Page 1

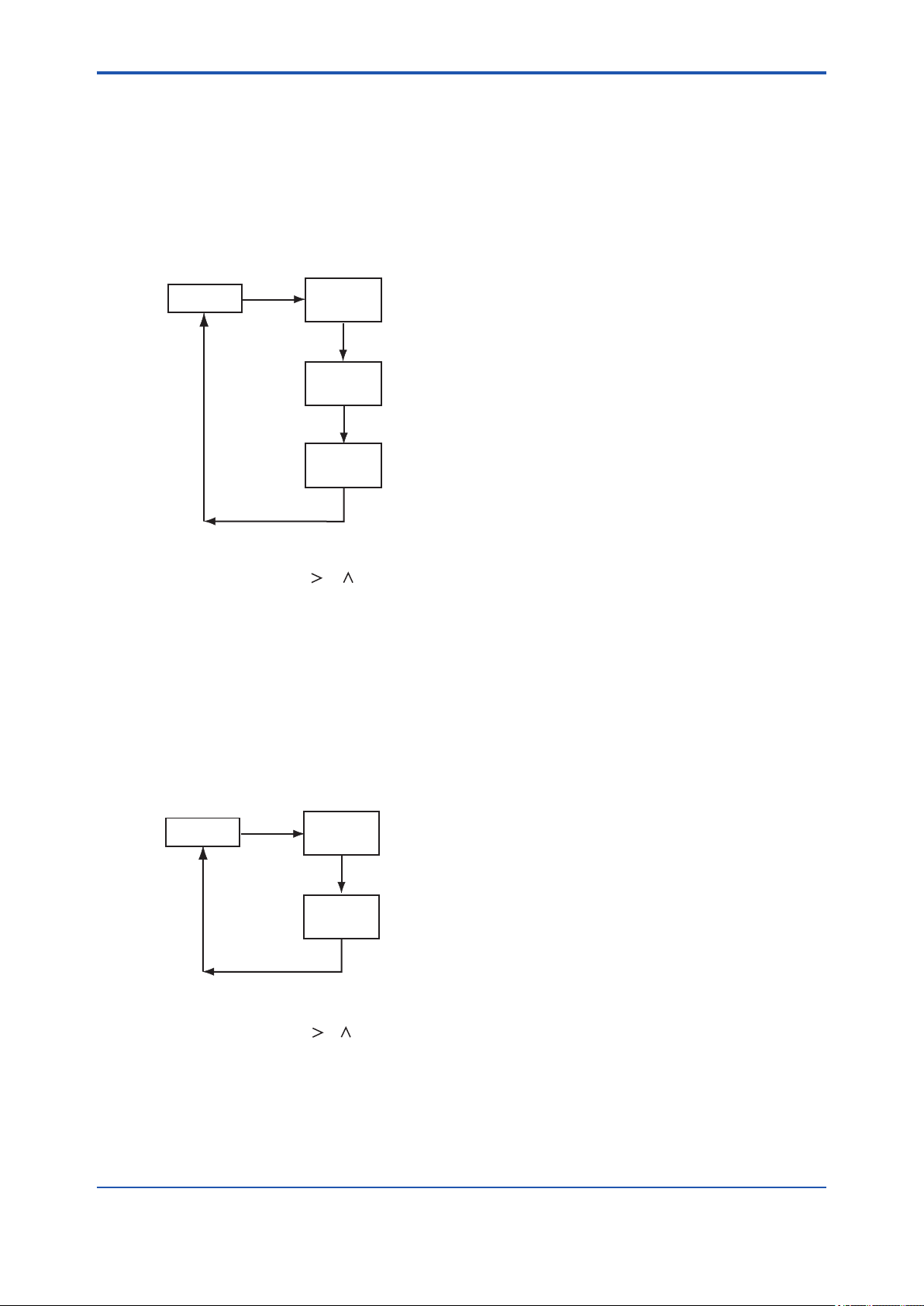

User’s

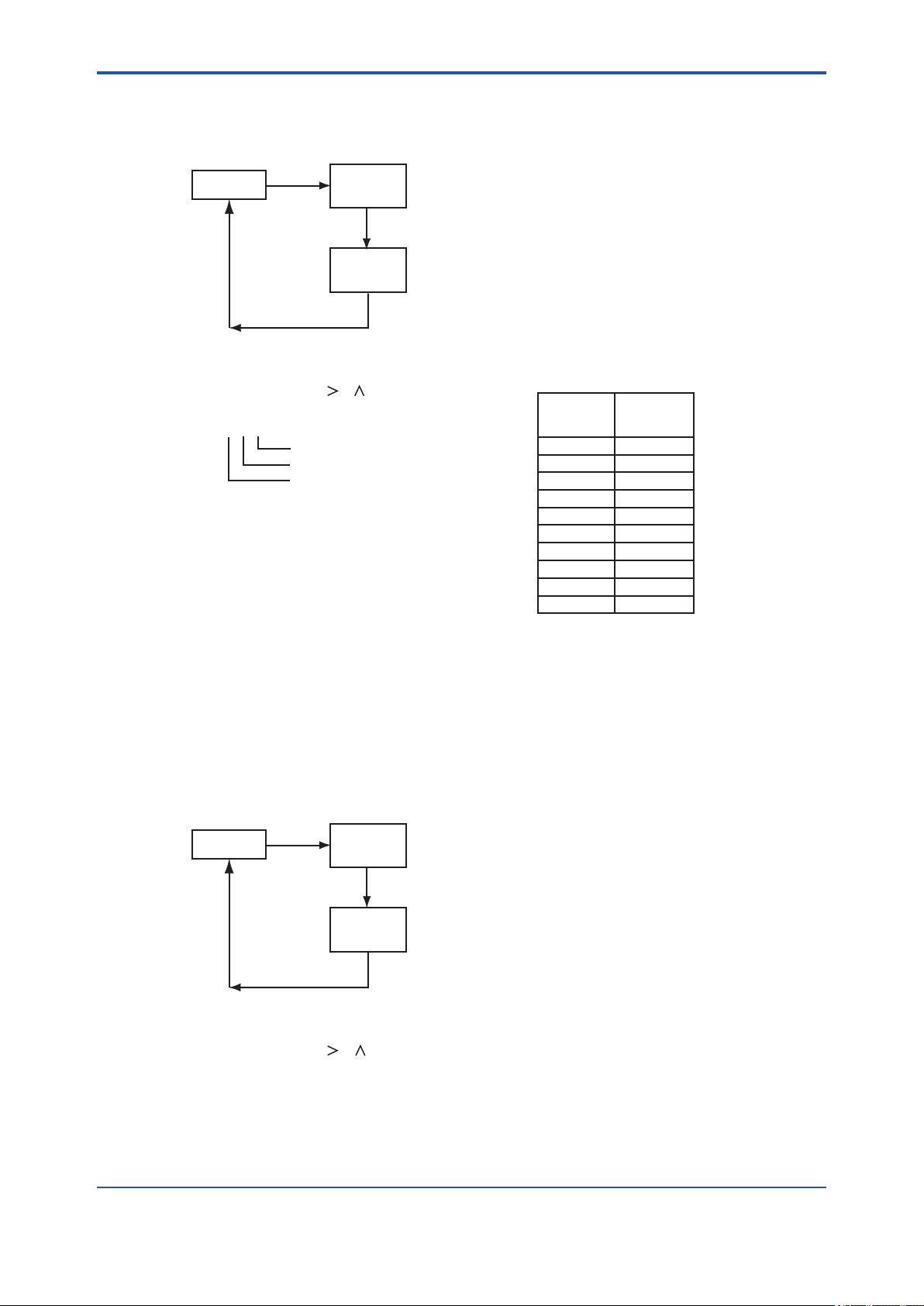

Manual

Model GD402

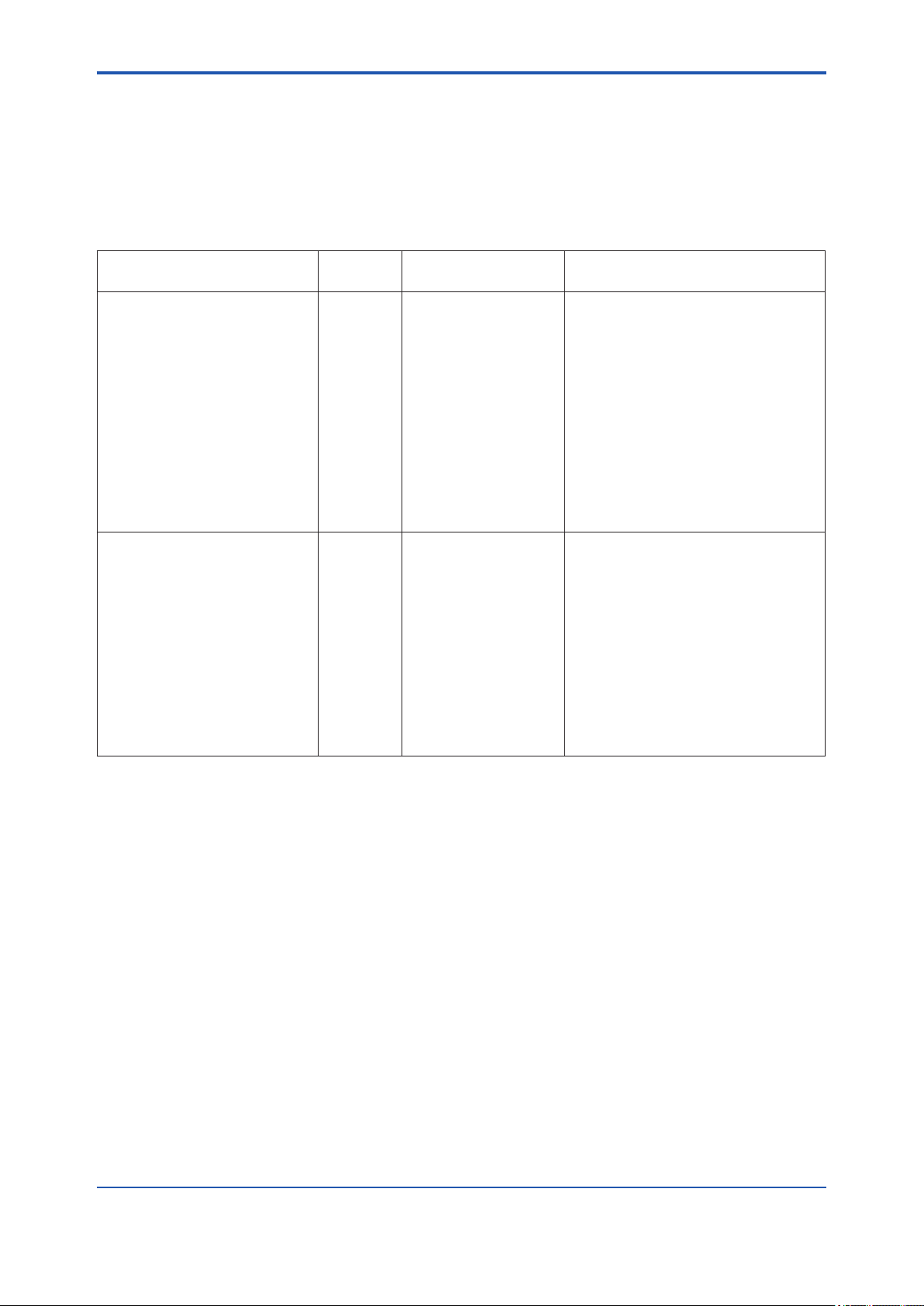

Gas Density Meter

IM 11T3E1-01E

R

IM 11T3E1-01E

7th Edition (YK)

Page 2

<Introduction>

Introduction

The GD402 gas density meter and the GD40 detector not only provide continuous measurement

of gas density, but also several other valuable parameters, including specic gravity and molecular weight. The GD40 detector is designed for intrinsically safe and ame-proof, explosion protected applications. It is designed to be virtually maintenance free for all accepted applications.

The GD402 is a rugged microprocessor-based converter designed in two versions to meet both

general area and explosion-proof application requirements. In addition to the display of several

key data items, the converter also provides the choice of three different means for calibration:

automatic; semi-automatic and one-touch manual operation.

Before use, read this manual thoroughly in order to fully realize the capabilities of the Meter.

The topics and information that require special attention when handling the product are given in

the text of this manual along with cautionary notes - WARNING or CAUTION - which reect the

importance of the information.

For safety reasons or to avoid possible damage to your equipment, strictly adhere to every

cautionary note that appears in this manual. Cautionary notes, such as a WARNING, that also

appear on the product itself are indicated together with the alert symbol shown below:

Throughout this user’s manual, you will nd several different types of symbols are used to identify

different sections of text. This section describes these icons.

i

WARNING

Identies instructions that must be observed in order to avoid physical injury and electric shock or

death of the operator.

CAUTION

Identies instructions that must be observed in order to prevent the software or hardware from

being damaged or the system from becoming faulty.

NOTE

Identies important information required to understand operations or functions.

TIP

Identies additional information.

SEE ALSO

Identies a source to be referred to.

Clicking a reference displayed in green can call up its source, while clicking a reference

displayed in black cannot.

Media No. IM 11T3E1-01E (CD) 7th Edition : June 2012 (YK)

All Rights Reserved Copyright © 1998, Yokogawa Electric Corporation

IM 11T3E1-01E

Page 3

<Introduction>

l Cross-Checking the Specications

CAUTION

The GD402 gas density meter is shipped after adjusting the both of detector and converter in

pairs. When installation, conrm whether the serial number on both of converter and detector are

in pairs or not. If mismatched in pairs, converter is to be out of order. When converter or detector

supplied individually, enter the detector constants, described on inside the lid of the GD40, into

converter so that the GD402 is going to be well.

In detail, please refer to Figure 5.30, Figure 6.31 or Figure 7.28.

Upon delivery of the purchased product, unpack it carefully and make sure it is completely free

from damage that may have occurred during transport. It must be shipped in strict conformance

to the purchaser's specications. By way of precaution, conrm that the equipment is the exact

model you ordered. Also check that all accessory components are included, when conrming the

specications, refer to the model and sufx codes indicated on the nameplate on the equipment.

For a description of the model and sufx codes, refer to Chapter1,''Specications.''

l Consideration of Operation Parameters

ii

The GD402 operates with the same parameters set when it was delivered (default data) , when it

is put into operation under these conditions.

Before starting measurement, check whether or not the default data meets your operating conditions. If necessary, re-set the parameters to suit your operating requirements.

To check the defaults, make use of the sheet, “Records of GD402’s Operation Parameter Settings,” in the back of this manual. It is advisable that, if any of the operation parameter settings

have been changed, the new data be noted in this record.

l Information Covered in This Manual

This manual covers all of the information for handling the GD402 converter and the GD40 detector, including instructions on installation, operation, setting of operation parameters, inspection

and maintenance.

CAUTION

Modication and adaptation of the instrument’s parts, wiring and construction are prohibited.

IM 11T3E1-01E

Page 4

<Introduction>

[Notational Conventions Specic to This Manual]

The following notational conventions apply to the representations of operation keys, information

shown on the display, and information indicated on the product itself when they are discussed

specically in the text of this manual.

l Operation Keys

Indicated with brackets [ ] or【 】as: [YES] Key or 【YES】key

l Information Shown on Display

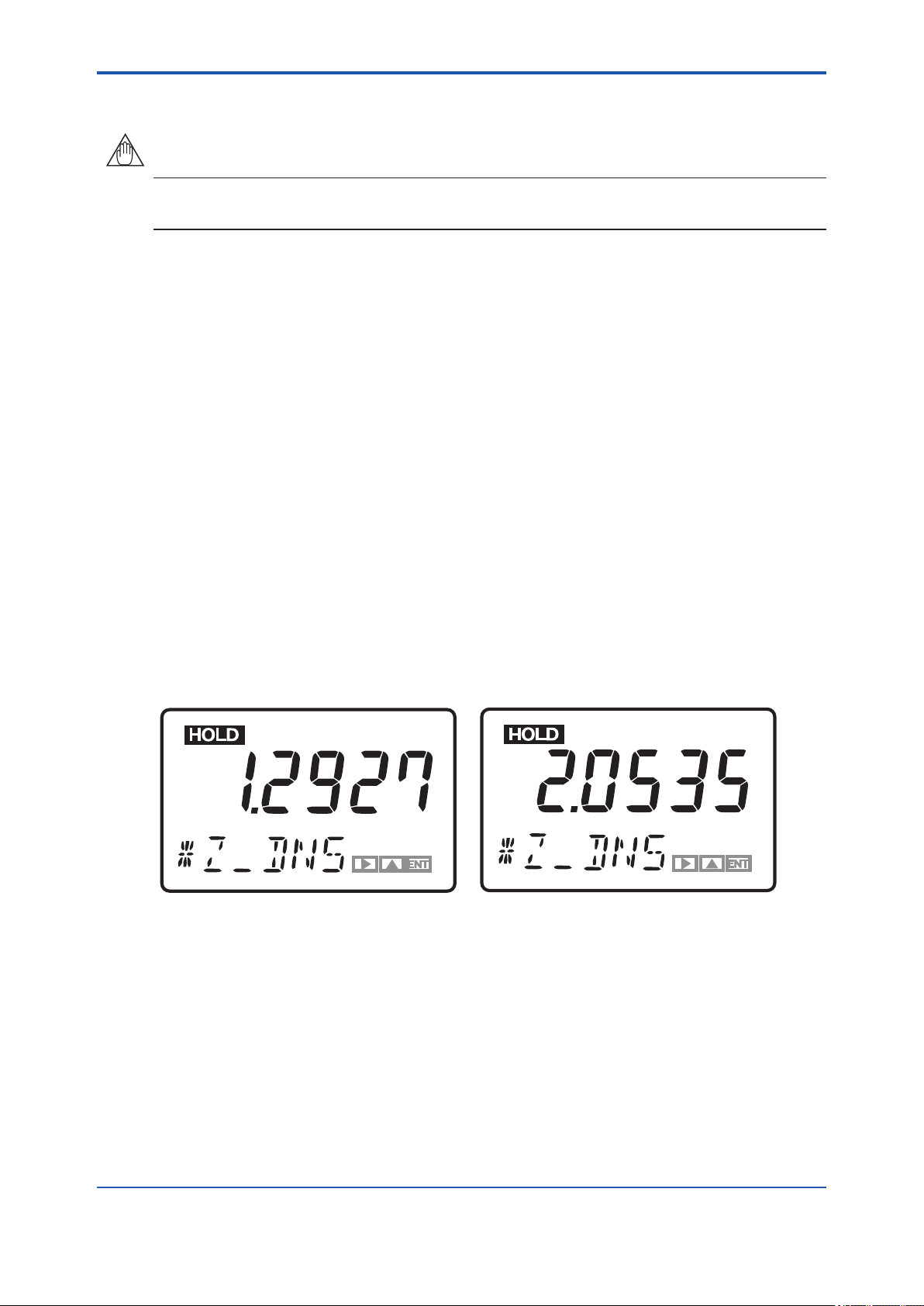

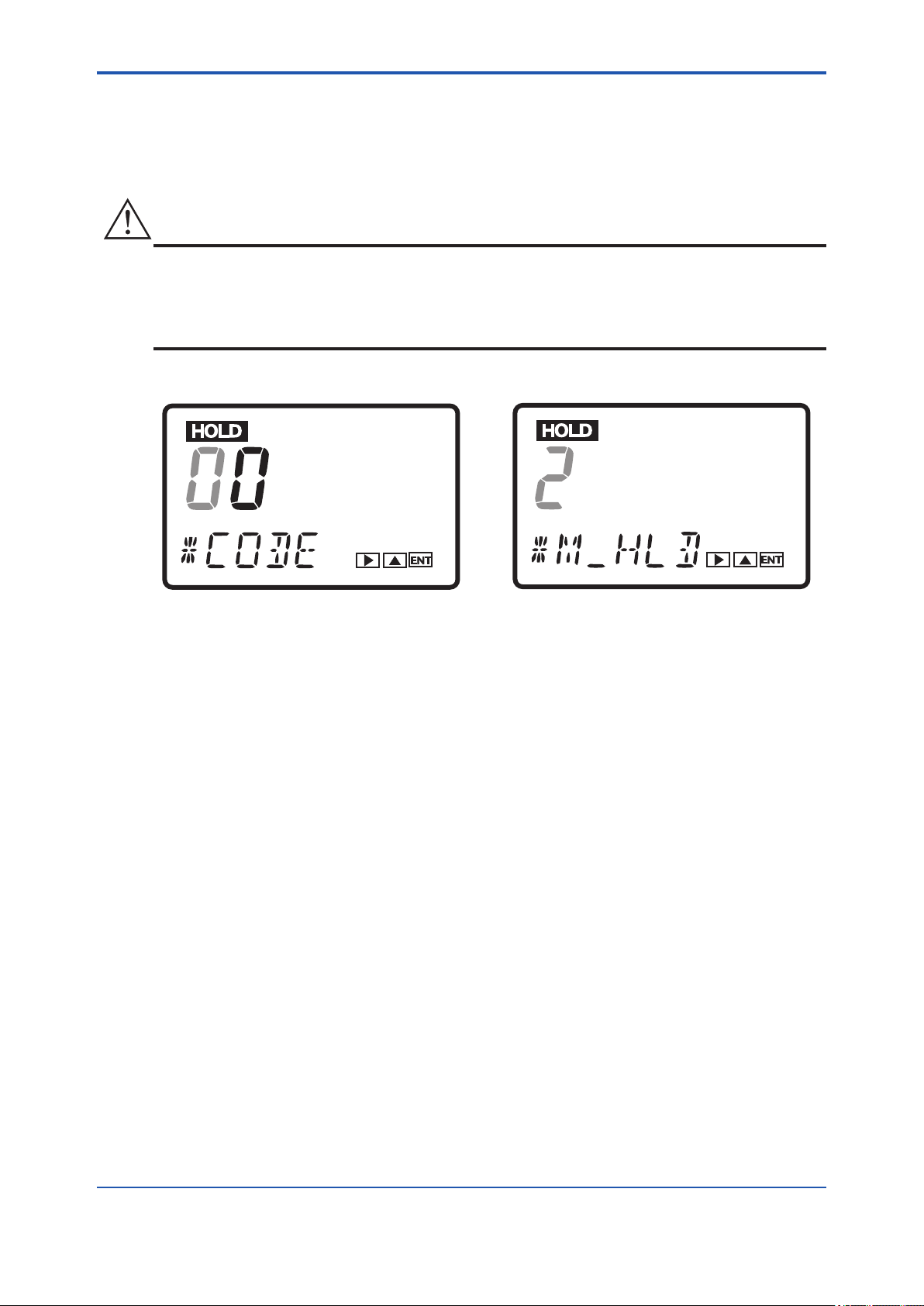

Indicated with braces 『 』as:

『HOLD』, meaning the status

『YES』, meaning the indicator on an operation key

『CALIB』, meaning a message

『205』 (lit) or 『205』 (blinking), meaning the data item shown along with its state

l Information Indicated on Product

Indicated with angle brackets < > as: <n> (lit) or <o> (unlit), meaning the contact output indicator

lamp along with its state

iii

<MEASURE> mode, meaning the mode of measurement

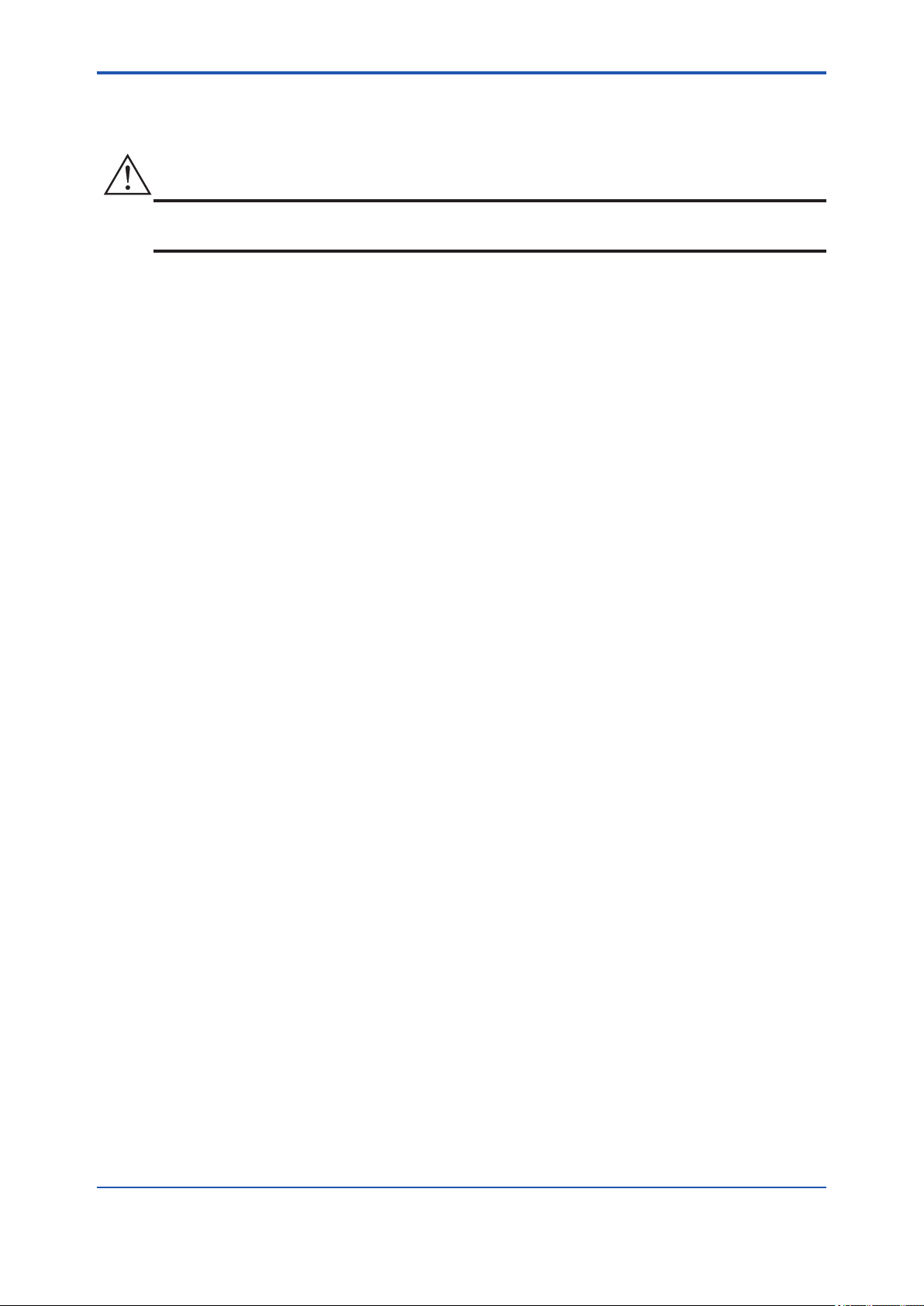

l Information on the State of Blinking

Indicated in shaded typography as:

, in contrast to (lit) (blinking)

[How to dispose the batteries]

This is an explanation about the new EU Battery Directive (DIRECTIVE 2006/66/EC). This direc-

tive is only valid in the EU.

Batteries are included in this product. Batteries incorporated into this product cannot be removed

by yourself. Dispose them together with this product.

When you dispose this product in the EU, contact your local Yokogawa Europe B.V.ofce. Do not

dispose them as domestic household waste.

Battery type: silver oxide battery

Notice : The symbol (see above) means they shall be sorted out and collected as ordained in ANNEX II in DIRECTIVE 2006/66/EC.

IM 11T3E1-01E

Page 5

<Introduction>

u After-sales Warranty

n Do not modify the product.

n During the warranty period, for repair under warranty carry or send the prod-

uct to the local sales representative or service ofce. Yokogawa will replace

or repair any damaged parts and return the product to you. Before returning a

product for repair under warranty, provide us with the model name and serial

number and a description of the problem. Any diagrams or data explaining the

problem would also be appreciated.

l If we replace the product with a new one, we won’t provide you with a repair report.

l Yokogawa warrants the product for the period stated in the pre-purchase quotation

Yokogawa shall conduct dened warranty service based on its standard. When the customer site is located outside of the service area, a fee for dispatching the maintenance engineer

will be charged to the customer.

n In the following cases, customer will be charged repair fee regardless of war-

ranty period.

iv

• Failure of components which are out of scope of warranty stated in instruction manual.

• Failure caused by usage of software, hardware or auxiliary equipment, which Yokogawa

Electric did not supply.

• Failure due to improper or insufcient maintenance by user.

• Failure due to modication, misuse or outside-of-specications operation which Yokogawa

does not authorize.

• Failure due to power supply (voltage, frequency) being outside specications or abnormal.

• Failure caused by any usage out of scope of recommended usage.

• Any damage from re, earthquake, storms and oods, lightning, disturbances, riots, warfare,

radiation and other natural changes.

n Yokogawa does not warrant conformance with the specic application at the

user site. Yokogawa will not bear direct/indirect responsibility for damage due

to a specic application.

n Yokogawa Electric will not bear responsibility when the user congures the

product into systems or resells the product.

n Maintenance service and supplying repair parts will be covered for ve years

after the production ends. For repair for this product, please contact the nearest sales ofce described in this instruction manual.

IM 11T3E1-01E

Page 6

<CONTENTS>

Model GD402

Gas Density Meter

IM 11T3E1-01E 7th Edition

CONTENTS

Introduction ..............................................................................................................i

u After-sales Warranty ...................................................................................................... iv

1. SPECIFICATIONS ..................................................................................... 1-1

1.1 Specications ....................................................................................................1-1

1.1.1 General Specications .......................................................................1-1

1.1.2 GD40G, T, V, R Detector ....................................................................1-5

1.1.3 GD402G, T, V, R Converter................................................................ 1-5

1.2 Model and Sufx Codes ...................................................................................1-7

1.2.1 Gas Density Converter ......................................................................1-7

1.2.2 Gas Density Detector .........................................................................1-7

1.2.3 Hardware for Connection with External Cables

(For Explosion-proof use) ..................................................................1-8

1.2.4 Two-core, Double-Shielded Cable ..................................................... 1-8

1.2.5 Brain Terminal (Optional) ................................................................... 1-9

1.2.6 Pressure transmitter (Optional)..........................................................1-9

1.3 External Views and Dimension ......................................................................1-10

1.3.1 GD402G Converter (General purpose) ...........................................1-10

1.3.2 Pipe- and Wall-Mounting Hardware (Optional) ................................ 1-11

1.3.3. GD402T, V, R Converter (Explosion-proof) .....................................1-12

1.3.4 GD40 Detector .................................................................................1-13

1.3.5 Detector Unit (Intrinsically Safe, Explosion-proof) ...........................1-14

1.3.6 Surge protector: K9215LP ...............................................................1-14

Toc-1

2. INSTALLATION, WIRING AND PIPING .................................................... 2-1

2.1 Installing the Detector ......................................................................................2-1

2.1.1 Selecting the Location ........................................................................ 2-1

2.1.2 GD40T (FM Explosion-proof and Intrinsically Safe Approval) ...........2-2

2.1.3 GD40V (CSA Explosion-proof and Intrinsically Safe Approval) ........2-3

2.1.4 Mounting the Detector........................................................................2-4

2.2 Installing the Converter ....................................................................................2-5

2.2.1 Selecting the Location ........................................................................ 2-5

2.2.2 GD402T (FM Explosion-proof Approval) ...........................................2-6

2.2.3 GD402V (CSA Explosion-proof Approval) .........................................2-7

2.2.4 Mounting the Converter .....................................................................2-8

IM 11T3E1-01E

Page 7

<CONTENTS>

2.3 Piping ...............................................................................................................2-10

2.4 Wiring ...............................................................................................................2-12

2.4.1 Wiring Procedure .............................................................................2-12

2.4.2 Cables Wired to Power Supply ........................................................2-16

2.4.3 Cables Wired to Outputs ..................................................................2-17

2.4.4 Cables Wired to Contact I/Os ..........................................................2-18

2.4.5 Cable Wired to GD40 Detector .....................................................2-19

2.4.6 Cables Wired to the Ground ............................................................2-20

3. OPERATION .............................................................................................. 3-1

3.1 Preparation for Operation ................................................................................3-1

3.1.1 Inspecting Installation, Piping and Wiring Workmanship .................. 3-1

3.1.2 Supplying Power ................................................................................ 3-2

3.1.3 Display on Operation Panel and Operation Keys ..............................3-3

3.1.4 Basic Key Operation ..........................................................................3-4

3.1.5 Checking the Setting Parameters .....................................................3-6

3.1.6 Calibrating the Analyzer for Correct Readings ..................................3-6

3.1.7 Checking the Analyzer for Performance ............................................3-7

3.2 Normal Operation .............................................................................................. 3-8

3.2.1 Starting Operation ..............................................................................3-8

3.2.2 Corrective Actions in Case of Failure ................................................. 3-8

3.2.3 Inspection and Maintenance ..............................................................3-9

3.3 Shutdown and Restart ......................................................................................3-9

3.3.1 Measures for Shutdown .....................................................................3-9

3.3.2 Measures for Restarting ....................................................................3-9

Toc-2

4. FUNCTIONS .............................................................................................. 4-1

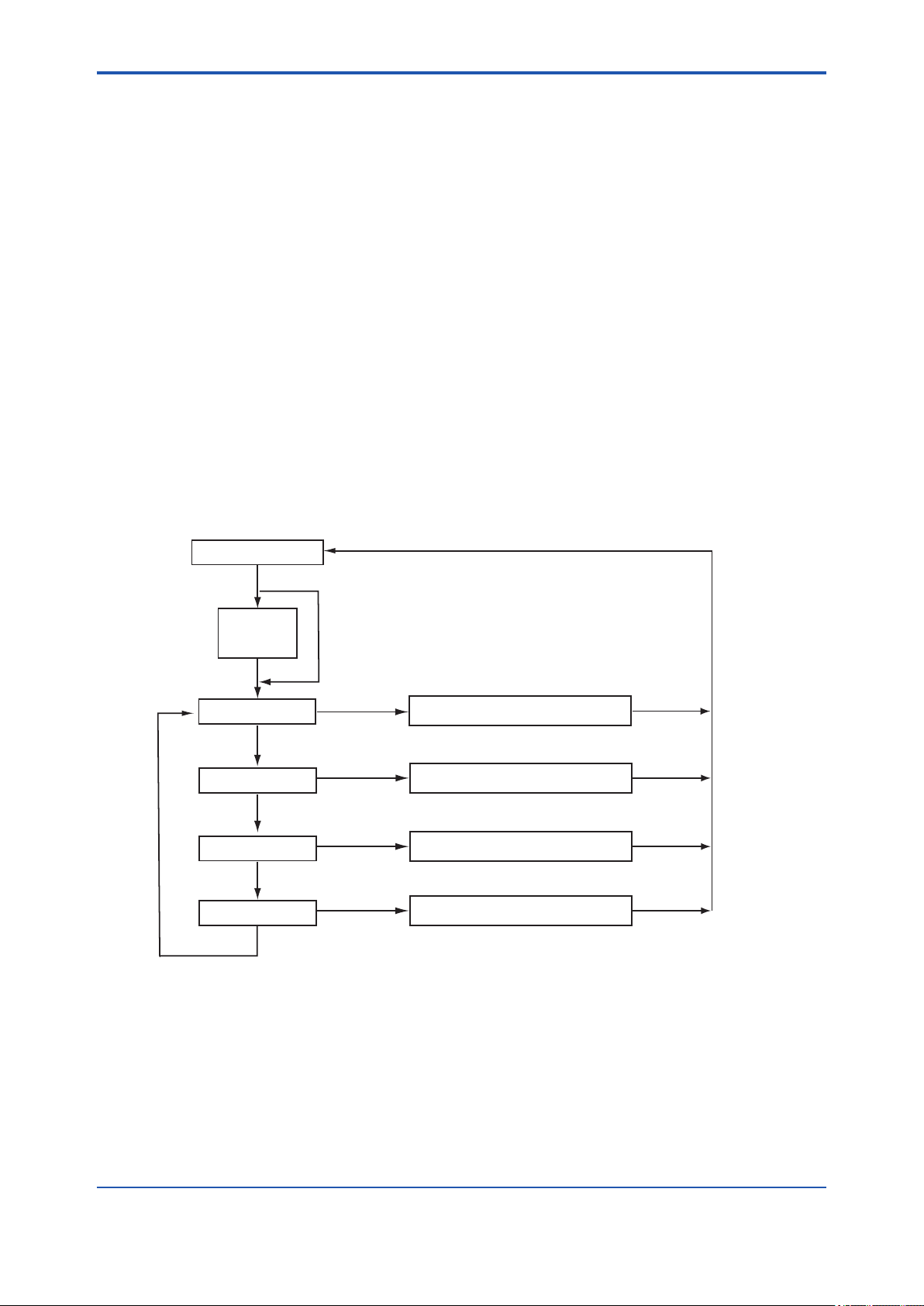

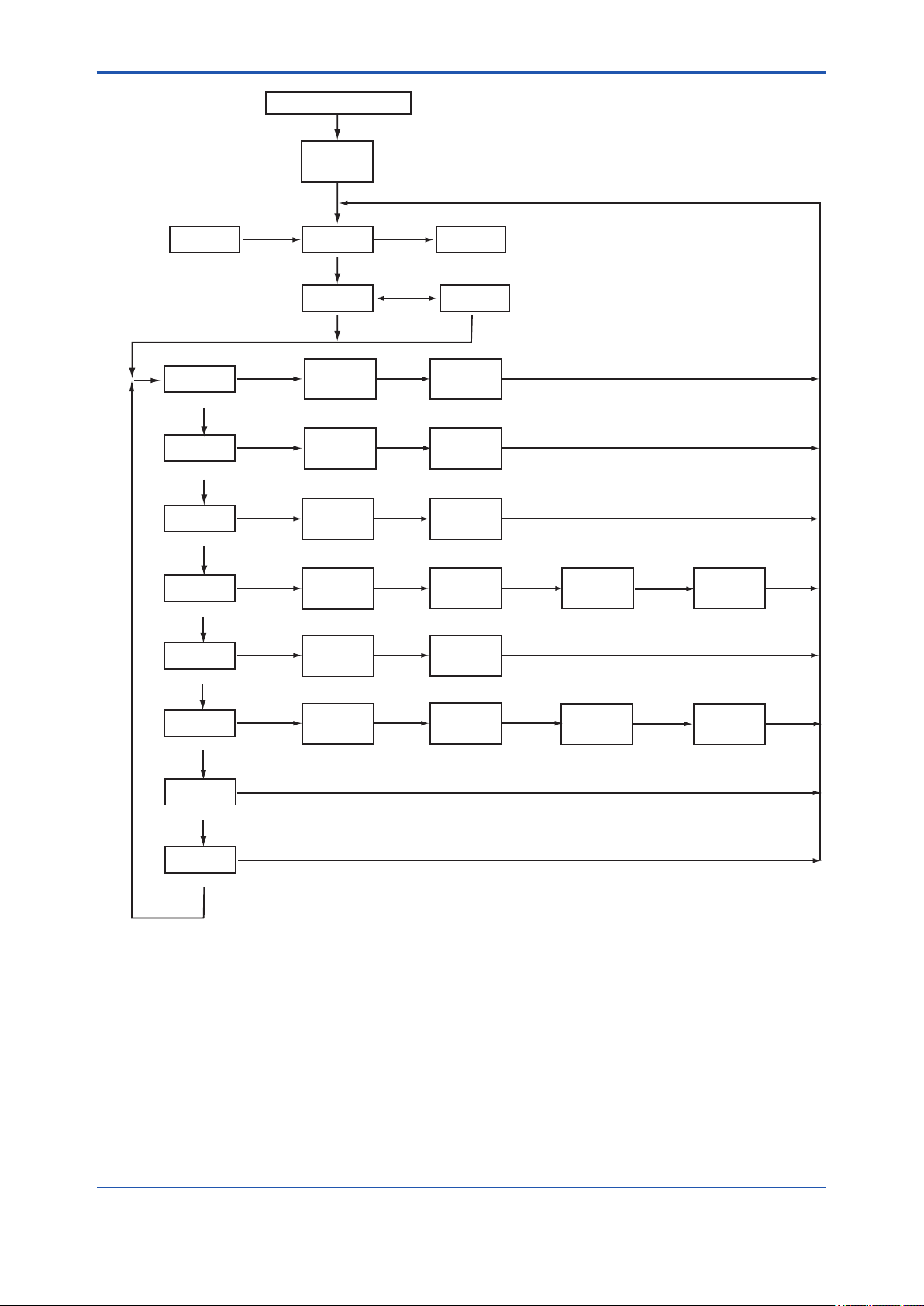

4.1 Summary of Setting Operations ...................................................................... 4-1

4.1.1 Measurement, Operation, Setting and Service .................................4-1

4.1.2 Key Operations ..................................................................................4-1

4.1.3 Points to Be Noted When Making Settings ........................................4-2

4.2 Setting Lists .......................................................................................................4-2

5. DENSITY / PARAMETER SETTING ......................................................... 5-1

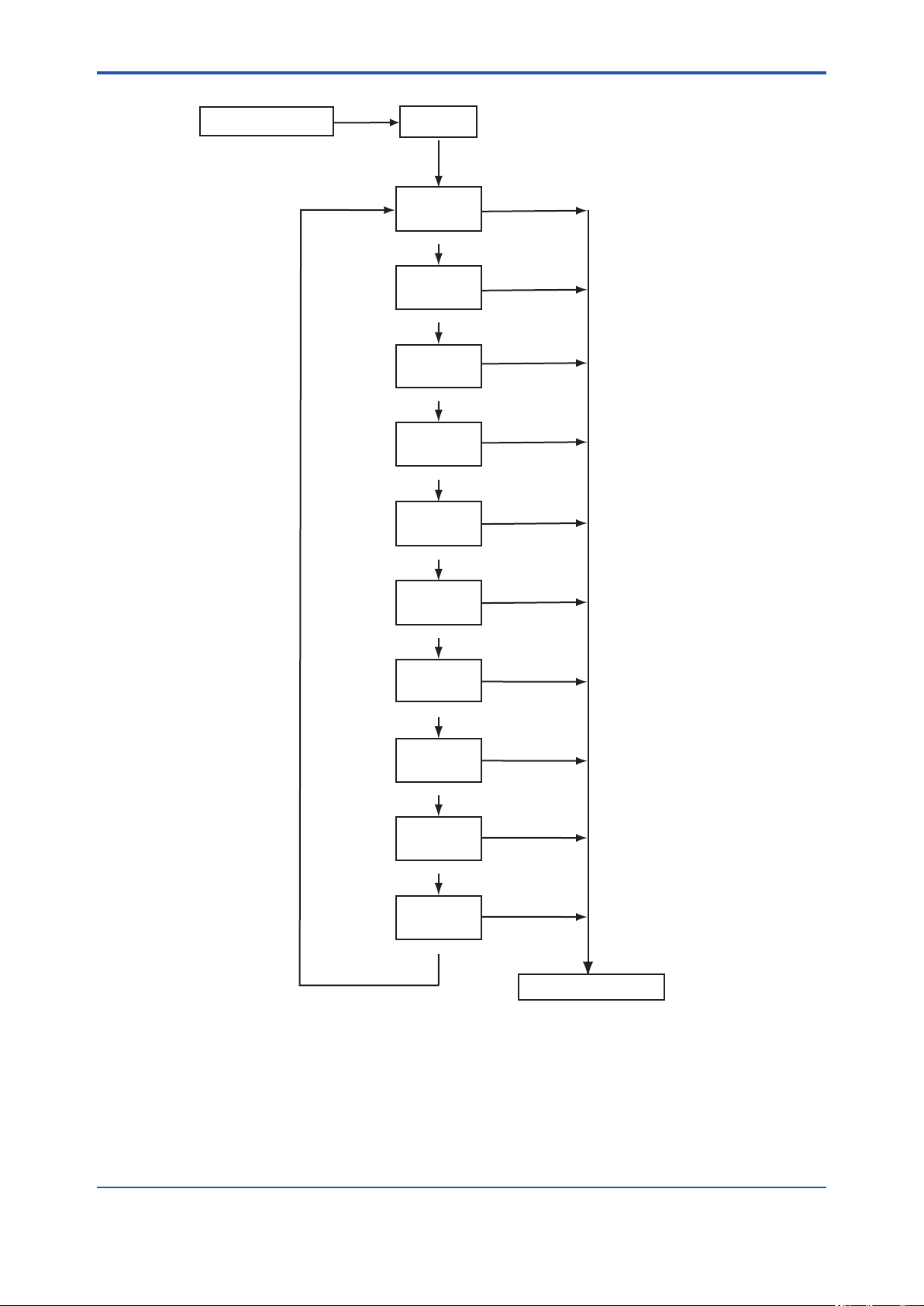

5.1 Setting Parameters ...........................................................................................5-2

5.1.1 Setting Parameters at Measurement Level .......................................5-2

5.1.2 Setting Parameters at Operation Level ............................................. 5-3

5.1.3 Setting Parameters at Setting Level ..................................................5-4

5.1.4 Setting Parameters at Service Level .................................................5-5

5.2 Parameter Setting .............................................................................................5-6

5.2.1 Parameter Setting at Operation Level ...............................................5-6

5.2.2 Parameter Setting at Setting Level ..................................................5-10

5.2.3 Parameter Setting at Service Level .................................................5-16

6. CALORIE / PARAMETER SETTING ........................................................ 6-1

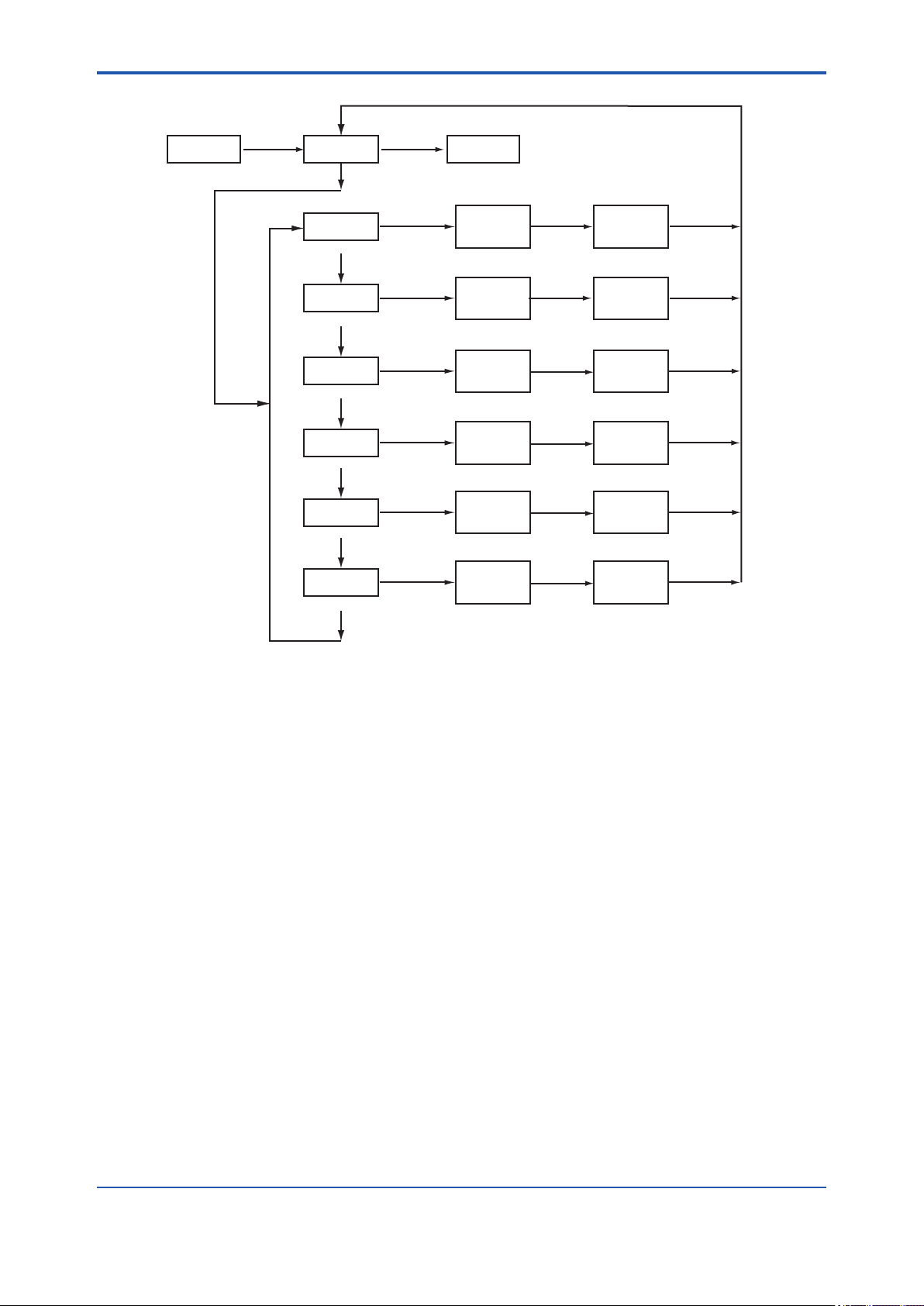

6.1 Setting Parameters ...........................................................................................6-2

IM 11T3E1-01E

Page 8

<CONTENTS>

6.1.1 Setting Parameters at Measurement Level .......................................6-2

6.1.2 Setting Parameters at Operation Level ............................................. 6-3

6.1.3 Setting Parameters at Setting Level ..................................................6-4

6.1.4 Setting Parameters at Service Level .................................................6-5

6.2 Parameter Setting .............................................................................................6-7

6.2.1 Parameter Setting at Operation Level ...............................................6-7

6.2.2 Parameter Setting at Setting Level ..................................................6-12

6.2.3 Parameter Setting at Service Level .................................................6-16

7. HYDROGEN PURITY/PARAMETER SETTING ....................................... 7-1

7.1 Setting Parameters ...........................................................................................7-2

7.1.1 Setting Parameters at Measurement Level .......................................7-2

7.1.2 Setting Parameters at Operation Level ............................................. 7-2

7.1.3 Setting Parameters at Setting Level ..................................................7-3

7.1.4 Setting Parameters at Service Level .................................................7-4

7.2 Parameter Setting .............................................................................................7-6

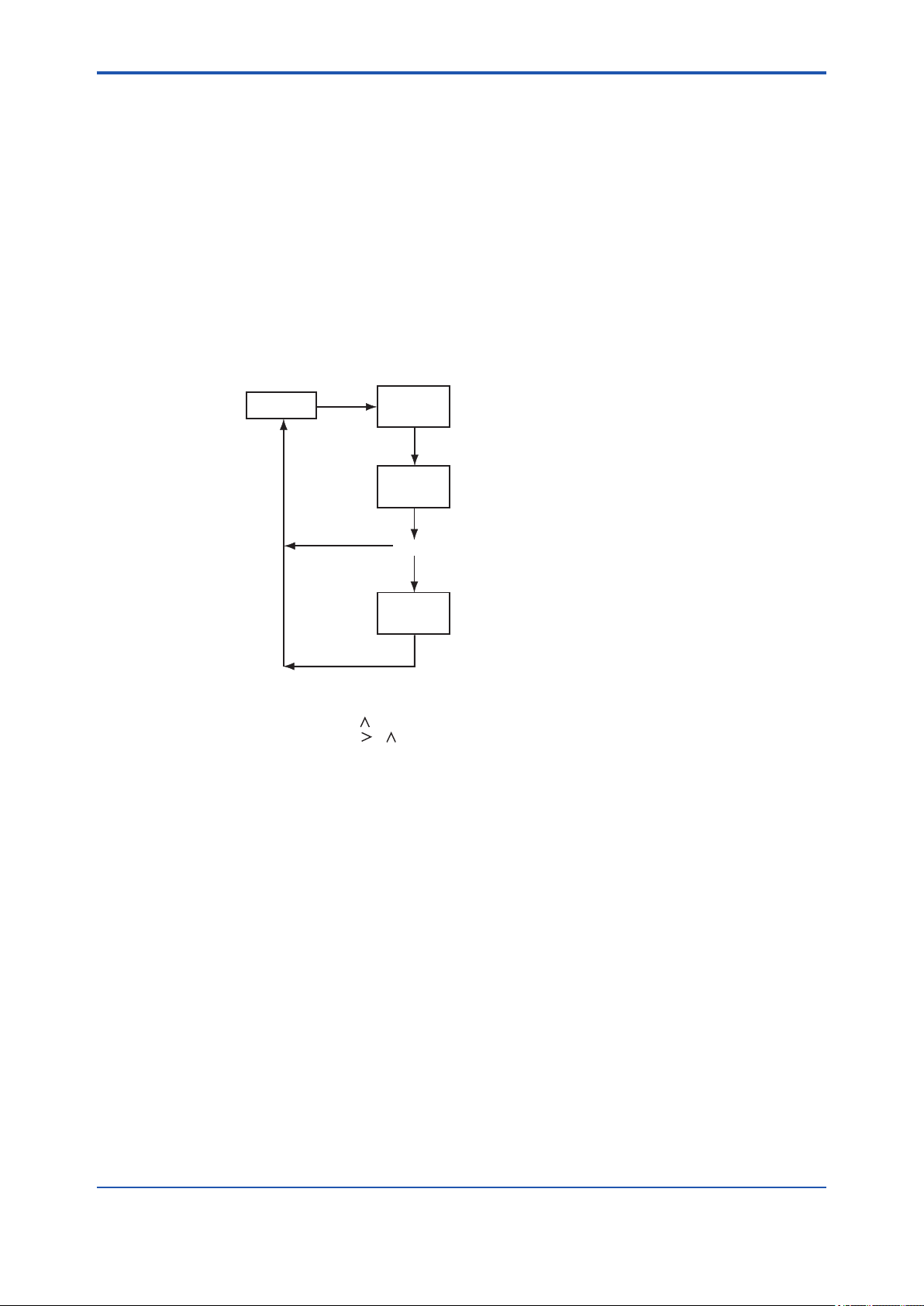

7.2.1 Parameter Setting at Measurement Level ......................................... 7-6

7.2.2 Parameter Setting at Operation Level ...............................................7-7

7.2.3 Parameter Setting at Setting Level ..................................................7-10

7.2.4 Parameter Setting at Service Level .................................................7-14

Toc-3

8. DENSITY /CALIBRATION PROCEDURE ................................................ 8-1

8.1 Basic Calibration Procedure ............................................................................8-1

8.2 Preparation for Calibration ..............................................................................8-1

8.2.1 Setting Type of Calibration and Checking Valve Operation ...............8-1

8.2.2 Setting Calibration Data ..................................................................... 8-3

8.3 Calibration .........................................................................................................8-4

8.3.1 Semi-automatic Calibration ............................................................... 8-4

8.3.2 Manual Calibration .............................................................................8-5

8.3.3 Automatic Calibration .........................................................................8-6

9. CALORIE /CALIBRATION PROCEDURE ................................................ 9-1

9.1 Basic Calibration Procedure ............................................................................9-1

9.2 Preparation for Calibration ..............................................................................9-1

9.2.1 Setting Type of Calibration and Checking Valve Operation ...............9-1

9.2.2 Setting Calibration Data ..................................................................... 9-3

9.3 Calibration .........................................................................................................9-5

9.3.1 Semi-automatic Calibration ............................................................... 9-5

9.3.2 Manual Calibration .............................................................................9-6

9.3.3 Automatic Calibration .........................................................................9-7

10. HYDROGEN PURITY /CALIBRATION PROCEDURE .......................... 10-1

10.1 Basic Calibration Procedure ..........................................................................10-1

10.2 Preparation for Calibration ............................................................................10-1

10.3 Calibration .......................................................................................................10-2

IM 11T3E1-01E

Page 9

<CONTENTS>

11. INSPECTION AND MAINTENANCE ...................................................... 11-1

11.1 Routine Inspection and Maintenance ........................................................... 11-1

11.1.1 Checking Readings and Calibrating the Analyzer ........................... 11-1

11.1.2 Checking the Flowrate of Sample Gas ............................................ 11-1

11.1.3 Periodic Replacement of the Detector's O-rings ............................. 11-1

11.1.4 Replacing the Fuse .......................................................................... 11-2

11.1.5 Cleaning ........................................................................................... 11-2

11.2 Inspection In Case of Failure ......................................................................... 11-3

11.2.1 Inspecting the Analyzer in an Alarm Status ..................................... 11-3

11.2.2 Inspecting the Analyzer in a FAIL Status ......................................... 11-4

Customer Maintenance Parts List ...........................................CMPL 11T3E1-01E

Customer Maintenance Parts List ...........................................CMPL 11T3E1-02E

Customer Maintenance Parts List ...........................................CMPL 11T3E1-03E

Revision Information ...............................................................................................i

Toc-4

IM 11T3E1-01E

Page 10

<1. Specications>

1. SPECIFICATIONS

1.1 Specications

The specications of the GD402 gas density meter as described below.

Certicate is approved for model GD402G, GD40G.

1.1.1 General Specications

l System Components

(1) GD40G, T, V, R Detector:Rainproof for outdoor use (equivalent to IP65/NEMA4X)

(see note under “1.1.2 Ambient conditions” on page1-5.)

Ambient Temperature : -10 to 60°C

Ambient Humidity : 5 to 95%RH

GD40G : General purpose detector.

1-1

(Non Explosion-proof)

Electrical connection : 1/2 NPT female

Process connection : 1/4 NPT female

GD40T : FM Explosion-proof and Intrinsically safe Approval.

Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G with Intrinsically

Safe sensor for Class I, II, III, Division 1, Groups B, C, D, E, F and G.

Enclosure : NEMA Type 4X

Temperature Code : T5

Electrical connection : 1/2 NPT female

Process connection : 1/4 NPT female

GD40V : CSA Explosion-proof and Intrinsically safe Approval.

Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G with Intrinsically

Safe sensor for Class I, II, III, Division 1, Groups B, C, D, E, F and G.

Enclosure : Type 4X

Temperature Code : T5

Electrical connection : 1/2 NPT female

Process connection : 1/4 NPT female

GD40R : TIIS Explosion-proof and Intrinsically safe Approval.

Explosion-proof code : Exd [ia] IIB+H2T5

Temperature Code : T5

Electrical connection : G1/2 female

Process connection : Rc1/4

IM 11T3E1-01E

Page 11

<1. Specications>

(2) GD402G, T, V, R Converter : Rainproof for outdoor use (equivalent to IP65 / NEMA 4X)

Ambient Temperature : -10 to 55°C

Ambient Humidity : 5 to 95%RH

GD402G : General purpose converter. (Non Explosion-proof).

Electrical connection : 21mm (0.9inch) in diameter. Pg 13.5 cable glands includ-

ed

GD402T : FM Explosion-proof Approval.

Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G.

Enclosure : NEMA Type 4X

Temperature Code : T6

Electrical connection : 1/2 NPT female

GD402V : CSA Explosion-proof Approval.

Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G.

1-2

Enclosure : Type 4X

Temperature Code : T6

Electrical connection : 1/2 NPT female

GD402R : TIIS Explosion-proof Approval.

Explosion-proof code : Exd IIB+H2T6

Temperature Code : T6

Electrical connection : G3/4 female

(3) EJA310 Absolute pressure transmitter (optional)

FM Explosion-proof Approval:

Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G.

Hazardous(classied locations, indoors and outdoors (NEMA 4X)

Temperature Code : T6

Ambient Temperature : -40 to 60°C

Ambient Humidity : 5 to 100%RH (at 40°C)

Electrical connection : 1/2 NPT female

Process connection : 1/4 NPT female

CSA Explosion-proof Approval:

Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G.

Division2 ‘SEALS NOT REQUIRED’

Enclosure : Type 4X

Temperature Code : T4, T5, T6

Max. Process Temp.: T4 120°C, T5 100°C, T6 85°C

Ambient Temperature : -40 to 80°C

IM 11T3E1-01E

Page 12

<1. Specications>

Ambient Humidity : 5 to 100%RH (at 40°C)

Electrical connection : 1/2 NPT female

Process connection : 1/4 NPT female

TIIS Explosion-proof Approval:

Explosion-proof code : Ex do IIC T4X

Temperature Code : T4

Ambient Temperature : -20 to 60 °C

Ambient Humidity : 5 to 100%RH (at 40°C)

Electrical connection : G1/2 female

Process connection : Rc1/4

l Sample Gas conditions

Sample gas: All gases except for corrosive gas and acetylene gas.

Temperature: -10 to 50 °C (non-condensing)

Pressure: Max. 588.5 kPa (abs)

Gas ow: 0.1 to 1 l/min

1-3

l Output Signals

Output 1: 4-20 mA DC

Isolated from inputs; load resistance: 600 W maximum (Load resistance of 250-

550 W required when in the BRAIN communication mode.)

Output 2: 4-20 mA DC

Isolated from inputs; load resistance: 600 W maximum

l Power Supply

Rated voltage range: 100 to 240 V AC, 24 V DC

Allowable voltage range: 85 to 264 V AC, 21.6 to 26.4 V DC

Rated frequency: 50 or 60 Hz

Allowable frequency range: 47 to 63 Hz

l Power Consumption

Approximately 12 W.

l Safety and EMC Compliance

Safety Standards: EN61010-1

EMC Standards:

(Applied only when GD402G converter is used with GD40G detector.)

Emission: EN61326 Class A

EN61000-3-2

EN61000-3-3

AS/NZS CISPR11

Immunity: EN61326 Annex A and F

KC Marking: Korea Electromagnetic Conformity Standard

IM 11T3E1-01E

Page 13

<1. Specications>

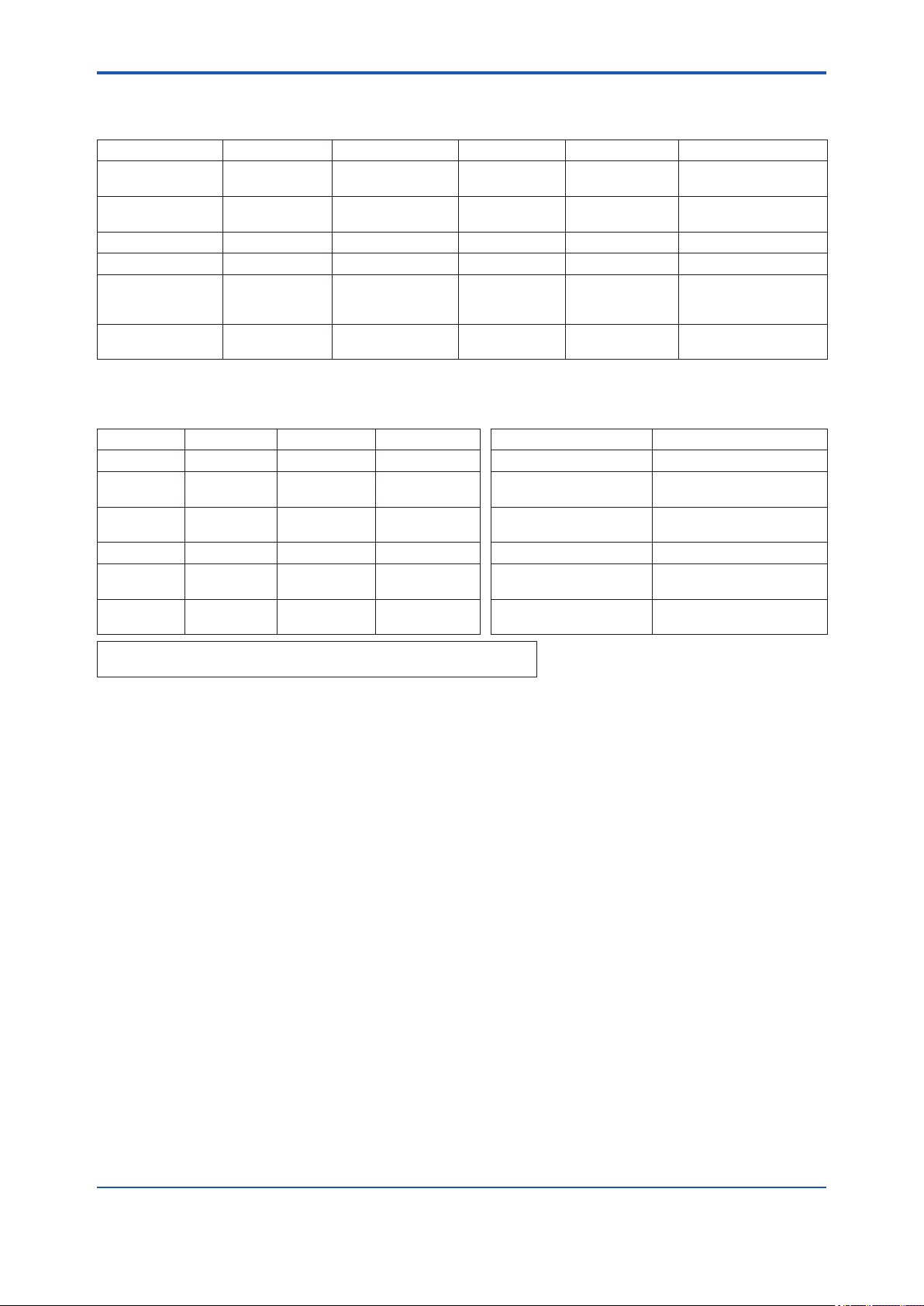

l Characteristics

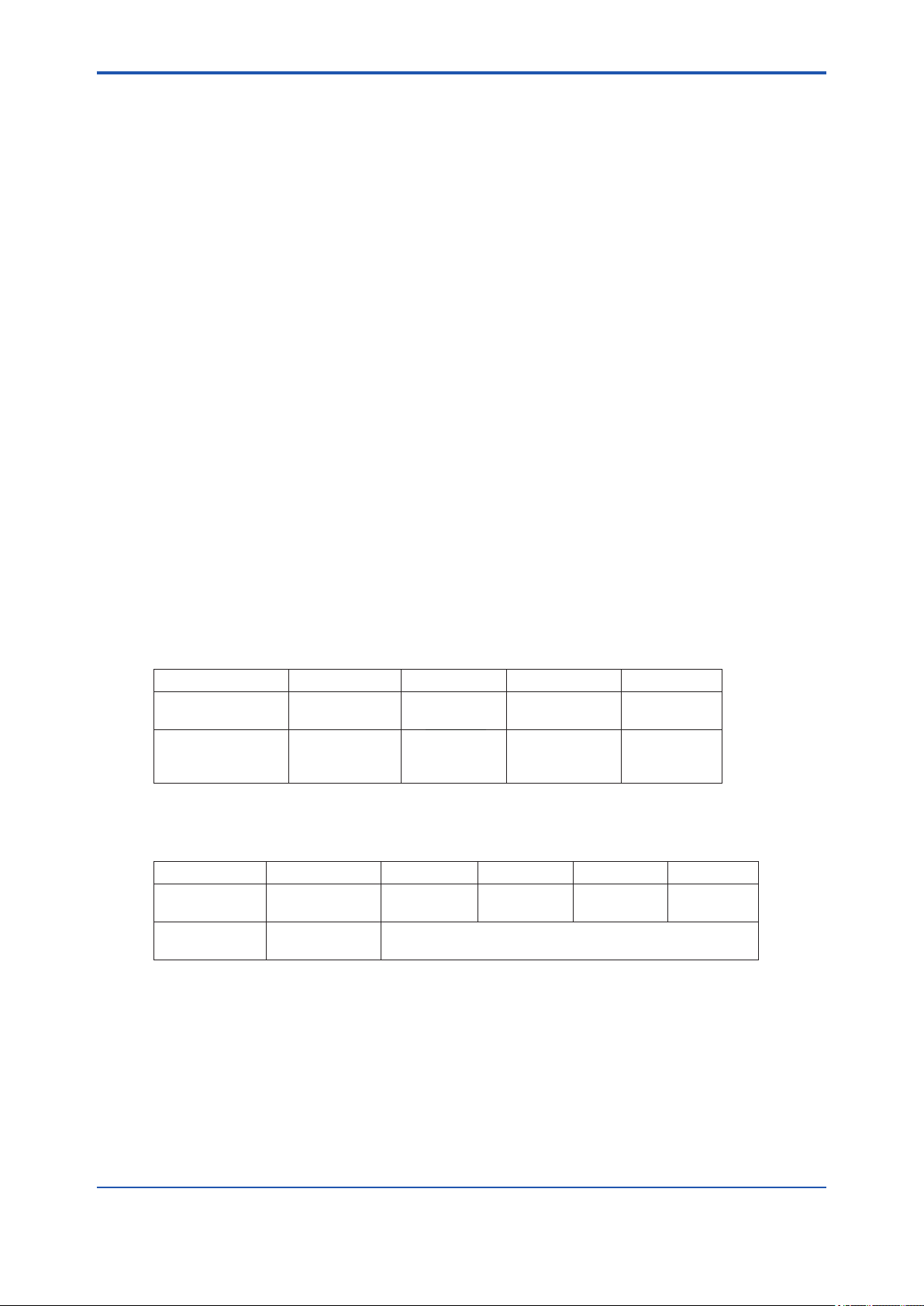

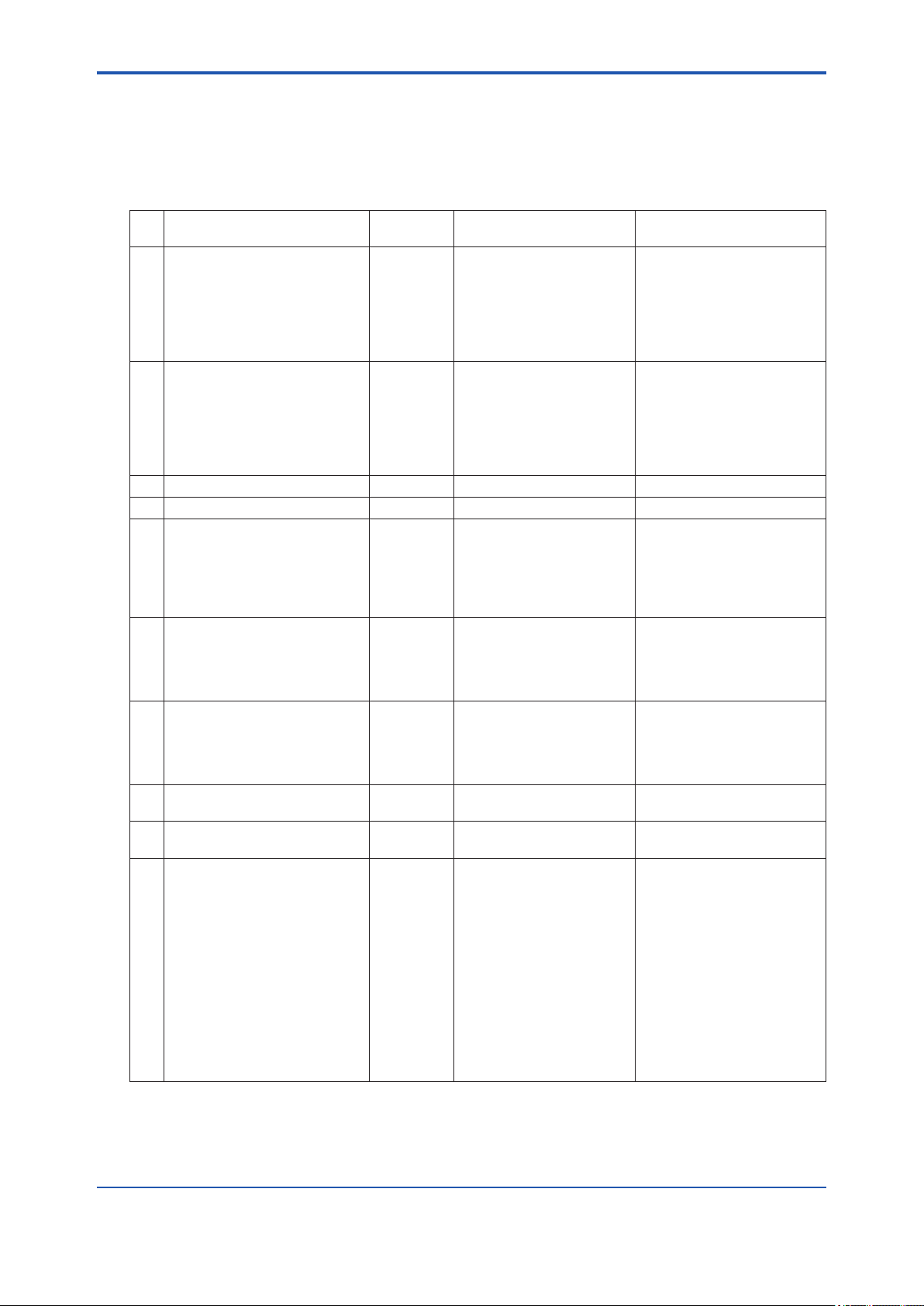

GD402 specication list

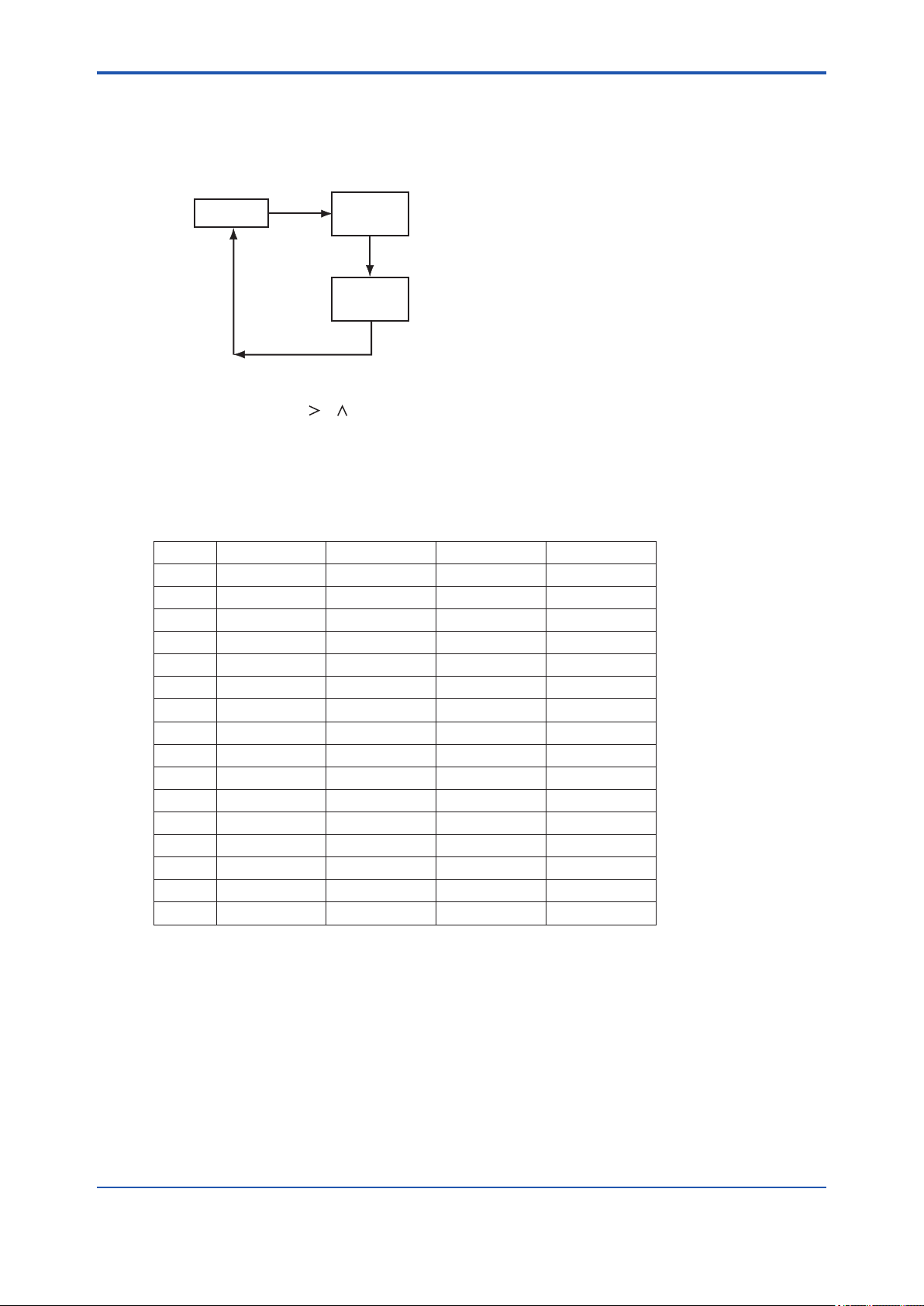

Item Density kg/m3 Density lb/ft3 Specic Gravity Molecular Weight Concentration vol%

Range

0 - 6 (compensated)

0 - 60 (physical)

Minimum Range 0.1 0.01 0.1 4

Response Time 90% approx. 5 sec approx. 5 sec approx. 5 sec approx. 5 sec approx. 5 sec

Linearity +/-1 % FS +/-1 % FS +/-1 % FS +/-1 % FS +/- 1

Repeatability

+/- 0.001

or +/-0.5%FS *

Long term stability +/- 0.003/month +/- 0.002/month +/- 0.003/month +/- 0.07/month

*: Whichever is greater

Density is the basic measurement, the other representations are derived from the Density data.

Item H2 in Air vol% H2 in CO2 vol% Air in CO2 vol% Caloric value MJ/m

Range 85 - 100 0 - 100 0 - 100 0 - 130 0 - 3.5

Minimum

Range

Response

Time 90%

Linearity +/- 1 +/- 1 +/- 1 +/- 1 % FS +/- 1 % FS

Repeatability +/- 0.5 +/- 0.5 +/- 0.5 +/- 0.5%FS or Caloric value

Drift +/- 0.5/month +/- 0.5/month +/- 0.5/month Caloric value equivalent to

– – –

approx. 5 sec approx. 5 sec approx. 5 sec approx. 5 sec approx. 5 sec

0 - 0.4 (compensated)

0 - 4 (physical)

+/- 0.0001

or +/-0.5%FS*

0 - 5 0 - 140 0 - 100

Concentration equivalent

to 100 kg/m3

+/- 0.001

or +/-0.5%FS*

+/- 0.02

or +/-0.5%FS*

+/- 0.5% or Concentration

equivalent to

+/-0.001kg/m3 *

Concentration equivalent

to +/- 0.003 kg/m3/month

3

British Thermal Unit KBTU/ft

Caloric value equivalent to

0.100 kg/m

3

Caloric value equivalent to

0.100 kg/m

+/- 0.5%FS or Caloric value

equivalent to 0.001kg/m3*

equivalent to 0.001kg/m3 *

Caloric value equivalent to

+/- 0.003kg/m3 /month

+/- 0.0025/month

3

1-4

3

Caloric Value and BTU are possible representations of the Density.

GD402 does not contain table information, only a single mathematical equation.

*: Whichever is greater

IM 11T3E1-01E

Page 14

<1. Specications>

1.1.2 GD40G, T, V, R Detector

l Material exposed to gas

SUS 316 stainless steel, Acrylonitrile Butadiene Rubber and Fluorine-contained Rubber

(O-ring)

l Ambient conditions

Temperature: -10 to 60 °C (14 to 140 °F)

Humidity: 5 to 95 %RH

Installation: Pipe-mounted or on panel

Construction: Explosion-proof and Intrinsically safe. (See 1.1.1 “System Components”)

Though the detector construction makes it relatively insensitive to sudden changes in

the gas temperature, extra precision can be achieved by keeping ambient temperature conditions as constant as possible. In measurements where optimum precision is

required it is therefore not recommended to install the detector in an outdoors environment, especially not if such installation is prone to direct sunlight.

l Finish

Cover: Equivalent to Munsell 0.6GY3.1/2.0

1-5

Case: Equivalent to Munsell 2.5Y8.4/1.2

l Weight

Approximately 7 kg (with pipe mounting bracket)

l Detector unit

When the system is ordered to be used as a hydrogen purity meter, an optional pressure

transmitter is required for pressure compensation.

• If /EJAJ1, /EJAF2, /EJAF3 or, /EJAF4 are ordered, the detector unit and the

pressure transmitter and the tubing in between will all be integrated on a single mounting

plate. This allows the space where the pressure transmitter is normally mounted to be used

effectively for other purposes.

1.1.3 GD402G, T, V, R Converter

l Display

Reading: Digital (6 digits maximum; resolution: 0.0001 kg/m3)

Data items shown:

Measured value: Always on display.

Alarm indications: Abnormal concentration, abnormal pressure range of input and abnormal

value of calibration.

Parameters for calibration: Time of calibration, settling time, starting time of calibration and

calibration cycle

Self-diagnostic indications: Sensor oscillation shutdown, abnormal oscillation frequency of

sensor, failure in sensor temperature detection, failure in A/D conversion

stage and memory failure.

Alarm settings: The contact state can be set to either “normally open (NO)” or “normally

closed (NC)” depending on the needs of the application.

Temperature: Temperature of gas being measured

IM 11T3E1-01E

Page 15

<1. Specications>

l Contact Outputs/Input

Contact output: Signals for Maintenance, Fail, Hi/Lo alarms

Contact capacity: 250 V AC at 3 A or 30 V DC at 3 A

Contact input: Signal for switching between the Hydrogen Purity meter and the Replace-

ment meter

l Calibration

Manual (one touch), Semi automatic, Automatic calibration

l Communication

Protocol: BRAIN communication

Data items that can be transmitted by the hand-held terminal are

numerical data, such as concentration, temperature and pressure,

alarm setpoint and self-diagnostic parameters.

l Ambient Conditions

Temperature: -10 to 55 °C (14 to 131°F)

Humidity: 5 to 95 %RH

l Installation

1-6

Non-explosion-proof models: Pipe-, panel- or wall-mounted

Explosion-proof models: Pipe- or panel-mounted

l Finish

GD402G (general purpose):

Front cover: Equivalent to Munsell 0.6GY3.1/2.0

Case: Equivalent to Munsell 2.5Y8.4/1.2

GD402T, V, R (explosion-proof):

Equivalent to Munsell 0.6GY3.1/2.0

l Weight

GD402G (general purpose): Approx. 3 kg (including mounting hardware)

GD402T, V, R (explosion-proof): Approx. 15 kg (including mounting hardware)

l Fuse

250 V 1 A quick acting type authorized VDE/SEMKO 100 to 240 V AC Model

250 V 2 A quick acting type authorized VDE/SEMKO 24 V DC Model

IM 11T3E1-01E

Page 16

<1. Specications>

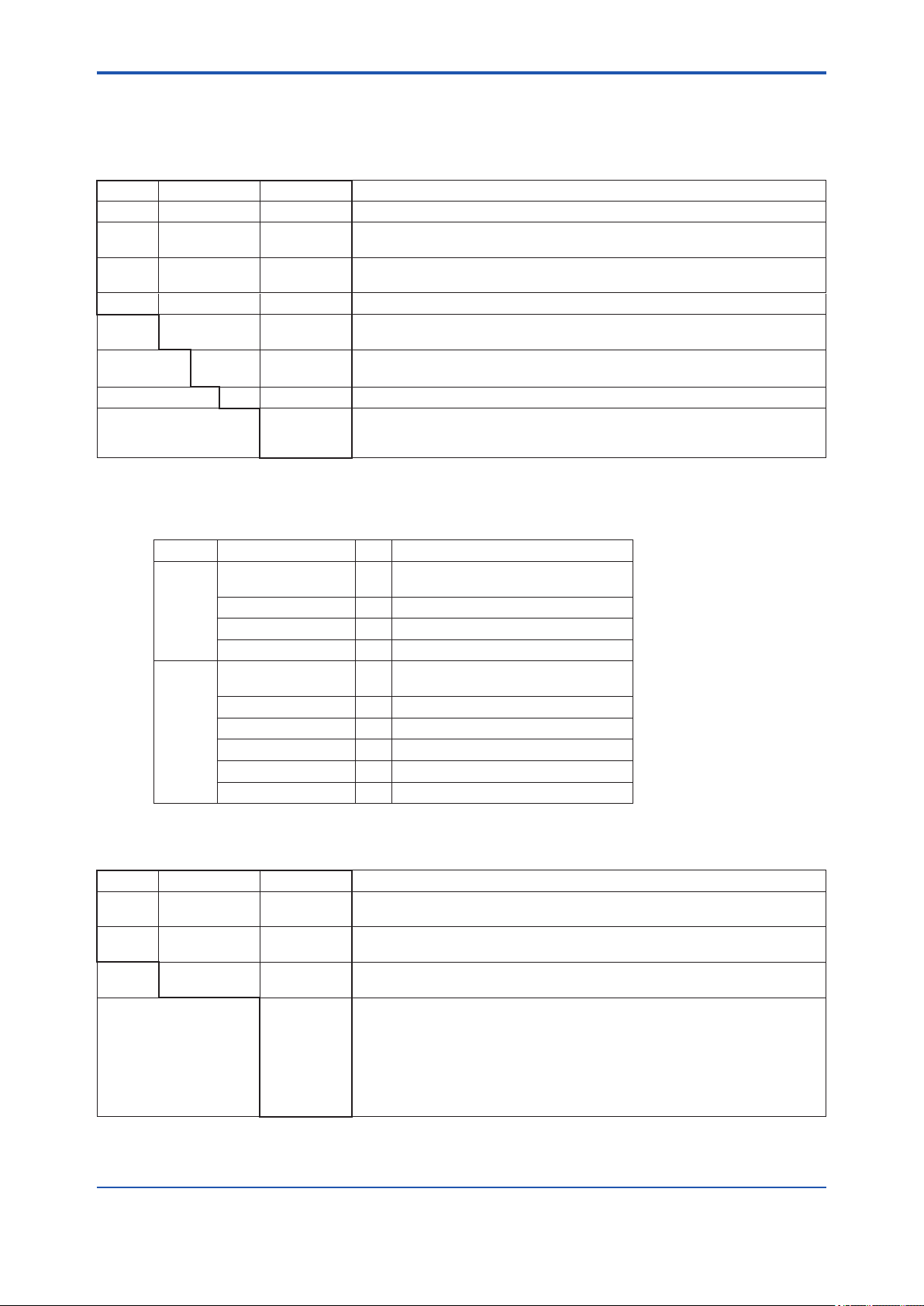

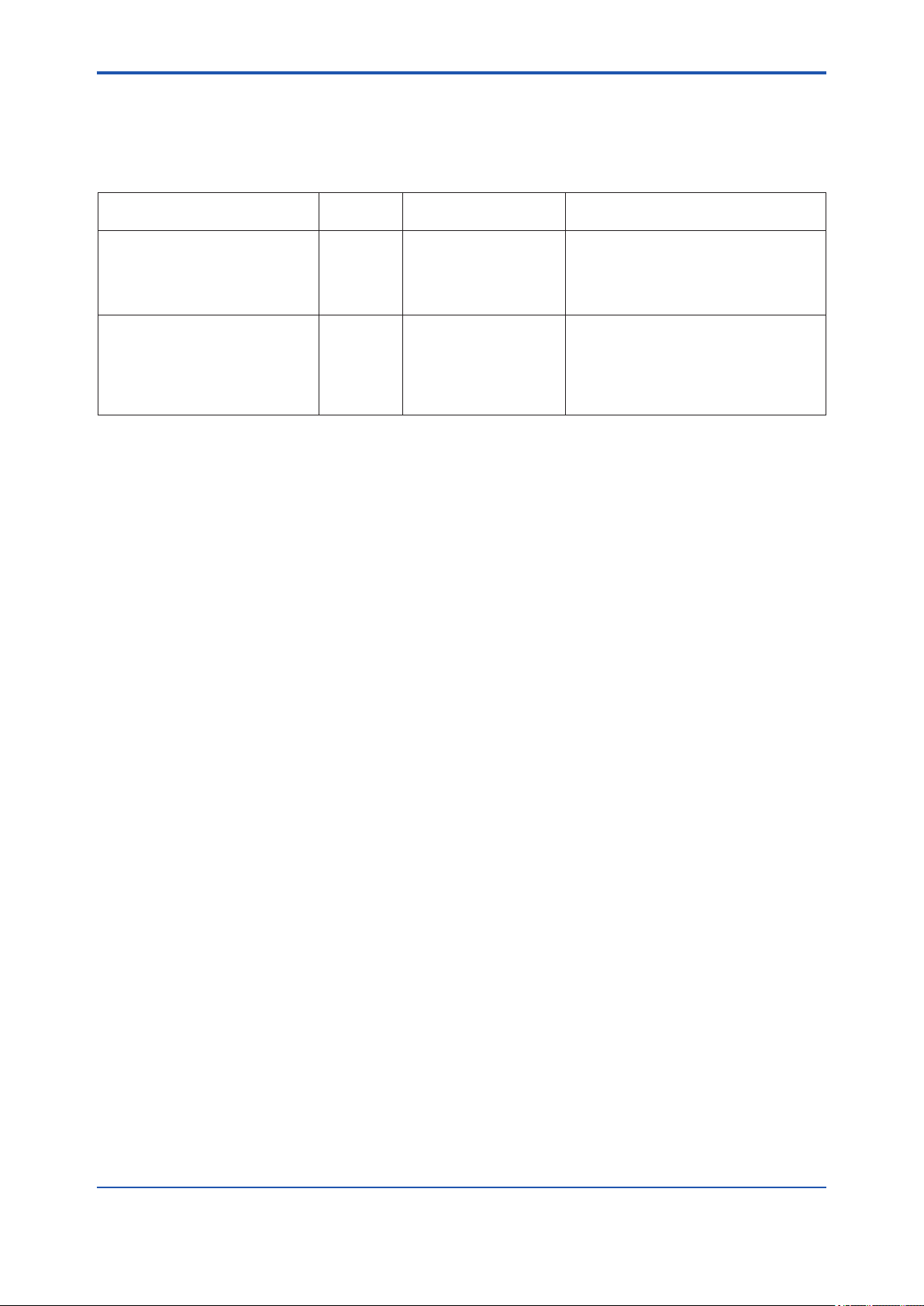

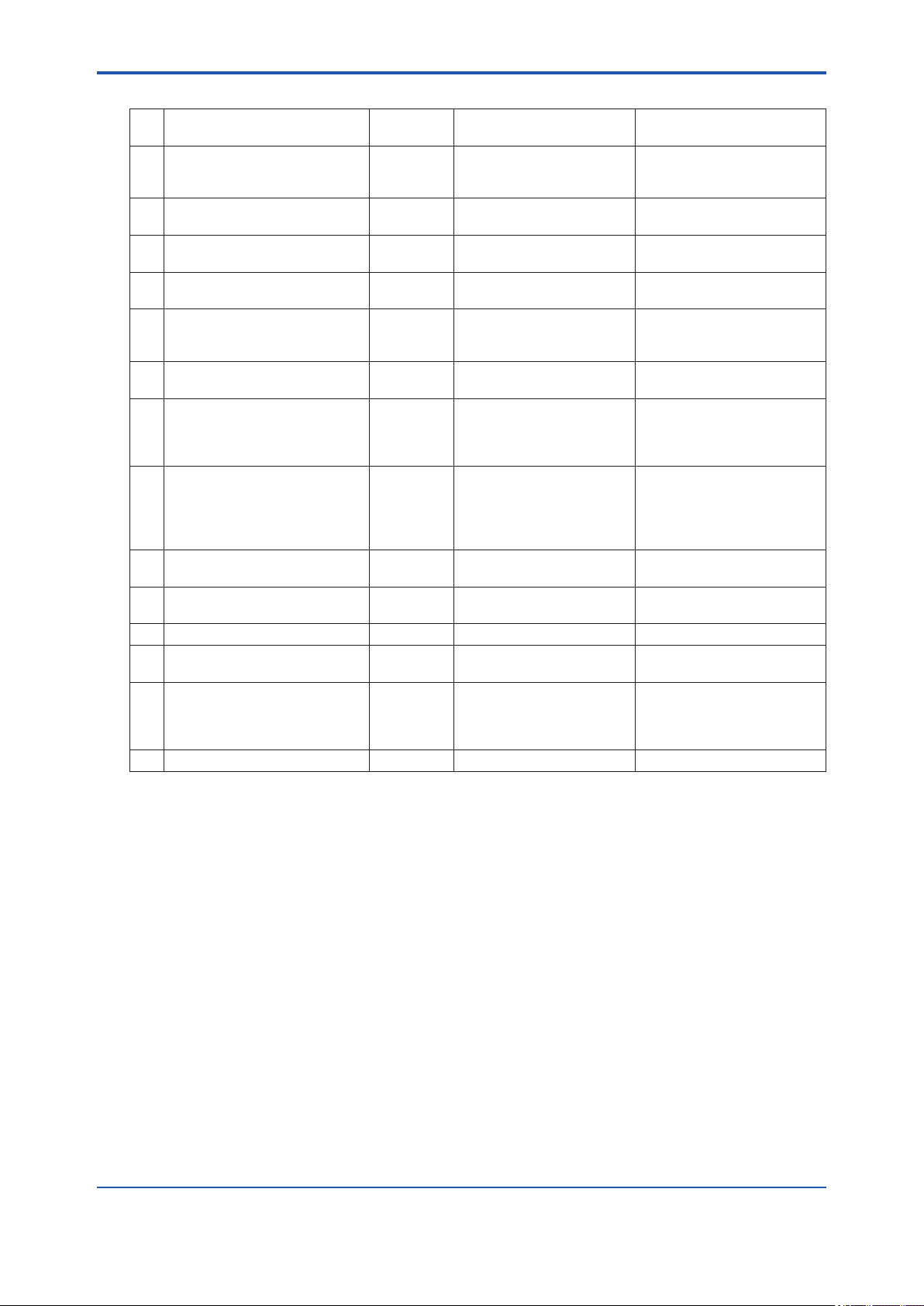

1.2 Model and Sufx Codes

1.2.1 Gas Density Converter

Model Sufx code Option code Description

GD402G - - - - - - - - - - - - - - - - - - - - - - - - - General purpose model, 6 cable glands included.

GD402T - - - - - - - - - - - - - - - - - - - - - - - - - FM certied explosion - proof model. Gland threads 1/2 NPT. No cable glands

GD402V - - - - - - - - - - - - - - - - - - - - - - - - - CSA certied explosion - proof model. Gland threads 1/2 NPT. No cable glands

GD402R - - - - - - - - - - - - - - - - - - - - - - - - - TIIS certied explosion - proof model. Gland threads G3/4. No cable glands included.

Power

supply-D-A

Label and

approval

Instruction Manual -E - - - - - - - - - - - - English

Options

(only GD402G)

Note: Explosion -proof models, GD402T, V, R have only pipe mounting hardware as standard.

-E

-J

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

/PA

/U

/H

included.

included.

24 V DC

100-240 V AC

English label

TIIS approval, English label (only GD402R)

Panel mounting

Universal (Pipe and Wall) Mounting

Mood

1-7

GD402 Standard Accessory List

Model Item Qty Part Number

GD402G

GD402R

GD402T

GD402V

Fuse 1 A1109EF (Power Supply: 100-240 V AC)

Universal Mount Set 1 K9171SS

Panel Mount Set 1 K9171ST

Surge Protector 1 K9215LP

Fuse 1 A1109EF (Power Supply: 100-240 V AC)

Blacket 1 K9214HD

Blacket 1 K9214HE

U-Bolt Assy 2 D0177XL-A

Bolt 1 Y9835NU

Bolt 2 Y9820NU

A1111EF (Power Supply: 24 V DC)

A1111EF (Power Supply: 24 V DC)

1.2.2 Gas Density Detector

Model Sufx code Option code Description

GD40G - - - - - - - - - - - - - - - - - - - - - - - - - General purpose detector. 1/4 NPT gas threads and 1/2 NPT gland threads. No cable

GD40R - - - - - - - - - - - - - - - - - - - - - - - - - TIIS certied explosion - proof detector. Rc1/4 gas threads and G1/2 gland threads.

Label

approval-E-J

Options /EJAJ1

- - - - - - - - - - - -

- - - - - - - - - - - -

/EJAJ1T

/EJAF2

/EJAF2T

gland included. Mounting hardware included.

Cable gland included. Mounting hardware included.

English label, no approval (only GD40G)

TIIS approval, English label (only GD40R)

TIIS certied EJA mounted with detector on mounting plate. Rc1/4 gas threads and

G1/2 gland thread. Cable gland included.(only GD40R)

TIIS certied EJA mounted with detector on mounting plate. Rc1/4 gas threads and

G1/2 gland thread. Cable gland included. EJA with TAG (only GD40R)

EJA mounted with detector on mounting plate.1/4 NPT gas threads and 1/2 NPT gland

threads. No cable gland included.(only GD40G)

EJA mounted with detector on mounting plate.1/4 NPT gas threads and 1/2 NPT gland

threads. No cable gland included. EJA with TAG (only GD40G)

IM 11T3E1-01E

Page 17

<1. Specications>

Model Sufx code Option code Description

GD40T - - - - - - - - - - - - - - - - - - - - - - - - - FM certied explosion - proof detector. 1/4 NPT gas threads and 1/2 NPT gland thread.

GD40V - - - - - - - - - - - - - - - - - - - - - - - - - CSA certied explosion - proof detector. 1/4 NPT gas threads and 1/2 NPT gland

Options /EJAF3

/EJAF3T

/EJAF4

/EJAF4T

No cable gland included. Mounting hardware included

thread. No cable gland included. Mounting hardware included.

FM certied EJA mounted with detector on mounting plate.1/4 NPT gas threads and

1/2 NPT gland thread. No cable gland included. (only GD40T)

FM certied EJA mounted with detector on mounting plate.1/4 NPT gas threads and

1/2 NPT gland thread. No cable gland included. EJA with TAG (only GD40T)

CSA certied EJA mounted with detector on mounting plate. 1/4 NPT gas threads and

1/2 NPT gland thread. No cable gland included. (only GD40V)

CSA certied EJA mounted with detector on mounting plate. 1/4 NPT gas threads and

1/2NPT gland thread. No cable gland included. EJA with TAG (only GD40V)

GD40 Standard Accessory

Item Qty Part Number

U-Bolt Assy*

Blacket*

Blacket*

Gland*

*1: Not supplied when option code “/EJAJ1”, “/EJAF2”, “/EJAF3” or “/EJAF4” is specied.

*2: Supplied only for GD40R.

1

4 D0177XL-A

1

1

2

1 K9214HD

1 K9214HE

1 G9601AM

1-8

1.2.3 Hardware for Connection with External Cables (For Explosion-proof use)

Part No. Description

L9811LL G3/4 explosion-proof cable gland.

Cable’s outside diameter 8 to 16 mm.

Used for the GD402R converter.

Note: Specify the number of cable glands for converter in hazardous area

1.2.4 Two-core, Double-Shielded Cable

Normally two conductor shielded cable can be used, but when failure arises from noises

disturbance, this cable is recommended for connection between the GD402 converter and

GD40 detector.

Model Basic code Description

GDW Two - core, double-shielded cable,

both ends nished with cable pins.

Length

-L

Length in meters, 500 meter maximum.

IM 11T3E1-01E

Page 18

<1. Specications>

1.2.5 Brain Terminal (Optional)

Model Sufx code Option code Description

BT200 - - - - - - - - - - - - - - - - - - - - - - - - - Brain terminal [Note]

Printer -N

-P

– 00 - - - - - - - - - - - - Always 00

Options

Note: The BT200 has following accessories, two communication cables, one with IC clips and another with alligator clips, handy

carrying case and ve AA 1.5 V dry batteries.

OPTIONS FOR BT200

Options Description Option codes

Communication cable

(Note 1)

Intrinsically safe type

(Note 1) (Note 2)

(Note 1) Optional code /C1 can not be combined with /CS1.

(Note 2) Applicable only for Model BT200-N00.

See GS 01C00A11-00EN for “BT200” brain terminal in detail.

- - - - - - - - - - - -

- - - - - - - - - - - -

/

With a 5-pin connector

(for the signal conditioner)

CSA Intrinsically safe approval

Class I, Groups A, B, C and D Temp. Code : T4

Standard type (without printer)

With printer

/C1

/CS1

1-9

1.2.6 Pressure transmitter (Optional)

/EJAJ1 means TIIS certied EJA310.

/EJAF2 means general purpose model EJA310.

/EJAF3 means FM certied EJA310.

/EJAF4 means CSA certied EJA310.

See GS 01C22D01-00E for “EJA310” pressure transmitter in detail if a different

selection from pre-selected options seems necessary.

IM 11T3E1-01E

Page 19

<1. Specications>

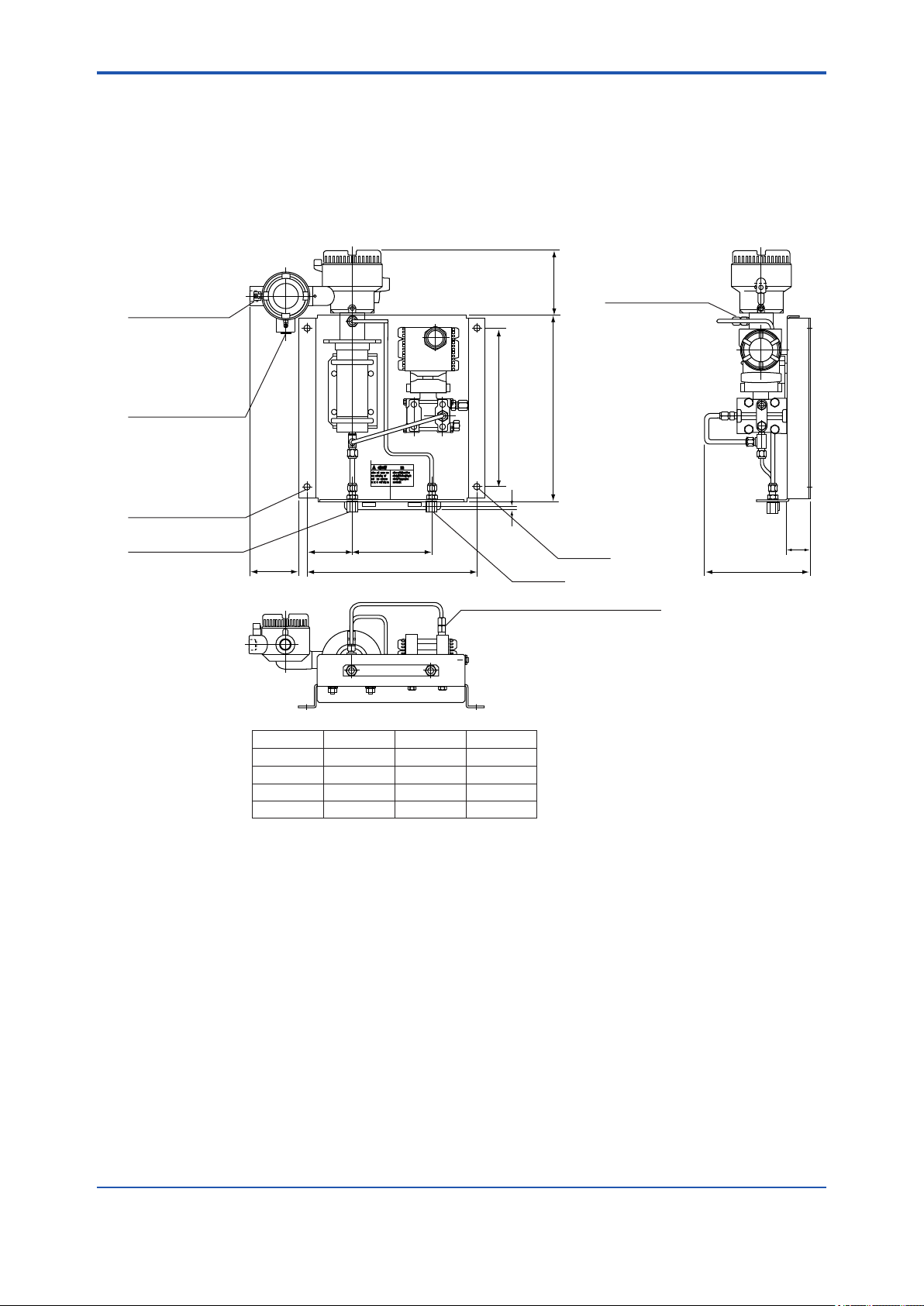

1.3 External Views and Dimension

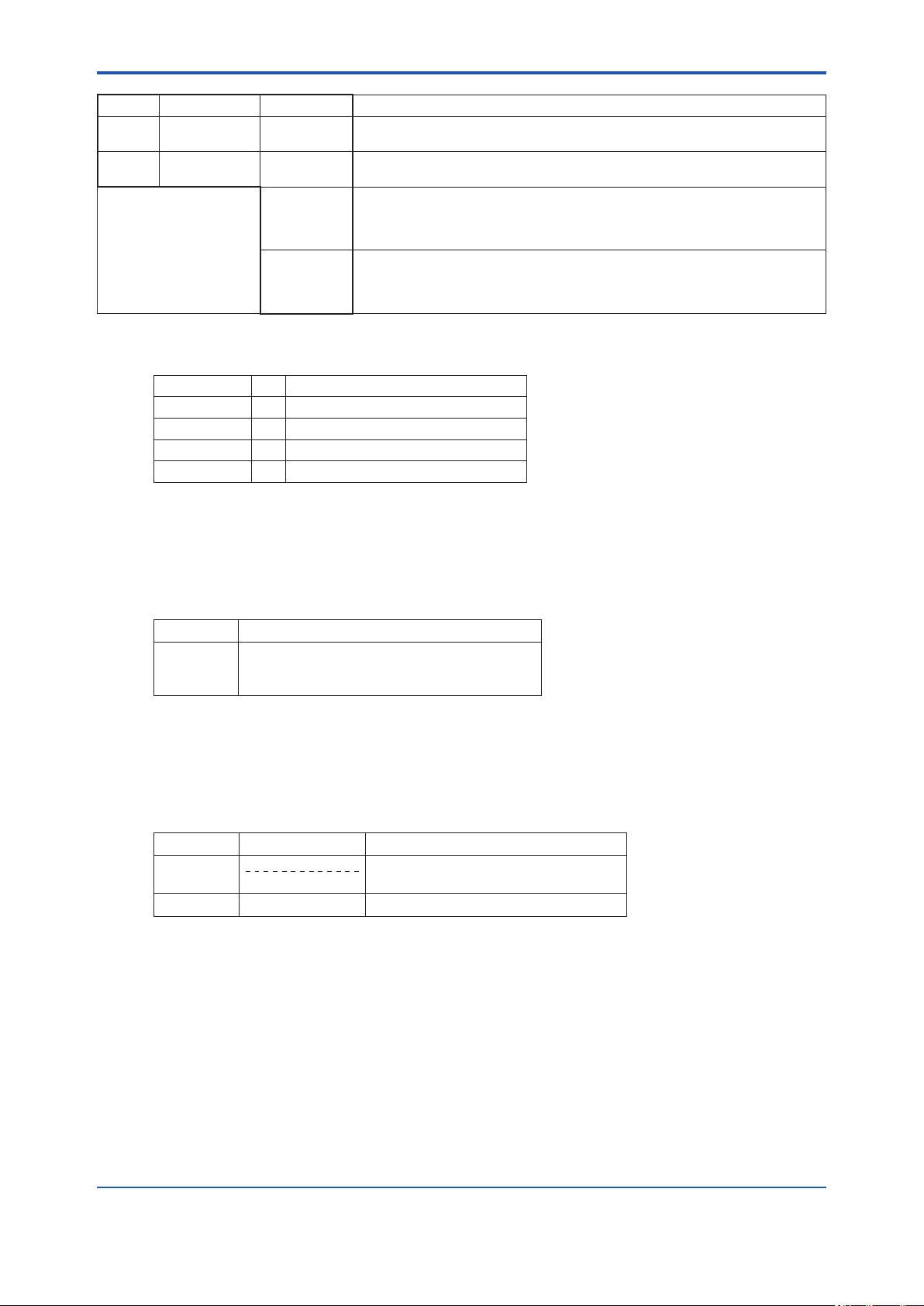

1.3.1 GD402G Converter (General purpose)

1-10

Unit: mm(in.)

184 (7.2)

144(5.7)

144 (5.7)

A B

D F

36 36

Grounding terminal (4 mm screws)

C

E

(1.4)(1.4)

Hood

(Option code: /H)

220 (8.7)

72 (2.8)

20 (0.8)

112 (4.4)

23

(0.9)

Cable inlet (21 mm in dia.)

Compatible with a PG 13.5 cable gland

Cable gland Connection

36

38

(1.4)

(1.5)

A, B

C

D, E

F

Four holes, 6 mm (0.24) in dia.,

8 mm deep M6

80 (3.1)

80 (3.1)

• Pressure transmitter

• Analog Output • Contact Input

• Detector

• Contact Output

• Power Supply

Weight : Approx. 3 kg (6.6 pounds)

(including mounting hardware)

F0101.ai

IM 11T3E1-01E

Page 20

<1. Specications>

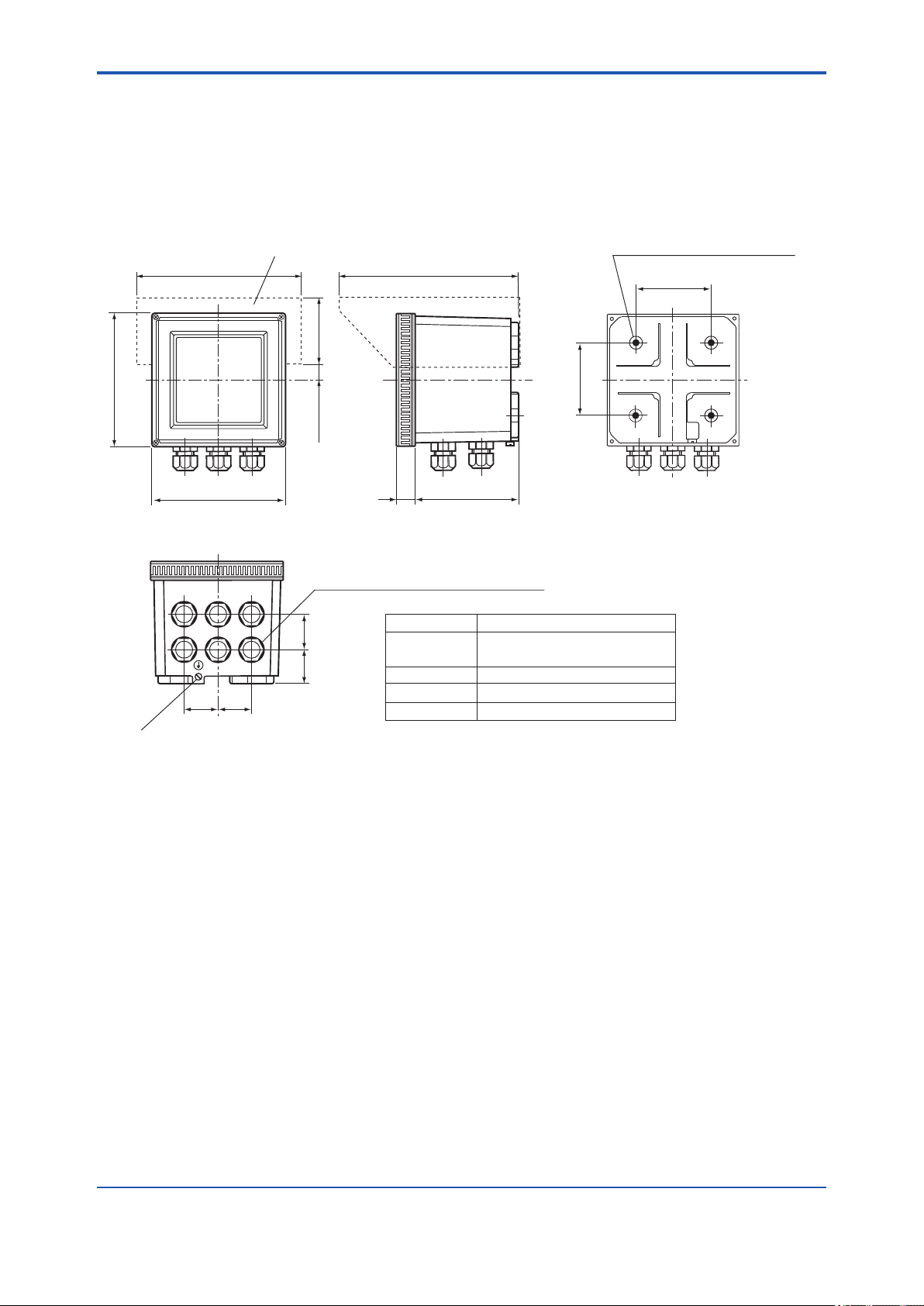

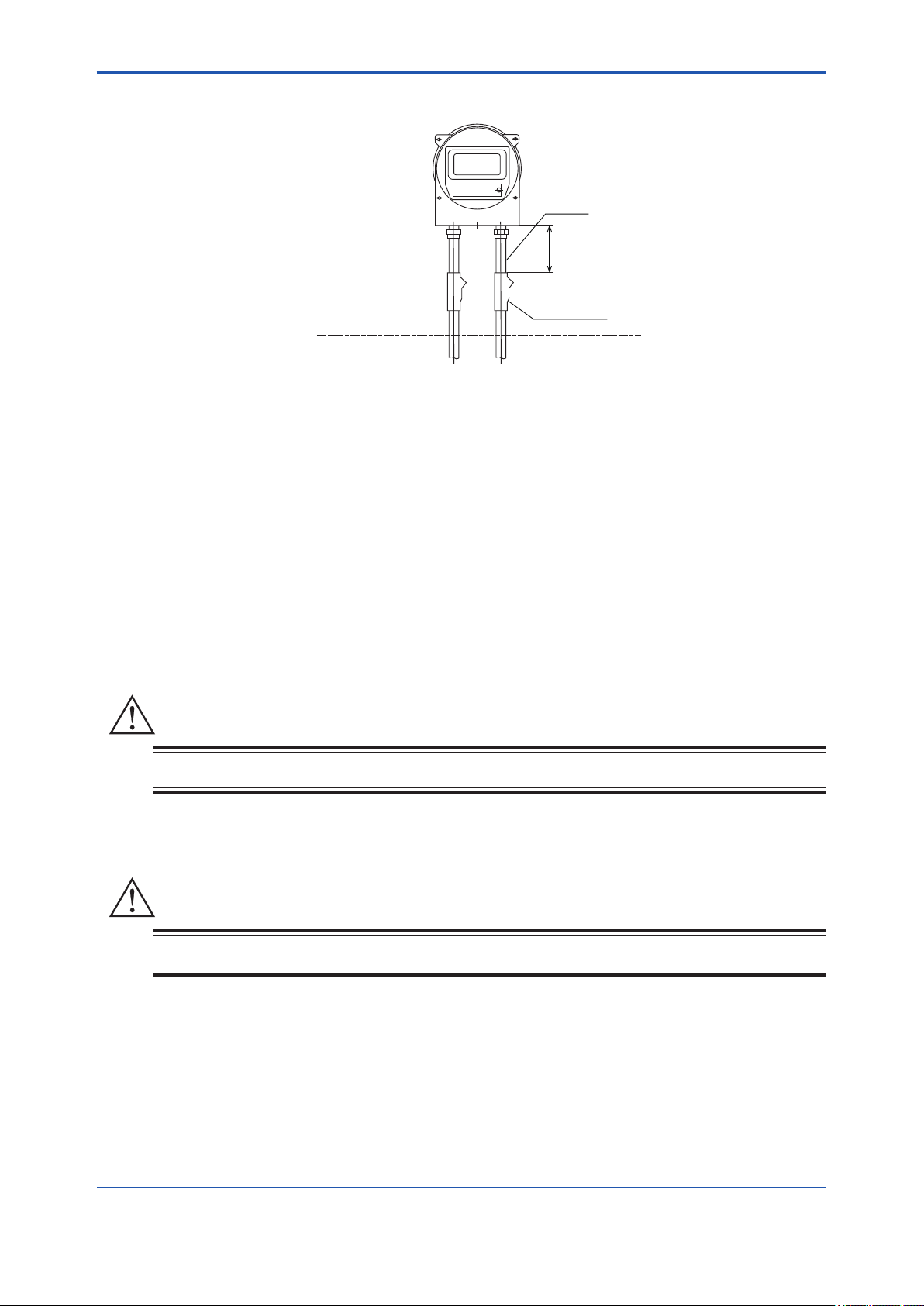

1.3.2 Pipe- and Wall-Mounting Hardware (Optional)

1-11

• Hardware for Pipe Mounting (Option code /U)

188 (7.4)

174 (6.9)

(2)

50

Mounting pipe of JIS 50 A (60.5 mm in outer dia.)

Optional

hardware

4 - M6 screws

• Hardware for Wall Mounting (Option code /U)

135 (5.3)

13

(0.51)

Unit : mm (in.)

Weight : Approx. 3 kg

200 (7.9)

100 (3.9)

4 - M6 screws

224 (8.8)

Optional

hardware

3-Ø10 holes

• Hardware for Panel Mounting (Option code /PA)

23

(0.9)

max. 12

(panel thickness)

100 (3.9)

4 - M6 screws

Optional

hardware

178 (7)

200 (7.9)

35

(1.4)

(0.6)

70 (2.8)

100 (3.9)

185 (7.3)

15

Dimensions of panel cutout

+1

139

0

+0.08

(5.47 )

0

139

+1

0+1 0

(5.47 )

F0102.ai

195 (7.7)

IM 11T3E1-01E

Page 21

<1. Specications>

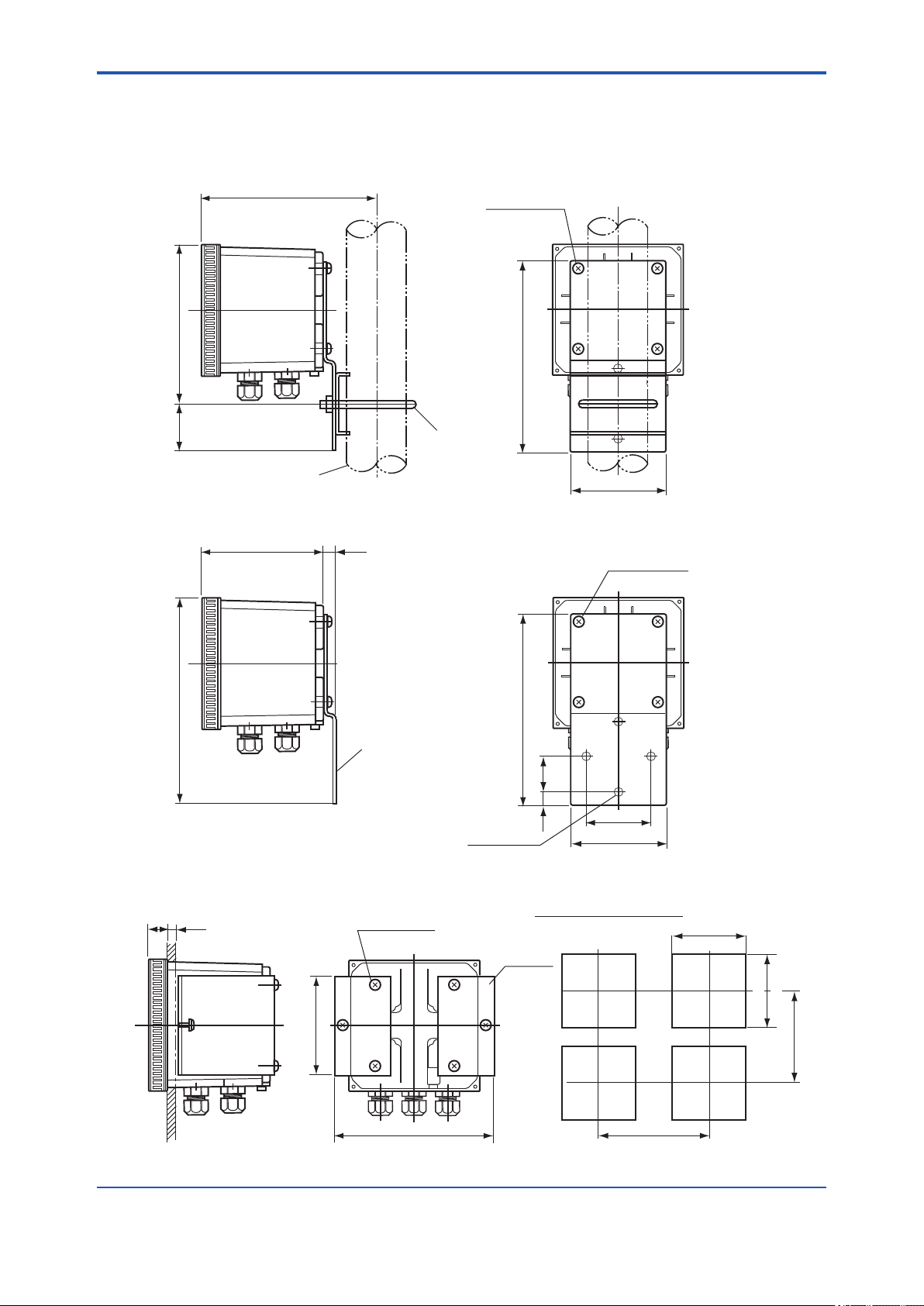

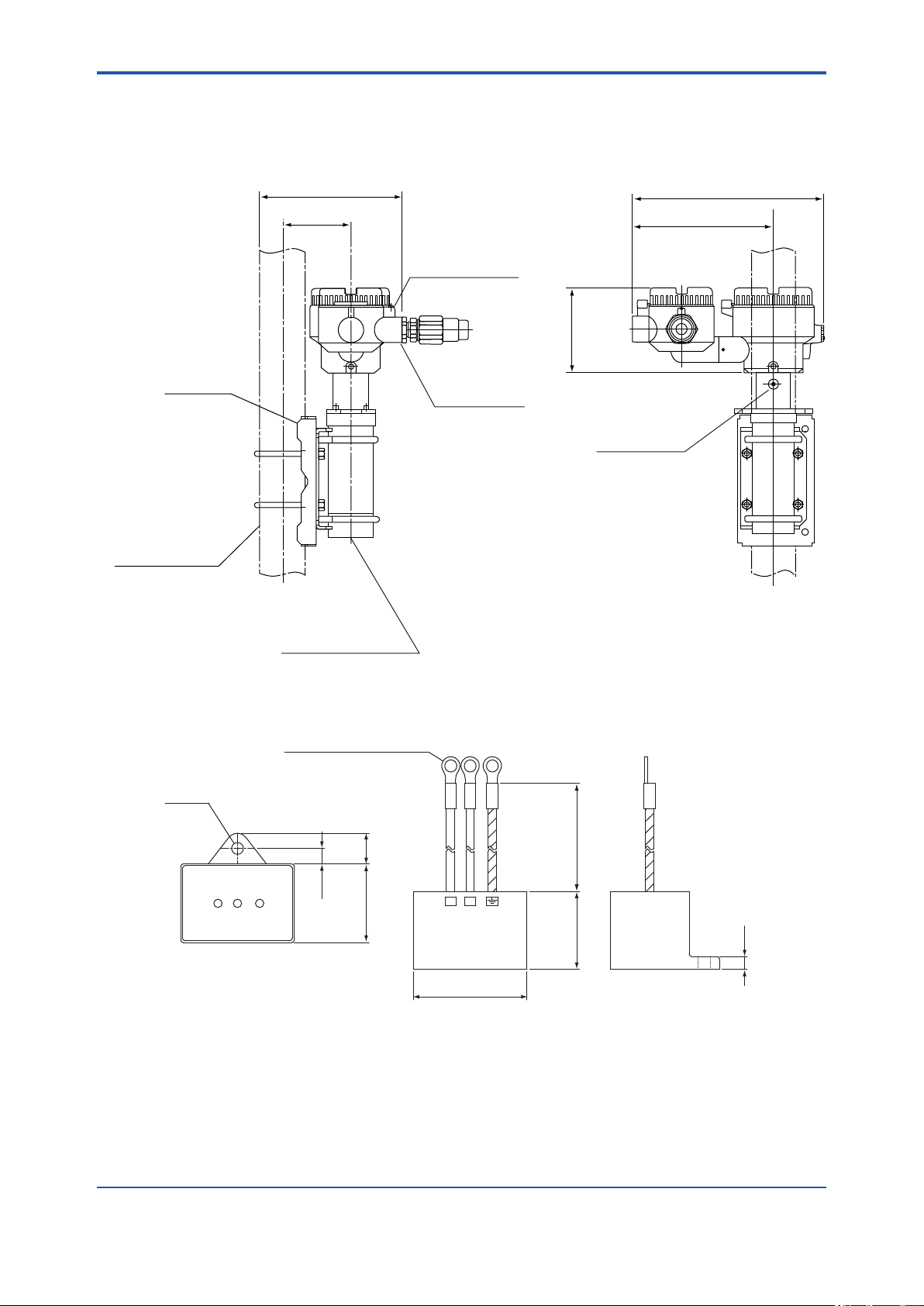

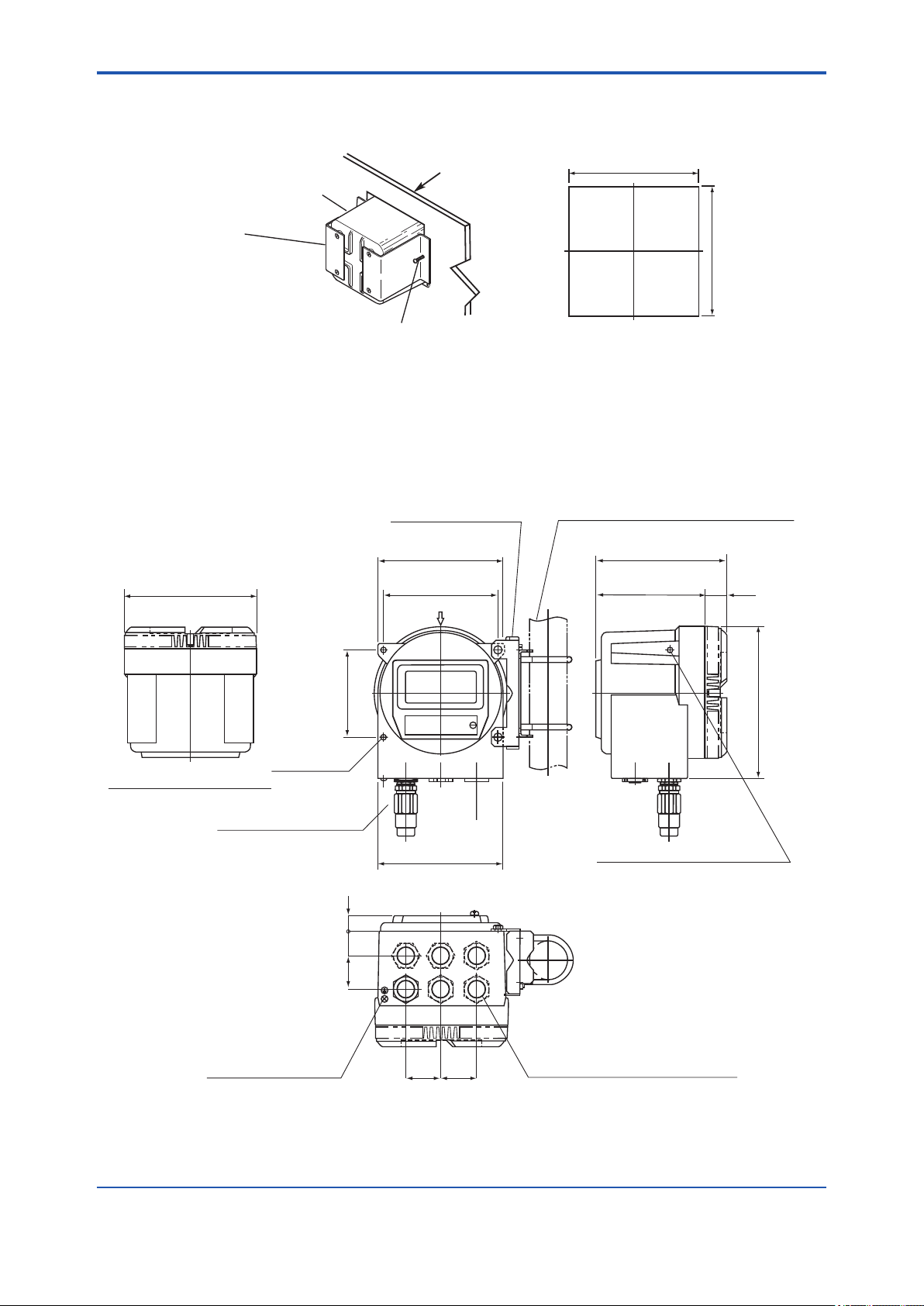

1.3.3. GD402T, V, R Converter (Explosion-proof)

Weight : approx. 15 kg (33.1 pounds)

Pipe-mounting hardware

Mounting pipe of JIS 50 A nominal size (Φ60.5)

1-12

Unit : mm (in.)

Φ212 (8.3)

Side view from arrow A direction

Cable glands not included

4 - M8 depth 20

140 (5.5)

24 (0.9)

39

(1.5)

54

(2.1)

200 (7.9)

182 (7.2)

A

200 (7.9)

A B

D ECF

209 (8.2)

173 (6.8)

2 - M8 depth 16 (one on each side)

(Used to fix the pipe-mounting hardware)

36 (1.4)

242 (9.5)

Grounding terminal (M5)

56

56

(2.2)

(2.2)

Cable gland Connection

A • Power Supply

B, C • Contact Output

D • Detector

E, F

• Pressure Transmitter

• Analog Output • Contact Input

Six wiring holes, G3/4 threaded (GD402R)

1/2 NPT threaded (GD402V, T)

F0103.ai

IM 11T3E1-01E

Page 22

<1. Specications>

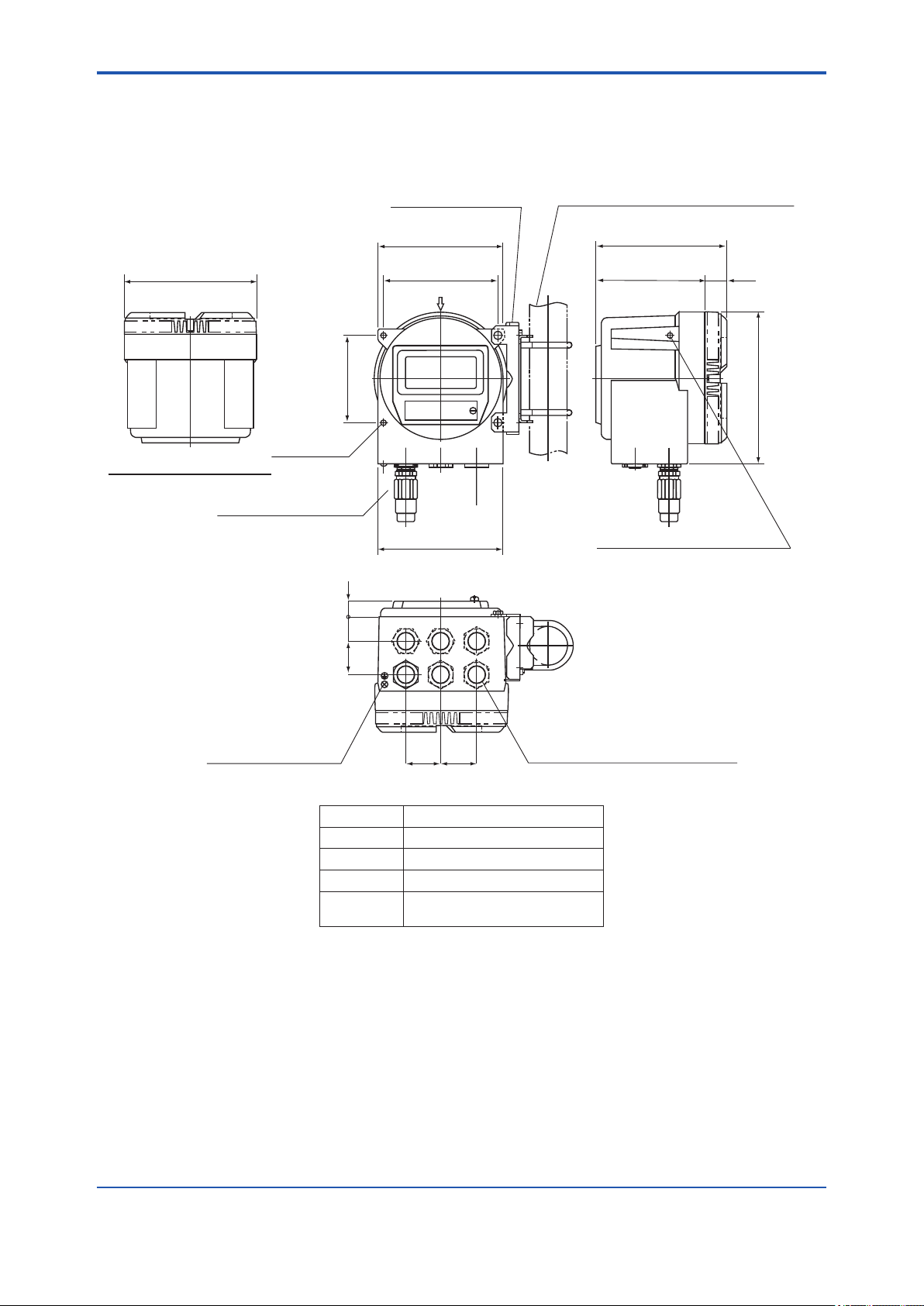

1.3.4 GD40 Detector

• Model GD40- /EJAJ1, /EJAF2, /EJAF3, /EJAF4

Weight: approx. 15 kg (27.8 pounds)

1-13

Unit: mm (in.)

GD40

Detector wiring port

See Table

Cable gland is included

only in EJAJ1

Four panel-mounting

holes, 12 mm in

diameter

Gas out

See Table

∆ abcdf m

abc cd nmv sc

abc vdfbjkosblm

xs xdcvbg vf

sbdgjklodenjhl;pk

ad xs cdnmn

nbdvf kggswba

z x d cdf vfg m

nscbxfk

150 (5.9)100 (3.9)

93 (3.7) 320 (12.6)

EJA wiring port

See Table

4-ø12 (0.47)

300 (11.8)

5

350 (13.8)

Gas in

See Table

120 (4.7)

Cable gland is included only in /EJAJ1

40

(1.6)

196 (7.7)

Option code GD40 wiring EJA wiring Gas out/in

/EJAJ1 G1/2 G1/2 Rc1/4

/EJAF2 1/2 NPT 1/2 NPT 1/4 NPT

/EJAF3 1/2 NPT 1/2 NPT 1/4 NPT

/EJAF4 1/2 NPT 1/2 NPT 1/4 NPT

F0104.ai

IM 11T3E1-01E

Page 23

<1. Specications>

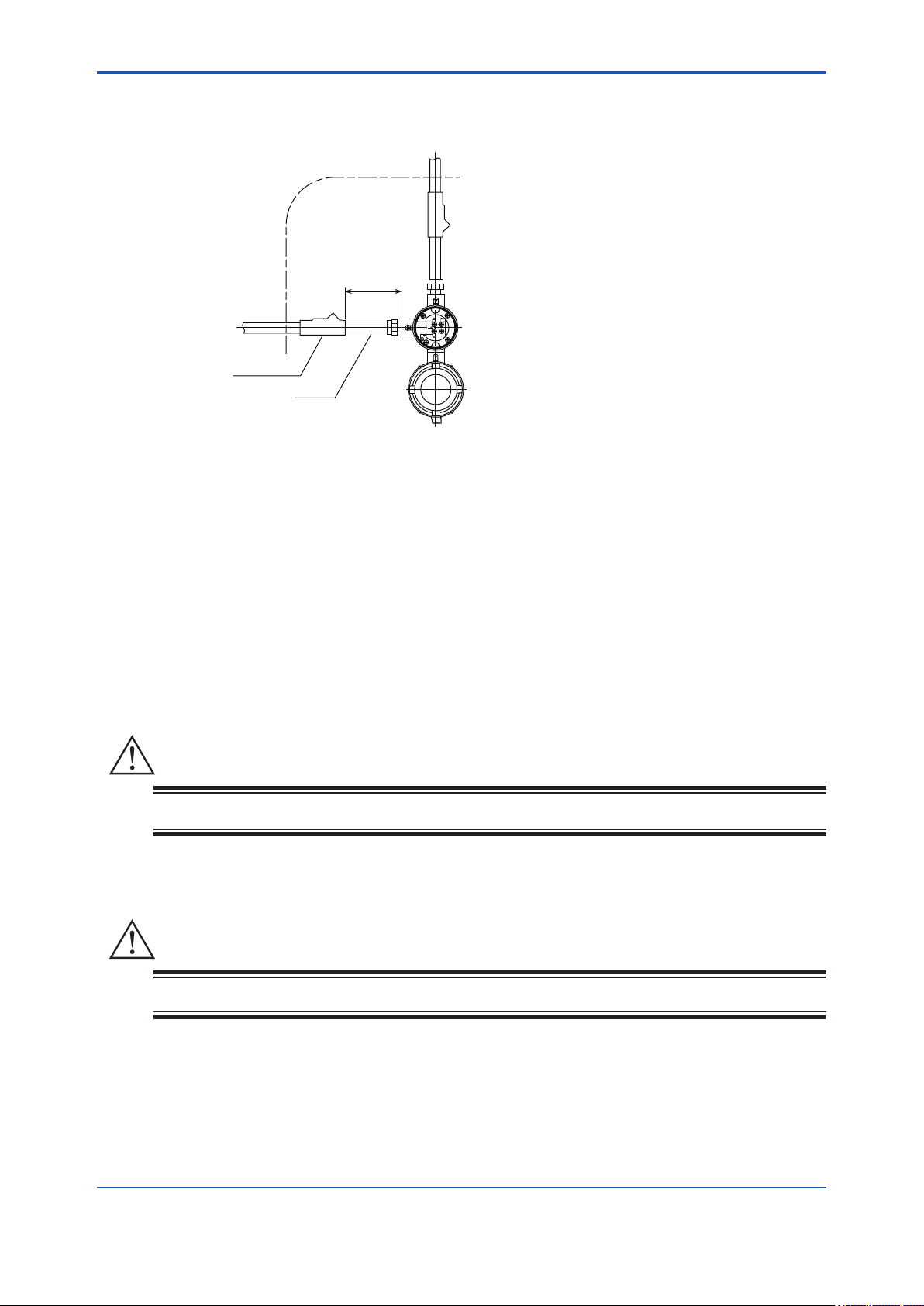

1.3.5 Detector Unit (Intrinsically Safe, Explosion-proof)

• Hardware for Pipe Mounting : GD40

1-14

Unit: mm (in.)

Pipe-mounting

hardware

Mounting pipe

(JIS 50 A (60.5 mm in

outer dia.) nominal size)

Approx. 191 (7.5)

Approx. 92 (3.6)

Sample gas outlet

GD40R: Rc1/4

GD40V: 1/4 NPT

GD40T: 1/4 NPT

GD40G: 1/4 NPT

Grounding terminal

(3 mm (0.11) screw)

Wiring hole,

GD40R: G1/2

GD40V: 1/2 NPT

GD40T: 1/2 NPT

GD40G: 1/2 NPT

Approx. 264 (10.4)

Approx. 193 (7.6)

Approx. 117 (4.6)

Sample gas inlet

GD40R: Rc1/4

GD40V: 1/4 NPT

GD40T: 1/4 NPT

GD40G: 1/4 NPT

Note: Cable gland is included only in GD40R.

F0105.ai

1.3.6 Surge protector: K9215LP

M4 SCREW TERMINAL

Ø4.2

(0.17)

1128.5

(0.43)

5.5

(0.22)

(1.12)

21

41

(1.61)

20028

(7.86)

(1.1)

Unit: mm (in.)

4.5

F0106.ai

(0.18)

IM 11T3E1-01E

Page 24

<2. Installation, Wiring and Piping>

2-1

2. INSTALLATION, WIRING AND PIPING

The GD402 Gas Density Meter is thoroughly inspected at the factory and carefully packed to

ensure the equipment does not suffer any damage during transportation.

The package should also be handled with care when unpacking to prevent the equipment from

undergoing severe mechanical shock. After unpacking, visually check the equipment to ensure

that it is free from any damage.

Although the detector has no controls on it, it may need to be accessed for inspection or for other

reasons. Install the detector in a location as close as possible to where the gas is sampled and

where maintenance can be easily carried out. The converter has a display with controls on it;

thus, you should install it so that the keys are positioned directly in front of you when working.

Note that there must be a clearance of at least 400 mm at the back of the converter GD402G,

GD402T, GD402V and GD402R since cables are wired to the back by removing the screwed

rear cover.

2.1 Installing the Detector

The GD40 detector is an explosion-proof with intrinsically safe sensor instrument. Install the

detector in a location where the following conditions are satised.

2.1.1 Selecting the Location

l Explosion-proof construction

Before installing the detector in an explosion-hazardous area, ensure that the area conforms to

the explosion-proof code noted above.

l No corrosive gases

Corrosive gases are not desirable because they may damage the electrical components in the

detector.

l Slight mechanical vibration

Although the detector is vibration-resistant, vibration may loosen the connections of the external

wiring.

l No exposure to direct sunlight

Exposure to direct sunlight may raise the temperature in the detector to abnormal levels, and

should therefore be avoided. Note that such abnormal temperature levels can also result from

heat irradiated from high-temperature equipment around the detector.

l Humidity maintained between 5% and 95 %RH

Avoid choosing a location that is likely to be exposed to abnormally high or low humidity over a

prolonged period. It is recommended that the detector be used at a humidity between 25% and

85 % RH.

l No exposure to rain water

Even though the detector is rainproof, whenever possible install it where it is protected from water

splashes. The reasoning for this is that the detector cover may need to be removed for maintenance or for other reasons.

l Altitude of installation site is lower than 2,000 m.

IM 11T3E1-01E

Page 25

<2. Installation, Wiring and Piping>

2.1.2 GD40T (FM Explosion-proof and Intrinsically Safe Approval)

2-2

NON-HAZARDOUS

LOCATIONS

Sealing Fitting

Figure 2.1

HAZARDOUS

LOCATIONS

475 mm (18") Max.

Conduit

GD40T

F0201.ai

1. GD40T Gas density detector for use in hazardous (classied) locations:

• Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G with Intrinsically

Safe sensor for Class I, II, III, Division 1, Groups B, C, D, E, F and G.

• Enclosure Rating: NEMA 4X

• Temperature Code: T5

• Ambient Temperature: -10 to 60°C

2. Wiring

• All wiring shall comply with National Electric Code ANSI/NAPA 70 and Local Electrical

Codes.

WARNING

Seal all conduits within 475 mm (18 inches). Refer to Figure 2.1.

3. Operation

• Note a warning label worded as follows.

WARNING

Open circuit before removing cover.

• Take care not to generate mechanical spark when access to the instrument and

peripheral devices in hazardous locations.

4. Maintenance and Repair

• The instrument modication or parts replacement by other than authorized representative

of Yokogawa Electric Corporation is prohibited and will void the approval of Factory

Mutual Research Corporation.

IM 11T3E1-01E

Page 26

<2. Installation, Wiring and Piping>

2.1.3 GD40V (CSA Explosion-proof and Intrinsically Safe Approval)

2-3

NON-HAZARDOUS

LOCATIONS

Sealing Fitting

Figure 2.2

HAZARDOUS

LOCATIONS

500 mm (20") Max.

Conduit

GD40V

F0203.ai

1. GD40V Gas density detector for use in hazardous (classied) locations:

• Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G with Intrinsically

Safe sensor for Class I, II, III, Division 1, Groups B, C, D, E, F and G.

• Enclosure Rating: Type 4X

• Temperature Code: T5

• Ambient Temperature: -10 to 60°C

2. Wiring

• All wiring shall comply with Canadian Electrical and Local Electrical codes.

• Note a warning label worded as follows.

WARNING

A seal shall be installed within 500 mm (20 inches) of the enclosure. Refer to Figure 2.2.

3. Operation

• Note a warning label worded as follows.

WARNING

• Open circuit before removing cover.

• Substitution of components may impair instrinsic safety.

• Take care not to generate mechanical spark when access to the instrument and

peripheral devices in hazardous locations.

4. Maintenance and Repair

• The instrument modication or parts replacement by other than authorized representative

of Yokogawa Electric Corporation is prohibited and will void the certication of CSA

International.

IM 11T3E1-01E

Page 27

<2. Installation, Wiring and Piping>

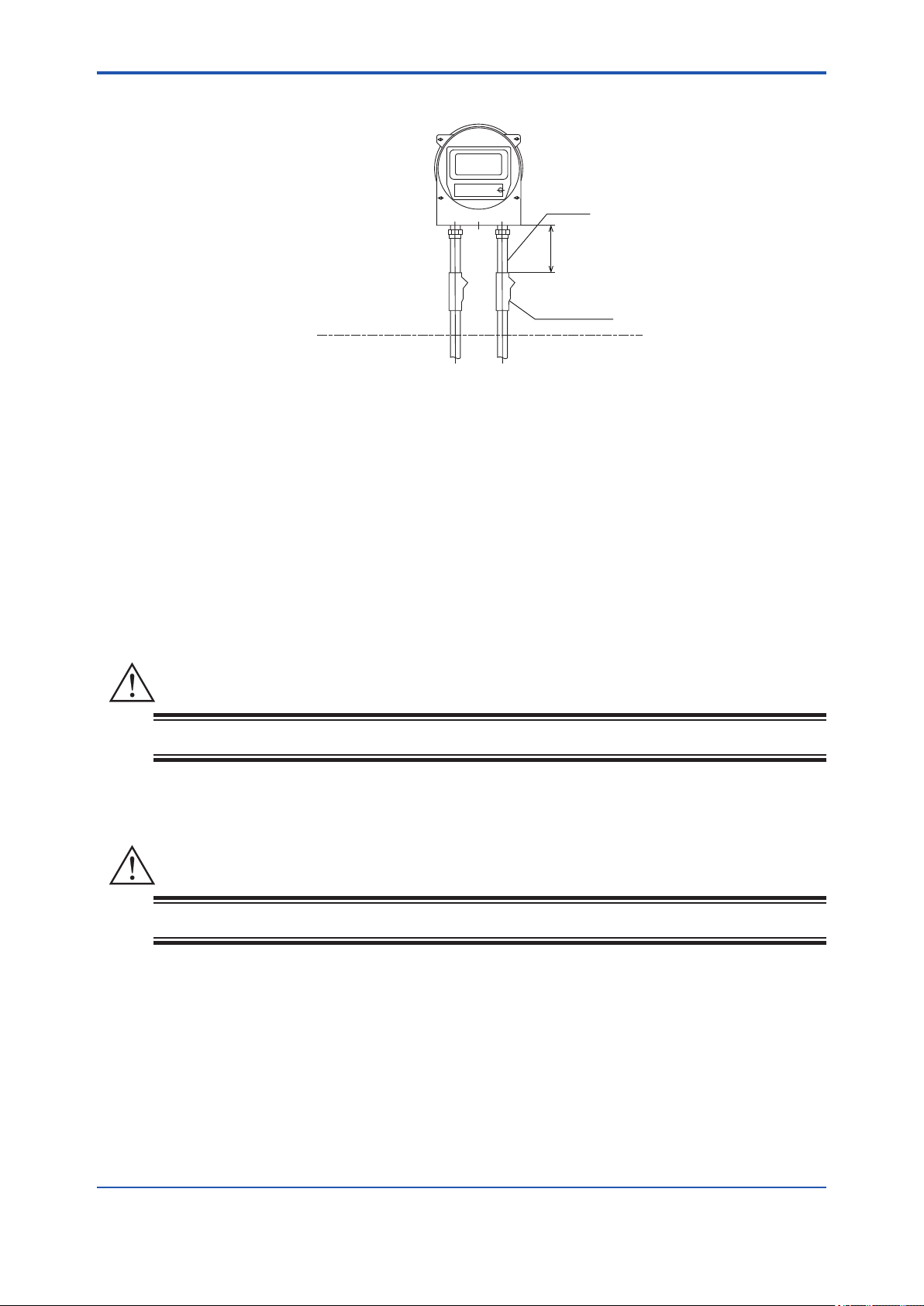

2.1.4 Mounting the Detector

The detector is designed for pipe mounting.

Pipe-mounting

hardware

Approx. 191 (7.5)

Approx. 92 (3.6)

Grounding terminal

(3 mm (0.11) screw)

Wiring hole,

GD40R: G1/2

GD40V: 1/2 NPT

GD40T: 1/2 NPT

GD40G: 1/2 NPT

Approx. 117 (4.6)

Sample gas inlet

GD40R: Rc1/4

GD40V: 1/4 NPT

GD40T: 1/4 NPT

GD40G: 1/4 NPT

Approx. 264 (10.4)

Approx. 193 (7.6)

2-4

Unit: mm (in.)

Mounting pipe

(JIS 50 A (60.5 mm in

outer dia.) nominal size)

Figure 2.3 Vertical Mounting

Sample gas outlet

GD40R: Rc1/4

GD40V: 1/4 NPT

GD40T: 1/4 NPT

GD40G: 1/4 NPT

Note: Cable gland is included only in GD40R.

F0205.ai

IM 11T3E1-01E

Page 28

<2. Installation, Wiring and Piping>

2.2 Installing the Converter

The GD402 converter comes in either the non-explosion-protected Model GD402G or explosionprotected Model GD402T, V, R (explosion-protection code: Refer to 1.1.1).

Choose the Model GD402T or V or R if the converter is to be used in a hazardous area.

2.2.1 Selecting the Location

l Ease of operation

Select a location where you can easily view the readings on the display and work with the keys.

Installing the converter closer to the detector will ease your maintenance work, including calibration.

l Explosion-proof construction

When installing the converter in an explosion-hazardous area, ensure that the area conforms to

the explosion-proof code noted above.

l No corrosive gases

Corrosive gases are not desirable because they may damage the electrical components in the

converter.

l Slight mechanical vibration

2-5

Although the converter is vibration-resistant, vibration may loosen the connections of the external

wiring.

l No exposure to direct sunlight

Exposure to direct sunlight may raise the temperature in the converter to abnormal levels, and

should therefore be avoided. Note that such abnormal temperature levels can also result from

heat irradiated from high-temperature equipment around the converter. If the converter is likely to

receive direct sunlight and the temperature in the converter will likely exceed the operating limits,

attach a hood (optional).

l Humidity maintained between 5% and 95% RH.

Avoid choosing a location that is likely to be exposed to abnormally high or low humidity over a

prolonged period. It is recommended that the converter be used at a humidity between 25% and

85 % RH.

l No exposure to rainwater

Even though the converter is rainproof, whenever possible install it where it is protected from

water splashes. The reasoning for this is that the converter cover may need to be removed for

maintenance or for other reasons

l Altitude of installation site is lower than 2,000 m.

IM 11T3E1-01E

Page 29

<2. Installation, Wiring and Piping>

2.2.2 GD402T (FM Explosion-proof Approval)

GD402T

2-6

HAZARDOUS

LOCATIONS

NON-HAZARDOUS

LOCATIONS

Figure 2.4

Conduit

475 mm (18") Max.

Sealing Fitting

F0202.ai

1. GD402T Gas density converter for use in hazardous (classied) locations:

• Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G

• Enclosure Rating: NEMA 4X

• Temperature Code: T6

• Ambient Temperature: -10 to 55°C

2. Wiring

• All wiring shall comply with National Electrical Code ANSI/NFPA 70 and Local Electrical

Codes.

WARNING

Seal all conduits within 475 mm (18 inches). Refer to Figure 2.4.

3. Operation

• Note a warning label worded as follows.

WARNING

Open circuit before removing cover.

• Take care not to generate mechanical spark when access to the instrument and

peripheral devices in hazardous locations.

4. Maintenance and Repair

• The instrument modication or parts replacement by other than authorized representative

of Yokogawa Electric Corporation is prohibited and will void the approval of Factory Mutual

Research Corporation.

IM 11T3E1-01E

Page 30

<2. Installation, Wiring and Piping>

2.2.3 GD402V (CSA Explosion-proof Approval)

GD402V

HAZARDOUS

LOCATIONS

Conduit

500 mm (20") Max.

Sealing Fitting

2-7

NON-HAZARDOUS

LOCATIONS

Figure 2.5

F0204.ai

1. GD402V Gas density converter for use in hazardous (classied) locations:

• Explosion-proof for Class I, Division 1, Groups B, C and D;

Dust Ignition-proof for Class II, III, Division 1, Groups E, F and G

• Enclosure Rating: Type 4X

• Temperature Code: T6

• Ambient Temperature: -10 to 55°C

2. Wiring

• All wiring shall comply with Canadian Electrical Code and Local Electrical Codes.

• Seal all conduits within 500 mm of the enclosure. Refer to Figure 2.5.

• Note a warning label worded as follows.

WARNING

A seal shall be installed within 500 mm (20 inches) of the enclosure.

3. Operation

• Note a warning label worded as follows.

WARNING

Open circuit before removing cover.

• Take care not to generate mechanical spark when access to the instrument and

peripheral devices in hazardous locations.

4. Maintenance and Repair

• The instrument modication or parts replacement by other than authorized representative

of Yokogawa Electric Corporation is prohibited and will void the certication of CSA International.

IM 11T3E1-01E

Page 31

<2. Installation, Wiring and Piping>

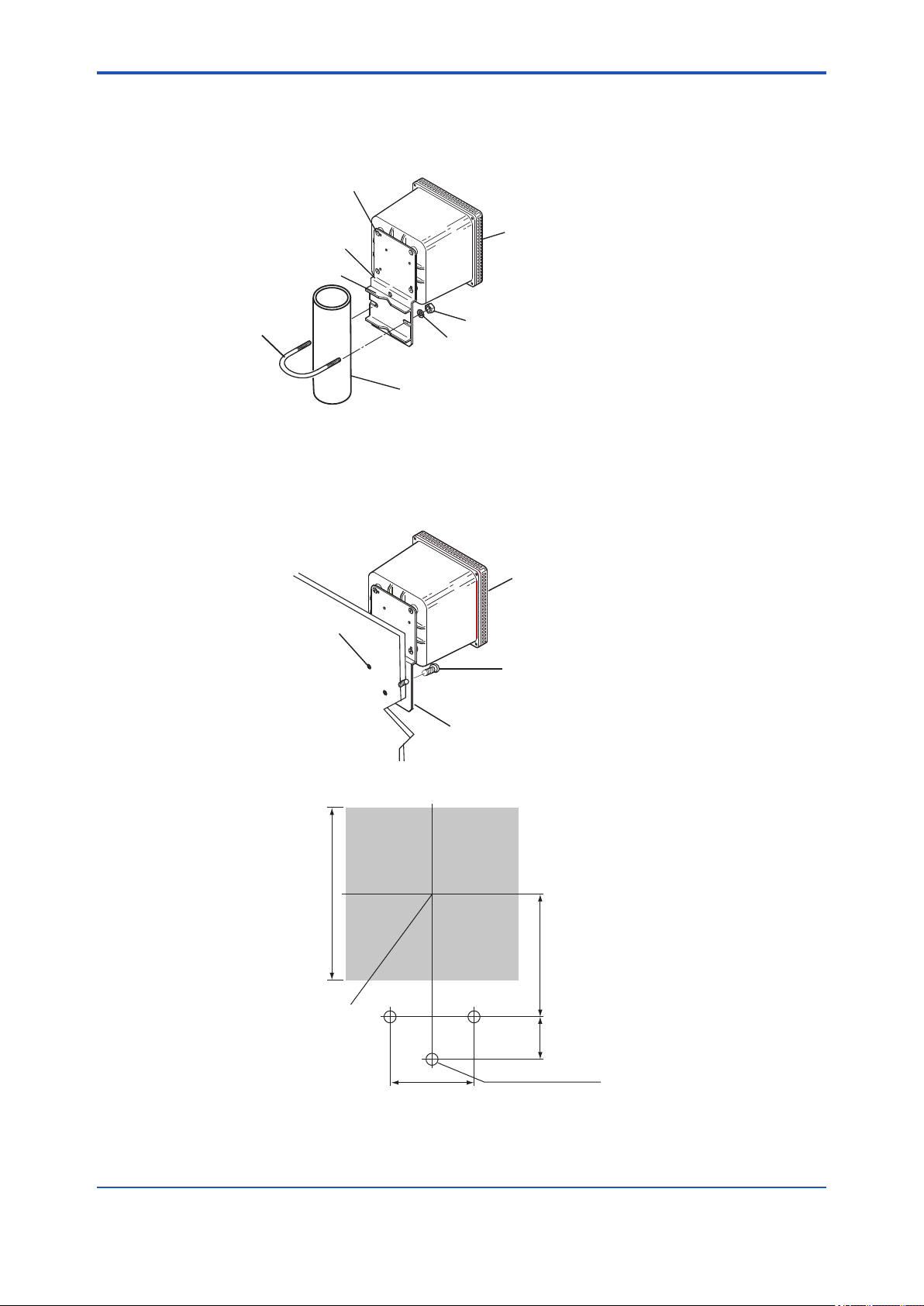

2.2.4 Mounting the Converter

(1) Mounting the GD402G Converter

● Pipe Mounting

Bracket mounting screws

2-8

Bracket

Pipe mounting bracket

U-bolt

Washers (2 pcs)

Stanchion(Ø60.5 mm pipe)

Converter

Nut (2 pcs)

Figure 2.6 Pipe Mounting

● Wall Mounting

Figure 2.3 shows how to mount the converter on a wall.

Converter

Mounting hole (3 places)

Note: The converter for wall

mounting comes with the same

mounting hardware as that of a

pipe-mounting model.

When installing the converter on

a wall, use the bracket only.

Bracket

M8 bolts (not supplied)

Provide bolts of a length suitable

for the mounting holes.

F0206.ai

F0207.ai

144

Center of

the converter

Dimension of cutout for wall mounting

Figure 2.7 Wall Mounting

70

Unit : mm

102

35

3-M8 screw-hole or

3-Ø10 through-holes

F0208.ai

IM 11T3E1-01E

Page 32

<2. Installation, Wiring and Piping>

● Panel Mounting

Figure 2.4 shows how to mount the converter on a panel.

2-9

Panel

Converter

Bracket

Insert the converter in

the panel cutout before

attaching the brackets.

Fixing screws (2 pcs)

Figure 2.8 Panel Mounting

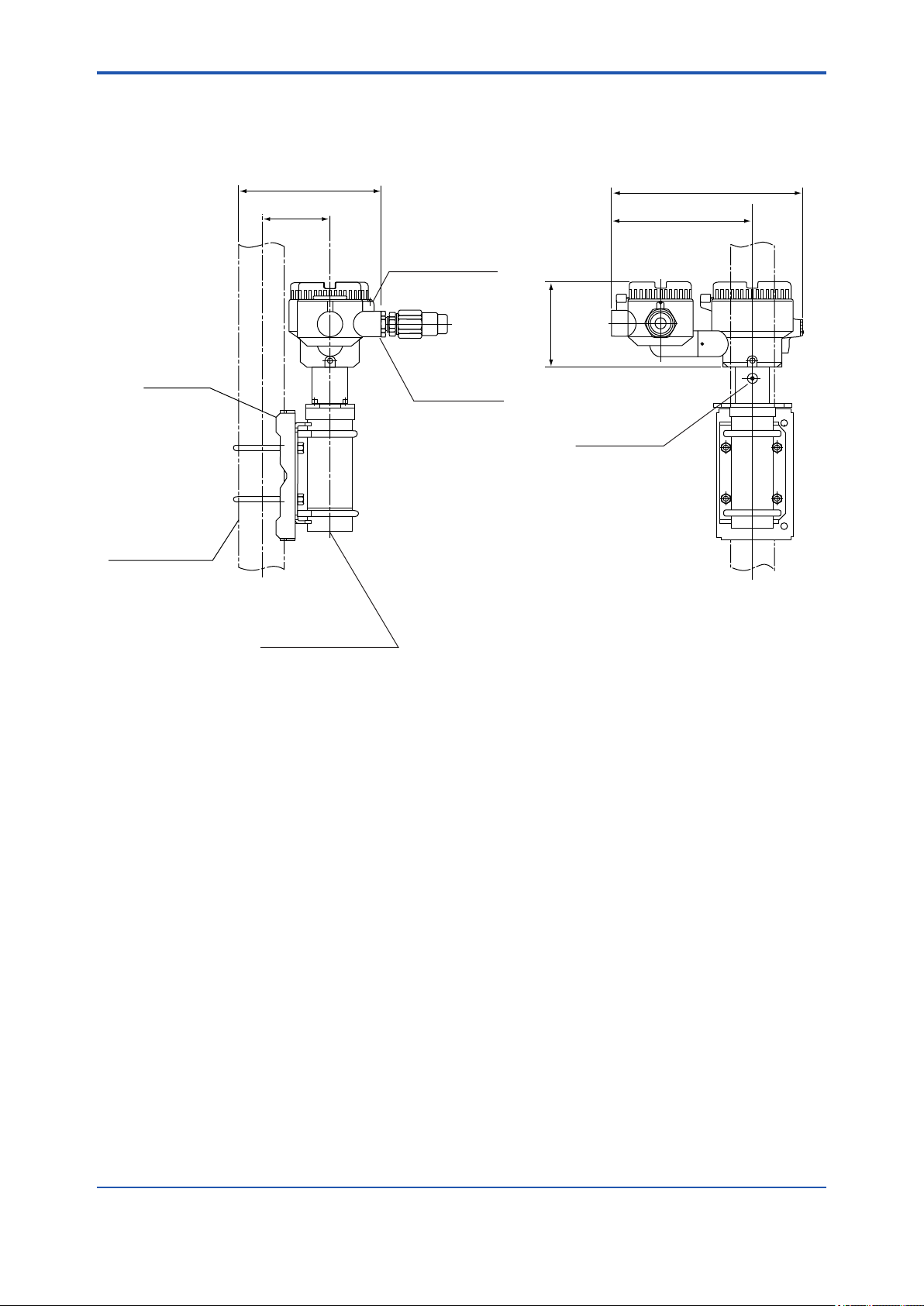

(2) Mounting the GD402T, V, R Converter

Pipe-mounting hardware

200 (7.9)

Φ212 (8.3)

182 (7.2)

A

+2

139

0

Dimensions of cutout for panel mounting

Weight : approx. 15 kg (33.1 pounds)

Mounting pipe of JIS 50 A nominal size (Φ60.5)

209 (8.2)

173 (6.8)

Unit : mm

139

Unit : mm (in.)

+2

0

F0209.ai

36 (1.4)

140 (5.5)

4 - M8 depth 20

Side view from arrow A direction

Cable glands not included

24 (0.9)

39

(1.5)

54

(2.1)

Grounding terminal (M5)

Figure 2.9 Mounting Explosion-proof Converter

200 (7.9)

A B

D ECF

56

56

(2.2)

(2.2)

242 (9.5)

2 - M8 depth 16 (one on each side)

(Used to fix the pipe-mounting hardware)

Six wiring holes, G3/4 threaded (GD402R)

1/2 NPT threaded (GD402V, T)

F0210.ai

IM 11T3E1-01E

Page 33

<2. Installation, Wiring and Piping>

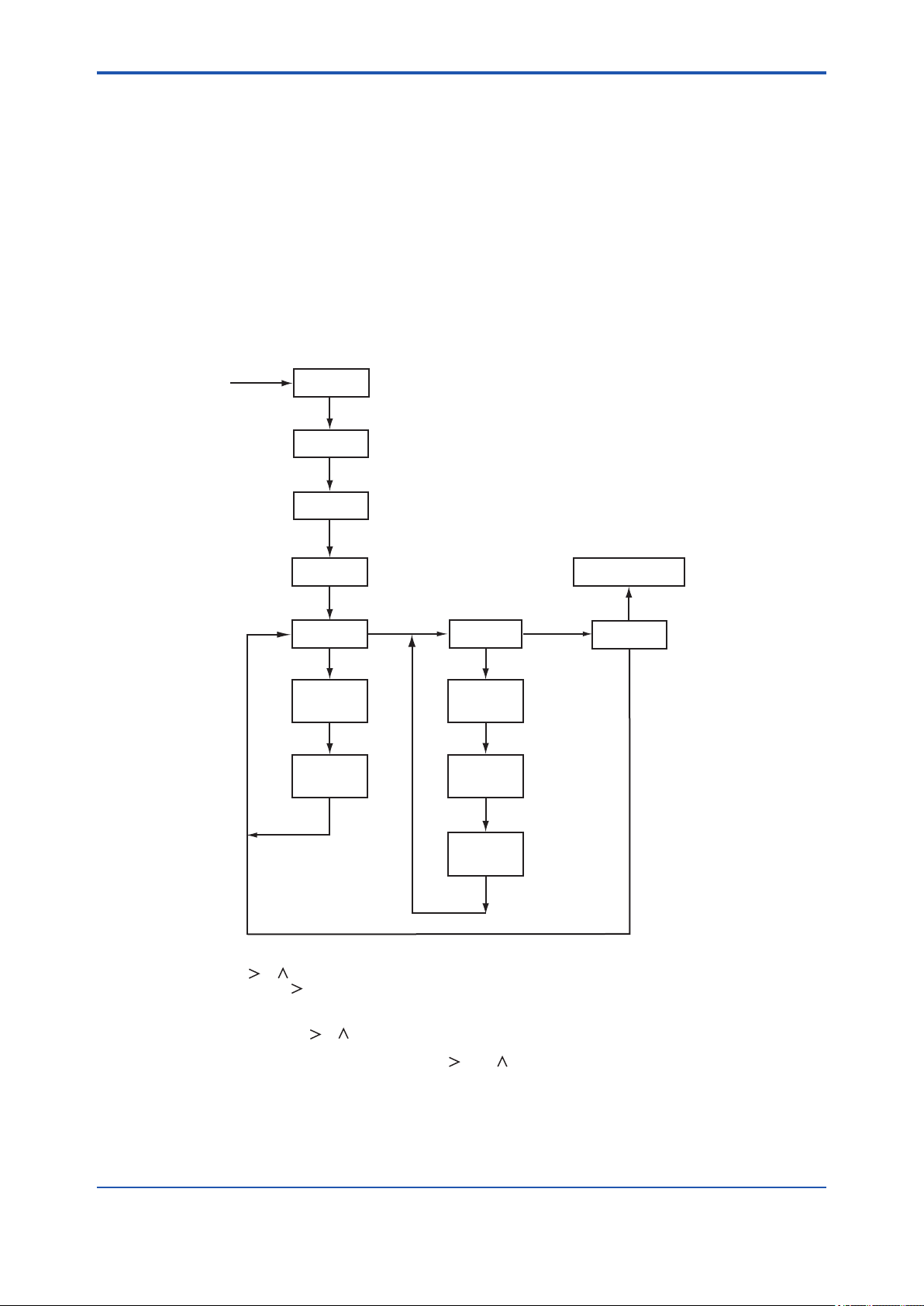

2.3 Piping

CAUTION

In the case of replacement range, H2 in CO2 or Air in CO2, the output happen to be uctuated by

pressure loading to detector. In order to reduce the effect, owmeter is to be set upper side of

detector so that the pressure loading to the detector is going to be about atmospheric pressure.

The piping connected to the analyzer comprises a line that feeds the gas under measurement to

the detector, a line that returns (or releases to the atmosphere) the gas exhausted after measurement, and lines that carry the zero and span calibration gases. The type of piping chosen

depends on the composition of the gas under measurement, its pressure, the amount of dust

mixed, and the response (dead time). It is advisable however to use stainless steel piping of sizes

from 6 mm and 4 mm in outer and inner diameters up to JIS 15 A (21.7mm in outer dia.).

Refer to the following instructions when connecting the analyzer piping.

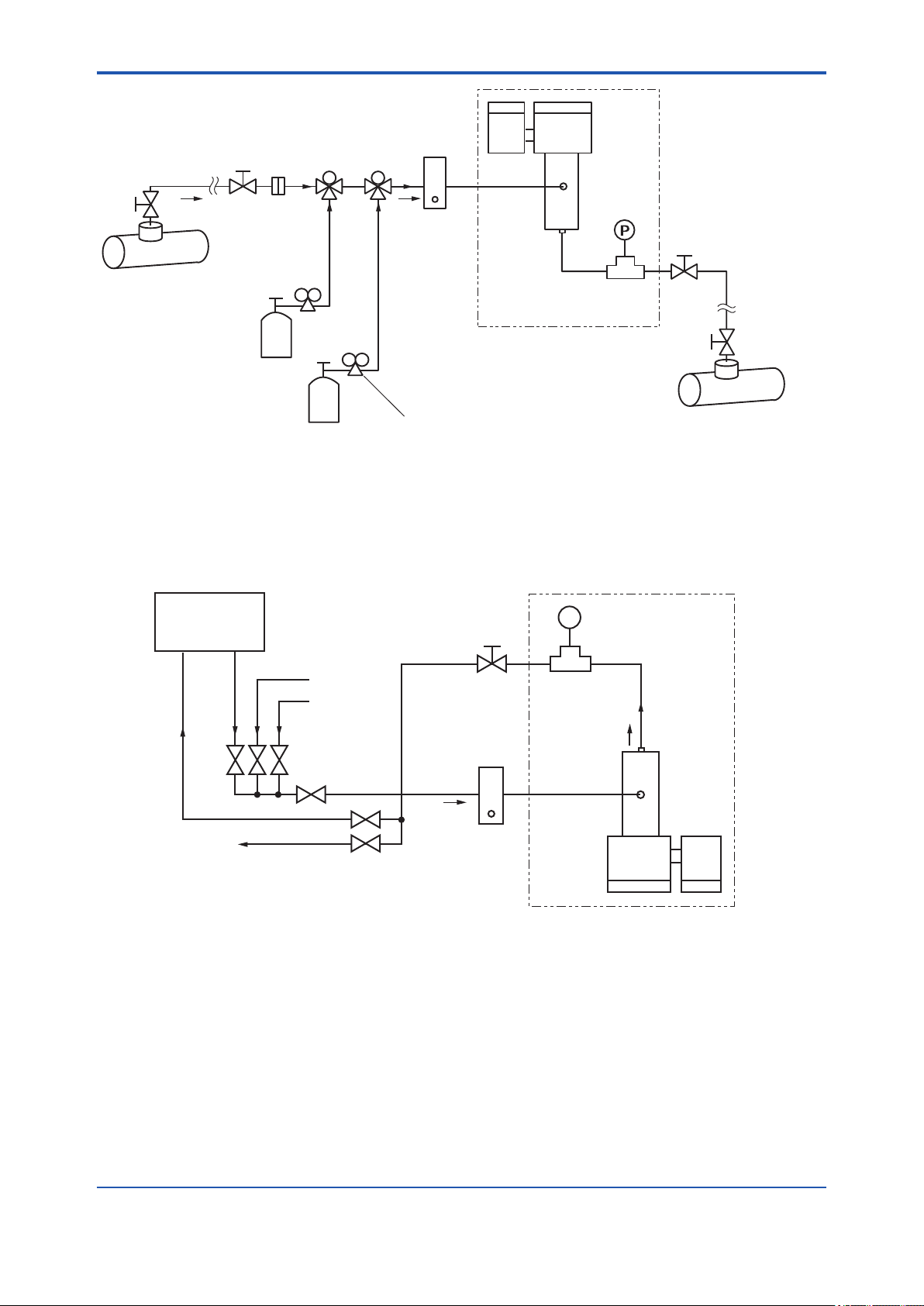

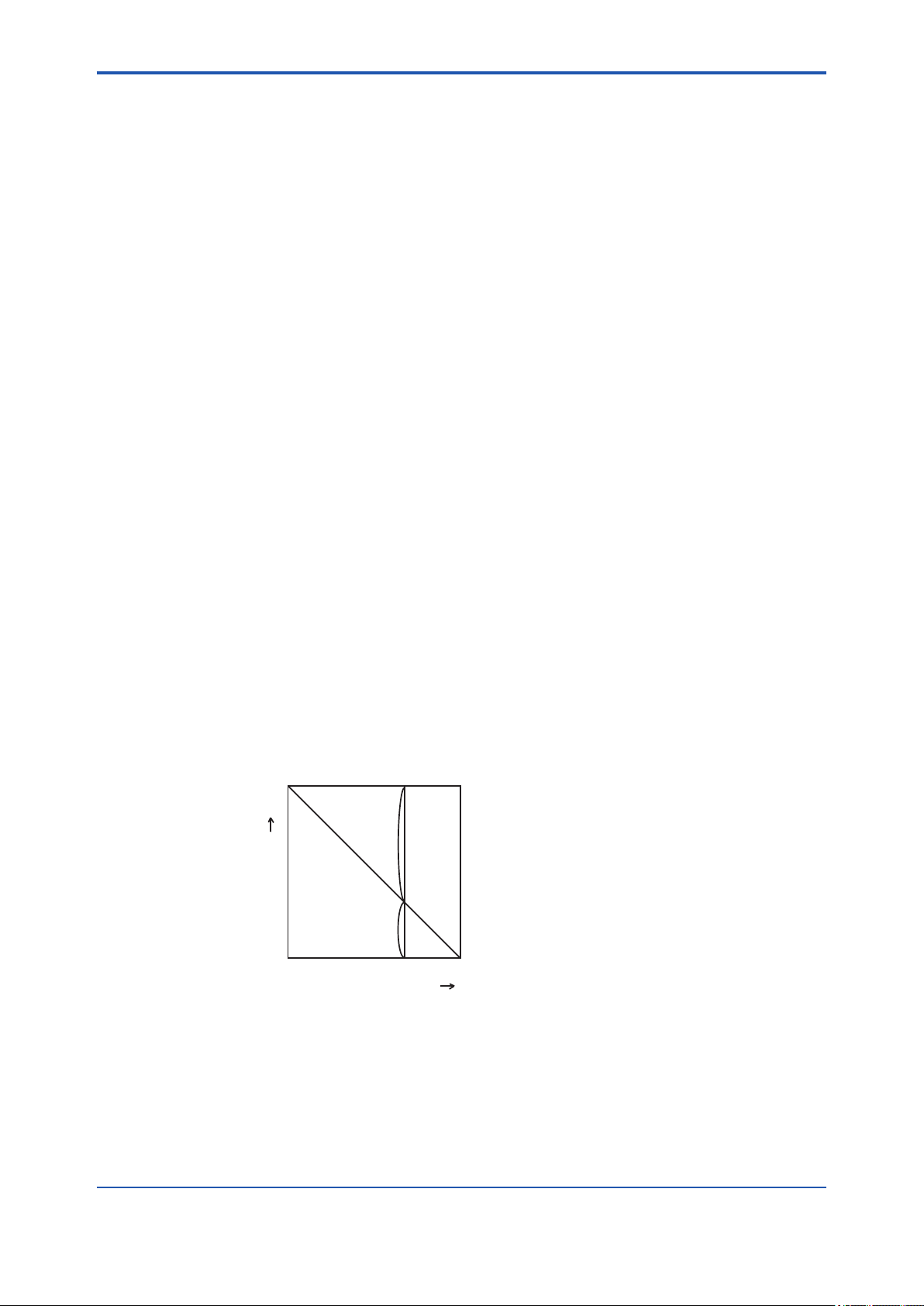

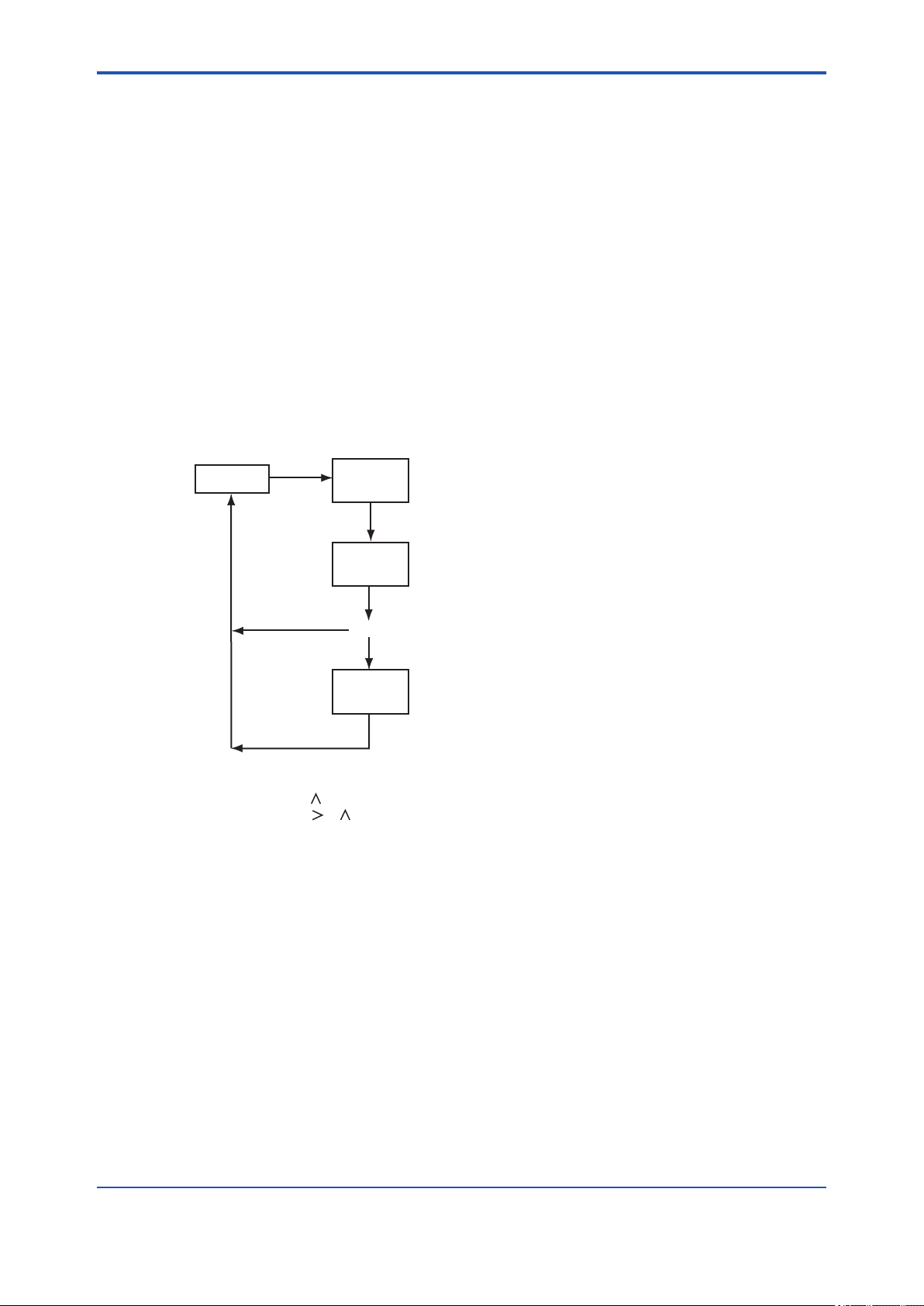

l Figure 2.10, "System Conguration," shows an example of piping. Connect the lines secure-

ly to ensure that there is no gas leakage in the system.

l Make sure the pressure of the sample gas is no greater than 0.5 MPa when measured at

the detector inlet. If the pressure is too high, use a pressure reducing valve to regulate the

pressure to a normal level. If the pressure is too low, it must be raised using a pump.

2-10

l If the gas under measurement contains dust, mist or moisture, such impurities must be

removed. Install a lter, mist separator or dehumidier to remove these impurities from the

gas.

l In order to return the gas exhausted after measurement, the difference in pressure between

the detector inlet and the point of returning the gas must be 0.5 kPa minimum. Choose piping with a large inner diameter to minimize pressure loss in the return gas line.

l ALWAYS install a stop valve at the point where the gas is sampled (or returned).

l The pressure transmitter for compensating pressure is designed to detect the pressure

inside the detector; install a pressure lead pipe as close to the detector as possible (preferably, no more than 0.5 m away).

IM 11T3E1-01E

Page 34

<2. Installation, Wiring and Piping>

2-11

Sample gas line

Note 1: P1 (Inlet pressure)

Note 2: P1 (Inlet pressure) - P2 (Outlet pressure)

Note 3: Flowrate = 0.1 to 1 l/min

Note 4: The cylinder pressure must be reduced to P1 (Inle t pressure).

(1) Example of Gas density and Calorie meters

Gas for zero

calibration

Gas for span

calibration

Switching valve

Filter

Note 4

Note 4

Supplied by customer.

<

Max. 0.5 MPa (71 psi)

=

Note 1

P1

Flowmeter

Note 3

Pressure regulator

for gas cylinder

>

0.5 kPa (0.071 psi) (depending on the size and length of the pipe)

=

Note 2

P2

EJA (Explosion-proof

pressure transmitter)

Detector unit (EJA and GD40 detector

mounted on plate)

(Supplied by Yokogawa)

F0211.ai

Generator

Calibration gas

CO

2

Note 4

AIR

Vent

Note 1 : P1 (Inlet pressure )

<

Max 0.5884 MPa (abs.)

=

Flowmeter

Note 2

Note 2 : Flowrate = 0.1 to 1 l/min

Note 3 : P1 (Input pressure ) - P2 (Output pressure )

>

0.5 kPa

=

Note 4 : The cylinder pressure must be reduced to P1(Inlet pressure).

(2) Example of Hydrogen purity meter

Figure 2.10 System Conguration

Explosion-proof

P

pressure transmitter

Note 1

P1

Detector unit

Note 3

P2

F0212.ai

IM 11T3E1-01E

Page 35

<2. Installation, Wiring and Piping>

2.4 Wiring

WARNING

Danger High Voltage !

Some parts of the meter’s internal assembly have high voltages. Inadvertent contact with those

parts may result in electrical shock or injury. ALWAYS turn off the power to the meter before

removing the rear or front cover by using external circuit breaker.

This section explains how to wire the GD402 Analyzers. Note that this document is limited to the

basic system conguration only (detector, converter and pressure transmitter).

For details on the wiring of instruments used to receive analog output signals or contact output

signals, see their respective instruction manuals.

CAUTION

The GD402 gas density meter is shipped after adjusting the both of detector and converter in

pairs. When installation, conrm whether the serial number on both of converter and detector are

in pairs or not. If mismatched in pairs, converter is to be out of order. When converter or detector

supplied individually, enter the detector constants, described on inside the lid of the GD40, into

converter so that the GD402 is going to be well.

In detail, please refer to Figure 5.30, Figure 6.31 or Figure 7.28.

2-12

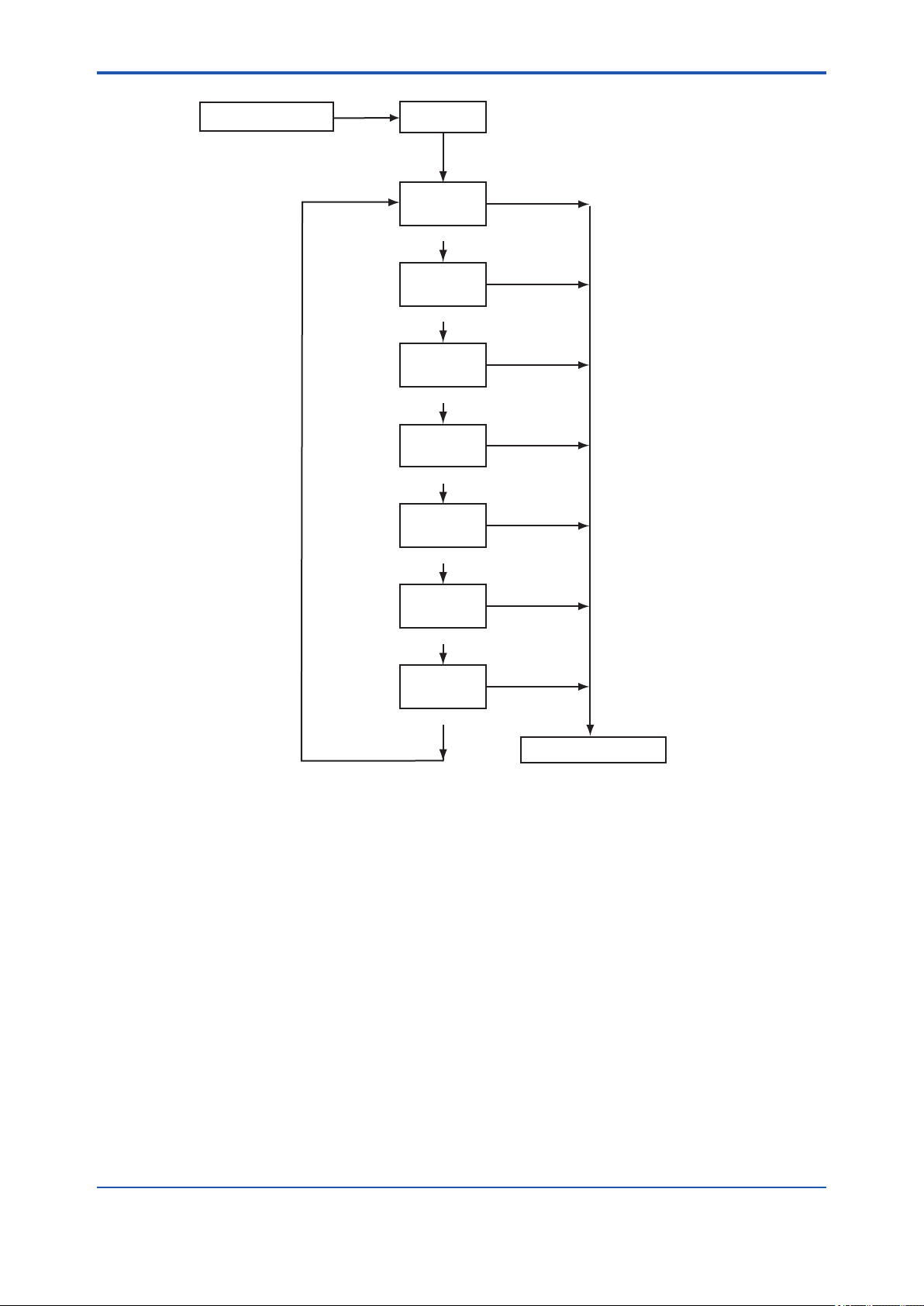

2.4.1 Wiring Procedure

(1) The types of cables wired to the GD402 Analyzers are:

• Cable wired to power supply

• Cable wired to detector input

• Cables wired to output signals (two) -- or one signal if BRAIN communication is used

• Cables wired to contact outputs (ve) -- provided as necessary

• Cable wired to contact input -- provided as necessary

• Cables wired to pressure transmitter

• Cables wired to the ground

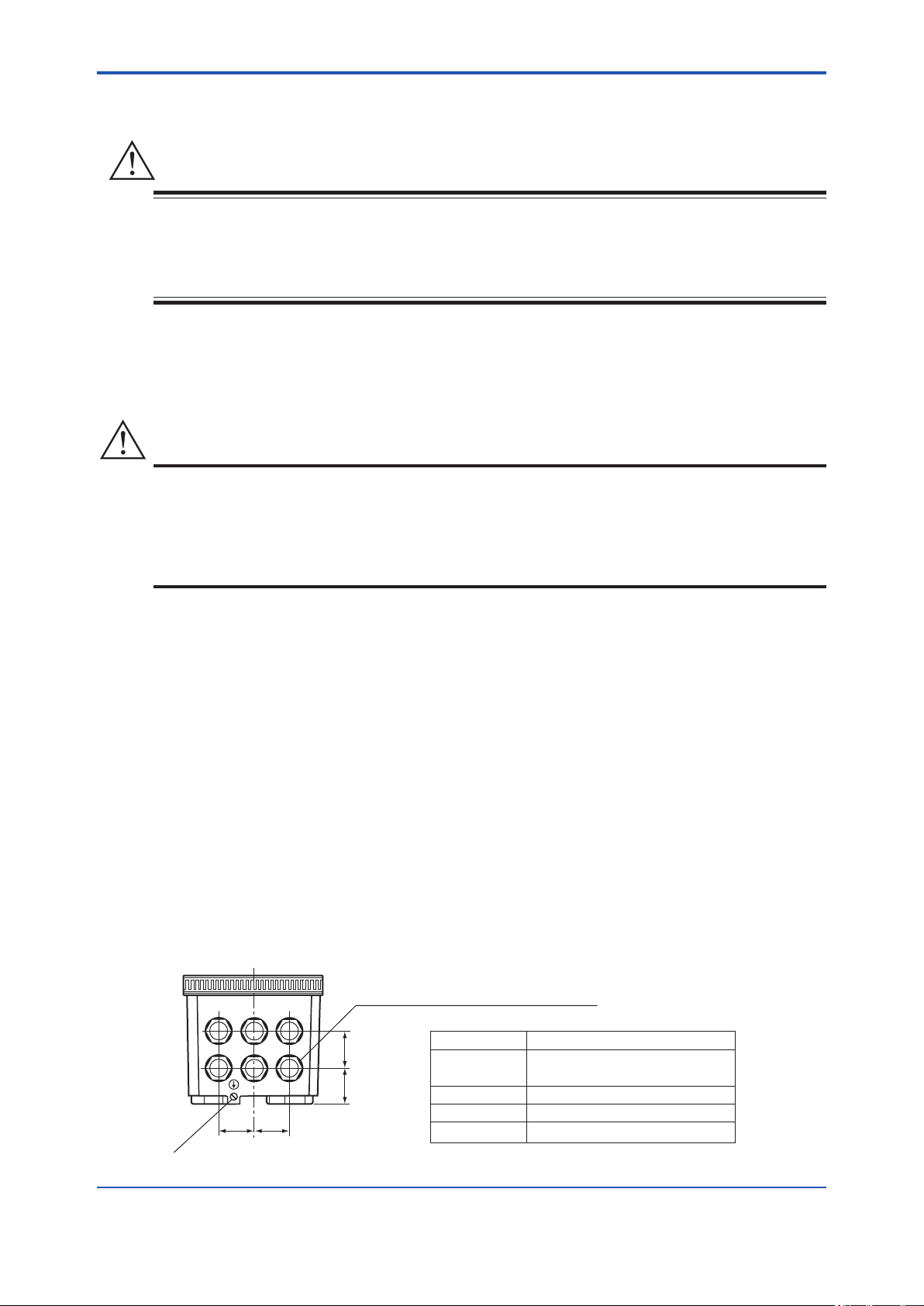

(2) The GD402 converter has six cable inlets for external wiring. Wire the converter through

cable glands. As a rule, choose cable glands as shown in Figure 2.11.

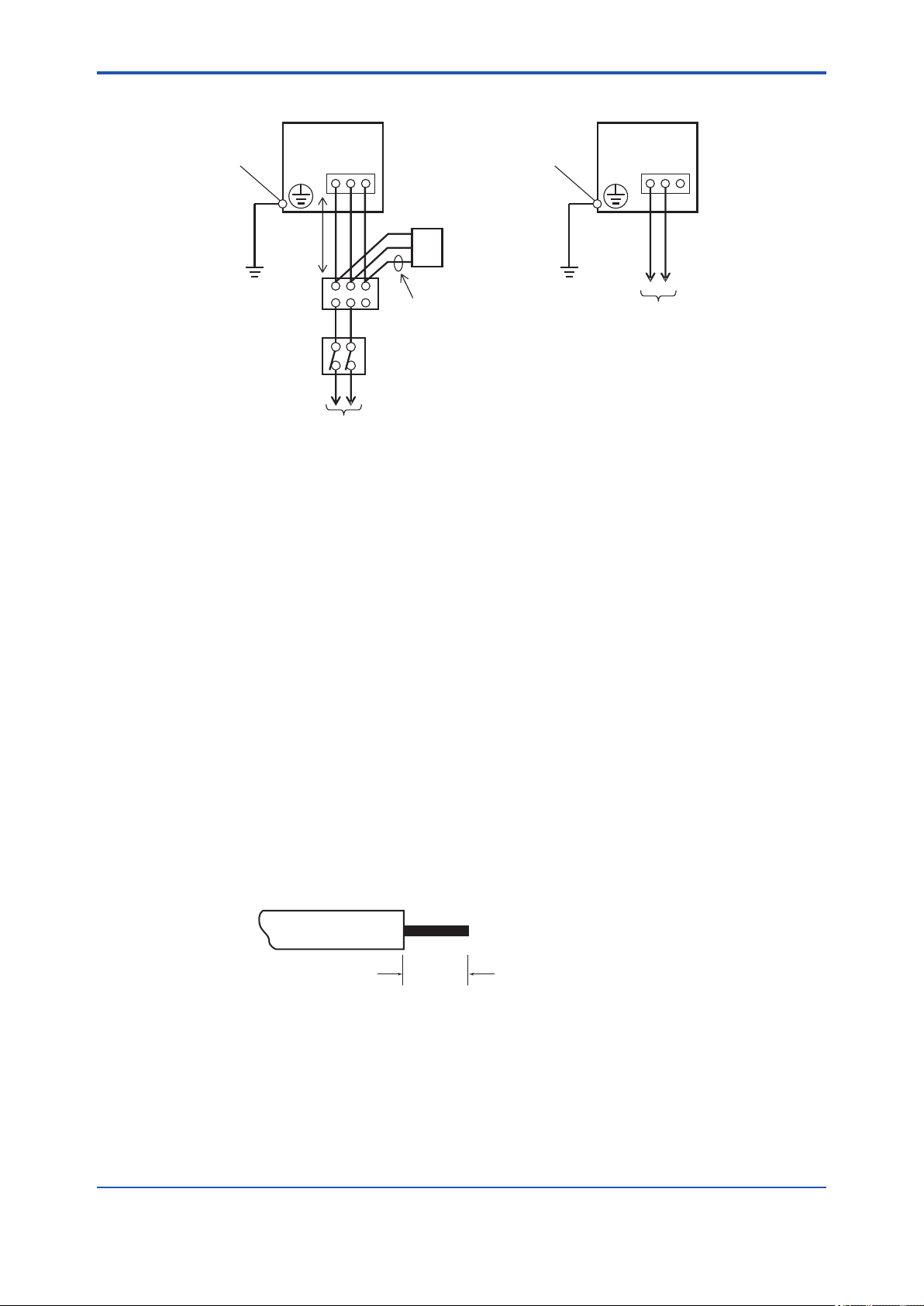

<GD402G>

Cable inlet (21 mm in dia.)

Compatible with a PG 13.5 cable gland

A B

D F

36 36

Grounding terminal (4 mm screws)

C

36

(1.4)

E

(1.4)(1.4)

38

(1.5)

Cable gland Connection

A, B

D, E

F

Weight : Approx. 3 kg (6.6 pounds)

(including mounting hardware)

• Pressure transmitter

• Analog Output • Contact Input

• DetectorC

• Contact Output

• Power Supply

Unit : mm (in.)

F0213.ai

IM 11T3E1-01E

Page 36

<2. Installation, Wiring and Piping>

<GD402T, V, R>

24 (0.9)

39

(1.5)

54

(2.1)

A B

D E

C

F

Cable gland

A

B, C

D

E, F

• Power Supply

• Contact Output

• Detector

• Pressure Transmitter

• Analog Output • Contact Input

2-13

Unit : mm (in.)

Connection

Grounding terminal (M5)

56

(2.2)

56

(2.2)

Six wiring holes, G3/4 threaded (GD402R)

1/2 NPT threaded (GD402V, T)

F0214.ai

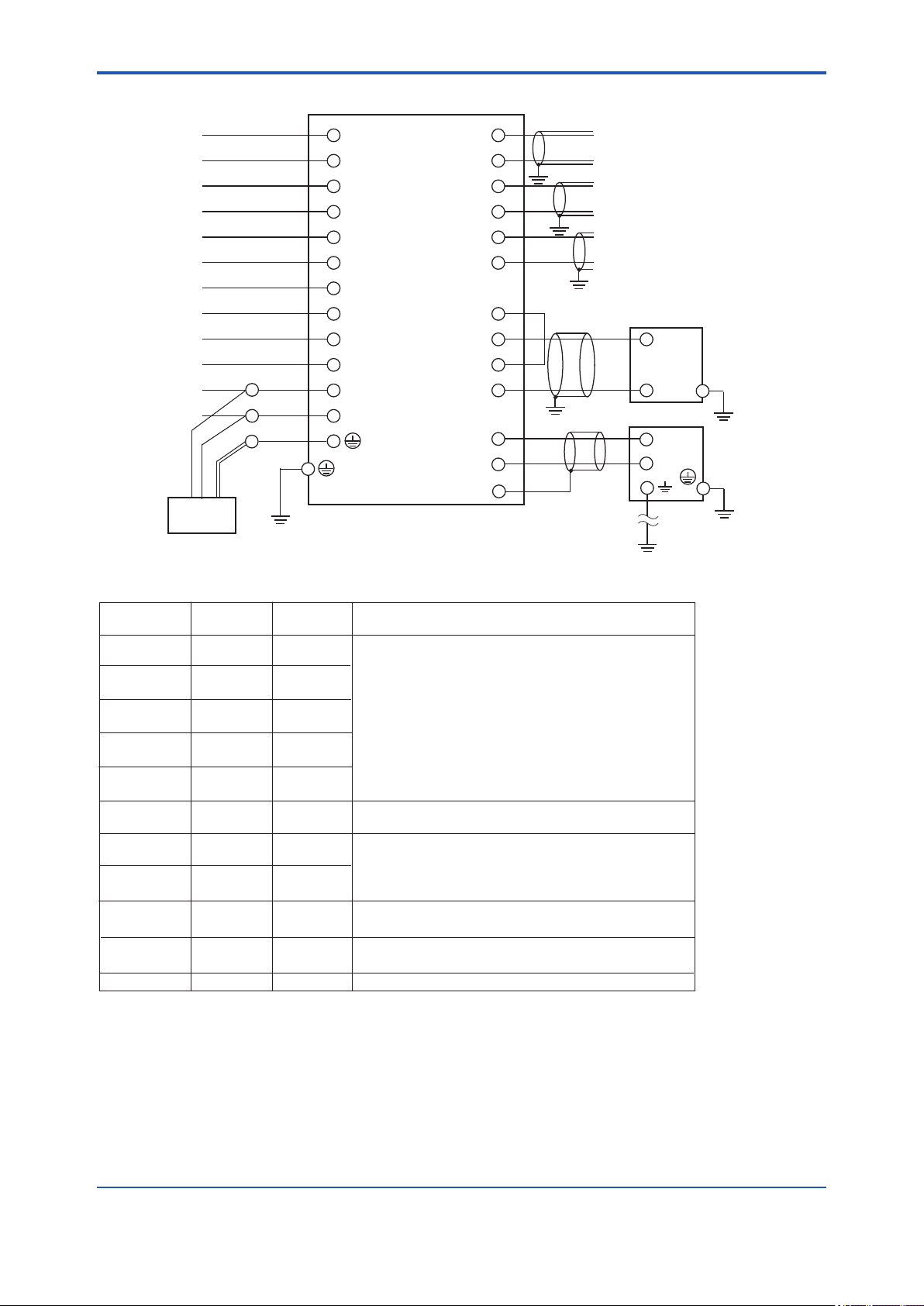

(3) The following explains the general wiring procedure for each type of converter.

<Wiring the GD402T, V, R converter>

CAUTION

The rear cover and the metal plugs at the external-wiring connections are xed onto the converter case with hex setscrews. Before removing the cover, be SURE to loosen the setscrews. If you

rotate the cover or a plug without loosening the setscrews, their threads may be severed, making

the cover unremovable.

When the rear cover or any of the cable glands or plugs are removed, handle them with utmost

care so that the threads are not damaged. When re-attaching it on to the converter, clean the

threads so they will not be damaged due to such foreign matters as dust.

• Loosen the setscrews and remove the rear cover by rotating it counterclockwise.

• Guide the required external-wiring cables through the cable glands to the converter.

Exercise care so as to avoid connecting them with the wrong polarities.

• After wiring, securely fasten the rear cover and cable glands.

<Wiring the GD402G converter>

• Loosen the setscrews in the four corners and remove the front cover.

• Remove the terminal cover. Guide the required external-wiring cables through the cable

glands to the converter. Beware of the correct polarities.

• After wiring, reinstall the terminal cover and front cover in place.

IM 11T3E1-01E

Page 37

<2. Installation, Wiring and Piping>

GD402 Converter

2-14

MAINTENANCE

Contact output

ALARM

Contact output

FAIL

Contact output

FUNCTION

Contact output

SELECT GAS

Contact output

Power supply

100 to 240 V AC

or 24 V DC

Surge protector

*1

14

MAINT

15

16

ALM

17

18

FAIL

19

20

SPAN/FUNC

21

22

ZERO/SEL GAS

23

24

L or + -

25

N or -

26

Case grounding

terminal

1

+

CONT

INP

ANLG

OUT1

ANLG

OUT2

SNSR

PWR

SNSR

INP

DET

INP

SHIELD

2

-

3

+

4

-

5

+

6

-

7

+

8

- -

9

+

10

11

+

12

-

13

Intrinsic safety

Grounding

Class A grounding

(grounding resistance

10 Ω or less)

Contact input

Isolated 4-20 mA Output

with BRAIN Communication

Isolated 4-20 mA Output

Pressure Transmitter

Case grounding

+

GD40 Detector

+

-

Case grounding

2

*

*4

terminal

terminal

Cable List

Terminal Indication

MAINTENANCE

Contact output

ALARM

Contact output

FAIL

Contact output

FUNCTION

Contact output

SELECT GAS

Contact output

Contact input CONT IN

Analog output1

Analog output2 ANLG OUT2

Pressure

transmitter input

Detector input

Supply

*1 Surge protector is not provided with GD402T/V/R type converter.

*2 Intrinsic safety grounding

GD402V, GD40V; All wiring should comply with Canadian Electrical Code and Local Electrical Codes.

GD402T, GD40T; All wiring should comply with National Electrical Code and ANSI/NFPA 70 and

Local Electrical Codes.

*3 Restriction on cable length does not apply to GD402T/V/R type converter.

*4 When select GD402T/V/R.

MAINT

ALM

FAIL

SPAN

ZERO

ANLG OUT1

SNSR PWR

SNSR INP

DET INP

SHIELD

L, N, G

Shield

Requirement

Unshielded

Unshielded

Unshielded

Unshielded

Unshielded

Shielded

Shielded

Shielded

Shielded

Shielded

Unshielded

Requirement

For outdoor wiring, cable length should be less than 30 m .

Shield should be grounded at one end only.

Total resistance should not exceed 50 Ω.

For outdoor wiring, cable length should be less than 30 m .

Shield should be grounded at one end only.

Maximum load resistance including wire resistance is 600Ω . When

BRAIN communication is used, it is 250 to 550 Ω.

Total resistance should not exceed 50 Ω.

For outdoor wiring, cable length should be less than 30 m

Shield should be grounded at one end only.

Total resistance should not exceed 50 Ω.

For outdoor wiring, cable length should be less than 30 m

Connect shield to SHIELD terminal on converter.

*

3

*

3

3

*

.

*

3

.

F0215.ai

Figure 2.11 Terminals on the Converter

IM 11T3E1-01E

Page 38

<2. Installation, Wiring and Piping>

CAUTION

The following instructions should be observed for the GD402G converter to meet the CE marking

requirements.

1. Connect the supplied surge protector to the power supply.

2. The length of the following cables should be less than 30 m. However, this restriction does

not apply when both detector and converter stay indoors and their cables do not run outdoors. For details, read Subsection 2.4.1, “Wiring Procedure.”

1) Detector input

2) Pressure transmitter input

3) Analog output1, 2

4) Contact input

Electrical Noise Protection

If a malfunction due to noise occurs, strengthen measures against noise.

For example, ground the detector body or use a double-shielded cable. If a double-shielded cable is used, ground shields of each conductor at one end. Ground one end of the outer shield on

the detector side to the detector case and connect the other end on the converter side to terminal

13. See the User’s Manual for more instructions on cable installation.

2-15

Contact Input Function of the Hydrogen Purity Meter

For hydrogen purity meter, the contact input is used for range selection.

Open: Concentration measurement for Air in CO2

Close: Concentration measurement for H2 in CO2.

Contact Output Specications

Indication Specication

MAINT Contact Type: Voltage free, dry contact (mechanical relay contact output)

ALM

FAIL Contact Type: Voltage free, dry contact (mechanical relay contact output)

SPAN/FUNC Function contact: Use distinguish between the Hydrogen purity meter and

ZERO/SEL GAS

Contact rating: 250 V AC 3 A or 30 V DC 3 A

Contact arrangement: NO/NC, selectable

Contact rating: 250 V AC 3 A or 30 V DC 3 A

Contact arrangement: NC, xed

the Replacement meter.

Select gas contact: Use distinguish measuring ranges in the Replacement meter.

Contact Type: Voltage free, dry contact (mechanical relay contact output)

Contact rating: 250 V AC 3 A or 30 V DC 3 A

Contact arrangement: NO/NC, selectable

IM 11T3E1-01E

Page 39

<2. Installation, Wiring and Piping>

2.4.2 Cables Wired to Power Supply

The GD402G bears the CE marking. When using the meter in a place where the CE marking is

obligatory, or when performance meeting the CE marking requirements is needed, the following

wiring is required. (Note that the following wiring is not required when the power supply is 24 V

DC.)

● Install an external switch or circuit breaker to the power supply of the converter.

● Use an external switch or circuit breaker that is rated at 5 A and conforms to IEC 947-1 or

IEC 947-3.

● Install the external switch or circuit breaker in the same room as the converter is installed.

● The external switch or circuit breaker should be installed in a location that allows operator

access and should be marked a power supply switch to the converter.

● Connect the supplied surge protector to the power supply. This protects the power supply

circuit of the converter from surge.

CAUTION

The GD402R, T, V converter contains a power switch and a fuse. The switch cannot be operated

however, if the converter is installed in an explosion-hazardous area; it must be left placed in the

ON position. When Power ON/OFF, use external circuit breaker

2-16

Wiring is for supplying power supply that meets specications to the GD402 converter.

Use a 3-conductor cable with a size of 1.25 to 2.5 mm2 and an outside diameter of 8 to 16 mm

for 100-240 V AC type and a 2-conductor cable for 24 V DC type. A surge protector is not provided with the GD402T, V, R type converter.

Wire the cable as instructed below:

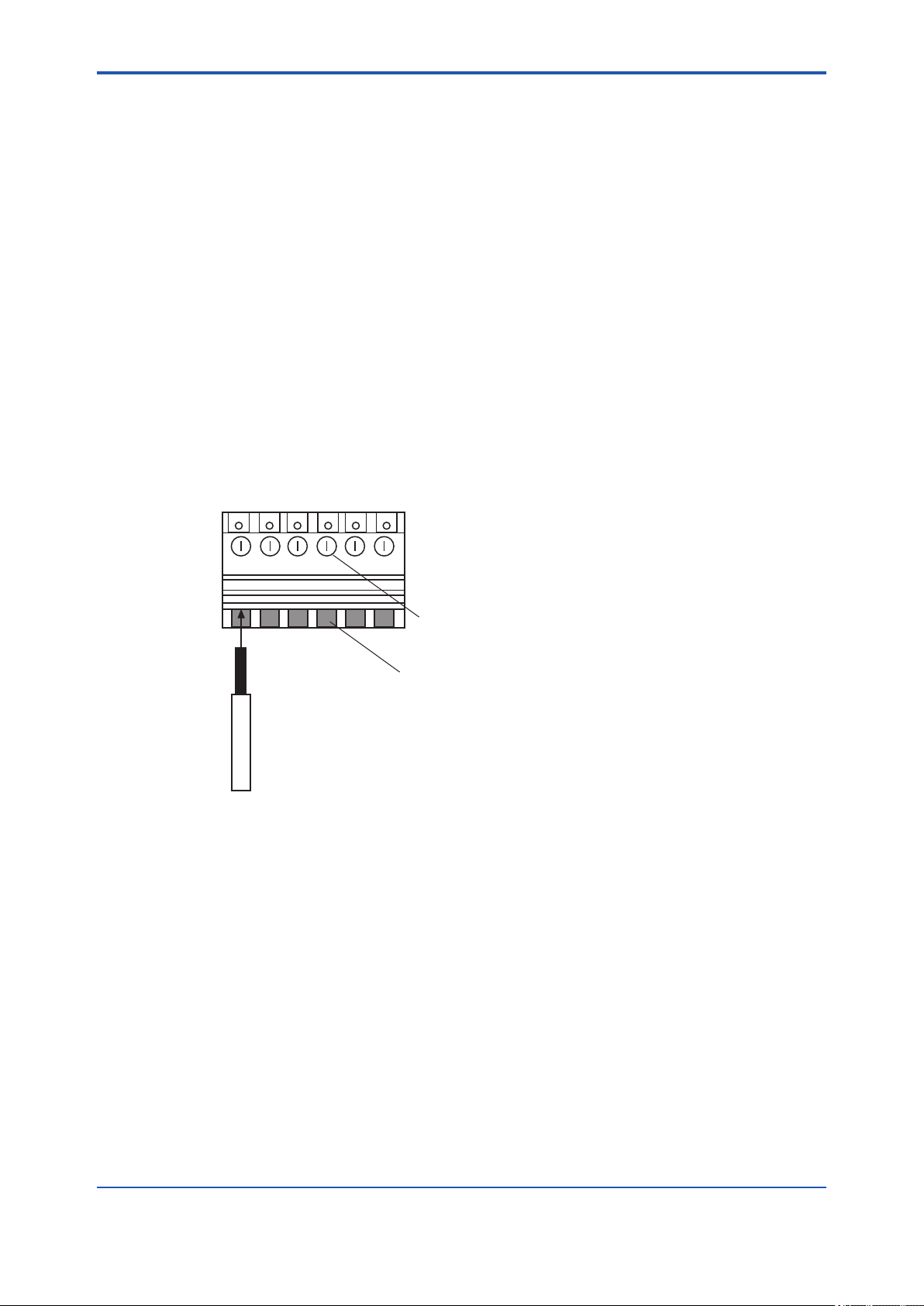

(1) Strip the sheath 7 mm at the cable end to be connected to the converter.

(2) Connect the cable to terminals L, N, and G or terminals + and - on the converter.

Loosen the terminal screw, insert the stripped part of the wire into the terminal hole,and x

the cable by tightening the screw. (adequate tightening torque: 0.4 N·m)

(3) The length of wire between the converter and a connecting device for the surge protector

should not exceed 1 m.

(4) To connect the surge protector, use a terminal box or relevant device. Wires of the surge

protector have a M4 ring terminal crimped.

(5) Connect black cables of the surge protector to terminals L and N, and the green cable to

terminal G. (Terminal G is internally connected to the case-grounding terminal.)

IM 11T3E1-01E

Page 40

<2. Installation, Wiring and Piping>

2-17

Case-grounding

terminal

GD402 Converter

100-240 V AC type

SUPPLY

L N G

1m

max

100 to 240 V AC

50/60Hz

1 Surge protector and terminal box should be installed in order to meet

*

the requirements of CE marking.

Surge Protector

Green cable

Terminal box

External circuit breaker

Rating: 5 A

Use IEC947-1 or IEC947-3 compliant product.

Figure 2.12 Cables Wired to Power Supply

1

*

Case-grounding

terminal

1

*

GD402 Converter

24 V DC type

SUPPLY

+ - G

24 V DC

F0216.ai

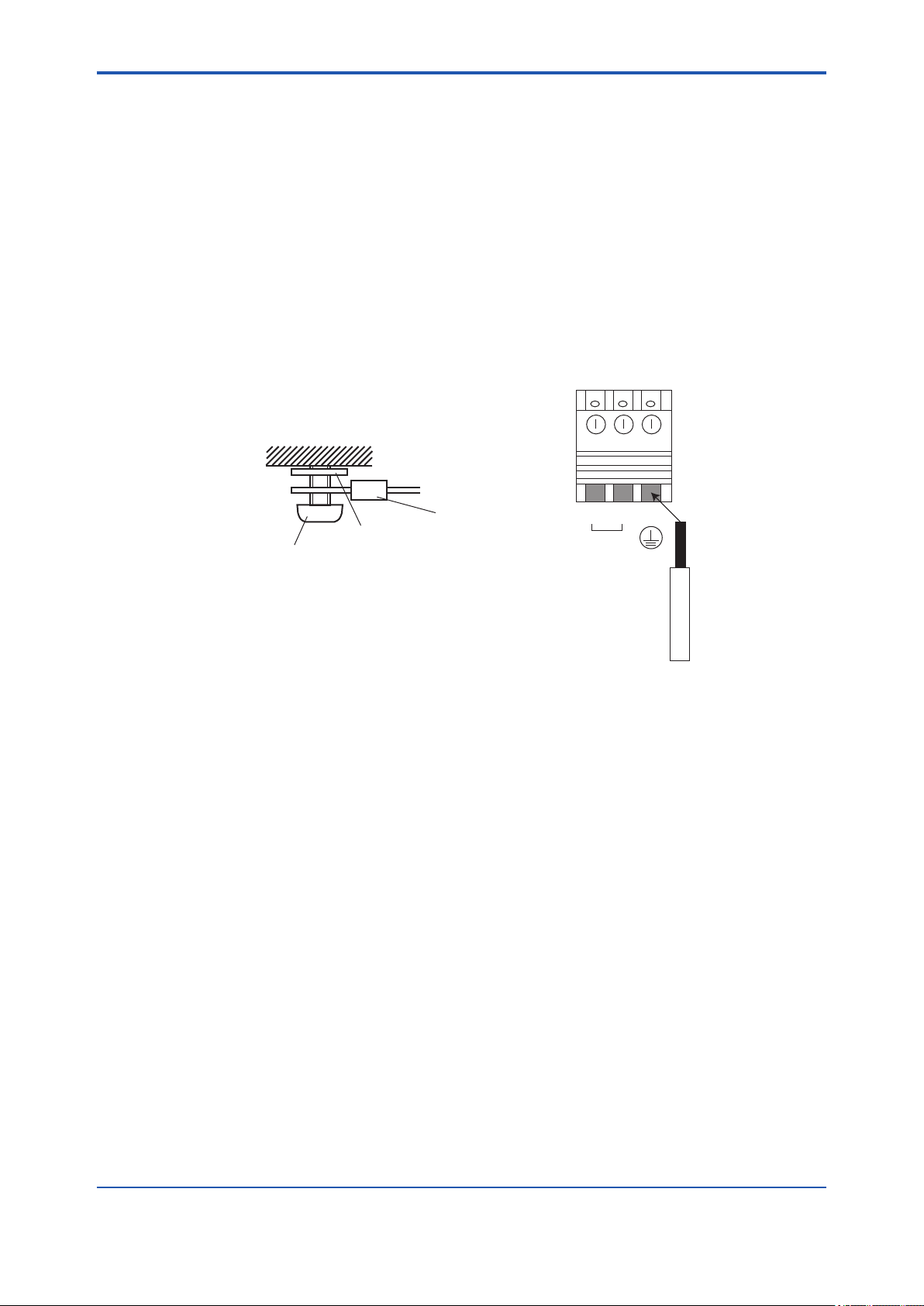

2.4.3 Cables Wired to Outputs

These cables are used to transmit 4-20 mA DC signals and carry out BRAIN communication.

Use shielded cables of 8 to 16 mm in nished outer diameter and 0.75 mm2 minimum in thickness (or a two-core shielded cable for single output).

Wire the cables as instructed below:

(1) Use cables that are 0.75 to 2.5 mm2 thick. Treat the cable ends by stripping the core wires

back 7 mm (see Figure 2.14).

(2) Wire the cable for output 1 to terminals 3 and 4 on the block and the cable for output 2 to

terminals 5 and 6 on the block. Beware of the correct polarities. Note that only terminals 3 and

4 (output 1) are effective for BRAIN communication.

Loosen the terminal screws, insert the stripped ends of the core wires into the terminals, and

fasten the screws to x the cables.