Page 1

November 2005

224-778-00C

Smart HART® Loop

Interface and Monitor

HIM

Loop

®

Interface and Monitor

Smart HART

HIM

Page 2

Table of Contents

The HIM ..............................................................................................................3

About this Manual ...............................................................................................................3

Specifications .....................................................................................................................4

HIM Dimensions .................................................................................................................5

Terminal Designations ........................................................................................................ 5

Configuring the HIM .........................................................................................6

Installing the HIM ..............................................................................................7

Installing the HIM into the Loop ........................................................................................... 7

Bench Checking the HIM ....................................................................................................9

PC Configuration Software............................................................................10

HART Parameters ............................................................................................................ 11

Display Parameters .......................................................................................................... 13

Alarms Parameters ........................................................................................................... 14

Analog Outputs Parameters ..............................................................................................16

Custom Curve Parameters ................................................................................................ 18

Scaling Parameters .......................................................................................................... 19

Customer Service ...........................................................................................20

Appendix A: HIM MODBUS Feature .............................................................21

2 The Interface Solution Experts

Page 3

HIM

Smart HART Loop

Interface and Monitor

The HIM

The Moore Industries HIM HART Interface Module

unlocks the full potential of new and in-place HART

multivariable transmitters, valves, meters and other

smart instruments.

Converts HART to 4-20mA Signals

The HIM allows up to three additional analog process

variable measurements from a multivariable transmitter or valve with no additional process penetrations.

Installed transparently across the 4-20mA instrument

loop, the HIM reads the HART digital process data that

rides on the loop wires. It converts the digital information for up to three isolated analog (4-20mA) process

signals that are readily accepted by in-place control

systems, such as a DCS or PLC.

Provides Process and Diagnostic Alarms

Relay alarm trips (optional) can be individually user-set

either to trip when unwanted high/low process conditions occur, or provide a diagnostic health warning to

alert of loop or instrument fault conditions.

Takes Advantage of Legacy Instruments

The device lets you leave existing smart HART transmitters and valves in place, yet still take advantage of

all the information they have to offer.

Works with every Smart HART Device

The instrument can be programmed in minutes to interface with every HART-compatible monitoring and control device.

About this Manual

Wherever you see a “

pay particular attention.

•A “

Note

” provides information to help you in

avoiding minor inconveniences during

calibration, installation or operation of the HIM.

•A “

Caution

to avoid procedures and practices that could risk

damage to the HIM or other equipment.

•A “

WARNING

take to avoid procedures and practices that could

pose safety risks to personnel.

Note

”, “

Caution

” provides information on steps to take

” provides information on steps to

”, or “

WARNING

”

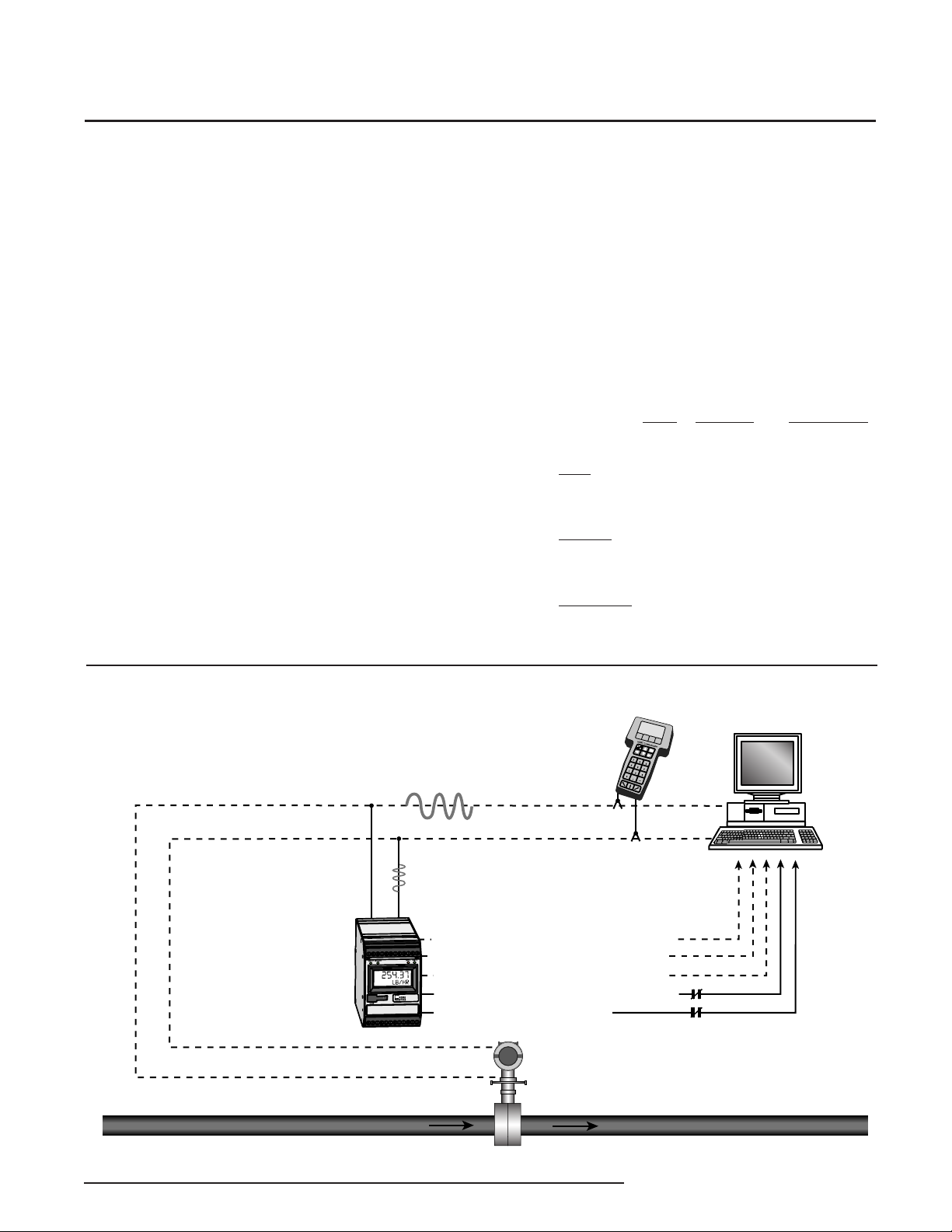

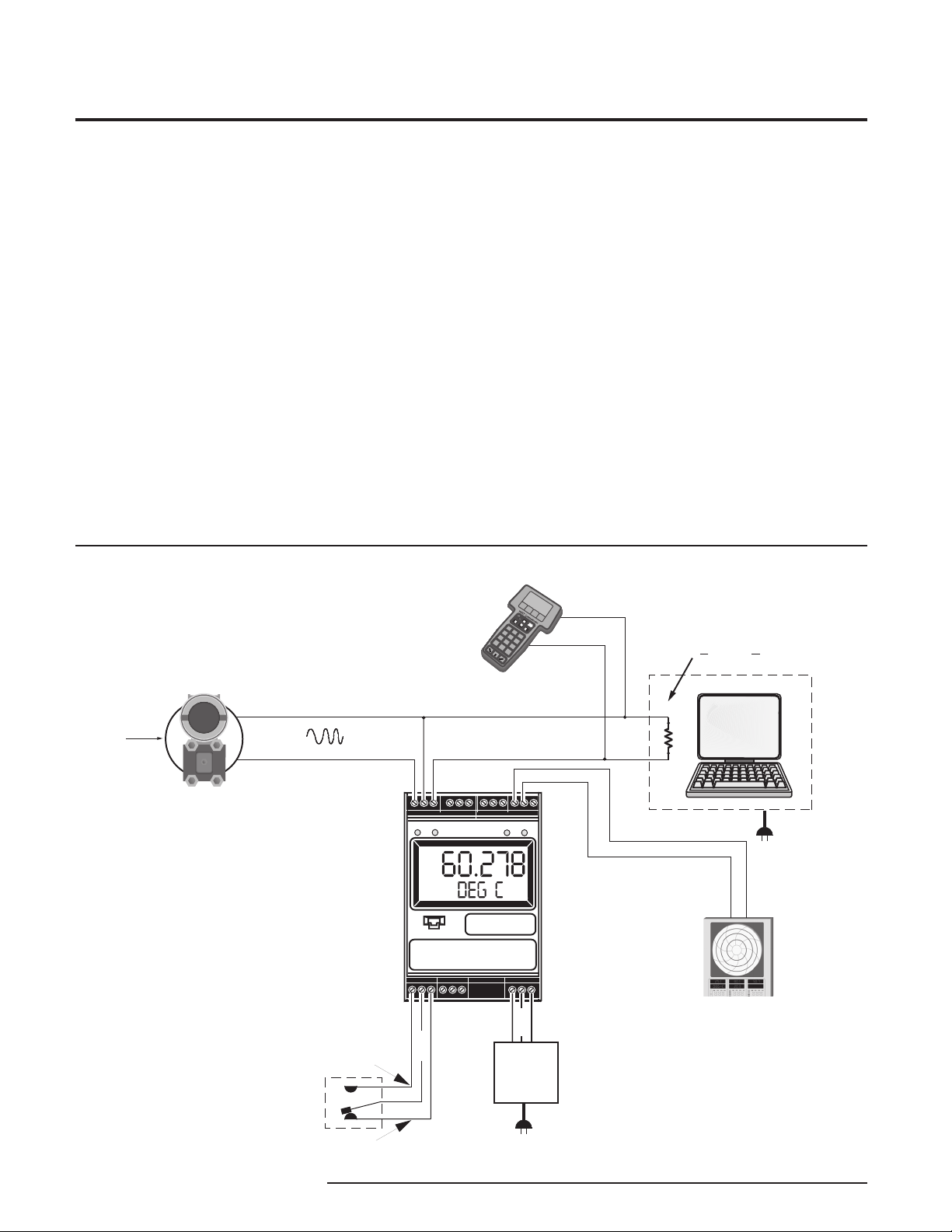

Figure 1. The HIM Accepts a Digital HART Signal and Outputs Both Analog Signals and Alarm Relays

HART Communicator can

be connected anywhere

along the 4-20mA loop

(HART Secondary Master)

4-20mA Representing the

Primary Variable (Mass Flow)

HART Digital Signal Carrying Primary,

Second, Third, Fourth Variable Process Data,

and Instrument Diagnostic Information

HIM HART Interface Module

"Breaks Out" Data from

Smart HART Instruments

(HART Primary Master)

4-20mA Proportional to 2nd Variable (DP)

4-20mA Proportional to 3rd Variable (P)

4-20mA Proportional to 4th Variable (T)

High Alarm in Response to 4th Variable (T)

HART Transmitter Fault Alarm

Smart HART

Multivariable

Mass Flow

Transmitter

Flow

Control System

(DCS or PLC)

The Interface Solution Experts 3

Page 4

HIM

Smart HART Loop

Interface and Monitor

Specifications

Performance

Specifications and information subject to change without notice.

4 The Interface Solution Experts

Input Accuracy: Reflects

the accuracy of the HART

field device

Input Impedance: Transmit

Mode: 150 ohms;

Receive Mode: Less than

5kohms

Input Over-Range

Protection: ±5Vdc

ANALOG OUTPUTS

Output Accuracy: ±0.015%

of maximum output span

(20mA). Includes the

combined effects of linearity,

hysteresis, repeatability and

adjustment resolution.

Output Response Time:

<120ms, 10-90%

Isolation: 500Vrms channelto-channel isolation;

1000Vrms between case,

input, outputs and power

terminals, and will withstand

1500Vac dielectric strength

test for one minute with no

breakdown

Ripple: Less than 10mV

peak-to-peak when

measured across a

250 ohm resistor

Output Limiting: 130% of

span maximum; 125% of

span typical

Output Protection:

Transient protection on

output

Load Capability:

0-20mA, 1100 ohms

maximum

Load Effect: ±0.01% of span

from 0 to maximum load

resistance

Line Voltage Effect:

±0.005% of output span for a

1% change in line voltage

Input Fail Modes: PC

programmable to fail high, fail

low, hold last, hold last then

fail high, or hold last then fail

low (configurable hold time, 060 seconds)

Output Limits on Input

Failure: 0-20mA: Fail Low to

0mA or Fail High to 23.6mA;

4-20mA: Fail Low to 3.6mA

or Fail High to 23.6mA;

X-20mA (0<X<4): Fail Low to

90% of XmA or Fail High to

23.6mA

Performance

(Continued)

Indicators

+TX Power Supply: 24.0Vdc

±10%@24mA

ALARM OUTPUTS

Digital Response Time:

Defined by HART protocol as

500msec maximum in Normal

HART Mode; 333msec

maximum in HART Burst

Mode

Alarm Response Time:

Digital Response Time +

150msec (Defined as time

from the field instrument’s

reporting a fault until the HIM

alarm is tripped)

Alarm Trip Delay:

Programmable from 0-120sec

MODBUS OUTPUTS

Type: Standard MODBUS

RTU protocol interface over

RS485 (parameters as

specified in U.S. Standard

EIA-RS485)

Address Range:

Configurable from 1 to 247.

Unit will assume a MODBUS

address of 01 by default

Baud Rate: Interface

supports the following: 300,

600, 1200, 4800, 9600, 19.2k.

MODBUS interface will

support even, odd and no

parities. Unit will assume a

baud rate of 9600 and no

parity by default

Character Format: One start

bit, 8 data bits and one stop

bit

Data Format: Userselectable Standard LSW

(Least Significant Word) or

Swapped MSW (Most

Significant Word). Unit will

assume Standard LSW by

default

Power Consumption:

2-3.5W, nominal; 4.5W

@24Vdc maximum for units

using transmitter excitation to

supply loop power a 2-wire

instrument

LCD Type: Two-line LCD;

Top Row, 10mm (0.4 in) high

black digits on a reflective

background; Bottom Row,

6mm (0.225 in) high digits

on a reflective background;

two-digit HART address

indicator

Indicators

(Continued)

Ambient

Conditions

Weight

Format: Top row is five

alphanumeric characters,

plus sign and decimal point;

bottom row is five

alphanumeric characters

Decimal Points: Userselectable for 0, 1, 2 or 3

places after the decimal point

or automatically adjusting with

a four decimal point maximum

Range: -99999 to 99999

Minimum Display Span:

1.00

Display Update Rate:

100msec

LED Type: Dual color

red/green indicate:

INPUT LED: Whether (green)

or not (red) the HART input is

connected and functioning

properly

READY LED: Whether

(green) or not (red) the HIM is

initialized and operating

properly

TRIP 1 and 2 LED: Shows the

status of alarm off (green) or

alarm on (red)

Operating & Storage

Range:

-40°C to +85°C

(-40°F to +185°F)

Display Range:

-25°C to +85°C

(-13°F to +185°F)

Relay Range:

-25°C to +70°C

(-13°F to +158°F)

Relative Humidity:

0-95%, non-condensing

Ambient Temperature

Effect: ±0.0065% of

span/°C maximum

RFI/EMI Immunity

(Standard):

20V/m@20-1000MHz, 1kHz

AM, when tested according to

IEC1000-4-3-1995

RFI/EMI Immunity (with

-RF Option): 30V/m@

20-1000MHz, 1kHz AM, when

tested according to IEC10004-3-1995

Noise Rejection: Common

Mode: 100dB@50/60Hz

567 grams (16 ounces)

Page 5

Figure 2. HIM Dimensions

65mm

(2.56 in)

T1

T5

T3

T2

T4

T7

T6

HIM

Smart HART Loop

Interface and Monitor

138mm

133mm

(5.25 in)

T8

T9

T10 T11

T12

(5.45 in)

READYINPUT

60.278

ADDR

0

B2

B1

Table 1. Terminal Designations

HART Input, 2 Analog Outputs (2AO)

HART Input, 3 Analog Outputs (3AO)

COM

B3

B4

DEG C

HIM

B5

INPUT / OUTPUT

B8

B7

B6

TRIP 2TRIP 1

HART INTERFACE

MODULE

B9

B11

B10

B12

100mm

(3.94 in)

T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12

+I Source

+TX

+TX

+IN

+IN

–IN

–IN

+I

Source

(AO3)

No Label

–I Source

or

+I Sink

(AO3)

–I Sink

(AO3)

(AO2)

+I Source

(AO2)

–I Source

–I Source

or

+I Sink

(AO2)

or

+I Sink

(AO2)

–I Sink

(AO2)

–I Sink

(AO2)

+I Source

(AO1)

+I Source

(AO1)

–I Source

or

+I Sink

(AO1)

–I Source

or

+I Sink

(AO1)

–I Sink

(AO1)

–I Sink

(AO1)

HART Input, 2 MODBUS Oututs

and 1 Analog Output (MB1AO)

HART Input, 2 MODBUS Outputs (MB)

ALARM RELAYS / POWER

No Alarm

Single Alarm (–1PRG)

Dual Alarm (–2PRG)

KEY:

+IN/–IN = Current input to HIM from HART device +TX = Transmitter Excitation Current

+I/–I Source = Analog Source Output +I/–I Sink = Analog Sink Output

A/B = MODBUS Output NO/NO# = Normally Open

NC/NC# = Normally Closed CM/CM# = Common

DC/DCC = 24VDC Connection (AO#) = Analog Output

+TX

+IN

–IN

Source

+TX

+IN

–IN

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12

No Label

NO1 CM 1 NC1

NO1 CM1 NC1 NO2 CM2 NC2

Relay 1

NO2 CM 2 NC2

Relay 1

A

+I

(AO)

Relay 2

–I Sink

–I Source

or

+I Sink

(AO)

No Label

NOTES:

1. The standard Single Alarm unit (1PRG) utilizes a DPDT relay.

2. Terminal blocks can accommodate 14-22 AWG solid wiring

(torque to 4 inch-pounds, maximum).

(AO)

MODBUS

MODBUS

B

MODBUS

2

B

MODBUS

2

No Label

MODBUS

MODBUS

2

A

2

The Interface Solution Experts 5

A

S

MODBUS

2

S

MODBUS

2

DC

DC

DC

B

MODBUS

1

A

MODBUS

1

DCC

DCC

DCC

S

MODBUS

1

1

S

B

MODBUS

1

1

Ground

Ground

Ground

Page 6

HIM

Smart HART Loop

Interface and Monitor

Configuring the HIM

One of the benefits of the HIM is that there are no

internal or external controls to adjust or settings to

change. All operating parameters are set using the PC

Configuration software.

Once these software settings are made, they are

downloaded to the monitor in the form of a Configuration

File and stored in the unit’s non-volatile memory. You

can choose to save a backup copy of the file on your

PC hard drive or external media. The HIM communicates with the PC through a proprietary communications cable to the PC’s serial (COM) port.

Begin by installing the PC Configuration Software.

Installing the PC Configuration Software

Refer to Table 2 for the equipment needed.

1. Insert the

PC Configuration Software

of the PC. Access the CD and open the

PC Configuration Software

2. Double-click the installation program located in

the folder. Follow the prompts to correctly

install the program.

Moore Industries Interface Solution

CD into the CD drive

HIM

folder.

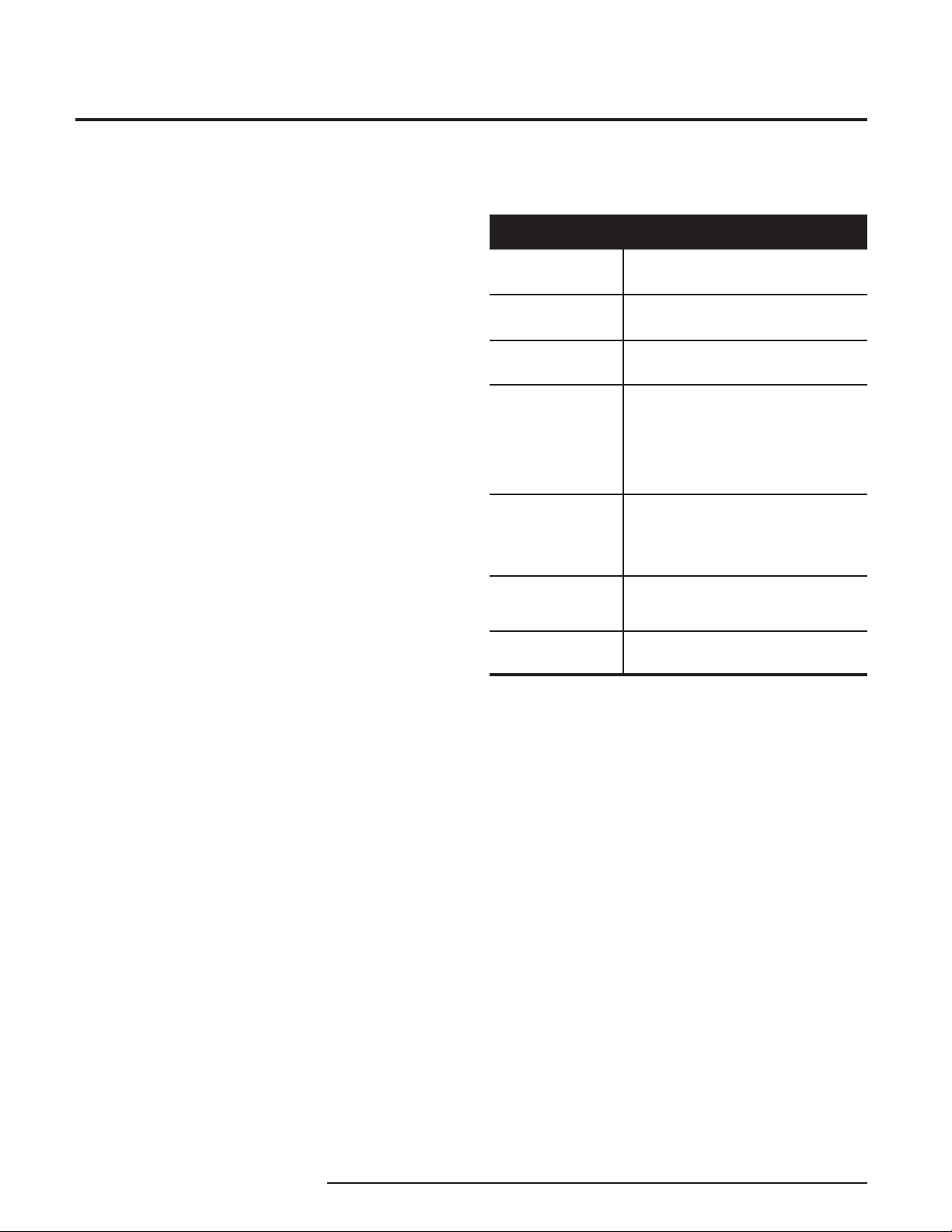

Table 2. Assembling the Necessary Equipment

Device Specifications

Precision Load

Resistor

Multimeter or

Ammeter

Power

Supply

Personal Computer

PC Operating

System

Moore Industries

PC Configuration

Software

Communication

Cable

250 ohms, ±0.01%

Accurate to ±0.009% of span;

e.g. HP Model 3487A

24Vdc, ±10%

80386-based(or faster) IBM PC, or 100%

compatible; (Pentium recommended)

CD Drive

4Mb free RAM; 16Mb recommended

20Mb free disk space on hard drive

1 (one) serial port (COM 1, 2, 3 or 4)

Microsoft Windows® 95, 98, 2000, ME, or

NT with Internet Explorer 4.0+

Microsoft Windows® NT with

Service Pack 3 or greater

Version 1.0 or higher, successfully

installed to the hard drive

Part Number: 803-053-26, or equivalent

or

Once the Configuration Program is installed on the PC,

the unit can be connected either into the loop or to test

equipment to simulate input and monitor output. With

the PC program, the user can then view and/or change

its operating parameters. To begin the process, connect

the HIM either into the loop (see

the Loop

Checking the HIM

6 The Interface Solution Experts

) or into a configuration setup (see

).

Installing the HIM into

Bench

Page 7

HIM

Smart HART Loop

Interface and Monitor

Installing the HIM

There are two methods for connecting the HIM for

Mounting

The HIM is designed to snap easily onto 32mm, G-type

(EN50035) or 35mm Top Hat (EN50022) DIN rails.

configuration. The recommended method requires you

to install the instrument into the loop before it is

configured. The secondary method allows you to bench

check the HIM by attaching it to test equipment that

will simulate the input and monitor the output.

Electrical Connections

After mounting, you are ready to connect the HIM to

the loop. Each unit comes equipped with a transmitter

excitation terminal which allows it to supply power to

the monitored HART instrument, if necessary. Figures

Installing the HIM into the Loop

Installation consists of physically mounting the unit,

2 and 3 show the connection diagrams for an HIM with

or without using the transmitter excitation current.

grounding the instrument, and completing the electrical

connections. To install the HIM into the loop for

configuration, use the equipment in Table 2 to hookup

the HIM into the loop as shown in Figure 3 (without

using the HIM to power a transmitter) or Figure 4 (using

the TX terminal to power a transmitter). If you need a

CE Conformity

Installation of any Moore Industries products that carry

the CE certification (Commission Electrotechnique)

must

adhere to the guidelines in

order to meet the requirements set forth in applicable

complete terminal description, refer to Table 1.

Figure 3. Installing a HIM Into the Loop Without Using the Transmitter Excitation (+TX) Terminal

HART Communicator

can be connected

anywhere on the loop

➤

➤

➤

7

➤

8

4

9

5

1

6

2

0

3

.

➤

—

➤

➤

Sensor

Input

24Vdc

Power

+–

+

4-20mA

Installing the HIM

R must be > 250 and <1100 Ohms

R

in

–

HART Multivariable

Field Instrument

(Temperature

Pressure, Level

and Flow)

NO (normally open)

COMMON

NC (normally closed)

+IN

NO

READYINPUT

ADDR

0

COM

COM

–IN

NC

TRIP 2TRIP 1

DC

DCC

24Vdc

Power

Source

GND

DCS

Analog Output tied to

Any Process Variable

50.7

25.1

80.1

deg-c

20.3

Event Recorder

The Interface Solution Experts 7

Page 8

HIM

Smart HART Loop

Interface and Monitor

EMC (Electromagnetic Compatibility) directives

(EN55011, EN 50082-1, EN50082-2, etc.). Consult the

factory for the most current information on products

that have been CE certified.

• All input signals to, and output signals

from, Moore Industries’ products should be

wired using a shielded, twisted pair

technique. Shields are to be connected to an

earth or safety ground at the unit itself.

Recommended Ground Wiring Practices

Moore Industries recommends the following ground

wiring practices:

• Any Moore Industries product in a metal

case or housing should be grounded.

• The protective earth conductor must be

connected to a system safety earth ground

before making any other connections.

• The maximum length of unshielded input

and output signal wiring should be 2 inches.

Power Sourcing Parameters for General

Locations, Intrinsically Safe, and

Non-Incendive/Type N applications

In accordance with IEC 1010.1 Annex H

(all models), the input terminals must be

connected to and/or supplied from a certified

energy limiting Class 2 or a Separate Extra Low

Voltage (S.E.L.V.) power supply separated from

all mains by double/reinforced insulation.

Figure 4. Installing a HIM Into the Loop Using the Transmitter Excitation (+TX) Terminal

➤

➤

➤

7

➤

8

4

9

5

1

6

2

0

3

.

➤

—

➤

➤

HART Communicator

can be connected

anywhere on the loop

R must be > 250 and <1100 Ohms

Sensor

Input

HART Multivariable

Field Instrument

(Temperature,

Pressure, Level

and Flow)

–

4-20mA

+

NO (normally open)

COMMON

NC (normally closed)

+IN

+TX –IN

READYINPUT

ADDR

0

COM

NO

NC

COM

TRIP 2TRIP 1

DC

24Vdc

Power

Source

DCC

R

DCS

Analog Output tied to

Any Process Variable

Event Recorder

GND

8 The Interface Solution Experts

Page 9

HIM

Smart HART Loop

Interface and Monitor

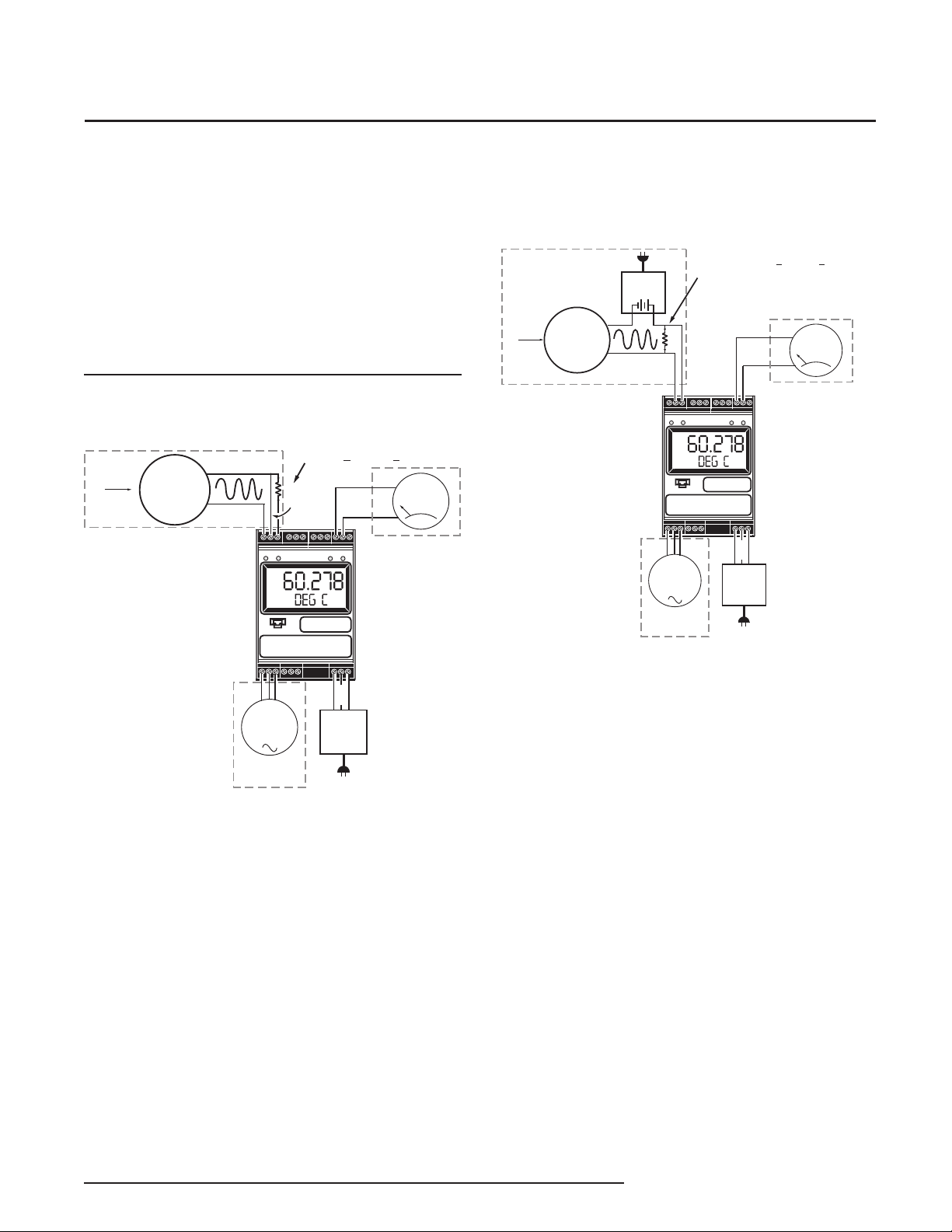

Bench Checking the HIM

If you would like to configure the HIM before

attaching it to the loop, you need to hook it up

with the equipment listed in Table 1. Refer to

Figures 5 and 6 for instructions on how to bench

check the HIM either with or without taking

advantage of the Transmitter Excitation (+TX)

terminal. If you need further descriptions of the

terminals, see Table 2.

Figure 5. Bench Checking the HIM Using the Transmitter

Excitation (+TX) Terminal to Power a Transmitter

Sensor

Input

HART

Field Device

or

Simulator

Equipment Hook-Up

for HART field device using

Transmitter Excitation

–

+

+TX

R must be > 250 and <1100 Ohms

R

+IN

–IN

+

–

READYINPUT

ADDR

0

COM

TRIP 2TRIP 1

+

Multimeter

–

Figure 6. Bench Checking the HIM Without Using the

Transmitter Excitation (+TX) Terminal to Power a Transmitter

For a HART Transmitter, the

resistor must be >250 and <1100 ohms.

For a HART Receiver, such as a

valve positioner, no resistor is necessary.

R

–IN

READYINPUT

ADDR

0

COM

NO

NC

COM

+

TRIP 2TRIP 1

DC

24Vdc

Power

–

DCC

GND

+

Multimeter

–

Sensor

Input

HART

Field Device

or

Simulator

Optional

24Vdc

Power

+–

+

–

+IN

Multimeter

Checks for

continuity

Optional

NO

COM

Multimeter

Checks for

continuity

Optional

NC

DC

24Vdc

Power

DCC

GND

The Interface Solution Experts 9

Page 10

HIM

Smart HART Loop

Interface and Monitor

PC Configuration Software

Figure 7. HIM PC Configuration Software Screen

1

3

2

The HIM PC Configuration Software can be used to

program all of the HIM’s parameters. Once the default

configuration has been saved, it is safe to program

other parameters. The PC Software is made up of

these sections:

1. HIM Status and Information Section–The left

side of the screen includes seven boxes that display

the different settings of the attached HIM.

Program Status–Displays the activity of the

connected HIM. It will show you if the unit is

Uploading, Downloading, Monitoring

HIM Device Info–Displays the individual charac

teristics of the attached HIM, such as its Identification, Hardware and Software Revisions, and the

last date that the device was configured.

HIM Tag–A phrase used to identify a HIM.

10 The Interface Solution Experts

or

Searching.

Idle,

HIM Device Status–Displays how the HIM is functioning, giving a brief summary of any errors or displaying

OK

if it is operating normally.

HIM Displayed Data–this display mirrors what the attached HIM is displaying.

Progress–This bar stays in motion any time the HIM

is monitoring, uploading or downloading.

Communication Status–monitors the PC Software’s

ability to communicate with the HIM.

2. HART/Display/ Alarms/Analog Outputs/Custom

Curve/ Scaling Tabs–These tabs change the right

side of the screen to allow you to set the appropriate

part of the HIM’s configuration. Refer to the associated pages in this document for additional information

on these tabs.

3. Menu Bar/Tool Bar– Dropdown menus and corre-

sponding icons allow you to perform various functions

throughout the PC Configuration Program.

Page 11

HIM

Smart HART Loop

Interface and Monitor

HART Parameters

To program the HART parameters, change the settings

in the

Communications Settings

Set

. See the descriptions below of the various

sections of the screen.

HART Address

The

HART Address

that the HIM will be monitoring.

Number of Retries

The

Number of Retries

and will determine how many times the HIM will

attempt to poll the HART transmitter (without success),

before it indicates a HART Fault condition.

Normal/Burst/Listen (Passive) Modes

The HIM can operate in one of four modes:

Burst

, or

Listen (Passive)

In each of these modes, the HIM attempts to find a

HART transmitter.

In

Normal

transmitter, then polls the HART instrument twice per

second, requesting the current process status and the

HART instrument’s diagnostic status. The HART

instrument responds with the requested data.

In

Burst

programmed to continuously transmit its process

variable and health status. The HIM samples the

continuous HART data three times per second.

Listen (Passive)

loop that already has primary and secondary HART

masters. In

connects passively, continuously sampling HART data

from a smart instrument without affecting normal loop

operation. When using this mode, either the monitored

smart HART instrument must be set in

HART master must be continuously polling the smart

HART slave device.

mode, the HIM polls the HART loop for a

mode, the monitored HART instrument is

Listen (Passive)

is the address of the HART device

can be set between 1 and 9,

mode allows the HIM to operate on a

box, then press

and

Listen (Specified Slave)

mode, the monitor

Burst Mode

Quick

Normal

,

or a

The HART protocol allows for two communications

masters on the loop, a Primary and a Secondary.

Setting the HIM to function as the Primary HART

Master in the application means that any other HART

device in the loop must be configured either as a HART

Secondary Master (1 per loop) or as a HART Slave (up

to 16 per loop). Conversely, setting the HIM to function

as the Secondary HART Master allows other HART

devices to function either as a Primary Master or as

slaves. Configuring more than one device on a single

loop as a Primary or Secondary HART Master will

cause a communications failure.

Listen (Specified Slave)

When multiple HART instruments are present, the

Listen (Passive)

returned from one instrument will overwrite the data

previously stored in the HIM. If multiple HART slave

instruments are communicating on the loop, the HIM

.

will overwrite its internal HART data sets with the latest

device read from the bus, no matter where the data

originates. To allow selective monitoring on a multiinstrument loop, and to allow multiple HIMs to be used

on a digital loop, the

used.

If the HIM is in “Listen” mode it is not a HART communication master and therefore is not in control of

communication. Other HART masters are controlling

the polling of slaves and the HIM can only “Listen”.

The HIM must be able to detect when it has not heard

from its assigned slave device so that it can declare a

“No HART” input and force outputs to the values

specified by the user. The HIM must therefore be told

to wait an appropriate amount of time for the slave

device to send its message before the HIM declares

“No HART”. This timing coordination is accomplished

with

Timeout Period

Timeout Period

must be greater than the period between polls by the

HART master of the Specified Slave. For example,

assume that there are five HART transmitters on the

same multi-drop loop as the HIM. The HART master is

configured to poll each device every second. It then

takes the HART master five seconds to repeat the poll

to the one device being monitored by the HIM. the HIM

Timeout Period

mode cannot be used because data

Listen (Specified Slave)

.

is a value between 1 and 30sec and

must be set at a value greater than five

feature is

The Interface Solution Experts 11

Page 12

HIM

Smart HART Loop

Interface and Monitor

seconds. In this example, we will use seven seconds.

The HIM then sees its slave device speak and waits

seven seconds for it to speak again. As long as the

HIM sees a new message from its slave device its

outputs are updated based upon the measured variables. If the slave device does not speak within the

seven second period, the HIM declares a “No HART”

situation and sends its outputs to the failed communications values.

To use this feature, proceed with the following steps:

1. Select the

2. Enter your desired value into the

text box.

Factory default is 5 seconds. The maximum Timeout

Period is 30 seconds.

3. Set the exact slave address of the instrument you

wish to monitor. Click the

This brings up the

Address Settings

information into the appropriate text boxes.

Listen (Specified Slave)

Set Slave Address

HART Slave Device Long Format

screen (Figure 8). Enter the required

button.

Timeout Period(s)

button.

To convert HEX to Decimal code, perform the

following steps:

Access the Calculator feature in Microsoft

Windows® by opening the

select

Programs

Calculator

Ensure that the Calculator is in

To do this, select the

and choose

Click the

code value.

Next, click the

converted into the Decimal value.

Enter the converted value into the proper param

eter.

The

the exact device to which the HIM will listen.

4. Once complete, press OK.

Hex

Device ID Number

then

.

Scientific

radio button and enter the HEX

Dec

button and the value will be

Start

menu. Next,

Accessories

View

dropdown menu

.

is the serial number of

and finally

Scientific

mode.

Figure 8. HART Slave Device Long Format Address Settings

Screen

The

Manufacturer’s ID

instrument that the HIM will listen to are available from

the HART Foundation website at www.hartcomm.org

and/or the instrument manufacturer.

Values obtained from the HART website are in HEX

code. The HIM does not use HEX code; you must

convert this value to Decimal code.

and

Device Type ID

for the

Download the information to your instrument once you

are finished.

Auto Clear Status Bit

Most HART instruments indicate when a device's

configuration has been changed. This indication

(status bit) can be reset by sending HART command

38–reset configuration changed. Checking the

Clear Status Bit

command whenever the HART instrument it is

monitoring has its configuration changed. However,

the HIM can also be set to alarm on this bit (see

Programming the Alarm Parameters

both set to alarm and to auto clear, then it will do

both–going into alarm mode and resetting that

indication.

Quick Read/Set

The

Quick Read

Software to read the communications information from

the attached HIM; the

software to configure the HIM’s communications

settings to match those of the PC Software.

box causes the HIM to issue this

). If the HIM is

button causes the PC Configuration

Quick Set

button causes the

Auto

12 The Interface Solution Experts

Page 13

HIM

Smart HART Loop

Interface and Monitor

HART Device Info

This box displays the identification and revision

information of the monitored HART instrument.

HART Device Status

The HART Device Status box displays the current

status of the monitored HART transmitter. In a small

double-box, the software displays the code (hex

number) associated with the status.

Variables

The device will monitor up to the first four HART

variables sent by your transmitter. This portion of the

screen displays those variables and the Loop Current.

HART Device Range & Limits

This portion of the screen displays the range and the

sensor limits of the monitored HART transmitter.

Display Parameters

The

Display

program the Display parameters, change the settings in

the

Display Source

the following descriptions of the various sections of the

screen.

Figure 9. Display Tab

tab configures the HIM’s LCD display. To

box, then press

Quick Set

. See

Toggle, Variable List

The

Toggle

display two HART variables in five second increments.

Directly below the

to select the variables that you would like to be

displayed. Notice that if you select a scaled variable,

it is important to check on the

that you have set all of the scaling parameters.

Use Custom Label

The

Custom Label

scaled variable. Clicking the

causes the HIM to always display the custom label as

Engineering Units (EGUs).

Precision

The

Precision

of decimal places displayed by the HIM.

Quick Set

The

Quick Set

information on the Display page.

Display Format

The HIM reads the dynamic process variable supported

by HART sensors. Generally, the HIM’s LCD displayed

values range from -99999 to 99999. Occasionally,

these process variable values may extend past this

range. To improve the displayed readings, values

below -XXXXX and above XXXXX are translated into

exponential form. Below is an example of the appearance of the display when certain values are sensed.

checkbox causes the HIM to sequentially

Toggle

is used to display a calculated or

buttons allow you to change the number

button programs the HIM with the

checkbox are two list boxes

Scaling

Use Custom Label

page to verify

box

Value Display

12345 12345

1234500 1.23E06

-500000 -5.00E05

The Interface Solution Experts 13

Page 14

HIM

Smart HART Loop

Interface and Monitor

Alarms Parameters

The Alarms tab controls the programmable alarm

trip(s) option. This screen will be grayed out if the

attached HIM is not equipped with at least one alarm

trip. To program the Alarm parameters, change the

settings in the

Quick Set

below.

Figure 10. Alarms Tab

Alarm1

. The sections of the screen are described

and/or

Alarm2

box, then press

Device Malfunction (Bit 7)

Relay trips whenever it detects that a hardware error or

failure has occurred in the connected HART device.

Configuration Changed (Bit 6)

Relay trips whenever it detects that the connected

HART device has had its configuration changed.

Cold Start (Bit 5)

Relay trips whenever the power to the HART device is

interrupted. It will also trip during a HART Master

Reset or Self Test Command.

Additional Status (Bit 4)

Relay trips whenever the connected HART device

reports a condition requiring HART Command #48,

which is Read Additional Information. This indicates

that the instrument needs attention from a device with

full HART command capability.

Output Current Fixed (Bit 3)

Relay trips whenever the HIM detects that the

connected HART device’s output is no longer

responding to changes in its input, and is being held at

a predefined level.

Trip/Fault Alarms

A

Trip Alarm

either when the variable exceeds a set value (Trip

High) or when the variable falls below a selected value

(Trip Low). The

monitored, while the

the alarm will trip. After the alarm trips, the

Band

determines how far past the trip point the

variable will have to go before the alarm condition

returns to normal.

There are two types of Fault Alarms. A

Alarm

trip whenever the internal error status word is set. For

example, if the HIM’s configuration file becomes

corrupt, this alarm will trip and the monitor will display

BAD_CONFIG. A

the health of the HART transmitter. This fault alarm

will trip for any of these eight malfunctions:

monitors a selected variable and trips

Source

monitors the health of the HART monitor. It will

specifies which variable will be

Trip Point

Field Device Fault Alarm

sets the point at which

HIM Fault

Dead

monitors

PV Analog Output Saturated (Bit 2)

Relay trips whenever it detects that both its analog and

digital representations of the Primary Variable are

outside rated operating limits, and no longer reflect the

true sensor input.

Non-PV Out of Limits (Bit 1)

Relay trips whenever one of the HART ancillary

variables (second, third or fourth), is operating outside

the limits that can be effectively measured.

PV Out of Limits (Bit 0)

Relay trips whenever the HART Primary Variable is

operating outside the limits that can be effectively

measured.

Delay & Fail Safe

By entering a value in the

how long (in seconds) the alarm condition needs to

exist before the alarm trips.

checked) de-energize when in alarm condition;

Non-Failsafe

alarms energize when tripped.

Delay

box, you can specify

Failsafe

alarms (box

14 The Interface Solution Experts

Page 15

HIM

Smart HART Loop

Interface and Monitor

HART Additional Status Alarm Bits

HART Additional Status also called “More Status” and

“Command 48” is where device manufacturers install

the custom diagnostics for the specific device. For

your particular application, you may choose all of these

diagnostics to cause the HIM relay to trip or just one

diagnostic bit to trip the HIM relay (or any combination

in between). The manufacturer of the HART device will

be the source for the specific diagnostic information.

Selecting the

Alarms

alarm states, when in fault mode, based on the bit

settings of the additional status information returned by

certain HART instruments. This provides flexibility to

the requirement of alarming on additional status information.

Choosing this feature, you are given the ability to

specify the bit(s) on which to alarm. To access this

feature, check the

button will appear in the

section of the screen. Clicking the

the

Additional HART Status Alarm Bits Settings

(Figure 11). Check the box(es) that correspond to the

bits you wish to use; click OK.

Field Device Fault Alarm

screen allows you to enable the HIM to set

Additional Status

HART Additional Status Bits

function in the

box. The

Edit

box brings up

Edit

window

Read & Quick Set Buttons

The

Read

button causes the PC Configuration Software

to read the alarm information from the attached HIM;

The

Quick Set

the HIM's alarm settings to match those currently

entered in the PC Software.

button causes the software to configure

Download the information to your instrument once you

are finished.

Figure 11. Additional HART Status Alarm Bits Settings Window

The Interface Solution Experts 15

Page 16

HIM

Smart HART Loop

Interface and Monitor

Analog Outputs Parameters

The HIM comes with either two (–2AO) or three (–3AO)

analog outputs. The

specify which HART variable is to be monitored as the

source of the analog output, the input range and output

range, and how the output will react when the variable

input is out of range. To program the Analog Outputs

parameters, change the settings in the

boxes, then press

below of the various sections of the screen.

Figure 12. Analog Outputs Tab

Analog Outputs

Quick Set

. See the descriptions

tab allows you to

Output1/2/3

For example, you have a vortex flow meter with an

imbedded RTD that measures the process

temperature, and that temperature is assigned to the

HART Secondary Variable. The full range of the RTD

sensor is from –400°F to +1760°F, but your flow

stream will always be between 0° and 400°F. To scale

the analog output, for Output 1, set the

Set the

Range

the new configuration file to the HIM.

Output Current Box

The

displays up-to-the-second information on the value, in

mA, of the analog output.

Fail Mode

The

respond when its monitored input fails. If

set to

or any detected error occurs in the HART transmitter,

the analog output will output a 23.6mA signal. If Fail

Mode is set to

range, or any detected error occurs in the HART

transmitter, the analog output will output a signal that

is 90% of the lower range value below 4mA; it will

output 0mA if the lower range is set to 0mA.

Input Range

to 4mA to 20mA. Click

Output Current

Fail Mode

High

and the measured input goes out of range,

to 0° and 400°F, and the

Quick Set

Box on the

setting determines how the HIM will

Low

and the measured input goes out of

Analog Outputs

Source

as SV.

Output

to download

Tab

Fail Mode

is

Source

Source

monitor. Notice that selecting one of the scaled

outputs will require you to make changes to the

Scaling

require you to make changes to the

Input/Output Range

The

source input and the range of the analog output.

These two sets of fields can be used to scale the

HIM’s output.

defines the variable that the analog output will

tab, and selecting the Custom Curve option will

Custom Curve

Input or Output Range

defines the range of the

tab.

If

Fail Mode

to output the last value it recorded before the input

failed. If

Hold Last Then Low

last value recorded for a set amount of time (according

to Hold Last Duration box), then either fail high or fail

low, respectively.

Quick Set Button

The

Quick Set

the instrument’s analog output settings to match those

currently entered in the PC Software.

Trim Button

The

Trim

to set the device’s output to match the reading of the

loop. Refer to the

Parameters

information.

is set to

Fail Mode

button brings up the Trim Menu, allowing you

section of this manual for more

Hold Last

is set to

, the HIM will continue to output the

button causes the software to configure

Programming the Trimming

, the HIM will continue

Hold Last Then High

or

16 The Interface Solution Experts

Page 17

HIM

Smart HART Loop

Interface and Monitor

Configuring Analog Output Trimming

The

Analog Output Trimming

allows you to match the HART monitors analog output

to the output measured by a calibration device. This

will require a calibrated multimeter, such as a HP Model

3478A or equivalent, accurate to ±0.009%.

Trimming the analog output of the monitor

nullifies any scaling that may have been

performed in the

Figure 13. Trimming Window

section of the software

Note:

Scaling

tab.

Fix Current Utility

The

Fix Current Utility

output any current value from 0-20mA. This can be

used to match the calibration of your other equipment.

To fix the current, simply enter the value in the

box (in mA) that you want the HIM to output, and click

Fix Output

press the

return to normal operation.

. When you are finished, make sure to

Unfix Output

allows you to force the HIM to

Current

button so that the HIM can

User Trimming

To trim the device, attach a multimeter to the analog

output, then click the

Read the value on the multimeter, enter it into the

Measured Output Loop Current

box, and press

analog output matches the minimum point (4mA for a

4-20mA output) when you click the

Point

button.

After the low point is trimmed, press the

High Point

enter it into the

of the

sequence until the analog output matches the

maximum point (20mA for a 4-20mA output) when you

click the

When finished, press the

button. Read the value on the multimeter,

Trimming

Fix Output at High Point button

Fix Output at Low Point

portion of the

Trim

. Repeat this sequence until the

Fix Output at Low

Measured Output Loop Current

box, and press

Trim

. Repeat this

Unfix Output

button.

Trimming

Fix Output at

.

button.

portion

The Interface Solution Experts 17

Page 18

HIM

Smart HART Loop

Interface and Monitor

Custom Curve Parameters

The custom curve tab allows you to set up a custom

curve of up to 128 points. A custom curve can either

be created from scratch or loaded from a previously

created comma separated value (.csv) file. To

program the Analog Outputs parameters, change the

settings in the

Table

. See the descriptions below of the various

sections of the screen.

Figure 14. Custom Curve Tab

Custom Curve

tab, then press

Download

Custom Curve Variable

The

Custom Curve Variable

information on the value of the Custom Curve. Press

the

Monitor

Custom Curve

The middle section of the screen displays the custom

curve table. After enabling custom curve mode and

setting the variable to be monitored, continue by

selecting the number of points for the curve. Enter the

actual linearization points into the custom curve table,

inserting the source variable into the X Column, and

the corresponding data (i.e. the °C, °F, Gallons, PSIG,

Millimeters, etc.) into the Y Column.

When entering data in the linearization table, make

sure that you enter a number into every open cell.

Custom Curve File

These buttons allow you to manipulate custom curve

files, including the important

will save a table to your hard drive.

Upload Table

Moves a custom curve file from the connected HIM to

the PC Software for editing or storage.

button to display the variable information.

displays up-to-the-second

Note:

Save Table

command that

Mode

Check the

custom curve.

Source Variable

The

custom curve will calculate. Notice that if you select a

scaled variable, you may need to click on the

tab and verify the settings for your scaled variable.

Quick Set

The

the HIM’s custom curve settings to match those

currently entered in the PC Software.

Enabled

Source Variable

Quick Set

box to begin programming the

button causes the software to configure

defines the variable that the

Scaling

Download Table

Configures the HIM by downloading the custom curve

table from the PC Software to the HIM.

Save Table

Saves a displayed custom curve table to memory on

your computer’s hard drive.

Load Table

Loads a previously saved custom curve table.

Clear Table

Clears the displayed custom curve table.

When you have finished changing all your settings,

download the information to the HIM using the

Download Table

variable, you should also click on the

set the scaling parameters.

button. If you have selected a scaled

Scaling

tab and

18 The Interface Solution Experts

Page 19

HIM

Smart HART Loop

Interface and Monitor

Scaling Parameters

The

Scaling

scaled variables. To scale the selected variable, enter

the values into the appropriate boxes, then click on the

Transfer

scaled values to the HIM. (If any scaled variable was

selected in the

then the corresponding scaled variable section will

become active for editing).

The HIM’s versatile scaling feature has many possible

applications, as is shown in the illustration below.

Suppose you are using a digital pressure (DP)

transmitter to measure the level of a tank in either

centimeters/inches or PSI. Since the tank is only 300

centimeters (10 feet) high, the full range of the primary

variable (PV) output from the DP transmitter is 0-4.3

PSI. You want to display the full level range (in

centimeters/inches of water) on the HIM. You also

need to control the level from 50% to 100%, since the

tank must be at least 50% full at all times. Finally,

your existing loop indicator and level controller needs

4-20mA to represent 150 to 300 centimeters (60 to 120

inches) of water. How do you do this?

Scaling Illustration

1. Since you want to display the full level range in

inches of water (in H2O) on the HIM, and the HIM is

reading PSI as the primary variable, first go to the

Display

source.

tab allows you to configure the values for

menu and click

Download

to transfer the new

Display, Alarm or Analog Outputs

tab and select

Scaled PV

as your display

tabs,

Figure 15. Scaling Tab

2. Go to the

PV Full

values.

be 4.3 (PSI).

Scaling

tab and set up the

values, and the

PV Zero

would be 0 (PSI) and

Scaled PV

Scaled PV Zero

PV Full

PV Zero

and

and

Full

would

would correlate to zero being

0 in H2O and full being 120 in H2O. The HIM should

now (after downloading) display the full range in

in H2O

.

3. To manipulate the HIM’s analog output, go to the

Analog Outputs

tab. Select

Scaled PV

as the Output 1

source. Since you need to control the level from 50%

to 100%, the

and the

Input Range

Output Range

should be 60 to 120 in H2O

should be 4mA to 20mA.

Figure 16. The HIM’s Scaling feature works to get the most out of your existing process instruments

Control

level

range

(50% to 100%

of total level)

Full

Primary

Variable

range

(in PSI)

Digital

Pressure

Transmitter

HART

Signal

Loop Display

(reads 0-100%

of control

level)

4-20mA

Signal

HART Monitor

(120 PSI)

4-20mA

Signal

The Interface Solution Experts 19

Controller maintaining

control from 50-100% of full scale

(60-120 inH 0/2.15-4.3 PSI).

4-20mA from HART Monitor

should represent 60-120

2

inH 0.

2

Page 20

HIM

Smart HART Loop

Interface and Monitor

Customer Support

Moore Industries is recognized as the industry leader

in delivering top quality to its customers in products

and services. We perform a battery of stringent quality

assurance checks on every unit we ship. If any Moore

Industries product fails to perform up to rated specifications, call us for help. Our highly skilled staff of

trained technicians and engineers pride themselves on

their ability to provide timely, accurate and practical

answers to your process instrumentation questions.

Factory phone numbers are listed on the back cover of

this manual.

If problems involve a particular instrument, there are

several pieces of information that can be gathered

before you call the factory

the answers you need

For fastest service, gather the complete model and

serial number(s) of the problem unit(s) and the job

number of the original sale.

that will help our staff get

in the shortest time possible.

20 The Interface Solution Experts

Page 21

HIM

Smart HART Loop

Interface and Monitor

Appendix A: HIM MODBUS Feature

The HIM PC program allows you to configure the

HART monitor. A HART Monitor with the MODBUS

option provides a digital MODBUS output to a connected MODBUS-based controller. Selecting the

MODBUS tab

munications parameters. Notice that the

will only be available in units with the MODBUS option.

Figure A-1. MODBUS Tab

allows you to set the MODSBUS com-

MODBUS

tab

Comms Settings

The Comms Settings include the following:

MODBUS Address

The

MODBUS Address

monitor uses to identify itself on the MODBUS network. The MODBUS address is configurable from 1 to

247. By default, it will assume a MODBUS address of

01.

Baud Rate

The

Baud Rate

should be set to match the baud rate of the attached

controller. The interface supports the following baud

rates: 300, 600, 1200, 2400, 4800, 9600 and 19200.

Parity

The HART monitor supports even, odd and no

The data format is one start bit, 8 data bits and one

stop bit.

Floating Point Word Order

By default, the HART monitor will use the

LSW

(least significant word) floating point word order

format. This stores the most significant bits in the

second register and the least significant bits in the first

register. Selecting

word)

will reverse the order, storing the most significant bits in the first register and the least significant

bits in the second register.

is the speed of data transmission. It

is the number that the HIM

Parity.

Standard

Swapped MSW (most significant

MODBUS Registers

The HART Monitor outputs a MODBUS signal to the

attached controller. To access the MODBUS registers

for variable, input/output or error information, refer to

Table A-1 (MODBUS Register Definitons table) and/or

Table A-2 (System Status Registers table).

The Interface Solution Experts 21

Page 22

HIM

Smart HART Loop

Interface and Monitor

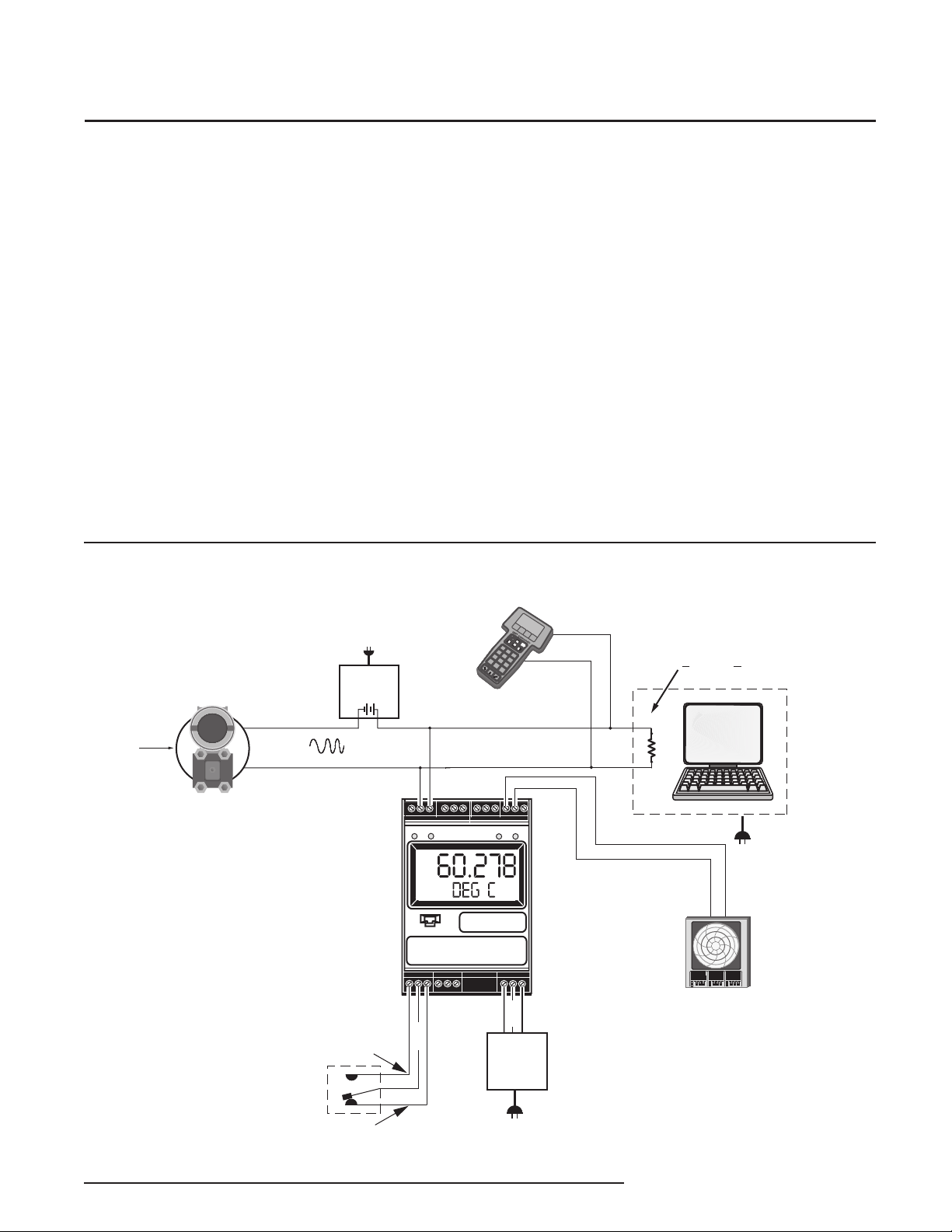

Figure A-2. Installing a HIM with MODBUS output into the loop using the Transmitter Excitation (+TX) terminal

HART Communicator

can be connected

anywhere on the loop

R must be > 250 ohms and <1100 ohms

Sensor

Input

Field Instrument

(Temperature,

Flow Multivariable)

HART

Pressure,

Level,

–

4-20mA

+

NO (normally open)

COMMON

NC (normally closed)

+IN

+TX –IN

READYINPUT

60.278

ADDR

0

COM

NO

NC

COM

DEG C

A

TRIP 2TRIP 1

DC

DCC

24Vdc

Power

Source

B

S

(with MODBUS option)

GND

R

RS485 / RS232

Converter

MODBUS output

DCS

TO serial

(COM) port

of PC

MODBUS Host

22 The Interface Solution Experts

Page 23

Table A-1. MODBUS Register Definitions

HIM

Smart HART Loop

Interface and Monitor

Register Range

0

1

2

3

4

5

6

7

8

9

10

Description

HART Primary variable

HART Secondary variable

HART Third variable

HART Fourth variable

PV scaled

SV scaled

TV scaled

FV scaled

Linearized variable

Analog Output 1 current x 100mA

Analog output 2 current x 100mA

11

12

13

Analog output 3 currentx 100mA

HIM Status Information

Bit 0 = hardware failure

Bit 1 = EEPROM fail

Bit 2 = EEPROM configuration checksum error

Bit 3 = EEPROM calibration checksum error

Bit 4 = EEPROM blank

Bit 5 = Out of range error

Bit 6 = Division by zero error

Bit 7 = Configuration data bad error

Bit 8 = COP SW fail

Bit 9 = RAM test fail

Bit 10-13 = not used

Bit 14 = HART device malfunction status bit set

Bit 15 = No HART communications status

HART status information (as per HART specification)

The Interface Solution Experts 23

Page 24

HIM

Smart HART Loop

Interface and Monitor

14 HART instrument PV EGU (MSB = 0, LSB = HART EGU code)

15

16

17

18

19

20

21

22

23

24

256-257

258-259

260-261

HART instrument SV EGU (MSB = 0, LSB = HART EGU code)

HART instrument TV EGU (MSB = 0, LSB = HART EGU code)

HART instrument QV EGU (MSB = 0, LSB = HART EGU code)

Device ID MSW

Device ID LSW

HART Device Manufacturer ID

HART Device, device type code

HART device, device ID MSW

HART Device, device ID LSW

HIM Alarm Status (Bit 0 = alarm 1, Bit 2 = alarm 2)

HART Primary variable (float format)

HART Secondary variable (float format)

HART Third variable (float format)

262-263

264-265

266-267

268-269

270-271

272-273

274-275

276-277

278-279

24 The Interface Solution Experts

Hart Fourth variable (float format)

Scaled Primary variable (float format)

Scaled Secondary variable (float format)

Scaled Third variable (float format)

Scaled Fourth variable (float format)

Linearized varialbe (float format)

Analog output 1 current x 100mA

Analog output 2 current x 100mA

Analog output 3 current x 100mA

Page 25

Table A-2. System Status Registers

HIM

Smart HART Loop

Interface and Monitor

MSB/LSB

Int 16

(16 bit integar)

MSB = device status

LSB = device error code

Bit Position Description

Bit 7

Bit 6

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

HART device no comms

HART device malfunction

HW fail

EEPROM fail

EEPROM checksum error

EEPROM calib data error

EEPROM blank

out of range value

division by zero

bad configuration

The Interface Solution Experts 25

Page 26

Declaration of Conformity

EMC Directive 89/336/EEC

• Manufacturer’s Name: Moore Industries-International, Inc.

• Manufacturer’s Address: 16650 Schoenborn Street

North Hills, CA 91343-6196

USA

Declares that the product(s):

• Product Name: HIM

MODEL / INPUT / OUTPUT / POWER / OPTIONS / HOUSING

• Model Number(s): HIM * * * * *

* Indicates any input, output, power, option and housing as listed on the product data sheet

• Conforms to the following EMC specifications:

EN 61326-1, 1998, Electromagnetic Compliance (EMC) requirements for electrical equipment for control use.

• Supplementary Information:

None

June 20, 2003

Date Fred Adt Robert Stockham

Quality Assurance Director Moore Industries-Europe General Mgr.

European Contact: Your Local Moore Industries Sales and Service Office

United States • info@miinet.com

Tel: (818) 894-7111 • FAX: (818) 891-2816

Australia • sales@mooreind.com.au

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

China • sales@mooreind.sh.cn

Tel: 86-21-62491499 • FAX: 86-21-62490635

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

Page 27

RETURN PROCEDURES

To return equipment to Moore Industries for repair, follow these four steps:

1. Call Moore Industries and request a Returned Material Authorization (RMA) number.

Warranty Repair –

If you are unsure if your unit is still under warranty, we can use the unit’s serial number

to verify the warranty status for you over the phone. Be sure to include the RMA

number on all documentation.

Non-Warranty Repair –

If your unit is out of warranty, be prepared to give us a Purchase Order number when

you call. In most cases, we will be able to quote you the repair costs at that time.

The repair price you are quoted will be a “Not To Exceed” price, which means that the

actual repair costs may be less than the quote. Be sure to include the RMA number on

all documentation.

2. Provide us with the following documentation:

a) A note listing the symptoms that indicate the unit needs repair

b) Complete shipping information for return of the equipment after repair

c) The name and phone number of the person to contact if questions arise at the factory

3. Use sufficient packing material and carefully pack the equipment in a sturdy shipping

container.

4. Ship the equipment to the Moore Industries location nearest you.

The returned equipment will be inspected and tested at the factory. A Moore Industries

representative will contact the person designated on your documentation if more information is

needed. The repaired equipment, or its replacement, will be returned to you in accordance with

the shipping instructions furnished in your documentation.

WARRANTY DISCLAIMER

THE COMPANY MAKES NO EXPRESS, IMPLIED OR STATUTORY WARRANTIES (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE) WITH RESPECT TO ANY GOODS OR SERVICES SOLD BY THE COMPANY. THE COMPANY DISCLAIMS ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING OR TRADE USAGE, AND

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY ACKNOWLEDGES THAT THERE ARE NO WARRANTIES IMPLIED BY CUSTOM OR

USAGE IN THE TRADE OF THE BUYER AND OF THE COMPANY, AND THAT

ANY PRIOR DEALINGS OF THE BUYER WITH THE COMPANY DO NOT IMPLY THAT THE COMPANY WARRANTS THE GOODS OR SERVICES IN ANY

WAY.

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY AGREES

WITH THE COMPANY THAT THE SOLE AND EXCLUSIVE REMEDIES FOR

BREACH OF ANY WARRANTY CONCERNING THE GOODS OR SERVICES

SHALL BE FOR THE COMPANY, AT ITS OPTION, TO REPAIR OR REPLACE

THE GOODS OR SERVICES OR REFUND THE PURCHASE PRICE. THE

COMPANY SHALL IN NO EVENT BE LIABLE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES EVEN IF THE COMPANY FAILS IN ANY ATTEMPT

TO REMEDY DEFECTS IN THE GOODS OR SERVICES , BUT IN SUCH CASE

THE BUYER SHALL BE ENTITLED TO NO MORE THAN A REFUND OF ALL

MONIES PAID TO THE COMPANY BY THE BUYER FOR PURCHASE OF THE

GOODS OR SERVICES.

ANY CAUSE OF ACTION FOR BREACH OF ANY WARRANTY BY THE

COMPANY SHALL BE BARRED UNLESS THE COMPANY RECEIVES

FROM THE BUYER A WRITTEN NOTICE OF THE ALLEGED DEFECT OR

BREACH WITHIN TEN DAYS FROM THE EARLIEST DATE ON WHICH THE

BUYER COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR BREACH, AND NO ACTION FOR THE BREACH OF ANY WARRANTY SHALL BE COMMENCED BY THE BUYER ANY LATER THAN

TWELVE MONTHS FROM THE EARLIEST DATE ON WHICH THE BUYER

COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR

BREACH.

RETURN POLICY

For a period of thirty-six (36) months from the date of shipment, and under

normal conditions of use and service, Moore Industries ("The Company") will

at its option replace, repair or refund the purchase price for any of its manufactured products found, upon return to the Company (transportation charges

prepaid and otherwise in accordance with the return procedures established

by The Company), to be defective in material or workmanship. This policy

extends to the original Buyer only and not to Buyer's customers or the users

of Buyer's products, unless Buyer is an engineering contractor in which case

the policy shall extend to Buyer's immediate customer only. This policy shall

not apply if the product has been subject to alteration, misuse, accident, neglect or improper application, installation, or operation. THE COMPANY

SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

United States • info@miinet.com

Tel: (818) 894-7111 • FAX: (818) 891-2816

Australia • sales@mooreind.com.au

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

Tel: 86-21-62491499 • FAX: 86-21-62490635

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

Specifications and Information subject to change without notice.© 2005 Moore Industries-International, Inc.

China • sales@mooreind.sh.cn

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

Loading...

Loading...