Page 1

LEGEND Digital Torque Amplifier

SGDG User’s Manual

Upon receipt of the product and prior to initial operation, read these instructions

thoroughly, and retain for future reference.

Page 2

Safety-Related Symbols

G

The followi ng sy mbo l s are used in this man ual acco r d ing to the s afe ty-r el ated co nte n t.

Be sure to observe text annotated with these safety symbols as their content is important.

WARNIN

CAUTION

YASKAWA manufactures compon ent parts that can be used in a wide variety

of industrial applications. The selection and application of YASKAWA products remain the responsibility of the equipment designer or end user.

YASKAWA accepts no responsibility for the way its products are incorporated

into the final syst em desi g n.

Under no circumstances should any YASKA WA product be incorporated into

any product or design as the exclusive or sole safety control. Without exception, all controls should be designed to detect faults dynamically under all circumstances. All products designed to incorporate a component part

manufactured by YASKAW A must be supplied to the end user with appropriate

warnings and instructions as to that part’s safe use and operation. Any warnings provided by YASKAWA must be promptly provided to the end user.

Mis-operation may result in a hazardous condition with the possibility of death or

serious injury.

Mis-operation may result in a hazardous condition with the possibility of serious or

light injury as well as material damage.

Furthermore, the items annotated with a may result in serious

consequences depending on the situation. Be sure to observe these as they highlight

important content.

CAUTION

WARNING

YASKAWA offers an express warranty only as to the quality of its products in

conforming to standards and specifications published in YASKAW A’ s manual.

NO OTHER W ARRA NTY, EXPRESS OR IMPL IED, I S O FFERED. YASKAWA

assumes no liability for any personal injury, property damage, losses, or

claims arising from misapplication of its products.

i

Page 3

Icon Display

The following icons were designe d so as to aid in understanding the type of descriptive

content. The icons are displayed where needed to aid in comprehension.

Major items which should be memorized. In addi tion 、 this can be a minor item which does

Important

Exp.

Supp.

Terminology?? This explains difficult- to-understand technical terminology and technical terms which

not reach the level of damage to the machine, such as the genera tion of an alarm display.

This shows programming, operation examples, etc.

This shows supplemental informat ion and convenient functions to remember.

have not been previously explain ed.

ii

Page 4

Outline of Manual

Thank you for purchasing the LEGEND Digital torque amplifier.

Use this product with a full understa nding of conditions such as product specific a tions, usage

limits, etc.

This manual explains the following areas for users of the LEGEND Digital torque amplifier.

• Methods for mounting and wiring servomotor an d amplif iers

• How to use the various functions

• Ratings and specificati ons for standard device types

• Maintenance and Inspection

For additional infor mation on Sigma II servomotor,please refer to the following documents:

• Sigma II Servo System Product Catalog Supplement

(Doc.# G-MI#99001x-Sigma II)

• Sigma II Series Servo System User’s Manual

(Doc.# YEA-S800-32.2x)

• Linear Servomotor Product Catalog

(Doc.#KAE-S800-39.10)

iii

Page 5

G

Safety Notes

In this manual, we will describe important cautionary items which should always be

observed regarding usa ge, inspection upon receipt of product, mounting, wiring,

operation, and maintenance/inspection.

■ Inspection Upon Receipt of Product

• Use the ser vomotors and am plifiers in the designated combinations. (See “3.5

Combinations” on page 39.)

Failure to do so may result in fire or unit failure.

■ Mounting

• Never use this produc t in an area where w ater may splash, in a corrosive or flammable

atmosphere, or next to flammable items.

Doing so may res u lt in electric shock or fire.

CAUTION

CAUTION

■ Wiring

WARNIN

• Be sure to connect the ground terminal of the digital torque amplifier to a grounding

electrode (100Ω or less).

Failure to do so may result in electric shock or fire.

CAUTION

Wiring Precautions

• Do not bundl e or run power and sig n al lines together in the same duct.

Keep power and signal lin e s at least 1 1.81” (30cm) apart.

• Use twisted pair or shielded multi-core twisted pair wires for signal and encoder (PG)

feedback lines.

• The maxim um lengths for signal lines are as follows :

• Maximum of 9.84ft (300cm) for reference input lines.

• Maximum of 65.6ft (20m ) for PG feedback lines.

• Use a cable type UL20276-SB for distanc es over 65.6ft (20m ).

iv

Page 6

CAUTION

G

G

• Do not connect a three-phase power supply to the digital torque amplifier output terminals

U, V, and W.

Doing so may result in in jury or fire.

• Securely fasten the screws for the power terminals and mo tor terminals.

Failure to do say may result in fire.

■ Operation

WARNIN

• To prevent unexpected accidents, test the motor with the motor shaft not conn ected to a

machine or load.

• T o prev ent une xp ected acc ident s , run w ith l imi t swit c hes or st op pe rs att ac hed to bot h end s

of the magne t track.

Failur e to do so may result in injury.

• Set parameters before operating the motor in connection with a machine..

Operatin g w ithout making these settings m ay result in mac hine runaway and damage.

• After mounting on the machine, prior to the star t of operation, make sure th e em ergency

stop can be applied at any time.

Failur e to do so may result in injury.

• Do not touch the heat sink while the unit is running.

The high tempe rature may result in burns.

■ Maintenance/Inspection

WARNIN

• Never touch the inside of the digital torque amplifier.

Doing so may result in electrical shock.

• Be sure no wir ing is exposed when power is turned ON.

Failure to do so may re su lt in el ectrical sh oc k .

• Do not touch the terminals for five minutes following power OFF .

Electrical shock may result due to residual voltage.

CAUTION

• Do not change the wiring while power is ON.

Doing so may result in electrical shock or injury.

v

Page 7

f

■ General Cautionary Items

Cautionary Items Regarding Usage

• The fig ures contai ned in this manua l may, for purposes of detailed explanation, be drawn with covers and

safety sh ields removed. When operating this product, be sure to return all standard covers and shields to

their original locations, and operate the product in accordanc e w ith this manual.

• The fig ures contain ed in this manual are representative examples, and may diff er from the produ ct

recieved.

• Appropr iate modifications may be made to this manual due to improvement s or specification changes in

the product, or to imp rove the ease of use of th e m anual itself. In the event of such changes, the document

number of the ma nual will be upda ted, and issued as a revision.

• To order additional copies of this manual, contact your Yasakwa representative, or the nearest Yaskawa

sales office printed on the back of this manual with the document number written on the cover.

• Yask a w a assumes no responsibil ity for products modified by the custo m er as they fall outside th e

warranty.

■ Warning Label

危険

WARNING

注意

CAUTION

必ずアース線を接続せよ

Use proper grounding techniques.

通電中および電源オフ後,5分間端子部にさわるな!感電のおそれあり

Disc onnect al l power and wait 5 m in.

before servicing. May cause electric shock.

通電中はヒートシンクにさわるな!火傷のおそれ あり

Do not touch heat sink when power is ON.

May cause burn.

Mounting Position o

Warning Label

Ground Mark

Figure A: Attachment Position of Warning Label and Ground Mark

vi

Page 8

Table of Contents

Safety-Related Symbols .......................................................................................... i

Icon Display ............................................................................................................. ii

Outline of Manual ................................................................................................... iii

Safety Notes............................................................................................................ iv

Inspection Upon Receipt of Product........................................................iv

Mounting .................................................................................................iv

Wiring......................................................................................................iv

Operation .................................................................................................v

Maintenance/Inspection ...........................................................................v

General Cautionary Items .......................................................................vi

Warning Label.........................................................................................vi

Chapter 1: Interpretation of Model Number ......................................................... 1

1.1 Rotary Motor Type ..................................................................................... 1

1.2 Linear Motor Type...................................................................................... 2

Motor Coils.............................................................................................. 2

1.3 Core-less Type .......................................................................................... 2

Motor Coil................................................................................................ 2

1.4 T-Type Iron Core ....................................................................................... 3

Motor Coil................................................................................................ 3

1.5 F-Type Iron Core ....................................................................................... 4

Motor Coil................................................................................................ 4

1.6 Digital Torque Amplifier ............................................................................. 5

1.7 Serial Converter Unit ................................................................................. 6

Chapter 2: Wiring ................................................................................................... 9

2.1 Main Circuit Wiring..................................................................................... 9

Main Circuit Terminal Names and Functions .......................................... 9

Example of Typical Main Circuit Wiring................................................. 12

Power ON Sequence Design ................................................................ 13

Power Line Size and Peripheral Devices .............................................. 13

Digital Torque Amplifier Power Loss ..................................................... 13

Main Circuit Terminal Block Wiring Method .......................................... 13

Power Terminal Processing .................................................................. 14

Peripheral Device Types and Capacities .............................................. 15

2.2 Input Signals ............................................................................................ 16

Page 9

Table of Contents

Example of I/O Signal Connection ........................................................ 16

Connector (CN1) Terminal Array List.................................................... 17

CN1 Specifications................................................................................ 17

I/O Signal Names and Their Functions ................................................. 18

Command Input Circuit and Interface ................................................... 20

Sequence Input Circuit and Interface.................................................... 20

Output Circuits and Interfaces............................................................... 21

2.3 Wiring to the Encoder .............................................................................. 22

2.4 Cable Specifications and Peripheral Devices.......................................... 24

2.5 Standard Connection Examples .............................................................. 26

Single-phase Power Specification (SGDG-01GT, SGDG-04GT).......... 26

3-Phase Power Specification (SGDG-10GT, SGDG-15GT) ................. 27

Chapter 3: Setup................................................................................................... 29

3.1 Linear Motor Mounting............................................................................. 29

3.2 Rotary Motor Mounting ............................................................................ 29

Storage Temperature............................................................................ 30

Mounting Location................................................................................. 30

Alignment .............................................................................................. 31

Mounting Direction ................................................................................ 31

Shaft Tolerance Ranges ....................................................................... 31

Oil and Water Countermeasures........................................................... 32

Cable Stress.......................................................................................... 32

Vibration Resistance ............................................................................. 33

3.3 Digital Torque Amplifier Installation ......................................................... 34

Storage Conditions................................................................................ 34

Mounting Conditions ............................................................................. 34

3.4 Switch Settings ........................................................................................ 37

SW1 Function Selection Switch (dip switches) ..................................... 37

SW2 Linear Scale Pitch Setting (rotary switch)..................................... 37

SW3 PG Divider Setting (rotary switch) ................................................ 38

3.5 Combinations........................................................................................... 39

Combinations with Rotary Motors ......................................................... 39

Linear Motor Combinations ................................................................... 40

Serial Conversion Unit and Applicable Motors...................................... 40

Chapter 4: Description of Functions .................................................................. 41

4.1 Torque/Force Control............................................................................... 41

4.2 Protection Sequence Design ................................................................... 41

Servo ON Input ..................................................................................... 42

DB OFF Input........................................................................................ 43

RUN Signal Output................................................................................ 43

4.3 Encoder Signal Output............................................................................. 44

I/O Signals............................................................................................ 45

Page 10

Table of Contents

Output Phase Form............................................................................... 45

PG Divider Setting................................................................................. 46

4.4 Analog Monitor......................................................................................... 47

4.5 Regenerative Resistor Selection ............................................................. 47

External Regen Resistors ..................................................................... 48

For Digital Torque Amplifiers of 400W Capacity or Less ...................... 48

For Digital Torque Amplifiers of 500W Capacity or More...................... 51

Calculating Regen Energy .................................................................... 51

Chapter 5: Servo System Maintenance/Inspection........................................... 53

5.1 Motor Inspection ...................................................................................... 53

5.2 Digital Torque Amplifier Inspection .......................................................... 54

Component Replacement Timeline....................................................... 54

Use Conditions...................................................................................... 54

5.3 Alarms...................................................................................................... 55

7-Segment LED..................................................................................... 55

Alarm List .............................................................................................. 55

Appendix A: Host Controller Connection Examples ........................................ 57

A.1 Connecting the Galil IMC-1900/2900 ...................................................... 57

A.2 Connecting the Delta Tau PMAC2 .......................................................... 58

A.3 Connecting the MEI PCX/DSP ................................................................ 59

A.4 Connecting the Acroloop ACR-8010 ....................................................... 60

Appendix B: Installation Conditions for EMC Directives ............................... 61

EMC Installation Conditions.................................................................. 61

The Cable Core..................................................................................... 64

Cable Clamp ......................................................................................... 64

Page 11

Page 12

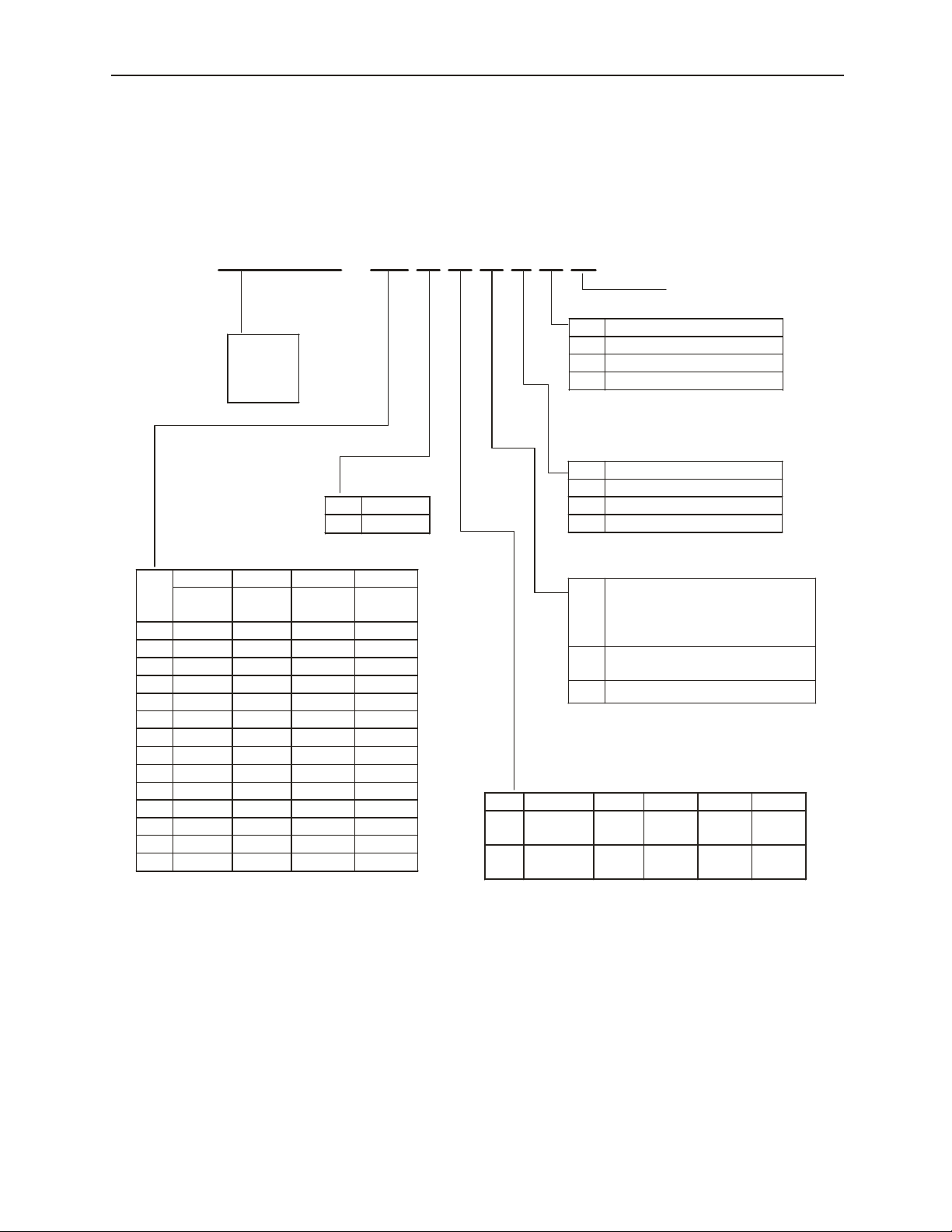

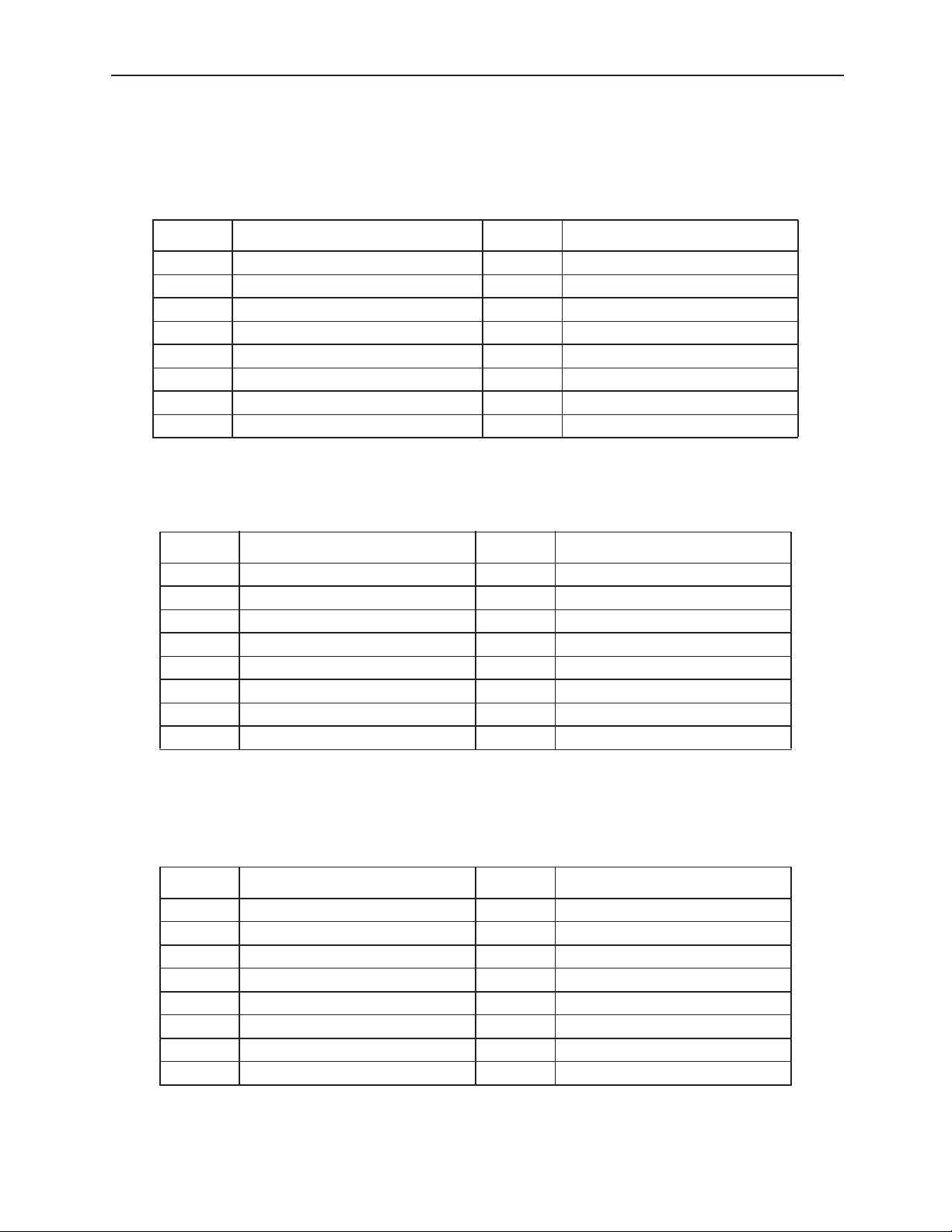

1.1 Rotary Motor Type

SGMPH - 01 A A A 2 S D

1. Interpretation of Model Number

1.1 Rotar y Moto r Type

Σ-II Series

Servo Motor

Series Name

SGMAH

SGMPH

SGMGH

SGMSH

② Voltage

1500

r / min

A 200V

B

100V

3000

r / min

*1

① Motor Capacity (kW)

SGMAH SGMPH SGMGH SGMSH

No.

3000

r / min

A3 0.03

A5 0.05

01 0.1 0.1

02 0.2 0.2

03

04 0.4 0.4

05 0.45

06

08 0.75 0.75

09 0.85

10 1.0

12

13 1.3

15 1.5 1.5

3000

r / min

SGMPH only

⑧ Brake/Oil S eal Specifications

w/o brake or oil seal

1

S w/ oil seal

C w/ 24V brake

E S+C

⑦ Shaft Specif ic a tio n

2 Straight, no key

4 Sra ight , w/ ke y

6 Straight, w/ key and ta p

8 Straight, w/ tap

④ Design Revision Order

SGMAH

A

SGMPH

SGMGH(1500 r/min)

SGMSH

SGMGH(1500 r/min)

C

For high-preci sion machine tool s

E SGMPH (Waterproof Spec. IP67)

③ Serial Encoder Specifications

No. SGMAH SGMPH SGMGH SGMSH

A

13-bit

Incremental

C

17-bit

Incremental

◎ ◎

◎

: Standard

◎

○

: Opt i on

◎

*1. 10 0V is only for us e with SGMA H , SG M PH

servo motors of 0.2kW or less.

1

Page 13

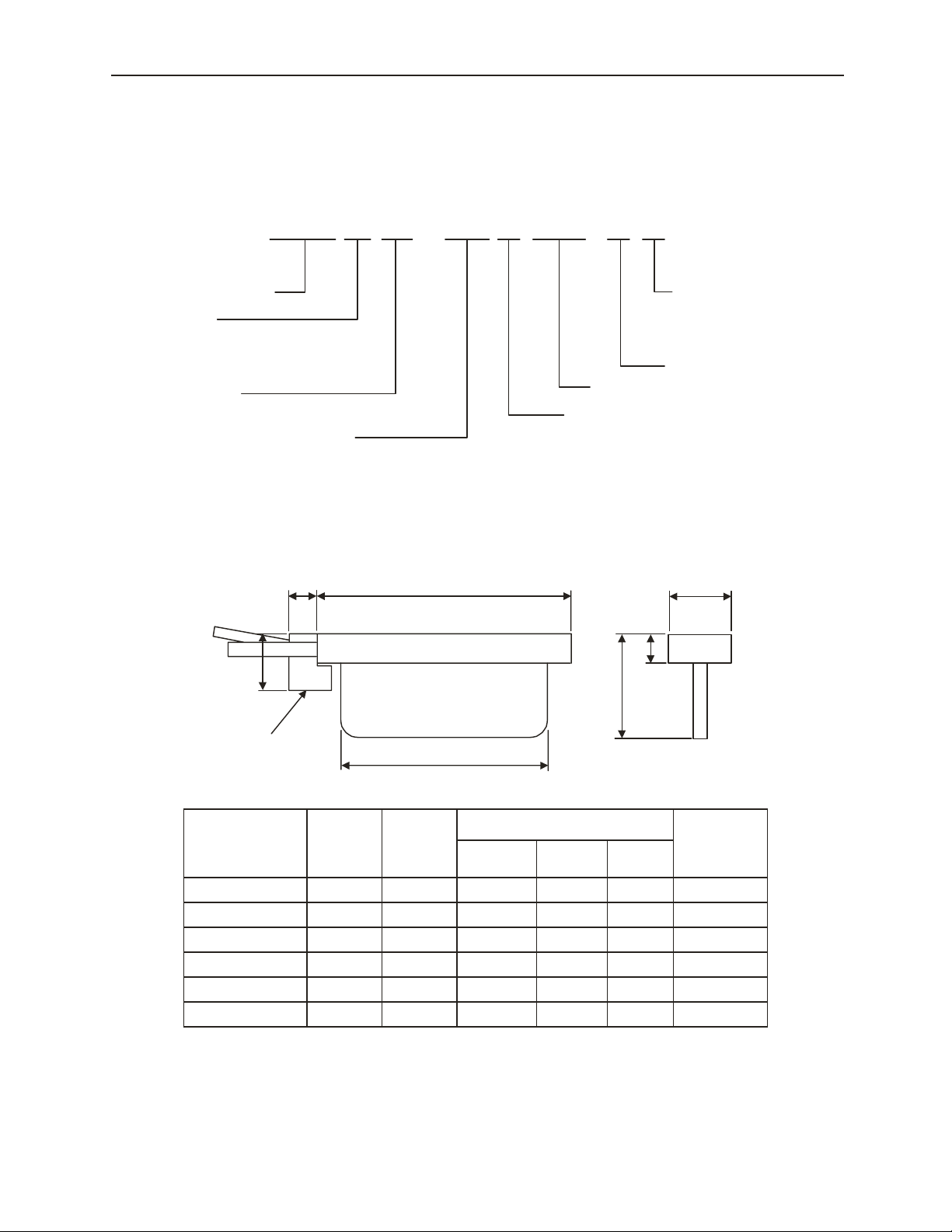

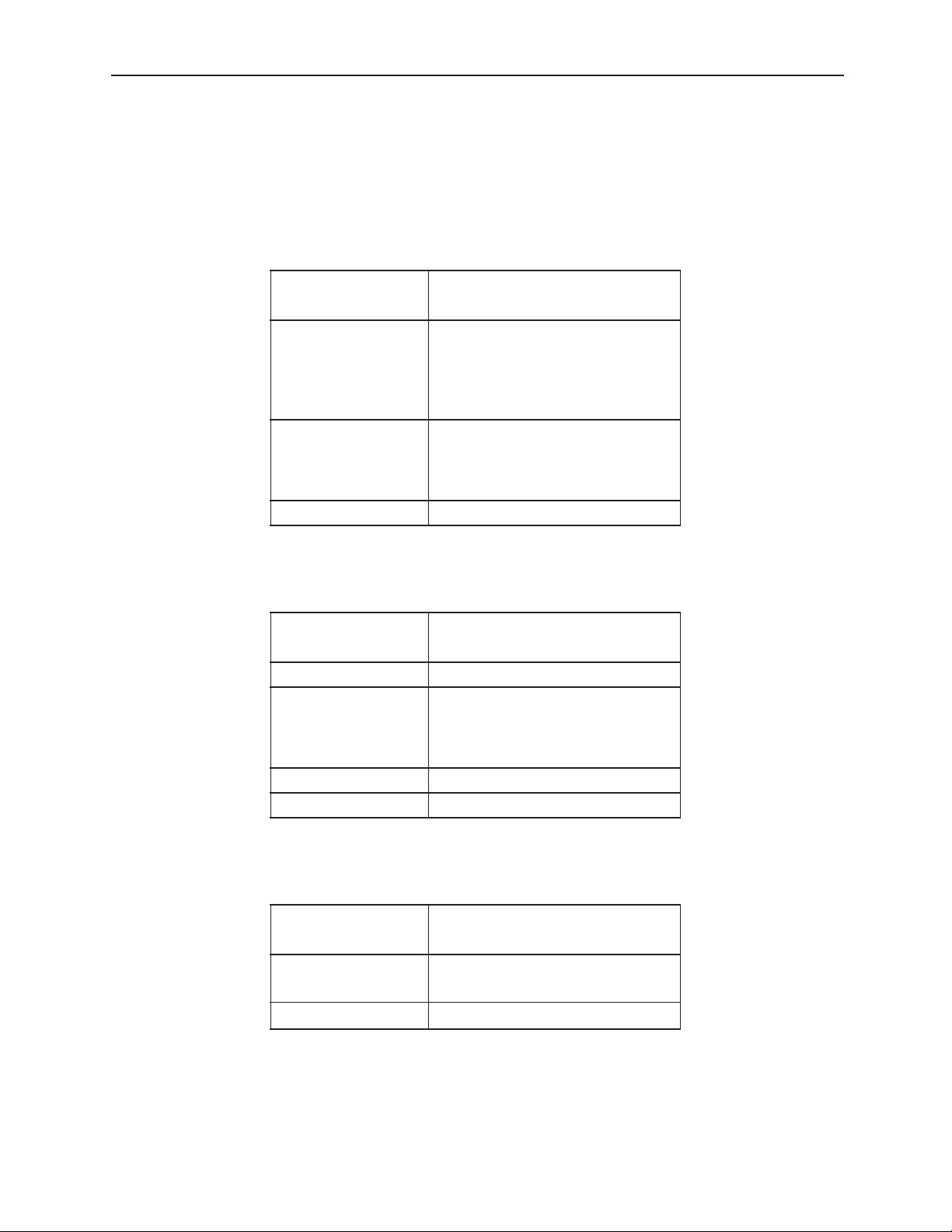

1.2 Linear Motor Type

1.2 Linear Motor Type

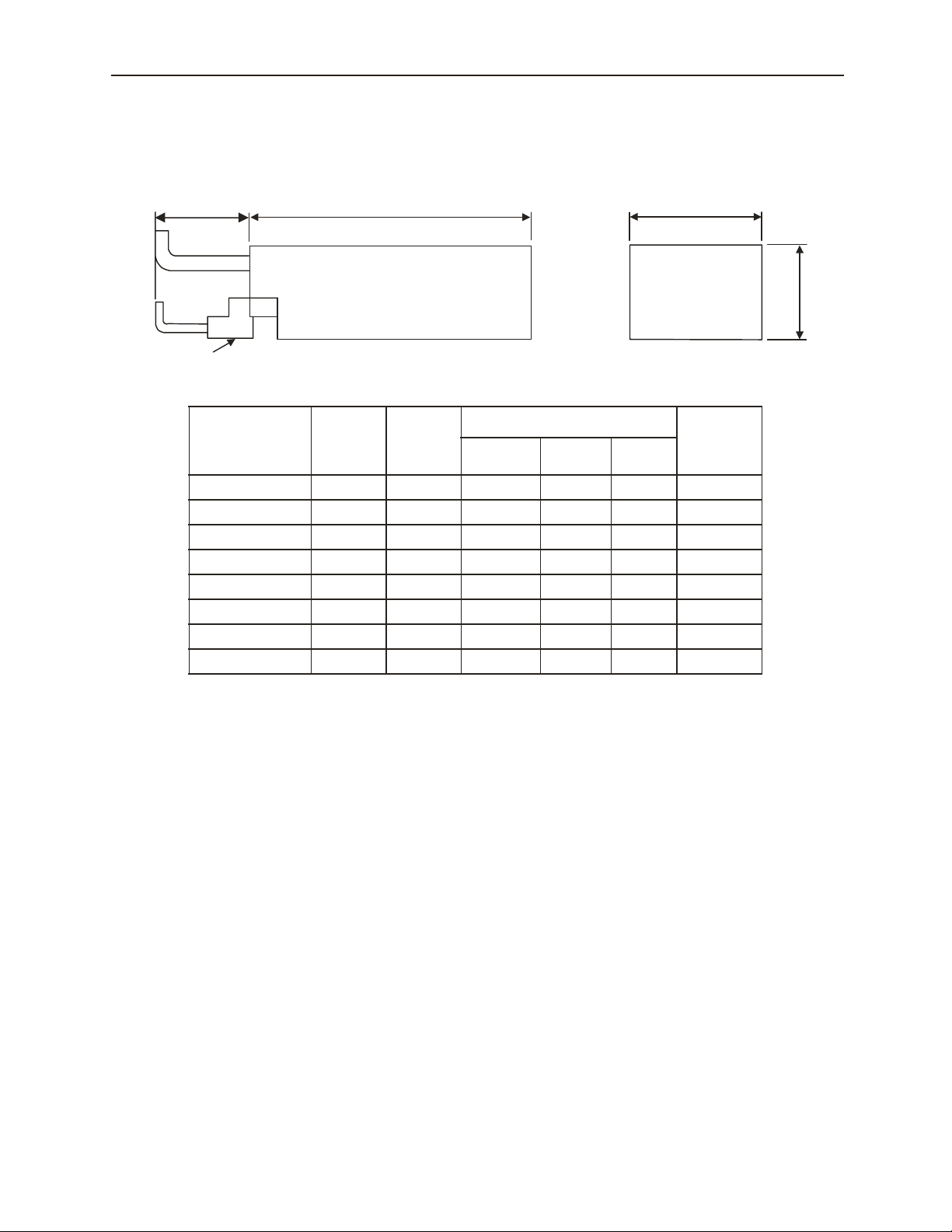

■ Motor Coils

SGL G W - 40 A 140 A

Linear Σ Series Motor

Motor Type

G: Core-less

T: T-type iron core

F: F-type iron core

Type

W: Motor Coil

Height of Magnets

1.3 Core-less Type

■ Motor Coil

16

30

L1

W

Option Specifications

P: w/ Hall sensor only.

W: w/ Hall se nsor and

Serial Converter. Th e

Serial Converter is

required f or operation with

LEGEND Digital Torque

Amplifiers.

Design Revision Orde r

Magnet Track Length

Voltage

A: 200V

25.4

15

H

Hall

Sensor

Model

SGLGW-

40A140A(P)

40A253A(P)

40A365A(P)

60A140A(P) 220 73 140 125 83 0.47

60A253A(P)

60A365A(P)

2

Max.

Thrust

(N)

140 47 140 125 63 0.39

280 93 252.5 237.5 63 0.65

420 140 365 350 63 0.91

440 147 252.5 237.5 83 0.80

660 220 365 350 83 1.13

Cont.

Thrust

(N)

L2

External Dimensions (mm)

L1 L2 H

Mass

(kg)

Page 14

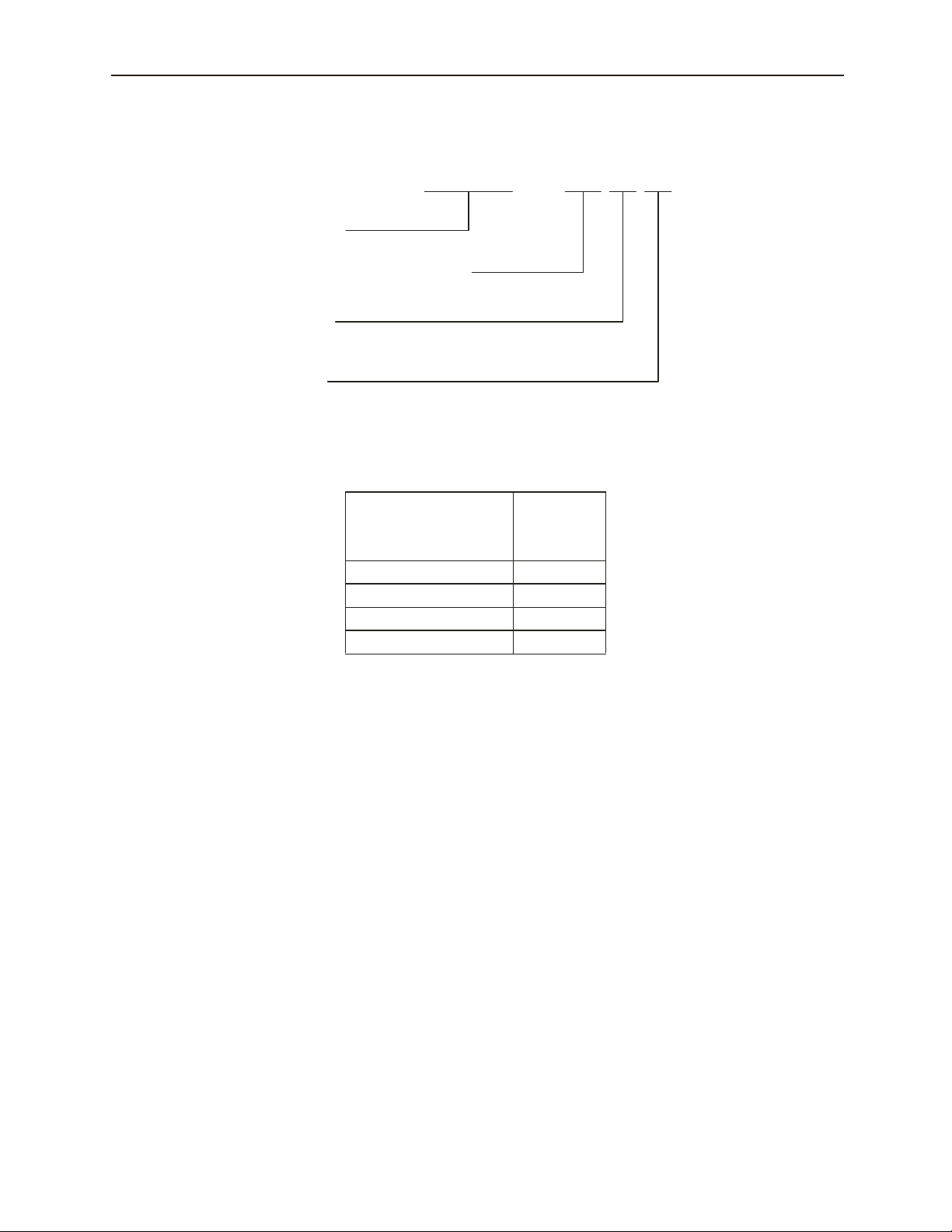

1.4 T-Type Iron Core

■ Motor Coil

Type: SGLTW-20A □□□ A(P), SGLTW -35A □□□ A(P)

1.4 T-Type Iron Core

W

50

H

Hall

Sensor

Type: SGLTW-40A □□□ A(P), SGLTW -80A □□□ A(P)

W

H

Min. 64

40

LMin. 100

L

Model

SGLTW-

20A170A(P)

20A320A(P)

20A460A(P)

35A170A(P)

35A320A(P)

35A460A(P)

40A400A(P)

40A600A(P)

80A400A(P)

80A600A(P)

Max.

Thrust

(N)

380 130 170 100 51 2.6

760 250 315 100 51 4.8

1140 380 460 100 51

660 220 170 100 66 3.7

1320 440 315 100 66 6.8

2000 670 460 100 66 10

2000 670 395 150 78 20

3000 1000 585 150 78 30

4000 1300 395 150 115 30

6000 2000 585 150 115 43

Cont.

Thrust

(N)

External Dimensions (mm)

L W H

Mass

(kg)

7

3

Page 15

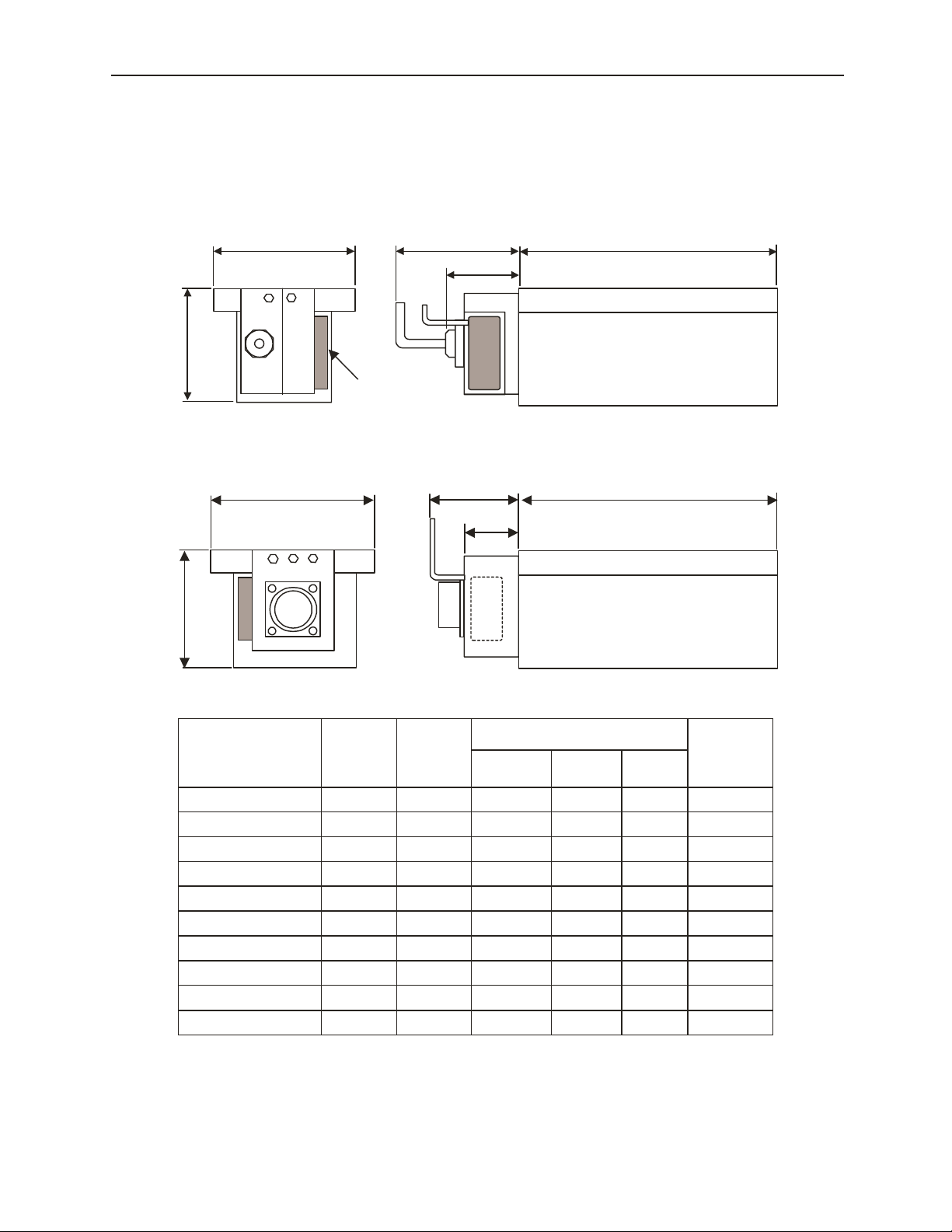

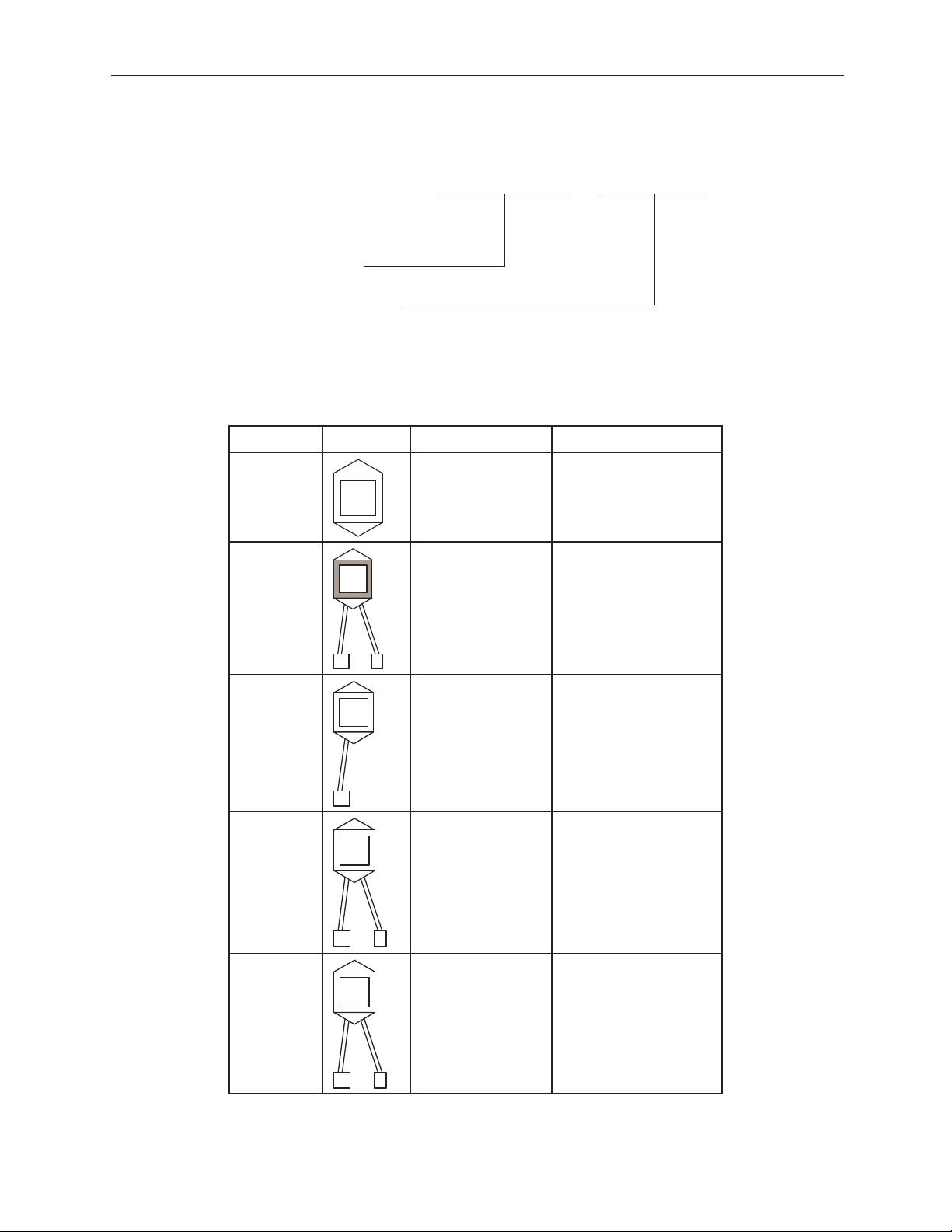

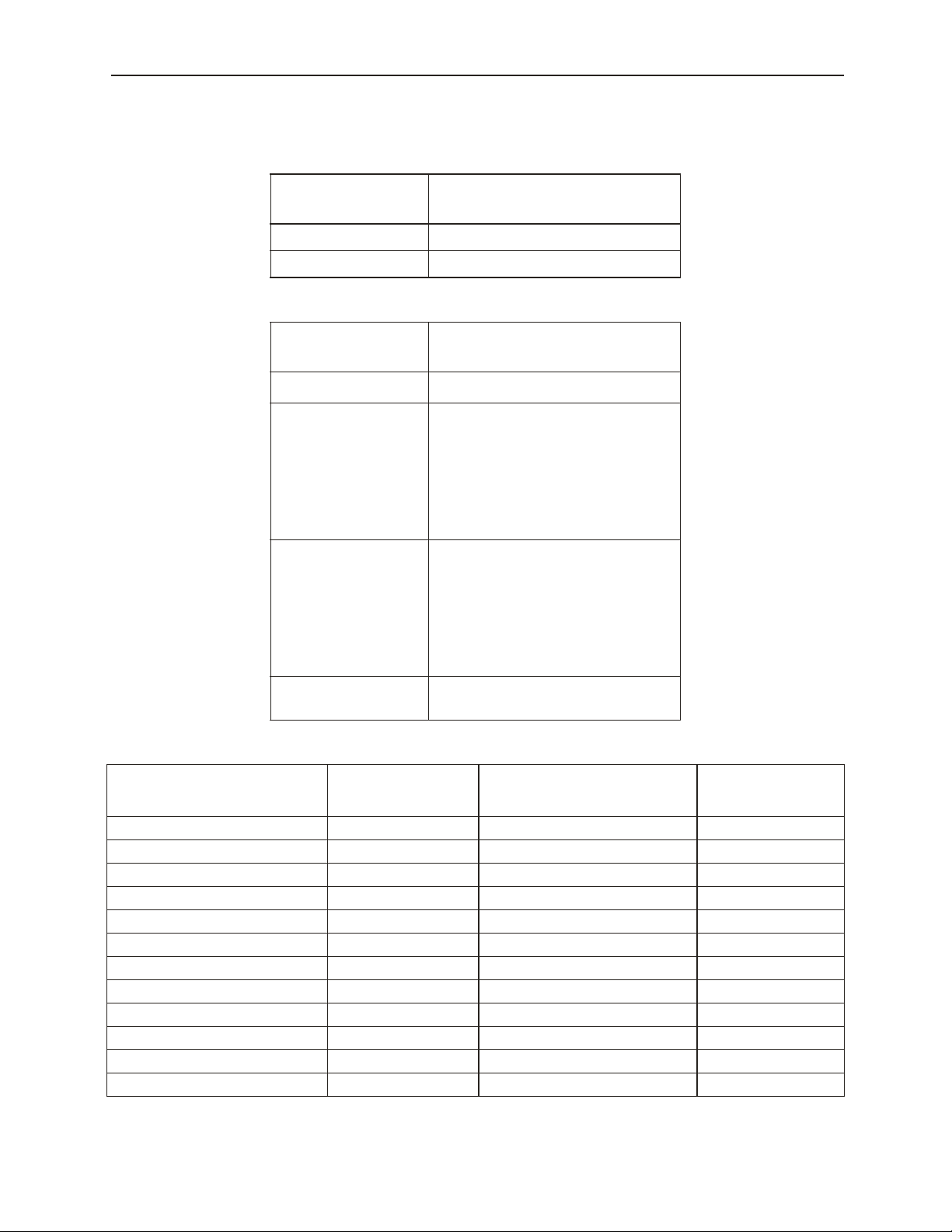

1.5 F-Type Iron Core

1.5 F-Type Iron Core

■ Motor Coil

Min. 50

L

Hall Sensor

Model

SGLFW-

20A090A(P) 86 25 91 40 34 0.7

20A120A(P)

35A120A(P)

35A230A(P) 440 160 235 55 34 2.3

50A200A(P)

50A380A(P)

1ZA200A(P) 1200 400 215 119 43 6.4

1ZA380A(P)

Max.

Thrust

(N)

125 40 127 40 34 0.9

220 80 127 55 34 1.3

600 200 215 71.5 43 3.7

1200 400 395 71.5 43 6.9

2400 800 395 119 43 12.2

Cont.

Thrust

(N)

External Dimensions (mm)

L W H

W

H

Mass

(kg)

4

Page 16

1.6 Digital Torque Amplifier

T

1.6 Digital Torque Amplifier

SGDG

LEGEND

SGDG Servo Amplifier

Maximum a pplied motor capacity

(see table below)

Voltage

G: 90V~253V

Model

@T: Torqu e/Force Con trol

10 G

-

Maximum Capacity of Applied Motor

Applied Motor

Maximum Ca pacity

Symbol

01 0.1

04 0.4

10 1.0

15 1.5

Capacity

(kW)

Note: Keep th e following in mind in SGDG digital to rque amplifier and SGDG/SGL□W

servomotor combinations:

The SGDG-01GT can drive motors of 30~200W rated output.

The SGDG-04GT can drive motors of 100~750W rated output.

The SGDG-10GT can drive motors of 300W~2kW rated output.

The SGDG-15GT can drive motors of 750W~3kW rated output.

Since LEGEND servo drives are applicable to a wider range motor and driver combinations,

the output power of the drive will dictate the available maximum motor power even if the

maximum output power of the motor is larger than that of the connected drive.

Specific speed/torque performance will vary depending on such power supply conditions as

voltage, number of available phases, etc.

5

Page 17

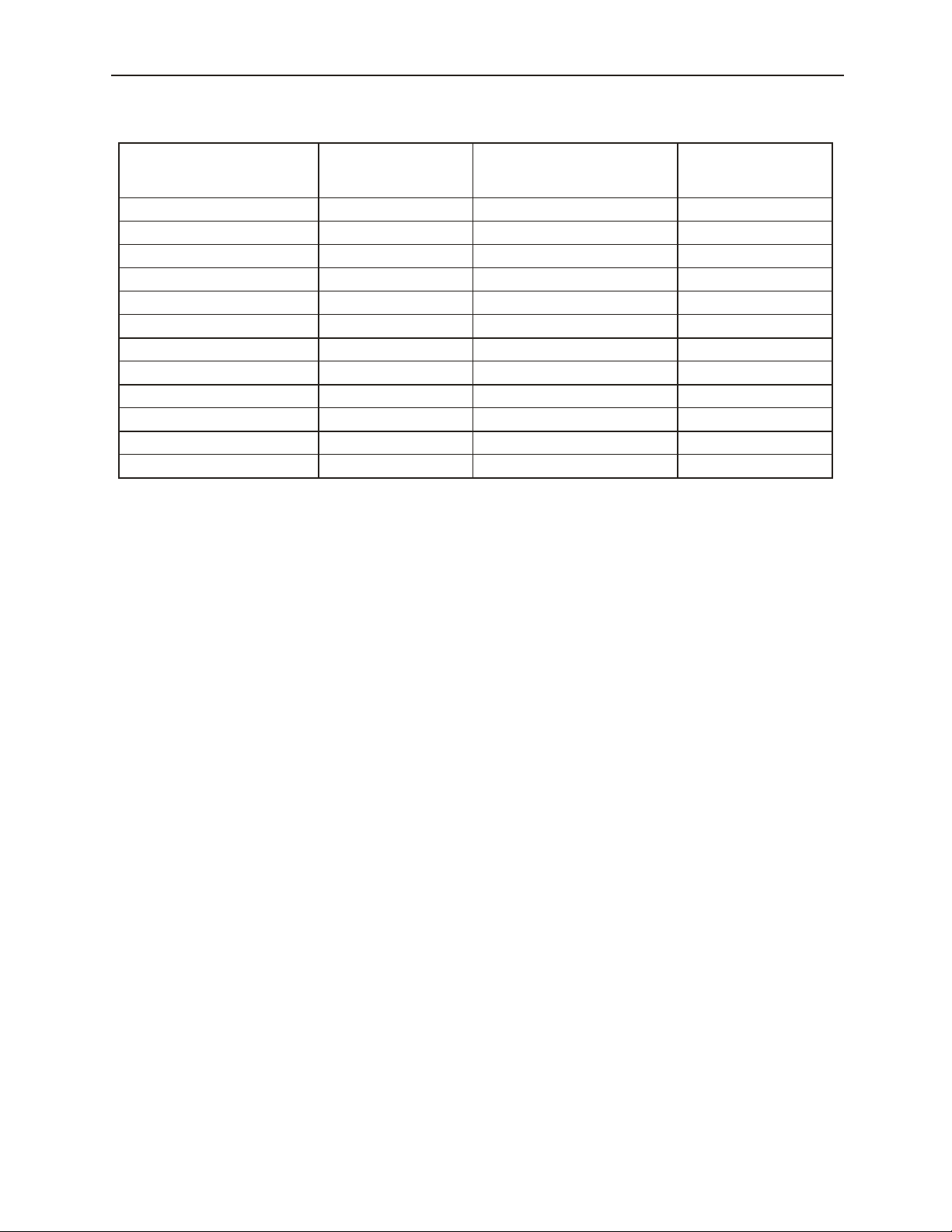

1.7 S erial Convert er Uni t

1.7 Serial Converter Unit

JZDP

Conversion unit type

(see ta bl e below)

Compatible Motor Numbers

Varies according to compatible motors

(see ta bl e below)

A○○○ △△△

-

-

Serial Converter Unit Type Model Classifications

Model Model Usage Scale Hall Sensor (Y/N?)

JZDPA003

JZDPA004

(Note)

US Marketdedicated

By Haidenhain

N

By Renishaw

Y

JZDPA005

JZDPA006

JZDPA008

By Renishaw

N

By Haidenhain

Y

By Renishaw

Y

6

Page 18

Serial Converter Units and Applied Motors

1.7 Serial Converter Unit

Serial Conver te r Unit Mode l

JZDP-A00 □ - □□□

001 SGLGW-40A140A(P) 013 SGLTW-20A460A(P)

002 SGLGW-40A253A(P) 014 SGLTW-35A170A(P)

003 SGLGW-40A365A(P) 015 SGLTW-35A320A(P)

004 SGLGW-60A140A(P) 016 SGLTW-35A460A(P)

005 SGLGW-60A253A(P) 017 SGLFW-20A090A(P)

006 SGLGW-60A365A(P) 018 SGLFW-20A120A(P)

007 SGLTW-40A400A(P) 019 SGLFW-35A120A(P)

008 SGLTW-40A600A(P) 020 SGLFW-35A230A(P)

009 SGLTW-80A400A(P) 021 SGLFW-50A200A(P)

010 SGLTW-80A600A(P) 022 SGLFW-50A380A(P)

011 SGLTW-20A170A(P) 023 SGLFW-1ZA200A(P)

012 SGLTW-20A320A(P) 024 SGLFW-1ZA380A(P)

Applied Motor

Serial Converter Unit Model

JZDP-A00 □ - □□□

Applied Motor

7

Page 19

Notes:

8

Page 20

2.1 Main Circuit Wiring

2. Wiring

2.1 Main Circuit Wiring

Here we will show representative examples of main circuit wiring, the functions of the main

circuit terminals, as well as the power input sequence, etc. Observe the following cautionary

items when wiring.

CAUTION

• Do not pass the power line and signal lines through the same duct or bundle them together. Keep the

power line and signal lines at least 30cm apart when wiring.

• Use a twist pair wire or multi-core twisted-pair bundled shield wire for the signal and encoder lines.

The maximum wiring length is 3m for the command input line, and 20m for the encoder feedback line.

• Do not touch the power terminal for 5 min. after power OFF as a high voltage may remain even after

power OFF.

Perform inspection work after checking that the CHARGE lamp has gone out.

• Do not turn the power ON/OFF frequently. Limit ON/OFF repetition to one time per minute.

Because the digital torque amplifier has a capacitor in its power unit, a large charging current (charging

time: 0.2sec.) will be fed at power ON. For this reason, frequent power ON/OFF switching degrades the

main circuit element within the digital torque amplifier.

• Suitable for use on a circuit capable of delivering not more than 5000 A

(symmetrical)

rms

■ Main Circuit Terminal Names and Functions

Table 2.1: Main Circuit Terminal Names and their Functions

Terminal

Code

L1, L2 or L1,

L2, L3

U, V, W

L1C, L2C

(2 places) Ground Terminal

Name Function

100W/400W

Main Circuit Power

Input Terminal

Motor Connection

Terminal

Control Power Input

Terminal

Single Phase 90~253 V

1.0kW~1.5kW

Three Phase 90~253 V

Connected to motor.

Single Phase 90~253 V

Perform “Ground Processing “ by connecting with the power

grounding terminal and the motor grounding terminal.

9

Page 21

2.1 Main Circuit Wiring

Table 2.1: Main Circuit Terminal Names and their Functions (Continued)

Terminal

Code

B1, B2 or

B1, B2, B3

⊕1,⊕2

Name Function

Connection not normally needed.

Connect an external regen resistor (provided by

External Rege n

Resistor Connection

Terminal

High-Frequency

Harmonic

Suppressing DC

100W/400W

1.0kW/1.5kW

This is normally sh orted between ⊕1-⊕2. If harmonic

frequency suppression is needed, connect a DC reactor

between ⊕1-⊕2.

customer) between B1-B2 if regen capability is

insufficient.

(Note)There is no B3 terminal.

B2-B3 is no rmally shorted (using the in te g rated

regen resistor)

If the capacity of the internal regen resistor is

insuf ficient, connect an external regen resistor

(provided by customer) between B1-B2 with B2B3 open (wiring removed).

Reactor Connection

Terminal

Main Circuit Load

Connection is normally not needed.

Terminal

10

Page 22

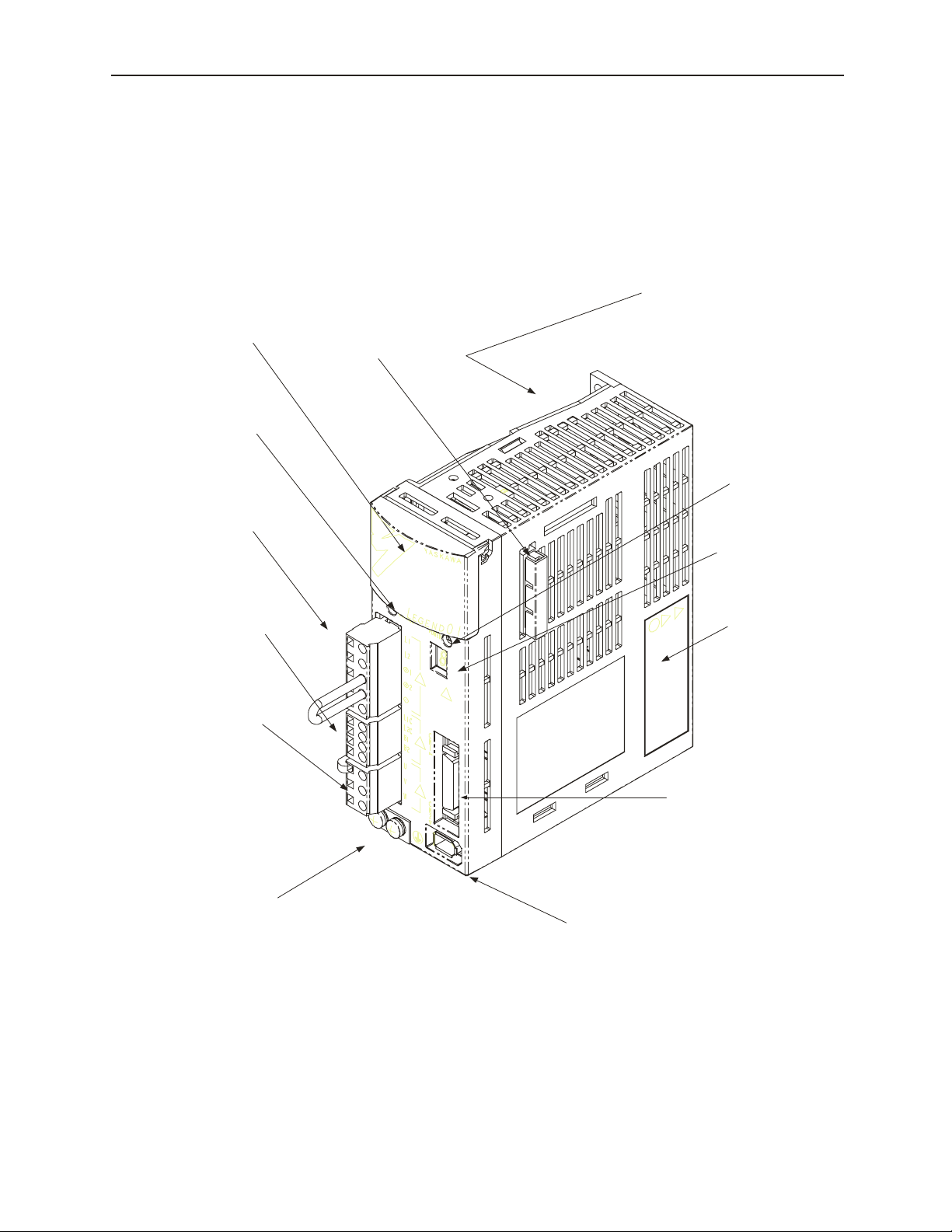

2.1 Main Circuit Wiring

SYSTEM

SWITCHES

(Under the cover)

MAIN

POWER

INDICATOR

MAIN

POWER

TERMINAL

CONTROL

POWER

TERMINAL

MOTOR

CONNECTION

TERMINAL

HEAT SINK

(Side)

OPTION BOARD

CONNECTOR

CONTROL

POWER

INDICATOR

STATUS

INDICATOR

WARNING

LABEL

GROUNDING

TERMINAL

I/O SIGNAL

CONNECTOR CN1

ENCODER CONNECTOR

CN2

11

Page 23

2.1 Main Circuit Wiring

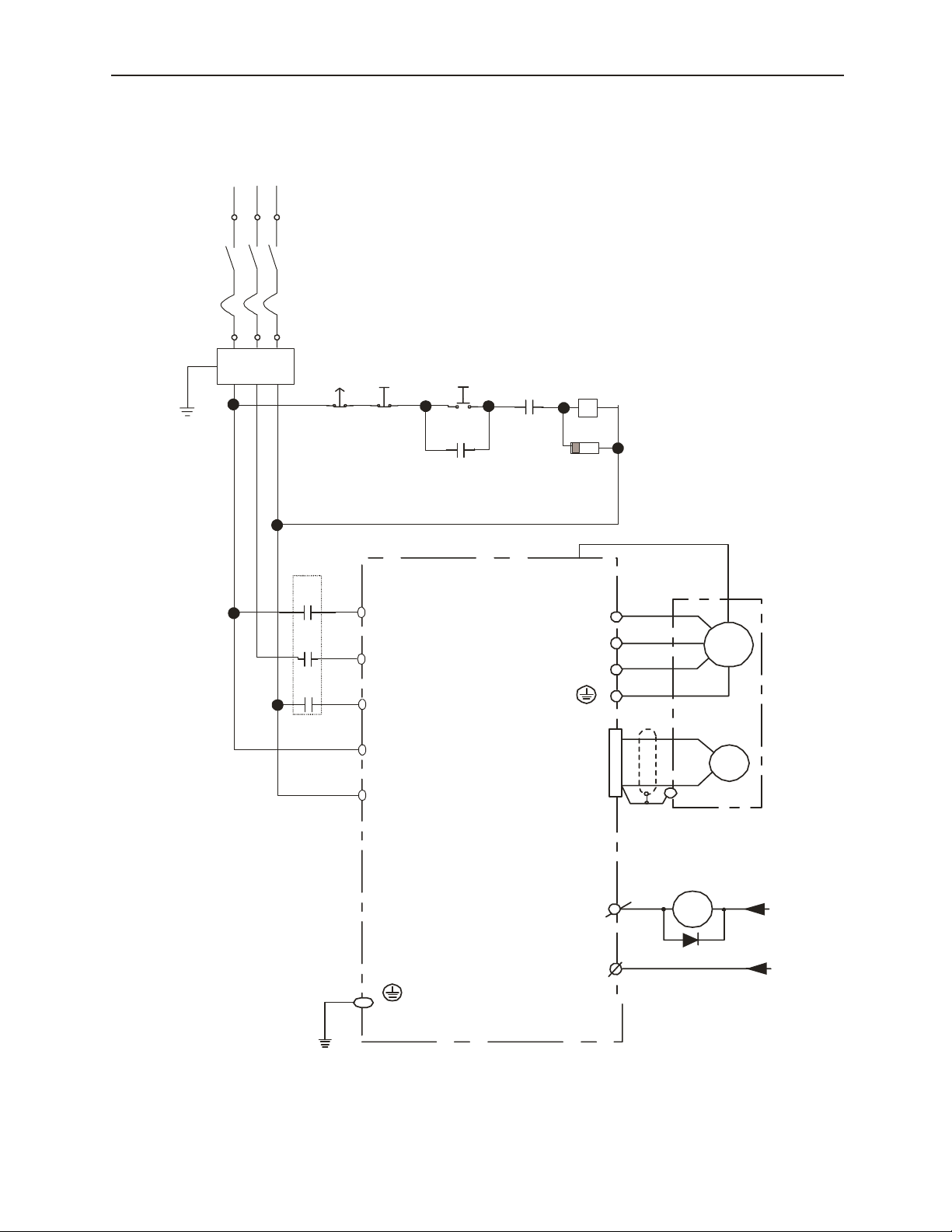

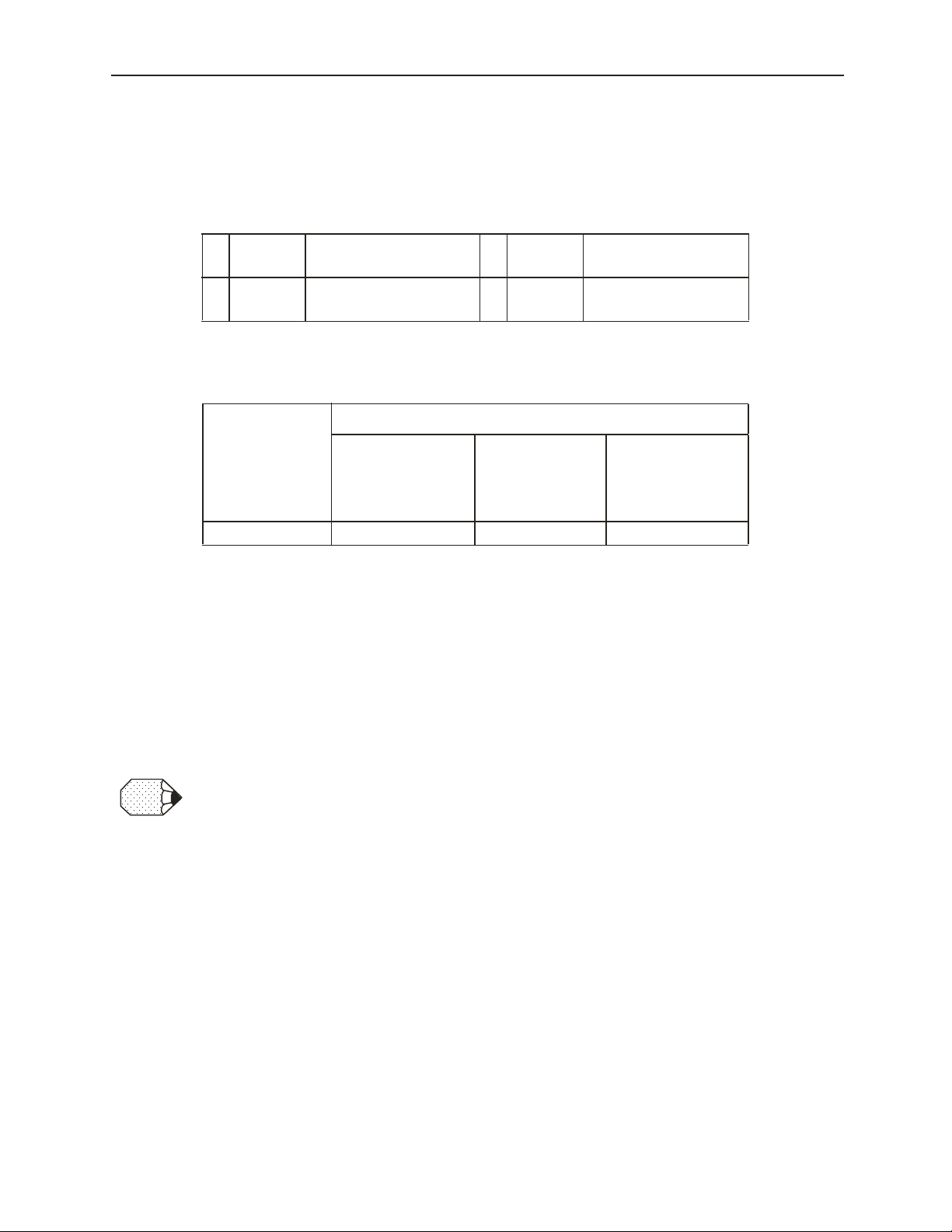

■ Example of Typical Main Circuit Wiring

A typical wiring example is shown in the figur e below.

Power 90V~253V

Noise Filter

Emergency

MC1

Stop

Power

L1

L2

L3

L1C

L2C

OFF

Power

ON

MC1

Digital Torque Amplifier

SGDG-□□GT

RY10

MC1

Surge

Supressor

FG

U

V

W

A

B

M

C

D

PG

12

ALM

ALM-SG

Figure A Main Circuit Wiring Example

CN1

31

32

Ry10

1D

0

+24V

24V

Page 24

■ Power ON Sequence Design

S

Keep the following in mind when designing a Power ON Sequence.

• Design the power feed sequence so that the power goes OFF if a “Servo Alarm” is

output. See “Figure A Main Circuit Wir ing Example” on page 12.

• Hold down the power ON button for at least two seconds. The digital tor que

amplifier will output a “Servo Alar m” signal for at most two seconds at power ON.

This is necessary for digital torqu e amplifier initial setting.

2.1 Main Circuit Wiring

Power

ervo Alarm (ALM) Output Signal

2.0s Max.

■ Power Line Size and Peripheral Devices

See the Sigma II Series Servo System User's Manual: Servo Selection and Data Sheet

edition. (Document Number: YEA-SIA-S800-32.2x)

■ Digital Torque Amplifier Power Loss

The digital torque amplifie r power loss at continuous output is shown in Table 2.2 below.

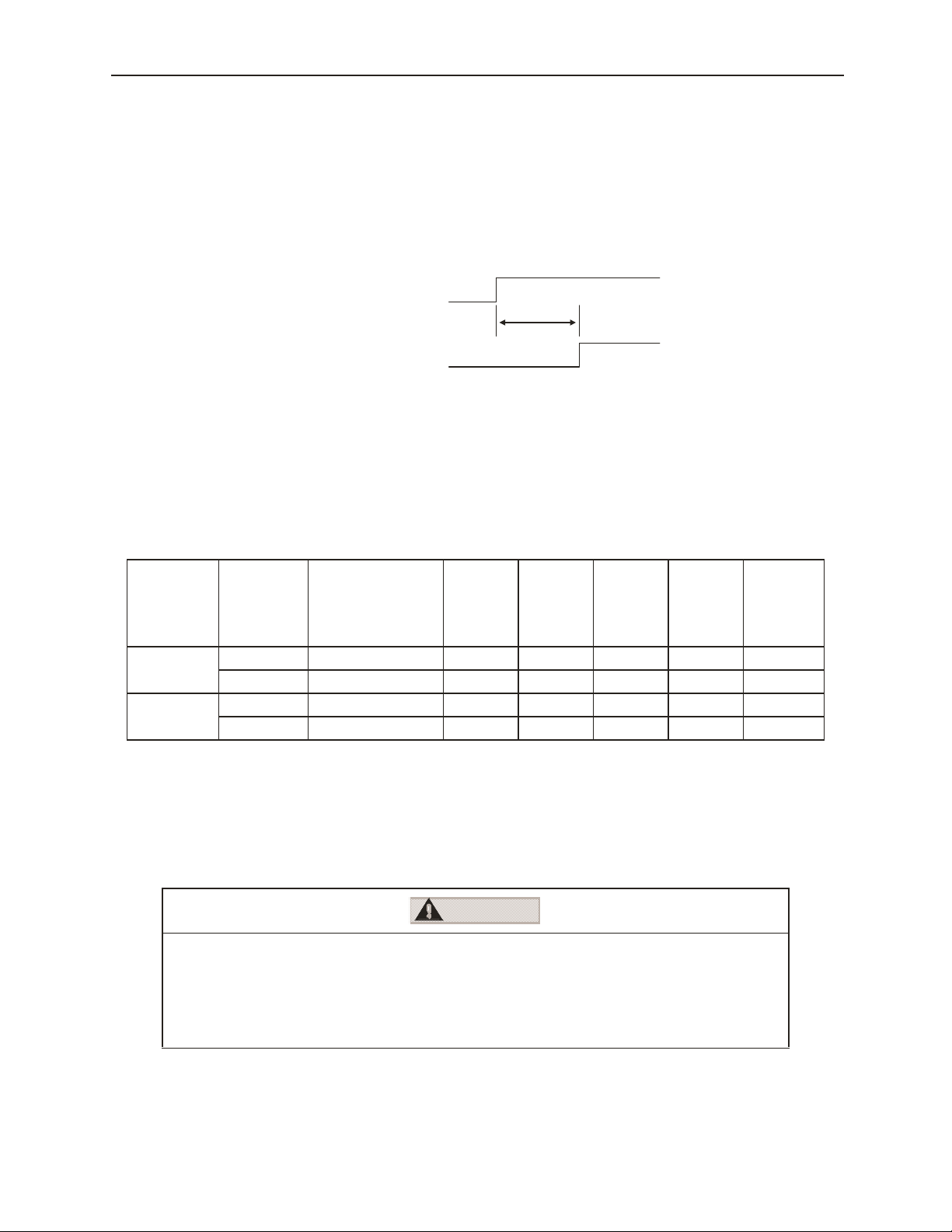

Table 2.2: Digital Torque Amplifier Power Loss at Continuous Output

Main

Circuit

Single-phase

200V

3-phase

200V

Max.

Applied

Motor

Capacity

0.10 SGDG–01GT 0.91 6.7 – 13 19.7

0.40 SGDG–04GT 2.8 20 – 13 33

1.0 SGDG–10GT 7.6 55 12 15 82

1.5 SGDG–15GT 11.6 123 14 15 152

Digital Torque

Amplifier Model

Output

Current

(actual)

A

Main

Circuit

Power

Loss W

Regen

Resistor

Power

Loss W

Control

Circuit

Power

Loss W

Total

Power

Loss W

Note: The regen res is tor power loss is the allowable power loss. Take the following measures if this

value is exceeded. Remove the lead wire of the digital torque amplifier' s integrated regen

resistor and install an external regen resistor. Furthermore, the external re gen re si stor is an

option. For details on regen resistors, see “

4.5 Regenerative Resistor Selection”.

■ Main Circuit Terminal Block Wiring Method

Observe the following cautionary items when wiring.

CAUTION

• Perform wiring after removing the terminal block from the digital tor que amplifier unit.

• Insert one wir e into each po wer line in sertion aperture in the termin al block.

• When inserting the pow er lines, be sure that they do not short against the surrounding material due to

exposed wir e cores.

• Power lines that have been mist akenly pulled out by excessive force should be re-stripped then connected .

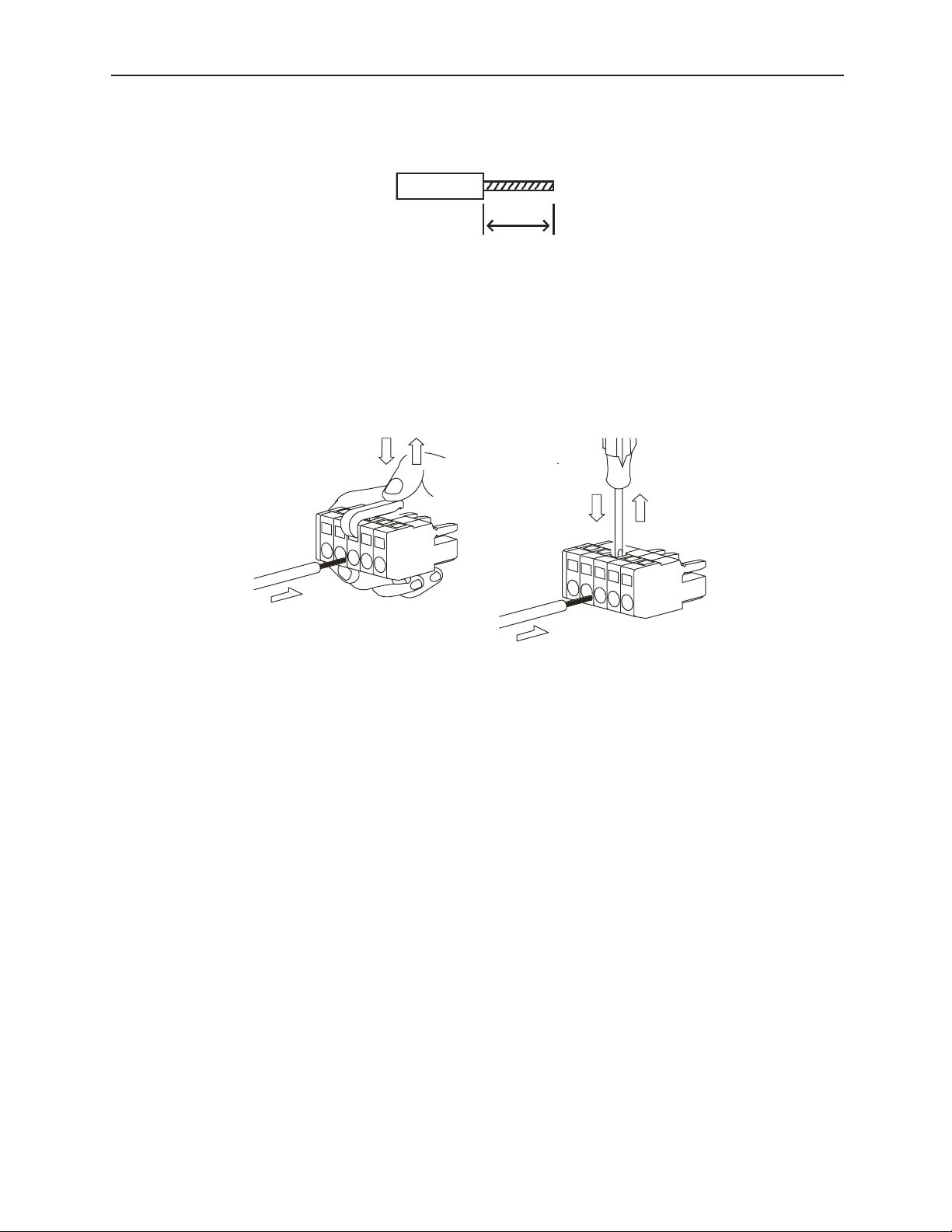

Servo amplifiers with capacities of 1.5kW or less consist of a connector-type terminal

block for the main circuit. Wire the terminal block by the following procedure.

13

Page 25

2.1 Main Circuit Wiring

.)

Connec tio n Me th od

1. Strip the insulation of the power lines used.

2. Open the terminal block wiring insertion area with a tool. There are two opening

methods as shown in figures A and B.

• Figure A shows opening by prying with an accessory lever.

• Figure B shows opening by forcibly pressi ng the driver insertion aperture with

8

9mm

~

(.315~.35 in

either a flathead screwdriver head width 3.0~3.5mm (.118~.138 in.) or a 210-120Jtype driver from Wago, Inc. The work can be done using either of the methods in

Figure A: or Figure B:.

Figure A :

Figure B:

3. Insert the core of the power line int o the opening. Release the lever or the pressure on

the driver after insertion.

■ Power Terminal Processing

Strip the insulation on the power line. The useable line sizes are as follows:

• Solid Conductor.. φ0.5~φ1.6mm

• Stranded Conductor ..AWG28~AWG12

14

Page 26

■ Peripheral Device Types and Capacities

Table 2.3 Shows Servopack device Types and capacities.

Table 2.3: Peripheral Device Types and Capacities

2.1 Main Circuit Wiring

Main

Circuit

Power

Supply

Single-Phase

200V

Three-Phase

200V

Model

Power Su ppl y

Capacity Per

Capacity

(kW)

0.1 01GT 0.40 4

0.4 04GT 1.2 8

1.0 10GT 2.3 7

1.5 15GT 3.2 10

* The FN □□□□ noise filter is manufactured by Schaffner Corp.

SGDG- Model

Amplifier

(KV A)

MCCB or

Fuse

Capacity

(Arms)

Recommended

Noise Filter*

Single-

FN2070-

6/07

Phase

250VAC

6A

Single-

FN2070-

10/07

Phase

250VAC

10A

Three-

FN258L-

16/07

Phase

480V

16A

Specifi-

cations

Magnetic

Contactor

10A or

Equivalent

20A or

Equivalent

20A or

Equivalent

15

Page 27

2.2 Input Signals

2.2 Input Signals

■ Example of I/O Signal Connection

• A typical example of I/O signal connecti on is shown below.

Power 90V~253V AC

24V~12V

Torque/

Force

Reference

Noise F ilter

Emergency

MC1

Stop

Power

OFF

L1

Power

ON

RY10

MC1

B2

B1

MC1

Surge

Supressor

FG

L2

L1C

L2C

CN1-26

CN1-27

3.3KΩ

CN1-13 CN1-34

RY1

/S-ON CN1-14 CN1-35

RY2

/DBOFF CN1-15

CMD-IN CN1-3

GND CN1-4 CN1-21

3.3KΩ

A/D

SGDG-□□GT

Digital Torque Am pl ifier

SV ON 5

DB_OFF

SV ON

ALM

DB OFF

RUN

PA

PB

PA

PC

PA

SN75ALS174 or similar product

CN1-7

CN1-10

CN1-20

CN1-22

CN1-23

CN1-24

CN1-25

W

CN

U

V

2

24V~12V

RY10

Motor

PG

ALM+

ALMRUN+

RUN-

PAO

/PAO

Encoder

PBO

Divided

/PBO

PCO

/PCO

Output

16

FG

Page 28

■ Connector (CN1) Terminal Array List

The CN1 terminal array and its specif ications are shown below.

CN1 Terminal Layout

2.2 Input Signals

1--- --- 19GND GND

Torque/

CMD

3

-IN

5 --- --- 23 *PB0

RUN+RUN Signal

7

9 --- --- 27

11 --- ---

13 +24V

DB

15

OFF

17 --- --- 35 ALM -

Force

Reference

Input

Output

External

Power Input

DB OFF

Signal Input

2 GND GND

4 GND GND 22 PBO

6 GND GND 24 PCO

8 --- --- 26 /S-ON5

10 RUN -

12 --- --- 30 --- ---

14 /S-ON

16 --- --- 34

18 --- --- 36 --- ---

RUN Signal

Output

Servo ON

Signal Input

21 *PAO

25 *PCO

DB

OFF5

Torque

29

Mon

31 --- ---

33 GND GND

Encoder

Divided

Output A

phaseEncoder

Divided

Output B

phase-

Encoder

Divided

Output C

phase-

DB OFF

Sign a l Input

Torque

Monitor

5V/Max.

Torque

Servo

Alarm

Output

Encoder

20 PAO

SPD-

28

MON

32 --- ---

ALM +Servo Alarm

Divided

Output A

phase+

Encoder

Divided

Output B

phase+

Encoder

Divided

Output C

phase+

Servo ON

Input

Speed

Monitor

1V/1000

RPM

Output

Note 1 Do not use empty terminals for relays.

Note 2 Connect the I/O signal cable shield wire to the connector shell. This is connected to the

frame ground on the digital torque amplifier side connector.

■ CN1 Specifications

Specification for

Connector Used in

Digital Torque

Amplifier

10236-52A2JL-type

Right Angle 36P

Soldering

Type

10136-3000VE 10336-52A0-008 Sumitomo 3M, Inc.

Applied Receptacle Model

Case Manufacturer Name

17

Page 29

2.2 Input Signals

■ I/O Signal Names and Their Functions

The names and functions of the digita l torque amplifier I/O signals are shown below.

Input Signals

Common

Torque

Common

Signal Name

/S-ON

DB - OFF

+24VIN

CMD-IN

Pin

No.

14

26

15

13

3

Function

Servo ON

• The inverter out put is enabled to provide power to the motor.

DB Release

• A free run st ate has resul ted by releasing the DB.

Sequence si gnal control pow er input

• +24V power supply provided by customer.

Torque/Force Reference Input

• -10~+10VDC 10V= Peak Motor Torque

Output Signals

Signal Name Pin No. Function

ALM+

ALM -

PAO 20

*PAO

PBO

*PBO 23

PCO

*PCO

RUN+

RUN - 10

SPD-MON 28 Speed Monitor (1V/1000rpm) , Linear Scale 1V/1000mm/sec

TORQUE-MON 29 5V/Max Torque

FG Shell

34

35

21

22

24

25

7

Servo Alarm

: Turns OFF due to error detection.

A-phase Signal

2-phase pu lse (A-phase, B-phase)

B-phase Signal

C-phase Signal

Base Block Release Signal

: Output du ring base block release

The frame ground in connected upon connection of the I/O signal cable

shield wire to the connector shell.

Conversion Encoder Output S ignal

and origin pulse (C-phase) signal

18

Page 30

Reserved

Output Signals (Continued)

Signal Name Pin No. Function

1

5

8

9

11

12

16

17

18

30

31

32

36

Open Te rmi nal

(Note) Do not use empty ter m inals for relays, etc.

2.2 Input Signals

19

Page 31

2.2 Input Signals

■ Interface Circuit

An example is given below of connection of the digi tal torque amplifier I/O signals to an

upper level device.

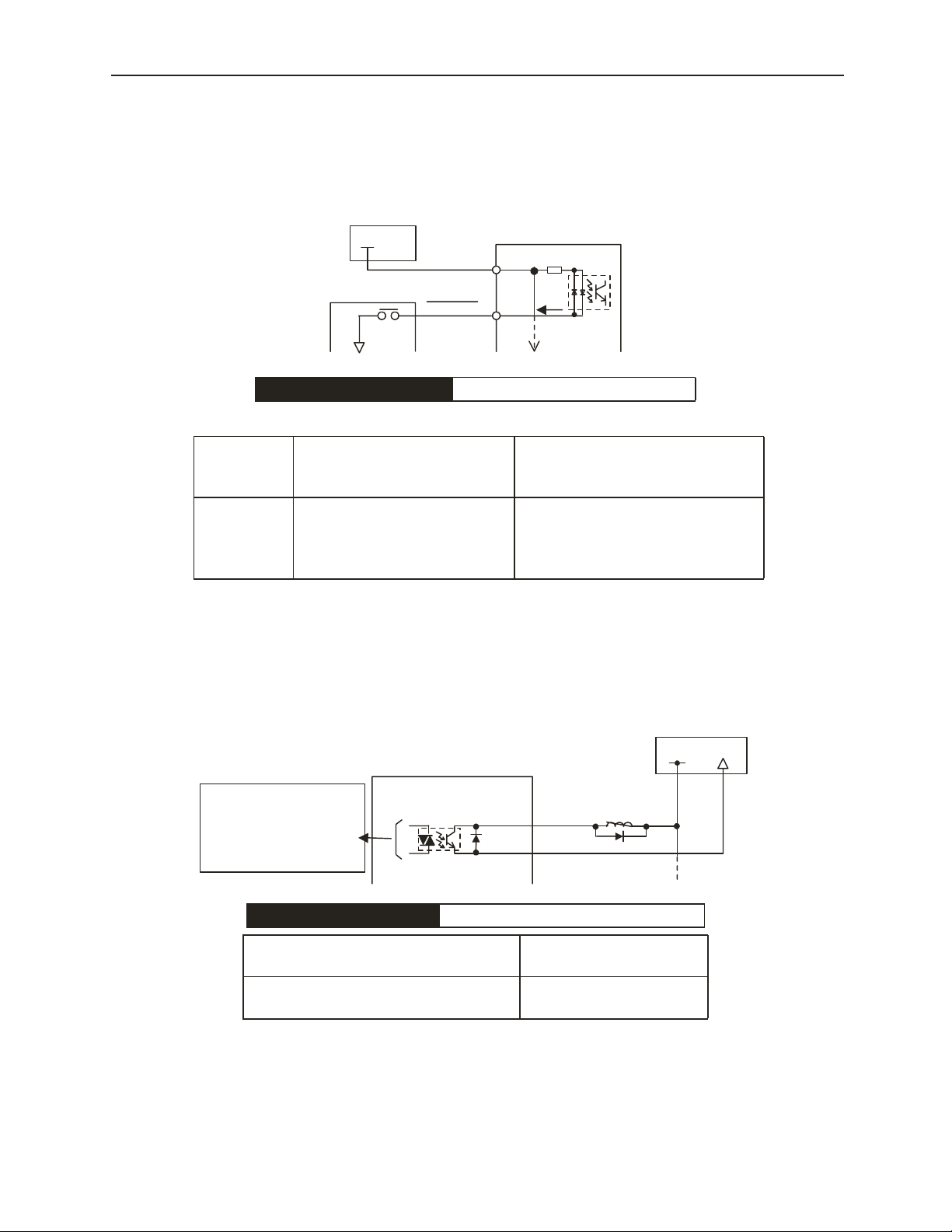

■ Command Input Circuit and Interface

Analog Input Circuit

The analog signal is the torque ref erence signal. The input impedance is as follows.

• Command Input (CMD-IN): Approx. 14kΩ

The maximum allowable voltage for the input signal is

• 10V= Peak Motor Torque

Amplifier

(1/2W)

1.8kΩ

12V

25HP-10B

2kΩ

or more

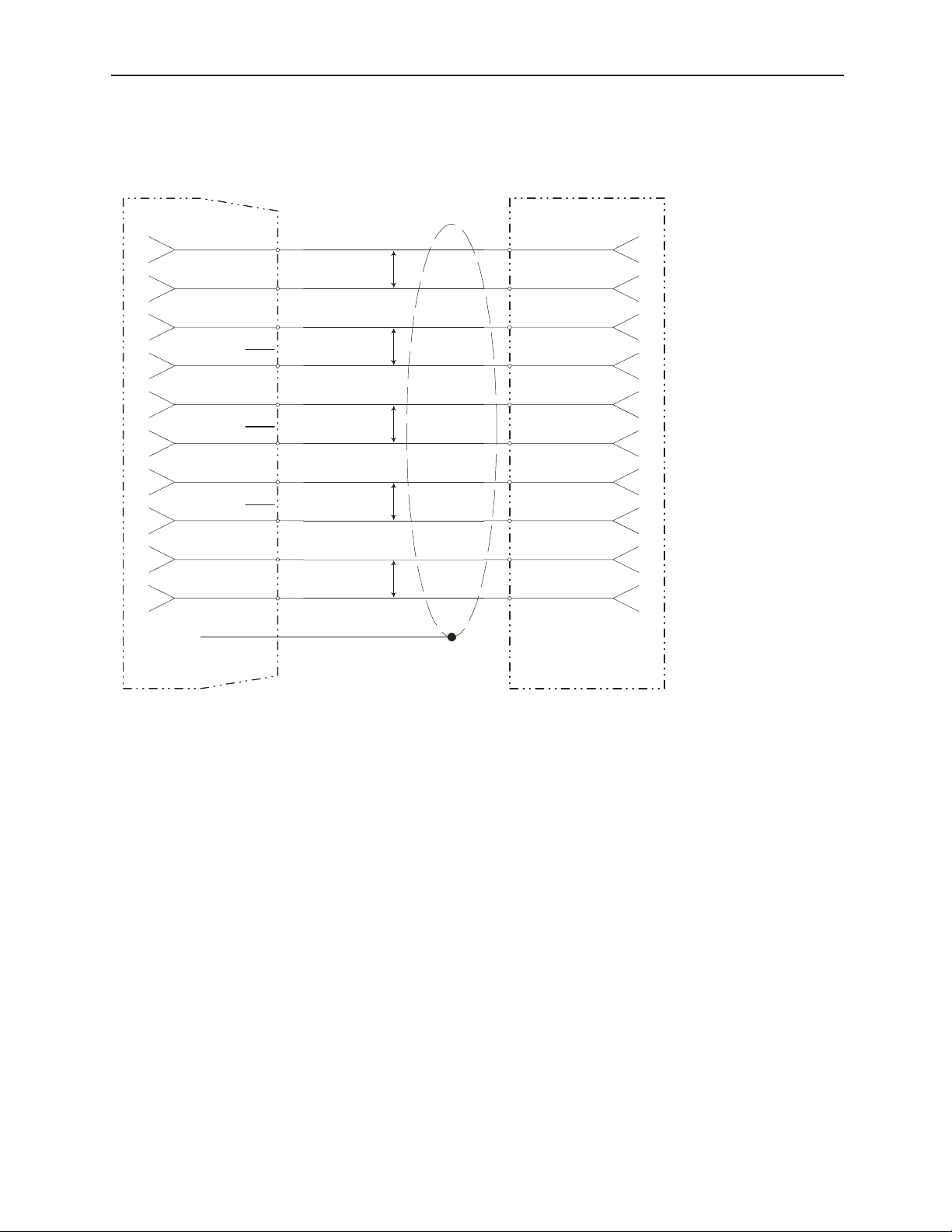

3

1

2

1000:1

CMD-IN

SG

Approx.14kΩ

0V

±12V

■ Sequence Input Circuit and Interface

+24VIN

/S-ON etc.

Amplifier

3.3k Ω

Amplifier

DC

DC24V

50mA or more

+24VIN

/S-ON etc.

3.3kΩ

24V

50mAor more

Amplifier

DC24V

50mA or more

+24VIN

/S-ONetc.

3.3kΩ

This is connected by a relay or open collector transistor circuit. Select a low current type

when connecting by relay. If low curre nt relay is not used, this may cause a connection

fault.

20

Page 32

2.2 Input Signals

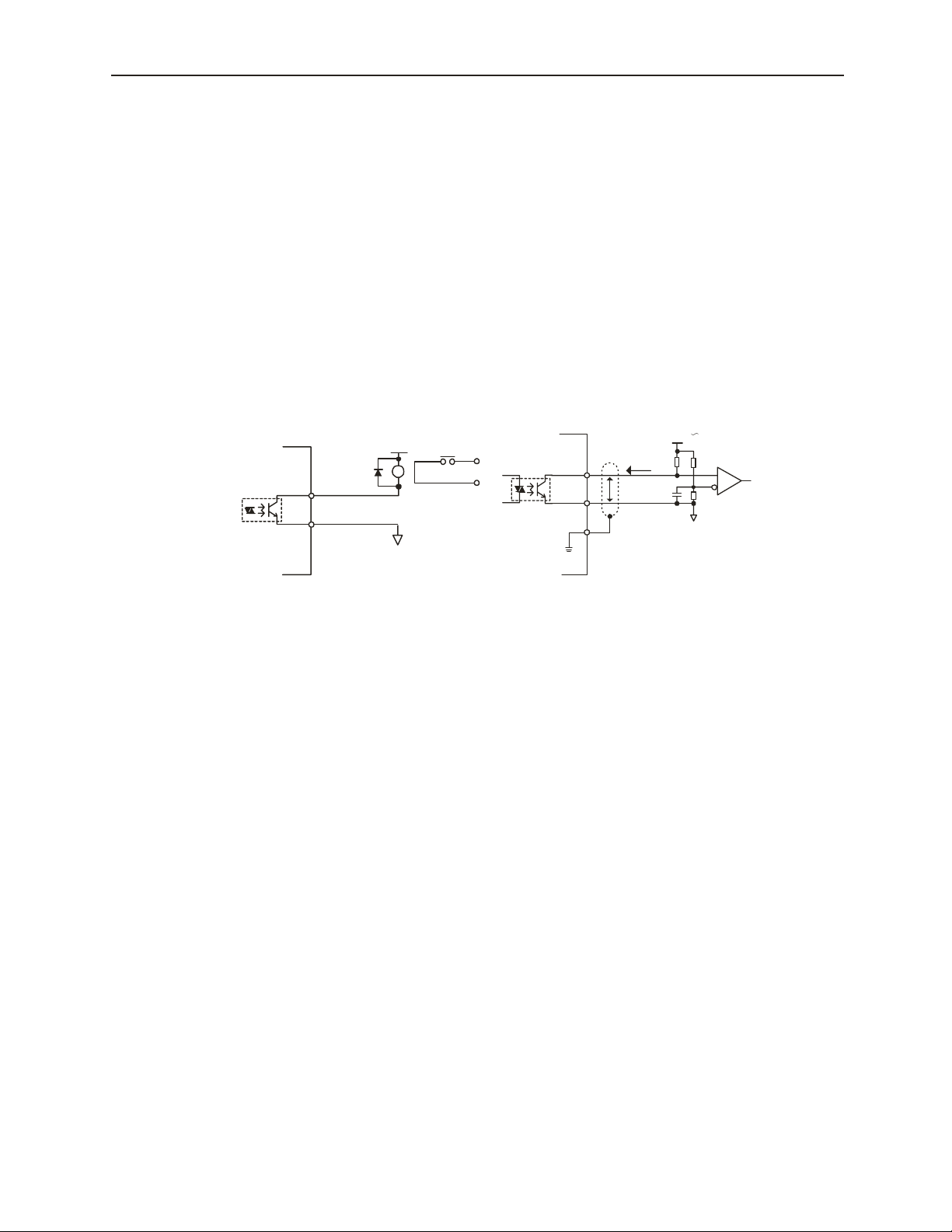

■ Output Circuits and Interfaces

The output signal circuits of the digital torque amplifier are of the three types shown

below. Configure the input circuit on the upper-level device to match each of these output

circuits.

• Connection with Line Driver Output Circuits

The output signals (PAO, *PAO, PBO, *PBO) where the encoder serial data was

converter to a 2-phase (A-phase, B-phase) pulse, and the origin pulse signal (PCO,

*PCO) are output by the line driver circui t. The upper- level device receives these

through the line receiver circuit. See “2.3 Wiring to the Encoder” for an example of

the connect io n circuit .

• Connection with Photocoupler Output Circuit

Servo alarms and other output signals f or sequence use are configured in the

photocoupler output circ uit. They are connected through the relay and line driver

circuits.

Digital Torque

Amplifier Side

DC5V~24V

0V

Relay

Digital Torque

Amplifier Side

P

DC5V~12V

0V

Note: The maximum allowable voltage and current capacity of the photocoupler output circuit are as

follows:

• Voltage: DC30V(Max.)

• Current: DC50mA(Max.)

21

Page 33

2.3 Wiring to the Encoder

2.3 Wiring to the Encoder

The wiring of the digital torqu e amplifier to the encoder is described here.

■ Connection to Encoder (CN2) and Output Signal Processing from Digital Torque

Amplifier (CN1)

Incremental *

Encoder

D(6)

PG

H(1)

G(2)

0.33mm

(Shell)

* S G M AH , SGMGH, S G M S H O n ly.

J

2

*

P

Shield

Wire

Digital Torque Amplifier

CN1

PG5V

PG0V

ov

Connector

Shell

1- 33

1-34

1-35

1-36

1-19

1-20

1-1

CN2

2-5

2-6

Output Line Driver

TI SN75ALS194

2-1

2-2

Connector

Shell

A-phase

B-phase

C-phaseC(5)

or equivalent

SG

PAO

*PAO

PBO

*PBO

PCO

*PCO

*

P

P

P

Applied Line

Receiver

TI SN75175

or equivalent

ov

(provided by customer)

22

Page 34

■ Encoder Connector (CN2) Terminal Array and Models

The CN2 terminal arrays and models are shown below.

CN2 Terminal Array

2.3 Wiring to the Encoder

1 PG5V

5 PS

Encoder Power

+5V

Encoder Serial Signa l

Input

2

PG0V

6

*PS

Encoder Power

0V

Encoder Serial Signal

Input

CN2 Connectors

CN2 Connectors

Model of

Connector Us ed

in Digital

Torque

Amplifier

53460-0611 55100-0600 54280-0600 Japan Molex, Inc.

Note: The plug and socket on the digital torque amplifier side are a set product FA1394 from Japan

Molex, Inc.

Note: The motor-side socket is connected to the connector for the SGMAH, SGMPH servomotor

encoder.

Note: The SGMGH and SGMSH servomotor enc oder connectors are shown belo w.

• Plug L-type: MS3108B20-29S or

• Straight: MS3106B20-29S

• Cable Clamp: MS3057-12A

Plug, soldered

type (digital

torque amplifier-

side connector)

Applied Plug (or socket) Model

Socket, soldered

type, (motor-side

connector)

Manufacturer

Name

Supp.

Yaskawa pro vi de s a dedi cat ed cab le fo r the en cod e r. Fo r det ai ls, see the fo llow i ng do cu me nt.

• Sigma II Servo System Product Catalog Supplement

(Doc.# G-MI#99001x-Sigma II)

23

Page 35

2.4 Cable Specifications and Peripheral Devices

2.4 Cable Specifications and Peripheral Devices

Ratings and specifications for peripheral devices, as well as cable specifications for digital

torque amplifiers are summarized in the tables below.

CAUTION

Wiring Precautions

• Do not bundle or run power and signal l ines together in the same duct.

Keep power and signal line s at le ast 11.81” (30cm) apart.

• Use twisted pa ir or shielded multi-core t wi s t e d pa ir wires for signal and

encoder (PG) feedback lines.

• The maximum length s for signal lines are as follows:

• Maximum of 9.84ft (300cm) for reference input lines.

• Maximum of 65.6ft (20m) for PG feedback lines.

• Use a cable with 164 ft (50m) specifications for distances over 65.6ft (20m).

■ Cable Specifications

SGDG

External Terminal Name

Terminal

Symbol

Main circuit power input terminals

Servomotor connection terminals U, V, W

Control power supply term inals L1C, L2C

Control I\O signal connector CN1 Twisted pair or shielded twisted pair wires

PG signal connector CN2

Ground terminal 14 AWG [HIV 0.003 (2.0)]

L1, L2

(Single Phase)

16 AWG [HIV 0.002

Core wire at least 28 AWG [0.0002

annealed copper t wis ted wires

Finished cable dimensions:

maximum

(6.8mm) for CN2.

Wire Size AWG [in

01GT 04GT

(1.25)]

16 AWG [HIV 0.002 (1.25)]

Φ0.63in (16mm) for CN1 and Φ0.27in

2

(mm2)]

14 AWG [0.003 (2.0)]

(0.12)], tinned,

Main circuit power input terminals L1, L2, L3

(Three-phase)

14 AWG [HI V 0 .003 (2.0)]

Servomotor connection terminals U, V, W

Control power supply terminals L1C, L2C

16 AWG [HIV 0.002 (1.25)]

Control I\O signal connector CN1 Twisted pair or shielded twisted pair wires

PG signal connector CN2

Core wire at least 28 AWG [0.0002

(0.12)], tinned,

annealed copper twisted wires

Finished cable dimensions: maximum Φ0.63in

(16mm) for CN1 and Φ0.27in (6.8mm) for CN2.

Ground terminal 14 AWG [HIV 0.003 (2.0)]

Notes: 1. Wire sizes were selected for three cables per bundle at 40°C ambient temperature with the rated current.

2. Use cables with a minim um withstand vol tage of 600V for main circuits.

3. If cables are bundled in PVC or metal ducts, consider the reduction ratio of the allowa ble current.

4. Use hea t-resistant cable under high ambient or panel temperat ures where normal vinyl cable will rapidly

deteriorate.

24

Page 36

2.4 Cable Specifications and Peripheral Devices

The following table shows types of cables. It is used in conjunction with the preceding

tables.

Cable Type

Temperature Rating of Conductor

Name Composition

PVC

IV

HIV

Standard polyvinyl chloride cable

600V PVC cable

Temperature-resistant vinyl cable

The following table specifies the appropriate cables for CN1 and CN2 digital torque amplif ier

connectors . Wire siz es we re s elect ed with the exp ec ta tio n of th ree ca bles per b und le, at an

ambient temperature of 40°C, at the rated current level.

Connector Name Signal Description Specification

Cable Use twisted pair or shielded twist e d pair wire.

Control I/O Signal

Connector

PG Signal

Connector

CN1

CN2

Applicable wire (AWG): 24, 26, 28, 30

Finished cable

Dimension

Cable Use Yaskawa cable, or shielded twisted pair wire.

Applicable wire

Finished cable

Dimension

Φ 0.63 (Φ16.0) maximum

(AWG): 24, 26, 28, 30

Use 22 AWG [0.000 5in

AWG [0.0002 in

wiring di stances up to 65.6ft (20m).

Φ 0.27 (Φ6.8) maximum

2

(0.34mm2)] for the encoder power supply and 26

2

(0.14mm2)] for other signals. These conditio ns permit

°C

—

60

75

25

Page 37

2.5 Standard Connection Examples

2.5 Standard Connection Examples

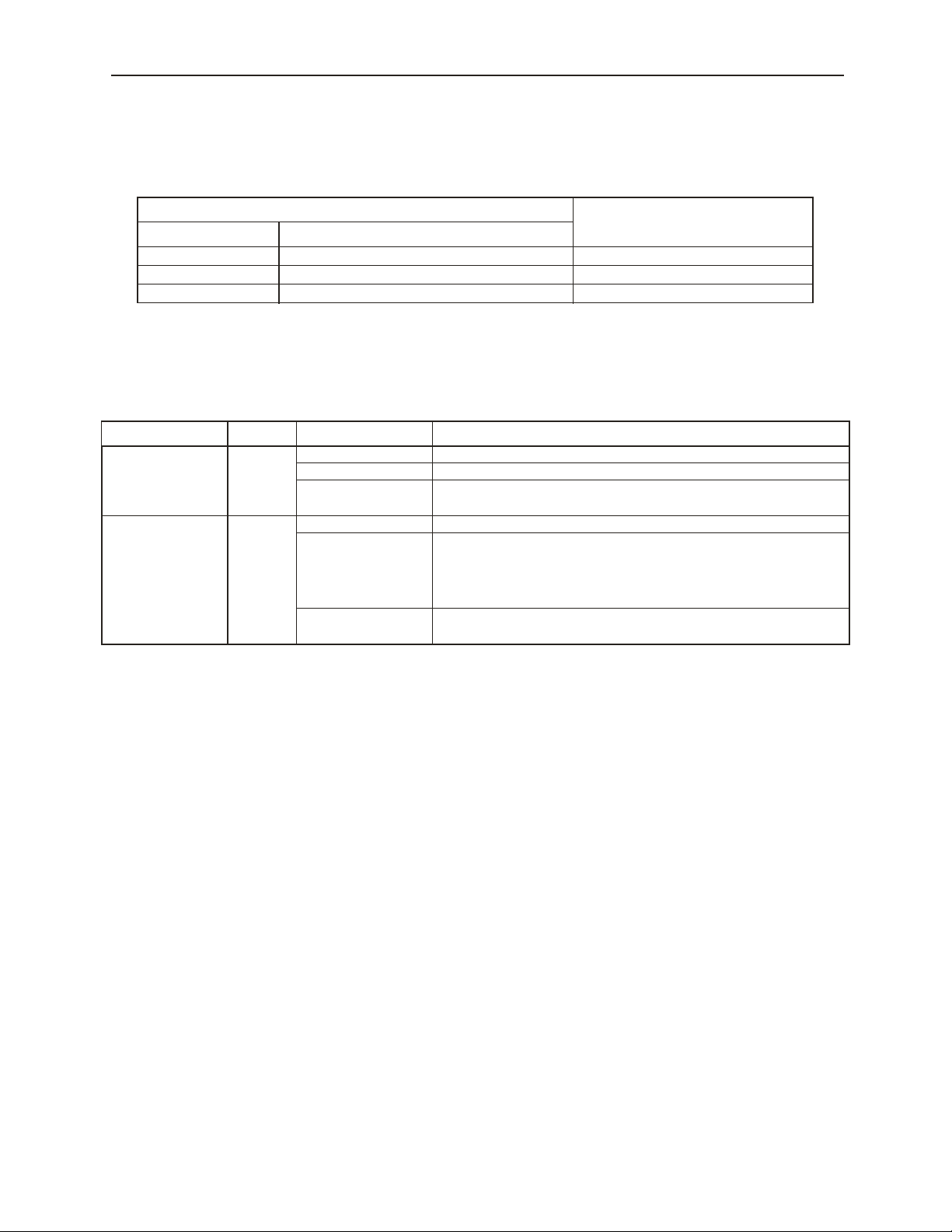

■ Single-phase Power Specification (SGDG-01GT, SGDG-04GT)

Power 90V~253V AC

24V~12V

Torque/

Force

Reference

Noise Filter

Emergency

Stop

MC1

Power

OFF

L1

Power

ON

RY10

MC1

B2

B1

MC1

Surge

Supressor

FG

L2

L1C

L2C

CN1-26

CN1-27

3.3KΩ

CN1-13 CN1-34

RY1

/S-ON CN1-14 CN1-35 ALM-

RY2

/DBOFF

CMD-IN CN1-3

GND CN1-4 CN1-21

3.3KΩ

CN1-15

A/D

SGDG-□□GT

Servo amplifier

SV ON 5

DB_OFF

SV ON

DB OFF

PA

PB

PC

ALM

RUN

SN75ALS174 or similar product

CN1-24

CN1-25

CN1-7

CN1-10

CN1-20

CN1-22

CN1-23

U

V

W

CN2

RY10

ALM+

RUN+

RUN-

PAO

/PAO

PBO

/PBO

PCO

/PCO

Motor

PG

24V~12V

Encoder

Divided

Output

26

FG

Page 38

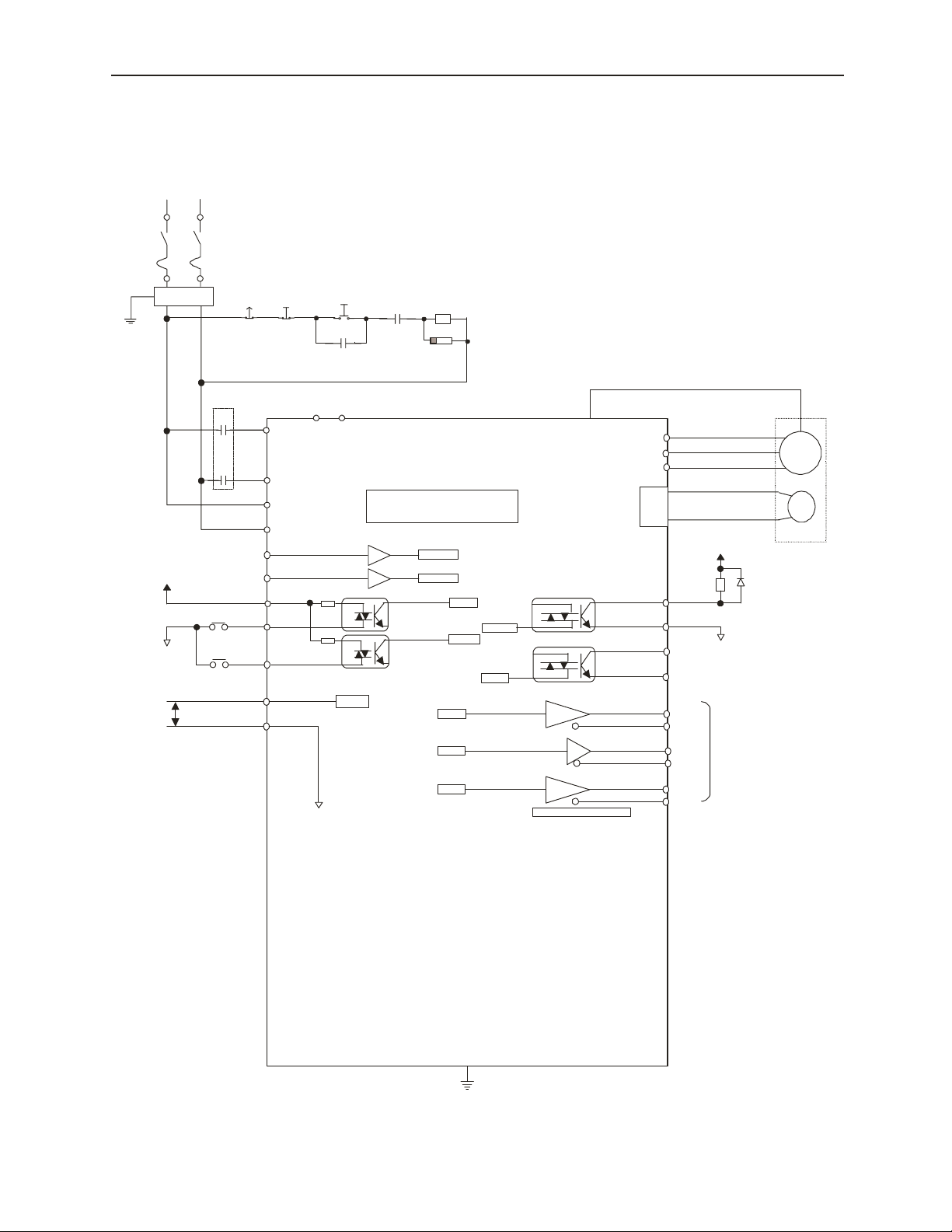

■ 3-Phase Power Specification (SGDG-10GT, SGDG-15GT)

Power 90V~253V Ac

Emergency

Noise Filter

Stop

Power

OFF

Power

ON

RY10

2.5 Standard Connection Examples

MC1

Torque/

Force

Reference

24V~12V

Surge

Supressor

FG

MC1

MC1

L1

B1

B3

B2

L2

L3

*

L1C

L2C

CN1-26

CN1-27

3.3KΩ

CN1-13

RY1

RY2

CN1-14

/S-ON

/DBOFF

CN1-3

CMD-IN

GND CN1-4 CN1-21

3.3KΩ

CN1-15

SGDG-□□GT Digital

Torque Amplifier

DB_OFF

A/D

SV ON 3

PA

PB

PC

SV ON

DB OFF

ALM

run

SN75ALS174 or similar product

CN1-34

CN1-35

CN1-7

CN1-10

CN1-20

CN1-22

CN1-23

CN1-24

CN1-25

U

W

CN2

V

RY10

ALM+

ALM-

RUN+

RUN-

PAO

/PAO

PBO

/PBO

PCO

/PCO

Motor

PG

24V~12V

Encoder

Divided

Output

* For single-phase

applications, use terminals

L1 + L3 for the main

power connection.

FG

27

Page 39

Notes:

28

Page 40

3. Setup

3.1 Linear Motor Mounting

CAUTION

• In the case of linear motors, various changes c an occur according to the direct ion of the motor mounting

and the dir ection of the en coder mounti ng. Therefor e, perform set up carefull y.

Careless setup may result in injury.

■ Motor Mounting and Encoder Mounting

Mount so that the motor forward direction matches the encoder forward direction.

■ Setting the Linear Encoder Scale Pitch

Upon completing mounting and wiring, feed control power only, input (SW2) the correct

linear scale pitch use d by each applic ation. Alarm 0 (SW setting error) is output at the initial

power ON because the initial value is assumed to be “0”. This ceases occurring if the correct

value is set in SW2 and the power cycled.

3.1 Linear Motor Mounting

3.2 Rotar y Moto r Mounting

The SGM□H servomotor can be mounted in both the horizontal or vertical direction.

However, mistaking the mounting direction or mounting in an inappropriate location may

shorten motor life or lead to unexpected accidents. Correctly mount the motor according to

the following caution ary items.

CAUTION

• Do not connect the servomotor directly to a

commercial power source. This will damage the

motor.

The servo mo tor will not run without a dedicated

digital to rq u e am pl if ie r.

29

Page 41

3.2 Rotary Motor Mounting

Before Mounting

Important

The shaft end is treated with a rust-preventative agent. Before mounting the motor, wipe

off this rust-preventative agent with a cloth soaked in thinner.

When removing the rust-preventative agent, be sure that the thinner does not contact any

other parts of the servomotor .

■ Storage Temperature

Store the servomotor withi n the temper ature range below when storing without electric al

feed.

-20 ~ +60°C Temperature Range

Rustpreventative

A gent

■ Mounting Location

The SGM□H servomotor is intended fo r use indoors. Use in an environment meeting the

following conditi ons.

• Indoors, in a location free from corro sive or explosive gas.

• A location with good ventilation, with little dust, grime, or steam

• A location with an ambient temperature between 0~40°C

• A location with a relative humidity of 20%~80%, no condensation

• A location easy to inspect and clean

30

Page 42

Important

3.2 Rotary Motor Mounting

■ Alignment

Upon mating to the machi n e, make sure the motor shaft core and the machine shaft cor e

are coupled in a straight line. Mount the servomotor so that it falls within the alignment

accuracy in th e figure below.

The maximum deviation at all four sides cannot

exceed 0.03mm (rotated with the coupling)

The maxi mum deviation at all four sides cann ot

exceed 0.03mm (rotated with the coupling)

(1) Improper alignment can lead to vibration, which risks damaging the shaft coupling.

(2) When mo unting the coupling, do not apply shock directly to the shaft. This may damage th e encoder mounted

on the shaft end opposite t h e load.

■ Mounting Direction

The SGM□H servomotor can be mounted in either the horizontal or vertical direc tions.

■ Shaft Tolerance Ranges

Design machine systems so that the thrust loads and radial loads1 applied to the

servomotor shaft during ope ration fall within the tolerances in Table 3.1.

The allowable radial loa ds shown in the table are the maximum loads that can be applied

to the end of the output shaft.

1. Thrust Load, Radial Load:

Thrust Load (Fs): The shaft load applied parrallel to the shaft core.

Radial Load (Fr): Shaft load ap p l ied at a right angle to th e shaft core.

Motor

Fr

Fs

Shaft

31

Page 43

3.2 Rotary Motor Mounting

Table 3.1: Allowable Radial Load/Allowable Thrust Load for Servomotors

Motor Model

SGMAH-

SGMPH-

SGMGH-

SGMSH-

Allowable

Radial Load Fr

[N(kgf)]

A3 68(7) 54(5.5)

01 78(8) 54(5.5)

02 245(25) 74(7.5)

04 245(25) 74(7.5)

08 392(40) 147(7.5) 35

01 78(8) 49(5) 20

02 245(25) 68(7)

04 245(25) 68(7)

08 392(40) 147(15)

15 490(50) 147(15)

05A □ A 490(50) 98(10)

13A □ A 686 (70) 343(35)

10A 686(70) 196(20)

15A 686(70) 196(20)

Allowable

Thrust Load Fs

[N(kgf)]

LR

[mm]

20A5 68(7) 54(5.5)

25

25

35

5809A □ A 490(50) 98(10)

45

Reference Diagram

LR

Fr

Fs

■ Oil and Water Countermeasures

It is possible to take protective measures for motor operation in areas where water or oil

may drip. However, use a motor with an oil seal atta ched when needed to set through to

1

the shaft section

. In addition, mount the motor with the connector s facing downward.

Through

Shaft Section

■ Cable Stress

Do not bend or stretch the power line.

In particula r, be care fu l to wire the signal cable so that they are n ot subj ec t to str ess

because its core is very thin (0.2, 0.3mm).

1. Through Shaft Section

This refers to the gap where the shaft protrudes from the end of the motor.

32

Page 44

3.2 Rotary Motor Mounting

■ Vibration Resistance

Mount the servomotor with the shaft positioned horizontally. The servomotor will

withstand the following le vels of vibration on all three axes: front-to- back (X),

vertical (Y), and side-to-side (Z).

2

• SGMAH, SGMPH: 49m/s

• SGMSH, SGMGH, SGMDH, and SGMUH: 24.5m/s

(5G)

2

(2.5G)

Side-to-side

3.2.1 Vibration Clas s

The vibration class for SGMH servomotors operating at rated speed is 15µm

(maximum).

Position for measuring vibration

Vertical

Front-to-back

Hor izontal shaft

Impact applied to the servomotor

33

Page 45

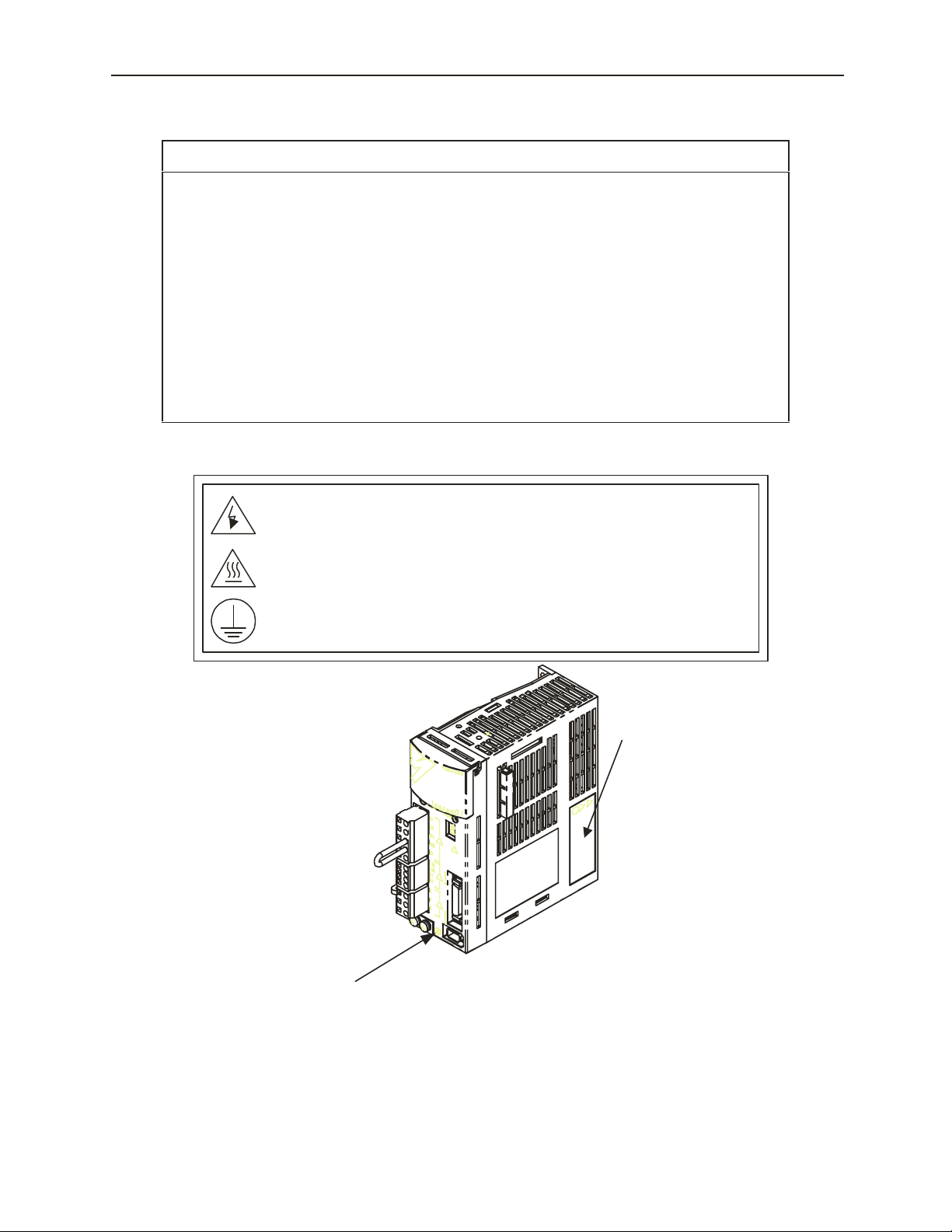

3.3 Digital Torque Amplifier Installation

3.3 Digital Torque Amplifier Installation

The SGDG digital torque amplifier is a base-mo unted digital torque amplifier. Mount it

properly according to the following cautionary items as mistakes in the mounting method can

lead to failure of the unit.

■ Storage Conditions

Store the digital torq ue amplifier within the temperature range bel ow when storing

without electrica l feed.

Temperature Range: -20~ +85°C

LEGEND SGDG Digital Torque Amplifier

■ Mounting Conditions

Location

The following points shoul d be kept in mind with regard to the mounting location.

Installation

Conditions

Mounted in a Control

Panel

Mounted Near a HeatGenerating Object

Mounted Near a

Vibration Source

Design the control panel size, digital torque amplifier

installati on, and cooling method so that the ambient

temper atu re of t he dig ita l torq ue amp li fie r does not exc eed

55

°C.

Suppress the temperature rise due to radiated heat and

convection from the heat-generating object so that the

ambient temperature of the digital torque amplifier does

not exceed 55

Attach vibrat ion- prevent ative bracket s to the dig it al torque

amplifier mount ing surface so that the vibrations are not

communicated to the digital tor que amplifier.

Cautions on Mounting

°C.

34

Page 46

3.3 Digital Torque Amplifier Installation

Installation

Conditions

Mounted in a Location

Exposed to Corrosive

Gas

Others

Take measures to prevent the influx of corrosive gas. The

gas will have no immedi ate effect, but will lead to device

failures in the electronic components and contact-related

devices.

Do not install in areas with high temperature or hum idity,

or where the atmosphere contains dust or iron particles.

Cautions on Mounting

Control Panel Environmental Conditions

• Digital Torque Amplifier Ambient Temperature: 0~55°C

• Humidity: 90% RH or less

2

• Vi bration: 0.5G (4.9m/s

)

• Do not allow freezing or condensation to occur.

• Use an am bient te mperature of 45°C or less to maintain long-term reliability.

Mounting Direction

Mount in a vertical direction on a wall as shown in the figure below. Cool the digital

torque amplifier eit her with natural convection or a fan. Be sure to maintain this

direction. Securely fix the digital torque amplifier to the mounting surface by using the

mounting holes at 2~4 locations (the number of holes will differ depending on capacity).

Surface

Mounting

Ventilation

Cooling

Mount the amplifier with suffic ient peripheral space around the digi tal torque amplifier

consideration of the above figure so as to achieve sufficient cooling by either a fan or

natural convecti on.

35

Page 47

3.3 Digital Torque Amplifier Installation

r

Digital Torque Amplifier Mounting Standards

Observe the standards for mount ing into a control panel shown in the figure below,

including those cases where multiple digital torque amplifiers are installed in parallel

within a control panel (hereafter referred to as a “parallel platform”).

FanFan

30mm or more 10mm or more

50mm o

more

50mm or

more

Mount the digital torque amplif ier so that the front side faces the operator .

Side-by-side Installation

When installing digital torque amplifier side by side as shown in the figure above, allow

at least 0.39in (10mm) between and at least 1.97in (50mm) above and below each digital

torque amplifier. Install cooling fans above the digital torque amplifie rs to avoid

excessive te mperature rise and to maintai n even tem perature inside the cont ro l panel .

36

Page 48

3.4 Switch Settings

3.4 Switch Settings

■ SW1 Function Selection Switch (dip switches)

Switch No. Function At OFF At ON Default Setting

1

2 Torque Reference Filter No Yes ON

3 Input Power Selection

4

5

6

7

8 Not used ON

Status After DB Stop

During Base Block

Linear Scale Polarity

Reversal

Regen Overload Alarm or

Warning

Feedback Pulse

B-phase Reversal

Command Direction

Reversal

Release DB after

motor stop

DC-Power Input

Compatible

B-phase progression:

U, V , W direction

No Yes ON

Reversed Not reversed ON

Reversed Not reversed ON

Continue DB af ter

motor stop

AC-Power Input

Compatible

A-phase progressio n:

U, V , W direction

ON

ON

ON

(enabled only when

linear motor is used)

■ SW2 Linear Scale Pitch Setting (rotary switch)

Setting Linear Scale Pitch Setting Setting Linear Scale Pitch Setting

0*

1

2

3

4

5

6

7 Not used F Not used

0μm

2μm

4μm

20μm

40μm

800μm

1000μm

8 Not used

9 Not used

A Not used

B Not used

C Not used

D Not used

E Not used

* The defaul t se tting is 0 (0μm).

37

Page 49

3.4 Switch Settings

■ SW3 PG Divider Setting (rotary switch)

Setting PG Divider Setting** Setting PG Divider Setting**

0* 8192 P/R 8 3000 P/R

1 8000 P/R 9 2500 P/R

2 7200 P/R A 2048 P/R

3 6000 P/R B 2000 P/R

4 5000 P/R C 1800 P/R

5 4096 P/R D 1600 P/R

6 4000 P/R E 1000 P/R

7 3600 P/R F Not used

* The default se tt in g is 0 (20 4 8 ×4). ** 4× at host controller

For a 13-bit Rotary Motor

For a 17-bit Rotary Motor

Setting PG Divider Setting** Setting PG Divider Setting**

0* 65,536 P/R 8 30000 P/R

1 64,000 P/R 9 24000 P/R

2 60,000 P/R A 16000 P/R

3 50,000 P/R B 131,072 P/R***

4 40,000 P/R C 120,000 P/R***

5 36,000 P/R D 100,000 P/R***

6 32,768 P/R E 80,000 P/R***

7 32,000 P/R F Not used

* The default setting is 0 (16384×4). ** 4× at host controller

*** Overspeed alar m will activate at motor speeds o f 2500rpm or higher.

For Linear Motors

Setting PG Divider Setting Setting PG Divider Setting

0* 1/20 8 1/32

1 1/256 9 1/16

2 1/250 A 1/10

3 1/200 B 1/8

4 1/128 C 1/5

5 1/100 D 1/4

6 1/64 E 1/2

7 1/40 F Not used

* The default setting is 0 (1/20).

38

Page 50

3.5 Combinations

Digital Torque amplifi er and motor combinations are shown below.

■ Combinations with Rotary Motors

3.5 Combinations

SGMAH

Digital Torque

Amplifier Model

SGDG-01GT SGMAH-A3B

SGDG-04GT SGMAH-01B

SGDG-10GT SGMAH-08A

Compatible Motor Models

SGMAH-A5B

SGMAH-A3A

SGMAH-A5A

SGMAH-01A

SGMAH-02B

SGMAH-02A

SGMAH-04A

SGMPH

Digital Torque

Amplifier Model

SGDG-01GT SGMPH-01A

SGDG-04GT SGMPH-01B

SGDG-10GT SGMPH-08A

SGDG-15GT SGMPH-15A

Compatible Motor Models

SGMPH-02B

SGMPH-02A

SGMPH-04A

Digital Torque

Amplifier Model

SGDG-10GT

SGDG-15GT

SGMGH

Compatible Motor Models

SGMGH-05 □ A

SGMGH-09 □ A

SGMGH-13 □ A

39

Page 51

3.5 Combinations

SGMSH

Digital Torque

Amplifier Model

SGDG-10GT

SGDG-15GT

■ Linear Motor Combinations

Digital Torque

Amplifier Model

SGDG-01GT

SGDG-04GT SGLGW-40A253A

SGDG-10GT SGLTW-20A320A

SGDG-15GT SGLFW-50A380A

Compatible Motor Models

SGMSH-10 □ A

SGMSH-15 □ A

Linear Motor Models

SGLGW-40A140A

SGLGW-40A365A

SGLGW-60A140A

SGLGW-60A253A

SGLFW-20A090A

SGLFW-20A120A

SGLFW-35A120A

SGLTW-35A170A

SGLTW-35A320A

SGLFW-35A230A

SGLFW-50A200A

SGLGW-60A365A

SGLTW-20A170A

SGLFW-1ZA200A

■ Serial Conversion Unit and Applicable Motors

Serial Conversion Unit Model

JZDP-A00 □ - □□□

001 SGLGW-40A140A(P) 013 SGLTW-20A460A(P)

002 SGLGW-40A253A(P) 014 SGLTW-35A170A(P)

003 SGLGW-40A365A(P) 015 SGLTW-35A320A(P)

004 SGLGW-60A140A(P) 016 SGLTW-35A460A(P)

005 SGLGW-60A253A(P) 017 SGLFW-20A090A(P)

006 SGLGW-60A365A(P) 018 SGLFW-20A120A(P)

007 SGLTW-40A400A(P) 019 SGLFW-35A120A(P)

008 SGLTW-40A600A(P) 020 SGLFW-35A230A(P)

009 SGLTW-80A400A(P) 021 SGLFW-50A200A(P)

010 SGLTW-80A600A(P) 022 SGLFW-50A380A(P)

011 SGLTW-20A170A(P) 023 SGLFW-1ZA200A(P)

012 SGLTW-20A320A(P) 024 SGLFW-1ZA380A(P)

40

Applicable Motors

Serial Conversion Unit Model

JZDP-A00 □ - □□□

Applicable Motors

Page 52

4. Description of Functions

CN1-3

CN1-4

4.1 Torque/Force Control

This is the torque/force control-dedicated mode.

This control mode inputs the torque/force reference from CMD-IN (CN1-3 & CN1-4).

Amplifier

CMD-IN

CMD-IN

SG

4.2 Protection Sequence Design

This section describes the methods for integrating a protective sequence for safety purposes

using I/O signals from the digital torque amplifier.

SG

CN1-3

CN1-4

4.1 Torque/Force Control

Servo Alarm Output

Digital Torque Amplifier

Digital T orque A m plifier

Photocoupler O utput pe r

Output

Max. Usage voltage: DC30V

Max. Usage Current: :DC50mA

Photocoupler

CN1-34

MAX 50mA

CN1-35

ALM+

ALM-

The basic method for continuin g alar m-related “output signals” is shown below.

Prepare an ext ernal 24V usage power source . No 24V powe r source is integrated in the digital

torque amplifier. The photocoupler output signal is handled as follows:

Output → ALM+ CN1-34

Output → ALM- CN1-35

Servo Alarm Output

Signal ground for servo alarm

output

24V P ow er

+24V

0V

The output is “ON” when the digital torque amplif ier detects an error.

41

Page 53

4.2 Protection Sequence Design

r

Be sure to configure the external circuit so that the main power to the digital torque ampli fier

goes OFF at alarm output.

ON State

OFF State

CN1–34, 35 is “closed”,

CN1–34 is level “Low”

CN1–34, 35 is “open”,

CN1–34 is level “High”

Normal State

Alarm State

■ Servo ON Input

Serial Input Signal: The basic connection method and for Servo ON (/S-ON) is displayed

below. This is used to forcibly stop the servomotor in a “non-powered” state.

24V

Power

+24V

Upper-Level

Device

0

V

+24VIN

S-ON

→ Input/S-ON CN1-14 Servo ON

Switches the motor between a powered and a non-powered state.

When ON

CN1-14 is

“L” level

When OFF

CN1-14 is

“H” level

Sends po w er to th e m o to r. This is

the normal RUN state. (this is called

the 4sta te )

Sets the motor to a “non-powered”

state. O peration is not possible (this

is the Servo OFF state). Do not

perform Se rvo O FF while th e mot or

is running except during an

emergency stop.

Amplifier

CN1-13 3.3kΩ

CN1-14

5mA

Servo ON

Servo OFF

Photocouple

Motor “Powered”

State

The motor runs

according to the

input signals

Motor Non- P o w ered

State

Operation is not

possible

Important

42

Do not start/stop the motor by using the (/S -ON) signal. Always start/stop the motor with an

input command.

Page 54

4.2 Protection Sequence Design

r

■ DB OFF Input

Sequence Input Signal: The basic connection and handling method for the (DB OFF)

signal is shown below. This is used to forcibly release the “DB stop state” during Servo

OFF from the upper-level device .

24VPower

+24V

Upper-Level

Device

0V

+24VIN

DB-OFF

Amplifier

CN1-13 3.3kΩ

CN1-15

5mA

Photocouple

→ Input DB OFF CN1-15 DB OFF

Switches the motor between a powered and a non-powered state.

When

ONCN1-15

is “L” level

When

OFFCN1-15

is “H” level

DB stop at Servo OFF DB ON

Releases the DB stop and goes to

free run at Servo OFF

DB OFF

DB Sto p State

DB stop at Servo OFF

DB Stop Release

Release DB stop

according to an input

signal

■ RUN Signal Output

Photocoupler Output Signa l: The basic connection method and handling method for the

“RUN” signal is shown below. This output signal indicates that the base block on the

output inverter is rel eased, and power is being applied to the motor.

Photocoupler Ou tput per

Output

Max. Use Voltage: DC30V

Max. Output Current :

DC50mA

Output → RUN CN1-7

ON State

OFF State

Digital Torque Amplifier

CN1-7

C N 1-10

RUN Signal Output

CN1–7, 10 is “clos ed”

CN1–7 is le ve l “ L”

CN1–7, 10 is “open” CN1–

7 is level “H”

+

RUN

RUN-

Base Block

Base Block Releas ed

24V Pow er

+24V 0V

43

Page 55

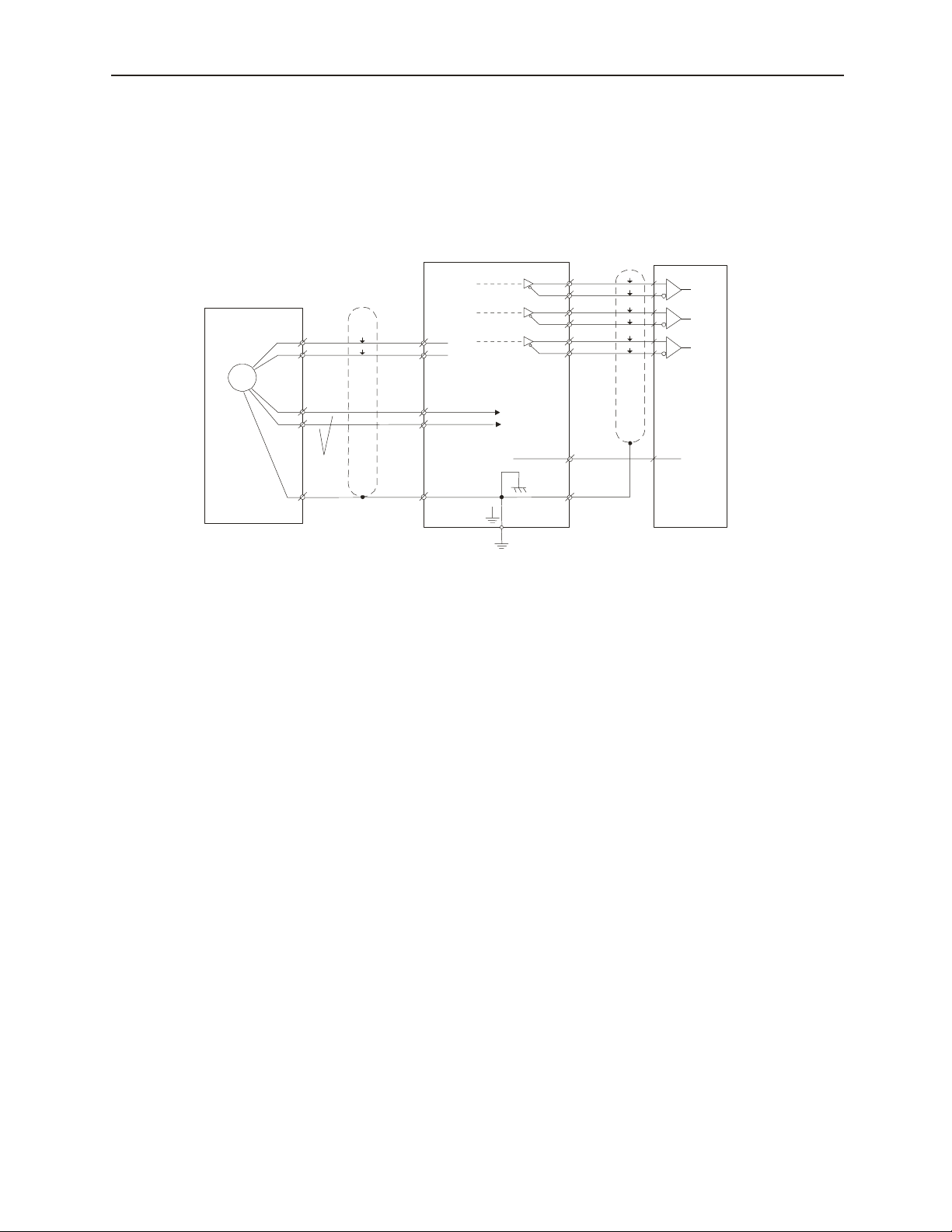

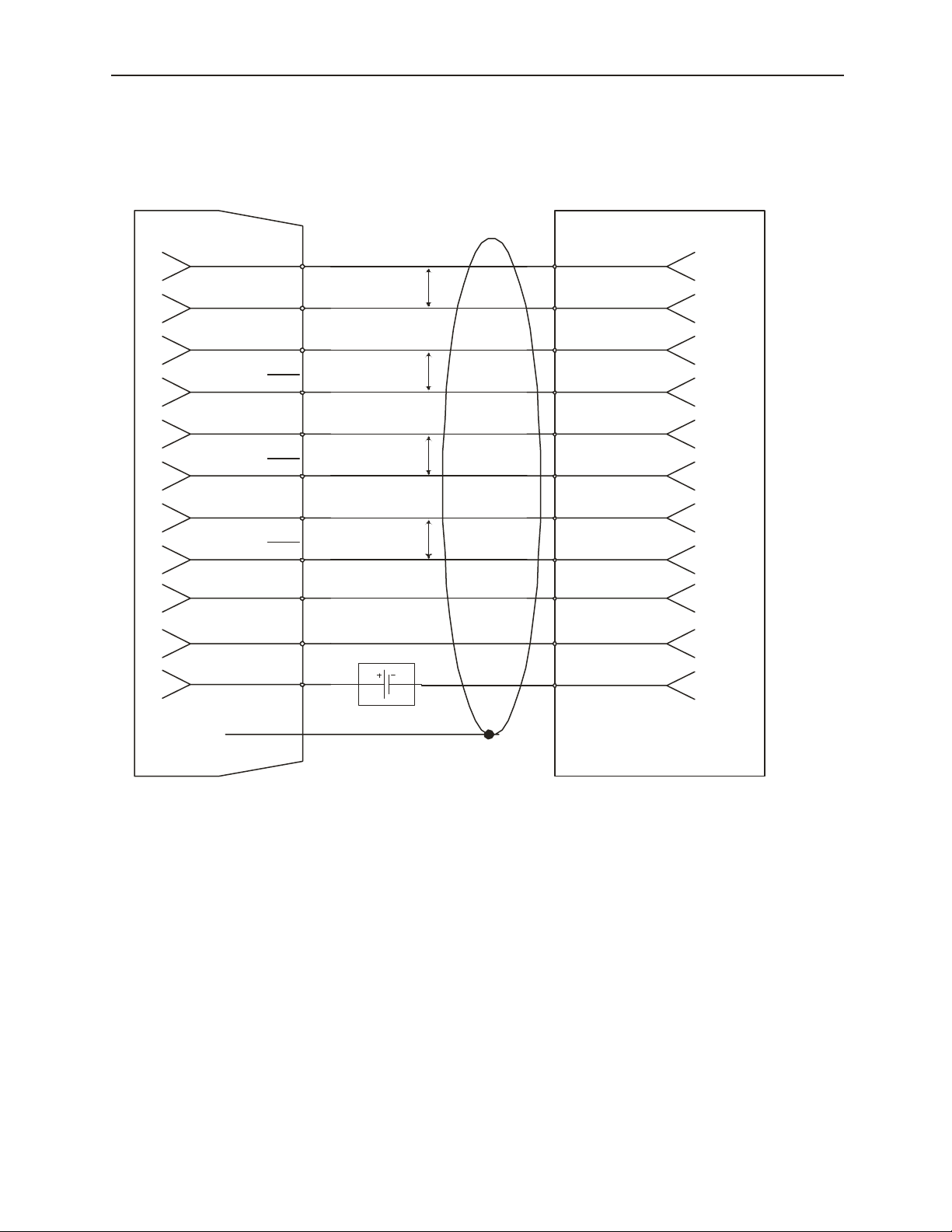

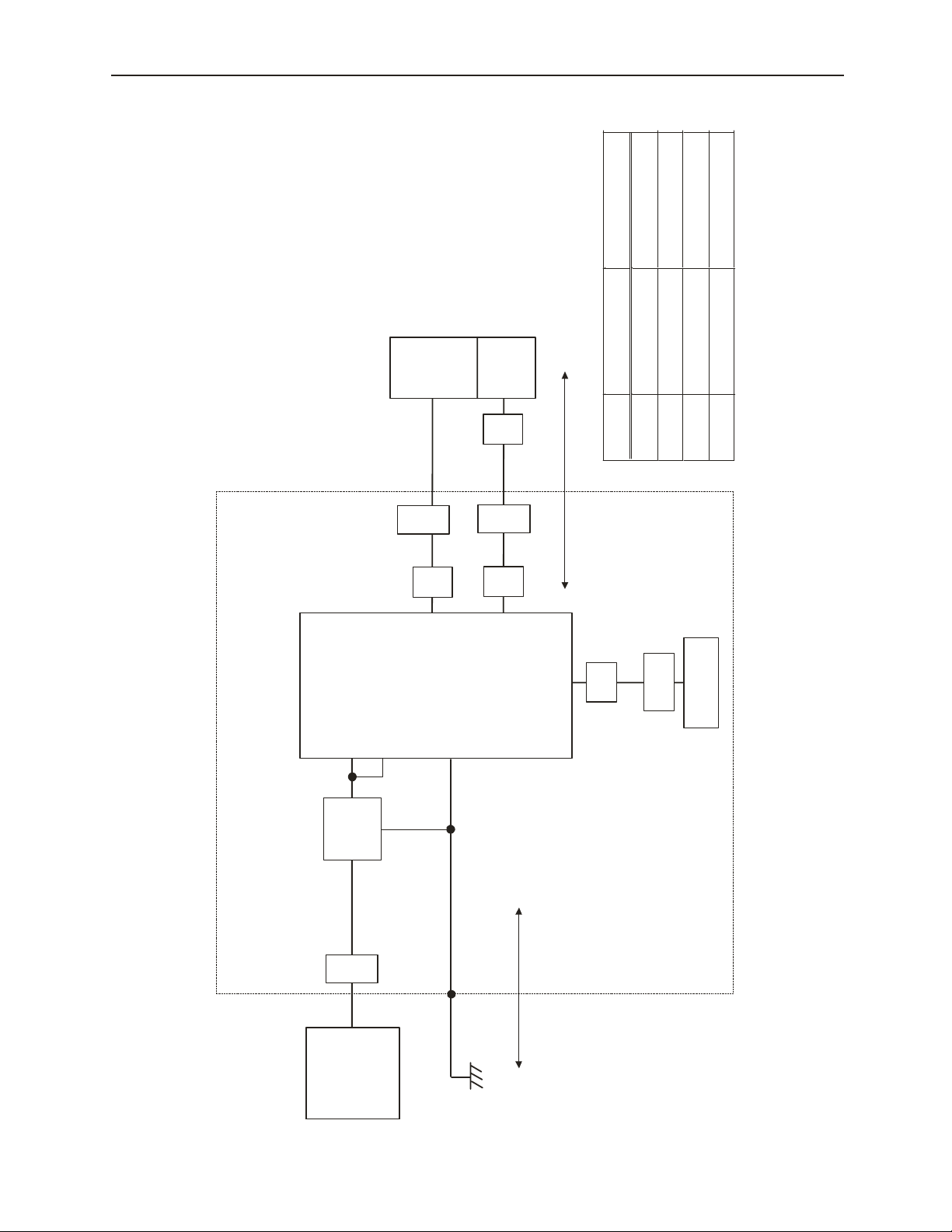

4.3 Encoder Signal Output

l

e

4.3 Encoder Signal Output

The output signa l following division within the digital torque amplifier of the enc oder output1

can be output to an external device.

Upper-Leve

Devic

Encoder

Serial Data

PG

Digital Torque

Amplifier

CN2 CN1

Division

Circuit

A-Phase

B-Phase

C-Phase

The output circuit is a line driver output. Connect in consideration of the following

circuit.

Digital Torque

A-Phase

B-Phase

C-Phase

Amplifier

OV

Connector Shell

CN1-20

CN1-21

CN1-22

CN1-23

CN1-24

CN1-25

CN1-1

PAO

*PAO

PBO

*PBO

PCO

*PCO

‚o

‚o

‚o

Shield Wire

Upper-Level Device

Line Receiv er

R

R

R

2

1

6

7

10

9

8‚bOV16

3

5

11

Choke

Coil

+5

V

+

-

Smoothing

Capacitor

A-Phase

B-Phase

C-Phase

+5

V

0V

‚o: Shows a twisted pair wire.

Applied Line Receiver: TI SN75175 or MC3486equivalent

R (Termination Resistance): 220~470Ħ

‚b (Decoupling Capa citor) : 0.1ƒÊF

1. After Division: This means the output conve rted to the set pulse ratio based on the pulse data from the

encoder mounted on the motor. The unit here is “No. of Pulses/Rotat ion”.

44

Page 56

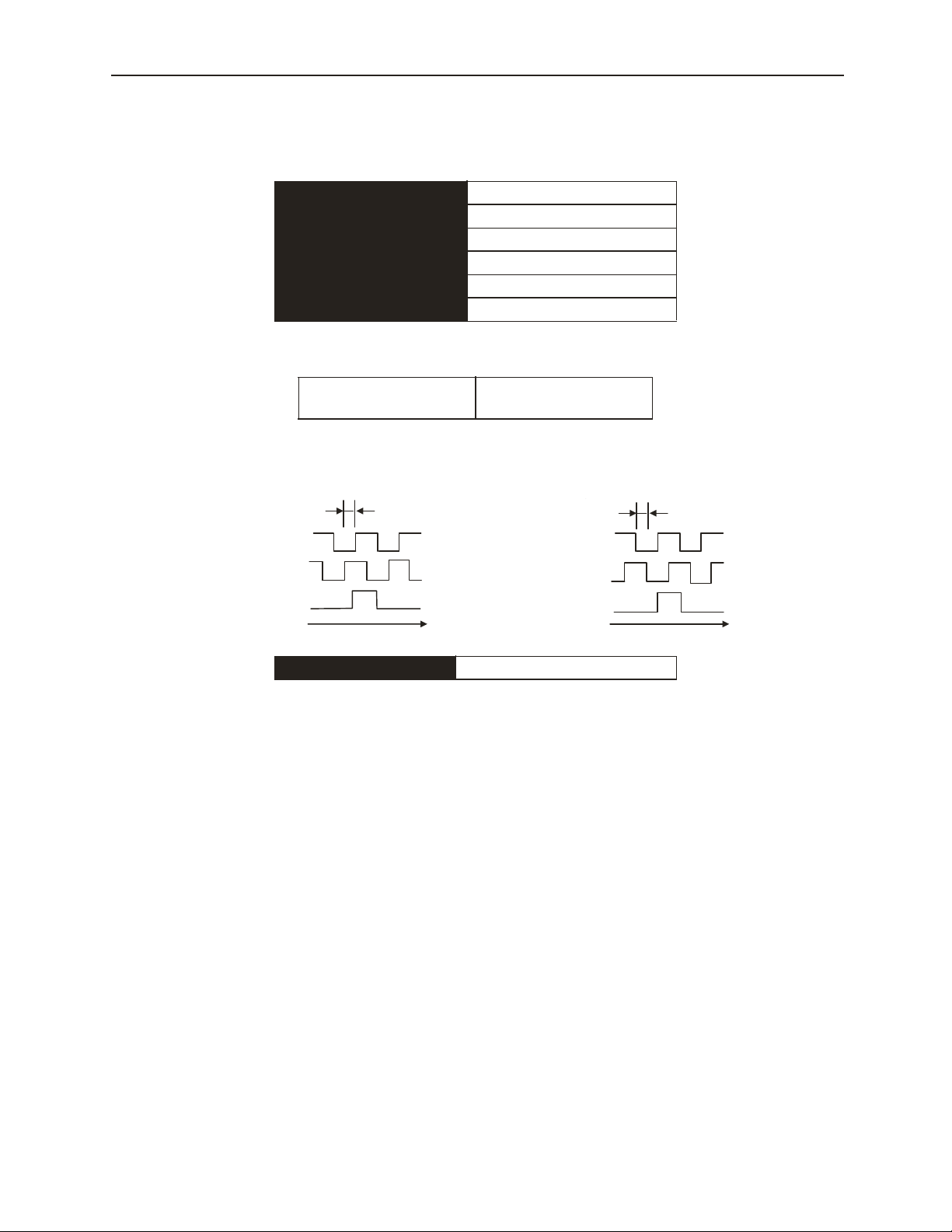

■ I/O Signals

In Reverse OperationIn Reverse Operation

In Forward Operation

The details on the output signal are as follows:

4.3 Encoder Signal Output

Output → PAO CN1-20

Output → *PAO CN1-21

Output → PBO CN1-22

Output → *PBO CN1-23

Output → PCO CN1-24

Output → *PCO CN1–25

Encoder Output A-phase

Encoder Output /A-phase

Encoder Output B-phase

Encoder Output /B-phase

Encoder Output C-phase

Encoder Output /C-phase

The divided encoder signal is output.

The division ratio is set in the fol lowing switches.

Encoder Di vision Ratio

Setting

SW3

■ Output Phase Form

In Forward Operation In Reverse Operation

A-Phase

B-Phase

C-Phase

90

K

A-Phase

B-Phase

C-Phase

tt

90

K

Output → SG CN1–2

Signal Ground

Signal Ground: Connect to “0V” on the upper- level device.

45

Page 57

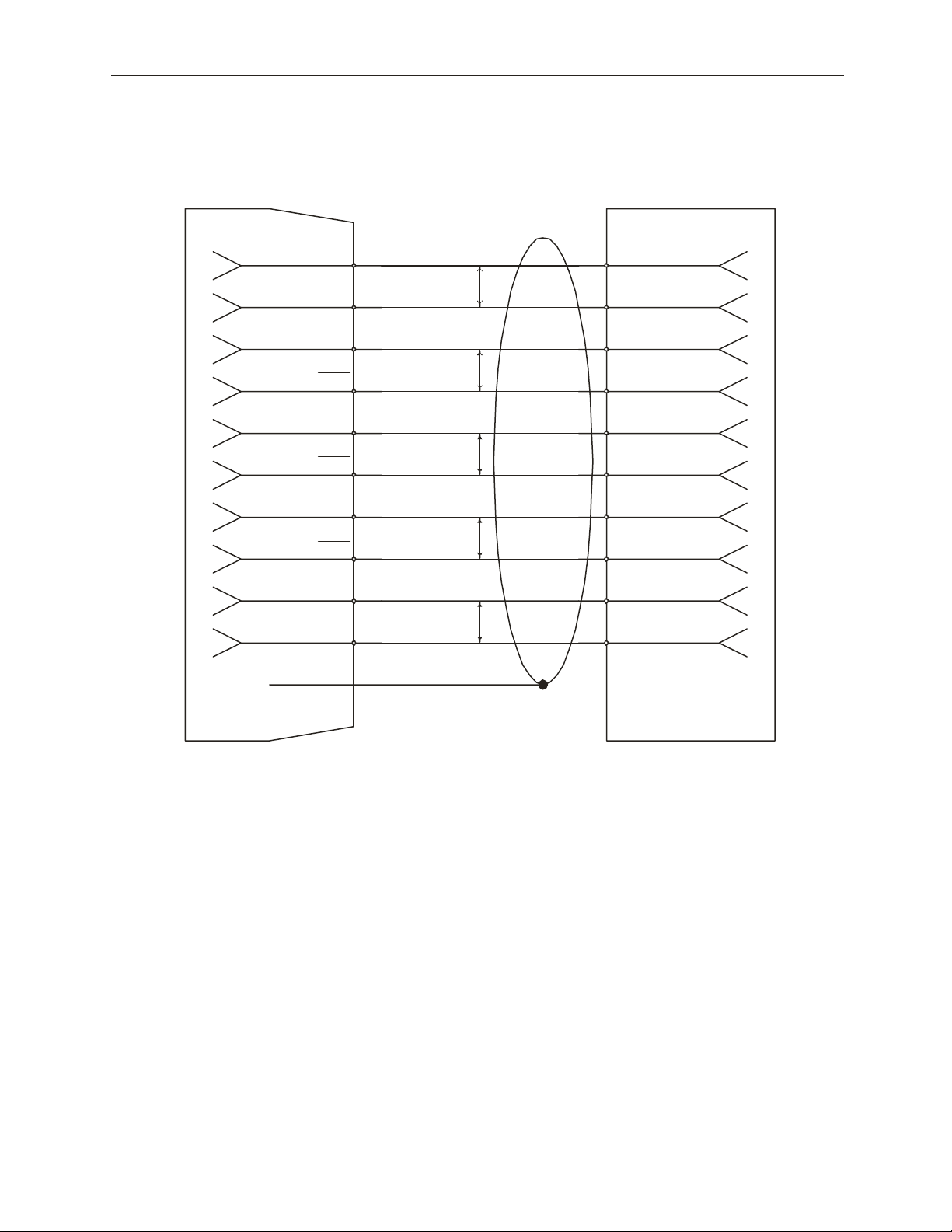

4.3 Encoder Signal Output

■ PG Divider Setting

Set the pulse division rat io by the following switches.

Delivery

Setting

SW3

PG Divider

Setting

Unit

P/R

Setting Range

16,000~131,072 (Rotary 17-bit) 65,536

1000~8192 (Rotary 13-bit) 8192

1/256~1/2 (Linear Motor) 1/20

Set the number of output pulses output by the encoder output signals (PAO, *PAO, PBO,

*PBO).

Output Terminals

PAO(CN1-20)

Servo Motor

Encoder

PG

Serial Data

Amplifier

Divider

*PAO(CN1-21)

PBO(CN1-22)

*PBO(CN1-23)

A-Phase

Output

B-Phase

This divides the pulses from the motor en coder (PG) by the number of pulses set there,

then outputs it. The setting value is the number of output pulses per motor rotation. Set

this to match the command unit of the machine controller. The setting range differs

according to the encoder used.

46

Page 58

4.4 Analog Monitor

The following signals can be monitor ed in the analog voltage form.

1CN Pin No. Signal Name Content

4.4 Analog Monitor

28

29 Analog Monitor 2 Torque = 5V/Max. Torque

Analog Monitor 1 Motor speed

: 1V/1000r/min or 1V/1000mm/sec

The analog monitor output volta ge is 8VDC (Max.). The output voltage will invert if it

exceeds 8VDC.

4.5 Regenerative Resistor Selection

When the servomotor is operated in electrical generator mode, the servo amplfier will absorb

electrical power . This is c alled regenerative power. Although the regenerative power is

absorbed by charging the smoo thing capacitor of the digital torque amplifier, the regenerative

power will be further consumed by the regen resistor if the chargeable energy limit of the

capacitor is exceeded. The servomotor is operated in the regen (electrical generator) mode in

the following situations:

• Deceleration to stop time during acceleration/deceleration operation

• Vertical axis load

• Continuous operation where the servomotor continues rotating from the load side

(overhauling load)

The capacity of the regenerative resistor integrated within the digital torque amplifier is

designed for short-term operation only, such as the deceleration to stop period. Operation is

not possible with an overhauling load. Install an external regen resi stor if the regen power

exceeds the processin g capab ility of the digital torque amplifier. The specifications of regen

resistors inte grated in digital torque amplifiers and the regen power the y can process

(average) are shown below.

Integrated Regen Resistor

Applied Digital T o rque

Amplifier

Resistance (Ω) Capacity (W)

SGDG-01GT/-04GT - - -

SGDG-10GT 50 60 12 40

SGDG-15GT 30 70 14 20

* The regen capa city (avera ge) which can be proc essed is a 20% rat ing of the regene rative resistor capacity

integrated within the digita l to rq u e amplifier.

Specifications

Regen Power

Processed by

Integrated

Resistor (W)

Minimum

Total

Resistance

(Ω)

40

When installing an external regen resistor, make the resistance the same as that of the resistor