Page 1

Limiting-current type

Oxygen Analyzer

OX100, OX102

OX100, OX102

Limiting-current type

Oxygen Analyzer

• One Instrument measures 100 ppm to 25% Oxygen

• Simple "One Touch" Calibration

• Self Diagnostics Assure High Reliability

• "One Touch" Sensor Replacement

• Compact Size

• Accessories to Assure Accuracy

• Dedicated Sampling Unit (Separate from Oxygen Analyzer)

(Removes Dust, Mist and Organic Solvents)

• Calibration Kit

Simple On-Site Calibration

(Using 1 liter Gas Cylinder)

Bulletin 11M10A01-03E

www.yokogawa.com/an/

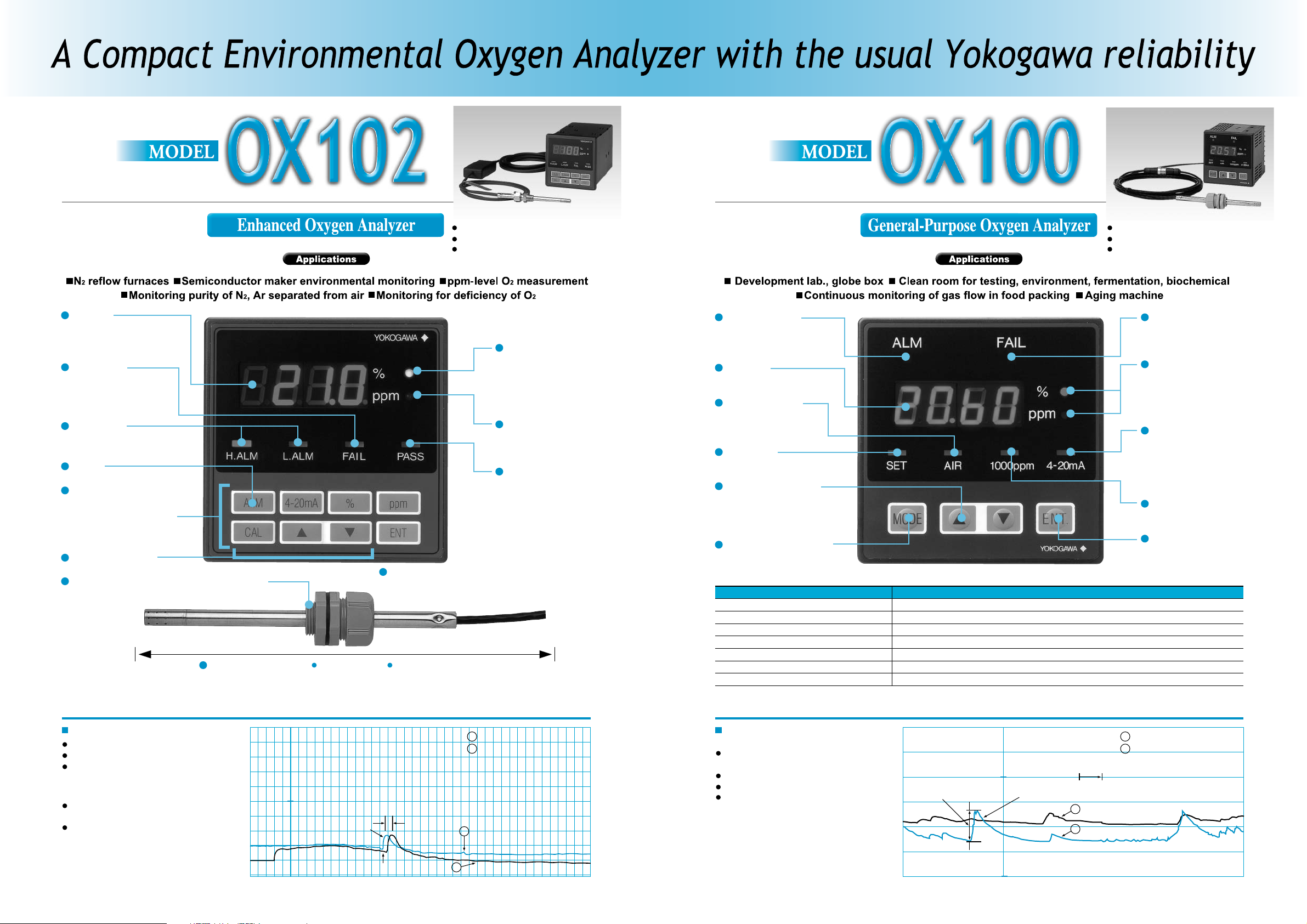

Page 2

Low range 0 to 100 ppm

Autoranging in four ranges from 0-100 ppm to 0-25%

High and Low Alarms

Spans 1000 ppm to 25%

Autoranging in two ranges, 0-1000 ppm and 0-25%

High Alarm or Low Alarm (depends on specification)

Oxygen

concentration

FAIL lamp

High, Low

Alarm lamps

Alarm

Fixed-range

4-20 mA / 1-5 V,

Autorange 4-20 mA,

keys

Calibration keys

Sensor holder: 17 mm

(* 1)

dia. or G3/8

Sensor

(* 2)

Plastic sensor holder

(Specify Option code /J

or L9811LA

(* 3)

)

Sensor plus cable: 5 m (OX100), 5, 10 or 30 m (OX102)

OX100 and OX102 sensors are not interchangeable

1 : When mount in 17 mm hole in panel, panel thickness can be up to 4 mm. 2 : Within 5 cm of sensor tip, can reach 250°C.

3 : Specify Option code /S, or Model K9424DB, for metal nipple.

Lit when range

is 1.0 to 25%

between 0 to 1.0% and

0 to 25% other than

0 to 10,000ppm

Lit when range is

0 to 10,000 ppm

Validates

parameter entry

High alarm or

Low alarm lamp

(depends on specification)

Oxygen

concentration

Calibration air

flow lamp

Lit during

alarm setting

Alarm setting key

Mode switching key

Main applications

Globe box (processing crystal parts)

Globe box (in research lab.)

2

reflow furnace / auto soldering

N

Clean room

Aging machine

Monitoring for deficiency of O

Foodstuffs

Measurement cautions * 1 : Sensor should not be exposed to silicone vapor, silicon gas.

2

* 2 : Corrosive or flammable gases, halogens, Freon, or organic solvents may adversely affect sensor.

Box is to be filled with inert gas

If organic solvents in box, use sampling unit

Use sampling unit, remove alcohol / flux from furnace

Use sampling unit if organic solvents present

High temperatures, so use metal nipple K9424DB

Use OX102 with Hi/Lo Alarms, or OX100-3 (Lo)

Use sampling unit if disinfectant is alcohol-based

Fail lamp

Units (% or ppm)

Lit when range is

0 to 10,000 ppm

not when range is

0 to 25%

Lit during 0 to

1000 ppm calibration

Entry setting key

Usage cautions

Example: N2 reflow furnace

Temperature : 120-130°C

Gas flow : 1m/sec.

Environment : Alcohol / Rosin / Flux,

Oxygen 100 ppm

Compared with oxygen

meter it replaced,

Response was faster, so changes were

quickly detected

Easy maintenance for Sampling unit

(easy replacement of filter, activated carbon)

10005000

Oxygen ppm

Fast response

Solder flux flow start

Approx. 6 sec.

A

OX102 oxygen analyzer

Installed oxygen analyzer

B

A

Difference

B

Example: Measuring oxygen

concentration in welding furnace

Temperature : Room temperature,

atmospheric pressure

Gas flow : 30 Nl/min. (N

Environment : Oxygen about 500 ppm in N

Low oxygen concentration in furnace:

safety precautions required

OX100 can detect atmospheric air leakage into

furnace which causes oxygen to rise to 200 ppm,

so can help with welding quality assurance.

2

)

2

200ppm

10005000

Air leak

Oxygen ppm

20mm/hr

B

A

A

OX100 oxygen analyzer

Dew point measurement

B

Page 3

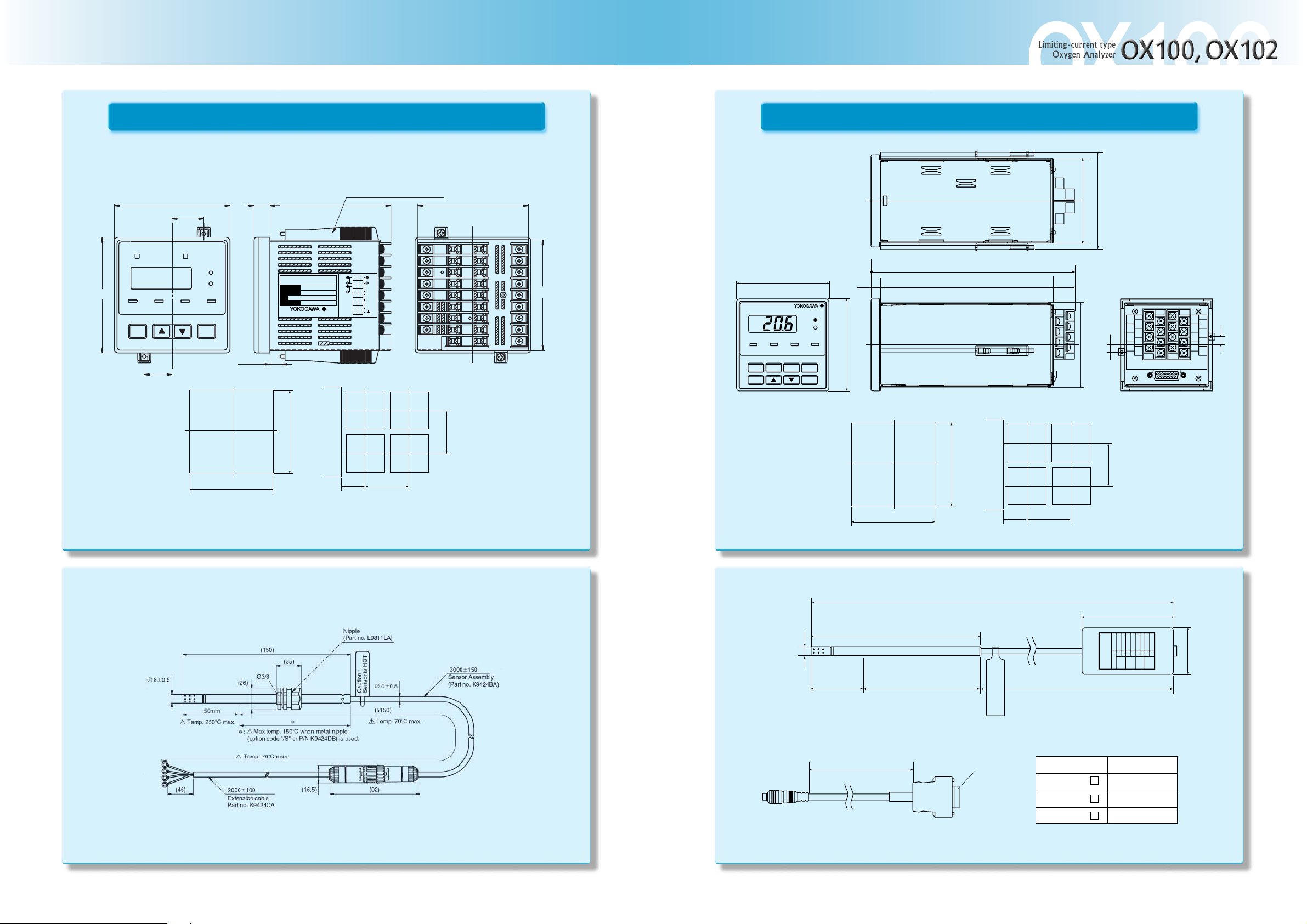

OX100 EXTERNAL DIMENSIONS

OX100 EXTERNAL DIMENSIONS

OX102 EXTERNAL DIMENSIONS

OX102 EXTERNAL DIMENSIONS

Convertor

96

MODE

96

26.2

ALM FAIL

AIRSET

1000ppm

23

13 100 91.6

Bracket (Parts : B9877BA)

1

2

3

4

5

6

7

8

ppm

%

4-20mA

ENT.

OXYGEN ANALYZER

MODEL

OX100

SUFFIX

-1151J

PART NoNoK9424AA

Made in Japan

19

4-20mA

SNSR

210

311

ALM

HTR

412

513

FAIL

614

715

100VAC

816

17

1~10

Panel thickness

+1

0

89

Other instrument

+1

0

89

100

55

Panel cut dimension Min. space for multiple installation

Unit : mm

9

10

11

12

91.6

13

14

15

16

17

Weight : Approx 0.6kg

100 *

* : Allow the minimum clearance of

115mm for removable installation.

Convertor

96

%

4-20mA

ALM

%

ppm

ppm

ENTCAL

Unit : mm

88 103

(212)

10

PASSFAL.ALMH.ALM IL

96

22180

1

+

4-20

5

+

1-5V

mA

2

-

6

-

3

+

RNG

7

88

7

NC

-

8

NC

9

ALM

13

NC

10

14

100-

11

240

FAIL

15

7

VAC

124

16

G

17

SNSR

Weight : Approx 1.2kg

+1

0

89

100 *

Other instrument

* : Allow a minimum distance of

+1

0

89

100

55

115mm for ease of removal.

Panel cut dimension Min. space for multiple installation

Sensor

Sensor

⭋8⫾0.5

Sensor External Dimension

(150)

50

Temp. 250⬚C Max.

Max temp. 70⬚C when plastic nipple

(option code "/J" or P/N L9811LA) is used.

Temp. 150⬚C Max.

L(m)

Unit : mmUnit : mm

(1190)

81

-19

-17

-65

-25

1.015

1.043

1.002

0.990

Sensor NO. XXXX

Sensor parameter Table

ABBAABA

Gain1

Gain2

Gain3

Gain4

1.429

B

Gain5

41

Temp. 70⬚C Max.

D-sub 15 pin

Male

Model Code

OX102-11

OX102-12

OX102-13

L (m)

4

9

29

Page 4

Sampling unit (K9424GA)

Measurement

gas inlet

Measurement

gas outlet

1

Membrane filter: removes dust / mist / flux

2

Sampling unit (K9424GA)

215 x 272 x 140 (mm), approx 4.8kg

Pump 100-240 V AC, 1.2A

3

Activated charcoal, membrane filter:

remove organic solvents

4

Flow meter: 0.1 to 1 liters / min.

Sampling Unit (K9424GA)

Sample inlet (Rc 1/4)

Sample outlet (Rc 1/4)

(220)

1

Filter

2

Pump

Needle valve

3 4

Activated charcoal,

membrane filter

Powe r line connector

240()

Needle valve

Power supply

Sensor

Flow

meter

Operating conditions:

Atmospheric pressure,

gas temperature 0 to 40°C

Mounting Rc 1/4

Power 100-240 V AC

connector

Pressure meter

(flow adjustment)

Gas outlet cock

(K9424JC, JD)

1000 ppm O

Quantity 6, one-liter

Calibration gas

cylinder (K9424JP)

Calibration kit (K9424JA, JB)

Gas outlet cock + Qty. 6, one

Calibration gas cylinder 210 x 75 x 335 mm, approx 800 g.

Unit:mm

2/N2

OX102 Standard Specifications

Model OX102

Meas. principle

Sampling

Gas sample

Measured gas

Mounting

Meas. ranges

Repeatability

Calibration

Fine tune mode

Analog output

Contact output

Alarm output

Self-diagnostics

Storage environment

Power supply

Converter size

Limiting-current type

Natural diffusion

Temperature 0 - 70°C, Humidity 20 - 80% RH (dew free), Pressure 1013 ± 40 hPa (Abs)

O2 in N2 or mixed gases; cannot be used with silicone vapor, combustible gases or organic solvents

Indoor, panel mounting

0-100 ppm / 0-1000 ppm / 0-10000 ppm / 0-25%, automatic / fixed switching mode

±15 ppm (Meas. range : 20-100 ppm), ±25 ppm (Meas. range : 100-1000 ppm),

±0.3%of reading (Meas. range : 1000-5000 ppm),

±7.5% of reading (Meas.range : 5000-10000 ppm), ±0.25% (Meas.range : 1-25%)

1. Atmospheric pressure calibration (between 15 to 25% O

2. 100 ppm calibration (between 80 and 120 ppm)

3. 1000 ppm calibration (between 900 and 1100 ppm)

4. 9000 ppm calibration (between 8500 and 9500 ppm)

5. Atmospheric pressure, 20, 100, 500, 1000 and 9000 ppm calibration

The measuring value can be adjusted to true analyzed value.

1. 4-20 mA DC isolated, fixed range

(0-100, 0-1000, 0-10000 ppm, 0-25% selectable),or 4-20 mA DC autoranging.

2. 1-5 V DC, fixed range (0-100, 0-1000, 0-10000 ppm, 0-25% selectable)

3. Zone signal output for 4-20 mA DC autoranging

Two outputs, rated 110 V AC, 24 V DC, 1 A

Hi or Lo alarm, sensor disconnected alarm

Hi or Lo alarm. setting range : 1 ppm to 24.9%.

Sensor disconnected

Sensor and converter temperature 0 to 70°C (dew free)

100-240V AC ±10%, 50/60Hz 15VA

96 x 96 x 190 mm

2

)

Activated

carbon filter

Flowmeter

Connector to joint sensor (ø8)

Calibration Kit (K9424JA, JB)

(90)

Gas vent tube

Pressure

gage

ø75

Approx. 300

Approx. 180

136()

146() 290()

Power line switch

Sensor

OX100/OX102 Sensor

1/8 Rc Piping connection for K9242JD

Unit : mm

K9424JC

NEEDLE VALVE ASSY

With Pressure gage and Capillary

Standard gas cylinder

(310)

Standard Gas

( 6 cylinders )

(255)

OX100 Standard Specifications

Model OX100

Meas. principle

Sampling

Gas sample

Measured gas

Mounting

Meas. ranges 0 to 1000 ppm, 0 to 25% (measuring range autoswitching)

Repeatability ±5% of span (for 0-1000 ppm range, with O2 being in the range 0 to 100 ppm).

Calibration

Analog output 4-20 mA DC isolated, fixed range (0-1000 ppm or 0-25%),

Contact output Two outputs, rated 250 V AC, 1 A

Alarm output High alarm contact output if concentration abnormal

Self-diagnostics Sensor disconnected

Storage environment

Power supply

Converter size

OX100 measuring principles, measured gas, and system configuration are same as for OX102

If you want an oxygen (concentration) control range of 1500 to 4500ppm, select the OX102.

Limiting-current type

Natural diffusion

Temperature 0 - 70°C, Humidity 20 - 80% RH (dew free), Pressure 1013 ± 40 hPa (Abs)

O2 in N2 or mixed gases; cannot be used with silicone vapor, combustible gases or organic solvents

Indoor, panel mounting

2

±2% of span (for 0-1000 ppm range, with O

being in the range 100 to 1000 ppm).

±2% of span (for 0 to 25% range).

1. Atmospheric pressure calibration (between 15 to 25% O

2

) 2. 1000 ppm standard gas calibration (1000±50 ppm)

(for 0-25%, 4 mA DC corresponds to 1500 ppm or less).

Hi or Lo alarm, sensor disconnected alarm

Hi or Lo alarm (depending on specification), setting range : 1 ppm to 24.9%

Sensor and converter temperature 0 to 70°C (dew free)

100 V AC ±10%, 50/60 Hz, 15 VA

96 x 96 x 190 mm

K9424JD

NEEDLE VALVE ASSY

Approx. 340

Restrictions

Can't be used in flammable or exhaust gas, corrosive gas, or organic solvent environment

To use in an environment with organic silicone, flow furnace, or N2 reflow furnace:

(1) Use a sampling unit(K9424GA), Can't use the OX100-1.

(2) The maintenance requirements (filter and activated charcoal) depend on the measured gas.

Be sure to read the manual and follow

the safety precautions in it.

Page 5

OX102 Limiting-current type Oxygen Analyzer

Model Suffix Code Option Code

OX102

Measuring range

Sensor

-1

1

2

3

N

Manual

J

E

Option code*

/S

/J

*Standard Product does not have a sensor holder. To get the sensor holder, specify " /S " or " /J".

(If using Sampling Unit, the sensor holder is not required.)

Enhanced Oxygen analyzer

0-100/1000/10,000 ppm / 0-25% O

With sensor (5 m; sensor assembly. 1m + cable 4 m)

With sensor (10 m; sensor assembly. 1m + cable 9 m)

With sensor (30 m; sensor assembly. 1m + cable 29 m)

Without sensor assembly

Japanese

English

Metal sensor holder

Plastic resin sensor holder

Description

2

OX100 Limiting-current type Oxygen Analyzer

Model

Suffix Code

Option Code

OX100

Application

-1

-2

-3

Measuring Range

Power supply

Sensor

1

5

1

N

Manual

J

E

L9811LA plastic resin sensor holder is provided as standard accessory.

*1 For measurement in the range of 1500 to 4500 ppm, use the OX102.

General purpose Oxygen Analyzer

Oxygen Analyzer (Can't use an activated carbon filter)*1

For (N

2

) reflow furnace

(Specify in case of using an activated carbon filter)*1

Monitoring for deficiency of Oxygen with low alarm, Measuring range 0-25%

0-1000 ppm / 0-25% O

100 V AC ±10%, 50/60 Hz

Sensor assy. cable 3m + extension 2m

Without sensor assembly

Japanese

English

Description

2

Sampling unit, Calibration kit

Part No. Description

K9424GA

K9424JA

Sampling unit

Calibration kit: Six 1-liter gas cylinder , gas outlet cock (with flow adjuster)

K9424JB Calibration kit: Six 1-liter gas cylinder , gas outlet cock (without flow adjuster)

Accessories

Part No. Description

K9424GY

K9424JC

K9424JD

K9424JP

K9424BA

K9424CA

B9877BA

K9424LA

K9424LB

K9424LC

K9424LD

K9424DB

L9811LA

Activated charcoal element, five per pack: for sampling unit

Gas outlet cock (with flow adjuster): qty. one

Gas outlet cock (without flow adjuster): qty. one

2/N2

Standard gas cylinder ( 1000 ppm O

) : qty. six

Sensor assy. cable 3 m for OX100 only

Extension cable, 2 m: for OX100 only

Bracket for mounting OX100, two per set.

Sensor assy. One per set : for OX102 only

Extension cable, 4 m: for OX102 only

Extension cable, 9 m: for OX102 only

Extension cable, 29 m: for OX102 only

Sensor holder (metal) for OX100 or OX102

Sensor holder (plastic) for OX100 or OX102

YOKOGAWA ELECTRIC CORPORATION

World Headquarters

9-32 Nakacho 2-chome, Musashino-shi,

To kyo 180-8750, JAPAN

Te l: +81-422-52-6316 Fax: +81-422-52-6619

http://www.yokogawa.com/an/

North America

YOKO GAWA C OR PORATION OF AMERICA

Georgia, U.S.A

http://www.yokogawa.com/us/

South America

YOKOGAWA AMERICA DO SUL LTDA.

BRAZIL

http://www.yokogawa.com.br/

Europe

YOKO GAWA E URO PE B.V.

European Headquarters

THE NETHERLANDS

http://www.yokogawa.com/eu/

YOKO GAWA E LE CTRIC CIS LTD.

RUSSIAN FEDERATION

http://www.yokogawa.ru/

Subject to change without notice.

All Rights Reserved, Copyright 2001, Yokogawa Electric Corporation.

c

Middle East

YOKOGAWA MIDDLE EAST B.S.C.(C)

http://www.yokogawa.com/bh/

Singapore

YOKOGAWA ENGINEERING ASIA PTE. LTD.

http://www.yokogawa.com/sg/

Korea

YOKOGAWA ELECTRIC KOREA CO., LTD.

http://www.yokogawa.com/kr/

China

YOKO GAWA C HI NA CO., LTD.

http://www.yokogawa.com/cn/

YOKOGAWA SHANGHAI INSTRUMENTATION CO., LTD.

http://www.ysi.com.cn/

YOKOGAWA SICHUAN INSTRUMENT CO., LTD.

http://www.cys.com.cn/

Tai wan

YOKOGAWA TAIWAN CORPORATION

http://www.yokogawa.com.tw/

India

YOKO GAWA I ND IA LTD.

http://www.yokogawa.com/in/

Australia

YOKOGAWA AUSTRALIA PTY. LTD.

http://www.yokogawa.com/au/

Represented by:

Vig-PMK-G·NL-10E

Printed in Japan, 107(KP) [Ed : 05/b]

Loading...

Loading...