Page 1

User’s

Manual

Models MV1004/MV1006/MV1008/MV1012/MV1024

MV2008/MV2010/MV2020/MV2030/MV2040/MV2048

MV1000/MV2000

Communication Interface

IM MV1000-17E

2nd Edition

Page 2

i

IM MV1000-17E

Thank you for purchasing the MV1000/MV2000 (hereafter referred to as the MV).

This Communication Interface User’s Manual contains information about the Ethernet

and serial interface communication functions. To ensure correct use, please read this

manual thoroughly before beginning operation.

Keep this manual in a safe place for quick reference in the event a question arises.

The following manuals, including this one, are provided as MV1000/MV2000 manuals.

Please read all of them.

• Electronic Manuals Provided on the Accompanying CD-ROM

Manual Title Manual No. Description

MV1000

First Step Guide

IM MV1000-02E Explains how to set up the MV1000 for

making measurements using the quick

settings function. Connection diagrams are

also provided to help you with the setup.

MV2000

First Step Guide

IM MV2000-02E Explains how to set up the MV2000 for

making measurements using the quick

settings function. Connection diagrams are

also provided to help you with the setup.

MV1000/MV2000

User’s Manual

IM MV1000-01E Explains all functions except communication

functions and procedures of the MV1000 and

MV2000.

MV1000/MV2000

Communication Interface

User’s Manual

IM MV1000-17E Explains the MV1000 and MV2000 Ethernet

and serial interface communication functions.

• Paper Manuals

Manual Title Manual No. Description

MV1000

First Step Guide

IM MV1000-02E This guide is also provided in the CD-ROM.

MV2000

First Step Guide

IM MV2000-02E This guide is also provided in the CD-ROM.

MV1000/MV2000

Control of Pollution

Caused by the Product

IM MV1000-91C

Provides information about pollution control.

• DAQSTANDARD Manuals

All manuals other than IM 04L41B01-66EN are contained in the DAQSTANDARD CD.

Manual Title Manual No.

DAQSTANDARD Viewer User's Manual IM 04L41B01-63EN

DAQSTANDARD Hardware Setup User's Manual IM 04L41B01-64EN

DAQSTANDARD DX100P/DX200P Hardware Configurator User's

Manual

IM 04L41B01-65EN

Installing DAQSTANDARD IM 04L41B01-66EN

Notes

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions. The gures

given in this manual may differ from those that actually appear on your screen.

•

Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or nd any errors, please

contact your nearest

YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without

YOKOGAWA’s permission is strictly prohibited.

•

The TCP/IP software of this product and the document concerning the TCP/IP software

have been developed/created by YOKOGAWA based on the BSD Networking Software

,

Release 1 that has been licensed from the Regents of the University of California.

2nd Edition : August 2010 (YK)

All Rights Reserved, Copyright © 2007 Yokogawa Electric Corporation

Page 3

ii

IM MV1000-17E

Trademarks

• MVAdvanced is a trademark of Yokogawa Electric Corporation.

• Microsoft and Windows are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

• Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

•

Company and product names that appear in this manual are registered trademarks or

trademarks of their respective holders.

• In this manual, the ™ and ® symbols do not accompany trademarks or registered

trademarks.

Revisions

• 1st Edition: December 2007

• 2nd Edition: August 2010

Page 4

iii

IM MV1000-17E

How to Use This Manual

The following symbols are used in this manual.

Unit

• k stands for 1000. Example: 5 kg, 100 kHz

• K stands for 1024. Example: 640 KB

Markings

The following safety notations are used in this manual.

Improper handling or use can lead to injury to the user or damage

to the instrument. This symbol appears on the instrument to

indicate that the user must refer to the user's manual for special

instructions. The same symbol appears in the corresponding place

in the user’s manual to identify those instructions. In the manual,

the symbol is used in conjunction with the word WARNING or

CAUTION.

WARNING

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

CAUTION

Calls attentions to actions or conditions that could cause light

injury to the user or damage to the instrument or user’s data, and

precautions that can be taken to prevent such occurrences.

Note

Calls attention to information that is important for proper operation

of the instrument.

Bold Characters

Bold characters are used to indicate text that appears on the screen or operation keys.

The ◊ symbol indicates key and menu operations.

Procedural Explanations

This manual mainly describes the MV1000 procedures. Where procedures differ between

the MV2000 and MV1000, the MV2000 procedures are also provided.

High-Speed and Medium-Speed Model Groupings

This manual uses the terms high-speed input model and medium-speed input model to

distinguish between MV models as follows:

Model Type Model

High-speed input model MV1004, MV1008, and MV2008

Medium-speed input model MV1006, MV1012, MV1024,

MV2010, MV2020, MV2030, MV2040, and MV2048

Page 5

iv

IM MV1000-17E

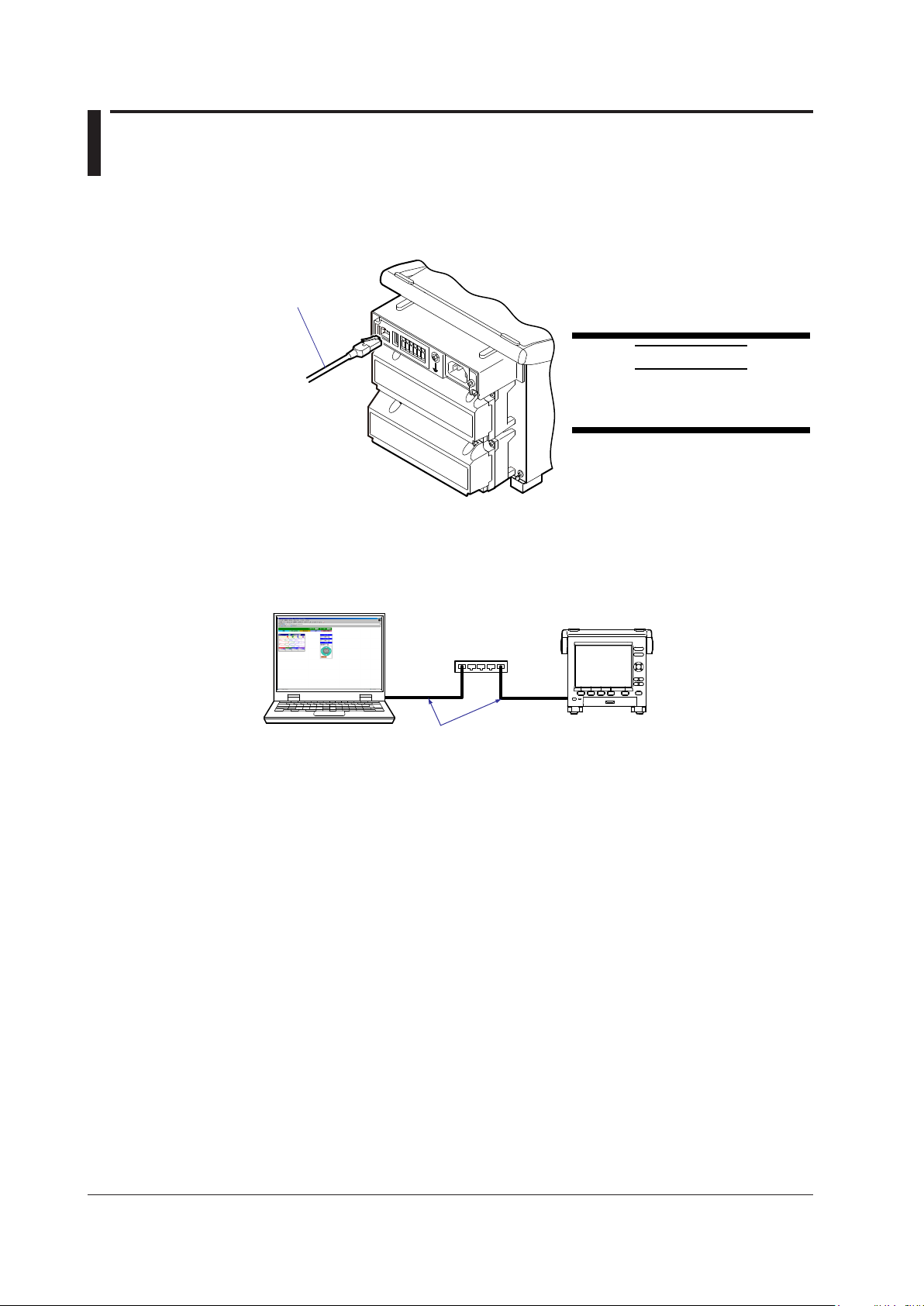

Communication Ports

Rear Panel

MV1000

RS-232 port (option)

A serial port provided with the

/C2 option.

RS-422/RS-485 port (option)

A serial port that is provided with the /C3 option.

Ethernet port

MV2000

RS-232 port (option)

A serial port provided with the

/C2 option.

RS-422/RS-485 port (option)

A serial port that is provided with the /C3 option.

Ethernet port

An Ethernet port that comes standard.

Page 6

v

IM MV1000-17E

1

2

3

4

5

6

7

App

Index

Contents

How to Use This Manual .................................................................................................................. iii

Communication Ports.......................................................................................................................iv

Chapter 1 Overview of Communication Functions

1.1 Ethernet Interface ................................................................................................................ 1-1

1.2 Serial Interface ..................................................................................................................... 1-7

1.3 Modbus Protocol .................................................................................................................. 1-8

Chapter 2 Using the Ethernet Interface

2.1 Workflow for Using the Ethernet Interface ........................................................................... 2-1

2.2 Connecting the MV .............................................................................................................. 2-2

2.3 Sending E-mail Messages ................................................................................................... 2-8

2.4 Monitoring the MV on a PC Browser ................................................................................. 2-17

2.5 A

cce

ssing Measured Data Files on the MV from a PC .....

..................................................... 2-23

2.6 Transferring Data Files from the MV .................................................................................. 2-25

2.7 Synchronizing the Time .....................................................................................................

2-28

2.8 Reading/Writing the MV Data from Another Device via Modbus

....................................... 2-30

2.9 Reading/Writing Data on Another Device from the MV via Modbus

.................................. 2-31

2.10 Usage Example of the Modbus Function ........................................................................... 2-40

Chapter 3 Using the Serial Interface

3.1 Workflow for Using the Serial Interface................................................................................ 3-1

3.2 Connecting the MV .............................................................................................................. 3-2

3.3 Configuring the Serial Interface ........................................................................................... 3-8

3.4 Reading/W

riting the MV Data from Another Device via Modbus

......................................... 3-9

3.5 Reading/Writing Data on Another Device from the MV via Modbus

.................................. 3-10

3.6 Usage Example of the Modbus Function ........................................................................... 3-13

Chapter 4 Commands

4.1 Command Syntax ................................................................................................................ 4-1

4.2 A List of Commands ............................................................................................................. 4-3

4.3 Setup Parameters ................................................................................................................ 4-8

4.4 Setting Commands (Setting) ..............................................................................................

4-10

4.5 Setting Commands (Control) ............................................................................................. 4-24

4.6 Basic Setting Commands .................................................................................................. 4-28

4.7 Output Commands (Control) .............................................................................................. 4-39

4.8 Output Commands (Setting/Measured/Computed Data Output) .......................................

4-40

4.9 Output Commands (RS-422/485 Commands) ................................................................... 4-42

4.10 Output Commands (Special Response Commands) .........................................................

4-43

4.11

Maintenance/Test Commands (available when using the maintenance/test server function

via the Ethernet interface) ..................................................................................................

4-43

4.12 Instrument Information Output Commands (available when using the instrument information

server function via the Ethernet interface) ......................................................................... 4-45

Page 7

vi

IM MV1000-17E

Chapter 5 Responses

5.1 Response Syntax ................................................................................................................. 5-1

5.2 Text Data Output Format ..................................................................................................... 5-6

5.3 Binary Data Output Format ................................................................................................ 5-27

5.4 Instrument Information Output Format

............................................................................... 5-32

Chapter 6 Status Reports

6.1 Status Information and Filter ................................................................................................ 6-1

6.2 Status Information Bit Structure ........................................................................................... 6-2

Chapter 7 Specifications

7.1 Ethernet Interface Specifications ......................................................................................... 7-1

7.2 Serial Interface Specifications ............................................................................................. 7-2

7.3 Modbus Protocol Specifications ........................................................................................... 7-3

Appendix

Index

Contents

Page 8

IM MV1000-17E

1-1

Overview of Communication Functions

1

1.1 Ethernet Interface

This chapter gives an overview of the MV Ethernet communication functions.

Modbus Communications

The MV can connect to a Modbus device and read and write to the device’s internal

registers. See section 1.3 for details.

Setting/Measurement Server

• You can use this feature to set almost all of the settings that can be configured from

the front panel keys. However, you cannot use this feature to turn the power ON/OFF,

register users, set the key lock password, or set the connection destination of the FTP

client function.

•

You can use this feature to transmit the following types of data.

• Measured, computed

1

, and external input data

2

• Files in the internal memory or files on an external storage medium

• Setup information and status byte

• Logs of operations errors, communications, etc.

• Alarm summaries and message summaries

• Relay status information

Measured, computed

1

, and external input2 data can be transmitted to a PC in binary

or ASCII format. Other types of data are transmitted in text format. For a description of

data output formats, see chapter 5.

1 /M1 option.

2 MV2000 with the /MC1 option.

• You can use setting mode commands (see sections 4.4 and 4.5), basic setting mode

commands (see section 4.6), and output commands (see sections 4.7 and 4.8) with

this feature.

•

You can use this feature via an Ethernet interface or serial interface (/C2 or /C3

option).

• If you want to use this feature via a serial interface, configure t

he serial interface

according to Chapter 3.

Maintenance/Test Server

• You can use this feature to transmit connection information, network statistics, and

other Ethernet communication information from the MV.

• You can use maintenance/test commands (see section 4.11) with this feature.

Chapter 1 Overview of Communication Functions

Page 9

IM MV1000-17E

1-2

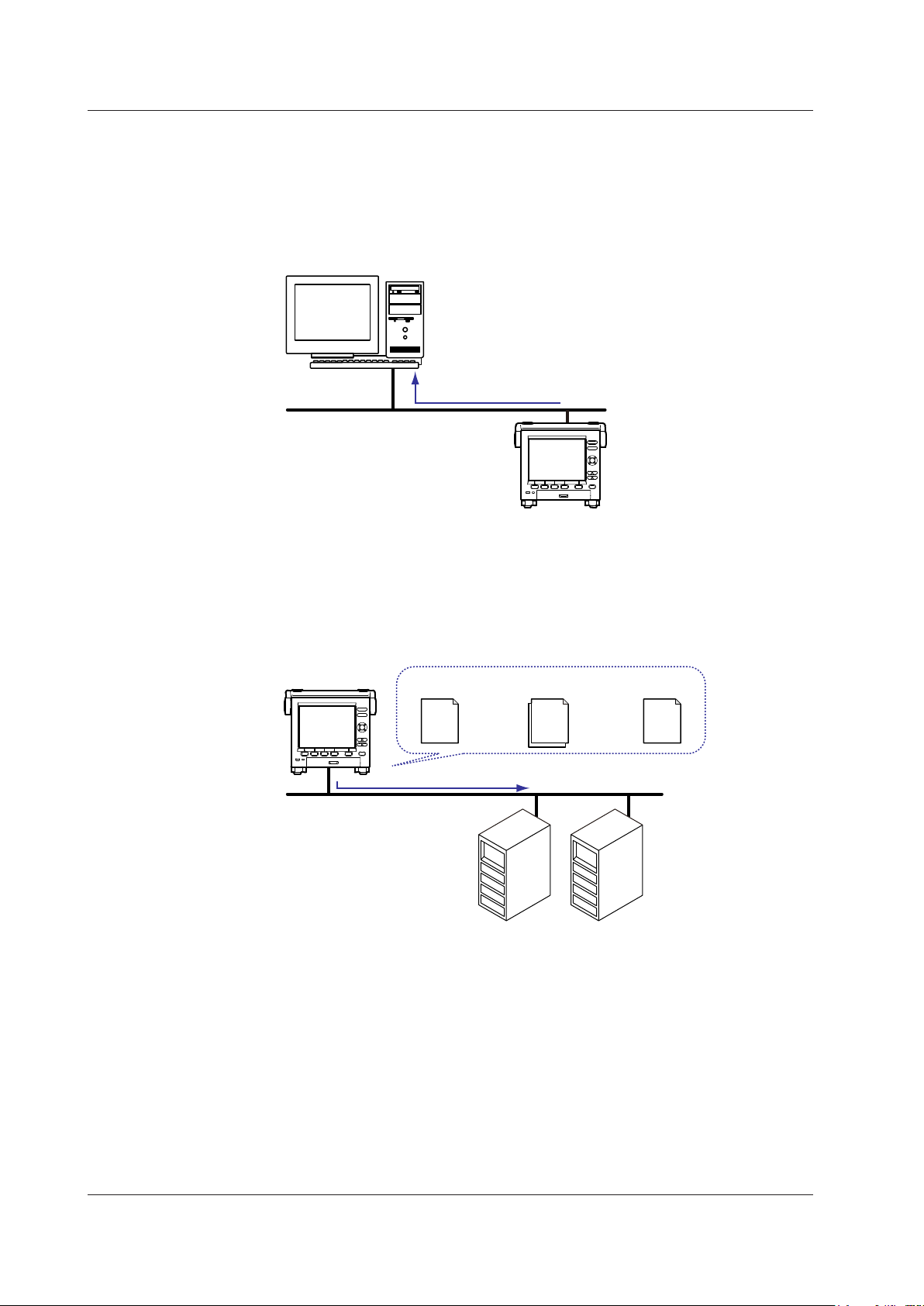

FTP Server

• You can access the MV from a PC via FTP. You can perform operations such as

retrieving directory and file lists and transferring and deleting files from an external

storage medium connected to the MV. You can also retrieve directory and file lists and

transfer files from the internal memory.

•

For the settings necessary to use this feature, see section 2.5.

Files on an external storage medium

PC

FTP server

Ethernet

MV

FTP Client

Automatic File Transfer

• You can use this feature to automatically transfer display, event, report, and snapshot

data files that are created in the MV internal memory to an FTP. The result of the

transfer is recorded in the FTP log. You can view the FTP log on the MV (see “Log

Display” described later) or transmit the log to a PC using commands.

Data files

FTP server

Primary

Secondary

Ethernet

Transfer destination

(FTP server) information

Transfer log

(FTP log)

Data files to

be transferred

FTP client

MV

You can specify two destination FTP servers: primary and secondary. If the primary

FTP server is down, the file is transferred to the secondary FTP server.

• For the settings necessary to use this feature, see section 2.6.

• FTP Test

• You can perform an FTP test by transferring a test file from the MV to an FTP

server.

• You can view the result of the FTP test on the FTP log screen.

•

For information on how to use this feature, see section 2.6.

1.1 Ethernet Interface

Page 10

IM MV1000-17E

1-3

Overview of Communication Functions

1

Instrument Information Server

• You can use this feature to output the serial number, model name, and other

information about an MV that is connected via an Ethernet network.

• You can use instrument information output commands (see section 4.12) with this

feature.

Login

• You can use this feature when accessing the setting/measurement server,

maintenance/test server, and FTP server functions via an Ethernet interface.

• For a description of the settings required to use this feature, see the MV1000/MV2000

User’

s Manual (IM MV1000-01E).

•

For the procedure to log into the setting/measurement server or the maintenance/test

server, see appendix 3.

User Registration

Users are registered using the MV login feature. There are two user levels: administrator

and user.

• Administrator

An administrator has privileges to use all the features of the setting/measurement

server, maintenance/test server, and FTP server.

• User

A user has limited privileges to use the features of the setting/measurement server,

maintenance/test server, and FTP server. For command limitations, see section 4.2.

• Setting/measurement server feature limitations

A user cannot change settings that affect the MV operation. A

user can output

measured data and setting data.

• Maintenance/test server feature limitations

A user cannot disconnect a connection between another PC and the MV.

A user

can disconnect the connection between the user’s own PC and the MV.

• FTP server feature limitations

A user cannot save or delete files on an external storage medium connected to the

MV

. A user can only load files.

• Application Timeout

This feature drops the connection with the PC if there is no data transfer for a given

time. It prevents a PC from being connected to the MV indefinitely which would

prohibit other users from making new connections.

1.1 Ethernet Interface

Page 11

IM MV1000-17E

1-4

Web Server

• The MV screen can be displayed in Microsoft Internet Explorer.

• The following two pages are available.

• Monitor page: A dedicated monitoring screen.

• Operator page: You can switch the MV display and change or write messages.

You can set access control (user name and password specified with the login

function) for each page.

• The MV screen can be refreshed at a constant interval (approximately 10 s).

• The following information can be displayed.

• Alarm summary

• Measured and computed values of all channels

• Log (message log, error log, etc.)

• For Web server feature settings, see section 2.4.

• For a description of the monitor page and operator page operations, see section 2.4.

1.1 Ethernet Interface

Page 12

IM MV1000-17E

1-5

Overview of Communication Functions

1

E-mail Transmission

E-mail Transmission

The available e-mail types are listed below. The MV can automatically transmit

each e-mail type. You can specify two destination groups and specify one of the two

destination groups for each e-mail type. You can also set a header string for each type.

•

Alarm e-mail

Reports alarm information when an alarm occurs or clears.

• System e-mail

When the MV recovers from a power failure, it reports the time of the power failure

and the time of recovery.

Reports the detection of a memory shortage when it is detecte

d.

Reports the error code and message when a media error occurs (when an error

occurs on an external storage medium or when data cannot be stored due to

insufficient free space on an external storage medium).

Reports the error code and message when an FTP

client error (when data transfer

fails using the FTP client feature) occurs.

• Scheduled e-mail

T

ransmits a message when the specified time is reached. You can use this feature to

check that the network and e-mail transmission functions are working properly

. You

can specify a reference time and e-mail transmission interval for each destination.

•

Report e-mail (only on models with the computation function, /M1 option)

Transmits report results.

You can specify POP

before SMTP if authentication is necessary before transmission.

For e-mail transmission settings, see section 2.3.

For e-mail transmission formats, see section 2.3.

For the procedure to start/stop e-mail transmission, see section 2.3.

From: MV1000@daqstation.com

Date: Tue, 22 Jan 2008 08:00:45 +0900 (JST)

Subject: Periodic_data

To: user1@daqstation.com, user2@mvadv.co.jp

LOOP1

TEMPERATURE

Time

Host name

MV1000

Time of transmission

01/05 08:00:01

Header 1

Subject

Example of an e-mail sent at a scheduled time

Header 2

E-mail Transmission Test

• You can test e-mail transmission by sending a test mail from the MV to a destination.

• You can view the test result in the e-mail log screen.

• For information on how to use this feature, see section 2.3.

1.1 Ethernet Interface

Page 13

IM MV1000-17E

1-6

SNTP Server/Client

The client feature retrieves time information from a specified SNTP server at a specified

interval.

The server feature can provide time information to MVs and other devices connected to

the same network.

DHCP Client

You can use this feature to automatically obtain an IP address from a DHCP server. You

can manually retrieve or release network information.

Other Features

Ethernet Interface Connection Status Check

You can check the Ethernet interface connection status on the MV rear panel or the MV

screen.

For a description of the connection status indicators, see section 2.2.

Keepalive (TCP extension feature)

This feature drops the connection if there is no response to a test packet that is

periodically transmitted at the TCP level.

For the settings necessary to use this feature, see section 2.2.

Log Display

You can display operation logs on the MV log screen. You can also check logs

using communication commands. The Web screen can also display logs (except

communication and DHCP logs).

•

Error log screen: A log of operation errors

•

Communication log screen: A setting/measurement server communication input/

output log

• FTP log screen:

A log of file transfers carried out using the FTP client

feature

• WEB log screen: A W

eb server operation log

• Mail log screen: A log of e-mail transmissions

• Login log screen: A login/logout log

• SNTP log screen: An SNTP server access log

• DHCP log screen: A DHCP server access log

• Modbus log screen: A Modbus status (master/client operating condition) log

For the procedure to show the log screen and details on the displayed contents, see the

MV1000/MV2000 User’s Manual (IM MV1000-01E).

For details on the Modbus status log, see section 2.8.

For details on how to output logs using communication commands, see section 5.2. For

details on how to show logs on the Web screen, see section 2.4.

1.1 Ethernet Interface

Page 14

IM MV1000-17E

1-7

Overview of Communication Functions

1

1.2 Serial Interface

The MV supports serial communications via the RS-232 and RS-422/RS-485. This

chapter gives an overview of the MV serial communication functions.

Modbus Communications

• The MV can connect to a Modbus device and read and write to the device’s internal

registers. See section 1.3 for details.

Setting/Measurement Server

• You can use this feature to set almost all of the settings that can be configured from

the MV front panel keys. See section 1.1 for details.

• For the settings necessary to use this feature, see section 3.3.

Page 15

IM MV1000-17E

1-8

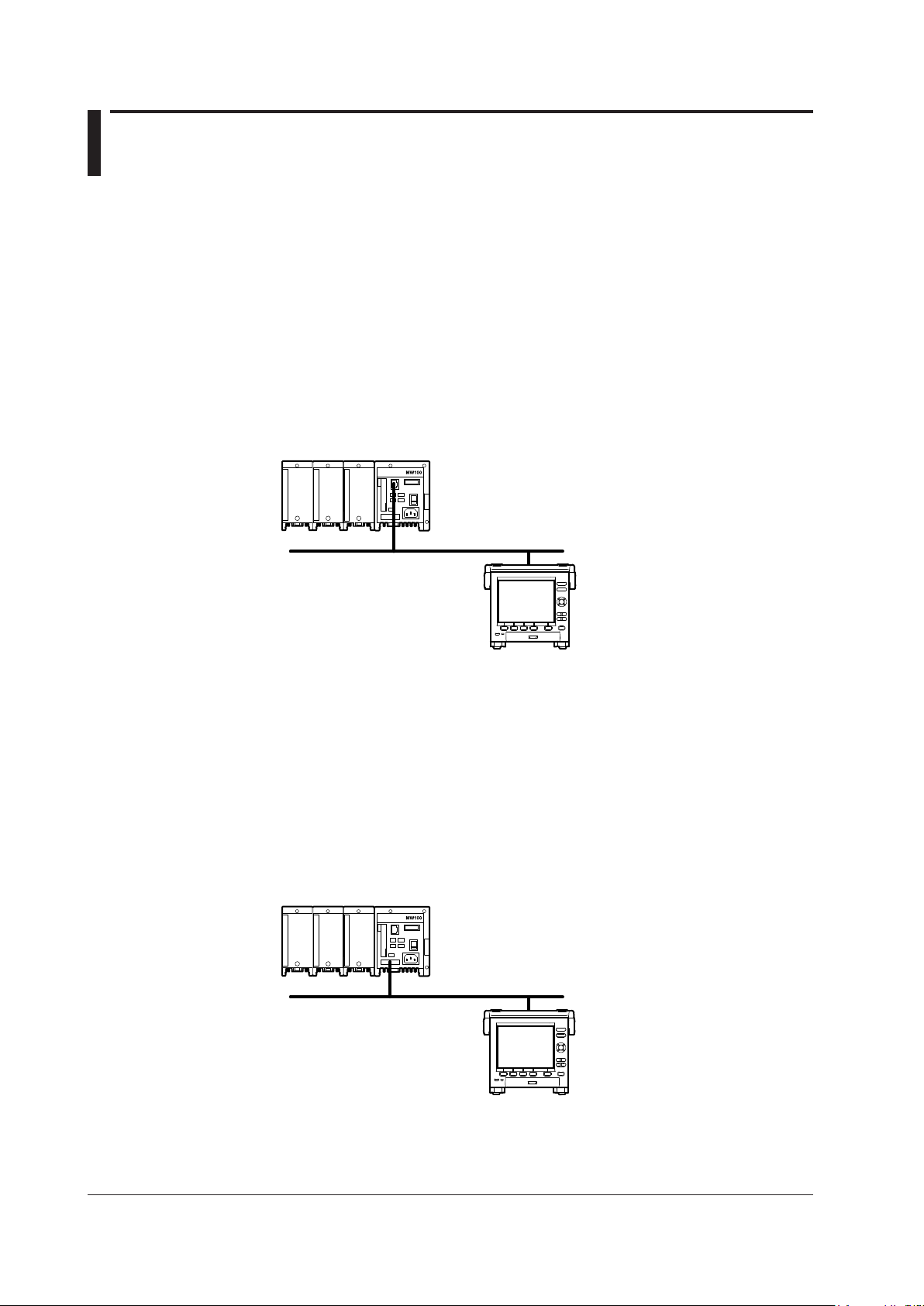

1.3 Modbus Protocol

Modbus Client/Master

• The MV can connect to a Modbus server or slave device and read and write to the

device’s internal registers.

The MV can handle the data that is read from the registers as communication input

data on a computation channel (computation function

1

). The MV can also handle the

data on an external input channel.

2

The MV can write measured and computed data to the registers.

1 /M1 option.

2 MV2000 with the /MC1 option.

• For details on the Modbus function codes that the MV supports, see section 7.3.

• For the settings to use the Modbus client feature, see section 2.9. For the settings to

use the Modbus master feature, see sections 3.3, 3.5, and 3.6.

Server Device Connection Example

Modbus server device

MV (client)

Ethernet

MV

Modbus Server/Slave

• A Modbus client (master) device can connect to an MV, a Modbus server (slave)

device, to read the measured, computed,

1

or external input2 data that is written in the

input register or to read or write data to communication input data

1

or to an external

input channel

2

through the MV hold register.

1 /M1 option.

2 MV2000 with the /MC1 option.

• For details on the Modbus function codes that the MV supports, see section 7.3.

• For the settings to use the Modbus client feature, see section 2.8. For the settings to

use the Modbus master feature, see sections 3.3, 3.4, and 3.6.

Example of a Connection with a Modbus Master Device

Modbus master device

MV (slave)

Serial communication

MV

Page 16

IM MV1000-17E

2-1

Using the Ethernet Interface

1

2

2.1 Workflow for Using the Ethernet Interface

Follow the flowchart below to configure Ethernet communication.

Set the host name

Fixed IP address

Automatically assigned IP address (DHCP)

Set the domain

name

Set the Obtain DNS

info item

Set the Host name

registration

Connect the ports

Start

Set the IP address

Set the host name

(optional)

IP address

assignment method

Set the domain

name (optional)

Set the subnet

mask

Set the default

gateway

Set the DNS server

search order

Set the domain suffix

search order

Set the DNS server

search order

Not set when Obtain

DNS info is set to Use.

Not set when Obtain

DNS info is set to Use.

End

Chapter 2 Using the Ethernet Interface

Page 17

IM MV1000-17E

2-2

2.2 Connecting the MV

Connecting to the Port

Ethernet Port

Connect an Ethernet cable to the Ethernet port on the MV rear panel.

Ethernet cable

CAUTION

Be sure to connect an Ethernet cable

with an FCC-compliant plug. Otherwise,

the MV may malfunction.

Connecting to a PC

Connect the MV to a PC via a hub. To make a one-to-one connection, see the figure

below. You can connect multiple MVs to a single PC in the same way.

Hub

MV

Ethernet cable

PC

Page 18

IM MV1000-17E

2-3

Using the Ethernet Interface

1

2

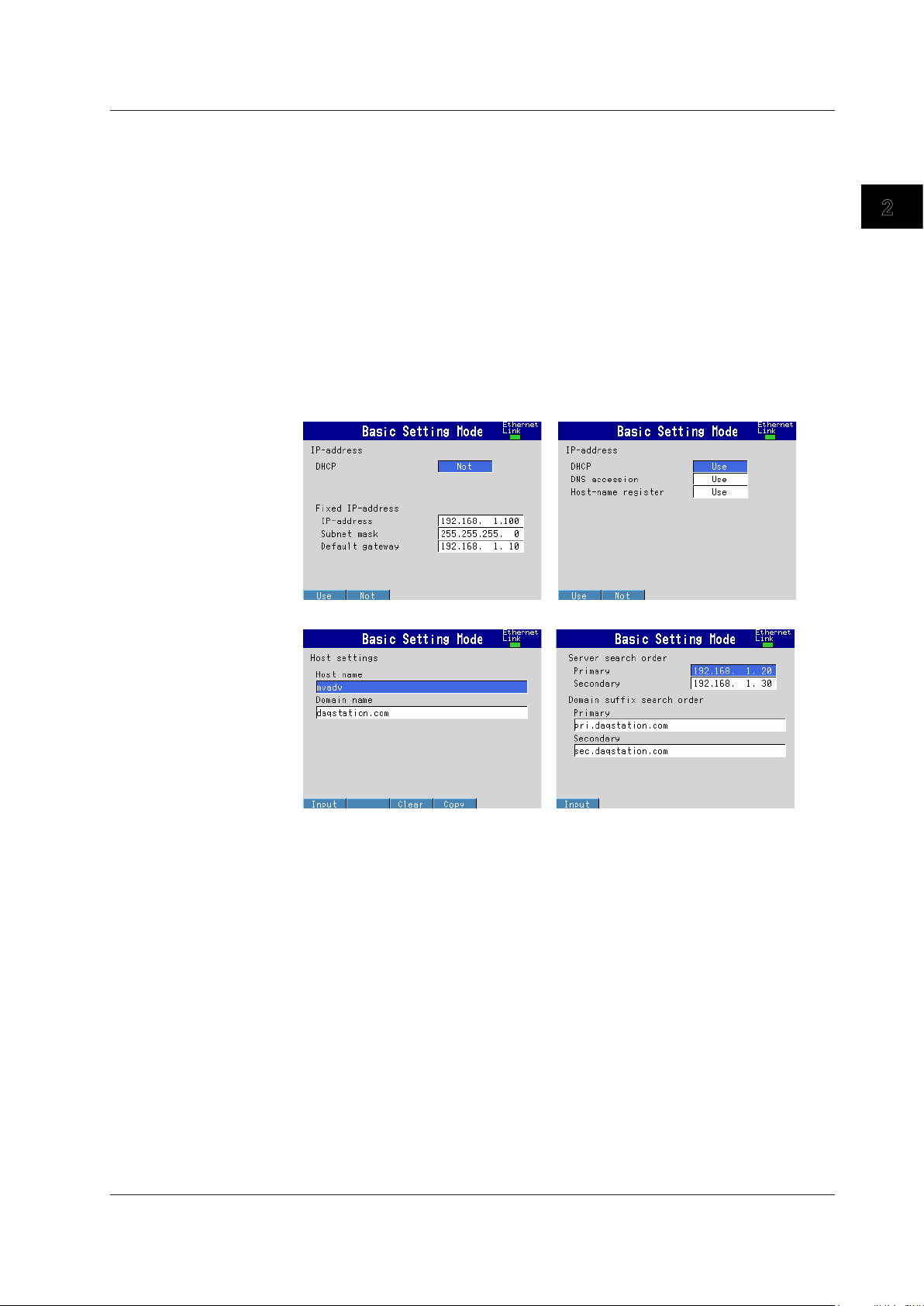

Setting the IP Address, Host Information, and DNS

MV1000

◊ Press MENU and then select Menu tab > Basic setting mode > Menu tab >

Communication (Ethernet) > IP address

◊

Press MENU and then select MENU tab >

Basic setting mode > Menu tab >

Communication (Ethernet) > Host settings

◊

Press MENU and then select MENU tab >

Basic setting mode > Menu tab >

Communication (Ethernet) > DNS settings

MV2000

◊

Press MENU and then select MENU tab >

Basic setting mode > Menu tab >

Communication (Ethernet) > IP address, Host settings

◊

Press MENU and then select Menu tab >

Basic setting mode > Menu tab >

Communication (Ethernet) > DNS settings

IP address settings (DHCP set to Not)

IP address settings (DHCP set to Use)

Host name settings DNS settings

Set the IP address to a fixed IP address or obtain it automatically (DHCP).

Consult with your network administrator for network parameters such as the IP address,

subnet mask, default gateway, and DNS.

2.2 Connecting the MV

Page 19

IM MV1000-17E

2-4

When Using a Fixed IP Address

• DHCP

Set DHCP to Not.

• IP address

Set the IP address to be assigned to the MV.

• Subnet mask

Set the subnet mask according to the system or network that the MV belongs to.

• Default gateway

Set the gateway IP address.

• Host name

Set the MV host name using up to 64 alphanumeric characters. You do not have to set

this parameter.

• Domain name

Set the name of the domain that the MV belongs to using up to 64 alphanumeric

characters. You do not have to set this parameter.

• Server search order

Register up to two IP addresses for the primary and secondary DNS servers.

• Domain suffix search order

Set up to two domain suffixes: primary and secondary.

When Obtaining an IP Address Automatically (DHCP)

• DHCP

Set DHCP to Use.

• Obtain DNS info

To automatically obtain the DNS server address, select Use. Otherwise, select Not. If

you select Not, you must set the server search order.

• Host name registration

To automatically register the host name to the DNS server, select Use.

• Host name

Set the MV host name using up to 64 alphanumeric characters.

• Domain name

Set the name of the domain that the MV belongs to using up to 64 alphanumeric

characters. This parameter is valid when Obtain DNS info is set to Not.

• Server search order

Register up to two IP addresses for the primary and secondary DNS servers.

• Domain suffix search order

Set up to two domain suffixes: primary and secondary.

2.2 Connecting the MV

Page 20

IM MV1000-17E

2-5

Using the Ethernet Interface

1

2

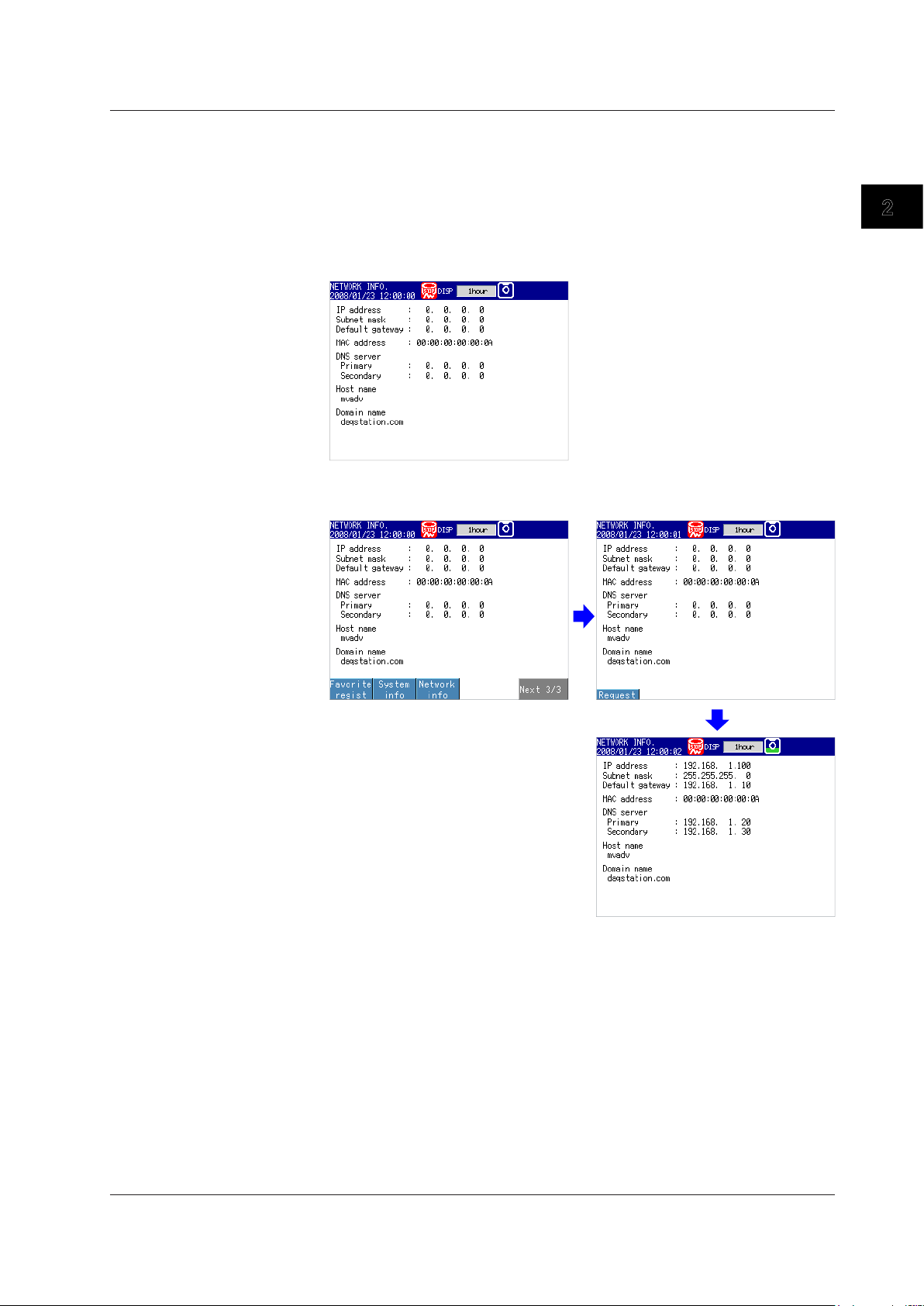

Requesting/Clearing Network Information through DHCP

You can manually request or release IP address and other network information. This

operation applies when DHCP is set to Use. First switch to the network information

screen and then execute the request or release (clear) operation.

Requesting Network Information

1.

Switch to the network information screen.

◊ Press FUNC > Network info

2.

Request network information.

◊ Press FUNC > Network info > Request

The retrieved network information appears.

2.2 Connecting the MV

Page 21

IM MV1000-17E

2-6

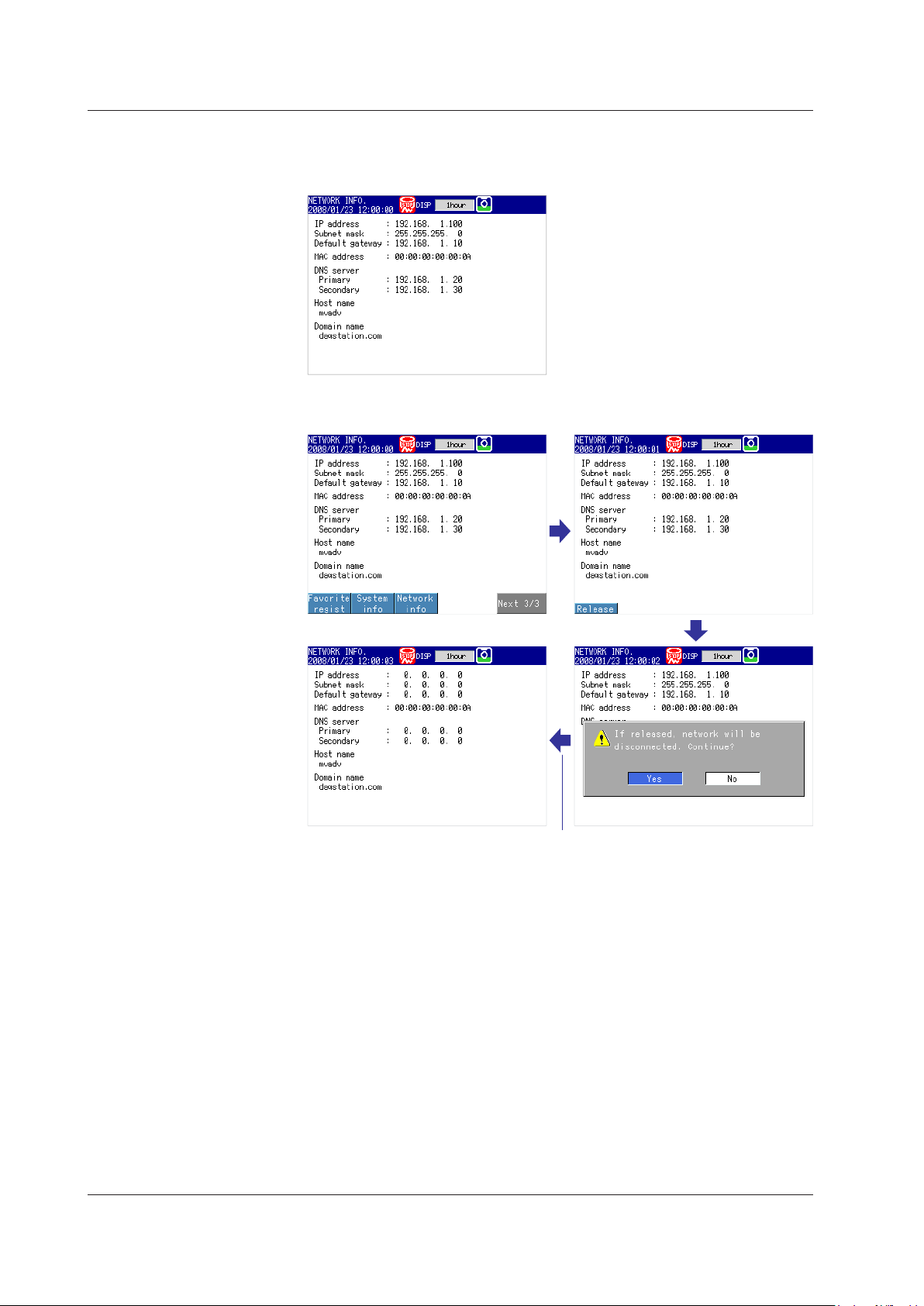

Clearing Network Information

1.

Switch to the network information screen.

◊ Press FUNC > Network info

2.

Release (clear) the network information.

◊ Press FUNC > Network info > Release

The network information is released.

DISP/ENTER key

2.2 Connecting the MV

Page 22

IM MV1000-17E

2-7

Using the Ethernet Interface

1

2

Setting the Communication Conditions

MV1000

◊ Press MENU and then select Menu tab > Basic setting mode > Menu tab >

Communication (Ethernet) > Keep alive, Timeout

MV2000

◊

Press MENU and then select Menu tab >

Basic setting mode > Menu tab >

Communication (Ethernet) > Keep alive, Application time out

Setting the Keepalive Feature

To disconnect when there is no response to the test packets that are periodically sent,

select On. Otherwise, select Off.

Setting the Application Timeout

• Selecting On or Off

To use the application timeout feature, select On. Otherwise, select Off. If you select

On, the Time parameter appears.

•

Time

Set the timeout value in the range of 1 to 120 (minutes).

Checking the Communication Status

You can check the Ethernet communication status with the LED lamp that is provided on

the MV rear panel Ethernet connector or the Ethernet link that is shown at the upper right

of the basic setting screen.

2.2 Connecting the MV

Page 23

IM MV1000-17E

2-8

2.3 Sending E-mail Messages

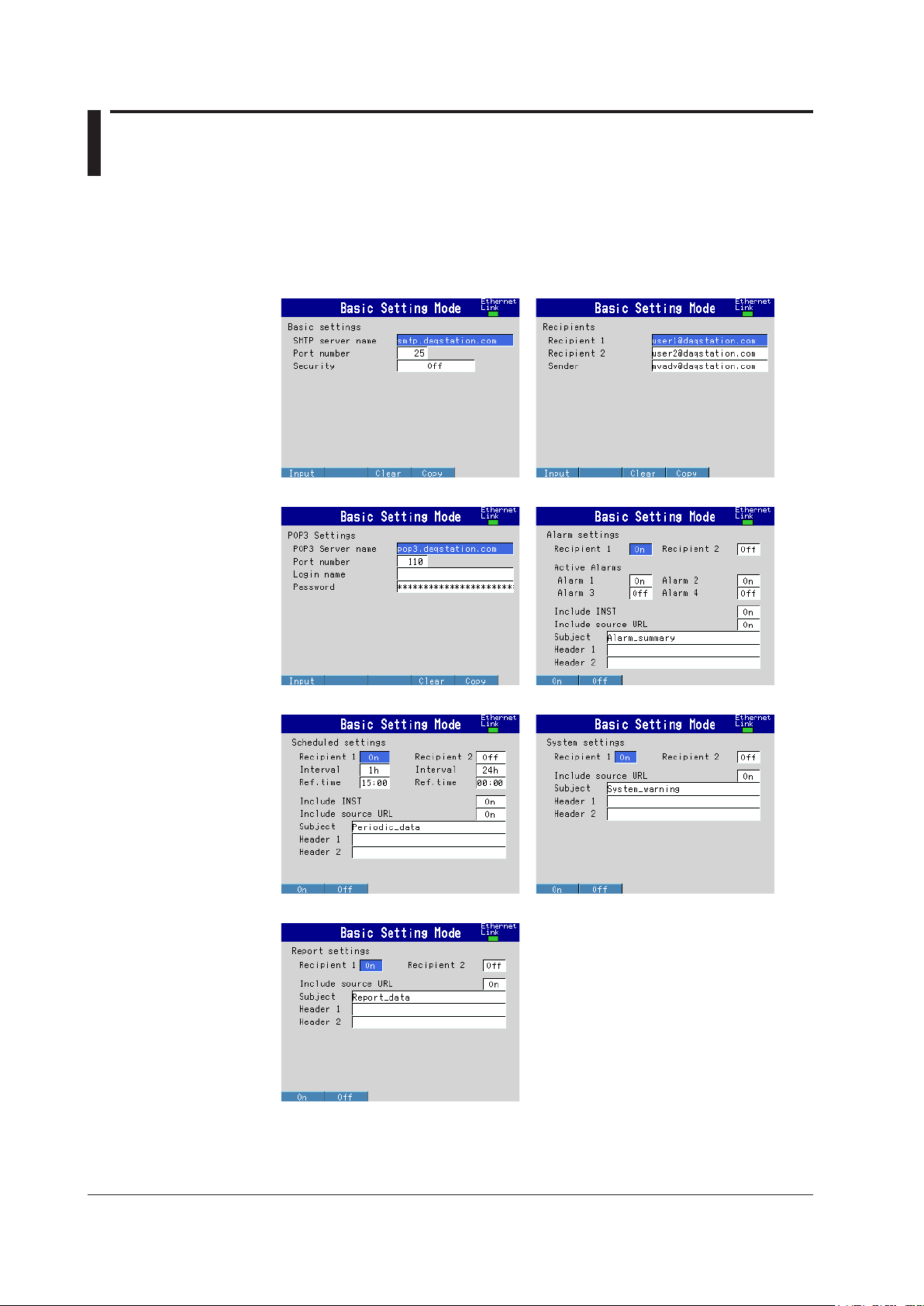

Conguring E-mail Transmission

Configure the server, and set the contents of the e-mail.

◊ Press MENU and then select Menu tab > Basic setting mode > Menu tab >

Communication (Ethernet) > E-Mail

Basic settings

Recipients

POP3 Settings Alarm settings

Scheduled settings

S

ystem settings

Report settings

Page 24

IM MV1000-17E

2-9

Using the Ethernet Interface

1

2

Basic Settings

Specify the SMTP server and POP before SMTP.

• SMTP server name

Enter the host name or IP address of the SMTP server.

• Port number

Unless specified otherwise, set the number to the default value. The default value is

25.

• Security

If you need to use POP before SMTP, set Security to PbS.

Recipients

Set the recipient e-mail addresses.

• Recipient 1 and Recipient 2

Enter e-mail addresses. You can enter multiple addresses in each recipient box.

Separate each address with a space. You can enter up to 150 characters.

• Sender

Enter the sender e-mail address. You can enter up to 64 characters.

POP3 Settings

If you need to use POP before SMTP, specify the POP3 server.

For the POP3 login procedure, see “Setting the POP3 Server Connection” in this section.

• POP3 Server name

Enter the host name or IP address of the POP3 server.

• Port number

Unless specified otherwise, set the number to the default value. The default value is

110.

• Login name

Enter the POP3 server login name.

• Password

Enter the POP3 server login password. You can enter up to 32 characters.

Alarm Settings

Specify the settings for sending e-mail when alarms occur or clear.

• Recipient 1 and Recipient 2

Specify the recipients. For Recipient 1 and Recipient 2, select On to send e-mail or

Off to not send e-mail.

• Active Alarms

Sends an e-mail when an alarm occurs or clears. For alarms 1 to 4, select On to send

e-mail or Off to not send e-mail.

• Include INST

Select On to attach instantaneous value data. The data that is attached is the

instantaneous value that is measured at the time the e-mail is transmitted.

• Include source URL

Select On to attach the source URL. You can attach the URL when the Web server is

enabled.

• Subject

Enter the subject of the e-mail using up to 32 alphanumeric characters. The default

subject is Alarm_summary.

• Header 1 and Header 2

Enter Header 1 and Header 2 using up to 64 characters.

2.3 Sending E-mail Messages

Page 25

IM MV1000-17E

2-10

Scheduled Settings

Specify the settings for sending e-mail at scheduled times.

• Recipients

Specify the recipients. For Recipient 1 and Recipient 2, select On to send e-mail or

Off to not send e-mail.

• Interval

For Recipient 1 and Recipient 2, set the interval for sending e-mail to 1, 2, 3, 4, 6, 8,

12, or 24 hours.

• Ref.time

Enter the time reference for sending e-mail to Recipient 1 and Recipient 2 at a

specified interval.

• Include INST, Include source URL, Subject, Header

These parameters are the same as those listed under “Alarm Settings.” The default

subject is Periodic_data.

System Settings

Specify the settings for sending e-mail when the MV recovers from a power failure, when

there is a memory shortage, and when an error occurs.

• Recipients

Specify the recipients. For Recipient 1 and Recipient 2, select On to send e-mail or

Off to not send e-mail.

• Include source URL, Subject, and Header

These parameters are the same as those listed under “Alarm Settings.” The default

subject is System_warning.

Report Settings

Specify the settings for sending e-mail when reports are generated.

• Recipients

Specify the recipients. For Recipient 1 and Recipient 2, select On to send e-mail or

Off to not send e-mail.

• Include source URL, Subject, and Header

These parameters are the same as those listed under “Alarm Settings.” The default

subject is Report_data.

2.3 Sending E-mail Messages

Page 26

IM MV1000-17E

2-11

Using the Ethernet Interface

1

2

Setting the POP3 Server Connection

Specify the operation for connecting to the POP server.

◊ Press MENU and then select Menu tab > Basic setting mode > Environment tab >

Communication > POP3 Details

Send delay [second]

Enter the wait time from POP3 server authentication until transmission. Set a value in the

range of 0 to 10 (seconds).

POP3 Login

To send the POP3 server login password without encryption, set POP3 Login to PLAIN.

To send the password with encryption, set POP3 Login to APOP.

E-mail Test

◊ Press FUNC and then select E-mail test > Recipient1 or Recipient2

You can send a test e-mail to check the e-mail settings.

Enabling/Disabling the E-mail Transmission Function

Enabling the E-mail Transmission Function

◊ Press FUNC and then select E-Mail start

The e-mail transmission function is enabled.

Disabling the E-mail Transmission Function

◊ Press FUNC and then select E-Mail stop

The e-mail transmission function is disabled. Unsent e-mail messages are discarded.

E-mail Retransmission

If an e-mail transmission fails, the MV retransmits the message up to three times at

30-s, 1-minute, or 3-minute intervals. If retransmission fails, the MV discards the e-mail

message.

2.3 Sending E-mail Messages

Page 27

IM MV1000-17E

2-12

E-mail Format

The formats of alarm, scheduled, system, report, and test e-mails are given below.

For details on the displayed items that are common to all e-mails, see “Display Items

Common to All Formats” in this section.

Alarm Notification E-mail Format

• Subject

Subject: [Alarm Summary]

• Syntax

header1CRLF

header2CRLF

CRLF

Alarm_summary.CRLF

<Host_name>CRLF

hostCRLF

CRLF

<CH>ccc···cCRLF

<Type>lqCRLF

<aaa>mo/dd_hh:mi:ssCRLF

CRLF

<Inst._value>CRLF

mo/dd_hh:mi:ssCRLF

ccc···c=ddd···dCRLF

·····························

CRLF

Access_the_following_URL_in_order_to_look_at_a_screen.CRLF

http://host.domain/CRLF

CRLF

cc c···c

Channel number or tag name

(Up to 16 characters. Channels set to Skip or Off are not transmitted.

See section 4.3 for channel numbers.)

l

Alarm level (1 to 4)

q

Alarm type (H, L, h, l, R, or r)

H

(high limit alarm), L(low limit alarm), h(difference high limit alarm),

l

(dif

ference low limit alarm), R(high limit on rate-of-change alarm),

and r(low limit on rate-of-change alarm)

aaa

Alarm status (

off

or on)

ddd···d

Measured/computed value (up to 10 digits including the sign and

decimal point) + unit (up to six characters)

+OVER:

Positive range-out

-OVER:

Negative range-out

Burnout:

Burnout data

*****: Error data

The MV transmits the channel numbers, alarm types, and alarm statuses for up to

10 events in a single e-mail.

2.3 Sending E-mail Messages

Page 28

IM MV1000-17E

2-13

Using the Ethernet Interface

1

2

Scheduled E-mail Format

• Subject

Subject: [Periodic Data]

• Syntax

header1CRLF

header2CRLF

CRLF

Periodic_data.CRLF

<Host_name>CRLF

hostCRLF

CRLF

<Time>CRLF

mo/dd_hh:mi:ssCRLF

CRLF

E-mail_message(s)_did_not_reach_intended_recipient(s).CRLF

ttt···t

Count=nnCRLF

mo/dd_hh:mi:ssCRLF

····························

CRLF

<Inst._value>CRLF

mo/dd_hh:mi:ssCRLF

ccc···c=ddd···dCRLF

····························

CRLF

Access_the_following_URL_in_order_to_look_at_a_screen.CRLF

http://host.domain/CRLF

CRLF

cc c···c

Channel number or tag name

(Up to 16 characters. Channels set to Skip or Off are not transmitted.

See section 4.3 for channel numbers.)

ttt···t

Type of discarded e-mail

Alarm_summary:

Alarm e-mail

Periodic_data:

Scheduled e-mail

System_warning:

System e-mail

Report_data:

Report e-mail

nn

Number of discarded e-mails

ddd···d

Measured/computed value (up to 10 digits including the sign and

decimal point) + unit (up to six characters)

+OVER:

Positive range-out

-OVER:

Negative range-out

Burnout:

Burnout data

*****: Error data

The time that follows the type and count of discarded e-mails is the time when the

last e-mail is discarded.

2.3 Sending E-mail Messages

Page 29

IM MV1000-17E

2-14

System E-mail (Power Failure) Format

• Subject

Subject: [System_warning]

• Syntax

header1CRLF

header2CRLF

CRLF

Power_failure.CRLF

<Host_name>CRLF

hostCRLF

CRLF

<Power_fail>mo/dd_hh:mi:ssCRLF

<Power_on>mo/dd_hh:mi:ssCRLF

CRLF

Access_the_following_URL_in_order_to_look_at_a_screen.CRLF

http://host.domain/CRLF

CRLF

System E-mail (Memory Full) Format

• Subject

Subject: [System_warning]

• Syntax

header1CRLF

header2CRLF

CRLF

Memory_full.CRLF

<Host_name>CRLF

hostCRLF

CRLF

<Memory_remain>ppp···pMbytesCRLF

<Memory_blocks>bbb/400CRLF

<Media_remain>rrr···rMbytesCRLF

CRLF

Access_the_following_URL_in_order_to_look_at_a_screen.CRLF

http://host.domain/CRLF

CRLF

ppp···p

Remaining amount of internal memory

bbb

Number of unsaved blocks (0 to 400)

rrr···r

Remaining free space on the external storage medium (when an

external storage medium is connected)

2.3 Sending E-mail Messages

Page 30

IM MV1000-17E

2-15

Using the Ethernet Interface

1

2

System E-mail (Error) Format

• Subject

Subject: [System_warning]

• Syntax

header1CRLF

header2CRLF

CRLF

Error.CRLF

<Host_name>CRLF

hostCRLF

CRLF

mo/dd_hh:mi:ssCRLF

ERROR:fffCRLF

····························

“

Operation_aborted_because_an_error_was_found_in_media.”CRLF

CRLF

Access_the_following_URL_in_order_to_look_at_a_screen.CRLF

http://host.domain/CRLF

CRLF

fff

Error number (200, 201, 211, or 281 to 285)

The displayed error message varies depending on the error type. For details on

errors, see the

MV1000/MV2000 User’s Manual (IM MV1000-01E).

Report E-mail Format

• Subject

Subject: [Report_data]

• Syntax

header1CRLF

header2CRLF

CRLF

ti_report.CRLF

<Host_name>CRLF

hostCRLF

CRLF

mo/dd_hh:mi:ssCRLF

<CH>ccc···cCRLF

<tp>eee···eCRLF

<tp>eee···eCRLF

<tp>eee···eCRLF

<tp>eee···eCRLF

<Unit>uuu···uCRLF

····························

CRLF

Access_the_following_URL_in_order_to_look_at_a_screen.CRLF

http://host.domain/CRLF

CRLF

ti

Contents of the report e-mail (hourly

, daily, weekly, or monthly report)

cc c···c

Channel number or tag name

(Up to 16 characters. Channels set to Skip or Off are not transmitted.

See section 4.3 for channel numbers.)

2.3 Sending E-mail Messages

Page 31

IM MV1000-17E

2-16

tp

Report content (average, maximum, minimum, instantaneous, and

sum. Four out of the five items above are transmitted.)

eee···e

Measured/computed value (up to 10 digits including the sign

and decimal point). However, sum values are transmitted as a

combination of the sign, mantissa, E, sign, and exponent such as in

–3.8000000E+02.

+OVER:

Positive range-out

-OVER:

Negative range-out

Burnout:

Burnout data

Empty data: Error data

uuu···u

Unit (up to six characters)

Test E-mail Format

• Subject

Subject: [Test]

• Syntax

Test_mail.CRLF

<Host_name>CRLF

hostCRLF

CRLF

<Time>CRLF

mo/dd_hh:mi:ssCRLF

CRLF

<Message>CRLF

x:msCRLF

····························

CRLF

x

Message number (1 to 10)

ms

Message content (only specified messages are transmitted.)

Display Items Common to All Formats

• Time information

mo

Month (01 to 12)

dd

Day (01 to 31)

hh

Hour (00 to 23)

mi

Minute (00 to 59)

ss

Second (00 to 59)

The MV transmits the month, day

, hour, minute, and second in the time information

in the order specified by the date format set in Basic Setting Mode.

• Host name, domain name, and header information

header1

Header 1 (displayed only when it is set)

header2

Header 2 (displayed only when it is set)

host

Host name or IP

address (IP address when the host name is not

assigned. In the case of an IP address, the <Host> section is set to

<IP address>.)

domain

Domain name

_

Space

2.3 Sending E-mail Messages

Page 32

IM MV1000-17E

2-17

Using the Ethernet Interface

1

2

2.4 Monitoring the MV on a PC Browser

Conguring the Web Server

From the Basic Setting Mode menu, set the server function and Web page for Ethernet

communication.

Setting the Web Server

◊ Press MENU and then select Menu tab > Basic setting mode > Menu tab >

Communication (Ethernet) > Server

• Web

Set the Web parameter under Server to Use or Not (don’t use). If set to Use, Web

page parameters appear in the Basic Setting Mode menu.

Port Number

The default value is 80. To change the value:

◊ Press MENU and then select Menu tab > Basic setting mode > Environment tab >

Communication > Service port

For the selectable range, see section 7.1.

Setting the Web Page

◊ Press MENU and then select Menu tab > Basic setting mode > Menu tab >

Communication (Ethernet) > Web page

Page 33

IM MV1000-17E

2-18

Page Types (displayed screen types)

• Monitor

Configure the monitor page. The monitor page can display the following items.

• Alarm summary

• Measured and computed values of all channels

• Log (message summary, error log, etc.)

• For screen examples, see “Monitoring with a Browser” in this section.

• Operator

Configure the operator page. You can carry out the following operations in addition to the

functions available on the monitor page.

• Switch the MV display by specifying the display type (trend, historical trend, digital,

bar graph, or overview). You can also specify the trend and historical trend groups.

•

Control the MV DISP/ENTER key, arrow keys, and HISTORY

key.

• Set and write MV messages.

• For screen examples, see “Monitoring with a Browser” in this section.

Configuring the Monitor Page

• Setting the page type

To configure the monitor page, select Monitor.

• Selecting On or Off

To display the monitor page on a browser, select

On

. Otherwise, select Off.

• Setting the access control

To use access control, select

On. Y

ou must enter a user name and password to

display the monitor page. You must set the security and login in the environmental

settings to use this function. For settings, see the MV1000/MV2000 User’s Manual (IM

MV1000-01E).

Configuring the Operator Page

• Setting the page type

To configure the operator page, select Operator.

• Setting the access control

This setting is the same as that for the monitor page.

• Selecting whether or not to use command input

To use the set and write commands for messages, select

On. Otherwise, select

Off.

2.4 Monitoring the MV on a PC Browser

Page 34

IM MV1000-17E

2-19

Using the Ethernet Interface

1

2

Monitoring the MV on a Browser

Setting the URL

Set the URL appropriately according to your network environment. You can access the

MV by setting the URL as follows:

http://host name.domain name/file name

• http: The protocol used to access the server.

• Host name.domain name:

The MV host name and domain name.

You can also use an IP address in place of the host name and domain name.

• File name: The file name of the MV monitor page or operator page.

File name of the monitor page: monitor.htm

File name of the operator page: operator.htm

Omitting the file name is equivalent to specifying the monitor page. However, if the

monitor page is disabled, it is equivalent to specifying the operator page.

Example

To display the operator page on a PC that is in the same domain as the MV, enter

the URL in the browser Address box as follows:

http://mv1000.daqstation.com/operator.htm or

http://192.168.1.100/operator.htm

(In this example, we assume that the domain name is daqstation.com, the host

name is mv1000, and the IP address is 192.168.1.100.)

Login

Enter the user name and login password. You do not have to enter these items if access

control is set to Off in the Web page setting.

• Monitor Page Contents

MV screen image

The displayed information is the same as that shown on the MV.

Automatically refreshes the screen

Turn this ON to automatically refresh

the screen.

All channel display

Displays measured values and alarm statuses

of all channels in a separate window.

Log display

Displays each log in a separate

window.

Refresh the screen

Display the alarm summary

Displays an alarm summary

in a separate window.

Zoom

Changes the zoom rate of

the screen.

MV1000: 100% and 200%

MV2000: 50% and 100%

Data list and print page

Displays the information in

a separate window.

2.4 Monitoring the MV on a PC Browser

Page 35

IM MV1000-17E

2-20

• If the MV is in Setting Mode* or Basic Setting Mode*, the monitor page cannot be

displayed. An error message will appear.

*

For details on modes, see the MV1000/MV2000 User’s Manual (IM MV1000-01E).

• Refreshing the monitor page

The monitor page can be refreshed automatically or manually.

•

Auto Refresh ON

The monitor page is refreshed at approximately 10-second intervals.

• Auto Refresh OFF

The monitor page is not automatically refreshed. You can refresh the page

manually

. The page will not be refreshed within approximately 10 seconds for the

last refreshing even if you try to refresh the page manually.

• Displaying the log

You can display the message summary

, error log, FTP log, login log, Web operation

log, e-mail log, SNTP

log, and Modbus log in a separate window. From the Log list,

select the log you want to display. Click Refresh to refresh the data. The window can

display up to 100 messages and 50 added messages.

Log display (example of a message log display)

• Refreshing the alarm summary display and all channel display

Click Refresh to refresh the data. The alarm summary can display up to 400 alarms.

Example of an alarm summary display

Example of an all channel display

2.4 Monitoring the MV on a PC Browser

Page 36

IM MV1000-17E

2-21

Using the Ethernet Interface

1

2

• Data list

You can easily retrieve files via FTP from the data list link without having to specify the

URL. You can also save the data that is being sampled to a file and retrieve the file.

For the procedure, see section 2.5.

• Print page

You can enter a title and comments in the screen image and print the image.

Title box

By default, the title box displays

the IP address or host name.

You can overwrite the default

title with your own.

Comment input box

Enter comments.

You can enter more than five

lines of comments, but only

the first five lines will be printed.

2.4 Monitoring the MV on a PC Browser

Page 37

IM MV1000-17E

2-22

• Operator Page Contents

MV screen image

The displayed information is

the same as that shown on

the MV.

Selects the trend screen

Directly selects the group you

want to display.

Data list and print page

Displays the information in a

separate window.

Automatically refreshes the screen

All channel

display

Log

display

Message input

Opens a separate window for

entering a message.

Refreshes

the screen

Displays the alarm summary

Zoom

Selects the historical display

Directly selects the group you

want to display.

Selects other displays

Selects the overview display,

numeric display, or bar graph

display.

HISTORY key

Performs the same operation

as the corresponding key on

the MV.

Arrow keys and DISP key

Performs the same operations

as the corresponding keys on

the MV.

You can carry out the following operations on the operator page in addition to the

operations available on the monitor page.

•

Switch between trend, historical trend, digital, bar graph, and overview displays.

For the trend and historical trend displays, you can switch the MV screen by specifying

the group you want to display.

• Control the MV using the DISP/ENTER key, arrow keys, and HISTORY

key on the

operator page.

You can carry out the same operations as the DISP/ENTER key, arrow keys, and

HISTOR

Y key on the MV.

• Set and write messages

You can set a message string to MV messages 1 through 10 (up to 32 alphanumeric

characters) and, at the same time, write it to the specified group. The existing

message is overwritten.

The following figure indicates an example in which the word

“ALARM” is written to all groups in message number 9, and the Command Response

box shows that the operation has been successfully completed.

Message entry example

2.4 Monitoring the MV on a PC Browser

Page 38

IM MV1000-17E

2-23

Using the Ethernet Interface

1

2

2.5 Accessing Measured Data Files on the MV from a PC

You can access data files stored on an external storage medium.

Conguring the FTP Server

◊ Press MENU and then select Menu tab > Basic setting mode > Menu tab >

Communication (Ethernet)> Server

• FTP

Set the FTP parameter under Server to Use or Not (don’t use).

Accessing the MV from a PC

You can use the following functions when the FTP server is enabled.

Accessing a Data File from a Web Page

• If the Data File to Be Retrieved Is Already Generated

1.

Click the Data list link.

2.

Click Memory or Media.

3.

Select the file you want to retrieve from the file list.

4.

Drag and drop the file to the desired folder on the PC.

Note

• The Internal memory link is ftp://hostname/MEM0/DATA.

• The External media link is ftp://hostname/DRV0/.

Page 39

IM MV1000-17E

2-24

• If the Data File to Be Retrieved Is Being Generated

1.

Click the Data list link.

2.

Click OK for retrieving the most recent data.

The

Confirmation

window opens.

3.

Read the information, and click OK.

4.

In the File status window, click Update.

If the file has been generated, the Final status window opens. If not, the File status window

will open. Wait for a little while, and click

Update

again.

5.

In the Final status window, click Get.

6.

In the File Download window, click Save.

Note

• You can retrieve files by carrying out the steps above when the data file contains display

data or event data stored in Free mode.

• The file is generated at different times from the specified file save interval.

Connecting to the MV from a PC via the FTP

An example of retrieving files using a browser is described below. In the Address box,

enter the following:

ftp://host name.domain name/file name

To retrieve data from the internal memory, drag the files from the /MEM0/DAT

A folder. To

retrieve data from an external storage medium, drag the files from the /DRV0 folder. You

can also use an IP address in place of the host name and domain name.

You can also retrieve files easily from the Data list link in the browser window. See

section 2.4 for details.

Login

If the security feature is enabled, you will be prompted for a login name and password.

Enter the login name and password to connect to the server.

Port Number

The default value is 21. To change the value:

◊ Press MENU and then select Menu tab > Basic setting mode > Environment tab >

Communication > Service port

For the selectable range, see section 7.1.

2.5 Accessing Measured Data Files on the MV from a PC

Page 40

IM MV1000-17E

2-25

Using the Ethernet Interface

1

2

2.6 Transferring Data Files from the MV

The MV can automatically transfer display and event data files, report data files, and

snapshot data files that are created in the MV internal memory via FTP as the files are

created.

Files to Be Transferred via FTP

The MV automatically transfers display and event data files and report data files to the

FTP destination at appropriate times.

File Type Description

Display data file Automatically transferred at the file save interval.

Event data file Automatically transferred each time the specified length of data is recorded.

Report data file Automatically transferred when a report file is closed (divided). For

example, a data file is transferred once per month if you configure the MV

to generate only daily reports.

Snapshot data file Automatically transferred when you take a snapshot.

*

Snapshot data files

are transferred regardless of the media storage settings.

* Snapshots taken using the FUNC key, the EV2 communication command,

the USER key, or the remote control function.

Conguring the FTP Client

◊ Press MENU and then select Menu tab > Basic setting mode > Menu tab >

Communication (Ethernet) > FTP client

FTP

transfer file settings FTP connection settings

Specifying the Files to be Transferred via FTP

• Disp&Event Data

Select On to automatically transfer display and event data files.

• Report

Select On to automatically transfer report data files.

• Snapshot

Select On to automatically transfer snapshot data files.

Page 41

IM MV1000-17E

2-26

Setting the FTP Connection Destination

Set the primary and secondary FTP servers, port number, login name, password,

account, PASV mode, etc. Consult your network administrator for the correct values.

• FTP connection

You can specify two destination FTP servers: primary and secondary. If the primary

FTP server is down, the file is transferred to the secondary FTP server.

• Server name

Enter the name of the destination FTP server using up to 64 alphanumeric characters.

• If you are using the DNS, you can set the host name for the server name. For DNS

settings, see section 2.2.

• You can also set the IP address. In this case, the DNS is not required.

• Port number

Enter the port number of the destination FTP server in the range of 1 to 65535. The

default value 21.

• Login name

Enter the login name for accessing the FTP server using up to 32 alphanumeric

characters.

• Password

Enter the password for accessing the FTP server using up to 32 alphanumeric

characters. The characters that you enter will be displayed as

*****

.

• Account

Enter the account ID for accessing the FTP server using up to 32 alphanumeric

characters.

• PASV mode

Select On when using the MV behind a firewall that requires the passive mode. The

default setting is Off.

• Initial path

Set the file transfer destination directory using up to 64 alphanumeric characters. The

delimiter for directories varies depending on the implementation of the destination FTP

server.

Example:

When transferring files to the “data” directory in the “home” directory of an

FTP server on a UNIX file system.

/home/data

If the file transfer to both primary and secondary destinations fails, the MV will abort the

file transfer. When the connection recovers, the MV will transfer the data that could not to

be transferred along with the new data file. However, because the data that could not be

transferred resides in the MV internal memory

, the data will be lost if it is overwritten.

2.6 Transferring Data Files from the MV

Page 42

IM MV1000-17E

2-27

Using the Ethernet Interface

1

2

Testing the FTP Transfer

You can transfer a test file from the MV to an FTP server.

◊ Press FUNC > FTP test

Items to Check Before Executing This Test

• Connect the Ethernet cable properly. For the connection procedure, see section 2.2.

• Check that the Ethernet interface settings are correct. For the setup procedure, see

section 2.2.

Viewing the FTP Test Result

• When you execute an FTP test, the MV transfers a test file named FTP_TEST.TXT to

the FTP connection destination initial path directory that you specified in this section.

• You can check the FTP test result on the FTP log (displayed o

n the MV (see the

User’s Manual), displayed on the Web screen (see section 2.4), or transmitted with

the FL command (see section 4.8)).

2.6 Transferring Data Files from the MV

Page 43

IM MV1000-17E

2-28

2.7 Synchronizing the Time

The MV time can be synchronized to the time on an SNTP server. You can also configure

the MV to run as an SNTP server.

Conguring the SNTP Client

You can configure the SNTP client to synchronize the MV time to an SNTP server.

◊ Press MENU and then select Menu tab > Basic setting mode > Menu tab >

Communication (Ethernet) > SNTP client

• Use/Not

To use the SNTP client function, select Use. Otherwise, select Not. If you select Use,

the SNTP client parameters appear.

• Server name

Enter the SNTP server name using up to 64 alphanumeric characters.

• If you are using the DNS, you can set the host name for the server name. For DNS

settings, see section 2.2.

• You can also set the IP address. In this case, the DNS is not required.

• Port number

Enter the SNTP server port number in the range of 1 to 65535. The default value is

123.

• Access interval

Set the time interval for synchronizing the time with the server to Off, 1, 8, 12, or 24h.

If you select Off, you can synchronize the time using the soft keys. The time is not

synchronized if the time difference between the MV and the server is greater than or

equal to 10 minutes.

• Access reference time

Set the reference time for making queries.

• Access timeout

Set the time that the MV will wait for a response from the SNTP server after making a

query to 10, 30, 90 s.

• Time adjust on Start action

Select On to synchronize the time with an SNTP server when memory start is

executed. Otherwise, select Off.

Manually Synchronizing the Time

You can synchronize the time at any time using the FUNC key. The SNTP client setting

must be enabled.

◊ Press FUNC > SNTP

Page 44

IM MV1000-17E

2-29

Using the Ethernet Interface

1

2

Conguring the SNTP Server

You can configure the MV to run as an SNTP server.

◊ Press MENU and then select Menu tab > Basic setting mode > Menu tab >

Communication (Ethernet) > Server

• SNTP

Set the SNTP parameter under Server to Use or Not (don’t use).

When an SNTP client on the network queries the MV for the time information, the MV

returns the time information.

Port Number

The default value is 123. To change the value:

◊ Press MENU and then select Menu tab > Basic setting mode > Environment tab >

Communication > Service port

For the selectable range, see section 7.1.

2.7 Synchronizing the Time

Page 45

IM MV1000-17E

2-30

2.8 Reading/Writing the MV Data from Another Device via Modbus

The MV is a Modbus server.

For Modbus specifications, see section 7.3.

Conguring the Modbus Server

You can configure the Modbus server so that another device will be able to read or write

the MV data via Modbus.

◊ Press MENU and then select Menu tab >

Basic setting mode > Menu tab >

Communication (Ethernet) > Server

• Modbus

Set the Modbus parameter under Server to Use. If you select Not (not use), you will

not be able to use the Modbus server function.

Port Number

The default value is 502. To change the value:

◊ Press MENU and then select Menu tab > Basic setting mode > Environment tab >

Communication > Service port

For the selectable range, see section 7.1.

Reading or Writing the MV Data from Another Device

Another device (client device) sends commands to the MV to read data from the MV or

write data to the MV.

For the function codes that the MV supports and the MV registers that the client device

can access, see “Modbus Server Function” in section 7.3.

Specifying the Register Number

Specify the MV register on the client device according to the instructions below.

•

If you are using a commercial SCADA system or something similar, specify the

register number (a number such as 400001; referred to as the “reference number”)

listed under Modbus Server Function in section 7.3, “Modbus Protocol Specifications.”

• If you are using a custom communication program, specify the

“relative number”

in relation to the reference number. Compute the relative number in the manner

indicated in the examples below.

Examples

The relative number for input register 300100 is 99, which is the dif

ference between

300100 and 300001.

300100 – 300001 = 99

The relative number for input register 400011 is 10, which is the difference between

400011 and 400001.

400011 – 400001 = 10

Page 46

IM MV1000-17E

2-31

Using the Ethernet Interface

1

2

2.9 Reading/Writing Data on Another Device from the MV via Modbus

The MV is a Modbus client.

For Modbus specifications, see section 7.3.

Conguring the Modbus Client

You can configure the Modbus client so that the MV will be able to read or write data to

another device via Modbus.

◊ Press MENU and then select Menu tab >

Basic setting mode > Menu tab >

Communication (Ethernet) > Modbus client

Basic settings

Destination server settings

Transmission command settings

Basic Settings

• Read cycle

Set the read cycle to 125m, 250m, 500m, 1s, 2s, 5s, or 10s.

• Retry interval

Set the interval for retrying the connection when the connection is interrupted for

some reason. Select Off, 10s, 20s, 30s, 1min, 2min, 5min, 10min, 20min, 30 min,

or 1h. If you select Off, the MV will not retry the connection. If communication fails,

communication will stop.

Page 47

IM MV1000-17E

2-32

Destination Server Settings

• Server number

Select registration numbers of the server you want to configure from 1 to 16.

• Port

Enter the port number for the selected server in the range of 0 to 65535. The default

value is 502.

• Modbus server name

Set the destination Modbus server name using up to 64 alphanumeric characters.

• If you are using the DNS, you can set the host name for the server name.

• You can also set the IP address. In this case, the DNS is not required.

• Unit

If the unit number of the destination server is not necessary, select Auto. If a fixed unit

number is necessary, select Fixed. If you select Fixed, the unit number parameter

appears.

• No.

Enter a fixed unit number in the range of 0 to 255.

Transmission Command Settings

• Client command number

Select numbers of the transmission commands you want to configure from 1 to 16.

• Command type

Set the command type to Off, R, R-M, W, or W-M. If you select a command type

other than Off, the client channel, server number, register, and data type parameters

appear.

R:

Read the data from the server into external input channels (16-bit signed

integer)

R-M:

Read the data from the server into communication input channels (32-bit

floating point)

W:

Write measurement channel data (16-bit signed integer) to the server

W

-M: Write computation channel data (32-bit signed integer) to the server

R is selectable on the MV2000 when external input channels (/MC1 option) is installed.

R-M and W-M are selectable when the computation function (/M1 option) is installed.

• First/Last (MV channels)

Enter the first and last channel numbers of input/output. The range of channels that

you can enter varies depending on the command type as follows:

R: 201 to 440, R-M: C01 to C60, W: 1 to 48, W-M: 101 to 160

• Server (server number)

Select a server number from 1 to 16.

• Regi. (server register)

Set the server register number.

Enter an input register in the range of 30001 to 39999 and 300001 to 365536 or a hold

register in the range of 40001 to 49999 and 400001 to 465536.

The register numbers that you can specify vary depending on the command type. See

section 7.3 for details.

• Type

The data type.

Select INT16, UINT16, INT32_B, INT32_L, UINT32_B, UINT32_L, FLOAT_B, or

FLOAT_L.

The data type that you can specify vary depending on the command type. See section

7.3 for details.

2.9 Reading/Writing Data on Another Device from the MV via Modbus

Page 48

IM MV1000-17E

2-33

Using the Ethernet Interface

1

2

Examples of Entering Commands

The following are examples of commands when the MV is operating as a Modbus client

device. If the MV is operating as a Modbus master device, read the word “client” as

“master” and “server” as “slave.”

Ethernet

MVAdvanced

(Modbus client)

Instrument A

(Modbus server 1)

Instrument B

(Modbus server 2)

Instrument C

(Modbus server 3)

Connection example

Loading Data into Communication Input Channels

The MV reads the data from the server device and enters the data into communication

input channels in floating point format.

• Example 1

Read a 16-bit signed integer value from instrument A’s register 30001 into C01.

C01 30001

Communication input data

Instrument A register

16-bit signed integer

Command

R-M C01 - C01 1 30001 INT16

• Example 2

Read a 32-bit signed integer value from instrument B’s registers 30003 and 30004

(lower bytes and higher bytes) into C03. Specify the smaller register number in the

command.

30003 Lower bytes

Higher bytes

30004

C03

32-bit signed integer

Instrument B register

Communication input data

Command

R-M C03 - C03 2 30003 INT32_L

• Example 3

Read a 16-bit signed integer value from instrument B’s registers 30001 and 30002 into

C01 and C02. Specify the smaller register number in the command.

30001 16-bit signed integer

16-bit signed integer

30002

C01

C02

Instrument B register

Communication input data

Command

R-M C01 - C02 2 30001 INT16

• Example 4

Read a 32-bit floating point value from instrument B’s registers 30005 and 30006

(lower bytes and higher bytes) into C04. Specify the smaller register number in the

command.

30005 Lower bytes

30006

C04

32-bit floating point

Instrument B register

Communication input data

Higher bytes

Command

R-M C04 - C04 2 30005 FLOAT_L

2.9 Reading/Writing Data on Another Device from the MV via Modbus

Page 49

IM MV1000-17E

2-34

Reading Data into External Input Channels (MV2000 only)

The MV reads the data from the server device and enters the data into external input

channels in 16-bit signed integer format.

• Example 1

Read a 16-bit unsigned integer value from instrument C’s register 30001 into external

input channel 201.

30001

201

16-bit unsigned integer

External input channel

Instrument C register

Command

R 201 - 201 3 30001 UINT16

• Example 2

Read a 32-bit unsigned integer value from instrument C’s register 32001 and 32002

into external input channel 202. Specify the smaller register number in the command.

32-bit unsigned integer

32001

32002

202

External input channel

Instrument C register

Higher bytes

Lower bytes

Command

R 202 - 202 3 32001 UINT32 _ B

Writing Measured Values to a Server

• Example

Write the measured value of channel 1 (16-bit signed integer) to instrument A’s

register 40001.

16-bit signed integer

Measurement channel

Instrument A register

001 40001

Command

W 001 - 001 1 40001 INT16

Writing Computed Values to a Server

• Example

Write the computed value of channel 101 (32-bit signed integer) to instrument A’s

40001 and 40002 registers, lower 16 bits first and then higher 16 bits. Specify the

smaller register number in the command.

32-bit signed integer

Computation channel

Instrument A register

101

Lower bytes

Higher bytes

40001

40002

Command

W-R 101 - 101 1 40001 INT32_L

2.9 Reading/Writing Data on Another Device from the MV via Modbus

Page 50

IM MV1000-17E

2-35

Using the Ethernet Interface

1

2

Checking the Modbus Operating Status

Displaying the Modbus Operating Status

◊ Press DISP/ENTER and then select INFORMATION > MODBUS CLIENT

Note

To show the MODBUS CLIENT on the display selection menu, you need to change the setting

using the menu customize feature. Carry out the following steps.

◊ Press

MENU and then select Menu tab >

M

enu customize > Display menu

1. Select

INFORMATION > MODBUS CLIENT using the arrow keys.

2.

Press the V

iew

soft key

.

Server device host names or IP addresses

Register numbers

MV channels

Detail code

Status lamp

Cursor used to select a command

(Used to resume command transmission from the front panel keys)

Communication conditions

• Communication Conditions