Page 1

User’s

Manual

R2.05

R1.01

AXF

Verication Tool

IM 01R01A11-01EN

IM 01R01A11-01EN

1st Edition

Page 2

Blank Page

Page 3

AXF

Verication Tool

IM 01R01A11-01EN 1st Edition

CONTENTS

1 INTRODUCTION ........................................................................................ 1-1

1.1 About This Manual ............................................................................................1-2

1.2 Safety and Modication Precautions .............................................................1-2

1.3 Trademarks ........................................................................................................1-3

1.4 Software License Agreement ..........................................................................1-3

2 OUTILINE ................................................................................................... 2-1

2.1 Conguration .................................................................................................... 2-2

2.2 Verication Item ................................................................................................2-3

2.3 Operation Procedure ........................................................................................2-4

Toc-1

3 PREPARATION .......................................................................................... 3-1

3.1 Package and Installation ..................................................................................3-2

3.2 AXF Write Protect Cancellation .......................................................................3-2

3.2.1 Before Verication ..............................................................................3-2

3.2.2 During Verication ..............................................................................3-3

4 START-UP FROM FieldMate .................................................................... 4-1

4.1 From “Segment Viewer”

(AXF is reading in “online” mode in FieldMate) ............................................4-2

4.2 From “Device Navigator” .................................................................................4-4

4.3 From “Verication Data” in “Device Maintenance Info” ............................... 4-6

4.4 From “History” ..................................................................................................4-8

5 LAUNCHING .............................................................................................. 5-1

5.1 Creating New Verication Data ........................................................................5-2

5.2 Loading Existing Verication Data .................................................................5-4

5.3 After Unexpected Termination.........................................................................5-5

6 OPERATION .............................................................................................. 6-1

6.1 Main Screen ....................................................................................................... 6-2

6.1.1 Load ...................................................................................................6-3

6.1.2 Save ...................................................................................................6-4

6.1.3 Print out ..............................................................................................6-8

6.1.4 Menu bar ............................................................................................6-9

1st Edition’ Aug. 2012

All Rights Reserved, Copyright © 2012, Yokogawa Electric Corporation

IM 01R01A11-01EN

Page 4

Toc-2

6.2 Standard VF ..................................................................................................... 6-11

6.2.1 “Circuit” check and “Device Status” check

(Verication Tool is in “online” mode) ...............................................6-12

6.2.2 Physical Appearance .......................................................................6-21

6.2.3 Standard VF Result ..........................................................................6-22

6.3 Enhanced VF ...................................................................................................6-23

6.3.1 Current Output ................................................................................6-25

6.3.2 Pulse Output ....................................................................................6-28

6.3.3 Converter .........................................................................................6-35

6.3.4 Insulation Resistance .......................................................................6-38

6.4 Result ...............................................................................................................6-39

7 VARIATION OF VERIFICATION DATA ..................................................... 7-1

7.1 Installation Data ................................................................................................7-1

7.2 Locked Data .......................................................................................................7-2

7.3 Others .................................................................................................................7-2

8 TERMINATION ........................................................................................... 8-1

8.1 Normal Termination ..........................................................................................8-1

8.1.1 When the verication data has not been changed after saving:........8-1

8.1.2 When the verication data has been changed after saving:..............8-1

8.2 Unexpected Termination ..................................................................................8-2

9 COMMUNICATION ERROR ...................................................................... 9-1

9.1 Error Message ...................................................................................................9-1

9.2 Device Address Setting ....................................................................................9-3

9.2.1 Multidrop Mode Canceling ................................................................ 9-3

9.2.2 Multidrop Mode Setting ......................................................................9-3

Revision Information ..............................................................................................1

IM 01R01A11-01EN

Page 5

<1 INTRODUCTION>

1 INTRODUCTION

This User’s Manual gives instructions on “AXF Verication Tool”.

This software is used to set up magnetic owmeter AXF; therefore, it is indispensable for users

to read, understand and follow the instructions on all the following user’s manual before actually

starting the operation.

Table 1.1.1 User’s Manuals for magnetic owmeter ADMAG AXF

Title IM No.

AXF Magnetic Flowmeter, Integral Flowmeter/ Remote Flowtube

[Hardware Edition]

AXFA11G Magnetic Flowmeter, Remote Converter

[Hardware Edition/Software Edition]

AXFA14G/C Magnetic Flowmeter Remote Converter

[Hardware Edition/Software Edition]

AXF Magnetic Flowmeter Integral Flowmeter [Software Edition]

Table 1.1.2 User’s Manuals for external instruments

Title IM No.

Models AM012 Magnetic Flowmeter Calibrator FY2-XJAM012-40-2E

CA150 HANDY CAL IM CA150E

IM 01E20D01-01E

IM 01E20C01-01E

IM 01E20C02-01E

1-1

Refer to FieldMate User’s Manual when using AXF Verication Tool.

Table 1.1.3 User’s Manuals for FieldMate

Title IM No.

FieldMate

Versatile Device Management Wizard

FieldMate Operational Precaution IM 01R01A01-91E

FieldMate

Wizard Getting Started

IM 01R01A01-01E

IM 01R01A04-01E

IM 01R01A11-01EN

Page 6

<1 INTRODUCTION>

1.1 About This Manual

• This manual should be provided to the end user.

• Before using the AXF Verication Tool, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed without prior notice.

• All rights are reserved. No part of this manual may be reproduced in any form without

Yokogawa’s written permission.

• Yokogawa makes no warranty of any kind with regard to this material, including, but not

limited to, implied warranties of merchantability and suitability for a particular purpose.

• All reasonable effort has been made to ensure the accuracy of the contents of this manual.

However, if any errors or omissions are found, please inform Yokogawa.

• Yokogawa assumes no responsibilities for this product except as stated in the warranty.

• Please note that this user’s manual may not be revised for any changes in specications,

construction changes or operating part changes that are not considered to affect function or

performance.

• If the customer or any third party is harmed by the use of this product, Yokogawa assumes

no responsibility for any such harm owing to any defects in the product which were not predictable, or for any indirect damages.

1-2

• This manual describes the operation of the AXF Verication Tool with FieldMate Advance.

For detail installation and operation of FieldMate and additional functions, please refer to the

FieldMate User’s Manual.

1.2 Safety and Modication Precautions

• The following general safety precautions must be observed during all phases of operation, service, and repair of this instrument. Failure to comply with these precautions or with

specic WARNINGS given elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Yokogawa assumes no liability for the

customer’s failure to comply with these requirements. If this instrument is used in a manner

not specied in this manual, the protection provided by this instrument may be impaired.

• Yokogawa will not be liable for malfunctions or damage resulting from any modication

made to this instrument by the customer.

• The following safety symbols are used in this user’s manual and on the instrument.

WARNING

A WARNING sign denotes a hazard. It calls attention to a procedure, practice, condition or the

like, which, if not correctly performed or adhered to, could result in injury or death of personnel

CAUTION

A CAUTION sign denotes a hazard. It calls attention to a procedure, practice, condition or the

like, which, if not correctly performed or adhered to, could result in damage to or destruction of

part or all of the product.

IM 01R01A11-01EN

Page 7

<1 INTRODUCTION>

IMPORTANT

An IMPORTANT sign denotes that attention is required to avoid damage to the instrument or

system failure.

NOTE

A NOTE sign denotes essential information for understanding operations and features.

1.3 Trademarks

All the brand names or product names of Yokogawa Electric used in this document are either

trademarks or registered trademarks of Yokogawa Electric Corporation.

All the brand names or product names of other companies mentioned in this document are either

trademarks or registered trademarks of their respective holders.

1-3

1.4 Software License Agreement

Refer to IM 01R01A01-01E Part A.

IM 01R01A11-01EN

Page 8

Blank Page

Page 9

<2 OUTILINE>

2 OUTILINE

AXF Verication Tool is a PC application software running in conjunction with FieldMate R2.05.00

or later.

Without having to remove the AXF magnetic owmeter from process line, its condition can be

veried by checking several items and this tool provides a certicate that the unit is operating in

accordance with YOKOGAWA standards. It is essentially an indication that the AXF is operating

to its standards and is useful in supporting plant maintenance practices. It differs from actual-ow

calibration at a manufacturing plant.

This tool stores verication data (*1) in a database (*2) in an organized manner, and can be used

to print a Verication Report that has not only the individual verication items (*3) result but also

the overall status of “passed” or “failed”. It is thus useful for device maintenance management.

*1: Verication data means the data saved by the user.

*2: Database means a collection of verication data saved in Device Maintenance Information.

*3: For the verication items, refer to 2.2.

2-1

IM 01R01A11-01EN

Page 10

<2 OUTILINE>

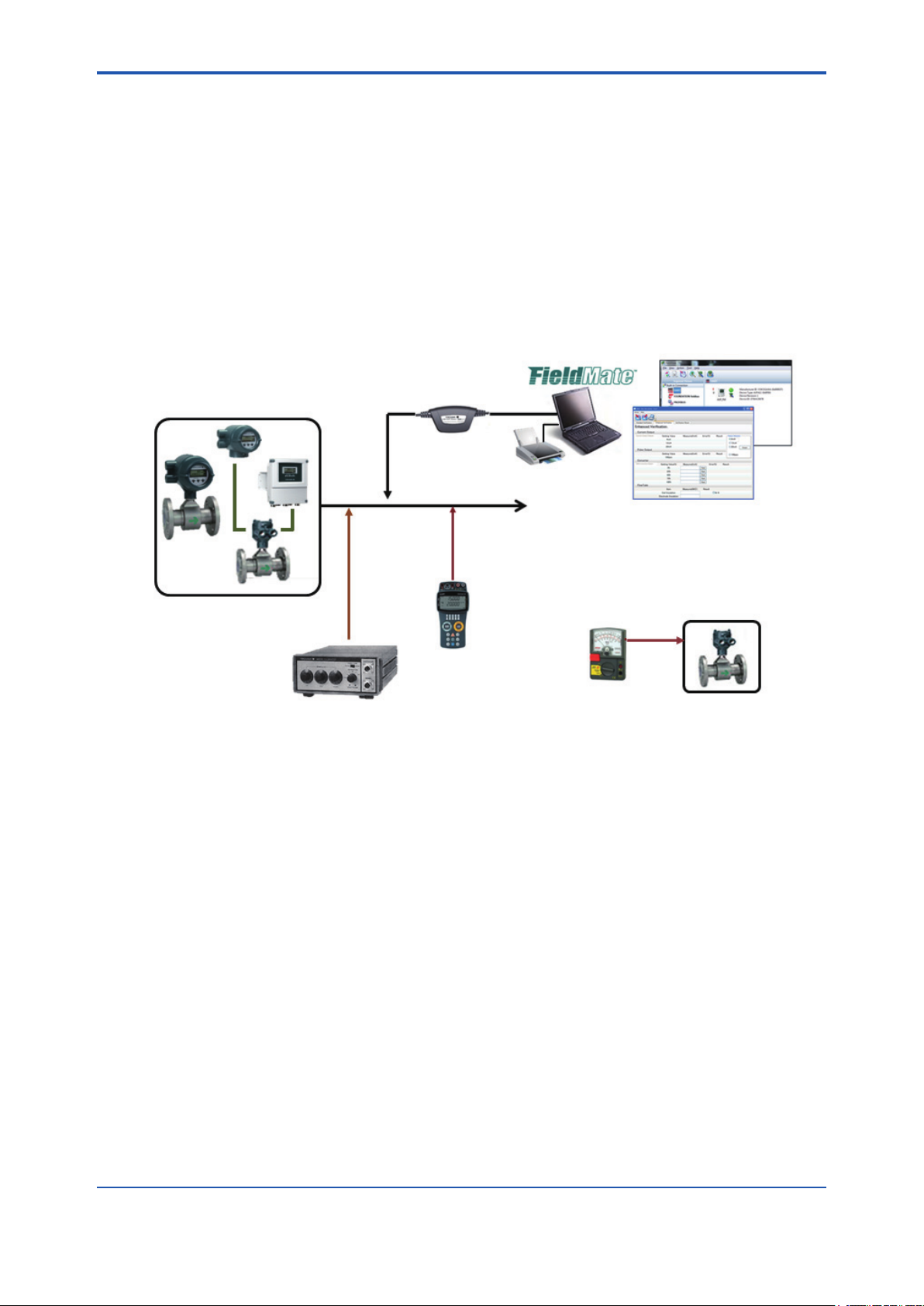

2.1 Conguration

The following equipment is required to use Verication Tool ver. 1.01.00;

• YOKOGAWA magnetic owmeter AXF with HART Communication (AXF Output Signal and

Communication sufx code: -E).

• PC (*1) and Printer

• Magnetic Flowmeter Calibrator AM012 (Only for Enhanced VF (*2), Optional)

• Handy Calibrator CA150 or equivalent (Only for Enhanced VF (*2), Optional)

• Insulation Checker (Only for Enhanced VF (*2), Optional)

*1: Regarding the PC environment, refer to IM 01R01A01-01E Part B,C.

*2: VF stands for “Verication”.

- Circuit Check

- Device Status Check

- Physical Appearance Check

USB FieldMate Modem

2-2

Magnetic Flowmeter

AXF

MA012

Calibrator

(Optional)

- Converter Check

Figure 2.1.1 Congurations

Output Signal

4-20mA or pulse

CA150

Handy Calibrator

(Multi-meter)

(Optional)

- Current Output Check

- Pulse Output Check

Printer

PC

Insulation checker

(Optional)

- Insulation Resistance

Check

Magnetic

Flowmeter

AXF

F020301.ai

IM 01R01A11-01EN

Page 11

<2 OUTILINE>

2.2 Verication Item

This Verication Tool has 2 modes, which can be run separately.

1. Standard Verication (Standard VF)

• This mode veries the condition of the AXF without difculty by checking its internal parameters. No external instruments are required.

• Some items are run only when FieldMate is in “online (*1)” mode.

2. Enhanced Verication (Enhanced VF) [Optional]

• This mode provides a more reliable verication by performing a detailed overview equivalent

to SERVICE.

• This mode is optional. If only this mode is completed, “Overall Status” is left blank.

• This mode veries AXF by using external instruments, such as Magnetic Flowmeter Calibrator AM012, Handy Calibrator CA150, and so on.

• Even when FieldMate is in “ofine (*2)” mode, this mode can be run; in this case, some settings must be made manually.

There are only 2 possible combinations:

1. Standard VF

2-3

2. Standard VF + Enhanced VF

Table 2.2.1 Verication Items

Mode Verication Item Description

Standard VF Circuit (*3)

Magnetic Circuit Checks the Magnetic Circuit.

Excitation Circuit Checks the Excitation Circuit.

Calculation Circuit Checks the Calculation Circuit.

Device Status (*3)

Alarm Check Checks occurring Alarms.

Alarm History Checks historical Alarms.

Physical Appearance

Flowtube Checks the Flowtube appearance.

Converter Checks the Converter appearance.

Enhanced VF Current Output (*4) Checks the Current Output.

Pulse Output (*4) Checks the Pulse Output.

Converter (*4) Checks the Converter Accuracy.

Insulation Resistance

Coil

Signal (Electrode)

Checks the Excitation Coil.

(Remote Flowtube Only)

Checks the Insulation Resistance.

(Remote Flowtube Only)

*1: Online: The status in which the software communicates with a device.

*2: Ofine: The status in which the software does not communicate with a device.

The communication status between FieldMate and AXF can be conrmed on the FieldMate window.

*3: These items are checked only when Verication Tool is in “online” mode.

*4: When Verication Tool is in “ofine” mode, manual setting is necessary.

IM 01R01A11-01EN

Page 12

<2 OUTILINE>

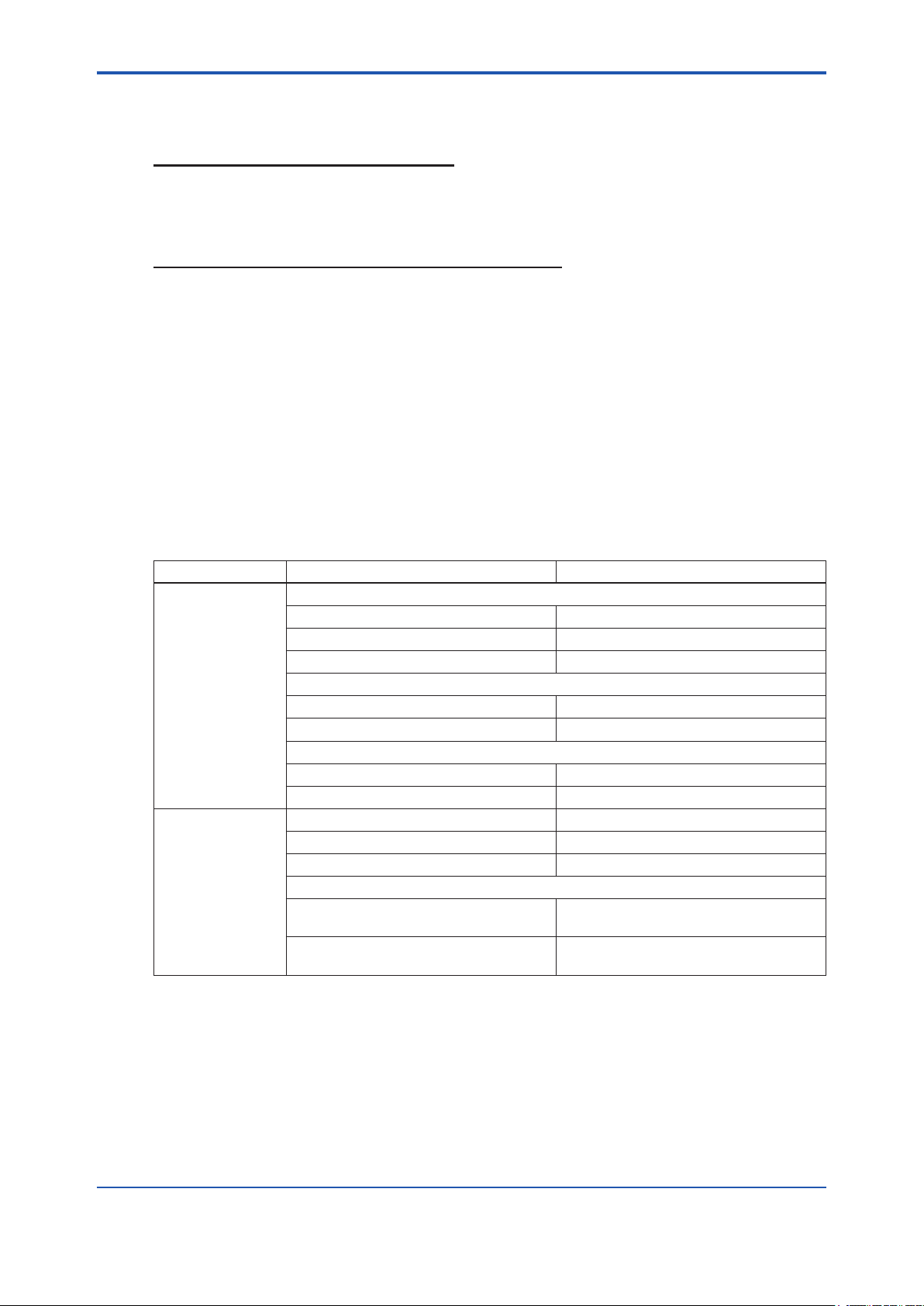

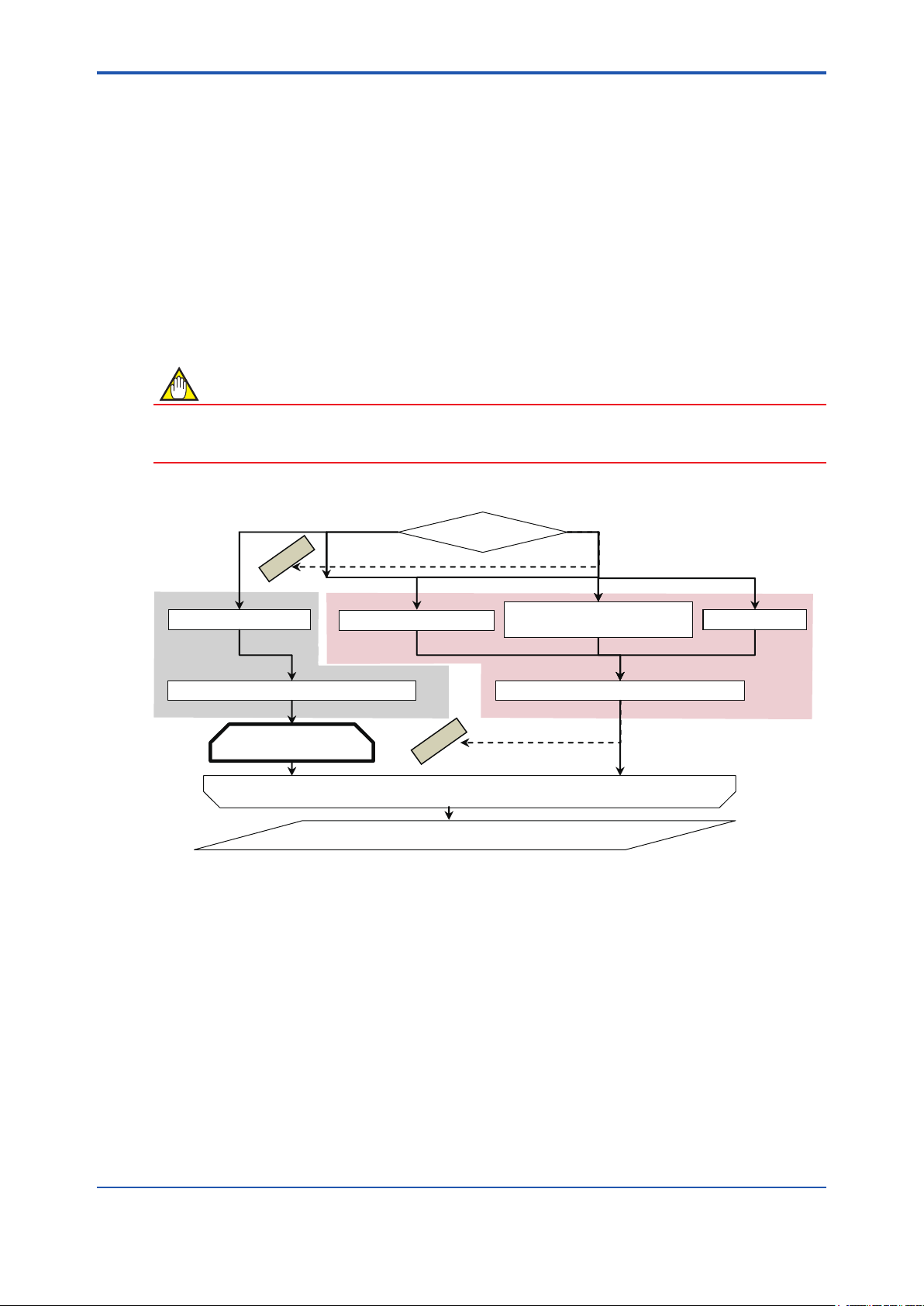

2.3 Operation Procedure

Figure 2.3.1 summarizes operation procedure.

To complete “Standard VF”, start-up Verication Tool from “Segment Viewer”. See 4.1.

1 to 3 PREPARATION

4 START-UP

2-4

Online Offline

IMPOSSIBLE

4.1 Segment Viewer 4.2 Device Navigator

No. New data Yes

5.3 General Information

Online

6.2 Standard VF

(Mandatory)

FieldMate and AXF

5 LAUNCHING

Use the existing data?

6.1 Main Screen

Verification Tool and AXF

6.3 Enhanced VF

4.3 Verification Data

in “Device Maintenance Info”

Verification Tool and AXF: OfflineVerification Tool and AXF: Online

IMPOSSIBLE

(Optional)

4.4 History

5.2 Load

Offline

Verification

Operation

No Yes

Figure 2.3.1 Operation Procedure

6.4 Result

Save the verification data ?

6.1.3 Print out

8 TERMINATION

6.1.2 Save

F020301.ai

IM 01R01A11-01EN

Page 13

<3 PREPARATION>

3 PREPARATION

3-1

WARNING

• Before running the Verication Tool, loop should be set to manual mode in the host system.

• The following applications may cause inadequate results:

- Signicantly-low ow rate

- Slurry liquid

- Stray current

• When “unexpected issue (*1)” occurs while running Verication Tool, follow “8.2 Unexpected Termination” and “9 Communication Error”

*1: “Unexpected issue” means disconnection between AXF and PC:

• Physical disconnection between AXF and PC

• Forced shutdown of PC

• Unforeseen AXF power-off

IM 01R01A11-01EN

Page 14

<3 PREPARATION>

3.1 Package and Installation

Regarding the packaging and installation procedure, refer to IM 01R01A01-01E Part B.

3.2 AXF Write Protect Cancellation

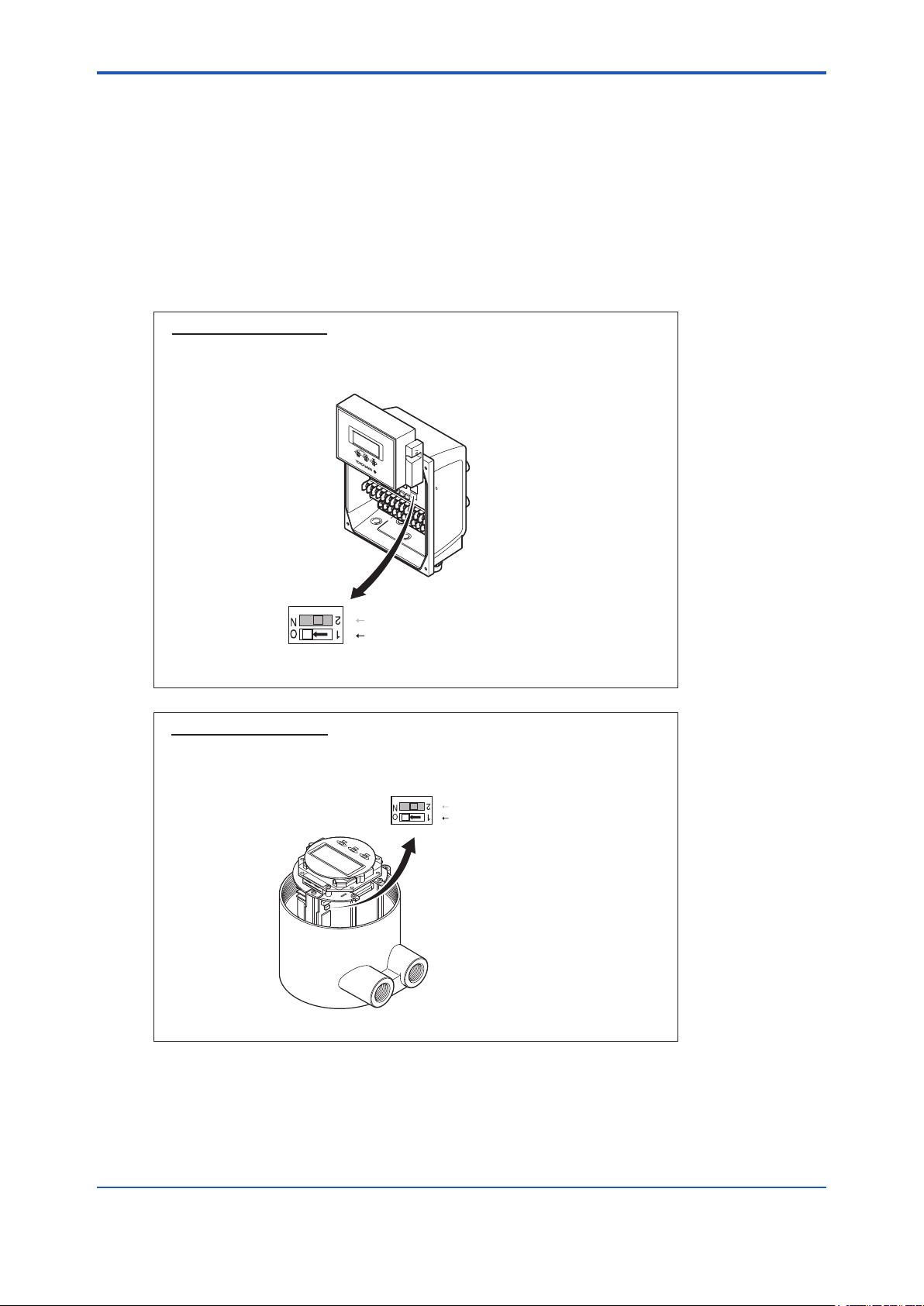

3.2.1 Before Verication

1) AXF parameters are changed during the verication process. Cancel the write protect

switch.

Hardware switch off

Set the "Write Protect Switch" to "Enable" before this verification.

Return the switch to the original position after this verification is

complete.

3-2

Switch 1

Switch 2

Enable Protect

(A) AXFA11

2 Burnout setting switch

1 Write protect setting switch

F030201-A.ai

Hardware switch off

Set the "Write Protect Switch" to "Enable" before this verification.

Return the switch to the original position after this verification is

complete.

Switch 1

Switch 2

Enable Protect

(B) AXFA14 or AXF Integral Flowmeter

Figure 3.2.1 Write Protect Cancellation

2 Burnout setting switch

Write protect setting switch

1

F030201-B.ai

2) After the verication is complete, return the switch to the original position.

IM 01R01A11-01EN

Page 15

<3 PREPARATION>

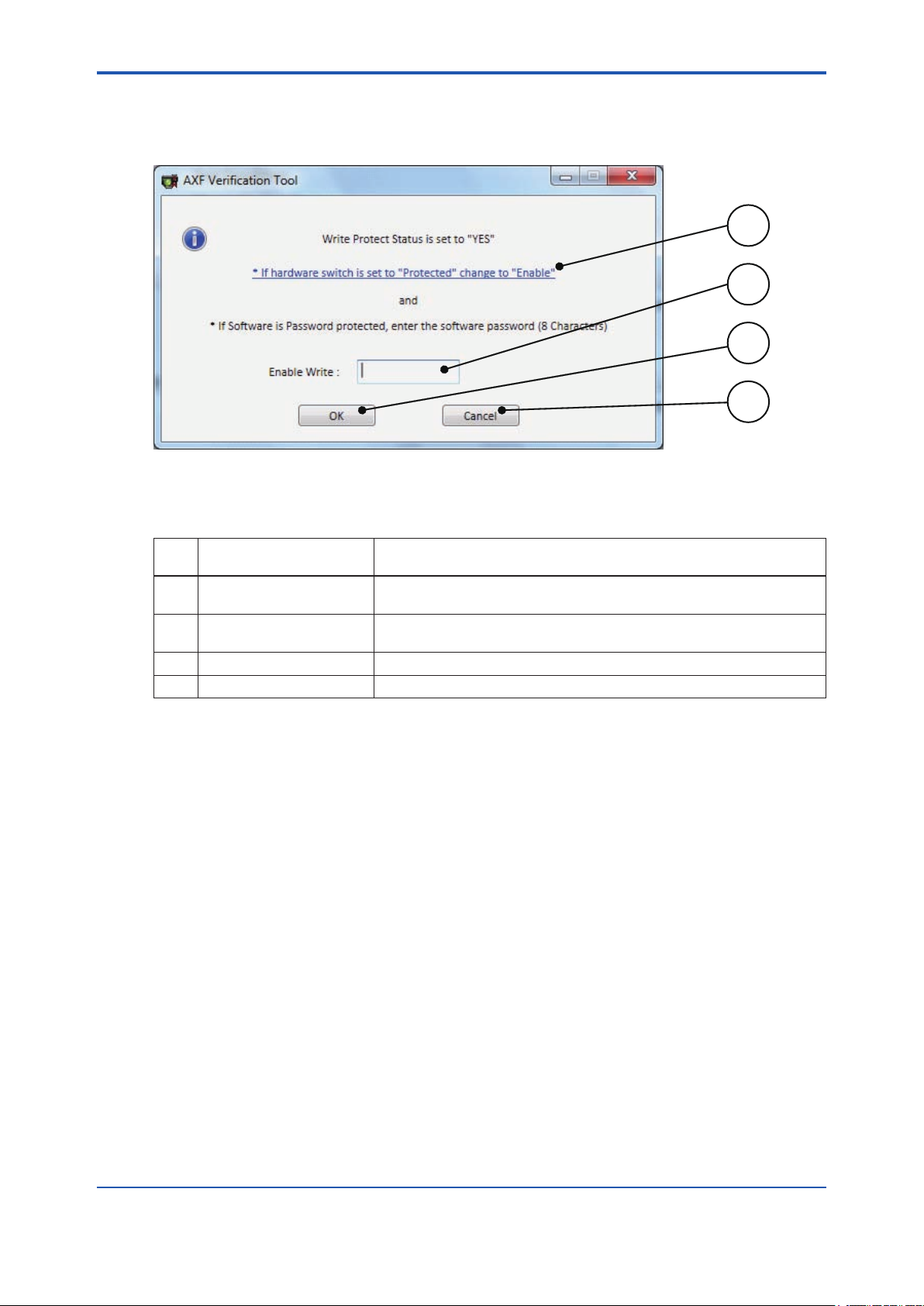

3.2.2 During Verication

1) If the AXF write protect function is set to “Protect” during the verication, Figure 3.2.2 will be

displayed.

Figure 3.2.2 “Write Protect Cancellation” Dialog

3-3

1

2

3

4

F030202.ai

Table 3.2.1 “Write Protect Cancellation” Dialog

Item

No.

1 ‘If hardware….’

2 Enable Write

3 OK Runs the software protection cancellation.

4 Cancel Cancels ‘Write Protect cancellation’

Item Name Description

Shows the gure of hardware switch. See Figure 3.2.1.

Click the text.

Cancels the software protection of the device.

Enter the password.

2) Set the “Write Protect Switch” to “Enable” .

Then, enter the password in (2) and click “OK (3)” in Figure 3.2.2.

3) Return the switch to the original position after this verication is complete.

IM 01R01A11-01EN

Page 16

Blank Page

Page 17

<4 START-UP FROM FieldMate>

4 START-UP FROM FieldMate

Verication Tool can be started by the following:

■ From “Segment Viewer” (FieldMate is online to AXF), see 4.1.

■ From “Device Navigator”, see 4.2.

■ From “Verication Data” in “Device Maintenance Info”, see 4.3.

■ From “History”, see 4.4.

Select the start-up procedure depending on the items to be veried and connection status be-

tween FieldMate and AXF.

NOTE

• To run Verication Tool in “online” mode, start the Verication Tool from “Segment Viewer”.

• To complete Standard VF, start Verication Tool from “Segment Viewer”.

4-1

Online

IMPOSSIBLE

4.1 Segment Viewer

6.2 Standard VF

(Mandatory)

Figure 4.1.1 “Start-up” Procedure

FieldMate and AXF

4.2 Device Navigator

IMPOSSIBLE

6.3 Enhanced VF

(Optional)

6.4 Result

Offline

4.3 Verification Data

in “Device Maintenance Info”

Verification Tool and AXF: OfflineVerification Tool and AXF: Online

4.4 History

F040101.ai

IM 01R01A11-01EN

Page 18

<4 START-UP FROM FieldMate>

4-2

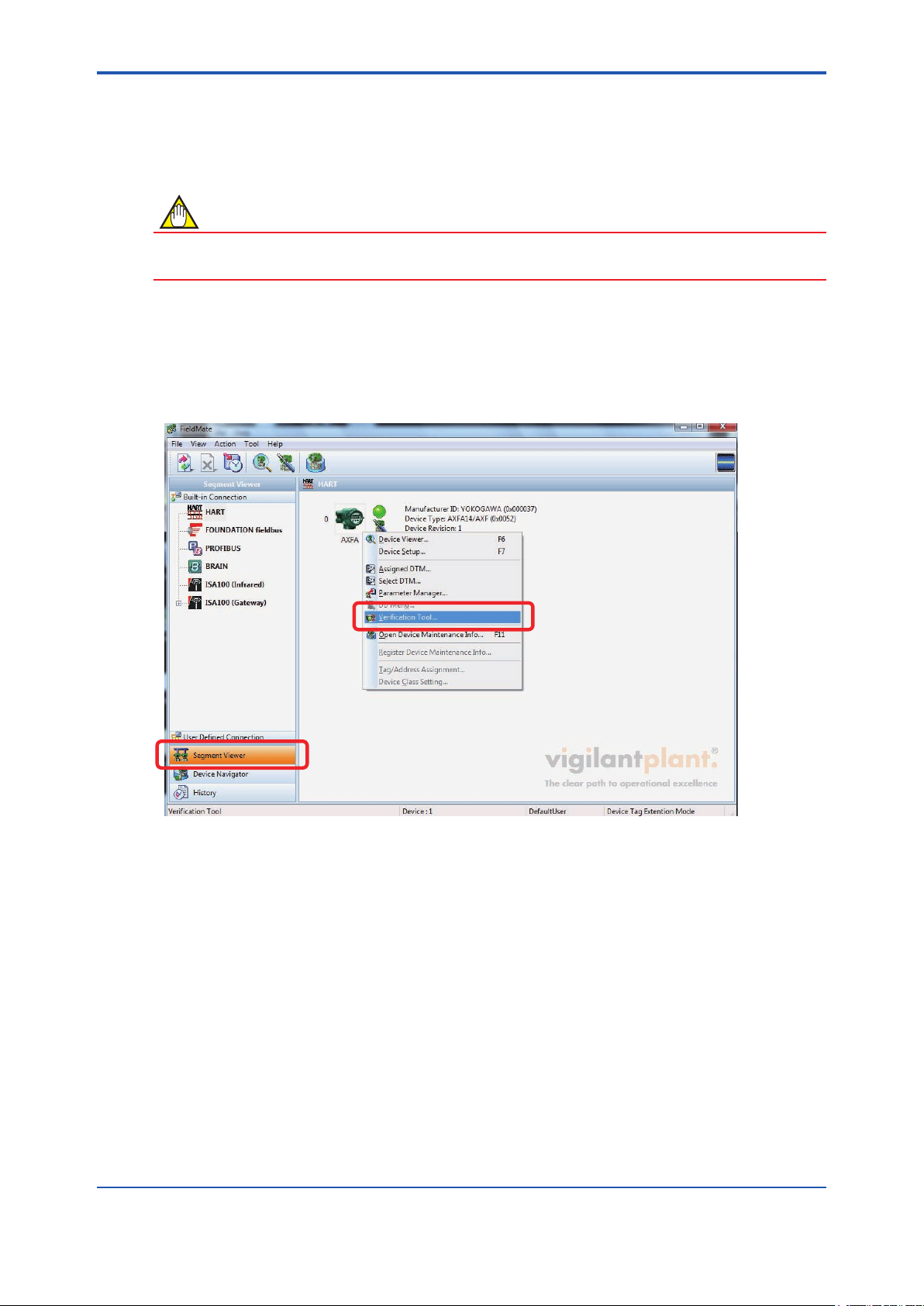

4.1 From “Segment Viewer” (AXF is reading in “online” mode in FieldMate)

NOTE

Set the device address to 0. Verication Tool can be started only when the device address is set

to 0. For details on how to set the device address, refer to 9.2.

From “Segment Viewer”, “Verication Tool” can be started by either method (A) or (B).

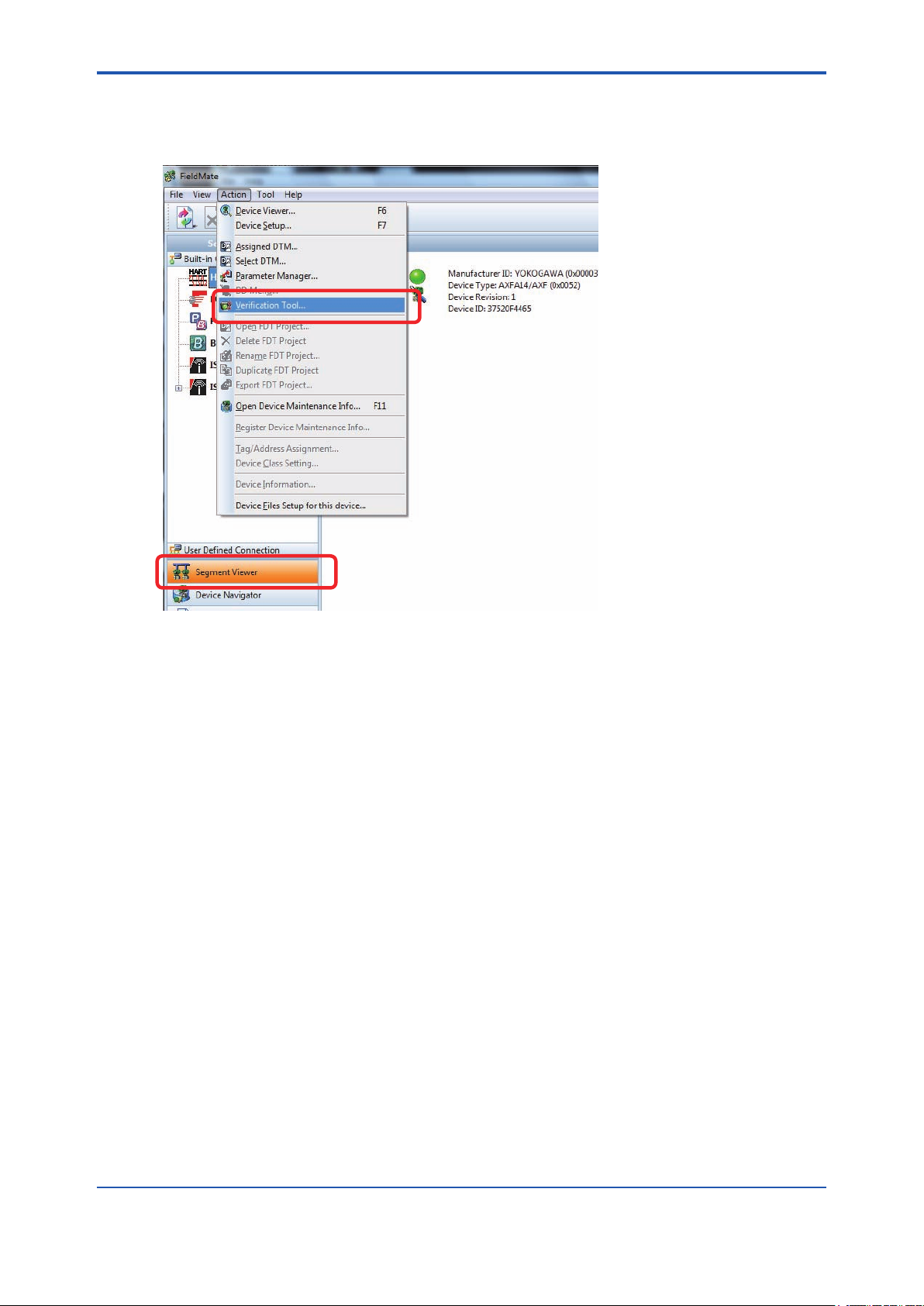

(A) By right-clicking

Right-click on the target (AXF) icon displayed at “Segment Viewer”, and select “Verication Tool”.

Figure 4.1.2 Start-up from “Segment Viewer” by Right-clicking

F040102.ai

IM 01R01A11-01EN

Page 19

<4 START-UP FROM FieldMate>

(B) By selecting menu “Action”

Select the target (AXF) icon displayed at “Segment Viewer”, and in the “FieldMate” menu bar,

select “Action - Verication Tool”.

4-3

F040103.ai

Figure 4.1.3 Start-up from “Segment Viewer” by Selecting the “Action” Menu

IM 01R01A11-01EN

Page 20

<4 START-UP FROM FieldMate>

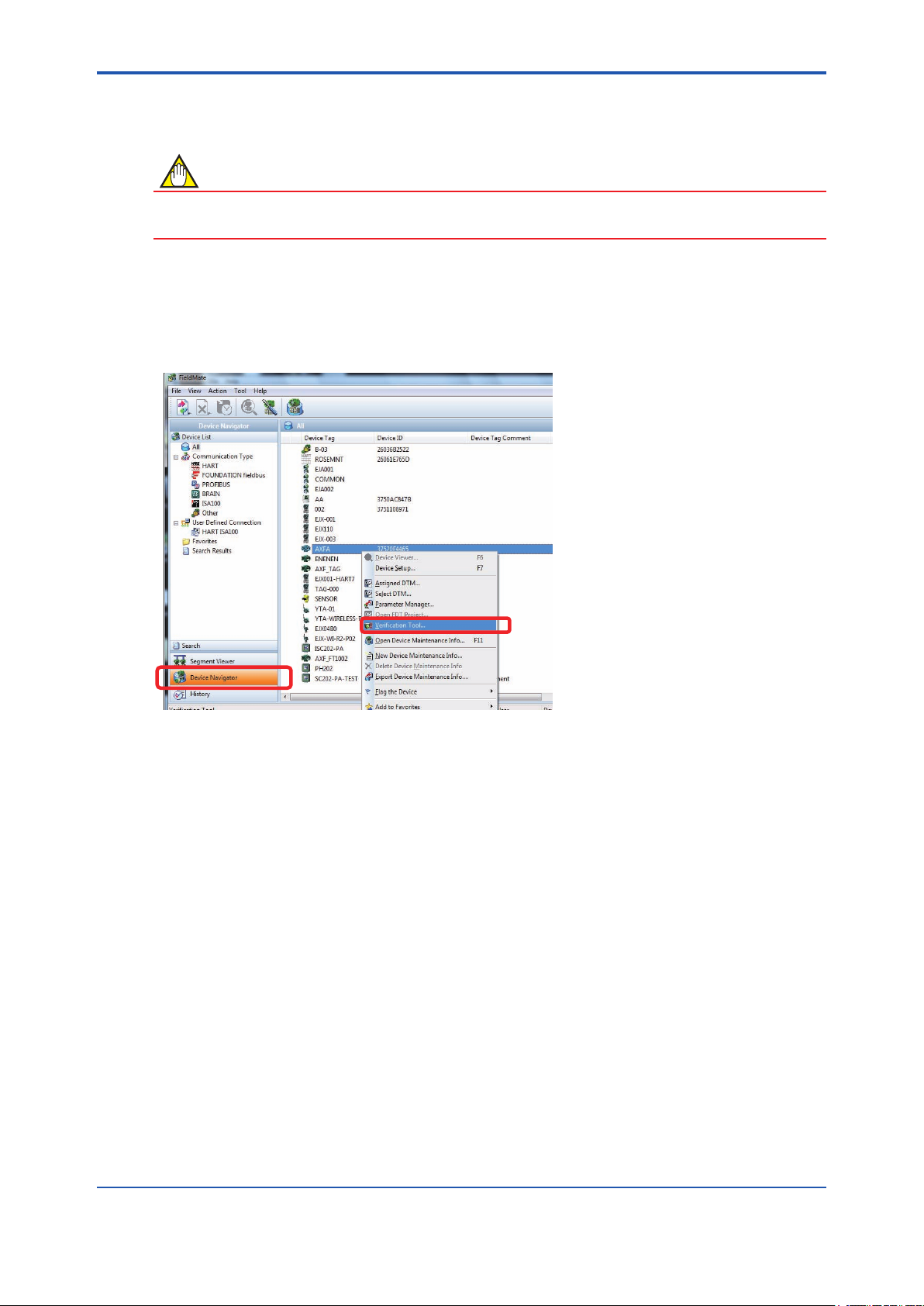

4.2 From “Device Navigator”

NOTE

When Verication Tool is started from “Device Navigator”, it will be in “ofine” mode even if the

AXF is in “online” mode in FieldMate.

From “Device Navigator”, “Verication Tool” can be started by either method (A) or (B).

(A) By right-clicking

Right-click on the target (AXF) icon displayed at “Device Navigator”, and select “Verication Tool”.

4-4

F040201.ai

Figure 4.2.1 Start-up from “Device Navigator” by Right-clicking

IM 01R01A11-01EN

Page 21

<4 START-UP FROM FieldMate>

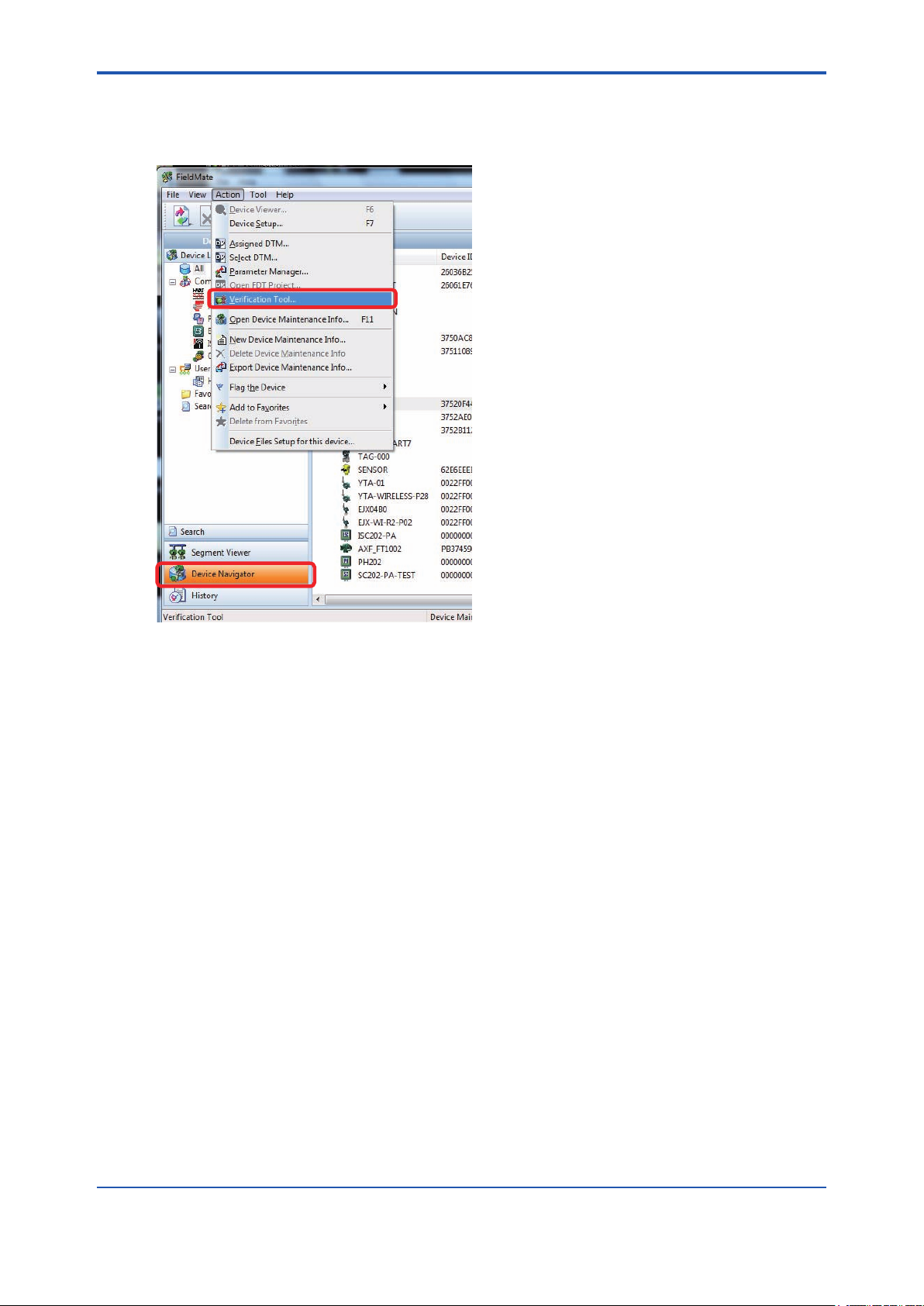

(B) By selecting menu “Action”

Select the target (AXF) icon displayed at “Device Navigator”, and in the “FieldMate” menu bar,

select “Action - Verication Tool”.

4-5

F040202.ai

Figure 4.2.2 Start-up from “Device Navigator” by Selecting the “Action” Menu

IM 01R01A11-01EN

Page 22

<4 START-UP FROM FieldMate>

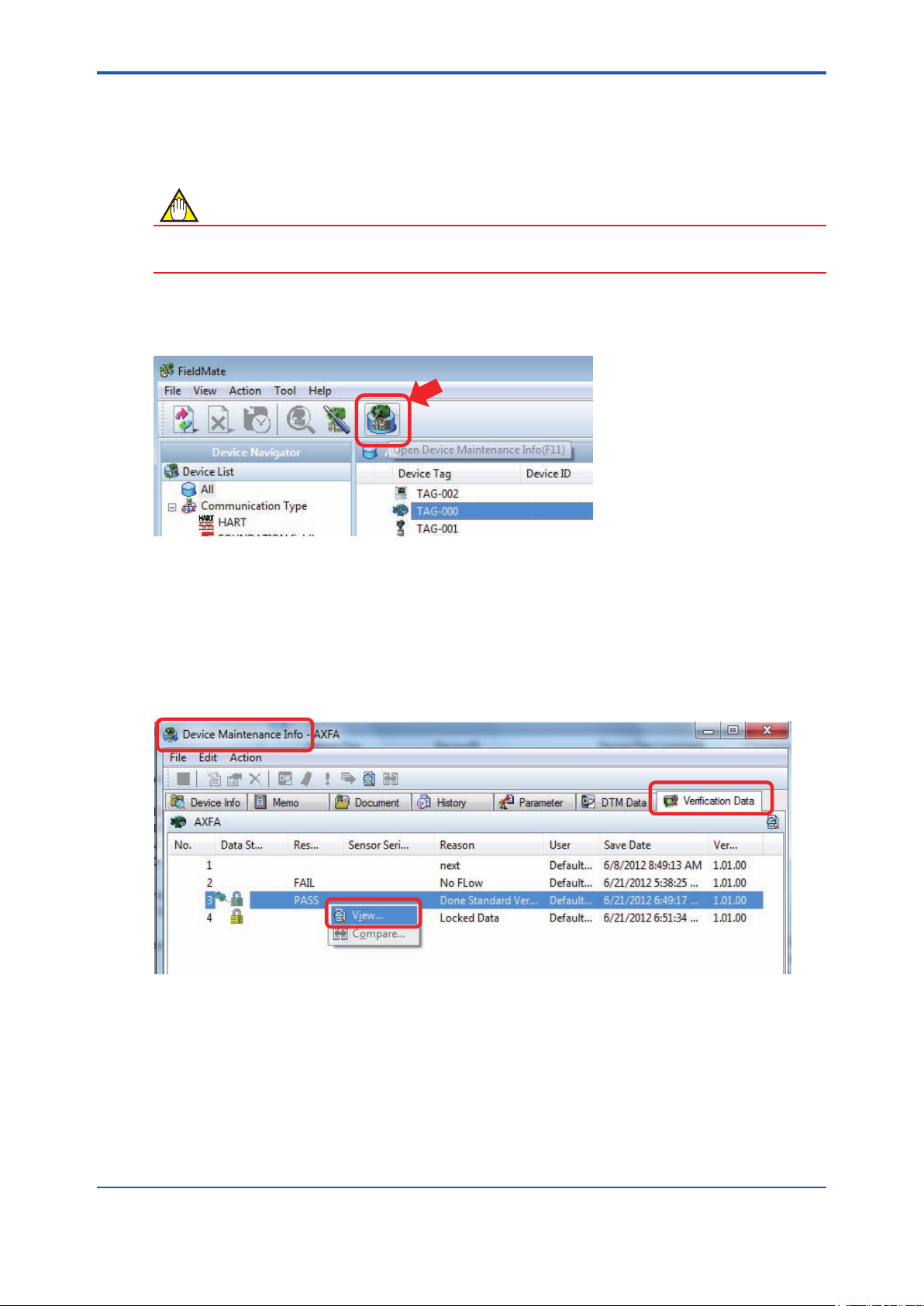

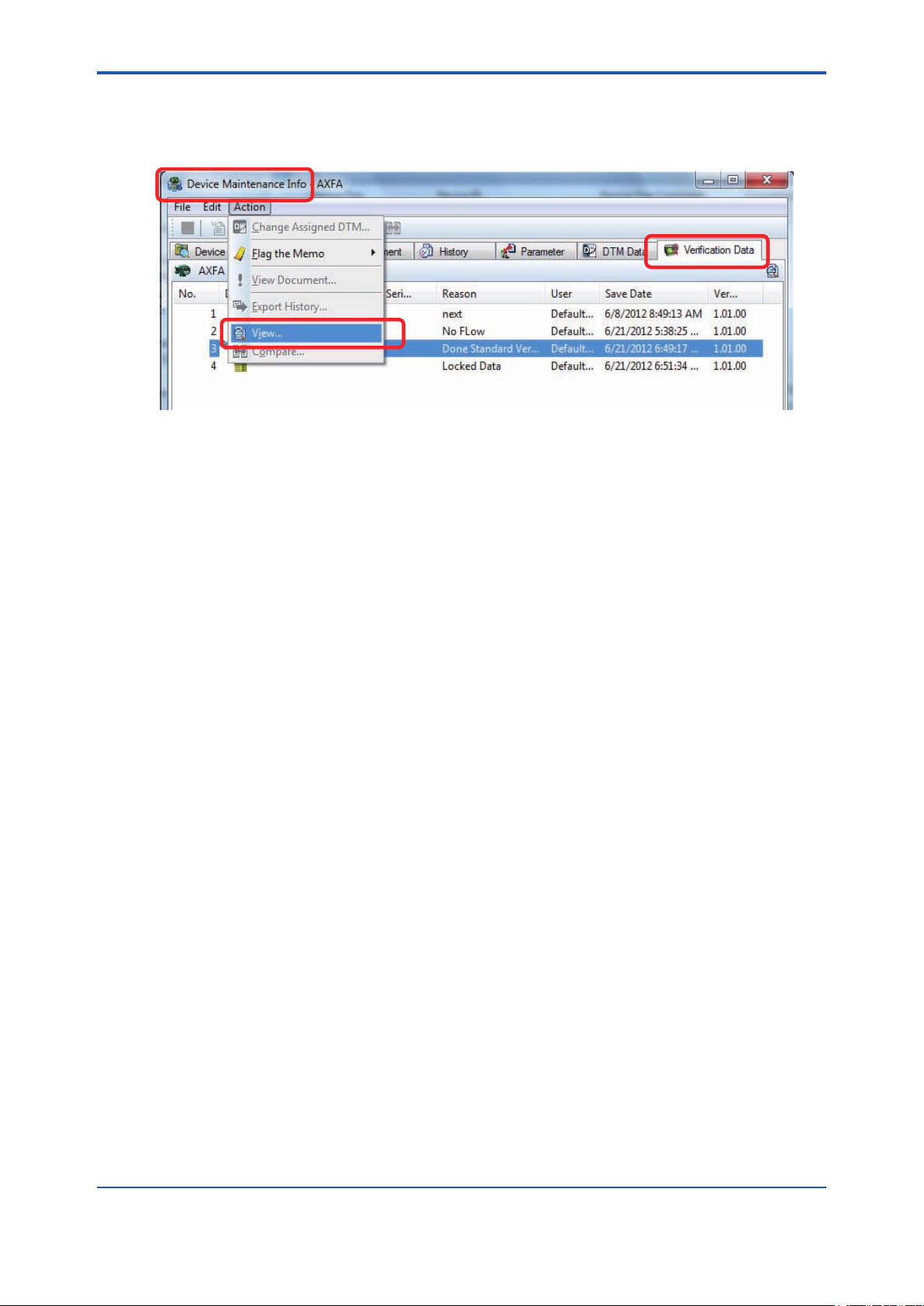

4.3 From “Verication Data” in “Device

Maintenance Info”

NOTE

When Verication Tool is started from “Device Maintenance Info”, it will be in “ofine” mode even

if the AXF is in “online” mode in FieldMate.

From the “Verication Data” tab in “Device Maintenance Info”, “Verication Tool” can be started

by either method (A) or (B). Select the target (AXF) icon and click the “Open Device Maintenance

Info” icon. The “Device Maintenance Info” screen appeares.

4-6

Figure 4.3.1 “Device Maintenance Info” Icon

(A) By right-clicking

Select the “Verication Data” tab on the “Device Maintenance Info” screen. Right-click on the

verication data listed on the “Verication Data” tab under “Device Maintenance Info, and select

“View”. Verication Tool is started up and the selected verication data is loaded.

Figure 4.3.2 Start-up from “Verication Data” in “Device Maintenance Info” by Right-clicking

F040301.ai

F040302.ai

IM 01R01A11-01EN

Page 23

<4 START-UP FROM FieldMate>

(B) By selecting menu “Action”

In the “Device Maintenance Info” menu bar, select “Action”-“View”. Verication Tool is started up

and the selected verication data is loaded.

Figure 4.3.3 Start-up from “Verication Data” in “Device Maintenance Info” by Selecting the “Action”

Menu

4-7

F040303.ai

IM 01R01A11-01EN

Page 24

<4 START-UP FROM FieldMate>

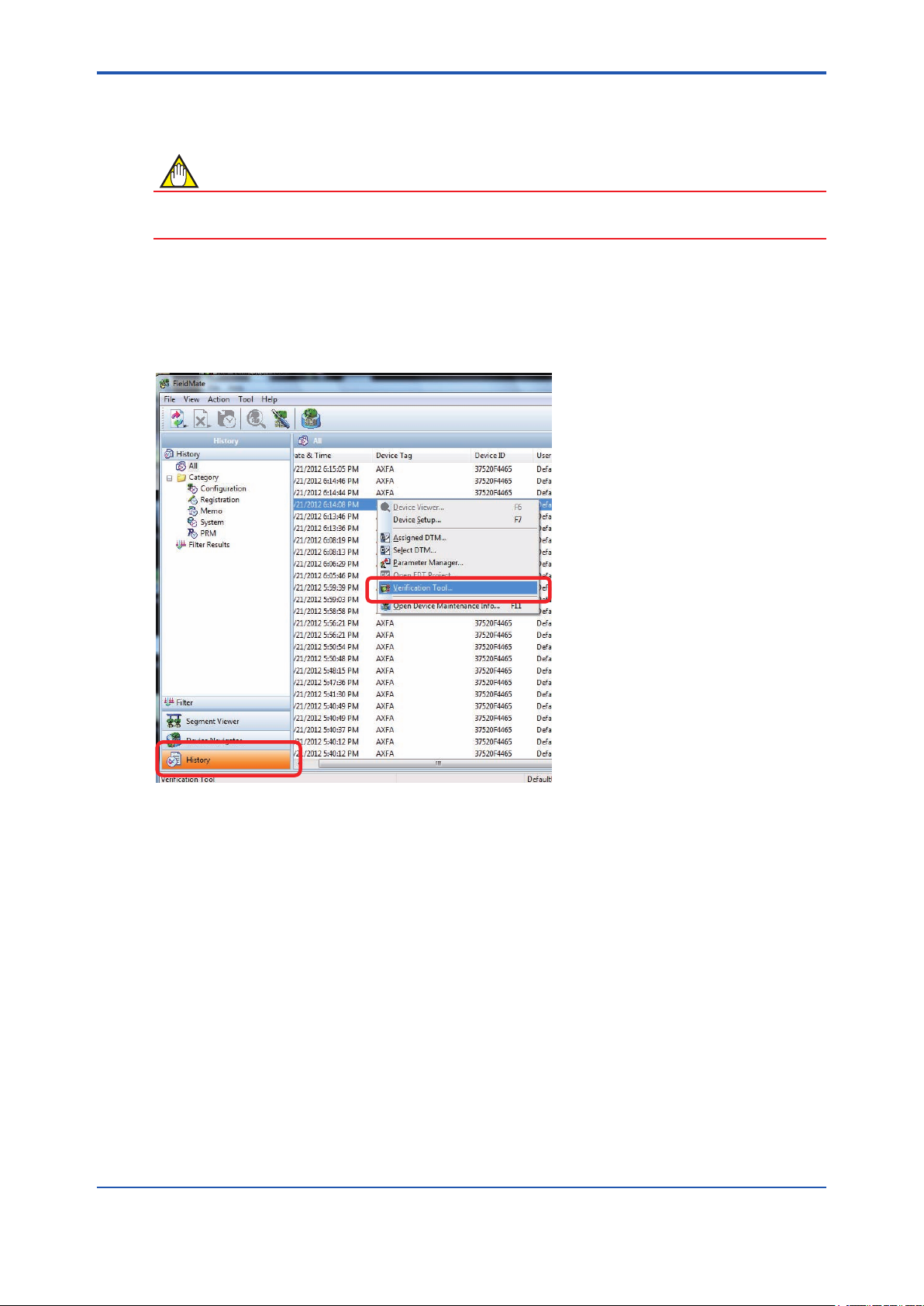

4.4 From “History”

NOTE

When Verication Tool is started from “History”, it will be in “ofine” mode even if the AXF is in

“online” mode in FieldMate.

From “History”, “Verication Tool” can be started by either method (A) or (B).

(A) By right-clicking

Right-click on the target device (AXF) listed in “History”, and select “Verication Tool”.

4-8

Figure 4.4.1 Start-up from “History” by Right-clicking

F040401.ai

IM 01R01A11-01EN

Page 25

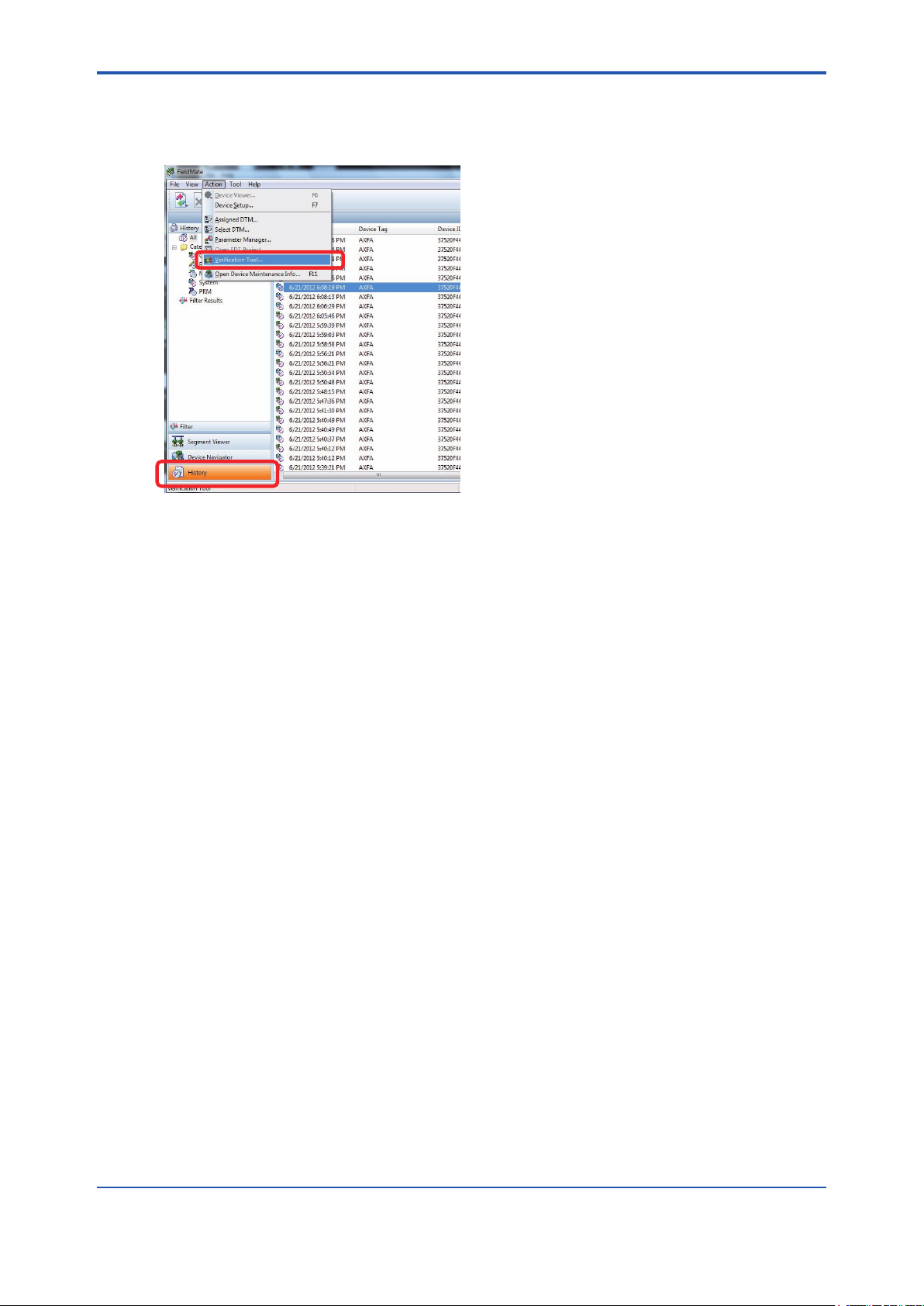

<4 START-UP FROM FieldMate>

(B) By selecting menu “Action”

Select the target (AXF) listed in “Device Maintenance Info”, and in the “FieldMate” menu bar,

select “Action”-“Verication Tool”.

F040402.ai

Figure 4.4.2 Start-up from “History” by Selecting the “Action” Menu

4-9

IM 01R01A11-01EN

Page 26

Blank Page

Page 27

<5 LAUNCHING>

5 LAUNCHING

When Verication Tool is launched, Figure 5.1.1 is displayed automatically.

F050101.ai

Figure 5.1.1 Splash Screen

Select the verication data to be used for the verication:

1. Creating new verication data: see 5.1.

5-1

2. Loading existing verication data: see 5.2.

3. After unexpected termination: see 5.3

IM 01R01A11-01EN

Page 28

<5 LAUNCHING>

5.1 Creating New Verication Data

1) After the “Splash Screen”,

1)-1 When there is no existing verication data in the database:

The splash screen is closed automatically, and then Figure 5.1.3 is displayed.

1)-2 When there is existing verication data in the database:

1)-2-1 The splash screen is closed automatically, and then Figure 5.1.2 is displayed.

1

2

F050102.ai

Figure 5.1.2 “Conrmation” Dialog

5-2

Table 5.1.1 “Conrmation” Dialog

Item

No.

1 Load

2 Cancel

Item Name Description

Loads the verication data from the database. See 5.2.

To load the verication data, click “Load”.

Creates new verication data and shows Figure 5.1.3.

To create new verication data, click “Cancel”.

1)-2-2 Click “Cancel (2)”.

If “Load (1)” is selected by accident, Figure 5.2.1 is displayed. Click “Cancel (3)” in

Figure 5.2.1.

IM 01R01A11-01EN

Page 29

<5 LAUNCHING>

2) “General Information” is displayed. See Figure 5.1.3.

Enter each eld and click “Next (8)”. Figure 6.1.1 is displayed automatically.

1

2

3

4

5

6

7

5-3

8

F050103.ai

Figure 5.1.3 “General Information” Dialog

Table 5.1.2 “General Information” Dialog

Item

No.

1 User Name (*)

2 Location. (*) Enter the user location.

3 Veried by (*) Enter the name of the person to operate the verication.

4 Tag (Converter)

5 Tag (Flowtube) Enter the tag number of the owtube.

6 Serial No. (Converter) Enter the serial number of the converter.

7 Serial No. (Flowtube) Enter the serial number of the owtube.

8 Next

*: Mandatory eld

Item Name Description

Enter the user name.

The user name of FieldMate is displayed by default. This eld can be

edited.

Enter the tag number of the converter. The value of HART parameter

“Tag” is displayed by default. This eld can be edited.

Even if a different value is input from the HART parameter, the HART

parameter is not overwritten.

Moves to “Main Screen”. See Chapter 6.

Is enabled only after the mandatory elds have been lled in.

Click “Next” to move to “Main Screen”.

IM 01R01A11-01EN

Page 30

<5 LAUNCHING>

5.2 Loading Existing Verication Data

NOTE

In terms of keeping the integrity of the data, loaded verication data cannot be copied, nor can it

be saved under a different name. Loaded verication data can only be overwritten by new saved

data, except for “Locked data” which cannot be modied.

1) After the “Splash screen” is closed automatically, Figure 5.1.2 is displayed.

2) Click “Load (1)” in Figure 5.1.2. Figure 5.2.1 is displayed.

3) Select the preferred data from “Data list (1)” and click “OK (2)” in Figure 5.2.1.

5-4

1

2

3

F050201.ai

Figure 5.2.1 “Select Verication Data” Dialog

Table 5.2.1 “Select Verication Data” Dialog

Item

No.

1 Data list

2 OK

3 Cancel

2) After loading, Figure 5.2.2 is displayed automatically. Click “OK”. “Main Screen” is dis-

played. See Chapter 6.

Item Name Description

Shows the verication data in the database.

For the meaning of the icon in the “Data Status”, see Chapter 7.

Loads the verication data.

To use the verication data in the database, select the preferred one

among “Data list” and click “OK”. Figure 5.2.2 is displayed.

Creates new verication data and shows Figure 5.1.3. See 5.1.

To create the new verication data, click “Cancel”.

F050202.ai

Figure 5.2.2 “Verication Data Loaded” Dialog

IM 01R01A11-01EN

Page 31

<5 LAUNCHING>

5.3 After Unexpected Termination

In case of launching after an unexpected termination of the program, see 8.2.

5-5

IM 01R01A11-01EN

Page 32

Blank Page

Page 33

<6 OPERATION>

6 OPERATION

This chapter describes how to use Verication Tool.

For details of the verication procedure, see 6.2 and 6.3.

NOTE

• Be sure to run Standard VF.

• “Overall Status” in “Result” is carried out only when “Standard VF” is complete. When

“Standard VF” is not complete, “Overall Status” is left blank.

• “Result sheet” can be printed even when “Standard VF” is not complete.

6-1

IM 01R01A11-01EN

Page 34

<6 OPERATION>

6.1 Main Screen

This screen performs the following actions:

■ Loads the verication data. See 6.1.1.

■ Saves the verication data. See 6.1.2.

■ Prints the result sheet. See 6.1.3.

■ Displays the “Standard” VF screen. See 6.2.

■ Displays the“Enhanced” VF screen. See 6.3.

■ Displays the “Result” screen. See 6.4.

4

1 2 3

6-2

Figure 6.1.1 Main Screen

Table 6.1.1 Main Screen

Item

No.

1 Load

2 Save

3 Print

4 Menu bar Shows the “File” and “Help” menus. See 6.1.4.

5 Standard Selects Standard VF mode. See 6.2.

6 Enhanced Selects Enhanced VF mode. See 6.3.

7 Result Displays the result sheet image. See 6.4.

Item Name Description

Loads the verication data from the database. See 6.1.1.

To load the verication data, click “Load”.

Saves the current data to the database. See 6.1.2.

To save the current data, click “Save”.

Prints out the result. See 6.1.3.

To print the verication result, click “Print”.

7

6

5

F060101.ai

IM 01R01A11-01EN

Page 35

<6 OPERATION>

6.1.1 Load

1) Click the “Load” icon.

F060102.ai

Figure 6.1.2 “Load” Icon

2) After clicking the “Load” icon, Figure 6.1.3 is displayed. Select the preferred data from “Data

list (1)”, then click “OK (2)”.

6-3

1

Figure 6.1.3 “Select Veri cation Data” Dialog

Table 6.1.2 “Select Veri cation Data” Dialog

Item

No.

1 Data list

2 OK

3 Cancel

Item Name Description

Shows the veri cation data in the database.

Select the preferred data.

Performs data loading.

To load the veri cation data from the database, click “OK”.

Cancels loading the veri cation data and returns to “Main Screen”. See

6.1.

4) After loading, Figure 6.1.4 is displayed automatically. Click “OK”.

2

3

F060103.ai

F060104.ai

Figure 6.1.4 “Veri cation Data Loaded” Dialog

IM 01R01A11-01EN

Page 36

<6 OPERATION>

6.1.2 Save

By clicking the “Save” icon, the veri cation data is saved to the database.

After clicking “Save”, the screen changes as follows:

• When “No Flow + Flow (*1)” is not complete, see (A).

• When “No Flow + Flow” is complete, see (B).

*1: “No Flow + Flow”;

“Circuit” check and “Device Status” check for both “No Flow” and “Flow” conditions. Refer to 6.2.1.

F060105.ai

Figure 6.1.5 “Save” Icon

6-4

(A) When “No Flow + Flow” is not complete:

1) After clicking the “Save” icon, Figure 6.1.6 is displayed.

1 2 3

Figure 6.1.6 “Saving Data When “No Flow + Flow” Uncompleted” Dialog

Table 6.1.3 “Saving Data When “No Flow + Flow” Uncompleted” Dialog

Item

No.

1 Reason

2 Saved as Installation Data.

3 Saved as Locked Data.

4 OK Saves the data.

5 Cancel Cancels saving the data and returns to “Main Screen”. See 6.1.

Item Name Description

Shows the reason or comment. It can be used as a marker when loading

veri cation data is selected. Refer to Figure 6.1.3.

Enter preferred text.

(Optional eld)

Saves the data as “Installation Data”. See 7.1.

This eld is disabled until “No Flow + Flow” is complete.

Saves the data as “Locked Data”. See 7.2.

To save the data as read-only, check the box.

(Always valid)

4

5

F060106.ai

IM 01R01A11-01EN

Page 37

<6 OPERATION>

2) Save the data as “Read-only” or “Editable”.

2)-1 To save the verication data as read-only:

Click “OK” after checking the “Saved as Locked Data” box in Figure 6.1.6.

Figure 6.1.7 is displayed. Click “Yes” in Figure 6.1.7.

1

2

F060107.ai

Figure 6.1.7 “Conrm Locked Data” Dialog

Table 6.1.4 “Conrm Locked Data” Dialog

6-5

Item

No.

1 Yes Saves verication data to the database as read-only.

2 No Cancels saving the data and returns to Figure 6.1.6.

Item Name Description

2)-2 To save the verication data as editable:

Click “OK” without checking the “Saved as Locked Data” box in Figure 6.1.6.

No dialogs appear.

3) Figure 6.1.8 is displayed automatically. Click “OK”.

F060108.ai

Figure 6.1.8 “Saving Completed” Dialog

IM 01R01A11-01EN

Page 38

<6 OPERATION>

(B) When “No Flow + Flow” is complete:

1) After clicking the “Save” icon, Figure 6.1.9 is displayed.

1 2 3

4

5

F060109.ai

Figure 6.1.9 “Saving Data When “No Flow + Flow” Completed” Dialog

Table 6.1.5 “Saving Data When “No Flow + Flow” Completed” Dialog

6-6

Item

No.

1 Reason

Saved as Installation Data.

2

(*1)

Saved as Locked Data.

3

(*1)

4 OK Saves the data.

5 Cancel Cancels saving the data and shows “Main Screen”. See 6.1.

*1: These items can be selected at the same time.

Item Name Description

Shows the reason or comment. It can be used as a marker when the loading verication data is selected. Refer to Figure 6.1.3.

Enter preferred text.

(Optional eld)

Saves the data as installation data. See 7.1.

To save the data as installation data, check the box.

Saves the data as locked data. See 7.2.

To save the data as locked data, check the box.

2) Select the preferred one accordingly.

2)-1 To save the verication data as “Installation Data”:

Click “OK” after checking the “Saved as Installation Data” box.

If there is no existing installation data in the database, no dialogs appear.

If there is existing installation data in the database, Figure 6.1.10 is displayed.

Click “Yes” in Figure 6.1.10.

1

Figure 6.1.10 “Conrm Replacing Data” Dialog

2

F060110.ai

IM 01R01A11-01EN

Page 39

<6 OPERATION>

Table 6.1.6 “Conrm Replacing Data” Dialog

6-7

Item

No.

1 Yes Replace the data.

2 No Cancels replacing the data and returns to Figure 6.1.9.

Item Name Description

2)-2 To save the verication data as read-only:

Click “OK” after checking the “Saved as Locked Data” box in Figure 6.1.9. Figure 6.1.11 is

displayed.

Click “Yes” in Figure 6.1.11.

1

2

F060111.ai

Figure 6.1.11 “Conrm Locked Data” Dialog

Table 6.1.7 “Conrm Locked Data” Dialog

Item

No.

1 Yes Saves the data as locked data.

2 No Cancels saving the data and returns to Figure 6.1.9.

Item Name Description

2)-3 To save the verication data as editable and non-installation data:

Click “OK” without checking any boxes in Figure 6.1.9.

No dialogs appear.

3) Figure 6.1.12 is displayed automatically. Click “OK”.

F060112.ai

Figure 6.1.12 “Saving Completed” Dialog

IM 01R01A11-01EN

Page 40

<6 OPERATION>

6.1.3 Print out

To print the result sheet, click the “Print” icon. Figure 6.1.14 is displayed.

F060113.ai

Figure 6.1.13 “Print” Icon

6-8

F060114.ai

Figure 6.1.14 Example of “Print” Dialog

The printed image is the same as the “Result” tab in “Main Screen”. See 6.4.

The recommended paper size is A4 or letter size.

• If the paper size is smaller than the recommended one, the printed size is reduced to t the

paper.

• If the paper size is bigger than the recommended one, the printed size will be the recommended one.

IM 01R01A11-01EN

Page 41

<6 OPERATION>

6.1.4 Menu bar

There are “File” and “Help” in the menu bar.

(A) File

Select the preferred menu.

1

2

3

4

F060115.ai

Figure 6.1.15 Menu bar

Table 6.1.8 Menu bar

6-9

Item

No.

Load from

1

Database

2 Save to Database Same as “Save” in Table 6.1.1. See 6.1.2.

3 Print Same as “Print” in Table 6.1.1. See 6.1.3.

4 Exit Terminates the Verication Tool. See 8.1.

Item Name Description

Same as “Load” in Table 6.1.1. See 6.1.1.

IM 01R01A11-01EN

Page 42

<6 OPERATION>

(B) Help

Upon selecting “About AXF Verication Tool…” in the “Help” menu, Figure 6.1.17 is displayed.

1

F060116.ai

Figure 6.1.16 Help Menu

Table 6.1.9 Help Menu

6-10

Item

No.

About AXF Verication

1

Tool…

Figure 6.1.17 Example of Version Information

Item Name Description

Shows the version of Verication Tool. See Figure 6.1.17.

F060117.ai

IM 01R01A11-01EN

Page 43

<6 OPERATION>

6.2 Standard VF

■ This mode veries the condition of the AXF without difculty, by checking its internal parameters. No external instruments are requied.

■ This mode is mandatory.

■ “Circuit” check and “Device Status” check are run only when Verication Tool is in “online”

mode.

■ Each item can be run separately.

6-11

1

2

Figure 6.2.1 “Standard VF” Screen

Table 6.2.1 “Standard VF” Screen

Item

No.

1 Circuit Checks the status of device circuits. See 6.2.1.

2 Device Status Checks the alarm in AXF parameters. See 6.2.1.

3 Physical Appearance Checks the physical appearance. See 6.2.2.

Item Name Description

3

F060201.ai

IM 01R01A11-01EN

Page 44

<6 OPERATION>

6.2.1 “Circuit” check and “Device Status” check

(Verication Tool is in “online” mode)

CAUTION

• “Circuit” check and “Device Status” check temporarily change the parameters of AXF. In

case of unexpected termination, follow 8.2.

• The AXF owtube should be completely lled with uid, otherwise the results may be

inadequate.

• These items are run only when Verication Tool is in “online” mode.

• These items are veried for 2 types. Each condition check can be run separately.

(A) “No Flow” condition:

Veries the condition of the AXF by checking;

- Circuits including the excitation circuit and the magnetic circuit inside the owtube when

the uid velocity is completely zero.

- The present and past history of alarms.

6-12

(B) “Flow” condition:

Veries the condition of the AXF by checking;

- Circuits including the excitation circuit and the operation circuit which calculates the ow

velocity when the uid velocity is sufcient.

- The present and past history of alarms.

• There are 3 combinations:

(1) No Flow

(2) Flow

(3) Flow + No Flow

• The check items of the “Circuit” check depend on the case as follows:

• Nominal size of the unit.

• With or without the optional code ELC (DC Noise Cut Circuit).

• Test condition type; “Flow” or “No Flow”.

For details, see Table 6.2.2.

IM 01R01A11-01EN

Page 45

<6 OPERATION>

1

6-13

2

3

4

5

6

7

Figure 6.2.2 “Circuit and Device Status” Screen

Table 6.2.2 “Circuit and Device Status” Screen

(1) Nominal size is 400mm or smaller, without optional code ELC

Item

No.

1

2 Test Condition

3

4

5

6

7

Item Name Description

No Flow

Flow

Circuit

Device

Status

Magnetic

Circuit

Excitation

Circuit

Calculation

Circuit

Alarm

Check

Alarm

History

Shows test condition.

Select the test condition

Shows operated test condition.

“No Flow” or ” Flow” or ” No Flow

+ Flow”

See Figure 6.2.13.

Shows the result of the

Magnetic Circuit check.

“Magnetic Circuit” means checking the magnetic circuit inside the

owtube.

Shows the result of the

Excitation Circuit check.

“Excitation Circuit” means checking the excitation circuit by the

excitation current measurement.

Shows the result of the

Calculation Circuit check.

“Calculation Circuit” means checking the operation circuit which

calculates the ow velocity.

Shows the result of the Alarm

Check.

“Alarm Check” means checking

the occurrence of alarms.

Shows the result of Alarm History

Check.

“Alarm History Check” means

checking the history of alarms that

occurred.

F060202.ai

Check is [possible/ not available]

No Flow Flow

Possible

Possible Possible Possible

Not Avail-

able

[Shows :N/A]

Possible Possible Possible

Possible Possible Possible

Not Avail-

able

[Shows: N/A]

Possible Possible

No Flow +

Flow

Possible

IM 01R01A11-01EN

Page 46

<6 OPERATION>

(2) Nominal size is over 400mm, without optional code ELC (DC Noise Cut Circuit)

6-14

Item

No.

1

2 Test Condition Same as Table 6.2.2 (1) “No.2”

3

4

5

6

7

(3) With optional code ELC (DC Noise Cut Circuit)

Item

No.

1

2 Test Condition Same as Table 6.2.2 (1) “No.2”

3

4

5

6

7

Item Name Description

No Flow

Flow

Magnetic

Circuit

Circuit

Device

Status

No Flow

Flow

Circuit

Device

Status

Excitation

Circuit

Calculation

Circuit

Alarm

Check

Alarm

History

Item Name Description

Magnetic

Circuit

Excitation

Circuit

Calculation

Circuit

Alarm

Check

Alarm

History

Same as Table 6.2.2 (1) “No.1”

Same as Table 6.2.2 (1) “No.3” Possible

Same as Table 6.2.2 (1) “No.4” Possible Possible Possible

Same as Table 6.2.2 (1) “No.5”

Same as Table 6.2.2 (1) “No.6” Possible Possible Possible

Same as Table 6.2.2 (1) “No.7” Possible Possible Possible

Same as Table 6.2.2 (1) “No.1”

Same as Table 6.2.2 (1) “No.3”

Same as Table 6.2.2 (1) “No.4” Possible Possible Possible

Same as Table 6.2.2 (1) “No.5”

Same as Table 6.2.2 (1) “No.6” Possible Possible Possible

Same as Table 6.2.2 (1) “No.7” Possible Possible Possible

Check is [possible/ not available]

No Flow Flow

Not Avail-

able

[Shows :N/A]

Not Avail-

able

[Shows :N/A]

Check is [possible/ not available]

No Flow Flow

Not Avail-

able

[Shows :N/A]

Not Avail-

able

[Shows :N/A]

Not Avail-

able

[Shows :N/A]

Not Avail-

able

[Shows :N/A]

Not Avail-

able

[Shows :N/A]

No Flow +

Flow

Possible

Not Avail-

able

[Shows :N/A]

No Flow +

Flow

Not Avail-

able

[Shows :N/A]

Not Avail-

able

[Shows :N/A]

IM 01R01A11-01EN

Page 47

<6 OPERATION>

(A) No Flow (The uid velocity is completely zero)

1) Fill the owtube with uid completely. Be sure that the uid velocity is completely zero.

1

2

3

6-15

F060203.ai

Figure 6.2.3 “Flow/ No Flow” Screen

Table 6.2.3 “Flow/ No Flow” Screen

Item

No.

1 No Flow Selects the “No Flow” test condition.

2 Start Verication (*1)

3 Cancel Stops running “Circuit” check and “Device Status” check.

*1: When the AXF protect function is set to “Protect”, Figure 3.2.2 is displayed. Follow 3.2.2.

Item Name Description

Runs “Circuit” check and “Device Status” check.

These checks are performed automatically. The Progress Bar is displayed

at the bottom left.

2) Select “No Flow (1)” and click “Start Verication (2)”.

3) Before running “Circuit” check and “Device Status” check, Figure 6.2.4 is displayed.

IM 01R01A11-01EN

Page 48

<6 OPERATION>

1

2

F060204.ai

Figure 6.2.4 “No Flow Conrmation” Dialog

Table 6.2.4 “No Flow Conrmation” Dialog

6-16

Item

No.

1 OK Runs “Circuit” check and “Device Status” check.

2 Cancel

Item Name Description

Stops running “Circuit” check and “Device Status” check, and displays

“Main Screen”.

4) Click “OK (1)“ after conrming that the owtube is lled with uid and the uid velocity is

completely zero. “Circuit” check and “Device Status” check are run. During these checks,

the status bar and remaining time are displayed. See Figure 6.2.5. Regarding the execution

time, see Table 6.2.5.

F060205.ai

Figure 6.2.5 “During ”Circuit” Check and “Device Status” Check” Screen

Table 6.2.5 Execution Time [No Flow]

No. Optional code Execution time

1 Without ELC 630 s

2 With ELC (DC Noise Cut Circuit) 120 s

IM 01R01A11-01EN

Page 49

<6 OPERATION>

5) After the “Circuit” check and “Device Status” check are completed for the “No Flow” condition, Figure 6.2.6 is displayed automatically. Click “OK”.

Figure 6.2.6 “No Flow Verication Completion” Dialog

6) “Result” is entered automatically. See Figure 6.2.13.

6-17

F060206.ai

IM 01R01A11-01EN

Page 50

<6 OPERATION>

(B) Flow (The uid velocity is sufcient)

1) Fill the owtube with uid. Be sure that the uid velocity is sufcient.

1

2

3

6-18

F060207.ai

Figure 6.2.7 “Flow/ No Flow” Screen

Table 6.2.6 “Flow/ No Flow” Screen

Item

No.

1 Flow Selects the “Flow” test condition.

2 Start Verication (*1)

3 Cancel Stops running “Circuit” check and “Device Status” check.

*1: When the AXF protect function is set to “Protect”, Figure 3.2.2 is displayed. Follow 3.2.2.

Item Name Description

Runs “Circuit” check and “Device Status” check.

Those checks are performed automatically. The progress bar is displayed

at the bottom left.

2) Select “Flow (1)” and click “Start Verication (2)”.

3) Before running “Circuit” check and “Device Status” check, Figure 6.2.8 is displayed auto-

matically.

IM 01R01A11-01EN

Page 51

<6 OPERATION>

1

2

F060208.ai

Figure 6.2.8 “Flow Conrmation” Dialog

Table 6.2.7 “Flow Conrmation” Dialog

6-19

Item

No.

1 OK Runs “Circuit” check and “Device Status” check.

2 Cancel

Item Name Description

Stops running “Circuit” check and “Device Status” check, and displays

“Main Screen”.

4) Click “OK (1)” after conrming that the owtube is lled with uid and the uid velocity is sufcient. “Circuit” check and “Device Status” check are run. During these checks, the status

bar and remaining time are displayed. See Figure 6.2.9. Regarding the execution time, see

Table 6.2.8.

F060209.ai

Figure 6.2.9 “During ”Circuit” Check and “Device Status” Check” Screen

Table 6.2.8 Execution time [Flow]

No. Optional code Execution time

1 Without ELC 630 s

2 With ELC (DC Noise Cut Circuit) 120 s

IM 01R01A11-01EN

Page 52

<6 OPERATION>

5) After the “Circuit” check and the “Device Status” check are completed for the “Flow” condition, Figure 6.2.10 is displayed automatically. Click “OK”.

Figure 6.2.10 “Flow Verication Completed” Dialog

6) “Result” is entered automatically. See Figure 6.2.13.

6-20

F060210.ai

IM 01R01A11-01EN

Page 53

<6 OPERATION>

6.2.2 Physical Appearance

1

2

3

F060211.ai

Figure 6.2.11 “Physical Appearance” Screen

Table 6.2.9 “Physical Appearance” Screen

6-21

Item

No.

1 Note Opens another window as shown in Figure 6.2.12. Click “Note”.

2 Flowtube Selects the result of the Flowtube Appearance Check.

3 Converter Selects the result of the Converter Appearance Check.

Item Name Description

Physical Appearance

A physical observation of the Flowmeter is required, check the following items:

Flowtube

Check the Flowtube and the Cables connected to the Flowtube for:

* Deformation, Damage, Corrosion, Cracking, Signs of Abrasion and any Leaks.

Converter

Check the Converter and the Cables connected to the Converter for:

* Corrosion, Damage, moisture in the housing, corroded terminals.

Observations are objective.

Figure 6.2.12 Example of Physical Appearance “Note”

1) Check the physical appearance of “Flowtube” and “Converter”.

For details, see Figure 6.2.12.

F060212.ai

2) Select an applicable result manually in Table 6.2.10.

Table 6.2.10 Physical Appearance

Result Description

Passed Is selected when the result is good and there is no problem.

Failed Is selected when the result is bad.

N/A Is selected when the appearance check is not possible.

3) “Total Result” is displayed automatically. See Figure 6.2.13.

IM 01R01A11-01EN

Page 54

<6 OPERATION>

6.2.3 Standard VF Result

6-22

Figure 6.2.13 Example of “Result of Standard VF”

F060213.ai

IM 01R01A11-01EN

Page 55

<6 OPERATION>

6.3 Enhanced VF

• This mode provides more reliable verication by performed inspections equivalent to SERVICE.

• This mode is optional.

• This mode veries AXF by using external instruments, such as Magnetic Flowmeter Calibrator AM012, Handy Calibrator CA150, and so on.

• Even when FieldMate is in “ofine” mode, this mode can be run, but some manual setting

will have to be performed.

NOTE

When Verication Tool is in “online” mode:

If Verication Tool turns to “ofine” mode due to wiring disconnections, reconnect FieldMate and

AXF. Verication Tool will restore to “online” mode again.

6-23

Figure 6.3.1 “Enhanced VF” Screen

1

2

3

4

5

F060301.ai

IM 01R01A11-01EN

Page 56

<6 OPERATION>

Table 6.3.1 “Enhanced VF” Screen

6-24

Item

No.

1 Current Output

2 Pulse Output

3 Output Selection

4 Converter

5 Insulation Resistance

Item Name Description

Checks the current output.

See 6.3.1.

Checks the pulse output.

See 6.3.2.

Outputs the current or pulse in accordance with the check items.

See 6.3.1 or 6.3.2

Checks the accuracy of the converter by using AM012.

See 6.3.3.

Checks the insulation resistance.

See 6.3.4.

IM 01R01A11-01EN

Page 57

<6 OPERATION>

6.3.1 Current Output

This item checks the current output from the converter.

1 2

F060302.ai

Figure 6.3.2 “Current Output” Screen

Table 6.3.2 “Current Output” Screen

6-25

3

4

Item

No.

1 Connection diagram Shows the connection diagram on another screen. See Figure 6.3.3.

2 Measured (mA) Enter the measured value manually.

Output (*1)

3

in Output Selection

Exit

4

in Output Selection

*1: When the AXF protect function is set to “Protect”, Figure 3.2.2 is displayed after clicking “Output”. Follow 3.2.2.

Item Name Description

Outputs the current.

By clicking “Output” after selecting each setting value, the preferred current is transferred to AXF.

(Only when Veri cation Tool is in “online” mode)

Stops the current output and enables other operations.

(Only when Veri cation Tool is in “online” mode)

IM 01R01A11-01EN

Page 58

<6 OPERATION>

Current Output

Use a Yokogawa CA150 Handy Calibrator or similar.

NOTE

Set the Digital MultiMeter (CA150 or similar) to measure the current in “mA”.

6-26

I+ I–

CUR OUT STATUS OUT ALARM OUT SIGNAL

POWER SUPPLY EXCITER

P–P+

PULSE OUT STATUS IN

SBBASACAL–AL+COMSO2+SO1+

COMSI2+SI1+EX2EX1L/+N/–

250 to 600

Digital

Multi Meter

F060303-A.ai

(A) AXFA11

Current Output

Use a Yokogawa CA150 Handy Calibrator or similar.

NOTE

Set the Digital MultiMeter (CA150 or similar) to measure the current in “mA”.

250 to 600

Digital

Multi Meter

(B) AXFA14 or AXF Integral Flowmeter

Figure 6.3.3 Current Output Connection Diagram

F060303-B.ai

IM 01R01A11-01EN

Page 59

<6 OPERATION>

1) Wire AXF and CA150 Handy Calibrator or similar as shown in Figure 6.3.3.

2) Set a current value to output.

2)-1 When Veri cation Tool is in “online” mode:

Select 4 mA, 12 mA, or 20 mA in “Output Selection” and click “Output”.

F060304.ai

Figure 6.3.4 “Output Selection” in “Current Output”

2)-2 When Veri cation Tool is in “of ine” mode:

Set the AXF HART parameter “Loop test” to the preferred value.

Table 6.3.3 Parameter Setting of “Current Output”

6-27

HART Parameter (DD)

Loop test Device Setup → Diag/Service → Output Test→ Loop test -

Parameter of

AXF Display

Setting Value

• 4 mA

• 20 mA

• Other (12 mA)

3) Measure the current output value by using CA150 Handy Calibrator or similar for each setting value.

4) Enter the measured current value in each “Mesured(mA)” manually. “Error(%)” is calculated

automatically.

F060305.ai

Figure 6.3.5 “Current Output” Result

5) End processing

5)-1 When Veri cation Tool is in “online” mode:

Click “Exit” in “Output Selection”. “Result” is displayed automatically after lling in all elds.

5)-2 When Veri cation Tool is in “of ine” mode:

“Result” is displayed after lling in all elds.

IM 01R01A11-01EN

Page 60

<6 OPERATION>

6.3.2 Pulse Output

This item checks the pulse output from the converter.

Check the Suf x Code of AXF converter or AXF integral owmeter.

■ Without optional code EM, see “(A) Pulse Output (without optional code EM)”.

■ With optional code EM, see “(B) Active Pulse Output (with optional code EM)”.

1 2 3

Figure 6.3.6 “Pulse Output” Screen

Table 6.3.4 “Pulse Output” Screen

6-28

4

5

F060306.ai

Item

No.

1 Connection diagram

2 Setting Value Selects and shows the setting pulse value.

3 Measured (pps) Shows the measured value. Enter the measured value manually.

Output (*1)

4

in Output Selection

Exit

5

In Output Selection

*1: When the AXF protect function is set to “Protect”, Figure 3.2.2 is displayed after clicking “Output”. Follow 3.2.2.

Item Name Description

Shows the connection diagram on another screen. The diagram is any of

those in Figure 6.3.9 or Figure 6.3.13 depending on the case.

Outputs the pulse.

By clicking “Output” after selecting “Pulse”, the pulse with the value of

“Setting value (2)” is transferred to AXF.

(Only when Veri cation Tool is in “online” mode)

Stops pulse output and enables other operations.

(Only when Veri cation Tool is in “online” mode)

IM 01R01A11-01EN

Page 61

<6 OPERATION>

(A) Pulse Output (without optional code EM)

1) Wire AXF and CA150 Handy Calibrator or similar as shown in Figure 6.3.9.

2) Select “100 pps” in “Setting Value”. See Figure 6.3.7.

F060307.ai

Figure 6.3.7 “Setting Value” in “Pulse Output”

3) Output

3)-1 When Veri cation Tool is in “online” mode:

Select “Pulse” in “Output Selection” and click “Output”. See Figure 6.3.8

6-29

F060308.ai

Figure 6.3.8 “Output Selection” in “Pulse Output”

3)-2 When Veri cation Tool is in “of ine” mode:

3)-2-1 Record the original AXF parameters, and then set them as shown below.

Table 6.3.5 Parameter Settings of “Pulse Output”

HART Parameter

Pulse Scale Device Setup → Easy Setup → Pulse Scale B33/E11 100

Pulse Width Device Setup → Pulse Set → Pulse Width E12 50% Duty

Pulse Unit Device Setup → Easy Setup → Pulse Scale B32/E10 Pulse/s

Test DO (*1) Device Setup → Diag/Service → Output Test→ Test DO N30 Pulse

DO Function(*1)

*1: Only for AXFA14 or AXF Integral Flowmeter

Device Setup → Con guration → Status Function

→ DO Function

Parameter of

AXF Display

F20 Pulse Output

Setting Value

3)-2-2 Output pulse by setting AXF HART parameter “Loop test” to “20 mA”.

Table 6.3.6 Parameter Setting of “Pulse Output”

HART Parameter (DD)

Loop test Device Setup → Diag/Service → Output Test→ Loop test - 20 mA

Parameter of

AXF Display

Setting Value

IM 01R01A11-01EN

Page 62

<6 OPERATION>

NOTE

■ Measure for more than 60 seconds.

■ If using a YOKOGAWA CA150, set the mode to “Contact Input” and the range to “CPM”.

4) Measure the pulse output value in “pps” with a Yokogawa CA150 Handy Calibrator or

equivalent to simplify the measurement of pulses. If such a device is unavailable, an appropriate load (30V DC, 0.2A max) is required and use the con guration shown in Figure 6.3.9.

30VDC , 0.2A. max

6-30

CUR OUT STATUS OUT ALARM OUT SIGNAL

POWER SUPPLY EXCITER

(A) AXFA11

Dashed box : Yokogawa CA150 Handy Calibrator or equivalent

P–P+

PULSE OUT STATUS IN

30VDC , 0.2A. max

SBBASACAL–AL+COMSO2+SO1+I+ I–

COMSI2+SI1+EX2EX1L/+N/–

External

power supply

Load

Electronic Counter

Dashed box : Yokogawa CA150 Handy Calibrator or equivalent

F060309-A.ai

Electronic Counter

Load

External

power supply

F060309-B.ai

(B) AXFA14 or AXF Integral Flowmeter

Figure 6.3.9 Pulse Output Diagram (without optional code EM)

5) Enter the measured value manually.

6) “Result” is displayed automatically.

Figure 6.3.10 “Pulse Output” Result

F060310.ai

IM 01R01A11-01EN

Page 63

<6 OPERATION>

7) End processing

7)-1 When Verication Tool is in “online” mode:

Click “Exit” in “Output Selection”.

7)-2 When Verication Tool is in “ofine” mode:

Set the AXF parameters back to their original values manually.

6-31

IM 01R01A11-01EN

Page 64

<6 OPERATION>

(B) Active Pulse Output (with optional code EM)

1) Wire AXF and CA150 Handy Calibrator or similar as shown in Figure 6.3.13.

2) Select “2 pps” in “Setting Value”. See Figure 6.3.11.

F060311.ai

Figure 6.3.11 “Setting Value” in “Active Pulse Output”

3) Output

3)-1 When Veri cation Tool is in “online” mode:

Select “Pulse” in “Output Selection” and click “Output”. See Figure 6.3.12.

6-32

F060312.ai

Figure 6.3.12 “Output Selection” in “Active Pulse Output”

3)-2 When Veri cation Tool is in “of ine” mode:

3)-2-1 Record the original AXF parameters, and then set them as shown below.

Table 6.3.7 Parameter Settings of “Active Pulse Output”

HART Parameter (DD)

Pulse Scale Device Setup → Easy Setup → Pulse Scale B33/E11 2

Pulse Width Device Setup → Pulse Set → Pulse Width E12 100ms

Pulse Unit Device Setup → Easy Setup → Pulse Scale B32/E10 Pulse/s

Test DO (*1) Device Setup → Diag/Service → Output Test→ Test DO N30 Pulse

DO Function(*1)

(*1) only for AXFA14 or AXF Integral Flowmeter

Device Setup → Con guration → Status Function

→ DO Function

Parameter of

AXF Display

F20 Pulse Output

Setting Value

3)-2-2 Output pulse by setting AXF HART parameter “Loop test” to “20 mA”.

Table 6.3.8 Parameter Setting of “Active Pulse Output”

HART Parameter (DD)

Loop test Device Setup → Diag/Service → Output Test→ Loop test - 20 mA

Parameter of

AXF Display

Setting Value

IM 01R01A11-01EN

Page 65

<6 OPERATION>

NOTE

• Measure for more than 60 seconds.

• If using a YOKOGAWA CA150, set the mode to “Frequency (FREQ) and Pulse” and the

range to “CPM”.

• An appropriate load (24 VDC ± 20%, 150 mA max) is required.

4) Measure the pulse output value in “pps” with a Yokogawa CA150 Handy Calibrator or

equivalent to simplify the measurement of pulses. If such a device is unavailable, use the

con guration shown in Figure 6.3.13.

Output voltage: 24 V DC ±20%

Current: 150 mA max

CUR OUT STATUS OUT ALARM OUT SIGNAL

POWER SUPPLY EXCITER

P–P+

PULSE OUT STATUS IN

SBBASACAL–AL+COMSO2+SO1+I+ I–

COMSI2+SI1+EX2EX1L/+N/–

6-33

Load

Electronic Counter

Dashed box : Yokogawa CA150 Handy Calibrator or similar

(A) AXFA11

Load

Dashed box : Yokogawa CA150 Handy Calibrator or similar

Output voltage: 24 V DC ±20%

Current: 150 mA max

Electronic Counter

(B) AXFA14 or AXF Integral Flowmeter

Figure 6.3.13 Active Pulse Output Diagram (with optional code EM)

5) Enter the measured value manually.

6) “Result” is displayed automatically.

F060313-A.ai

F060313-B.ai

Figure 6.3.14 “Active Pulse Output” Result

F060314.ai

IM 01R01A11-01EN

Page 66

<6 OPERATION>

7) End processing

7)-1 When Verication Tool is in “online” mode:

Click “Exit” in “Output Selection”.

7)-2 When Verication Tool is in “ofine” mode:

Set the AXF parameters back to their original values manually.

6-34

IM 01R01A11-01EN

Page 67

<6 OPERATION>

6.3.3 Converter

6-35

WARNING

Follow User’s Manual FY2-XJAM012-40-2E for correct operation and safe handling.

This item checks the accuracy of the AXF converter with Magnetic Flowmeter Calibrator AM012.

1 2 3

4

5

F060315.ai

Figure 6.3.15 “Converter” Screen

Table 6.3.9 Converter

Item

No.

1 Connection diagram

2 Span

3 Read Span

4 Measured (m/s)

5 Read

Item Name Description

Shows the connection diagram on another screen. The diagram is (A) or

(B) in Figure 6.3.16 depending on the case.

Shows the Span of the converter.

This eld can be edited.

Reads the Span of the converter. Press “Read Span”.

(Only when Verication Tool is online to AXF)

Shows the measured value.

This eld can be edited.

Reads the measured value. Press “Read”.

(Only when Verication Tool is online to AXF)

AXFA11

(White)

F060316-A.ai

SB

BASAC

(Black)

COMSI2+SI1+

AM012

AM012

CUR OUT STATUS OUT ALARM OUT SIGNAL

POWER SUPPLY EXCITER

(Shield) (White) (Black)

AL–AL+COMSO2+SO1+I+ I–

(Shield)

EX2EX1

L/+N/–

PULSE OUT STATUS IN

P–P+

(A) AXFA11 (B) AXFA14 or AXF Integral Flowmeter

Figure 6.3.16 “Converter” Connection Diagram

Junction Box Terminal

(Shield)

(Shield)

(White)

(Black)

(Black)

N/

–

L/

+

+

SA

–

(White)

+

–

SB

+

–

F060316-B.ai

IM 01R01A11-01EN

Page 68

<6 OPERATION>

1) For details of the calibration procedures, follow User’s Manual FY2-XJAM012-40-2E.

Record the following original parameters and set the AXF parameters as shown below

manually. (These settings are described in FY2-XJAM012-40-2E.)

Table 6.3.10 AXF parameter setting of Converter Check

6-36

HART Parameter (DD)

Select Flow

Tube (*1)

Nominal Size

Nominal Size

MF Set

Low MF

High MF

Low MF (EDF)

(*2)

High MF (EDF)

(*2)

*1: Only for AXFA11

*2: Only for optional code HF1 or HF2 (Enhanced Dual Frequency Excitation)

*3: Only for optional code HF1 or HF2, select “Enhanced DF”.

Device setup → Detailed Setup → Basic Setup →Select Flow Tube

Device setup → Detailed Setup → Basic Setup

→Nominal Size

Device setup → Detailed Setup → Basic Setup

→Nominal Size unit

Device setup → Detailed Setup → Basic Setup→MF

Set

Device setup → Detailed Setup → Basic Setup→MF

Set → Standard DF → Low MF

Device setup → Detailed Setup → Basic Setup→MF

Set → Standard DF → High MF

Device setup → Detailed Setup → Basic Setup→MF

Set → Enhanced DF → Low MF (EDF)

Device setup → Detailed Setup → Basic Setup→MF

Set → Enhanced DF → High MF (EDF)

2) Enter the span on the “Converter” screen.

Parameter of

AXF Display

C30 Calibrator

C32

C31 mm

C20

(Measure Mode)

C21 1.0

C22 1.0

C23 1.0

C24 1.0

nominal size in

Enhanced DF (*3)

Setting Value

Enter owtube

“mm” unit

Standard DF

or

2)-1 When Verication Tool is in “online” mode:

Click “Read Span (3)” in Figure 6.3.15. The value of parameter “Velocity Check” is entered

automatically. If the AXF parameters are different from those in Table 6.3.10, the following

error message is displayed. Set the AXF parameters to those in Table 6.3.10.

F060317.ai

Figure 6.3.17 Example of “Parameter Error” Dialog

IM 01R01A11-01EN

Page 69

<6 OPERATION>

2)-2 When Verication Tool is in “ofine” mode:

Read the value of parameter “Velocity Check” manually. Refer to Table 6.3.11. And enter

the value in “cell (2)” in Figure 6.3.15 manually.

Table 6.3.11 AXF Parameter Settings of Converter Check

6-37

HART Parameter (DD)

Velocity Check Device setup → Detailed Setup → Basic Setup →Velocity Check C44

Parameter of

AXF Display

3) Measure the output accuracy at the preferred setting (0%, 25%, 50%, 75%, or 100%). After

setting the value, let the AM012 stabilize at least for 1 minute.

For operation procedure, follow User’s Manual FY2-XJAM012-40-2E.

4) Enter the measured value.

4)-1 When Verication Tool is in “online” mode:

Click “Read (5)” in Figure 6.3.15. The value of instantaneous ow rate is entered automati-

cally.

4)-2 When Verication Tool is in “ofine” mode:

Read the value of parameter “PV” or “PV %rnge” manually. Refer to Table 6.3.12, and

convert the value in “m/s” unit.

Enter the calculated value in “cell (4)” in Figure 6.3.15 manually.

Table 6.3.12 AXF Measured Value of “Converter” Check

Parameter of

AXF Display

A20

A10

PV

PV %rnge

HART Parameter (DD)

■ Process Variables → PV

or

■ Device Status → Process Variable → PV

■ Process Variables → PV %rnge

or

■ Device Status → Process Variable → PV %rnge

5) “Error (%)” is calculated automatically.

6) “Result” is displayed automatically after lling in all elds.

Figure 6.3.18 “Converter” Result

7) Set the AXF parameters back to their original values manually.

F060318.ai

IM 01R01A11-01EN

Page 70

<6 OPERATION>

F060319-A.ai

6.3.4 Insulation Resistance

6-38

WARNING

Follow User’s Manual IM 01E20D01-01E for correct operational and safe handling.

Where the insulation resistance check is not possible, select “N/A”

1) Check the insulation resistance in the terminal box in accordance with the tables below. Follow User’s Manual IM 01E20D01-01E.

(A) Coil

Table 6.3.13 Coil Insulation Resistance Check

Test Terminals Test Voltage

Between terminals EX1 and C 500 V DC (Use an insulation tester or equivalent.)

(B) Signal (Electrode)

Table 6.3.14 Electrode Insulation Resistance Check

Test Terminals Test Voltage

- Between terminals A and C

- Between terminals B and C

500 V DC (Use an insulation tester or equivalent.)

2) Enter the measured value manually.

Where the insulation resistance check is not possible, select “N/A”.

Where the measured value is over-range, select “Open Loop (O.L.)”.

3) “Result” is displayed automatically.

(A) Example 1

(B) Example 2

Figure 6.3.19 “Insulation Resistance” Result

F060319-B.ai

IM 01R01A11-01EN

Page 71

<6 OPERATION>

6.4 Result

The results of Standard VF and Enhanced VF are available in the “Result” tab. Uncompleted

check items are displayed as blank.

6-39

Figure 6.4.1 “Result” Screen

F060401.ai

IM 01R01A11-01EN

Page 72

<6 OPERATION>

The result in full view is shown Figure 6.4.2.

If the user needs a hard copy of the report, refer to 6.1.3.

6-40

1

Figure 6.4.2 “Result” in Full View

2

3

4

5

6

F060402.ai

IM 01R01A11-01EN

Page 73

<6 OPERATION>

Table 6.4.1 Result

6-41

Item

No.

Tag (Converter)

Tag (Flowtube)

1

Serial No. (Converter)

Serial No. (Flowtube)

2 Overall Status

3 Comments

4 Veried by

5 Signature

6 Legend symbols

Item Name Description

Shows AXF device information. The contents entered in General Information are displayed by default. This elds can be edited in the “Result” tab.

Shows the result of the whole verication.

• Passed

This owmeter was veried to be functioning within +/- □% of the original

factory calibration.

• Failed

This owmeter did not pass the verication test.

Shows user comment. This item can be edited.

Enter any comment (e.g. user’s document No.).

Shows the name of the person who performed the verication. The name

entered in General Information is displayed by default. This eld can be

edited in the “Result” tab.

Shows the signature of the person who performed the verication.

The person should sign this eld on the printout.

Shows the meaning of symbols in “Result” elds.

● [----] : Inconclusive

● [ ] : Not performed

IM 01R01A11-01EN

Page 74

Blank Page

Page 75

<7 VARIATION OF VERIFICATION DATA>

7-1

7 VARIATION OF VERIFICATION DATA

In terms of keeping its own data integrity, veri cation data cannot be copied, nor can it be saved

as other name. Veri cation data except for “Locked data” can be saved only by newly saving or

over-writing.

There are 3 types of veri cation data:

1. Installation data

2. Locked data

3. Others

1

2

Figure 7.1.1 Variation of veri cation data

Table 7.1.1 Variation of veri cation data

Item

No.

1 Installation data

2 Locked data

3 Others See 7.3.

Item Name Icon Description

7.1 Installation Data

“Installation data” functions as a reference. Each device can have only one “Installation data”.

When the veri cation data is saved by checking the “Save as installation data” box in Figure

6.1.9, the data becomes the “Installation data”.

Only when “No Flow + Flow (*1)” is complete, veri cation data can be saved as an “Installation

data”. See 6.1.2.

3

F070101.ai

See 7.1.

See 7.1 and 7.2.

Save the rst veri cation data after the delivery as “Installation data”. (Recommended)

When the user wants to edit “Installation data” later:

Save the veri cation data by checking only the “Saved as installation data” box in Figure

6.1.9. The icon in Data Status is “

When it is necessary to save installation data as read-only:

Save the veri cation data by checking the “Saved as installation data” box and the “Save as

locked data box” in Figure 6.1.9. The icon in Data Status is “

*1: “No Flow + Flow”:

“Circuit” check and “Device Status” check for both “No Flow” and “Flow” conditions. Refer to 6.2.1.

“.

”.

IM 01R01A11-01EN

Page 76

<7 VARIATION OF VERIFICATION DATA>

7.2 Locked Data

“Locked data” is saved as read-only. The icon in Data Status is “ ”.

After verication data is saved as “Locked data”, the data:

• can be loaded.

• can be printed out.

• cannot be over-written.

When verication is complete, save the verication data as “Locked data” to prevent unexpected

over-writing or falsifying, before printing. (Recommended)

7.3 Others

Verication data which is neither “Installation data” nor “Locked data” can be edited. When verication is to be continued later, do not save as either “Installation data” or “Locked data”.

7-2

IM 01R01A11-01EN

Page 77

<8 TERMINATION>

8-1

8 TERMINATION

This chapter describes “Normal Termination” and “Unexpected Termination”.

8.1 Normal Termination

Select “File”-“Exit” or click the “Close” button at the upper-right corner of “Main Screen”.

F080101.ai

Figure 8.1.1 Normal Termination

8.1.1 When the verication data has not been changed after

saving:

This tool is terminated without any dialogs appearing.

8.1.2 When the verication data has been changed after

saving:

1) Figure 8.1.2 is displayed.

1

2

F080102.ai

Figure 8.1.2 “Conrmation” Dialog

Table 8.1.1 “Conrmation” Dialog

Item

No.

1 Yes Saves the verication data by over-writing. See 6.1.2.

2 No Cancels saving the data.

Item Name Description

2) Select whether the latest verication data is saved to the database or not.

2)-1 To save the latest verication data:

Select “Yes (1)”. See 6.1.2.

2)-2 When the latest verication data is not saved:

Select “No (2)”. No dialogs appear and the data is not saved.

3) This Verication Tool is terminated automatically.

IM 01R01A11-01EN

Page 78

<8 TERMINATION>

8.2 Unexpected Termination

If an unexpected termination occurs, follow this procedure.

1) When an unexpected termination occurs, be sure to re-connect FieldMate and AXF, and

reboot Verication Tool. If the AXF parameters have been changed from the original setting,

Figure 8.2.1 “Error Recovery” Dialog is displayed after reboot.

1

2

8-2

F080201.ai

Figure 8.2.1 “Error Recovery” Dialog

Table 8.2.1 “Error Recovery” Dialog

Item

No.

1 Error contents

2 OK

Item Name Description

Shows “Last verication error date” and “Parameter items which will be

recovered”.

Resets the AXF internal parameters to their original values.

Click “OK (2)”.

2) To reset the AXF parameters to their original values, click “OK (2)”. Figure 8.2.2 is displayed

and then the AXF parameters are recovered.

Figure 8.2.2 “Recovering” Screen

F080202.ai

IM 01R01A11-01EN

Page 79

<9 COMMUNICATION ERROR>

9 COMMUNICATION ERROR

9.1 Error Message

This chapter shows error dialogs. See Table 9.1.1 for details.

After termination, follow 8.2.

F090101.ai

Figure 9.1.1 Error Dialog 1

9-1

Figure 9.1.2 Error Dialog 2

Figure 9.1.3 Error Dialog 3

Figure 9.1.4 Error Dialog 4

F090102.ai

F090103.ai

F090104.ai

IM 01R01A11-01EN

Page 80