Page 1

YASKAWA 1000-Series Option

LED Operator

Installation Manual

Type: JVOP-182

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

安川1000シリーズオプション

LED

オペレータ

取扱説明書

形 式

JVOP-182

製品を安全にお使い頂くために,この取扱説明書を必ずお読みください。

また,本書をお手元に保管していただくとともに,最終的に本製品をご使用になる

ユーザー様のお手元に確実に届けられるよう,お取り計らい願います。

MANUAL NO. TOBP C730600 35D

Page 2

Copyright © 2008 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, mechanical, electronic, photocopying,

recording, or otherwise, without the prior written permission of Yaskawa. No patent liability

is assumed with respect to the use of the information contained herein. Moreover, because

Yaskawa is constantly striving to improve its high-quality products, the information

contained in this manual is subject to change without notice. Every precaution has been

taken in the preparation of this manual. Yaskawa assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the

information contained in this publication.

2 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 3

Table of Contents

1 PREFACE AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 RECEIVING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4 OPTION COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . .19

6 BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 RELATED PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . .28

8 OPTION FAULT DIAGNOSTICS. . . . . . . . . . . . . . . . . . . . . . 31

9 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

10 REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

YAS KAWA ELE CTR IC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 3

Page 4

1 Preface and Safety

1 Preface and Safety

Yaskawa manufactures products used as components in a wide variety of industrial systems

and equipment. The selection and application of Yaskawa products remain the responsibility

of the equipment manufacturer or end user. Yaskawa accepts no responsibility for the way its

products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety

control. Without exception, all controls should be designed to detect faults dynamically and

fail safely under all circumstances. All systems or equipment designed to incorporate a

product manufactured by Yaskawa must be supplied to the end user with appropriate

warnings and instructions as to the safe use and operation of that part. Any warnings

provided by Yaskawa must be promptly provided to the end user. Yaskawa offers an express

warranty only as to the quality of its products in conforming to standards and specifications

published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS

OFFERED. Yaskawa assumes no liability for any personal injury, property damage, losses,

or claims arising from misapplication of its products.

4 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 5

1 Preface and Safety

◆ Applicable Documentation

The following manuals are available for the JVOP-182 LED Operator Option:

LED Operator

J1000

Yaskawa AC Drive 1000-Series

Option LED Operator

Installation Manual

Manual No: TOBP C730600 35

(this book)

RS-232C Interface Option

Yaskawa AC Drive-J1000 Option

RS-232C Interface

Technical Manual

Yaskawa Unit

Yaskawa AC Drive

1000-Series Quick Start Guide

Yaskawa AC Drive

1000-Series Technical Manual

YASKAWA D1000 Series

Power Regenerative Converter

Instruction Manual

YASKAWA R1000 Series

Power Regenerative Unit

Instruction Manual

Read this manual first.

The installation manual is packaged with the option

and contains information required to install the

option and set up related unit parameters.

The Technical Manual is packaged with the RS232C Interface Option and contains a basic

overview of wiring, settings, functions, and fault

diagnoses.

The unit manuals cover basic installation, wiring,

operation procedures, functions, troubleshooting,

and maintenance information.

The manuals also include important information

about parameter settings and unit tuning. Access

these sites to obtain Yaskawa instruction manuals:

U.S.: http://www.yaskawa.com

Europe: http://www.yaskawa.eu.com

Japan: http://www.e-mechatronics.com

For questions, contact your local Yaskawa sales

office or the nearest Yaskawa representative.

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 5

Page 6

1 Preface and Safety

◆ Terms

Note: Indicates a supplement or precaution that does not cause unit damage.

≥ PRG: 1010: Indicates a unit feature or function that is only available in unit software

LED: Light emitting diode.

Option: YASKAWA 1000-Series Option LED Operator

Unit:

Drive:

Converter: YASKAWA D1000 Series Power Regenerative Converter

Regenerative Unit: YASKAWA R1000 Series Power Regenerative Unit

version 1010 or greater.

• YASKAWA AC Drive 1000-Series

• YASKAWA D1000 Series Power Regenerative Converter

• YASKAWA R1000 Series Power Regenerative Unit

• YASKAWA AC Drive 1000-Series A1000 High Performance Vector

Control Drive

• YASKAWA AC Drive 1000-Series V1000 Compact Vector Control Drive

• YASKAWA AC-Drive 1000-Series J1000 Compact V/f Control Drive

◆ Registered Trademarks

Company names and product names listed in this manual are the registered trademarks of

those companies.

◆ Supplemental Safety Information

Read and understand this manual before installing, operating or servicing this option. The

option must be installed according to this manual and local codes.

The following conventions are used to indicate safety messages in this manual. Failure to

heed these messages could result in serious or fatal injury or damage to the products or to

related equipment and systems.

DANGER

Indicates a hazardous situation, which, if not avoided, will result in death or serious

injury.

6 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 7

1 Preface and Safety

W ARNING

CAUTION

NOTICE

Indicates a hazardous situation, which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation, which, if not avoided, could result in minor or

moderate injury.

Indicates an equipment damage message.

■ General Safety

General Precautions

• The diagrams in this section may include options and units without covers or safety shields to

illustrate details. Be sure to reinstall covers or shields before operating any devices. The option board

should be used according to the instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only and

may not apply to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the

manual may be changed without notice to improve the product and/or the manual.

• When ordering a new copy of the manual due to damage or loss, contact your Yaskawa

representative or the nearest Yaskawa sales office and provide the manual number shown on the

front cover.

DANGER

Heed the safety messages in this manual.

Failure to comply will result in death or serious injury.

The operating company is responsible for any injuries or equipment damage resulting

from failure to heed the warnings in this manual.

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 7

Page 8

1 Preface and Safety

NOTICE

Do not expose the unit to halogen group disinfectants.

Failure to comply may cause damage to the electrical components in the option.

Do not pack the unit in wooden materials that have been fumigated or sterilized.

Do not sterilize the entire package after the product is packed.

8 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 9

2 Product Overview

2 Product Overview

◆ About This Product

The option provides an enhanced unit user interface that can operate the Yaskawa unit from

up to 3 meters away. The option is an LED display that simplifies the task of interfacing with

the unit to perform these tasks:

• Read or modify unit parameters.

• Read and copy unit parameter settings to another Yaskawa unit.

• Operate the unit.

• Monitor unit operation status.

All keys except for the STOP key on the units built-in LED operator will not function when

the option is connected to V1000 and J1000.<1>

<1> If desired, to also disable the STOP key on the units built-in LED operator, set parameter o2-02 (STOP Key

Function Selection) to 0 (Disabled).

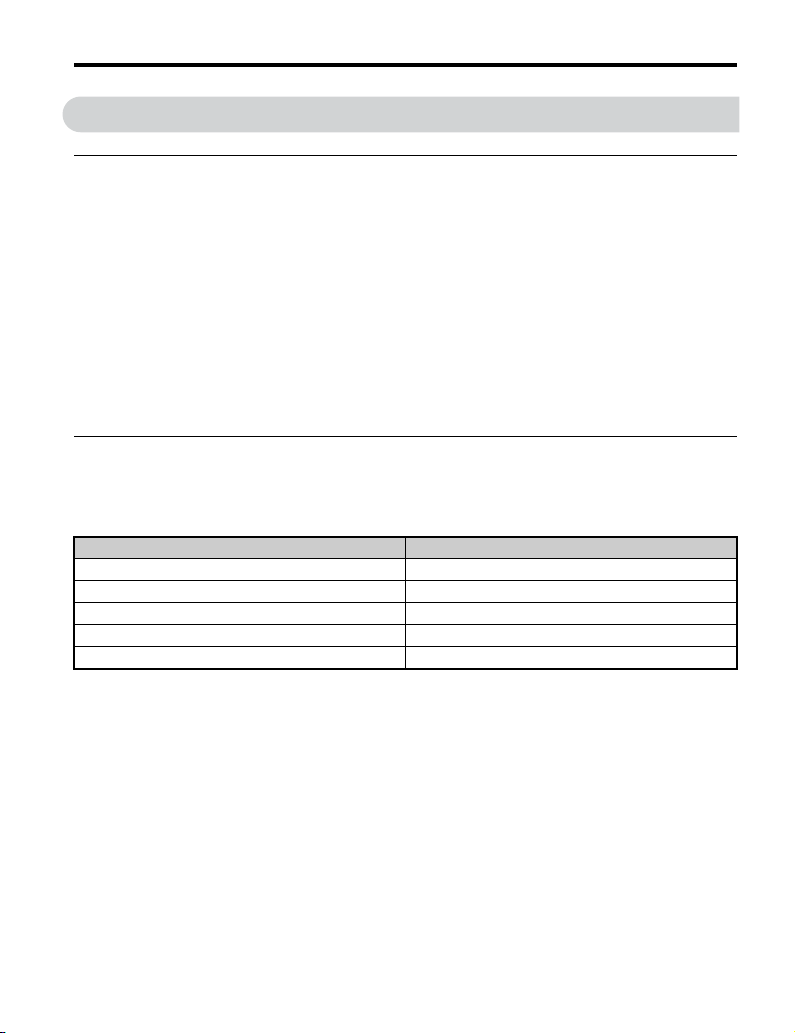

◆ Applicable Models

The option can be used with the unit models in Tab le 1 .

Table 1 Applicable Unit Models

Unit Unit Software Version <1>

A1000 All versions

V1000 ≥ PRG: 1016

J1000 All versions

D1000 All versions

R1000 All versions

<1> See “PRG” on the unit nameplate for software version number.

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 9

Page 10

3 Receiving

MANUAL

3 Receiving

Perform the following tasks after receiving the option:

• Inspect the option for damage.

If the option appears damaged upon receipt, contact the shipper immediately.

• Verify receipt of the correct model by checking the model number printed on the Name

plate of the option.

• If you have received the wrong model or the option does not function properly, contact

your supplier.

◆ Contents and Packaging

Table 2 Contents of Package

Description: Option Installation Manual

–

Quantity: 11

■

Parts Sold Separately

Proper installation of the option requires a digital operator cable (sold separately). A

communication cable may be purchased from Yaskawa or recommended LAN cables may

be used.

Installation support kit A or B (sold separately) may also be required depending on the

option installation method. Refer to Table 3. Refer to Installing the Option on page 20 for

more information regarding installation methods.

To order a communication or an installation support kit, contact Yaskawa directly or your

nearest Yaskawa distributor.

10 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 11

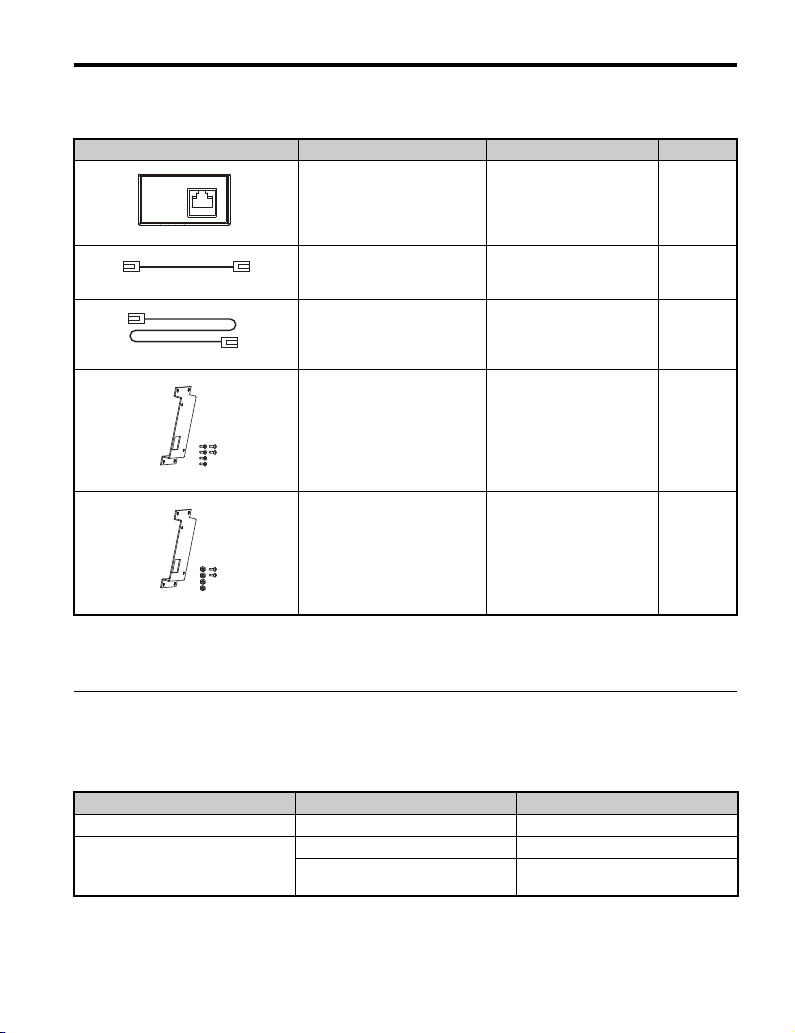

Table 3 Item Names and Part Numbers (Sold Separately)

Item

Yaskawa Part Number Notes Page

3 Receiving

J1000

RS-232C Interface Option

Digital Operator Cable 1 m (3 ft.)

Digital Operator Cable 3 m (10 ft.)

Installation Support Kit A

Installation Support Kit B

<1> Digital Operator Cable: Used to connect the digital operator to the drive (sold separately).

<2> Use Installation Support Kit B when weld studs are on the back of the panel.

<3> To connect the option to J1000, install the RS-232C Interface Option to the unit.

Part number for the Americas:

<1>

Part number for the Americas:

<1>

<2>

SI-232/J

WV001

UWR0051

WV003

UWR0052

EZZ020642A

EZZ020642B

Alternate cables (customer-

supplied), RJ45 8-pin Straight

Connector UTP Cat5e cable

Alternate cables (customer-

supplied), RJ45 8-pin Straight

Connector UTP Cat5e cable

For use with holes through

For use with panel-mounted

<3> 24

Sold Separately;

the panel

Sold Separately;

threaded studs

◆ Tool Requirements

The tools listed in Table 4 are required to install the option on an enclosure panel door.

Table 4 Required Tools

Installation Location Installation Support Required Tools

External/Face Mount – Phillips screwdriver, M3

Internal/Flush Mount

Installation Support Kit A Phillips screwdriver, M3, M4

Installation Support Kit B

Phillips screwdriver, M3

Box end or adjustable wrench, M4

23

23

22

22

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 11

Page 12

4 Option Components

A

4 Option Components

◆ Option

Figure 1

B

D

A – Data Display Area

B – LED Indicators E – Nameplate

C – Keys F – Communication Cable Connector

<1> REV: Display option version.

S /N : J007XE273710001

C

F

D – Installation Mounting Holes

<1>

Figure 1 Option Components

E

D

12 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 13

4 Option Components

U

U

◆ Keys

Refer to Figure 2 and Table 5 for details on key names and functions.

Figure 2

14 13 12

DIGITAL OPERATOR JVOP-182

REV DRV FOUT

ALM

11

10

1

ESC

2

9

RUN STOP

LO

RE

ENTERRESET

8

7

345 6

Figure 2 Keys

Table 5 Key Names and Functions

No. Key Name Function

• Returns to the previous display.

• Moves the cursor one space to the left.

1ESC Key

2 RESET Key

3 RUN Key Starts the unit and motor.

N

• Pressing and holding this button will return to the following display:

Drive: Frequency Reference

Converter: DC Bus Voltage Reference

Regenerative unit: DC Bus Voltage

• Moves the cursor to the right.

• Resets the unit to clear a fault situation.

4 Up Arrow Key

Scrolls up to display the next item, selects parameter numbers and

increments setting values.

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 13

Page 14

4 Option Components

SOO

P

No. Key Name Function

5

Down Arrow

Key

Scrolls down to display the previous item, selects parameter numbers and

decrements setting values.

Stops unit operation.

6STOP Key

Note: The STOP key can be enabled or disabled when operating from the

external terminal or network communications by setting parameter o2-02.

7ENTER Key

8

LO/RE

Selection Key

9 RUN Light

10 LO/RE Light Illuminated while the option is selected to run the unit (LOCAL mode).

11

12

<2>

LO

RE

ALM LED

Light

REV LED

Light

• Enters parameter values and settings.

• Selects a menu item to move between displays.

Switches unit control between the operator (LOCAL) and an external

source (REMOTE) for the Run command and frequency reference.

Note: The LOCAL/REMOTE key is only effective when the unit is

stopped in Drive Mode. As a safety precaution, it is possible to disable the

LO/RE Selection Key by setting parameter o2-01 (LOCAL/REMOTE

Key Function Selection) to 0 (disabled).

<1>

Illuminated during an operation.

Refer to Option LED Status Indicators on page 15 for details.

Refer to LED Screen Display on page 18

13

DRV LED

Light

14

<1> o2-01 (LOCAL/REMOTE Key Function Selection) is not compatible with J1000. LO/RE Selection Key is always

<2>

effective.

FOUT LED

Light

<2> These LEDs are not lit in D1000.

14 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 15

4 Option Components

RE

LO

Flashing

quickly

Flashing

ON ON

ON

ON ON

ON

1 s

◆ Option LED Status Indicators

■ Connecting the Option to A1000, V1000, or J1000

Table 6 LED Status and Meaning

LED Illuminated Flashing <1>

When the option is

selected for Run

command and

frequency reference

control (LOCAL).

• During decelera tion to

During run.

RUN

Examples

<1> Refer to Figure 3 for the difference between “flashing” and “flashing quickly”.

Figure 3

• When a Run

––

stop.

command is input and

the frequency

reference is 0 Hz.

Flashing Quickly <1> Off

• During deceleration

when a Fast Stop

command was

entered.

• During stop by

External Fault digital

input.

When a device other

than the option is

selected for Run

command and

frequency reference

control (REMOTE).

During stop.

Figure 4

Drive output frequency

RUN STOP

/

Frequency setting

RUN LED

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 15

During stop

0 Hz

Figure 3 RUN LED Status

RUN

6 Hz

OFF ON

Figure 4 RUN LED and Drive Operation

STOP STOP

OFF

Flashing

RUN

OFF

Page 16

4 Option Components

RUN

Flashing

quickly

Flashing

ON ON

ON

ON ON

ON

1 s

/

RUN STOP

RUN LED OFF OFFON

DC bus voltage reference

DC bus voltage

STOP

RUN

■ Connecting the Option to D1000

Table 7 LED Status and Meaning

LED Illuminated Flashing Quickly <1> Off

When the option is selected

LO

RE

for Run command and

frequency reference control

(LOCAL).

During run.

–

During stop by External Fault

digital input.

Examples

<1> Refer to Figure 5 for the difference between “flashing” and “flashing quickly”.

Figure 5

When a device other than the

option is selected for Run

command and frequency reference

control (REMOTE).

During stop.

Figure 6

Figure 6 RUN LED and Converter Operation

Figure 5 RUN LED Status

16 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 17

4 Option Components

RUN

/

RUN STOP

RUN LED OFF OFFON

STOP

RUN

■ Connecting the Option to R1000

Table 8 LED Status and Meaning

LED Illuminated Flashing Quickly <1> Off

LO

RE

When the run command is

selected from the LED

operator (LOCAL).

During run.

–

During stop by External Fault

digital input.

Examples

<1> Refer to Figure 7 for the difference between “flashing” and “flashing quickly”.

Figure 7

1 s

When a device other than the

option is selected for Run

command and frequency reference

control (REMOTE).

During stop.

Flashing

ON

ON ON

Flashing

quickly

Figure 7 RUN LED Status

Figure 8

Figure 8 RUN LED and Regenerative Unit Operation

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 17

ON

ON ON

Page 18

4 Option Components

ALMREV

DRV

FO

D

FOU

DIG

ALM

ALMREV

DRV

FO

D

◆ LED Screen Display

Display

Lit Flashing Off

When the unit detects an alarm

or error

Motor is rotating in reverse – Motor is rotating forward

<1>

Drive Mode – Programming Mode

Displays output frequency (Hz) – –

<1>

As illustrated

in this manual

IGITAL OPERATOR JVOP-182

DRV

UT

<1> These LEDs are not lit in D1000 or R1000.

• When an alarm occurs

• oPE detected

ITAL OPERATOR JVOP-182

T

Normal state (no fault or alarm)

IGITAL OPERATOR JVOP-182

UT

DRV

18 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 19

5 Installation Procedure

NOTICE

5 Installation Procedure

◆ Section Safety

Damage to Equipment

Use only Yaskawa connection cables or recommended cables.

Failure to comply may cause the unit or option to function incorrectly.

Properly connect the connectors.

Failure to comply may prevent proper operation and possibly damage equipment.

Do not exceed communication cable bend radius specifications.

Failure to comply may result in broken wires or loose connections.

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 19

Page 20

5 Installation Procedure

S /N : J007XE273710001

90 (3. 54)

78 (3. 07)

60 (2. 36)

7. 9

(0. 31)

minimum

50 (1. 97)

Unit: mm (in.)

12. 2

(0. 48)

1.6 (0.06)

Ins tallat ion holes (2- M3 sc rews, depth 5 (0.2))

44 (1. 73)

15 (0. 59)

<1>

◆ Option Dimensions

Figure 9

<1> Use only Yaskawa cables or cables recommended by Yaskawa. Refer to Item Names and Part Numbers (Sold

Separately) on page 11

Figure 9 Dimensions

◆ Installing the Option

The option mounts to an enclosure two different ways:

• External/face-mount installs the operator outside the enclosure panel.

• Internal/flush-mount installs the operator inside the enclosure panel.

Table 9 Option Installation Methods

Installation Method Description Notes

External/Face-mount

Internal/Flush-mount

20 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Simplified installation with the option is

mounted on the outside of the panel with two

screws.

Encloses the option in the panel. The front of

the option is flush with the outside of the

panel.

–

Requires purchase of separate items. Refer

to Item Names and Part Numbers (Sold

Separately) on page 11.

Page 21

5 Installation Procedure

22 (0.87)

22(0.87)

14

(0.55) Unit : mm (in.)

26

(1.02)

22

(0.87)

78 (3.07)

2 (0.08)

NOTICE: Prevent foreign matter such as metal shavings or wire clippings from falling into the unit during

installation and project construction. Failure to comply could result in damage to the unit. Place a temporary

cover over the top of the unit during installation. Remove the temporary cover before startup, as the cover

will reduce ventilation and cause the unit to overheat.

■ External/Face-mount Installation

1. Cut an opening in the enclosure panel for the option according to Figure 10.

2. Position the option so the LED display faces outwards, and mount it to the

Figure 10

Figure 11

enclosure panel as shown in Figure 10.

Opt io n

Figure 10 External/Face-mount Installation

M3 × 6 (0.24)

Phillips recessed

pan head machine screw × 2

Encl osure panel

Unit: mm (in.)

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 21

Figure 11 Panel Cut-out Dimensions (External/Face-mount Installation)

Page 22

5 Installation Procedure

Enclosure panel

Unit: mm (in.)

Option

Installation Support Kit A

M4 × 10 (0.39)

Phillips truss head screw × 4

(for panel widths between

1 (0.04) and 1.6 (0.06))

M3 × 6 (0.24)

Phillips recessed

pan head machine screw × 2

120 (4.72)

Unit : mm (in.)

45 (1.77)

89

+0.5

0

35 )(

+0.02

0

59

+0.5

0

2.32 )(

+0.02

0

■ Internal/Flush-mount Installation

The internal flush-mount installation method requires an installation support that is

purchased separately. Refer to Item Names and Part Numbers (Sold Separately) on

page 11 for information regarding the installation support and mounting hardware.

Figure 12 illustrates how to install Installation Support Kit A.

1. Cut an opening in the enclosure panel for the option according to Figure 13.

2. Mount the option to the installation support (sold separately).

3. Mount the installation support and option to the enclosure panel.

Figure 12

Figure 12 Internal/Flush Mount Installation

Note: For environments with a significant amount of dust or other airborne debris, use a gasket

Figure 13

between the enclosure panel and the option.

Figure 13 Panel Cut-out Dimensions (Internal/Flush-mount Installation)

22 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 23

5 Installation Procedure

◆ Connecting the Option to the Unit

This section contains instructions for connecting the option to units.

■ Connecting the Option to V1000

Plug the customer-supplied communication cable into the communication cable connector of

the option and the drive communications port as shown in Figure 15. Ensure both cable

ends are firmly connected. Refer to Item Names and Part Numbers (Sold Separately) on

page 11 for information regarding recommended cables.

Note: Use only Yaskawa recommended cables. Using a cable not specified may cause the option or

drive to malfunction.

Note: The STOP key on the built-in LED operator of the drive is the only functional key on the drive

when the option is connected and parameter b1-02 is set to 0 (LCD Operator or Option). Set

Figure 14

parameter o2-02 (STOP Key Function Selection) to 0 (Disable) to disable the STOP key.

Drive

Option (JVOP-182)

Built-in LED

Operator

STOP

V1000

周波数指令

正転逆転選択

出力周波数

出力電流

出力電圧

モニタ

ベリファイ

セットアップ

パラメータ設定

オートチューニング

WARNING

Risk of electric shock.

Read manual before installing.

Wait 5 minutes for capacitor discharge after

disconnecting power supply.

To conform to requirements, make sure

to ground the supply neutral for 400V class.

けが、感電のおそれがあります。

危 険

据え付け、運転の前には必ず取扱説明書を読むこと。

通電中および電源遮断後

分以内はフロントカバーを

5

外さないこと。

級インバータの場合は、電源の中性点が接地

400V

されていることを確認すること。( 対応)

:

:

:

:

:

:

:

:

:

:

(Hz)

(Hz)

(A)

(V)

Comm Port

S /N : J007XE273710001

Communication Cable Connector

Figure 14 Communication Cable Connection

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 23

Page 24

5 Installation Procedure

■ Connecting the Option to J1000

Note: Attach the RS-232C Interface Option (SI-232/J) to the drive before connecting the option to the

drive.

Plug the customer-supplied communication cable into the communication cable connector of

the option and the drive communications port of the RS-232C Interface Option (SI-232/J) as

shown in Figure 15. Ensure both cable ends are firmly connected. Refer to Item Names and

Part Numbers (Sold Separately) on page 11 for information regarding recommended

cables.

NOTICE: Use only Yaskawa recommended cables. Using a cable not specified may cause the option or

drive to malfunction.

Note: The STOP key on the built-in LED operator of the drive is the only functional key on the drive

when the option is connected and parameter b1-02 is set to 0 (LCD Operator or Option). Set

Figure 15

parameter o2-02 (STOP Key Function Selection) to 0 (Disable) to disable the STOP key.

Drive

Option (JVOP-182)

Built-in LED

Operator

STOP

S /N : J007XE273710001

J1000

RS-232C

Interface

Option

:

6

モニタ

1

周波数指令

:

7

ベリファイ

2

正転逆転選択

:

8

セットアップ

3

出力周波数

:

9

パラメータ設定

4

出力電流

5

出力電圧

:

WARNING

Risk of electric shock.

Read manual before installing.

Wait 1 minute for capacitor discharge after

disconnecting power supply.

To conform to requirements, make sure

to ground the supply neutral for 400V class.

けが、感電のおそれがあります。

危 険

据え付け、運転の前には必ず取扱説明書を読むこと。

分以内はフロントカバー を

通電中および電源遮断後

1

外さないこと。

級インバータの場合は、電源の中性点が接地

400V

されていることを確認すること。( 対応)

Figure 15 Communication Cable Connection

24 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Comm Port

:

:

:

:

Communication Cable Connector

Page 25

5 Installation Procedure

Comm Port

Communication Cable Connector

OptionUnit

S /N : J007XE273710001

■ Connecting the LCD Operator Option to A1000, D1000, or R1000

Plug the customer-supplied communication cable into the communication cable connector of

the option and the unit communications port as shown in Figure 15. Ensure both cable ends

are firmly connected. Refer to Item Names and Part Numbers (Sold Separately) on page 11

for information regarding recommended cables.

Note: Use only Yaskawa recommended cables. Using a cable not specified may cause the option or

Figure 16

unit to malfunction.

Figure 16 Communication Cable Connection

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 25

Page 26

6 Basic Operation

6 Basic Operation

◆ Basic Operation for Option

The option operates in the same way as the option or built in the unit.

Refer to the J1000 Manuals for option main structure and basic Operation.

◆ Functions characteristic of the Option

■ Read/Copy Function Procedure

Read

Reads and saves parameter settings from the unit to the option.

The option can perform the Read function an estimated 100,000 times.

Copy

Copies parameter settings from the option to another Yaskawa unit.

These parameters control the Copy function of the digital operator. The Copy function stores

parameter settings into the memory of the digital operator to facilitate the transfer of those

settings to other units that are the same model, capacity, and same control mode setting.

Note: Parameter settings can only be copied to other units that are the same model, capacity, and have

the same control mode setting.

Verify

Verifies parameter settings in the unit match parameter settings saved to the option.

26 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 27

6 Basic Operation

The following procedure is used to read parameters from the unit.

Note: 1. Set parameter o3-02 (Read Allowable) to 1 (Enable) to read the parameter settings from the unit. Set

parameter o3-02 to 0 (Disable) to protect the parameter settings in the option.

2. If D1000 is used, refer to the D1000 Installation Manual.

Step Display/Result

1. Turn on the power to the unit. The initial display appears.

2. Press ・ to select the Parameter Setting and

Press .

3. Press ・・to select o3-01 (Copy Function

Selection) and press .

4. Press ・ to select 01.

5. Press and the option will read parameter settings from the unit.

6. Automatically return to the Copy Function Selection display.

7. Press repeatedly until the display returns to the initial display.

DIGITAL OPERATOR JVOP-182

REV DRV FOUT

DRV

DIGITAL OPERATOR JVOP-182

REV DRV FOUT

DRV

ALM

ALM

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 27

Page 28

7 Related Parameters

7 Related Parameters

Parameters related to the use of the option are listed in Table 10. Set these parameters as

needed for the application.

Table 10 Related Parameters

No. Name

Frequency

b1-01

Reference

Selection 1

Run

b1-02

Command

Selection 1

Frequency

b1-15

Reference 2

Run

b1-16

Command

Source 2

J1000

YES YES N/A N/A

YES YES YES YES

N/A YES N/A N/A

N/A YES N/A N/A

A1000/

V1000

Unit

D1000 R1000

Description Values

Selects the source of the frequency

reference.

0: LED operator or LCD operator -Digital

preset speed d1-01 to d1-17

1: Terminals - Analog input terminal A1

or A2

2: MEMOBUS/Modbus serial

communications

3: Option PCB

4: Pulse Input (Terminal RP)

Selects the Run command input source.

0: LED operator or LCD operator -RUN

and STOP keys on the LED Operator

Option

1: Digital input terminals S1 to S7

2: MEMOBUS/Modbus serial

communications

3: Option PCB

Selects the frequency reference input

source.

0: LED operator or LCD operator Digital preset speed d1-01 to d1-17

1: Terminals - Analog input terminal A1

or A2

2: MEMOBUS/Modbus serial

communications

3: Option PCB

4: Pulse Input (Terminal RP)

Selects the Run command input source.

0: LED operator or LCD operator - RUN

and STOP keys on the LED Operator

Option

1: Digital input terminals S1 to S7

2: MEMOBUS/Modbus serial

communications

3: Option PCB

<1>

<1>

Default: 1

Range: 0 to 4

Default: 1

Range: 0 to 3

Default: 0

Range: 0 to 4

Default: 0

Range: 0 to 3

28 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 29

7 Related Parameters

No. Name

Voltage

b1-18

Reference

Source

LOCAL/

REMOTE

o2-01

Key Function

Selection

STOP Key

o2-02

Function

Selection

Frequency

Reference

o2-05

Setting

Method

Selection

Operation

Selection

when LED

o2-06

Operator

Option is

Disconnected

Unit

A1000/

J1000

N/A N/A YES N/A

N/A YES YES YES

YES YES YES YES

YES YES N/A N/A

YES YES YES YES

V1000

D1000 R1000

Description Values

Sets the input source for the DC bus

voltage reference.

0: LED operator or LCD operator

1: Control circuit terminal (analog input)

2: MEMOBUS/Modbus communications

3: Option card

7: Input voltage based control 1

8: Input voltage based control 2

Enables/Disables the option LOCAL/

REMOTE key.

0: Disabled

1: Enabled

Enables/Disables the operator panel

STOP key when the unit is operated form

external sources (not operator).

0: Disabled

1: Enabled

Selects if the ENTER key press is

required when inputting the frequency

reference by the digital operator.

0: Data/Enter key must be pressed to

enter a frequency reference.

1: Data/Enter key is not required. The

frequency reference is adjusted by the up

and down arrow keys.

Sets unit action when the option is

removed in LOCAL mode or with b1-02

= 0.

0: The drive, converter, or regenerative

unit will continue operation.

1: The drive, converter, or regenerative

unit will trigger a fault (oPr) and the

motor will coast to stop.

Default: 0

Range:

0 to 3, 7, 8

Default: 1

Range: 0, 1

Default: 1

Range: 0, 1

Default: 0

Range: 0, 1

Default: 0

Range: 0, 1

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 29

Page 30

7 Related Parameters

No. Name

Copy

o3-01

Function

Selection

Copy

o3-02

Allowable

<1> b1-01 = 4 and b1-02 = 3 are not compatible with the J1000.

J1000

YES YES YES YES

YES YES YES YES

A1000/

V1000

Unit

D1000 R1000

Description Values

This parameter controls the copying of

parameters to and from the option.

0: COPY SELECT (no function)

1: All parameters are copied from the unit

to the LED Operator Option or LCD

Operator Option.

2: All parameters are copied from the

LED Operator Option or LCD Operator

Option to the drive, converter, or

regenerative unit.

3: Parameter settings in the drive,

converter, or regenerative unit are

compared to those in the LED Operator

Option or LCD Operator Option.

Note: When using the copy function, the

drive model number (o2-04), software

number (U1-14), and control method

(A1-02) must match or an error will

occur.

Enables or disables reading of unit

parameter settings.

0: Disabled - Read not allowed

1: Enabled - Read allowed

Default: 0

Range: 0 to 3

Default: 0

Range: 0, 1

30 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 31

8 Option Fault Diagnostics

8 Option Fault Diagnostics

◆ Error Code and Connection Messages

Fault/Error code text will appear on the option display to indicate a specific fault. The fault

codes in Table 11 are displayed on the LED operator built in the drive and/or the option

displays. For information on the fault codes not listed in Table 11, refer to the unit manual.

When an option fault occurs, ensure that the communication cable is properly connected to

the option and it is not loose.

Contact your nearest Yaskawa representative or sales department if the cable appears to be

connect properly but still no message appears to indicate the error.

Note: If A1000, D1000, or R1000 is used, the fault codes are displayed on the option only.

Table 11 Fault/Error Code Displays

LED Operator

(JVOP-182)

Communication cable between the optio n and the

unit is not properly connected.

Problem with the option. Replace the option.

Problem with the control circuit in the unit.

LED Operator

(JVOP-182)

Connector on the option cable is loose or

damaged.

Problem with the option. Replace the option.

Problem with the control circuit in the unit.

LED Operator

(V1000 and J1000

built-in)

<1>

Cause Possible Solution

LED Operator

(V1000 and J1000

built-in)

<1>

Cause Possible Solution

LED Operator (JVOP-182) Communication Error 1

Occurs when the unit cannot communicate with the option within

5 seconds after the power is switched on.

Remove and reconnect the option.

• Cycle power to the unit.

• Replace the unit.

LED Operator (JVOP-182) Communication Error 2

Occurs when the unit does not respond to the option for longer

than 2 seconds.

Remove and reconnect the option.

• Cycle power to the unit.

• Replace the unit.

Description

Description

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 31

Page 32

8 Option Fault Diagnostics

LED Operator

(JVOP-182)

Option is not properly connected to the unit.

<1> Display will vary depending on operation status.

LED Operator

(V1000 and J1000

built-in)

Cause Possible Solution

Description

LED Operator Option Connection Fault

Data should appear on the LED operator built in the unit. By

reconnecting the option to the unit, data should also appear on the

option display.

An oPr fault will occur when both of the following conditions are

true:

Output is interrupted when the option is disconnected (o2-06 = 1).

The Run command is assigned to the option (b1-02/b1-16= 0 and

LOCAL is selected).

• Check the connection between the option and the unit.

• Replace the cable if damaged.

• Turn off the unit input power and disconnect the option.

Reconnect the option and reapply unit input power.

32 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 33

9 Specifications

Table 12 Option Specifications

Model JVOP-182

Connector RJ-45

Power Supply Powered from the unit (DC +5 V ±5%)

Operating Temperature -10 to +50 °C (+14 to +122 °F)

Humidity up to 95% RH (no condensation)

Storage Temperature

Area of Use Indoor (free of corrosive gas, airborne particles, etc.)

Altitude Up to 1000 m (3280 ft.)

Shock

Read Function

Limitation

-20 to +60 °C (-4 to +140 °F)

(allowed for short-term transport of the product)

10 to 20 Hz: 9.8 m/s

20 to 55 Hz: 5.9 m/s

Estimated 100,000 times

2

2

9 Specifications

YASKAWA ELECT RIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual 33

Page 34

10 Revision History

MANUAL NO. TOBP C730600 35A

Published in Japan September 2008 08-3

Date of

publication

Date of original

publication

Revision number

1

65432

1

10 Revision History

The revision dates and numbers of the revised manuals are given on the bottom of the back

cover.

Date of

Publication

November 2013

March 2013

October 2010

August 2010 Back cover Revision: Address

December 2008 All chapters Revision: Application to the A1000 and V1000

September 2008 Back cover Revision: Address

March 2008 −−First edition

Rev. No. Section Revised Content

All Chapters Revision: Application to the R1000

Back cover Revision: Address

All chapters Revision: Application to the D1000

Back cover Revision: Address

Front cover,

back cover

Revision: Document name, format

34 YASKAWA ELECTRIC TOBP C730600 35D 1000-Series Option JVOP-182 Installation Manual

Page 35

YASKAWA 1000-Series Option

LED Operator

Installation Manual

DRIVE CENTER (INVERTER PLANT)

2-13-1, Nishimiyaichi, Yukuhashi, Fukuoka, 824-8511, Japan

Phone: 81-930-25-3844 Fax: 81-930-25-4369

http://www.yaskawa.co.jp

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-6891, Japan

Phone: 81-3-5402-4502 Fax: 81-3-5402-4580

http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: 1-800-YASKAWA (927-5292) or 1-847-887-7000 Fax: 1-847-887-7310

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL LTDA.

Avenida Piraporinha 777, Diadema, São Paulo, 09950-000, Brasil

Phone: 55-11-3585-1100

http://www.yaskawa.com.br

YASKAWA EUROPE GmbH

Hauptstrasse 185, 65760 Eschborn, Germany

Phone: 49-6196-569-300 Fax: 49-6196-569-398

http://www.yaskawa.eu.com

YASKAWA ELECTRIC KOREA CORPORATION

9F, Kyobo Securities Bldg., 26-4, Yeouido-dong, Yeongdeungpo-gu, Seoul, 150-737, Korea

Phone: 82-2-784-7844

http://www.yaskawa.co.kr

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-02A, New Tech Park, 556741, Singapore

Phone: 65-6282-3003

http://www.yaskawa.com.sg

YASKAWA ELECTRIC (CHINA) CO., LTD.

12F, Carlton Bld., No.21 HuangHe Road, HuangPu Distr ict, Shanghai 200003, China

Phone: 86-21-5385-2200

http://www.yaskawa.com.cn

YASKAWA ELECTRIC (CHINA) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No. 1 East Chang An Ave.,

Dong Cheng District, Beijing, 100738, China

Phone: 86-10-8518-4086

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei, 104, Taiwan

Phone: 886-2-2502-5003

YASKAWA INDIA PRIVATE LIMITED

#17/A Electronics City, Hosur Road Bangalore 560 100 (Karnataka), India

Phone: 91-80-4244-1900

http://www.yaskawaindia.in

Fax: 55-11-3585-1187

Fax: 82-2-784-8495

Fax: 65-6289-3003

Fax: 86-21-5385-3299

Fax: 86-10-8518-4082

Fax: 886-2-2505-1280

Fax: 91-80-4244-1901

YASKAWA ELECTRIC CORPORATION

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be sure

to follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 2008-2013 YASKAWA ELECTRIC CORPORATION. All rights reserved.

MANUAL NO. TOBP C730600 35D

Published in Japan November 2013 08-3

13-7-11

6 -0

Loading...

Loading...