Page 1

User's

Manual

GC1000 Mark II

Process Gas Chromatograph

Overview

IM 11B03A03-01E

IM 11B03A03-01E

3rd Edition

Page 2

<T oc> <Ind> <Rev> <Introduction>

◆ Notice

● Regarding This Manual

1. This Manual should be passed on to the end user.

2. Read this manual carefully and fully understand how to operate this product before

you start operation.

3. Y okogawa makes no warranty of any kind with regard to this material, but not limited

to, implied warranties of merchantability for particular purpose.

4. All rights reserved. No part of this manual may be reproduced in any form without

Y okogawa’ s written permission.

5. Great effort has been expended to ensure that the descriptions in this manual are

correct. Should you, however, come across a questionable area or note an inconsistency , a telephone call or letter to Yokogawa.co.,ltd. noting the questionable area

would be highly appreciated.

6. The contents of this manual are subject to change without prior notice.

i

● Regarding Protection, Safety , and Prohibition Against Unauthorized Modifica-

tion.

1. For the protection and safe use of the product and the system controlled by it, be sure

to follow the instructions on safety described in this manual when handling the product. In addition, if you handle the product in contradiction to these instructions, our

company does not guarantee safety .

2. The following safety symbol marks are used on the product concerned or in this

Manual :

WARNING

A WARNING sign denotes a hazard. It calls attention to procedure, practice, condition

or the like, which, if not correctly performed or adhered to, could result in injury or

death of personnel.

CAUTION

A CAUTION sign denotes a hazard. It calls attention to a procedure, practice, condition or the like, which, if not correctly performed or adhered to, could result in damage

to or destruction of part or all of the product.

IMPORT ANT :

Indicates that operating the hardware or software in this manner may damage it or

lead to system failure.

NOTE:

Draws attention to information essential for understanding the operation and features.

TIP:

Gives information that complements the present topic.

All Rights Reserved Copyright © 2001, Y okogawa Electric Corporation

IM 11B03A03-01EMedia No. IM 11B03A03-01E 3rd Edition : Aug. 2006 (YK)

3rd Edition : Aug. 23. 2006-00

Page 3

<T oc> <Ind> <Rev> <Introduction>

See Also:

Gives the reference locations for further information on the topic.

Protective ground terminal:

In order to provide protection against electrical shock in case of a fault. This symbol

indicates that the terminal must be connected to ground prior to operation of equipment.

Function ground terminal:

In order to provide protection against noise. This symbol indicates that the terminal

must be connected to ground prior to operation of equipment.

Alternating current

ii

3. If protection / safety circuits are to be used for the product or the system controlled by

4. When you replace parts or consumables of the product, use those specified by our

5. Do not modify the product.

Indicates the power switch state “ON”.

Indicates the power switch state “Stand - by”.

Indicate the power switch state “OFF”.

it, they should be installed outside of the product.

company .

● Exemption from Responsibility

1. Y okogawa Electric Corporation does not make any warranties regarding the product

except those mentioned in the WARRANTY that is provided separately.

2. Y okogawa Electric Corporation assumes no liability to any party for any loss or damage, direct or indirect, caused by the use or any unpredictable defect of the product.

● Regarding Software and set including Software Supplied by Y OKOGA WA

1. Y okogawa makes no other warranties expressed or implied except as provided in its

warranty clause for software supplied Y okogawa.

2. Use this software with one specified computer only.

Y ou must purchase another copy of the software for use with each additional com-

puter.

3. Copying this software for purposes other than backup is strictly prohibited.

4. Store the streamer or floppy disk (original medium) in a secure place.

5. Reverse engineering such as the disassembly of software is strictly prohibited.

6. No portion of the software supplied by Y okogawa may be transferred, exchanged, or

sublet or leased for use by any third party without prior permission by Y okogawa.

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 4

<T oc> <Ind> <Rev> <Introduction>

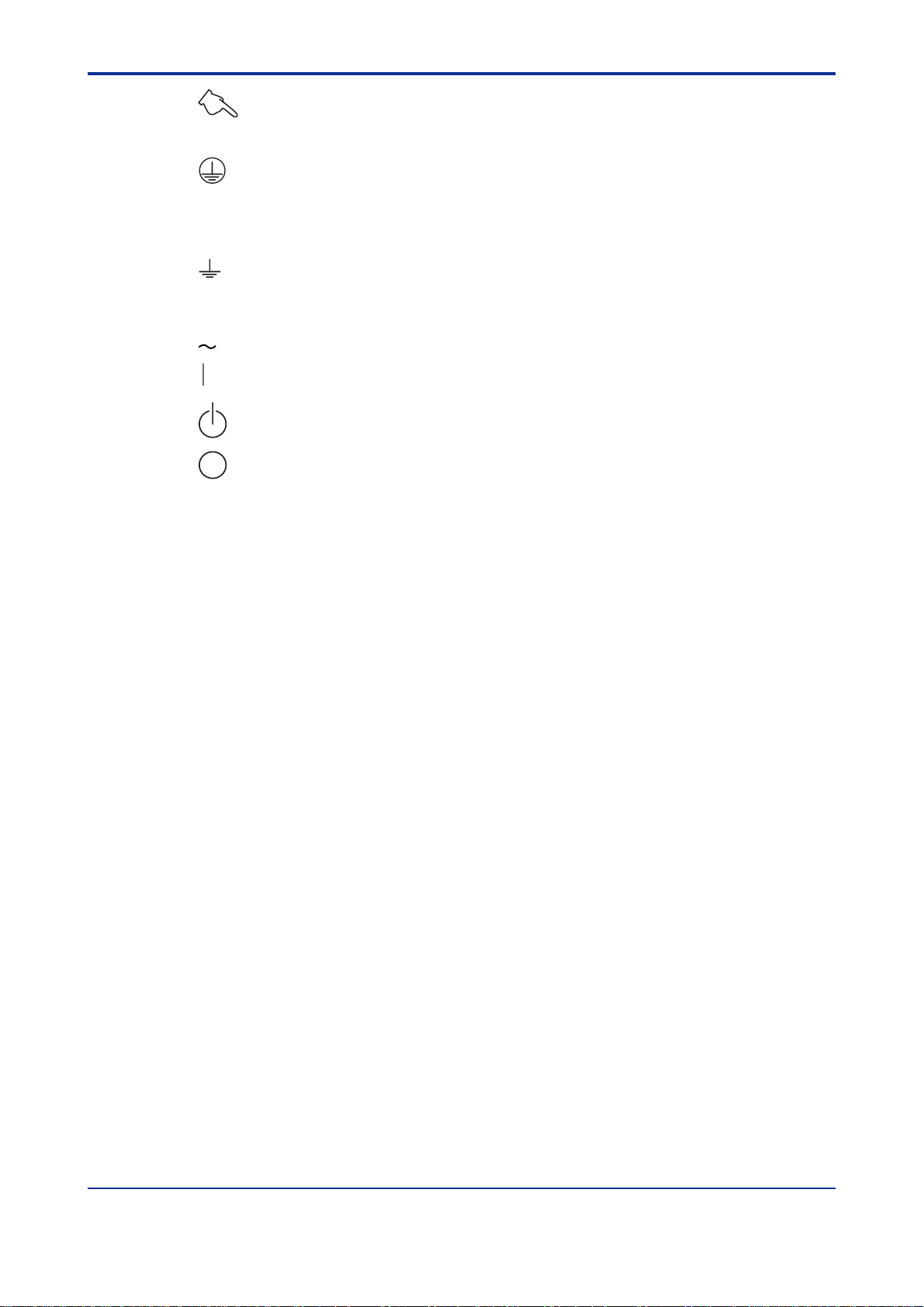

◆ Warning/Caution Labels

● T o ensure safety operation of this equipment, warning/caution labels are at-

tached on the equipment as follows. Check these labels for your safety operation.

D

A

C

B

E

iii

[Left side] [Front] [Right side] [Back]

F0001.EPS

AB

C

The inside of the enclosure is high temperature after turning off the power.

Don’t touch the inside of the enclosure or the compponents, the protective gas

should be suoolied for more than one hour after turning off the power.

D

E

F0002.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 5

<T oc> <Ind> <Rev> <Introduction>

◆ Introduction

Thank you for purchasing the GC1000 Mark II process gas chromatograph.

This manual describes the technical information on overview of Model GC1000D /

GC1000S / GC1000T / GC1000E / GC1000W / GC1000C (Hereafter , it is abbreviated as

GC1000 Mark II) Process Gas Chromatograph.

Please lead the following respective documents before installing and using the GC1000

Mark II system.

● Documents Related to the GC1000 Mark II Process Gas Chromatograph

1. Instruction manuals

The product comes with the following instruction manuals.

■ Instruction manuals that do not depend upon the specifications of the product

(1) Overview (IM 1 1B03A03-01E)

(2) Basic Operation and Startup (IM 1 1B03A03-02E)

(3) Maintenance and Inspection Manual (IM 1 1B03A03-04E)

iv

(4) LCD Panel Operation Manual (IM 1 1B03A03-05E)

(5) Alarm Message Manual (IM 1 1B03A03-06E)

(6) Password Manual (IM 1 1B03A03-07E)

and Installation Manual (TI 1 1B03A03-13E)

■ Instruction manuals that depend upon the specifications of the product

(1) GCMT Gas Chromatograph Maintenance Terminal Software Package Operation

Guide (IM 1 1B03G03-03E)

(2) Capture It! Manual (IM 1 1B3G1-02E)

■ Instruction manuals for related products

(1) PCAS PC Analyzer Server Software (IM 11B06B01-01E)

(2) ASET Analyzer Server Engineering Terminal Software (IM 1 1B06C01-01E)

(3) GCET GC Engineering Terminal Software (IM 1 1B06D01-01E)

(4) ASGW Analyzer Server Gateway Software (IM 11B06E01-01E)

(5) ASIU Analyzer Server Interface Unit Software (IM 11B06F01-01E)

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 6

<T oc> <Ind> <Rev> <Introduction>

2. Operation Data

Operation data is supplied with the operation manuals in the delivered package and contains the following required to use the gas chromatographs.

● Process conditions and measurement range

● Instrument specifications and operating conditions

● Standard sample for calibration

● Column system and column

● Miscellaneous data

Chromatogram, base line, repeatability , power supply voltage variation, etc.

● Analyzer flow diagram and installation

● Parts composition table

● General connection diagram

● Sampling system diagram (only if supplied by Yokogawa)

● Is the System Ready?

Before reading this manual, the following preparations must have been completed.

● The system must be unpacked and installed in the correct place.

v

● The piping for the utility gases such as carrier and calibration gases must be completed, followed by leak checking.

● The wiring for the power supply and others must be completed.

If these have not been completed yet, see the Installation Manual (TI 1 1B03A03-13E).

After completion, return to this manual and do the following:

● If the system power is on, turn off the power .

● Shut off all the gases at the flow control units.

Please read the following respective cautions (General Precautions, Caution of

using Explosion-Protection Instruments, on Piping Construction, and on Piping

Work) before installing and using the GC1000 system.

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 7

<T oc> <Ind> <Rev> <Introduction>

● General Precautions

WARNING

(1) In order to analyze gases, process gas chromatographs use a sample of the process

gas and utility gases.

Since these gases are typically combustible, combustion-sustaining, toxic,

odorous, resolvable, polymerizing, or corrosive, refer to the “Safety Information” in our approval drawings and others to ensure safety thoroughly before

using these analyzers.

(2) Up to two protection systems, each of which weighs approximately 10 kg, are installed

on top of the GC1000. Therefore, the center of gravity is higher than the center of the

analyzer body .

Take great care when carrying and installing (piping- wiring) the GC1000. The

GC1000 must be carried and installed very carefully (including piping and

wiring) by more than one person (at least four people are recommended).

(3) Since the GC1000 are precision instruments, take care when handling not to jolt

of knock them.

(4) Use the GC1000 within the range of your purchase specifications.

vi

Y okogawa assumes no responsibility for problems resulting from use by the customer

outside the purchase specifications.

If the GC1000 need to be modified or repaired, please contact your nearest Y okogawa

representative. Yokogawa assumes no responsibility for results where the customer or

any third party has attempted to modify or repair these products.

(5) When touching LCD Panel switches

When touching LCD Panel switches, first, discharge Electro Static Charge of the body .

Then, touch the LCD Panel switches. If not, LCD display may be changed by Electro

Static Discharge.

IMPORT ANT :

(1) Read the attached instruction manual before operating the GC1000

(2) The instruments must be installed and operated according to the installation manual,

instruction manual, approval drawings, and operation data.

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 8

<T oc> <Ind> <Rev> <Introduction>

● CA UTIONS OF USING EXPLOSION-PRO TECTION INSTR UMENTS

The GC1000 Process Gas Chromatographs are designed to protect against explosion.

When these analyzers are used in a hazardous area, observe the following precautions.

Since the applicable standard differs depending on the specifications of the analyzer to be

used, check the specifications of your analyzer.

(1) Kinds of explosion protection

To assure explosion protection, the GC1000 Process Gas Chromatographs have a pressurized and flameproof construction, or type X purging and explosionproof construction

meeting the following standards :

<GC1000D / GC1000S>

• JIS Expd IIB + H2 T1 (programmed-temperature oven 320˚C max., isothermal oven

225˚C max., liquid-sample valve 250˚C max.)

• JIS Expd IIB + H2 T2 (programmed-temperature oven 225˚C max., isothermal oven

225˚C max., liquid-sample valve 225˚C max.)

• JIS Expd IIB + H2 T3 (programmed-temperature oven 145˚C max., isothermal oven

145˚C max., liquid-sample valve 145˚C max.)

vii

• JIS Expd IIB + H2 T4 (programmed-temperature oven 95˚C max., isothermal oven

95˚C max., liquid-sample valve 95˚C max.)

<GC1000W / GC1000C>

CENELEC (A TEX directive) certified : Group II Category 2G

• EEx pd II B +H2 T1 (programmed-temperature oven 320°C max, isothermal oven

225°C max., liquid-sample valve 250°C max.)

• EEx pd II B +H2 T2 (programmed-temperature oven 225°C max, isothermal oven

225°C max., liquid-sample valve 225°C max.)

• EEx pd II B +H2 T3 (programmed-temperature oven 145°C max, isothermal oven

145°C max., liquid-sample valve 145°C max.)

• EEx pd II B +H2 T4 (programmed-temperature oven 95°C max, isothermal oven 95°C

max., liquid-sample valve 95°C max.)

<GC1000T / GC1000E>

FM Type X purging and Explosionproof for CLI, DIV1, GPS B, C & D, NEMA3R.

Type Y purging and Type X purging for CLI, DIV1, GPS.B, C & D, NEMA3R.

• T1 (programmed-temperature oven 320˚C max., isothermal oven 225˚C max., liquidsample valve 250˚C max.)

• T2 (programmed-temperature oven 225˚C max., isothermal oven 225˚C max., liquidsample valve 225˚C max.)

• T3 (programmed-temperature oven 145˚C max., isothermal oven 145˚C max., liquidsample valve 145˚C max.)

• T4 (programmed-temperature oven 95˚C max., isothermal oven 95˚C max., liquidsample valve 95˚C max.)

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 9

<T oc> <Ind> <Rev> <Introduction>

CSA Type X purging and Explosionproof for CLI, DIV1, GPS B, C & D, NEMA3R.

Type Y purging and T ype X purging for CLI, DIV1, GPS.B, C & D, NEMA3R.

• T1 (programmed-temperature oven 320˚C max., isothermal oven 225˚C max., liquidsample valve 250˚C max.)

• T2 (programmed-temperature oven 225˚C max., isothermal oven 225˚C max., liquidsample valve 225˚C max.)

• T3 (programmed-temperature oven 145˚C max., isothermal oven 145˚C max., liquidsample valve 145˚C max.)

• T4 (programmed-temperature oven 95˚C max., isothermal oven 95˚C max., liquidsample valve 95˚C max.)

(2) Precautions for Explosionpr oof section (The analyzer with optional

code "FM/CSA T ype Y purging" does not have the e xplosionproof

section.)

When handling the screws on the cover of the Protection system, note the following to

avoid damaging the screws since they cannot be repaired.

(1) The enclosure is pressurized. Before removing the cover, reduce the internal pres-

sure by loosening the sealing plug for wiring on the enclosure or relevant means.

viii

(2) When removing the cover, prevent any dirt or foreign matter from contaminating the

screw part.

(3) When installing the cover, tighten the screws by hand ; never use tools.

(4) Since the screws are coated with MOL YKOTE, do not lubricate them.

(3) Precautions when using hydrogen gas

When using hydrogen gas as the carrier gas, the FID or FPD combustion gas, to ensure

safety , install the analyzer in a location equipped with a ventilator or where there is sufficient ventilation. Make sure there are no gas leaks from the pipe joints and inspect for

leaks.

(4) Installation site and environment

The analyzer specifications allow it to be used in hazardous areas as defined by Zone1 IIB

+ H

, T2, T3, T4 (JIS / CENELEC) or DIV1, GPS B, C & D, T1, T2, T3, T4 (FM / CSA).

2T1

However, never install the analyzer in an area where the density of explosive gas persists

for a long time.

(5) Wiring works

Model GC1000D / GC1000S, analyzer obtains explosion proof authorization by the complete set including metal fittings of the attachment.

When performing wiring, always use the attached sealing fittings and flameproof packing

adapter.

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 10

<T oc> <Ind> <Rev> <Introduction>

(6) Maintenance and inspection

During usual maintenance and inspection, it is not necessary to check the explosionprotected section.

Before opening the door of the explosion-protected section for maintenance and inspection, be sure to turn off the power . After completing maintenance and checks, close the

door completely then turn on the power after checking that the specified explosion protection performance is guaranteed. The parts to be checked are described in the Maintenance

and Inspection Manual (IM 1 1B03A03 - 04E).

If any of the following damage occurs, contact a Yokogawa sales representative or the

Y okogawa sales division

(1) If the screws securing the Protection System (explosionproof construction) are dam-

aged

(2) If the exterior or light transmission section of the enclosures is damaged

(3) If packings are cracked or conspicuously deformed

(7) Override function (The analyzer with optional code "FM/CSA T ype Y

purg ing" does not have this function.)

ix

WARNING

• When the override function is used, Analyzer becomes an ignition source and the high

temperature and the high voltage part will be exposed.

• Please confirm that in the ambient atmosphere, the concentration of explosive gases

is less than the allowable limit, by using a gas detector.

To return to the normal operation, turn off “the override switch” and then close the door as it

was before turning on power.

In this analyzer, if the pressure of the pressurized / type X purged enclosure system (oven,

electronic section) drops while the power is on, the pressurized explosion protection section is activated to stop power supply . Therefore, in case of opening the door of the oven or

of the electronic section inadvertently , for maintenance, while the power is on, the protection system is activated to cut off the power .

The “override function” intensively releases this function of protection system.

The override switch is installed in section.

(8) Replacing parts

Always use parts specified by Yokogawa when replacing parts, for replacement, refer to the

Maintenance and Inspection Manual (IM 1 1B03A03 - 04E).

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 11

<T oc> <Ind> <Rev> <Introduction>

(9) Operation

WARNING

<CENELEC>

* Only trained persons may use this instrument in a hazardousl location.

* Do not open when energized.

<FM>

For type X purging:

* This equipment contains components that operate at high temperature. The equip-

ment shall be deenergized for 60 minutes to permit those components to cool before

the enclosure is opened unless the area is demonstrated to be nonhazardous at the

time.

* Enclosure shall not be opened unless the area is known to be nonhazardous, or

unless all devices within have been de-energized.

x

* Power shall not be restored after enclosure has been opened until enclosure has

been purged for 12 minutes. (When the internal pressure is restored, the system

automatically purges over the 12 minutes, then turns on the power again.)

For explosionproof enclosure:

* Seal all conduits within 18 inches

* Open circuit before removing cover.

For type Y purging:

* Enclosure shall not be opened unless the area is known to be non-hazardous, or

unless all devices within have been de-energized. Power shall not be restored after

enclosure has been opened until enclosure has been purged for 12 minutes at specified pressure indicated by the pressure gauge labeled “EL.BOX” in the pressure and

flow control section.

* Alarm shall be provided and connected to alarm contact output.

(a) The alarm shall generate a visual or audible signal that attracts attention

(b) The alarm shall be located at constantly attended location.

(c) Electrical alarms shall be approved for the location in which they are installed.

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 12

<T oc> <Ind> <Rev> <Introduction>

<CSA>

For type X purging:

* This equipment contains components that operate at high temperature. The equip-

ment shall be deenergized for 60 minutes to permit those components to cool before

the enclosure is opened unless the area is demonstrated to be nonhazardous at the

time.

* Enclosure shall not be opened unless the area is known to be non-hazardous, or

unless all devices within the enclosure have been de-energized. Power must not be

restored after enclosure has been opened until enclosure has been purged for 12

minutes at a flow rate of 0.05m

* Power will automatically be removed when purge pressure falls below 40 mm (1.6 in)

of water column.

For explosionproof enclosure:

* A seal shall be installed within 50 cm of the enclosure.

* Open circuit before removing cover.

For type Y purging:

* Enclosure shall not be opened unless the area is known to be non-hazardous, or

unless all devices within the enclosure have been de-energized. Power must not be

restored after enclosure has been opened until enclosure has been purged for 12

minutes at a flow rate of 0.05m

3

/min.

3

/minute min.

xi

* Remove power below 40mm (1.6in) of water column.

Take care not to generate mechanical spark when accessing to the instrument and peripheral devices in hazardous locations.

Do not press prick the keyboard of LCD panel (operation and display section) using such

as knives and sticks.

(10) Maintenance and Repair

The instrument modification or parts replacement by other than authorized representative

of Yokogawa Electric Corporation is prohibited and will void the approval of Factory Mutual

Research Corporation and CSA certification and CENELEC certification .

IM 11B03A03-01E

3rd Edition : Aug. 23. 2006-00

Page 13

<T oc> <Ind> <Rev> <Introduction>

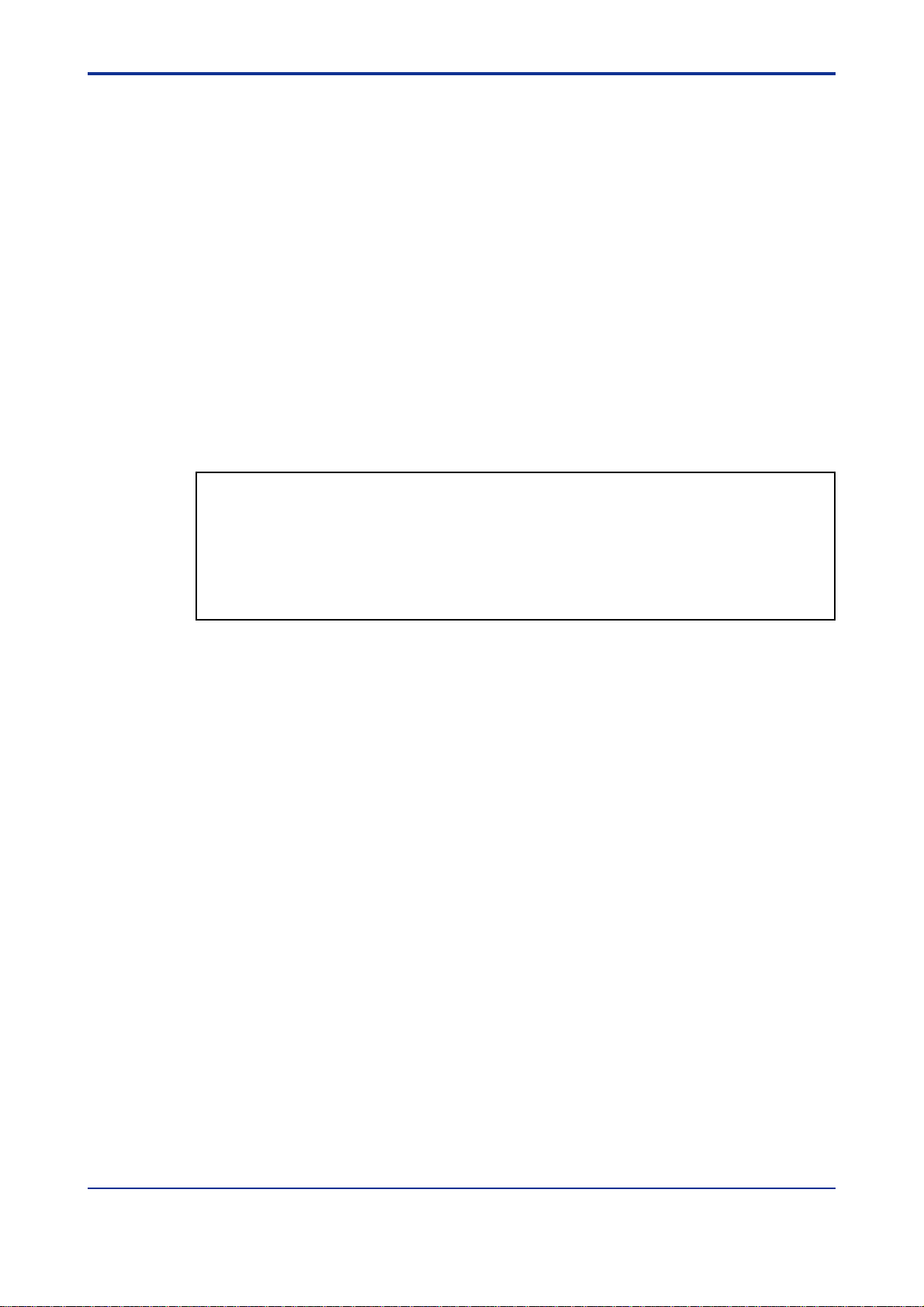

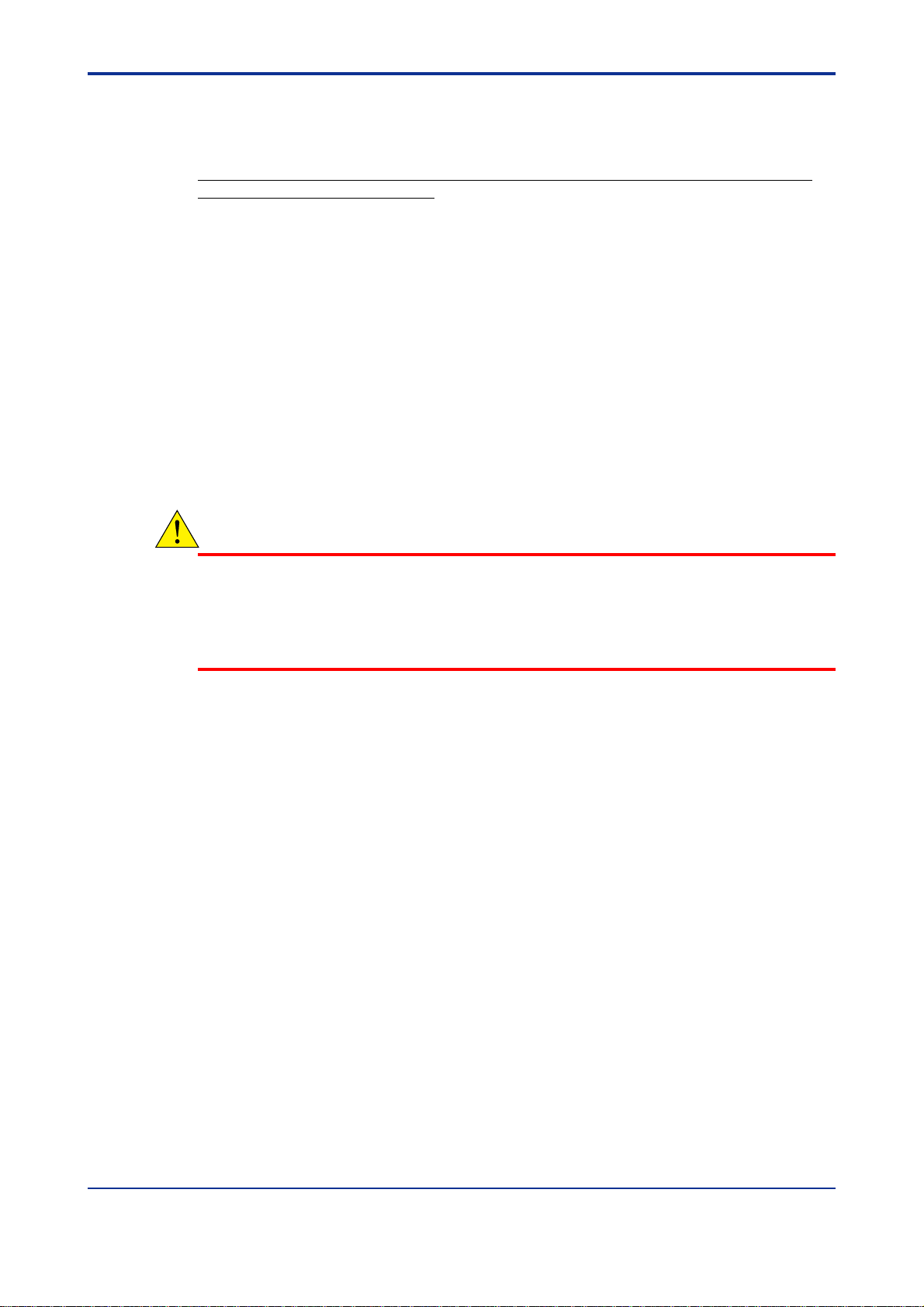

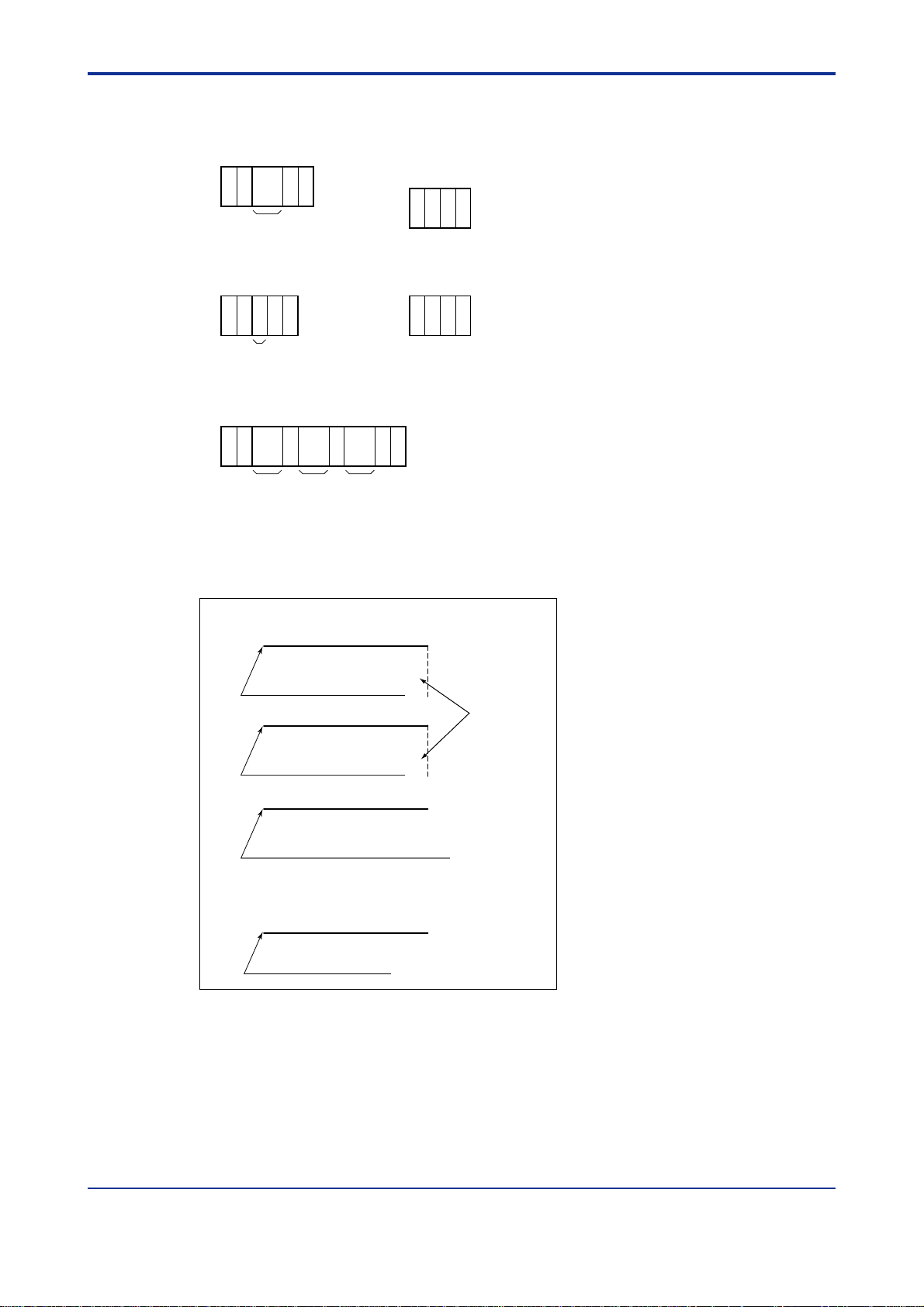

● Precautions Against Electrostatic Pr oblems

The GC1000 system uses numerous IC components. When handling cards with IC

components mounted on them for maintenance or setting changes, take full precautions against electrostatic problems.

These precautions are summarized below.

(a) When storing or carrying cards, enclose them in a conductive bag or antistatic

bag. (Cards as shipped by Yokogawa are enclosed in a conductive bag or

antistatic bag labeled with cautions against electrostatic problems.)

(b) Whenever mounting or demounting cards into or from a product, wear a wrist

strap grounded via a 1 MΩ resistance. Connect the wrist strap to any ground

terminal near the ground wire or to any unpainted part of the grounded frame.

xii

List strap

Sheet

1M‰

Using a wrist strap and conductive sheet Using a Conductive Sheet

Gard

List strap

F0003.EPS

(c) When servicing cards on the bench, place them on a conductive sheet

grounded via a 1 MΩ resistance, wearing a wrist strap as in (2) above. Keep

easily-chargeable plastic materials away from the bench.

(d) Never touch components mounted on the cards, the pattern side, connectors,

pin components, etc. with bare hands, unless using a wrist strap and a conductive sheet.

(e) Wrist straps and conductive sheets are available from Yokogawa Engineering

Service (YSV).

IM 11B03A03-01E

3rd Edition : Aug. 23. 2006-00

Page 14

<Int> <Ind> <Rev>

GC1000 Mark II Process Gas Chromatograph

Overview

CONTENTS

◆ Notice .......................................................................................................... i

◆ W arning/Caution Labels............................................................................iii

◆ Introduction ...............................................................................................iv

1. Principle of Gas Chr omatograph ........................................................... 1-1

1.1 Sampling Mechanism ..................................................................................... 1-1

1.2 Component Separation Using Column.......................................................... 1-2

1.3 Detector ........................................................................................................... 1-3

2. Terminology ............................................................................................ 2-1

Toc-1

IM 11B03A03-01E 3rd Edition

2.1 Operation Terminology ................................................................................... 2-1

2.2 Instrument Terminology.................................................................................. 2-2

3. System Configuration ............................................................................ 3-1

3.1 T ype and Appearance..................................................................................... 3-1

3.2 Components and Their Functions.................................................................. 3-2

3.2.1. Protection System ............................................................................ 3-2

3.2.2 Electronic Section............................................................................. 3-2

3.2.3 Pressure and Flow Control Section................................................... 3-2

3.2.4 Isothermal Oven ............................................................................... 3-2

3.2.5 Programmed-temperature Oven ....................................................... 3-3

3.2.6 Analyzer Base Sampling Section ...................................................... 3-3

3.3 Block Diagram................................................................................................. 3-4

3.4 Internal Piping System Diagram .................................................................... 3-7

3.5 External Input and Output Signals............................................................... 3-12

4. Outline of Software................................................................................. 4-1

4.1 Status and Operation Mode............................................................................ 4-1

4.1.1 Process ............................................................................................ 4-2

4.1.2 Manual ............................................................................................. 4-5

4.1.3 Lab ................................................................................................... 4-5

4.2 Stream ............................................................................................................. 4-6

4.3 Method............................................................................................................. 4-7

4.4 Description of Actions.................................................................................... 4-9

4.4.1 Actions of Stream Sequence........................................................... 4-10

4.4.2 Actions of Stream (Continuous) .......................................................4-11

4.4.3 Actions of Stream (1 cycle) ............................................................. 4-13

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 15

<Int> <Ind> <Rev>

5. Actions of External Input and Output Signals ....................................... 5-1

Toc-2

4.4.4 Actions of Calibration...................................................................... 4-14

4.4.5 Actions of V alidation........................................................................ 4-17

4.5 Computation and Processing ...................................................................... 4-20

4.5.1 Peak Processing............................................................................. 4-20

4.5.2 Deviation processing ...................................................................... 4-20

4.5.3 Additional processing...................................................................... 4-20

4.5.4 Signal Processing........................................................................... 4-21

4.6 Alarm Processing ......................................................................................... 4-22

5.1 Analog Hold Output ........................................................................................ 5-1

5.1.1 When Actual Stream is Specified for Stream Number (without Stream

Identification Signal) ......................................................................... 5-2

5.1.2 When Actual Stream is Specified for Stream Number (with Stream

Identification Signal) ......................................................................... 5-3

5.1.3 When "99" is Specified for Stream Number (with Stream Identification

Signal) .............................................................................................. 5-4

5.2 Contact Output................................................................................................ 5-5

5.2.1 Stream Sequence............................................................................. 5-5

5.2.2 Stream.............................................................................................. 5-6

5.2.3 Operation Mode................................................................................ 5-6

5.2.4 Alarm................................................................................................ 5-6

5.2.5 Timing............................................................................................... 5-6

5.3 Contact Input................................................................................................... 5-7

5.4 Communication Input and Output ................................................................. 5-8

5.4.1 GC6 T ype Output Data Format (Fixed to 45 Characters)................... 5-8

5.4.2 GC6 T ype Input Data Format ............................................................ 5-9

5.4.3 GC8/GC1000 Type Output Data Format (Fixed to 45 Characters)....5-1 1

5.4.4 GC8/GC1000 T ype Input Data Format............................................ 5-12

5.4.5 MODBUS Communication Data Specification................................. 5-14

◆ Revision Record ......................................................................................... i

IM 11B03A03-01E

3rd Edition : Aug. 23. 2006-00

Page 16

<Toc> <Ind> <1. Principle of Gas Chromatograph >

1. Principle of Gas Chromatograph

A gas chromatograph is an analyzer which first sends a fixed volume of the sampled multicomponent gas mixture to a column, separates it in the column, then measures the concentrations of the components with a detector. The process gas chromatograph analyzes

intermittently , allowing periodic analysis in a specified sequence, thus automatic sampling

is possible.

This chapter explains the measurement principle of the GC1000 Process Gas Chromatographs.

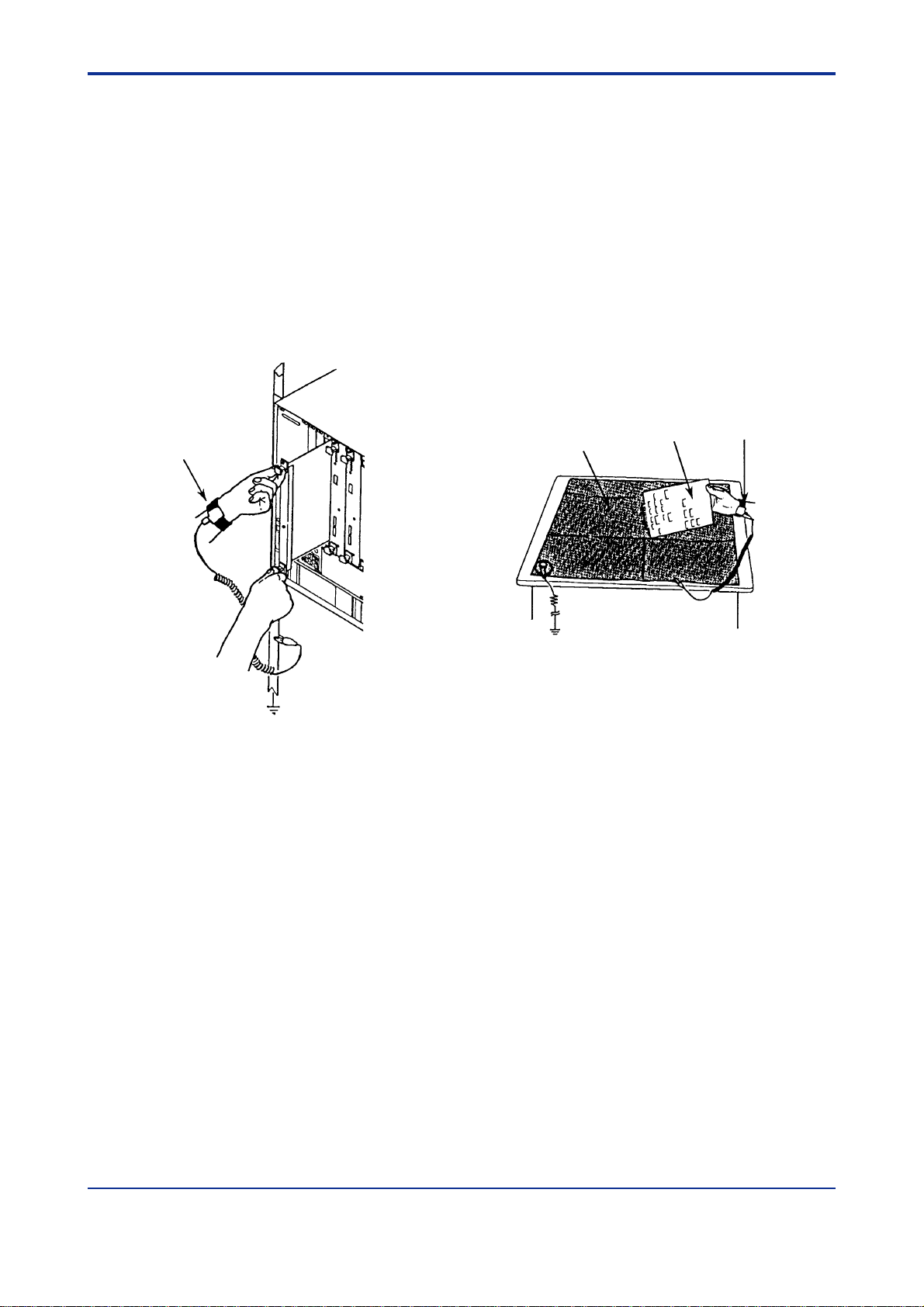

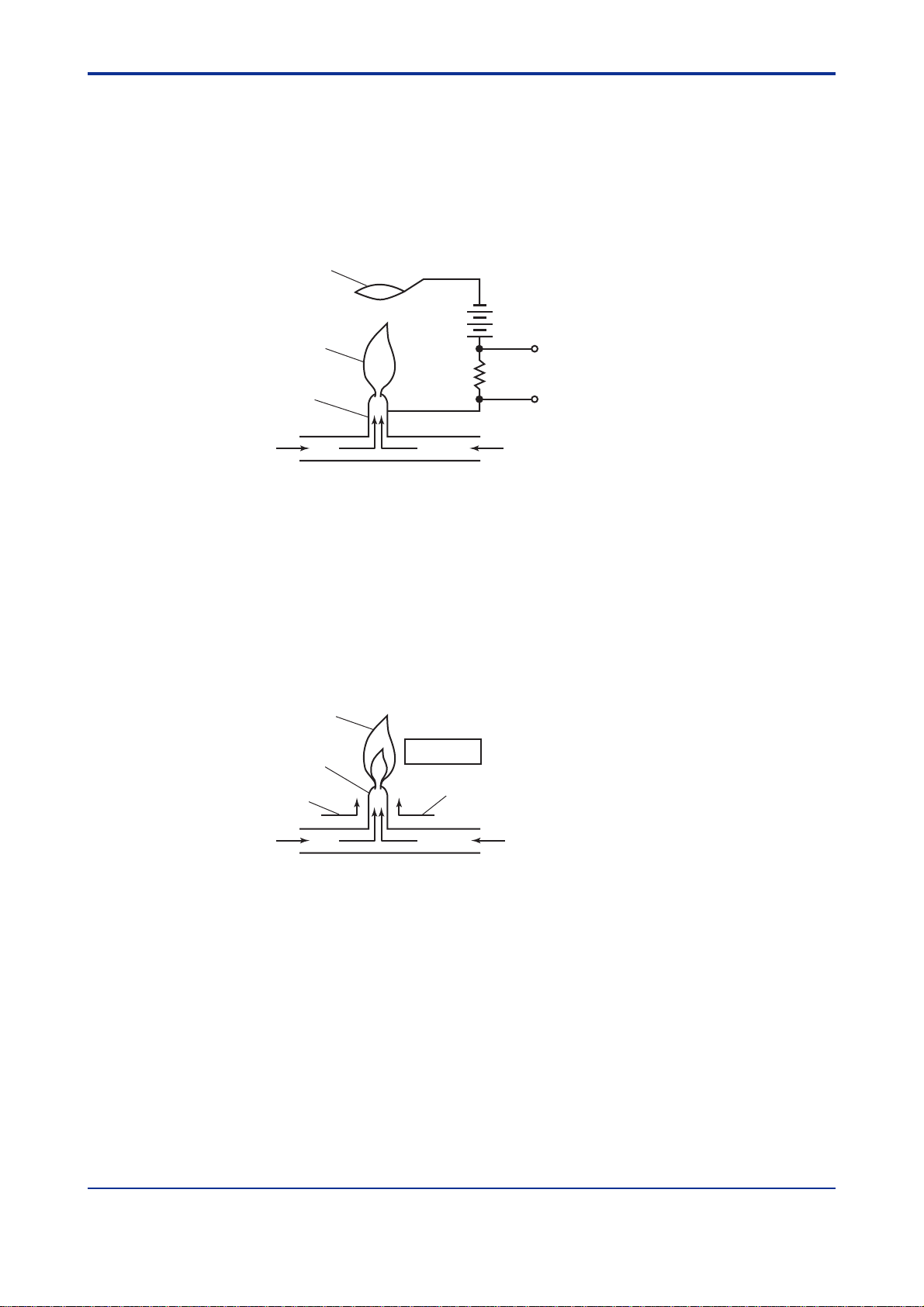

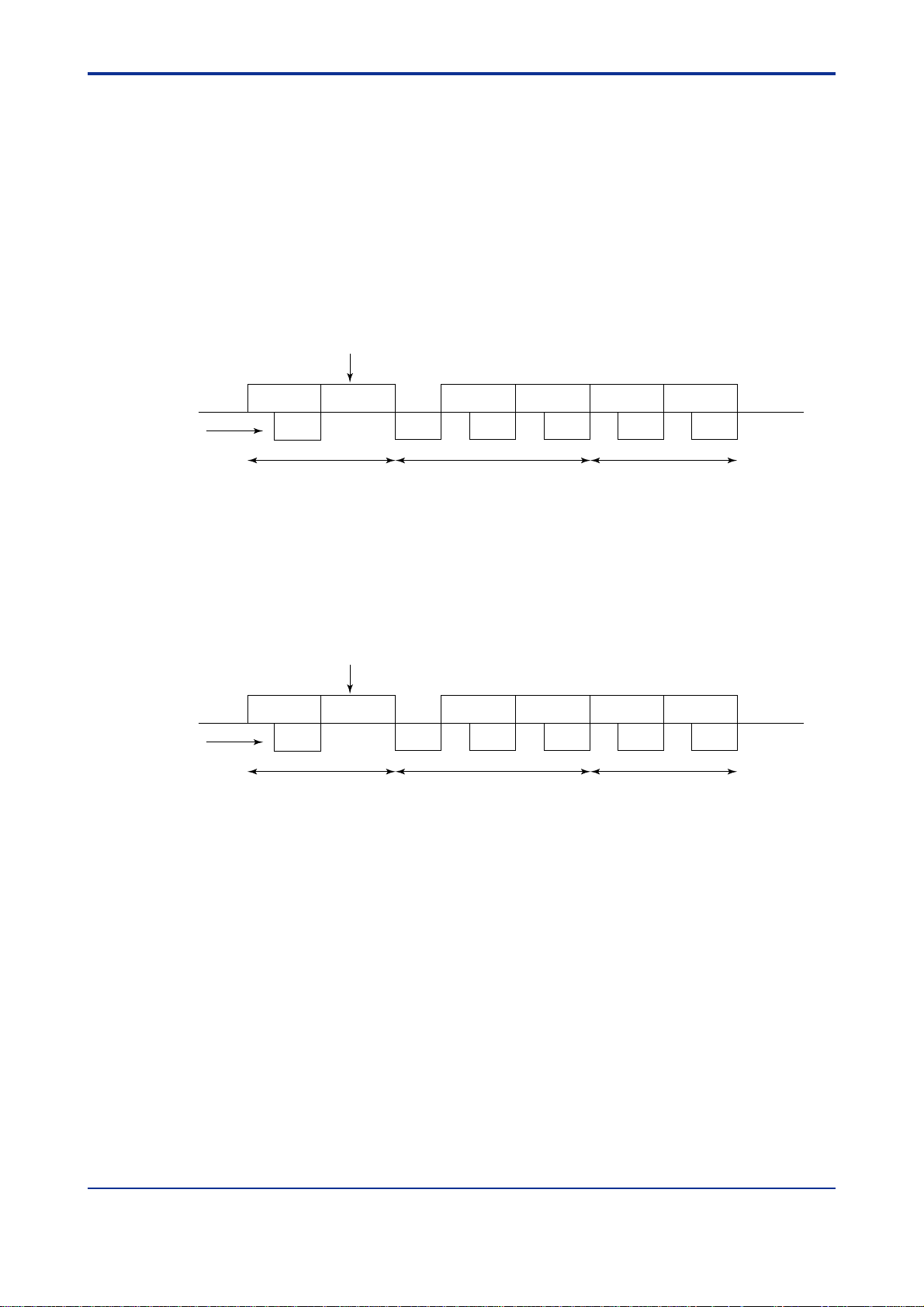

1.1 Sampling Mechanism

The process gas chromatograph consists of a sampling mechanism, a column and a

detector.

Sampling is carried out by switching a sampling valve. When separating components or

detecting concentrations, the sampling valve is set to allow the gas (liquid) to be measured

to flow through the sample column. When sampling, the sampling valve leads the gas

(liquid) to be measured to a column on a carrier gas. (See Figure1.1)

There are two important points regarding sampling: a regular volume is sampled since

repeated sampling is required; and samples are taken quickly and securely . The volume is

fixed by measuring a specific gas (liquid) of controlled temperature and pressure using a

sample measurement tube. Samples are taken quickly and securely by ensuring that the

gas to be measured always flows without interrupt.

1-1

Sample

Carrier gas

Sample

Carrier gas

Component separation and

concentration detection

Measuring tube

Sample valve

Vent

Column Detector

Electric signal

Status of sampling

Measuring tube

Sample valve

Vent

Column Detector

Electric signal

Figure 1.1 Basic Configuration of Gas Chromatograph

F0101.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 17

<T oc> <Ind> <1. Principle of Gas Chromatograph >

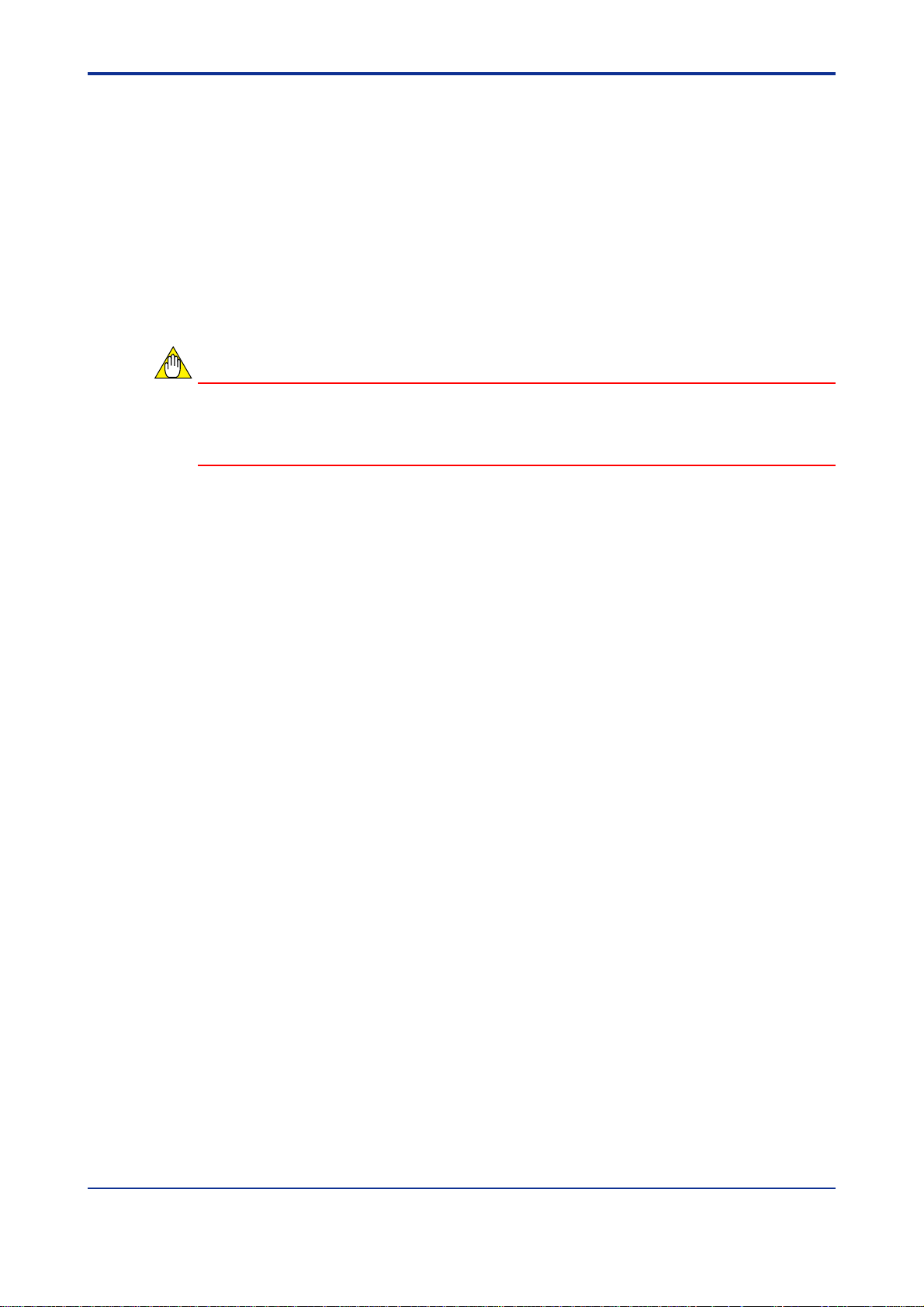

1.2 Component Separation Using Column

Three types of columns are available for the GC1000 Process Gas Chromatographs: the

packed column, the mega-bore column and the capillary column.

The packed column consists of a stainless pipe, 2 mm in diameter and 0.2 to 2.0 m in

length and filled with a bulking agent called a stationary phase.

The mega-bore and capillary columns, of approximate diameter 0.5 mm and 0.3 mm

respectively , are coated inside a certain phase called a stationary phase.

The components in the multi-component gas mixture sample with carrier gas, which called

mobil phase move through the column, repeatedly absorbing the stationary phase and

dissolving from the stationary phase at a certain cyclic rate conforming to a fixed partition

coefficient * that is unique to each component.

Since the transfer rates differ depending on the partition coefficient, a multi-component gas

mixture gradually separates into discrete components and is separated in the order of the

transfer rates.

* Partition coefficient : The concentration ratio of the components, calculated by dividing the component concentration which

is in equilibrium in the stationary phase by the concentration which is in equilibrium in the mobile

phase.

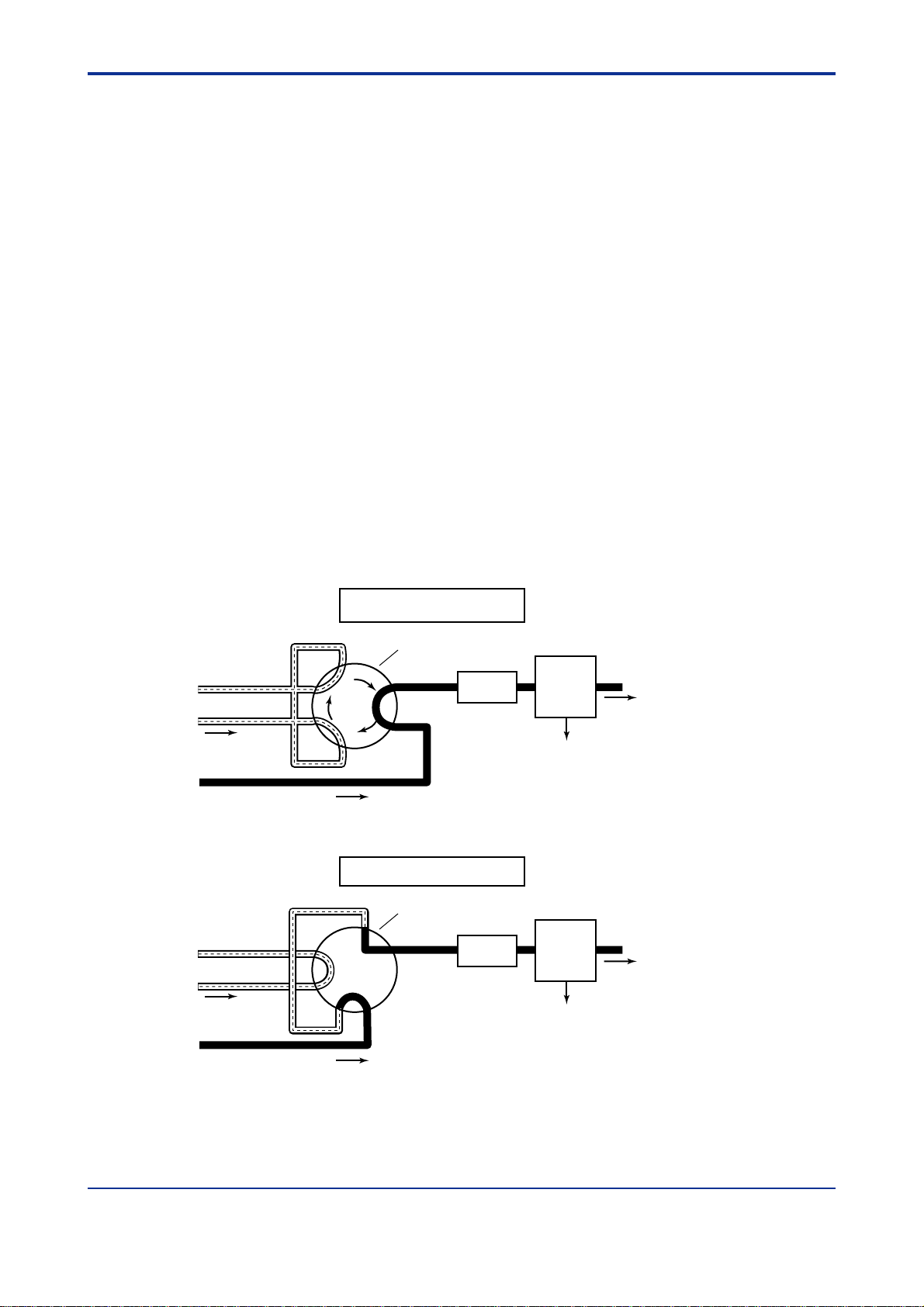

Figure 1.2 shows a diagram of how the multi-component gas mixture is led to a column and

separated into its discrete components over time.

1-2

Multi-component

gas mixture

Sampling

(1st round)

Time

(2nd round)

Figure 1.2 Separating Components Using a Column

(Intake) (Outlet)Column

Injection

:Component A, :Component B, :Component C

Detector Concentration signal

Carrier gas

Carrier gas

A

B

C

F0102.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 18

<Toc> <Ind> <1. Principle of Gas Chromatograph >

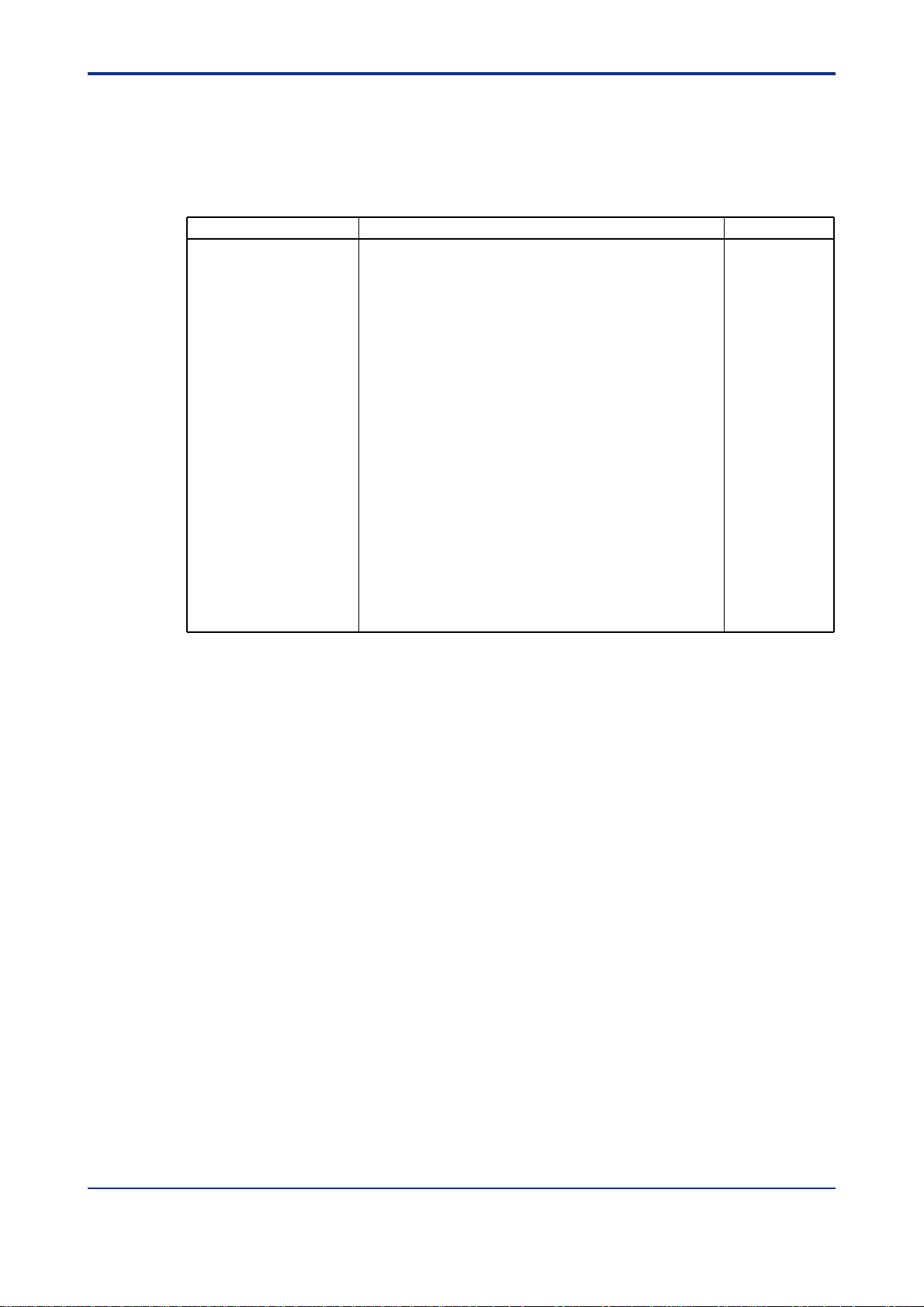

1.3 Detector

The components separated in the column are led to the detector where the concentration

of each component is measured.

The GC1000 Process Gas Chromatographs can be fitted with thermal conductivity detectors (TCD), flame ionization detectors (FID) or flame photometric detectors (FPD). The

thermal conductivity detector can measure almost all non-corrosive components but

sensitivity is relatively low. On the other hand, the hydrogen flame ionization detector can

measure hydrocarbon and the flame photometric detector can measure sulfur compounds,

respectively with high sensitivity .

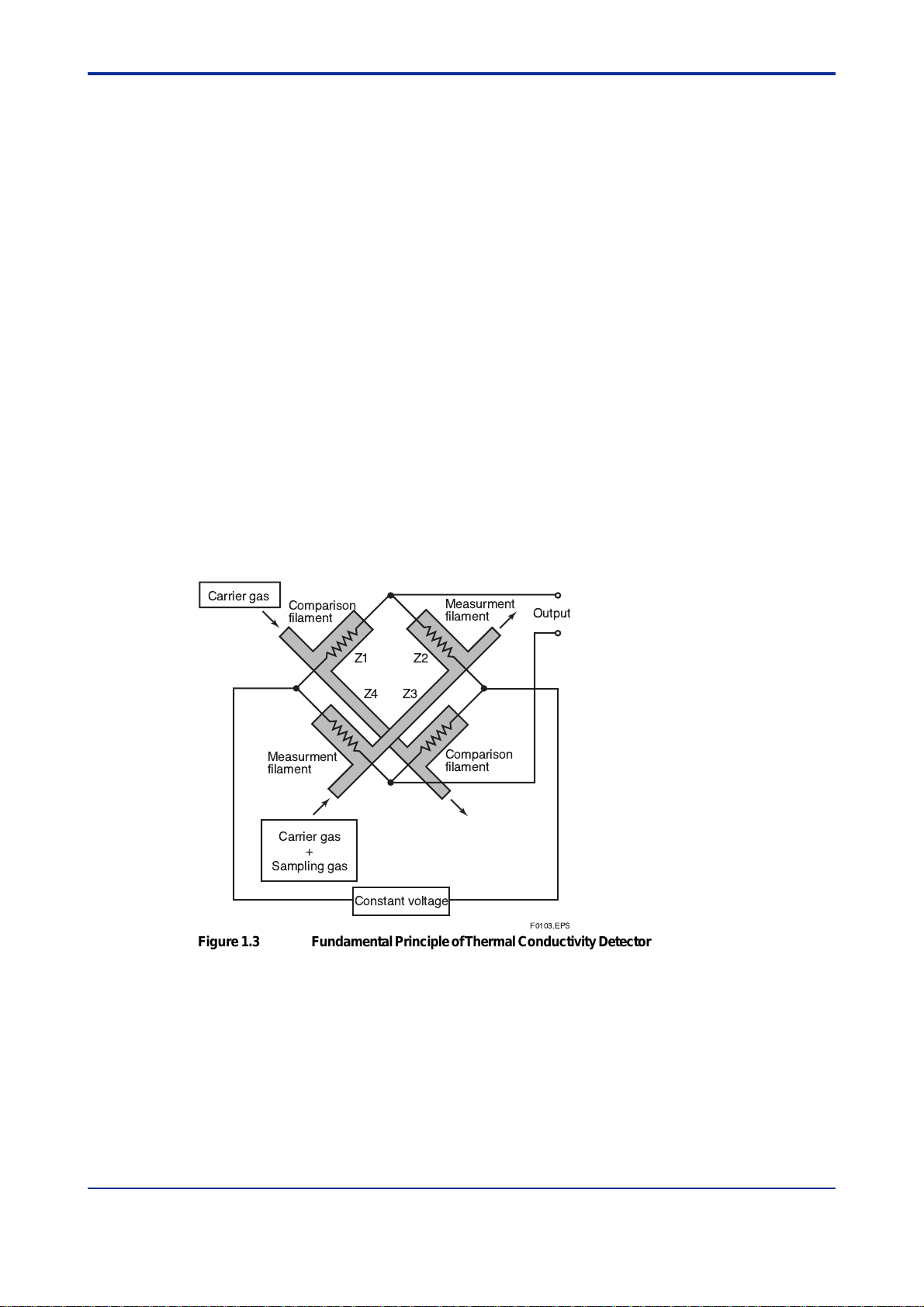

(1)Thermal Conductivity Detector (TCD)

The TCD utilizes the difference in the thermal conductivity between the measured gas and

the carrier gas and detects the unbalanced voltage produced in a bridge circuit as a measure of concentration.

Figure 1.3 shows the fundamental principle of the TCD. As shown, there are two streams,

each having two filaments. One stream passes the carrier gas only and the other, connected to the column outlet, allows the measured gas to pass during analysis. The filaments in the two streams form a bridge circuit such that the filament in one stream is

adjacent to the filament in the other stream. The unbalanced voltage in the bridge is proportional to the concentration of the measured gas (liquid) component.

1-3

The TCD is frequently used to measure the component concentration of the measured gas

(liquid).

Carrier gas

Figure 1.3 Fundamental Principle of Thermal Conductivity Detector

Comparison

filament

Measurment

filament

Carrier gas

+

Sampling gas

Z1 Z2

Z4 Z3

Constant voltage

Measurment

filament

Comparison

filament

Output

F0103.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 19

<T oc> <Ind> <1. Principle of Gas Chromatograph >

(2)Flame Ionization Detector (FID)

The FID utilizes the phenomenon that carbon molecules in the measured component

(hydrocarbon) are ionized in a hot hydrogen flame. That is, it detects the ionization current

which flows between electrodes to which a high voltage is applied. The ionization current is

proportional to the concentration of the measured component.

The FID is used to measure the component concentration of gases containing low concentrations of hydrocarbons.

Ion collector coil

+

-

-

+

+

Hydrogen flame

Jet pipe (nozzle)

+

-

+

-

Output

1-4

Carrier gas

+

Sampling gas

Figure 1.4 Fundamental Principle of Flame Ionization Detector

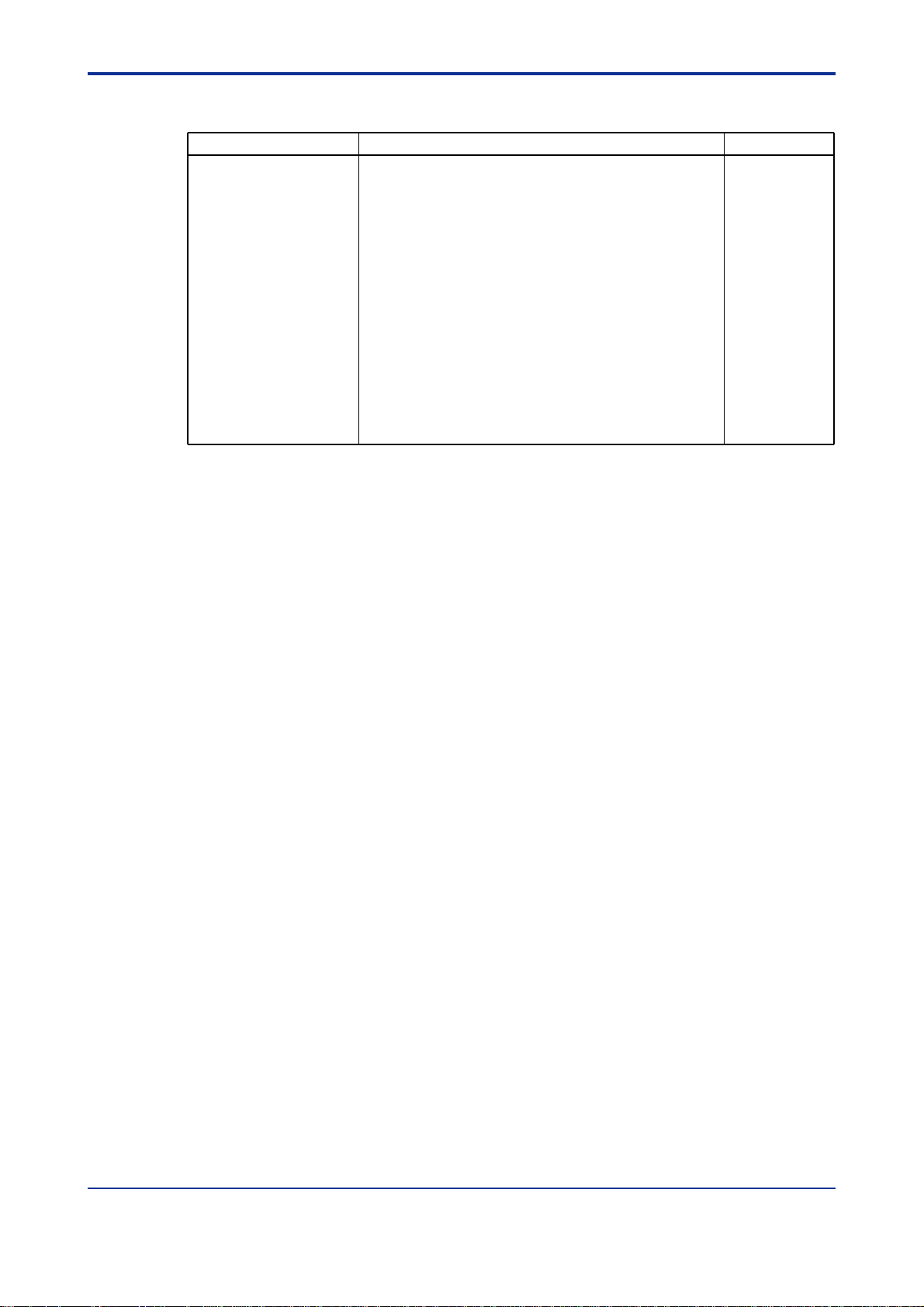

(3)Flame Photometric Detector (FPD)

Figure 1.5 shows the structure of the FPD. As the sample gas containing a sulfur component is led into the excess hydrogen flame, the component containing the sulfur atoms is

excited. The FPD detects the luminous intensity of the light emitted when this excited

component return to its base state using multiplier phototube and converts it to a voltage.

This voltage represents the concentration of the sulfur component in the measured gas.

The FPD can measure on the sulfur component with a high sensitivity of 1 ppm.

Hydrogen flame

Jet pipe (nozzle)

Hydrogen gas

for combustion

Carrier gas

+

Sampling gas

Figure 1.5 Basic Configuration of Flame Photometric Detector

Photomultiplier tube

Hydrogen gas for combustion

F0104.EPS

Hydrogen gas for combustion

Air fo combustion

F0105.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 20

<Toc> <Ind> <2. T erminology >

2. Terminology

2.1 Operation Terminology

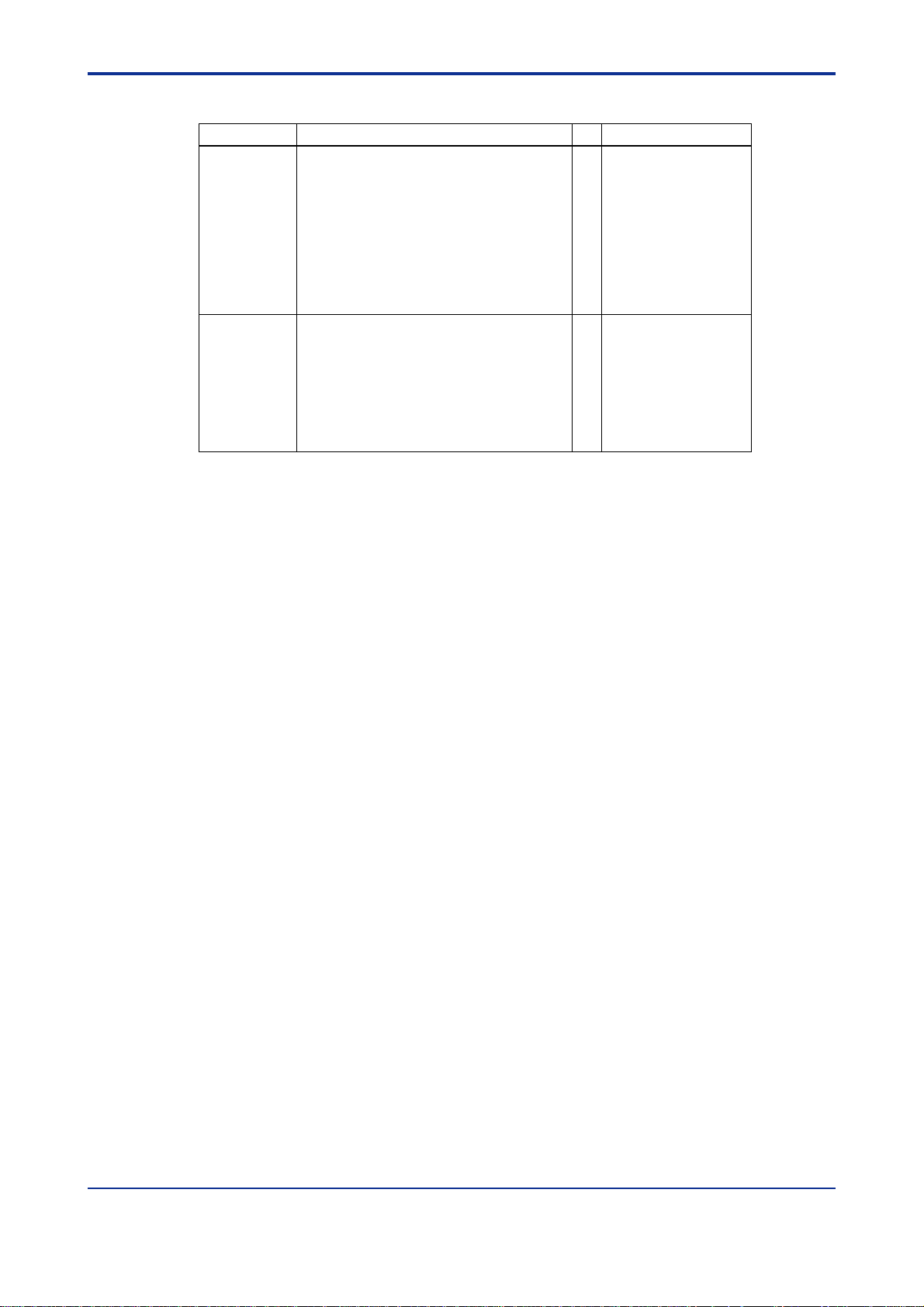

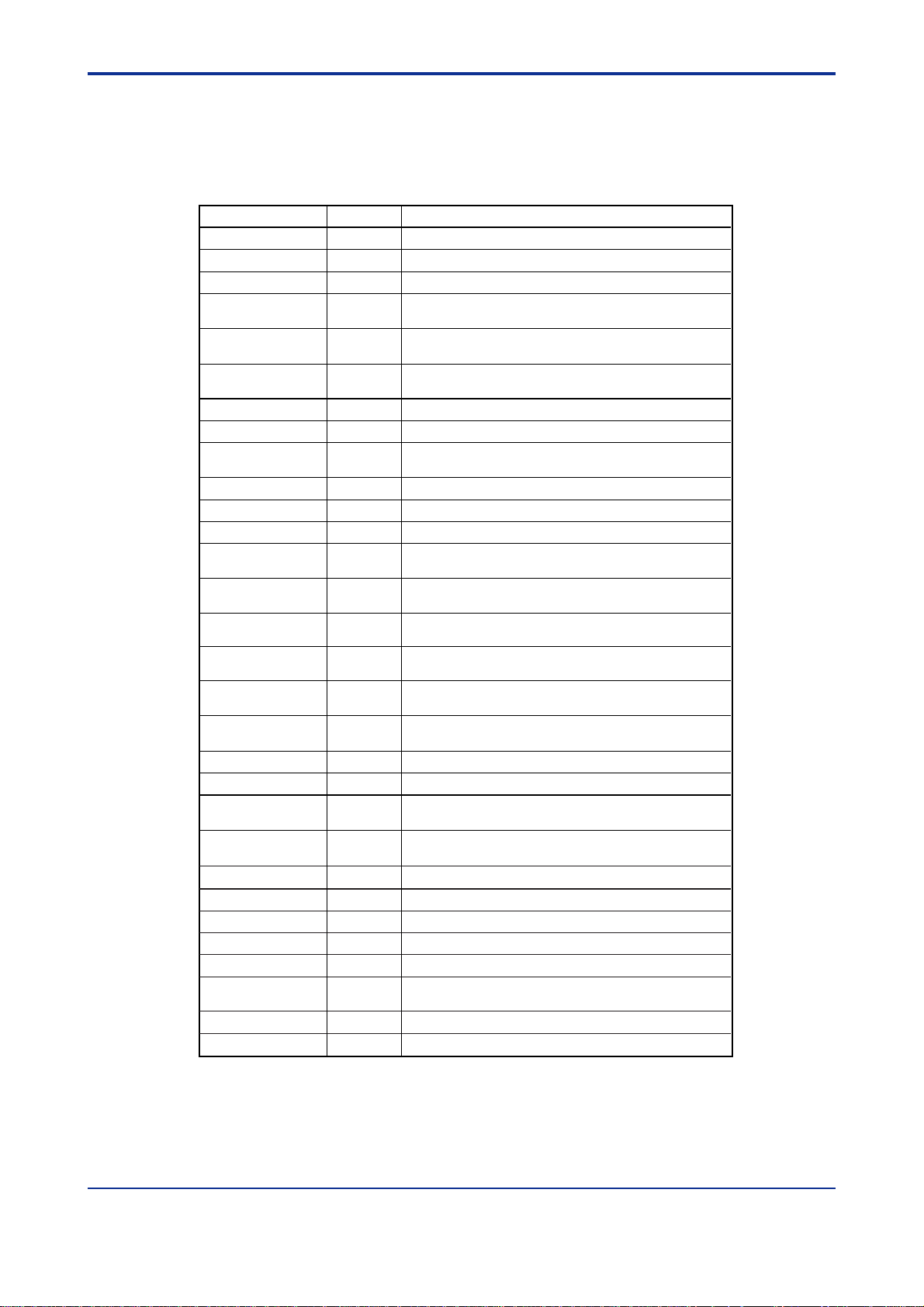

Term Description Notes

Remote Mode

Local Mode

Status

Process

Manual

Lab

Operation Mode

Run

Pause

Stop

Measurement Status

Stream Sequence

Stream (continuous)

Stream (1 cycle)

Calibration

Validation

Method

Analysis Cycle

Warming Up Time

Peak Detection Stop Time

Pause Time

Purging

Status accessible without password,

LCD/key: used only for reference

GCMT: connectable

Status accessible by entering password

LCD/key: used for changing settings

Normal measurement and calibration

Manual operation

Measurement with automatic peak detection, like a lab GC

Mode in which measurement is running

Mode in which measurement pauses

Mode in which measurement stops

Continuously measures streams in order specified in Stream Sequence

Continuously measures the specified stream

Measures the specified stream once

Performs calibration of the specified number

Performs validation of the specified number

Configures action timing of various valves and other parameters

Time from start (0 second) to stop of analysis

Time for displacement in sample streams

Time to stop peak detection of chromatogram compulsorily

Time for measurement pause

Displacement of the gas in the pressurized/Type X purged enclosures

with a protection gas

2-1

T0201.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 21

<T oc> <Ind> <2. T erminology >

2.2 Instrument Terminology

Term Explanation Notes

TCD

FID

FPD

LSV

Restrictor

Methane converter

Sampling valve

Back-flush valve

Column switching valve

Atmospheric-pressure balancing

valve

Protection gas

Flame arrester

Splitter

Pressurized enclosure

Temperature protection circuit

Protection device

EPC

A thermal conductivity detector

A flame ionization detector

A flame photometric detector

A liquid sampling valve

A variable resistor

A methane reaction system : Methanizer

A valve for inputting samples

A switching valve for back flush

A valve for switching between columns

A balancing valve for sampling gases

Air

A device for protecting against "flame runaway"

A flow splitter

An enclosure whose internal pressure is kept high with protection gas

A circuit for turning off the heater to prevent overheating

A device for detecting a pressure drop in the analyzer to shut down the

power supply

Electric pressure controller

2-2

T0202.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 22

<Toc> <Ind> <3. Overview >

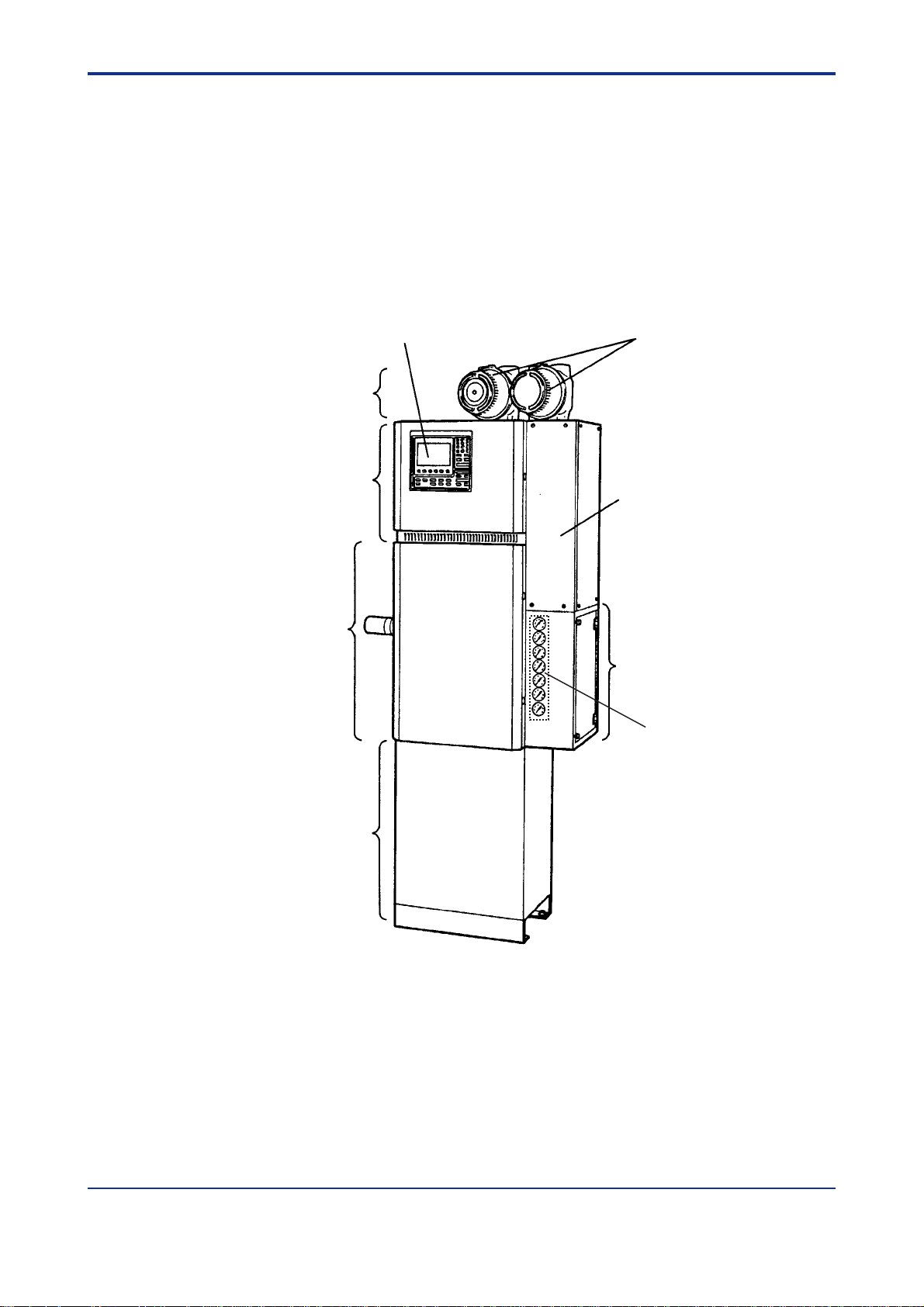

3. System Configuration

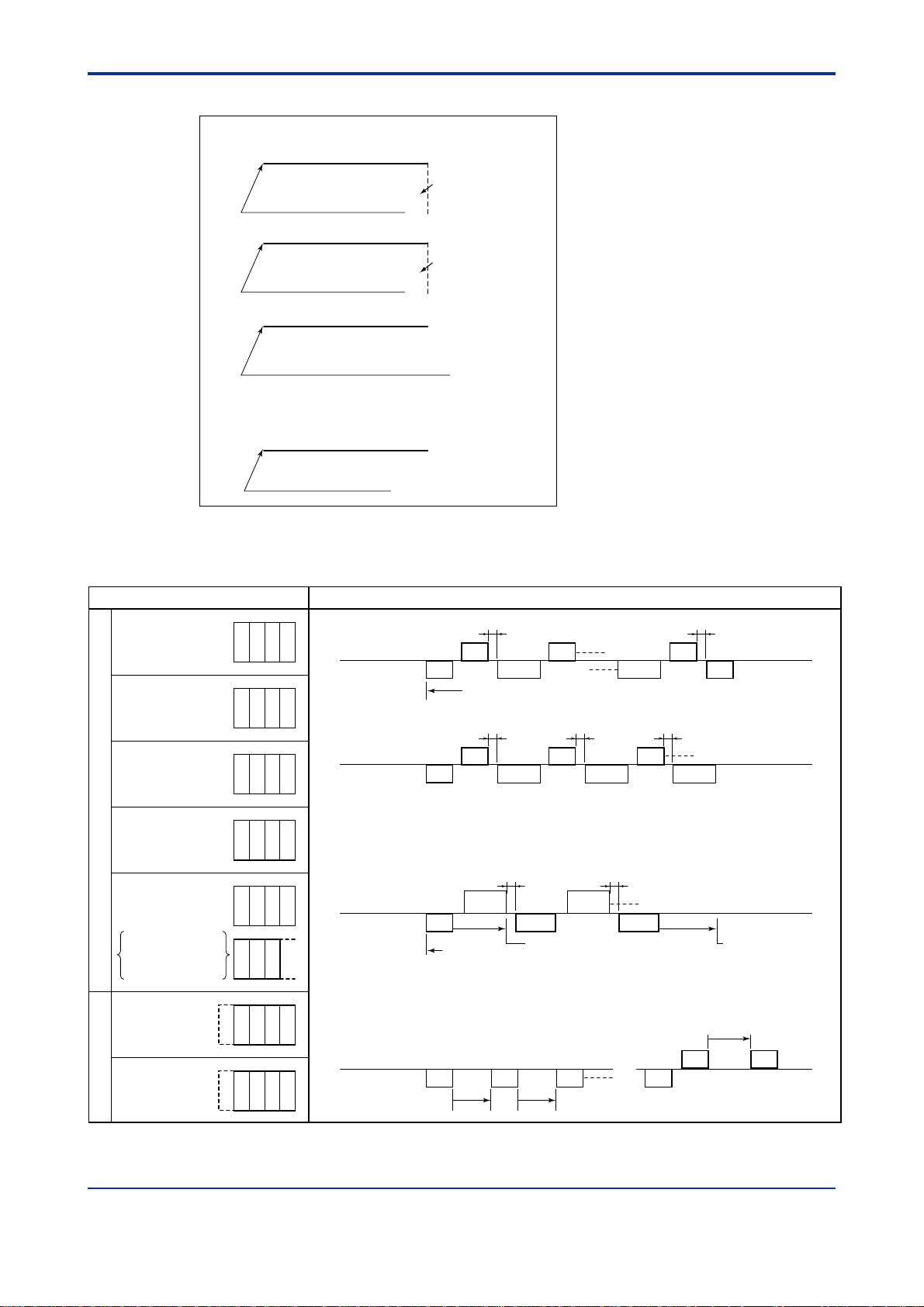

3.1 T ype and Appearance

The GC1000 Process Gas Chromatographs consist of (A) a protection system, (B) an

electronic section, (C) a pressure and flow control section, (D) an isothermal oven, (E) a

programmed-temperature oven (GC1000D / GC1000T / GC1000W) and (F) an analyzer

base sampling section (see Figure 3.1).

Note: There are two types of analyzer base sampling section, either the built-in type within GC1000 (the sample processor is

embedded), or the external type (the sample processor is separate). Select the type best suited to the intended usage.

Display Explosion proof enclosures

(number depends on

specifications)

(A) Protection system

(B) Electronic section

Terminal section

3-1

(D) Isothermal oven

(E) Programmed-temperature

oven

(F) Analyzer base

sampling section

(Note)

Figure 3.1Analyzer Components

(C) Pressure and

flow control section

EPC box

(in the case that EPC is installed)

F0301.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 23

<T oc> <Ind> <3. Overview >

3.2 Components and Their Functions

3.2.1. Protection System

The protection system has a explosion-proof construction and is equipped with a built-in

protection circuit. The power relay , pressure switch, timer , relays, override switch, etc. are

internal to the instrument. The override function is particularly important for maintenance,

since it allows the power to be turned on even if there is an internal pressure loss. The

system monitors the internal pressures of the electronic section, isothermal oven and the

programmed-temperature oven (GC1000D / GC1000T / GC1000W), and if any of them

indicates an internal pressure lower than 392 Pa, it shuts down the power supply to those

components. After a power shut-down, when the internal pressure is restored, the system

automatically purges over the 12 minutes, then turns on the power again. Analyzers of nonexplosion-proof type and with FM/CSA T ype Y purging do not have this protection system.

3.2.2 Electronic Section

The electronic section has a pressurized protection/Type X purged structure and is designed for control of a detector, an isothermal oven, various valves and others, for processing and computation, and for output of the results. The LCD and operation keys on the

front of the electronic section allow manual operation of the GC1000 Mark II.

3-2

3.2.3 Pressure and Flow Control Section

The pressure and flow control sections control and indicate the pressures of sample gases,

standard gases, carrier gases, FID or FPD hydrogen (or nitrogen) for combustion, or FID or

FPD air for combustion. Regulator values or EPC is installed. It also contains pressurereducing valves for controlling purge gases, the air for actuating valves or the vortex tube,

an air-actuated valve for balancing atmospheric pressure, a vortex tube and a hydrogen

restriction system.

3.2.4 Isothermal Oven

The isothermal oven has an pressurized protection / T ype X purged structure. The temperature is set at a fixed level from 55 to 225°C (setting by 1°C unit). The isothermal oven

contains valves such as the sample valve which is air-activated, the back flush valve, the

column for separating a multi-component gas mixture into its individual components and

leading the components to the detector in sequence, the detector for detecting the components, and the restrictor for controlling the gas flow rate, etc.

There are three types of detector, the thermal conductivity detector (TCD), the flame

ionization detector (FID) and the flame photometric detector (FPD); either one or two of

these detectors can be used simultaneously (however, the FPD can only be installed in the

combustion chamber).

The component signals picked up by the detector are led to the electronic section for signal

processing.

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 24

<Toc> <Ind> <3. Overview >

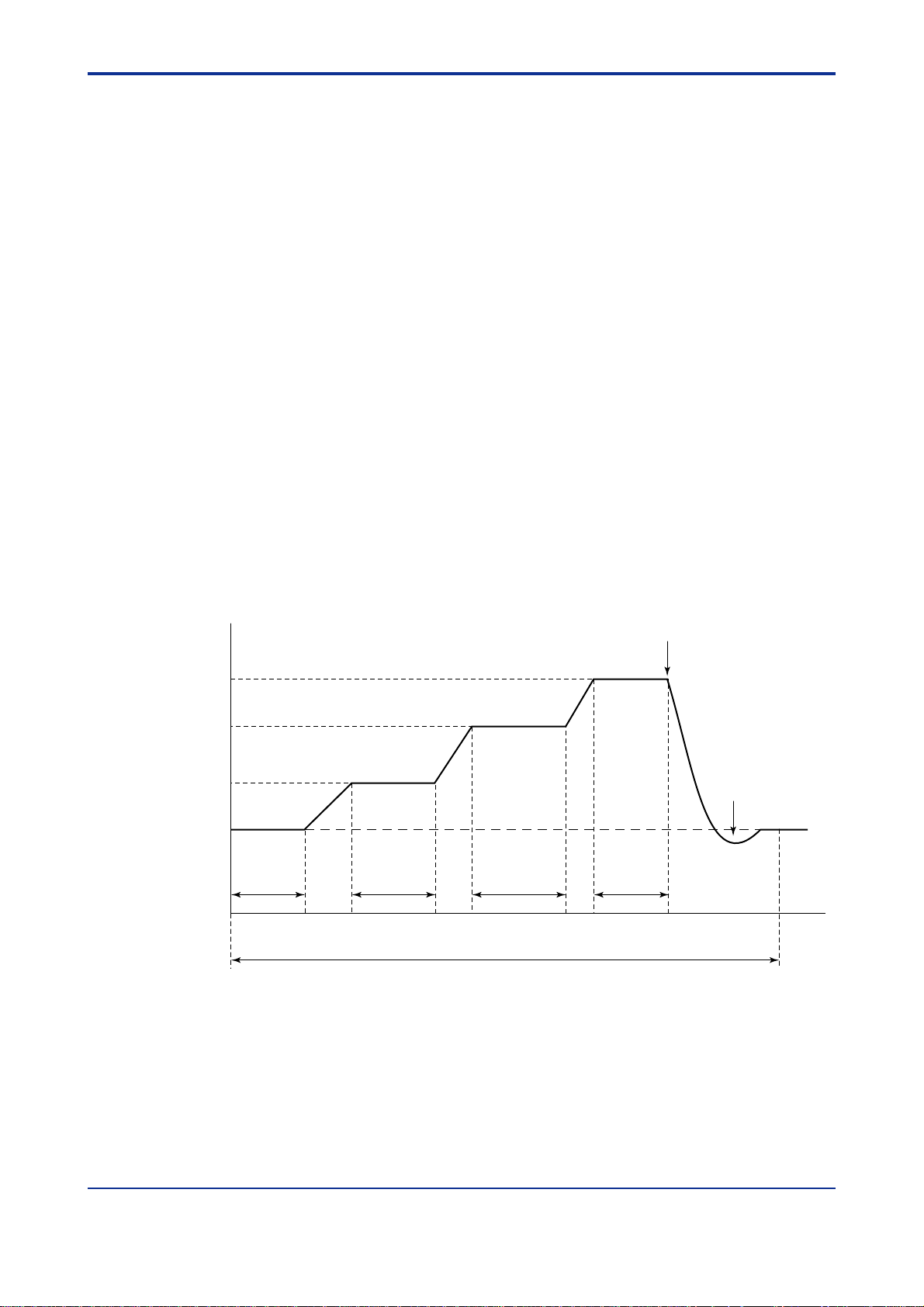

3.2.5 Programmed-temperature Oven

The programmed-temperature oven has an internal pressure protection / T ype X purged

structure. It contains a column that separates multi-component mixture samples into

individual components and leads them to the detector in sequence. The temperature can

be set to a fixed setting or it can be programmed. The allowable temperature range is 60 to

320°C without a cooling system, or 5 to 320°C with a cooling system, and the temperature

can be set to rise from between 0.1 to 30°C/min (setting by 0.1°C unit). Up to three temperature-rise patterns can be programmed.

3.2.6 Analyzer Base Sampling Section

The analyzer base sampling section is equipped with sample and standard gas streams,

and controls the sample pressure and flow rate. It also selectively sends the sample to be

analyzed in a stream, and can switch the standard gas to the isothermal or the programmed-temperature oven by a valve depending on the signal sent from the electronic

section.

If the analyzer does not contain the analyzer base sampling section, then samples can be

processed externally by supplying air to a separate sampling section.

3-3

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 25

<T oc> <Ind> <3. Overview >

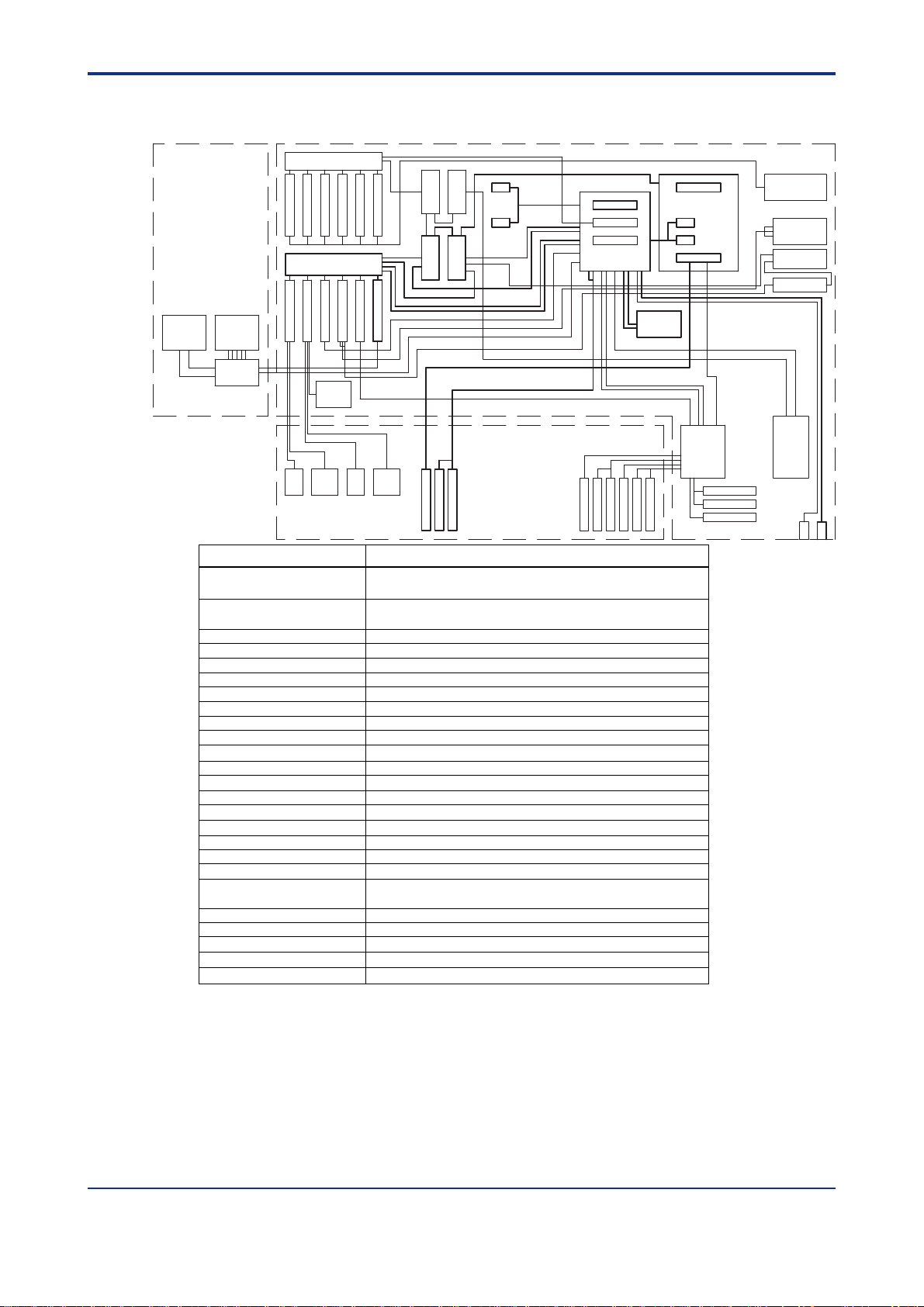

3.3 Block Diagram

(1) GC1000D/GC1000T/GC1000W T ype X Purging

3-4

SHEETKEY LCD

LCD.KEY

BOARD

AO MOTHER BOARD

AO BOARD

AO BOARD

AO BOARD

BACKBOARD

AI CARD

DET2 CARD

DET1 CARD

P .SW P.SWP .SW

P.M B O ARD

AC/DC 24VAC/DC 24V

AO BOARD

AO BOARD

AO BOARD

AC/DC 15VAC/DC 3.3V

COM BOARD

COM BOARD

COM BOARD

MARSHALING.X

BOARD

Terminal

RELAY BOARD

Relay Relay

Terminal

POWER UNIT

SSRSSR

Terminal

Ether (*A) or (*B) is selected.

AO TERMINAL

BOARD

HUB TP

BOARD

(*A)

OPT CONVERTER

(*B)

TERMINAL

CPU CARD

TEMP CARD

ETHERNET CARD

DET1DET2

I.Oven Heter

C.Oven Heter

FID2 Heter

I.Oven PT100

I.Oven PT100

C.Oven PT100

C.Oven PT100

FID1 Heter

FID2 PT100

FID2 PT100

LSV2 Heter

FID1 PT100

FID1 PT100

LSV2 PT100

EV IF

BOARD

TEMP IF

BOARD

LSV1 Heter

LSV1 PT100

LSV2 PT100

LSV1 PT100

EPC

BOARD

P .SW

P .SW

F0302.EPS

(2) GC1000T Type Y Purging

AO MOTHER BOARD

AO BOARD

AO BOARD

AO BOARD

AO BOARD

BACKBOARD

AI CARD

DET1 CARD

LCDSHEETKEY

LCD.KEY

BOARD

DET2 CARD

ETHERNET CARD

DET2 DET1

Ether (*A) or (*B) is selected.

P.SW

AC/DC 3.3V AC/DC 15V

I.Oven PT100

C.Oven Heter

C.Oven PT100

P.SW

P.SW

C.Oven PT100

FID2 Heter

FID2 PT100

FID2 PT100

FID1 Heter

AO BOARD

AO BOARD

AC/DC 24V AC/DC 24V

CPU CARD

TEMP CARD

I.Oven Heter

I.Oven PT100

FID1 PT100

FID1 PT100

COM BOARD

COM BOARD

COM BOARD

MARSHALING.Y

BOARD

LSV2 Heter

LSV1 Heter

LSV2 PT100

LSV2 PT100

EV IF

BOARD

LSV1 PT100

LSV1 PT100

Terminal

POWER UNIT

SSR SSR

SSR SSR

Terminal

TEMP IF

BOARD

AO TERMINAL

BOARD

HUB TP

BOARD

OPT CONVERTER

TERMINAL

EPC

BOARD

(*A)

(*B)

P.SW

P.SW

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 26

<Toc> <Ind> <3. Overview >

(3) GC1000S/GC1000E/GC1000C Type X Pur ging, with One Protection

System

3-5

SHEETKEY LCD

LCD.KEY

BOARD

AO MOTHER BOARD

AO BOARD

AO BOARD

AO BOARD

AO BOARD

BACKBOARD

DET2 CARD

DET1 CARD

ETHERNET CARD

FPD AMP

BOARD

MC MC

P .SW P.SW

P.M B O ARD

AC/DC 24VAC/DC 24V

AO BOARD

AO BOARD

AC/DC 15VAC/DC 3.3V

COM BOARD

COM BOARD

COM BOARD

MARSHALING.X

BOARD

Terminal

RELAY BOARD

Relay Relay

Terminal

POWER UNIT

SSR

Terminal

Ether (*A) or (*B) is selected.

AO TERMINAL

BOARD

HUB TP

BOARD

(*A)

OPT CONVERTER

(*B)

TERMINAL

CPU CARD

TEMP CARD

DET1DET2

I.Oven Heter

I.Oven PT100

I.Oven PT100

LSV2 Heter

LSV2 PT100

EV IF

BOARD

TEMP IF

BOARD

FPD PT100

FPD PT100

LSV1 Heter

LSV1 PT100

LSV2 PT100

LSV1 PT100

FPD Heter

EPC

BOARD

P .SW

P .SW

(4) GC1000S/GC1000E/GC1000C Type X Pur ging, with T wo Pr otection

Systems

SHEETKEY LCD

LCD.KEY

BOARD

AO MOTHER BOARD

AO BOARD

AO BOARD

AO BOARD

AO BOARD

BACKBOARD

AI CARD

DET2 CARD

DET1 CARD

ETHERNET CARD

FPD AMP

BOARD

MC MC

P.SW P.SW

P.M BOARD

AC/DC 24VAC/DC 24V

AO BOARD

AO BOARD

CPU CARD

TEMP CARD

DET1DET2

AC/DC 15VAC/DC 3.3V

I.Oven Heter

I.Oven PT100

I.Oven PT100

COM BOARD

COM BOARD

COM BOARD

MARSHALING.X

BOARD

LSV1 Heter

LSV2 Heter

LSV2 PT100

LSV2 PT100

LSV1 PT100

EV IF

BOARD

LSV1 PT100

Terminal

RELAY BOARD

Relay Relay

Terminal

POWER UNIT

SSR

Terminal

TEMP IF

BOARD

FPD PT100

FPD PT100

FPD Heter

Ether (*A) or (*B) is selected.

AO TERMINAL

BOARD

HUB TP

BOARD

OPT CONVERTER

TERMINAL

EPC

BOARD

(*A)

(*B)

P.SW

P.SW

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 27

<T oc> <Ind> <3. Overview >

(5) GC1000E T ype Y Purging

AO MOTHER BOARD

AO BOARD

AO BOARD

AO BOARD

BACKBOARD

P.SW

AO BOARD

AO BOARD

AO BOARD

AC/DC 24V AC/DC 24V

P.SW

AC/DC 3.3V AC/DC 15V

COM BOARD

COM BOARD

COM BOARD

MARSHALING.Y

BOARD

Terminal

POWER UNIT

SSR

SSR

Terminal

3-6

Ether (*A) or (*B) is selected.

AO TERMINAL

BOARD

HUB TP

BOARD

(*A)

OPT CONVERTER

(*B)

TERMINAL

LCDSHEETKEY

LCD.KEY

BOARD

AI CARD

DET1 CARD

DET2 CARD

FPD AMP

BOARD

DET2 DET1

CPU CARD

TEMP CARD

ETHERNET CARD

MCMC

I.Oven Heter

I.Oven PT100

Name Description

CPU CARD

Controls the whole GC1000 analyzer system (controls the

temperature or the isothermal oven).

TEMP CARD

Controls the temperature of the components other than the

isothermal oven.

ETHERNET CARD

AI CARD

TCD CARD

FID CARD

FPD CARD

BACK BOARD

RELAY BOARD

P.M BOARD

AI TERMINAL BOARD

Controls the TPC/IP.

Controls the analog input.

Controls the TCD.

Controls the FID.

Controls the FPD.

Connects various cards.

Controls the relay inside the protection system.

Monitors the inner pressure.

Equipped with the connection terminal for the analog input.

I.Oven PT100

LSV2 Heter

LSV2 PT100

LSV2 PT100

LSV1 Heter

EV IF

BOARD

LSV1 PT100

LSV1 PT100

TEMP IF

BOARD

FPD PT100

FPD PT100

FPD Heter

EPC

BOARD

P.SW

P.SW

LCD.KEY BOARD

MARSHALING.X BOARD

MARSHALING.Y BOARD

COM BOARD

FPD AMP BOARD

EV IF BOARD

TEMP IF BOARD

EPC BOARD

AO TERMINAL BOARD

HUB TP BOARD

AO MOTHER BOARD

AO BOARD

Relays among the LCD, sheet key an CPU card.

Relays among various boards.

Relays among various boards (for Y purging).

Controls various communications.

An amplifier board for the FPD.

For solenoid valves.

Relays among the heaters except for the isothermal oven,

sensors, and TEMP CARD.

Controls the EPC.

Equipped with the connection terminal for the analog output.

A relay board for the analyzer bus.

Controls the analog output.

An analog output board.

T0301.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 28

<Toc> <Ind> <3. Overview >

3.4 Internal Piping System Diagram

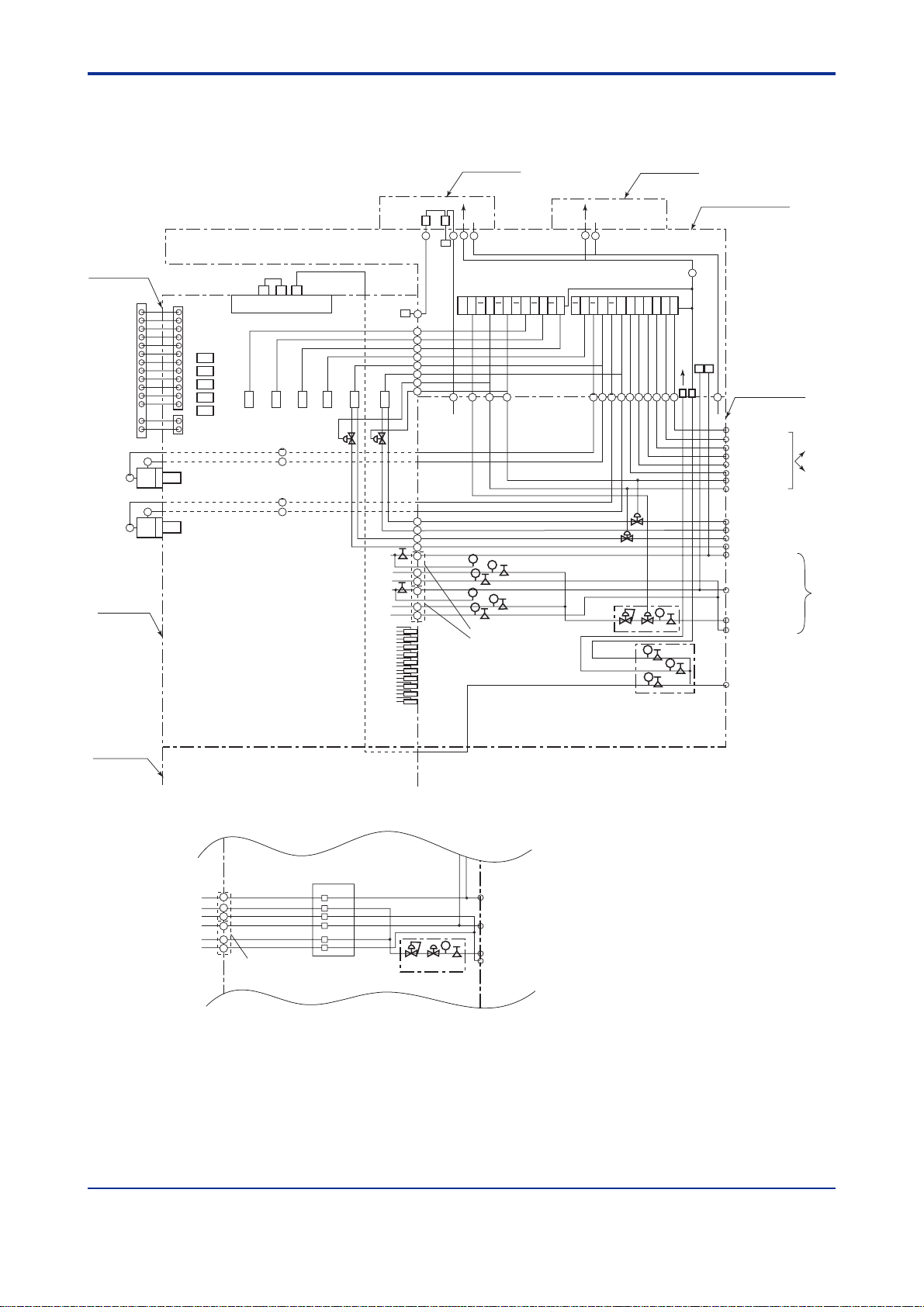

(1) GC1000D/GC1000T/GC1000W T ype X Purging

3-7

Isothermal oven

SPLIT1 Vent

B.F .1 Vent

TCD1 Vent

REF .1 Vent

SPLIT2 Vent

B.F .2 Vent

TCD2 Vent

REF .2 Vent

FID1 Vent

FID2 Vent

8

7

Programmed

temperature

oven

Sampling base

LSV2

LSV1

Explosionproof

enclosure 2

Internal pressure

detection

switch

Fan

Pressure

detection

FID1

FID2

Valve 2

TCD1

TCD2

Valve 6 Valv e 5 Valv e 4

8

7

Pressure

detection

Atomospher

pressure balancing

valve

8

8

7

7

Valve 3

Valve 1

Atomospher pressure

balancing valve

Fan

REF

Purge Purge

27

21

2223

24

Pressure

detection

16 15 14 14 13 13 12 12 11 11 10 10 9 9 8 8 7 7 6 5 4 3 2 1

24

23

12

11

10

9

8

7

14

13

1

V

2

V2

C1

F1

A1

C2

F2

A2

Restrictor 1

Restrictor 2

Restrictor 3

Restrictor 4

Restrictor 5

Restrictor 6

P

P

P

P

P

P

Flame arrester 1

Flame arrester 2

Forced cooling

valve

Cooling air

Voltex

tube

27

21

8

Atomospher pressure

balancing valve

Hydrogen

limitter

Electromagnetic

Purge for air chamber

Isothermal oven

Programed temperature oven

7

Flow rate

limitter

Cooling

Forced cooling

Explosionproof

enclosure 1

Purge

123456781314151622

Atomospher

pressure

balancing valve

P

Shut off

P

P

P

P

P

Regulator

Electric section

(pressurized enclosure)

27

Carrier

pressure

switch

Pressure regulator

21

Electromagnetic output 1

Electromagnetic output 2

Electromagnetic output 3

Electromagnetic output 4

Electromagnetic output 5

Electromagnetic output 6

Electromagnetic output 7

Electromagnetic output 8

Sample 1

Sample vent 1

Sample 2

Sample vent 2

Carrier 1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier 2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

Manifold

pressure

regulator

Purge air

To sampling system

Piping length: 10 m max.

To external

sampling

system

Samplin

base

(*)

High tempreture air

) In the case that EPC is installed.

(

*

C1

F1

A1

C2

F2

A2

Flame arrester

EPC1

EPC3

EPC5

EPC2

EPC4

EPC6

Hydrogen

limitter

Flow rate

limitter

Shut off

P

Carrier1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

F0312.EPS

IM 11B03A03-01E

F0307.EPS

3rd Edition : Aug. 23. 2006-00

Page 29

<T oc> <Ind> <3. Overview >

(2) GC1000T Type Y Purging

Electric section

(pressurized enclosure)

3-8

Isothermal oven

SPLIT1 Vent

B.F .1 Vent

TCD1 Vent

REF .1 Vent

SPLIT2 Vent

B.F .2 Vent

TCD2 Vent

REF .2 Vent

FID1 Vent

FID2 Vent

8

7

Programmed

temperature

oven

Sampling base

LSV2

LSV1

Internal pressure

detection

switch

Fan

Pressure

detection

FID1

FID2

Valve 2

TCD1

TCD2

Valve 6 Valv e 5 Valv e 4

8

7

Pressure

detection

Atomospher

pressure balancing

valve

8

8

7

7

Valve 3

Valve 1

Atomospher pressure

balancing valve

Fan

REF

2223

24

Pressure

detection

16 15 14 14 13 13 12 12 11 11 10 10 9 9 8 8 7 7 6 5 4 3 2 1

24

23

12

11

10

9

8

7

14

13

1

V

2

V2

C1

F1

A1

C2

F2

A2

Restrictor 1

Restrictor 2

Restrictor 3

Restrictor 4

Restrictor 5

Restrictor 6

P

P

P

P

P

P

Flame arrester 1

Flame arrester 2

8

Atomospher pressure

balancing valve

Hydrogen

limitter

Electromagnetic

Purge for air chamber

Isothermal oven

Programed temperature oven

Forced cooling

valve

Cooling air

Voltex

tube

Cooling

Forced cooling

7

Flow rate

limitter

Atomospher

pressure

balancing valve

Shut off

P

P

Regulator

Carrier

pressure

switch

Purge

Manifold

pressure

regulator

Pressure regulator

To sampling system

Piping length: 10 m max.

Electromagnetic output 1

Electromagnetic output 2

Electromagnetic output 3

Electromagnetic output 4

Electromagnetic output 5

Electromagnetic output 6

Electromagnetic output 7

Electromagnetic output 8

Sample 1

Sample vent 1

Sample 2

Sample vent 2

Carrier 1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier 2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

To external

sampling

system

Samplin

base

(*)

123456781314151622

P

P

P

P

Purge air

High tempreture air

) In the case that EPC is installed.

(

*

C1

F1

A1

C2

F2

A2

Flame arrester

EPC1

EPC3

EPC5

EPC2

EPC4

EPC6

Hydrogen

limitter

Flow rate

limitter

Shut off

P

Carrier1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

F0312.EPS

F0308.EPS

IM 11B03A03-01E

3rd Edition : Aug. 23. 2006-00

Page 30

<Toc> <Ind> <3. Overview >

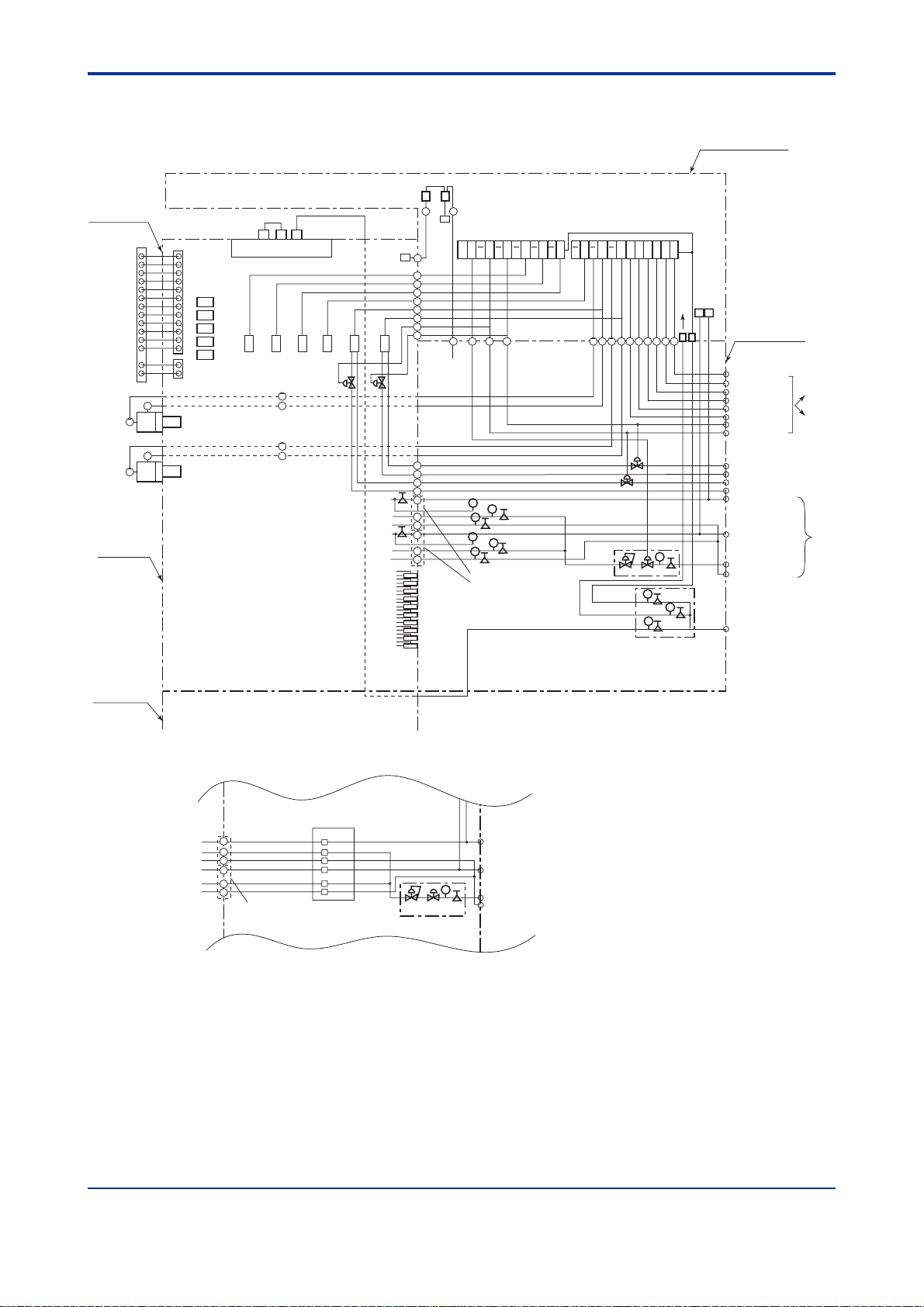

(3) GC1000S/GC1000E/GC1000C Type X Pur ging, with One Protection

System

Explosionproof

enclosure 1

Electric section

(pressurized enclosure)

27

Isothermal oven

Internal pressure

detection

switch

24

REF

22

Pressure

detection

Purge

27

21

3-9

SPLIT1 Vent

B.F .1 Vent

TCD1 Vent

REF .1 Vent

F .F.1-1 Vent

F .F.1-2 Vent

TCD2 Vent

REF .2 Vent

SPLIT2 Vent

B.F .2 Vent

F .F.2-1 Vent

F .F.2-2 Vent

FID1 Vent

FID2 Vent

8

LSV2

7

LSV1

Programmed

temperature

oven

Sampling base

Fan

Pressure

detection

FID1

FID2

Methan

Converter

TCD1

TCD2

Valve 6 Valv e 5 Valv e 4

8

8

7

8

7

7

Valve 2

Valve 3

Atomospher

pressure balancing

valve

Valve 1

Atomospher pressure

balancing valve

16 15 14 14 13 13 12 12 11 11 10 10 9 9 8 8 7 7 6 5 4 3 2 1

24

12

11

10

9

8

7

14

13

1

V

2

V2

C1

F1

A1

C2

F2

A2

Restrictor 1

Restrictor 2

Restrictor 3

Restrictor 4

Restrictor 5

Restrictor 6

Restrictor 7

Restrictor 8

Restrictor 9

Restrictor 10

P

P

P

P

P

P

Flame arrester 1

Flame arrester 2

8

Atomospher pressure

balancing valve

Hydrogen

limitter

Electromagnetic

Purge for air chamber

Isothermal oven

7

Atomospher

pressure

balancing valve

P

Flow rate

Shut off

limitter

P

P

P

Manifold pressure regulator

Purge

1234567813141522

Carrier

pressure

switch

21

Pressure regulator

To sampling system

Piping length: 10 m max.

Electromagnetic output 1

Electromagnetic output 2

Electromagnetic output 3

Electromagnetic output 4

Electromagnetic output 5

Electromagnetic output 6

Electromagnetic output 7

Electromagnetic output 8

Sample 1

Sample vent 1

Sample 2

Sample vent 2

Carrier 1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier 2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

Purge air

To external

sampling

system

Samplin

base

(*)

) In the case that EPC is installed.

(

*

C1

F1

A1

C2

F2

A2

Flame arrester

EPC1

EPC3

EPC5

EPC2

EPC4

EPC6

Hydrogen

limitter

Flow rate

limitter

Shut off

P

Carrier1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

F0312.EPS

IM 11B03A03-01E

F0309.EPS

3rd Edition : Aug. 23. 2006-00

Page 31

<T oc> <Ind> <3. Overview >

(4) GC1000S/GC1000E/GC1000C T ype X Purging, with Two Protection

Systems

3-10

Isothermal oven

SPLIT1 Vent

B.F .1 Vent

TCD1 Vent

REF .1 Vent

F .F.1-1 Vent

F .F.1-2 Vent

TCD2 Vent

REF .2 Vent

SPLIT2 Vent

B.F .2 Vent

F .F.2-1 Vent

F .F.2-2 Vent

FID1 Vent

FID2 Vent

8

7

Programmed

temperature

oven

LSV2

LSV1

Explosionproof

enclosure 2

Internal pressure

detection

switch

Fan

Pressure

detection

FID1

FID2

Methan

Converter

TCD1

TCD2

Valve 6 Valv e 5 Valv e 4

8

8

7

8

7

7

Valve 2

Valve 3

Atomospher

pressure balancing

valve

Valve 1

Atomospher pressure

balancing valve

REF

Purge

27

21

22

24

Pressure

detection

16 15 14 14 13 13 12 12 11 11 10 10 9 9 8 8 7 7 6 5 4 3 2 1

24

12

11

10

9

8

7

14

13

1

V

2

V2

C1

F1

A1

C2

F2

A2

Restrictor 1

Restrictor 2

Restrictor 3

Restrictor 4

Restrictor 5

Restrictor 6

Restrictor 7

Restrictor 8

Restrictor 9

Restrictor 10

P

P

P

P

P

P

Flame arrester 1

Flame arrester 2

Purge

27

21

8

Atomospher pressure

balancing valve

Hydrogen

limitter

Electromagnetic

Purge for air chamber

Isothermal oven

Explosionproof

enclosure 1

7

Atomospher

pressure

balancing valve

P

Flow rate

Shut off

limitter

P

P

P

Manifold pressure regulator

Electric section

(pressurized enclosure)

27

Carrier

pressure

switch

Purge

21

1234567813141522

Pressure regulator

To sampling system

Piping length: 10 m max.

Electromagnetic output 1

Electromagnetic output 2

Electromagnetic output 3

Electromagnetic output 4

Electromagnetic output 5

Electromagnetic output 6

Electromagnetic output 7

Electromagnetic output 8

Sample 1

Sample vent 1

Sample 2

Sample vent 2

Carrier 1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier 2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

Purge air

To external

sampling

system

Samplin

base

(*)

Sampling base

) In the case that EPC is installed.

(

*

C1

F1

A1

C2

F2

A2

Flame arrester

EPC1

EPC3

EPC5

EPC2

EPC4

EPC6

Hydrogen

limitter

Flow rate

limitter

Shut off

P

Carrier1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

F0312.EPS

F0310.EPS

IM 11B03A03-01E

3rd Edition : Aug. 23. 2006-00

Page 32

<Toc> <Ind> <3. Overview >

(5) GC1000E T ype Y Purging

Electric section

(pressurized enclosure)

3-11

Isothermal oven

SPLIT1 Vent

B.F .1 Vent

TCD1 Vent

REF .1 Vent

F .F.1-1 Vent

F .F.1-2 Vent

TCD2 Vent

REF .2 Vent

SPLIT2 Vent

B.F .2 Vent

F .F.2-1 Vent

F .F.2-2 Vent

FID1 Vent

FID2 Vent

8

7

Programmed

temperature

oven

LSV2

LSV1

Internal pressure

detection

switch

Fan

Pressure

detection

FID1

FID2

Methan

Converter

TCD1

TCD2

Valve 6 Valv e 5 Valv e 4

8

8

7

8

7

7

Valve 2

Valve 3

Atomospher

pressure balancing

valve

Valve 1

Atomospher pressure

balancing valve

REF

22

24

Pressure

detection

16 15 14 14 13 13 12 12 11 11 10 10 9 9 8 8 7 7 6 5 4 3 2 1

24

12

11

10

9

8

7

14

13

1

V

2

V2

C1

F1

A1

C2

F2

A2

Restrictor 1

Restrictor 2

Restrictor 3

Restrictor 4

Restrictor 5

Restrictor 6

Restrictor 7

Restrictor 8

Restrictor 9

Restrictor 10

P

P

P

P

P

P

Flame arrester 1

Flame arrester 2

8

Atomospher pressure

balancing valve

Hydrogen

limitter

Electromagnetic

Purge for air chamber

Isothermal oven

7

Atomospher

pressure

balancing valve

P

Flow rate

Shut off

limitter

P

P

P

Manifold pressure regulator

Purge

1234567813141522

Carrier

pressure

switch

Pressure regulator

To sampling system

Piping length: 10 m max.

Electromagnetic output 1

Electromagnetic output 2

Electromagnetic output 3

Electromagnetic output 4

Electromagnetic output 5

Electromagnetic output 6

Electromagnetic output 7

Electromagnetic output 8

Sample 1

Sample vent 1

Sample 2

Sample vent 2

Carrier 1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier 2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

Purge air

To external

sampling

system

Samplin

base

(*)

Sampling base

) In the case that EPC is installed.

(

*

C1

F1

A1

C2

F2

A2

Flame arrester

EPC1

EPC3

EPC5

EPC2

EPC4

EPC6

Hydrogen

limitter

Flow rate

limitter

Shut off

P

Carrier1

H2(N2)-1 for combustion

Air-1 for combustion

Carrier2

H2(N2)-2 for combustion

Air-2 for combustion

H2

Air for combustion

F0312.EPS

F0311.EPS

IM 11B03A03-01E

3rd Edition : Aug. 23. 2006-00

Page 33

<T oc> <Ind> <3. Overview >

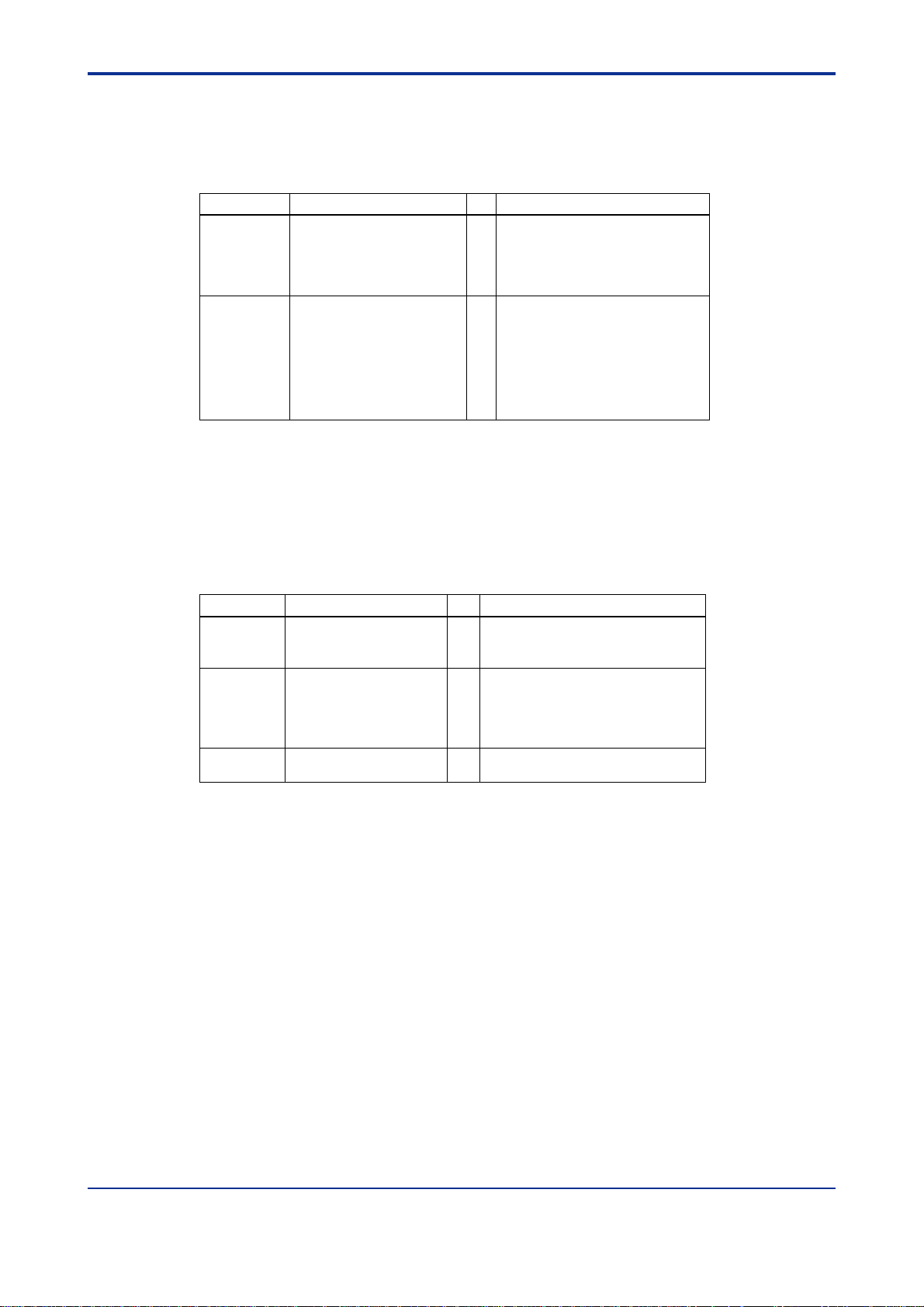

3.5 External Input and Output Signals

(1)Input

Item Signal level No. Description

Analog Input

Contact Input

*1) : 2-wire transmitter

*2) : It means the data which is averaged by every 1 second

after filtered by a constant which the analog data is scanned by every 200msec. It can be output

by DCS communication (Modbus protocol).

*3) : It means the current value which is set time in a cycle time.

Isolated

4-20mA DC

1-5V DC

4-20mA DC

(with 24 or 28V DC of Power)

Specification :

5V DC, 20mA DC or more

Input

ON signal: 200Ω or less

OFF signal: 100kΩ or more

On operation:

NC or NO (selectable)

*1)

48Accuracy :

±0.5%FS (-10 to 50˚C)

Function :

Output of Current value

and Av erage value

Function :

Alarm from outside

Following command request

Stream sequence assign

Stream (cont.) assign

Stream (1 cycle) assign

Cal (Val) assign

Change of Operation mode

*2)

*3)

T0302.EPS

3-12

(2)Output

Item Signal level No. Description

Analog

Output

Contact

Output

Air output for

stream valve

*1) : Analysis result (concentration, simulated distillation result,

base level, signal level, noise level, Deviation calculation, Liner calculation1-5, Ratio,

Separation coefficient, Calorific value, Density, Compressive factor, Wobbe Index)

Isolated or No-isolated

4-20mA DC

Load: 300Ω or less

Specification (relay) :

Voltage: 30V DC

Current: 100mA DC

On operation:

NO or NC (selectable)

Air press : 350kPa

Analysis result

MAX.

36

System alarm1

8

System alarm2

Component alarm (Conc./RT)

Timing signal

Code signal for stream ID

MAX.

Binary code signal for 9 to 31 stream

(max.)

8

*1)

(Max. 5 points)

T0303.EPS

IM 11B03A03-01E

3rd Edition : Aug. 23. 2006-00

Page 34

<Toc> <Ind> <3. Overview >

(3)Communication

Item Signl level No. Description

DCS

communi-cation

Standard :

RS422 (4wires, Full-Duplex)

Specification :

Start bit 1, Stop bit 1, Parity 1, ASCII7 bit,

Without procedure or Hand shake

Speed :

1200/2400/4800/9600/19200 bps(selectable)

For explosion protection :

RS422/RS232C converter is provided.(2 wires

of power line is needed except the signal line)

The transmission type is full duplex for RS232C.

PC

communi-cation

Standard :

RS422 (4wires, Full-Duplex)

Speed :

19.6/33.6kbps

For explosion protection :

RS422/RS232C converter is provided.(2 wires

of power line is needed except the signal line)

The transmission type is full duplex for RS232C.

*1) : Analysis result(concentration, simulated distillation result,

base level, signal level, noise level, Deviation calculation, Liner calculation1-5, Ratio, Separation

coefficient, Calorific value, Density, Compressive factor, Wobbe Index)

*2) : Operation request, (Stream sequence assign, Stream

(cont.) assign, Run command, Stop command, Pause command, Range change)

*3) : Operation Information(Chromatogram, Oven

temperature, measuring stream, Valve ON/OFF etc...)

11Transmission :

Analysis result

Calibration coefficient

Alarm

Reception :

Operation request

GCMT

(GC Maintenance Terminal)

Transmission :

Analysis result

Operation information

Parameter list

Reception :

Operation request

Change of Parameter list

*4)

*5)

*4)

*5)

T0304.EPS

3-13

*6)

IM 11B03A03-01E

3rd Edition : Aug. 23. 2006-00

Page 35

Blank Page

Page 36

<Toc> <Ind> <4. Outline of Software >

4. Outline of Software

4.1 Status and Operation Mode

The GC1000 Mark II has the following statuses:

• Process: Normal measurement, calibration and validation

• Manual: Manual operation

• Lab: Measurement with automatic peak detection, like a laboratory GC

The GC1000 Mark II has the following operation modes:

• Stop: Mode in which the measurement stops

• Run: Mode in which the measurement is running

• Pause: Mode in which the measurement pauses

Figure 4.1 shows the transitions of statuses and operation modes.

4-1

Stop

command

Stop mode

Lab

Run mode

Run

command

Figure 4.1 Status and Operation Mode Transition Diagram

Pause mode Run mode Run mode

Stop command

Change the status Change the status

Process Manual

Run command

Pause command

Pause

command

Stop mode Stop mode

Run

command

Stop command

Stop

command

When the LCD panel on the GC1000 Mark II or the LCD emulator on a personal computer

(PC) connected with the GC1000 Mark II is used, by changing the operation panel to the

manual operation panel or lab operation panel, the status will change from Process to

Manual or Lab. Likewise, by changing the manual operation panel or lab operation panel

to the operation panel, the status will change from Manual or Lab to Process.

When the GCMT on a PC connected with the GC1000 Mark II is used, the status can be

changed through command button operation or menu-driven operation.

The following pages describe each status and operation in detail.

Run

command

F0401.EPS

IM 11B03A03-01E 3rd Edition : Aug. 23. 2006-00

Page 37

<T oc> <Ind> <4. Outline of Software >

4.1.1 Process

In the Process status normal process measurements, calibration, and validation are performed. When power is applied, the status enters Process.

The Process status contains the following measurement statuses.

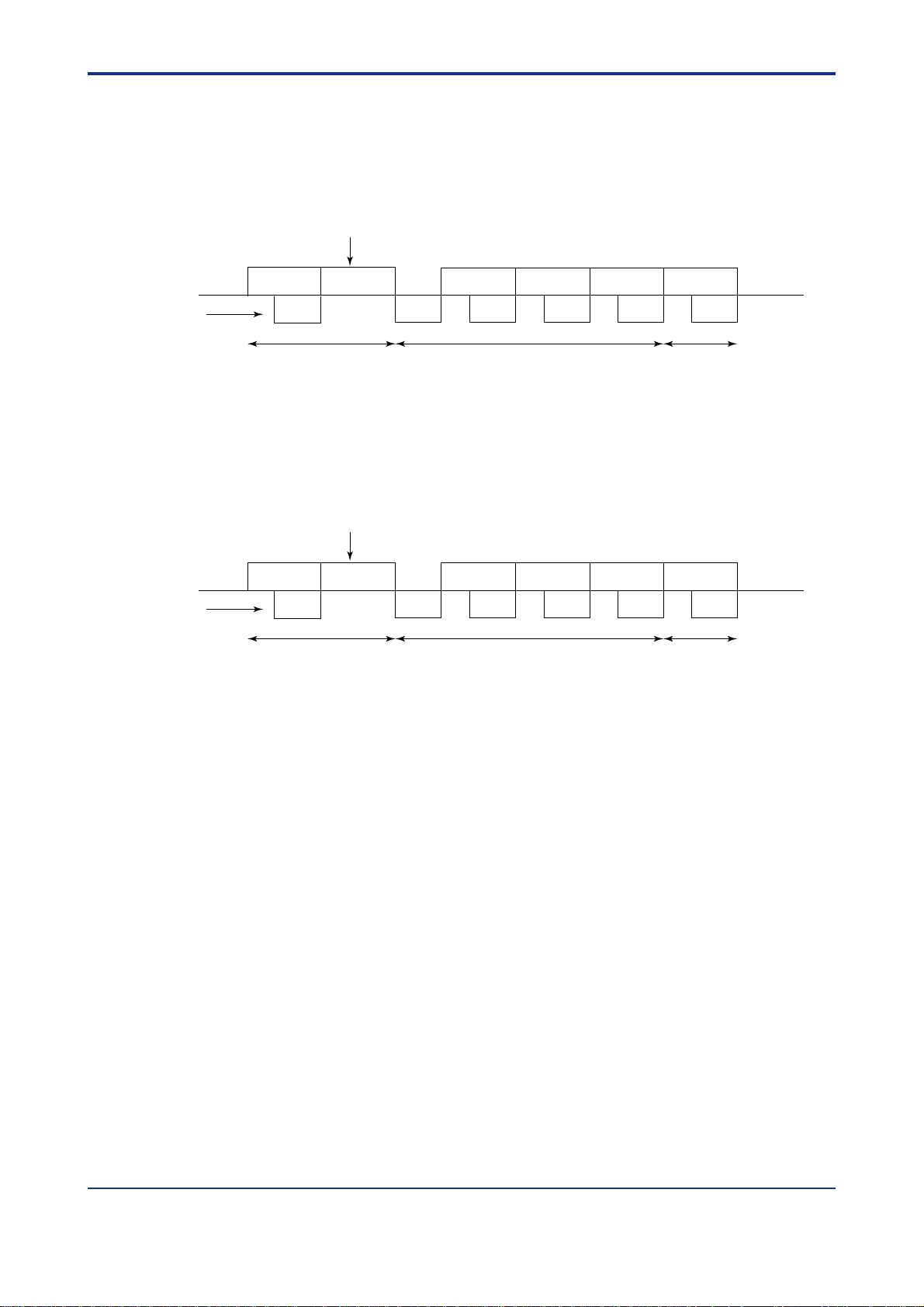

• Stream Sequence: Continuously measures streams in order specified in Stream

Sequence

• Stream (continuous): Continuously measures the specified stream

• Stream (1 cycle): Measures the specified stream once

• Calibration/V alidation: Performs calibration or validation of the specified number

Figure 4.2 shows the transitions of measurement statuses.

4-2

Stream Sequence

(Same as the status)

Note: When Calibration/V alidation has been specified from Stream Sequence, the measurement status returns to Stream

Sequence after the completion of calibration/validation. When Calibration/Validation has been specified from Stream

(continuous), the measurement status returns to Stream (continuous) after the completion of calibration/validation.

Figure 4.2 Measurement Status Transition Diagram

Stream (coninuous)

Cal/ValStream (1 cycle) Cal/Val

F0402.EPS

The following explain each measurement status in detail.

(1) Stream Sequence