Page 1

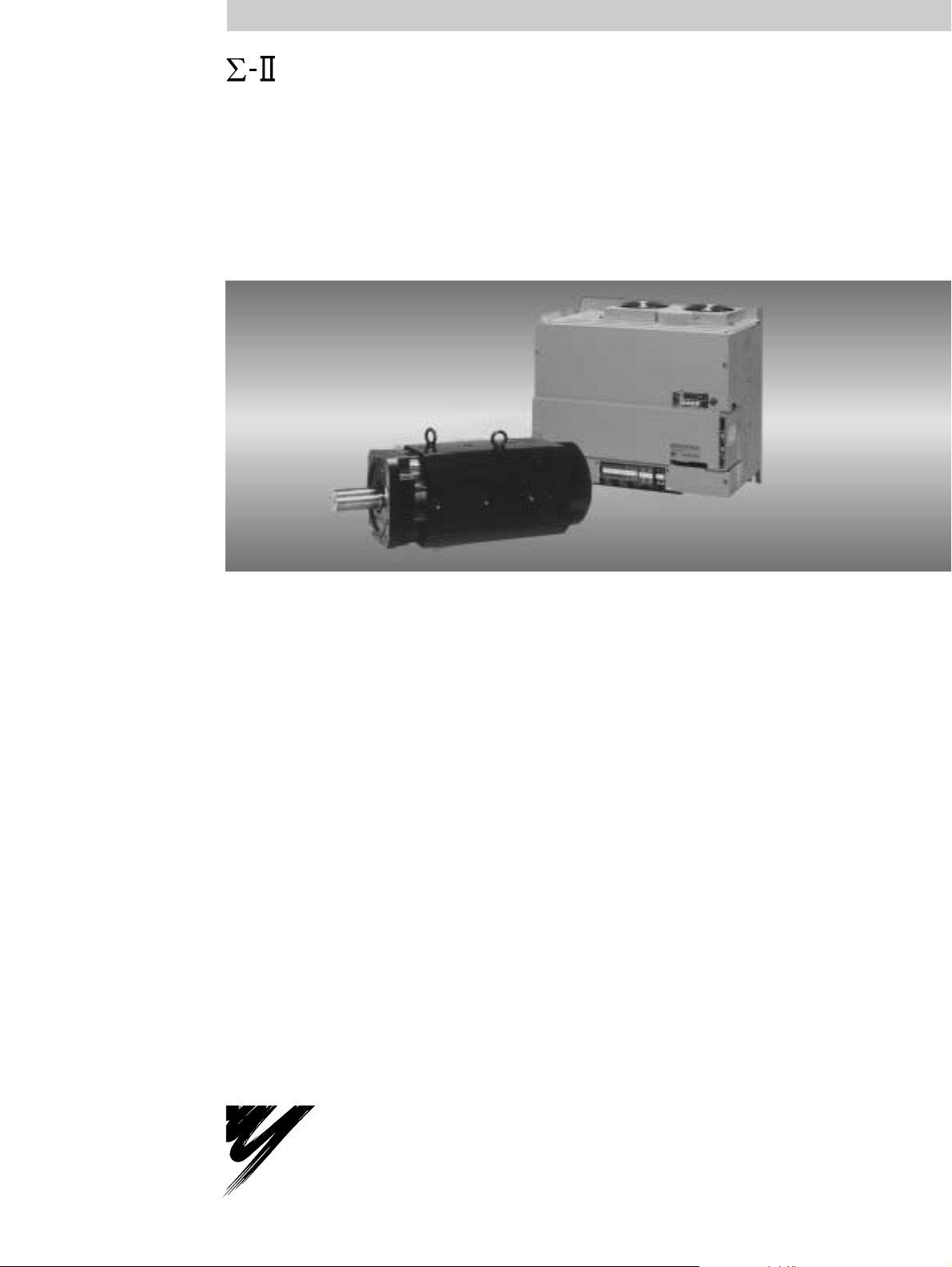

YASKAWA

Series SGMBH/SGDH

USER’S MANUAL

AC Servodrive (400 V, 22 to 55 kW)

SGMBH Servomotor

SGDH SERVOPACK

YA S K A WA

MANUAL NO. SIE-S800-32.4

Page 2

Copyright © 2002 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

About this Manual

This manual provides the following information for the Σ-II Series SGMBH/SGDH

Servodrives.

• Procedures for installing and wiring the servomotor and SERVOPACK.

• Procedures for trial operation of the Servodrive.

• Procedures for using functions and adjusting the servodrives.

• Procedures for using the built-in Panel Operator and the Hand-held Digital Operator.

• Ratings and specifications for standard models.

• Procedures for maintenance and inspection.

Intended Audience

This manual is intended for the following users.

• Those designing Σ-II Series servodrive systems.

• Those installing or wiring Σ-II Series servodrives.

• Those performing trial operation or adjustments of Σ-II Series servodrives.

• Those maintaining or inspecting Σ-II Series servodrives.

Description of Technical Terms

In this manual, the following terms are defined as follows:

• Servomotor = Σ-II Series SGMBH servomotor.

• SERVOPACK = Σ-II Series SGDH SERVOPACK.

• Servodrive = A set including a servomotor and Servo Amplifier.

• Servo System = A servo control system that includes the combination of a servodrive

with a host computer and peripheral devices.

Indication of Reverse Signals

In this manual, the names of reverse signals (ones that are valid when low) are written with a

forward slash (/) before the signal name, as shown in the following example:

• S-ON

• P-CON

= /S-ON

= /P-CON

iii

Page 4

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

IMPORTANT

INFO

EXAMPLE

TERMS

Indicates important information that should be memorized, including precautions such as

alarm displays to avoid damaging the devices.

Indicates supplemental information.

Indicates application examples.

Indicates definitions of difficult terms or terms that have not been previously explained in

this manual.

The text indicated by this icon explains the operating procedure using Hand-held type Digi-

tal Operator (Type: JUSP-OP02A-2).

JUSP-OP02A-2

iv

Page 5

Related Manuals

Refer to the following manuals as required.

Also, keep this manual in a safe place so that it can be referred to whenever neces-

sary.

Σ Series/Σ-ΙΙ Series

Servopacks Personal

Computer Monitoring

Software Operation Manual

Σ-ΙΙ Series

SGMH/SGDM

Digital Operator

Operation Manual

Safety Information

Manual Name Manual Number Contents

SIE-S800-35 Describes the applications and operation of

software for the Σ Series/Σ-II Series servodrive monitoring devices for use on personal computers.

TOE-S800-34 Provides detailed information on the opera-

tion of the JUSP-OP02A-2 Digital Operator, which is an optional product.

WARNING

CAUTION

PROHIBITED

The following conventions are used to indicate precautions in this manual.

Failure to heed precautions provided in this manual can result in serious or possibly even

fatal injury or damage to the products or to related equipment and systems.

Indicates precautions that, if not heeded, could possibly result in loss of life or seri-

ous injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

Indicates actions that must never be taken.

v

Page 6

Safety Precautions

The following precautions are for checking products upon delivery, installation, wiring,

operation, maintenance and inspections.

Checking Products upon Delivery

CAUTION

• Always use the servomotor and SERVOPACK in one of the specified combinations.

Not doing so may cause fire or malfunction.

Installation

CAUTION

• Never use the products in an environment subject to water, corrosive gases, inflammable gases, or

combustibles.

• Doing so may result in electric shock or fire.

vi

Page 7

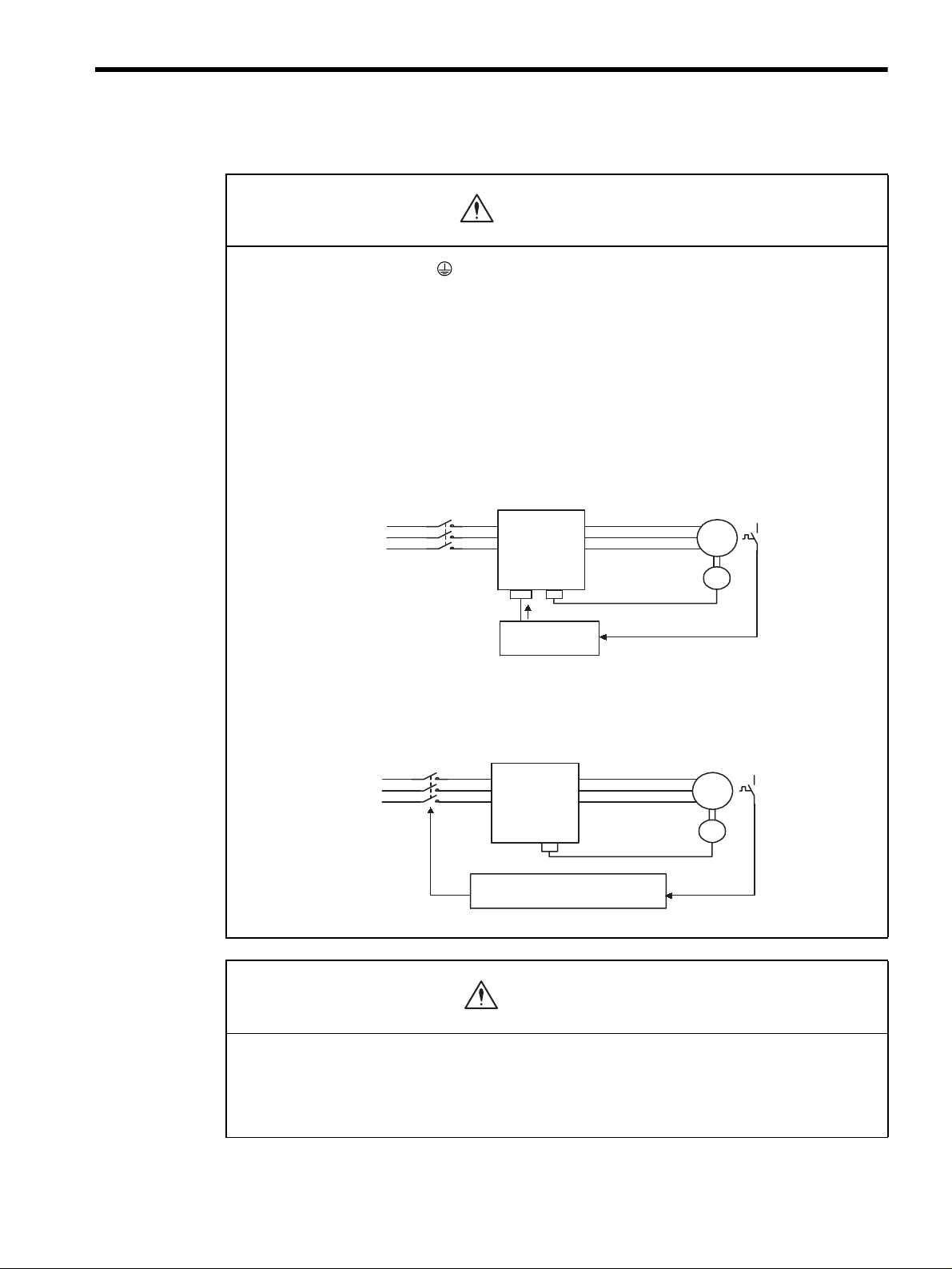

Wiring

WARNING

• Connect the ground terminal to electrical codes (ground resistance: 100 Ω or less).

Improper grounding may result in electric shock or fire.

• Use the thermal protector built into the servomotor according to either of the two following meth-

ods.

SGMBH servomotors are cooled by a fan. If the fan is defective or power to the fan is disconnected, heat

from the motor may result in burns or fire.

Method 1:

• Wire the output from the thermal protector to the host controller and turn OFF the servo when the

thermal protector operates.

Maincircuit

contactors

Maincircuit

powersupply

SGDH

SERVOPACK

M

PG

Thermal

protector

ServoOFF

HostController

Method 2:

• Wire the thermal protector to the operating circuit of the main circuit contactors or the host control-

ler and turn OFF the main circuit when the thermal protector operates.

Main

circuit

contactors

Maincircuit

powersupply

Tomaincircuit

contactors

SGDH

SERVOPACK

Hostcontrolleroroperating

circuitofmaincircuitcontactors

M

PG

Thermal

protector

CAUTION

• Do not connect a three-phase power supply to the SERVOPACK’s U, V, or W output terminals.

Doing so may result in injury or fire.

• Securely fasten the power supply terminal screws and motor output terminal screws.

Not doing so may result in fire.

vii

Page 8

Operation

WARNING

• Never touch any rotating motor parts while the motor is running.

Doing so may result in injury.

CAUTION

• Conduct trial operation on the servomotor alone with the motor shaft disconnected from machine to

avoid any unexpected accidents.

Not doing so may result in injury.

• Before starting operation with a machine connected, change the settings to match the parameters

of the machine.

Starting operation without matching the proper settings may cause the machine to run out of control or malfunction.

• Before starting operation with a machine connected, make sure that an emergency stop can be

applied at any time.

Not doing so may result in injury.

• Do not touch the heat sinks during operation.

Doing so may result in burns due to high temperatures.

Maintenance and Inspection

WARNING

• Never touch the inside of the SERVOPACKs.

Doing so may result in electric shock.

• Do not remove the panel cover while the power is ON.

Doing so may result in electric shock.

• Do not touch terminals for five minutes after the power is turned OFF.

Residual voltage may cause electric shock.

CAUTION

• Do not disassemble the servomotor.

Doing so may result in electric shock or injury.

• Do not attempt to change wiring while the power is ON.

Doing so may result in electric shock or injury.

viii

Page 9

General Precautions

Note the following to ensure safe application.

• The drawings presented in this manual are sometimes shown without covers or protective guards. Always

replace the cover or protective guard as specified first, and then operate the products in accordance with

the manual.

• The drawings presented in this manual are typical examples and may not match the product you received.

• This manual is subject to change due to product improvement, specification modification, and manual

improvement. When this manual is revised, the manual code is updated and the new manual is published

as a next edition.

• If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or one

of the offices listed on the back of this manual.

• Yaskawa will not take responsibility for the results of unauthorized modifications of this product.

Yaskawa shall not be liable for any damages or troubles resulting from unauthorized modification.

SGDH SERVOPACK Standards and Certification

SGDH SERVOPACKs conform to the following standards. However, because this product is

a built-in type, reconfirmation is required after being installed in the final product.

• EN55011 group 1 class A

• EN50082-2

ix

Page 10

CONTENTS

1 For First-time Users of AC Servos

1.1 Basic Understanding of AC Servos - - - - - - - - - - - - - - - - - - 1-2

1.1.1 Servo Mechanisms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.2 Technical Terms- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2 Configuration of Servo System - - - - - - - - - - - - - - - - - - - - - 1-5

1.3 Features of

1.3.1 Outline - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.3.2 Using the SGDH SERVOPACK - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

Σ-ΙΙ Series Servos - - - - - - - - - - - - - - - - - - - - - 1-10

2 Basic Operation

2.1 Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.2.1 Checking on Delivery - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.2.2 Installing the Servomotor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.2.3 Allowable Radial and Thrust Loads - - - - - - - - - - - - - - - - - - - - - - - - 2-10

2.2.4 Installing the SERVOPACK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

2.2.5 Power Loss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13

2.3 Connection and Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - 2-14

2.3.1 Connecting to Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - - - 2-14

2.3.2 Main Circuit Wiring and Power ON Sequence- - - - - - - - - - - - - - - - - 2-18

2.4 I/O Signals- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-21

2.4.1 Examples of I/O Signal Connections - - - - - - - - - - - - - - - - - - - - - - - 2-22

2.4.2 List of CN1 Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-23

2.4.3 I/O Signal Names and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - 2-24

2.4.4 Interface Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-26

2.5 Wiring Encoders- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-30

2.5.1 Connecting an Encoder (CN2) and Output Signals

from the SERVOPACK (CN1) - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-30

2.5.2 Terminal Layout and Types of CN2 Encoder Connector- - - - - - - - - - 2-31

2.5.3 Examples of Connecting I/O Signal Terminals- - - - - - - - - - - - - - - - - 2-32

3 Trial Operation

3.1 Two-step Trial Operation - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.1 Step 1: Trial Operation for Servomotor without Load - - - - - - - - - - - - - 3-3

3.1.2 Step 2: Trial Operation with the Servomotor Connected

to the Machine - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-9

x

Page 11

3.2 Supplementary Information on Trial Operation - - - - - - - - - 3-10

3.2.1 Servomotors with Brakes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-10

3.2.2 Position Control by Host Controller- - - - - - - - - - - - - - - - - - - - - - - - - 3-11

3.3 Minimum Parameters and Input Signals - - - - - - - - - - - - - - 3-12

3.3.1 Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-12

3.3.2 Input Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-13

4 Parameter Settings and Functions

4.1 Settings According to Device Characteristics - - - - - - - - - - - 4-4

4.1.1 Switching Servomotor Rotation Direction - - - - - - - - - - - - - - - - - - - - -4-4

4.1.2 Setting the Overtravel Limit Function - - - - - - - - - - - - - - - - - - - - - - - -4-5

4.1.3 Limiting Torques - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-9

4.2 Settings According to Host Controller - - - - - - - - - - - - - - - - 4-14

4.2.1 Speed Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-14

4.2.2 Position Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-16

4.2.3 Using the Encoder Signal Output - - - - - - - - - - - - - - - - - - - - - - - - - -4-22

4.2.4 Sequence I/O Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-26

4.2.5 Using the Electronic Gear Function - - - - - - - - - - - - - - - - - - - - - - - - 4-29

4.2.6 Contact Input Speed Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-33

4.2.7 Using Torque Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-38

4.2.8 Torque Feed-forward Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-44

4.2.9 Speed Feed-forward Function - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-46

4.2.10 Torque Limiting by Analog Voltage Reference, Function 1- - - - - - - -4-47

4.2.11 Torque Limiting by Analog Voltage Reference, Function 2- - - - - - - - 4-48

4.2.12 Reference Pulse Inhibit Function (INHIBIT) - - - - - - - - - - - - - - - - - -4-50

4.3 Setting Up the SERVOPACK - - - - - - - - - - - - - - - - - - - - - - 4-52

4.3.1 Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-52

4.3.2 JOG Speed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-53

4.3.3 Input Circuit Signal Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-53

4.3.4 Output Circuit Signal Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - -4-57

4.3.5 Control Mode Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-59

4.4 Setting Stop Functions - - - - - - - - - - - - - - - - - - - - - - - - - - 4-62

4.4.1 Adjusting Offset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-62

4.4.2 Using the Dynamic Brake - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-63

4.4.3 Using the Zero Clamp Function - - - - - - - - - - - - - - - - - - - - - - - - - - -4-64

4.4.4 Using the Holding Brake - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-66

4.5 Forming a Protective Sequence- - - - - - - - - - - - - - - - - - - - 4-70

4.5.1 Using Servo Alarm and Alarm Code Outputs- - - - - - - - - - - - - - - - - -4-70

4.5.2 Using the Servo ON Input Signal - - - - - - - - - - - - - - - - - - - - - - - - - -4-72

4.5.3 Using the Positioning Completed Output Signal - - - - - - - - - - - - - - - - 4-73

4.5.4 Speed Coincidence Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-75

4.5.5 Using the Running Output Signal - - - - - - - - - - - - - - - - - - - - - - - - - - 4-76

xi

Page 12

4.5.6 Using the Servo Ready Output Signal - - - - - - - - - - - - - - - - - - - - - - 4-77

4.5.7 Using the Warning Output Signal- - - - - - - - - - - - - - - - - - - - - - - - - - 4-78

4.5.8 Using the Near Output Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-80

4.5.9 Handling Power Loss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-81

4.6 External Regenerative Resistors - - - - - - - - - - - - - - - - - - - 4-83

4.7 Absolute Encoders - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-84

4.7.1 Interface Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-85

4.7.2 Selecting an Absolute Encoder - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-86

4.7.3 Handling Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-86

4.7.4 Absolute Encoder Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-87

4.7.5 Absolute Encoder Reception Sequence - - - - - - - - - - - - - - - - - - - - - 4-90

4.7.6 Multiturn Limit Setting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-95

4.8 Special Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-99

4.8.1 Wiring Precautions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-99

4.8.2 Wiring for Noise Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-101

4.8.3 Using More Than One Servodrive - - - - - - - - - - - - - - - - - - - - - - - - 4-105

4.8.4 Extending Encoder Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-106

5 Servo Adjustment

5.1 Smooth Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.1 Using the Soft Start Function- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.2 Smoothing- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.1.3 Adjusting Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

5.1.4 Adjusting Offset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

5.1.5 Setting the Torque Reference Filter Time Constant - - - - - - - - - - - - - - 5-5

5.1.6 Notch Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5

5.2 High-speed Positioning - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5.2.1 Setting Servo Gain- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5.2.2 Using Feed-forward Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8

5.2.3 Using Proportional Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8

5.2.4 Setting Speed Bias - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

5.2.5 Using Mode Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.2.6 Speed Feedback Compensation - - - - - - - - - - - - - - - - - - - - - - - - - - 5-14

5.3 Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-16

5.3.1 Online Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-17

5.3.2 Machine Rigidity Settings for Online Autotuning - - - - - - - - - - - - - - - 5-19

5.3.3 Saving Results of Online Autotuning - - - - - - - - - - - - - - - - - - - - - - - 5-22

5.3.4 Parameters Related to Online Autotuning- - - - - - - - - - - - - - - - - - - - 5-25

5.4 Servo Gain Adjustments - - - - - - - - - - - - - - - - - - - - - - - - - 5-27

5.4.1 Servo Gain Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-27

5.4.2 Basic Rules of Gain Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - 5-27

5.4.3 Making Manual Adjustments - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-29

xii

Page 13

5.4.4 Gain Setting Reference Values - - - - - - - - - - - - - - - - - - - - - - - - - - -5-34

5.5 Analog Monitor- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-36

6 Using the Digital Operator

6.1 Basic Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Connecting the Digital Operator - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-2

6.1.2 Functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-3

6.1.3 Resetting Servo Alarms- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-4

6.1.4 Basic Mode Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-5

6.1.5 Status Display Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-6

6.1.6 Operation in Parameter Setting Mode- - - - - - - - - - - - - - - - - - - - - - - -6-9

6.1.7 Operation in Monitor Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-15

6.2 Applied Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-20

6.2.1 Operation in Alarm Traceback Mode- - - - - - - - - - - - - - - - - - - - - - - - 6-21

6.2.2 Controlling Operation Through the Digital Operator - - - - - - - - - - - - -6-22

6.2.3 Automatic Adjustment of the Speed and Torque Reference Offset - - - 6-25

6.2.4 Manual Adjustment of the Speed and Torque Reference Offset- - - - - 6-28

6.2.5 Clearing Alarm Traceback Data - - - - - - - - - - - - - - - - - - - - - - - - - - -6-33

6.2.6 Checking the Motor Model- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-35

6.2.7 Checking the Software Version - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-38

6.2.8 Zero-point Search Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-39

6.2.9 Initializing Parameter Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-42

6.2.10 Manual Zero Adjustment and Gain Adjustment of

Analog Monitor Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-44

6.2.11 Adjusting the Motor Current Detection Offset - - - - - - - - - - - - - - - - - 6-49

6.2.12 Password Setting (Write Prohibited Setting) - - - - - - - - - - - - - - - - -6-53

6.2.13 Clearing Option Unit Detection Results - - - - - - - - - - - - - - - - - - - - -6-55

7 Servo Selection and Data Sheets

7.1 Selecting a S-II Series Servodrives - - - - - - - - - - - - - - - - - - 7-3

7.1.1 Selecting Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-3

7.1.2 Selecting SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-8

7.2 Servomotor Ratings and Specifications - - - - - - - - - - - - - - - 7-9

7.2.1 Ratings and Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-9

7.2.2 Mechanical Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-11

7.3 SERVOPACK Ratings and Specifications - - - - - - - - - - - - 7-13

7.3.1 Combined Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-13

7.3.2 Ratings and Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-14

7.3.3 Overload Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-18

7.3.4 Starting and Stopping Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-19

7.3.5 Load Moment of Inertia - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-19

7.3.6 Overhanging Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-20

xiii

Page 14

7.4 Servodrive Dimensional Drawings - - - - - - - - - - - - - - - - - - 7-21

7.4.1 Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-21

7.4.2 SERVOPACKs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-24

7.5 Specifications and Dimensional Drawings

for Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - - - - 7-27

7.5.1 Cable Specifications and Peripheral Devices - - - - - - - - - - - - - - - - - 7-27

7.5.2 Digital Operator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-31

7.5.3 CN1 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-32

7.5.4 Connector Terminal Block Converter Unit - - - - - - - - - - - - - - - - - - - - 7-34

7.5.5 Cable With CN1 Connector and One End Without Connector- - - - - - 7-36

7.5.6 CN2 Encoder Connector at SERVOPACK - - - - - - - - - - - - - - - - - - - 7-37

7.5.7 Encoder Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-37

7.5.8 Absolute Encoder Battery - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-41

7.5.9 Brake Power Supplies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-42

7.5.10 Molded-case Circuit Breaker (MCCB) - - - - - - - - - - - - - - - - - - - - - 7-44

7.5.11 Noise Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-44

7.5.12 Surge Suppressor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-46

7.5.13 Regenerative Resistor Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-46

7.5.14 Dynamic Brake (DB) Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-50

7.5.15 Thermal Relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-56

7.5.16 Variable Resistor for Speed Setting - - - - - - - - - - - - - - - - - - - - - - - 7-59

7.5.17 Encoder Signal Converter Unit - - - - - - - - - - - - - - - - - - - - - - - - - - 7-59

7.5.18 Cables for Connecting PCs to a SERVOPACK - - - - - - - - - - - - - - - 7-61

8 Inspection, Maintenance, and Troubleshooting

8.1 Servodrive Inspection and Maintenance - - - - - - - - - - - - - - 8-2

8.1.1 Servomotor Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.1.2 SERVOPACK Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-3

8.1.3 Replacing Battery for Absolute Encoder - - - - - - - - - - - - - - - - - - - - - - 8-4

8.2 Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-5

8.2.1 Troubleshooting Problems with Alarm Displays- - - - - - - - - - - - - - - - - 8-5

8.2.2 Troubleshooting Problems with No Alarm Display - - - - - - - - - - - - - - 8-35

8.2.3 Alarm Display Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-37

8.2.4 Warning Displays- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-39

8.2.5 Internal Connection Diagram and Instrument Connection

Examples - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-40

Appendix A List of Parameters

INDEX

xiv

Page 15

1

For First-time Users of AC Servos

This chapter is intended for first–time users of AC servos. It describes the

basic configuration of a servo mechanism and basic technical terms relating to

servos. Users who already have experience in using a servo should also take a

look at this chapter to understand the features of Σ-ΙΙ Series AC Servos.

1.1 Basic Understanding of AC Servos - - - - - - - - - - - - - - - - - - - 1-2

1.1.1 Servo Mechanisms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.2 Technical Terms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2 Configuration of Servo System - - - - - - - - - - - - - - - - - - - - - - 1-5

1.3 Features of Σ-ΙΙ Series Servos - - - - - - - - - - - - - - - - - - - - - 1-10

1.3.1 Outline - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.3.2 Using the SGDH SERVOPACK - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1

1-1

Page 16

For First-time Users of AC Servos

1

1.1.1 Servo Mechanisms

1.1 Basic Understanding of AC Servos

This section describes the basic configuration of a servo mechanism and technical terms relating

to servos and also explains the features of Σ-ΙΙ Series AC Servos.

1.1.1 Servo Mechanisms

You may be familiar with the following terms:

• Servo

• Servo mechanism

• Servo control system

In fact, these terms are synonymous. They have the following meaning:

A control mechanism that monitors physical quantities such as specified positions.

In short, a servo mechanism is like a servant who does tasks faithfully and quickly according

to his master’s instructions. In fact, “servo” originally derives from the word “servant.”

1

Servo system could be defined in more detail as a mechanism that:

• Moves at a specified speed and

• Locates an object in a specified position

TERMS

1

Servo mechanism

According to Japanese Industrial Standard (JIS) terminology, a “servo mechanism” is defined as a

mechanism that uses the position, direction, or orientation of an object as a process variable to control

a system to follow any changes in a target value (set point). More simply, a servo mechanism is a control mechanism that monitors physical quantities such as specified positions. Feedback control is normally performed by a servo mechanism. (Source: JIS B0181)

1-2

Page 17

1.1 Basic Understanding of AC Servos

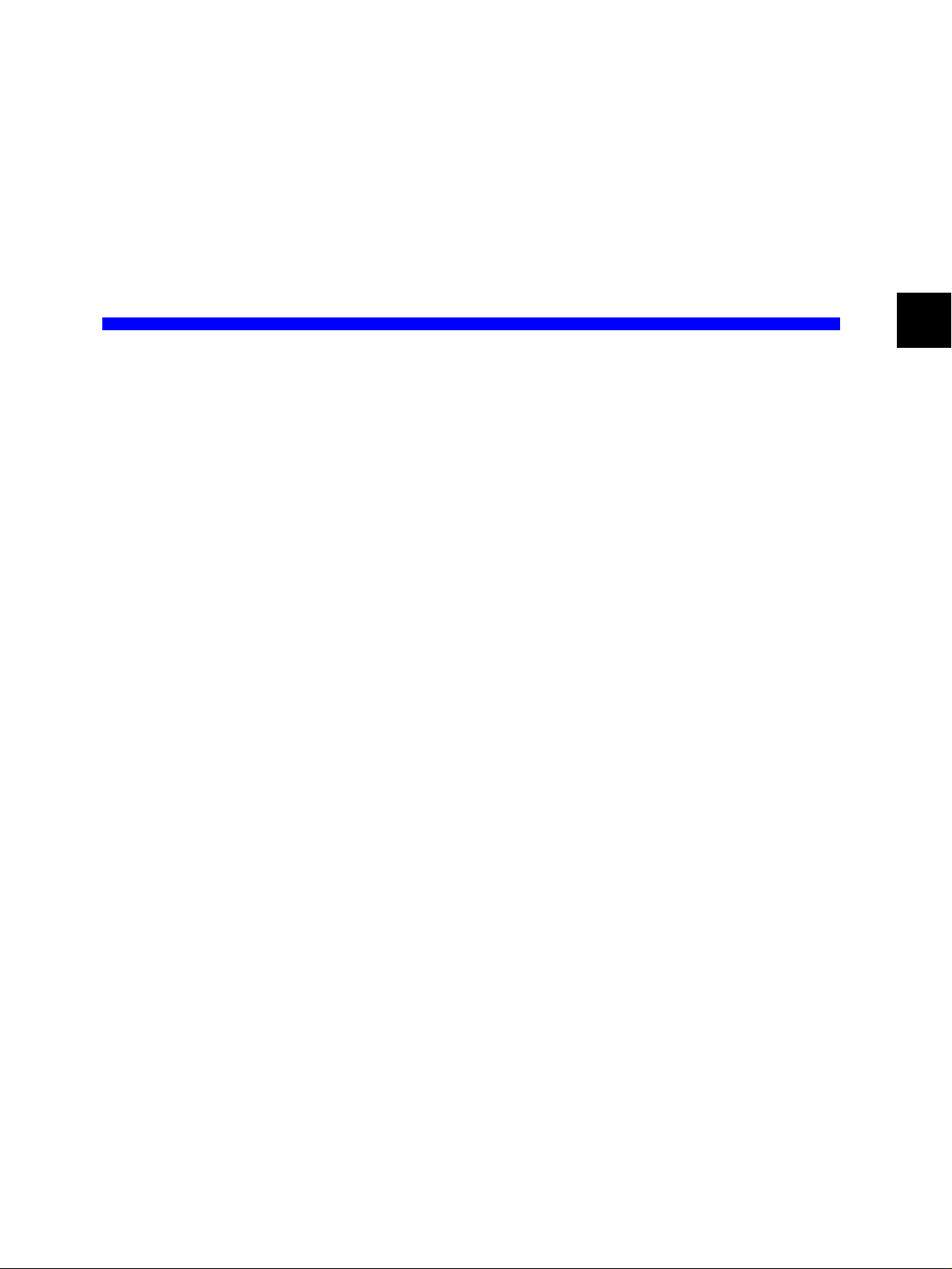

To develop such a servo system, an automatic control system involving feedback control1

must be designed. This automatic control system can be illustrated in the following block

diagram:

ConfigurationofServoSystem

Specifiedposition

input

+

-

Servo

amplifier

Servomotor

Feedbackpart

Detector

Controlled

machine

(load)

Machineposition

output

This servo system is an automatic control system that detects the machine position (output

data), feeds back the data to the input side, compares it with the specified position (input

data), and moves the machine by the difference between the compared data.

In other words, the servo system is a system to control the output data to match the specified

input data.

If, for example, the specified position changes, the servo system will reflect the changes.

In the above example, input data is defined as a position, but input data can be any physical

quantities such as orientation (angle), water pressure, or voltage.

Position, speed, force (torque), electric current, and so on are typical controlled values for a

servo system.

1

TERMS

1

Feedback control

A control method in which process variables are returned to the input side to form a closed loop. It is

also called closed-loop control. If a negative signal is returned to the input side, it is called negative

feedback control. Normally, negative feedback control is used to stabilize the system. If feedback is

not returned, the control method is called open-loop control.

1-3

Page 18

For First-time Users of AC Servos

1

1.1.2 Technical Terms

1.1.2 Technical Terms

The main technical terms used in this manual are as follows:

• Servo mechanism

• Servo

Normally, servo is synonymous with servo mechanism. However, because “mecha-

nism” is omitted, the meaning becomes somewhat ambiguous. Servo may refer to the

entire servo mechanism but may also refer to an integral part of a servo mechanism such

as a servomotor or a servo amplifier. This manual also follows this convention in the use

of the term “servo.”

• Servo control system

Servo control system is almost synonymous with servo mechanism but places the focus

on system control. In this manual, the term “servo system” is also used as a synonym of

servo control system.

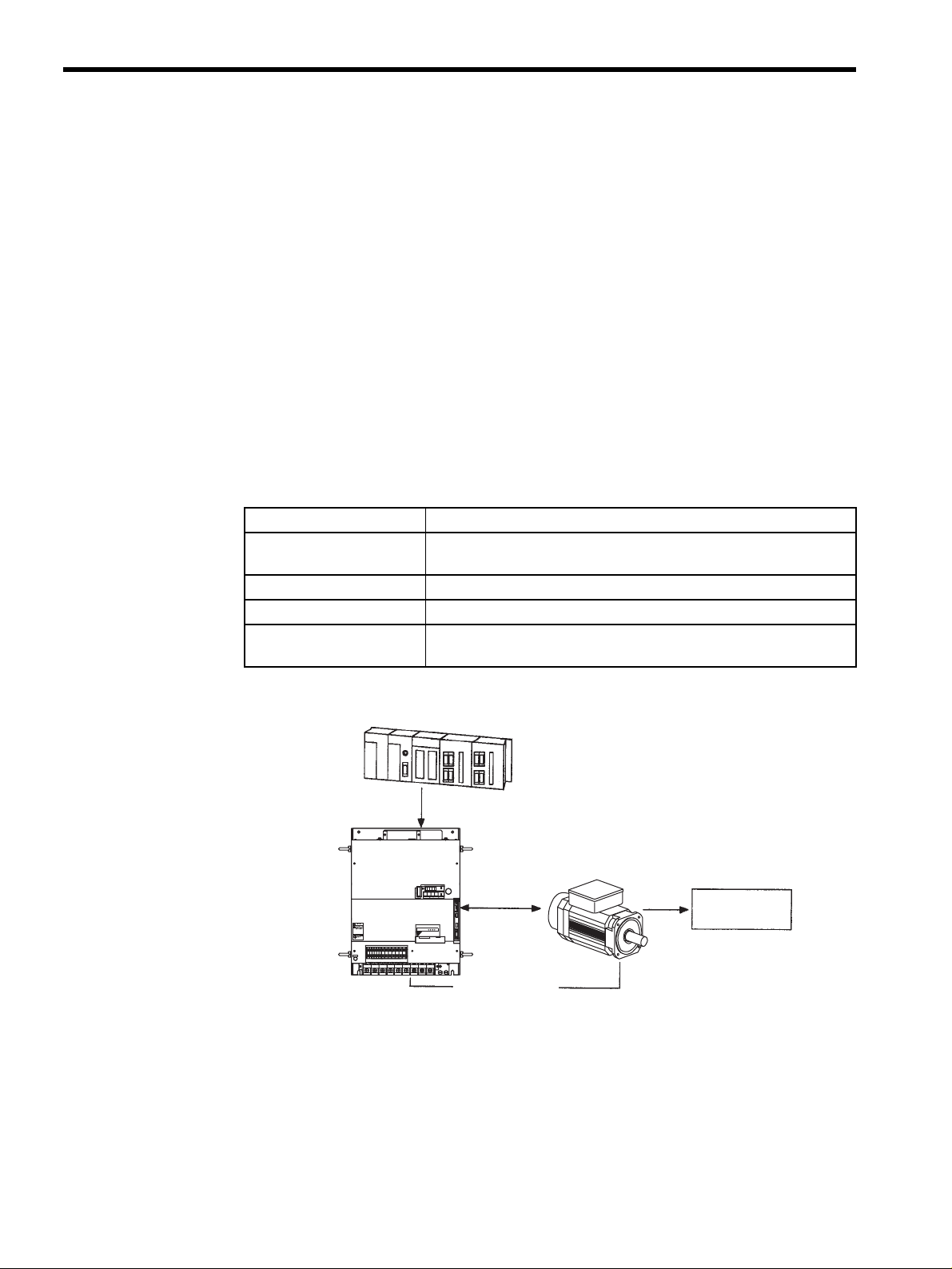

Related Terms Meaning

Servomotor General servomotors or Yaskawa SGMBH servomotors. In some cases,

a position detector (encoder) is included in a servomotor.

SERVOPACK Trademark of Yaskawa servo amplifier “SGDH SERVOPACK.”

Servo drive A servomotor and amplifier pair. Also called “servo.”

Servo system A closed control system consisting of a host controller, servo drive and

controlled system to form a servo mechanism.

Hostcontroller

Reference

Amplifier

POWER

8CN

TDATA/SEEMOD/

CN5

KSERVOPAC

AYASKAW

(SERVOPACK)

O

P

E

R

A

T

O

R

CN3

WARNING

5

!

Maycause

electricshock.

Disconnectallpower

andwait5min.

beforeservicing.

Useproper

groundingtechniques.

480V460

CHARGE

S-HDG

DC

DC

400V0V440

380

DU

DWDV B1

B2

24N

24P

V

V

V

L1/R L2/S

+2-+1

UVW

L3/T

Servomotor

Operate

Controlled

system

Servodrive

Servosystem

1-4

Page 19

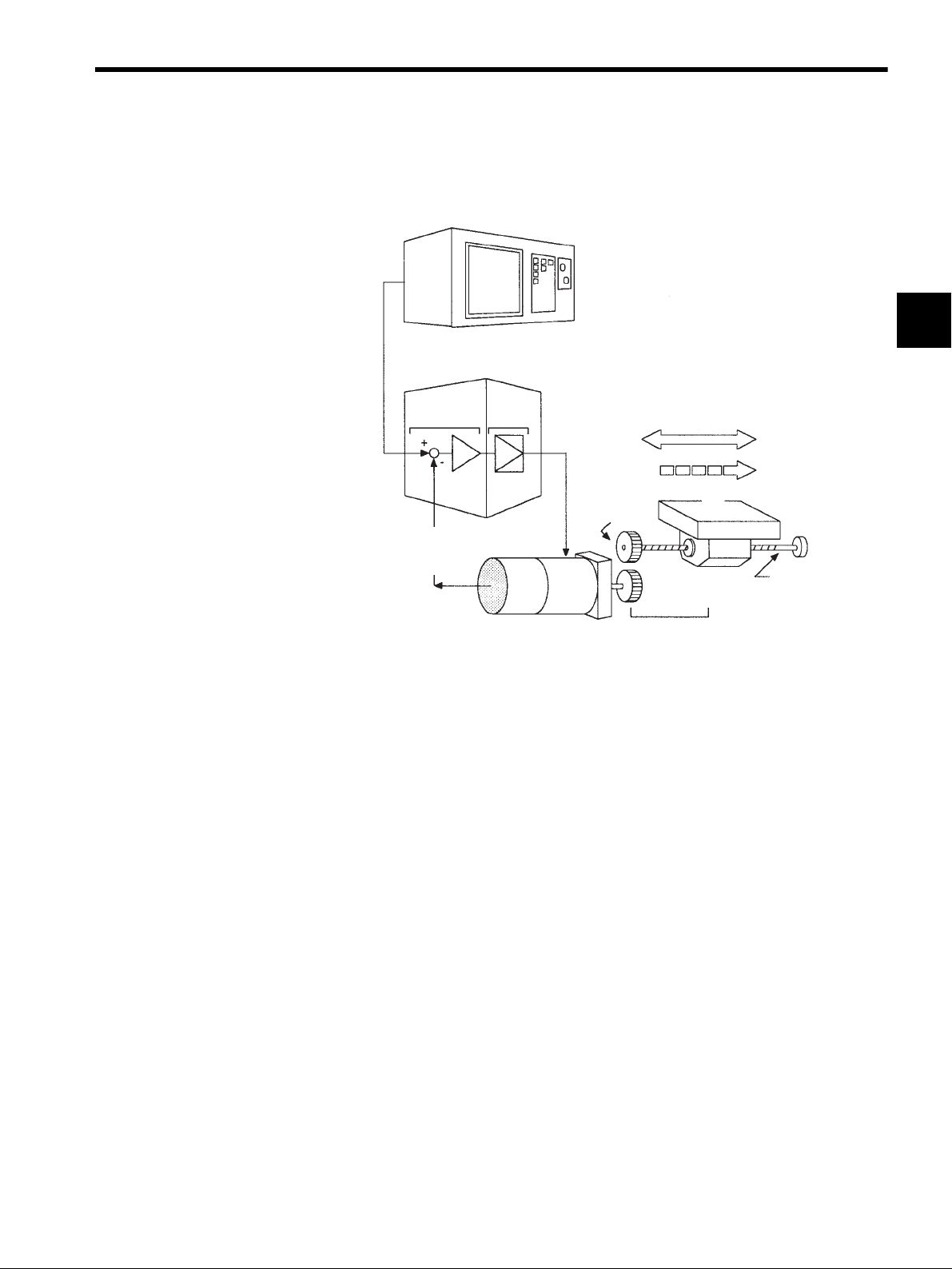

1.2 Configuration of Servo System

The following diagram illustrates a servo system in detail:

Positionor

speed

reference

Comparator

(Input)

Positionor

speed

feedback

Power

amplifier

(3) (2)

Hostcontroller

(5)

Servoamplifier

(4)

Motor

drive

circuit

Gear

1.2 Configuration of Servo System

(Output)

Position

Speed

(1)

Controlled

system

Movabletable

Ballscrew

1

Drivesystem

(1) Controlled

system:

Detector

servomotor

Mechanical system for which the position or speed is to be controlled. This

includes a drive system that transmits torque from a servomotor.

(2) Servomotor: A main actuator that moves a controlled system. Two types are available: AC ser-

vomotor and DC servomotor.

(3) Detector: A position or speed detector. Normally, an encoder mounted on a motor is used as

a position detector.

(4) Servo amplifier: An amplifier that processes an error signal to correct the difference between a ref-

erence and feedback data and operates the servomotor accordingly. A servo

amplifier consists of a comparator, which processes error signals, and a power

amplifier, which operates the servomotor.

(5) Host controller: A device that controls a servo amplifier by specifying a position or speed as a set

point.

1-5

Page 20

For First-time Users of AC Servos

1

1.1.2 Technical Terms

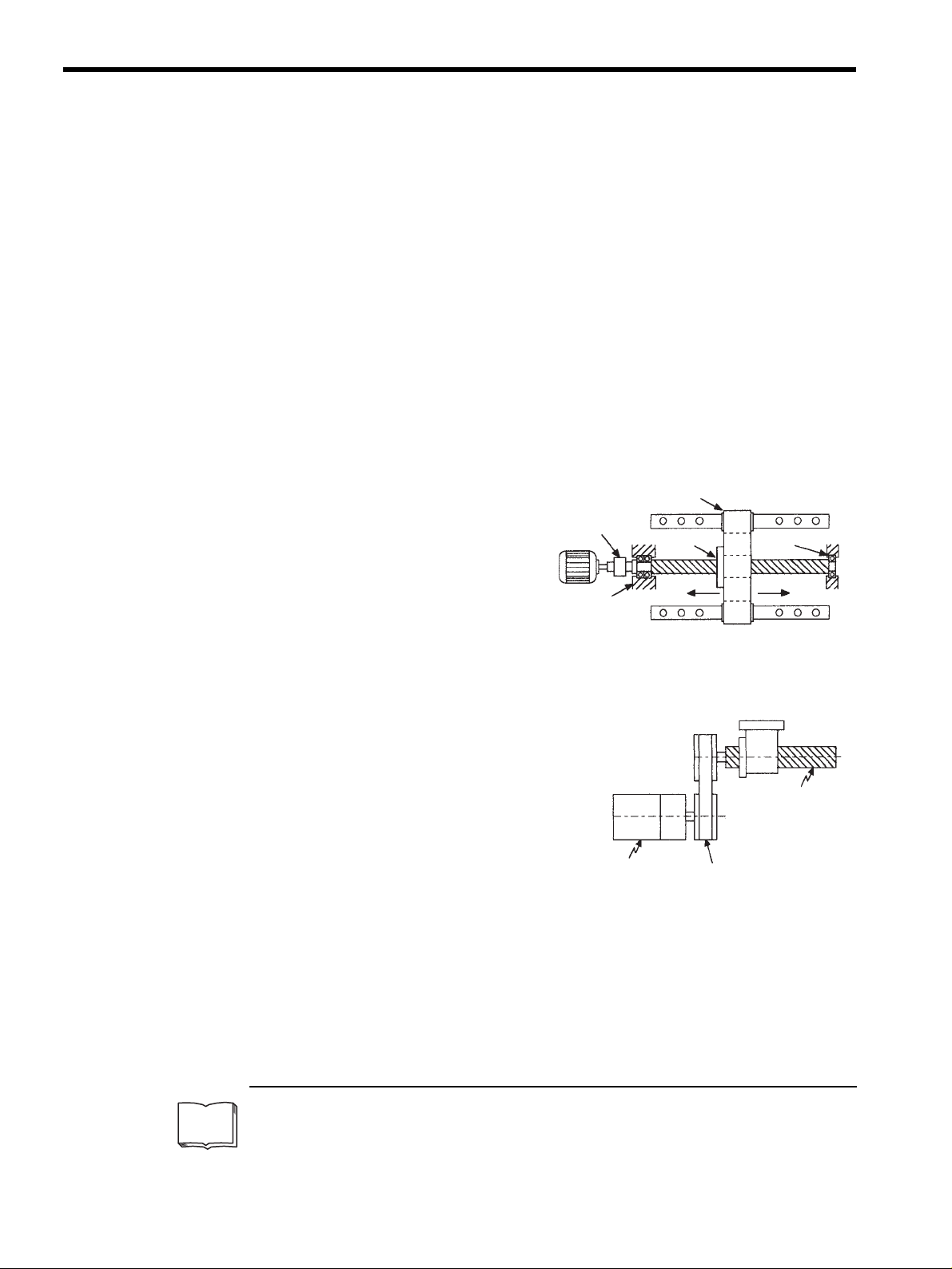

Servo components (1) to (5) are outlined below:

1. Controlled System

In the previous figure, the controlled system is a movable table for which the position or

speed is controlled. The movable table is driven by a ball screw and is connected to the

servomotor via gears. So, the drive system consists of:

• Gears + Ball Screw

This drive system is most commonly used because the power transmission ratio (gear

ratio) can be freely set to ensure high positioning accuracy. However, play in the gears

must be minimized.

The following drive system

1

is also possible when the controlled system is a movable

table:

• Coupling + Ball Screw

When the power transmission ratio is

1 : 1, a coupling is useful because it

has no play.

This drive system is widely used for

machining tools.

Coupling

Housing

Rolling-contact

guide

Ballscrew

Rolling-contact

bearing

TERMS

• Timing Belt + Trapezoidal Screw Thread

A timing belt is a coupling device that allows

the power transmission ratio to be set freely

and that has no play.

A trapezoidal screw thread does not provide

excellent positioning accuracy, so can be

Trapezoidal

screwthread

treated as a minor coupling device.

To develop an excellent servo system, it is

important to select a rigid drive system that

Servomotor

Timingbelt

has no play.

Configure the controlled system by using an appropriate drive system for the control

purpose.

1

Drive system

Also called a drive mechanism. A drive system connects an actuator (such as a servomotor) to a controlled system and serves a mechanical control component that transmits torque to the controlled system, orientates the controlled system, and converts motion from rotation to linear motion and vice

versa.

1-6

Page 21

1.2 Configuration of Servo System

2. Servomotor

• DC Servomotor and AC Servomotor

Servomotors are divided into two types: DC servomotors and AC servomotors.

DC servomotors are driven by direct current (DC). They have a long history. Up until

the 1980s, the term “servomotor” used to imply a DC servomotor.

From 1984, AC servomotors were emerging as a result of rapid progress in micropro-

cessor technology. Driven by alternating current (AC), AC servomotors are now widely

used because of the following advantages:

• Easy maintenance: No brush

• High speed: No limitation in rectification rate

Note however that servomotors and SERVOPACKs use some parts that are subject to

mechanical wear or aging. For preventive maintenance, inspect and replace parts at reg-

ular intervals. For details, refer to Chapter 8 Inspection, Maintenance, and Trouble-

shooting.

• AC Servomotor

1

AC servomotors are divided into two types: Synchronous type and induction type. The

synchronous type is more commonly used.

For a synchronous type servomotor, motor speed is controlled by changing the fre-

quency of alternating current.

A synchronous type servomotor provides strong holding torque when stopped, so this

type is ideal when precise positioning is required. Use this type for a servo mechanism

for position control.

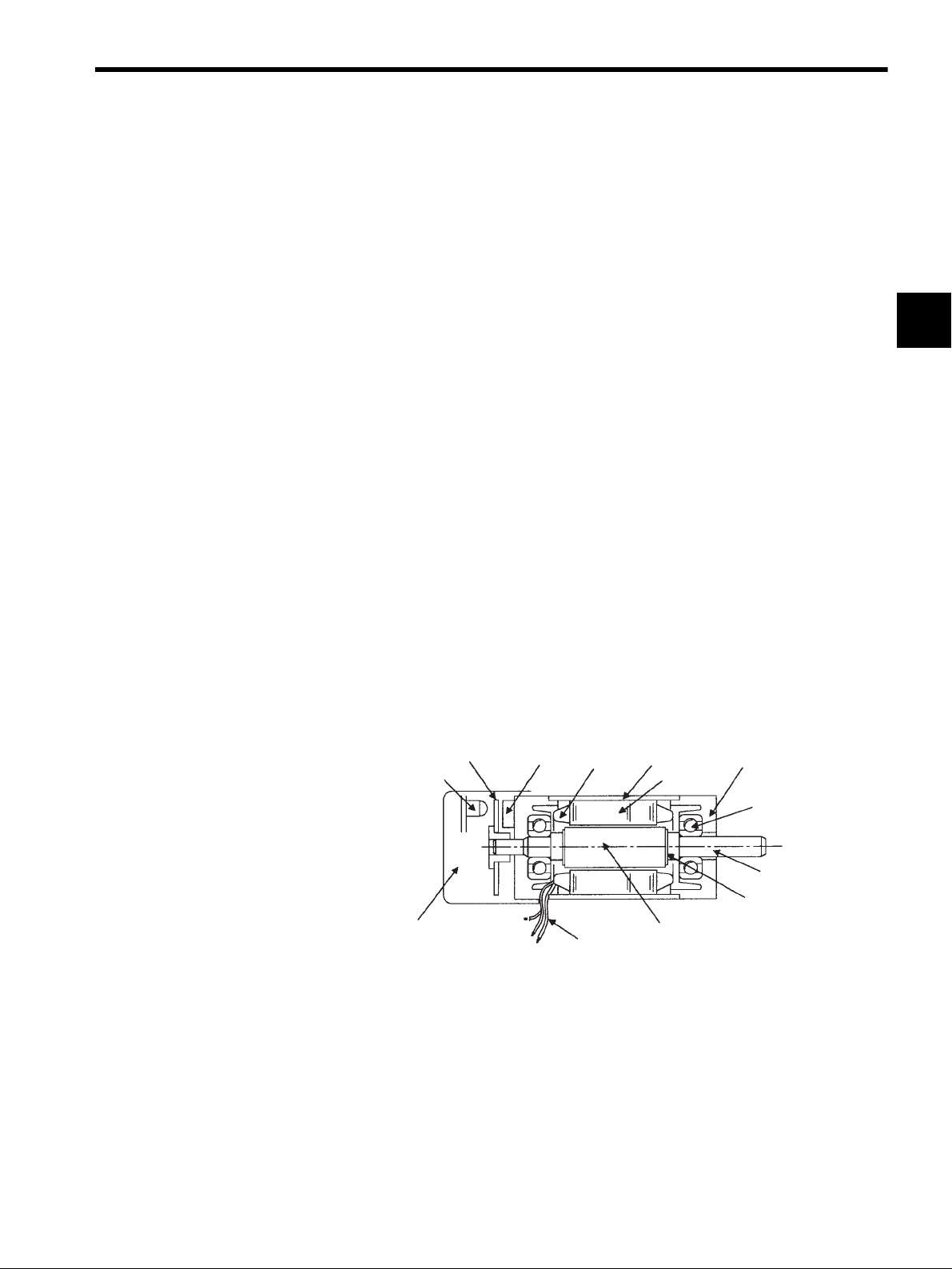

The following figure illustrates the structure of a synchronous type servomotor:

Rotary disc

Light-emitting

element

Position detector

(encoder)

Light-receiving

element

Armature

wire

Lead wire

Housing

Stator core

Magnet

Front cap

Ball bearing

Shaft

Rotor core

Yaskawa SGMBH servomotors are of the synchronous type.

• Performance of Servomotor

A servomotor must have “instantaneous power” so that it can start as soon as a start ref-

erence is received. The term “power rating (kW/s)” is used to represent instantaneous

power. It refers to the electric power (kW) that a servomotor generates per second. The

greater the power rating, the more powerful the servomotor.

1-7

Page 22

For First-time Users of AC Servos

1

3. Detector

A servo system requires a position or speed detector. It uses an encoder mounted on a

servomotor for this purpose. Encoders are divided into the following two types:

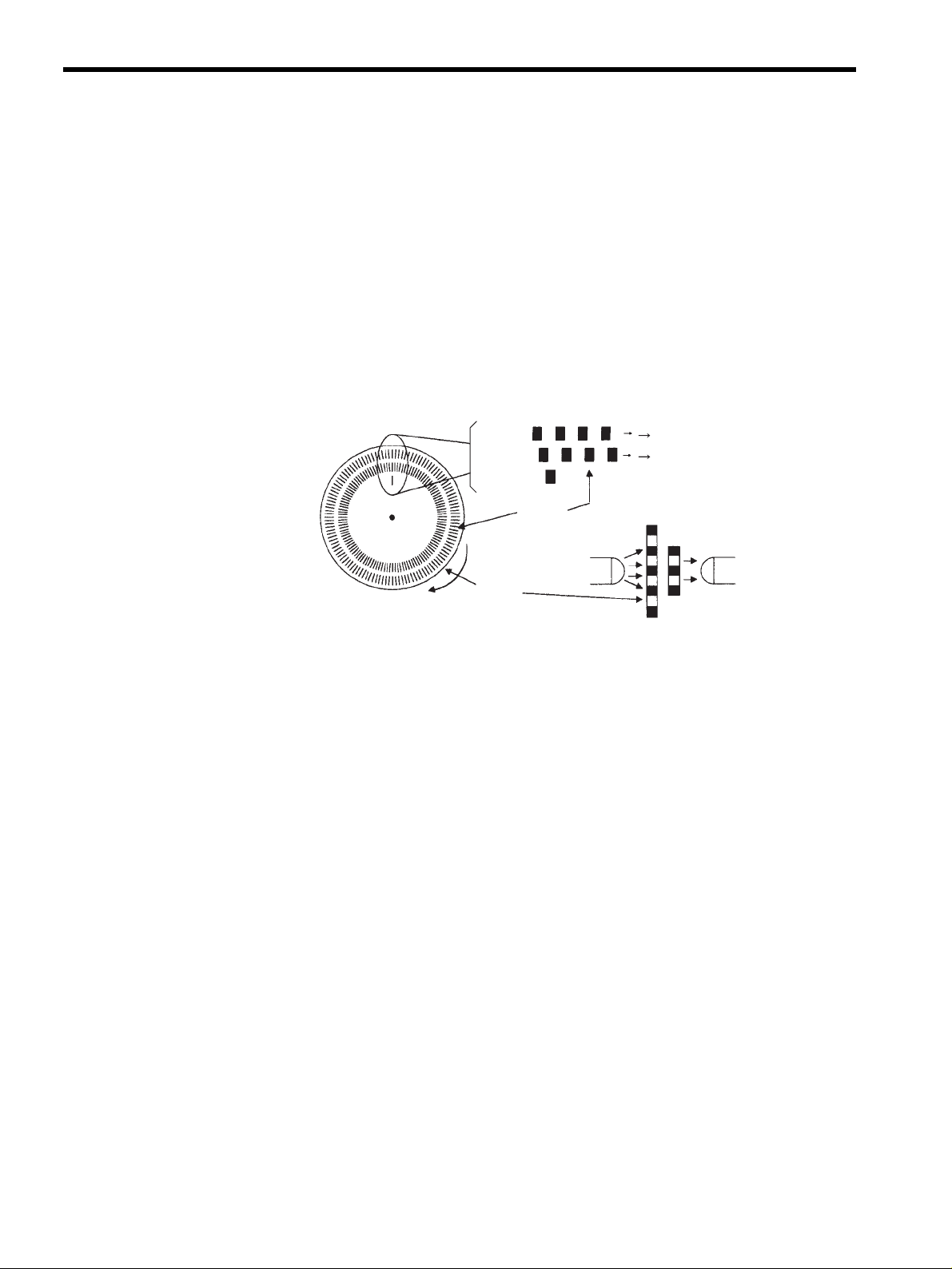

• Incremental Encoder

An incremental encoder is a pulse generator, which generates a certain number of pulses

per revolution (e.g., 2,000 pulses per revolution). If this encoder is connected to the

mechanical system and one pulse is defined as a certain length (e.g., 0.001 mm), it can

be used as a position detector. However, this encoder does not detect an absolute posi-

tion and merely outputs a pulse train. Hence zero point return operation must be per-

formed before positioning. The following figure illustrates the operation principle of a

pulse generator:

Phase A pulse train

Phase B pulse train

Fixed slit

Light-receiving

element

Center of

revolution

Phase A

Phase B

Phase Z

Rotary

disc

Slit

Light-emitting

element

Rotary slit

• Absolute Encoder

An absolute encoder is designed to detect an absolute angle of rotation as well as to per-

form the general functions of an incremental encoder. With an absolute encoder, there-

fore, it is possible to create a system that does not require zero point return operation at

the beginning of each operation.

• Difference between an Absolute and Incremental Encoder

An absolute encoder will keep track of the motor shaft position even if system power is

lost and some motion occurs during that period of time. The incremental encoder is

incapable of the above.

1-8

Page 23

1.2 Configuration of Servo System

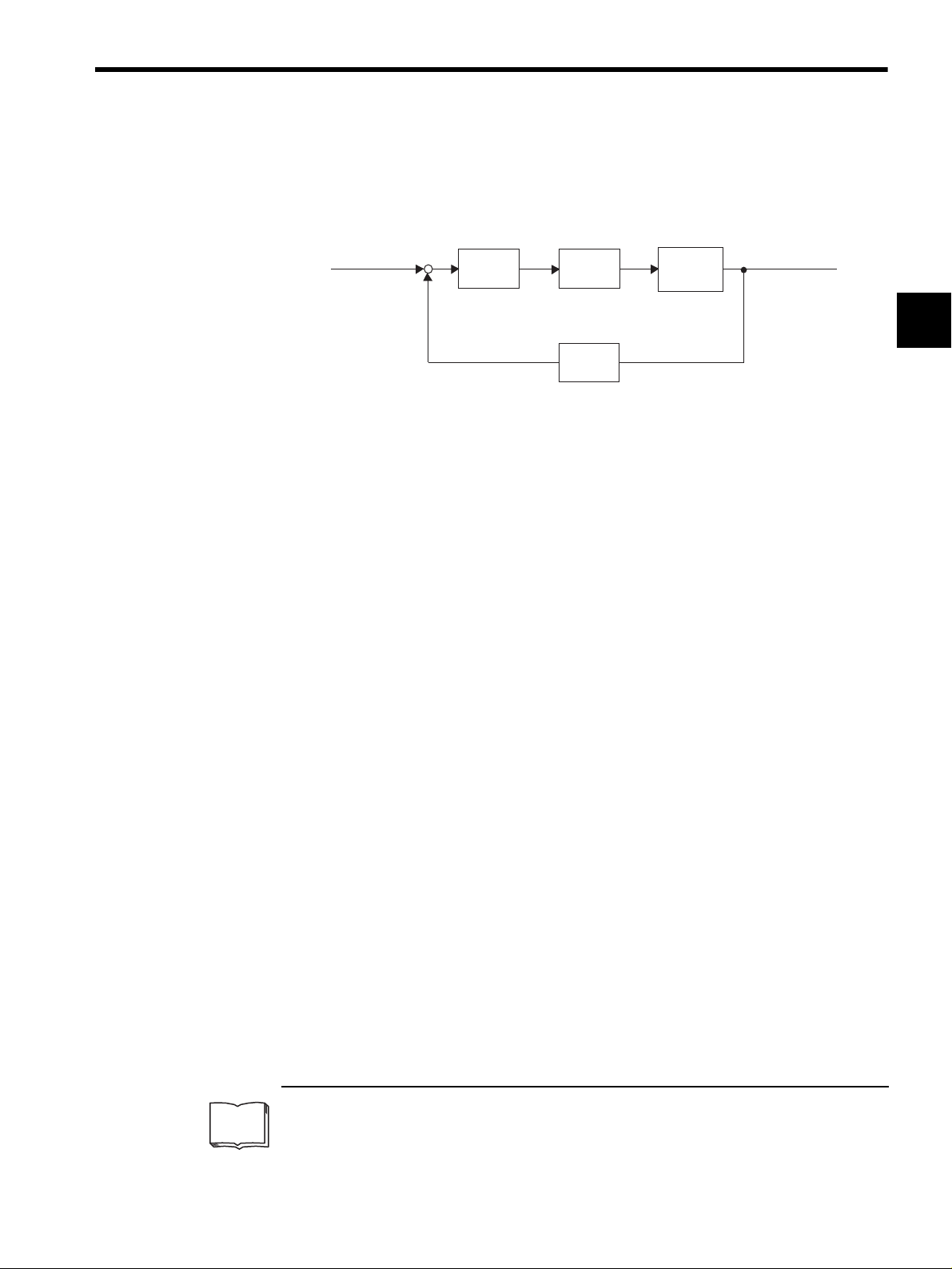

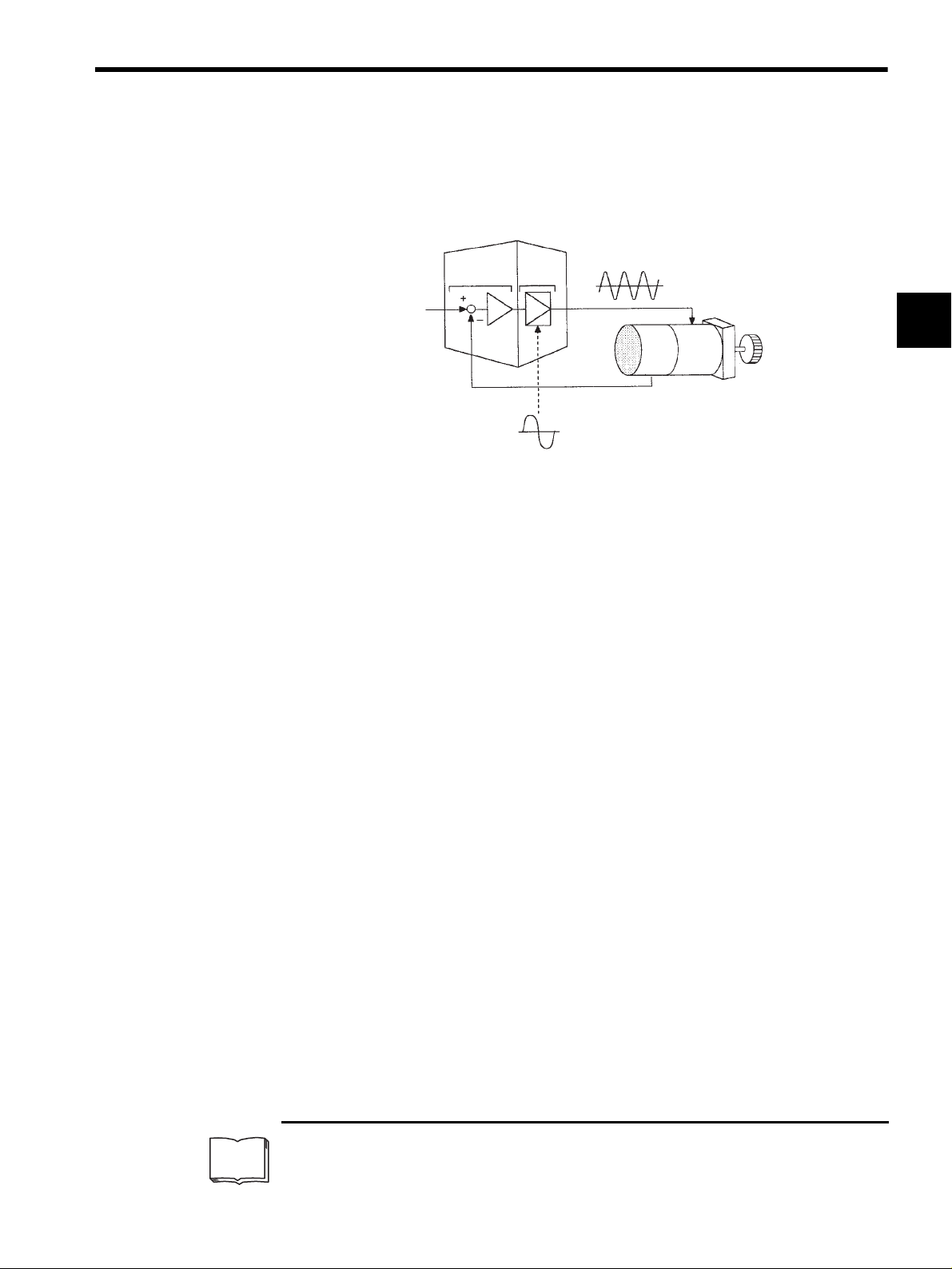

4. Servo Amplifier

A servo amplifier is required to operate an AC servomotor. The following figure illus-

trates the configuration of a servo amplifier:

Servo amplifier

Motor driving AC power

Reference

input

Comparator

Power

amplifier

1

Feedback

Commercial AC power

Servomotor

A servo amplifier consists of the following two sections:

• Comparator

A comparator consists of a comparison function and a control function. The comparison

function compares reference input (position or speed) with a feedback signal and gener-

ates a differential signal.

The control function amplifies and transforms the differential signal. In other words, it

performs proportional (P) control or proportional/integral (PI) control

1

. (It is not impor-

tant if you do not understand these control terms completely at this point.)

• Power Amplifier

A power amplifier runs the servomotor at a speed or torque proportional to the output of

the comparator. In other words, from the commercial power supply of 50/60 Hz, it gen-

erates alternating current with a frequency proportional to the reference speed and runs

the servomotor with this current.

5. Host Controller

A host controller controls a servo amplifier by specifying a position or speed as a set

point.

TERMS

For speed reference, a position control loop may be formed in the host controller when a

position feedback signal is received. Yaskawa machine controller MP920 is a typical

host controller.

1

Proportional/integral (PI) control

PI control provides more accurate position or speed control than proportional control, which is more

commonly used.

1-9

Page 24

For First-time Users of AC Servos

1

1.3.1 Outline

1.3 Features of Σ-ΙΙ Series Servos

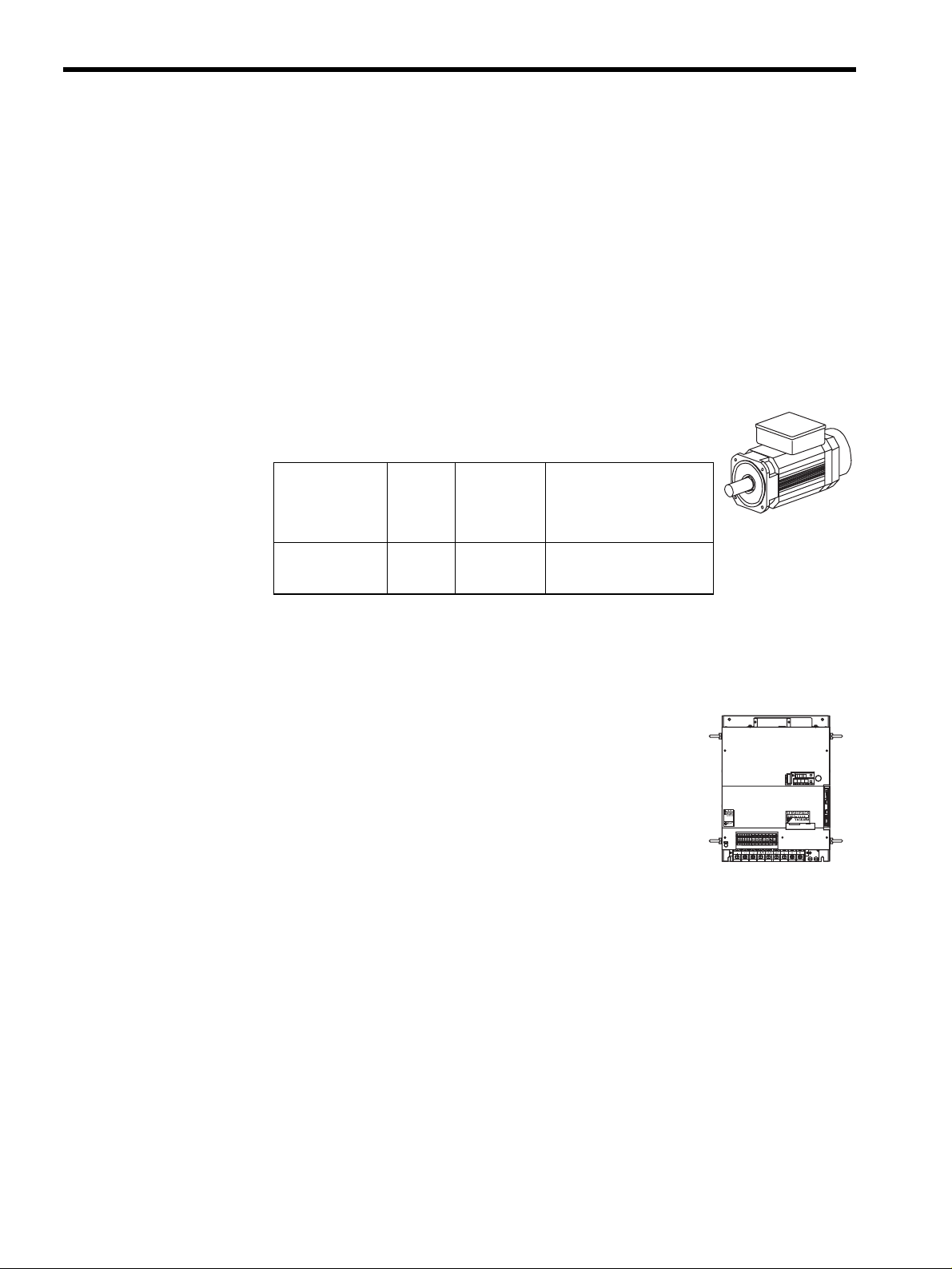

A Σ-ΙΙ Series Servo consists of an SGMBH servomotor and an SGDH SERVOPACK.

1.3.1 Outline

This section outlines SGMBH servomotor types and the control types of SGDH SERVO-

PAC Ks .

SGMBH Servomotor Type

Σ-ΙΙ Series SGMBH servomotors are synchronous type servomo-

tors and have the following features:

Rated Motor

Speed

Voltage Maximum

To rq u e

Rated Output

Maximum

Motor Speed

1500 min

2000 min

-1

-1

400 V 200 % 22 to 55 kW (10 models)

Control Types of SGDH SERVOPACK

SGDH SERVOPACKs allow the control of speed, position and torque.

Speed Control (Analog Reference)

Accepts an analog voltage speed reference.

Position Control (Pulse Reference)

Accepts a pulse train position reference.

Torque Control (Analog Reference)

Accepts an analog voltage torque reference.

SGMBH

Servomotor

WARNING

5

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

SGDH SERVOPACK

1-10

Page 25

1.3.2 Using the SGDH SERVOPACK

Using the SERVOPACK for Speed Control

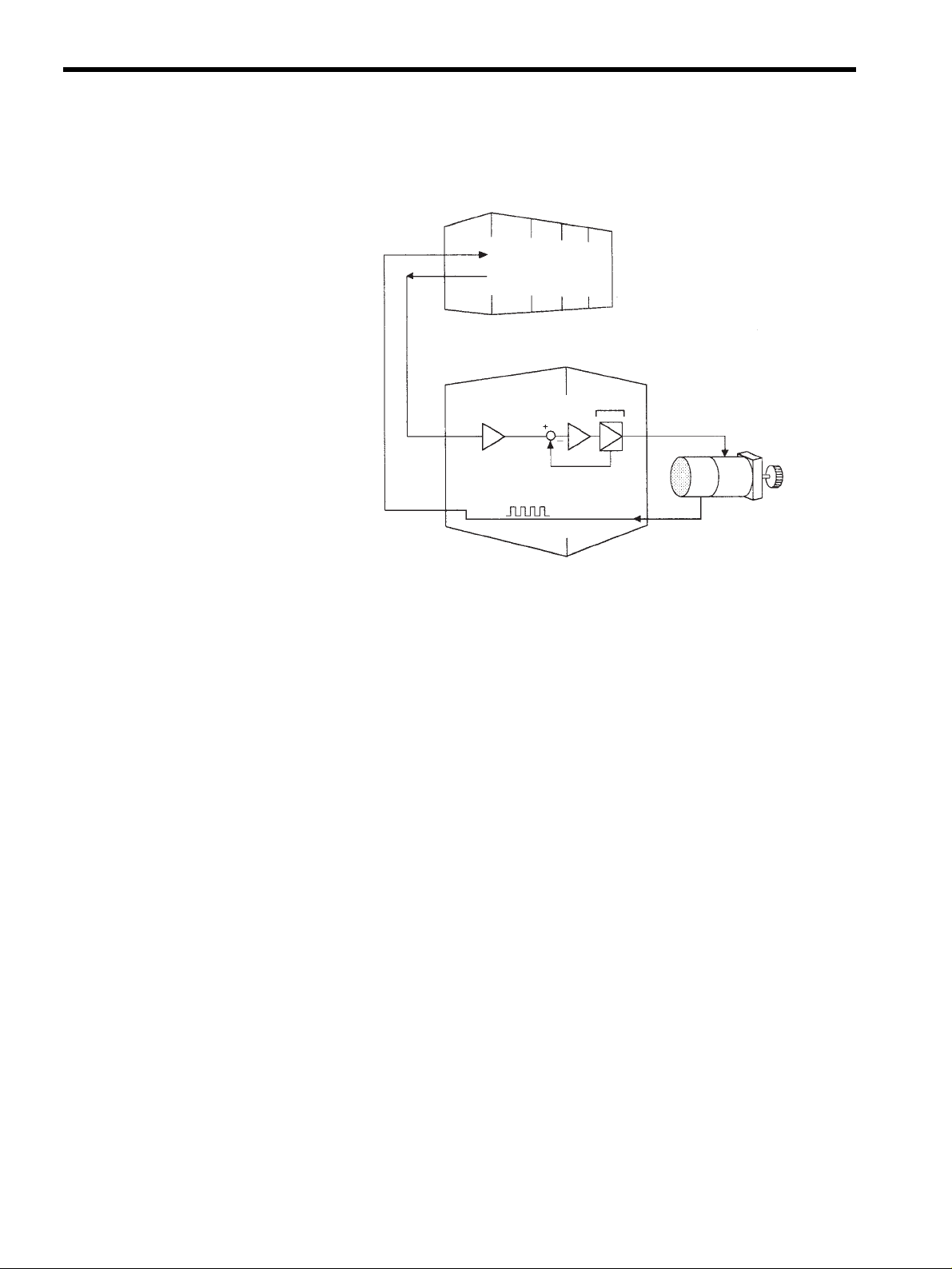

The most common use of a SERVOPACK for speed control is shown below:

1.3 Features of Σ-ΙΙ Series Servos

Host controller

Position reference

Position

feedback

(Analog

voltage)

+

Speed

reference

+

-

Position

-

Convert

Position feedback

Position control loop

SERVOPACK

(speed control mode)

Power

amplifier

+

-

Speed

Pulse train

Servomotor

Torque

(current)

feedback

Encoder

As shown in the above figure, a position control loop is formed in the host controller. The

host controller compares a position reference with a position feedback signal and sends the

processed result to the SERVOPACK as a speed reference.

In this way the host controller can be freed from performing the servo mechanism control.

The SERVOPACK undertakes the speed control loop and subsequent control processing.

1

The Yaskawa machine controller MP920 is used as a typical host controller.

1-11

Page 26

For First-time Users of AC Servos

1

1.3.2 Using the SGDH SERVOPACK

Using the SERVOPACK for Torque Control

The SERVOPACK can be used for torque control as shown below.

Host controller

Position

monitoring

Position

information

Torque

reference

(Analog

voltage)

Position feedback Encoder

SERVOPACK

(torque control mode)

Power

amplifier

Servomotor

Torque (current)

feedback

Pulse train

The host controller outputs a torque reference to control the SERVOPACK. It also receives a

pulse train (position information) from the SERVOPACK and uses it to monitor the position.

1-12

Page 27

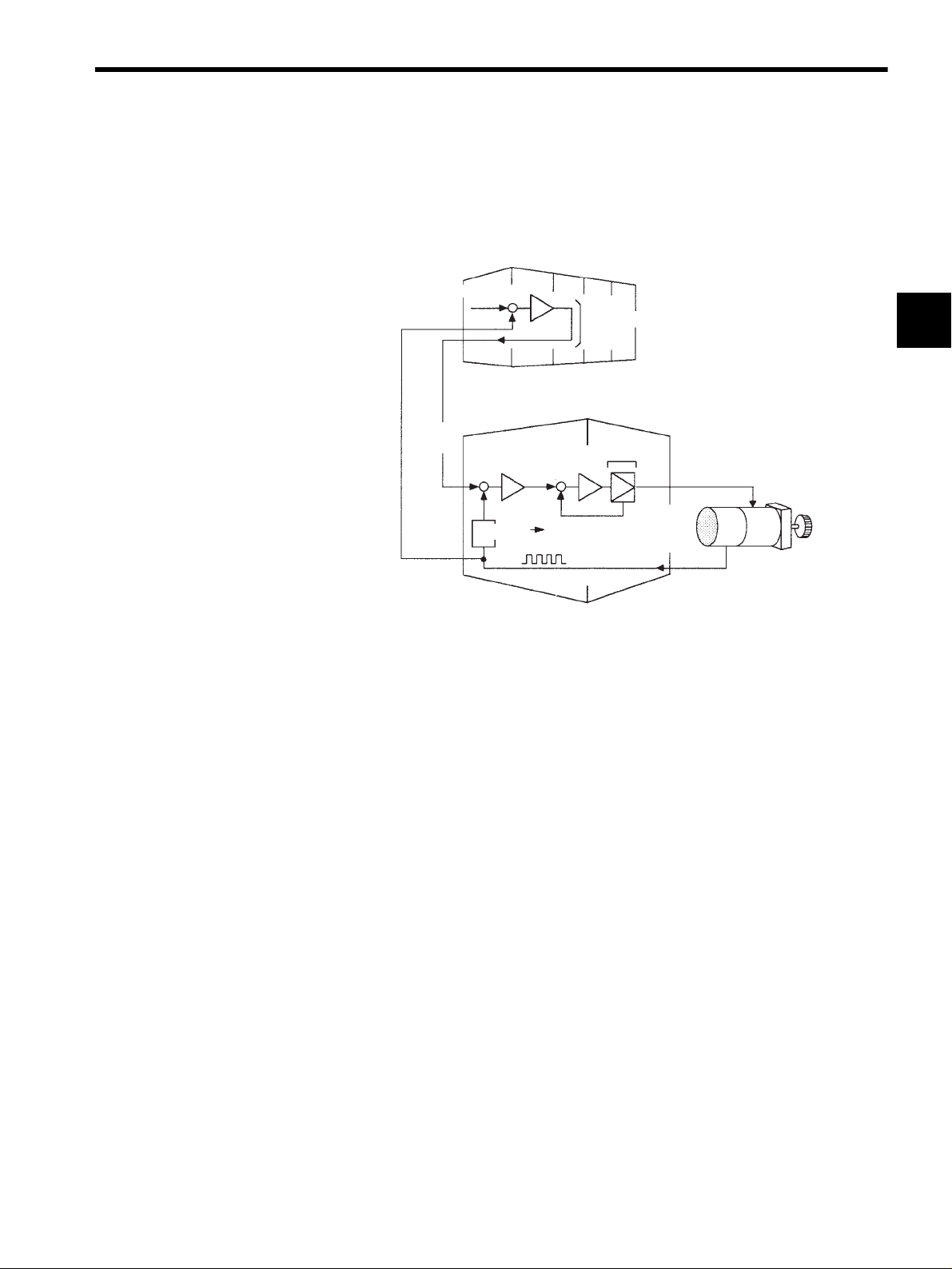

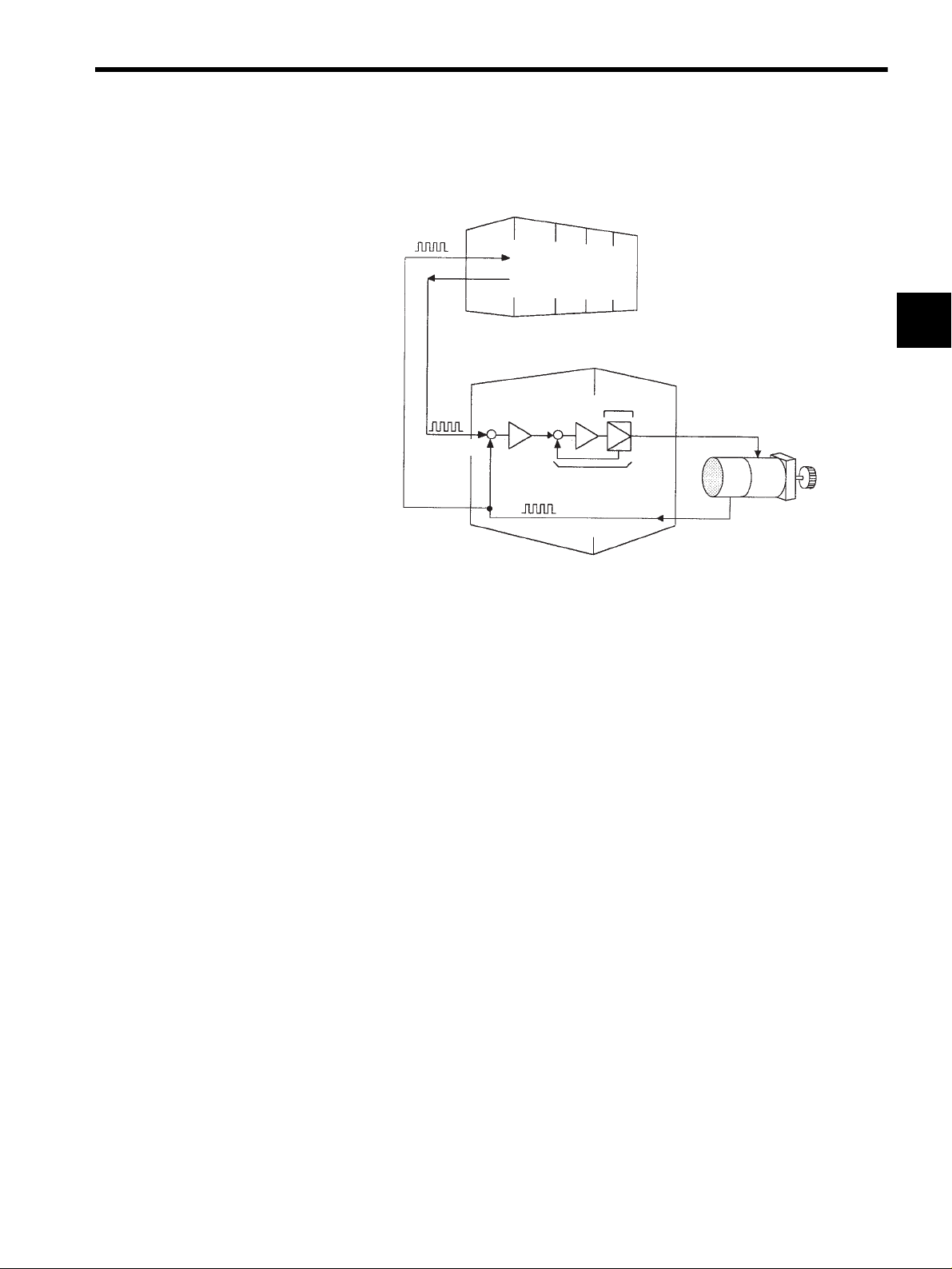

Using the SERVOPACK for Position Control

The SERVOPACK can be used for position control as shown below.

Host controller

Position

monitoring

1.3 Features of Σ-ΙΙ Series Servos

Position

information

Position

reference

Pulse

train

+

+

--

Speed/current loop

Position feedback

SERVOPACK

(position control mode)

Power

amplifier

Servomotor

Pulse train

Encoder

The host controller can send a position reference (pulse train) to the SERVOPACK to per-

form positioning or interpolation. This type of SERVOPACK contains a position control

loop.

Parameters can be used to select either of the following pulse trains:

• Sign + pulse train

• Two-phase pulse train with 90° phase difference

• Forward and reverse pulse trains

The host controller receives a pulse train (position information) from the SERVOPACK and

uses it to monitor the position.

1

Parameter Setting

A Digital Operator can be used to set parameters for a SERVOPACK as follows:

• Setting parameters to enable or disable each function

• Setting parameters required for functions to be used

Set parameters according to the servo system to be set up.

1-13

Page 28

2

Basic Operation

This chapter describes the first things to do when Σ-II Series products are

delivered. It also explains the most fundamental ways of connecting and oper-

ating Σ-II Series products. Both first-time and experienced servo users must

read this chapter.

2.1 Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

2.2 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-5

2.2.1 Checking on Delivery - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.2.2 Installing the Servomotor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.2.3 Allowable Radial and Thrust Loads - - - - - - - - - - - - - - - - - - - - - - - - 2-10

2.2.4 Installing the SERVOPACK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

2.2.5 Power Loss - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13

2

2.3 Connection and Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - 2-14

2.3.1 Connecting to Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - - - 2-14

2.3.2 Main Circuit Wiring and Power ON Sequence - - - - - - - - - - - - - - - - - 2-18

2.4 I/O Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-21

2.4.1 Examples of I/O Signal Connections - - - - - - - - - - - - - - - - - - - - - - - 2-22

2.4.2 List of CN1 Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-23

2.4.3 I/O Signal Names and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - 2-24

2.4.4 Interface Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-26

2.5 Wiring Encoders - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-30

2.5.1Connecting an Encoder (CN2) and Output Signals

from the SERVOPACK (CN1) - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-30

2.5.2 Terminal Layout and Types of CN2 Encoder Connector - - - - - - - - - - 2-31

2.5.3 Examples of Connecting I/O Signal Terminals - - - - - - - - - - - - - - - - 2-32

2-1

Page 29

Basic Operation

2

2.1 Precautions

This section provides notes on using Σ-II Series products.

Use a 400-VAC power supply.

Use a 400-VAC power supply.

Do not connect the servomotor directly to a commercial power line.

Direct connection to the power frequency sup-

ply will damage the servomotor. The servomo-

tor cannot be operated without an SGDH

SERVOPACK.

power supply

Do not change wiring when power is ON.

Always turn the power OFF before connecting

or disconnecting a connector. (Except for Digi-

tal Operator (Model: JUSP-OP02A-2))

400 VAC

WARNING

5

!

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

480 V460

400 V 0 V440

380

V

V

V

CHARGE

Direct

connection

Damage will result!

OFF

POWER

8CN

TDATA/SEEMOD/

CN5

KSERVOPAC

AYASKAW

(POWER and

CHANGE lamp)

O

P

E

R

A

T

O

R

CN3

S-HDG

DC

DC

DU

DWDV B1

B2

24N

24P

L1/R L2/S

+2-+1

UVW

L3/T

Always turn the

power OFF before

connecting a

connector.

Before inspecting, always wait 5 minutes after turning power OFF.

Even after the power is turned OFF, residual

electric charge still remains in the capacitor

inside the SERVOPACK. To prevent an electric

shock, always wait for the CHARGE lamp to go

OFF before starting inspection (if necessary).

2-2

CHARGE lamp

Page 30

Always follow the specified installation method.

2.1 Precautions

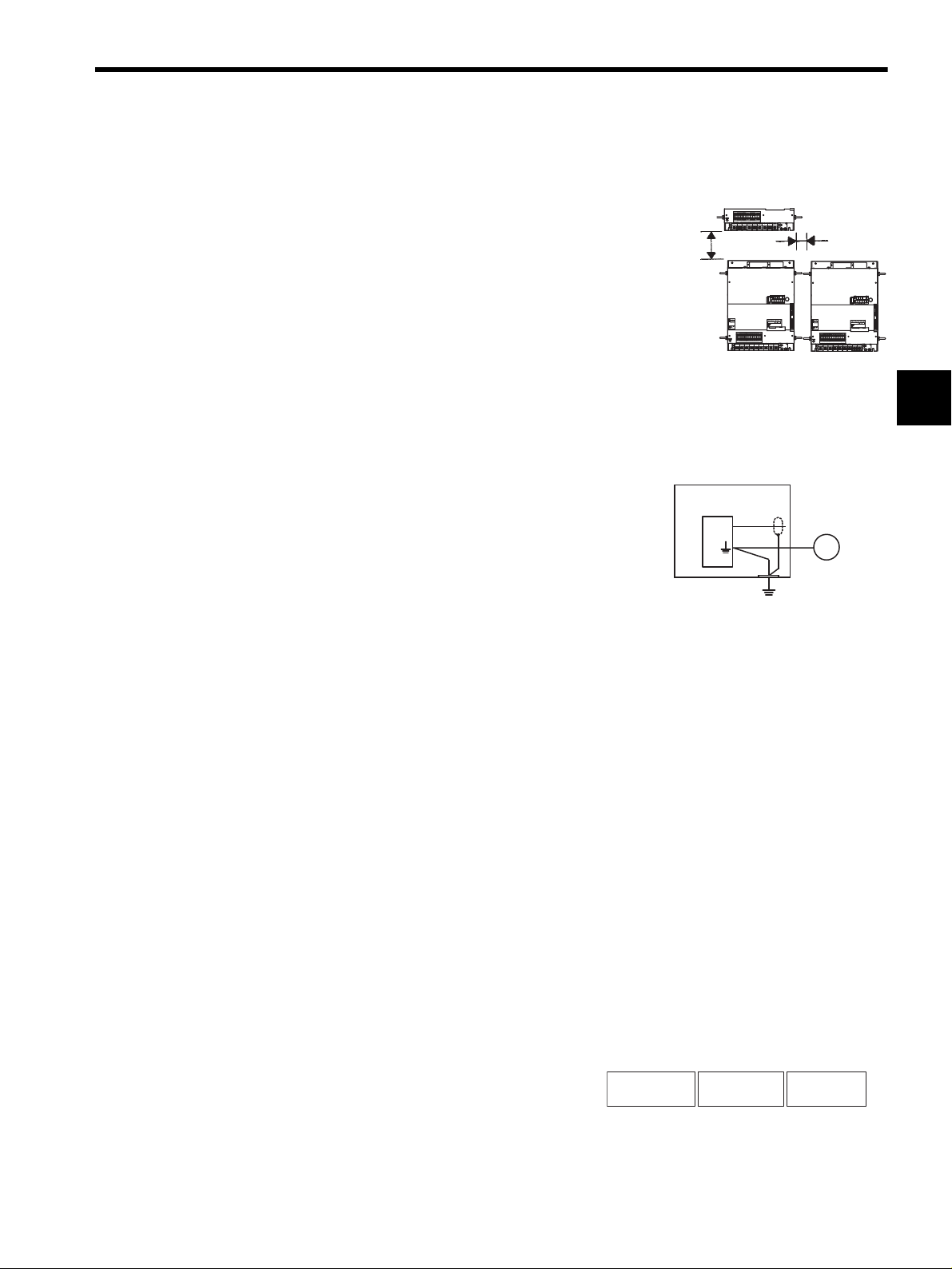

When installing SERVOPACKs side by side as

Provide sufficient clearance

shown in the figure on the right, allow at least 10

mm (0.39 in) between and at least 50 mm (1.97 in)

above and below each SERVOPACK. The SERVO-

50 mm

or more

PACK generates heat. Install the SERVOPACK so

that it can radiate heat freely. Note also that the

SERVOPACK must be in an environment free from

condensation, vibration and shock.

Ambient temperature: 0 to 55°C

Perform noise reduction and grounding properly.

If the signal line is noisy, vibration or malfunction will result.

• Separate high-voltage cables from low-voltage

cables.

• Use cables as short as possible.

• Perform the grounding with the ground resis-

tance of 100 Ω or less for the servomotor and

SERVOPACK.

• Never use a line filter for the power supply in

the motor circuit.

SERVOPACK

480 V460

400 V 0 V440

380

DU

V

V

V

CHARGE

+2-+1

WARNING

5

!

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

480 V460

400 V 0 V440

380

V

V

V

CHARGE

Casing

Single

line

DC

DC

DWDV B1

B2

24N

24P

L1/R L2/S

UVW

L3/T

POWER

8CN

O

P

E

R

A

T

O

R

T DATA/SEEMOD/

CN5

CN3

KSERVOPAC

S-HDG

AYASKAW

DC

DC

DU

DWDV B1

B2

24N

24P

L1/R L2/S

+2-+1

UVW

L3/T

Servomotor

Ground

(with resistance

of 100 Ω or less)

10 mm

or more

WARNING

5

!

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

480 V460

400 V 0 V440

380

DU

V

V

V

CHARGE

+2-+1

M

POWER

8CN

O

P

E

R

A

T

O

R

TDATA/SEEMOD/

CN5

CN3

KSERVOPAC

S-HDG

AYASKAW

DC

DC

DWDV B1

B2

24N

24P

L1/R L2/S

UVW

L3/T

2

Conduct a voltage resistance test under the following conditions.

• Voltage: 1500 Vrms AC, one minute

• Current limit: 100 mA

• Frequency: 50/60 Hz

• Voltage application points: Between 480 V, 460 V, 440 V, 400 V, 380 V, 0 V terminals,

L1/R, L2/S, L3/T terminals, and frame ground (connect terminals securely).

Contact your Yaskawa representative before applying voltage to points not specified above,

e.g., when performing standards certification tests.

Use a fast-response type ground-fault interrupter.

For a ground-fault interrupter, always use a

fast-response type or one designed for PWM

inverters. Do not use a time-delay type.

GOOD

Fast-response

type

Ground-fault interrupter

GOOD

For PWM

inverter

POOR

Time-delay

type

2-3

Page 31

Basic Operation

2

Do not perform continuous operation under overhanging load.

Continuous operation cannot be performed

by rotating the motor from the load and

applying regenerative braking. Regenerative

braking by the SERVOPACK can be applied

only for a short period, such as the motor

deceleration time.

The servomotor cannot be oper-

ated by turning the power ON and OFF.

Frequently turning the power ON and OFF

causes the internal circuit elements to deteri-

orate. Always start or stop the servomotor by

using reference pulses.

Do not apply regenerative

braking continuously.

Powe r

supply

Do not start or stop by

tuning power ON and OFF.

Servomotor

SERVOPACK

380 to 480 V

0V

L1/R

L2/S

L3/T

2-4

Page 32

2.2 Installation

This section describes how to check Σ-II Series products on delivery and how to install them.

2.2.1 Checking on Delivery

Check the following items when Σ-II Series products are delivered.

Check Items Comments

Are the delivered products the ones

that were ordered?

Does the servomotor shaft rotate

smoothly?

Is there any damage? Check the overall appearance, and check for damage or scratches

Are there any loose screws? Check screws for looseness using a screwdriver.

2.2 Installation

Check the model numbers marked on the nameplates of the servomotor and SERVOPACK. (See the following.)

The servomotor shaft is normal if it can be turned smoothly by

hand. Servomotors with brakes, however, cannot be turned manually.

that may have occurred during shipping.

2

If any of the above items are faulty or incorrect, contact your Yaskawa sales representative

or the dealer from whom you purchased the products.

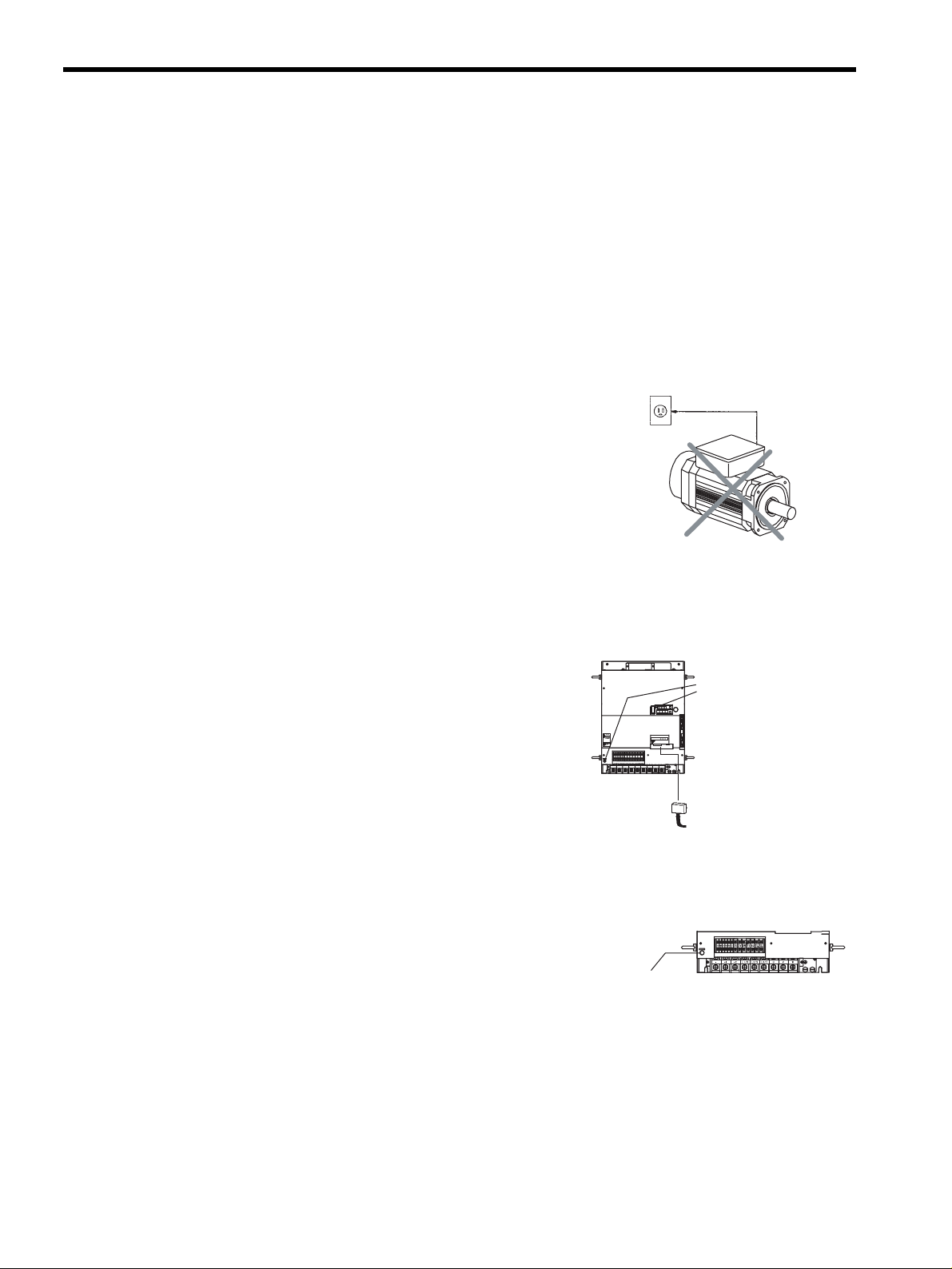

Servomotors

External Appearance and Nameplate Examples

(Example)

Rated output

Servomotor model

AC SERVO MOTOR

SGMBH - 2BDCA

SGMBH

servomotor

TYPE

kw N.m

22

-1

min

1500

RATING

CONT.

SER.NO.

DATE

9708

YASKAWA ELECTRIC CORPORATION

140

A

58

K7A500 101 - 004

Munufacturing date

Serial number

Rated rotation speed

ENCODER

UTMAH- B12BDYR11

17 bit

JAPAN

2-5

Page 33

Basic Operation

2

2.2.1 Checking on Delivery

Model Numbers

SGMBH -2BD C A

Σ-II Series

Servomotor

Servomotor Capacity

2B: 22 kW 4E: 45 kW

3Z: 30 kW 5E: 55 kW

3G: 37 kW

Supply Voltage

D: 400 V

Encoder Specifications

2: 17-bit absolute encoder

3: 20-bit absolute encoder (optional)

C: 17-bit incremental encoder

SERVOPACKs

External Appearance and Nameplate

POWER

8CN

O

P

E

R

A

T

O

R

T DATA/SEEMOD/

CN5

CN3

WARNING

5

!

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

DC

480 V460

400 V 0 V440

380

DU

DWDV B1

B2

24N

V

V

V

CHARGE

L1/R L2/S

+2-+1

Σ-II Series SGDH

SERVOPACK

DC

24P

L3/T

S-HDG

UVW

KSERVOPAC

AYASKAW

Options

1: With V-type oil seal

B: With V-type oil seal, 90-VDC holding brake

C: With V-type oil seal, 24-VDC holding brake

S: With S-type oil seal

D: With S-type oil seal, 90-VDC holding brake

E: With S-type oil seal, 24-VDC holding brake

Shaft End Specifications

2: Flange mounted, straight without key

6: Flange mounted, straight with key and tap

K: With foot, straight without key

L: With foot, straight with key and tap

Design Revision Order

A: Maximum torque 200%

(Example)

SERVOPACK model

SERVOPACK

MODEL

VOLTS 380- 480

Hz 50/60

PHASE 3

AMPS 145

S / N R7C303 - 221 - 4

Serial number

Applicable power supply

SGDH - 3ZDE

AC-INPUT AC - OUTPUT

YASKAWA ELECTRIC

MADE IN JAPAN

VOLTS 0- 480

PHASE 3

AMPS 175

kW (HP)

30.0 (40.2)

Output power

Model Numbers

SGDH -2BD E

Σ-II Series

SGDH SERVOPACK

Rated Output (motor capacity)

2B: 22 kW 4E: 45 kW

3Z: 30 kW 5E::55 kW

3G: 37 kW

Supply Voltage

D:400 V

Model

E: For speed/torque control and position control

2-6

Page 34

2.2.2 Installing the Servomotor

SGMBH servomotors can be installed either horizontally or vertically. The service life of the

servomotor will be shortened or unexpected problems will occur if the servomotor is

installed incorrectly or in an inappropriate location. Always observe the following installa-

tion instructions.

Prior to Installation

The end of the motor shaft is coated with anticorrosive paint. Thoroughly remove the paint

using a cloth moistened with thinner prior to installation.

2.2 Installation

IMPORTANT

Anticorrosive paint is

coated here.

Avoid getting thinner on other parts of the servomotor when cleaning the shaft.

Storage Temperature

Store the servomotor within the following temperature range if it is stored with the power

cable disconnected.

Between -20 to 60 °C.

Installation Site

SGMBH servomotors are designed for indoor use. Install the servomotor in environments

that satisfy the following conditions.

• Free of corrosive or explosive gases.

• Well-ventilated and free of dust and moisture.

• Ambient temperature of 0 to 40 °C.

• Relative humidity of 20% to 80% (non-condensing)

• Facilitates inspection and cleaning.

• Altitude : 1000 m max.

2

TERMS

Install a protective cover over the servomotor if it is used in a location that is subject to

water or oil mist. Also use a servomotor with an oil seal to seal the through shaft

1

section.

Install the electrical connector with the cable facing downward or in a horizontal position.

1

Through Sections of the shaft

This refers to the gap where the shaft protrudes from the end of

the motor.

2-7

Shaft

opening

Page 35

Basic Operation

2

2.2.2 Installing the Servomotor

Alignment

Align the shaft of the servomotor with that of the equipment to be controlled, then connect

the shafts with flexible couplings. Install the servomotor so that alignment accuracy falls

within the following range.

Measure this distance at four different positions in the circumference.

The difference between the maximum and minimum measurements

must be 0.03 mm or less. (Turn together with couplings)

Measure this distance at four different positions in the

circumference. The difference between the maximum

and minimum measurementsmust be 0.03 mm or less.

(Turn together with couplings)

IMPORTANT

1. Vibration that will damage the bearings will occur if the shafts are not properly aligned.

2. Do not allow direct impact to be applied to the shafts when installing the coupling. Otherwise the

encoder mounted on the opposite end of the shaft may be damaged.

3. Before mounting the pinion gear directly to the motor output shaft, consult your Yaskawa sales rep-

resentative.

Wiring the Servomotor Power Lines

Connect the servomotor power lines (U, V, and W) to the servomotor terminal block (M10)

in the servomotor terminal box. Connect the ground wire to the ground screw in the terminal

box.

Wiring the Servomotor Thermostat

The servomotor has a built-in thermostat. Wire the thermostat leads (l, lb) to the terminal

block (M4) in the servomotor’s terminal box.

Wiring the Servomotor Fan

Wire the servomotor fan leads U(A), V(B), and W(C) so that the direction of air flows

according to the following diagram. If the air flows in the opposite direction, change the wir-

ing of any of the two phases U, V, and W.

Direction of

cool air

Servomotor

2-8

Page 36

2.2 Installation

Protecting the Servomotor Fan

The servomotor fan has a built-in thermal protector, as shown in the following diagram, that

operates at 140°C ±5 %. To protect the servomotor fan from overcurrent, use with a 2-A no-

fuse breaker.

U

V

W

Installing the Servomotor Fan

To maximize the cooling capacity of the servomotor fan, install the fan at least 200 mm

(7.87 in) from the inlet side of the servomotor as shown in the following diagram.

Cool air

200 mm min.

Servomotor

Servomotor Connector Specifications

• Encoder Connector at Servomotor

The connector specifications for the encoder on the servomotor are as follows:

2

L-shaped

JA08A-20-29S-JA-EB

or

MS3108B20-29S

* 1. Connector at servomotor is already provided.

* 2. Manufactured by Japan Aviation Electronics Industry, Ltd.

* 3. Waterproof.

Encoder Connectors

Plug Cable Clamp

Straight

*2, *3

JA06A-20-29S-J1-EB

or

MS3106B20-29S

To be prepared by the customer

*2, *3

JL04-2022CKE (**)

MS3057-12A

** indicates the cable diameter.

2-9

Receptacle

*2, *3

or

97F-3102E20-29P

*1

*3

Page 37

Basic Operation

2

2.2.3 Allowable Radial and Thrust Loads

• Fan Connector on Servomotor

Plug Cable Clamp

L-shaped

CE05-8A18-10SD-B-BAS

*2, *3

or

MS3108B18-10S

* 1. Connector at servomotor is already provided.

* 2. Manufactured by Daiichi Denshi Kogyo Co., Ltd.

* 3. Waterproof.

2.2.3 Allowable Radial and Thrust Loads

The connector specifications for the fan on the servomotor are as follows:

Fan Connectors

Receptacle

Straight

CE05-6A18-10SD-B-BSS

or

MS3106B18-10S

To be prepared by the customer

*2, *3

CE3057-10A-* (D265)

or

MS3057-10A

** indicates the cable diameter.

*2, *3

CE05-2A18-10PD-B

*1

*3

Design the mechanical system so radial and thrust loads1 applied to the servomotor shaft end

during operation falls within the ranges shown in the following table.

Servomotor Model

SGMBH-

2BD

3ZD

3GD

4ED

5ED

Note: Allowable radial and thrust loads shown above are the maximum val-

ues that could be applied to the shaft end from motor torque or other

loads.

Allowable Radial Load

Fr [N]

5880 2156 100

6272 2156 100

7448 2156 100

7840 2156 100

8428 2156 110

Allowable Thrust Load

Fs [N]

LR

Fr

Fs

LR

[mm]

TERMS

1

Radial and thrust loads

Thrust load (Fs): Load applied parallel to the centerline of the shaft.

Radial load (Fr): Load applied perpendicular to the centerline of

the shaft.

2-10

Motor

Fr

Fs

Page 38

2.2.4 Installing the SERVOPACK

The SGDH SERVOPACK is a base-mounting servo controller. Incorrect installation will

cause problems. Always observe the installation instructions below.

Storage Temperature

Store the servomotor within the following temperature range if it

is stored with the power cable disconnected.

Between -20 to +85 °C.

Installation Site

Take the following precautions at the installation site.

Situation Notes on Installation

Installation in a Control Panel Design the control panel size, unit layout, and cooling method

Installation Near a Heating Unit Minimize heat radiated from the heating unit as well as any tem-

Installation Near a Source of Vibration

Installation at a Site Exposed to Corrosive Gas

Other Situations Do not install the SERVOPACK in hot and humid locations or

2.2 Installation

WARNING

5

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

SGDH SERVOPACK

so the temperature around the SERVOPACK does not exceed

55

°C.

perature rise caused by natural convection so the temperature

around the SERVOPACK does not exceed 55

°C.

Install a vibration isolator beneath the SERVOPACK to avoid

subjecting it to vibration.

Take appropriate action to avoid corrosive gas. Corrosive gas

does not have an immediate effect on the SERVOPACK, but

will eventually cause electronic components and contactorrelated devices to malfunction.

locations subject to excessive dust or iron powder in the air.

2

Orientation

Install the SERVOPACK perpendicular to the wall as shown in the figure.

50 mm min.

(ventilation exhaust)

120 mm min.

POWER

8CN

O

P

E

R

A

T

O

R

TDATA/SEEMOD/

CN5

CN3

WARNING

5

!

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

DC

480 V460

400 V 0 V440

380

DU

DWDV B1

B2

24N

V

V

V

CHARGE

L1/R L2/S

+2-+1

50 mm min.

50 mm min. (ventilation intake)

S-HDG

DC

24P

UVW

L3/T

50 mm min.

KSERVOPAC

AYASKAW

120 mm min.

2-11

Air flow

Air flow

Page 39

Basic Operation

2

2.2.4 Installing the SERVOPACK

Installation

Follow the procedure below to install multiple SERVOPACKs side by side in a control

panel.

Fan

Fan

50 mm

or more

WARNING

5

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

30 mm or more

WARNING

5

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

10 mm or more

WARNING

5

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

WARNING

5

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

Use proper

grounding techniques.

50 mm

or more

SERVOPACK Orientation

Install the SERVOPACK perpendicular to the wall so the front panel containing connectors

faces outward.

Cooling

As shown in the figure above, allow sufficient space around each SERVOPACK for cooling

by cooling fans or natural convection.

Side-by-side Installation

When installing SERVOPACKs side by side as shown above, allow at least 10mm (0.39 in)

between and at least 50mm (1.97 in) above and below each SERVOPACK. Install cooling

fans above the SERVOPACKs to avoid excessive temperature rise and to maintain even tem-

perature inside the control panel.

Environmental Conditions in the Control Panel

• Ambient Temperature: 0 to 55 °C

• Humidity: 90% RH or less

• Vibration: 4.9 m/s

• Condensation and Freezing: None

• Ambient Temperature for Long-term Reliability: 45°C max.

2

2-12

Page 40

2.2.5 Power Loss

Power loss of SERVOPACK is given below:

2.2 Installation

SERVOPACK

Model

SGDH-

2BDE

3ZDE

3GDE

4EDE

5EDE

Output Current

(Effective Value)

[A]

60 650 120 770

88 970 1090

105 1140 1260

135 1440 1560

160 1720 1840

Main Circuit

Power Loss

[W]

Control Circuit

Power Loss

[W]

Total Power Loss

[W]

2

2-13

Page 41

Basic Operation

2

2.3.1 Connecting to Peripheral Devices

2.3 Connection and Wiring

This section describes how to connect Σ-II Series products to peripheral devices and explains a

typical example of wiring the main circuit. It also describes an example of connecting to main

host controllers.

2.3.1 Connecting to Peripheral Devices

This section shows a standard example of connecting Σ-II Series products to peripheral

devices and briefly explains how to connect to each peripheral device.

2-14

Page 42

400 V Series

cMolded-case circuit

breaker (MCCB)

Used to protect power

supply line.

dNoise filter

Used to eliminate external noise from power

supply line.

eMagnetic contactor

(HI Series)

Turns the servo ON or

OFF.

fBrake power supply

Used for servomotor with

brake.

LPSE-2H01

(for 200 V input)

gPower transformer

Used to switch between

200 V to 400 V.

hDynamic Brake (DB)

Unit

Used if dynamic brake

function is required for

SERVOPACK.

Use a surge suppressor

*

for themagnetic contactor.

Power supply

Three-phase 400 VAC

RST

c

*

d

SGDH SERVOPACK

CN3

CN1

DC

480 V460

V

CHARGE

DC

400 V 0 V440

380

DU

DWDV B1

B2

24N

24P

V

V

CN1

Host controller

MP910, MP920, MP930,

and MP-SG1 with a Motion Module

POWER

8CN

O

P

E

R

A

T

O

R

TDATA/SEEMOD/

CN5

CN3

KSERVOPAC

S-HDG

AYASKAW

CN2

Connect the SGDH SERVOPACK to a

Yaskawa host controller.

2.3 Connection and Wiring

CN3

Digital Operator

Allows the user to set parameters or

operation reference and display

operation status or alarm status.

Hand-held type

(JUSP-OP02A-2)

1-meter (3.3-ft.) cable included

Personal computer

Cable model:

JZSP-CMS01 to 03

2

g

380 to 480 V

0V

e

e

L1

f

Brake power supply

DC power

supply

(24 VDC)

+

-

Power supply for

cooling fan

Note: The Dynamic Brake (DB) Unt's DBON and

DB24 terminals can be used with SERVOPACKs of 37 kW or more only.

DU

DV

DW

DBON

DB24

U

V

W

B1

B2

DC24P

DC24N

L2

L3

DB24

DV

DW

DBON

Regenerative

Resistor

DU

h

Dynamic Brake Unit

SGMBH

servomotor

2-15

Page 43

Basic Operation

2

2.3.1 Connecting to Peripheral Devices

Connector terminal block converter unit (Model: JUSP-TA50P)

The terminal block allows connection to a host con-

troller.

Cable with CN1 connector and one end without connector

1m (3.3ft): JZSP-CKI01-1

2m (6.6ft): JZSP-CKI01-2

CN1

0.5 meter cable with

CN1 connector

3m (9.8ft): JZSP-CKI01-3

CN1

CN1 connector kit

Model: JZSP-CKI9

Cable for PG

This cable is used to connect the encoder of servomotor to the SERVOPACK.

The following cables are available according to encoder types.

• Cable only (without connector at either end)

Cable Type Cable Model Length Remarks

Standard Encoder Cable JZSP-CMP09-05

JZSP-CMP09-10

JZSP-CMP09-15

JZSP-CMP09-20

50-m Specifications Encoder

Cable

JZSP-CMP19-30

JZSP-CMP19-40

JZSP-CMP19-50

5 m (196.85 in)

10 m (393.70 in)

15 m (590.55 in)

20 m (787.40 in)

30 m (1181.10 in)

40 m (1574.80 in)

50 m (1968.50 in)

CN1

The maximum allowable cable length is

20 m.

The maximum allowable cable length is

50 m.

Cable

L

2-16

Page 44

2.3 Connection and Wiring

• Cable with a single connector (without connector on encoder end)

Cable Model Length

JZSP-CMP03-03

JZSP-CMP03-05

JZSP-CMP03-10

JZSP-CMP03-15

JZSP-CMP03-20

3 m (118.11 in)

5 m (196.85 in)

10 m (393.70 in)

15 m (590.55 in)

20 m (787.40 in)

• Cable with connectors on both ends (straight plug on encoder end)

Applicable Servomotors Cable Model Length

SGMBH

Servomotors

With Straight

Plug

With L-Shape

Plug

Connector for PG

Connector on

SERVOPACK End Only

Connector on

Servomotor End Only

JZSP-CMP01-03

JZSP-CMP01-05

JZSP-CMP01-10

JZSP-CMP01-15

JZSP-CMP01-20

JZSP-CMP02-03

JZSP-CMP02-05

JZSP-CMP02-10

JZSP-CMP02-15

JZSP-CMP02-20

55102-0600

(Manufactured by Molex

Japan Co., Ltd.)

54280-0600

(Manufactured by Molex

Japan Co., Ltd.)

2

3 m (118.11 in)

5 m (196.85 in)

10 m (393.70 in)

15 m (590.55 in)

20 m (787.40 in)

3 m (118.11 in)

5 m (196.85 in)

10 m (393.70 in)

15 m (590.55 in)

20 m (787.40 in)

Connector kit: JZSP-CMP9-1

-

2-17

Page 45

Basic Operation

2

2.3.2 Main Circuit Wiring and Power ON Sequence

2.3.2 Main Circuit Wiring and Power ON Sequence

This section shows typical examples of main circuit wiring for Σ-II Series servo products,

functions of main circuit terminals, and the power ON sequence.

400-V Power Supply

• SERVOPACK Main Circuit Terminal Names and Descriptions

The following table shows the name and description of each main circuit terminal.

Table 2.1 SERVOPACK Main Circuit Terminals

Terminal

Functions Description

Symbol

L1/R, L2/S,

Main power input terminals

L3/T

U, V, W Servomotor connection

terminal

DC24P,

Control power input terminal

DC24N

(Two)