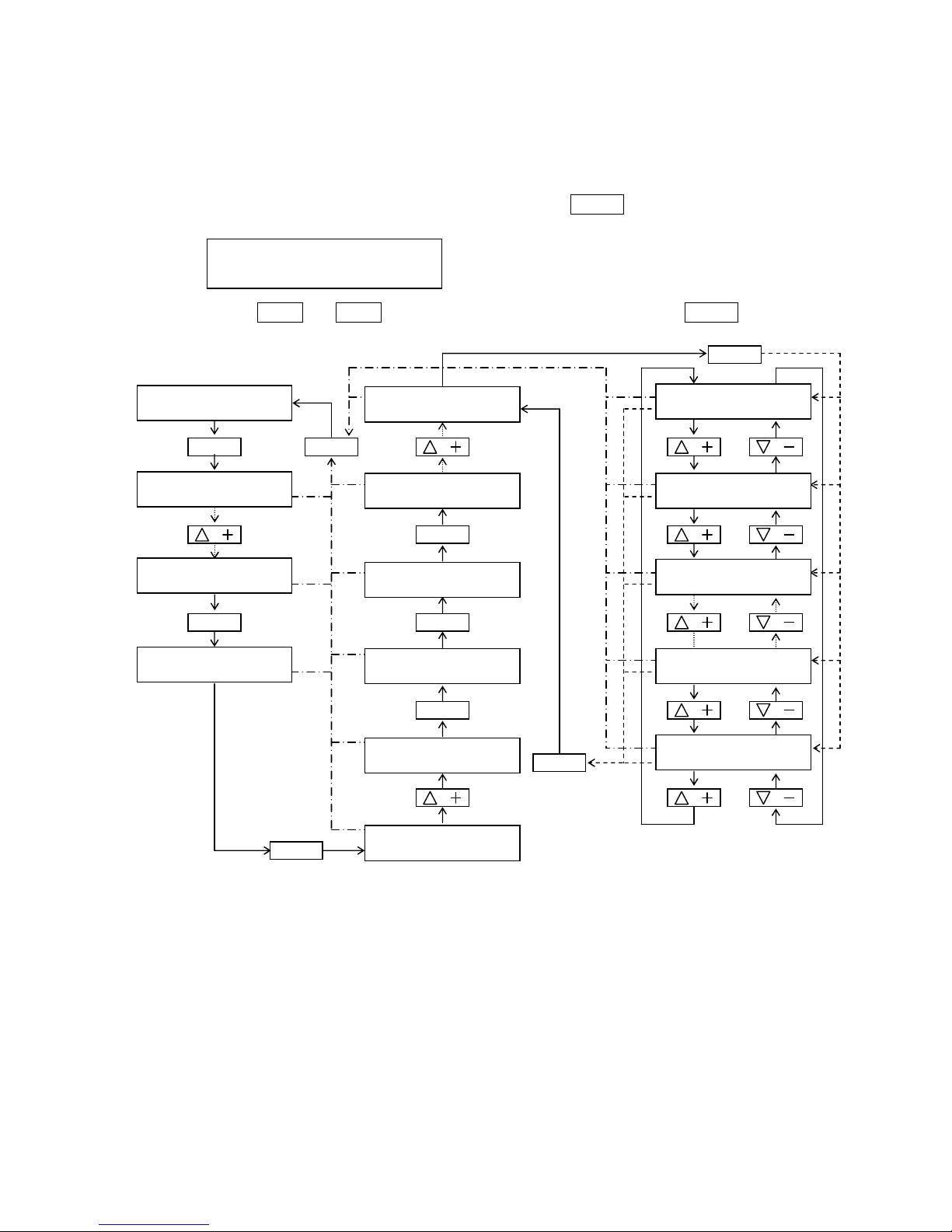

Chapter 2 I/F SET-UP

Set the protocol of the each input and output serial ports for corresponding with each equipment.

Setting items is as follows.

NOTE

In case of you changed

In case of you changed In case of you changed

In case of you changed setting item, please carry out the settlement of

setting item, please carry out the settlement of setting item, please carry out the settlement of

setting item, please carry out the settlement of ③③③③ I/F SET

I/F SET I/F SET

I/F SET----UP

UPUP

UP....

① Hardware setting(Set the Protocol)

② Software setting (Set the input and output condition)

③ Settlement of I/F set-up

1. Select the I/F set-up data

(1) Press the ENTER

ENTERENTER

ENTER key after displayed "

MAINTENANCE 1 …

"on the data display.

The data display is displayed I/F SET-UP mode.

(2) Press △△△△ ++++ or ▽▽▽▽ ---- key to change the item.

①⇔②⇔③⇔④⇔①

①

Set the protocol of each setting port

②

Set the input /output condition of each setting port

③

Settlement of the data inputs

④

Press ENTER

ENTERENTER

ENTER key after selected the item. The function of the item becomes valid mode.

Please refer to the tree of I/F SET-UP

I/F SET

-

UP

…

HARDWARE SET

I/F SET

-

UP

…

SOFTWARE SET

I/F SET

-

UP

…

SET-UP DATA FIX

I/F SET

-

UP

…

<EXIT>

Page 10

2-2

SM80B22M02E

Refer to

Item①

①①①①

②②②②

Refer to

Item②

<The tree of the I/F SET-UP>

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP

…

HARDWARE SET

I/F HARD SET

-UP…

PORT= GYRO

GYRO HARD

…

BAUD RATE= ####

GYRO HARD

BAUD RATE= 1200

GYRO HARD

BAUD RATE= 2400

GYRO HARD

BAUD RATE= 4800

GYRO HARD

BAUD RATE= 9600

I/F HARD SET

-UP…

PORT= AUX.COMP

I/F SET

-

UP

…

SET-UP DATA FIX

I/F HARD SET

-UP…

PORT= INS/GPS

GYRO HARD

…

DATA BITS = #

GYRO HARD

…

DATA BITS = 7

GYRO HARD

…

DATA BITS = 8

GYRO HARD

…

PARITY = aaaa

GYRO HARD

…

PARITY = None

GYRO HARD

…

PARITY = Even

GYRO HARD

…

PARITY = Odd

GYRO HARD

…

STOP BITS = #

GYRO HARD

…

STOP BITS = 1

GYRO HARD

…

STOP BITS = 2

I/F SOFT SET

-UP…

PORT= GYRO

I/F SOFT SET

-UP…

PORT= AUX.COMP

I/F SET

-

UP

…

SOFTWARE SET

GYRO COMP. SOFT

…

FORMAT= NONE

GYRO COMP. SOFT

…

FORMAT= EXIT

GYRO COMP. SOFT

…

FORMAT= NEW

GYRO NEW

…

ADDRESS= $aaaaa

GYRO NEW

…

START POS.= #

GYRO NEW

…

INTERVAL= ##.#s

GYRO NEW

…

CHECK SUM = aaa

I/F SOFT SET

-UP…

PORT= INS/GPS INP

I/F SOFT SET

-UP…

PORT= INS/GPS OUT

I/G INP SOFT

…

XTE

I/G INP SOFT

…

SET COURSE

Set the current format

(Refer to next page)

③③③③

③③③③

Refer to

Item①

Refer to

Item②

Refer to

Item②

Refer to

Item②

I/F SOFT SET

-UP…

PORT= LOG

Refer to

Item②

Page 11

2-3

SM80B22M02E

GYRO EXIST

…

=aaaaaaaaaaaaaaa

GYRO COMP. SOFT

…

FORMAT= EXIST

I/F SOFT SET

-UP…

PORT= GYRO

Setting of the Gyrocompass

input format

AUX.COMP. EXIST

…

=aaaaaaaaaaaaaaa

AUX.COMP. EXIST

…

FORMAT= EXIST

I/F SOFT SET

-UP…

PORT= AUX.COMP

Setting of the Aux. compass

input format

GYRO5EXIST

12345

…

=NMEA6HEHDT23456

GYRO5EXIST

12345

…

=NMEA6xxHDT23456

GYRO5EXIST

12345

…

=NMEA6HDT0&2ROT6

GYRO5EXIST

12345

…

=YOKOGAWA0HEHRC6

GYRO5EXIST

12345

…

=NMEA6xxHDG23456

GYRO5EXIST

12345

…

=NMEA6HCHDT23456

GYRO5EXIST

12345

…

=NMEA6xxHDM23456

GYRO5EXIST

12345

…

=NUNOTANI:$HCHDM

GYRO5EXIST

12345

…

=NUNOTANI:$HCHRC

GYRO5EXIST

12345

…

=NAVIGAT-2100456

AUX.COMP.

0

EXIST

…

=NMEA6HEHDT23456

AUX.COMP.

0

EXIST

…

=NMEA6xxHDT23456

AUX.COMP.

0

EXIST

…

=NMEA6HDT0&2ROT6

AUX.COMP.

0

EXIST

…

=YOKOGAWA0HEHRC6

AUX.COMP.

0

EXIST

…

=NMEA6xxHDG23456

AUX.COMP.

0

EXIST

…

=NMEA6HCHDT23456

AUX.COMP.

0

EXIST

…

=NMEA6xxHDM23456

AUX.COMP.

0

EXIST

…

=NUNOTANI:$HCHDM

AUX.COMP.

0

EXIST

…

=NUNOTANI:$HCHRC

AUX.COMP.

EXIST

…

=NAVIGAT-2100456

Page 12

2-4

SM80B22M02E

Setting of the INS/GPS output

format

Setting of the LOG input (serial)

format

I/F SOFT SET

-UP…

PORT=INS/GPS INP

Setting of the INS/GPS input

format

XTE4INP8

EXIST

45…

=xxXTE7&9Mode456

XTE4INP8EXIST

45…

=xxXTE7890123456

XTE INP EXIST

…

=aaaaaaaaaaaaaaa

XTE INP SOFT

…

FORMAT= EXIST

I/G INP SOFT

…

XTE

SETC. INP EXIST

…

=NMEA0183:$xxHSC

SETC. INP EXIST

…

=INS-1

SETC. INP EXIST

…

=JRC5CAT-B&C3456

SETC. INP EXIST

…

=INS-27(Type3A)6

SETC. INP EXIST

…

=aaaaaaaaaaaaaaa

SETCRS INP SOFT

…

FORMAT= EXIT

I/G INP SOFT

…

SET COURSE

SETC. INP EXIST

…

=Super Bridge

SETC. INP EXIST

…

=Furuno8CAT-B456

SETC. INP EXIST

…

=Transas9CAT-C56

SETC. INP EXIST

…

=Kelvin8INS-1456

SETC. INP EXIST

…

=Tokimec90123456

I/G OUT EXIST

…

=$AGHTD(JRC)

I/G OUT EXIST

…

=$AGHTD(Furuno)

I/G OUT EXIST

…

= $AGDRR

I/G OUT EXIST

…

=aaaaaaaaaaaaaaa

I/G OUT SOFT

…

FORMAT= EXIT

I/F SOFT SET

-UP…

PORT=INS/GPS OUT

I/G OUT EXIST

…

=$AGHTD & $AGDRR

I/G OUT EXIST

…

=$AGHTD(Transas)

I/G OUT EXIST

…

=$AGHTD(Kelvin)

I/G OUT EXIST

…

=$AGHTD(Tokimec)

LOG EXIST

…

=NMEA xxVHW

LOG EXIST

…

=NMEA xxVBW (W)

LOG SOFT EXIST

…

=aaaaaaaaaaaaaaa

LOG SOFT

…

FORMAT= EXIT

I/F SOFT SET

-UP…

PORT= LOG

LOG EXIST

…

=NMEA xxVBW (G)

LOG EXIST

…

=YOKOGAWA VMVSD

LOG EXIST

…

=NMEA xxVTG

Page 13

2-5

SM80B22M02E

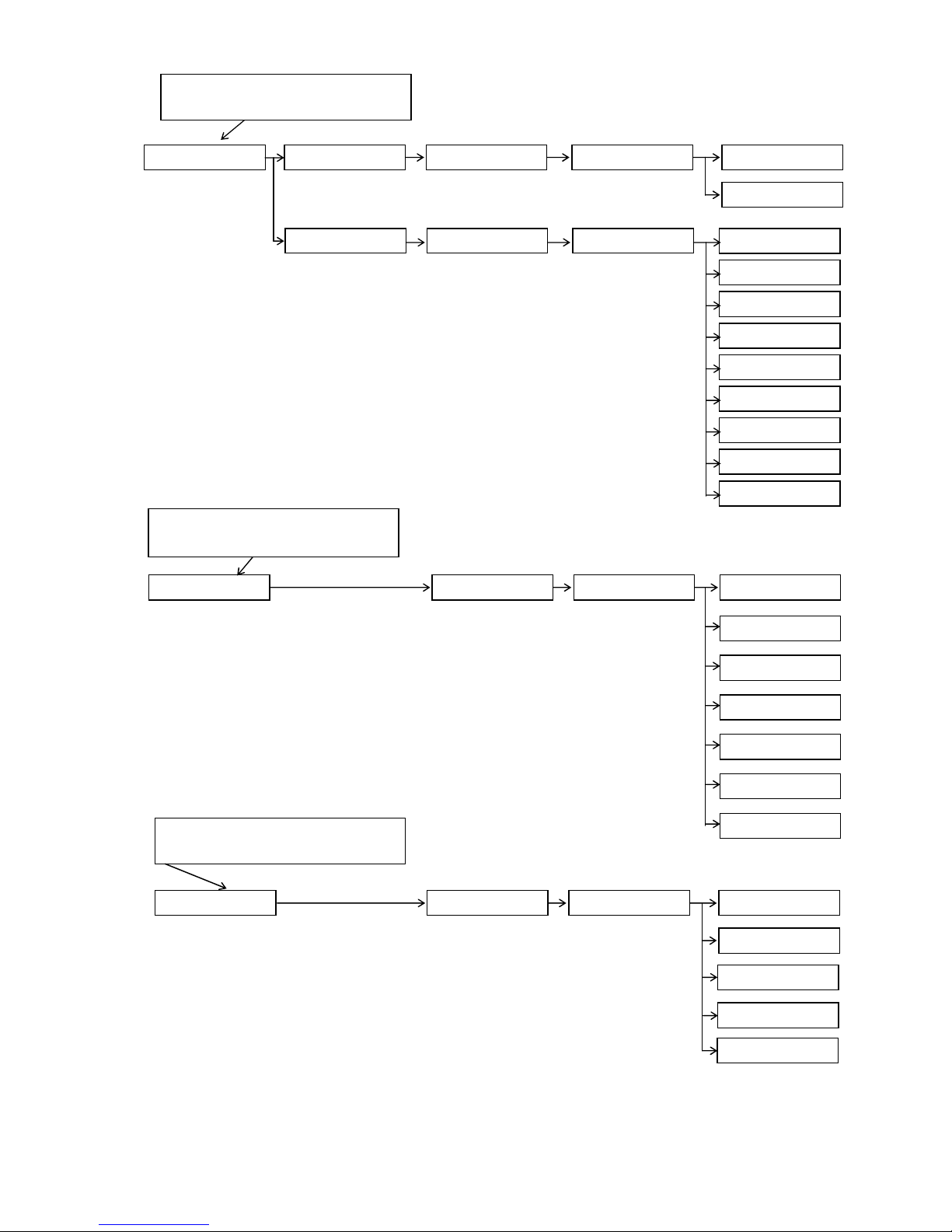

2. Hardware setting

Set the protocol for Gyro compass and Auxiliary compass ,INS/GPS.

Setting item is as follows.

① Hardware setting of the Gyrocompass

② Hardware setting of the Auxiliary compass

③ Hardware setting of the INS/GPS

④ Hardware setting of the LOG

(1)Set the ,then press ENTER

ENTERENTER

ENTER key.

Data display becomes a Hardware setting ready mode for each input port.

(2)Change the setting mode by using the △△△△ ++++ or ▽▽▽▽ ---- Keys.

①⇔②⇔③⇔④⇔⑤⇔⑥⇔①

①

Set the protocol of the Gyro compass port.

②

Set the protocol of the Auxiliary compass port.

③

Set the protocol of the INS/GPS port.

④

Set the protocol of the LOG port.

⑤

Back to the previous mode.

⑥

Back to the I/F setup top menu mode.

Press the ENTER

ENTERENTER

ENTER key after you selected the setting mode. It become the each protocol setting mode .

I/F HARD SET

-

UP

…

PORT= GYRO

I/F HARD SET

-

UP

…

PORT= AUX.GYRO

I/F HARD SET

-

UP

…

PORT= INS/GPS

MAINTENANCE 1 …

I/F SET-UP

MAINTENANCE 1 …

I/F SET-UP

I/F HARD SET

-

UP

…

PORT= [PREV]

I

/F HARD SET

-

UP

…

PORT= [TOP]

I/F HARD SET

-

UP

…

PORT= LOG

Page 14

2-6

SM80B22M02E

2.1 Hardware setting of the Gyrocompass

Set the protocol of the Gyrocompass. Setting item is as follows.

①Baud rate

②Length of the character

③Parity check

④Length of the stop bit

(1)Set the mode,

then press ENTER

ENTERENTER

ENTER key.

Data display becomes a Hardware setting ready mode for Gyrocompass protocol port.

(2)Change the setting mode by using the △△△△ ++++ or ▽▽▽▽ ---- key.

①⇔②⇔③⇔④⇔⑤⇔⑥⇔①

①

Baud rate

②

Length of the character

③

Parity check

④

Length of the stop bit

⑤

Back to the previous mode.

⑥

Back to the I/F setup top menu mode.

Press the ENTER

ENTERENTER

ENTER key after you selected the setting mode. It become the each protocol setting mode .

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

HARDWARE SET

I/F HARD

SET

-UP…

PORT= GYRO

GYRO HARD

…

BAUD RATE = ####

GYRO HARD

…

DATA BITS = #

GYRO HARD

…

PARITY = aaaa

GYRO HARD

…

STOP BITS = #

GYRO HARD

…

[PREV]

GYRO HARD

…

[TOP]

Page 15

2-7

SM80B22M02E

2.1.1 Baud rate

(1)Press ENTER

ENTERENTER

ENTER key when it is displayed the "

BAUD RATE = ####

" on the data display.

Data display become under setting mode.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the baud rate value. Then press ENTER

ENTERENTER

ENTER key.

SP D A UTO 13 . 5 k t

HE ADI NG- G 2 3 5. 8 ˆ

AD JUS T MO D E 1

…

DI MME R/C O NT R AS

AD J UST M ODE

99 …

MA INT ENA N CE MO D E

MA INT ENA N CE 1

…

I/ F S ET- U P

GY RO HAR D

…

BA UD RA T E = X XXX

I/ F H ARD SE T

-

UP …

PO RT = G YR O

I / F S ET

-

UP

…

HA RDW ARE SE T

GY RO HAR D

BA UD R AT E < 12 0 0

GY RO HAR D

BA UD R AT E < 24 0 0

GY RO HAR D

BA UD R A TE < 48 0 0

GY RO HAR D

BA UD R A TE < 96 0 0

ADJUST

ENTER

ENTER

ENTER

ADJUST

ENTER

ENTER

ENTER

GYRO HARD

BAUD RATE < 2400

Page 16

2-8

SM80B22M02E

2.1.2 Length of the character

(1)Press ENTER

ENTERENTER

ENTER key when it is displayed the "

DATA BITS = #

" on the data display.

Data display become under setting mode.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the character length. Then press ENTER

ENTERENTER

ENTER key.

GYRO HARD

DATA BITS < 7

SP D A UTO 13 . 5 k t

HE ADI NG- G 2 3 5. 8 ˆ

AD JUS T MO D E 1

…

DI MME R/C O NT R AS

AD J UST M ODE

99 …

MA INT ENA N CE MO D E

MA INT ENA N CE 1

…

I/ F S ET- U P

GY RO HAR D

…

BA UD RA T E = # ###

I/ F H ARD SE T

-

UP …

PO RT = G YR O

I / F S ET

-

UP

…

HA RDW ARE SE T

GY RO HAR D

DA TA B I TS < 7

GY RO HAR D

DA TA B I TS < 8

ADJUST

ENTER

ENTER

ENTER

ADJUST

ENTER

ENTER

ENTER

GY RO HAR D

…

DA TA BIT S = #

ENTER

Page 17

2-9

SM80B22M02E

2.1.3 Parity check

(1)Press ENTER

ENTERENTER

ENTER key when it is displayed the "

PARITY = aaaa

" on the data display.

Data display become under setting mode.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the parity check. Then press ENTER

ENTERENTER

ENTER key.

GYRO HARD

PARITY < None

SP D A UTO 13 . 5 k t

HE ADI NG- G 2 3 5. 8 ˆ

AD JUS T MO D E 1

…

DI MME R/C O NT R AS

AD J UST M ODE

99 …

MA INT ENA N CE MO D E

MA INT ENA N CE 1

…

I/ F S ET- U P

GY RO HAR D

…

BA UD RA T E = # ###

I/ F H ARD SE T

-

UP …

PO RT = G YR O

I / F S ET

-

UP

…

HA RDW ARE SE T

GY RO HAR D

PA RIT Y < N one

GY RO HAR D

PA RIT Y < E ven

ADJUST

ENTER

ENTER

ENTER

ADJUST

ENTER

ENTER

ENTER

GY RO HAR D

…

PA RIT Y = a aa a

ENTER

GY RO HAR D

PA RIT Y < Odd

Page 18

2-10

SM80B22M02E

2.1.4 Stop bit

(1)Press ENTER

ENTERENTER

ENTER key when it is displayed the "

STOP BITS = #"

on the data display.

The data display become under setting mode.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the stop bit. Then press ENTER

ENTERENTER

ENTER key.

GYRO HARD

STOP BITS < 1

SP D A UTO 13 . 5 k t

HE ADI NG- G 2 3 5. 8 ˆ

AD JUS T MO D E 1

…

DI MME R/C O NT R AS

AD J UST M ODE

99 …

MA INT ENA N CE MO D E

MA INT ENA N CE 1

…

I/ F S ET- U P

GY RO HAR D

…

BA UD RA T E = # ###

I/ F H ARD SE T

-

UP …

PO RT = G YR O

I/ F SE T

-

UP

…

HA RDW ARE SE T

GY RO HAR D

ST OP B I TS < 1

GY RO HAR D

ST OP B I TS < 2

ADJUST

ENTER

ENTER

ENTER

ADJUST

ENTER

ENTER

ENTER

GY RO HAR D

…

ST OP BIT S = #

ENTER

Page 19

2-11

SM80B22M02E

2.2 Hardware setting of the Auxiliary compass

Set the protocol of the Auxiliary compass. Setting item is as follows.

①Baud rate

②Length of the character

③Parity check

④Length of the stop bit

(1)Set the mode.

Then press ENTER

ENTERENTER

ENTER key.

Data display becomes a Hardware setting ready mode for Auxiliary compass protocol port.

(2)Change the setting mode by using the △△△△ ++++ or ▽▽▽▽ ---- Keys.

①⇔②⇔③⇔④⇔⑤⇔⑥⇔①

①

Baud rate

②

Length of the character

③

Parity check

④

Length of stop bit

⑤

Back to the previous mode.

⑥

Back to the I/F setup top menu mode.

Press the ENTER

ENTERENTER

ENTER key after you selected the setting mode. It become the each protocol setting mode .

Following setting item is the same as Gyrocompass hardware setting

Refer to Gyrocompass hardware setting.

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

HARDWARE SET

I/F HARD SET

-UP…

PORT= AUX.COMP

AUX. COMP. HARD

…

BAUD RATE = ####

AUX. COMP. HARD

…

DATA BITS = #

AUX. COMP. HARD

…

PARITY = aaaa

AUX. COMP. HARD

…

STOP BITS = #

AUX. COMP. HARD

…

[PREV]

AUX. COMP.

HARD

…

[TOP]

Page 20

2-12

SM80B22M02E

2.3 Hardware setting of the INS/GPS

Set the protocol of the INS/GPS. Setting item is as follows.

①Baud rate

②Length of the character

③Parity check

④Length of the stop bit

(1)Set the mode.

Then press ENTER

ENTERENTER

ENTER key.

Data display becomes a Hardware setting ready mode for INS/GPS protocol port.

(2)Change the setting mode by using the △△△△ ++++ or ▽▽▽▽ ---- Keys.

①⇔②⇔③⇔④⇔⑤⇔⑥⇔①

①

Baud rate

②

Length of the character

③

Parity check

④

Length of stop bit

⑤

Back to the previous mode.

⑥

Back to the I/F setup top menu mode.

Press the ENTER

ENTERENTER

ENTER key after you selected the setting mode. It become the each protocol setting mode .

Following setting item is the same as Gyrocompass hardware setting

Refer to Gyrocompass hardware setting.

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

HARDWARE SET

I/F HARD SET

-UP…

PORT= INS/GPS

INS/GPS HARD

…

BAUD RATE = ####

INS/GPS HARD

…

DATA BITS = #

INS/GPS HARD

…

PARITY = aaaa

INS/GPS HARD

…

STOP BITS = #

INS/GPS HARD

…

[PREV]

INS/GPS HARD

…

[TOP]

Page 21

2-13

SM80B22M02E

2.3 Hardware setting of the LOG

Set the protocol of the LOG. Setting item is as follows.

①Baud rate

②Length of the character

③Parity check

④Length of the stop bit

(1)Set the mode.

Then press ENTER

ENTERENTER

ENTER key.

Data display becomes a Hardware setting ready mode for LOG protocol port.

(2)Change the setting mode by using the △△△△ ++++ or ▽▽▽▽ ---- Keys.

①⇔②⇔③⇔④⇔⑤⇔⑥⇔①

①

Baud rate

②

Length of the character

③

Parity check

④

Length of stop bit

⑤

Back to the previous mode.

⑥

Back to the I/F setup top menu mode.

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

HARDWARE SET

I/F HARD SET

-UP…

PORT= LOG

LOG HARD

…

BAUD RATE = ####

LOG HARD

…

DATA BITS = #

LOG HARD

…

PARITY = aaaa

LOG HARD

…

STOP BITS = #

LOG HARD

…

[PREV]

LOG HARD

…

[TOP]

Page 22

2-14

SM80B22M02E

3. Software setting

Set the protocol for Gyro compass input and Auxiliary compass input , INS/GPS input and output.

Setting item is as follows.

① Software setting of the Gyrocompass input

② Software setting of the Auxiliary compass input

③ Software setting of the INS/GPS input

④ Software setting of the INS/GPS output

⑤ Software setting of the LOG input

(1)Set the key.

Then press ENTER

ENTERENTER

ENTER key.

Data display become a Hardware setting ready mode for each inputting port.

(2)Change the setting mode by using the △△△△ ++++ or ▽▽▽▽ ---- Keys.

①⇔②⇔③⇔④⇔⑤⇔⑥⇔⑦⇔①

①

Set the Input signal of the Gyrocompass data

②

Set the Input signal of the Auxiliary compass data

③

Set the Input signal of the INS/GPS data

④

Set the output signal of the INS/GPS data

⑤

Set the Input signal of the LOG data

⑥

Back to the previous mode.

⑦

Back to the I/F setup top menu mode.

Press the ENTER

ENTERENTER

ENTER key after you selected the setting mode. It become the each protocol setting mode .

MAINTENANCE

1 …

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT= GYRO

I/F SOFT SET

-UP…

PORT= AUX.COMP

I/F SOFT SET

-UP…

PORT=INS/GPS INP

I/F SOFT SET

-UP…

PORT=INS/GPS OUT

I/F SOFT SET

-UP…

[PREV]

I/F SOFT SET

-UP…

[TOP]

I/F SOFT SET

-UP…

PORT=LOG INP

Page 23

2-15

SM80B22M02E

3.1 Software setting of the Gyrocompass input

Set the input data of the Gyrocompass data

(1)Set the mode.

Then press the ENTER

ENTERENTER

ENTER key.

Display the current setting item for Gyrocompass heading data on the Data display.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the Gyrocompass format. Then press ENTER

ENTERENTER

ENTER key.

(3)In case of you change the input data. Back to(1)item , then Press ENTER

ENTERENTER

ENTER key.

Data display become under setting mode

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. Alter the display,

NONE

⇔

EXIST

⇔

NEW

⇔

NONE

.

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

If you choose the

EXIST

or

NEW mode, move to the 3.1.1 or 3.1.2 setting item.

GYRO SOFT

…

FORMAT = EXIST

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT= GYRO

GYRO SO

FT

…

FORMAT = EXIST

GYRO SOFT

…

[PREV]

GYRO SOFT

…

[TOP]

GYRO SOFT

…

FORMAT < aaaaa

Page 24

2-16

SM80B22M02E

3.1.1 Set the existing gyrocompass heading input format

(1)Set the

mode. Then press ENTER

ENTERENTER

ENTER key/

Display the current existing format on the data display.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the existing Gyrocompass format.

(3)In case of you choose the existing gyrocompass format. Back to(1)item , then Press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

The part of a....a is displayed setting condition.

Refer the contents to next page.

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. Alter the display of the existing format.

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

GYRO

EXIST

…

=

HEHDT

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT= GYRO

GYRO SOFT

…

FORMAT = aaaaa

GYRO SOFT

…

FORMAT < EXIST

GYRO EXIST

…

= HEHDT

GYRO EXIST

<aaaaaaaaaaaaaaa

GYRO

EXIST

…

= [PREV]

GYRO

EXIST

…

= [TOP]

Page 25

2-17

SM80B22M02E

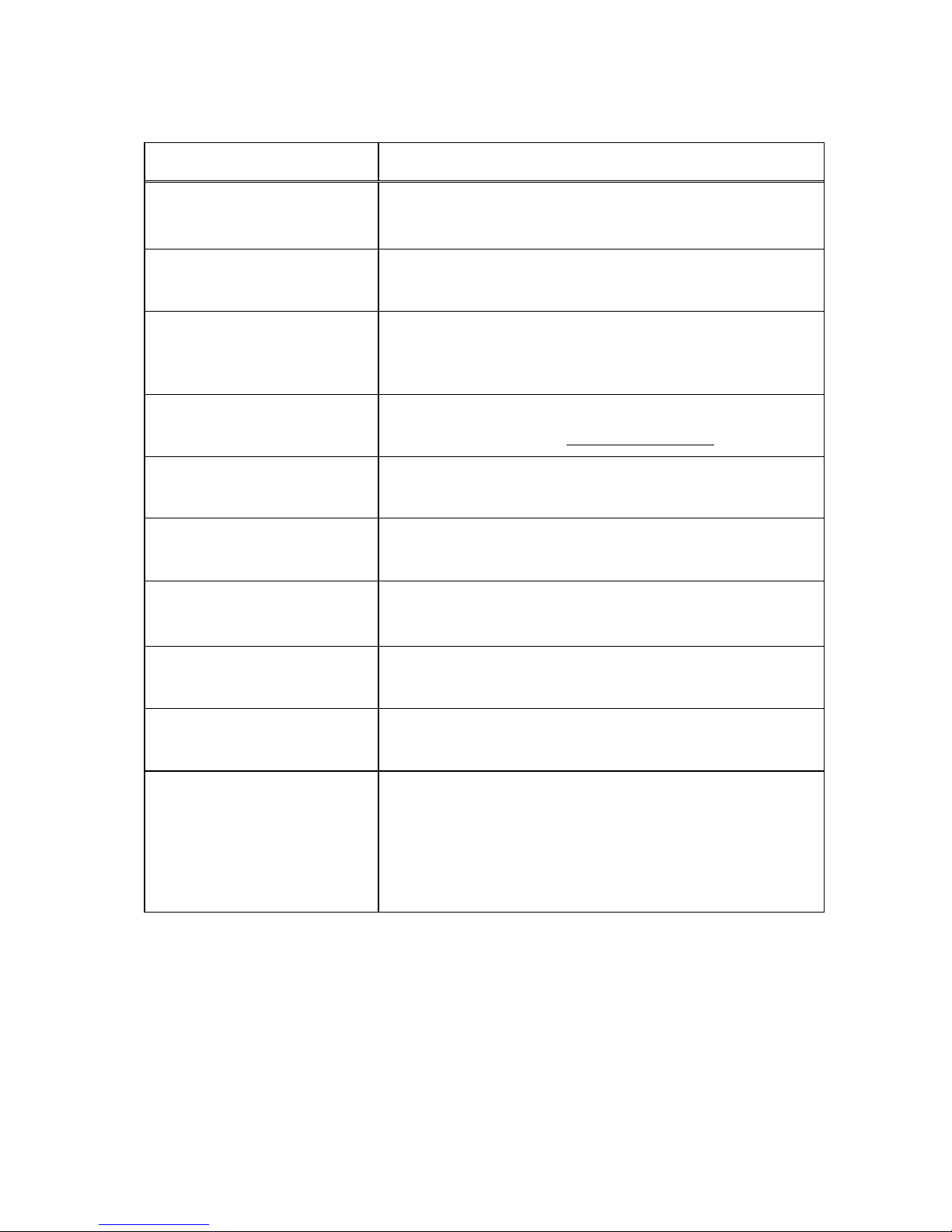

Selection Data Contents

NMEA HEHDT NMEA0183

$HEHDT (Taker ID should be only “HE”.)

Check-sum is required.

NMEA xxHDT NMEA0183

$xxHDT (Taker ID “xx” is not checked)

Check-sum is required.

NMEA HDT&ROT NMEA0183

$xxHDT and $xxROT messages are required.

(Taker ID “xx” is not checked)

Check-sum is required.

YOKOGAWA HEHRC CMZ300X format

$HEHRC/$HCHRC

(The name was changed to YOKOGAWA HEHRC.)

NMEA xxHDG NMEA0183

$xxHDG (Taker ID “xx” is not checked)

Check-sum is required.

NMEA HCHDT NMEA0183

$HCHDT (Taker ID should be only “HC”.)

Check-sum is required.

NMEA xxHDM NMEA0183

$xxHDM (Taker ID “xx” is not checked)

Check-sum is not required.

NUNOTANI:$HCHDM MUNOTANI’s TMC format

$HCHDM(Taker ID should be only “HC”.)

Check-sum is required.

NUNOTANI:$HCHRC MUNOTANI’s TMC format

$HCHRC(Taker ID should be only “HC”.)

Check-sum is required.

NAVIGAT-2100 NAIGAT-2100 format

-$HEHDT(GYRO) or $HCHDT(MAG)

-$HEROT

Heading and ROT data are used.

When $HEHDT is received, the data is used as GYRO input.

When $HCHDT is received, the data is used as Magnet input.

Page 26

2-18

SM80B22M02E

3.1.2 New format setting of the gyrocompass heading format

Setting item is as follows.

① Reception Header

② Position of the input field

③ Check sum Valid/Invalid

④ Transmission data output interval

3.1.2.1 Select the GYRO SOFT FORMAT<NEW

(1)Set the

mode. Then press the ENTER

ENTERENTER

ENTER key.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting item.

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT= GYRO

GYRO SOFT

…

FORMAT = aaaaa

GYRO SOFT

…

FORMAT < NEW

GYRO NEW

…

START POS.= #

GYRO NEW

…

ADDRESS = $aaaaa

GYRO NEW

…

CHECK SUM = aaaa

GYRO NEW

…

INTERVAL=##.#sec

GYRO NEW

…

[PREV]

GYRO NEW

…

[TOP]

Page 27

2-19

SM80B22M02E

3.1.2.2 Setting of the reception header

Set the reception header

The Header consists of five character from $ to reception discrimination data.

(1) When you are displayed "ADDRESS = $aaaaa" on the data display ,then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode.

←Cursor position is inputting point

(2)Press △△△△ ++++ or ▽▽▽▽ ---- key to set the cursor point. Then change the data by turning the Set

course dial. Turn to the clockwise direction , data is increased and turn to the counter

clockwise direction ,data is decreased. (Data is A to Z alphabet)

(3)After input the header , then press ENTER

ENTERENTER

ENTER key.

ADJUST

ENTER

ENTER

ENTER

ADJUST

ENTER

ENTER

ENTER

GYRO NEW

ADDRESS < $AAAAA

GYRO NEW

ADDRESS < $GPABC

AD J UST M ODE

99 …

MA INT ENA N CE MO D E

MA INT ENA N CE 1

…

I/ F S ET- U P

AD J UST M O DE

1 …

DI MME R/C O NT R AS T

SP D A UTO 13 . 5 K t

HE ADI NG- G 2 3 5. 8 ˆ

GY RO NEW

…

AD DRE SS = $ a aa a a

GY RO SO FT

…

FO RMA T = NE W

I/ F S OFT S E T

-

UP

…

PO RT = GYRO

I/ F S ET

-

UP

…

SO FTW ARE SE T

I/ F SE T

-

UP

…

HA RDW ARE SE T

GY RO NEW

…

AD DRE SS < $ A AA A A

GY RO NEW

…

AD DRE SS < $ A AA A A

GY RO NEW

…

AD DRE SS < $ A AA A A

GY RO NEW

…

AD DRE SS < $ A AA A A

GY RO NEW

…

AD DRE SS < $ A AA A A

Page 28

2-20

SM80B22M02E

3.1.2.3 Setting of the data field position

Set the data field position of the reception data

Example)

”$ABCDE,123.3,456.7,890.1,234.5*”

In case of set the data field at“3”above text data ,reception data become “890.1”.

(1)When you displayed the "

START POS.= ##

" on the data display, press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting mode. Then press ENTER

ENTERENTER

ENTER key.

ADJ

UST ENTER

ENTER

ENTER

ADJUST

ENTER

ENTER

ENTER

ENTER

GYRO NEW

START POS.< 1

AD J UST M ODE

99 …

MA INT ENA N CE MO D E

MA INT ENA N CE 1

…

I/ F S ET- U P

AD J UST M O DE

1 …

DI MME R/C O NT R AS T

SP D A UTO 13 . 5 K t

HE ADI NG- G 2 3 5. 8 ˆ

GY RO NEW

…

AD DRE SS = $ a aa a a

GY RO SO FT

…

FO RMA T = NE W

I/ F S OFT S E T

-

UP

…

PO RT = GYRO

I/ F S ET

-

UP

…

SO FTW ARE SE T

I/ F SE T

-

UP

…

HA RDW ARE SE T

GY RO NEW

…

ST ART P O S. = ##

GY RO NEW

ST ART PO S .< 1

GY RO NEW

ST ART PO S .< 2

GY RO NEW

ST ART PO S .< 3

GY RO NEW

ST ART PO S .< 98

GY RO NEW

ST ART PO S .< 99

Page 29

2-21

SM80B22M02E

3.1.2.4 Set the valid /invalid condition of the check sum

Select the valid / invalid condition of the check sum

When occurred the check sum error as the valid condition , communication become no reception

condition.

(1)When displayed the "

CHECK SUM = aaaa

" , press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting mode. Then press ENTER

ENTERENTER

ENTER key.

ADJUST

ENTER

ENTER

ENTER

ADJUST

ENTER

ENTER

ENTER

ENTER

GYRO NEW

CHECK SUM < WITH

AD J UST M ODE

99 …

MA INT ENA N CE MO D E

MA INT ENA N CE 1

…

I/ F S ET- U P

AD J UST M O DE

1 …

DI MME R/C O NT R AS T

SP D A UTO 13 . 5 K t

HE ADI NG- G 2 3 5. 8 ˆ

GY RO NEW

…

AD DRE SS = $ a aa a a

GY RO SO FT

…

FO RMA T = NE W

I/ F S OFT S E T

-

UP

…

PO RT = GYRO

I/ F S ET

-

UP

…

SO FTW ARE SE T

I/ F SE T

-

UP

…

HA RDW ARE SE T

GY RO NEW

…

CH ECK SU M = aa a a

GY RO NEW

…

CH ECK SU M < Wi t h

GY RO NEW

…

CH ECK SU M < No n e

Page 30

2-22

SM80B22M02E

3.1.2.5 Set the transmission data output interval

Time out of the reception data is selected the longer time value either 3 second or 3 times of the

data output interval time

(1)When displayed the "

INTERVAL= XX.Xsec

" , press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting mode. Then press ENTER

ENTERENTER

ENTER key.

ADJUST

ENTER

ENTER

ENTER

ADJUST

ENTER

ENTER

ENTER

ENTER

GYRO NEW

INTERVAL<##.#sec

AD J UST M ODE

99 …

MA INT ENA N CE MO D E

MA INT ENA N CE 1

…

I/ F S ET- U P

AD J UST M O DE

1 …

DI MME R/C O NT R AS T

SP D A UTO 13 . 5 K t

HE ADI NG- G 2 3 5. 8 ˆ

GY RO NEW

…

AD DRE SS = $ a aa a a

GY RO SO FT

…

FO RMA T = NE W

I/ F S OFT S E T

-

UP

…

PO RT = GYRO

I/ F S ET

-

UP

…

SO FTW ARE SE T

I/ F SE T

-

UP

…

HA RDW ARE SE T

GY RO NEW

…

IN TER VAL = ## . #s e c

GY RO NEW

…

IN TER VAL < 0 . 1s e c

GY RO NEW

…

IN TER VAL < 0 . 2s e c

GY RO NEW

…

IN TER VAL < 0 . 3s e c

GY RO NEW

…

IN TER VAL < 19 . 0s e c

GY RO NEW

…

IN TER VAL < 20 . 0s e c

Page 31

2-23

SM80B22M02E

3.2 Software setting of the Auxiliary compass input

(1)Set the key.

Then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting item.

(3)In case of you choose the existing Aux. compass format. Back to(1)item , then Press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. Alter the display “

NONE

⇔

EXIST

⇔

NEW

⇔

NONE”

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

EXIST

and

NEW

setting item is the same as Gyrocompass software setting

Refer to 3.1 Soft ware setting of the Gyrocompass setting input .

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT= AUX.COMP

AUX. COMP SOFT

…

FORMAT = EXIST

AUX. COMP SOFT

…

FORMAT =

EXIST

AUX. COMP SOFT

…

[PREV]

AUX. COMP SOFT

…

[TOP]

AUX. COMP. SOFT

FORMAT < aaaaa

Page 32

2-24

SM80B22M02E

3.3 Software setting of the INS/GPS input

(1)Set the key.

Then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting item.

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

I/G INP SOFT

…

XTE

I/G INP SOFT

…

XTE

I/G INP SOFT

…

[PREV]

I/G INP SOFT

…

[TOP]

I/G INP SOFT

…

SET COURSE

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT=INS/GPS INP

Page 33

2-25

SM80B22M02E

3.3.1 Software setting of the XTE input

(1)Set the

key. Then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting item.

(3)In case of you choose the existing format. Back to(1)item , then Press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. Alter the display “

NONE

⇔

EXIST

⇔

NEW

⇔

NONE”

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

XTE INP SOFT

…

FORMAT = EXIST

XTE INP SOFT

…

FORMAT =

EXIST

XTE INP SOFT

…

[PREV]

XTE INP SOFT

…

[TOP]

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT=INS/GPS INP

I/F SOFT SET

-UP…

XTE

XTE INP SOFT

…

FORMAT < aaaaa

Page 34

2-26

SM80B22M02E

3.3.2 Software setting of the XTE existing format

Set the NMEA0183 format of XTE (Cross track error)

(1)Set the

key. Then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting item.

In case of you choose the existing format. Back to(1)item , then Press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

The part of a....a is displayed setting condition.

Refer the contents to next page.

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. Alter the display of the existing format.

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT=INS/GPS INP

I/F SOFT SET

-UP…

XTE

XTE INP EXIST

…

=

XTE

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

XTE INP SOFT

…

=XTE

XTE INP SOFT

…

[PREV]

XTE INP SOFT

…

[TOP]

XTE INP EXIST

…

<aaaaaaaaaaaaaa

a

Page 35

2-27

SM80B22M02E

Selection Data Contents

xxXTE NMEA0183

$xxXTE (Taker ID “xx” is not checked)

Check-sum is required.

xxXTE & Mode NMEA0183 Ver. 2.30

$xxXTE (Taker ID “xx” is not checked)

Check-sum is required.

Mode indicator of XTE message is checked.

Page 36

2-28

SM80B22M02E

3.3.3 New format setting of the XTE format

Setting item is as follows.

① Reception Header

② Position of the input field

③ Check sum Valid/Invalid

④ Transmission data output interval

Setting item and a way is the same as Gyrocompass software setting

Refer to 3.1.2 Gyrocompass software setting.

Page 37

2-29

SM80B22M02E

3.3.4 Software setting of the Set course input format

(1)Set the

key. Then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting item.

(3)In case of you choose the existing format. Back to(1)item , then Press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. Alter the display of the existing format.

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT=INS/GPS INP

I/F SOFT SET

-UP…

SET COURSE

SETCRS

INP SOFT

…

FORMAT = EXIST

SETCRS INP SOFT

…

[PREV]

SETCRS INP SOFT

…

[TOP]

SETCRS INP SOFT

…

FORMAT = EXIST

SETCRS INP SOFT

FORMAT < aaaaa

Page 38

2-30

SM80B22M02E

3.3.5 Set the set course input of the existing format

(1)Set the

keys. Then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting item.

(3)In case of you choose the existing format. Back to(1)item , then Press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

The part of a....a is displayed setting condition.

Refer the contents to next page.

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. Alter the display of the existing format.

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key.

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT=INS/GPS INP

I/G INP SOFT

…

SET COURSE

SETCRS INP SOFT

…

FORMAT = aaaaa

SETCRS INP SOF

T…

FORMAT < EXIST

SETC. INP EXIST

…

=

NMEA 0183:$xxHSC

SETC. INP EXIST

…

=

NMEA 0183:$xxHSC

SETC. INP EXIST

…

[PREV]

SETC. INP

EXIST

…

[TOP]

SETC. INP EXIST

<aaaaaaaaaaaaaaa

Page 39

2-31

SM80B22M02E

Selection data Contents

NMEA 0183:$xxHSC $xxHSC (Taker ID “xx” is not checked)

The first field data is used as the set course data.

The second field data should be “T”.

Super Bridge

For MITSUBISHI super bridge I/F

$xxTRC format

Taker ID “xx” should be either EC, EI, II or IN.

INS-1

For interfacing with ECDIS made by JRC

(Correspondence to a style approval previous ATOS version)

① $xxHTC

② $xxXTE

Taker ID “xx” should be either EC, EI, II or IN.

JRC CAT-B&C

(for MED TCS

(for MED TCS (for MED TCS

(for MED TCS

type approval

type approvaltype approval

type approval))))

For interfacing with ECDIS made by JRC

The following four(4) messages are required.

① $xxHTC

② $xxXTE (set by XTE setting)

③ $xxHSC

④ $xxVDR

Taker ID “xx” should be either EC, EI, II or IN.

INS-2 (Type A) For interfacing with ECDIS made by FURUNO (At present, not

used.)

$xxHTC

Taker ID “xx” should be either EC, EI, II or IN.

Furuno CAT-B

(for MED TCS

(for MED TCS (for MED TCS

(for MED TCS

type approval

type approvaltype approval

type approval))))

For interfacing with ECDIS made by FURUNO

The following two(2) messages are required.

① $xxHTC

② $xxVTG

Taker ID “xx” should be either EC, EI, II or IN.

Transas CAT-C

(for MED TCS

(for MED TCS (for MED TCS

(for MED TCS

type approval

type approvaltype approval

type approval))))

For interfacing with ECDIS made by TRANSAS

$xxHTC

Taker ID “xx” should be either EC, EI, II or IN.

Kelvin INS-1 For interfacing with ECDIS made by KELVIN HUGHES

The following two(2) messages are required.

$xxHTC

Taker ID “xx” should be either EC, EI, II or IN.

Tokimec For interfacing with ECDIS made by TOKIMEC

$xxHTC

Taker ID “xx” should be either EC, EI, II or IN.

Page 40

2-32

SM80B22M02E

3.3.6 New format setting of the set course format

Setting item is as follows.

① Reception Header

② Position of the input field

③ Check sum Valid/Invalid

④ Transmission data output interval

Setting item and way is the same as Gyrocompass software setting

Refer to 3.1.2 Gyrocompass software setting.

Page 41

2-33

SM80B22M02E

3.4 Software setting of the INS/GPS output

Set theINS/GPS output specification

(1)Set the key.

Then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting item.

(3)In case of you change the input data. Back to(1)item , then Press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. Alter the display “

NONE

⇔

EXIST

⇔

NEW

⇔

NONE”

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

Note ) NEW setting is not available. It is not able to access to NEW.

I/G OUT SOFT

…

FORMAT = EXIST

I/G OUT SOFT

[PREV]

I/G OUT SOFT

[TOP]

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT=INS/GPS OUT

I/G OUT SOFT

…

FORMAT = EXIST

I/G OUT SOFT

…

FORMAT < EXIST

Page 42

2-34

SM80B22M02E

3.4.1 Software setting of the INS/GPS existing output format

(1)Set the

keys.

Then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the setting item.

(3)In case of you change the format. Back to(1)item , then Press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode

The part of a....a is displayed setting condition.

Referto the contents to next page.

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. Alter the display of the existing format.

After selected the setting mode , Press ENTER

ENTERENTER

ENTER key..

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT=INS/GPS OUT

I/G OUT SOFT

…

FORMAT = aaaaa

I/G OUT

SOFT

…

FORMAT < EXIST

I/G OUT EXIST

…

= $AGDRR

I/G OUT EXIST

…

[PREV]

I/G

OUT EXIST

…

[TOP]

I/G OUT EXIST

…

<aaaaaaaaaaaaaaa

I/G OUT EXIST

…

=

$

AGDRR

Page 43

2-35

SM80B22M02E

Data Contents

$AGDRR

123456789012345678901234567890123456

$AGDRR,axx.x,axx.x,axx.x,aa*hh<CR><LF>

8:Course deviation P=Port , S=Stbd

9..12:Course deviation(deg)

14:Rudder P=Port , S=Stbd

15..18:Rudder (deg)

20:Rate of turn P=Port , S=Stbd

21..24:Rate of turn(deg/min)

26:H=HAND mode , R=R/C , F=N.F. ,

C=Alter the course(AUTO) , K=Course keeping(AUTO) ,

O=Override

27:N=NOT NAVI , E=NAVI

29..30:Check sum

$AGHTD(JRC)

JRC ECDIS tracking format or VDR format

Send the 3 formats

(for TCS-B & C Type approval)

① $AGHTD format

② $AGRSA format

③ $PYDKS format

$AGHTD(Furuno)

FURUNO ECDIS comply with TCS interface format or VDR

(for TCS-B Type approval)

Send the 2 format

① $AGHTD format

② $AGRSA format

$AGHTD & $AGDRR

FURUNO ECDIS comply with Simplify tracking control or VDR

Send the following 3 format

① $AGHTD format

② $AGRSA format

③ $ AGDRR,axx.x,axx.x,axx.x,aa*hh<CR><LF>

(Refer to the above contents for detail information)

$AGHTD(Transas)

TRANSAS ECDIS interface format or VDR

(for TCS-C Type approval)

① $AGHTD format

② $AGRSA format

③ $PYDKD,CRA format (for INS)

$AGHTD(Kelvin)

KELVIN HUGHES ECDIS interface format or VDR

Send the 2 format

① $AGHTD format

② $AGRSA format

(It is during developing.)

$AGHTD(Tokimec)

TOKIMEC ECDIS interface format or VDR

Send the 2 format

① $AGHTD format

② $AGRSA format

Page 44

2-36

SM80B22M02E

3.5 Software setting of LOG input format

Set the input data of the LOG data

(1)Set the mode.

Then press the ENTER

ENTERENTER

ENTER key.

Display the current setting item for LOG data on the Data display.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the LOG format. Then press the ENTER

ENTERENTER

ENTER key.

(3)In case of you change the input data. Back to (1) item, Then press the ENTER

ENTERENTER

ENTER key.

Data display become under setting mode

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. After the display,

NONE

⇔

EXIST

⇔

NEW

⇔

NONE

.

After selected the setting mode, press the ENTER

ENTERENTER

ENTER key.

If you choose the EXIST or NEW mode, move to the 3.5.1 or 3.5.2 setting item.

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT= LOG

LOG SOFT

…

FORMAT = EXIST

LOG SOFT

…

FORMAT =

EXIST

LOG SOFT

…

[PREV]

LOG

SOFT

…

[TOP]

LOG SOFT

…

FORMAT< aaaaa

Page 45

2-37

SM80B22M02E

3.5.1 Set the existing LOG input format

(1) Set the

mode. Then press the ENTER

ENTERENTER

ENTER key.

Display the current existing format on the data display.

(2)Press the △△△△ ++++ or ▽▽▽▽ ---- key to select the existing LOG format.

(3)In case of you change the existing LOG input data. Back to (1) item, Then press the ENTER

ENTERENTER

ENTER key.

The data display becomes under setting mode

The part of a….a is displayed setting condition.

Refer to the contents to next page.

(4)Press the △△△△ ++++ or ▽▽▽▽ ---- key. After the display, of the existing format.

After selected the setting mode, press the ENTER

ENTERENTER

ENTER key.

MAINTENANCE 1

…

I/F SET-UP

I/F SET

-

UP …

SOFTWARE SET

I/F SOFT SET

-UP…

PORT= LOG

LOG SOFT

…

FORMAT = aaaaa

LOG SOFT

…

FORMAT < EXIST

LOG EXIST

…

=NMEA xxVBW (W)

LOG

EXIST

…

=NMEA xxVBW (W)

LOG

EXIST

…

= [PREV]

LOG

EXIST

…

= [TOP]

LOG EXIST

<aaaaaaaaaaaaaaa

Page 46

2-38

SM80B22M02E

Selection Data Contents

NMEA xxVBW(W)

(speed through the water : STW)

NMEA0183

$xxVBW (Taker ID “xx” is not checked)

Check-sum is required.

Fore-Aft STW speed is used. The data valid status is checked.

NMEA xxVHW

(speed through the water : STW)

NMEA0183

$xxVHW (Taker ID “xx” is not checked)

Check-sum is required.

The speed data is used. The status of [kt] is checked.

YOKOGAWA VMVSD

(speed through the water : STW)

EML201 format

$VMVSD (The name was changed to YOKOGAWA VMVSD.)

NMEA xxVBW(G)

(speed over the ground : SOG)

NMEA0183

$xxVBW (Taker ID “xx” is not checked)

Check-sum is required.

Fore-Aft SOG speed is used. The data valid status is checked.

NMEA xxVTG

(speed over the ground : SOG)

NMEA0183

$xxVTG (Taker ID “xx” is not checked)

Check-sum is required.

The speed data is used. The status of [kt] is checked.

Page 47

2-39

SM80B22M02E

3.5.2 New format setting of the LOG input format

Setting item is as follows;

① Reception Header

② Position of the input field

③ Check sum Valid/Invalid

④ Transmission data output interval

Setting item and way is the same as Gyrocompass software setting

Refer to 3.1.2 Gyrocompass software setting.

Page 48

2-40

SM80B22M02E

Page 49

3-1

SM80B22M02E

Chapter 3 Memory access-FIX (1 bite)

This is the function for changing the contents in the RAM. You can change the contents and address

number in the RAM by inputting the HEX code

The data of the display is refreshed every 1 second.

(1)Select the "

MAINTENANCE 2 …

" mode on the data display. Then press ENTER

ENTERENTER

ENTER key.

The data display become under setting mode.

←Cursor position is inputting point

(2)Press △△△△ ++++ or ▽▽▽▽ ---- key to alter the cursor position. Then change the address by turning the

course setting dial .

Turn to the clockwise the course setting dial, data is increased . Turn to the counterclockwise it ,data is

decreased. (HEX data is from o to F.)

←Data is changed by course setting dial.

(3)Press ENTER

ENTERENTER

ENTER key. Display the contents of the address

(4)Press △△△△ ++++ or ▽▽▽▽ ---- key to alter the cursor position. Then change the data by turning the course

setting dial .

Turn to the clockwise the course setting dial, data is increased . Turn to the counterclockwise it ,data is

decreased. (HEX data is from o to F.)

(5)Press ENTER

ENTERENTER

ENTER key, data is refreshed .

Note 1) It is not possible to refresh the data except the RAM, Backup RAM,NVRAM.

Note 2) When you change the some contents, it has potential that the program become hang-up

Note 3) You couldn’t change the I/O Device data.

Note 4) It is not possible to refresh the data when you pressed the ENTER

ENTERENTER

ENTER key only.

ADDRESS=

0

12DF5

FIX[AA] = AA

Flicker the data every 1 second

ADDRESS<

0

12DF

5

FIX[ ] =

ADDRESS=

0

12DF5

FIX[AA] = 84

ADDRESS<

012DF5

FIX[84] = 84

ADDRESS<

000000

FIX[ ] =

Page 50

Page 51

4-1

SM80B22M02E

Chapter 4 Memory Access-FLX(4bite)

This is the function for changing the contents in the RAM. You can change the contents and address

number in the RAM by inputting the HEX code

(1)Select the "

MAINTENANCE 3 …

" mode on the data display. Then press EN

ENEN

ENTER

TERTER

TER key.

The data display become under setting mode.

←Cursor position is inputting point

(2)Press △△△△ ++++ or ▽▽▽▽ ---- key to alter the cursor position. Then change the address by turning the

course setting dial .

Turn to the clockwise the course setting dial, data is increased . Turn to the counterclockwise it ,data is

decreased. (HEX data is from o to F.)

←Data is changed by course setting dial.

(3)Press ENTER

ENTERENTER

ENTER key. Display the contents of the address

(4)Press △△△△ ++++ or ▽▽▽▽ ---- key to alter the cursor position. Then change the data by turning the course

setting dial .

Turn to the clockwise the course setting dial, data is increased . Turn to the counterclockwise it ,data is

decreased. (HEX data is from o to F.)

(5)Press ENTER

ENTERENTER

ENTER key, data is refreshed .

Note 1) It is not possible to refresh the data except the RAM, Backup RAM,NVRAM.

Note 2) When you change the some contents, it has potential that the program become hang-up

Note 3) In case of you change the real number value, it is necessary to change the floating point style.

Note 4) It is not possible to refresh the data when you press the only ENTER

ENTERENTER

ENTER key.

ADDRESS<

0

0000

0

FIX = [ ]

ADDRESS<

0

12DF

5

FIX = [ ]

12DF5=[3E99

999A]

FIX < 00000000

12DF5=[3E99

999A]

FIX < 3E12345F

ADDRESS<

0

12DF

5

FIX = [ ]

Page 52

Page 53

5-1

SM80B22M02E

Chapter 5 DAC Output

Output the rudder value based on the DAC and display the Rudder feedback angle value at every 0.5

second. Output value can select the Rudder angle (

P45~S45)

or DAC value

(0~

FFF).

The actual control routine is bypassed under this operation.

(1)

Select the "

MAINTENANCE 4 …

" mode on the data display. Then press

ENTER

ENTERENTER

ENTER

key.

Rudder output become Mid ship position.

The data display become under setting mode.

(2)

Press

△△△△ ++++

or

▽▽▽▽ ----

key to alter the cursor position.

①⇔②⇔③⇔①

①

←

DAC value input

②

←

Rudder value

③

(3)

Select the AUTO RUDDER OUT of DAC value input, then press the

ENTER

ENTERENTER

ENTER

key.

The data display become under setting mode.

←

Cursor position is inputting point

(4)

Press

△△△△ ++++

or

▽▽▽▽ ----

key to alter the cursor position. Then change the address by turning the

course setting dial .

Turn to the clockwise the course setting dial, data is increased . Turn to the counterclockwise it ,data is

decreased. (HEX data is from o to F.)

←

Cursor position is inputting point

(5)

Press

ENTER

ENTERENTER

ENTER

key. Rudder order from the DAC value shall be supplied.

←

Cursor position is inputting point

Rudder feedback

angle

Rudder angle

(P45~S45)

DAC

value

(0h~FFFh)

AUTO RUDDER OUT

=[800] 0 a###.#

AUTO RUDDER OUT

=[800] 0 a###.#

AUTO RUDDER OUT

= 800[ 0]S###.#

AUTO RUDDER OUT

= <EXIT>

AUTO RUDDER OUT

<[800] 0 a###.#

AUTO RUDDER OUT

<[CB0] 0 a###.#

AUTO RUDDER OUT

=[CB0]P30 a###.#

Page 54

5-2

SM80B22M02E

(6)

Press

△△△△ ++++

or

▽▽▽▽ ----

key to select the AUTO RUDDER OUT. Then press

ENTER

ENTERENTER

ENTER

key.

The data display become under setting mode.

←

Rudder value

(7)

Press

△△△△ ++++

or

▽▽▽▽ ----

key ,the data increase and decrease.

Press

ENTER

ENTERENTER

ENTER

key after setting the data. Then auto steering unit outputs the rudder value.

ADC

value

MSB LSB

HEX

Voltage

[V]

Rudder

Value

[°]

111111111111 0xFFF

111111111110 0xFFE

111111010000 0xFD0

+5.0 S 50.0

100000000001 0x801

+0.0025 S 0.025

100000000000 0x800

0.0 0.0

011111111111 0x7FF

-0.0025 P 0.025

000000110000 0x030

-5.0 P 50.0

000000000001 0x001

000000000000 0x000

AUTO RUDDER OUT

< 800[ 0] a###.#

AUTO RUDDER OUT

< 418[S25] a###.#

Page 55

6-1

SM80B22M02E

Chapter 6 Actual rudder angle output

Output the DAC value based on rudder order

The actual control routine is bypassed under this operation.

(1)

Select the "

MAINTENANCE 5 …

" mode on the data display. Then press

ENTER

ENTERENTER

ENTER

key.

①

(2)

Press

△△△△ ++++

or

▽▽▽▽ ----

key to alter the item

①⇔②⇔①

①

②

(3)

Select the RDA OUT , then press

ENTER

ENTERENTER

ENTER

key.

The data display become under setting mode.

(4)

Press

△△△△ ++++

or

▽▽▽▽ ----

key ,the data increase and decrease.

Press

ENTER

ENTERENTER

ENTER

key after setting the rudder value.

Then auto steering unit outputs the DAC value.

RDA OUT

…

= 0

RDA OUT

…

= 0

RDA OUT

…

= <EXIT>

RDA OUT

< 0

RDA OUT

< S33

Page 56

Page 57

7-1

SM80B22M02E

Chapter 7 Course deviation output

Output the DAC value based on course deviation value

The actual control routine is bypassed under this operation.

(1)

Select the "

MAINTENANCE 6 …

" mode on the data display. Then press

ENTER

ENTERENTER

ENTER

key.

①

(2)

Press

△△△△ ++++

or

▽▽▽▽ ----

key to alter the item

①⇔②⇔①

①

②

(3)

Select the CDV OUT , then press

ENTER

ENTERENTER

ENTER

key.

The data display become under setting mode.

(4)

Press

△△△△ ++++

or

▽▽▽▽ ----

key ,the data increase and decrease.

Press

ENTER

ENTERENTER

ENTER

key after setting the course deviation value.

Then auto steering unit outputs the DAC value.

RDA OUT

…

= 0

CDV OUT

…

= 0

CDV OUT

…

= <EXIT>

CDV OUT

< 0

CDV OUT

< P22

Page 58

Page 59

8-1

SM80B22M02E

Chapter 8 Display of the analogue input

Display the ADC value of the each analogue input

ADC value is refreshed every 0.5 second .

(1))

Select the "

MAINTENANCE 7 …

" mode on the data display. Then press

ENTER

ENTERENTER

ENTER

key.

①

←

ADCValue

(2)

Press

△△△△ ++++

or

▽▽▽▽ ----

key to alter the item

①⇔②⇔③⇔④⇔⑤⇔⑥⇔⑦⇔⑧⇔①

(3)

Point number

A-1:No.1

Rudder feedback angle

A-2:No.1

Rudder order value

A-3:No.2

Rudder feedback value

A-4:No.2

Rudder order value

A-5:No.3

Rudder feedback value

A-6:No.3

Rudder order value

A-7:No.4

Rudder feedback value

A-8:No.4

Rudder order value

(

Note

)ADC

value is 0.10/deg = 40

①

②

⑧

ADC POINT DISP

…

POINT:A-1= ####

ADC POINT DISP

…

POINT:A-1= ####

ADC POINT DISP

…

POINT:A-2= ####

ADC POINT DISP

…

POINT:A-8= ####

Page 60

Page 61

9-1

SM80B22M02E

Chapter 9 Program version number

Display the current program version number

(1)Select the "

MAINTENANCE 8 …

" mode on the data display. Then press ENTER

ENTERENTER

ENTER key.

Identification of

ECDIS

Contents

0 Tracking interface with other maker’s ECDIS

1 TCS IF for JRC ECDIS

2 TCS IF for FURUNO ECDIS

3 Interface with MITSUMISHI Super Bridge

4 TCS IF for TRANSAS ECDIS

5 Interface with Kelvin Huge ECDIS

6 Interface with TOKIMEC ECDIS

Example of indication

Auto steering unit

ID, Version and

Revision of Autopilot

ID, Version and

Revision of TCS

Application

PB343 CR155J23 TCS-1A01 For JRC TCS IF

PB343 CR155K10 TCS-2A01 For FURUNO TCS IF

PB343 CR155K10 TCS-4A01 For TRANSAS TCS IF

(2)Press ENTER

ENTERENTER

ENTER key. Back to the maintenance item mode.

Version TCS

-

xa##

'YY/MM/DD xxxa##

Version No.A~Z

Date of master ROM

Month of master ROM

Year of master ROM

Revision No.01~99

Maste

r ROM ID

TCS software version

TCS software versionTCS software version

TCS software version

x:Identification of ECDIS

a:Version No. A ~ Z

##:Revision No.01 ~ 99

AUTOPILOT

AUTOPILOTAUTOPILOT

AUTOPILOT

software version

software version software version

software version

This

ThisThis

This information

informationinformation

information appear

appear appear

appearssss

only when TCS interface

only when TCS interface only when TCS interface

only when TCS interface

protocol has been set.

protocol has been set.protocol has been set.

protocol has been set.

Page 62

Page 63

10-1

SM80B22M02E

Chapter 10 Program cold start

Program cold start means the reset function of RAM area.

(1)

Press the

ENTER

ENTERENTER

ENTER

key after displayed "

MAINTENANCE 9 …

"on the data display.

Data display become resetting item of RAM area.

(2)

Change the setting mode by using the

△△△△ ++++

or

▽▽▽▽ ----

Keys.

①⇔②⇔③⇔④⇔⑤⇔⑥⇔⑦⇔①

①

Ship’s parameter(NVRAM)

②

Ship’s Parameter of each draft mode

(

NVRAM)

③

Key input value(Back up RAM)

④

I/F set up data

(

Back up

RAM)

⑤

Error log (Back up

RAM)

⑥

Start the cold start mode

⑦

(3)

If you want to reset some data in RAM. Press

ENTER

ENTERENTER

ENTER

key after selected the reset item.

(4)

Press the

△△△△ ++++

or

▽▽▽▽ ----

key. Alter the display

INIT.

⇔

UNINTIT.

⇔

INIT

Press

ENTER

ENTERENTER

ENTER

key after selected the setting mode ,..

(5)

In case of you do the cold start Press

ENTER

ENTERENTER

ENTER

key after selected the item ⑥.

PROG.COLD START

…

PARAM.SW=UNINIT.

PROG.COLD START

…

D-PARAM = INIT.

PROG.COLD START

…

KEY SET = INIT.

PROG.COLD S

TART

…

I/Fsetup= INIT.

PROG.COLD START

…

<EXIT>

PROG.COLD START

…

<C-START:[ENTER]

PROG.COLD START

…

ERR.LOG = INIT.

Page 64

Page 65

11-1

SM80B22M02E

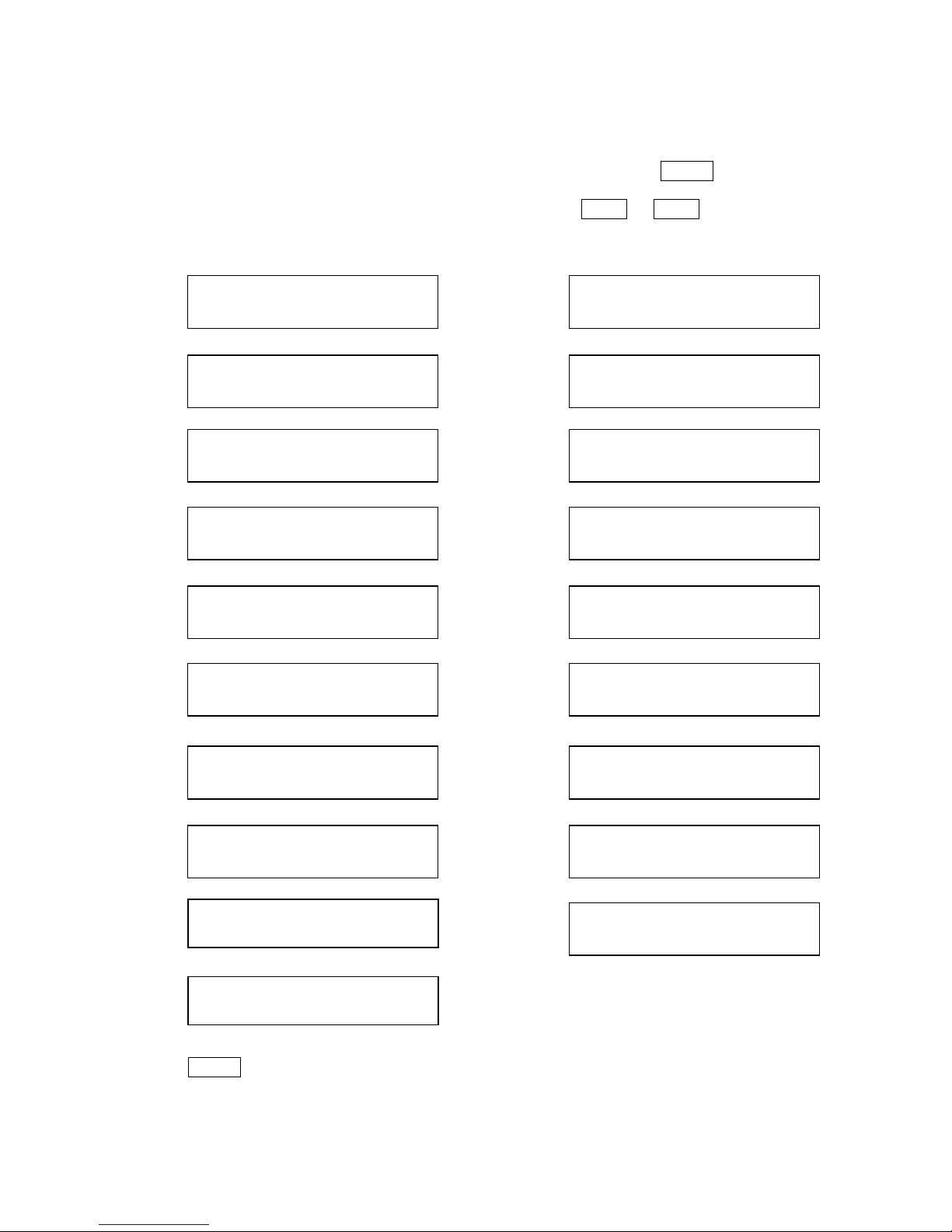

Chapter 11 Input and Calculate the ship’s parameter (PT500A)

Input the following item for calculating the ship’s parameter

①

Kind of vessels

②

Length between perpendiculars (LPP)

③

Molded breadth (B-mld)

④

Designed full load draft (D-Full load)

⑤

Designed full load displacement (Full load displacement)

⑥

Block coefficient (Cb)

⑦

Area pf rudder (Ar)

⑧

Navigation speed (VS)

⑨

Ship’s maneuverability (T,K)

⑩

Display of the ship’s maneuverability

1.

Select the ship’s parameter

(1) Press the

ENTER

ENTERENTER

ENTER

key after displayed "

MAINTENANCE 10 …

"on the data display.

The data display is displayed ship’s parameter mode.

(2) Press

△△△△ ++++

or

▽▽▽▽ ----

key to change the item.

①⇔②⇔③⇔④⇔⑤⇔⑥⇔⑦⇔⑧⇔⑨⇔⑩⇔①

①

⑦

②

⑧

③

⑨

④

⑩

⑤

⑪

⑥

Press

ENTER

ENTERENTER

ENTER

key after selected the item. The function of the item become valid mode .

SHIP PARA. CALC

…

SHIP'S Type= #

SHIP PARA. CALC

…

LPP= ###.##

SHIP PARA. CALC

…

B-mld= ##.##

SHIP PARA. CALC

…

D-Full= ##.##

SHIP PARA. CALC

…

Cb= #.####

SHIP PARA. CALC

…

Full Disp=######

SHIP PARA. CALC

…

Rud-Area=###.##

SHIP PARA. CALC

…

Speed= ##.#

SHIP PARA. CALC

…

CALCULATION

SHIP PARA. CALC

…

CALC PARA. DISP

SHIP PARA. CALC

…

<EXIT>

Page 66

11-2

SM80B22M02E

1.1

Kind of ship

Set the kind of the ship

(1)

Press

ENTER

ENTERENTER

ENTER

key when it is displayed the "

SHIP'S Type=

" on the data display.

Data display become under setting mode.

# is kind of the ship

(2)

Press the

△△△△ ++++

or

▽▽▽▽ ----

key to select the Setting No. . Then press

ENTER

ENTERENTER

ENTER

key.

Kind of the ship

Kind of the ship

Setting

No.

PASSENGER SHIP

PASSENGER SHIP

CARGO PASSENGER SHIP

PASSENGER CAR FERRY

CRUSING SHIP

1

GENERAL CARGO SHIP

LINER

TRAMPER

MULTI-PURPOSE CARGO SHIP : MPC

1

UNIT LOAD CARRIER

CONTAINER CARRIER

BARGE CARRIER

1

BULK CARRIER

BULK CARRIER

ORE CARRIER

COAL CARRIER

2

COMBINATION CARRIER

ORE/OIL CARRIER : O/0

ORE/BULK/OIL CARRIER : O/B/O

2

SPECIAL CARGO SHIP

LUMBER CARRIER,TIMBER CARRIER

CHIP CARRIER

HEAVY LIFTER

PEFRIGERATED CARGO SHIP

PURE CAR CARRIER :PCC

CAR BULK CARRIER

1

TANKER

CRUDE OIL CARRIER

VLCC

(VERY LARGECRUDE OIL CARRIER

ULCC

(ULTRA LARGECRUDE OIL CARRIER)

PRODUCTS CARRIER

2

SPECIAL TANKER

LPG

(LIQUEFIED PETROLEUM GAS CARRIER)

LNG

(LIQUEFIED NATURAL GAS CARRIER)

CHEMICAL TANKER

1

SHIP PARA. CALC

SHIP'S Type< #

Page 67

11-3

SM80B22M02E

1.2

Input the Length between perpendiculars

(LPP)

Refer to fig.1 for LPP

(1)

When you are displayed "

LPP= ###.##

" on the data display ,then press

ENTER

ENTERENTER

ENTER

key.

The data display become under setting mode.

←

Cursor position is inputting point

(2)

Press

△△△△ ++++

or

▽▽▽▽ ----

key to set the cursor point. Then change the data by turning the Set

course dial. Turn to the clockwise direction , data is increased and turn to the counter

clockwise direction ,data is decreased. (Data is 0 to 9 Numerical value)

(3)

After input the LPP data , then press

ENTER

ENTERENTER

ENTER

key.

1.3

Input the Molded breadth

(B-mld)

Refer to fig.1 for B-mld.

(1)

When you are displayed "

B-mld= ##.##

" on the data display ,then press

ENTER

ENTERENTER

ENTER

key.

The data display become under setting mode.

←

Cursor position is inputting point

(2)

Press

△△△△ ++++

or

▽▽▽▽ ----

key to set the cursor point. Then change the data by turning the Set

course dial. Turn to the clockwise direction , data is increased and turn to the counter

clockwise direction ,data is decreased. (Data is 0 to 9 Numerical value)

(3)

After input the B-mld data , then press

ENTER

ENTERENTER

ENTER

key.

SHIP PARA. CALC

B-mld< ##.##

SHIP PARA. CALC

B-mld< 65.65

SHIP PARA. CALC

LPP< ###.##

SHIP PARA. CALC

LPP< 123.45

Fig.1

B-mld D-full

LPP

Page 68

11-4

SM80B22M02E

1.4

Input the Designed full load draft (D-Full load)